Press-down reduction box for four-roller reversible tungsten-molybdenum hot rolling mill

A technology of a reducer and a hot rolling mill, which is applied to the driving device of a metal rolling mill, metal rolling, and mechanical equipment, etc., can solve the problems of oil leakage, unreasonable structure setting of the reducer device, inconvenient disassembly, etc. Installation process, saving production costs, and ensuring the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

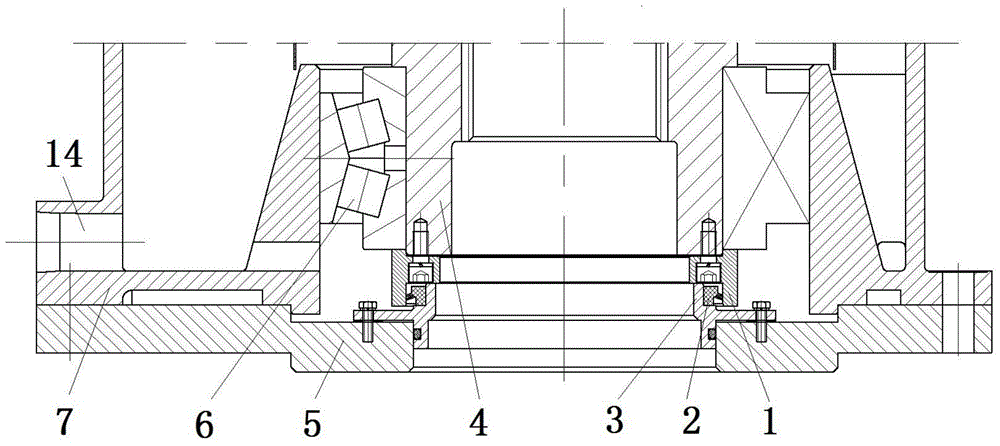

[0020] Such as figure 1 , the lower structure of the existing four-roll reversible tungsten-molybdenum hot rolling mill pressing the reducer is that the oil return hole 14 of the reducer is arranged on the side of the lower box 7 of the reducer, and the distance between the axis line of the oil return hole 14 and the bottom surface of the reducer is It is small and cannot be piped. In order to pipe, a backing plate 5 is added under the reducer, and a mounting piece is added, which brings trouble to the installation. At the same time, the height from the top surface of the rack to the top surface of the reducer is increased. Due to the height of the workshop and the Due to structural limitations, the oil return hole 14 is too high relative to the lower bearing retaining ring 1 and seal 2, and the lower bearing retaining ring 1 and seal 2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com