Coaxiality detector

A technology of coaxiality and detectors, which is applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of time-consuming and labor-intensive, high operation requirements, etc., achieve the effect of small installation error and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

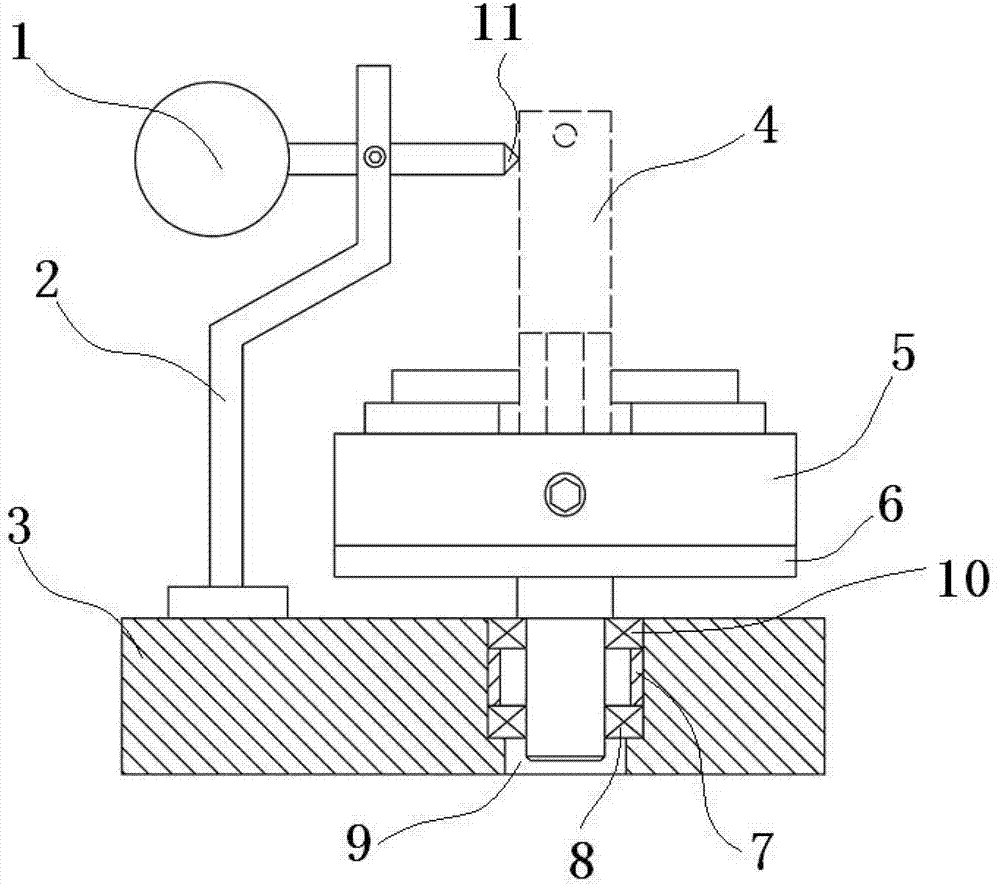

[0014] refer to figure 1 , the present invention provides a coaxiality detector for detecting the coaxiality of the hexagonal shaft 4, comprising a base 3, a clamping mechanism, a rotary mechanism and a detection device, the clamping mechanism is used for clamping the hexagonal shaft 4; the rotary mechanism It is rotatably installed on the base 3 for supporting and driving the clamping mechanism to rotate around the central axis of the hexagonal shaft 4; the detection device is installed on the base 3 for detecting the coaxiality of the hexagonal shaft 4; the rotary mechanism includes a turntable 6 , the center of the turntable 6 is provided with a stepped shaft, the base 3 is provided with a stepped hole 9, and the stepped hole is equipped with a first bearing 10, a distance sleeve 7 and a second bearing 8 in sequence, and the stepped shaft passes through the first bearing 10 and the second bearing 8 inner holes, and transition fit with the first bearing 10 and the second bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com