Transmission shaft intermediate support connecting structure capable of adjusting mounting position

A technology of intermediate support and installation position, applied in the direction of control device, transportation and packaging, vehicle components, etc., can solve the problems of high manufacturing cost, installation error cannot be adjusted accordingly, and achieve low production cost and reduce installation. Error, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

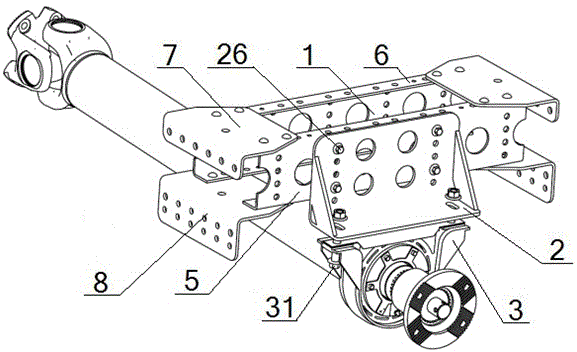

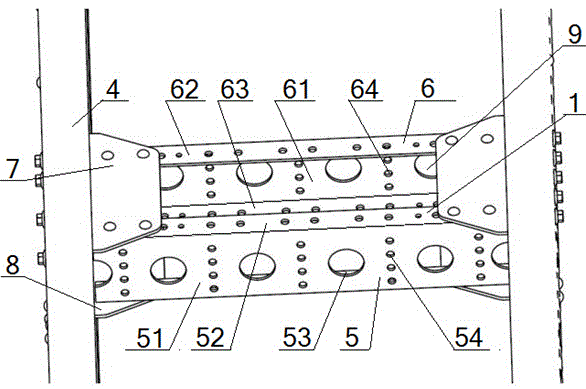

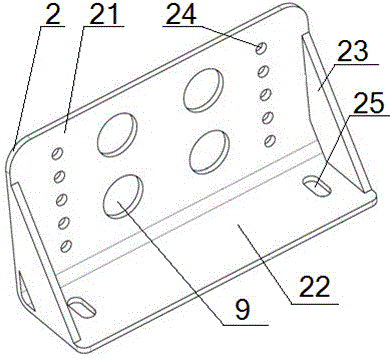

[0044] see figure 1 – image 3 , a transmission shaft intermediate support connection structure with adjustable installation position, comprising a crossbeam assembly 1 and a transmission shaft intermediate support assembly 3 fixedly connected to its middle, the two ends of the crossbeam assembly 1 are respectively connected to the longitudinal beams of two vehicle frames 4. Fixed connection, the transmission shaft intermediate support connection structure also includes a connecting bracket 2, the top of the transmission shaft intermediate support assembly 3 is fixedly connected to the middle part of the beam assembly 1 through the connecting bracket 2; the connecting bracket 2 includes a vertical plate 21 and horizontal plate 22, the bottom of the vertical plate 21 is fixedly connected to the rear end of the horizontal plate 22, and the two sides of the vertical plate 21 are respectively fixedly connected with the two sides of the horizontal plate 22 through two reinforcing r...

Embodiment 2

[0046] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0047] The middle part of the rear beam plate 61 is provided with a plurality of rear plate through-holes 64 corresponding to the bracket fixing holes 24, and the connecting bolts 26 provided through the through-holes 64 of the rear plate sequentially pass through the bracket fixing holes 24, the rear plate The through hole 64 is threadedly connected with the connecting nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com