Patents

Literature

465results about How to "Reduce installation errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

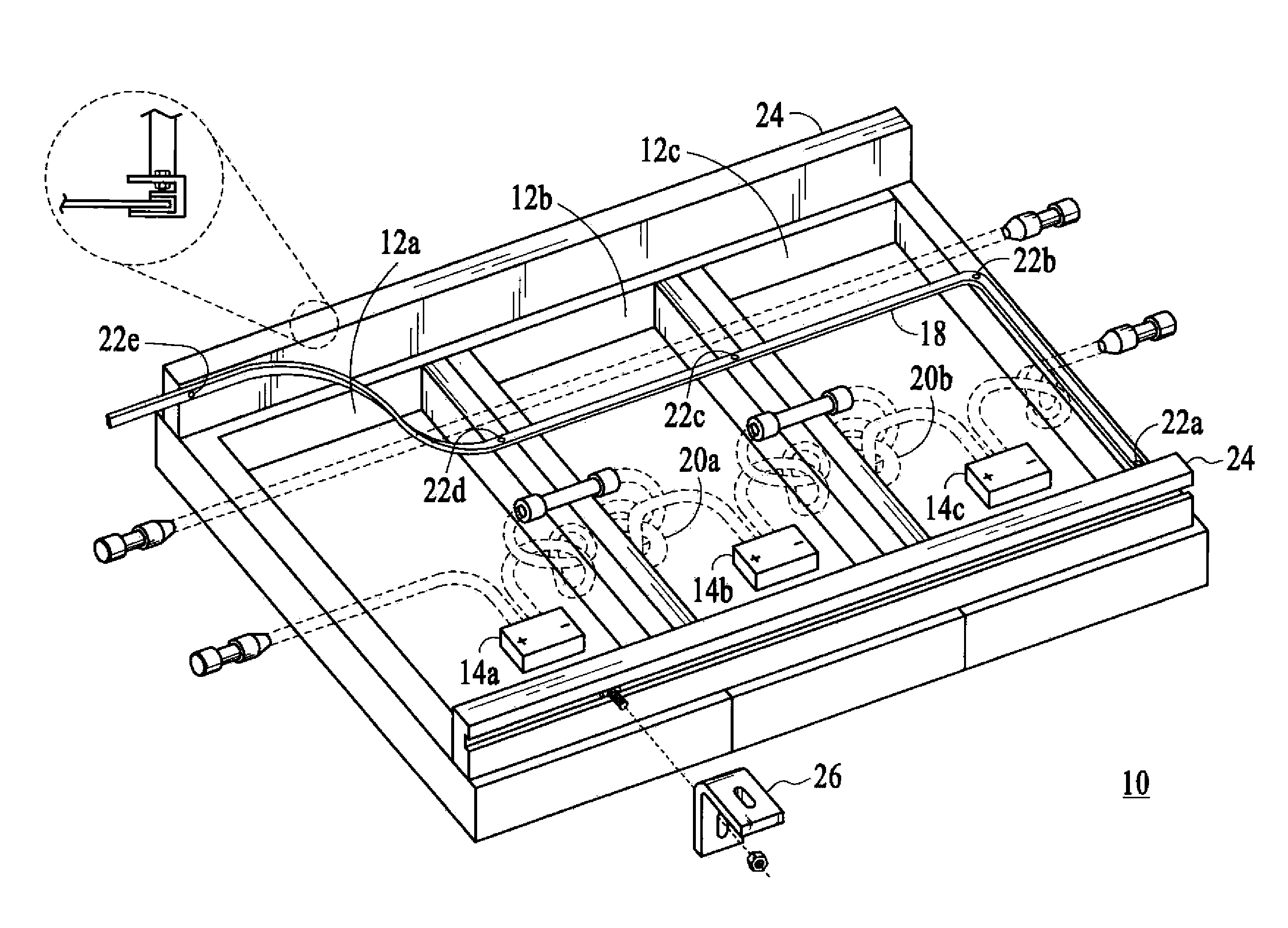

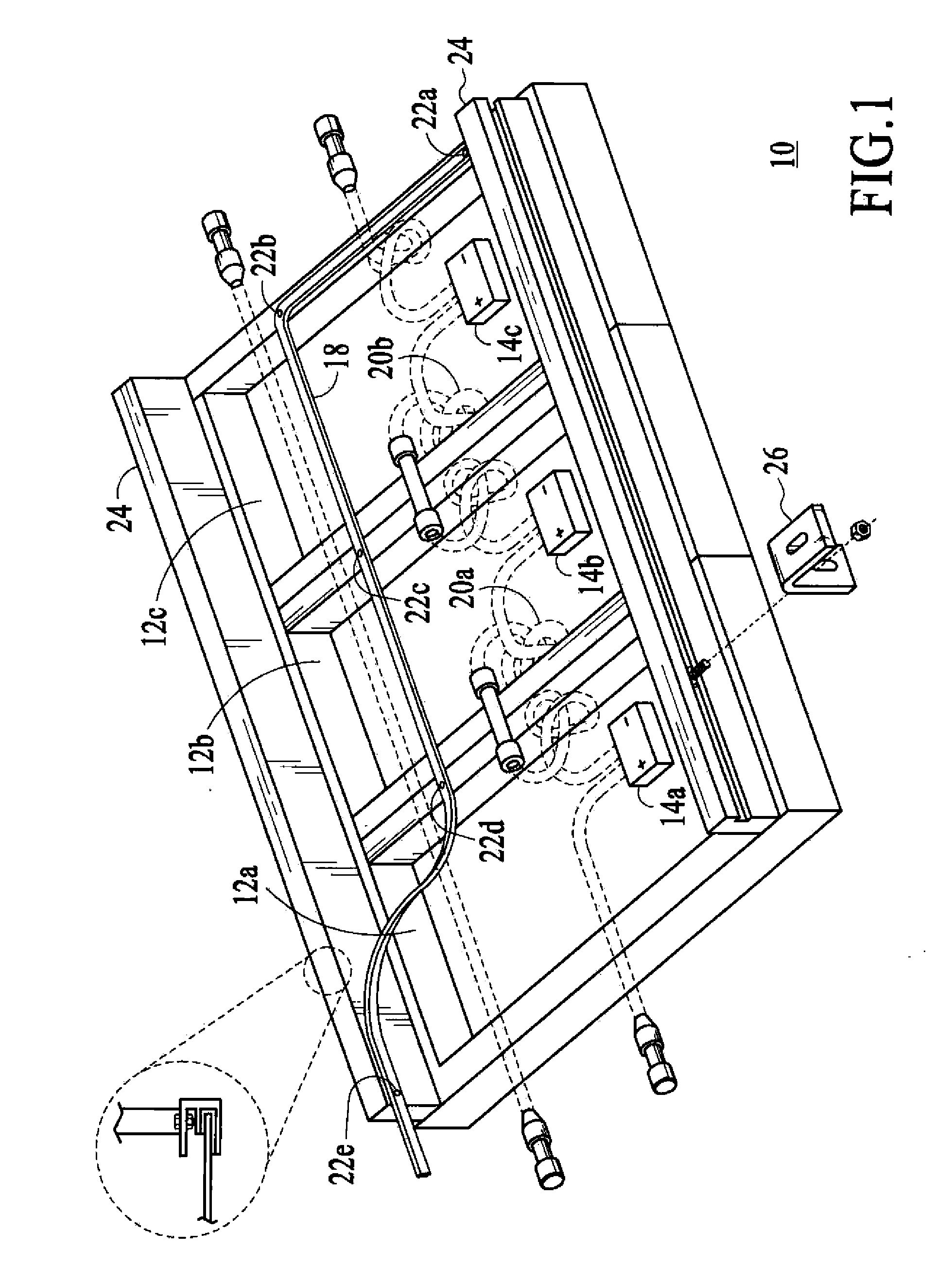

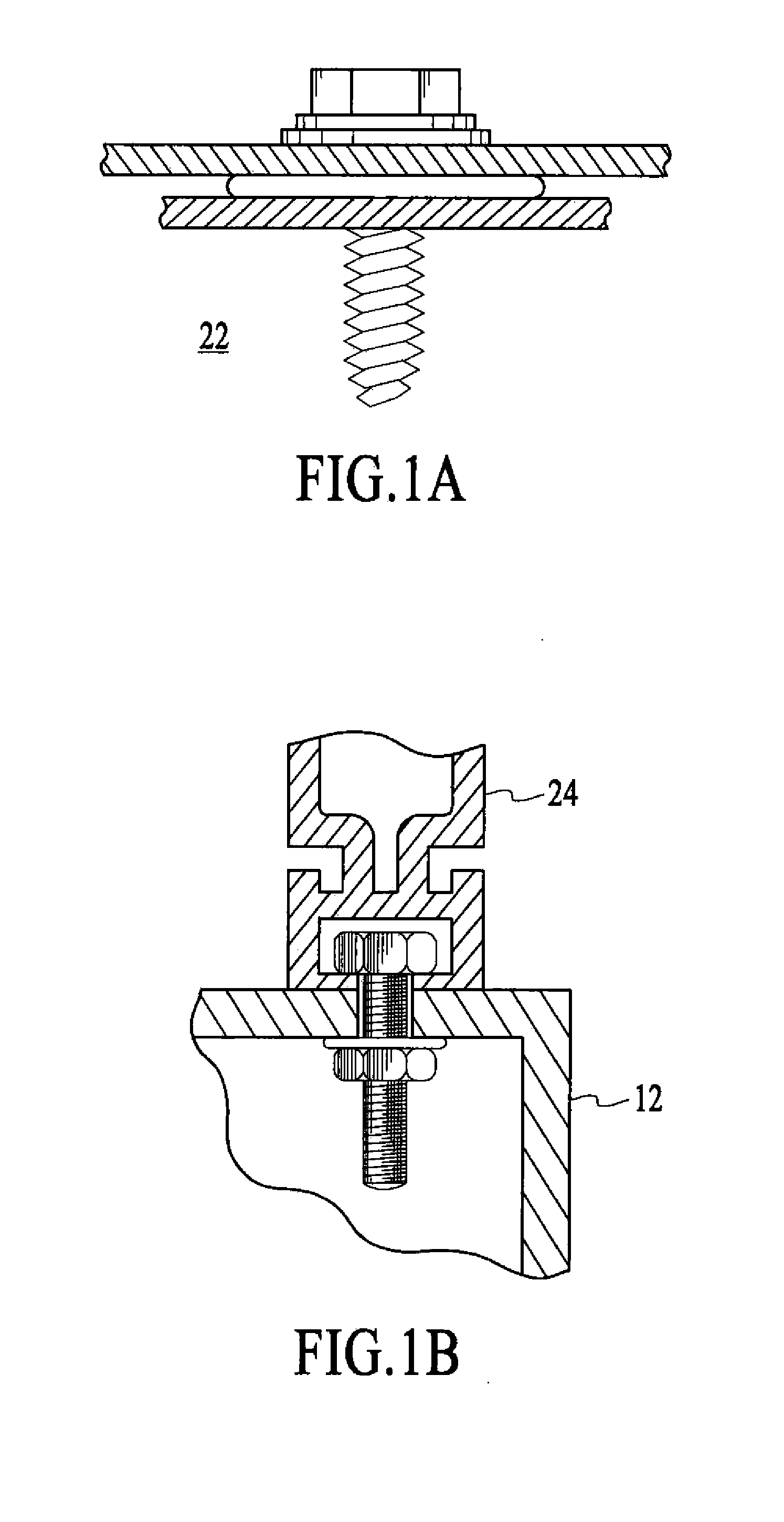

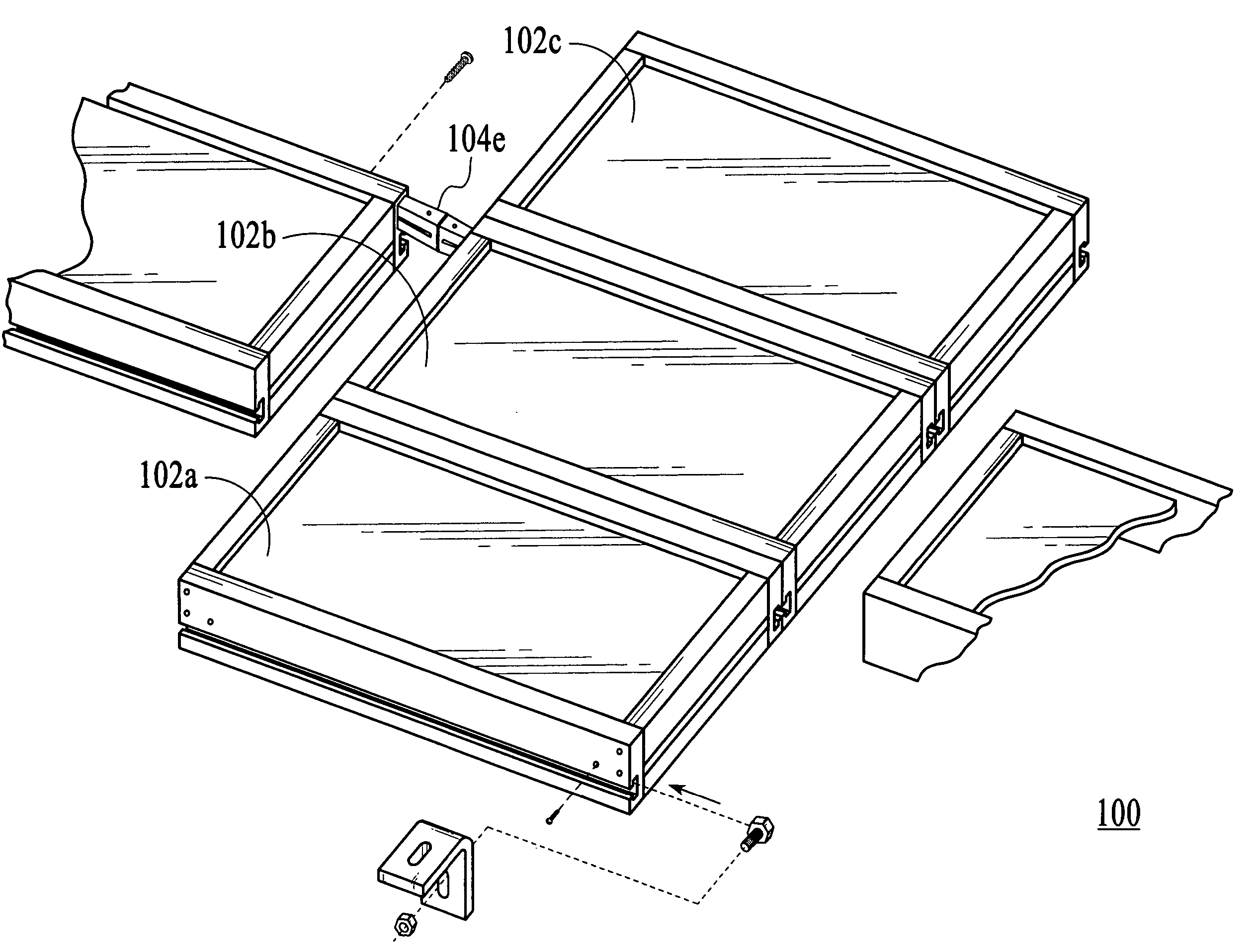

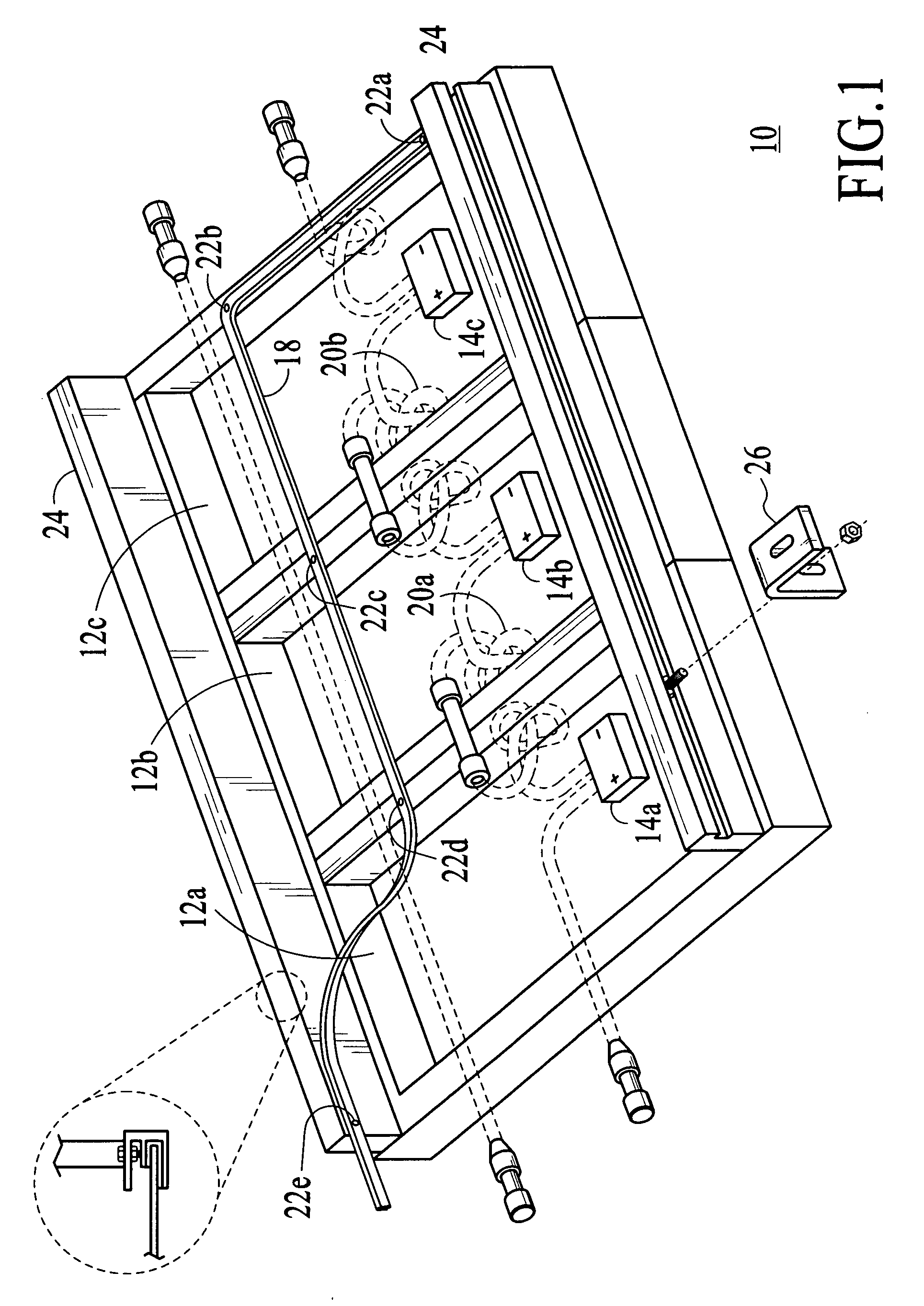

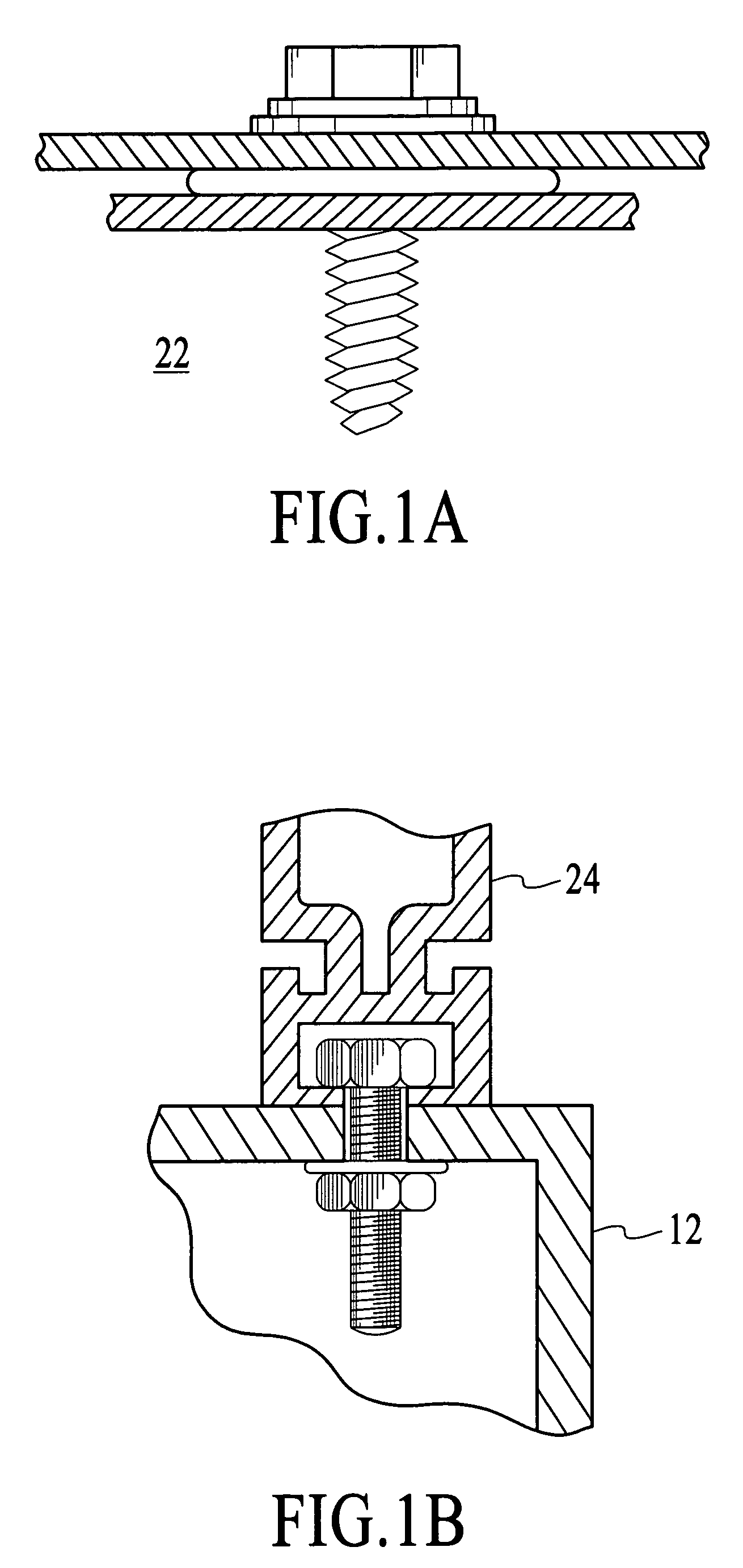

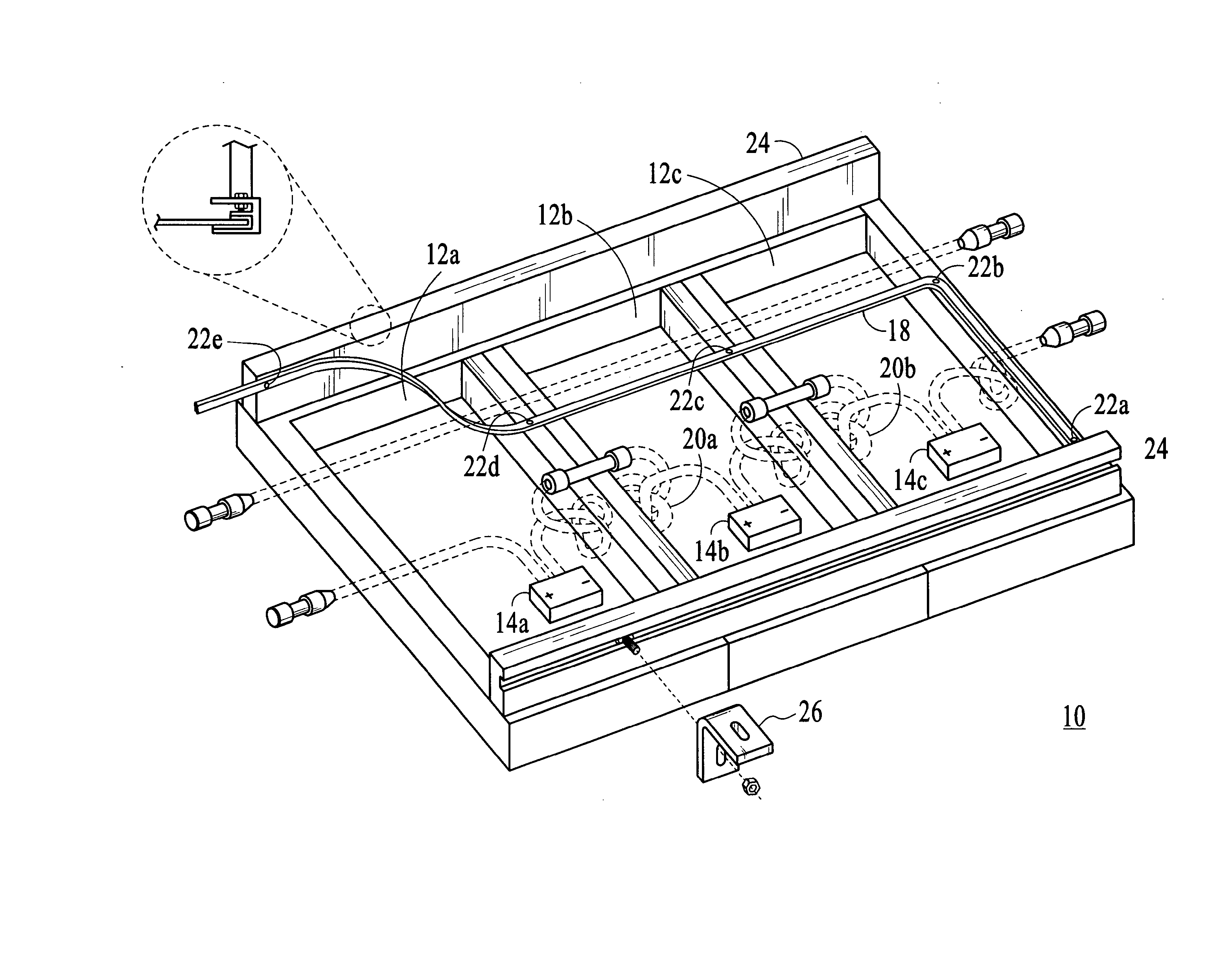

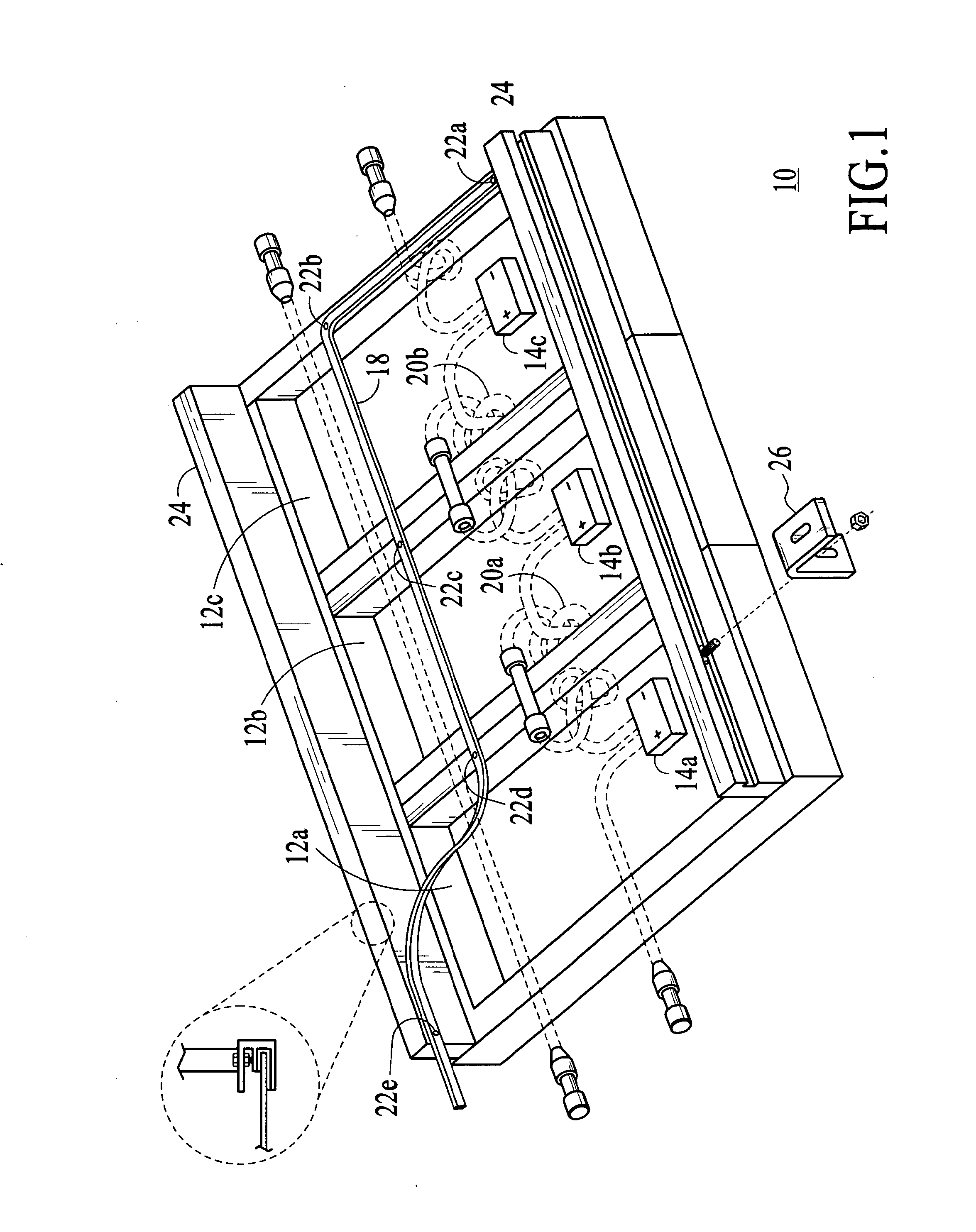

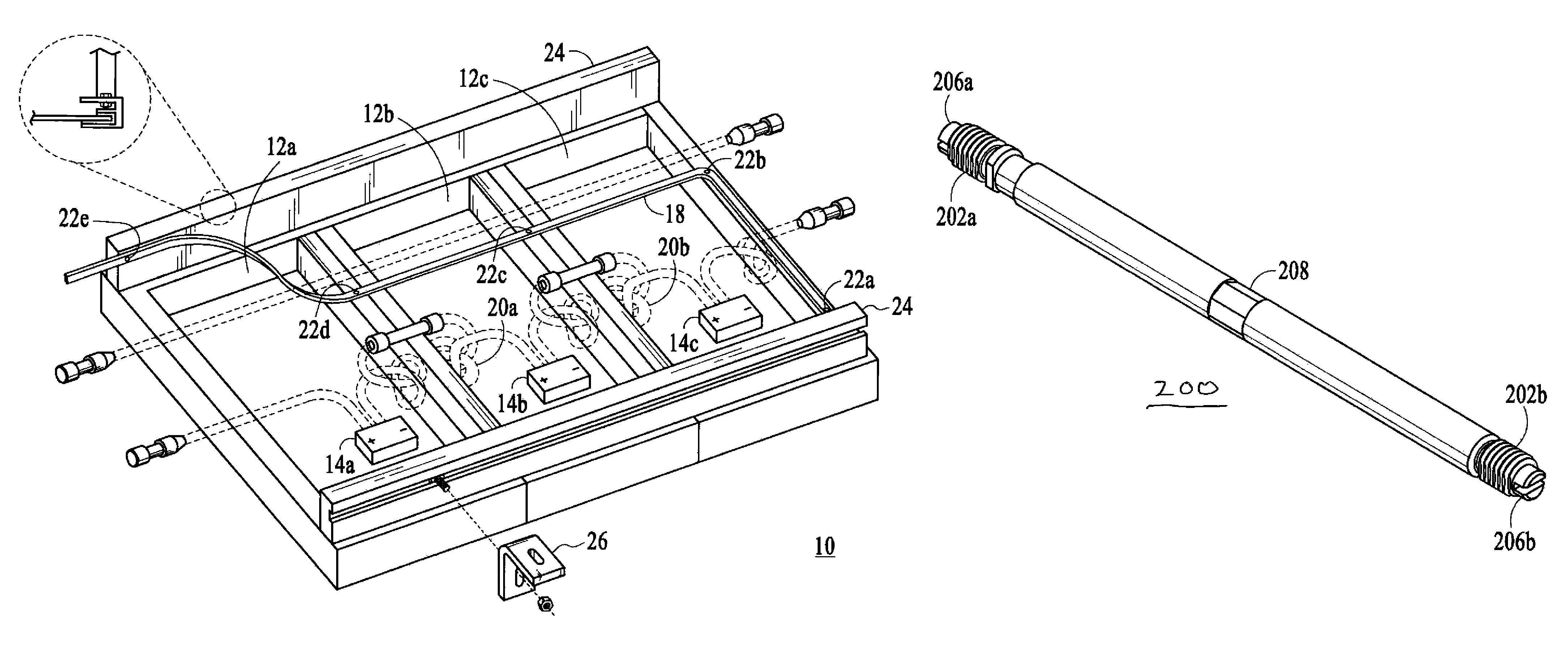

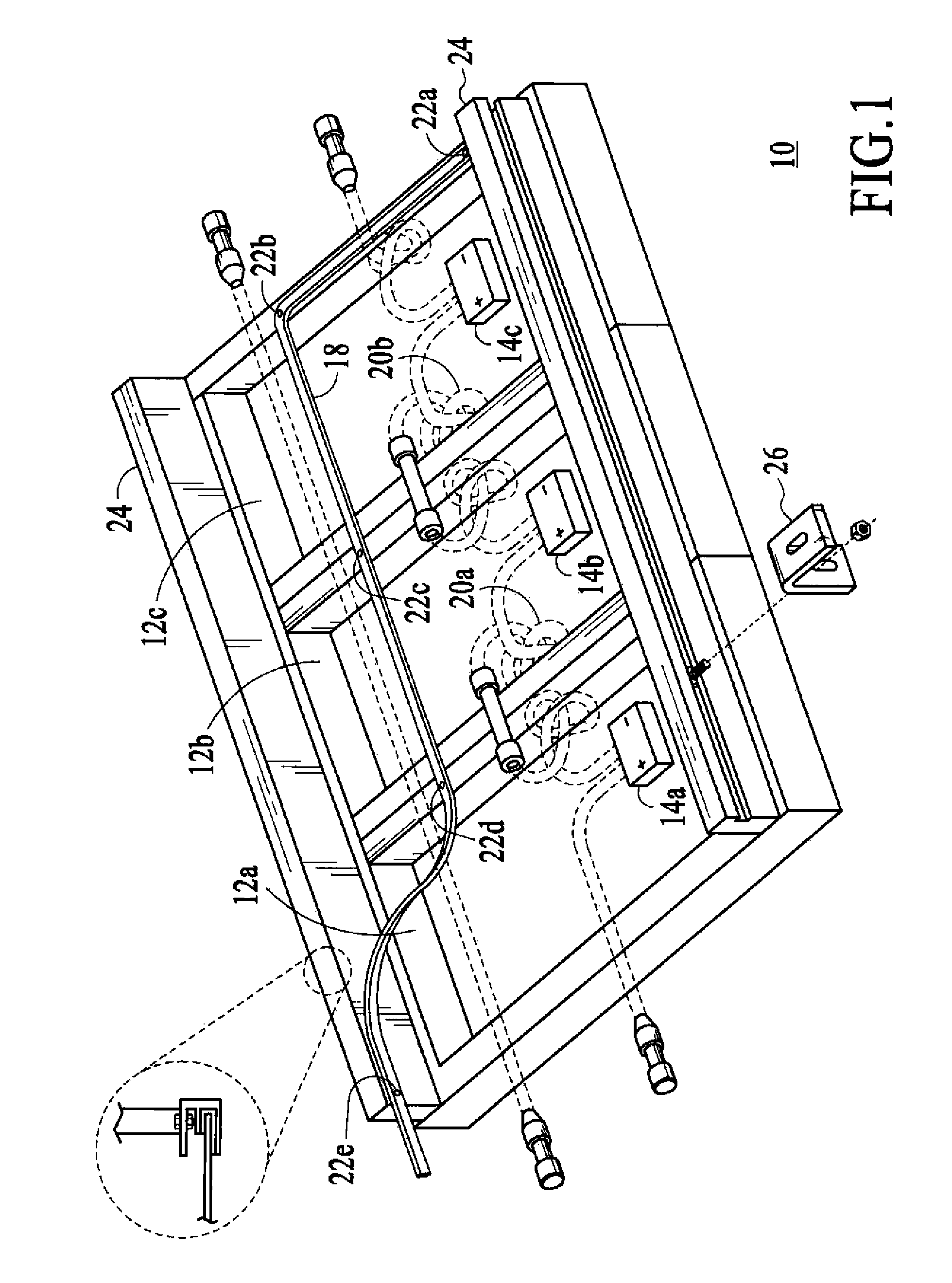

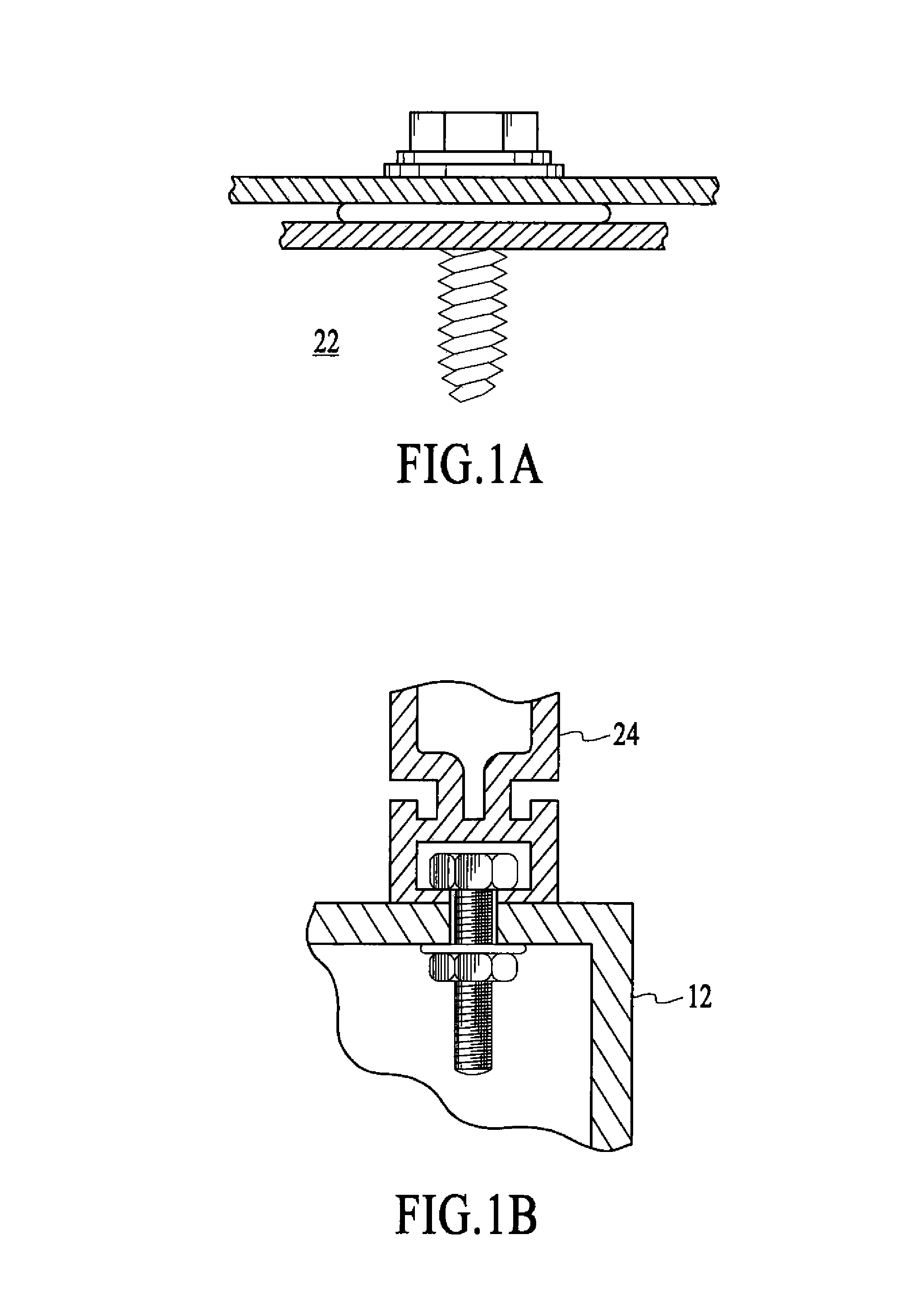

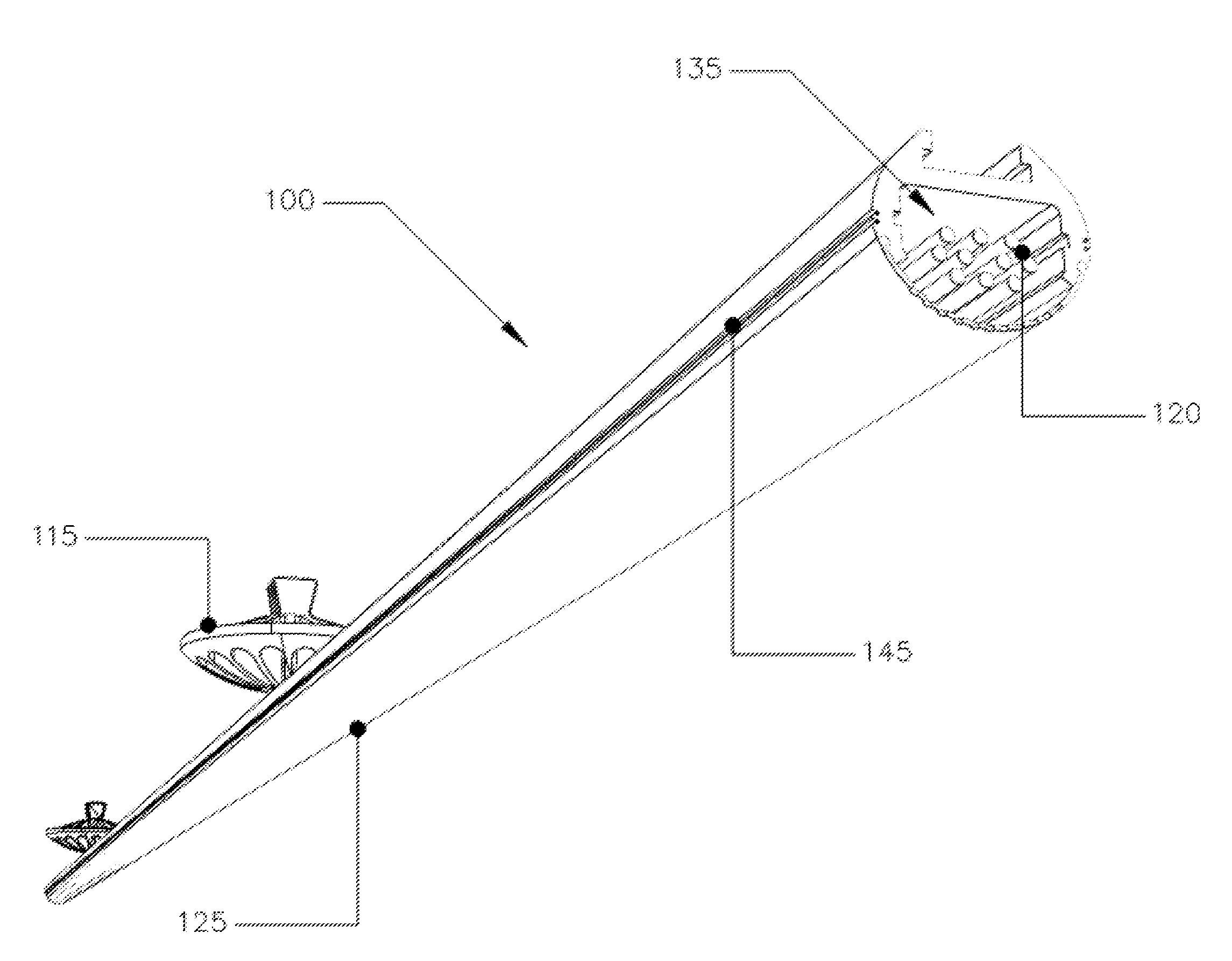

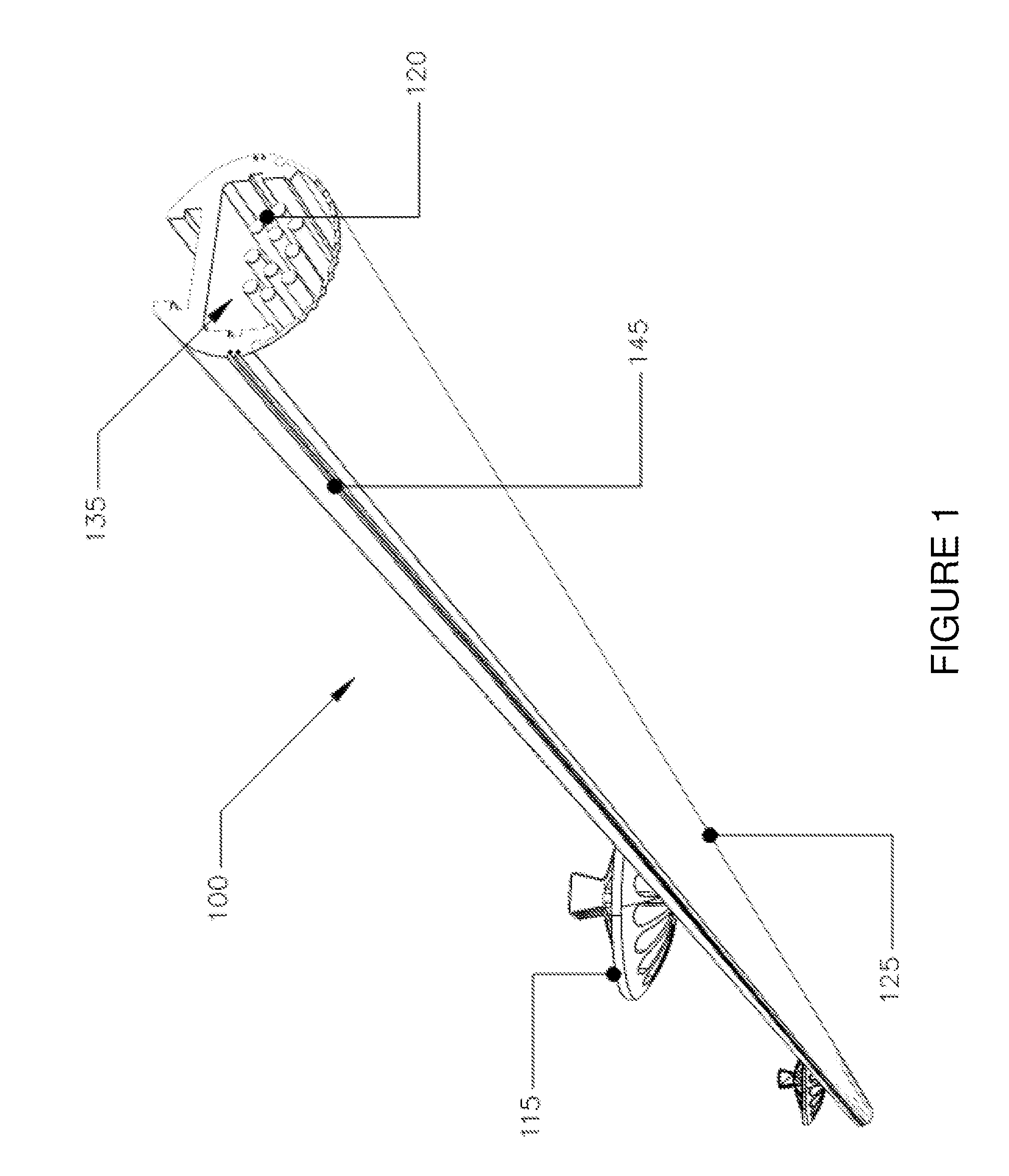

Mounting system for solar panels

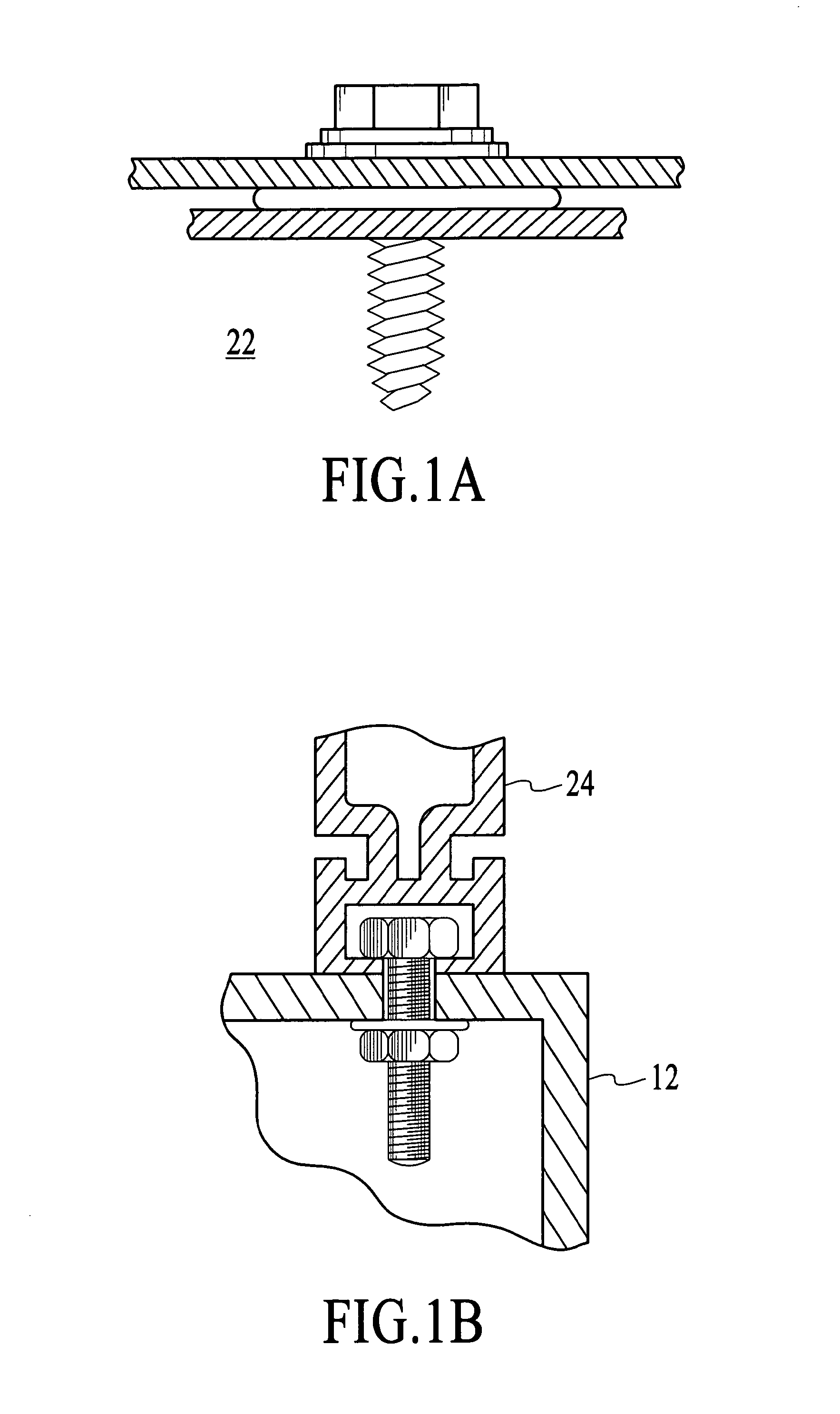

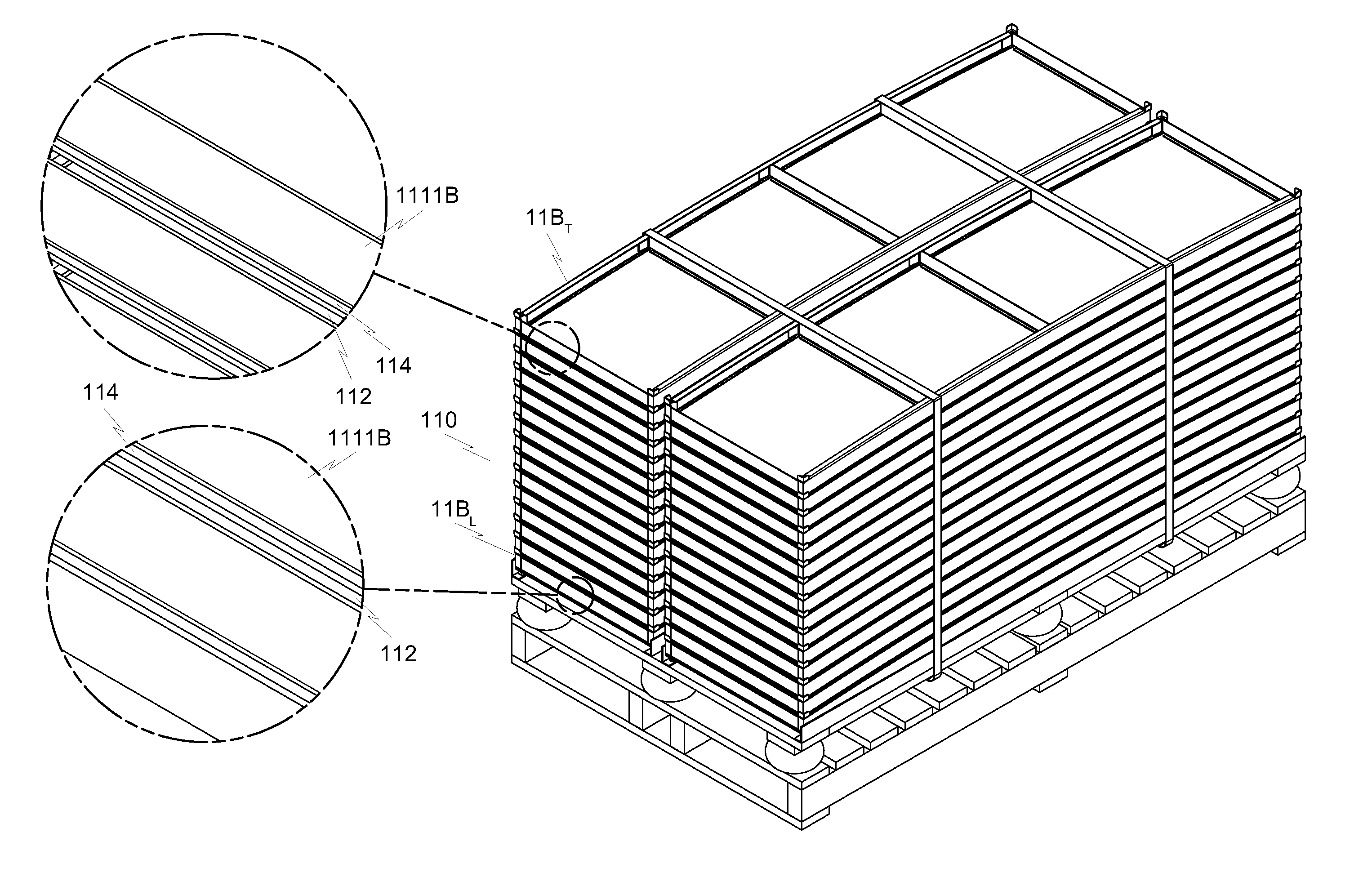

InactiveUS20090078299A1Simplify assembly of moduleChange defectsPhotovoltaic supportsSolar heating energyComputer moduleEngineering

An integrated module frame and racking system for a solar panel is disclosed. The solar panel comprises a plurality of solar modules and a plurality of splices for coupling the plurality of solar modules together. The plurality of splices provide a way to make the connected modules mechanically rigid both during transport to the roof and after mounting for the lifetime of the system, provide wiring connections between modules, provide an electrical grounding path for the modules, provide a way to add modules to the panel, and provide a way to remove or change a defective module. Connector mount assemblies are provided on the sides of the modules to simplify the electrical assembly of modules when the modules are connected together with splices and to simplify the final connection of external wiring to the module.

Owner:ANDALAY SOLAR

Mounting system for a solar panel

InactiveUS20050257453A1Simplify electrical assembly of moduleChange defectsPhotovoltaic supportsSolar heating energyEngineeringSolar module

An integrated module frame and racking system for a solar panel is disclosed. The solar panel comprises a plurality of solar modules and a plurality of splices for coupling the plurality of solar modules together. The plurality of splices provide a way to make the connected modules mechanically rigid both during transport to the roof and after mounting for the lifetime of the system, provide wiring connections between modules, provide an electrical grounding path for the modules, provide a way to add modules to the panel, and provide a way to remove or change a defective module. Connector sockets are provided on the sides of the modules to simplify the electrical assembly of modules when the modules are connected together with splices.

Owner:ANDALAY SOLAR

Mounting system for a solar panel

InactiveUS20070295393A1Simplify electrical assembly of moduleChange defectsPhotovoltaic supportsSolar heating energySolar moduleSolar energy

An integrated module fame and racking system for a solar panel is disclosed. The solar panel comprises a plurality of solar modules and a plurality of splices for coupling the plurality of solar modules together. The plurality of splices provide a way to make the connected modules mechanically rigid both during transport to the roof and after mounting for the lifetime of the system, provide wiring connections between modules, provide an electrical grounding path for the modules, provide a way to add modules to the panel, and provide a way to remove or change a defective module. Connector sockets are provided on the sides of the modules to simplify the electrical assembly of modules when the modules are connected together with splices.

Owner:ANDALAY SOLAR

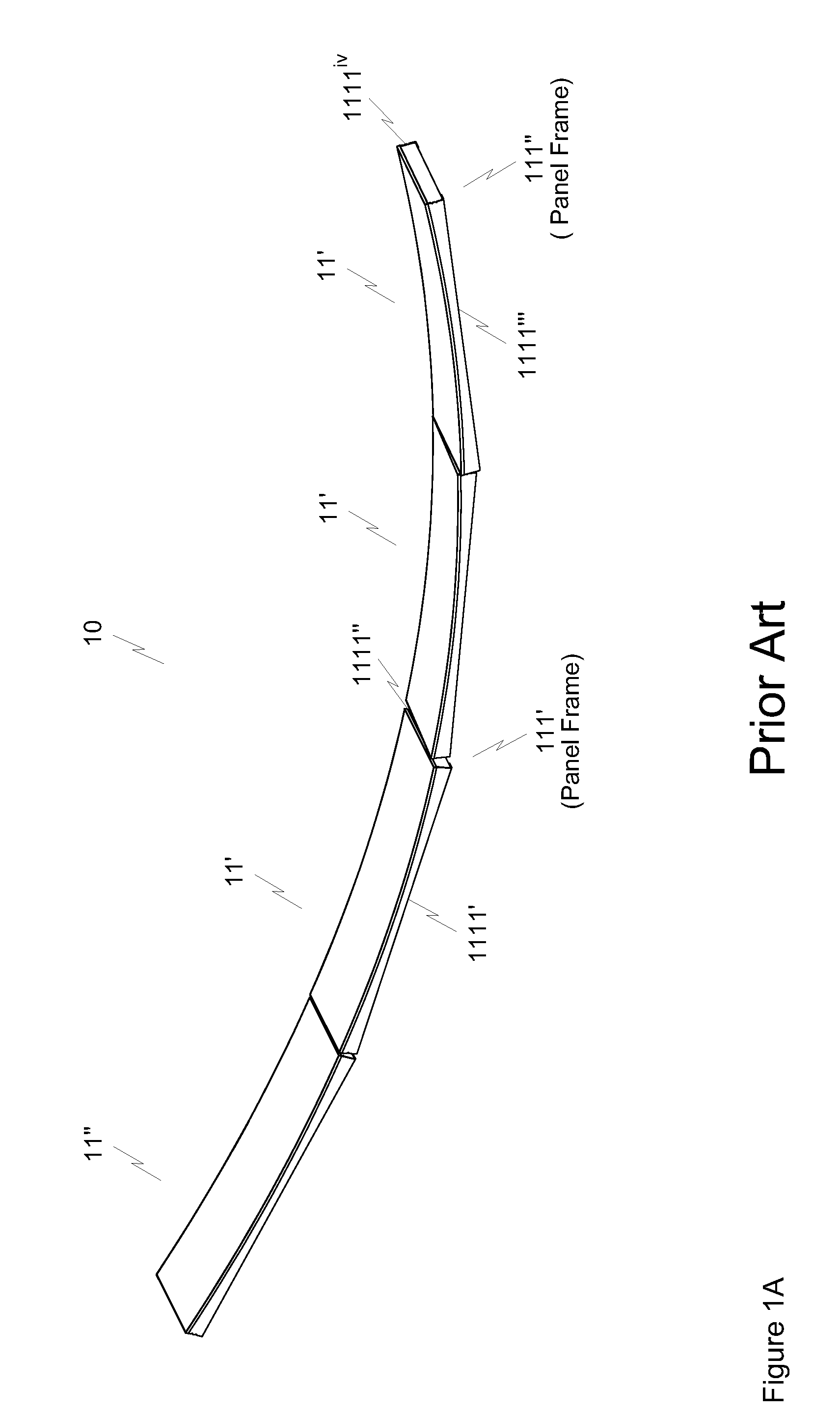

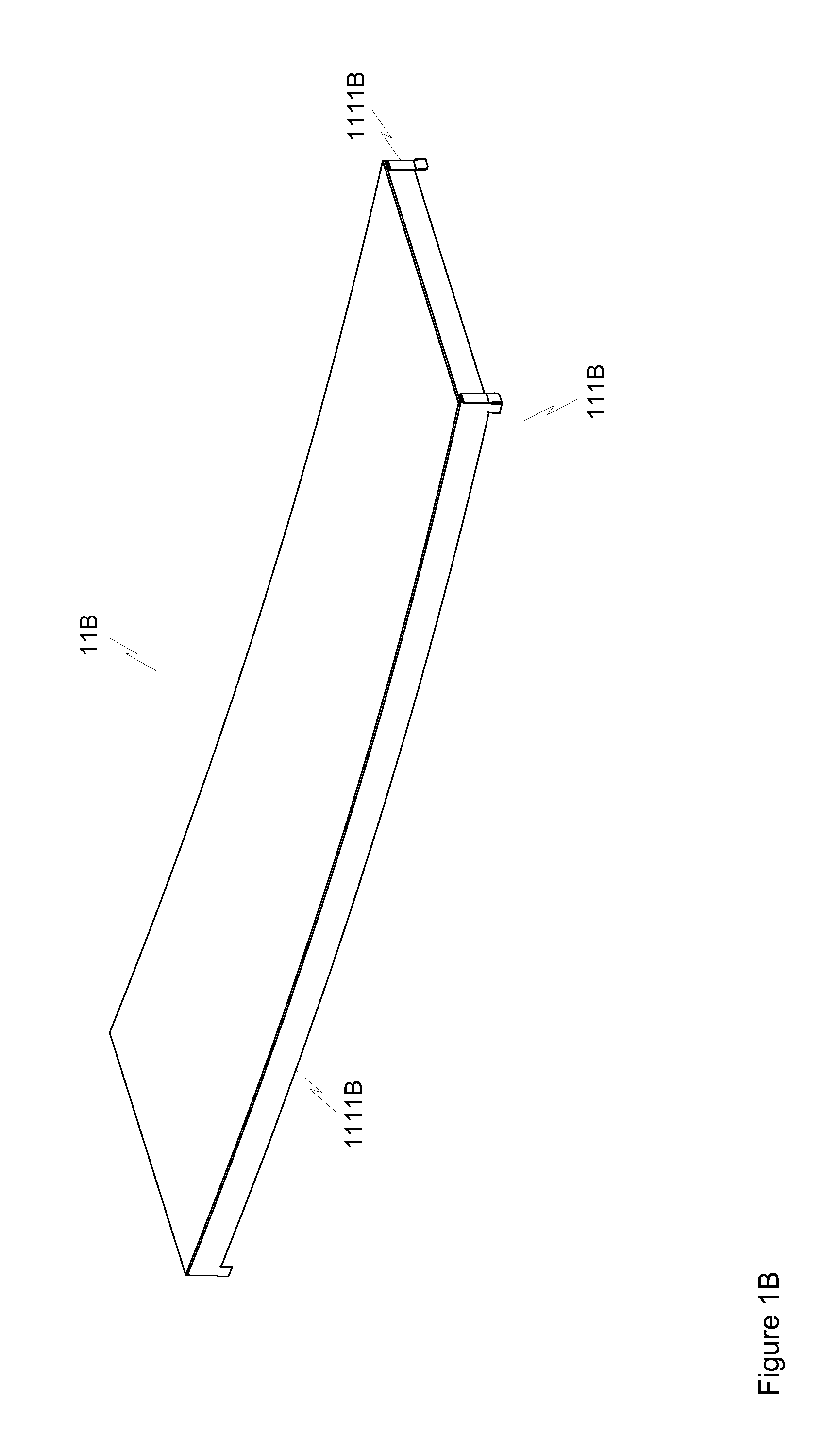

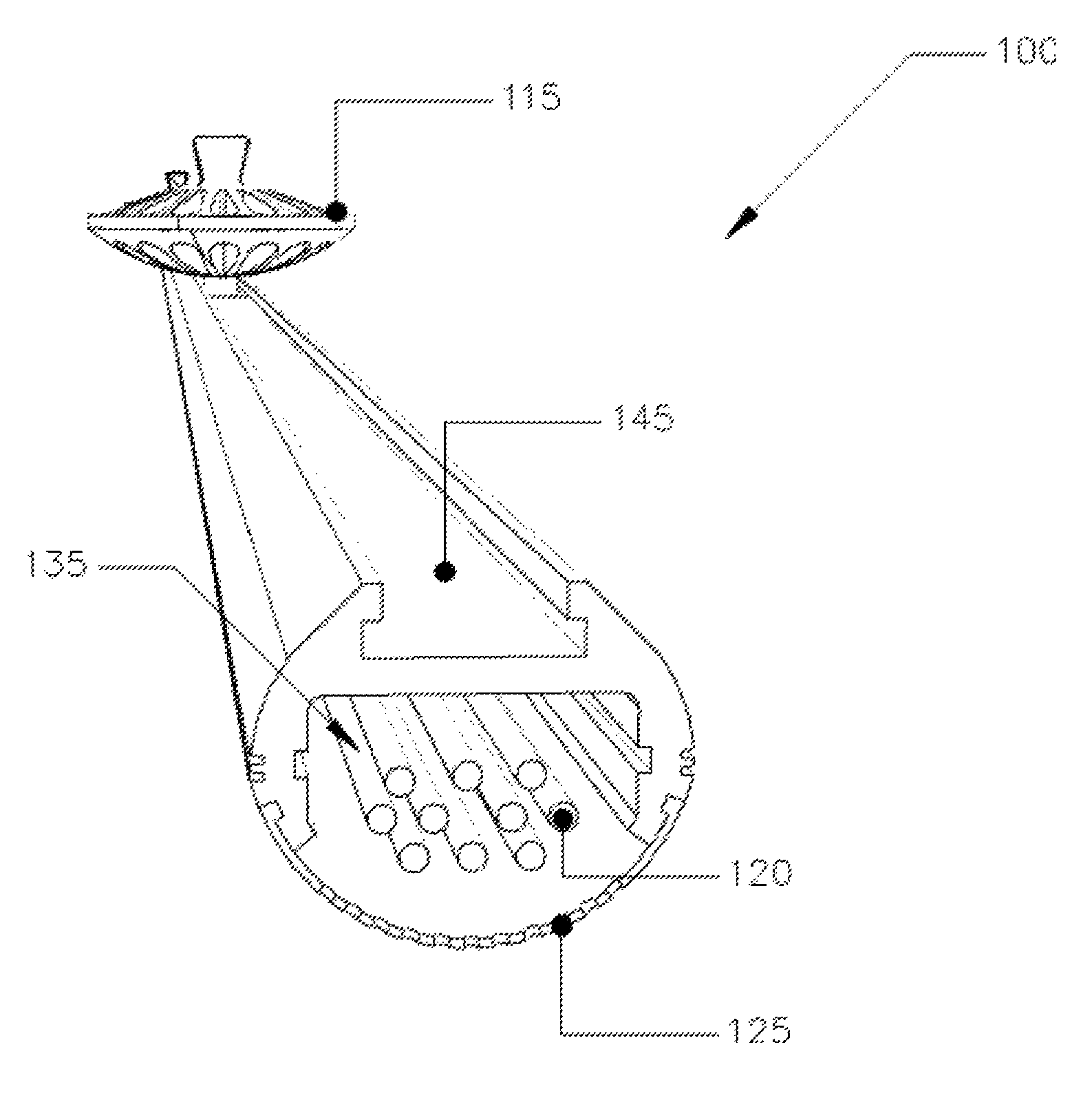

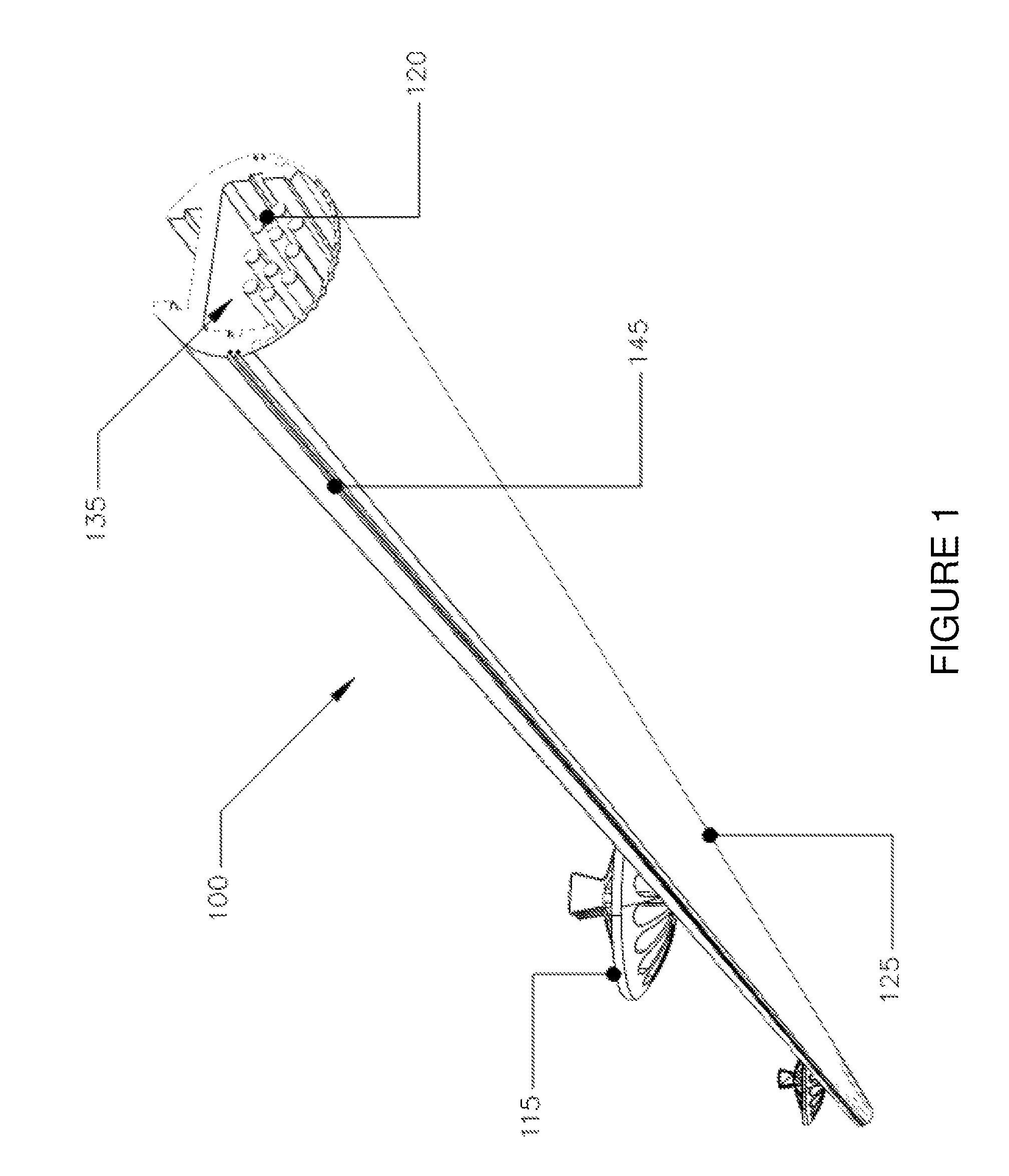

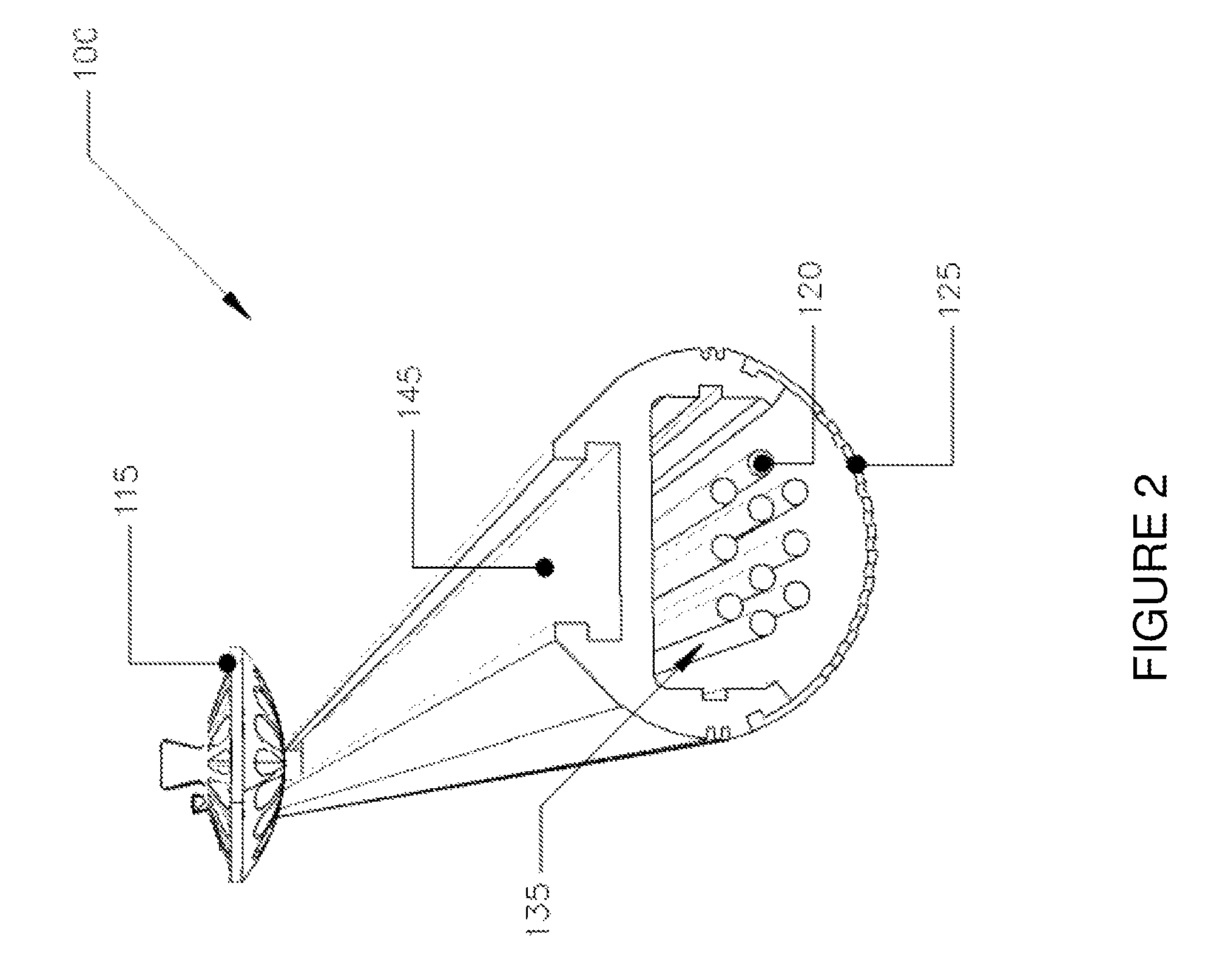

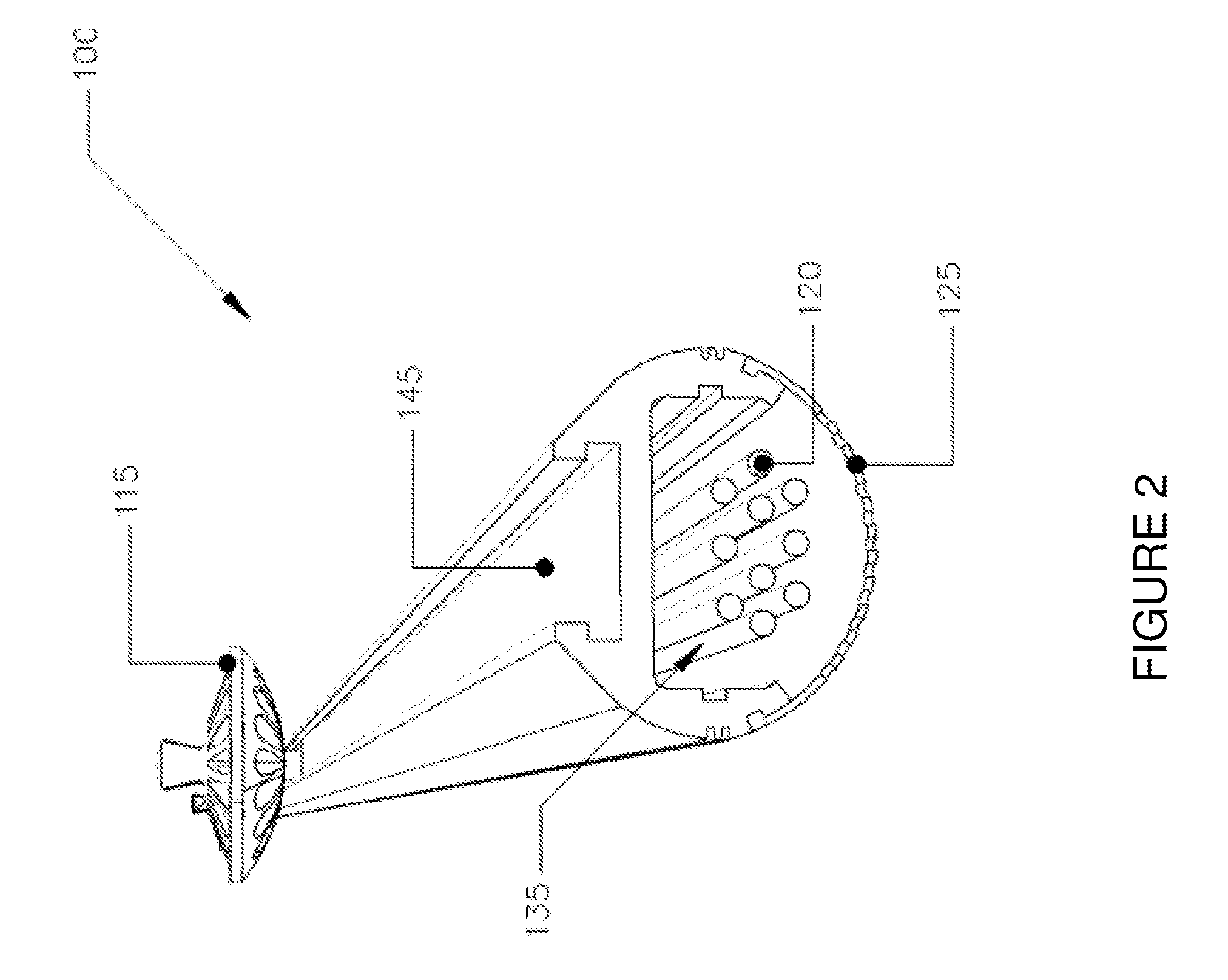

Systems for cost effective concentration and utilization of solar energy

InactiveUS20120037206A1Reduce absorptionLow dispersionPhotovoltaic supportsSolar heating energyHigh concentrationEngineering

The present invention is primarily directed to improvements to cost-effective systems for concentrating and using solar energy. The present invention co-optimizes the frame and the primary mirrors and secondary concentrator for a cost-effective very high concentration quasi-parabolic dish system that uses no moulded optics for the primary concentration, and also optimizes fabrication jigs for the main components of that design. The present invention also optimizes cell contacts and provides cost effective receiver cooling for dense receiver arrays for very high concentration photovoltaic systems. The present invention also includes a semi-dense receiver array that can provide a higher acceptance angle than a dense receiver array, and finally includes mutual-shading impact minimization methods and apparatus compatible with very high concentration photovoltaic systems.

Owner:NORMAN RICHARD

Mounting system for solar panels

InactiveUS8813460B2Easy to assembleChange defectsPhotovoltaic supportsSolar heating energyComputer moduleEngineering

An integrated module frame and racking system for a solar panel is disclosed. The solar panel comprises a plurality of solar modules and a plurality of splices for coupling the plurality of solar modules together. The plurality of splices provide a way to make the connected modules mechanically rigid both during transport to the roof and after mounting for the lifetime of the system, provide wiring connections between modules, provide an electrical grounding path for the modules, provide a way to add modules to the panel, and provide a way to remove or change a defective module. Connector mount assemblies are provided on the sides of the modules to simplify the electrical assembly of modules when the modules are connected together with splices and to simplify the final connection of external wiring to the module.

Owner:ANDALAY SOLAR

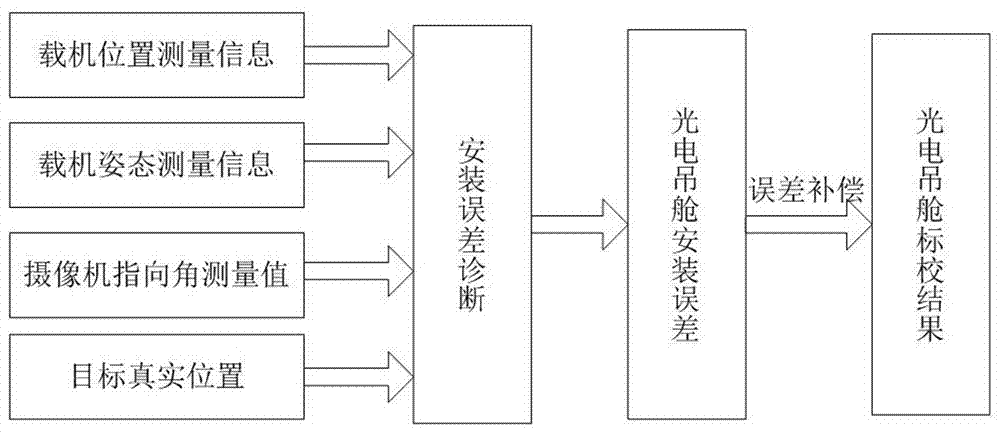

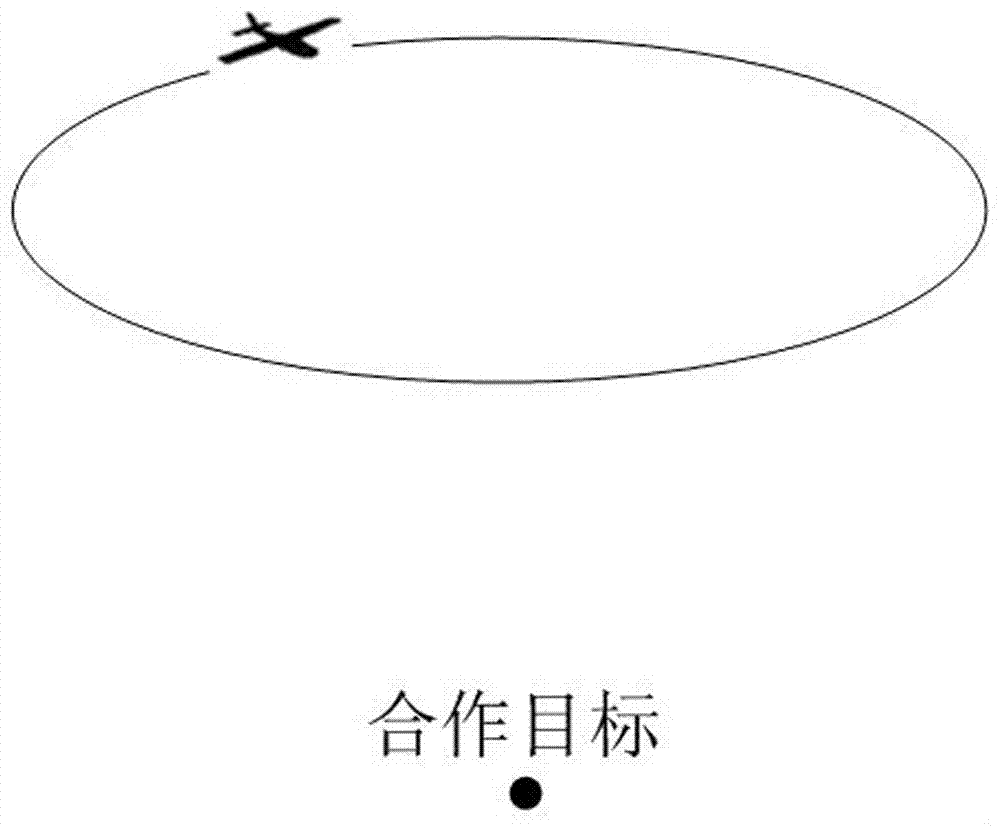

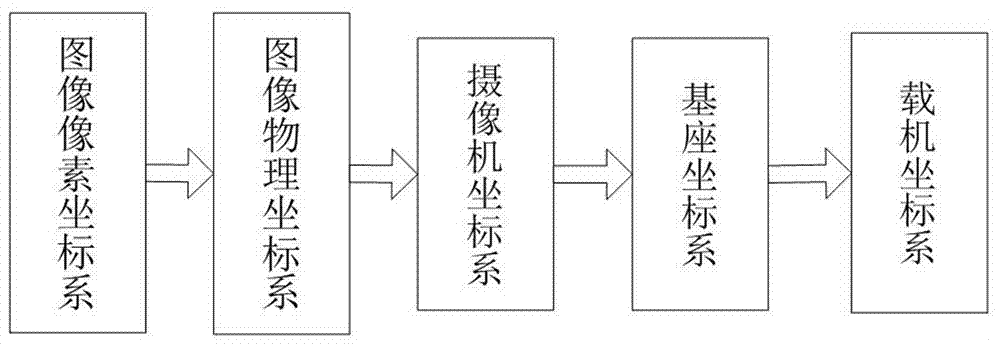

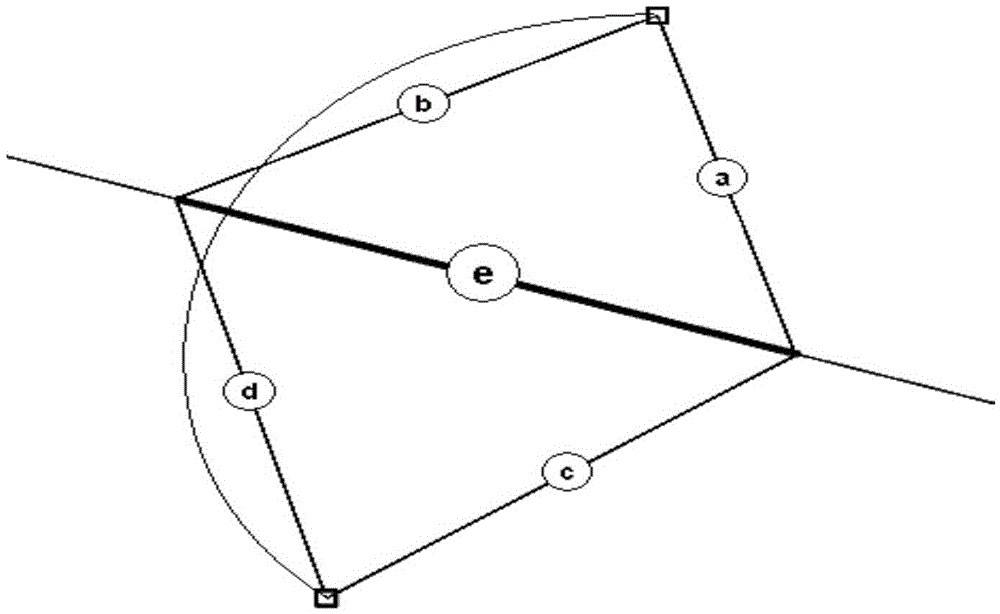

Method for calibrating installation error of optoelectronic pod of unmanned aerial vehicle

ActiveCN106871927AReduce installation errorsImprove efficiencyMeasurement devicesUncrewed vehicleLongitude

The invention discloses a method for calibrating the installation error of an optoelectronic pod of an unmanned aerial vehicle. The method comprises the following concrete steps: 1, firstly, determining a ground cooperation target point, and using a high precision differential global positioning system (GPS) to acquire longitude, latitude and elevation of the target point; 2, determining a flight alignment route of the unmanned aerial vehicle according to the cooperation target point; observing the cooperation target point, acquiring and recording image point coordinates of the cooperation target point, and carrying out coordinate transformation; 3, establishing an installation error diagnosis model; 4, identifying unknown parameters in the installation error diagnosis model and compensating for the installation error of the optoelectronic pod during a subsequent positioning process. According to the method, the installation angle error of the optoelectronic pod is obtained mainly by analyzing flight alignment data, and correction is performed during coordinate transformation, so that the problems that at present, the installation error calibration of the optoelectronic pod of an existing unmanned aerial vehicle is complicated to implement and inefficient are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Methods and apparatus for ceiling mounted systems

ActiveUS8172435B2Shorten the timeLow costPoint-like light sourceLighting support devicesModularityEngineering

Owner:LIGHTING DEFENSE GRP LLC

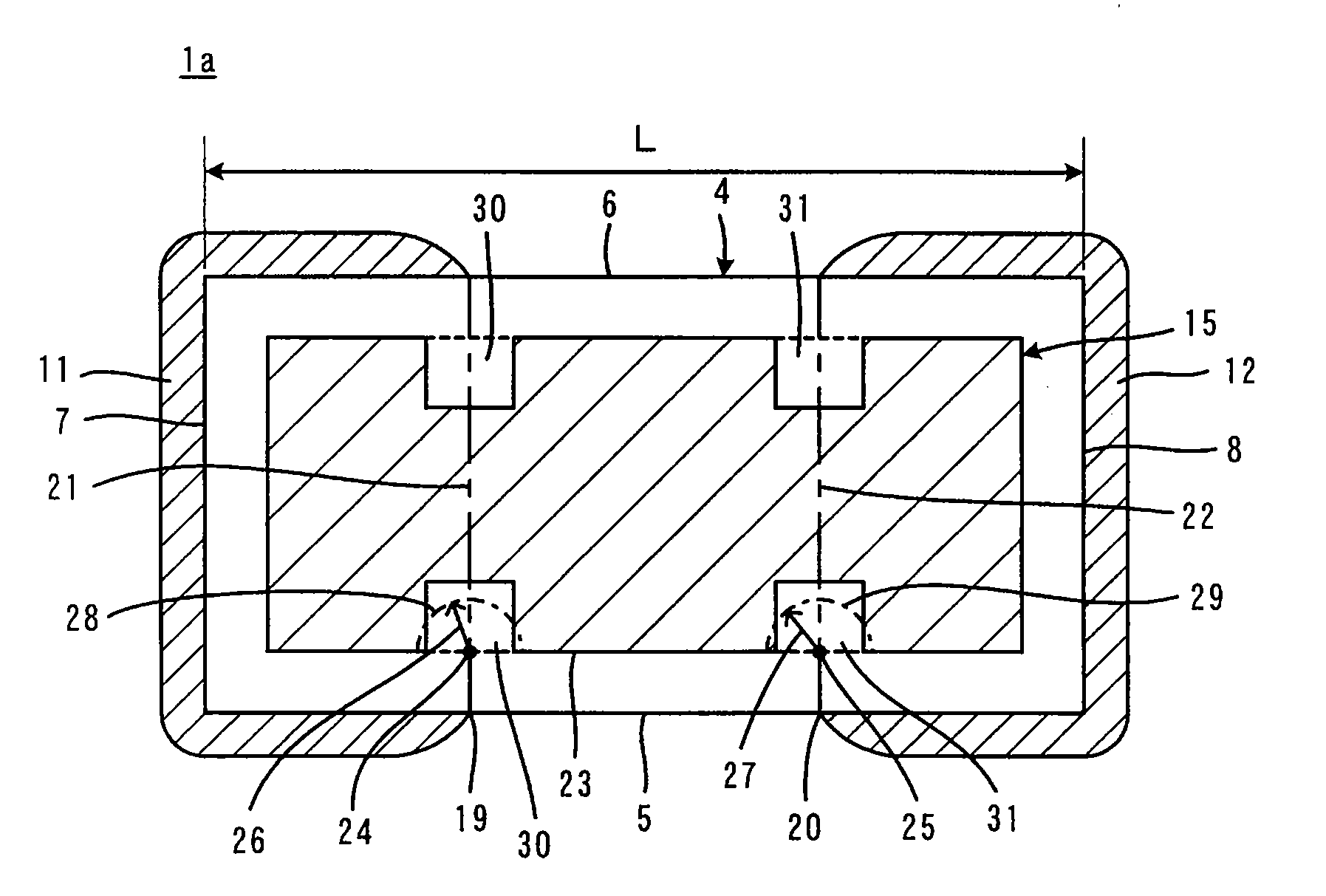

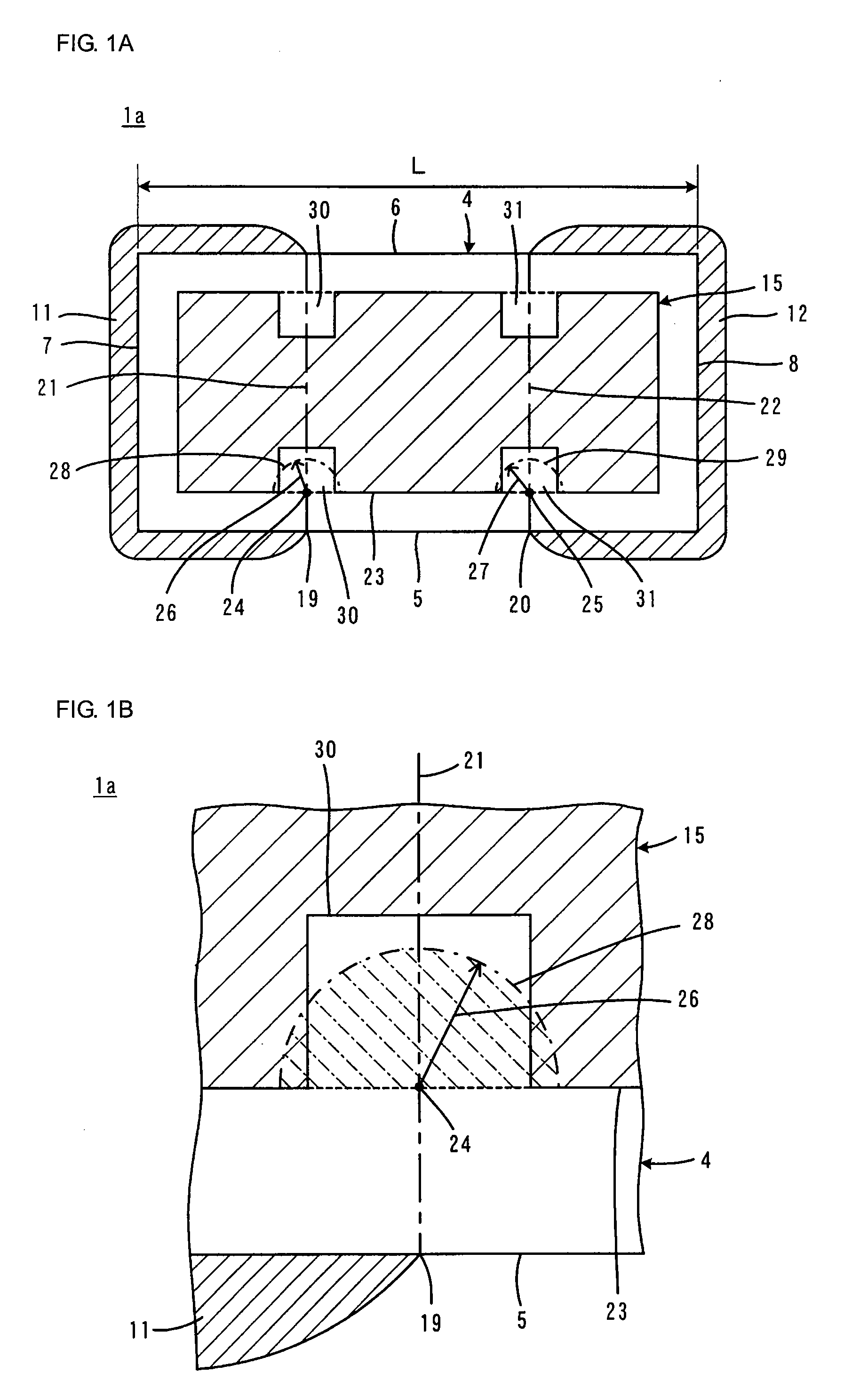

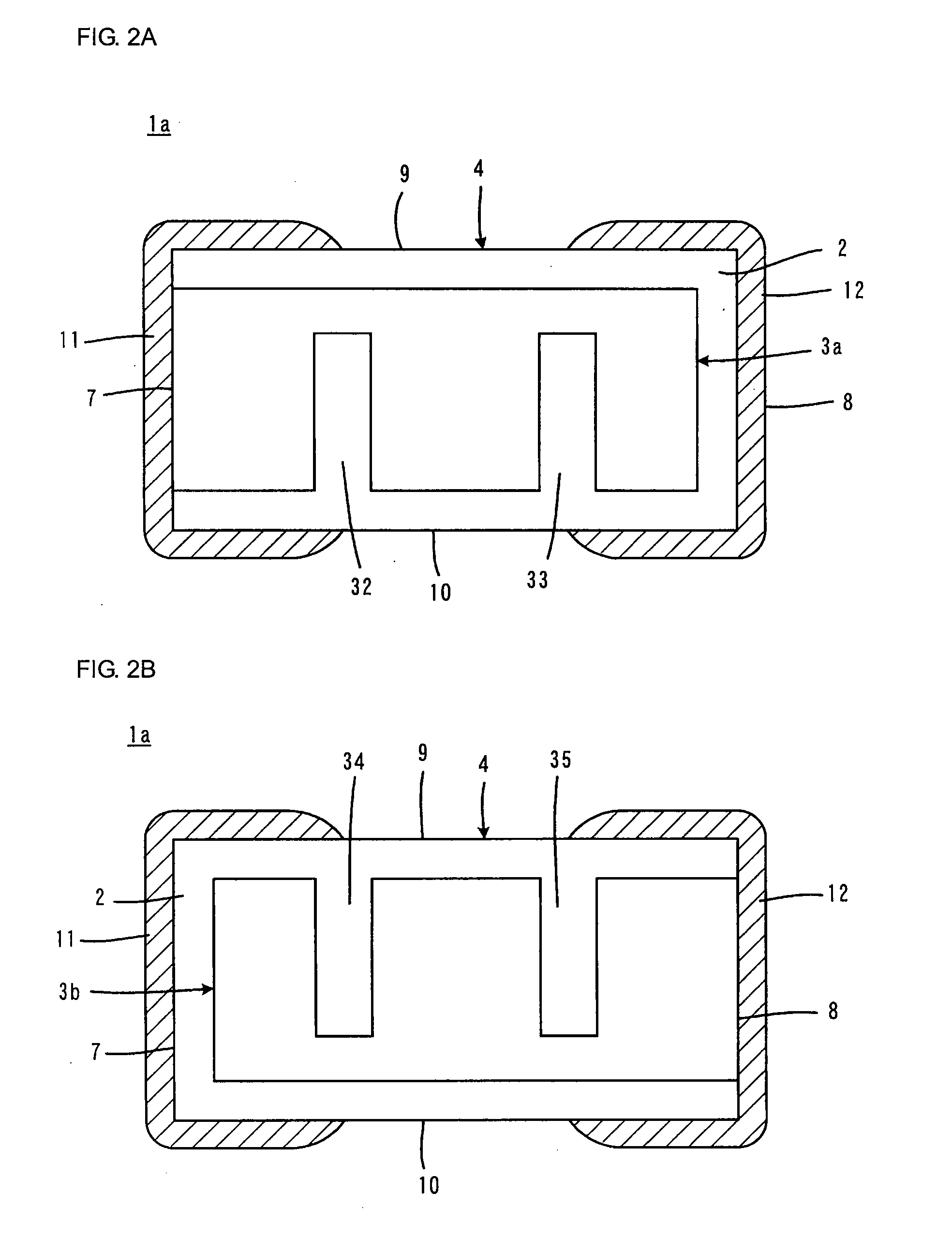

Multilayer ceramic capacitor

ActiveUS20080130198A1Distortion in low-activity regionSacrificing capacitanceFixed capacitor electrodesFixed capacitor dielectricCapacitanceLow activity

The “squeal” that occurs when an electric field is applied to a multilayer ceramic capacitor mounted on a substrate is suppressed by providing in an active part contributing to formation of capacitances between internal electrodes facing each other in a capacitor body, low-activity regions positioned near respective end edges of respective external electrodes. A facing area of the internal electrodes in the low-activity regions is less than or equal to one fifth that of the internal electrodes in a normal region having the same volume as that of the low-activity regions. This makes it possible to suppress occurrence of electric-field-induced distortion near the external electrodes bonded to a substrate and reduce the force that causes the substrate to bend.

Owner:MURATA MFG CO LTD

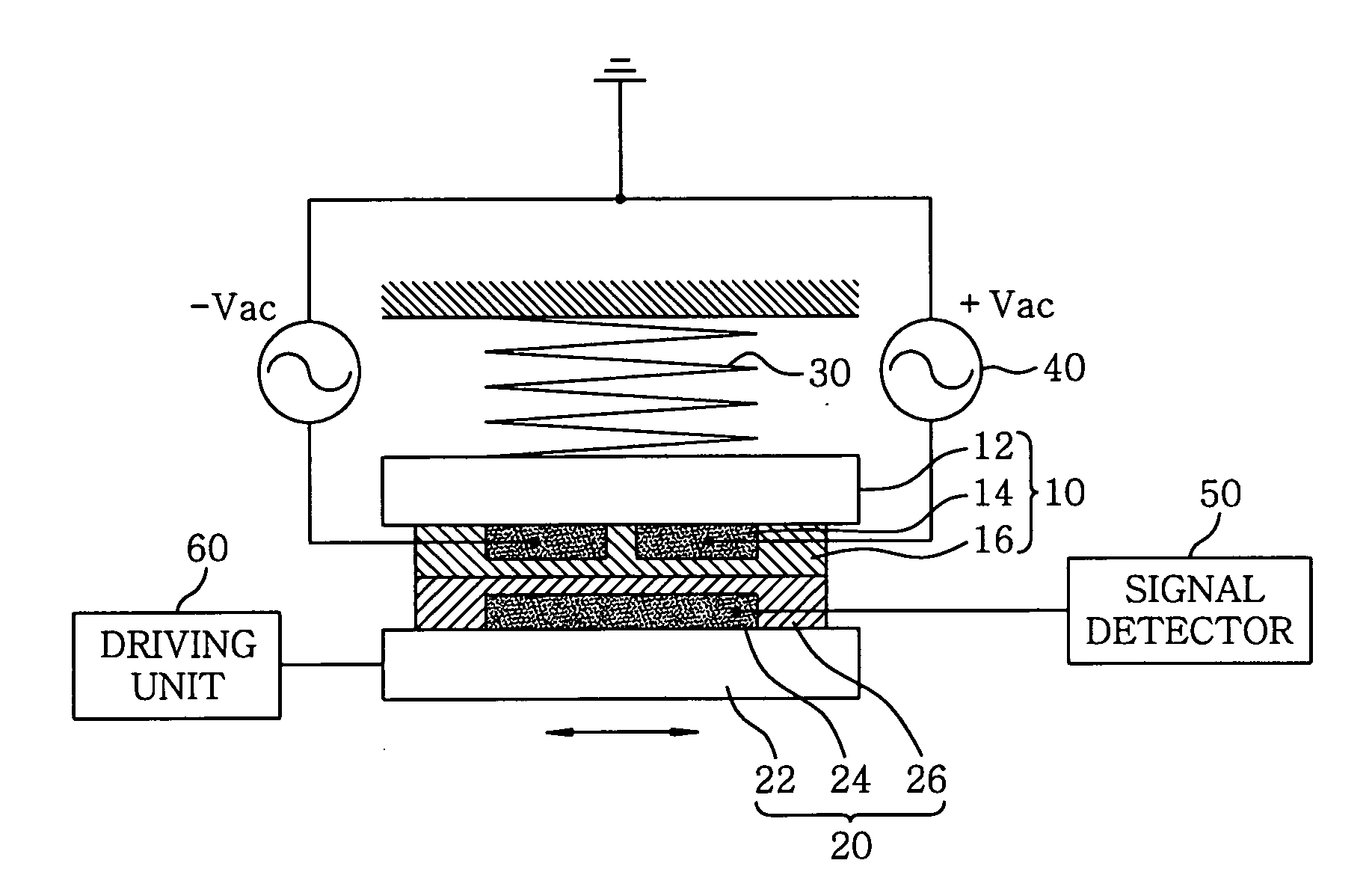

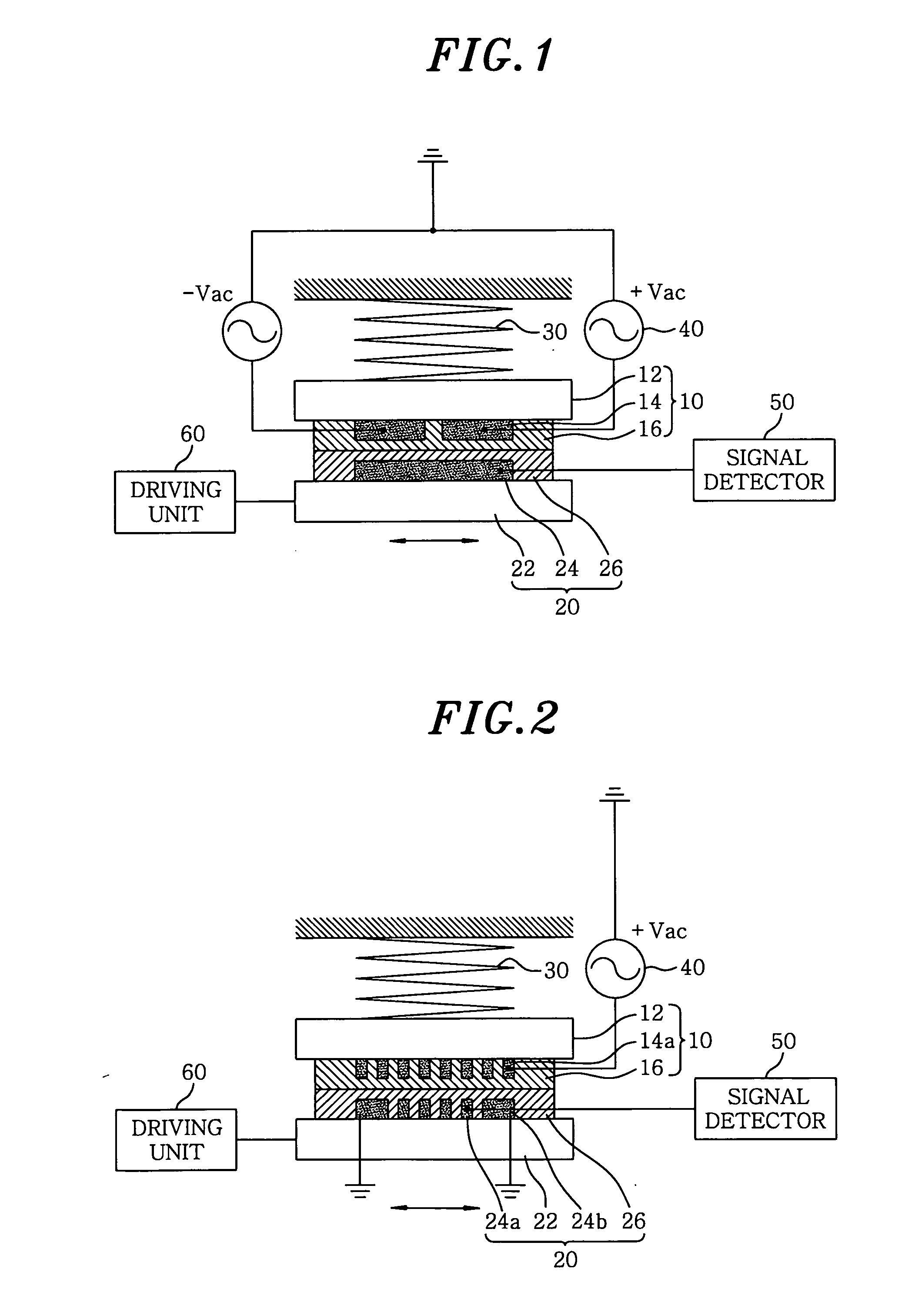

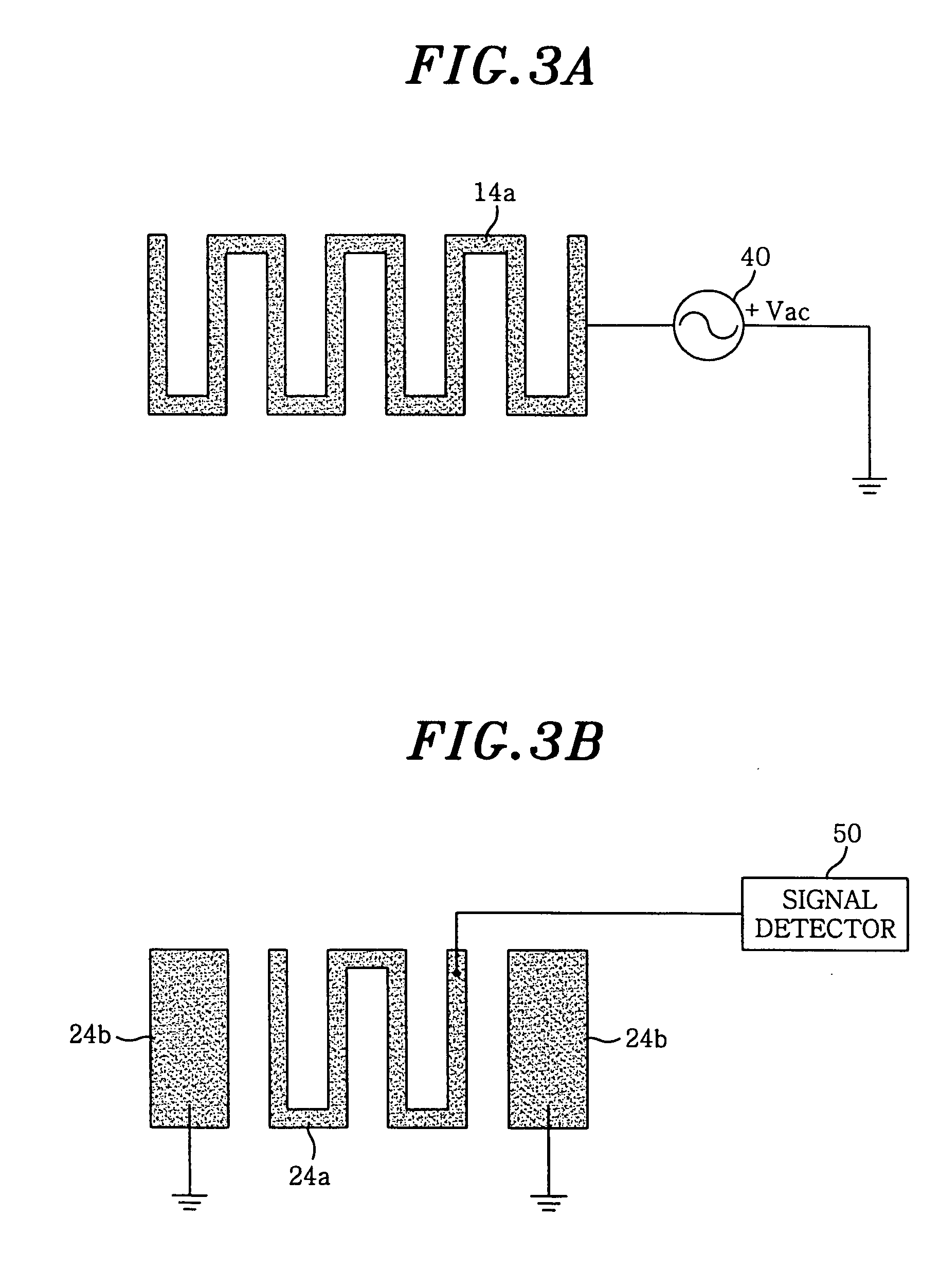

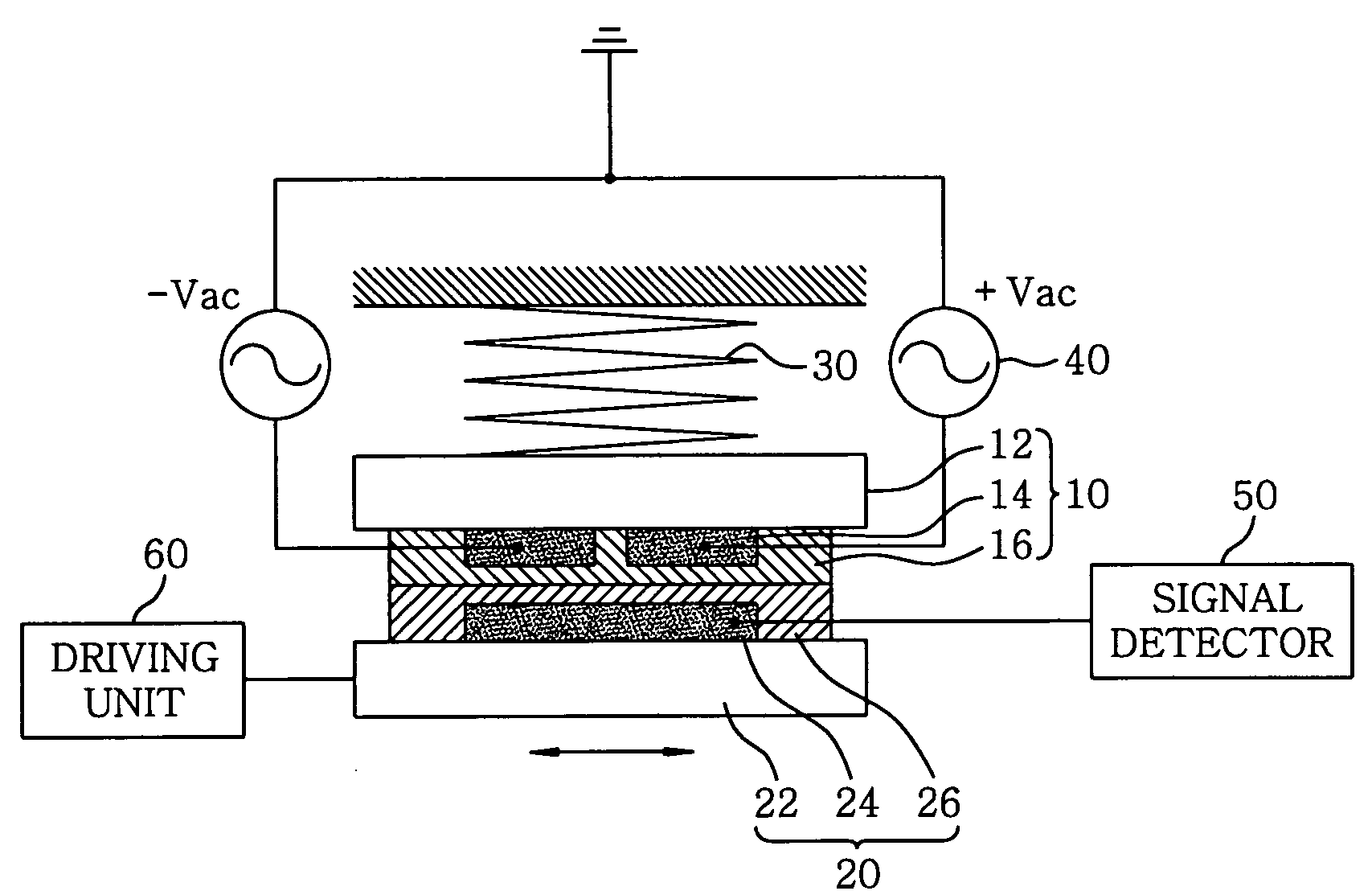

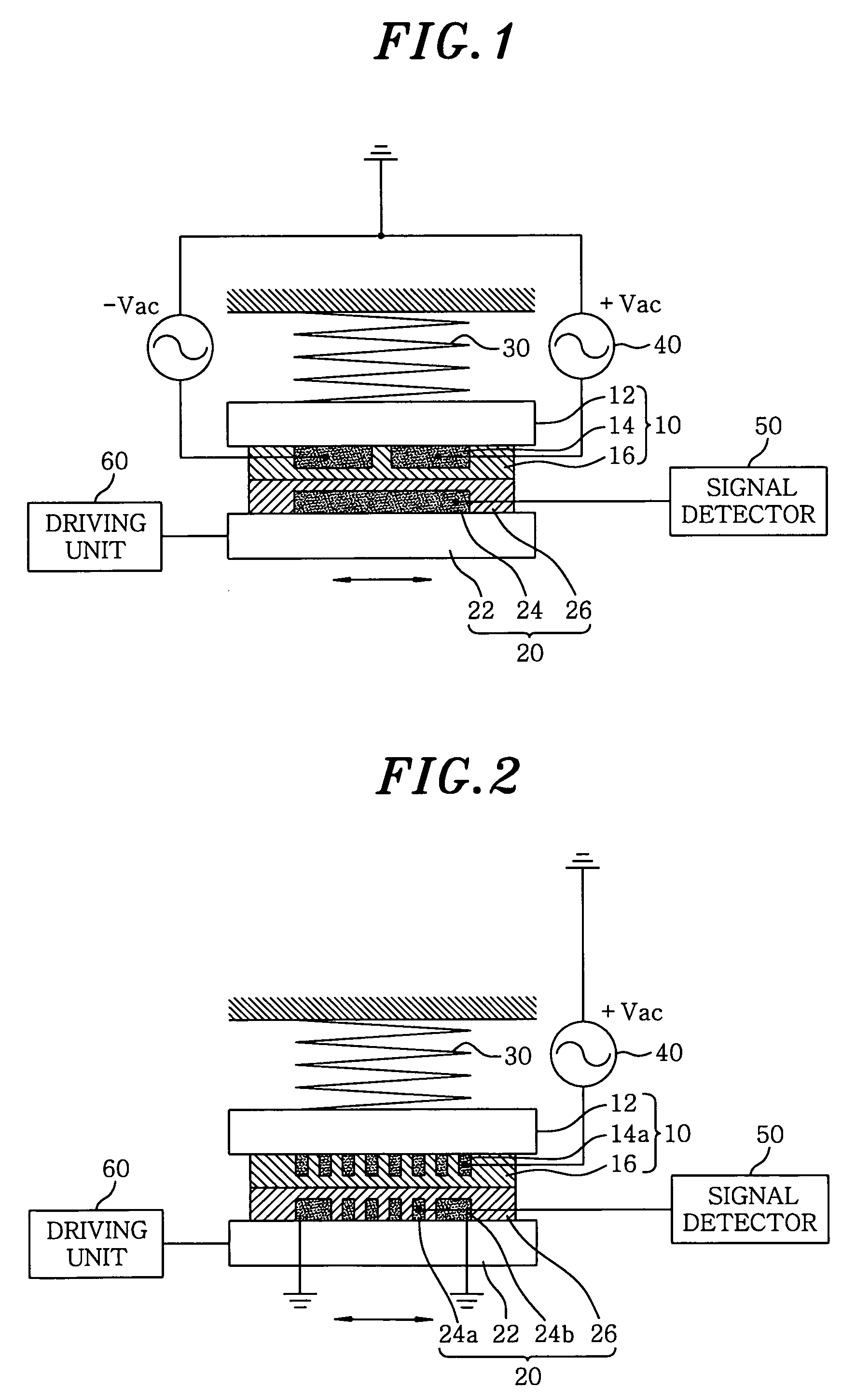

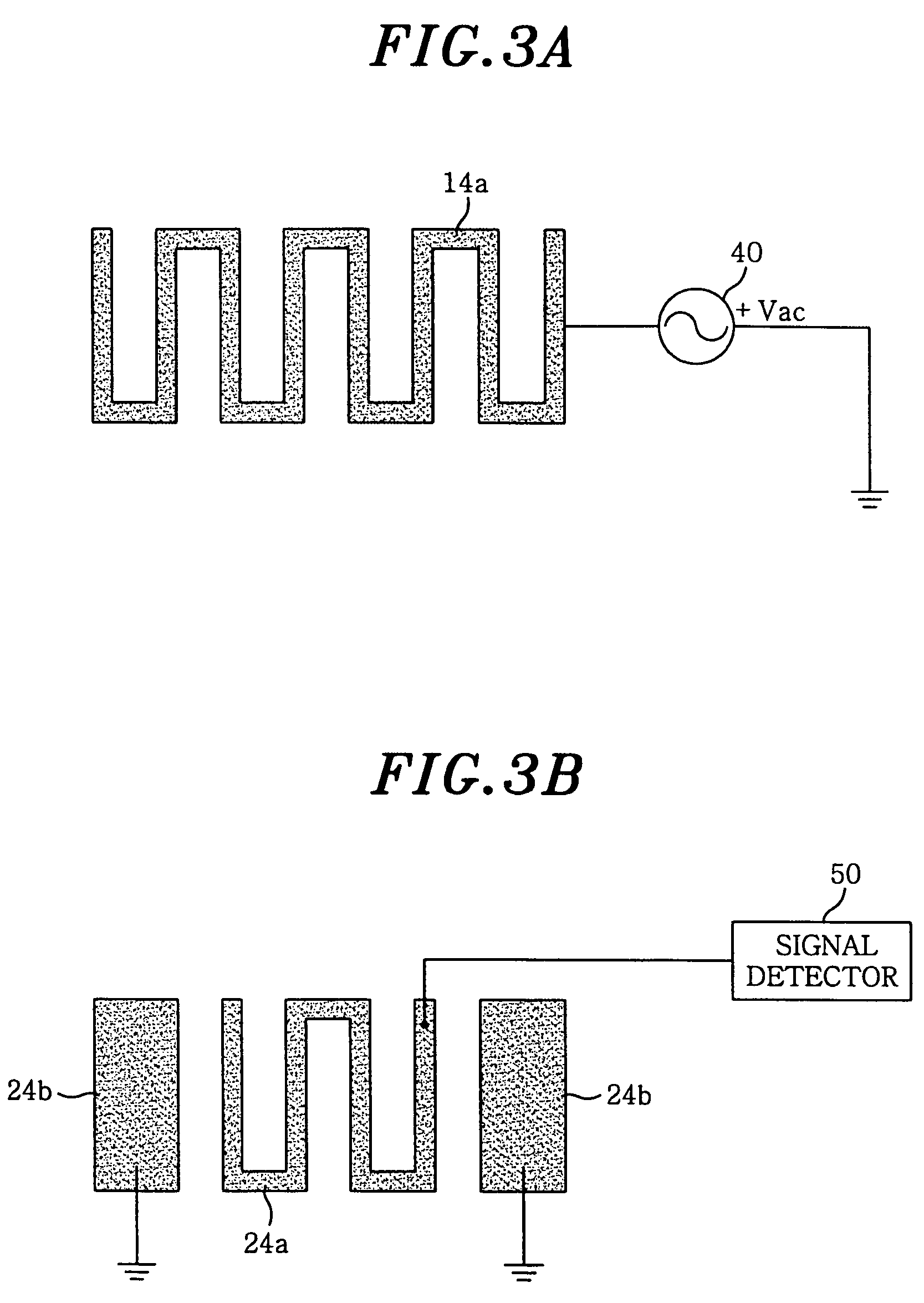

Contact-type electric capacitive displacement sensor

InactiveUS20070034013A1Reduce installation errorsSave installation spaceForce measurementUsing electrical meansElectrical conductorContact type

A contact-type electric capacitive displacement sensor includes a stationary element having a stationary plate, a stationary conductive pattern formed on the stationary plate and an insulation film coated on the stationary plate and a displaceable element having a displaceable plate, a displaceable conductive pattern formed on the displaceable plate and an insulation film coated on the displaceable plate. The stationary and the displaceable conductive patterns have a cyclic pattern of conductor to thereby produce a variation of capacitance therebetween when moving relative to each other.

Owner:MOON WONKYU

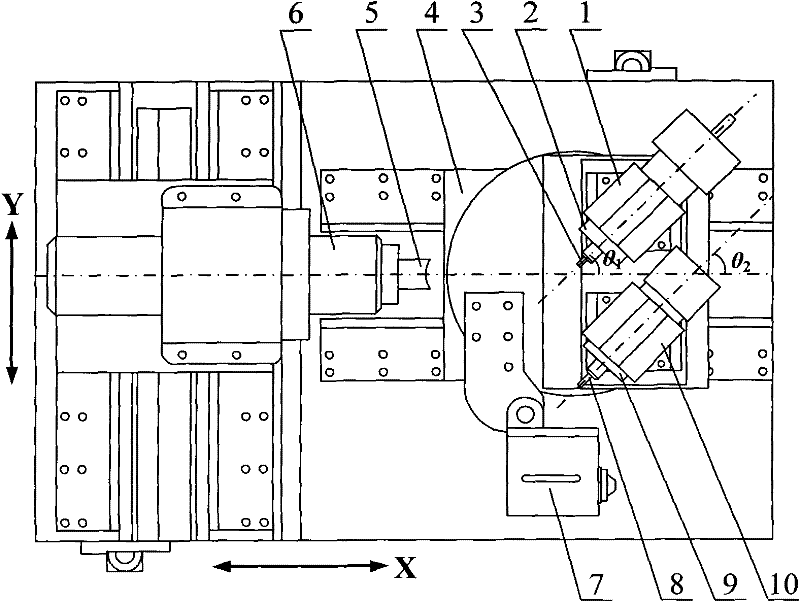

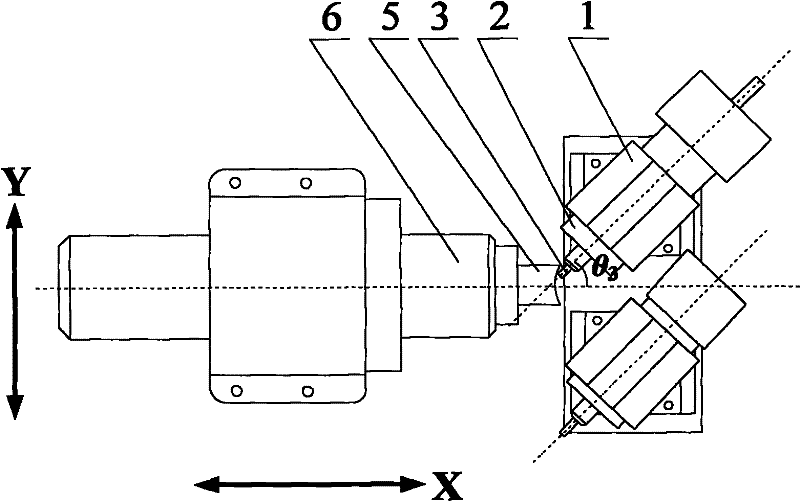

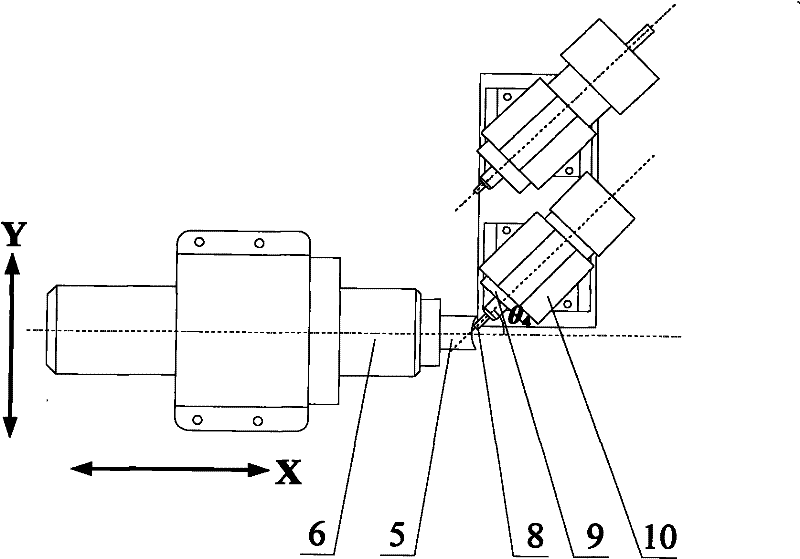

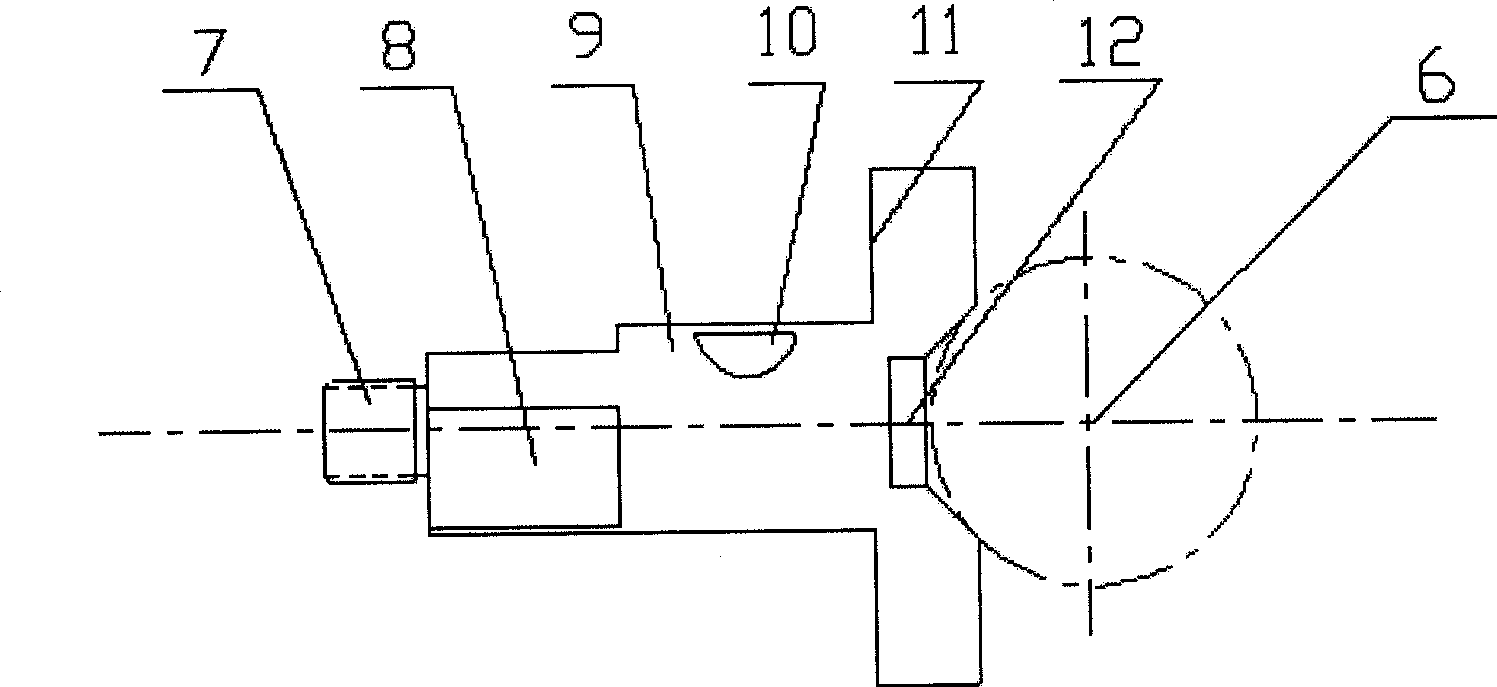

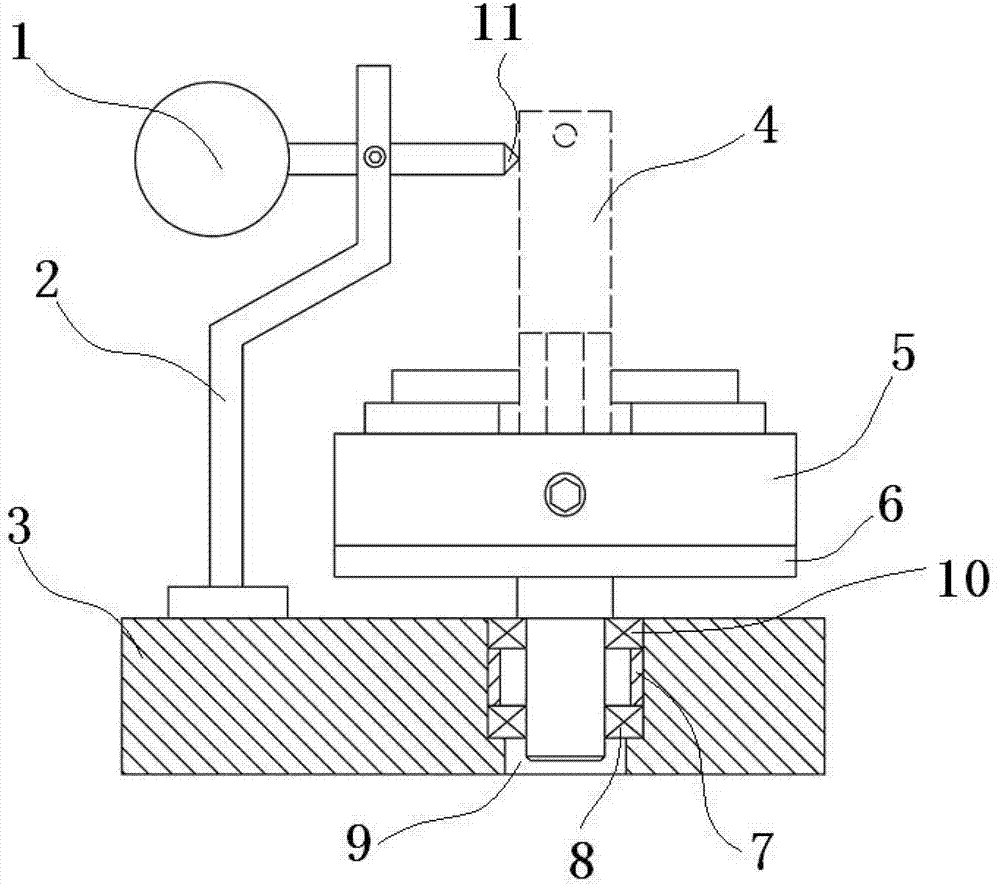

Small-caliber aspherical composite precise processing method

InactiveCN102161169AReduce installation errorsReduce tool setting errorsInterference phenomenonEngineering

The invention relates to a small-caliber aspherical composite precise processing method. The method comprises the following steps of: 1. clamping a workpiece (5) on a precise machine tool, wherein axes of a grinding wheel spindle (2) and a grinding head spindle (9) are parallel, separated from a sliding table (4) and intersected with the axis of a workpiece spindle (6); and grinding and processing an inclined shaft of the workpiece (5) by a micropowder grinding wheel (3); 2. carrying out in-place measurement on the workpiece (5) by using a detecting device (7) to generate a compensation processing track, and then processing along the track by the mocropowder grinding wheel (3); and 3. using a grinding head (8) to grind and polish the workpiece (5) to finally obtain a finished product. In the small-caliber aspherical composite precise processing method, precise inclined axis mirror grinding and inclined axis magnetorheological polishing and grinding are integrated into a single machine tool, so that the installation and the tool setting errors are reduced, the working hours are also reduced, the accuracy and the efficiency are improved, the interference phenomenon is prevented, the controllability is good, and continuous processing can be achieved.

Owner:HUNAN UNIV

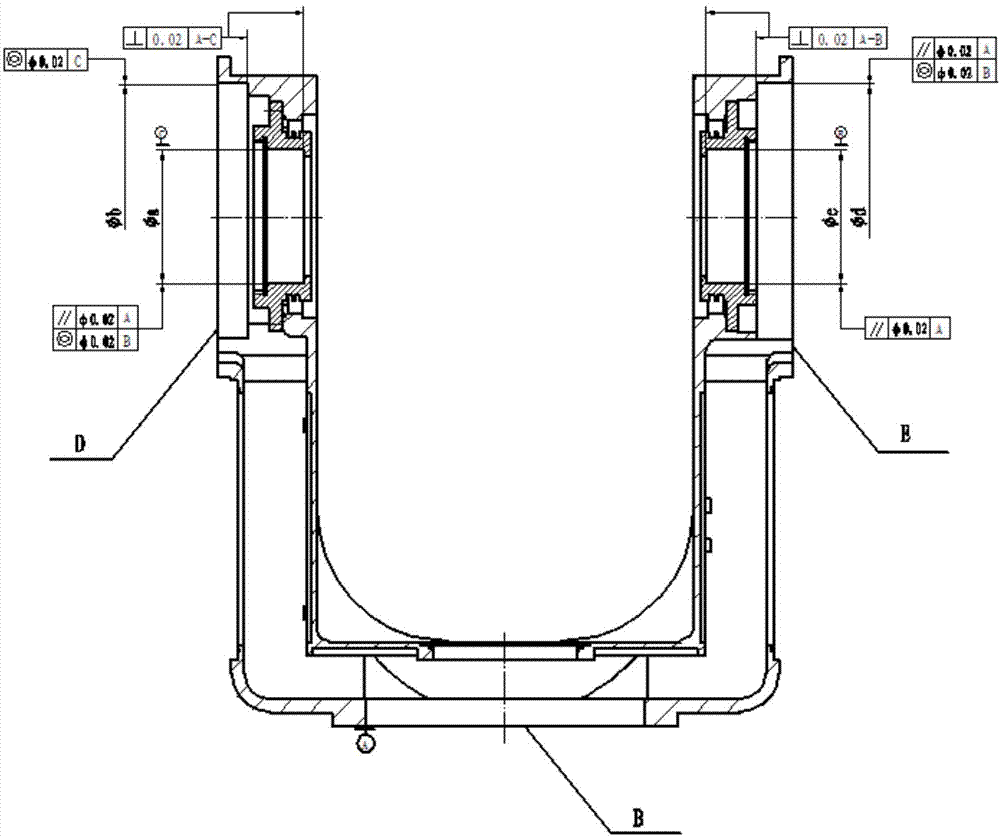

Technology for controlling coaxiality precision of U-shaped support combination

The invention relates to a technology for controlling the coaxiality precision of a U-shaped support combination. The technology comprises the first step of casting; the second step of rough machining; the third step of heat processing; the fourth step of finish-milling of a technology platform top A and fine scraping of the technology platform top A through a bench worker, wherein the flatness is not more than 0.01 mm; the fifth step of positioning a milling face B allowance at a time with the technology platform face A as a cardinal plane and enabling the precision of a half schlichtaufbohren phi c to be H7 for positioning; the sixth step of surface coating; the seventh step of finish-scraping of the technology platform top A, wherein the flatness is not more than 0.01 mm; the eighth step of installing a left bearing base and a right bearing base into a support, fastening a screw and screwing a pin; the ninth step of finishing machining; the tenth step of removing a technology platform.

Owner:HEBEI HANGUANG HEAVY IND

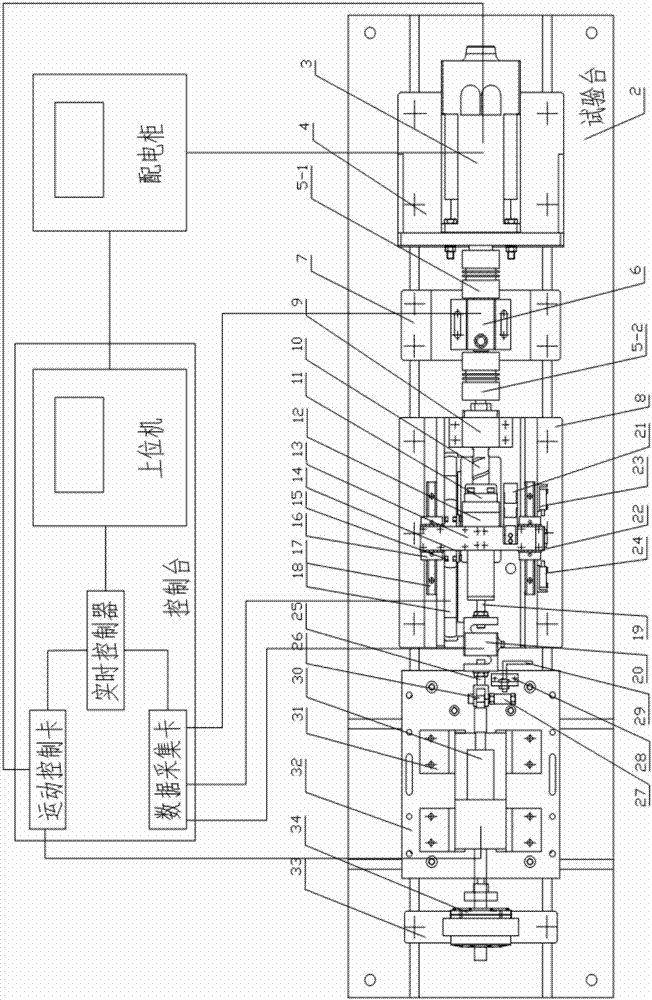

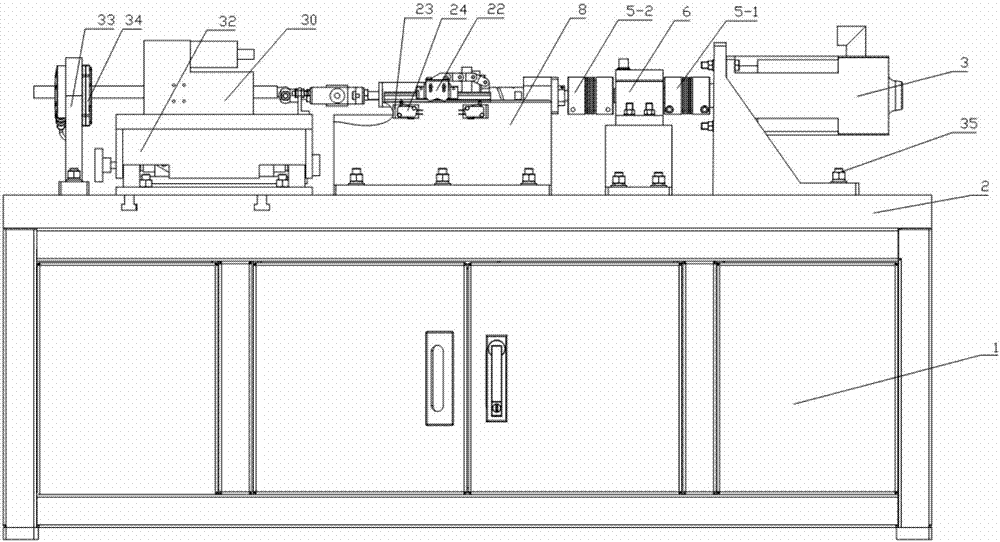

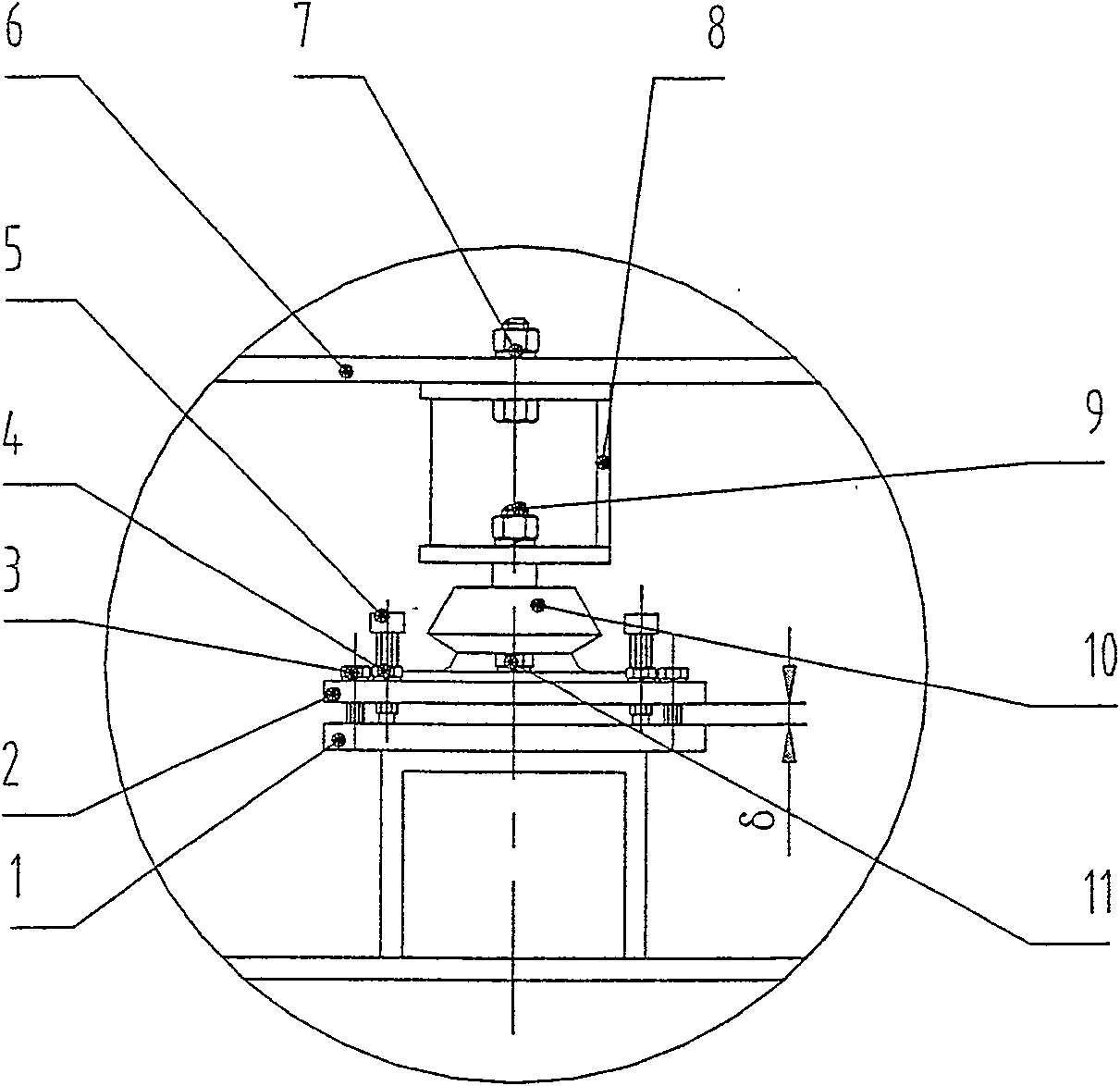

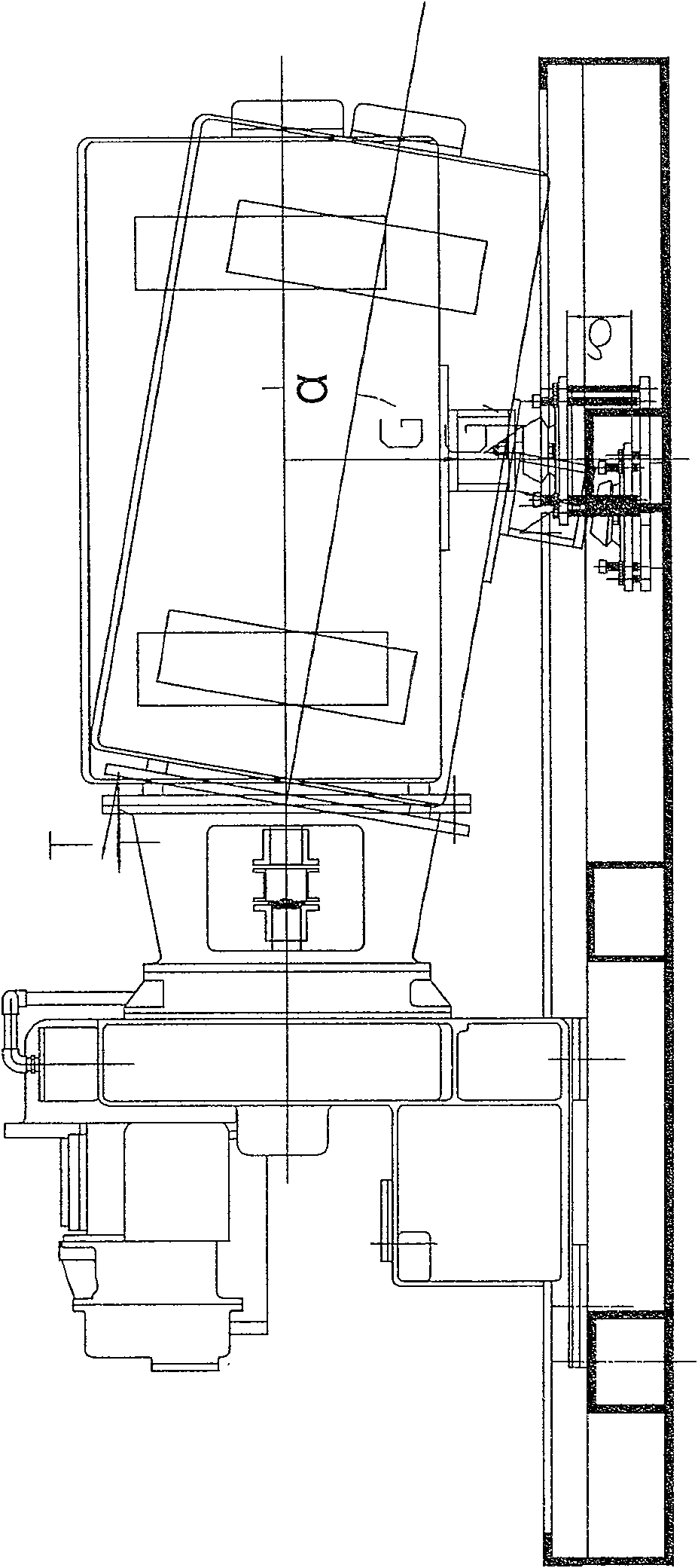

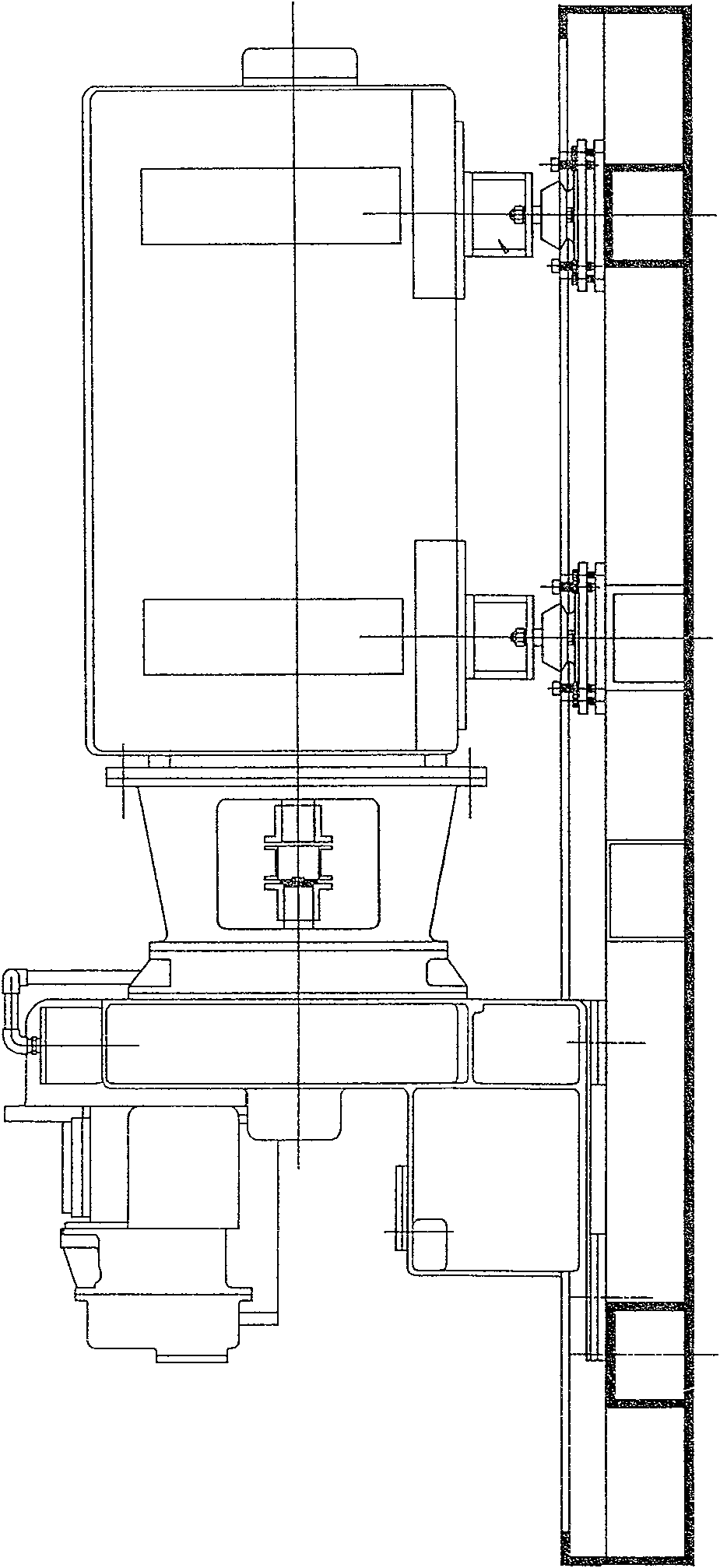

Electric servo linear loading testing system

The invention discloses an electric servo linear loading testing system, and the system comprises a test bench, a control console, and a power distribution cabinet. The test bench comprises a base rack, a servo loading system, a movement conversion system, a tested servo system, and a sensor system. The system employs a ball screw pair as a movement conversion structure, and combines with a linear guide rail to limit the rotation output, so the system achieves the linear force loading. The linear guide rail, a ball screw pair supporting unit and a grating ruler are integrated on the same platform, thereby reducing the installation error, and guaranteeing the overall performance. A rotating part in the movement conversion system is just provided with a screw, so the rotational inertia is small and the improvement of the loading performance is facilitated. In order to solve an electro-hydraulic loading problem, a servo motor is employed for replacing a hydraulic valve so as to form the electric loading system. The system is quick in response, is small in size, is simple in structure, is low in cost, and is convenient to control. Compared with the active loading mode of taking a linear servo motor as an execution mechanism, the system employs the passive loading, is mature in technology, and is high in cost performance.

Owner:NANJING UNIV OF SCI & TECH

Small-caliber aspherical composite precise processing machine tool

InactiveCN102161168AReduce installation errorsReduce tool setting errorsControllabilitySmall caliber

The invention relates to a small-caliber aspherical composite precise processing machine tool, comprising a tool body (22) with a shock absorber (16), wherein the tool body (22) is provided with a first sliding table (20) which is provided with a spindle bracket (1); a second sliding table (13) is arranged correspondingly to the first sliding table (20) and is provided with a rotating bracket (17) and a supporting plate (9); the rotating bracket (17) is provided with a detecting device (18); and an inclined axis mirror grinding device (10) with a triaxial fine-tuning frame and an inclined axis magnetorheological grinding and polishing device (14) are arranged in parallel on the supporting plate (9). In the small-caliber aspherical composite precise processing machine tool, the precise inclined axis mirror grinding device and the inclined axis magnetorheological grinding and polishing device are integrated on a single tool body; through the combination of the two techniques of the precise inclined axis mirror grinding and the inclined axis magnetorheological grinding and polishing, the good controllability of the processing path is achieved, and the phenomenon of the interference is effectively prevented; and by in-place measurement of the shape of a workpiece, the error compensation processing of the workpiece is realized, and the accuracy of the shape of the workpiece is improved.

Owner:HUNAN UNIV

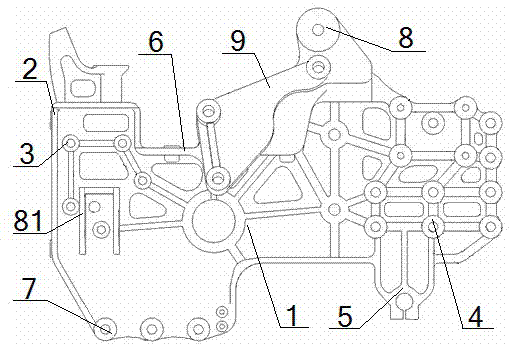

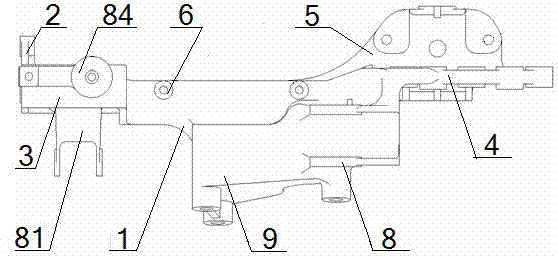

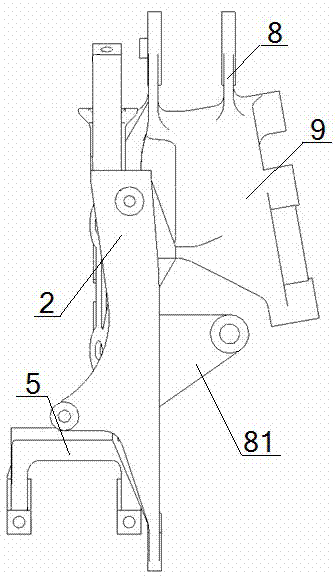

Integrated frame longitudinal beam connecting support

ActiveCN103921842AHigh mechanical strengthReduce in quantityUnderstructuresLoading-carrying vehicle superstructuresVehicle frameEngineering

An integrated frame longitudinal beam connecting support comprises a base and a bumper mounting portion, a beam assembly mounting portion, a frame fixing portion and a plate spring mounting portion which are arranged on the base. The back of the bumper mounting portion is fixedly connected to the front end of the frame fixing portion through the beam assembly mounting portion, the bottom of the frame fixing portion is fixedly connected to the plate spring mounting portion, a sunken water tank mounting portion and a cab front suspension turning arm mounting portion are arranged between the beam assembly mounting portion and the frame fixing portion, a front-lower protective supporting base fixing portion is fixedly connected to the lower portion of the beam assembly mounting portion, and a front suspension vibration absorber mounting support is fixedly connected to the side of the beam assembly mounting portion; the base is integrated with the bumper mounting portion, the beam assembly mounting portion, the frame fixing portion, the plate spring mounting portion, the sunken water tank mounting portion, the front-lower protective supporting base fixing portion, the cab front suspension turning arm mounting portion and the front suspension vibration absorber mounting support. The support is in high integrated level, is reasonable in structure and has high mechanical strengthen.

Owner:DONGFENG COMML VEHICLE CO LTD

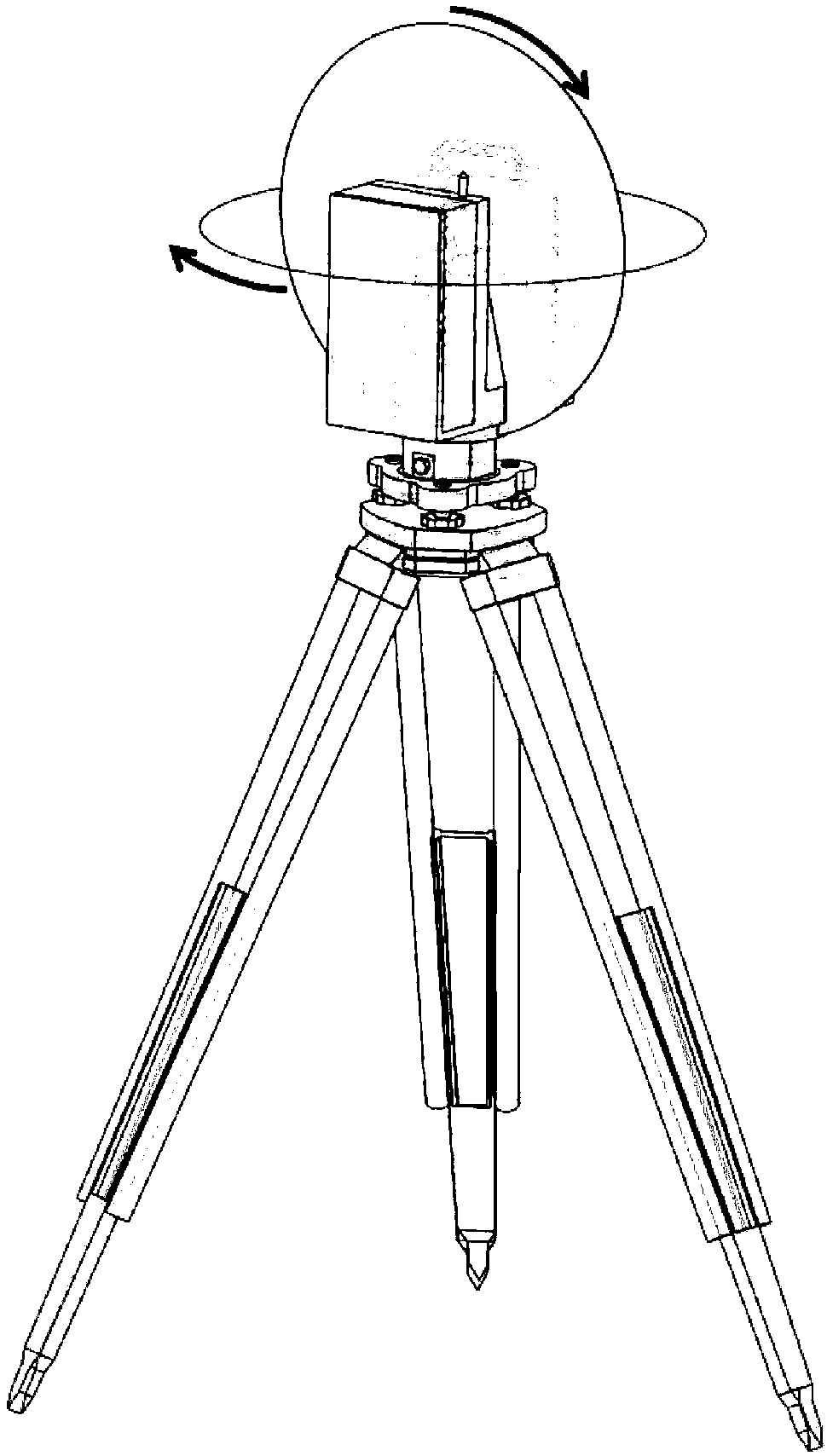

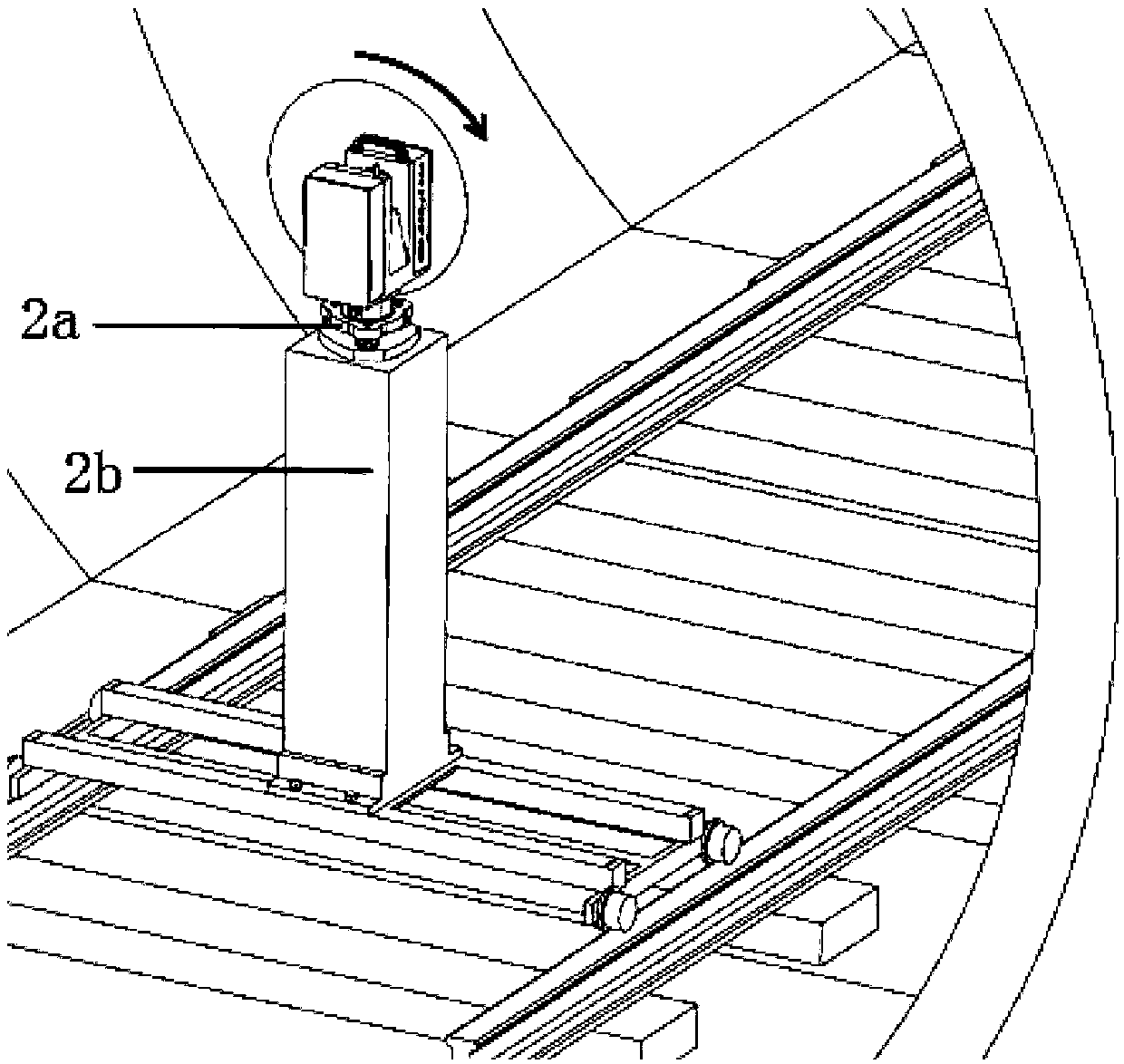

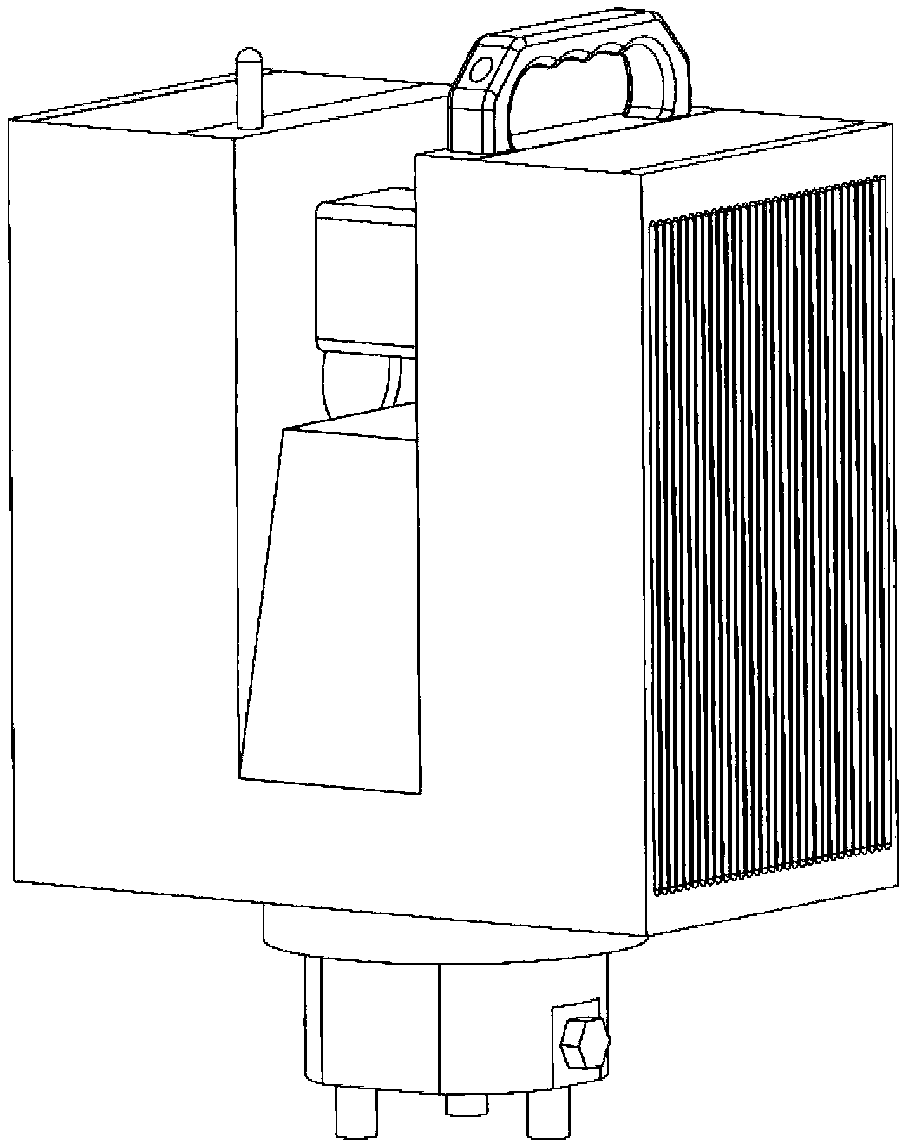

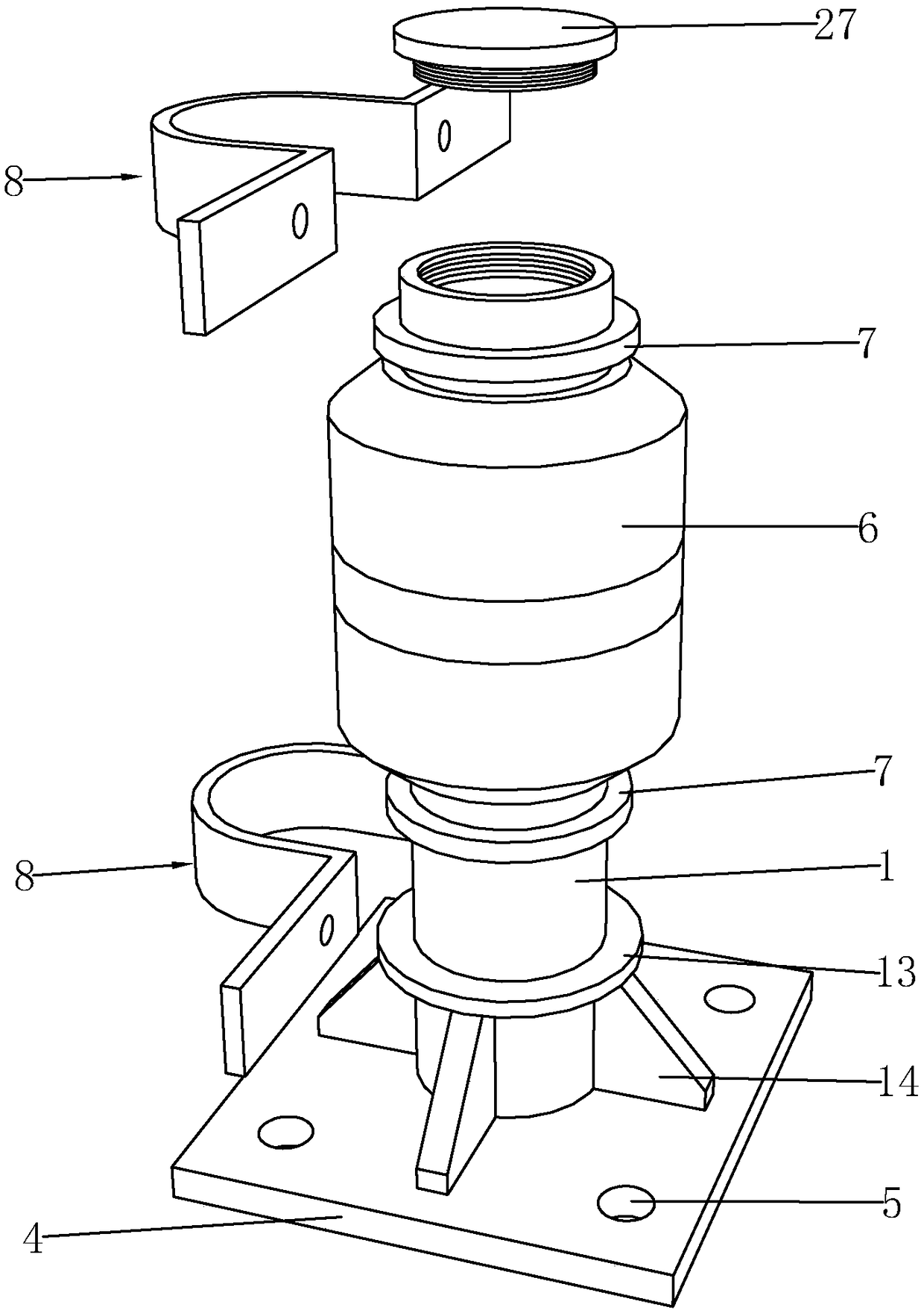

Three-dimensional laser scanner fixing mechanism, and subway tunnel acquisition system and method

PendingCN107941151AReduce installation errorsOverall goodMining devicesUsing optical meansData transmissionDistance sensors

The invention provides a three-dimensional laser scanner fixing mechanism, and a subway tunnel acquisition system and method. The subway tunnel acquisition system comprises a three-dimensional laser scanner fixing mechanism, a railway car module, a range sensor, an RFID reader-writer and a host computer. A three-dimensional laser scanner continuously acquires point cloud data of tunnel segments, the range sensor acquires mileage data in real time and transmits the mileage data to the host computer, the RFID reader-writer returns read and written RFID smart tag signals to the host computer in real time, and the host computer complete multi-source data fusion and storage. According to the invention, the problem that when the three-dimensional laser scanner is in a profile scanning mode, an automatic motor cannot be locked is solved, and damage to the scanner caused by maloperation is avoided. By means of the integrated design of two modules including the constant-speed railway car and the three-dimensional laser scanner, the quality of acquired data is improved, automatic acquisition of tunnel deformation data and disease information is achieved, the labor cost is reduced, and the detection efficiency is improved.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

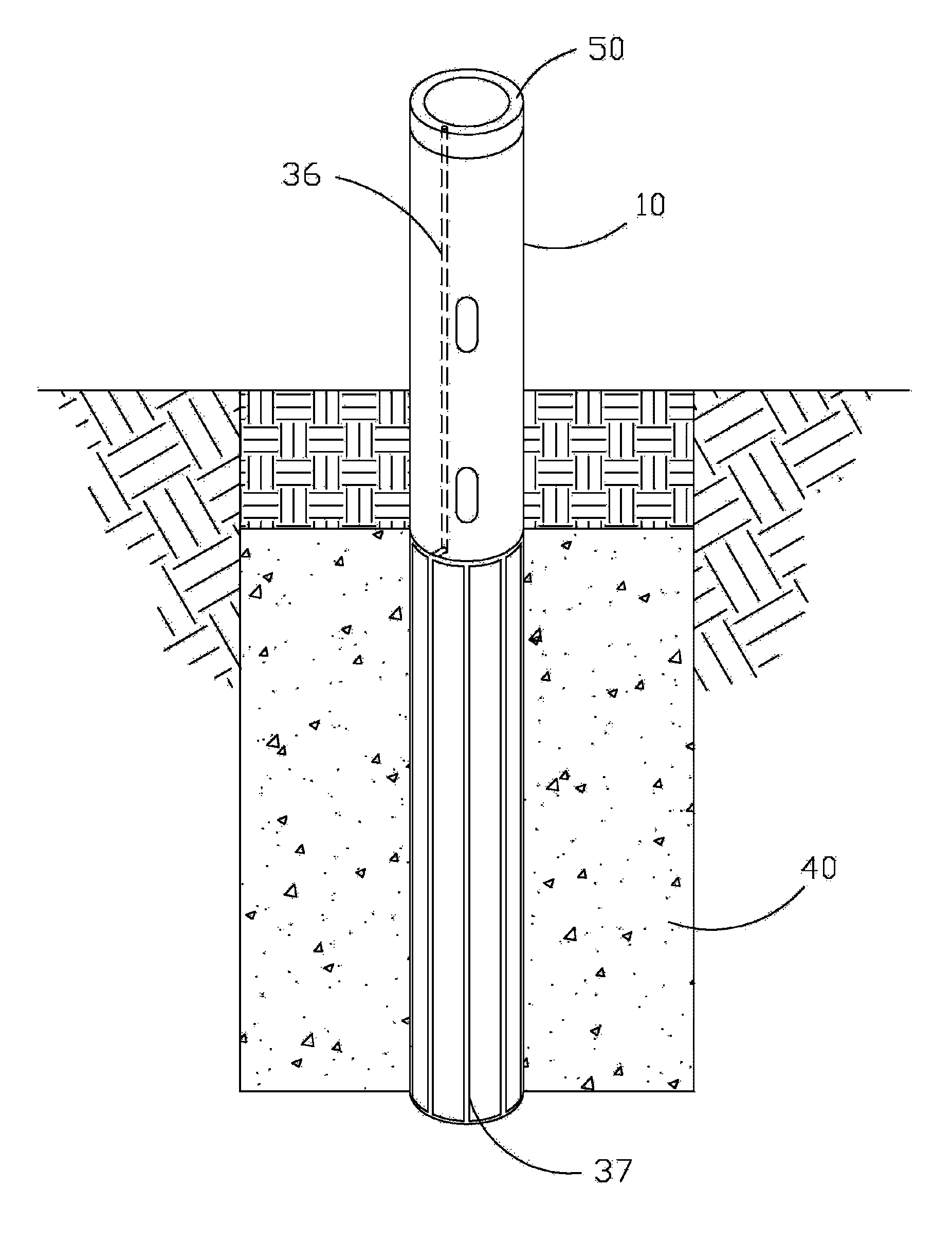

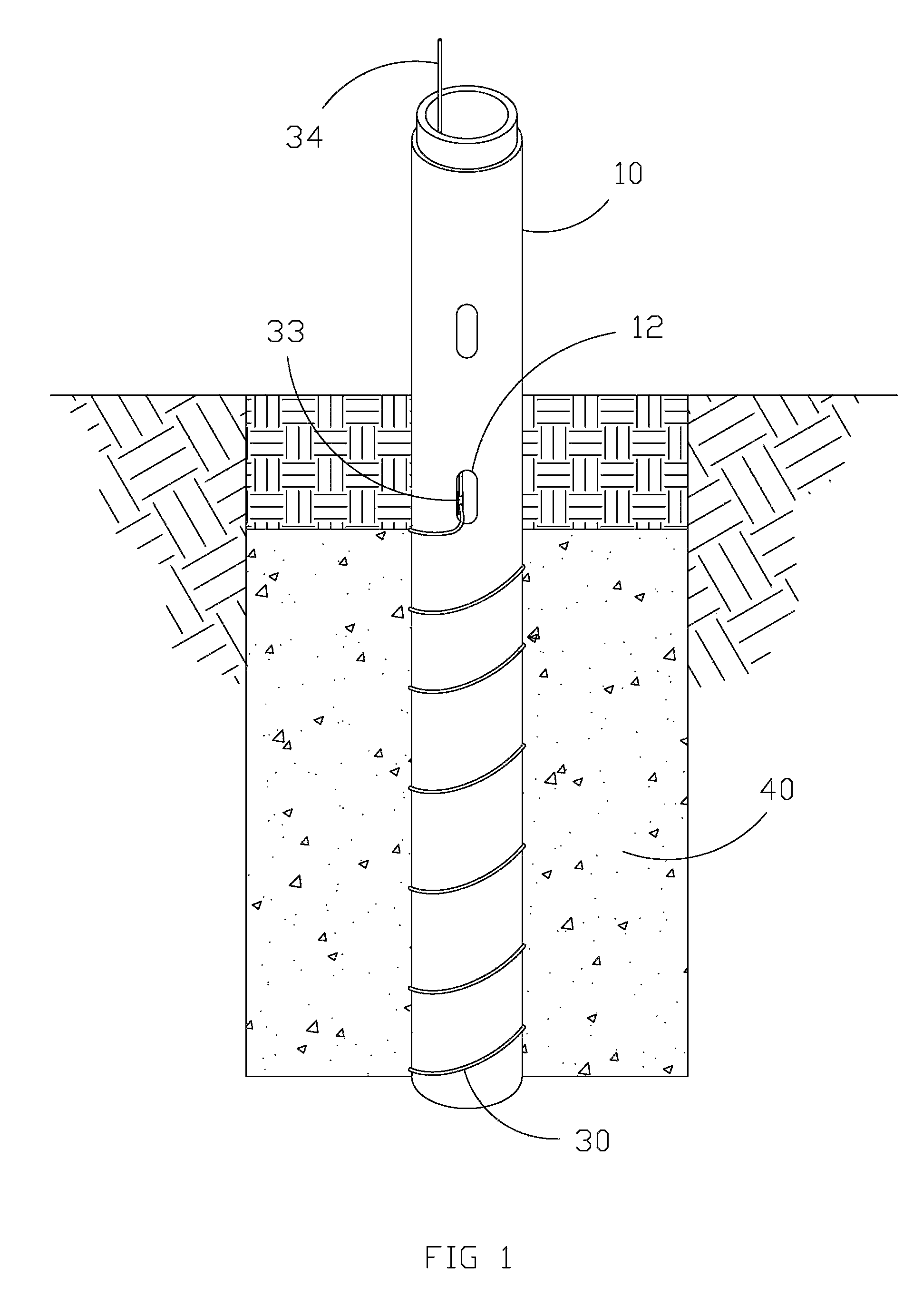

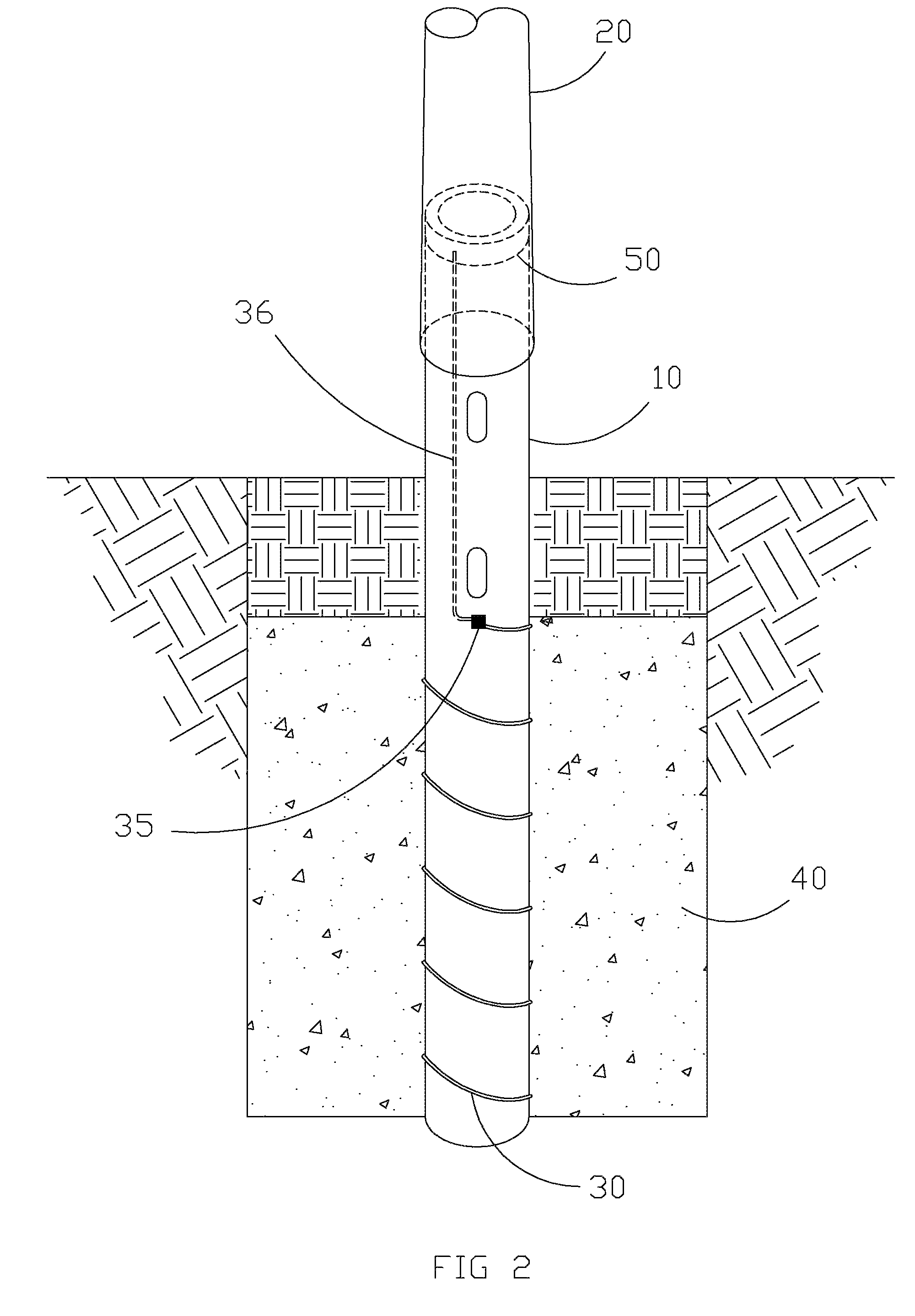

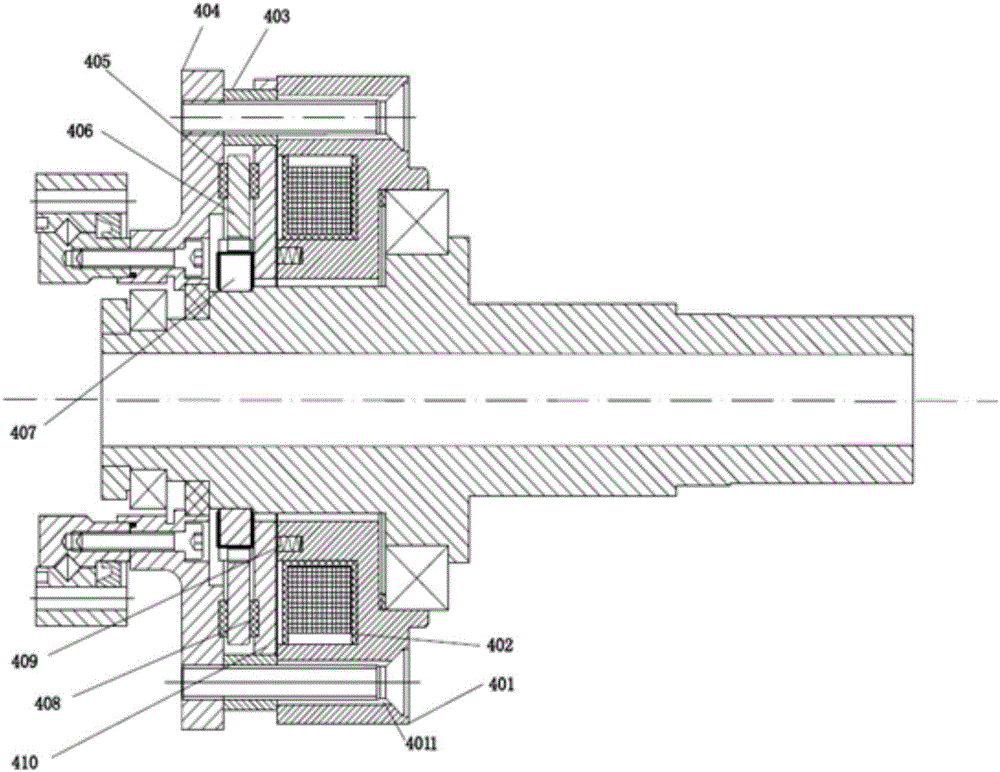

Apparatus, method, and system for grounding support structures using an integrated grounding electrode

ActiveUS8163993B2Reduce installation errorsIncreased ease of installationPipe supportsWave amplification devicesEngineeringInstallation Error

Disclosed herein are apparatus, methods, and systems for grounding outdoor light poles, as well as other structures, which may be exposed to lightning or other adverse electrical effects and may require a low impedance path to ground. Inventive aspects include a combination of apparatus integral to the pole or other structure and installation considerations whereby the ease of installation, reduction of onsite installation error, and reduction of impedance may be tailored to each installation. An apparatus can include a pre-installed earth grounding electrode at the lower end of the pole or structure to be inserted into the earth. A method can include installing an earth grounding electrode to / on / in a lower end of a pole or structure prior to insertion into the earth.

Owner:MUSCO

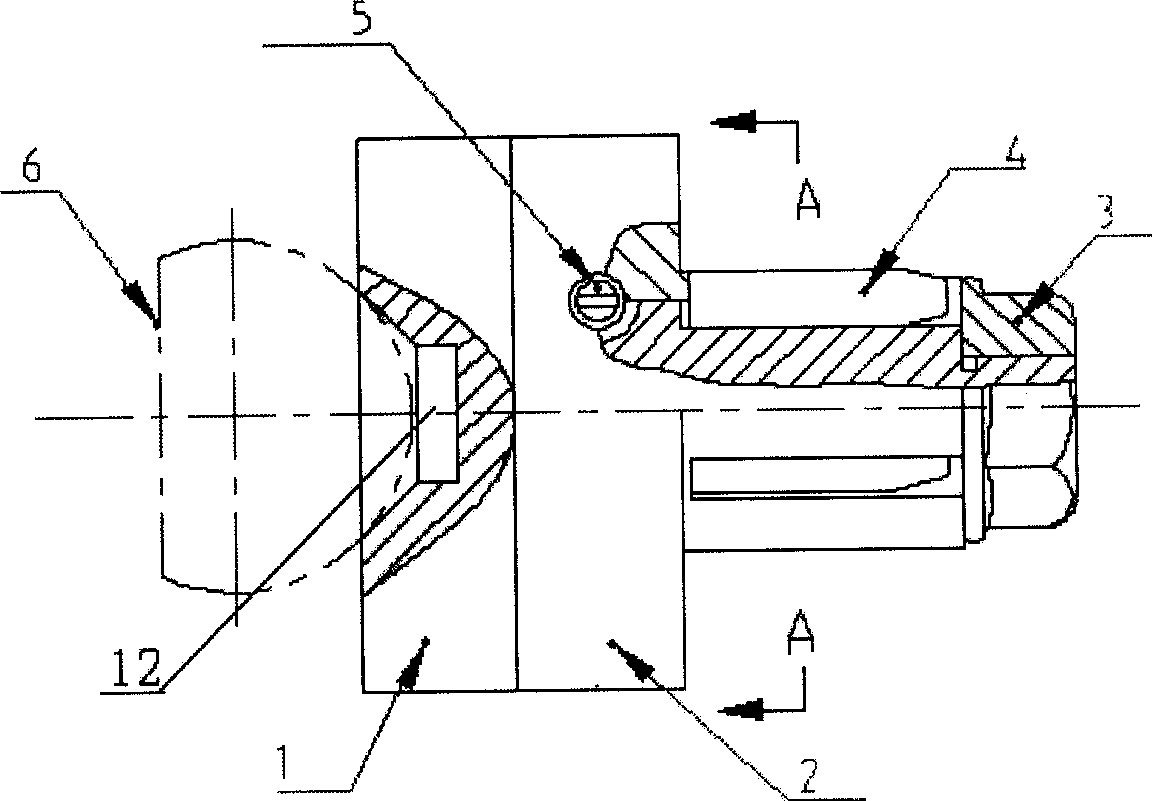

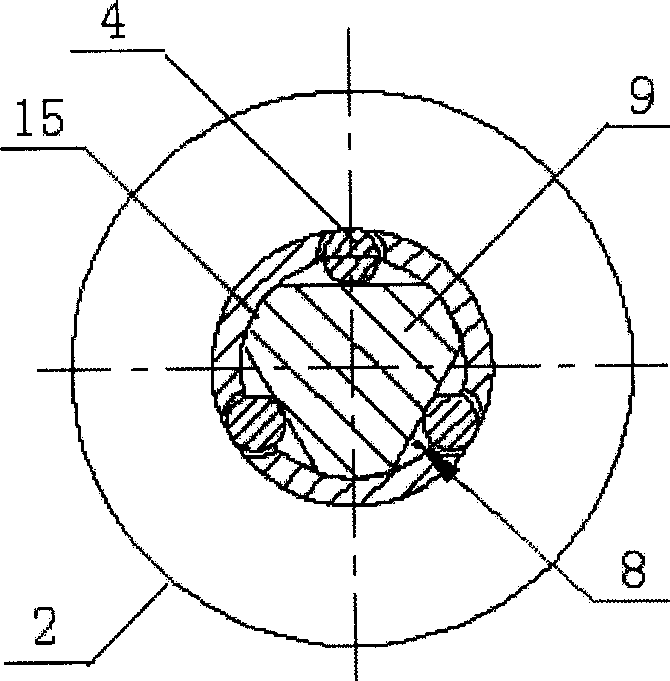

Self-locking auto-centering target ball mounting seat

ActiveCN101446481AReduce installation errorsNot easy to looseUsing optical meansElectromagnetic wave reradiationSelf lockingLaser

The invention discloses a self-locking auto-centering target ball mounting seat used for mounting the target ball of a laser tracer; the inner wall circle of a locating central hole (15) of the sleeve (2) of the target ball seat is provided with needle roller slots (14) which are at least arranged in trisection and used for arranging a needle roller (4); at least one cross surface of the coaxial direction of a locating guide column (9) is a polygon; and the coaxial squeezing surface (8) on each side is corresponding to one needle roller (4) assembled in the needle roller slot (14). As squeezing force is generated to the needle roller when the central saddle of the target ball is rotated, the needle roller is led to move outwards to squeeze and clamp a measured hole, so as to automatically lock and fix the target ball mounting seat, thus realizing the excellent tight static matching between the guide column of the central saddle and the measured hole. The target ball automatically centered in the central saddle of the target ball is led to be automatically positioned to the center of the mounting hole and be able to reduce the mounting error of the target ball mounting seat. The invention is suitable for measuring the mounting holes with the hole tolerance less than IT12 and the diameter between 10mm and 50mm.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

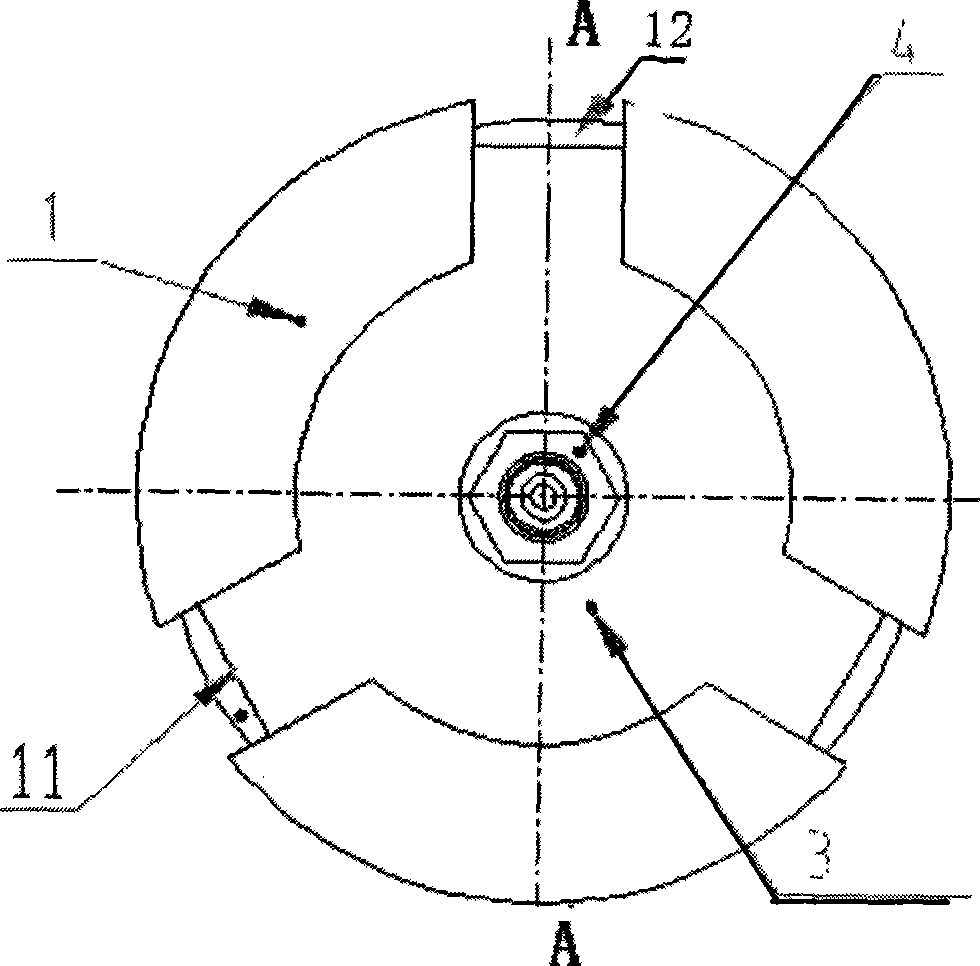

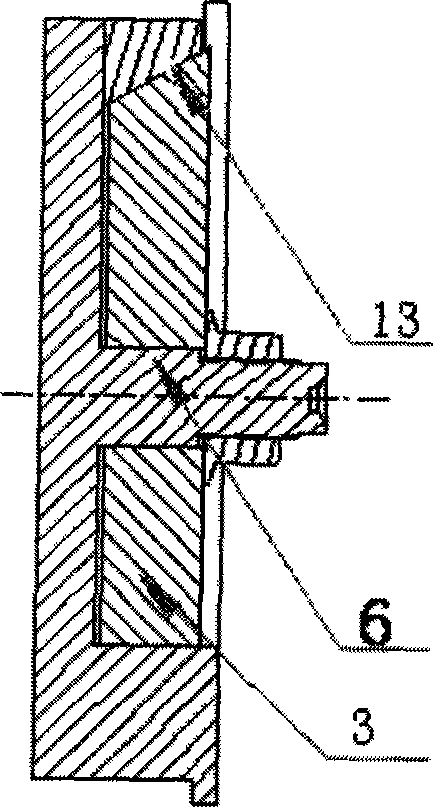

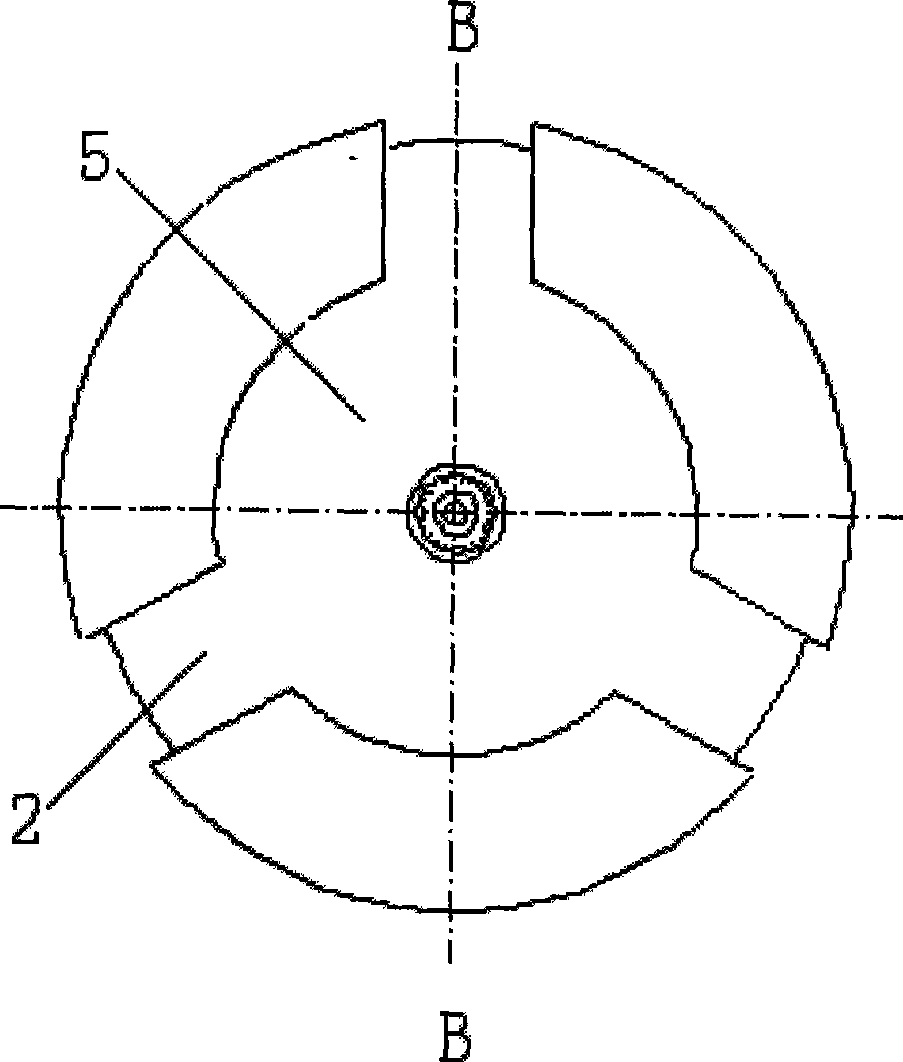

Coaxiality detector

InactiveCN102901433AEasy clampingEasy to disassembleMechanical measuring arrangementsEngineeringInstallation Error

The invention provides a coaxiality detector. The coaxiality detector is used for detecting the coaxiality of a hexagonal shaft, and comprises a base, a clamping mechanism, a slewing mechanism and a detection device, wherein the clamping mechanism is used for clamping the hexagonal shaft; the slewing mechanism is movably arranged on the base, and is used for supporting and driving the clamping mechanism to rotate around the central axis of the hexagonal shaft; and the detection device is arranged on the base and is used for detecting the coaxiality of the hexagonal shaft. The coaxiality detector provided by the invention adopts a precision three-jaw chuck and is connected with the base through a bearing, so that the precision three-jaw chuck cannot jump when the precision three-jaw chuck rotates in the center of the base freely; and simultaneously, the hexagonal shaft is clamped on and detached from the three-jaw chuck very conveniently; the installation error is low; and the detection precision is improved.

Owner:宁波培源股份有限公司

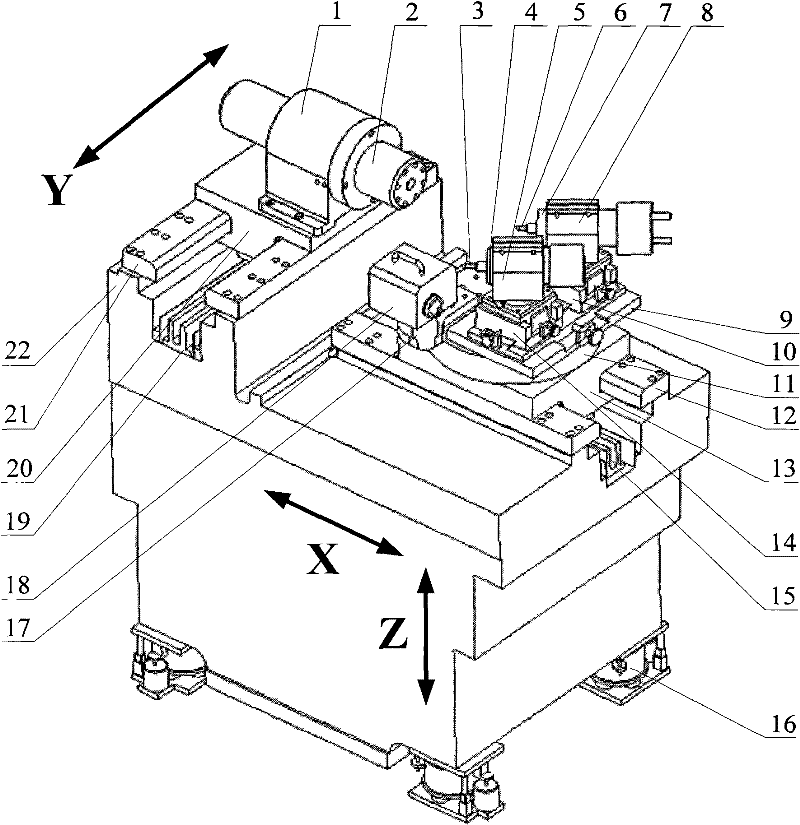

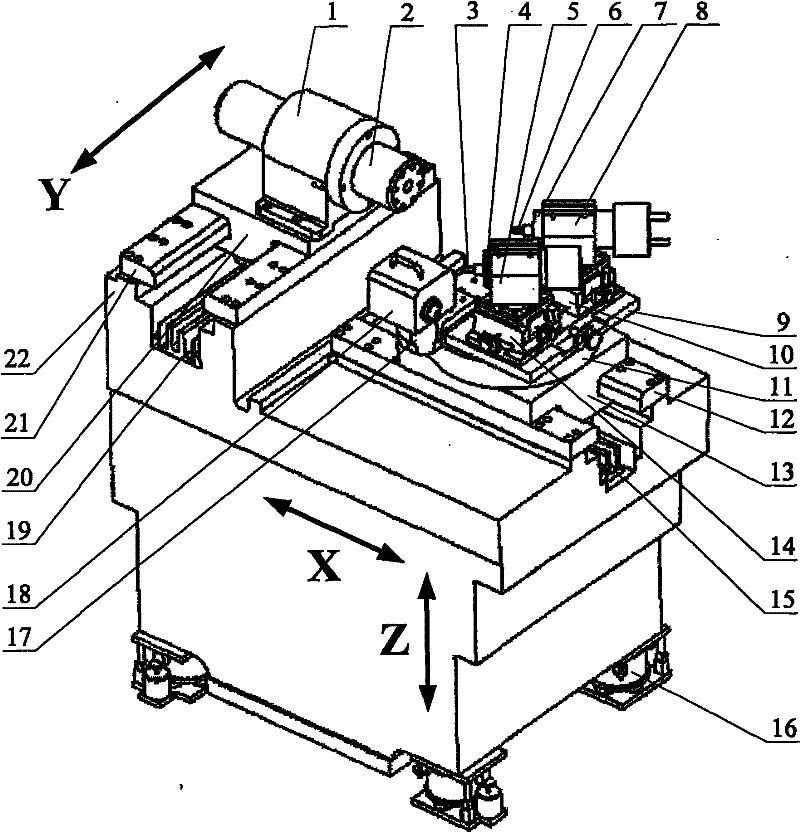

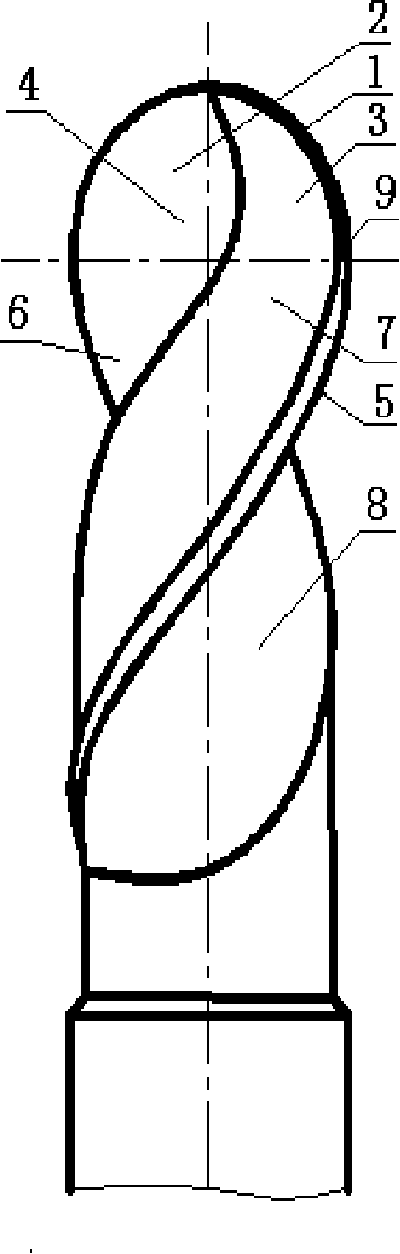

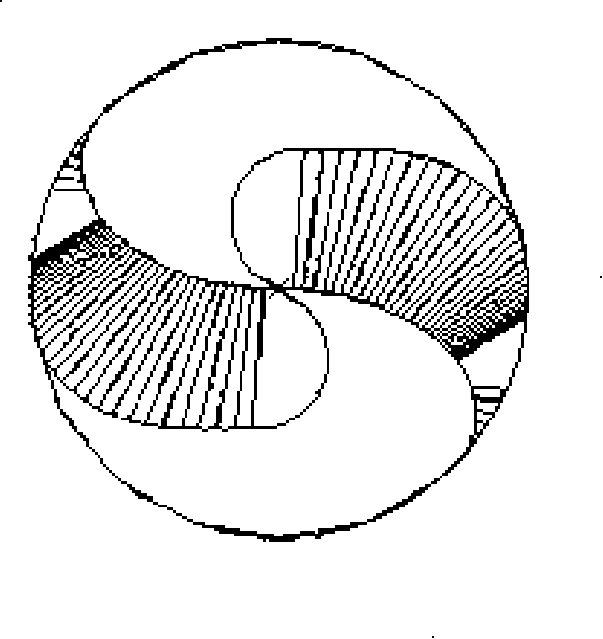

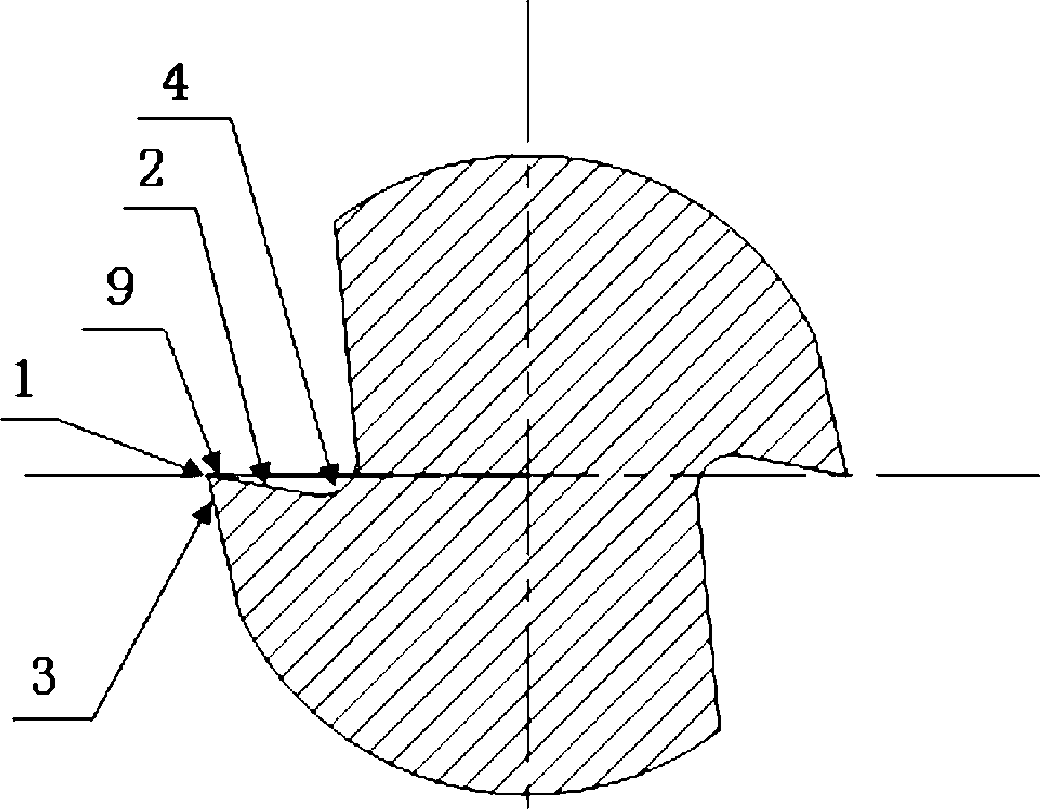

Bulb slotting cutter and its abrasive machining four-shaft linkage equipment

InactiveCN101239406AImprove accuracy and qualityWide range of applicationsMilling cuttersAgricultural engineeringMilling cutter

The invention discloses a bulb end milling cutter and a milling processing four-shaft associated device thereof. An S-shape bulb edge (1) is connected with a spiral circumferential edge (5), a bulb edge front face is connected smoothly with the circumferential edge front face (6), the bulb rear face (3) is connected with the circumferential edge rear face (7), and the bulb edge spiral groove (4) is connected with the circumferential edge spiral groove (8); the front angle of the bulb edge front face (2) is a rather big positive front angle, and is distributed with a small-big-small mode from inside to outside; the milling processing four-shaft associated device of the bulb end milling cutter comprises a latch bed (10), a horizontal longitudinal X axis straight-line motion flat stage (11), a horizontal transversal Y-axis straight-line motion flat stage (12), a vertical Z axis straight-line motion flat stage (13), a workpiece rotating shaft (14), and a front tool face milling head (15), and a rear tool face milling head (16). The invented devices are provided with characteristics of stable milling, smooth chip removal, simple structure, low cost, moderate price, and economic.

Owner:GUIZHOU UNIV

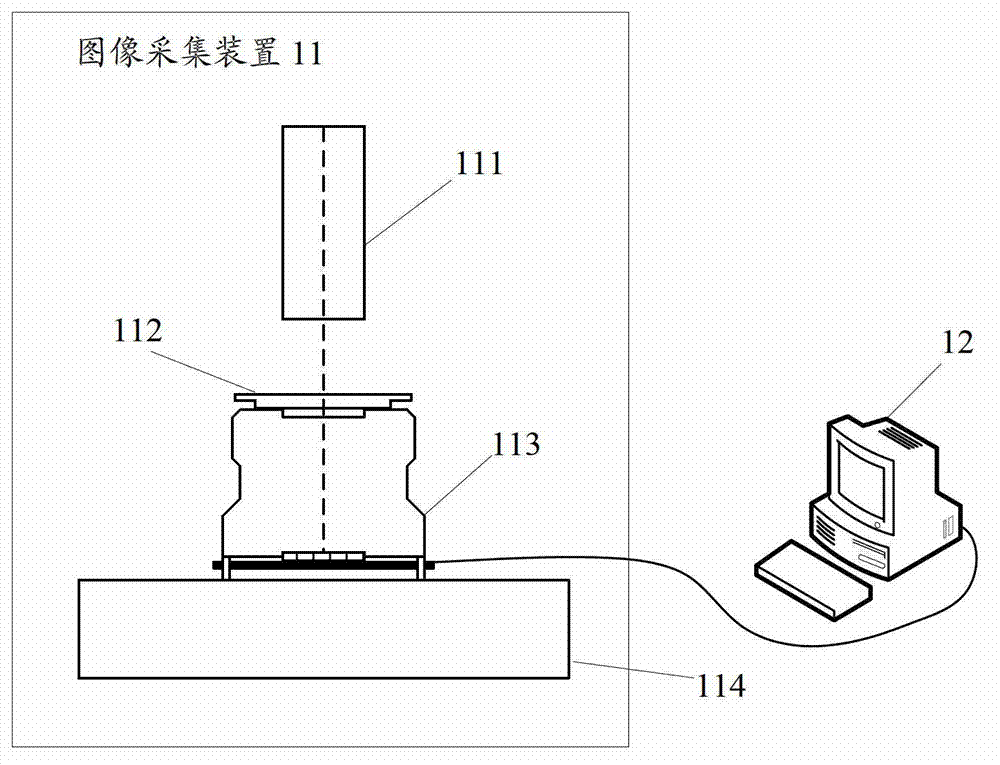

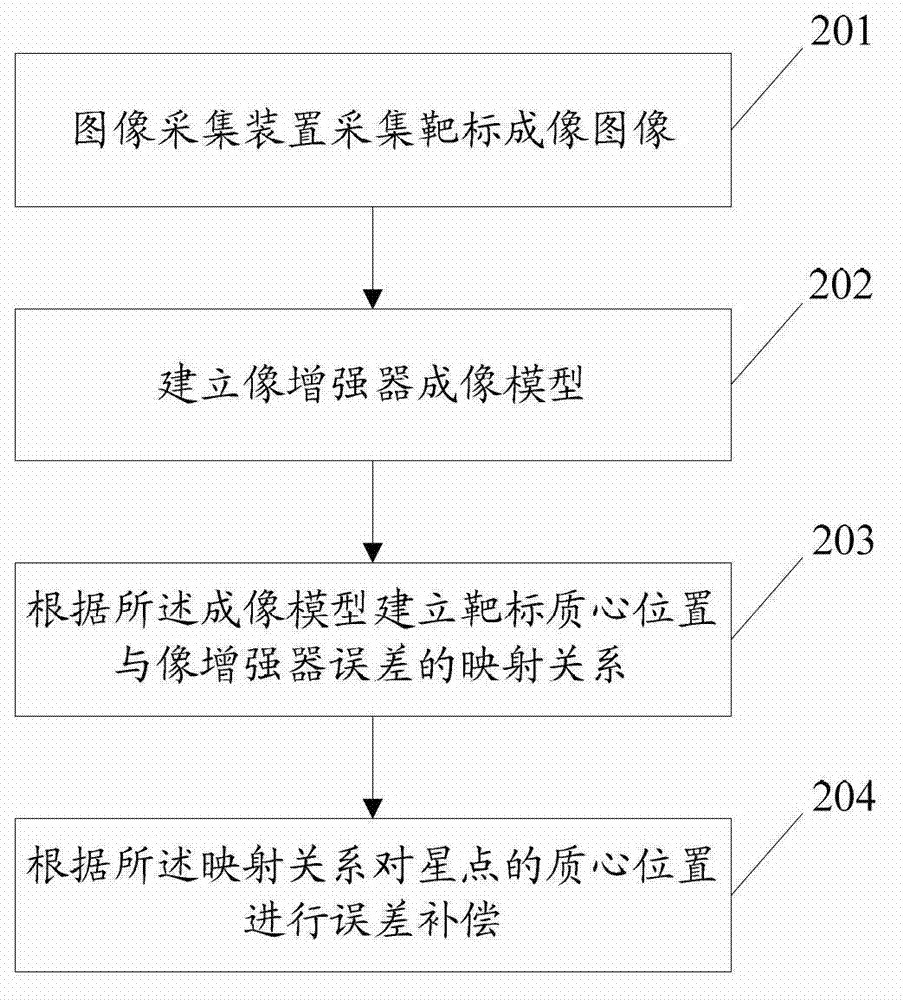

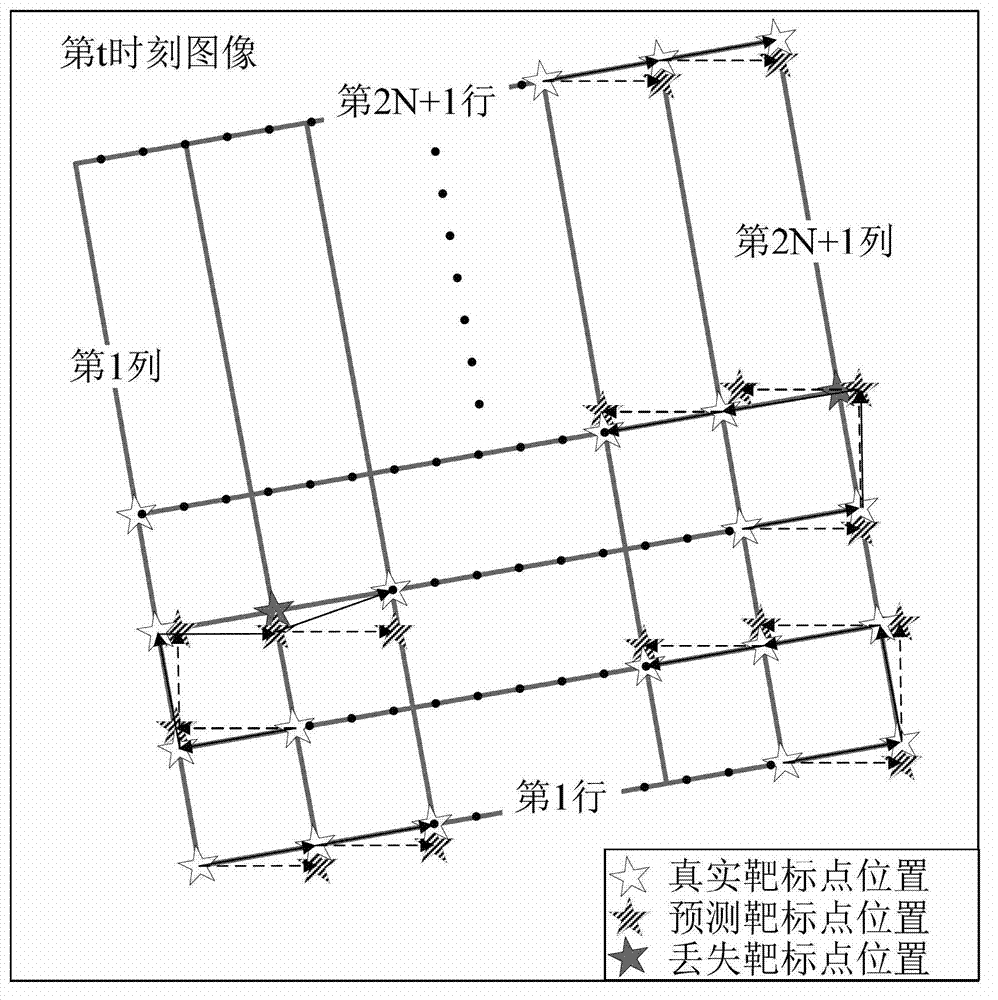

Method and device for high-dynamic star sensor image intensifier error compensation

ActiveCN103162711AImprove test accuracySpeed up error compensationMeasurement devicesComputer visionStar sensor

The invention discloses a method for high-dynamic star sensor image intensifier error compensation. The method comprises the following steps: collecting target imaging images through an image collecting device, establishing image intensifier imaging models, establishing the mapping relations of target mass center positions and the errors of the image intensifier according to the imaging models, and conducting error compensation to the mass center positions of a star point according to the mapping relations. The invention further discloses a device for high-dynamic star sensor image intensifier error compensation. By means of the method and the device for high-dynamic star sensor image intensifier error compensation, the errors of the image intensifier can be fast and accurately compensated, the speed of image intensifier error compensation is greatly accelerated, the time of error compensation is shortened, and the testing precision of the high-dynamic star sensor is improved.

Owner:BEIHANG UNIV

Methods and apparatus for ceiling mounted systems

ActiveUS20110068711A1Shorten the timeLow costPoint-like light sourceLighting support devicesEngineeringLight source

Owner:LIGHTING DEFENSE GRP LLC

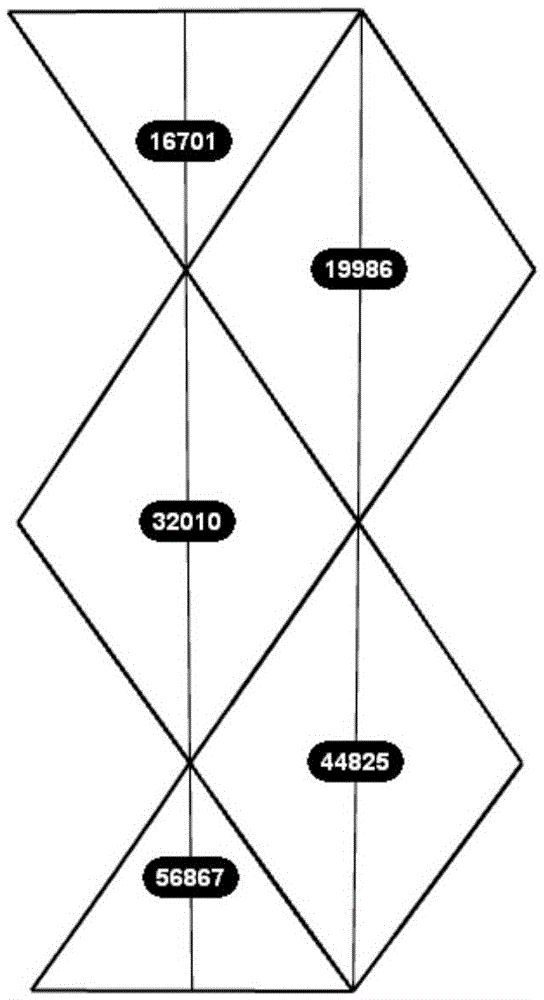

Single-curved plate fitting hyperbolic modeling method for curtain wall design and construction

The invention relates to a single-curved plate fitting hyperbolic modeling method for curtain wall design and construction. The method comprises the steps of acquiring preliminary measurement point data; determining plate bending arc radius by an optimal algorithm; then, carrying out plate form-finding operation to obtain a glass processing model. According to the method, theory space model formation logic is selected to be maintained, and key modeling constraint data such as grid division level elevation and grid division parts in a unit interval is controlled. The grid division size is adjusted according to the actual status of a steel structure, so that all curtain wall grid division lines are maintained to be consistent with the variation trend of main structure abnormity; under the premise that the design idea of the original building is maintained visually, the adjusted grid division lines are close to the structure in reality, so that the installation error is greatly reduced.

Owner:武汉凌云建筑装饰工程有限公司

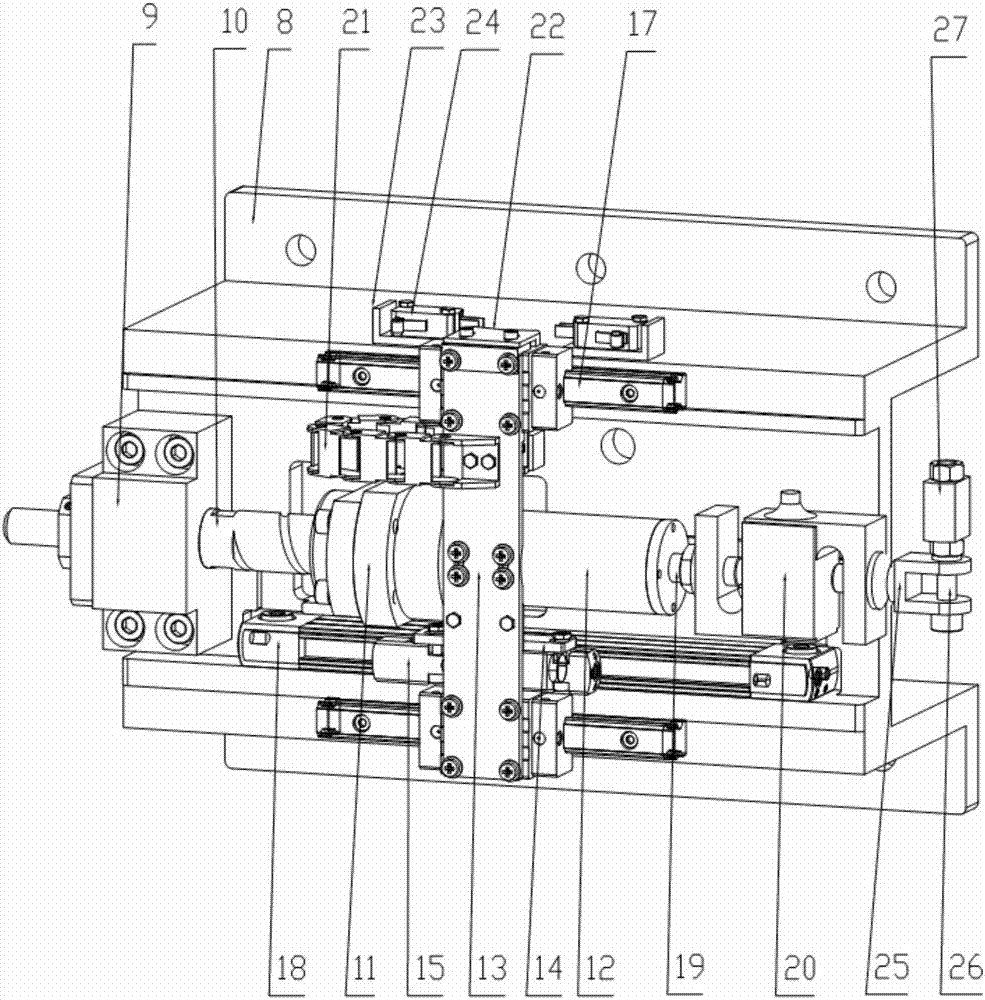

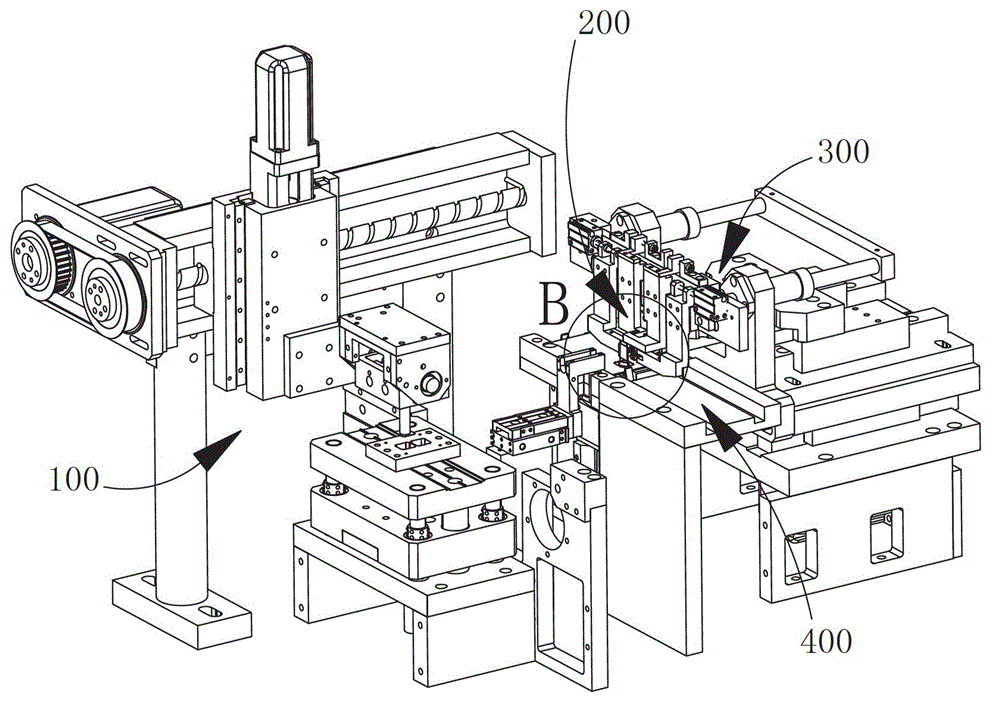

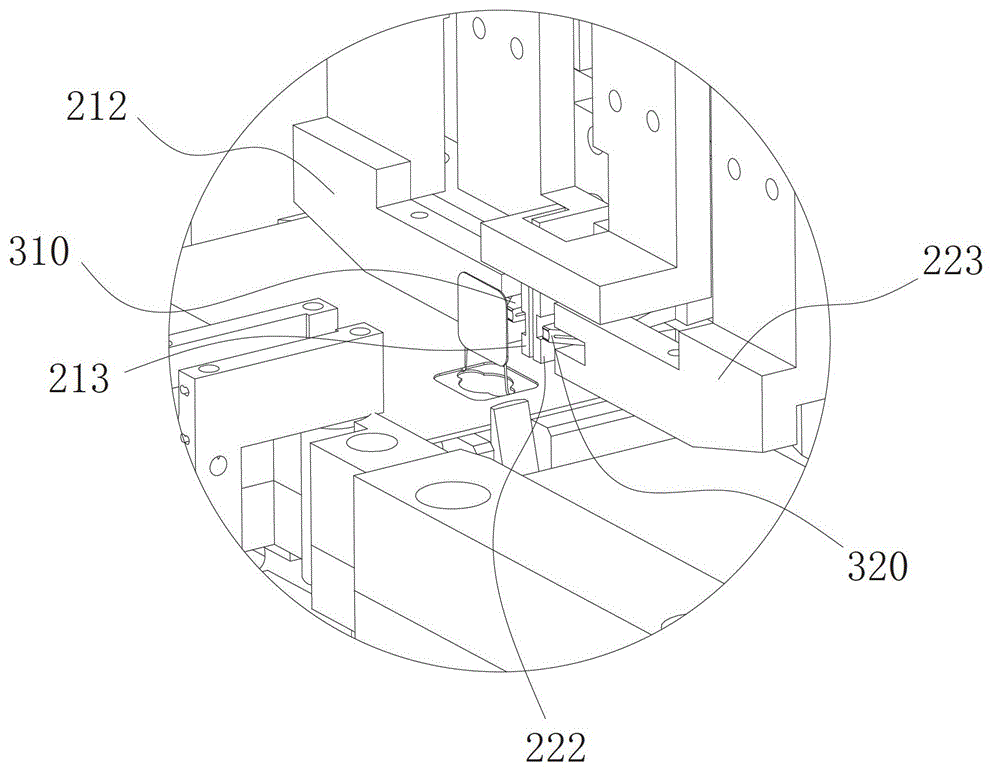

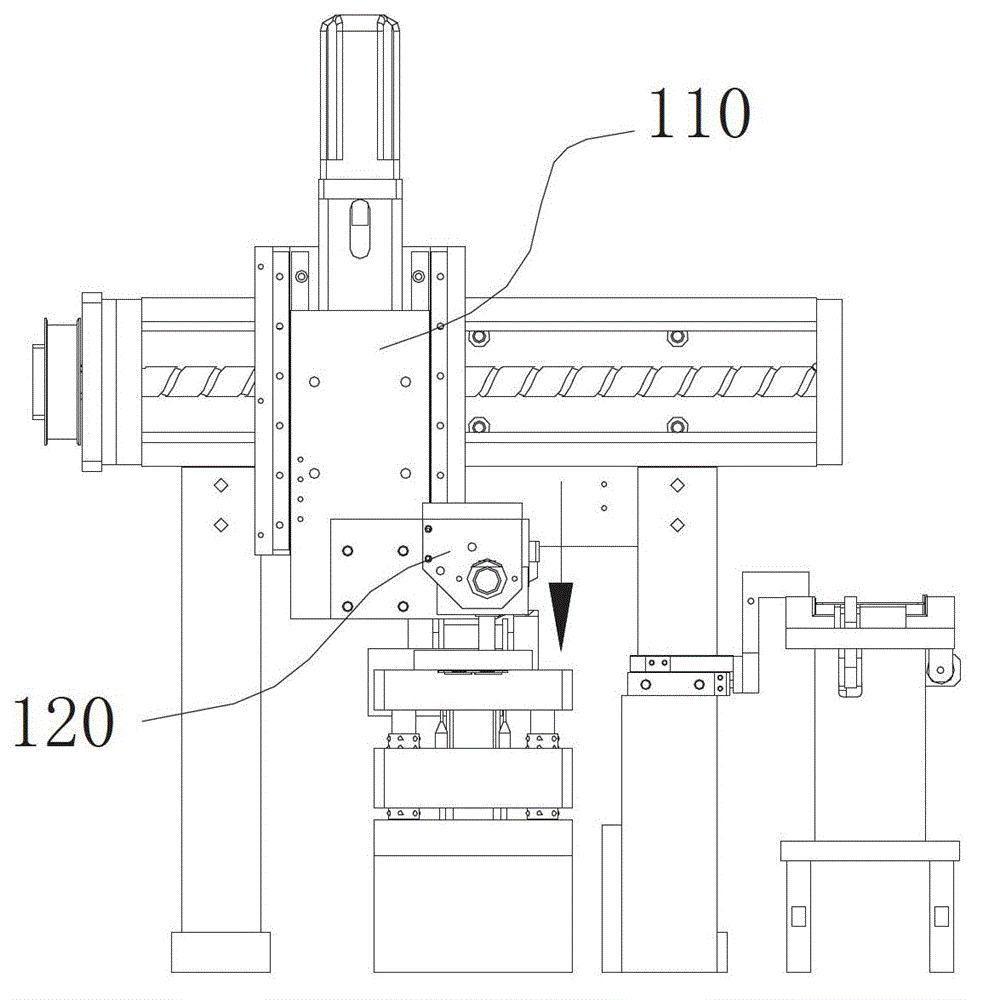

Chip welding method of dual-interface card and equipment thereof

InactiveCN103182577AImprove work efficiencyReduce labor intensitySoldering apparatusEngineeringElectrical and Electronics engineering

The invention discloses a chip welding method of a dual-interface card. The chip welding method of the dual-interface card comprises the following steps: 1, a card body is conveyed by a card body conveying device to a position on which the chip is to be welded, wherein the two ends of an antenna of the card body are at an erect state; and a chip pickup device picks up a chip and reaches the position on which the chip is to be welded to be welded; 2, an antenna clamping device clamps the two ends of the antenna at the same time and positions the antenna at the welded position of the chip; 3, a dual-touch welding head welds the two ends of the positioned antenna on the chip; and 4, after welding, all components return and the card body conveying device takes away the welded card body. The invention further discloses chip welding equipment of the dual-interface card for implementing the chip welding method of the dual-interface card. The chip welding equipment of the dual-interface card comprises the chip pickup device, the antenna clamping device, the card body conveying device and the dual-touch welding head, wherein the chip pickup device is arranged on one side of the antenna clamping device; and the dual-touch welding head is arranged on the other side of the antenna clamping device. By the chip welding method and the chip welding equipment, the two ends of the antenna can be welded on the chip by one step.

Owner:GUANGZHOU MINGSEN TECH CO LTD

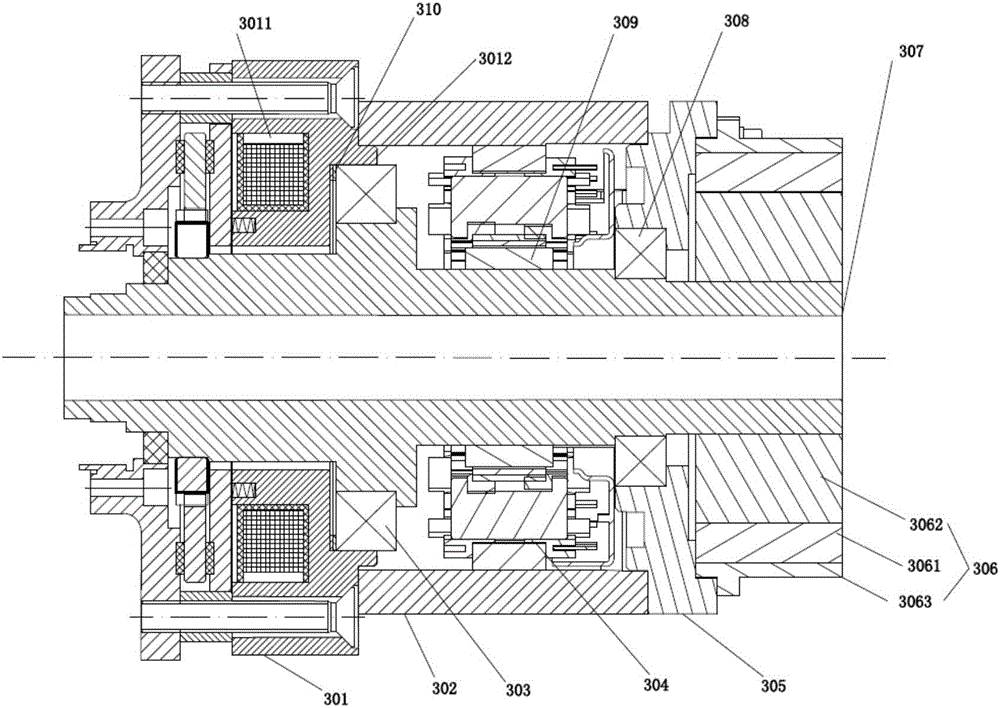

Adjustable elastic support structure

InactiveCN100555806CEliminate manufacturing errorsEliminate installation errorsSupports/enclosures/casingsCouplingEngineering

The invention relates to an adjustable elastic support structure, specifically for the support connection between rotary machines (screw compressors, motors, etc.) and machine bases, and belongs to the technical field of support devices. It mainly adopts the shock absorber to be connected with the bottom plate and the bracket respectively, the motor is connected with the bracket, the chassis is supported by the top screw, the nut locks the top screw, and the bottom plate and the chassis are connected by the connecting bolt. The invention has a simple, compact and reasonable structure; the elastic support can eliminate and reduce the transmission of motor vibration; the adjustable support can eliminate the manufacturing error and installation error of each component, so that each support point can obtain ideal support force and reduce additional vibration and noise ; It can reduce the additional bending moment on the connecting cylinder and the additional force of the connecting bolts, so as to ensure the smooth operation of the machine.

Owner:WUXI COMPRESSOR CO LTD

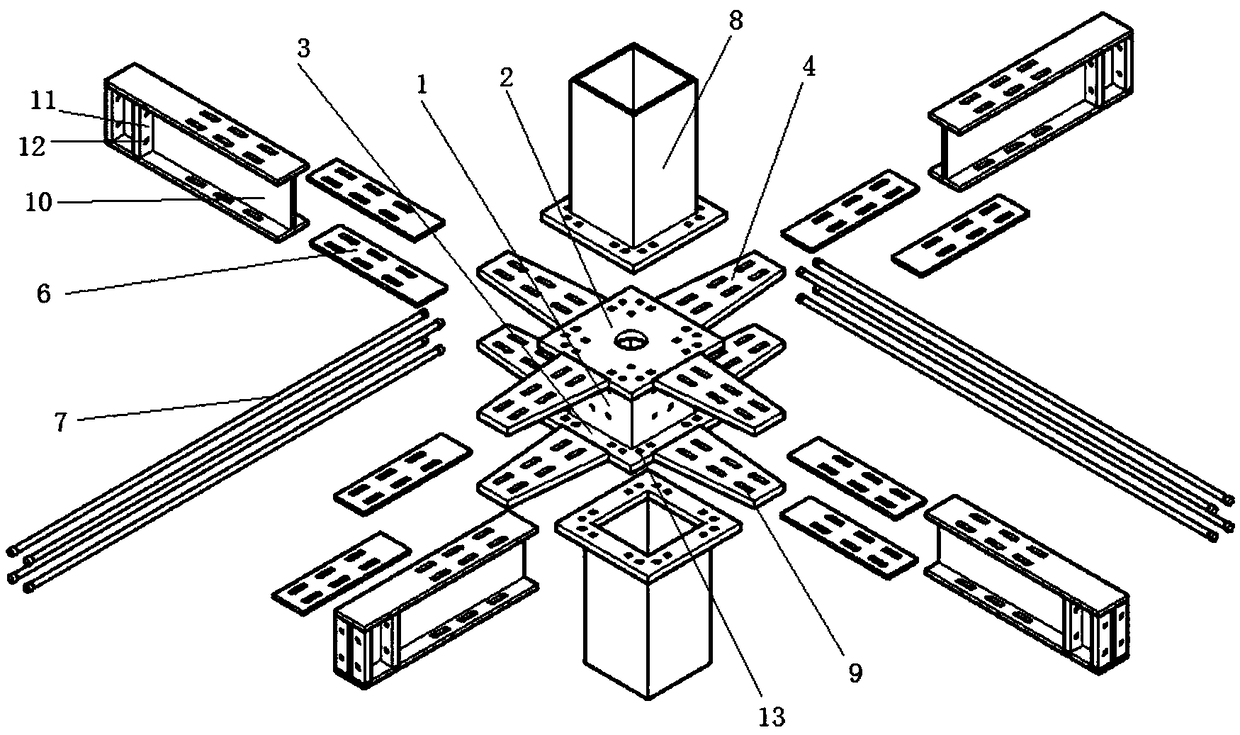

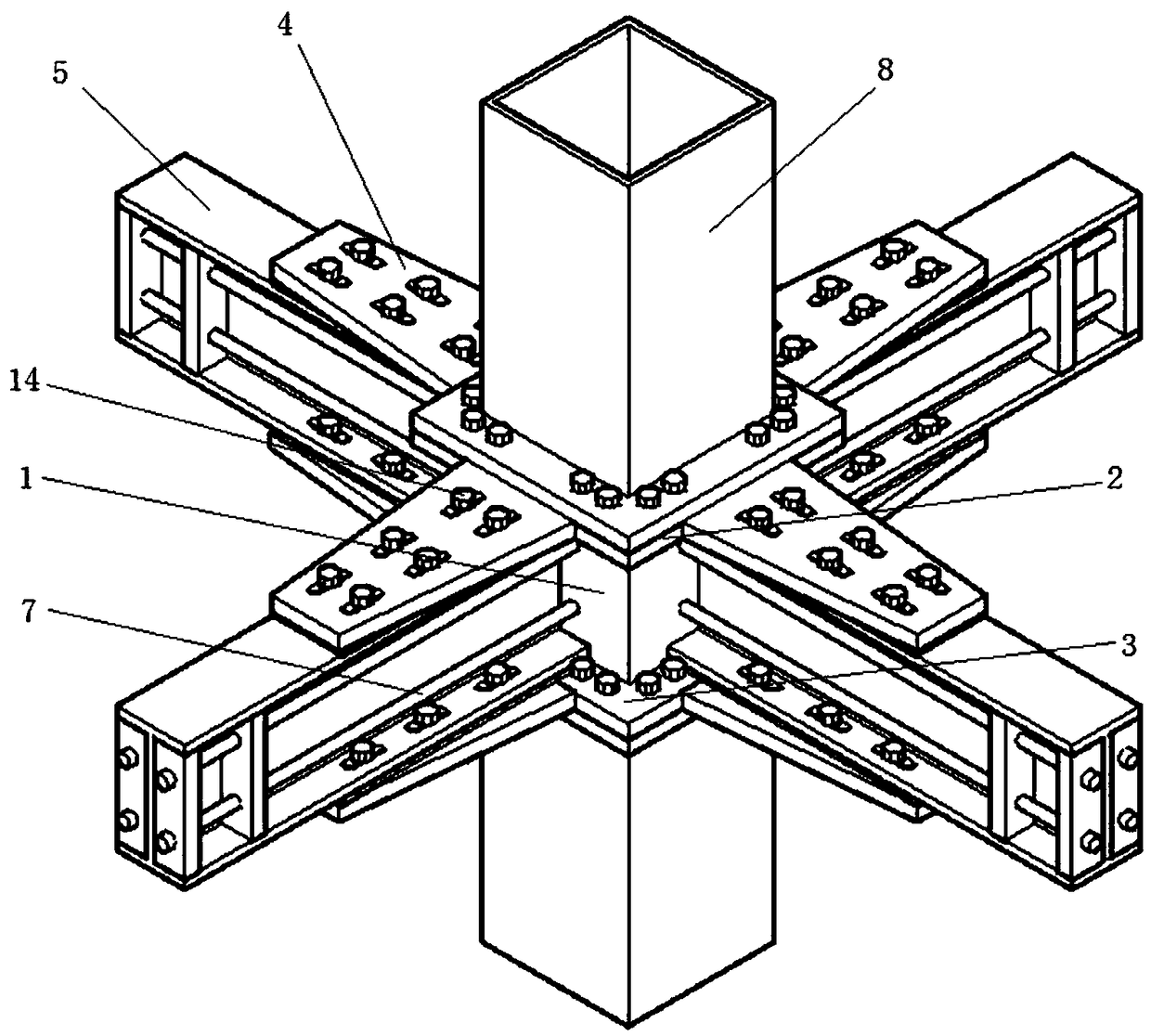

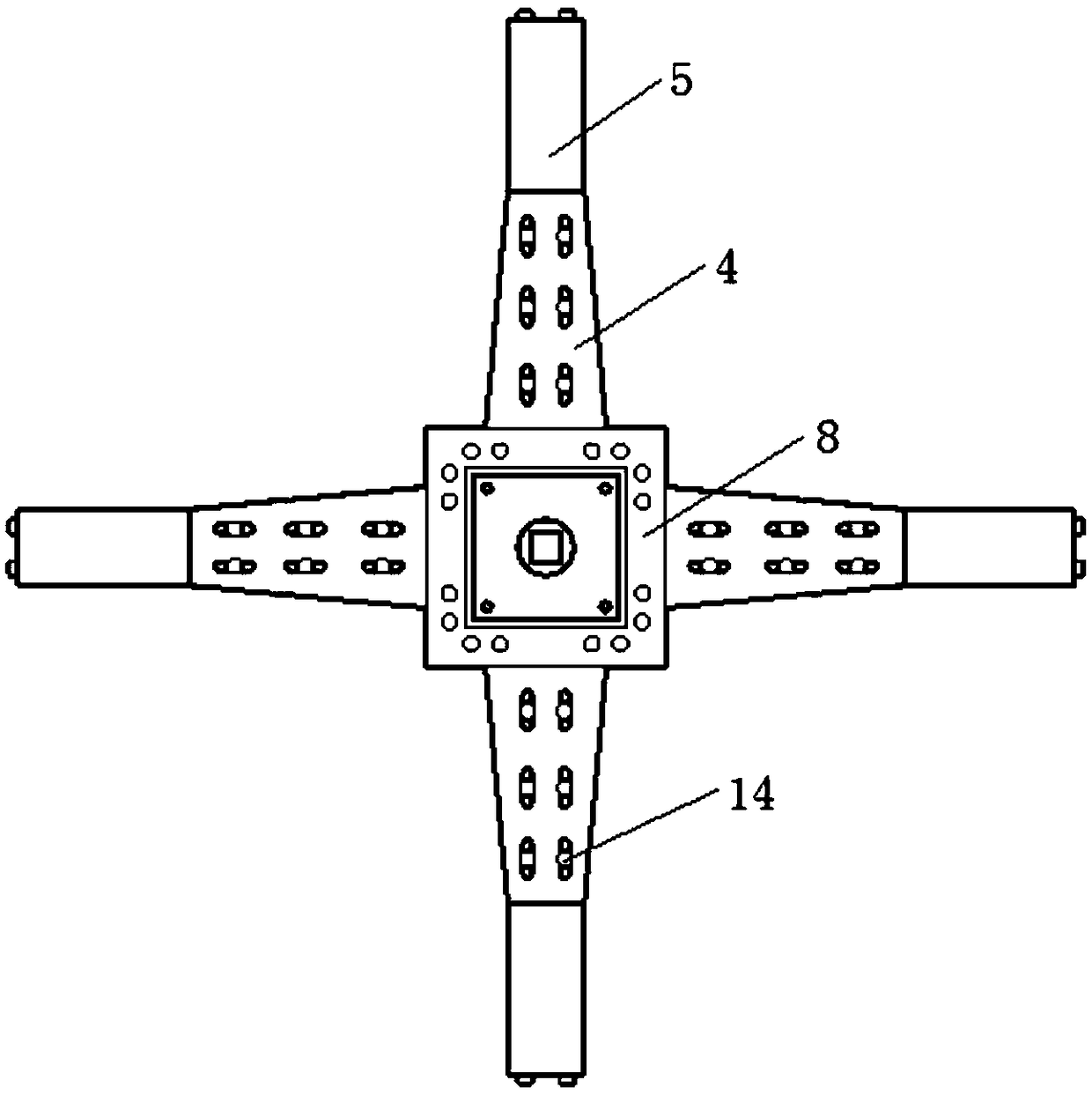

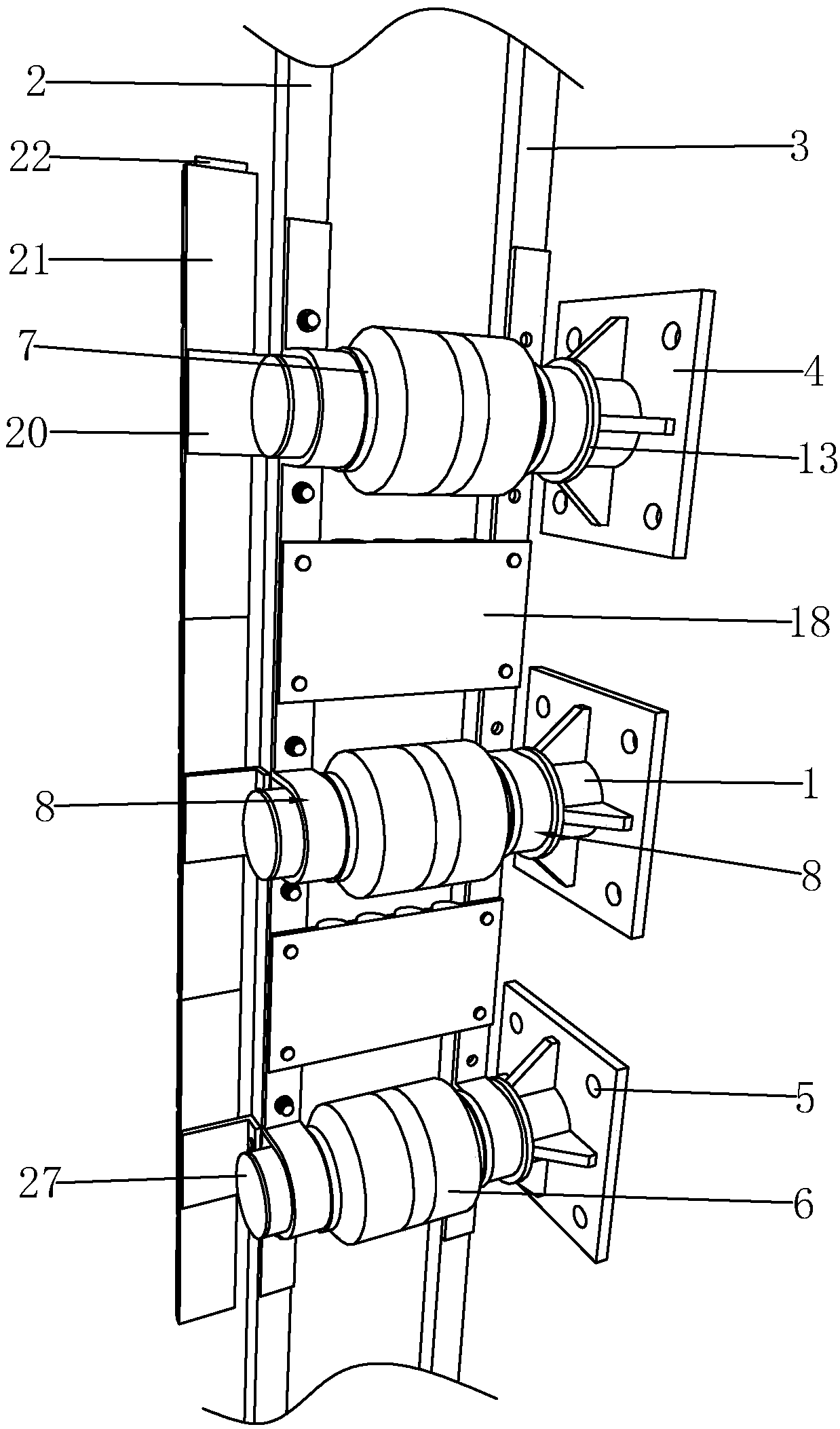

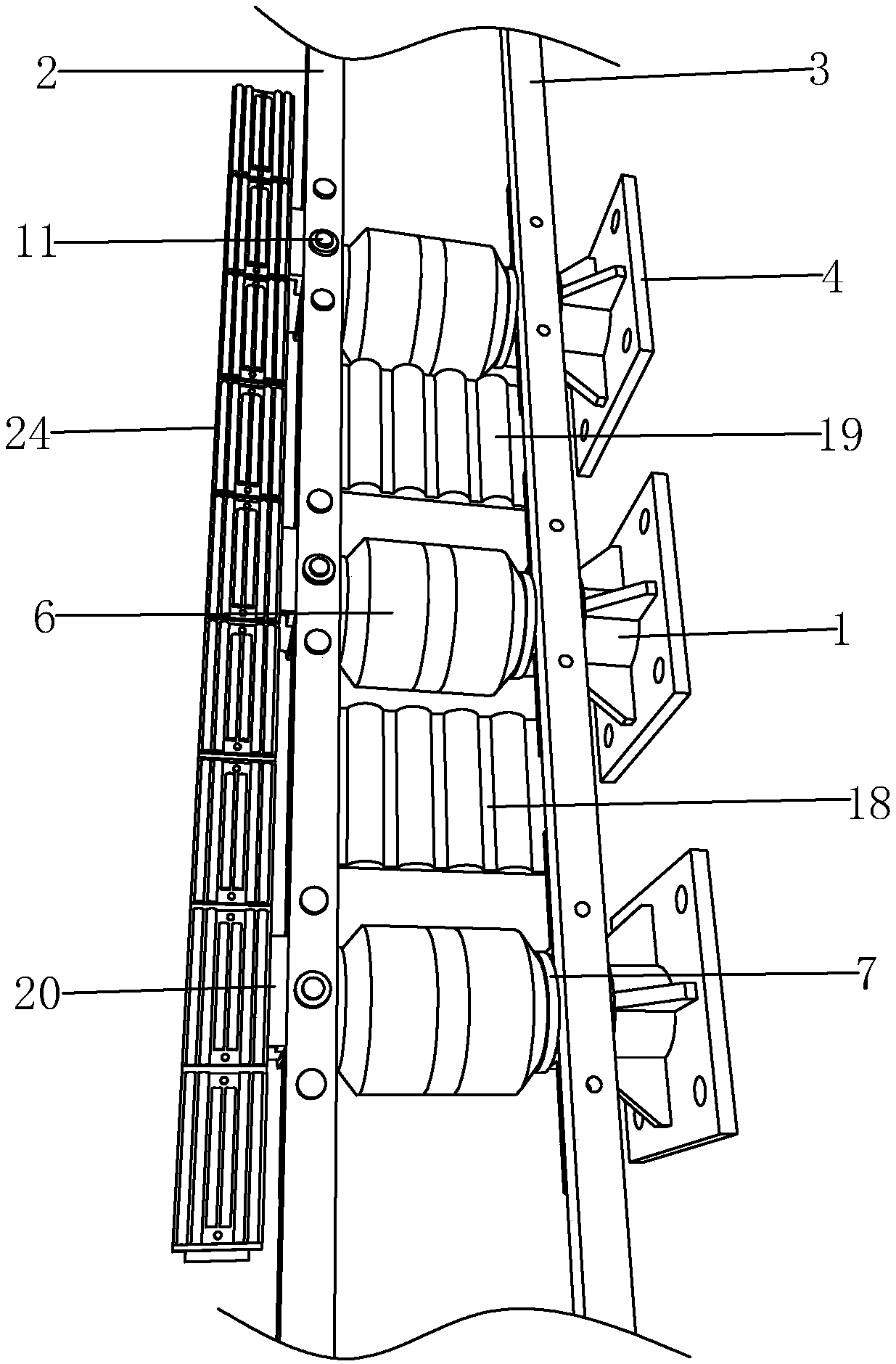

Prefabricated friction-energy-consuming self-resetting baffle communication node

InactiveCN109138179AIncrease frictional energy dissipation functionAvoid damageProtective buildings/sheltersBuilding reinforcementsPre stressInstallation Error

Provided in the invention is a prefabricated friction-energy-consuming self-resetting baffle communication node comprising node-domain rectangular steel tube concrete columns. A first baffle plate anda second baffle plate are arranged at the upper ends and the lower ends of the node-domain rectangular steel tube concrete columns respectively; and extending arms are arranged around the first baffle plate and the second baffle plate; H-shaped steel beams are arranged between the extending arms arranged in parallel between the first baffle plate and the second baffle plate; rubber gaskets are arranged between upper and lower flanges of the H-shaped steel beams and the extending arms; and the H-shaped steel beams and the node-domain rectangular steel tube concrete columns that are arranged inopposite are connected by high-strength prestressed steel strands with cables. The flange-included node-domain rectangular steel tube concrete columns are arranged at the top of the first baffle plate and the bottom of the second baffle plate. According to the prefabricated friction-energy-consuming self-resetting baffle communication node, the installation error is reduced; the prefabrication ofthe factory is realized; the node quality is improved; the node has the self-resetting function; the post-earthquake maintenance costs are lowered; and the anti-seismic capacity is enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

A bridge anti-collision guardrail and a construction method thereof

InactiveCN109056523AIncrease impact forcePlay a protective effectBridge structural detailsBridge erection/assemblyCushioningArchitectural engineering

The invention discloses a bridge anti-collision guardrail and a construction method thereof, Collision barriers include columns, An upper rail and a low rail are respectively sleeved with a buff cylinder and a swirling ring on that upright column, the two ends of the upright column are fix on the upper rail through a limiting seat, the lower rail is provided with a fixing ring on the upright column, the fixing ring is in contact with the limiting seat located below, an L-shaped mounting plate is provided on the upper rail, an L-shaped mounting plate is provided with an anti-collision plate, and a cushioning guardrail plate is provided on the anti-collision plate; The construction method comprises the following steps: (a) route marking; (b) Post positioning; (c) Installation of lower railings; (d) installation of an upper railing; (e) Installation of cushion shields; (f) Installation of bumper plates; (g) Installation of remaining uprights. The anti-collision guardrail of the inventionhas the advantages of high stability, convenient installation, cushioning and anti-collision, high safety, easy operation, orderly and reasonable construction, fast and convenient construction, time and labor saving, low construction intensity and convenient maintenance in the later period. The invention has the advantages of high stability, convenient installation, cushioning and anti-collision,high safety, easy operation, orderly and reasonable construction method, fast and convenient construction, and low construction intensity.

Owner:ZHEJIANG COLLEGE OF CONSTR

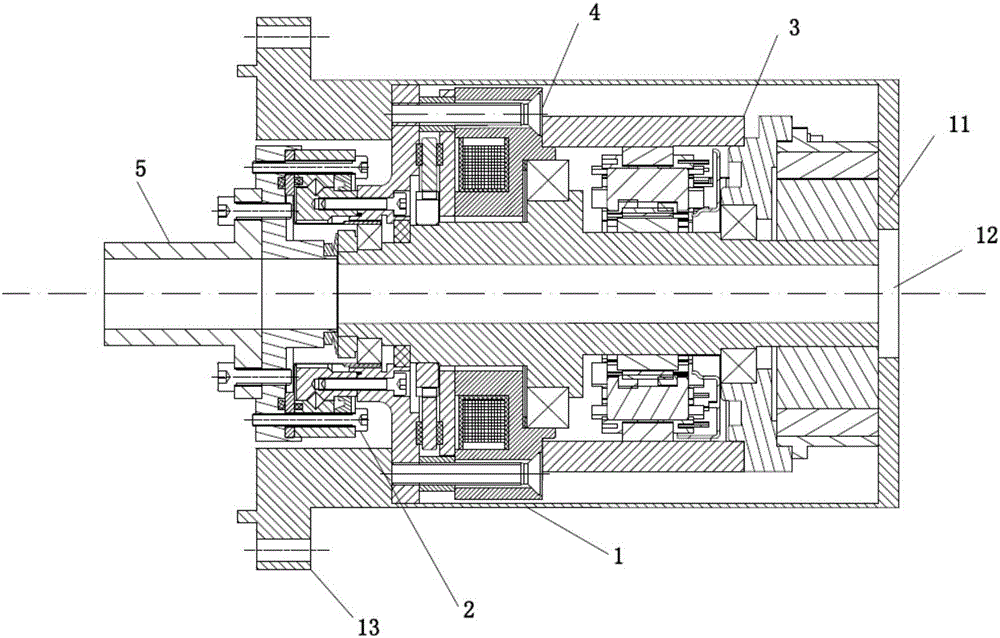

One-body motor integrating brake

ActiveCN106411040AReduce designReduce installation errorsMechanical energy handlingEngineeringInstallation Error

The present invention provides an one-body motor integrating a brake. The motor comprises a casing; a servo motor including a motor casing, a front end cover, a rear end cover, a spindle which is located in the motor casing, wherein the front end cover is cyclic annular, and the front side of the front end cover is provided with a front annular groove and a plurality of blind holes, and the partial cross section of the front end of the spindle is elliptical; a brake consisting of a coil, a movable iron core, a friction plate, a brake disc, a fixing plate, an external gear and a plurality of brake springs, wherein the coil is embedded in the first annular groove, the movable iron core is located at the outer sides of the front end cover and the coil, one end of each brake spring inserts one blind hole, the other one end of each brake spring is sleeved and fixed at the front end of the spindle, the brake disc is located at the outer side of the movable iron core and is provided with inner teeth engaged with the external gear, the fixing plate is located at the outer side of the brake disc, and the friction plate is arranged between the movable iron core and the brake disc and between the fixing plate and the brake disc; and an output shaft. The one-body motor integrating a brake at least integrates the servo motor and the brake so as to reduce the design and installation error caused by the split-type structure.

Owner:CHINA ELECTRONIC TECH ROBOT CO LTD

Target sphere mounting stand suitable for large aperture self-centering

ActiveCN101476872AReduce installation errorsGuaranteed coincidenceUsing optical meansElectromagnetic wave reradiationEngineeringLaser

The invention discloses a target ball mount which is used for mounting target balls of a laser tracking instrument and suitable for large-aperture self-centering, wherein an equant sliding chute (2) which is around the circumference of a central groove (5), intersected with the circle center by being symmetrical with an axial line, and extended outwards in the radial direction is arranged on a target ball mounting base (1); a screw target ball mounting head (7) is arranged on a positioning pin (6), positioned in the center of the central groove, extended upwards vertically, and extended out of the end face; a central slider (3) of which the shape and the dimension are consistent with those of the central groove provided with the equant sliding chute (2) is arranged inside a central sliding chute through a central positioning hole of the central slider (3); a slider bevel (11) is arranged on the central slider (3); and lug bevels (13) are arranged on uniformly distributed movable lugs (12) in equant parts. The invention utilizes the slider bevel to fix the target ball mount on a hole to be measured with large common difference, guarantees superposition of the center of the target ball mount and the center of the hole to be measured, and reduces mounting errors; and the target ball mount is convenient to assemble and disassemble, and suitable for laser tracing measurement of target balls with the aperture between 30 and 80 millimeters and the aperture common difference less than IT12.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

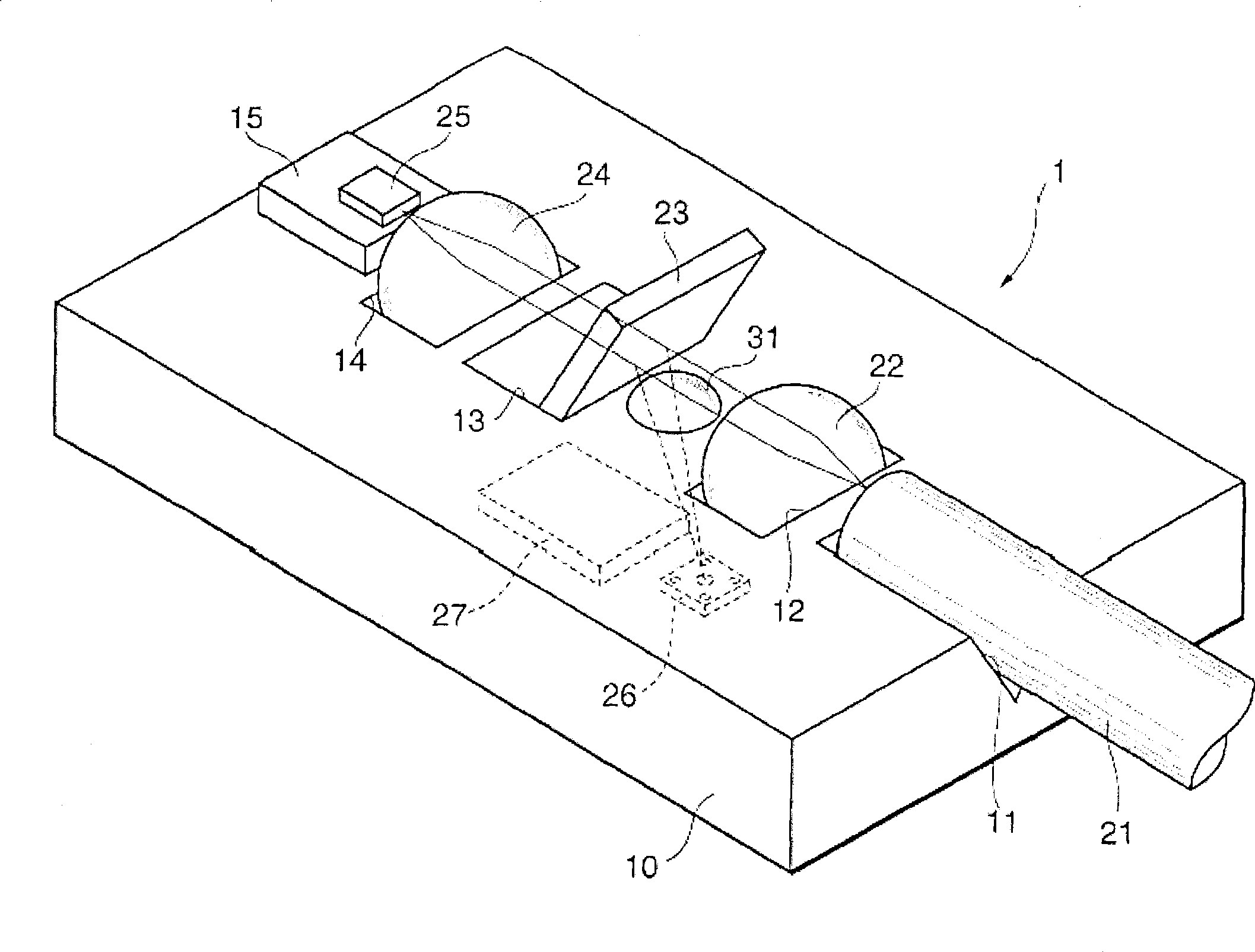

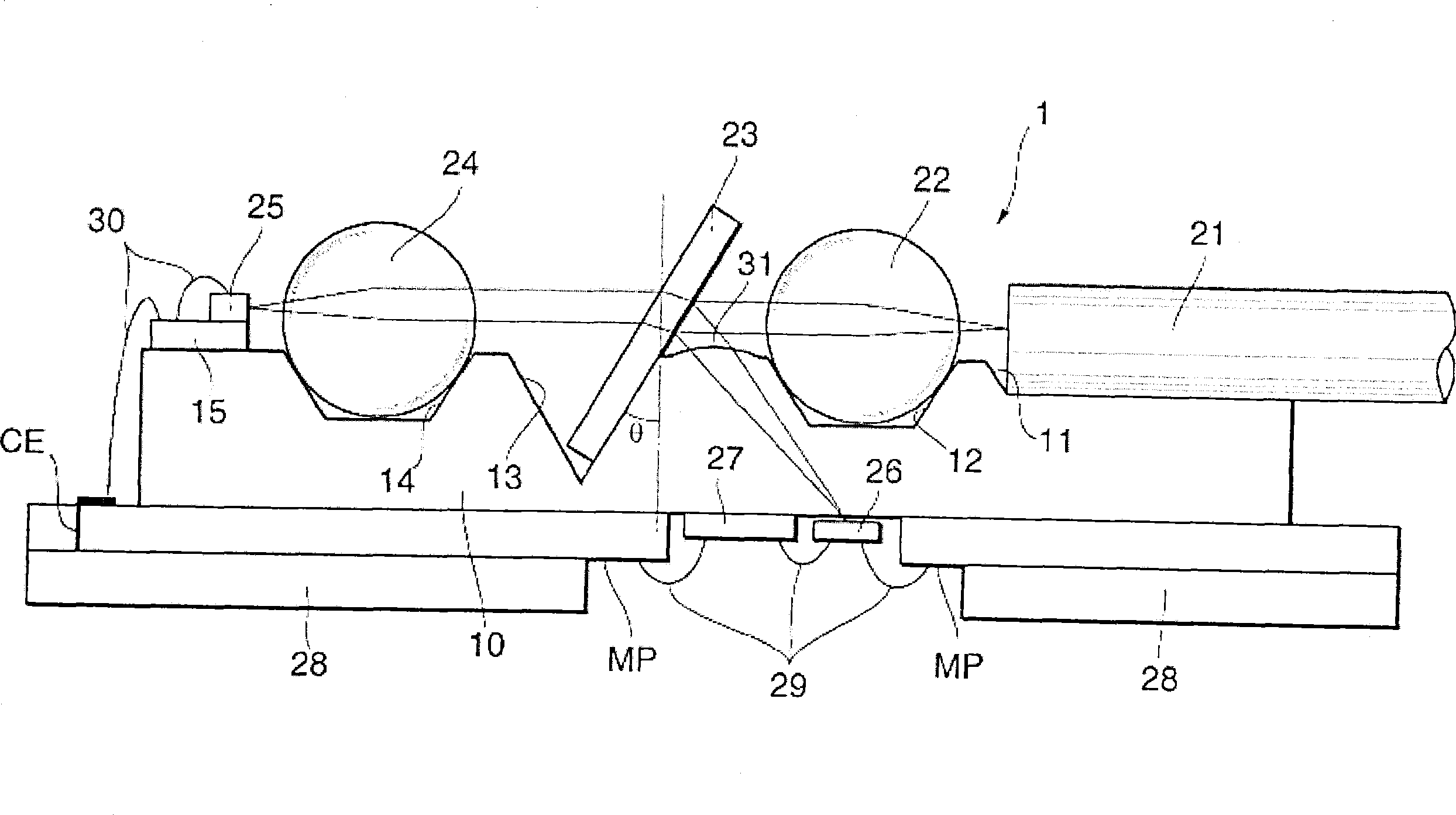

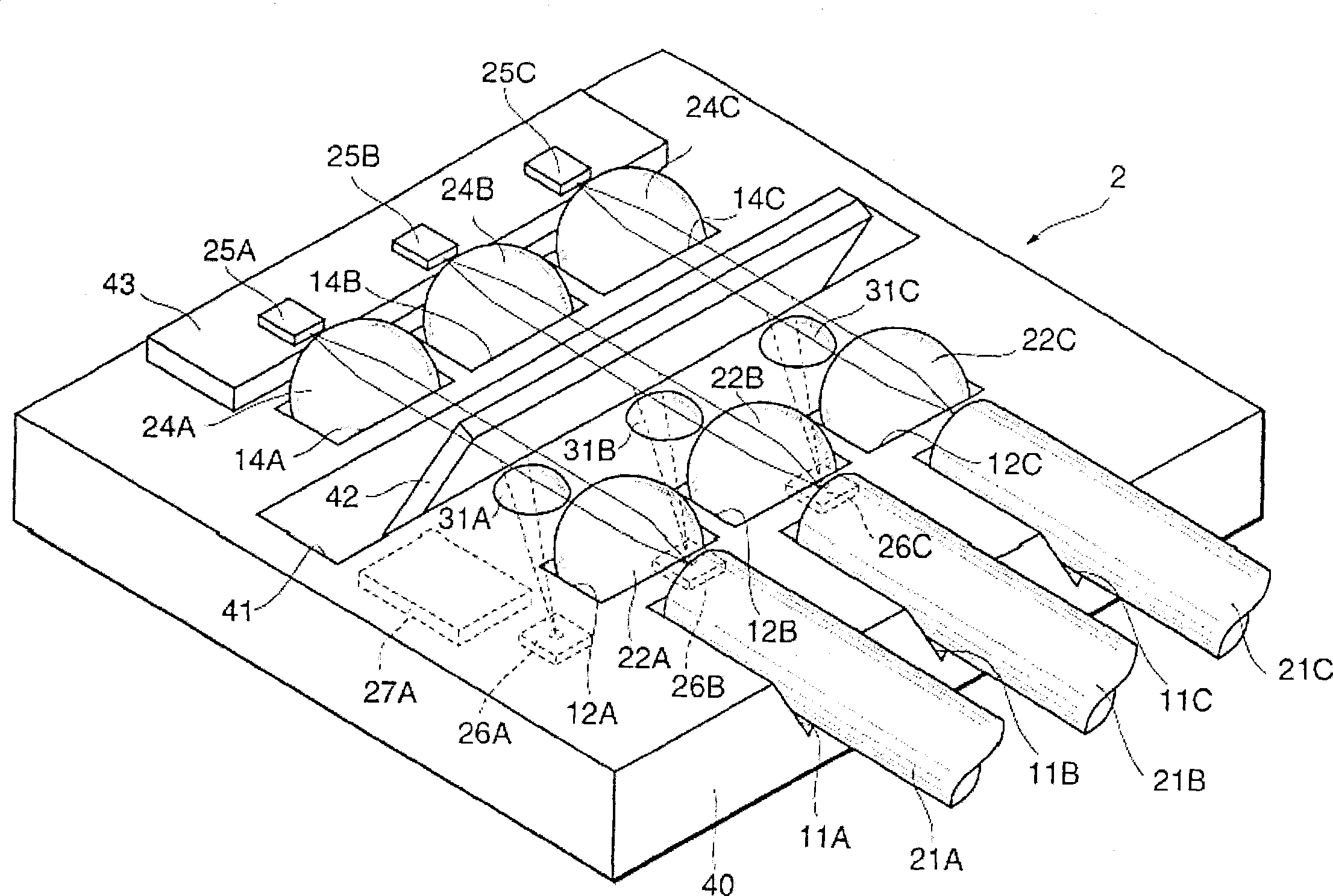

Optical transmitting/receiving module

InactiveCN1918497AReduce installation errorsHigh positioning accuracyLaser detailsCoupling light guidesDielectricComputer module

An optical transmitting / receiving module in which spatial restriction can be relaxed by eliminating the need for providing a substrate with a submount for a photodiode. A optical transmitting / receiving module (1) comprises a light transmitting substrate (10). A groove (13) for filter is formed in the surface of the light transmitting substrate (10) and a dielectric multilayer film filter (23) is placed in the groove (13) for filter. An optical fiber (21) and a laser diode (25) are arranged oppositely on the opposite sides of the dielectric multilayer film filter (23). Furthermore, a photodiode (26) is provided on the rear side of the light transmitting substrate (10). The photodiode (26) is arranged right under a line connecting the optical fiber (21) and the laser diode (25).

Owner:HAMAMATSU PHOTONICS KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com