Patents

Literature

42results about How to "Good sealing environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

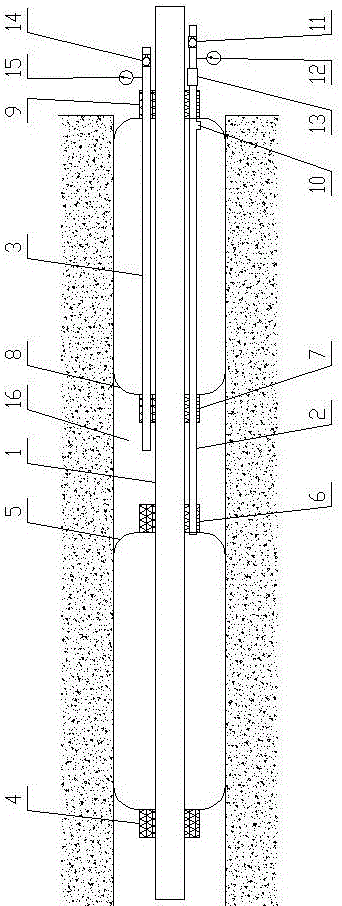

Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

InactiveCN105756599ALow costEasy to operateGas removalSealing/packingAir compressionCoal mine methane

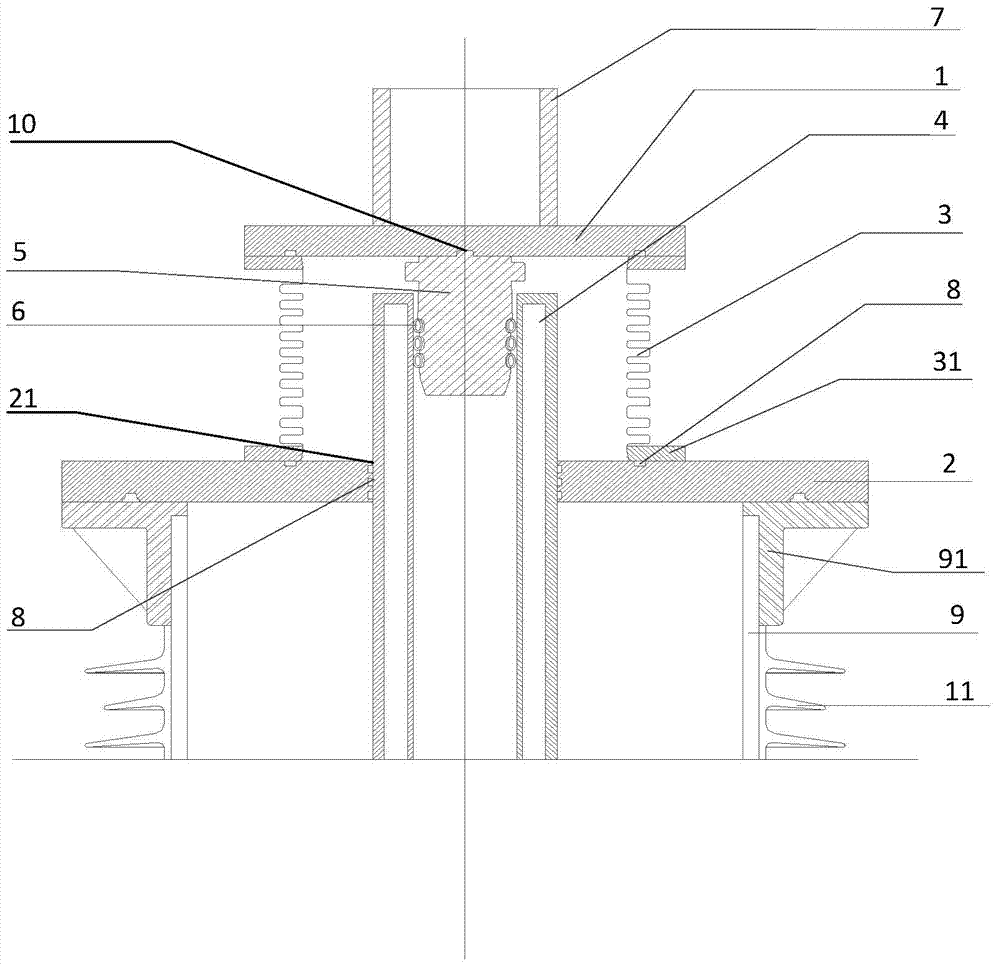

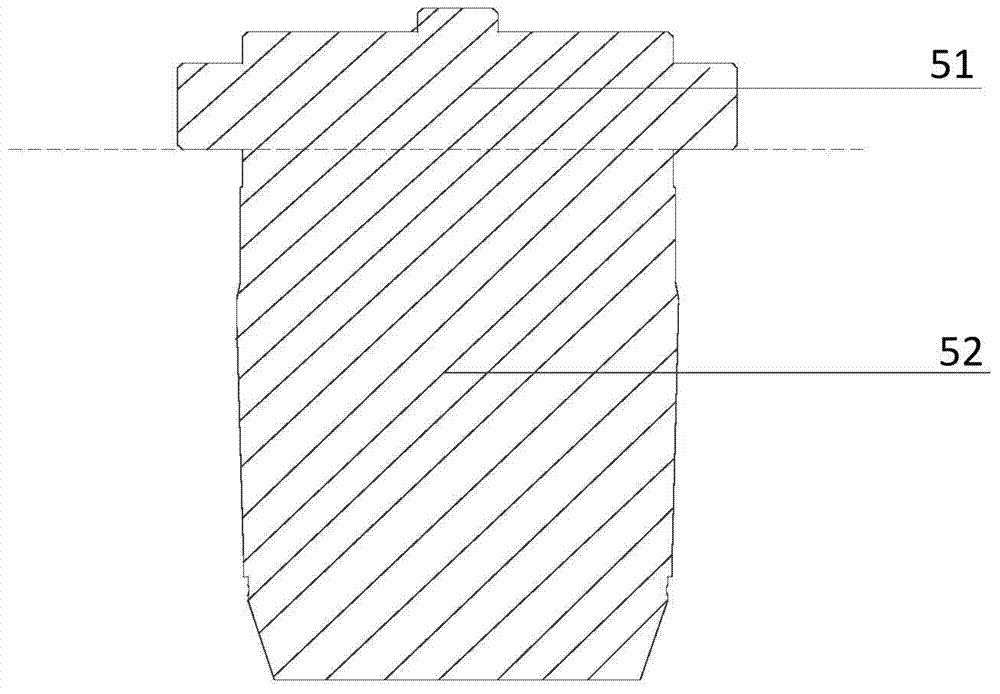

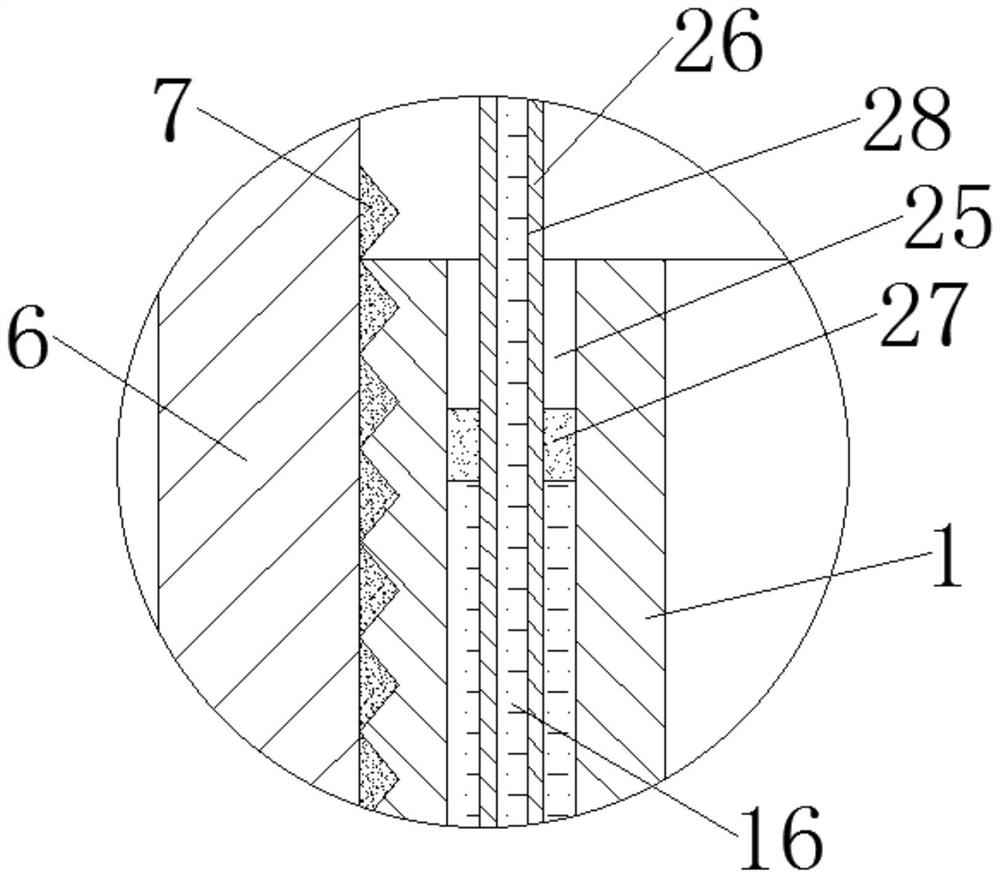

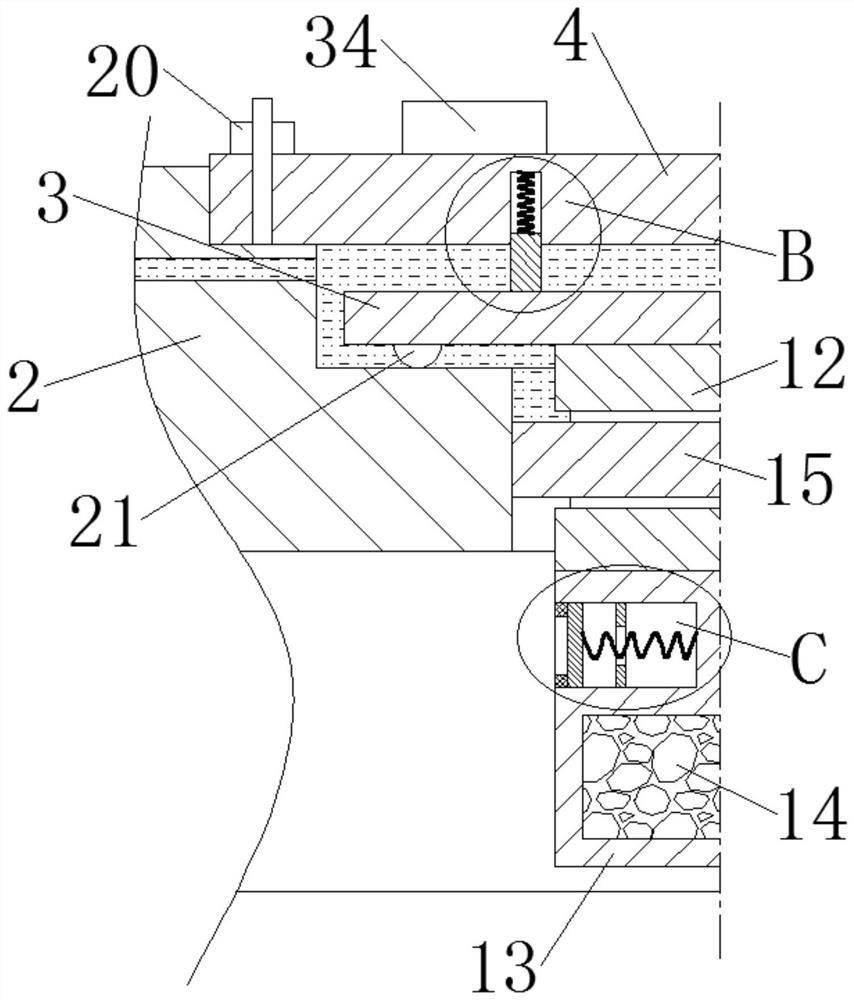

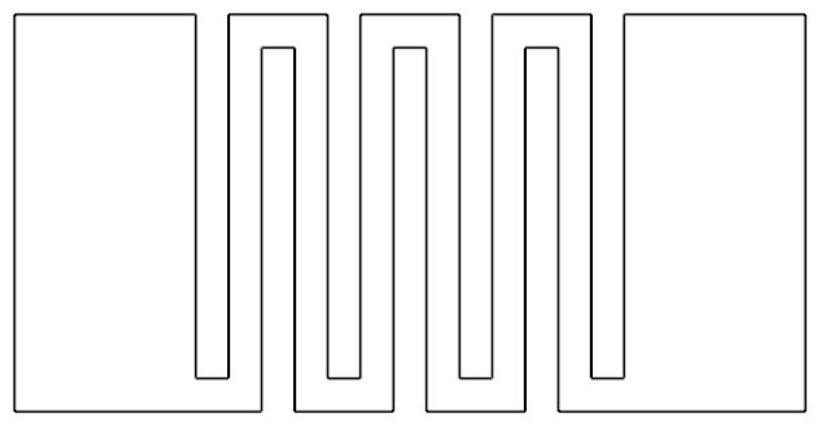

A coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device comprises a gas extraction pipe, a gas injection pipe and a water injection pipe which are arranged in parallel.A first limiting block, a first expansion gas bag, a second limiting block, a third limiting block, a second expansion gas bag and a fourth limiting block are sequentially arranged on the gas extraction pipe from inside to outside, an inner end opening of the gas injection pipe is communicated with the interior of the first expansion gas bag, a gas injection hole communicated with the interior of the second expansion gas bag is formed in the gas injection pipe, and an inner end opening of the water injection pipe is located between the second limiting block and the third limiting block.The invention further discloses a hole sealing method.Cheap water and air are adopted as hole sealing materials in the device and the method and can be supplemented through an underground air compression system and a water supply system as needed to ensure good hole sealing quality, the whole device can be recycled and reused after the extraction work is finished, pollution to a coal body, underground water and underground air can be avoided, the safety level of a mine is improved, and popularization of the novel coal mine gas treatment technology can be easily promoted.

Owner:关红星

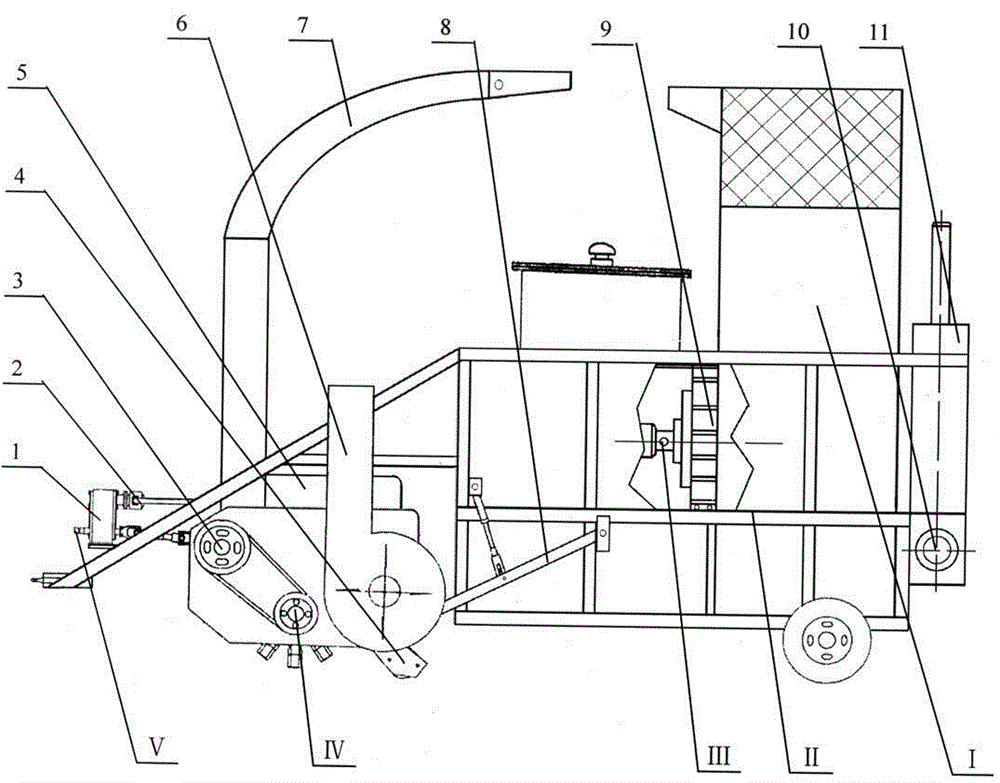

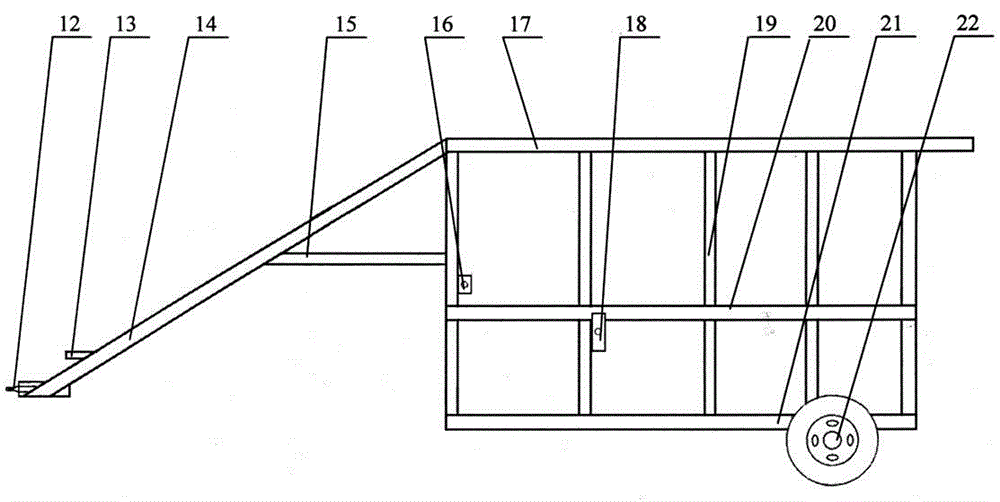

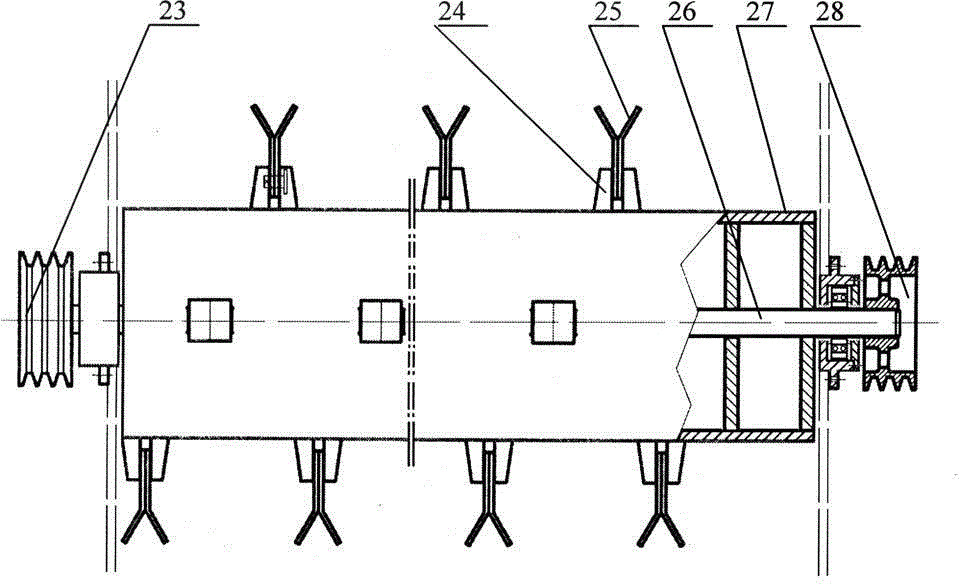

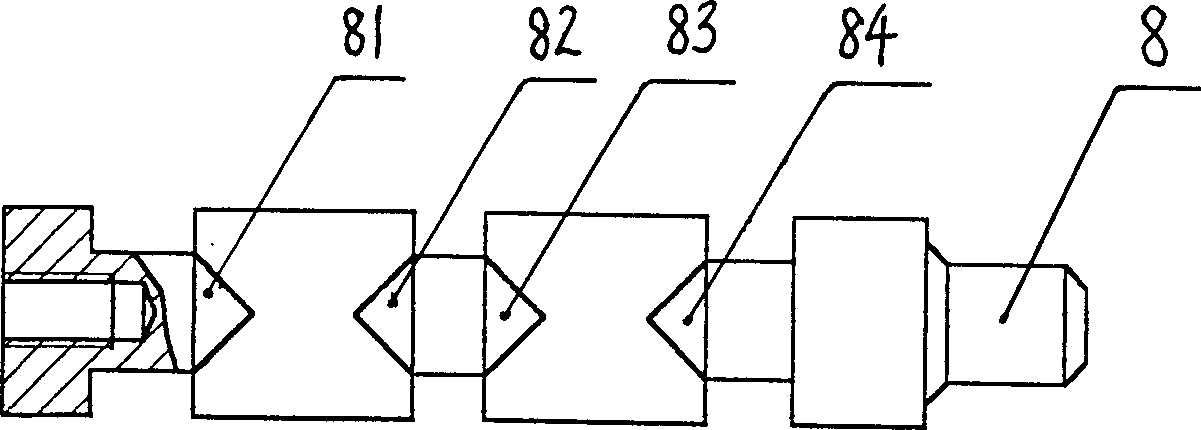

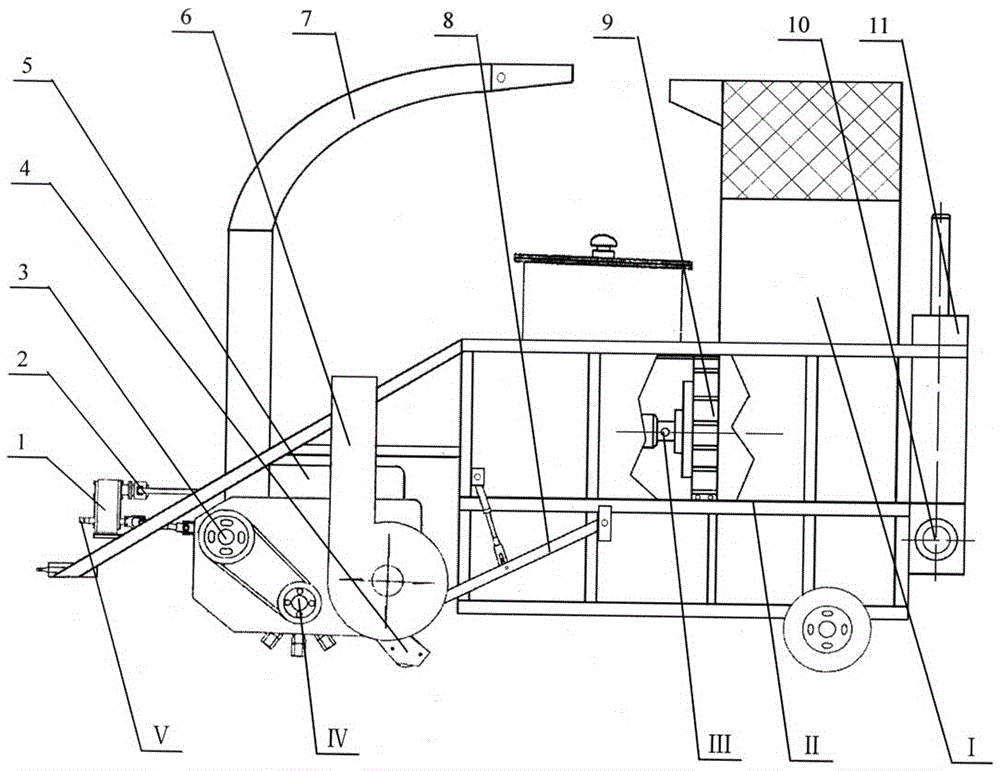

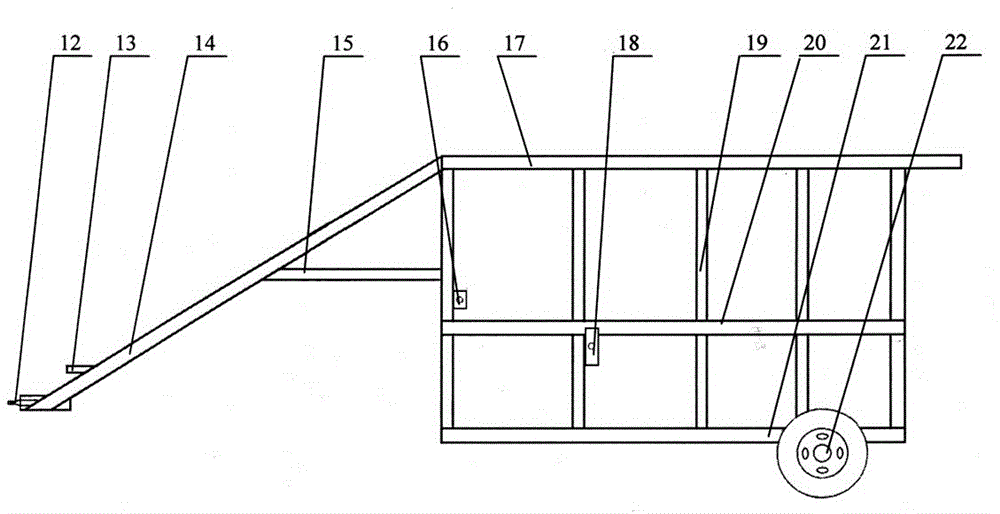

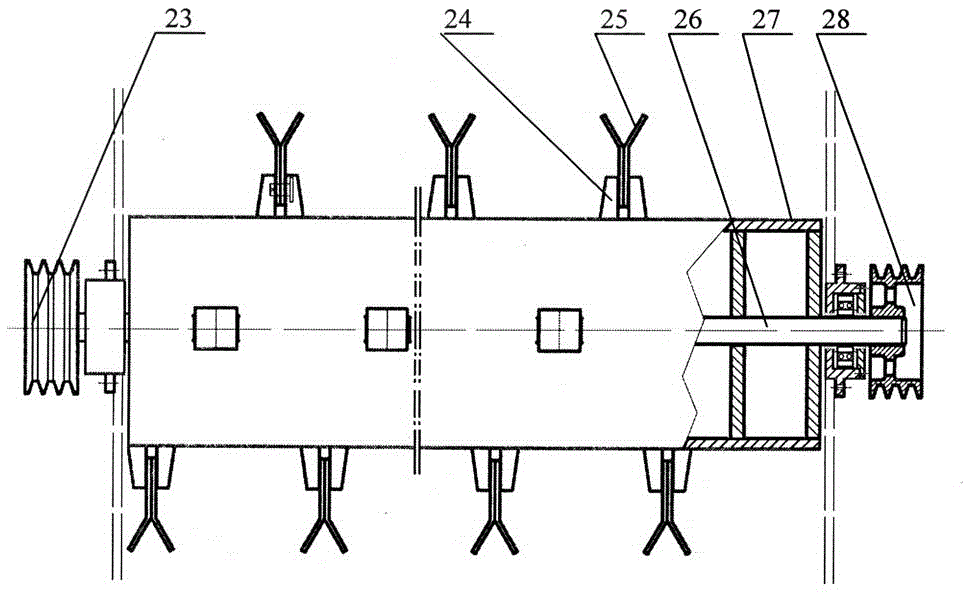

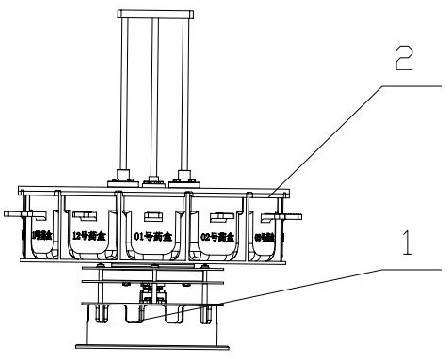

Pull-type picking, kneading, bundling and bagging machine for straw feed

ActiveCN104904437AGood rigidityGood precise shape and position benchmarkLoadersBalingGrazingEngineering

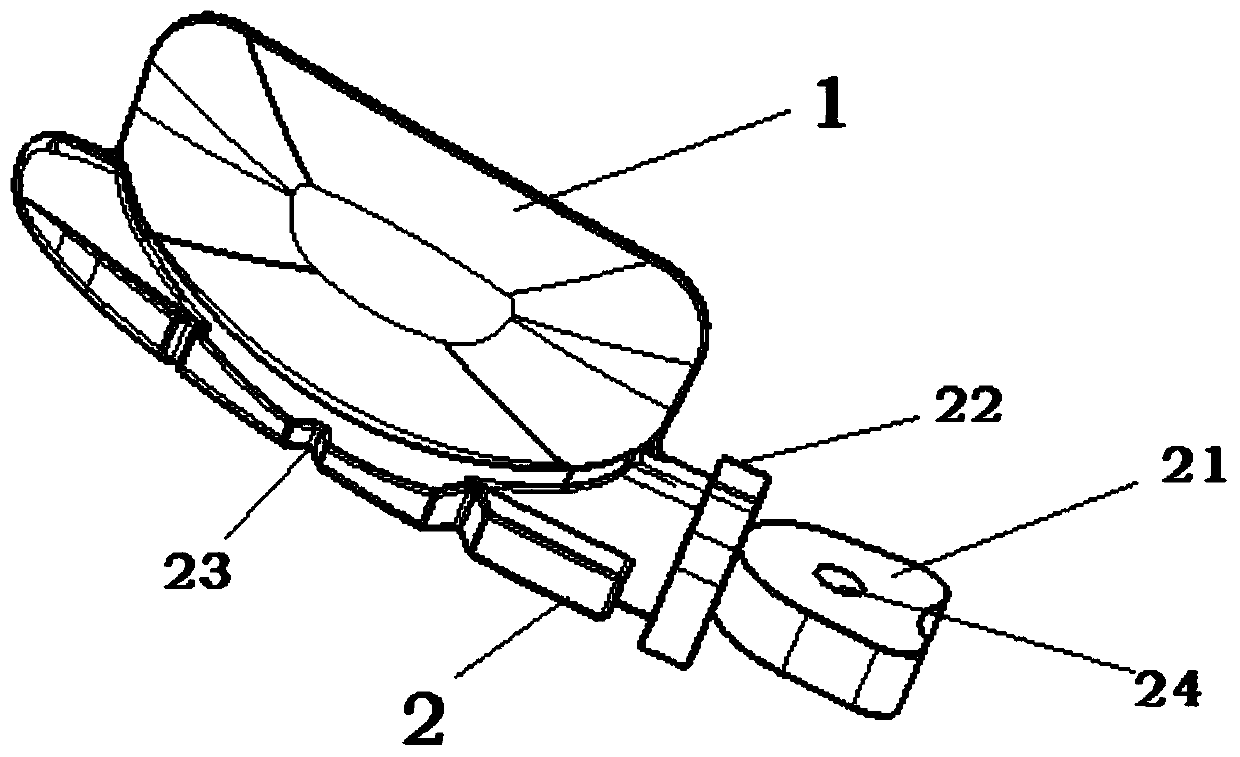

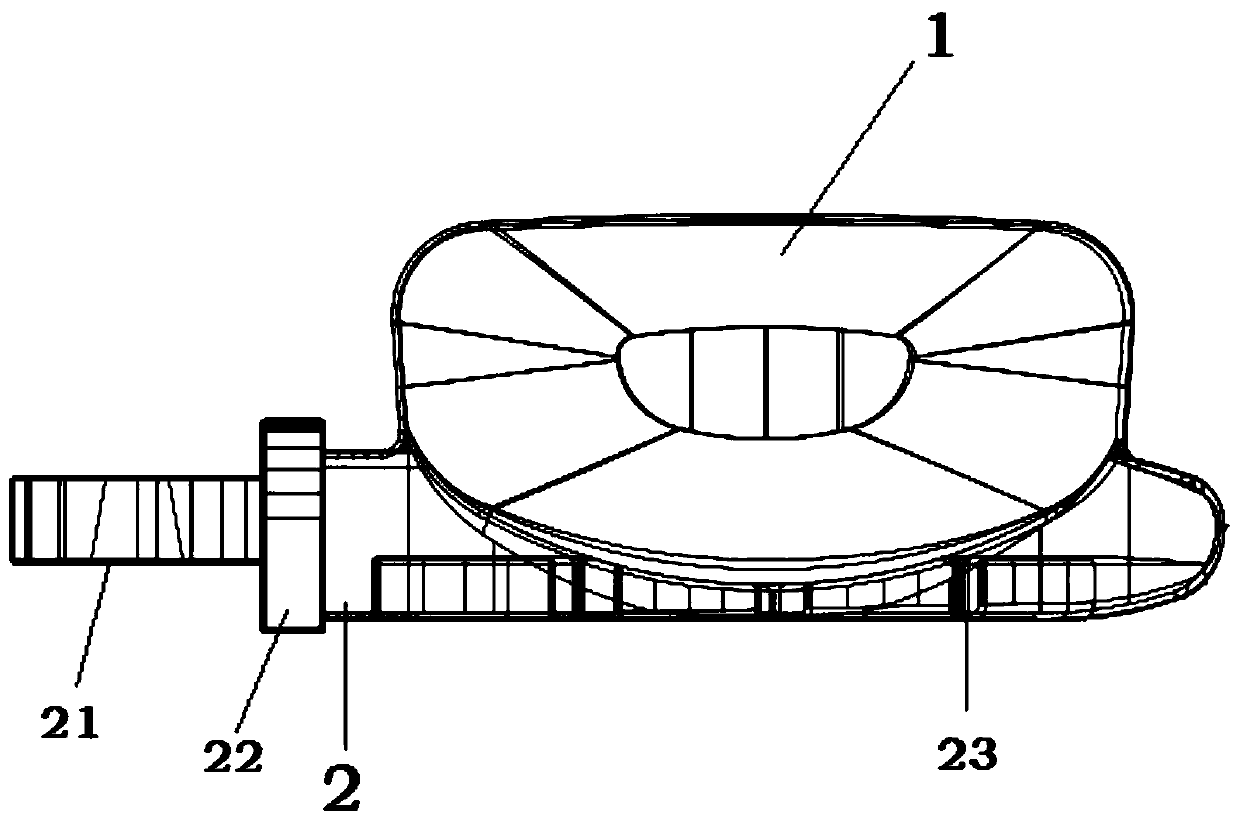

The invention discloses a pull-type picking, kneading, bundling and bagging machine for straw feed. The pull-type picking, kneading, bundling and bagging machine comprises an integral rack, a picking, kneading and transporting device, a straw smashing filling bin, a straw compacting, bundling and bagging device and a powder transmission system. The innovative technologies such as the picking kneading and transporting device being front-arranged to suspend and hydraulically lift, deep tearing, kneading and smashing processing conducted on coarse hard section head and dense surface of corn straw, straw smashing three-direction hydraulic strong compaction and bundling to transport, straw compaction bundling, automatic packing after manual bagging are adopted, and combination processes of picking and smashing, compacting and bundling, bagging and packing are conducted on corn straw in the field. And the pull-type picking, kneading, bundling and bagging machine for the straw feed has the advantages that the technology is advanced, the structure is reasonable, the production efficiency is high, and the working quality is good. Straw feed compaction bales made by the machine has good sealing environment, microbial fermentation action can also occur in a natural condition, the slaking degree is improved, the nutrition ingredient is increased, and the palatability, the grazing rate and the digestion and absorption rate are improved when cattle and sheep are fed.

Owner:四平市顺邦农机制造有限公司

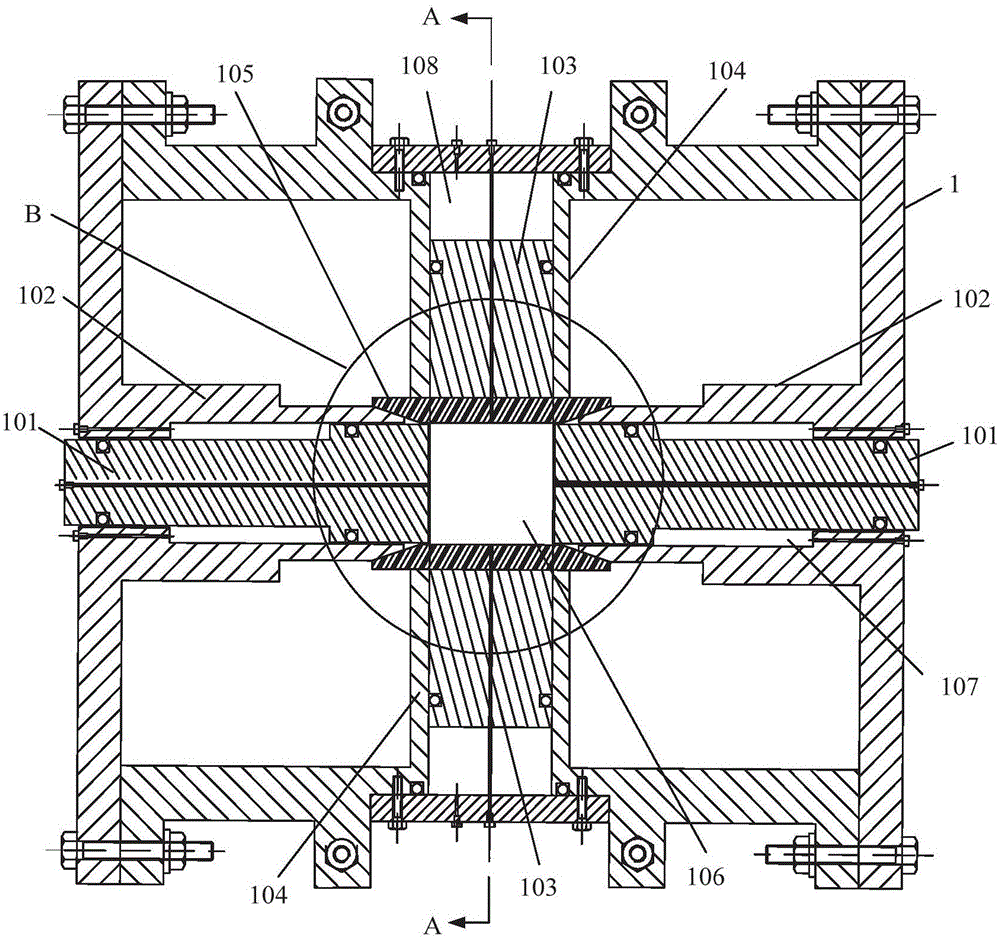

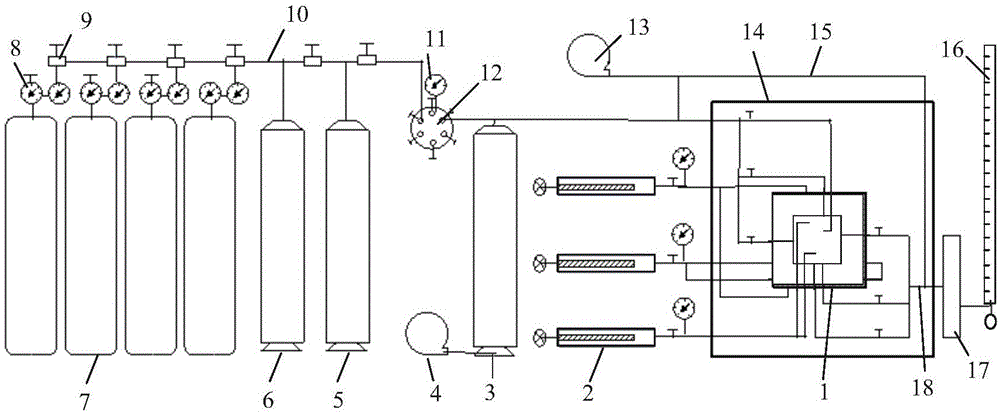

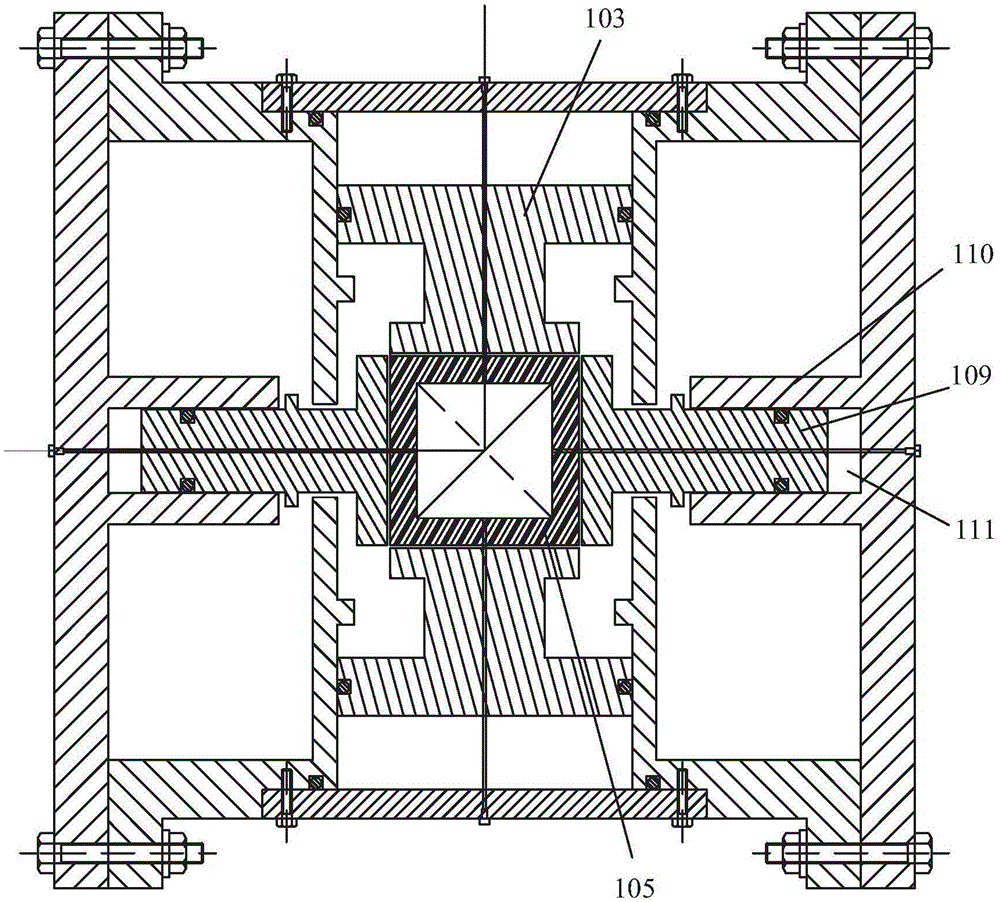

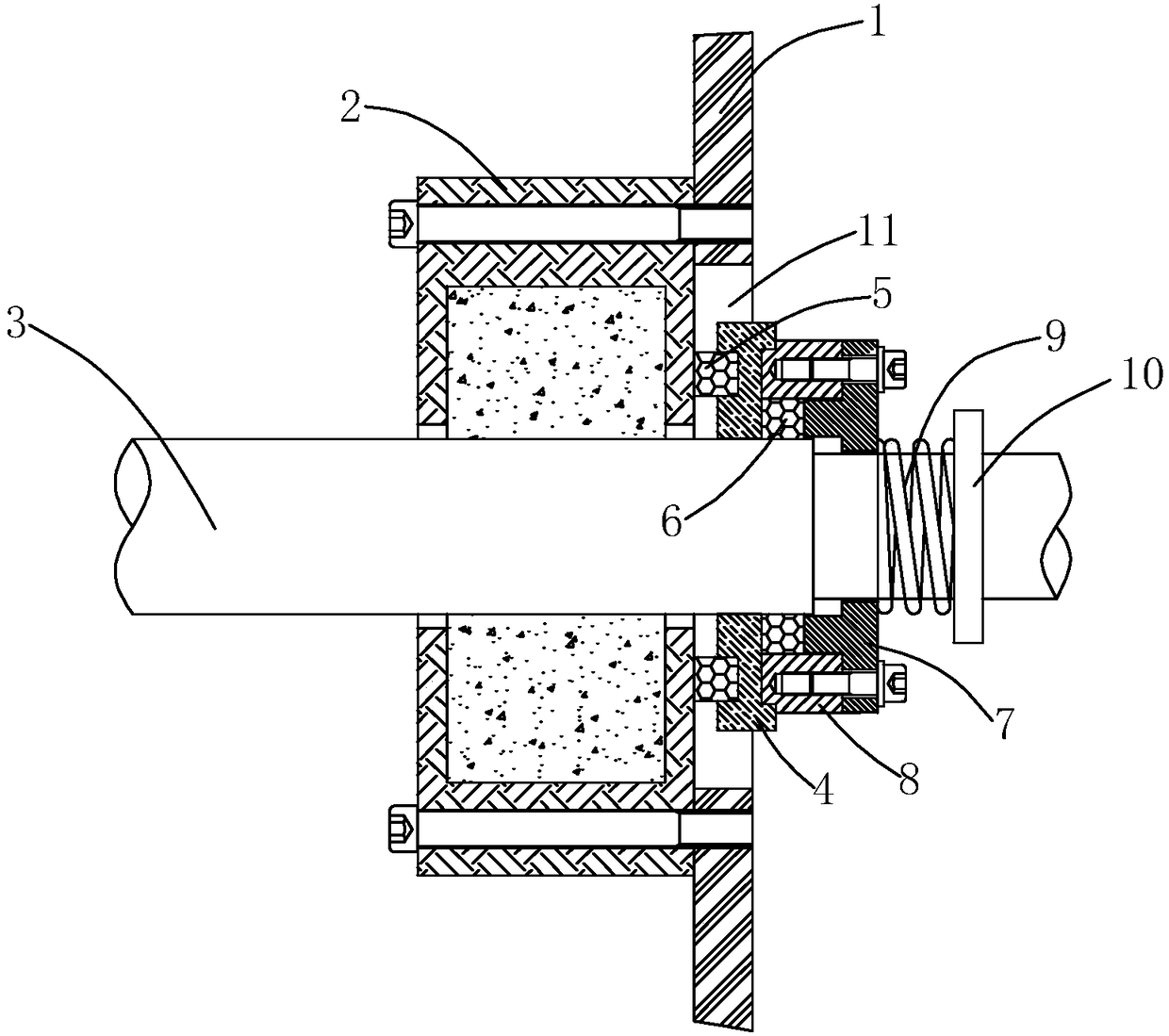

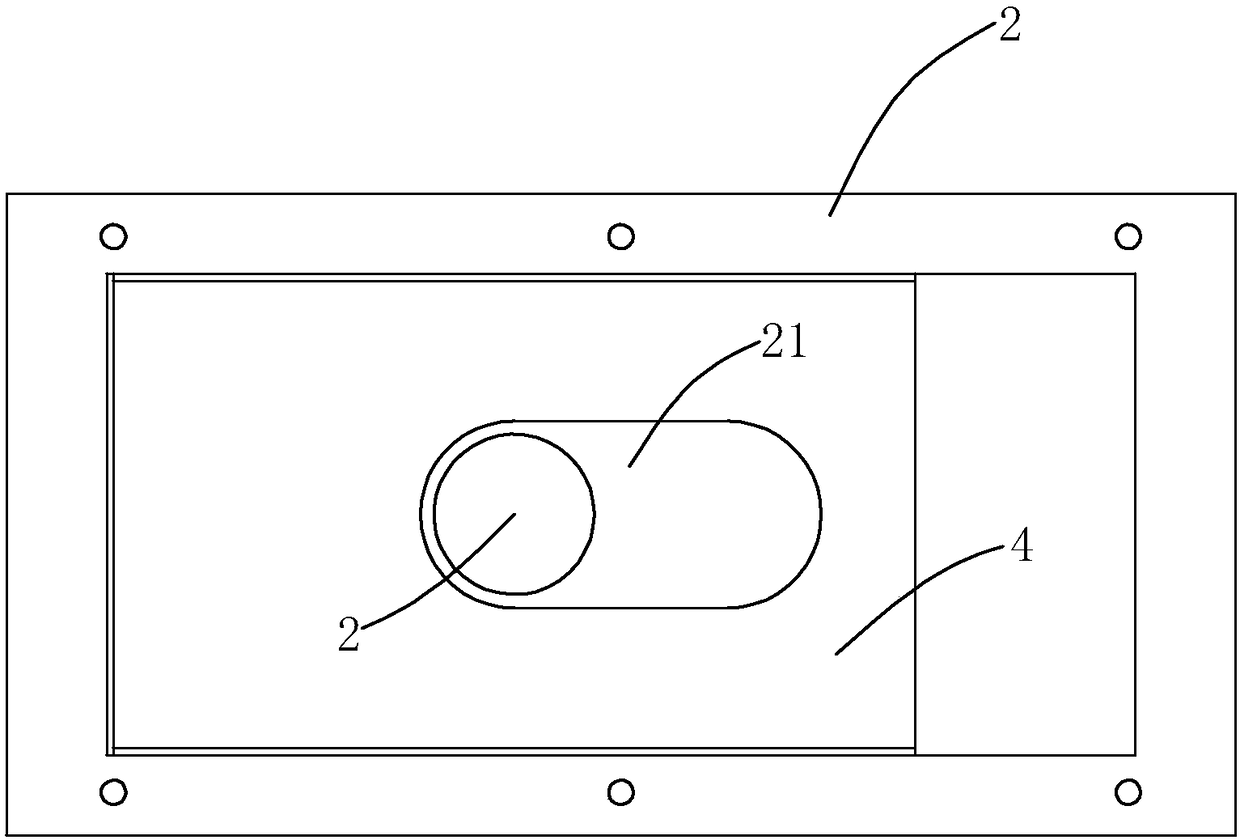

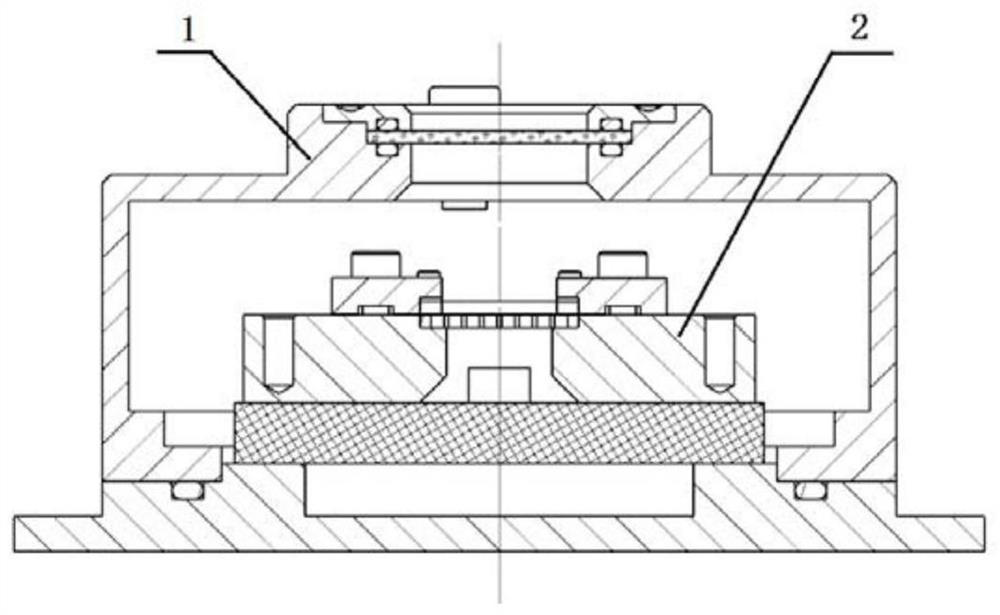

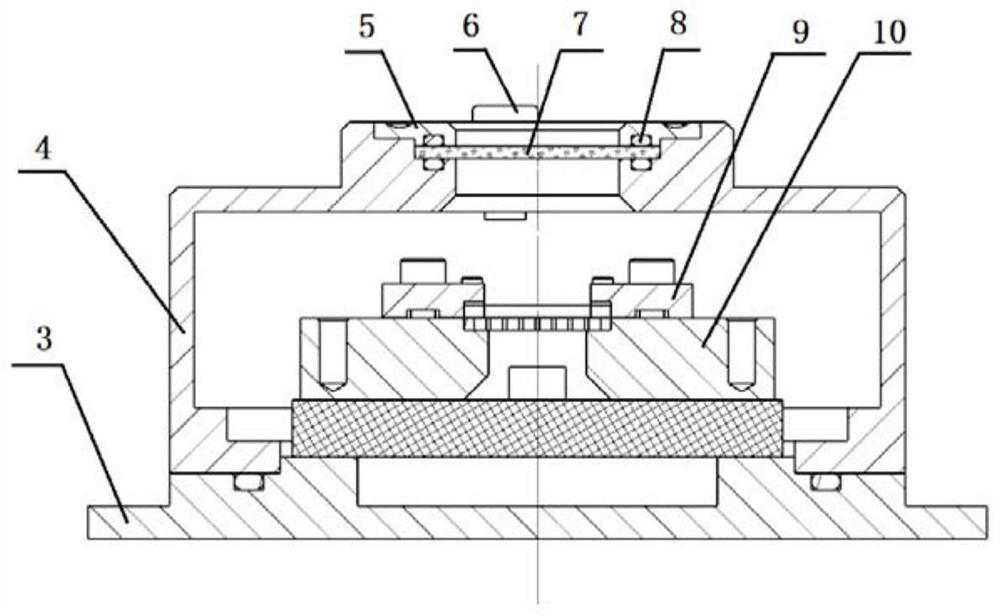

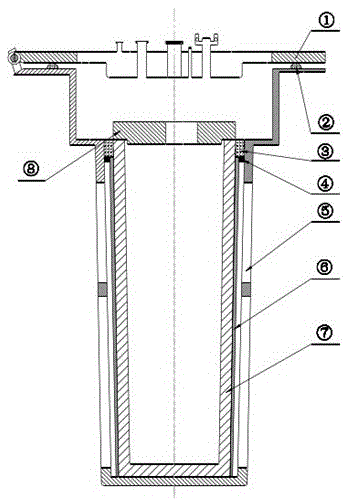

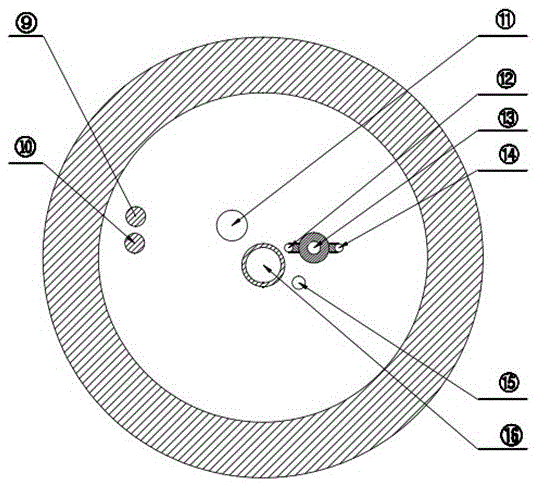

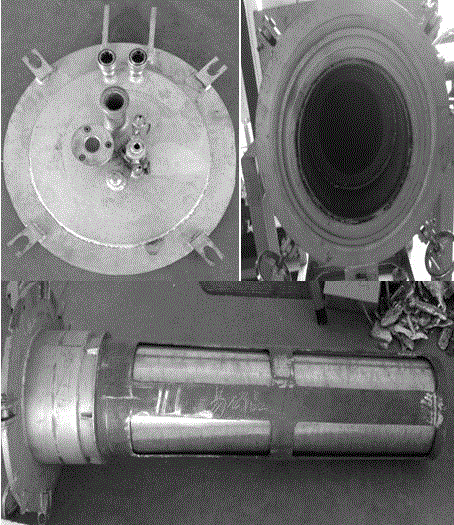

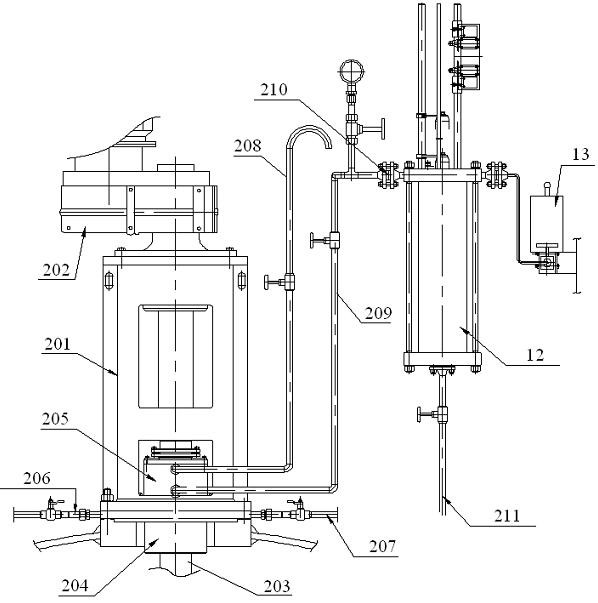

Simulation apparatus and method for researching permeability of coal rock

The present invention relates to a simulation apparatus and a method for researching the permeability of coal rock. The simulation apparatus comprises: a stress loading cavity; a sealing sleeve configured into a sealing cavity for arranging coal rock; a fluid container communicated to the sealing cavity; and a stress loading shaft arranged in the stress loading cavity and used for applying stress on the coal rock by extruding the sealing sleeve. According to the present invention, with the simulation apparatus, the condition close to the actual situation in the stratum during the research of the permeability of the coal rock can be achieved, and the influence of the matrix desorption shrinkage, the fracture closure and the combination of the matrix desorption shrinkage and the fracture closure on the permeability change under the stress anisotropy simulating condition during the discharging-extracting process can be respectively and quantitatively measured, such that the stimulated measurement of the coal rock directional permeability and the dynamic process of the coal rock directional permeability change along with the pore pressure reducing during the discharging-extracting process can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

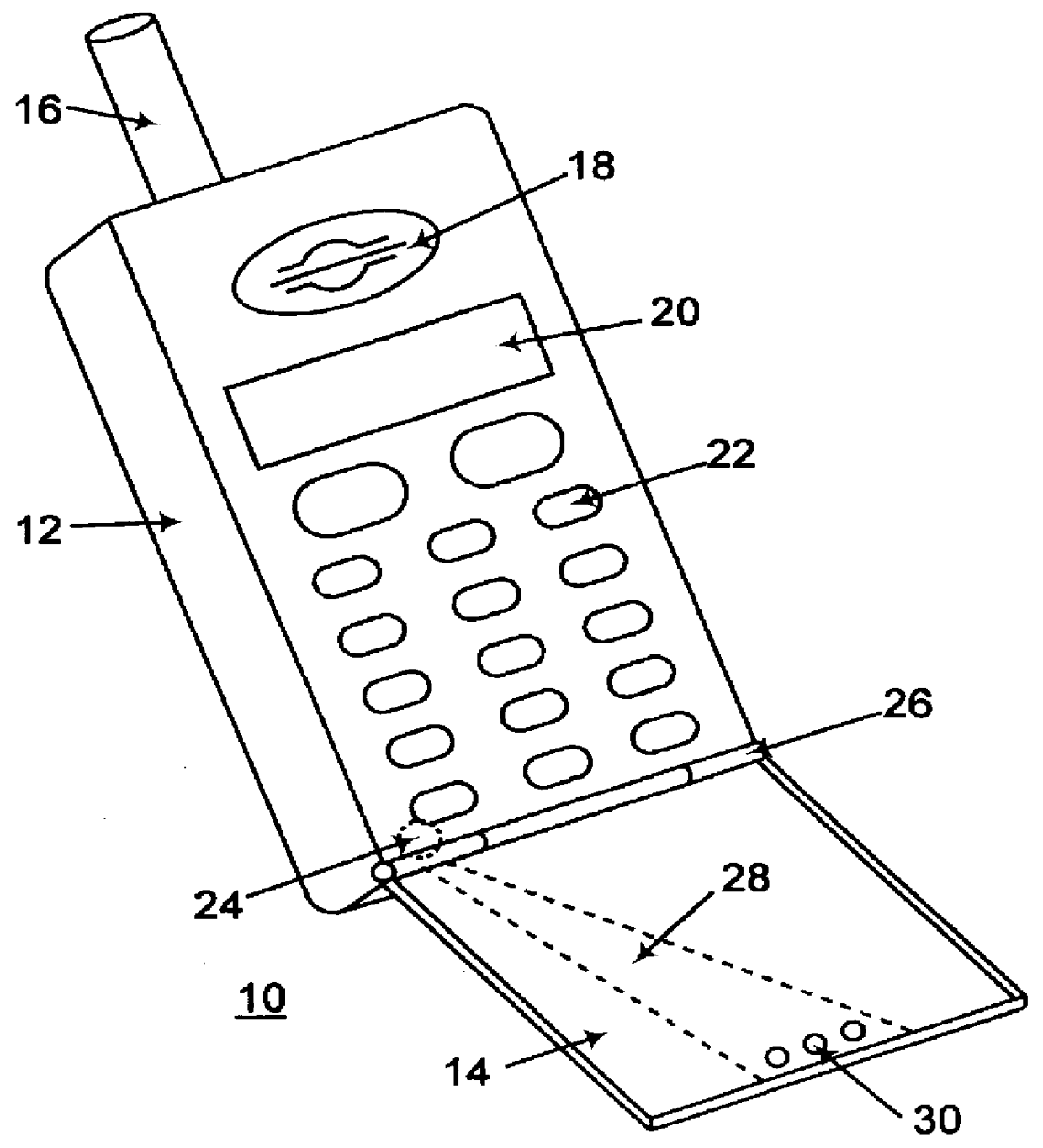

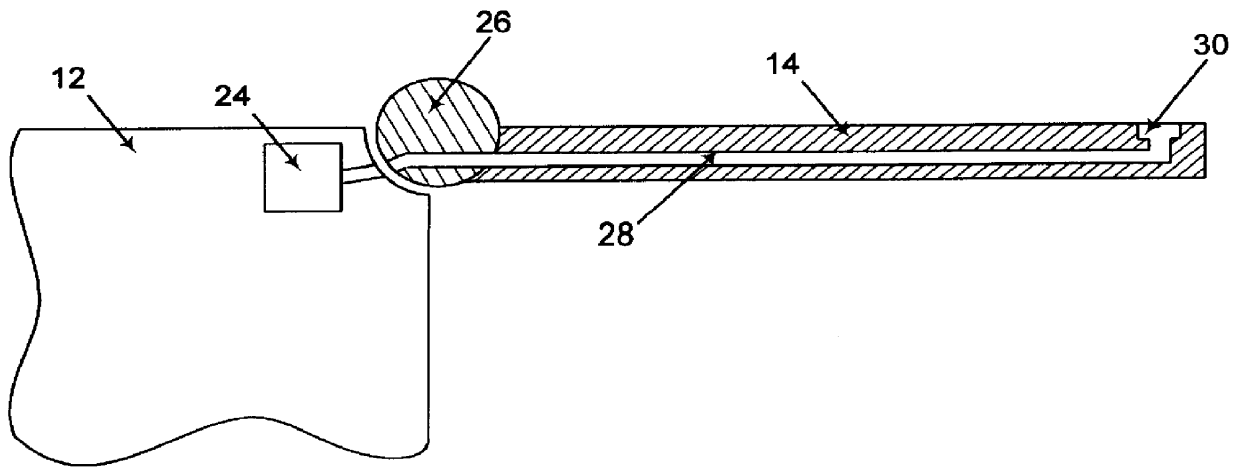

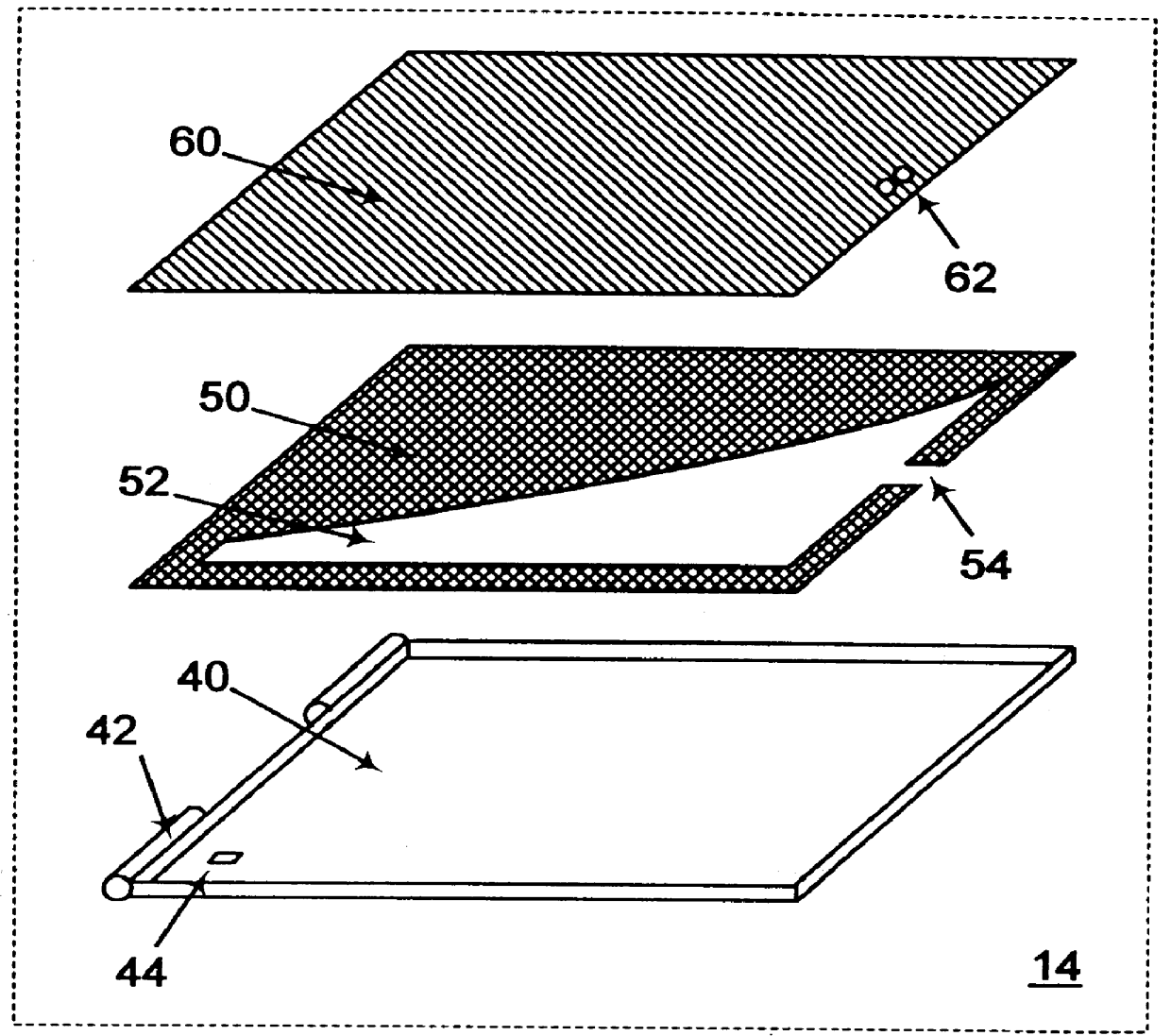

Portable speech communication apparatus with sound channel in swingable flip

InactiveUS6091964AReduce manufacturing costGood sealing environmentInterconnection arrangementsRadio/inductive link selection arrangementsEngineeringSpeech sound

A portable speech communication apparatus, preferably a radio telephone, has a flip (14) which is swingable from the apparatus (10). A sound channel is arranged in the flip for guiding sound from at least one speech opening (54, 62) in the flip to a microphone (24) located in the apparatus. The sound channel is formed as a recess (52) in a plate means (50, 60), which is arranged on an essentially even inside (40) of the flip (14).

Owner:BLACKBERRY LTD

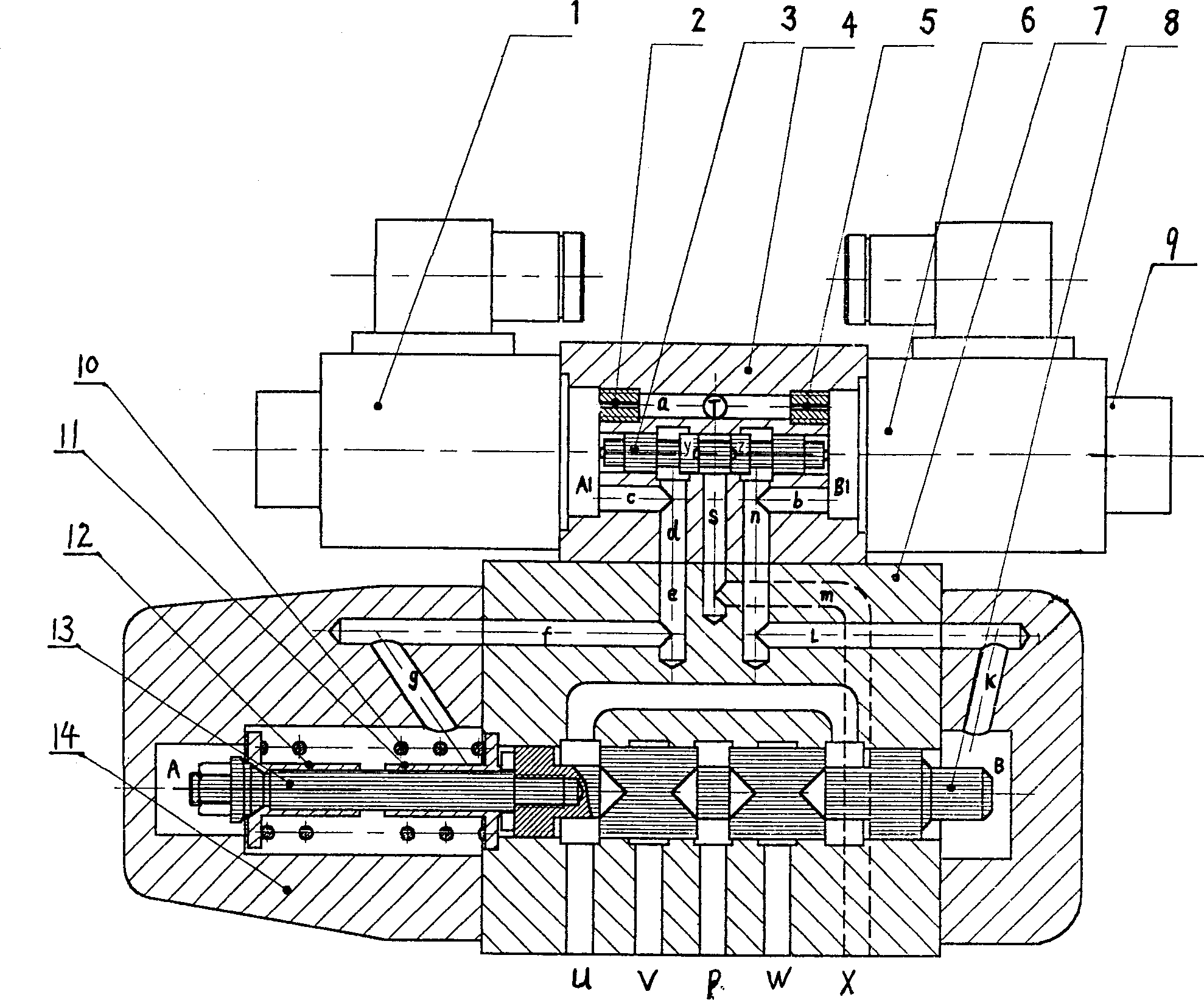

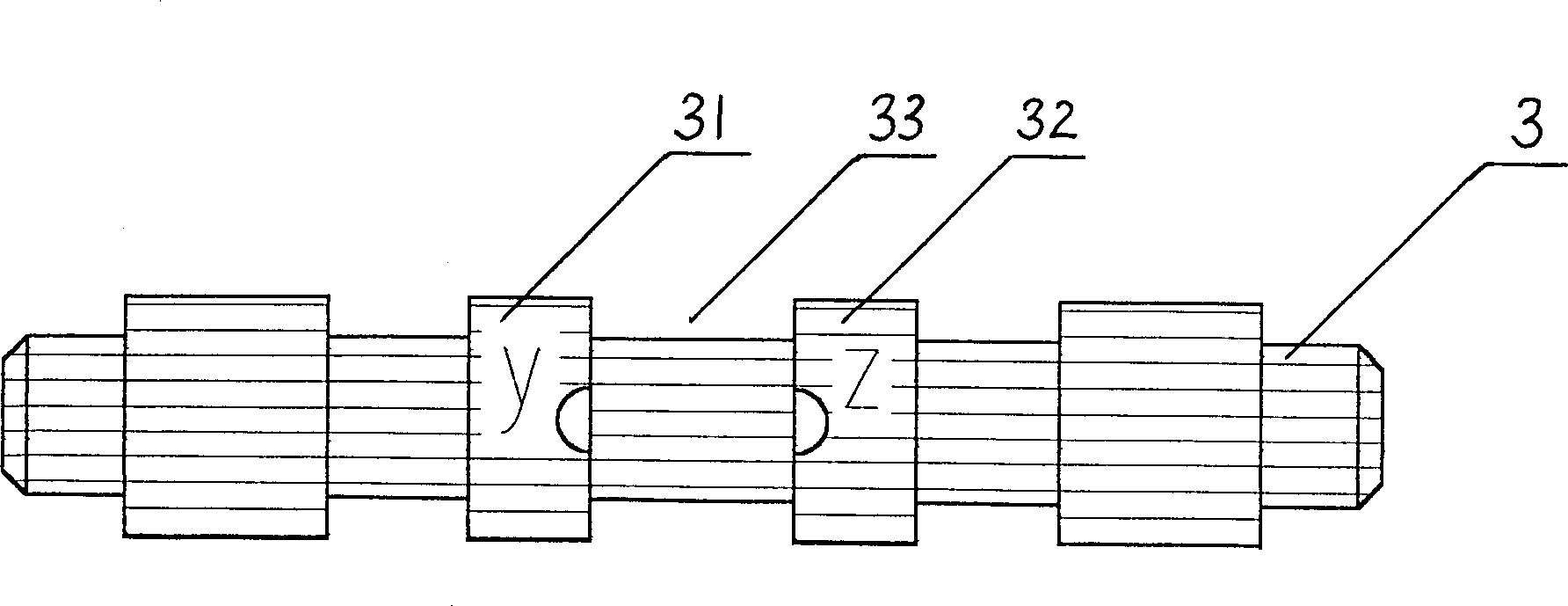

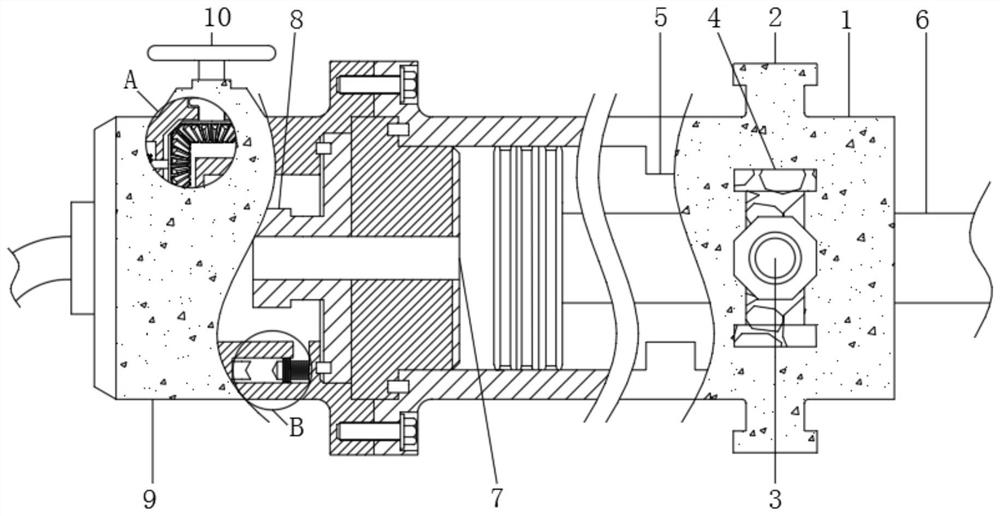

Proportional direction valve

InactiveCN1447032AImprove the sealing environmentReduced sealing requirementsServomotor componentsMagnetControl channel

This invention discloses a proportional direction valve including a pilot valve and a main valve in which, the pilot valve includes right and left proportional magnet, a valve and a core in the valve, the main valve constitutes a main valve and a core in it characterizing in that a lateral oil channel is designed in the said pilot valve with right / left proportional electromagnetic pin-lift oil recess at both sides, a spill port at the channel midle, damping screws are set at the port of the recess. A control oil port of the main valve is connected with the control channel at the middle of thepilot valve via the oil channel, and stops at two ring under cut slots and flow-save windows are designed on two shoulders of the pilow valve.

Owner:NINGBO HOYEA MACHINERY MFG

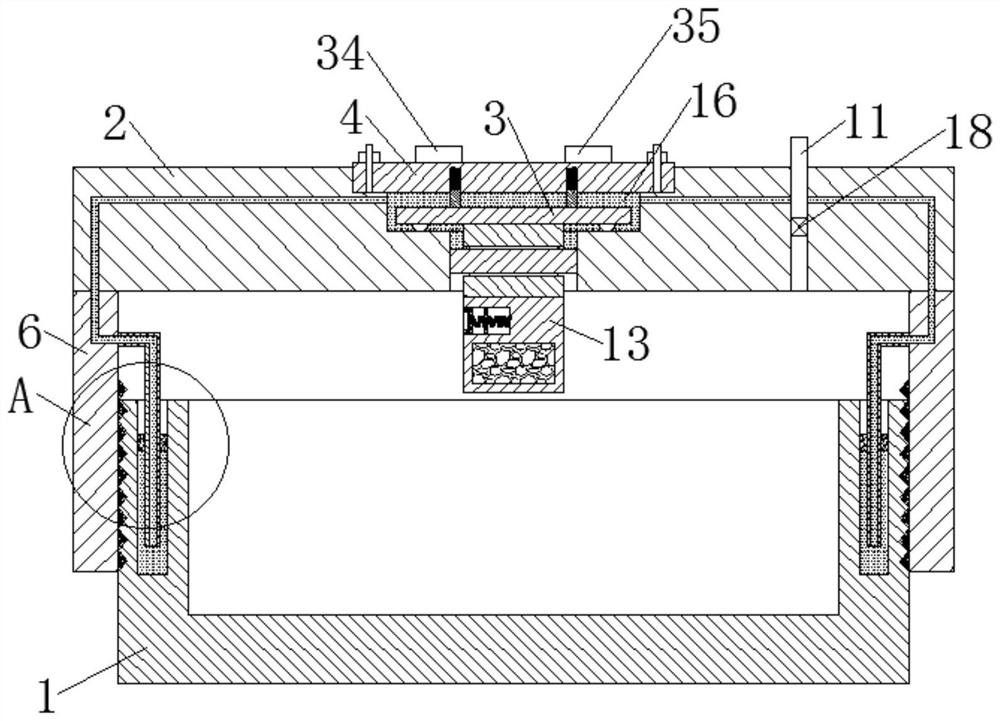

Deep-sea non-contact electric power transmission packaging structure

InactiveCN102364818AGood sealing environmentEasy to operateElectromagnetic wave systemTransformersElectric power transmissionState of art

The invention discloses a deep-sea non-contact electric power transmission packaging structure. By using the prior art, a deep-sea severe environment can not be coped with and robot operation can not be performed conveniently under the sea. The packaging structure of the invention comprises: a primary coupling joint and a secondary coupling joint. The primary coupling joint is designed with a magnetic core cavity, a control cavity and a card hook groove. The secondary coupling joint is designed with the magnetic core cavity, the control cavity, a guide plate and a card hook mechanism. Primary and secondary docking mechanisms are arranged out of the two joints. After the primary coupling joint and the secondary coupling joint form a coaxial docking, magnetic cores in the two left and right magnetic core cavities of contact surfaces are correctly coupled with each other and electric power is transmitted. After the transmission ends, the docking mechanisms break. In the invention, a reasonable sealing structure is designed. A waterproof connector is connected with an underwater cable. The deep-sea extreme environment, such as a high pressure and strong corrosion can be coped with. The structure is stable and reliable. The internal system is not easy to be influenced by seawater disturbance. A plugging form is simple. The underwater robot is very suitable for the docking operation. A service life is long.

Owner:ZHEJIANG UNIV

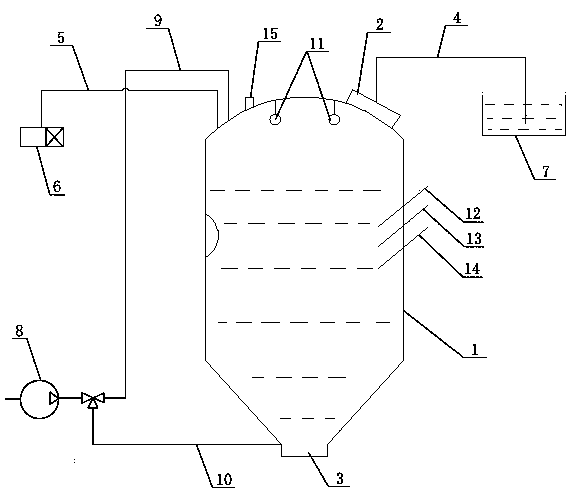

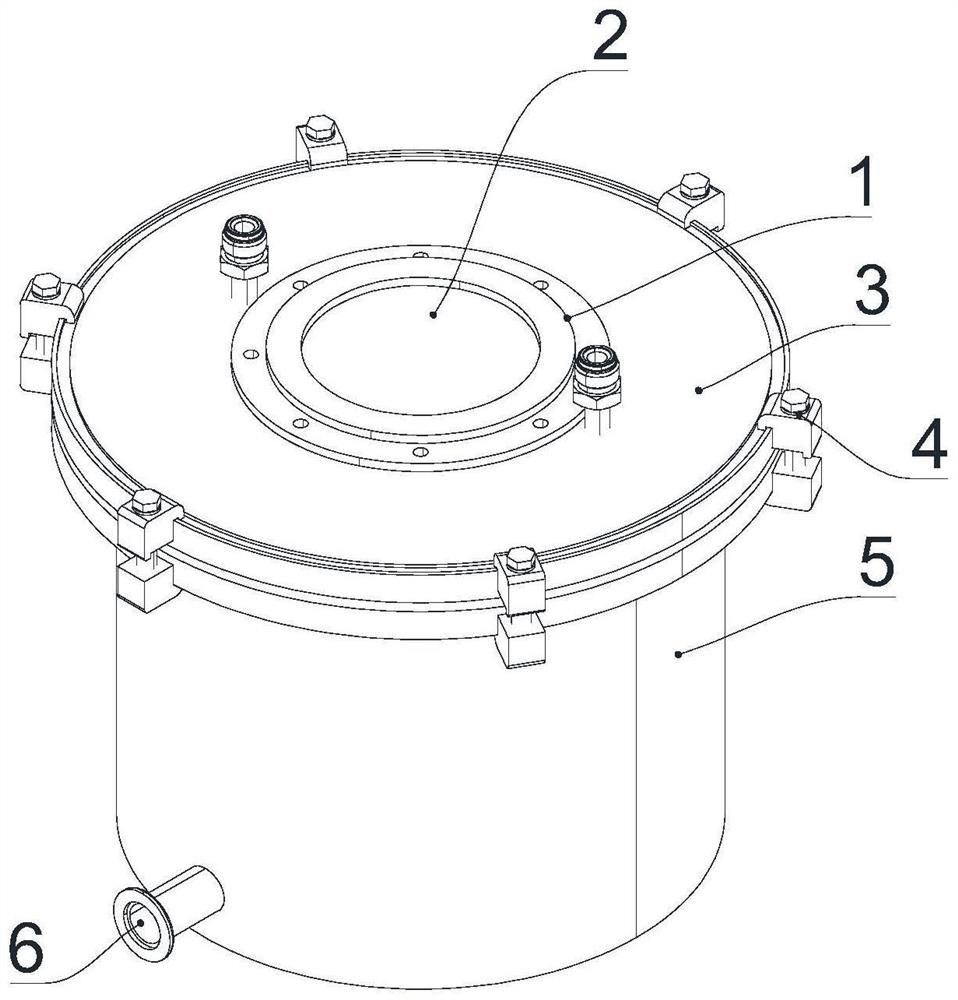

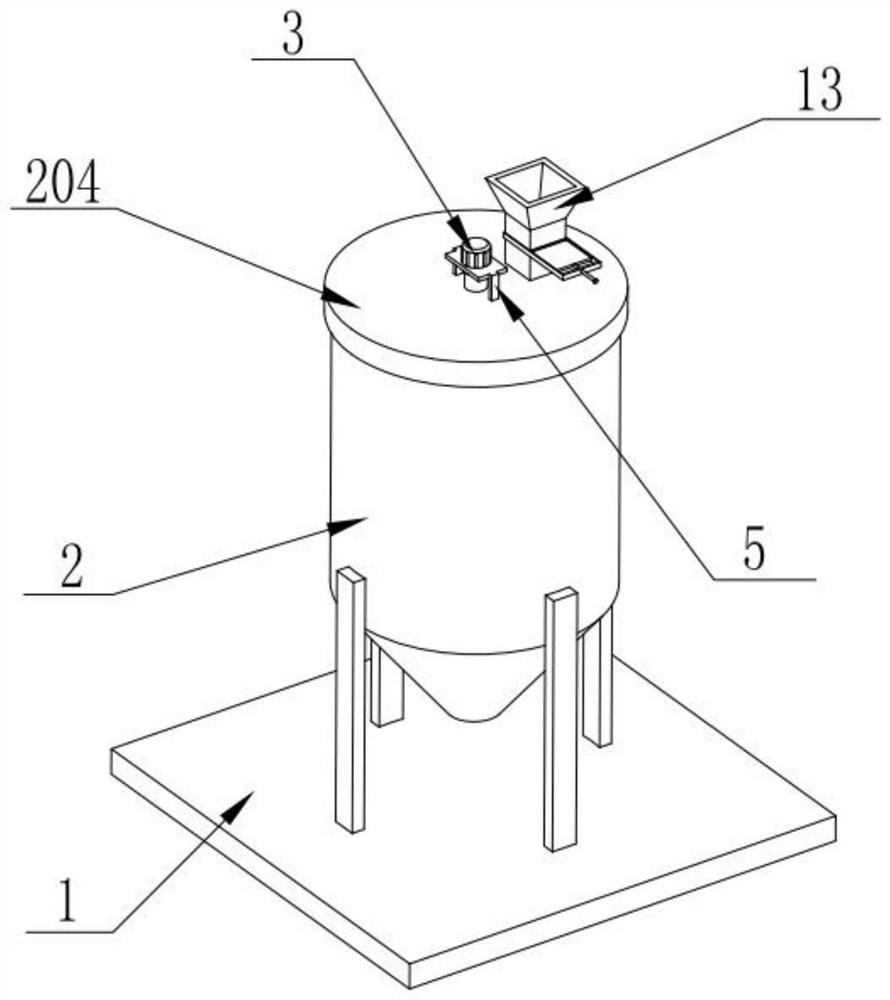

Pickled vegetable fermentation device and automatic feed and discharge process of the pickled vegetable fermentation device

InactiveCN104187511AGood sealing environmentQuick and automatic entry and exitLiquid transferring devicesBulk conveyorsPositive pressurePulp and paper industry

The invention discloses a pickled vegetable fermentation device and an automatic feed and discharge process of the the pickled vegetable fermentation device. The pickled vegetable fermentation device comprises a fermentation tank body, wherein a material inlet is formed in the upper part of the fermentation tank body, a material outlet is formed in the bottom of the fermentation tank body, the fermentation tank body is connected with an automatic feed mechanism and an automatic discharge mechanism respectively, the automatic feed mechanism comprises a feed pipe, an exhaust pipe and a vacuum pump, one end of the feed pipe is communicated with a material storage tank, the other end of the feed pipe is communicated with the material inlet, one end of the exhaust pipe is communicated with a closed space above material liquid level in the fermentation tank body, the other end of the exhaust pipe is communicated with an air inlet of the vacuum pump, the automatic discharge mechanism comprises an air compressor and an air inlet pipe, one end of the air inlet pipe is communicated with an air outlet of the air compressor, and the other end of the air inlet pipe is communicated with the closed space above the material liquid level in the fermentation tank body. The pickled vegetable fermentation device disclosed by the invention can fast and automatically feed and discharge materials in the fermentation tank body by adopting a way of feeding under negative pressure and discharging under positive pressure, so that the labor intensity is greatly reduced and the large-scale and industrial production of pickled vegetables is realized.

Owner:吉香居食品股份有限公司 +2

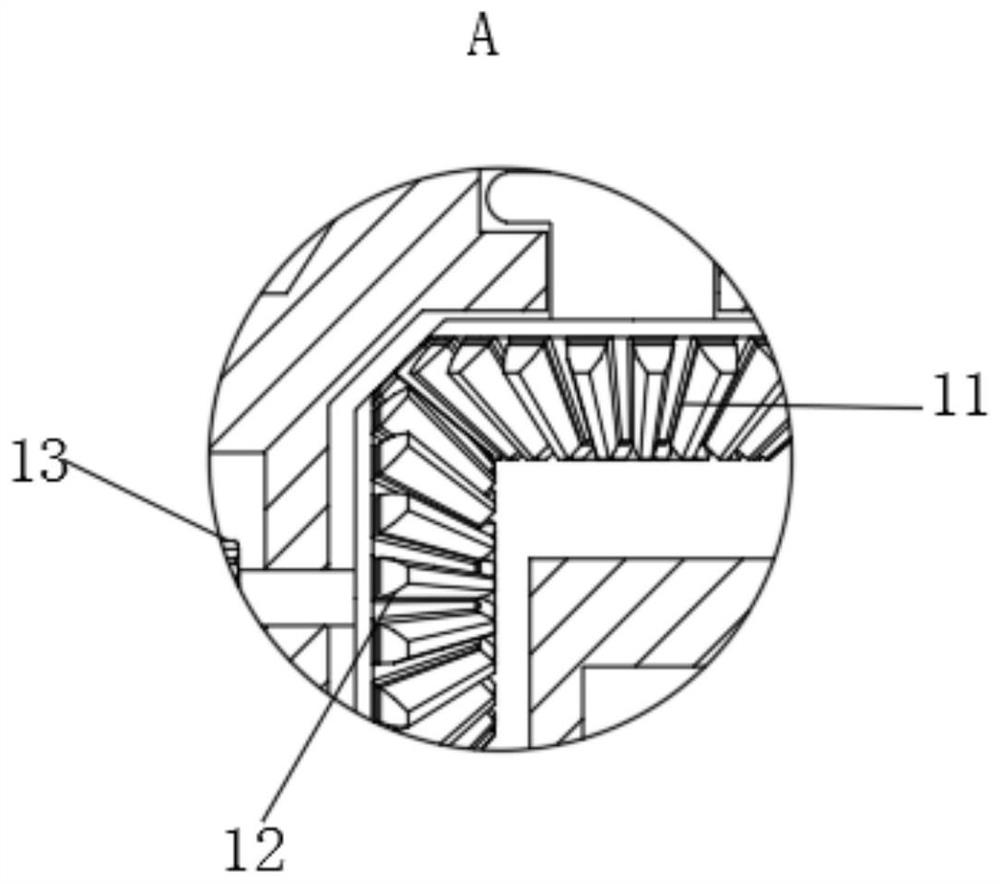

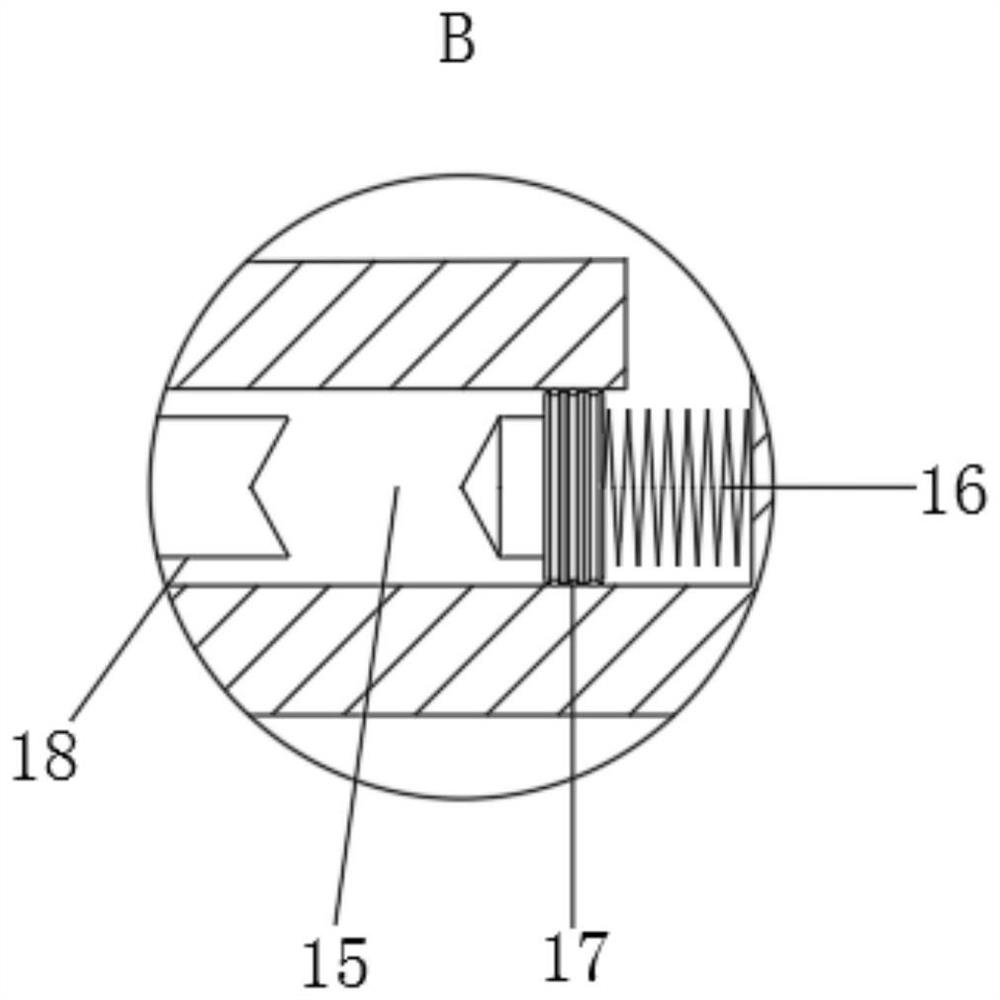

Ultrahigh-voltage direct-current sleeve joint

ActiveCN104505784AIncrease contactSolve electric field distortionElectrical apparatusTime costDirect current

The invention provides an ultrahigh-voltage direct-current sleeve joint. The ultrahigh-voltage direct-current sleeve joint comprises a conducting pipe as well as an epoxy pipe and a supporting cover plate which are arranged coaxially relative to the conducting pipe, wherein the supporting cover plate is provided with a through hole which is vertical to the axial direction of the supporting cover plate and coaxial with the conducting pipe and the epoxy pipe; the conducting pipe passes through the through hole and is connected with a top cover plate; a part, surrounded between the supporting cover plate and the top cover plate, of the conducting pipe is provided with a corrugated pipe which is positioned at the upper end of the supporting cover plate and connected with the supporting cover plate and the top cover plate. Compared with the prior art, the ultrahigh-voltage direct-current sleeve joint disclosed by the invention has the advantages of solving the problem of extension and contraction of the conducting pipe by enabling the corrugated pipe to extend and contract correspondingly along with the extension and contraction of the conducting pipe, solving the problem of metal friction caused by hard connection between parts, improving the sealing reliability, guaranteeing good leakproofness of a sleeve chamber body, improving the problem of easy loosening caused by own gravity of the parts, simplifying the installation process of the conducing pipe and lowering the time cost.

Owner:STATE GRID CORP OF CHINA +1

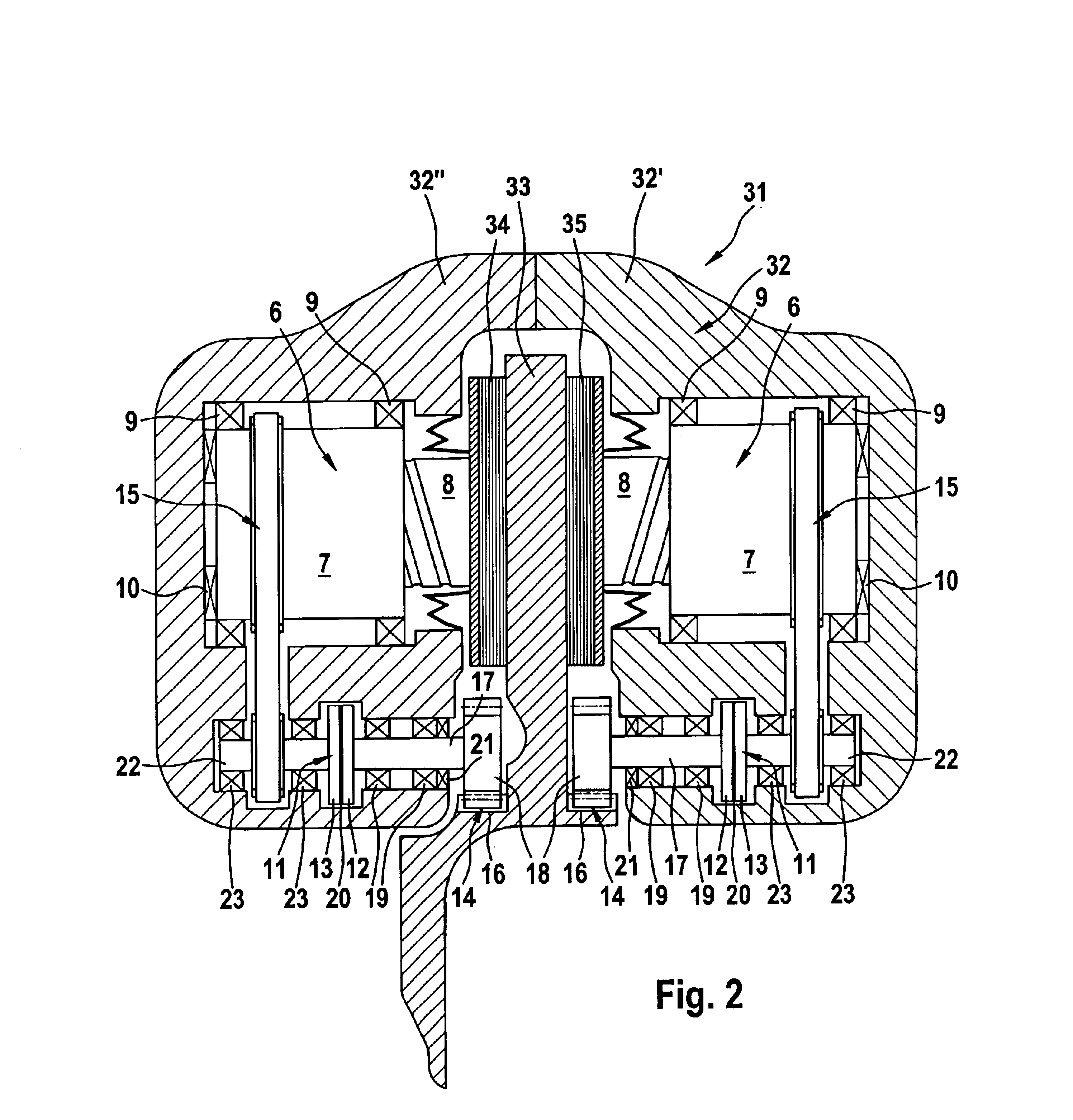

Friction brake

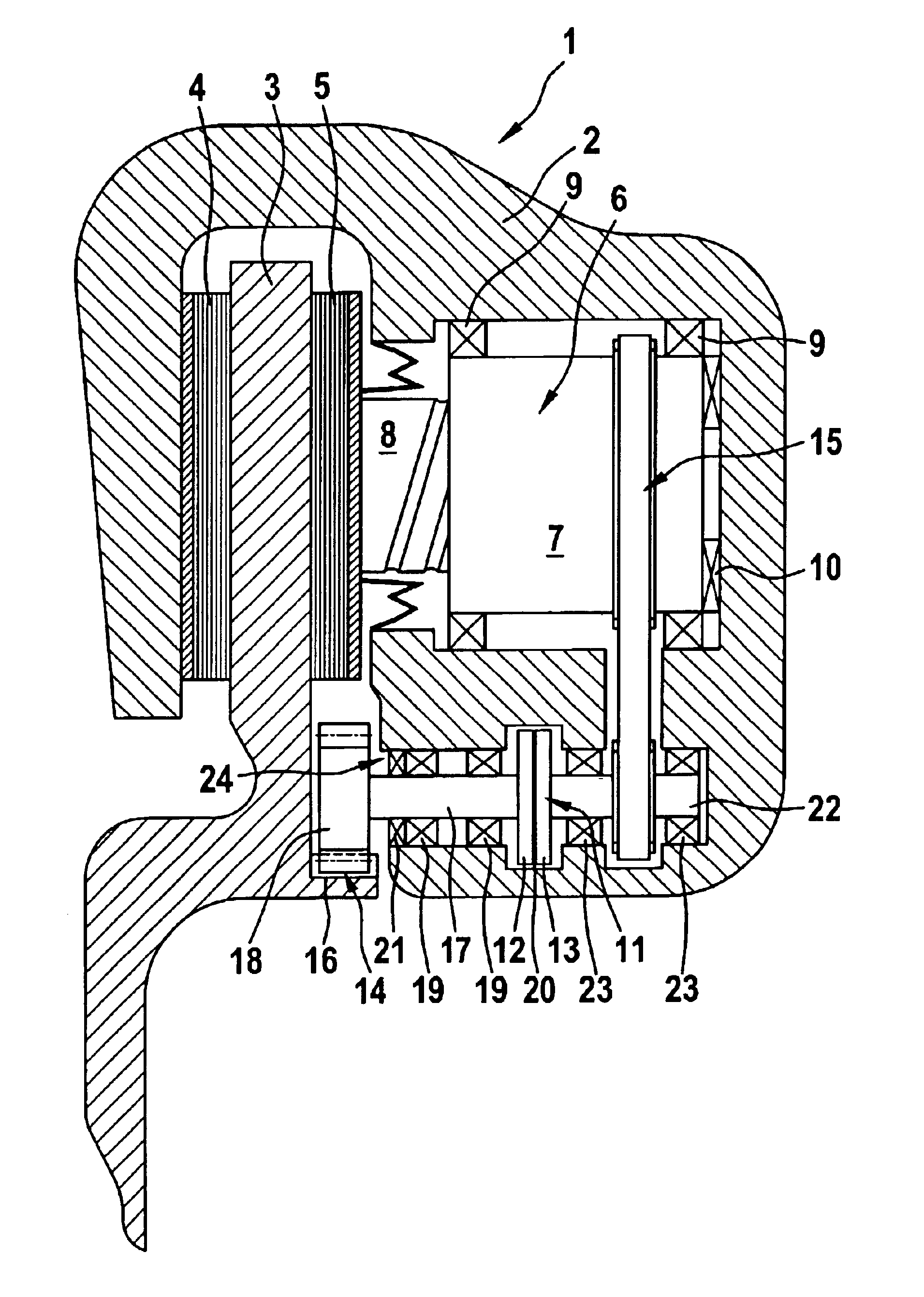

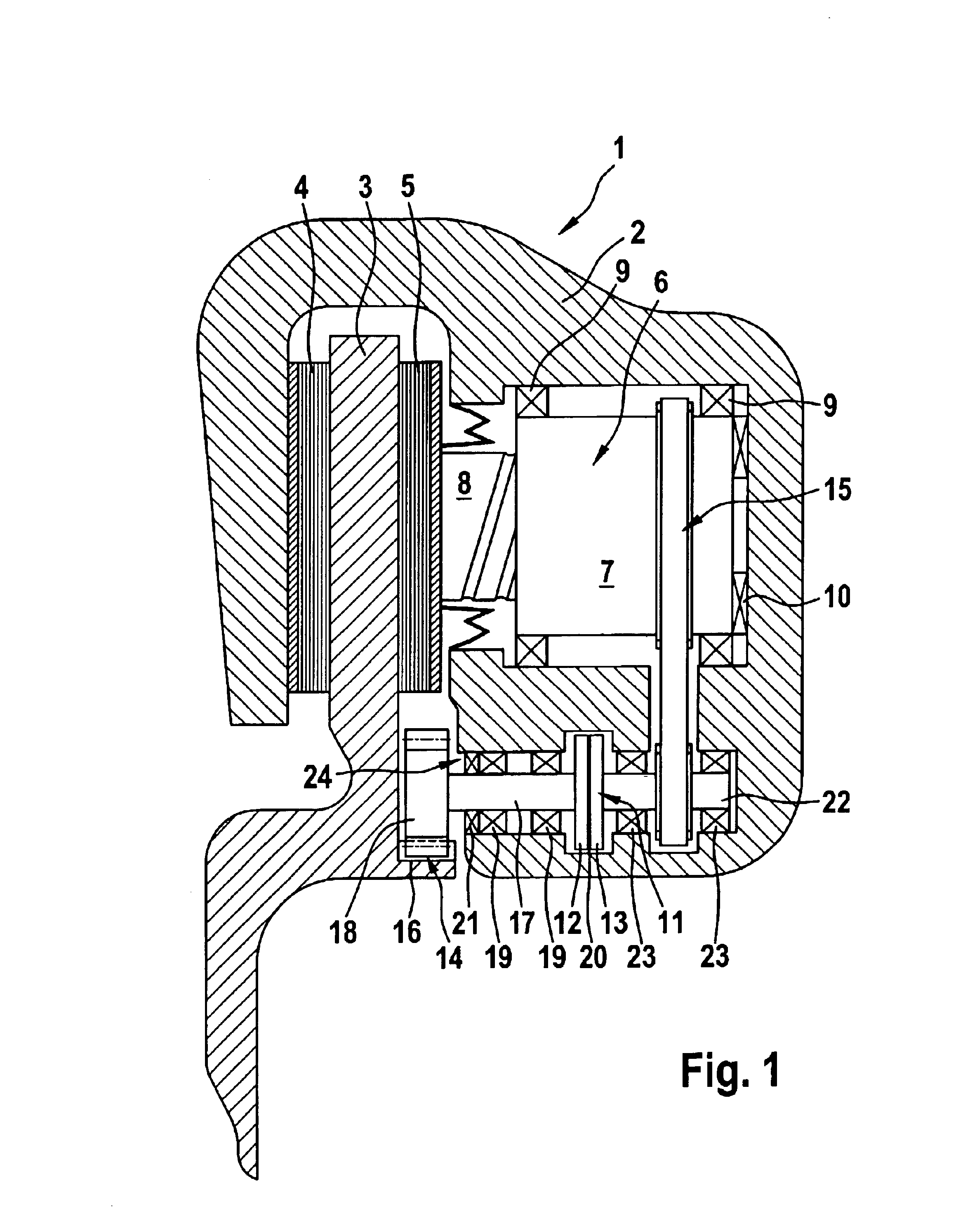

InactiveUS6923295B2Function increaseGood sealing environmentMechanically actuated brakesBrake actuating mechanismsMobile vehicleEngineering

The present invention relates to a friction brake, in particular a disc brake, for a motor vehicle with a friction element, e.g. a brake disc, coupled to the rotation of a vehicle wheel, forming a friction pairing of the friction brake with at least one associated brake lining, and with at least one clamping device for pressing at least one brake lining to the friction element. At least one controllable friction clutch is provided for using the rotational energy of the friction element in order to obtain the clamping force of the friction brake, the friction clutch being coupled on its input end to the rotation of the friction element and on its output end to the clamping device. Functional advantages are achieved because a friction pairing of the friction clutch is provided independently of the friction pairing of the friction brake. This eliminates undesired mutual influences. Altogether, such a friction brake obviates the need for an additional energy source for generating a brake clamping force.

Owner:CONTINENTAL TEVES AG & CO OHG

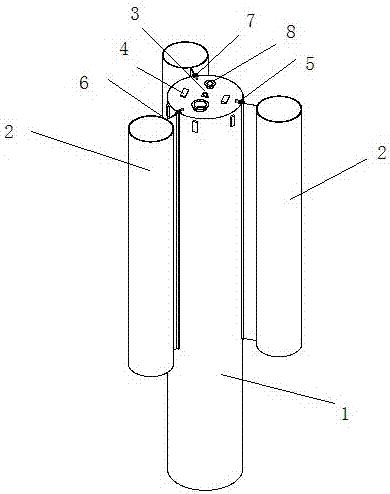

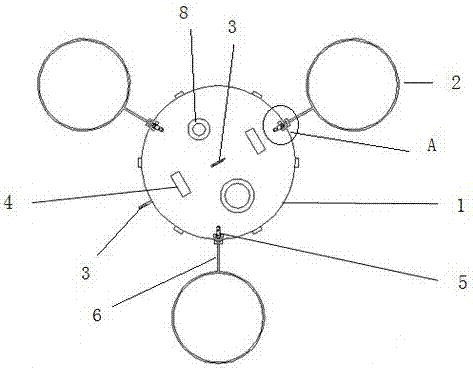

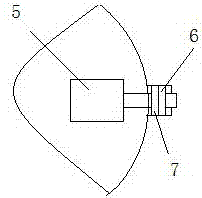

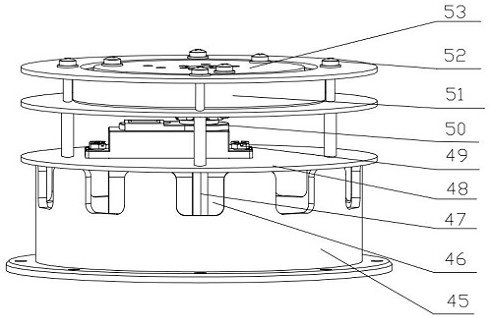

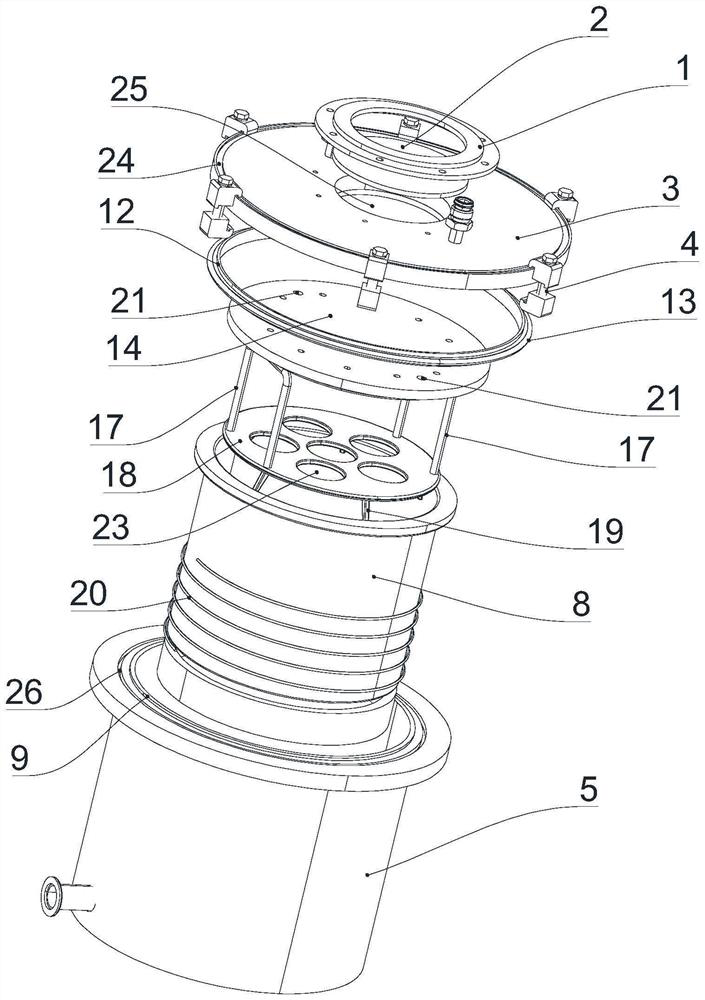

Detachable multiple cylinder base large bearing capacity suction foundation device

InactiveCN106930317AIncrease initial gravity penetration depthExpand the area of actionArtificial islandsUnderwater structuresSuction stressPenetration depth

The invention discloses a detachable multiple cylinder base large bearing capacity suction foundation device comprising a main anchoring cylinder and wing cylinders. The main anchoring cylinder comprises the cylinder wall, a pumping hole, a hoisting block, anode blocks used for preventing corrosion, T-shaped sliding ways and locking devices. The T-shaped sliding ways are arranged on the outer side of the wall of the main anchoring cylinder; first fixing holes are formed in the tops of the T-shaped sliding ways; sliding rails matched with the T-shaped sliding ways are arranged on the wing cylinders; and the main anchoring cylinder and the wing cylinders are connected through the T-shaped sliding ways arranged on the outer side of the main anchoring cylinder and the sliding rails arranged on the outer sides of the wing cylinders in a matched mode. According to the detachable large bearing capacity suction foundation device, compared with the prior art, through the composite design of the main anchoring cylinder and the wing cylinders, the anchoring soil action area is increased under the situation that the penetration depth is not changed basically, and the actual action area of the suction foundation is effectively increased, so that the bearing and anchoring properties of the suction foundation are improved. After the anchoring target is finished, the main anchoring cylinder and the lateral wing cylinders can be disassembled, and the main anchoring cylinder with high price is recycled to achieve recycling of a suction anchor.

Owner:SHANDONG KERUI PUMP

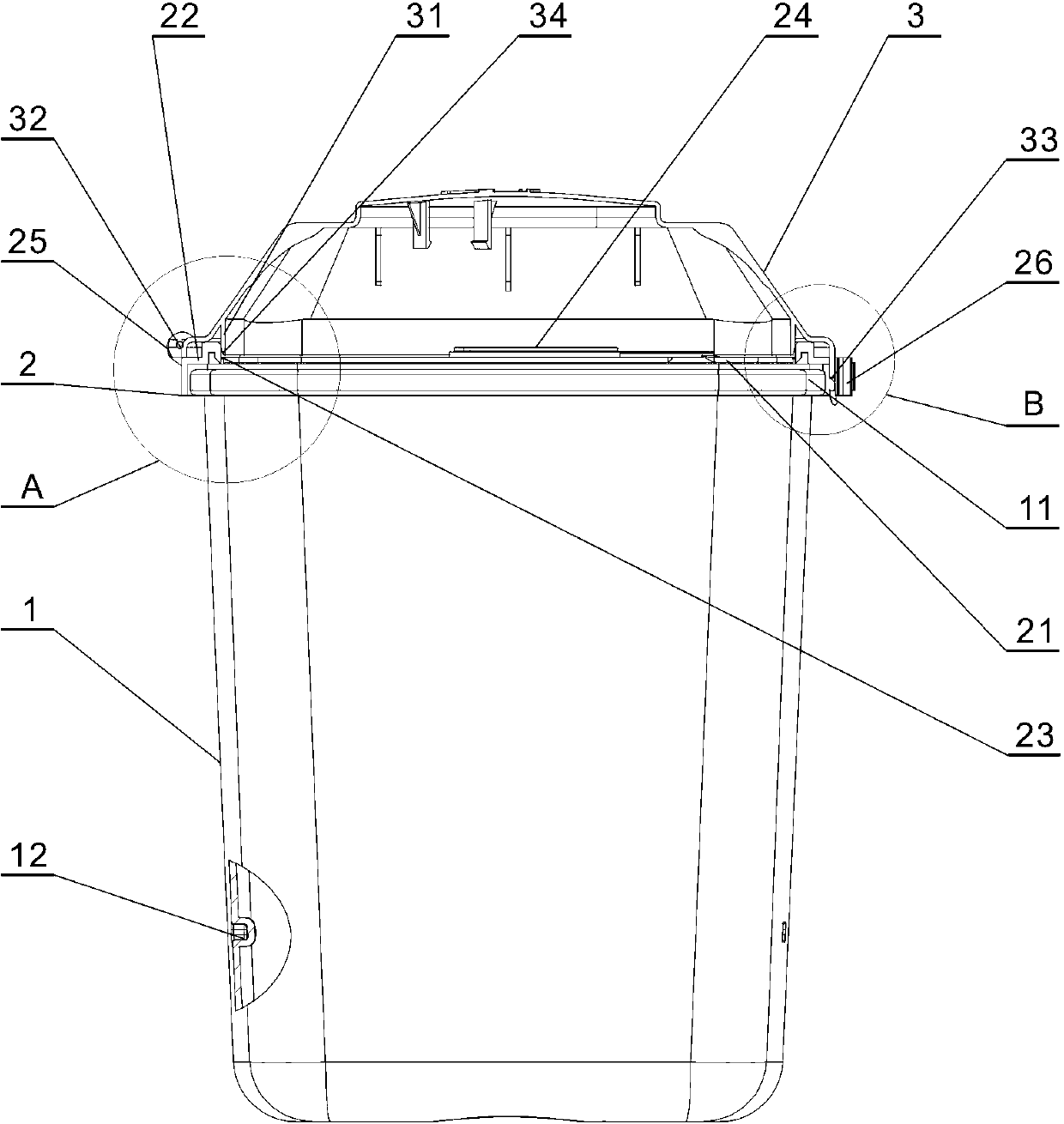

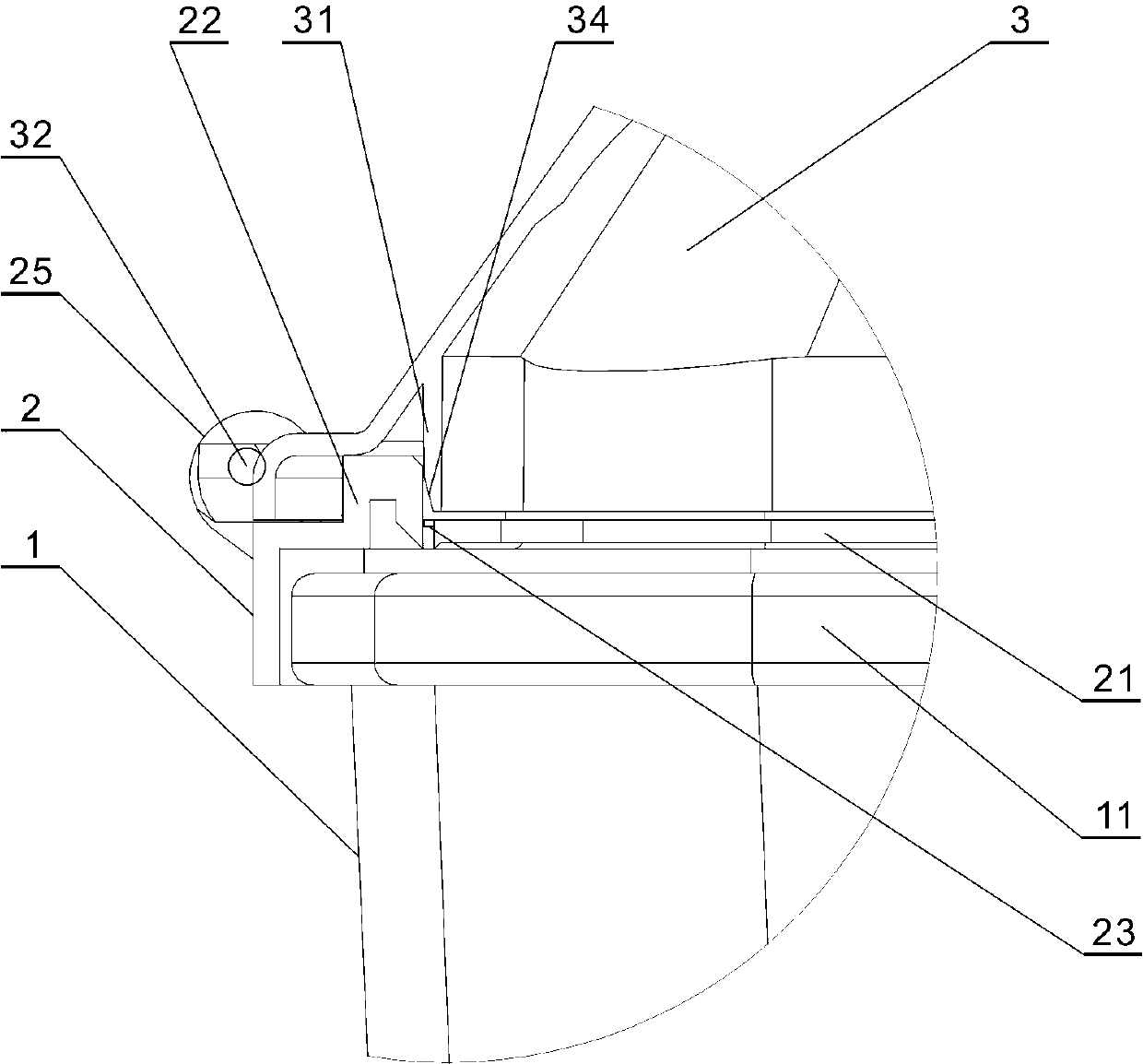

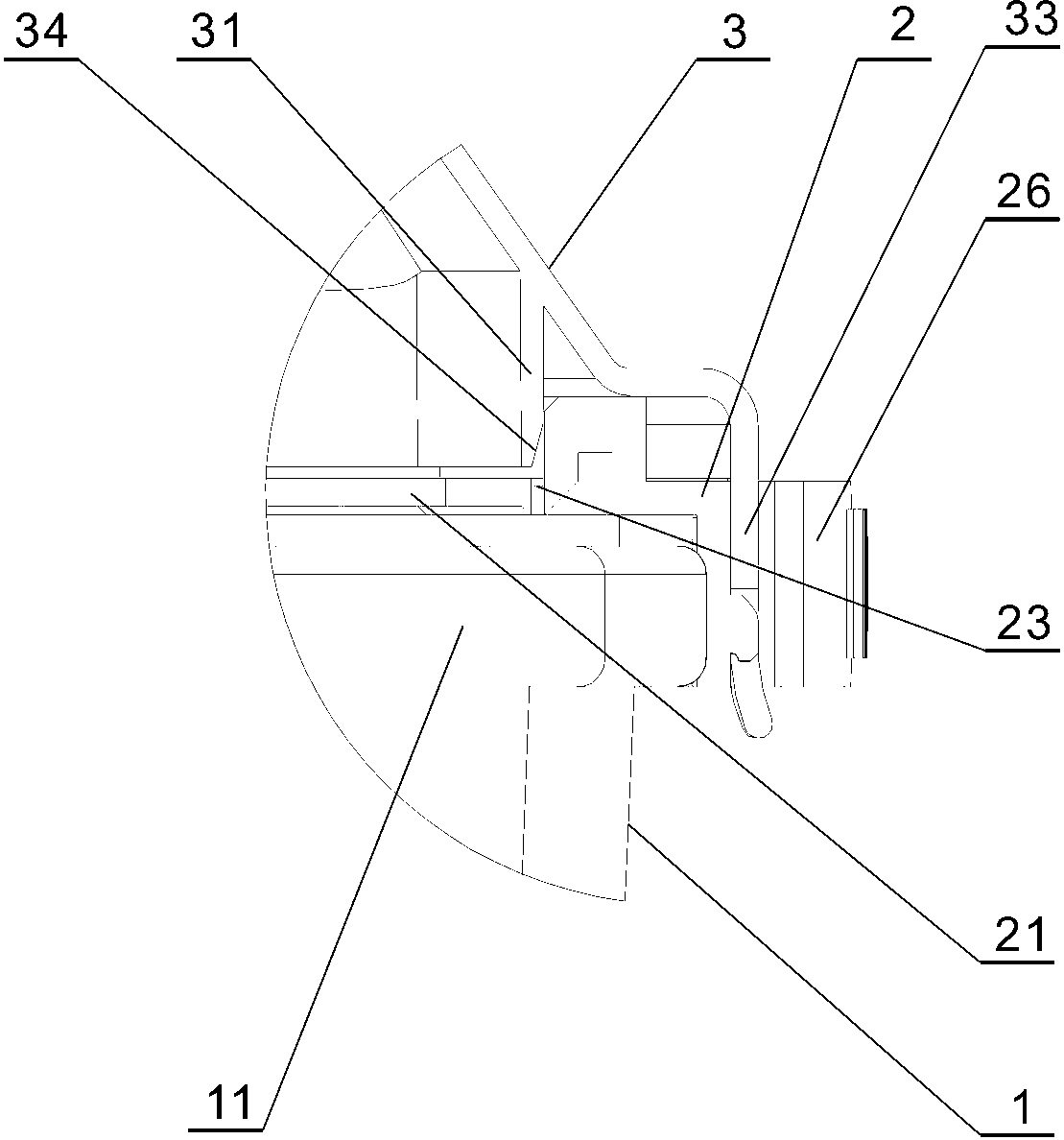

Square food packaging tin

The invention discloses a square food packaging tin which comprises a tin body, an inner cover and an outer cover, wherein a turned edge and protrusions are arranged on an upper opening of the tin body, a shaft seat and a lock catch are arranged on the inner cover, a hinged shaft and a tearing buckle are arranged on the outer cover, the inner cover is buckled on the outer side of the turned edge of the tin body, the outer cover is buckled on the inner cover, the hinged shaft of the outer cover is hinged to the shaft seat of the inner cover, and the tearing buckle of the outer cover is connected with the lock catch of the inner cover in a buckled mode. The structure including the tin body, the inner cover and the outer cover is adopted, the tin body is open in the production procedure so that filling can be conveniently and rapidly conducted, the inner cover is pressed so that the food can be conveniently sealed, the outer cover and the tin body are not separated after the inner cover is opened so that the outer cover can be conveniently and repeatedly opened through the hinged shaft in the using process and a good sealing environment can be kept for food, and the square food packaging tin has the advantages of being simple in structure and convenient to use.

Owner:SHANGHAI JND PLASTIC PRODS

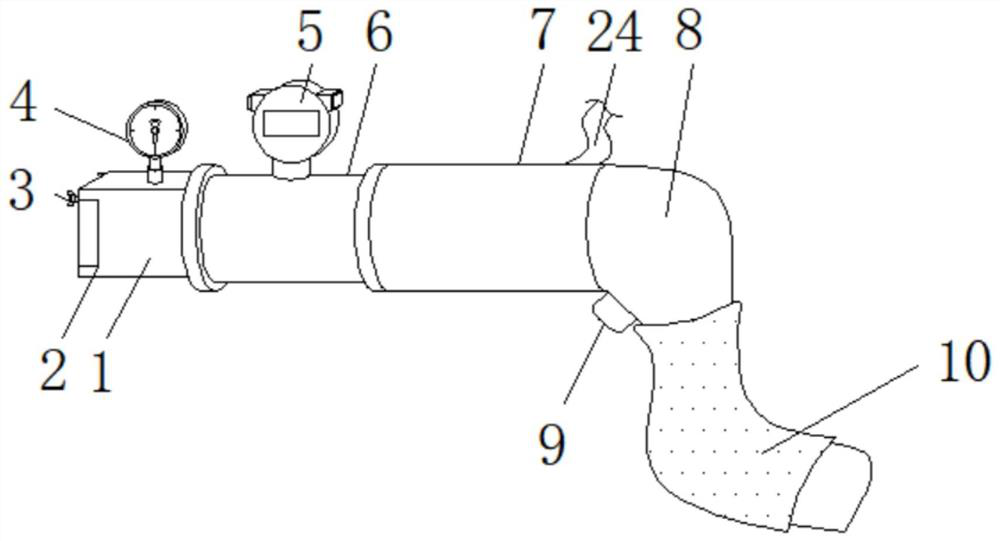

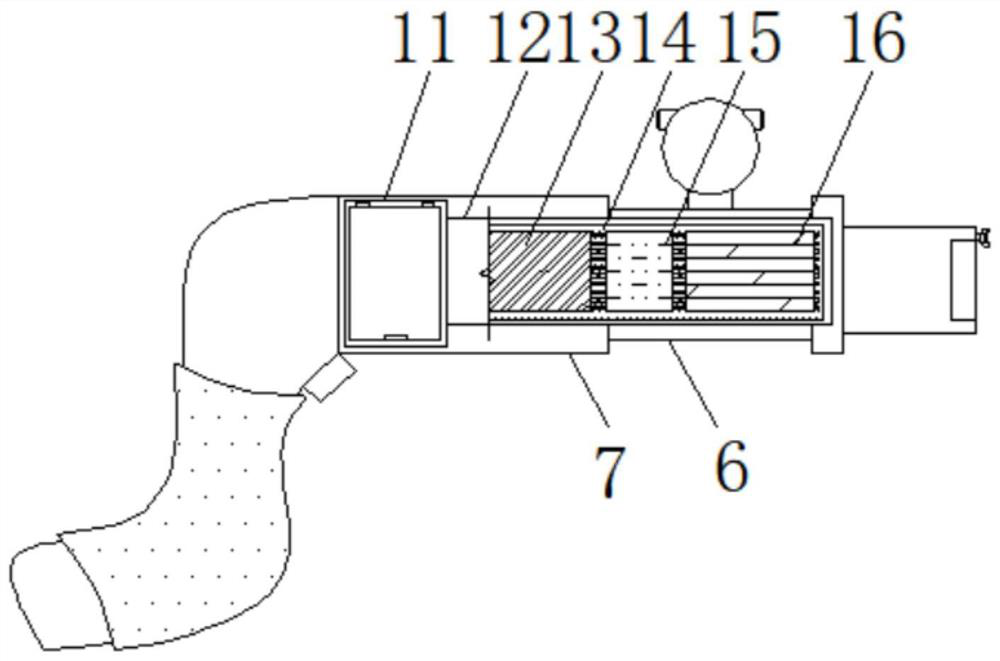

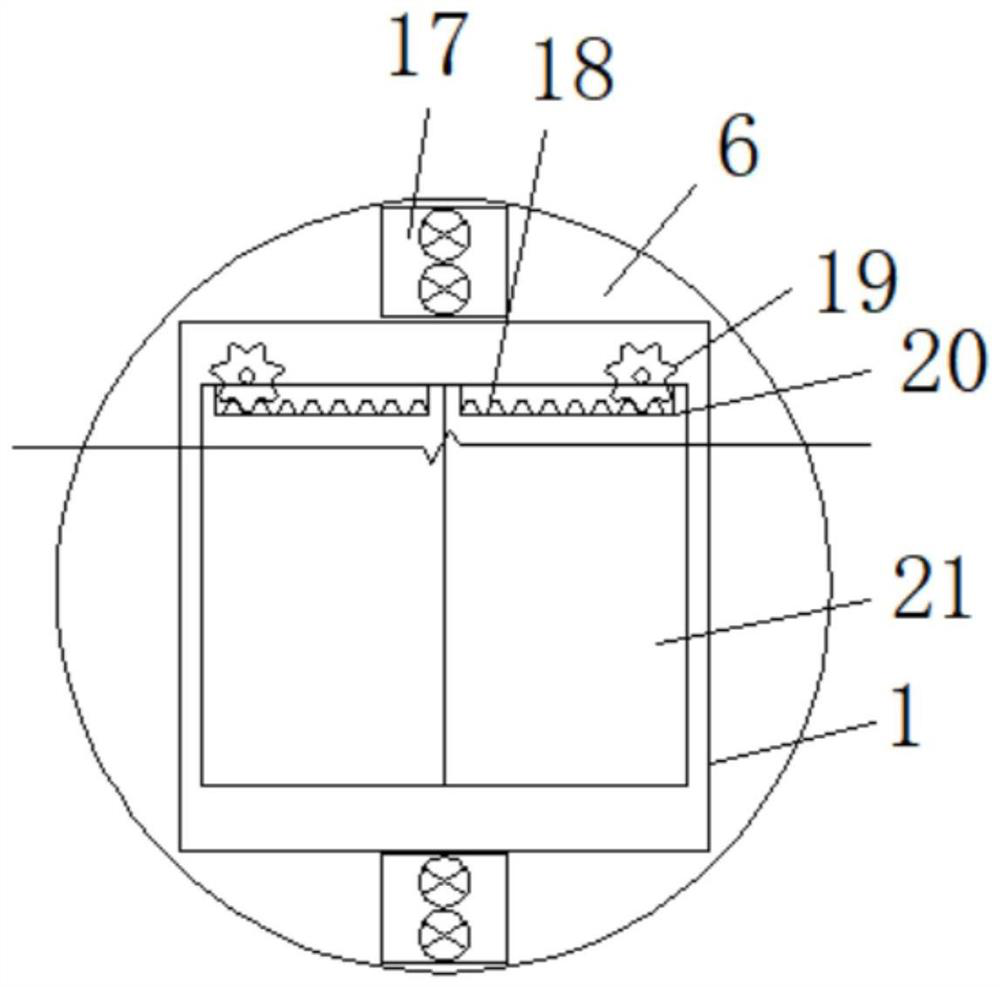

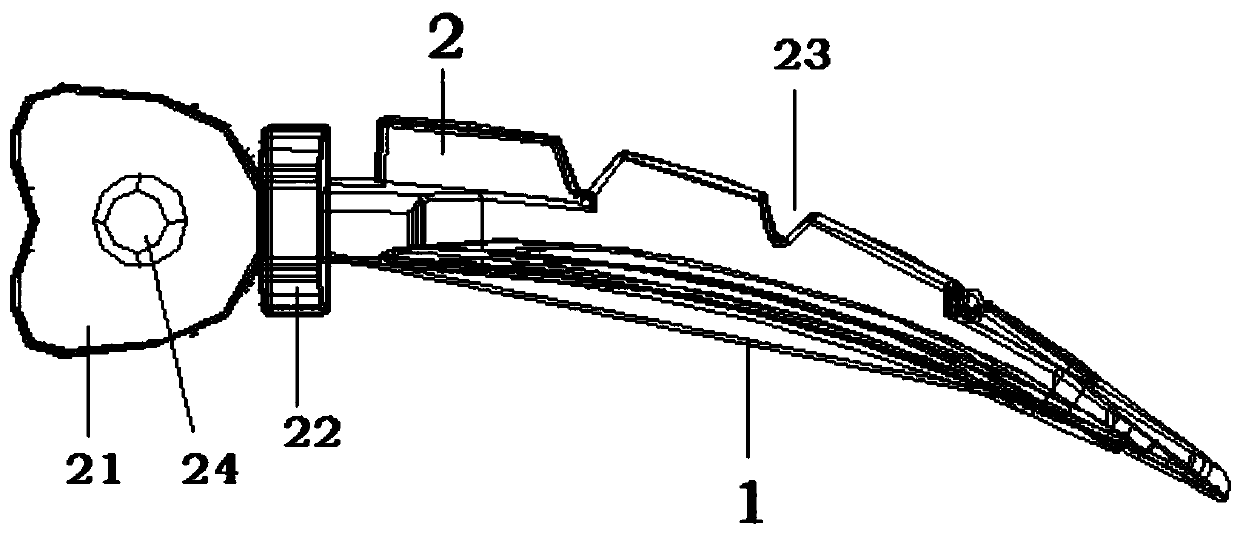

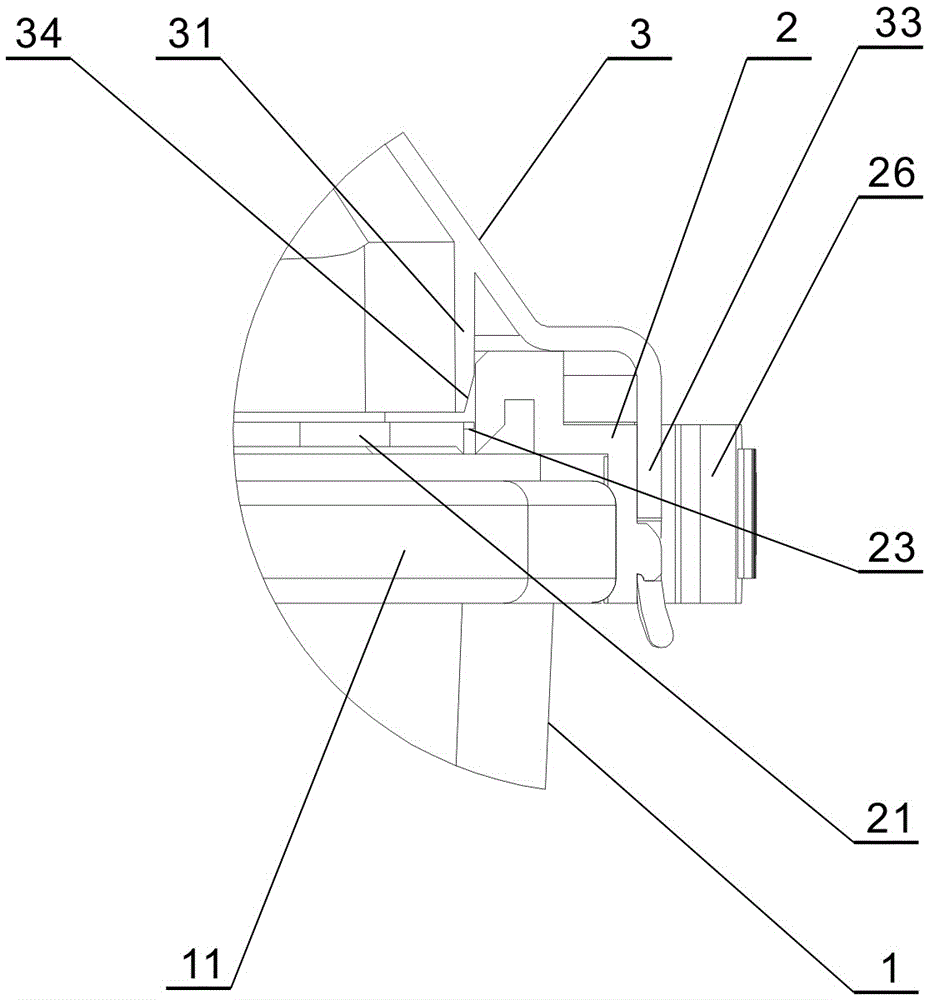

Intelligent spray gun for spraying

InactiveCN111822174ARealize intelligent controlChange sizeLiquid spraying apparatusEngineeringStructural engineering

The invention discloses an intelligent spray gun for spraying, and relates to the technical field of paint spraying assemblies. The intelligent spray gun for spraying comprises a spray gun nozzle, a connecting pipe, a main pipe, a handle, a rear shell, a distance sensor and transmission teeth, wherein the main pipe is fixedly mounted at one end of the handle, the connecting pipe is fixedly mountedat one end of the main pipe, a liquid flow sensor is fixedly mounted on the connecting pipe, the spray gun nozzle is fixedly installed at one end of the connecting pipe, a pressure gauge is fixedly mounted at the top of the spray gun nozzle, a battery box and the rear shell are fixedly mounted on the outer wall of the rear side of the main pipe, an electric plate is fixedly mounted inside the rear shell, and a data receiving chip, a data storage device and a single-chip microcomputer are fixedly mounted on the electric plate from left to right. According to the intelligent spray gun, the pressure gauge and the liquid flow sensor are mounted outside so that the paint spraying pressure and flow can be monitored during use, intelligent control over the pressure and flow in the spray gun is achieved, the distance between the nozzle and the spraying surface can be automatically sensed to automatically adjust the pressure, and the effect of being intelligent is achieved.

Owner:山东方大工程有限责任公司

Seal structure of motive shaft of high temperature furnace

PendingCN108413038AGood sealing environmentMeet the needs of useEngine sealsBlock matchMechanical engineering

Owner:JIANGMEN LVRUN ENVIRONMENTAL SCI TECH CO LTD

Traction-type straw feed picking, kneading, bundling and bagging machine

ActiveCN104904437BIncrease productivityExpand the scope of collectionLoadersBalingGrazingAgricultural engineering

The invention discloses a pull-type picking, kneading, bundling and bagging machine for straw feed. The pull-type picking, kneading, bundling and bagging machine comprises an integral rack, a picking, kneading and transporting device, a straw smashing filling bin, a straw compacting, bundling and bagging device and a powder transmission system. The innovative technologies such as the picking kneading and transporting device being front-arranged to suspend and hydraulically lift, deep tearing, kneading and smashing processing conducted on coarse hard section head and dense surface of corn straw, straw smashing three-direction hydraulic strong compaction and bundling to transport, straw compaction bundling, automatic packing after manual bagging are adopted, and combination processes of picking and smashing, compacting and bundling, bagging and packing are conducted on corn straw in the field. And the pull-type picking, kneading, bundling and bagging machine for the straw feed has the advantages that the technology is advanced, the structure is reasonable, the production efficiency is high, and the working quality is good. Straw feed compaction bales made by the machine has good sealing environment, microbial fermentation action can also occur in a natural condition, the slaking degree is improved, the nutrition ingredient is increased, and the palatability, the grazing rate and the digestion and absorption rate are improved when cattle and sheep are fed.

Owner:四平市顺邦农机制造有限公司

Vacuum packaging equipment with failure alarm function for optical lens

InactiveCN112678304AQuick seal releaseSeal releasePackaging under vacuum/special atmosphereSealingCircular discMagnetorheological fluid

The invention discloses vacuum packaging equipment with a failure alarm function for an optical lens. The vacuum packaging equipment with the failure alarm function for the optical lens comprises a box body, a cover plate, a disc and a permanent magnet disc, wherein a mounting groove, a liquid storage groove and a through groove are formed in the cover plate; the disc is arranged in the liquid storage groove; the lower part of the disc is fixedly connected with a containing box through a connecting rod; a getter is contained in the containing box; a sealing ring is fixedly connected to the position, corresponding to the through groove, on the connecting rod; and magnetorheological fluid is contained in the liquid storage groove. Due to the arrangement of the permanent magnet disc, the magnetorheological fluid, the connecting rod and the sealing ring, a limiting block, the connecting rod and the sealing ring can form an integral liquid seal by utilizing the morphological transformation of the magnetorheological fluid in a zero magnetic field environment and a strong magnetic field environment, and the magnetorheological fluid cannot flow again when being used for conducting liquid seal on the through groove; a groove is formed in the containing box; a limiting ring and a piezoelectric plate are fixedly connected into the groove; a sliding plate is further connected into the groove through a telescopic spring; and a controller and an alarm are fixedly connected onto the permanent magnet disc.

Owner:宜昌华悦光电科技有限公司

Integrally formed wedge

InactiveCN109758239AImprove toughnessImprove sealingTeeth fillingTeeth cappingTransmittanceEngineering

The invention discloses an integrally formed wedge, and belongs to the technical field of dental medicine. The wedge comprises a forming piece, a wedge body and a handle. The lower edge of the formingpiece is fixedly connected with the upper surface of the wedge body, the front end of the wedge body is a tip end, and the tail end of the wedge body is fixedly connected with the handle. The formingpiece is integrally formed with the wedge body, and the forming piece and the wedge body are made of a transparent plastic material. The wedge and the forming piece can smoothly enter the interdentalspace and reach the optimal closed position, and provide a good seal for a matrix filled in a tooth to ensure the therapeutic effect of the tooth decay. A medical worker does not need to put the appropriate type of the wedge body and the model of the forming piece, and greatly reduces the operation difficulty and the workload of the medical worker. The integrally formed wedge adopts the transparent plastic material with high strength, good toughness and low cost, is easy to shape, can be closely adhered to the tooth body to complete precise positioning and is good in light transmittance. A photocuring machine can be adopted for curing after the matrix is filled.

Owner:HUANGHUA PROMISEE DENTAL CO LTD

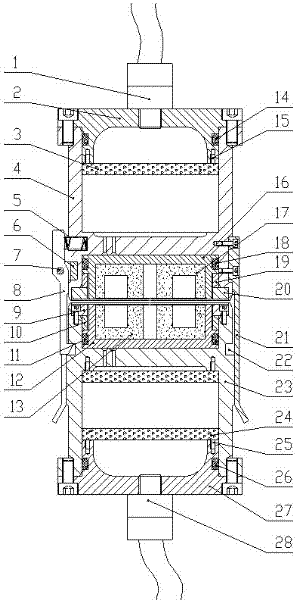

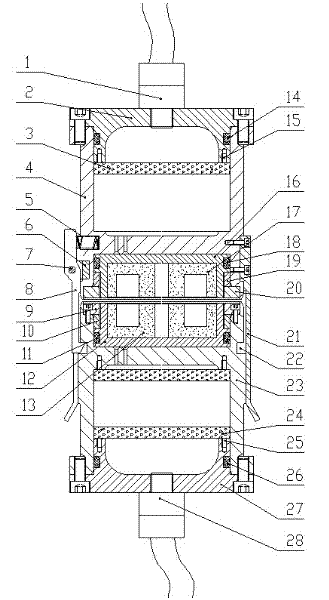

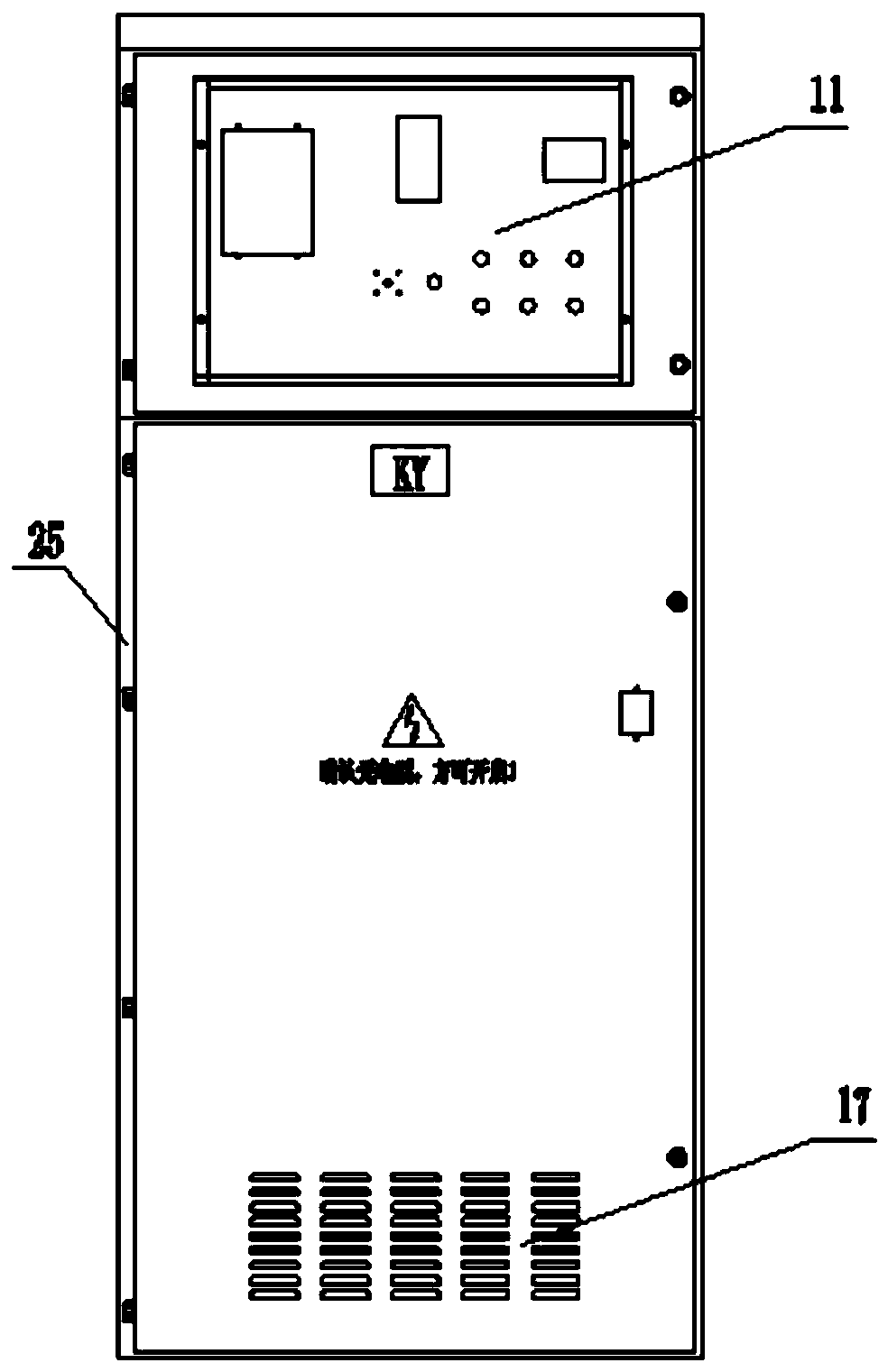

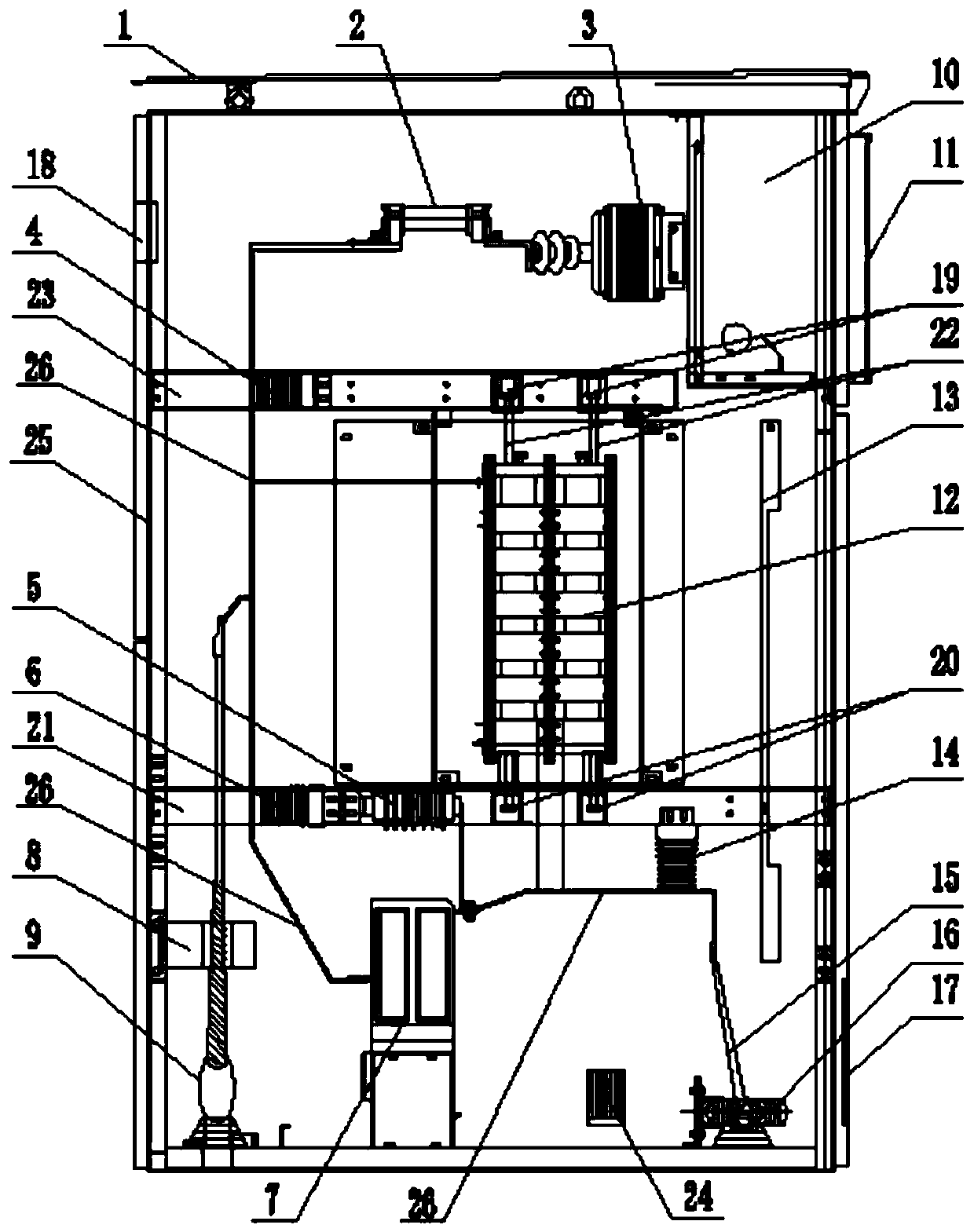

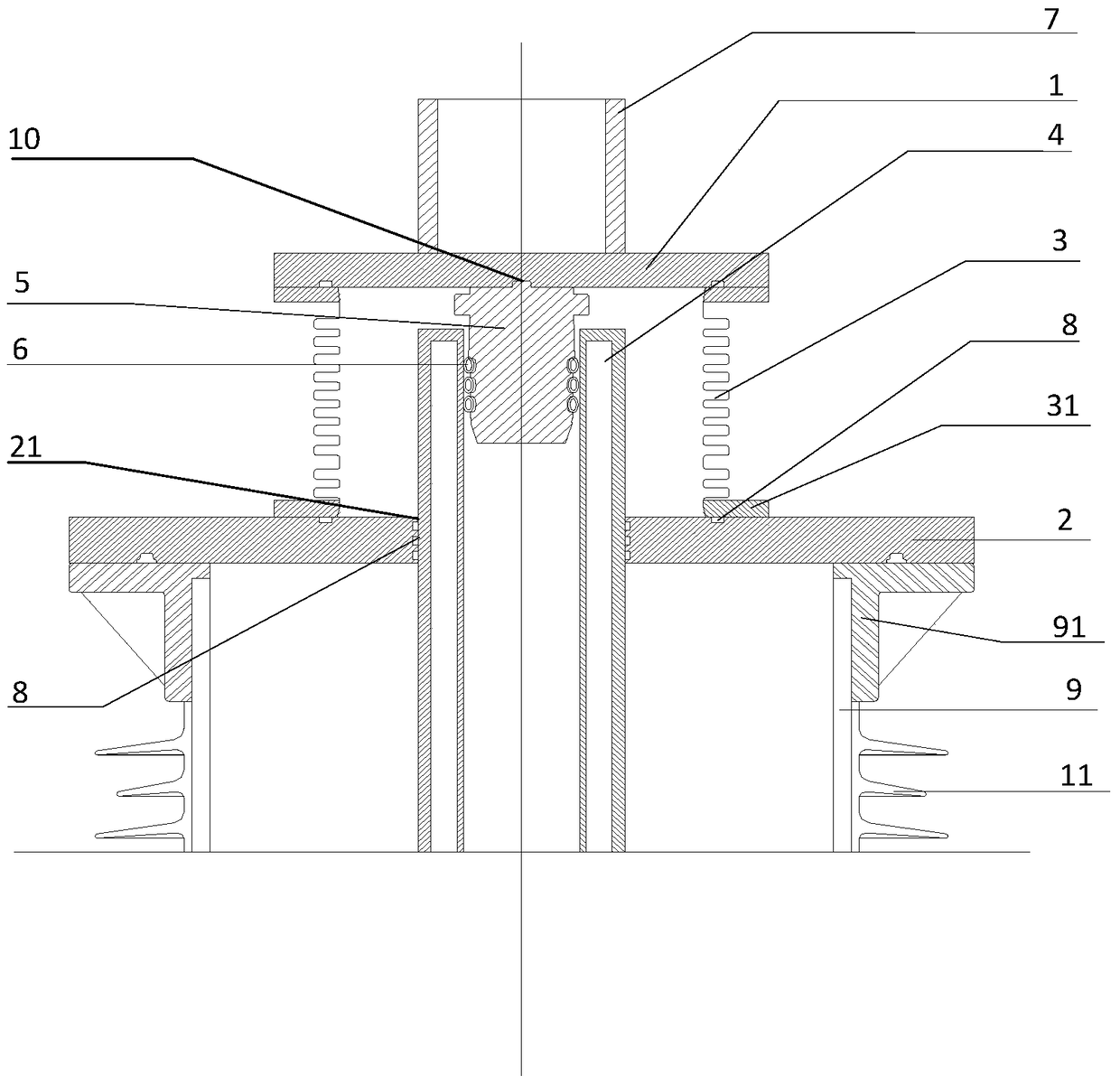

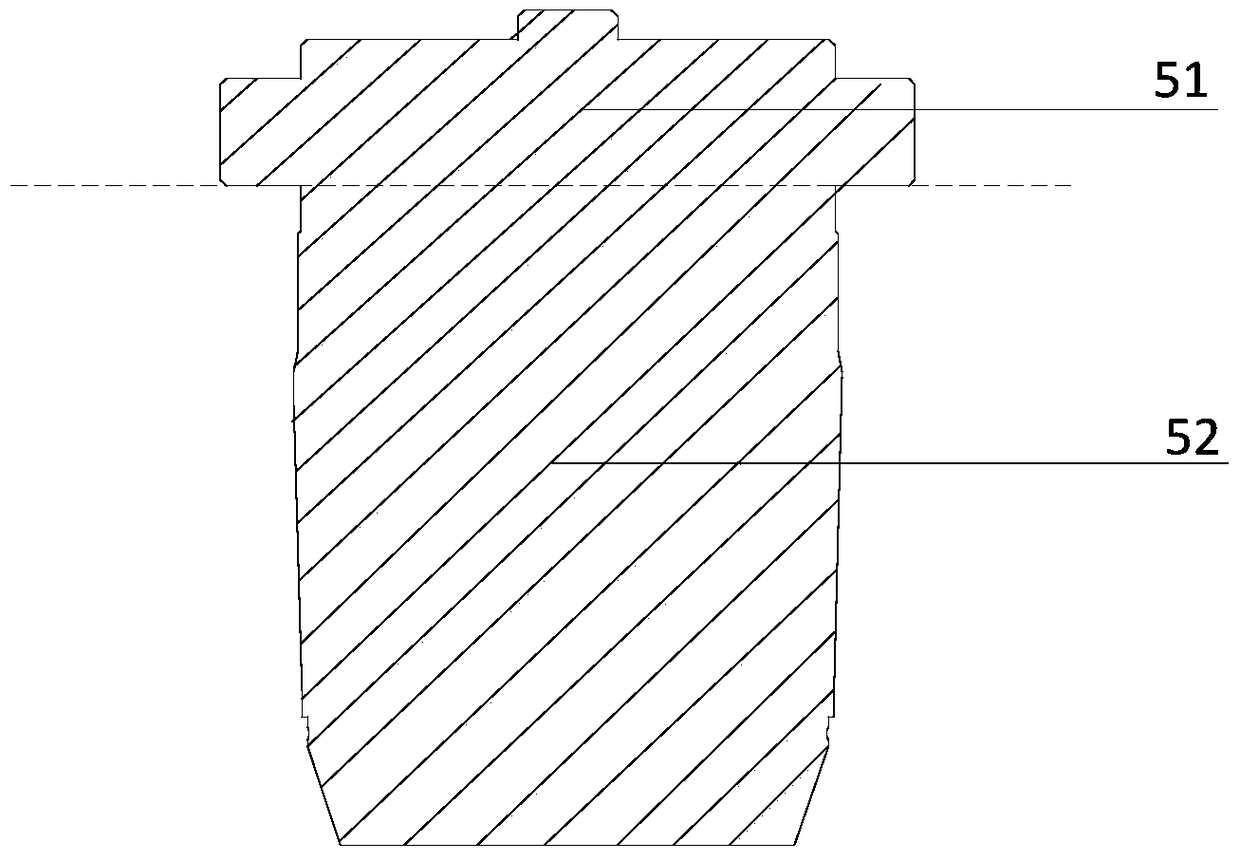

Mine integrated high voltage solid soft starting device

PendingCN110311592AEliminate shockEasy to controlStarter detailsPolyphase induction motor starterEngineeringHigh pressure

The invention discloses a mine integrated high voltage solid soft starting device which comprises a support protection structure, an upper device module, a silicon controlled module and a lower electrical component. The upper layer device module comprises a device chamber (10) and a high voltage fuse (2) and a voltage transformer (3) which are arranged on one side of the device chamber (10). The silicon controlled module comprises a silicon controlled valve group (12), an upper beam insulator (4) and an incoming call sensor (6). The lower electrical component comprises a high voltage vacuum contactor (7), a current transformer (8), an incoming cable (9) and an outgoing cable (15). The incoming cable (9) penetrates through the current transformer (8) to be connected with a copper bar (26).According to the starting device, the soft starting device with excellent controllability of voltage and current is provided for the mine passage without gas and dust explosion danger so that the impact of motor start-up on the electric network can be effectively eliminated and accurate control of the motor can be realized.

Owner:襄阳赛克斯电气股份有限公司

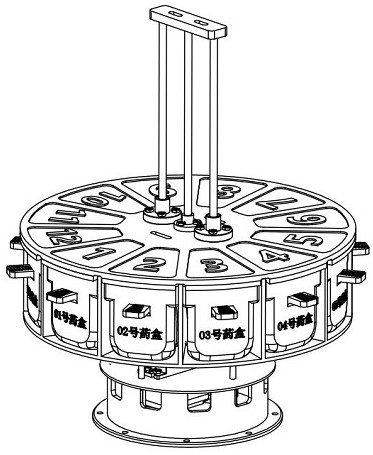

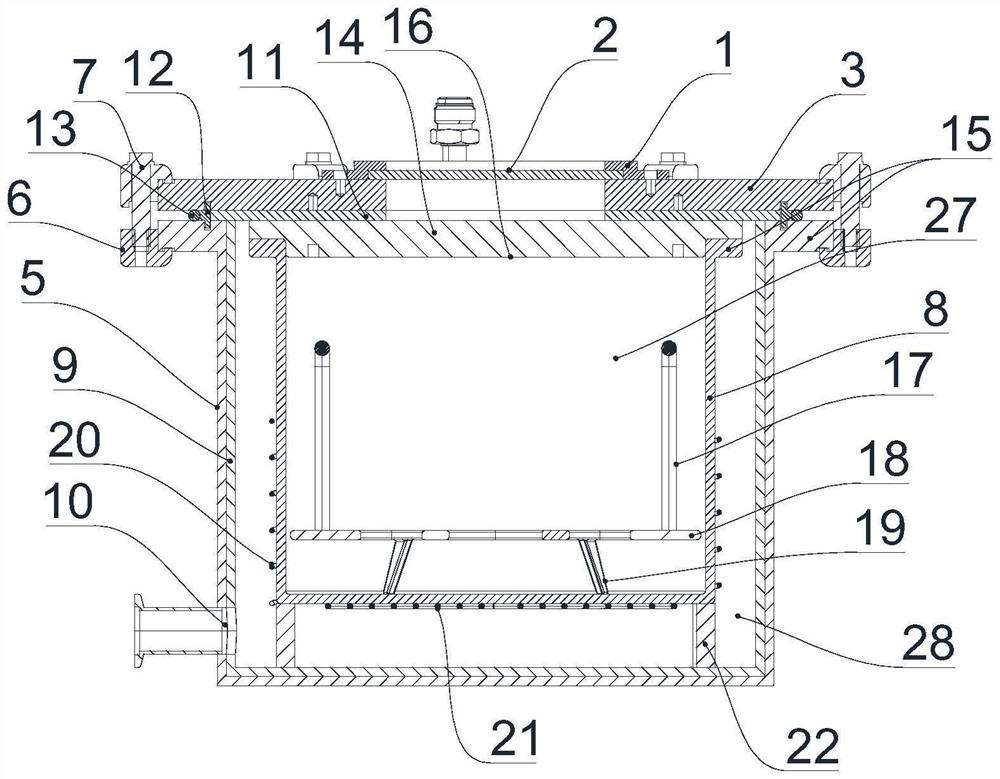

Medicine box storage chamber system based on rotating holder

PendingCN112245285AWith automatic guidance functionExtended service lifeSmall article dispensingPharmaceutical containersPharmacy medicineEngineering

The invention discloses a medicine box storage chamber system based on a rotating holder. The medicine box storage chamber system comprises a rotating holder part system and a medicine box storage chamber part system. A medicine box storage chamber is rotated through the rotating holder, a sealing cover is lifted through a lead screw module, and therefore corresponding medicine is obtained. The sealing cover is made of partition plate gum materials, and the leakproofness in a medicine storage box is guaranteed. The storage chamber is divided into 12 parts through a partition rotary disc in themedicine box, and therefore the placed medicine is classified. The system can be driven through an Internet of things system, and therefore medicine obtaining is more intelligent and more automatic.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Evaporation and concentration device for ultra-clean high-purity electronic chemicals and application of evaporation and concentration device

PendingCN114130045AEvaporation and concentration is fast and efficientAvoid pollutionEvaporator accessoriesVacuum pumpingEngineering

The invention discloses an evaporation and concentration device for ultra-clean high-purity electronic chemicals and application of the evaporation and concentration device. The evaporation and concentration device comprises an outer shell, an inner shell, vacuum pumping equipment and a heating assembly, an inner cavity of the outer shell is a first-stage vacuum cavity, an inner cavity of the inner shell is a second-stage vacuum cavity, and the first-stage vacuum cavity and the second-stage vacuum cavity are respectively connected with the vacuum pumping equipment; the inner shell is arranged in the first-stage vacuum cavity, top cover sealing assemblies used for sealing top openings of the first-stage vacuum cavity and the second-stage vacuum cavity are arranged at the tops of the outer shell and the inner shell, and the top cover sealing assemblies are detachably arranged at the tops of the outer shell and the inner shell. The heating end of the heating assembly acts on the inner shell. And a fixing frame for fixing a beaker filled with a sample is arranged in the secondary vacuum cavity. The device realizes evaporation and concentration of ultra-clean high-purity electronic chemicals, and is rapid, efficient and low in maintenance cost.

Owner:JIHUA LAB

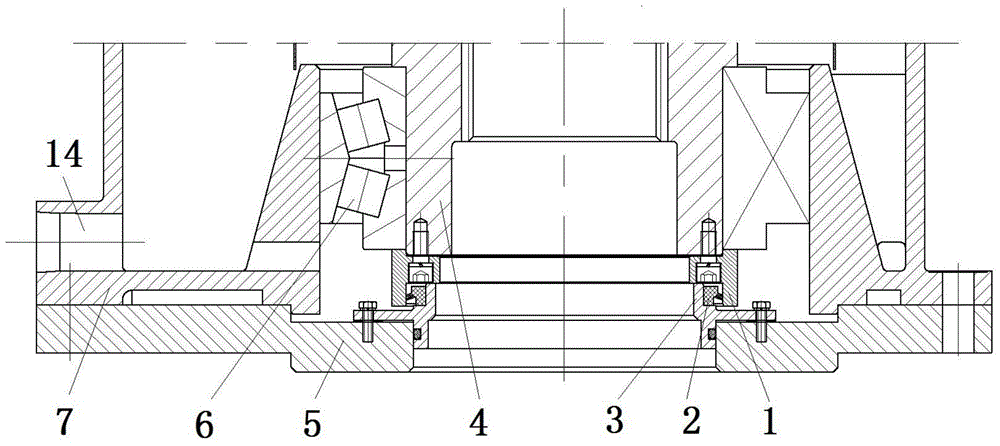

Press-down reduction box for four-roller reversible tungsten-molybdenum hot rolling mill

InactiveCN105032942AEasy pipingReduce installation linksRolling mill drivesGearing detailsButt jointEngineering

The invention discloses an press-down reduction box for a four-roller reversible tungsten-molybdenum hot rolling mill. An oil stopping ring is arranged in a lower box body of the reduction box, and the oil stopping ring is upwards in butt joint with a lower bearing check ring. The lower bearing check ring is fixed connected with a worm wheel shaft, and the circumference of the lower end of the worm wheel shaft is sleeved with a worm wheel lower bearing. The worm wheel lower bearing is located on the lower bearing check ring, and a seal is arranged between the oil stopping ring and the lower bearing check ring. An oil returning hole is formed in the bottom of the lower box body of the reduction box, and the upper port edge of the oil returning hole is lower than the lower edge of the seal. A sleeve cup is fixedly installed on an upper box cover of the reduction box, and a worm wheel upper bearing is sleeved with the sleeve cup. The worm wheel upper bearing is connected with the upper portion of the worm wheel shaft in a sleeving mode, and an upper bearing check ring is arranged at the upper end of the worm wheel upper bearing. An upper end cover is arranged at the upper end of the sleeve cup and is provided with a protection cover. The worm gear upper bearing is in loose fit with the worm wheel shaft. The press-down reduction box does not leak oil and is convenient to demount and mount.

Owner:MCC SFRE HEAVY IND EQUIP

An infrared point source deflection device and control method

ActiveCN111521068BMeet high frame rate requirementsSimple structureDefence devicesEngineeringMetal sheet

The invention relates to the field of infrared simulation. The invention discloses an infrared point source deflection device and a control method. The device includes: a metal sheet in contact with an electrode, used for simulating the infrared radiation characteristics of a target at a frame rate and a temperature range that can be achieved through heating up and natural cooling processes . The control method includes: determining the energized voltage according to the infrared radiation characteristics of the target; and energizing and heating the metal sheet according to the energized voltage. The invention satisfies the requirement of high frame frequency and is used for simulating the infrared radiation characteristics of important targets; it provides a solid technical guarantee for the use of important ground defenses, and can be used as the last protection means for important ground after missile interception fails. New solutions for existing technology research and development ideas.

Owner:哈尔滨新光光电科技股份有限公司

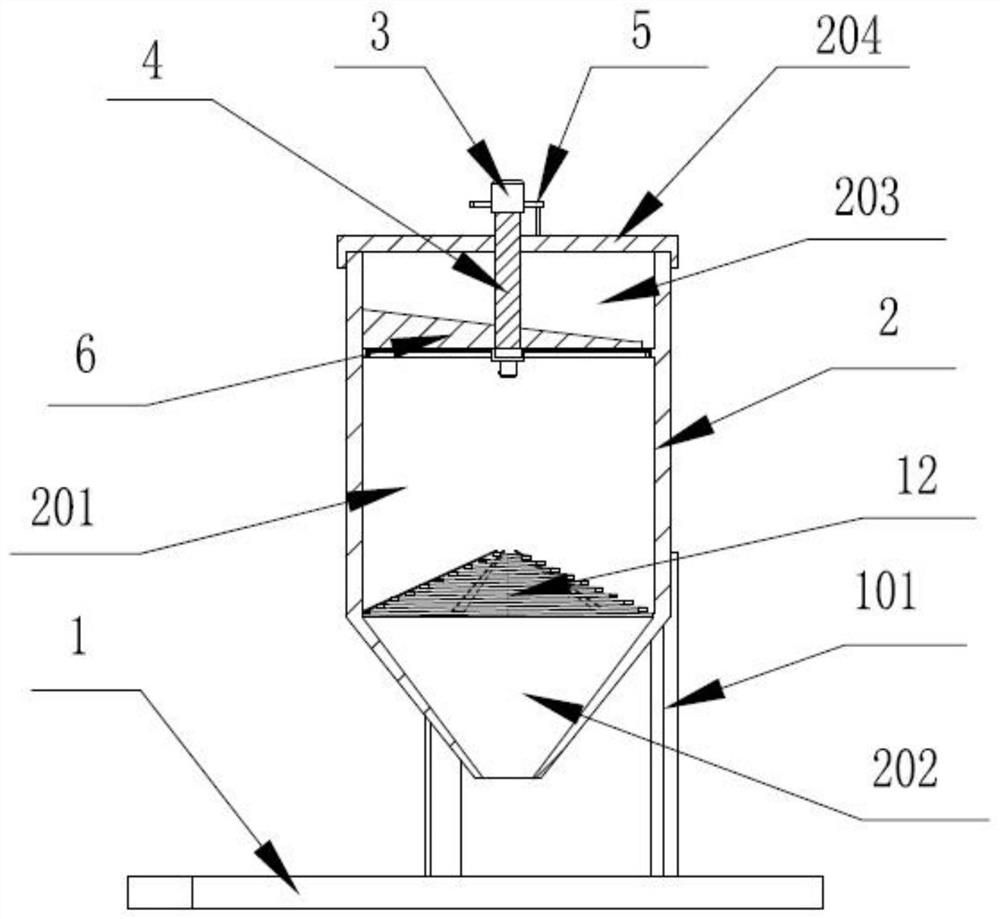

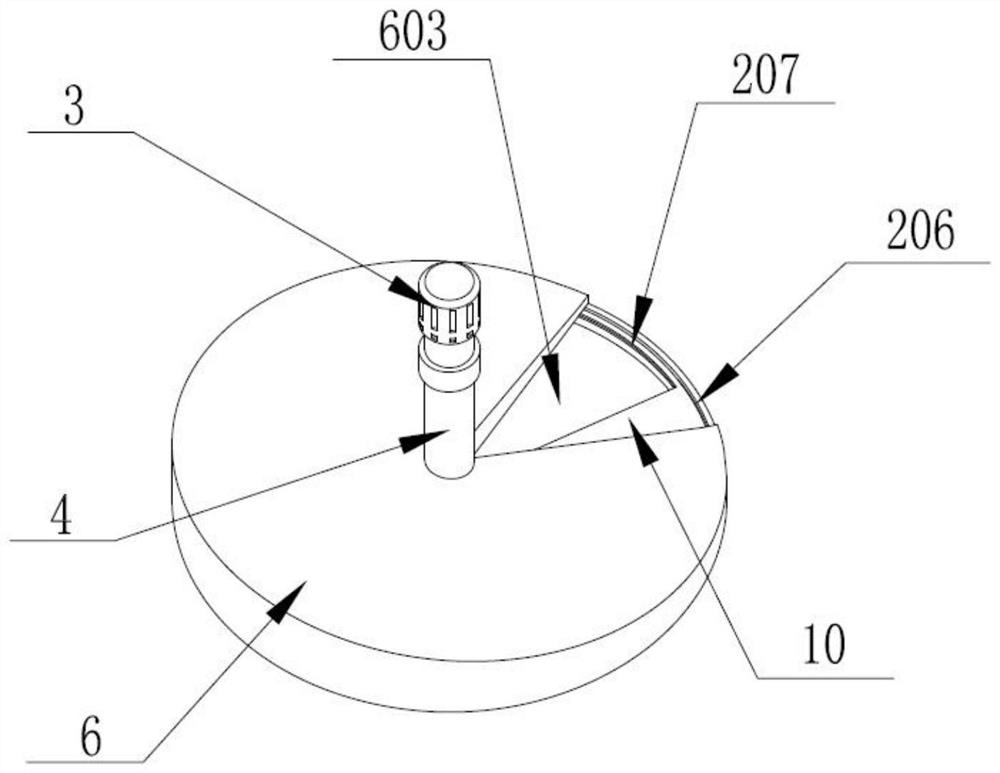

Garbage water vapor catalytic gasification device capable of recording data and using method

ActiveCN112694916AImprove gasification effectAvoid feed notGasifier feeding meansGasification processes detailsSlagEngineering

The invention discloses a garbage water vapor catalytic gasification device capable of recording data and a using method. The device comprises a gasification furnace, a pre-feeding cavity, a gasification cavity and a slag discharging cavity are sequentially formed in the gasification furnace from top to bottom, a boss is fixedly arranged on the inner wall of a cavity body at the top of the gasification cavity, and a rotary disc is rotatably connected to the upper surface of the boss; the upper surface of the turntable is coaxially and fixedly connected with a rotating shaft;an opening penetrates through the upper and lower surfaces of the rotary disc; a rotating block is coaxially and rotatably arranged on the bottom end face of the rotary disc, a rotating plate is horizontally and fixedly connected to the outer surface of the circumference of the rotating block, a sensor is fixedly arranged on the lower surface of the rotating plate, and the rotating plate can cover the opening of the rotating disc to block communication between the pre-feeding cavity and the gasification cavity. The garbage temperature can be monitored through the sensor, different amounts of garbage can be controlled according to different temperature areas, and the gasification reaction efficiency in the gasification furnace is improved.

Owner:HEBEI NORTH UNIV

square food packaging jar

Owner:SHANGHAI JND PLASTIC PRODS

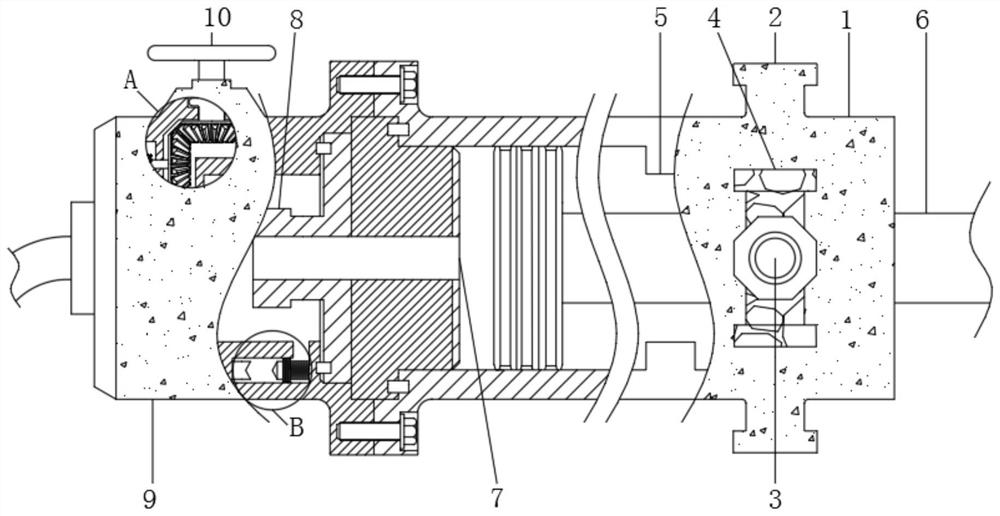

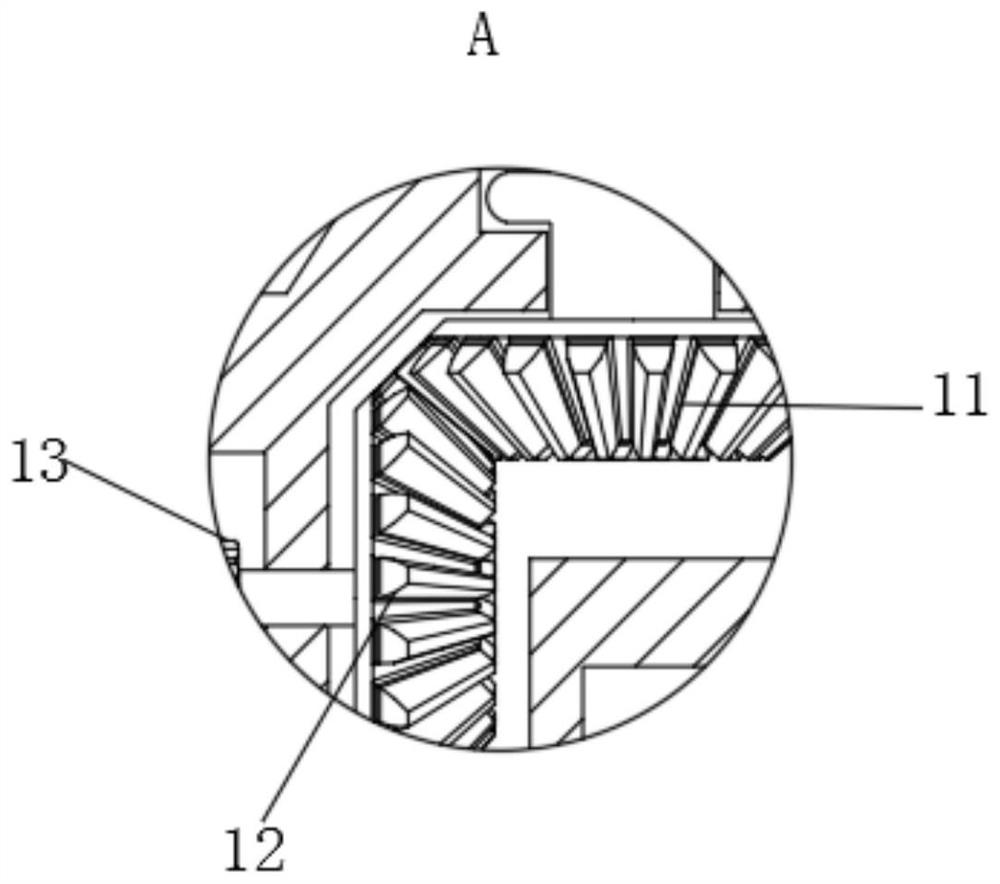

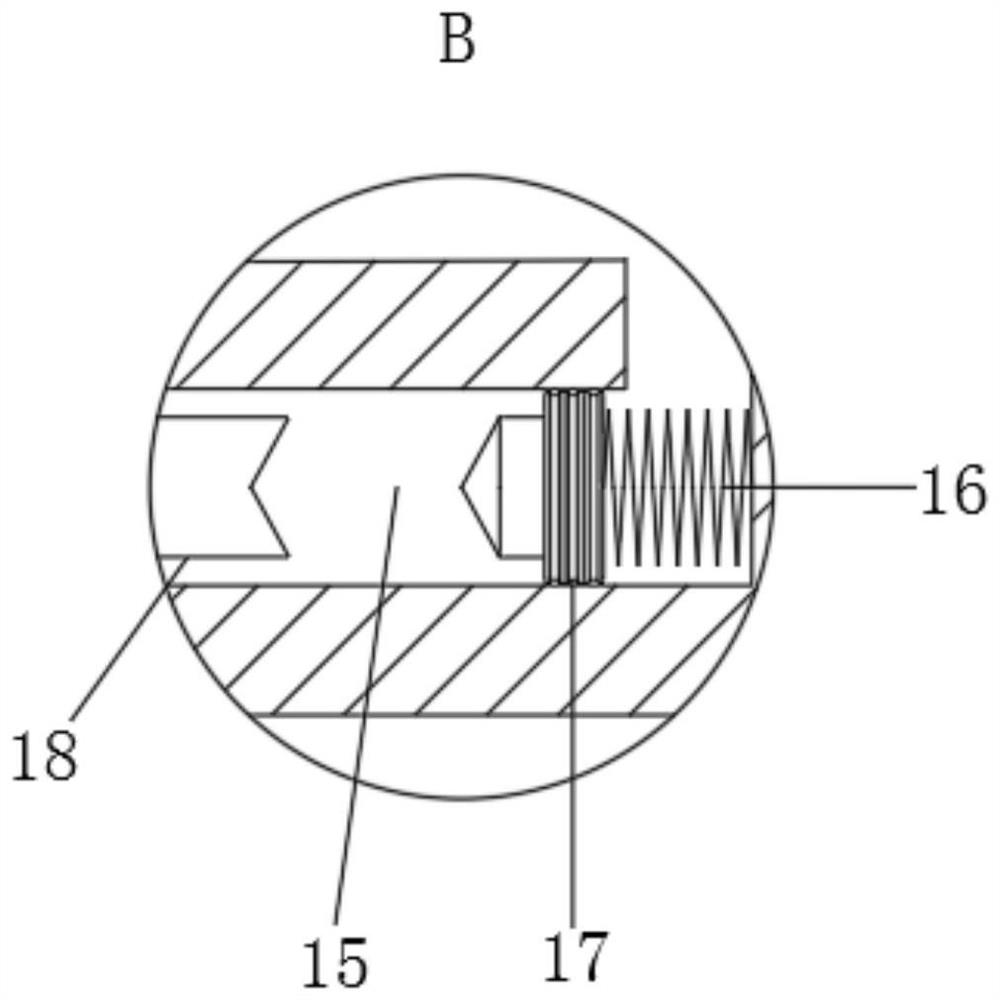

Hydraulic cylinder provided with device for automatically detecting and processing liquid leakage

ActiveCN113323938AImprove detection performanceReduce wearFluid-pressure actuator testingServomotor componentsFluid LeakBevel gear

The invention relates to the field of hydraulic power mechanical elements, and discloses a hydraulic cylinder provided with a device for automatically detecting and processing liquid leakage. The hydraulic cylinder comprises a hydraulic cylinder shell, a hydraulic oil branch port is formed in an upper end of the hydraulic cylinder shell, a right hydraulic oil valve is fixedly connected to the front end of the hydraulic cylinder shell, a hydraulic oil main opening is formed in an upper end of the right hydraulic oil valve, a limiting block is arranged inside the hydraulic cylinder shell, a power rod is movably connected to the right end of the hydraulic cylinder shell, a cylinder cover is fixedly connected to an opening of the hydraulic cylinder shell, a left hydraulic oil valve is arranged at the left end of the cylinder cover, the left side of the hydraulic cylinder shell is fixedly connected with a detection device, an upper end of the detection device is movably connected with a switch, and the lower end of the switch is fixedly connected with a main bevel gear. The device can provide a good sealing environment for the detection device through cooperative use of a sealing door and a latex block, and the detection performance of a detection state is improved.

Owner:山东福阳液压科技有限公司 +1

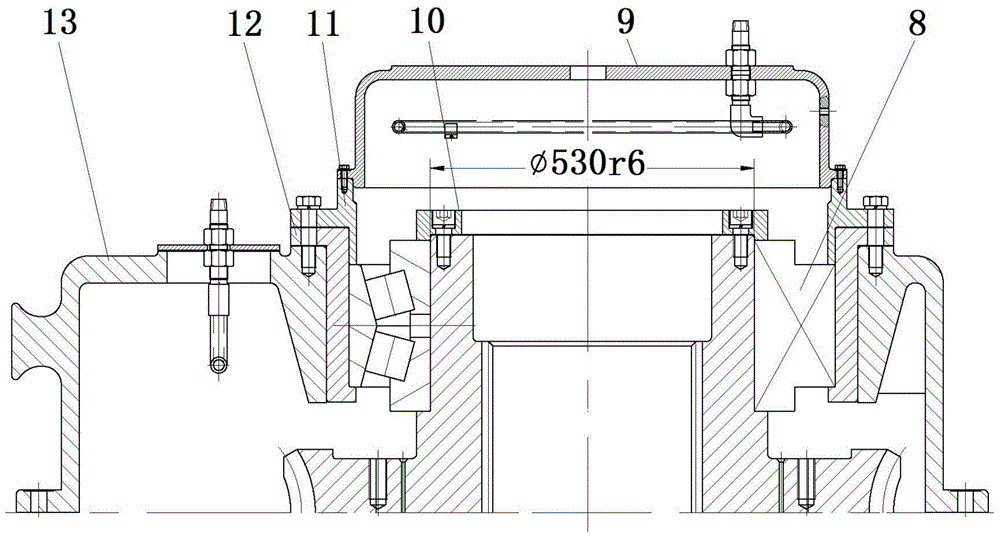

A furnace device and method for preparing ultra-high-purity aluminum

ActiveCN104263969BExtended service lifeReduce bearing deformationWorking capacityElectromagnetic stirring

The invention belongs to the technical field of metal purification, and relates to a furnace pipe device and a method for preparing ultra-high purity aluminum. The furnace pipe device is characterized by sequentially comprising a furnace pipe outer frame, a thin-wall seal sleeve and a graphite crucible from outside to inside, wherein a hinge furnace lid is arranged at the upper part of the furnace pipe; a water inlet hole, a water outlet hole, an observation hole, an air exhaust hole, an air inlet hole, an exhaust vent, a temperature measuring hole and a pressure measuring hole are formed in the furnace lid; a rubber seal strip is arranged between the furnace lid and the furnace pipe outer frame; and the furnace lid is connected and fastened with the furnace pipe through buckles and bolts. The furnace pipe device disclosed by the invention is capable of melting aluminum one time; the crystal is 65Kg; the height of a crystal aluminum ingot can reach 90cm; the single production can be increased by 2.5 times in comparison with that of a conventional high-purity aluminum production technology; an argon protection environment is only kept in the furnace pipe; the furnace pipe device has no environmental requirements on heating and electromagnetic stirring devices, and is strong in continuous working ability; compared with a conventional production technology, the furnace pipe device and the method have the advantages that the power consumption is reduced by 2 / 3; and the energy consumption cost is saved by 3 / 5.

Owner:江苏金海铝业有限公司

A hydraulic cylinder equipped with a device that automatically detects and treats leaks

ActiveCN113323938BGood sealing environmentEasy to detectFluid-pressure actuator testingServomotor componentsHydraulic cylinderMechanical components

The invention relates to the field of hydraulic power mechanical components, and discloses a hydraulic cylinder equipped with a device for automatically detecting and processing liquid leakage. The front end of the cylinder casing is fixedly connected with a right hydraulic oil valve, the upper end of the right hydraulic oil valve is provided with a hydraulic oil main port, a limit block is arranged inside the hydraulic cylinder casing, and the right end of the hydraulic cylinder casing is movable A power rod is connected, a cylinder cover is fixedly connected to the opening of the hydraulic cylinder shell, a left hydraulic oil valve is arranged on the left end of the cylinder cover, and a detection device is fixedly connected to the left side of the hydraulic cylinder shell. The upper end of the detection device is movably connected with a switch, and the lower end of the switch is fixedly connected with a main helical gear. The device can provide a good sealing environment for the detection device and improve the detection performance of the detection state through the cooperation of the closed door and the latex block. .

Owner:山东福阳液压科技有限公司 +1

A UHV DC bushing joint

The invention provides an ultrahigh-voltage direct-current sleeve joint. The ultrahigh-voltage direct-current sleeve joint comprises a conducting pipe as well as an epoxy pipe and a supporting cover plate which are arranged coaxially relative to the conducting pipe, wherein the supporting cover plate is provided with a through hole which is vertical to the axial direction of the supporting cover plate and coaxial with the conducting pipe and the epoxy pipe; the conducting pipe passes through the through hole and is connected with a top cover plate; a part, surrounded between the supporting cover plate and the top cover plate, of the conducting pipe is provided with a corrugated pipe which is positioned at the upper end of the supporting cover plate and connected with the supporting cover plate and the top cover plate. Compared with the prior art, the ultrahigh-voltage direct-current sleeve joint disclosed by the invention has the advantages of solving the problem of extension and contraction of the conducting pipe by enabling the corrugated pipe to extend and contract correspondingly along with the extension and contraction of the conducting pipe, solving the problem of metal friction caused by hard connection between parts, improving the sealing reliability, guaranteeing good leakproofness of a sleeve chamber body, improving the problem of easy loosening caused by own gravity of the parts, simplifying the installation process of the conducing pipe and lowering the time cost.

Owner:STATE GRID CORP OF CHINA +1

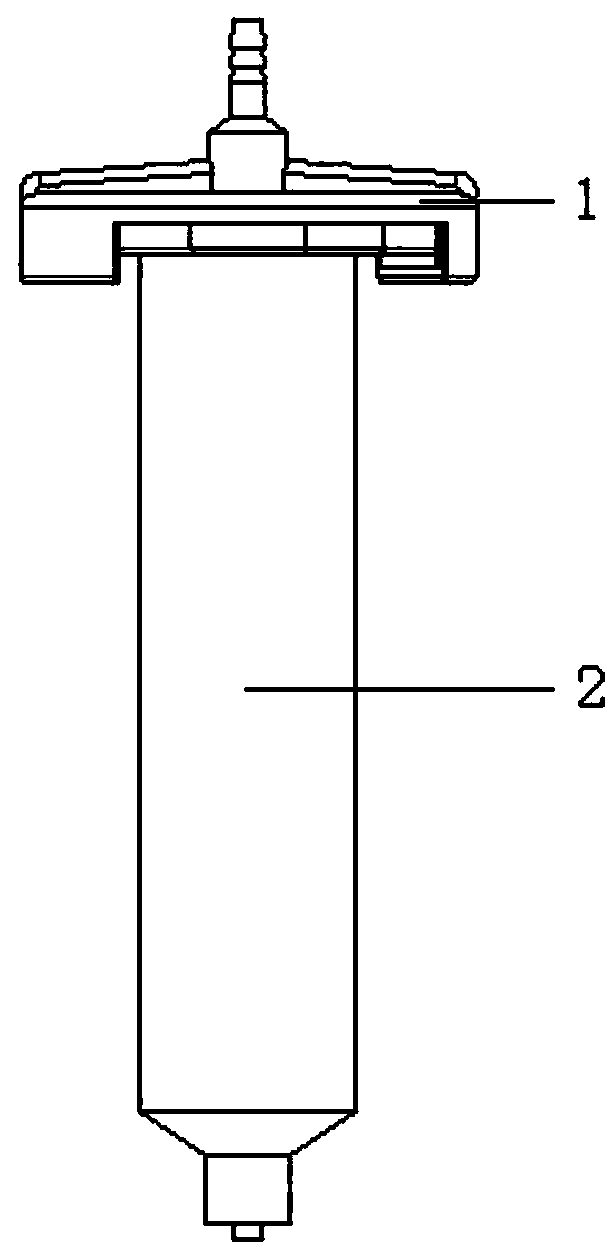

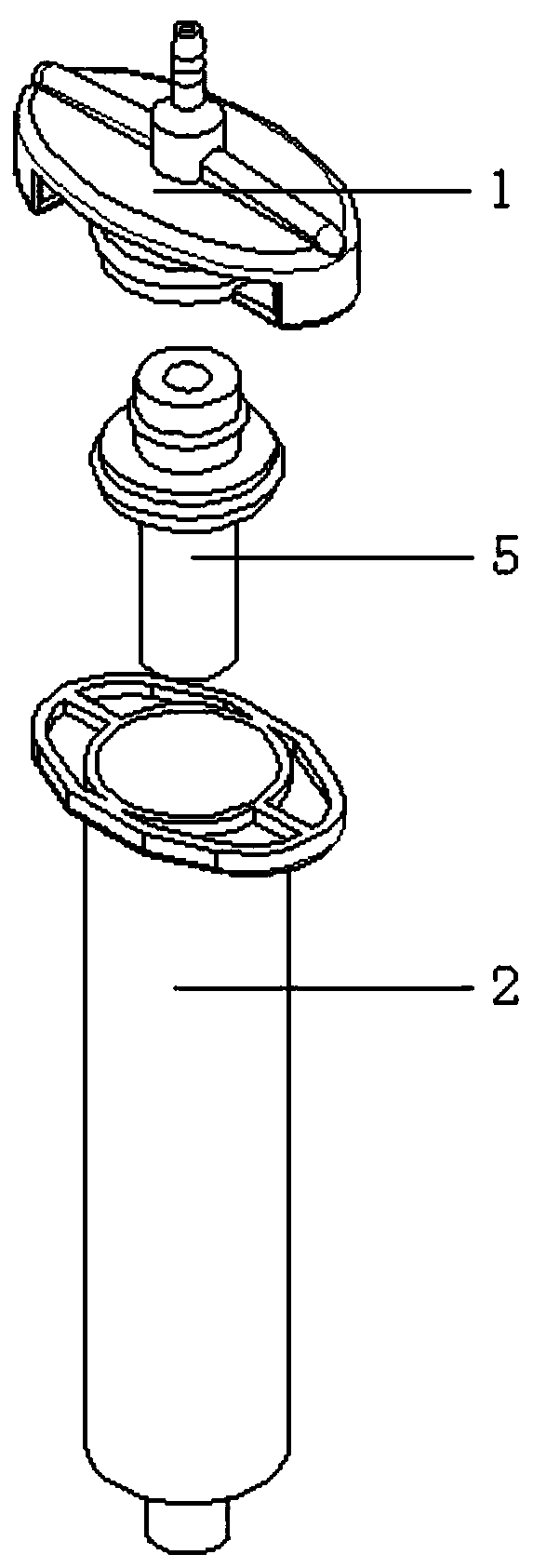

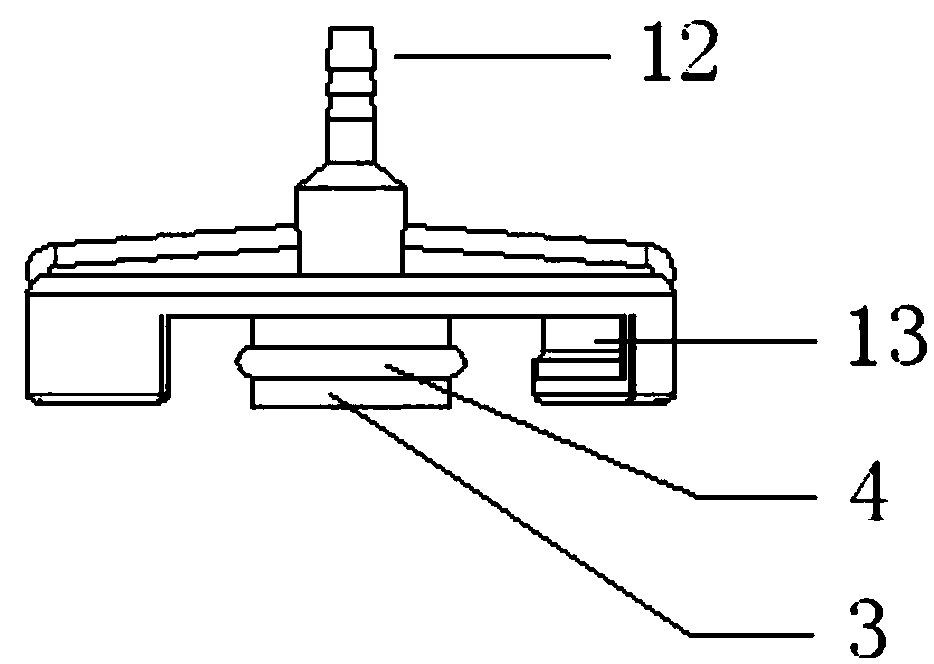

Gas pressure protection device capable of preventing glue from flowing back

PendingCN109277259AStrengthen the sealed environmentImprove convenienceLiquid surface applicatorsCoatingsEngineeringBackflow

The invention discloses a gas pressure protection device capable of preventing glue from flowing back. The gas pressure protection device comprises a fixed base and a barrel body installed on the fixed base. A connector is arranged at the lower end of the fixed base. A first plug ring is arranged on the outer wall of the connector and abuts against the inner wall of the barrel body. A barrel coreis movably arranged in the connector. A sealing head is arranged at the upper end of the barrel core. A second plug ring is arranged on the outer wall of the sealing head and abuts against the inner wall of the connector. A middle ring is arranged at the middle end of the barrel core. A third plug ring is arranged on the outer wall of the middle ring and abuts against the inner wall of the barrelbody. A lower rod is arranged at the lower end of the barrel core. A middle hole is further formed in the barrel core and penetrates the barrel core. A first full-closed area is formed by making the first plug ring abut against the inner wall of the barrel body, and therefore glue backflow caused when quick drying glue flows back due to gas pressure is prevented. A second full-closed area is formed by making the third plug ring abut against the inner wall of the barrel body, the quick drying glue in the barrel body is isolated from the first closed area, the sealed environment in the barrel body is further enhanced, and the convenience degree of use of the quick drying glue is greatly improved.

Owner:DONGGUAN KAILAI ELECTRONICS CO LTD +1

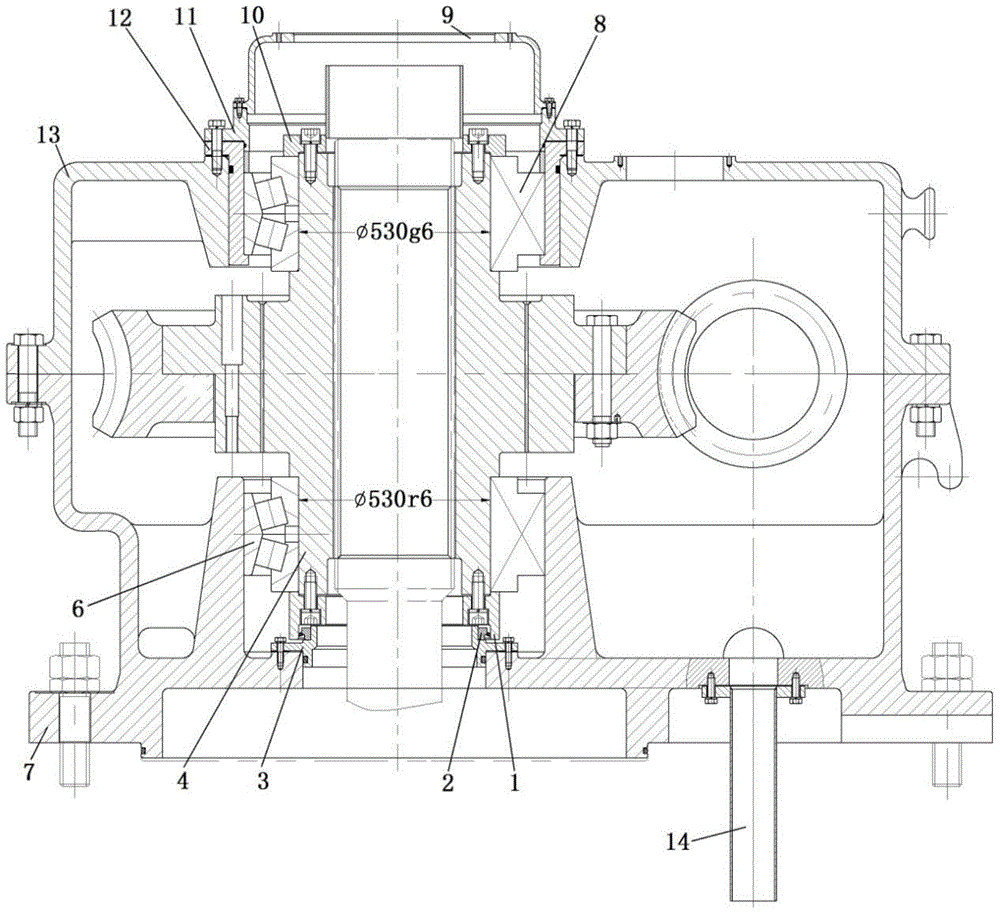

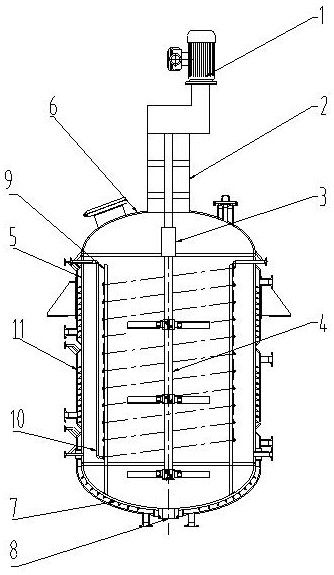

Large-scale equipment of selective molecular sieve gel-forming crystallization kettle

PendingCN113750934AWell mixedReduce depositionChemical/physical/physico-chemical stationary reactorsFeed devicesMolecular sieveCoupling

The invention relates to large-scale equipment of a selective molecular sieve gel-forming crystallization kettle, the equipment is a vertical stirring kettle with a jacket and a full volume of 52 m < 3 >, and comprises a stirring device and an inner kettle body. The stirring device is of a vertical stirring structure and is formed by sequentially connecting a motor, an upper transmission sealing assembly with a balance tank, a coupling assembly and a stirring assembly from top to bottom. The stirring assembly is a three-layer four-inclined-blade turbine type stirring paddle, and the stirring paddle at the bottommost layer is close to the bottom of the inner kettle body; the inner kettle body is formed by connecting an upper elliptical head, a straight cylinder section and a lower elliptical head; the top of the upper elliptical head is provided with a feed port and an exhaust port, and the bottom is provided with a discharge port; a heating coil is arranged in the straight cylinder section; a jacket is arranged on the outer sides of the straight cylinder section and the lower elliptical head, and a spiral guide plate is arranged in the jacket; an emptying pipe and a sealing liquid output pipe are arranged on one side of the upper transmission sealing assembly, and the sealing liquid output pipe is connected with a balance tank. According to the invention, the product quality can be ensured, the labor intensity is reduced, and the productivity of a single reaction kettle is improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

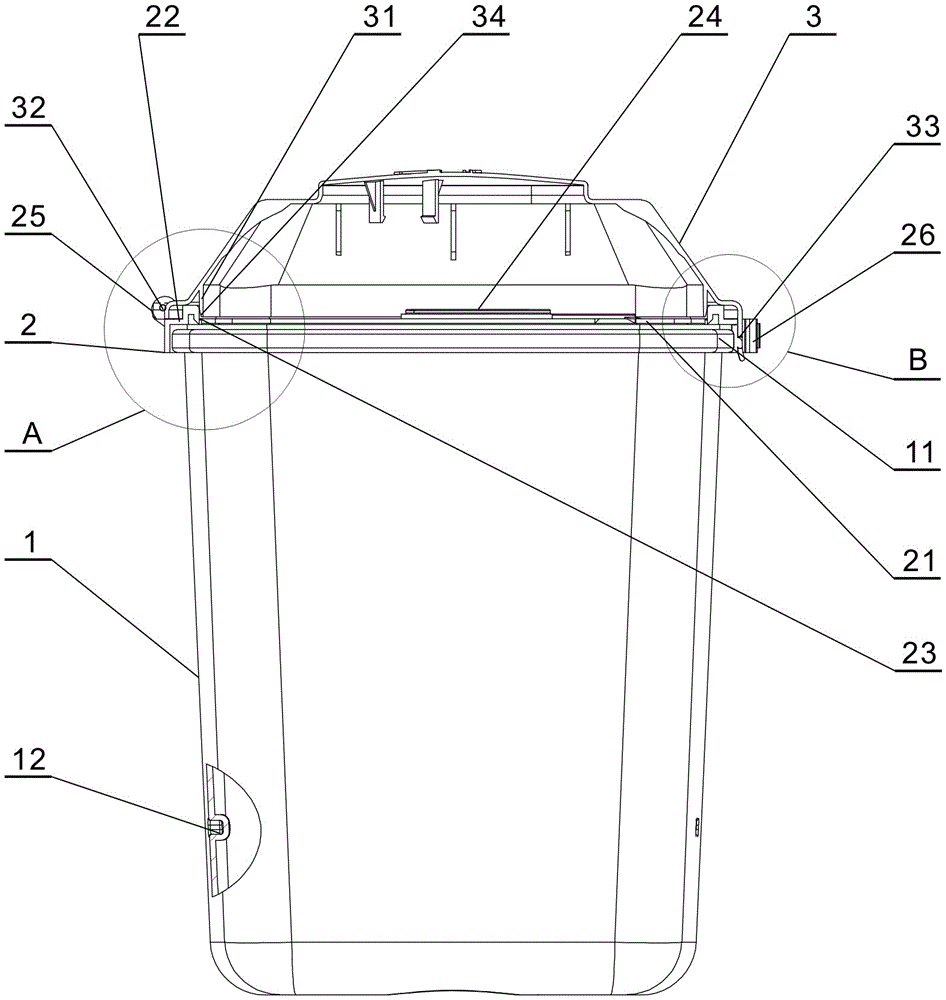

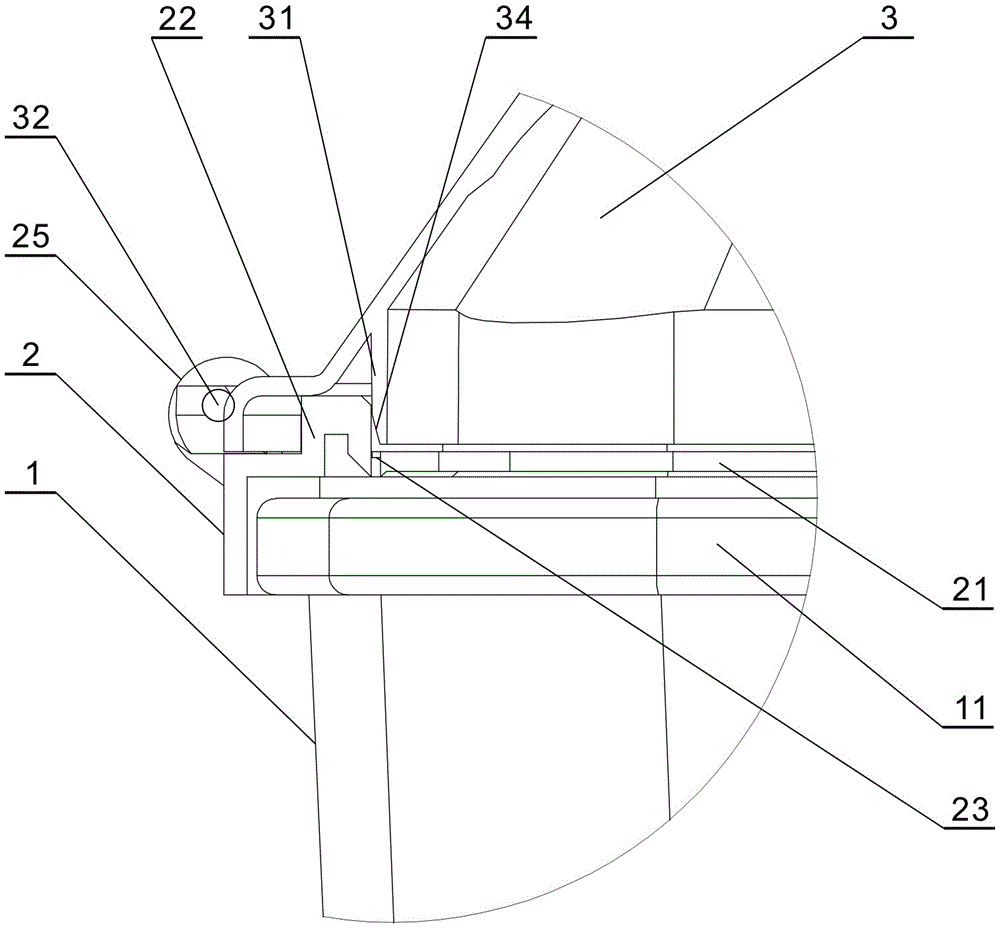

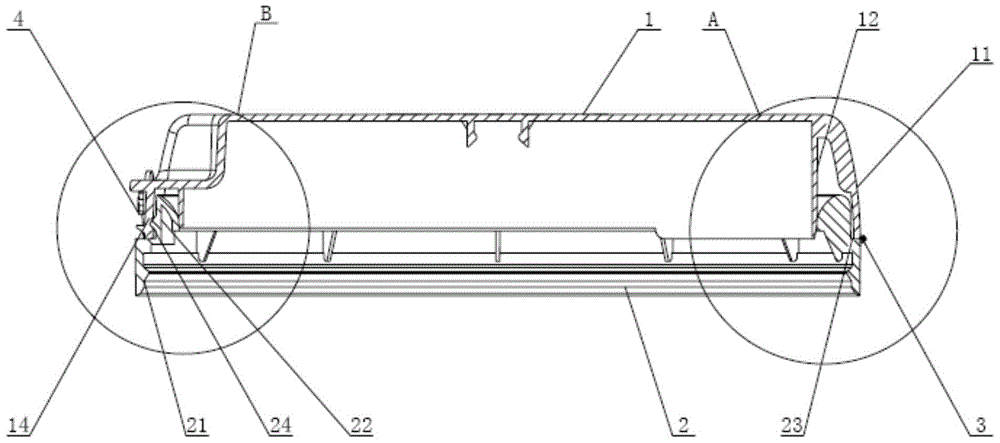

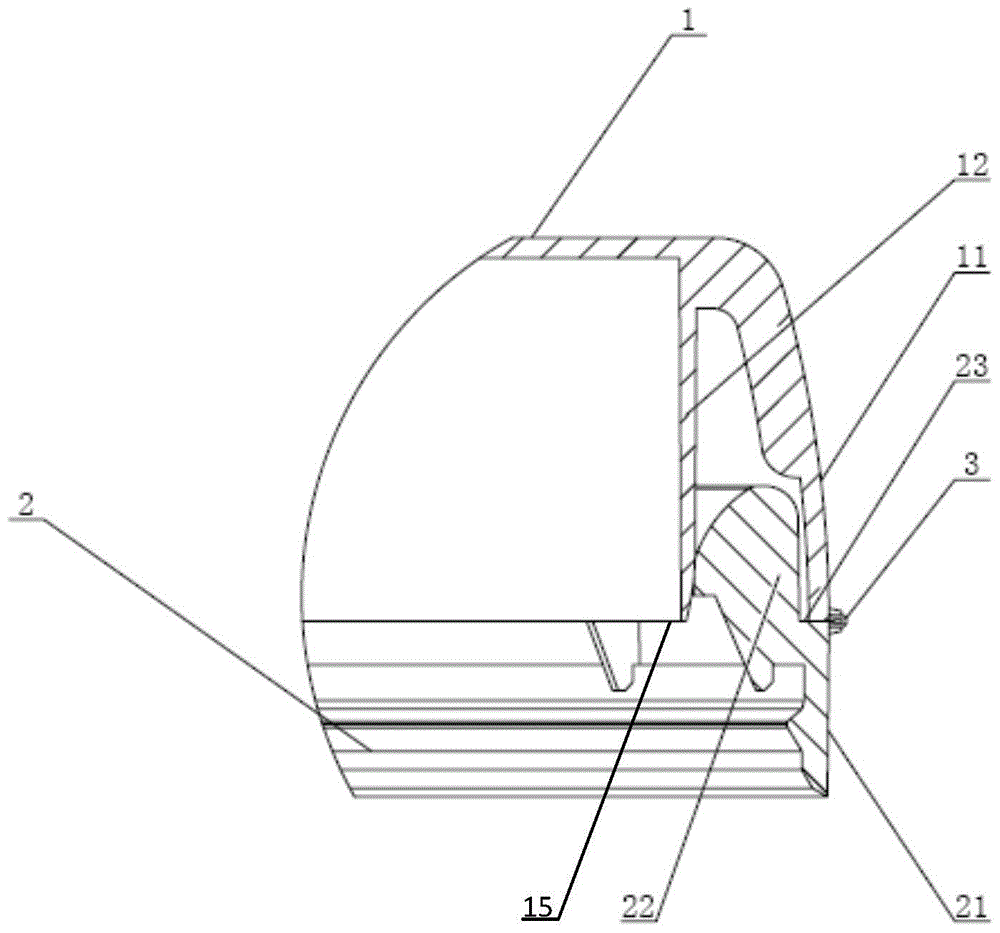

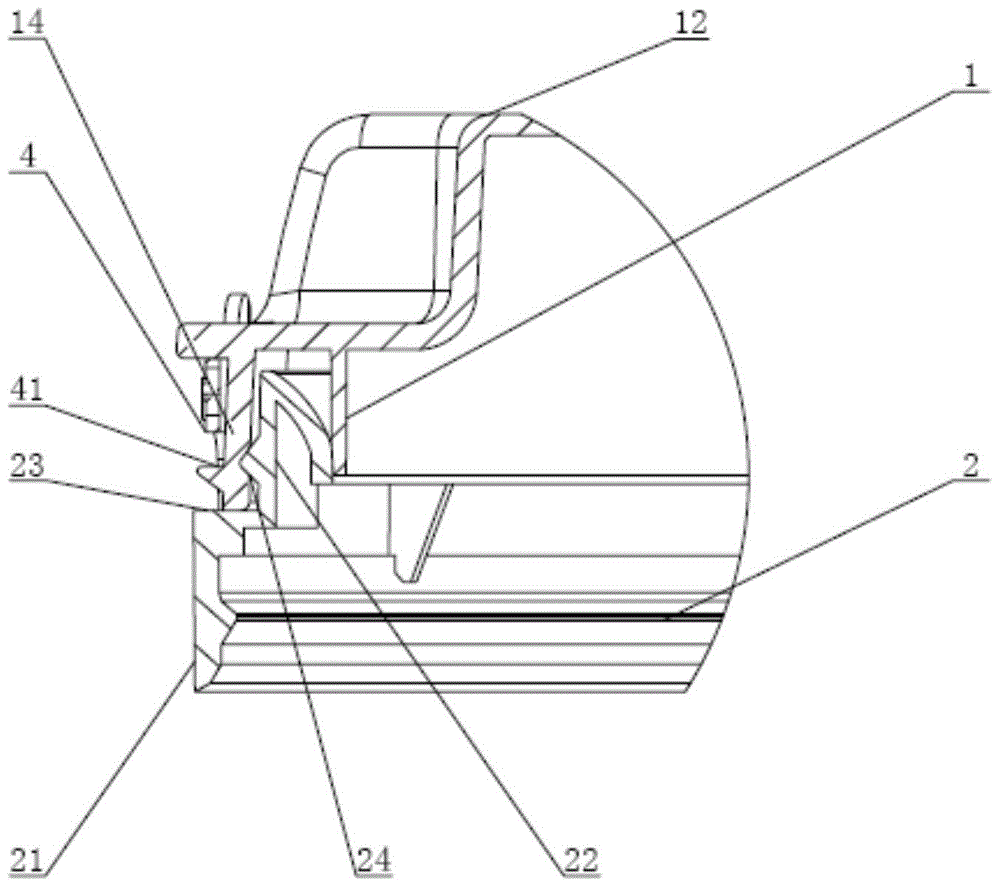

Packaging lid of a milk powder can

ActiveCN103786963BGood sealing environmentEasy to slideSealingNon-removalbe lids/coversPackaging TankEngineering

The invention relates to a packaging lid of a milk powder tank. The packaging lid comprises a lid body, a lid ring, a hinge and a locking plate. An outer wall, an inner wall and an opening are arranged on the periphery of the lid body. A lock catch is arranged at the position of the opening. The lid ring is composed of a base ring and a sealing ring. A convex rib is arranged on the inner wall of the base ring. A lock catch base is arranged on the sealing ring. A step is arranged at the position where the base ring is connected with the sealing ring. The lid body is buckled on the step of the lid ring. The lock catch of the lid body is connected to the lock catch base of the sealing ring in a clamped mode. The hinge is connected between the lid body and the lid ring. An extending edge is arranged at the portion, located at the edge of the bottom of one side of the hinge, of the inner wall of the lid body. According to the packaging lid of the milk powder tank, the composite structure of the lid body and the lid ring is adopted; in the filling link, filling can be completed conveniently and rapidly; during sealing, the lid body and the lid ring seal the packaging tank; in the using link, due to the guiding of the extending edge, when the lid body is closed, the inner wall can conveniently slide into the inner side of the lip edge of the sealing ring, and use is more convenient.

Owner:SHANGHAI JND PLASTIC PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com