Patents

Literature

241results about How to "Adjustable installation position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

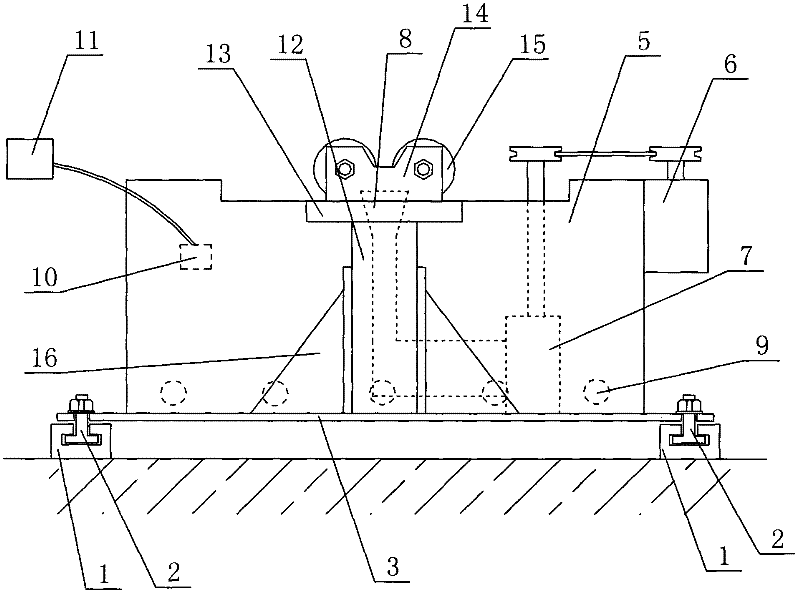

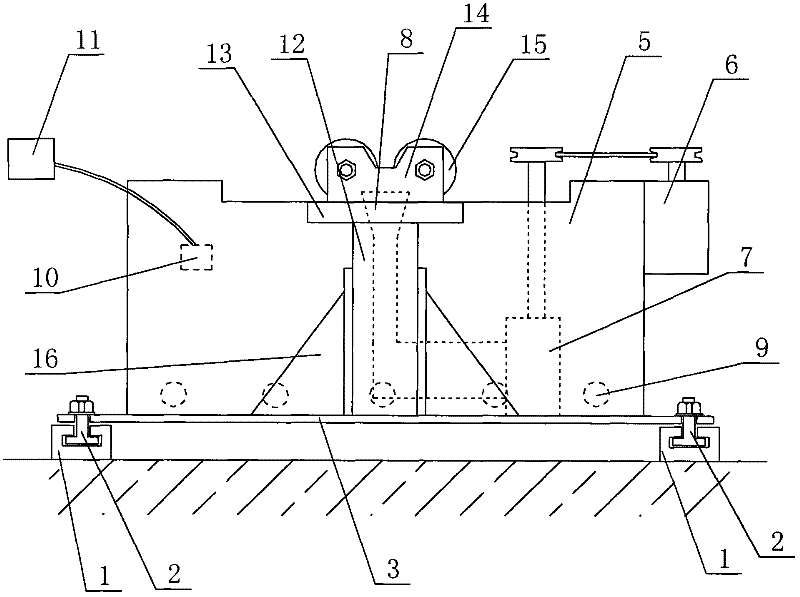

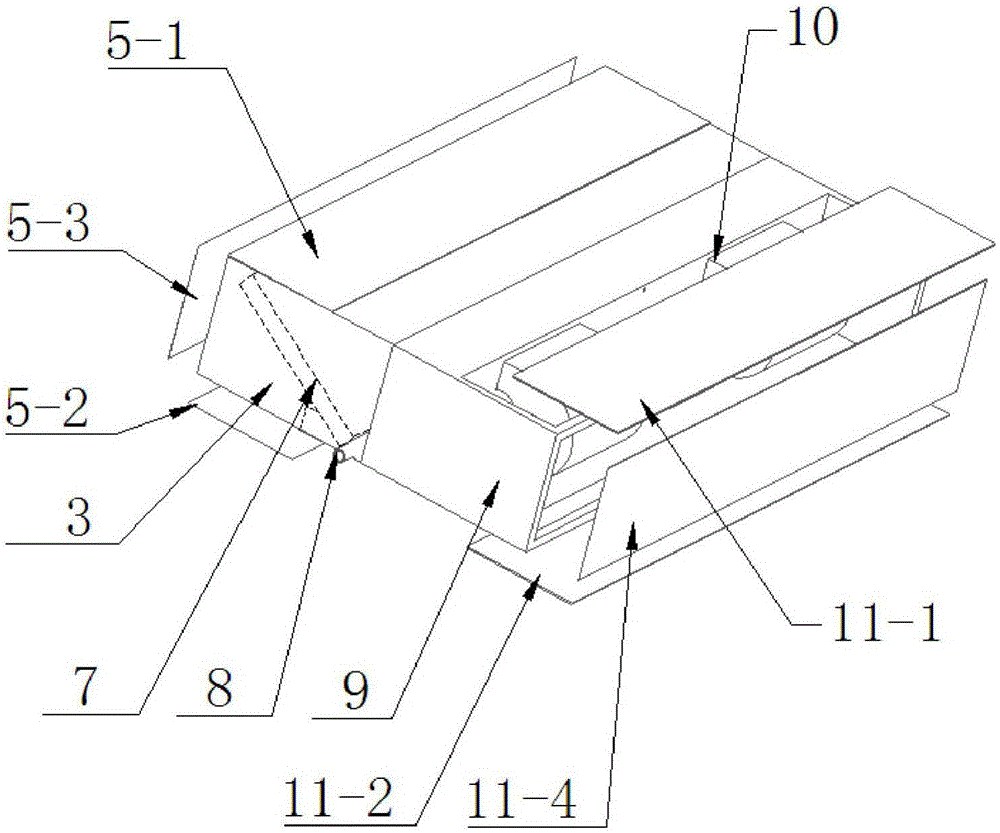

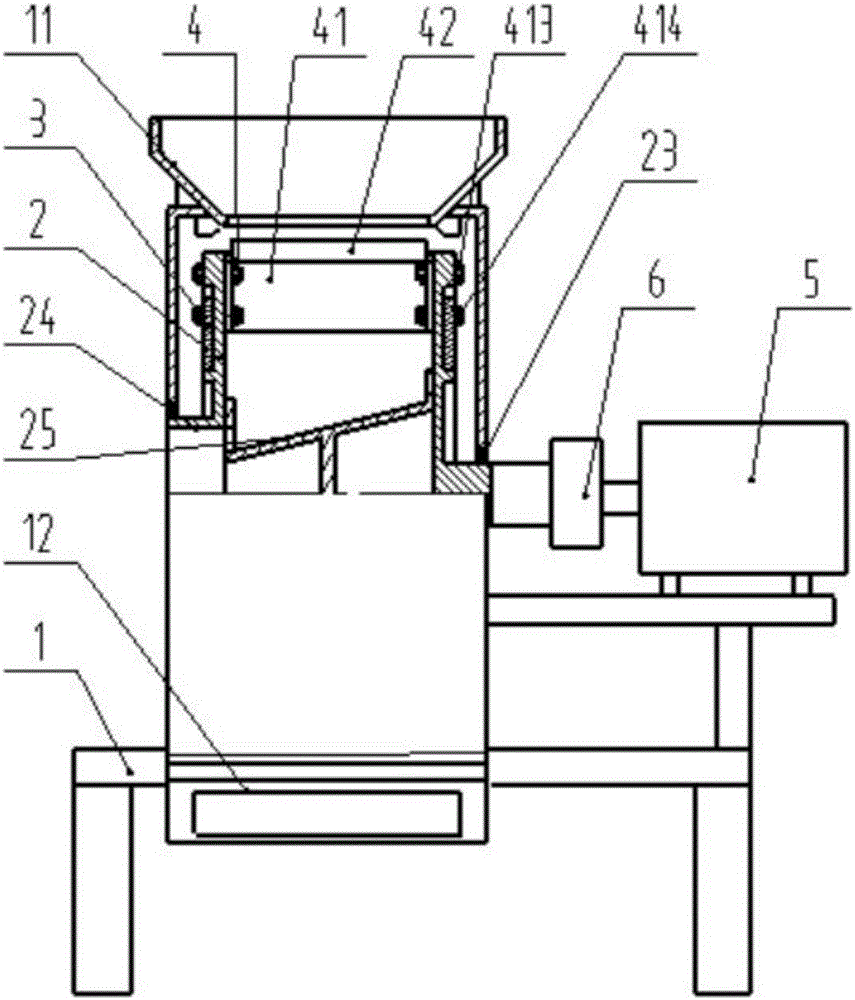

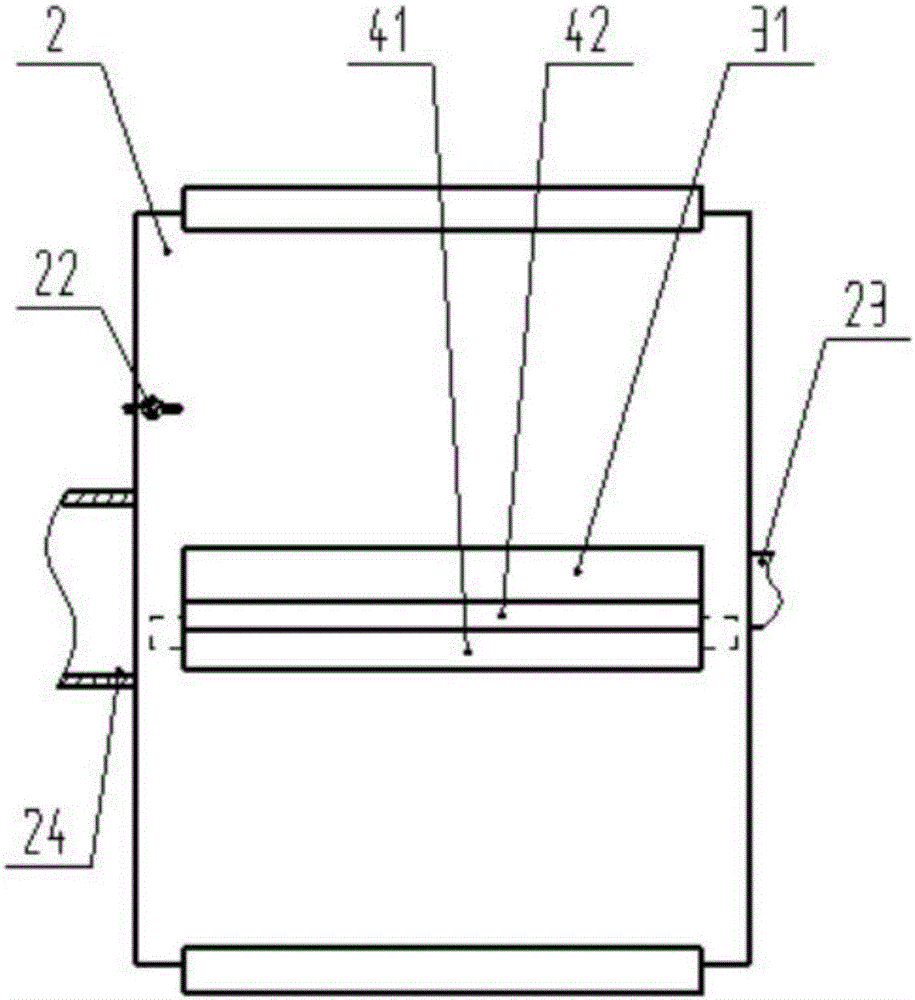

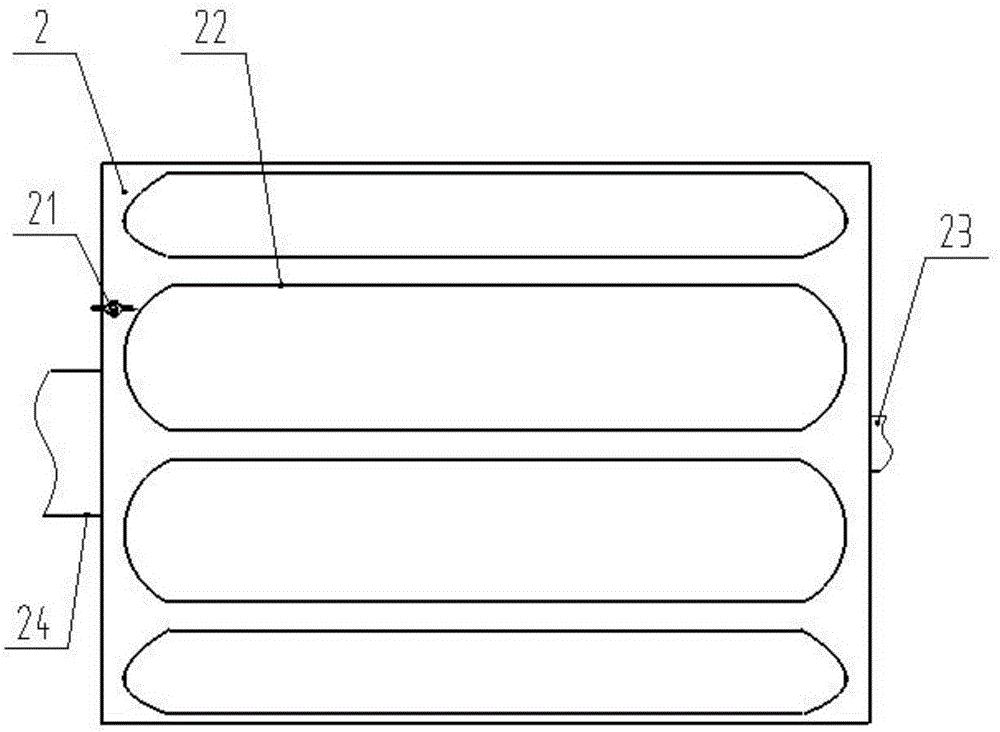

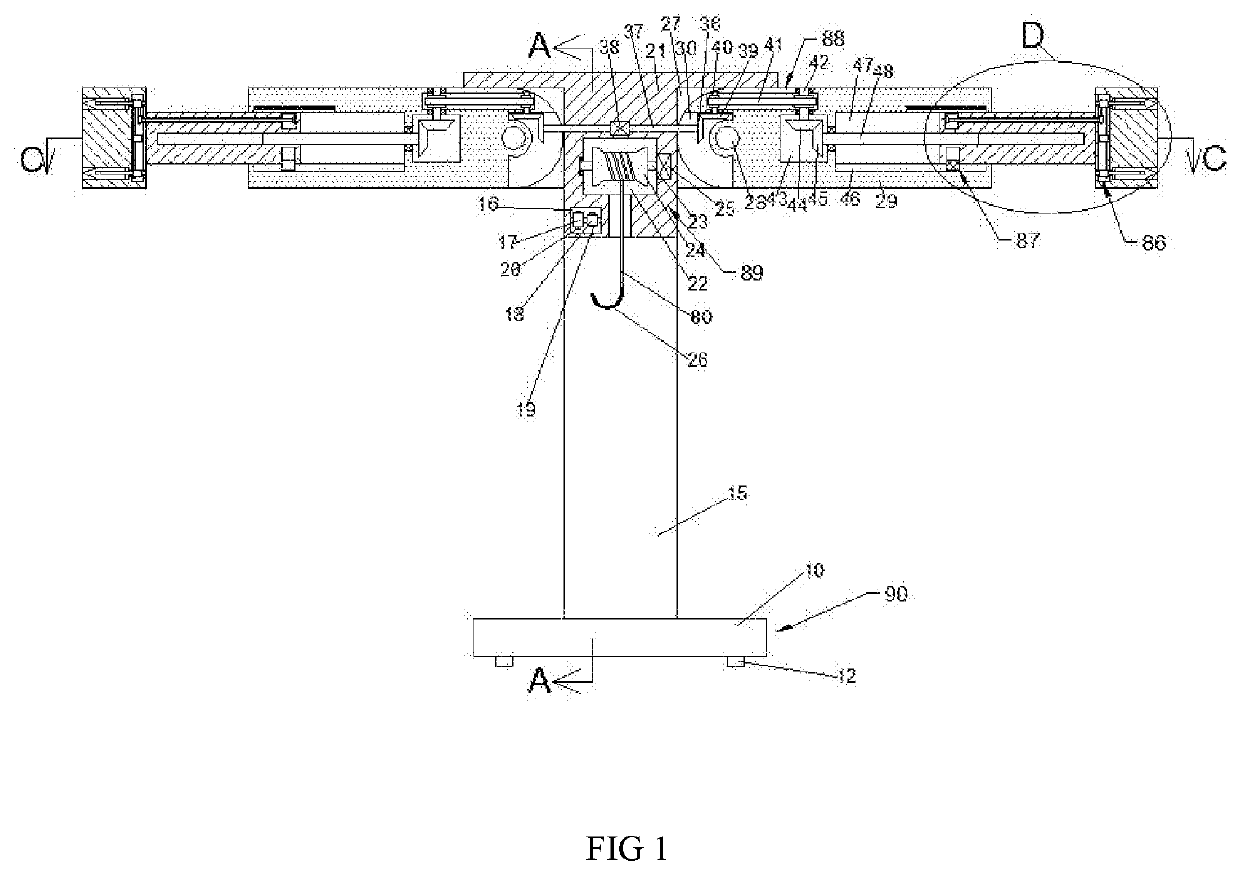

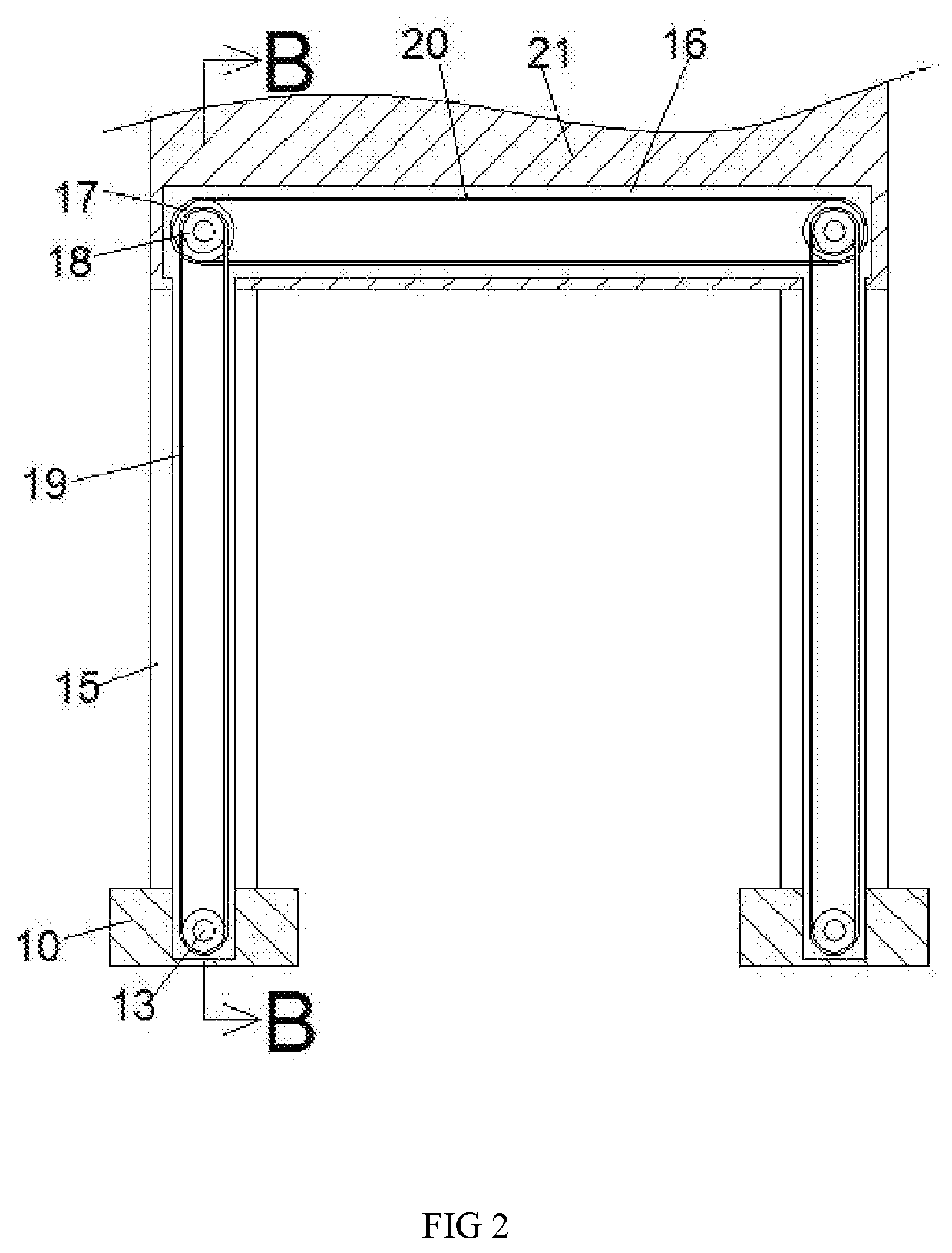

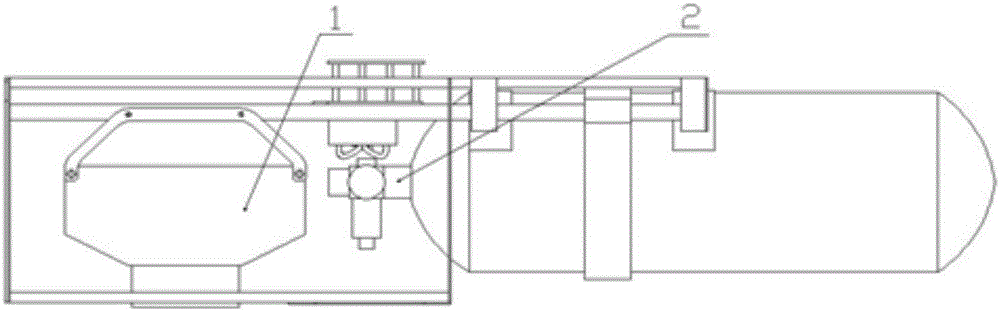

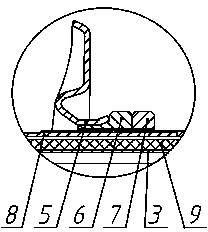

Tin soldering device for commutator and armature wire

InactiveCN102389997AAdjustable installation positionImprove welding qualityMetal working apparatusSolder feeding devicesSpray nozzleEngineering

The invention discloses a tin soldering device for a commutator and an armature wire, which is used for welding the commutator and the armature wire of a motor, and comprises a base, a tin basin and supports, wherein the tin basin is arranged on the base; the supports are arranged at both sides of the tin basin; one side of the tin basin is provided with a drive motor; the drive motor is connected with a tin spraying pump arranged in the tin basin; the tin spraying pump is communicated with a spray nozzle arranged in the tin basin; heating pipes are arranged in the tin basin; the inner wall of the tin basin is provided with a temperature sensor; and the temperature sensor is electrically connected with a controller. In the tin soldering device for the commutator and the armature wire, a motor rotor is arranged above rollers of the supports, so that the connected faces of the armature wire and the commutator on the motor rotor are just located above the spray nozzle in the tin basin; the drive motor is started to drive the tin spraying pump to spray molten tin onto the connected faces of the armature wire with the commutator, and simultaneously, the motor rotor is rotated to implement welding, thereby, not only is the welding efficiency high, but also the welding quality is good.

Owner:无锡先锋电机有限公司

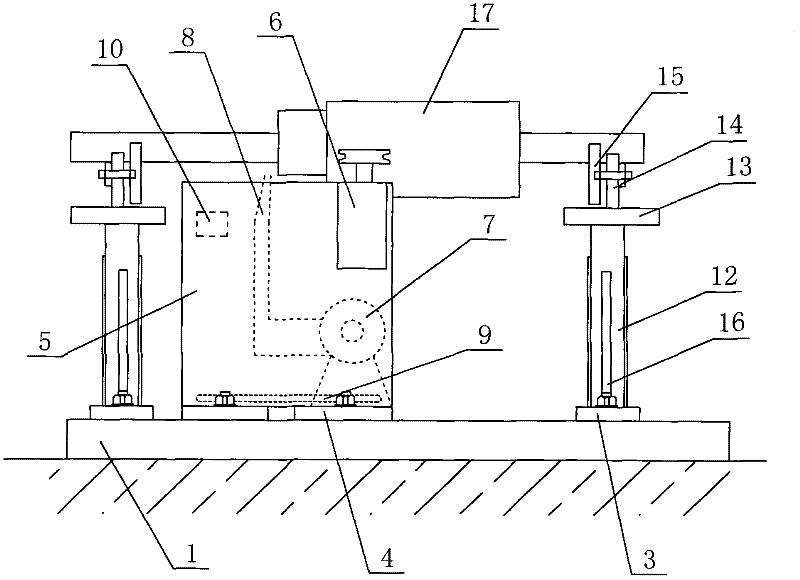

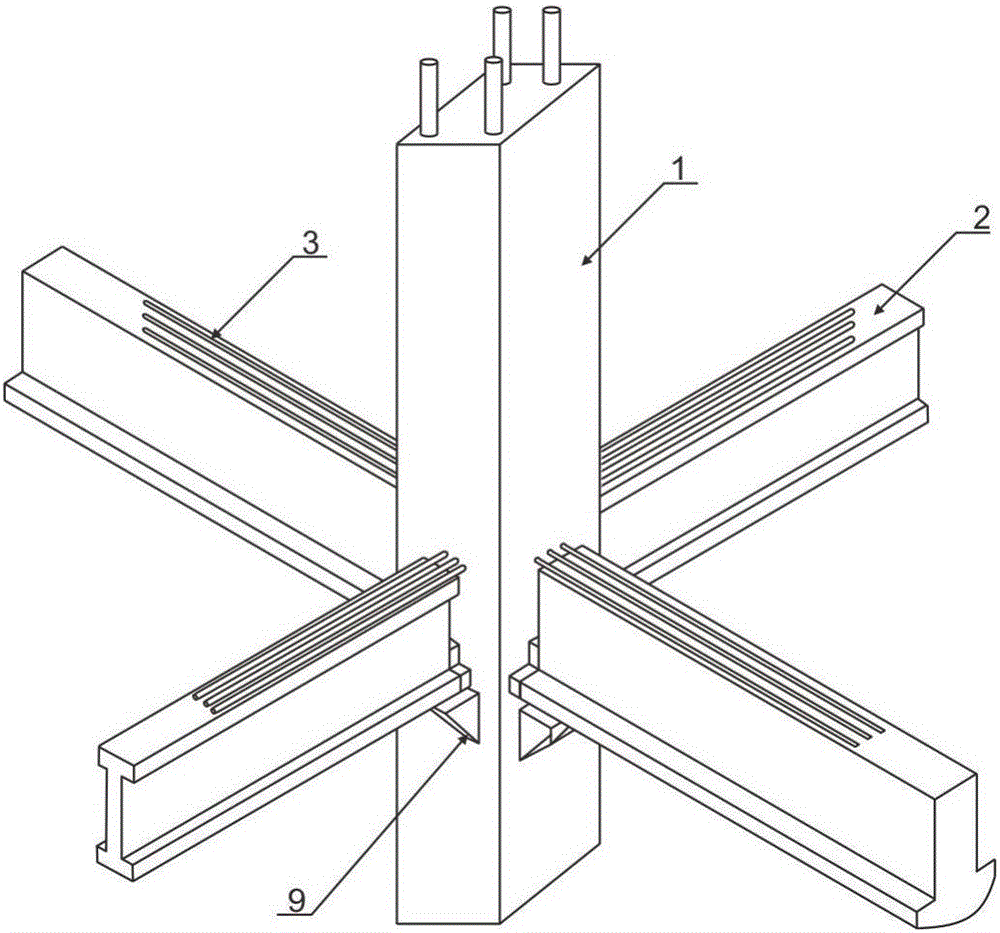

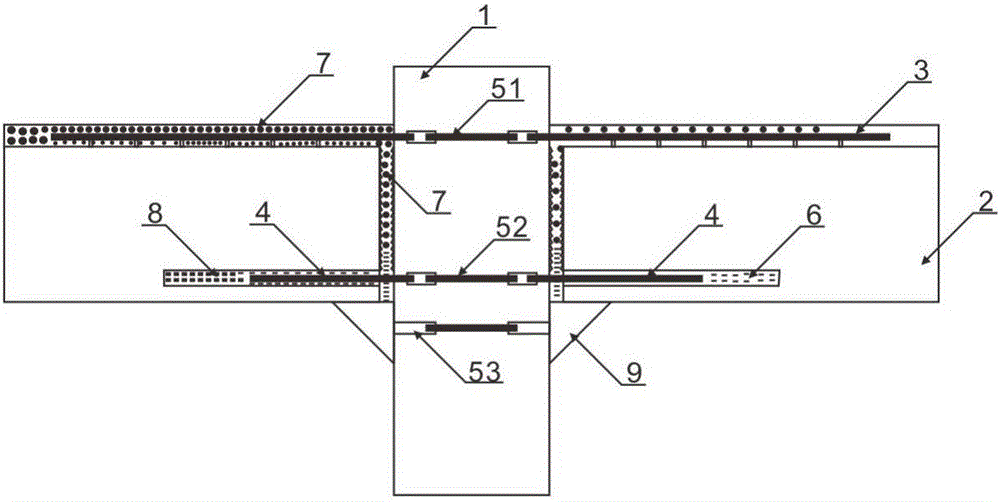

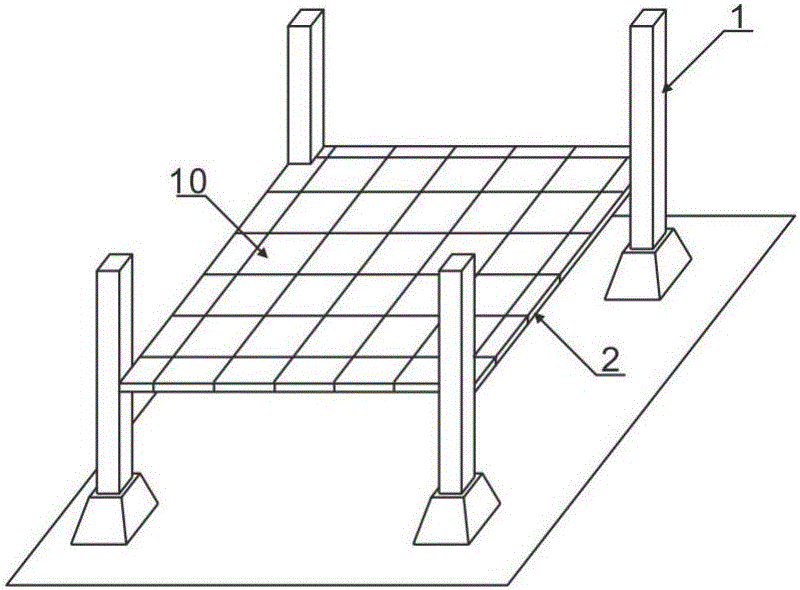

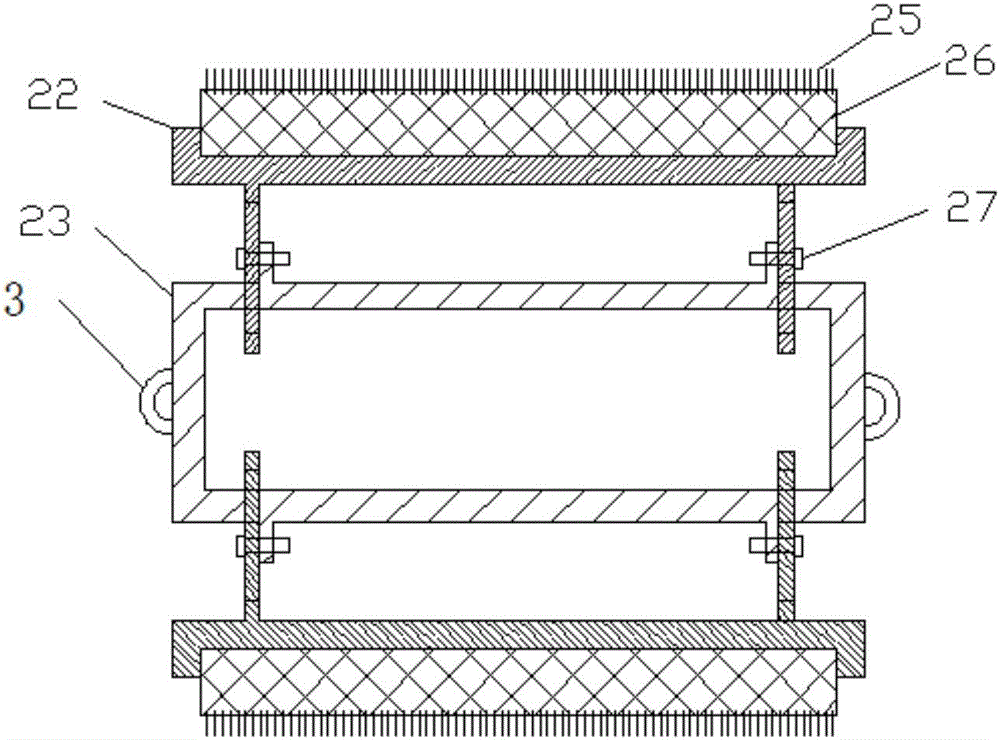

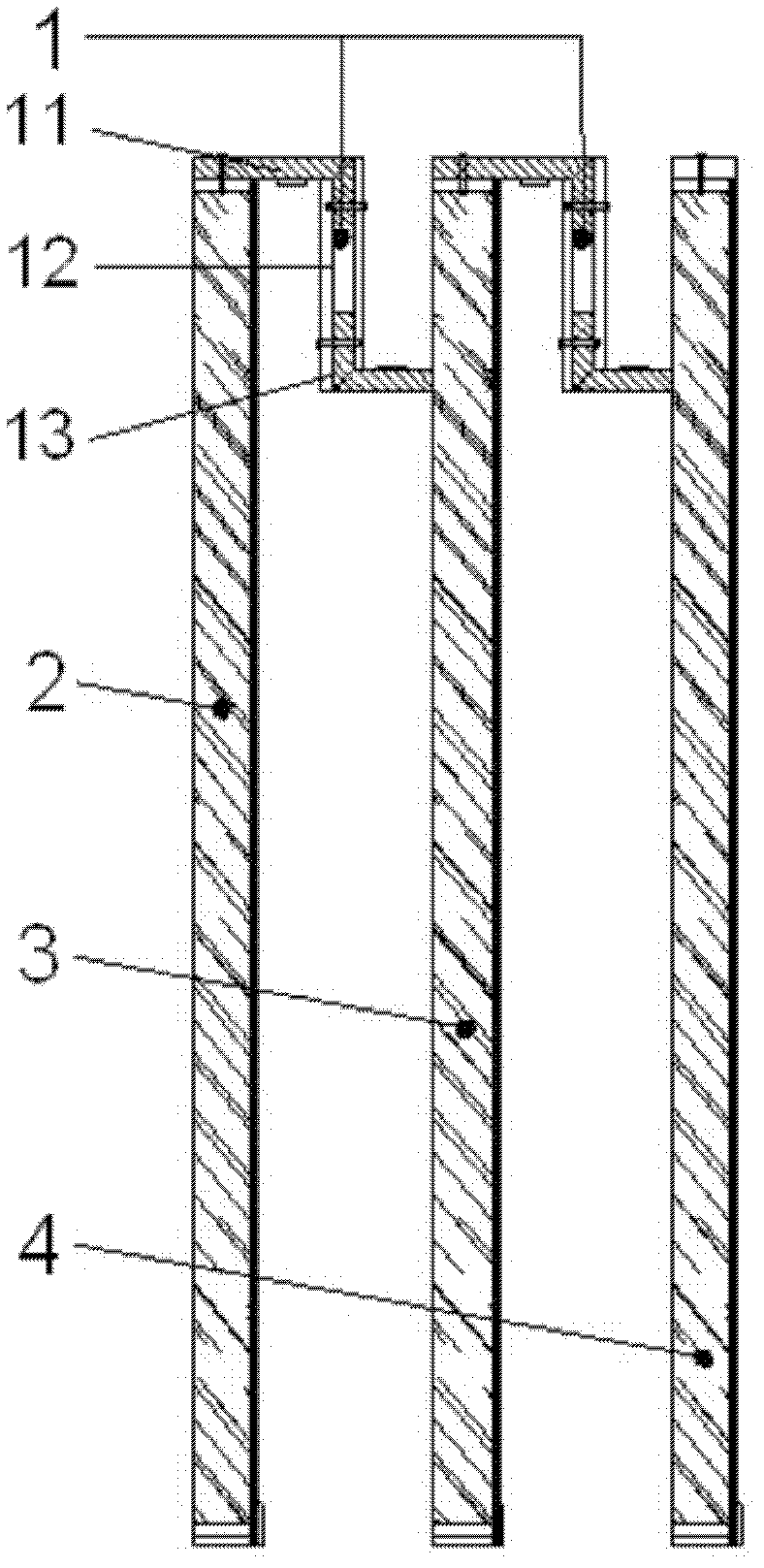

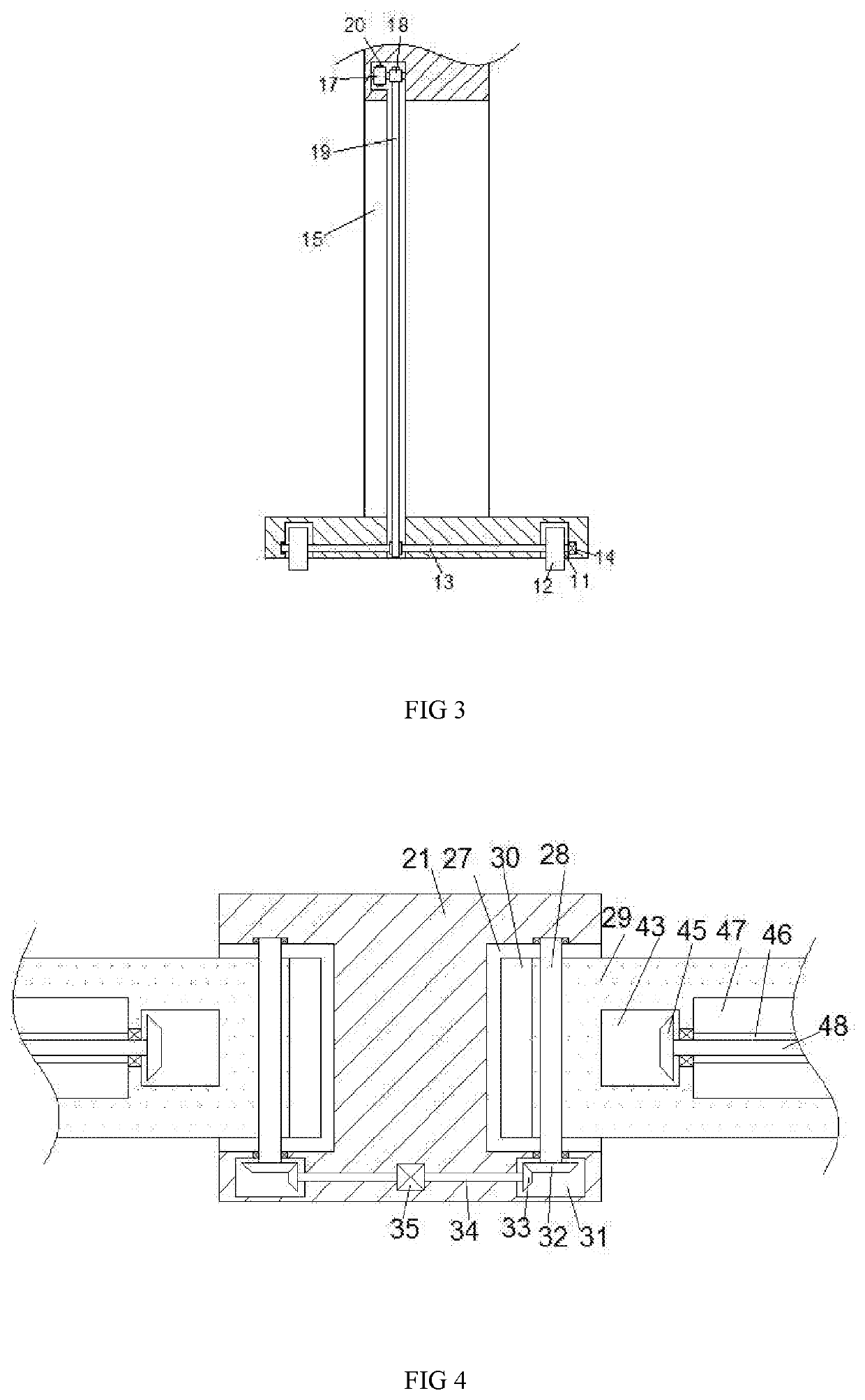

Prefabricated assembly type beam column joint connecting process

InactiveCN105863046AFirmly connectedImprove structural stabilityBuilding reinforcementsRebarStructural stability

The invention discloses a prefabricated assembly type beam column joint connecting process. The process comprises the steps that a frame column comprising three rows of threaded sleeves is prefabricated; a pore passage is reserved in the lower end of each prefabricated frame beam, a connecting steel bar on the lower portion of each frame beam is inserted in the corresponding reserved pore passage, and a gap is kept between each frame beam and the frame column; a connecting steel bar on the upper portion of each frame beam is connected with the upper threaded sleeves, the connecting steel bar on the lower portion of each frame beam is connected with the lower threaded sleeves, and detachable supporting pieces are connected with the reinforced threaded sleeves; the reserved pore passages are filled with high-strength mortar; a prefabricated plate is hoisted and placed on each frame beam, and beam and plate laminating layers are formed in a pouring mode through concrete to complete wet joint connection. By means of the process, the frame beams on the two sides of the frame column can be connected together, the overall structural stability can be improved, no weld spot exists, high-altitude welding operation is avoided, the safety risk is lowered, and connection between the frame column and the frame beams is more stable and reliable by means of pouring of the wet joint concrete and the high-strength mortar; moreover, construction is fast, and the construction efficiency is improved.

Owner:四川省第四建筑有限公司 +1

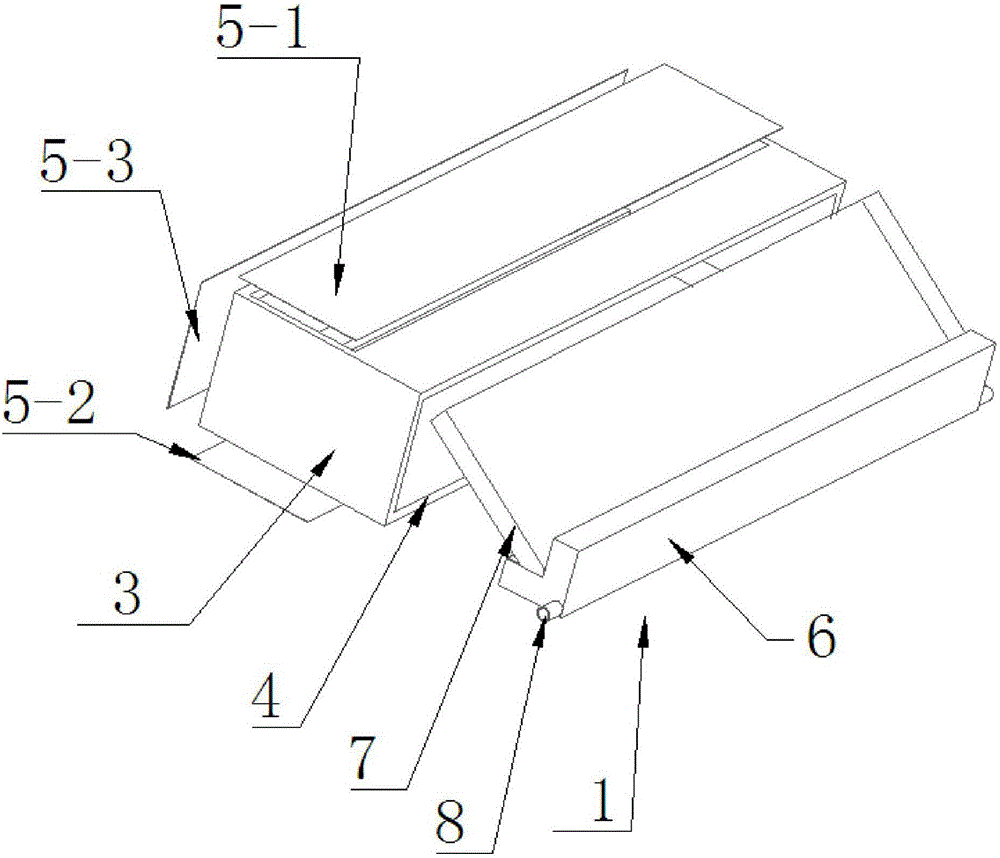

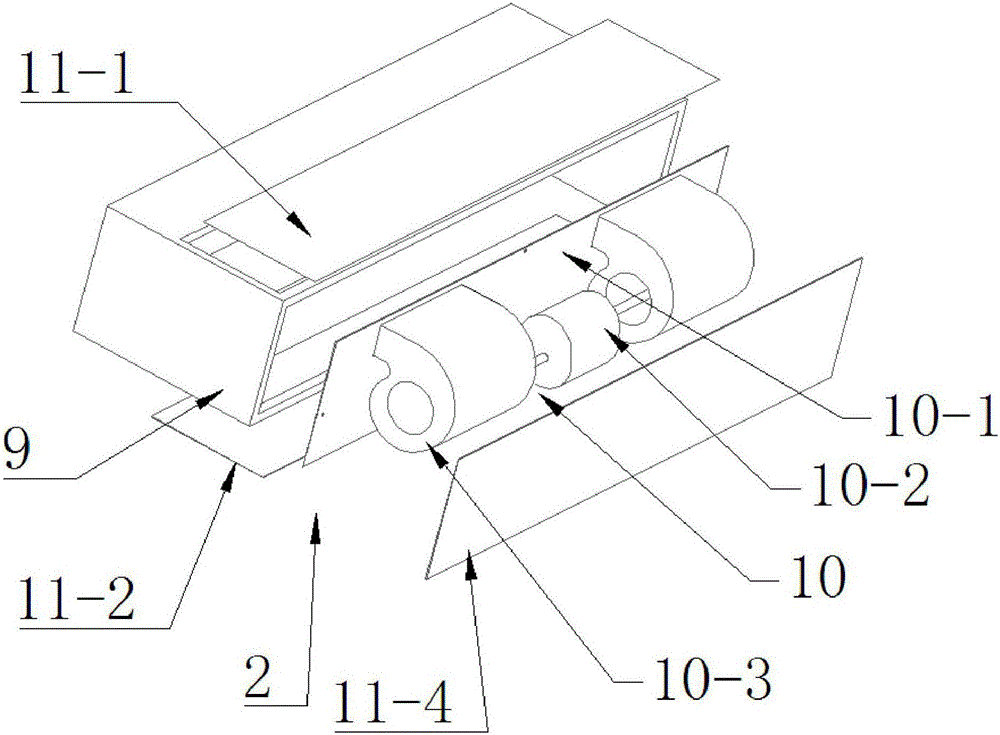

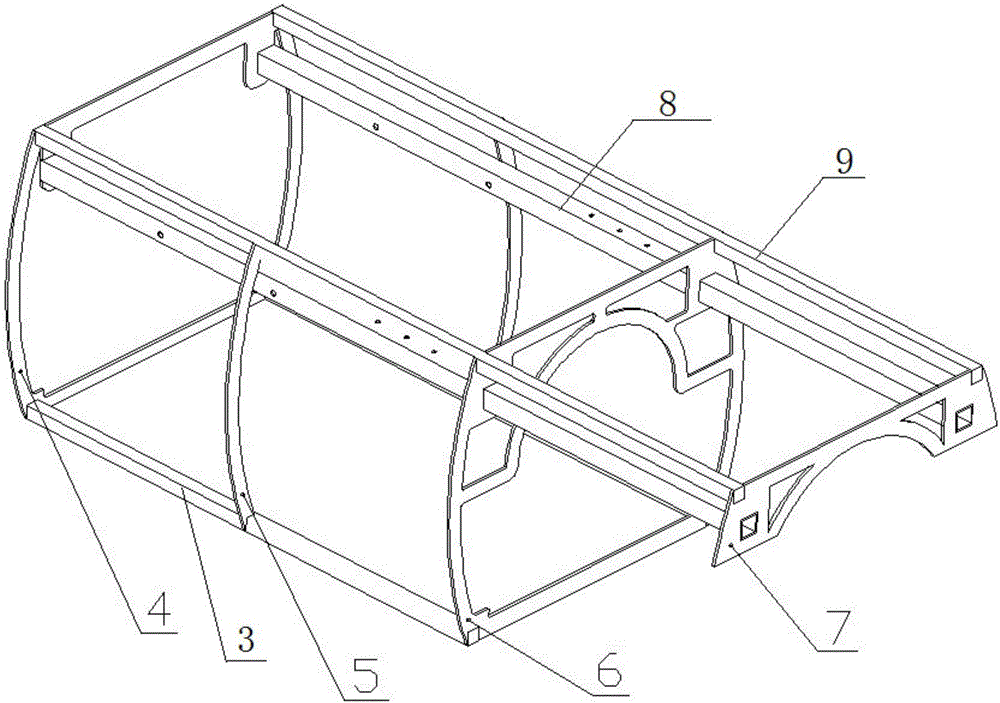

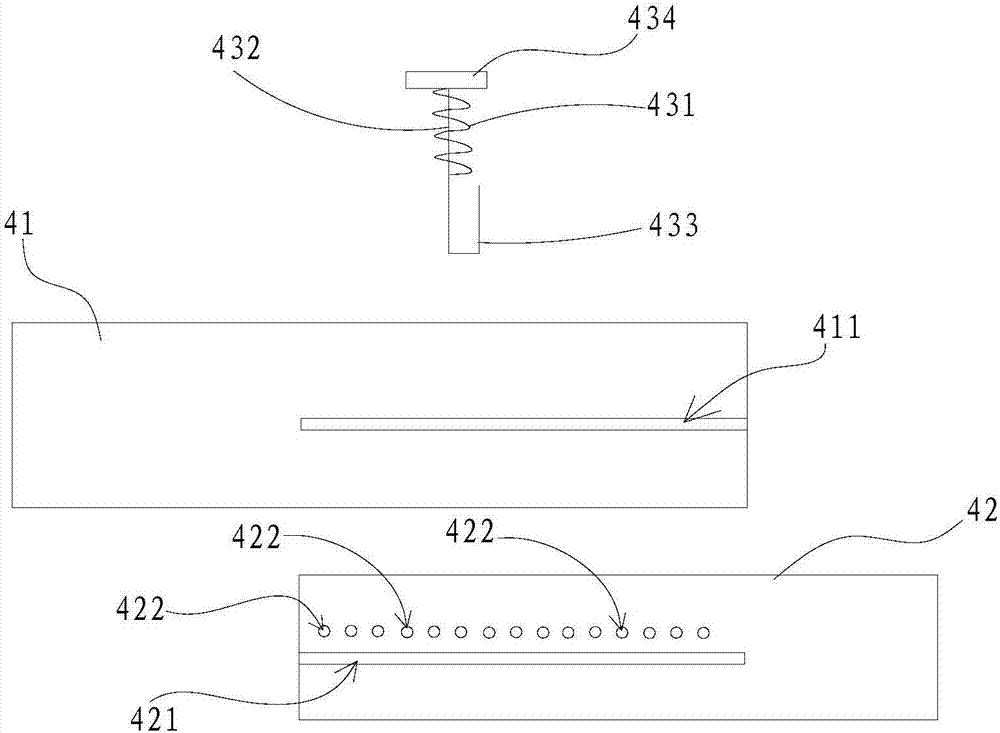

Modular wind tube machine and air conditioner

ActiveCN105020790AAdjust the direction of the windAdjust the direction of return airCondensate preventionLighting and heating apparatusEngineeringWater collection

The invention relates to a modular wind tube machine and an air conditioner. The modular wind tube machine comprises an air outlet module and an air returning module. The air outlet module comprises an air outlet box body; an opening is formed in one end face of the air outlet box body; air outlet box baffles are detachably installed on other end faces of the air outlet box body; a water receiving tray is arranged inside the air outlet box body; a heat exchanger is arranged above the water receiving tray; the water receiving tray is provided with a water collection tray drainage pipe enabling the water receiving tray and the outer side of the air outlet box body to be communicated. The air returning module comprises an air returning box body; a draught fan assembly is arranged on one end face of the air returning box body; air returning box baffles are detachably installed on other end faces; the draught fan assembly is arranged inside the air returning box body; the end face, with the opening, of the air outlet box body and the end face, with the draught fan assembly, of the air returning box body are detachably and fixedly connected. The air outlet box baffles and the air returning box baffles can be detached and mounted as needed, so that the installation modes of the whole device are switched according to the field mounting environments so as to adapt to different mounting environments.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

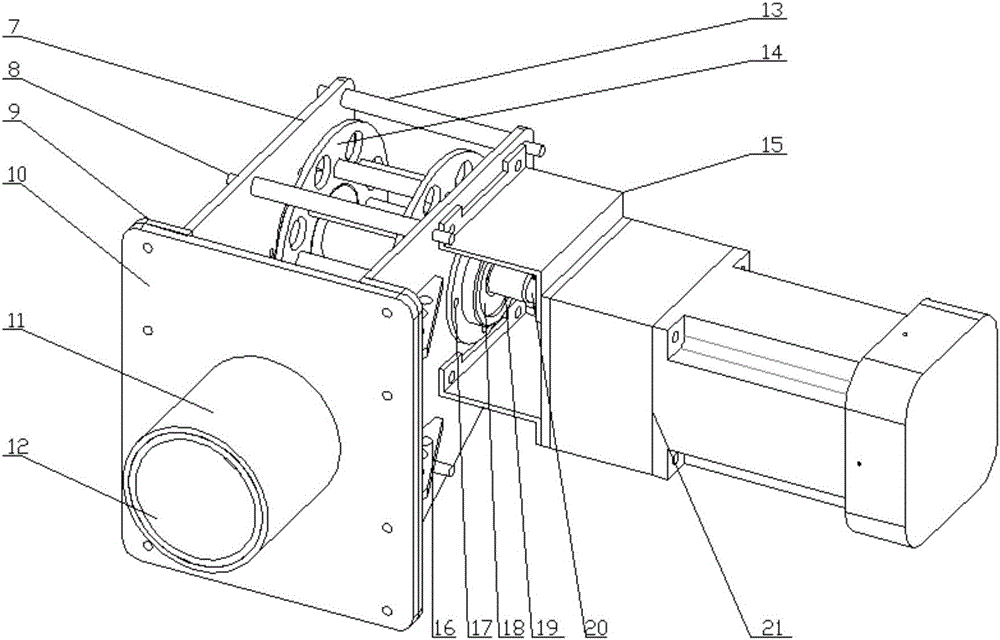

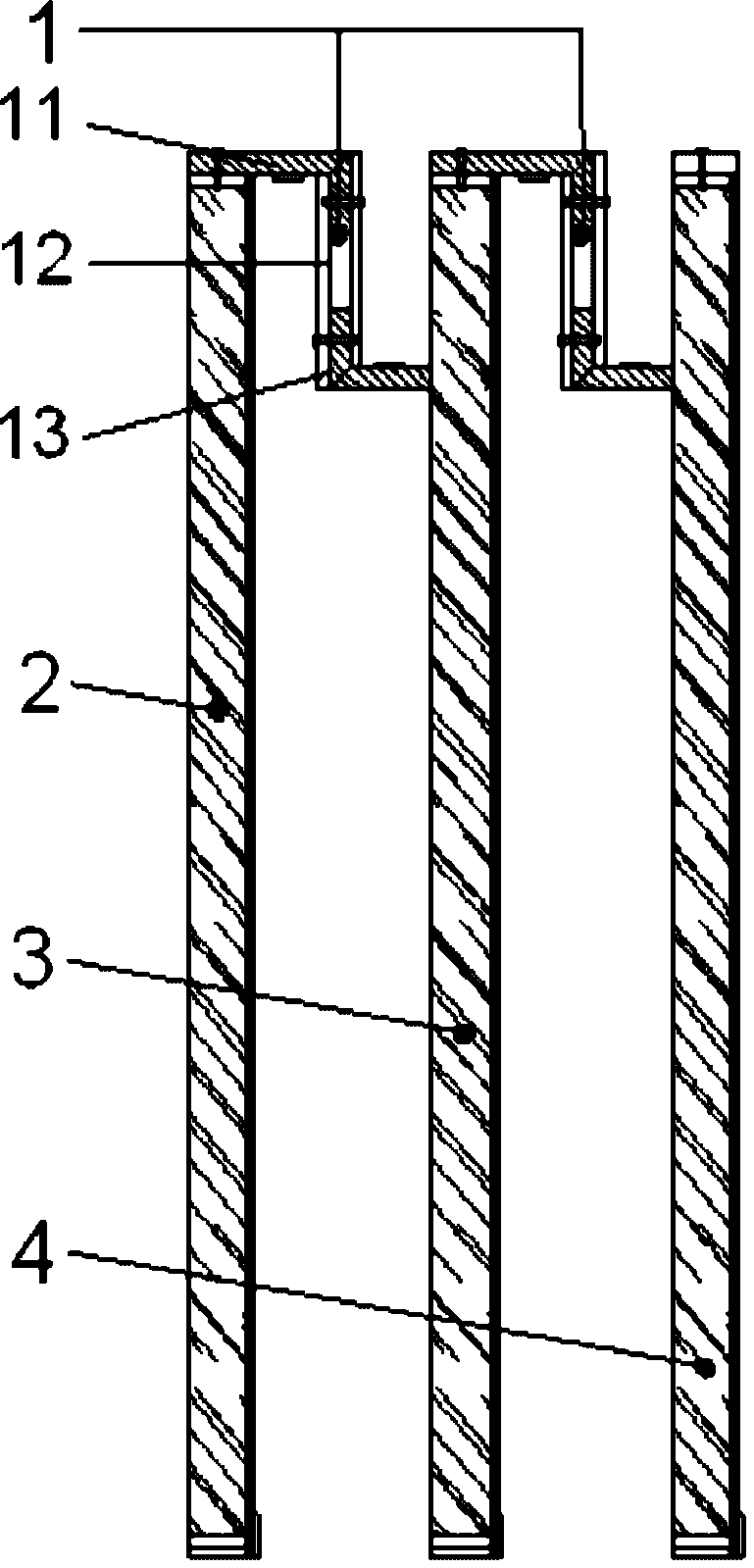

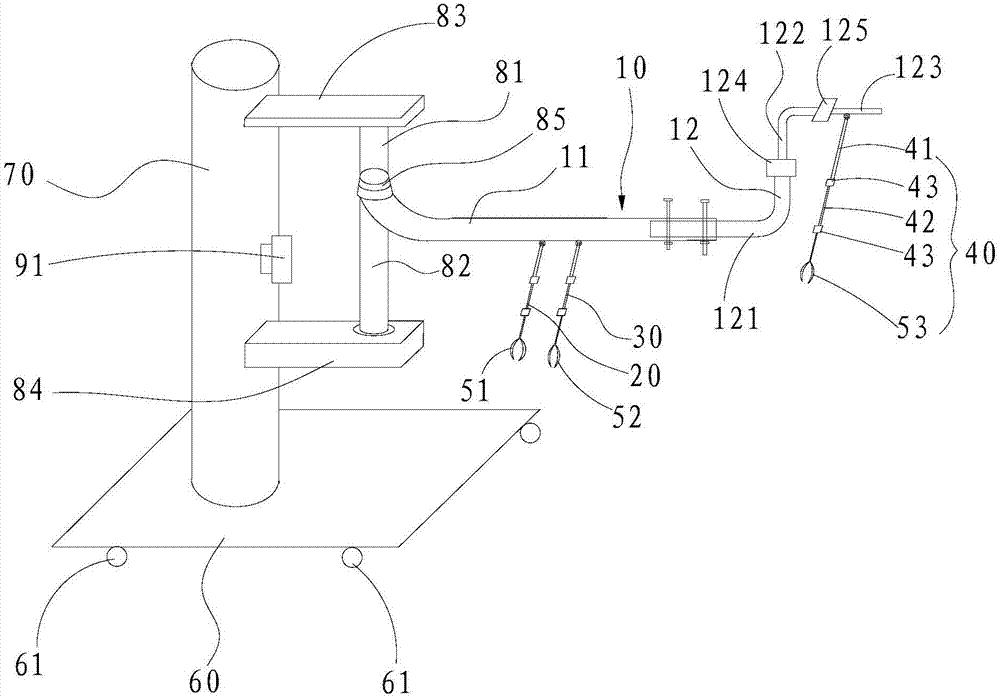

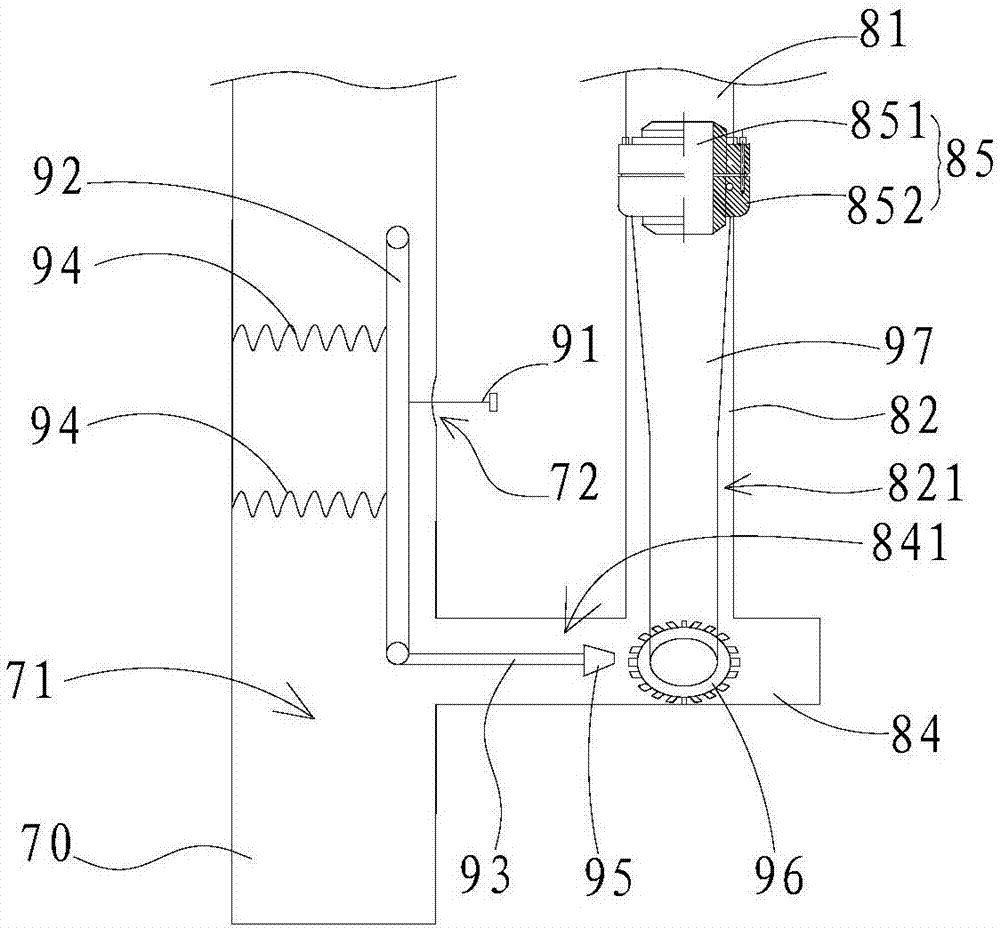

Portable pipeline interior washing device

ActiveCN106583361ALow working environment requirementsTotal light weightHollow article cleaningBristleEngineering

The invention discloses a portable pipeline interior washing device. The portable pipeline interior washing device comprises a first power working device, a second power working device, a brush head used for pipe interior washing and two sections of steel wire ropes connected with the two sides of the brush head, wherein the first power working device and the second power working device are arranged at the two ends of a pipeline; one ends of the two sections of steel wire ropes are connected to the first power working device and the second power working device, and the other ends of the two sections of steel wire ropes are connected with the two ends of the brush head; the structure of the first power working device and the structure of the second power working device are the same, the steel wire ropes are wound through a gear motor, the brush head is pulled to do back-and-forth motion in the pipeline, and therefore the pipeline washing work is done; and the installation positions of a brush bristle barrel and a brush bristle body are changed so that pipelines with different diameters can be washed. The portable pipeline interior washing device is simple in structure, easy to disassemble and maintain and low in environmental requirement; the brush head is adopted for washing, damage to a pipeline inner bore is avoided, and meanwhile washing of the pipelines with different diameters can be completed.

Owner:NANJING UNIV OF SCI & TECH

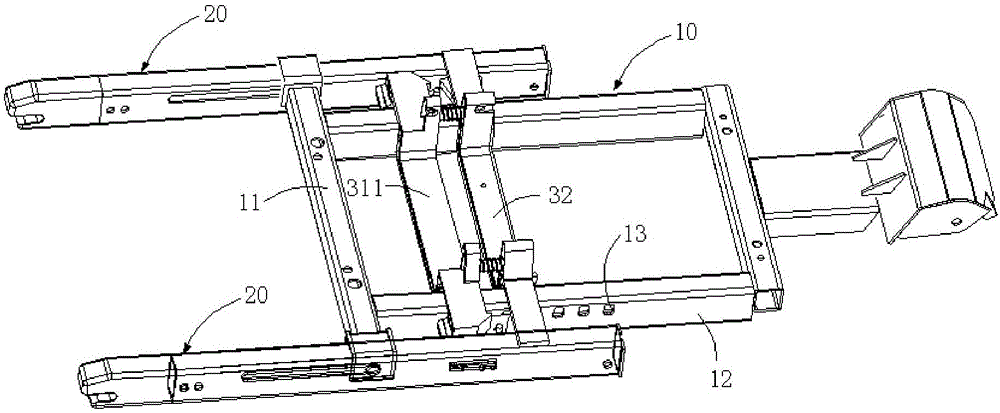

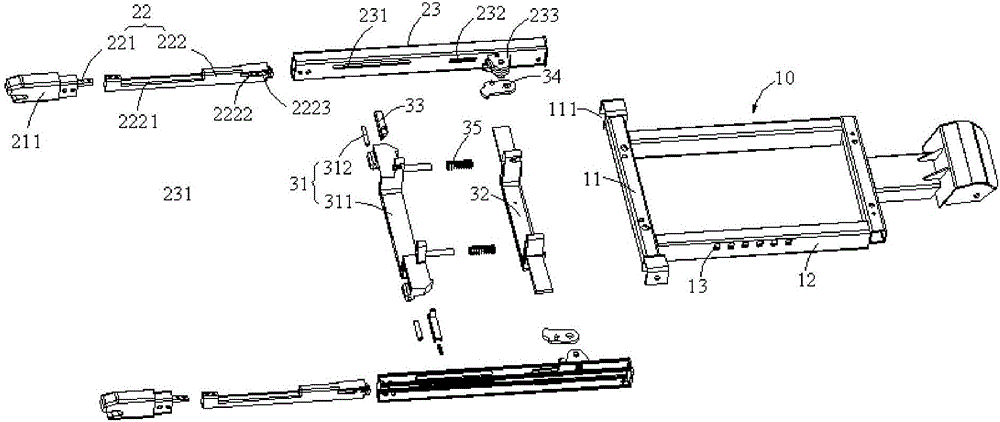

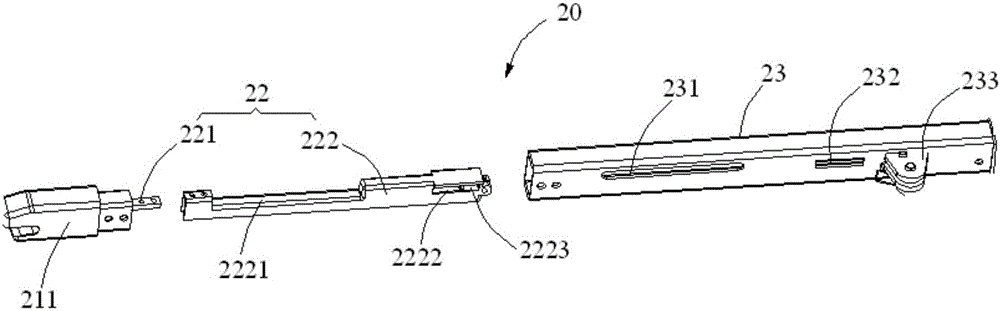

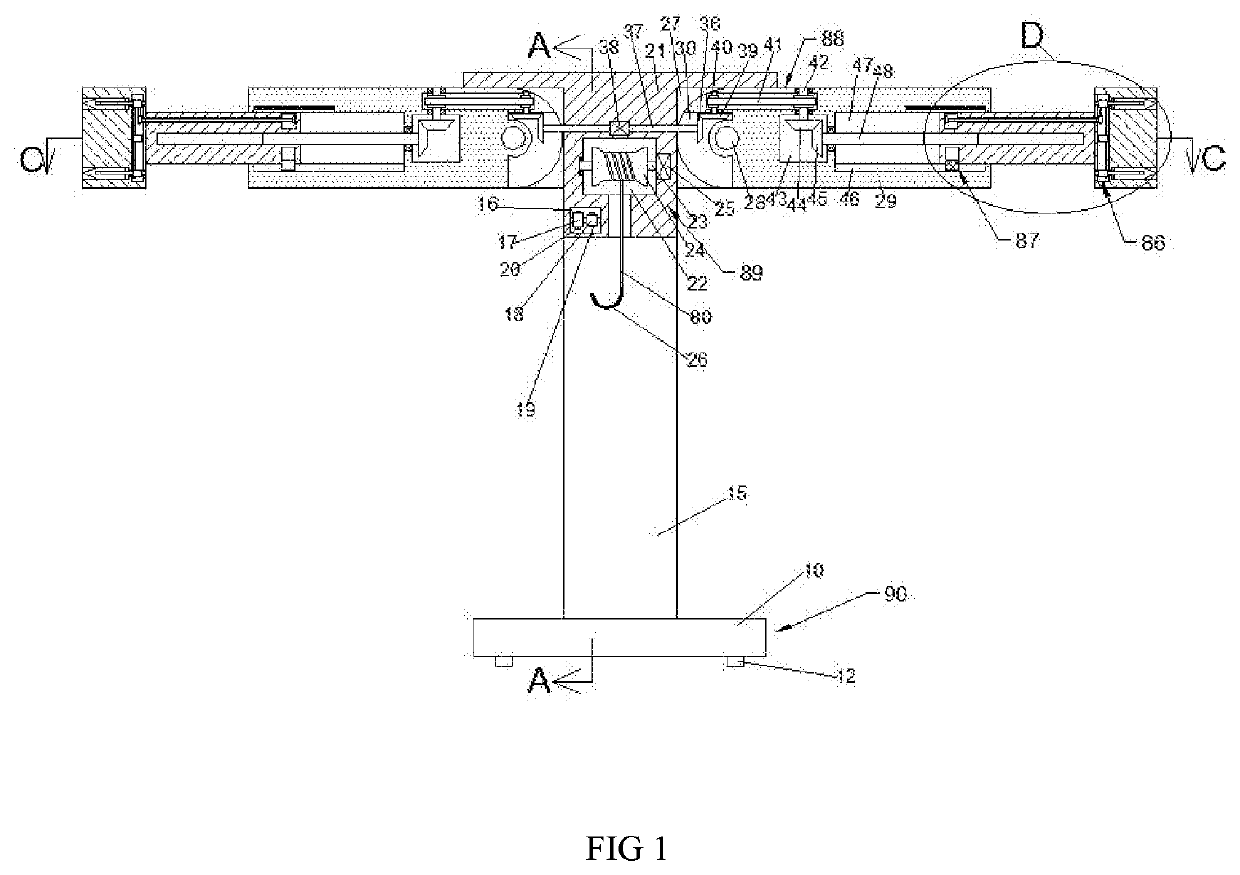

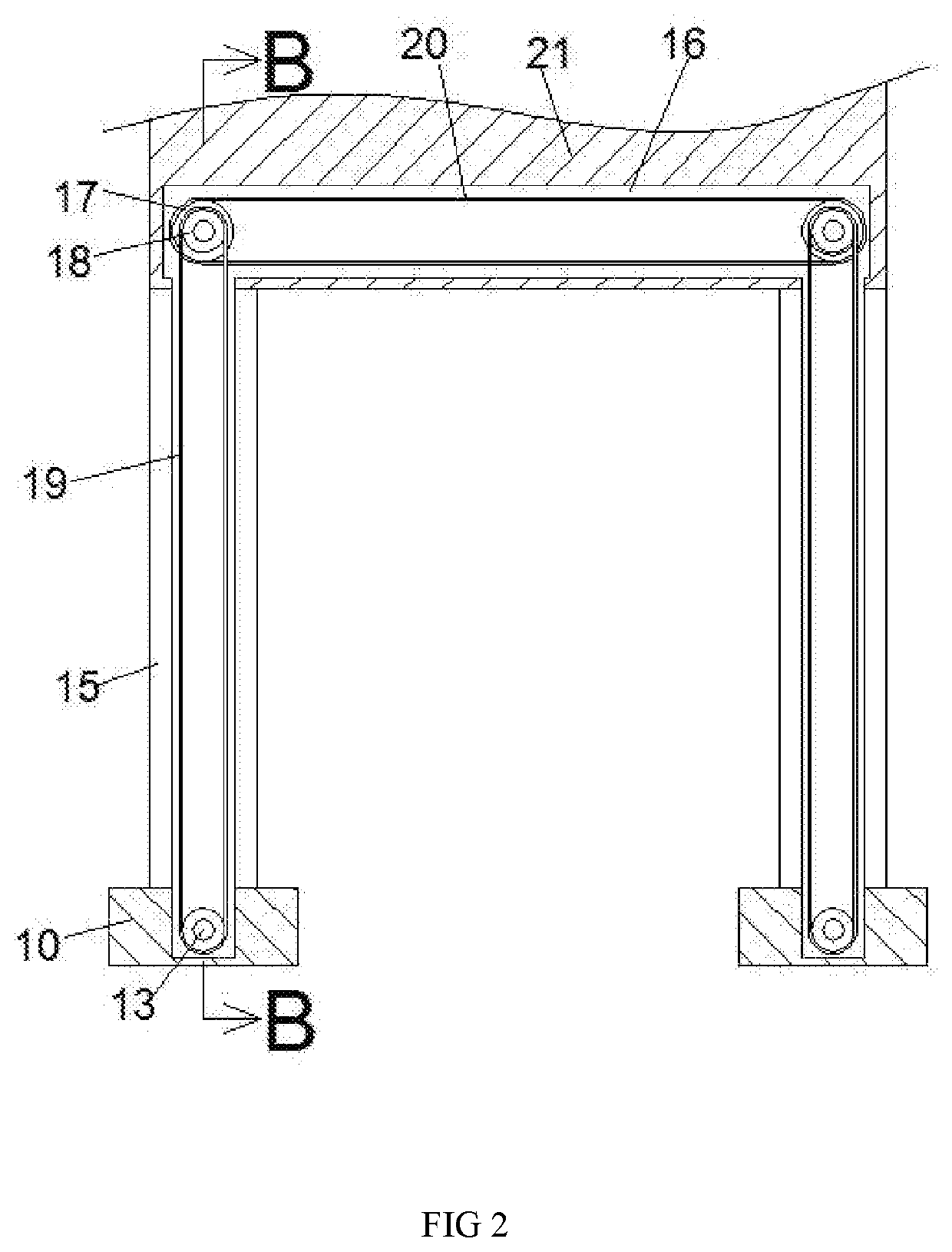

Tooling vehicle for assembly of passenger vehicle rear axle

The invention discloses a tooling vehicle for assembly of a passenger vehicle rear axle, comprising an underframe, a bearing platform and an adjusting platform; the moving underframe and the bearing platform are connected through a lifting mechanism; the lifting mechanism includes a first link, a second link and a hydraulic cylinder; a support seat is fixed on the adjusting platform. By using the moving underframe to horizontally move tooling, it is convenient to move the passenger vehicle rear axle; the height of the passenger vehicle rear axle is adjusted by using the lifting mechanism; it is convenient to adjust the height during installation, and positional adjustment is improved for installation and fixation; the adjusting platform is used to adjust tilting angle of the passenger vehicle rear axle, the installation position of the passenger vehicle rear axle is precisely adjusted, and installation can be achieved with a passenger vehicle body being in unsmooth position.

Owner:ANHUI ANKAI AUTOMOBILE

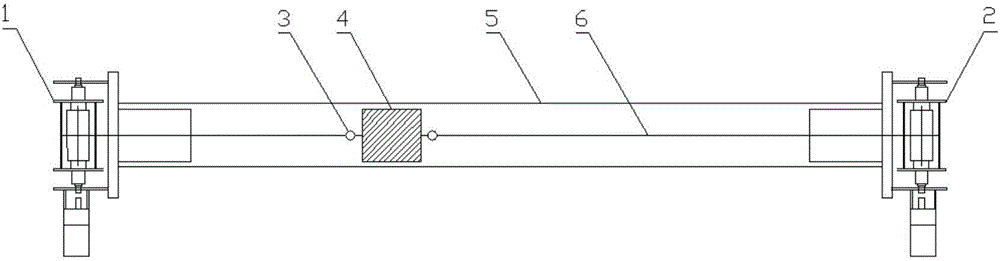

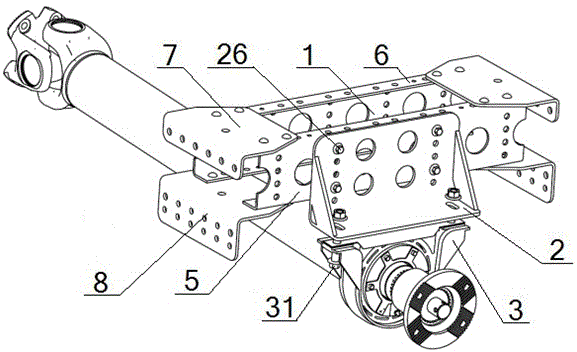

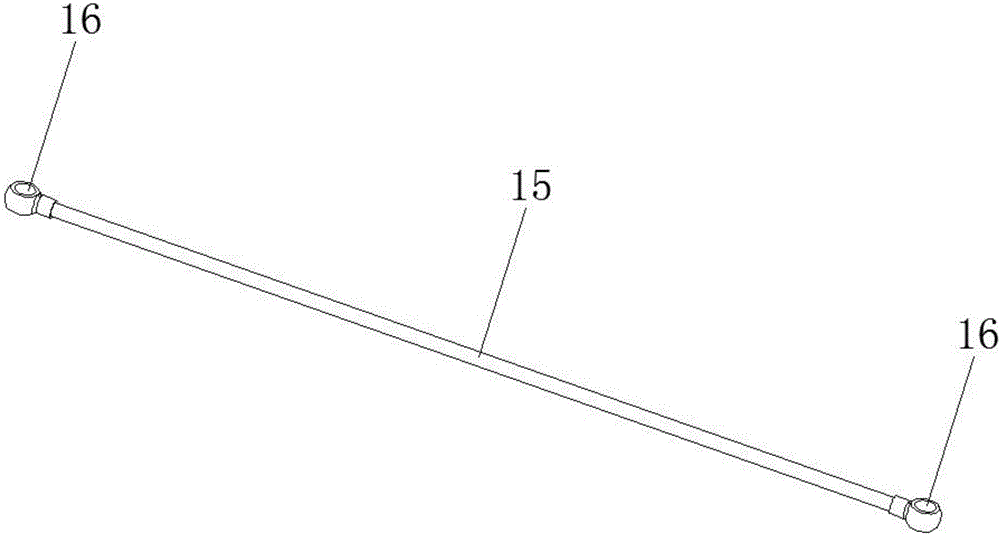

Transmission shaft intermediate support connecting structure capable of adjusting mounting position

InactiveCN103978895AReduced versatilityHigh design versatilityControl devicesVehicle frameSlant angle

The invention discloses a transmission shaft intermediate support connecting structure capable of adjusting a mounting position. The transmission shaft intermediate support connecting structure comprises a beam assembly and a transmission shaft intermediate support assembly fixedly connected with the middle part of the beam assembly, wherein both ends of the beam assembly are respectively and fixedly connected with two longitudinal members; the transmission shaft intermediate support connecting structure also comprises a connecting yoke; the top part of the transmission shaft intermediate support assembly is fixedly connected with the middle part of the beam assembly through the connecting yoke. According to the design, the mounting height of the transmission shaft intermediate support assembly can be adjusted by adjusting the mounting position of the connecting yoke; for the mounting angle problem of the transmission shaft intermediate support assembly, only adaptive connecting yokes need to be designed according to different transmission shaft slant angles, and the production design cost is lower. The transmission shaft intermediate support connecting structure not only is good in universality but also is firm in structure and lower in production design cost.

Owner:DONGFENG COMML VEHICLE CO LTD

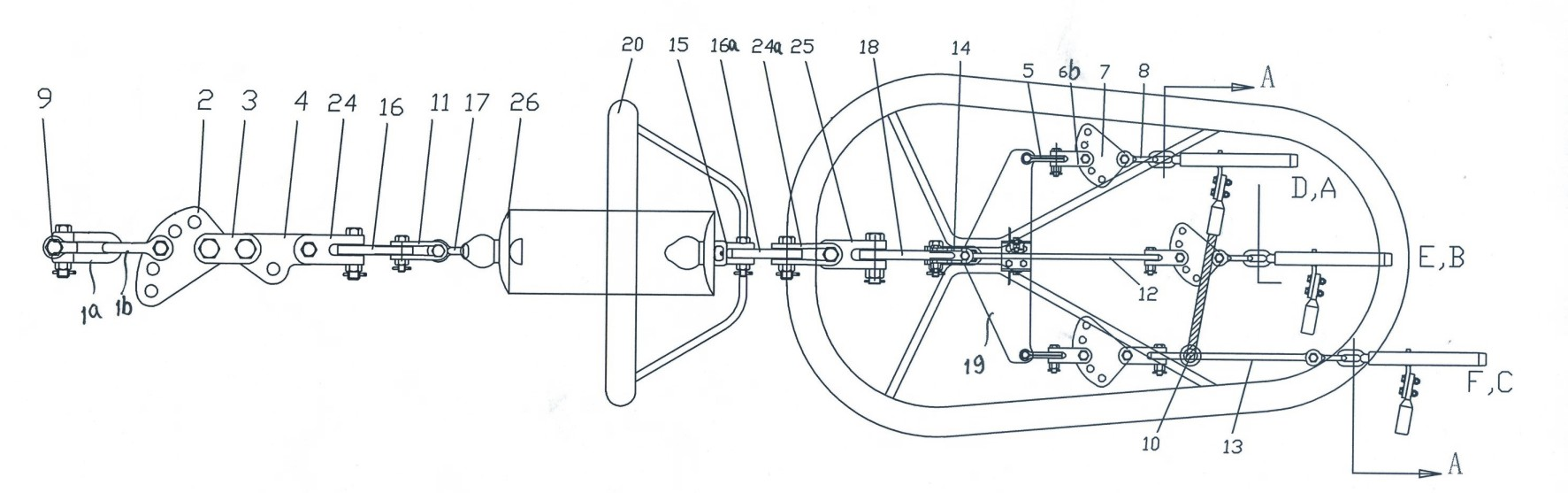

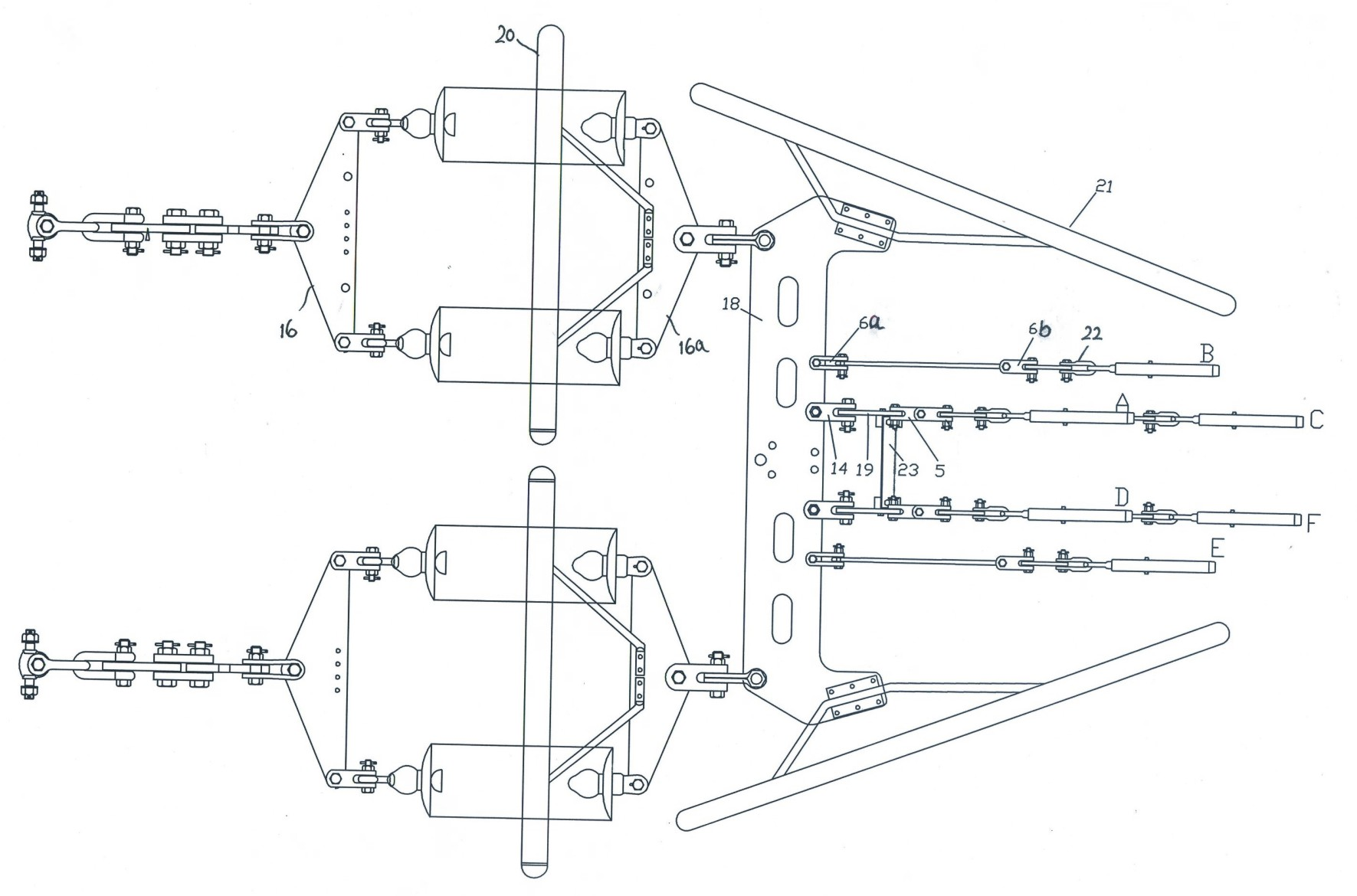

Four-link tension string for +/-800KV heavy ice area

The invention provides a four-link tension string for a + / -800KV heavy ice area, belonging to fitting strings for construction of transmission lines. The four-link tension string comprises two hanging point fittings connected with a tower, wherein after being connected with the same fitting, each hanging point fitting is connected at the left end of a first yoke plate by a bolt; the right end of the first yoke plate is connected with two insulators by a ball head hanging ring; two of the four insulators are connected on a second yoke plate and the other two insulators are connected on the other second yoke plate; the two second yoke plates are respectively connected with a combined yoke plate by a right-angle hung plate; an equalizing ring is arranged on two insulators; the equalizing ring is in open type or two-leg split type; the combined yoke plate is formed by connecting a two-variable four-link plate, two right-angle hung plates and two one-variable two-link plates by bolts; and two shielding rings are fixed at the upper and lower ends of the two-variable four-link plate by brackets. The four-link tension string has the characteristics of convenience for installation of the equalizing ring, stable structure and high strength.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP +2

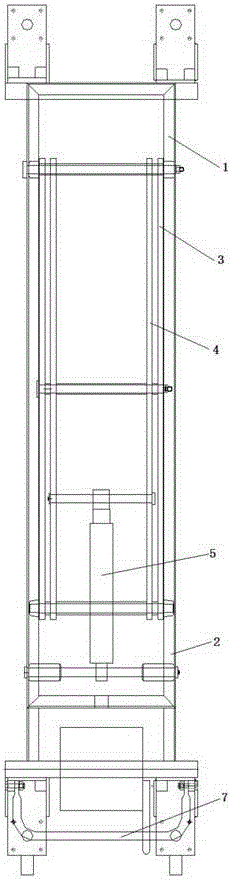

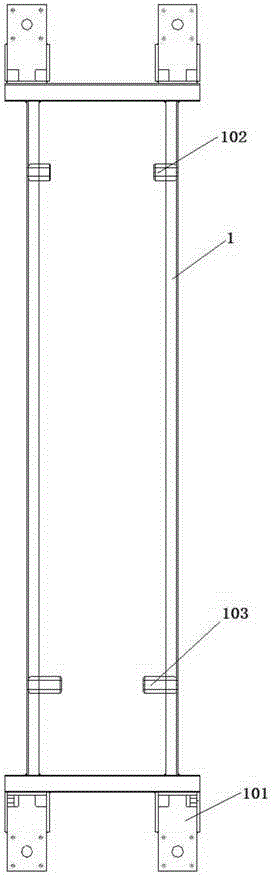

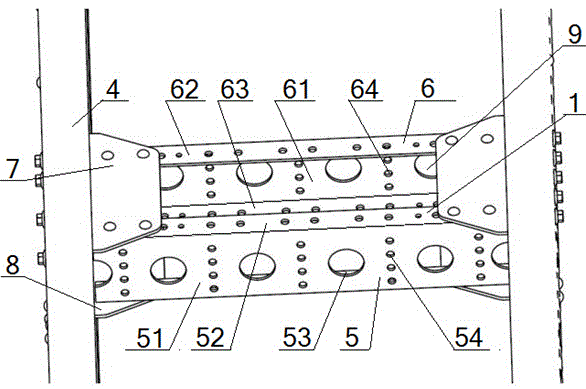

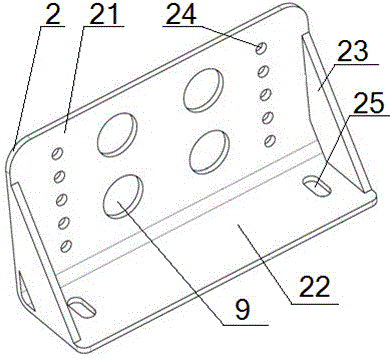

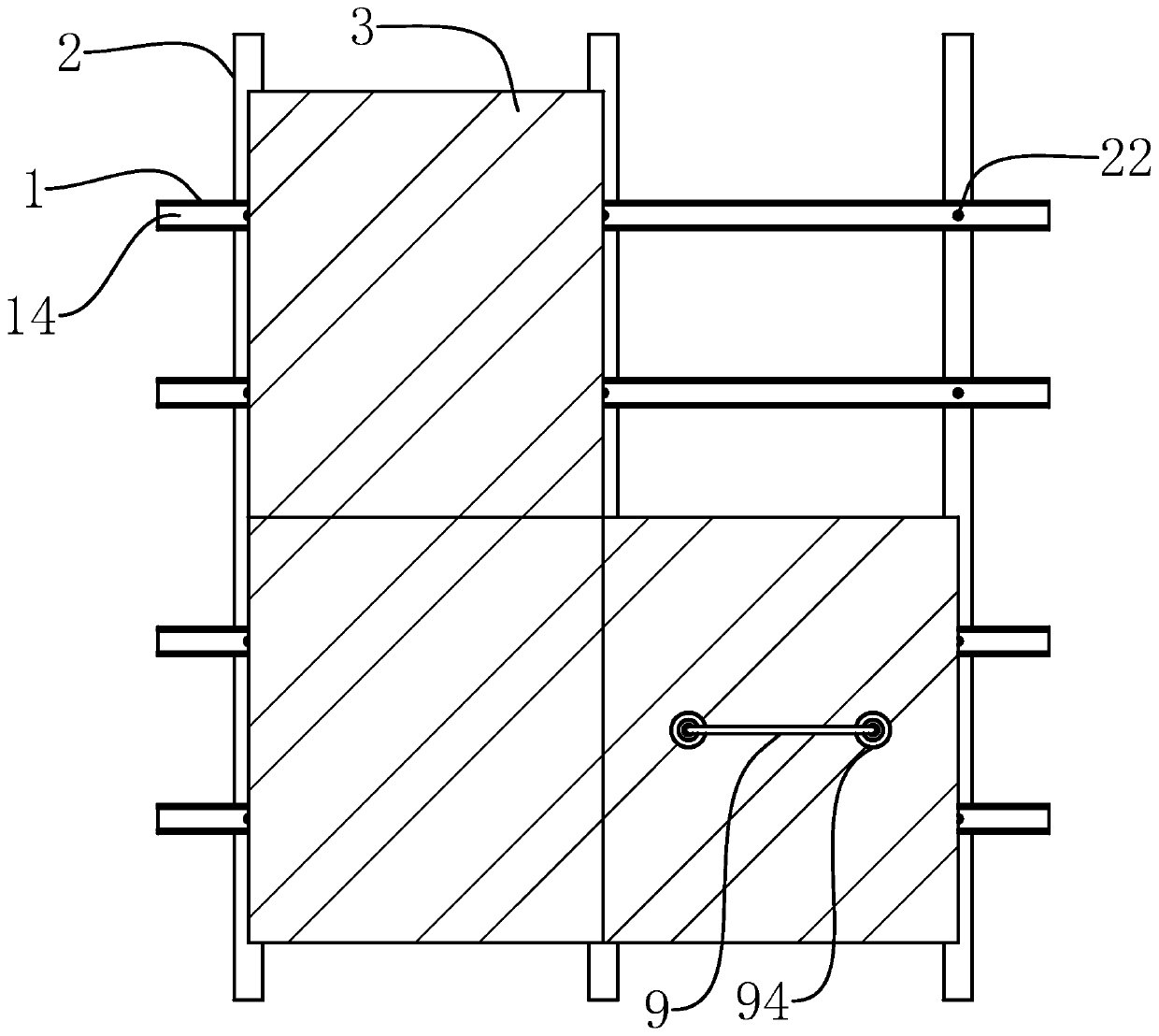

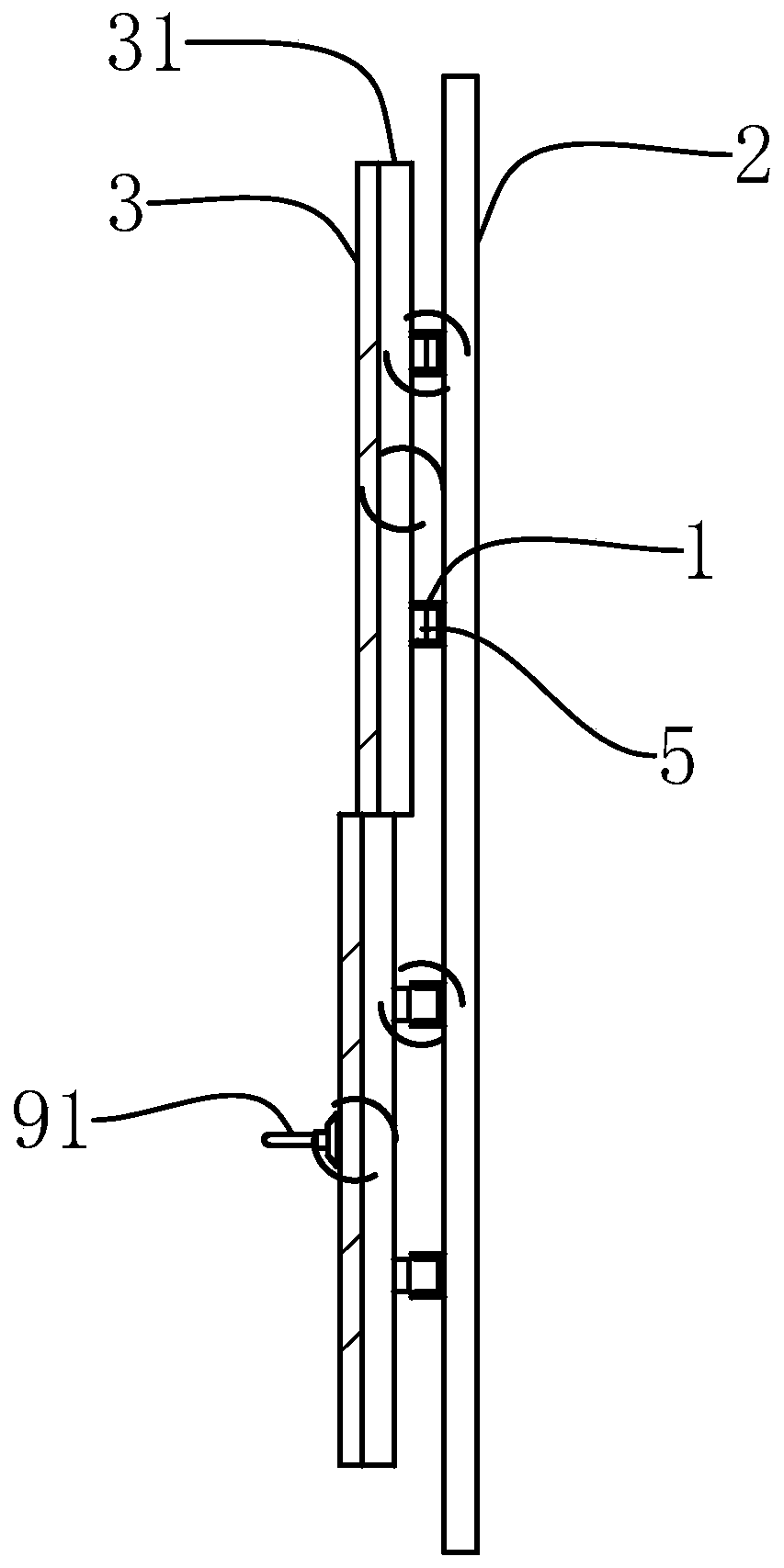

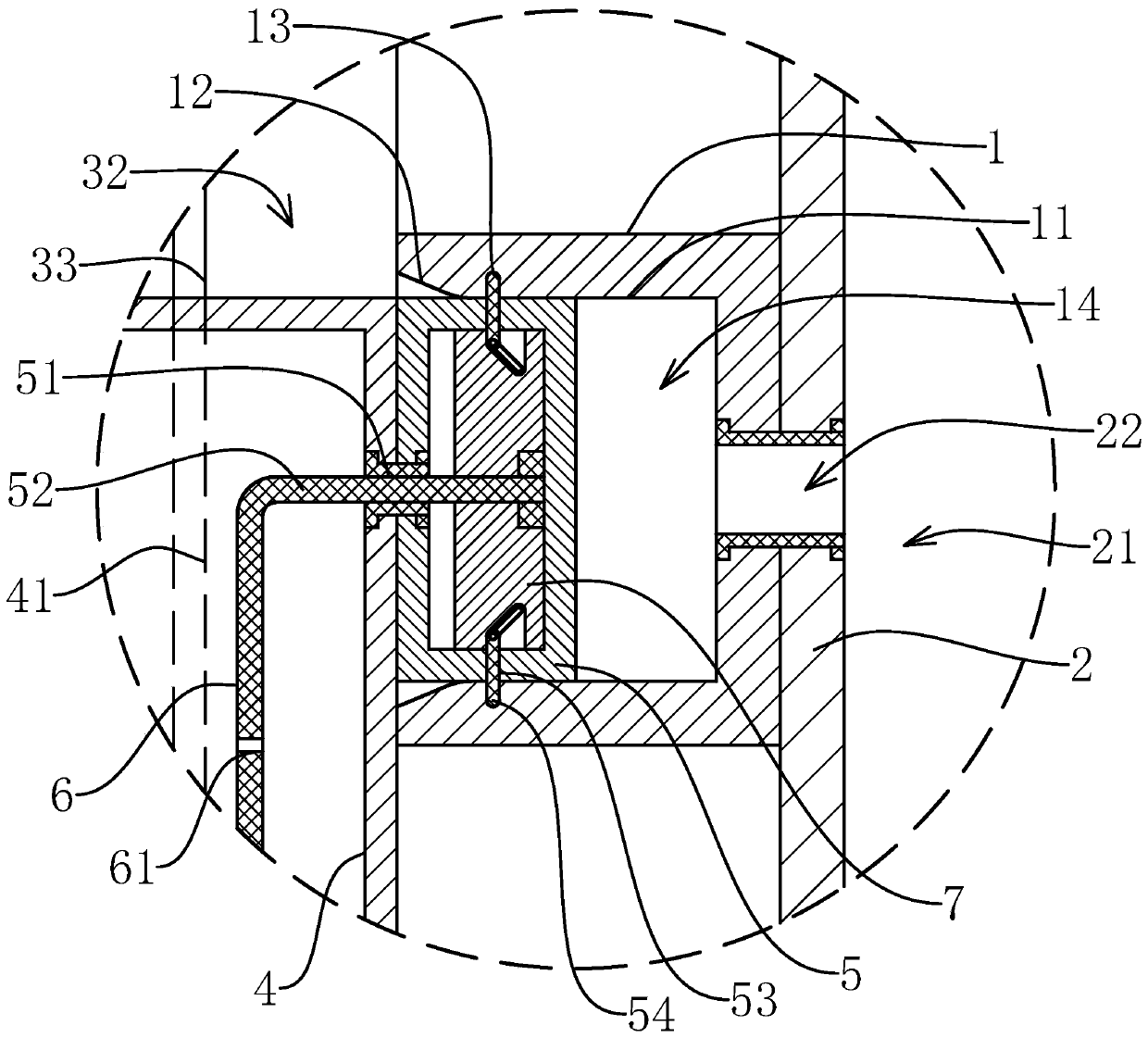

Unit curtain wall structure, constructing tool and constructing method

The invention provides a unit curtain wall structure, a constructing tool and a constructing method, and belongs to the field of curtain walls. The problems that an existing curtain wall cannot form atrue fully-concealed frame structure, the installing positions of face plates cannot be adjusted, and construction is troublesome are solved. The unit curtain wall structure comprises keels and faceplates. Transverse slide rails are arranged on the keels. Connecting mechanisms are installed on the face plates. Each connecting mechanism comprises two vertical slide rails fixed to the back face ofthe corresponding face plate. Vertical slide grooves are formed in the vertical slide rails. Each connecting mechanism further comprises a sliding connector and a locking connector. Each sliding connector comprises two vertical slide strips of a box iron structure and two transverse slide strips of a hollow rectangular pipe structure, wherein the two vertical slide strips are located in the two vertical slide grooves in a sliding fit mode, and the two transverse slide strips are fixed to the rear sides of the two vertical slide strips. Each locking connector comprises four connecting rods, two vertical straight-rod-shaped locking rods and two transverse strip-shaped platy locking plates. The curtain wall can form the fully-concealed frame structure, the installing positions of the face plates can be freely adjusted, and construction is convenient.

Owner:中晋华泰建设有限公司

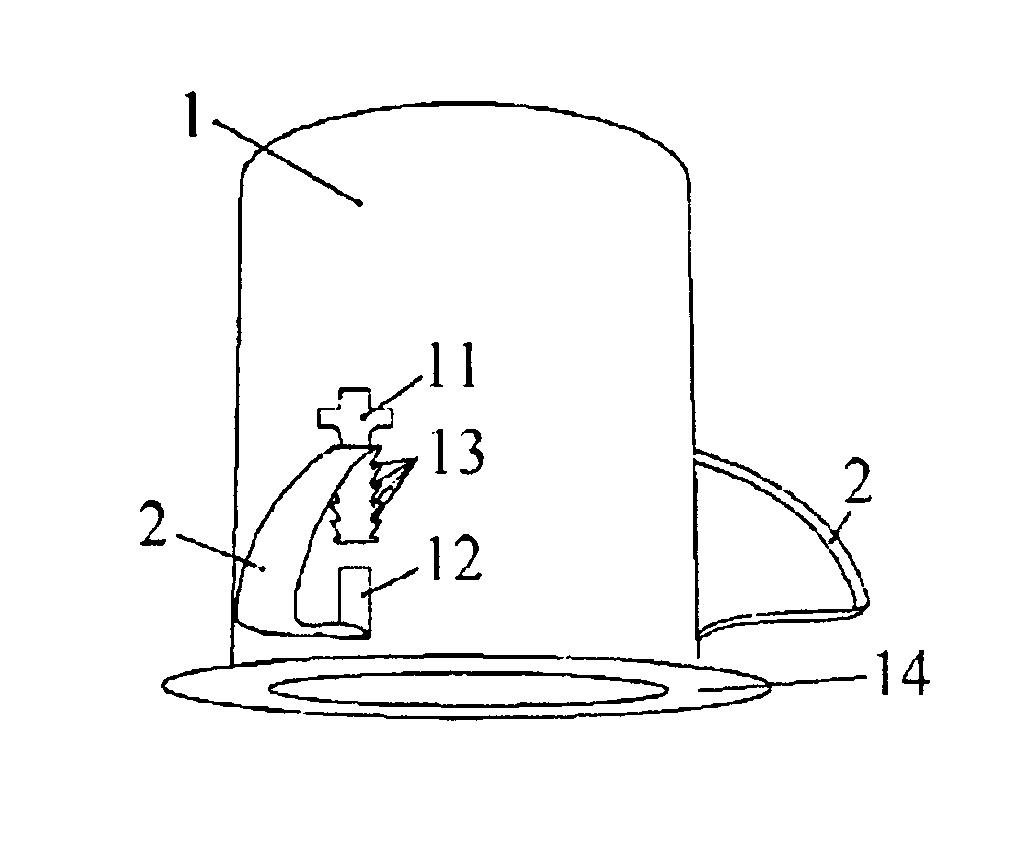

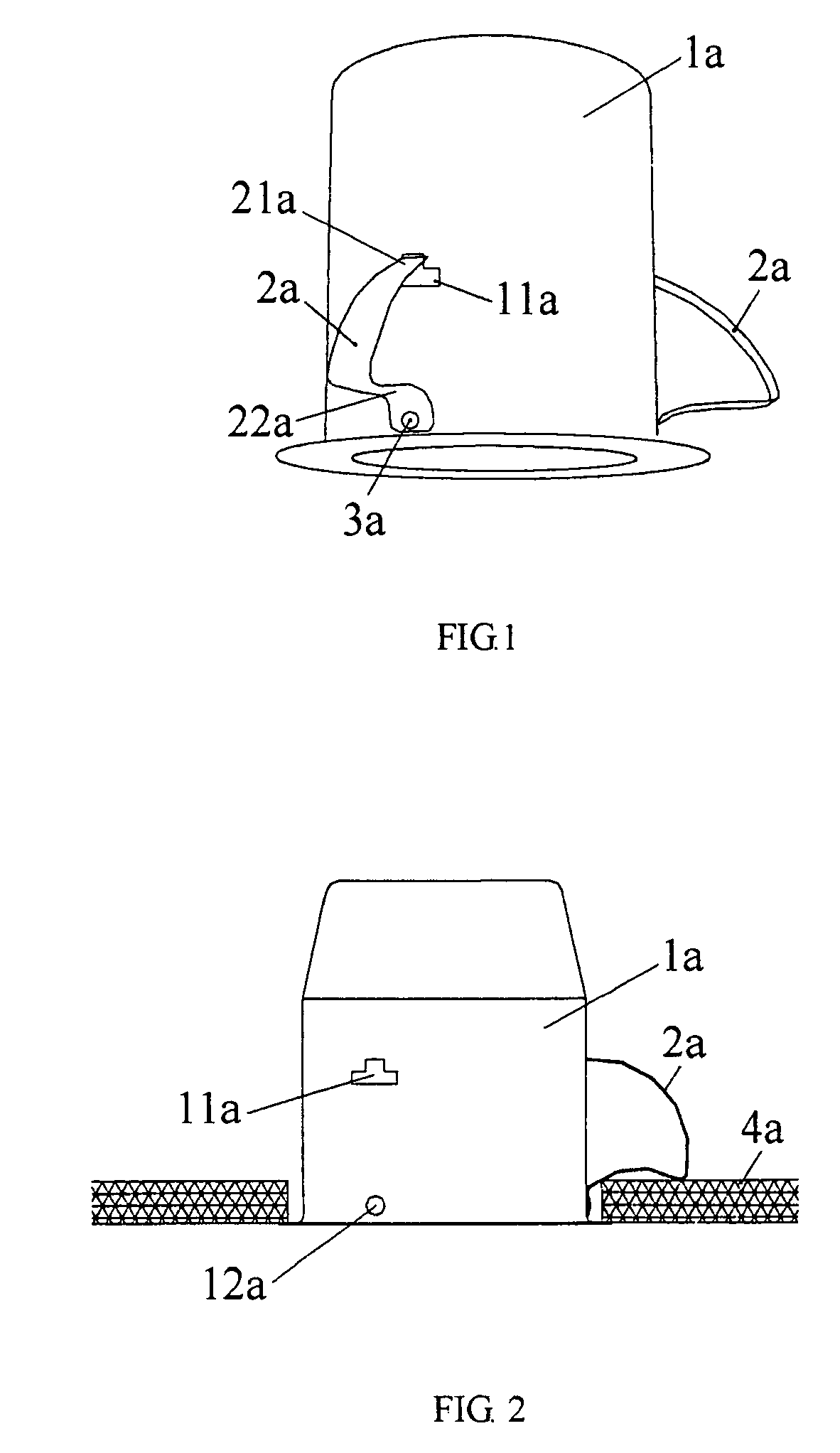

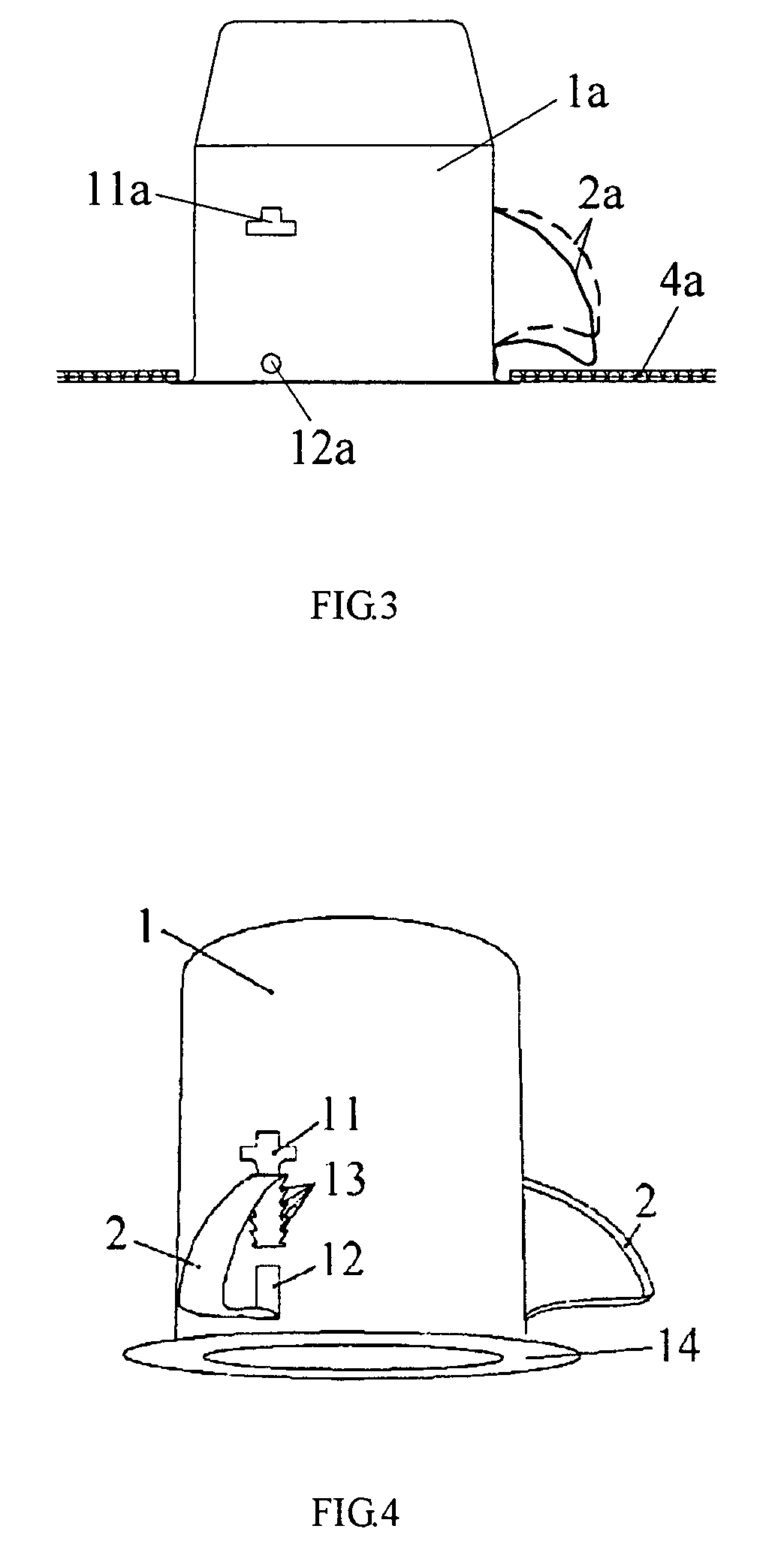

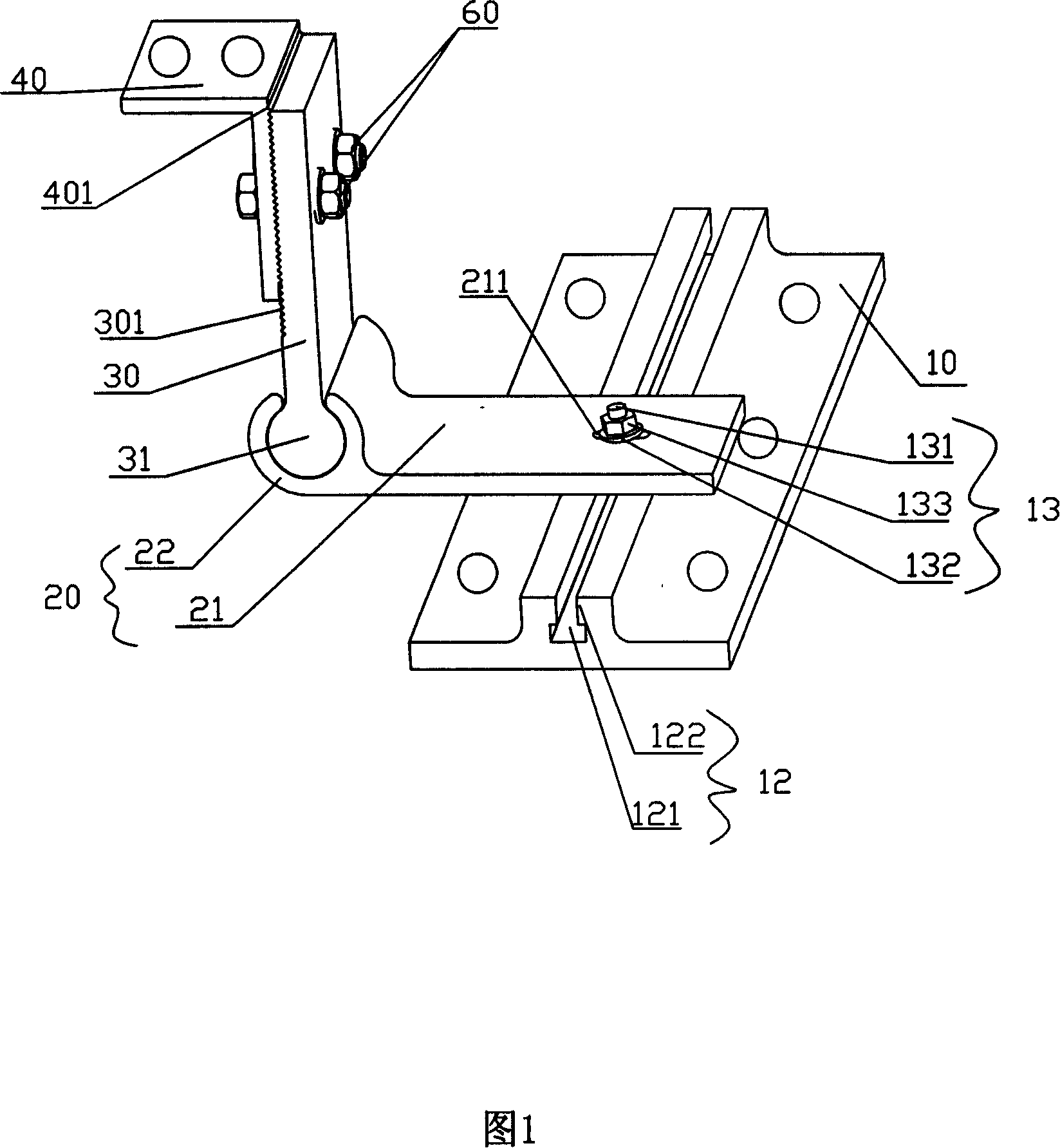

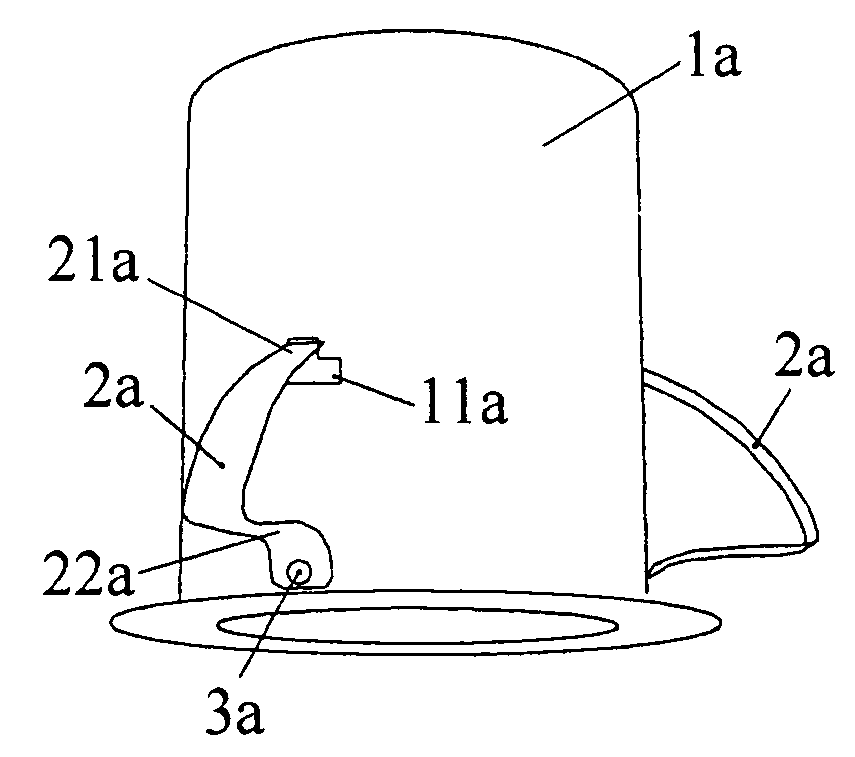

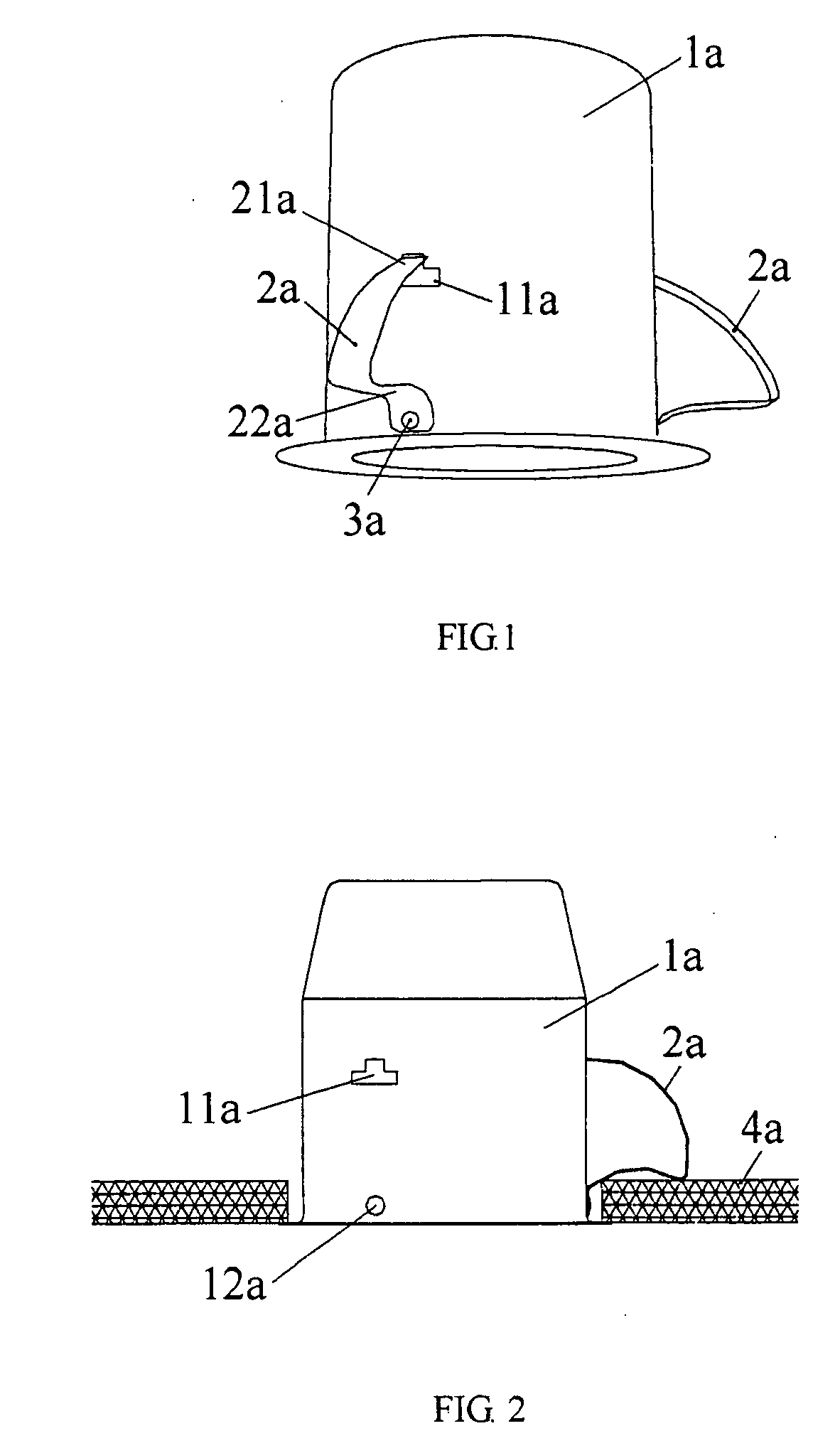

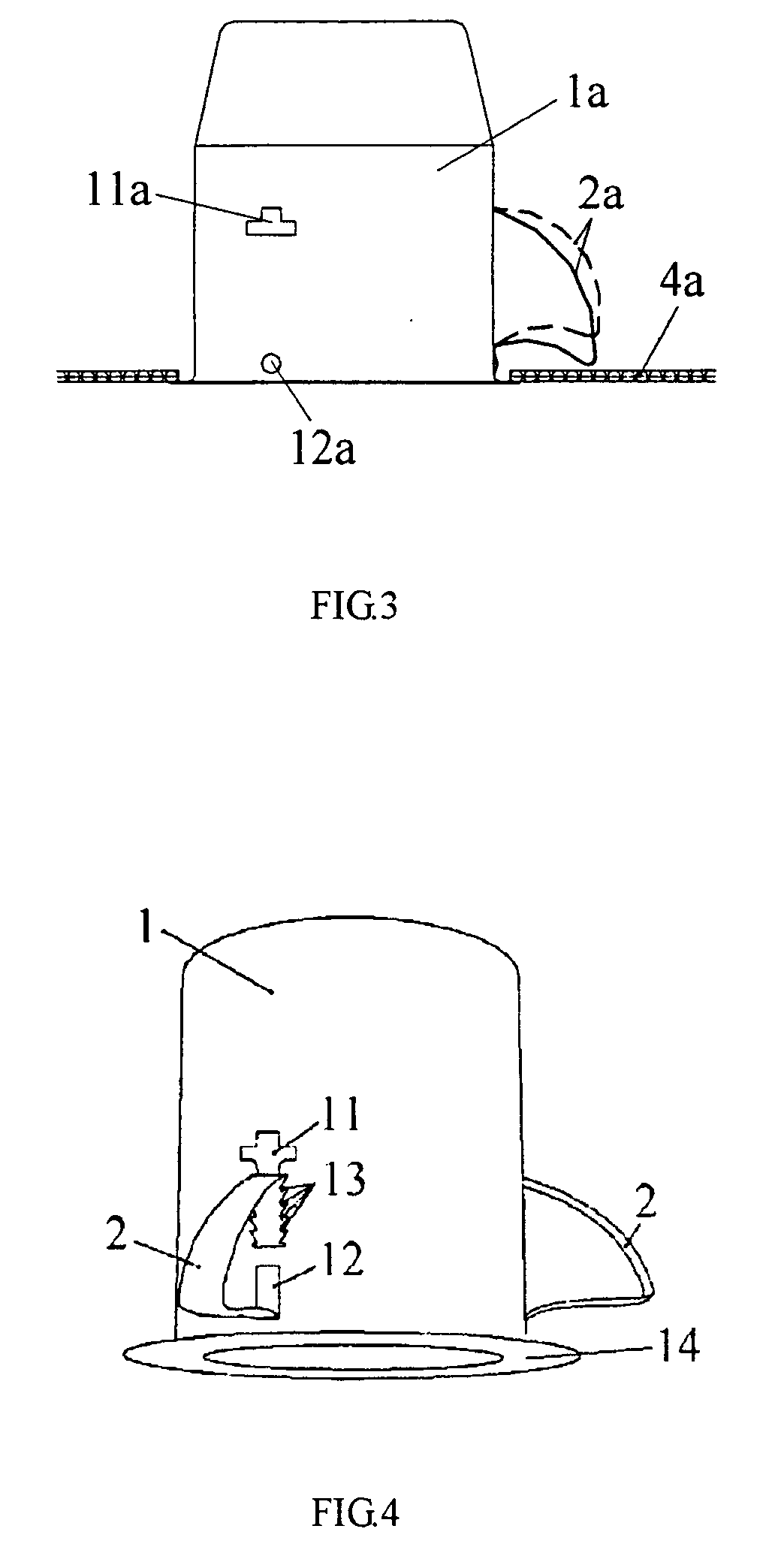

Adjustable-installed recessed lighting

InactiveUS7513658B2Improve installabilityAdjustable installation positionLighting support devicesVehicle interior lightingEffect lightMechanical engineering

Owner:SHEN TIANLIN

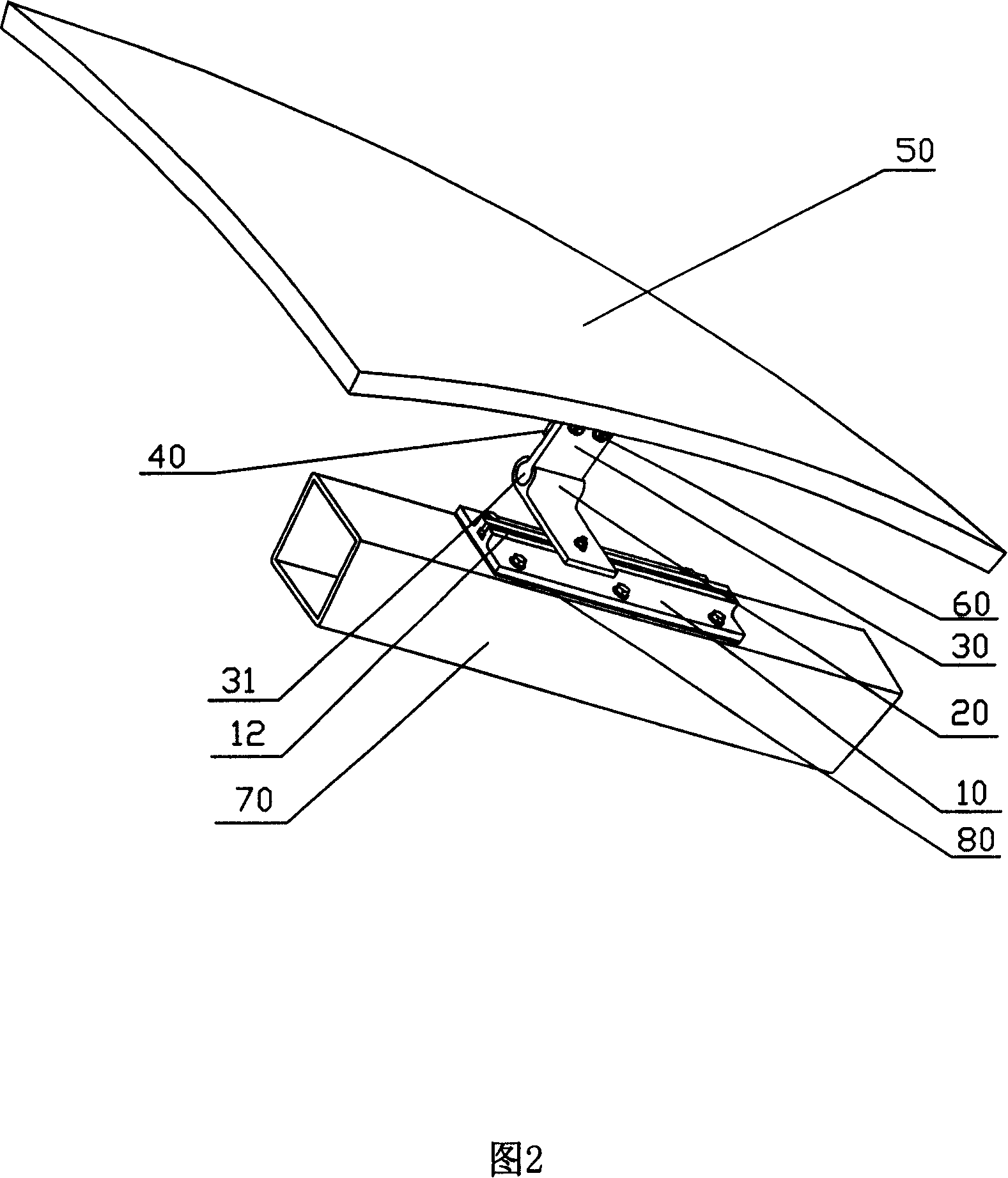

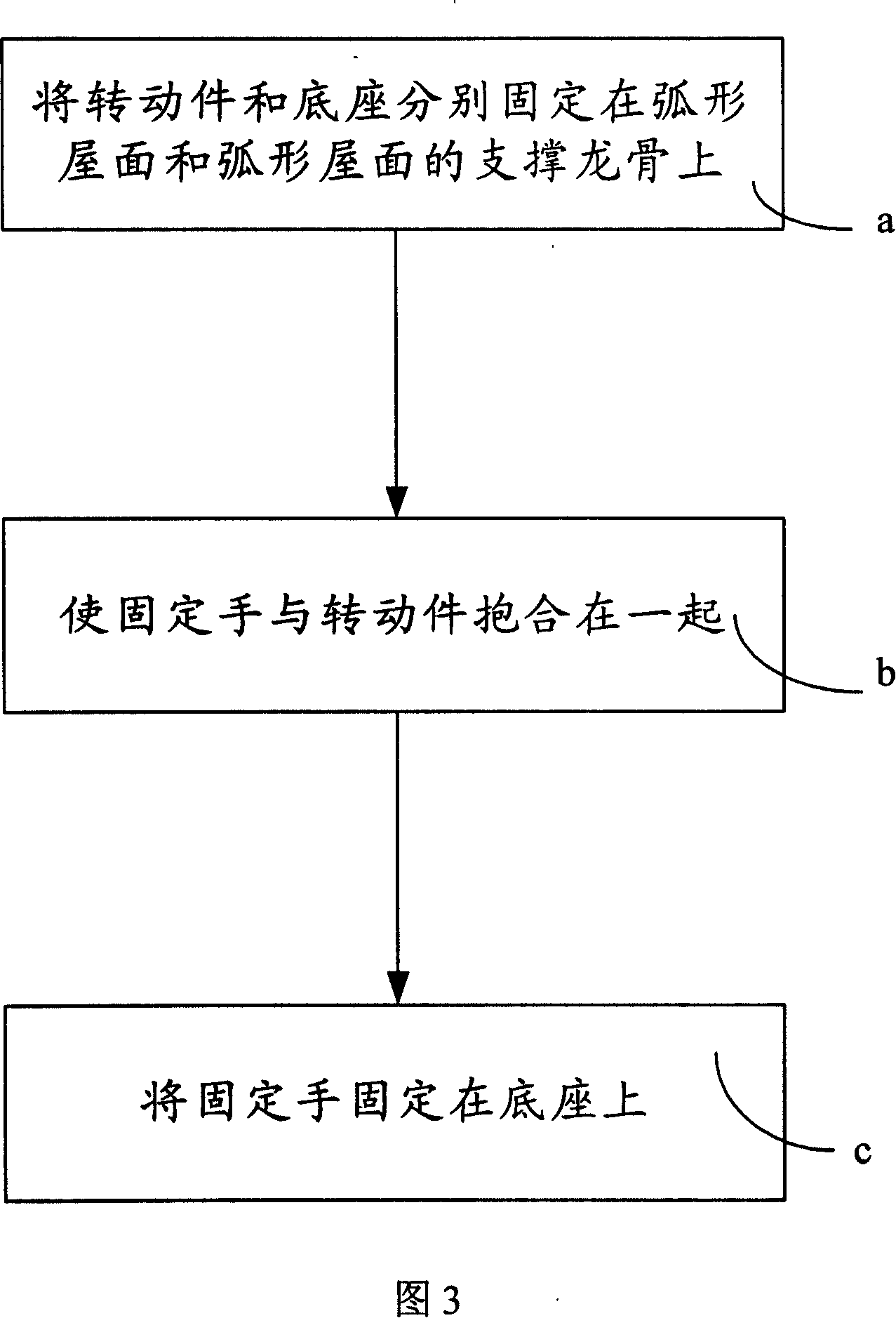

Arcuated roof connecting mechanism and installation method thereof

InactiveCN101153512AAdjustable installation positionBuilding roofsRoof covering using slabs/sheetsEngineeringMechanical engineering

The invention discloses an arc-shaped roof covering connecting device which comprises a base, a fixing hand connected with the base, and a rotary piece having one end embracing with the fixing hand, wherein, the rotary piece can rotate in the fixing hand. The arc-shaped roof covering connecting device is characterized in that: one end of the rotary piece embraces with the fixing hand, and the rotary piece can rotate in the fixing hand. In this way, the arc-shaped roof covering connecting device achieves the effect of adjusting the assembly angle of the arc-shaped roof covering. The invention also discloses the assembling method of the arc-shaped roof covering connecting device.

Owner:晶力技术有限公司

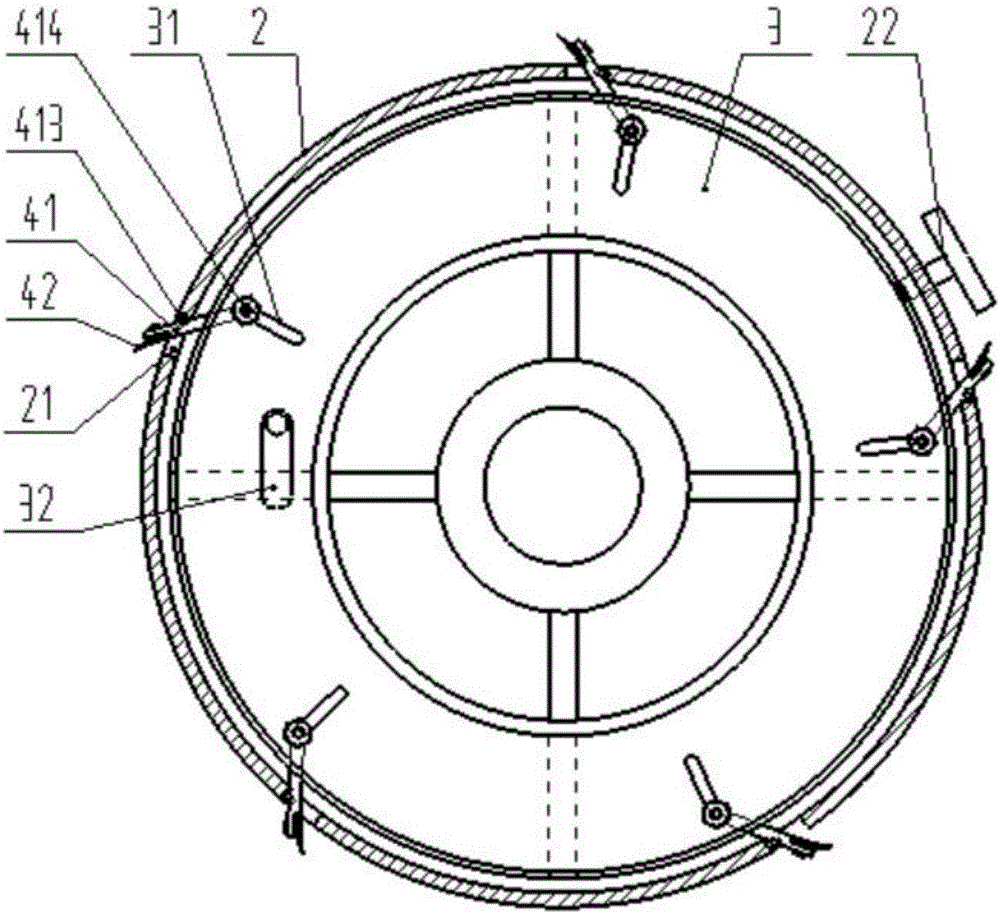

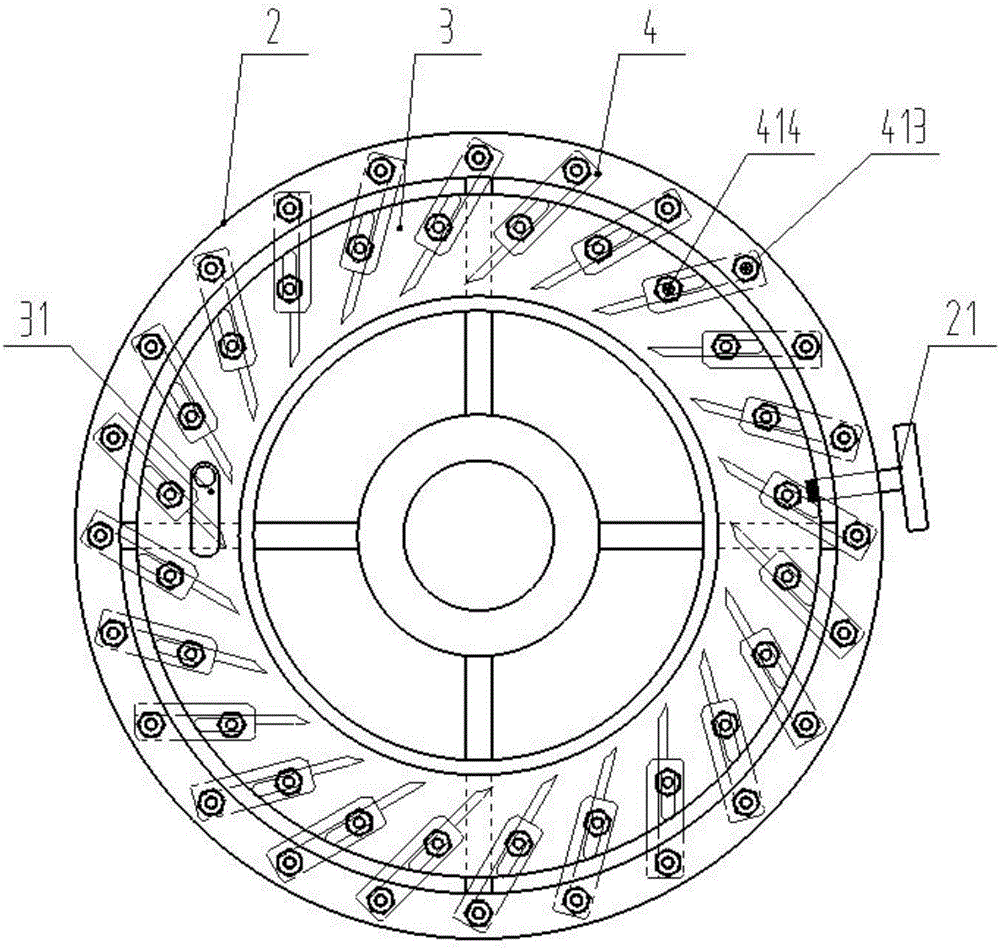

Novel tool cylinder for wood shaving machine

ActiveCN106493821AEasy to adjustMeet the needs of fast switching functionsWood working apparatusWood shavingsClamp connection

The invention discloses a novel tool cylinder for a wood shaving machine. The novel tool cylinder for a wood shaving machine comprises a rotary tool cylinder body. The rotary tool cylinder body comprises a hollow cylinder body, two rotary rings and a plurality of cutter assemblies, wherein one rotary ring is in clamping connection with one end of the cylinder body, the other rotary ring is in clamping connection with the other end of the cylinder body, the rotary rings can rotate around the axis of the cylinder body, and a plurality of guide holes are formed in each rotary ring in the axial direction in a uniform distribution manner. Each tool assembly comprises a tool rest and a blade arranged on the tool rest, the tool rest is inserted into the inner cavity of the cylinder body in the manner of being attached to one side wall of a material guiding hole while the blade is placed outside the circumferential wall of the cylinder body, the tool rest is in rotary connection with the end of the material guiding hole through a first bolt, the tool rest is connected with the rotary rings through second bolts, and therefore it is achieved that the tool rest is driven by the rotating rotary rings to rotate around the first bolt. According to the novel tool cylinder for a wood shaving machine, because more than one tool assembly is evenly distributed on the wall of the cylinder body to be used for carrying out rotary cutting outside the cylinder body, a cutting interval is formed between each tool rest and the side wall, opposite to the tool rest, of the corresponding material guiding hole, the angles and the positions of all the tool assemblies can be adjusted synchronously at one time, and it is effectively achieved that the cutting intervals of wood can be rapidly adjusted.

Owner:WUXI COUNTY YUXING BUILDING MATERIALS

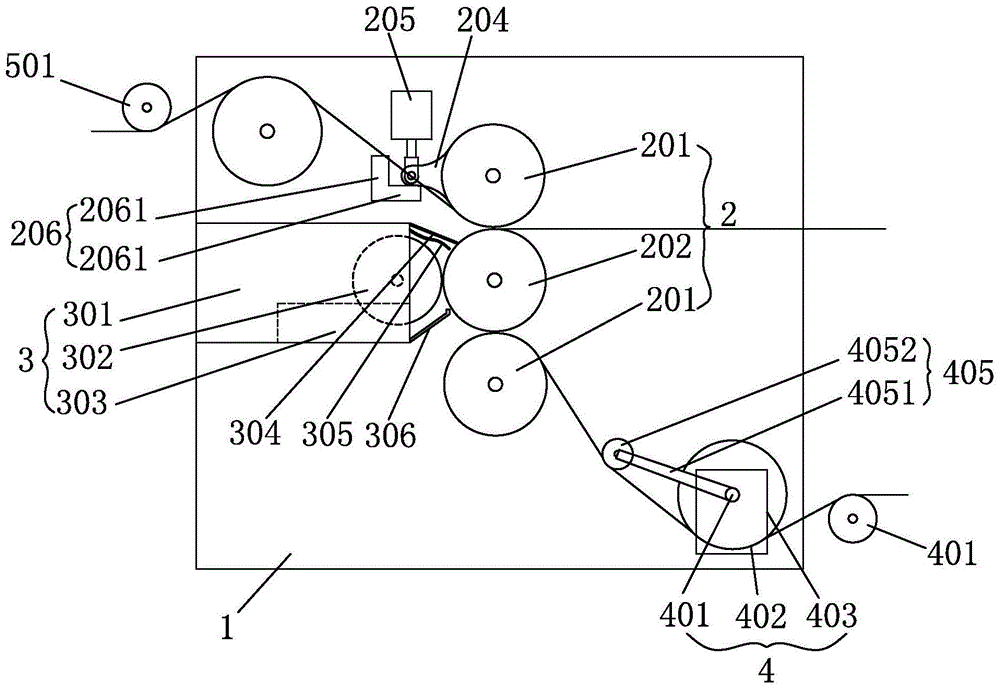

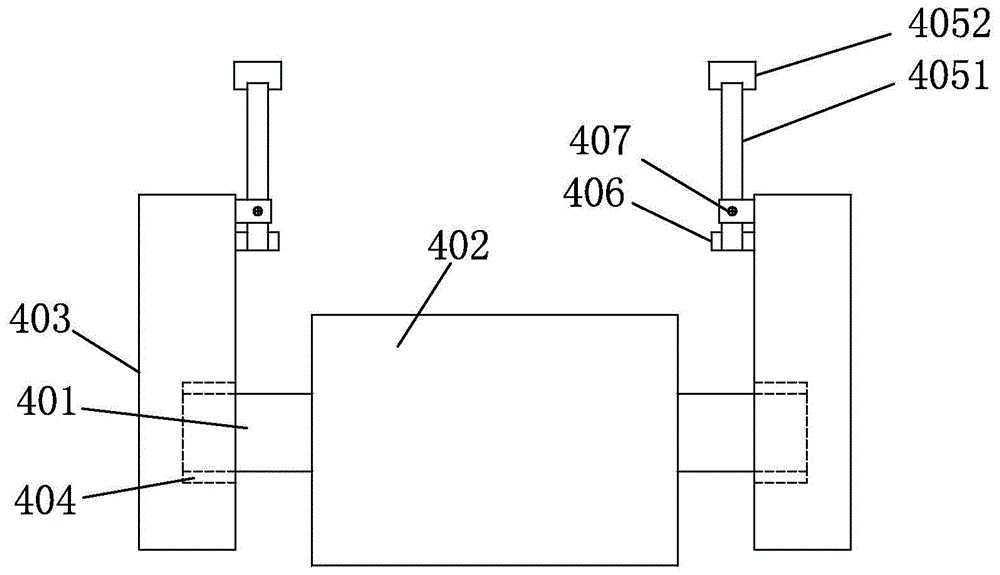

Corrugating machine

InactiveCN104816509AAdjustable installation positionApplicable bondingMechanical working/deformationPulp and paper industry

The invention discloses a corrugating machine. The corrugating machine comprises a corrugating machine module and a core paper preheating cylinder, wherein the corrugating machine module comprises pressure rollers, an upper pressing roller and a lower pressing roller; the pressure rollers are arranged above the upper pressing roller, and the upper pressing roller and the lower pressing roller are meshed for transmission; the core paper preheating cylinder comprises a rotating shaft, a cylinder body connected to the rotating shaft, a heating device arranged in the cylinder body and mounting plates arranged on the two sides of the cylinder body; a fixed lug is arranged on the pressure rollers, and is connected with the air cylinder; the air cylinder pushes the pressure rollers to compress the upper pressing roller, and a limiting block is arranged below the fixed lug; the position of the limiting block is vertically adjustable, and the fixed plug abuts against the limiting block, and therefore the mounting height of the pressure roller can be limited; bearings are arranged at the two ends of the rotating shaft, and the rotating shaft is fixed to the mounting plates; a tension adjusting device is arranged on the mounting plates, and can adjust the mounting height of the pressure rollers; tension of core paper can be adjustable, and therefore the rolling pressing quality of the core paper is improved.

Owner:浙江惠通全成重工机械科技有限公司

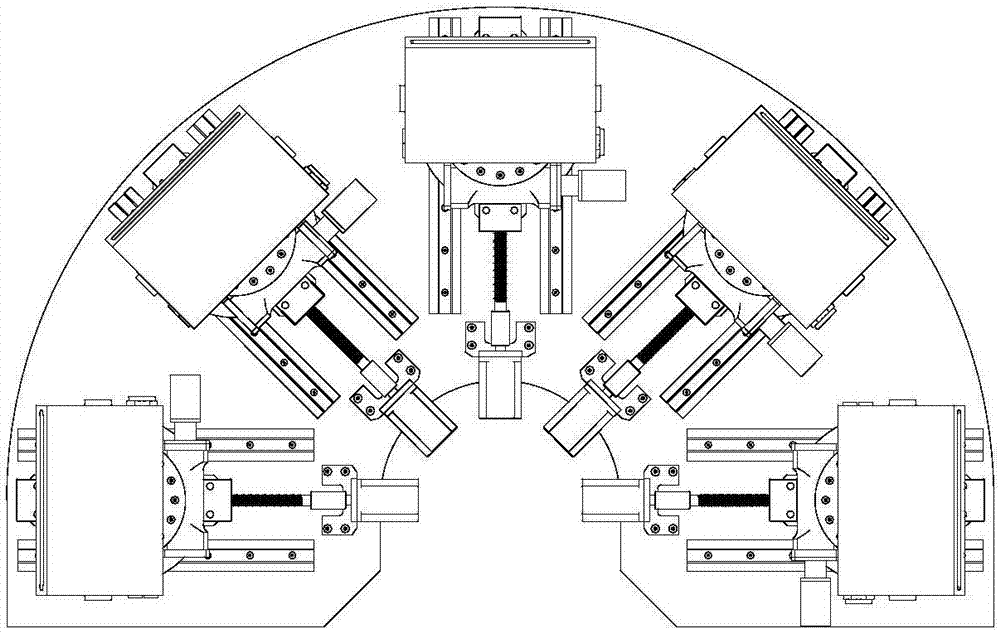

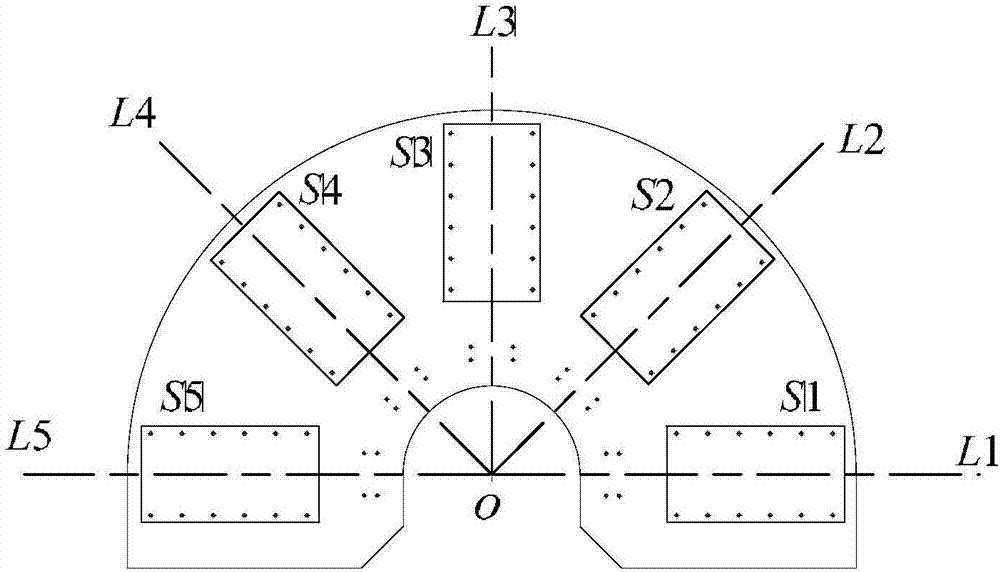

Multi-freedom-degree adjustable image acquisition device

InactiveCN106908448AAdjustable installation positionHigh degree of intelligenceTelevision system detailsColor television detailsMachine visionLaser light

The invention relates to a multi-freedom-degree adjustable image acquisition device. Five sets of same moving execution mechanisms are distributed on a supporting platform of the multi-freedom-degree adjustable image acquisition device; the center line of each moving execution mechanism passes through the center point of the supporting platform, and a plurality of included angles are formed by the center lines and the horizontal direction; each moving execution mechanism consists of guide rails, sliding blocks, a moving platform, a screw rod and a servo motor; each rotary execution mechanism consists of a slewing drive, a posture adjusting platform and a servo motor. According to the multi-freedom-degree adjustable image acquisition device disclosed by the invention, the multi-freedom-degree execution mechanisms are applied to the field of vision acquisition, so that the multi-freedom-degree adjustable image acquisition device of which the intelligent degree is high is formed; under the effect of the moving execution mechanisms and the rotary execution mechanisms, the position and the posture of each digital camera and the position and the posture of each laser light source can be independently adjusted according to the shape of a measured article and vehicle disturbance, so that a plurality of technical difficult problems caused during applying a conventional machine vision technology in a highway are solved.

Owner:SHANXI PROVINCIAL RES INST OF COMM

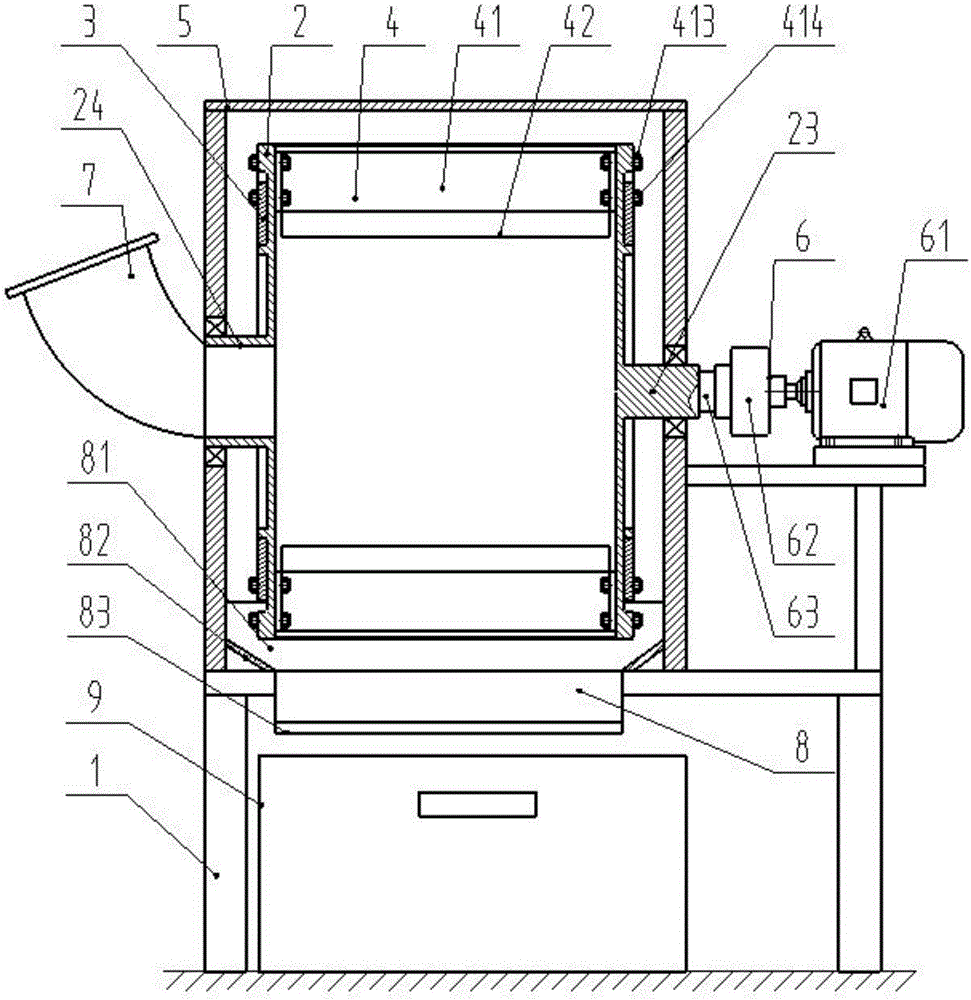

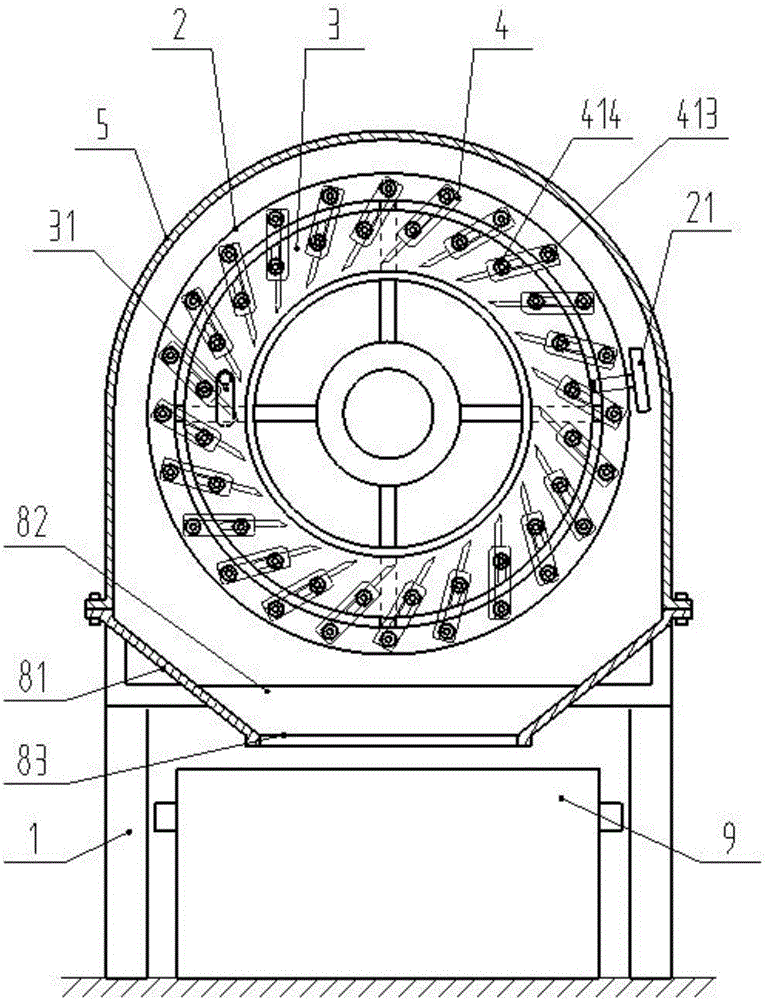

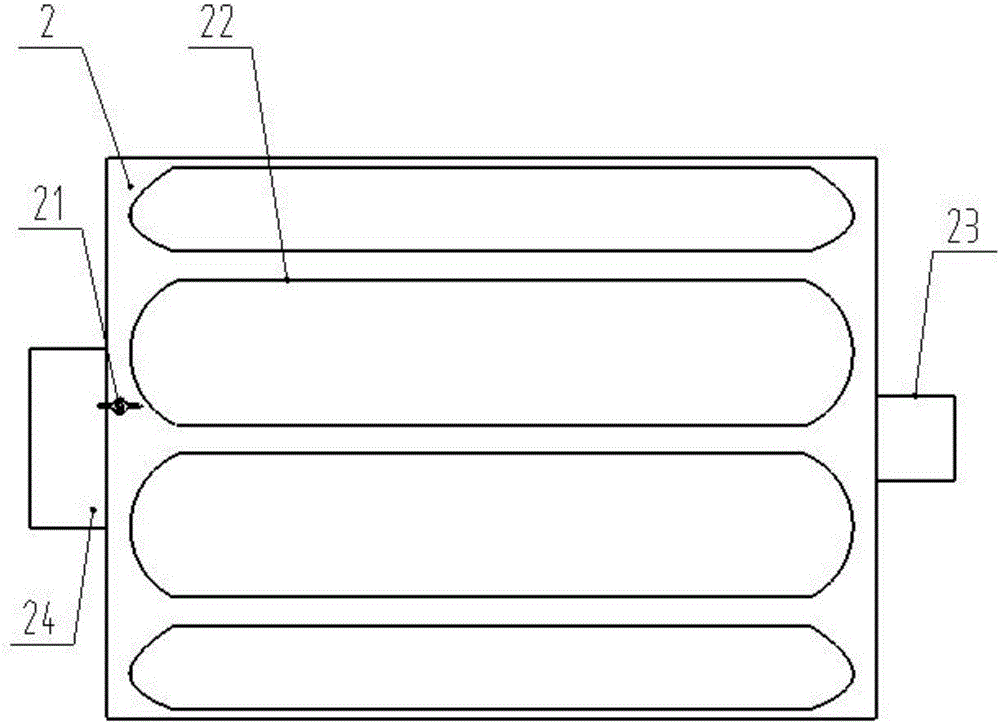

Wood shaving machine

ActiveCN106514823AEasy to adjustMeet the needs of fast switching functionsWood working apparatusWood shavingsEngineering

The invention discloses a wood shaving machine, which comprises a bracket, a machine cover arranged on the bracket, and a drive mechanism arranged beside the machine cover. A rotary cutter cylinder is arranged in the machine cover, and comprises a hollow cylinder body, swivels arranged on two ends of the cylinder body, and a plurality of cutter components uniformly distributed on the circumferential wall of the cylinder body; the swivels are fastened with the end parts of the cylinder body and can rotate around the axis of the cylinder body; the cutter components comprise cutter holders and blades arranged on the cutter holders; one end of the rotary cutter cylinder is driven by the drive mechanism to rotate; and a through hole for feeding is formed in the other end of the rotary cutter cylinder and communicates with a feed hopper arranged close to the outer side of the machine cover. According to the wood shaving machine provided by the invention, a working principle that the cutter components are uniformly distributed on the circumferential outer wall of the cylinder body so as to apply circumferential cutting on an inner cavity is adopted, so that angle positions of the all cutter components can be adjusted synchronously at a time, the fast adjustment of timber cutting intervals can be realized, and the fast switch function requirement on processing wood shavings with different thicknesses is met.

Owner:WUXI COUNTY YUXING BUILDING MATERIALS

Adjustable-installed recessed lighting

InactiveUS20080030997A1Easy to installImprove installabilityLighting support devicesVehicle interior lightingEngineeringMechanical engineering

Owner:SHEN TIANLIN

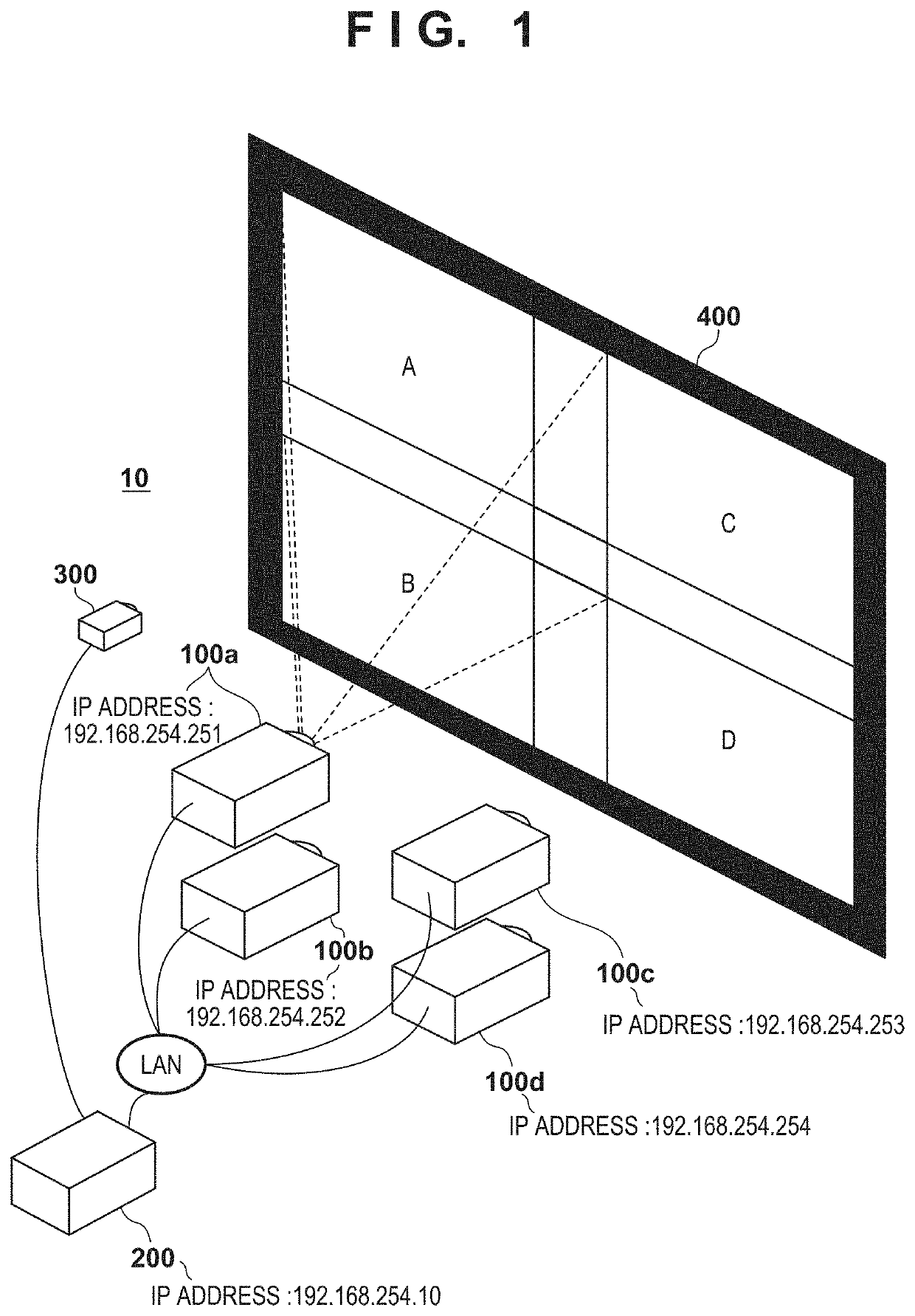

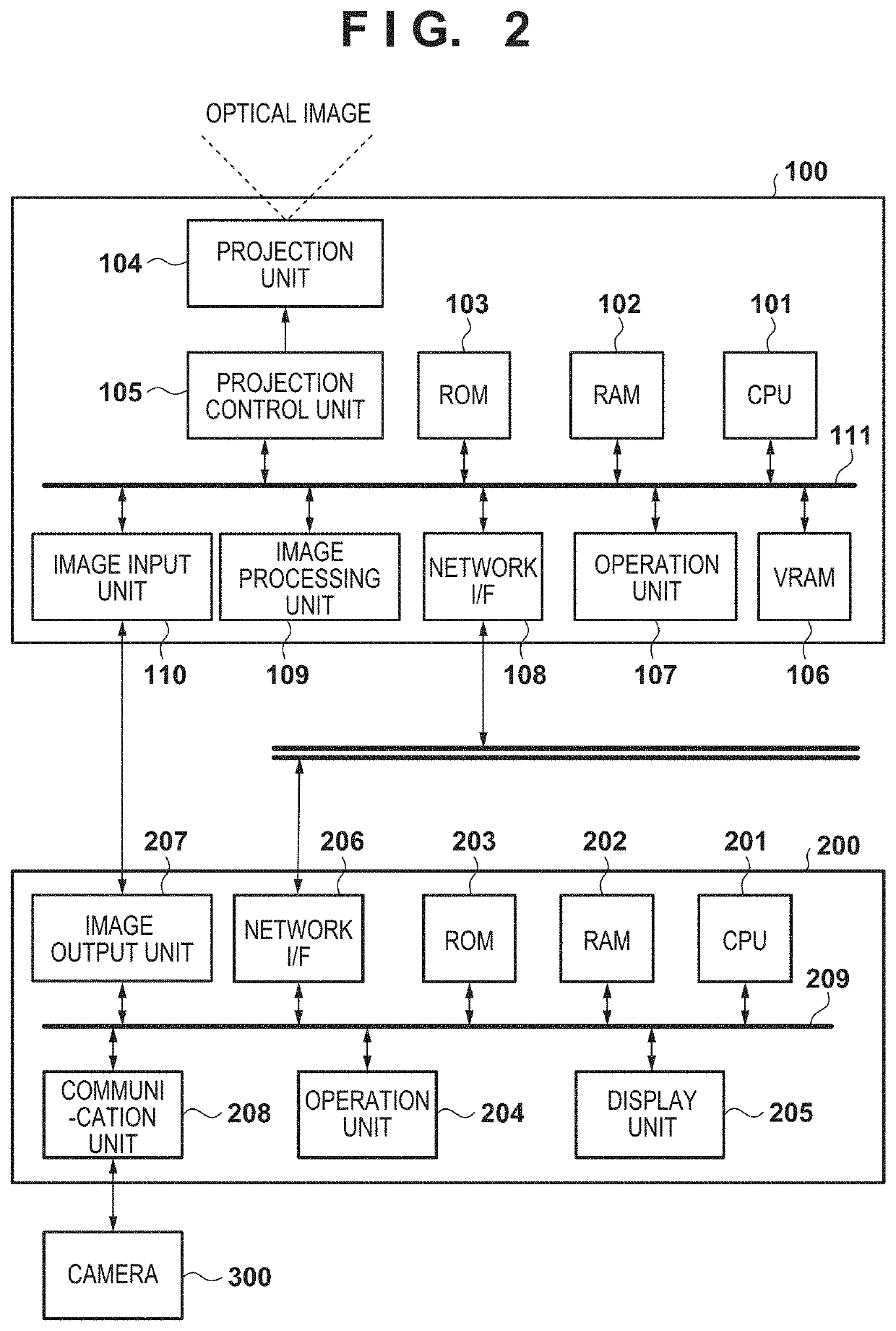

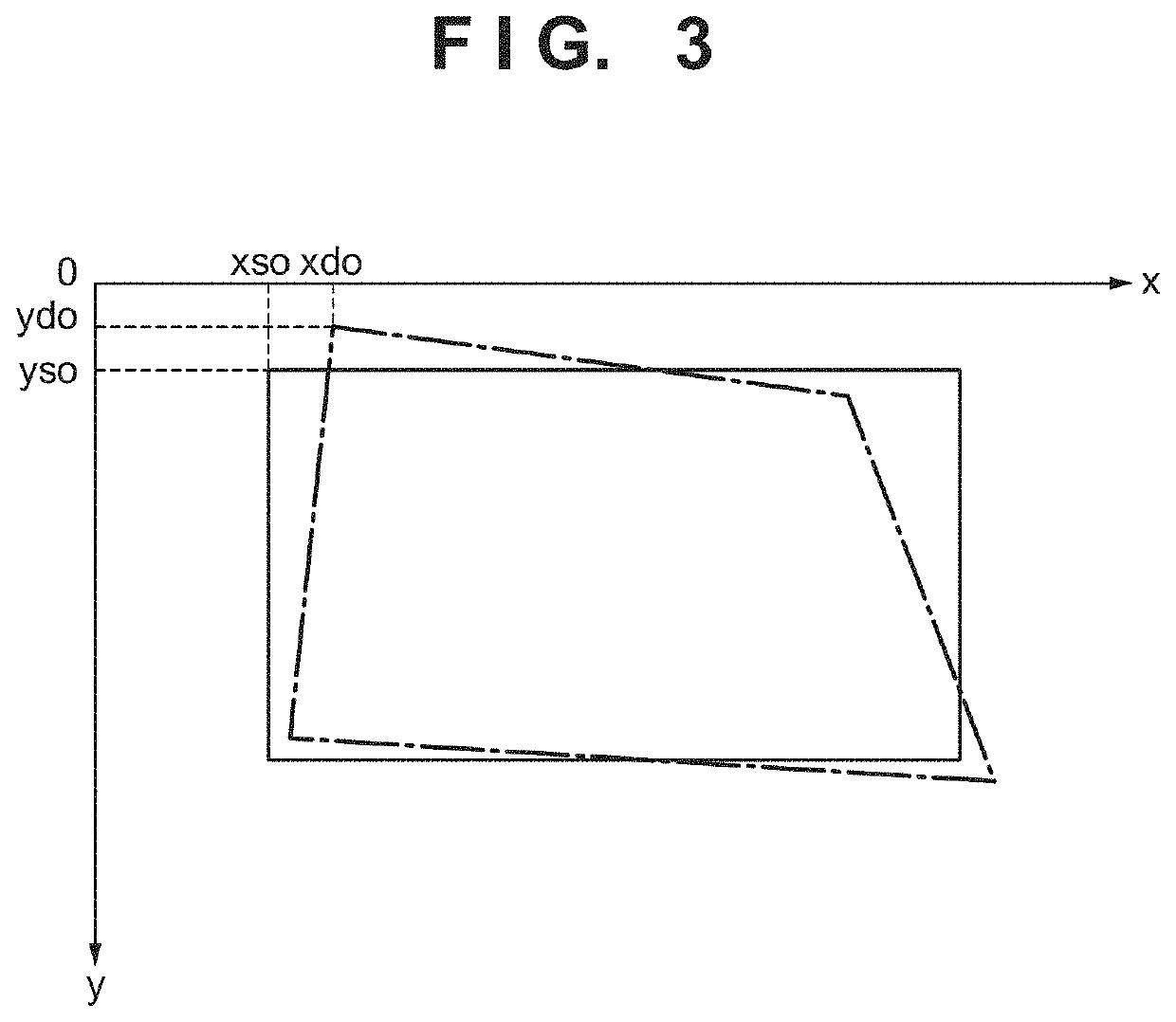

Projection control apparatus, control method of the same, and projection system

InactiveUS20200169706A1Adjustable installation positionPicture reproducers using projection devicesProjection opticsComputer graphics (images)

A projection control apparatus for controlling projection performed using projectors is disclosed. The control apparatus, for each of the projectors, detects a projection area, being on a projection surface, in which an optical image is projected, based on a captured image of the projection surface. The control apparatus then causes an indicator indicating a target projection area for one of the projectors to be displayed by one or more other projectors. The control apparatus finally determines a projector that is to project the indicator from among the one or more other projectors based on a detection result of the detection.

Owner:CANON KK

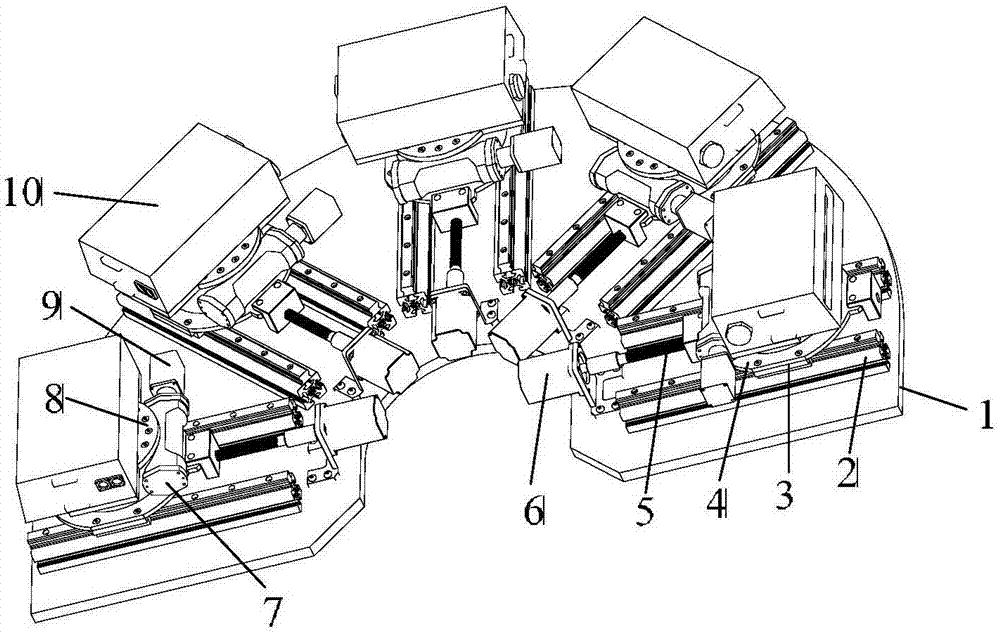

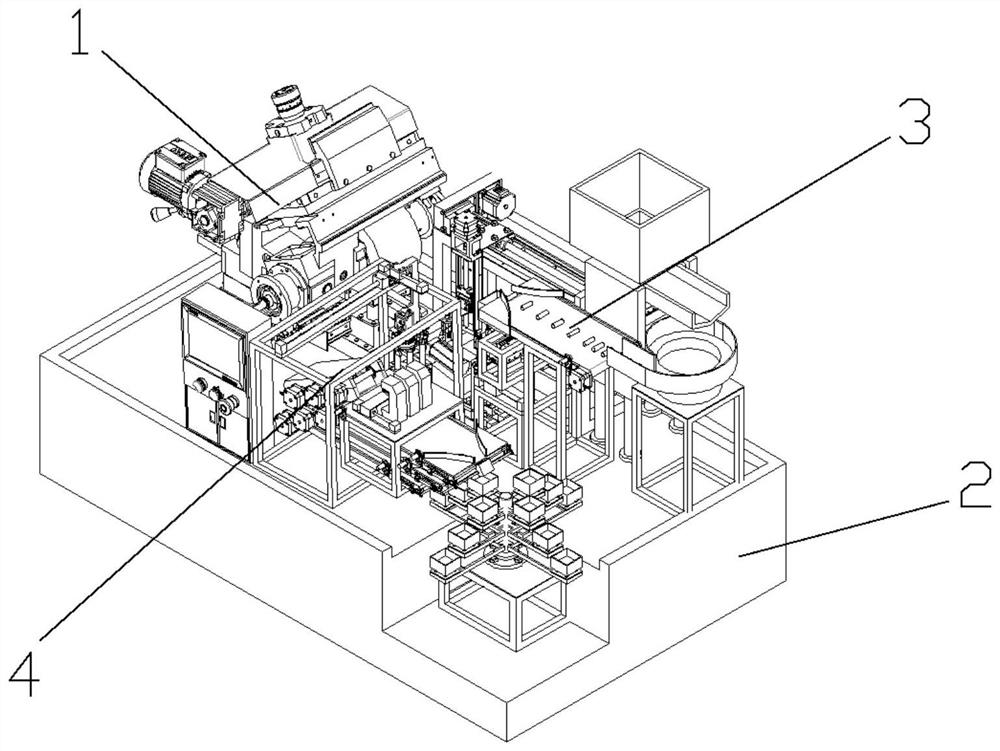

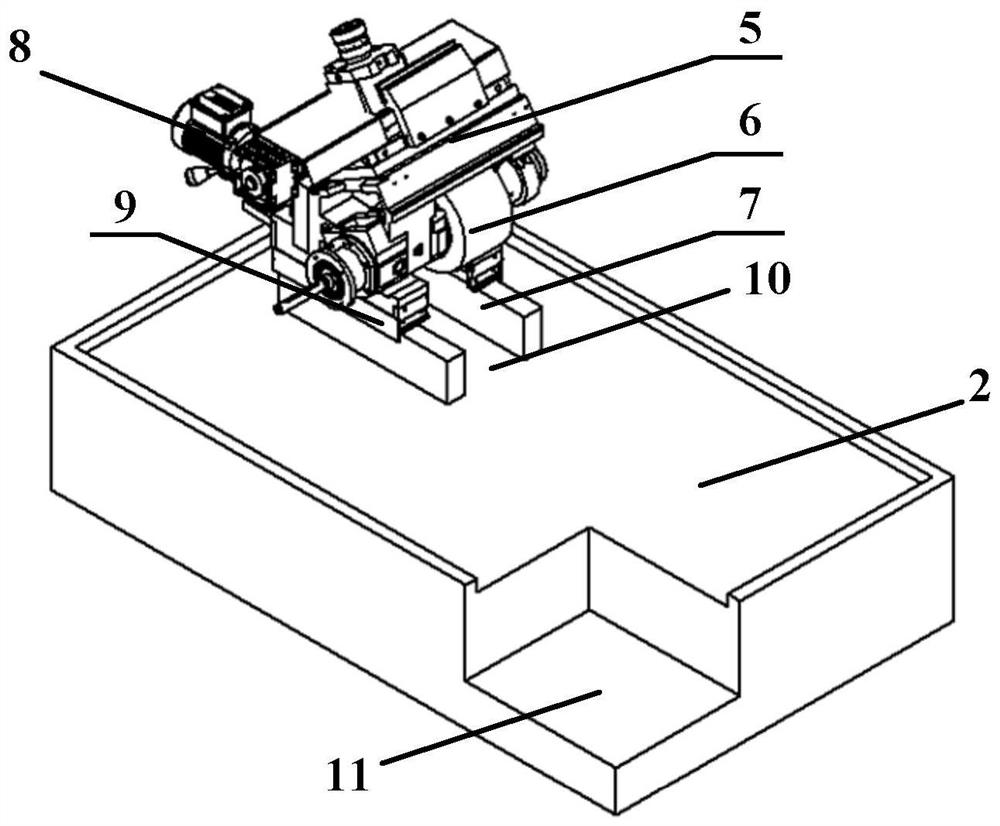

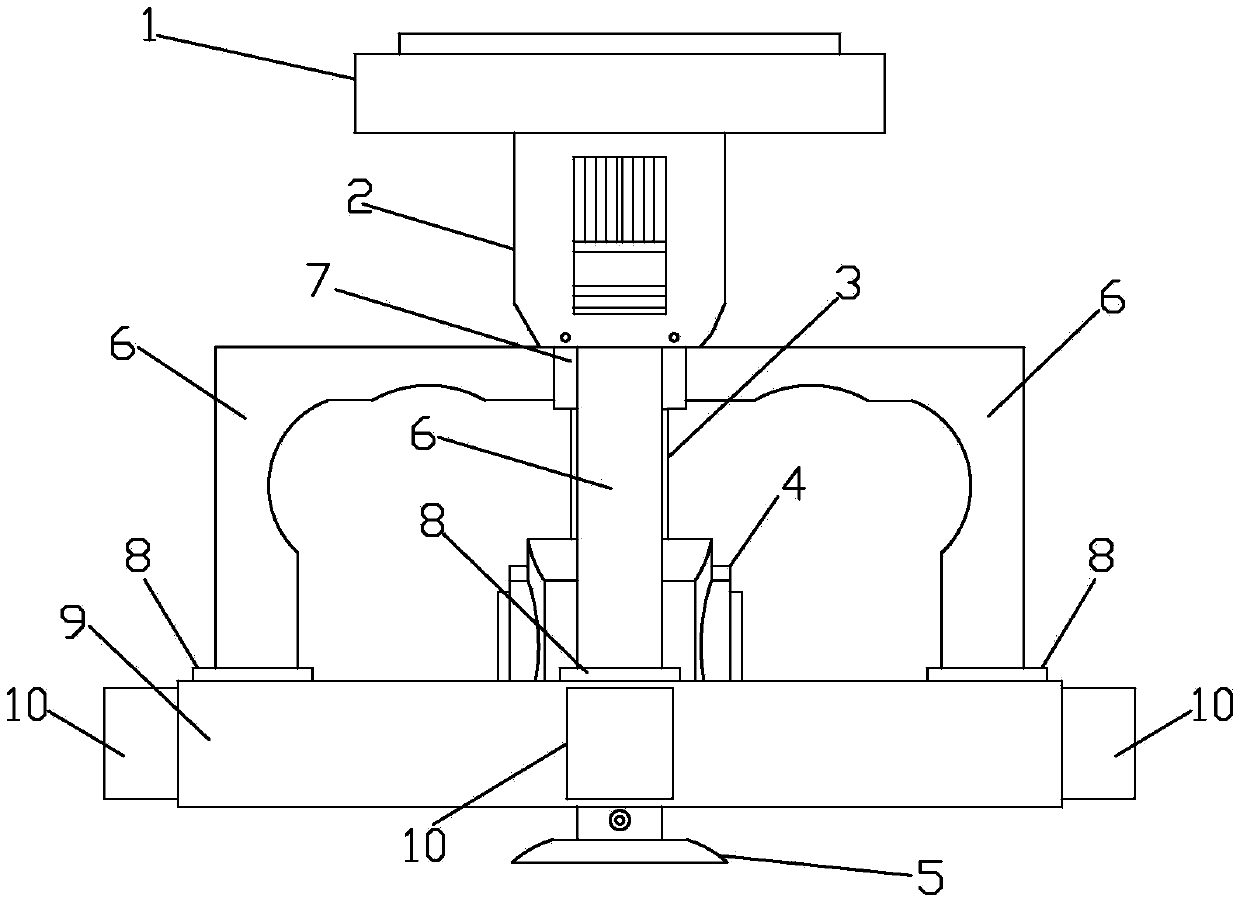

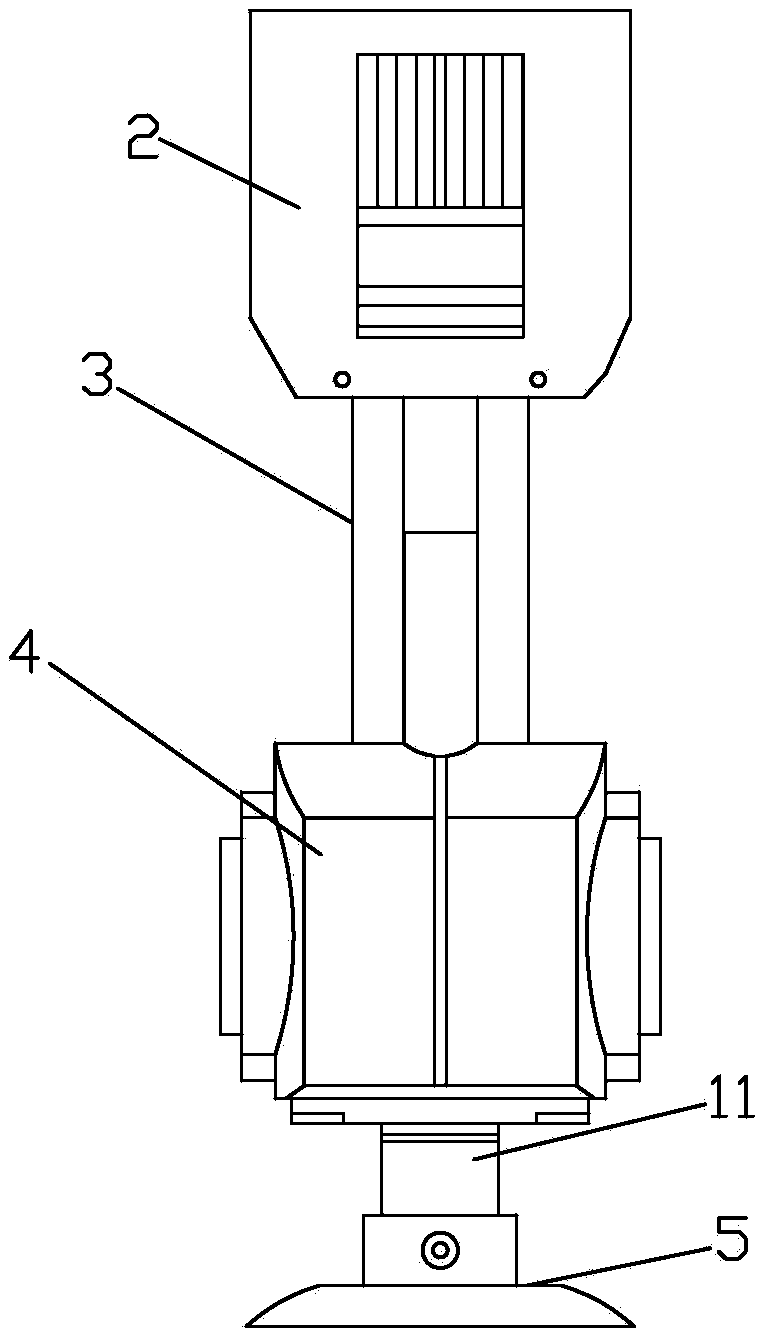

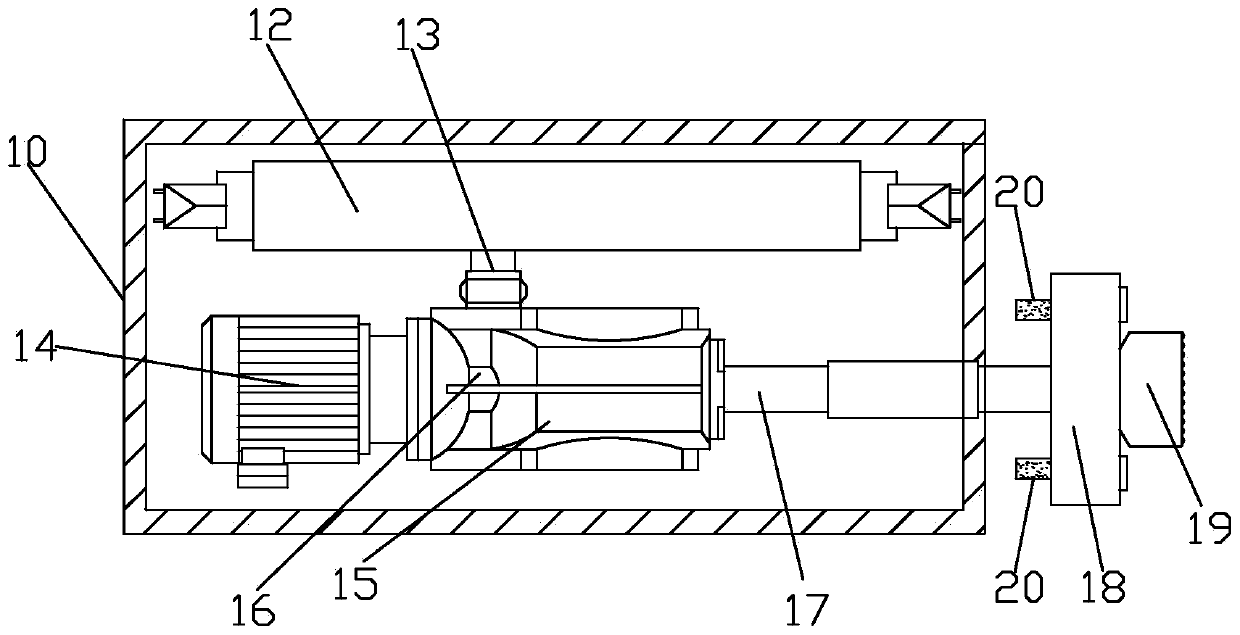

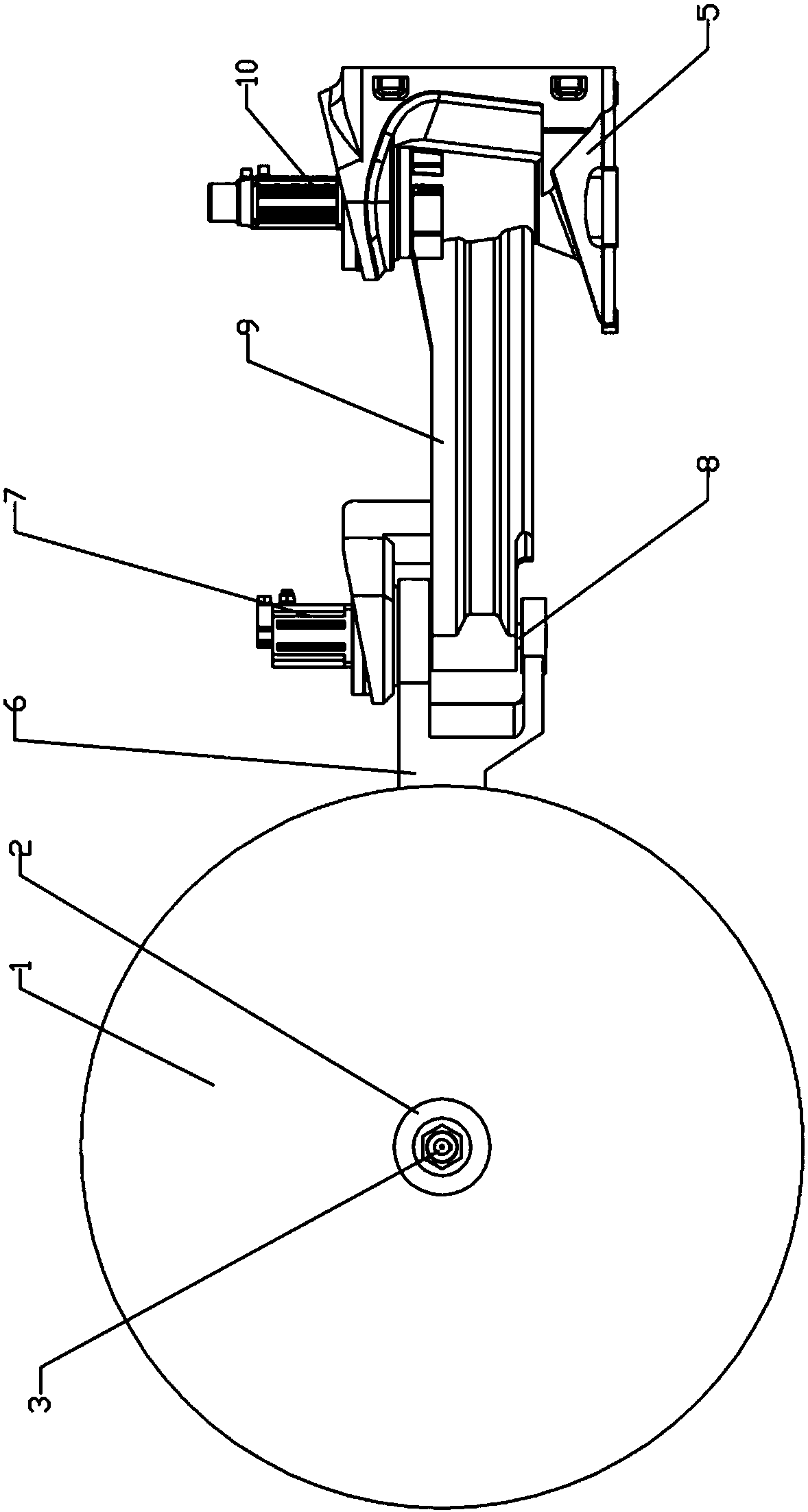

Full-automatic grinding machine for ultrasonic vibration auxiliary grinding of outer circle of hard and brittle single crystal cylinder

ActiveCN111805309ARealize automatic feeding processImprove work efficiencyGrinding carriagesGrinding feed controlMachine partsEngineering

The invention discloses a full-automatic grinding machine for ultrasonic vibration auxiliary grinding of an outer circle of a hard and brittle single crystal cylinder, and relates to the technical field of mechanical equipment. The full-automatic grinding machine aims to solve the problems in the prior art that when the outer circle surface of the hard and brittle single crystal cylinder is ground, the adopted grinding liquid is alkaline or acidic, a machine tool can be corroded after long-term use, the clamping precision of a workpiece is reduced, the surface precision of a machined part is reduced, and the working efficiency is low due to the fact that feeding is carried out in a manual mode. An automatic feeding mechanism and an automatic classifying and storing mechanism are distributed in parallel, the full-automatic grinding machine is perpendicular to the automatic feeding mechanism and the automatic classifying and storing mechanism, a storage mechanism base table is arranged at one corner of the upper surface of a grinding machine base, and the upper surface of the storage mechanism base table is lower than the upper surface of the grinding machine base and is used for containing the automatic classifying and storing mechanism. The full-automatic grinding machine is suitable for grinding the outer circle surface of the hard and brittle single crystal cylinder.

Owner:HARBIN INST OF TECH

Small waste rubber pressure molding device

InactiveUS20200207591A1Lower the volumeEasy to handleBase supporting structuresBraking devices for hoisting equipmentsWaste rubberStructural engineering

The invention discloses a mining crane which is easy to install, and includes a base which is symmetrical in front and back. A support column is fixed on the upper end surface of the base, and a fixed block is fixed on the upper end of the support column. The fixed block, the support column and A traveling device is arranged between the bases, and the traveling device includes four rotatable traveling wheels. When the traveling wheels rotate, the fixed block is moved, and a lifting device is provided in the fixed block. The heavy device includes a rewindable hook for lifting the heavy ore. The traveling device can drive the whole to adjust the installation position through the traveling device. The device has two installation and support methods that can directly abut the mine wall and drill into the mine wall. According to the actual situation of the mine and mining area, it can be reasonably selected to expand its scope of application, without being restricted by the region. Secondly, the support rod and telescopic rod can be contracted and rotated to reduce the overall volume of the present invention, which is convenient for movement and handling, and convenient for loading and unloading.

Owner:QIU TAO

Cutter barrel for wood shaving machine

ActiveCN106738165AEasy to adjustMeet the needs of fast switching functionsWood working apparatusWood shavingsEngineering

The invention discloses a cutter barrel for a wood shaving machine. The cutter barrel comprises a rotary cutter barrel which comprises a hollow barrel body, rotary rings arranged at the two ends of the barrel body and a plurality of cutter assemblies uniformly arranged on the peripheral wall of the barrel body, wherein the rotary rings are clamped at the ends of the barrel body and can rotate around the axis of the barrel body; each cutter assembly comprises a cutter frame and a cutter blade detachably connected to the cutter frame; a through hole is formed in the end of the cutter frame; a long-striped hole is formed at the lower part of the through hole; a first bolt for rotary connection of the cutter frame and the end of the barrel body is arranged through the through hole; and the long-striped hole is provided with a second bolt for connecting the cutter frame and the rotary rings so as to realize the rotation of the cutter frame around the first bolt under the rotary driving of the rotary rings. The cutter barrel for the wood shaving machine has the beneficial effects that the plurality of cutter assemblies are uniformly arranged on the wall of the barrel body to actualize the working principle of the peripheral cutting of an inner cavity and are designed in a modularized manner; the adjustment of angle positions of all the cutter assemblies can be simultaneously completed at one time; and the rapid adjustment of wood cutting gaps is effectively realized.

Owner:WUXI COUNTY YUXING BUILDING MATERIALS

Convenient-to-mount edging device applied to glass production line

InactiveCN105364664AAchieve continuous edgingAvoid safety hazardsEdge grinding machinesGrinding work supportsProduction lineImpeller

The invention discloses a convenient-to-mount edging device applied to a glass production line. The convenient-to-mount edging device comprises a grabbing mechanism and an edging mechanism. An electromagnetic chuck is disposed at the upper end of the grabbing mechanism; the grabbing mechanism comprises a lifting motor, a lifting connecting rod, a hydraulic cylinder and a hydraulic chuck; the edging mechanism comprises a connecting assembly, a rotary table and an edging device; the edging device is matched with the hydraulic chuck; a motor and a horizontal air cylinder are disposed in the edging device; the motor is connected with a motor shaft; an edging wheel is connected with the other end of the motor shaft; an edging head is connected with the other end of the edging wheel; the motor shaft is connected with the edging head; an impeller is disposed in the edging wheel; the impeller is connected to the motor shaft; dust absorbing holes are formed in the surface of the edging wheel and dust absorbing tubes are disposed on the surface of the edging wheel. Glass is directly grabbed on the production line by the aid of the grabbing mechanism, moved to the edging position through the lifting movement and then subjected to edging treatment through the edging mechanism, the operation is conducted circularly in this way, and continuous edging treatment on the glass production line is achieved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

Cutting device for digging robot

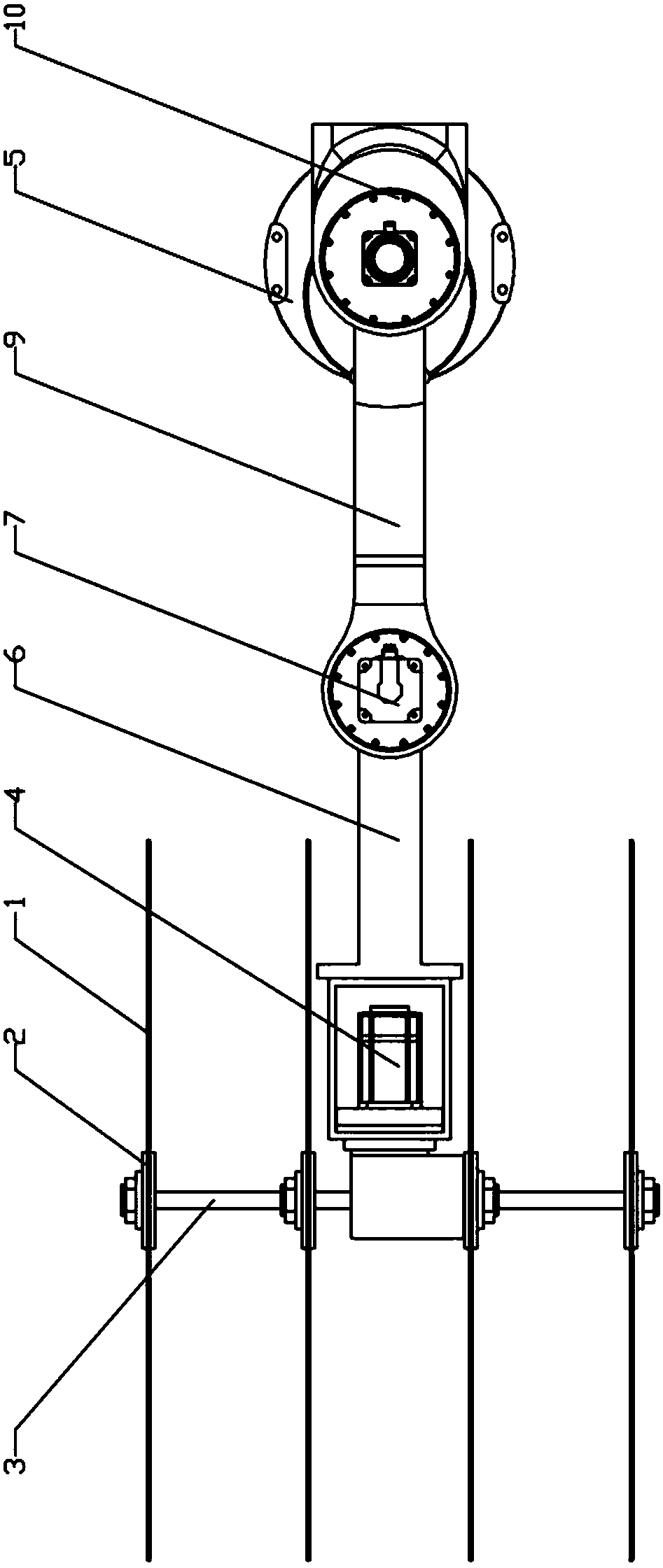

InactiveCN108127649AExpand the scope of workAvoid destructionProgramme-controlled manipulatorTunnelsSingle degree of freedomEngineering

The invention discloses a cutting device for a digging robot. The device comprises a mechanical arm and a cutting machine which is driven by the mechanical arm to move in the space; the mechanical armcomprises a machine base, an inner arm which is rotatably connected to the machine base at the single degree of freedom in the vertical direction, an outer arm which is rotatably connected to the inner arm at the single degree of freedom in the vertical direction, a first driving device for driving the outer arm to rotate relative to the inner arm and a second driving device for driving the innerarm to rotate relative to the machine base. Therefore, the mechanical arm with high length and weight can be adopted for the cutting device for the digging robot, the bending moment generated under the gravity of the mechanical arm is prevented from damaging the driving devices (usually gear motors), and accordingly the operation range of the cutting device for the digging robot is greatly enlarged.

Owner:CHONGQING PENG TECH

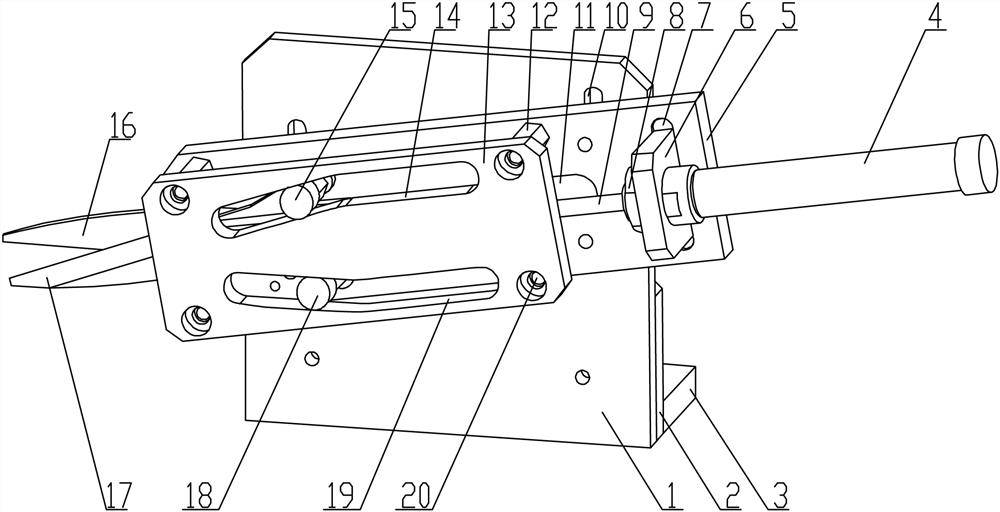

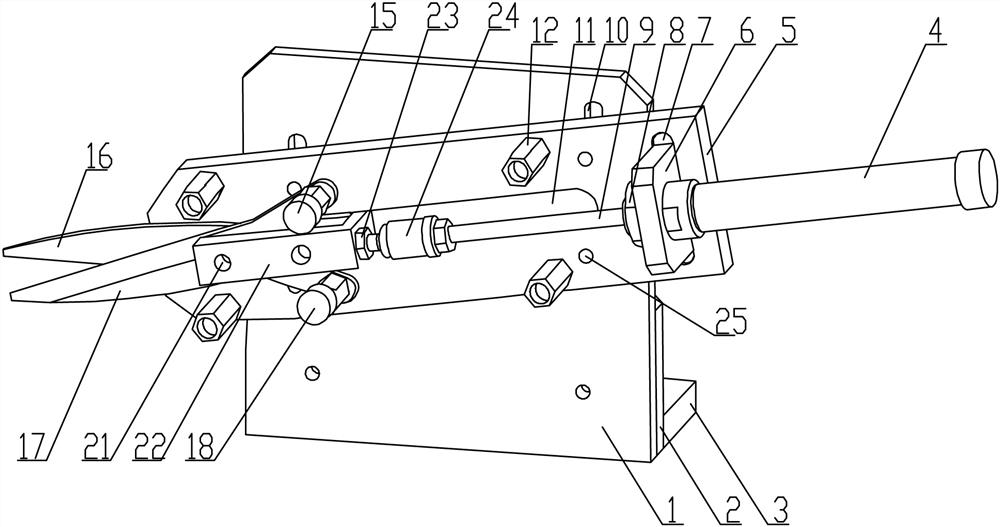

Mask ear band shearing device based on sliding groove mechanism and using method

InactiveCN113084897AGuaranteed stabilityGuaranteed reliabilityMetal working apparatusClassical mechanicsStructural engineering

The invention provides a mask ear band shearing device based on a sliding groove mechanism and a using method. The mask ear band shearing device comprises a vertical plate, the vertical plate is fixedly installed on a rack of a mask machine through a vertical plate base, and an inclined knife rest plate is installed on the outer side wall of the vertical plate. A sliding groove is machined in the knife rest plate, a sliding base is in sliding fit with the sliding groove, and a first scissor body and a second scissor body which are arranged in a crossed mode are hinged to the sliding base through a pin shaft. The tail parts of the first scissor body and the second scissor body are matched with a roller guide mechanism and are used for realizing the closing and separating actions of the scissor heads. The sliding base is connected with a sliding device used for driving the sliding base to slide along a sliding groove.

Owner:CHINA THREE GORGES UNIV

Sound absorption unit capable of being installed quickly

Owner:SHANGHAI HUABO INFORMATION SERVICE +1

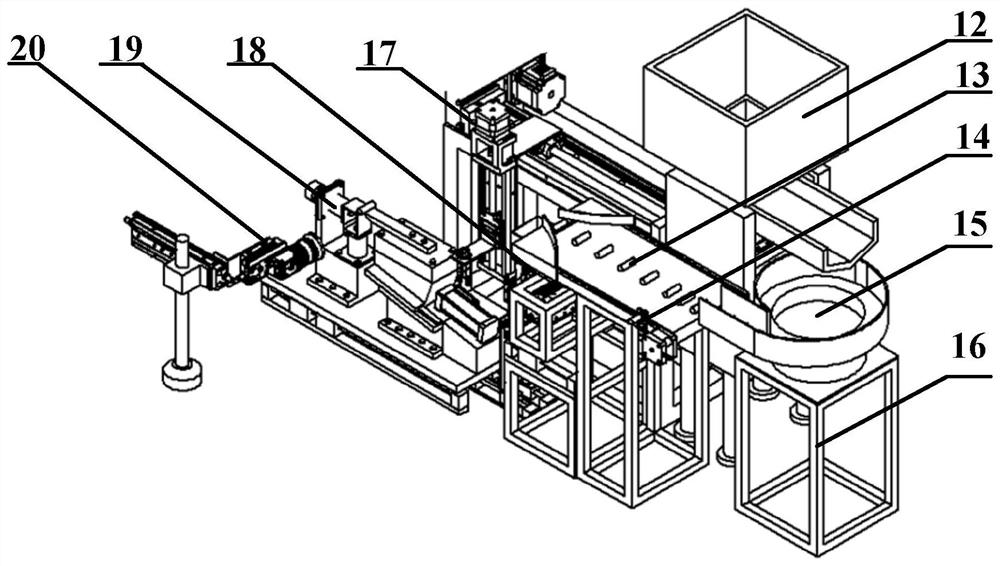

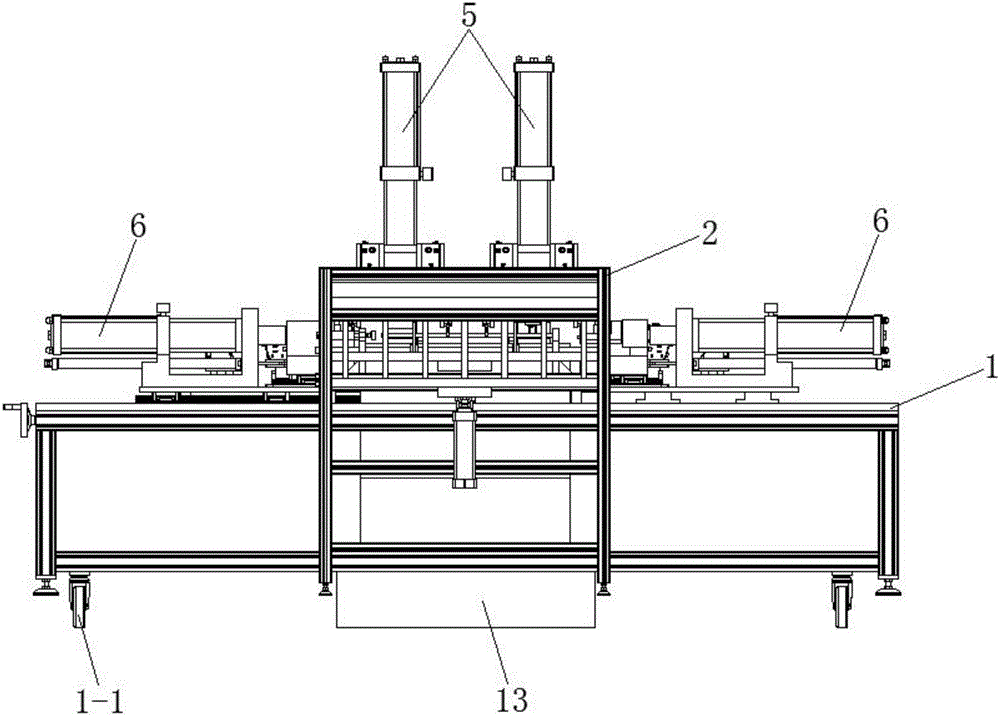

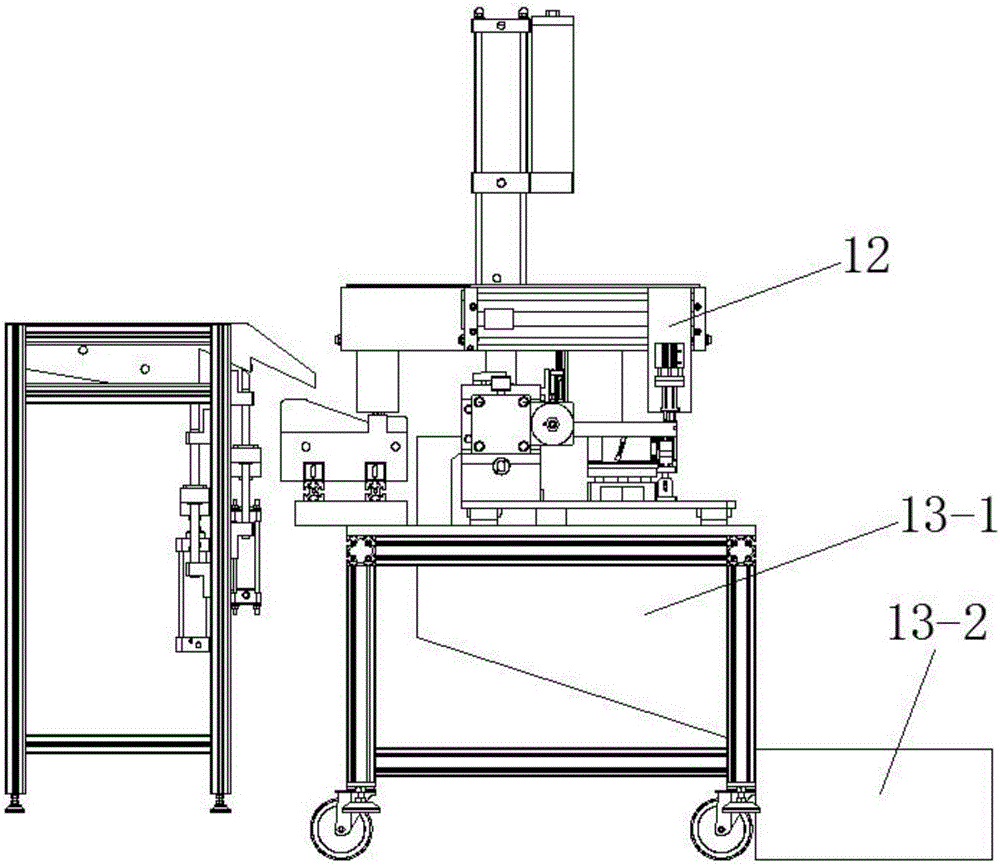

Automatic press-mounting machine for automobile oil pipe

ActiveCN106670328AIncrease productivityReduce labor costsMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention discloses an automatic press-mounting machine for an automobile oil pipe. Two pipe loading manipulators carry pipes at the output end of an automatic pipe loading mechanism onto two pipe location fixtures, and carry the oil pipes completing press-mounting to the inlet of an unloading mechanism; two vertical booster cylinders are arranged above the two pipe location fixtures respectively; two horizontal booster cylinders are located at the outer sides of the two pipe location fixtures respectively; two slide rails are arranged between the two pipe location fixtures and the two horizontal booster cylinders respectively; two slide support seats are slidably connected with the two slide rails respectively; two ball head location fixtures are installed on the two slide support seats respectively; two corner pressing cylinders are fixed to the two ball head location fixtures respectively; two ball head loading manipulators carry ball heads on two vibration discs onto the two ball head location fixtures respectively; and the unloading mechanism carry away the oil pipes completing assembly from the two pipe location fixtures. The automatic press-mounting machine disclosed by the invention greatly increases the production efficiency and effectively lowers the labour cost.

Owner:龙口市通达油管有限公司

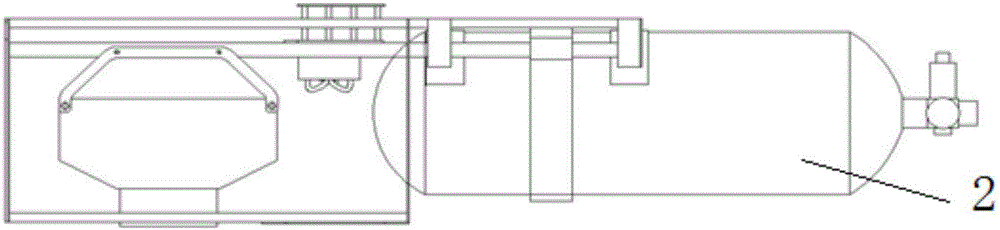

Power cabin

ActiveCN106531925ASimple structureReduce weightAircraft power plant componentsCell component detailsGas cylinderComputer module

The invention discloses a power cabin. The power cabin comprises a frame structure and a pair of main beams, wherein a space is arranged in the frame structure and is used for accommodating an electric stack and a part of a gas cylinder, one end of each main beam is oppositely fixed in the frame structure, the other ends of the main beams both penetrate out of the frame structure, a gas cylinder locking piece is fixedly arranged at parts, penetrating out of the frame structures, of the pair of main beams so as to fix a gas cylinder, and an electric stack installation rack is arranged on the main beam, far away from the gas cylinder, of the frame structure. In the power cabin, the electric stack and a gas cylinder module are integrated, the electric stack and a gas cylinder main part are sealed in the power cabin, water and dust prevention on the electric stack is achieved, and the reliability of the whole power system is improved; and the power cabin is installed by employing a fixed rack mode and can be arranged on a carrier by a screw.

Owner:WUHAN TROOWIN POWER SYST TECH

One-click child chair unlocking device

Owner:SUZHOU JIBAO CHILDRENS PROD CO LTD

Mining crane which is convenient to install

InactiveUS20200198937A1Lower the volumeEasy to handleBase supporting structuresBraking devices for hoisting equipmentsStructural engineeringMechanical engineering

The invention discloses a mining crane which is easy to install, and includes a base which is symmetrical in front and back. A support column is fixed on the upper end surface of the base, and a fixed block is fixed on the upper end of the support column. The fixed block, the support column and A traveling device is arranged between the bases, and the traveling device includes four rotatable traveling wheels. When the traveling wheels rotate, the fixed block is moved, and a lifting device is provided in the fixed block. The heavy device includes a rewindable hook for lifting the heavy ore. The traveling device can drive the whole to adjust the installation position through the traveling device. The device has two installation and support methods that can directly abut the mine wall and drill into the mine wall. According to the actual situation of the mine and mining area, it can be reasonably selected to expand its scope of application, without being restricted by the region. Secondly, the support rod and telescopic rod can be contracted and rotated to reduce the overall volume of the present invention, which is convenient for movement and handling, and convenient for loading and unloading.

Owner:LAN JIN

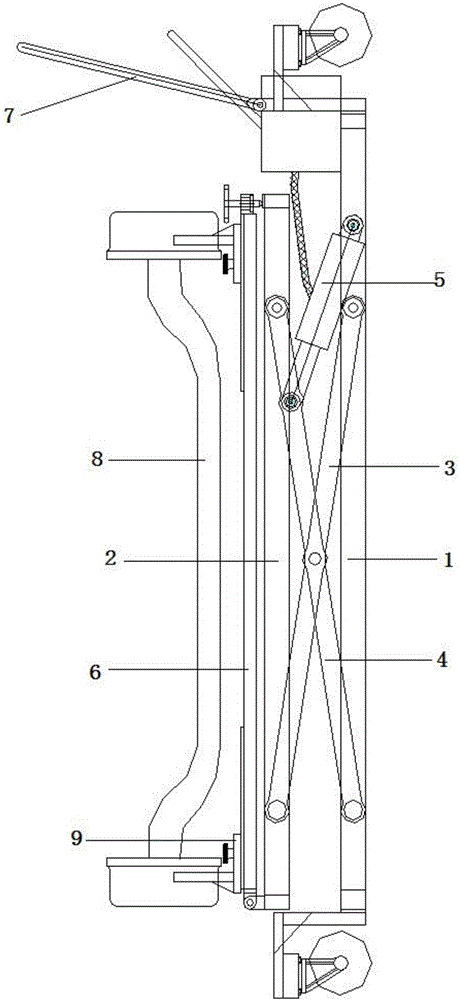

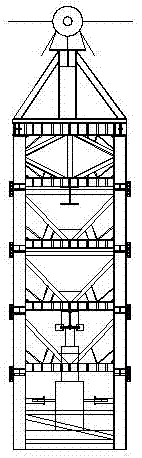

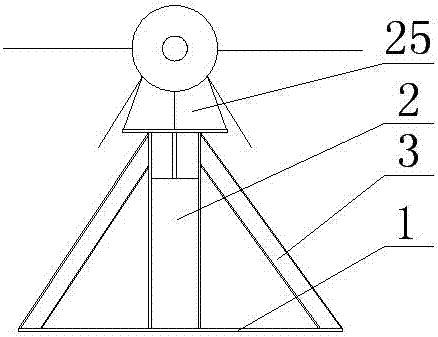

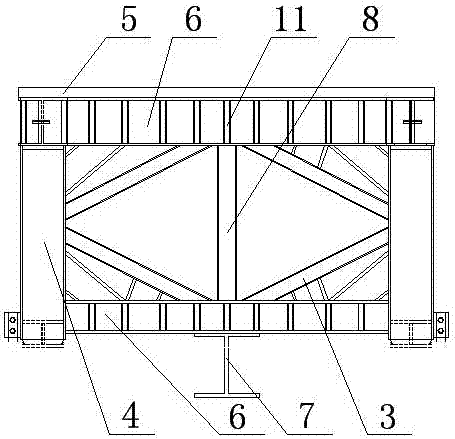

Jacking adjustment device for aloft net frame

ActiveCN107060348AAdjust the installation heighAdjustable installation positionBuilding material handlingBraced frameArchitectural engineering

Owner:CHINA MCC5 GROUP CORP

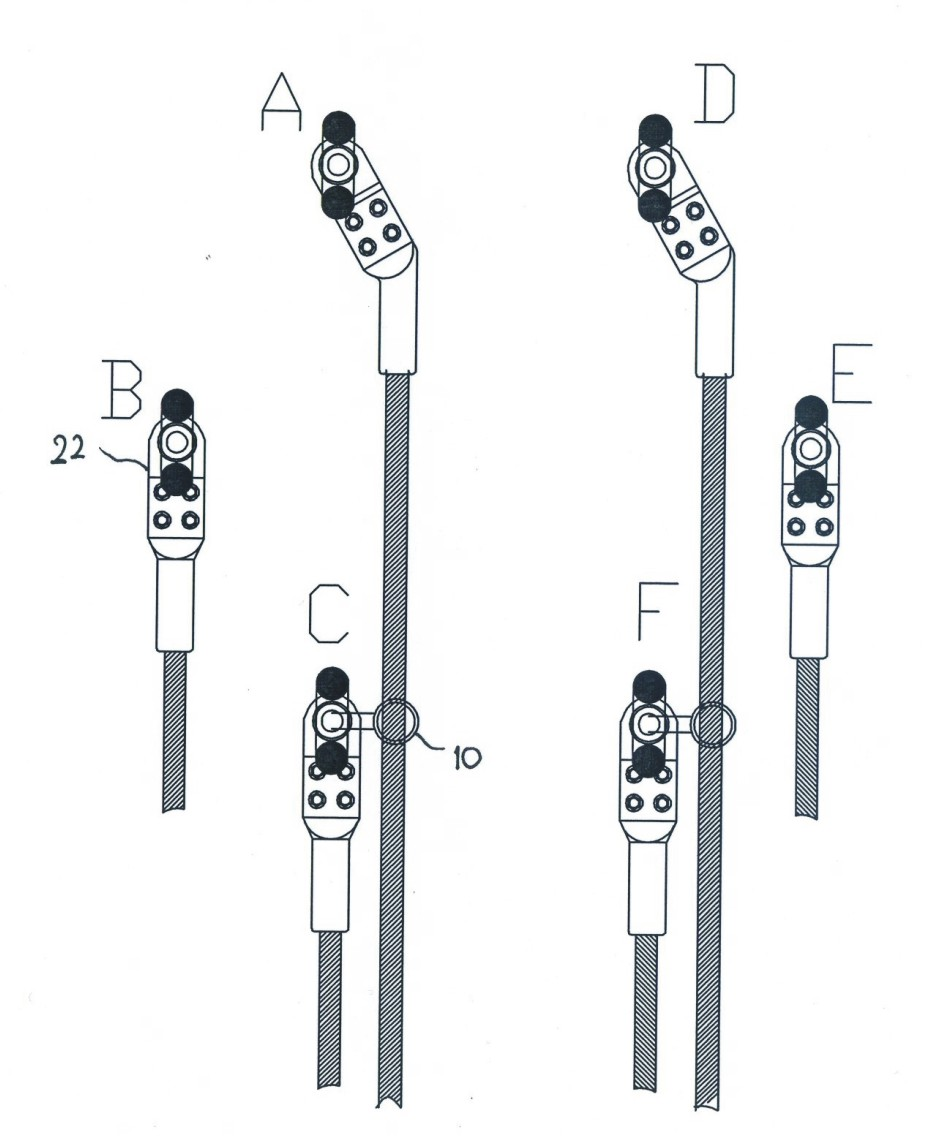

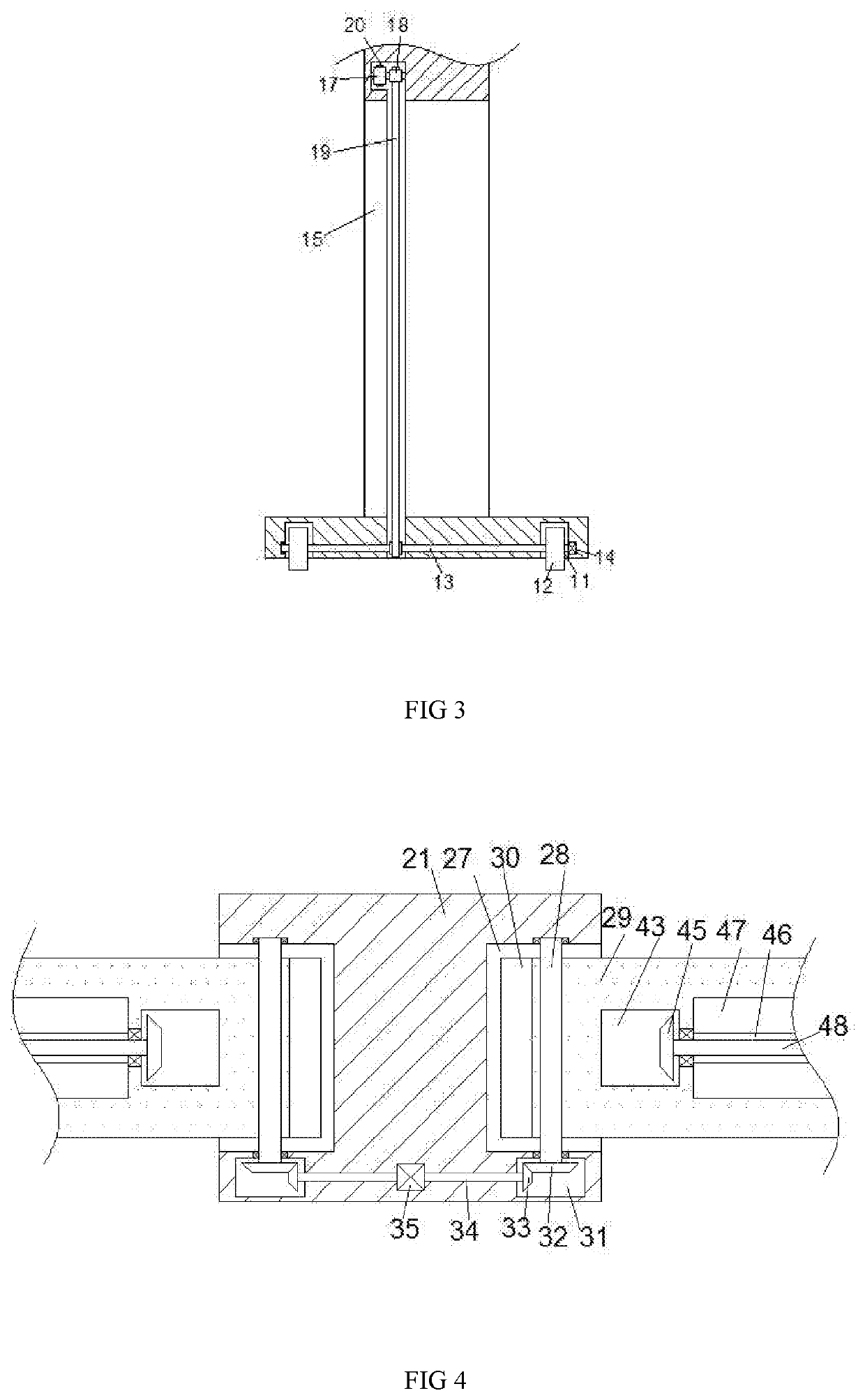

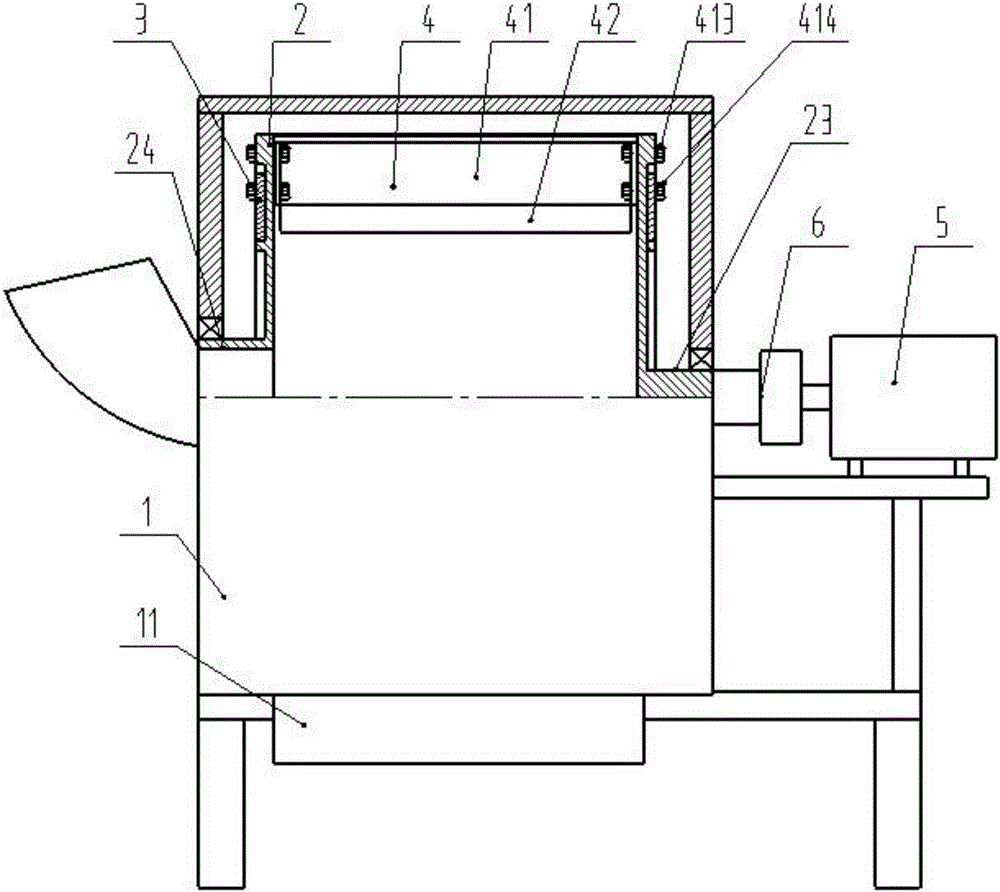

Mounting device for digital radiography (DR) detection equipment

ActiveCN106949352AAdjustable installation positionFirmly connectedStands/trestlesMaterial analysis by transmitting radiationEngineeringDigital radiography

The invention relates to a mounting device for digital radiography (DR) detection equipment. The mounting device comprises a suspension rod, a first telescopic piece, a second telescopic piece, a third telescopic piece, a first connecting piece, a second connecting piece and a third connecting piece. One end of the first telescopic piece is movably connected with the suspension rod, and the other end of the first telescopic piece is connected with the first connecting piece. The first connecting piece is used for being connected with the rear portion of a DR machine. One end of the second telescopic piece is movably connected with the suspension rod, and the other end of the second telescopic piece is connected with the second connecting piece. The second connecting piece is used for being connected with the front portion of the DR machine. One end of the third telescopic piece is movably connected with the suspension rod, and the other end of the third telescopic piece is connected with the third connecting piece. The third connecting piece is used for being connected with an imaging plate. By means of the mounting device for the DR detection equipment, the mounting positions of the DR machine and the imaging plate can be adjusted conveniently, and the detection efficiency is high.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

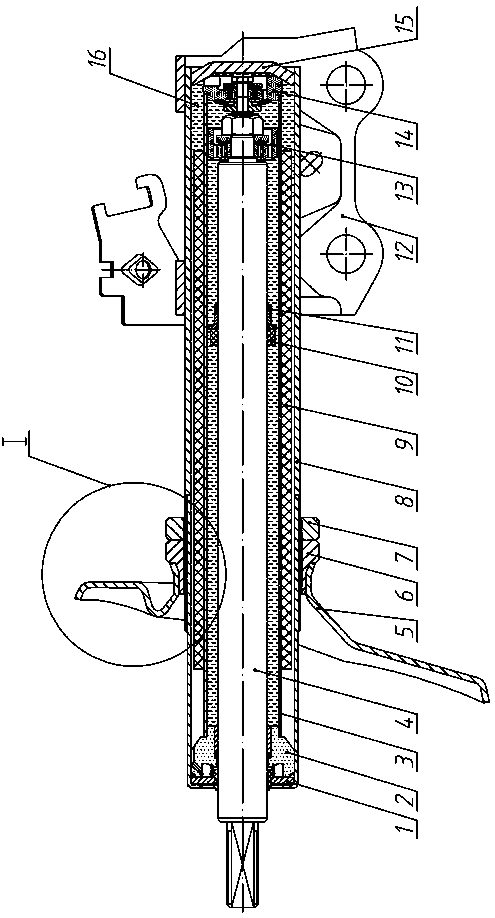

Foamed rubber filled type/adjustable elastic car shock absorber

InactiveCN104389938AGood compression rebound rateReduce backlashSpringsLiquid based dampersPiston rodShock absorber

The invention relates to an automobile part, in particular to a foamed rubber filled type / adjustable elastic car shock absorber. The foamed rubber filled type / adjustable elastic car shock absorber has an oil storage reservoir, wherein a working cylinder and a piston rod are installed in the oil storage reservoir, an oil seal and a guider are installed at the front end of the working cylinder, a compression valve subassembly and an oil storage reservoir tail seat are installed at the tail end of the working cylinder, a piston subassembly is installed at the tail end of the piston rod, a spring disc is installed at the middle section of the outer wall of the oil storage reservoir and a connecting support installed at the rear section. The foamed rubber filled type / adjustable elastic car shock absorber is characterized in that a foamed rubber sleeve is installed between the oil storage reservoir and the working cylinder, and a gap exists between the foamed rubber sleeve and the inner wall of the oil storage reservoir or the outer wall of the working cylinder, or an axial oil through groove is formed in the inner wall or the outer wall of the foamed rubber sleeve. The foamed rubber filled type / adjustable elastic car shock absorber effectively solves the problems of fault at morning and idle running of the existing shock absorber, can improve the automobile stability and comfort, and is mainly applicable to car suspension systems.

Owner:WUXUE YANGFEI SHOCK ABSORBER MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com