Patents

Literature

43results about How to "Lower oil level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

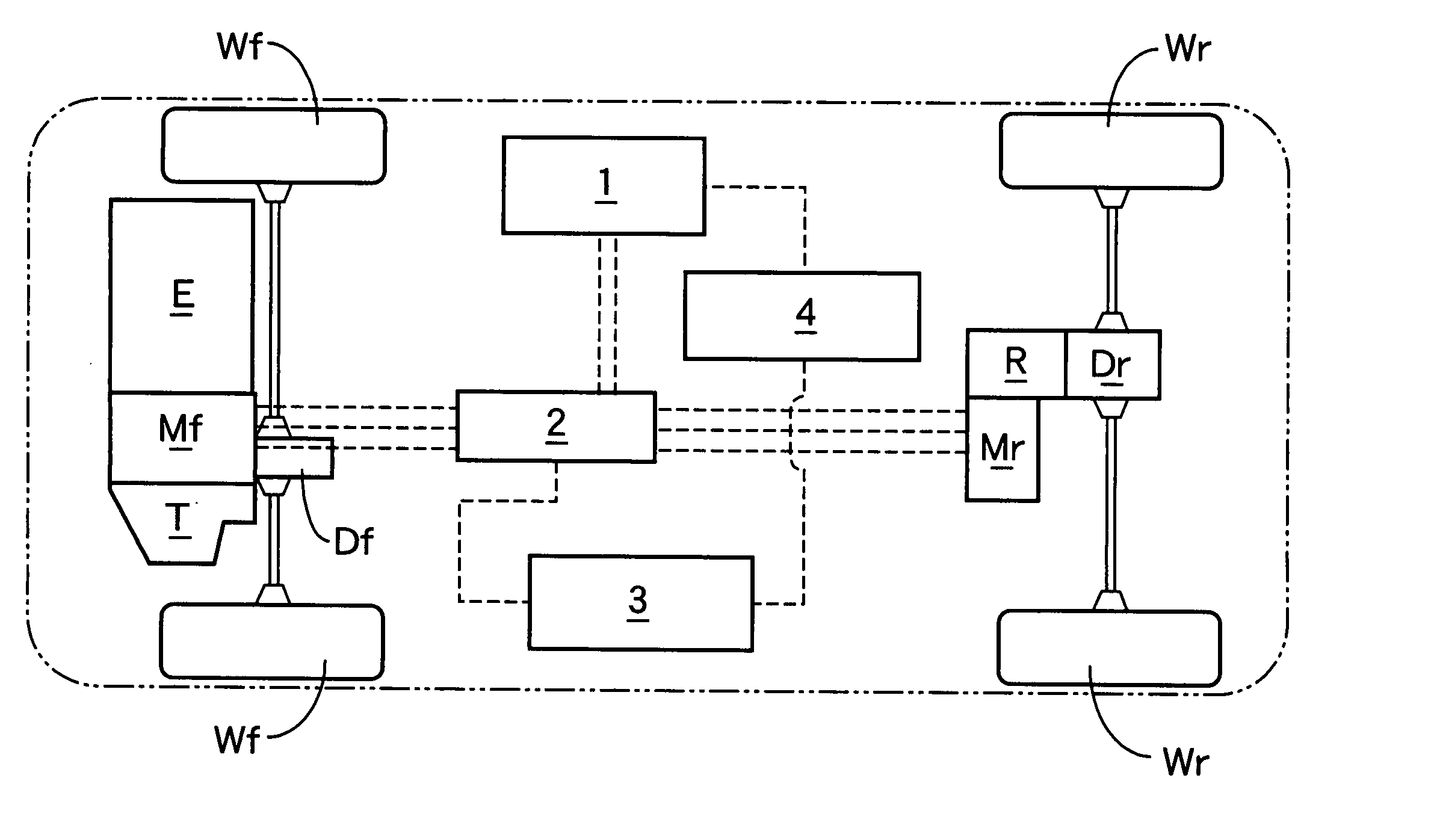

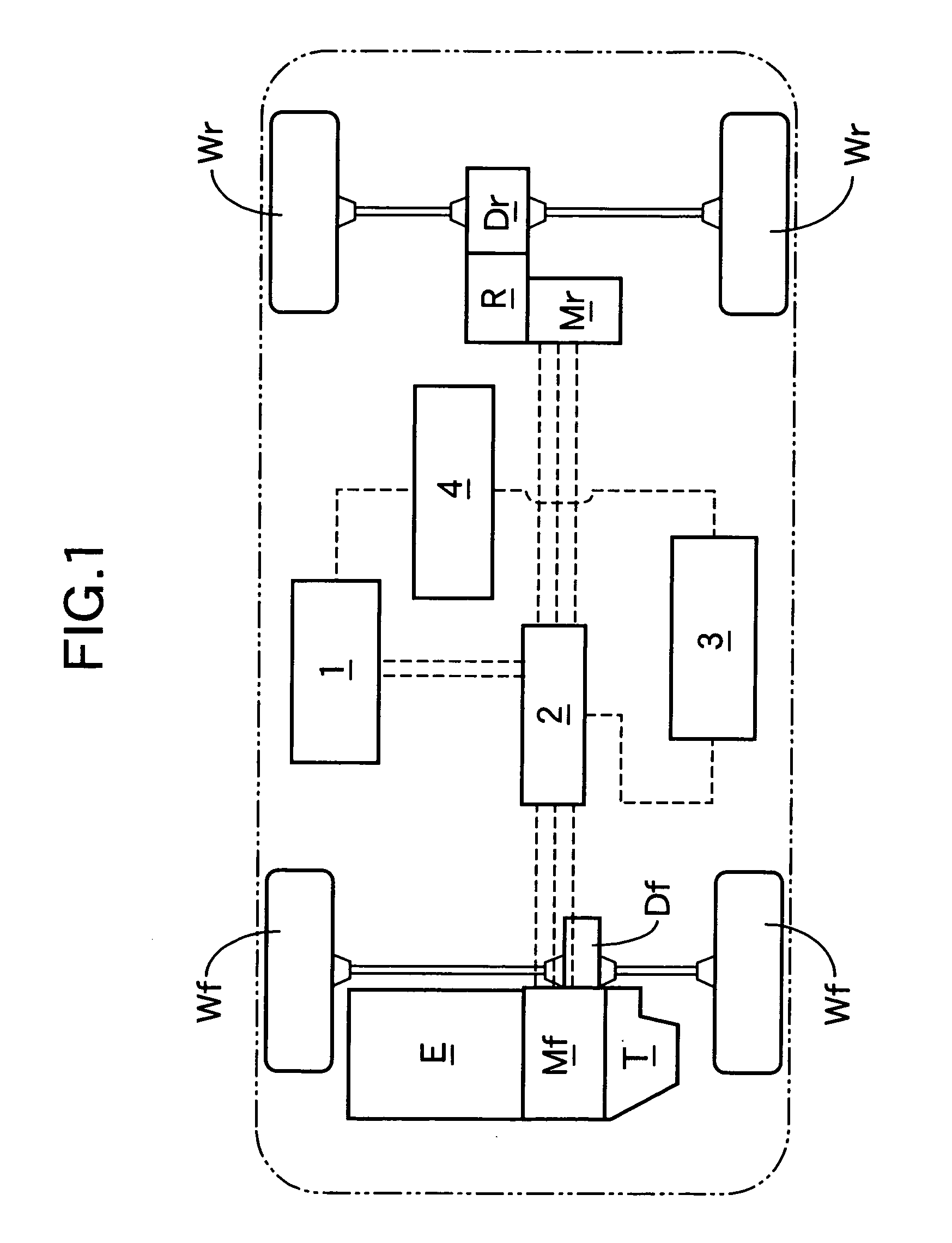

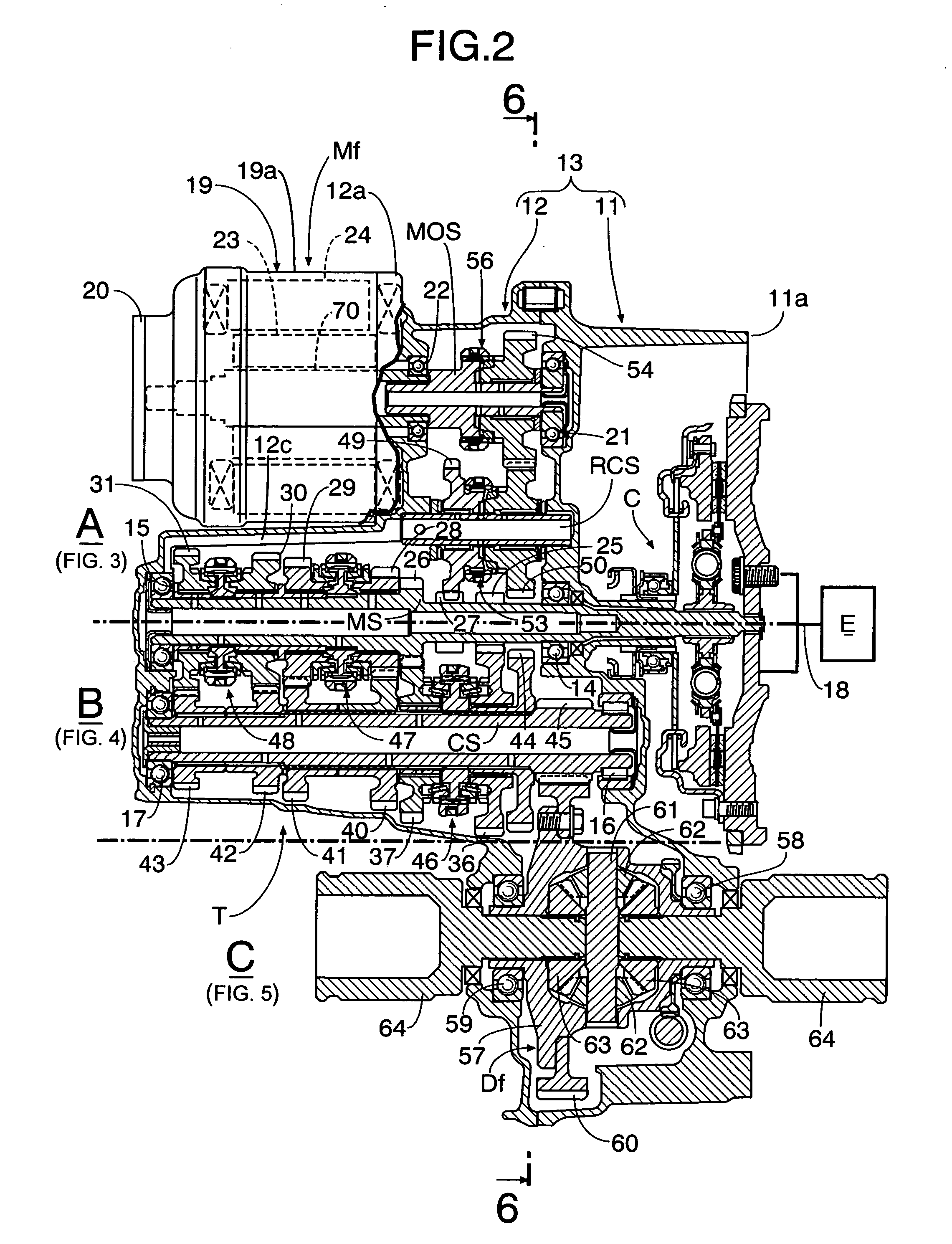

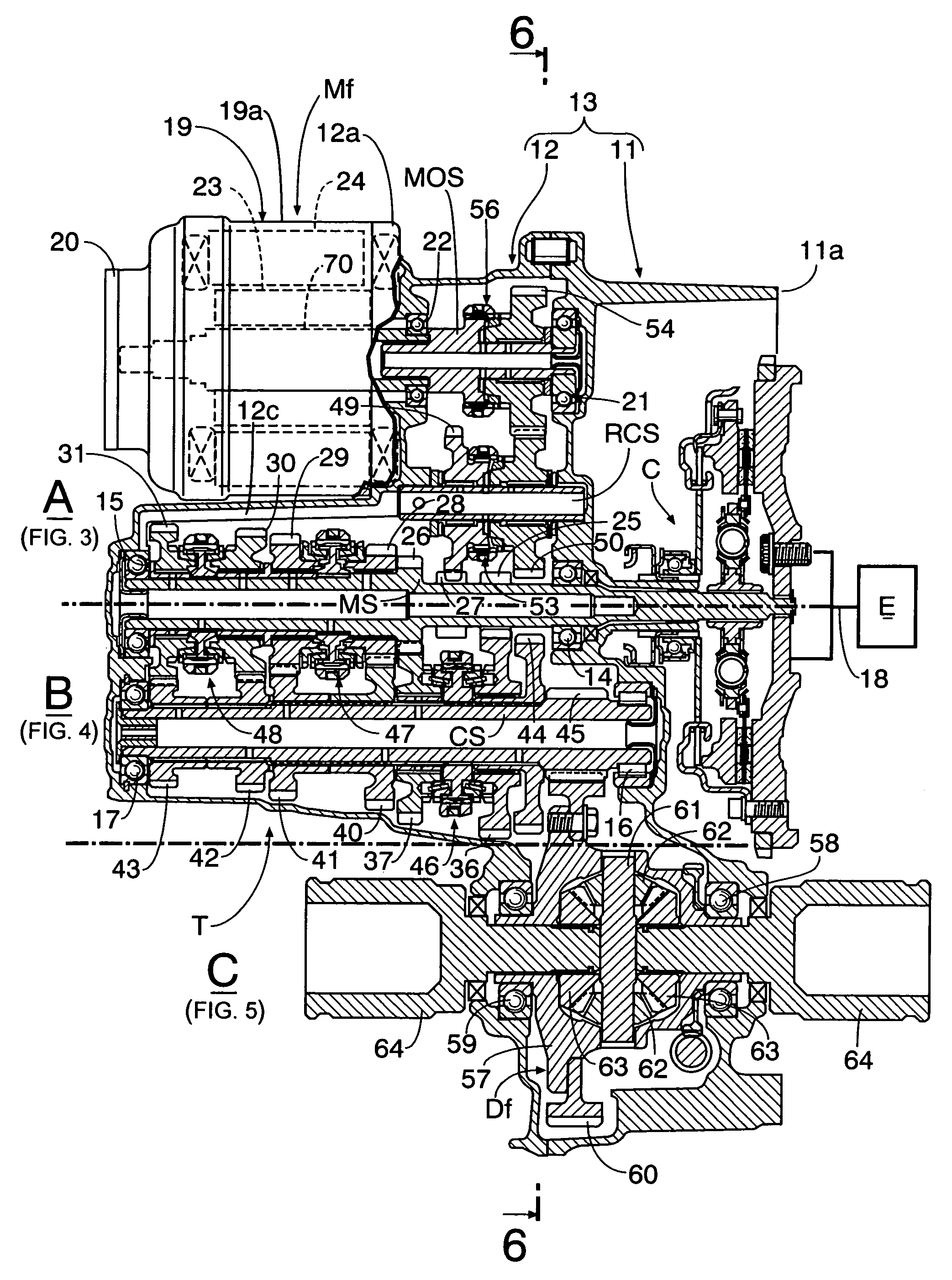

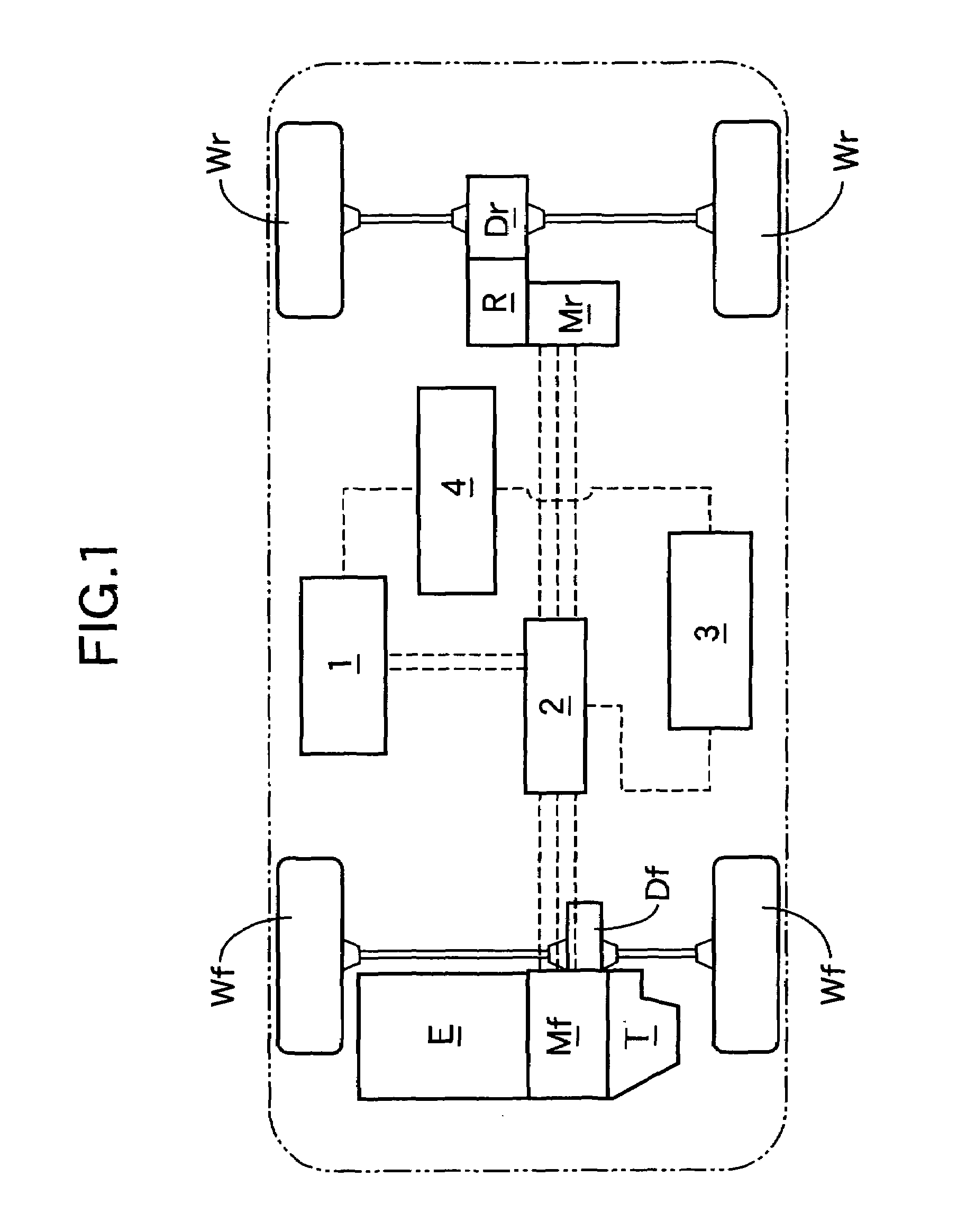

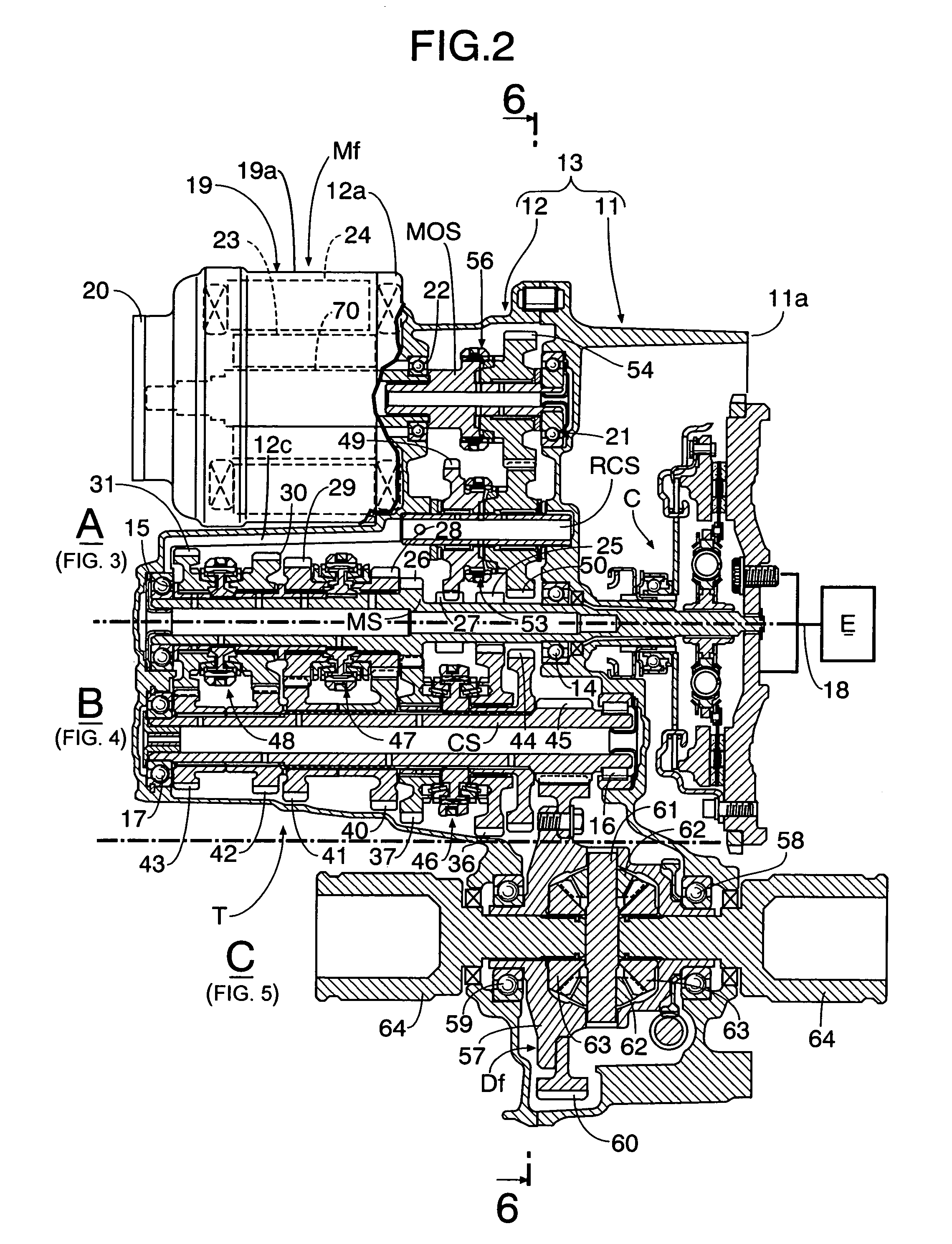

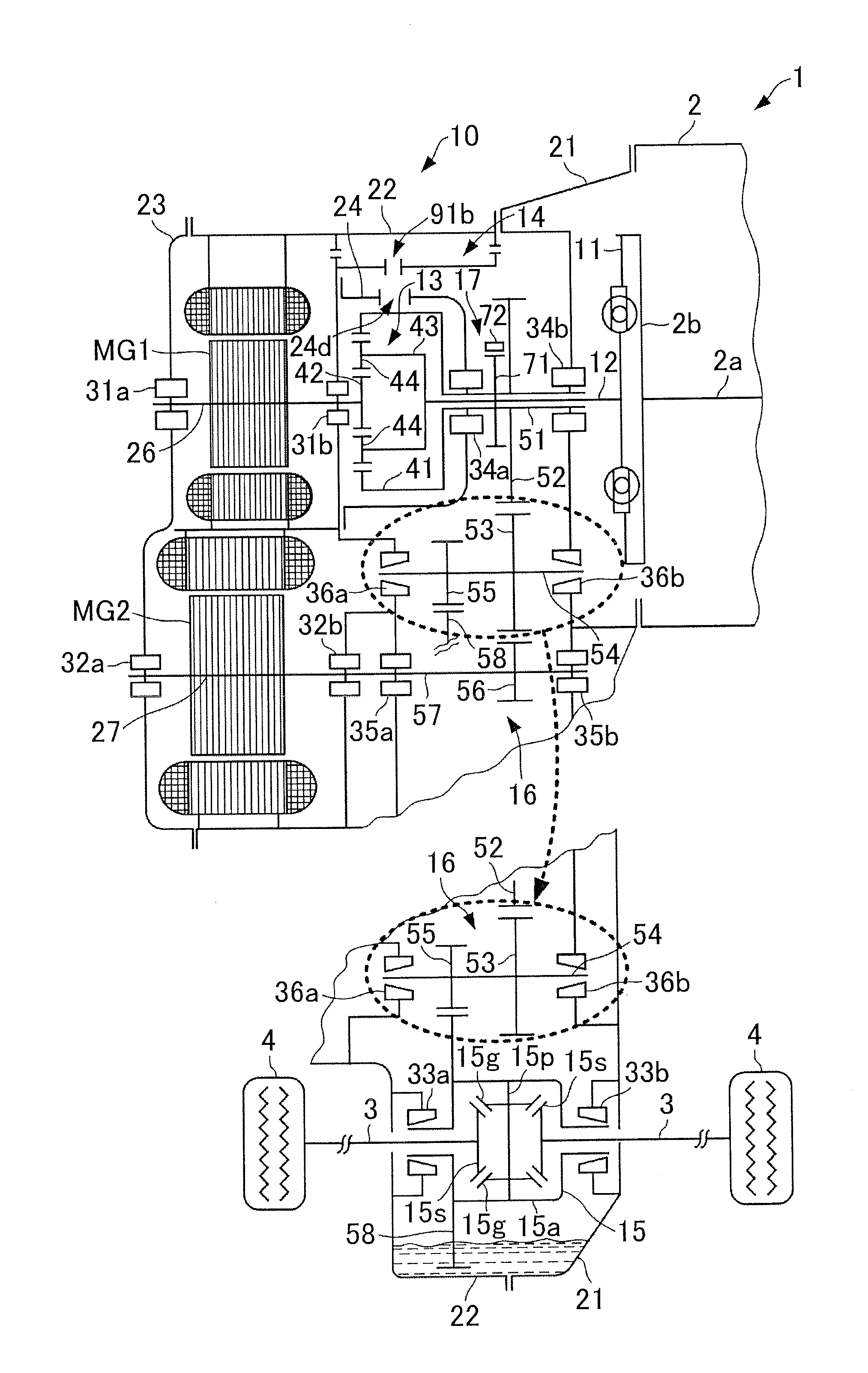

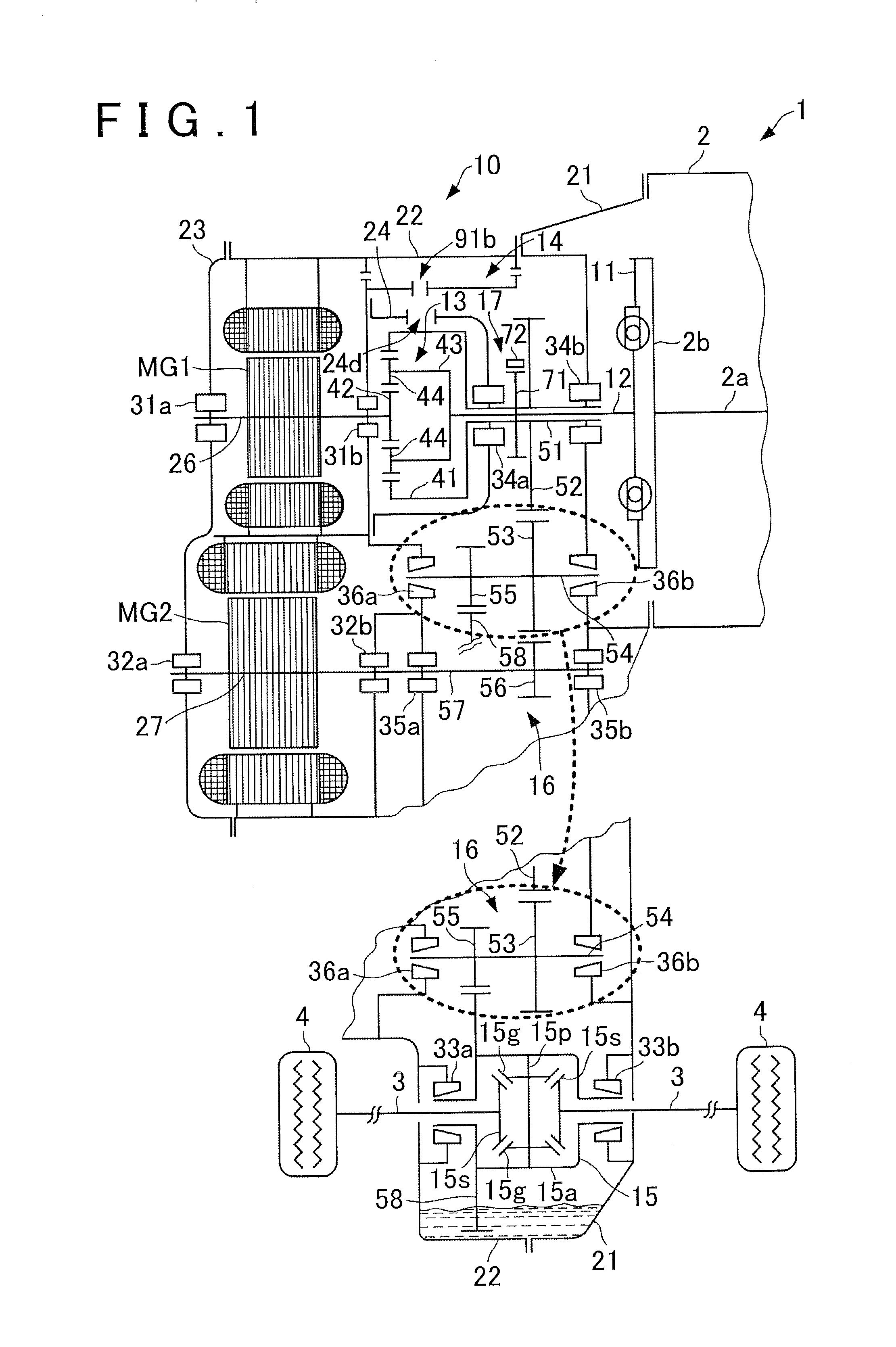

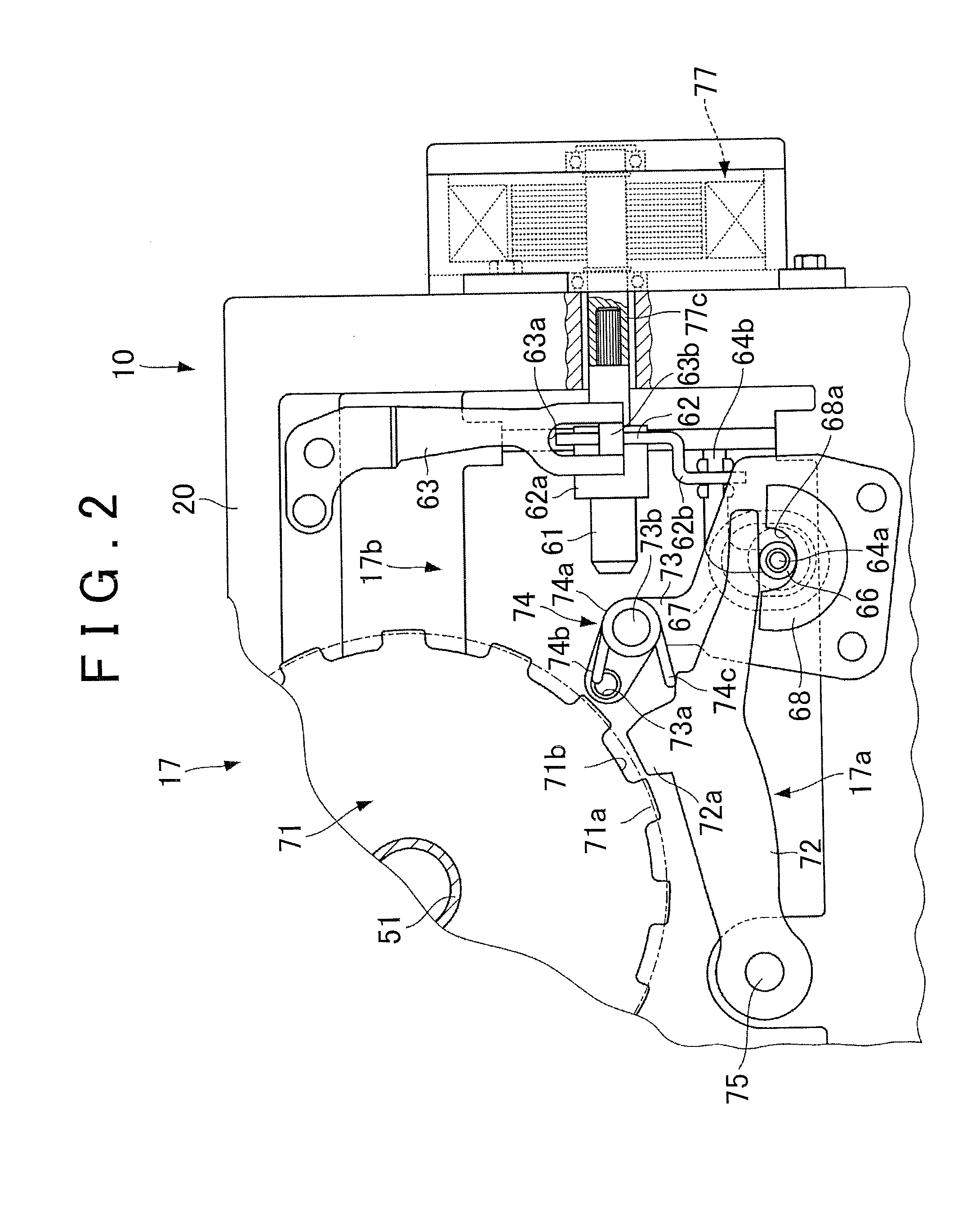

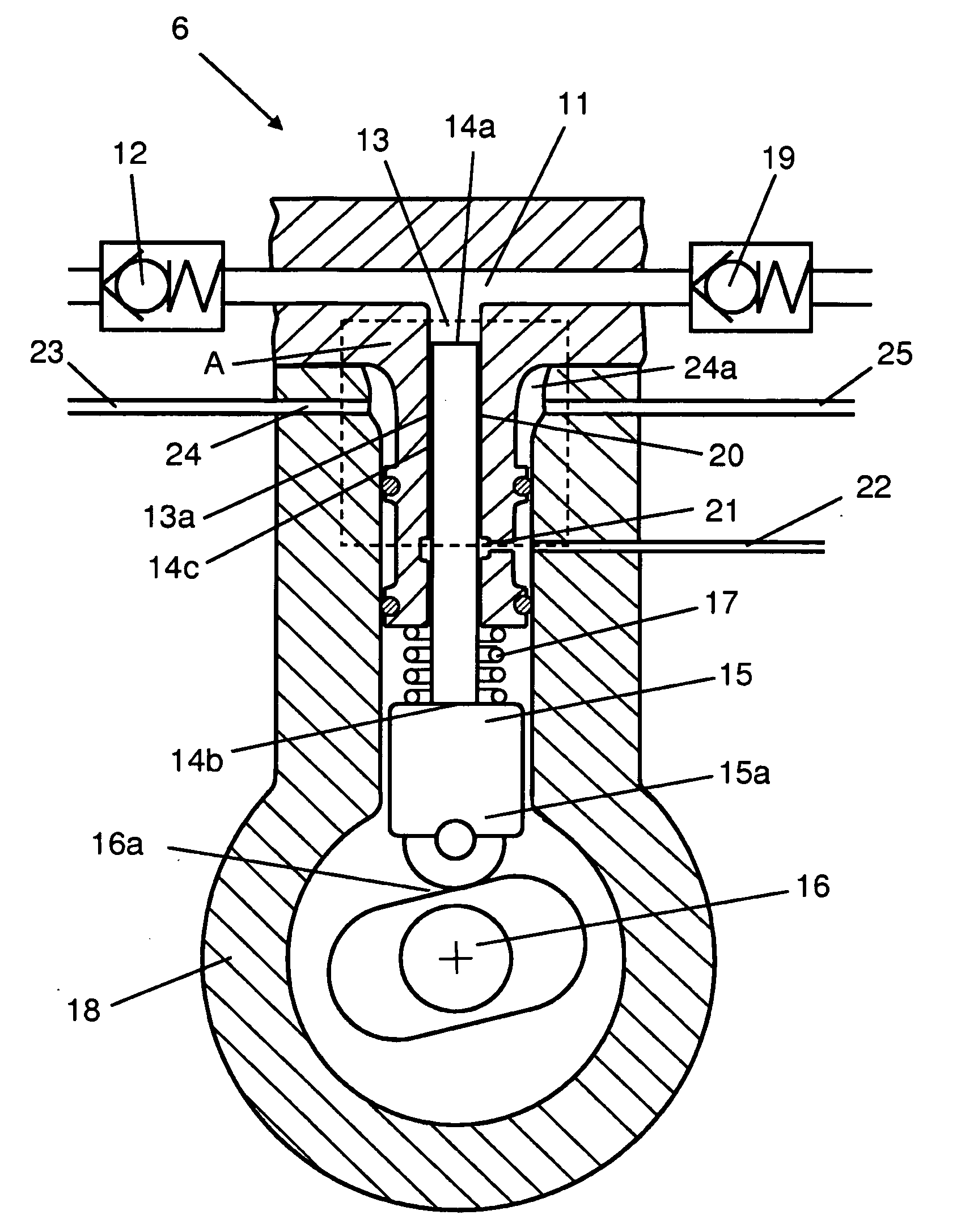

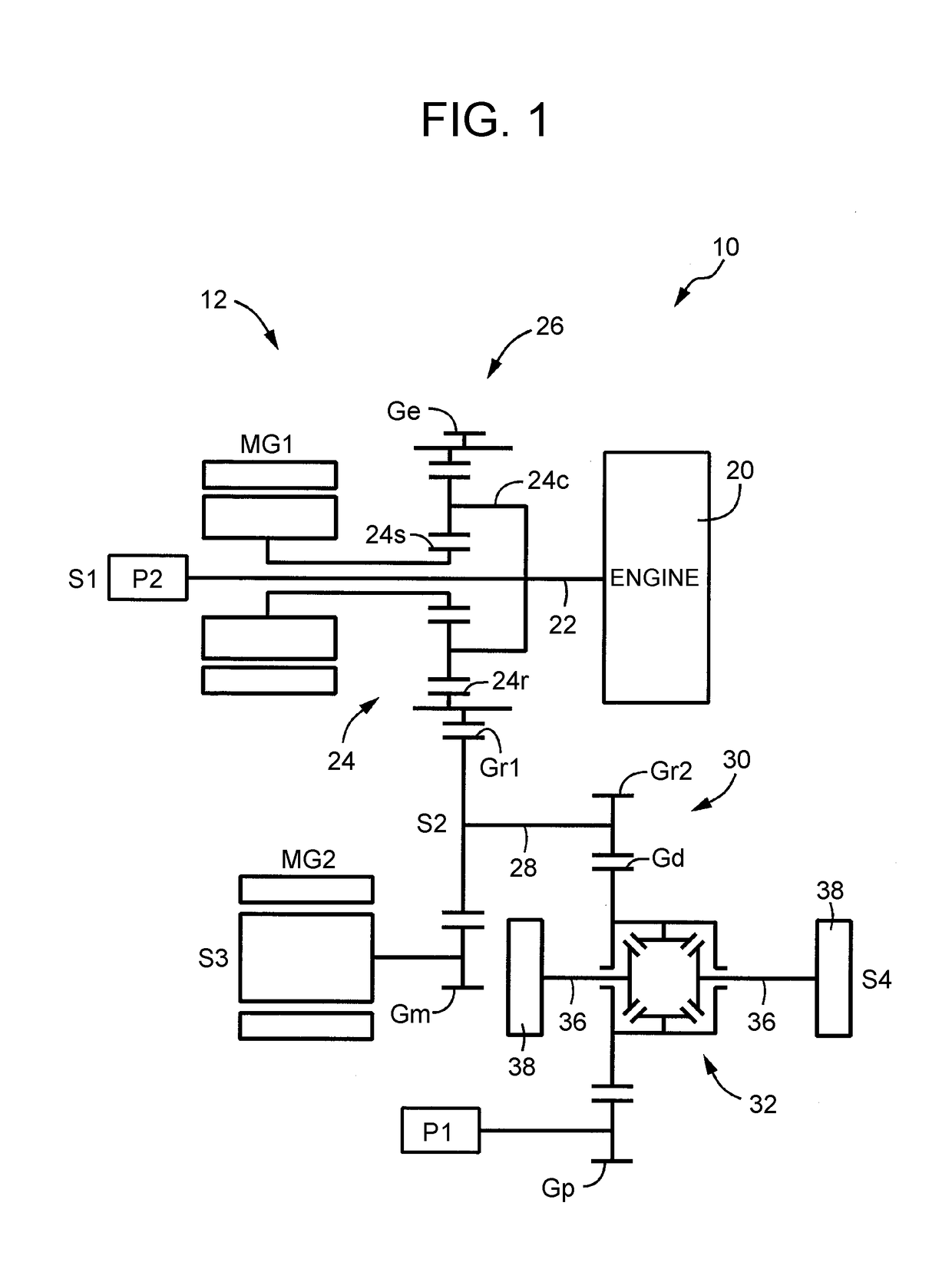

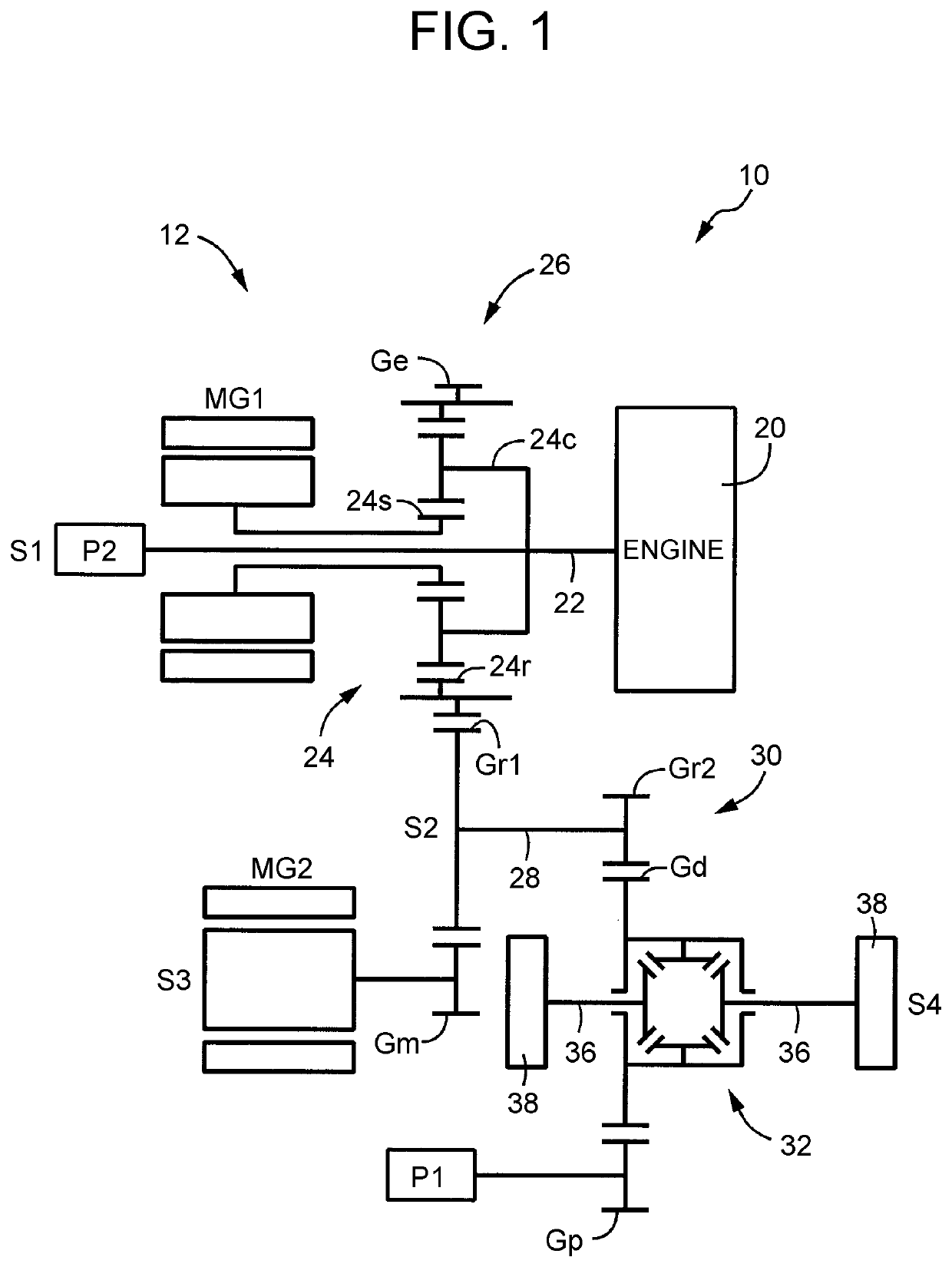

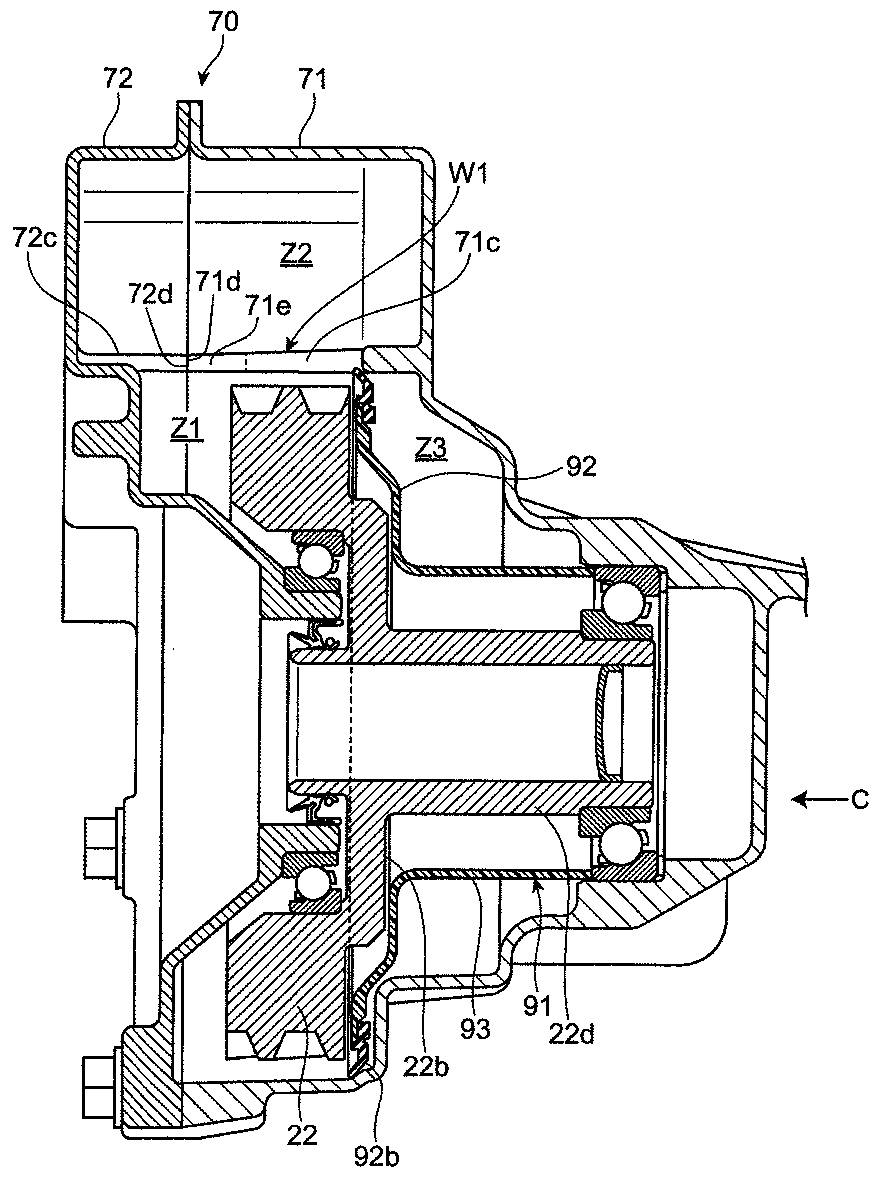

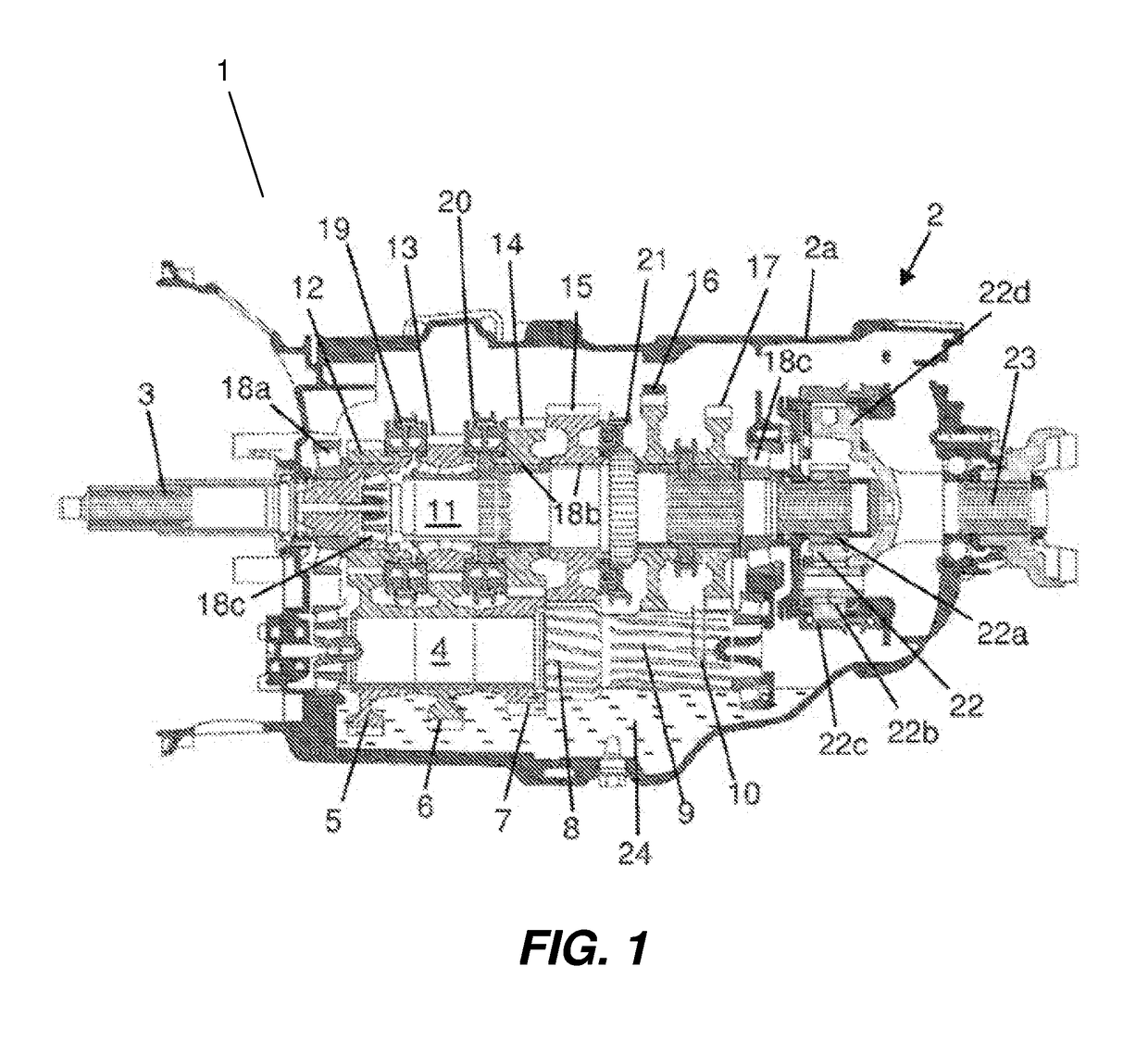

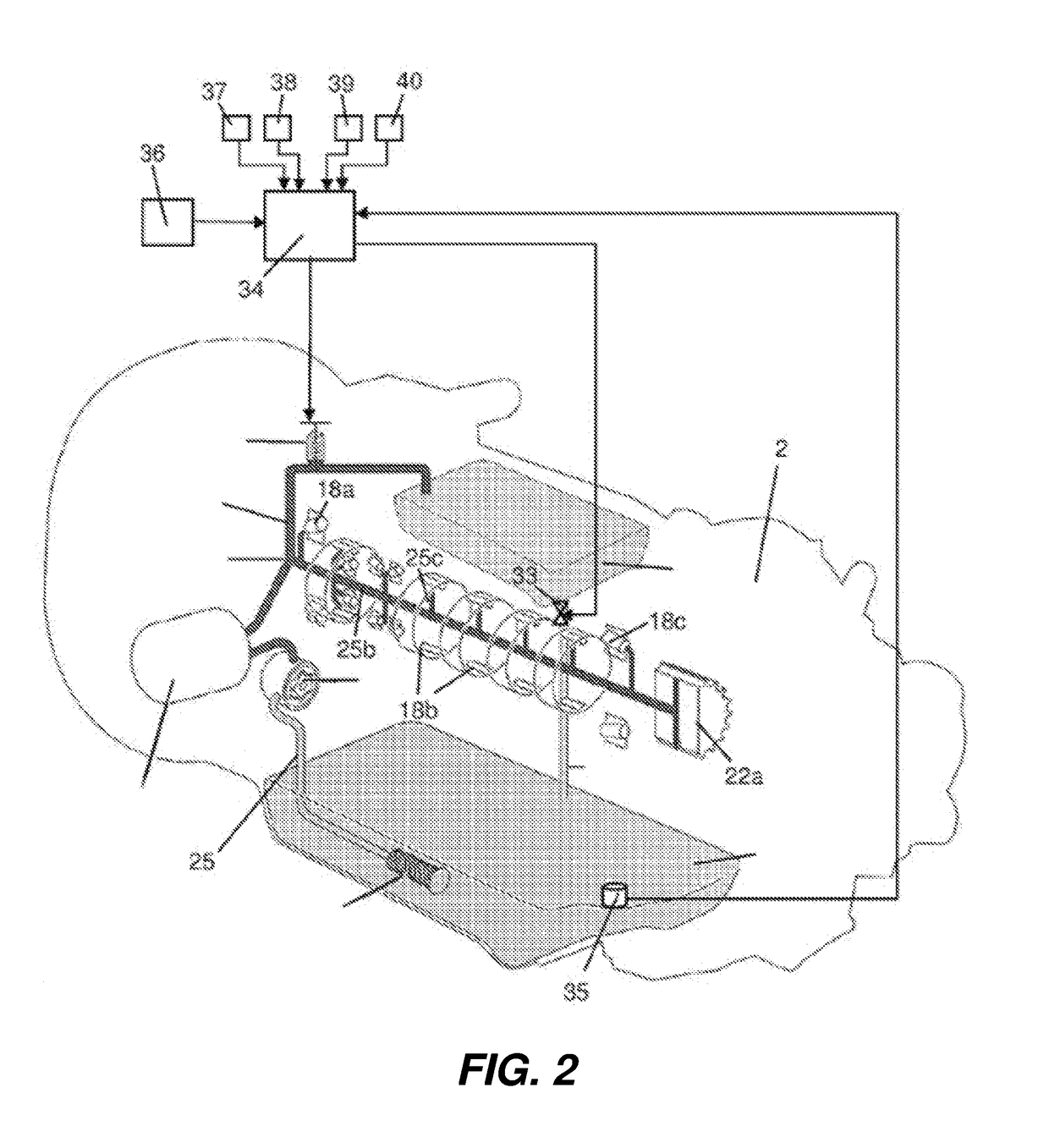

Vehicular drive system

ActiveUS20050139401A1Minimize loss in driving forceLoss of driving forceGearboxesMechanical actuated clutchesVariatorPower transmission

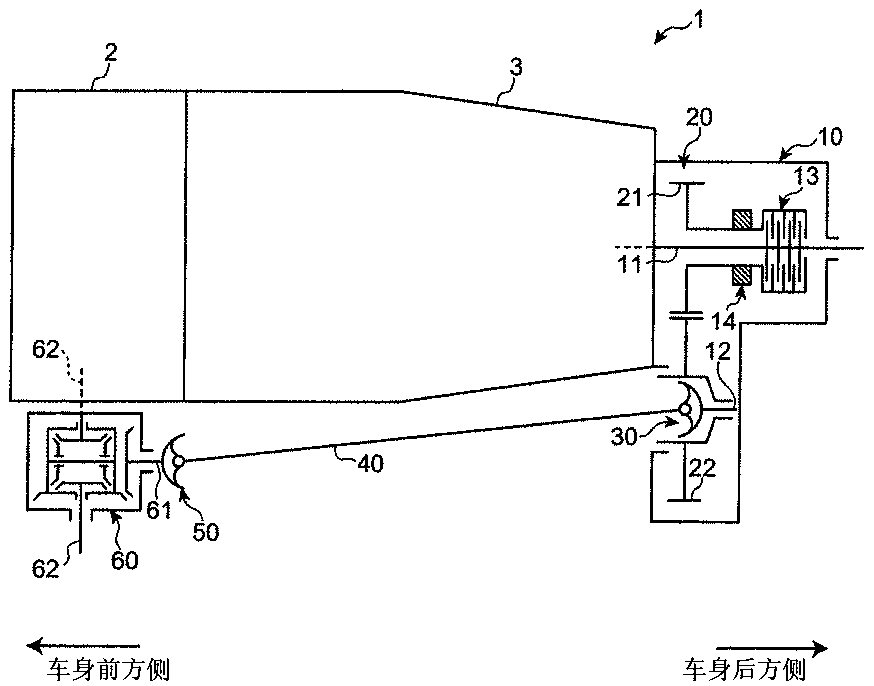

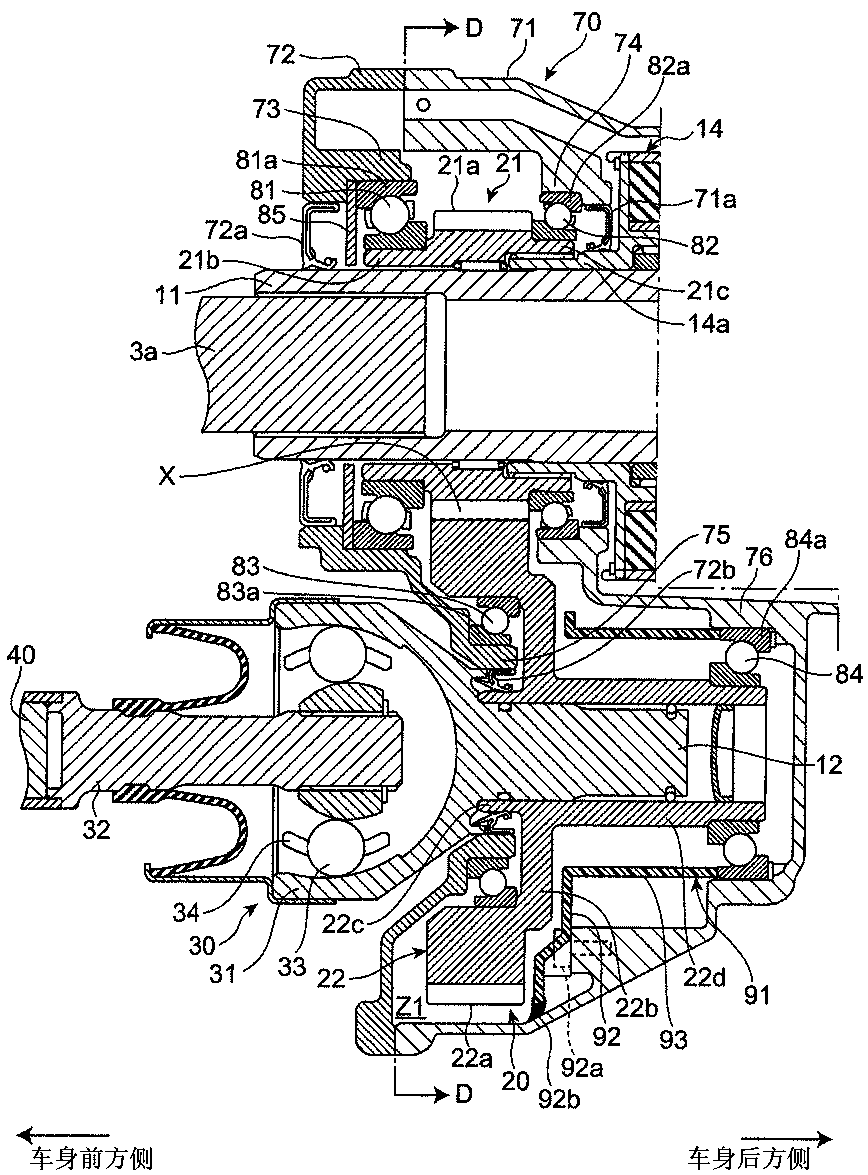

In a vehicular drive system for a hybrid vehicle, in which driving forces of an engine and a motor are transmitted through a power transmission mechanism to driven wheels, a common oil stored in a transmission case and a motor case is used for lubricating the power transmission mechanism and the motor. During travel by means of an engine, when a synchromesh mechanism operated by a shift fork isolates the motor from the power transmission mechanism, an oil return hole blocking rod, provided in the shift fork, blocks an oil return hole providing communication between the motor case and the transmission case, thereby preventing oil in the motor case from flowing into the transmission case, to lower oil level in the transmission case. Thus, during travel of the hybrid vehicle, driving force loss due to motor drag resistance and oil stirring resistance is minimized.

Owner:HONDA MOTOR CO LTD

Vehicular drive system

ActiveUS7211025B2Loss of driving forceEliminate resistanceGearboxesMechanical actuated clutchesDrive wheelEngineering

In a vehicular drive system for a hybrid vehicle, in which driving forces of an engine and a motor are transmitted through a power transmission mechanism to driven wheels, a common oil stored in a transmission case and a motor case is used for lubricating the power transmission mechanism and the motor. During travel by using an engine, when a synchromesh mechanism operated by a shift fork isolates the motor from the power transmission mechanism, an oil return hole blocking rod, provided in the shift fork, blocks an oil return hole providing communication between the motor case and the transmission case, thereby preventing oil in the motor case from flowing into the transmission case, to lower oil level in the transmission case. Thus, during travel of the hybrid vehicle, driving force loss due to motor drag resistance and oil stirring resistance is minimized.

Owner:HONDA MOTOR CO LTD

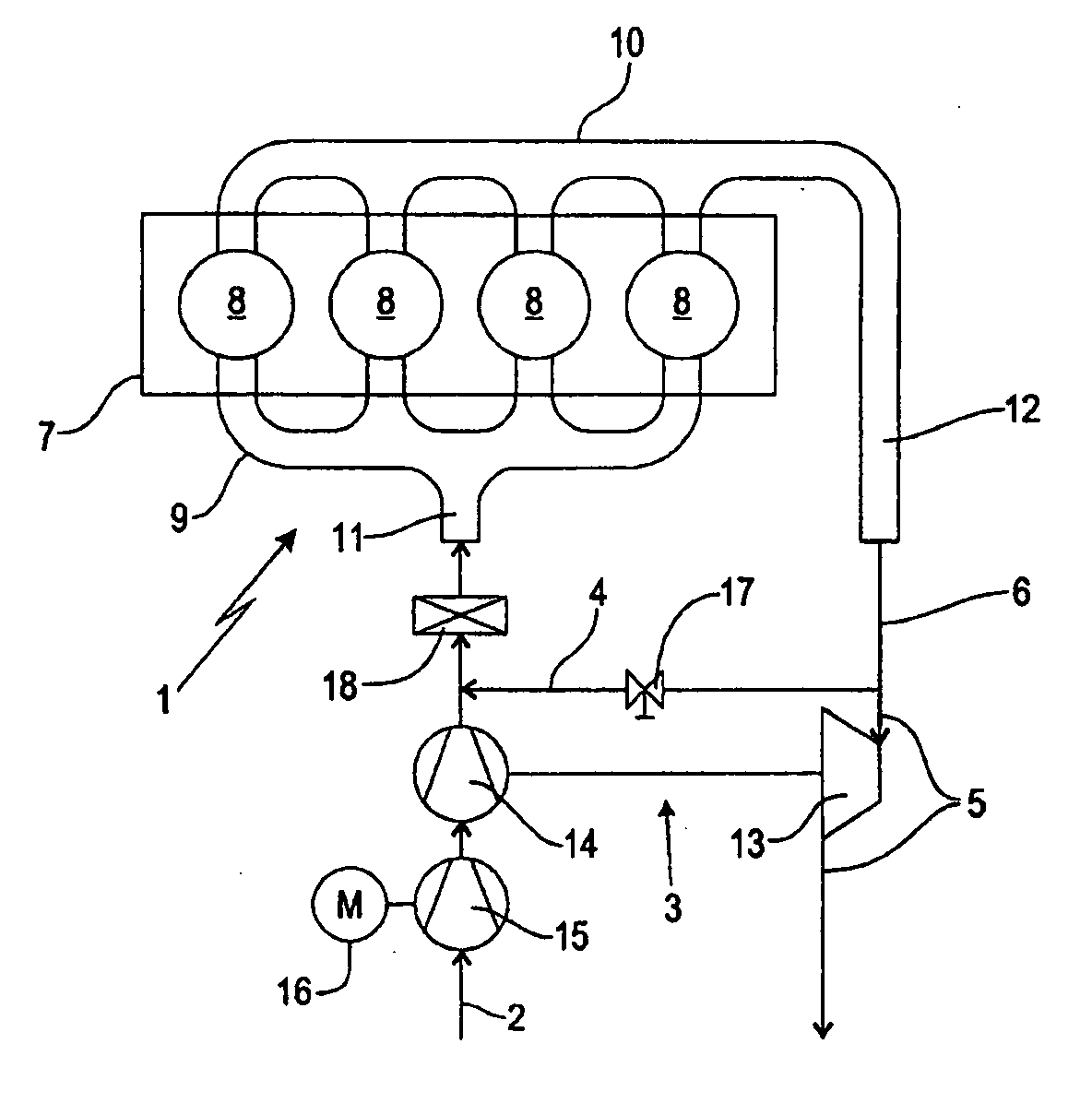

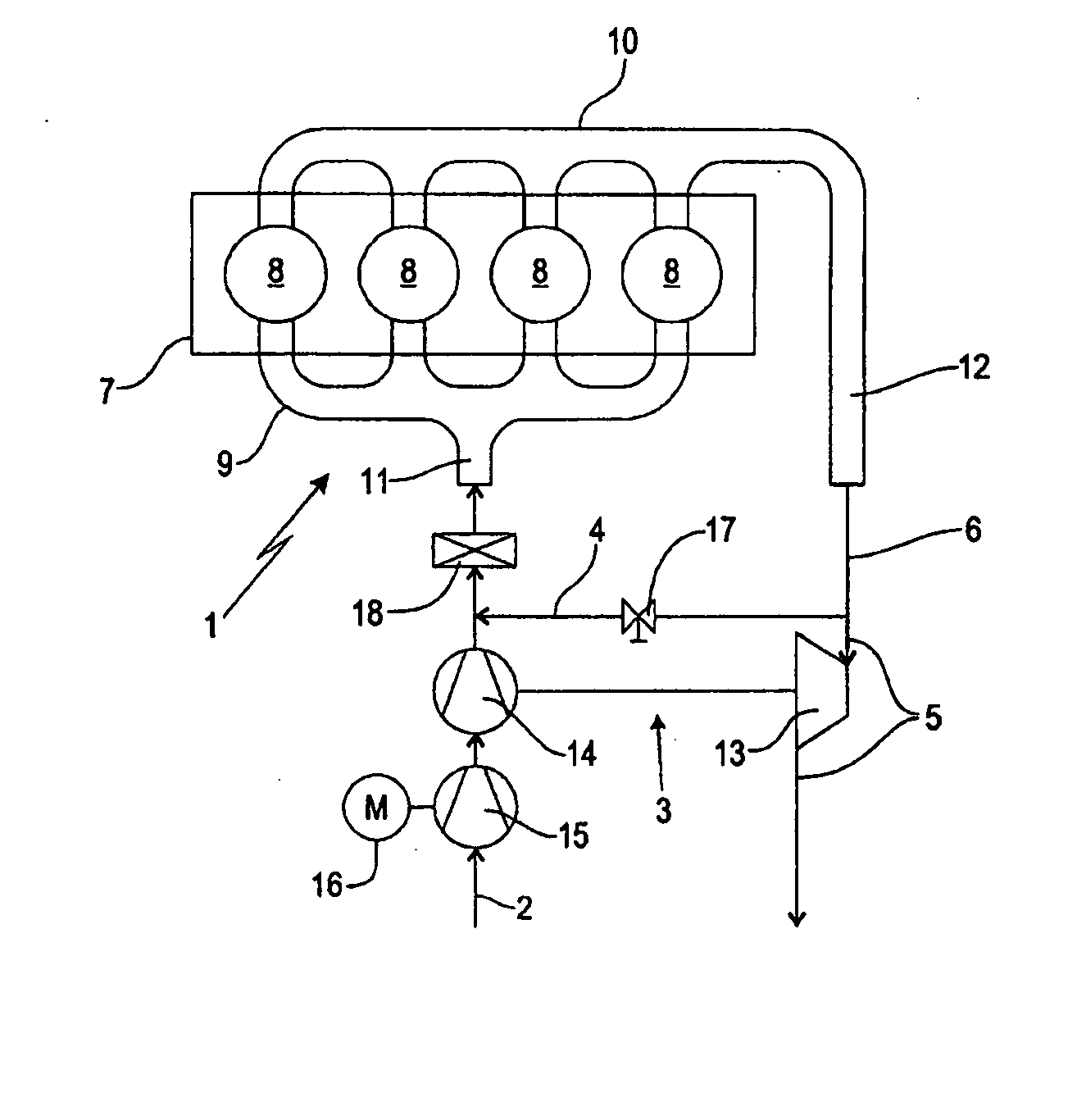

Method for operating a spark ignition engine

ActiveUS20090173319A1Lower temperature levelAdequate power levelValve arrangementsElectrical controlBattery chargerExhaust gas

In a method for operating a spark ignition engine, wherein the inlet valves of the spark ignition engine are closed very early or very late, and a combustion air flow which is supplied to the spark ignition engine is compressed by means of a charger, and, under full load operation, the inlet valves are closed either early or late to avoid knocking of the engine, a partial flow of re-circulated exhaust gas is supplied to the combustion air flow supplied to the engine also during full load engine operation.

Owner:DAIMLER AG

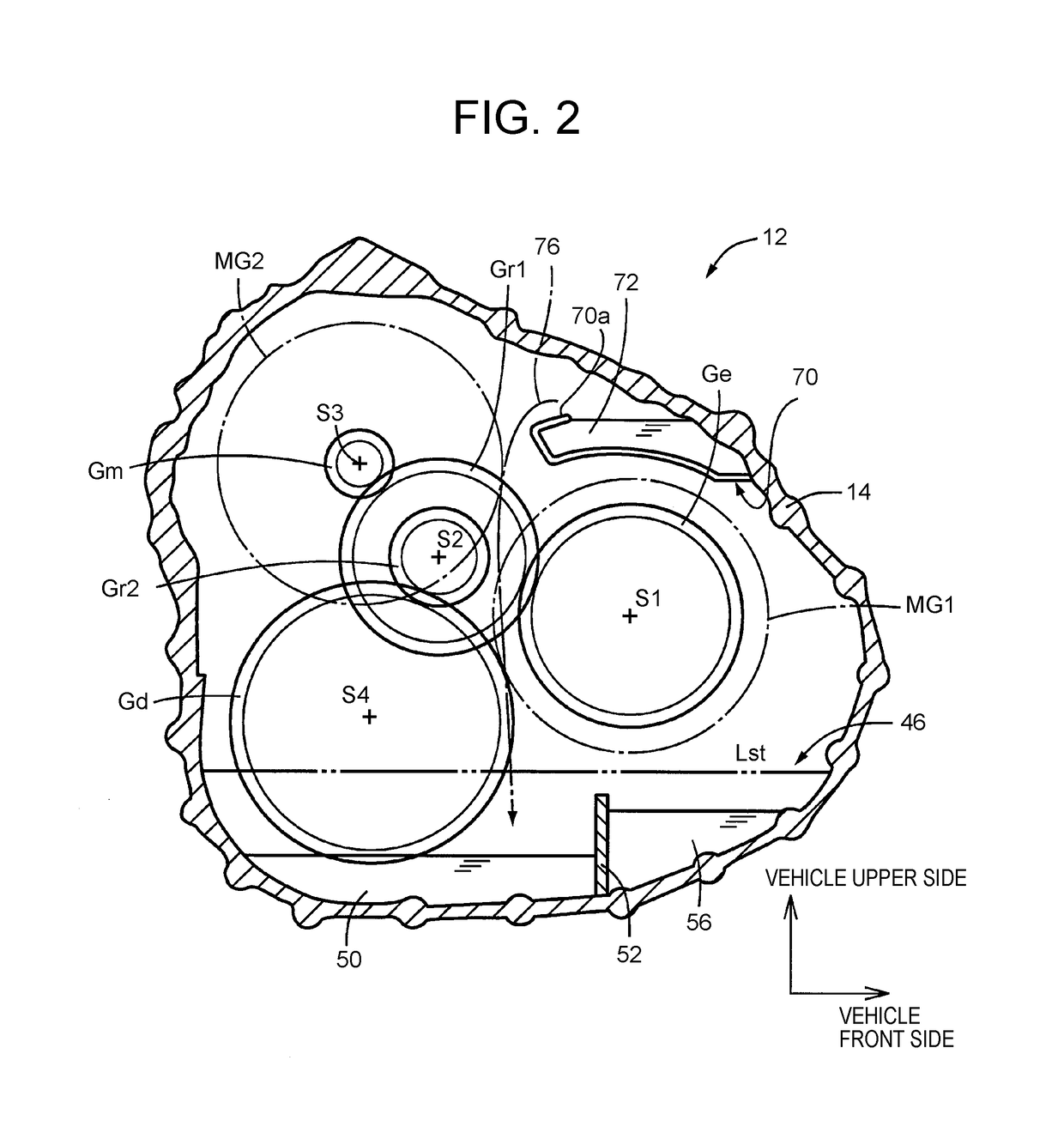

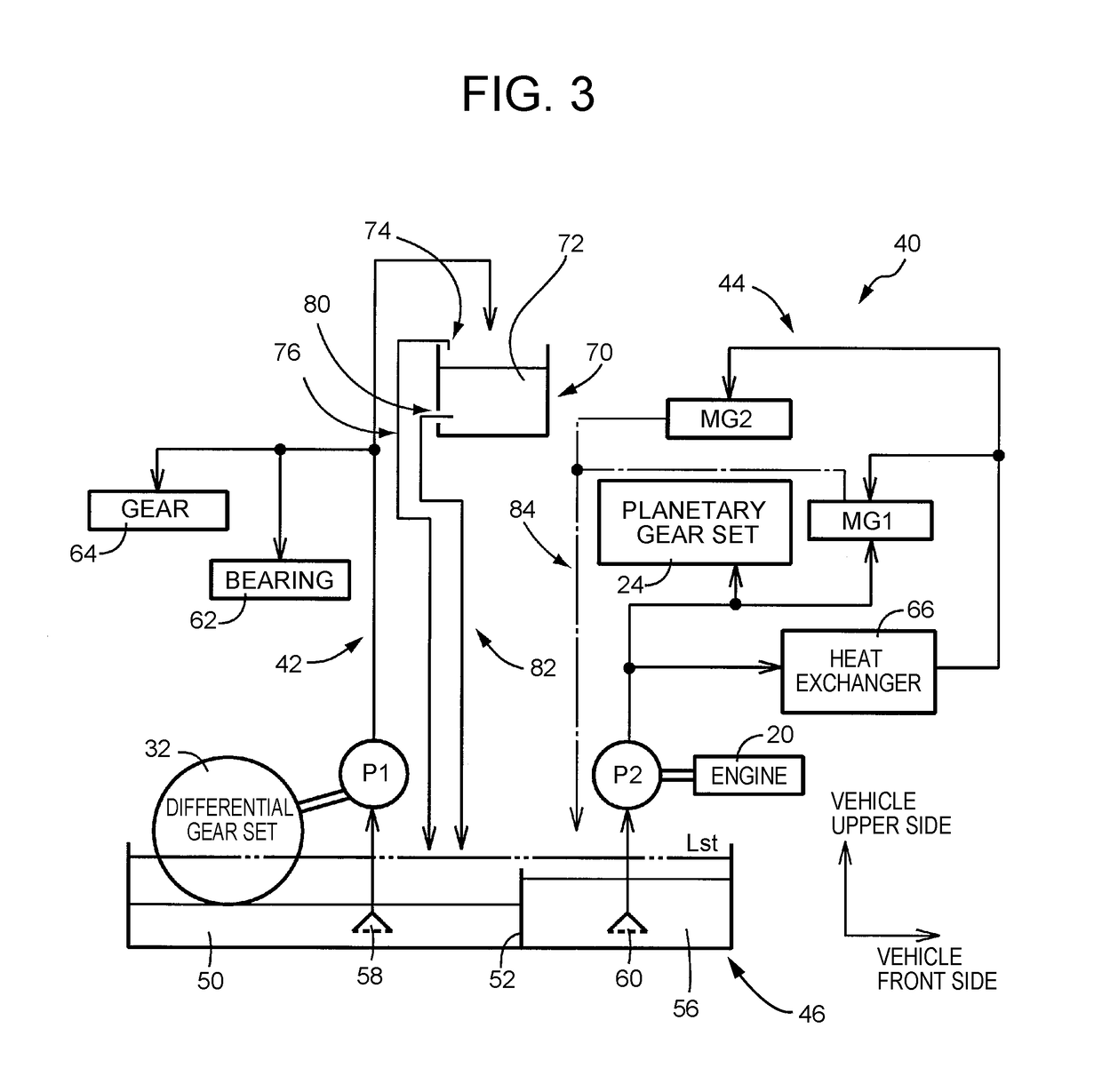

Lubricating oil supply apparatus

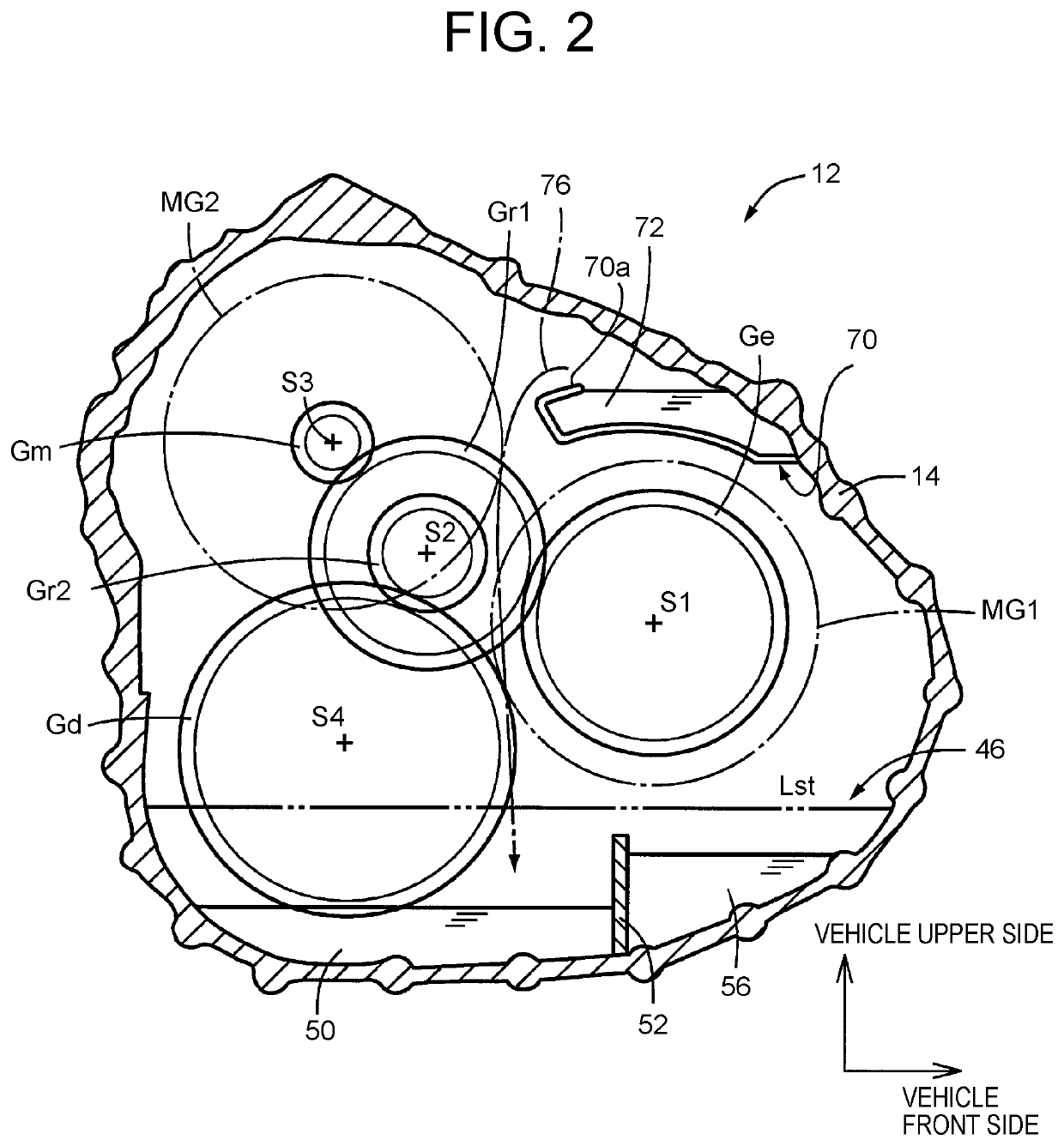

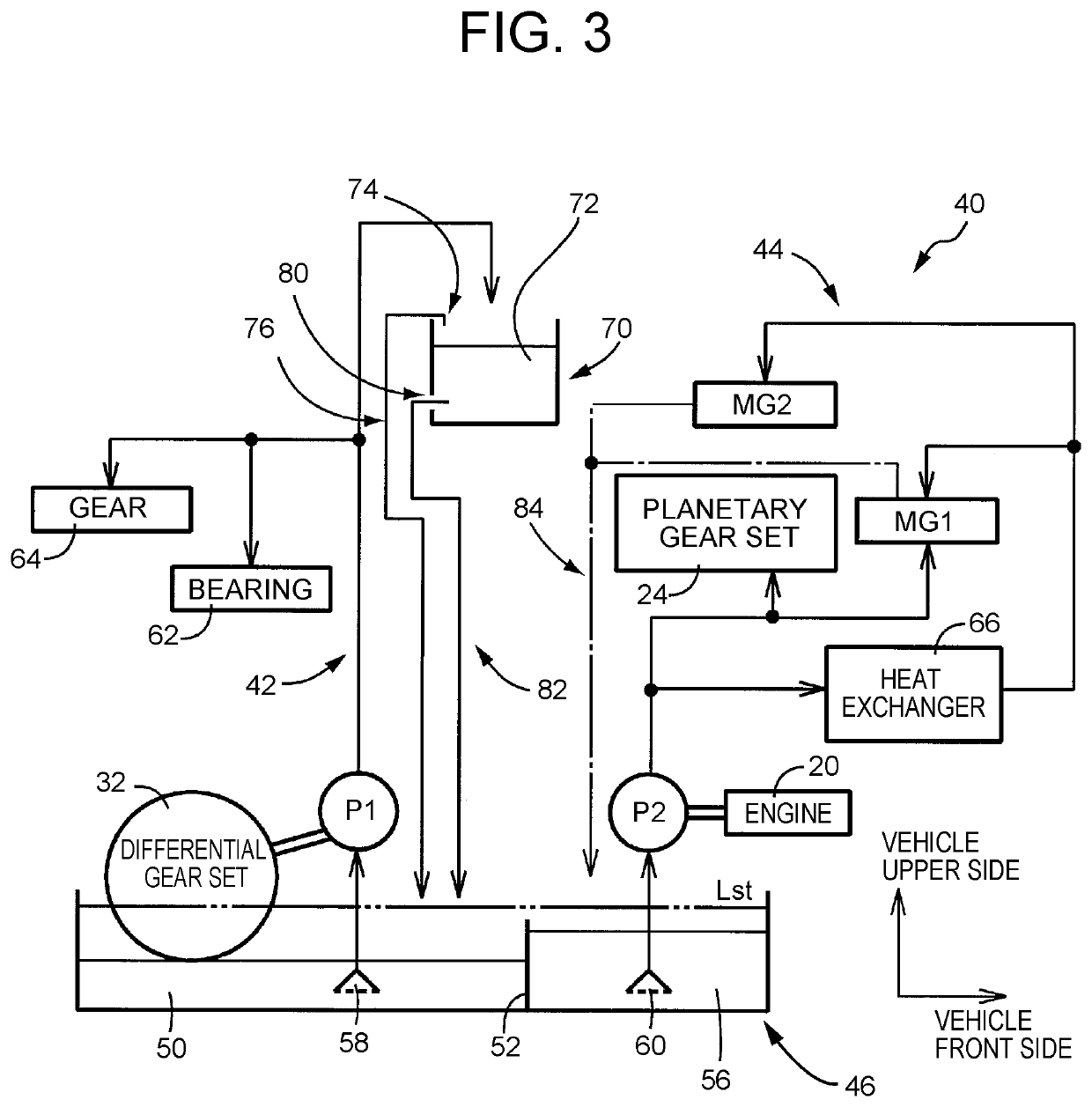

InactiveUS20140155214A1Improve the lubrication effectReduce power lossHybrid vehiclesSpeed controllerEngineeringTransaxle

A lubricating oil supply apparatus arranged in a transaxle case includes a differential ring gear, a catch tank that stores lubricating oil picked up by the differential ring gear, a first flow path arranged higher than a highest position of an outer diameter of the differential ring gear, a gear with a higher center position than the differential ring gear, and a second flow path that guides the lubricating oil picked up by the gear to the catch tank. The first flow path guides the lubricating oil picked up by the differential ring gear to the catch tank. The gear is in mesh with the differential ring gear, and picks up the lubricating oil picked up by the differential ring gear. The second flow path is arranged lower than a highest position of an outer diameter of the gear.

Owner:TOYOTA JIDOSHA KK

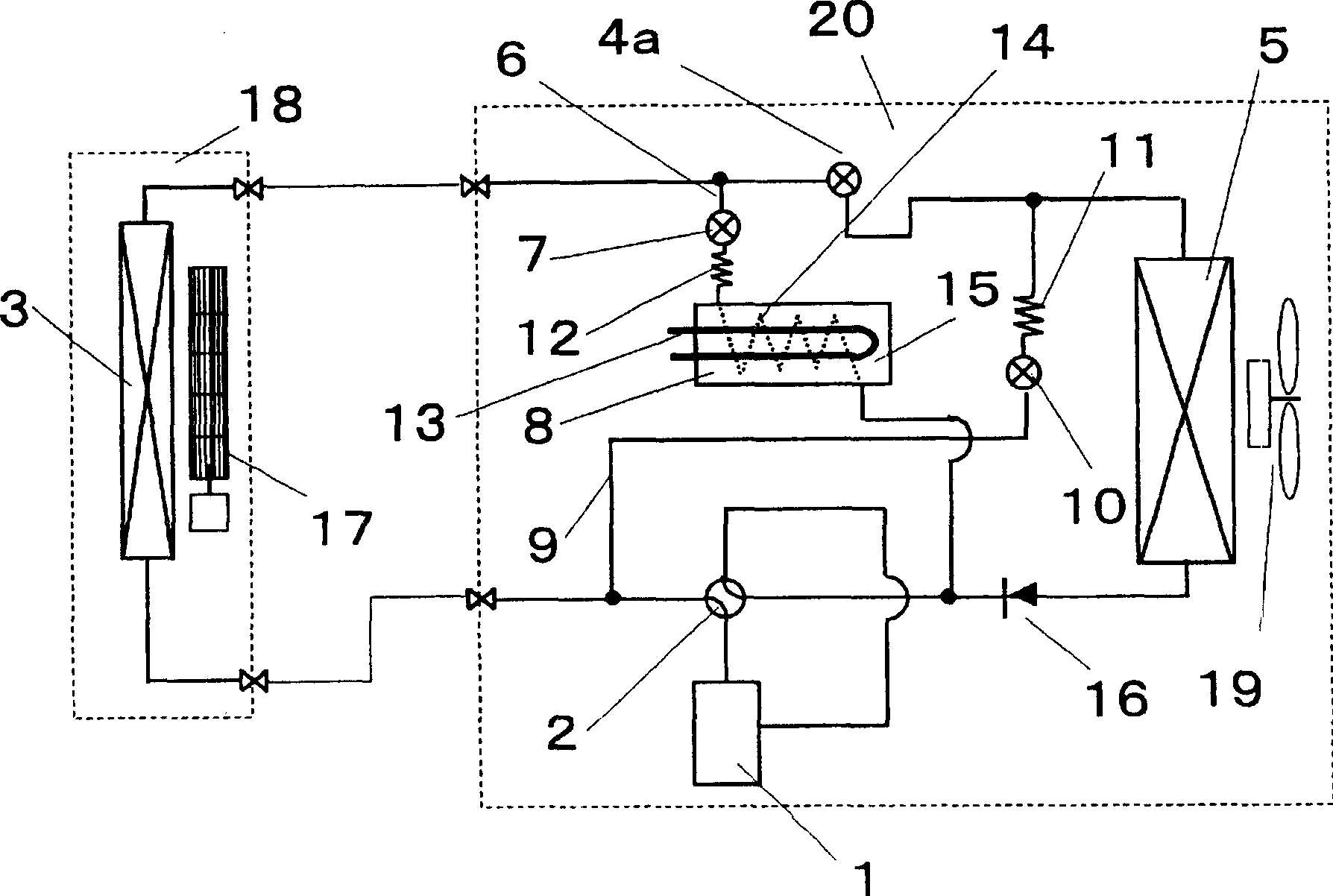

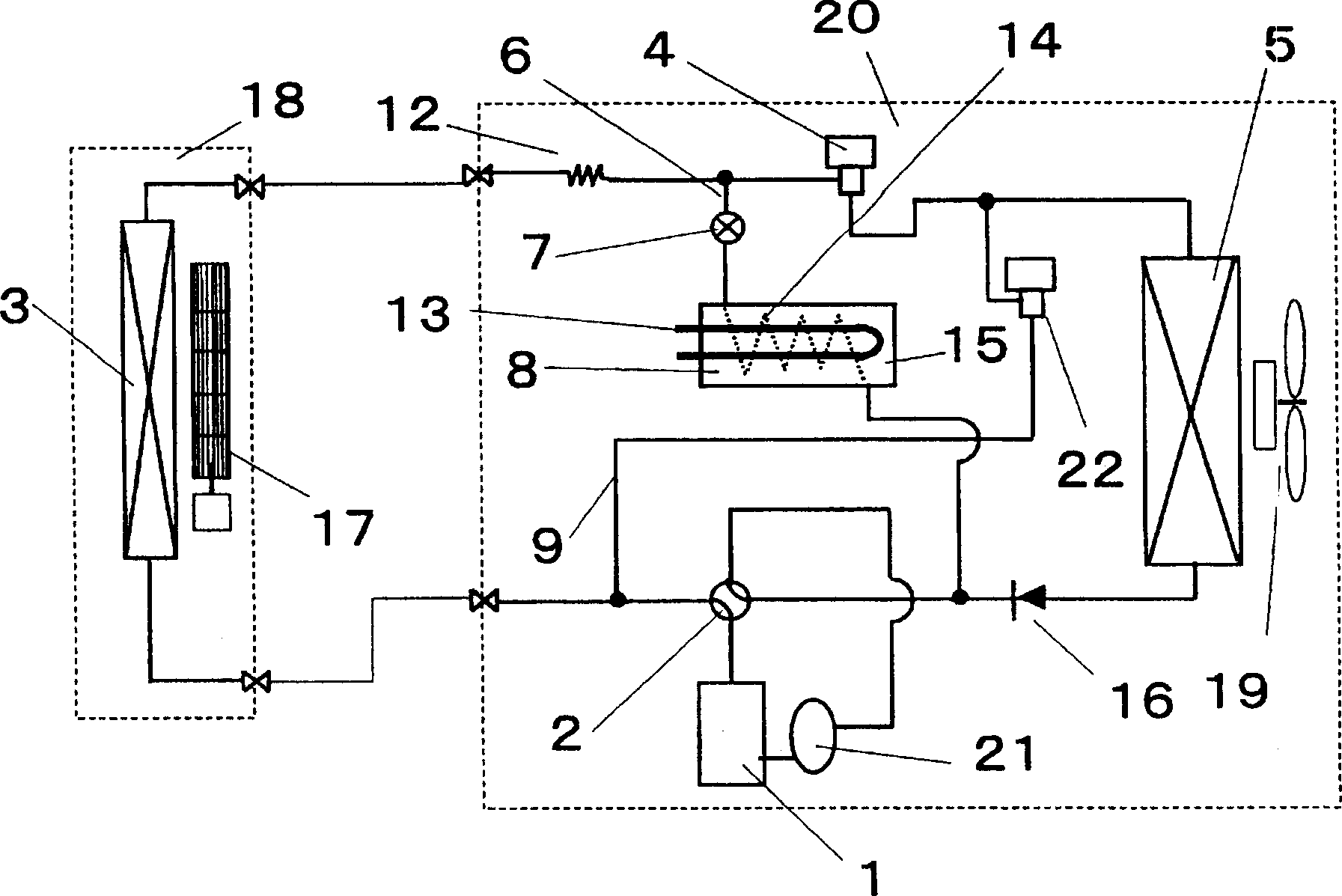

Air conditioner

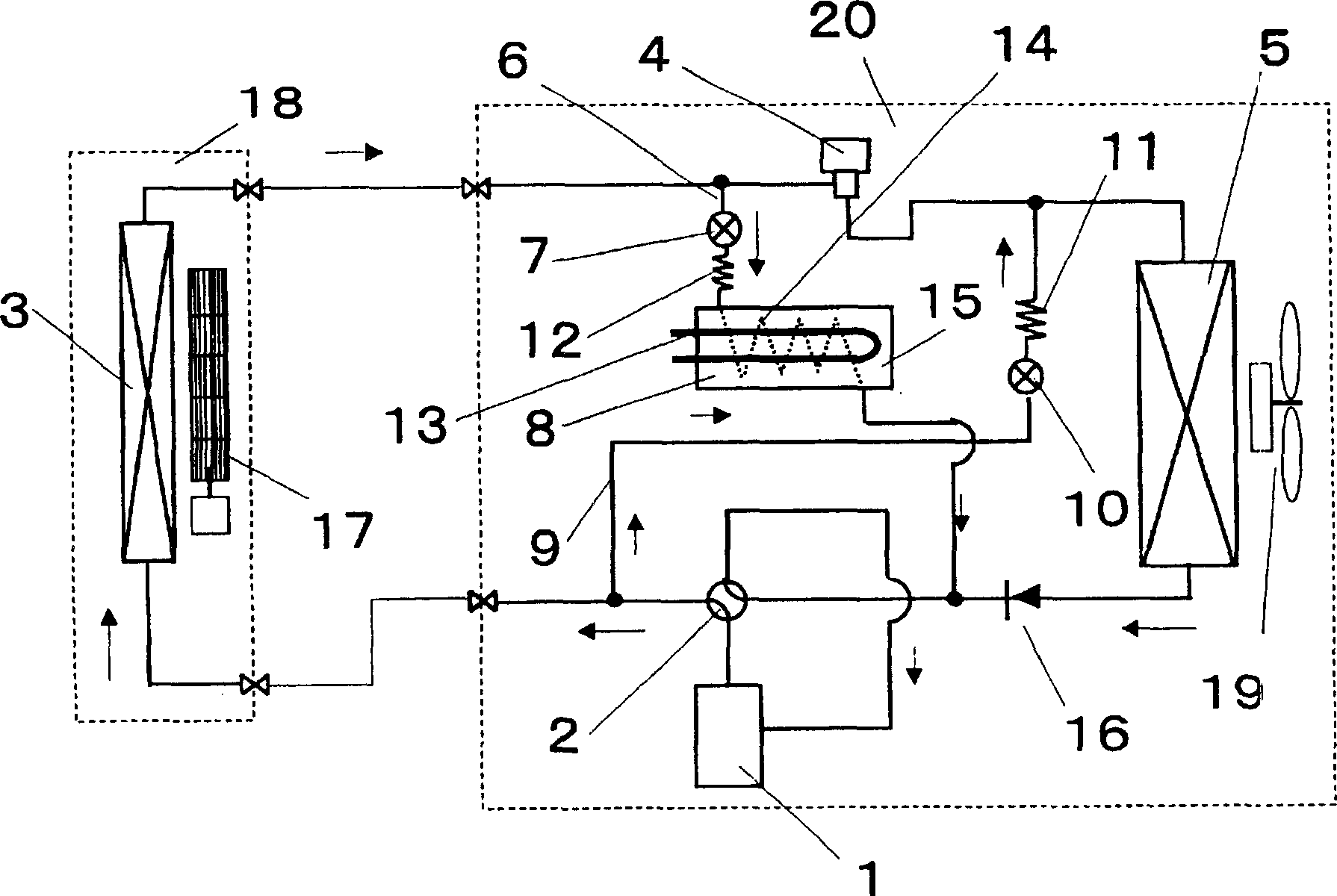

InactiveCN1769819ALittle changeImprove operational reliabilityMechanical apparatusCorrosion preventionFour-way valveEngineering

The invention provides an air conditioner that continues heating operation and defrost operation at the same time, which is provided with: an indoor heat exchanger (3) and a pressure reducer (4) in a heat pump refrigeration loop. A first bypass circuit (6) is connected between the pipe and the suction side of the compressor (1). The first bypass circuit is provided with a two-way valve (7) and a refrigerant heater (8). In addition, the present invention is also provided with a pipeline and a pressure reducer (4) between the four-way valve (2) connected to the refrigeration loop and the indoor heat exchanger (3) and the outdoor heat exchanger (5). There is a second bypass circuit (9) connected by pipelines therebetween, and a two-way valve (10) is provided on the second bypass circuit. When defrosting the outdoor heat exchanger (5), open the two-way valve (7) on the first bypass circuit (6) and the two-way valve (10) on the second bypass circuit (9), and execute Heating and defrosting operations.

Owner:PANASONIC CORP

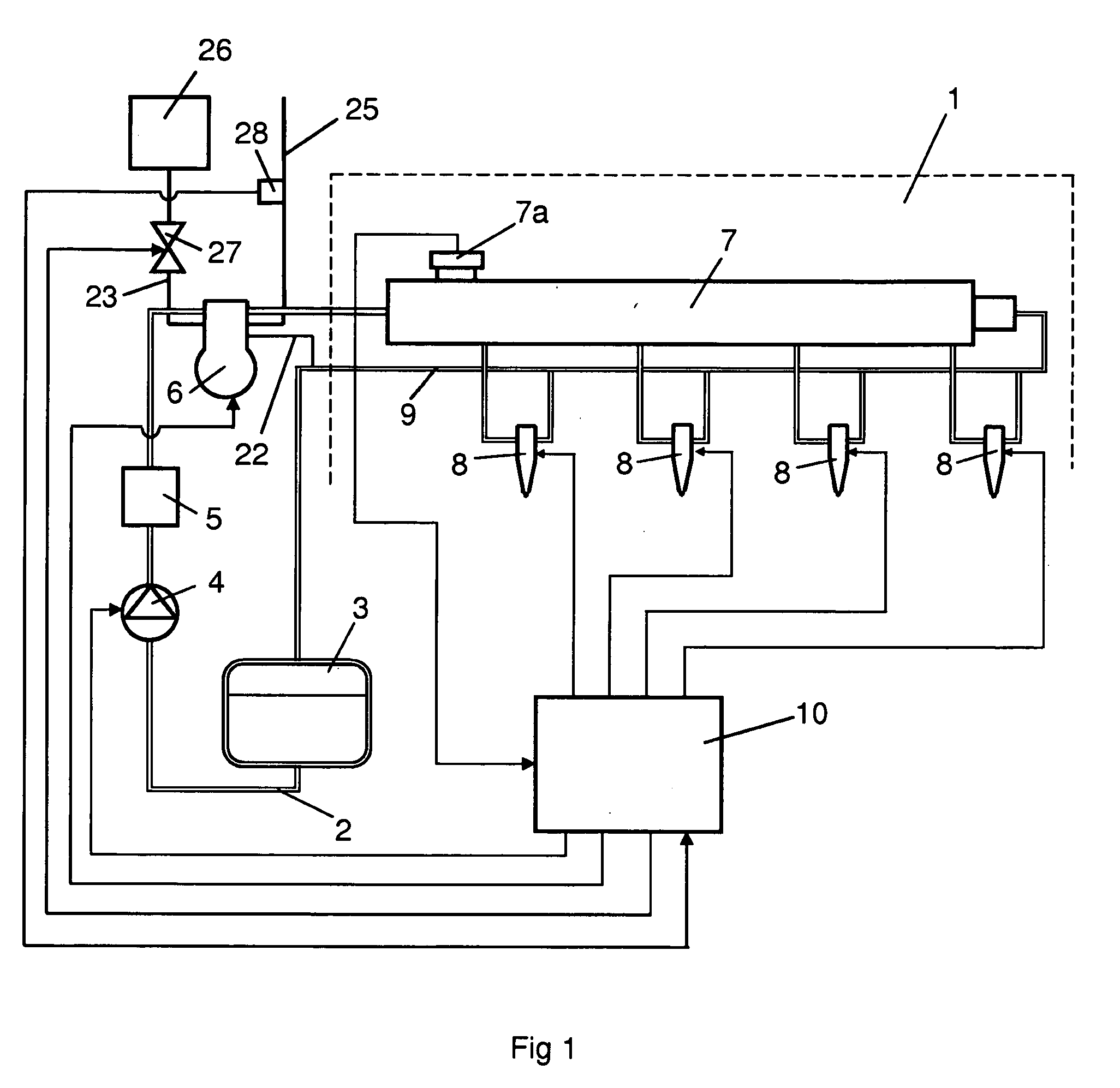

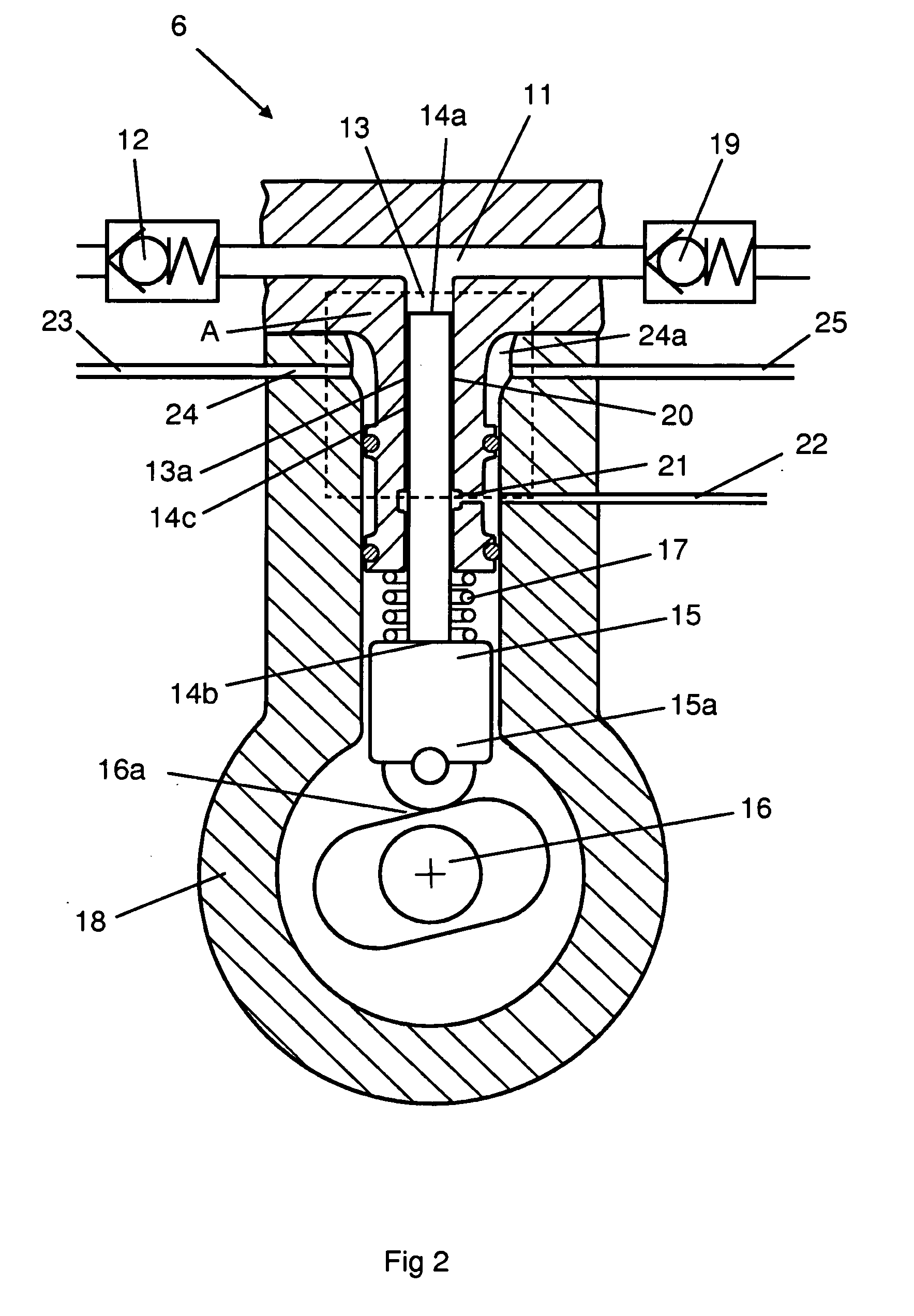

Fuel pump device

ActiveUS20100047084A1Lower oil levelImprove efficiencyPositive displacement pump componentsFuel injecting pumpsEngineeringHigh pressure

A fuel pump device includes a fuel pump in which pressure-generating components in the form of a movable piston movable through a cylinder in the fuel pump together are operable to pressurize the fuel in a chamber exposed to the components to high pressure. To prevent the clearance between the pressure-generating components from increasing with increased heating of the fuel pump and to maintain a predetermined clearance between the piston and the surrounding cylinder, a temperature-regulator maintains a temperature within a predetermined temperature range in a region of the fuel pump which includes the clearance and at least portions of the pressure-generating components.

Owner:SCANIA CV AB

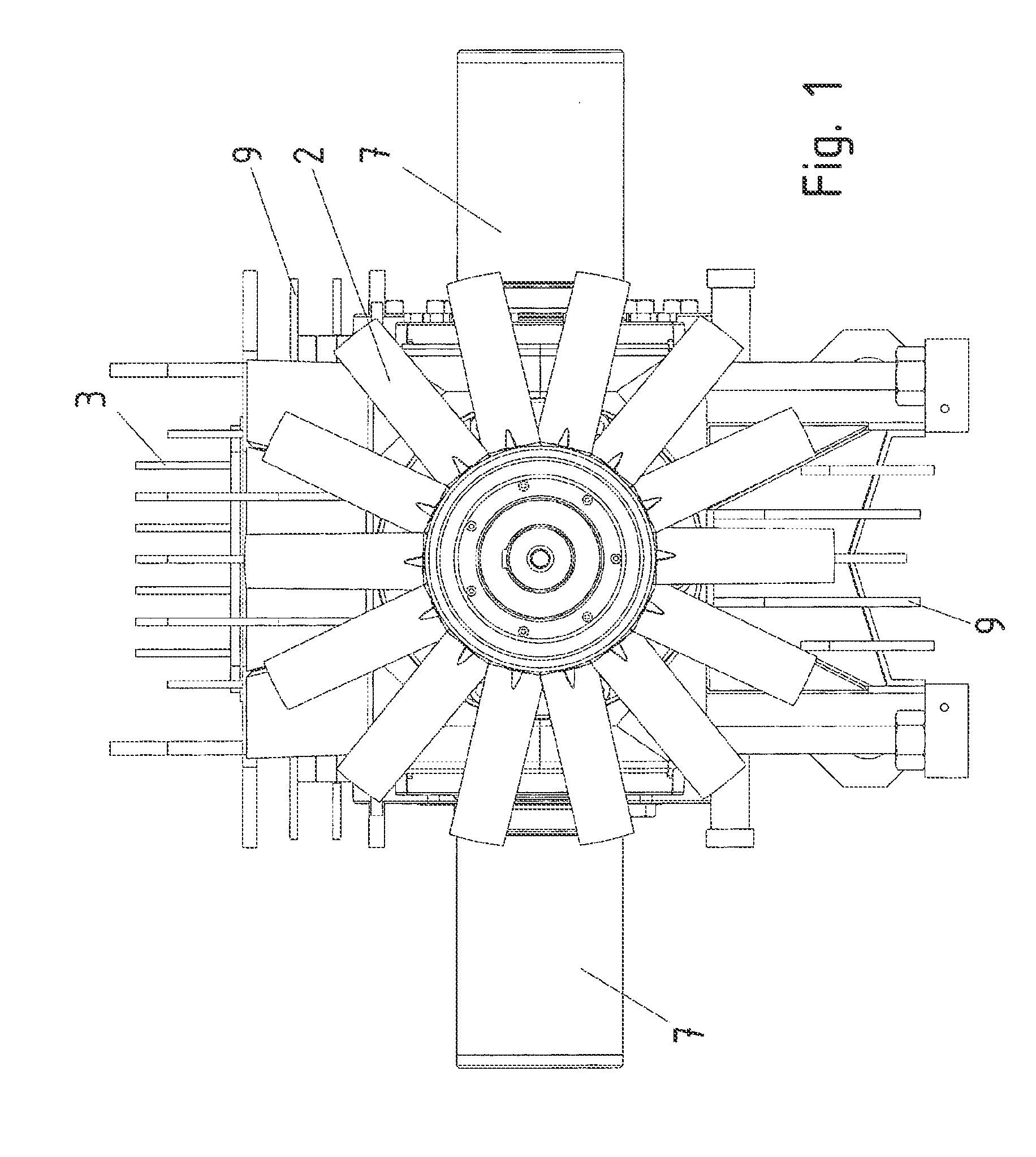

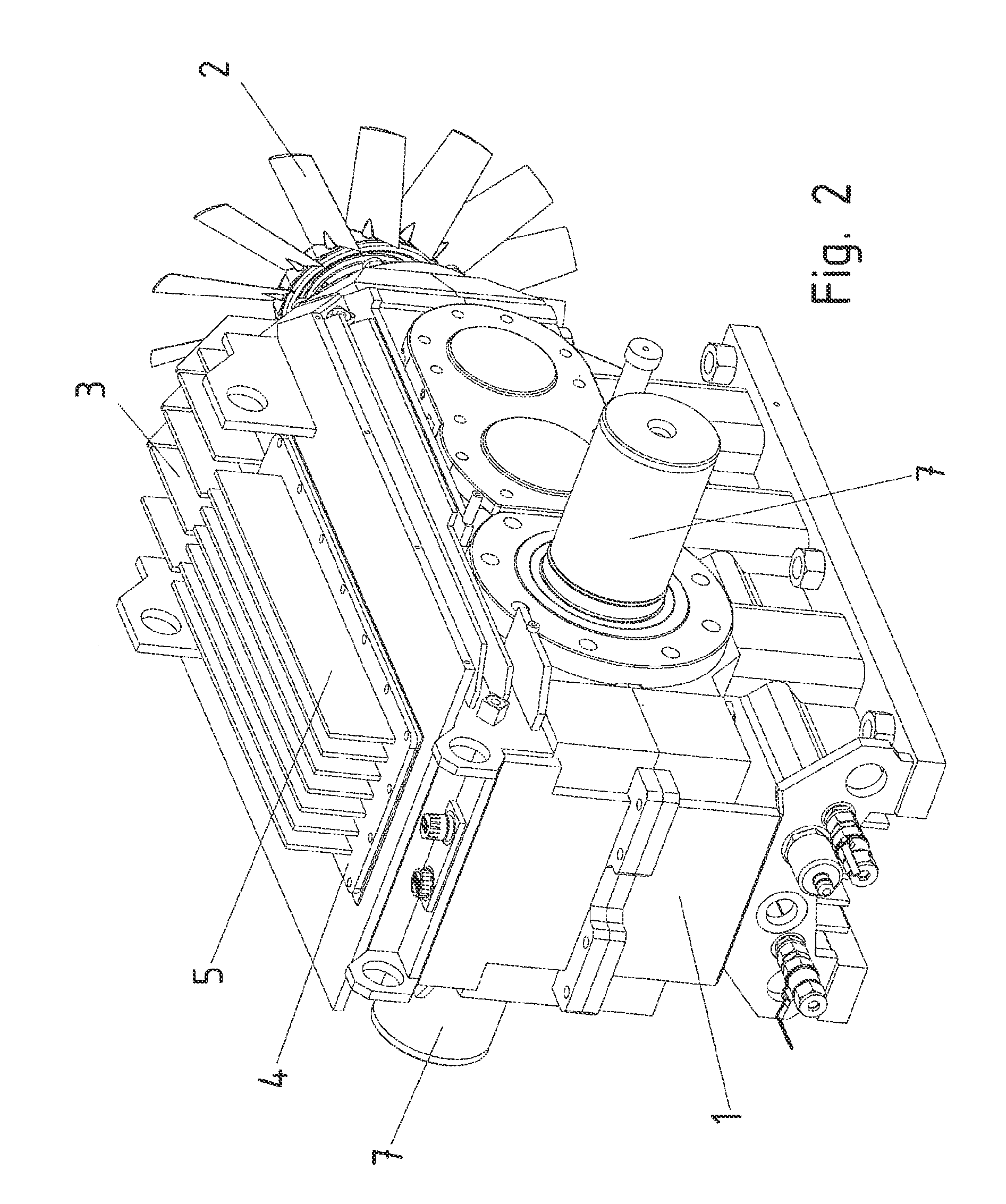

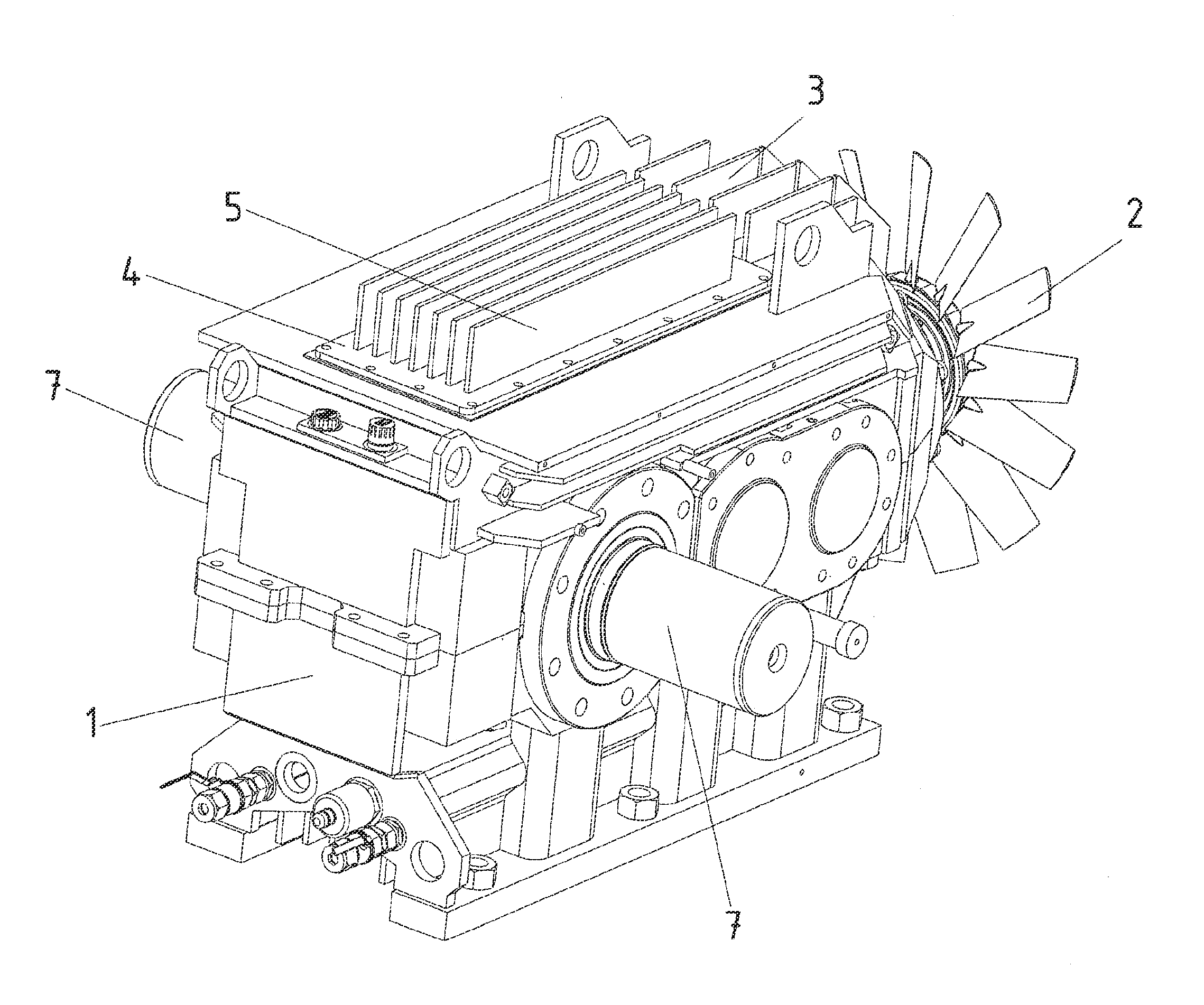

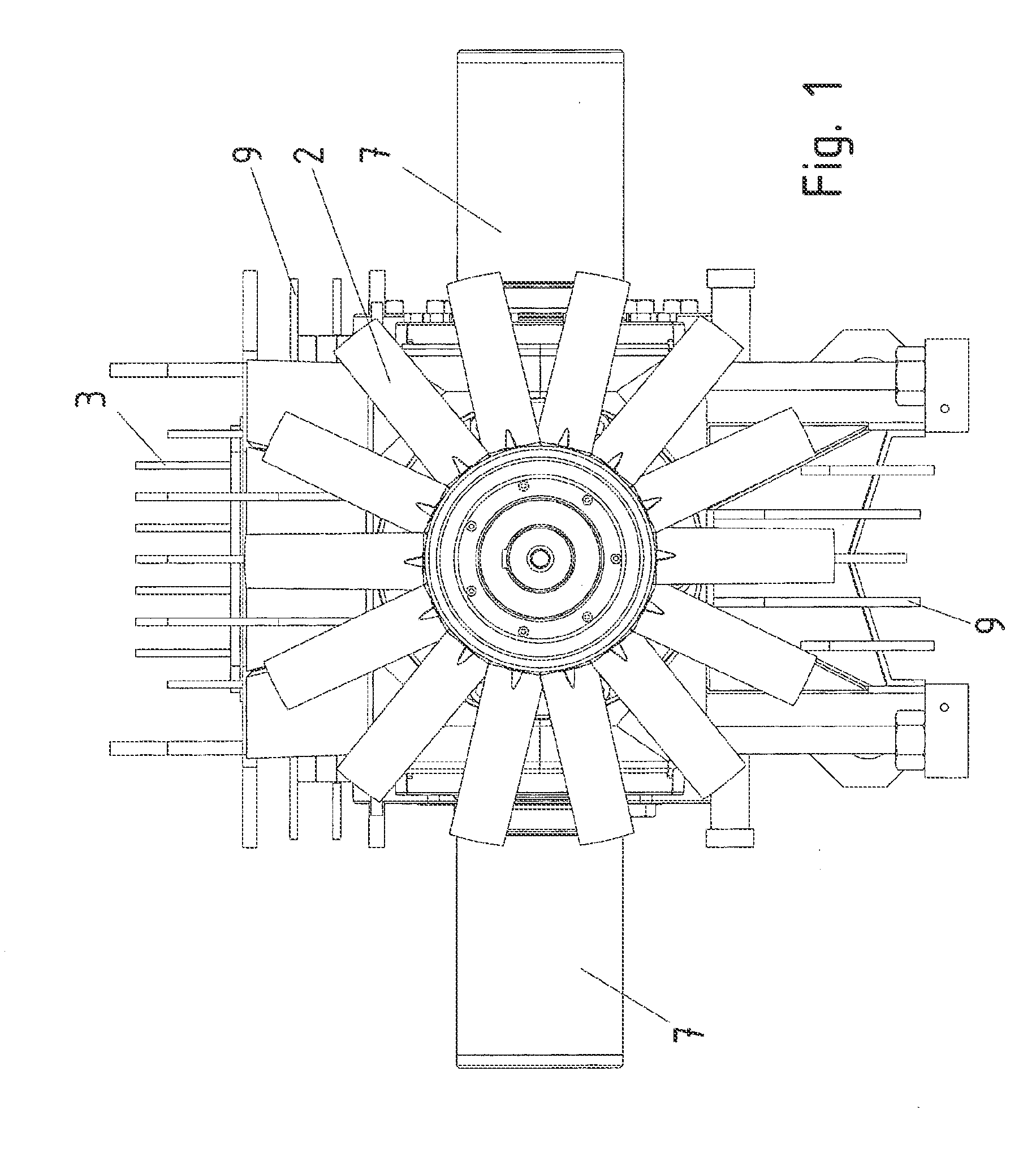

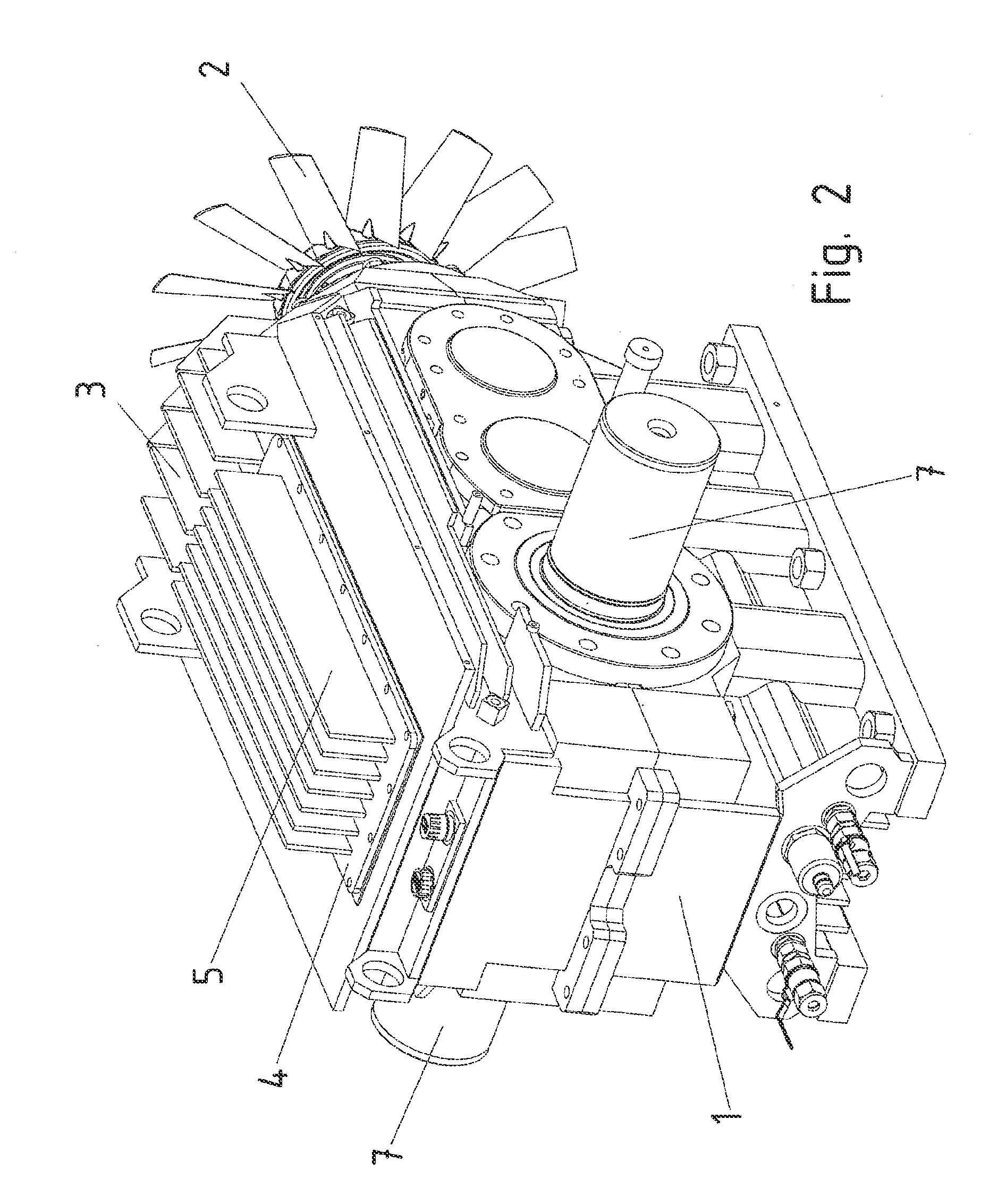

Gear unit

ActiveUS8833193B2Kinetic energyReduce frictionGearboxesGear lubrication/coolingGear wheelEngineering

Owner:SEW-EURODRIVE GMBH & CO KG

Lubricating system of vehicle transmission device

A lubricating system of a vehicle transmission device includes a third oil storage part that is provided above a first oil storage part and a second oil storage part in a vehicle height direction. The third oil storage part stores lubricating oil, and includes a first outlet that allows the lubricating oil to flow out by gravity toward the first oil storage part without passing through the second oil storage part. As the lubricating oil is thus returned from the first outlet to the first oil storage part without passing through the second oil storage part, the oil level in the first oil storage part can be stably maintained with the lubricating oil supplied thereto regardless of the oil level in the second oil storage part.

Owner:TOYOTA JIDOSHA KK

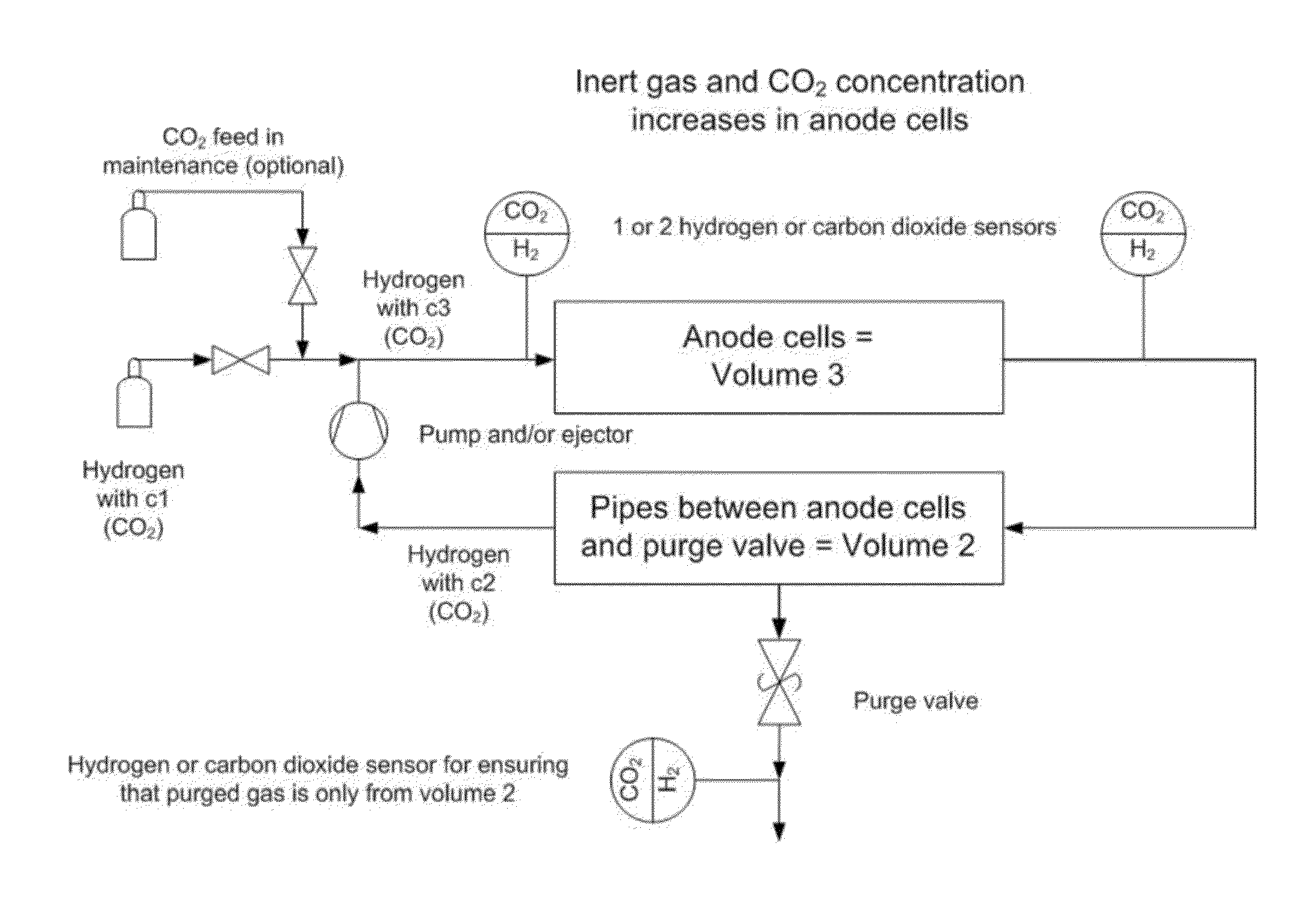

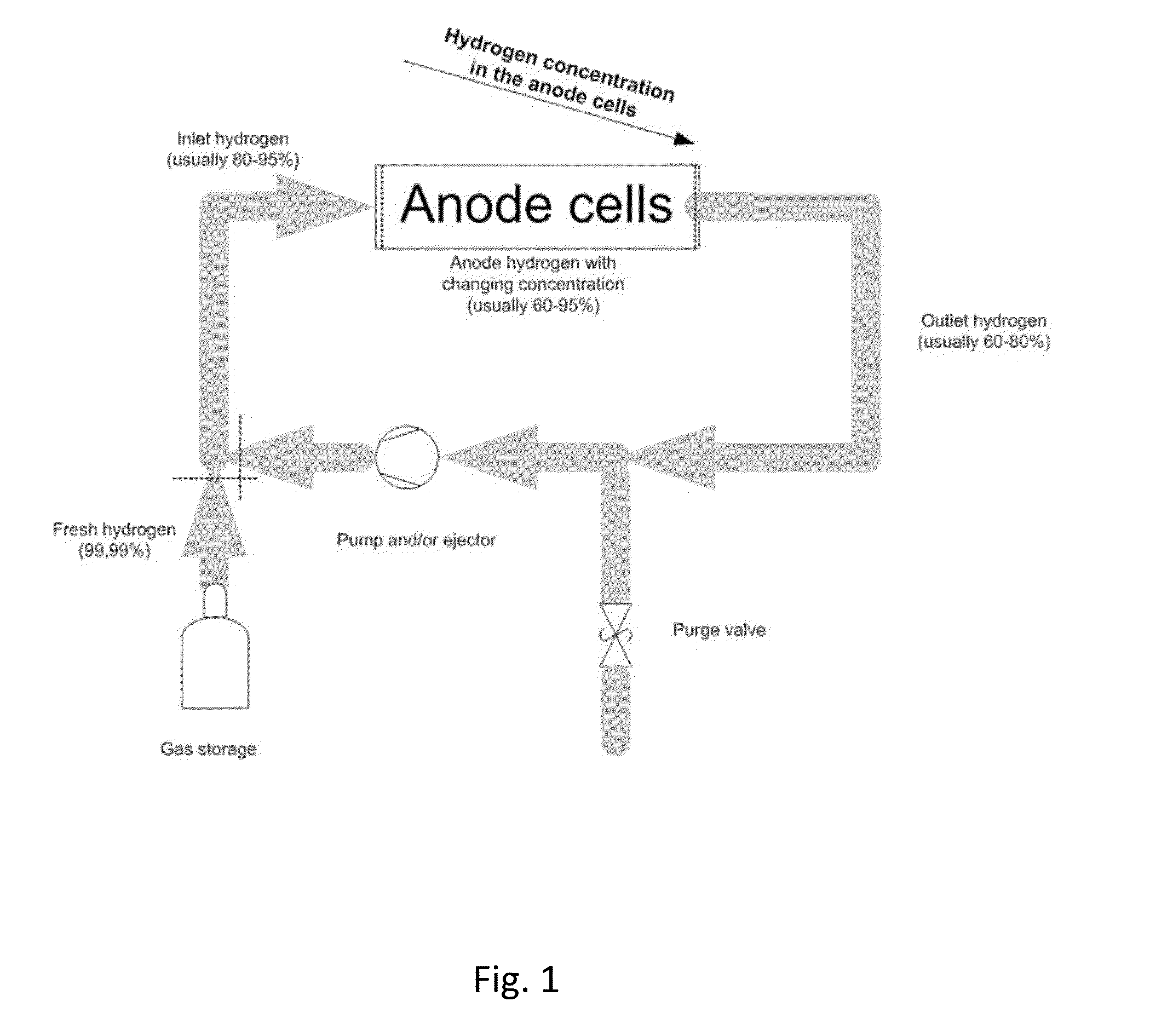

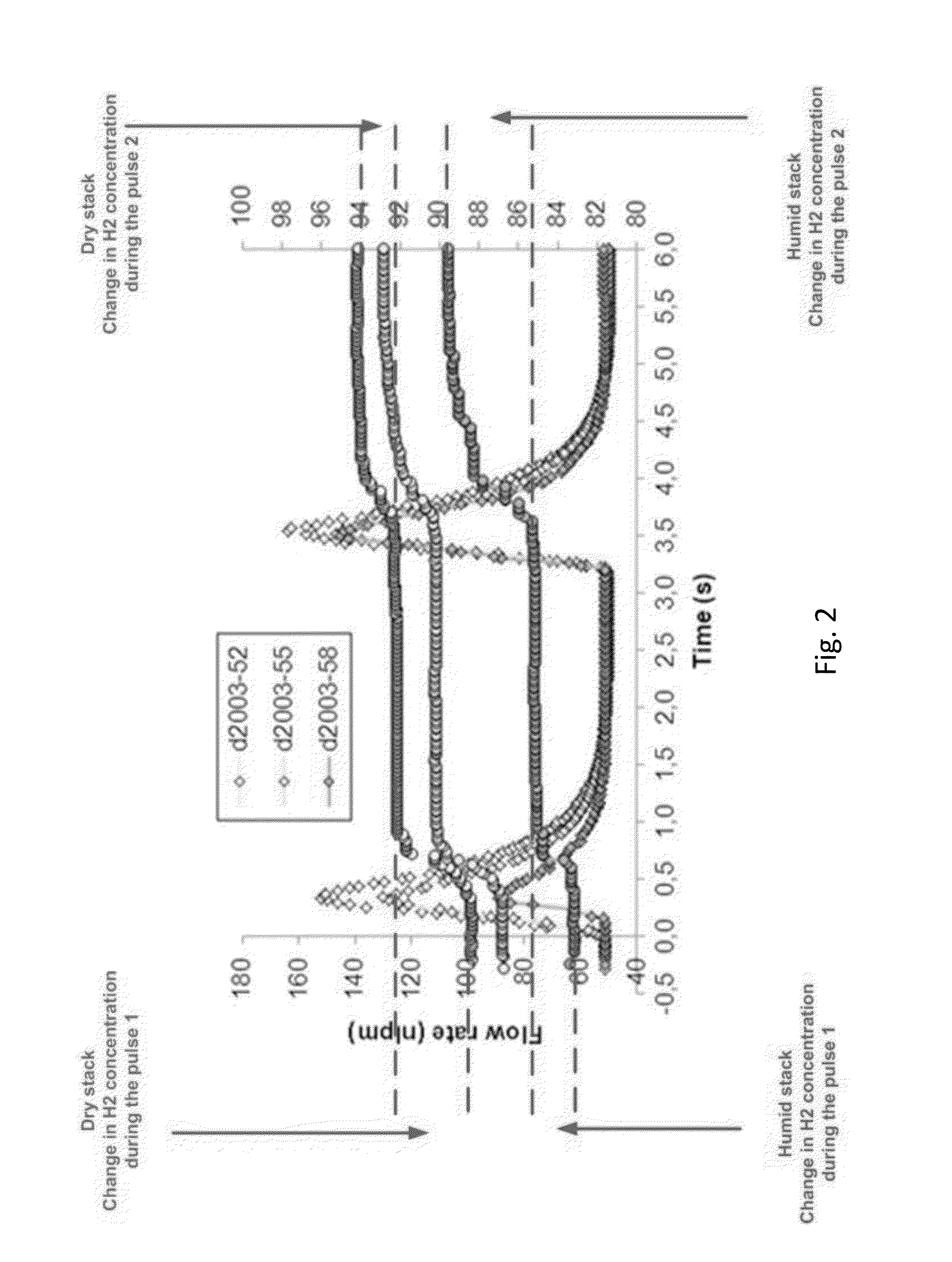

Methods relating to monitoring fuel cells

ActiveUS20160099478A1Reliably determinedLower oil levelSolid electrolytesFuel cell auxillariesFuel cellsEngineering

The invention relates to a method of determining water accumulation in and or removal from a fuel cell, the method comprising circulating fuel gas in the anode side of the fuel cell for producing electric energy in a fuel cell process, providing at least two purge pulses from the fuel circulation, analyzing the composition and / or volume of purged gas of said at least two gas purge pulses for determining the amount of water accumulation in and / or removal from the fuel cell.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

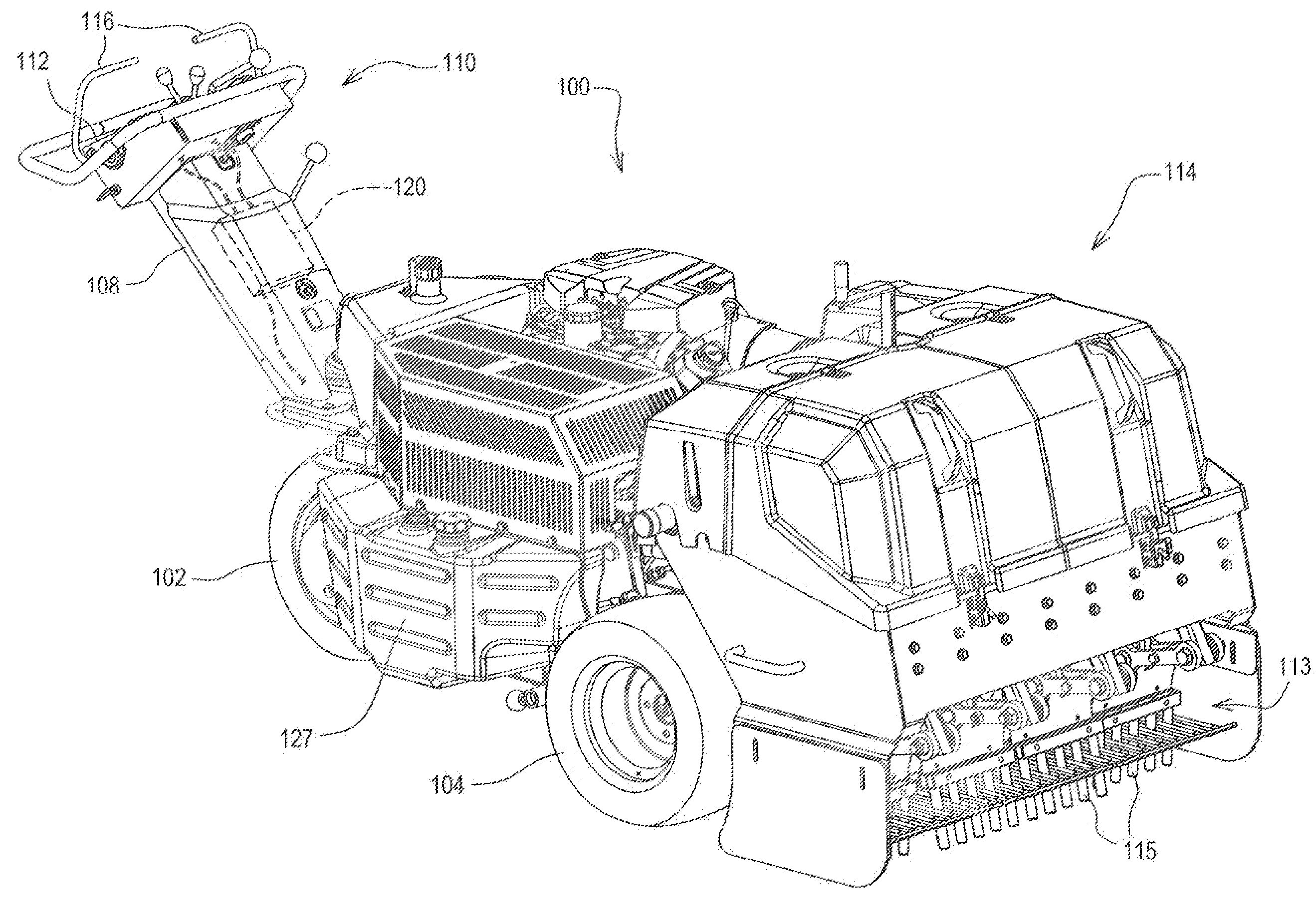

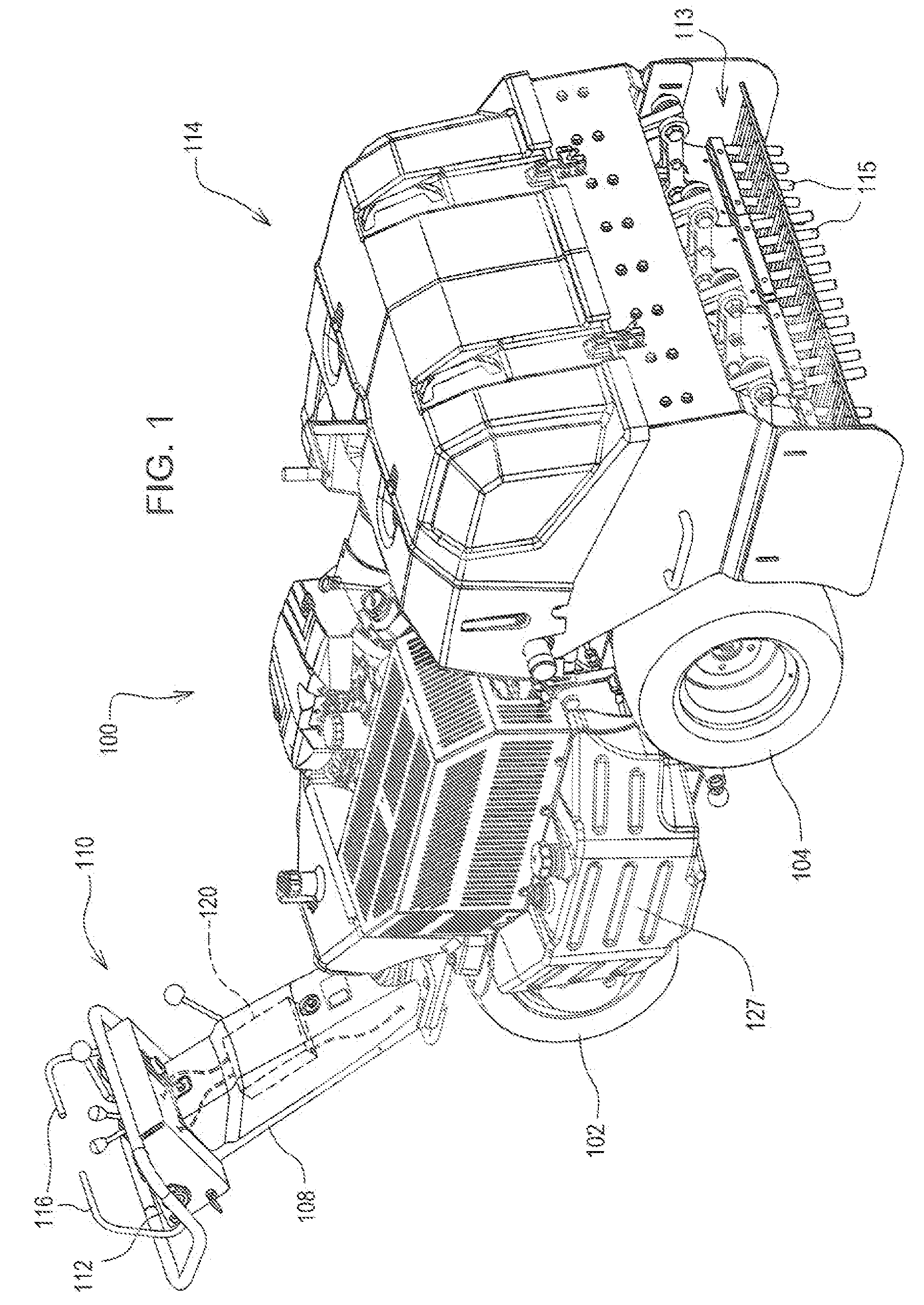

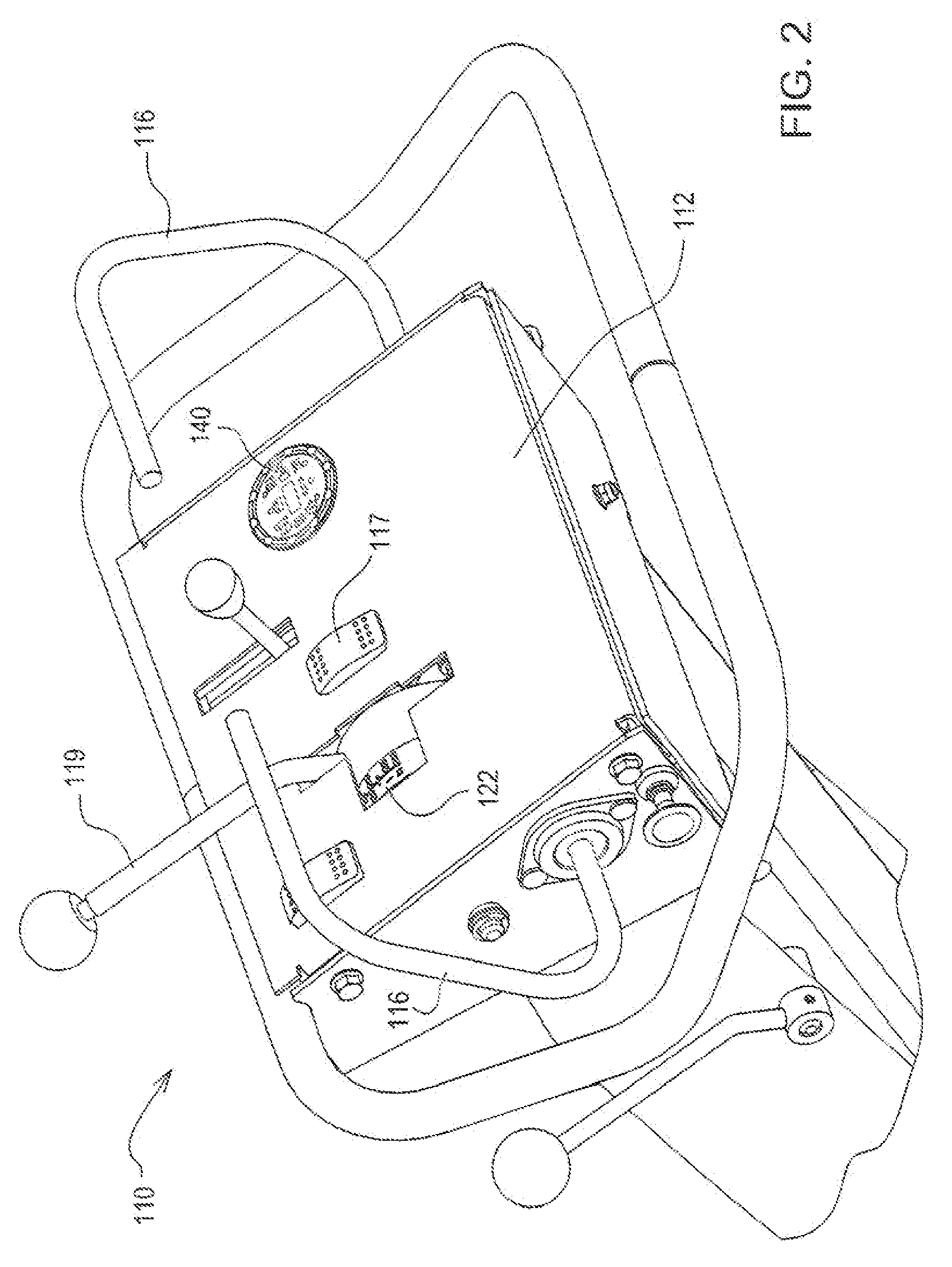

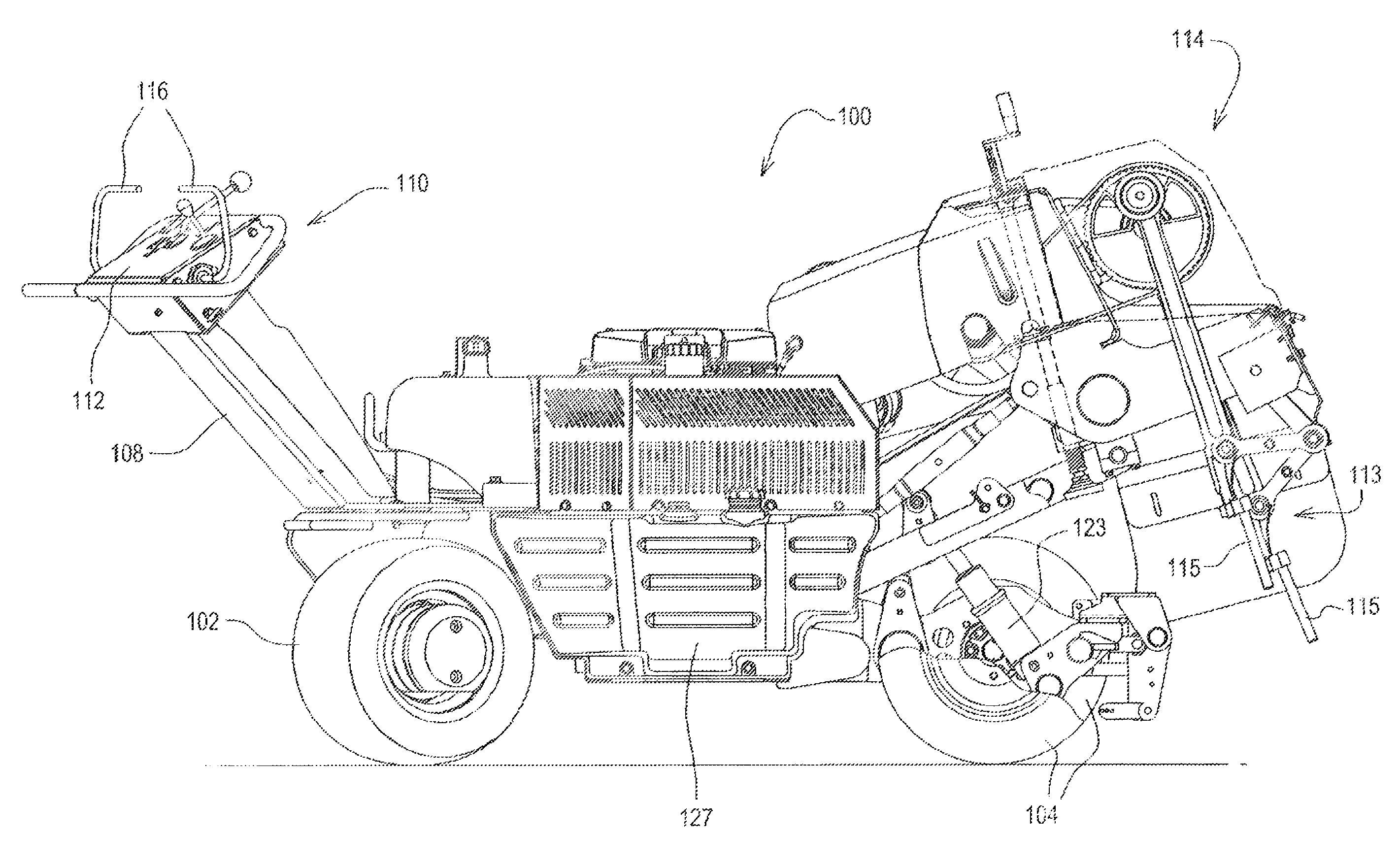

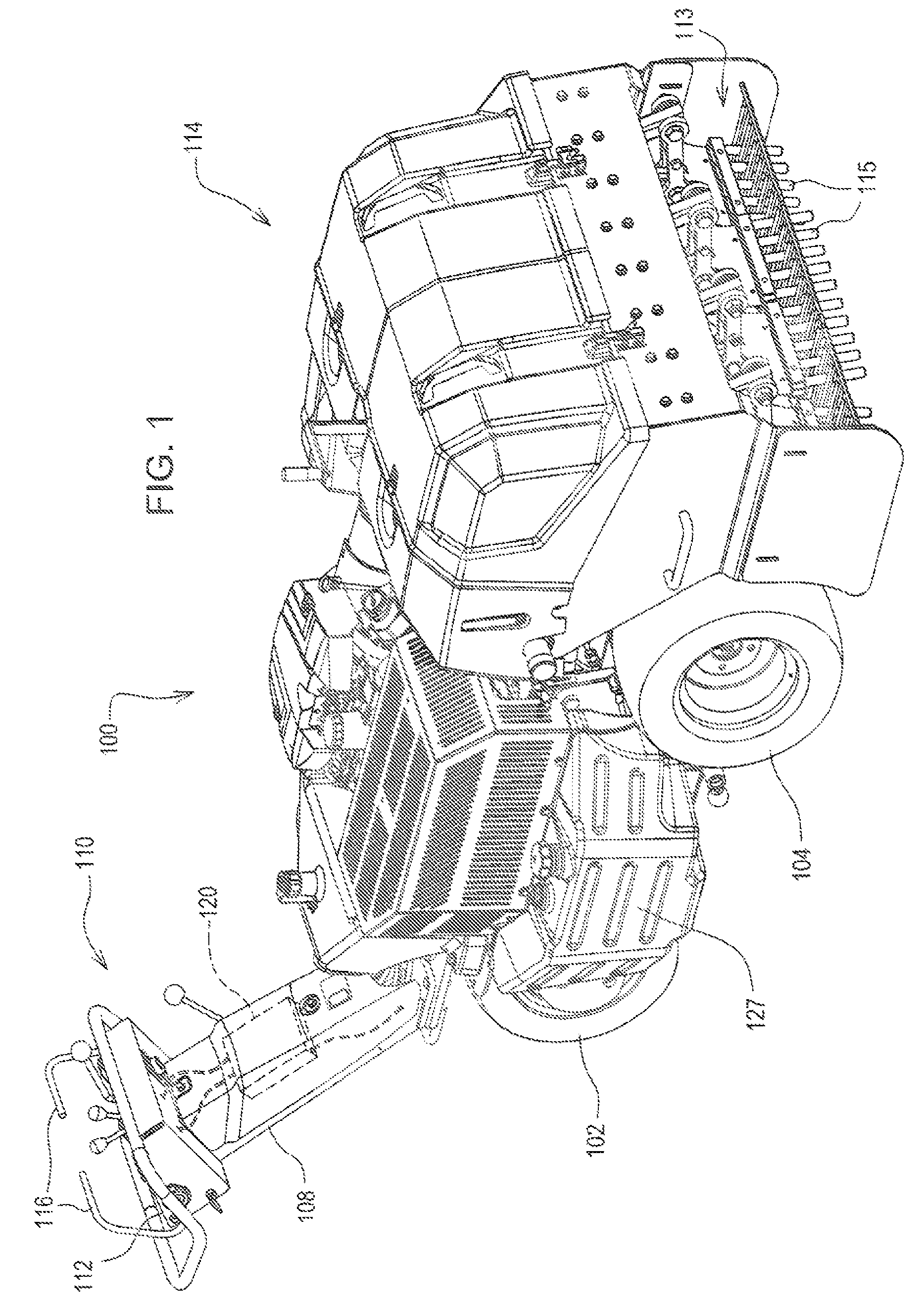

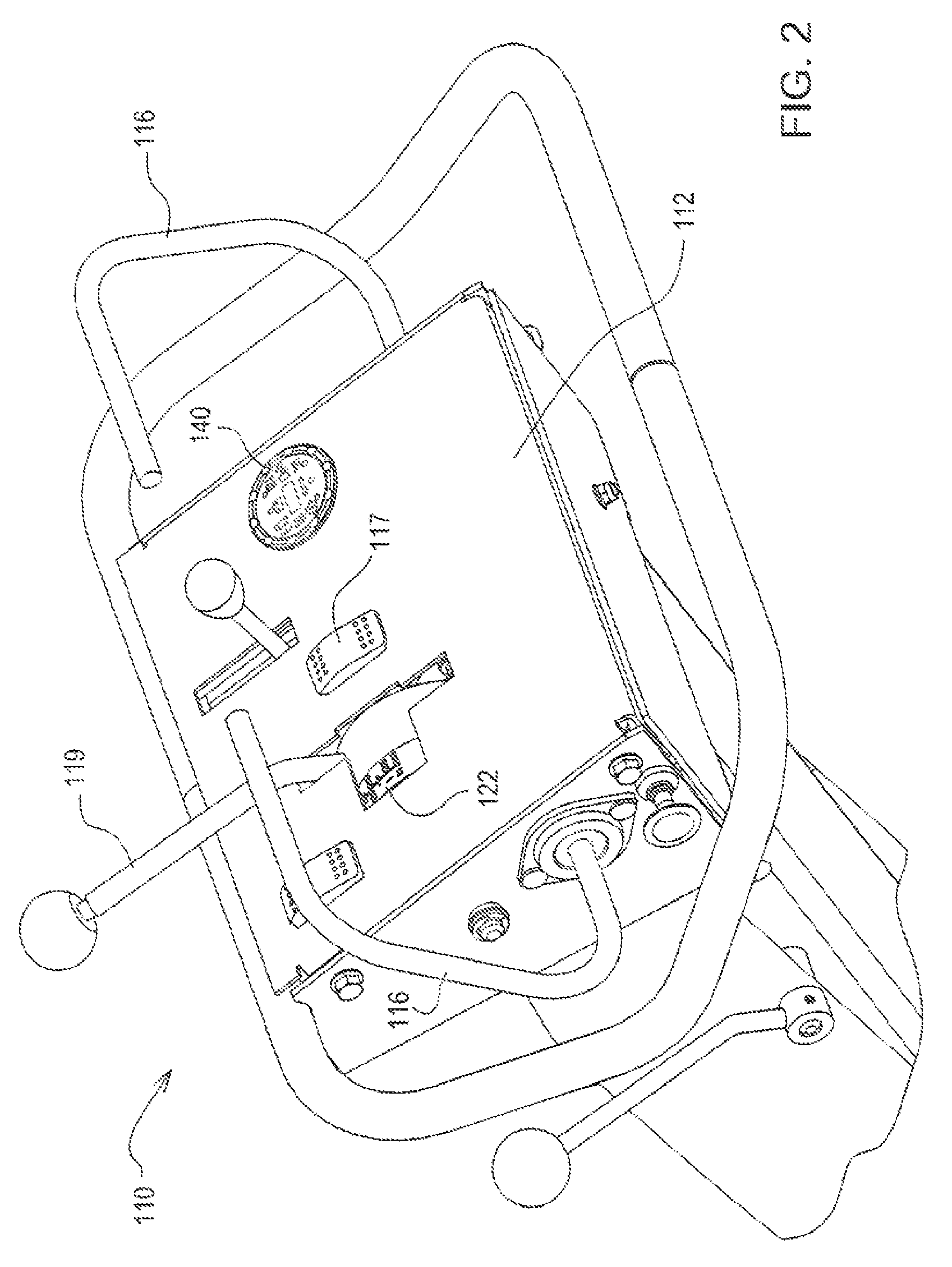

Aerator With Low Fuel Level Control

ActiveUS20130255975A1Easy to operateRisk minimizationAgricultural machinesLawn machinesElectricityLevel sensor

An aerator with low fuel level control includes a low fuel level sensor, and a controller electrically connected to the low fuel level sensor and to the coring head that provides a warning to the operator and raises the coring head and / or prevents lowering the coring head into the operating position after the low fuel level sensor indicates a low fuel level in the fuel tank.

Owner:DEERE & CO

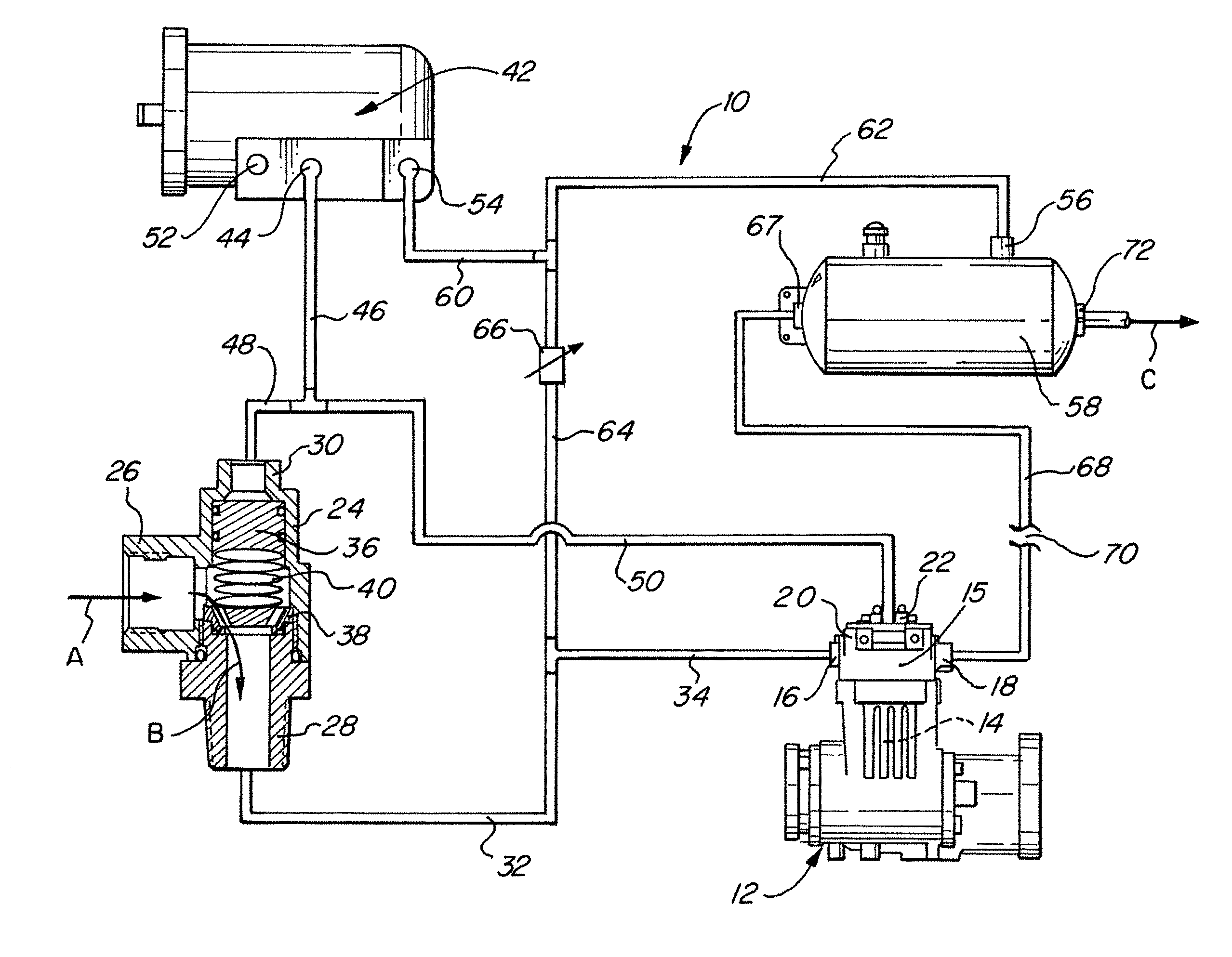

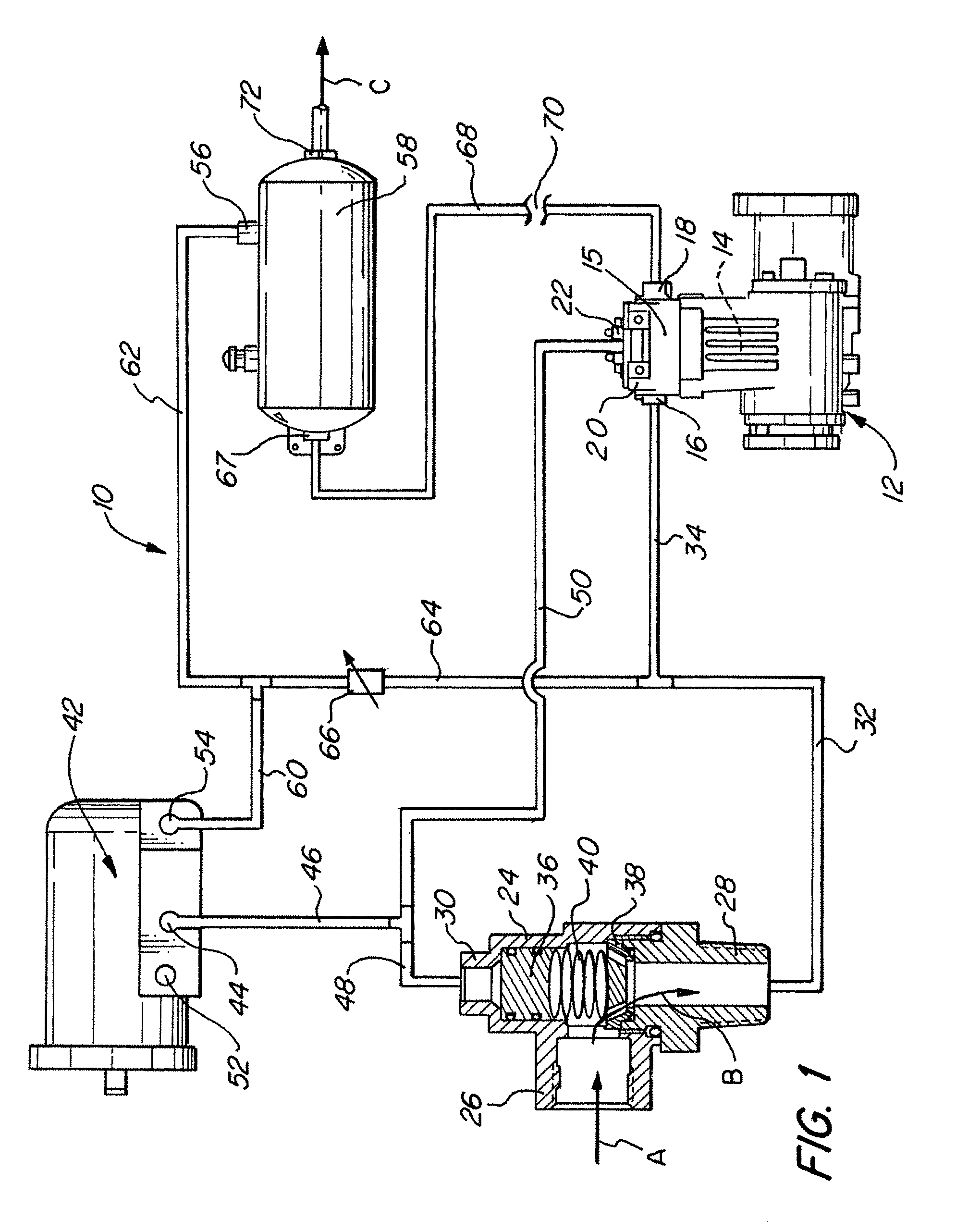

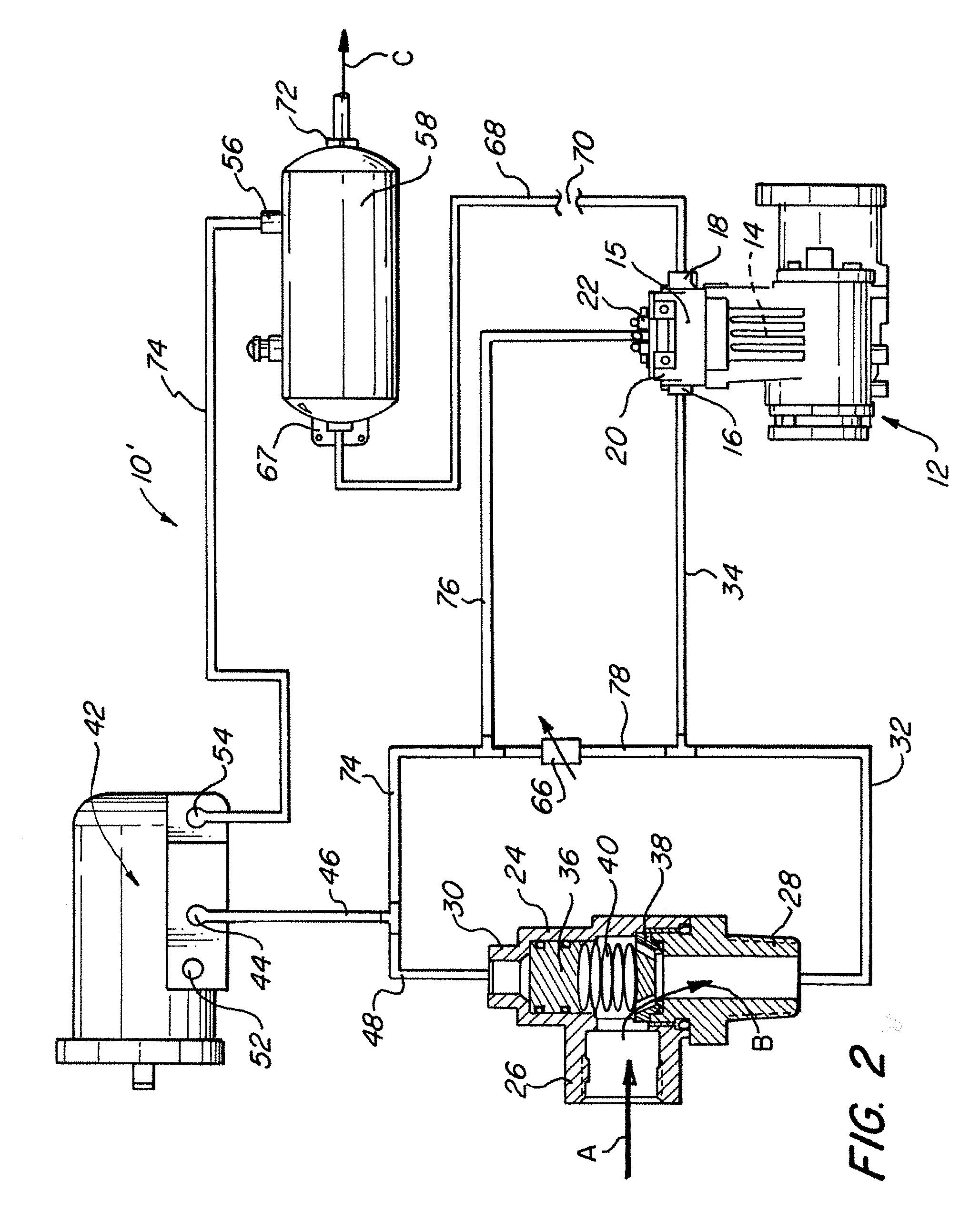

Air supply system with reduced oil passing in compressor

InactiveUS20080050250A1Efficient in operationEconomical to manufactureServomotorsPump controlEngineeringCompressed air

An air supply system includes a compressor having a compression chamber, an inlet port through which air flows into the compression chamber and an outlet port through which air exits the compression chamber, an unloader which causes the compressor to be in an unloaded state when a desired system air pressure is maintained, an isolation valve preventing inlet air from flowing into the inlet port of the compressor when the compressor is in the unloaded state, and a source of pressurized air supplying pressurized air to the inlet port of the compressor at least when the isolation valve prevents inlet air from flowing into the inlet port of the compressor.

Owner:HALDEX BRAKE

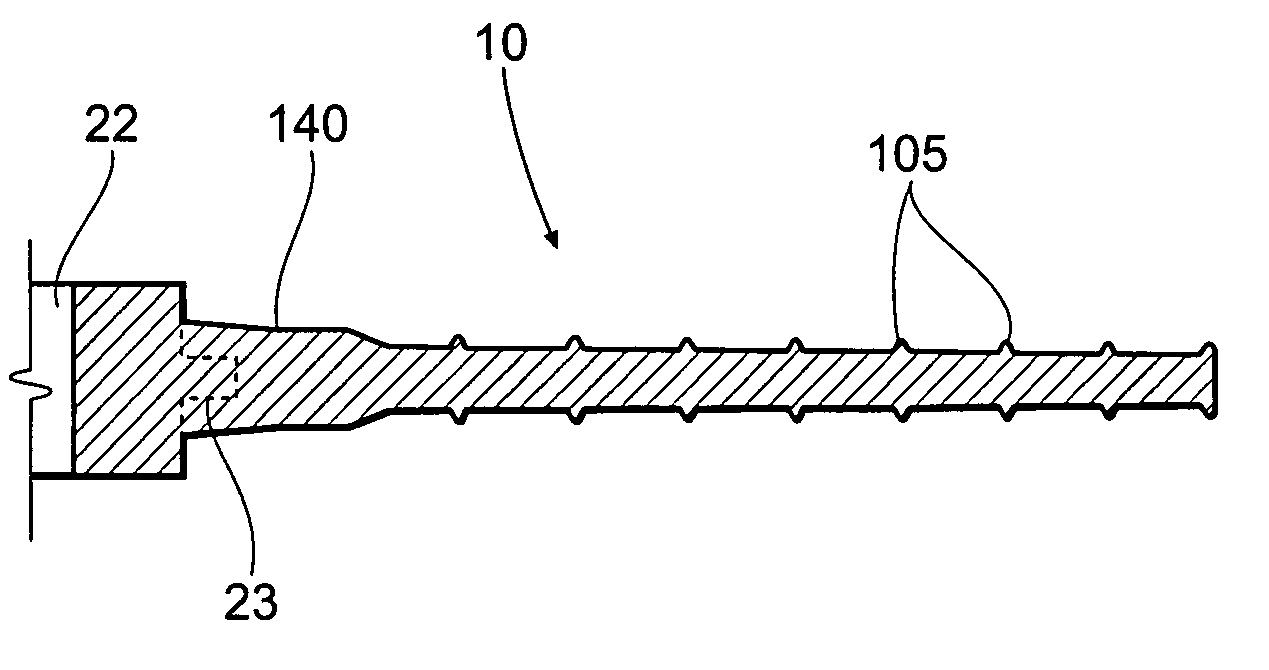

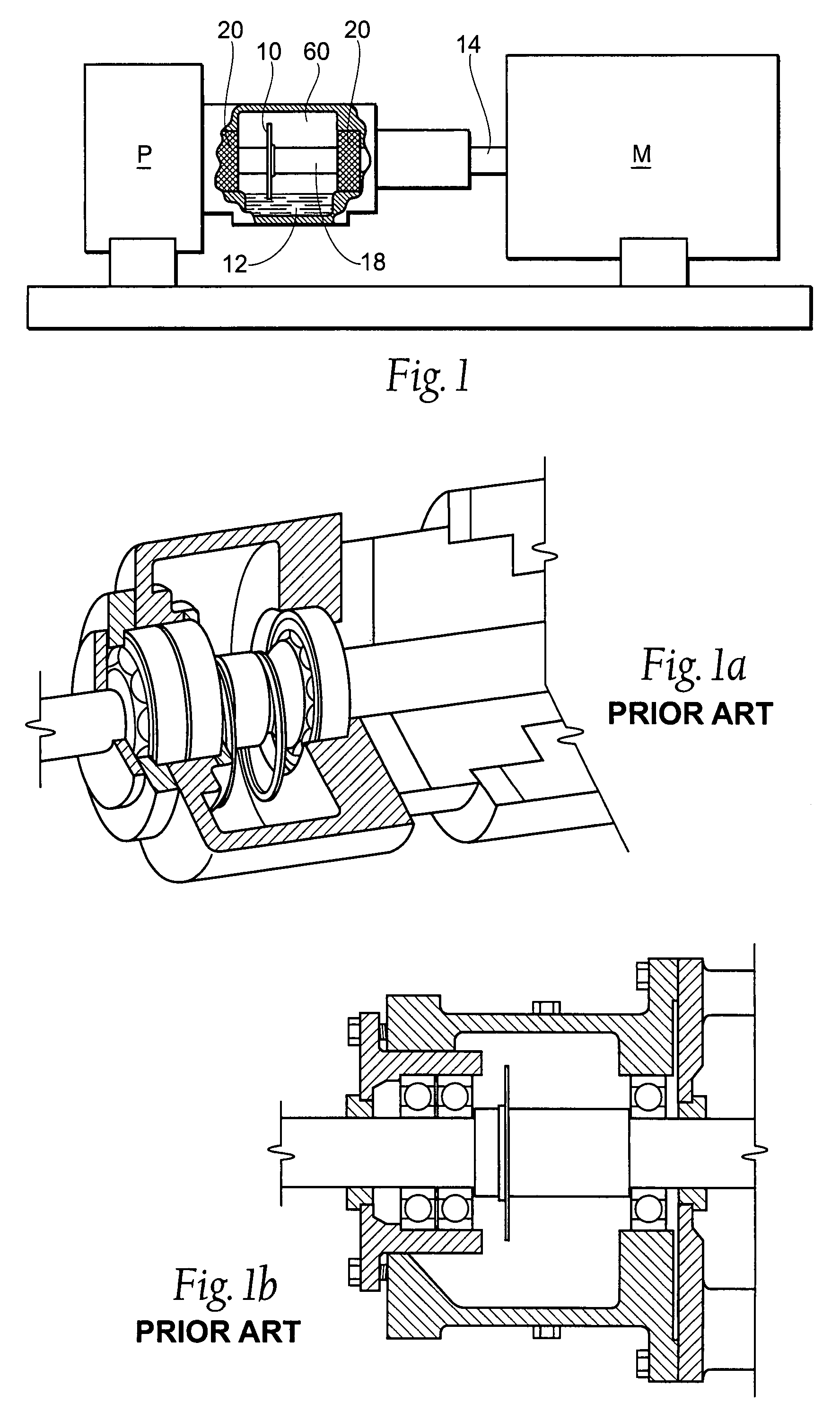

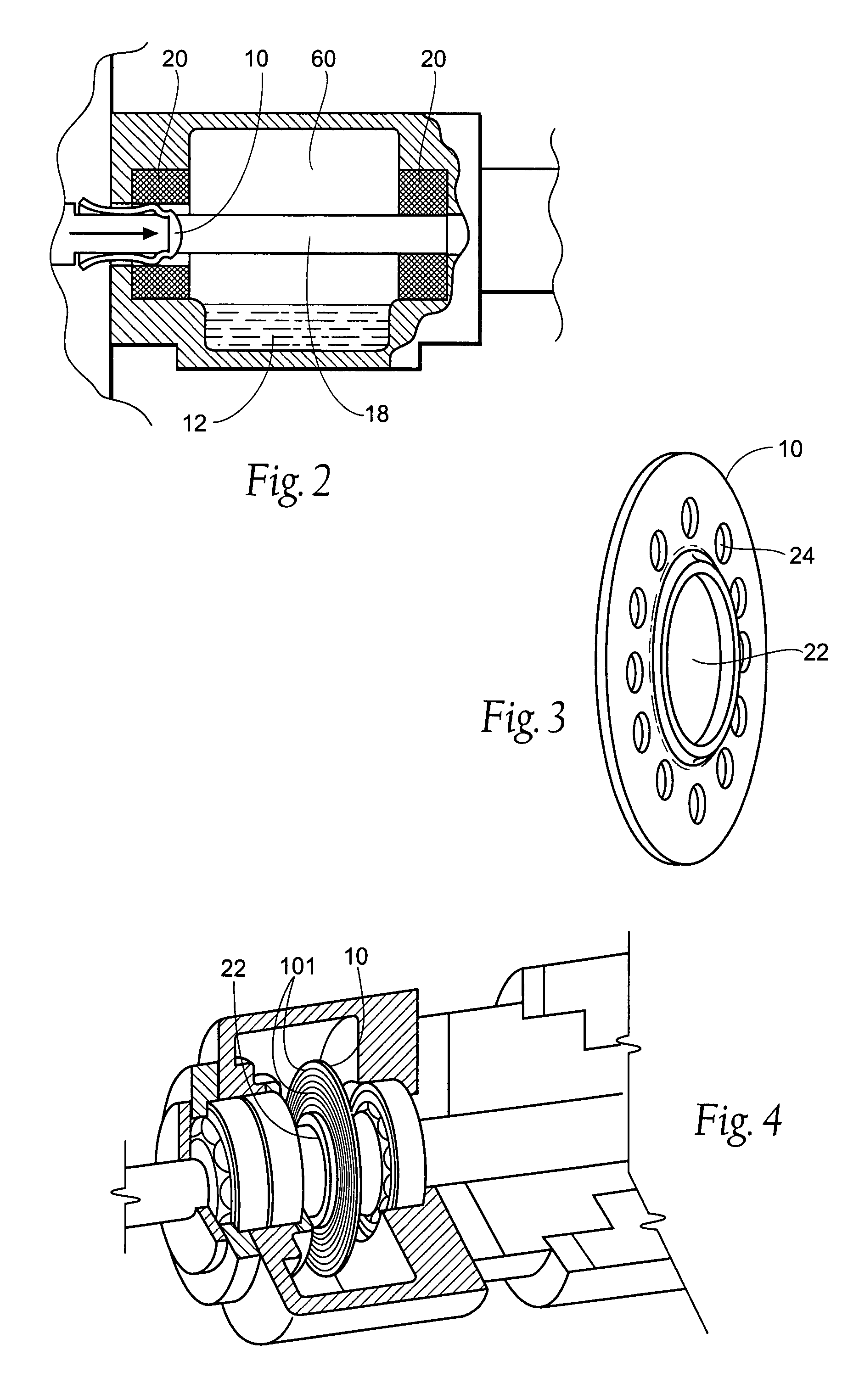

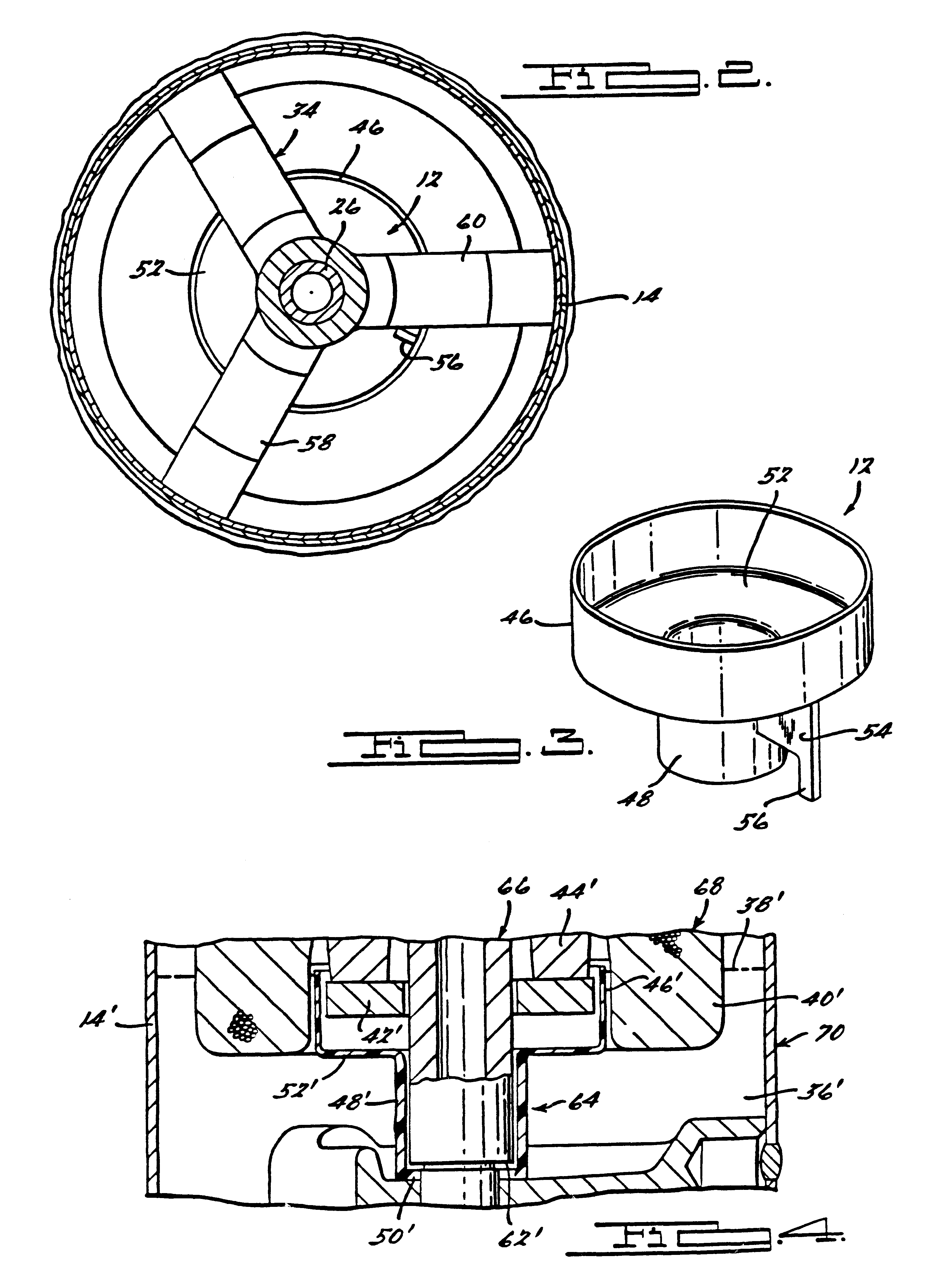

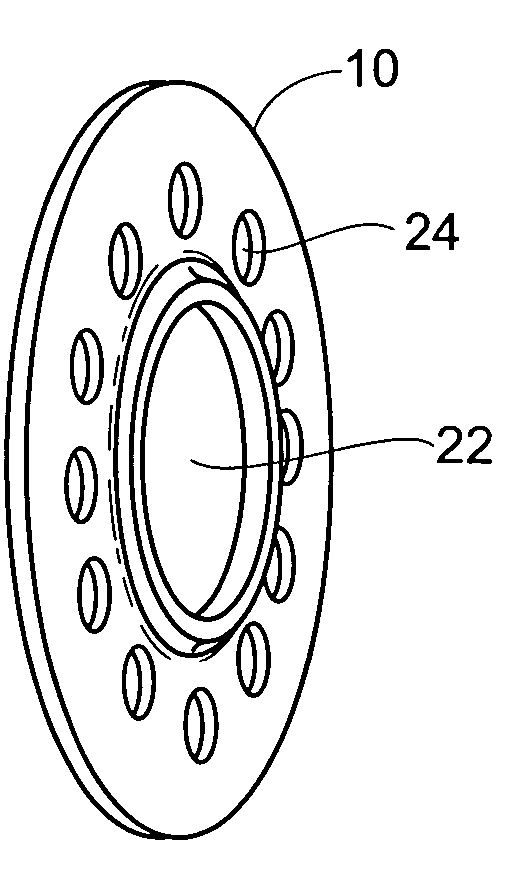

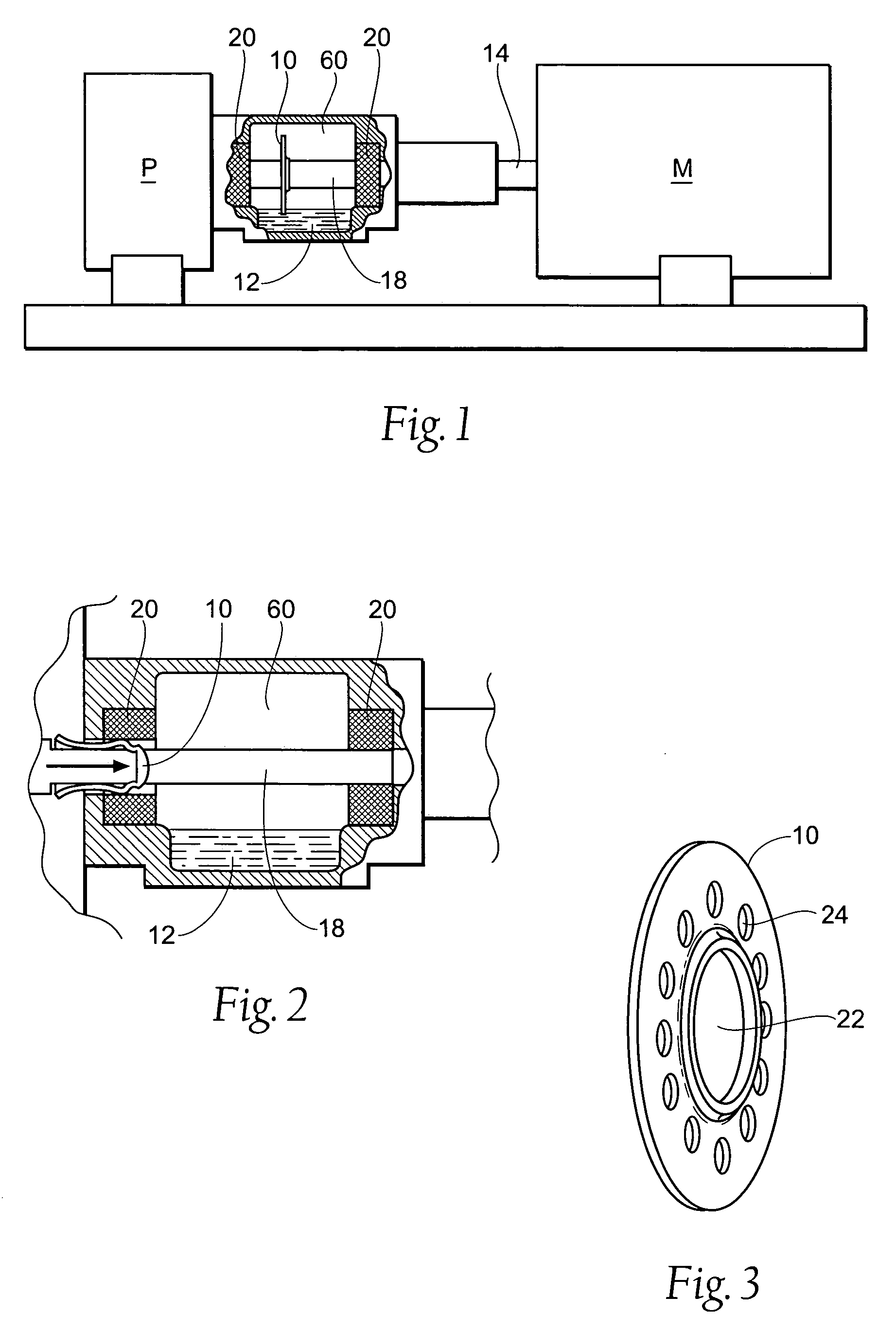

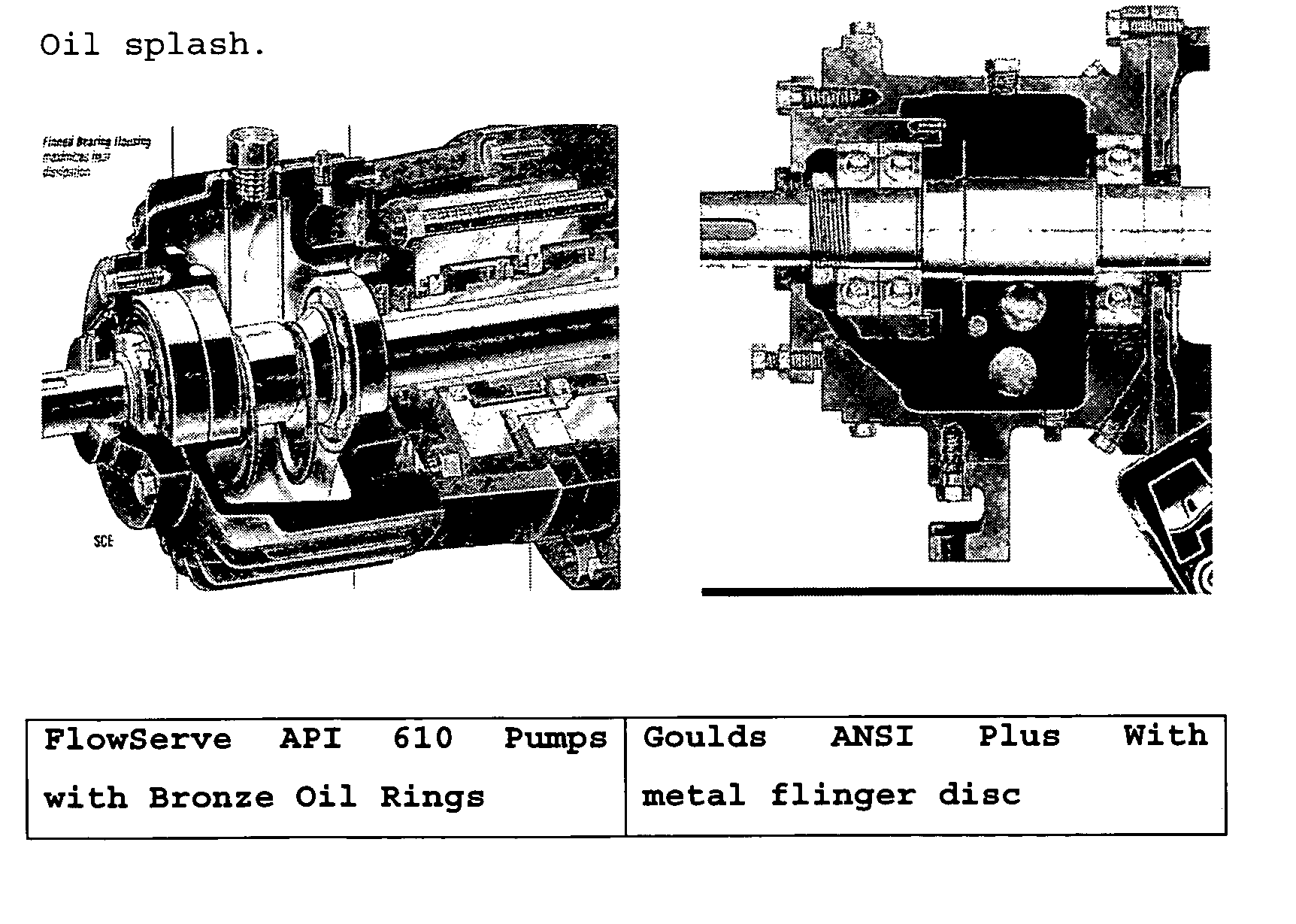

Flinger disc

ActiveUS7862875B2Easy to assemble and disassembleReduce the temperatureDrip or splash lubricationLayered productsEngineeringLubrication

To achieve proper lubrication, a bearing housing or reservoir is filled with a predetermined amount of lubricant. When the machine, of which a bearing is a component, is operated, a flexible flinger disc provides proper lubrication by disturbance of the lubricant.

Owner:TRICO CORP

Aerator with low fuel level control

An aerator with low fuel level control includes a low fuel level sensor, and a controller electrically connected to the low fuel level sensor and to the coring head that provides a warning to the operator and raises the coring head and / or prevents lowering the coring head into the operating position after the low fuel level sensor indicates a low fuel level in the fuel tank.

Owner:DEERE & CO

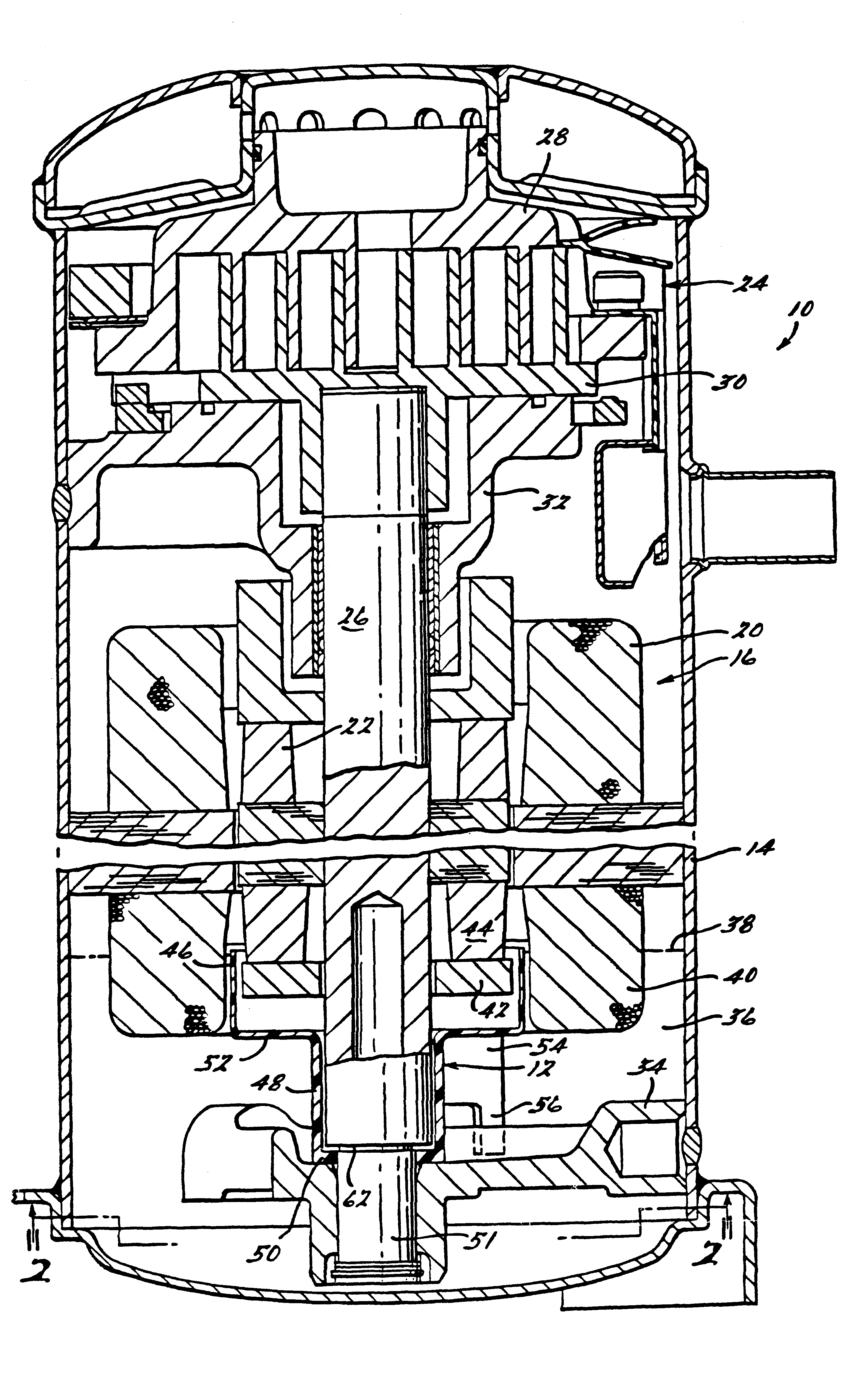

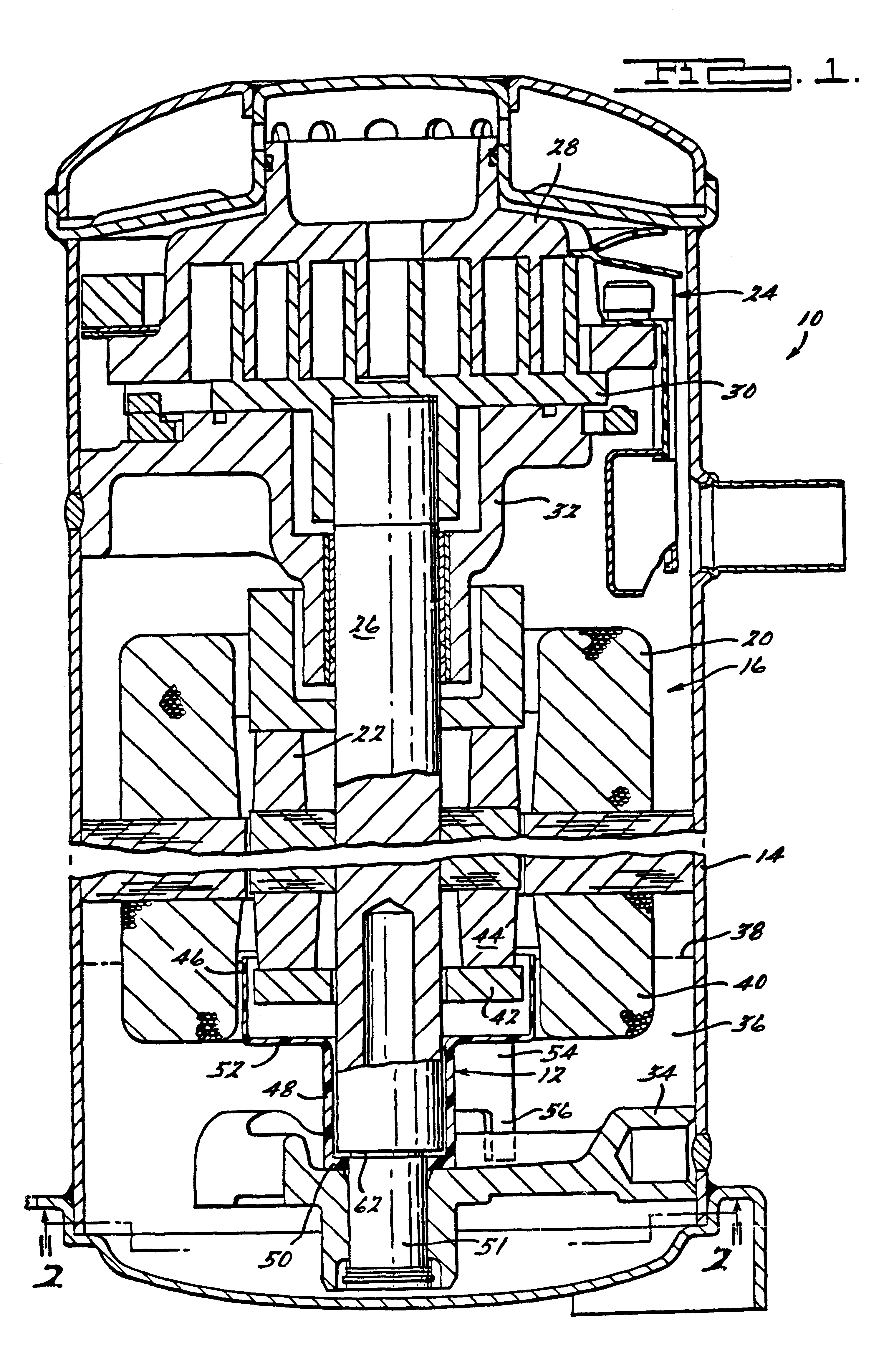

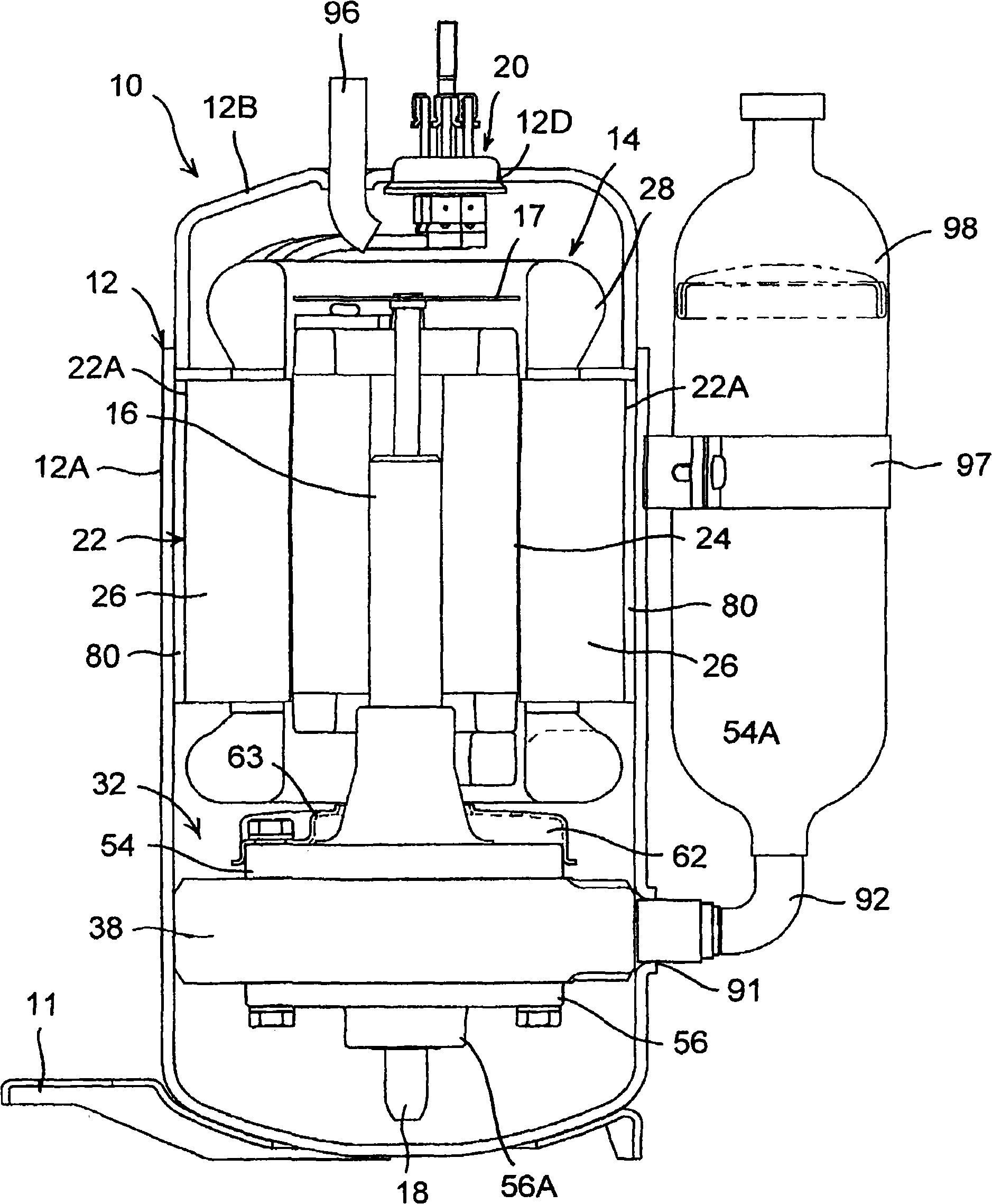

Refrigeration compressor

InactiveUSRE37019E1Reducing lubricating oil levelOperation efficiency can be improvedCompressorPositive displacement pump componentsRefrigeration compressorDrive shaft

A refrigeration motor compressor assembly has a housing including a lubricant sump in the bottom thereof into which the lower end of the drive shaft and associated rotor extend. A shield is provided which is positioned by the drive shaft and extends above the oil level in the sump in surrounding spaced relationship to the lower end of the rotor. As the rotor rotates within the shield, lubricant contained therein is thrown out of the surrounding shield and a close fit between the shield and the shaft restricts return flow of lubricant into the area occupied by the rotating rotor.

Owner:EMERSON CLIMATE TECH INC

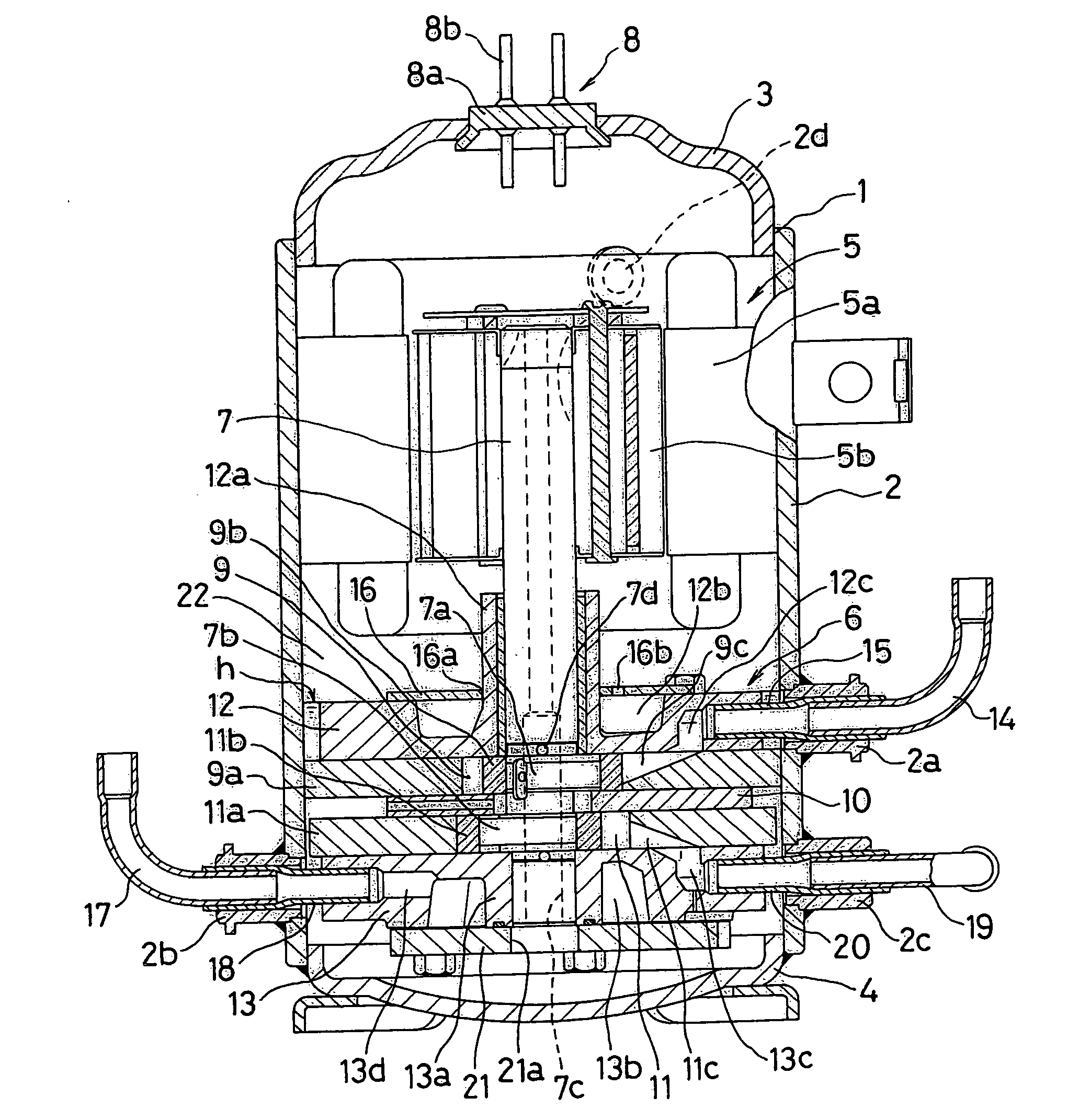

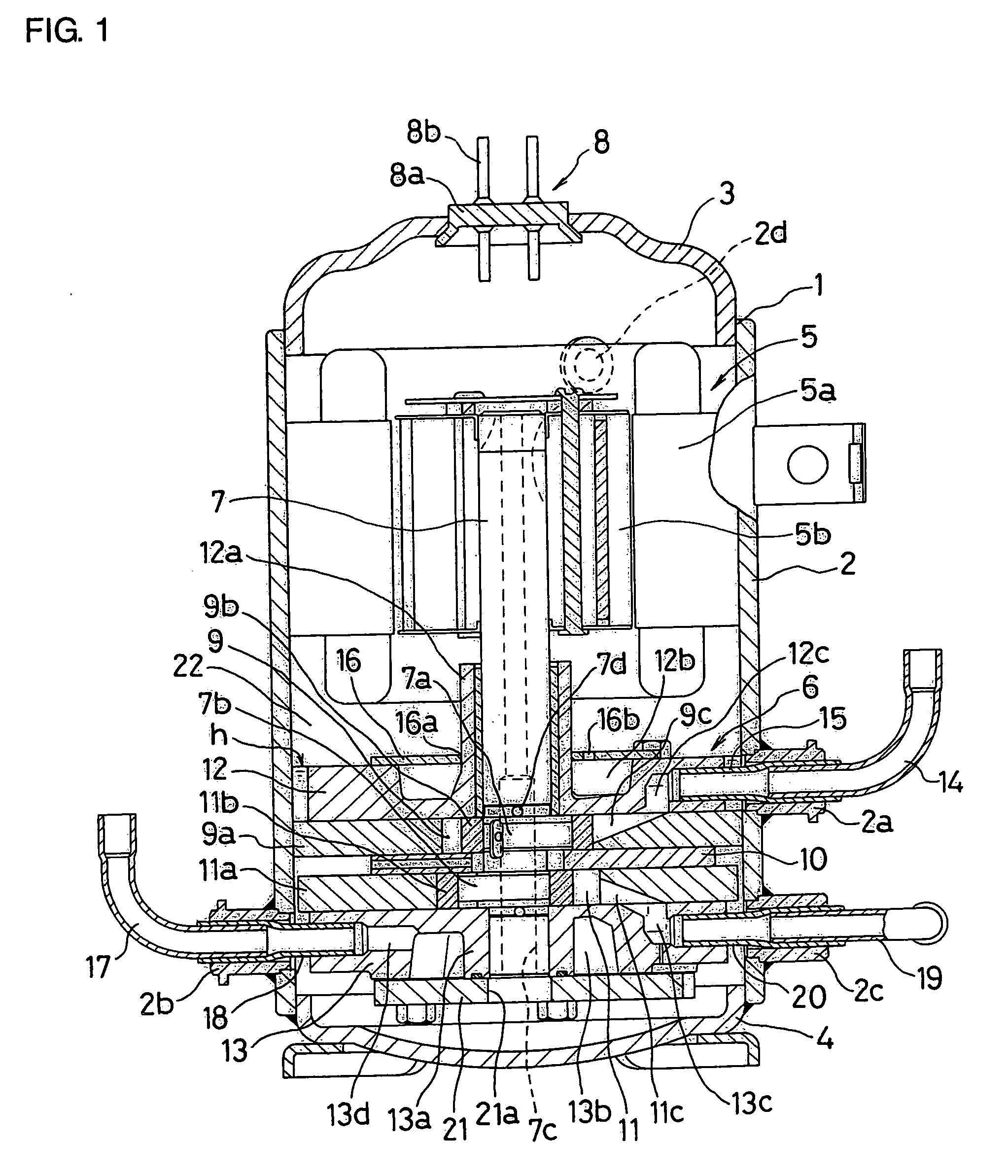

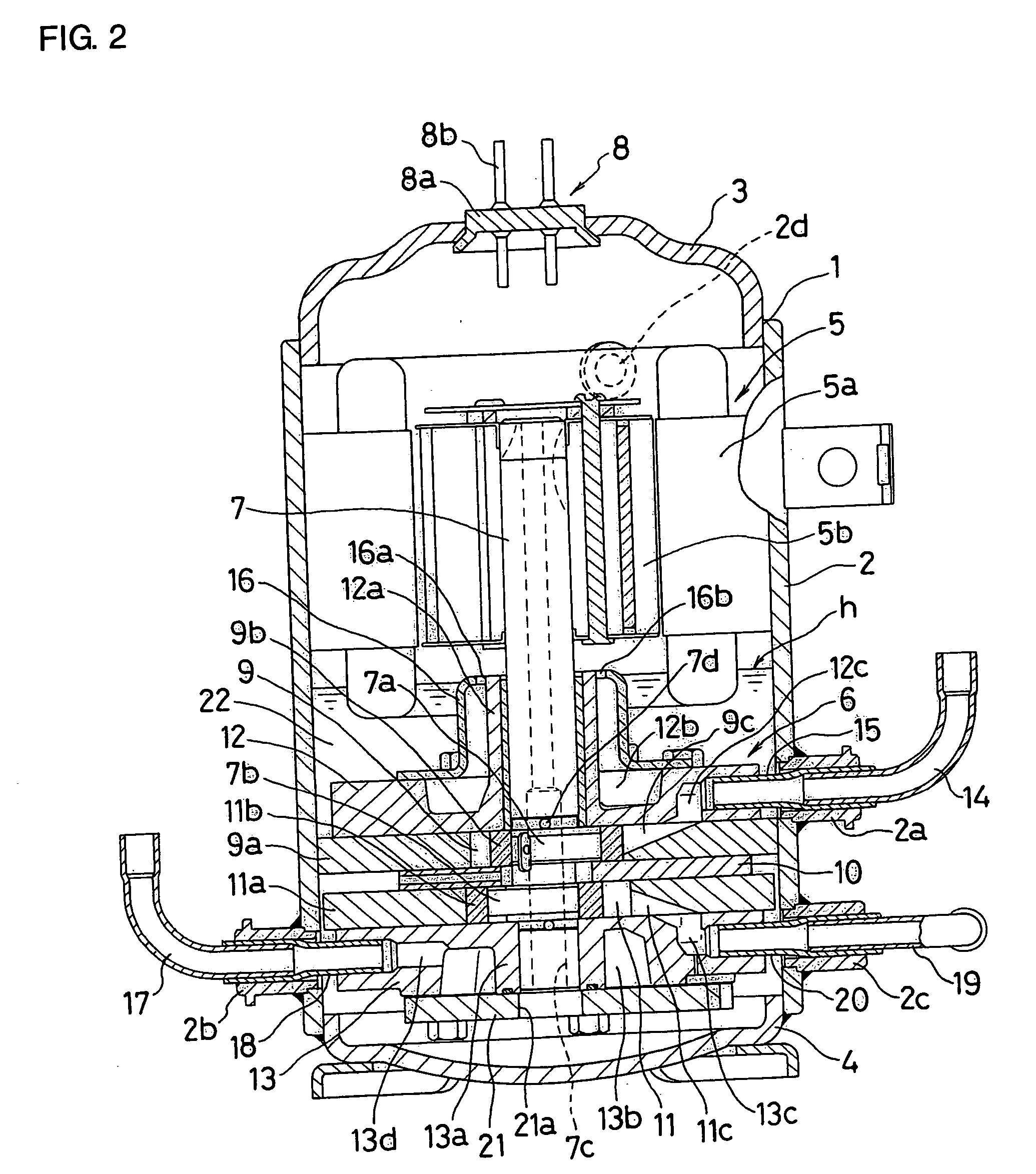

Multistage rotary compressor

InactiveUS20050214138A1Oil separation in be efficientlyIncrease in amountRotary/oscillating piston combinations for elastic fluidsCleaning machinesRefrigerantOil separation

The present invention relates to a multistage rotary compressor. In the multistage rotary compressor, a motor-operating element 5 and a rotary compressing element 6 are provided at upper and lower portions in a closed vessel 1. In the rotary compressing element 6, a low stage side rotary compressing element 9 and a high stage side rotary compressing element 11 are positioned on the upper and lower sides respectively. An upper supporting member 12 is attached onto the low stage side rotary compressing element 9, and a substantially cup-shaped cover material 16 is attached onto the upper supporting member 12 to close an opening surface of a muffling chamber 12b formed in the upper supporting member 12. The substantially cup-shaped cover material 16 is formed in a high dimension so that the upper end of the cover material 16 is positioned at an upper end or near an upper end of a bearing portion 12a formed in the upper supporting member 12. Further, a discharge hole 16b for discharging a refrigerant gas is provided in the upper end surface of the cover material 16 near an outer diameter portion of the bearing portion 12a. Consequently, the level h of the oil surface for oil filled in the closed vessel 1 can be set so as to be near the upper end of the cover material 16. According to the present invention, the amount of oil filled in the closed vessel can be increased and the oil separation in the closed vessel can be efficiently made.

Owner:SANYO ELECTRIC CO LTD

Gear Unit

A gear unit, an oil scraping device being provided on the front of a rotatably supported gear wheel, in particular on a plane area of the front of a gear wheel.

Owner:SEW-EURODRIVE GMBH & CO KG

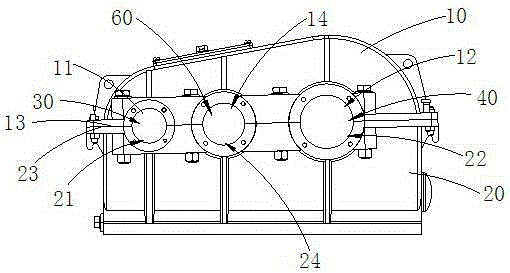

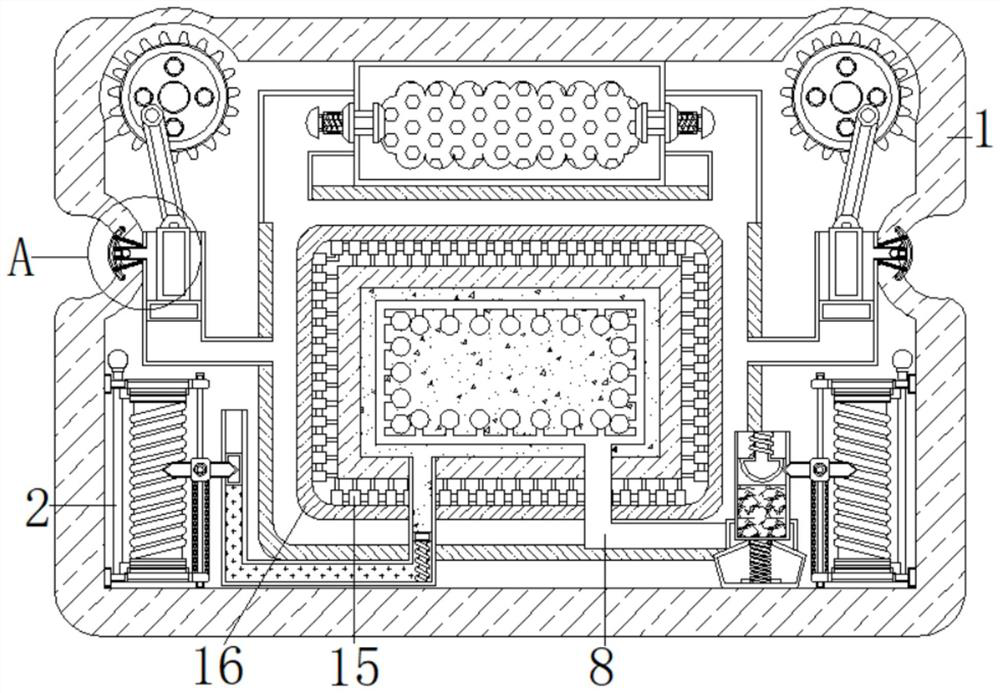

Speed reducing chassis

InactiveCN106641194ALower thermal equilibrium temperatureIncrease thermal powerGearboxesGear lubrication/coolingLow speedReducer

The invention provides a speed reducing chassis. The speed reducing chassis comprises an upper box body, a lower box body, a high-speed shaft mounting hole, a low-speed shaft mounting hole and a chip collecting module; the upper box body is provided with a high-speed shaft upper half mounting hole and a low-speed shaft upper half mounting hole; the lower box body is provided with a high-speed shaft lower half mounting hole and a low-speed shaft lower half mounting hole; the upper box body is bonded with the lower box body; the high-speed shaft upper half mounting hole and the high-speed shaft lower half mounting hole form a high-speed shaft mounting hole; the low-speed shaft upper half mounting hole and the low-speed shaft lower half mounting hole form a low-speed shaft mounting hole; the set position of the high-speed shaft mounting hole corresponding to the bottom of the lower box body is lower than the set position of the low-speed shaft mounting hole; the chip collecting module includes a chip collecting tank and a magnet ring; the chip collecting tank is formed in the lower box body; and the magnet ring is mounted in the chip collecting tank. Compared with the prior art, the speed reducing chassis lowers the set position of the high-speed shaft mounting hole, reduces the lowest oil level of lubricating oil in a speed reducer, reduces the quantity demand of the lubricating oil, and meanwhile, is provided with the magnet ring for collecting free iron chips to prolong the service life of the speed reducer.

Owner:天津市同仁铝压铸件有限公司

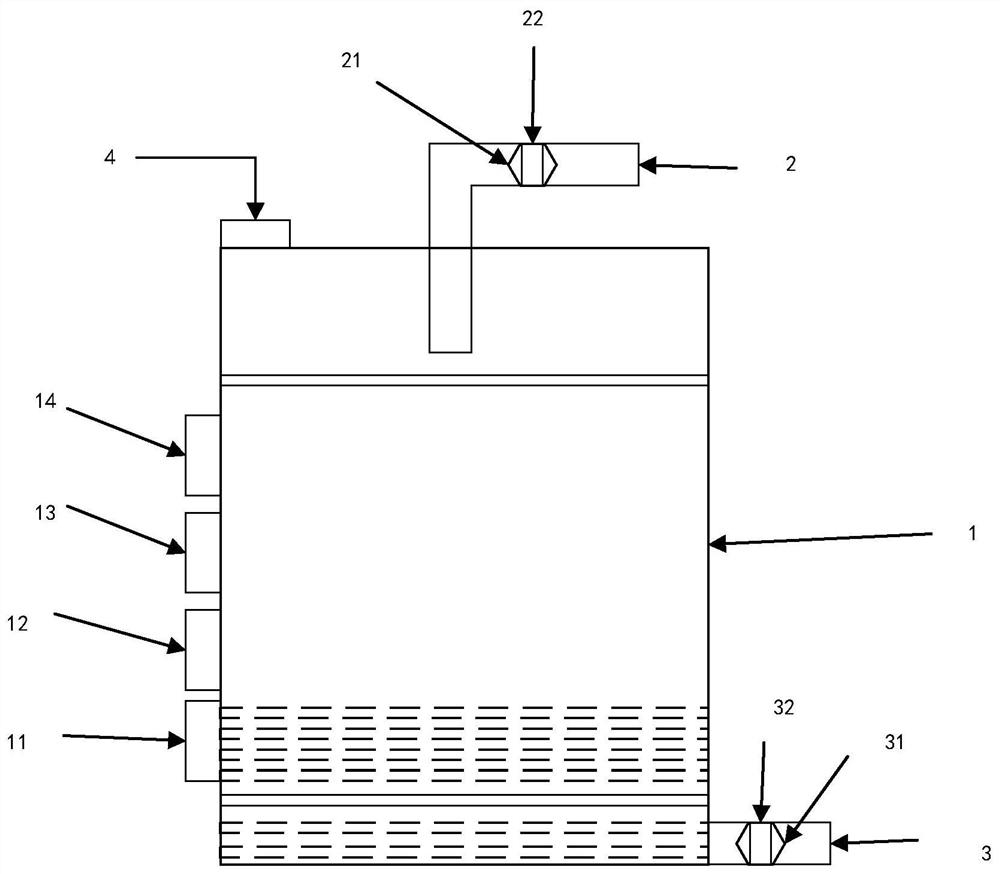

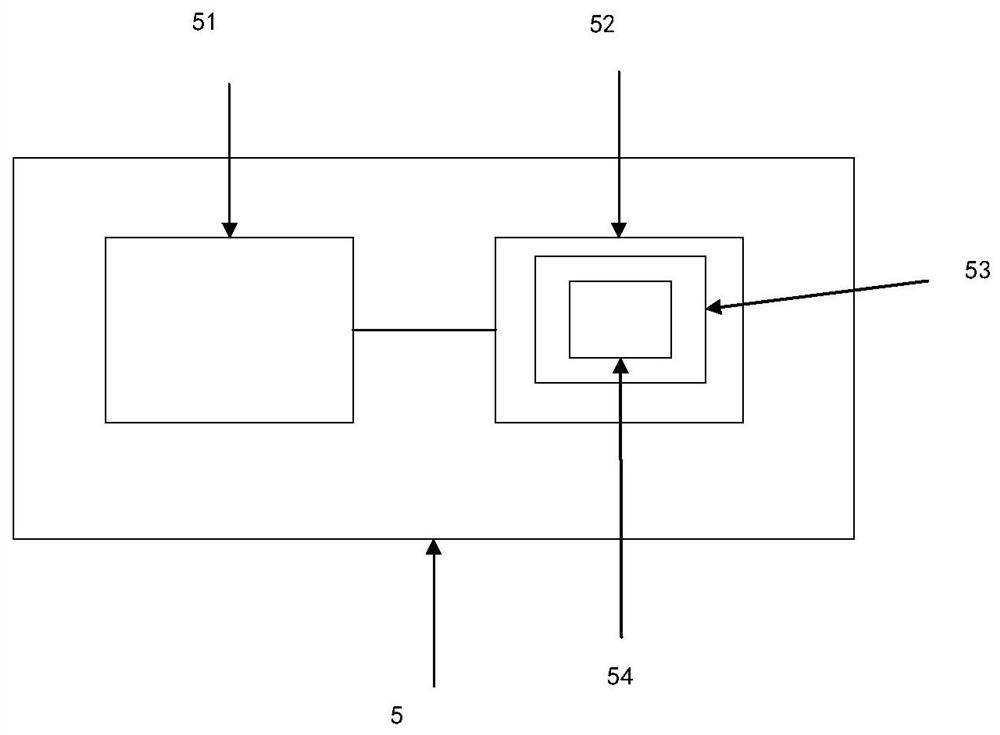

Oil field metering and detecting device

ActiveCN112320124AThe oil inlet speed is reducedIncrease oil output speedLarge containersOil fieldOil storage

The invention relates to an oil field metering and detecting device. The oil field metering and detecting device comprises an oil storage tank, an oil level height measuring meter, a temperature sensor, a bubble density detecting device, a control unit, a first control valve and a second control valve, wherein the oil storage tank is used for detecting the oil level height in the oil storage tankin real time, the bubble density detecting device is used for detecting the bubble density in the oil storage tank in real time, the temperature sensor is used for detecting the temperature in the oilstorage tank in real time, the control unit is used for obtaining all real-time parameter information in the oil storage tank in real time and generating a real-time measurement oil storage tank parameter matrix Q (H, A, T), and all parameters of the real-time measurement oil storage tank parameter matrix Q (H, A, T) are changed by adjusting the first control valve and the second control valve. Therefore, the oil level height of oil in the oil storage tank and the bubble density can be accurately controlled to ensure that the temperature in the oil storage tank is kept in a proper range, andthe safety and the utilization rate of the oil storage tank are improved.

Owner:SINOPEC SHENGLI OILFIELD

Lubricating system of vehicle transmission device

ActiveUS10738878B2Maintain levelLower oil levelGear lubrication/coolingProcess engineeringOil storage

A lubricating system of a vehicle transmission device includes a third oil storage part that is provided above a first oil storage part and a second oil storage part in a vehicle height direction. The third oil storage part stores lubricating oil, and includes a first outlet that allows the lubricating oil to flow out by gravity toward the first oil storage part without passing through the second oil storage part. As the lubricating oil is thus returned from the first outlet to the first oil storage part without passing through the second oil storage part, the oil level in the first oil storage part can be stably maintained with the lubricating oil supplied thereto regardless of the oil level in the second oil storage part.

Owner:TOYOTA JIDOSHA KK

Transfer structure for vehicle

InactiveCN109296738ALess oil level changesSmall sizeGear lubrication/coolingVehicle sub-unit featuresLow speedEngineering

Provided is a transfer structure of a vehicle, so as to reduce the oil level of the oil storage part of the transfer device during the high-speed driving, and improve the insufficient lubrication during the low-speed driving, and the insufficient lubrication brought by unbalance of oil supply amount of helical gear. In a transfer device which comprises a driving gear, a driven gear disposed at a position lower than the driving gear, and an accommodating space receiving the gear, the lower part of the accommodating space is stored with lubrication oil. A first lubrication oil storing space anda second lubrication oil storing space, which are respectively adjacent to the accommodating space and used for storing lubrication oil, are respectively isolated from the accommodating space througha first isolating wall and a second isolating wall. The first and the second isolating wall are respectively provided with a through hole communicating with the accommodating space under the state oflimiting flow. The first isolating wall is set to be below the regulated oil level, and the second isolating wall is set to be above the oil level.

Owner:MAZDA MOTOR CORP

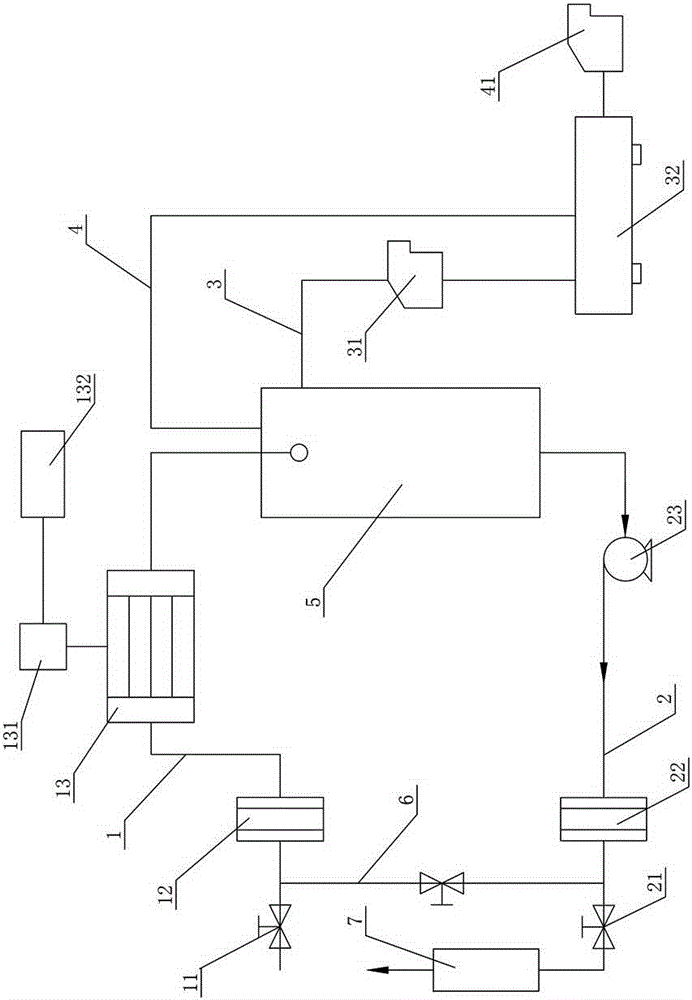

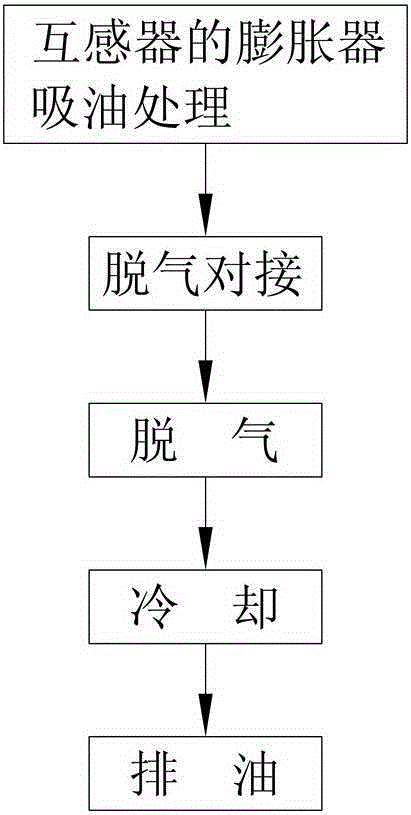

Mutual inductor insulating oil degassing device and degassing method thereof

The invention discloses a mutual inductor insulating oil degassing device and a degassing method thereof. The device comprises a vacuum flasher, and an oil inlet pipeline, an oil outlet pipeline, a drainage pipeline and an exhaust pipeline which are connected with the vacuum flasher, wherein the oil inlet pipeline and the oil outlet pipeline are respectively butted with the mutual inductor; a bypass pipeline is arranged between the oil inlet pipeline and the oil outlet pipeline; and a cooler is arranged on the oil outlet pipeline. The method comprises the following steps: S1, absorbing oil of an expander of the mutual inductor; S2, degassing and butting; S3, degassing; S4, cooling; and S5, discharging oil. The device disclosed by the invention has the advantages that the operation is simple, the core of the mutual inductor can be prevented from being polluted, and the filtering and degassing effects are good.

Owner:STATE GRID CORP OF CHINA +2

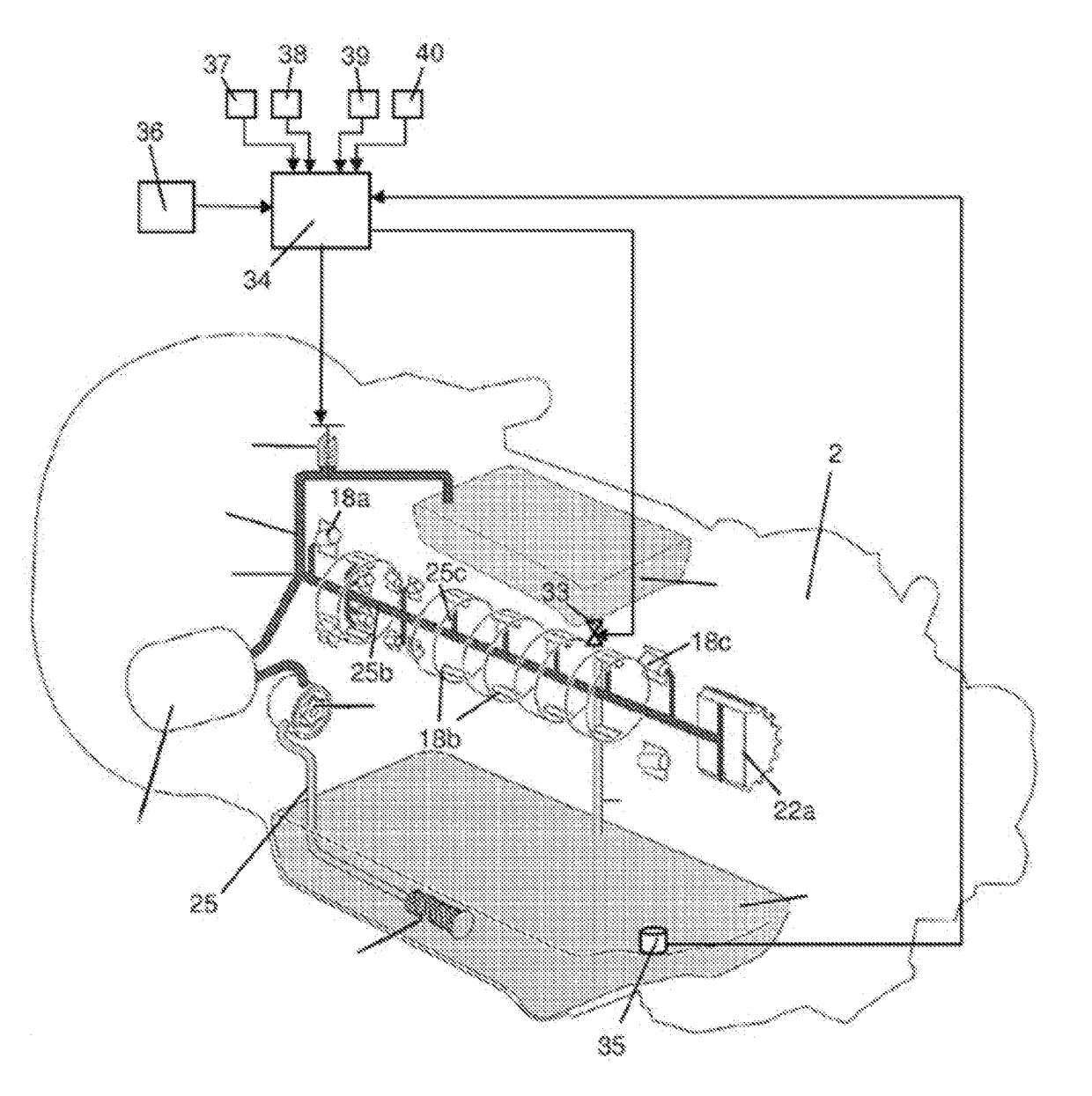

Lubrication system and a method for controlling the lubrication system

ActiveUS20180087655A1Reduce power lossLess energy consumptionToothed gearingsGear lubrication/coolingLubricationControl unit

The invention relates to a lubrication system and method for controlling the lubrication system. The lubrication system comprises a bypass line by which it is possible to lead a part of the oil flow in the oil line past a component to be lubricated and back to the oil sump, a first valve configured to regulate the oil flow through the bypass line and a control unit. The control unit is configured to receive information from at least one parameter related to the oil flow to said component to estimate a required oil flow to said component in view of said parameter and to regulate the first valve such that a part of the oil flow in the oil line is led to the bypass line and that a remaining part of the oil flow, which corresponds to the required oil flow, is led to said component.

Owner:SCANIA CV AB

Flinger disc

InactiveUS20060073303A1Easy to assemble and disassembleReduce the temperatureLayered productsBearing componentsCircular discFuel tank

To achieve proper lubrication, a bearing housing or reservoir is filled with a predetermined amount of lubricant. When the machine, of which a bearing is a component, is operated, a flexible flinger disc provides proper lubrication by disturbance of the lubricant.

Owner:TRICO CORP

Energy-saving environment-friendly high-temperature-resistant oil tank capable of giving alarm when there is no oil and used for mining speed reducer

InactiveCN112303216AChange resistanceAutomatically adjust oil temperatureGear lubrication/coolingVisible signalling systemsDry iceReducer

The invention relates to the technical field of mining speed reducers, and discloses an energy-saving environment-friendly high-temperature-resistant oil tank capable of giving an alarm when there isno oil and used for mining speed reducer. The oil tank comprises an oil tank body. A U-shaped pipe is fixedly connected to the bottom of the inner wall of the oil tank body, and the other end of the U-shaped pipe is movably connected with a first slide rheostat through a floating block. The top of the first slide rheostat is fixedly connected with an alarm lamp, the top of a heat transfer block isfixedly connected with a mercury bin, and the mercury bin is movably connected with a second slide rheostat through a floating plate. The surface of the oil tank is fixedly connected with a cooling pipe through a heat dissipation unit, and the top of the cooling pipe is fixedly connected with a dry ice bin. The inner wall of an exhaust pipe is movably connected with a piston. According to the principle of the U-shaped pipe, the resistance of the first slide rheostat is controlled, an alarm is given when there is no oil, the resistance value of the second slide rheostat is changed through thermal expansion and cold contraction of mercury, a rotating wheel is controlled to rotate, and the piston is driven to do simple harmonic motion, so that dry ice enters the cooling pipe to cool the oiltank body.

Owner:温州南陌贸易有限公司

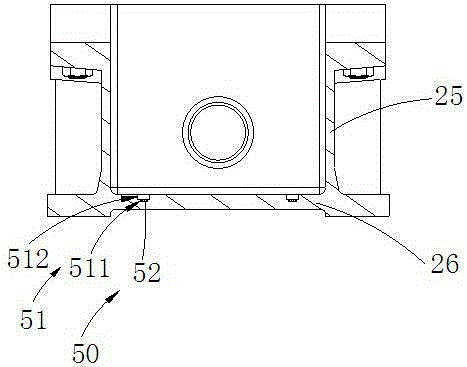

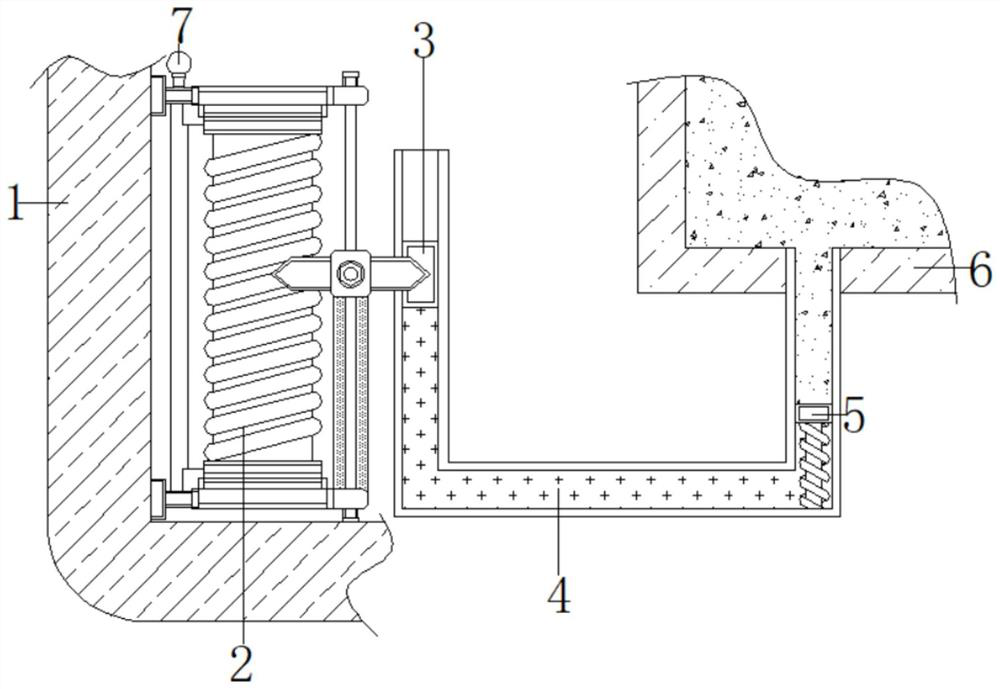

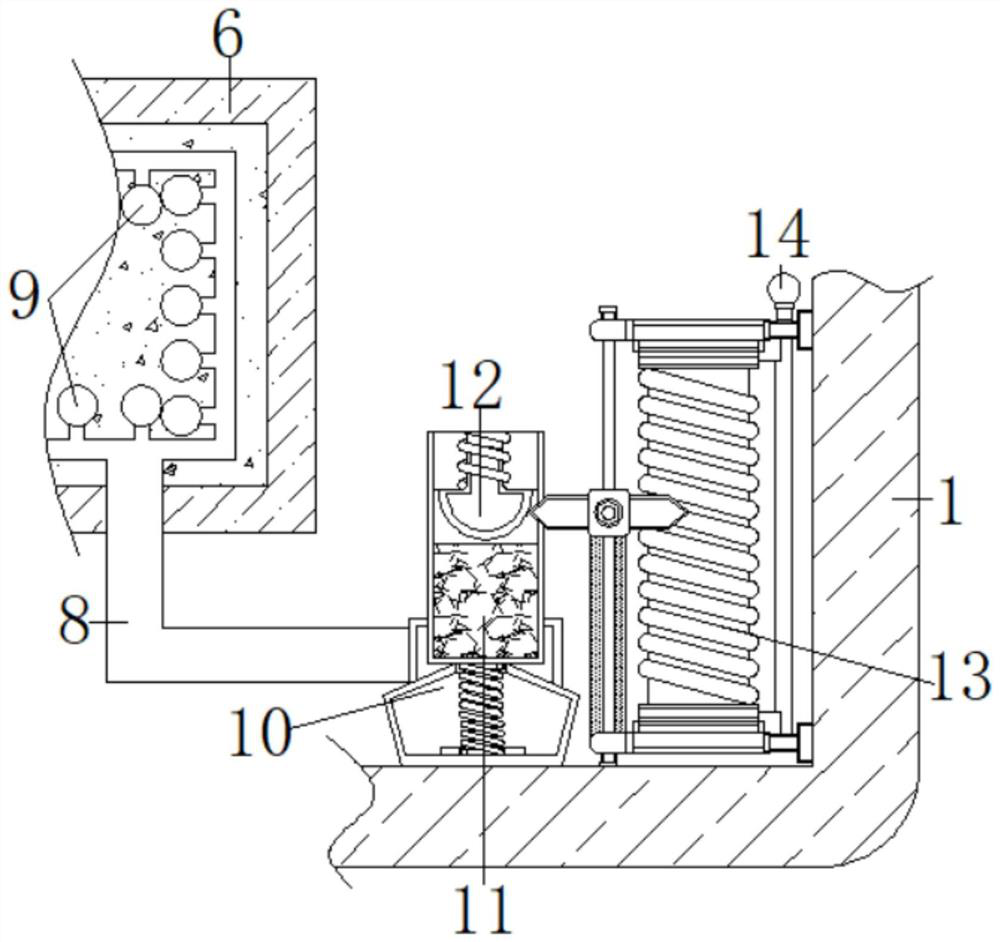

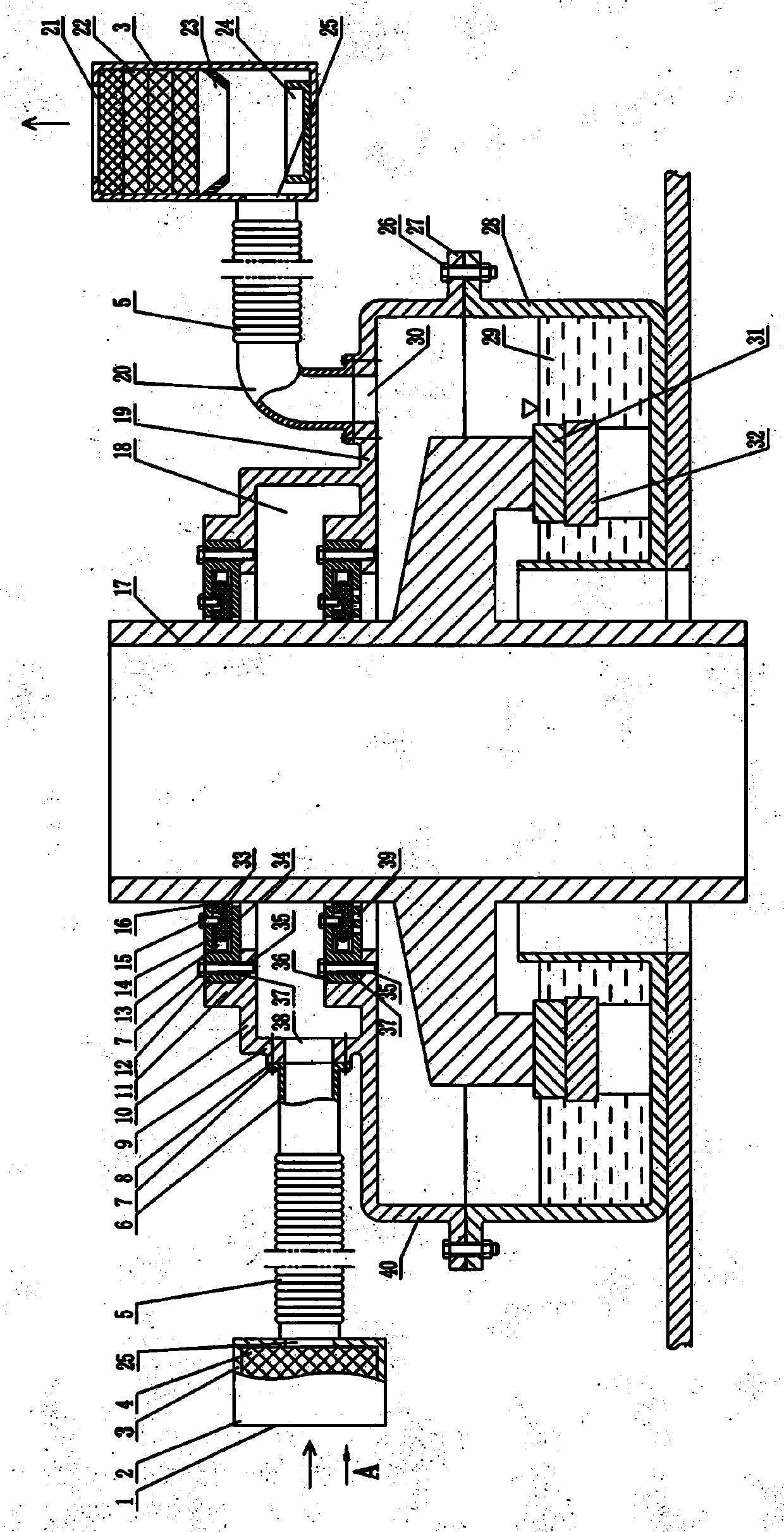

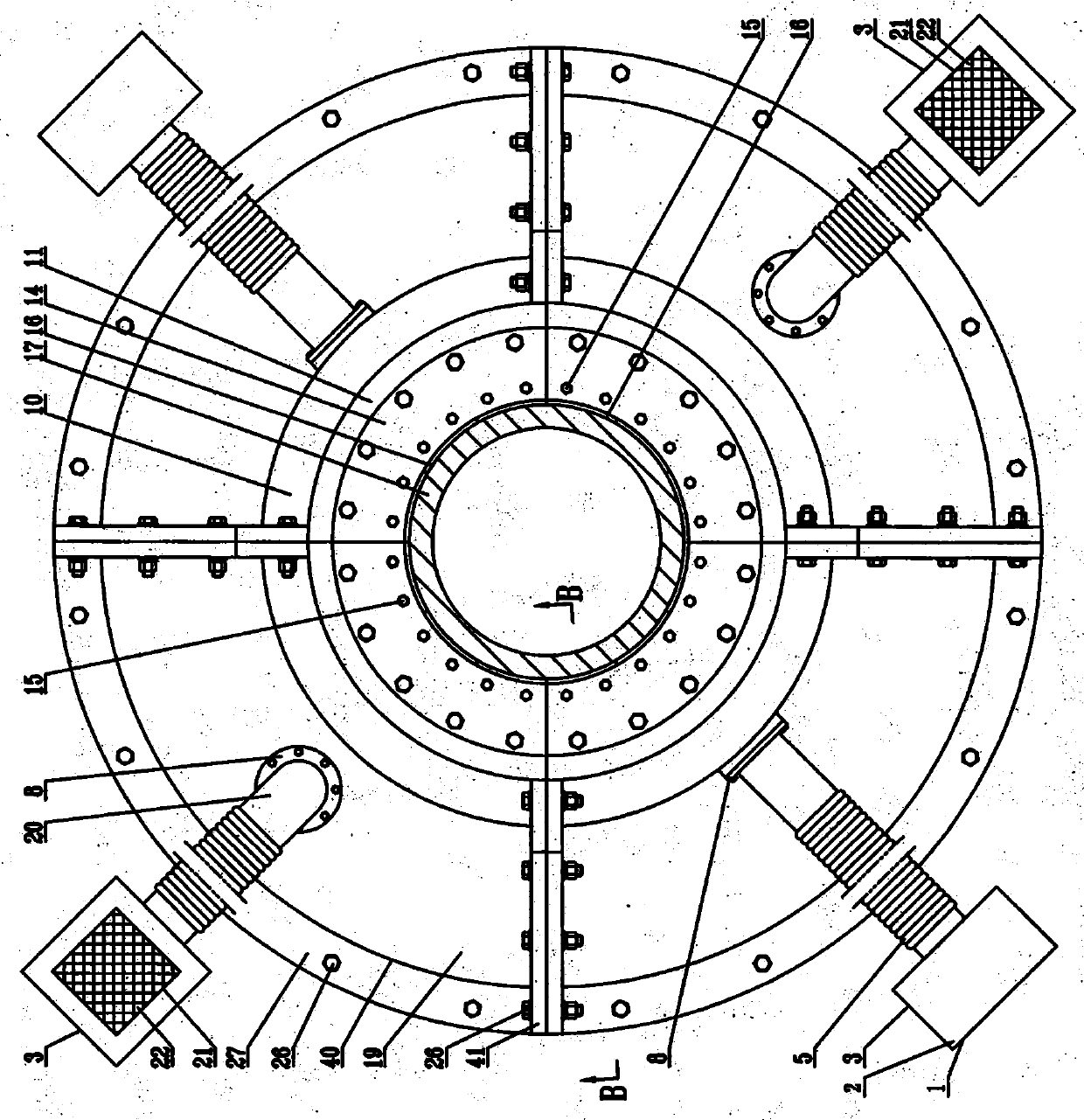

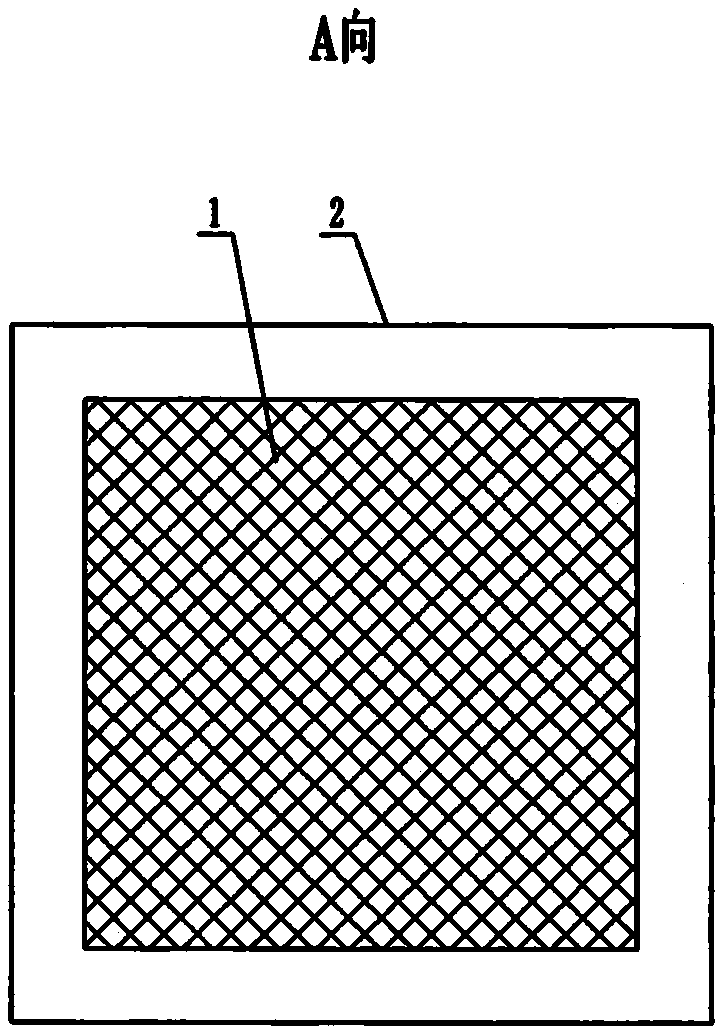

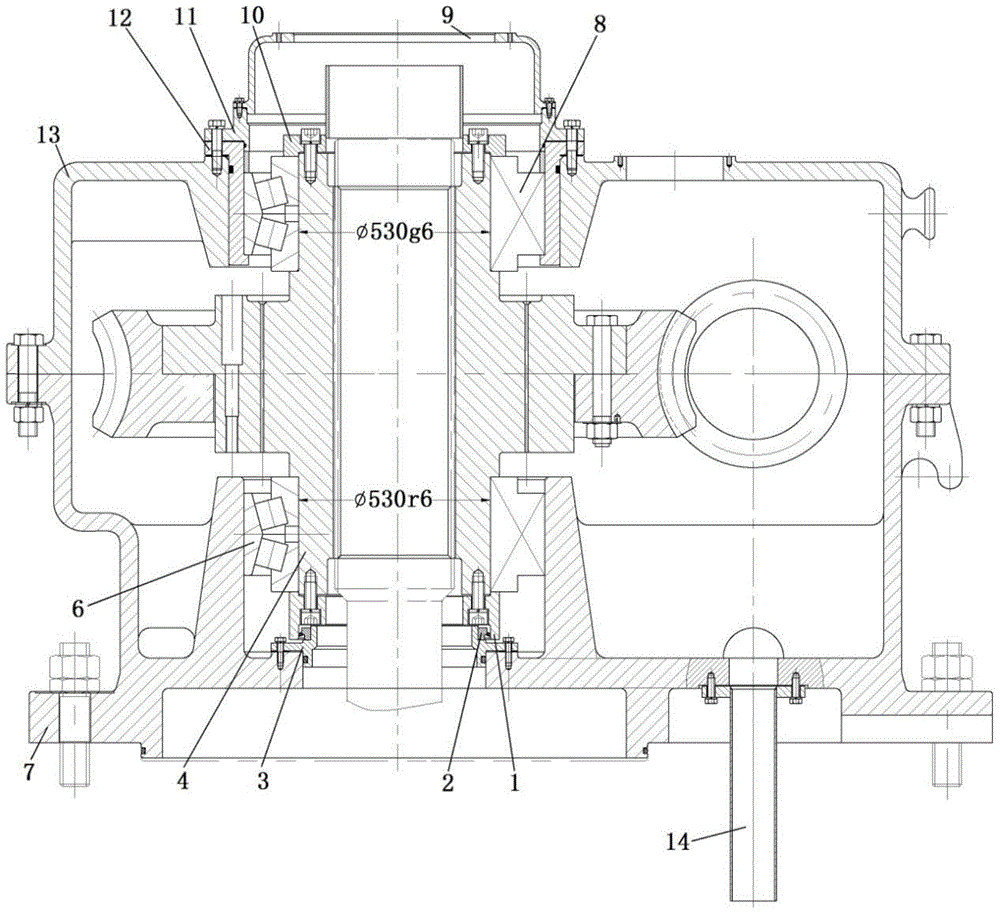

Unpowered non-force self-flat-pressing oil groove integrated flotation seal device

PendingCN111396230ASmall sizeIncrease work intensityLeakage preventionHydro energy generationAir filterStructural engineering

The invention discloses an unpowered non-force self-flat-pressing oil groove integrated flotation seal device. Baffle rings are mounted on the upper ring face and the lower ring face of a sectioning seat ring with a seat ring flange and an occlusal face, upper integrated rectangular groove rings internally provided with 4 to 16 sectioning floating seal bodies are fixed to a baffle ring inner sideupper ring face, the 4 to 16 sectioning floating seal bodies are mounted inside, lower integrated rectangular groove rings with rectangular groove lower rings provided with oil filling holes are fixedto a baffle ring inner side lower ring face, an air inlet hole in a vertical ring face communicates with an air filter with a flat pressing hole and an air opening and internally provided with an airfilter body through a connecting pipe and a connecting hose, a flat pressing through hole in the lower ring face communicates with a shell with a flat pressing hole, provided with a flat pressing opening in the upper portion, and internally provided with a multi-layer oil mist filter body, a flow guide frame and an oil collection box through a flat pressing pipe and a connecting hose, the sectioning seat ring forms a whole circle through the occlusal face via occlusal bolts, through the seat ring flange, the occlusal bolts are used for fixing the whole sectioning seat ring to an oil groove, and the device can be widely applied to the field of hydro-generators and the like.

Owner:HARBIN XUNPU TECH DEV

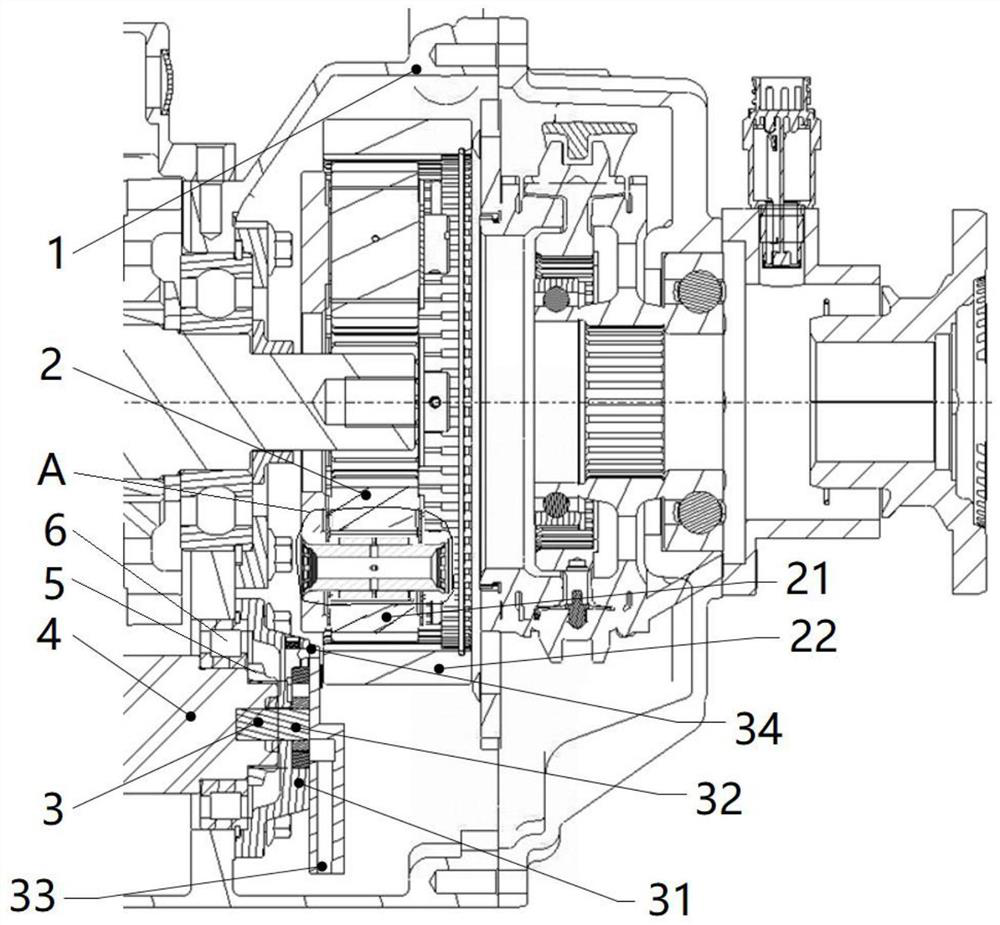

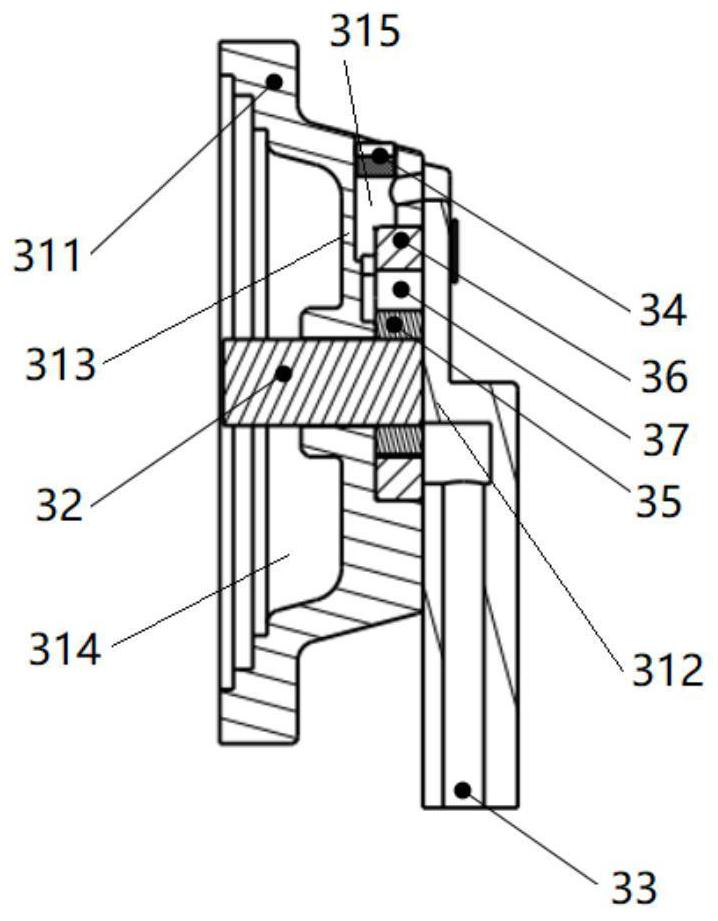

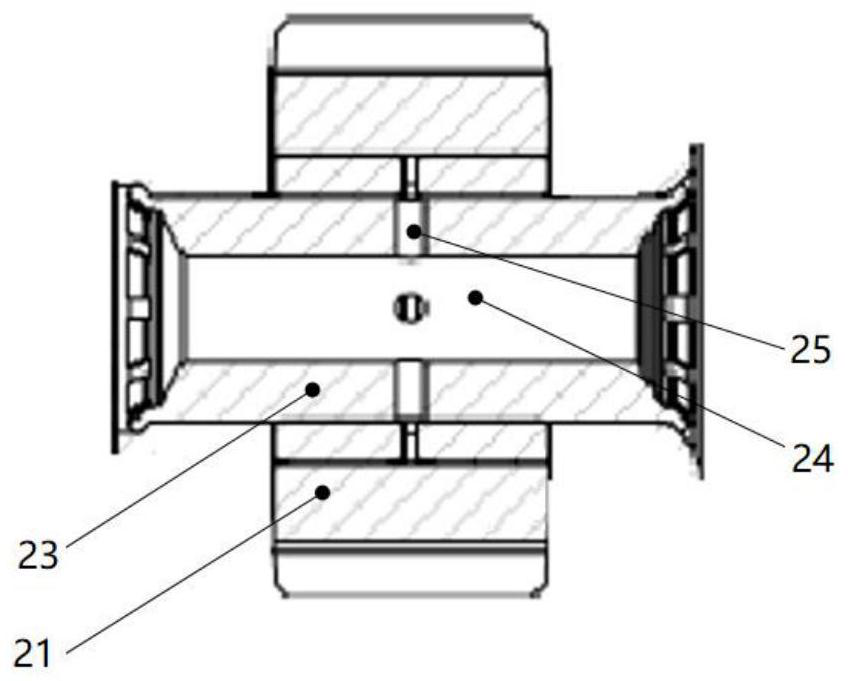

Self-lubricating planet gear transmission sub-gearbox

InactiveCN111998056AImprove the lubrication effectGuaranteed reliabilityGearboxesGear lubrication/coolingEngineeringAtmospheric sciences

The invention discloses a self-lubricating planet gear transmission sub-gearbox. The self-lubricating planet gear transmission sub-gearbox comprises a planetary structure arranged in a transmission case and a pumped oil spraying device. The self-lubricating planet gear transmission sub-gearbox is characterized in that the pumped oil spraying device comprises a pump case connected with the transmission case and a rotating shaft which is positioned in the pump case and is connected with an intermediate shaft of a transmission; an oil suction port of the pumped oil spraying device is positioned at the bottom of the transmission case; and an oil nozzle is positioned on the lower edge side of the planetary structure and faces an engaged area of a planet gear of the planetary structure and a biggear ring. The lubrication of the planetary structure of a rear sub-gearbox is enhanced by using the pumped oil spraying device arranged at the rear end of the intermediate shaft, so that the workingreliability of the planetary structure is ensured. By use of the pumped oil spraying device arranged at the rear end of the intermediate shaft, the lubrication of the planetary structure of the rearsub-gearbox is enhanced, the oil-level height of a transmission assembly is reduced, and the problems that as the oil-level height is improved, the churning loss of the transmission is increased, further the temperature of the transmission is raised, early failure of an oil product is caused, the transmission efficiency is low and the like are effectively solved.

Owner:DONGFENG COMML VEHICLE CO LTD

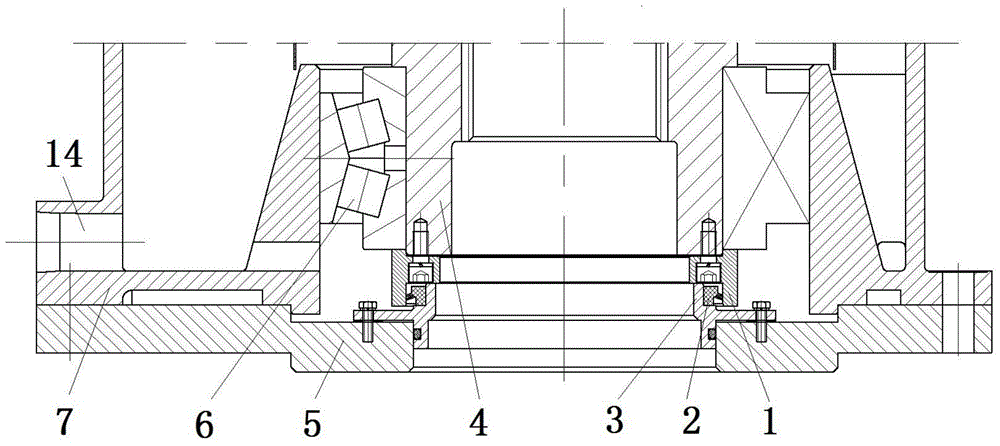

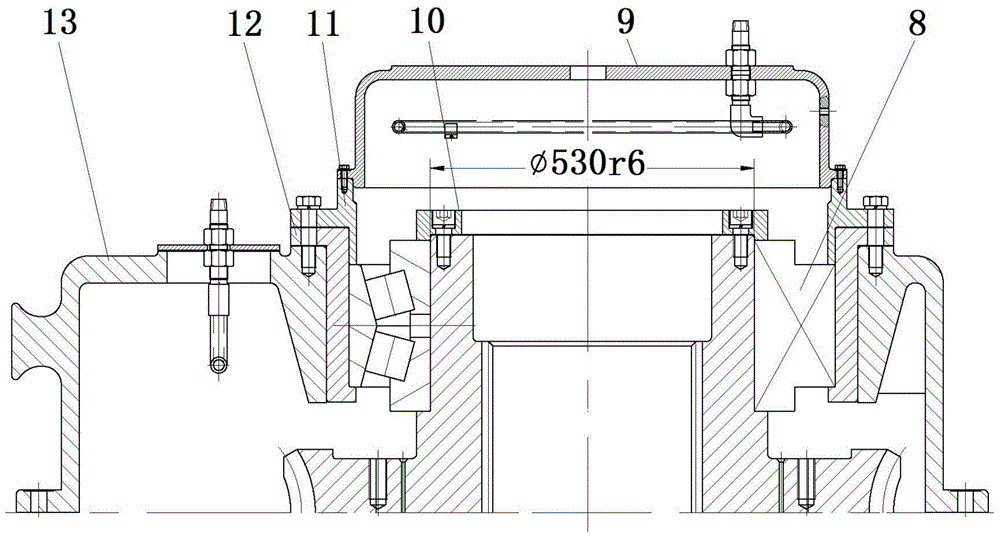

Press-down reduction box for four-roller reversible tungsten-molybdenum hot rolling mill

InactiveCN105032942AEasy pipingReduce installation linksRolling mill drivesGearing detailsButt jointEngineering

The invention discloses an press-down reduction box for a four-roller reversible tungsten-molybdenum hot rolling mill. An oil stopping ring is arranged in a lower box body of the reduction box, and the oil stopping ring is upwards in butt joint with a lower bearing check ring. The lower bearing check ring is fixed connected with a worm wheel shaft, and the circumference of the lower end of the worm wheel shaft is sleeved with a worm wheel lower bearing. The worm wheel lower bearing is located on the lower bearing check ring, and a seal is arranged between the oil stopping ring and the lower bearing check ring. An oil returning hole is formed in the bottom of the lower box body of the reduction box, and the upper port edge of the oil returning hole is lower than the lower edge of the seal. A sleeve cup is fixedly installed on an upper box cover of the reduction box, and a worm wheel upper bearing is sleeved with the sleeve cup. The worm wheel upper bearing is connected with the upper portion of the worm wheel shaft in a sleeving mode, and an upper bearing check ring is arranged at the upper end of the worm wheel upper bearing. An upper end cover is arranged at the upper end of the sleeve cup and is provided with a protection cover. The worm gear upper bearing is in loose fit with the worm wheel shaft. The press-down reduction box does not leak oil and is convenient to demount and mount.

Owner:MCC SFRE HEAVY IND EQUIP

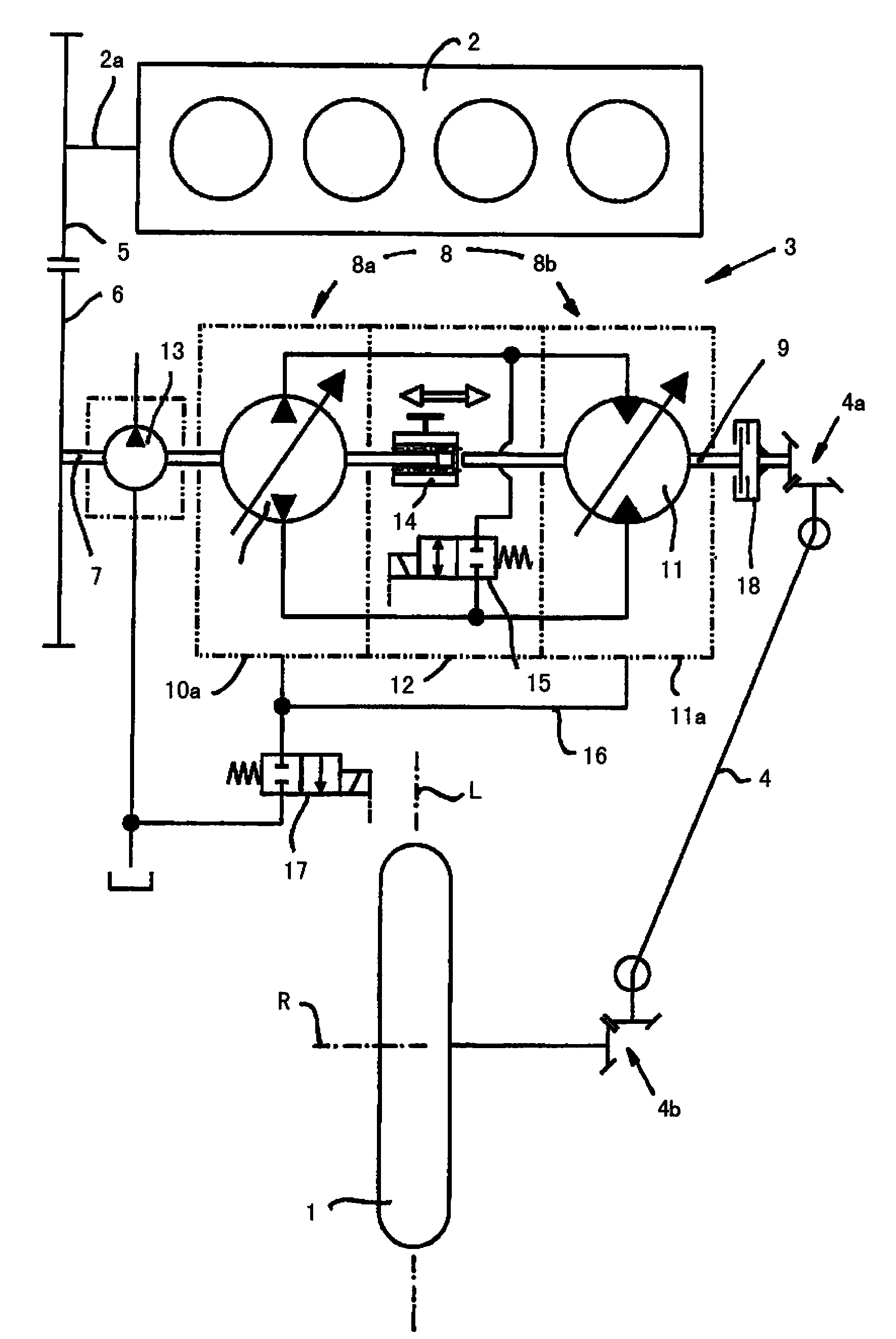

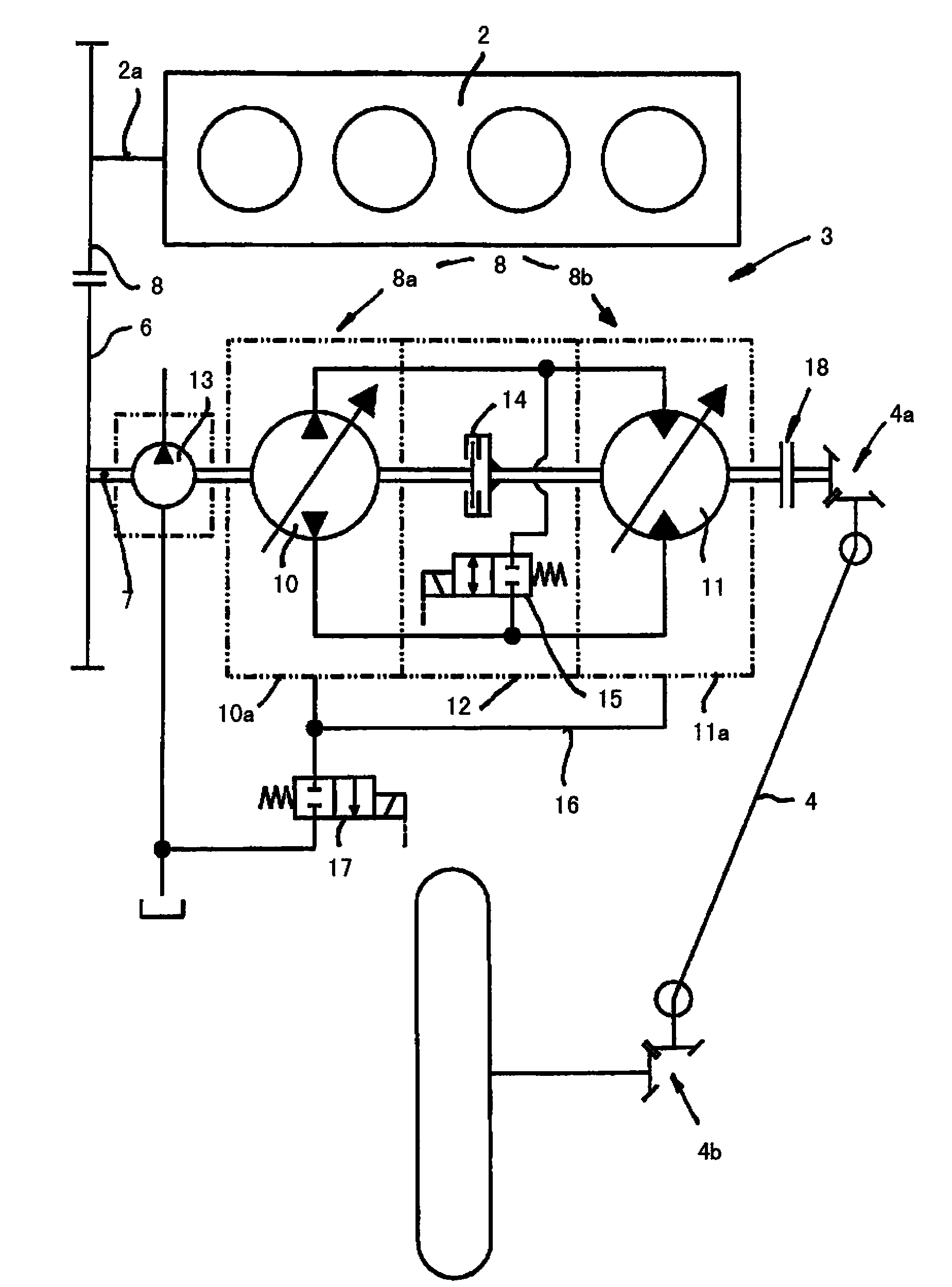

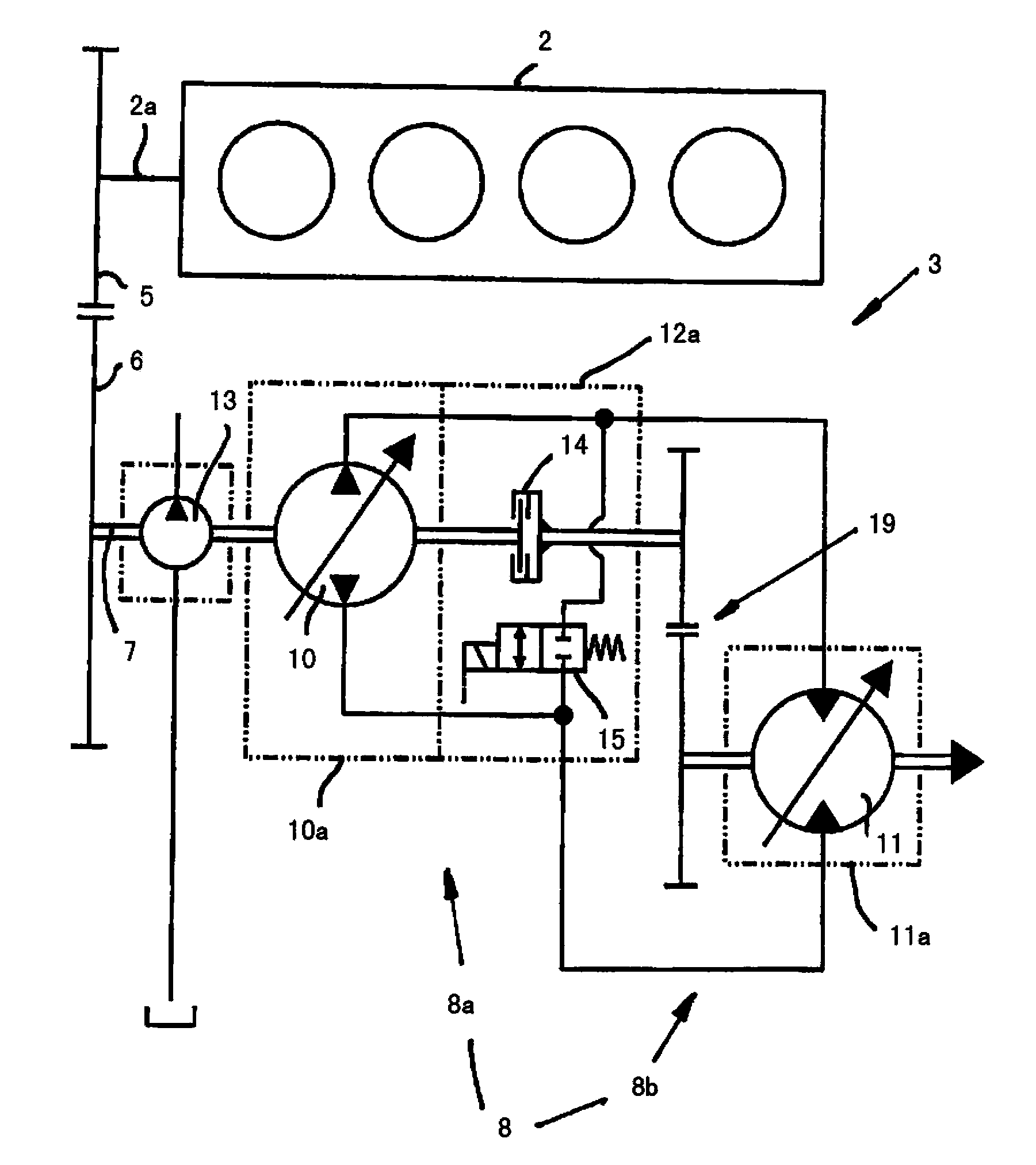

Power assembly system with internal combustion engine and continuously variable transmission

InactiveCN104088988ANo lossEliminate Flow LossGearboxesControl devicesExternal combustion engineEngineering

The invention relates to a power assembly system which comprises an internal combustion engine (2) and a continuously variable transmission (3). To achieve relatively small loss with small consumption, particularly within a relatively high rotation speed range under the condition of compact structure manner, according to the power assembly system, a first speed change mechanism machine unit (8a) and a second speed change mechanism machine unit (8b) which is in action connection with the first speed change mechanism machine unit (8a) can be mechanically connected with each other through a switchable clutch (14).

Owner:LINDE HYDRAULICS

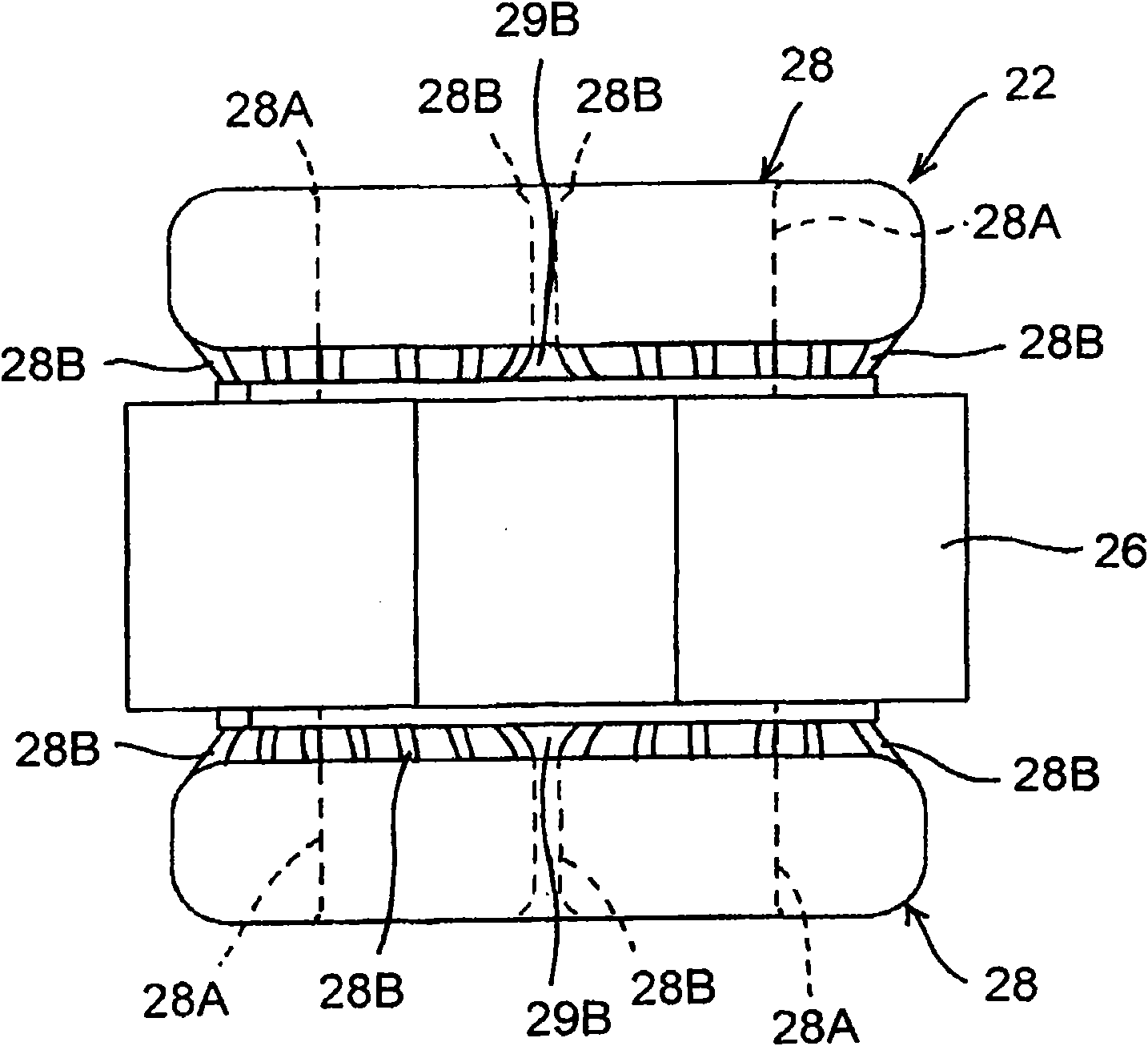

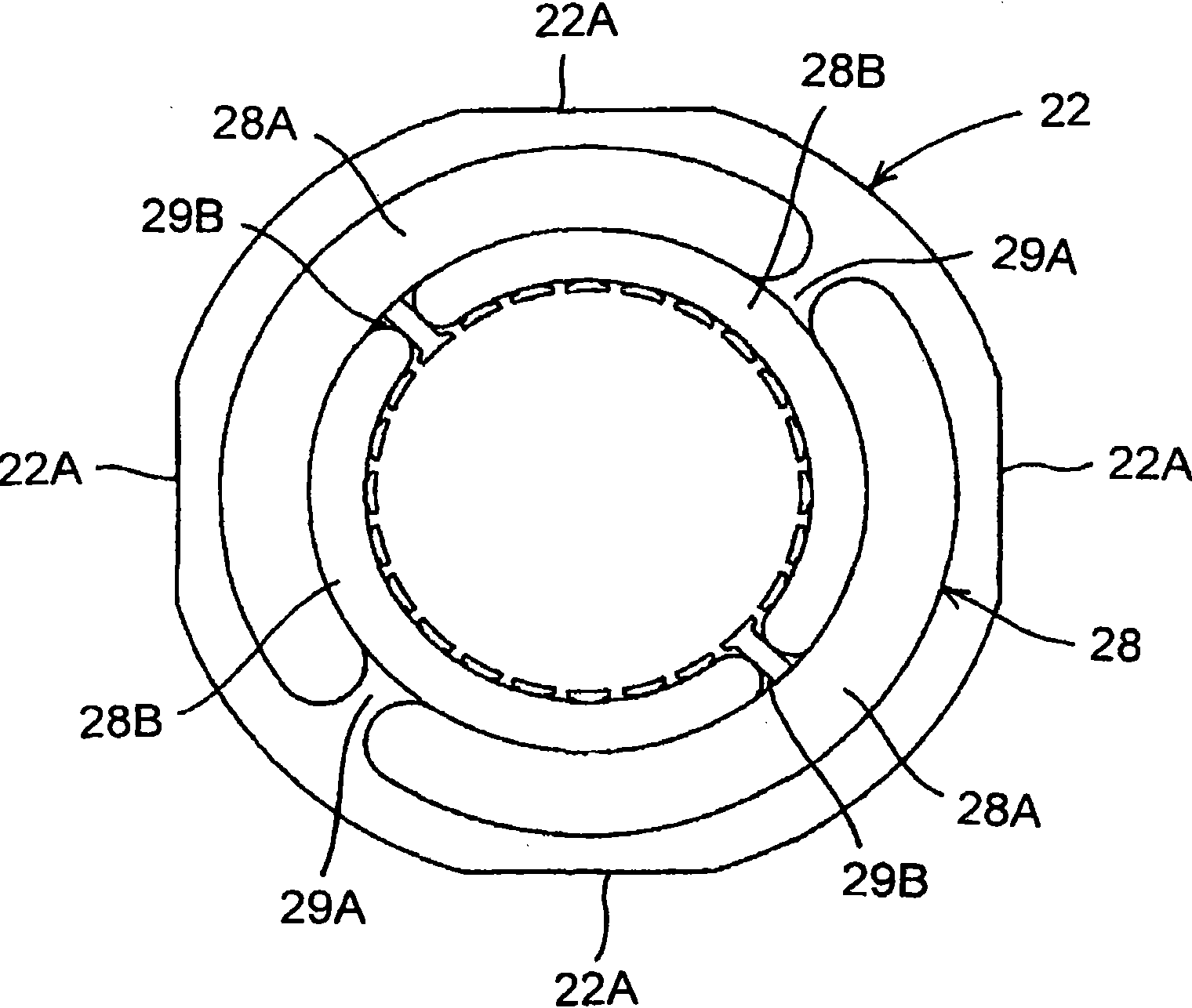

Electric compressor

InactiveCN102032189APrevent oil level dropImprove performance and reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsStatorEngineering

The invention provides an electric compressor. Since possibility of insufficient oil caused by a possible increase of an oil jet amount toward the external of an electric compressor and lowering of an oil face of an oil accumulating part exists, a rotating compressor (electric compressor) (10) receives an electric essential element (14) and a rotating compression element (compression element) (32) driven by the electric essential element (14) in a closed container (12), the electric essential element (14) is formed by a stator (22) provided with a stator winding (28) and a rotor (24) rotating in the stator (22), wherein, the rotating compressor (10) is provided with a cut (22) formed at the outer edge part of the stator (22), an oil drainback passage (80) is formed between the cut (22A) and the closed container (12), joints (29A, 29B)of coil terminals of the stator winding (28) are configured at positions deviate from the range of the cut (22A).

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com