Water cooling nozzle without air pump

A technology of water cooling and air pump, which is applied in the direction of exhaust device, air quality improvement, noise reduction device, etc. It can solve the problems of nozzles and internal structures that are easy to freeze and crack, cannot realize timely pressure compensation, and shorten service life, so as to avoid frostbite, The effect of compact structure and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

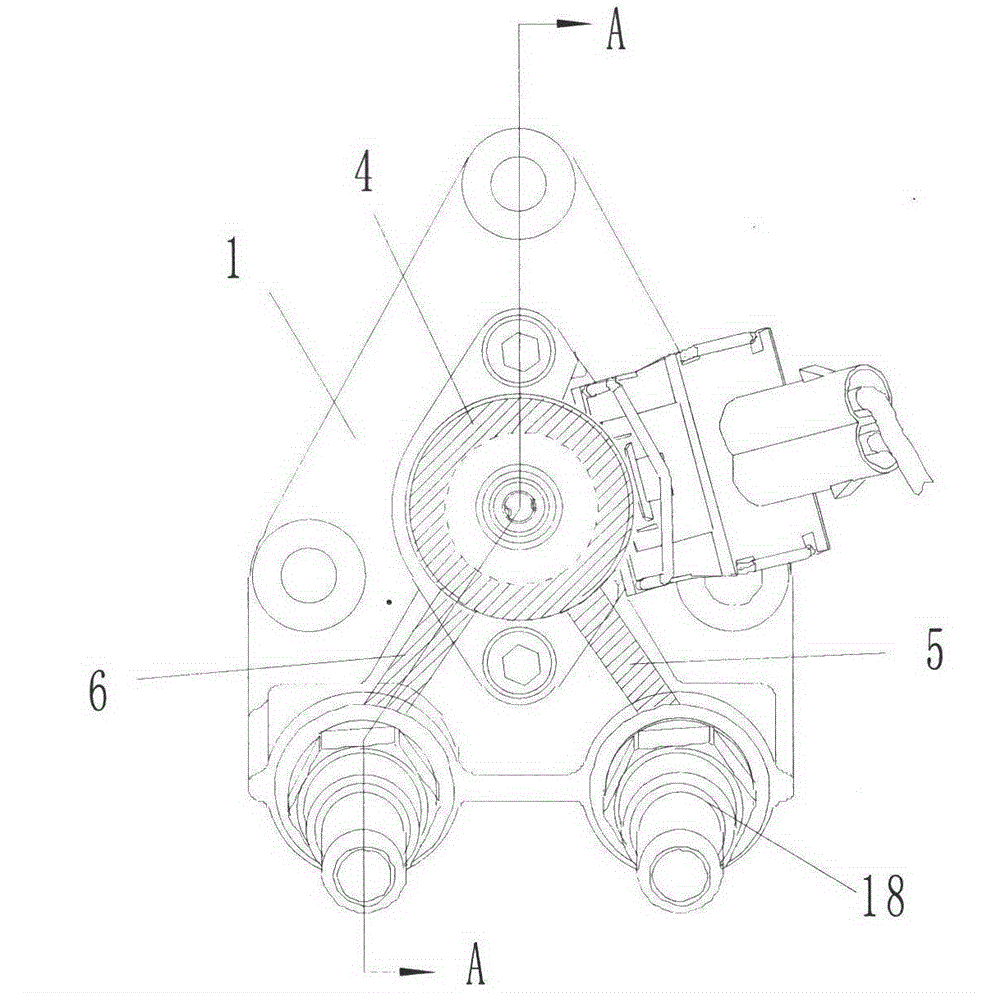

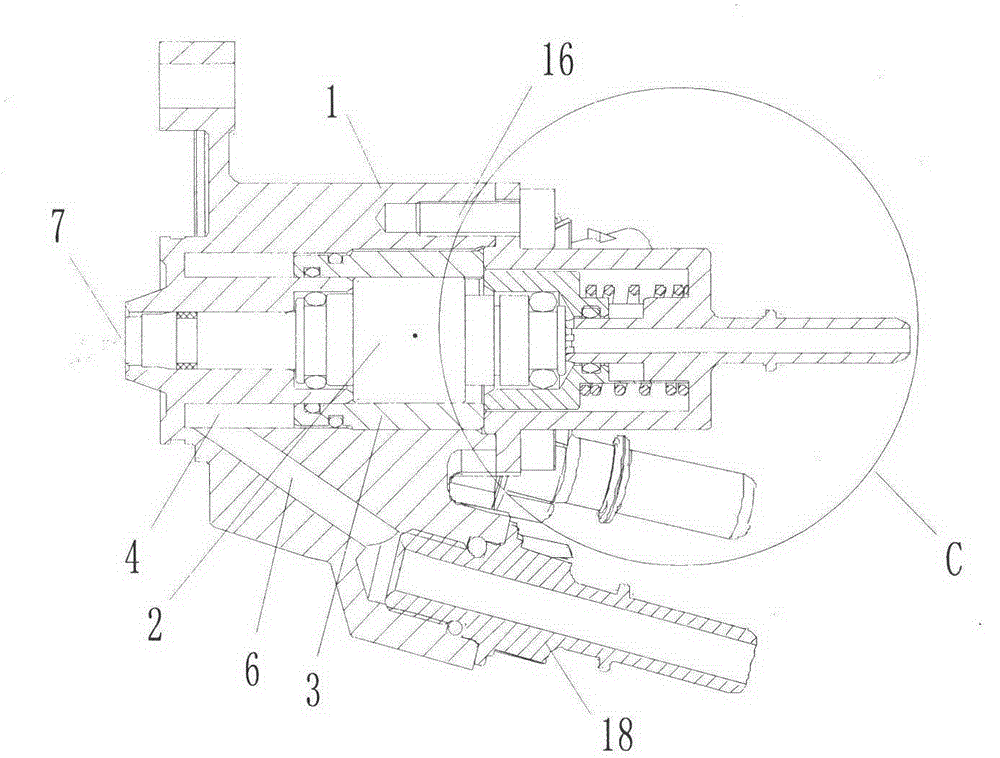

[0037] An airless pump water cooling nozzle such as figure 2 shown, combined with figure 1 , including a housing 1, a through hole is opened in the center of the housing 1, a metering valve 2 is placed in the through hole, and one end of the through hole is connected with the nozzle of the metering valve 2 to form an injection port 19.

[0038]A cooling chamber 4 and a blocking cover 3 are provided on the housing 1, and the blocking cover 3 and the cooling chamber 4 surround the periphery of the metering valve 2, specifically, openings in the housing 1 An annular channel, the channel is located at the periphery of the metering valve 2, and the plugging cover 3 is embedded in the channel, and the blocking cover 3 can seal the upper half of the channel, so that The lower half of the passage forms the cooling chamber 4 of the closed structure, referring to figure 1 , the housing 1 is provided with a water inlet passage 5 and a water outlet passage 6, and the water inlet passa...

Embodiment 2

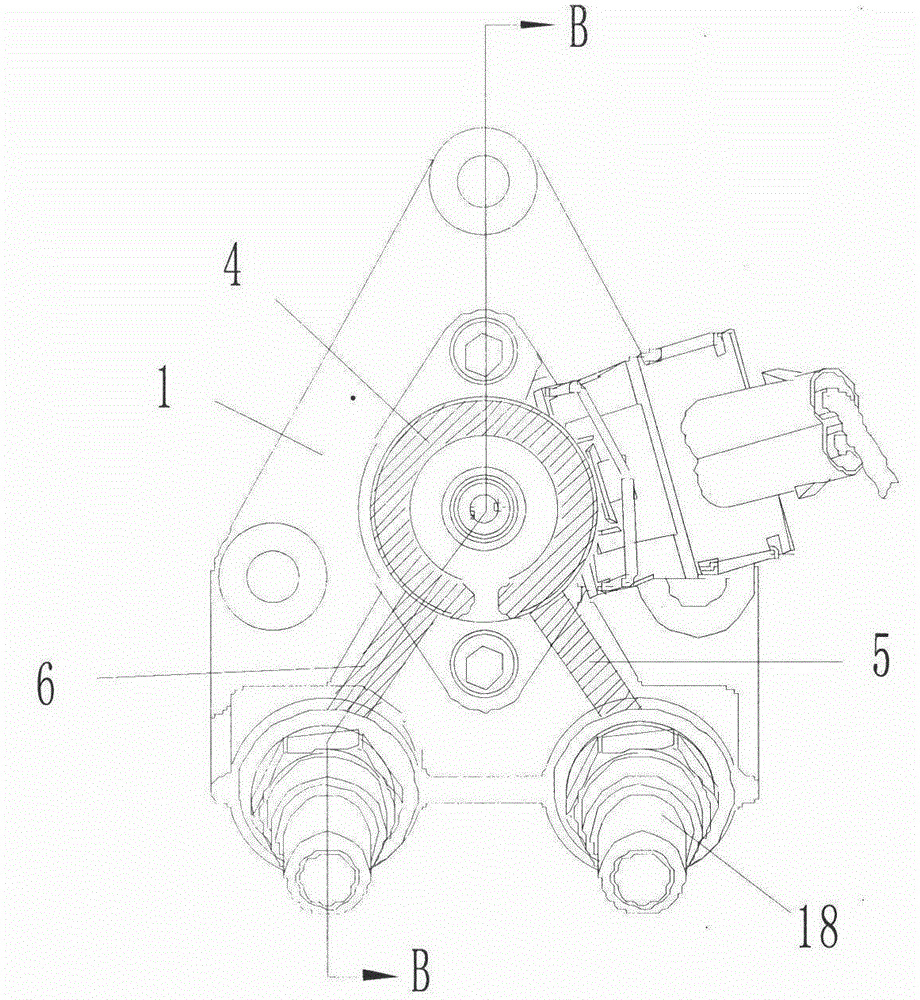

[0049] A water-cooled nozzle without an air pump, including a housing 1, referring to Figure 4 , and combined with image 3 , a metering valve 2 is installed in the housing 1, a cooling chamber 4 and a plugging cover 3 are arranged on the housing 1, the cooling chamber 4 is formed by a semi-circular structure channel, and the plugging cover 3 is fixed on The bottom end of the housing 1, its top surface is formed at the bottom of the cooling chamber 4, the fixing method of the blocking cover 3 and the housing 1 can be fixed by welding or limit pin 17, the main The purpose is to play a positioning role and a sealing effect.

[0050] A liquid inlet joint 18 is installed on the housing 1, combined with Figure 6 , the head of the metering valve 2 is covered with a telescopic sleeve 8, the bottom of the telescopic sleeve 8 and the bottom of the liquid inlet connecting pipe 18 are fixed to the housing 1, and the rest are the same as in Embodiment 1. The advantage of the embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com