Target sphere mounting stand suitable for large aperture self-centering

A technology of mounting seat and mounting base, which is applied to measurement devices, optical devices, and re-radiation of electromagnetic waves, etc., can solve the problems of low precision, the accuracy of the positioning column of the target ball mounting seat cannot realize the gap-free fit of the measurement holes, etc. The effect of improving measurement accuracy and reducing installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

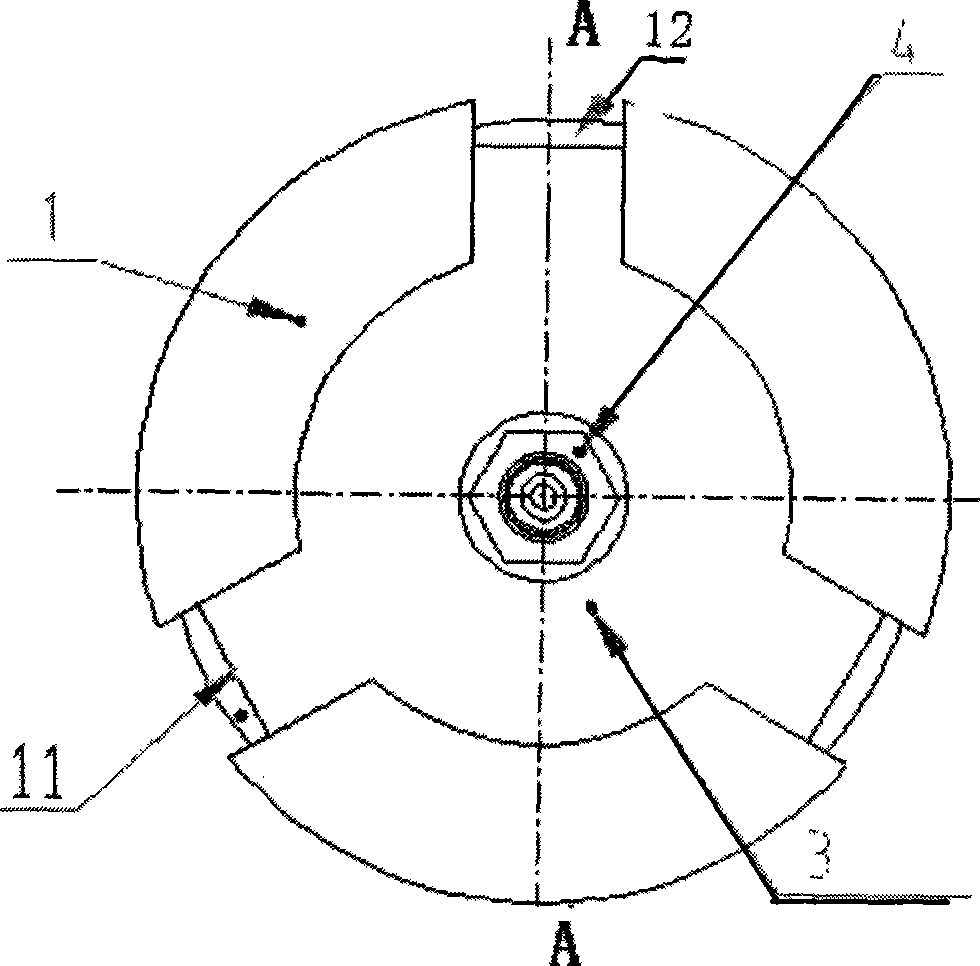

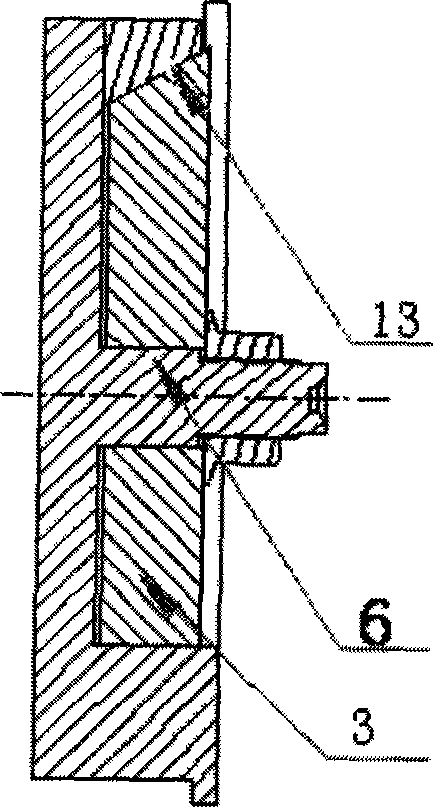

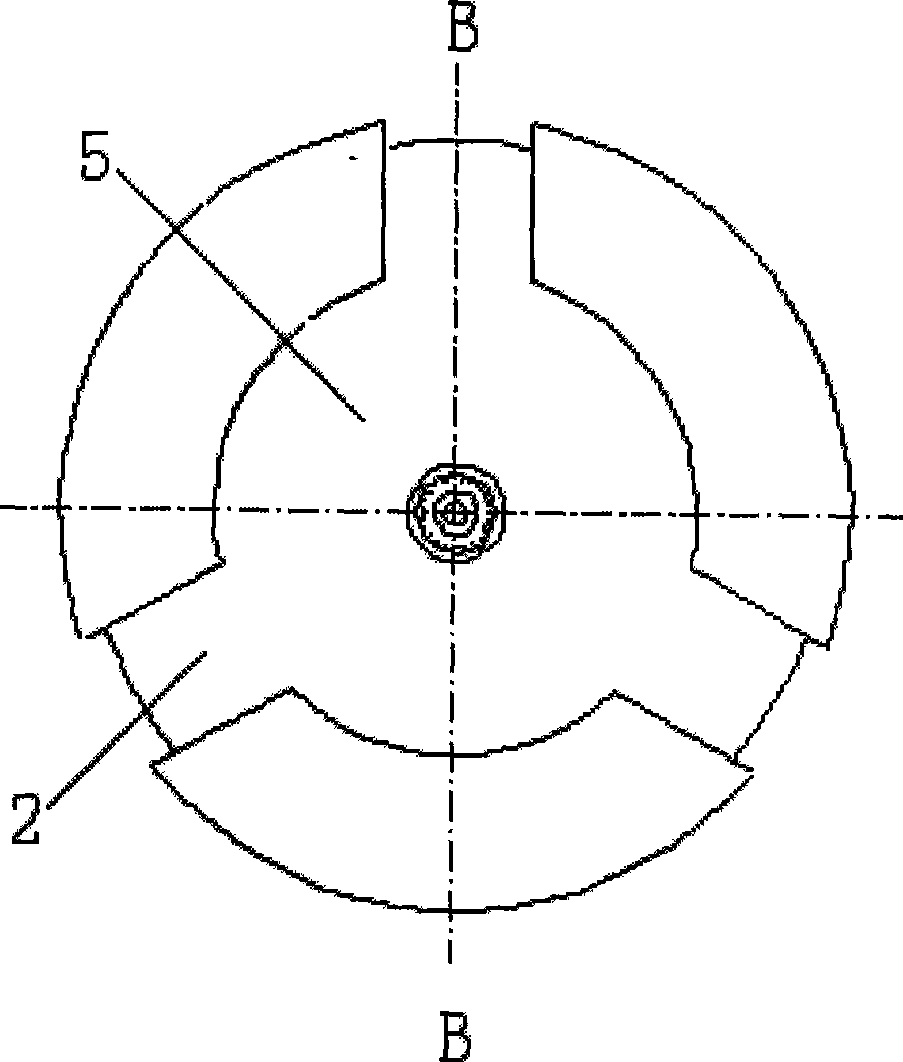

[0017] exist Figure 1 ~ Figure 4 Among them, on the end face of the target ball installation base 1 with positioning post 6, be shaped on image 3 As shown, around the circumference of the central groove 5, it extends radially outward, and its axis of symmetry intersects the chute 2 at the center of the circle. The outer edge of center slide block 3 is shaped on slide block inclined-plane 11. Three chutes are equally distributed along the 120 ° of center groove 5 circumferences. The positioning column 6 is located in the center of the central groove and extends vertically upwards, and protrudes from the end surface. On the positioning column 6, there is a screw type target ball installation head 7. The free end end face of screw type target ball mounting head 7 is shaped on the conical mouth surface sinking hole of laying target ball 9, and a cylindrical magnet 8 that sucks target ball 9 is housed in the hole. The target ball 9 can be a sphere with corner cube mirrors or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com