Method for trimming resin base circle arc diamond grinding wheel by adopting rotary green silicon carbide grinding bar

A diamond grinding wheel and green silicon carbide technology, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low machining accuracy, deviation of the grinding wheel installation position, workpiece shape accuracy, etc., and achieve processing efficiency High, high trimming accuracy, the effect of improving shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

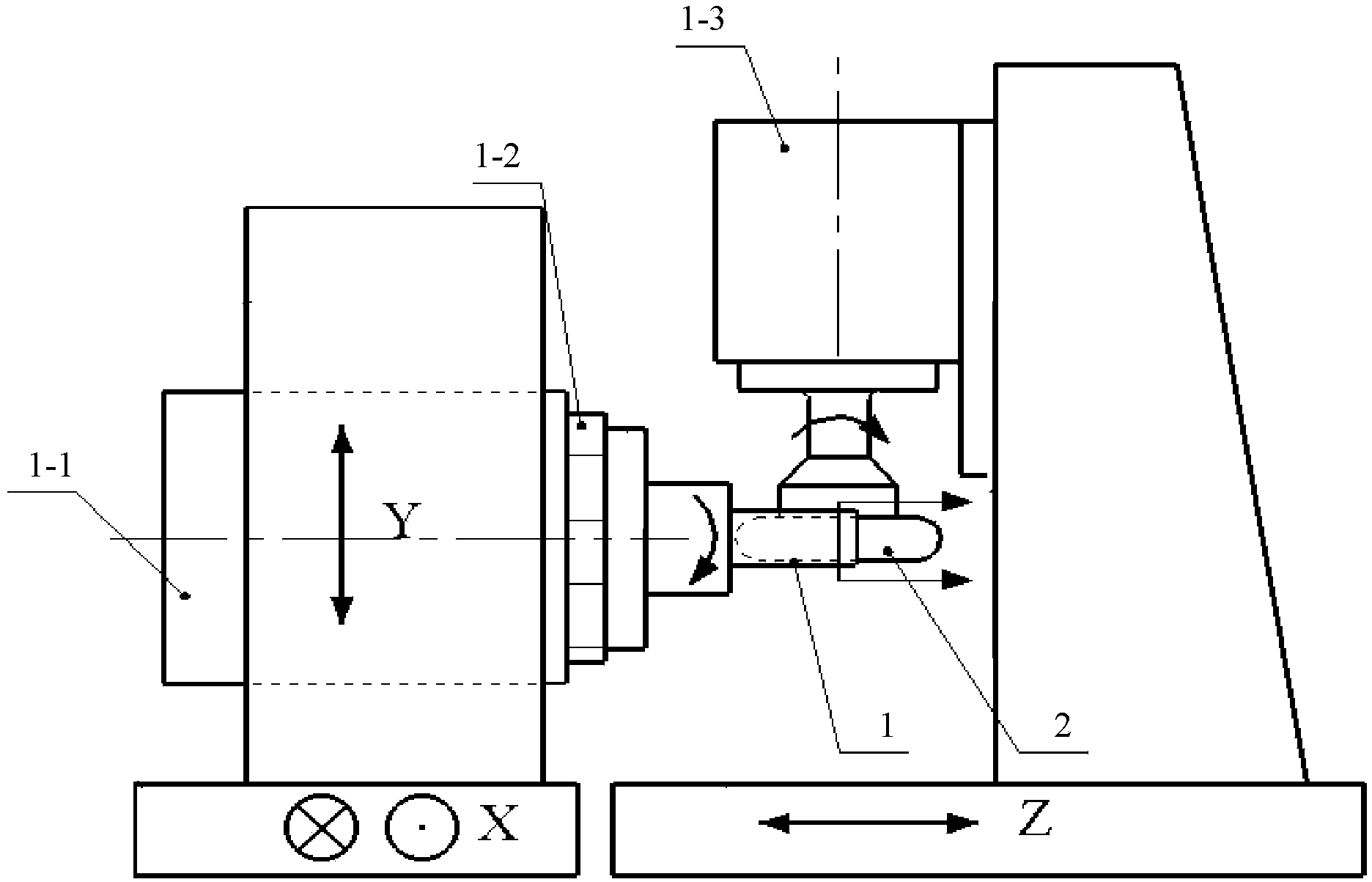

[0023] Specific implementation mode one: the following combination figure 1 and figure 2 Illustrate the present embodiment, the method for using the rotating green silicon carbide grinding rod to dress the resin-based arc-shaped diamond grinding wheel described in the present embodiment is characterized in that it comprises the following steps:

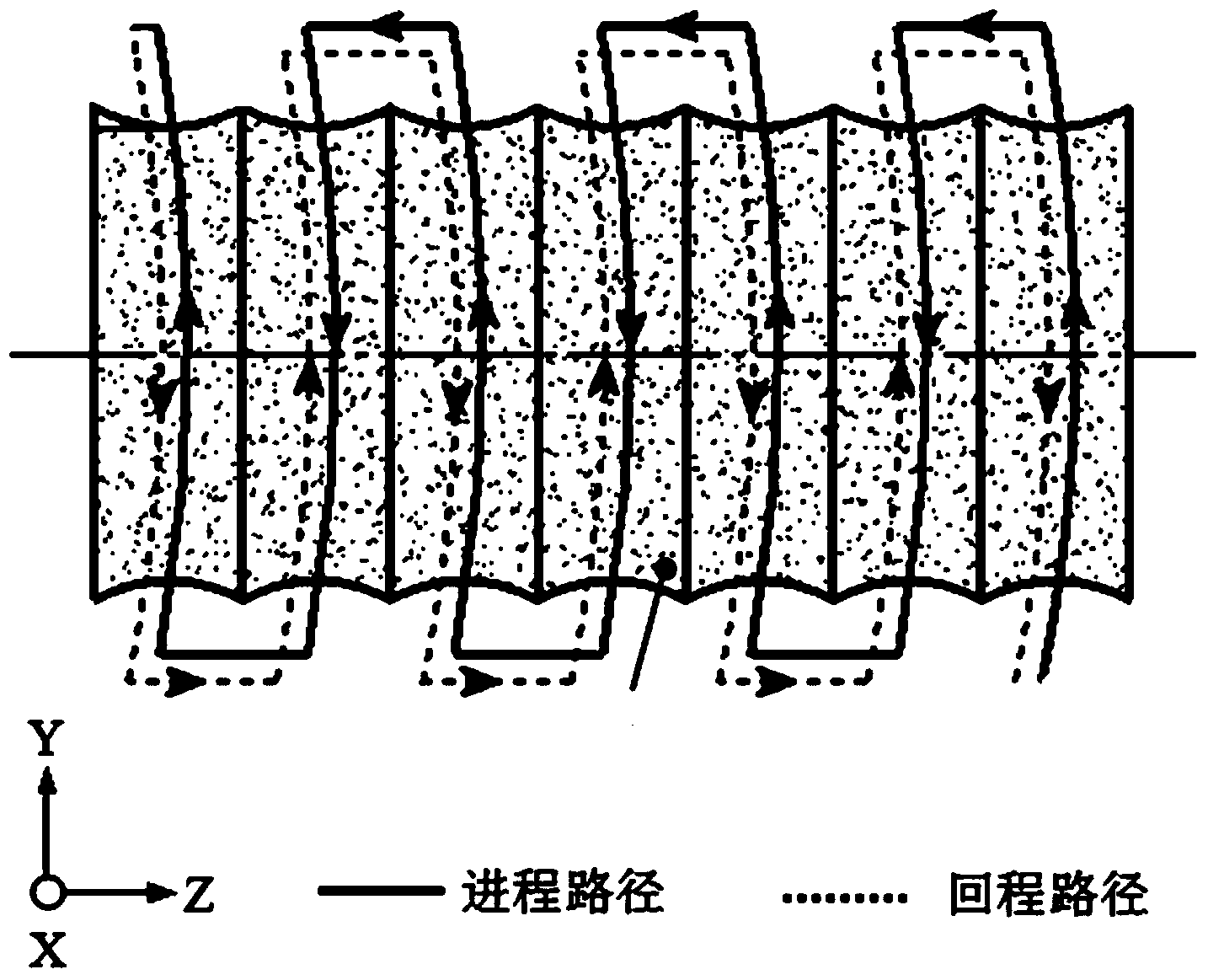

[0024] Step 1: Install the green silicon carbide grinding rod 1 on the vacuum chuck 1-2 of the workpiece spindle 1-1 of the three-linear axis linkage machine tool, and install the grinding wheel 2 on the lower end of the grinding spindle 1-3 of the three-linear axis linkage machine tool Department, adjust the initial positional relationship between the green silicon carbide grinding rod 1 and the grinding wheel 2 through the vertical Y spindle, horizontal X spindle and horizontal Z spindle of the three-linear axis linkage machine tool; The position in the XY plane is controlled by the Y spindle in the vertical direction and the X sp...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further explain the first embodiment. The vertical Y spindle, the horizontal X spindle and the horizontal Z spindle of the three-linear axis linkage machine tool are used to adjust the green silicon carbide grinding rod 1 and the grinding wheel 2. The specific method of the initial position relationship is:

[0029] First, determine the Y-direction position of the center plane of the grinding wheel 2 and the green silicon carbide grinding rod 1:

[0030] Move the Y spindle in the vertical direction so that the green silicon carbide grinding rod 1 is in contact with the upper surface of the abrasive layer of the grinding wheel 2, and record the Y-direction position coordinate Y of the workpiece spindle 1-1 axis at this time 1 , move the Y spindle in the vertical direction to make the green silicon carbide grinding rod 1 contact the lower surface o...

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment further describes Embodiment 1 or 2, and the value of B ranges from 3 to 5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com