Fuse trimming and adjusting circuit

A technology for trimming circuits and fuses, applied in logic circuits, electrical components, pulse technology, etc., can solve problems such as large inventory costs, expensive machines, and the influence of physical characteristics of chips, and achieve the goal of improving trimming accuracy and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

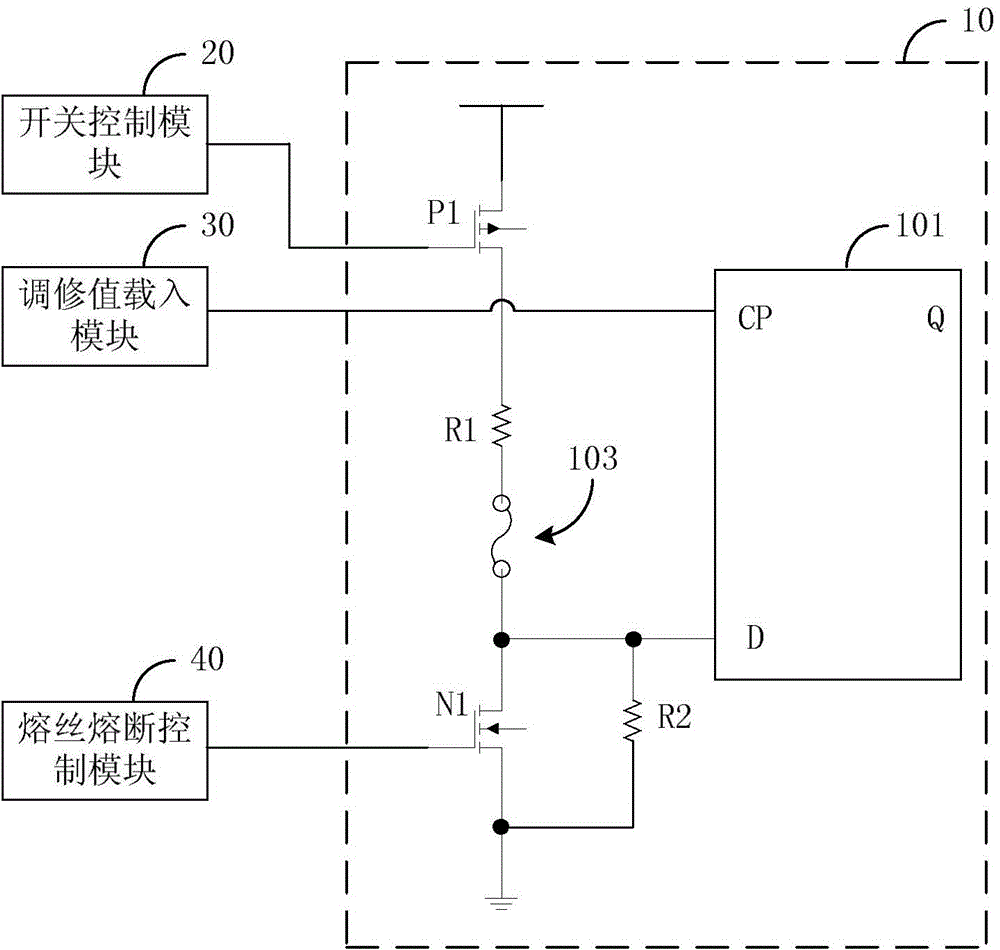

[0015] See figure 1 , figure 1 It is a circuit structure diagram of a fuse trimming circuit according to a preferred embodiment of the present invention.

[0016] like figure 1 As shown, the fuse trimming circuit of the present invention includes a switch control module 20 , a trimming value loading module 30 , a fuse blowing control module 40 and a trimming module 10 . Wherein, the trimming module 10 includes a PMOS (positive channel Metal Oxide Semiconductor, P-channel Metal Oxide Semiconductor Field Effect Transistor) transistor P1, a first resistor R1, a fuse 103, an NMOS (Negative channel Metal Oxide Semiconductor, N-channel metal oxide semiconductor) transistor N1, a second resistor R2 and a D flip-flop 101.

[0017] The circuit connections of the above modules are as follows: the source of the PMOS transistor P1 is connected to the regulated power supply (not marked), the gate of the PMOS transistor P1 is connected to the switch control module 20, and the drain of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com