Large-scale equipment of selective molecular sieve gel-forming crystallization kettle

A type-selective molecular sieve and crystallization kettle technology, applied in chemical/physical/physical-chemical processes, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc., can solve the problem of long heating time and easy deposition. Crystallization, outlet blockage, etc., to reduce the deposition of crystallized materials, improve the heat transfer coefficient, and prevent poor material discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

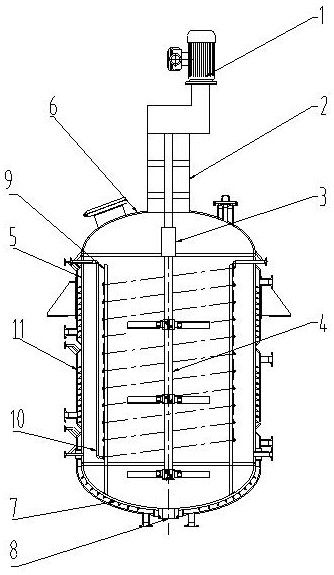

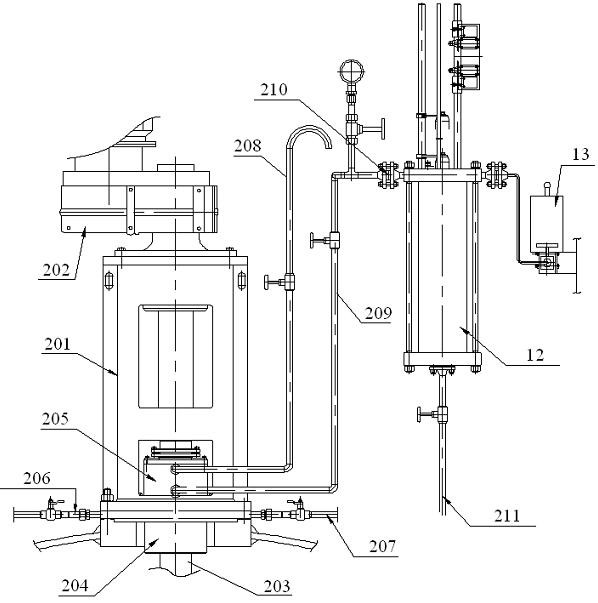

[0029] like figure 1 As shown, a type-selective molecular sieve forming colloidal crystallization kettle large-scale equipment, the equipment has a total volume of 52m 3 A vertical stirred tank with a jacket 11, which includes a stirring device and an inner kettle body.

[0030] The stirring device is a vertical stirring structure, which is composed of a motor 1, an upper transmission seal assembly 2 with a balance tank 12, a coupling assembly 3 and a stirring assembly 4 from top to bottom; the stirring assembly 4 is a three-layer four-slope blade Turbine-type stirring paddle, the bottom stirring paddle is close to the bottom of the inner kettle body.

[0031] The inner kettle body is composed of an upper elliptical head 6, a straight section 5 and a lower elliptical head 7; the top of the upper elliptical head 6 is provided with a feed port and an exhaust port, and the bottom is provided with a discharge port 8; The inside of the straight section 5 is provided with a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com