Single-curved plate fitting hyperbolic modeling method for curtain wall design and construction

A plate and bending technology, which is applied in the field of curtain wall design and construction of single-curved curved plates to fit hyperbolic shapes, can solve the problems of inability to install plates and out-of-shape building appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

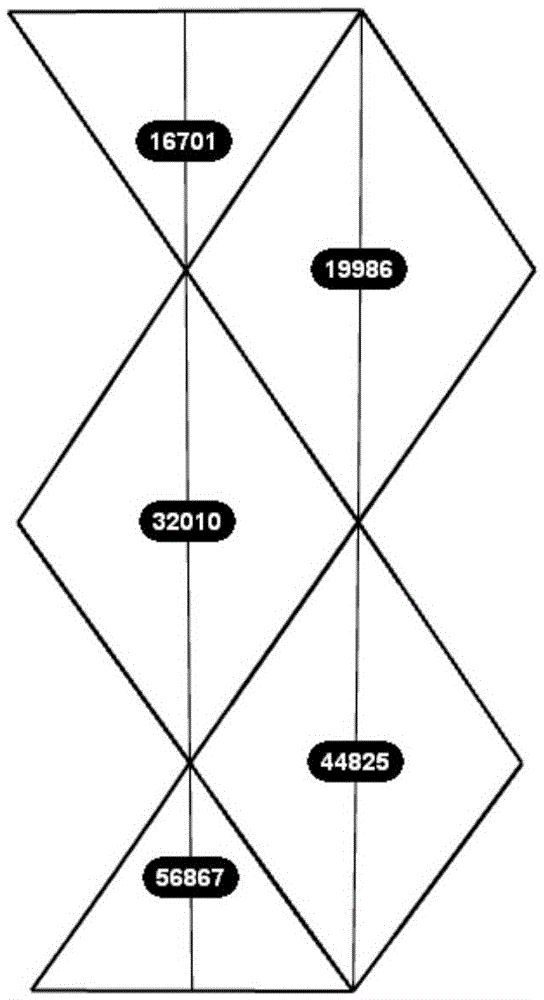

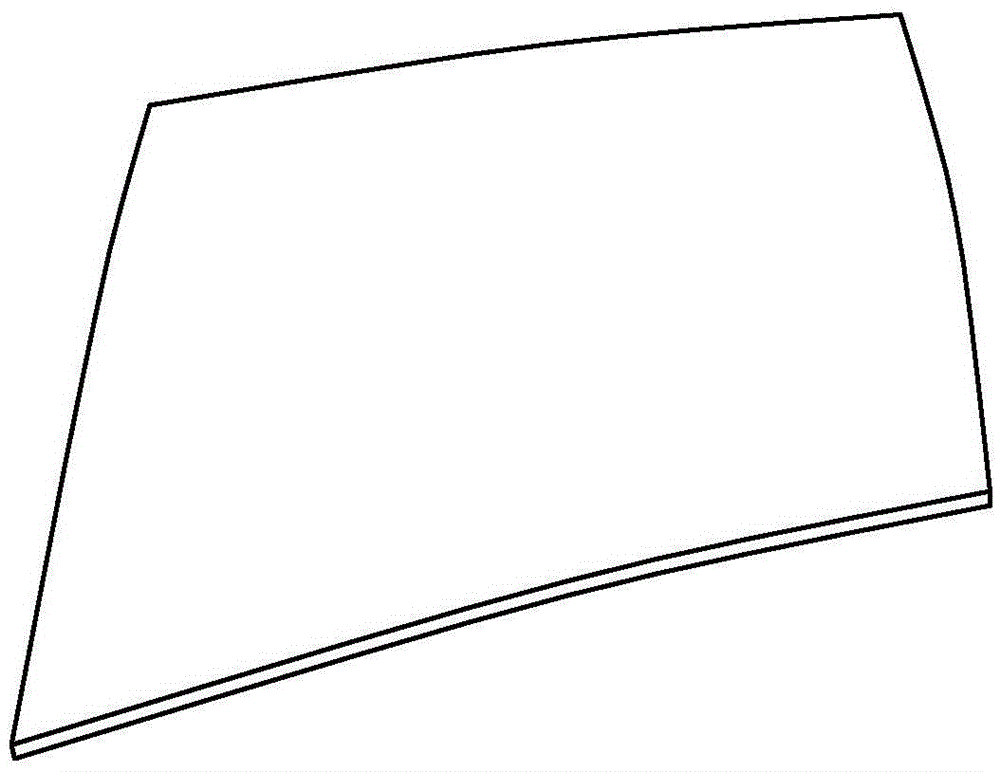

[0033] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 Shown is the assembled state of the curtain wall panels of the present invention. The figure shows an embodiment of vertical bending. The numbers in the figure are the calculation results of the bending radius after vertical bending and fitting through the technical solution of the present invention. For the overall curtain wall effect, see Figure 4 . Before the technical solution of the present invention, the splicing gaps and height edge errors caused by panel installation far exceeded the standard requirements. If the reverse ruler was measured completely according to the state of the site, the appearance of the building would be out of shape. The solution of the present invention can greatly reduce the installation error by the following steps, and better complete the design intention of the building appearance.

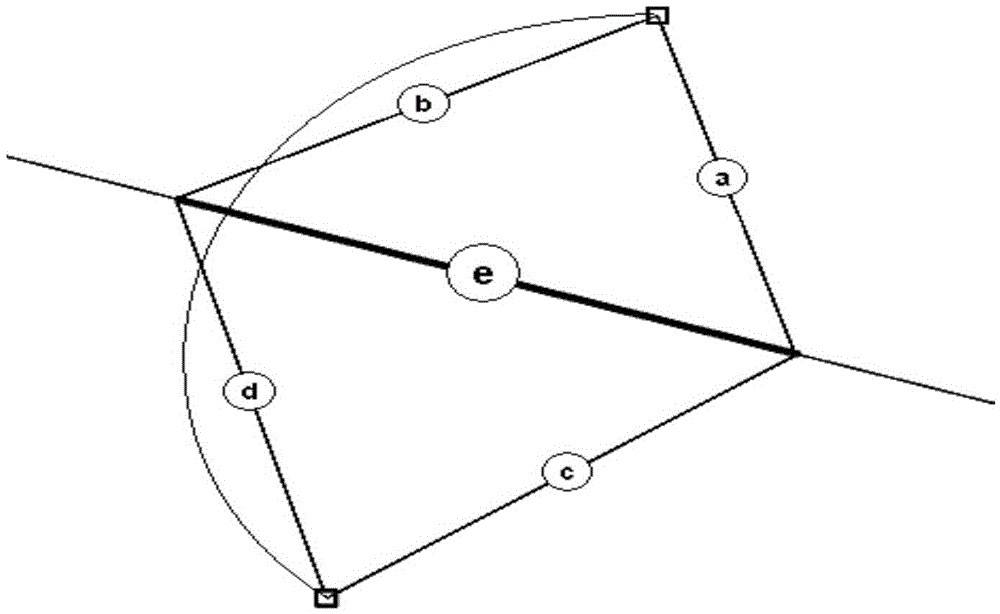

[0034] The plate design of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com