Novel centrifugal machine static balancing device

A centrifuge and balancing technology, applied in centrifuges and other directions, can solve the problems of increased labor and material costs, uneven force on the synchronous belt, complicated operation of the synchronous belt, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

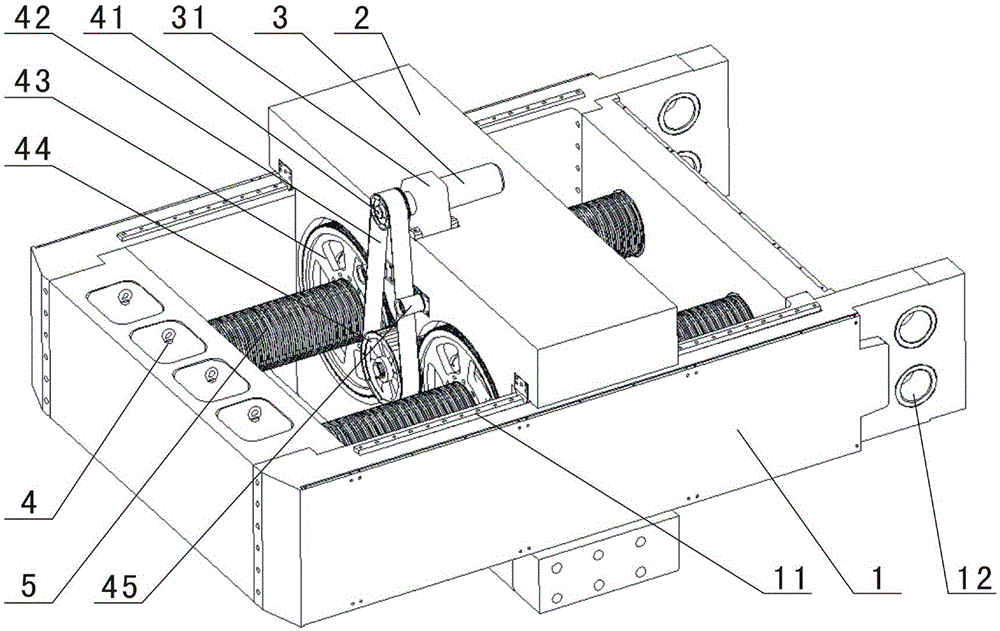

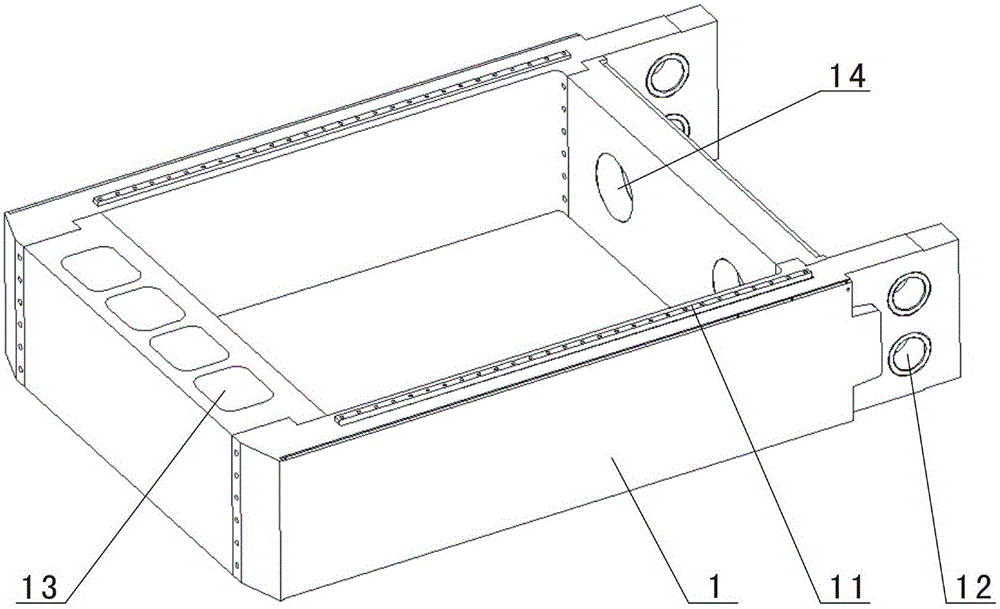

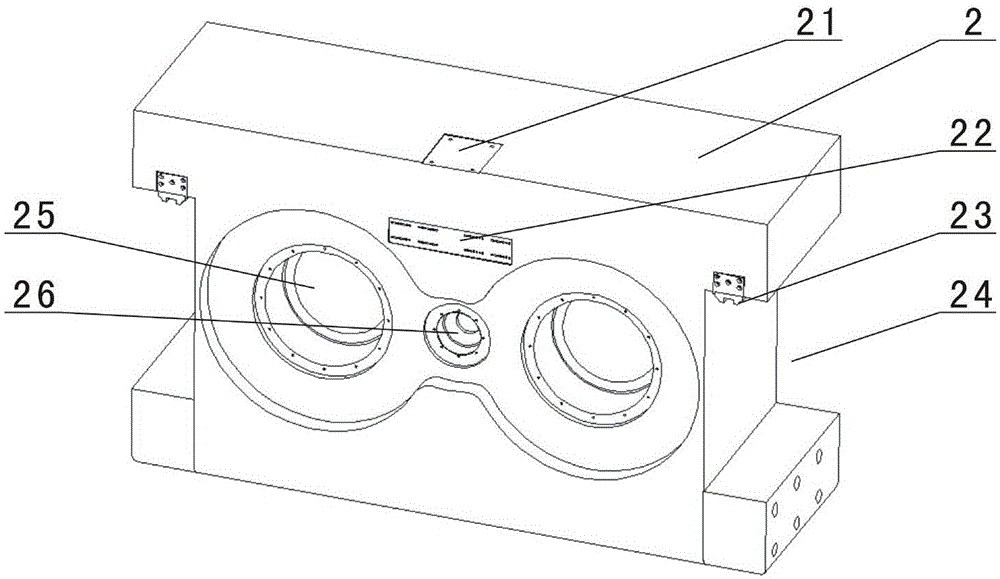

[0021] The present invention will be further explained below in conjunction with the drawings:

[0022] Such as Figure 1-Figure 4 As shown, the static balancing device of the novel centrifuge of the present invention includes a balancing frame 1, a lead screw 5, a moving counterweight 2, a motor 3, a rotating transmission device and a walking nut 48. The first end of the balancing frame 1 is provided with The rotating arm of the centrifuge (not shown) is connected to the connecting hole 12, the second end of the trim frame 1 is provided with a fixed weight hole 13, and the fixed weight hole 13 is installed with a fixed weight 4, and the balance frame 1 Two rails 11 are respectively provided on the upper surfaces of both sides and the two rails 11 are parallel to each other. The two ends of the movable counterweight 2 are respectively installed on the two guide rails 11 and can move, and the motor 3 is installed on the movable counterweight 2; The weight 2 is provided with a cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com