Patents

Literature

79results about How to "Stable differential pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

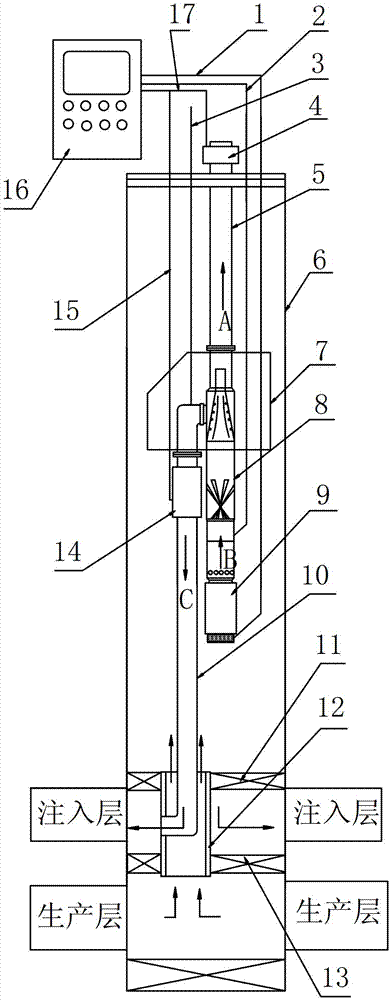

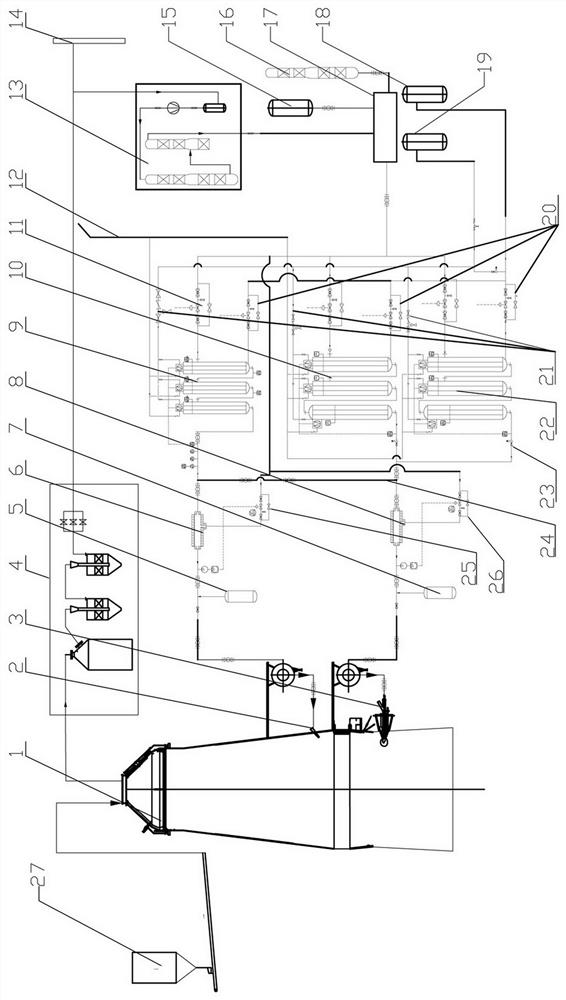

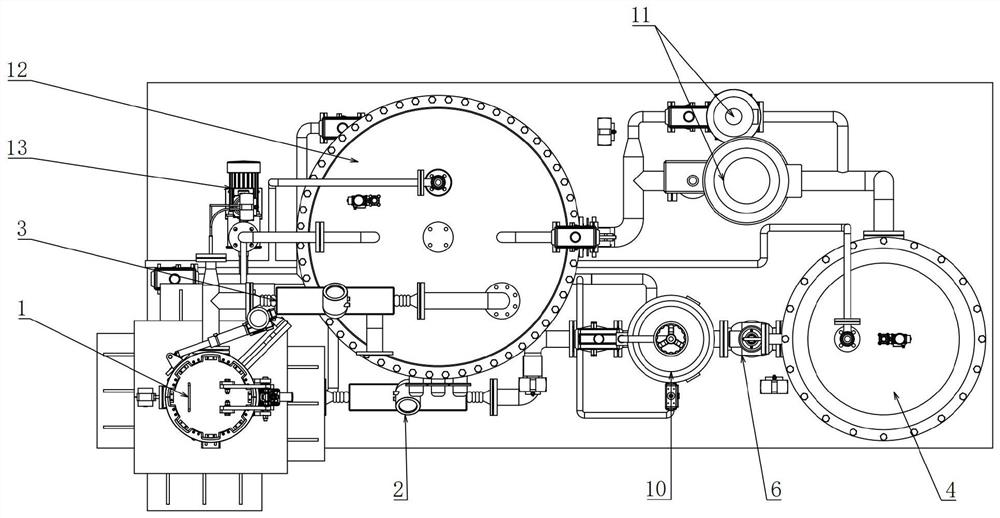

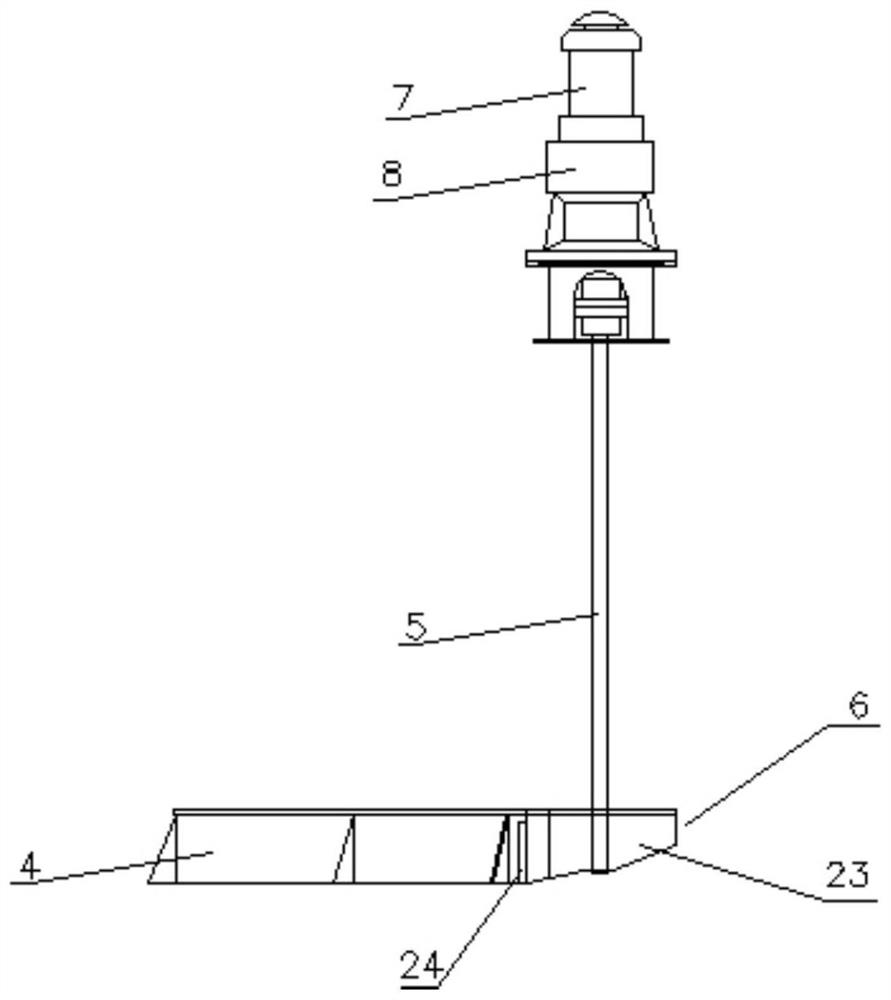

Real-time adjustable and controllable hanging type underground oil and water separating system

ActiveCN102828736AImprove work efficiencyImprove job stabilitySurveyFluid removalStreamflowInstrumentation

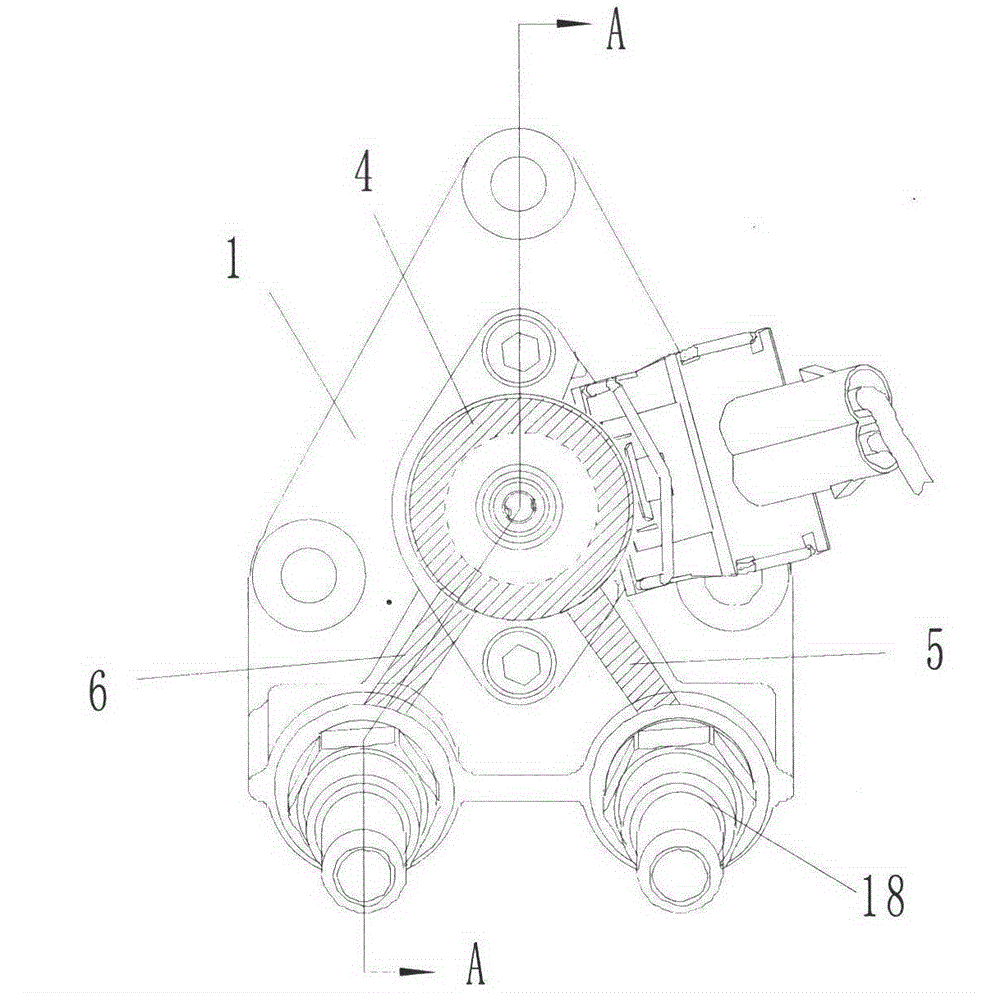

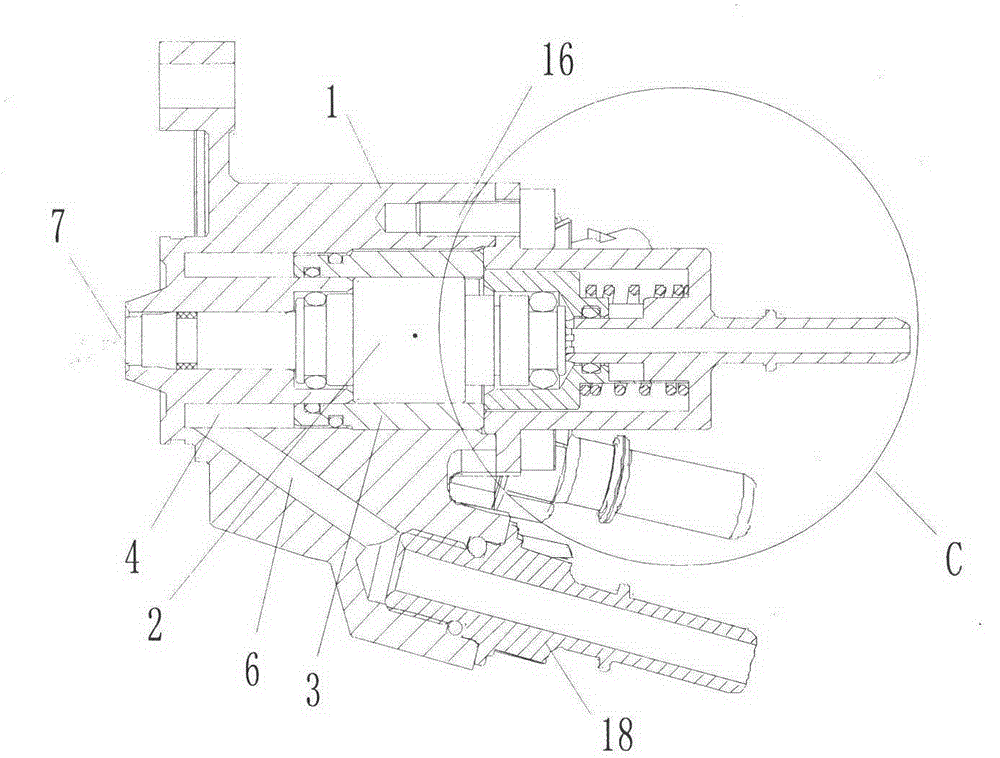

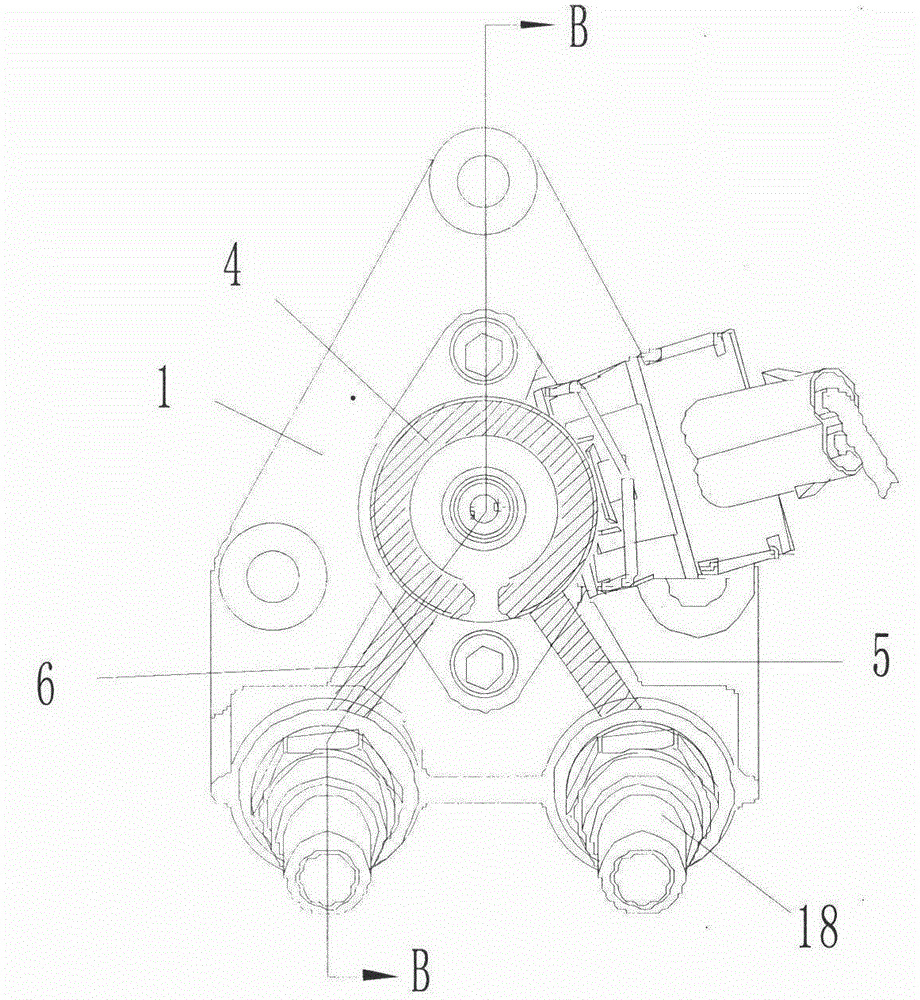

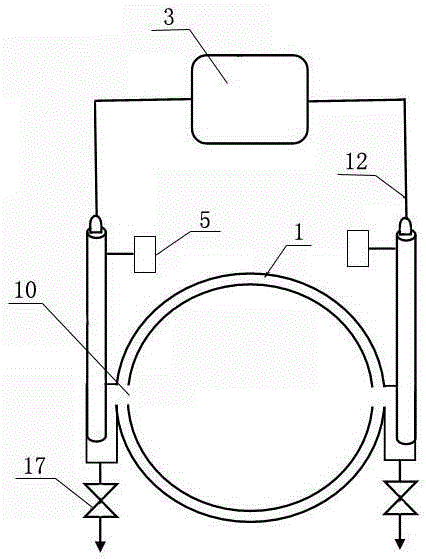

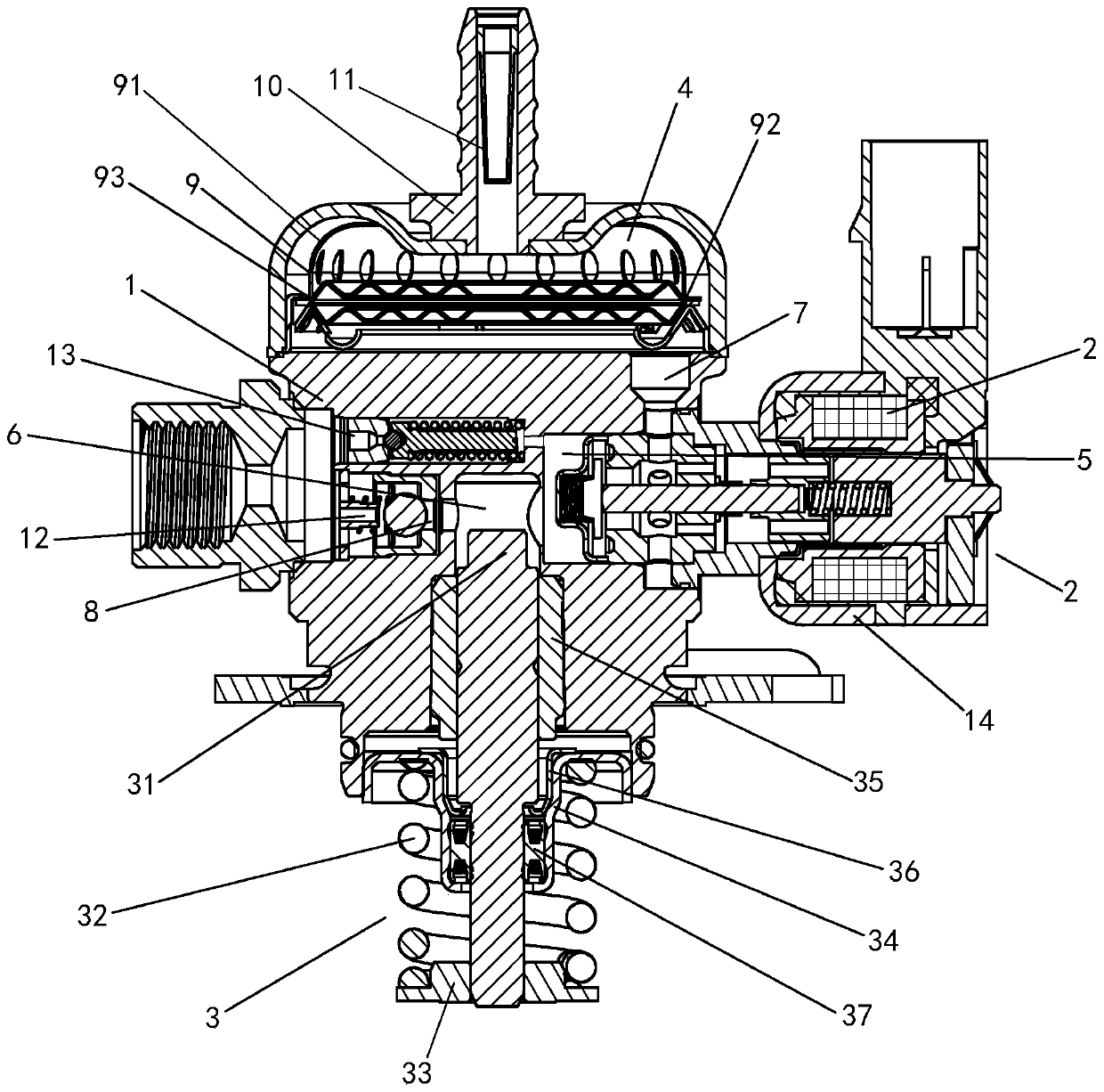

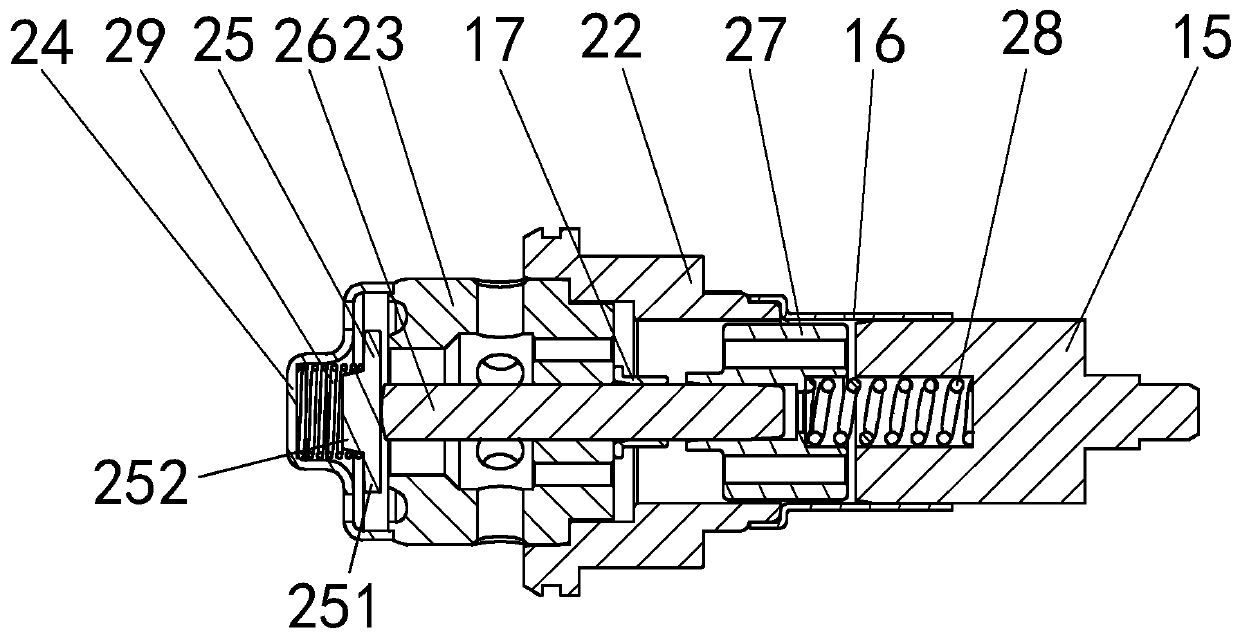

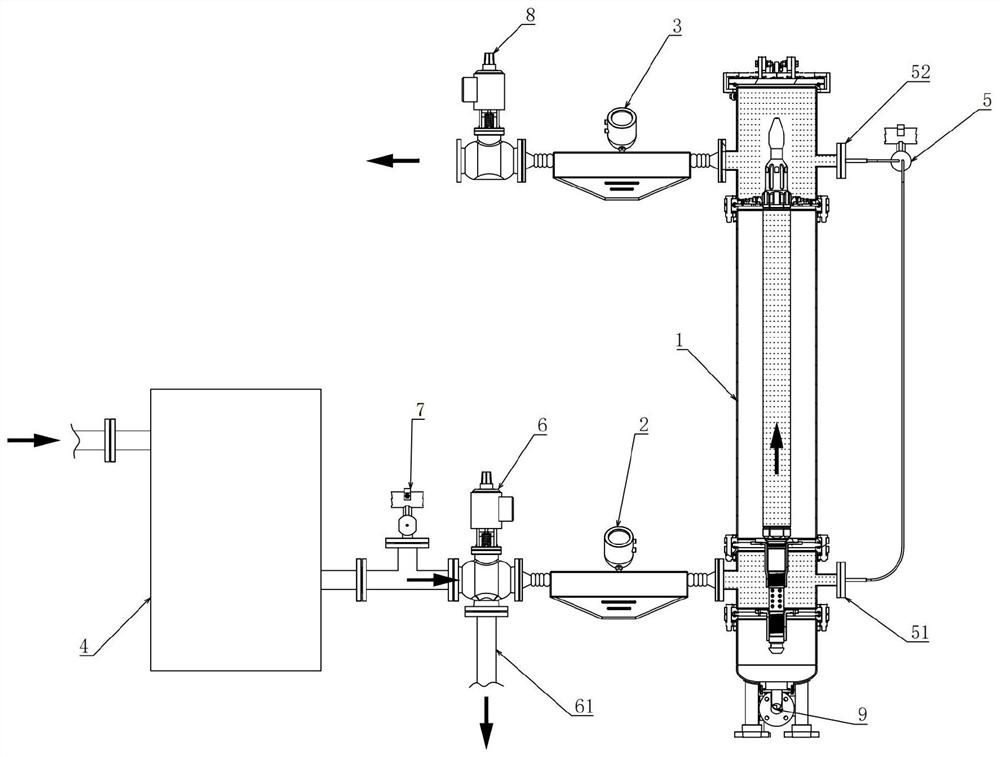

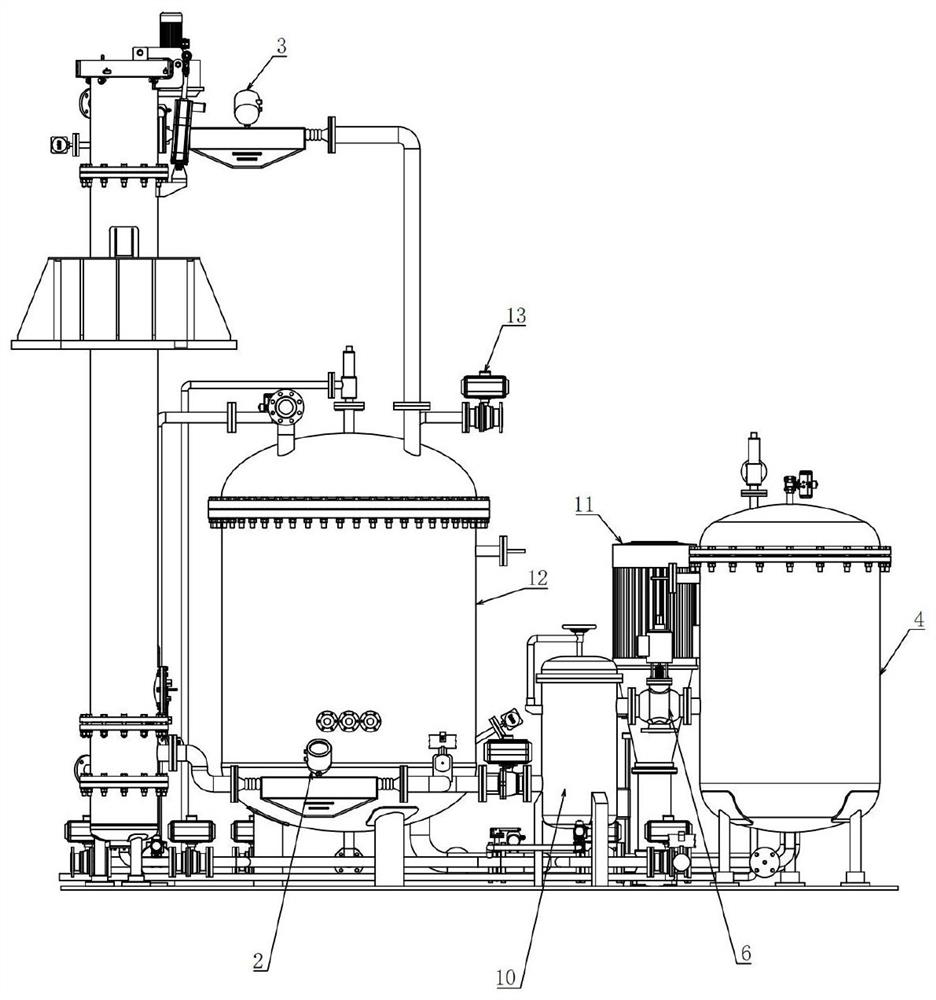

The invention discloses a real-time adjustable and controllable hanging type underground oil and water separating system, which comprises an underground sleeve pipe, a water injection oil pipe, an oil extracting oil pipe and a flow rate control valve, wherein the flow rate control valve is arranged at the wellhead part, the aboveground ground is provided with a visual control device, a hanging type three-way joint connected with the oil extracting oil pipe, an oil and water separator and the water injection oil pipe is arranged in the sleeve, the oil and water separator is connected with an electric submersible pump unit, a water injection pressure regulating device is arranged on the water injection oil pipe, a flow rate and pressure monitoring instrument is arranged in the electric submersible pump unit, a flow rate and pressure monitoring instrument and a regulating valve are arranged in the flow rate control valve, monitoring instrument cables and signal transmission cables are respectively connected among the electric submersible pump unit, the water injection pressure regulating device, the flow rate control valve and the visual control device, the visual control device converts received real-time flow rate and pressure signals into visual data to be output, and the work of the whole system is regulated and controlled. The hanging type underground oil and water separating system has the advantages that the stability is high, the treatment capability is high, and the hanging type underground oil and water separating system can be widely applied to an oilfield same-well production injection process.

Owner:CNOOC ENERGY TECH & SERVICES

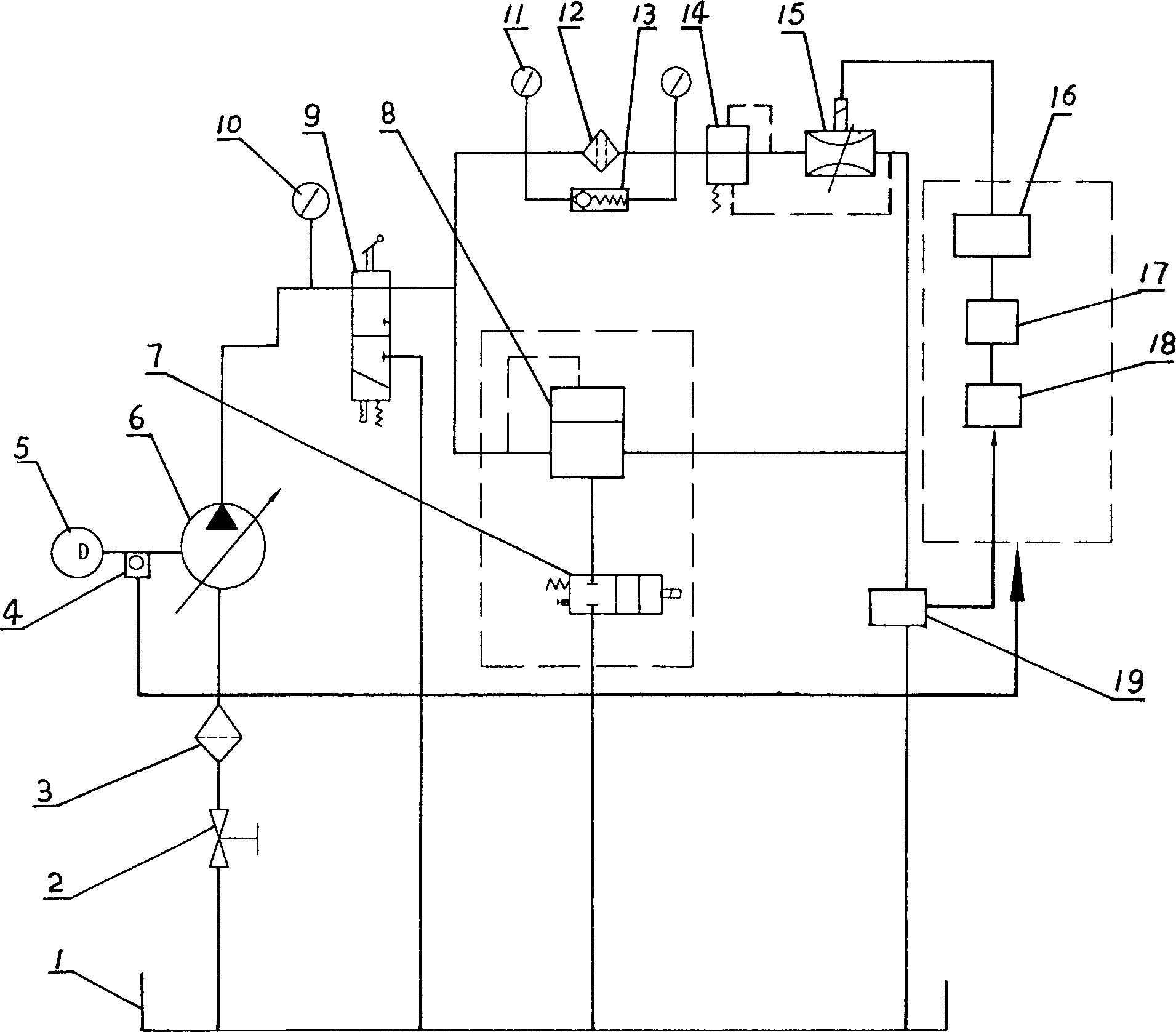

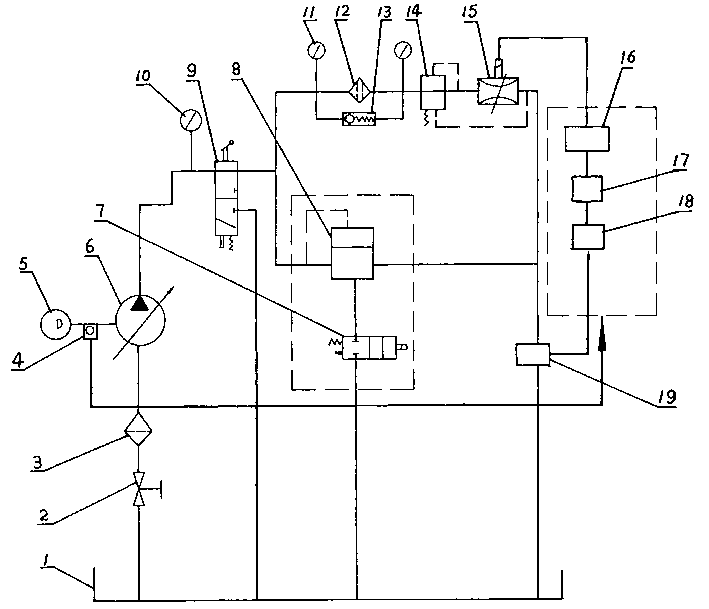

Hydraulic arrester with capabilities of speed adjustment and soft braking

InactiveCN1415509AStable differential pressureAvoid pollutionConveyorsLiquid resistance brakesHigh pressureThrottle

A hydraulic speed regulation type soft brake for the underhung conveyer is composed of hydraulic system and electric control system. The said hydraulic system consists of braking pump and hydraulic pump station which comprises manual reverse valve, electromagnetic overflow valve, proportional throttle valve, filters, oil tank, pressure meter, cut-off valve and sensors (flow sensor and rotation speed sensor). Its advantages are high braking stability, and no need of cooler.

Owner:TAIYUAN UNIV OF TECH

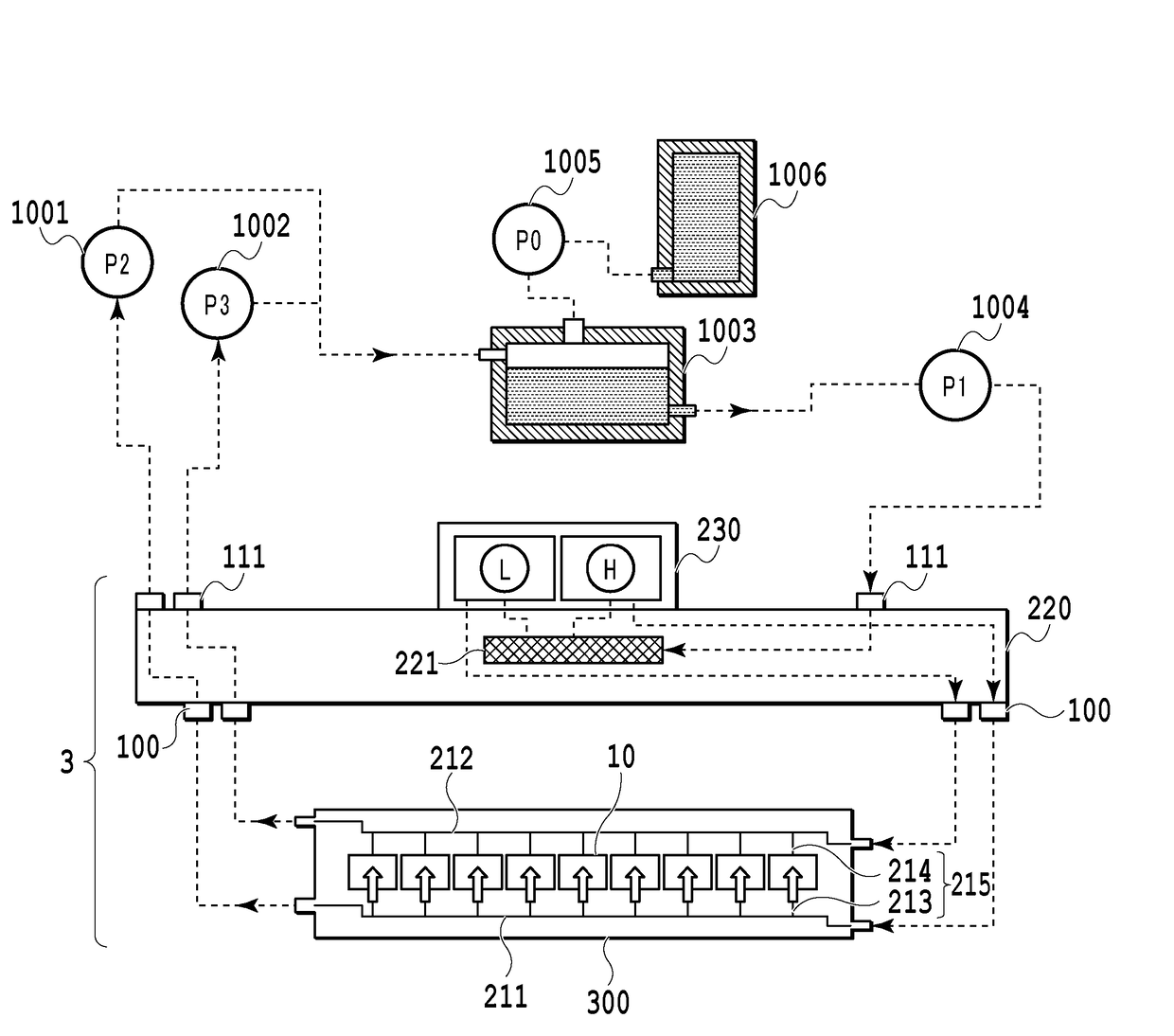

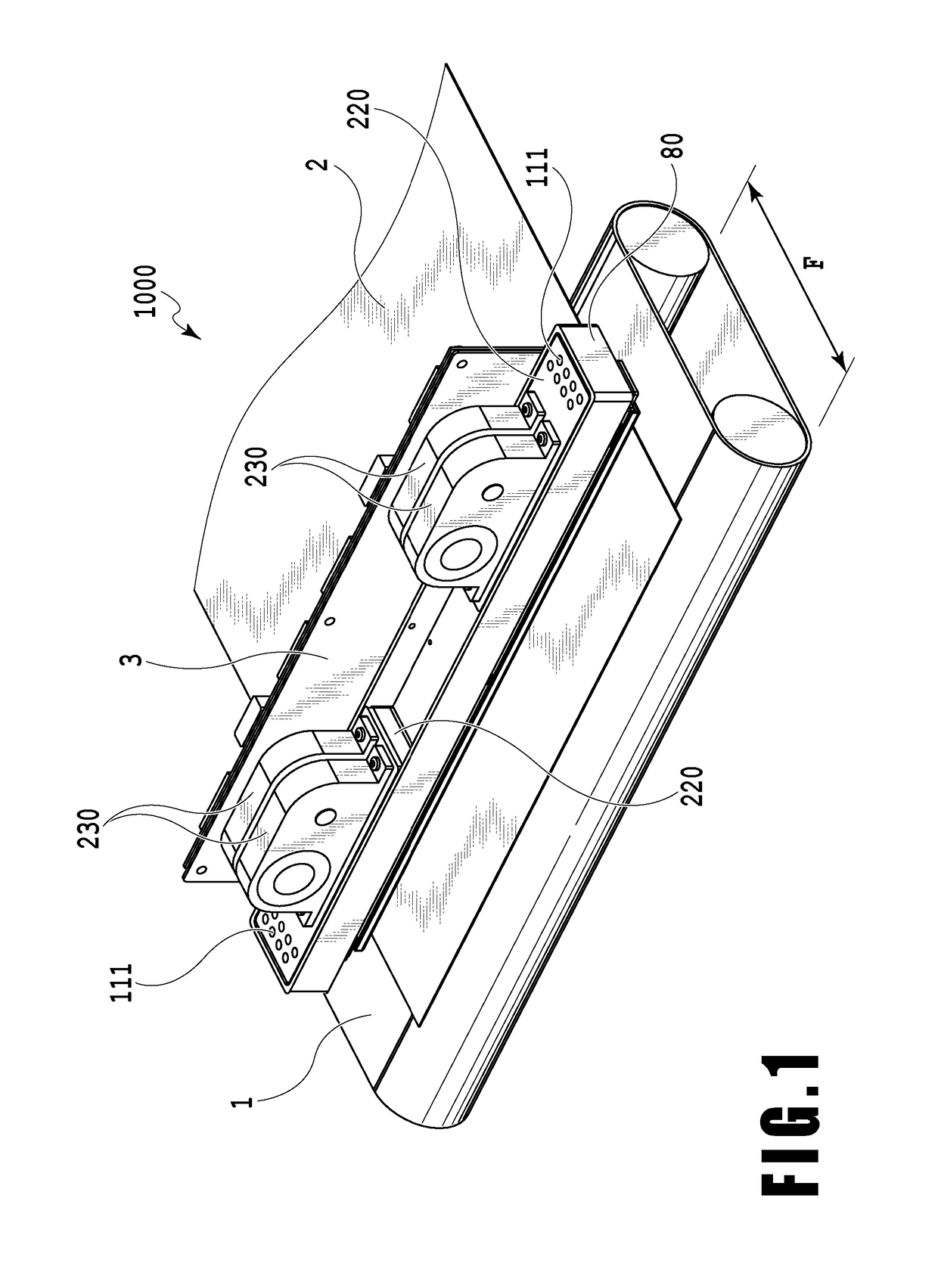

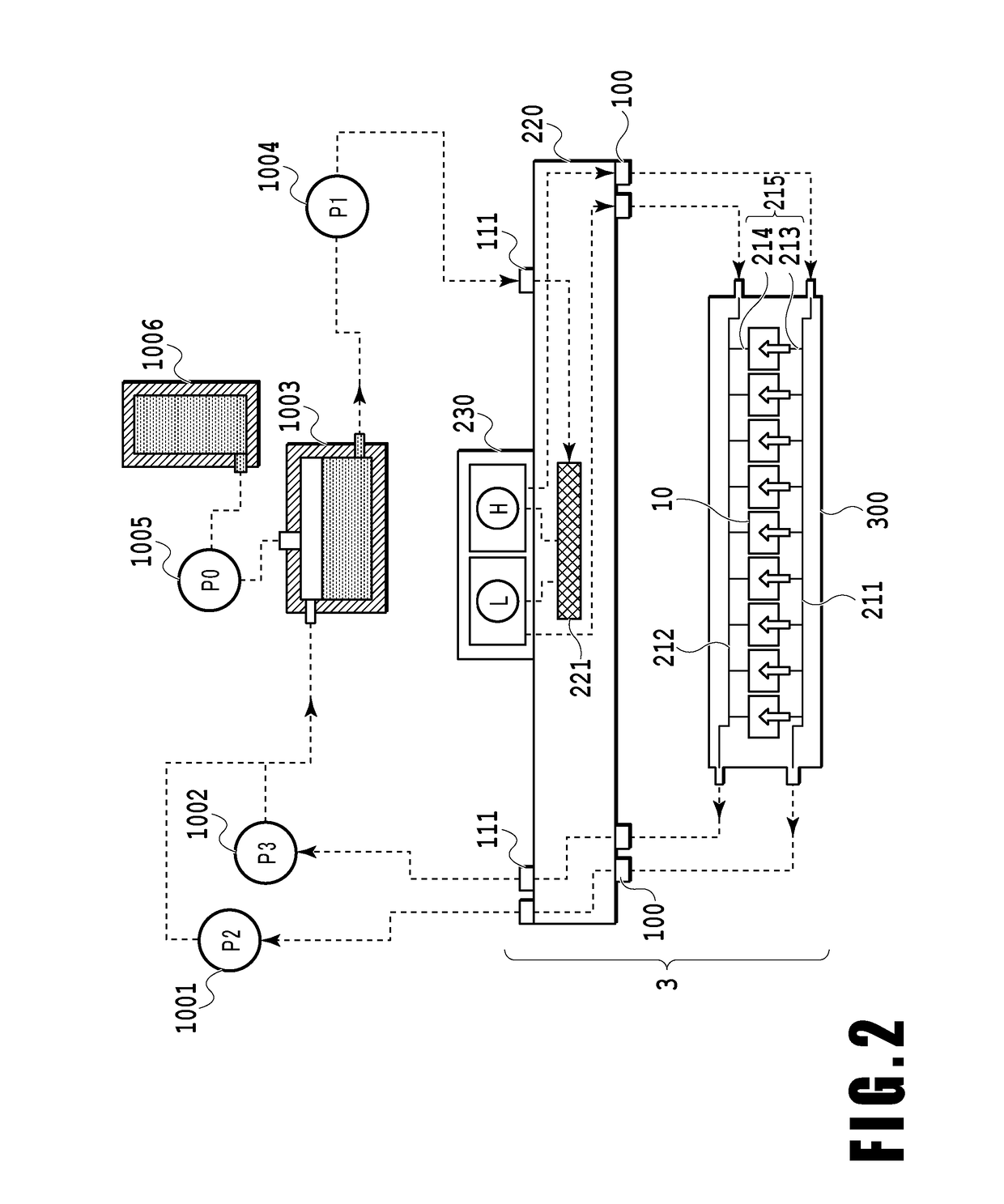

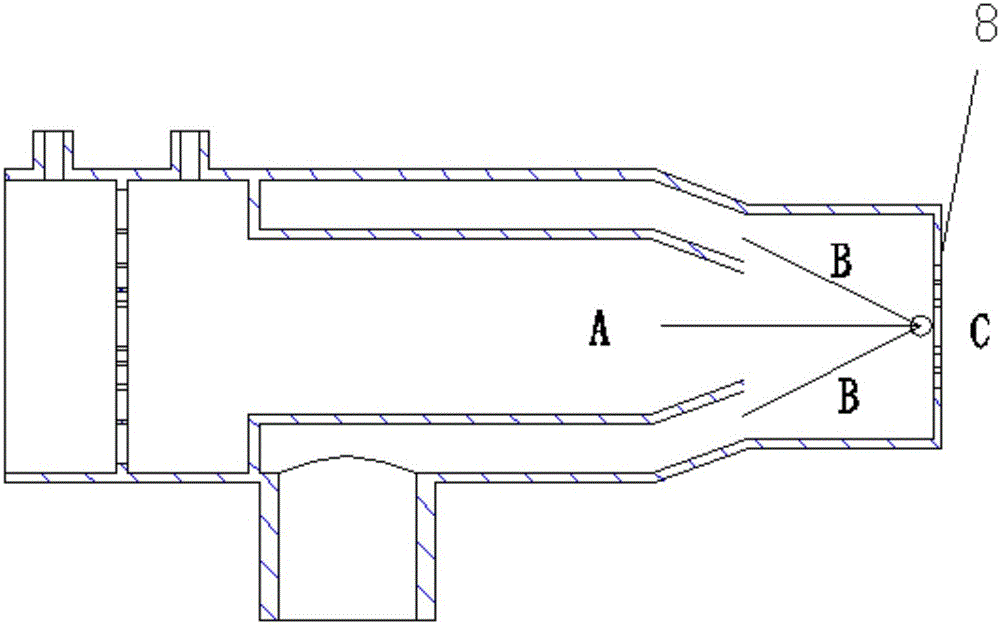

Liquid ejection printing apparatus and liquid ejection head

A liquid ejection printing apparatus includes a pressure control assembly that generates a pressure for causing the same liquid to flow to the ejection opening communication passage communicating with an ejection opening of a liquid ejection head. The pressure control assembly includes a first pressure adjustment mechanism that causes a liquid supplied from a first upstream passage to flow therefrom at a first pressure and a second pressure adjustment mechanism that causes a liquid supplied from a second upstream passage therefrom at a second pressure different from the first pressure. The first upstream passage and the second upstream passage communicate with each other and a first downstream passage communicating with the first pressure adjustment mechanism and a second downstream passage communicating with the second pressure adjustment mechanism are respectively connected to the same ejection opening communication passage communicating with the ejection opening.

Owner:CANON KK

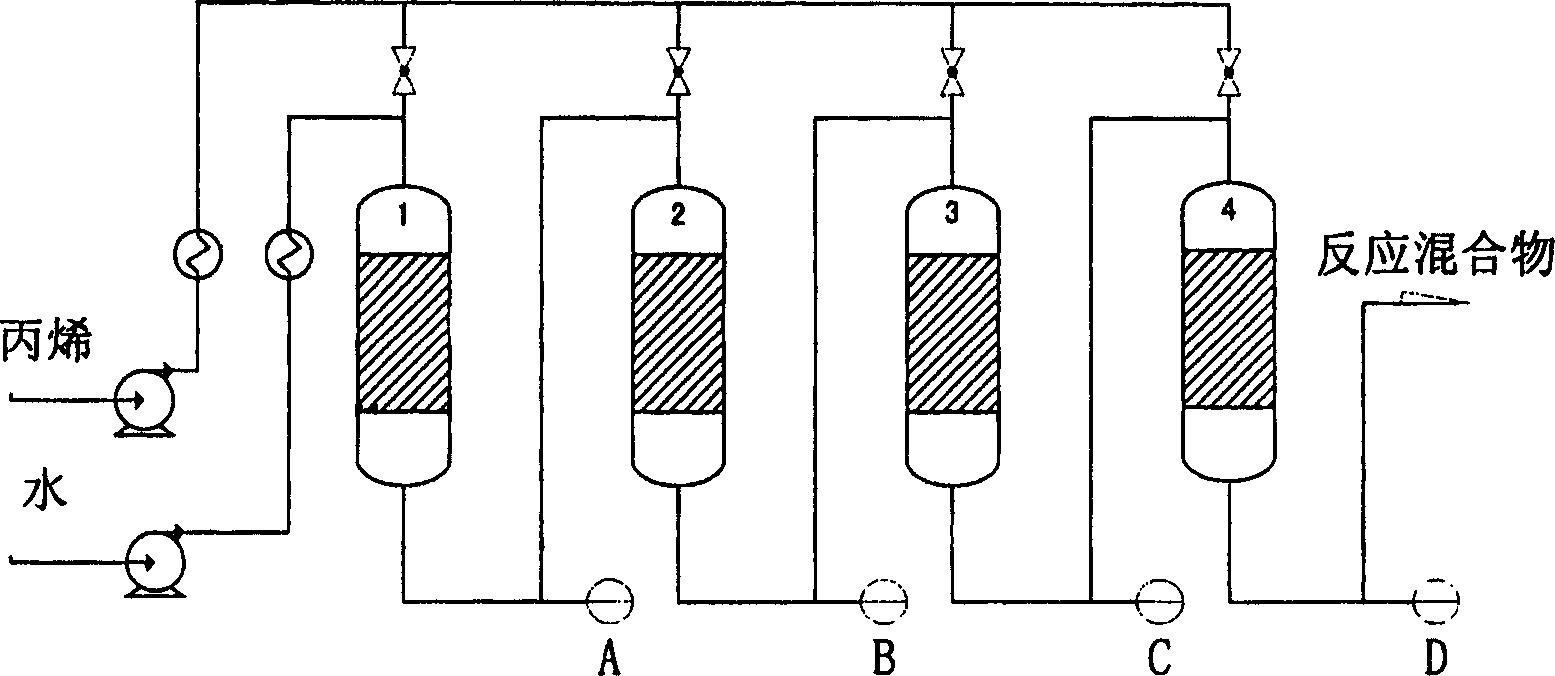

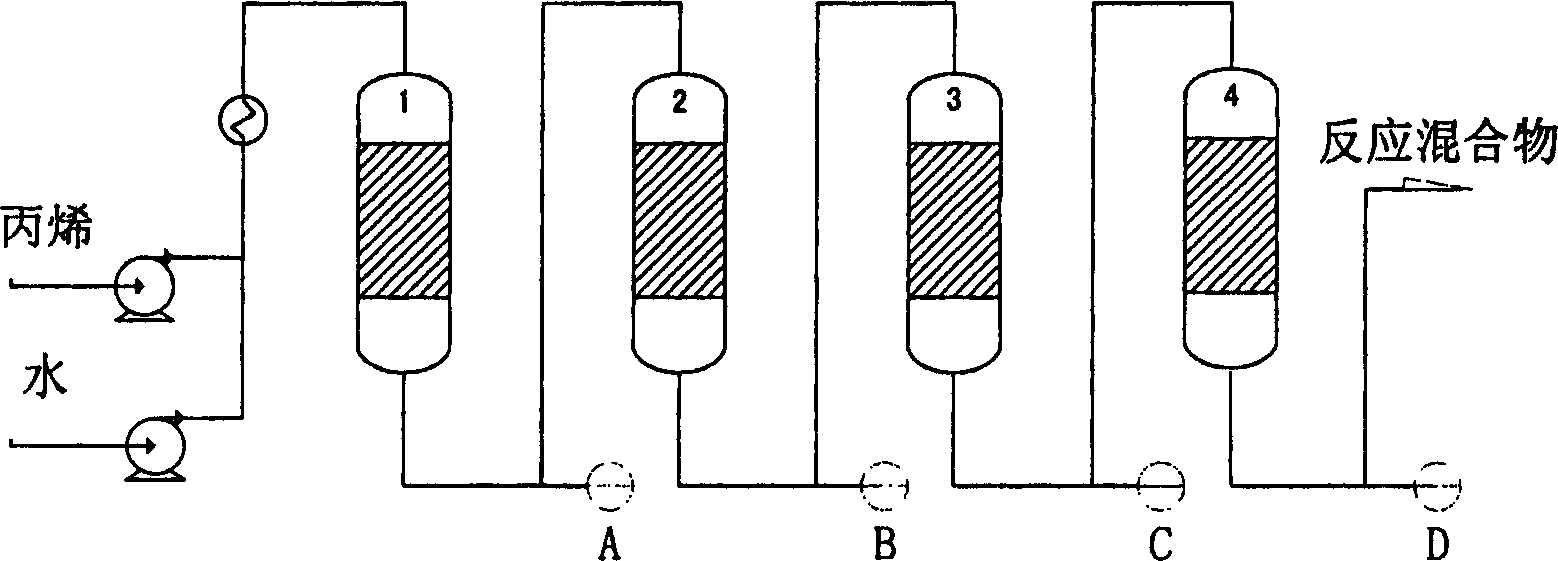

Process for producing lower alcohol by direct hydration of low carbon olefin

ActiveCN1670006AExtended service lifeStable differential pressurePreparation by hydroxy group additionCarbon numberHydration reaction

The invention discloses a method for producing lower alcohol by lower carbon number hydrocarbons direct hydration, which comprises: in the action of solid catalysts (such as cationic catalysts, molecular sieve catalysts or phosphate bergmeal), catalyze hydration synthesizing the lower alcohol by lower carbon number hydrocarbons with 2-5 carbon atoms using segmented feeding with mole ratio between combined feed water to lower carbon number hydrocarbons as 0.1-30 in the temperature of 80-200 Deg. C and in the pressure of 2.0-20.0 MPa. The production is alcohol and a compound of alcohol and ether with 2-5 carbon atoms correspondingly, and separating the alcohol of production flow to get the final production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

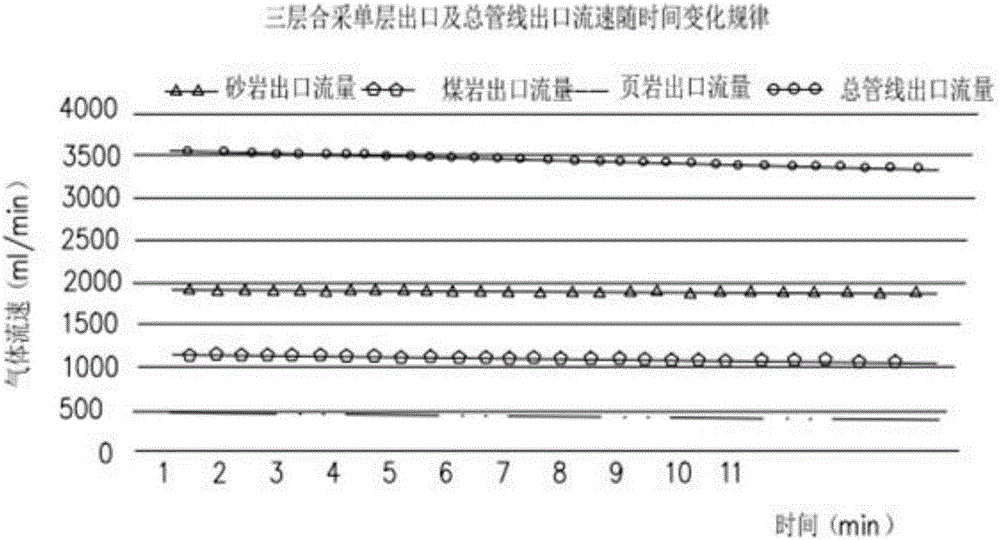

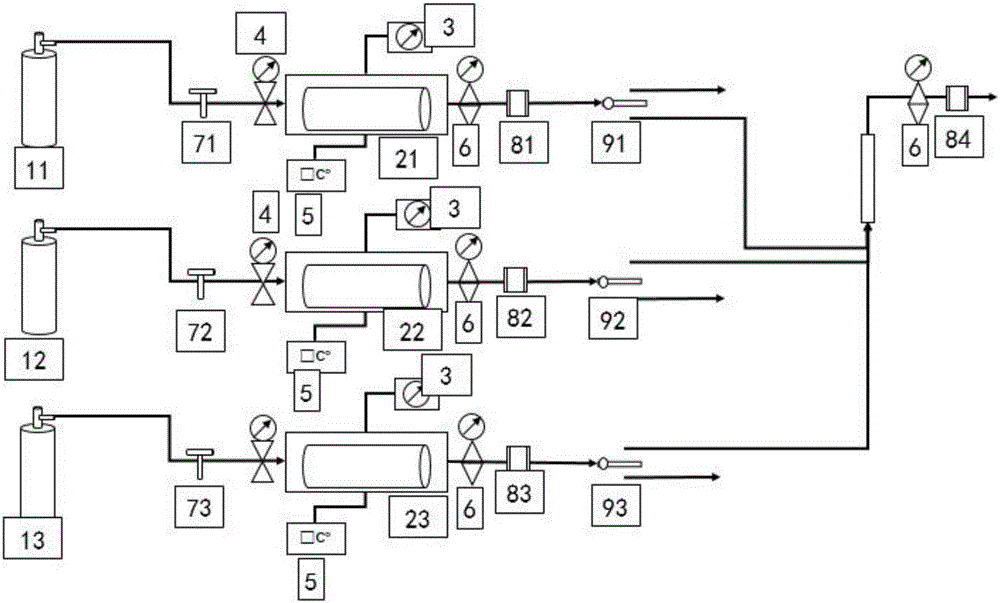

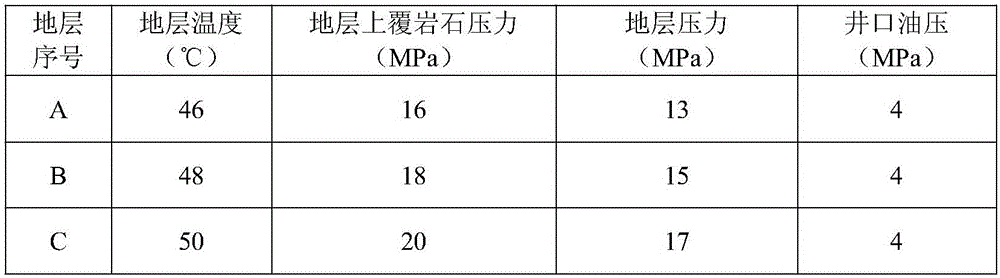

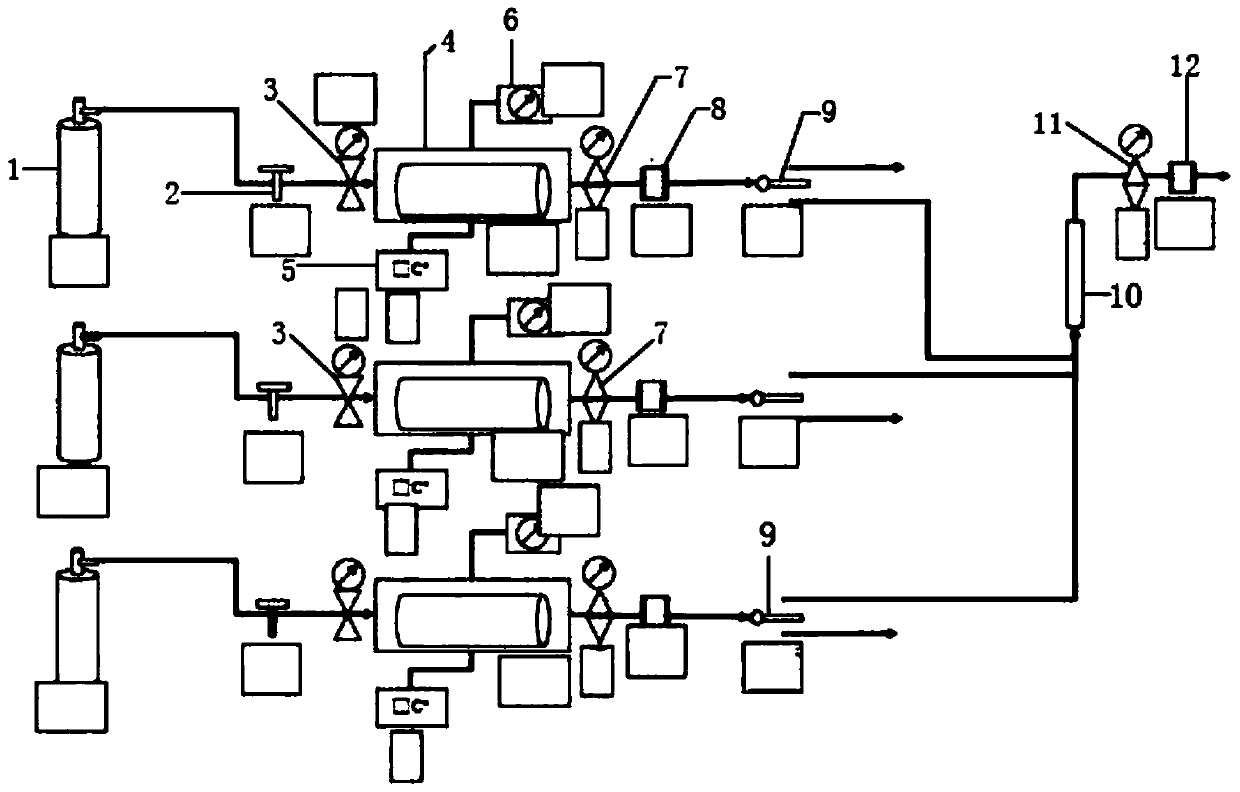

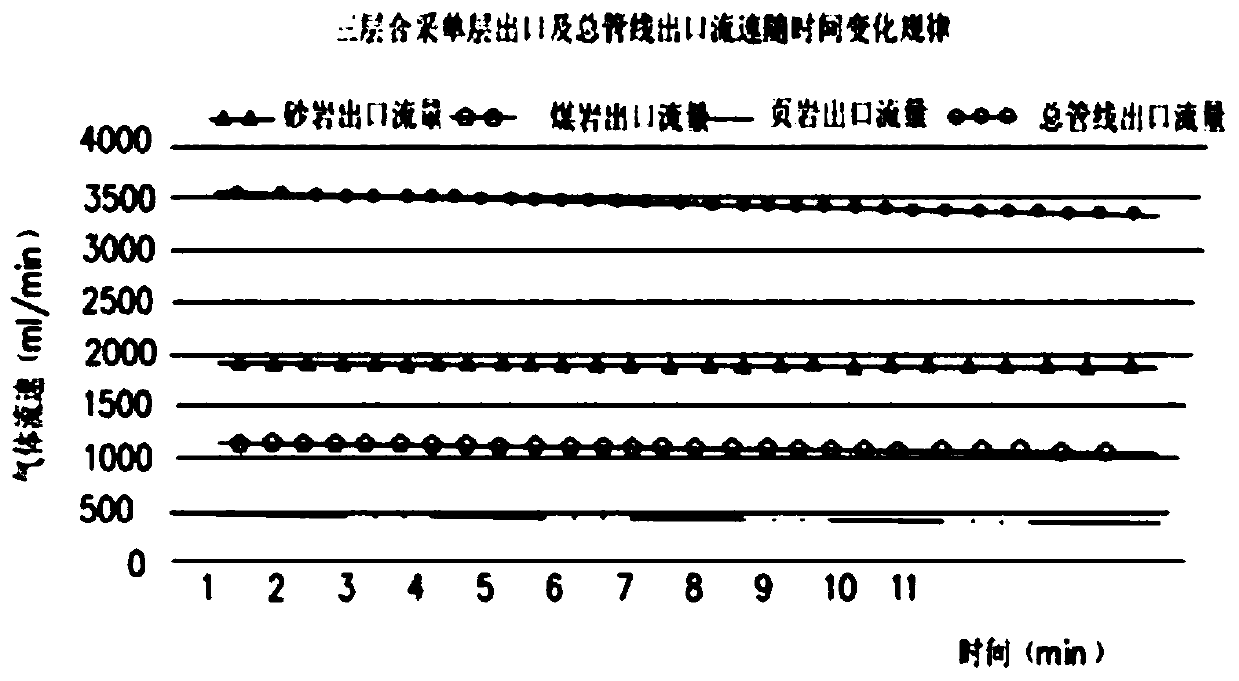

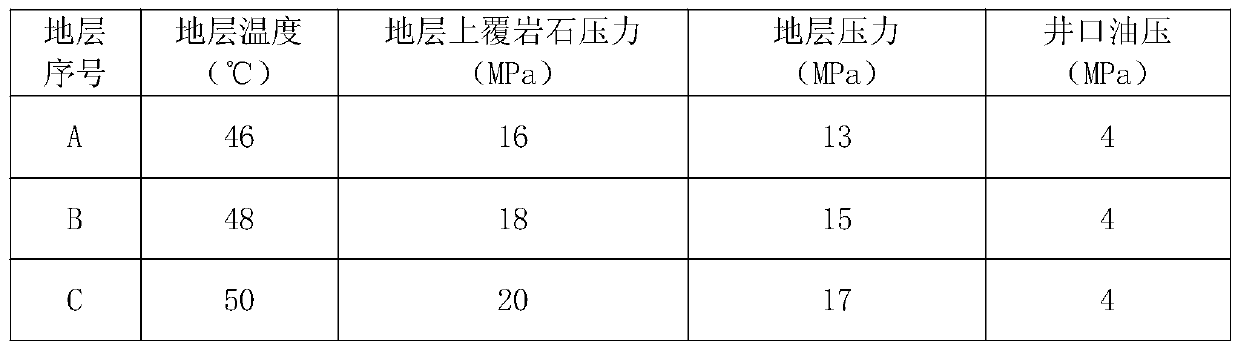

Simulation experiment method of multi-layer commingling capacity of natural gas reservoir

The invention aims at providing a simulation experiment method convenient to operate and capable of accurately simulating gas capacity quantitative evaluation under the condition of natural gas multi-layer commingling operation process, of multi-layer commingling capacity of a natural gas reservoir. The simulation experiment method of the multi-layer commingling capacity of the natural gas reservoir comprises a plurality of pressure gas containing bottles; a gas outlet of each pressure gas containing bottle is connected with a gas inlet of each reducing valve correspondingly, and a gas outlet of each reducing valve is connected with a gas inlet of each rock core clamp tube body correspondingly; a temperature measuring unit and a confining pressure measuring unit are installed on the wall of each rock core clamp tube body correspondingly, a gas outlet of each rock core clamp tube body is connected with an entrance of each bi-directional valve through a pipeline which is in series connection with a branch-pipe backpressure valve and a branch-pipe flow meter correspondingly, and an exit of each bi-directional valve is connected with the lower portion of a cylindrical container through a pipeline correspondingly; and the top of the cylindrical container is connected with outside air through a pipeline which is in series connection with a header pipe backpressure valve and a header pipe flow meter.

Owner:YANGTZE UNIVERSITY

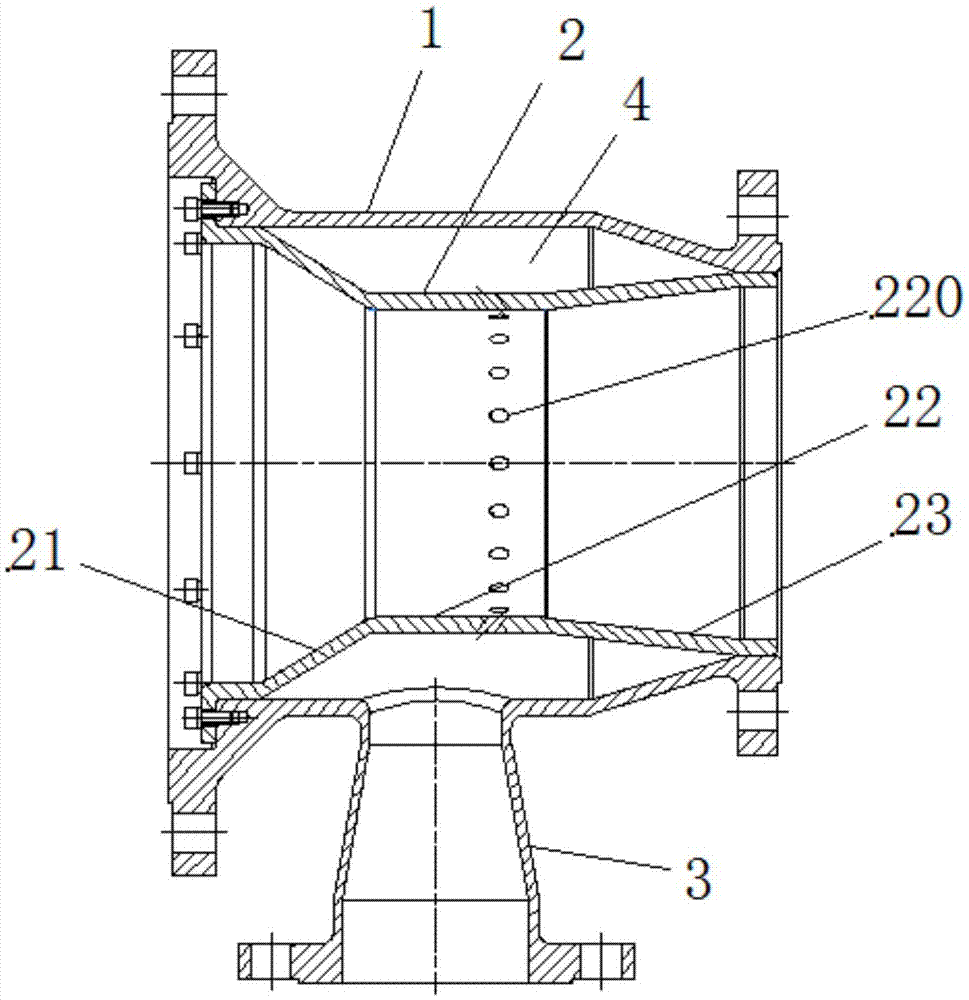

Venturi mixer with drainage function

InactiveCN105435669APlay a drainage roleStable differential pressureFlow mixersTransportation and packagingPressure stabilizationInlet channel

The invention discloses a venturi mixer with a drainage function. The venturi mixer comprises an outer pipeline, an inner pipeline and a fuel gas inlet channel which is vertically arranged on the outer pipeline, wherein a closed circuit chamber is formed between the outer pipeline and the inner pipeline; the inner pipeline comprises a contracting section, a throat section and a flaring section; gas inlets are uniformly formed on one circle along the circumferential direction of the throat section; the gas inlets are formed in an inclined form along the wall of the inner pipeline; the fuel gas inlet channel is arranged as a gradual reducing pipeline. The fuel gas firstly enters into the closed circuit chamber through the fuel gas inlet channel, and then enters into a main runner through a circle of gas inlets uniformly distributed on the throat section, and mixes with air entering from the inlet of the main runner, so that the smooth entering of the fuel gas is ensured while the uniform gas entering along the circumference of the throat section is realized, the buffering and pressure stabilization for the fuel gas are realized, the stable differential pressure between the fuel gas inlet channel and the main runner is formed and the uniform stable running field of the main runner is maintained, and furthermore, the gas inlets are formed in the inclined form on the throat section, so that the fuel gas can form the confluence at a certain degree, the influence on air entering is reduced and the air flow collision loss is reduced.

Owner:CHONGQING PUSH MECHANISM

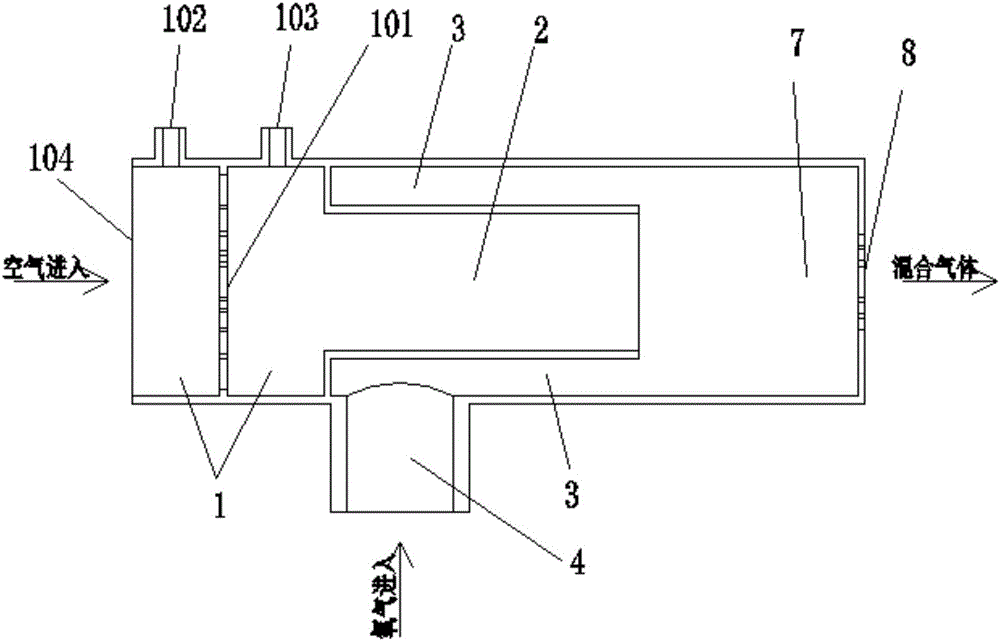

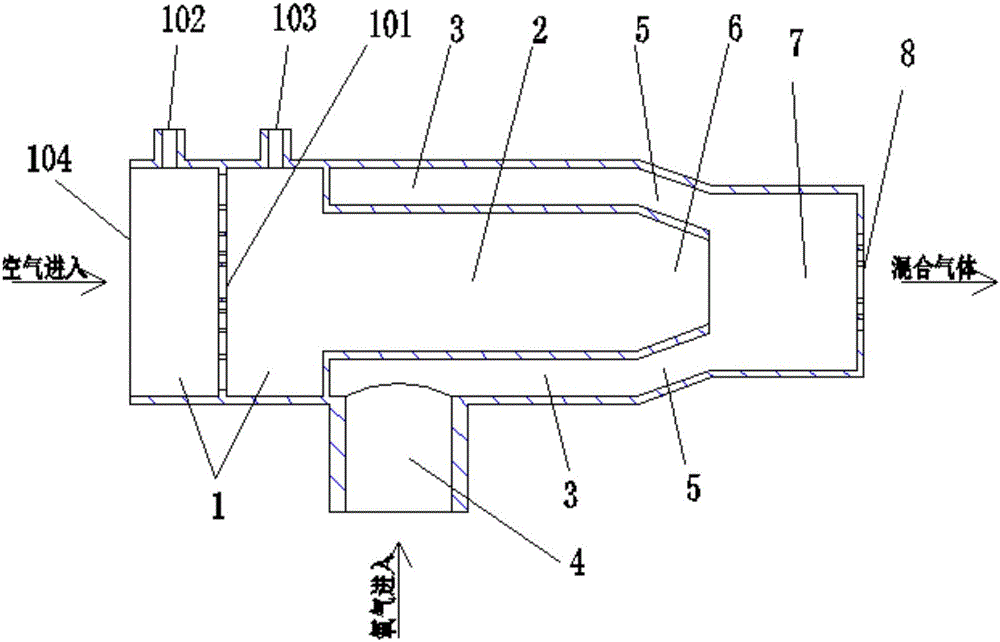

Air-oxygen mixing structure for breathing machine and breathing machine

The invention provides an air-oxygen mixing structure for a breathing machine and the breathing machine. The air-oxygen mixing structure comprises an air flow detecting cavity, an oxygen guide cavity, an air guide cavity and a mixing cavity. The inlet end of the air flow detecting cavity is an air inlet, and the outlet end of the air flow detecting cavity is communicated with the inlet end of the air guide cavity. A pressure-drop holed wall is arranged in the air flow detecting cavity, and a flow detecting port I and a flow detecting port II are respectively arranged on the front side and the rear side of the pressure-drop holed wall. The air guide cavity is a circular-ring-shaped cavity arranged on the periphery of the air guide cavity, and an oxygen inlet is formed in the outer wall of the oxygen guide cavity. The inlet end of an oxygen mixing guide cavity and the inlet end of an air mixing guide cavity are respectively communicated with the oxygen guide cavity and the air guide cavity, and the outlet ends of the two cavities are both communicated to the mixing cavity. The outlet end of the mixing cavity is provided with a mixing holed wall. The air-oxygen mixing structure is used for the breathing machine and has the advantages of being simple in structure, capable of preventing turbulent flows from influencing flow detection and making gases be mixed fully.

Owner:HUNAN MICOME ZHONGJIN MEDICAL SCI & TECH DEV CO LTD

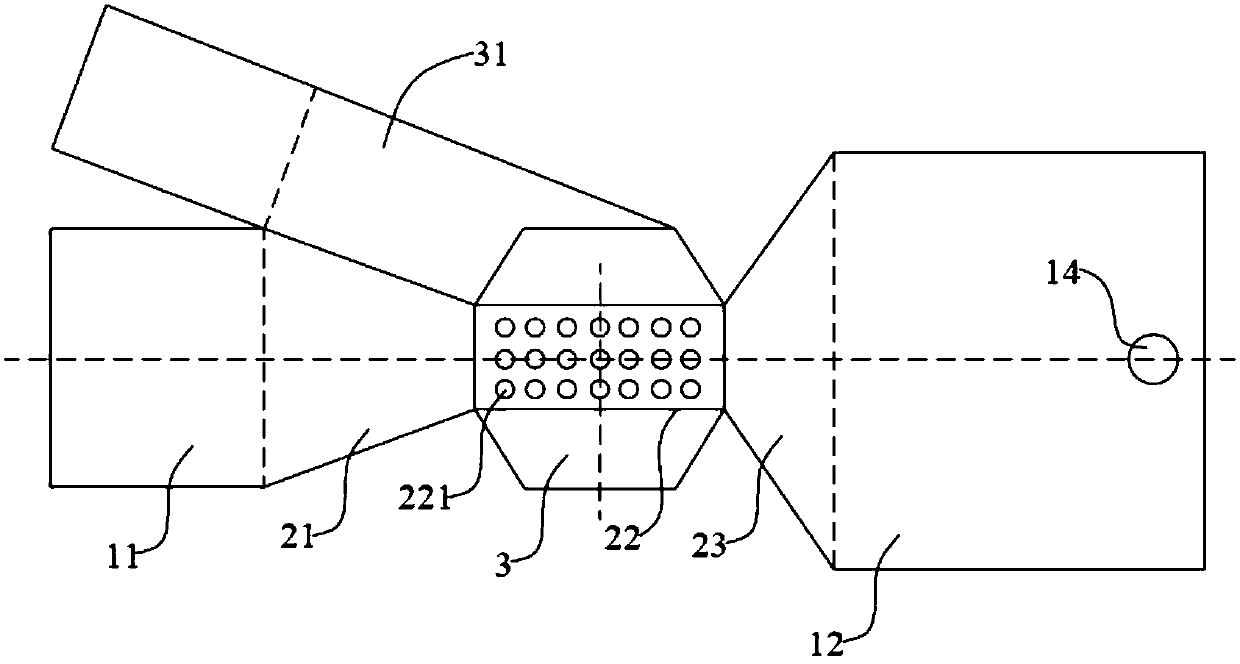

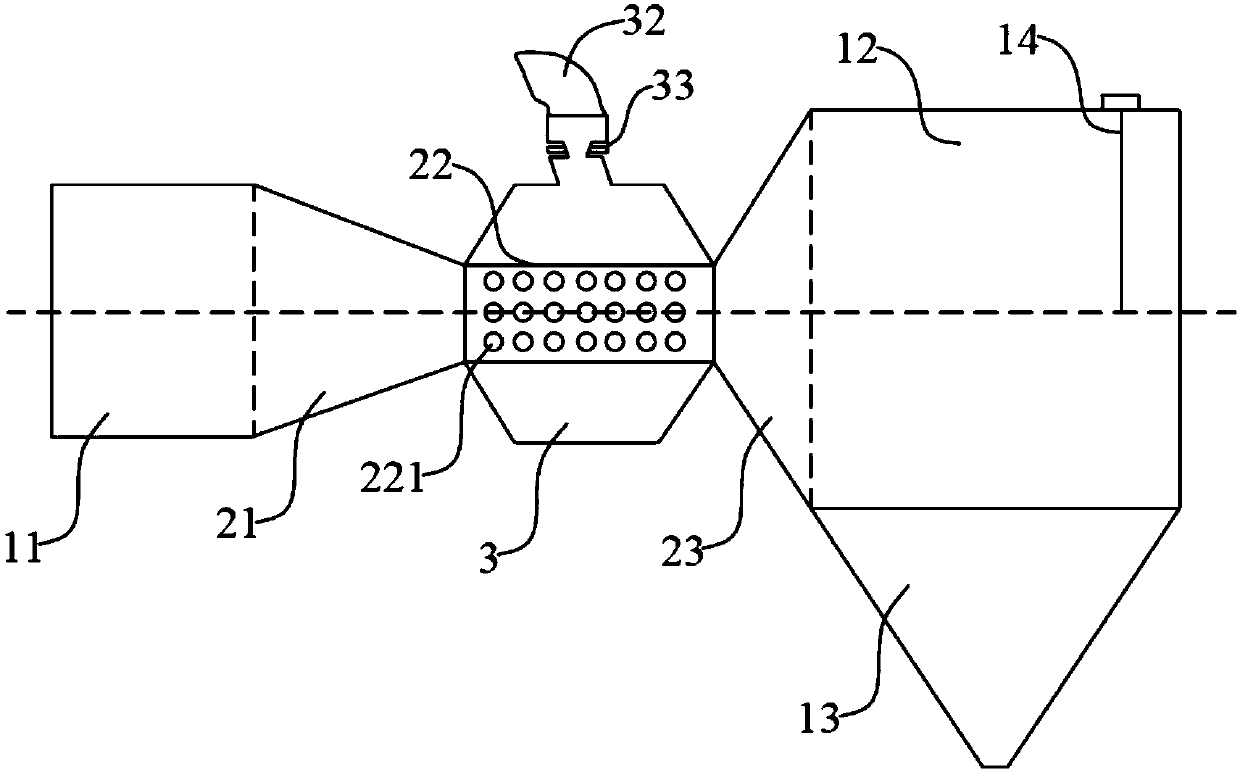

Flue gas mixing device and method

ActiveCN108014667ASolve the problem of energy consumptionPlay a drainage roleFlow mixersTransportation and packagingFlue gasHigh energy

The invention discloses a flue gas mixing device and method and relates to the technical field of gas mixing. The flue gas mixing device comprises a flue inlet section, a throat section and a flue outlet section which are sequentially communicated, wherein multiple gas inlet holes are circumferentially formed in the side wall of the throat section, and an annular channel cavity is formed in the periphery of the throat section and connected with an annular cold waste gas branch pipe. The main body of the flue gas mixing device is designed into a venture tube structure, so that circulating fluegas can accelerate and guide annular cold waste gas when flowing into the throat section, the annular cold waste gas can be fully mixed without being boosted by an annular cold fan to enter a circulating flue, the annular cold waste gas passes through an annular channel cavity and the gas inlet holes sequentially and can also guide the circulating flue gas, and the problems of high energy consumption and poor flue gas mixing effect of existing flue gas mixing devices are solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Water cooling nozzle without air pump

InactiveCN104948277AReduce precisionTake away quicklyExhaust apparatusSilencing apparatusAir pumpExhaust gas

The invention discloses a water cooling nozzle without an air pump and relates to the technical field of automobile exhaust processing. The water cooling nozzle comprises a shell, a metering valve is arranged in the shell, and a cooling room defined by a blocking cover is arranged on the periphery of the metering valve. The cooling room can achieve efficient cooling on the metering valve. A telescopic sleeve is arranged on the head of the metering valve, the metering valve is connected with a liquid inlet connecting pipe, an elastic part is arranged between the telescopic sleeve and the liquid inlet connecting pipe, and a buffering cavity is formed between the telescopic sleeve and the metering valve. The effects of stabilizing pressure and storing energy can be achieved through the buffering cavity, the metering precision is ensured, residual liquid in the metering valve can be removed in time through the elastic part, and therefore the metering valve is prevented from being frozen to be damaged.

Owner:SUZHOU POWERGREEN EMISSION SOLUTION SYST

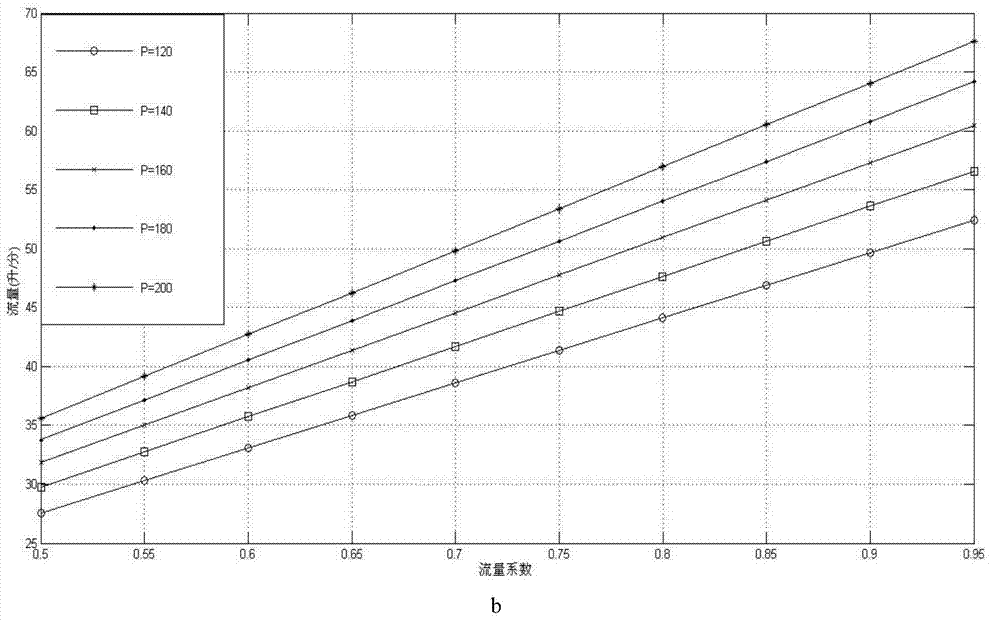

Final-stage channel flow measuring method and device

InactiveCN104568026AHigh precisionSmall rangeVolume/mass flow by differential pressureMicrocontrollerAgricultural irrigation

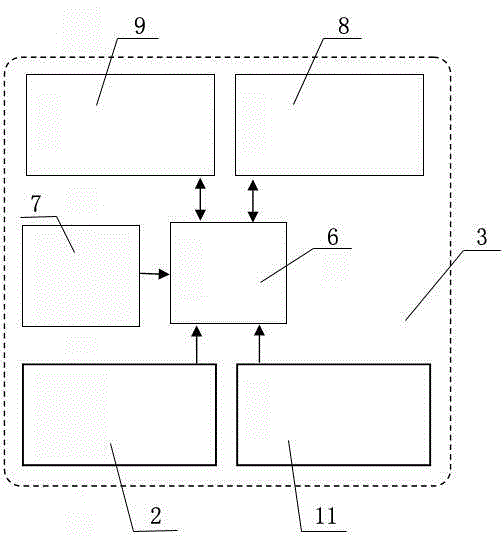

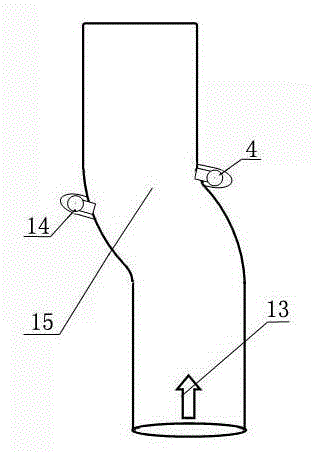

The invention relates to a final-stage channel flow measuring method and device and belongs to the technical field of agricultural irrigation flow metering. According to the technical scheme, two pressure sensors are arranged on two sides of a main pipeline (1) in a matched manner, and the output ends of the pressure sensors are connected to a monitoring terminal (3); the pressure sampling points of the two pressure sensors are opposite on the main pipeline, one point faces to the water incoming direction of the main pipeline obliquely, and the other point is opposite to the water incoming direction of the main pipeline obliquely; the monitoring terminal comprises a single chip processor (6), a lithium-ion battery (7), a remote communication module (8) and a radio frequency communication module (9), the radio frequency communication module matches with a radio frequency communication module of mobile communication equipment, and the remote communication module matches with a remote monitoring computer. The continuous flow monitoring can be performed in the field final-stage channels, the efficiency and measuring accuracy can be improved, the problem of 'agricultural irrigation last one kilometer metering' can be solved, and the effect of saving water is achieved.

Owner:唐山现代工控技术有限公司

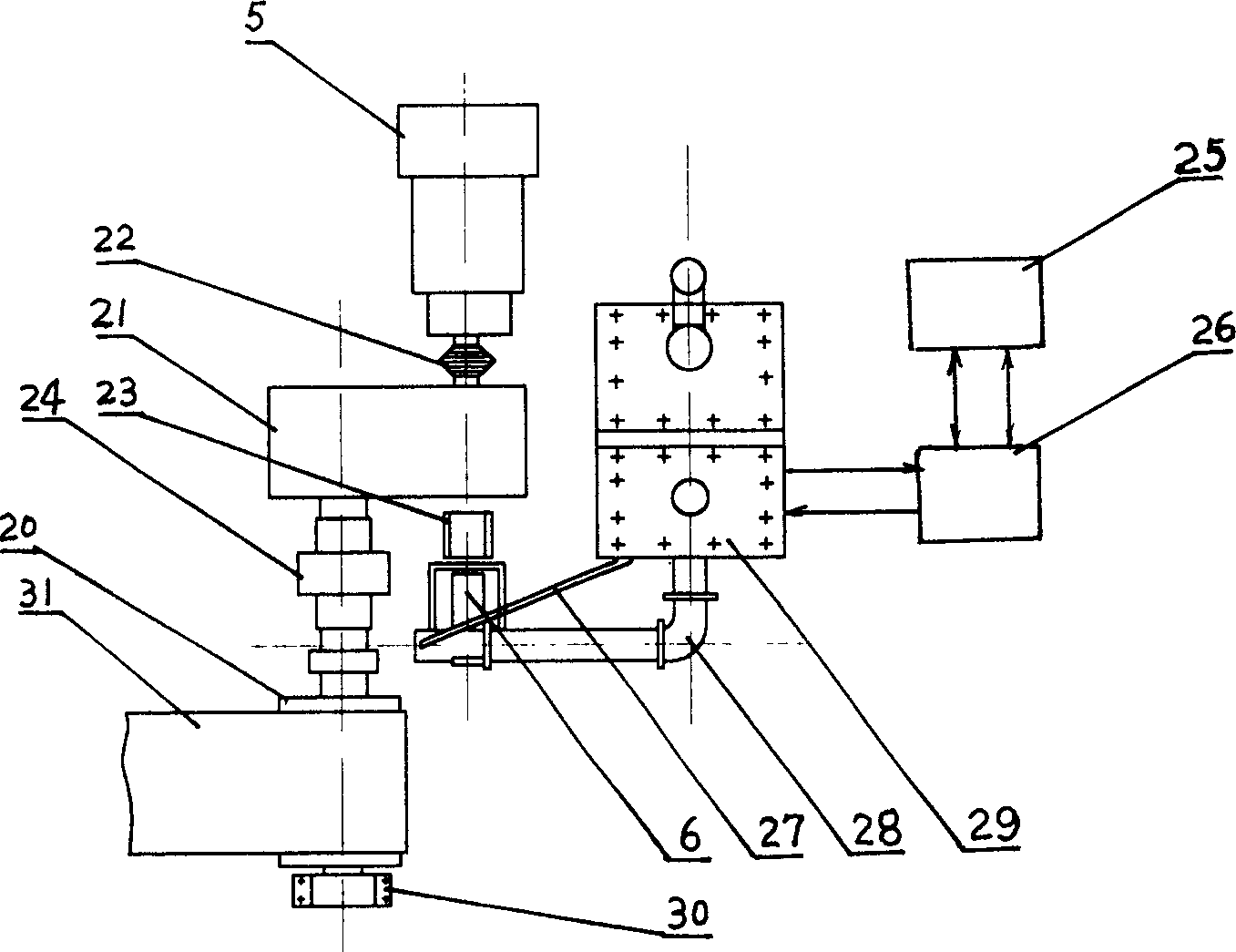

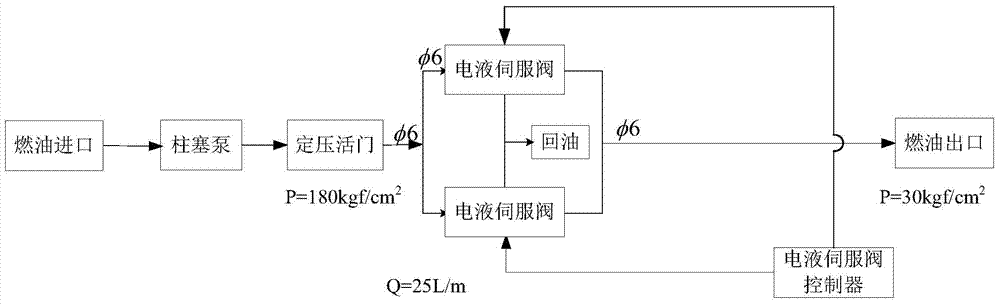

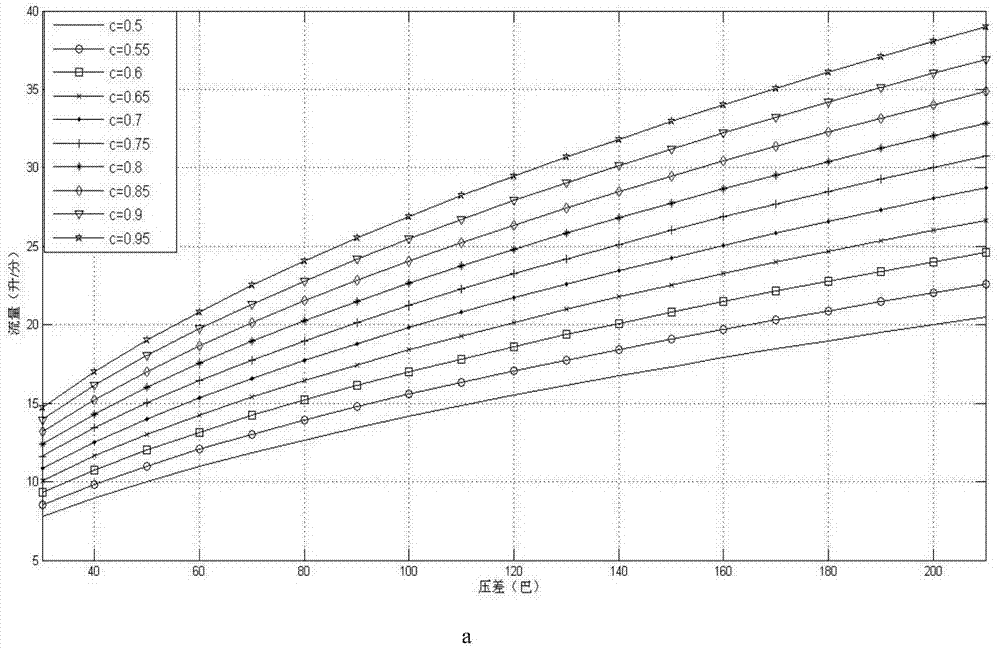

Hot backup dual-redundancy electro-hydraulic servo valve control system based on pipeline fluid parameter design

InactiveCN103939406AStable differential pressureAvoid switchingServomotor componentsFluid-pressure actuator componentsControl systemDifferential pressure

The invention relates to a hot backup dual-redundancy electro-hydraulic servo valve control system based on pipeline fluid parameter design. A constant-pressure valve is arranged on an inlet of an electro-hydraulic servo valve to ensure stable differential pressure between a fluid on the inlet and a fluid on an outlet, according to the differential pressure between the fluid on the inlet and the fluid on the outlet and required maximum flow, the diameter of an inlet and outlet pipe is matched through selection, and meanwhile an adapter block is designed to connect two independent electro-hydraulic servo valve pipelines in parallel to construct the hot backup dual-redundancy electro-hydraulic servo valve control system. No dual-redundancy electro-hydraulic servo valve exists in the domestic market at present, and compared with the prior art, the hot backup dual-redundancy electro-hydraulic servo valve control system has the advantages that the urgent requirement for the dual-redundancy electro-hydraulic servo valve of an existing high-reliability system is met, switching between two electro-hydraulic servo valves when faults occur is avoided through the constructed hot backup electro-hydraulic servo valve, and reliability of the system is improved; the problems that at present, a domestic dual-redundancy electro-hydraulic servo valve is low in design, manufacturing, machining technology levels and low in reliability are solved, the complex problems are simplified, development cost and risks are reduced, and the development period is shortened.

Owner:AIR FORCE UNIV PLA

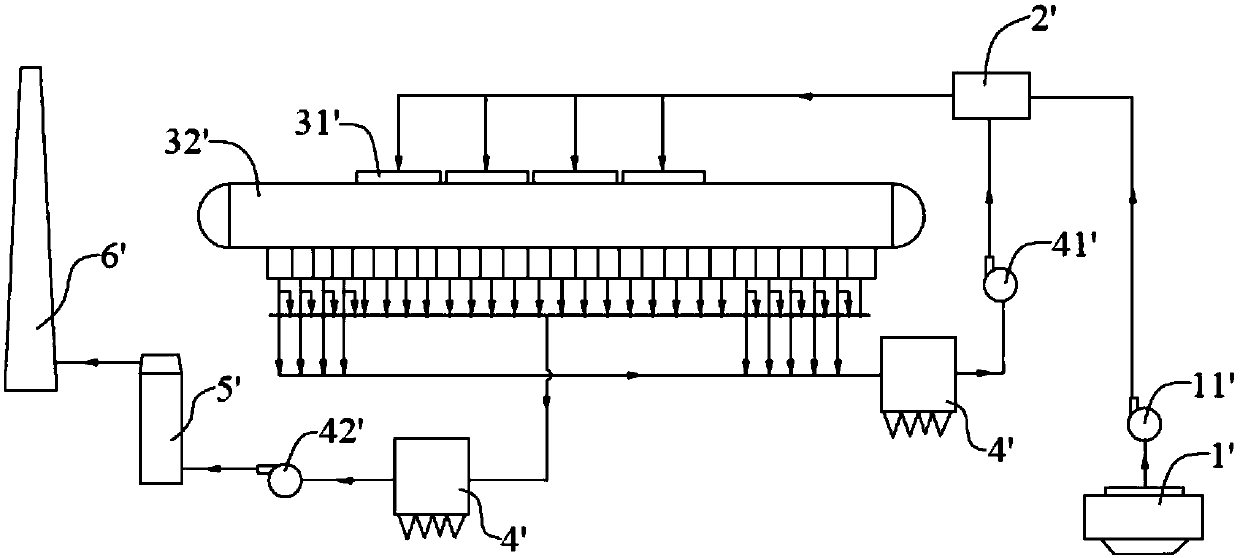

Gas heating system for high-temperature gas injection of hydrogen-carbon-rich circulating blast furnace

ActiveCN114457202AReduce dosageIncrease the amount of gasFluidised-bed furnacesThermodynamicsGas heating

The invention discloses a gas heating system for high-temperature gas injection of a hydrogen-carbon-rich circulating blast furnace, which is characterized in that the top of the hydrogen-carbon-rich circulating blast furnace is sequentially connected with a wet dust removal and dehydration decompression system and a hydrogen-rich furnace gas decarbonization device through pipelines, and hydrogen-rich furnace decarbonization gas, European smelting furnace decarbonization gas and coke oven gas are mixed in a mixing device; the mixing volume is 10-23% of the introduction volume of the hydrogen-carbon-rich circulating blast furnace high-temperature upgrading coal gas, the mixed coal gas is divided into three paths to respectively enter three groups of electric heaters for heating, and meanwhile, the entered coal gas is subjected to flow regulation or accident cut-off through a coal gas inlet quick switching device and a flow regulation device of the electric heaters; after the coal gas heated by the first group of electric heaters is uniformly mixed with cold coal gas to reach 950 DEG C, spraying the mixture into the furnace body; and after the coal gas heated by the second group of electric heaters and the third group of electric heaters is uniformly mixed with the cold coal gas to reach 1100 DEG C, the coal gas and the cold coal gas are subjected to pressure stabilizing and buffering through the tuyere coal gas pressure stabilizing buffer and then are sprayed into the hearth through a composite tuyere of the tuyere.

Owner:XINJIANG BAYI IRON & STEEL

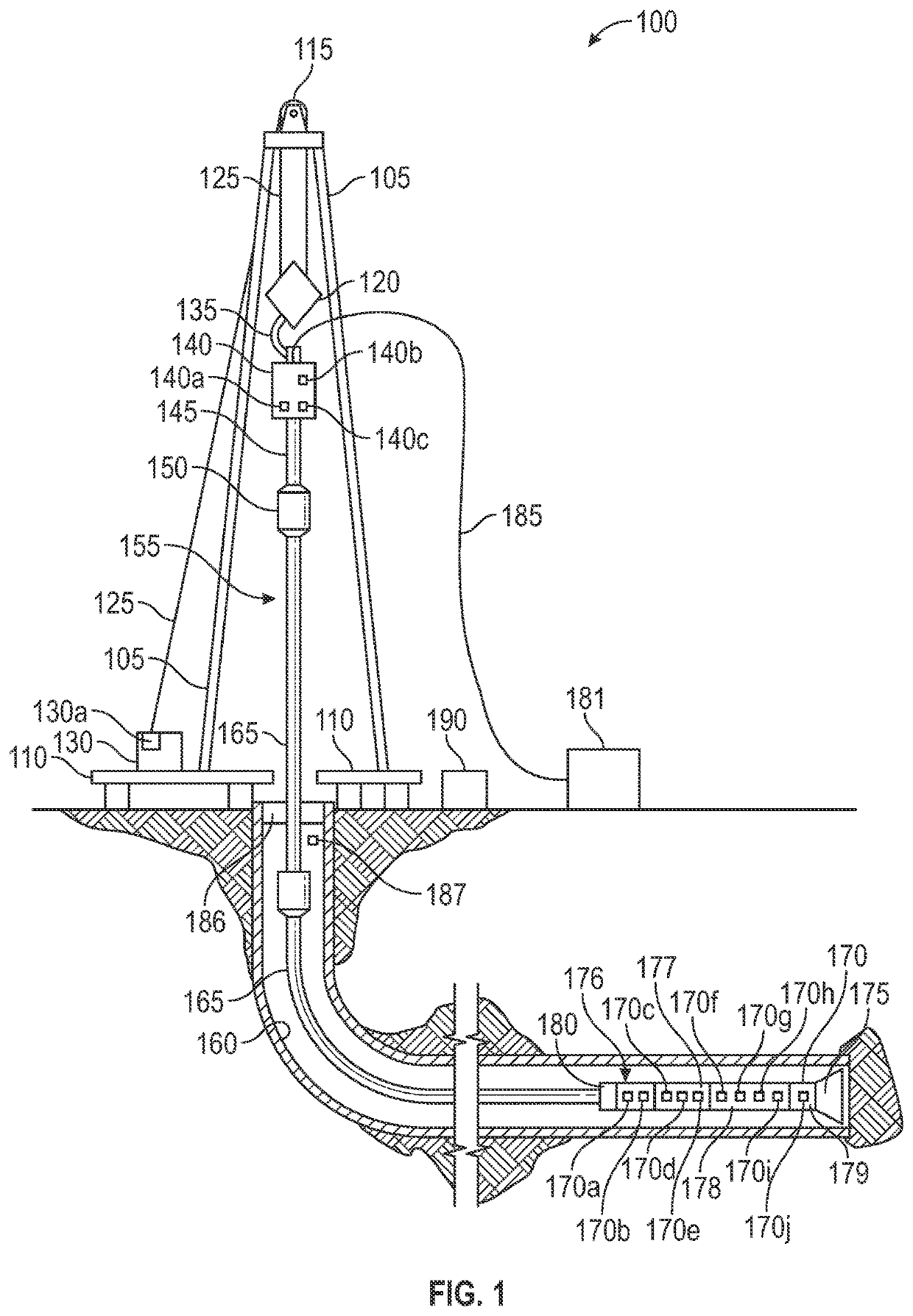

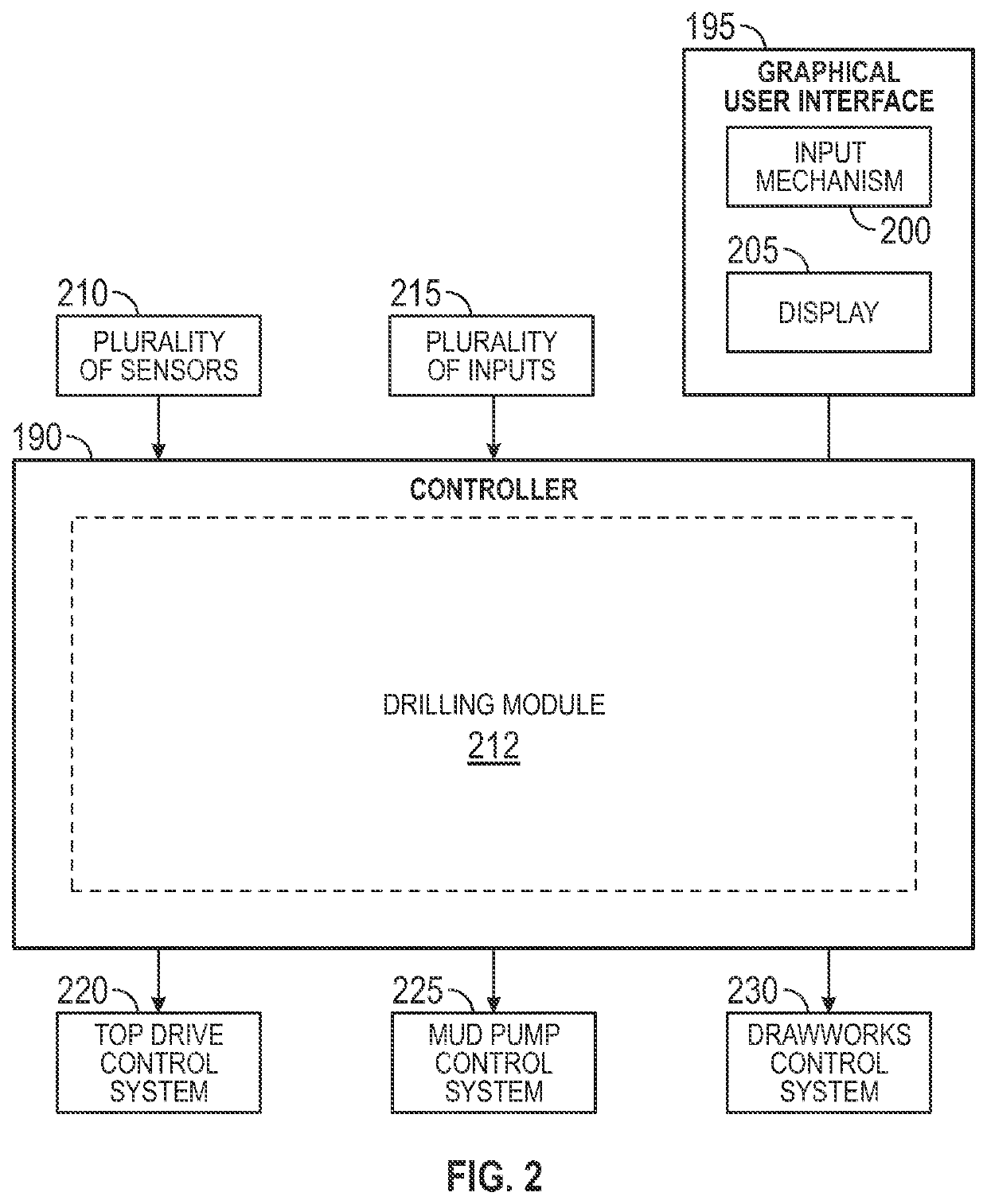

Method and apparatus for identifying a potential problem with drilling equipment using a feedback control loop system

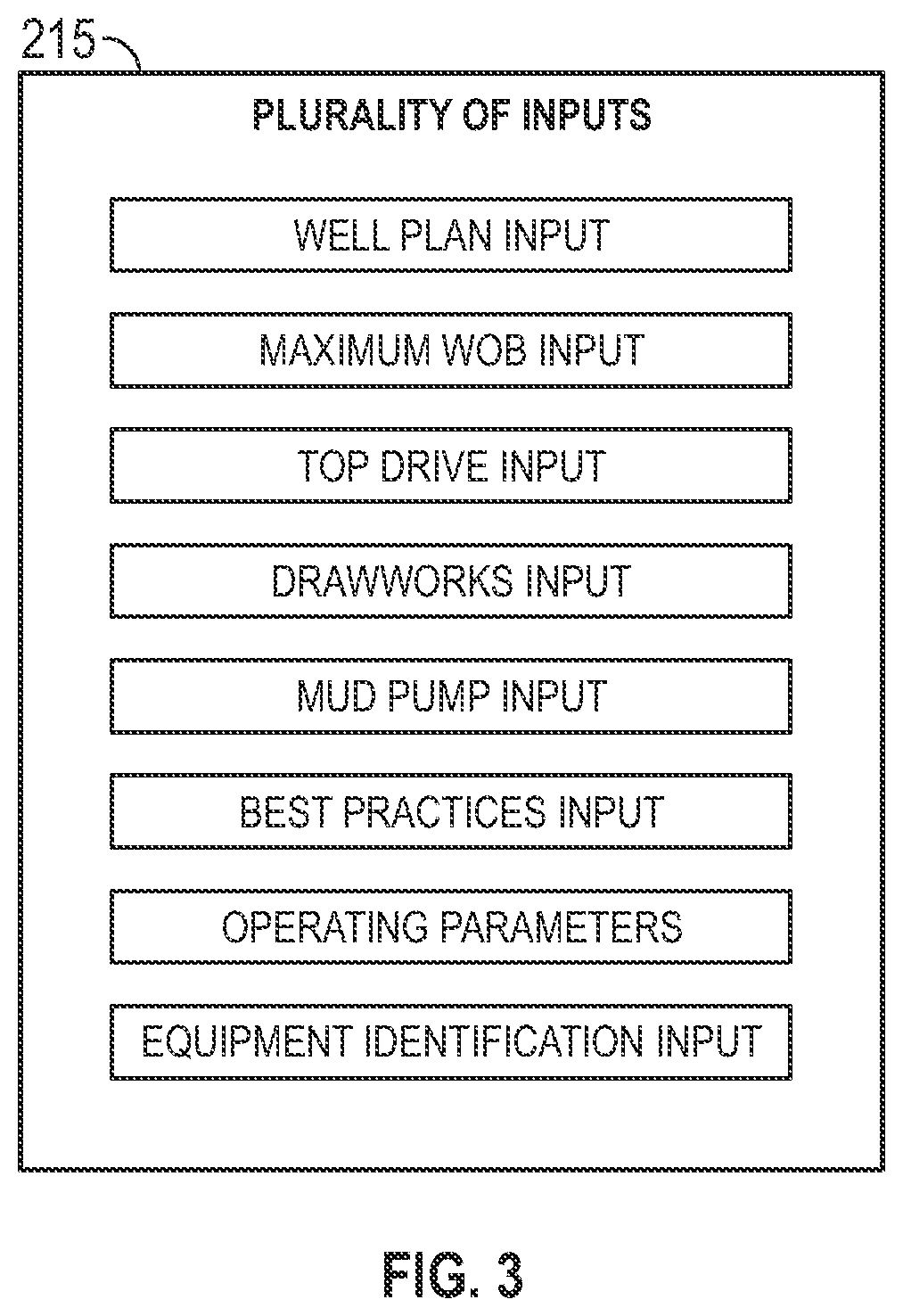

ActiveUS20220098968A1Decrease in drilling performanceReduce controlSurveyConstructionsControl systemWell drilling

An apparatus for, and method of identifying a potential problem with, drilling equipment that is used in a drilling operation. The method includes monitoring an actual drilling parameter associated with the drilling operation; comparing the actual drilling parameter to a target drilling parameter to determine a deviation between the actual and target drilling parameters; creating, using the controller and in response to the deviation, instructions for a control system that controls an aspect of the drilling operation; drilling, using the instructions and the controller, the wellbore; monitoring, using the controller, a change in deviation in response to drilling using the instructions; determining that the change in deviation is below a threshold; and determining, based on the change in deviation being below the threshold, that there is a potential problem with the drilling equipment.

Owner:NABORS DRILLING TECH USA INC

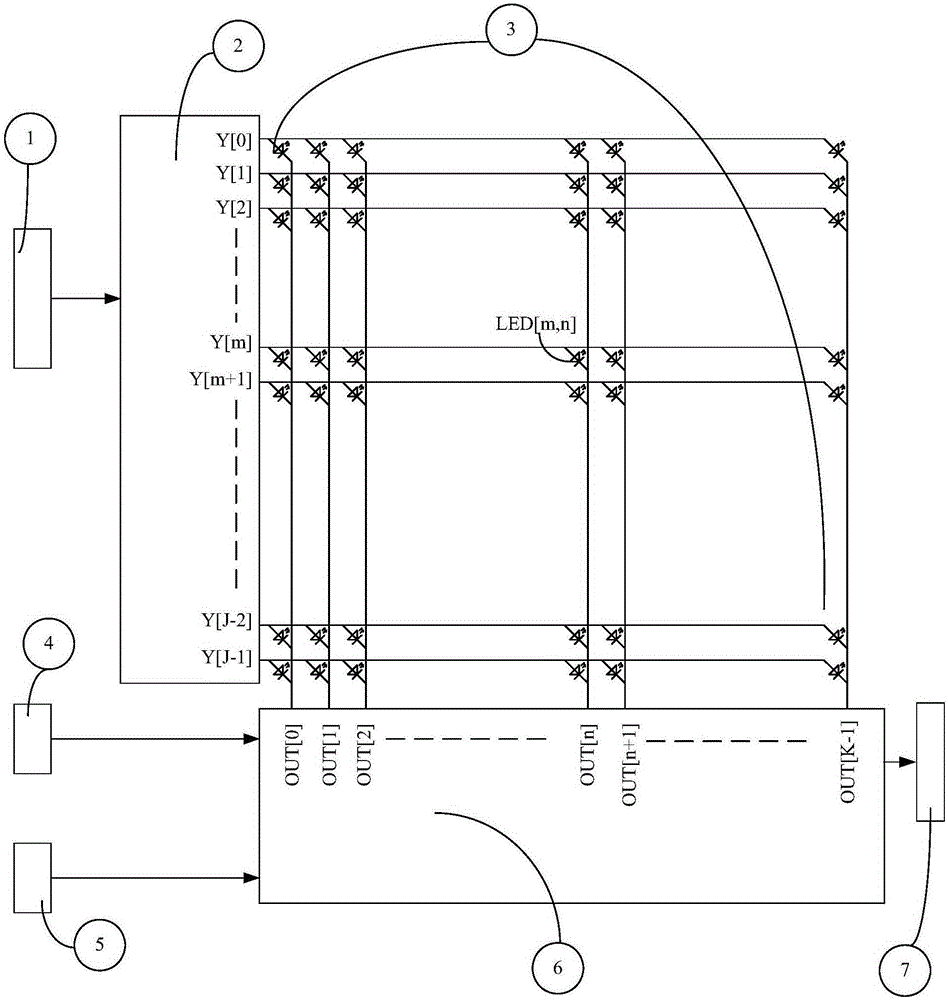

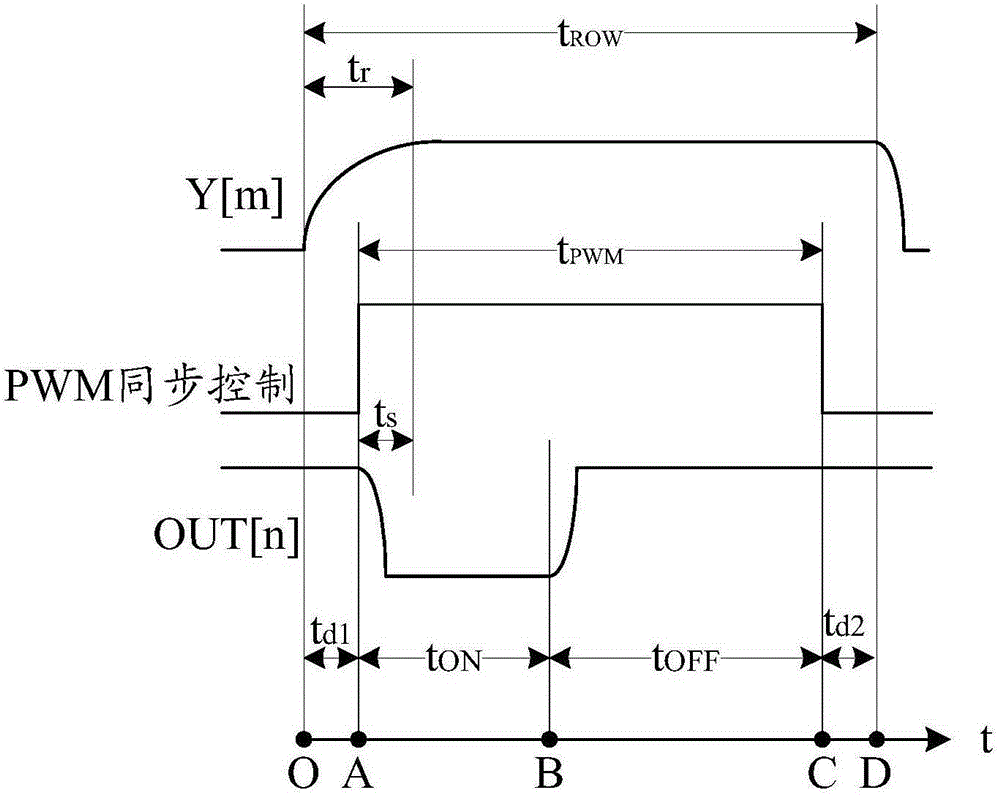

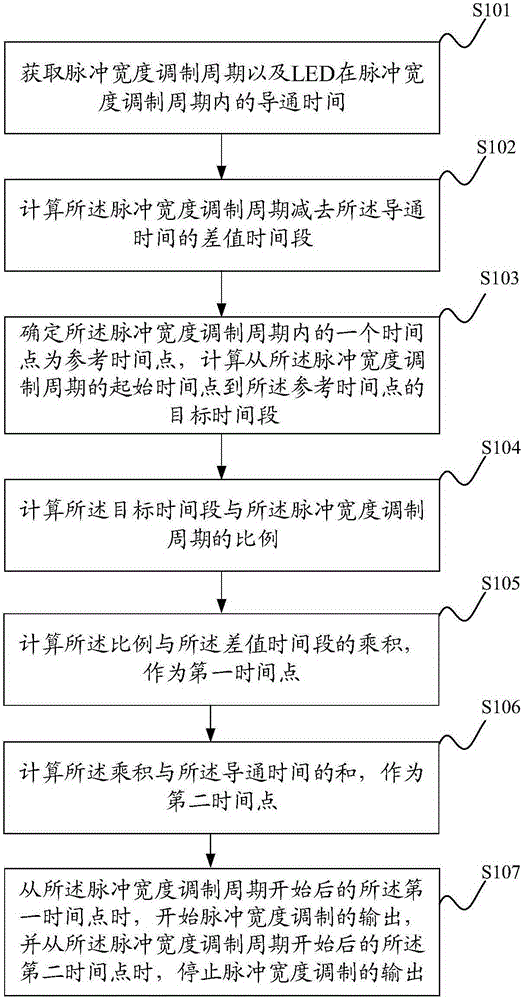

Pulse width modulation switching-on method and system of LED display driving

ActiveCN105185297AStable currentStable Current DropoutStatic indicating devicesStart timeLED display

The invention discloses a pulse width modulation switching-on method and system of LED display driving. The method includes the following steps that: a pulse width modulation period tPMW and the switching-on time tON of an LED in the tPMW are obtained; a difference value time period which is obtained through subtracting tON from tPMW can be obtained; a time point in tPMW is determined as a reference time point, and a target time period from a starting time point to the reference time point of tPMW is calculated; and the ratio x of the target time period to tPMW is calculated; the product of x and the difference value time period is adopted as a first time point; the sum of the product and the switching-on time is adopted as a second time points; after tPMW begins, the output of pulse width modulation is initiated at the first time point, and the output of pulse width modulation is stopped at the second time point; a time period length value from the first time point to the reference time point is equal to the product value of the switching-on time and the ratio, and line output voltage is stabilized before PWM switching on, and therefore, the voltage difference of the line output voltage and column current is stable in the PWM switching-on time, and current flowing through the LED is stable.

Owner:SUPEC SUZHOU

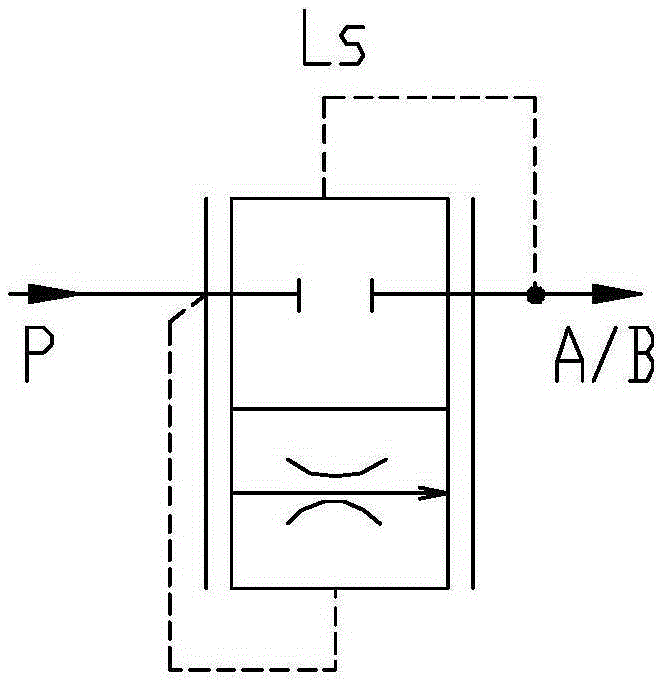

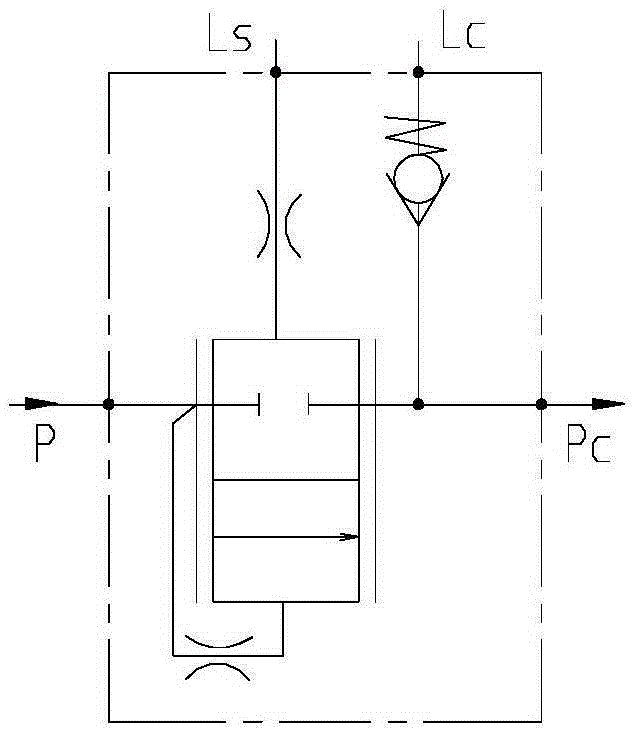

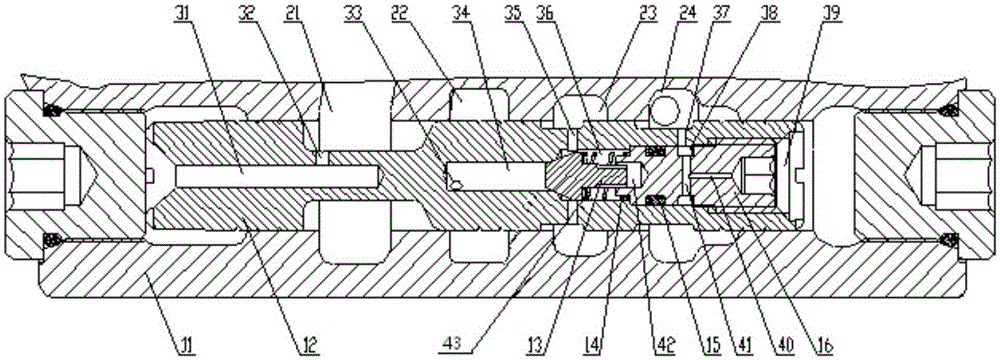

Pressure Compensation Valves and Load Sensing Systems

ActiveCN103925254BStable differential pressureStable compensation functionServomotor componentsLoad sensingLow load

The invention relates to a pressure compensation valve and a load-sensitive system. The pressure compensation valve includes a valve body and a pressure compensation valve core arranged inside the valve body. It also includes a one-way valve. The valve body has an oil inlet chamber, a pressure control chamber, and a load-sensitive system. cavity and load control cavity. The oil inlet cavity is connected to a control end of the pressure compensation valve core through an oil passage with a damping hole. The pressure control cavity and the load control cavity are connected to the oil inlet and return port of the one-way valve respectively. The load sensing chamber is connected to the other control end through an oil passage with a damping hole. The pressure oil input from the oil inlet chamber passes through the pressure compensation valve core and is output from the pressure control chamber. The one-way valve provided between the pressure control chamber and the load control chamber of the present invention can prevent the pressure signal of the high-load working link from being transmitted reversely to the pressure control chamber of the pressure compensation valve on the low-load working link, so that both ends of the pressure compensation valve The pressure difference is stable, ensuring the compensation function of the pressure compensation valve is stable and reducing fluctuations.

Owner:XCMG CONSTR MACHINERY

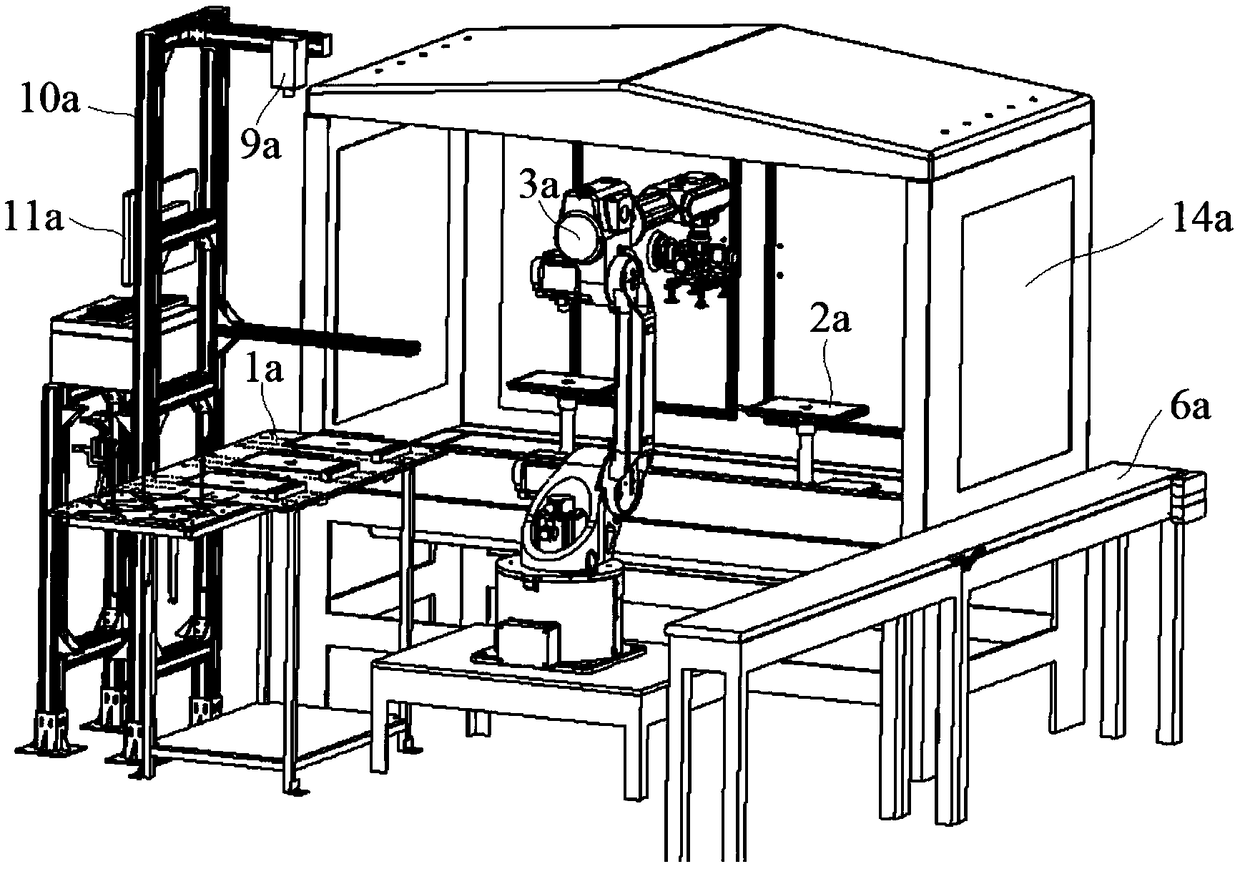

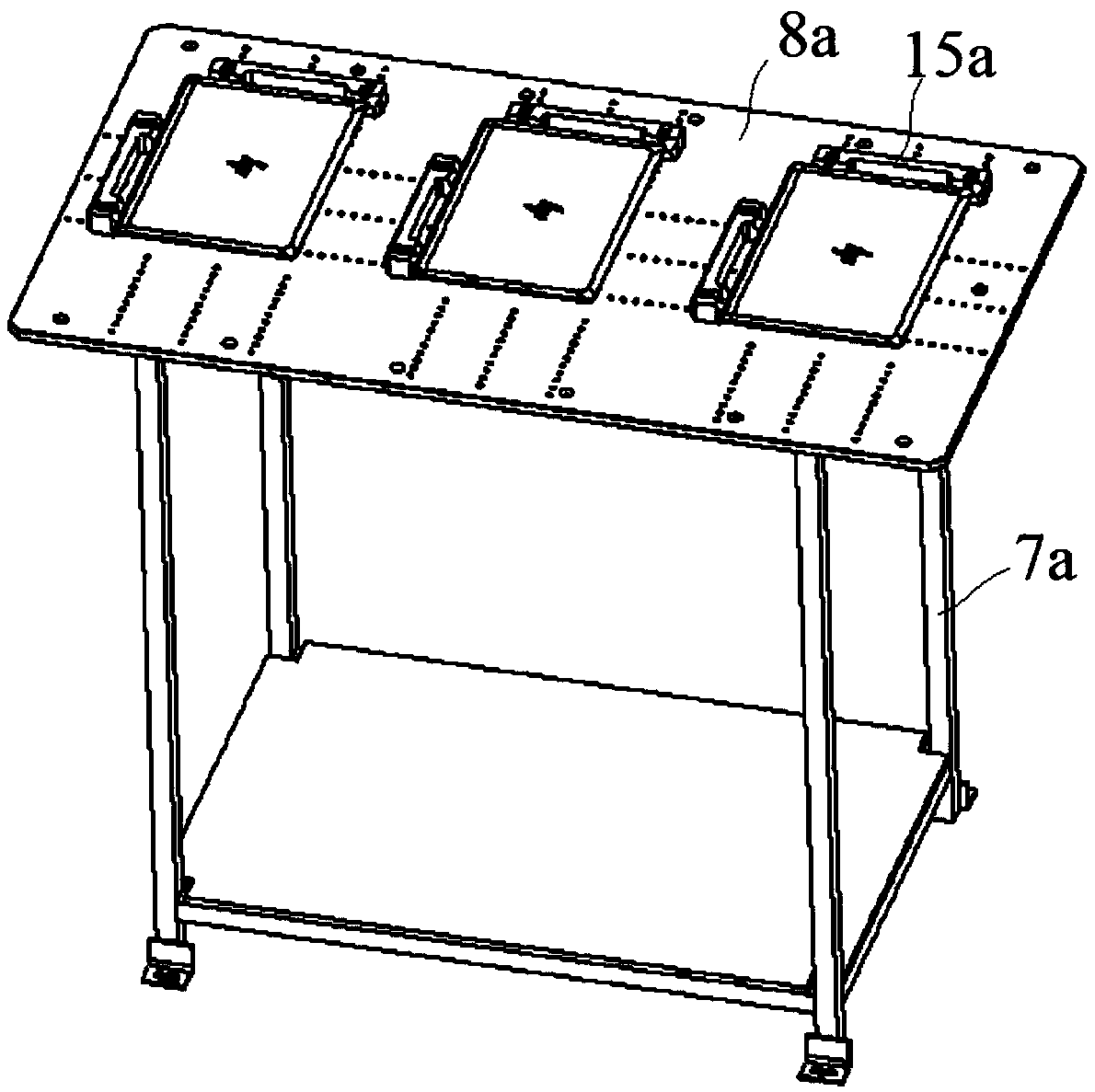

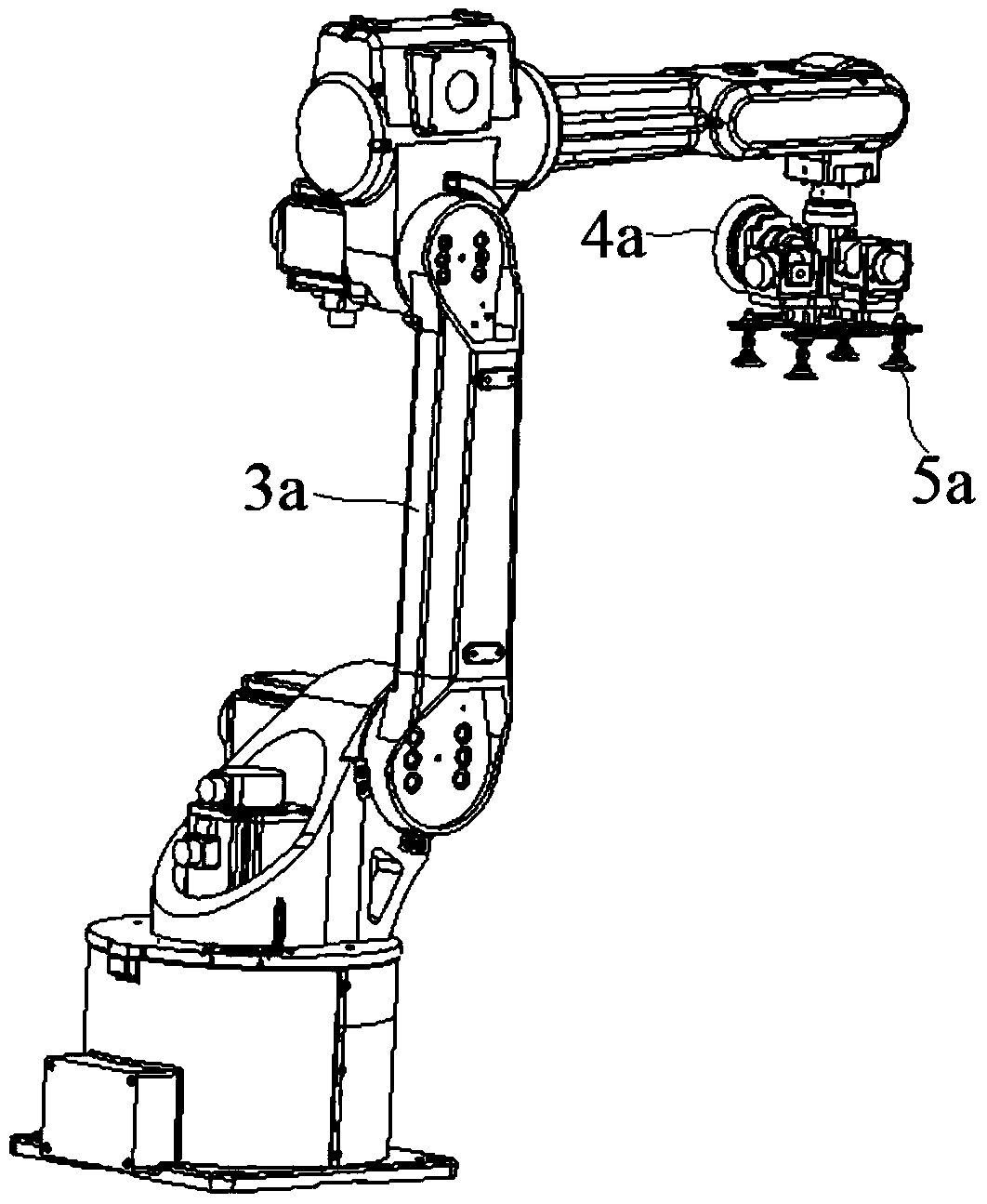

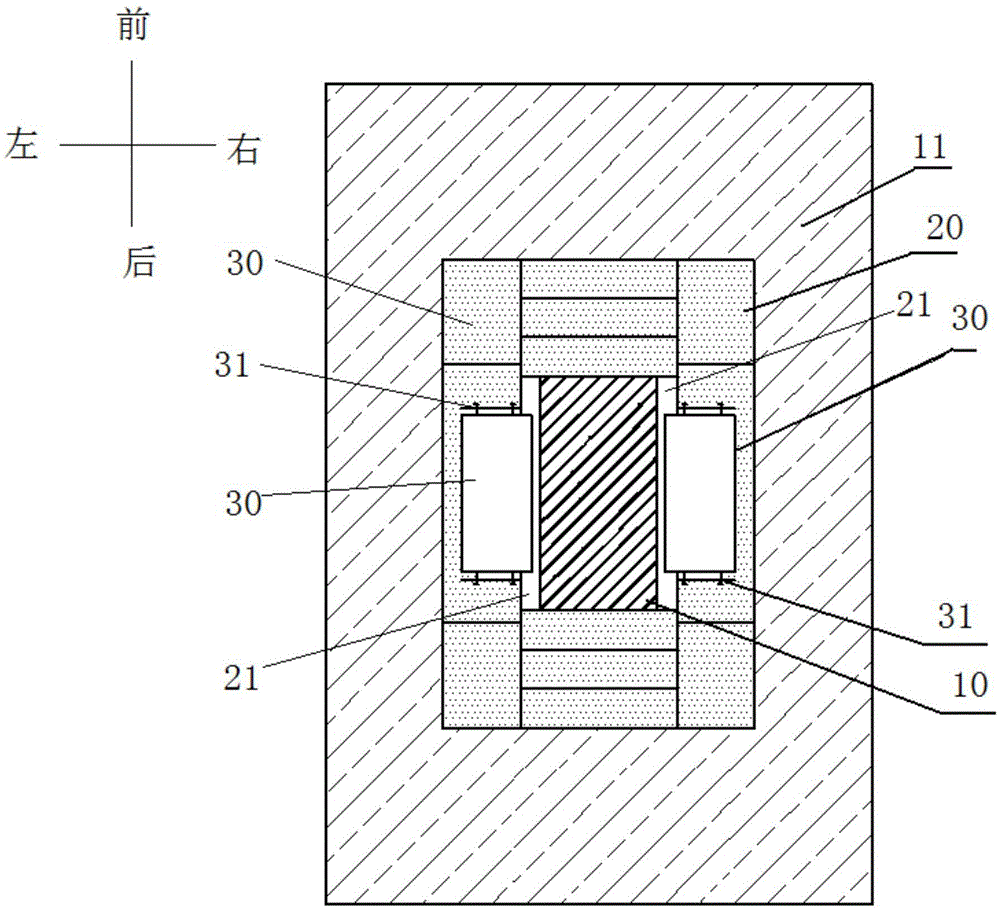

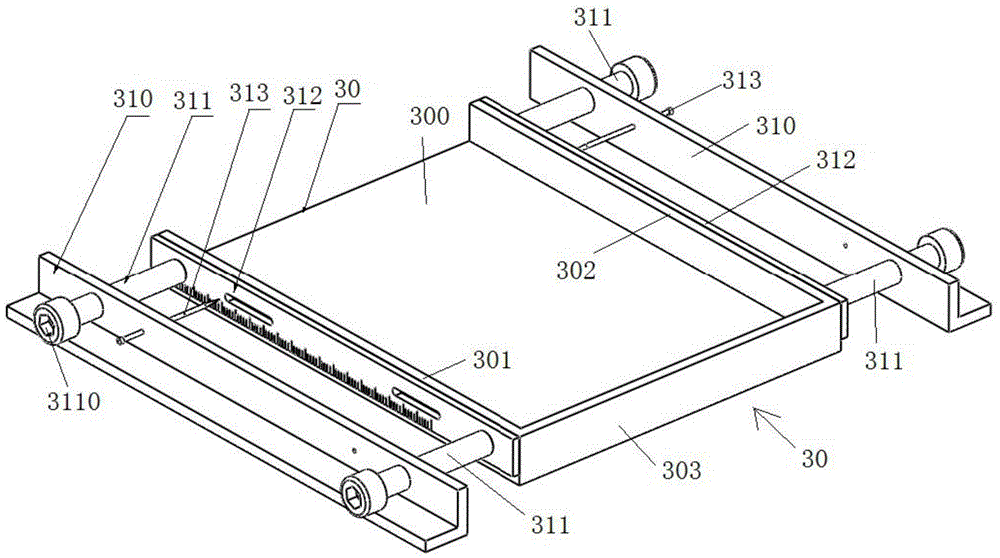

Surface treatment device for notebook-computer shell

PendingCN109382728AGuaranteed imaging accuracyGuaranteed accuracyGrinding carriagesGrinding machinesL-shellClosed state

The invention discloses a surface treatment device for a notebook-computer shell. The surface treatment device comprises a feeding support, a polishing support, multiple mechanical arms, a polishing head and a transporting clamp, wherein the polishing head and the transporting clamp are connected with tail end nodes of the mechanical arms respectively, and the feeding support and the polishing support are circumferentially arranged along the mechanical arms; the feeding support comprises a supporting frame and a feeding table installed on the supporting frame, multiple blade grooves are formedin a core body at equal intervals in the circumferential direction, and driving blades are embedded into the blade grooves respectively; an air inlet and an air outlet are formed in an outer shell, the air inlet is communicated with a first cavity, and the air outlet is communicated with the second cavity. As an air pipe installing base and an air pipe are arranged on the surface treatment devicefor the notebook-computer shell, the air inlet and an air outlet in the outer shell can be in the closed state, it is completely isolated that liquid used in the polishing process enters a shell fromthe air inlet or the air outlet, the service life of the polishing head is prolonged, the cost is saved, and the production efficiency is improved.

Owner:苏州丰川电子科技有限公司

Device for controlling pressure difference between forming department and hot-cutting department of glass substrate

ActiveCN105621862AGuaranteed stabilityStable differential pressureGlass forming apparatusEngineeringPressure difference

The invention discloses a device for controlling a pressure difference between a forming department and a hot-cutting department of a glass substrate. The device comprises the forming department and the hot-cutting department partitioned by a partition plate, wherein a mounting hole is formed in the partition plate; an annealing furnace penetrates through the mounting hole and is spaced from the mounting hole to form an annular gap surrounding the annealing furnace; a pedal is used for partially sealing the annular gap, vent holes located in the left and right sides of the annealing furnace respectively are formed between the pedal and the annealing furnace; the vent holes extend along the length direction of the annealing furnace; a baffle used for adjusting the openness of the vent holes is arranged on the pedal; fixed components are fixed to the front and rear sides of the baffle respectively to clamp or loosen the baffle. The fixed components on the left and right sides of the baffle can be adjusted, the distance between the baffle and the annealing furnace is adjusted, the openness of the vent holes is adjusted, the pressure difference between the forming department and the hot-cutting department is further controlled, and the fixed components are fixed to the pedal, thereby keeping the stable pressure difference between the forming department and the hot-cutting department, and ensuring the stability of quality of a product.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

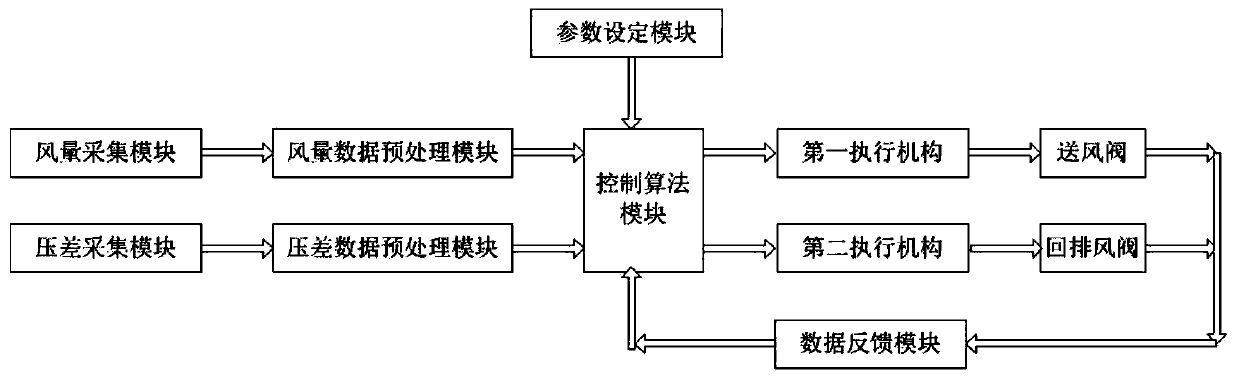

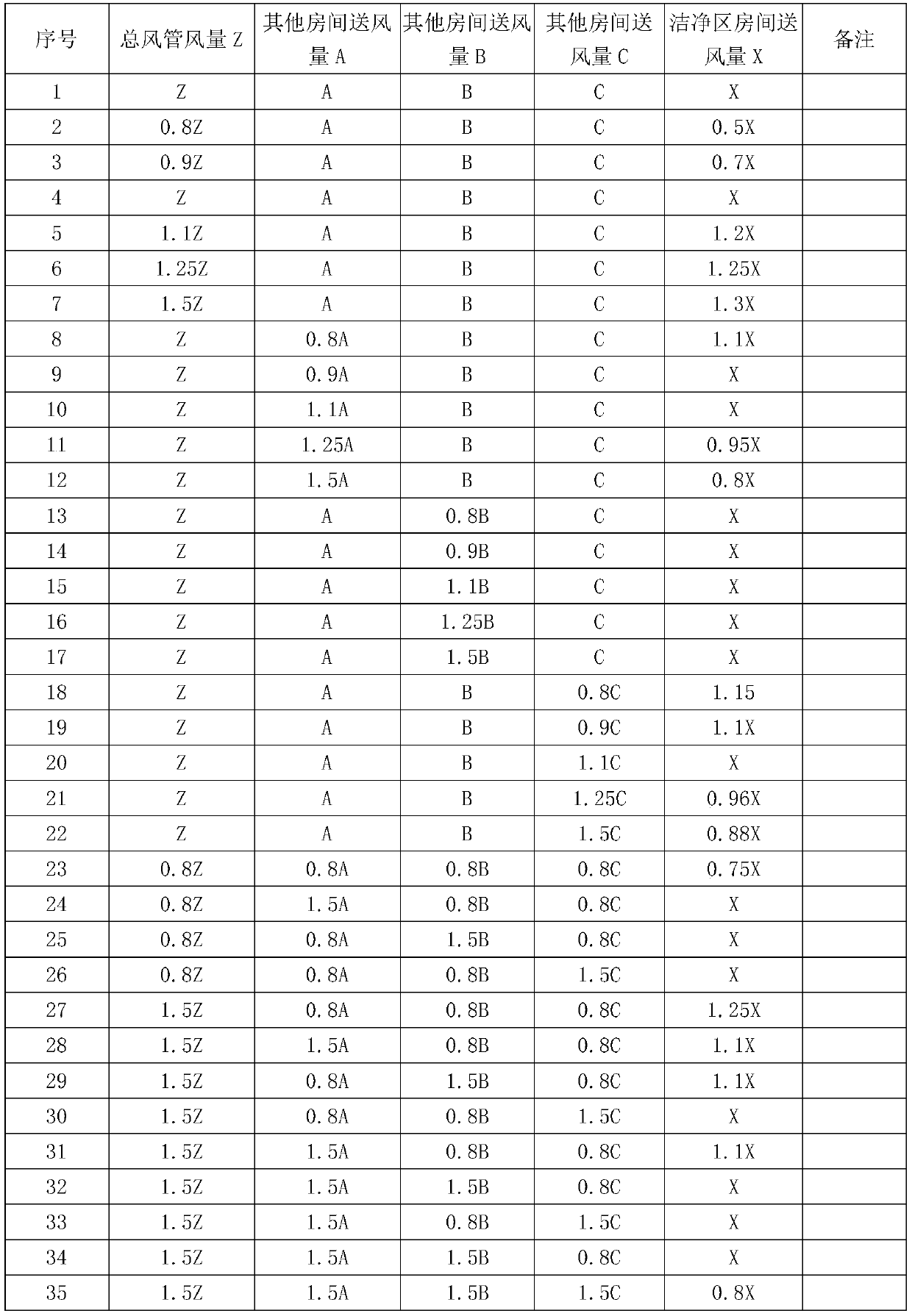

Clean area room pressure difference adaptive control system

ActiveCN110262239AStable differential pressureMeet GMP requirementsMechanical apparatusEfficient regulation technologiesSelf adaptiveAir volume

The invention discloses a clean area room pressure difference adaptive control system, which comprises an air volume acquisition module for acquiring air volume data in real time, an air volume data preprocessing module for filtering the acquired air volume data, a differential pressure acquisition module for acquiring differential pressure data of a clean area room, a differential pressure data preprocessing module for filtering the differential pressure data, a control algorithm module for calculating and processing the data and acquiring adjustment parameters, a first execution mechanism used for adjusting an opening degree of an air supply valve according to the adjustment parameters to realize clean area room pressure difference control, and a second execution mechanism used for adjusting an opening degree of an air return and discharge valve according to the adjustment parameters to realize clean area room pressure difference control. The clean area room pressure difference adaptive control system has the remarkable effects that the clean area room pressure difference adaptive control system adaptively controls the pressure difference in the clean area room, meets the room pressure difference requirements, and has small input cost.

Owner:SINOPHARM CHONGQING PHARMA & MEDICAL IND DESIGN INST

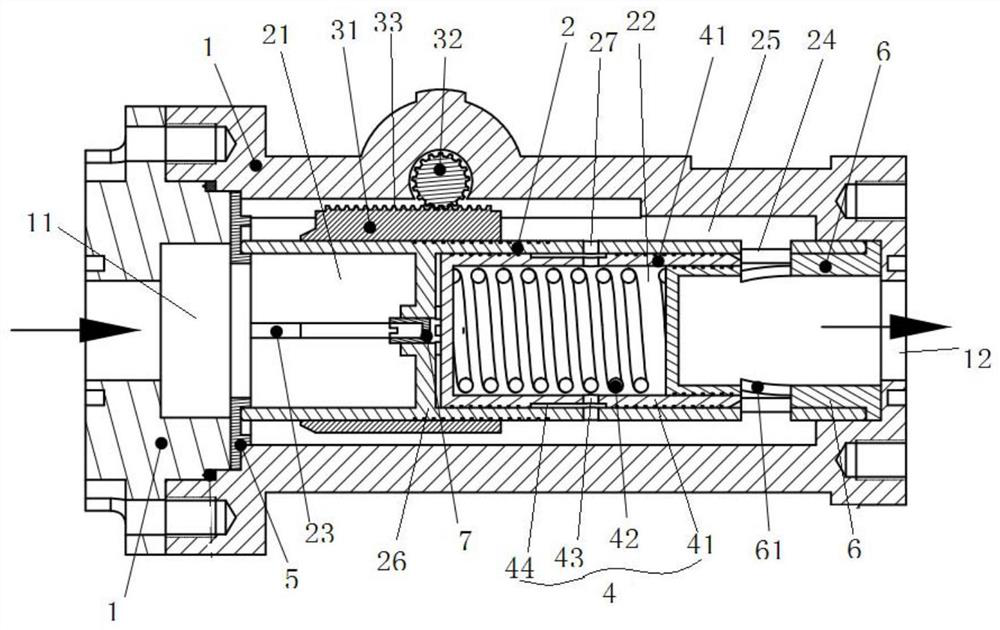

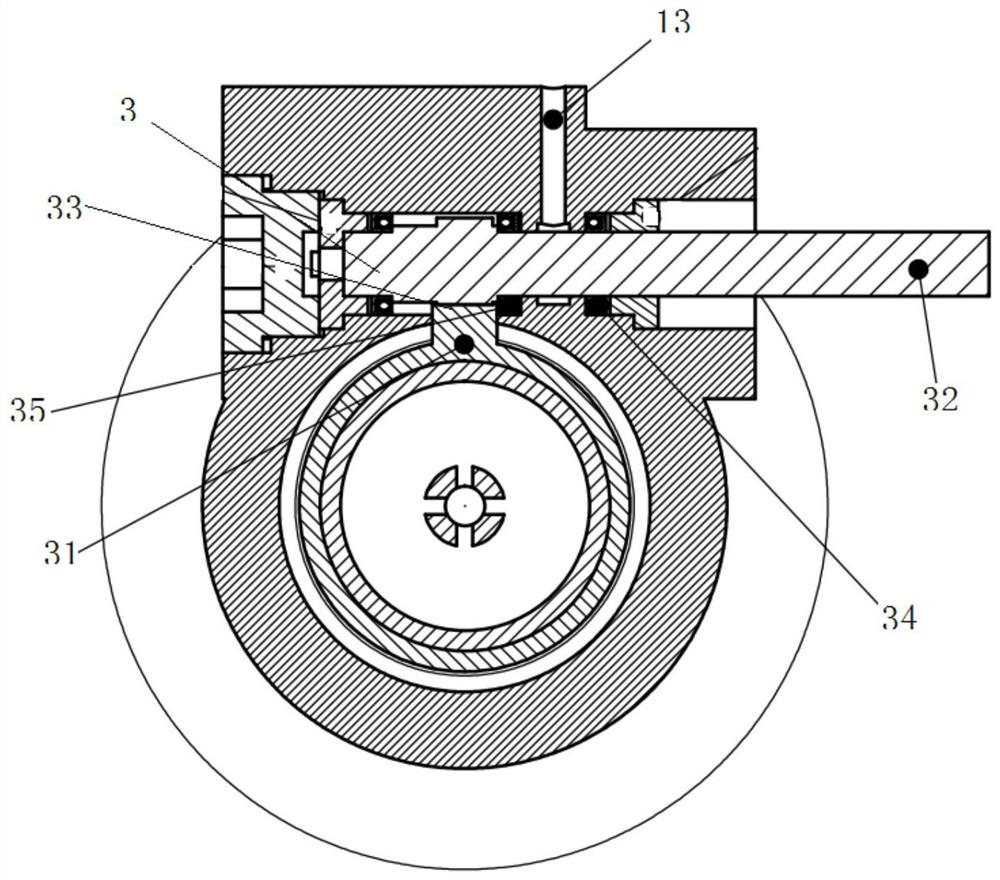

Flow valve, liquid rocket fuel supply system and liquid rocket

PendingCN111622865AStable differential pressureGuaranteed stabilityRocket engine plantsEngineeringRocket

The invention relates to the technical field of hydraulic valves, in particular to a flow valve, a liquid rocket fuel supply system and a liquid rocket. The flow valve comprises a throttling chamber and a pressure stabilizing chamber, fluid flowing from an inflow port achieves a throttling function under the action of a first throttling opening in the throttling chamber, and the pressure of the fluid on the front and rear portions of the first throttling opening changes to guarantee that the pressure difference between the front and rear portions of the first throttling opening is stable. Thepressure stabilizing chamber is formed in the flow valve, when the pressure difference of the front and rear portions of the first throttling opening changes, an elastic part in the pressure stabilizing chamber senses the pressure change and drives a second adjusting part to move, the moving second adjusting part controls the opening degree of a second throttling opening, the second throttling opening communicates with an outflow port, and the opening degree of the second throttling opening is adjusted to adjust the pressure in a cavity behind the first throttling opening, so that it is ensured that the pressure difference of the front and rear portions of the first throttling opening is stable, under the condition that the pressure difference is stable, the flow stability of liquid flowing through the flow valve can be ensured, and therefore the stability of fluid supply is ensured.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +2

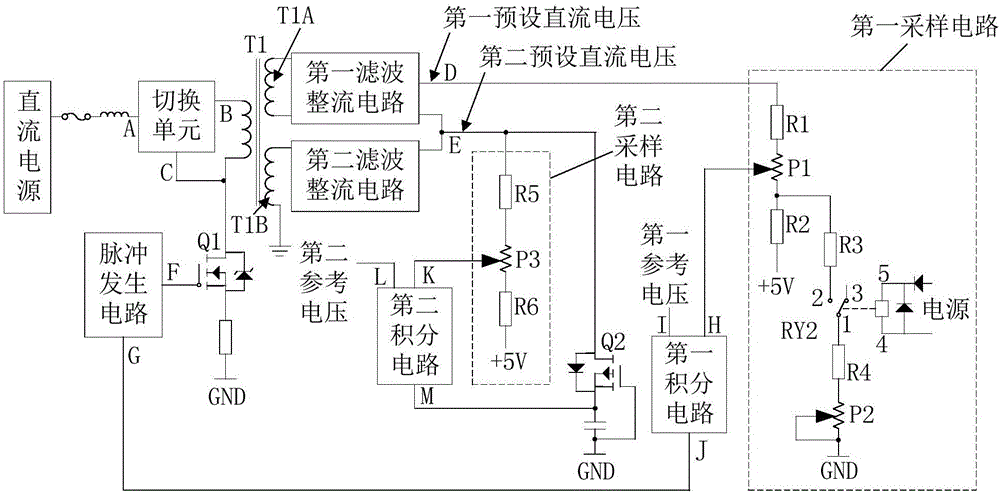

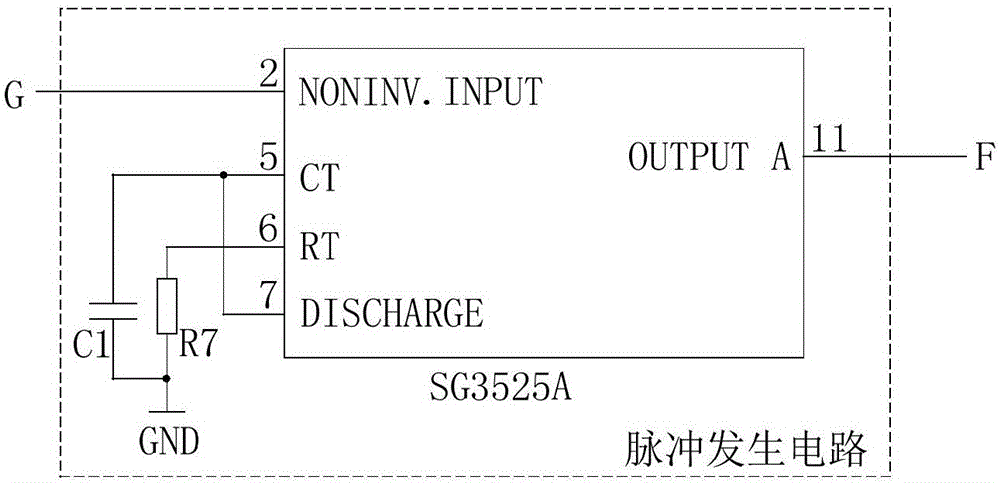

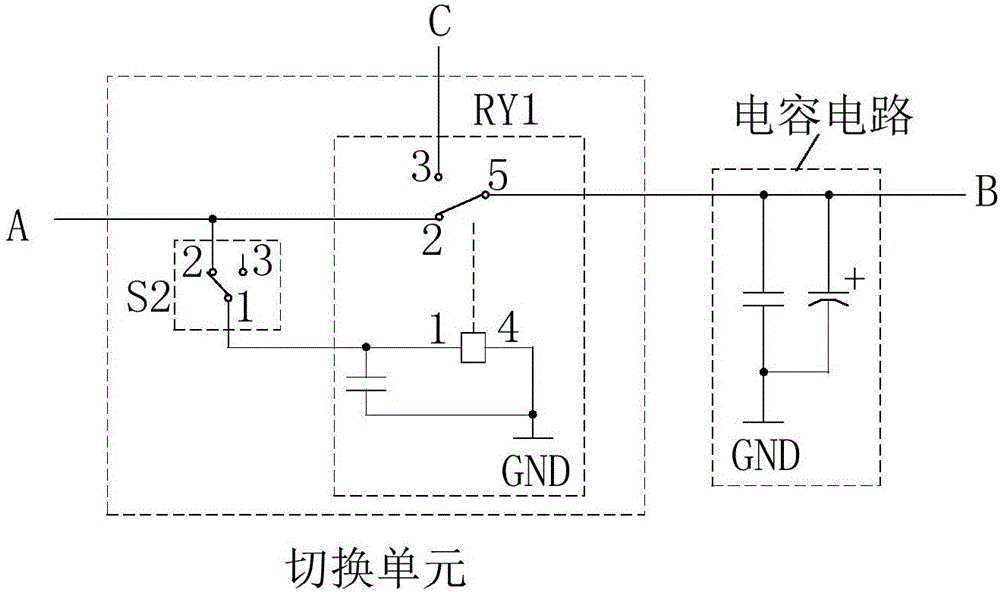

High-voltage generator and photoelectric detection device

ActiveCN106505867AStable differential pressureSmall ripple factorDc-dc conversionElectric variable regulationControl switchConductor Coil

The invention discloses a high-voltage generator and a photoelectric detection device. The high-voltage generator comprises a transformer, a first controllable switch, a pulse generation circuit, a first rectifier and filter circuit and a second filter and rectifier circuit, wherein one end of a primary side of the transformer is connected with a DC power supply, a secondary side comprises a first winding and a second winding, one end of the first winding is connected with one end of the second winding and the other end of the second winding is grounded; two ends of a controlled switch of the first controllable switch are connected to a primary side loop of the transformer in series; the pulse generation circuit is used for generating a pulse signal with a preset frequency; the pulse generation circuit is connected with a control terminal of the first controllable switch; the first filter and rectifier circuit is used for filtering and rectifying boosted voltage and then outputting first preset DC voltage; and the second filter and rectifier circuit is used for filtering and rectifying the boosted voltage and then outputting second preset DC voltage. According to the high-voltage generator disclosed by the invention, stable first preset DC voltage and second preset DC voltage can be simultaneously provided.

Owner:昆山书豪仪器科技有限公司 +1

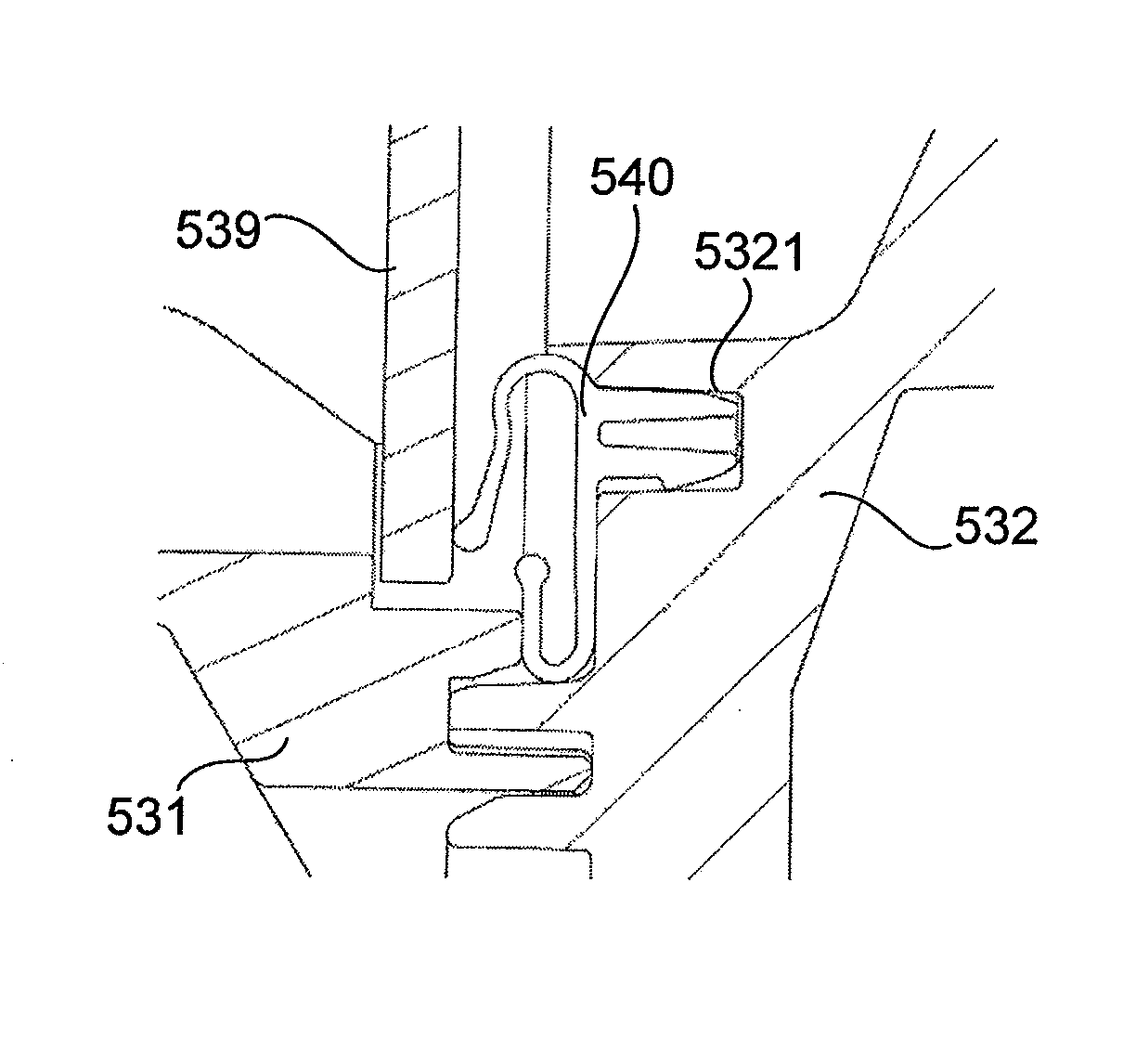

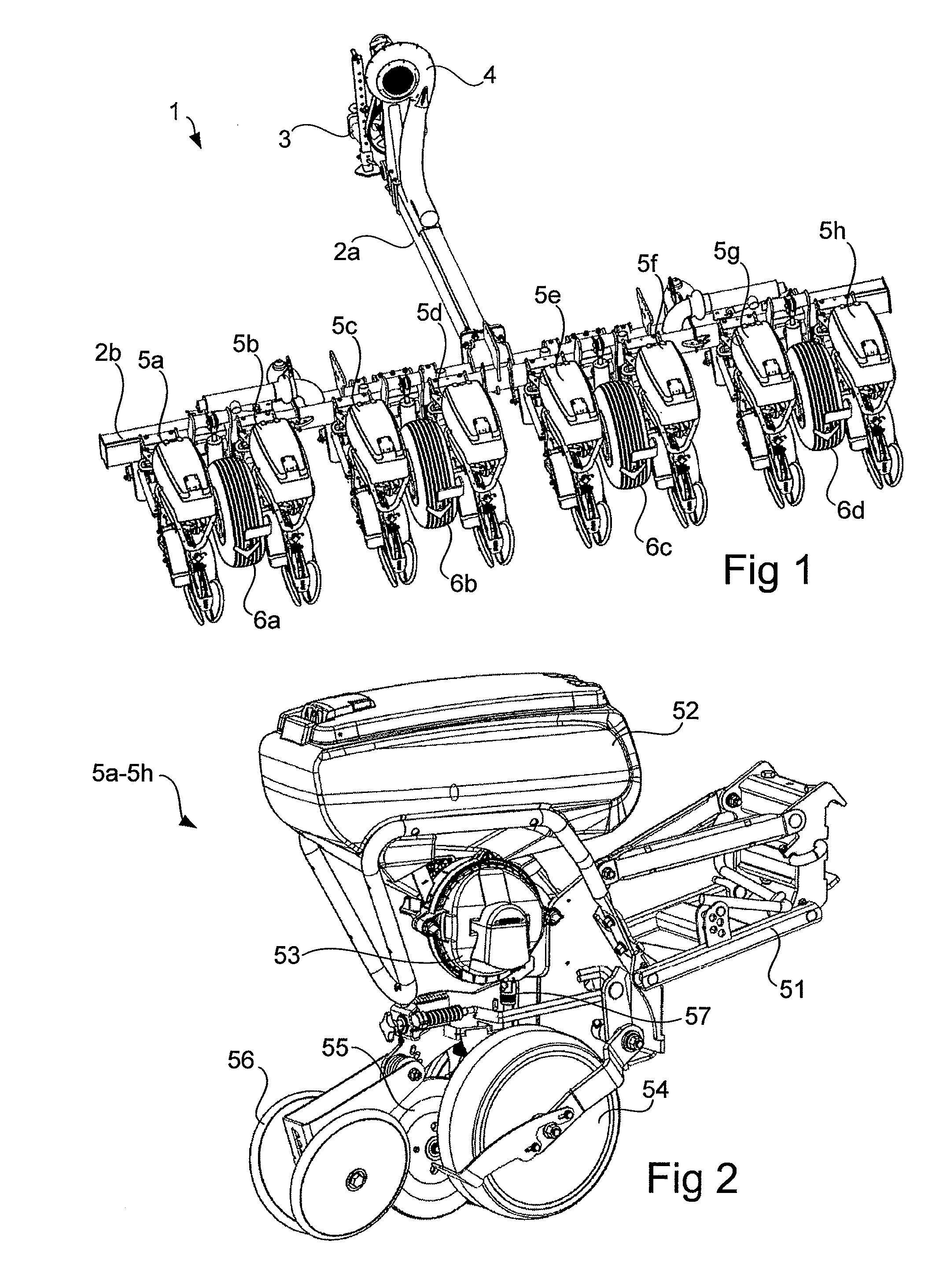

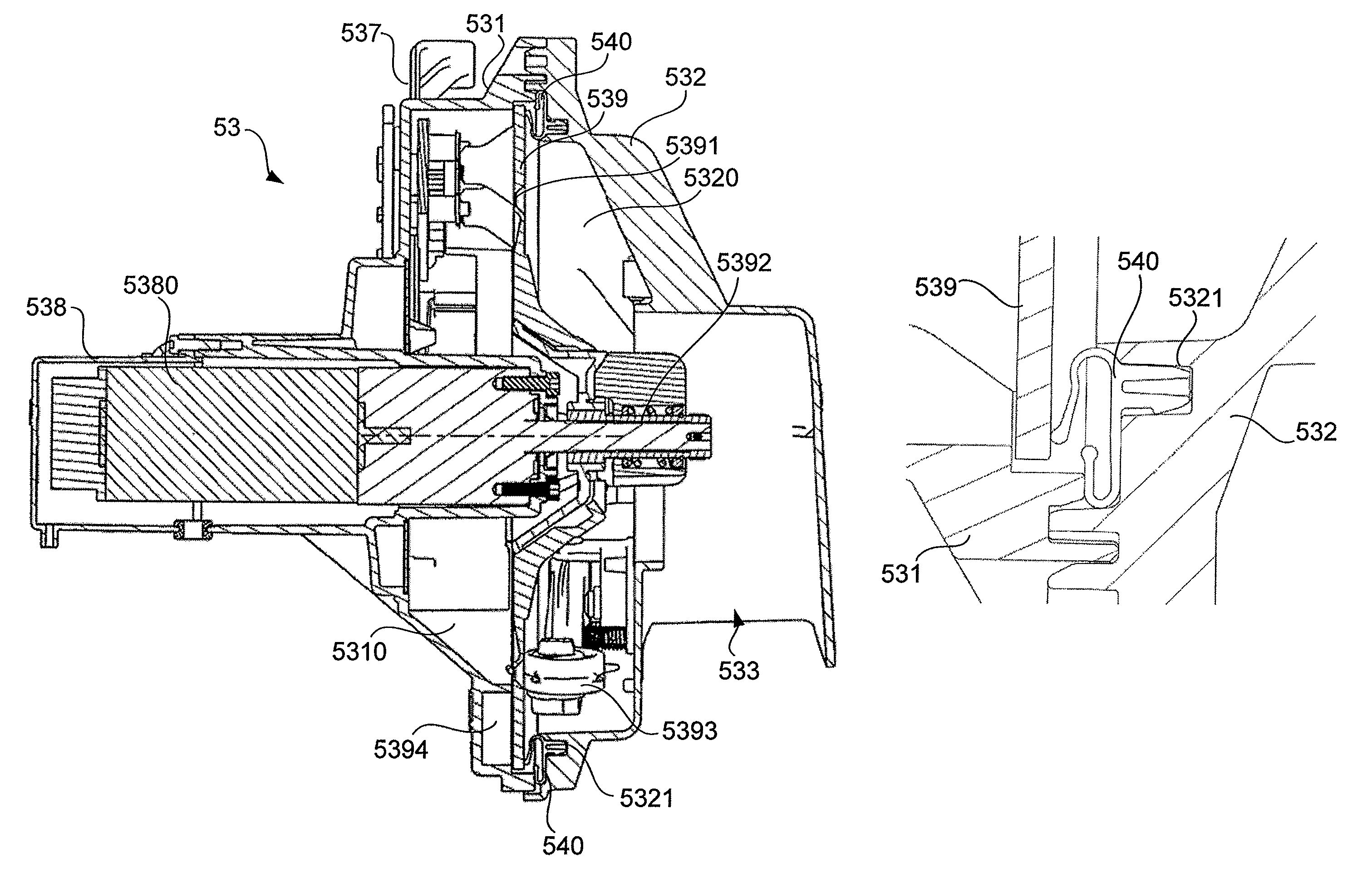

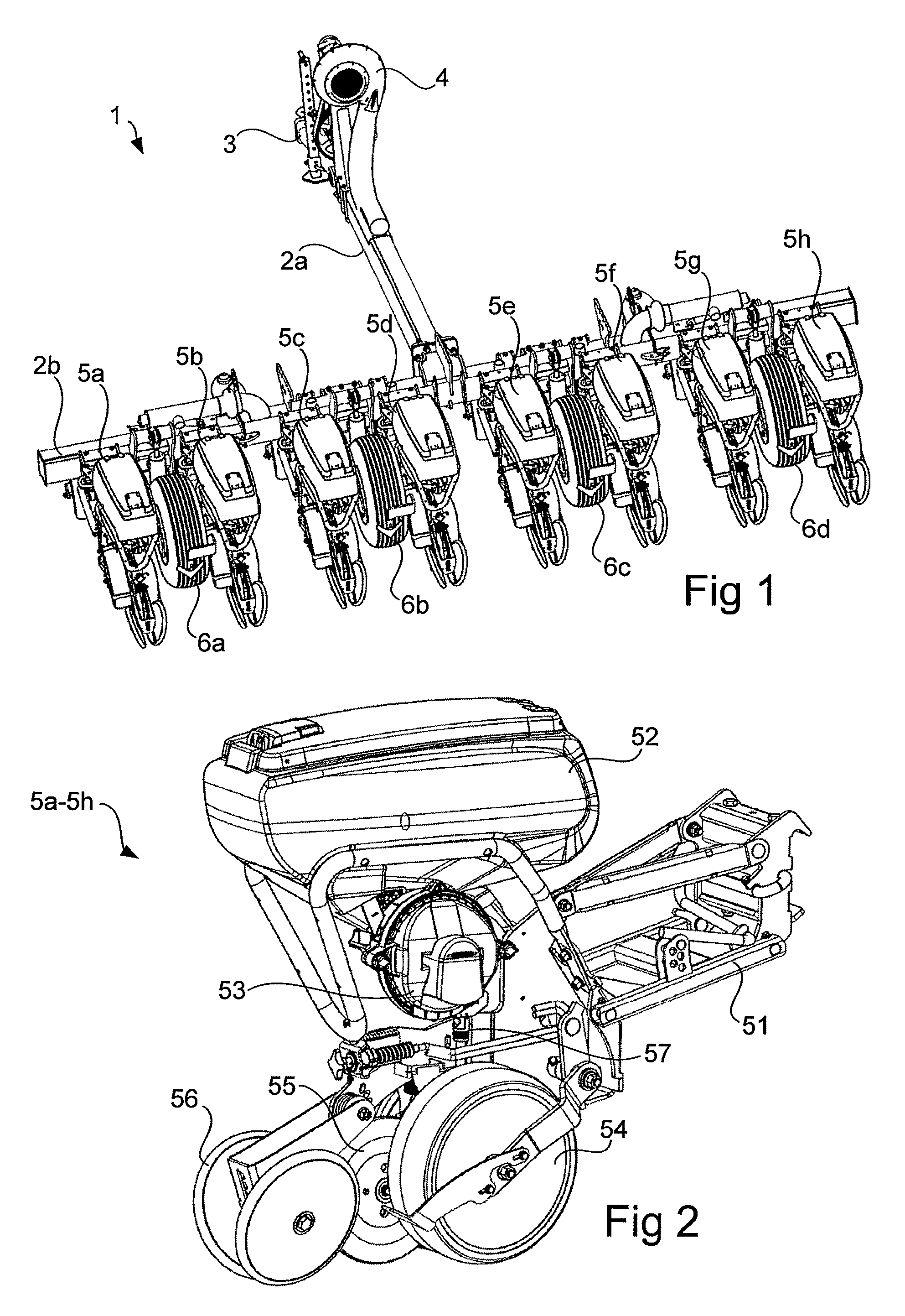

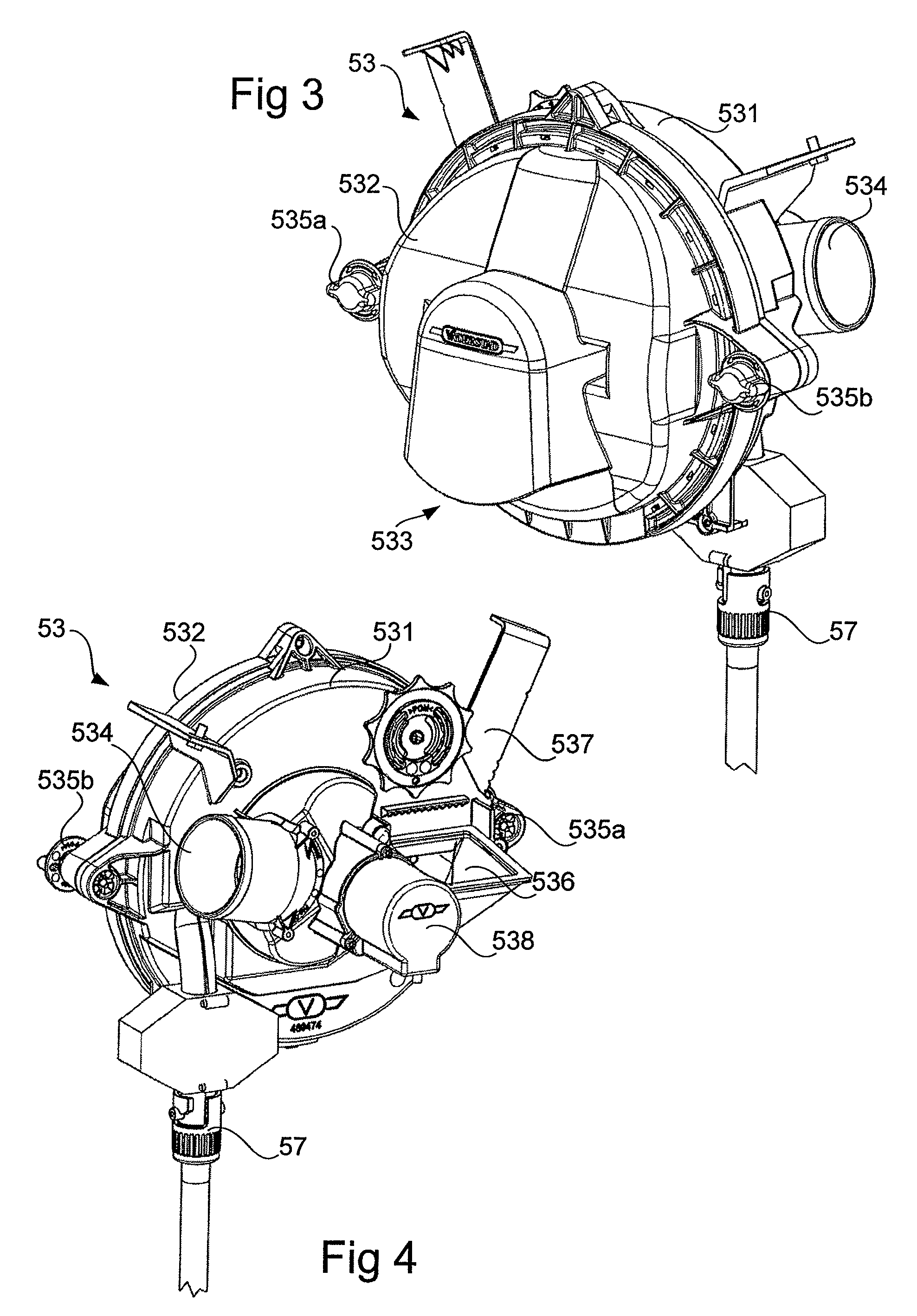

Sealing gasket and seed housing for a seeder and seeder comprising such a seed housing

ActiveUS20140041564A1Locking action can be improvedEasy to replaceEngine sealsPotato plantersSeederRubber material

A sealing gasket made of a resilient rubber material or rubber-like material. The sealing gasket is formed as a rotationally symmetric body with a substantially constant cross-sectional profile. The cross-sectional profile includes: a first sealing part located furthest away from a center of rotation of the body and a second sealing part located radially inside the first sealing part, as viewed in the radial direction. An open space is defined by the first and second sealing parts. The second sealing part essentially curves through an angle away from the center of rotation. A seed housing can include such a seal and a seeder can include such a seed housing.

Owner:VADERSTAD HLDG

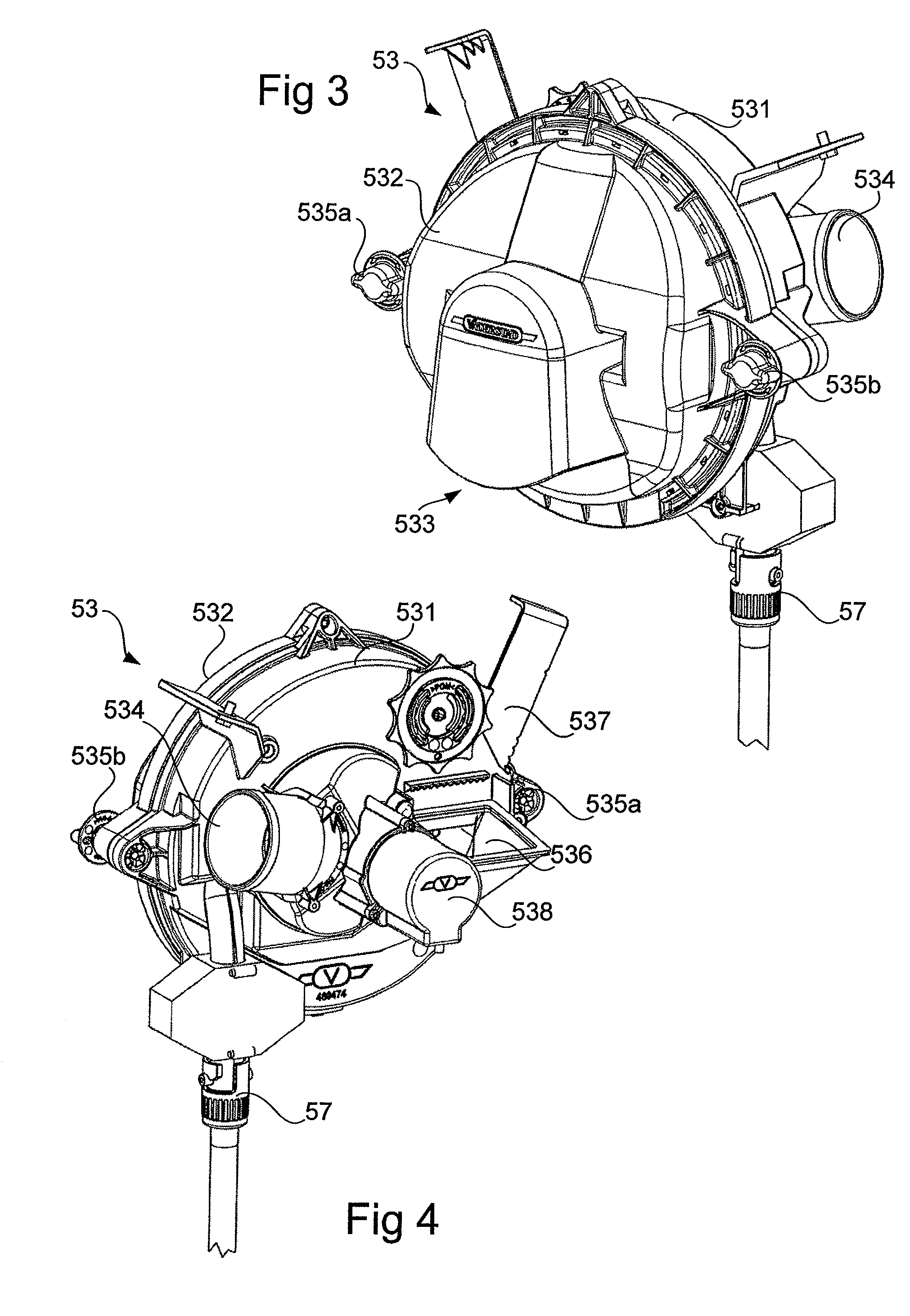

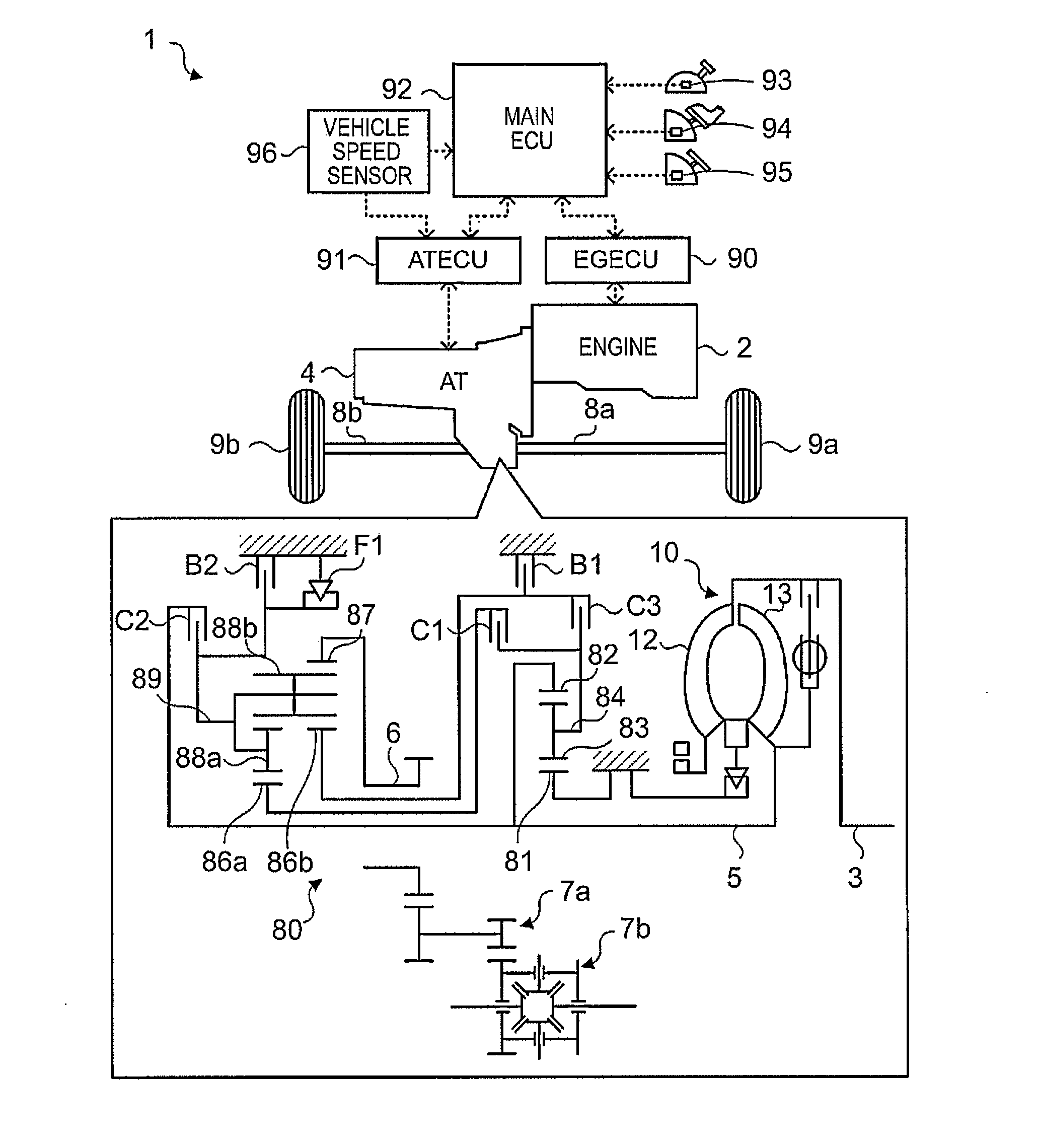

Hydraulic control device

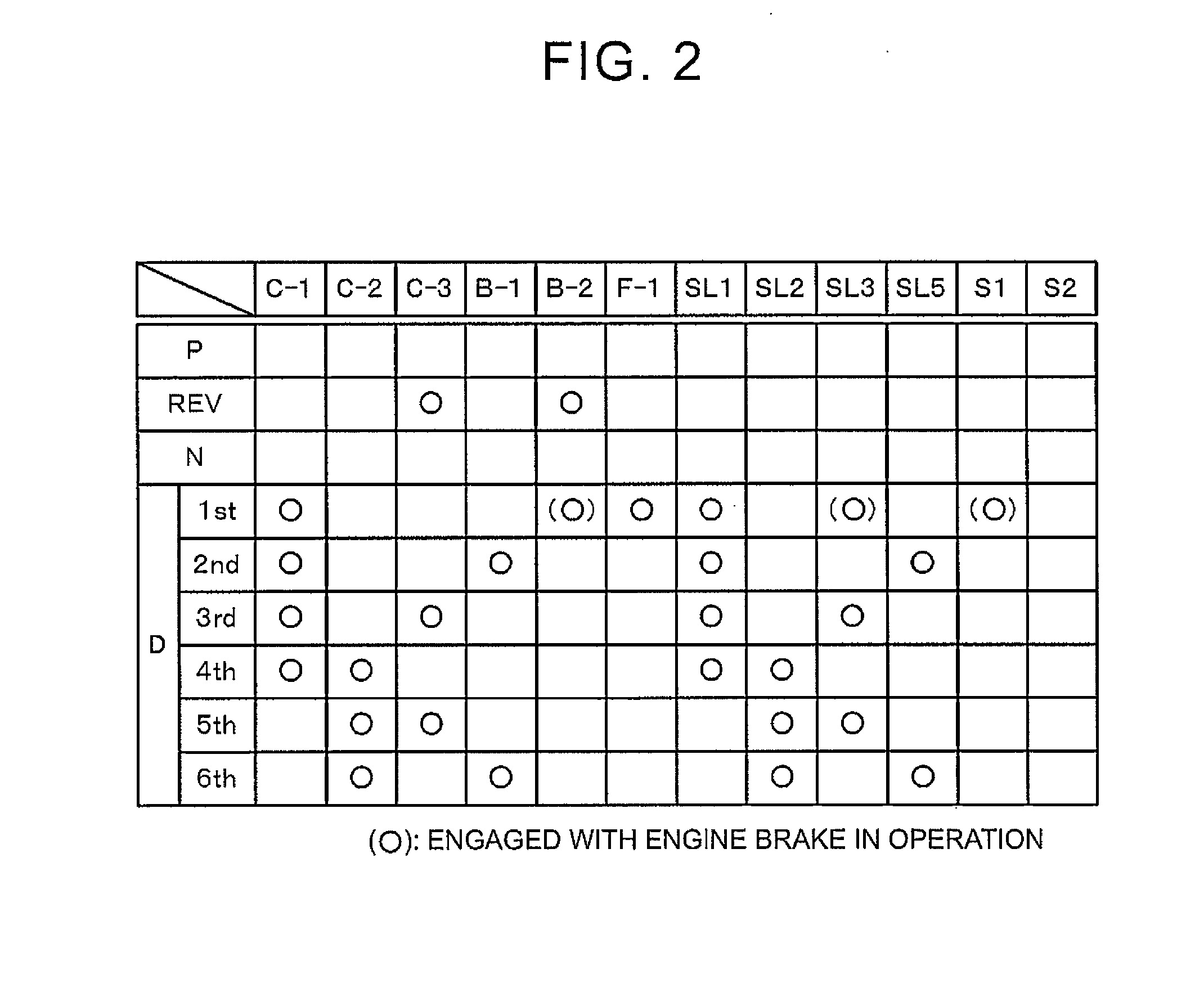

ActiveUS20140231205A1Stable differential pressureImprove controllabilityRotary clutchesGearing controlRelay valveBlocked Connection

A hydraulic control device includes a lock-up control valve that regulates a line pressure to generate a control pressure, and a lock-up relay valve that switches between paths through which a hydraulic pressure is supplied to and discharged from a torque converter. The lock-up relay valve is formed to be capable of switching between a path that connects between a control pressure oil passage to which the control pressure is output and a lock-up oil passage communicated with a lock-up oil chamber and that connects between a control pressure oil passage to which the control pressure is output and a circulation input oil passage communicated with a converter oil chamber, and a path that blocks connection between the control pressure oil passage and the lock-up oil passage and that blocks connection between the control pressure oil passage and the circulation input oil passage.

Owner:AISIN AW CO LTD

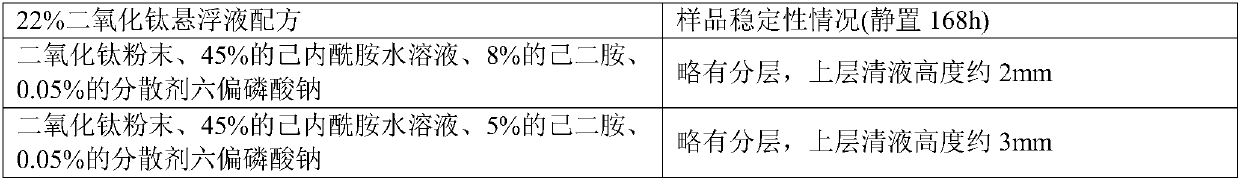

Titanium dioxide suspension for chinlon polymerization and preparation method thereof

InactiveCN109778331AImprove stabilityReduce shockArtifical filament manufactureMonocomponent polyamides artificial filamentEmulsion polymerizationSolution polymerization

The invention relates to the field of chinlon preparation, and discloses a titanium dioxide suspension for chinlon polymerization and a preparation method thereof. The titanium dioxide suspension is prepared from titanium dioxide, caprolactam, diamine modifier and water. The diamine modifier is added while titanium dioxide and a caprolactam water solution are mixed, amino acids of the diamine modifier can be bonded with carboxyl on the titanium dioxide through chemical bonds, meanwhile, other amino acids of diamine and carboxyl in caprolactam can be bonded through chemical bonds, and thereforecrosslinking points are formed between the titanium dioxide and caprolactam, the bonding force between the titanium dioxide and caprolactam is increased, and the suspension has the advantages that the dispersed stability of titanium dioxide can be improved, agglomeration generation is relieved, and impact generated by polymerization is smaller. Meanwhile, due to the fact that little deposition condition is caused after the reaction type titanium dioxide suspension enters a polymerization pipe nest, the scaling condition is obviously improved.

Owner:浙江恒逸锦纶有限公司

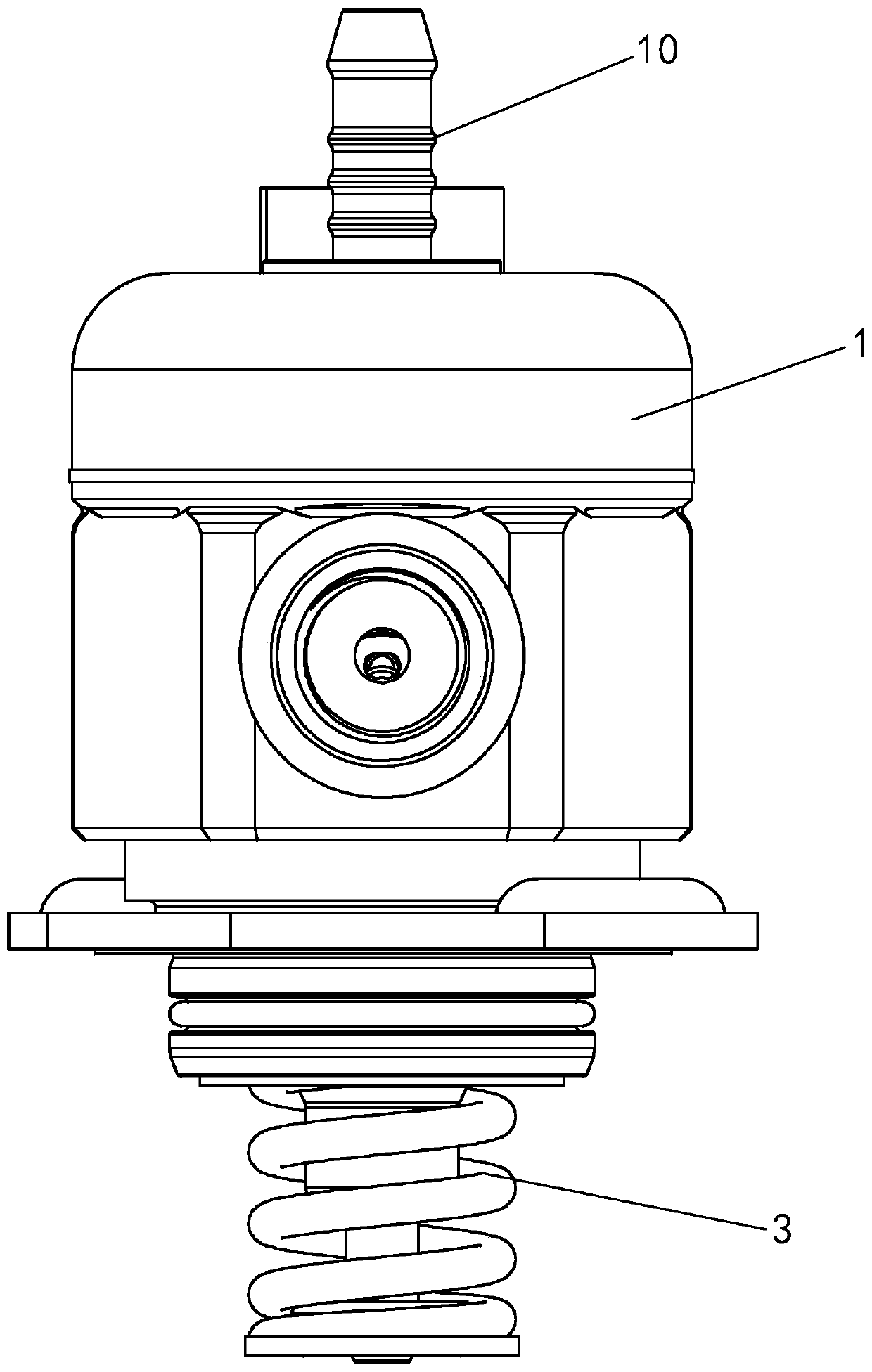

In-cylinder direct-spray high-pressure pump

PendingCN110185565AImprove reliabilityReduced stiffness requirementsMachines/enginesFuel injecting pumpsSolenoid valveEngineering

The invention relates to an in-cylinder direct-spray high-pressure pump. The in-cylinder direct-spray high-pressure pump comprises a pump body, wherein an oil inlet and an oil outlet are formed in thepump body; a stable-pressure cavity, a low-pressure cavity, a high-pressure cavity, a first connecting oil path and a second connecting oil path are arranged in the pump body; the oil inlet communicates with the first connecting oil path through the stable-pressure cavity; the first connecting oil path communicates with the second connecting oil path through the low-pressure cavity and the high-pressure cavity in sequence; the second connecting oil path communicates with the oil outlet; a solenoid valve is arranged in the low-pressure cavity; a plunger piston device is arranged in the high-pressure cavity; the oil outlet is equipped with a pressure release valve; the pressure release cavity communicates with the low-pressure cavity or the high-pressure cavity; the pressure release valve comprises a sealing base with a through hole therein, a stud and a ball body arranged between the sealing base and the stud; the ball body and the sealing base can be connected in a sealing mode; the ball body is linked and matched with the stud; and a pressure release valve spring is arranged between the stud and the inner wall of the pressure release cavity. The pressure release valve structure is changed into spherical surface seal from plane seal, so that sealing effect is good, a sealing form is more stable, the closing effect is quicker, and oil supply efficiency of the high-pressure pumpis improved.

Owner:JIANGSU BATON TECH CO LTD

Workpiece internal structure detection equipment

PendingCN112730755AStable differential pressureReduce measurement noiseMass flow measurement devicesMaterial analysisEngineeringMechanical engineering

The invention is applicable to the technical field of workpiece detection, and provides workpiece internal structure detection equipment, which comprises a first mass flow meter used for detecting the mass flow of liquid flowing into a workpiece working chamber; a second mass flow meter which is used for detecting the mass flow of the liquid flowing out of the workpiece working chamber; a pressure stabilizing device which is used for inputting liquid with constant pressure into the first mass flow meter; and a differential pressure gauge which is used for detecting the differential pressure between the communication part of the first mass flow meter and the working chamber and the communication part of the second mass flow meter and the working chamber. Compared with the prior art, the change of the mass flow of the liquid flowing through the workpiece is detected by taking the mass of the liquid as the reference under the condition that the pressure difference between the inlet and the outlet of the working chamber is stable, measurement interference items are reduced, and the detection result is more accurate; and secondly, the pressure stabilizing device is arranged, and liquid with constant pressure is outputted through the pressure stabilizing device so that the inlet and outlet pressure difference of the working chamber can be kept stable, and the measurement error is smaller.

Owner:CHONGQING KEBEN TECH

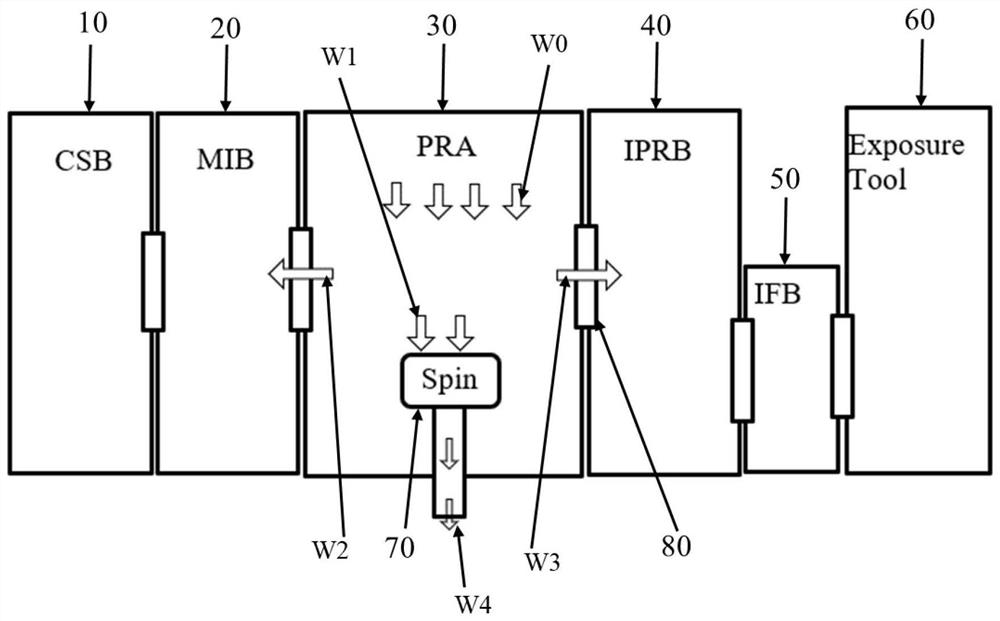

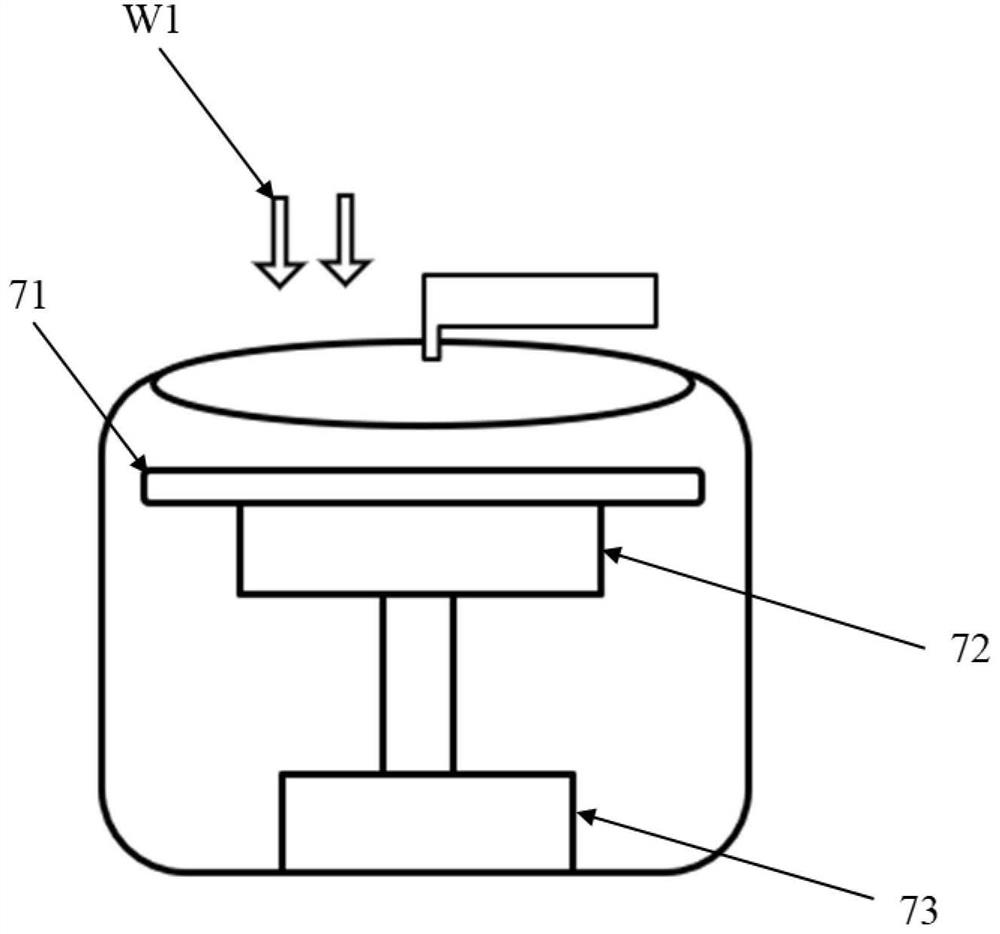

Voltage stabilizing device for glue coating and developing equipment and glue coating and developing equipment

ActiveCN112558431BExtended service lifeReduce rework ratePhotomechanical exposure apparatusMicrolithography exposure apparatusCrankWafer

The present invention provides a voltage stabilizing device for glue-coating and developing equipment and the glue-coating and developing equipment. The voltage stabilizing device for glue-coating and developing equipment includes a wind tunnel, which has an air inlet end and an air outlet that axially penetrate both ends of the wind tunnel. The through hole at the air end, the side wall of the through hole is provided with a limit opening; the bearing is axially arranged in the through hole; the piston cooperates with the limit opening to open or close the through hole; the spring, the spring One end close to the limit port is fixed on the bearing through a spring limit rod on the bearing; the crank and crank connecting rod are arranged on the side of the spring far away from the air inlet end, and the The crank is connected to the end of the spring far away from the limiting opening; the propeller is arranged on the end of the bearing close to the air outlet. The technical solution provided by the invention can stabilize the pressure difference between the glue application developing chamber and the outside atmosphere, thereby enabling the uniformity of the film thickness on the surface of the wafer to be controlled within the specification and reducing the rework rate of the wafer.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

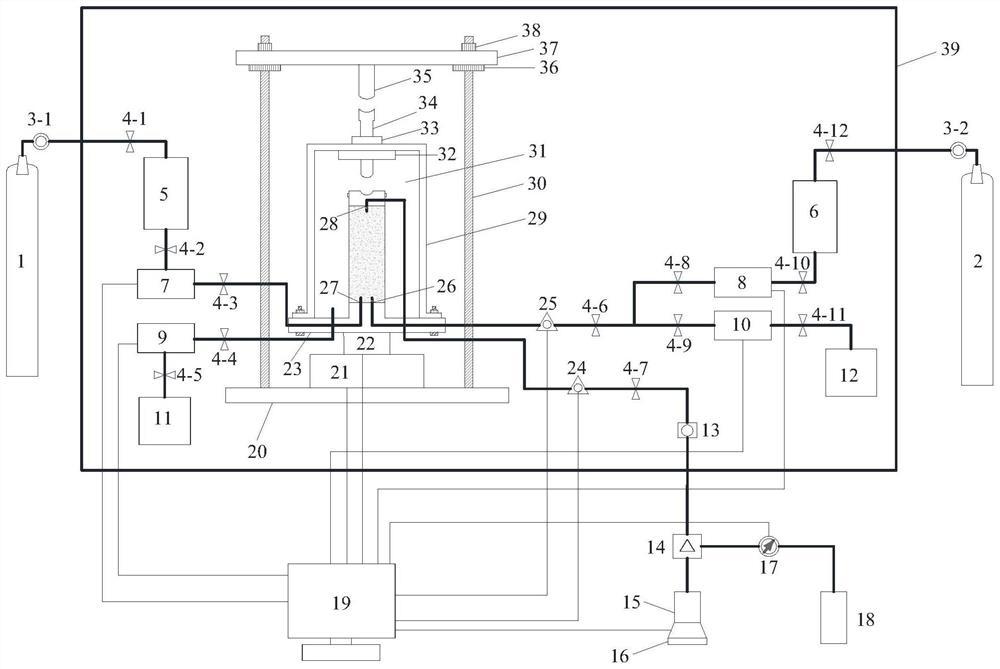

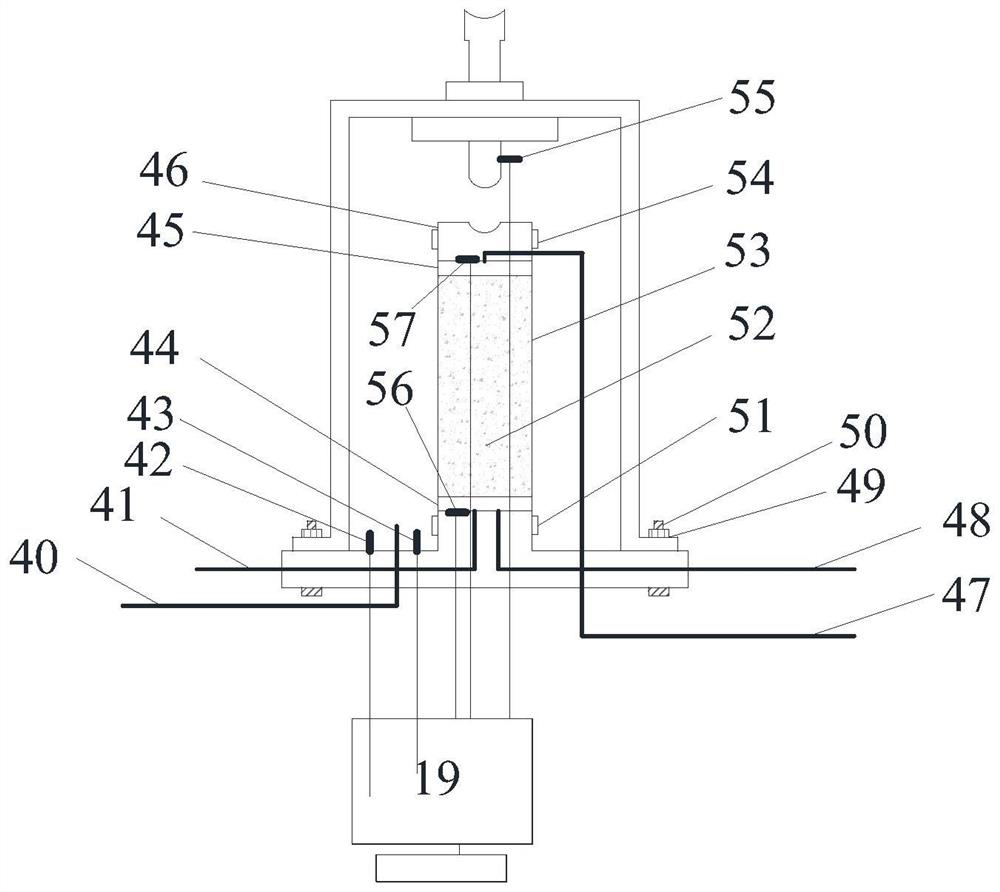

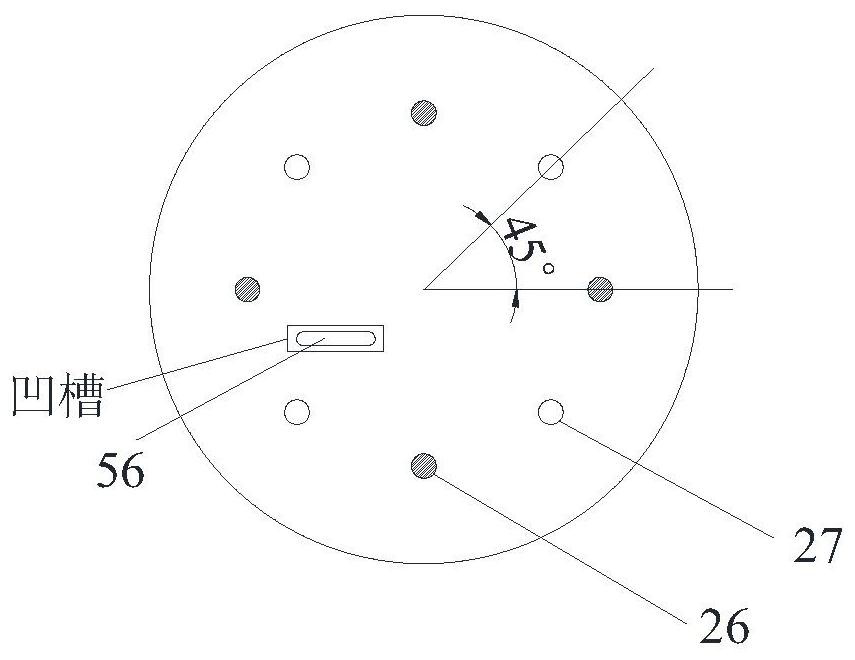

Triaxial shearing and seepage integrated experimental method for hydrate-containing sediments

ActiveCN112710554AAdd in-situ synthesis equipmentSolve decouplingSurface/boundary effectMaterial strength using tensile/compressive forcesExperimental methodsSediment

The invention belongs to the technical field of geotechnical experiments, and particularly relates to a triaxial shearing and seepage integrated experimental method for hydrate-containing sediments. The method comprises the following steps: (1) generating hydrate; (2) preparing a shearing and seepage coupling experiment; (3) carrying out an experiment. The special integrated experimental device is utilized, seepage and stress coupling analysis in the hydrate triaxial shear failure process can be achieved, and different seepage experiments of liquid and gas and liquid can be achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Experimental method for productivity simulation of multi-layer co-production of natural gas reservoirs

The invention aims at providing a simulation experiment method convenient to operate and capable of accurately simulating gas capacity quantitative evaluation under the condition of natural gas multi-layer commingling operation process, of multi-layer commingling capacity of a natural gas reservoir. The simulation experiment method of the multi-layer commingling capacity of the natural gas reservoir comprises a plurality of pressure gas containing bottles; a gas outlet of each pressure gas containing bottle is connected with a gas inlet of each reducing valve correspondingly, and a gas outlet of each reducing valve is connected with a gas inlet of each rock core clamp tube body correspondingly; a temperature measuring unit and a confining pressure measuring unit are installed on the wall of each rock core clamp tube body correspondingly, a gas outlet of each rock core clamp tube body is connected with an entrance of each bi-directional valve through a pipeline which is in series connection with a branch-pipe backpressure valve and a branch-pipe flow meter correspondingly, and an exit of each bi-directional valve is connected with the lower portion of a cylindrical container through a pipeline correspondingly; and the top of the cylindrical container is connected with outside air through a pipeline which is in series connection with a header pipe backpressure valve and a header pipe flow meter.

Owner:YANGTZE UNIVERSITY

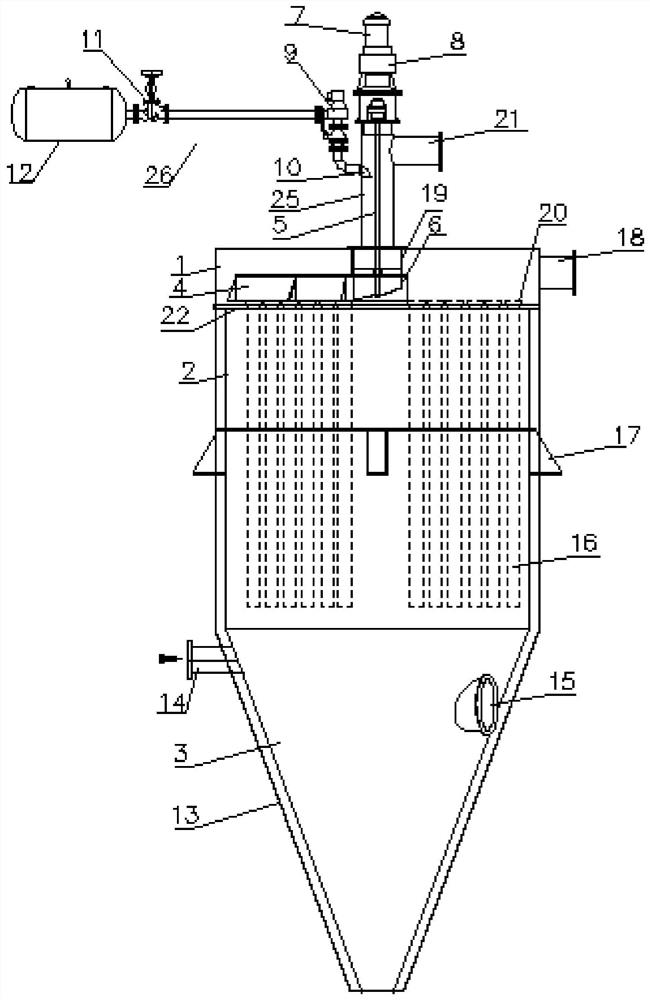

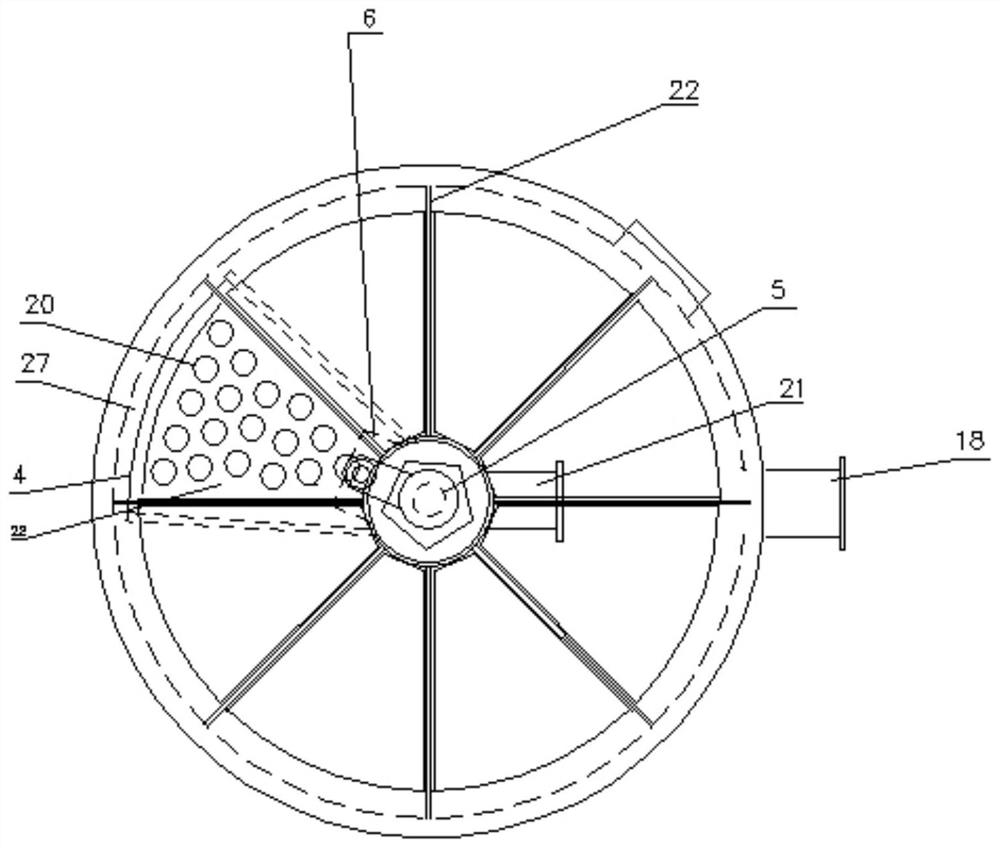

Special pulse bag-type dust collector for purifying tail gas of closed submerged arc furnace

PendingCN114669130ASave nitrogen resourcesAvoid flash explosionDispersed particle filtrationExhaust gasEngineering

A special pulsed jet cloth filter for tail gas purification of a closed submerged arc furnace comprises an upper box body, a middle box body and an ash bucket, the upper end of the middle box body and the lower end of the upper box body are communicated through a pattern plate and a filter bag, the lower end of the middle box body is communicated with the upper end of the ash bucket, the upper box body and the middle box body are both of a cylindrical structure, and the ash bucket is of a conical structure. An ash removal rotating cover and an ash removal rotating nozzle are arranged in the upper box body and fixed to the lower end of the rotating shaft, a pipe shaft of an ash removal back-blowing pipe is perpendicular to the upper end face of the upper box body and arranged in the center of the upper box body, the ash removal back-blowing pipe is communicated with the upper box body, and a gear motor is fixed to the upper end of the ash removal back-blowing pipe in a sealed mode. The left side of the ash-cleaning back-blowing pipe is communicated with an ash-cleaning spray pipe of the nitrogen ash-cleaning device, the right side of the ash-cleaning back-blowing pipe is communicated with a gas conveying pipe of a back-blowing system, the overlook structure of the ash-cleaning rotary cover is fan-shaped or circular, and a surrounding plate perpendicular to the fan-shaped or circular surface is arranged on the periphery of the fan-shaped or circular surface.

Owner:湖北江环环保科技有限公司

Sealing gasket and seed housing for a seeder and seeder comprising such a seed housing

ActiveUS9151388B2Easy to replaceStable differential pressureEngine sealsSingle grain seedersSeederRubber material

A sealing gasket made of a resilient rubber material or rubber-like material. The sealing gasket is formed as a rotationally symmetric body with a substantially constant cross-sectional profile. The cross-sectional profile includes: a first sealing part located furthest away from a center of rotation of the body and a second sealing part located radially inside the first sealing part, as viewed in the radial direction. An open space is defined by the first and second sealing parts. The second sealing part essentially curves through an angle away from the center of rotation. A seed housing can include such a seal and a seeder can include such a seed housing.

Owner:VADERSTAD HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com