Air type solar energy heat-collecting ventilation system

A solar heat collection and ventilation system technology, applied in the field of air-type solar heat collection and ventilation systems, can solve the problems of fan power and noise, to prevent chemical pollution, improve heat collection/heat exchange efficiency, and prevent the earth The effect of the greenhouse phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

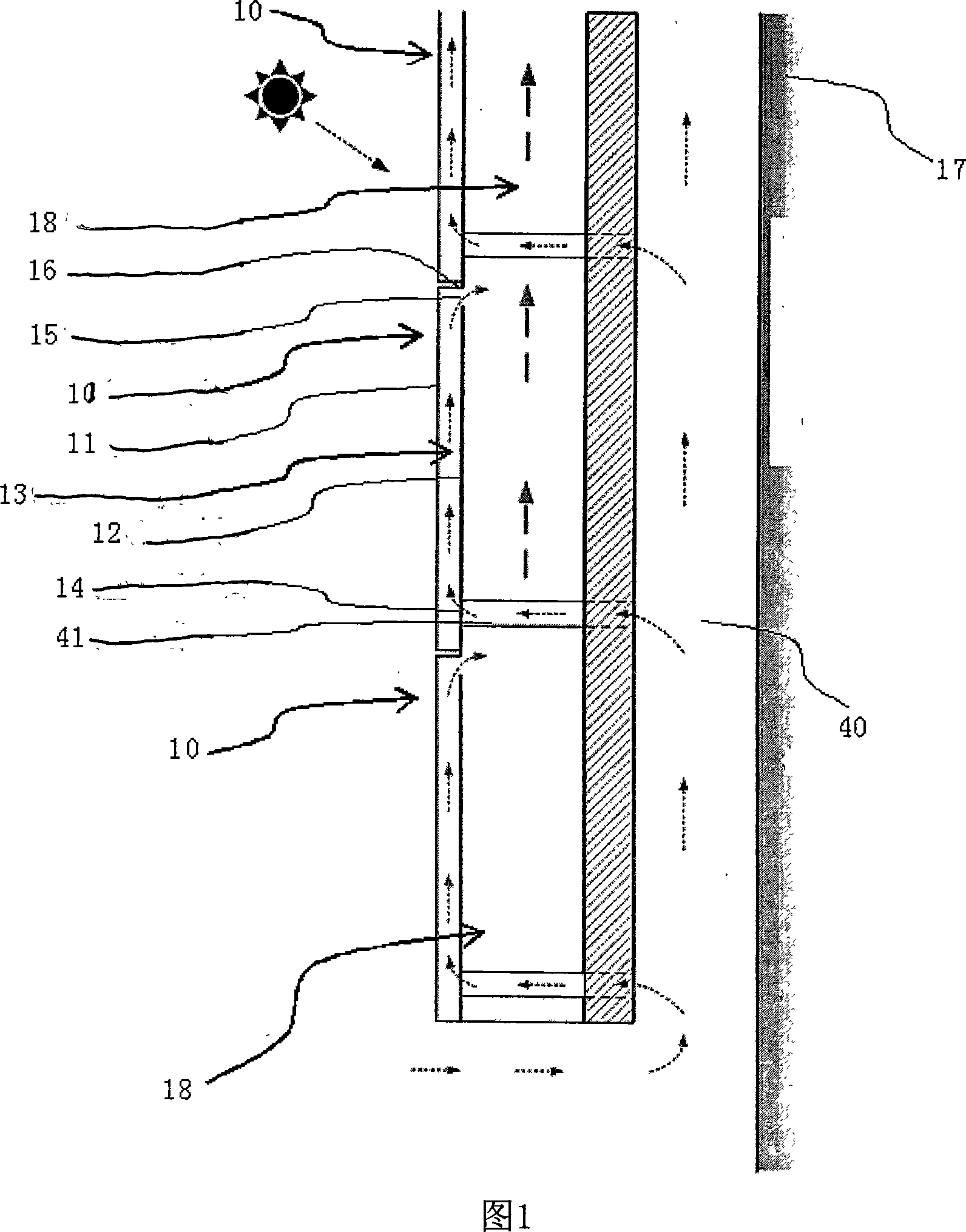

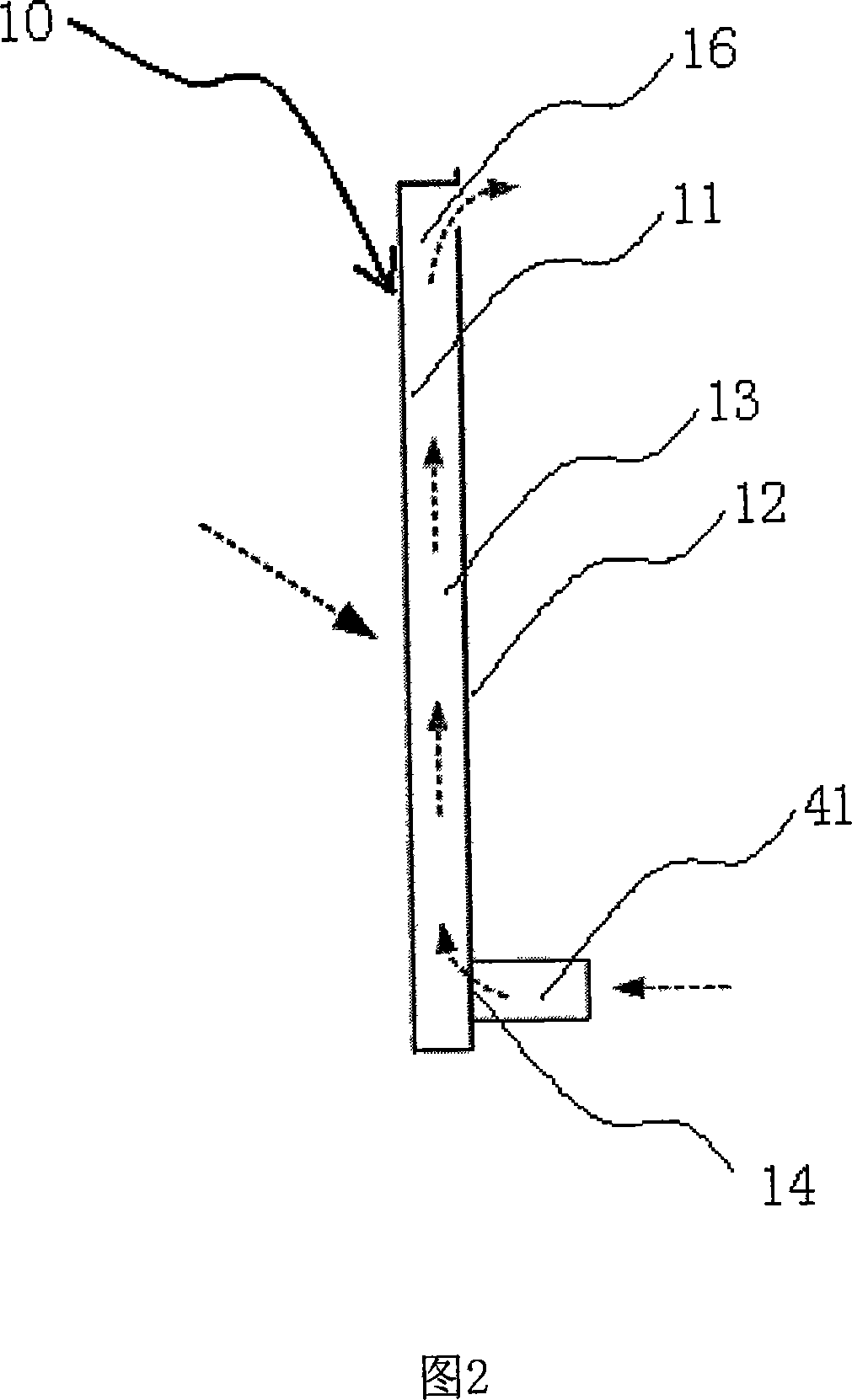

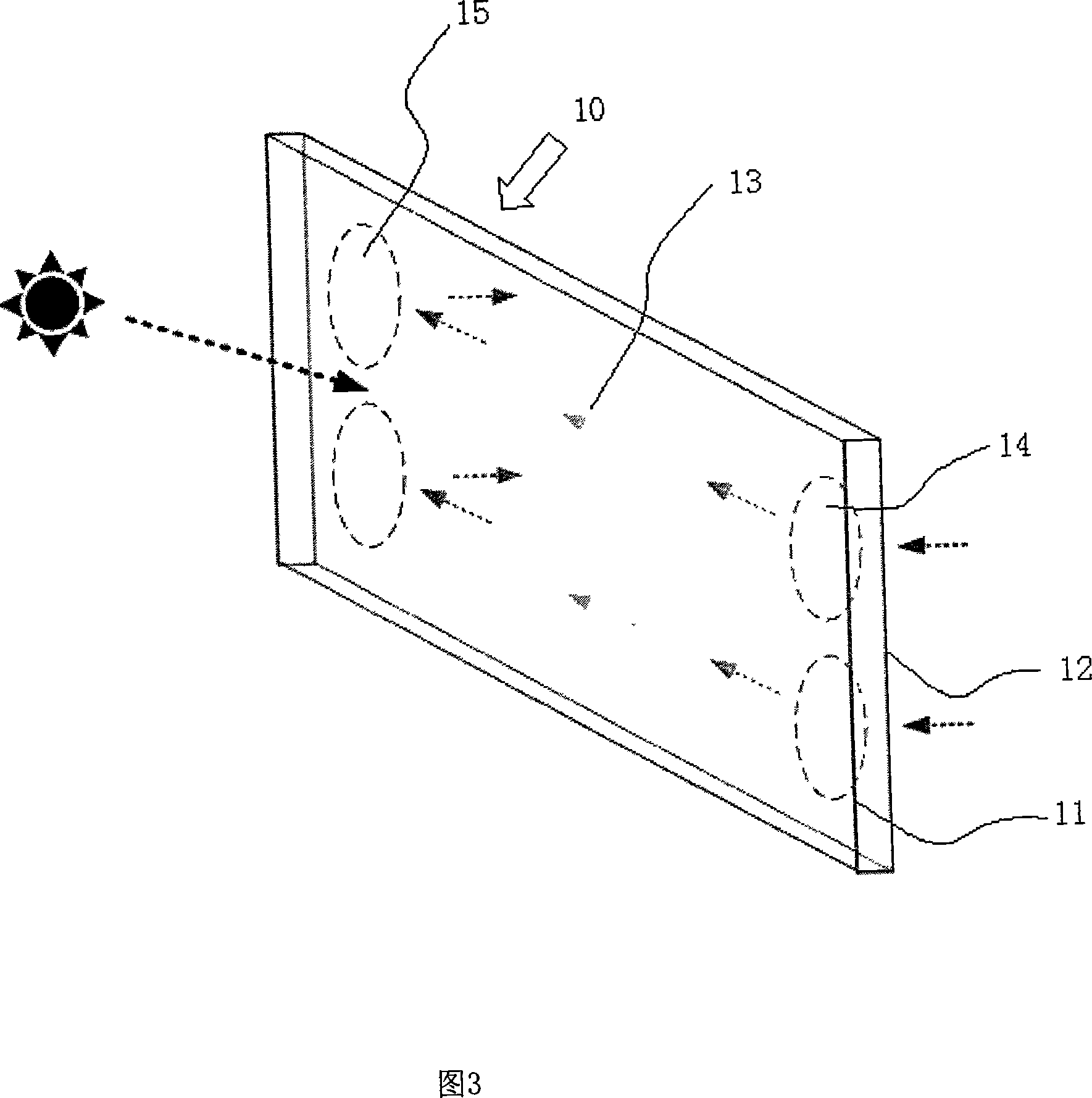

[0069] Fig. 1 is a longitudinal sectional view of a first embodiment of an air-type solar heat collection and ventilation system. 10 among the figure, also shown in Fig. 2, 3, is the very thin air-permeable layer 13 of about 15mm (for example 8mm) below the distance between solar radiation light-receiving plate 11 and backlight plate material heat-absorbing plate 12, installed in parallel Flat plate-shaped body. The plate-shaped body 10 may also have a curved shape. Moreover, the light-receiving plate 11 as shown in FIG. 7 may also have a corrugated plate with concavities and convexities, so as to increase the light-receiving area.

[0070] The ultra-thin ventilation layer 13, due to the thinning of the ventilation layer, improves the contact efficiency between the light-receiving plate and the air flowing through the ventilation layer, and improves the heat exchange performance. Its thickness is about 15mm or less, and the preferred thickness is about 8mm. (However, if the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com