Patents

Literature

262results about How to "Inhomogeneous suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

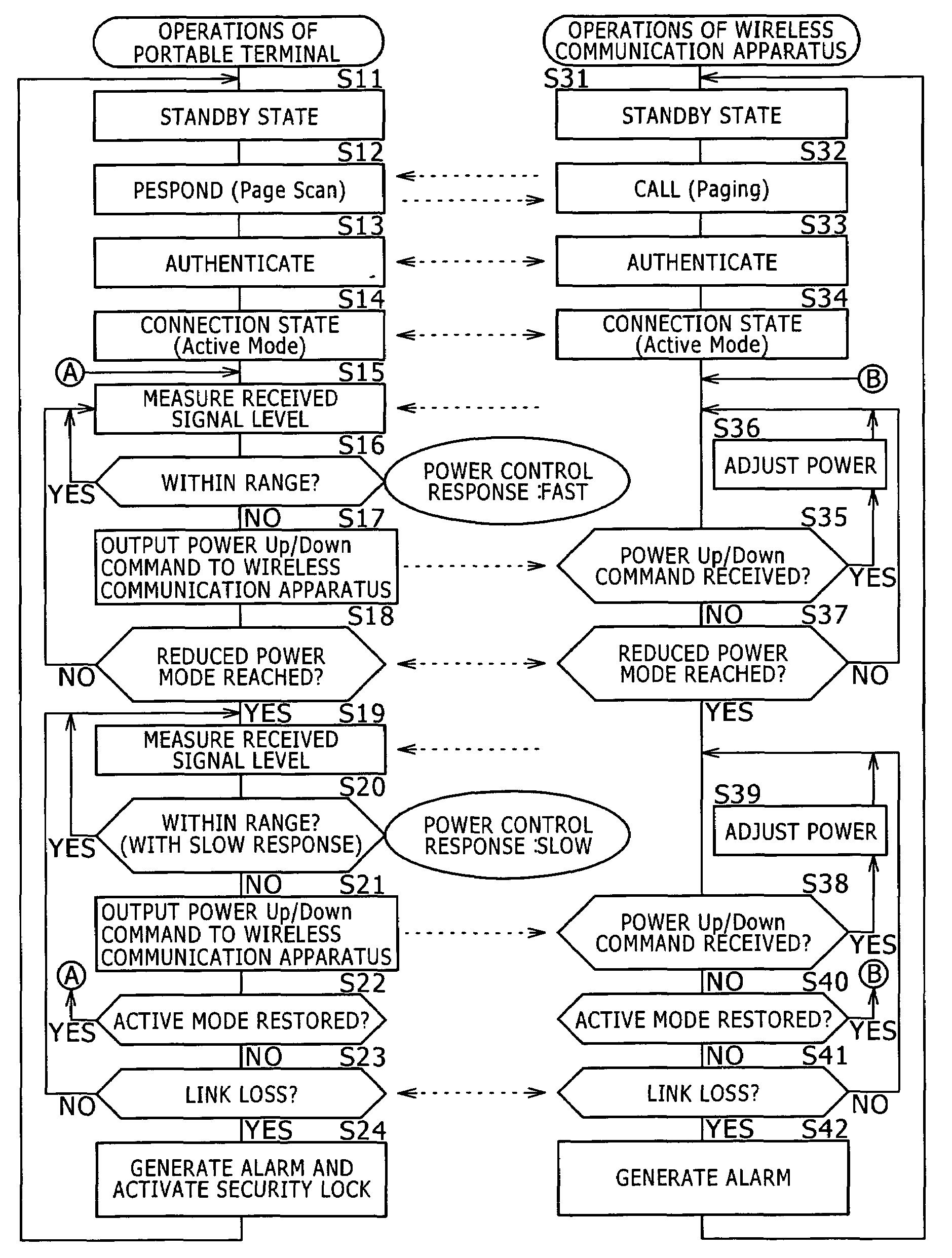

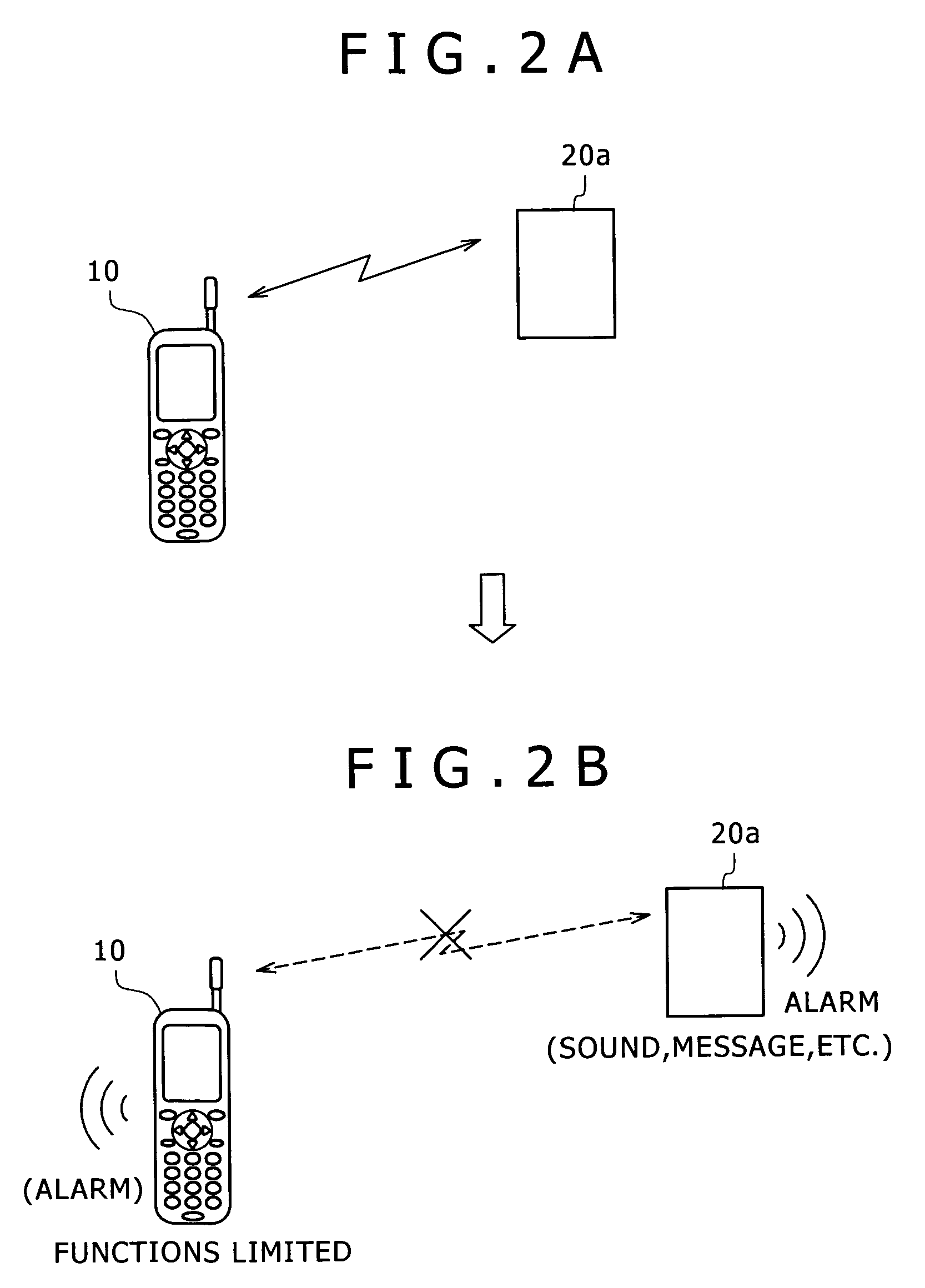

Short range wireless communication system, portable terminal apparatus, and wireless communication apparatus

ActiveUS7336929B2Increase transmit powerResponse speedEnergy efficient ICTTime-division multiplexCommunications systemTime segment

A portable terminal monitors a signal level of a short-range wireless signal from a wireless communication apparatus. If the signal level drops so low that a state of connection for short-range wireless communications cannot be maintained between the two apparatuses, use of predetermined functions of the portable terminal is limited. A short-range wireless communication facility of the portable terminal and the wireless communication apparatus move into a particular operation mode if communications do not occur therebetween at least for a predetermined time period. In monitoring the signal level of the wireless signal from the wireless communication apparatus in the particular operation mode, the portable terminal reduces a response speed at which to detect a signal level change. This causes the wireless communication apparatus to delay issuing a request for an increase in transmission power, thereby reducing unevenness of the working distance at which to alert a user to the unusual distance traveled between the two apparatuses or beyond which to limit the use of some functions of the portable terminal.

Owner:SONY CORP

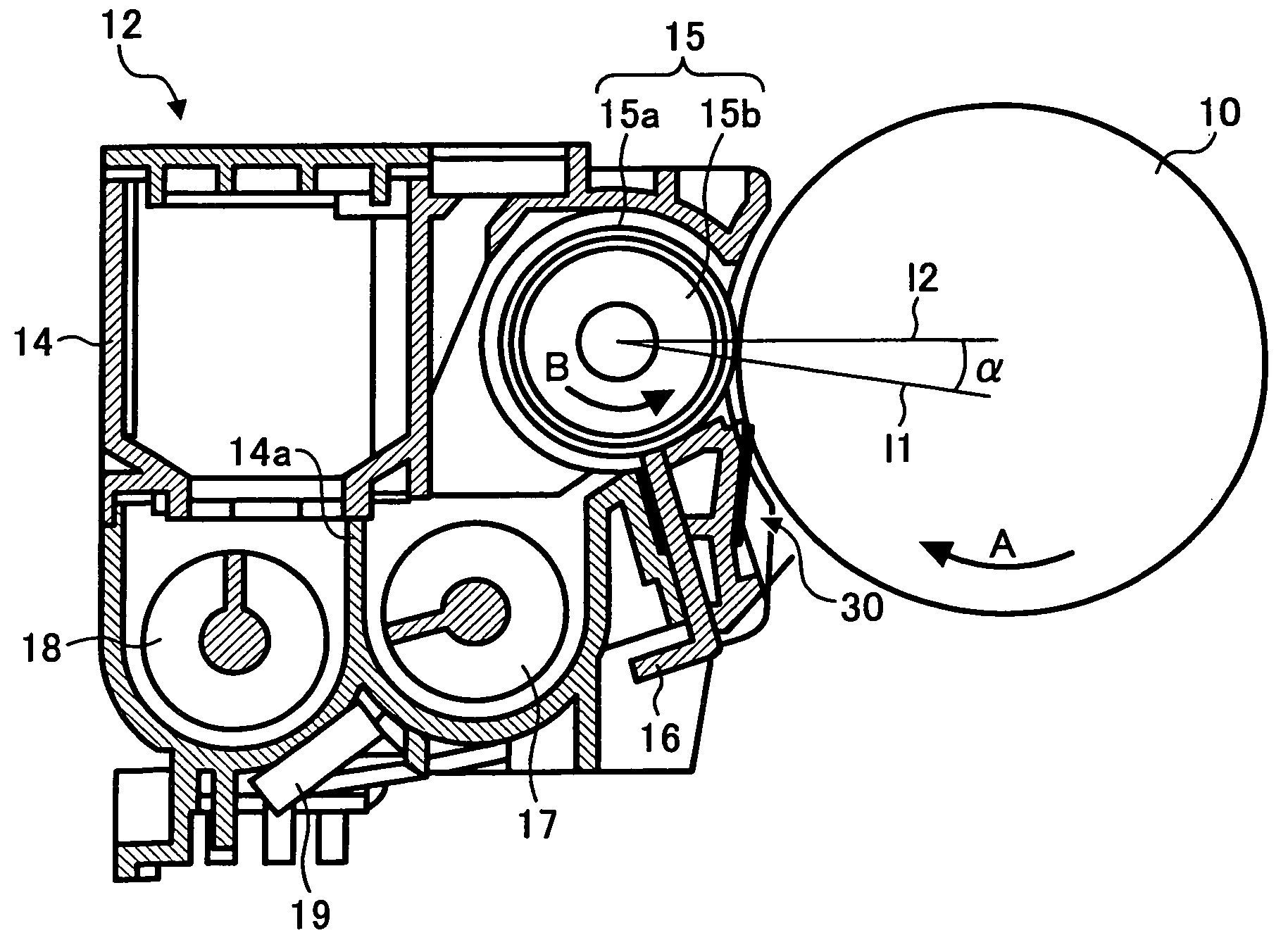

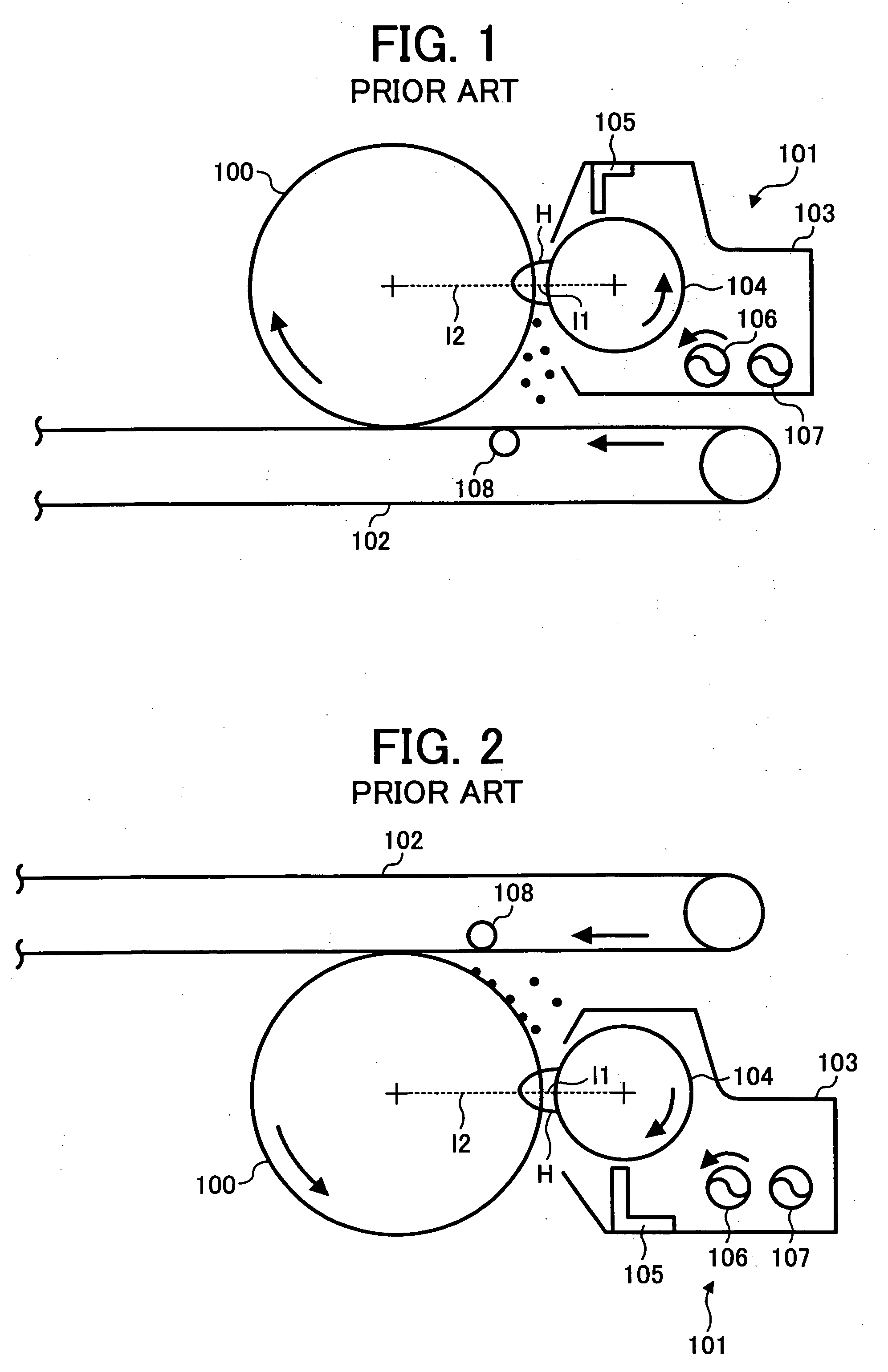

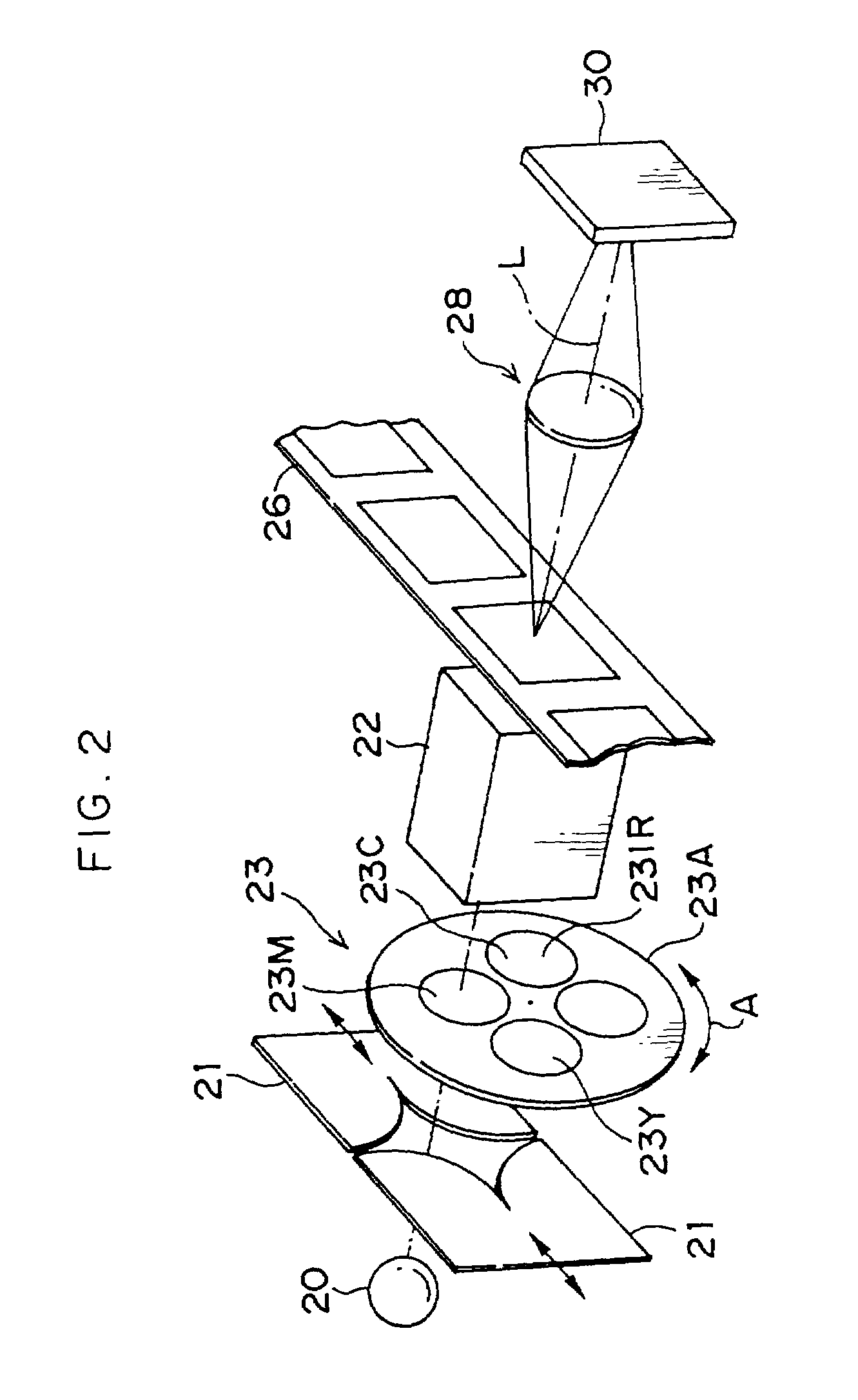

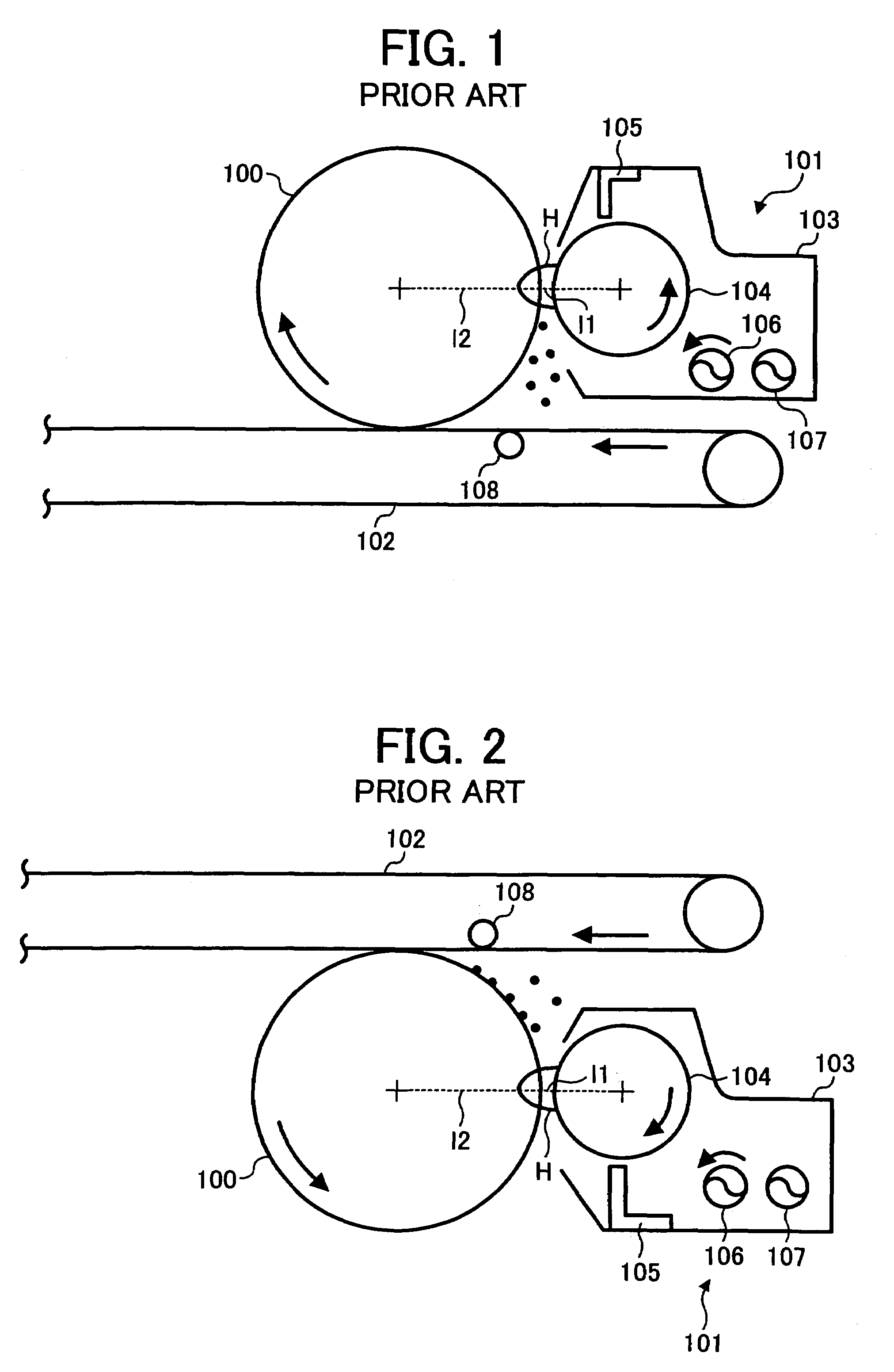

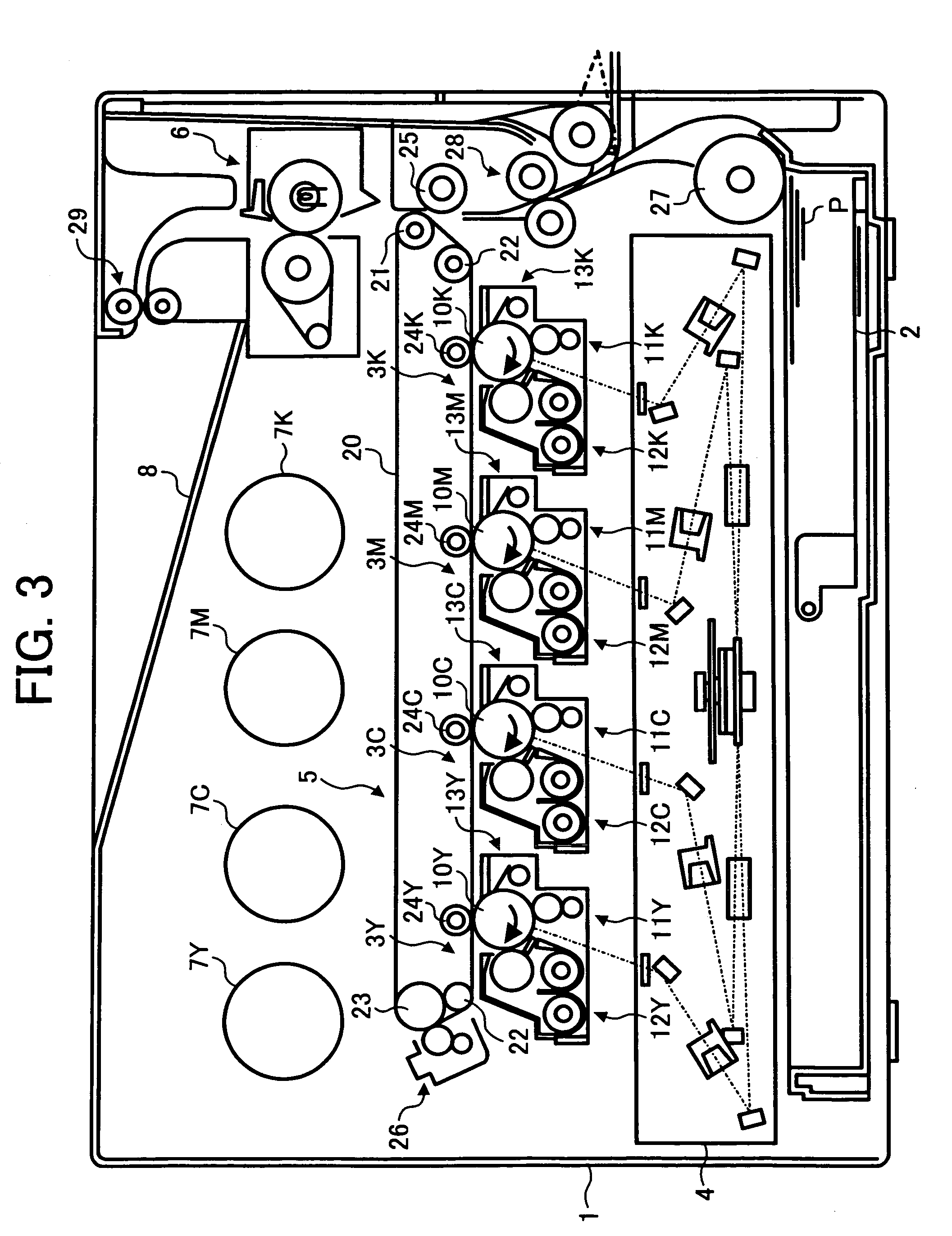

Image forming apparatus

InactiveUS20060029435A1Reduce generationImprove the development effectElectrographic process apparatusElectrographic processes using charge patternImage formationEngineering

It is an object of the present invention to provide a process unit and an image forming apparatus in which generation of loss of image density due to flying off of developer and the edge effect occurring as a side-effect under developing conditions aimed at improving development performance can be reduced, even when a DC bias development system is adopted, and which can suppress developing density unevenness caused by impact occurring on contact of the teeth of gears in the drive system.

Owner:RICOH KK

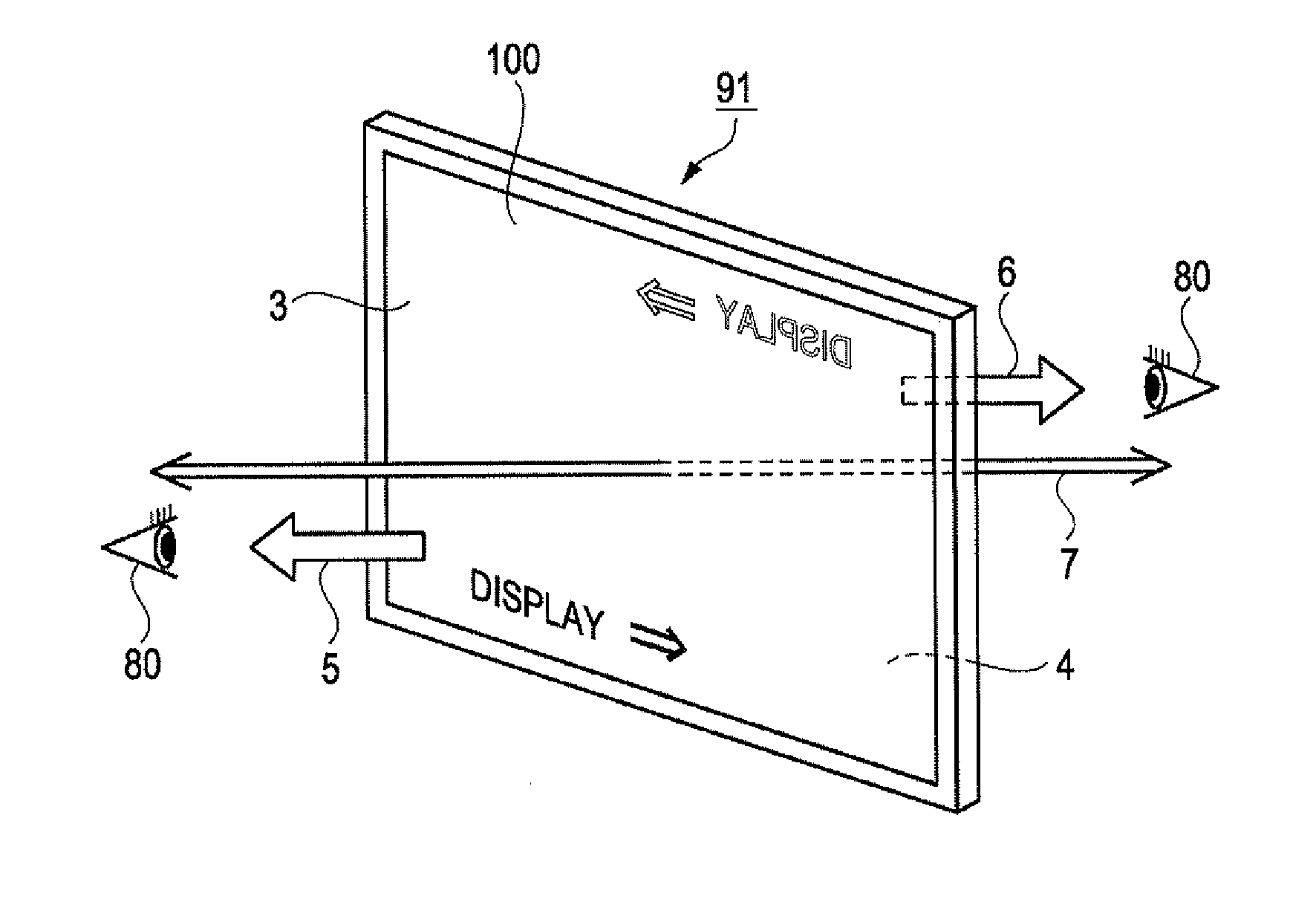

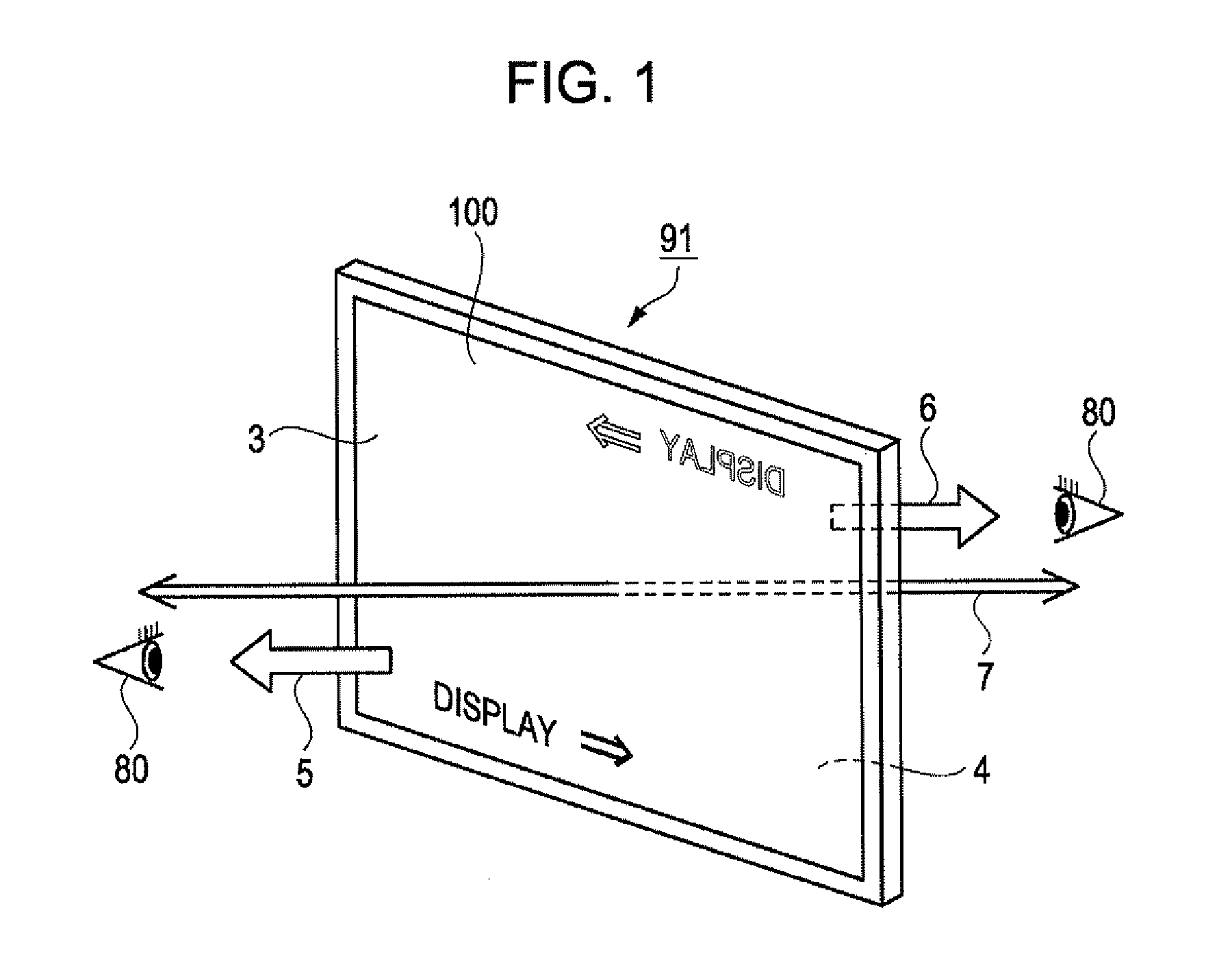

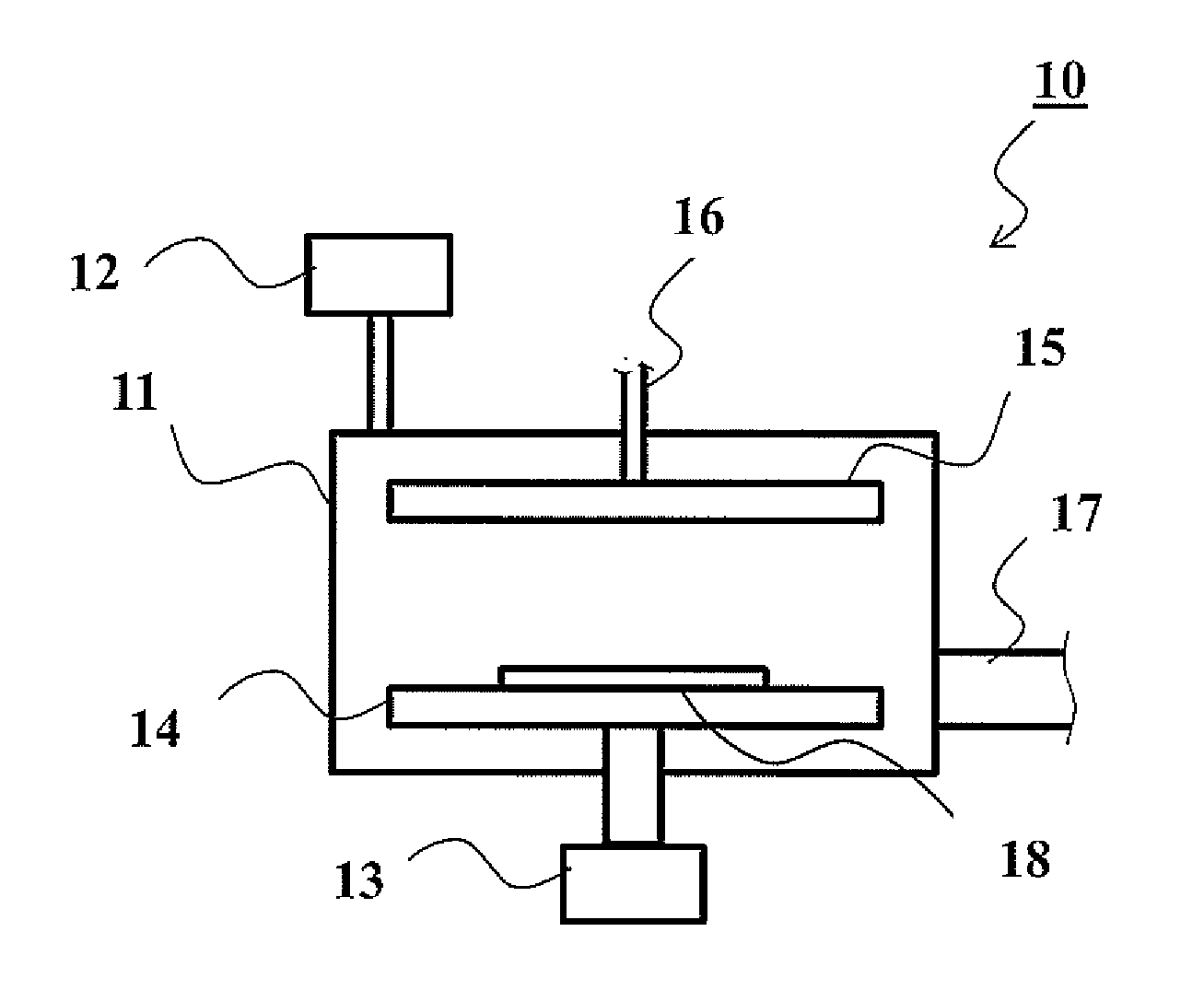

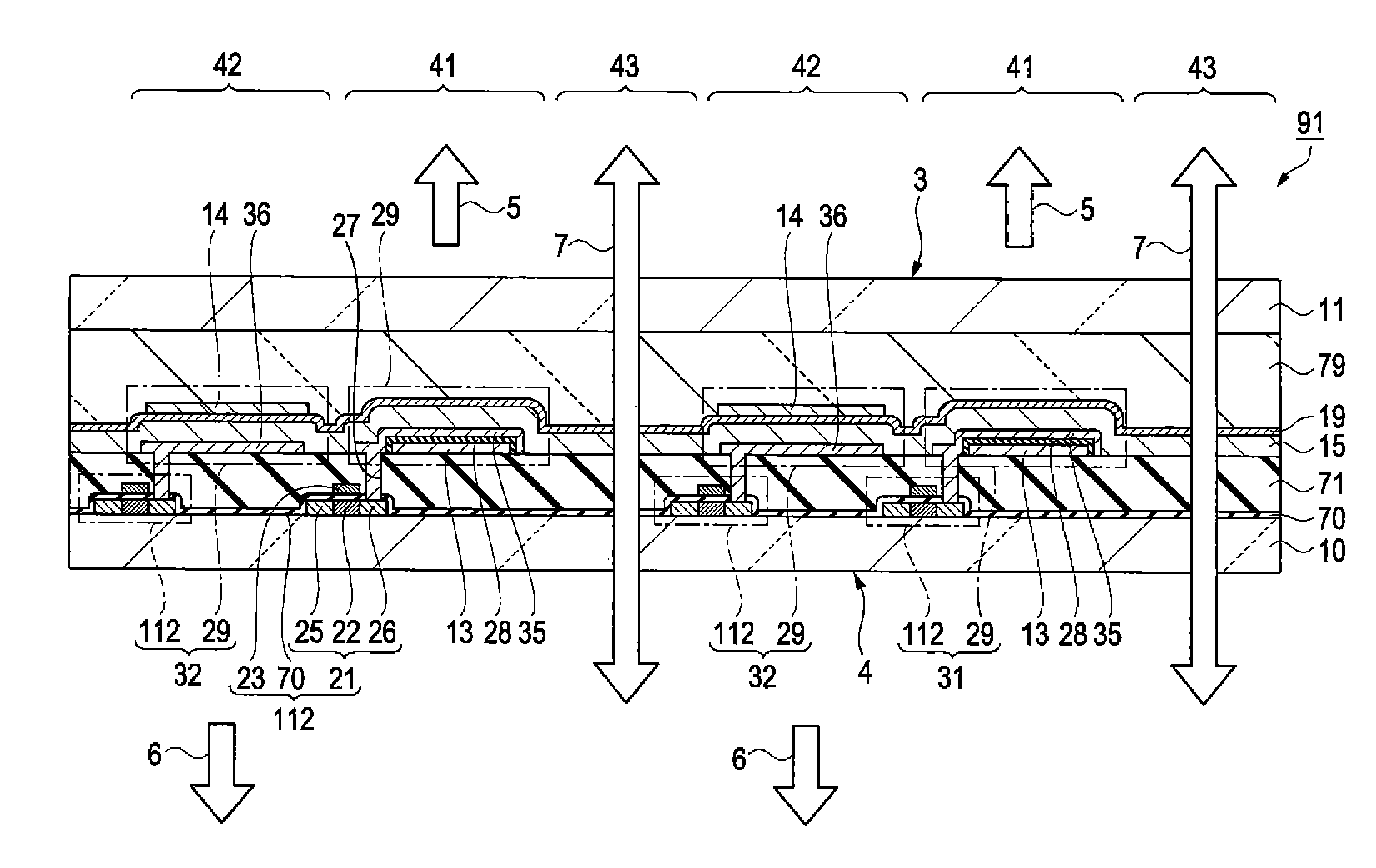

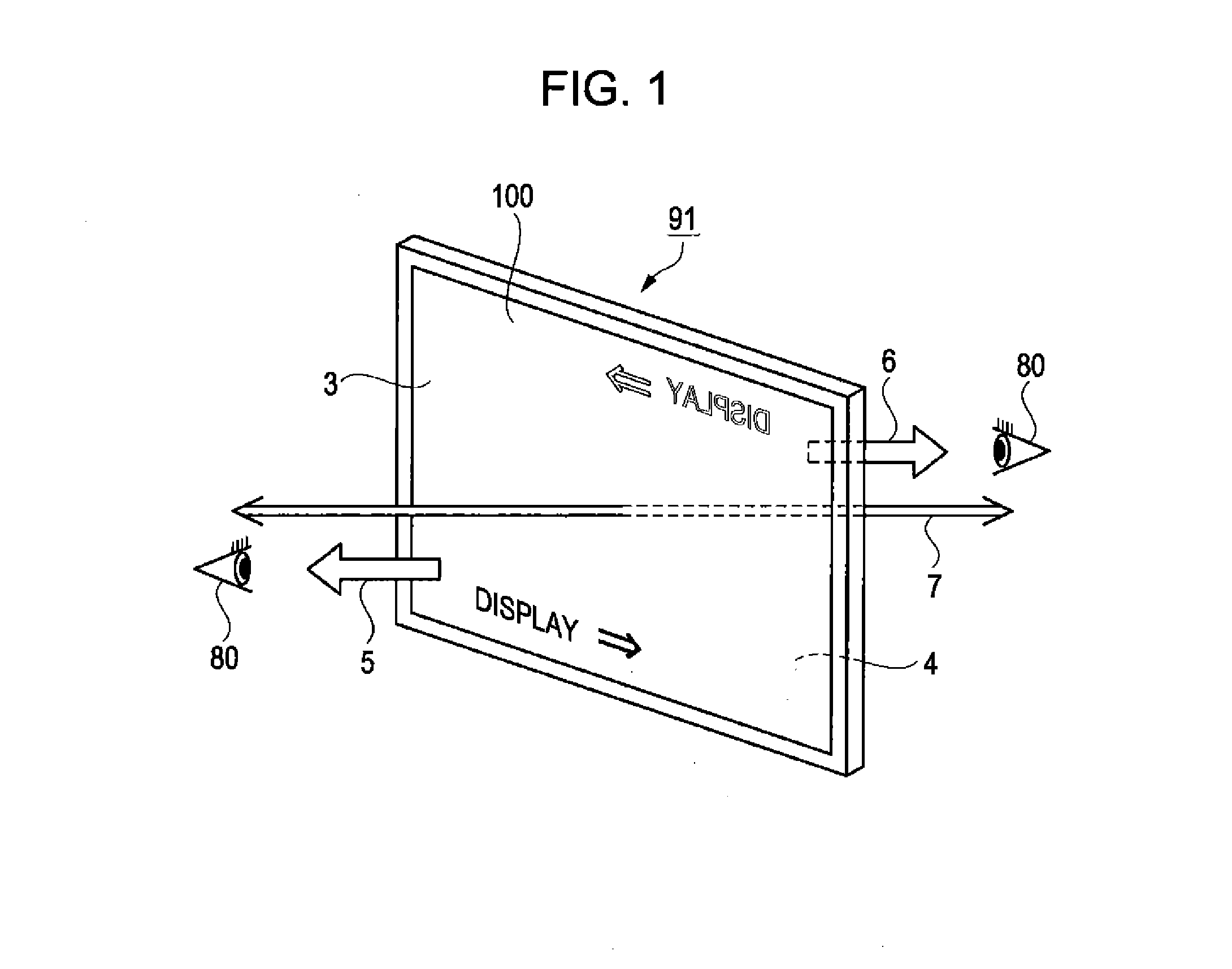

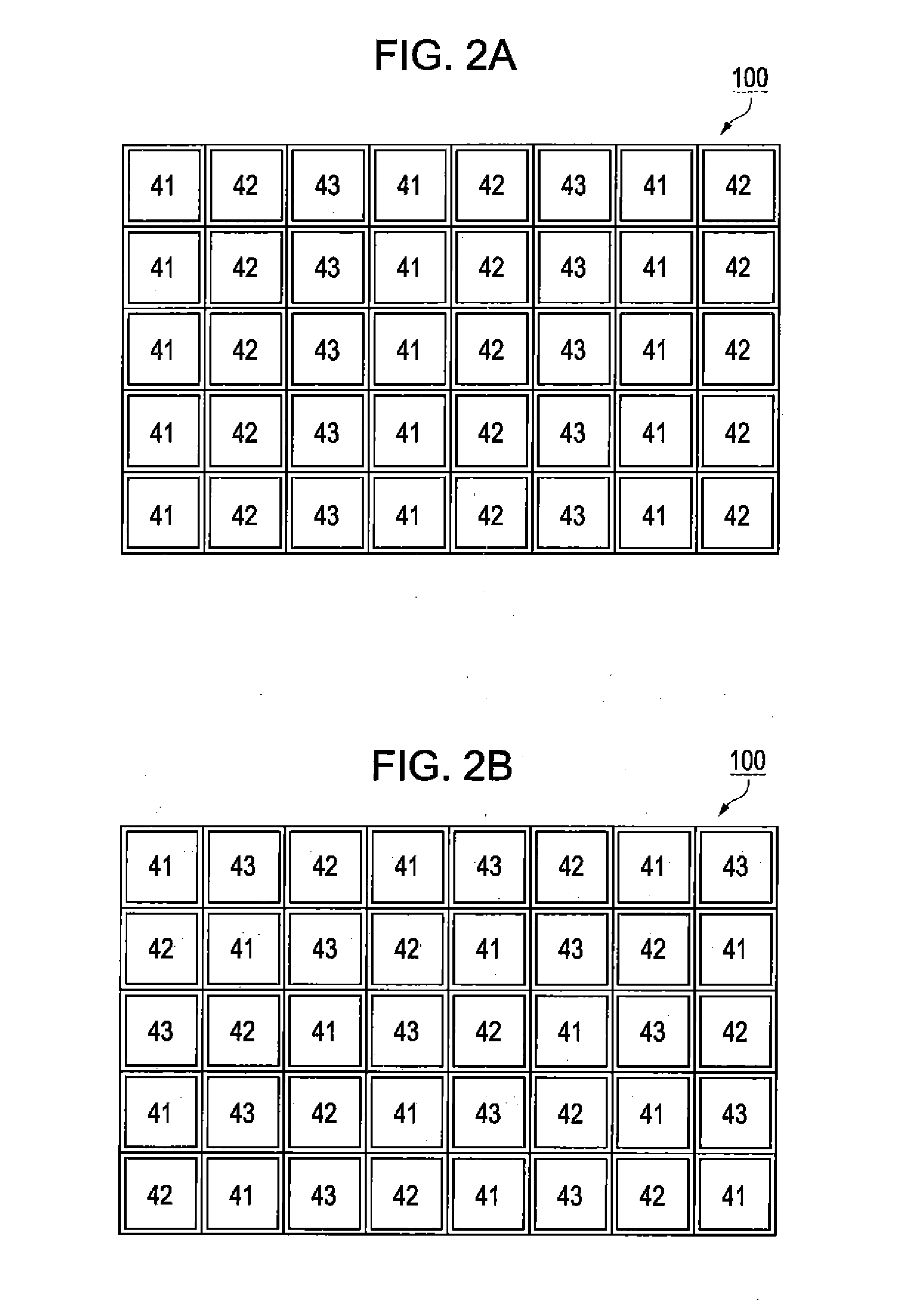

Display device

ActiveUS20110148944A1Increase the number ofIncrease manufacturing costSolid-state devicesDiodeDisplay deviceDriven element

A display device includes a light emitting functional layer disposed between a first and second substrates; a first pixel which emits light to the second substrate and has a first pixel electrode disposed between the light emitting functional layer and the first substrate, a second electrode disposed between the light emitting functional layer and the second substrate, and a first reflecting layer disposed between the first pixel electrode and the first substrate; a second pixel which emits light to the first substrate side and has a second pixel electrode disposed between the light emitting functional layer and the first substrate, a second electrode disposed between the light emitting functional layer and the second substrate, and a second reflecting layer disposed between the second electrode and the second substrate; and a driving element which drives the first and second pixel electrodes is disposed above first substrate.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

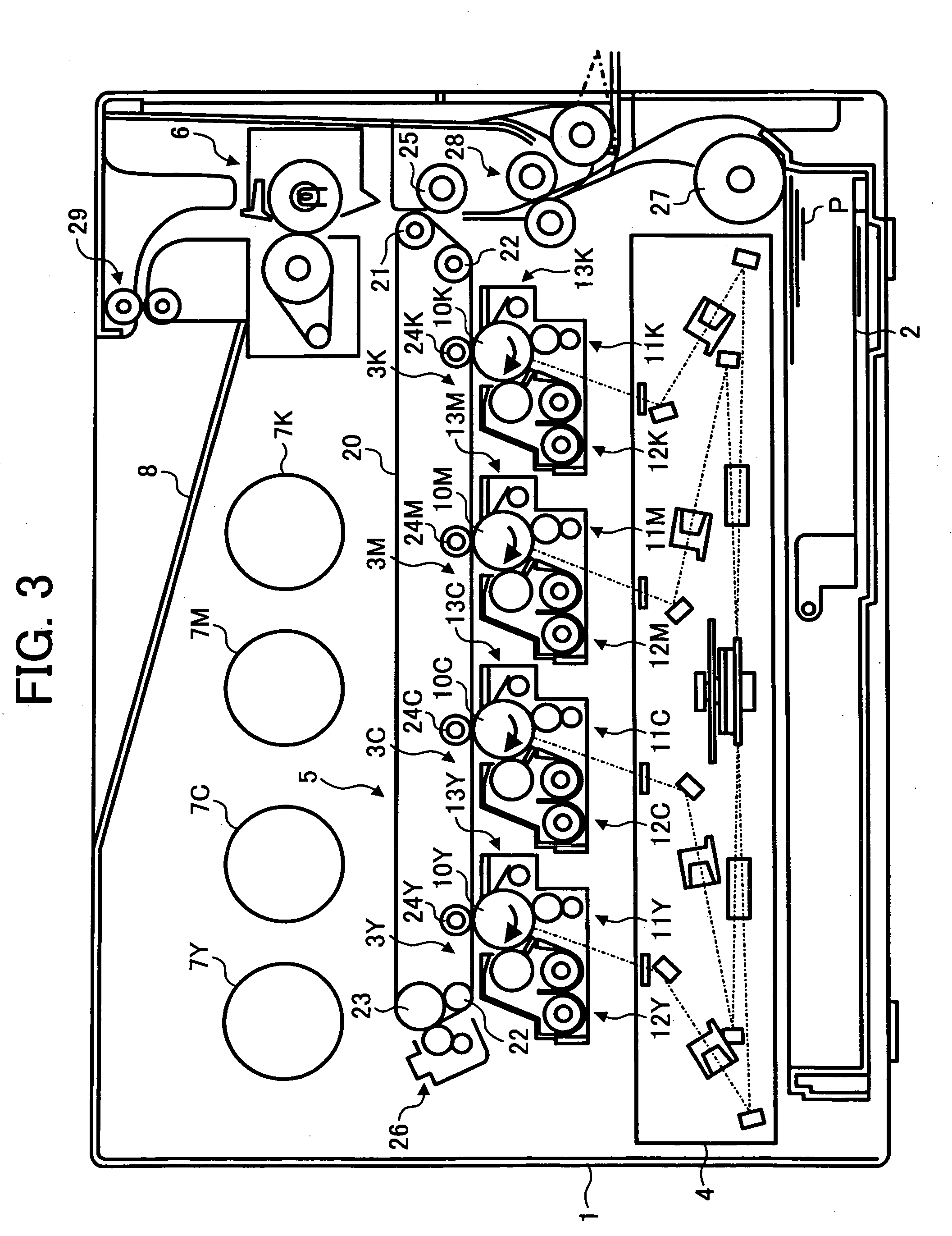

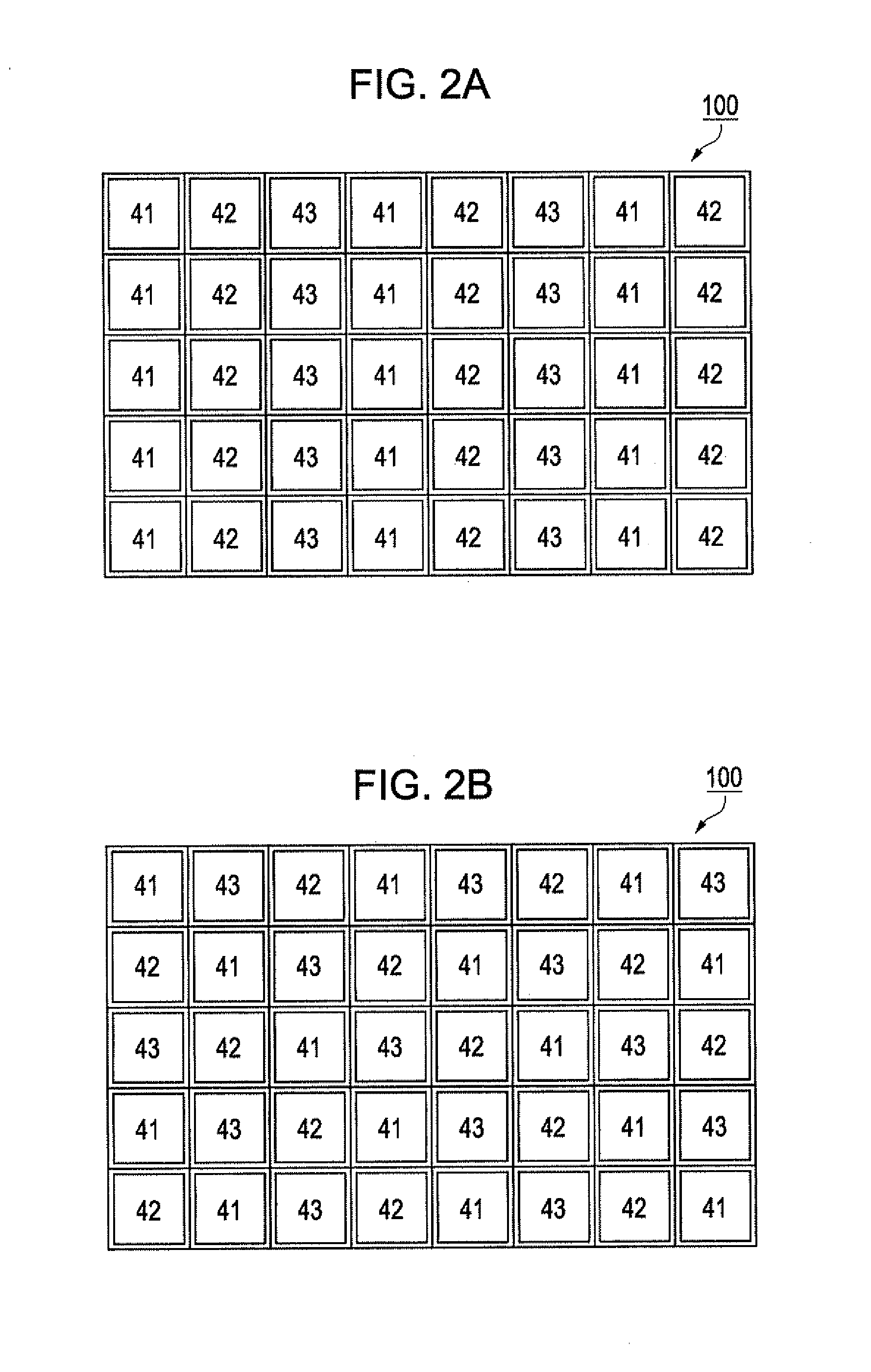

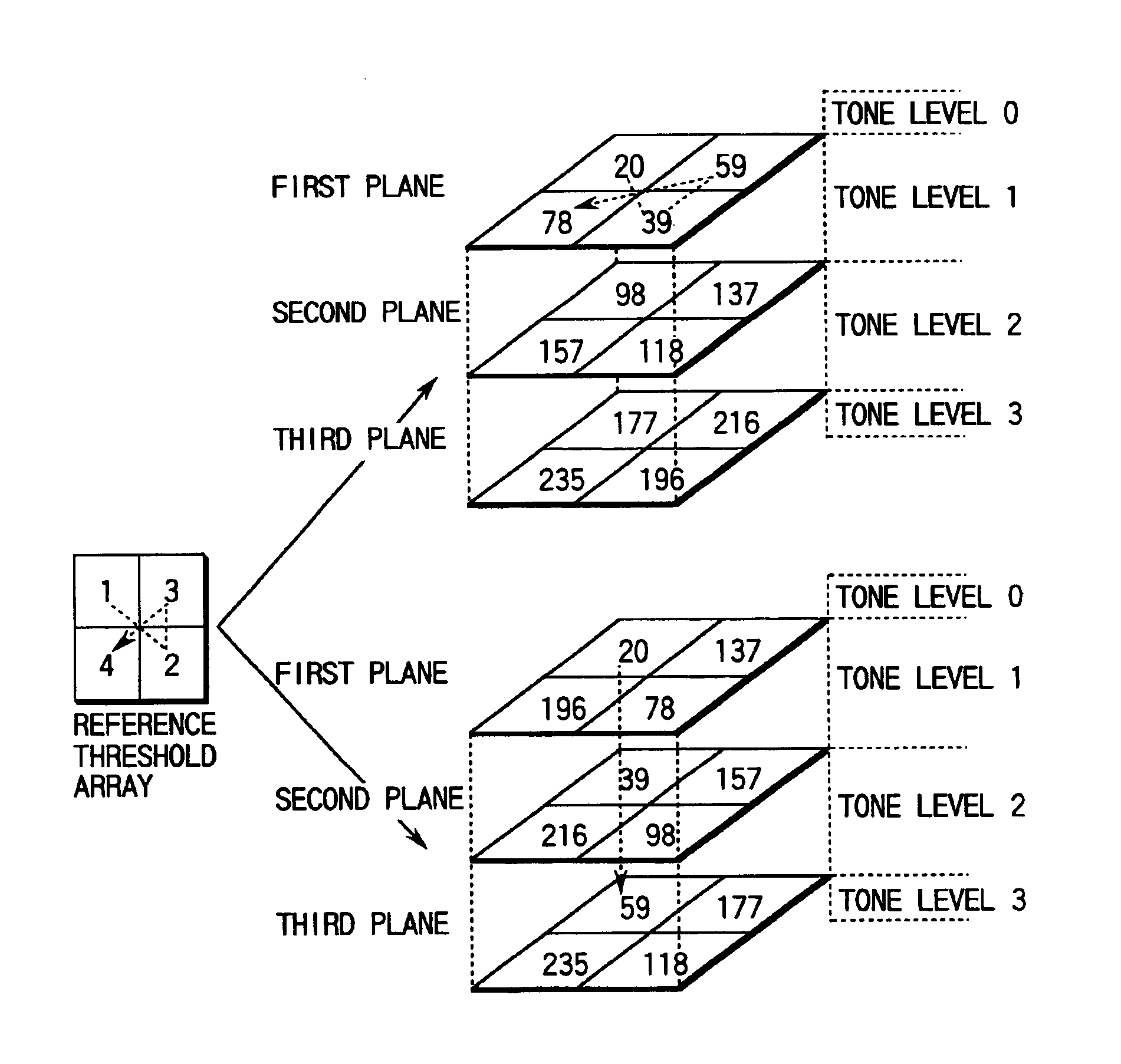

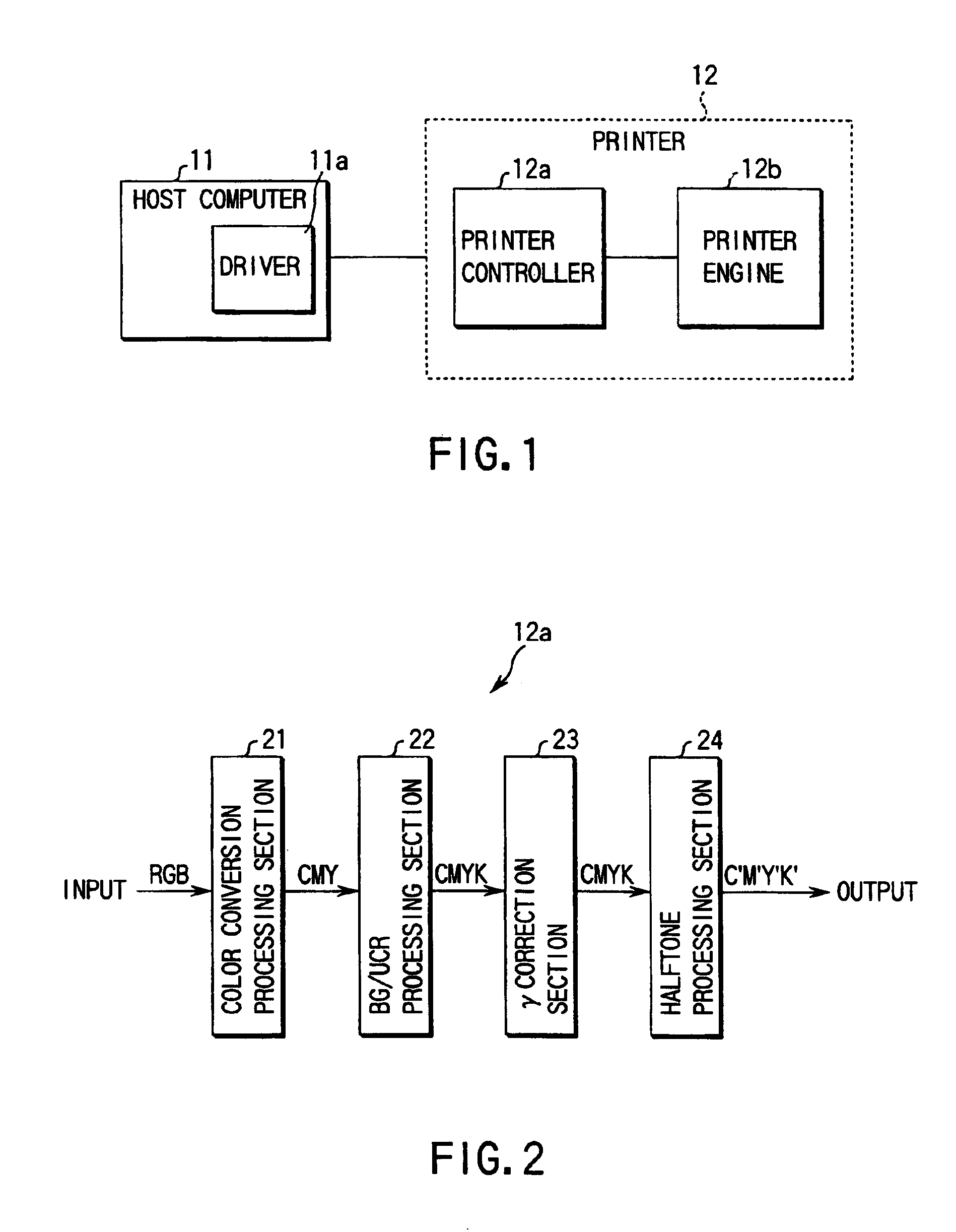

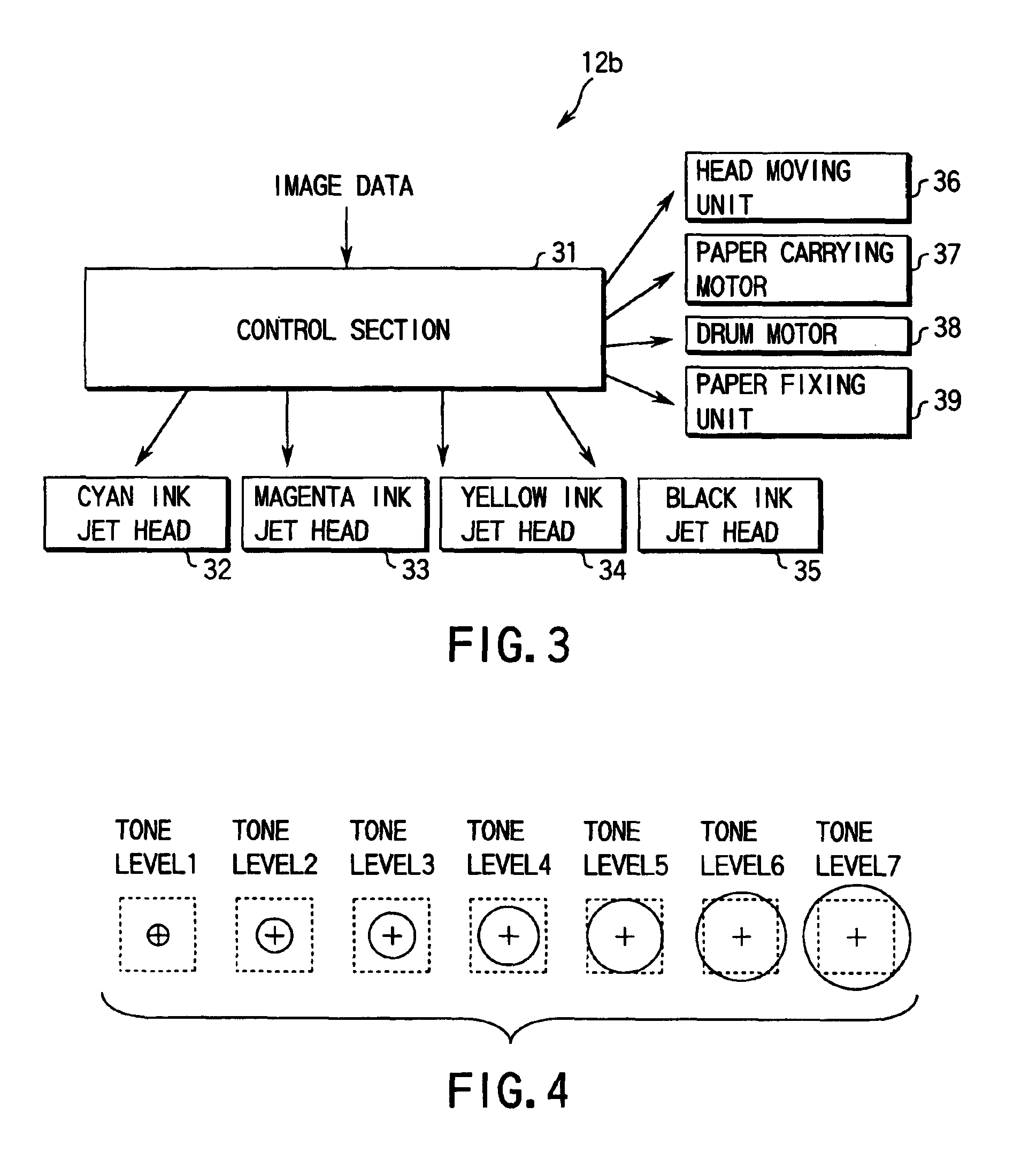

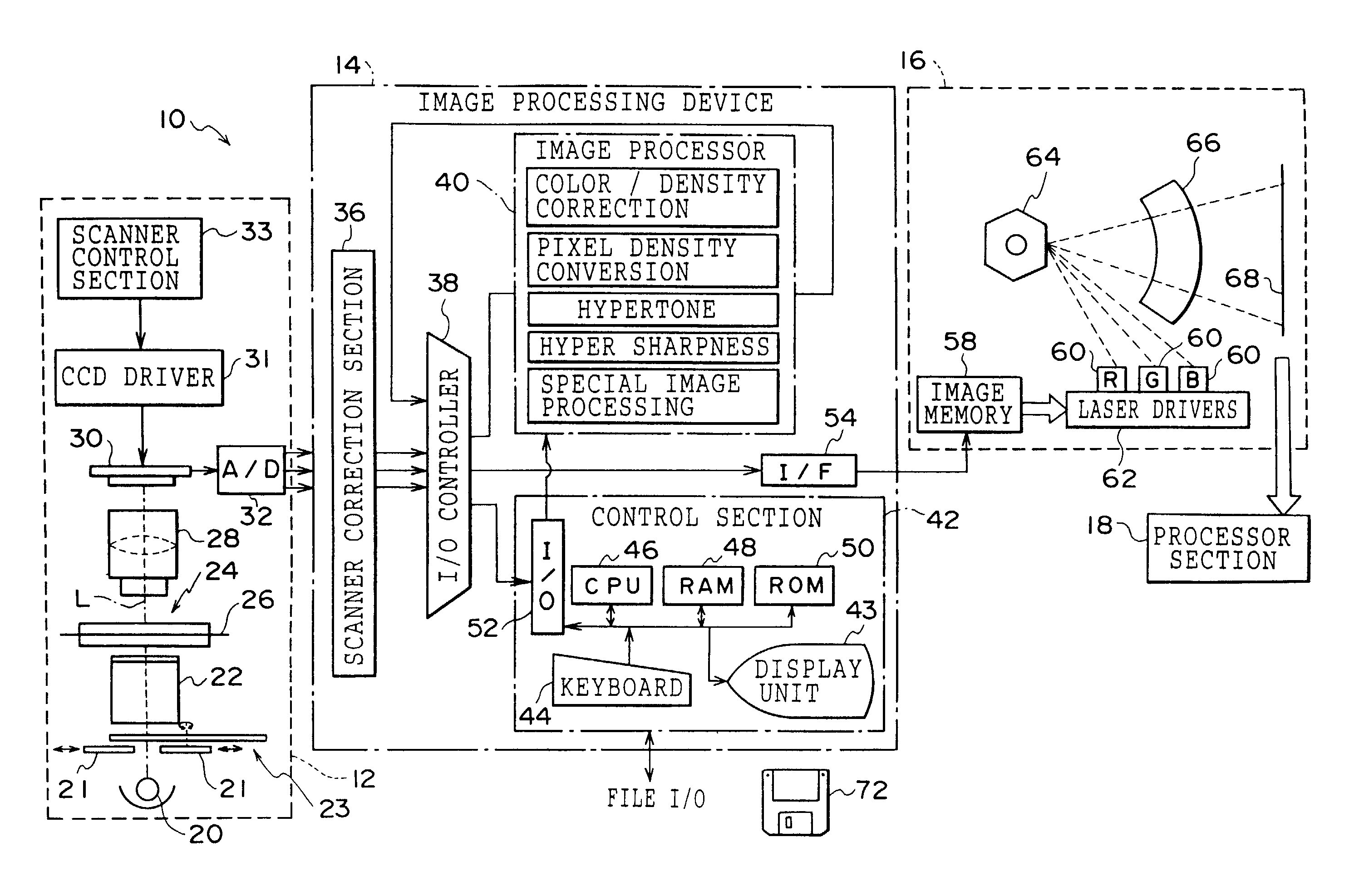

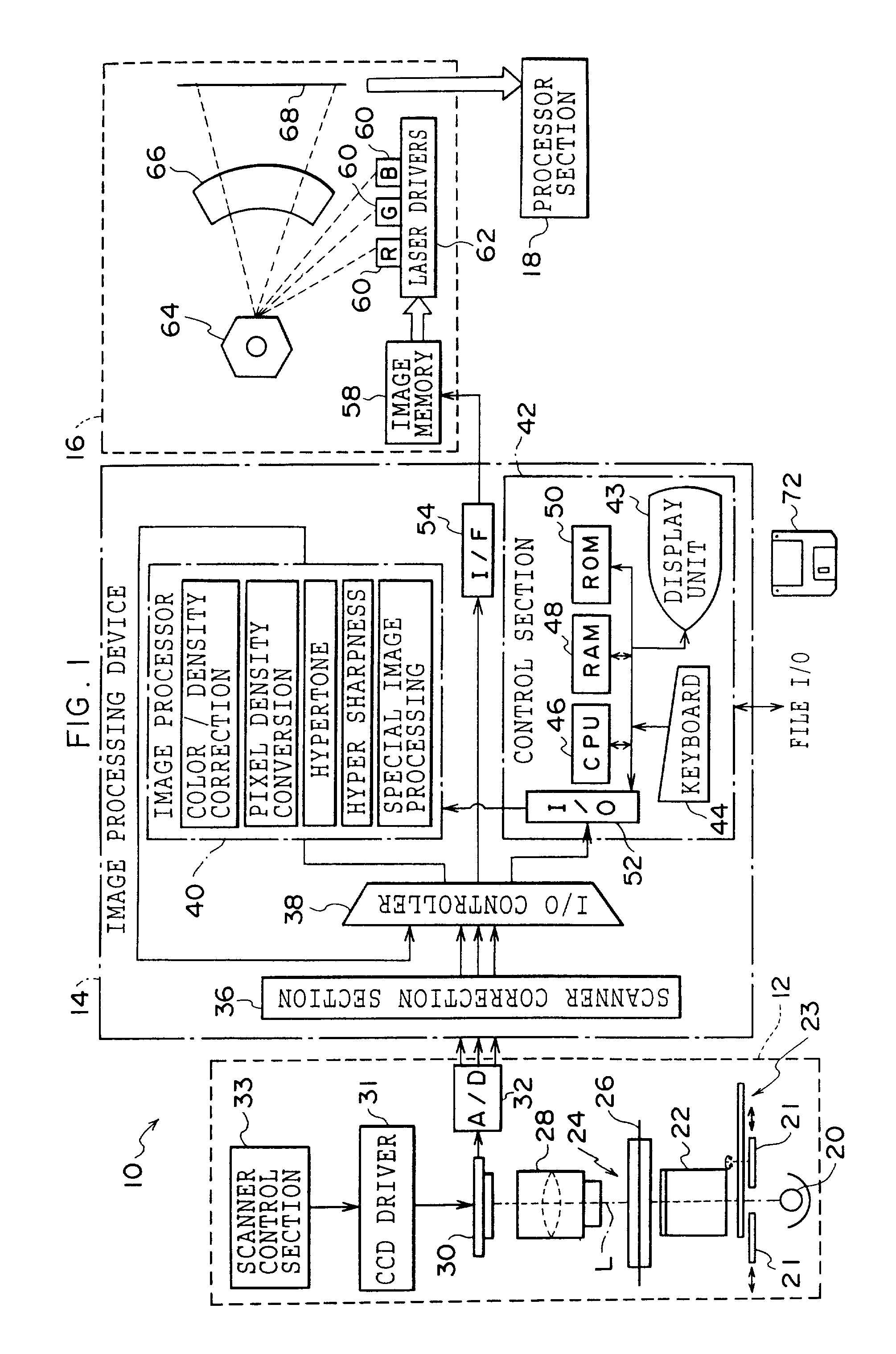

Image processor and color image processor

InactiveUS6906825B1Preventing deterioration of tone reproducibilityInhomogeneous suppressionDigitally marking record carriersDigital computer detailsImaging dataDither

A halftone processing section halftone-processes input image data using a plurality of dither threshold planes. An image output section having different output position accuracies between a main scan direction and a sub-scan direction outputs an image corresponding to halftone-processed image data. Each of the dither threshold planes consists of a plurality of the same unit threshold matrixes. In the unit threshold matrix, a relatively medium to high threshold array in a predetermined threshold range corresponding to the entire tone range of the input image data is an aperiodic array and an anisotropic array with neighboring thresholds having close values, in a direction coincident with a scan direction, in which the output position accuracy of the image output means is low. With this configuration, the image output section outputs an image having serial medium and high tone dots in the scan direction.

Owner:TOSHIBA TEC KK

Display device

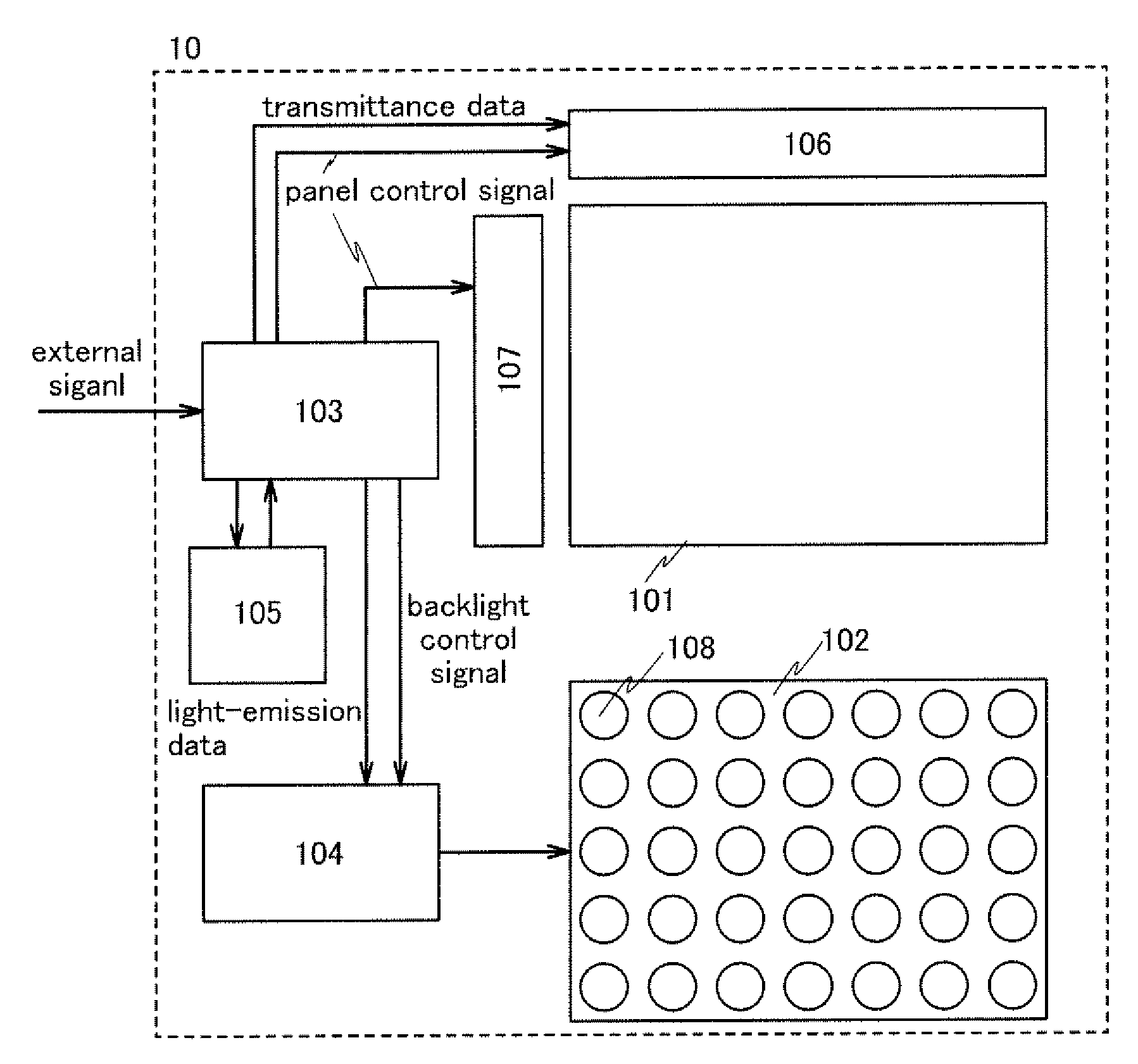

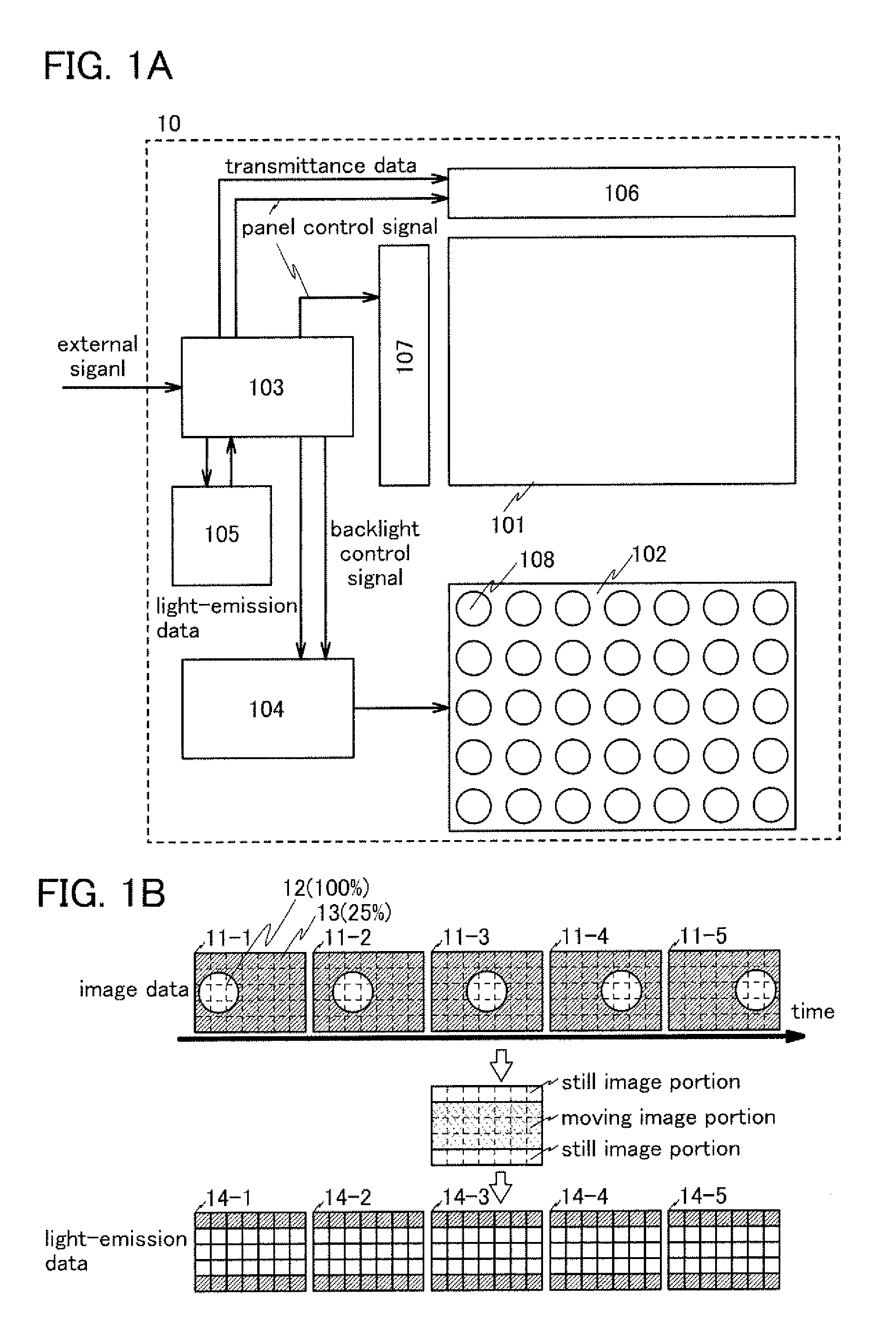

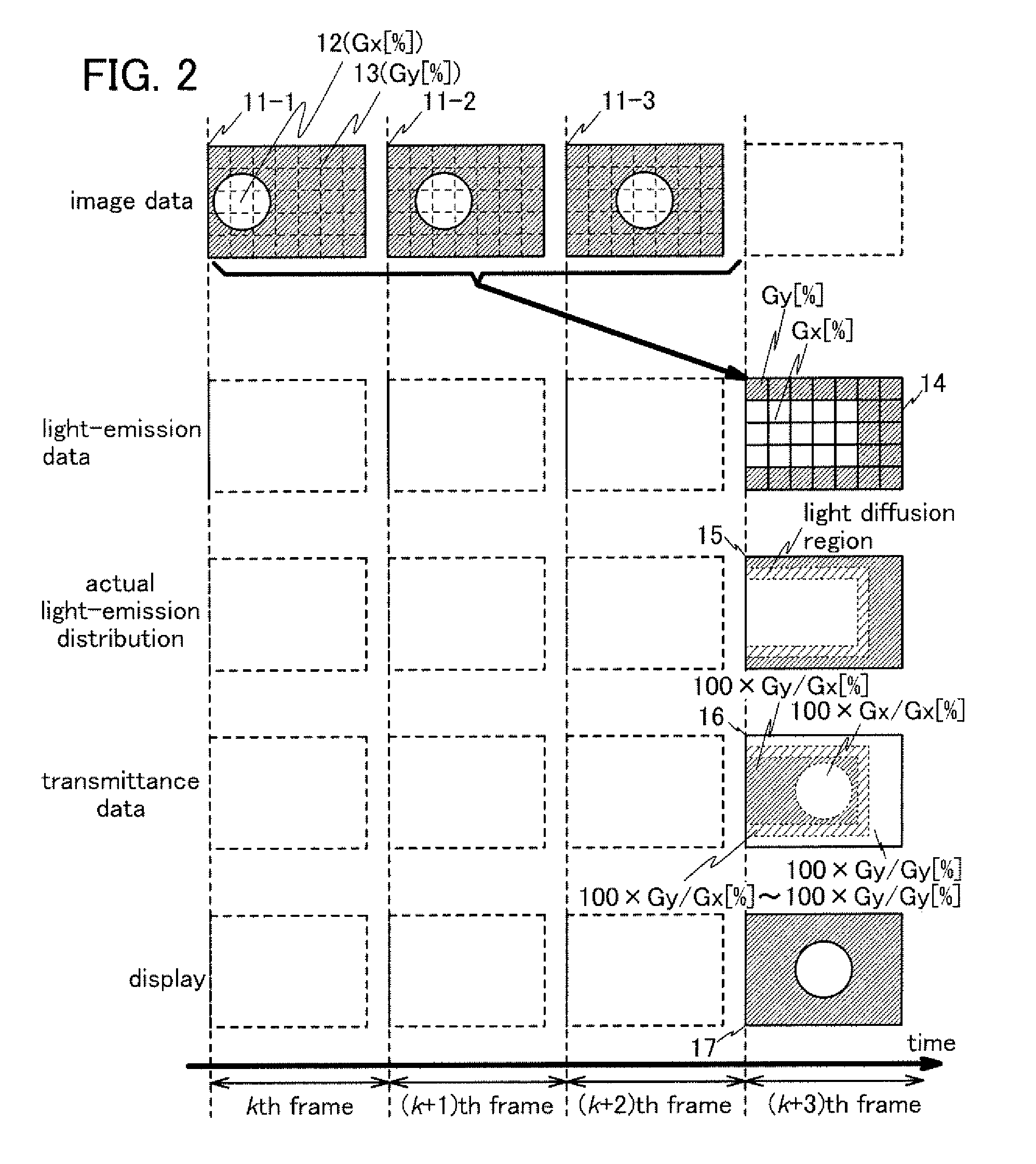

ActiveUS20100103089A1Slow changeInhomogeneous suppressionStatic indicating devicesNon-linear opticsImaging qualityDisplay device

It is an object to improve image quality in displaying a still image and a moving image by suppressing flickers, a display malfunction, or the like of a display device. A method for controlling the light emission state of a backlight is made different between a still image portion and a moving image portion included in an image to be displayed. In specific, the amount of light emission in the still image portion is made as small as possible in a corresponding divided region of the backlight, and the amount of light emission in the moving image portion is controlled so as not to be changed as much as possible in a corresponding divided region of the backlight.

Owner:SEMICON ENERGY LAB CO LTD

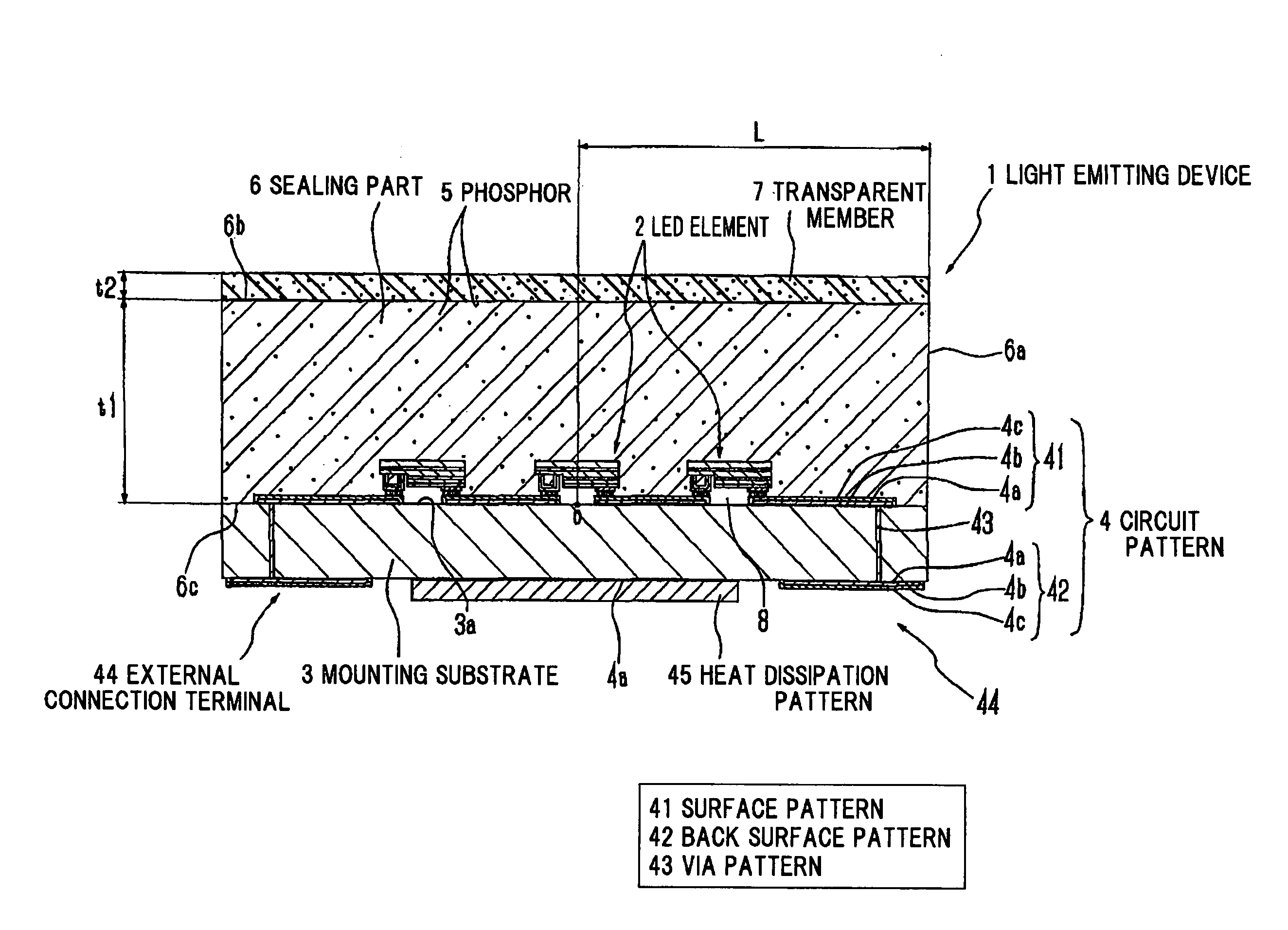

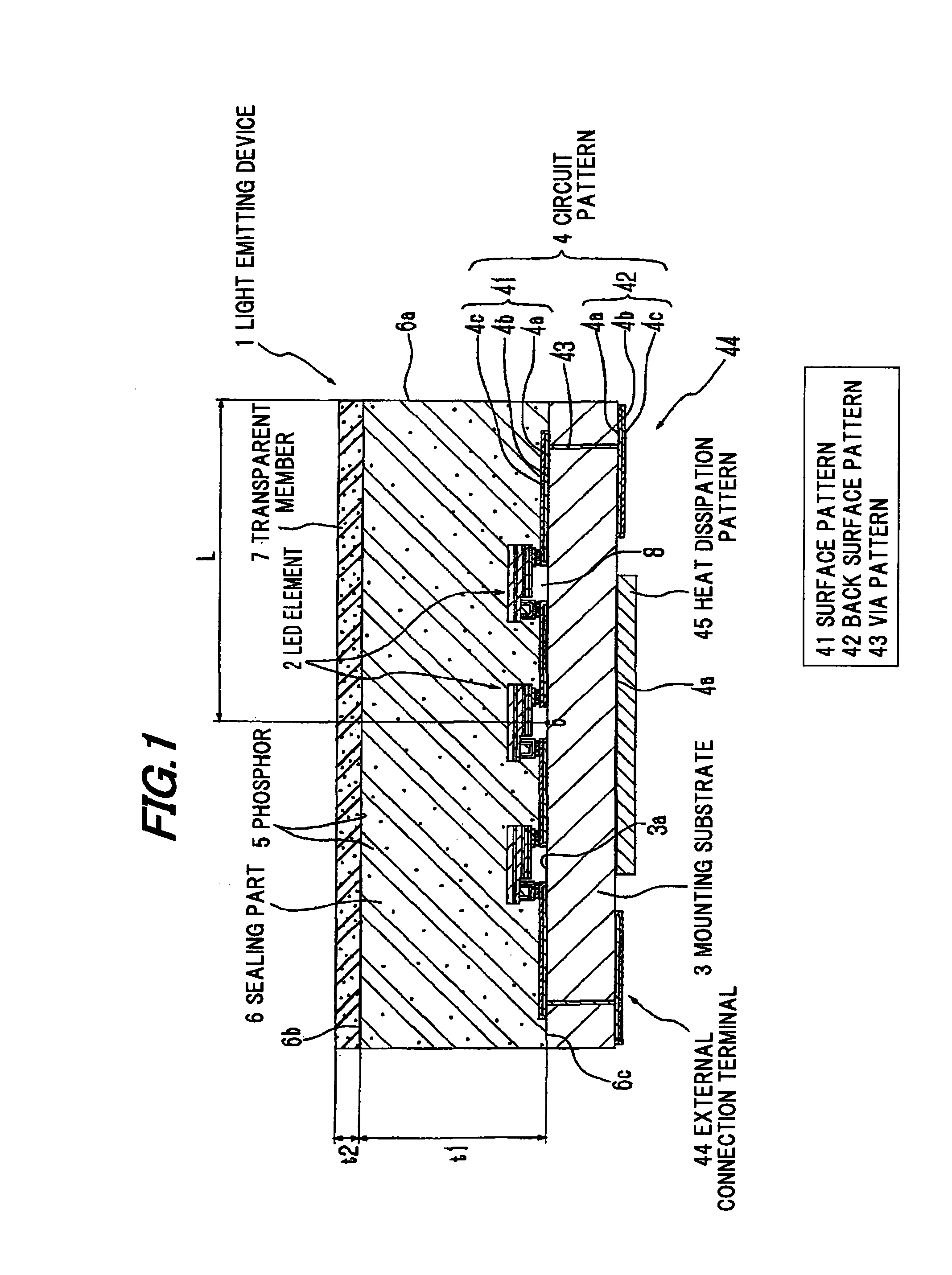

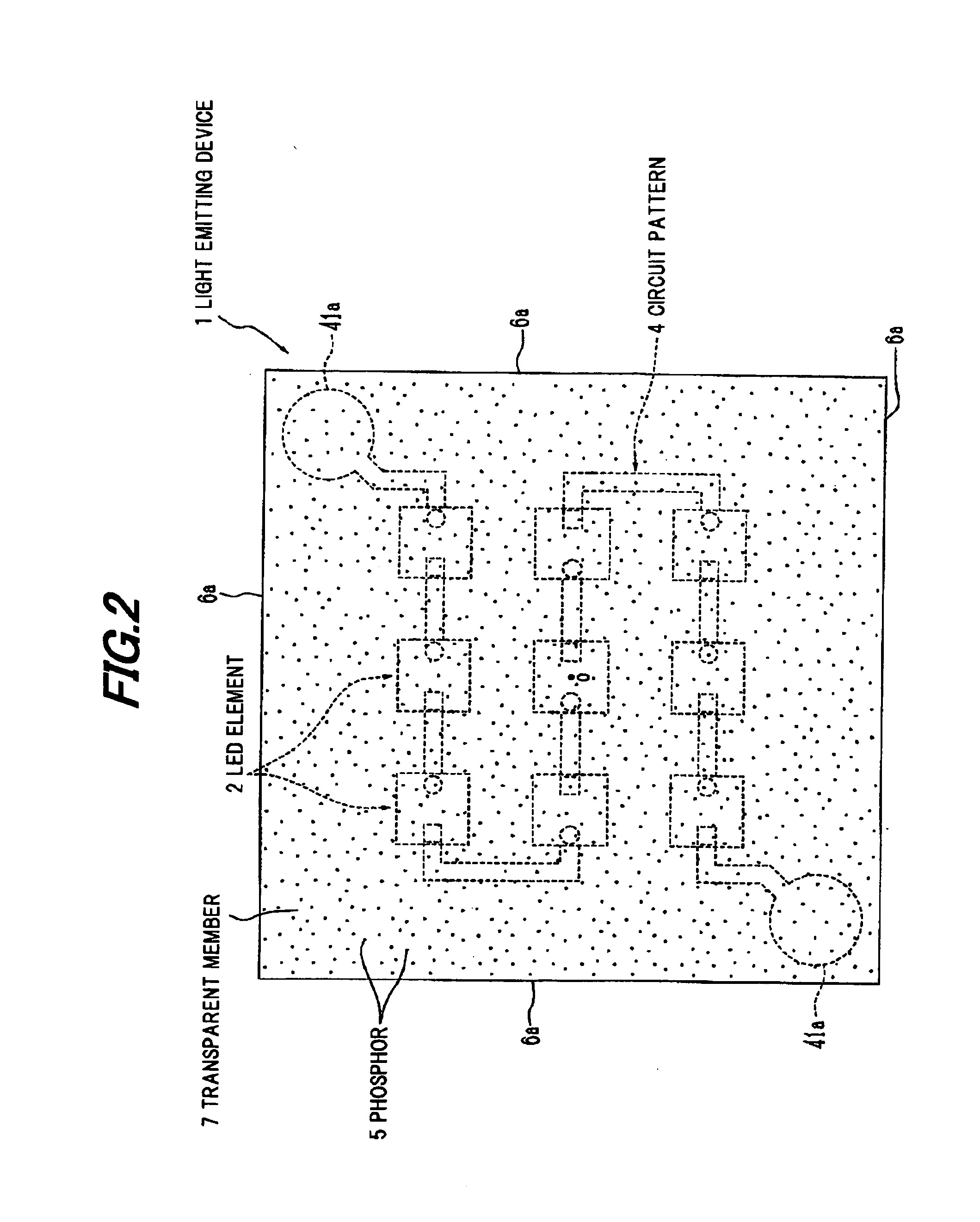

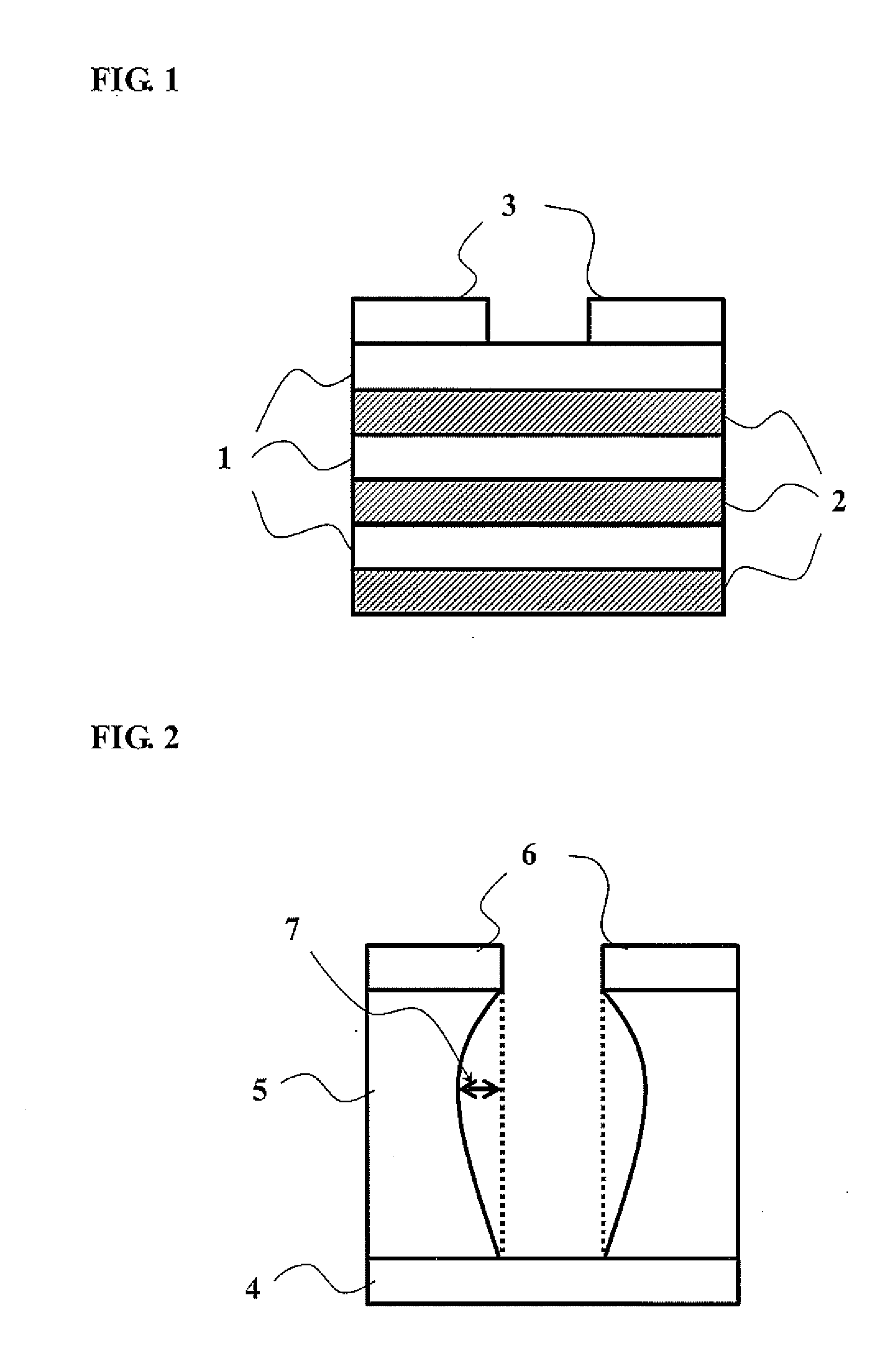

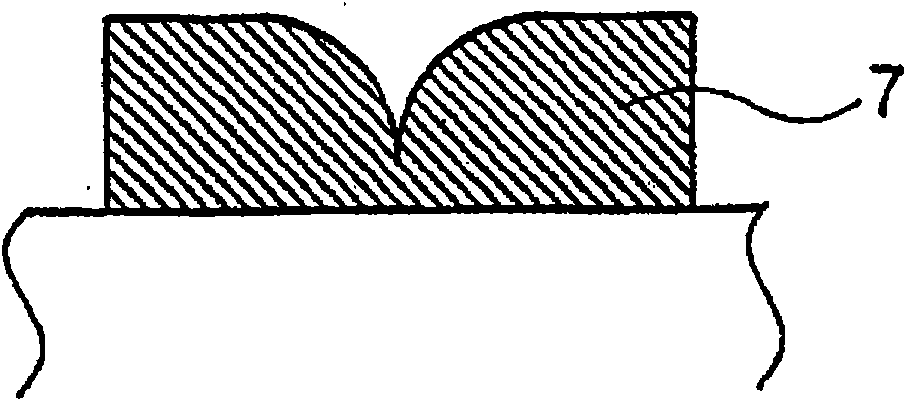

Light emitting device and light emitter

ActiveUS20080284315A1Sensitively sense unevenness in chromaticityReduce chroma differenceDischarge tube luminescnet screensLamp detailsPhosphorWavelength conversion

A light emitting device includes a light emitting element, a substrate with a flat mounting surface for mounting the light emitting element thereon, a sealing part for the light emitting element on the mounting surface of the substrate. The sealing part is formed of glass including a phosphor to be excited by light emitted from the light emitting element to radiate a wavelength conversion light. The sealing part is shaped like a rectangular solid wherein a lateral length is defined as a distance between a center of a bottom surface of the sealing part bonded to the mounting surface and a side face perpendicular to the mounting surface, a vertical length is defined as a distance between the mounting surface and a top surface of the sealing part, and at least one of the lateral length is longer than the vertical length. The device further includes a transparent member formed on the top surface of the sealing part. The transparent member includes the phosphor at a concentration higher than the sealing part.

Owner:TOYODA GOSEI CO LTD

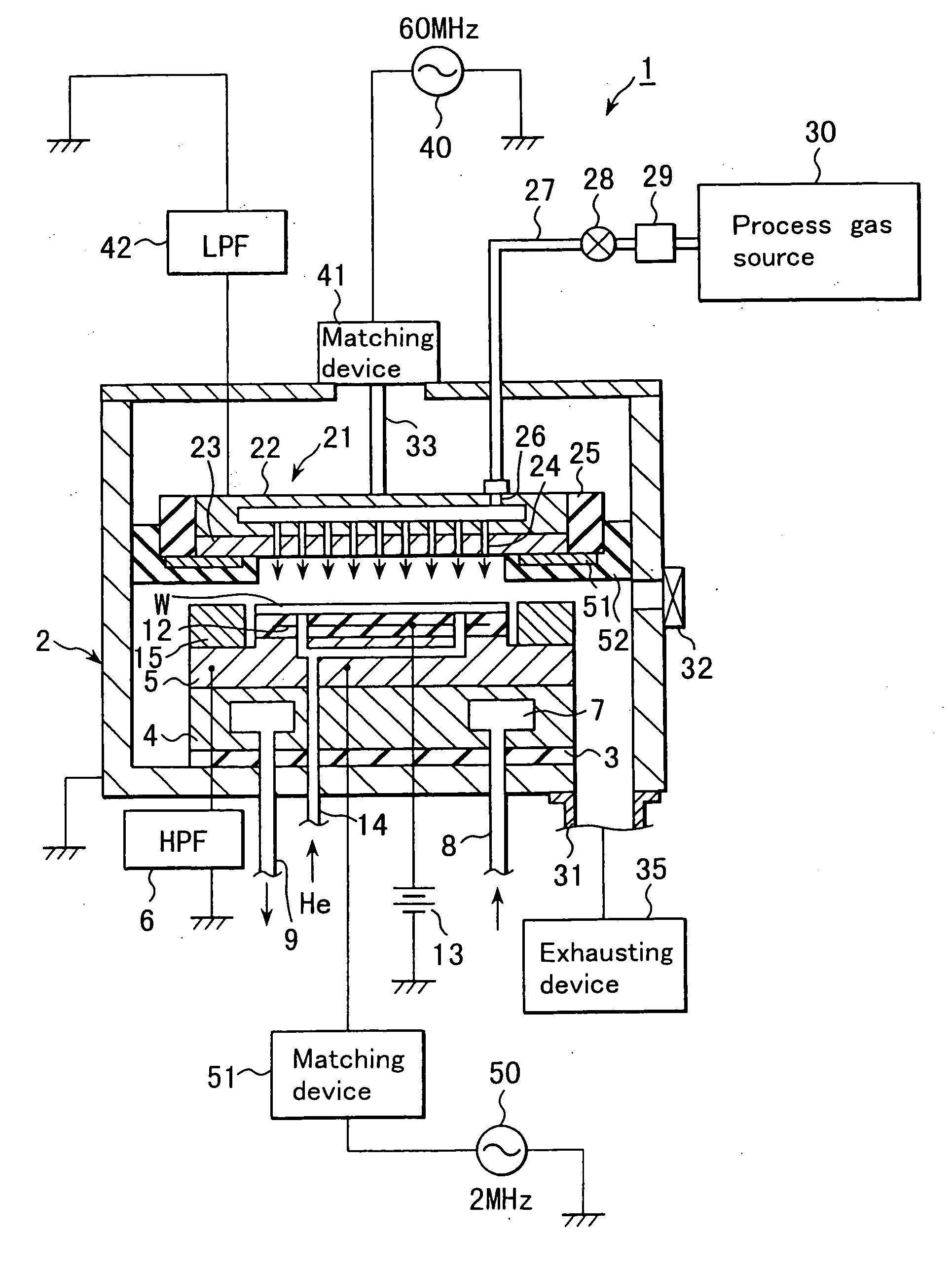

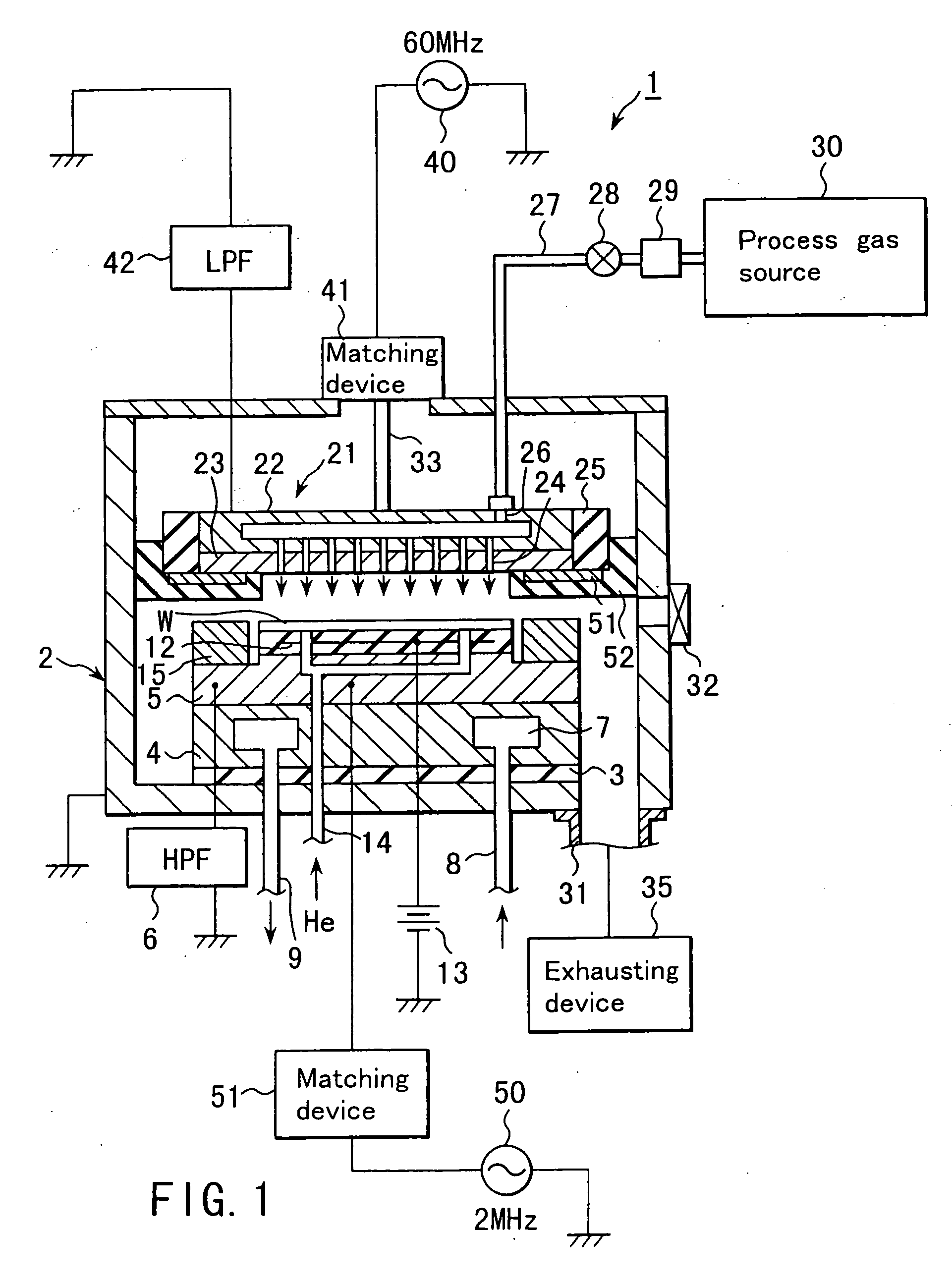

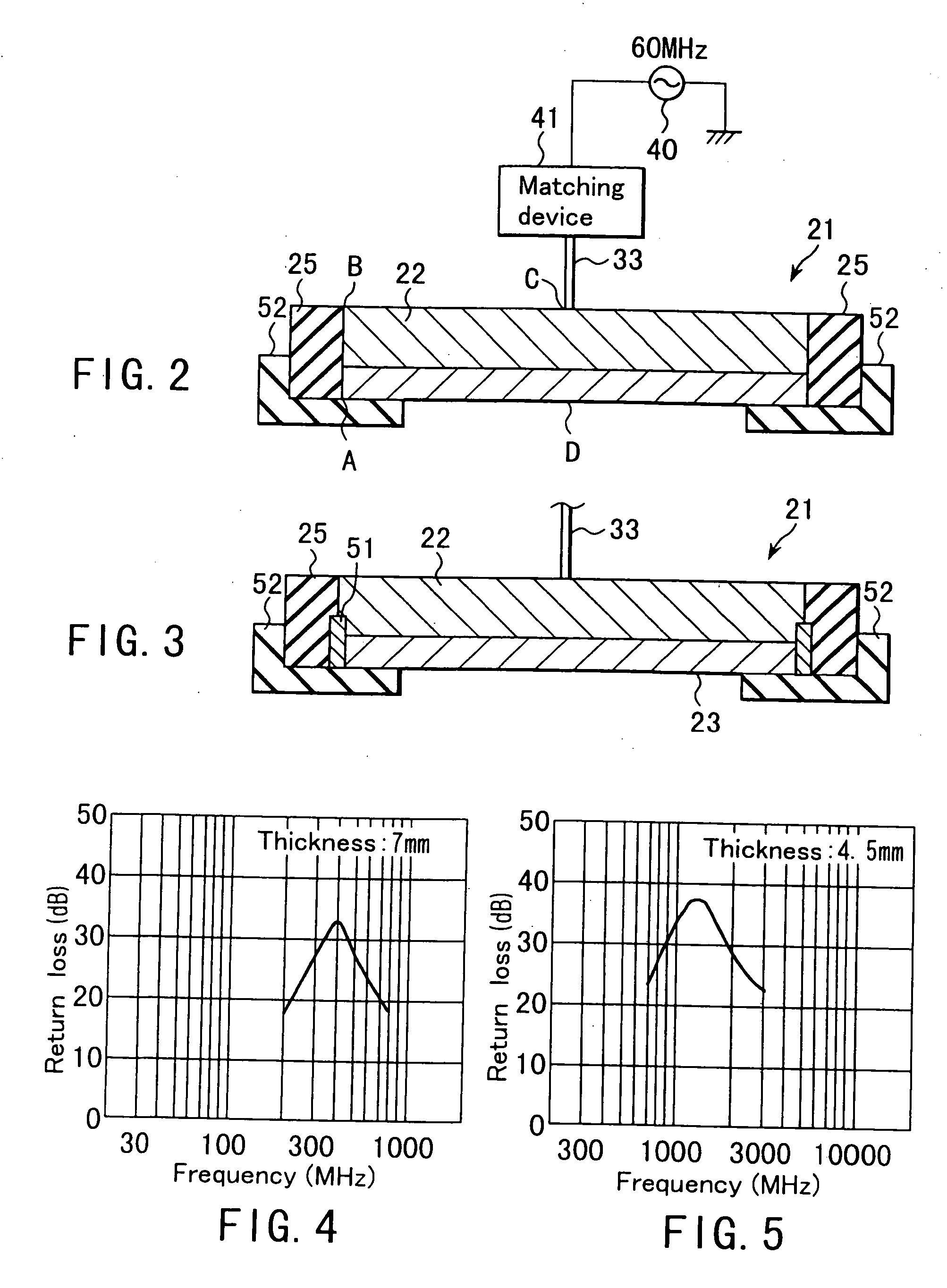

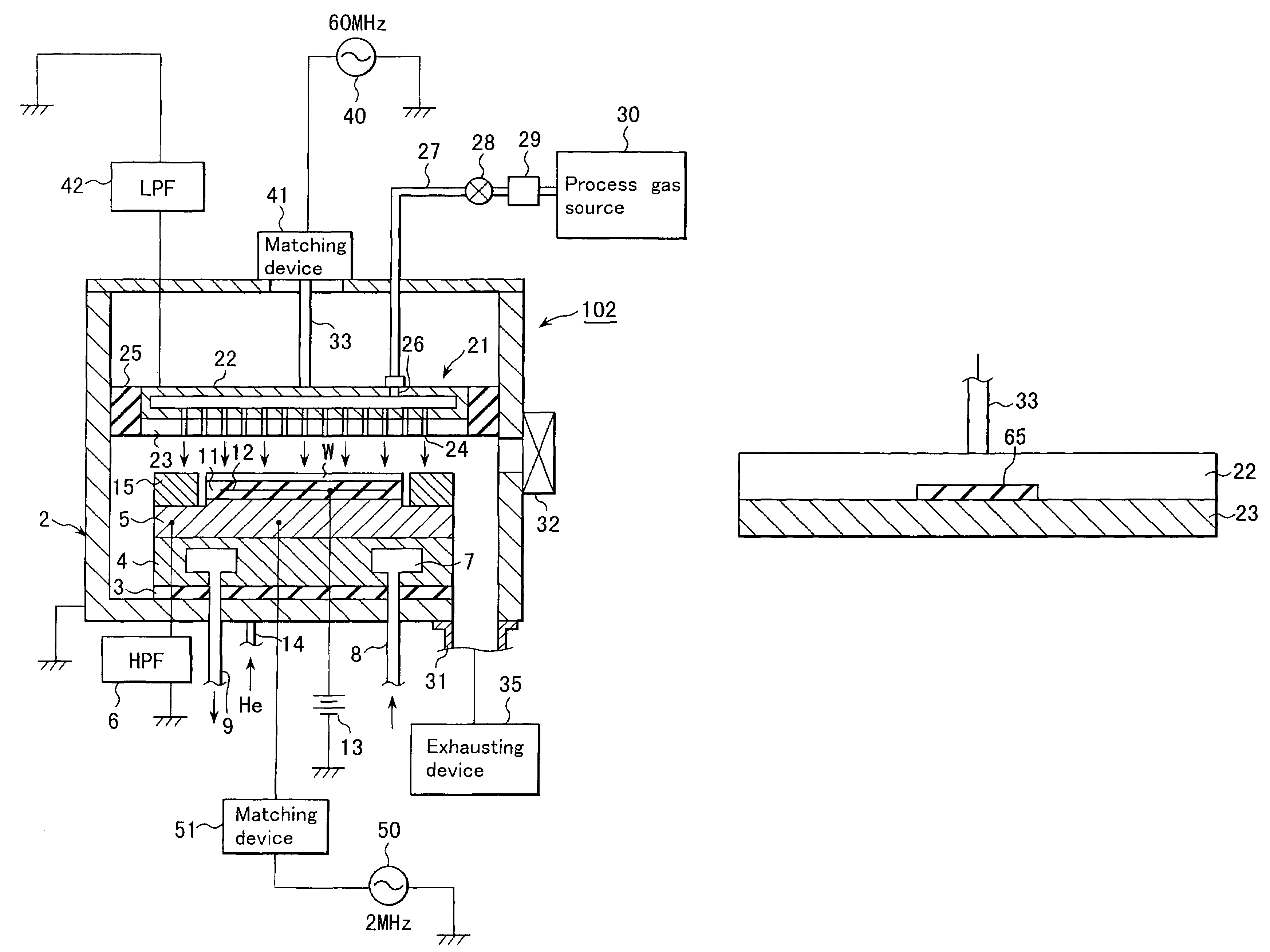

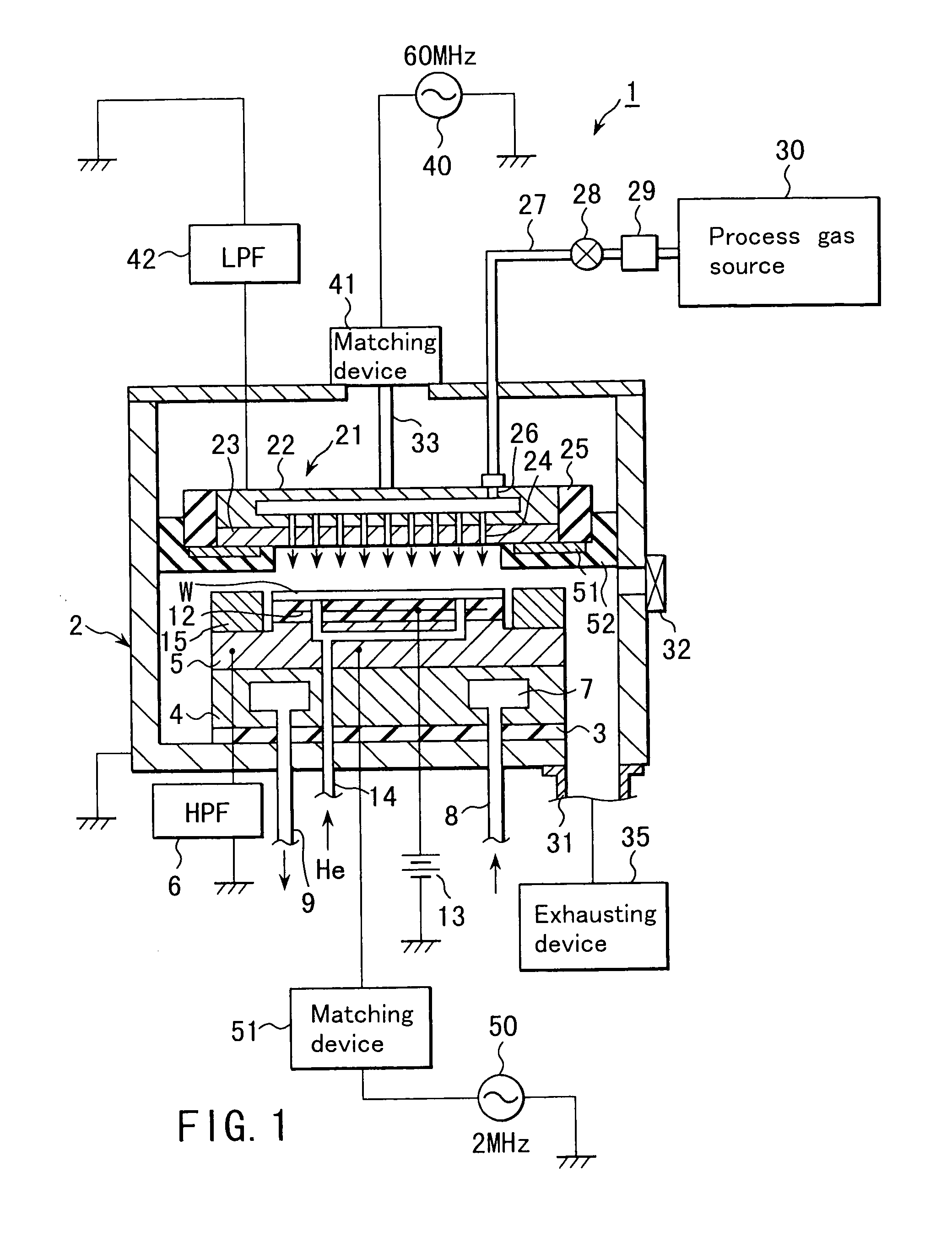

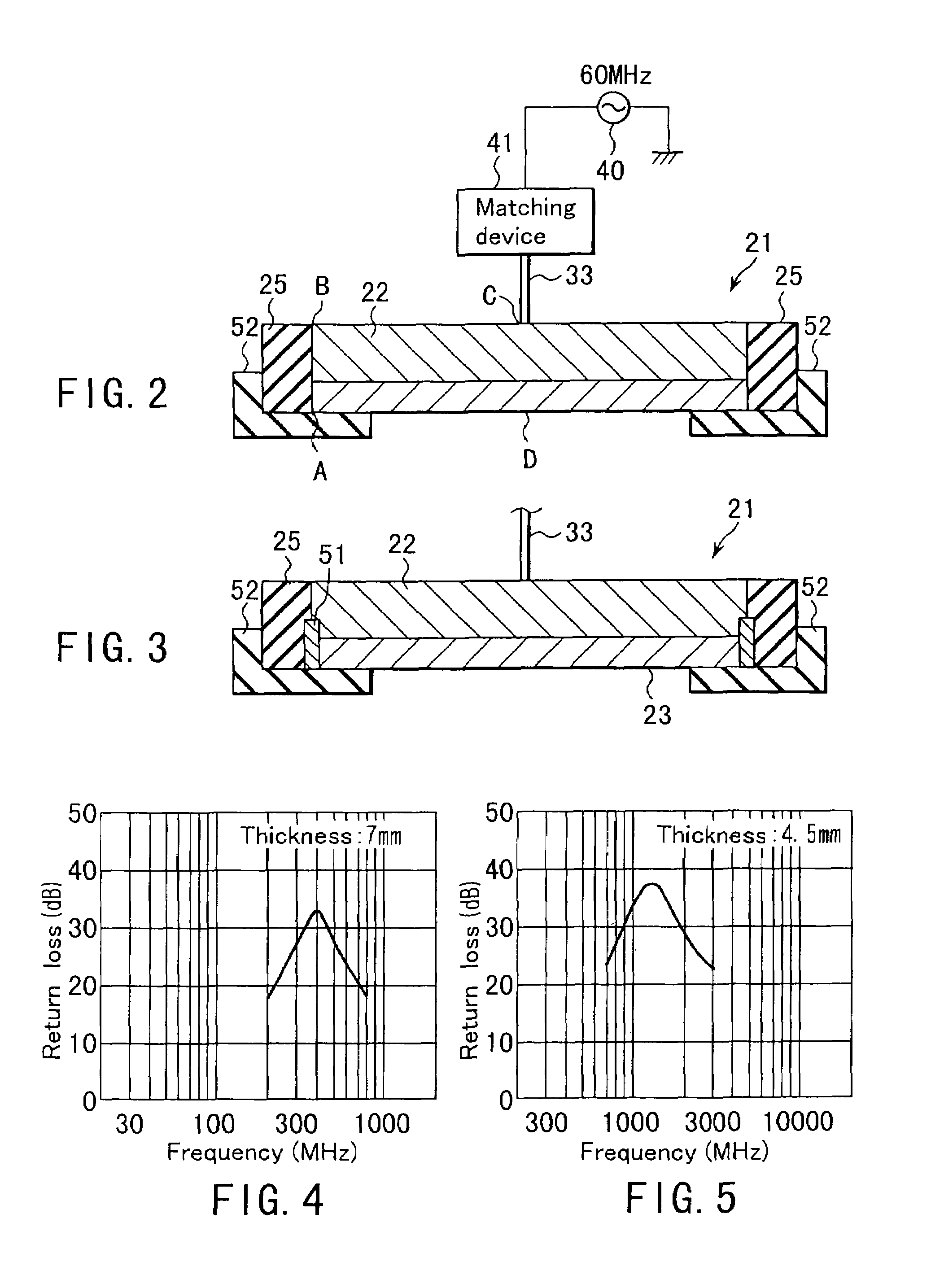

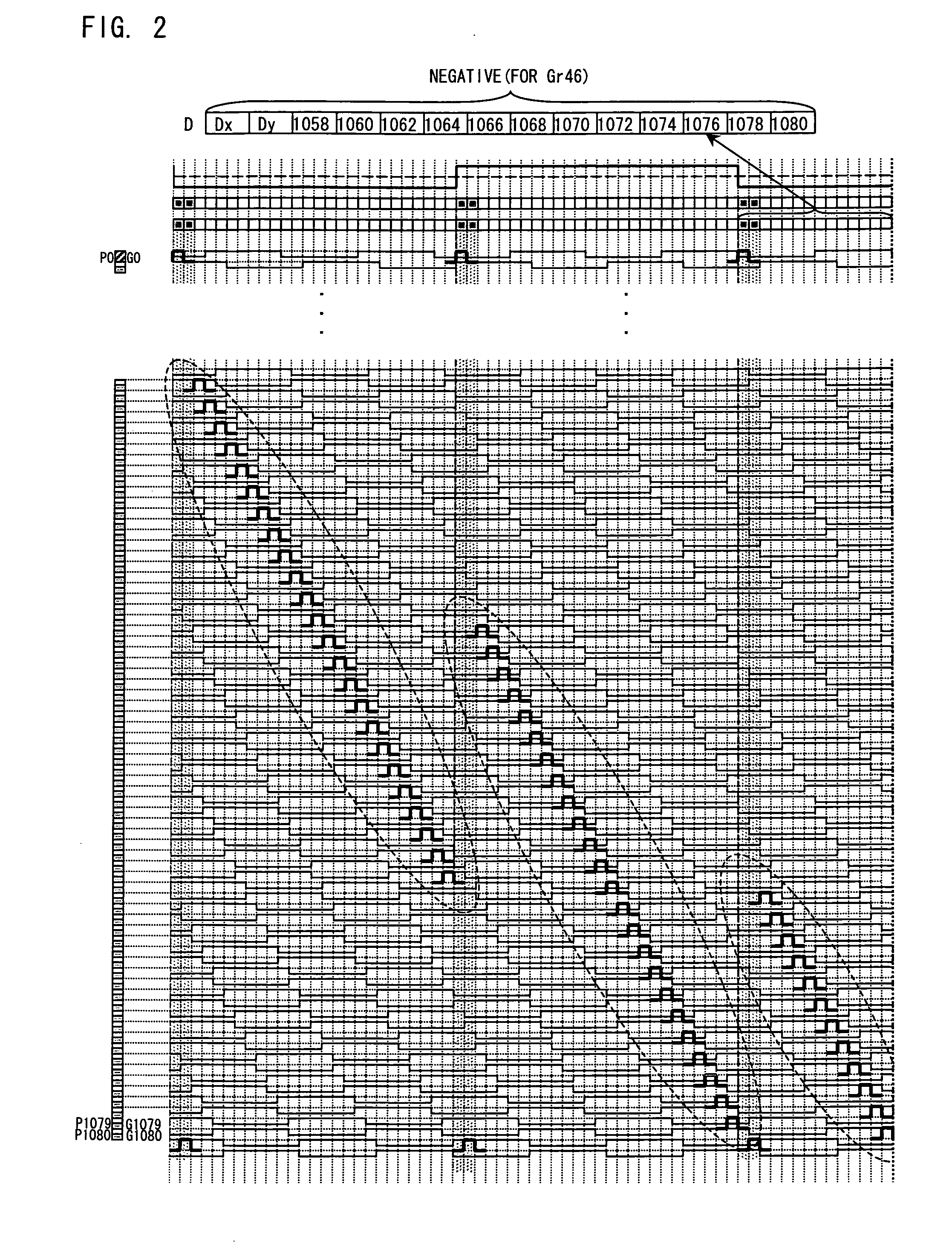

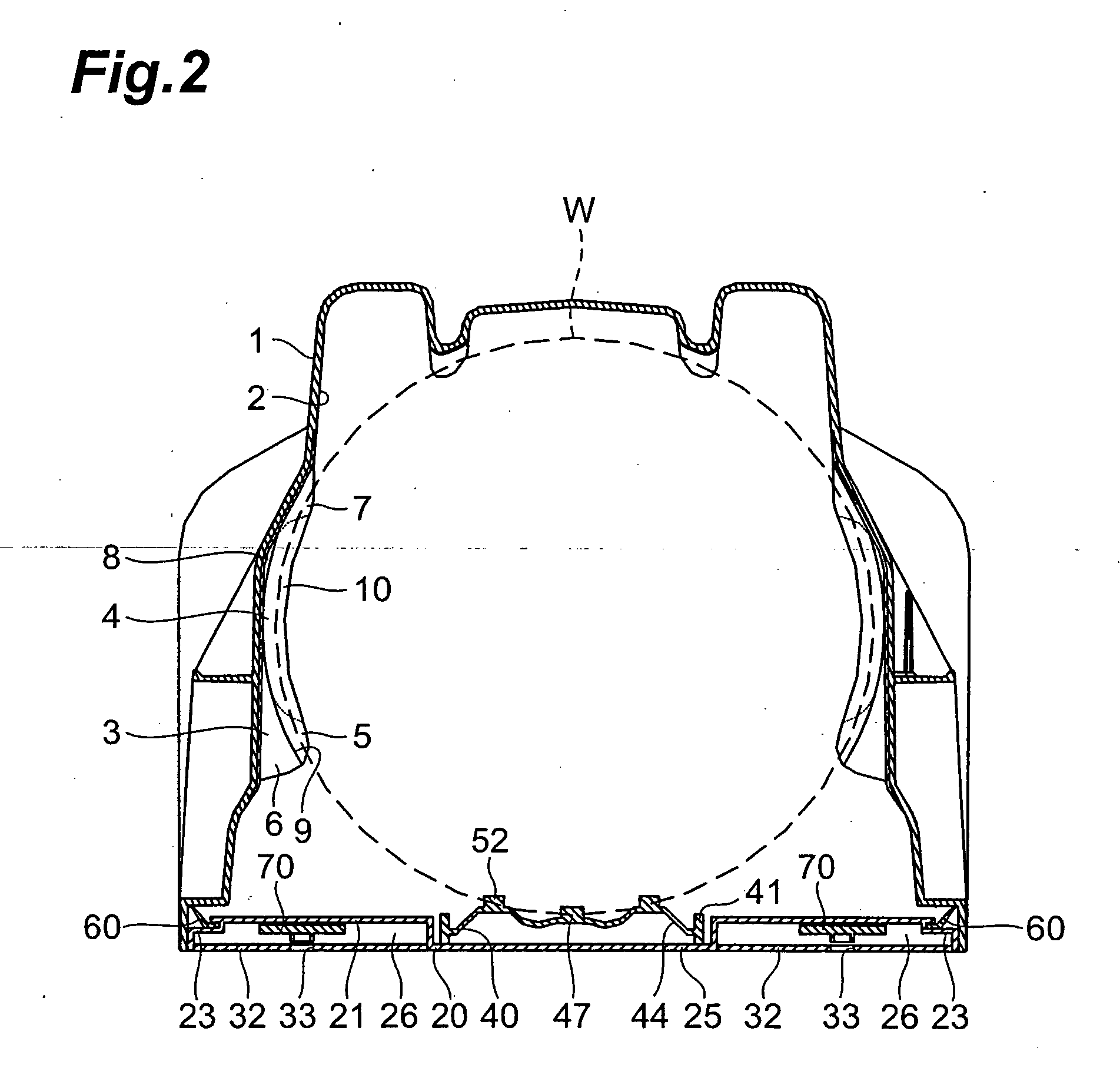

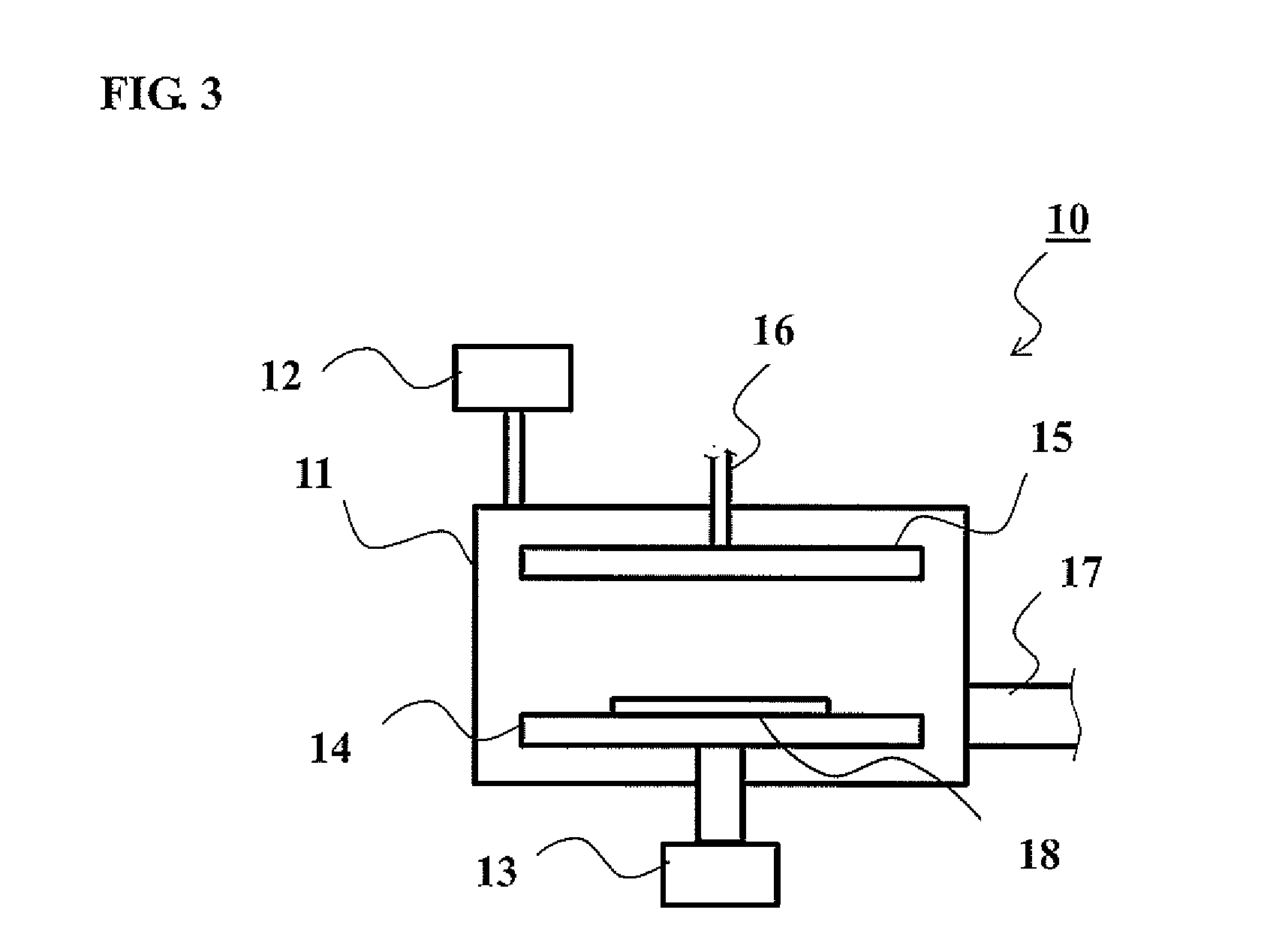

Plasma processing apparatus

InactiveUS20050061445A1Inhomogeneous suppressionDensity of plasma is made evenElectric discharge tubesSemiconductor/solid-state device manufacturingHarmonicElectric power

In the plasma processing apparatus of the present invention, a first electrode (21) for connecting a high frequency electric power source (40) in a chamber is arranged to be opposed to a second electrode (5). A substrate (W) to be processed is placed between the electrodes. There is provided a harmonic absorbing member (51) for being able to absorb harmonics of the high frequency electric power source (40) so as to come in contact with a peripheral portion or circumference of a face of the first electrode 21, which is opposite the second electrode (5). The harmonic absorbing member absorbs the reflected harmonic before the harmonic returns to the high frequency electric power source. By absorbing the harmonic in this manner, the standing wave due to the harmonic will be effectively prevented from being generated, and the density of plasma is made even.

Owner:TOKYO ELECTRON LTD

Printing method using ink jet recording

InactiveUS20120176455A1Excellent resistanceConcentration unevenness be suppressDuplicating/marking methodsInksChemistryLiquid composition

Printing is performed on a non-ink absorbing or low-ink absorbing recording medium, by providing a drying process, using an aqueous ink composition at least containing glycol ethers having an HLB value calculated by the Davis method in the range of 4.2 to 8.0 and 1,2-alkyldiols having 4 to 8 carbon atoms and a liquid composition at least containing glycol ethers having an HLB value calculated by the Davis method in the range of 4.2 to 8.0 and 1,2-alkyldiols having 4 to 8 carbon atoms.

Owner:SEIKO EPSON CORP

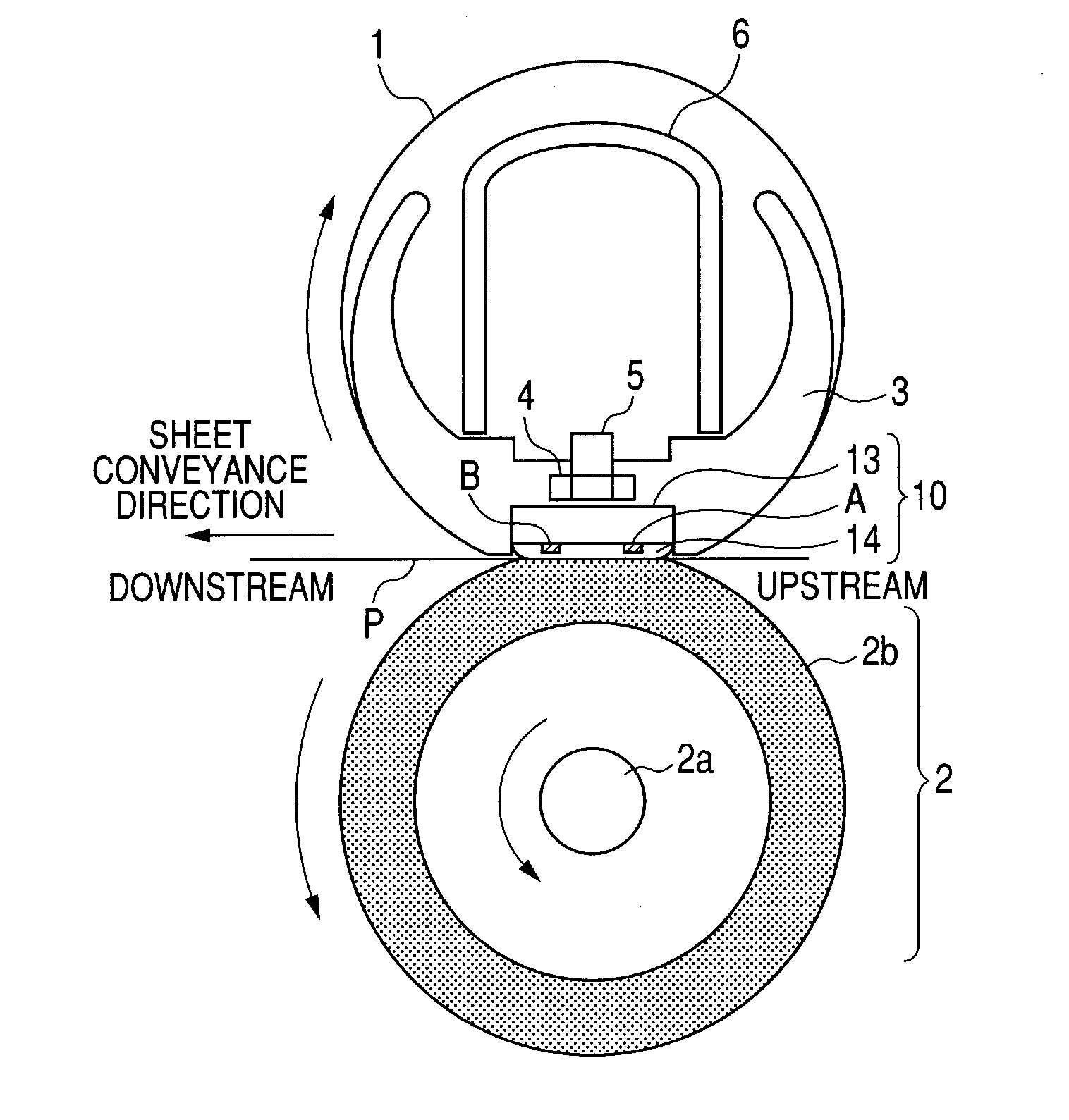

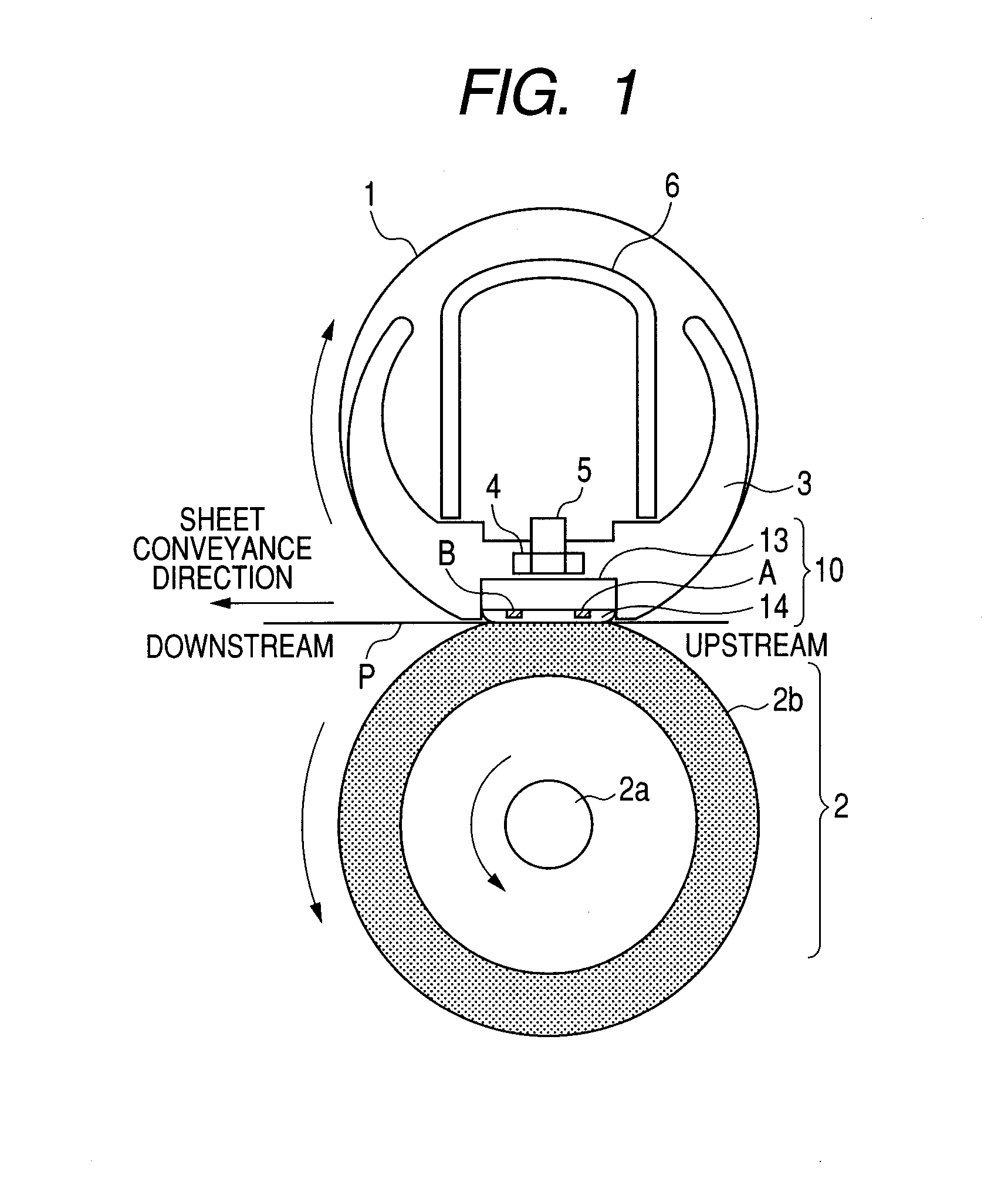

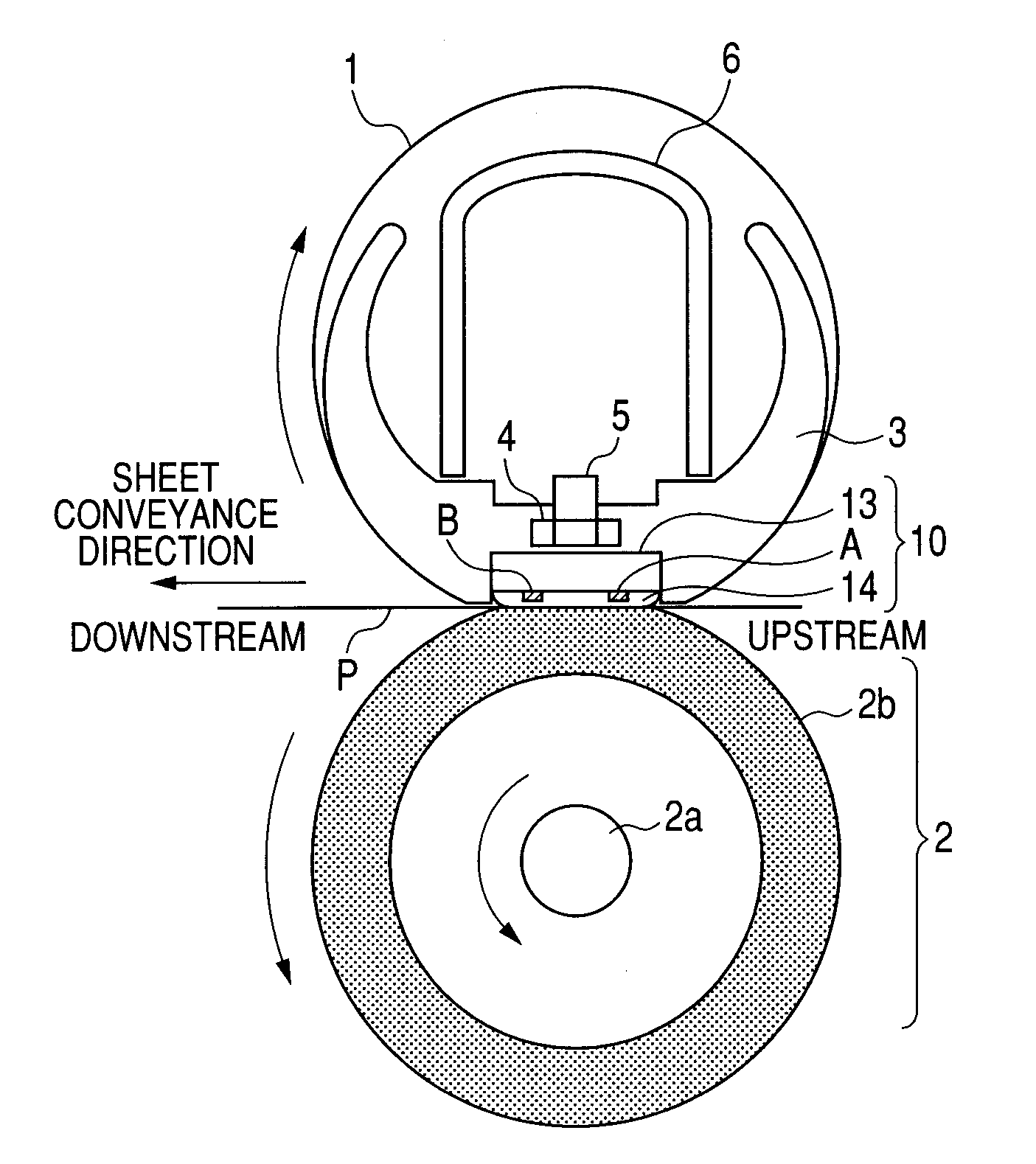

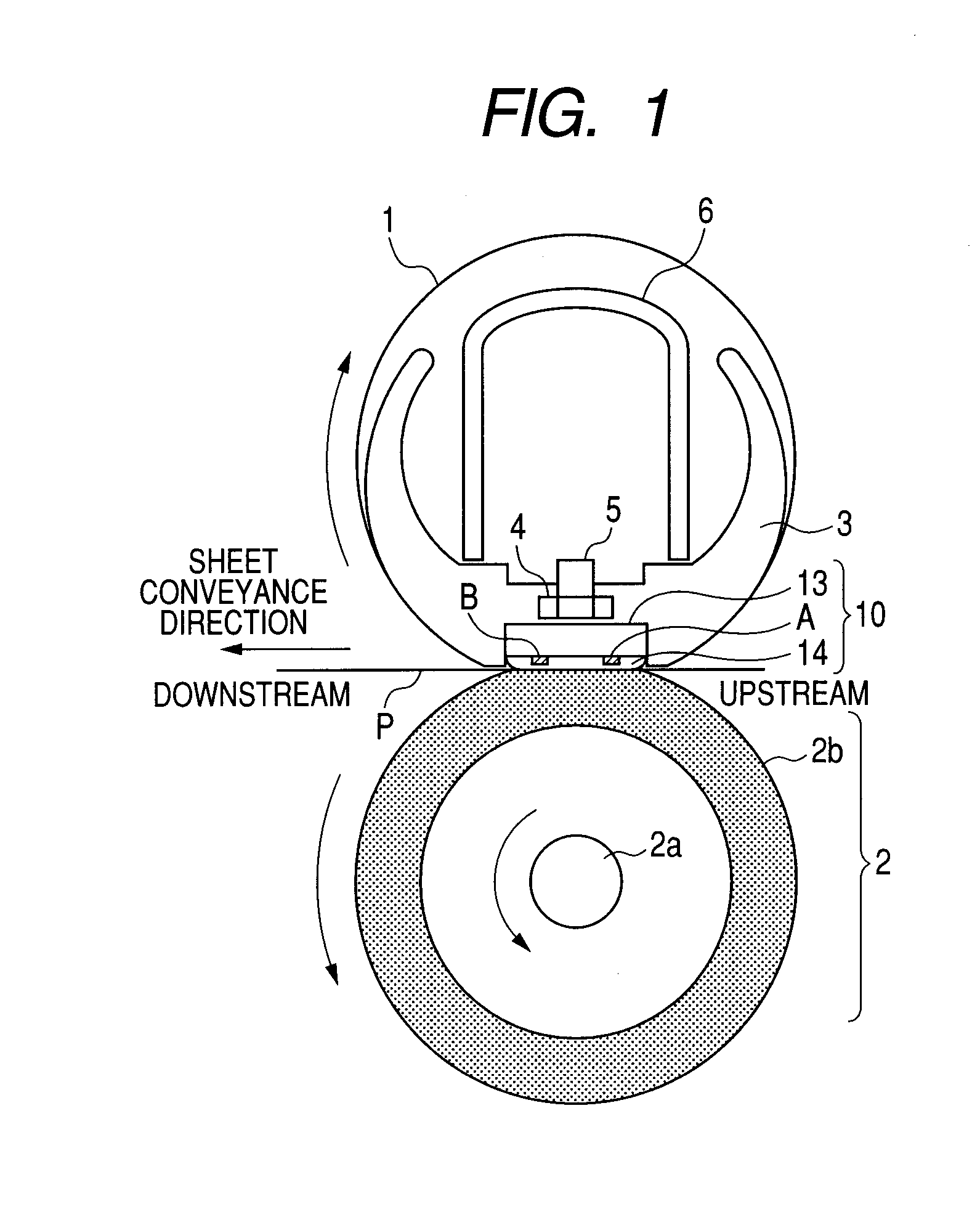

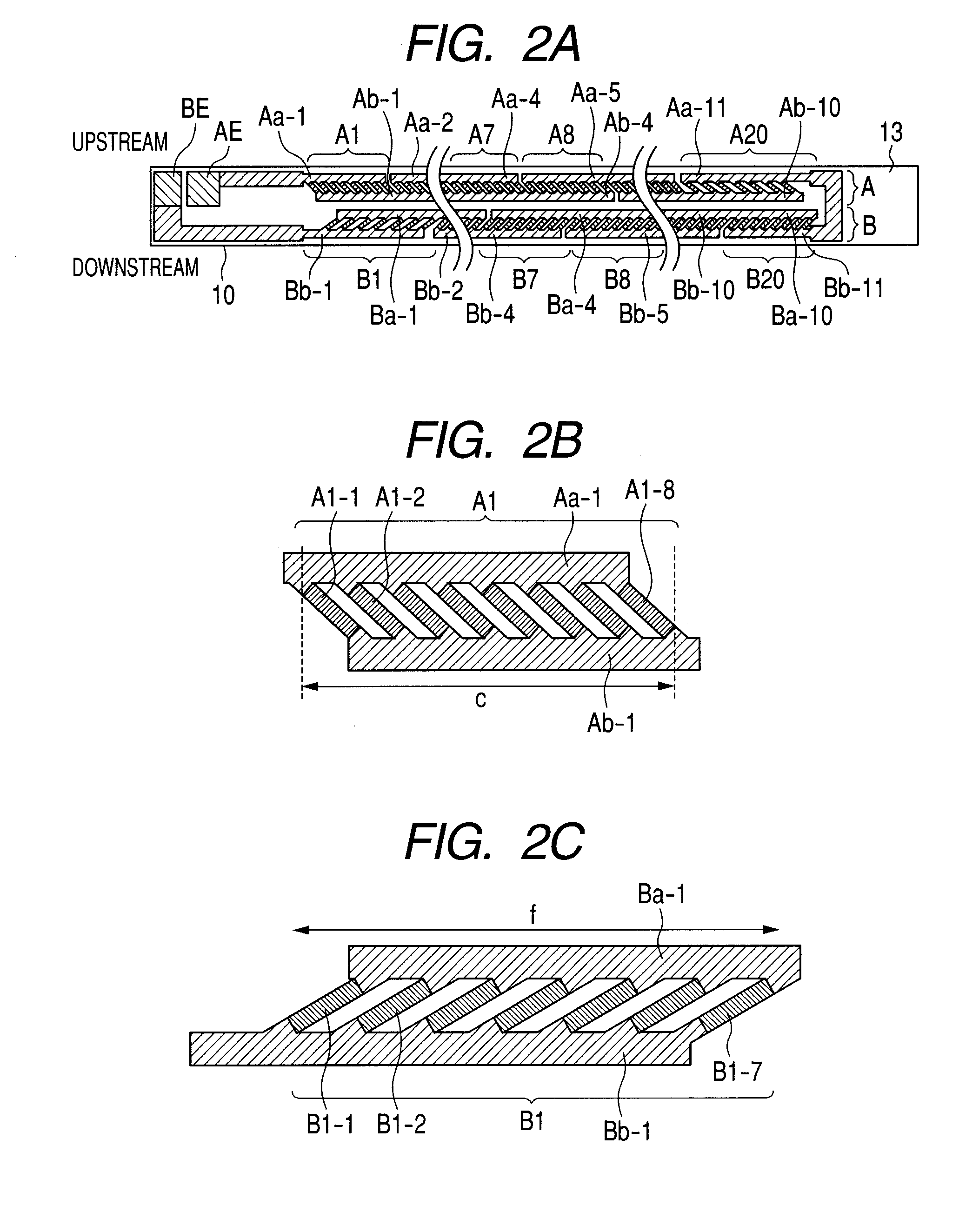

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS20120121306A1Uneven heat generationInhomogeneous suppressionOhmic-resistance heating circuitsHeater elementsElectricityHotline

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

Apparatus for plasma processing

InactiveUS7537672B1Making density of plasma evenInhomogeneous suppressionElectric discharge tubesSemiconductor/solid-state device manufacturingHarmonicVolumetric Mass Density

In the plasma processing apparatus of the present invention, a first electrode (21) for connecting a high frequency electric power source (40) in a chamber is arranged to be opposed to a second electrode (5). A substrate (W) to be processed is placed between the electrodes. There is provided a harmonic absorbing member (51) for being able to absorb harmonics of the high frequency electric power source (40) so as to come in contact with a peripheral portion or circumference of a face of the first electrode 21, which is opposite the second electrode (5). The harmonic absorbing member absorbs the reflected harmonic before the harmonic returns to the high frequency electric power source. By absorbing the harmonic in this manner, the standing wave due to the harmonic will be effectively prevented from being generated, and the density of plasma is made even.

Owner:TOKYO ELECTRON LTD

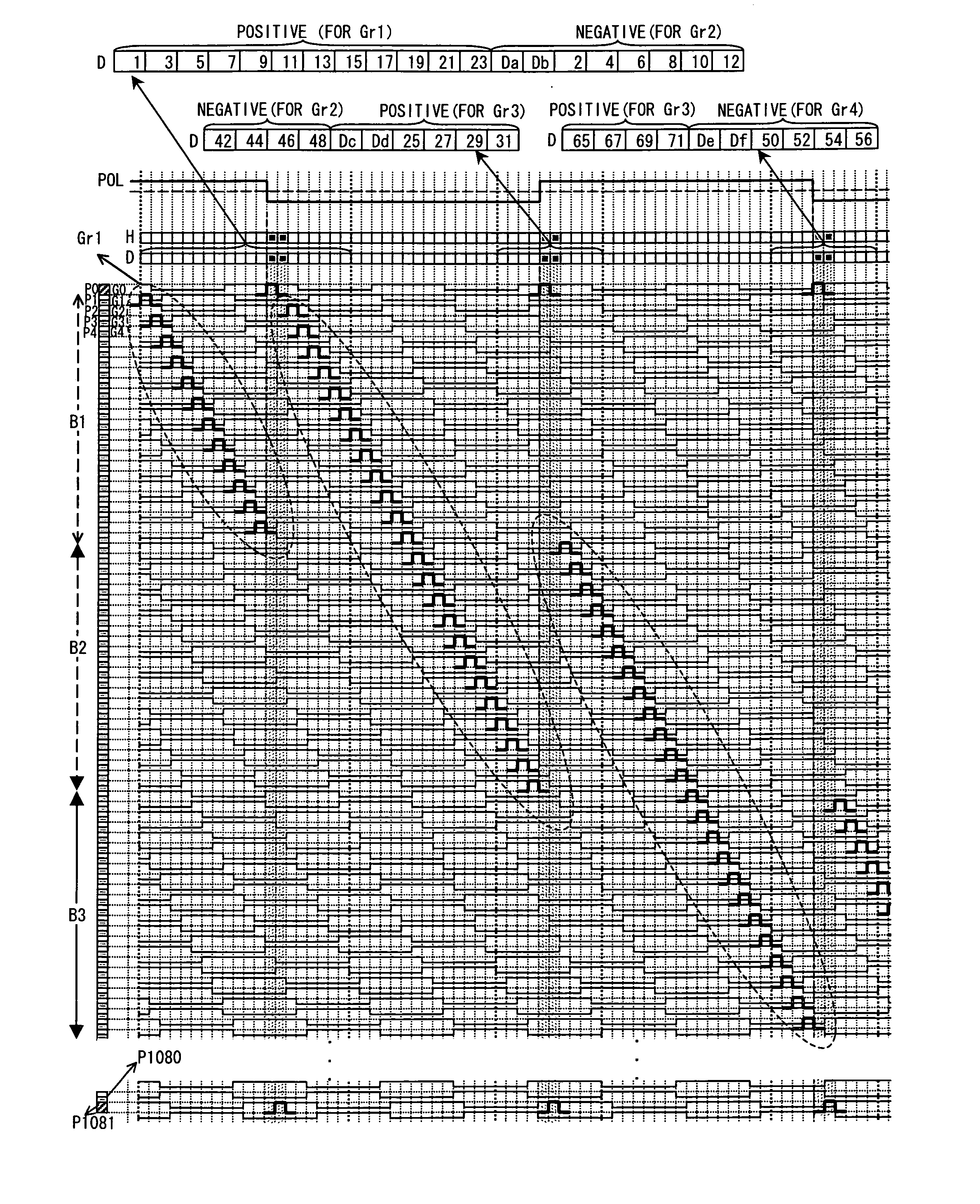

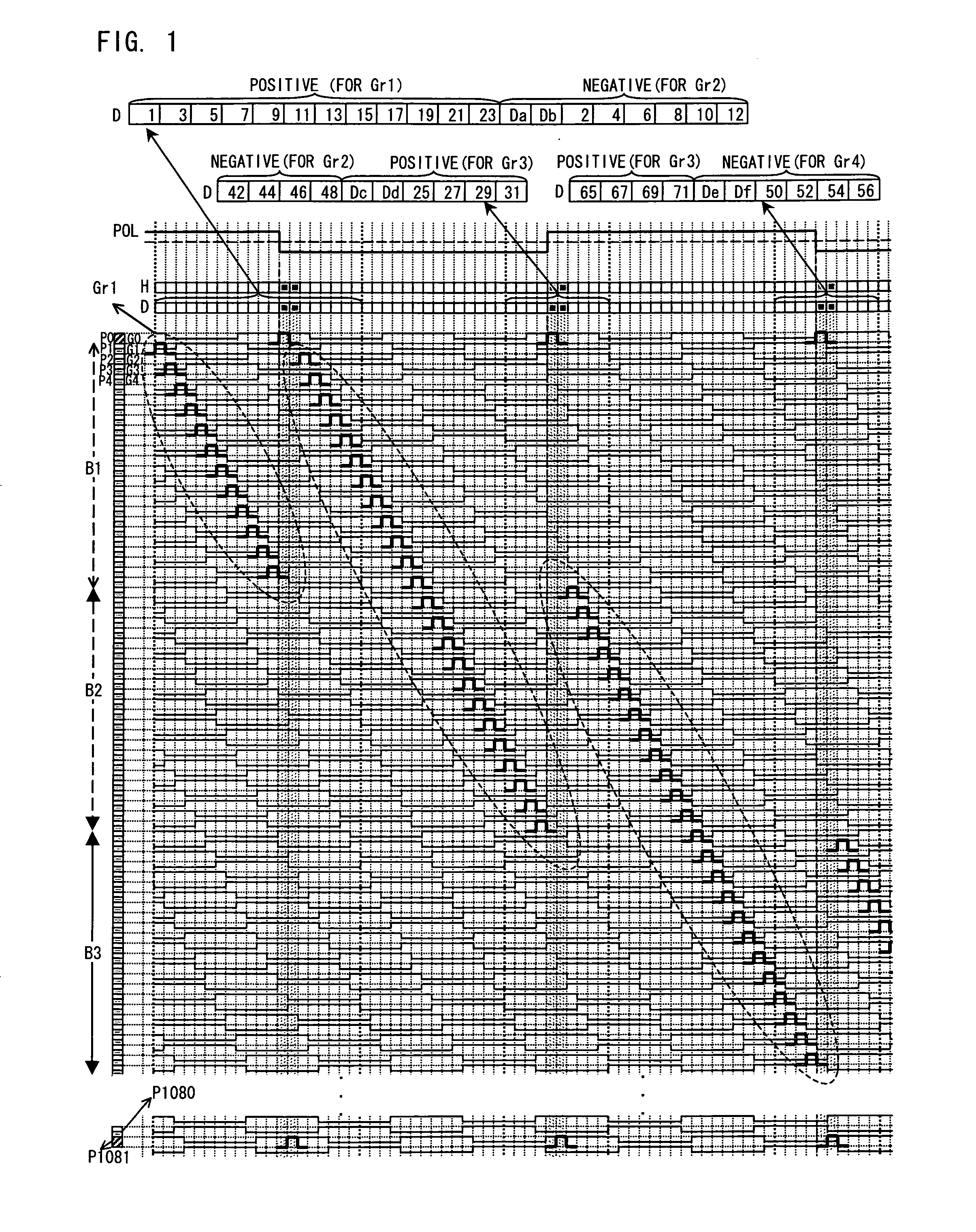

Liquid crystal display device, method for driving liquid crystal display device, and televesion receiver

InactiveUS20110221970A1Reduce the differenceSuppressing horizontal-striped unevennessTelevision system detailsCathode-ray tube indicatorsLiquid-crystal displayElectrical polarity

At least one embodiment of a liquid crystal display device including: scanning signal lines provided in a display area; and a dummy scanning signal line provided in a non-display area, the scanning signal lines being divided into groups each of which includes a plurality of scanning signal lines, the groups being sequentially selected, signal electric potentials of an identical polarity being sequentially supplied to a data signal line while scanning signal lines belonging to a selected group are sequentially scanned horizontally, the polarity of the signal electric potentials being inverted when the selected group is changed from a preceding group to a succeeding group which is selected immediately after the preceding group, a dummy scanning period being inserted between a horizontal scanning period corresponding to last horizontal scanning in the preceding group and a horizontal scanning period corresponding to first horizontal scanning in the succeeding group, and the dummy scanning signal line being subjected to dummy scanning during the dummy scanning period. With the arrangement, it is possible to suppress horizontal-shaped unevenness that occurs in a case where block inversion driving is carried out.

Owner:SHARP KK

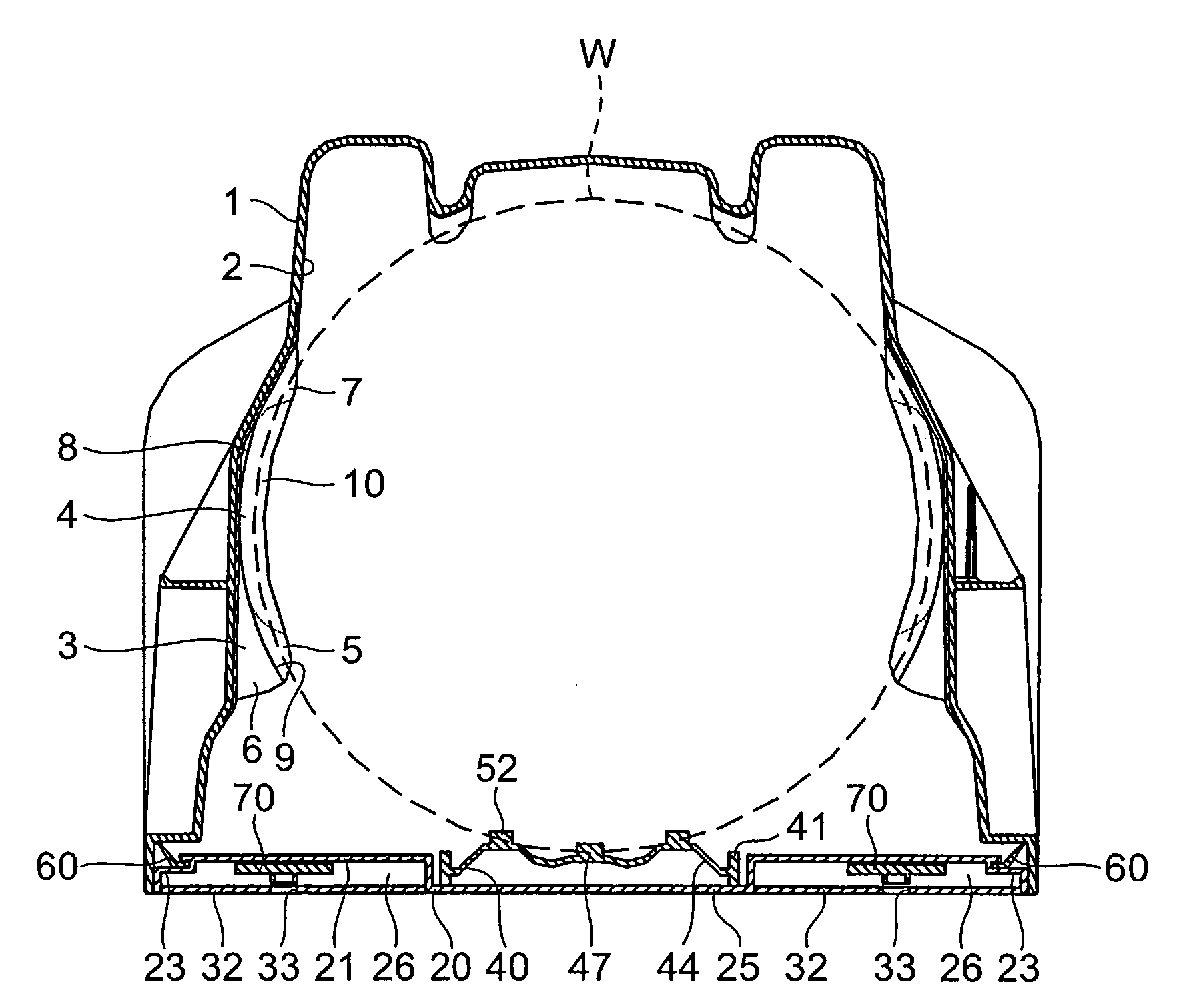

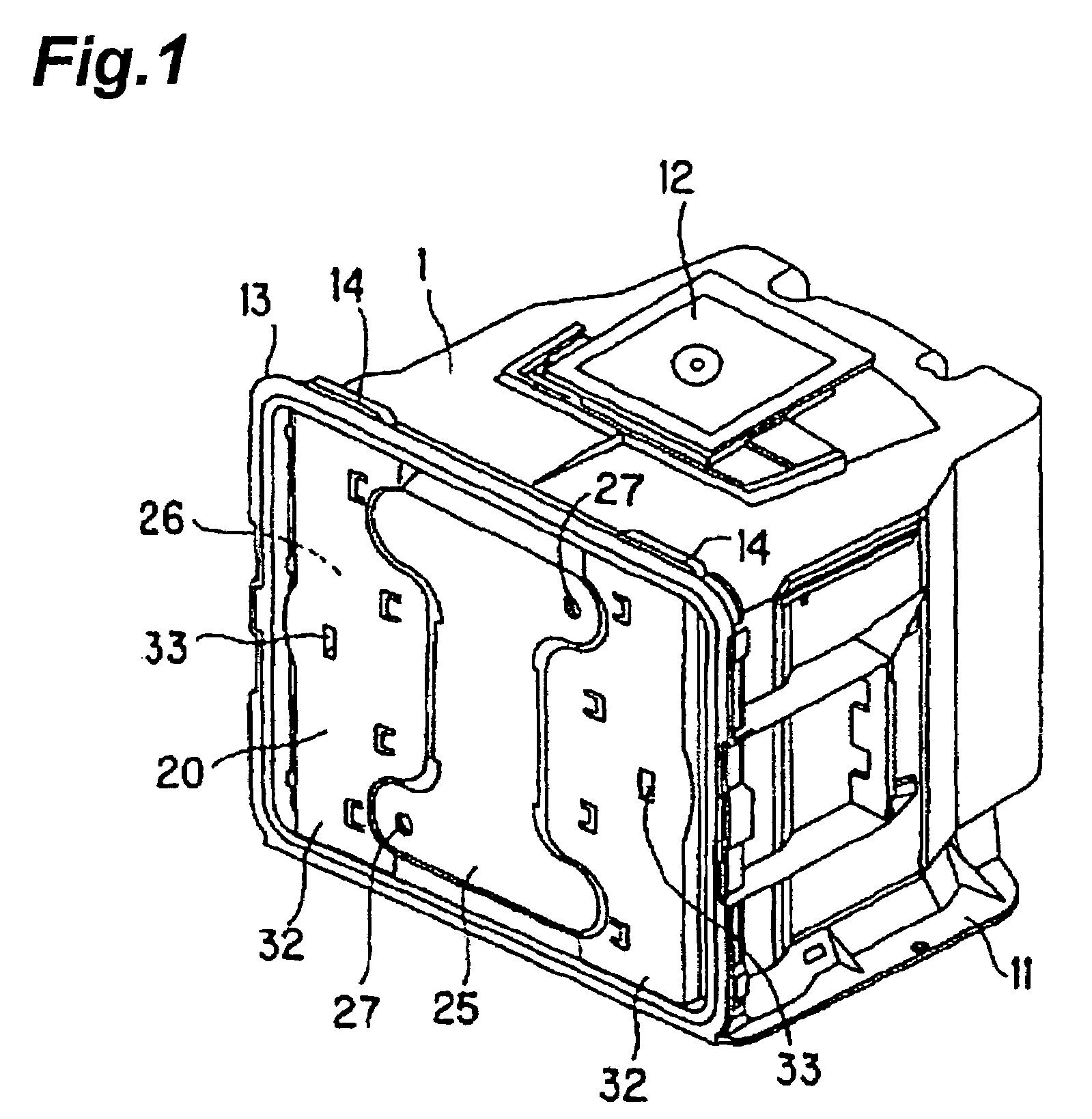

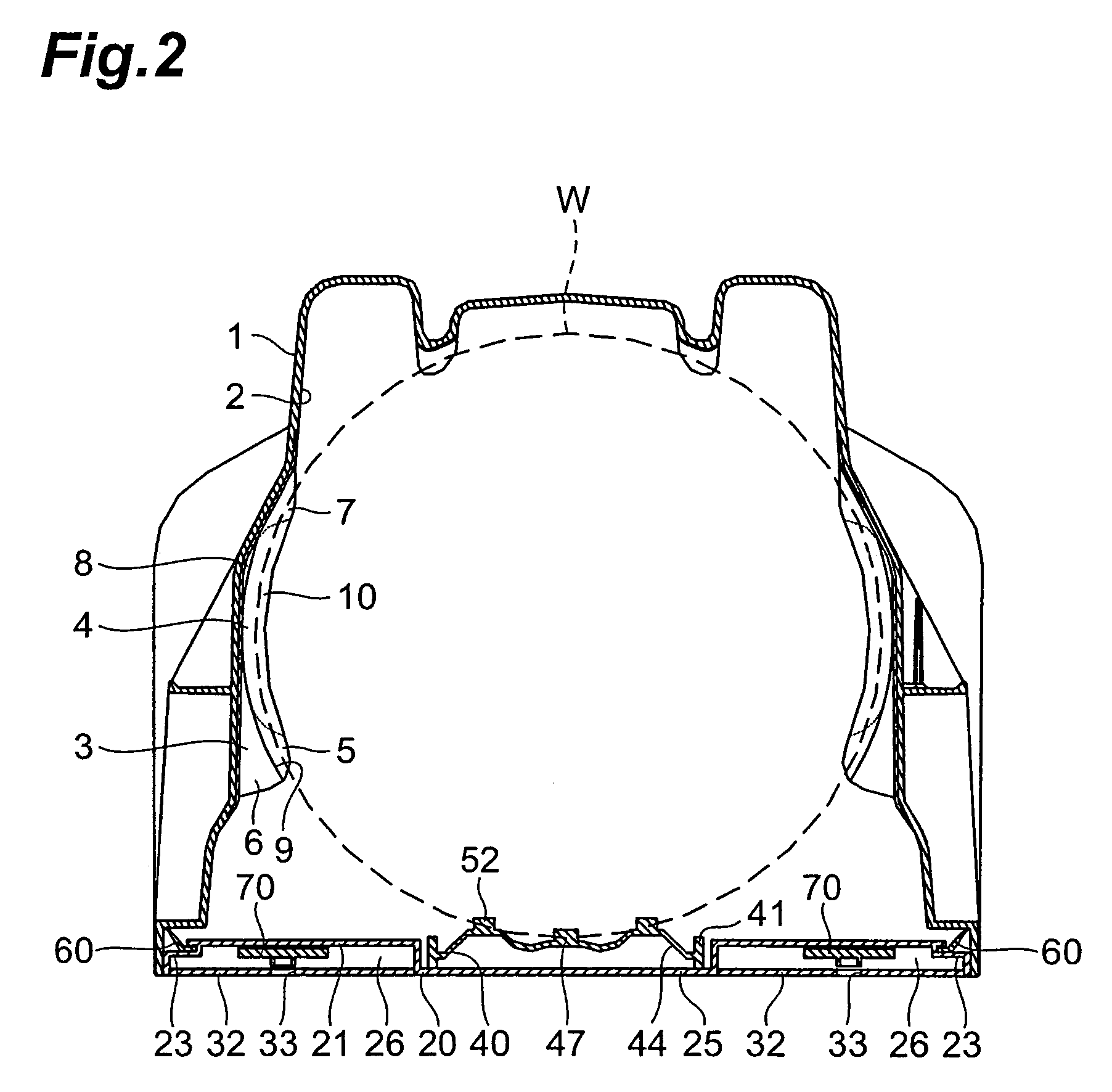

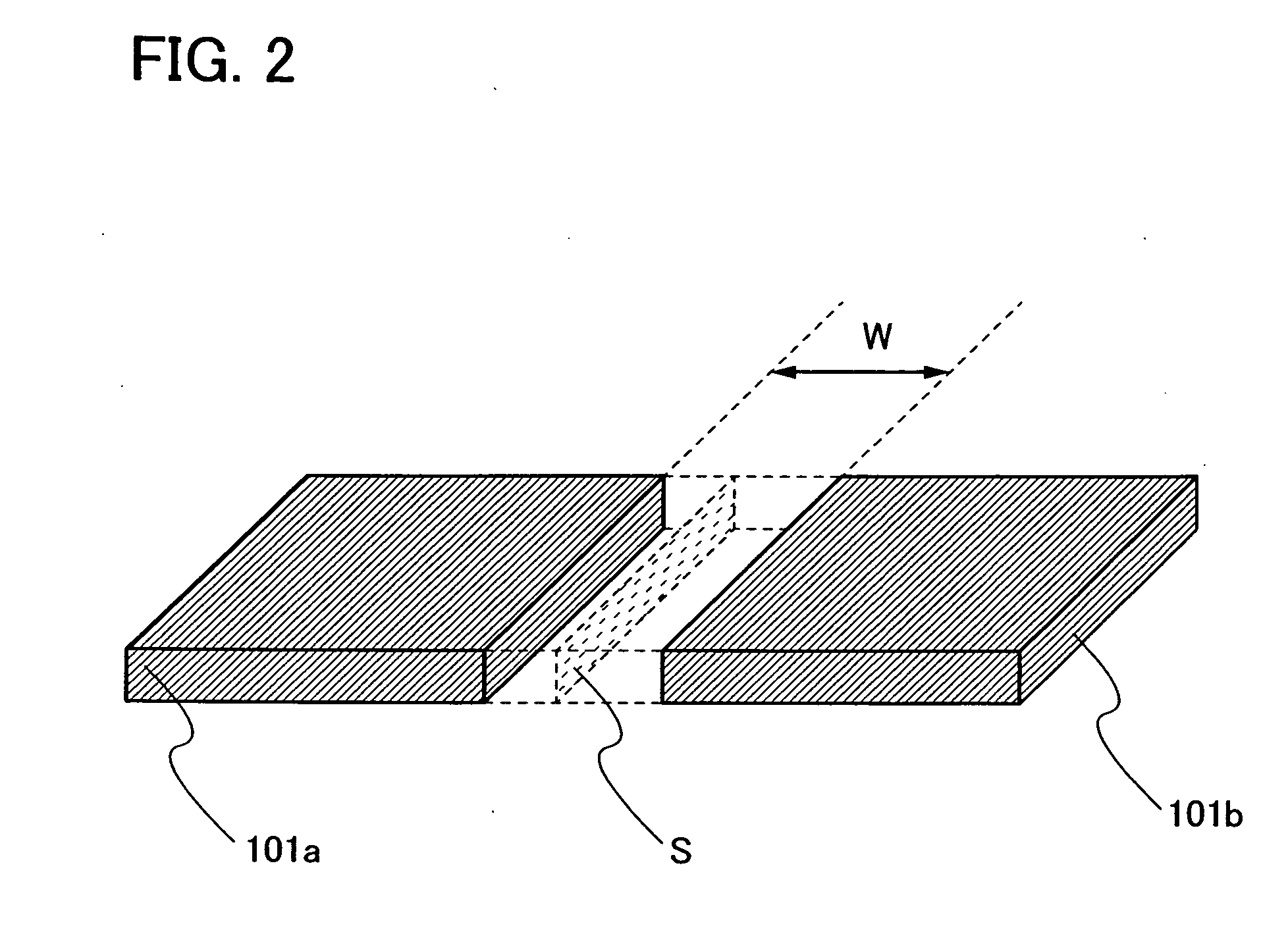

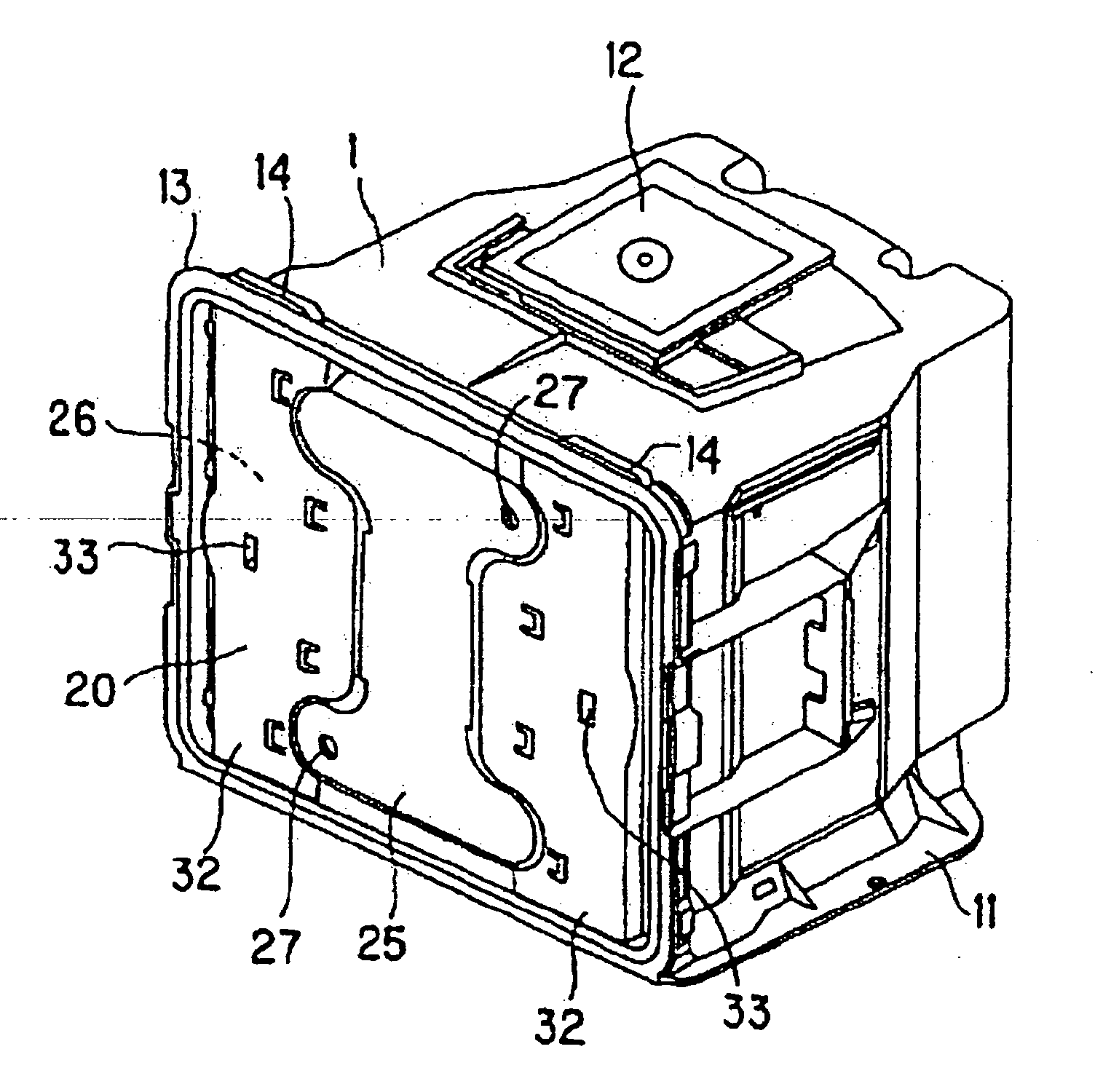

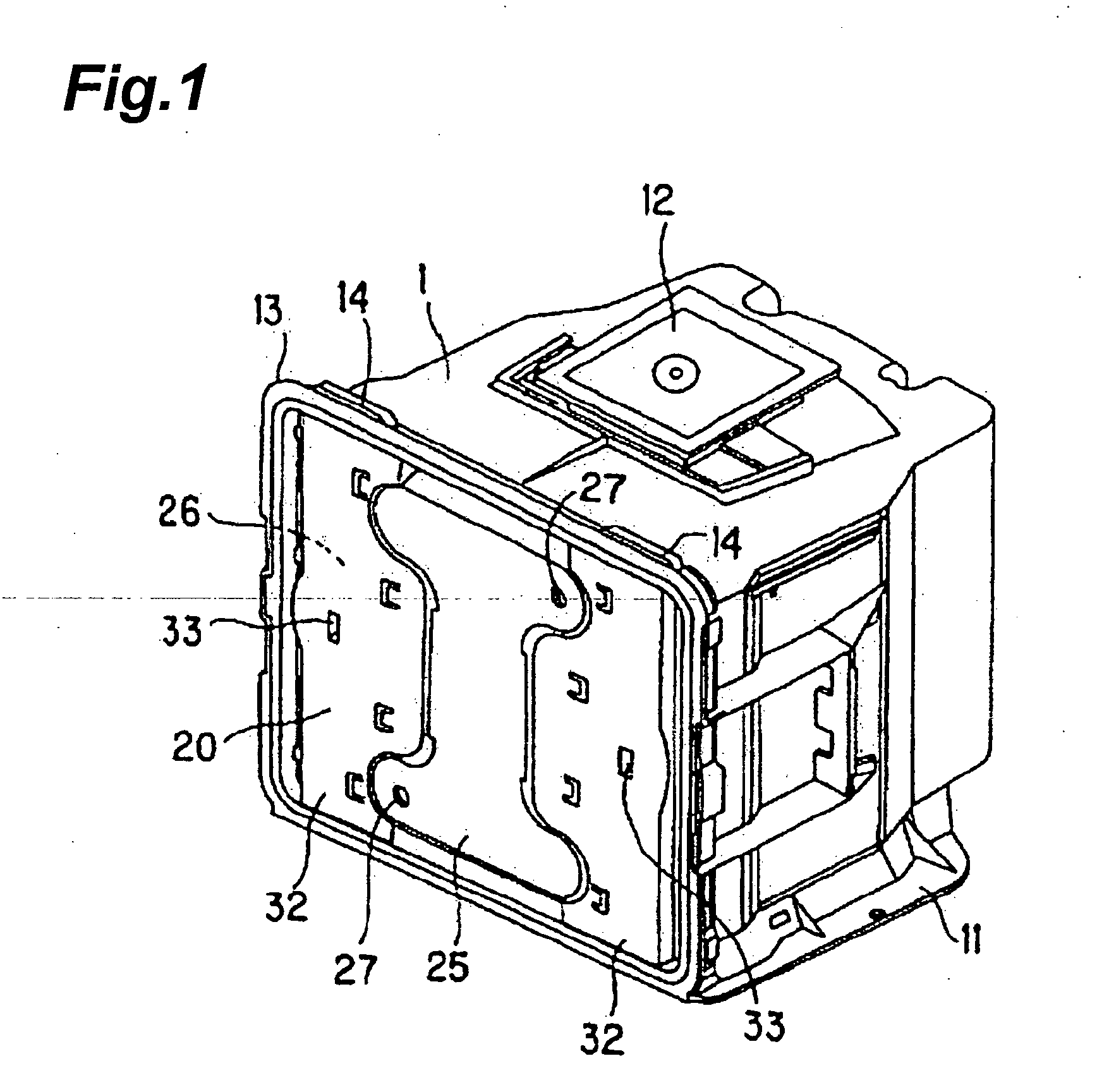

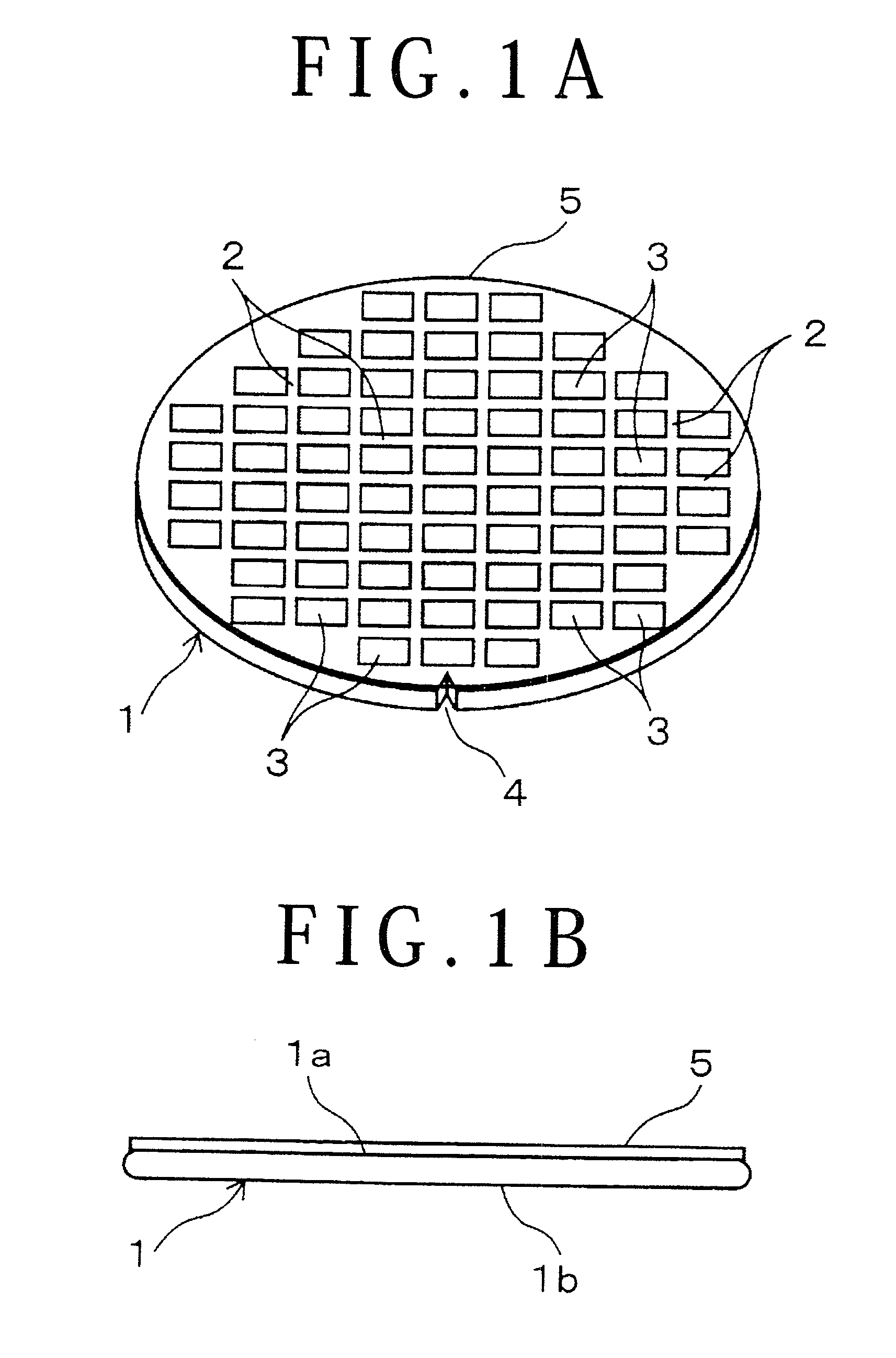

Substrate storage container

ActiveUS7344031B2Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesEngineeringGasket

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover; and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

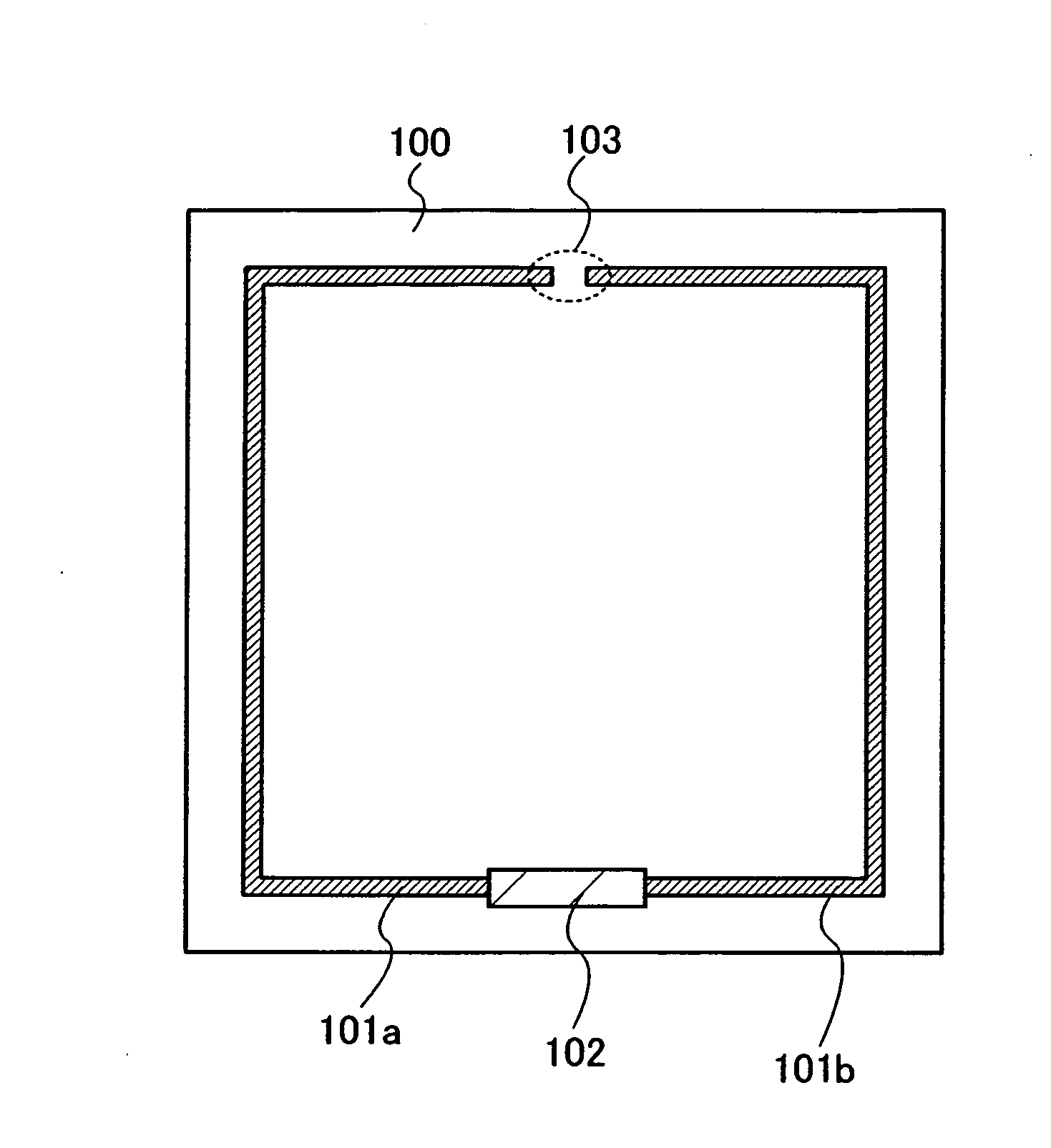

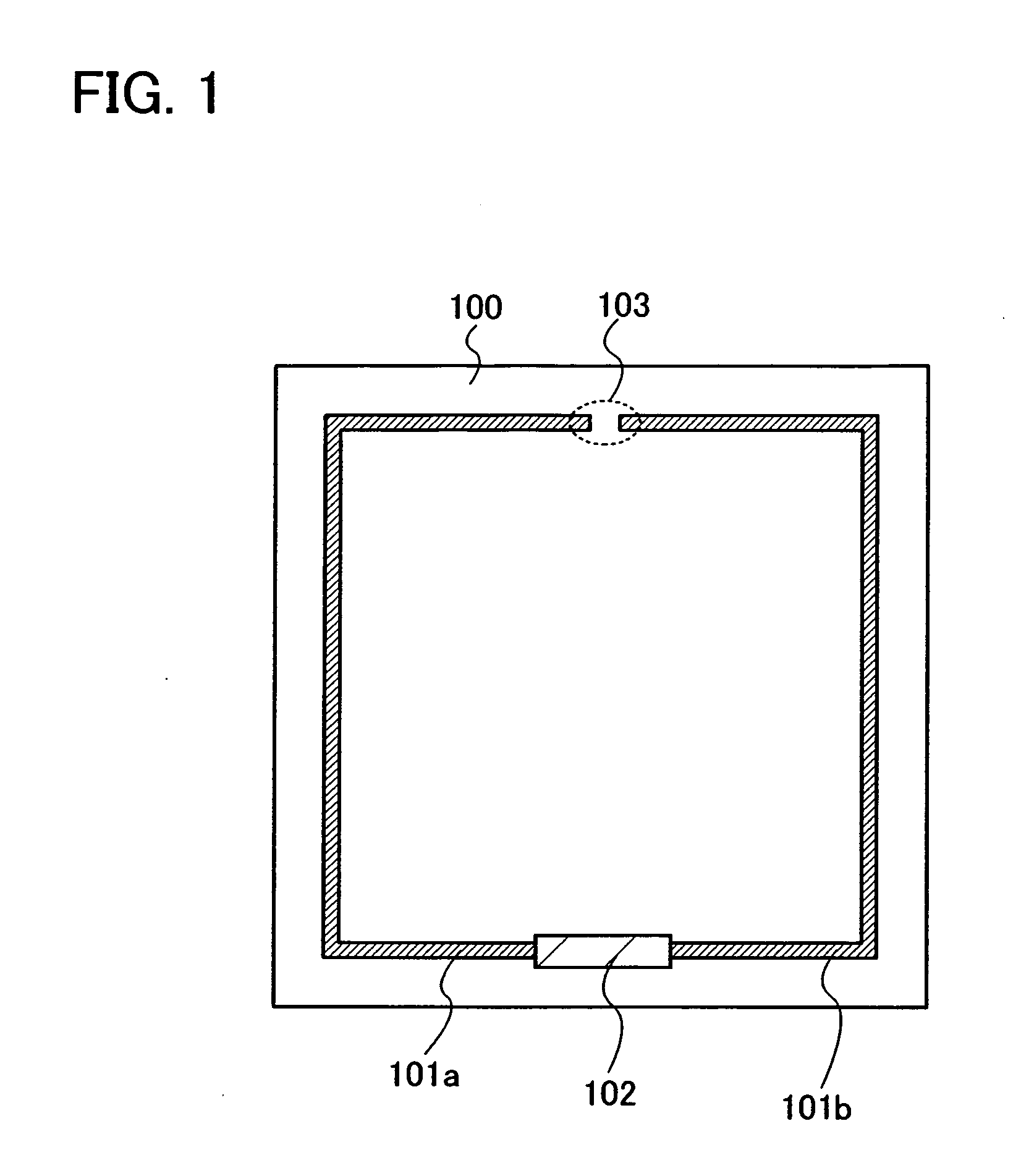

Antenna and semiconductor device having the same

InactiveUS20080158092A1Uneven currentReduce distortion problemsRadiating elements structural formsLoop antennasDistortionIntegrated circuit

An antenna for an electromagnetic induction method, in which unevenness in current density distribution is suppressed so that a magnetic field with reduced distortion is generated. In addition, a semiconductor device with less variation in response frequency and communication distance is also provided. The antenna has a loop-like shaped conductive structure with a cut portion in a part thereof and cross-sectional surfaces of the conductive structure face each other in the cut portion. In addition, the conductive structure of the antenna is electrically coupled to have capacity in the cut portion. The semiconductor device has the antenna and an integrated circuit which is connected to the antenna in a power feeding portion.

Owner:SEMICON ENERGY LAB CO LTD

Substrate storage container

ActiveUS20050274645A1Damage can be suppressedPrevent particle generationSemiconductor/solid-state device manufacturingOther accessoriesGasketEngineering

A substrate storage container comprises: a container casing having an aperture through which a plurality of substrates are placed in or taken out; a cover adapted to fit into the aperture of the container casing; a sealing gasket capable of elastic deformation provided between the container casing and the cover, and a retainer, mounted on the cover, capable of retaining the periphery of the substrates. The retainer has: a supporting body mounted on the inside face of the cover; a plurality of elastic pieces provided in elastically deformable fashion on the supporting body; and a block provided on each of the elastic pieces, the block retaining the periphery of one of the substrates. A relation 10.8×w<y<34.3×w is satisfied when a substrate retaining force of each of the elastic pieces is y [unit: N] and a weight per the substrate is w [unit: kg].

Owner:SHIN-ETSU POLYMER CO LTD

Dry Etching Method

ActiveUS20160218015A1Reduce bumpsReduce depressionSemiconductor/solid-state device manufacturingSilicon oxidePlasma Gases

Disclosed is a dry etching method for a laminated film in which at least one silicon layer and at least one silicon oxide layer are laminated together. The dry etching method includes generating a plasma gas from a dry etching agent and etching the laminated film with the plasma gas under the application of a bias voltage. The dry etching agent contains an unsaturated hydrofluorocarbon represented by the following formula: C3HxFy where x is an integer of 1 to 5; y is an integer of 1 to 5; and x and y satisfy a relationship of x+y=4 or 6, and iodine heptafluoride. The volume of the iodine heptafluoride in the dry etching agent is 0.1 to 1.0 times the volume of the unsaturated hydrofluorocarbon in the dry etching agent.

Owner:CENT GLASS CO LTD

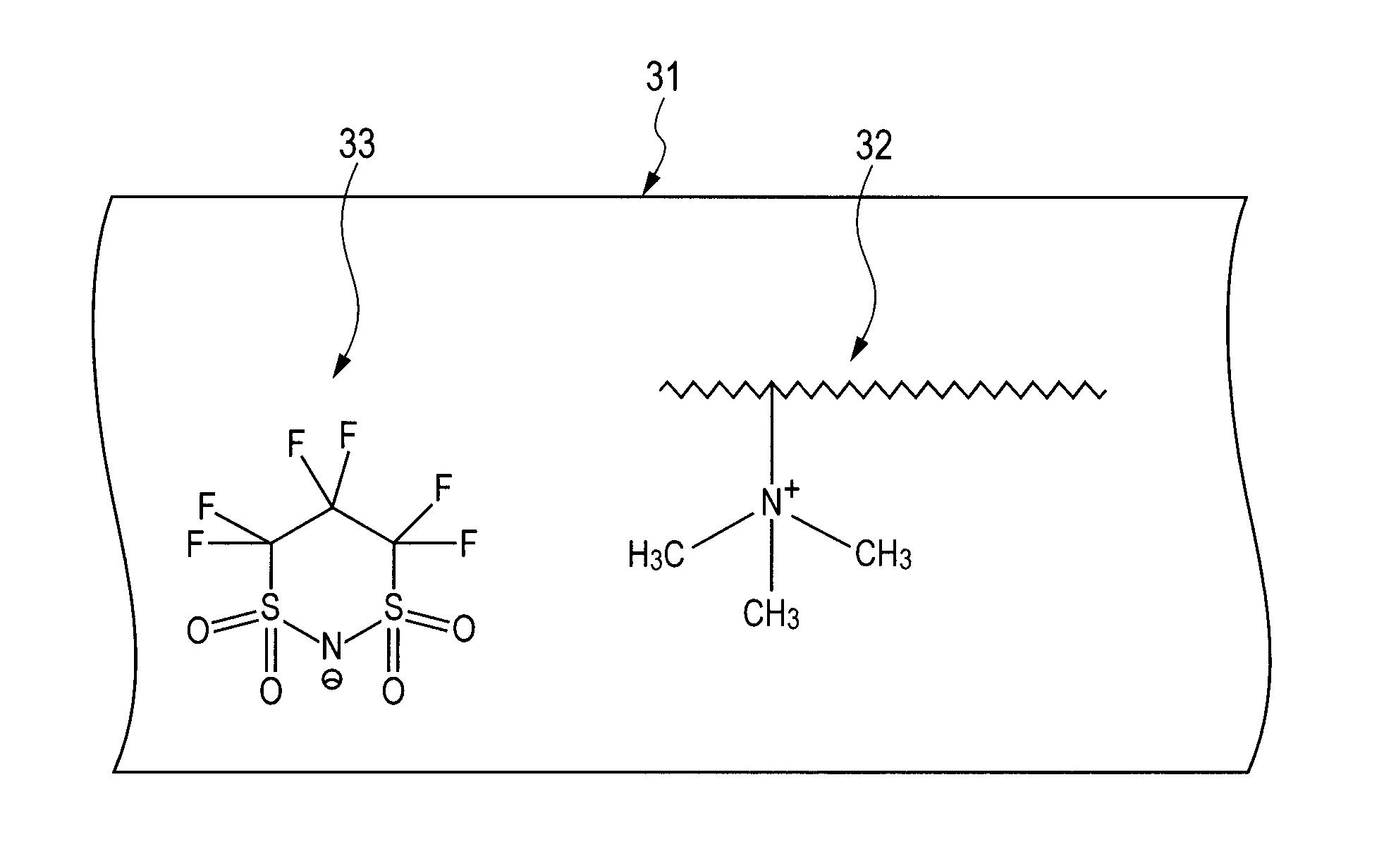

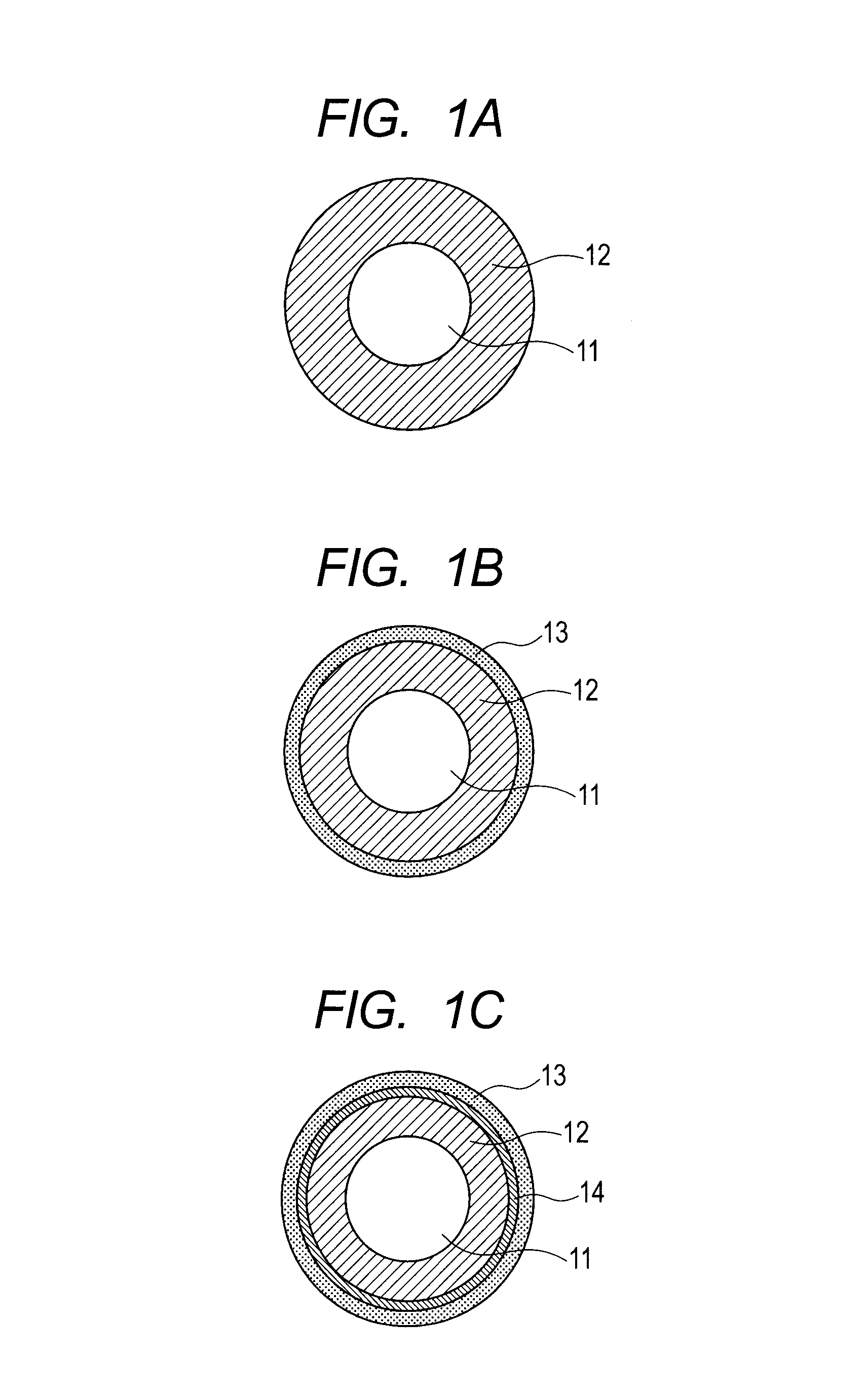

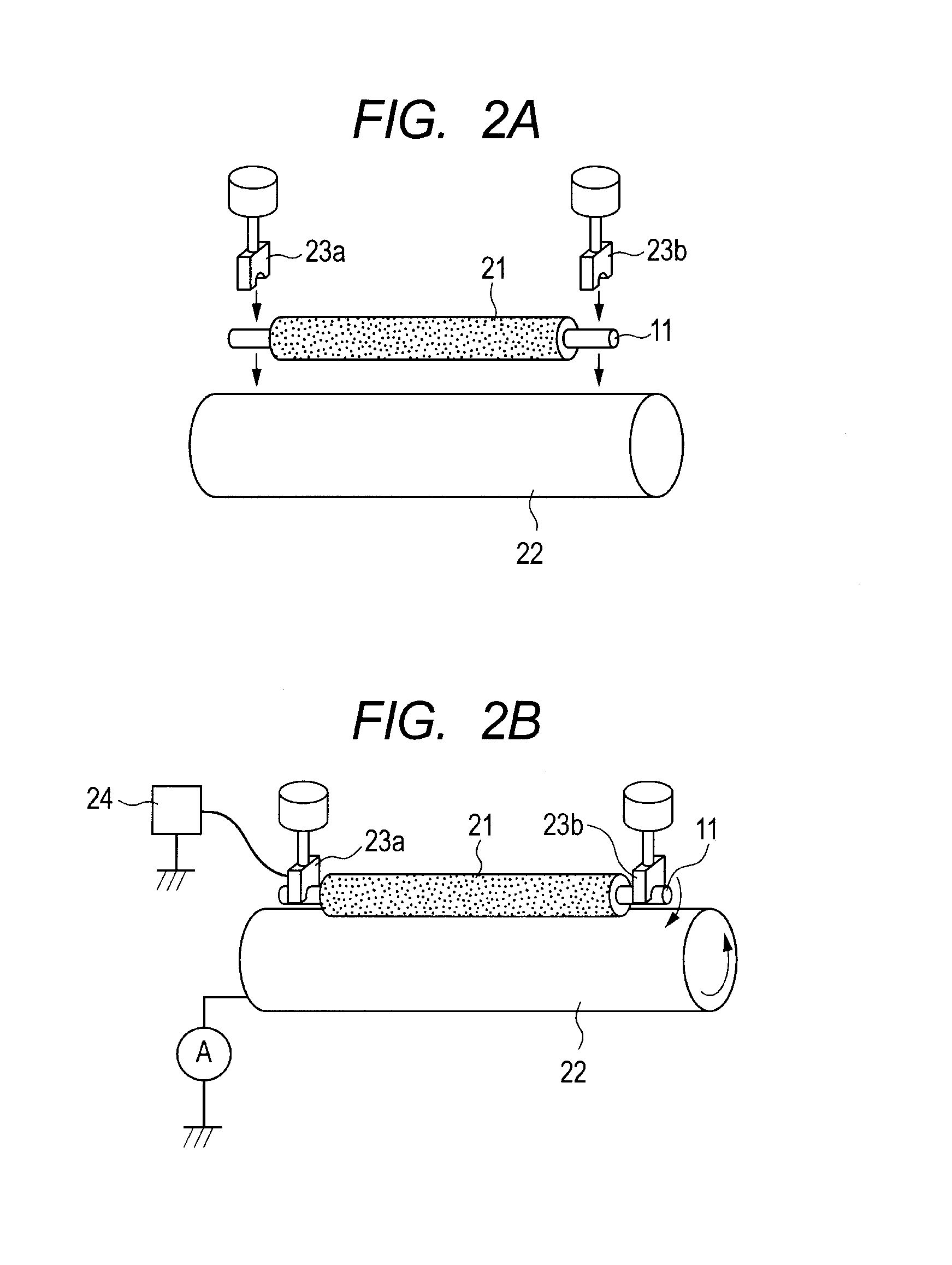

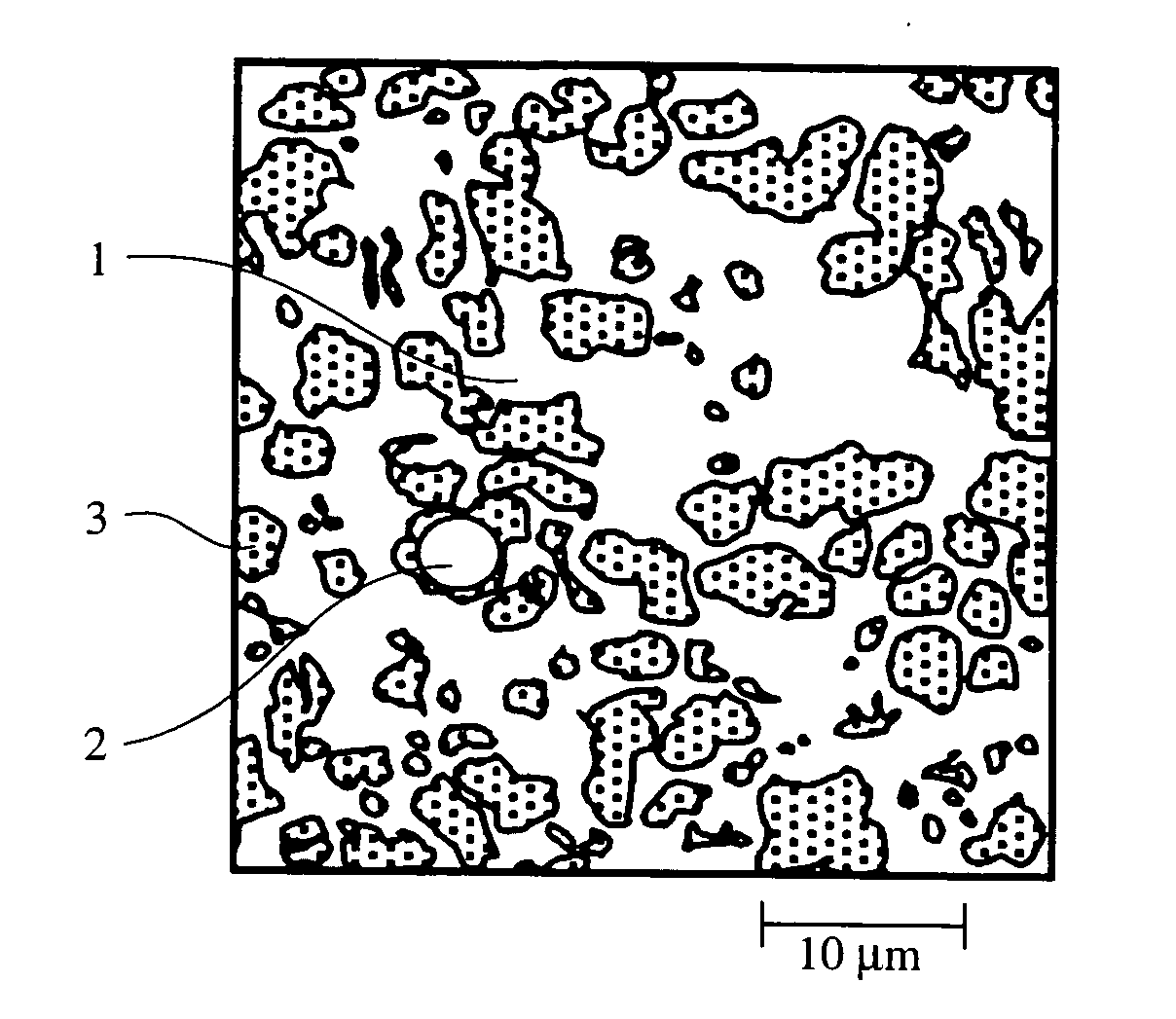

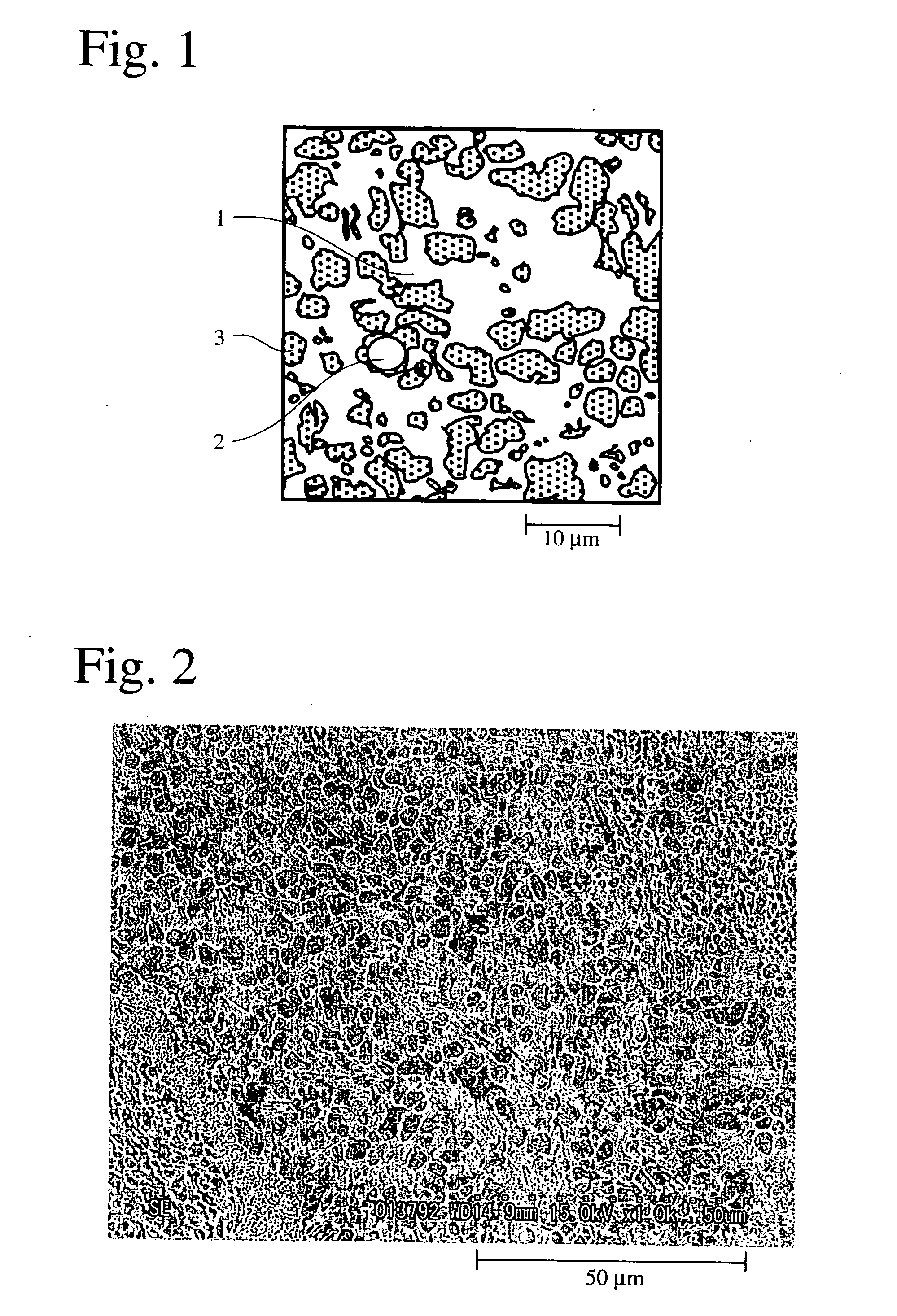

Electrophotographic electrically conductive member

ActiveUS8668987B2Inhomogeneous suppressionIncrease the number ofShaft and bearingsLayered productsConductive polymerQuaternary ammonium ions

Owner:CANON KK

Co alloy target and its production method, soft magnetic film for perpendicular magnetic recording and perpendicular magnetic recording medium

InactiveUS20050223848A1Reduce unevennessReduce particlesBase layers for recording layersTransportation and packagingAlloyImpurity

Owner:HITACHI METALS LTD

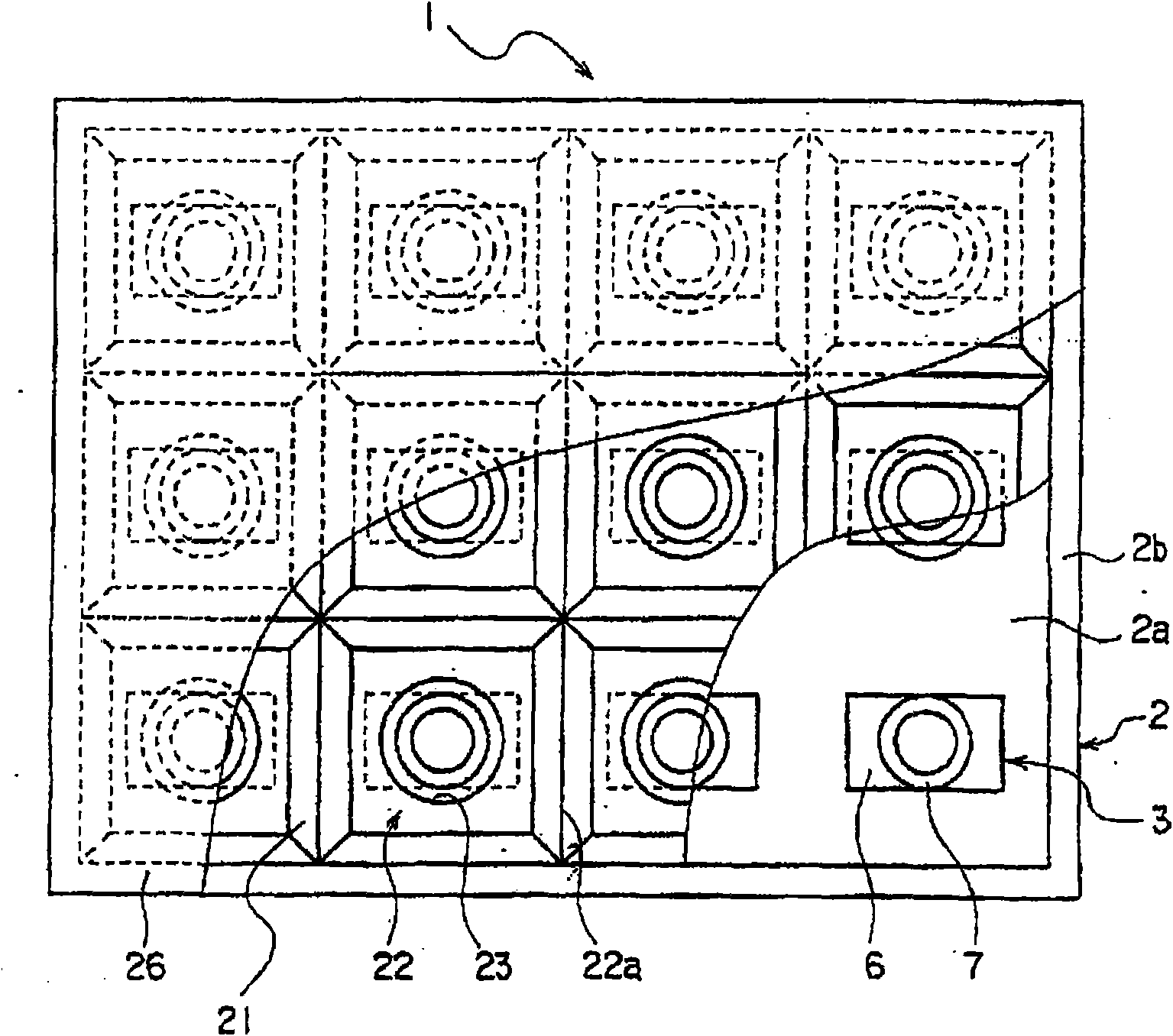

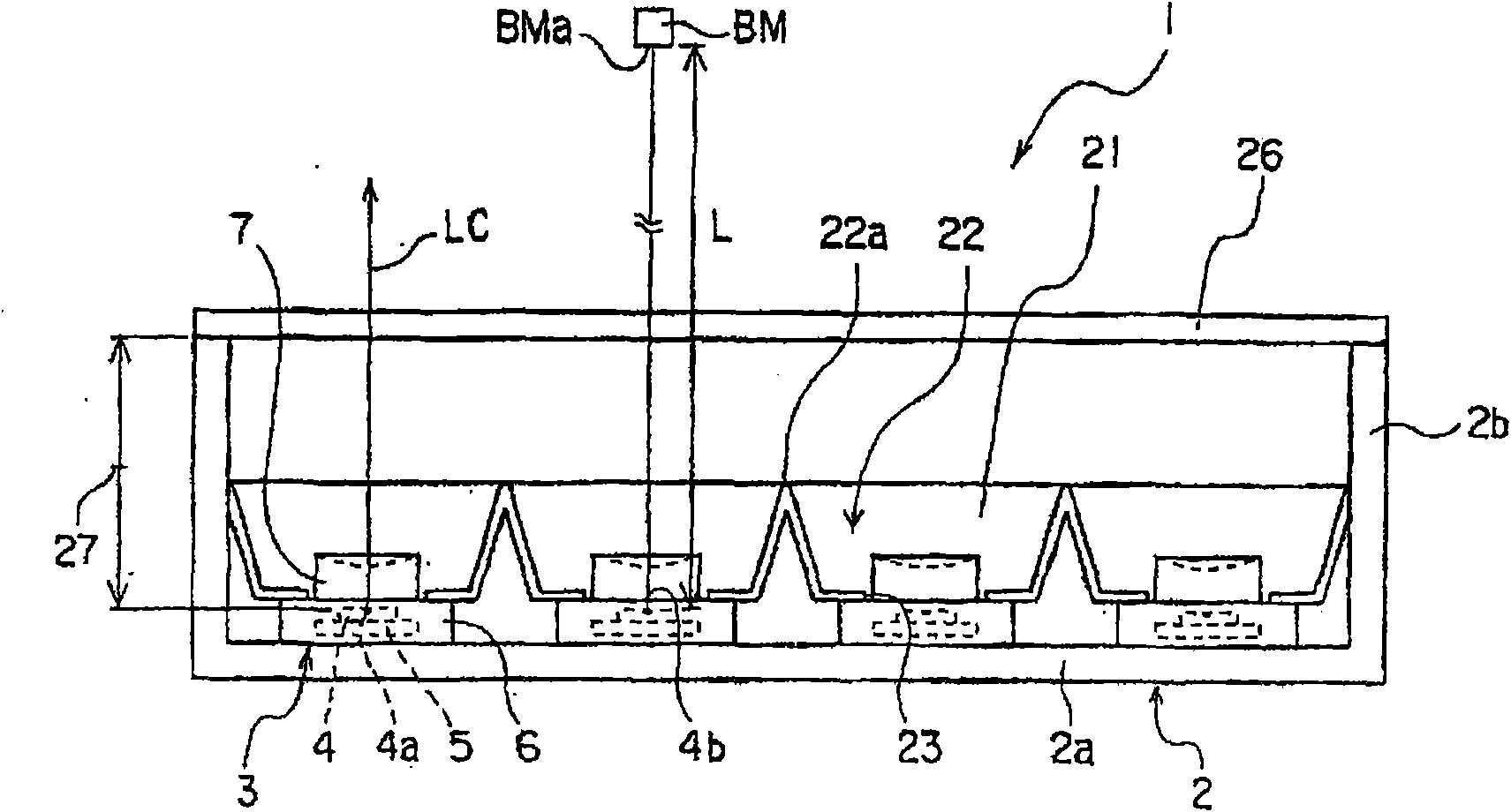

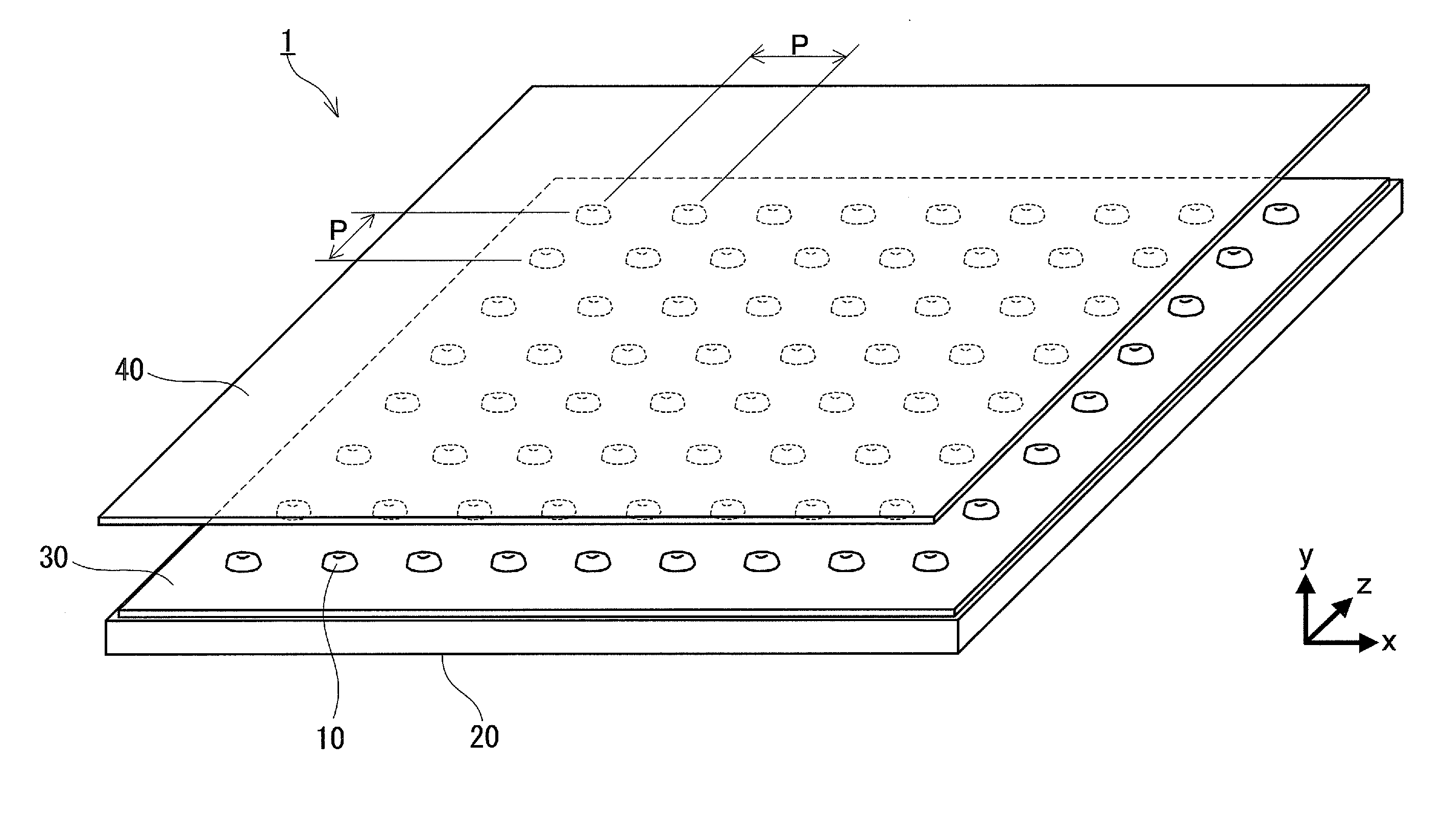

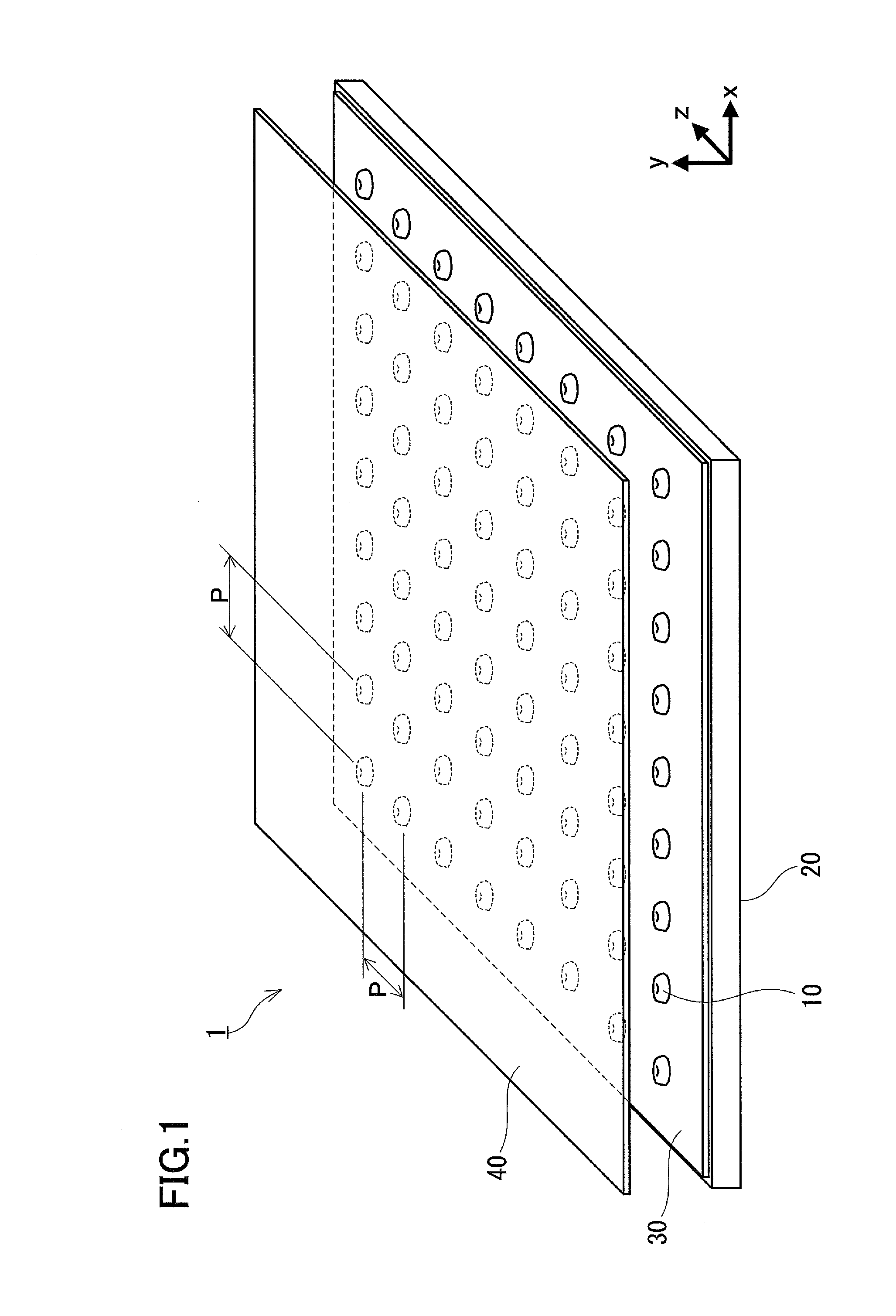

Light box

InactiveCN101641547AInhomogeneous suppressionEfficient reflectionElectric lightingNon-linear opticsIlluminanceOptoelectronics

To provide a thin light box employing a light source of strong directivity such as an LED, or a light box in which occurrence of unevenness in surface illuminance is suppressed even when the number ofLEDs is reduced by a factor of 4-9 as compared with prior art. ¢MEANS FOR SOLVING PROBLEMS! The light box (1) comprises a plurality of spot light sources (4), and a light reflector (21) having recesses (22) surrounding the spot light sources (4), respectively. The spot light sources are inserted into insertion holes (23) formed in the bottom of the containing recesses (22), respectively. When theincident angle of light exiting the spot light source (4) is 0 DEG and the spot light sources (4) are spaced apart by 350 mm, the illuminance is 15000 cd / m<2> or less and the light exiting the spotlight source (4) is reflected partially or entirely on the inner surface of the containing recesses (22) before offering illumination.

Owner:FURUKAWA ELECTRIC CO LTD

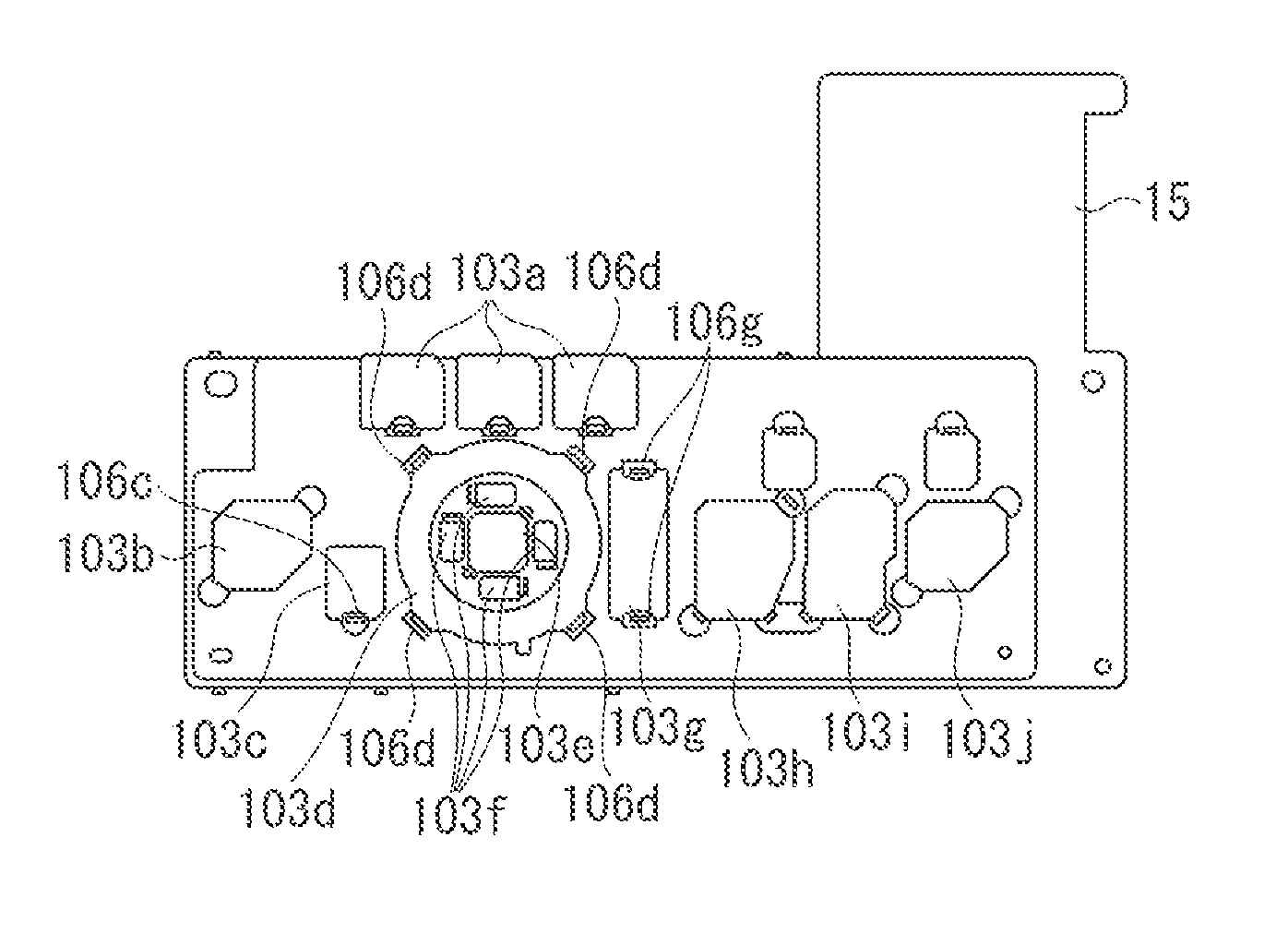

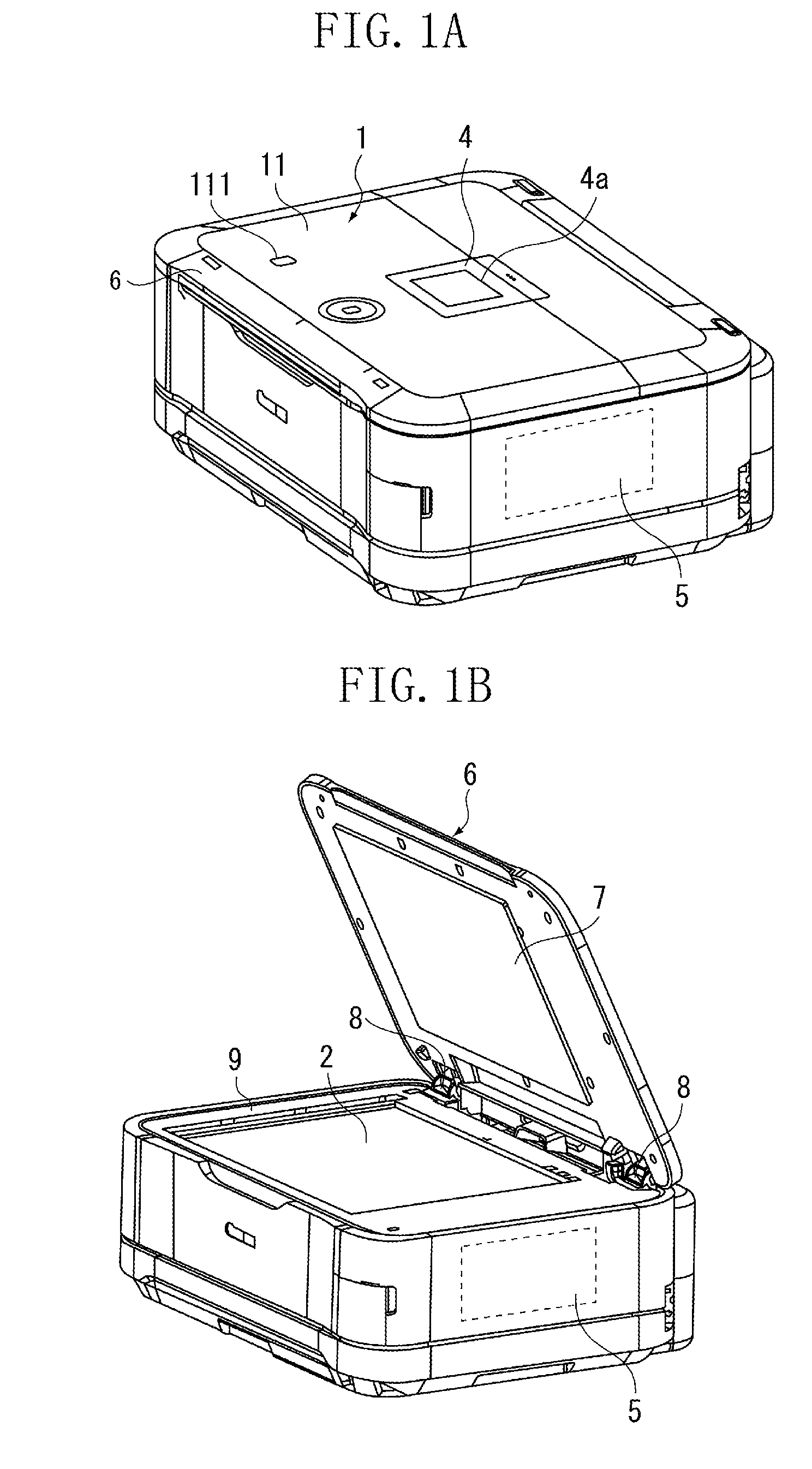

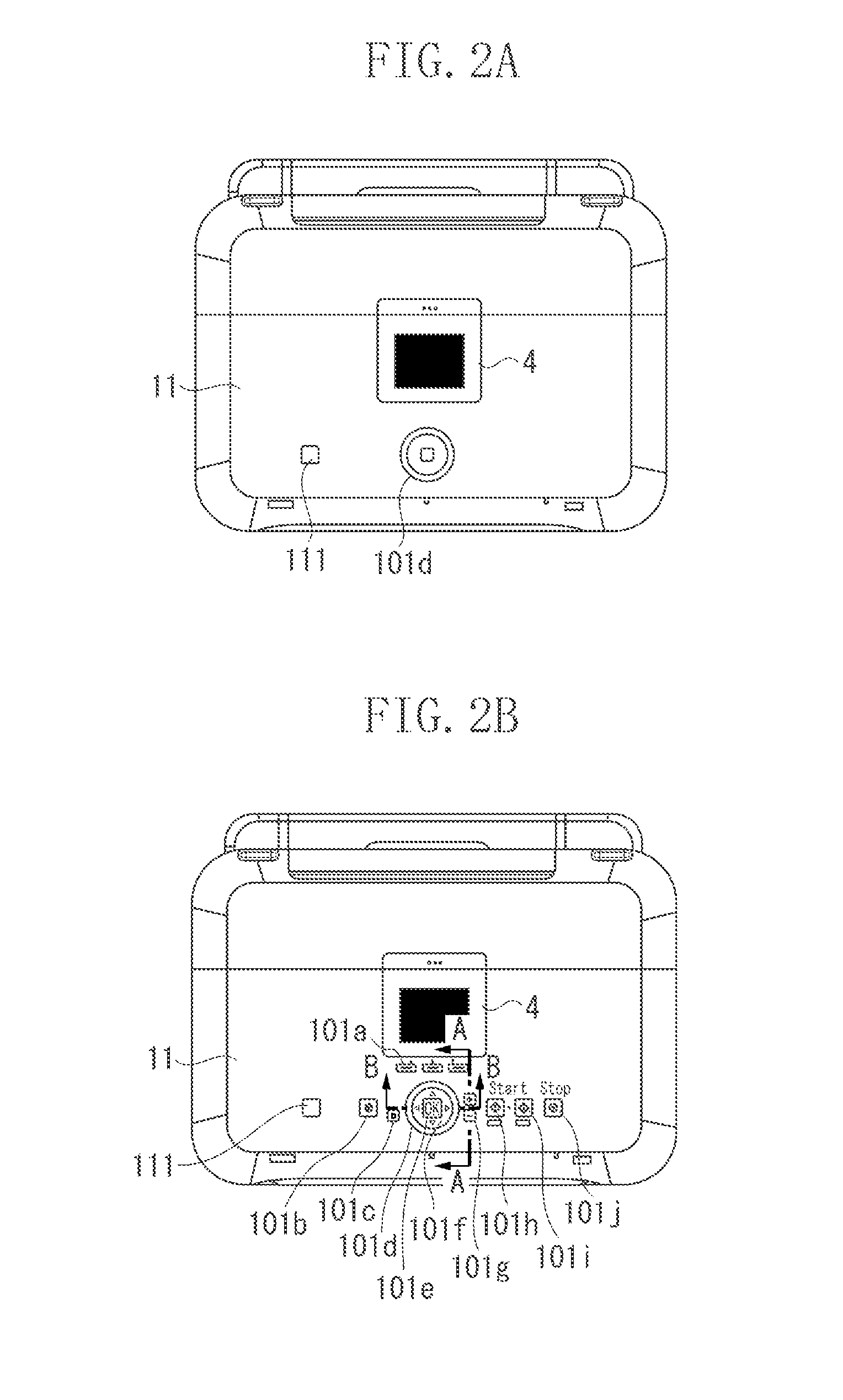

Operation device and image reading apparatus

ActiveUS20110299129A1Suppress brightness unevennessSuppression of uneven brightnessMechanical apparatusElectronic switchingTouch panelLight guide

A touch panel includes a ring-like shaped light-transmissive portion. A ring-shaped diffusion surface is formed on the bottom surface of a light guide element. The ring-like shape includes a second region provided at a location corresponding to two light sources adjacent to a first region corresponding to one light source. A distance from a location of the ring-shaped light-transmissive portion to a periphery of the ring close to the light source is greater in the second region than in the first region. Light emitted from the light source and incident to the light guide element is diffusion-reflected on the diffusion surface and a part of the diffusion-reflected light illuminates the light-transmissive portion.

Owner:CANON KK

Image processing device, image processing method and recording medium

InactiveUS7408569B1Accurate correctionHigh precisionImage enhancementCharacter and pattern recognitionImaging processingComputer science

The present invention provides an image processing device, an image processing method, and a recording medium that enable various defect portions to be accurately corrected. R, G, B, and IR are respectively read in an image recorded on a photographic film and transverse chromatic aberration correction is performed on each of the R, G, B, and IR image data. Subsequently, defect portions in the image being processed are detected based on the IR data, and predetermined feature amounts are calculated for the image portion being processed. Based on the results of this calculation, either one of the interpolation method or brightness adjustment method is selected as the correction method for the defect portion being processed, or the ranges in which each of these correction methods is to be applied are decided. Consequently, either one of the two correction methods or both correction methods are applied and the correction values decided, and the final correction values are then determined.

Owner:FUJIFILM HLDG CORP +1

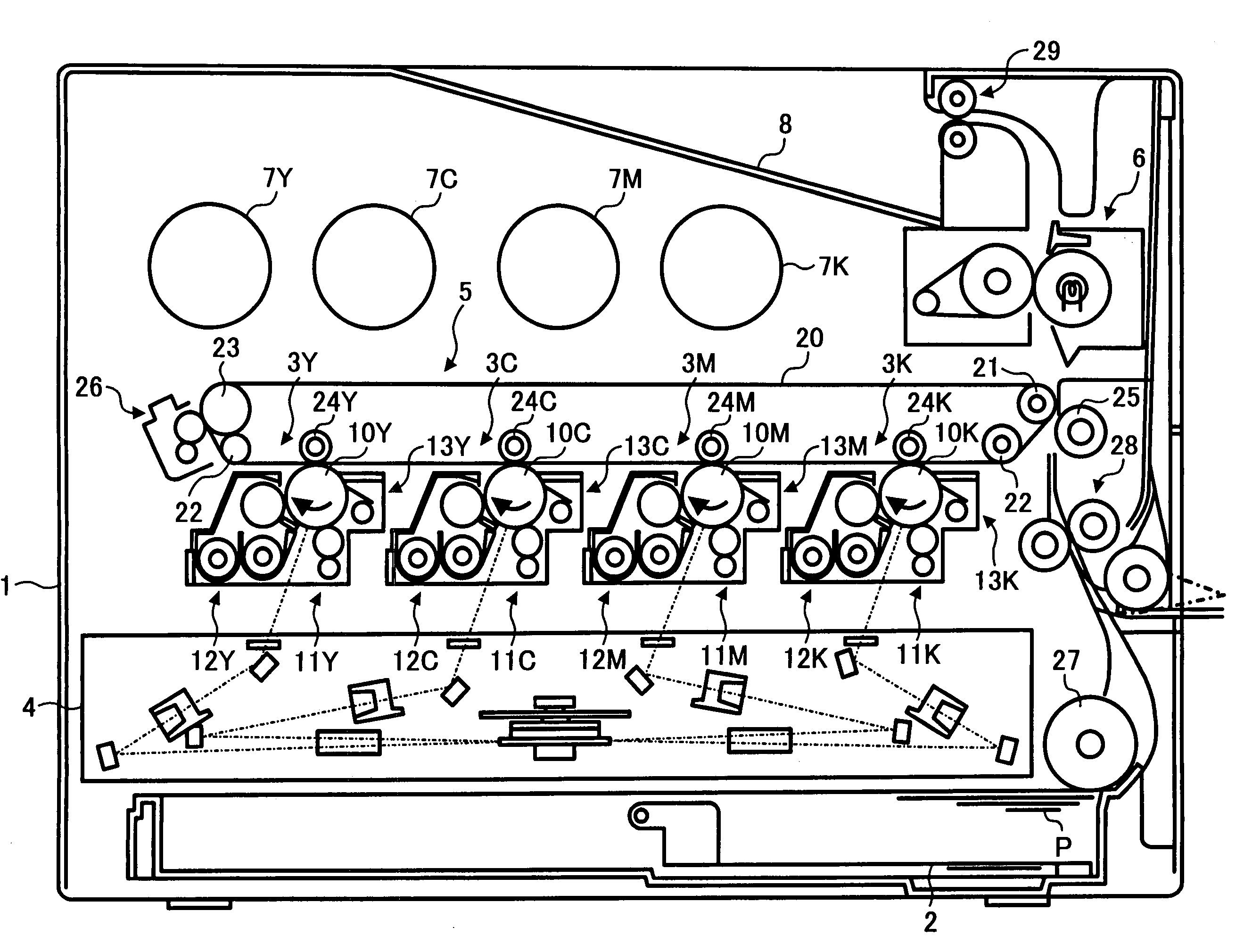

Image forming apparatus including a magnetic brush developing system using a two-component developer comprising toner and carrier

InactiveUS7457570B2Reduce generationImprove the development effectElectrographic process apparatusElectrographic processes using charge patternSide effectEdge effects

It is an object of the present invention to provide a process unit and an image forming apparatus in which generation of loss of image density due to flying off of developer and the edge effect occurring as a side-effect under developing conditions aimed at improving development performance can be reduced, even when a DC bias development system is adopted, and which can suppress developing density unevenness caused by impact occurring on contact of the teeth of gears in the drive system.

Owner:RICOH KK

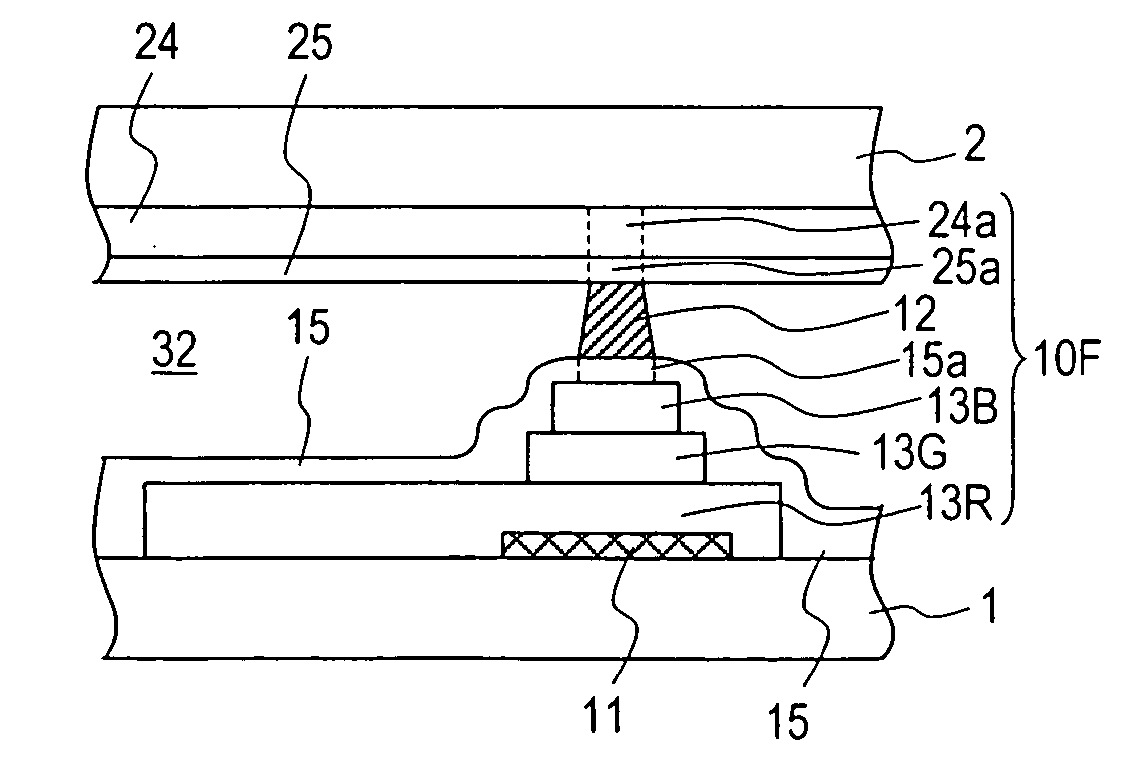

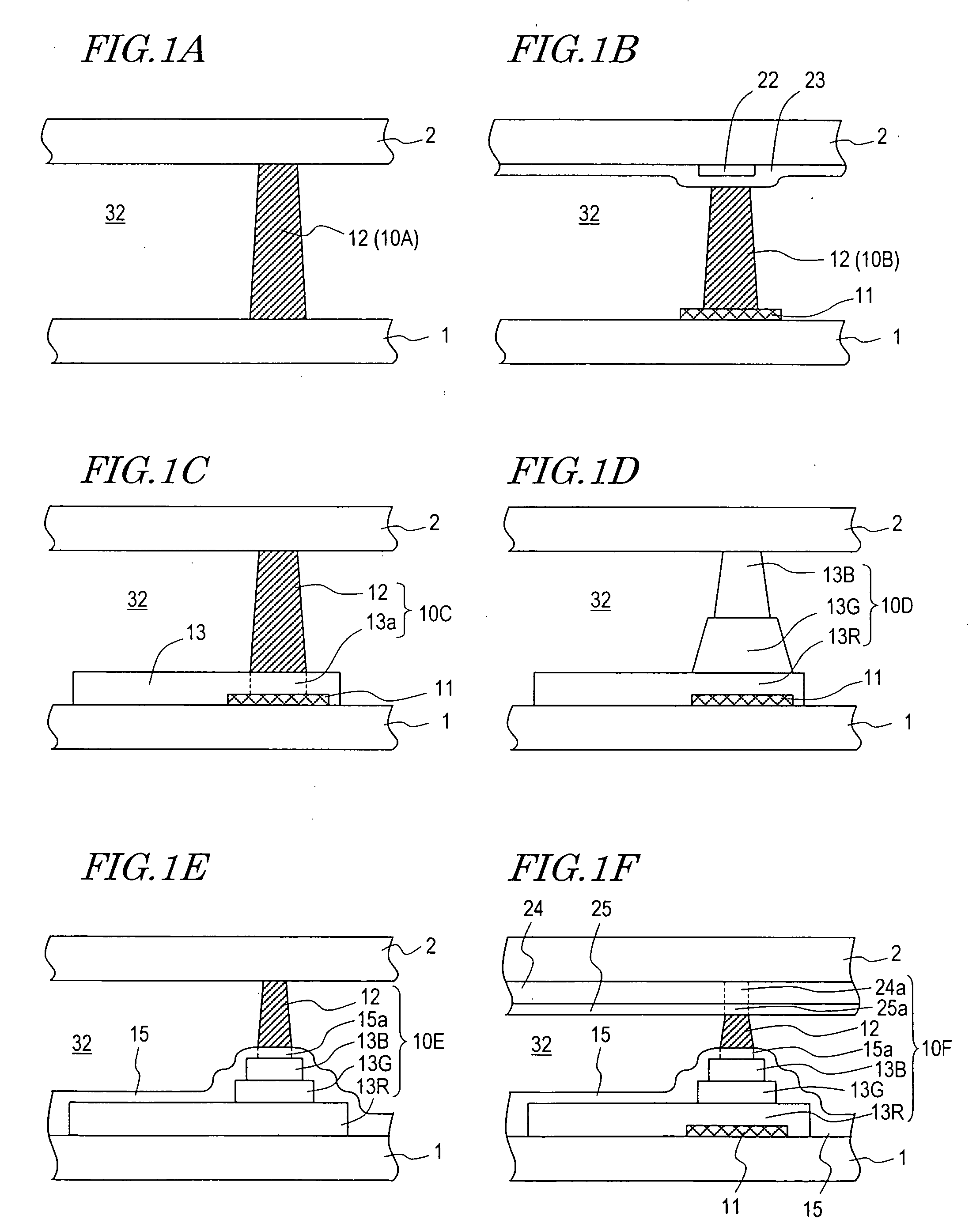

Display device

InactiveUS20140252336A1Improve display qualitySuppress lightStatic indicating devicesSolid-state devicesDisplay deviceDriven element

A display device includes a light emitting functional layer disposed between a first and second substrates; a first pixel which emits light to the second substrate and has a first pixel electrode disposed between the light emitting functional layer and the first substrate, a second electrode disposed between the light emitting functional layer and the second substrate, and a first reflecting layer disposed between the first pixel electrode and the first substrate; a second pixel which emits light to the first substrate side and has a second pixel electrode disposed between the light emitting functional layer and the first substrate, a second electrode disposed between the light emitting functional layer and the second substrate, and a second reflecting layer disposed between the second electrode and the second substrate; and a driving element which drives the first and second pixel electrodes is disposed above first substrate.

Owner:SEIKO EPSON CORP

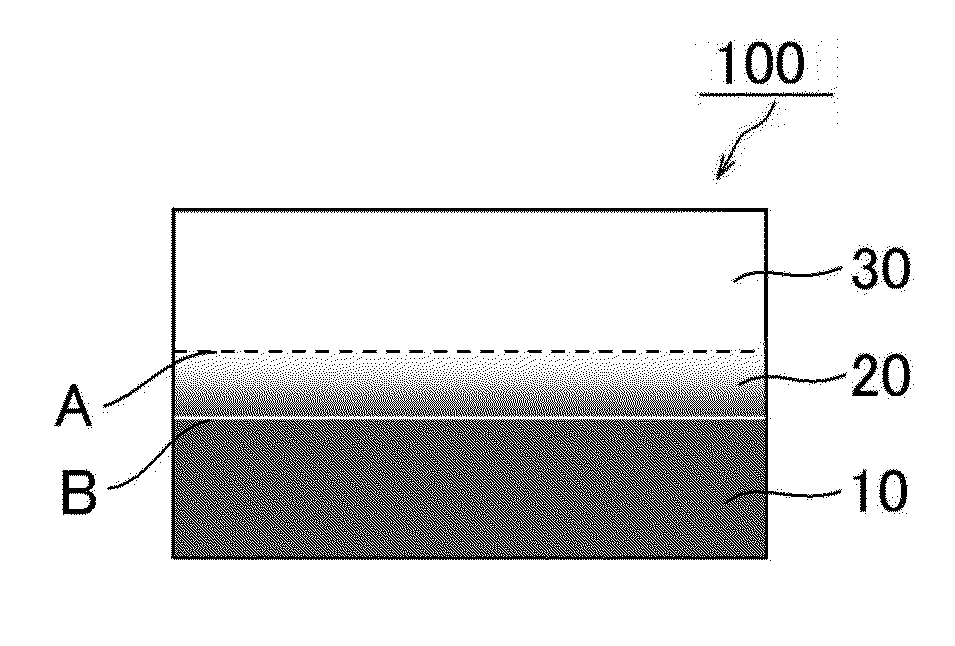

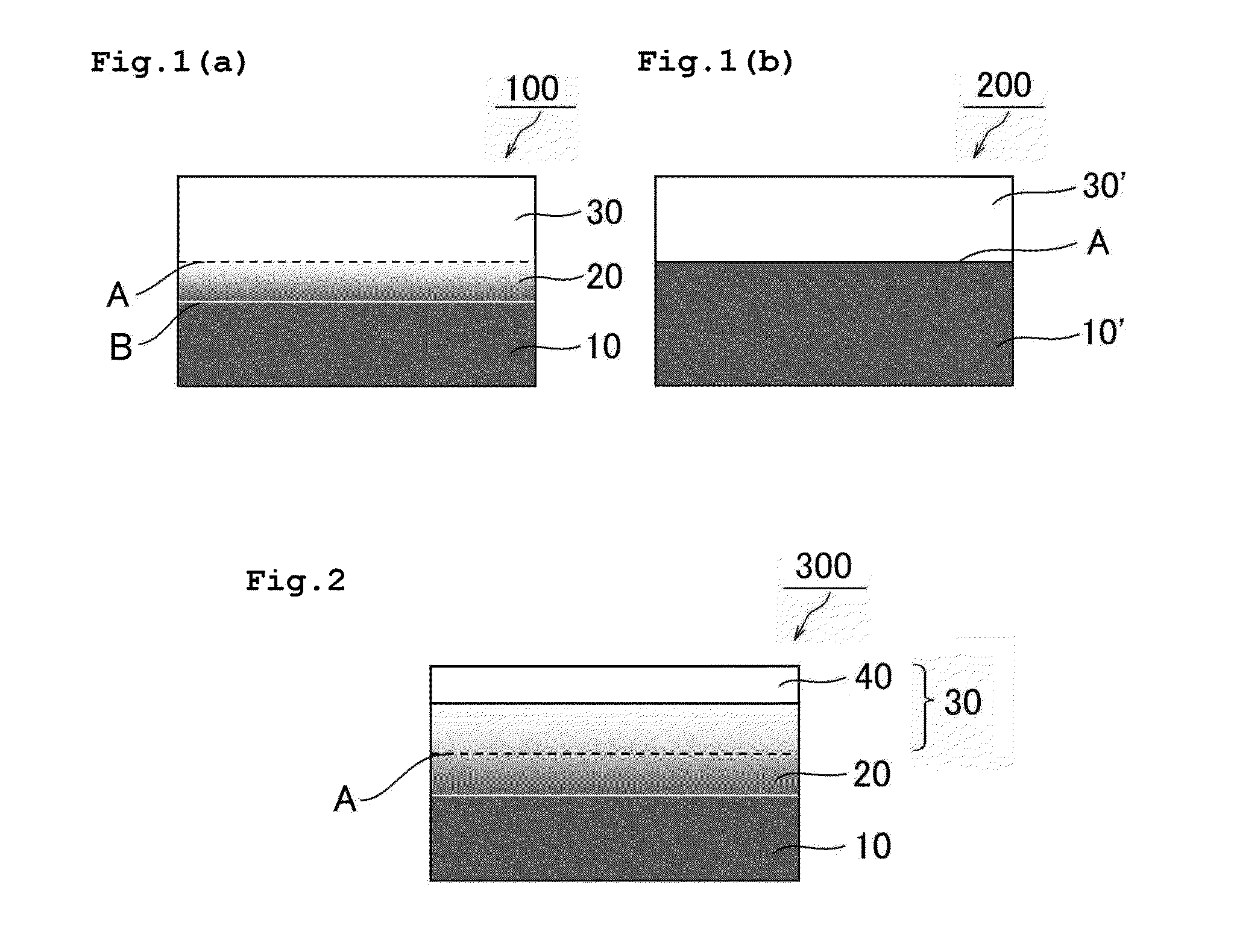

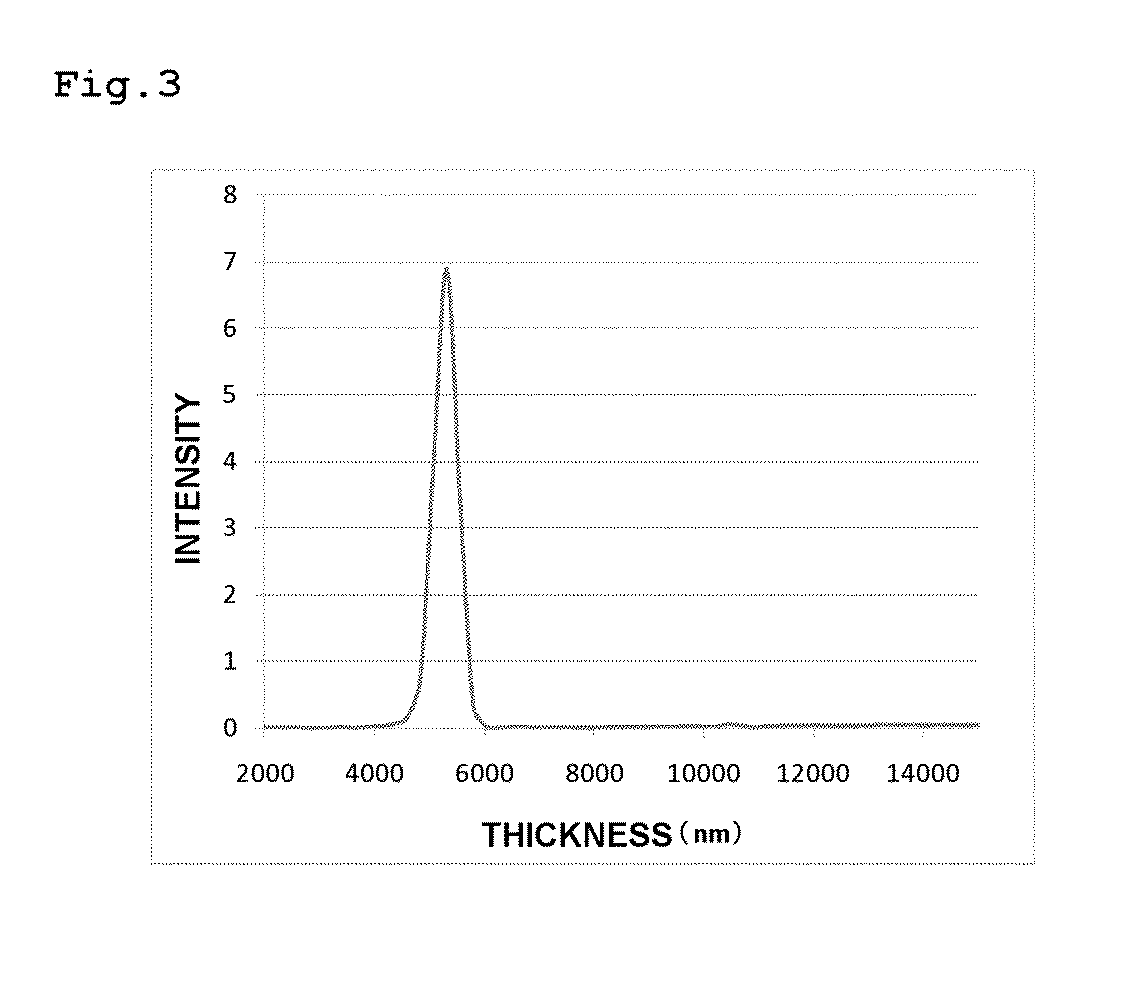

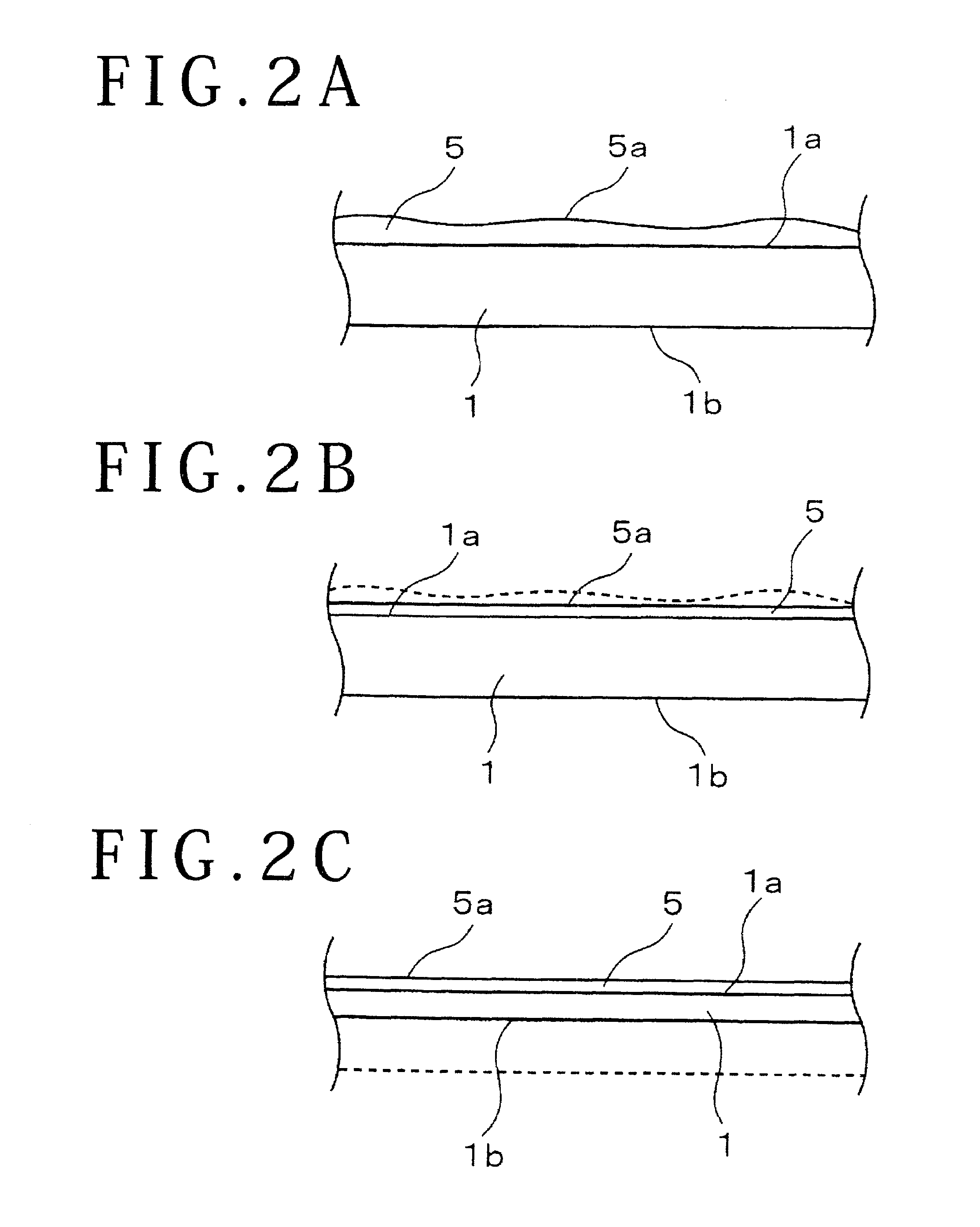

Optical laminate

ActiveUS20140227482A1Improve adhesionSuppressed interference unevennessMirrorsDiffusing elementsMeth-Acrylic resin

There is provided an optical laminate excellent in adhesiveness between a (meth)acrylic resin film (base material film) having low moisture permeability and a UV absorbing ability and a hard coat layer, and has suppressed interference unevenness. An optical laminate according to an embodiment of the present invention includes: a base material layer formed of a (meth)acrylic resin film; a hard coat layer formed by applying a composition for forming a hard coat layer to the (meth)acrylic resin film; and a penetration layer formed through penetration of the composition for forming a hard coat layer into the (meth)acrylic resin film, the penetration layer being placed between the base material layer and the hard coat layer, wherein the penetration layer has a thickness of 1.2 μm or more.

Owner:NITTO DENKO CORP

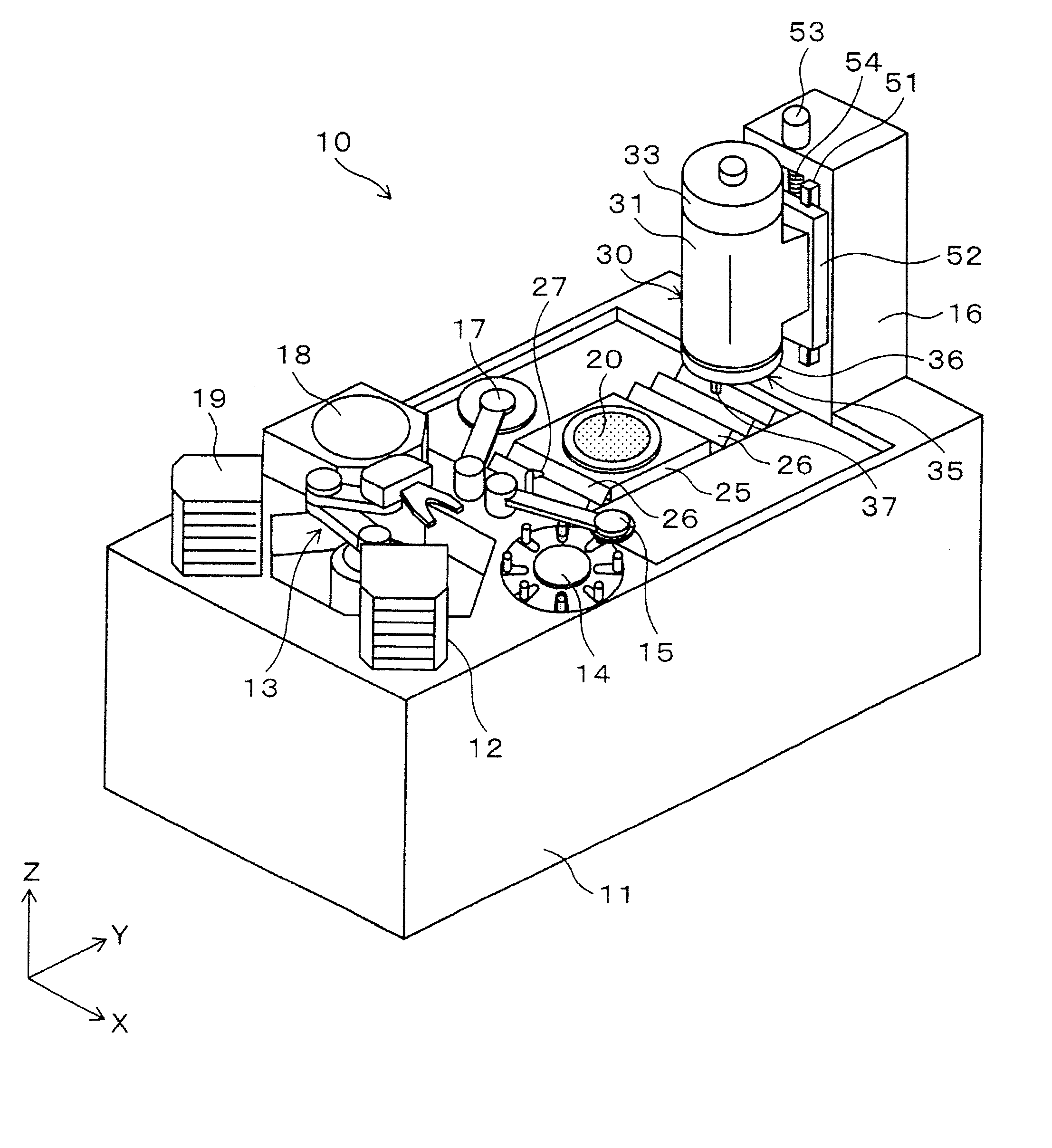

Back grinding method for wafer

ActiveUS20090042488A1Uniform thicknessImprove accuracyGrinding feed controlAutomatic grinding controlEngineeringSuction surface

A back grinding method for a wafer includes covering a face-side surface of the wafer with a resin film, and cutting the surface of the resin film to form a flat surface parallel to the face-side surface of the wafer. The wafer is held with the surface of the resin film in contact with a suction surface of a chuck table in a grinding apparatus, and the exposed back-side surface of the wafer is ground. Unevenness in thickness of the resin film is suppressed, whereby the thickness of the wafer subjected to back grinding is made to be uniform.

Owner:DISCO CORP

Lighting device, surface light source, and liquid-crystal display apparatus

ActiveUS20110013116A1Inhomogeneous suppressionInhibitionPoint-like light sourceStatic indicating devicesExit surfaceLiquid-crystal display

A lighting device includes a light emitting element that emits a first colored light; a phosphor layer disposed on the light emitting element; and a lens part that is disposed so as to cover the light emitting element and the phosphor layer, and radiates light entering inside of the lens part so as to spread the light radially. The phosphor layer allows a part of the first colored light to transmit therethrough and converts another part of the first colored light into a second colored light having a wavelength longer than that of the first colored light. The lens part has: a base portion forming a light entrance surface through which the first colored light and the second colored light enter the lens part; and a diffraction portion forming a light exit surface through which the first colored light and the second colored light exit the lens part, the diffraction portion being configured so that a refracting power with respect to the second colored light is larger than a refracting power with respect to the first colored light.

Owner:PANASONIC CORP

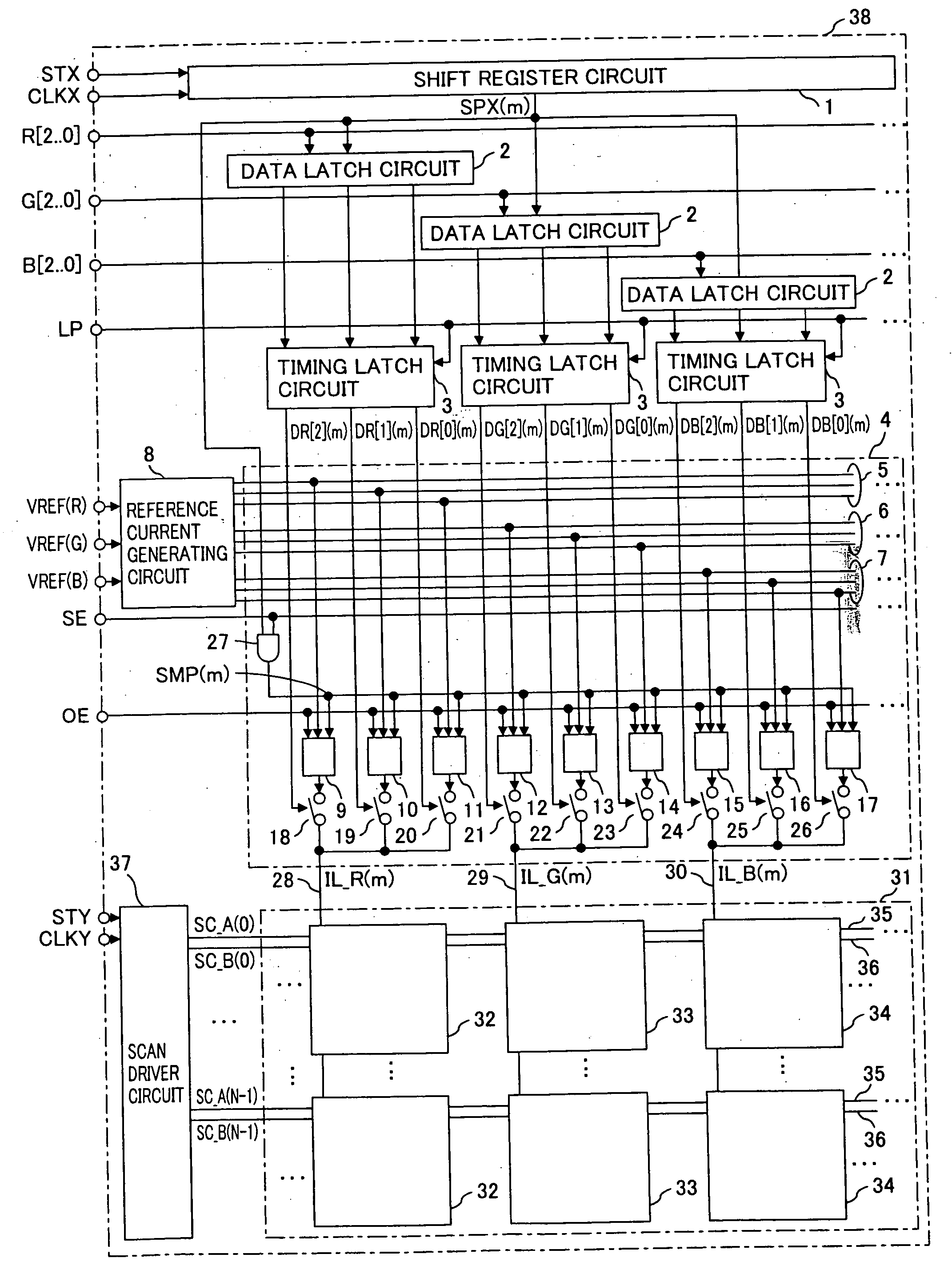

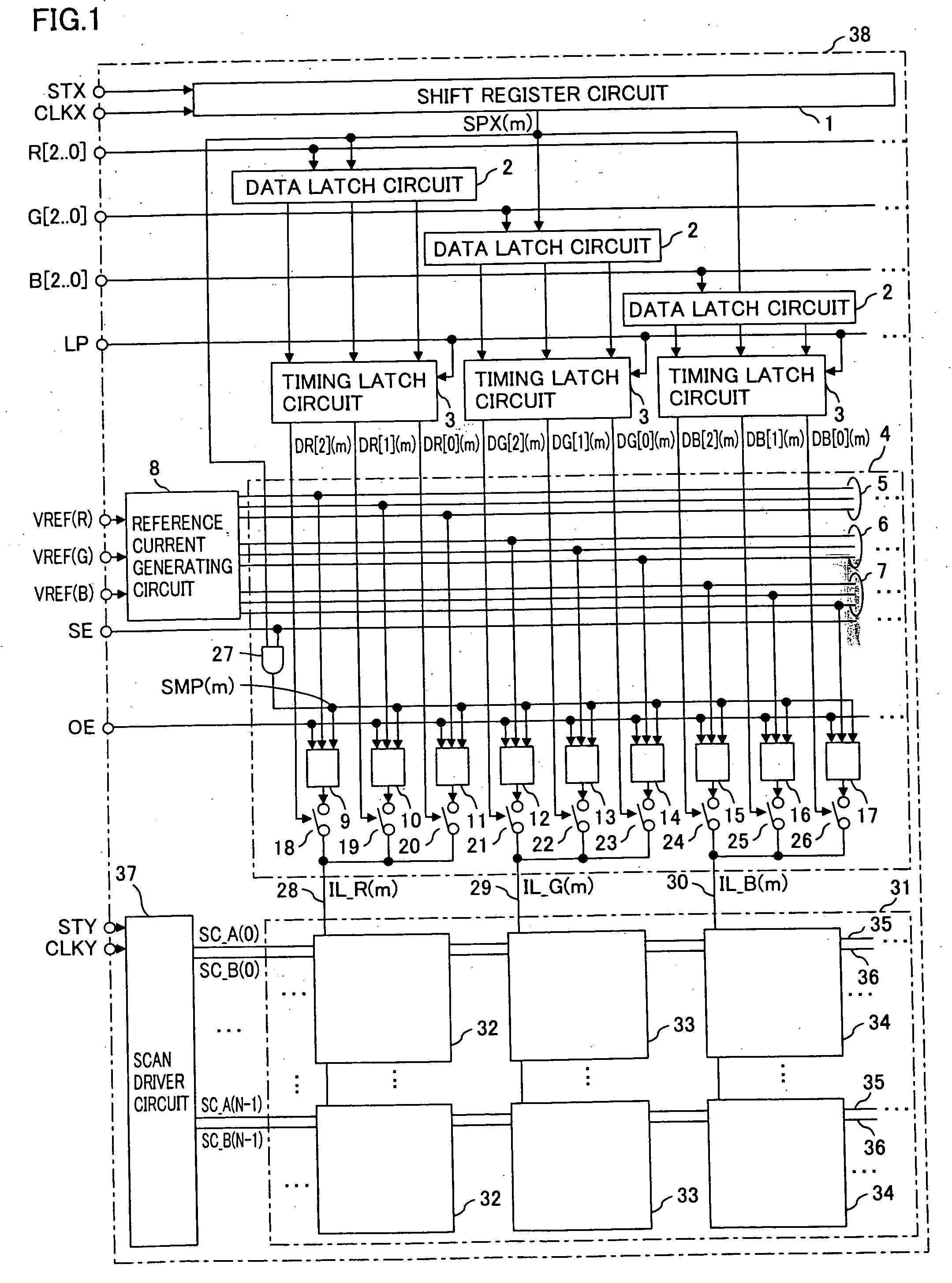

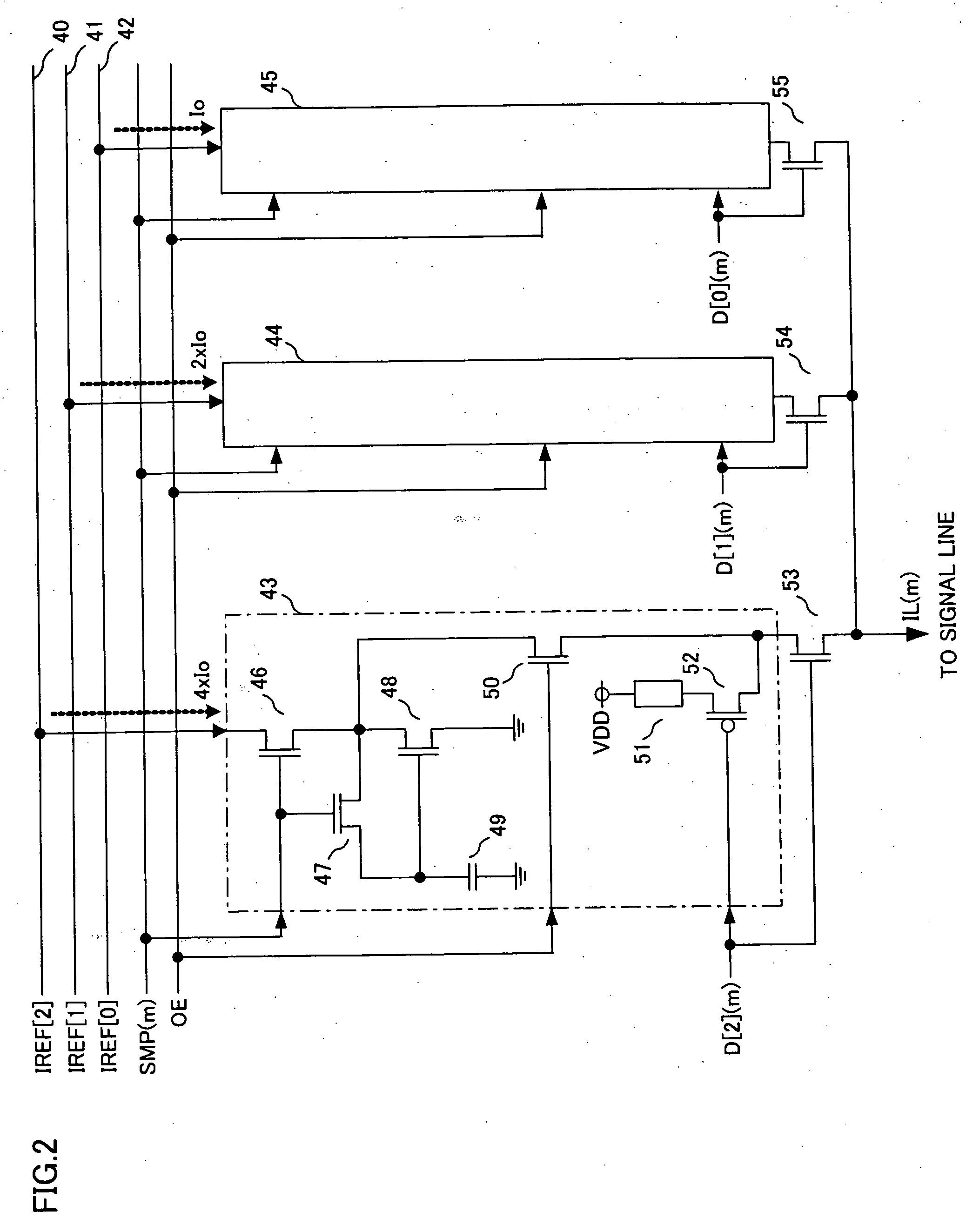

Display device

ActiveUS20050174306A1Efficient current transmitting circuitInhomogeneous suppressionStatic indicating devicesReference currentDisplay device

Owner:RAKUTEN GRP INC

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS20140169846A1Inhomogeneous suppressionSolve even heatingOhmic-resistance heating circuitsHeater elementsElectricityImage formation

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

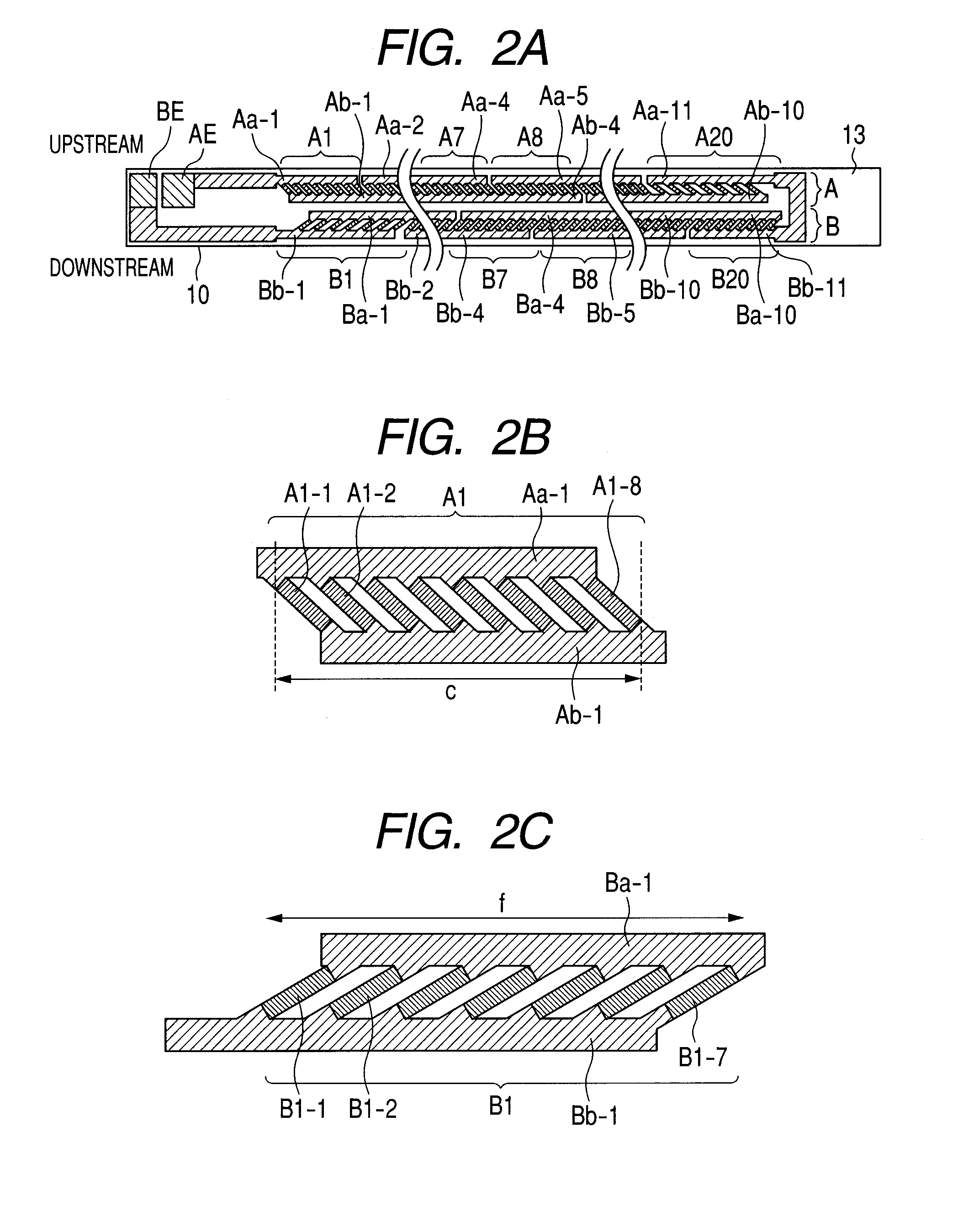

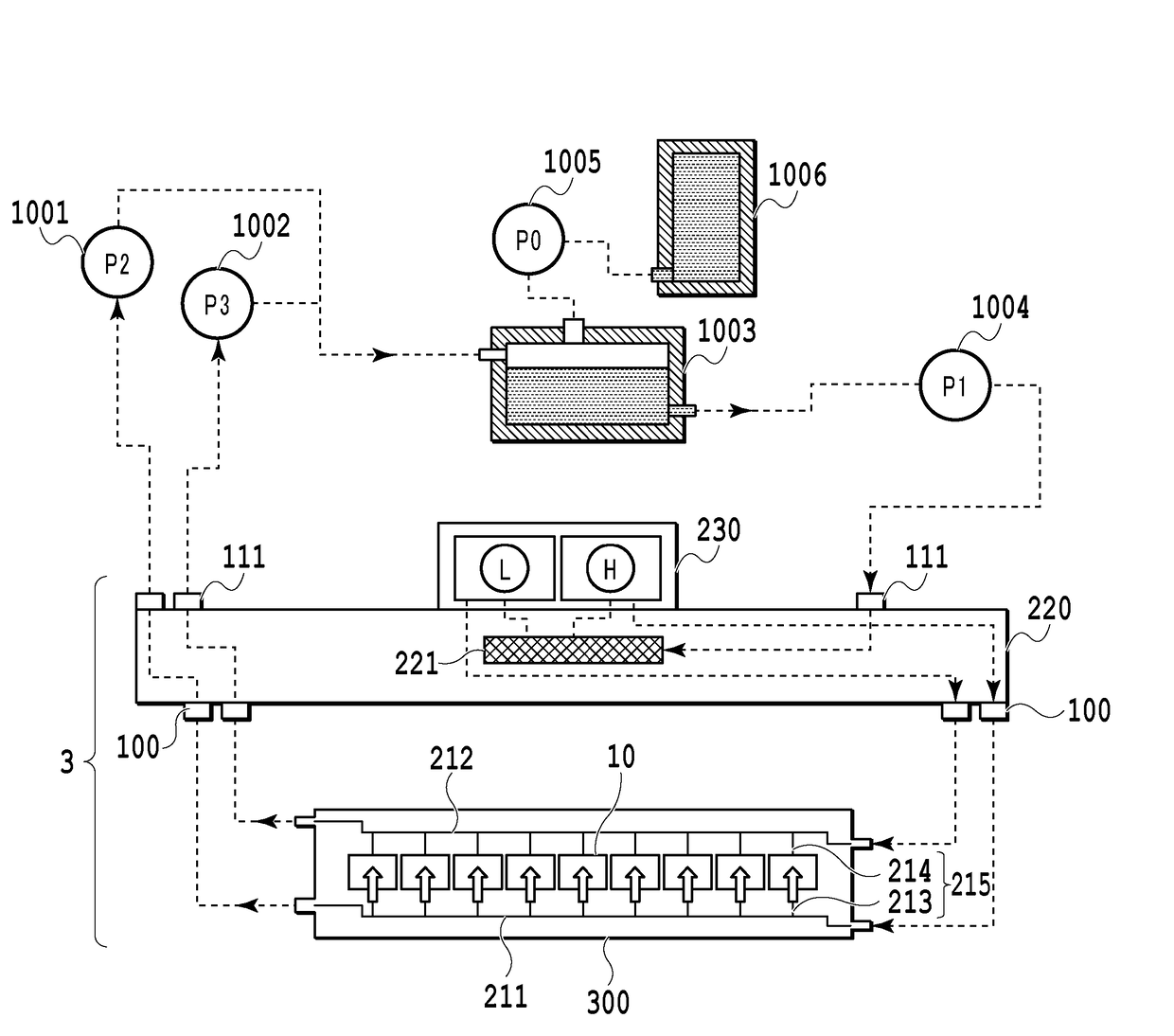

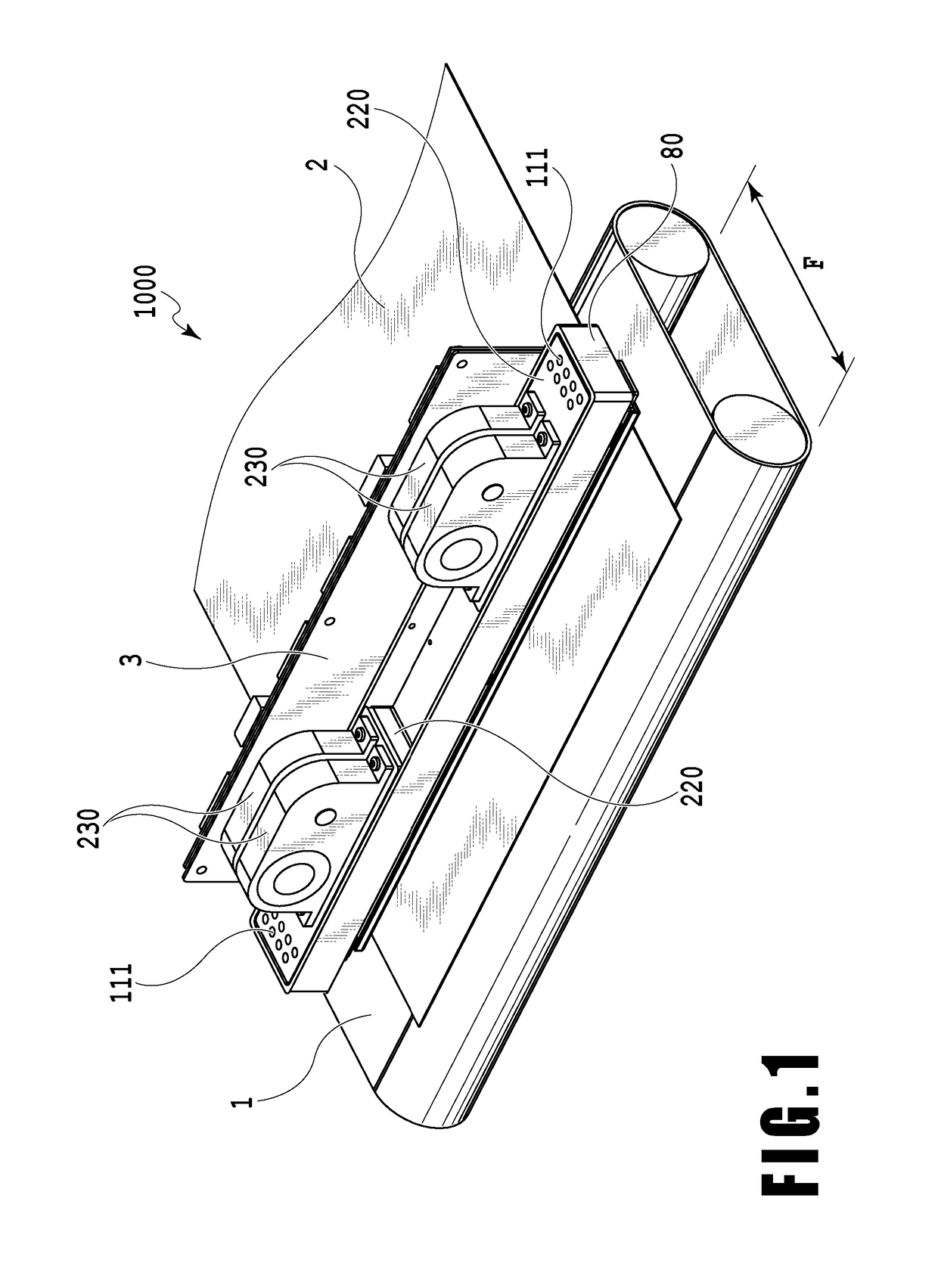

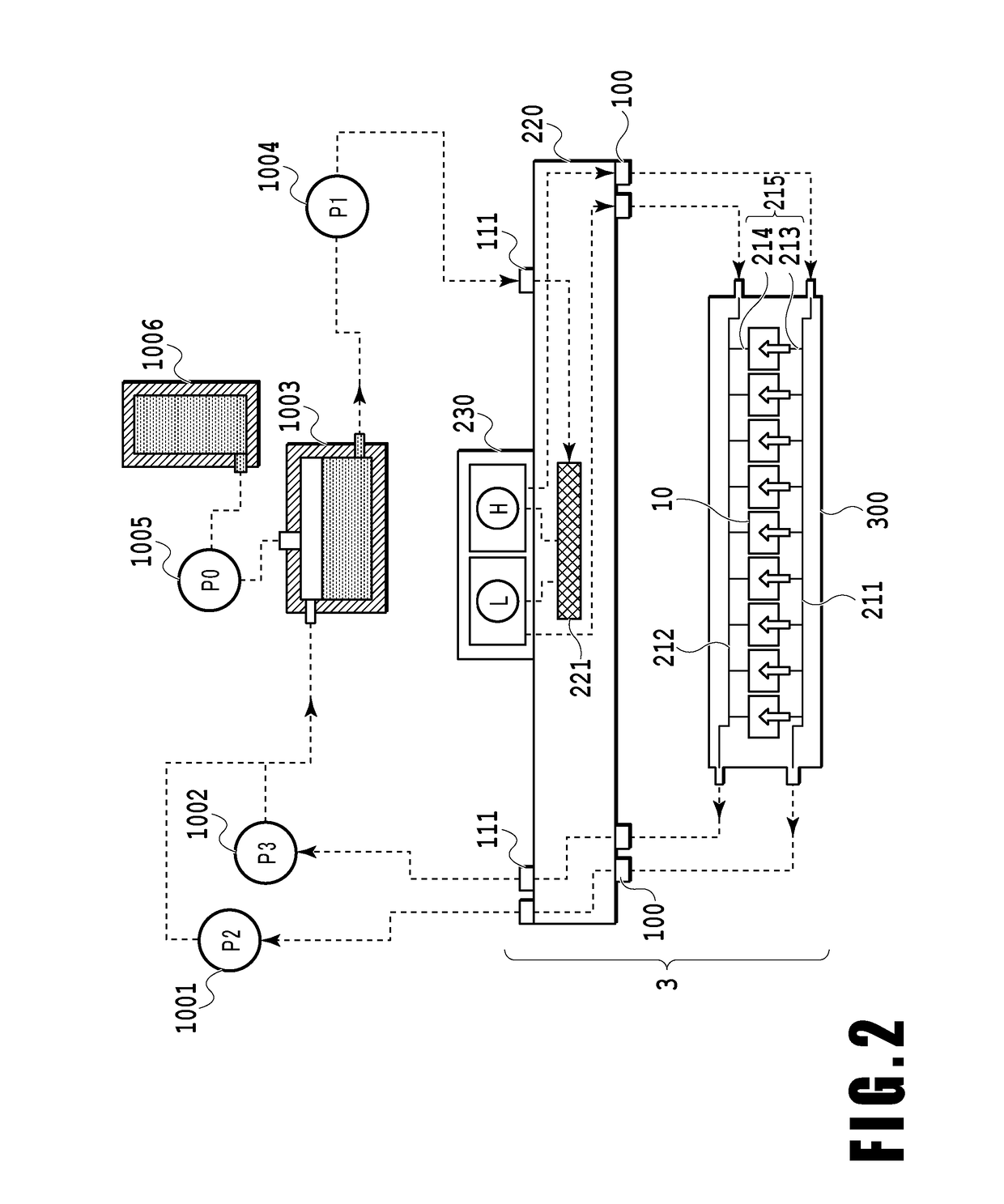

Liquid ejection printing apparatus and liquid ejection head

A liquid ejection printing apparatus includes a pressure control assembly that generates a pressure for causing the same liquid to flow to the ejection opening communication passage communicating with an ejection opening of a liquid ejection head. The pressure control assembly includes a first pressure adjustment mechanism that causes a liquid supplied from a first upstream passage to flow therefrom at a first pressure and a second pressure adjustment mechanism that causes a liquid supplied from a second upstream passage therefrom at a second pressure different from the first pressure. The first upstream passage and the second upstream passage communicate with each other and a first downstream passage communicating with the first pressure adjustment mechanism and a second downstream passage communicating with the second pressure adjustment mechanism are respectively connected to the same ejection opening communication passage communicating with the ejection opening.

Owner:CANON KK

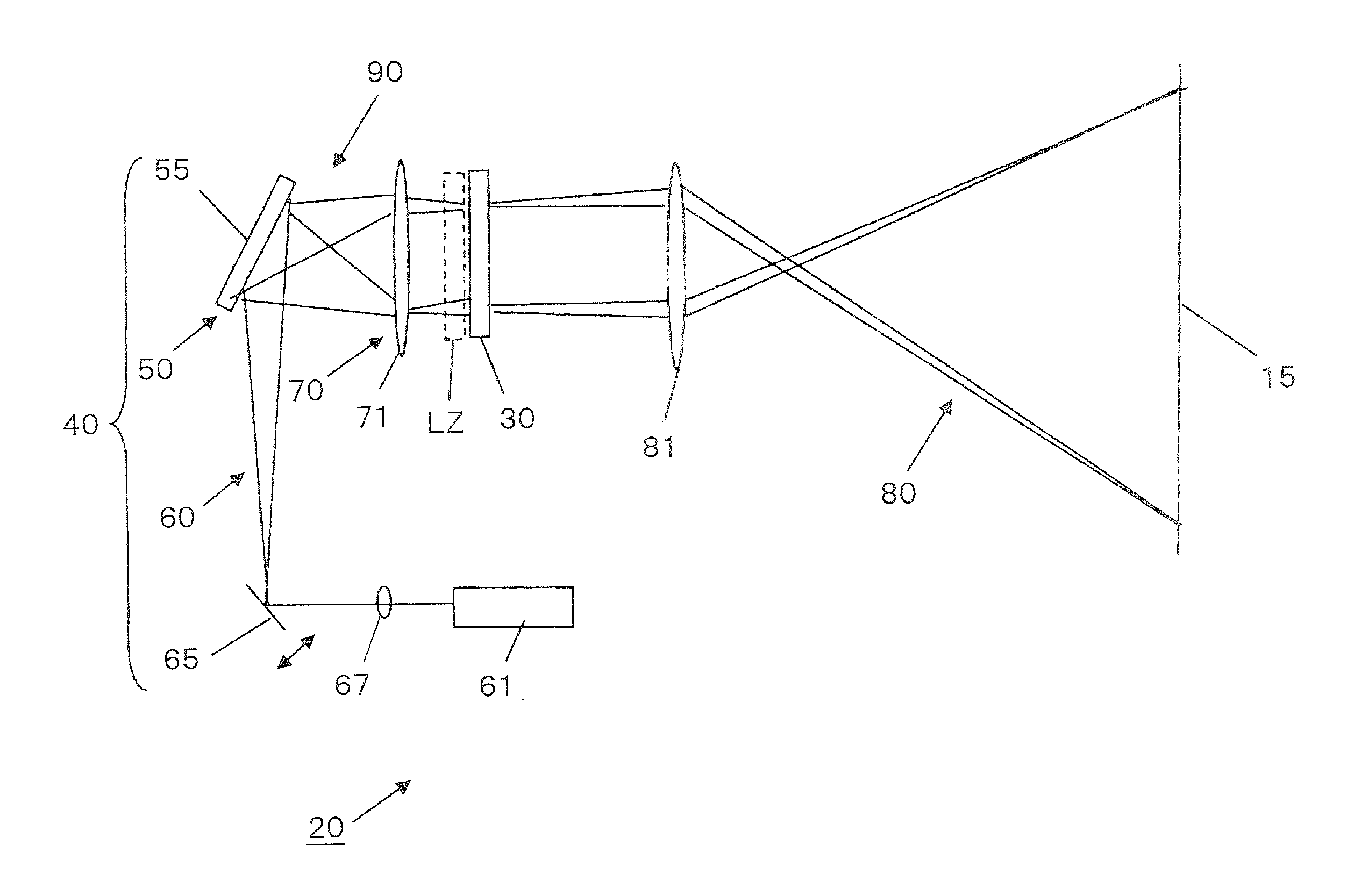

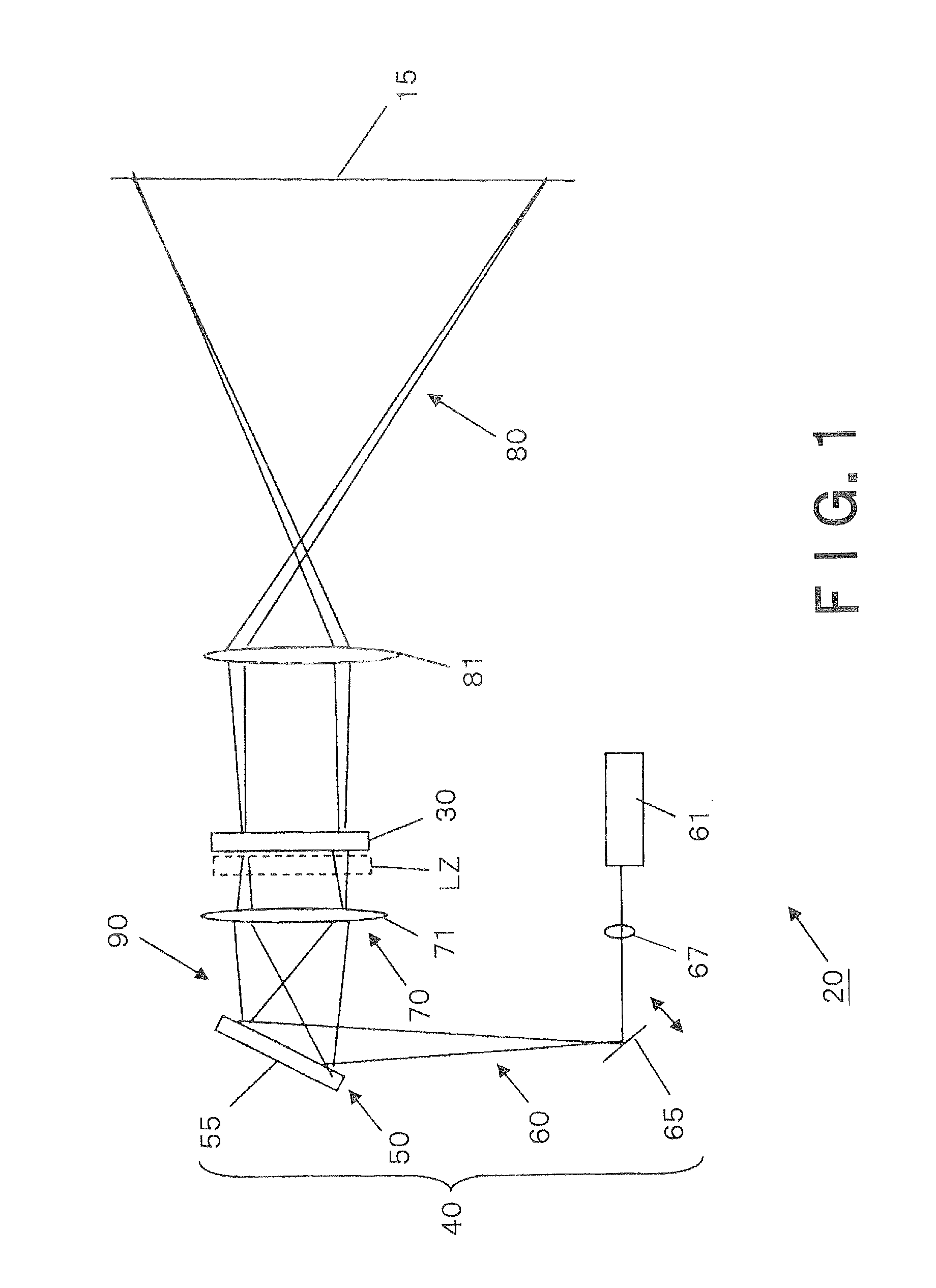

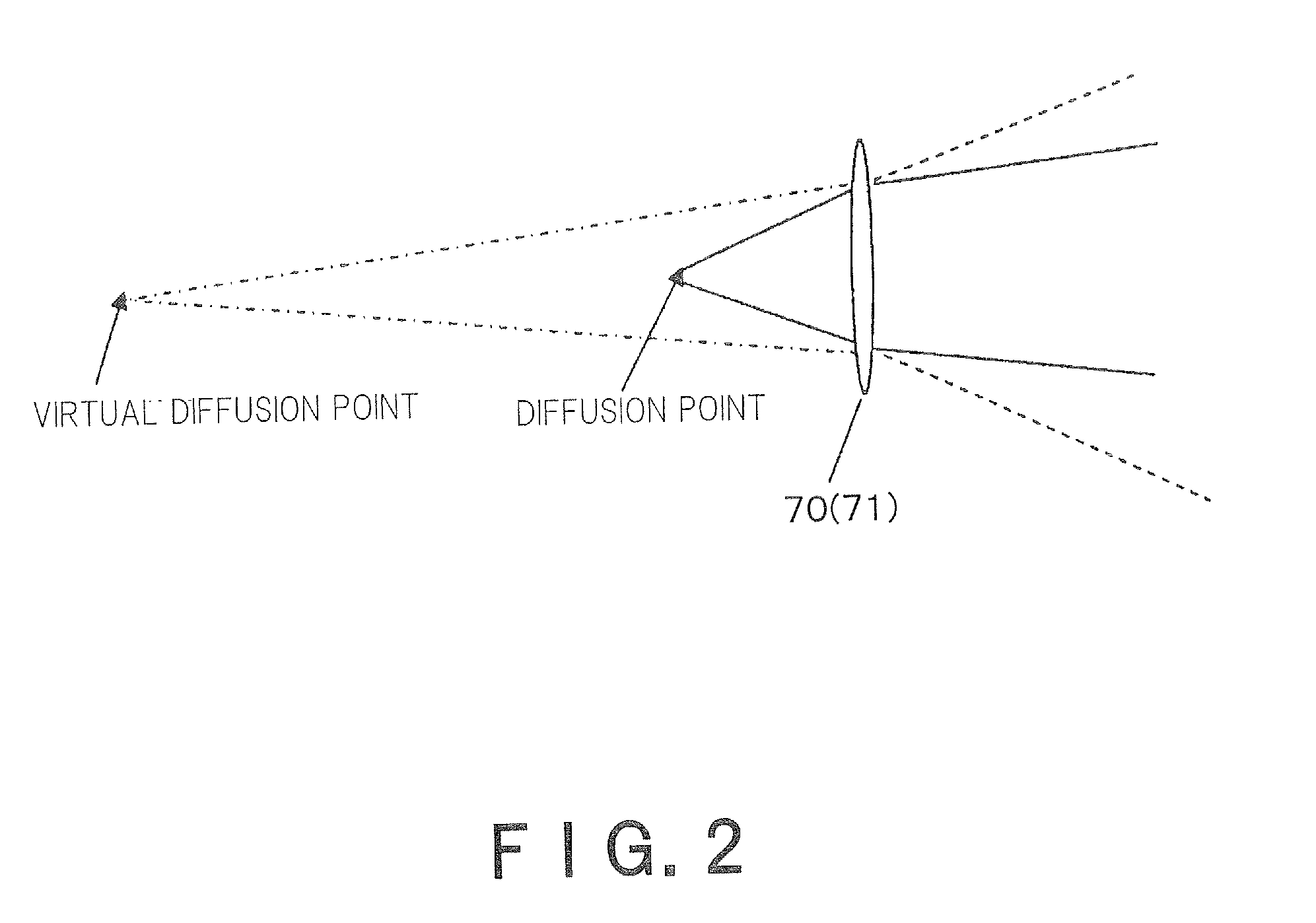

Projection apparatus and projection control apparatus

ActiveUS20140043591A1Efficient preparationInhomogeneous suppressionProjectorsColor television detailsLight beamIrradiation

A projection apparatus has an optical device configured to be capable of diffusing coherent light beams, an irradiation unit configured to irradiate the coherent light beams to the optical device so that the coherent light beams scan the optical device, a light modulator that is illuminated by coherent light beams incident on and diffused at respective points of the optical device from the irradiation unit, a projection optical system configured to project a modulated image generated by the light modulator onto a scattering plane, and an intermediate optical system provided between the optical device and the light modulator, configured to restrict an diffusion angle of coherent light beams diffused by the optical device.

Owner:DAI NIPPON PRINTING CO LTD

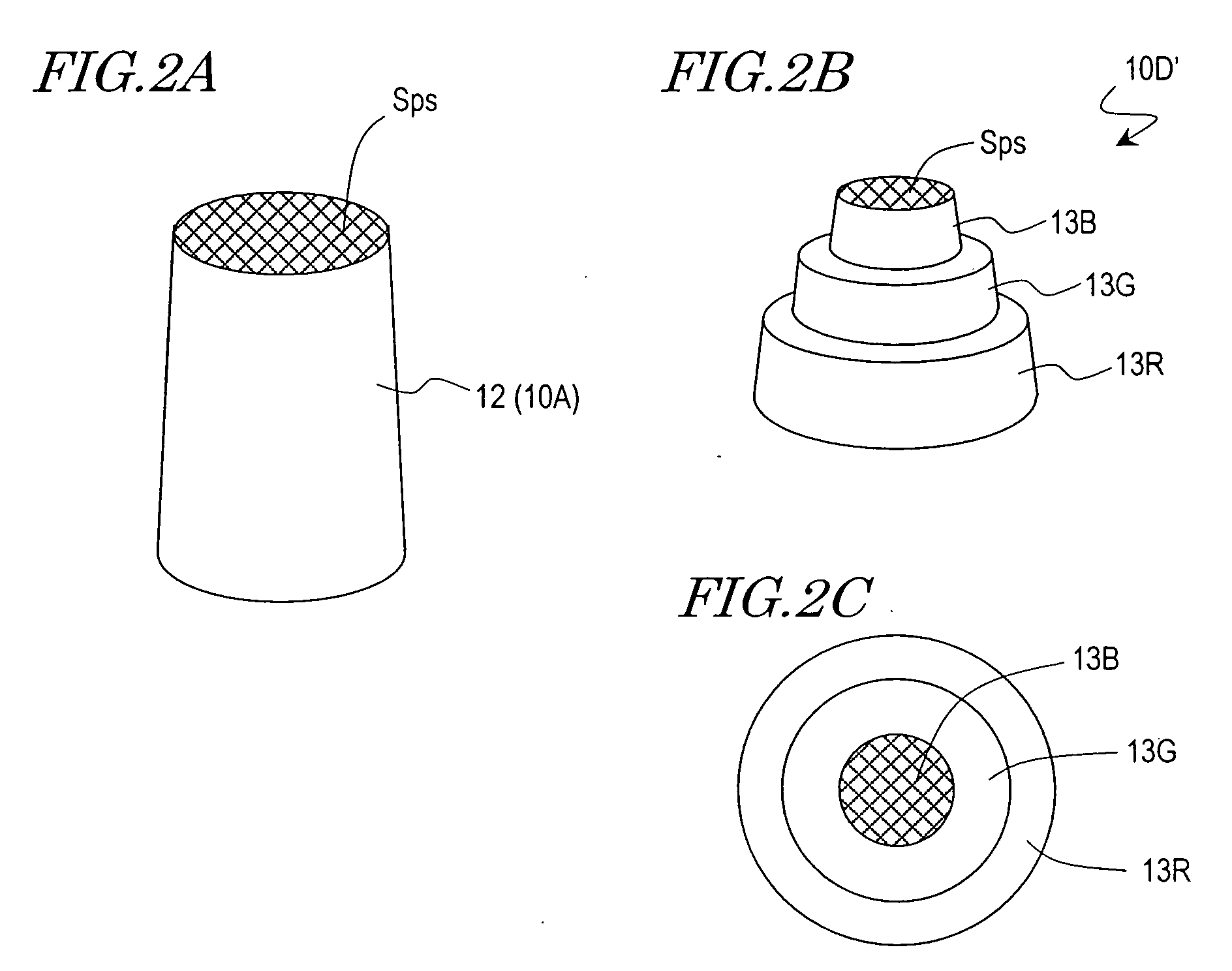

Liquid crystal display device and substrate to be used for liquid crystal display device, and methods for producing the same

InactiveUS20050270472A1Improve display qualityLittle unevenness in luminanceNon-linear opticsLiquid-crystal displayEngineering

It is intended to facilitate optimization of the configuration and distribution density of columnar spacers for realizing a liquid crystal display device having reduced low-temperature voids, lower bulging, and pressure-induced unevenness. A method of producing a substrate for a liquid crystal display device includes the steps of: providing a sample substrate; forming a columnar spacing structure sample on the sample substrate, the columnar spacing structure having at least one resin layer; determining a spring modulus k0(mN / μm) of the columnar spacing structure sample and a cross-sectional area Sps0 of a smallest portion of the columnar spacing structure sample, and calculating a spring modulus Kps(=k0 / Sps0) of the columnar spacing structure sample per unit area; and with respect to an area S of a display region of the liquid crystal display device, a cross-sectional area Sps of a smallest portion of a columnar spacing structure to be formed on the substrate for the liquid crystal display device, and a number n of columnar spacing structures in the display region, prescribing the number n of columnar spacing structures and the cross-sectional area Sps of the smallest portion so that a spring modulus Kpt per unit area of display region, defined as Kps×(Sps×n / S), is within a range of no less than 0.00008 mN / μm3 and no more than 0.00237 mN / μm3.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com