Control method for ship-body section carrying accuracy based on OTS

A control method and precision technology, which is applied to ship parts, ship construction, ships, etc., can solve the problems of reset and high rate of segmental reset of head and tail lines, and achieve the effect of reducing reset time, fast loading, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

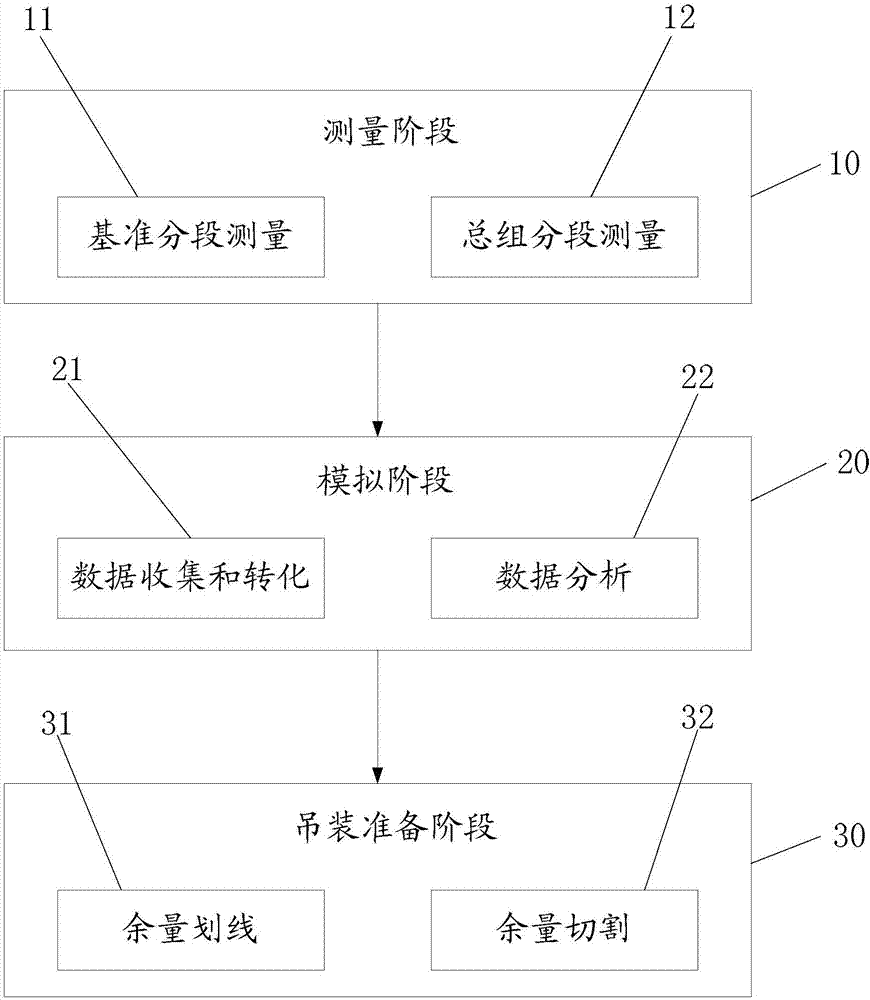

Method used

Image

Examples

specific Embodiment approach

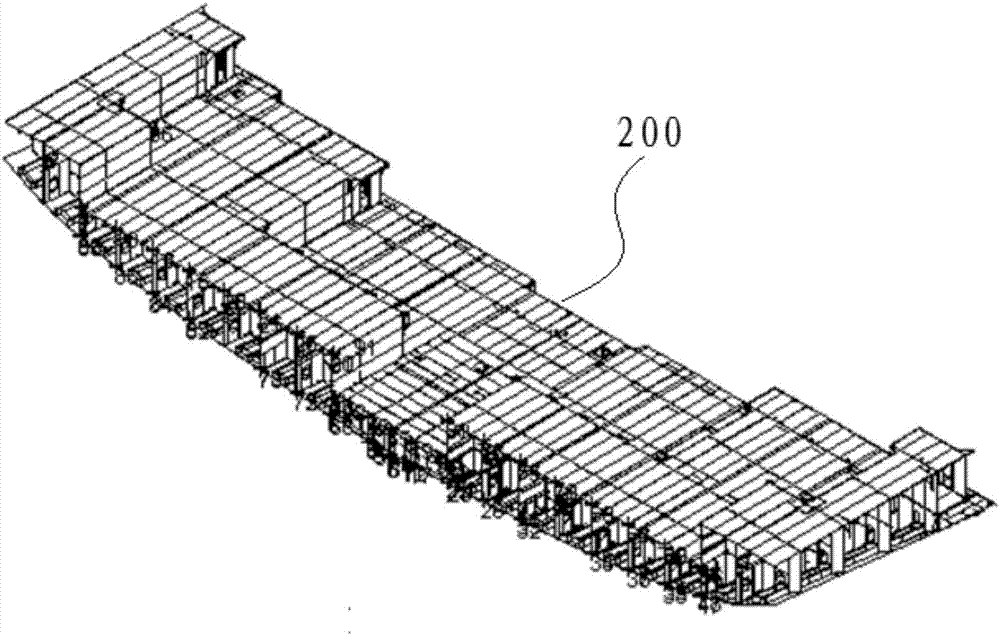

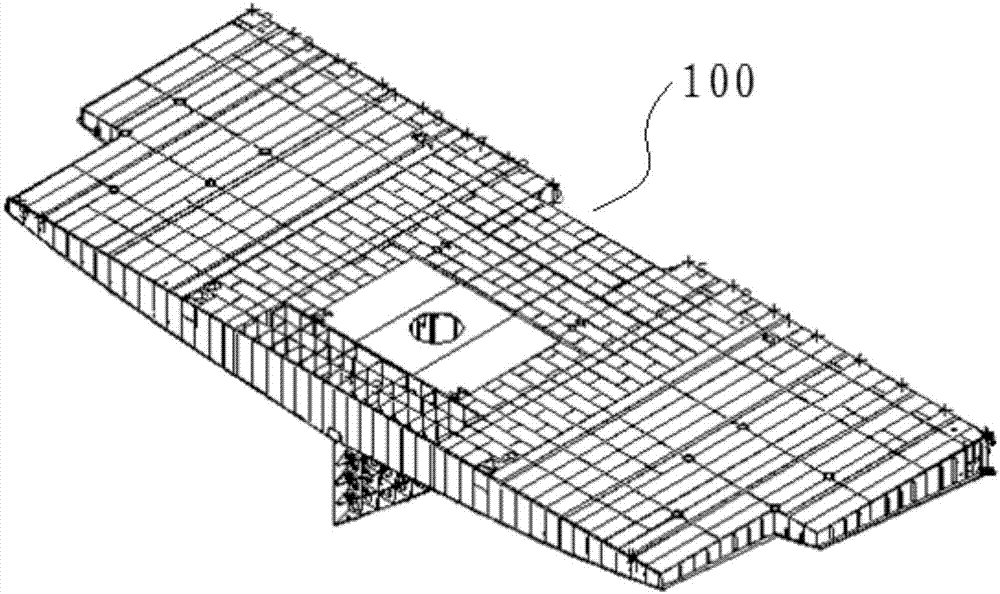

[0042] see again Figure 2a to Figure 4 , the specific embodiment of the present invention is as follows:

[0043] When performing measurement phase 10,

[0044] First select ten precision attention points on the reference segment 200 in the dock, and these ten accuracy attention points are all located at an end face that will be connected with the 11A subsection 100; then measure ten accuracy attention points with a total station 3D coordinates, and save the measurement data in the memory of the total station;

[0045] On the 11A subsection 100 on the platform, twenty-six precision attention points are selected, wherein the positions of twenty-one precision attention points are located at the end connecting with the reference segment 200, and the other five precision attention points are Located at the end facing away from the reference segment 200 , the five precision focus points are mainly for analyzing the deviation between the centerline of the stern shaft hole and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com