Patents

Literature

68 results about "Mouth surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

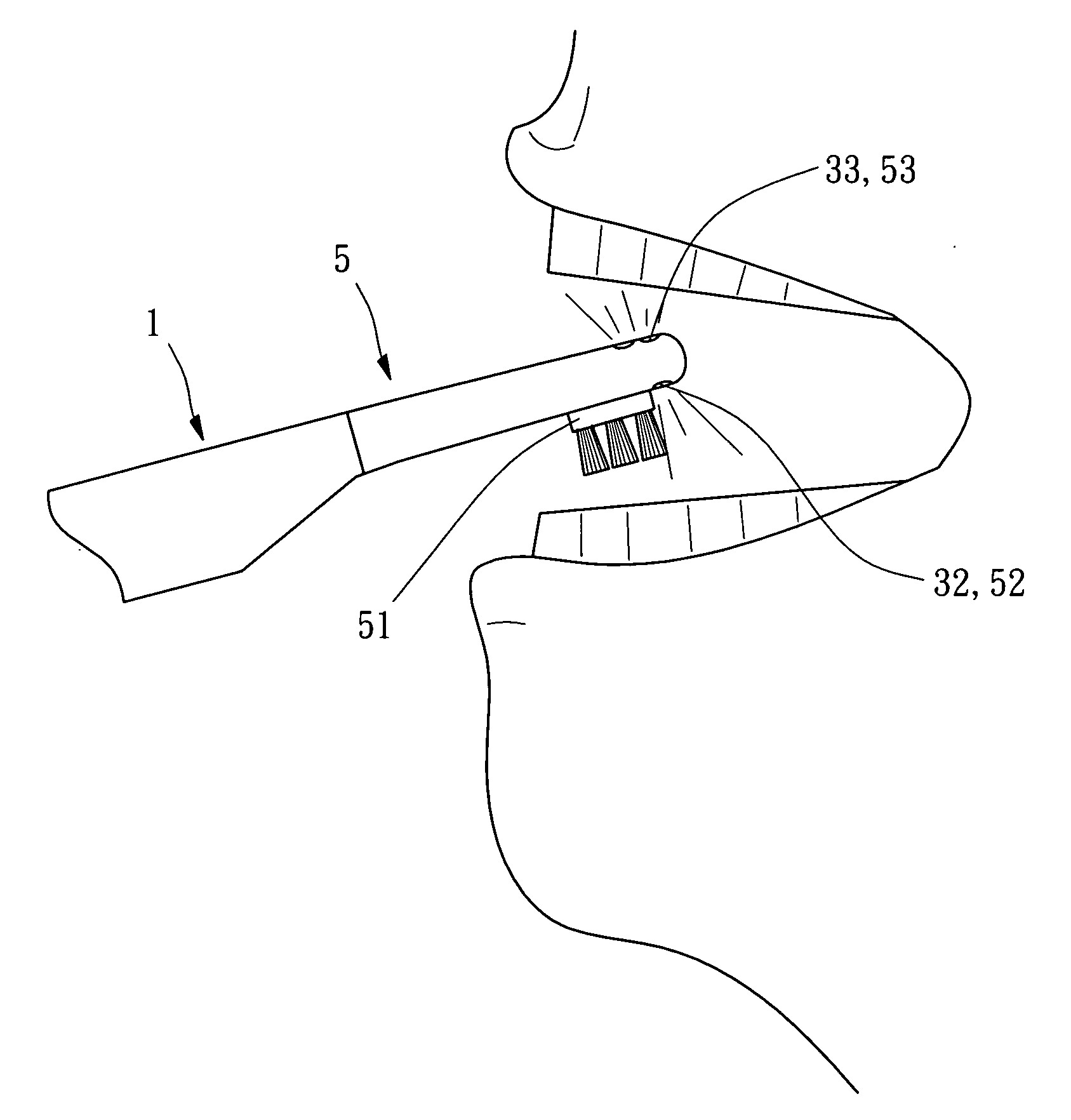

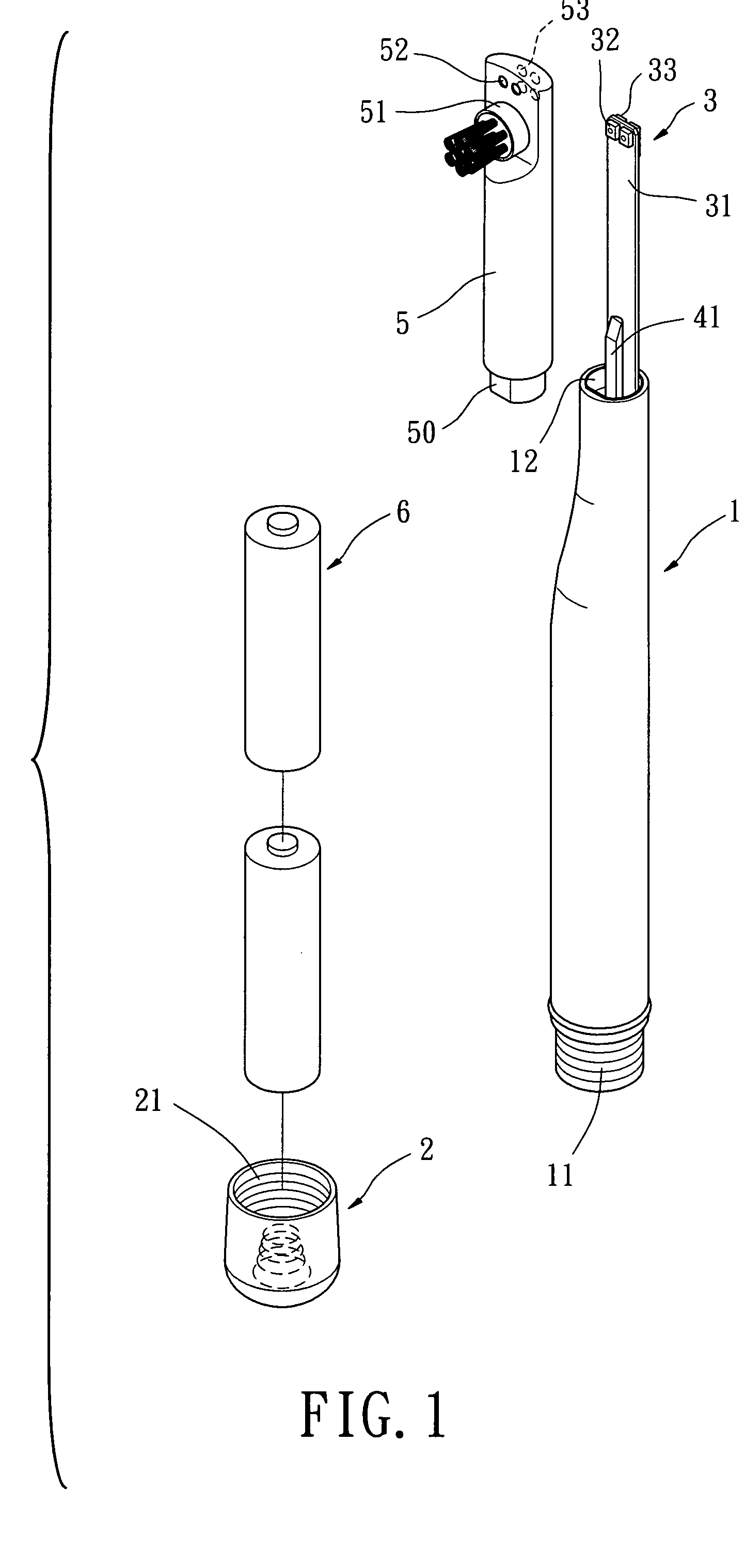

Phototherapeutic toothbrush

InactiveUS20060183071A1Enhance light therapyImprove the bactericidal effectTeeth fillingDental toolsBristleEngineering

A phototherapeutic toothbrush comprises a handle, a circuit board and a brush jacket. The handle can accommodate the circuit board, which is fitted with an extension board extending outside of the handle. The extension board is equipped with at least one light source. When brush jacket with a brush head is linked to the handle, the light source can duly generate phototherapeutic and bactericidal light to irradiate and cure the mouth surfaces and sterilize the bristle of brush head.

Owner:HSUCH PEI HSIEN

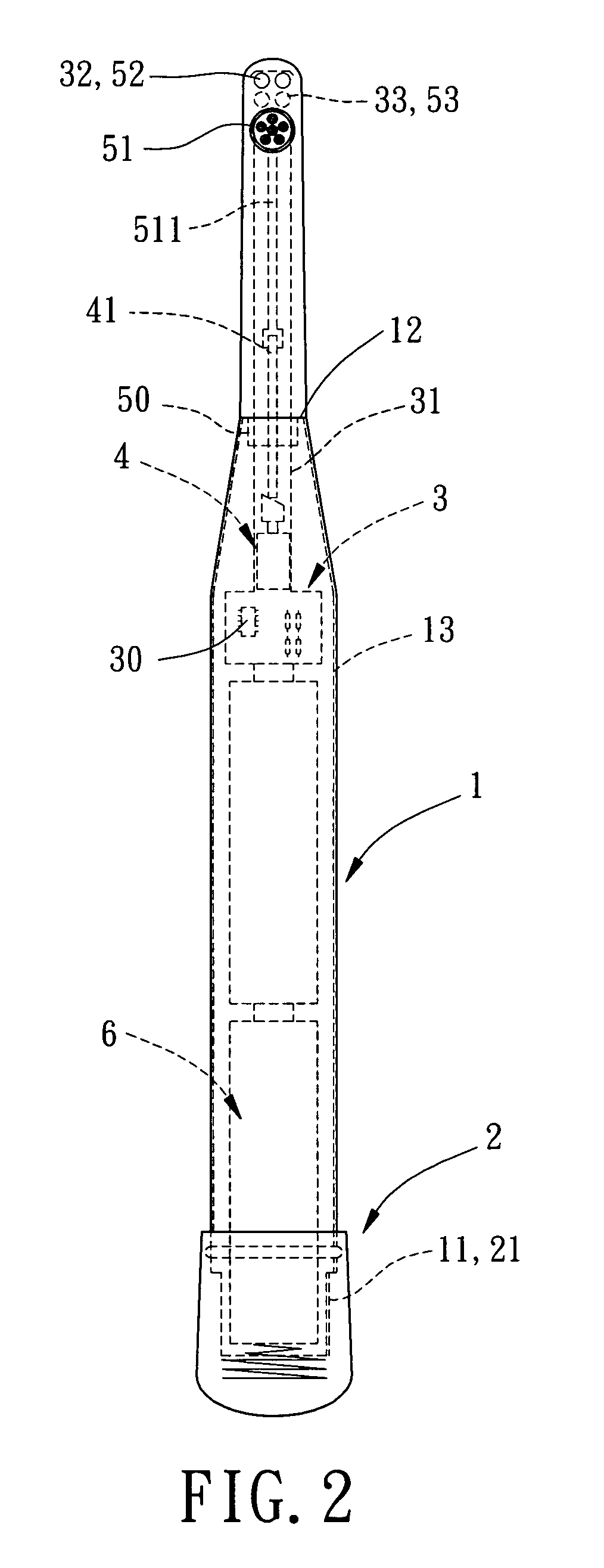

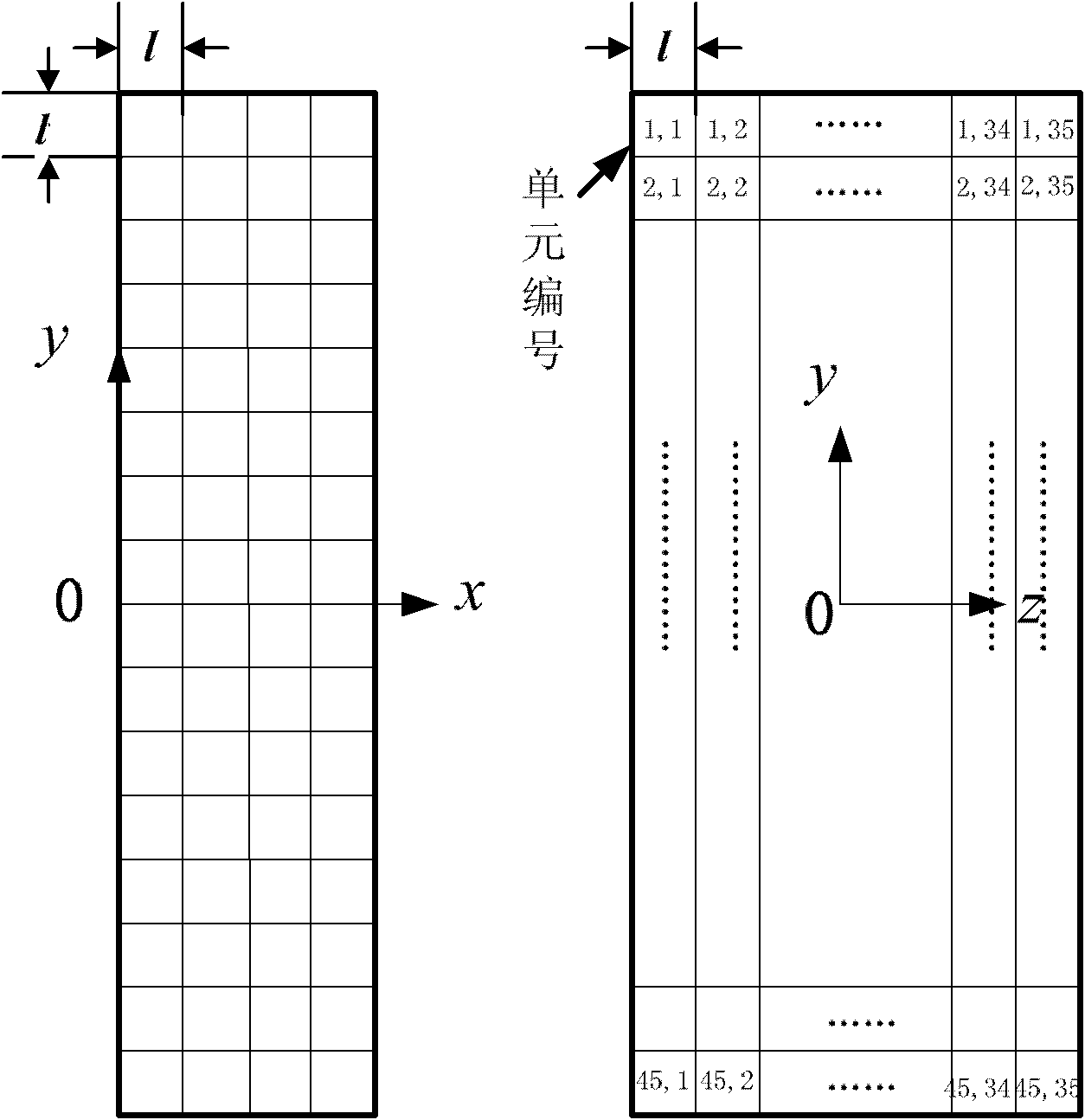

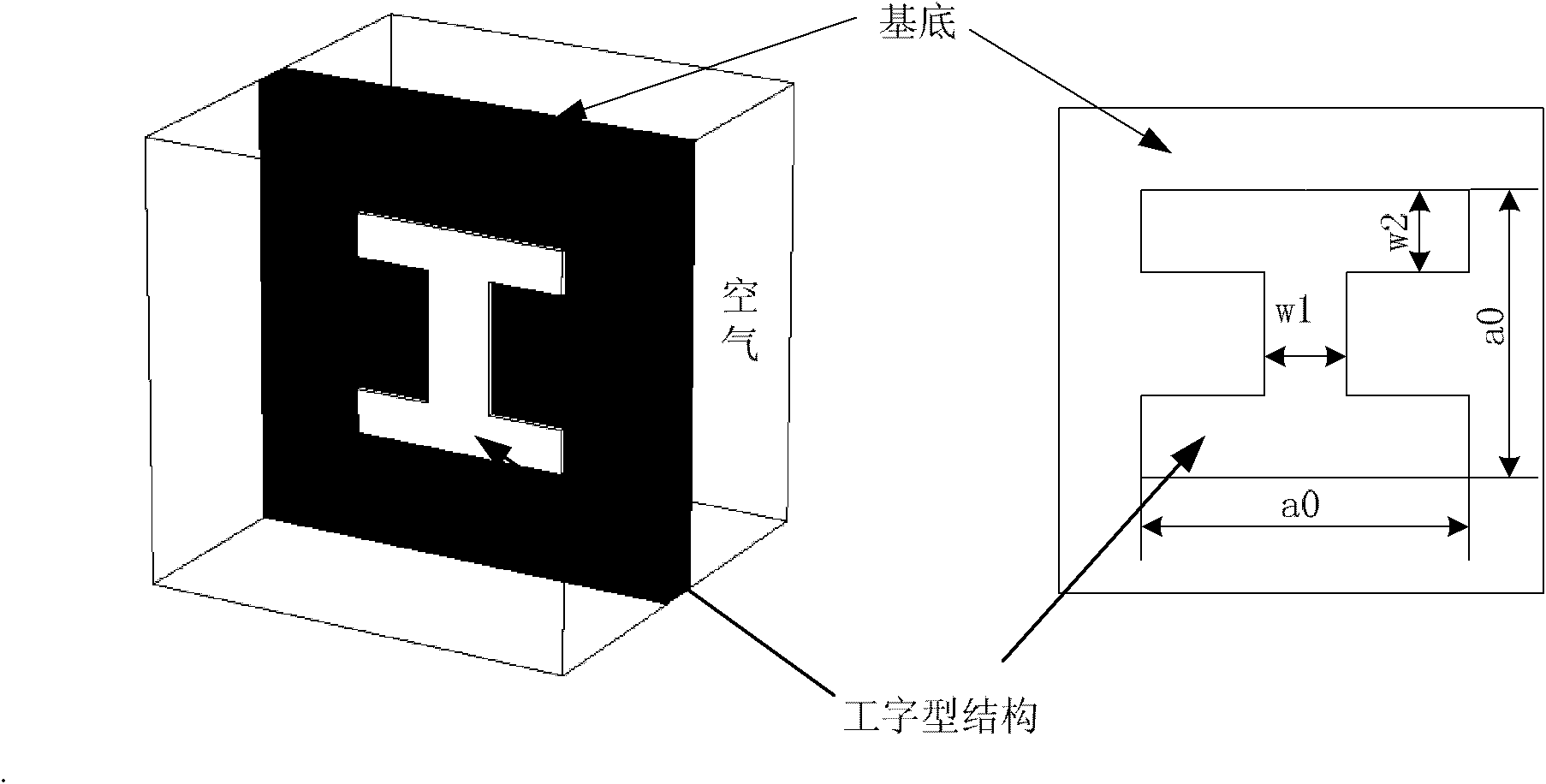

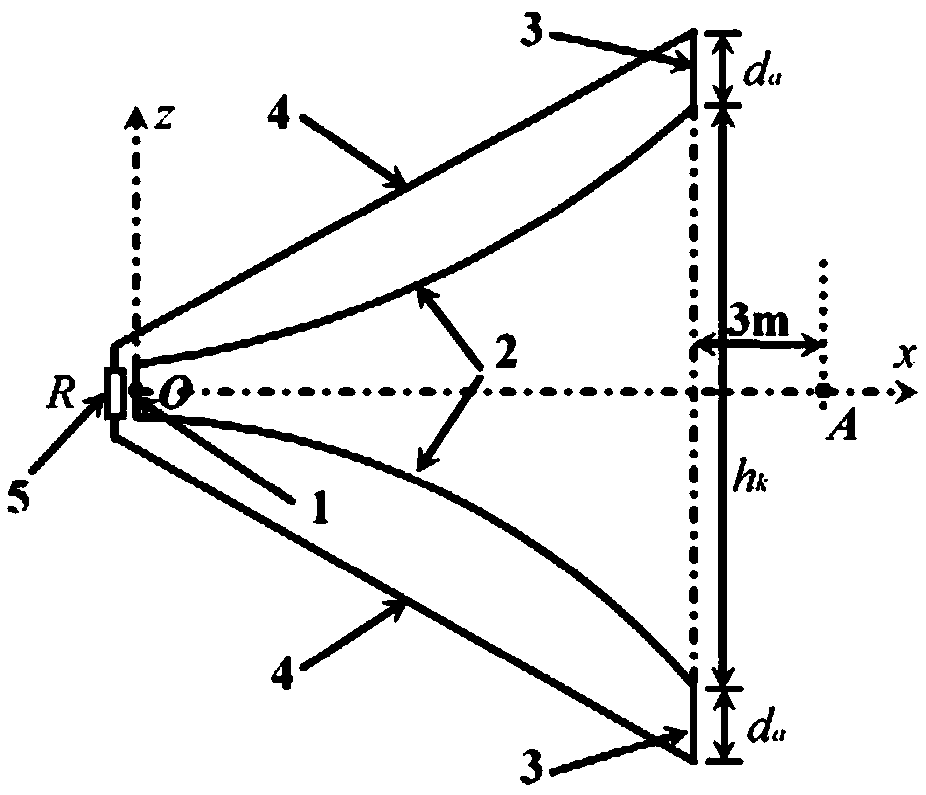

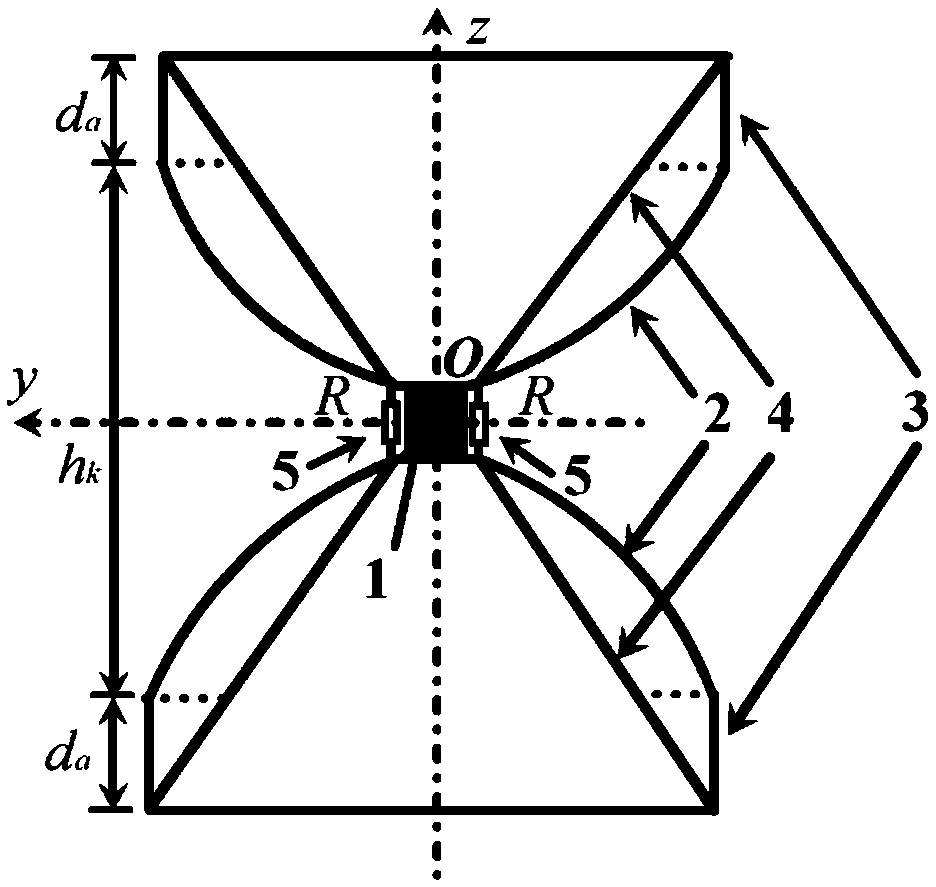

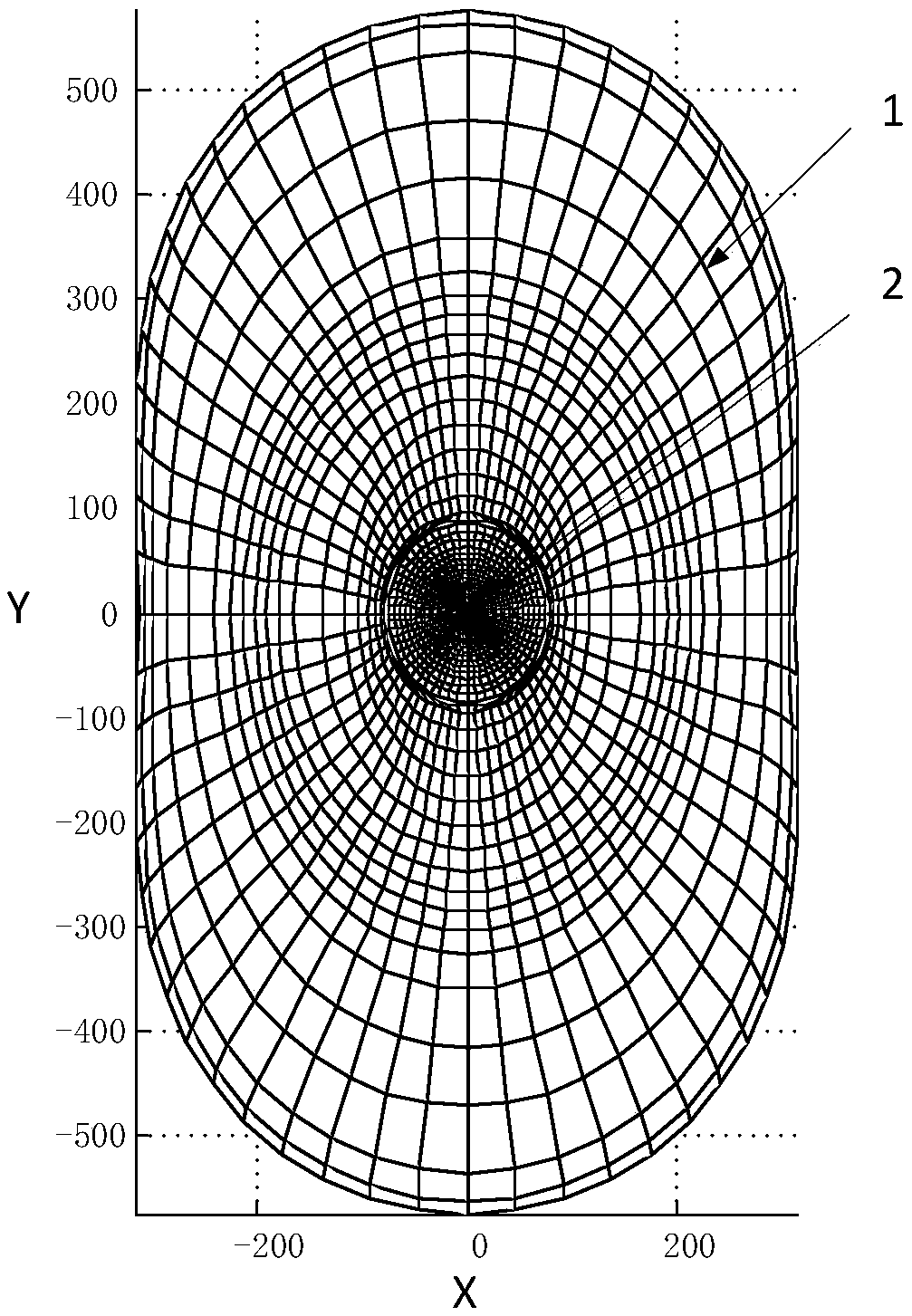

High-gain horn antenna based on inhomogeneous medium

The invention discloses a high-gain horn antenna based on an inhomogeneous medium, which is made by the following steps of: (1) determining a central frequency f for the operation of the antenna; (2) designing the ordinary horn antenna operated in the central frequency according to a general designing method for the horn antenna, wherein the aperture of an H side of the antenna is a, the aperture of an E side is b, and the length of a horn is h; (3) determining a refractive index profile n (x, y) of the inhomogeneous medium placed on a mouth surface of the horn; and (4) building the inhomogeneous medium with refractive indexes distributed according to the n (x, y) by using a reverse H-shaped sub-wavelength artificial structural material, and evaluating the structural size of a reverse H-shaped sub-wavelength artificial structural material unit corresponding to each refractive index in a mode of emulation by finite element software.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

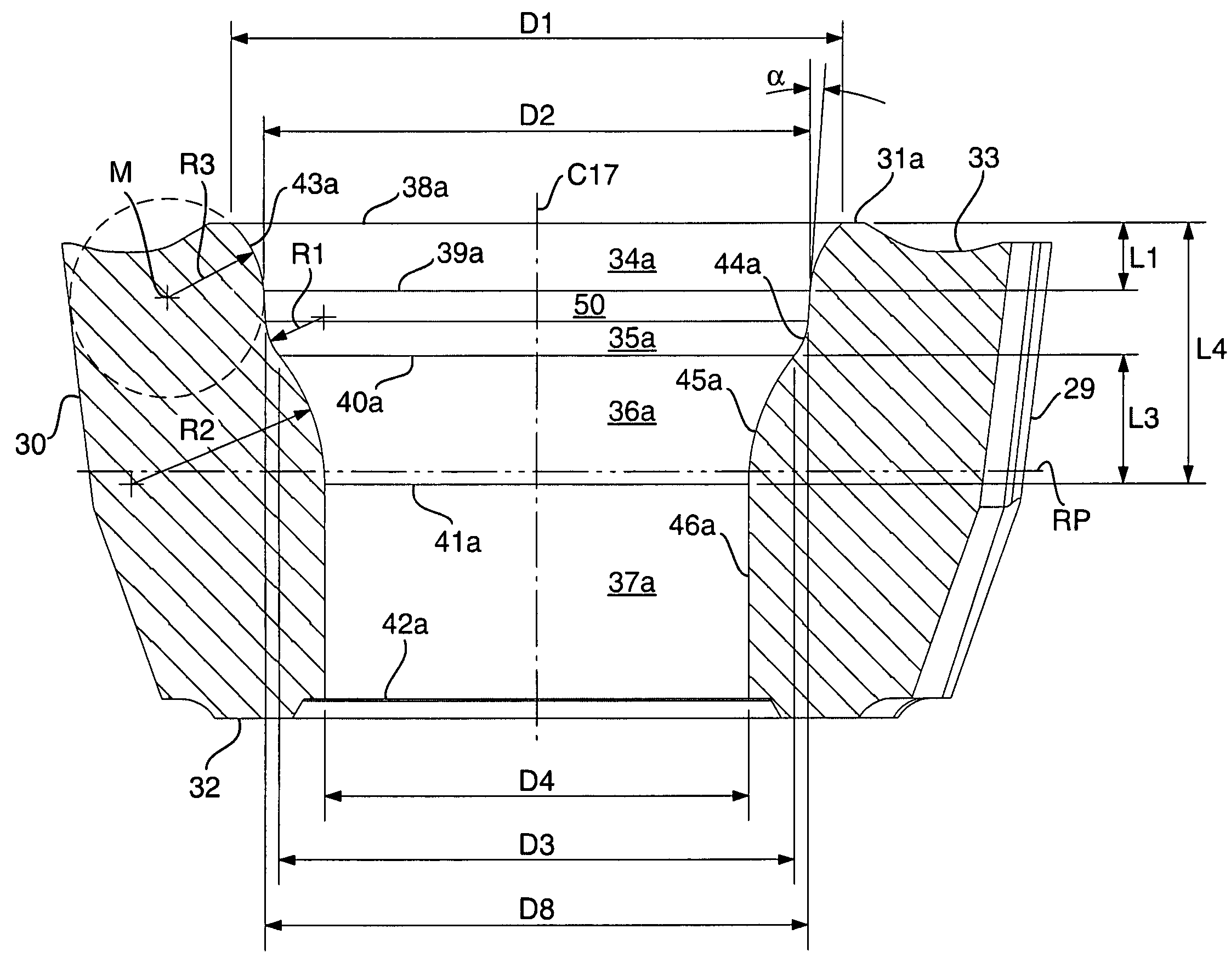

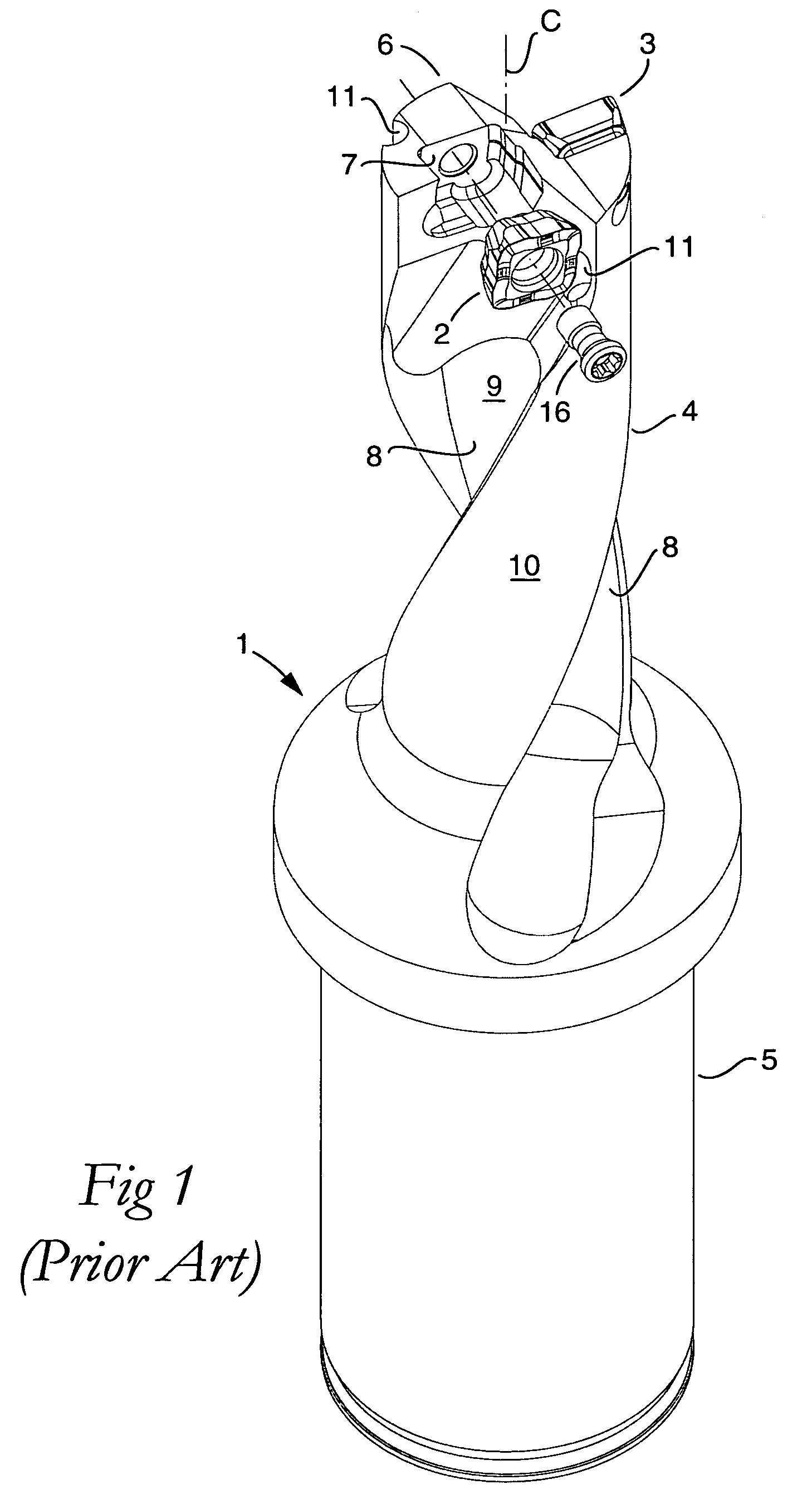

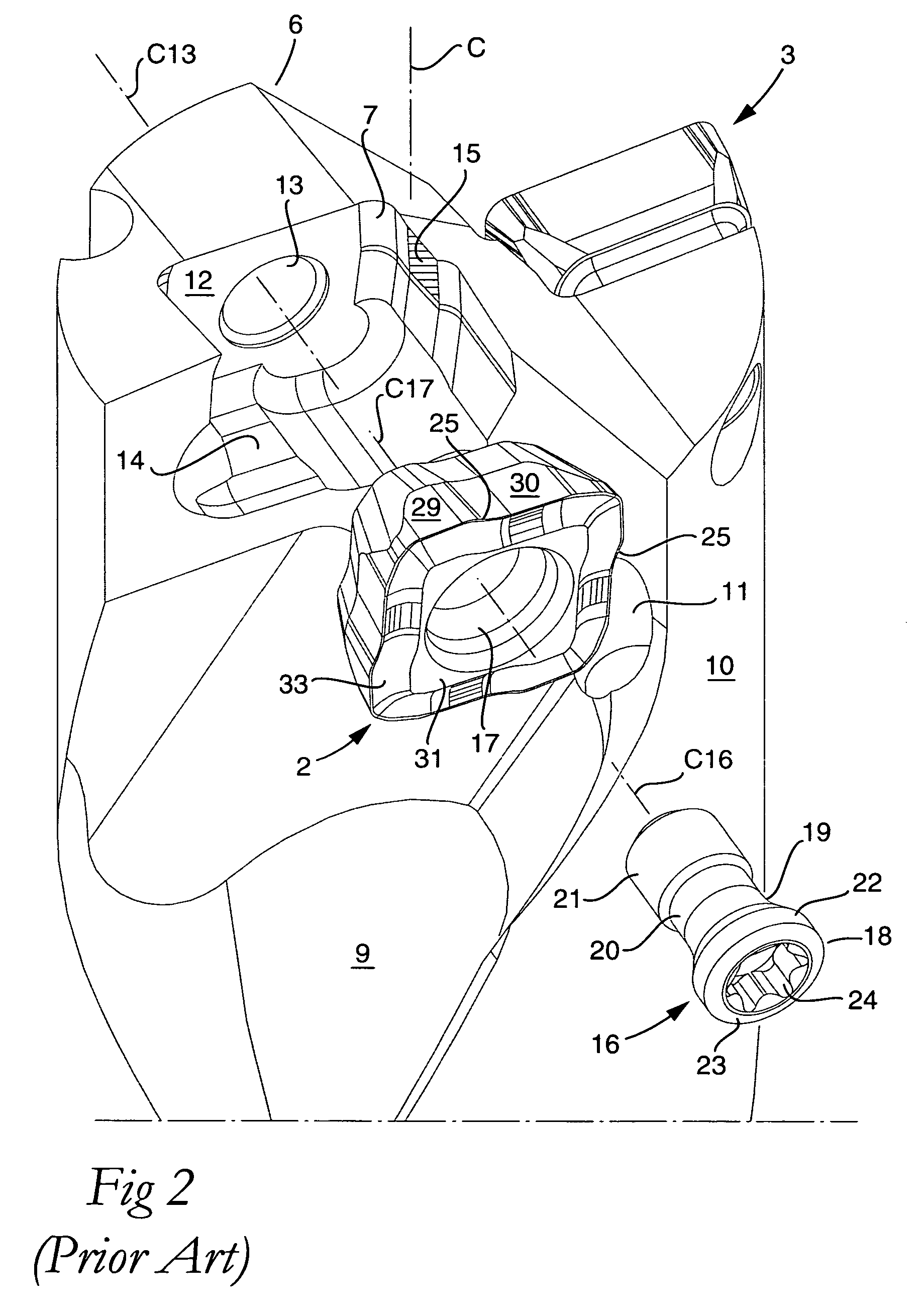

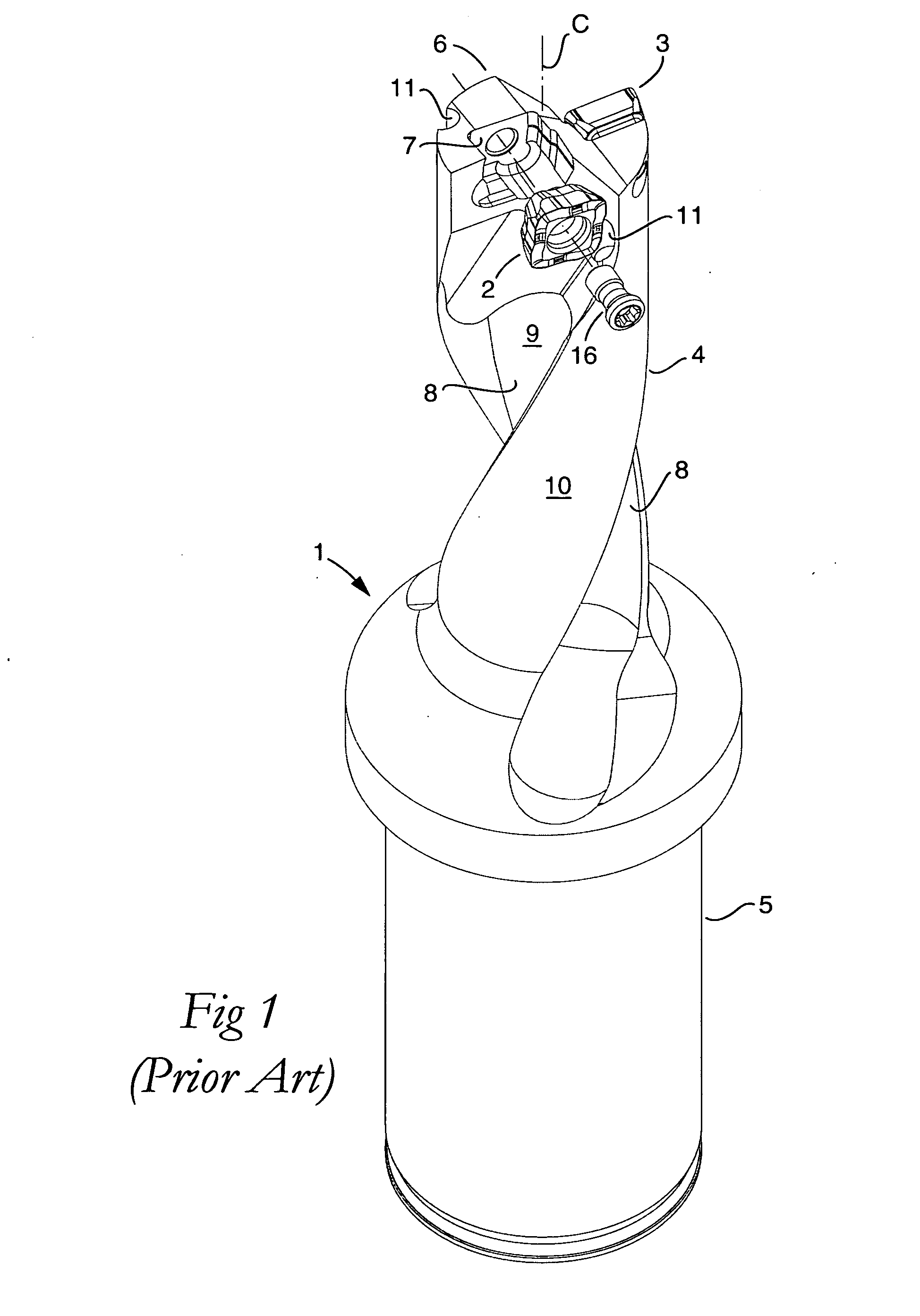

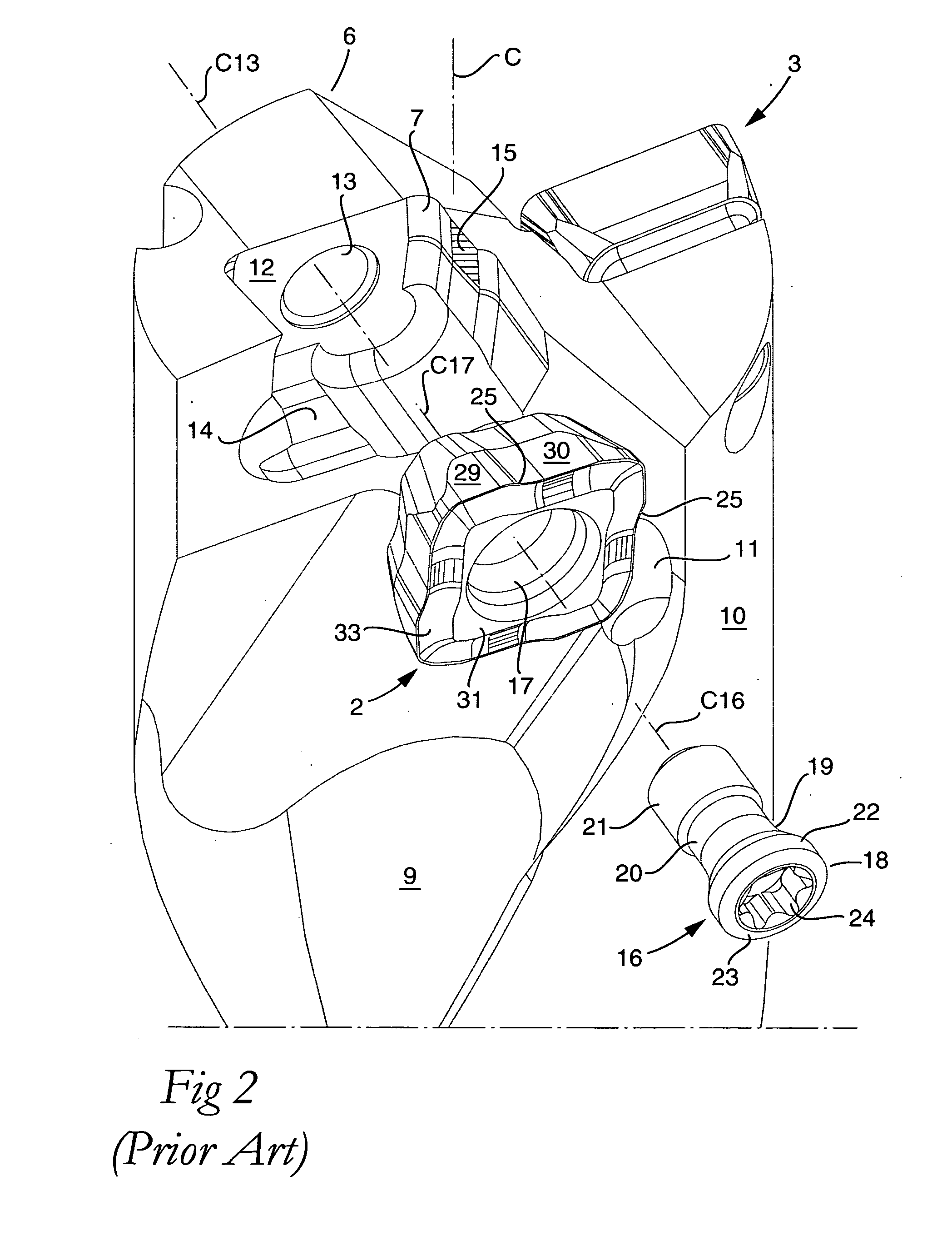

Drill and a drill cutting insert

InactiveUS7677845B2Smoothly pass mouth surfaceRisk minimizationThread cutting toolsWood turning toolsFluteDrill cuttings

A drill for chip removing machining, including a drill body, and a replaceable cutting insert mounted in a pocket formed in a front tip of the drill body. A chip flute extends backwardly from the pocket along the drill body, and the cutting insert is fixed in the pocket by a screw including a head and a shank having a male thread. The cutting insert includes a through hole extending between a topside and an underside. The hole has a basic shape that is rotationally symmetrical in relation to a center axis, and is delimited by a series of surfaces including a mouth surface, converging downward from the topside, and a shoulder surface. The head of the screw is kept pressed against the shoulder surface when the male thread of the screw is tightened in a female thread included in a hole that mouths in a bottom of the pocket. The mouth surface in the hole of the cutting insert has a trumpet-like, cross section-wise convex shape adjacent to the topside of the cutting insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

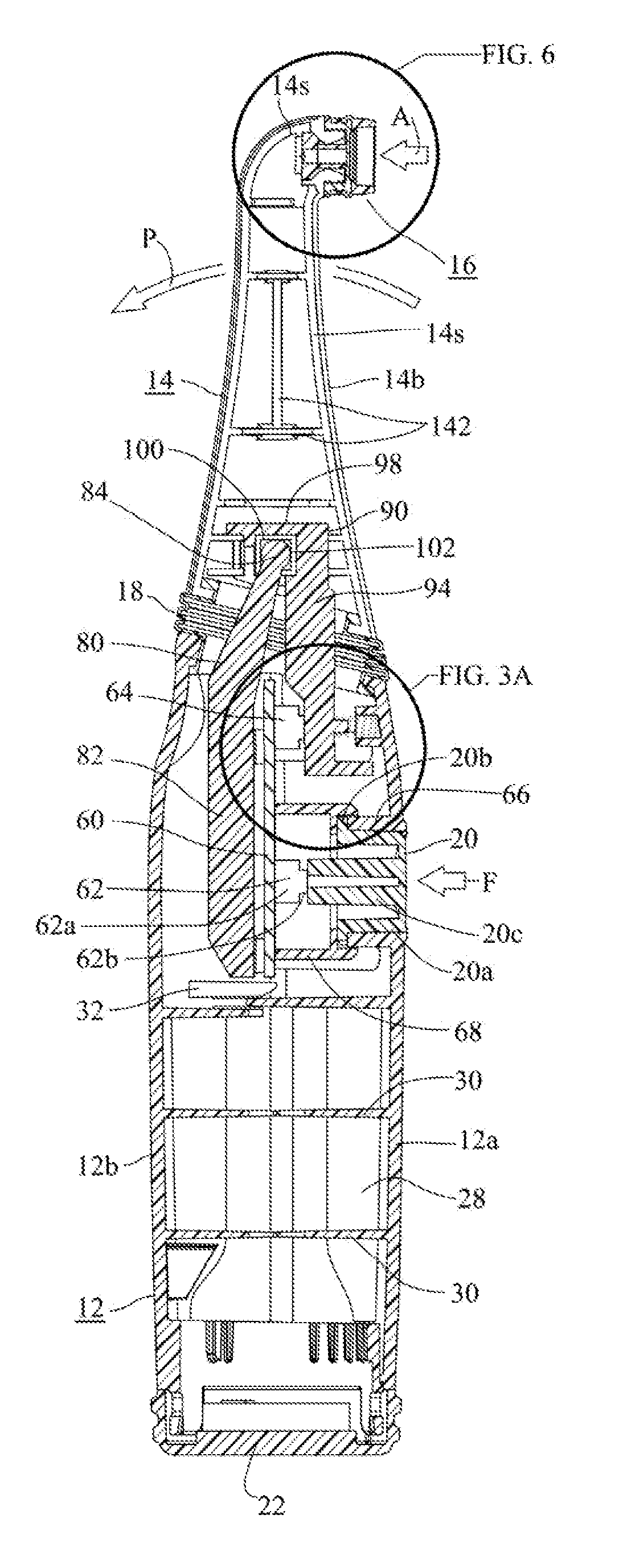

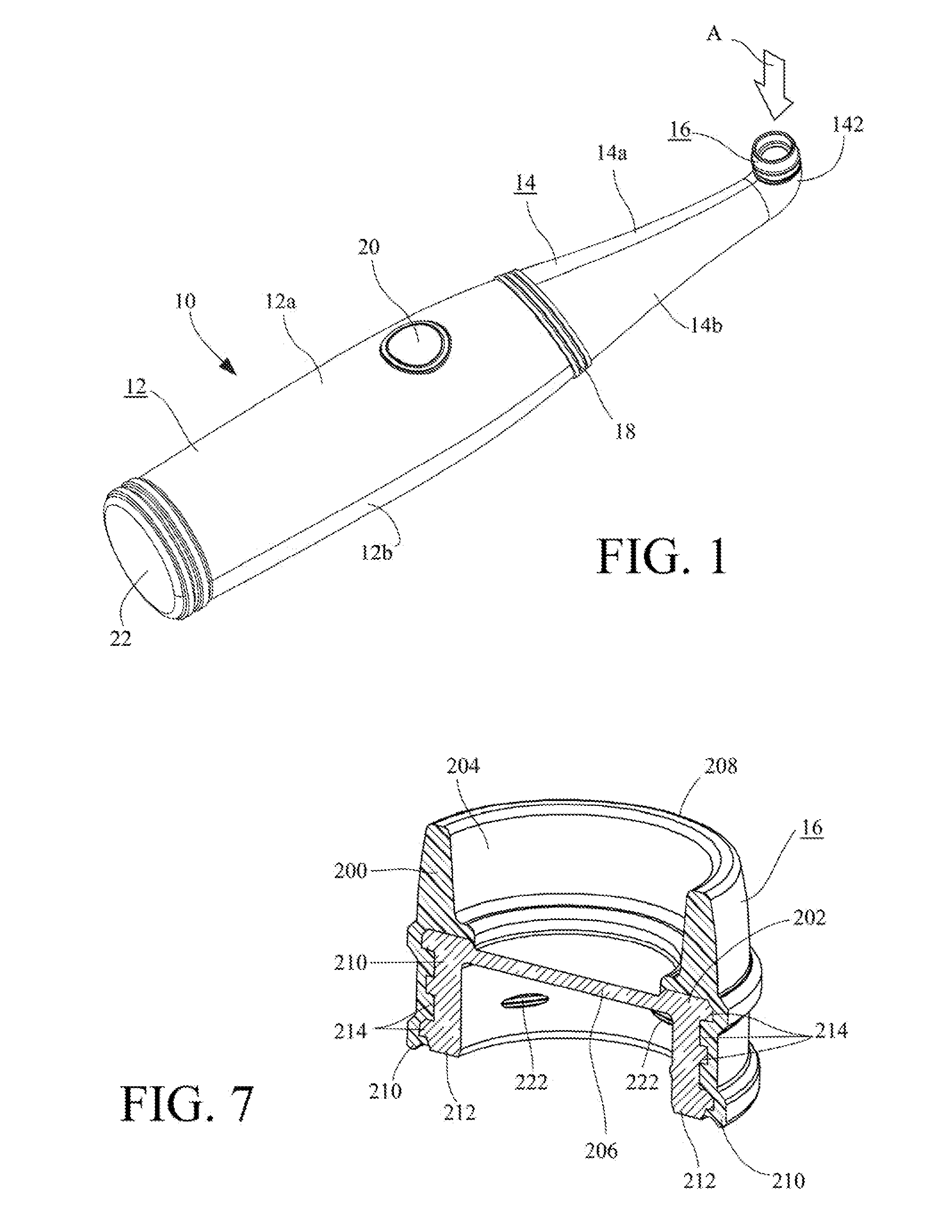

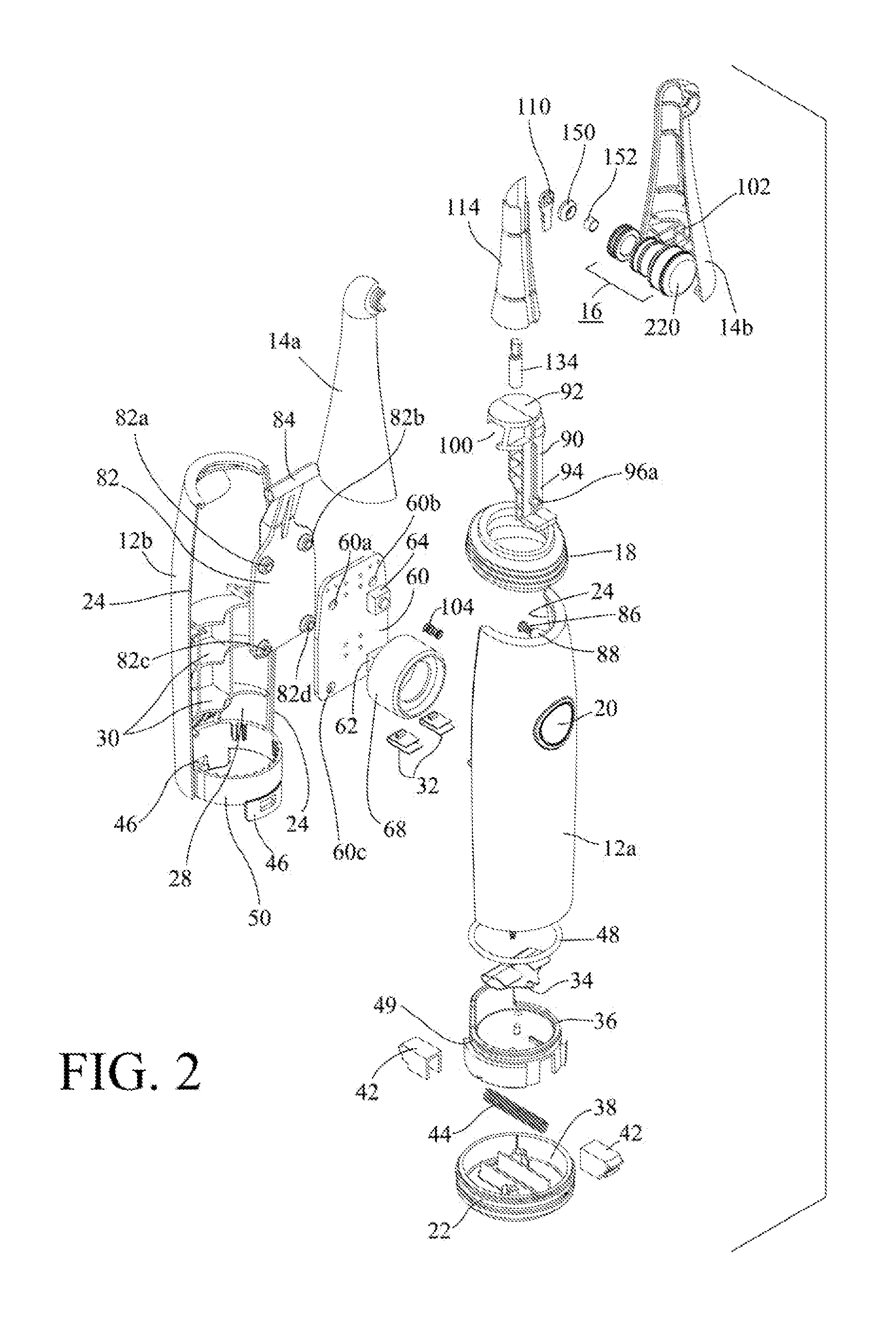

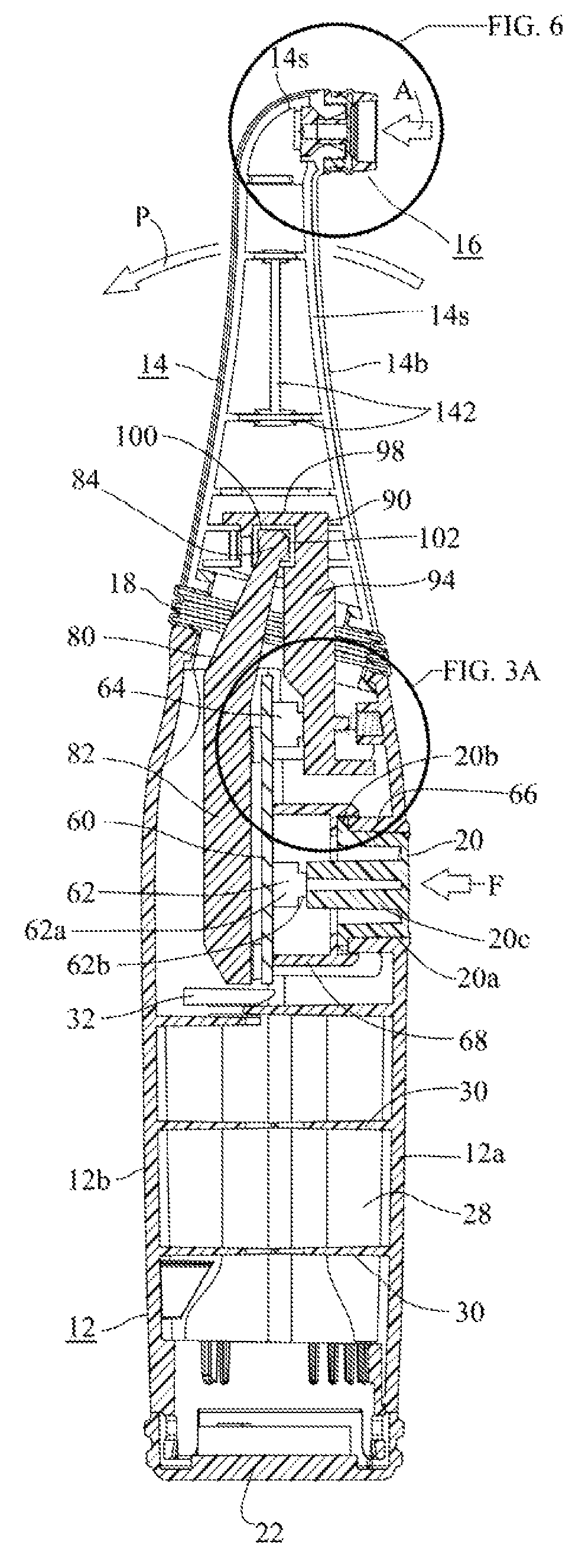

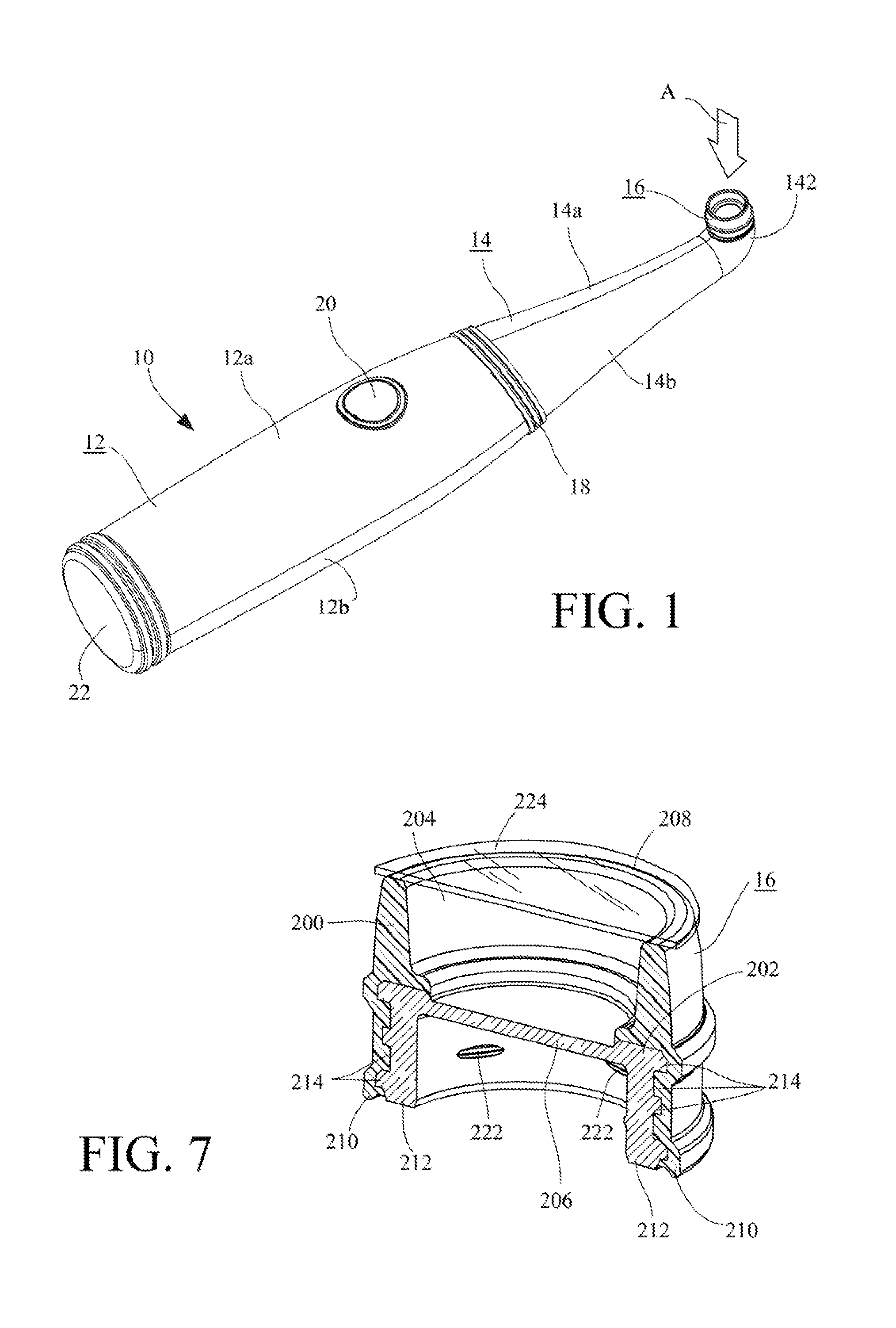

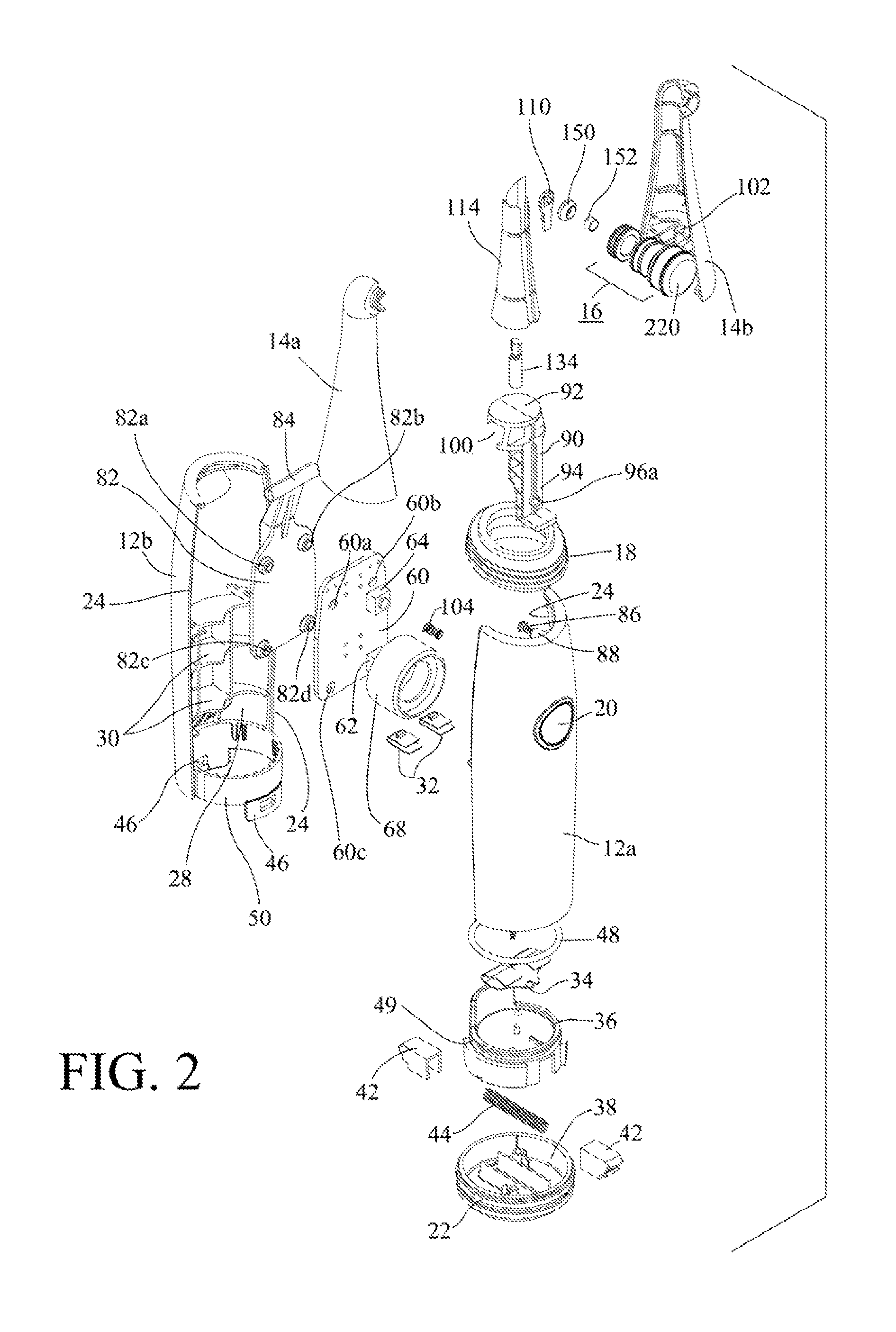

Hand-held tooth whitening instrument with applicator reservoir for whitening composition and methods of using same

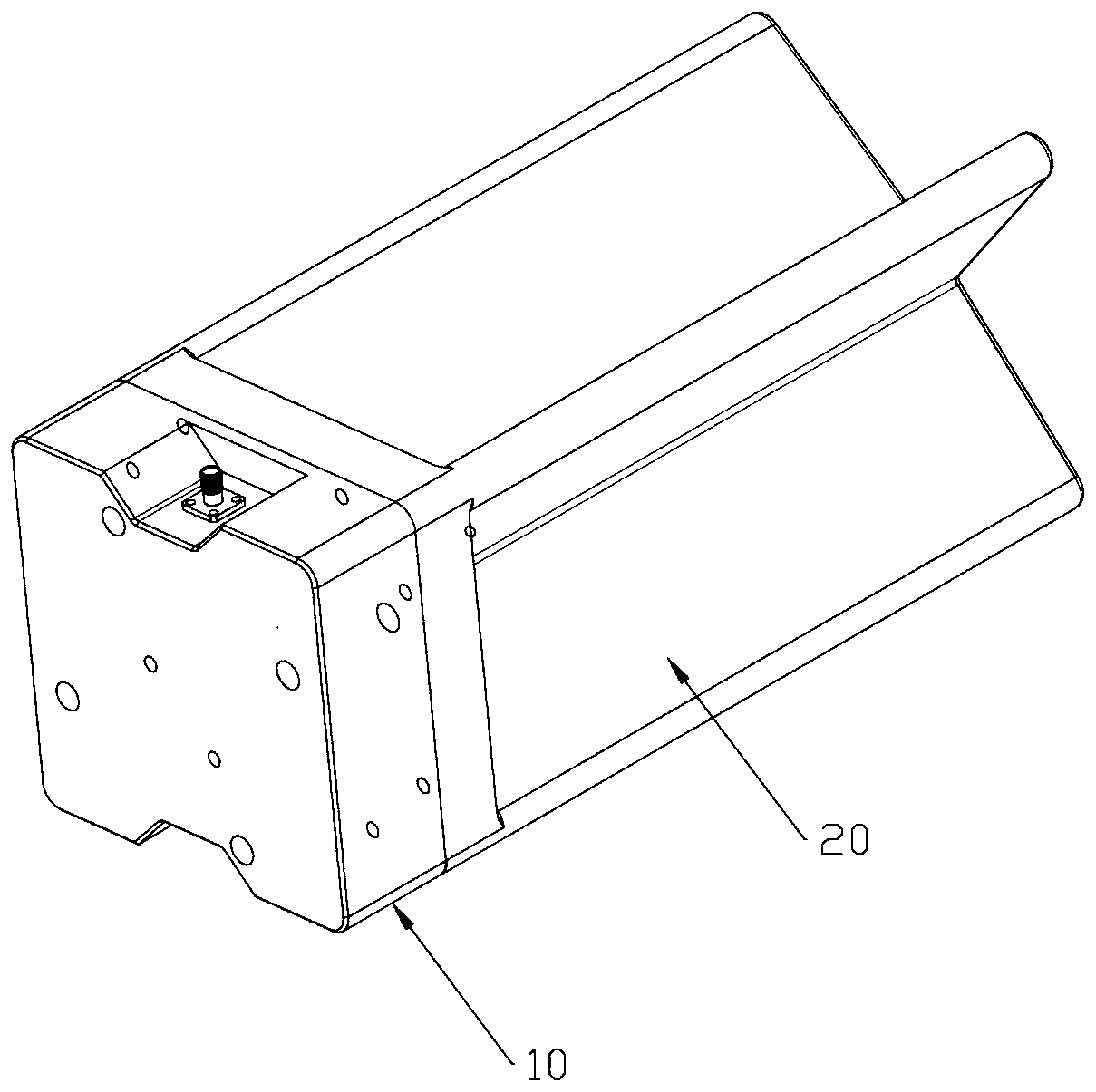

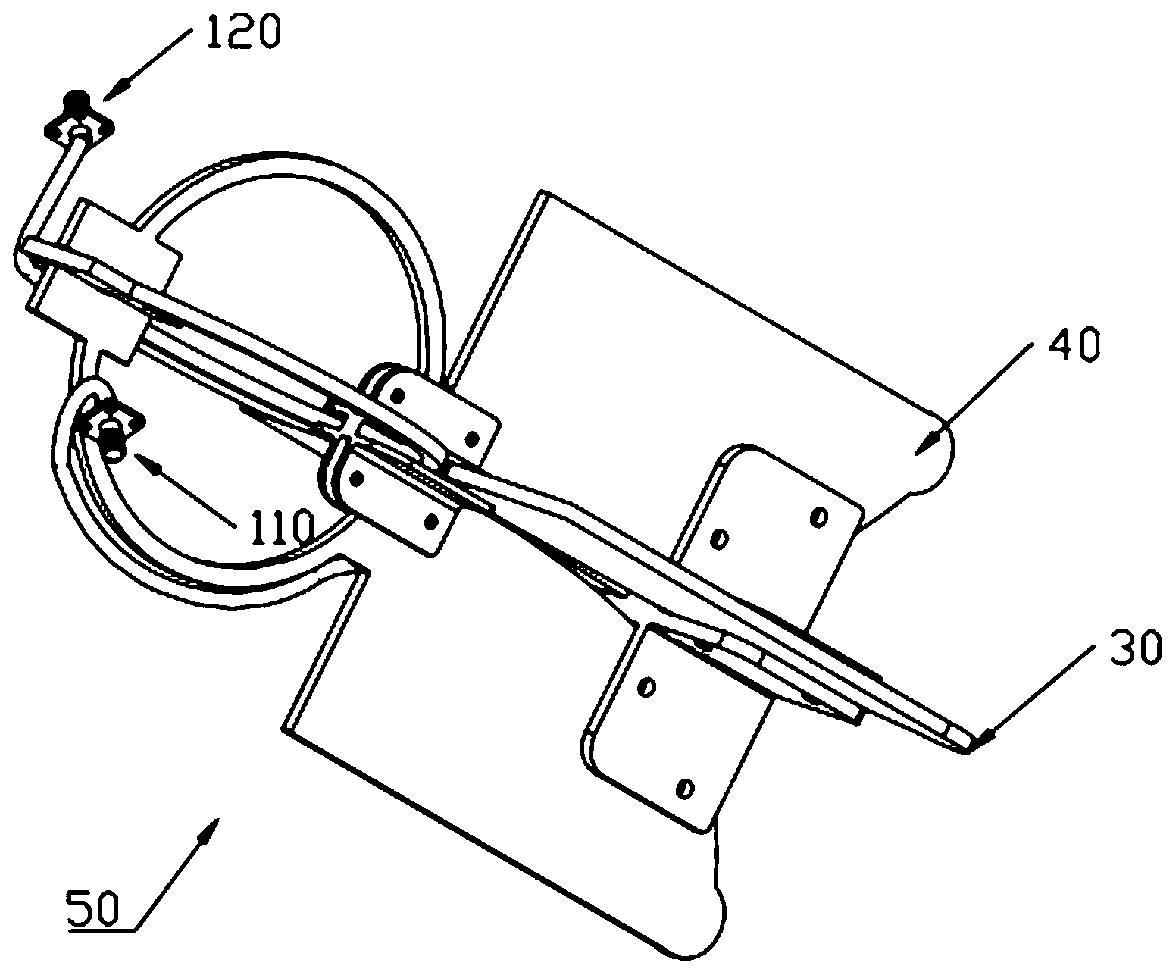

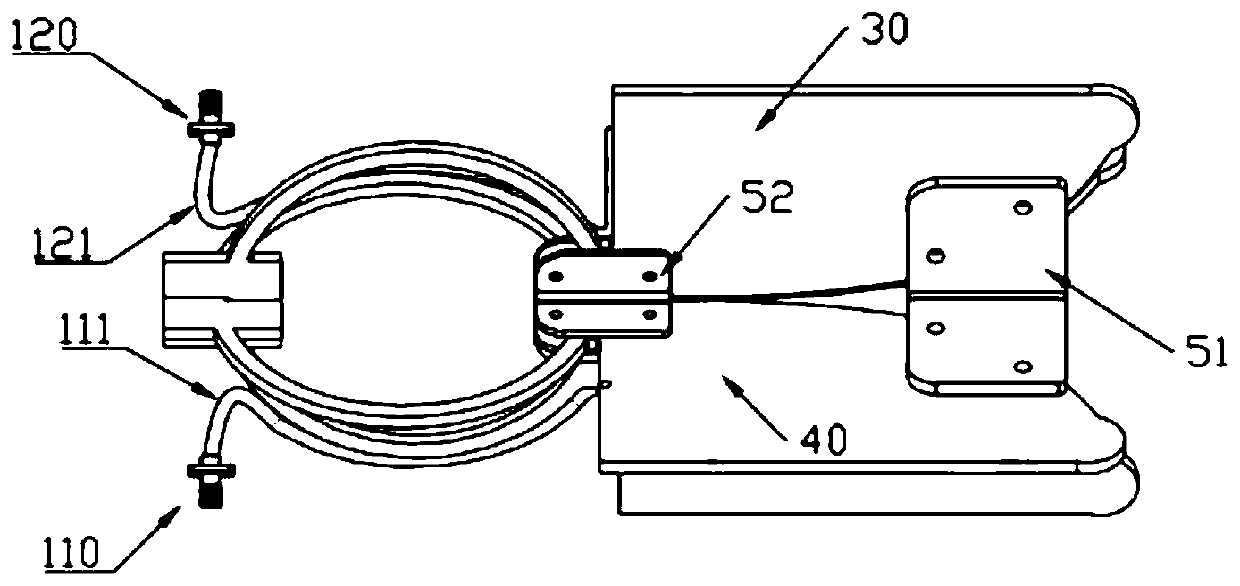

ActiveUS20140315142A1Reduce the numberReduce typesGum massageTeeth fillingUltrasound attenuationLight energy

A hand-held, ergonomic instrument with an LED that emits actinic light in visible wavelengths mounts a replaceable applicator cup with a reservoir for a tooth whitening composition held in place against a user's tooth during a whitening procedure. Actinic light is directed onto the tooth surface through a window in the cup and the tooth whitening composition substantially without attenuation, delivering at least about 100 milliwatts per square centimeter of light energy to the tooth surface. The cup includes a rigid body for mounting the cup to the instrument and an opaque flexible sleeve molded in place over the outside of the body to form a seal with the tooth surface and prevent exposure of soft mouth surfaces to the actinic radiation during a whitening procedure. A safety switch disables the LED when the applicator cup is not in contact with a tooth surface.

Owner:ORAL CARE PROD LLC A DELAWARE LLC +1

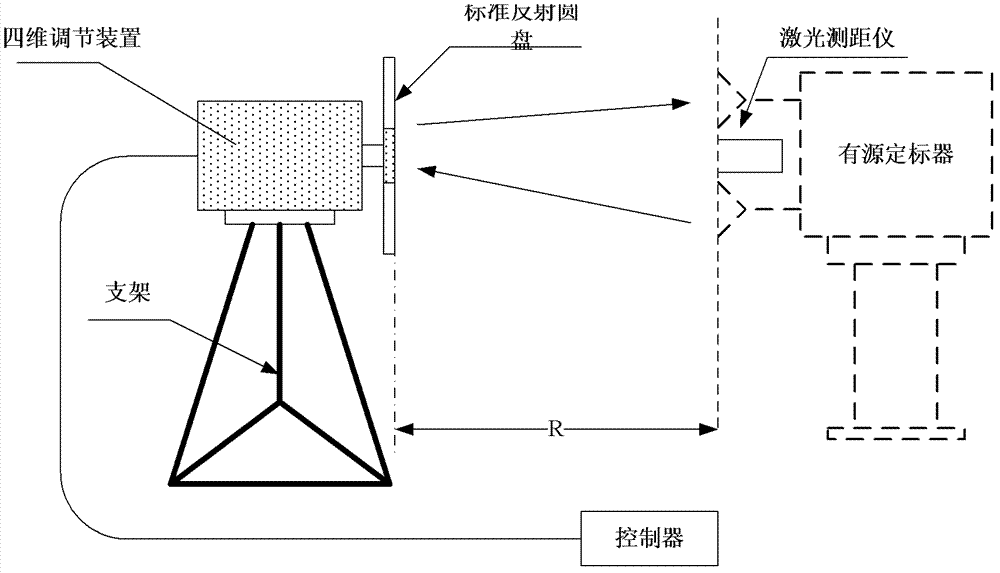

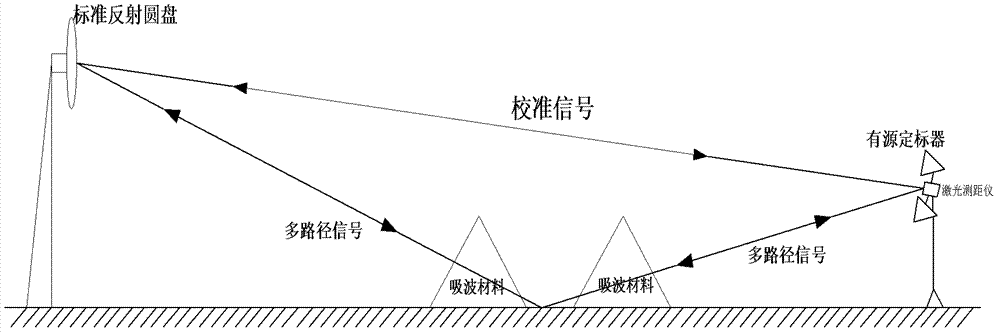

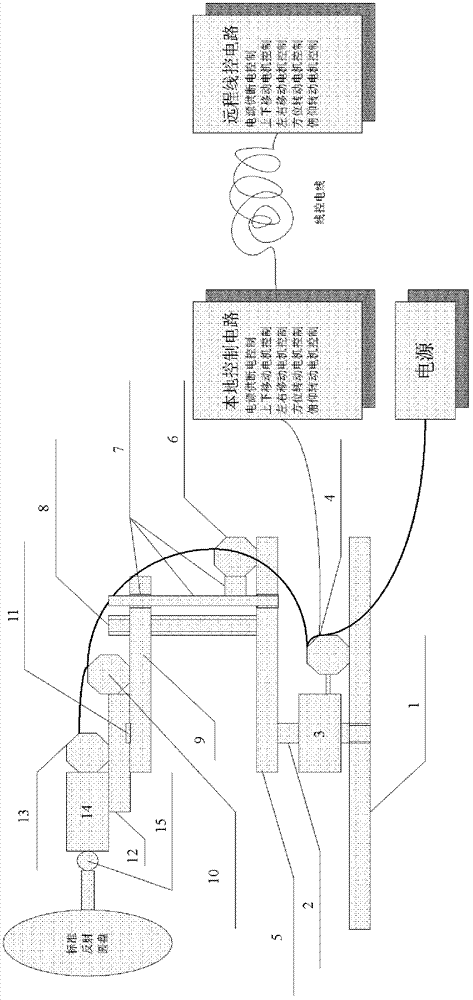

Outer calibration system for high-precision SAR (Synthetic Aperture Radar) active scaler

ActiveCN103245935AAccurate measurementAlignment method is simpleRadio wave reradiation/reflectionLaser rangingSynthetic aperture sonar

The invention discloses an outer calibration system for an SAR (Synthetic Aperture Radar) active scaler, and relates to the remote sensing satellite technology. The outer calibration system comprises a laser range finder, a standard reflection device, and wave-absorbing materials, wherein the laser range finder is fixed at the symmetric central line of a sending antenna and a receiving antenna of the active scaler through a switching device, and the fact that the direction which a laser beam points to is parallel to the mouth surface normals of the two antennas is ensured; the standard reflection device comprises a standard reflection disk, a four-dimensional adjusting mechanism and a support; the standard reflection disk can be used as a standard to reflect laser to further realize the alignment with the active scaler, has the function of reflecting electromagnetic signals and providing sectional area standard of a radar, and enables the active scaler to be aligned with the reflection disk through the servo transmission of the four-dimensional adjusting mechanism and the adjustment of a control mechanism; the support supports the standard reflection disk to a certain height; the wave-absorbing materials are laid at an appropriate position between the active scaler and the standard reflection disk to reduce the interference of multipath noise signals.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

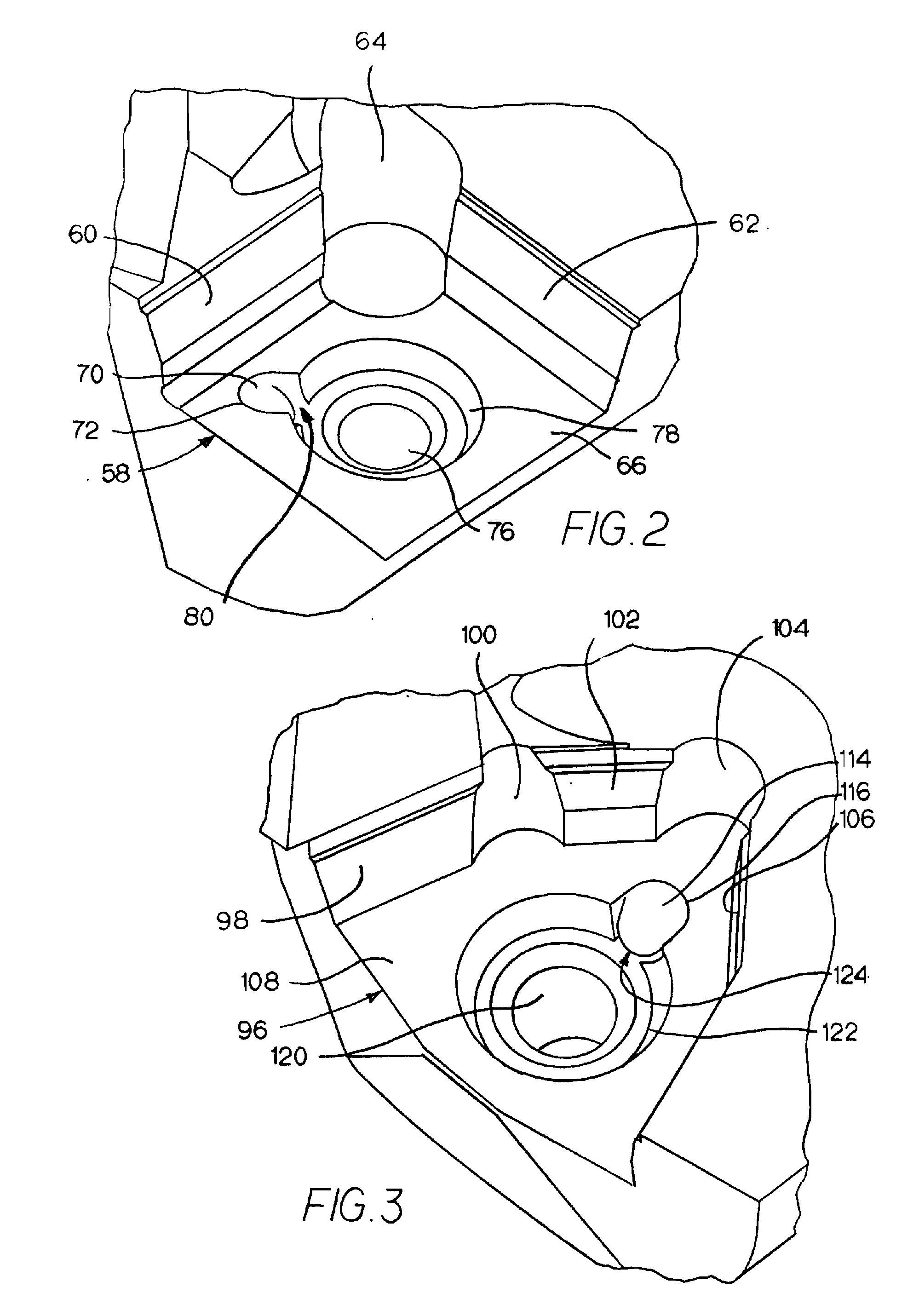

Indexable cutting insert with coolant delivery

InactiveUS20150063926A1Facilitate enhanced deliveryReduce heatTransportation and packagingCutting insertsEngineeringCoolant

An indexable cutting insert includes a rake face, a flank surface, a bottom surface, and a central aperture defined by an aperture side wall. The indexable cutting insert further has a mouth defined by a mouth surface. There is a primary coolant trough that has an aperture section in the side wall contained in the aperture side wall, a mouth section contained in the mouth surface, and a rake face section contained in the rake face. There is a radial angular coolant trough, which has an entrance end opening into a selected one of the primary coolant trough and the mouth. The radial angular coolant trough has an orientation wherein the central longitudinal axis thereof is generally perpendicular to a corresponding discrete cutting edge whereby during operation a coolant stream is directed toward the corresponding discrete cutting edge.

Owner:KENNAMETAL INC

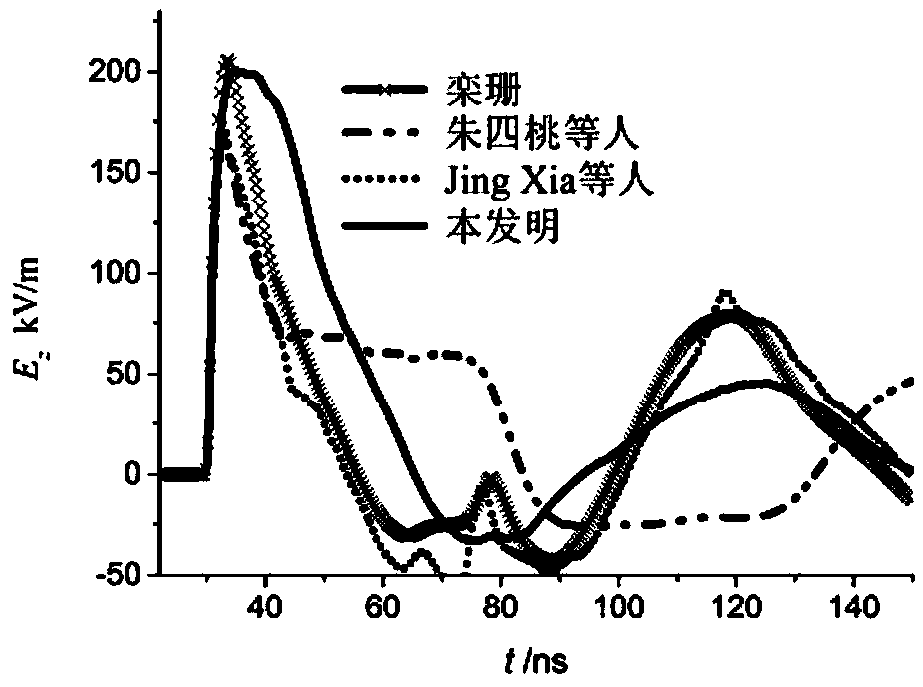

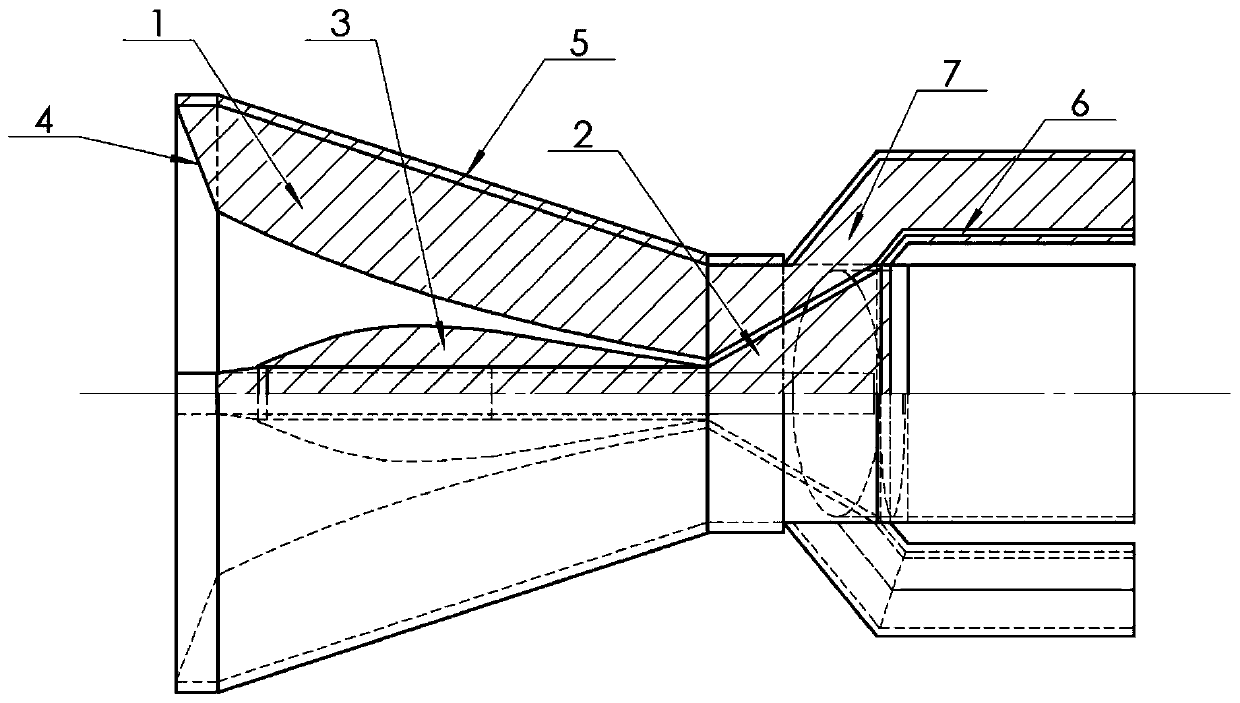

TEM loudspeaker-based movable electromagnetic pulse radiation wave simulator

ActiveCN109324245ASmall sizeWaveguide hornsElectrical measurement instrument detailsElectrical resistance and conductanceElectricity

The invention provides a TEM loudspeaker-based movable electromagnetic pulse radiation wave simulator, and aims at meeting the requirements of strong low-frequency radiation capability and small size.The TEM loudspeaker is an exponential gradual loudspeaker, namely, the heights of upper and lower plates are changed exponentially; a metal straight plate having a same width with the mouth surface of the exponential TEM loudspeaker is loaded at the end of the mouth surface; an inclined metal plate is added; and. the beginning end of the inclined metal plate is electrically connected via a resistor. In such way, diversion is carried out for twice by using the metal plates, so that the problem that the conventional TEM loudspeakers have relatively strong reflection at the ends is avoided and the enhancement of low-frequency radiation capability is realized; the resistor at the beginning end of the inclined plate not only absorbs the current on the inclined plate, but also avoids the reflection interference of a forward radiation field of the simulator; and the inclined plate is inclined from the mouth surface toward the vicinity of a feeding end, thereby achieving the effect of reducing the size of the simulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

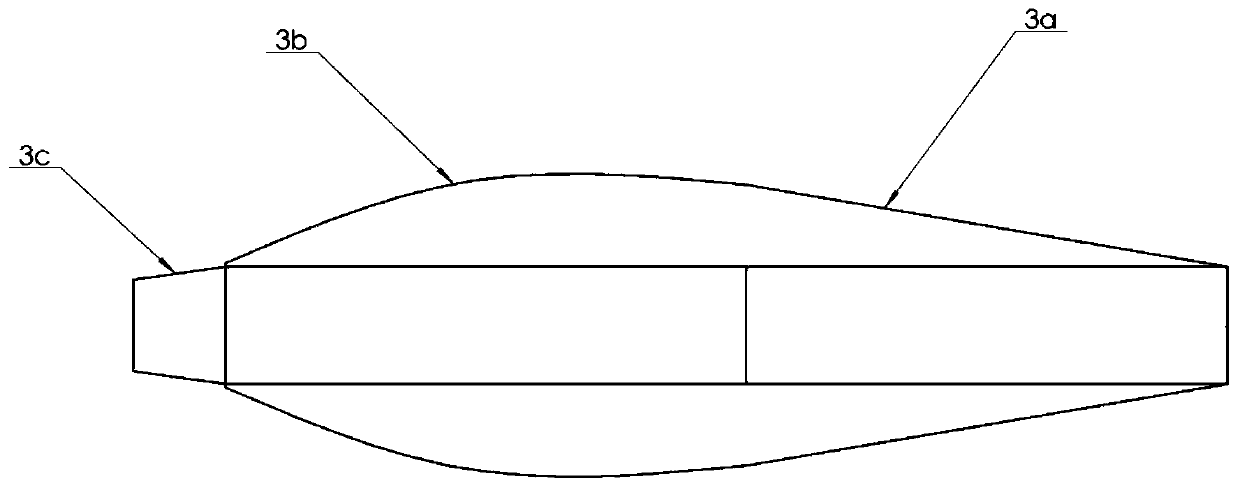

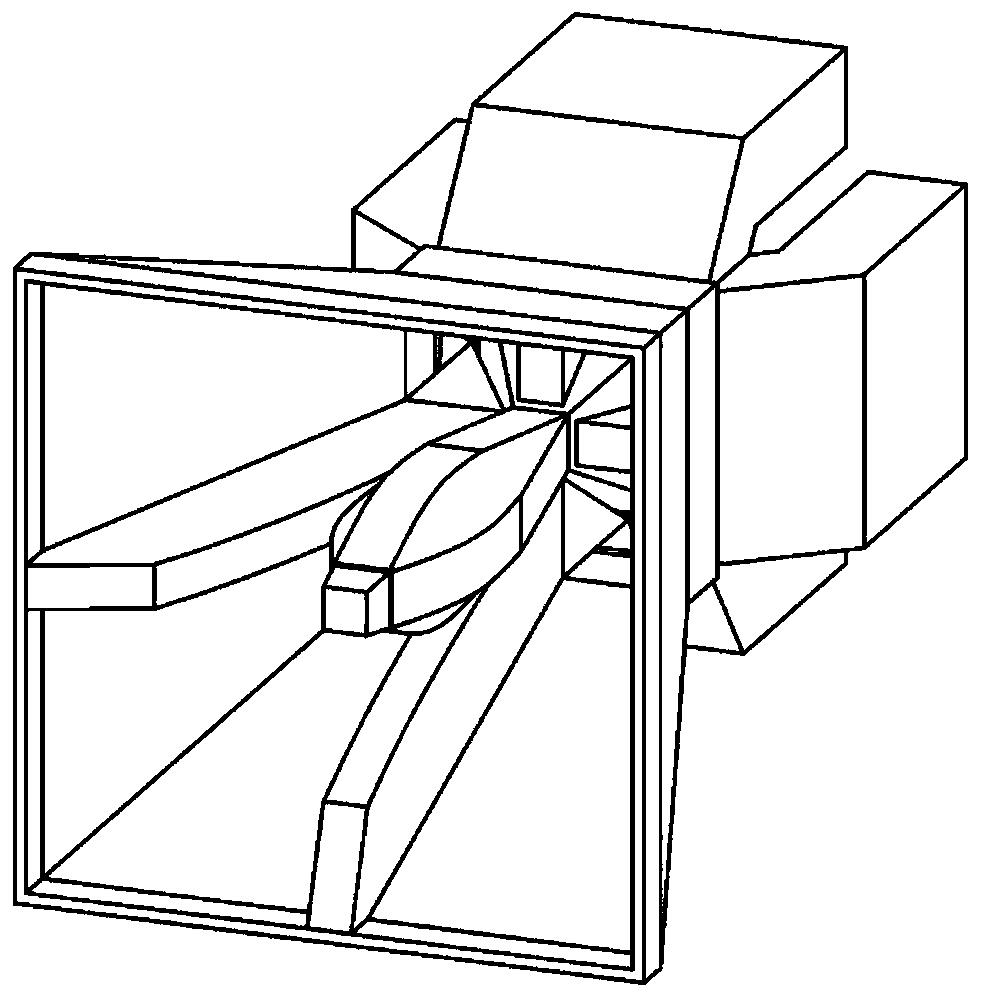

Dual-polarization feed source fed by broadband ridged orthogonal mode converter

ActiveCN109755750ASolving Poor Cross-Polar PerformanceReduce difficultyWaveguide hornsSimultaneous aerial operationsCross polarizationWaveguide

The invention relates to a dual-polarization feed source fed by a broadband ridged orthogonal mode converter. The dual-polarization feed source comprises a ridged horn antenna and an orthogonal mode converter integrated with the antenna, wherein the orthogonal mode converter is matched and connected with four side ridges (1) of the horn antenna, and a matching frustum (2) in the middle of the orthogonal mode converter extends to form a central ridge (3) of the horn antenna. Based on the structure, the toroidal field components formed by the four side ridges (1) of the horn antenna can be effectively suppressed, so that the cross polarization performance of the whole feed source antenna can be optimized, an electric field of the high frequency part generates a phase taper, and the beam width of the high frequency can be further improved. In addition, a port where the ridged horn antenna normally radiates outwards and the taper is arranged is provided with a section of extended mouth surface (4) that vertically extends outwards, and a good low-frequency standing wave matching effect is achieved. The input end of the orthogonal mode converter can be connected with a feed waveguide, orcan be connected with the waveguide and fed by a coaxial cable after coaxial conversion, wherein the feed waveguide can have a rectangular cross section or an elliptical cross section.

Owner:BEIHANG UNIV

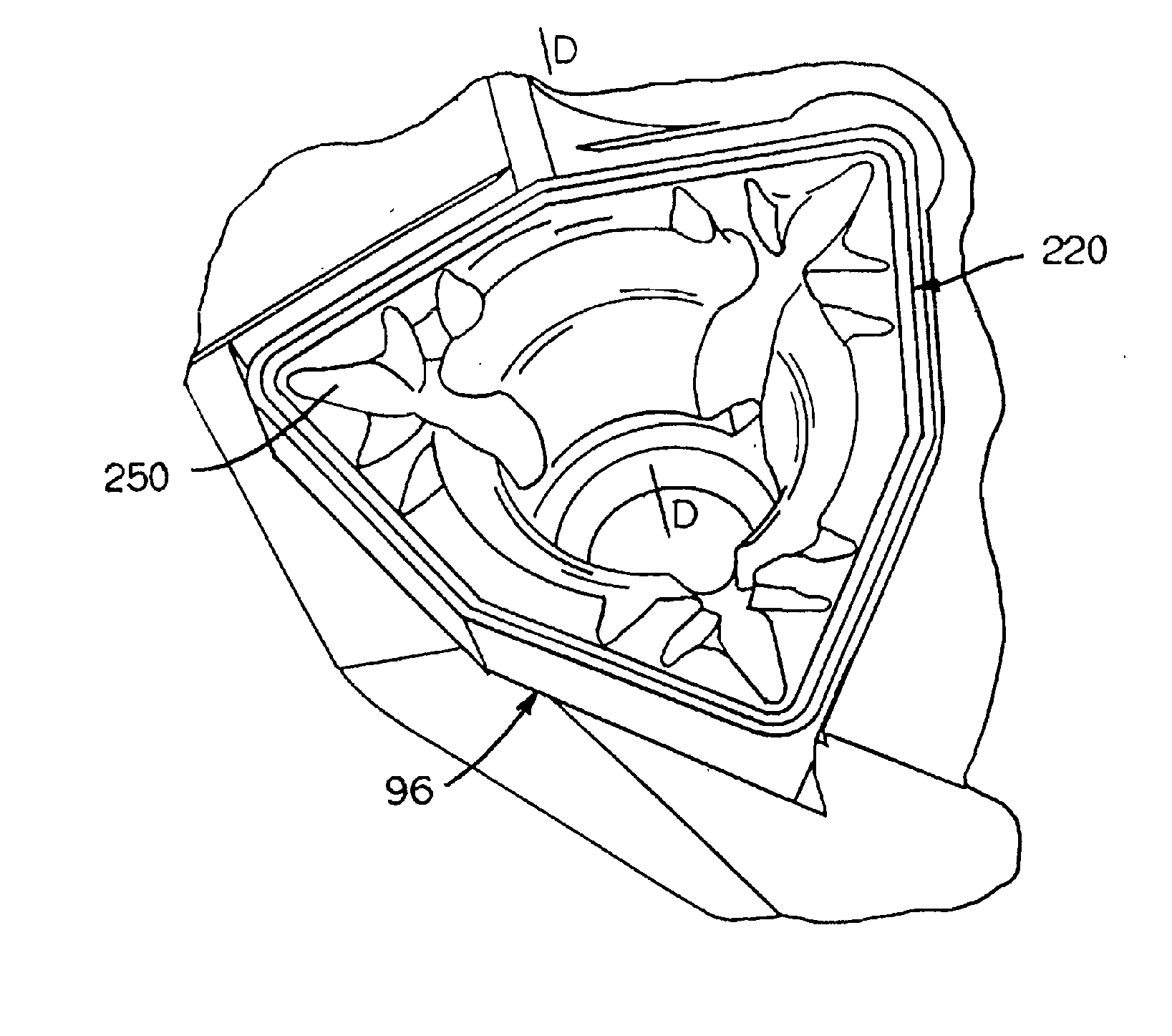

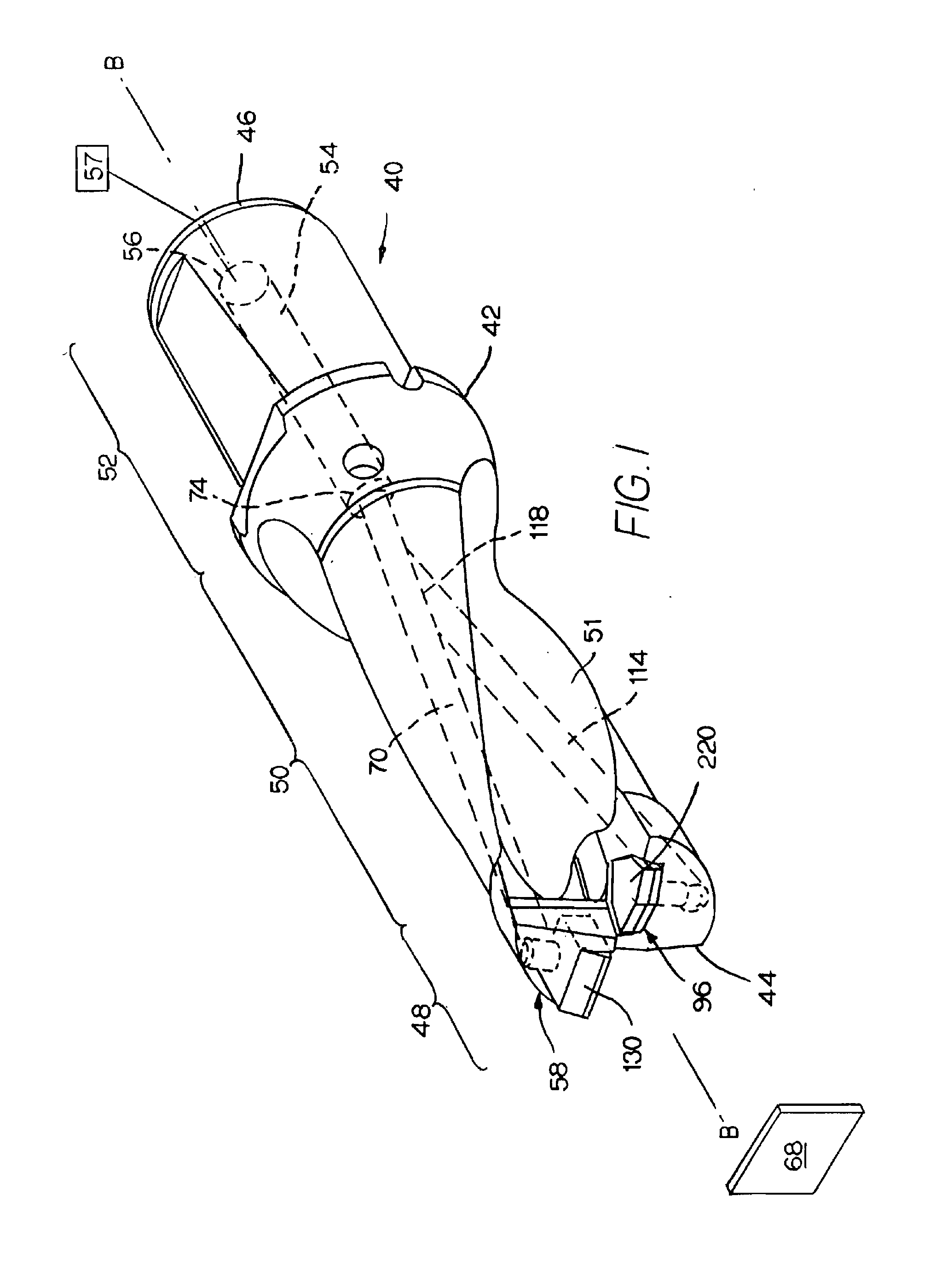

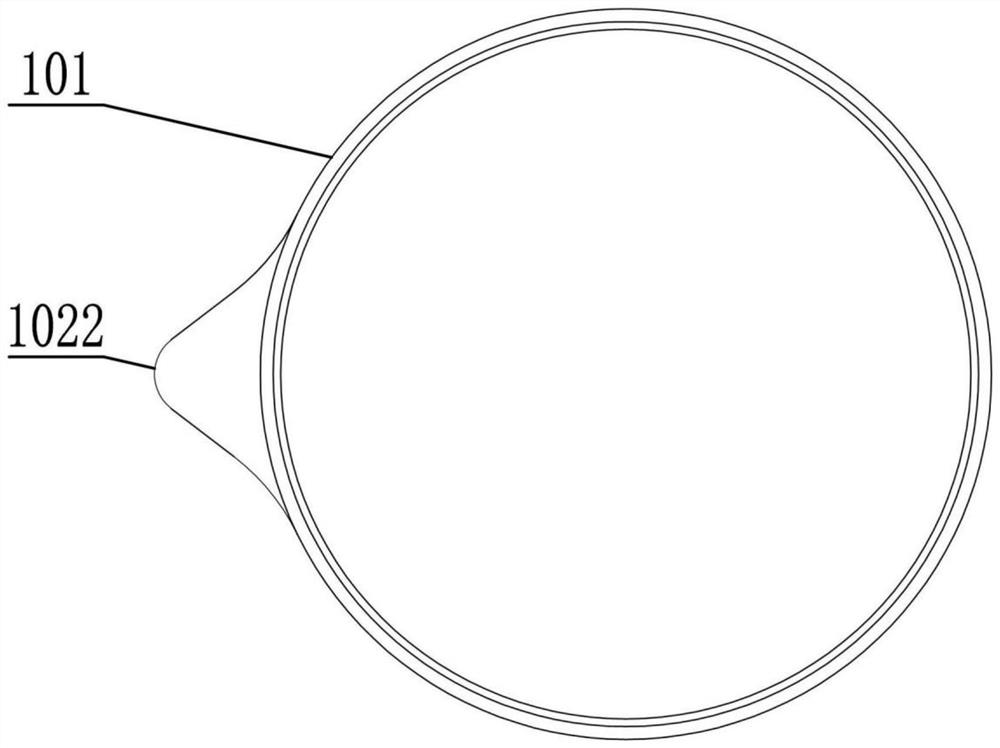

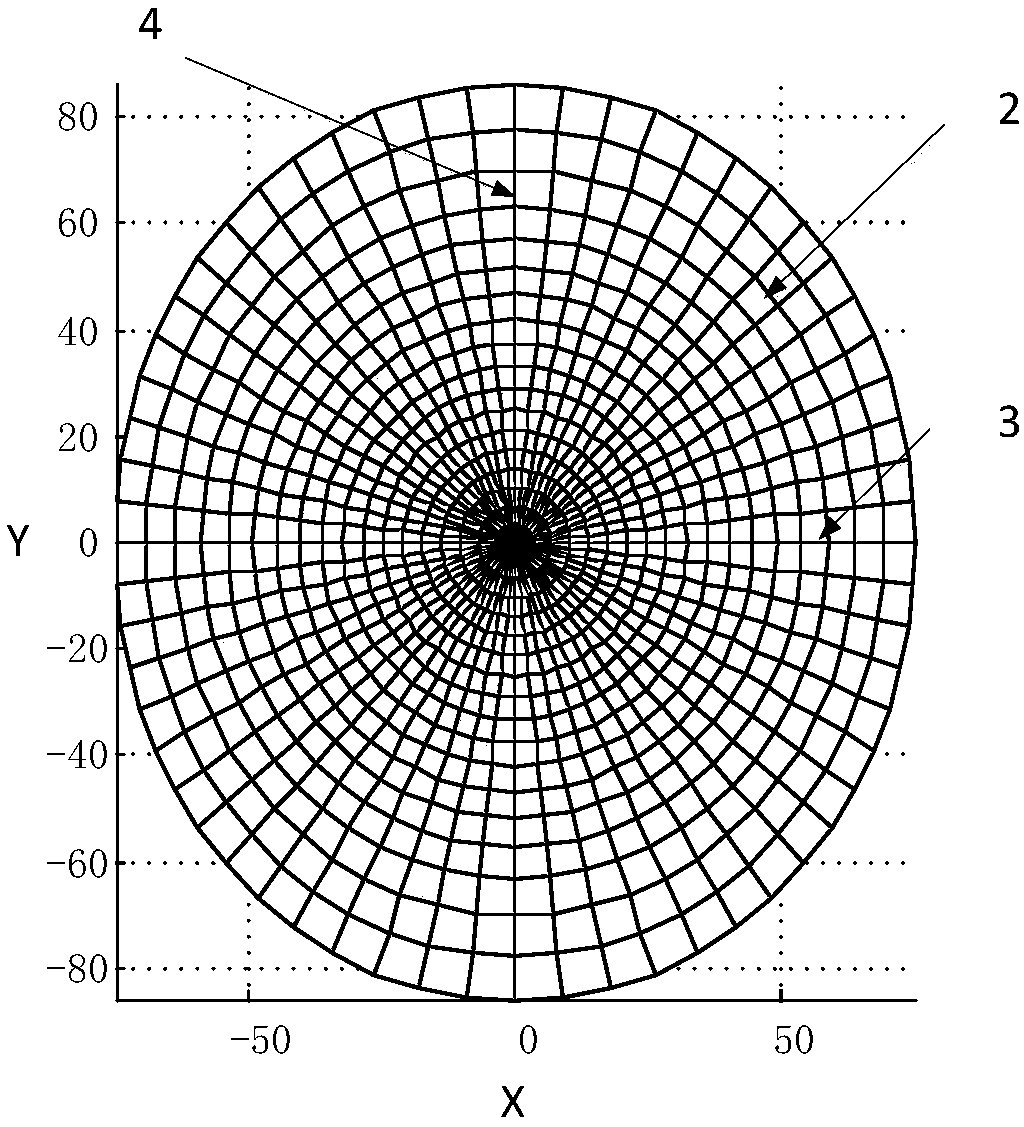

Drill and drill a cutting insert

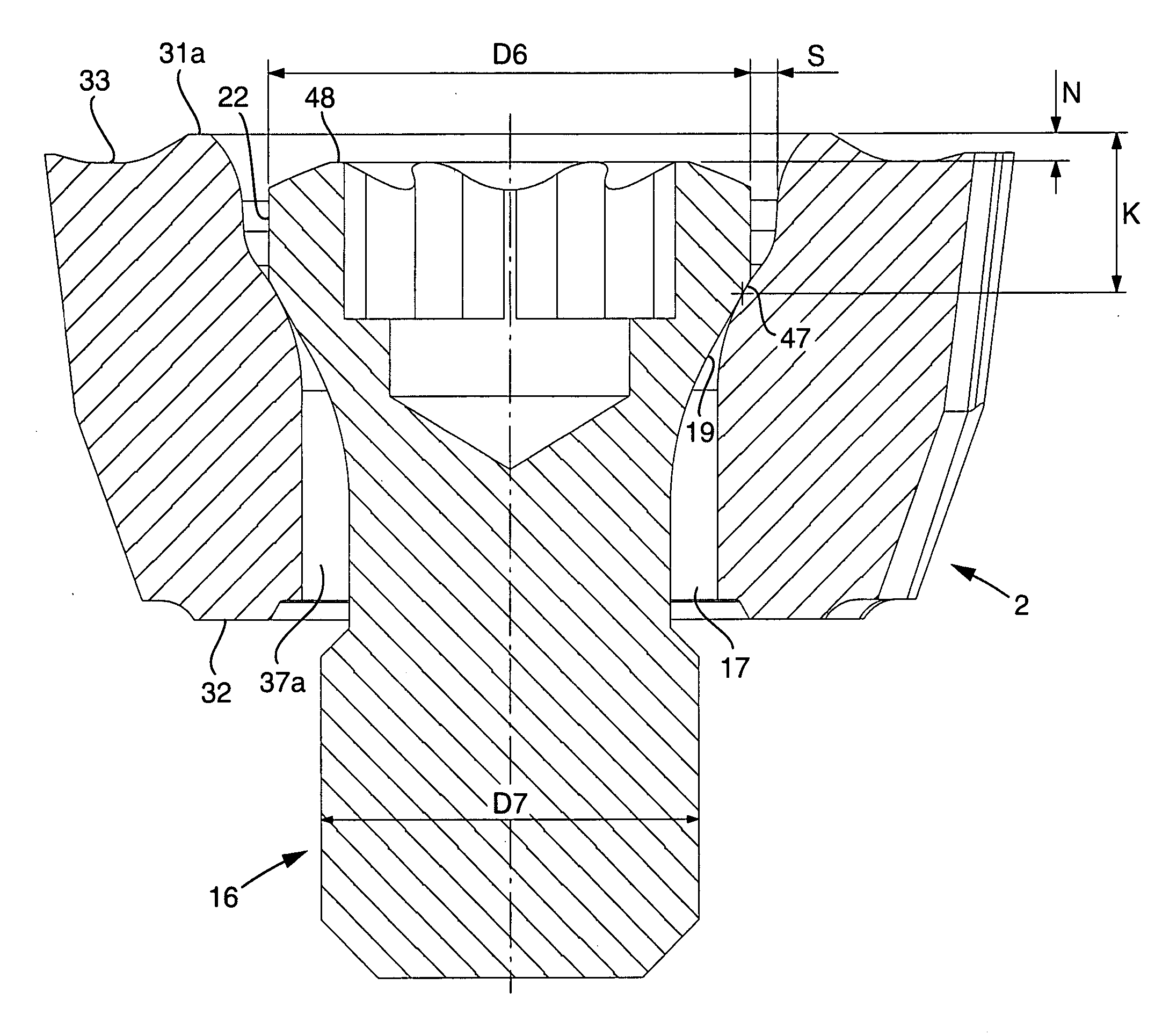

InactiveUS20070201962A1Smoothly pass mouth surfaceRisk minimizationThread cutting toolsWood turning toolsFluteEngineering

A drill for chip removing machining, including a drill body, and a replaceable cutting insert mounted in a pocket formed in a front tip of the drill body. A chip flute extends backwardly from the pocket along the drill body, and the cutting insert is fixed in the pocket by a screw including a head and a shank having a male thread. The cutting insert includes a through hole extending between a topside and an underside. The hole has a basic shape that is rotationally symmetrical in relation to a center axis, and is delimited by a series of surfaces including a mouth surface, converging downward from the topside, and a shoulder surface. The head of the screw is kept pressed against the shoulder surface when the male thread of the screw is tightened in a female thread included in a hole that mouths in a bottom of the pocket. The mouth surface in the hole of the cutting insert has a trumpet-like, cross section-wise convex shape adjacent to the topside of the cutting insert.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

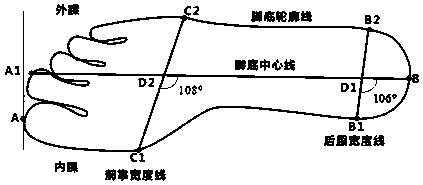

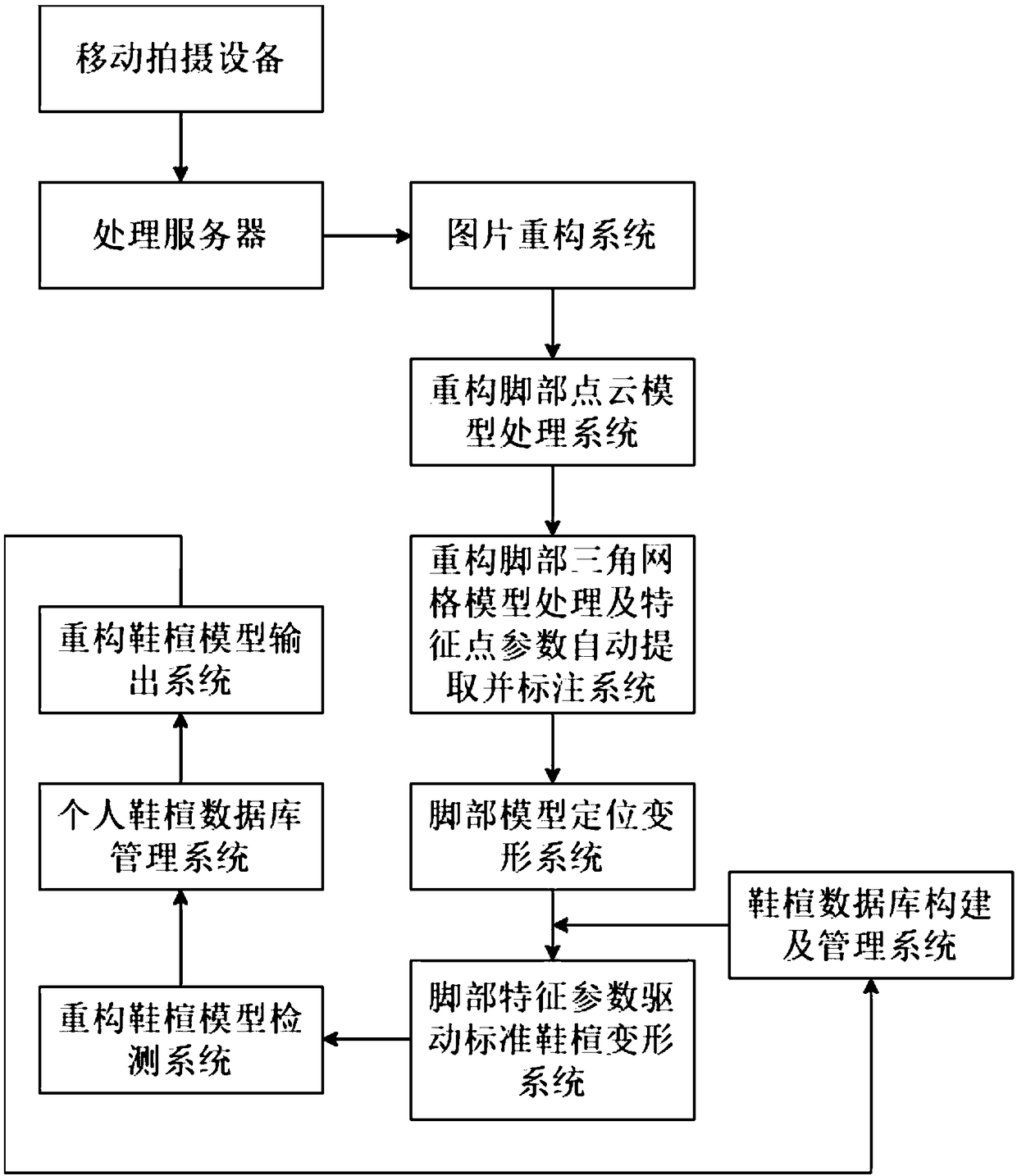

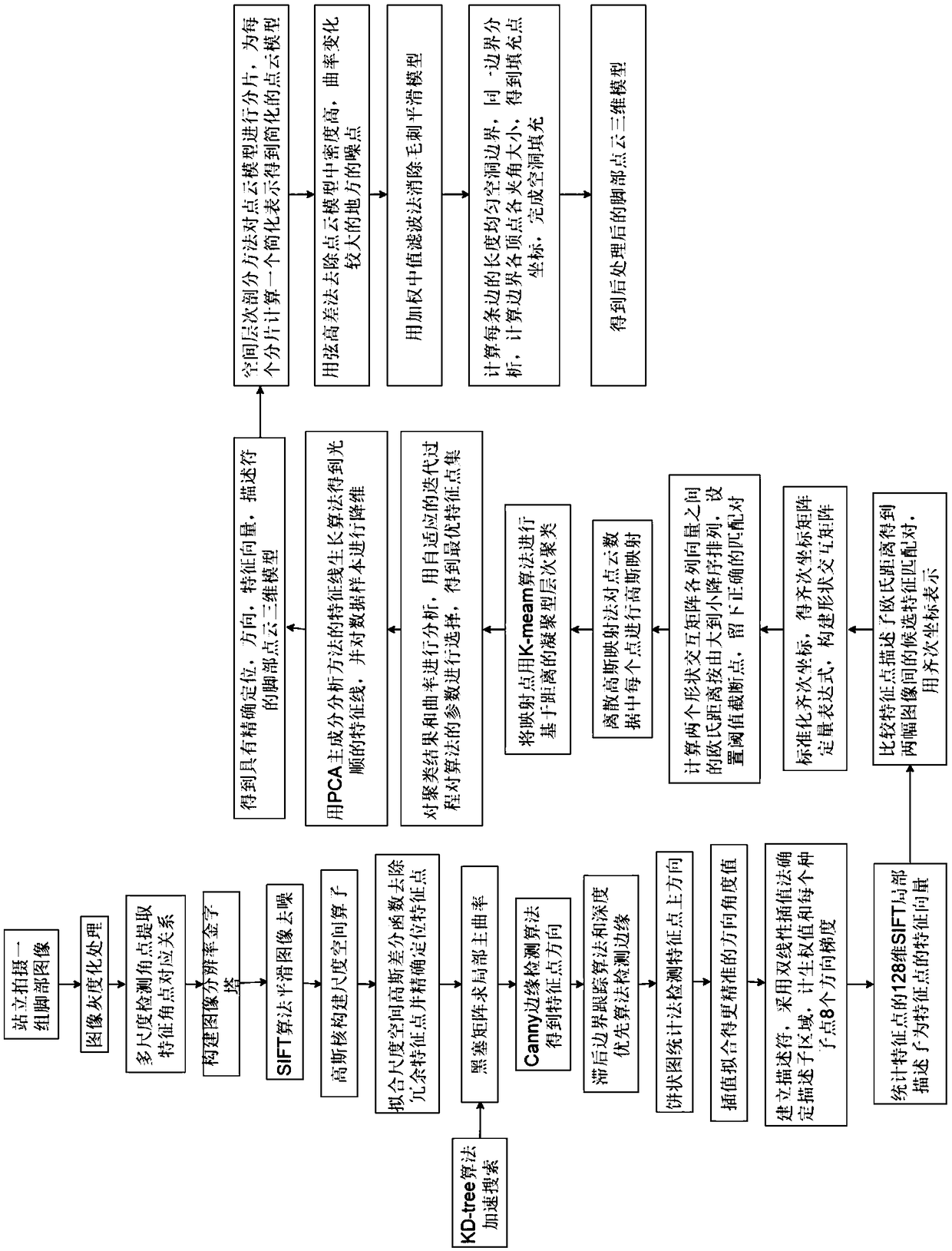

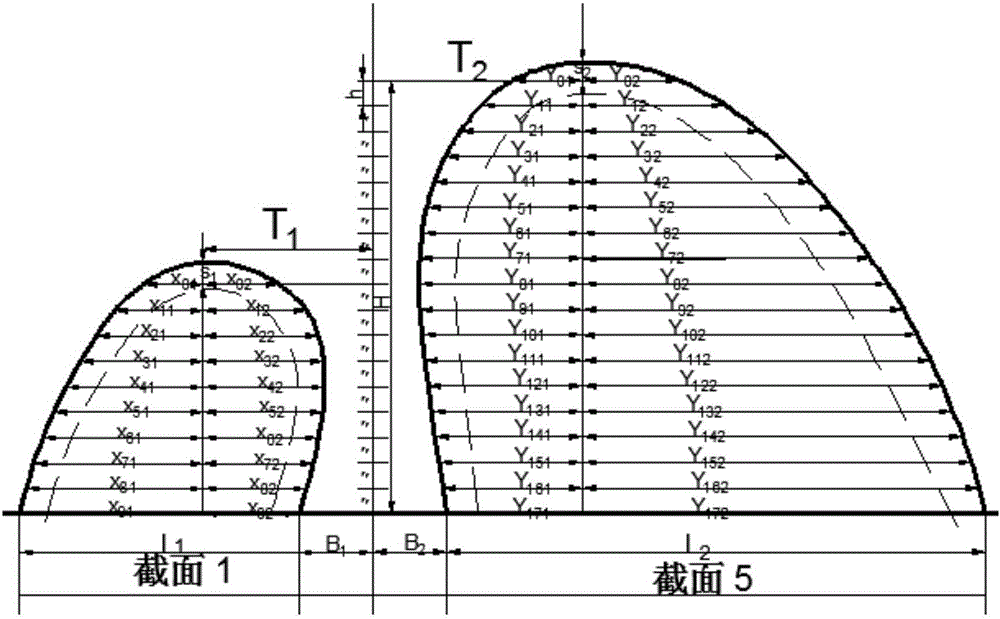

Method and system for foot characteristic parameter to drive standard shoe tree to deform

The invention relates to a method and a system for foot characteristic parameters to drive a standard shoe tree to deform. The method comprises the following steps: generating a final shoe tree control line; generating a shoe tree surface according to the generated shoe tree control line, and boundary lines and a circumference line in the tree surface region forming the surface of each part; connecting the surfaces based on continuity and smoothness of the surfaces, so that the boundary lines of the adjacent surfaces have the same number of points and orders, and that the adjacent surfaces satisfy second-order continuity on the boundary, and singular points or superfluous inflection points do not exist, and curvature changes between the surfaces being small; meanwhile, joining the surfaceswith each other, stitching the smoothly connected surfaces with a bottom surface of the tree and the mouth surface to form a solid closed integrated body. Thus, a shoe tree model based on the foot picture reconstruction model is obtained, and for the adjusted shoe tree standard model, corresponding adjustment can be made on the reconstructed shoe tree model according to parameter correspondence among different types of standard shoe trees according to different selected footwears, shoe types, and heel heights.

Owner:东莞时谛智能科技有限公司

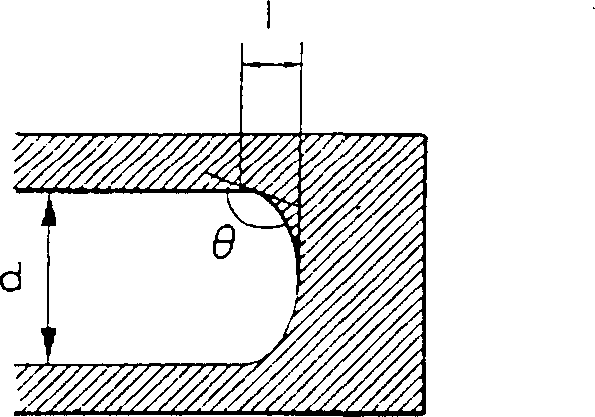

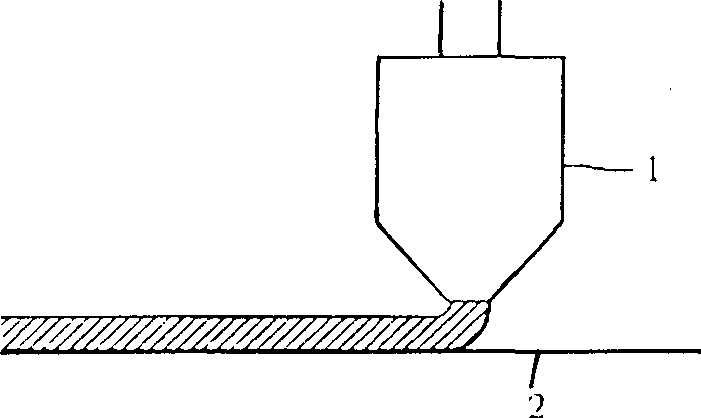

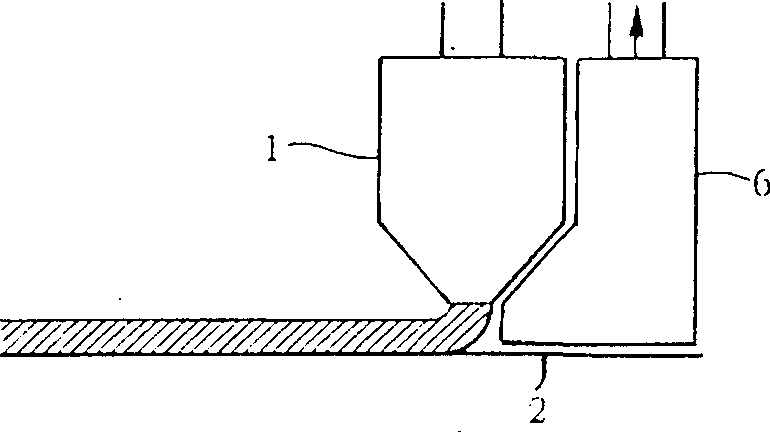

Casting head for solution preparing of film

A method to increase productivity by preventing skinning, to avoid cleaning the peel-off remnants due to the inefficient periodic drying of the peel-off point on the support and to eliminate the hostile influence on the casting head. The subject of this invention is to solve the problem by a casting head for solution preparing of film, and the casting head with an angle theta of more than 120 DEG between mouth surface and mouth side surface on the cross-section of the two ends belong to the front part of mouth section.

Owner:FUJIFILM CORP

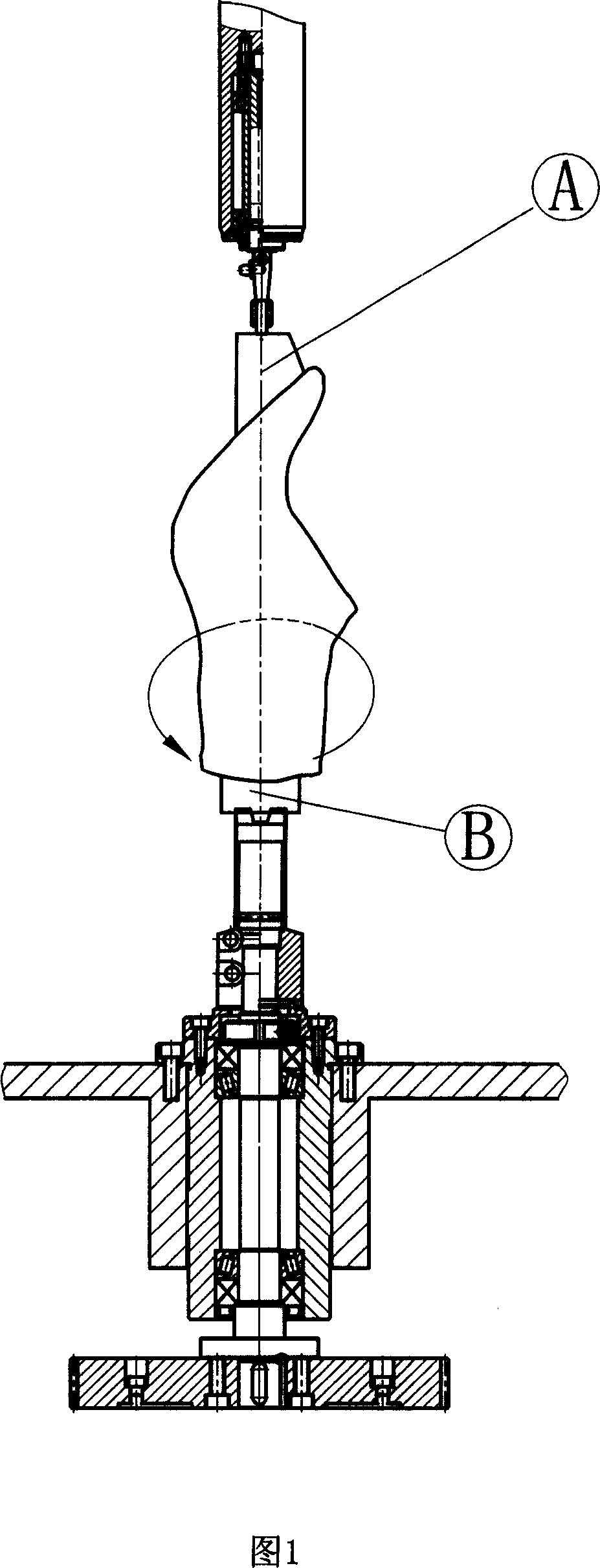

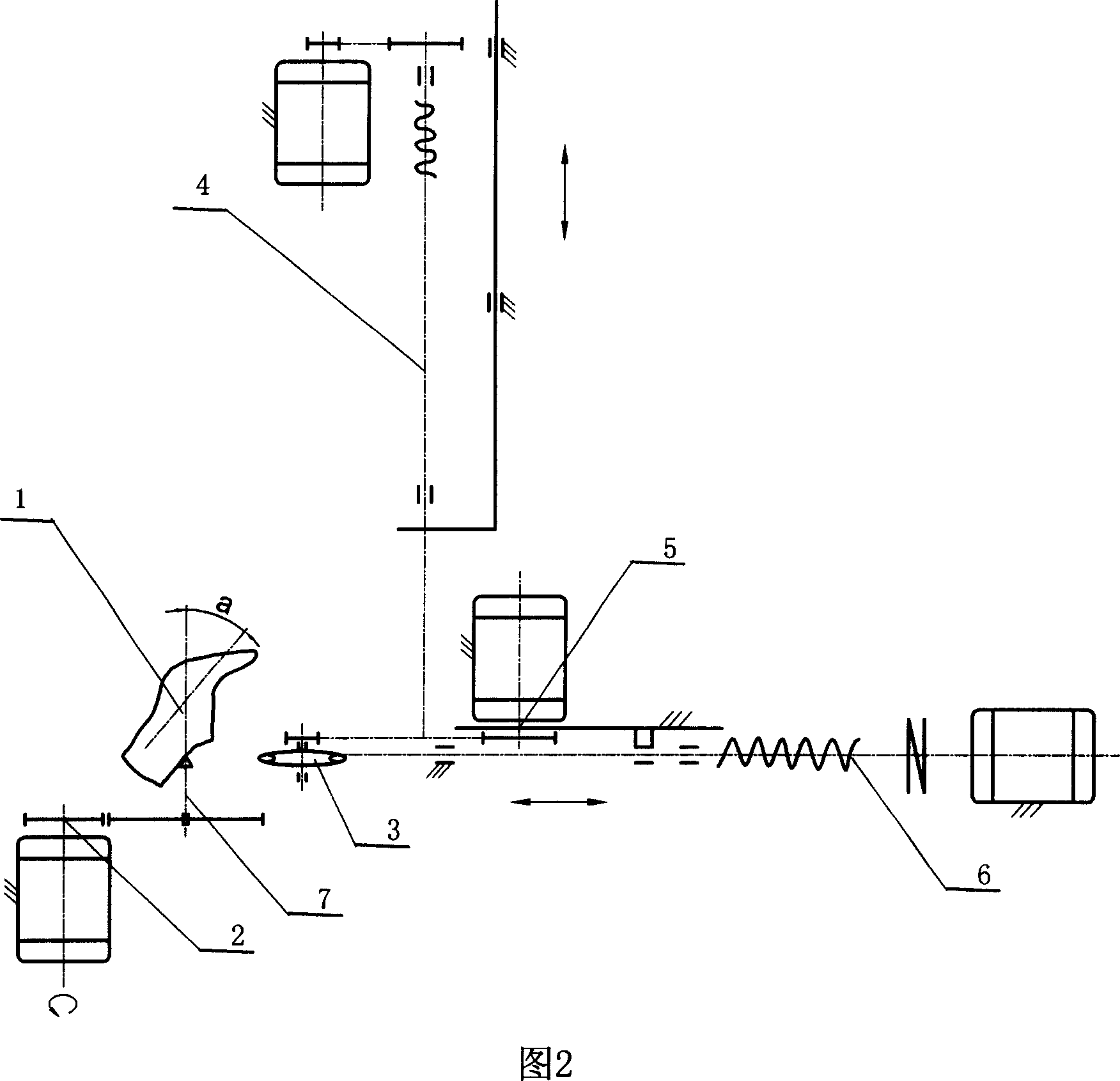

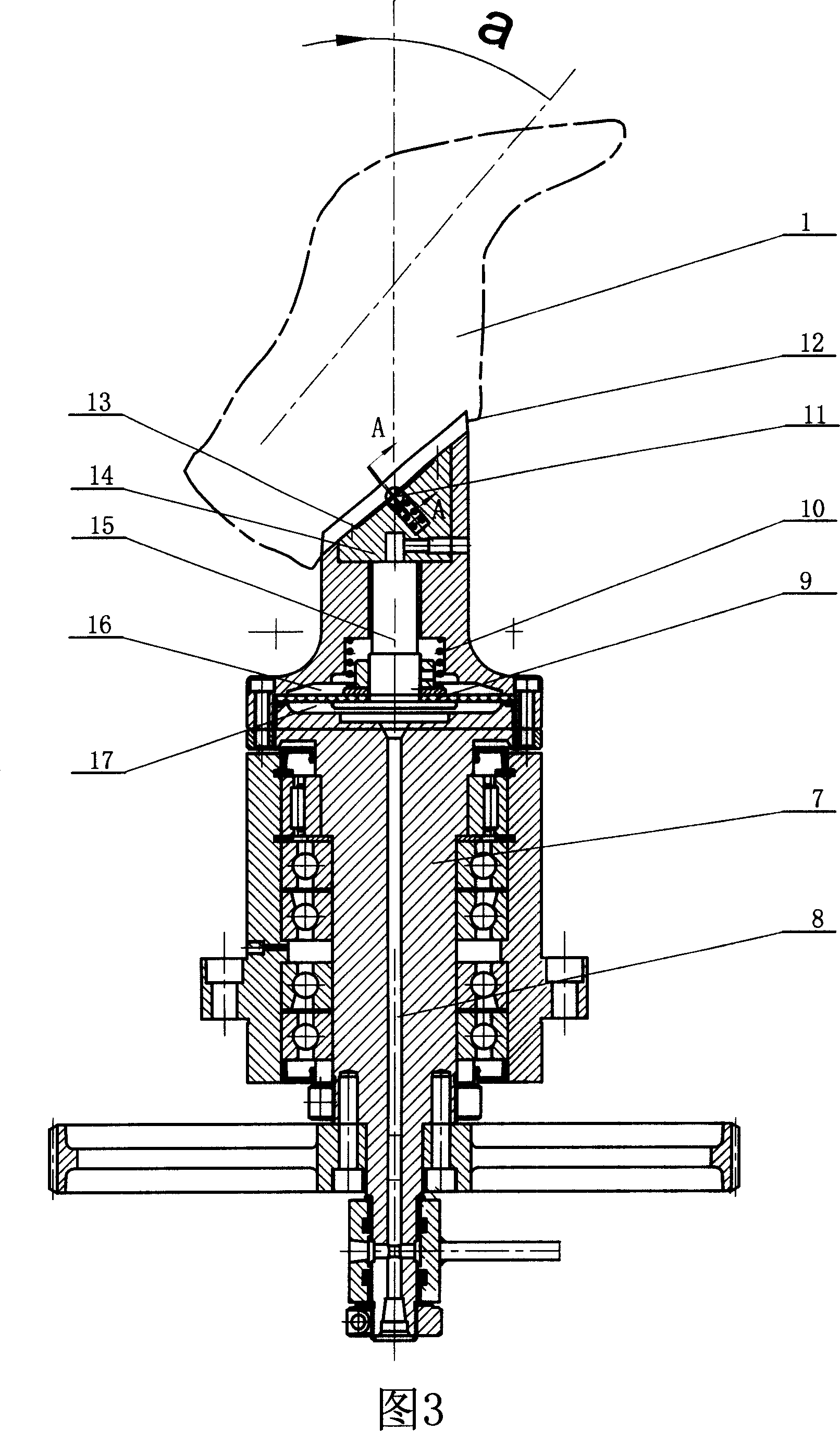

High-imitation manual tea leaf fixing machine

ActiveCN102113577AImprove uniformityQuality improvementPre-extraction tea treatmentEngineeringShaft length

The invention belongs to a tea leaf fixing machine which is also known as a tea frying machine, which is characterized in that the tea leaf fixing is performed according to the principle which is similar to manual fixing, thereby improving the quality of fixing processing; and equipment comprises a round pot and a heating device for heating the round pot, wherein a rotating shaft is arranged in the middle position of the round pot, the rotating shaft is driven by a driving device, the shaft length direction of the rotating shaft is almost parallel to the mouth surface of the round pot, a stirring part is arranged on the rotating shaft, one end of the stirring part is connected with the rotating shaft, and the shape of the end surface at the other end of the stirring part is in the shape of an arc and jointed with the inner wall of the round pot; when the stirring part is used for stir-frying tea leaves, as any part of the round pot has downward radian, the tea leaves which are stirredup by the stirring part are easier to re-fall to the bottom of the pot, and then the stirring up and falling process is repeated. Therefore, all the tea leaves in the pot almost have the same probability of being heated and stirred up, and the uniformity of the fixing processing is improved.

Owner:汪兴林

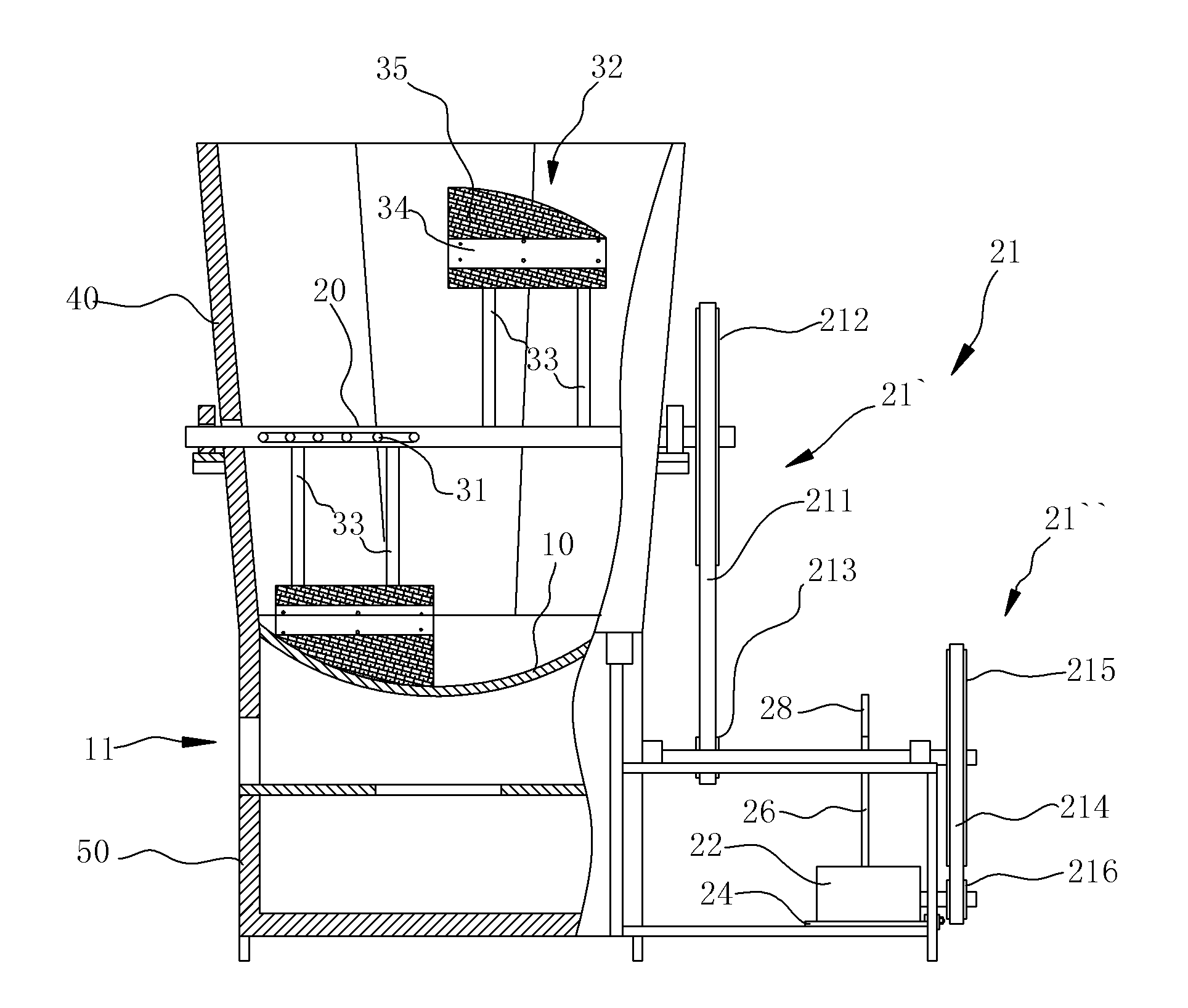

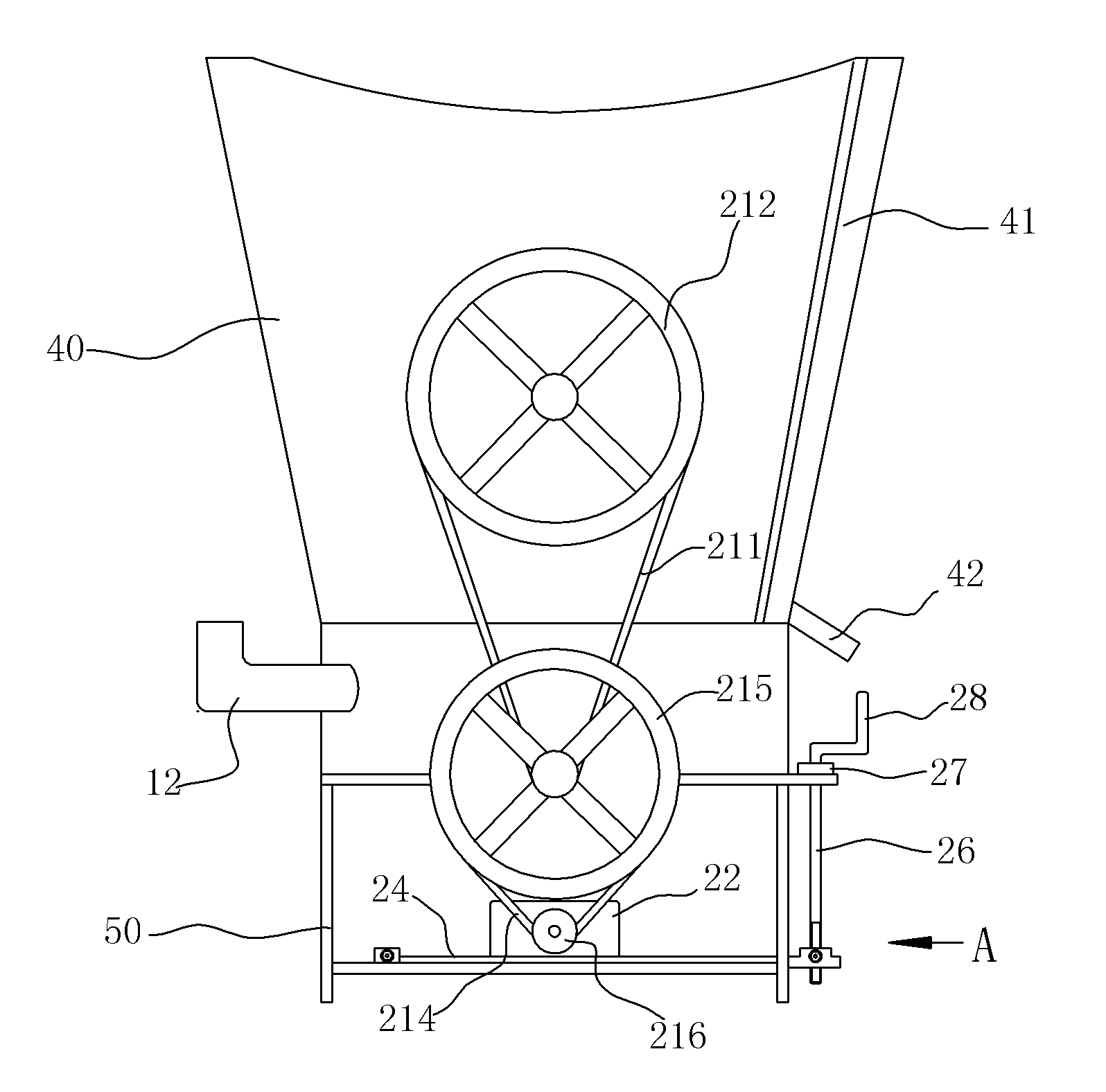

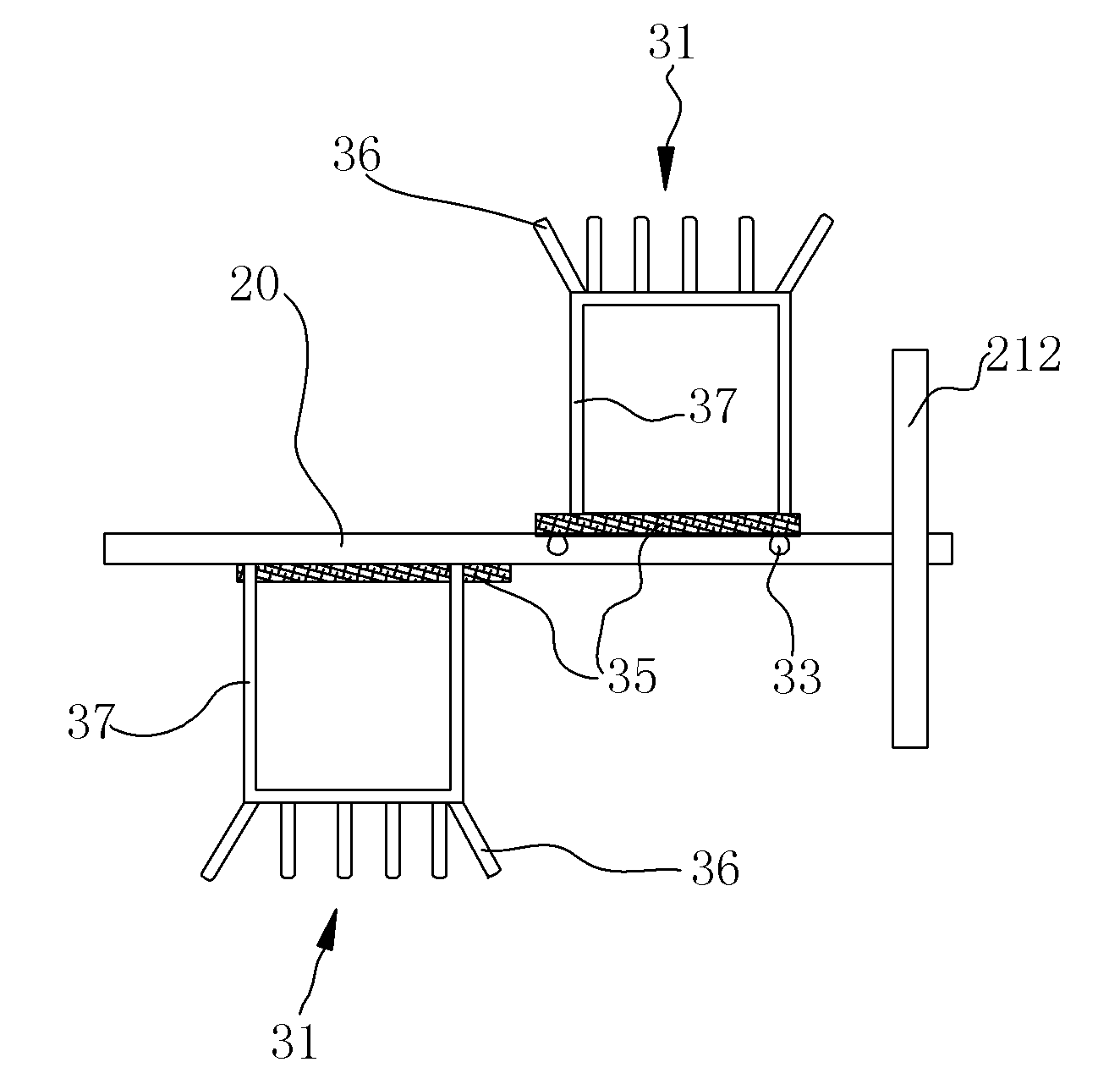

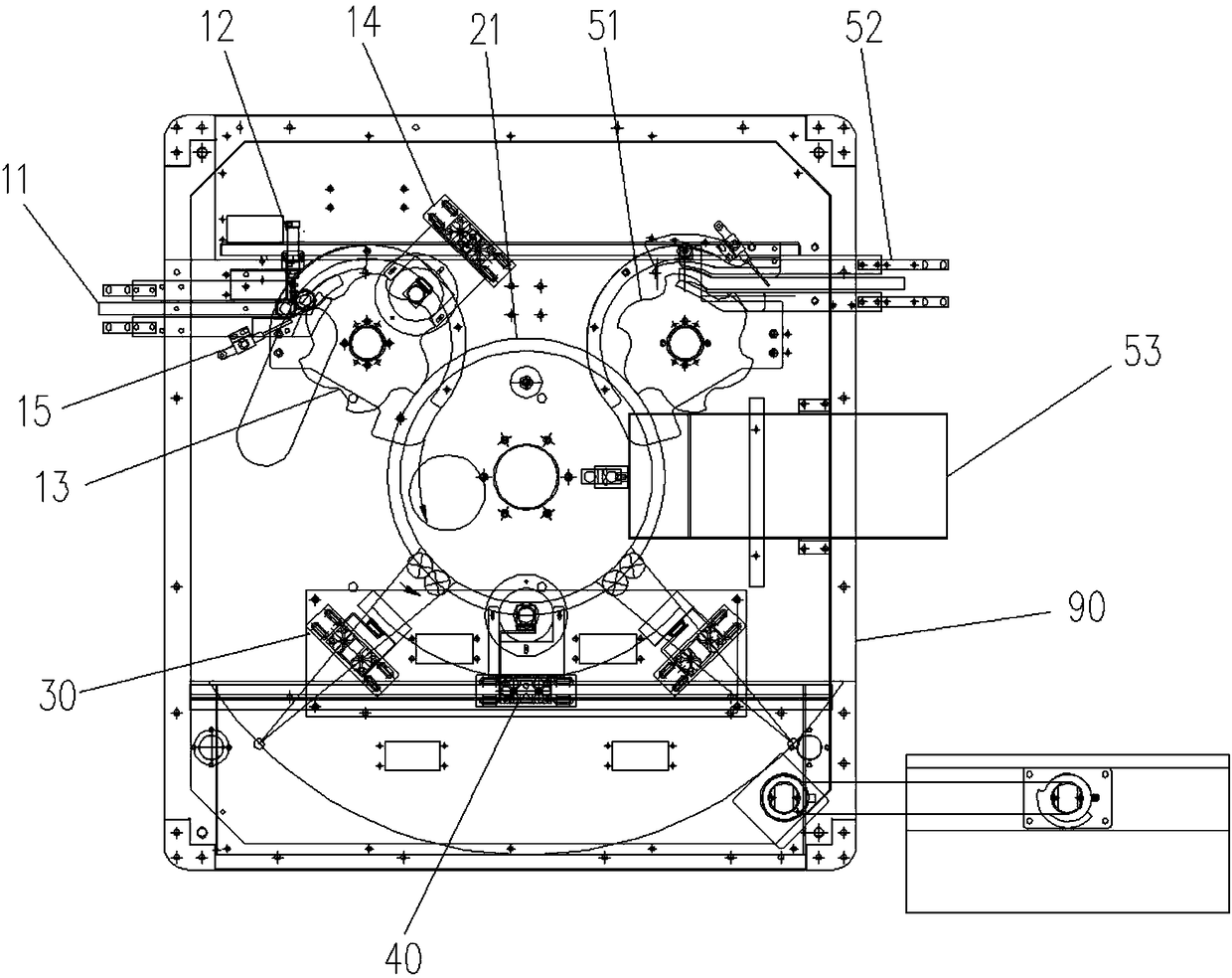

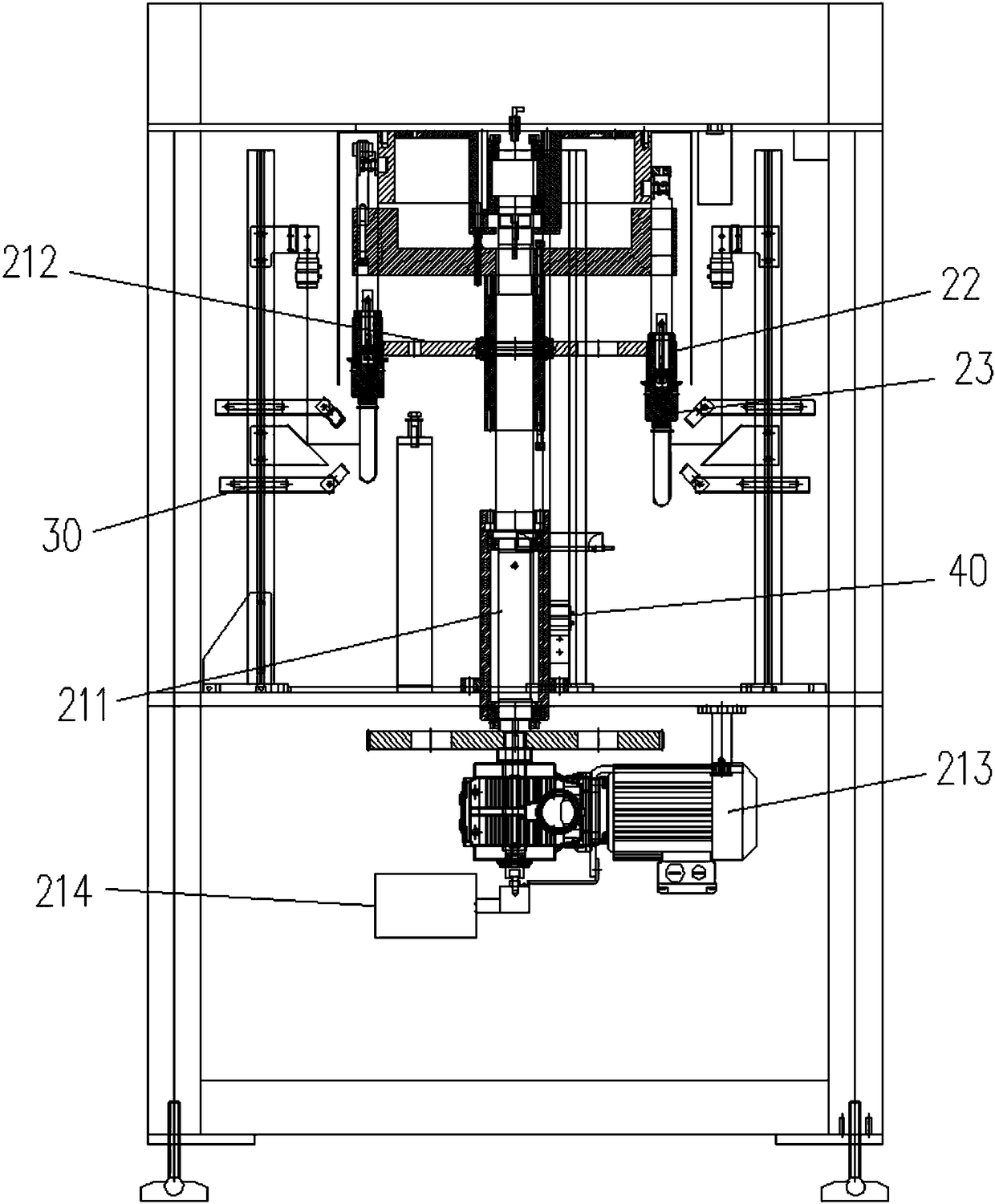

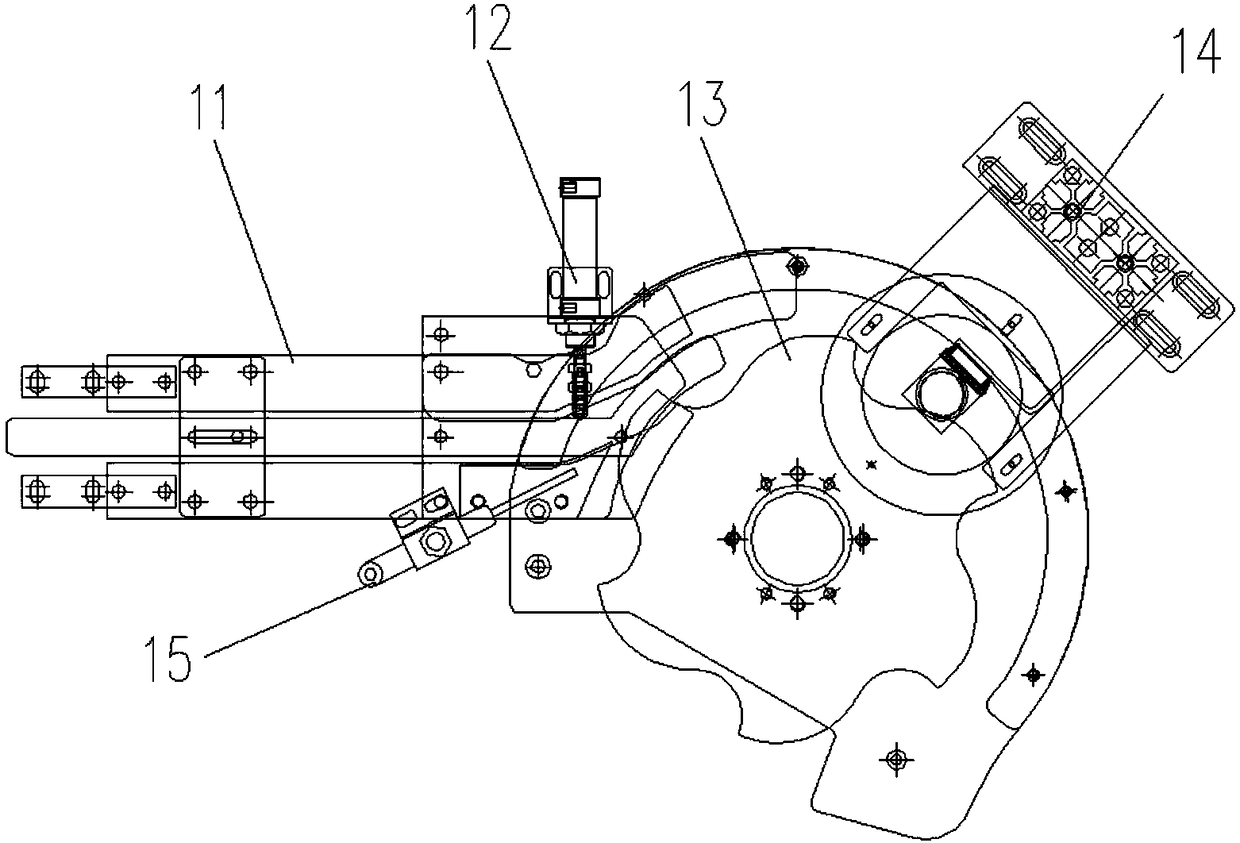

Automatic online bottle blank omni-directional visual inspection machine

The invention relates to an automatic online bottle blank omni-directional visual inspection machine. The machine comprises a blank feeding part, a three-axis multi-station part, a blank discharging part and a control part; the blank feeding part comprises a blank feeding conveying mechanism, a blank stopping mechanism, a blank feeding star wheel mechanism and a blank mouth surface photographing mechanism; the three-axis system multi-station part comprises a bottle blank conveying mechanism, a blank body photographing mechanism and a blank bottom photographing mechanism; one end of the bottleblank conveying mechanism is connected with the blank feeding star wheel mechanism, and the other end of the bottle blank conveying mechanism is connected with the blank discharging part; and the blank body photographing mechanism and the blank bottom photographing mechanism are arranged in sequence in the conveying direction of the bottle blank conveying mechanism, the blank body photographing mechanism is located on the outer side of a conveying track, and the blank bottom photographing mechanism is located below the conveying track. According to the automatic online bottle blank omni-directional visual inspection machine, accurate, fast and multi-surface multi-station visual detection can be achieved by mechanically combining a visual system, industrial automatic production is well realized by the whole set of machine, and high-quality, high-speed, high-efficiency and high-yield processes of the food making and packaging industry are guaranteed and promoted.

Owner:广州市博仕机电工贸有限公司

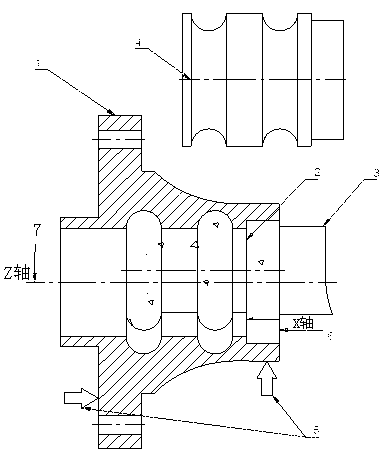

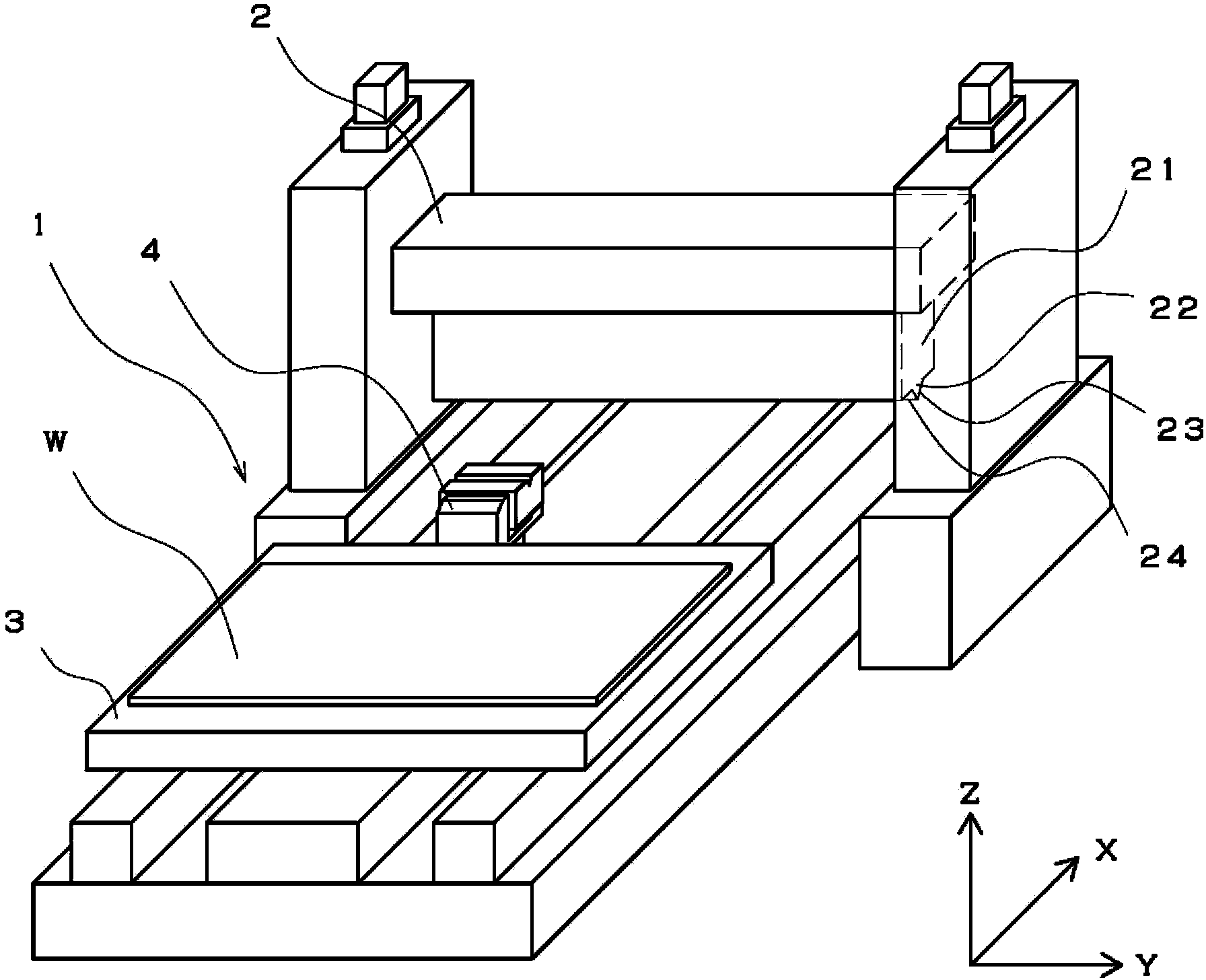

Third-generation grinding method for outer flange of automotive hub ball bearing

InactiveCN103302575ASolve the problem of inconsistent accuracyGuaranteed accuracyGrinding machinesElectricityBall bearing

A third-generation grinding method for an outer flange of an automotive hub ball bearing mainly comprises the following steps: 1, processing double channels and a lock mouth surface of the outer flange (1) of the automotive hub ball bearing according to the composite plunge-cut grinding technology of a diamond roller (4) and a form grinding abrasive wheel (2); 2, conducting high-speed form trimming on the form grinding abrasive wheel (2) with the diamond roller (4) of which the outline profile is required to be coincident with the required profile of the outer flange (1), so as to ensure that the profile of the form grinding abrasive wheel (2) is coincident with that of the outer flange (1). An electromagnetic centerless clamp (5) serves as a grind positioning tool of the outer flange (1); the outer flange (1) rotates with the speed of 200 turns per minute to 400 turns per minute; the form grinding abrasive wheel (2) under the driving of an abrasive wheel electric spindle (3) with a built-in motor rotates fast with the linear speed of 60 m / second and grinds in the same direction as the rotation of the outer flange (1). Therefore, the channels and the lock mouth surface of the outer flange (1) can be formed in one step through composite grinding. The grinding method provided by the invention has the advantages that the machining precisions are consistent, reliable and guaranteed; and the quality of an automotive hub ball bearing component is improved.

Owner:LUOYANG PRECISION MACHINE TOOLS

Digital controlled block cutting machine

InactiveCN101007417AHigh speedHigh precisionWood working apparatusAgricultural engineeringMechanical equipment

The invention involves the shoemaking industry mechanical equipment, particularly relates to a digital control carving shoe-tree machine. It is characterized by: the top end of rotate axle is equipped with shoe-tree head blank positioning device and shoe-tree head blank clamping device which match with shoe-tree head tubular mouth surface. It aims at designing a digital control carving shoe-tree machine which can improve shoe-tree processing speed and precision. Compared with the prior technology, it has advantages of the shoe-tree shape is same before or after processing, accurate and perfect, saving materials, low cost, obvious efficiency improvement.

Owner:郑豪迈

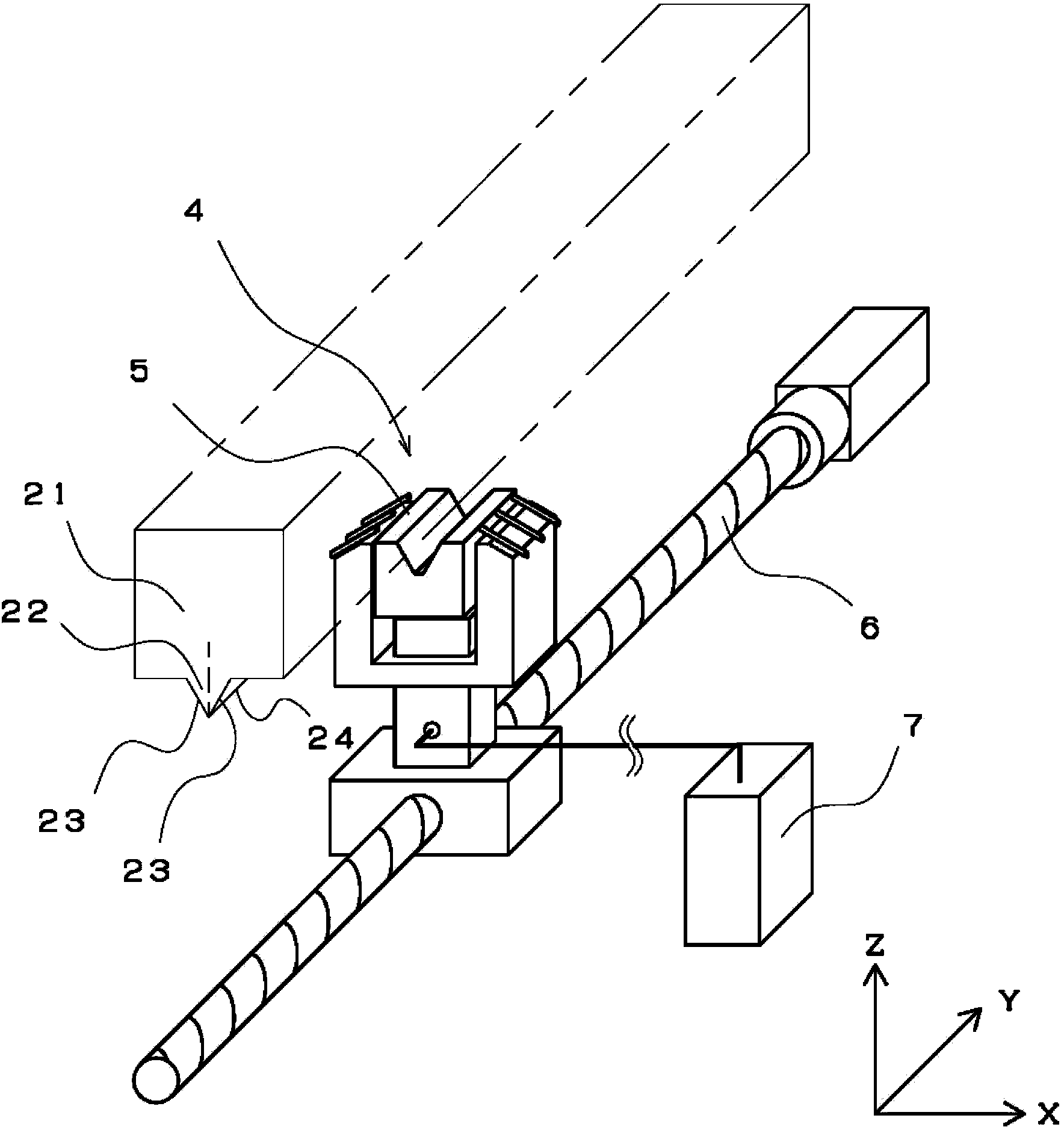

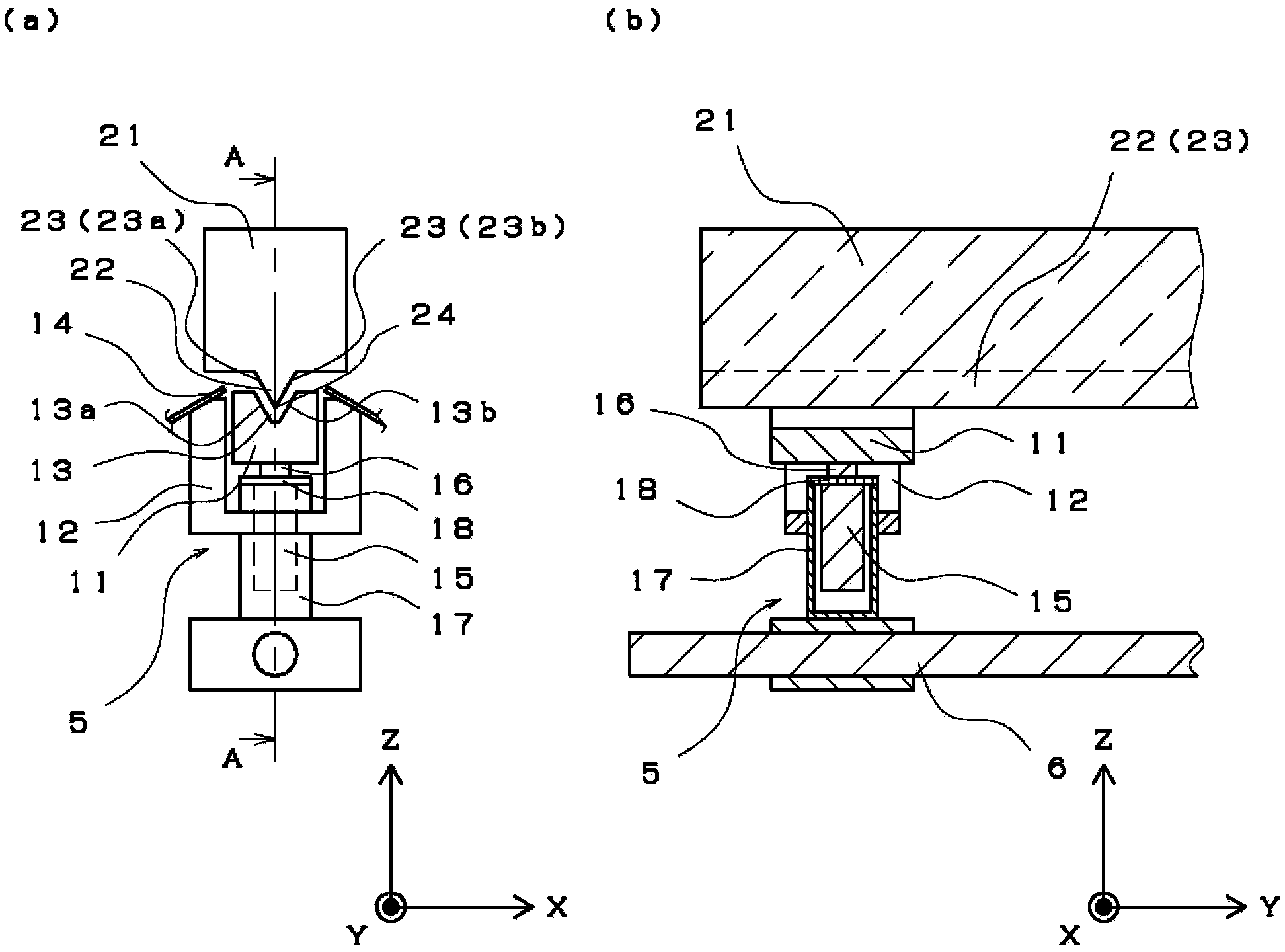

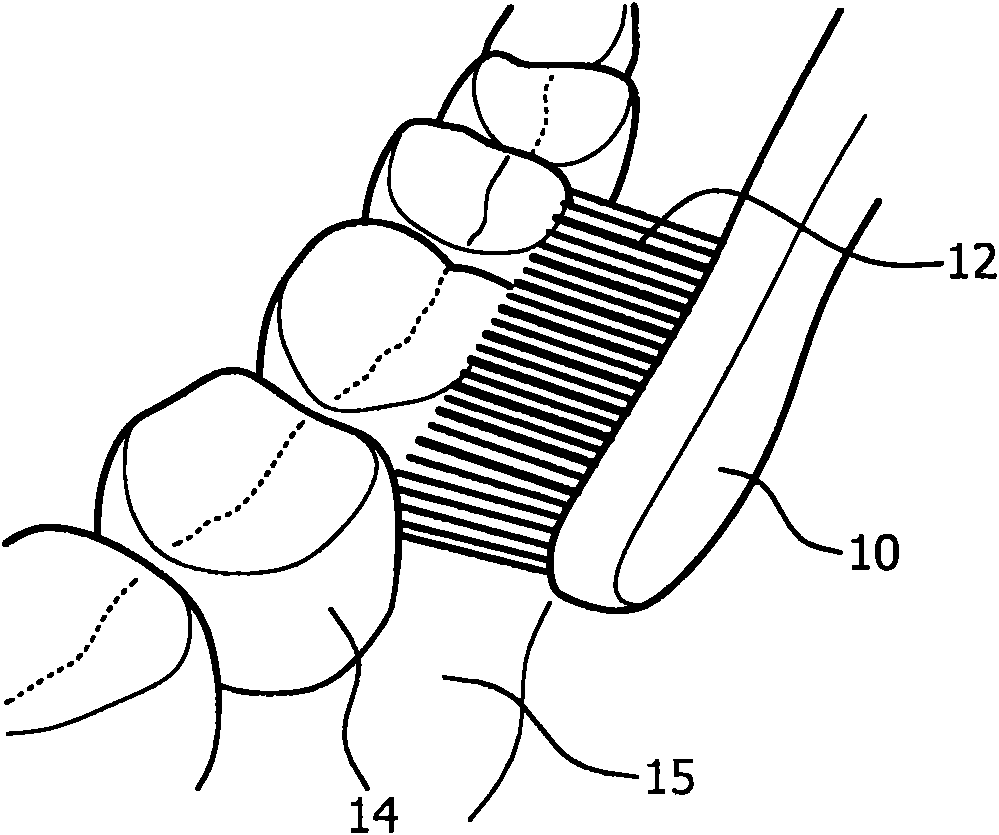

Cleaning device and cleaning method

ActiveCN103506238APowerful removalLiquid surface applicatorsSpraying apparatusCleaning methodsCleansing Agents

The invention provides a cleaning device and a cleaning method which can forcefully remove adhesive matter on a mouth and is low in cost. The cleaning device (4) comprising a cleaning unit (5), and a cleaning solution supply mouth (14) which supplies a cleaning solution for cleaning a mouth surface (23), the mouth surface is cleaned through a moving device (6) while the cleaning unit and the cleaning solution supply mouth move towards a long dimension direction of the mouth surface, the cleaning unit comprises an ultrasonic vibrating part (11) on which an ultrasonic vibrator (15) is mounted and opposite grooves are formed (13), by enabling the opposite grooves to approach the mouth surface, and supplying the cleaning solution from the cleaning solution supply mouth to a gap between the opposite grooves and the mouth surface, a dipping part (19) is formed, under such a state, partial cleaning of the mouth surface is performed by generating ultrasonic wave vibration by the ultrasonic wave vibrating part, and by enabling the cleaning unit and the cleaning solution supply mouth to move towards the long dimension direction, the mouth surface is cleaned along the long dimension direction..

Owner:TORAY ENG CO LTD

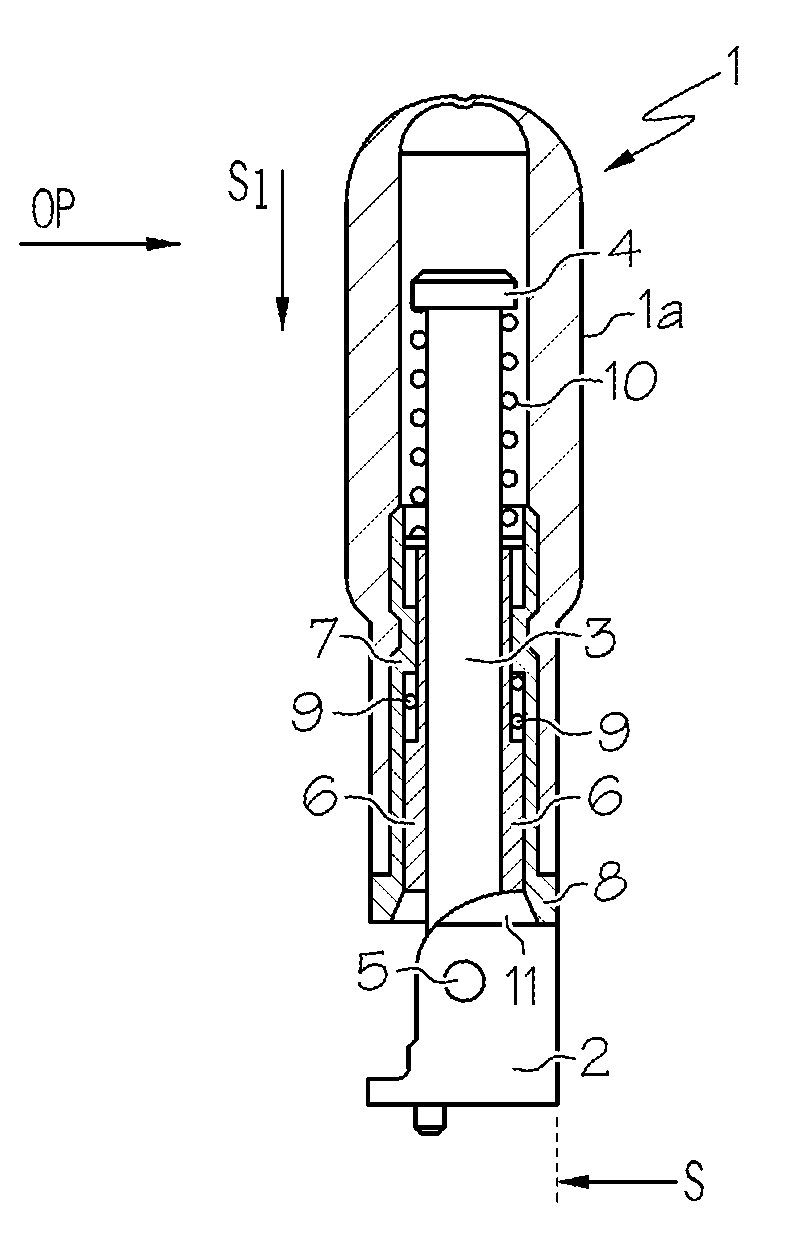

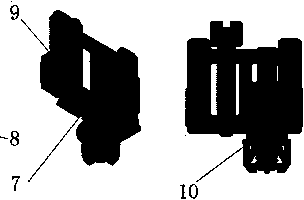

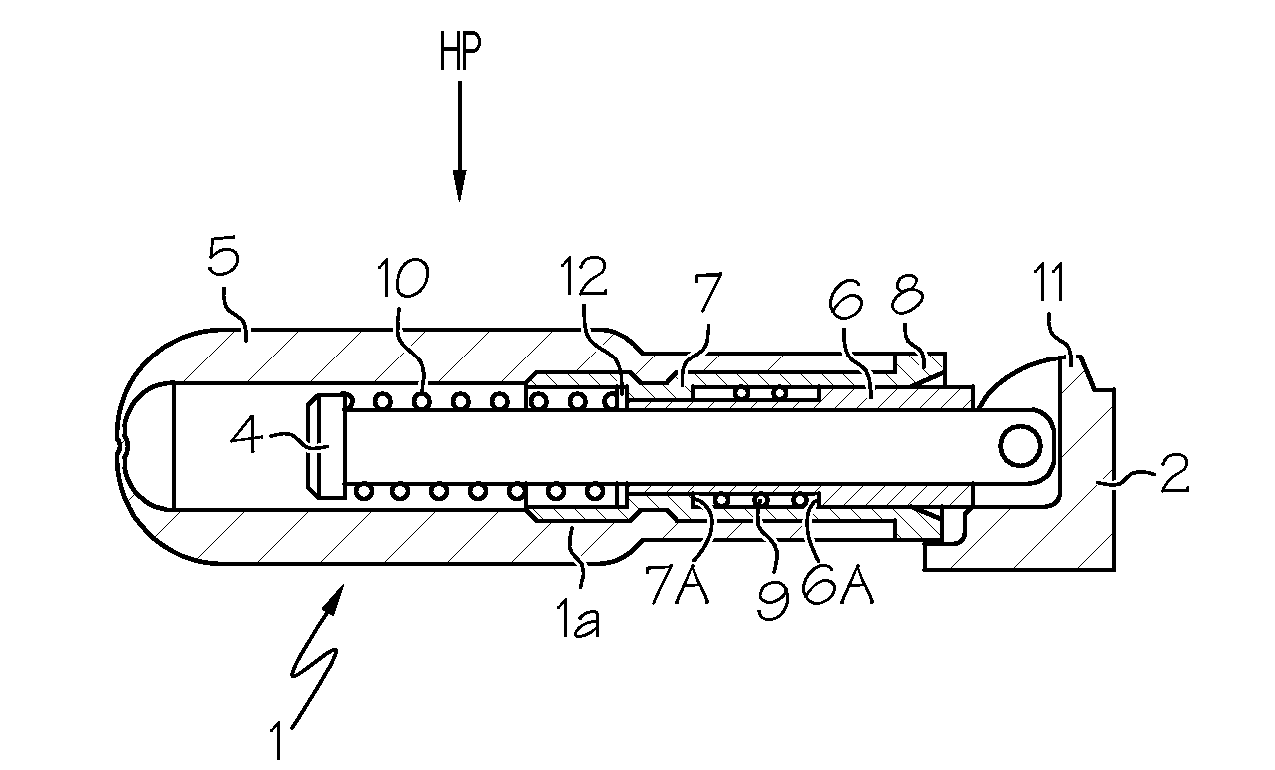

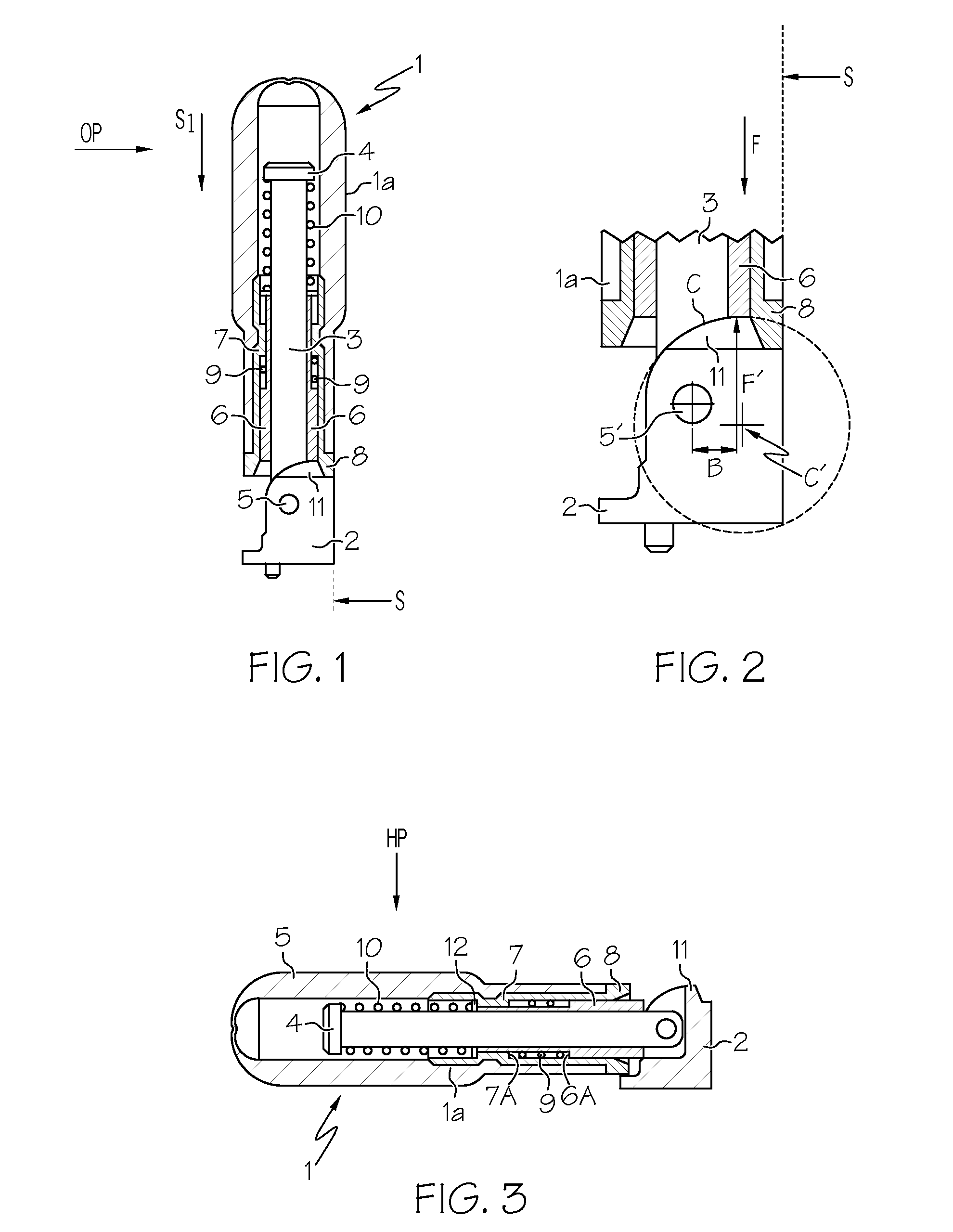

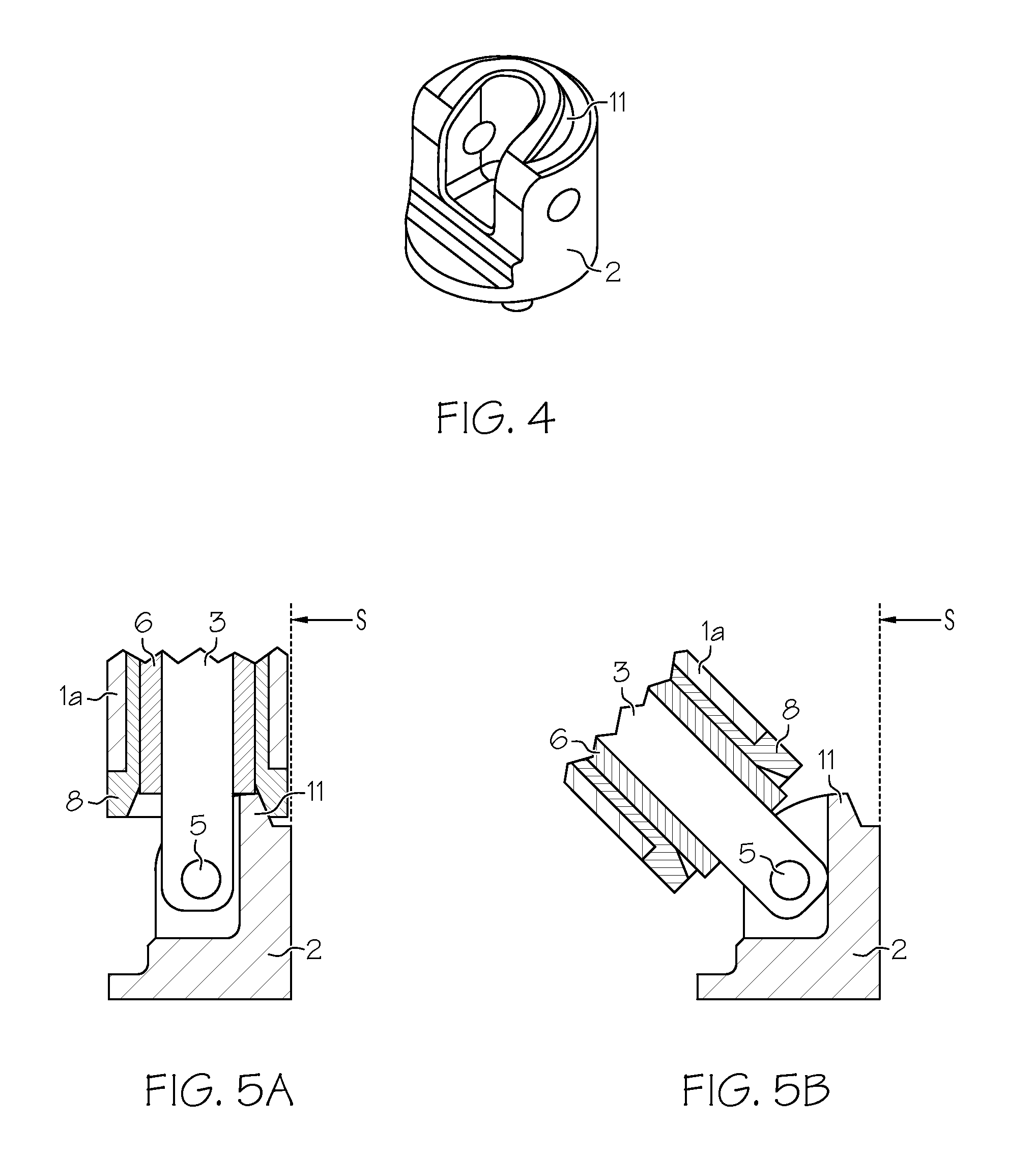

Safety fold-away handle

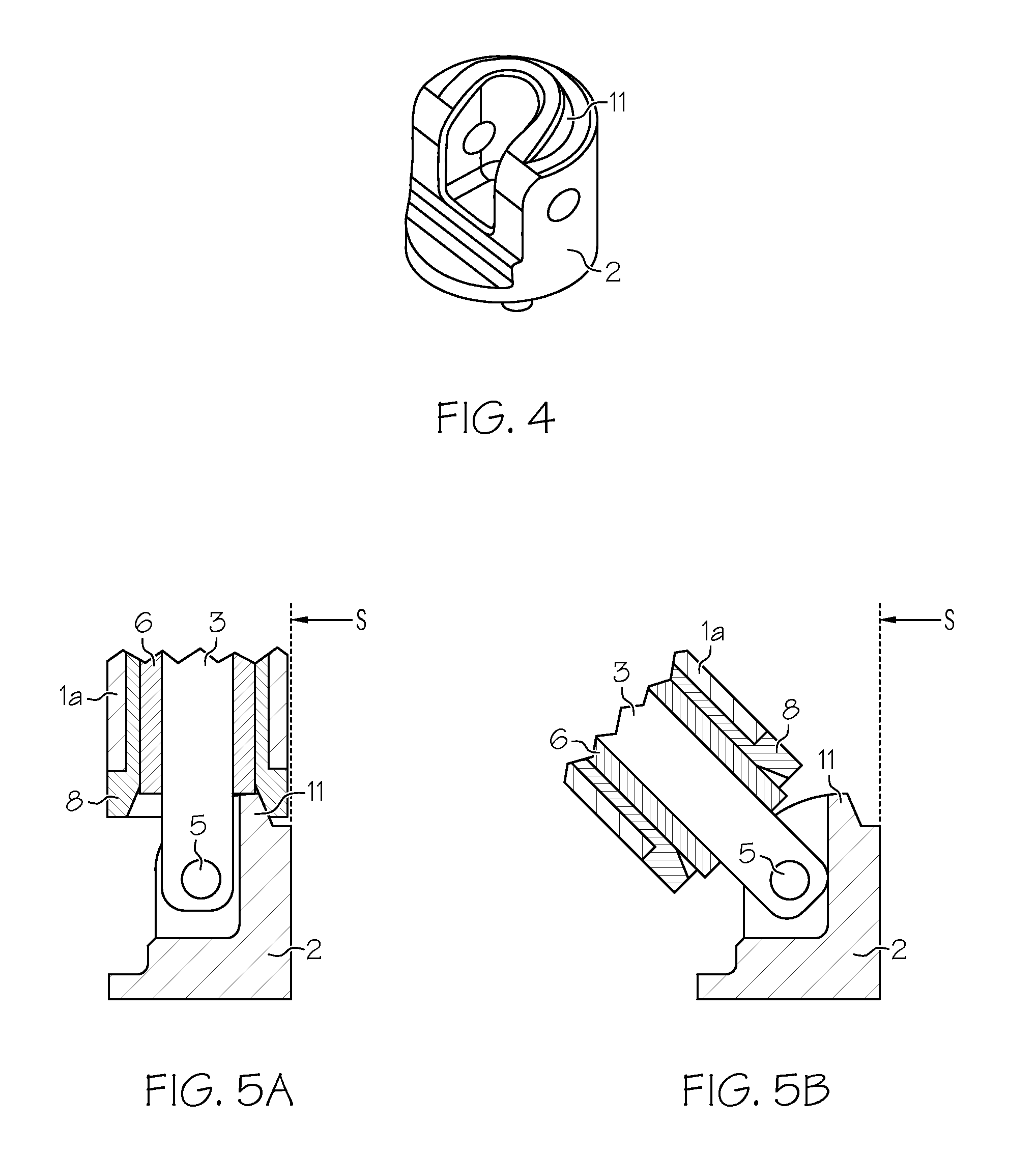

A safety grip for a handwheel which is movable between an operating position and a home position is comprised of an elongated and ergonomic body (1) and of a support (2), which is anchored to the body of a maneuvering member, such as a handwheel. The body (1) is comprised of an outer case (1a), a rod-like inner core (3) with a head (4), a bushing (6) slidably mounted on the core (3), a sleeve (7) in sliding engagement on the bushing (6), an axial thrust spring (9) arranged between two opposite shoulders (6a) and (7a) of the bushing (6) and of the sleeve (7), and a second thrust spring (10) arranged between the head (4) and the top of the bushing (6). The body (1) is connected to the support (2) at a pivot point (5). An end of the sleeve (7) engages a contact surface of the support (2) through a collar (8). The collar (8) has an inner conical mouth surface that engages a shaped rib (11) on the top of said support (2), where the shaped rib (11) has a frusto-conical outer surface.

Owner:ELESA

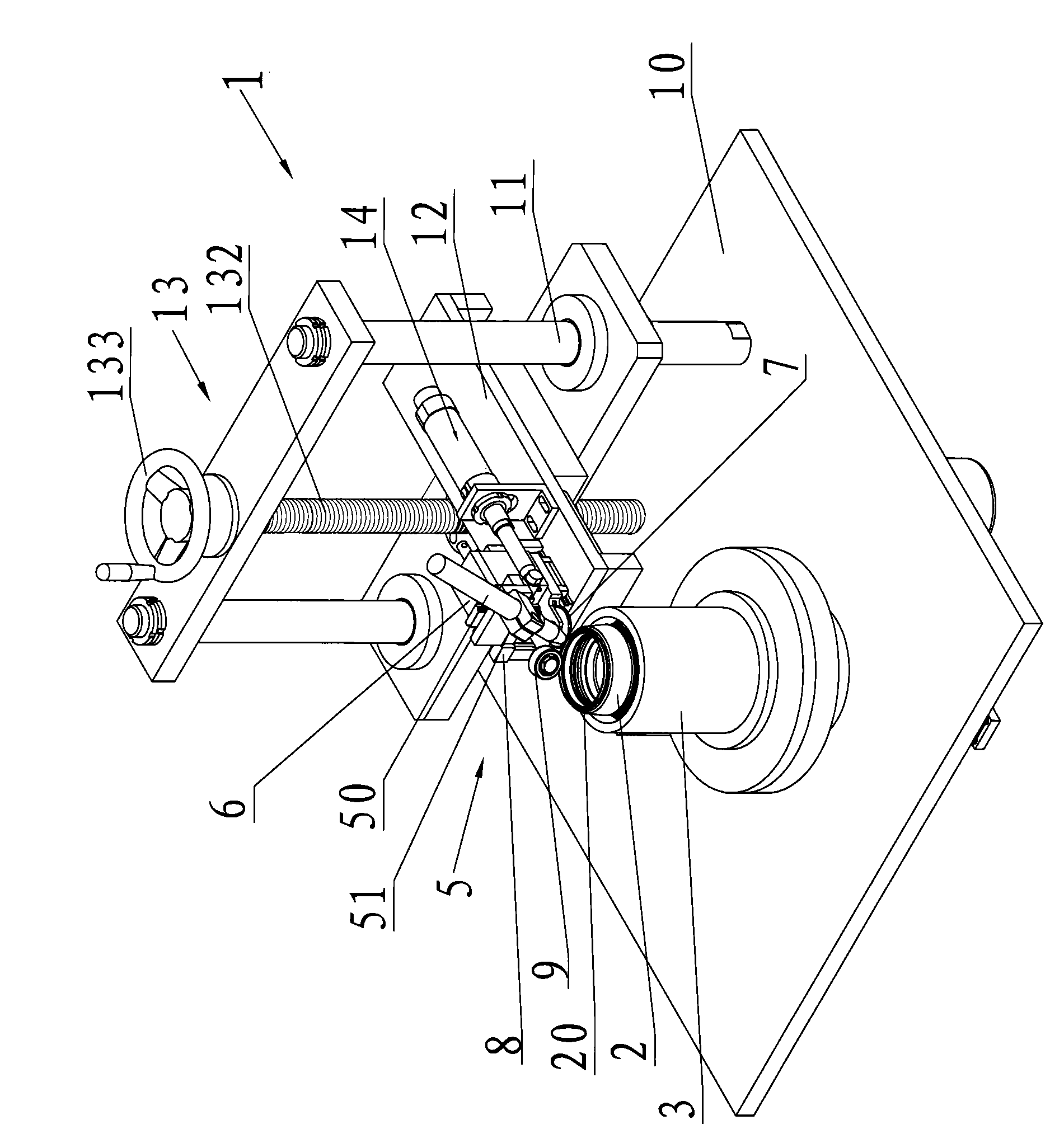

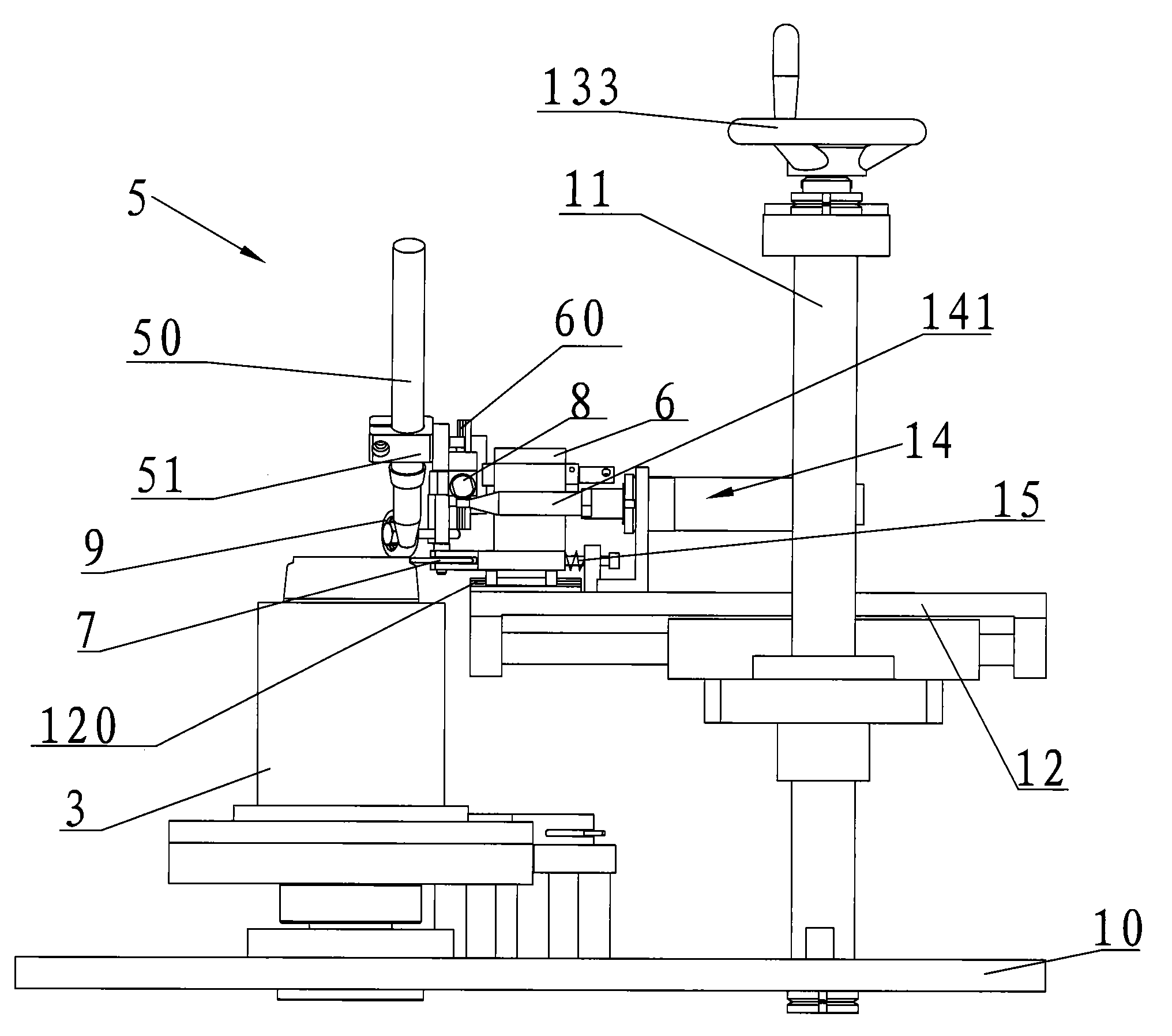

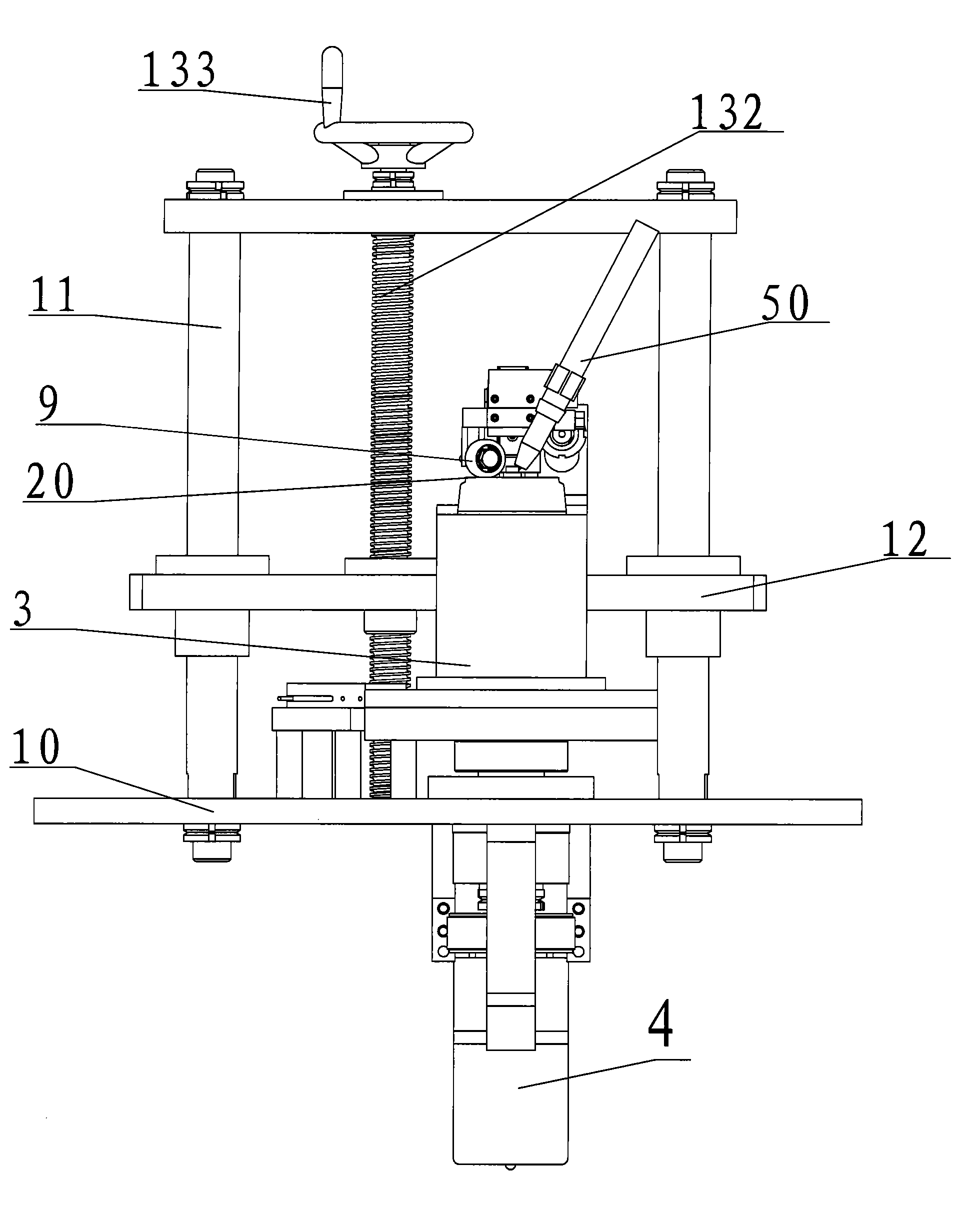

Cup-mouth copying rotary welding machine

The invention relates to a cup-mouth copying rotary welding machine, which comprises a stander, a rotatable rotation fixing mould which is arranged on the stander and is used for fixing a cup, and a welding device. The welding device comprises a welding torch, a fixing seat for fixing the welding torch, a horizontal sliding seat which is slidingly arranged on the stander in the radial direction of the cup, a horizontal pinch roller which is rotatablely arranged on the horizontal sliding seat, a vertical sliding seat which is slidingly arranged on the horizontal sliding seat in the vertical direction, and a vertical pinch roller which is rotationally connected with the vertical sliding seat through a pivot. The outer periphery of the vertical pinch roller is pressed tightly on the cup-mouth upper surface of the cup, and the outer periphery of the horizontal pinch roller is butted against the cup-mouth outer wall surface of the cup; and the vertical sliding seat is fixedly connected with the fixing seat. The rotary welding machine has the advantages of good welding quality, smooth welded cup-mouth surface and beautiful product.

Owner:庄添财

Hand-held tooth whitening instrument with applicator reservoir for whitening composition and methods of using same

ActiveUS9320580B2Enhanced photobleachingAvoid exposureDiagnosticsDental toolsTooth whiteningSquare Centimeter

A hand-held, ergonomic instrument with an LED that emits actinic light in visible wavelengths mounts a replaceable applicator cup with a reservoir for a tooth whitening composition held in place against a user's tooth during a whitening procedure. Actinic light is directed onto the tooth surface through a window in the cup and the tooth whitening composition substantially without attenuation, delivering at least about 100 milliwatts per square centimeter of light energy to the tooth surface. The cup includes a rigid body for mounting the cup to the instrument and an opaque flexible sleeve molded in place over the outside of the body to form a seal with the tooth surface and prevent exposure of soft mouth surfaces to the actinic radiation during a whitening procedure. A safety switch disables the LED when the applicator cup is not in contact with a tooth surface.

Owner:ORAL CARE PROD LLC A DELAWARE LLC +1

Flexible screw claw tool, visual guidance covering device and covering method

InactiveCN104229694AGuaranteed accuracyHigh degree of automationCapsClosure using capsEngineeringPneumatic motor

The invention discloses a flexible screw claw tool, a visual guidance covering device and a covering method, wherein the flexible screw claw tool comprises a flexible screw claw which comprises a rotating body, a spring seat, a spring, a compressing seat and a screw claw; when a barrel mouth surface is not parallel to the surface of the screw claw, the lower end of the rotating body is a spherical surface, the compressing seat is connected with the rotating body by the elastic force of the spring, so that the spring is compressed upwards by the compressing seat under the action of the pressure of a barrel cover and a barrel mouth, the compressing seat forms a certain angle together with the barrel surface so as to enable the barrel cover to be parallel to the barrel mouth, and the barrel cover is firmly pressed on the barrel mouth by the compressing seat under the action of the spring. Furthermore, when the rotating body is driven to rotate by a pneumatic motor, an angle is formed by the rotating body and the barrel cover all the time, so that the barrel cover is screwed into the barrel mouth, and the cover can be closed when the barrel mouth is not flat. After the flexible screw claw tool, the visual guidance covering device and the covering method are adopted, the cover is automatically covered under the condition that the barrel surface is not flat, so that the intelligence of a covering machine and the efficiency of covering work are improved, and the personal safety of workers can be guaranteed.

Owner:CHANGCHUN BEIFANG INSTR EQUIP

Chewing gum for treating bleeding gingiva

InactiveCN101468109ASubstrate is highly viscousPromote secretionDigestive systemPharmaceutical delivery mechanismArteriolar VasoconstrictionAdditive ingredient

The present invention relates to a chewing gum for treating gingival hemorhang, belonging to the traditional Chinese medicine chewing gum field. The chewing gum is mainly composed of purple beautyberry 400-600 weight part; lotus node 200-500 weight part; mint oil 150-350 weight part and eucalyptus oil 150-350 weight part. The groundmass of chewing gum has very strong viscosity. The chewing gum is capable of removing food debris on the tooth surface. The masticatory movement and mechanical stimulus can promote the secretion of saliva and wash mouth surface. The purple beautyberry and lotus node has function of local vasoconstriction and coagulation-time reduction. The chewing gum combines the stypticity of traditional Chinese medicine with the mouth cleaning function and health-car function of the chewing gum, therefore the gingival hemorhang is prevented and treated during chewing the chewing gum.

Owner:TIANJIN ZHONGBAO PHARMACY

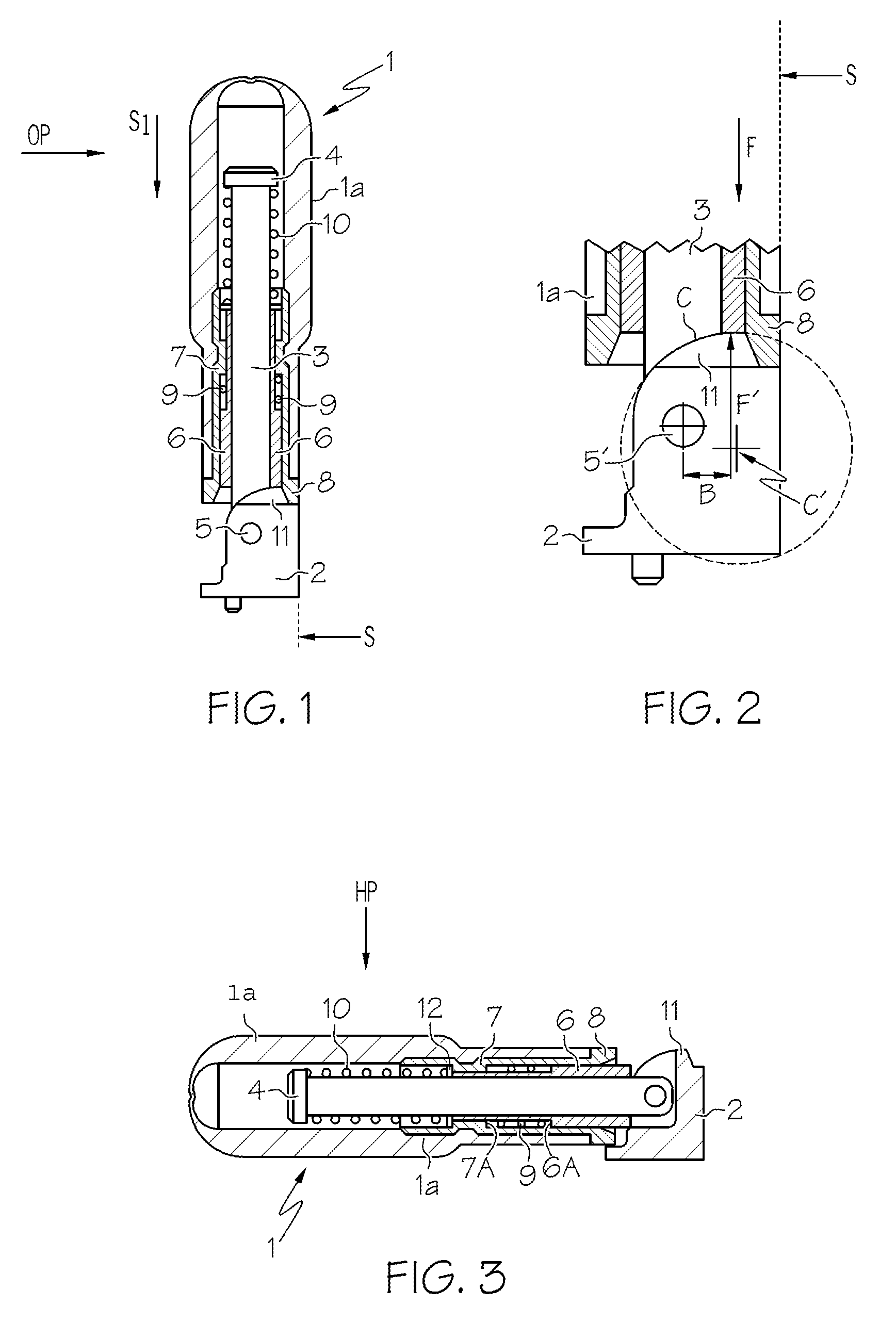

Safety fold-away handle

A safety grip for a handwheel which is movable between an operating position and a home position is comprised of an elongated and ergonomic body (1) and of a support (2), which is anchored to the body of a maneuvering member, such as a handwheel. The body (1) is comprised of an outer case (1a), a rod-like inner core (3) with a head (4), a bushing (6) slidably mounted on the core (3), a sleeve (7) in sliding engagement on the bushing (6), an axial thrust spring (9) arranged between two opposite shoulders (6a) and (7a) of the bushing (6) and of the sleeve (7), and a second thrust spring (10) arranged between the head (4) and the top of the bushing (6). The body (1) is connected to the support (2) at a pivot point (5). An end of the sleeve (7) engages a contact surface of the support (2) through a collar (8). The collar (8) has an inner conical mouth surface that engages a shaped rib (11) on the top of said support (2), where the shaped rib (11) has a frusto-conical outer surface.

Owner:ELESA

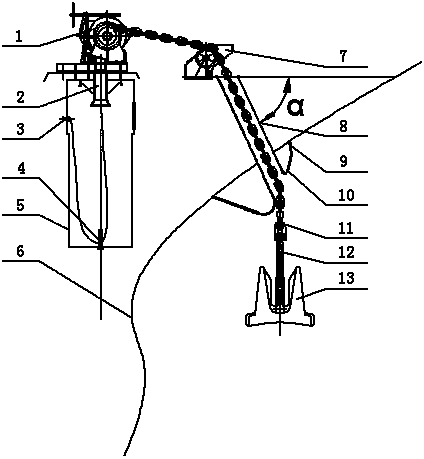

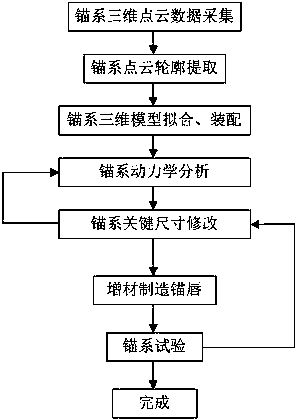

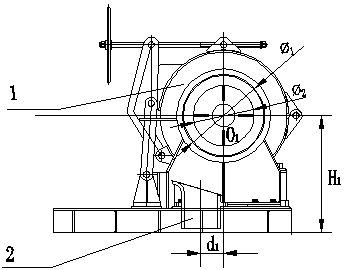

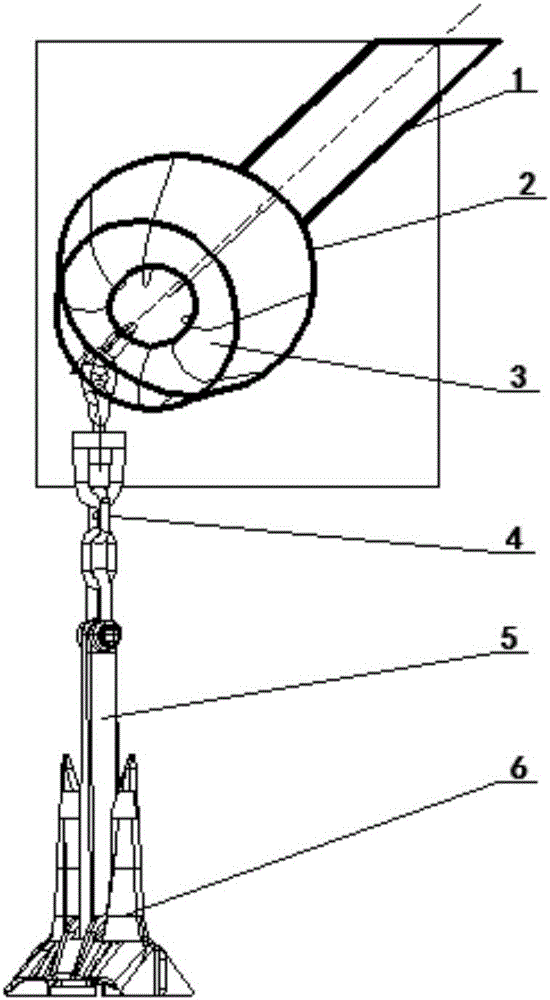

Method for ship anchoring system for failure diagnosing and additional material repairing

ActiveCN107480405AMake up for construction deficienciesImprove accuracyGeometric CADDesign optimisation/simulationManufacturing technologyPoint cloud

The invention relates to a method for ship anchoring system for failure diagnosing and additional material repairing. The method is mainly applied to a three-dimensional scanning reverse engineering technology and an additional material manufacturing technology; coordinates of a relative zero point of the ship anchoring system, a three-dimensional measurement anchoring machine characteristic size and the coordinates of a key point, a three-dimensional measurement guide chain roller characteristic size and the coordinates of a key point, coordinates of an upper opening point and a lower opening point of a three-dimensional measurement anchoring chain cylinder and the inner diameter and outer diameter of the anchoring cylinder are selected, three-dimensional block scanning is conducted on point cloud data on the anchor mouth surface, anchor mouth profile point cloud data is processed, a computer virtual simulation anchor experiment is conducted, an anchor mouth is subjected to layered additional material manufacturing through rotary 3D printing equipment, and finally the ship anchor system is assembled to complete the error diagnosis and repair of the ship anchor system. The ship anchoring system has the advantages that in the design period, the failure of the ship anchoring system is accurately diagnosed and repaired, the defect in the building aspect of a current ship anchoring system is made up for, and the ship anchoring system has very significant importance whether in on civil ship building error control or warship building error control.

Owner:JIANGSU UNIV OF SCI & TECH +1

Manufacturing method of kettle

ActiveCN113714744AGuaranteed stabilityReduce machining errorsDomestic vesselsHeat conservationPumping vacuum

The invention discloses a manufacturing method of a kettle. The manufacturing method comprises the following steps of: a, taking a pipe for water swelling; b, cutting to obtain a kettle mouth blank with a small convex part, then shaping, and cutting again to form a kettle mouth; c, cutting the kettle mouth blank to obtain a kettle mouth connecting body, and then turning a connecting step; d, taking an inner container, aligning the kettle mouth connecting body with the inner container, and then welding; e, taking a shell, aligning the shell with the connecting step, and then welding; f, taking a shell bottom, aligning the shell bottom with the shell, and then welding to obtain a kettle body semi-finished product; g, carrying out vacuumizing operation to form a vacuum layer; and h, taking a handle, and connecting the handle with the shell and the kettle mouth connecting body to complete the manufacturing of the kettle. Through the steps, when the kettle with the kettle mouth is manufactured, scratches such as drawing wires cannot be formed on the surface of the kettle mouth, the deformation of the inner container and the shell cannot be caused, and the welding position of the inner container and the shell cannot be damaged, so that the kettle mouth with a smooth surface can be obtained, and the heat preservation effect of the obtained kettle can be guaranteed.

Owner:ZHEJIANG FEIJIAN IND & TRADE

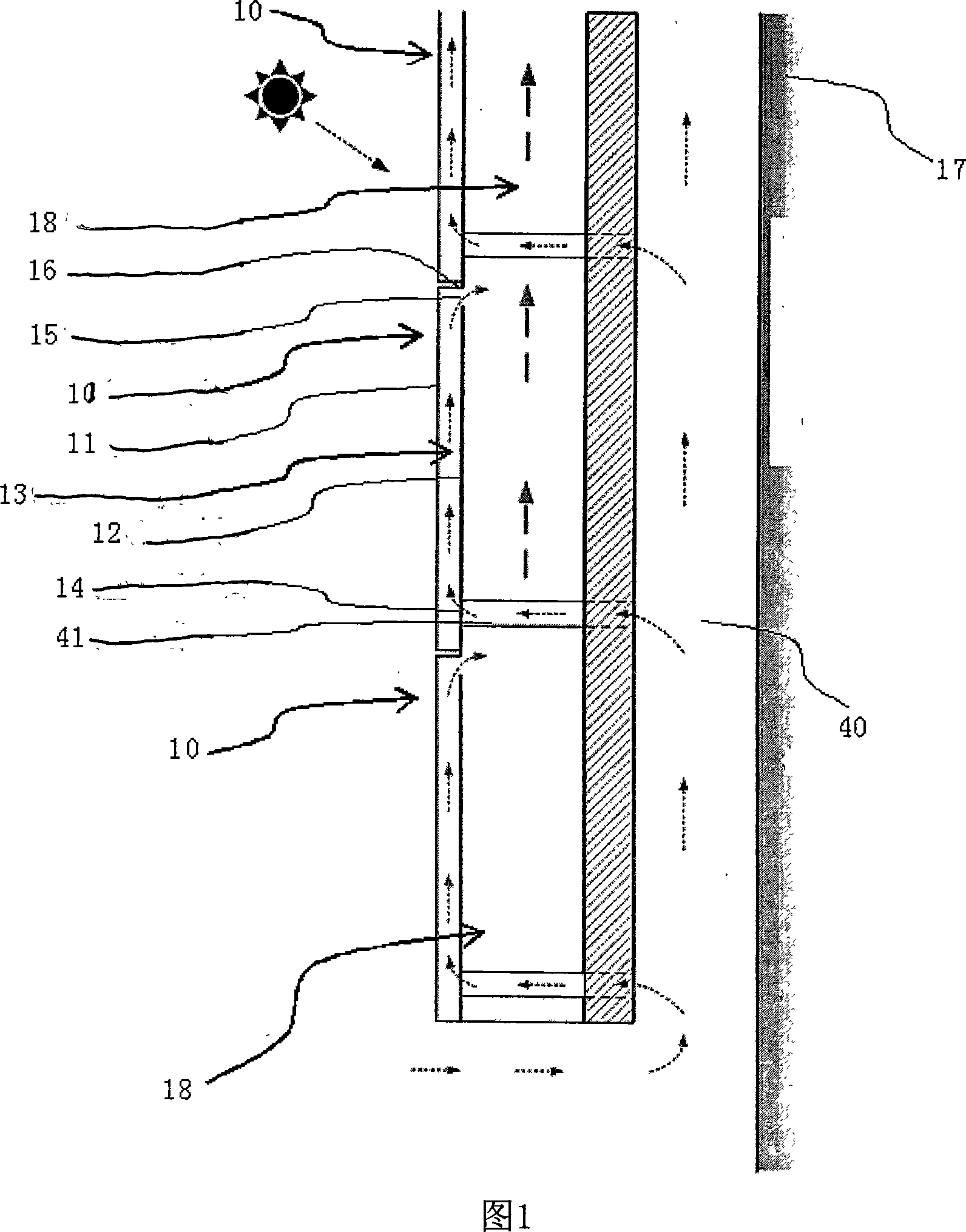

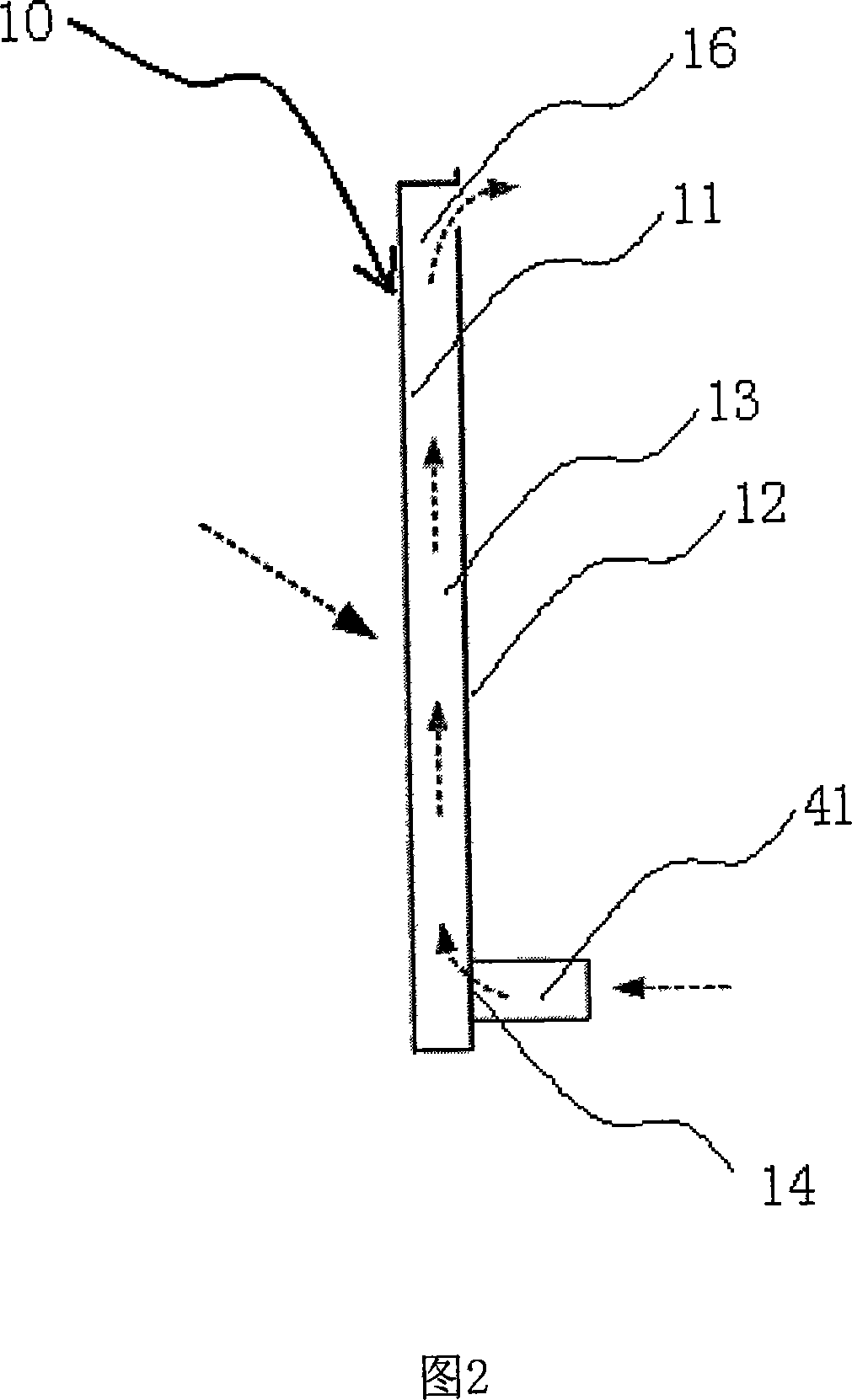

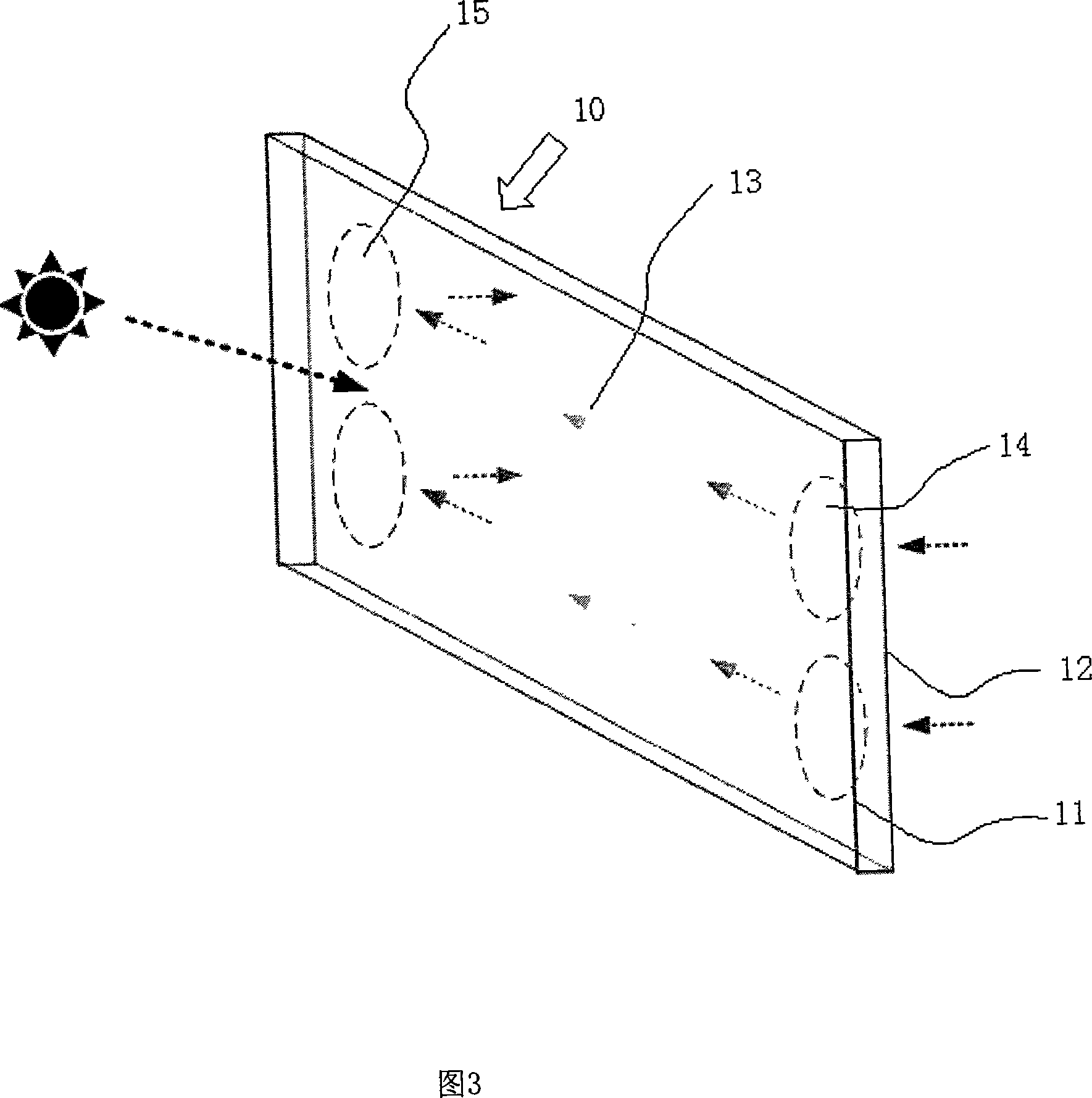

Air type solar energy heat-collecting ventilation system

InactiveCN101059279ASolve the problem of suction blockageReduce the influence of wind etc.Solar heat devicesSolar thermal energy generationCold seasonGreenhouse

The present invention discloses an air-type solar heat-collecting ventilation system. An extremely thin venting layer is formed between the solar radiation lighted side plate and the shaded side plate, and the thickness of the extremely thin venting layer is less than 15 mm, the length is ranged from several centre meters to several meters and the section inner flow rate is less than 5m / s, one end of the venting layer is air inlet and another end is air blowing mouth, the plate bodies of the end mouth surface formed by facing solar lighted side and shaded side are fully arranged and installed on the solar radiation lighted surface as air-type heat-collecting materials, the air blowing out mouth faces the collecting venting layer formed by the solar radiation lighted side and shaded side of plate bodies, at the same time the continuous space of plate bodies used for venting and connected with said air inlet is formed. The invention can provide adequate indoor ventilation to prevent chemical pollution, condensation and moldy and insects, on the other hand, the use of solar energy to release the cold venting air temperature in cold seasons, it plays an active role of preventing global greenhouse phenomenon and the problem of inadequate energy.

Owner:EOM

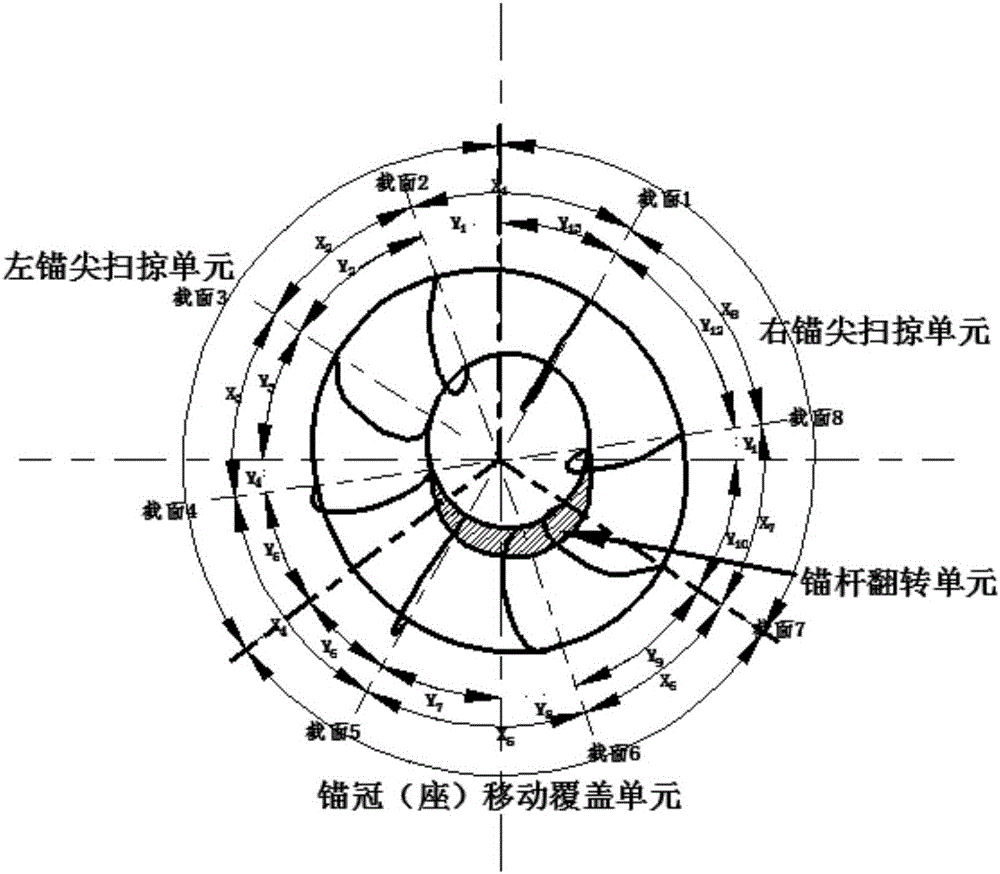

Side anchor mouth curved surface element generation design method

ActiveCN105956217AShorten the design cycleReduce manufacturing costGeometric CADSpecial data processing applicationsContact typeEngineering

The invention discloses a side anchor mouth curved surface element generation design method. The method comprises the steps of: according to the contact type of an anchor rod, an anchor crown and an anchor mouth surface, dividing an anchor mouth into four units: a left anchor tip sweep unit, a right anchor tip sweep unit, an anchor rod turnover unit and an anchor crown mobile cover unit; by reference to the geometric profile of the anchor rod and the anchor crown, making a generation processing formed cutter according to a proportion of 1:1; anchor pulling and releasing actions are carried out repeatedly, utilizing the formed cutter to perform rough blank generation processing to form an anchor mouth curved surface shape preliminarily; changing different anchor weighing states to generate different types of cutting paths so as to complete smoothing design of the anchor mouth curved surface; and representing the shape of each section of the anchor mouth by means of contour line anchor mouth section profile definition method. The method provided by the invention can realize anchor mouth section profile design and anchor pulling reliability test verification simultaneously, integrates design and manufacturing links, and realizes simultaneous design and manufacturing of anchor mouths meeting a variety of ship types.

Owner:JIANGSU UNIV OF SCI & TECH

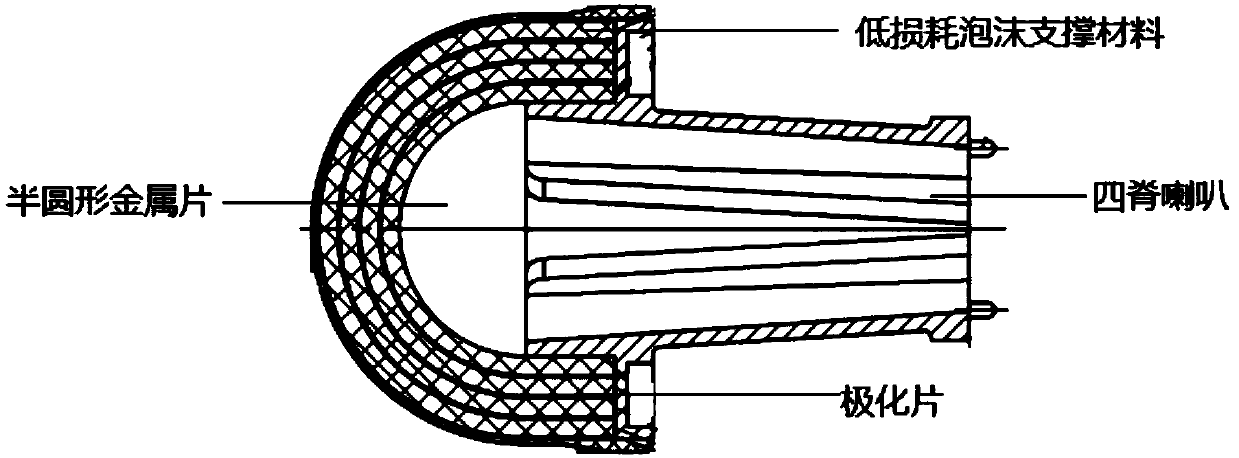

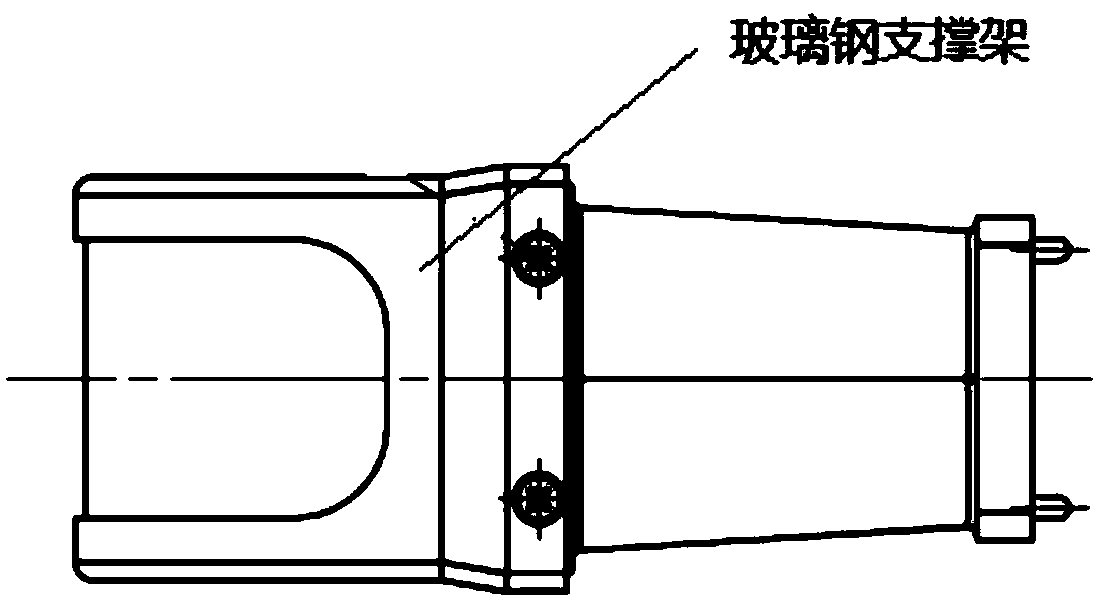

Implementation method and structure of wideband high-gain wide beam oblique polarization horn antenna

The invention relates to the technical fields of electromagnetic fields and microwaves, in particular to an implementation method of a wideband high-gain wide beam oblique polarization horn antenna. The method includes the following steps of: using an E-surface dual-ridged guided wave to excite a four-ridged horn to obtain a wide beam, and forming E-surface radial field distribution at the four-ridged horn mouth surface; arranging a semi-circular metal piece at the four-ridged horn mouth surface to perform shaping of the antenna wide beam; arranging an oblique polarizer at the antenna mouth surface to achieve polarization torsion. The method of E-surface dual-ridged guided wave exciting the four-ridged horn and the semi-circular metal piece performing shaping in a direction map is employedto achieve the miniaturization problem of the radial mode horn to allow the horn antenna radiation direction map to be close to the radial mode horn, reduce the mouth diameter for 40% and allow the bandwidth to be 3:1. The gain is not smaller than 3dB in the range from -45 degrees to 45 degrees on the azimuth plane. The present invention further discloses a structure of a wideband high-gain widebeam oblique polarization horn antenna.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

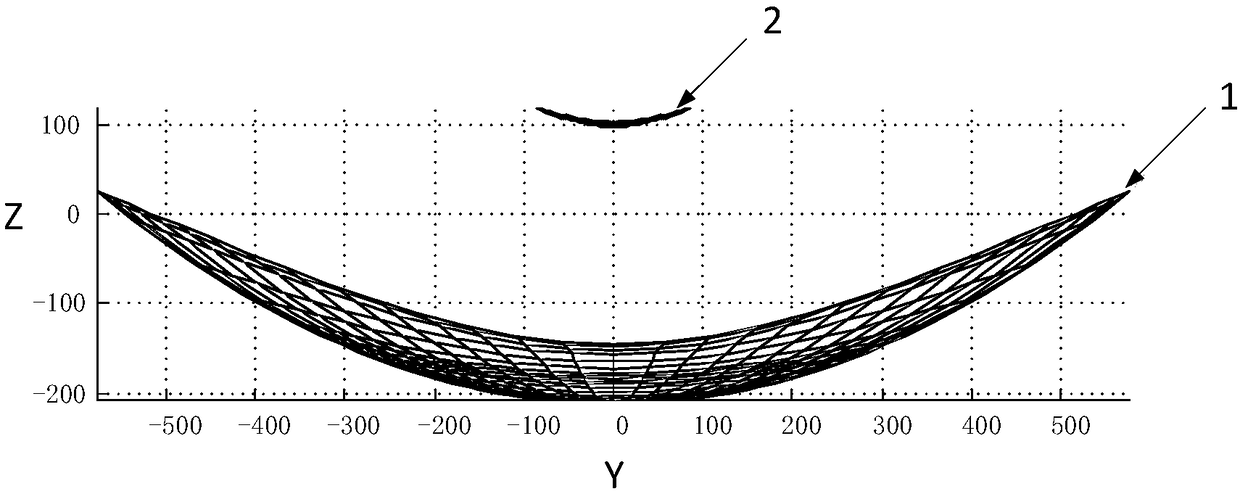

A design method of an elliptical beam Cassegrain antenna

ActiveCN109408986AAchieving low sidelobesRealize widebandSpecial data processing applicationsAntenna designField function

The invention discloses a design method of an elliptical beam Cassegrain antenna, and belongs to the technical field of satellite communication antenna design. The method comprises the steps of parameterization of a mouth surface field function and a transition function; forming population individuals by using the parameters of the mouth-surface field function and the transition function, and performing population iteration based on a DEGL algorithm; and shaping the antenna by using the optimal individual in the last generation of population to obtain the optimal design of the elliptical beamCassegrain antenna. The method provided by the invention can quickly optimize and design the high-efficiency, low-sidelobe, low-cross-polarization and large-axial-ratio elliptical beam antenna, and isan important improvement on the existing antenna design method.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

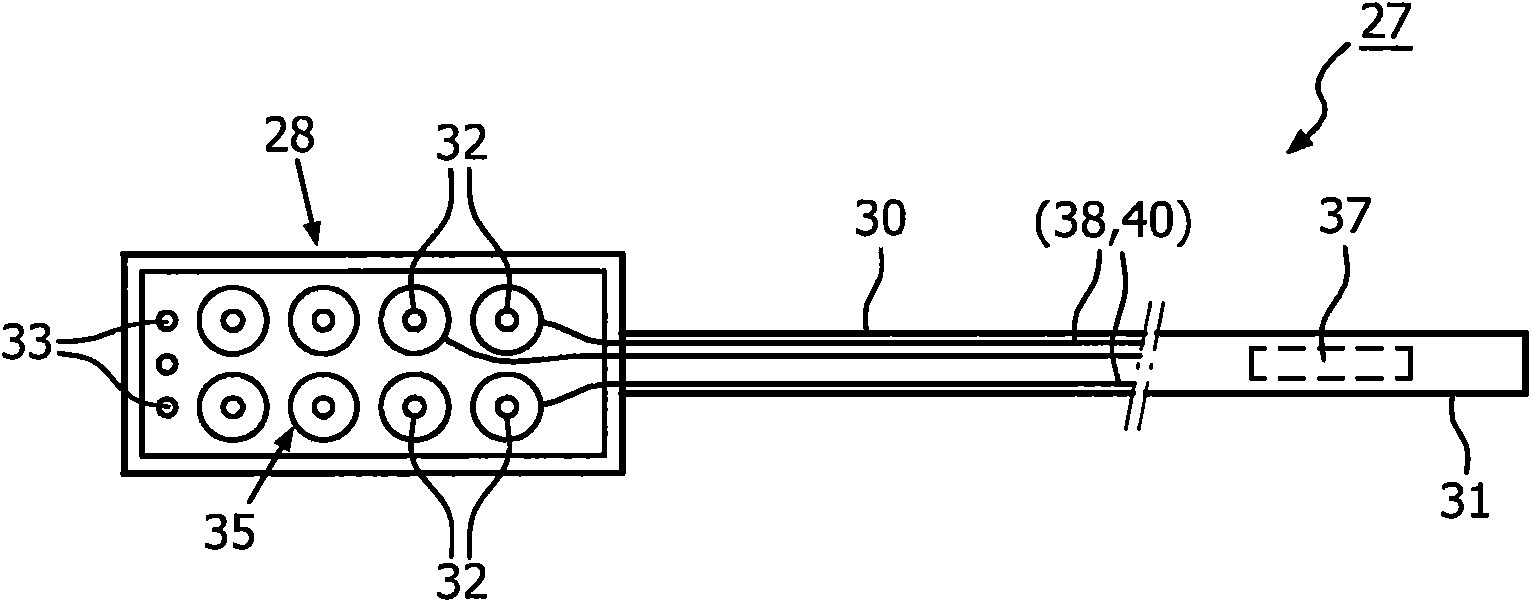

System for protection of soft tissues against a teeth whitening substance

The appliance includes a brushhead having conductive fiber bristles by which a potential is applied to electrochemically activate a teeth whitening substance, such as peroxide, in the vicinity of the teeth. An impedance appliance system (62) or an optical appliance system (27) provides information concerning whether the conductive fiber bristles are adjacent a tooth surface or gum region. The impedance system uses an electrical signal through the fiber to determine the impedance of a circuit which includes the tooth or gum surface, the impedance being different, depending on whether a tooth or gum surface is in the circuit. The optical system generates a light beam which is directed to the mouth surface through a conductive fiber, the color of the returning light indicating whether the surface is a tooth or gum region. If a tooth is determined, the teeth whitening substance is activated at that bristle, while if gum tissue is determined, the teeth whitening substance is not activated at that bristle.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Antenna unit, dual-polarized antenna and antenna device

PendingCN110085983AImproving impedanceImprove featuresAntenna supports/mountingsRadiating elements structural formsBroadbandPhysics

The invention discloses an antenna unit, which comprises a first radiation sheet, a second radiation sheet and a grounding ring, wherein the first radiation sheet and the second radiation sheet are oppositely arranged and form an exponential shaped slot therebetween; the grounding ring is connected to the outer sides of the edges at the starting ends of the first radiation sheet and the second radiation sheet so as to enable the first radiation sheet and the second radiation sheet to be in short-circuit connection. The invention further discloses a dual-polarized antenna and an antenna device.According to the implementation of the invention, the reflection at the horn mouth surface can be reduced, the impedance and band characteristics of the antenna can be significantly improved, and broadband requirements of more than 15 times of frequency interval can be met. In addition, the antenna unit is simple in structure and wide in application range.

Owner:FRAGRANT MOUNTAIN MICROWAVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com