Patents

Literature

886 results about "Drill cuttings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drill cuttings are the broken bits of solid material removed from a borehole drilled by rotary, percussion, or auger methods and brought to the surface in the drilling mud. Boreholes drilled in this way include oil or gas wells, water wells, and holes drilled for geotechnical investigations or mineral exploration.

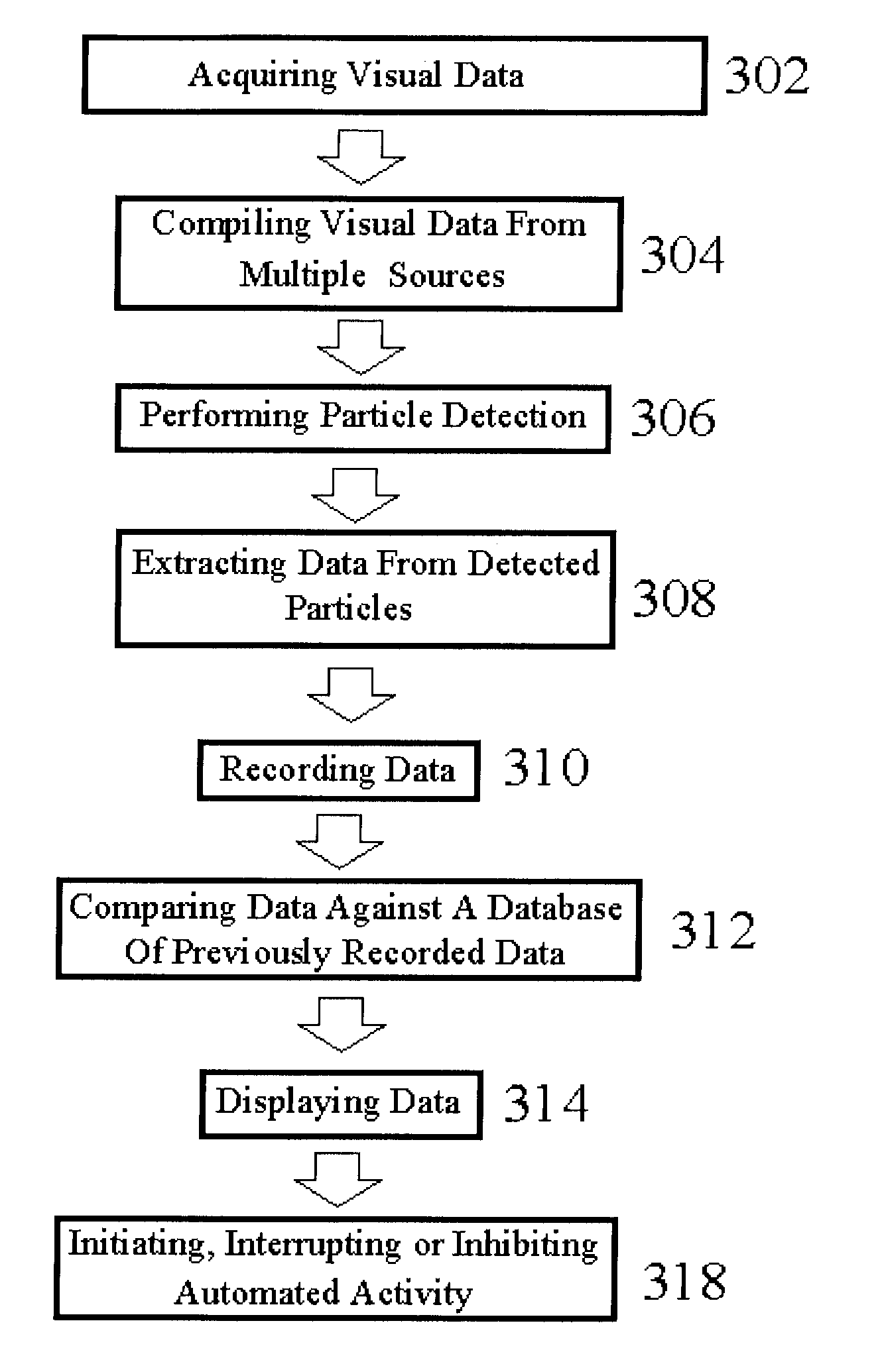

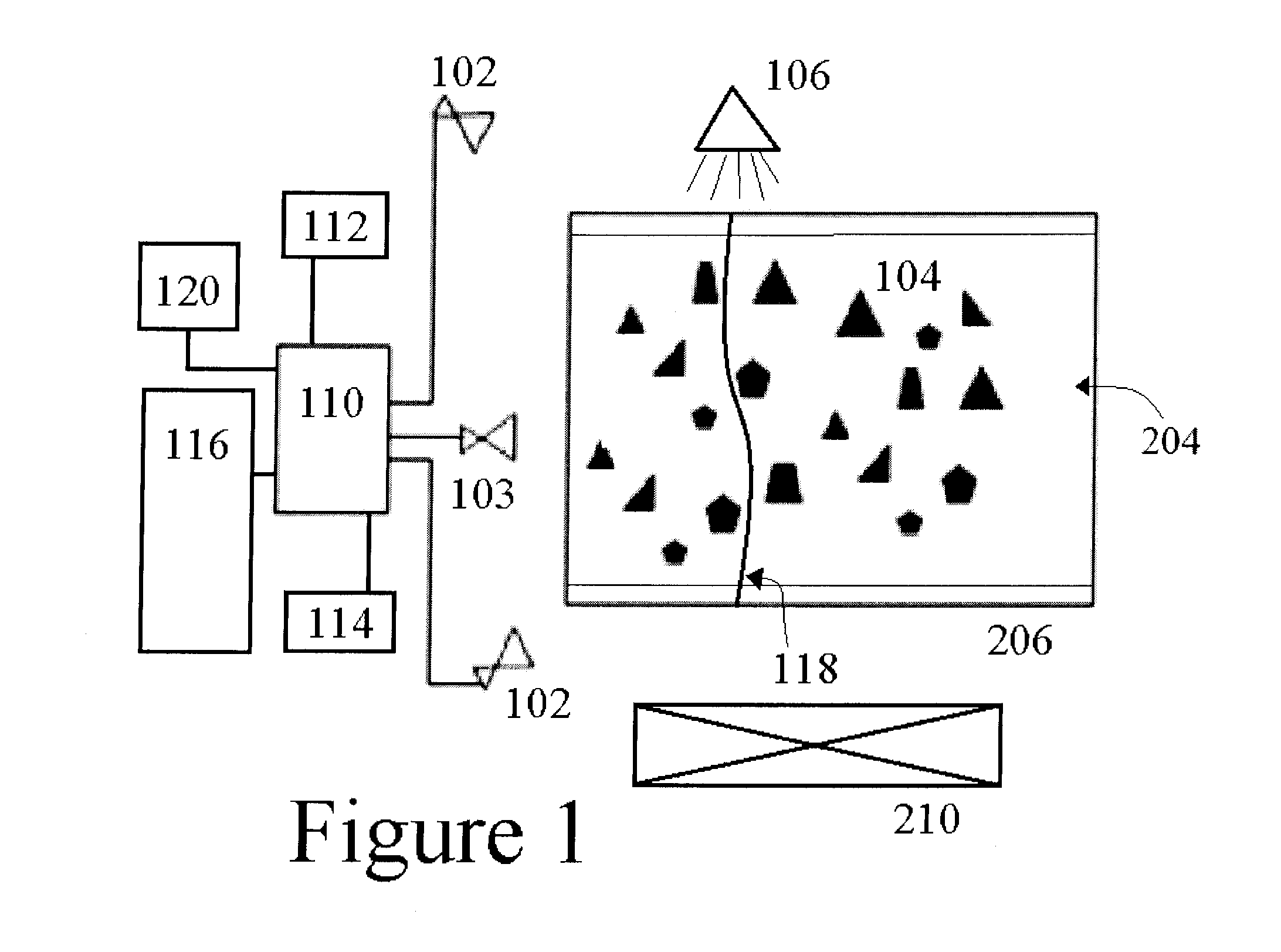

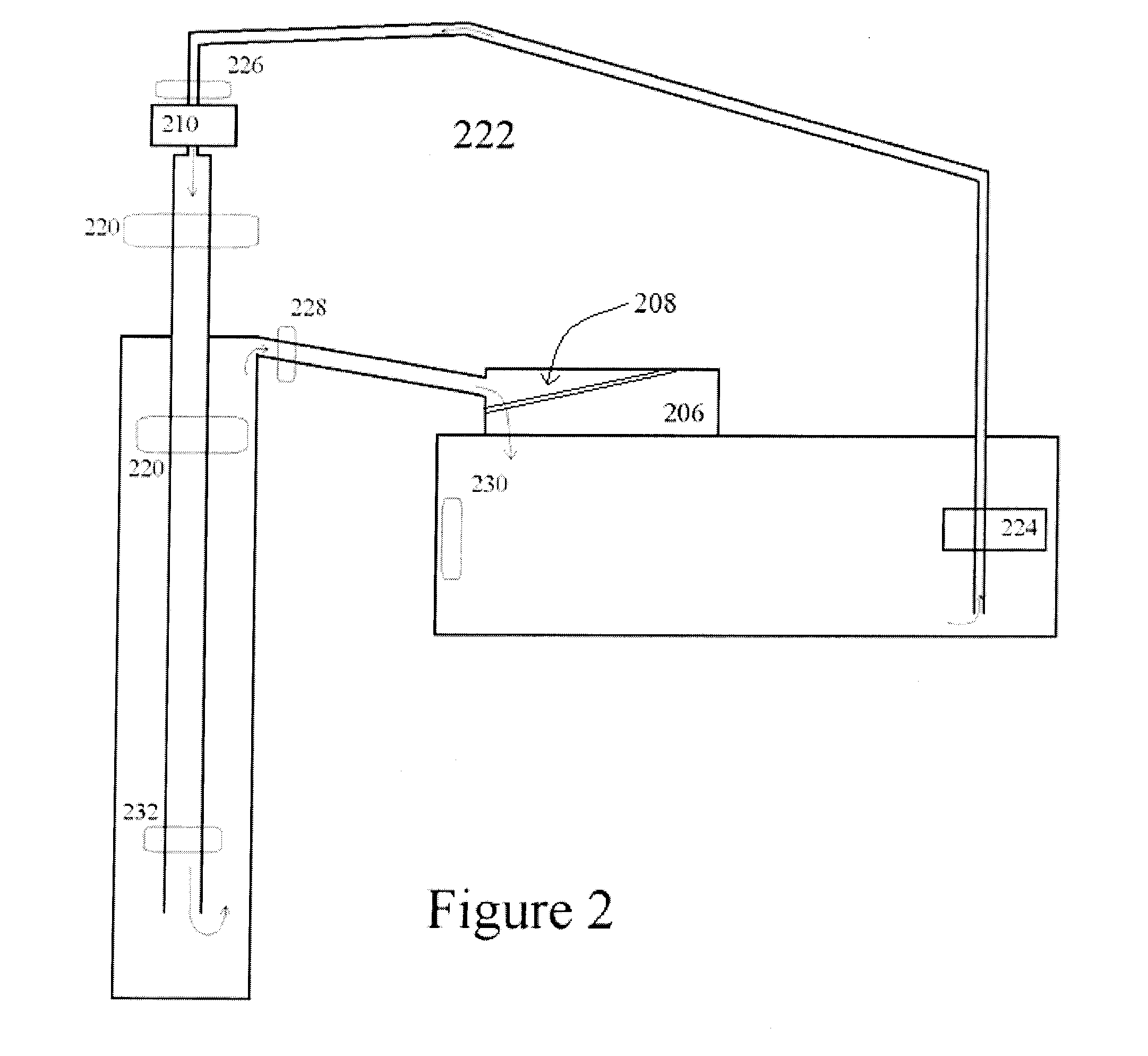

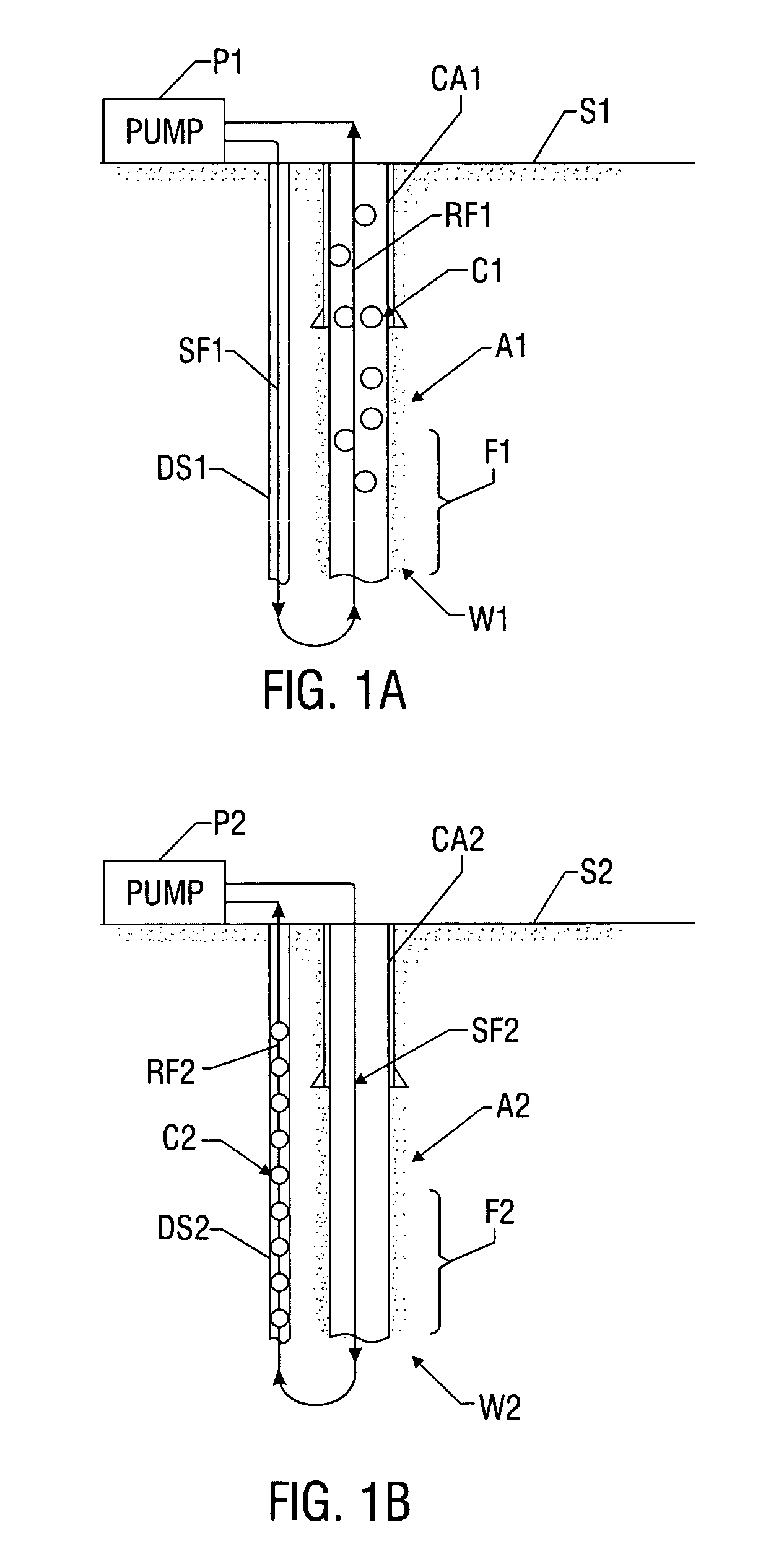

System and method for measuring characteristics of cuttings and fluid front location during drilling operations with computer vision

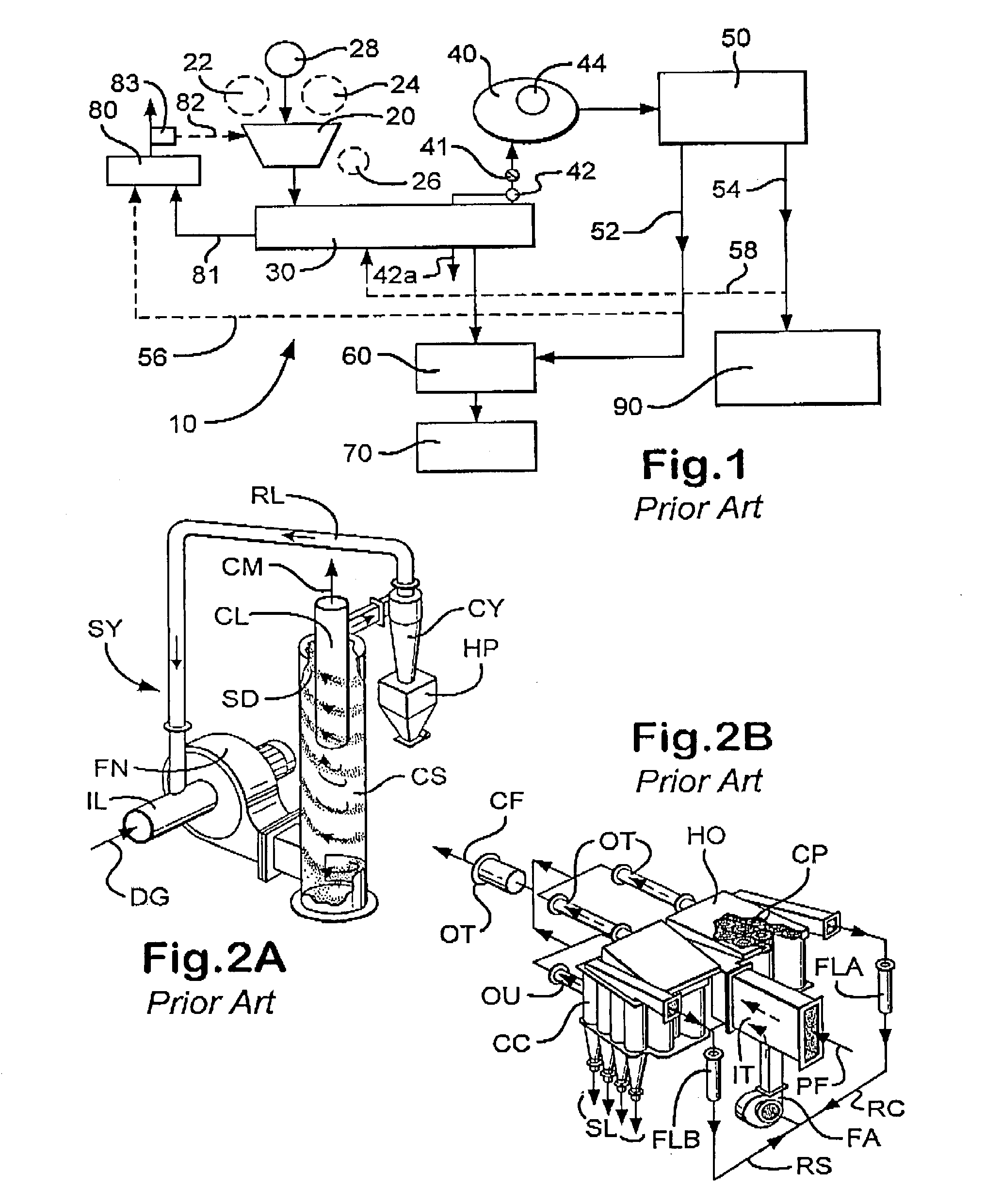

ActiveUS20160130928A1Improve performanceLow costSampled-variable control systemsComputer controlWell drillingFeature data

The invention relates to a system and method of for measuring the characteristics and volume of drill cuttings. The system comprises at least one camera operably connected to a processor for recording characteristics of drill cutting particles wherein said processor is configured to perform particle detection, extract features of said particles, or both. The processor is typically configured to initiate, interrupt or inhibit an automated activity based on the particle characteristics. The method comprises acquiring visual data from at least one camera, performing particle detection using said data, extracting feature data of any detected particles, alerting an operator and / or initiating, interrupting, or inhibiting automated activity.

Owner:HELMERICH & PAYNE TECH LLC

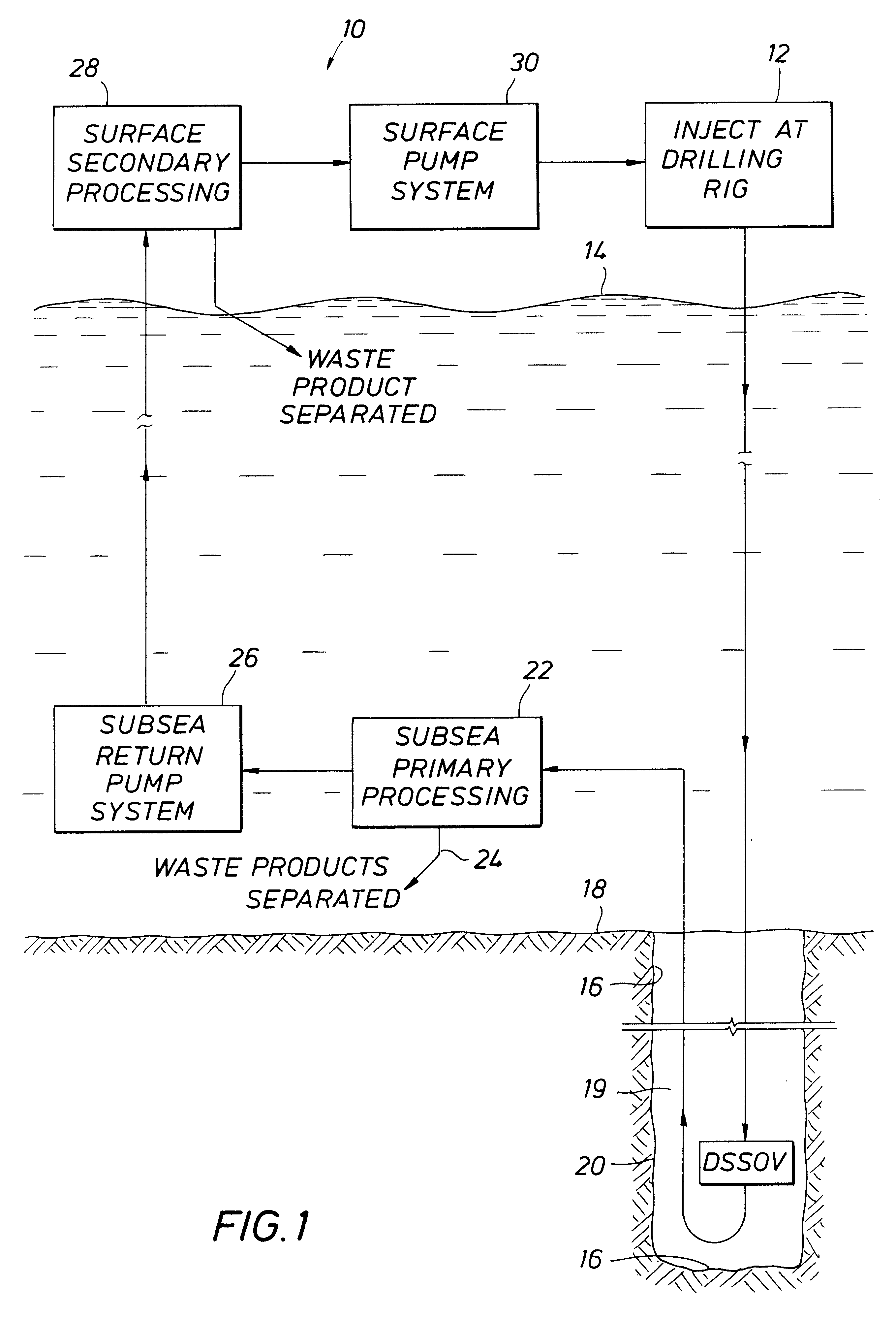

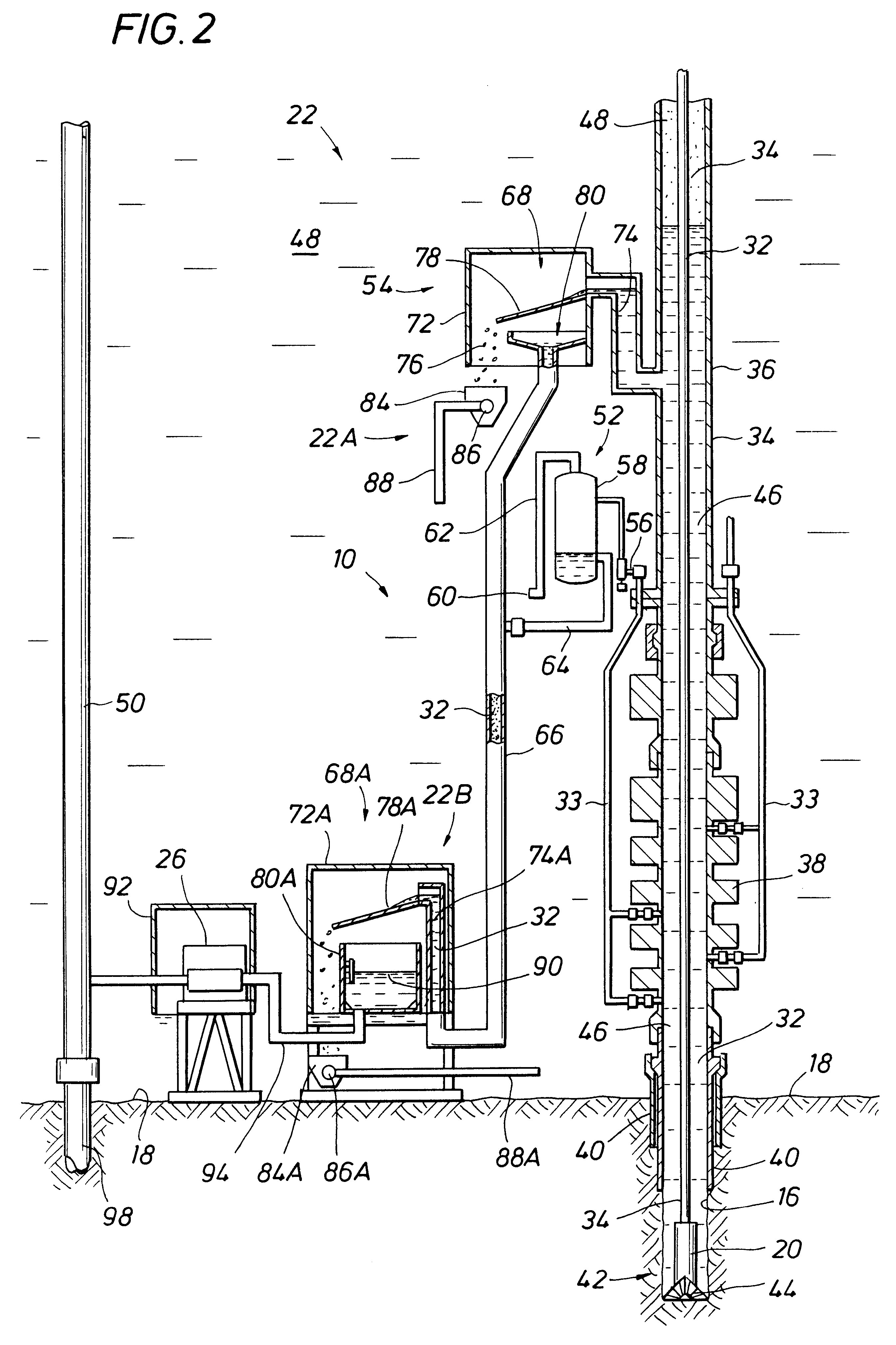

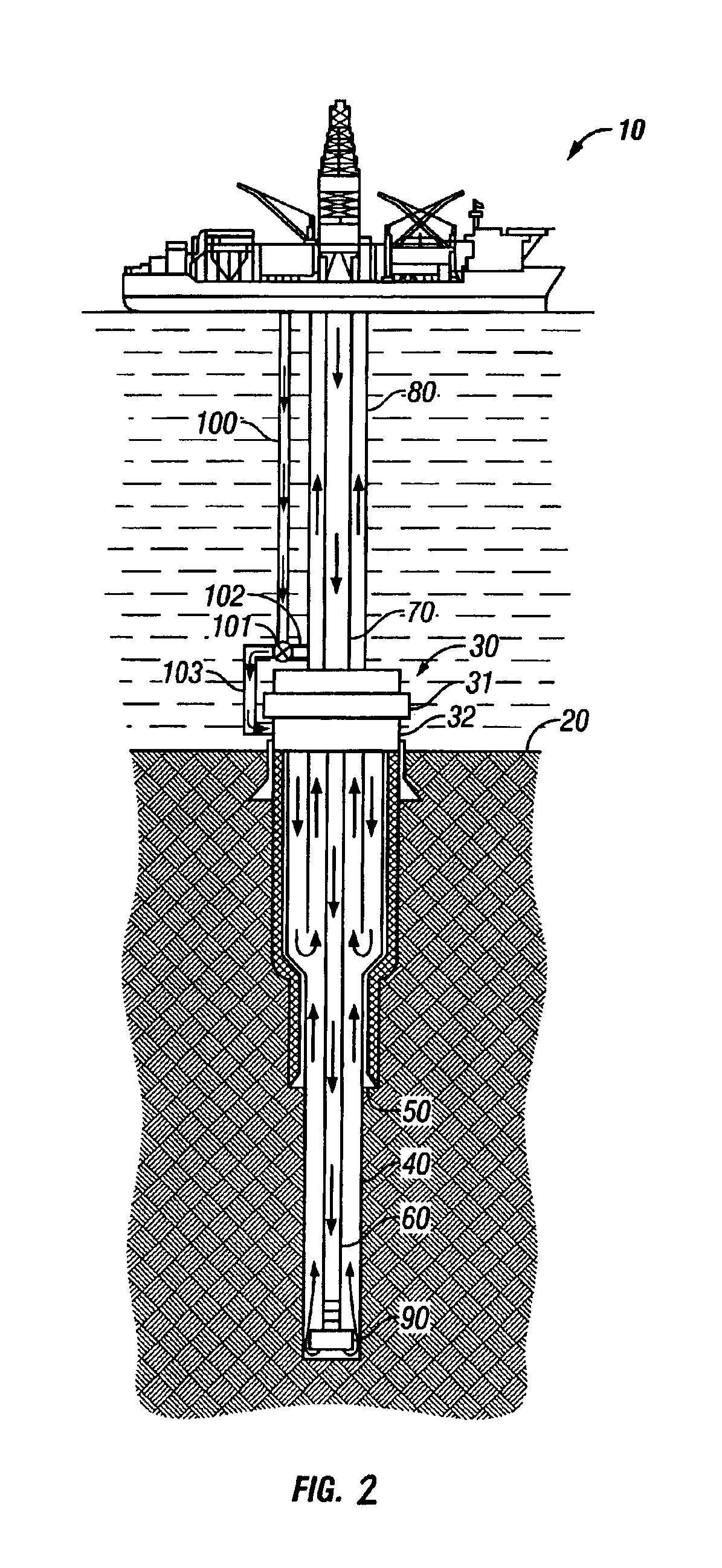

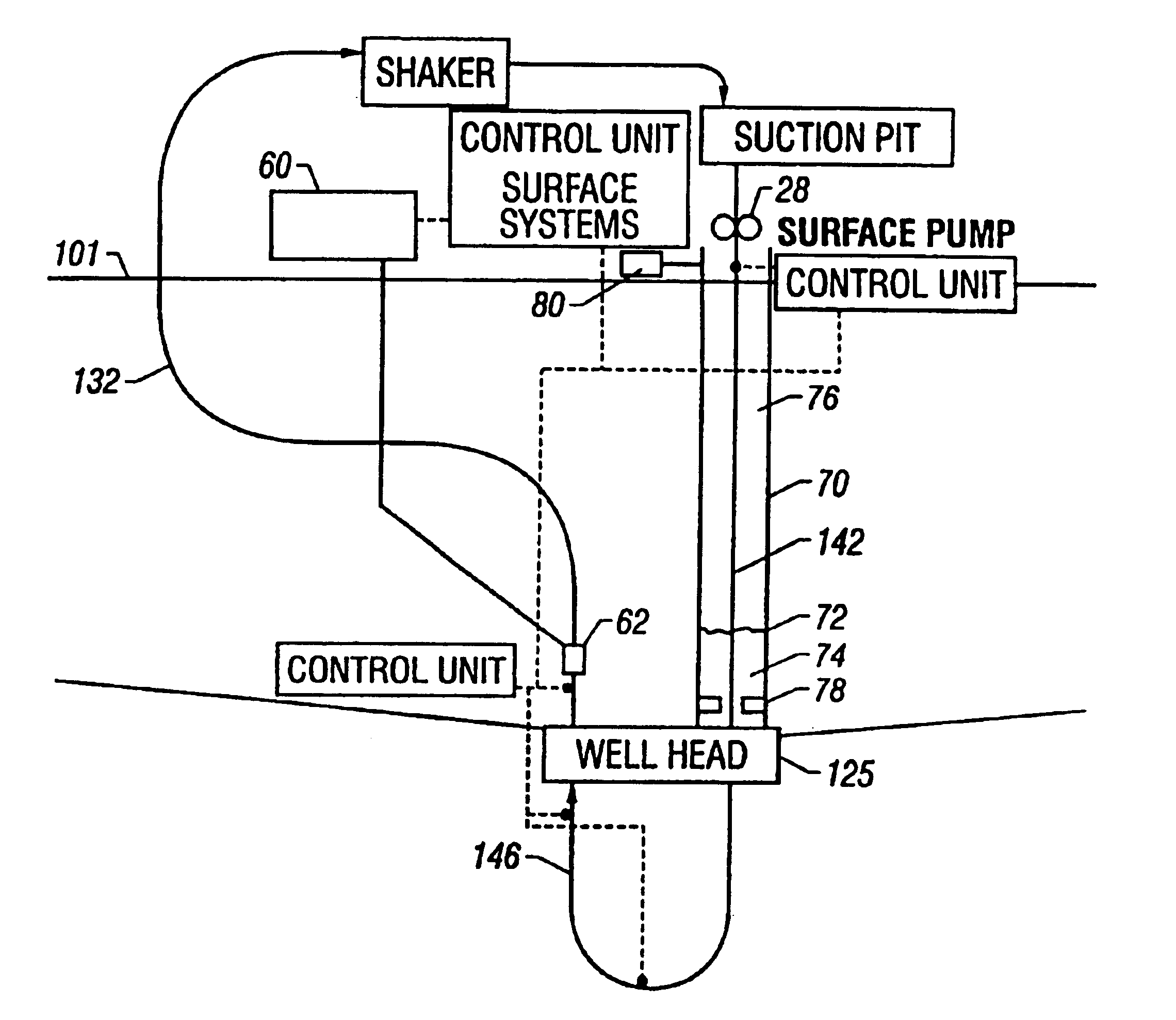

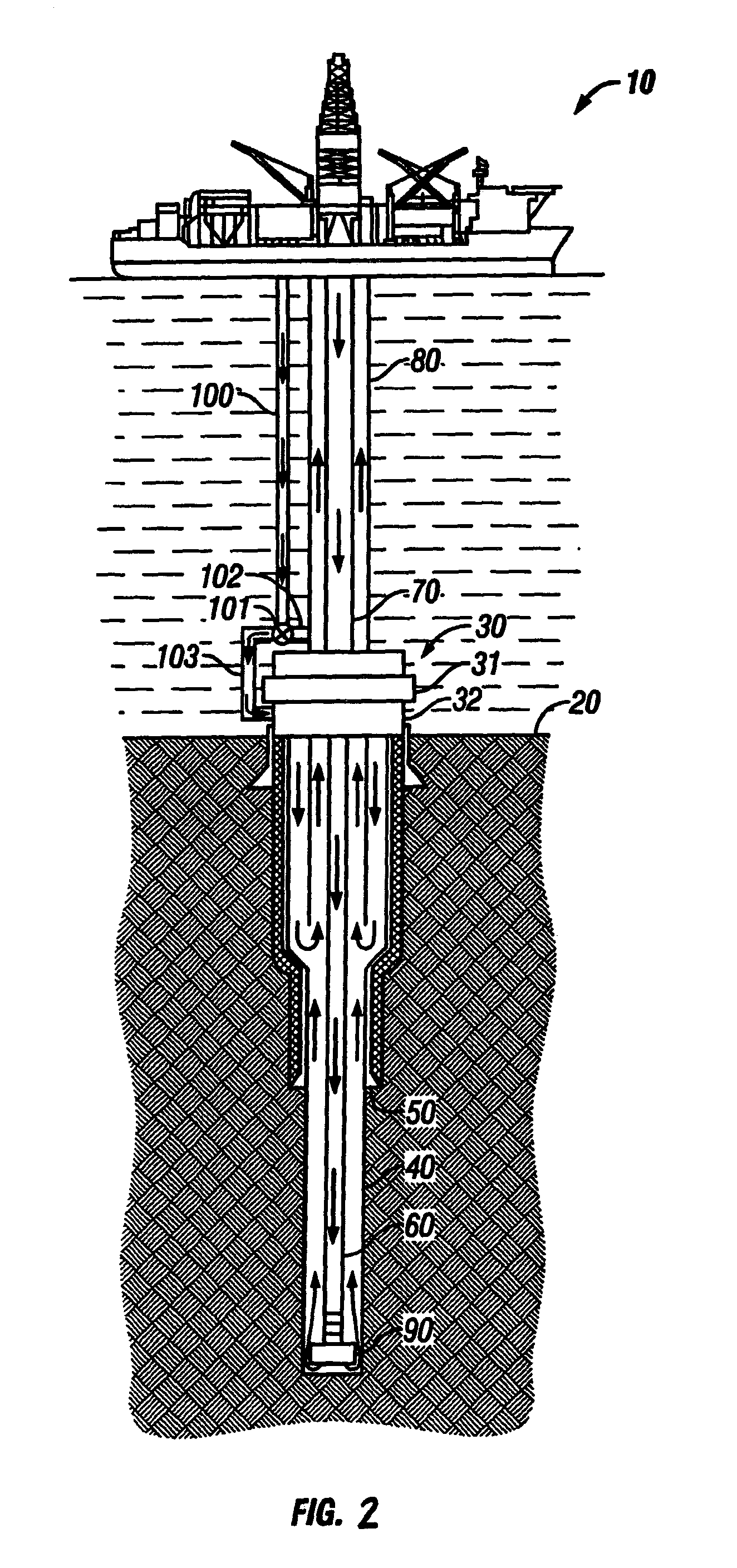

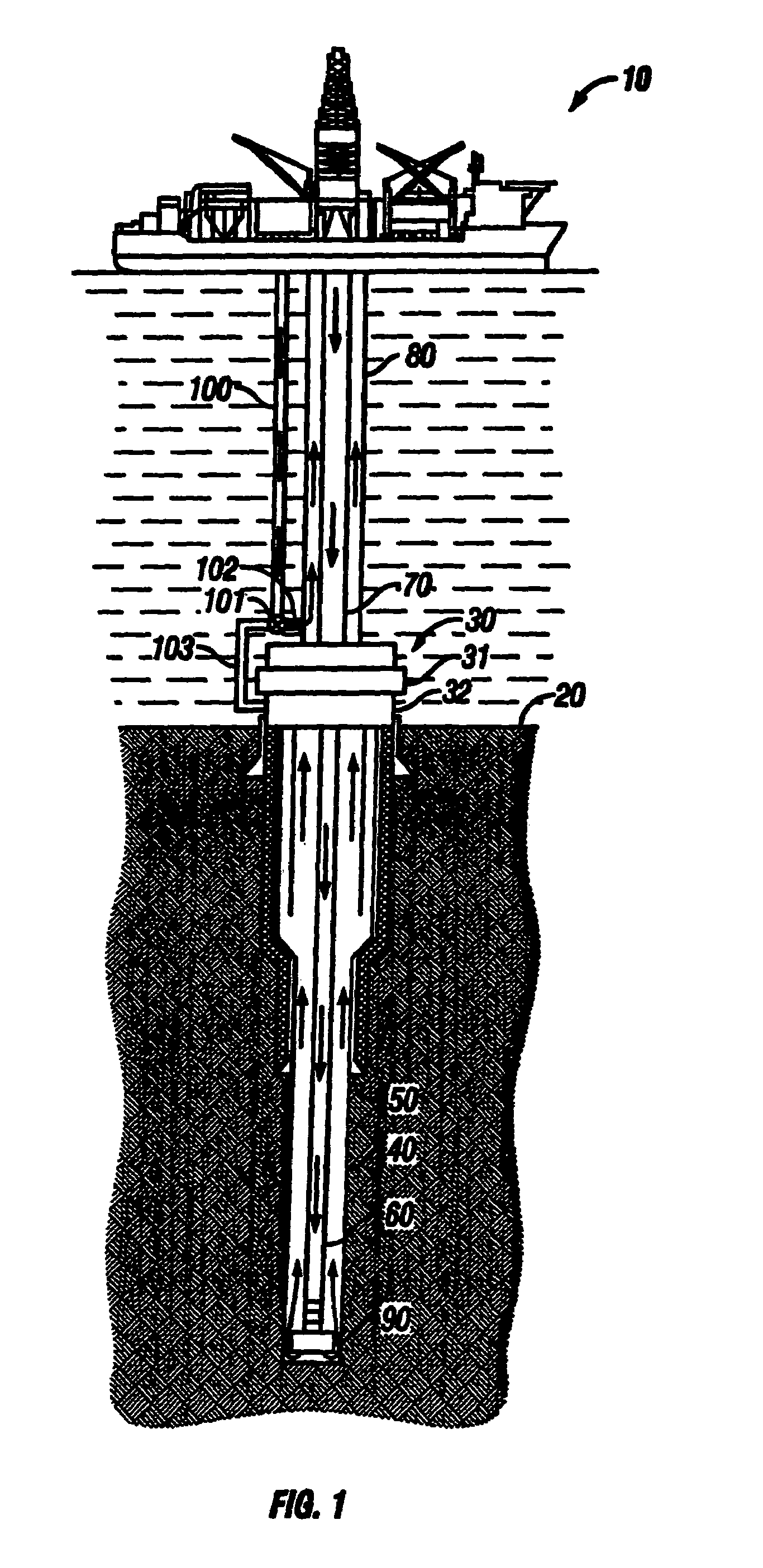

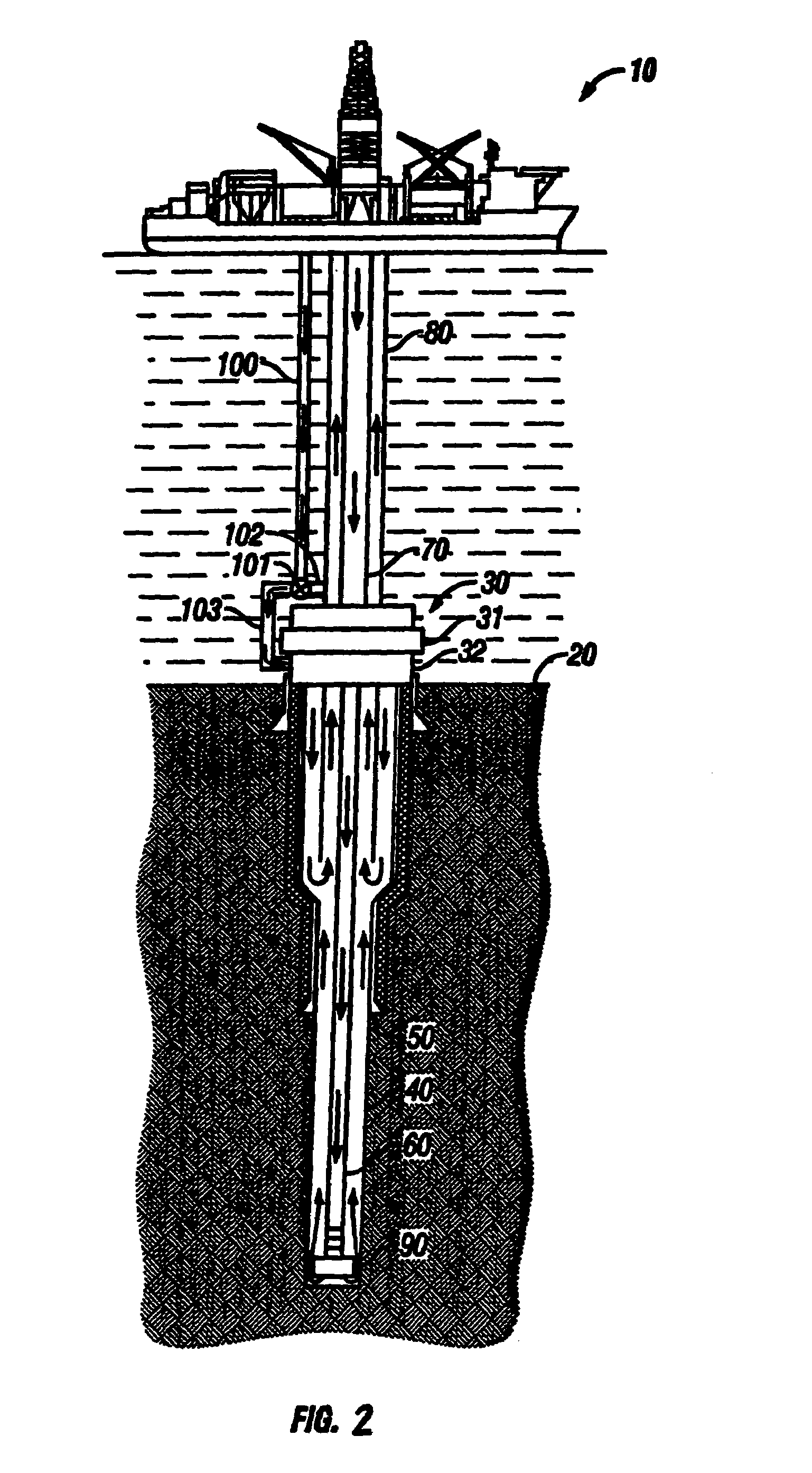

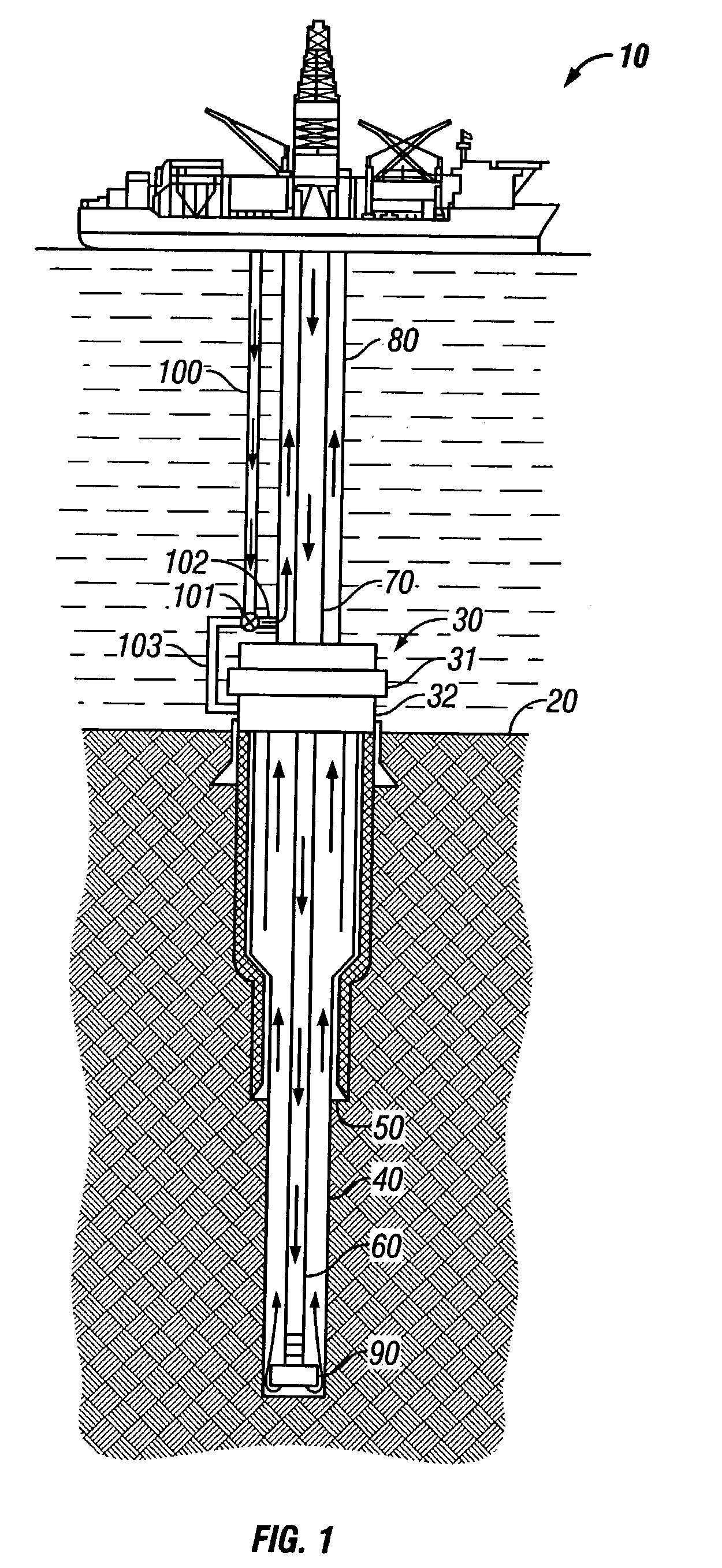

Subsea pumping system and method for deepwater drilling

A method is disclosed for offshore drilling in which a bit is driven at a far end of a drill string, drilling fluid is injected into the drill string from surface drilling facilities, and drilling fluid passes through the far end of the drill string and flushes the borehole at the bit and entrains cuttings into the drilling fluid which circulates up the casing / drill string annulus. The drilling fluid drawn off near the mudline and is treated through a subsea primary processing stage to removing the cuttings from the drilling fluid. The treated drilling fluid is then returned to the surface with a subsea return pump system and passes to surface drilling facilities for injection and recirculation.

Owner:SHELL OFFSHORE

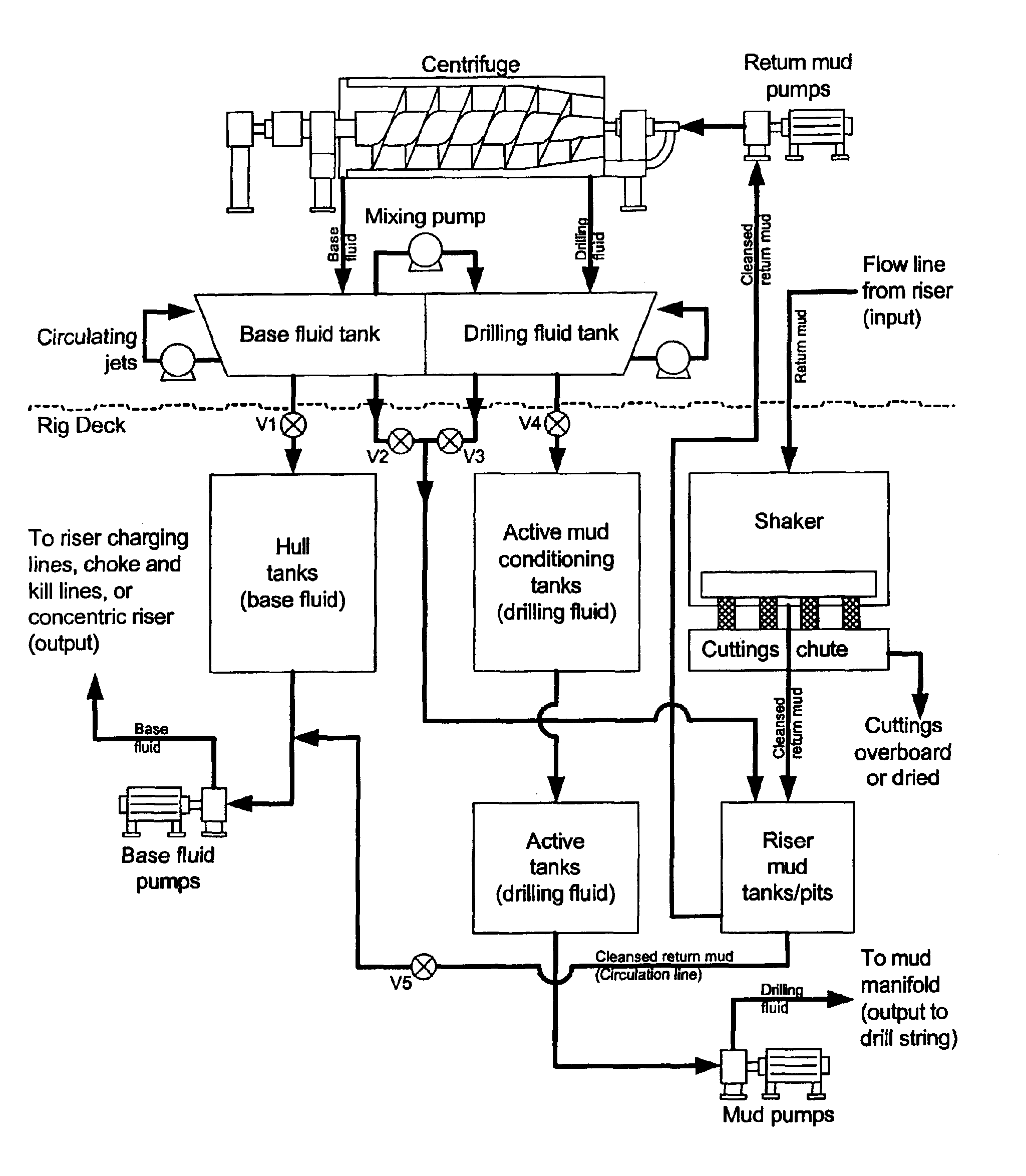

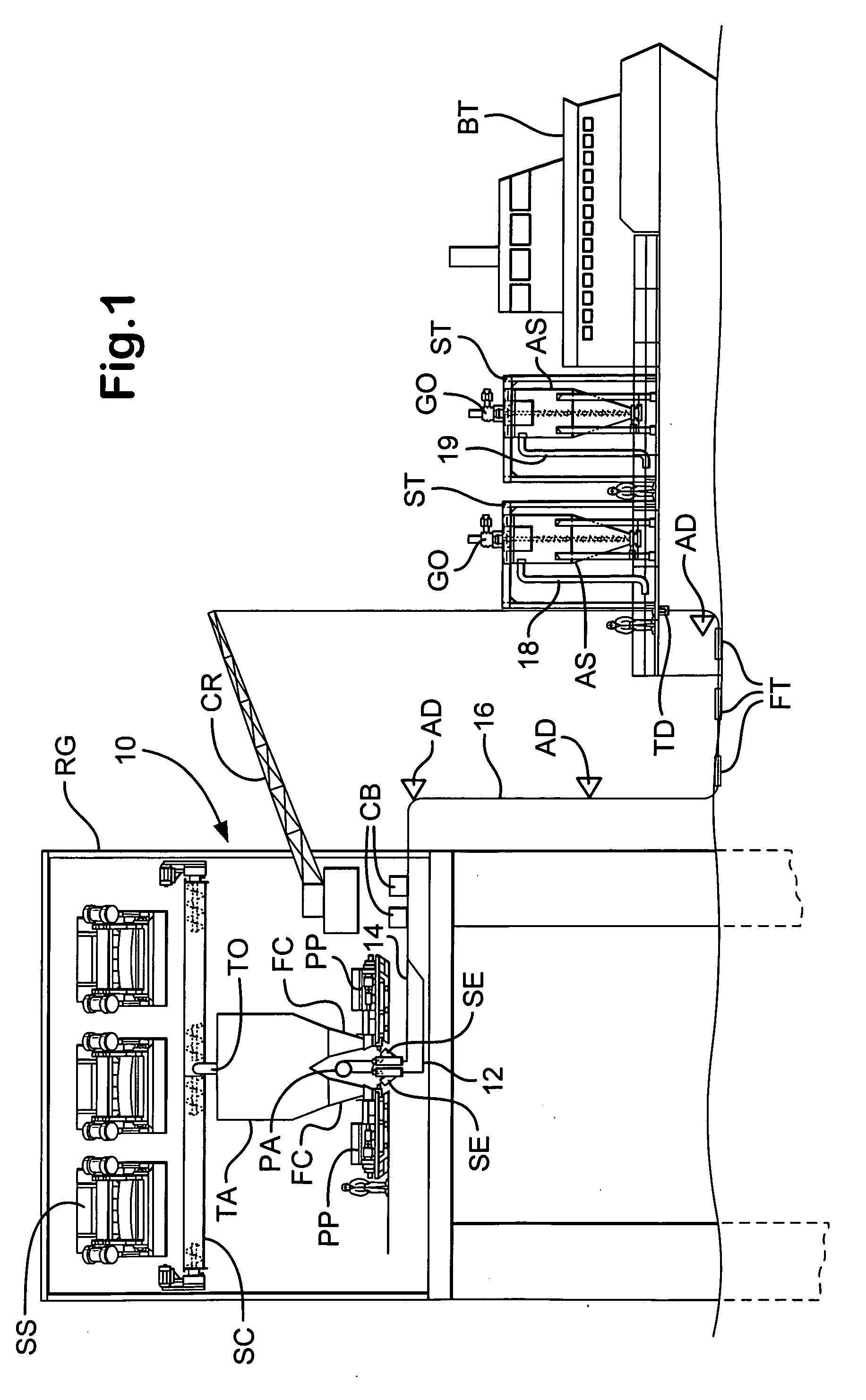

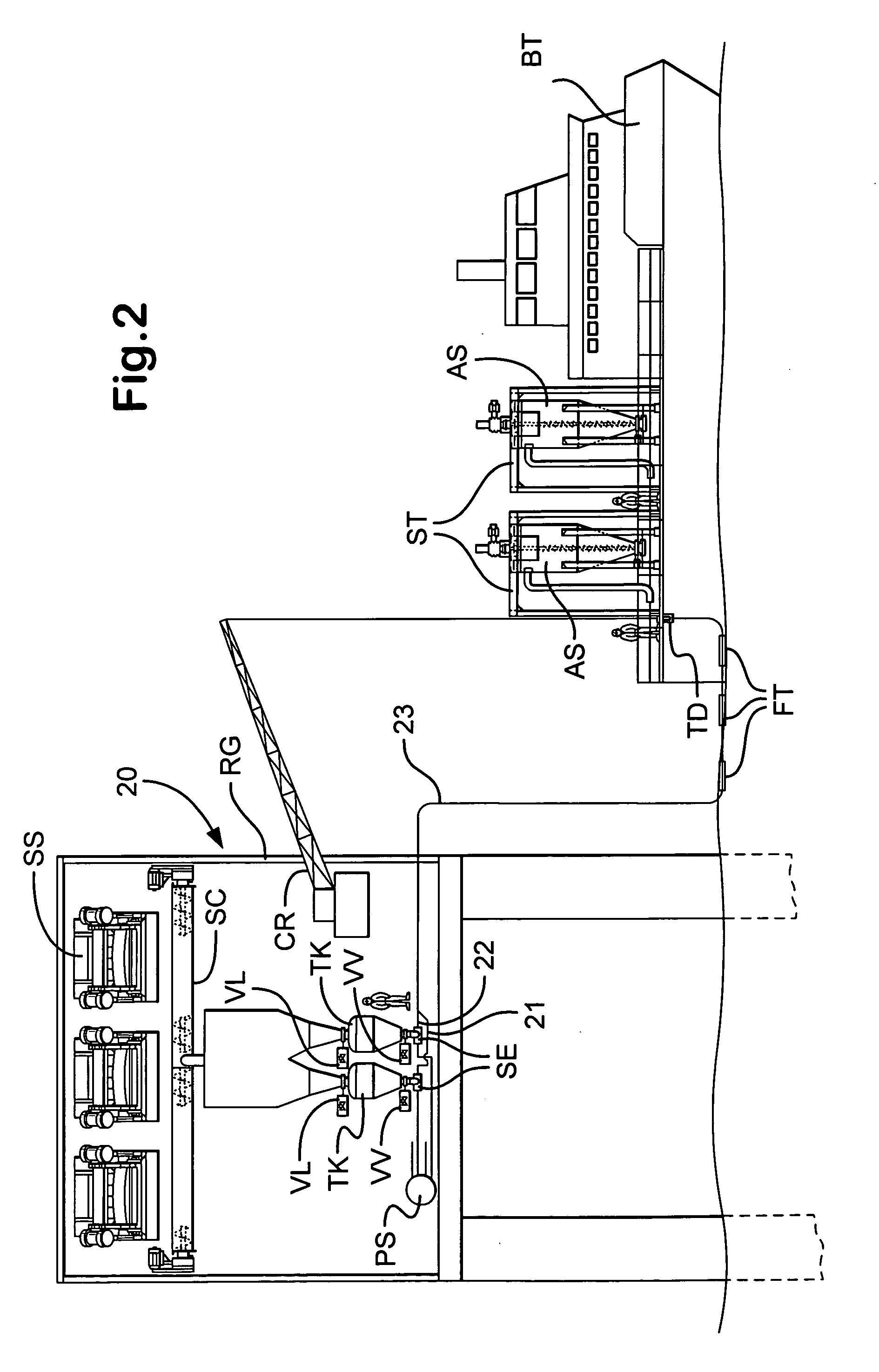

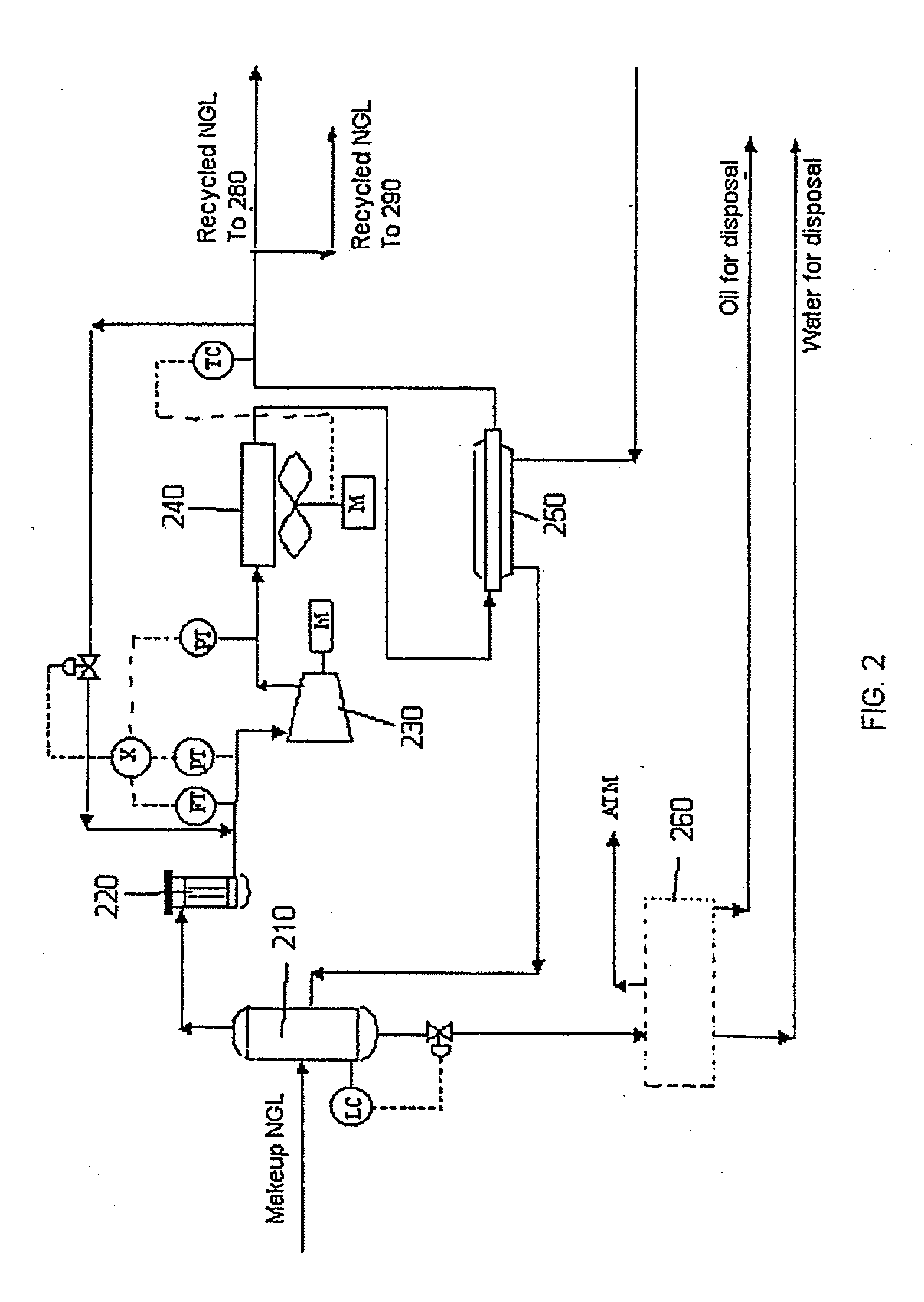

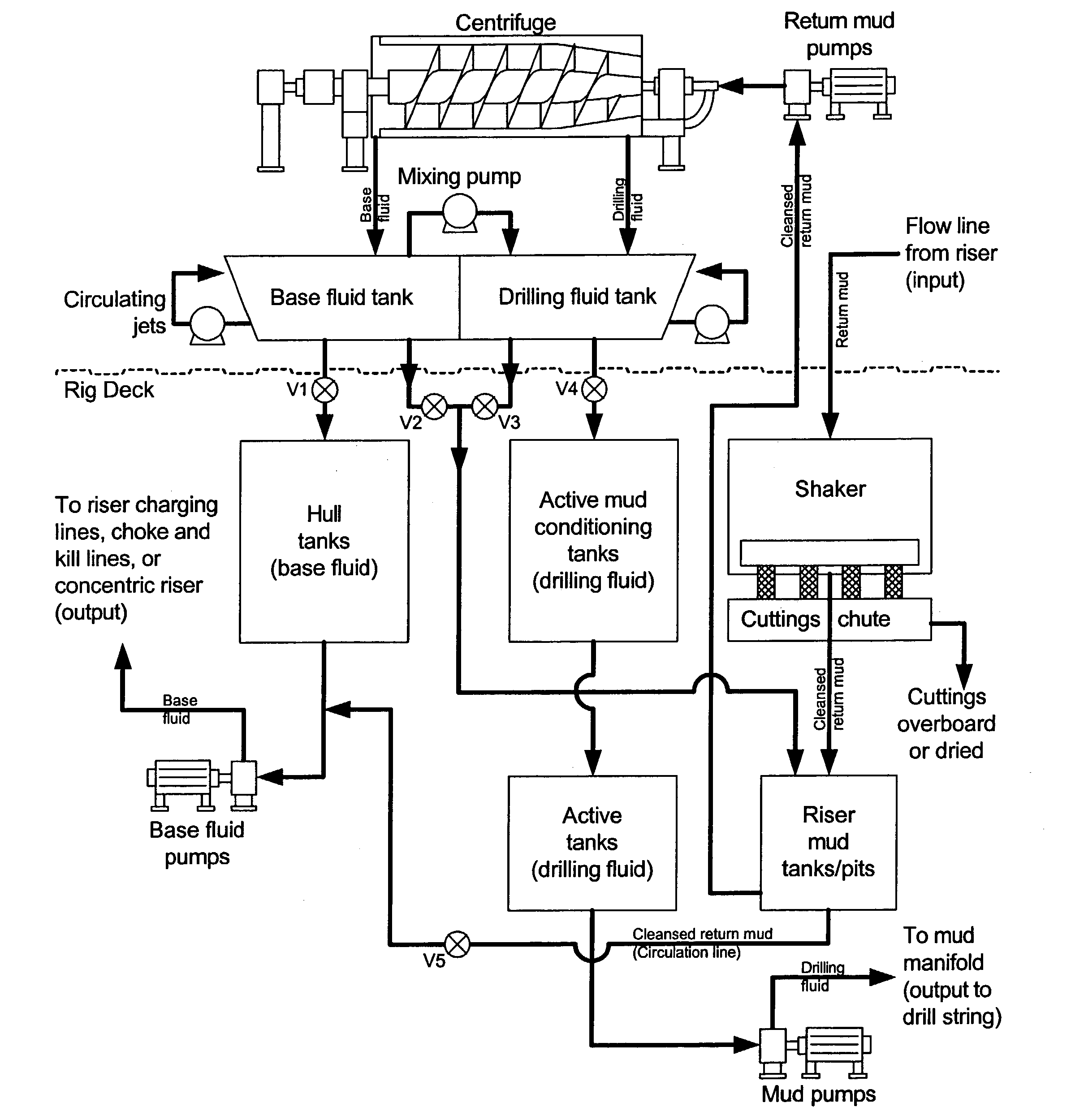

System and method for treating drilling mud in oil and gas well drilling applications

A system and method for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in deep water and ultra deep water applications. A base fluid of lesser density than the drilling mud required at the wellhead is used to produce a diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, a diluted riser mud density at or near the density of seawater may be achieved. The present invention also includes a wellhead injection device for injecting the base fluid into the rising drilling mud. The riser charging lines are used to carry the low density base fluid to the injection device for injection into the return mud. At the surface, the diluted return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the heavier drilling mud from the lighter base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

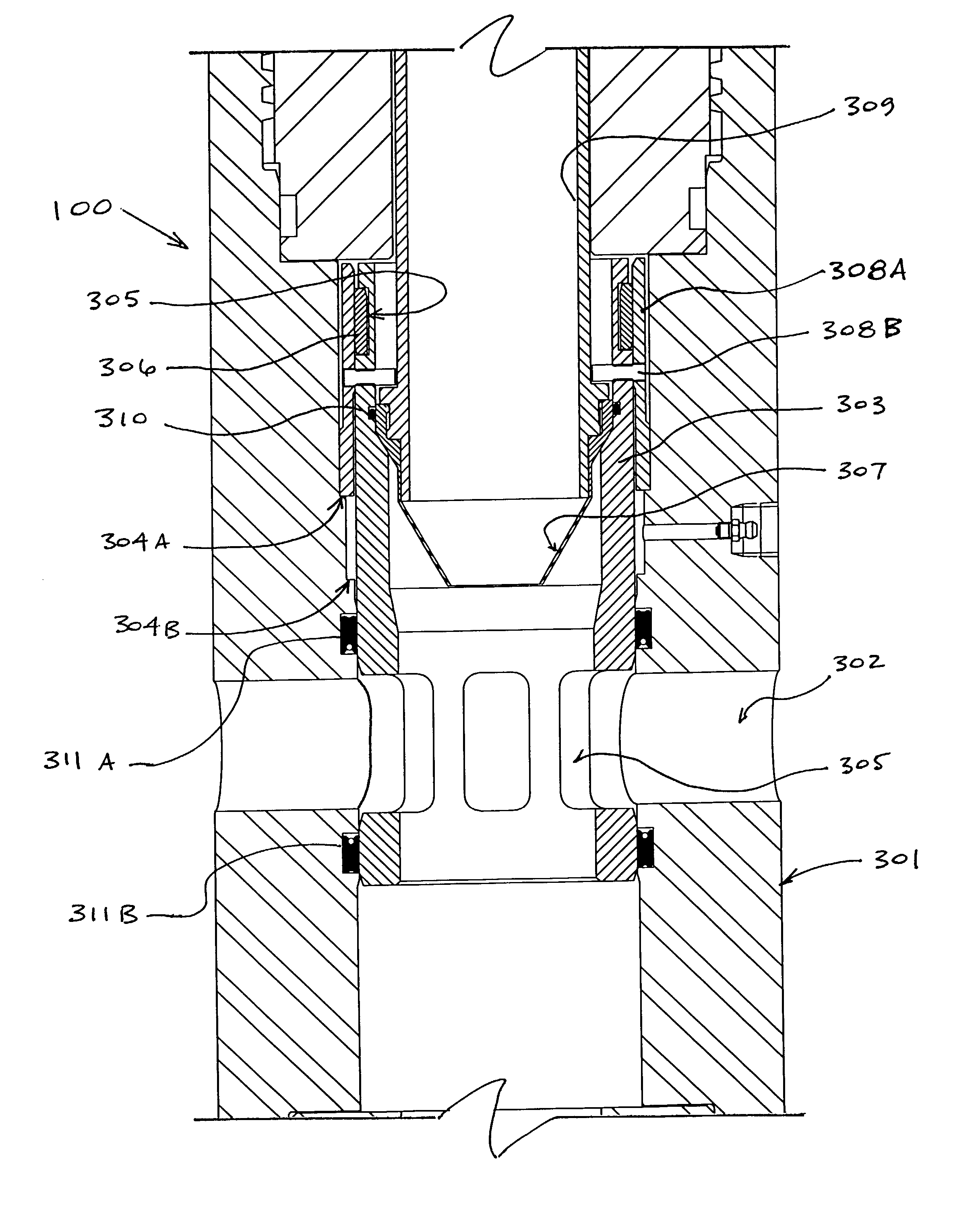

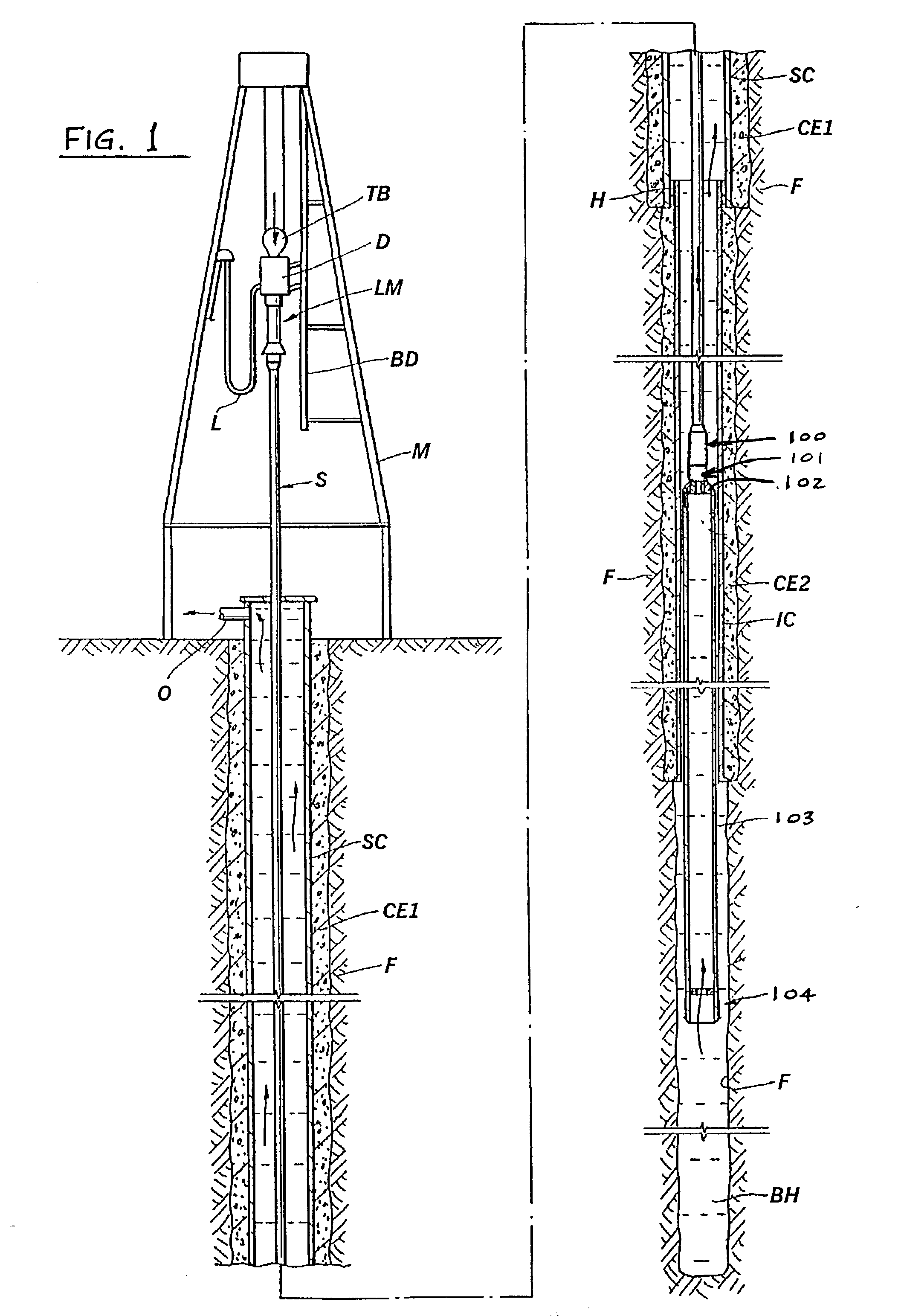

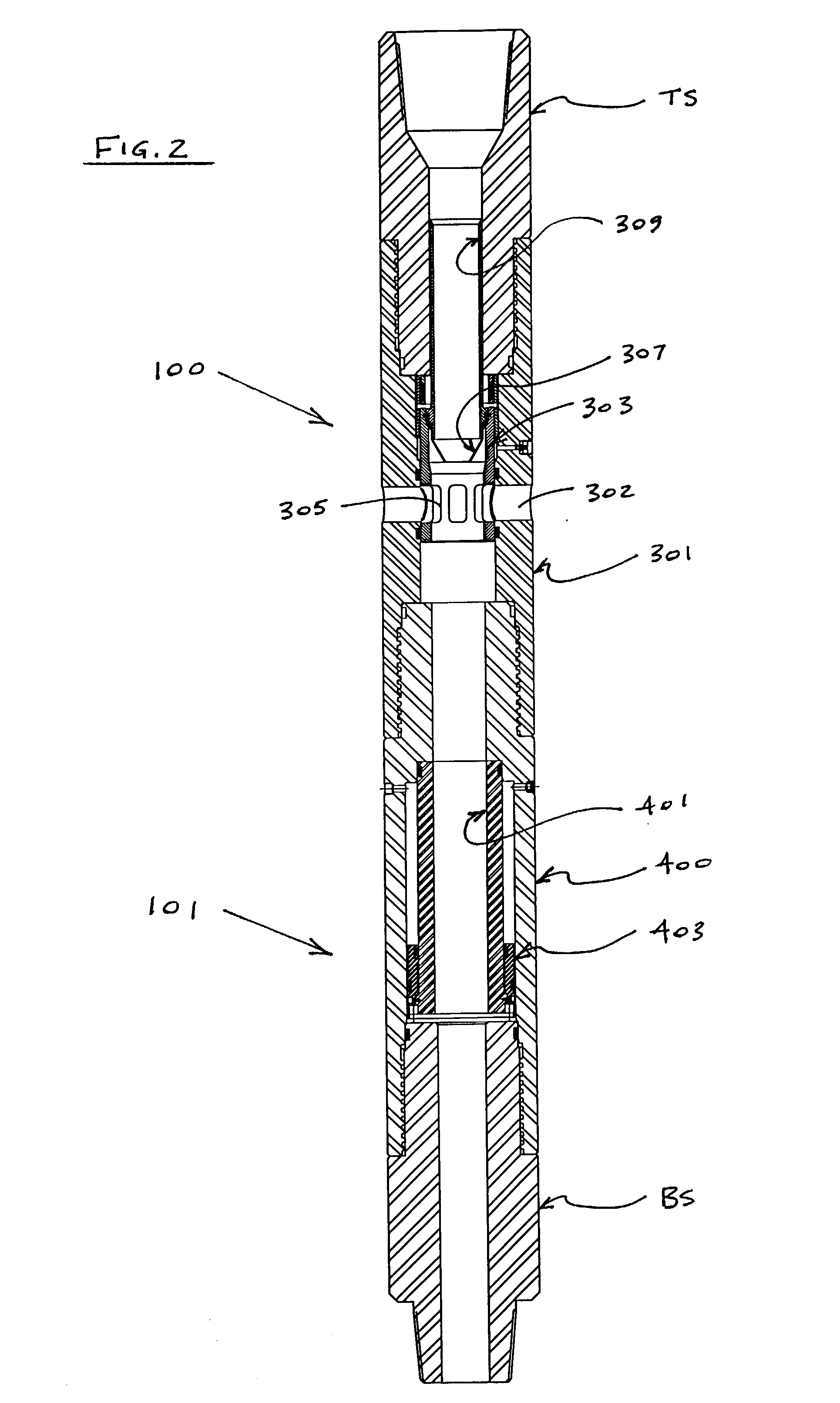

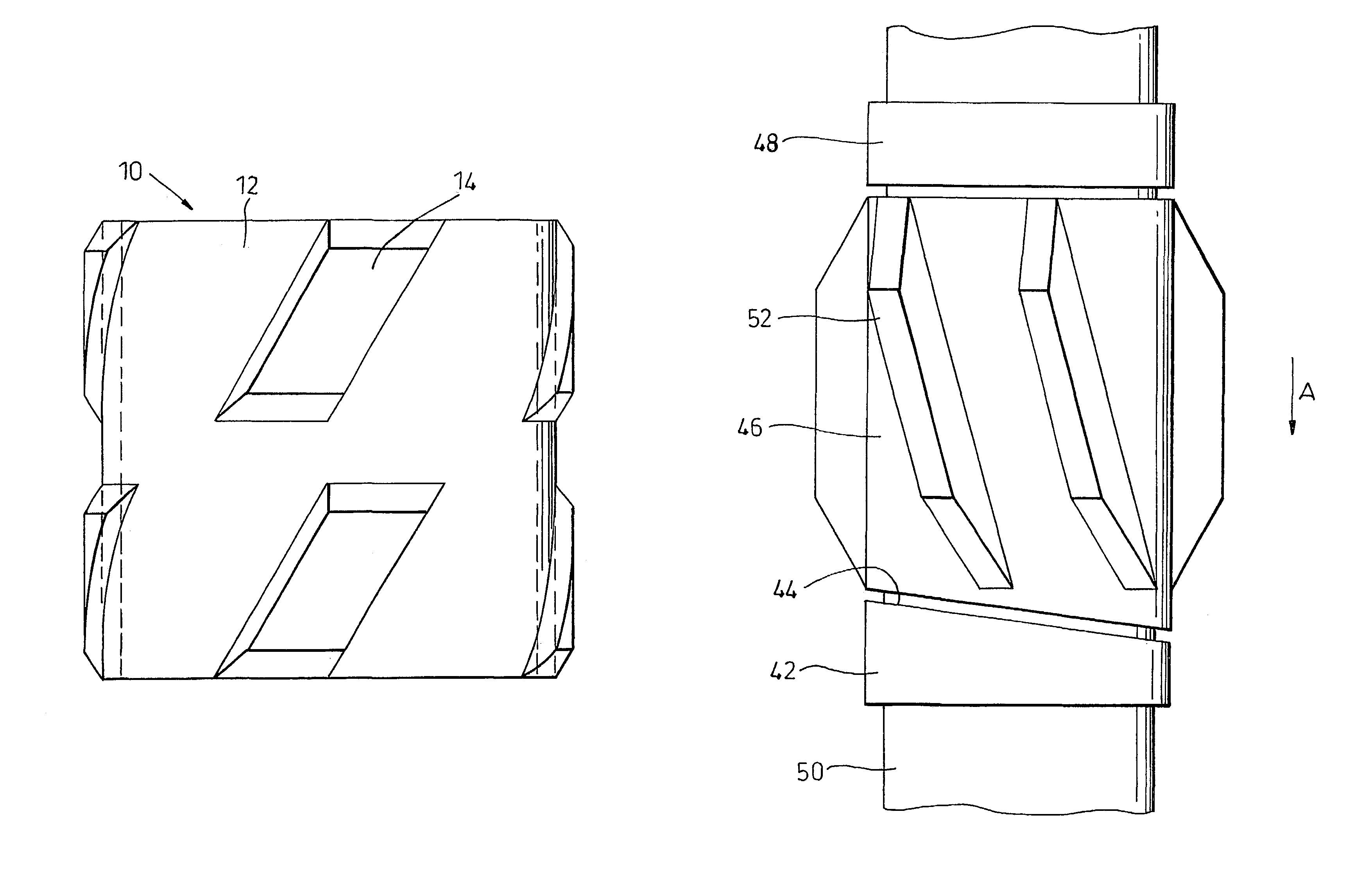

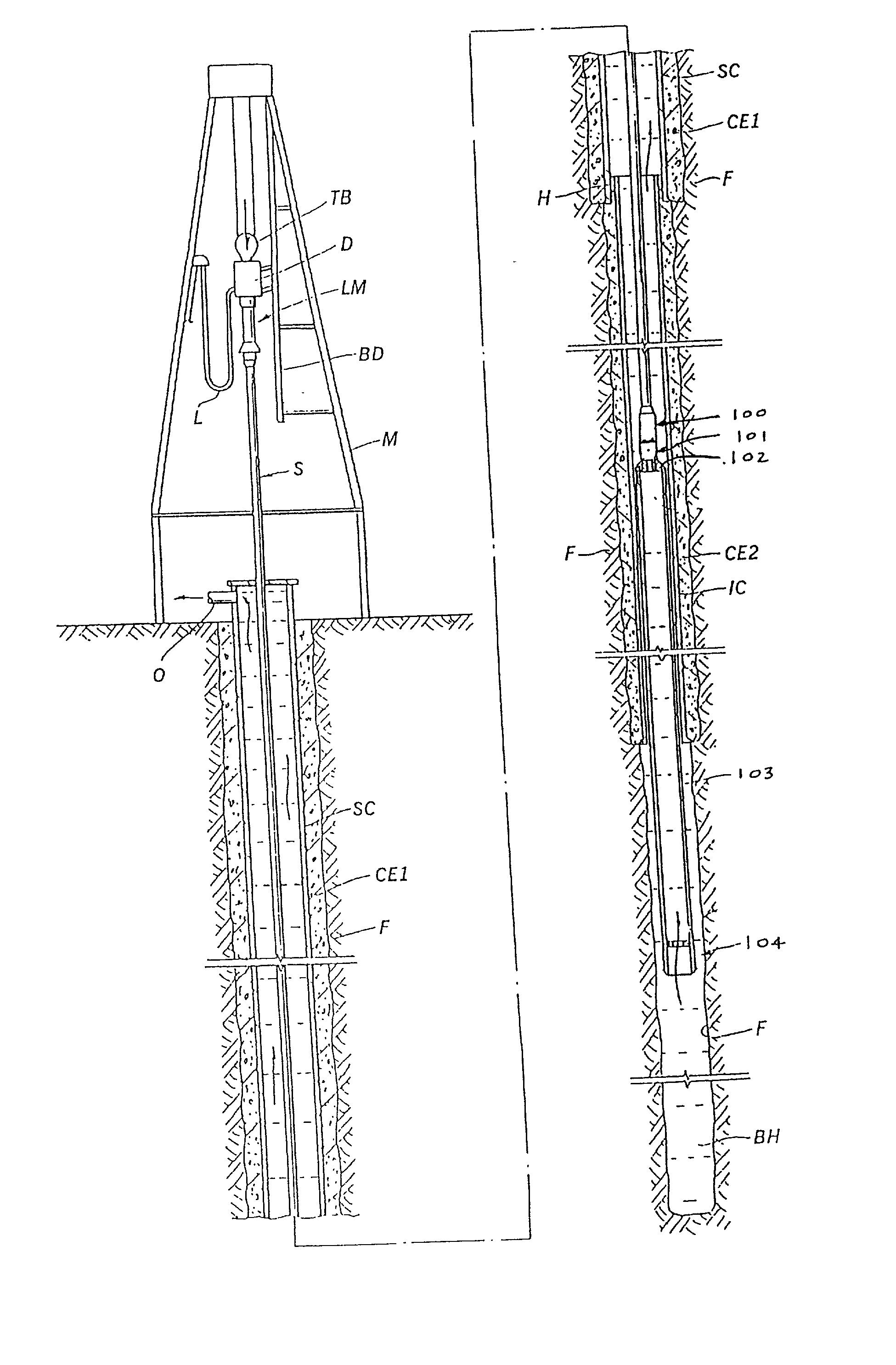

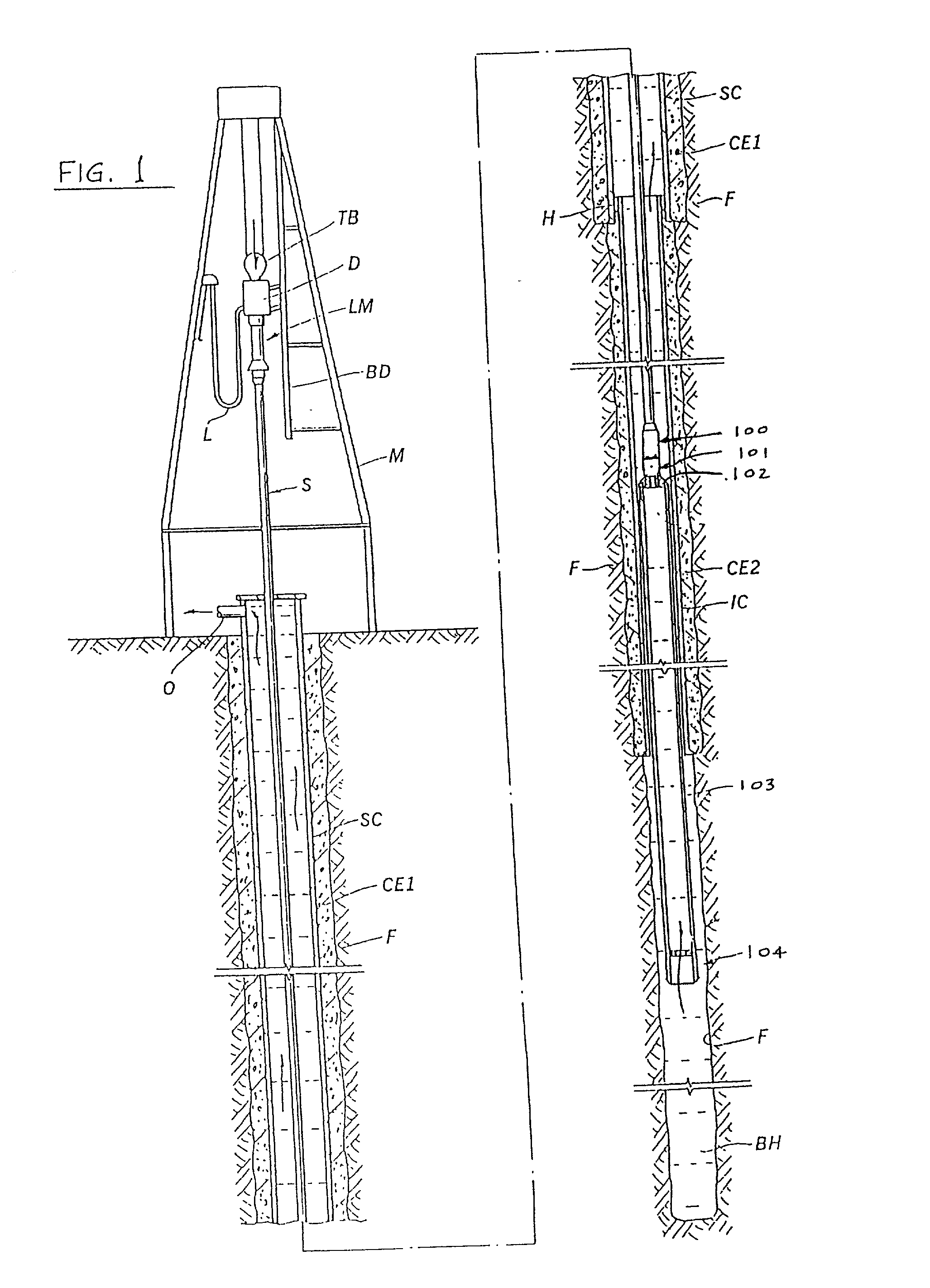

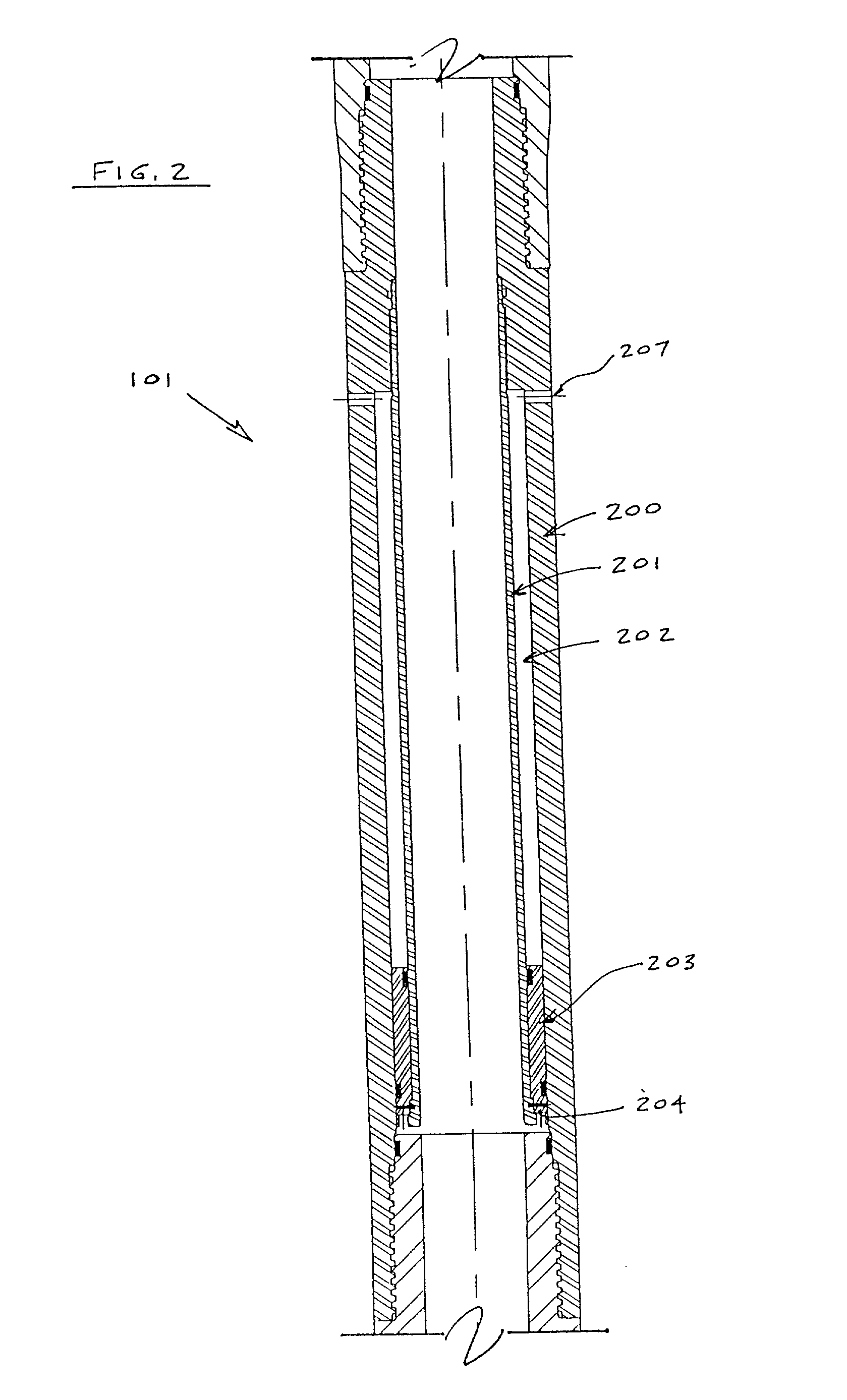

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

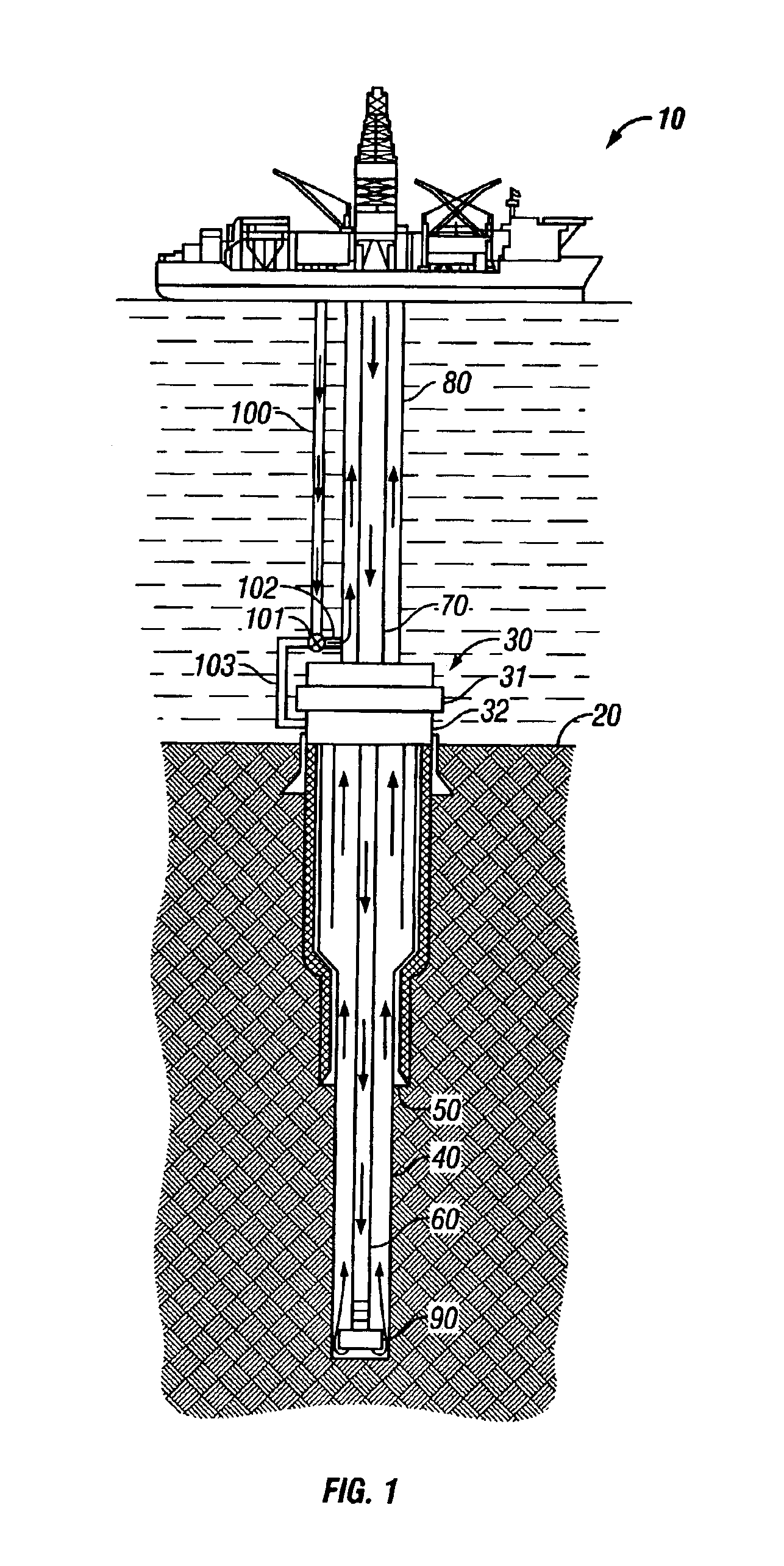

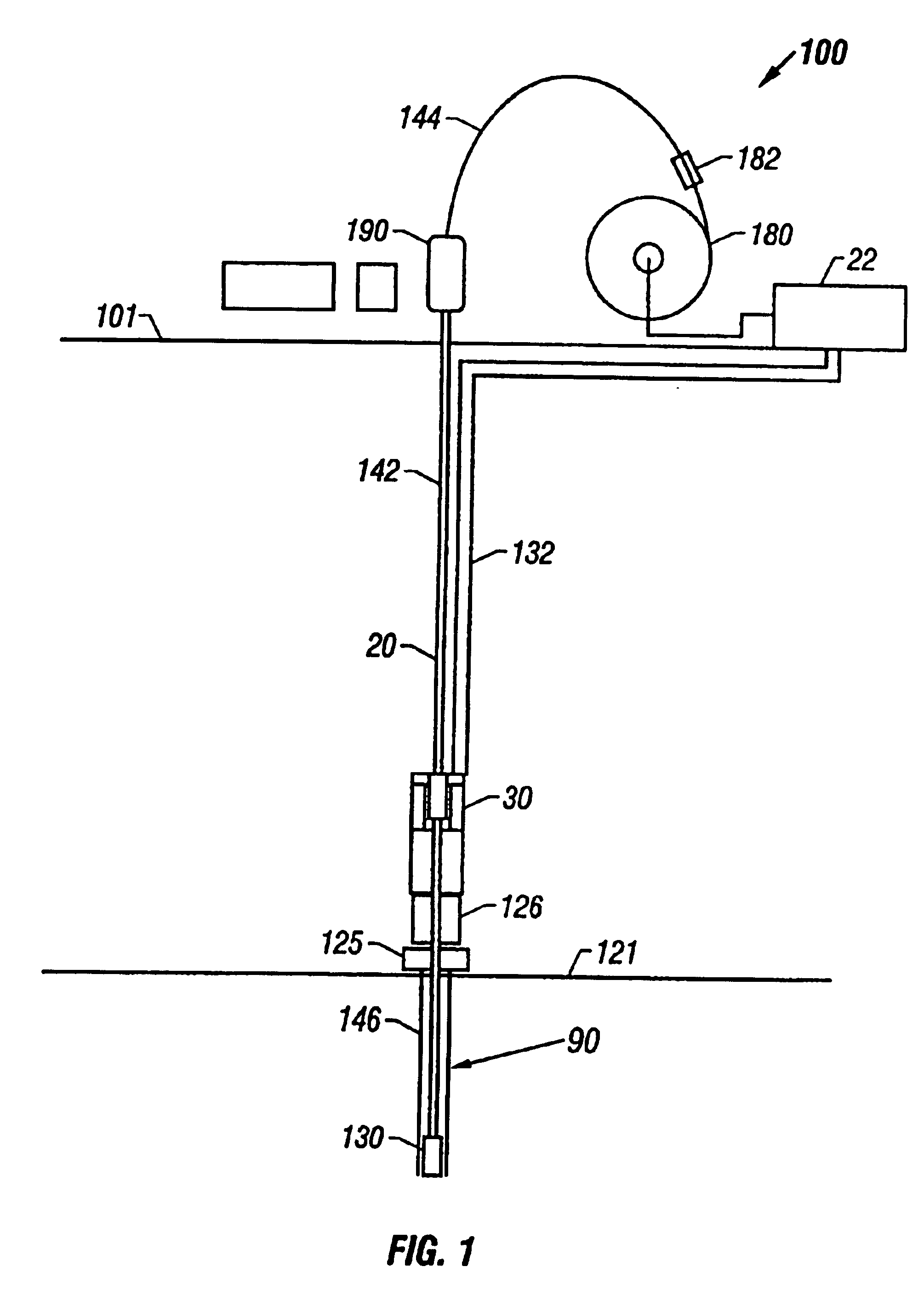

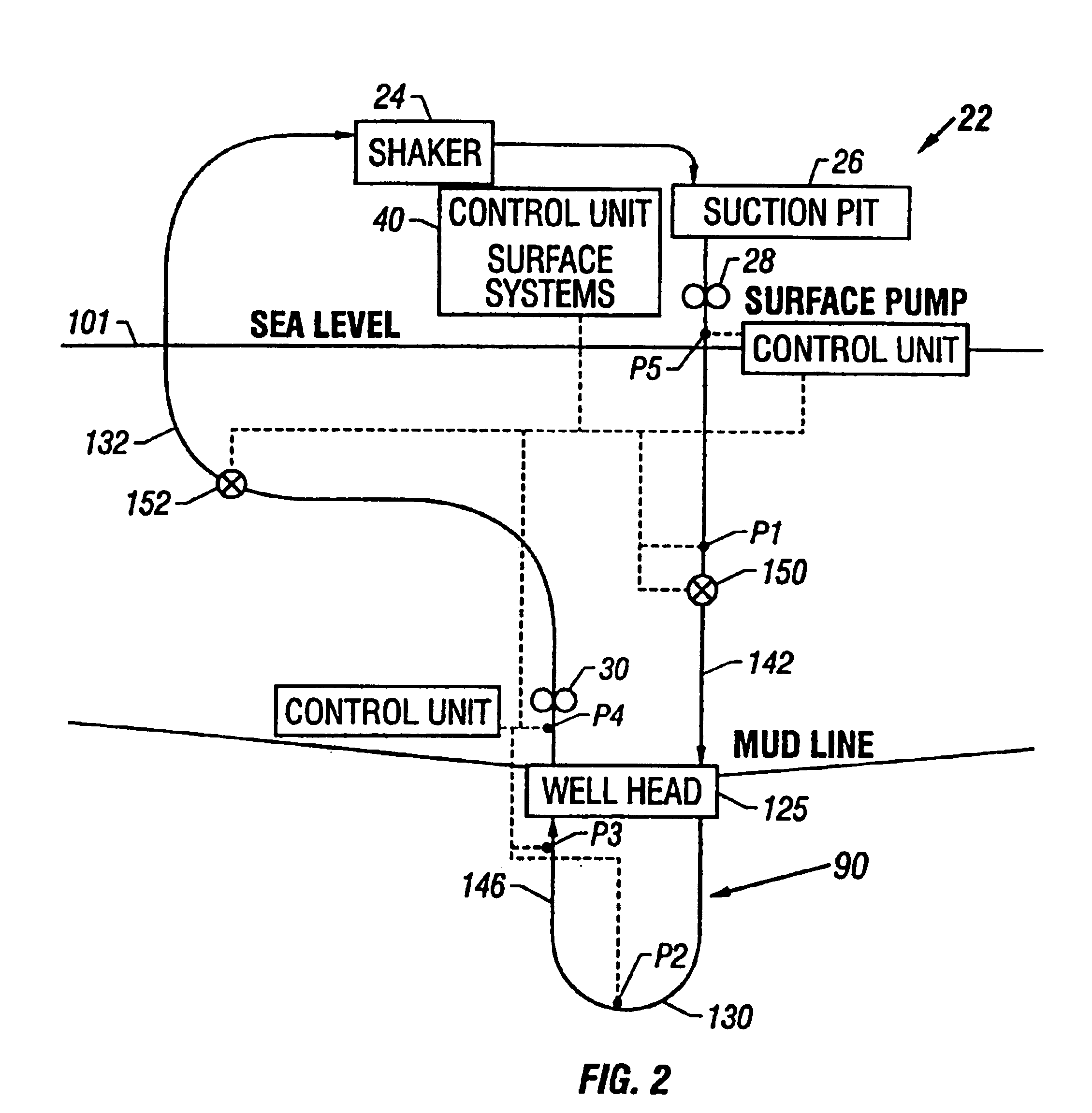

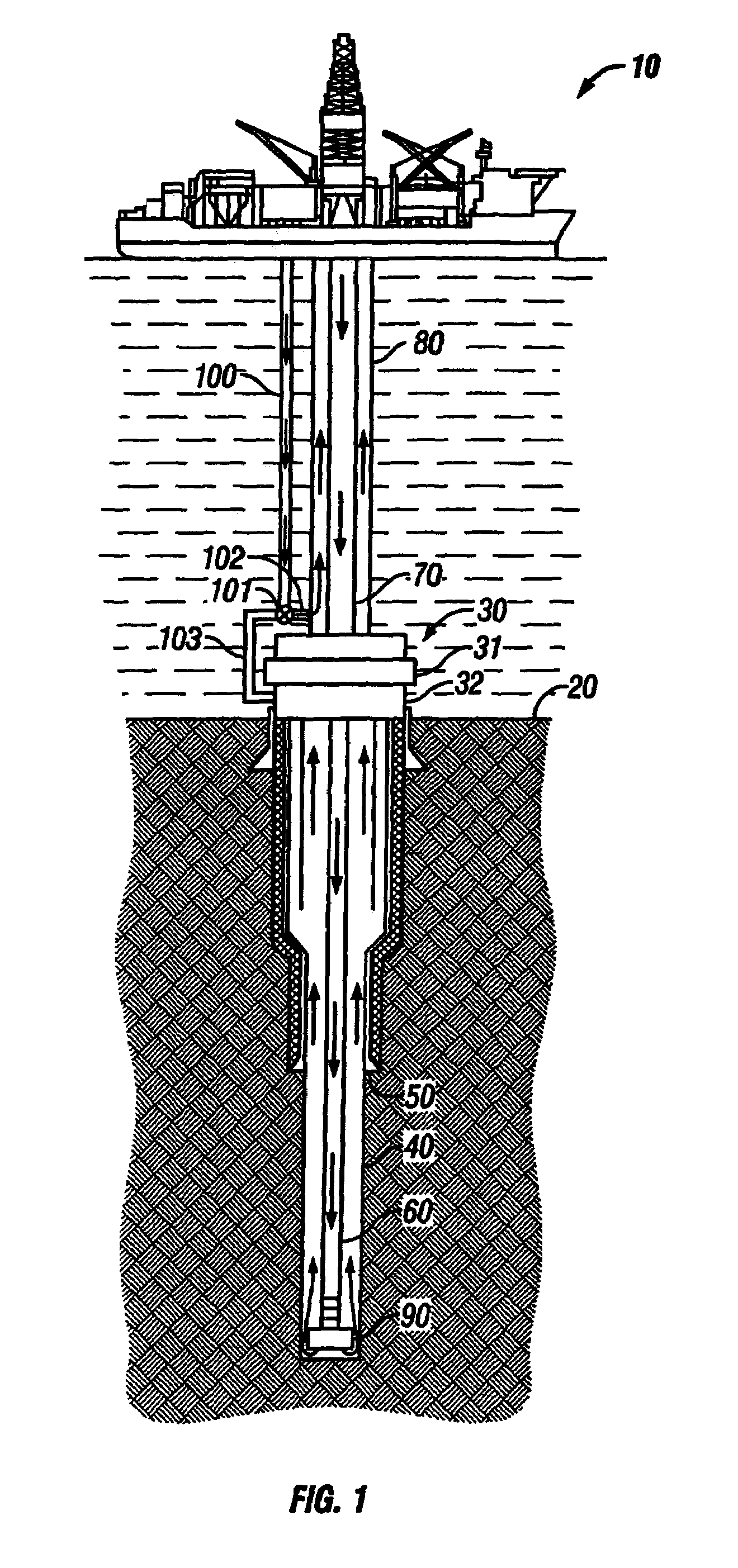

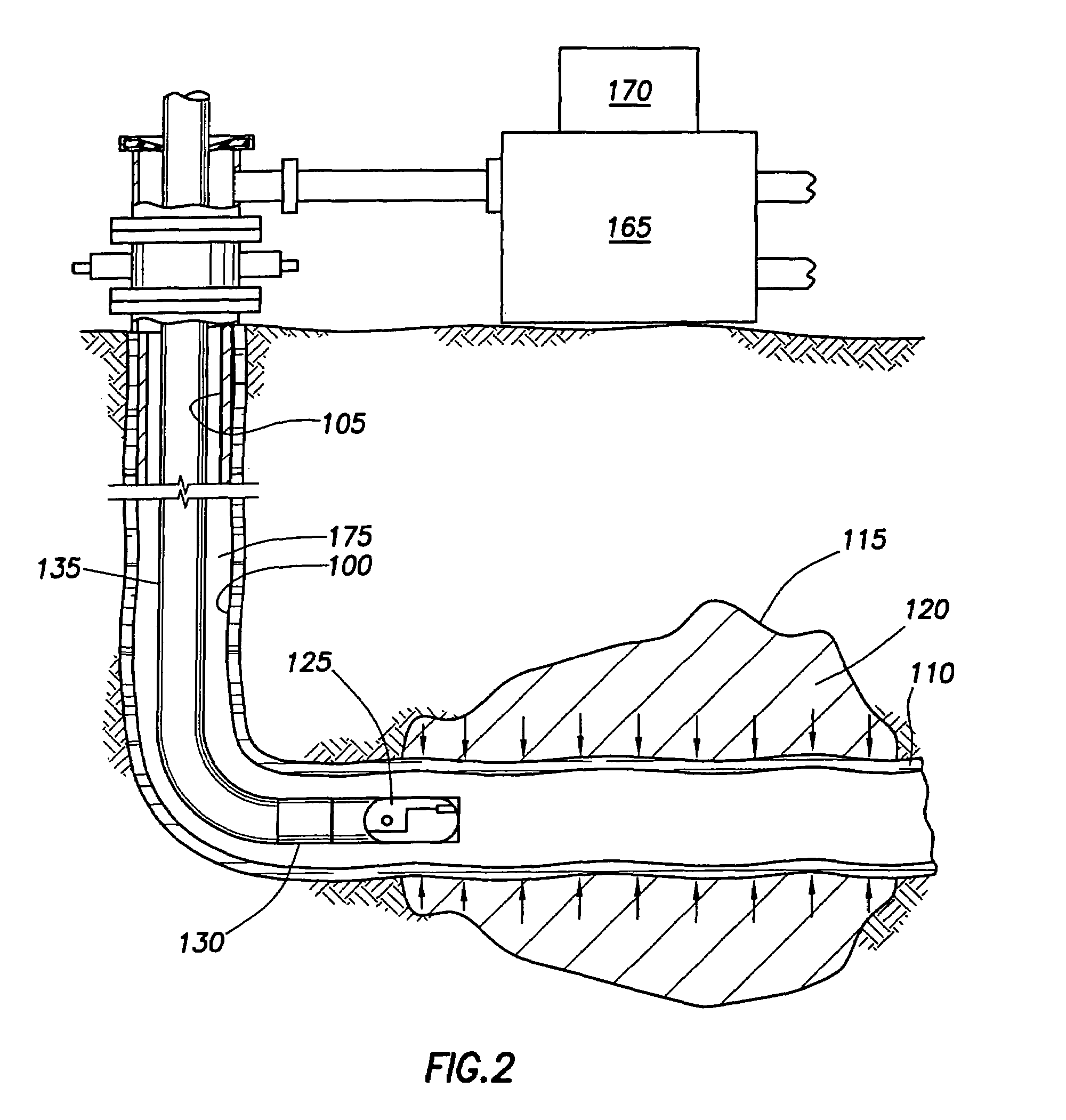

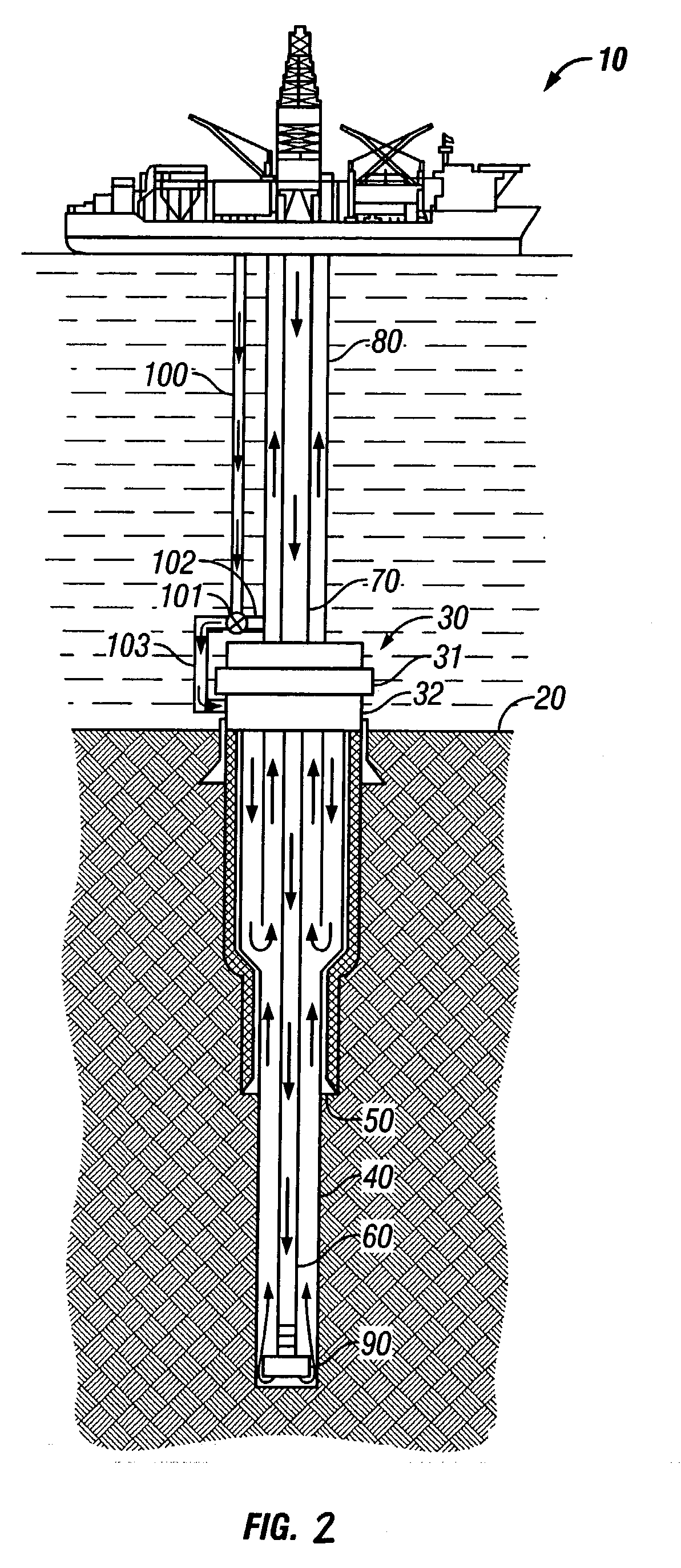

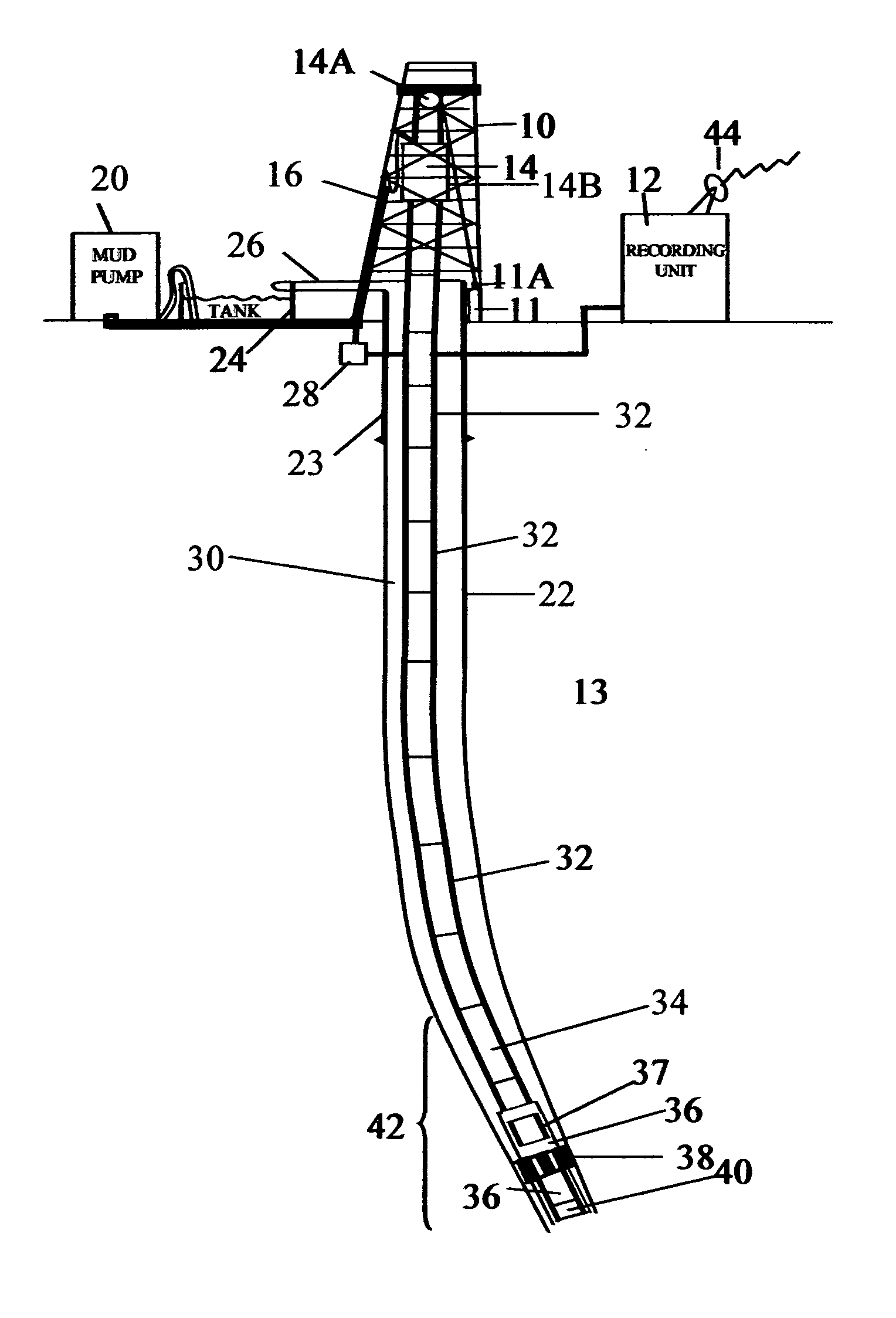

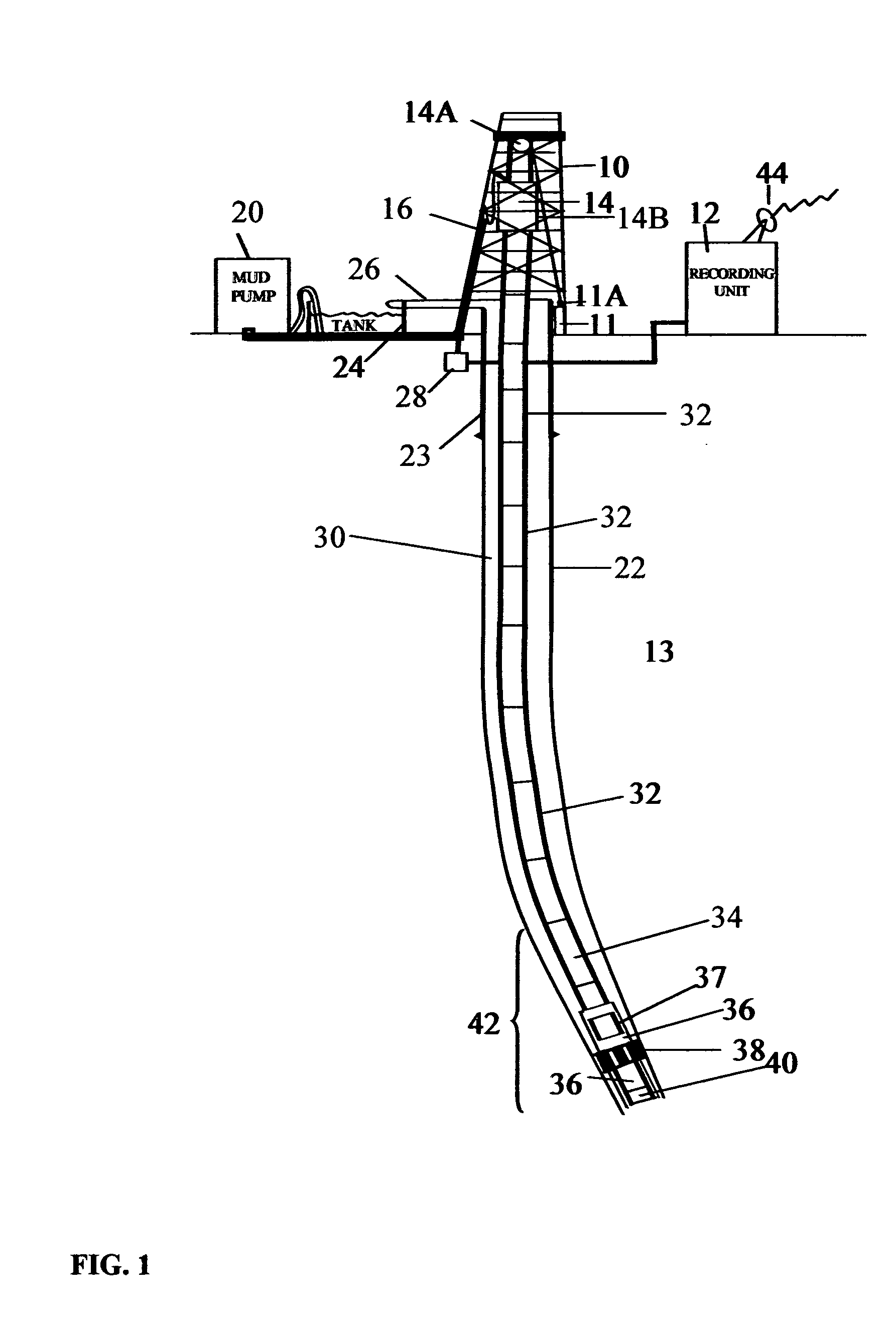

Subsea wellbore drilling system for reducing bottom hole pressure

InactiveUS6854532B2Easy to deployFaster and effective subsea downhole operationDrilling rodsConstructionsDelivery systemBottom hole assembly

The present invention provides drilling systems for drilling subsea wellbores. The drilling system includes a tubing that passes through a sea bottom wellhead and carries a drill bit. A drilling fluid system continuously supplies drilling fluid into the tubing, which discharges at the drill bit bottom and returns to the wellhead through an annulus between the tubing and the wellbore carrying the drill cuttings. A fluid return line extending from the wellhead equipment to the drilling vessel transports the returning fluid to the surface. In a riserless arrangement, the return fluid line is separate and spaced apart from the tubing. In a system using a riser, the return fluid line may be the riser or a separate line carried by the riser. The tubing may be coiled tubing with a drilling motor in the bottom hole assembly driving the drill bit. A suction pump coupled to the annulus is used to control the bottom hole pressure during drilling operations, making it possible to use heavier drilling muds and drill to greater depths than would be possible without the suction pump. An optional delivery system continuously injects a flowable material, whose fluid density is less than the density of the drilling fluid, into the returning fluid at one or more suitable locations the rate of such lighter material can be controlled to provide supplementary regulation of the pressure. Various pressure, temperature, flow rate and kick sensors included in the drilling system provide signals to a controller that controls the suction pump, the surface mud pump, a number of flow control devices, and the optional delivery system.

Owner:BAKER HUGHES INC

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

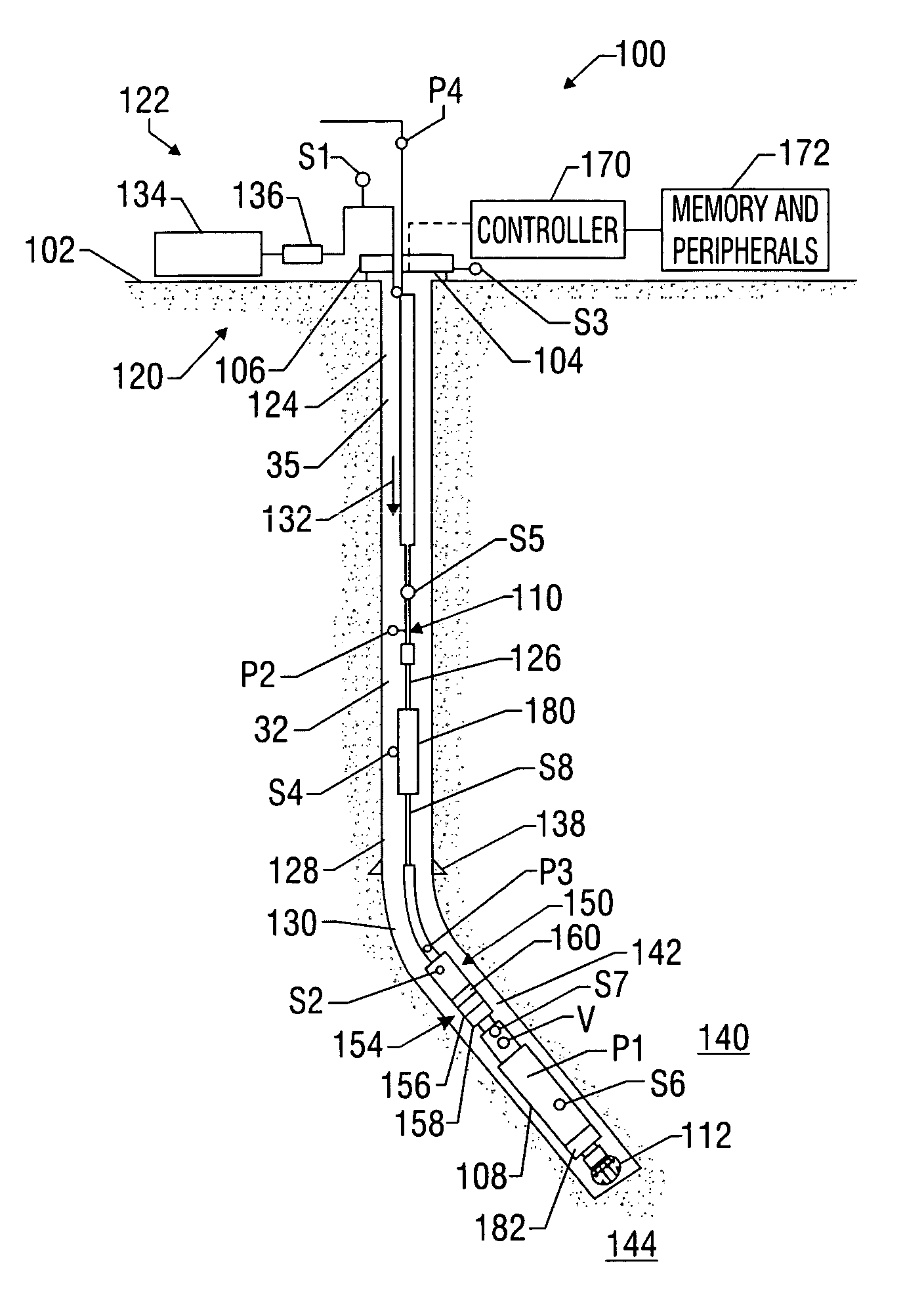

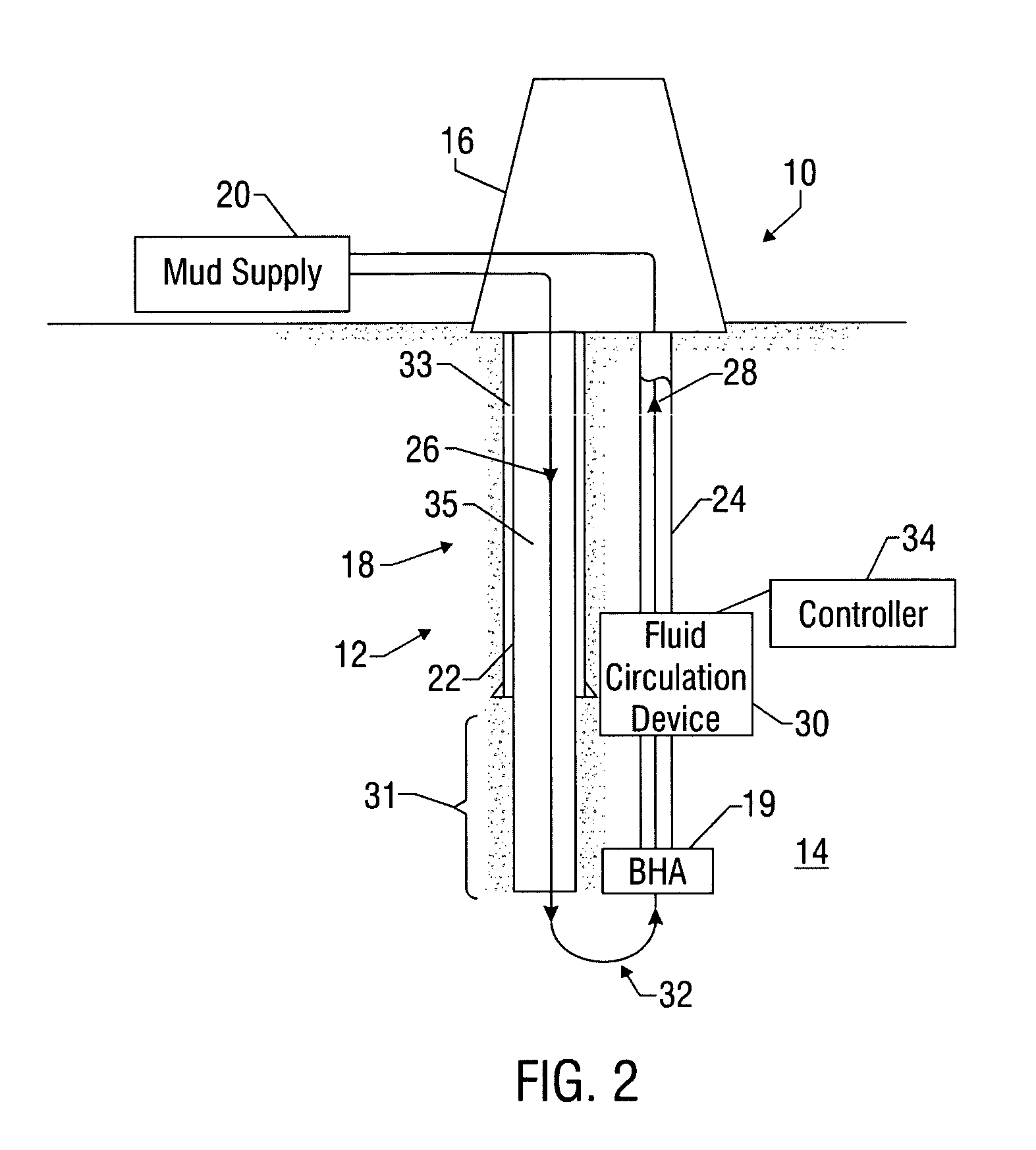

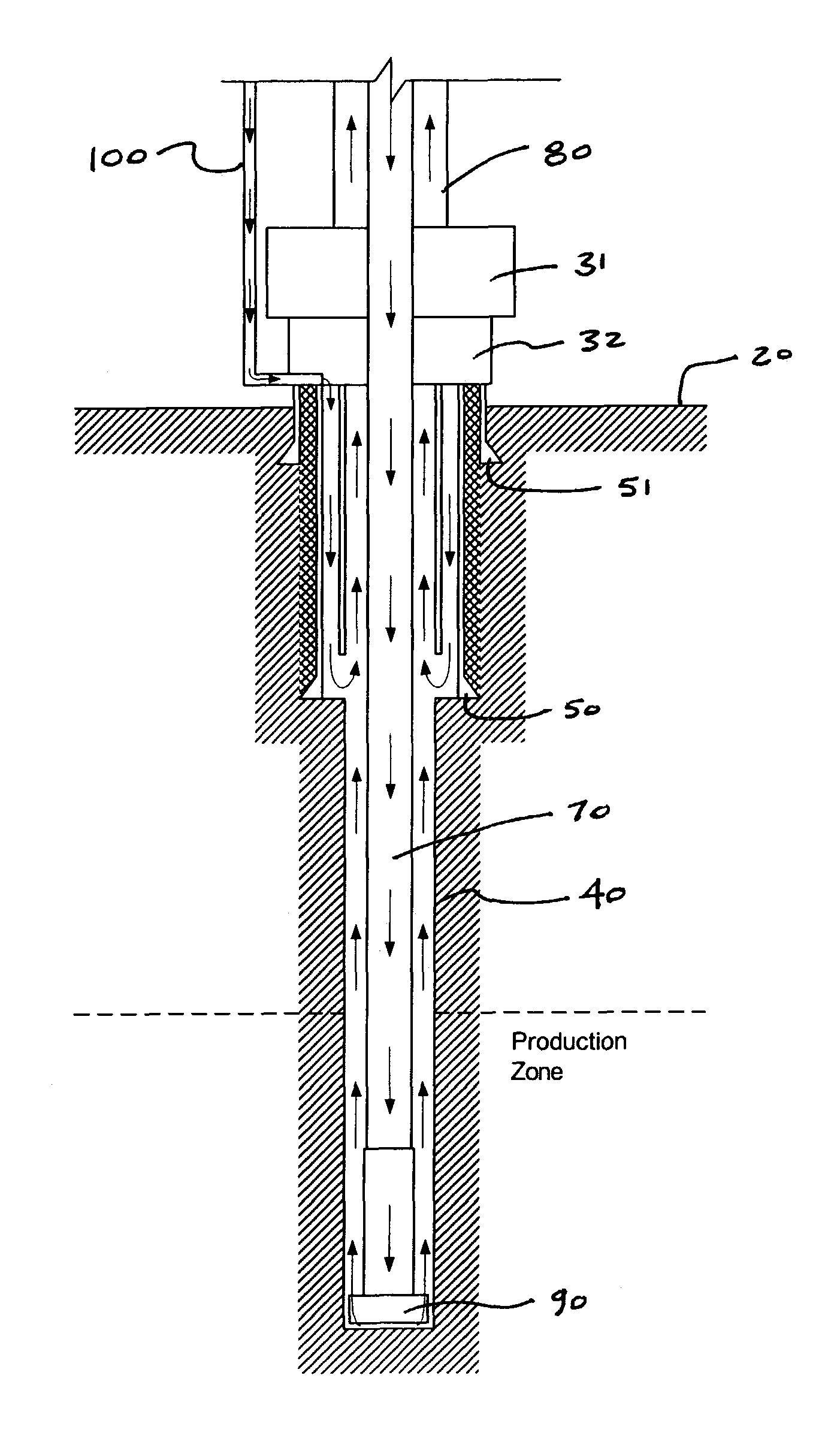

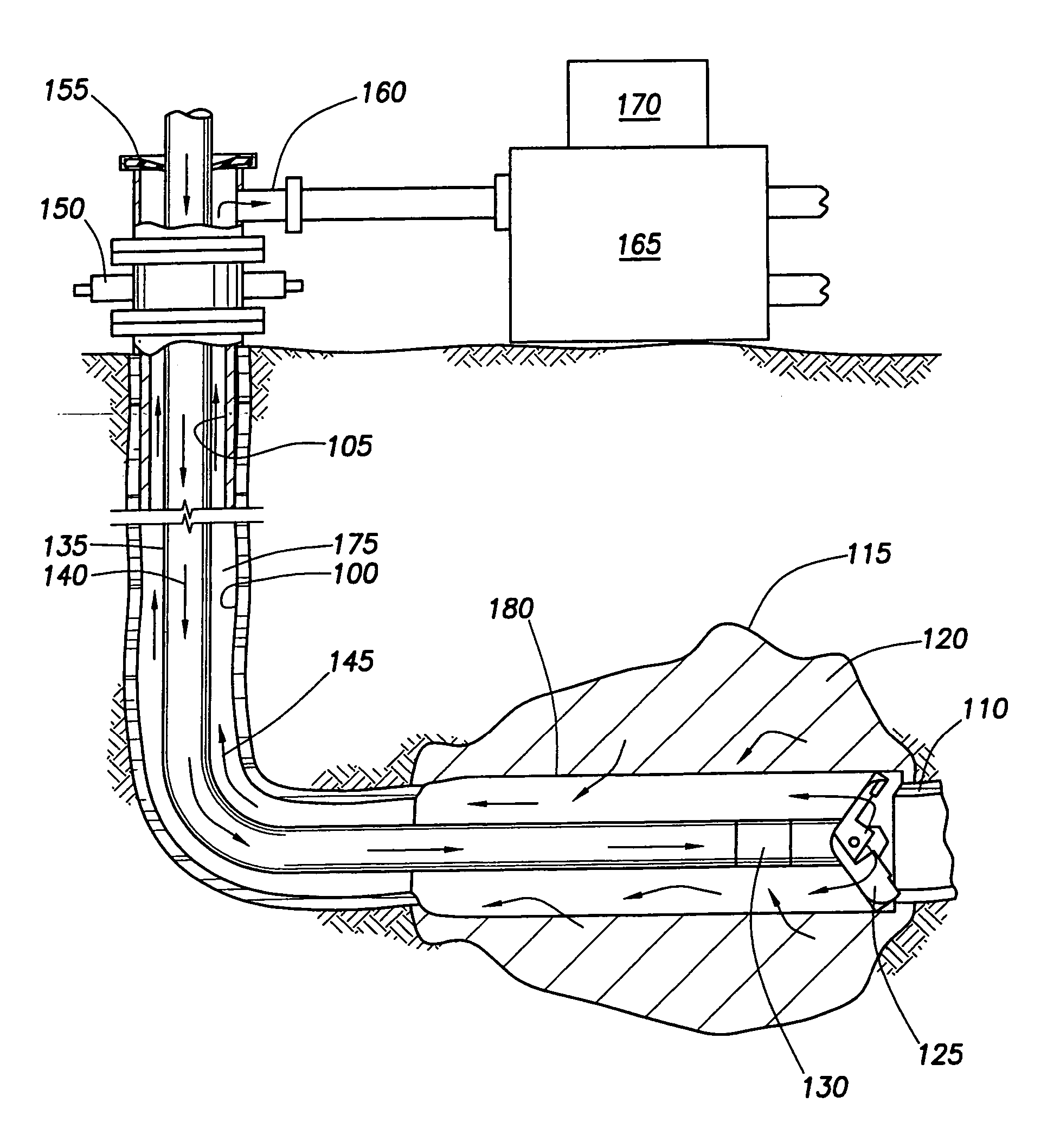

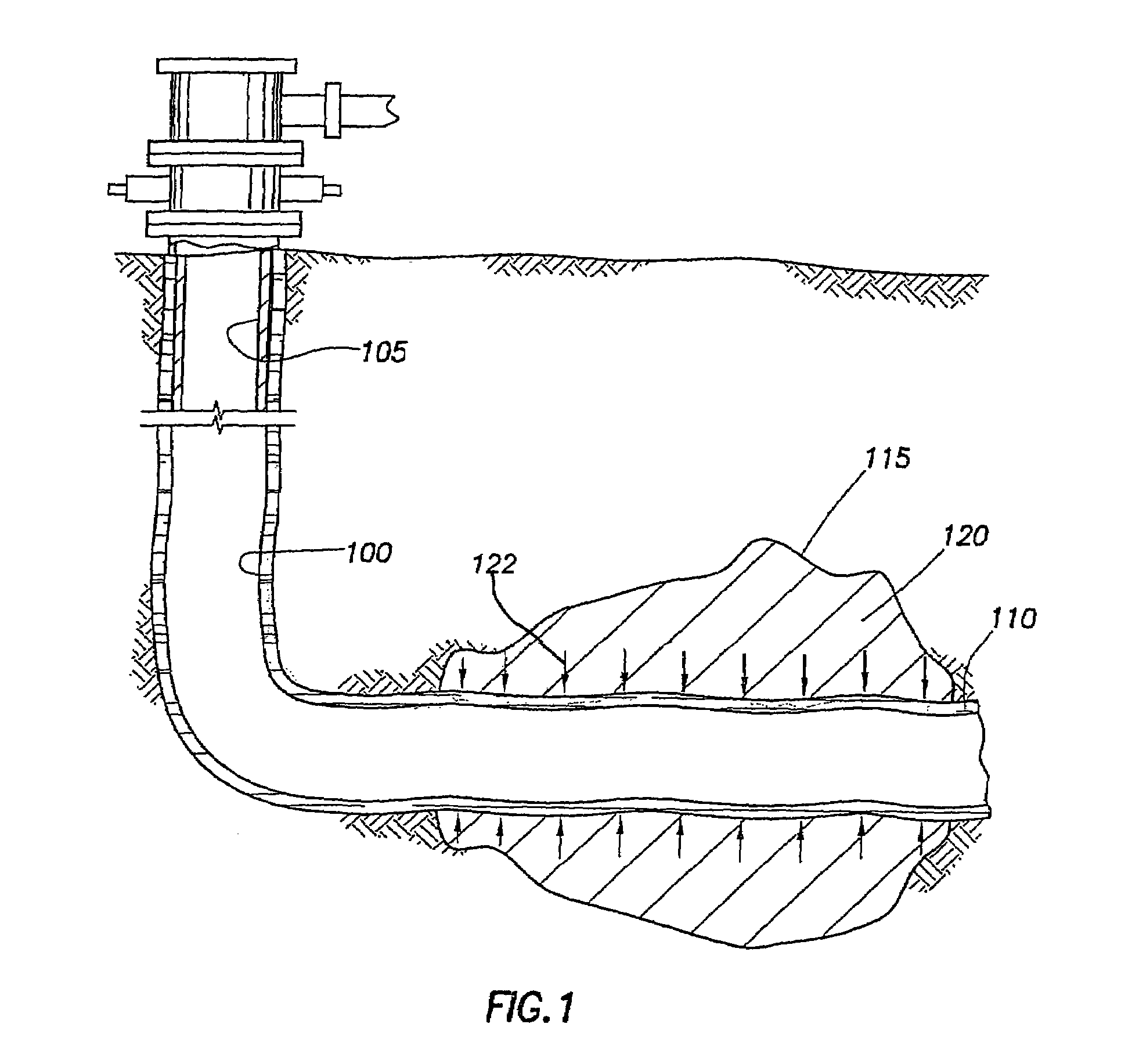

Wellbore fluid circulation system and method

ActiveUS7055627B2Improve bit cleaningLoss of circulationConstructionsFluid removalLine tubingWell drilling

The present invention provides drilling systems for drilling wellbores. The drilling system includes an umbilical that passes through a wellhead and carries a drill bit. A drilling fluid system supplies drilling fluid into an annulus (supply line) between the umbilical and the wellbore, which discharges at the drill bit bottom and returns to the wellhead through the umbilical (return line) carrying the drill cuttings. A fluid circulation device, such as a turbine or centrifugal pump, is operated in the return line to provide the primary motive force for circulating drilling fluid through a fluid circuit formed by the supply line and return line. Optionally, a secondary fluid circulation device in fluid communication with the return line can cooperate with the fluid circulation device to circulate drilling fluid and / or a near bit fluid circulation device can be used to provide localized flow control or suction pressure to improve bit cleaning.

Owner:BAKER HUGHES INC

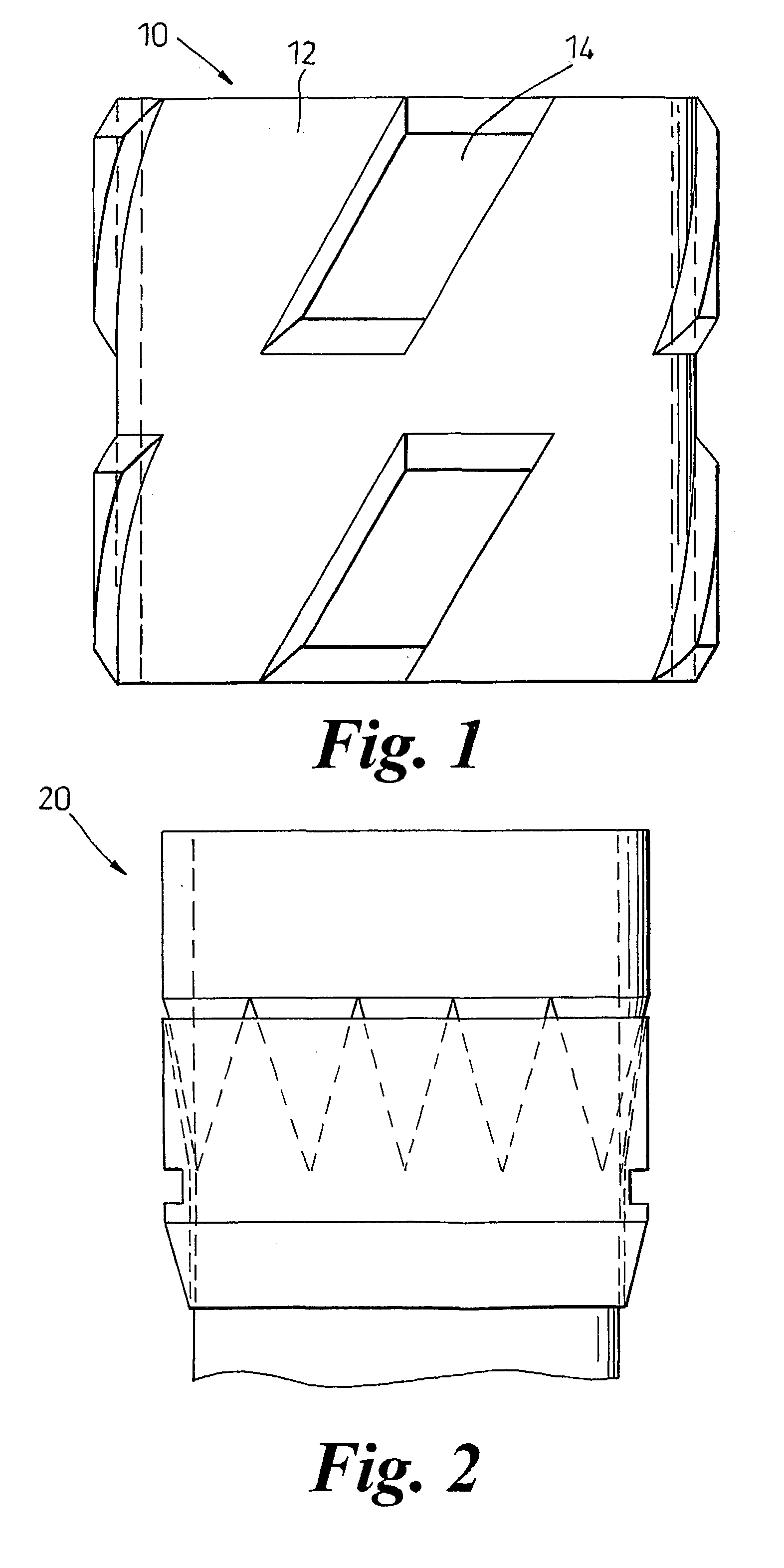

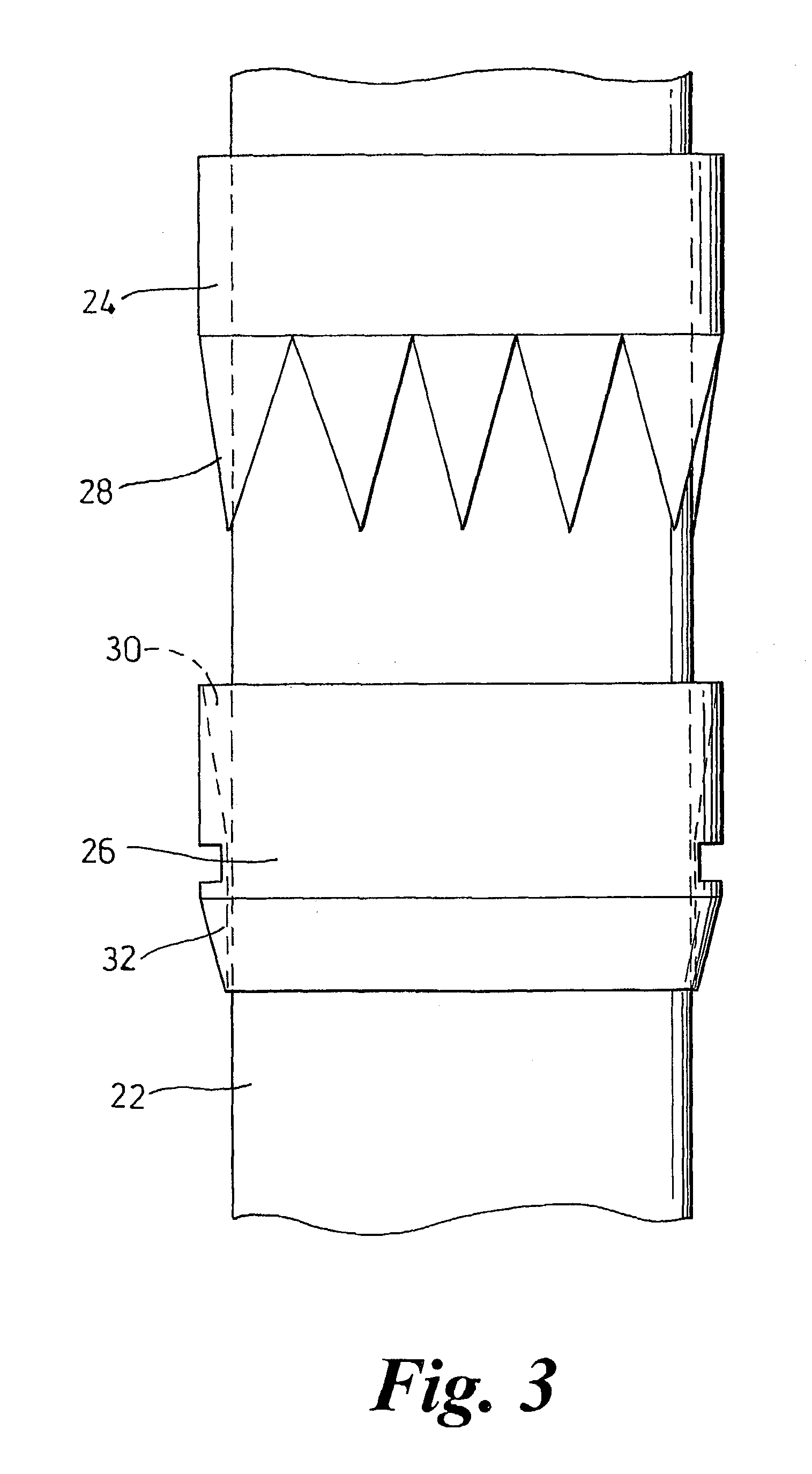

Centralizer

InactiveUS7159668B2Improve deformationRestrict movementDrill bitsDrilling rodsEngineeringDrill cuttings

A centralizer 10 for mounting on a tubular member such as a section of casing, together with one or more stops 42, 48 for retaining the centralizer thereon. The stops 42, 48 are provided with profiles for engaging the centralizer to restrict rotation thereof. The centralizer 10 may be selectively permitted or restricted from rotation by selection of appropriate stops, and by relative movement of the stops and centralizer on the tubular. Certain embodiments of the centralizer 10 may also include blades 14 on the body thereof, the blades being formed such that the velocity and kinetic energy of fluid flow across the blades is altered, so reducing settling of drill cuttings within the bore and on the centralizer.

Owner:DEEP CASING TOOLS LTD

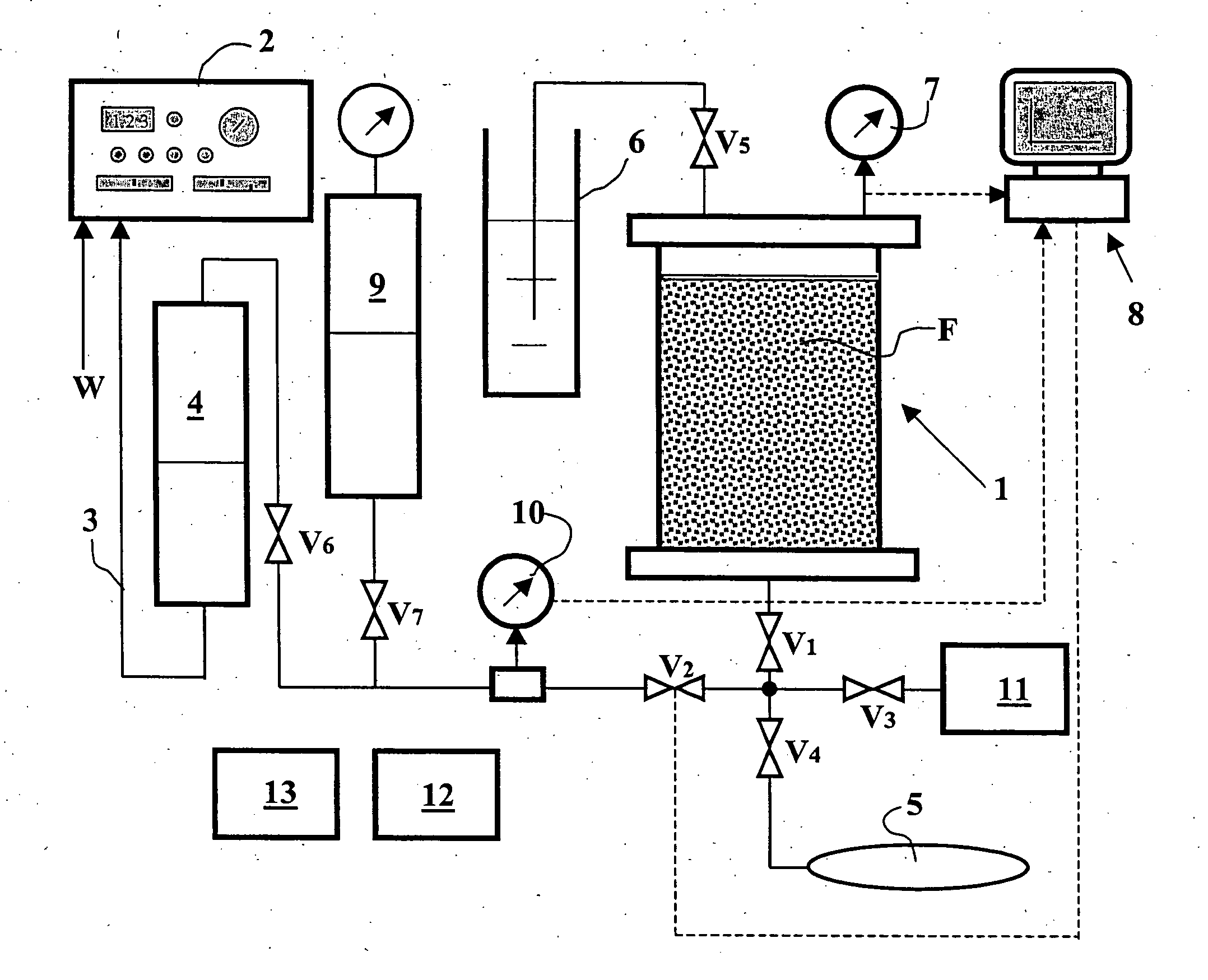

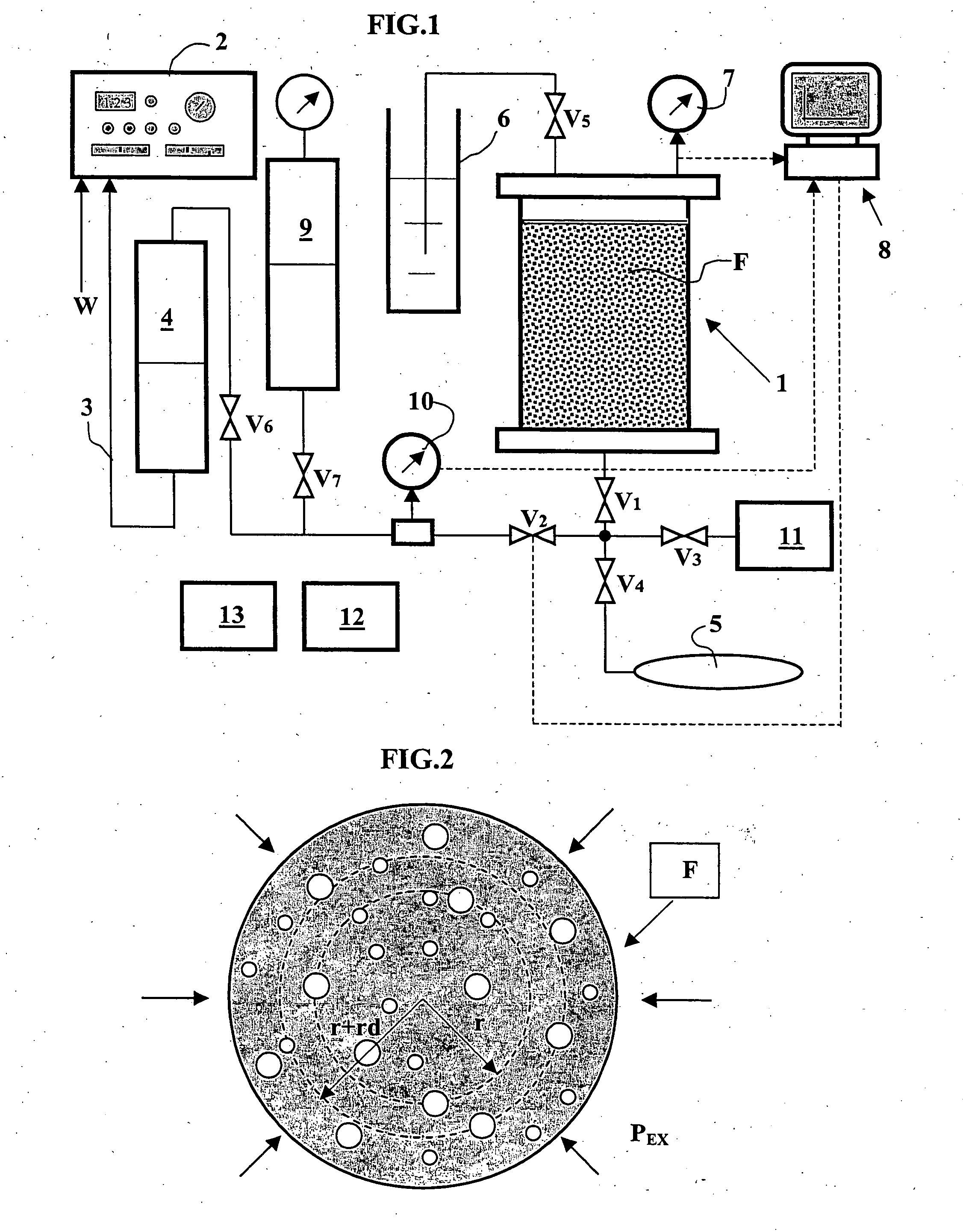

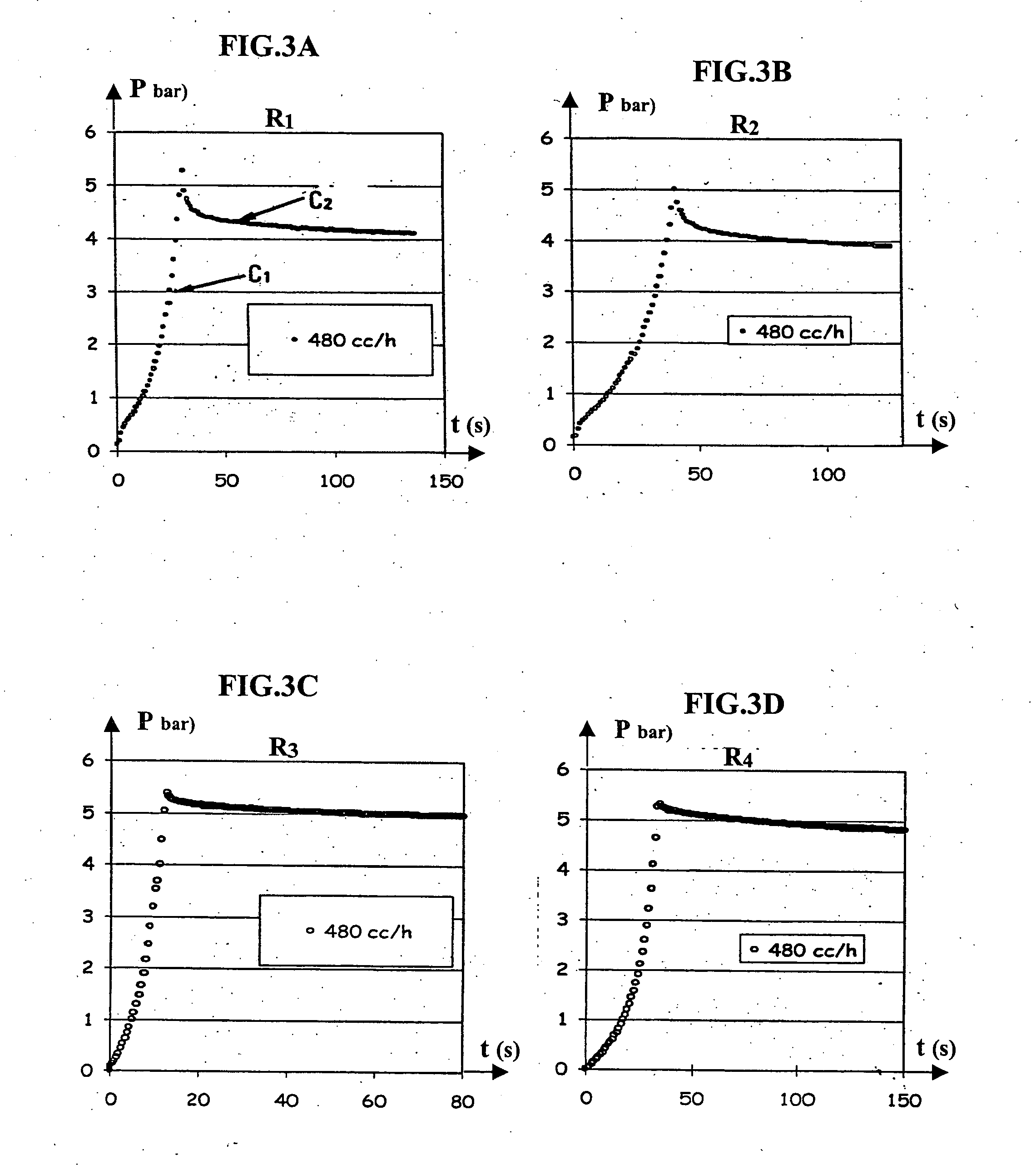

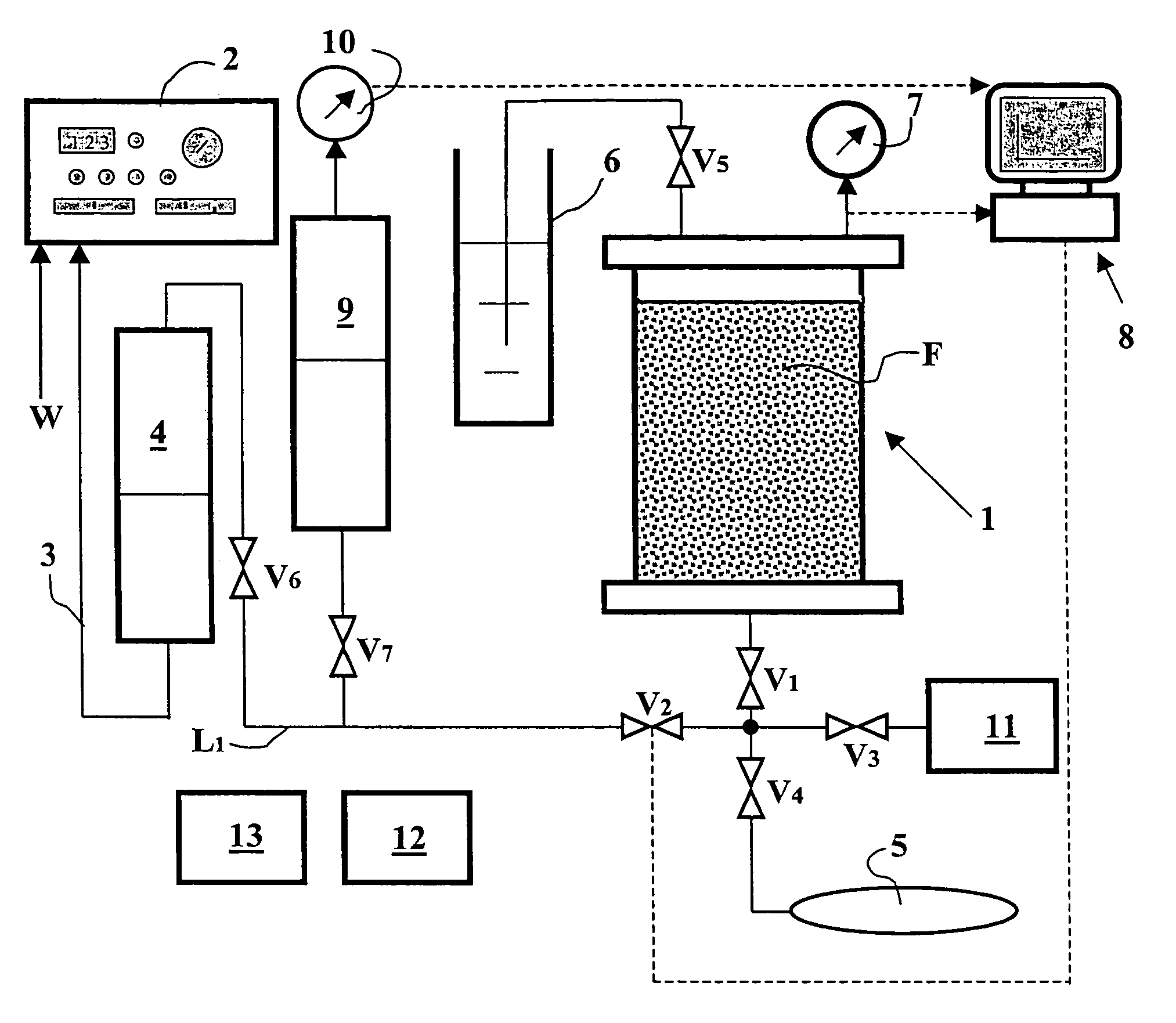

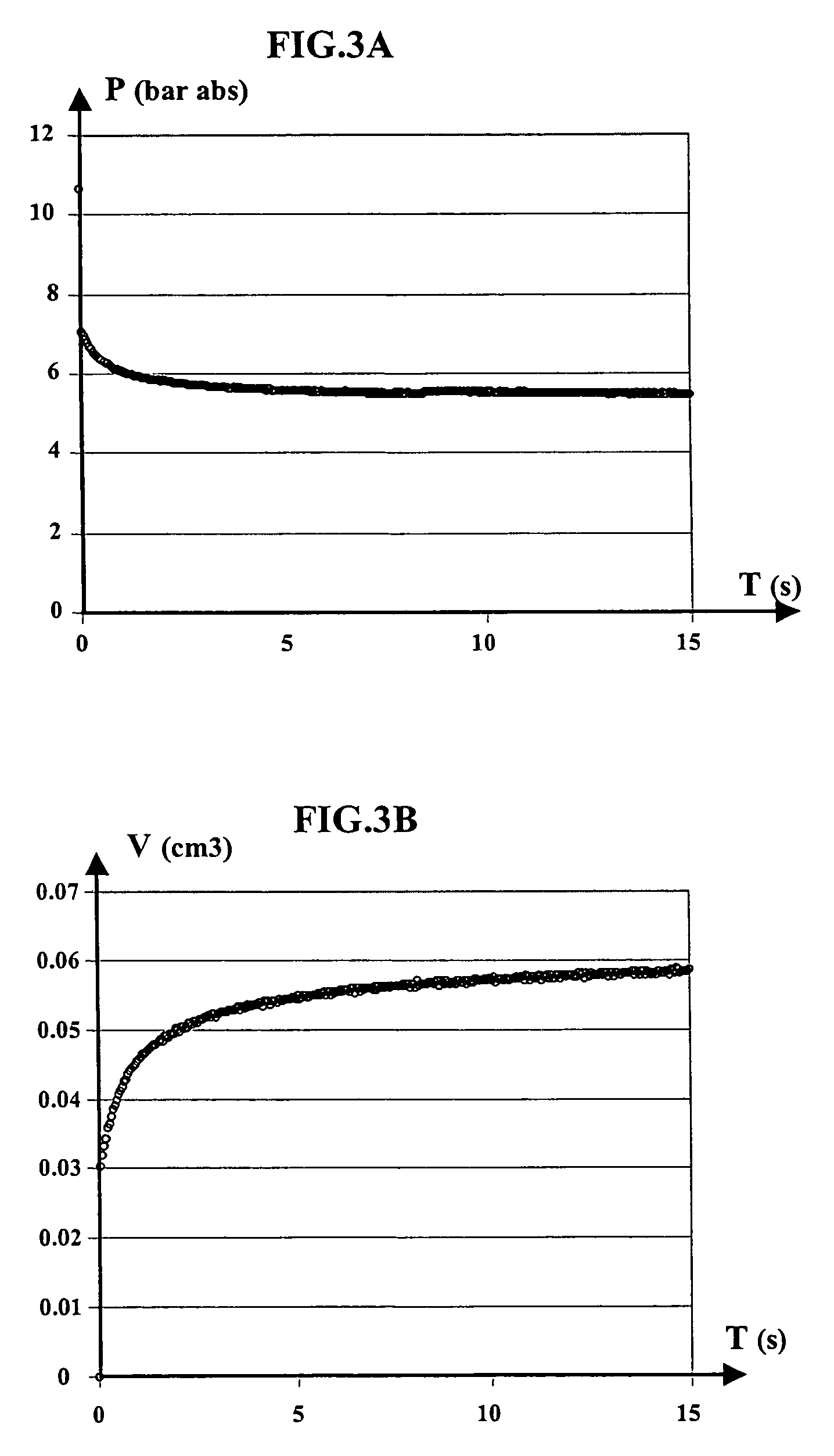

Method and device for evaluating physical parameters of an underground deposit from rock cuttings sampled therein

InactiveUS20050178189A1Short timeLimited spaceElectric/magnetic detection for well-loggingPermeability/surface area analysisMedicinePorous medium

Method and device for evaluating simultaneously, with the same equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented natural or artificial porous medium The porosity of the fragments is measured by means of helium pressure tests according to a protocol known in the art. The chamber (1) containing the fragments is communicated with a tank (11) whose volume is also known and containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the fragments mass are also measured. Combining these measurements allows to determine the porosity of the samples and the density of the rock. Their permeability is then measured by immersing them in a viscous fluid and by communicating the chamber with viscous fluid at a determined pressure contained in a vessel (9) so as to compress the gas trapped in the pores of the rock, according to two different protocols. The values of the physical parameters are determined by modelling the evolution of the pressure or of the volume in the chamber and by means of an iterative adjustment. Applications: petrophysical measurements from drilling cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

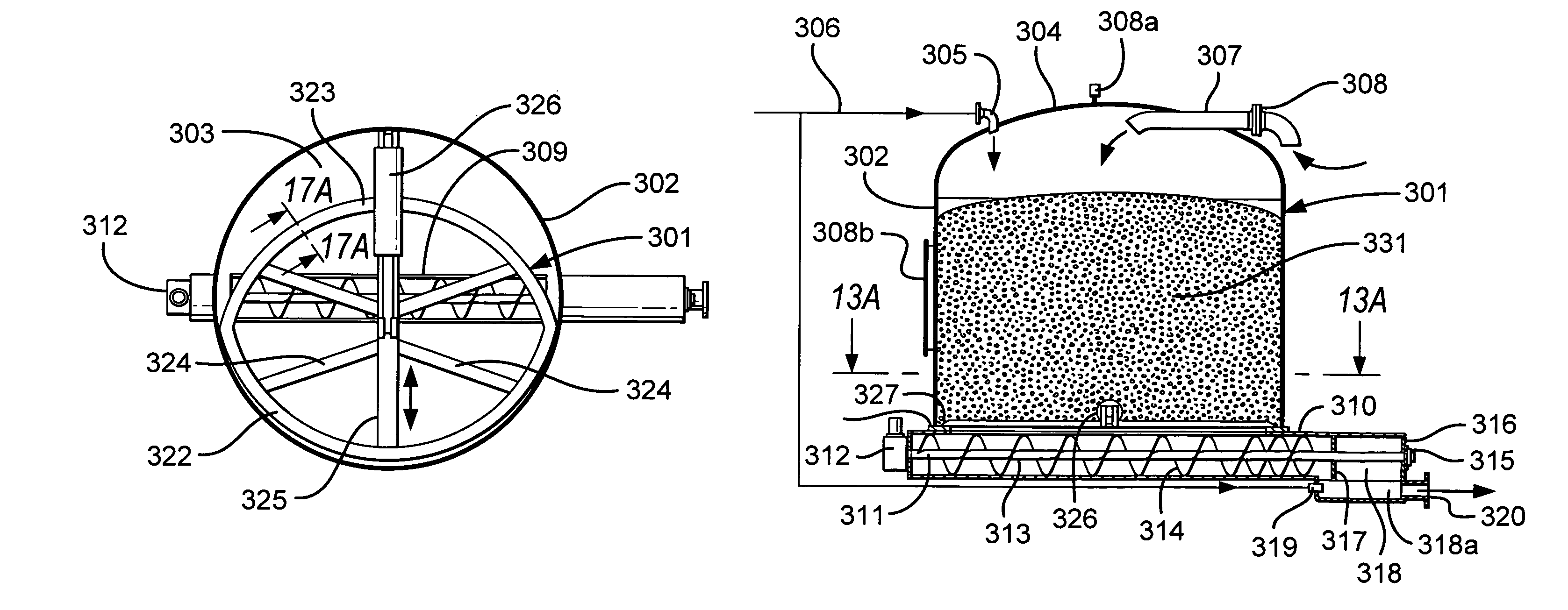

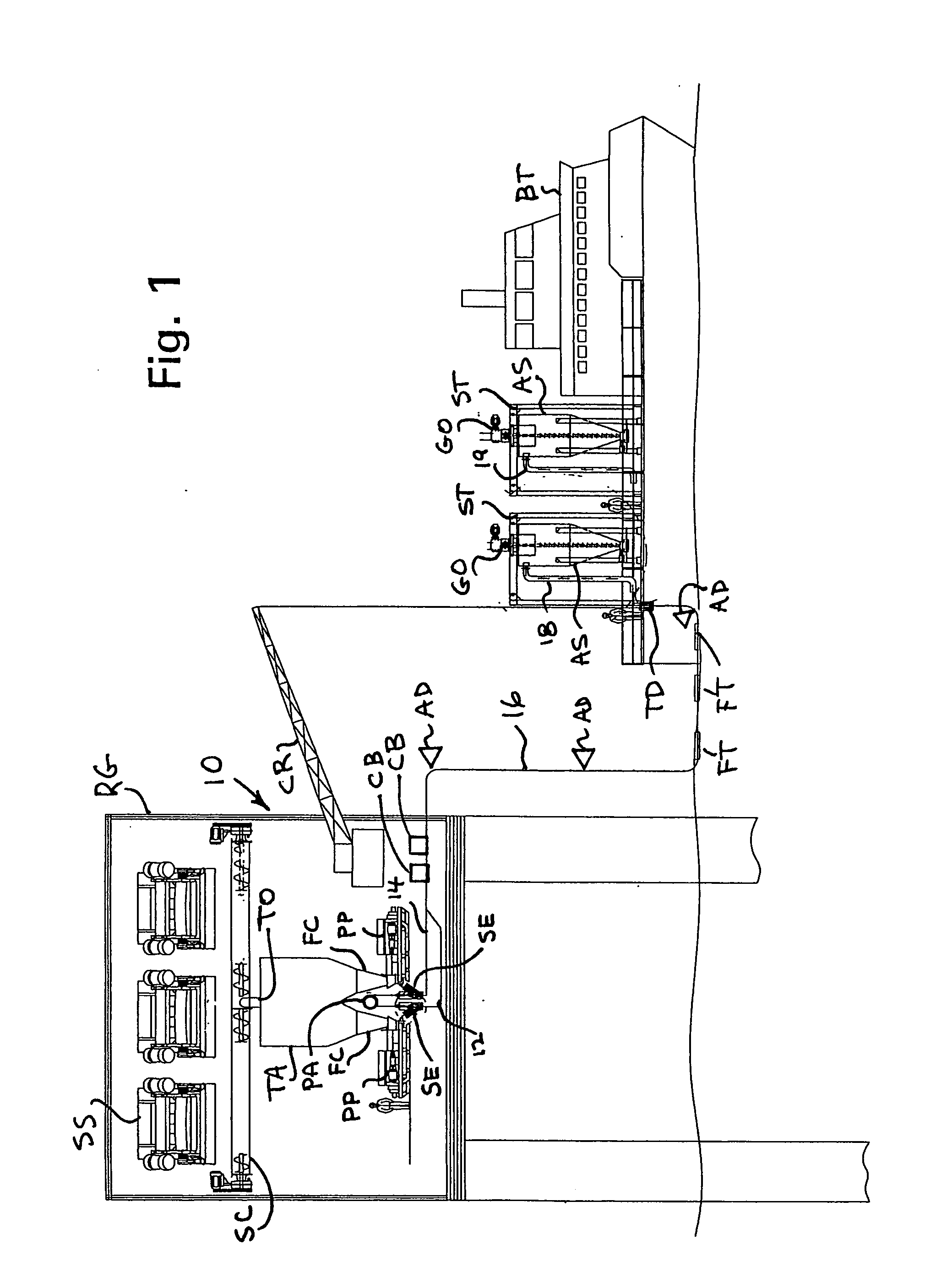

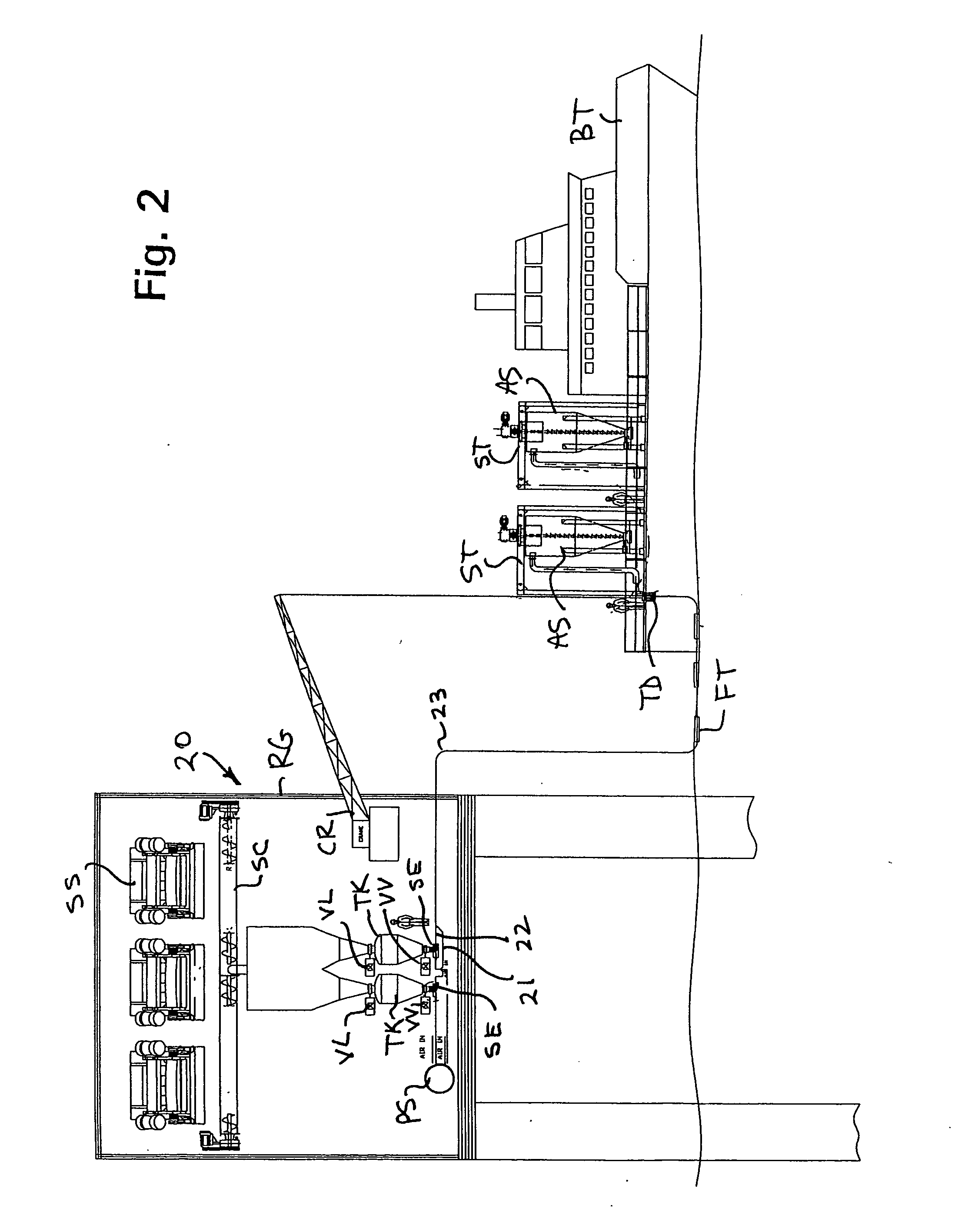

Systems and methods for storing and handling drill cuttings

Vessels for selectively holding drilling cuttings material and methods employing such vessels; the vessels, in at least certain aspects, having a body with a hollow container with an interior space for receiving drilling cuttings material and from which the material may exit from the body; a first opening through which the material enters into the container; a second opening through which the material passes out from the container; and movement apparatus with a movement member within the container movable adjacent the second opening to facilitate passage of the material into the second opening; and in certain aspects, the vessels having moisture-content sensor apparatus on the body for sensing moisture content of material within a vessel; conduit apparatus for conducting drilling cuttings from the exit opening; valve apparatus for selectively controlling flow of material in the conduit apparatus; and a controller in communication with the moisture-content sensor apparatus and the valve apparatus for selectively controlling flow in the conduit apparatus.

Owner:VARCO I P INC

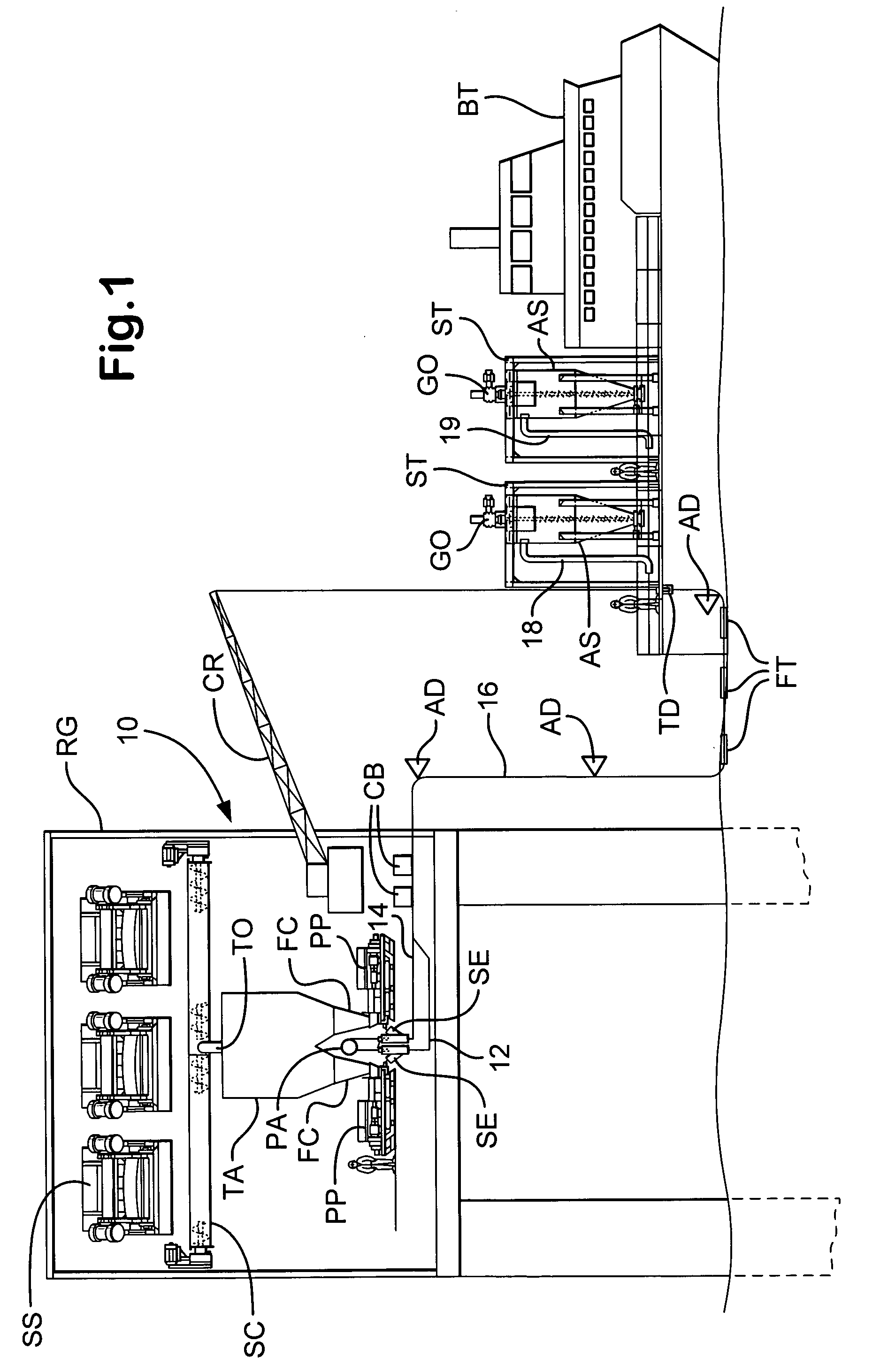

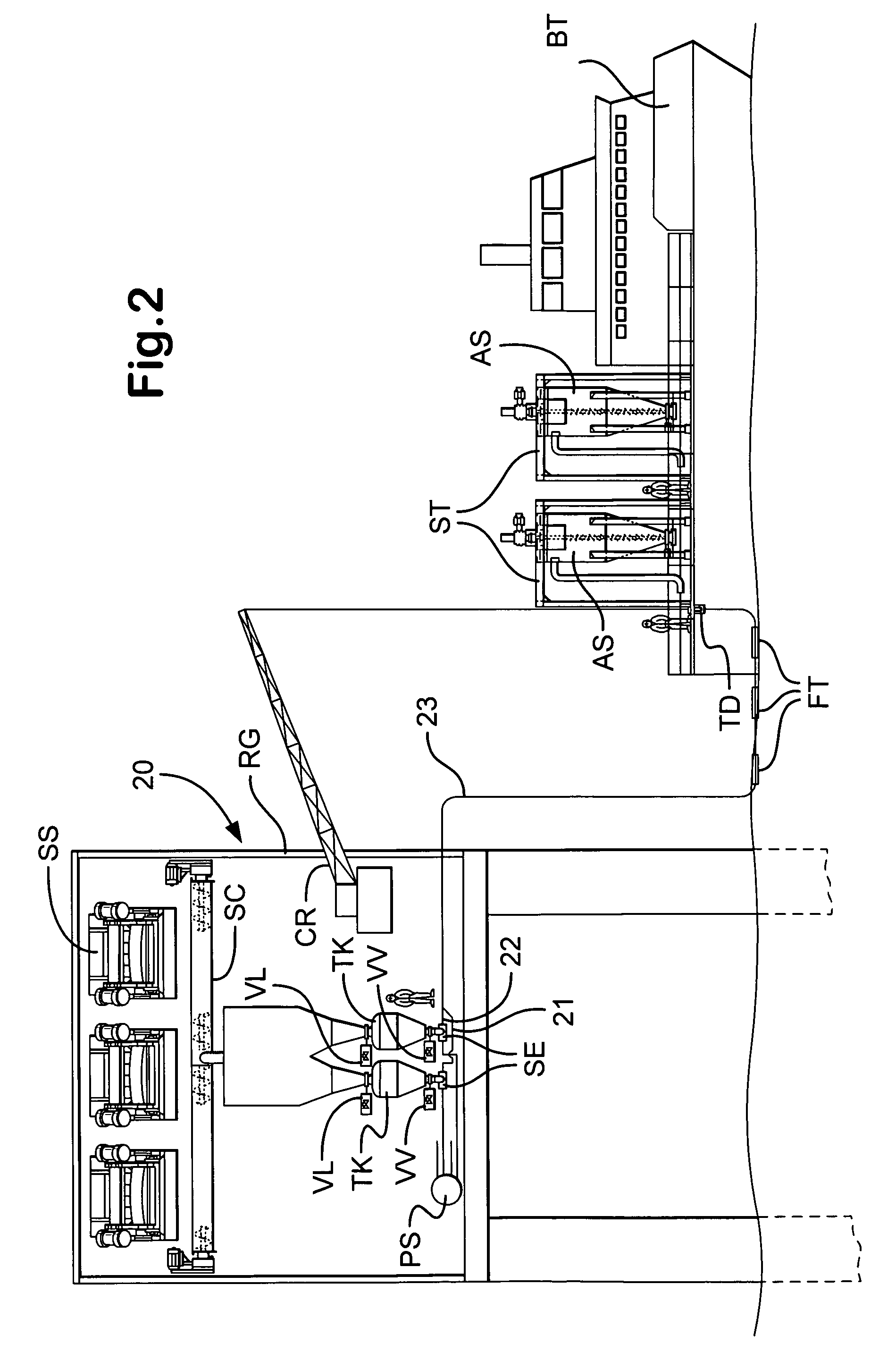

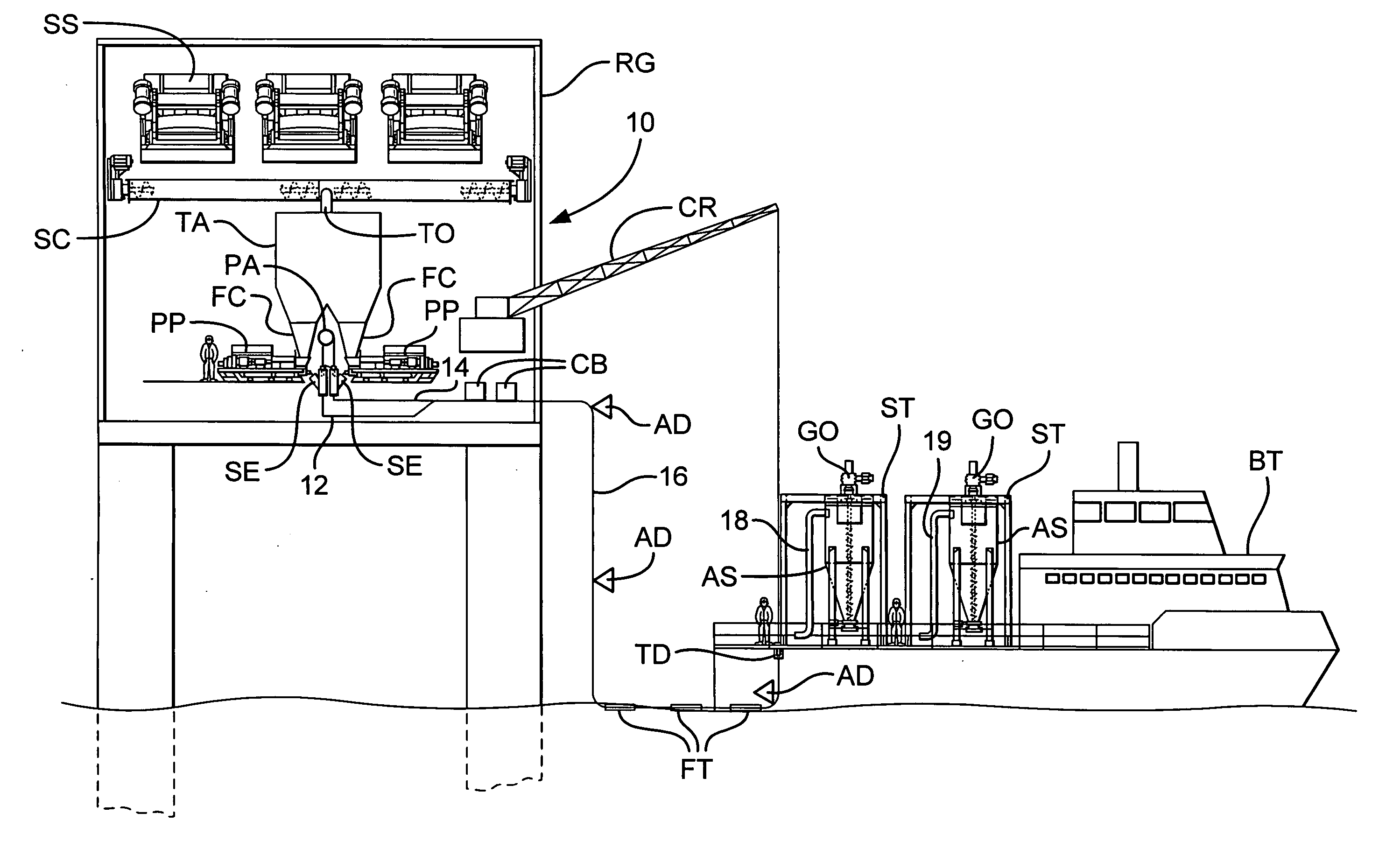

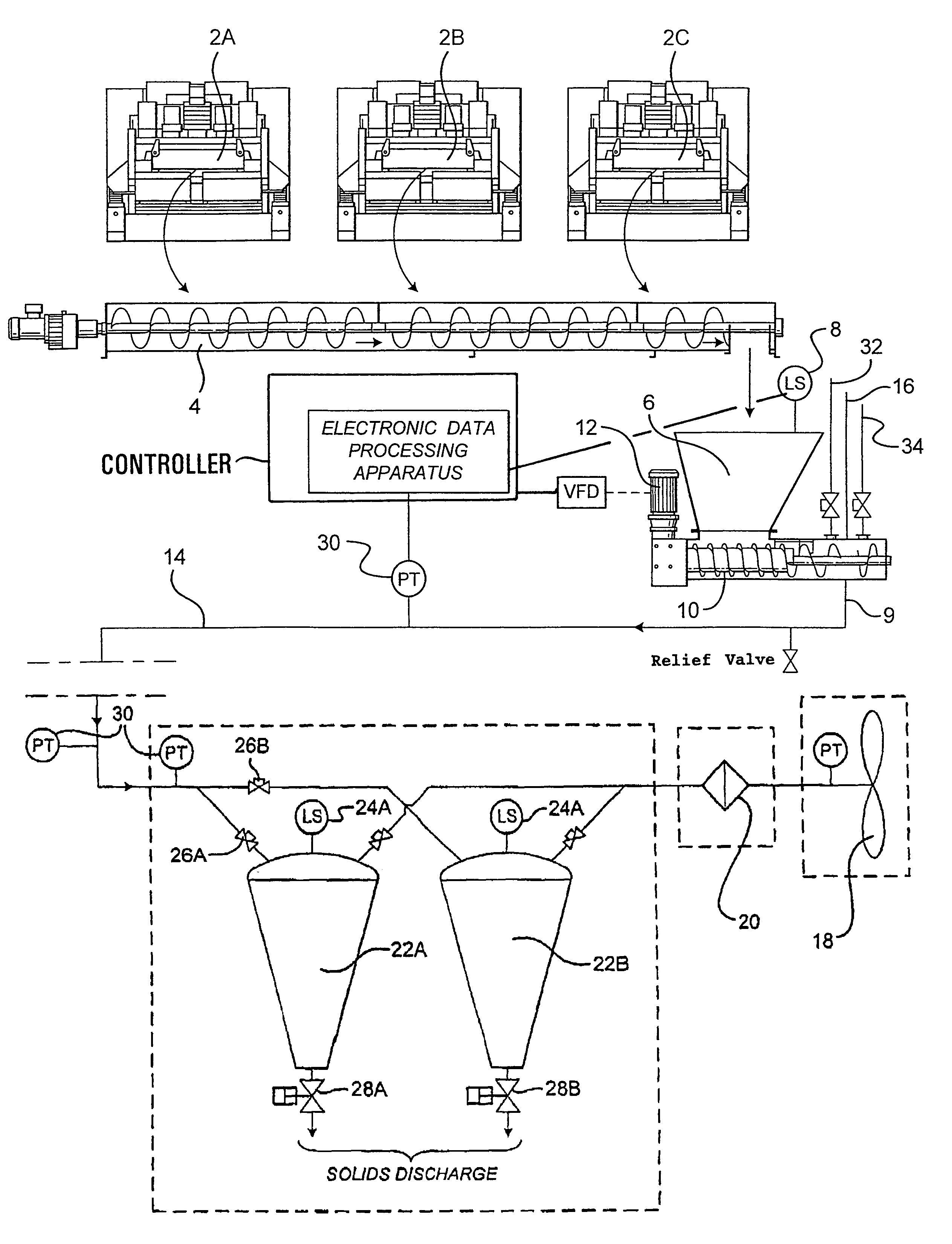

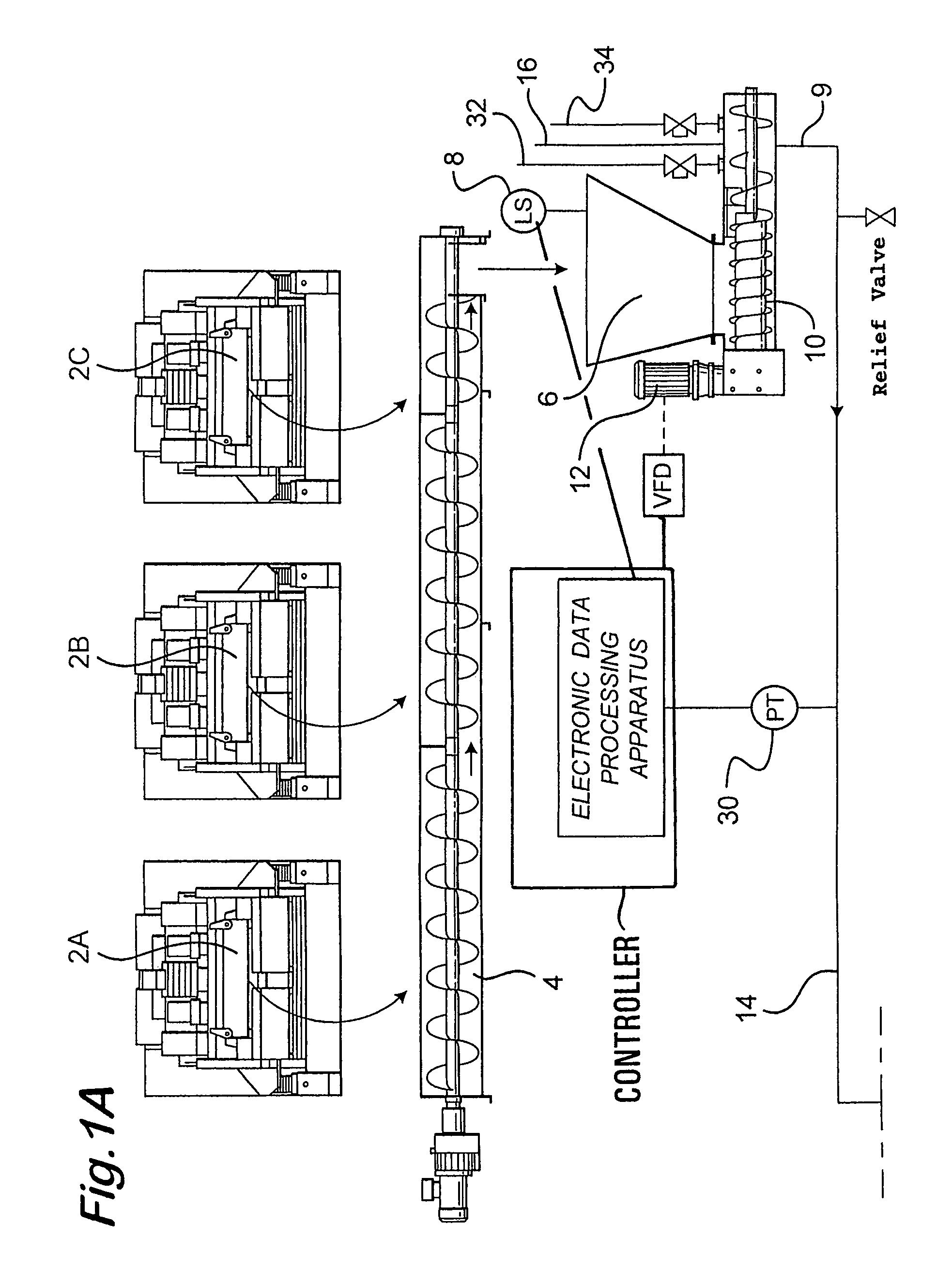

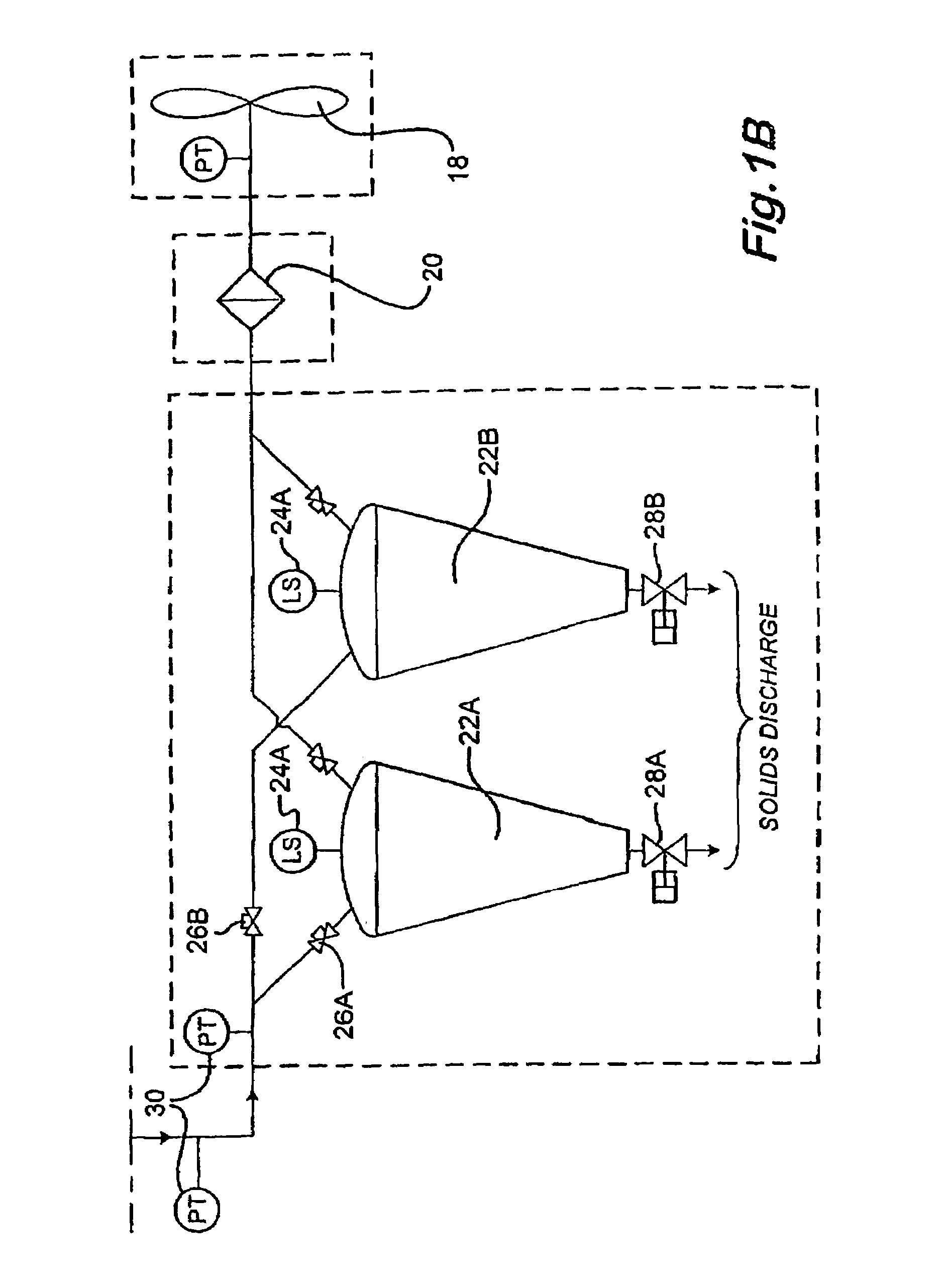

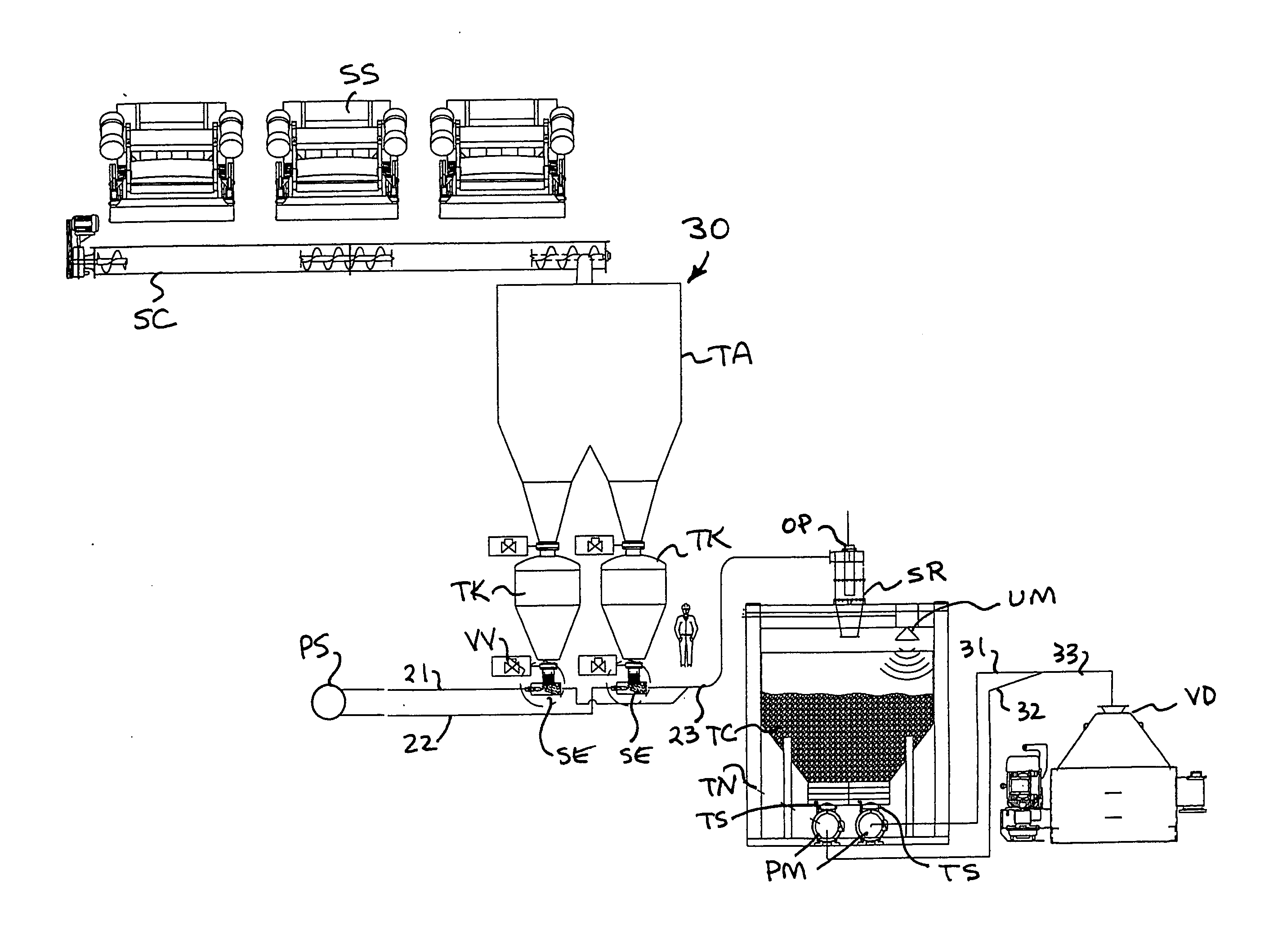

Drill cuttings conveyance systems and methods

ActiveUS20060102390A1Low densityEasy accessCargo handling apparatusDispersed particle separationPressure senseDrill cuttings

Vessels, system and methods for conveying drilling cuttings material, which, in certain aspects, include a system for conveying material from a vessel, the system having a vessel for receiving material to be conveyed, a first conduit for conveying air, a second conduit for receiving air from the first conduit and for conveying air into the vessel, a metering screw for receiving material from the vessel and for moving the material from the vessel, a discharge line for receiving the material from the metering screw, the discharge line having an exit end, pressure sensor apparatus for sensing pressure in the discharge line, and control apparatus for automatically controlling the metering screw in response to a pressure sensed by the pressure sensor apparatus.

Owner:VARCO I P INC

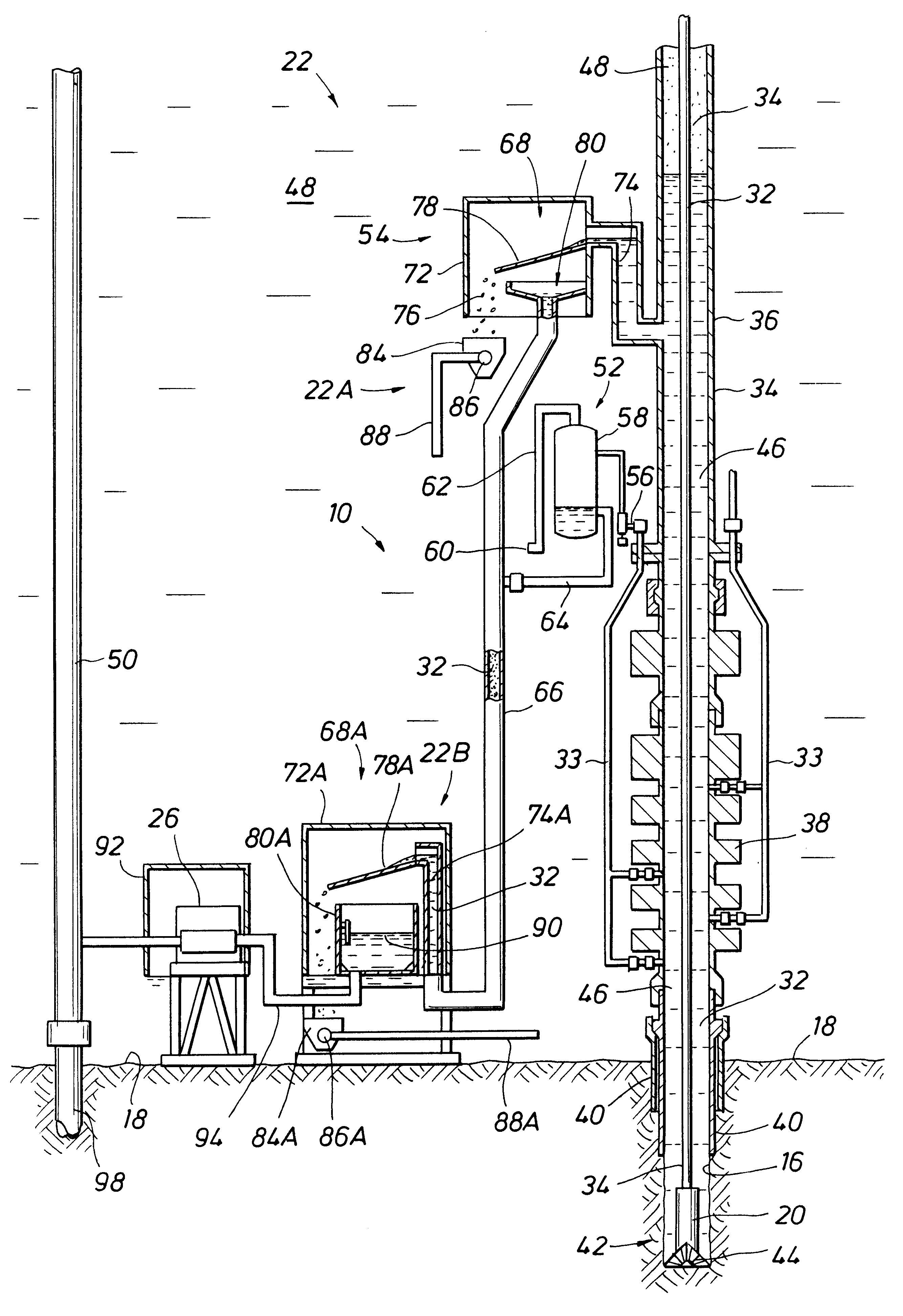

System for drilling oil and gas wells by varying the density of drilling fluids to achieve near-balanced, underbalanced, or overbalanced drilling conditions

InactiveUS7090036B2Decreasing/increasing densityHigh speedConstructionsDerricks/mastsWell drillingLand based

A system for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in offshore and land-based drilling applications is disclosed. The present invention combines a base fluid of lesser / greater density than the drilling fluid required at the drill bit to drill the well to produce a combination return mud in the riser. By combining the appropriate quantities of drilling mud with a light base fluid, a riser mud density at or near the density of seawater may be achieved to facilitate transporting the return mud to the surface. Alternatively, by injecting the appropriate quantities of heavy base fluid into a light return mud, the column of return mud may be sufficiently weighted to protect the wellhead. At the surface, the combination return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the drilling fluid from the base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

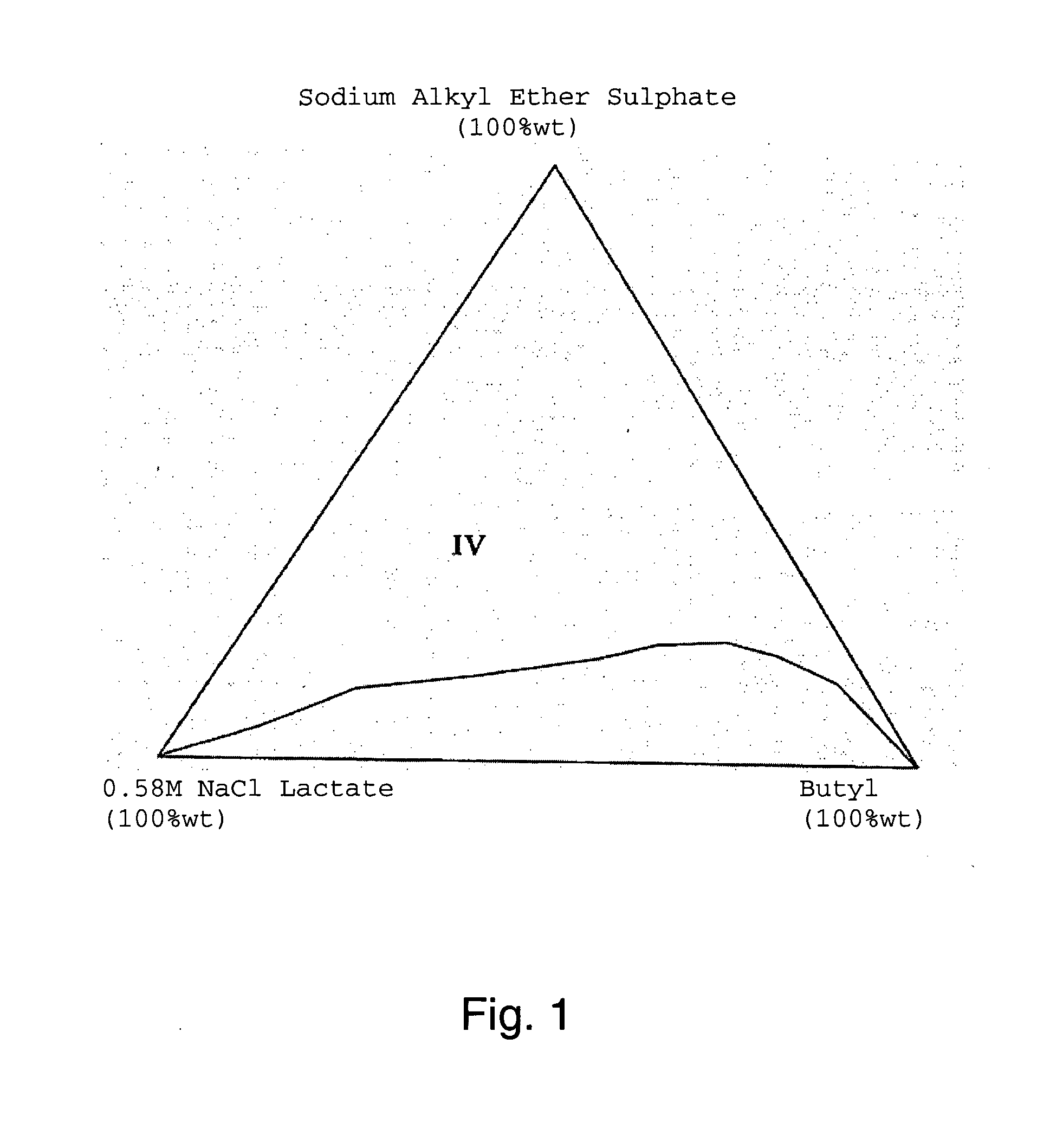

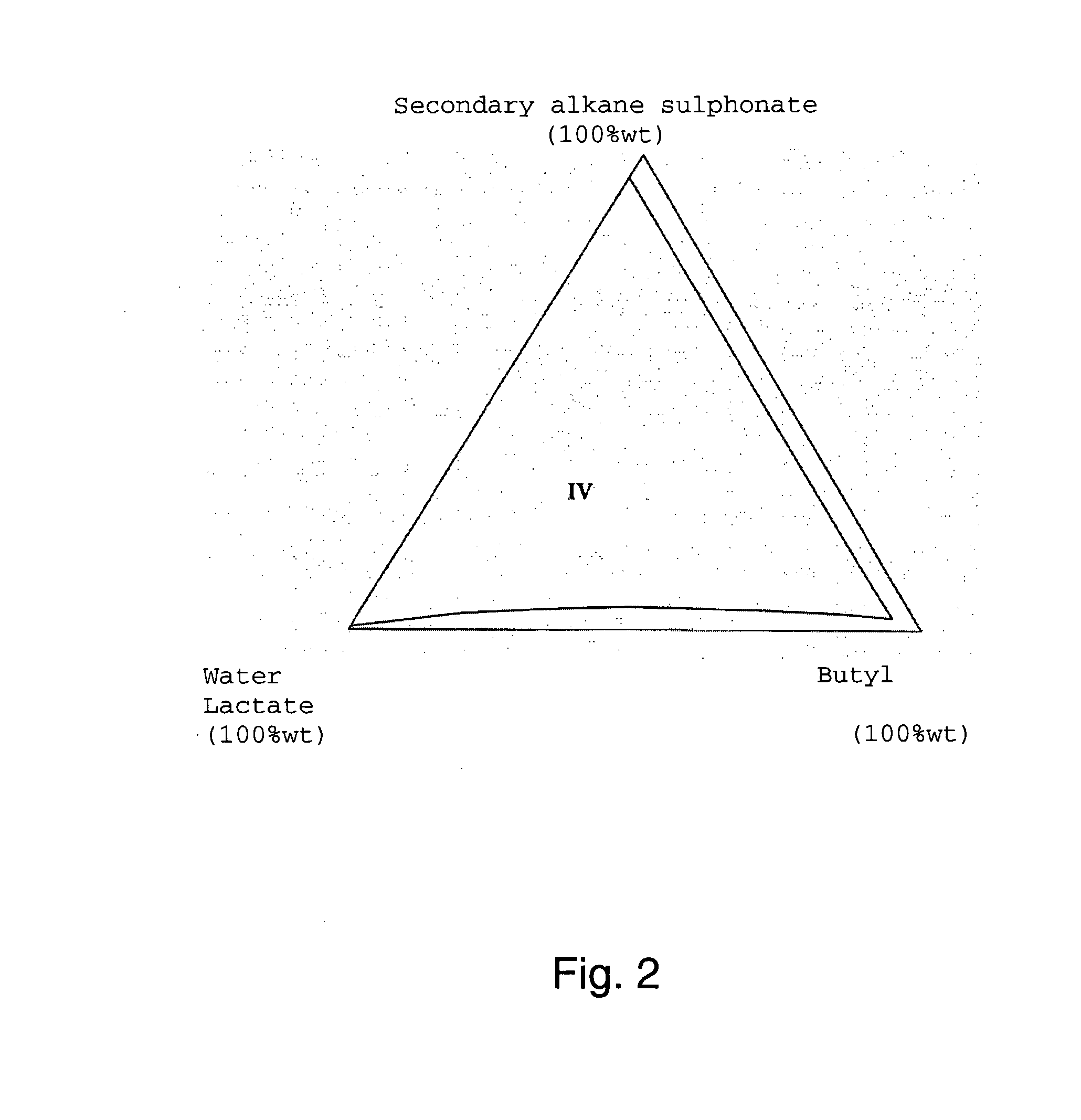

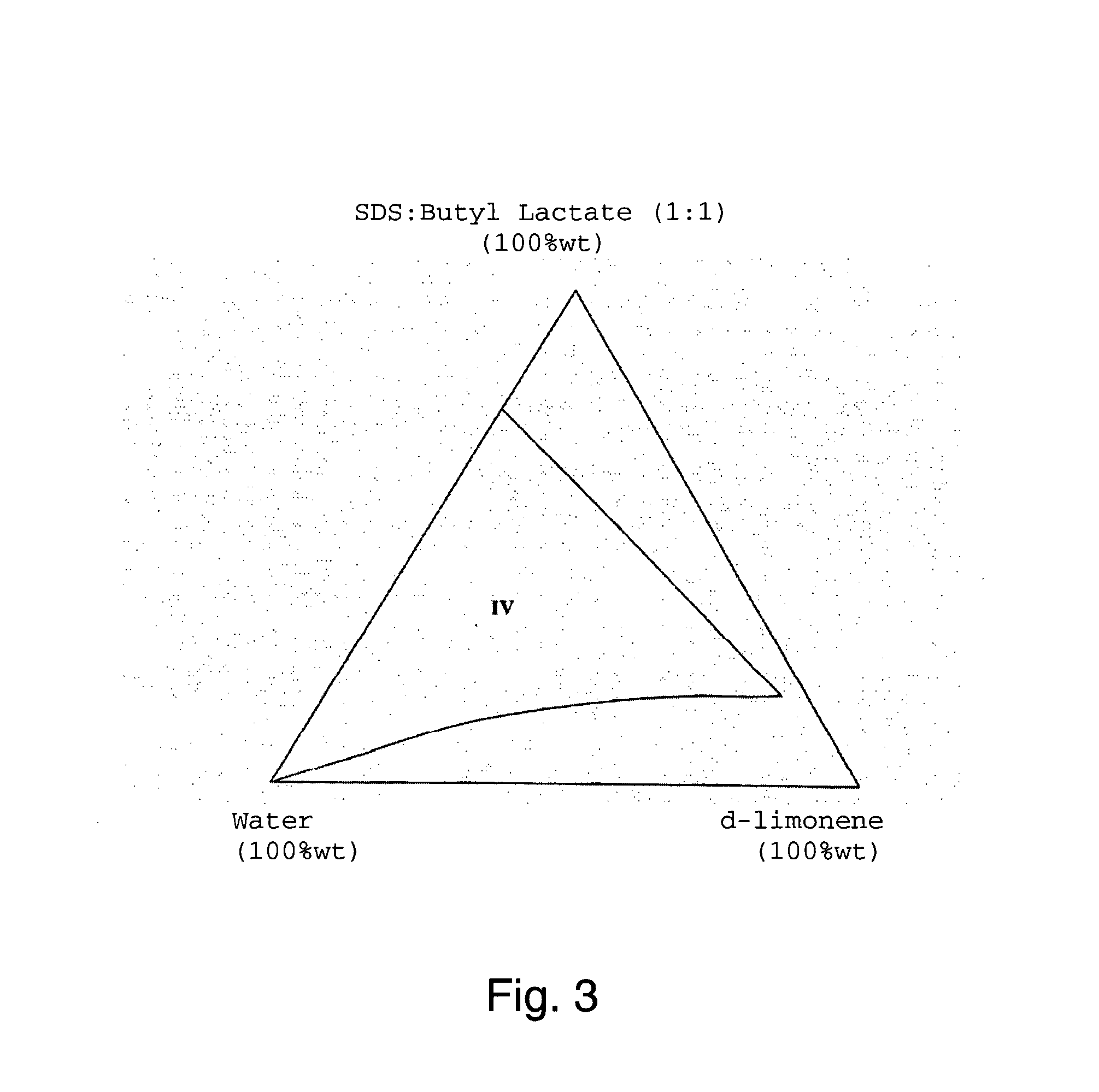

Surfactant System Method

InactiveUS20070295368A1Improve cleaning efficiencyAvoid damageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSurface cleaning

The invention relates to the formulation and application of water based predominantly pH neutral microemulsions and microemulsion forming surfactant systems essentially comprising a surfactant or surfactant˜end, lactates)—esters) of lactic acid—and water / brine and optionally solvent. Uniquely the formulations are acid and caustic free and also do not make use of alcohol, glycol and glycol ether components in the systems as co surfactant, co-solvent or mutual solvent. In particular the invention relates to the methods and the application of this microemulsion technology for use in industrial hard surface cleaning applications especially the inks and printing industries and the oil and gas industry. In addition the formulations can be used in the production of microemulsion based drilling muds (which may or may not be Oil Based Muds—OBMs) and they may be used to enhance the drill cuttings slurrification processes for re-injection purposes or for facilitated cuttings transport.

Owner:SURFACTANT TECH +1

Apparatus and method for transporting waste materials

InactiveUS7080960B2Reduce feed rateHigh speedControl devices for conveyorsFlushingDrill cuttingsWaste material

Owner:VARCO I P INC

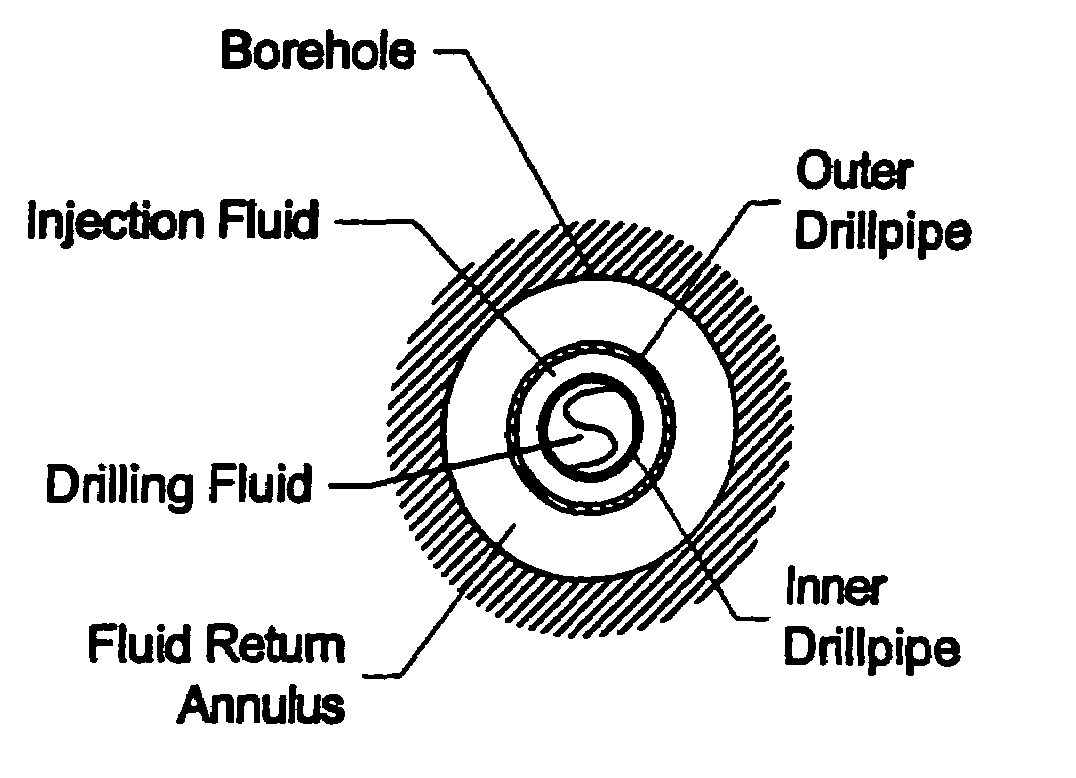

System for drilling oil and gas wells using a concentric drill string to deliver a dual density mud

InactiveUS7093662B2Decreasing/increasing densityHigh speedSurveyConstructionsSeawaterTreatment system

A system for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in offshore and land-based drilling applications is disclosed. The present invention combines a base fluid of lesser / greater density than the drilling fluid required at the drill bit to drill the well to produce a combination return mud in the riser. By combining the appropriate quantities of drilling mud with a light fluid, a riser mud density at or near the density of seawater may be achieved to facilitate transporting the return mud to the surface. Alternatively, by injecting the appropriate quantities of heavy fluid into a light return mud, the column of return mud may be sufficiently weighted to protect the wellhead. At the surface, the combination return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the drilling fluid from the base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

Methods for increasing production from a wellbore

The present invention generally relates to a method for recovering productivity of an existing well. First, an assembly is inserted into a wellbore, the assembly includes a tubular member for transporting drilling fluid downhole and an under-reamer disposed at the end of the tubular member. Upon insertion of the assembly, an annulus is created between the assembly and the wellbore. Next, the assembly is positioned near a zone of interest and drilling fluid is pumped down the tubular member. The drilling fluid is used to create an underbalanced condition where a hydrostatic pressure in the annulus is below a zone of interest pressure. The under-reamer is activated to enlarge the wellbore diameter and remove a layer of skin for a predetermined length. During the under-reaming operation, the hydrostatic pressure is maintained below the zone of interest pressure, thereby allowing wellbore fluid to migrate up the annulus and out of the wellbore. After the under-reaming operation, back-reaming may be performed to remove any excess wellbore material, drill cuttings and fines left over from the under-reaming operation and to ensure no additional skin damage is formed in wellbore. Upon completion, the under-reamer is deactivated and the assembly is removed from the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

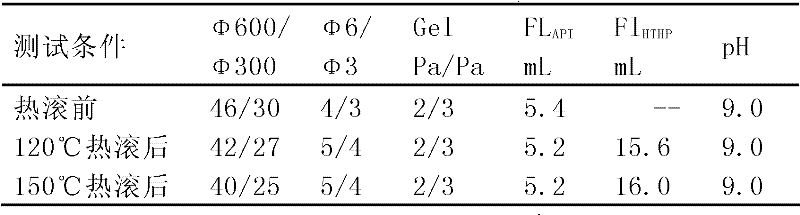

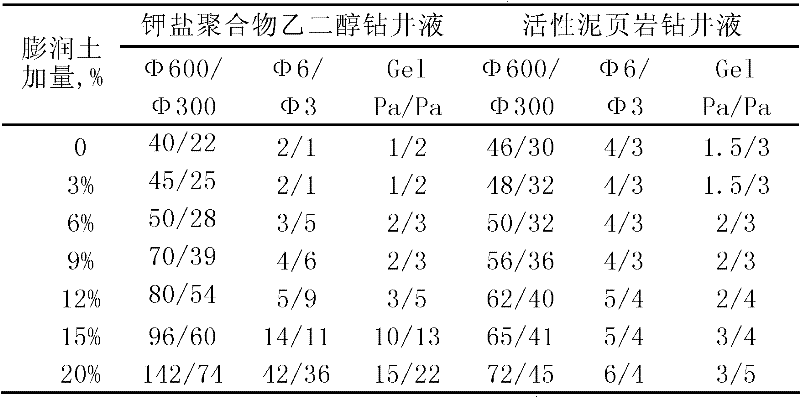

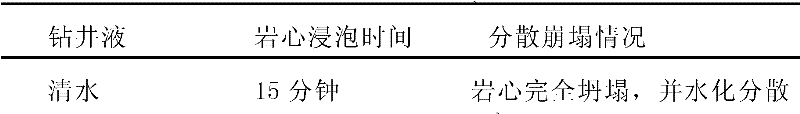

Drilling fluid used for active mud shale drilling

The invention relates to a drilling fluid used for active mud shale drilling, and the drilling fluid is used in oilfield drilling. The drilling fluid comprises the following components in percentages by weight: 2-6% of bentonite, 0.2-0.5% of coated inhibitor, 0.2-1.0% of flow pattern regulator, 0.2-0.5% of high-temperature-resistant polymer filtrate reducer, 4-7% of potassium chloride, 1-3% of polymeric alcohol, 0.5-1.0% of polyamine inhibitor, 0.5-1.0% of anti-balling fast drilling agent and 45-85% of water. The drilling fluid has the inhibition property and lubricating property approximate to that of an oil-based drilling fluid, solves the problems that the mud making of the mud shale is severe, mud escapes from a vibrating screen, the viscous shearing of the drilling fluid increases and the rheological properties of the drilling fluid deteriorates during strong-mud-making active mud shale drilling, prevents destabilization of the active mud shale, dispersion of drill cuttings, balling of drill bit, and adhesion and coalescence of the mud shale, and increases the drilling speed of the active mud shale.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

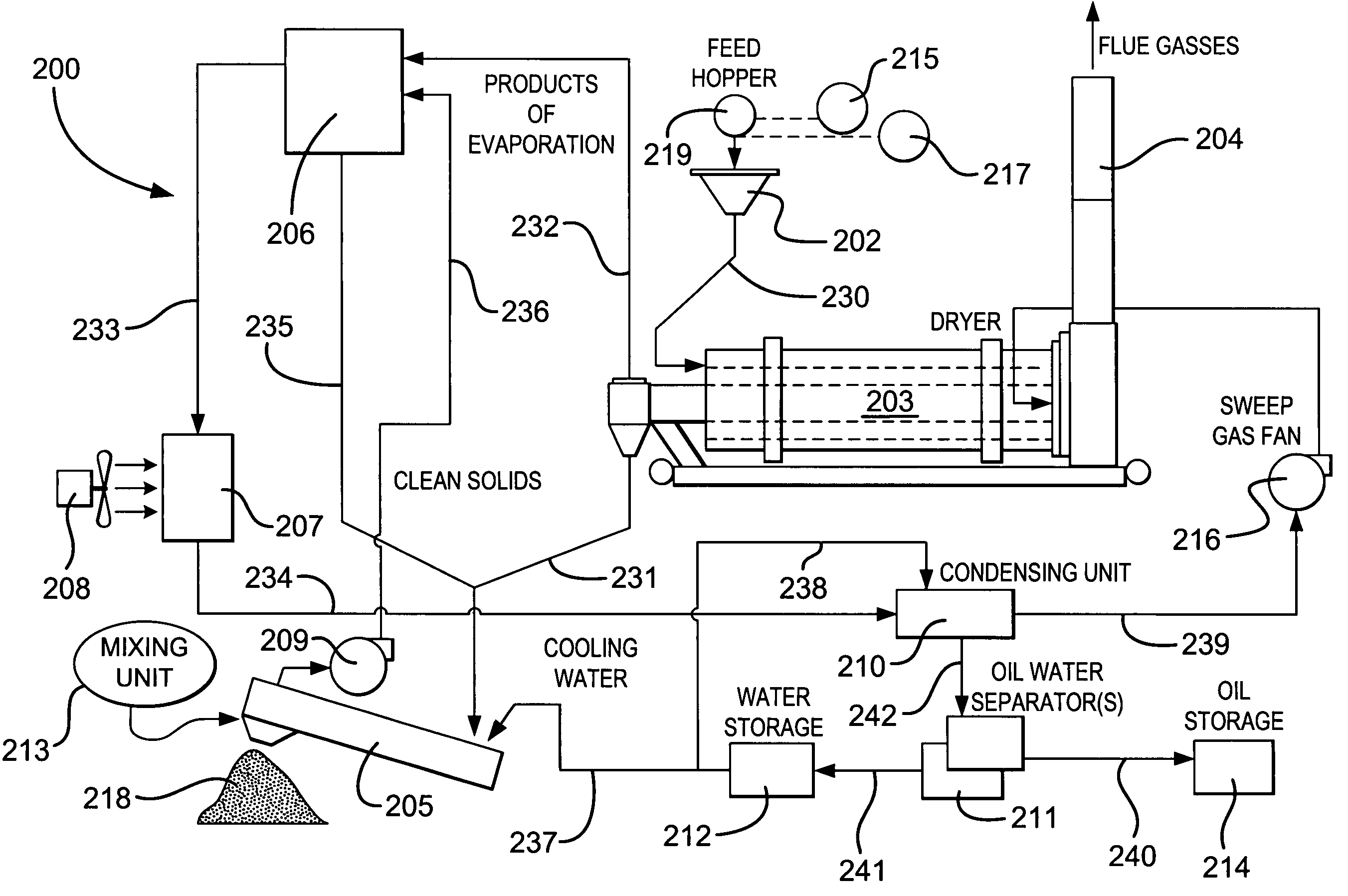

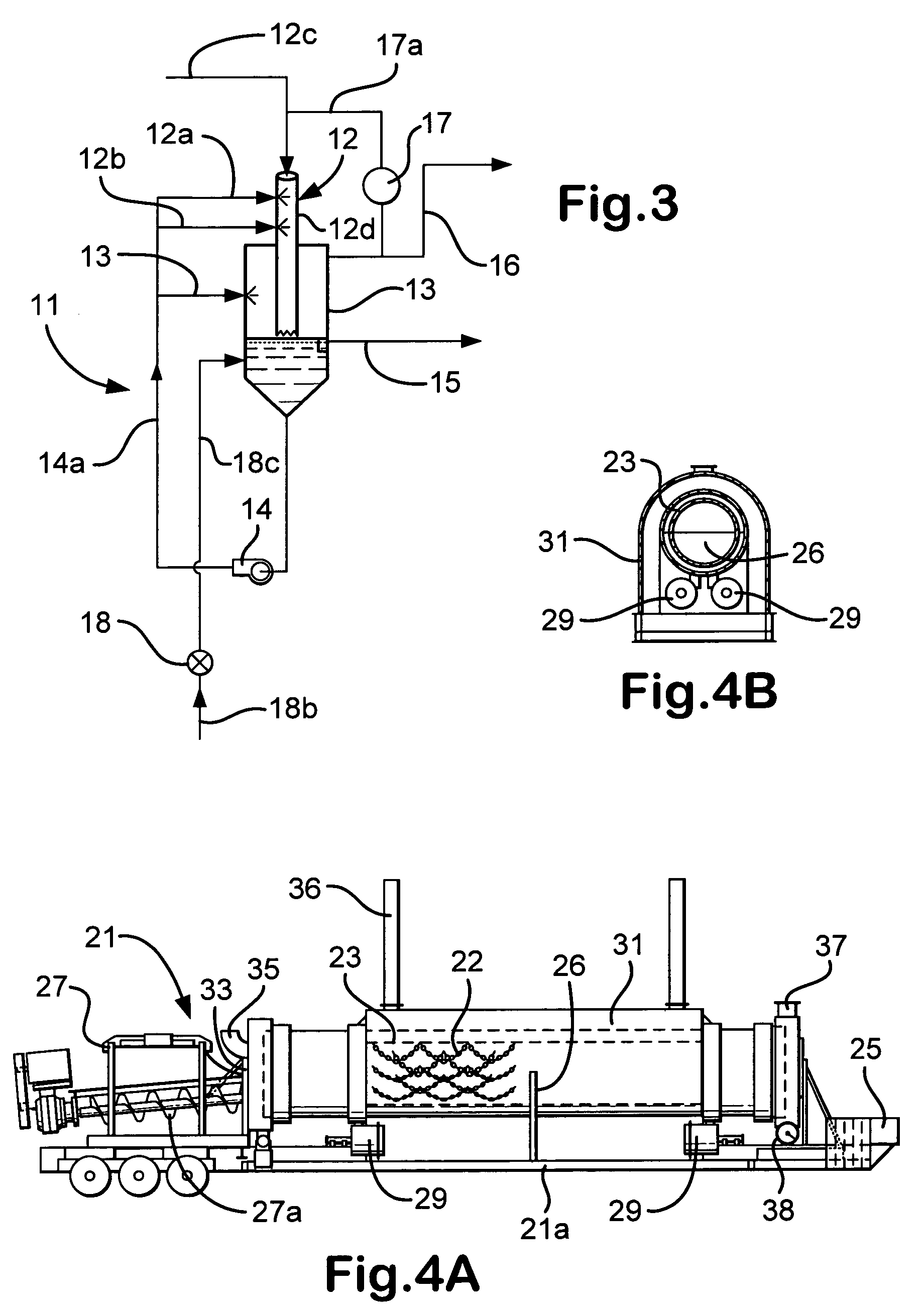

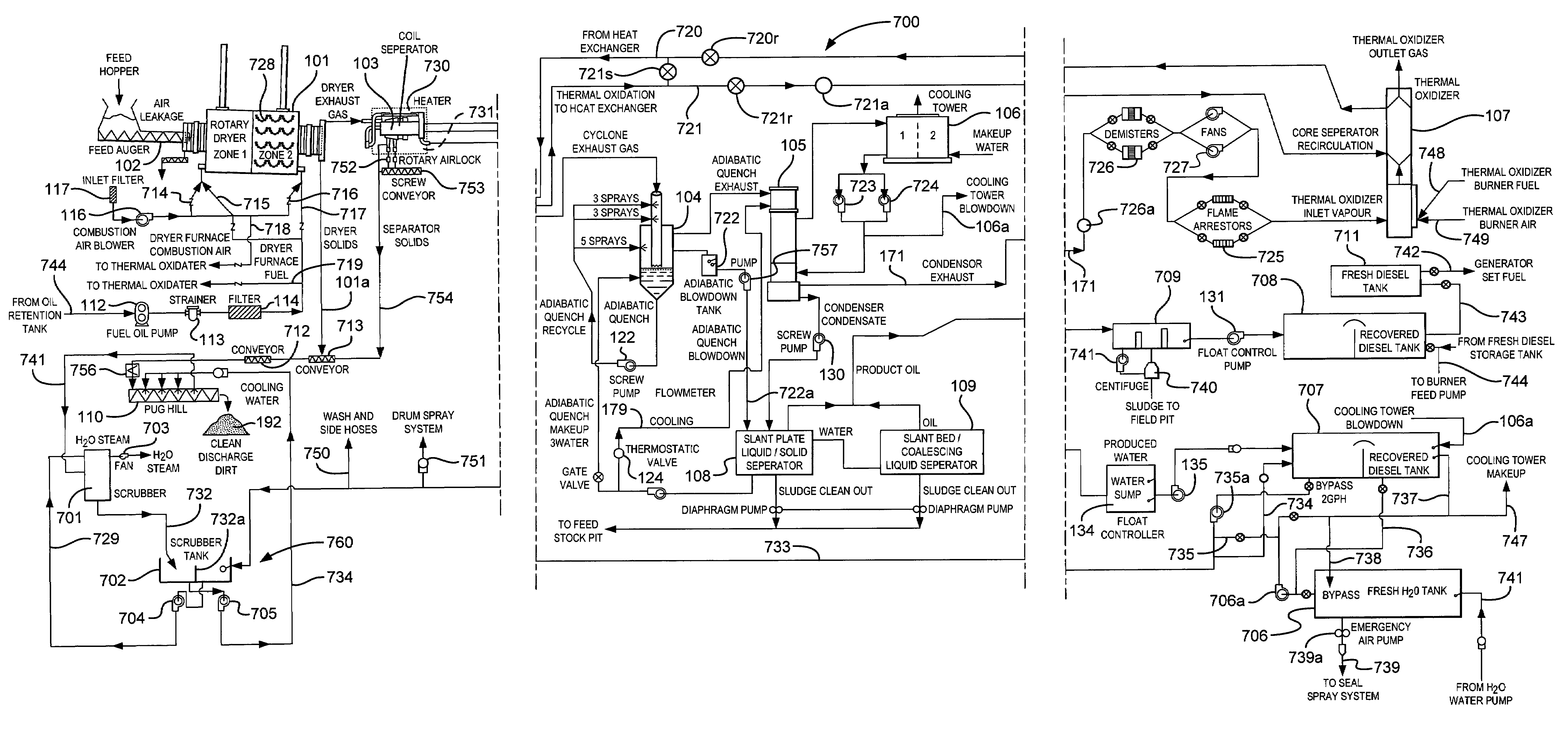

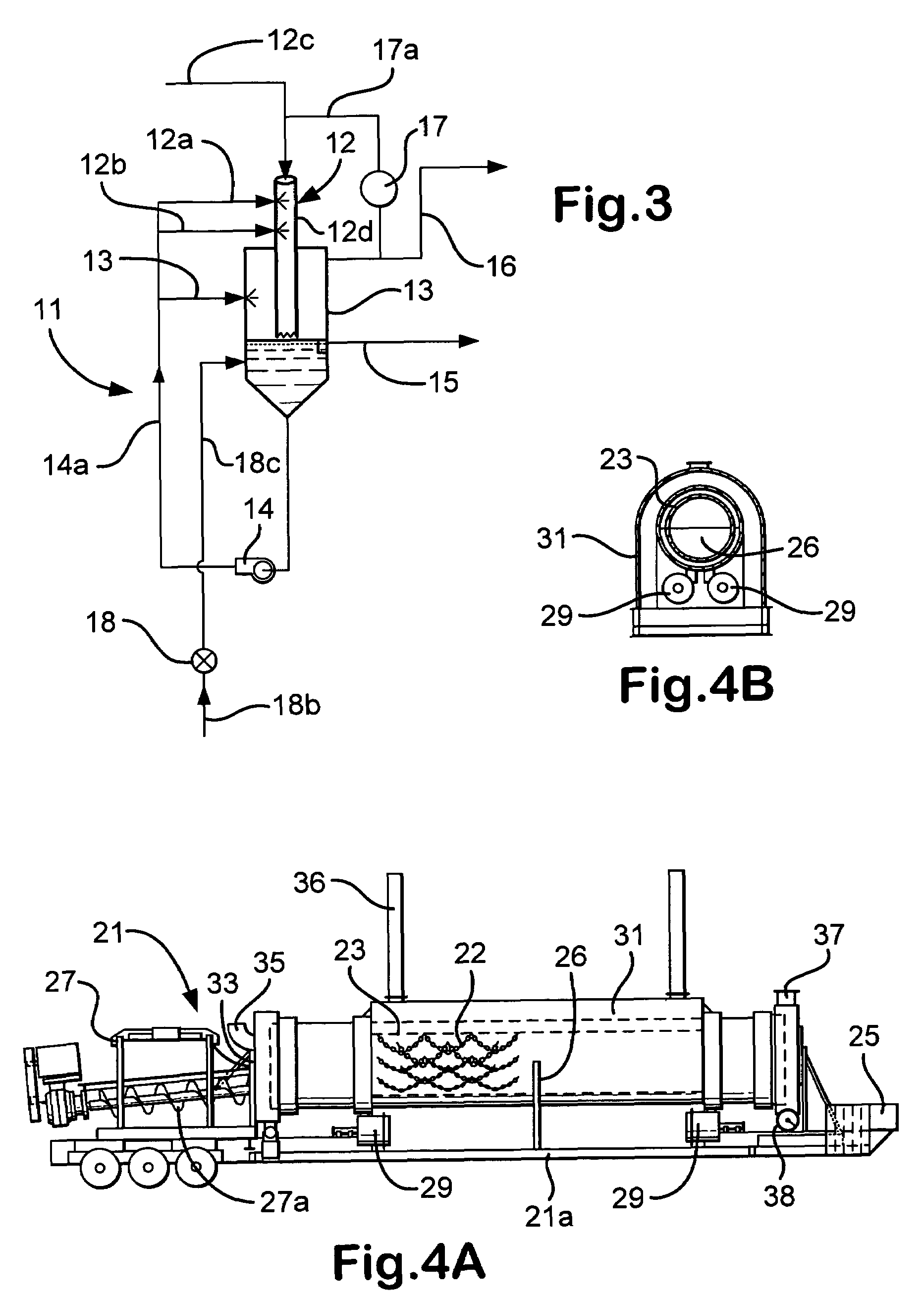

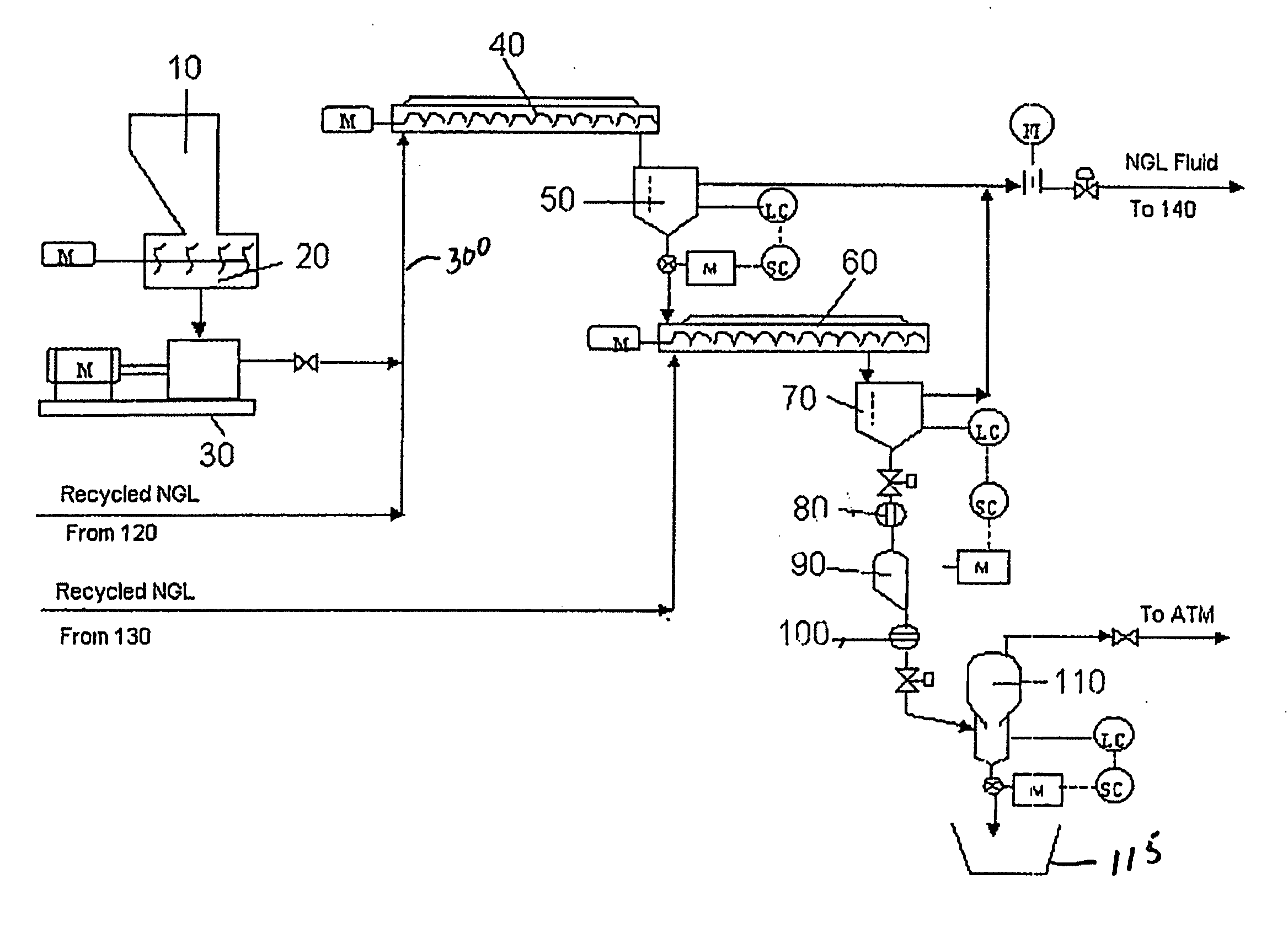

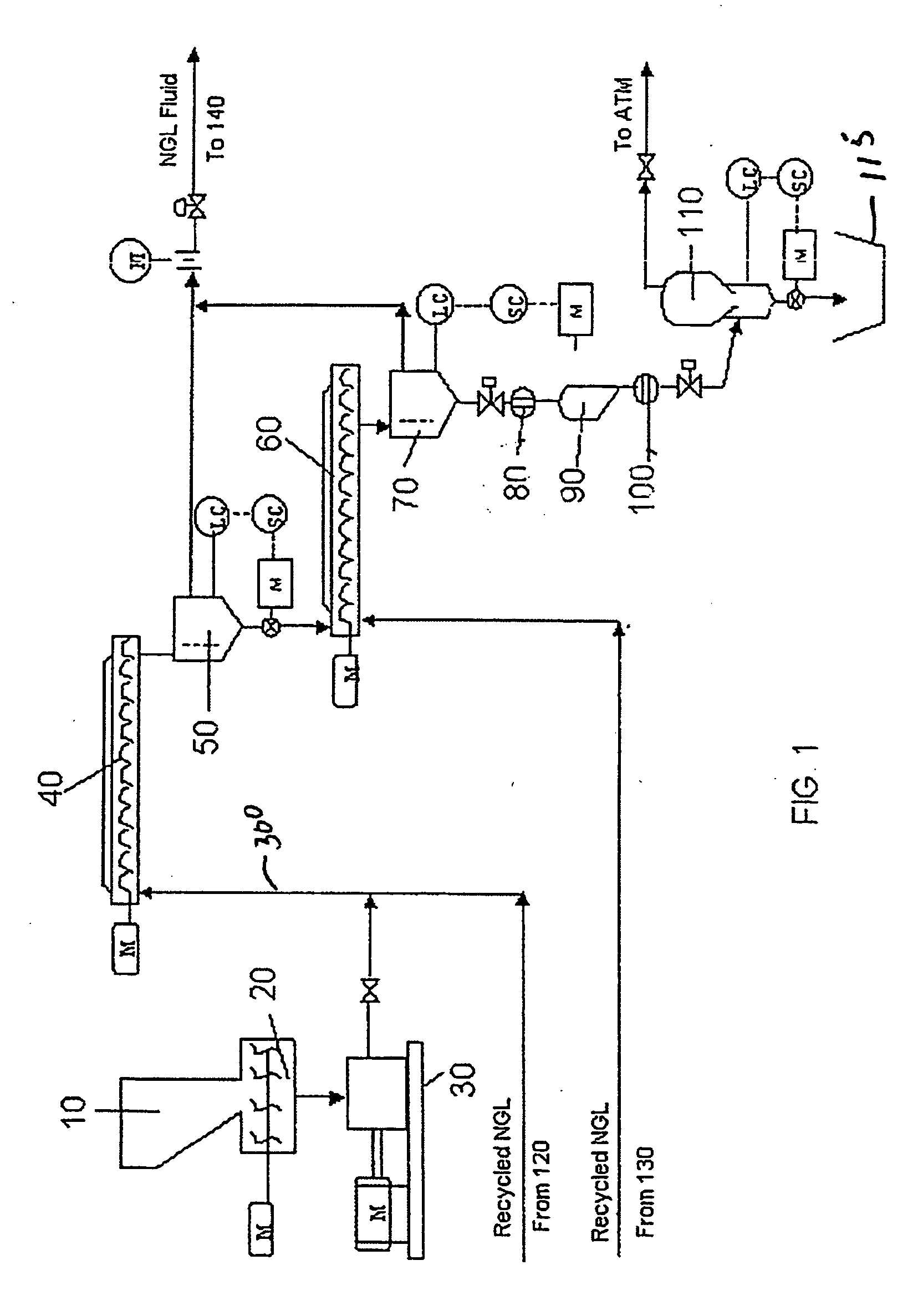

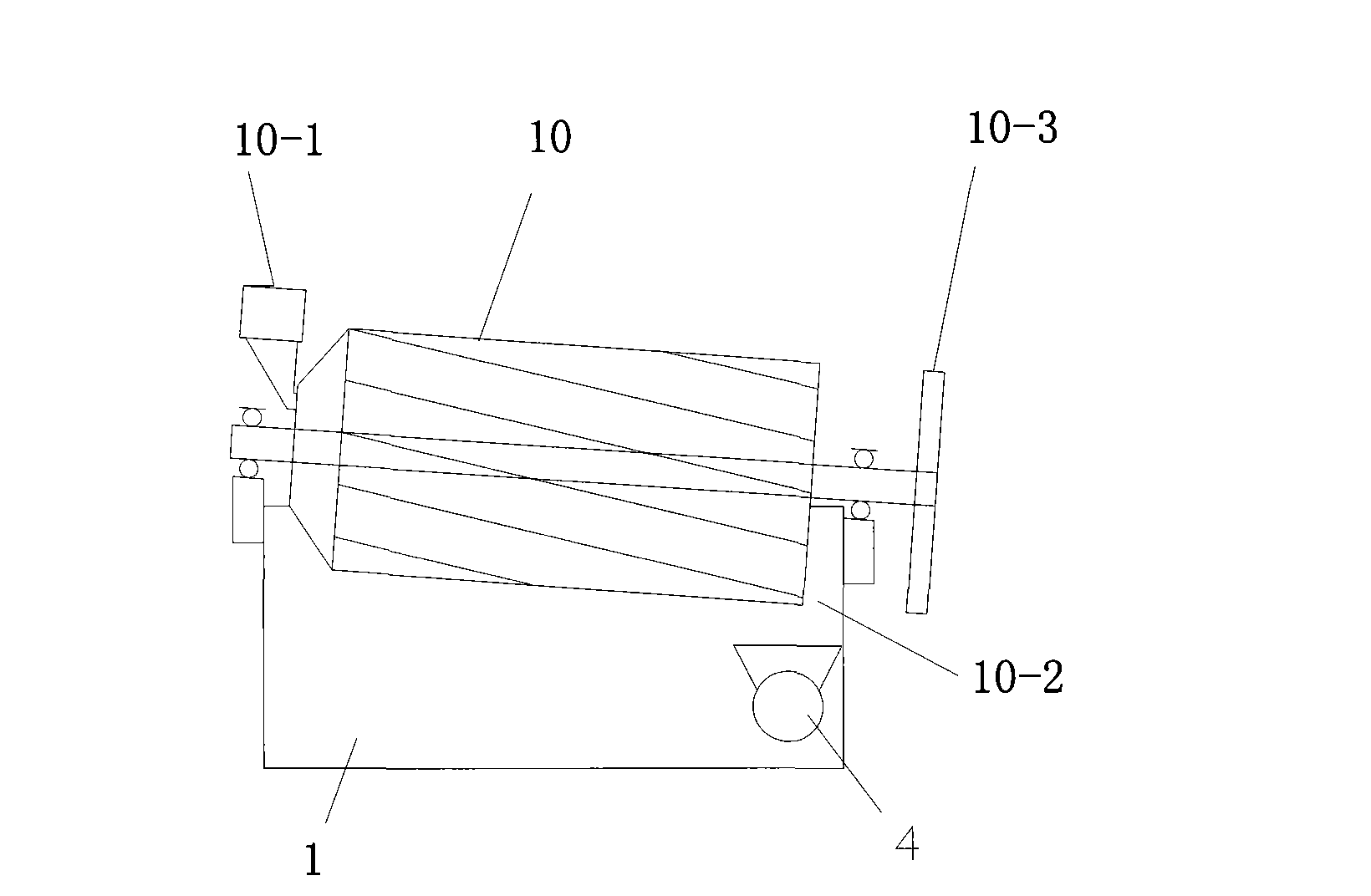

Thermal drill cuttings treatment with weir system

InactiveUS20050279715A1Small sizeImprove pollutionWater/sewage treatment by centrifugal separationHollow article cleaningSlurryDrill cuttings

A method for treating material, the material contaminated with contaminants, the method including: introducing material with contaminants to a system for remediation including a thermal treatment system, a quench system, a weir tank system and a condensing system; feeding a slurry of the material to the thermal treatment system and heating the material therein producing heated discharge solids and a discharge stream with liquid and solids therein; optionally, discharging the heated discharge solids and feeding them to a mill system; feeding the discharge stream to a quench system producing a cooled discharge stream which is fed to the weir tank system; the weir tank system having a clean side and a dirty side; the cooled discharge stream fed to the dirty side of the weir tank system, and from the weir tank system producing at least one stream of cleaned liquid and a stream with contaminants therein; and, in one particular aspect, remediating drilled cuttings material using such a method.

Owner:VARCO I P INC

Thermal drill cuttings treatment with weir system

InactiveUS7306057B2Small sizeImprove pollutionWater/sewage treatment by centrifugal separationHollow article cleaningSlurryDrill cuttings

A method for treating material, the material contaminated with contaminants, the method including: introducing material with contaminants to a system for remediation including a thermal treatment system, a quench system, a weir tank system and a condensing system; feeding a slurry of the material to the thermal treatment system and heating the material therein producing heated discharge solids and a discharge stream with liquid and solids therein; optionally, discharging the heated discharge solids and feeding them to a mill system; feeding the discharge stream to a quench system producing a cooled discharge stream which is fed to the weir tank system; the weir tank system having a clean side and a dirty side; the cooled discharge stream fed to the dirty side of the weir tank system, and from the weir tank system producing at least one stream of cleaned liquid and a stream with contaminants therein; and, in one particular aspect, remediating drilled cuttings material using such a method.

Owner:VARCO I P INC

Drilling fluids, drilling fluids additives and methods useful for limiting tar sands accretion on metal surfaces

Owner:ARKON SOLUTIONS CORP

Systems and methods for storing and handling drill cuttings

ActiveUS20050183574A1Easy accessDrilling rodsDispersed particle separationControl flowInterior space

Vessels for selectively holding drilling cuttings material and methods employing such vessels; the vessels, in at least certain aspects, having a body with a hollow container with an interior space for receiving drilling cuttings material and from which the material may exit from the body; a first opening through which the material enters into the container; a second opening through which the material passes out from the container; and movement apparatus with a movement member within the container movable adjacent the second opening to facilitate passage of the material into the second opening; and in certain aspects, the vessels having moisture-content sensor apparatus on the body for sensing moisture content of material within a vessel; conduit apparatus for conducting drilling cuttings from the exit opening; valve apparatus for selectively controlling flow of material in the conduit apparatus; and a controller in communication with the moisture-content sensor apparatus and the valve apparatus for selectively controlling flow in the conduit apparatus.

Owner:VARCO I P INC

Drill cutting deoiling

InactiveUS20050236015A1Various problemReadily apparentElectrostatic cleaningFlushingDrill cuttingsSolvent

The present invention features a method and system for extraction of oil from drill cuttings. The extraction is carrying out by using a solvent. The extraction conditions preferably include a temperature and pressure each elevated above ambient and optionally to at least the critical point of the solvent. The cleaned drill cuttings may include not more than 1 wt. % oil.

Owner:HALLIBURTON ENERGY SERVICES INC

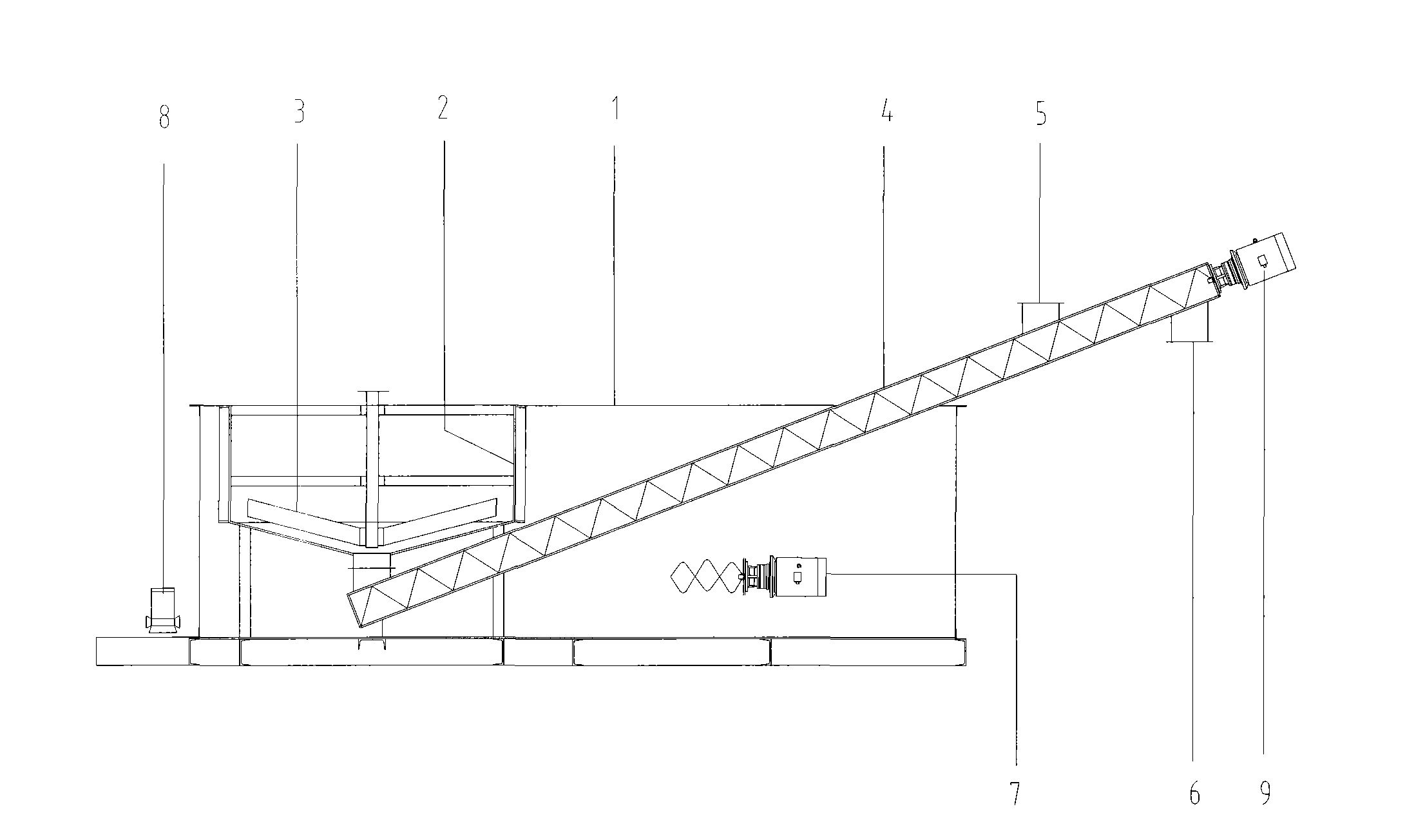

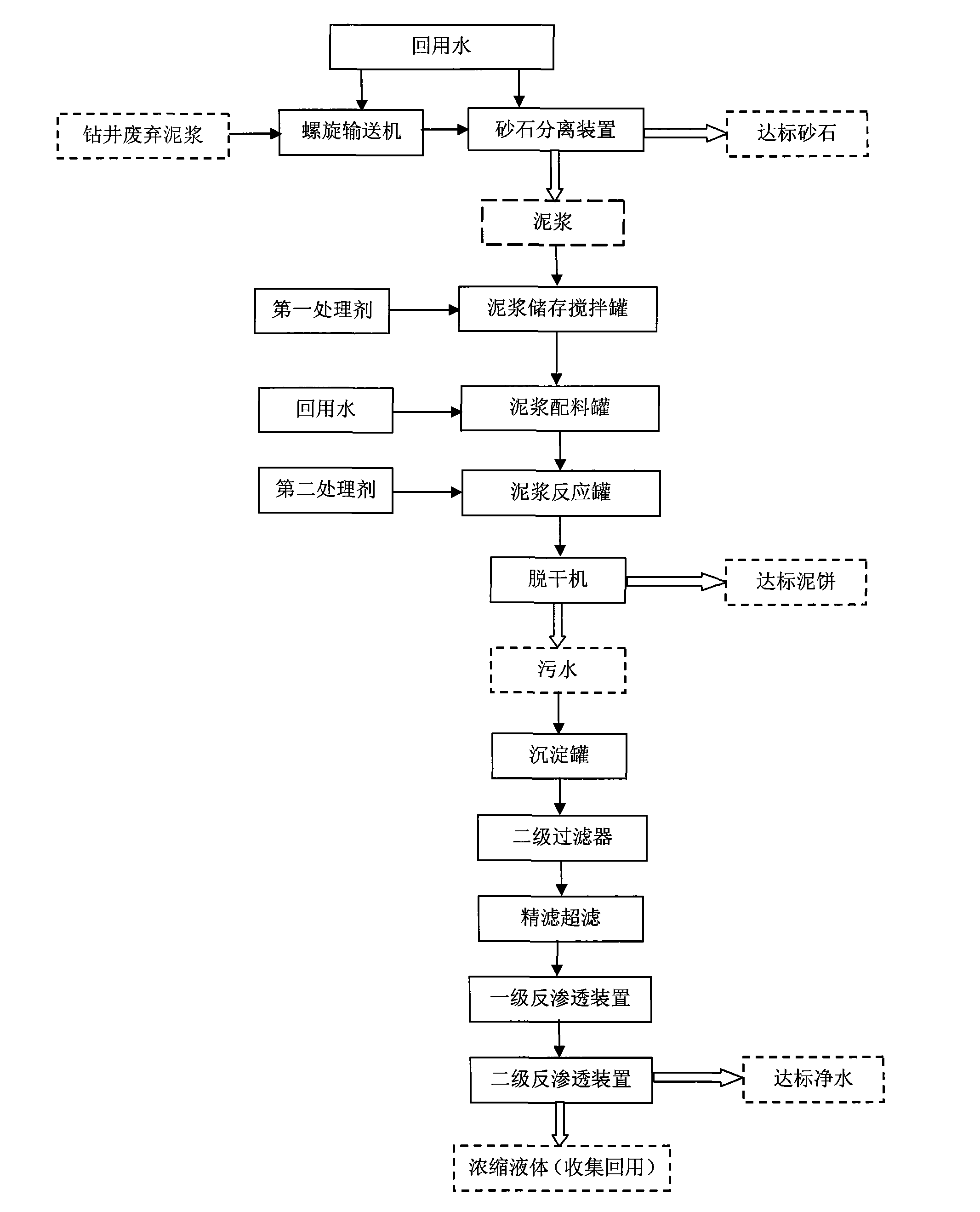

Method for processing waste slurry

ActiveCN101538096ASave land resourcesObvious technical advantagesWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningFiltrationWell drilling

The invention discloses a method for processing waste slurry, comprising the following steps: firstly, a sand-stone segregation apparatus separates, washes and discharges the drill cuttings sand and stone in the slurry; the pH value of the remaining slurry is adjusted and the COD value thereof is reduced; the solid and the liquid are separated from each other in a way of composite flocculating; water solution is separated out from the solid in a way of mechanical drying; the dried solid isolate meets the relative standard so as to be processed in a way of stacking or land filling; finally the separated water solution is processed in a way of filtration and reverse osmosis so as to obtain fresh water which is recycled or discharged on the spot. The method can be carried out by matching with an unit device and make continuously impending treatment of the well drilling waste slurry during drilling synchronously with normal well drilling production so as to continuously process the efflux hazardous waste to meet the discharge standard with out loading in the well drilling of oil-gas field, change the prior traditional whole efflux curingprocess mode, and fills the gap of an environmentally friendly governing field of oil drilling in the domestic.

Owner:北京华盛坤泰环境科技股份有限公司

Surge pressure reduction apparatus with volume compensation sub

InactiveUS20030136563A1Promote circulationEasy to operateFluid removalFlushingOcean bottomWell drilling

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. A surge pressure reduction tool in accordance with the present invention includes a diverter device having a set of flow holes which diverter device can be shifted between a "surge pressure reduction" mode and a "cementing" or "circulation" mode. A tool in accordance with the present invention further includes a volume compensation device which enables the diverter device to shift axially downward into the cementing or circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement / drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annulus between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:FRANKS INT +1

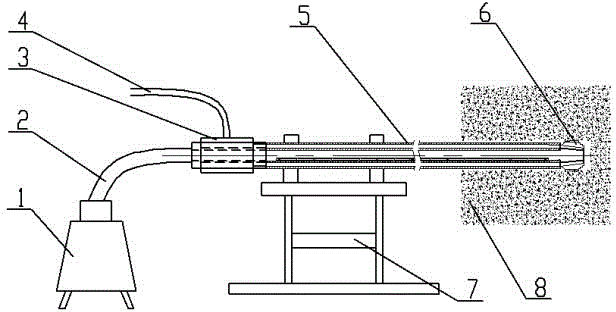

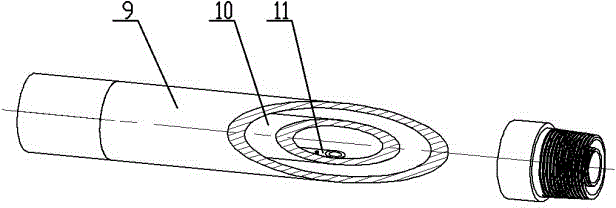

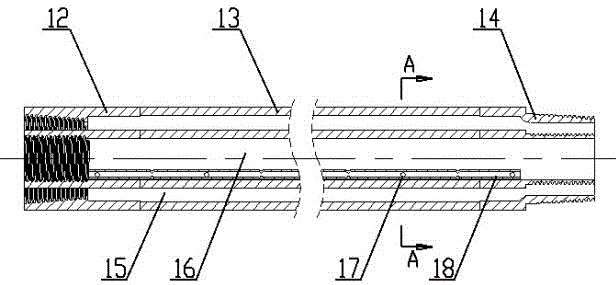

Double-layer internal deslagging and anti-blocking drilling tool for soft and outburst coal seam drilling, and use method of drilling tool

ActiveCN103556944AExternal setup is simpleEfficient dust removalDrilling machines and methodsSlagCoal

The invention discloses a double-layer internal deslagging and anti-blocking drilling tool for soft and outburst coal seam drilling, and a use method of the drilling tool. The drilling tool comprises a rotary sealing water supply device or a rotary sealing air supply device, a double-layer internal deslagging and anti-blocking drilling rod and a central backflow drilling bit, wherein the rotary sealing water supply device or the rotary sealing air supply device is connected with the double-layer internal deslagging and anti-blocking drilling rod on a drilling machine, and the central backflow drilling bit is mounted at the front end of the double-layer internal deslagging and anti-blocking drilling rod. The use method of the drilling tool comprises the steps that a drilling system is started; an air flow or a water flow enters an outer layer channel of the double-layer internal deslagging and anti-blocking drilling rod and reaches the bottom of a drilling hole; the air flow or the water flow reverses out drilling cuttings formed by drilling bit coal breaking along an inner layer channel of the double-layer internal deslagging and anti-blocking drilling rod to enter a slag tapping dust collector connected with the tail part of the drilling rod; and deslagging and dust collection are accomplished. The drilling tool is novel in design; the deslagging is accomplished in a cavity of the drilling rod, so that influences of drilling hole shrinkage and hole wall buckling failure on a drilling hole deslagging space can be avoided effectively; the deslagging is accomplished in the inner layer channel of the drilling rod, so that the dust collection is more effective; and drilling, anti-sloughing and dust collection integrated operation is realized.

Owner:HENAN POLYTECHNIC UNIV

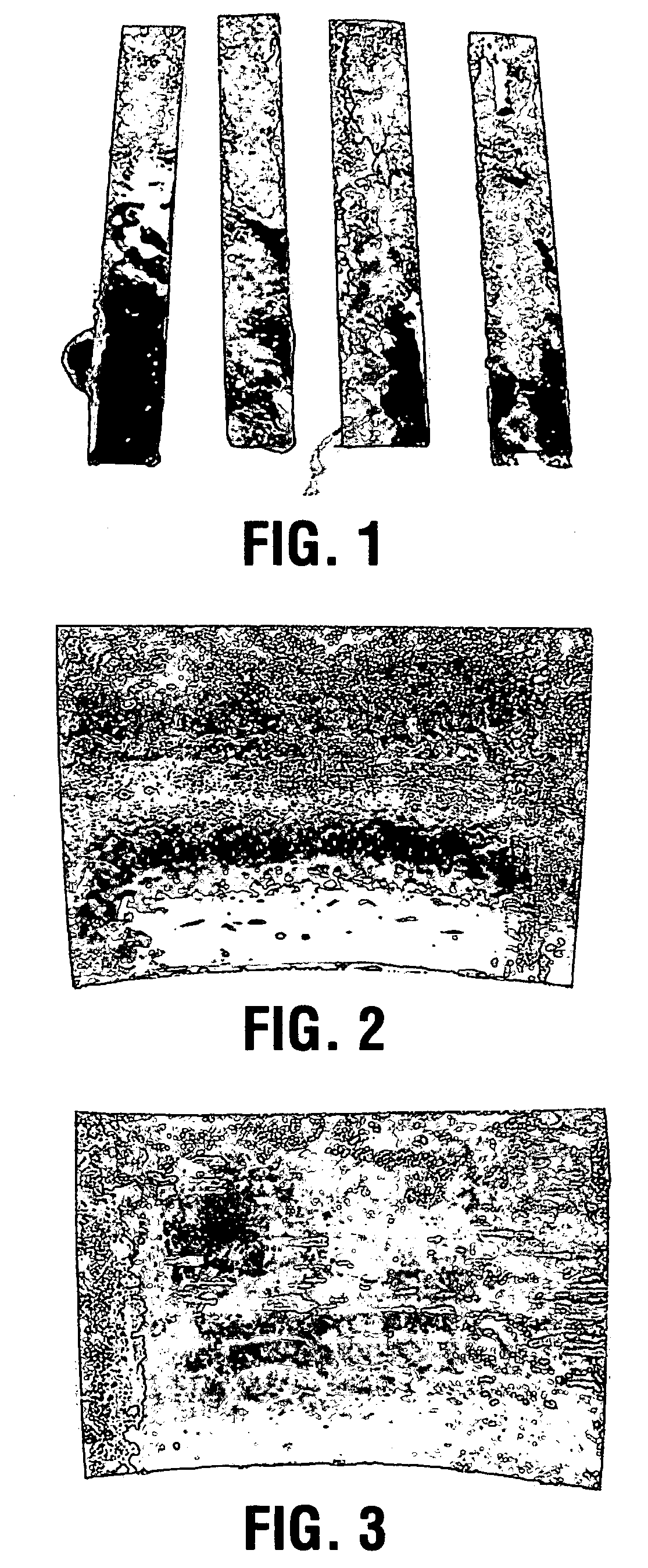

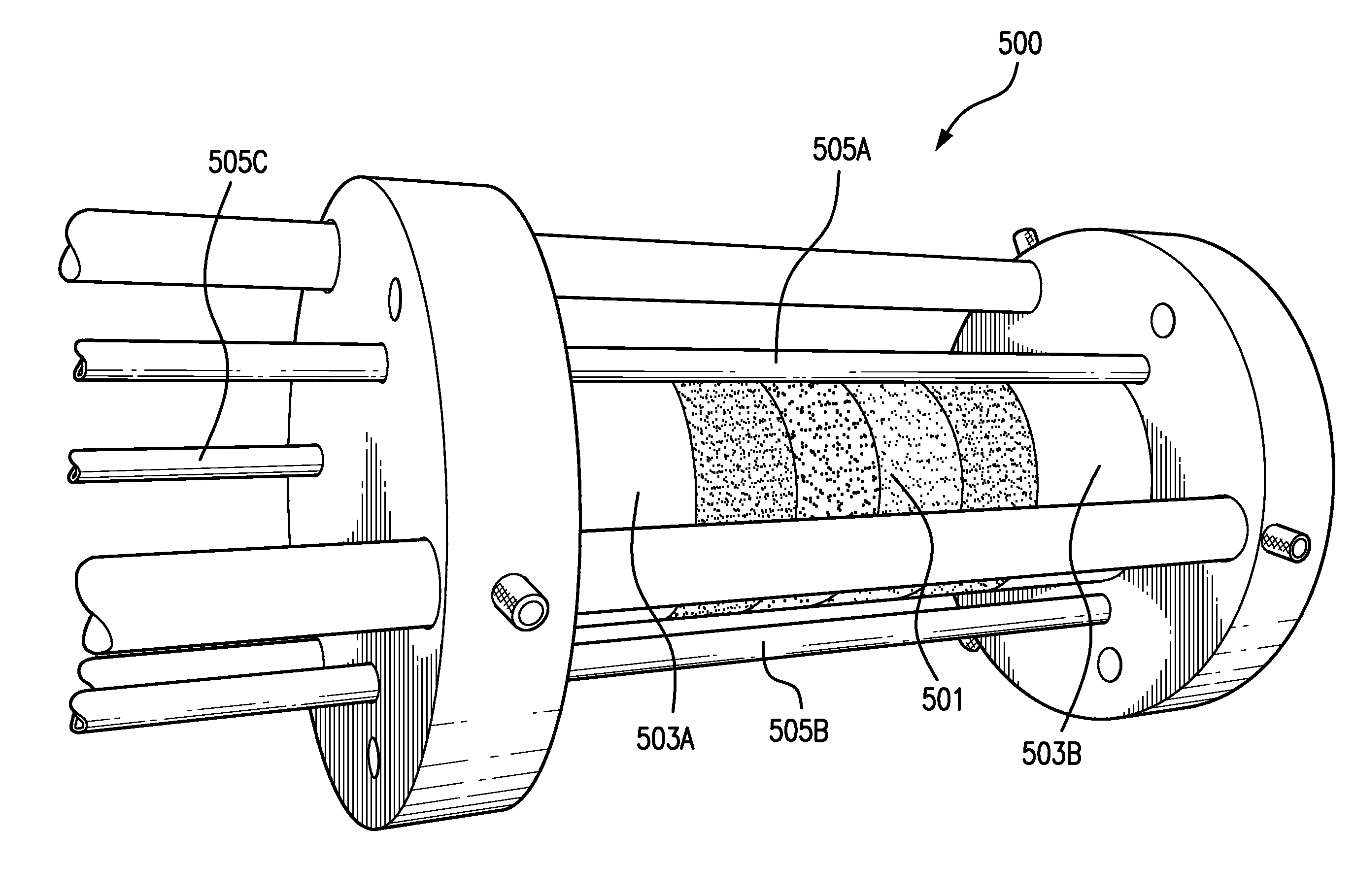

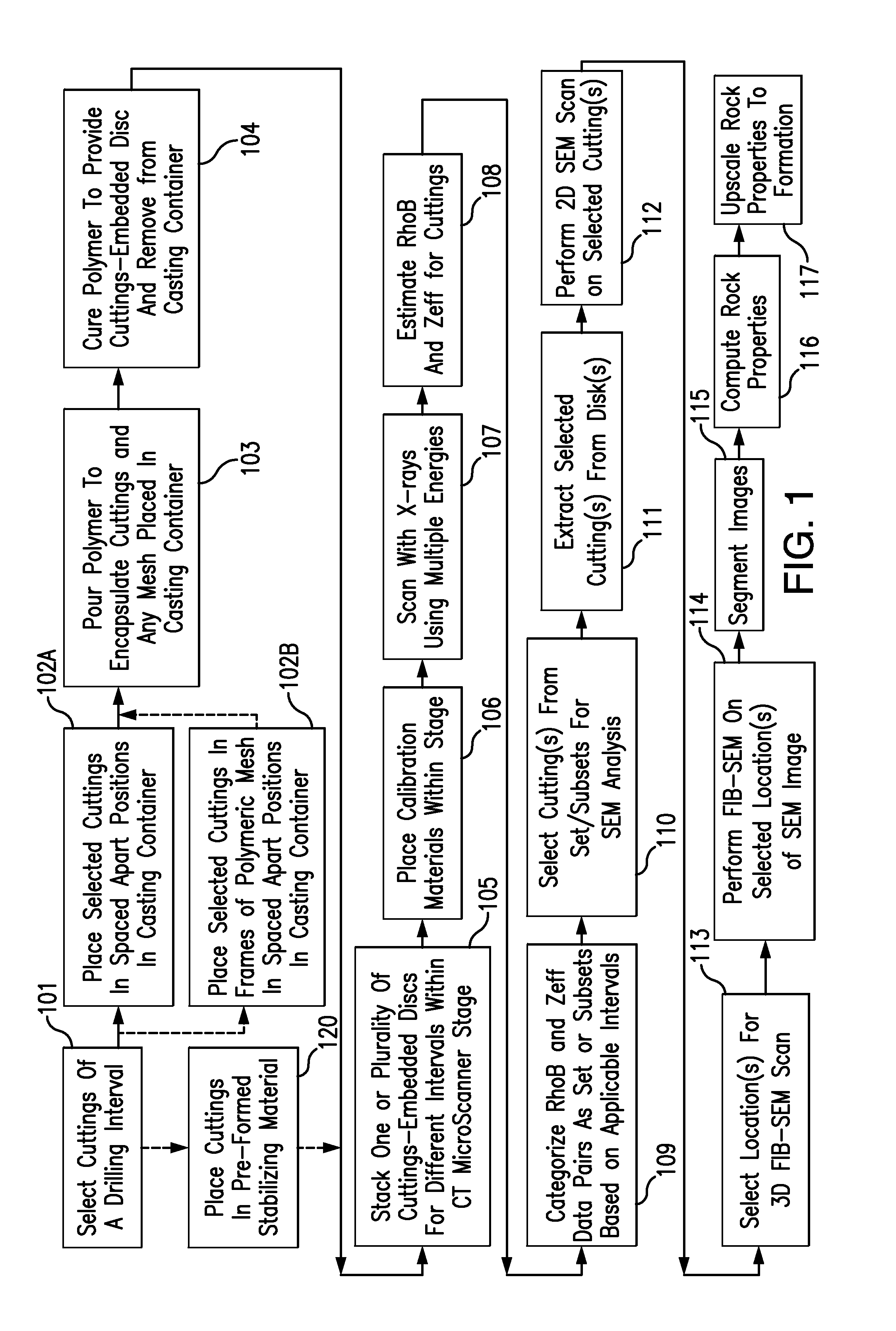

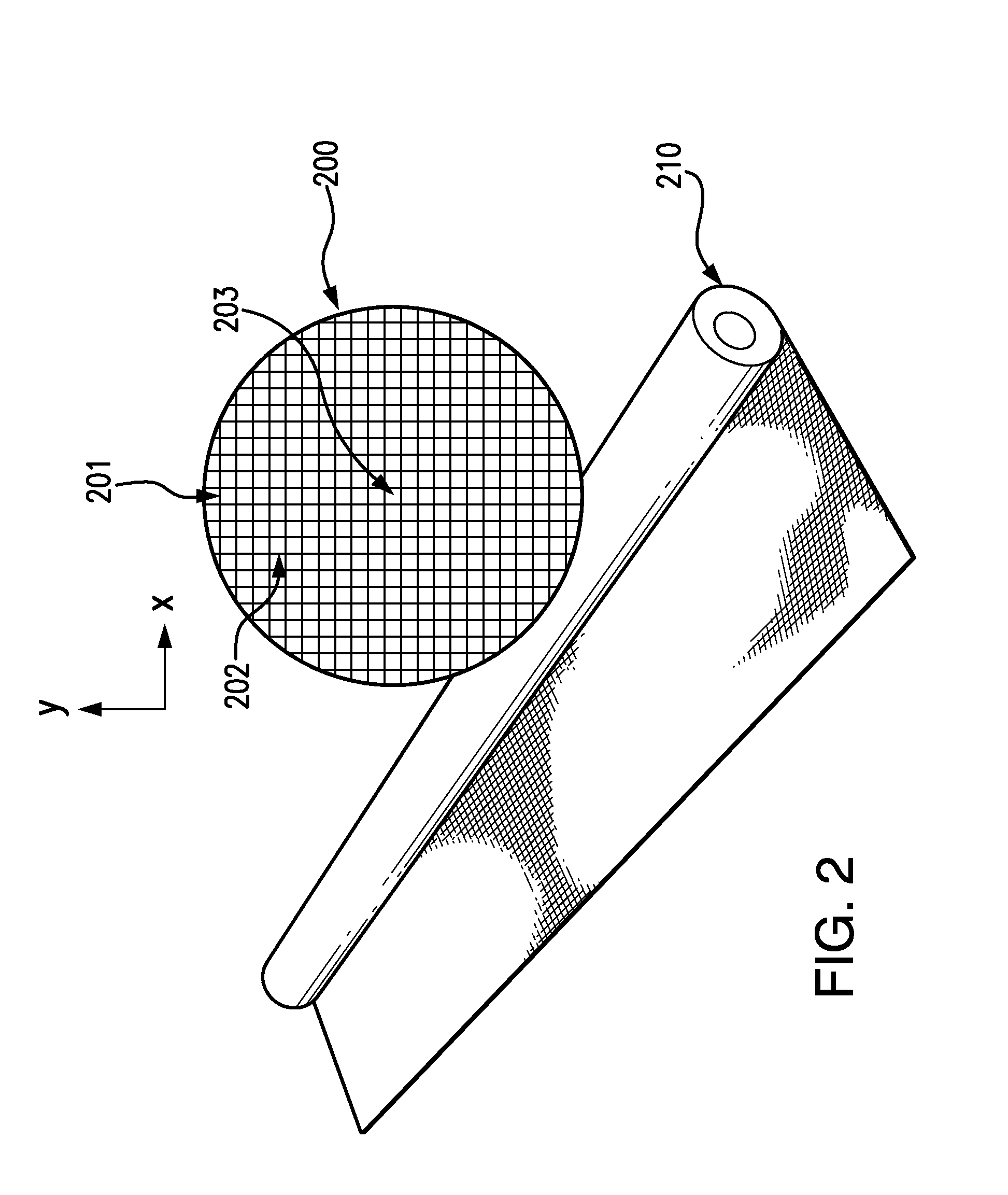

Method And System For Multi-Energy Computer Tomographic Cuttings Analysis

ActiveUS20130301794A1Simple processImprove analysisRadiation/particle handlingPreparing sample for investigationFractographyPorous medium

A method and a system are provided to prepare a plurality of cuttings or other rock fragments or other porous media, such as cuttings from a drilling interval or multiple intervals, for computer tomographic scanning at the same time. A method and system also are provided to allow organization of mass quantities of cuttings or other rock fragments obtained from intervals of a well to more accurately categorize the cuttings to assist selections thereof for more detailed digital rock analysis, such as using SEM and FIB-SEM systems, are provided. A method and system also are provided to allow characterization of facies occurrence frequency of a depth interval using drill cuttings or other rock fragments. Computerized systems, computer readable media, and programs for performing the methods are also provided.

Owner:HALLIBURTON ENERGY SERVICES INC

System and method for treating drilling mud in oil and gas well drilling applications

A system and method for controlling drilling mud density at a location either at the seabed (or just above the seabed) or alternatively below the seabed of wells in deep water and ultra deep water applications are disclosed. The present invention combines a base fluid of lesser density than the mud required at the wellhead to produce a diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, a riser mud density at or near the density of seawater may be achieved. The present invention also includes a wellhead injection device for injecting the base fluid into the rising drilling mud. The riser charging lines are used to carry the low density base fluid to the injection device for injection into the return mud. At the surface, the diluted return mud is passed through a treatment system to cleanse the mud of drill cuttings and to separate the heavier drilling mud from the lighter base fluid. The present invention further includes a control unit for manipulating drilling fluid systems and displaying drilling and drilling fluid data.

Owner:DUAL GRADIENT SYST

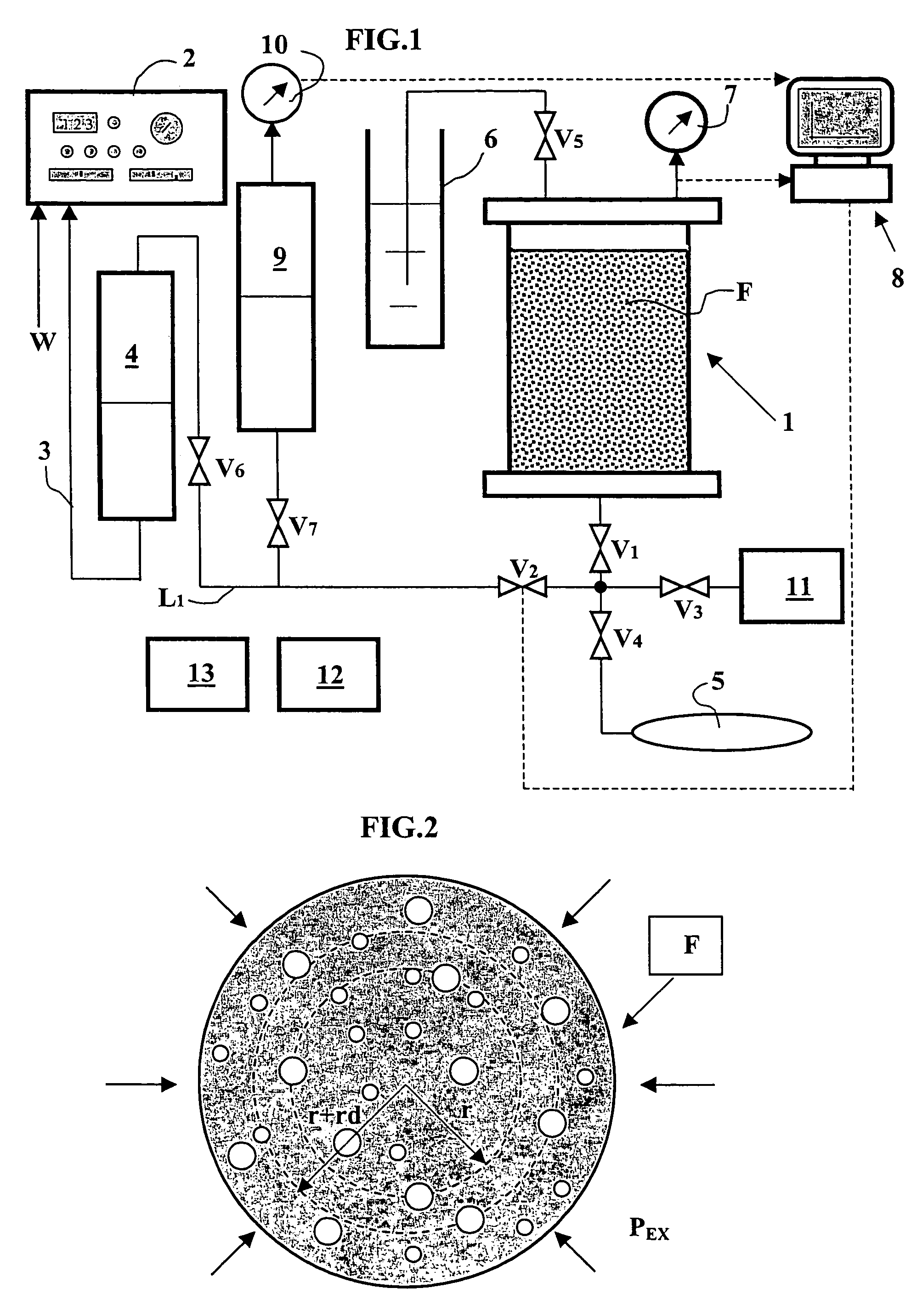

Method and device for evaluating physical parameters of an underground reservoir from rock cuttings taken therefrom

Method and device for evaluating, simultaneously and with a single equipment, physical parameters such as the absolute permeability and the porosity of fragments taken from a fragmented artificial or natural porous medium.The porosity of the fragments is measured by means of pressure tests using helium or any other gas, according to a protocol known in the art. Chamber (1) in which they are contained is communicated with a tank (11) of known volume containing helium at a known pressure. At pressure balance, the value of the solid volume can be deduced. The rock envelope volume and the mass in fragments are also measured. The porosity of the samples and the density of the rock are determined by combining these measurements. Their permeability is then measured by immersing them in a liquid and by communicating the chamber with a liquid initially at a predetermined pressure contained in an accumulator (9) so as to compress the gas trapped in the pores of the rock. The values of the physical parameters are determined by modelling the evolution of the volume of liquid injected in the chamber and by means of an iterative adjustment.Applications: petrophysical measurements from drill cuttings or crushed cores for example.

Owner:INST FR DU PETROLE

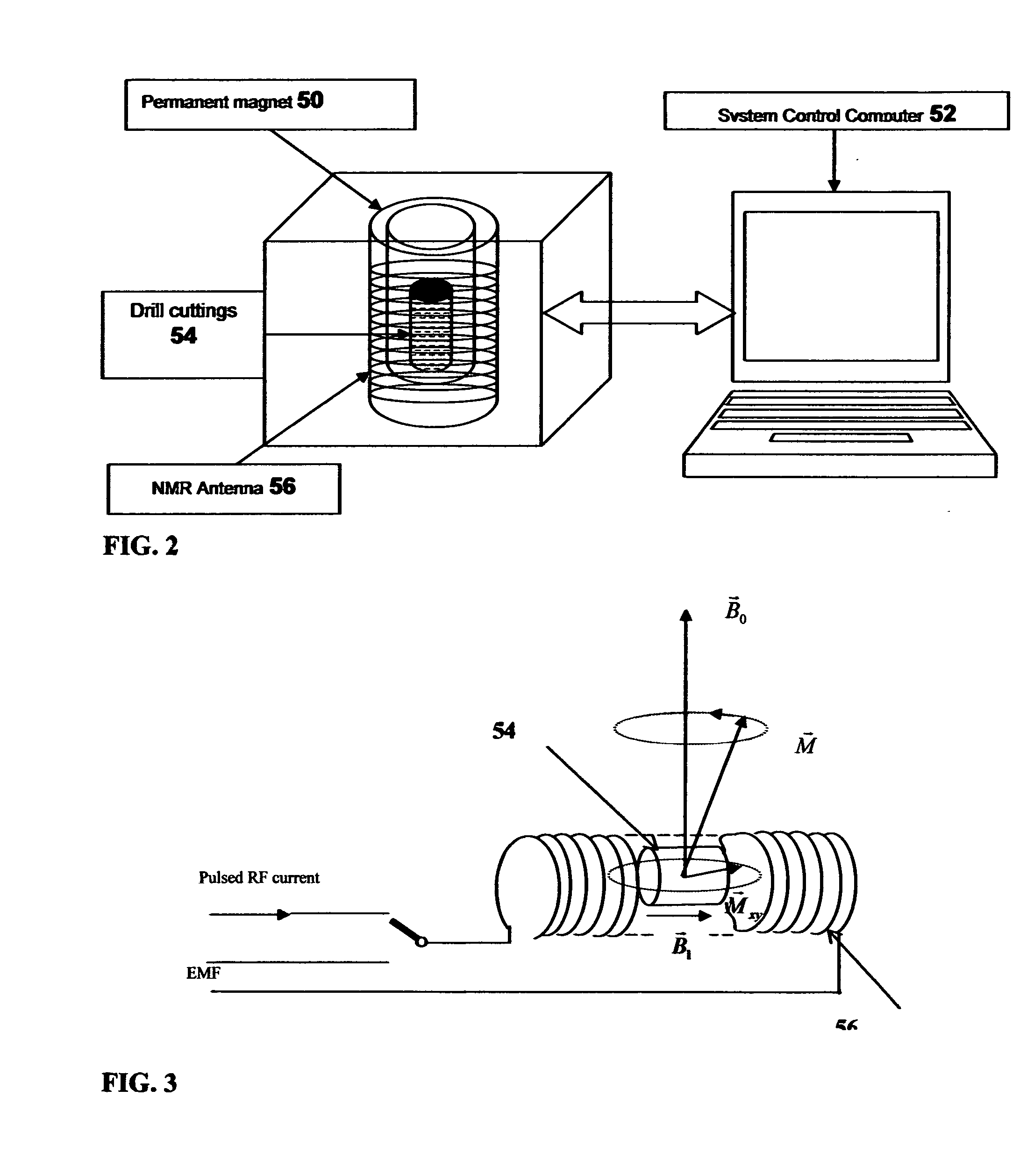

Method for analyzing drill cuttings using nuclear magnetic resonance techniques

A method for evaluating permeability of Earth formations includes determining a transverse nuclear magnetic relaxation spectrum by performing a nuclear magnetic resonance experiment directly on drill cuttings of the Earth formation removed from a wellbore, and estimating permeability from the transverse nuclear magnetic relaxation spectrum.

Owner:YU GANG +4

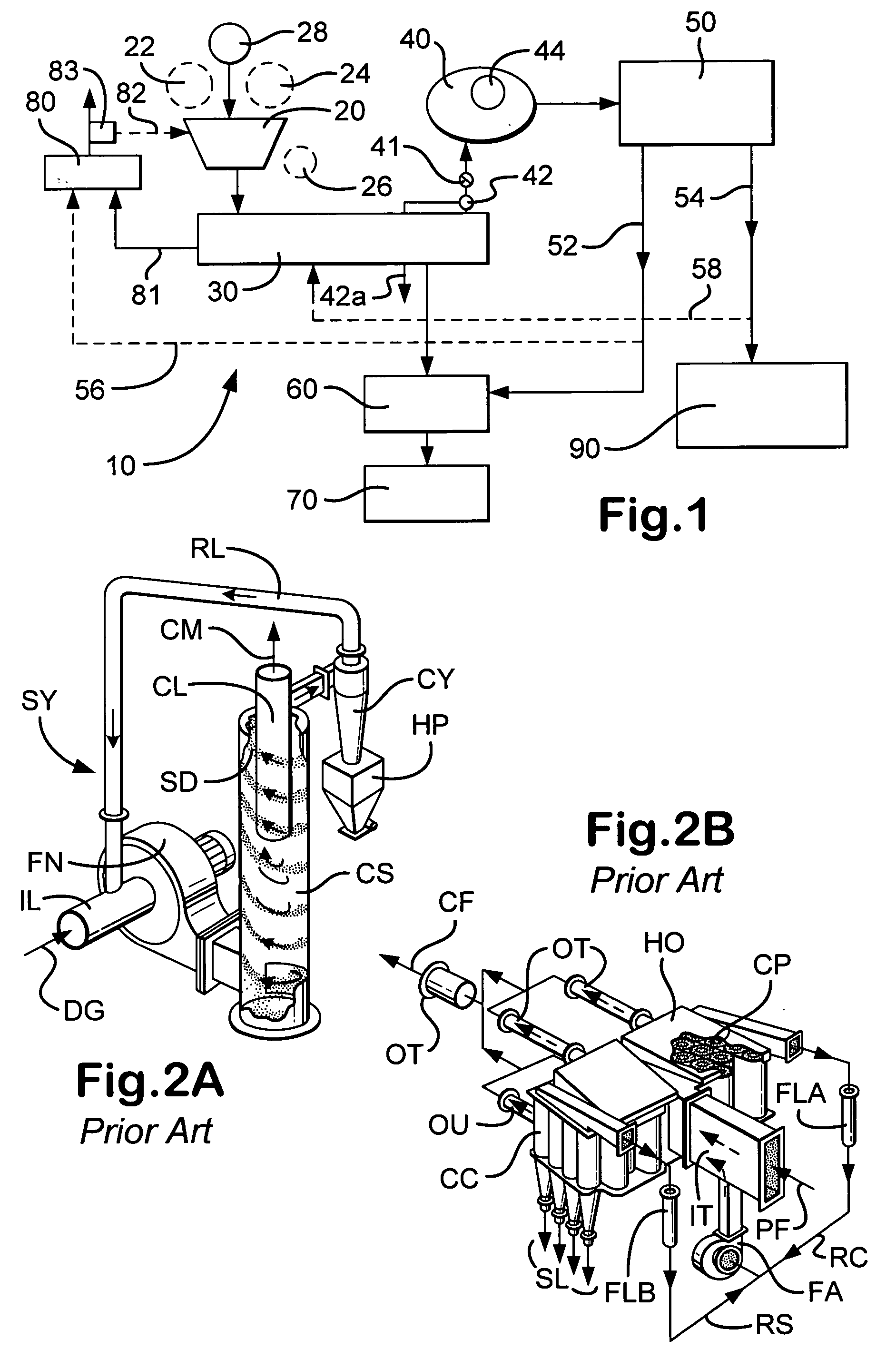

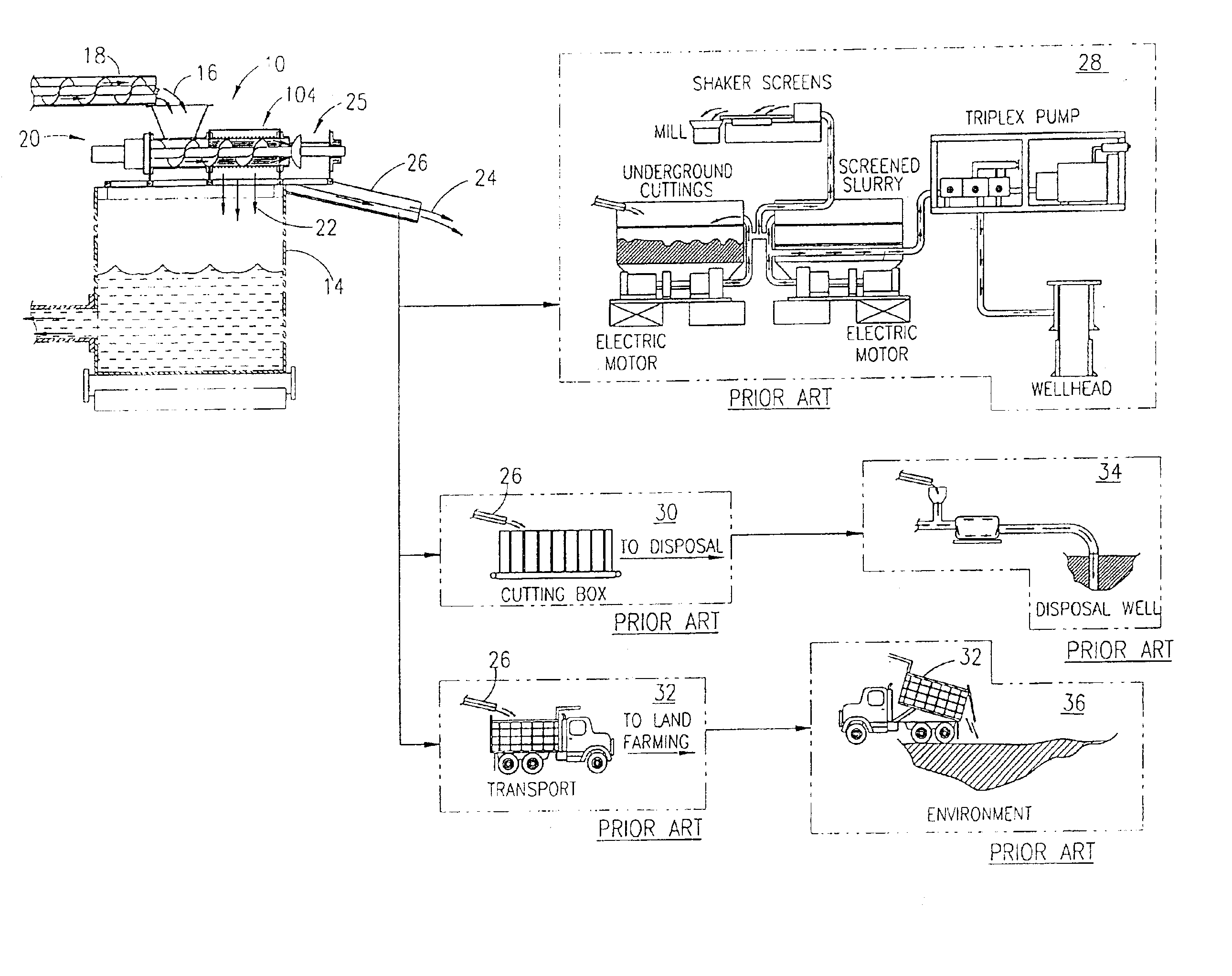

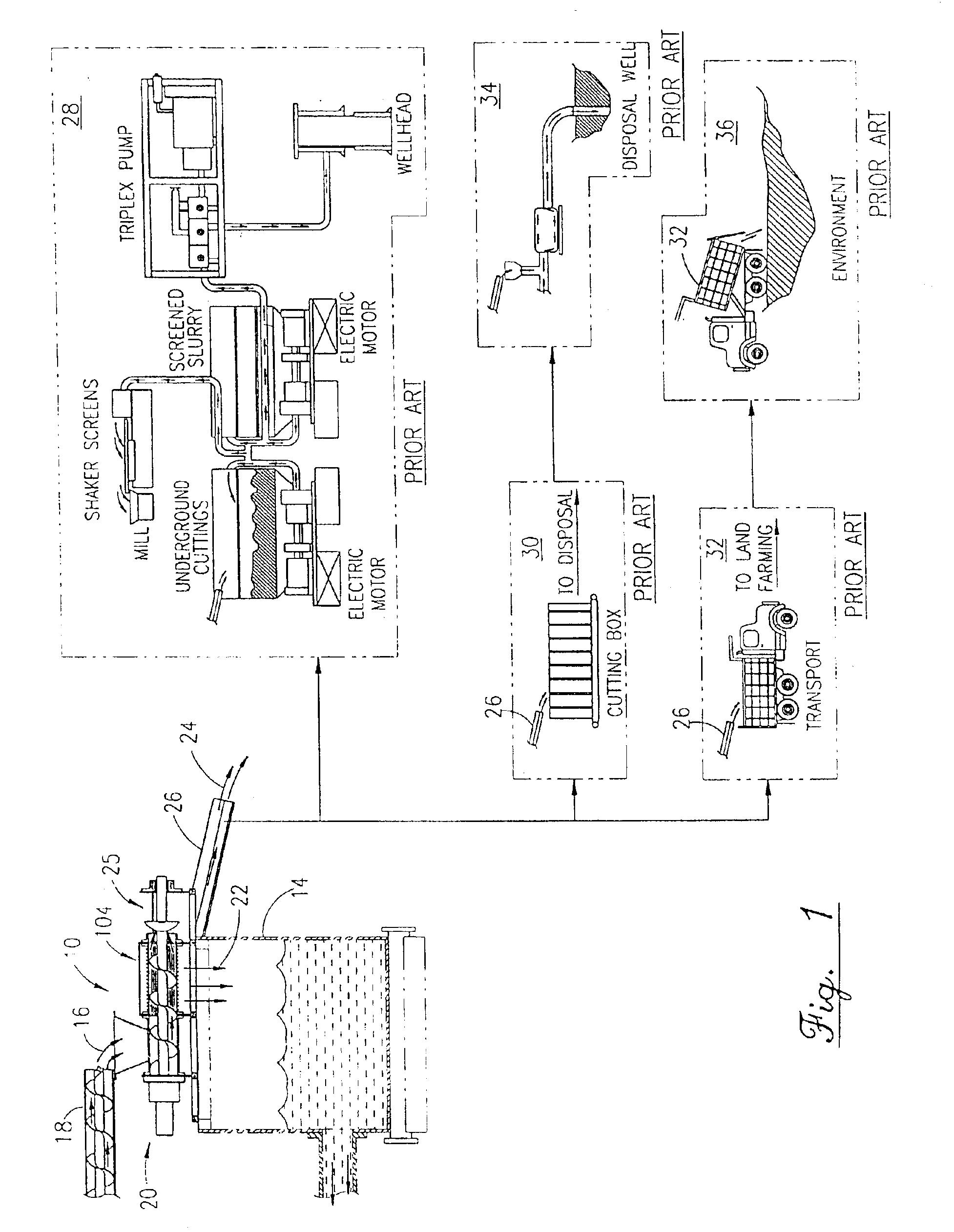

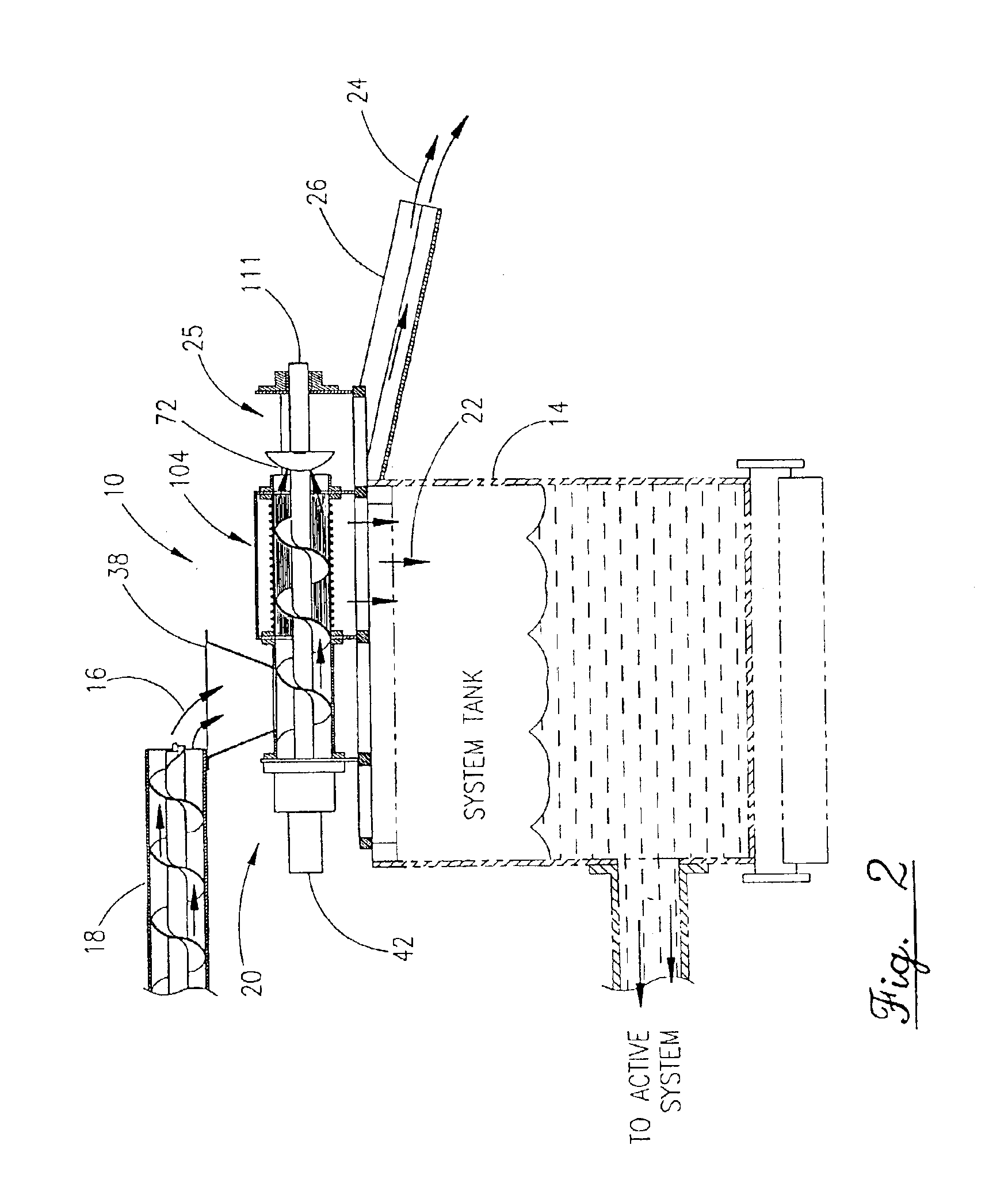

Drilling fluid recovery and cuttings processing system

InactiveUS6910411B2Reduce liquid contentDischarge volume reductionFlushingDrilling compositionProcess systemsDistillation

A drill cuttings slurry process system is disclosed for defluidizing earth drill cuttings, thereby extracting valuable drilling additives and returning them to the drilling system while producing a dense, drier material which may be discharged directly in the environment at or near the well being drilled or chemically treated for distillation and / or better dissolution into the environment, thereby reducing, cost in transportation and environmental treatment chemicals thus reducing environmental contamination. The system comprising a cuttings press having solids / fluids separation a dryer and / or a retort for flashing off any residual petroleum residue and moisture, a fines grinder and a chemical injection system. The retort including an analyzer system for weighing and determining rate of throughput and analyzing the cuttings for residual petroleum residue content prior to discharge to environment or further refinement prior to reinjection into the well or transport to environmental depository sites.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com