Patents

Literature

50results about How to "Excellent resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

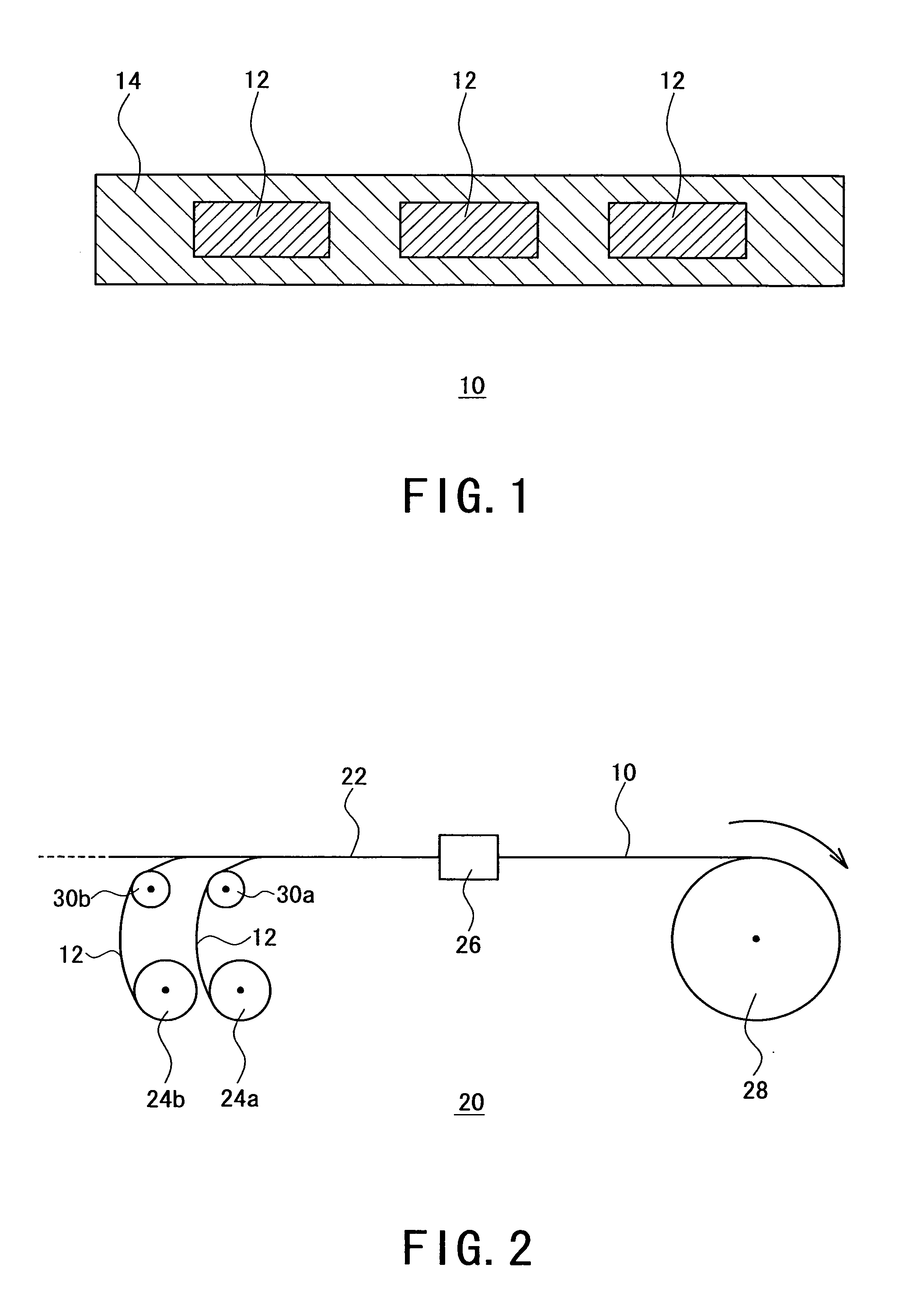

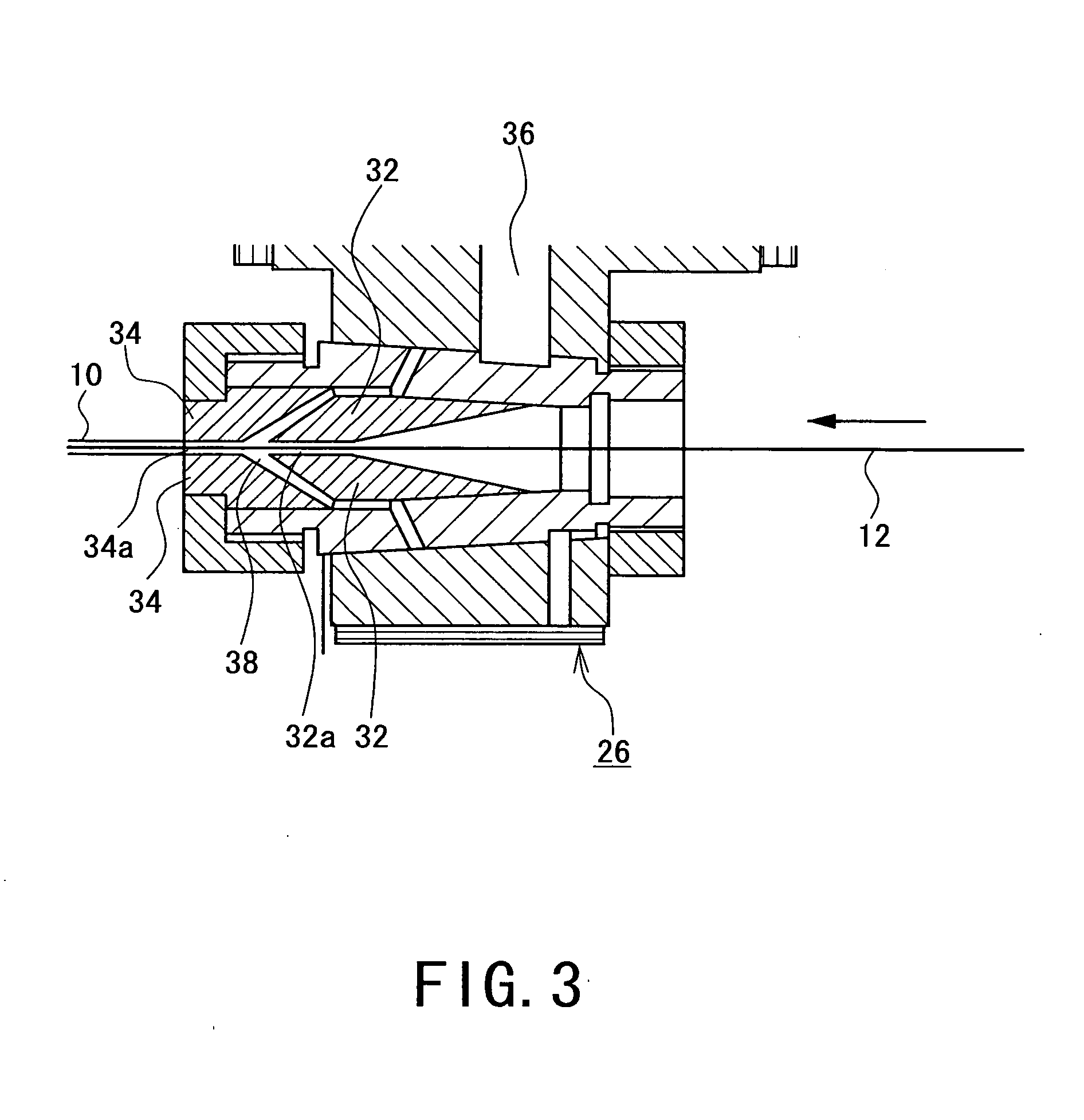

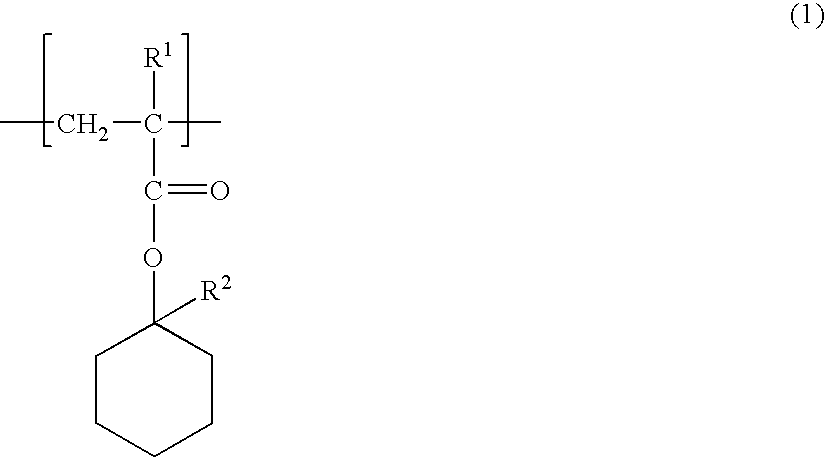

Process for producing laminated exfoliated graphite composite-metal compositions for fuel cell bipolar plate applications

InactiveUS20090151847A1Excellent resistanceHigh areal conductivityNon-conductive material with dispersed conductive materialDomestic articlesElectrically conductiveGraphite composite

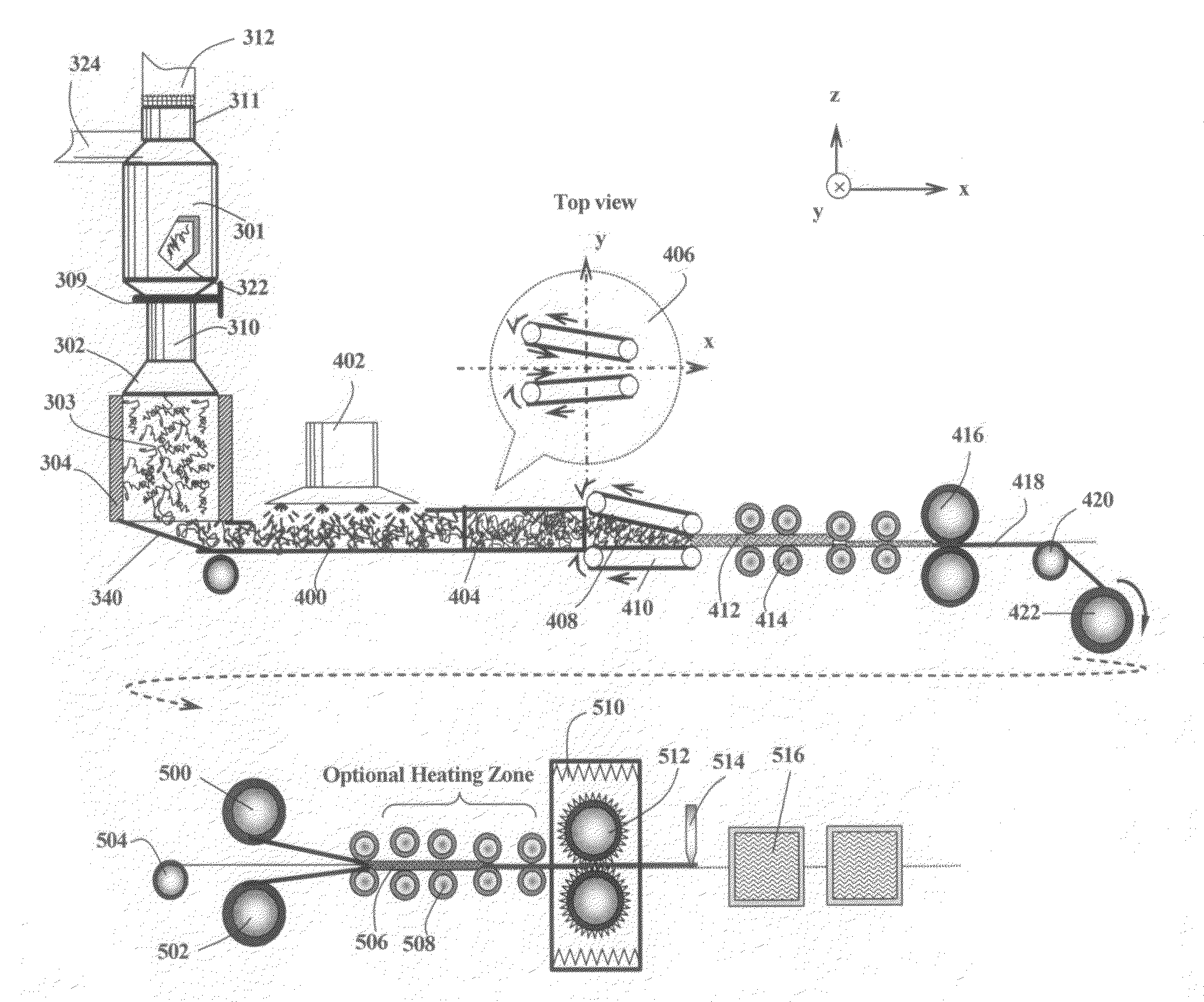

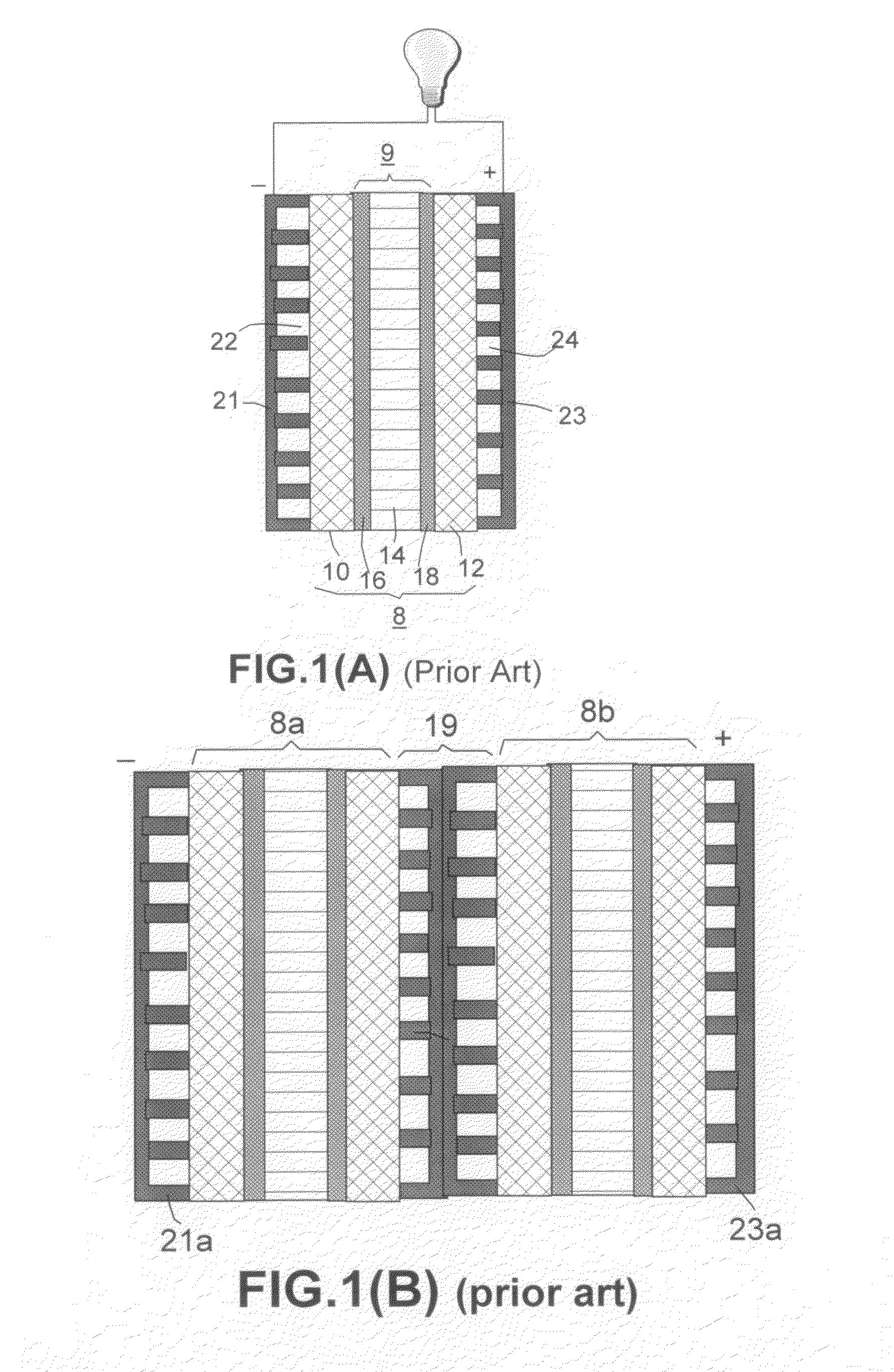

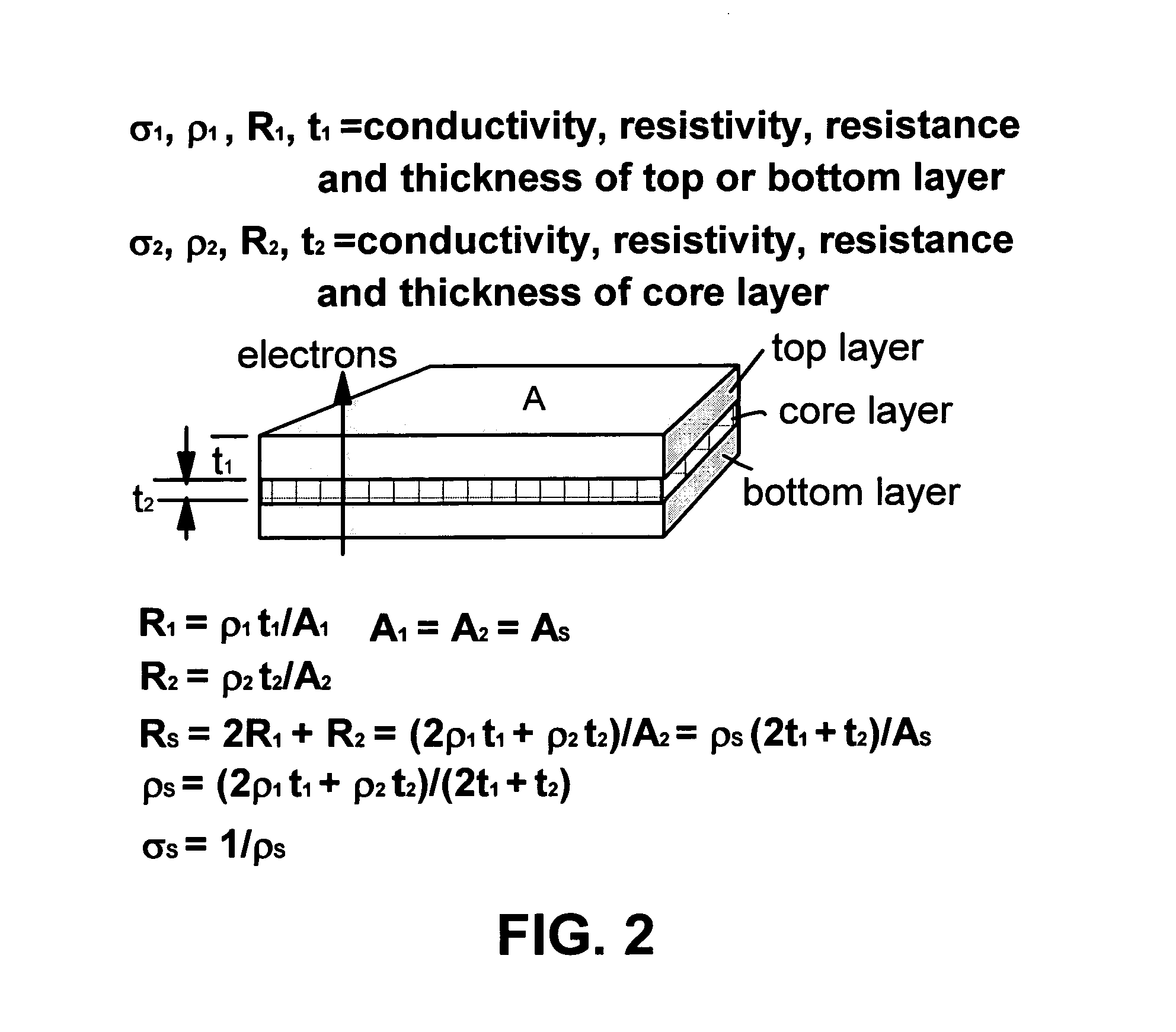

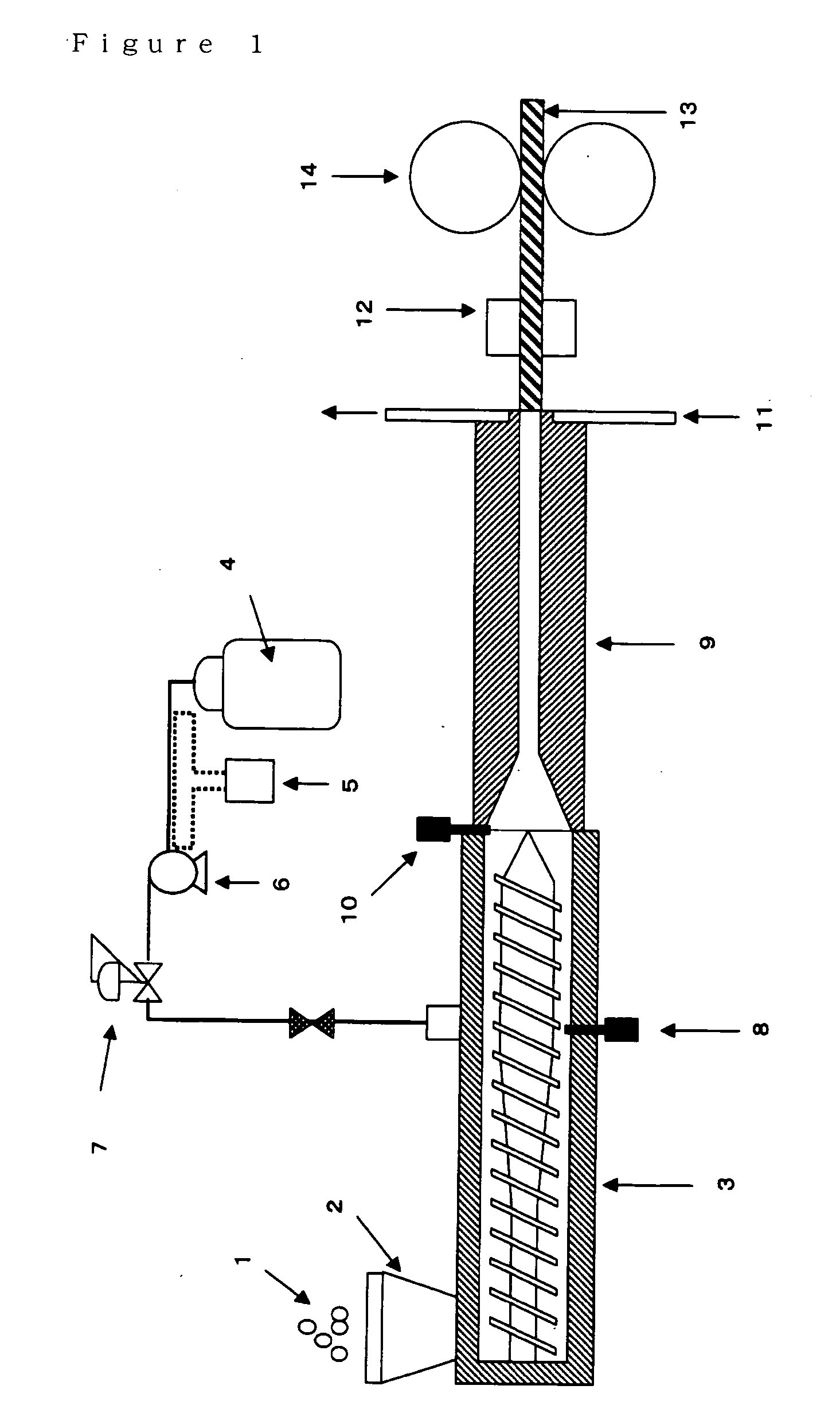

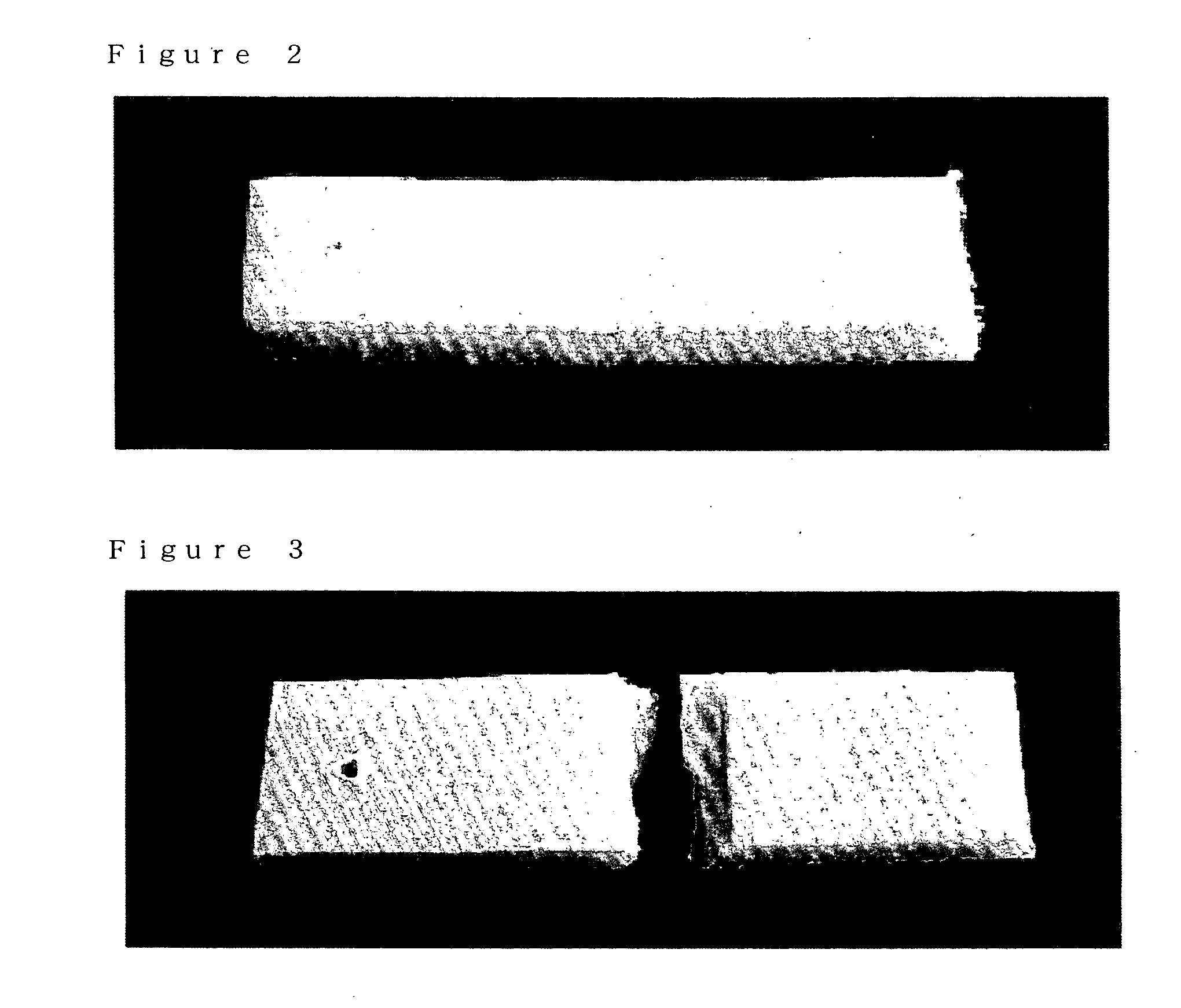

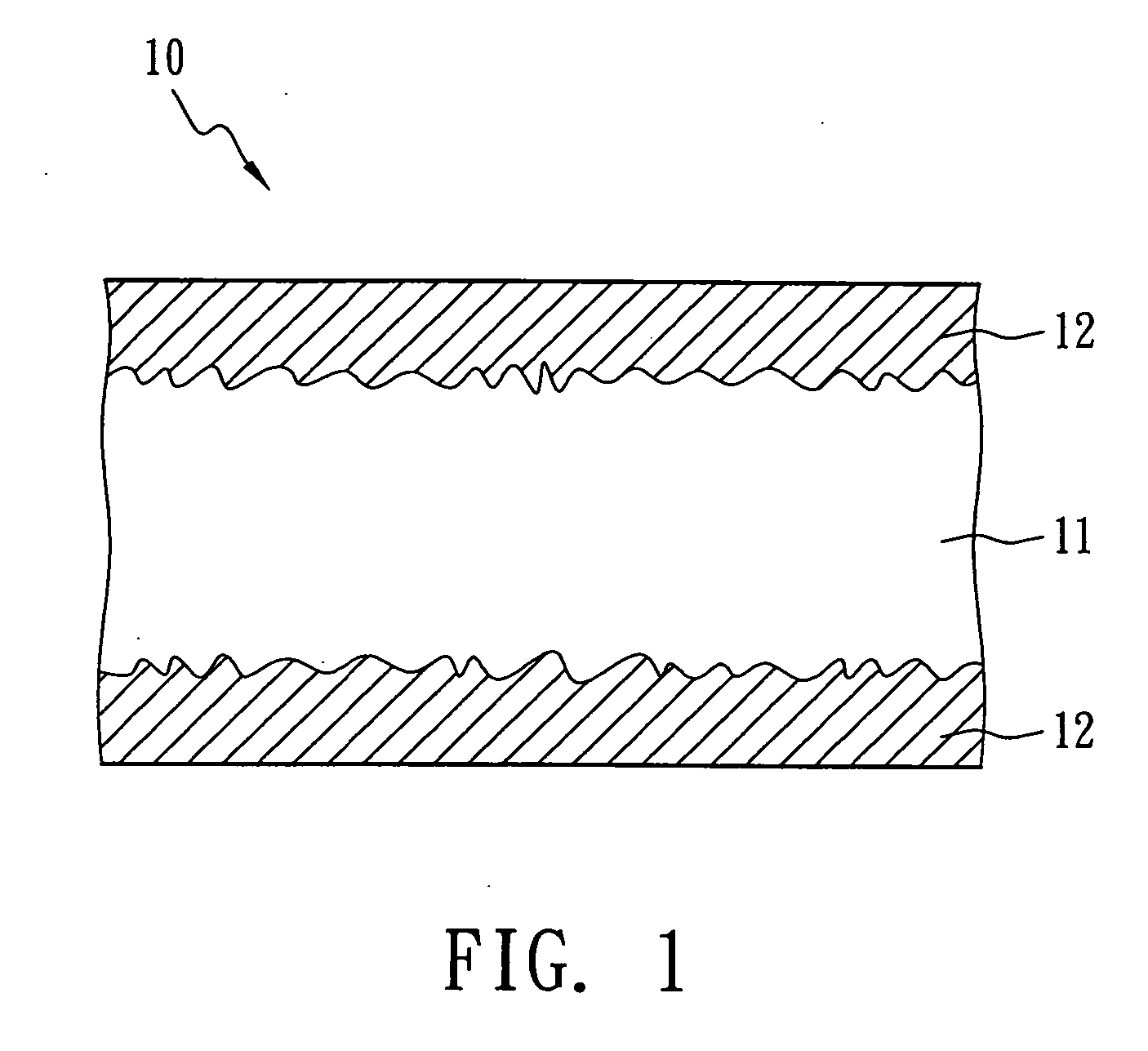

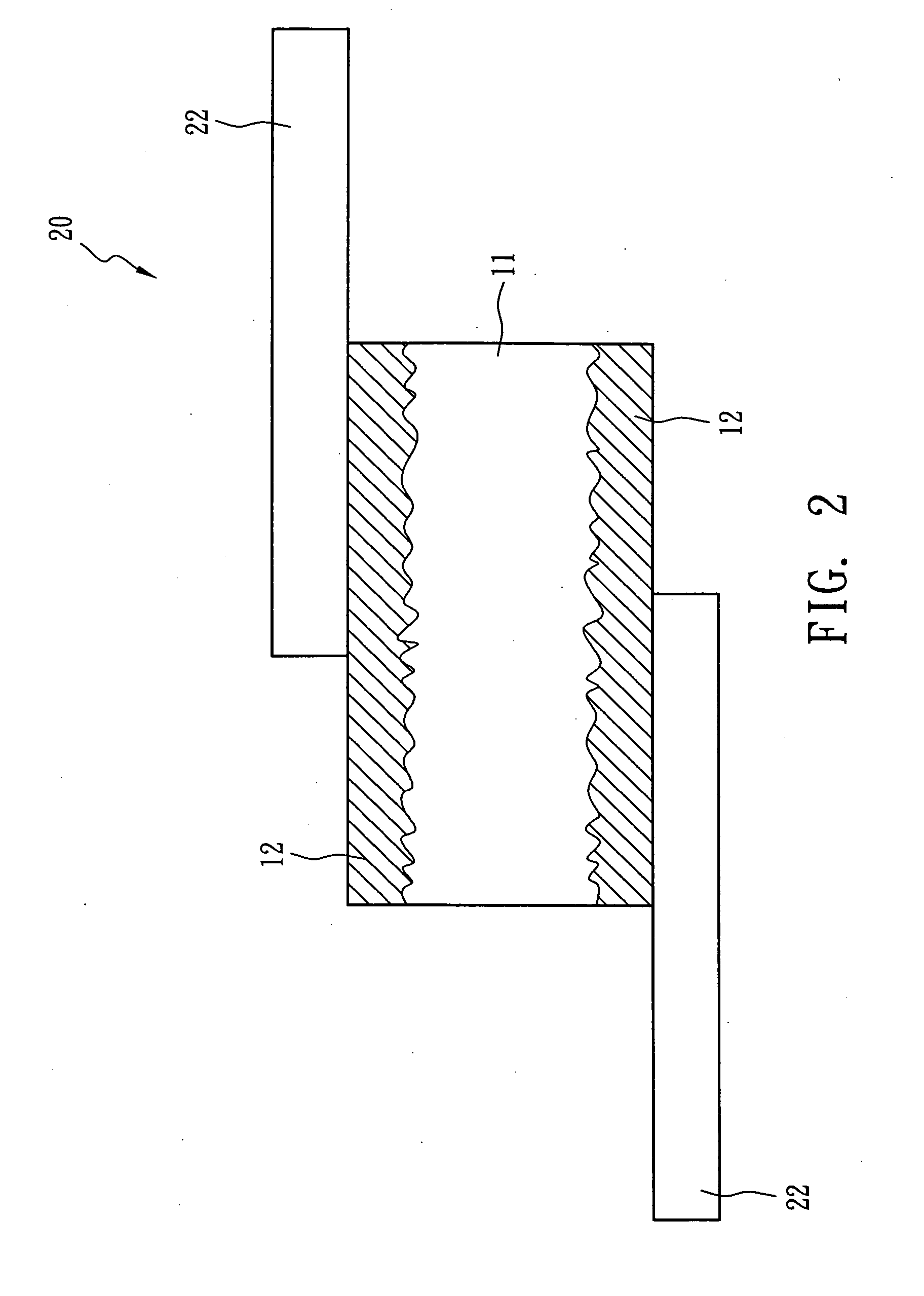

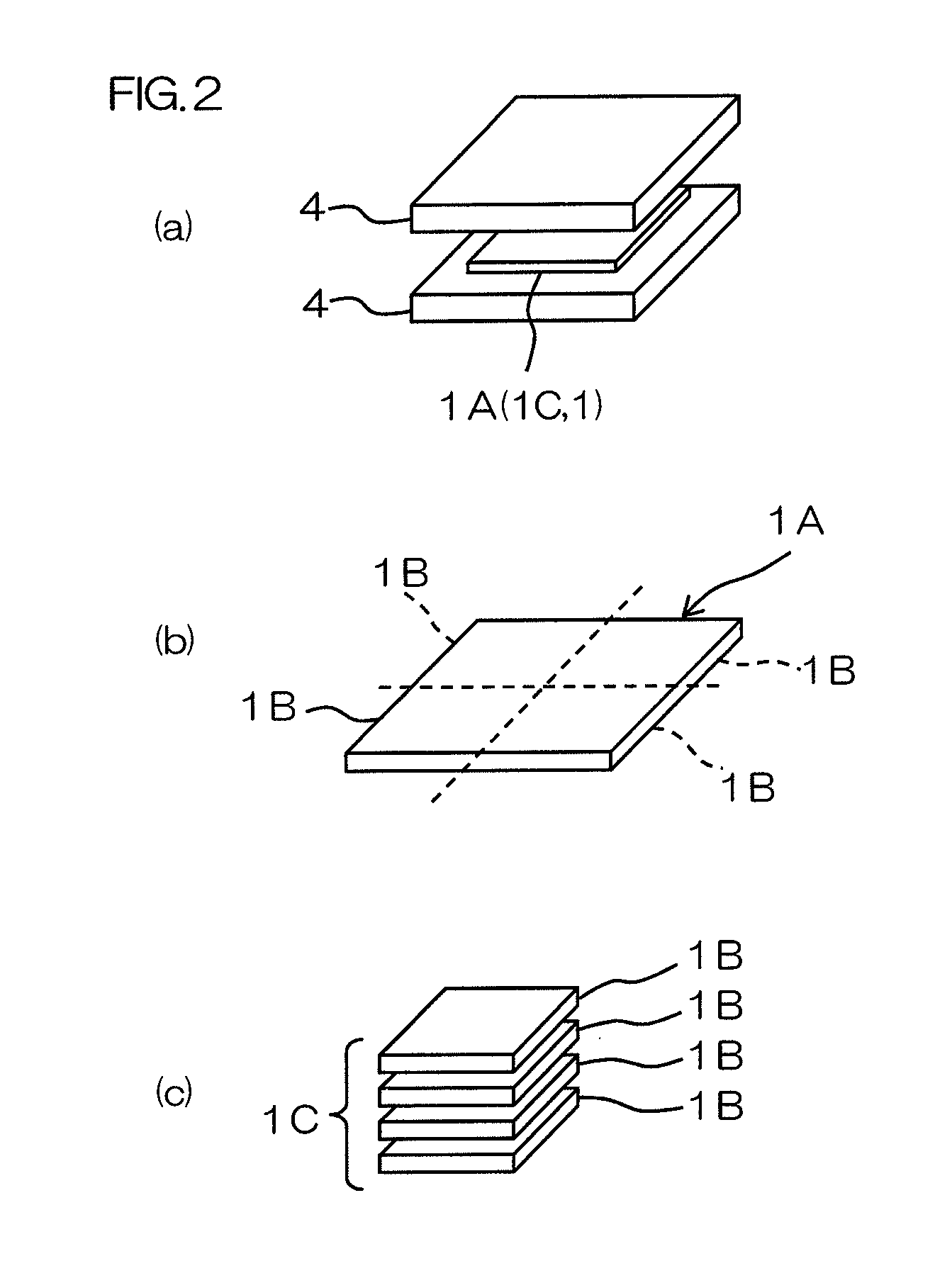

A process for producing an electrically conductive laminate composition for fuel cell flow field plate or bipolar plate applications. The process comprises: (a) feeding a thin metal sheet, having a first surface and a second surface, into a consolidating zone; and (b) feeding a first exfoliated graphite composite sheet onto the first surface of the metal sheet to form a two-layer precursor laminate in this consolidating zone; wherein the exfoliated graphite composite sheet comprises (i) expanded or exfoliated graphite and (ii) a binder or matrix material to bond the expanded graphite to form a cohered. The process preferably further comprises (c) feeding a second exfoliated graphite composite sheet onto the second surface of the metal sheet to form a three-layer precursor laminate. Both the first and second exfoliated graphite composite sheet may further comprise particles of non-expandable graphite or carbon in the amount of between 3% and 60% by weight based on the total weight of the non-expandable particles and the expanded graphite. Surface flow channels and other desired geometric features can be built onto the exterior surfaces of the laminate to form a flow field plate or bipolar plate by a procedure such as in-line embossing or molding. The resulting laminate has an exceptionally high thickness-direction conductivity and excellent resistance to gas permeation.

Owner:NANOTEK INSTR GRP LLC

Printing method using ink jet recording

InactiveUS20120176455A1Excellent resistanceConcentration unevenness be suppressDuplicating/marking methodsInksChemistryLiquid composition

Printing is performed on a non-ink absorbing or low-ink absorbing recording medium, by providing a drying process, using an aqueous ink composition at least containing glycol ethers having an HLB value calculated by the Davis method in the range of 4.2 to 8.0 and 1,2-alkyldiols having 4 to 8 carbon atoms and a liquid composition at least containing glycol ethers having an HLB value calculated by the Davis method in the range of 4.2 to 8.0 and 1,2-alkyldiols having 4 to 8 carbon atoms.

Owner:SEIKO EPSON CORP

Formed article, method for producing the formed article, member for electronic device, and electronic device

ActiveUS20120064321A1Excellent gas barrier capabilityExcellent resistanceSynthetic resin layered productsVacuum evaporation coatingOxygen atomChemistry

A formed article includes a gas barrier layer that is formed of a material including at least an oxygen atom and a silicon atom, a surface area of the gas barrier layer having an oxygen atom content rate of 60 to 75%, a nitrogen atom content rate of 0 to 10%, and a silicon atom content rate of 25 to 35%, based on the total content of oxygen atoms, nitrogen atoms, and silicon atoms, and having a film density of 2.4 to 4.0 g / cm3. A method of producing a formed article includes implanting ions into a surface layer part of a polysilazane compound-containing layer of a formed body that includes the polysilazane compound-containing layer in its surface layer part. An electronic device member includes the formed article. An electronic device includes the electronic device member. The formed article exhibits an excellent gas barrier capability, excellent folding resistance, and excellent transparency.

Owner:LINTEC CORP

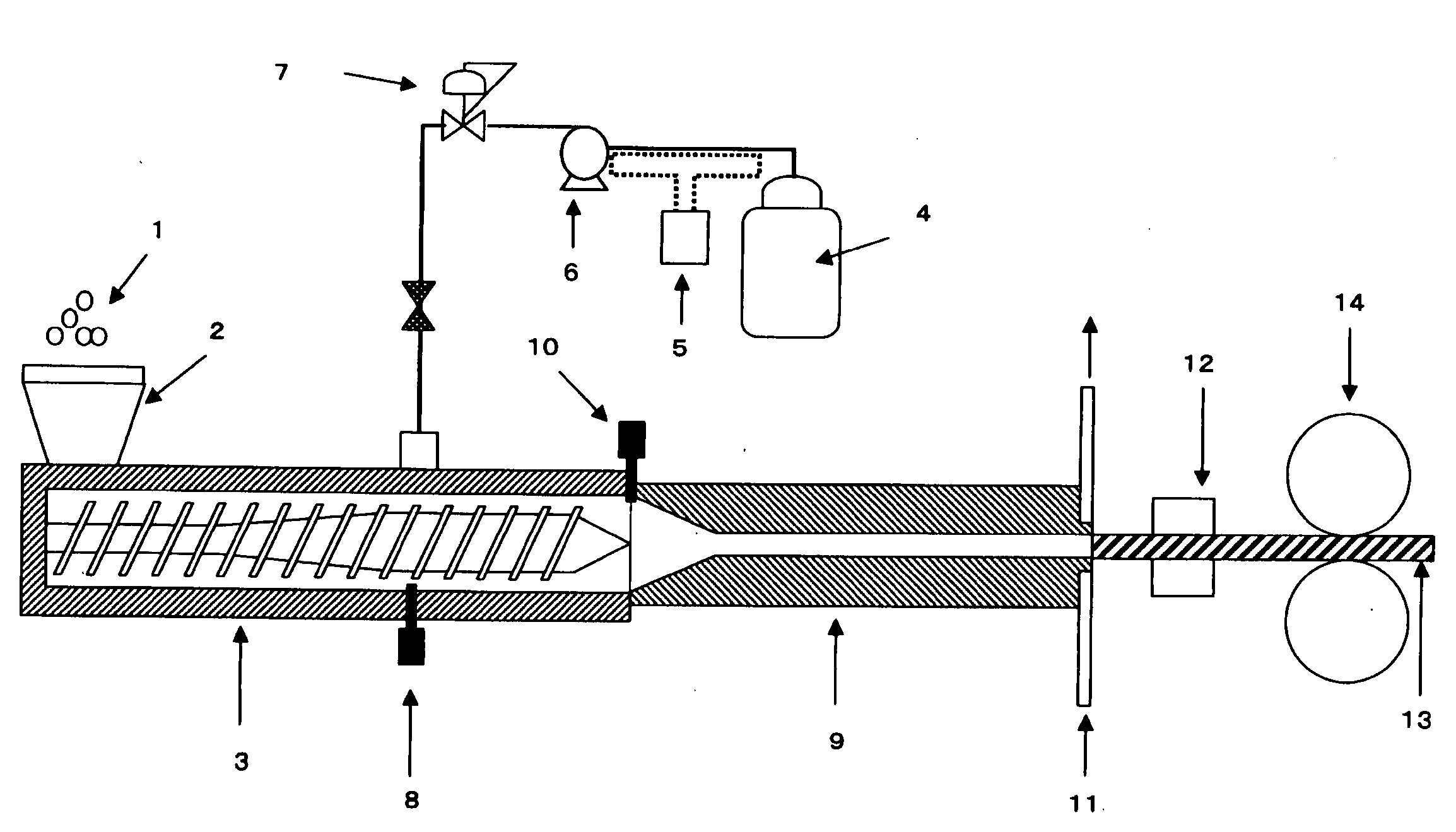

Foam of ultra high molecular weight polyethylene and process for the preparation of the same

InactiveUS20060234033A1Good external appearanceExcellent resistanceLayered productsThin material handlingPliabilityLubrication

The expanded product of the present invention is an expanded product having a density of from 0.02 to 0.7 g / cm3, which is obtained by expanding ultra-high-molecular-weight polyethylene having a viscosity average molecular weight of from 300,000 to 10,000,000. This expanded product can be prepared by adding carbon dioxide to ultra-high-molecular-weight polyethylene in the molten state in an extruder, and expanding the resin by extrusion such that each of the surface temperature and the central part temperature of the resin immediately after discharge from the die may be a predetermined temperature, while at the same time setting the residence time and pressure of the resin at the die section to specific values. Based on these, the invention provides an expanded product with good external appearance, having a skin layer to which the functions such as light weight, insulating property, sound absorption, low dielectric constant, impact absorption, flexibility and the like can be imparted without significantly deteriorating the excellent features of abrasion resistance, self-lubrication, impact strength, cryogenic properties and chemical resistance that are inherent to ultra-high-molecular-weight polyethylene; and a process for preparation of the expanded product stably.

Owner:MITSUI CHEM INC

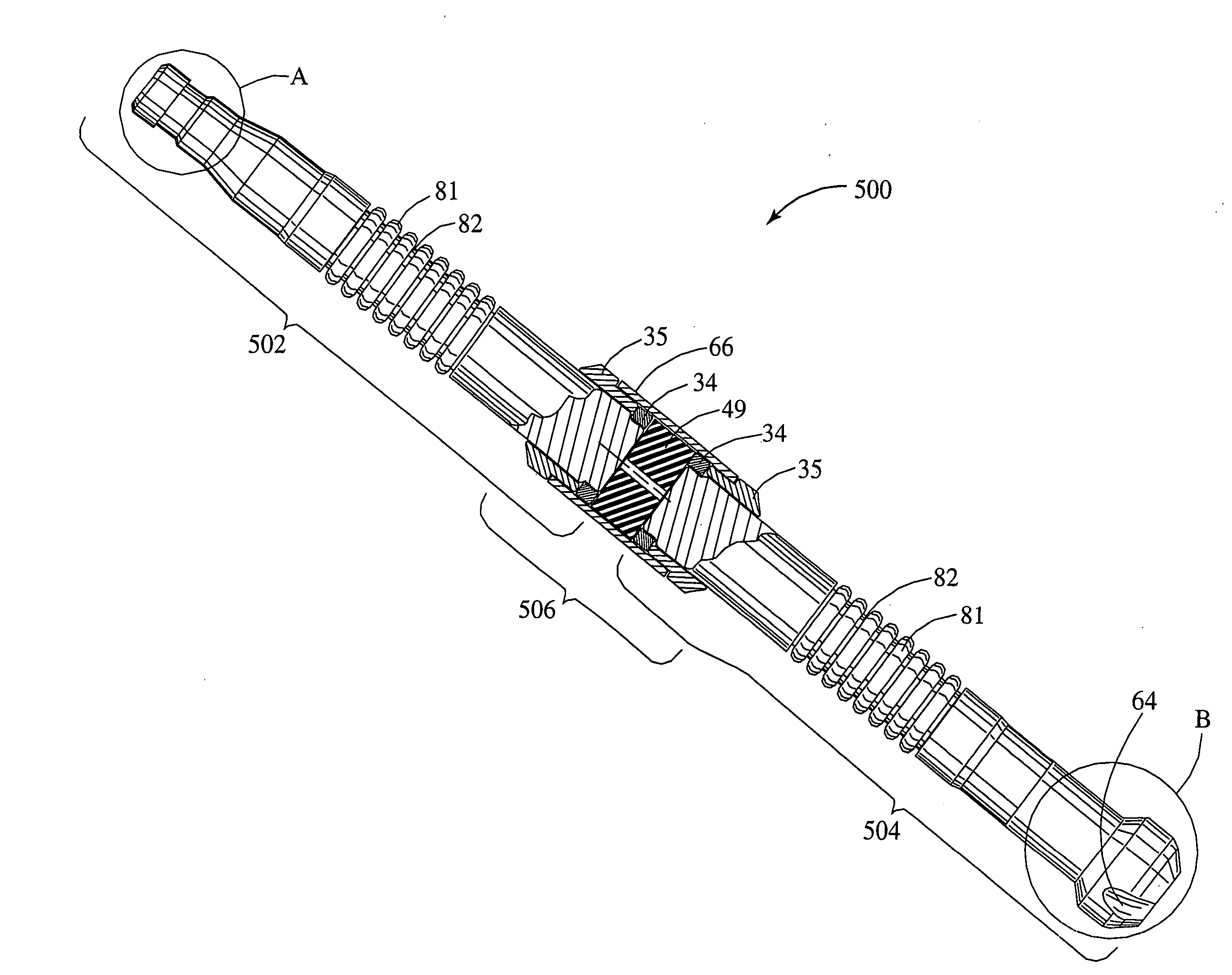

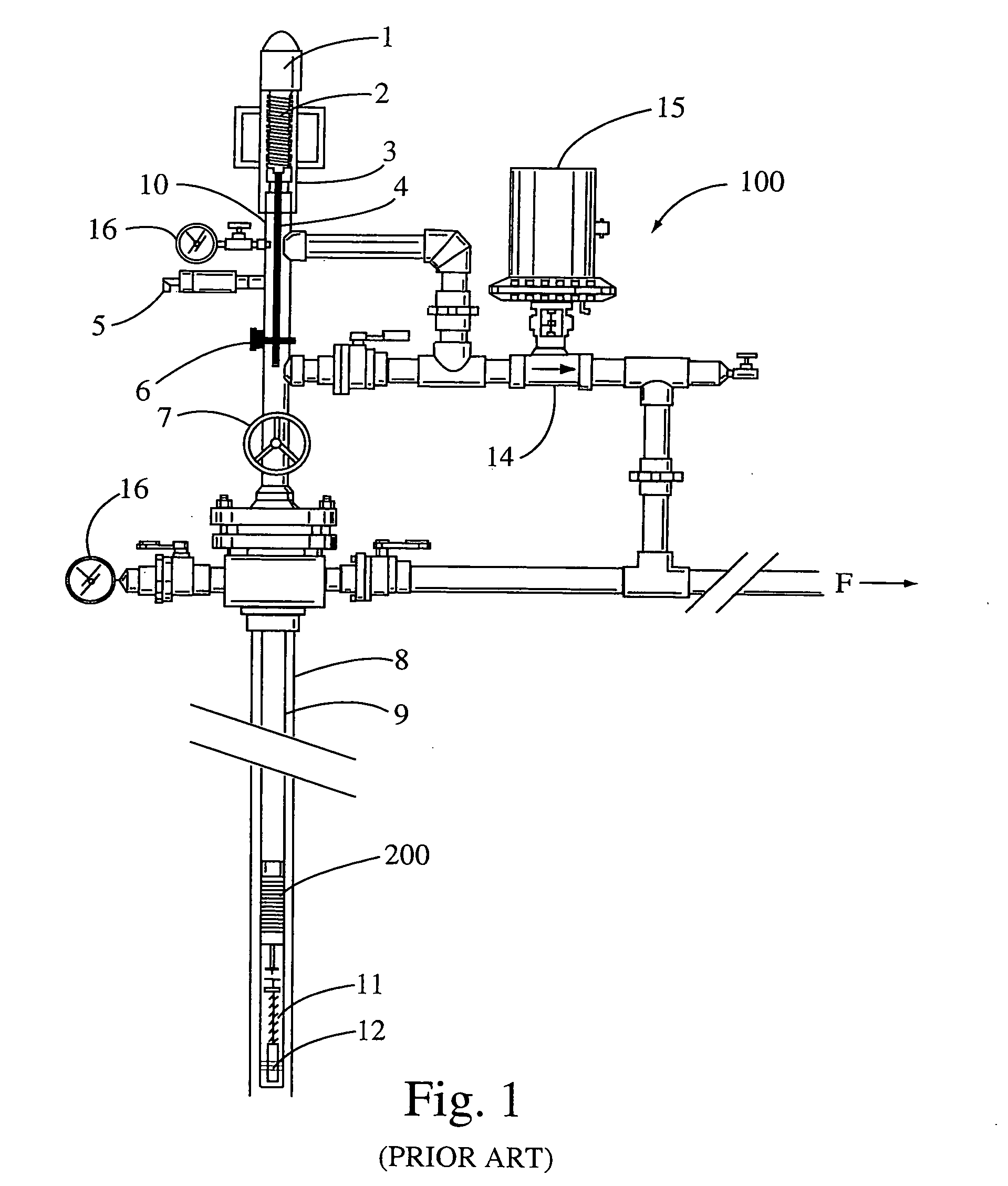

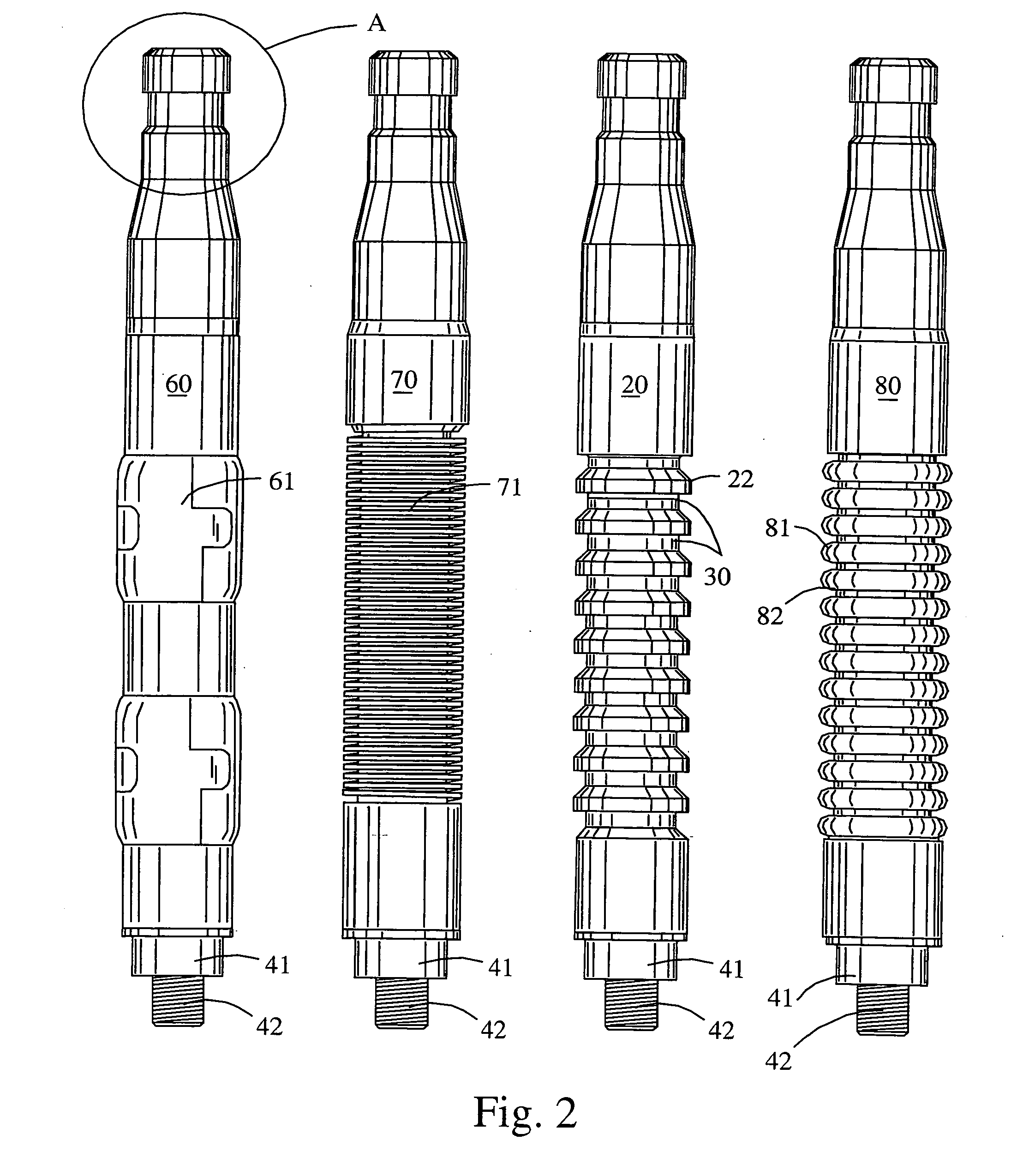

Internal shock absorber plunger

ActiveUS20060124292A1Increase lifeExcellent resistanceDrilling rodsPositive displacement pump componentsWave shapeCoil spring

An improved plunger mechanism apparatus has an internal shock absorber to increase plunger life and increases life of components found at a top and well bottom. The internal shock absorber can be an elastomer spring, die coil spring or wave spring. An actuator rod within the plunger hits the bottom of the well and compresses the internal spring, absorbing all or part of the impact shock. Likewise, when a plunger rises to the well top with a high velocity, damage is avoided as the top of the plunger hits well top apparatus. Reduction in well bottom bumper spring collapses, spring damage, and plunger damage is obtained. Damage to well bottoms having no bumper springs is avoided. Efficiency of well flow is increased by the increase in the reliability of the well operation.

Owner:PCS FERGUSON

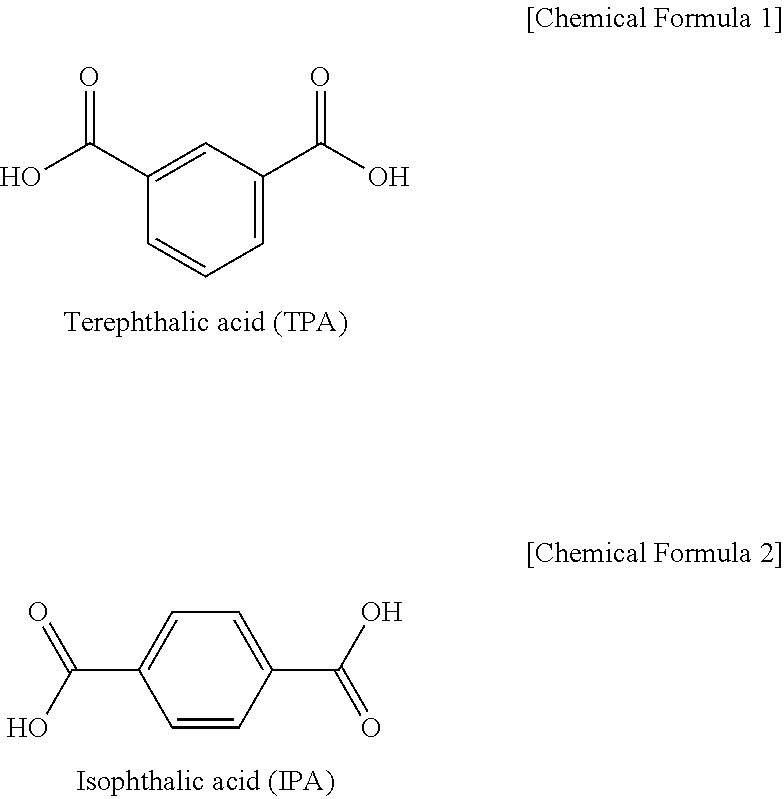

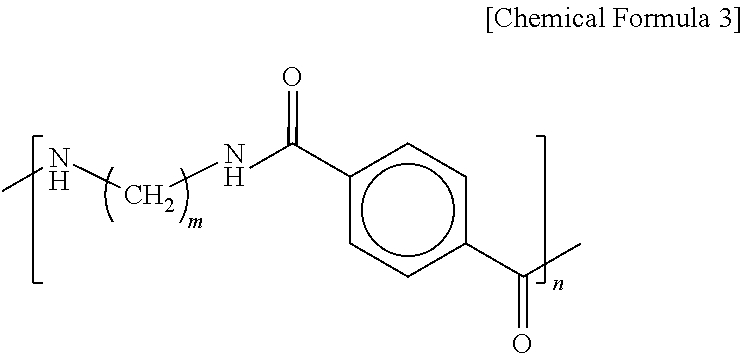

Polyamide Resin Composition with Excellent Reflectivity, Heat Resistance, and Water Resistance

ActiveUS20130281587A1Excellent heat resistanceExcellent water resistanceOther chemical processesPhosphorus organic compoundsPolymer chemistryWater resistance

Owner:LOTTE ADVANCED MATERIALS CO LTD

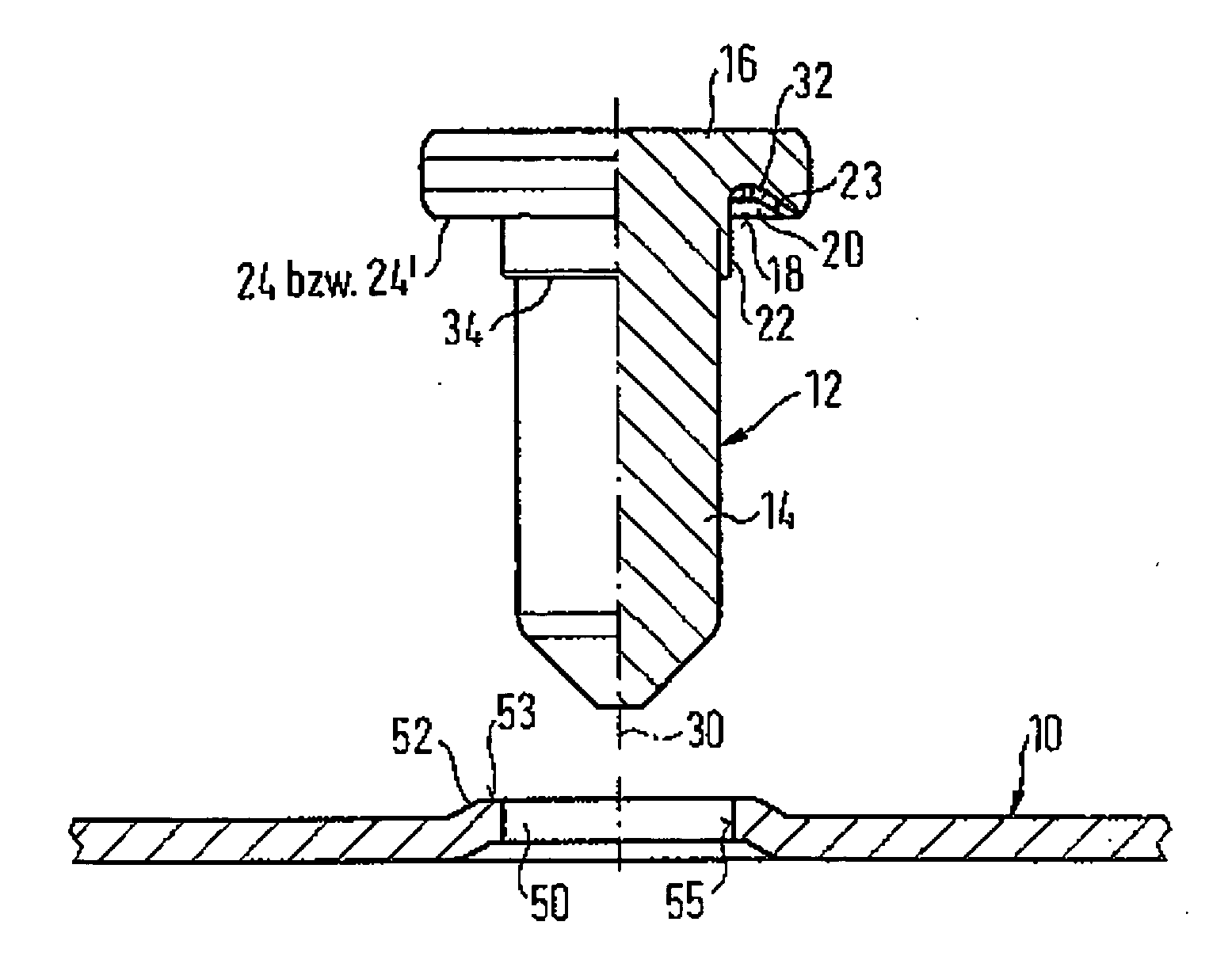

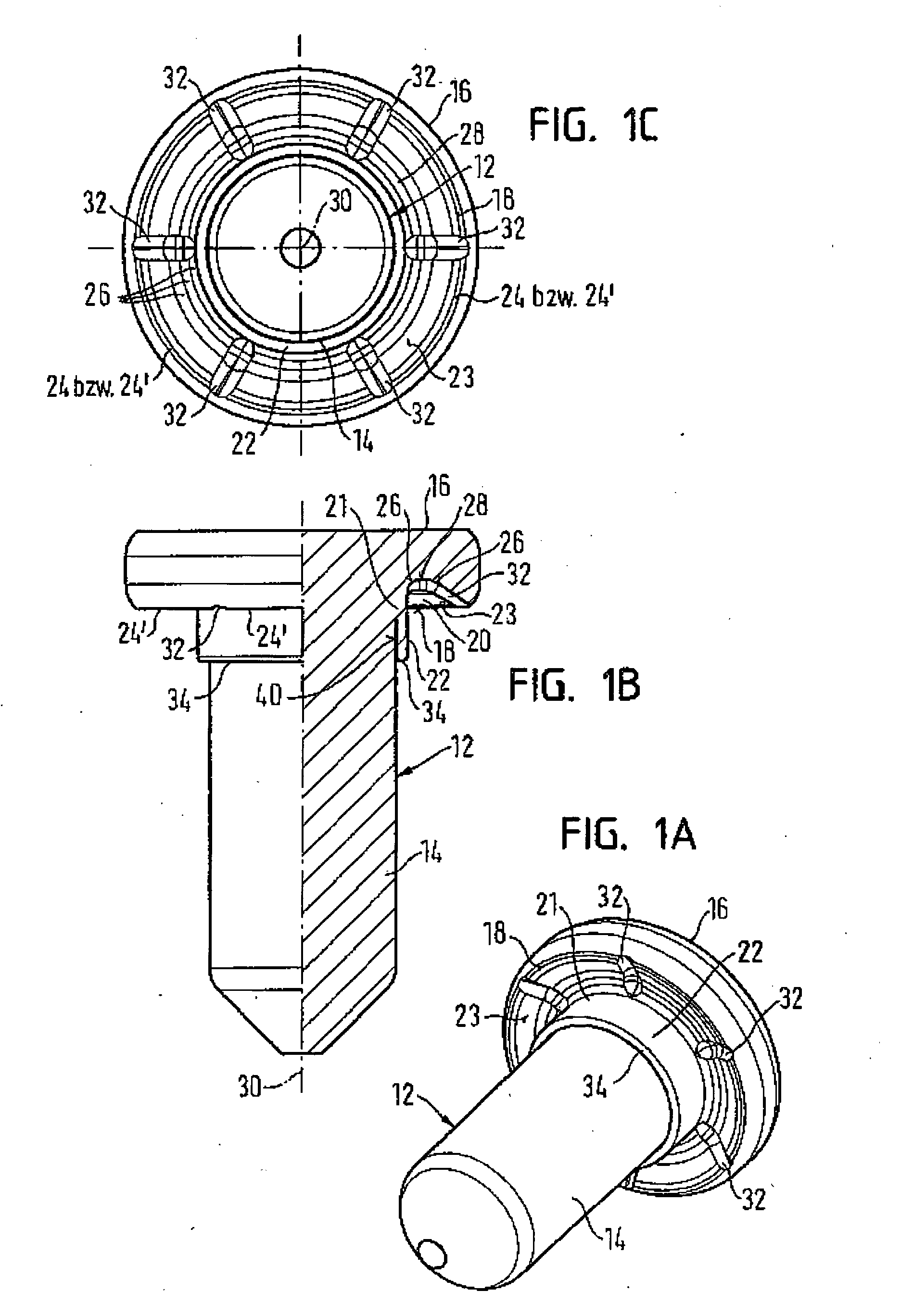

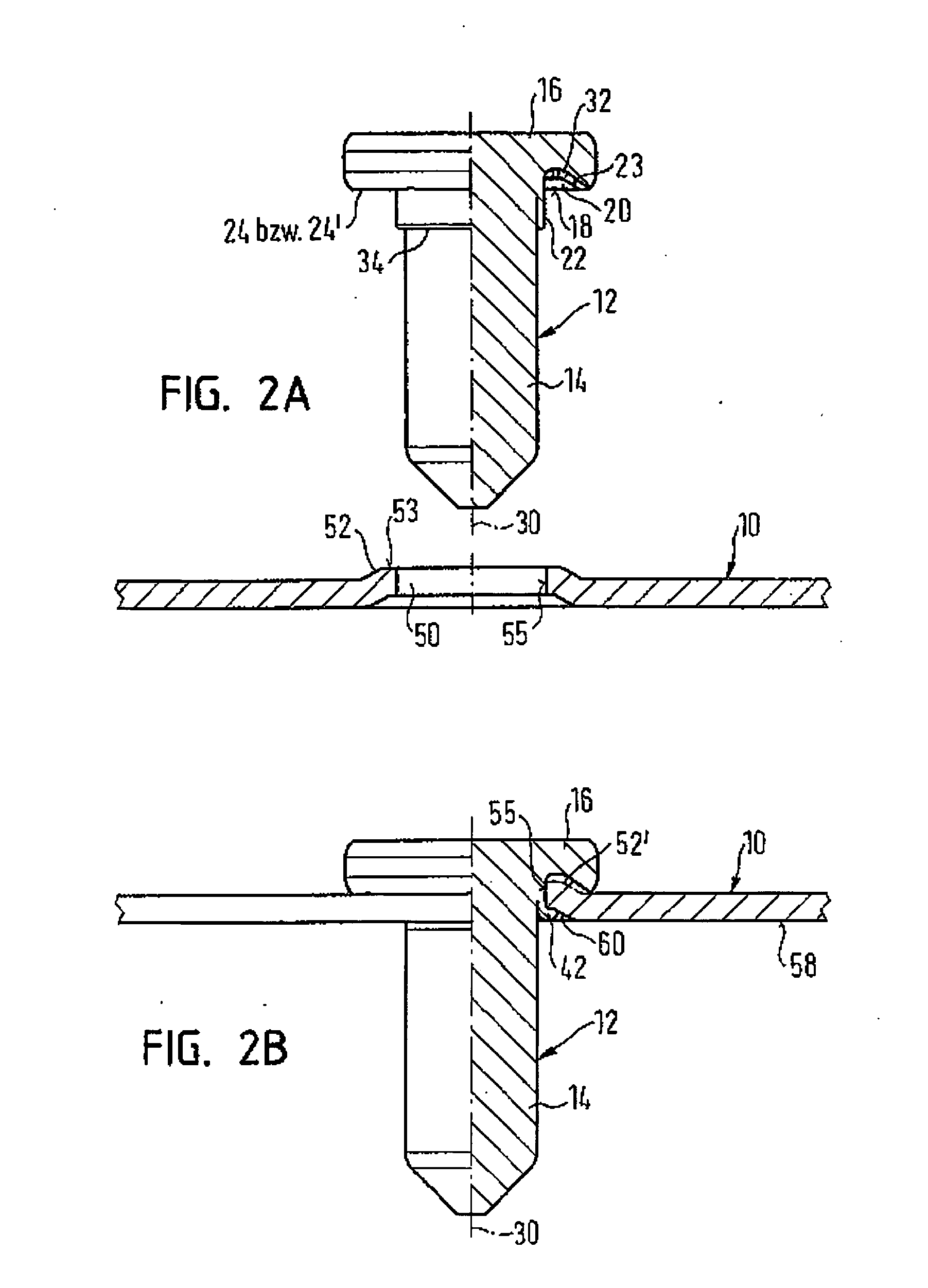

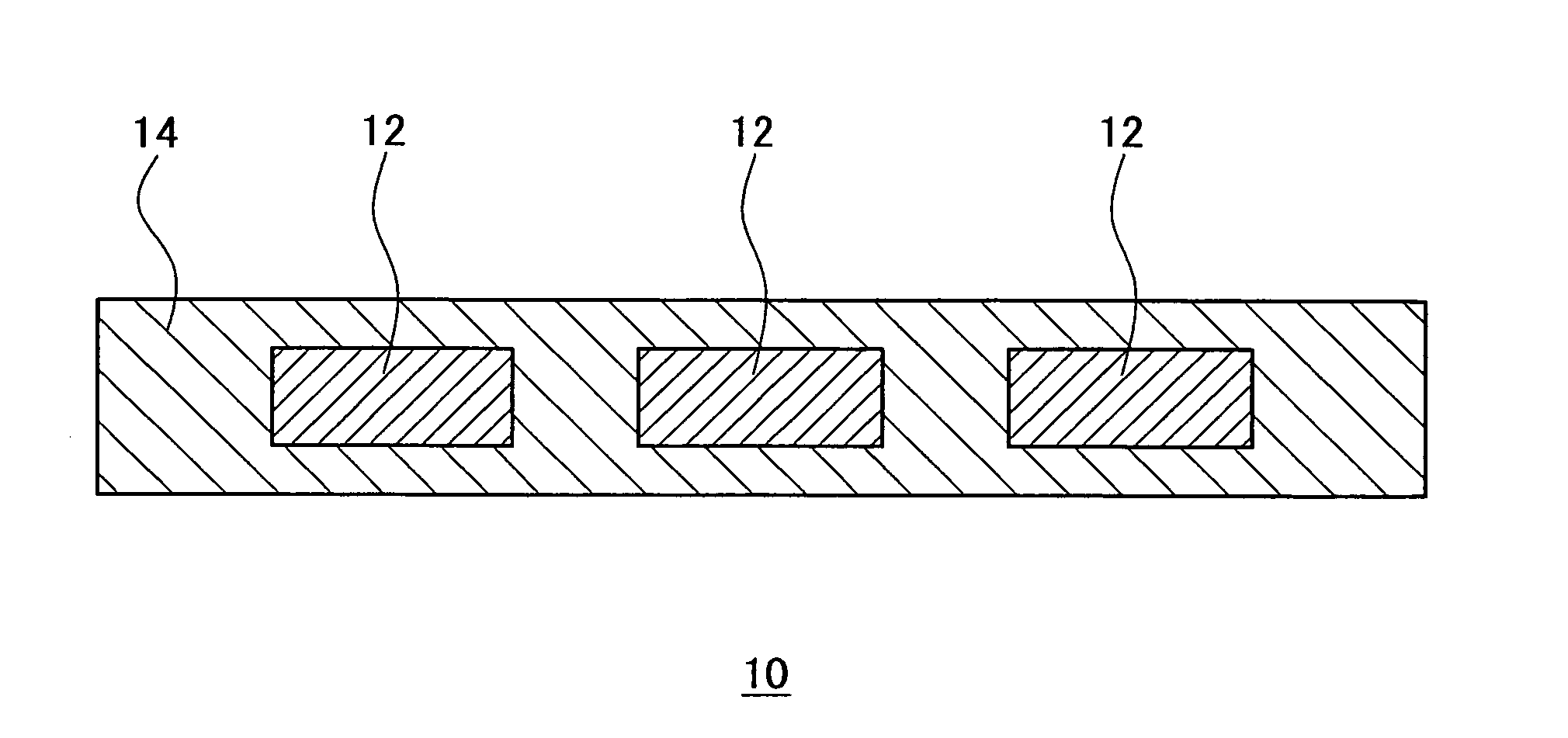

Element attachable by riveting to a sheet metal part and also a component assembly and a method for the production of the component assembly

ActiveUS20060137166A1Excellent resistanceImprove the immunityNutsBoltsManufacturing engineeringRivet

An element attachable to a sheet metal part by riveting, in particular an element in the form of a centering bolt, having a shaft part and a head part, wherein the head part has at its side confronting the sheet metal part an at least approximately ring-like ring recess which merges at the radially inner side into a cylinder section of the head part which in turn merges into the shaft part and into a tubular rivet section which surrounds the shaft part in the region of the head part, is disposed within a ring-like contact surface arranged radially outside of the ring recess and merges at the radially outer side via an at least approximately conical wall into the ring-like contact surface, is characterized in that at least one local recess and preferably a plurality of in particular uniformly distributed local recesses is or are provided in the conical wall of the ring recess and / or in an optionally present ring-like base surface of the ring recess. A component assembly comprising the element and a sheet metal part and also a method for the manufacture of such a component assembly are also described.

Owner:HVB BANQUE LUXEMBOURG

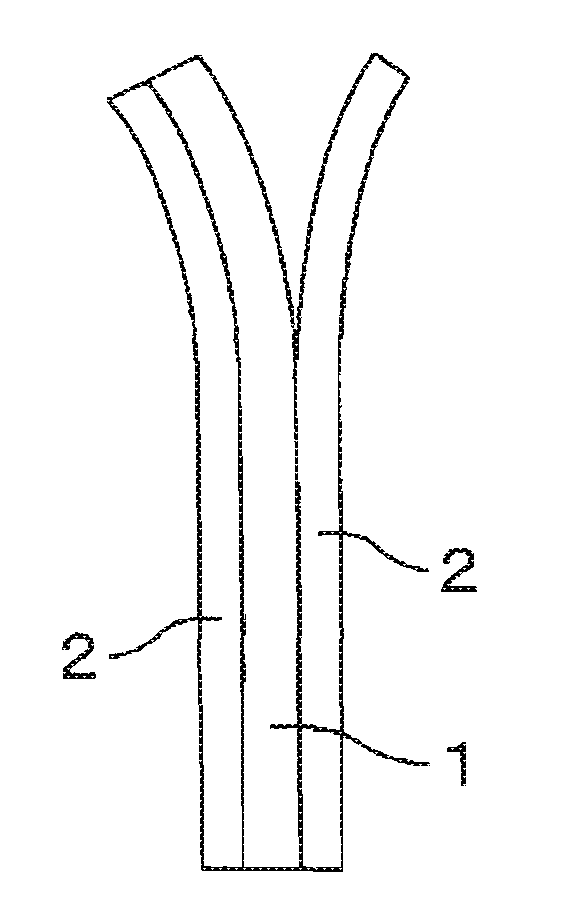

Flat cable

InactiveUS20100044071A1Excellent resistanceAdequate flexibilityFlat/ribbon cablesFlexible cablesEngineeringElectrical conductor

A flat cable which is excellent in resistance to sliding and bending. A flat cable includes a plurality of conductors which are arranged in parallel apart from each other, and an insulation having a flexural modulus of no less than 200 MPa and less than 800 MPa, with which the conductors are extrusion-coated. It is preferable that the flexural modulus of the insulation is no less than 250 MPa and no more than 450 MPa. In addition, it is preferable that the insulation contains one or more than one kind of high polymer.

Owner:AUTONETWORKS TECH LTD +2

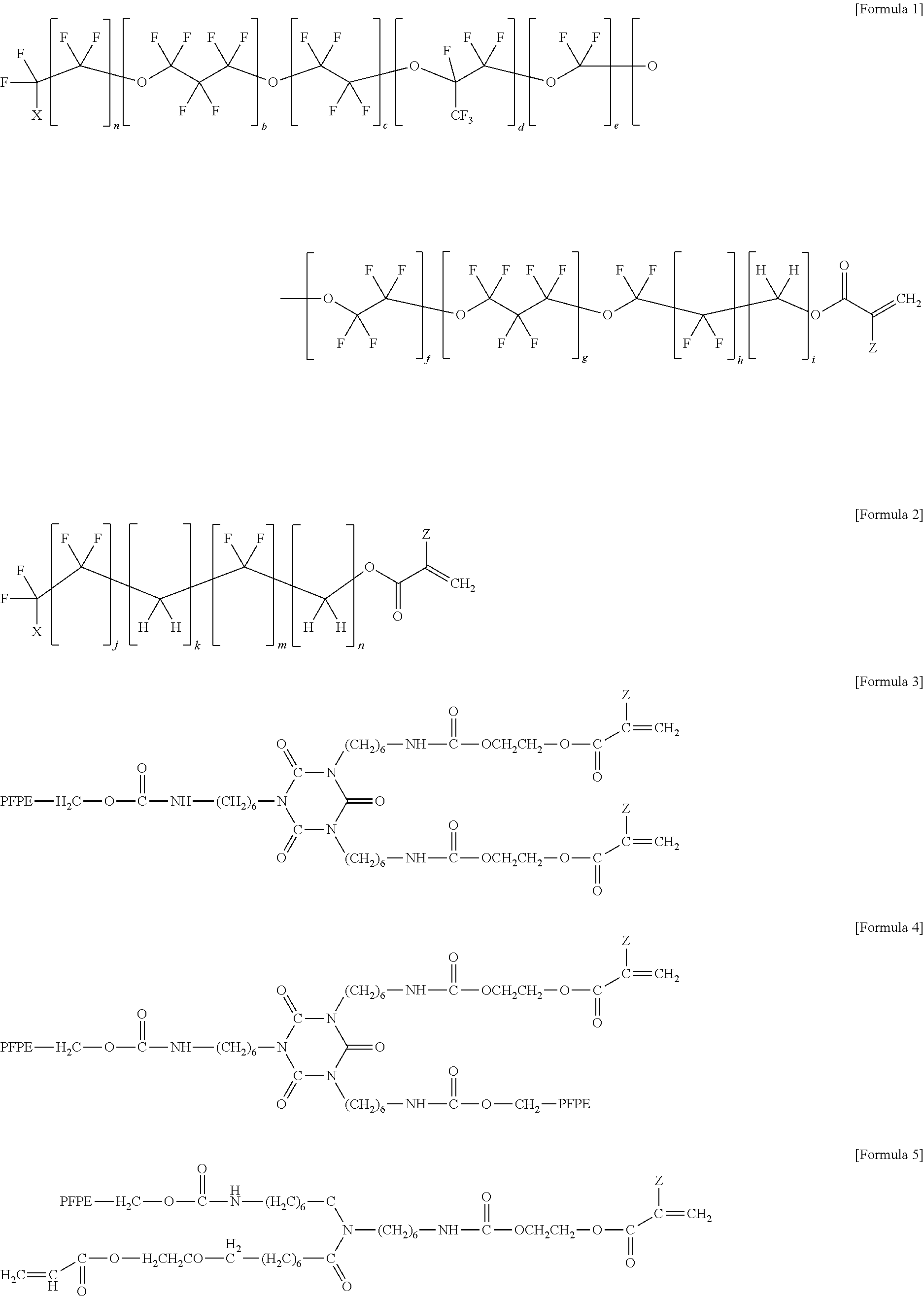

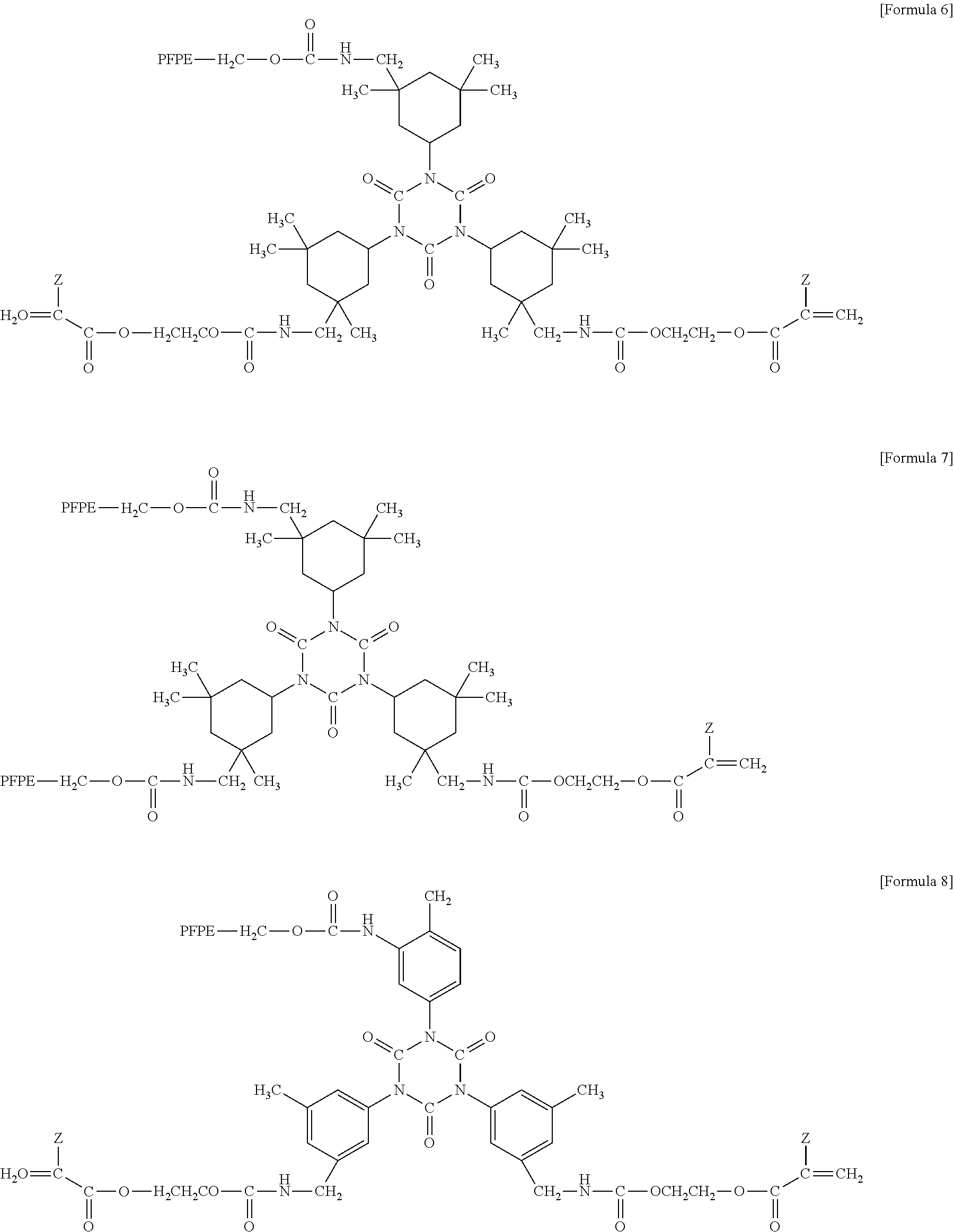

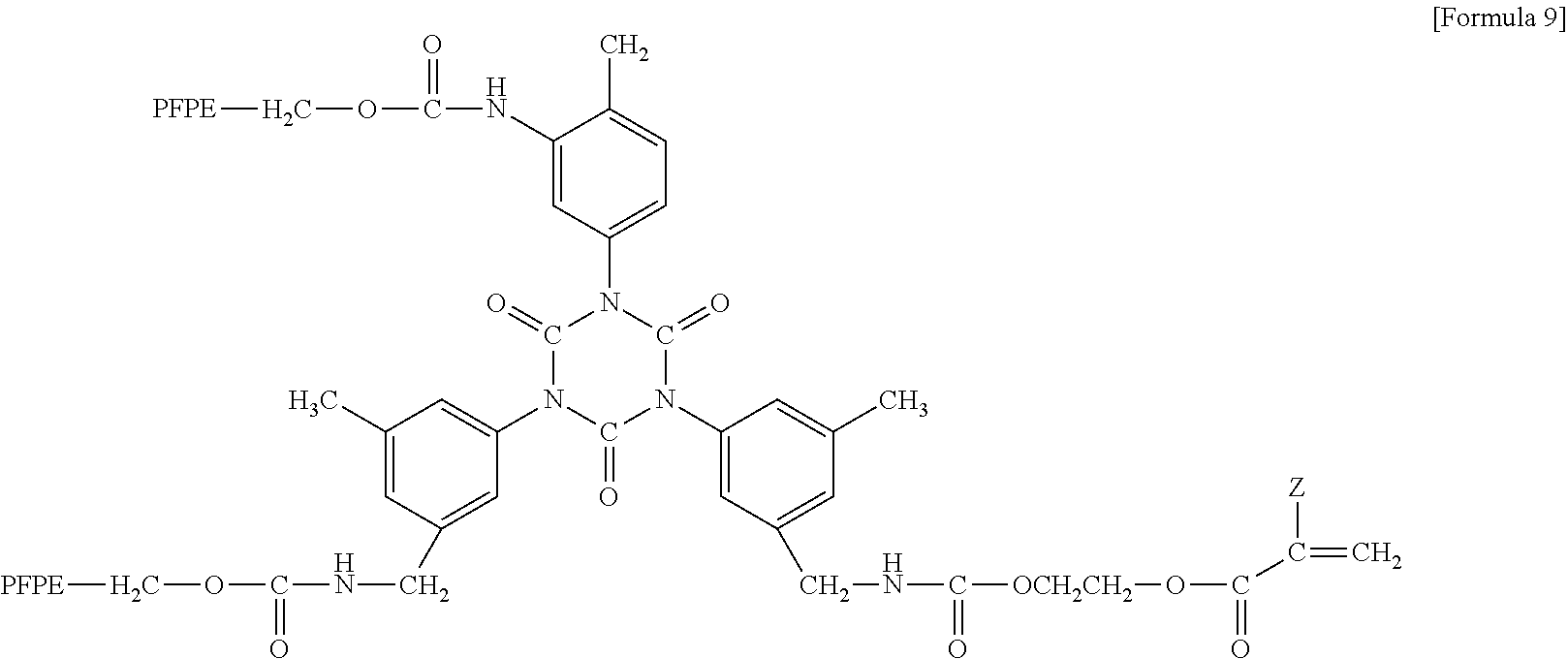

Anti-smudge agent, smudge proof coating composition, smudge proof film, and article coated with smudge proof film

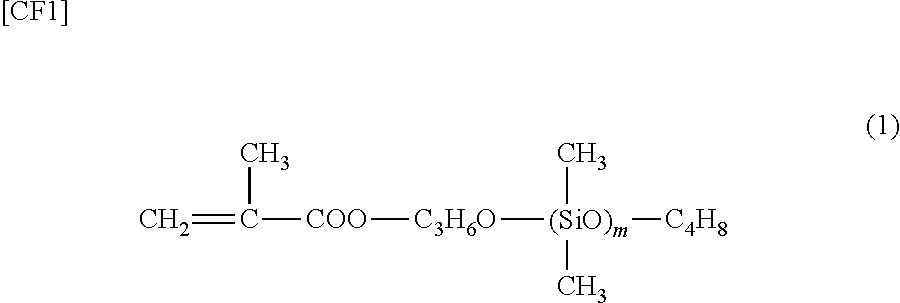

InactiveUS20070243394A1High resistanceExcellent resistanceLayered productsSkin careSilicone resinChemistry

An anti-smudge agent which is added to a coating composition for imparting smudge proof property with the coating composition, comprising a silicone resin containing a fluorine atom-containing organic group, which has a number average molecular weight of at least 1,000 and a molar ratio of the fluorine atom to the silicon atom (F / Si) of 3 to 50, said silicone resin being the one produced by hydrolyzing or condensing an organosilicon compound having a fluorine atom-containing organic group represented by the following general formula (I):R1R2mSiX3-m (I)wherein R1 is a fluorine atom-containing organic substituent, R2 is a substituted or unsubstituted alkyl group or phenyl group containing 1 to 10 carbon atoms, X is a hydrolyzable group or OH group, and m is 0 or 1; or a hydrolysate or a partial condensate thereof.When the coating composition having the anti-smudge agent of the present invention blended therein is used for the coating, the surface will provided with the smudge proof property simultaneously with the functions realized by the base resin of the coating composition by one coating, and provision of two separate coatings is no longer necessary. This is economically by far advantageous.

Owner:SHIN ETSU CHEM CO LTD

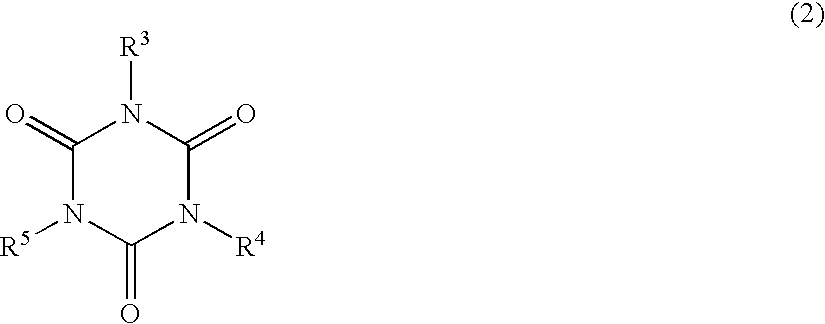

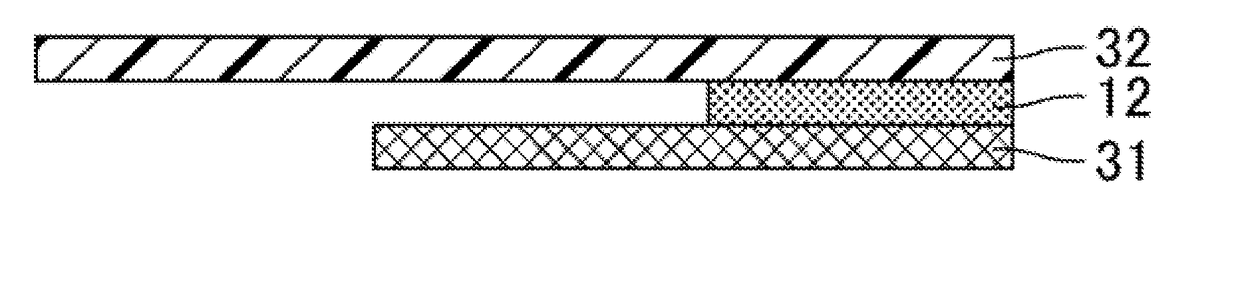

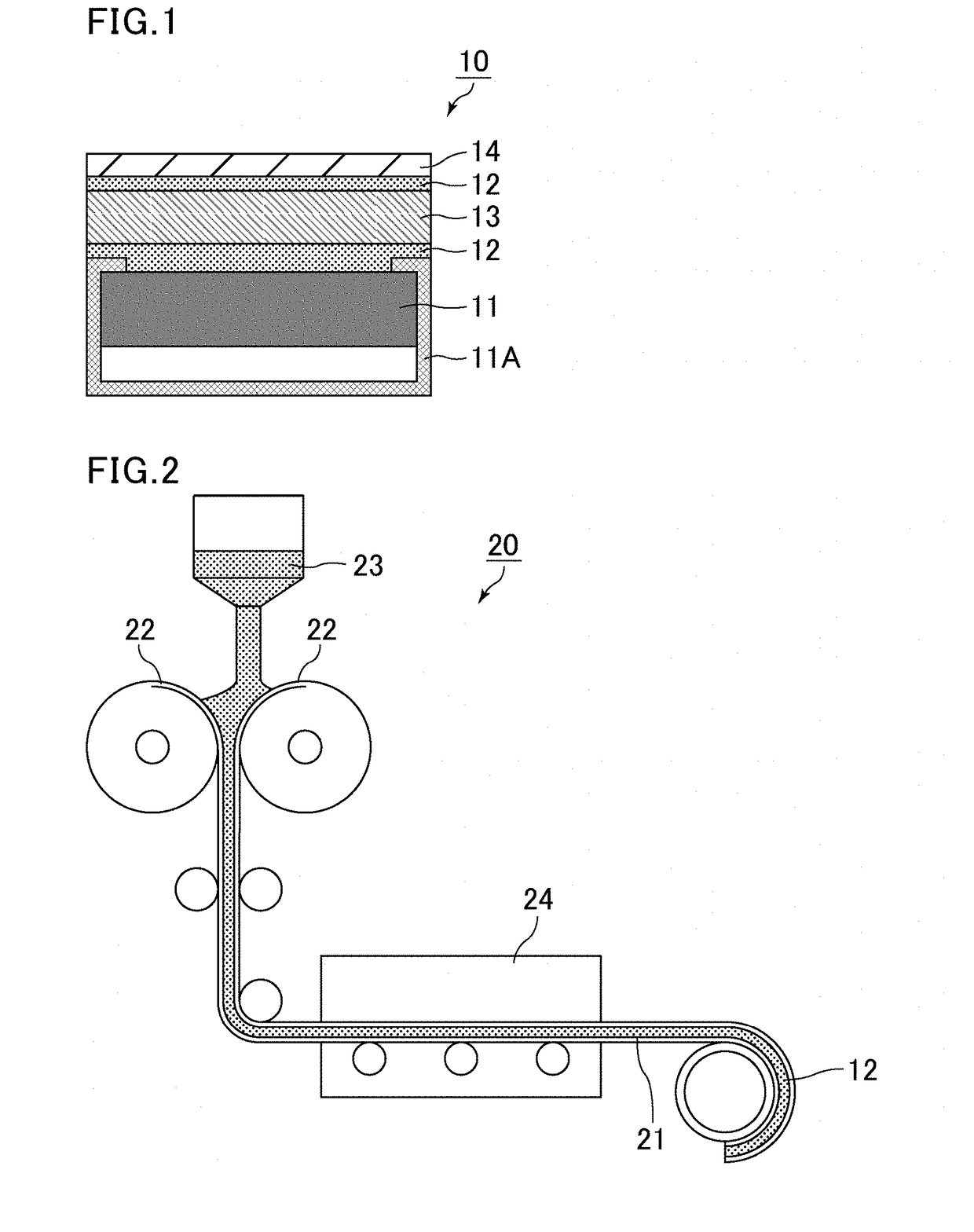

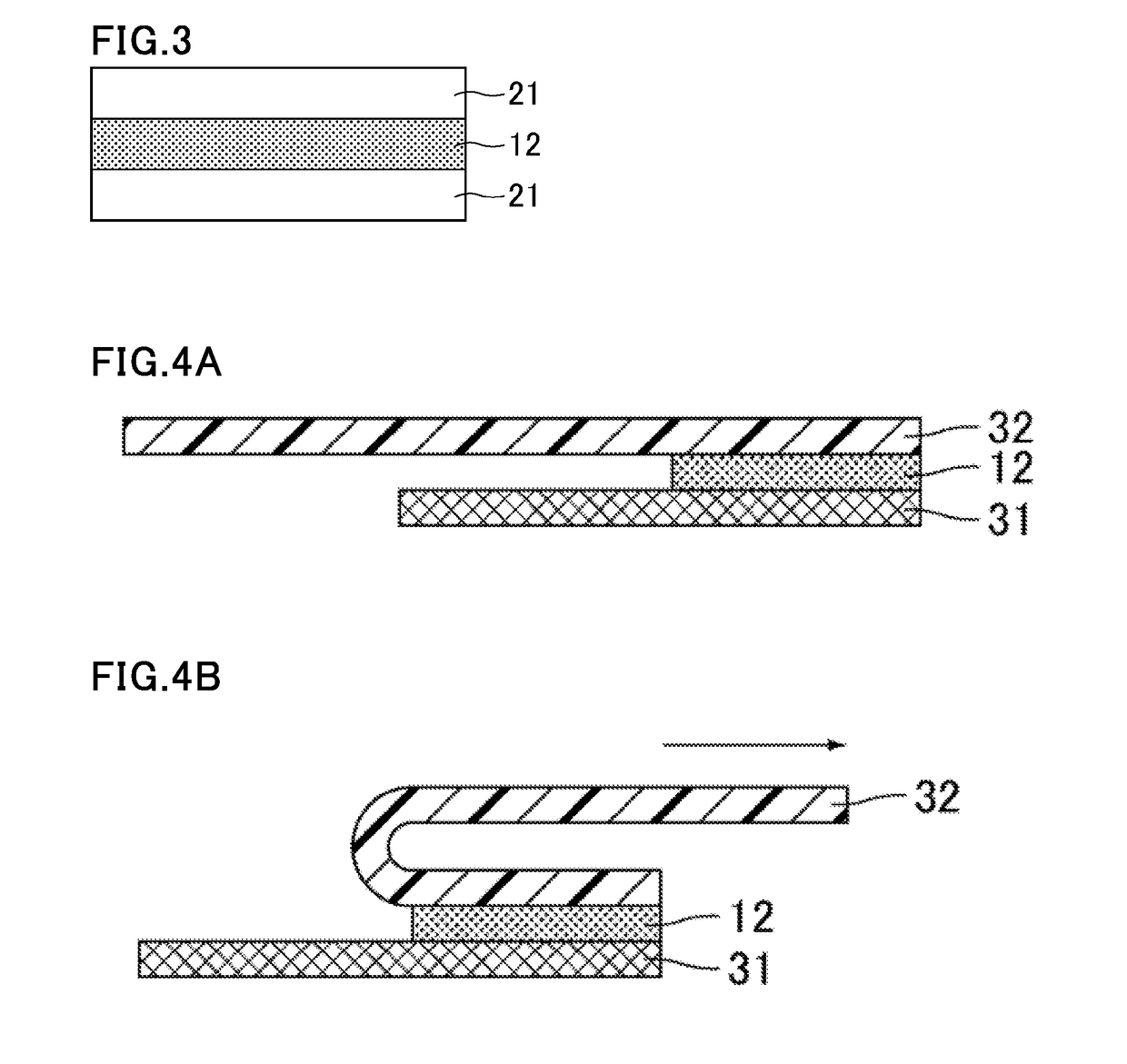

Chemically amplified positive photoresist composition for thick film, thick-film photoresist laminated product, manufacturing method for thick-film resist pattern, and manufacturing method for connection terminal

ActiveUS20060141389A1Good shapeExcellent resistanceRadiation applicationsPhotomechanical apparatusPhotoresistResist

A chemically amplified positive photoresist composition for thick film that is used for forming a thick-film photoresist layer with a film thickness of 10 to 150 μm on top of a support, including (A) a compound that generates acid on irradiation with active light or radiation, and (B) a resin that displays increased alkali solubility under the action of acid, wherein the component (B) includes a resin formed from a copolymer containing a structural unit (b1) with a specific structure.

Owner:TOKYO OHKA KOGYO CO LTD

Electrode for electricity storage device, slurry for electrode, binder composition for electrode, and electricity storage device

InactiveUS20140038041A1Excellent resistanceExcellent charge-discharge rate characteristicNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesCurrent collectorPolymer chemistry

An electrical storage device electrode includes a collector, and an active material layer that is formed on a surface of the collector, the active material layer including at least a polymer and an active material, and the active material layer having a polymer distribution coefficient of 0.6 to 1.0 and a density of 1.3 to 1.8 g / cm3.

Owner:JSR CORPORATIOON

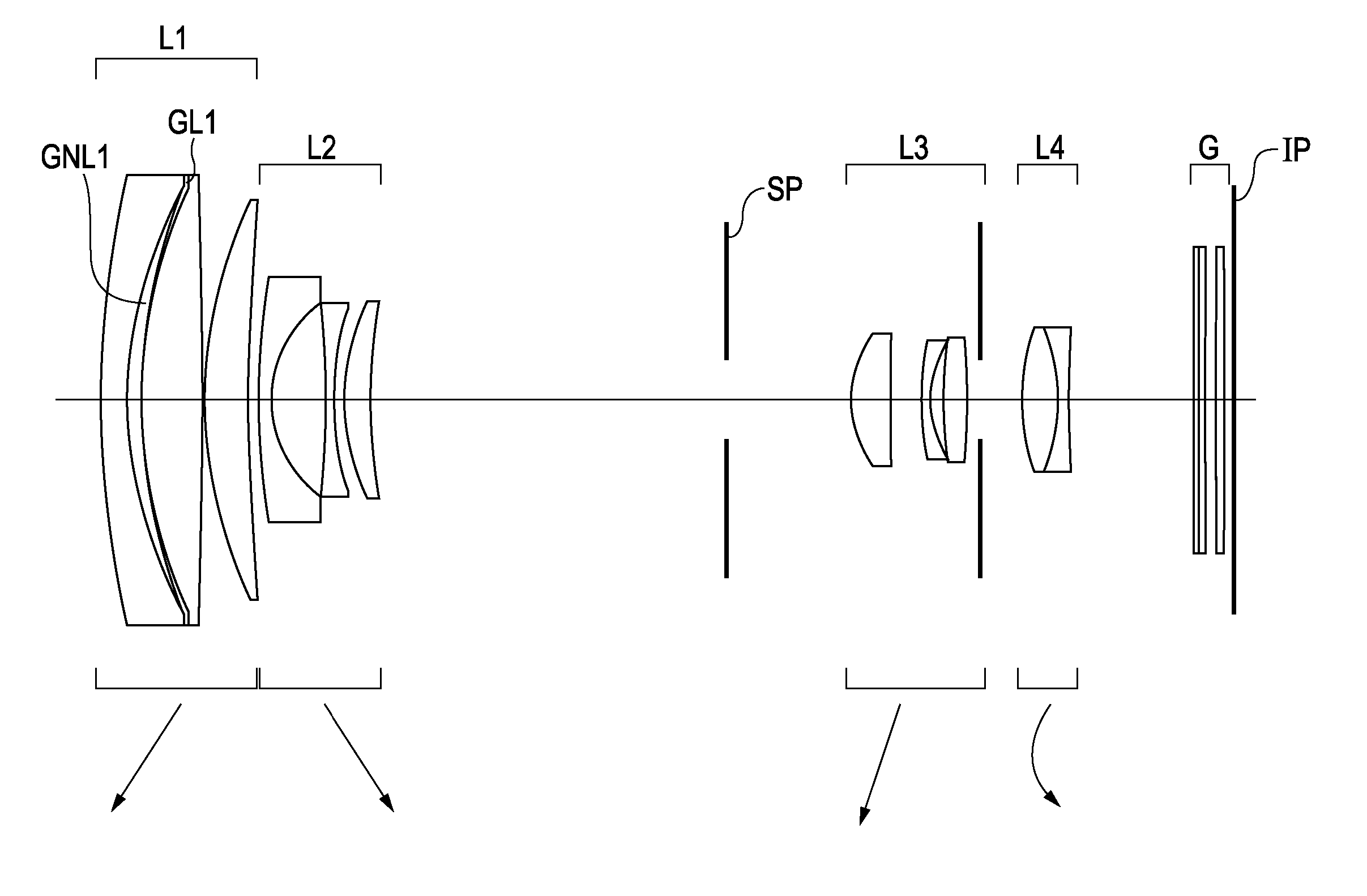

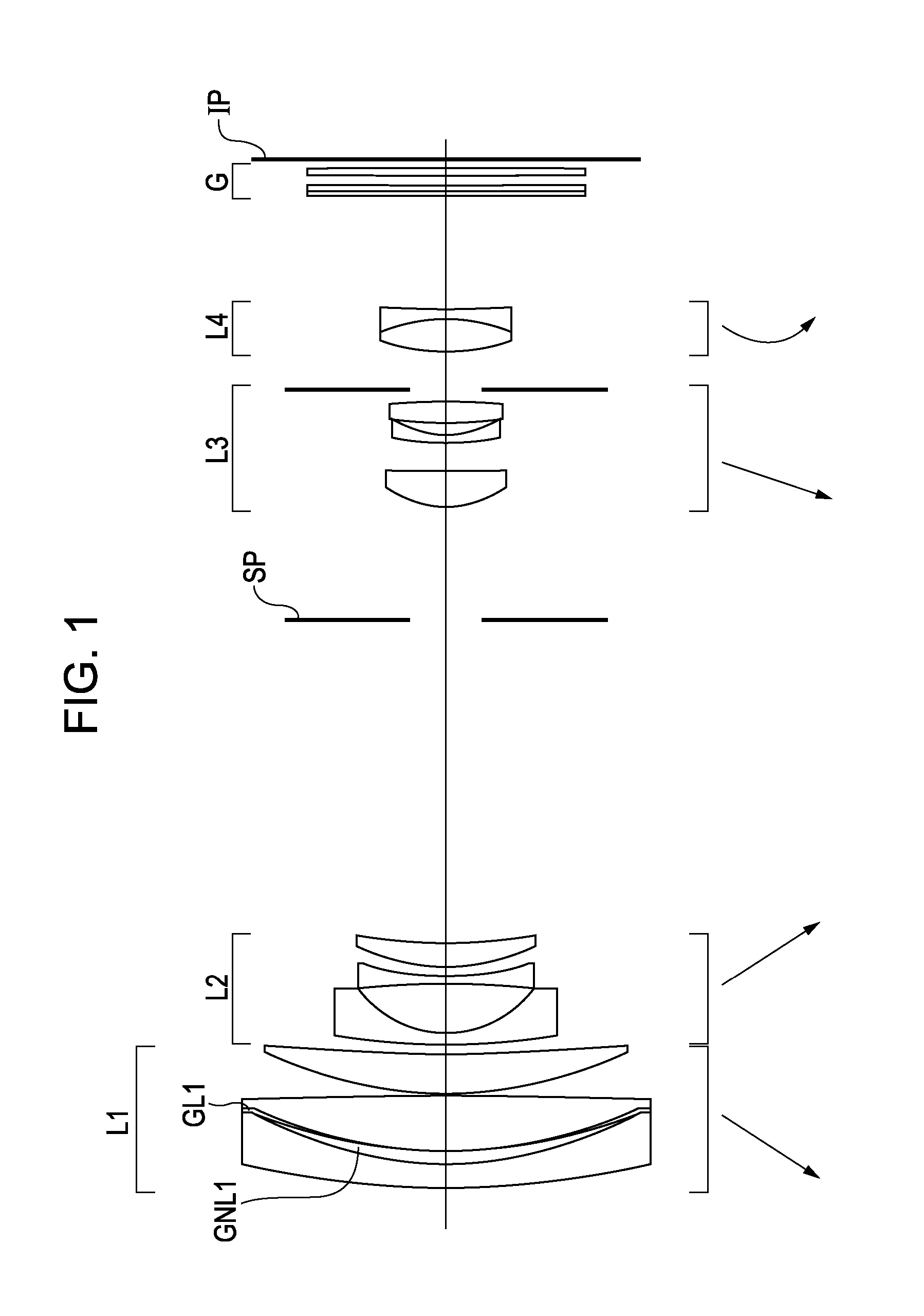

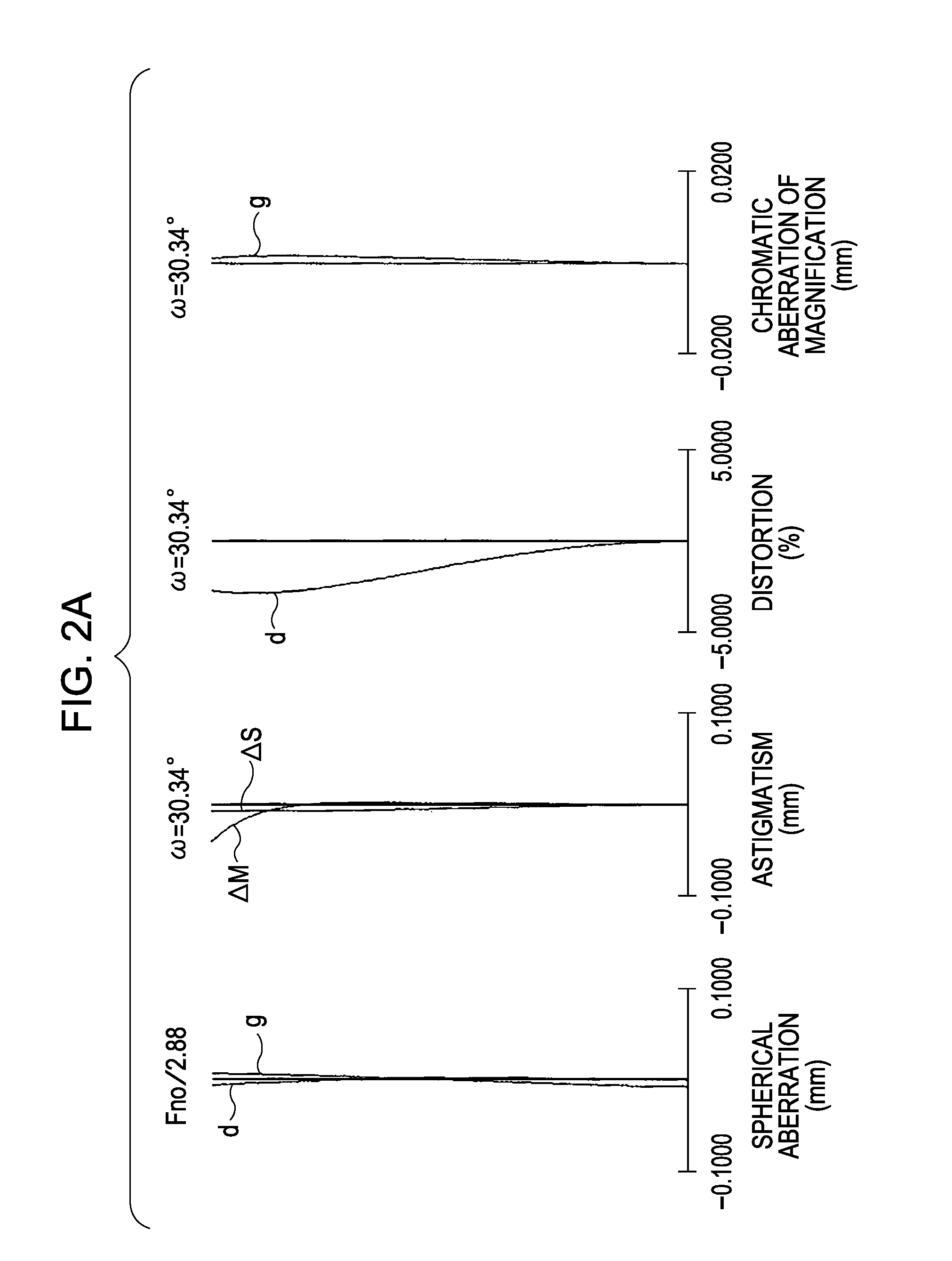

Optical system and optical apparatus including optical system

InactiveUS20080130141A1Easily fabricateExcellent resistanceOptical elementsConditional expressionOptical axis

An optical system includes a first optical element and a second optical element on at least one of an enlargement side and a reduction side relative to a point P at which a light axis and a paraxial chief ray intersect. Each of the first optical element and second optical element is composed of a solid material having a refractive light incident surface and a refractive light emergent surface. The optical system satisfies the following conditional expressions: ΔθgF1>0.0272, ΔθgF2<−0.0278, and f1×f2<0 where ΔθgF1 and ΔθgF2 denote anomalous partial dispersion values of the first and second optical elements for the g-line and F-line, respectively, and f1 and f2 denote focal lengths of the first and second optical elements, respectively, when the light incident surfaces and the light emergent surfaces of the first and second optical elements are in contact with air.

Owner:CANON KK

Polyacetal resin composition

InactiveUS20090312466A1Excellent resistanceSuppress generation of formaldehydeOrganic chemistryInksChemistryPhenols

The present invention provides a polyacetal resin composition having an excellent processability and stability, significantly suppressing the generation of formaldehyde from molded articles thereof, preventing exudation of components, and being excellent in weathering (light) resistance. Specifically, (A) a polyacetal copolymer having 1.0 mmol / kg or smaller quantity of a hemiformal terminal group, 2.0 mmol / kg or smaller quantity of a formyl terminal group, and 0.5% by weight or smaller quantity of an unstable terminal group is blended with (B) a hindered phenol-based antioxidant; (C) at least one compound selected from (c-1) a guanamine compound and (c-2) a hydrazide compound; (D) a hindered amine stabilizer in which the nitrogen in a piperidine derivative having a steric hindrance group is tertiary; and (E) a UV absorber in specified quantities and mixing ratios.

Owner:POLYPLASTICS CO LTD

Over-current protection device

ActiveUS20070035378A1Excellent resistanceFast tripNon-metal conductorsCurrent responsive resistorsMetal foilElectrically conductive

An over-current protection device comprises two metal foils and a positive temperature coefficient (PTC) material layer. The PTC material layer is sandwiched between the two metal foils and comprises plural crystalline polymers with at least one polymer melting point below 115° C., and a non-oxide electrically conductive ceramic powder. The non-oxide electrically conductive ceramic powder exhibits a certain particle size distribution. The PTC material layer has a resistivity below 0.1 Ω-cm. The initial resistance of the device is below 20 mΩ, and the area of the PTC material layer is below 30 mm2. The over-current protection device exhibits a surface temperature below 100° C. under the trip state of over-current protection.

Owner:POLYTRONICS TECH

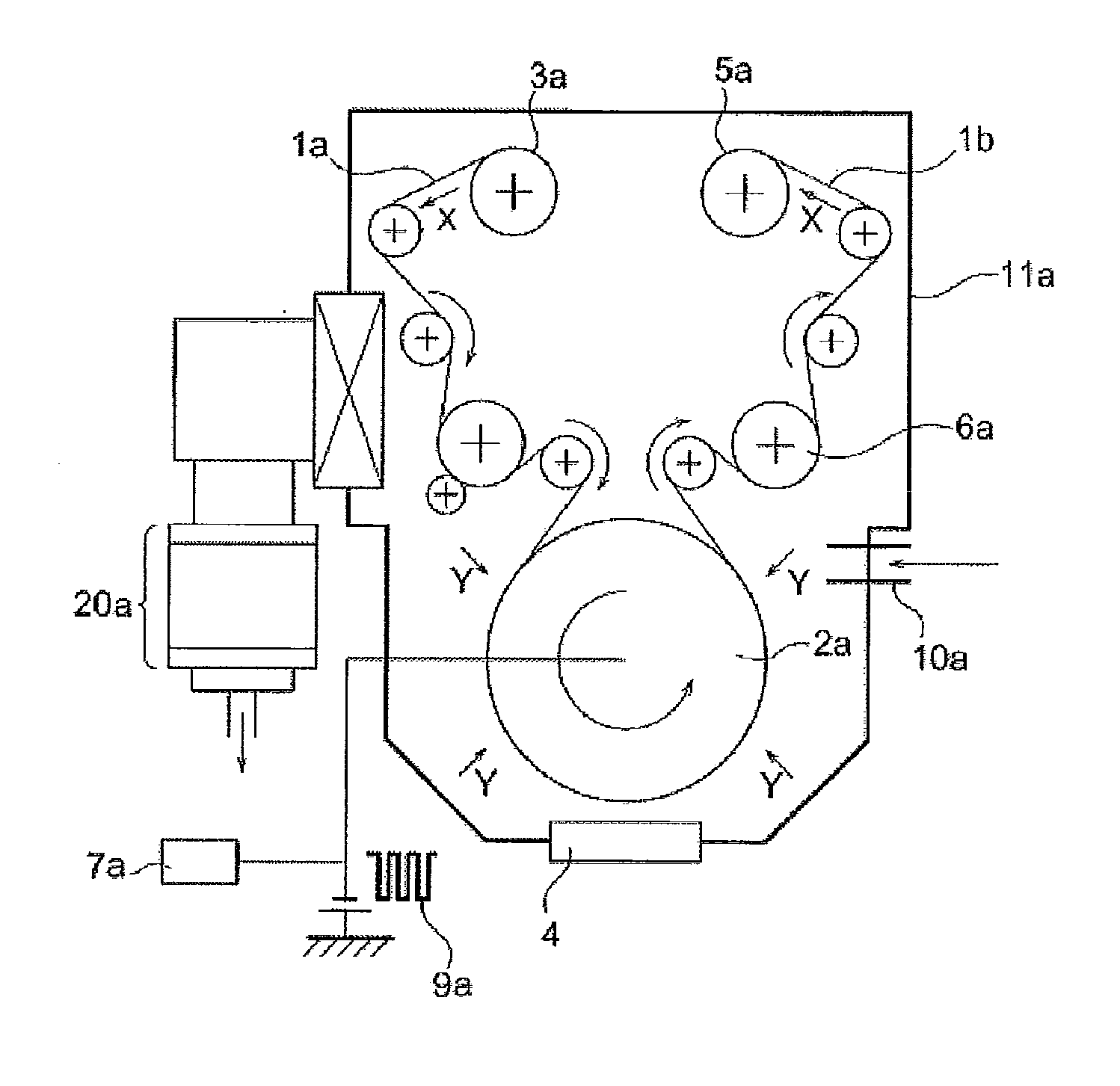

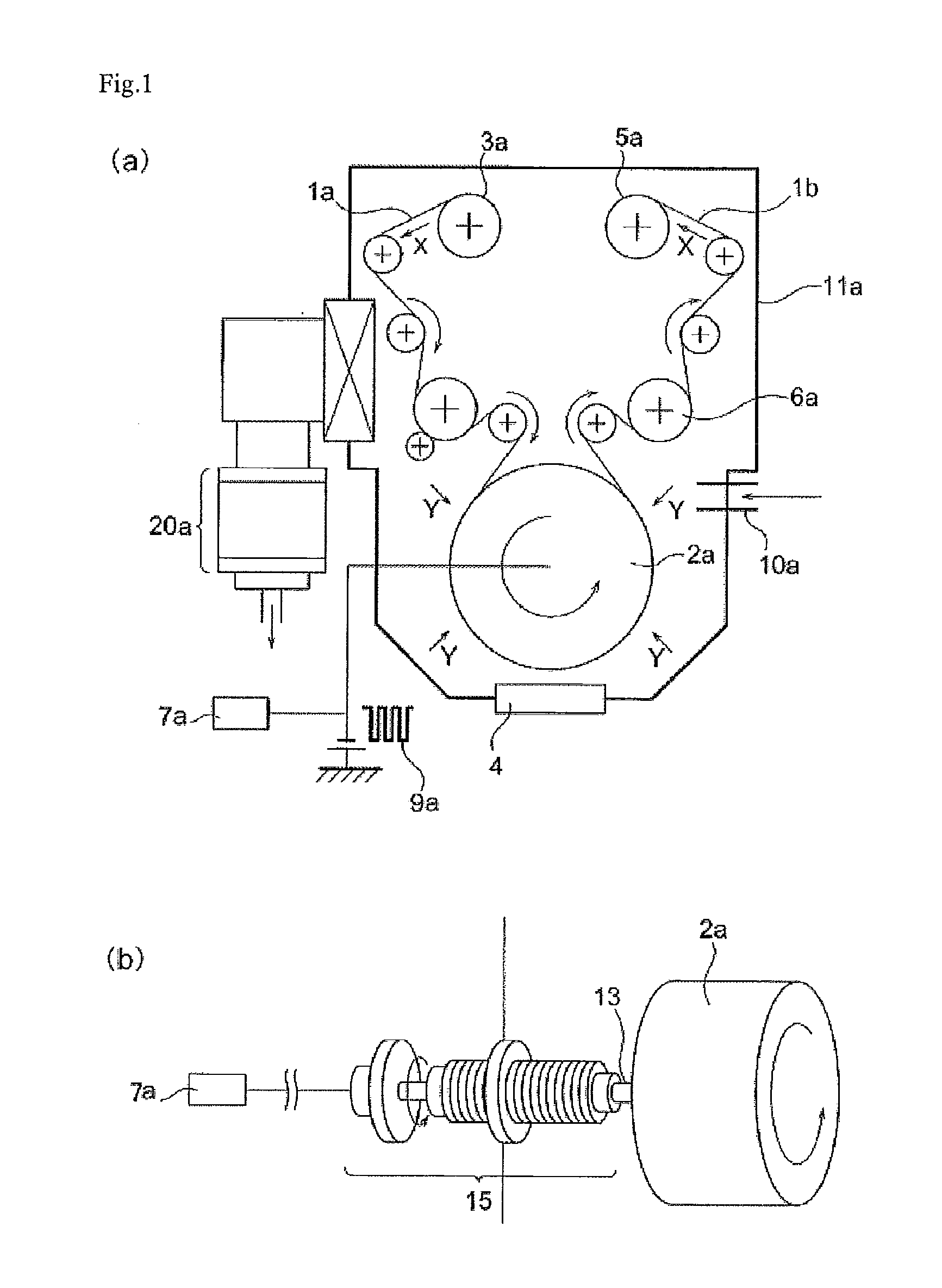

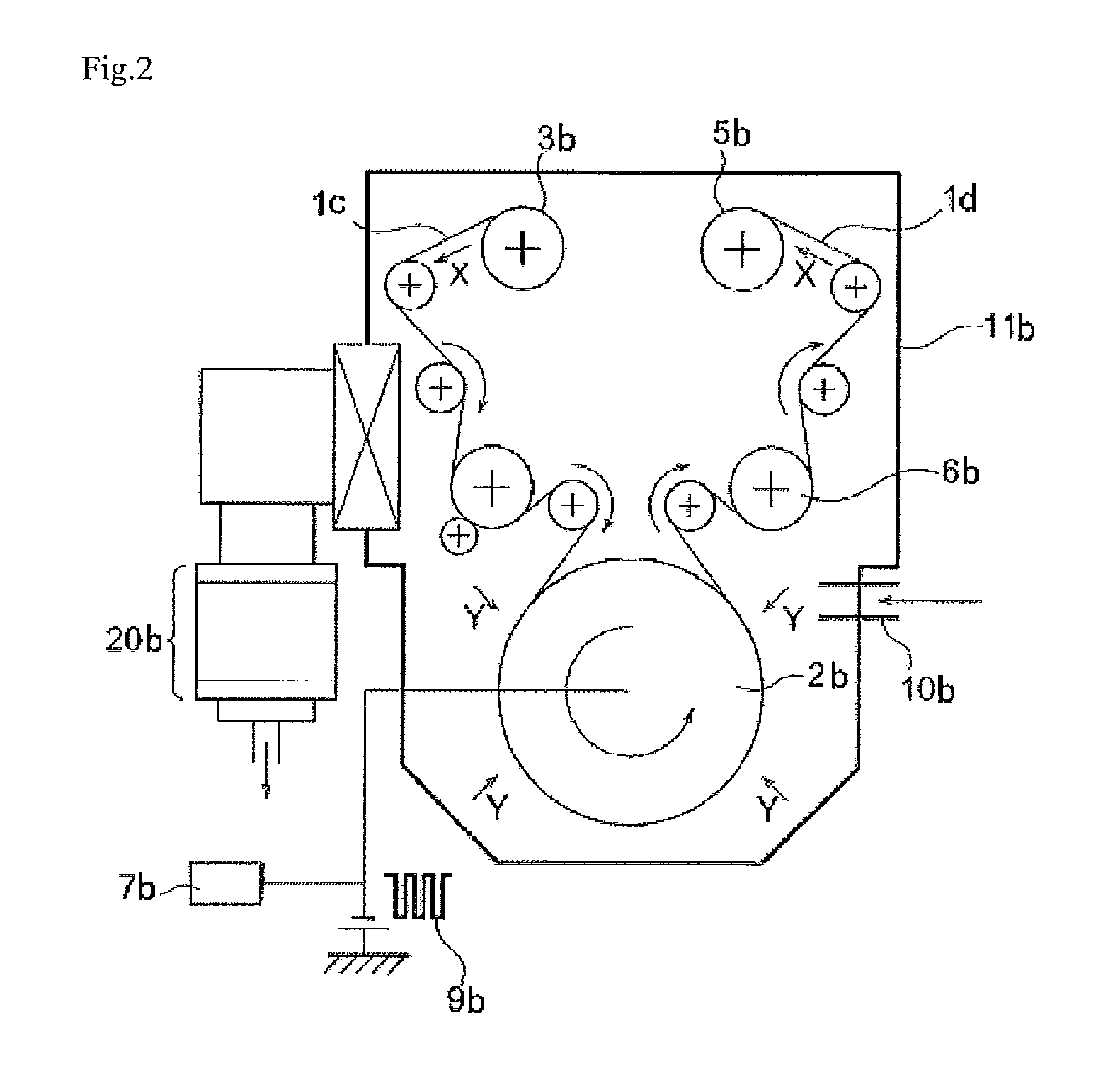

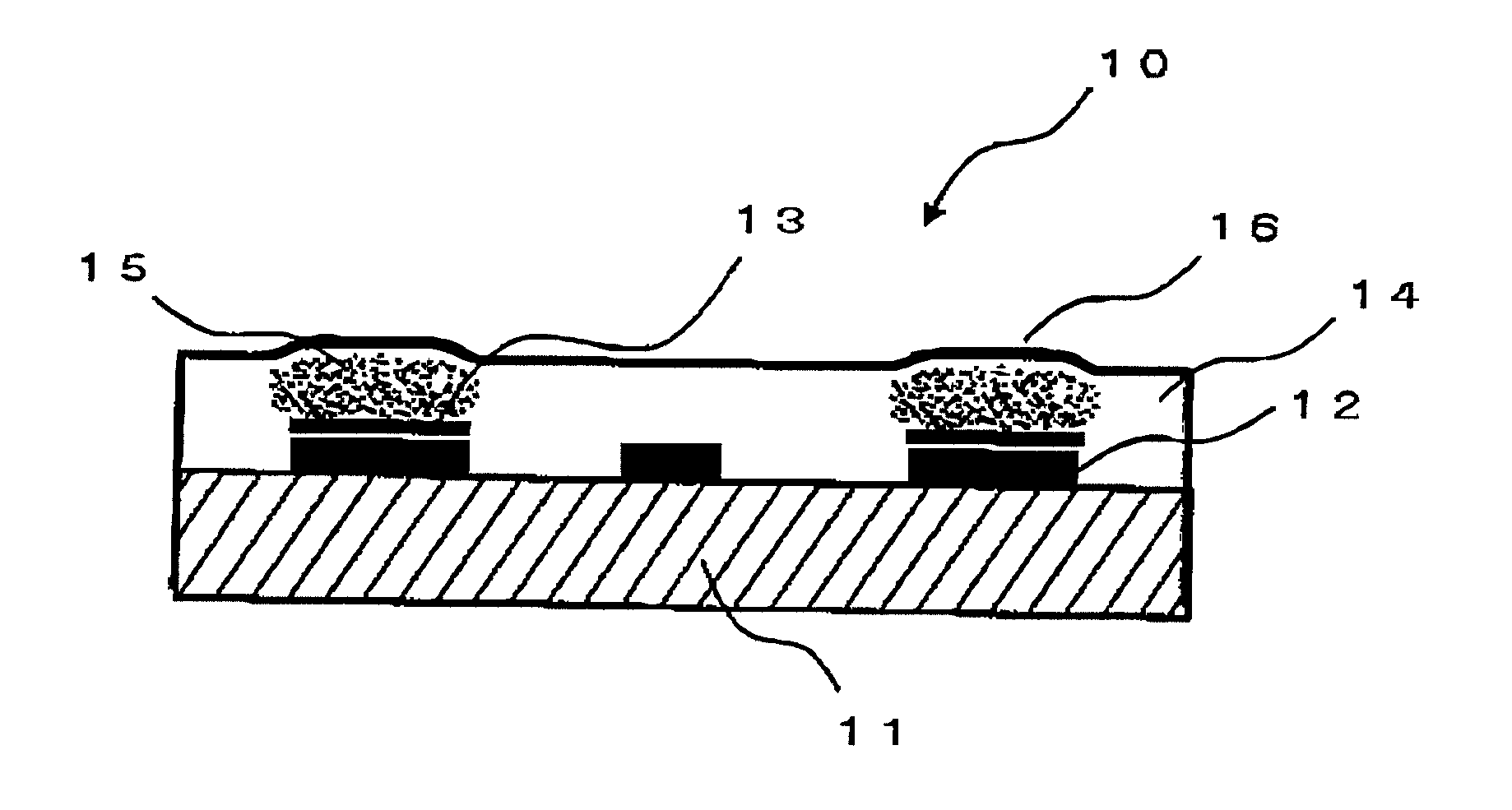

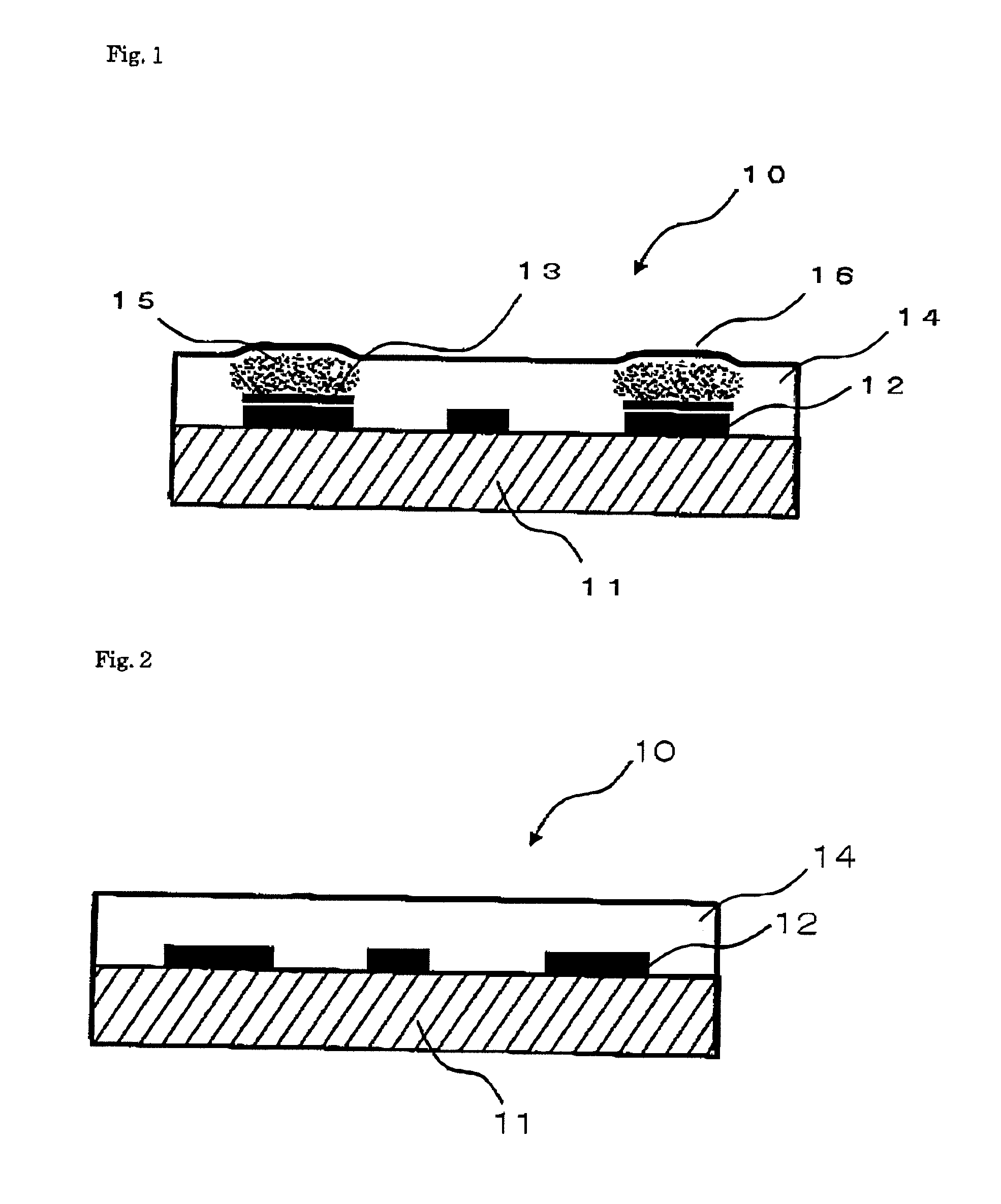

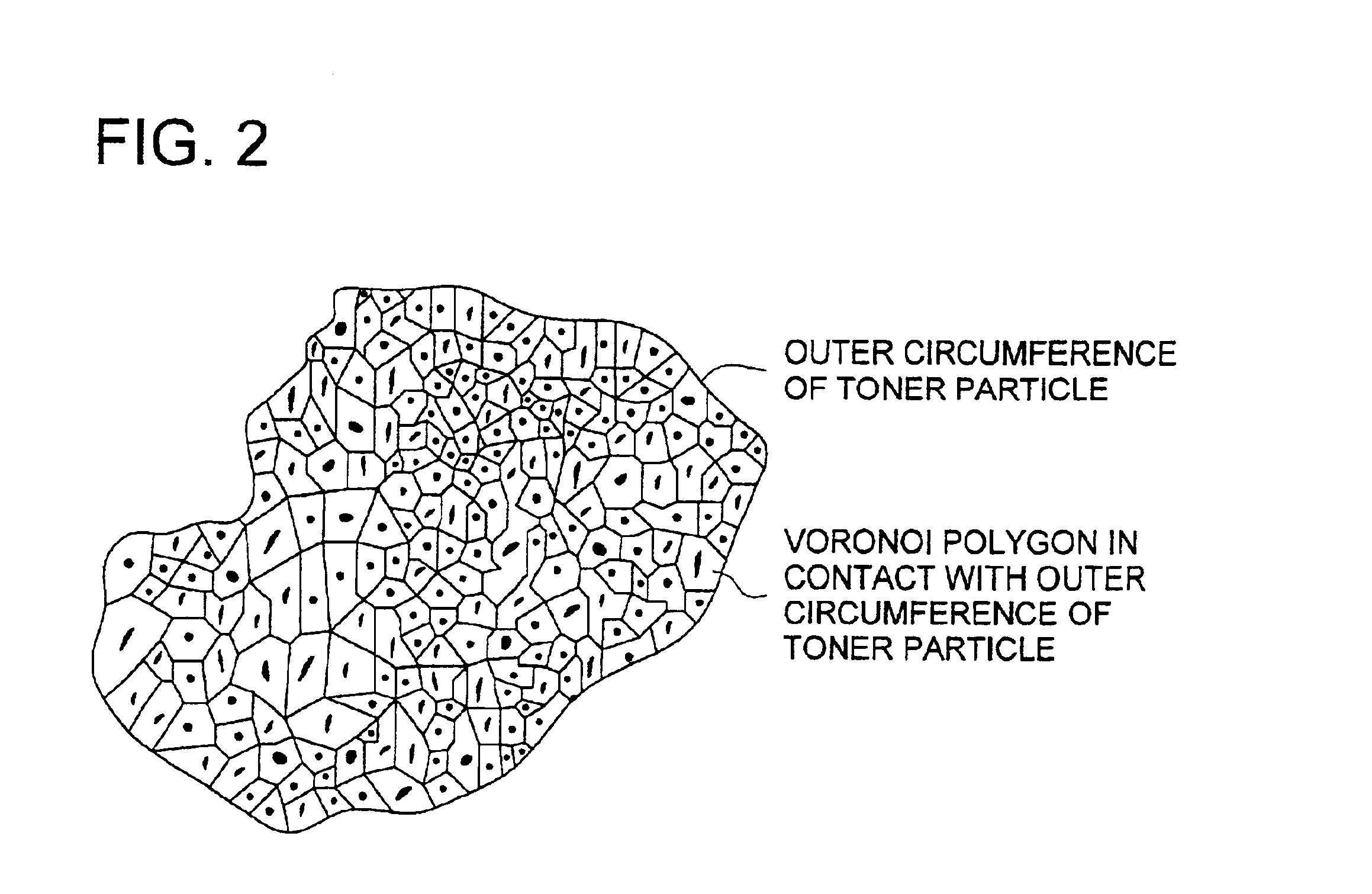

Electrophotographic photosensitive member, electrophotographic apparatus, and process cartridge

ActiveUS6998210B2Abrasion resistance be excellentExcellent resistanceElectrographic process apparatusCorona dischargeEngineeringHardness

The present invention relates to an electrophotographic photosensitive member comprising a surface layer excellent in adhesiveness and abrasion resistance, having a hardness and a toughness, and not degrading the charge transport property. One aspect of the present invention provides an electrophotographic photosensitive member comprising a photosensitive layer on a conductive support, wherein a surface layer of the photosensitive member contains a crosslinked epoxy-modified resol type phenolic resin, and at least one of a charge transport material and a conductive fine particle.

Owner:CANON KK

Decorative sheet, process for producing decorative resin molded product, and decorative resin molded product

ActiveUS20110143128A1Excellent resistanceGood moldabilityFilm/foil adhesivesSynthetic resin layered productsChemistryStatic friction coefficient

The present invention relates to a decorative sheet for insert molding prepared by laminating at least a surface protective layer on a support comprising an ABS resin, wherein the above support has a flexural modulus of 1500 to 3000 MPa; the above support has a thickness of 100 to 500 μm; the above surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition; and the above ionizing radiation curable resin composition has a tensile modulus of more than 100 MPa to less than 1000 mPa which is measured by the following method and a static frictional coefficient of 1.0 or less on a surface and a decorative sheet for insert molding comprising at least a picture layer, a low glossy picture ink layer provided partially and a surface protective layer in this order on a support, wherein the above surface protective layer is present on the low glossy picture ink layer and brought into contact therewith, and it is coated over a whole surface including an area where the above low glossy picture ink layer is formed and an area where the low glossy picture ink layer is not formed; the surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition; and the surface protective layer has a thickness of 1 to 30 μm.Capable of being provided are a decorative sheet which has a high abrasion resistance and a high scratch resistance and is provided with a good moldability and which has a surface protective layer causing no cracks and is provided with a high design property and used for molding a decorated molding, a production process for a decorated resin molding by using the above decorative sheet and a decorated resin molding produced by the above production process.

Owner:DAI NIPPON PRINTING CO LTD

Catalyst for polymerization of conjugated diene and method of polymerization conjugated diene using the catalyst, rubber composition for tires, and rubber composition for golf balls

InactiveUS20090105401A1High activityExcellent resistanceOrganic-compounds/hydrides/coordination-complexes catalystsSpecial tyresIonConjugated diene

[Subject] a catalyst for polymerization of conjugated diene is provided, which facilitates manufacture of a conjugated diene polymer with a high 1,4-cis structure content, leaves less aluminum residue on polymerization, and has high activity. A method of manufacturing conjugated diene polymers using the catalyst is also provided.[Solution] A catalyst for polymerization of conjugated diene comprises (A) an yttrium compound; (B) an ionic compound including a non-coordinate anion and a cation; and (C) an organometallic compound including an element selected from the groups 2, 12 and 13 of the periodic table.

Owner:UBE IND LTD

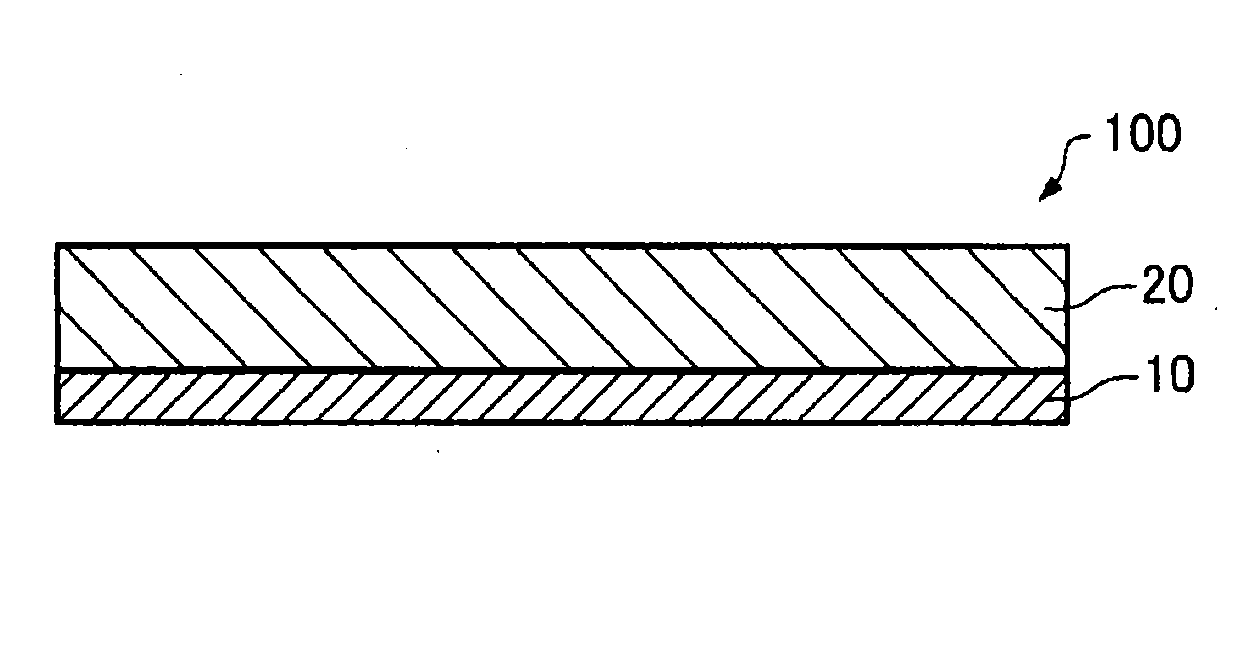

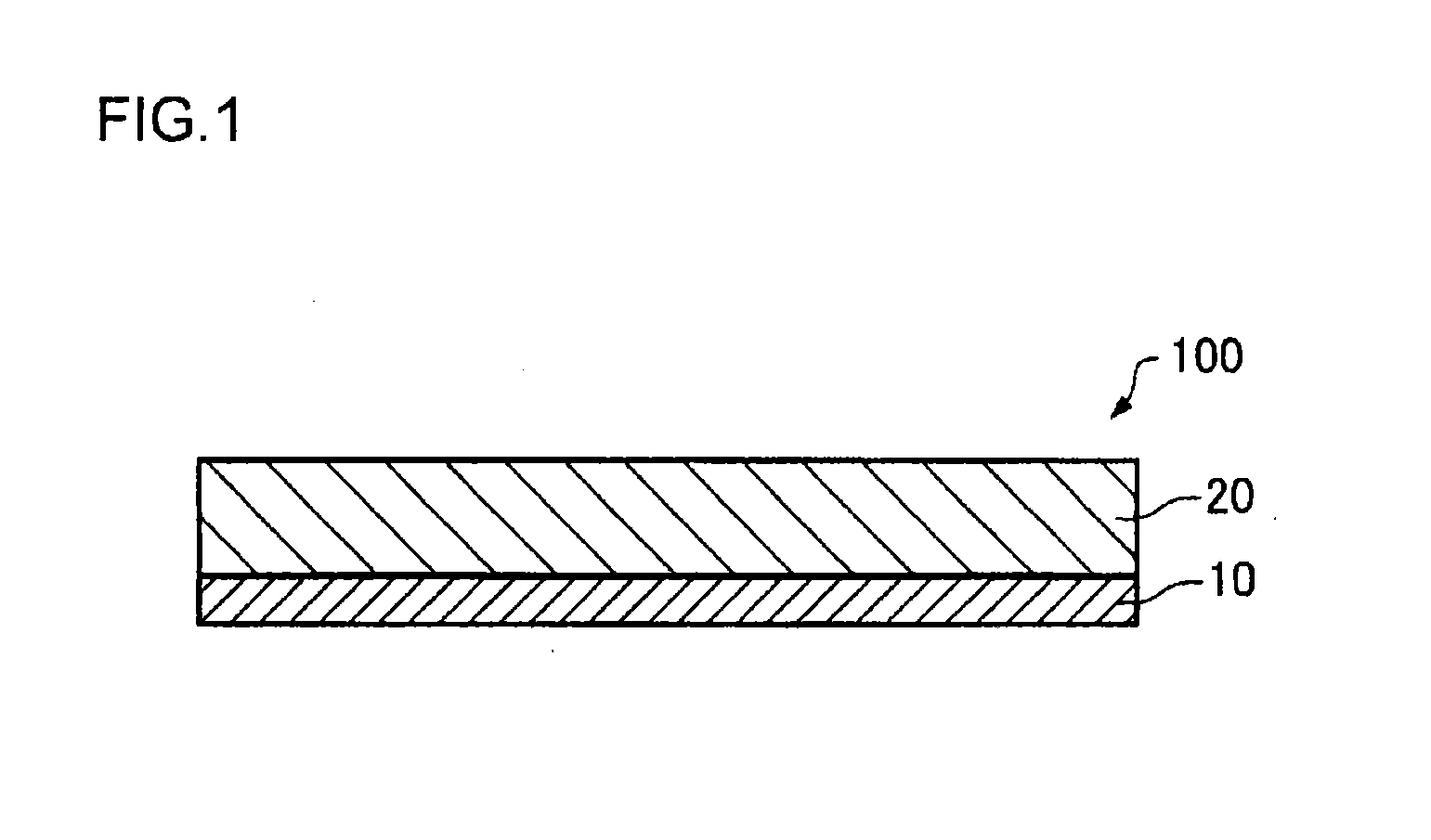

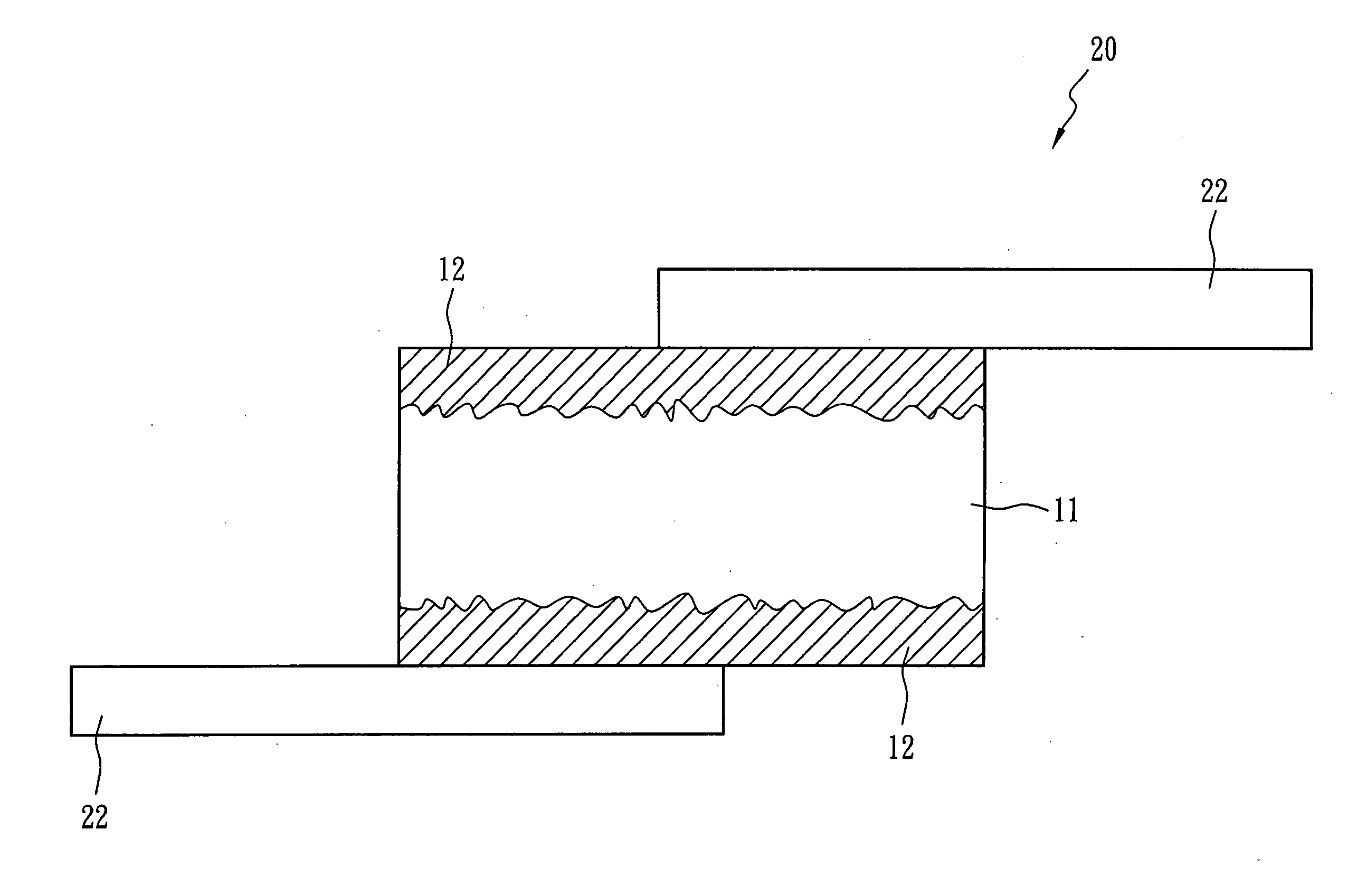

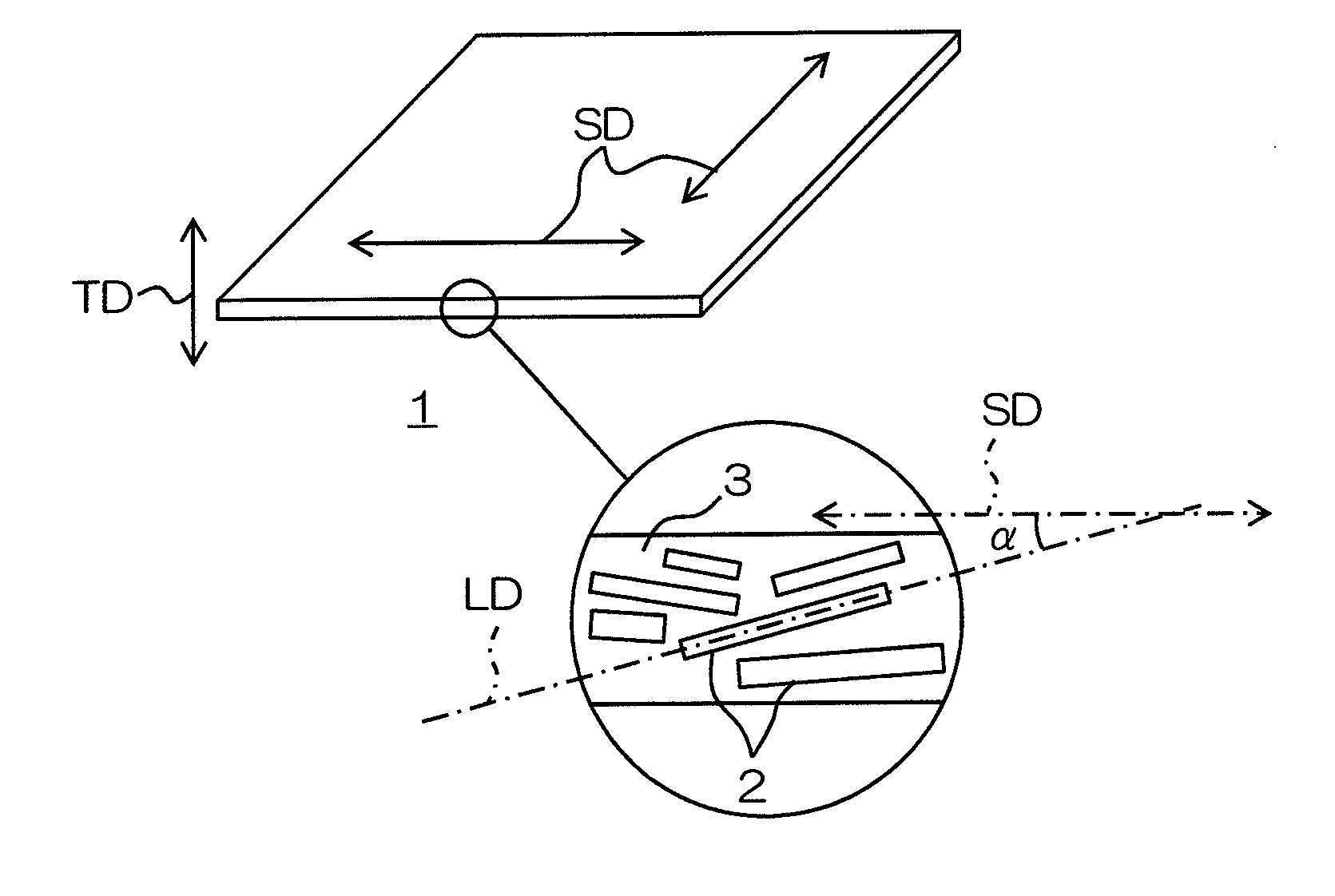

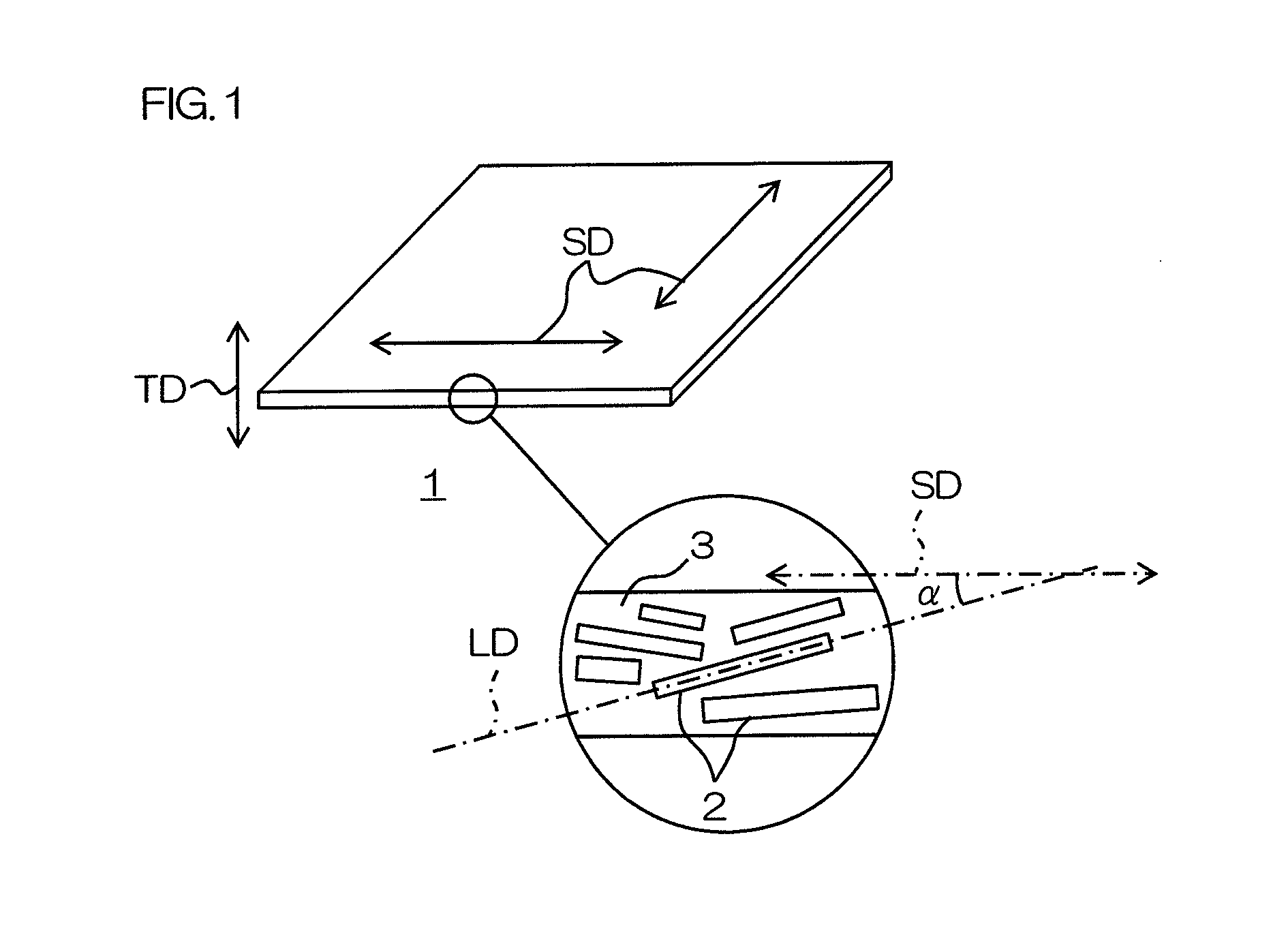

Thermal conductive sheet

InactiveUS20110259564A1Excellent thermal conductivityExcellent resistanceSolid-state devicesLaminationThermal conductivityThermal transmittance

A thermal conductive sheet contains a plate-like boron nitride particle, wherein the thermal conductivity in a direction perpendicular to the thickness direction of the thermal conductive sheet is 4 W / m·K or more. The breakdown voltage of the thermal conductive sheet as measured in conformity with JIS C 2110 (2010) is 10 kV / mm or more.

Owner:NITTO DENKO CORP

Microporous polyolefin membrane and method for producing the same

InactiveUS20090098341A1Large pore diameterExcellent resistanceMembranesSemi-permeable membranesSolventPolyolefin

The microporous polyolefin membrane obtained by stretching a gel molding comprising a polyolefin and a membrane-forming solvent at least uniaxially, heat-setting it, removing the membrane-forming solvent, and re-stretching it at least uniaxially has a large pore diameter and excellent air permeability, mechanical strength and compression resistance.

Owner:TORAY BATTERY SEPARATOR FILM

Reading-out amplifier and MRAM (Magnetic Random Access Memory) chip

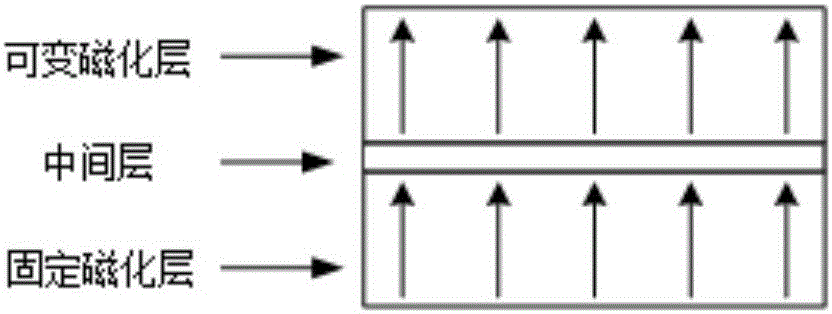

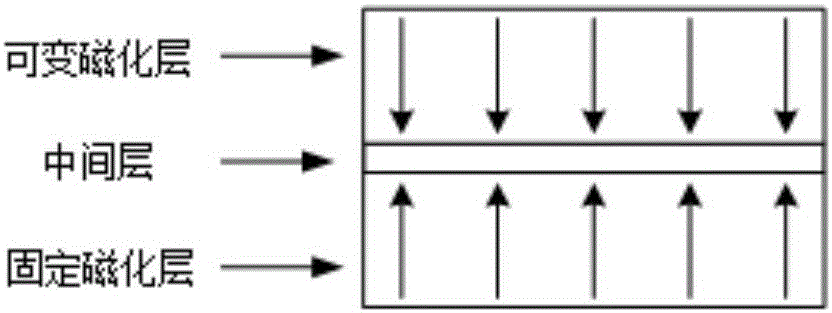

ActiveCN105761745AImprove MRAM chip yieldExcellent resistanceDigital storageSense amplifierOutput compare

The invention provides a reading-out amplifier. The reading-out amplifier comprises an input part and a differential current output part, wherein the input part and the differential current output part are connected at a first input end V_in and a second input end V_in_n of the input part; the first input end V_in is used for inputting current passing through a storage unit; the second input end V_in_n is used for inputting current passing through a reference unit; the differential current output part is used for comparing two currents input by the input part and outputting a comparing result. The invention further provides an MRAM (Magnetic Random Access Memory) chip. According to the reading-out amplifier and the MRAM chip, provided by the invention, the resistance is optimal, so that the reading-out speed is rapider and reading-out operation saves more power; the distribution of reference resistance becomes narrow, the fault probability for judging a high-resistance state and a low-resistance state is reduced and the yield of the MRAM chip is improved; parameters are selected so that the resistance of a combined reference unit is mostly close to an optimal selection, and furthermore, the yield of the MRAM chip is improved.

Owner:SHANGHAI CIYU INFORMATION TECH

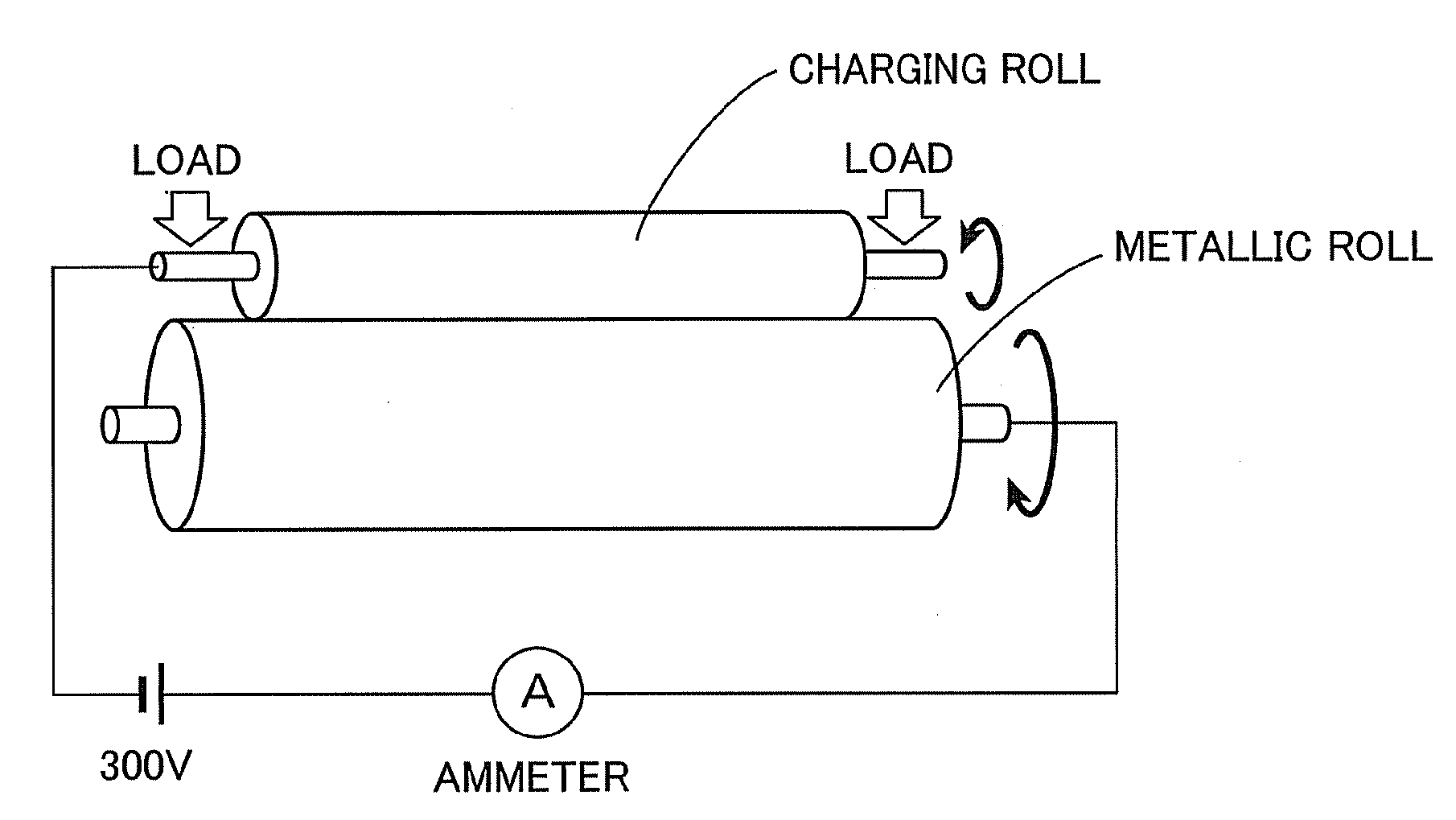

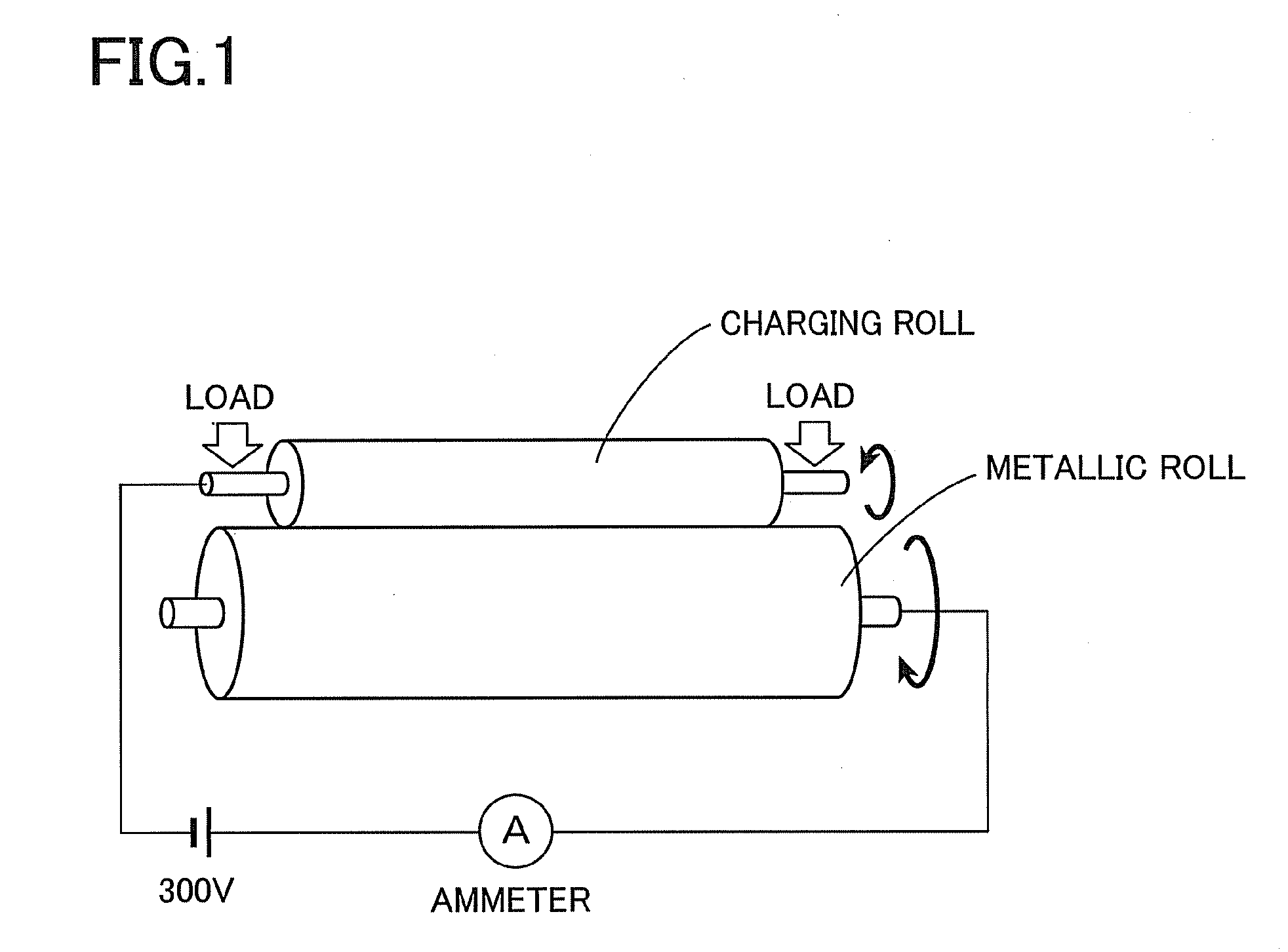

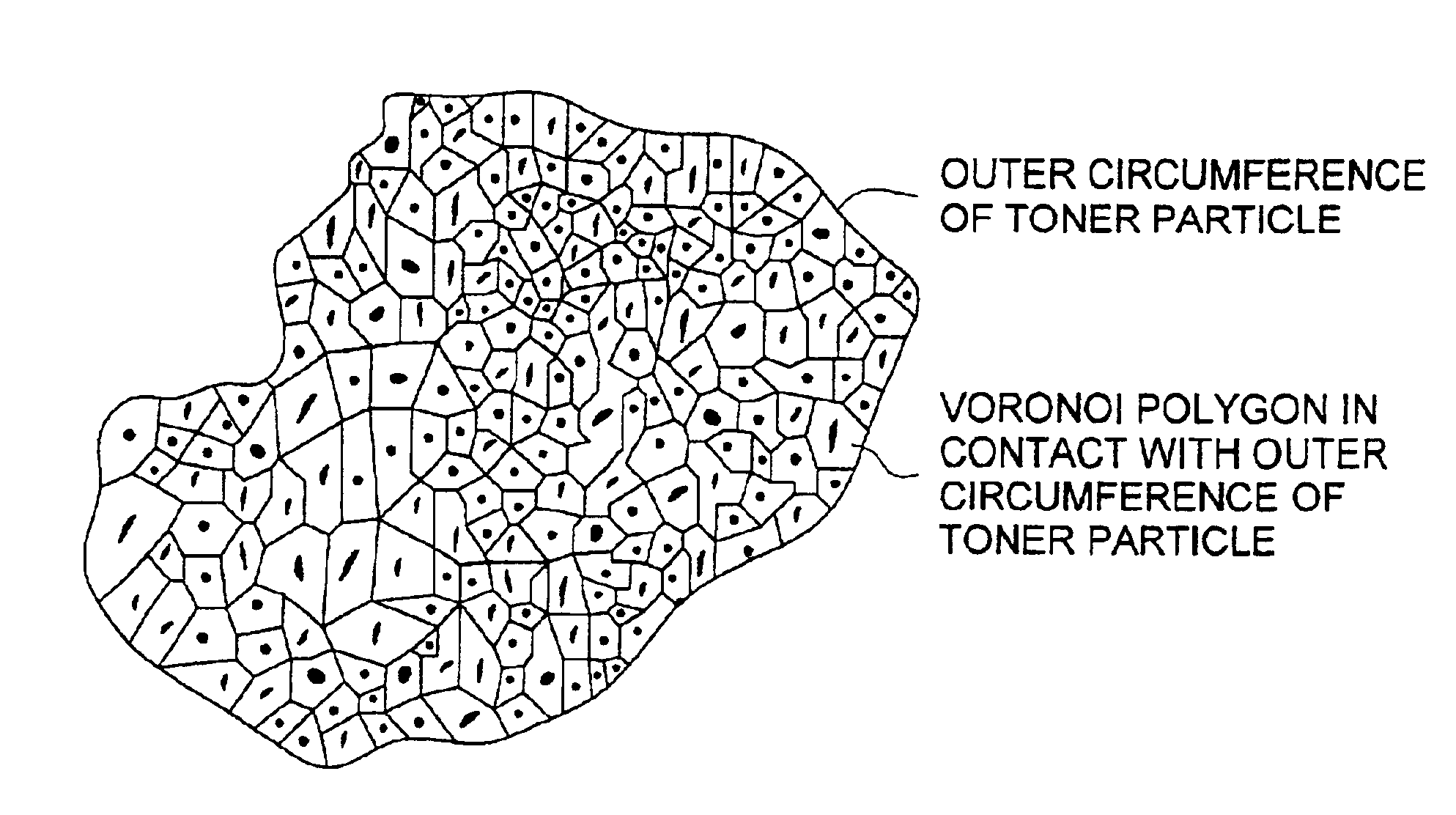

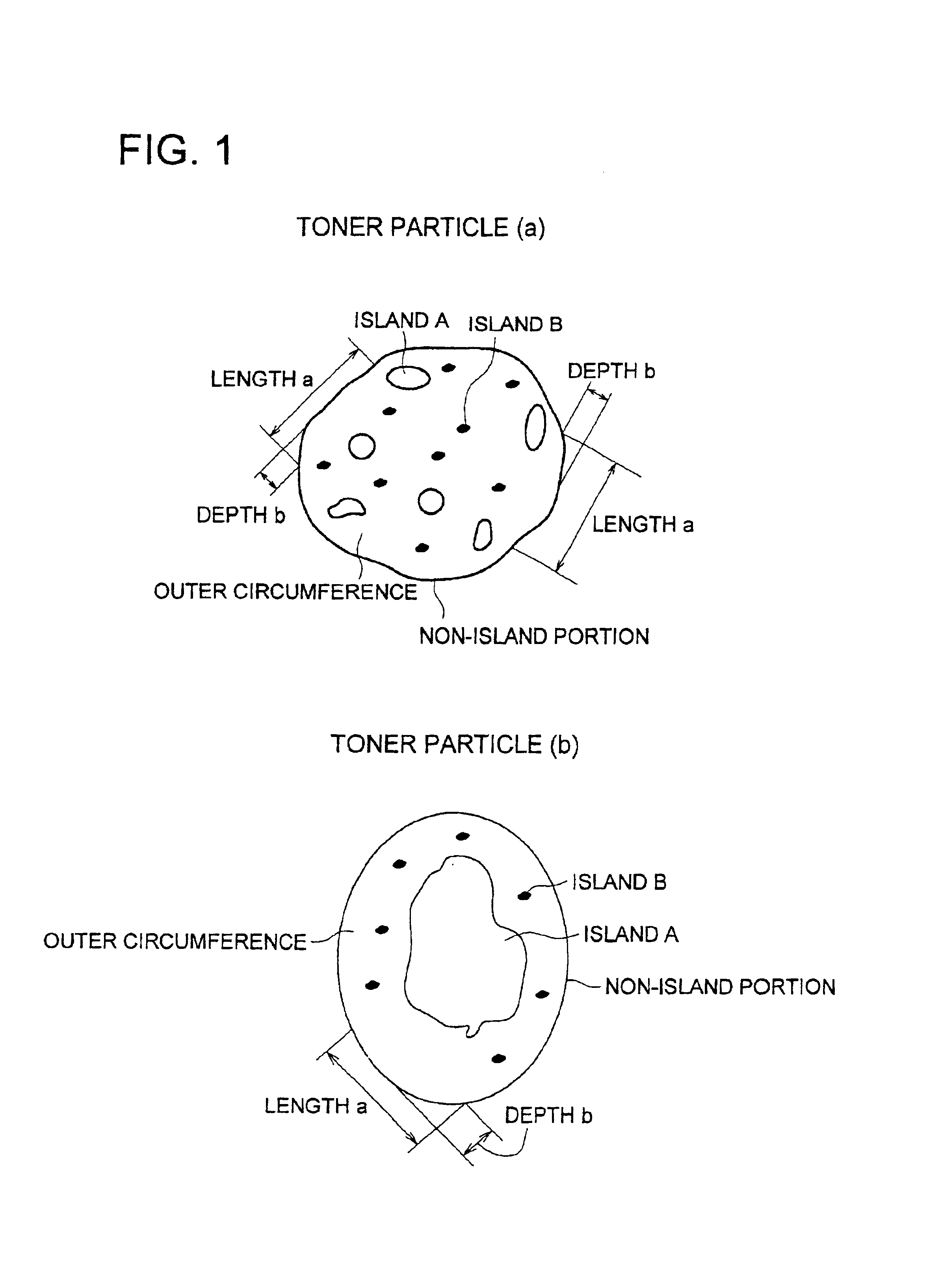

Charging roll

ActiveUS20090005225A1Hardness be lowExcellent resistanceLiquid surface applicatorsShaft and bearingsIonEngineering

A charging roll includes a shaft and an ionically conductive elastic layer formed around the shaft. The ionically conductive elastic layer is formed of a rubber composition free of any electron-conductive agent and containing 0.7 to 1.0 parts by weight of a peroxide cross-linking agent per 100 parts by weight of an ion-conductive rubber. The ion-conductive rubber is formed of at least one of an epichlorohydrin rubber and a nitrile rubber, and a percentage of a rubber component in the ionically conductive elastic layer measured by thermogravimetric analysis is 90% or more by weight.

Owner:TOKAI RUBBER IND LTD

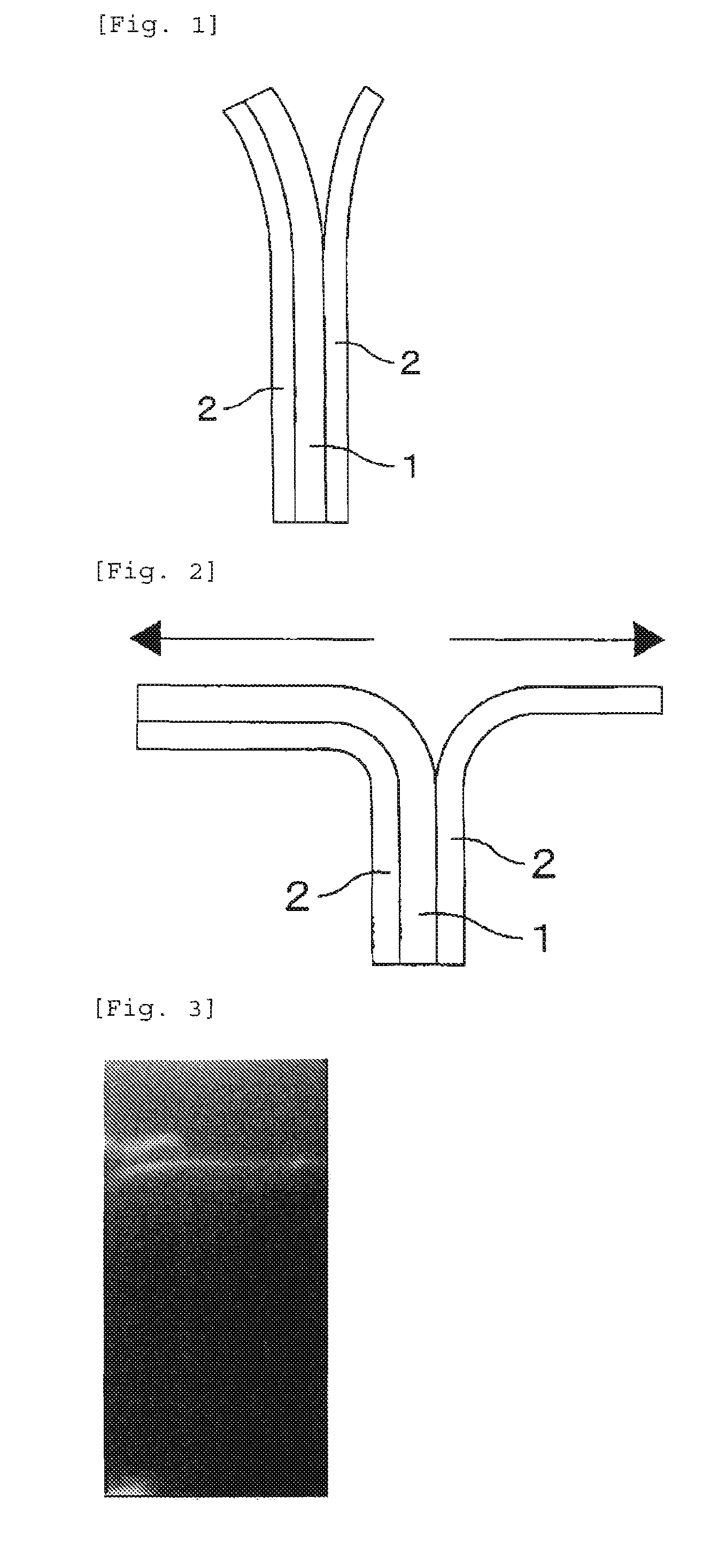

Heat shrinkable multilayer film and heat shrinkable label

InactiveUS20130337278A1Excellent resistanceExcellent in low temperature shrinkabilityStampsBottlesChemistryPolystyrene

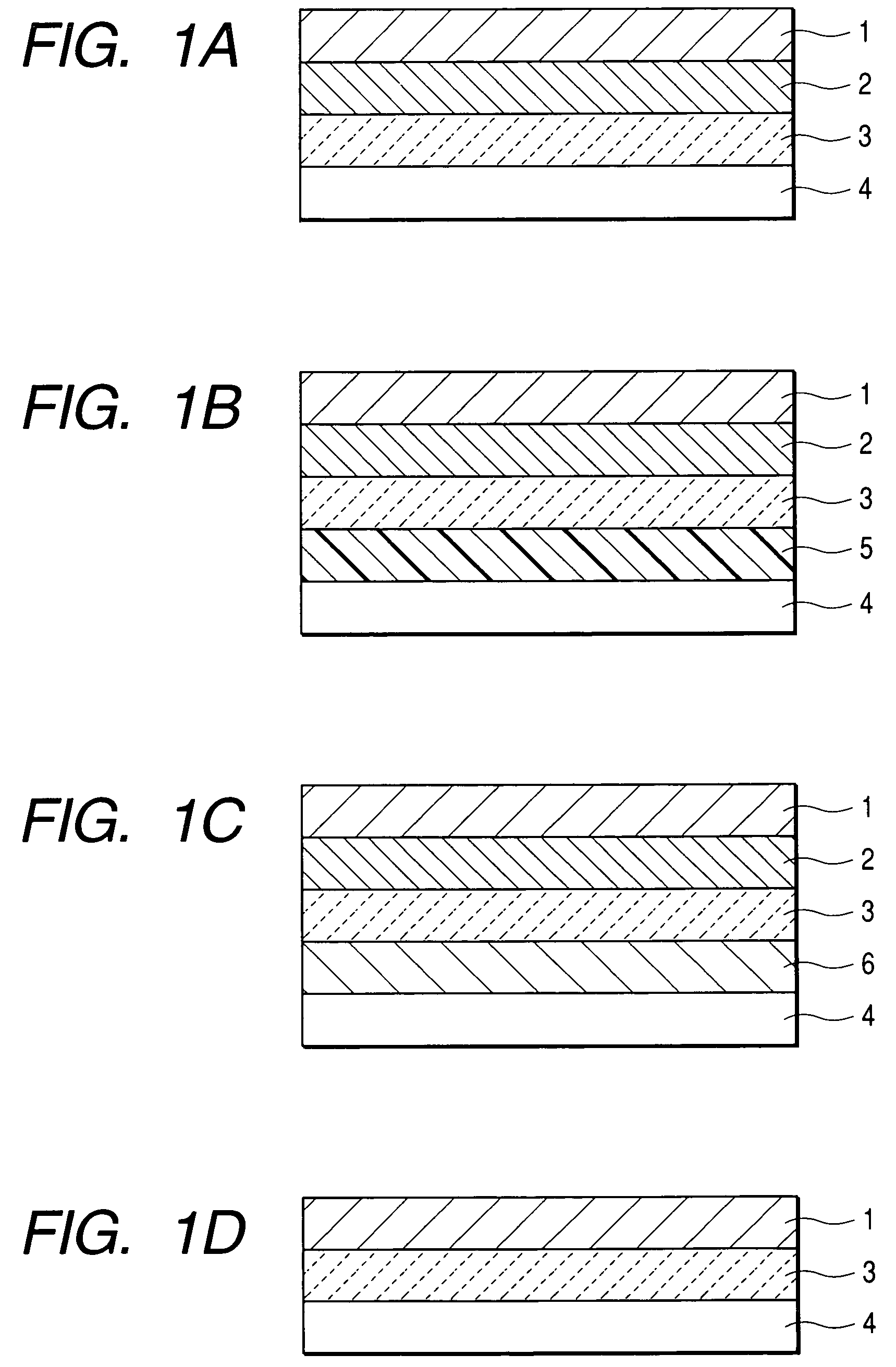

The present invention provides a heat shrinkable multilayer film excellent in crease-whitening resistance and perforation aptness as well as excellent in low-temperature shrinkability. The present invention also provides a heat shrinkable label formed from the heat shrinkable multilayer film. The heat shrinkable multilayer film of the present invention includes: front and back layers each containing a polyester resin; an interlayer containing a polystyrene copolymer; and adhesive layers each containing 60 to 85% by weight of a polyester resin and 15 to 40% by weight of a polystyrene copolymer. The front and back layers and the interlayer are stacked with the adhesive layers interposed therebetween. The multilayer film has a tensile elongation at break of 30% or higher in the main shrinkage direction.

Owner:GUNZE LTD

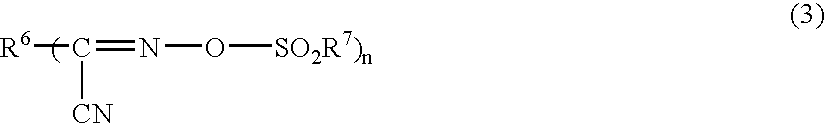

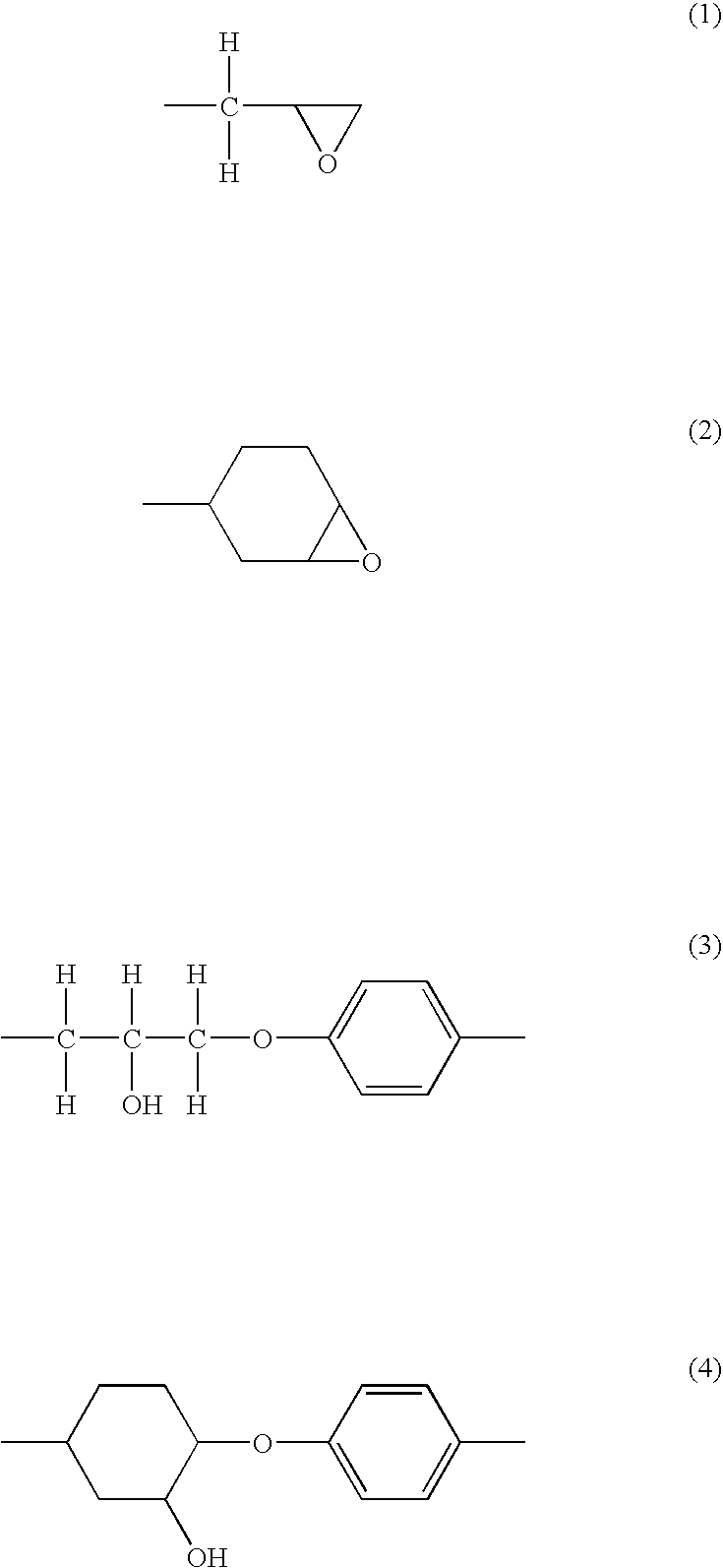

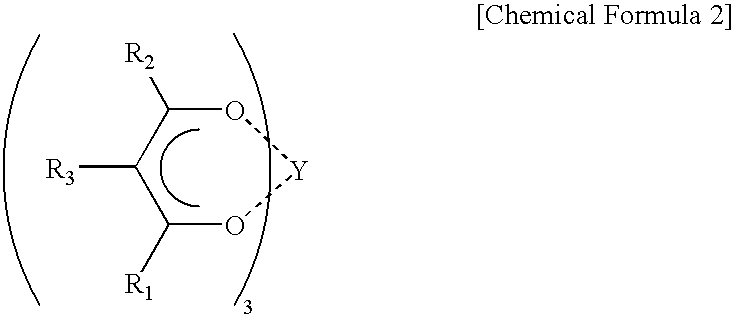

Compound containing phenolic hydroxy group, photosensitive composition, composition for resists, resist coating film, curable composition, composition for resist underlayer films, and resist underlayer film

ActiveUS20160159962A1Excellent heat resistanceExcellent resistanceOrganic chemistryPhotosensitive materialsResistPhenols

Provided is a compound containing a phenolic hydroxy group which has excellent heat resistance, a resist composition which has excellent thermal decomposition resistance, optical sensitivity and resolution, and a composition for a resist underlayer coating which has excellent thermal decomposition resistance and dry etching resistance. The compound containing a phenolic hydroxy group has a molecular structure represented by Structural Formula (1) below:wherein R1 is a hydrogen atom, an alkyl group or an aryl group, n is an integer of 2 to 10, R2 is any one of an alkyl group, an alkoxy group, an aryl group, an aralkyl group and a halogen atom, m is an integer of 0 to 4, and when m is 2 or greater, a plurality of R2's may be the same as or different from each other and may be bonded to either one of two aromatic rings of the naphthylene skeleton.

Owner:DAINIPPON INK & CHEM INC

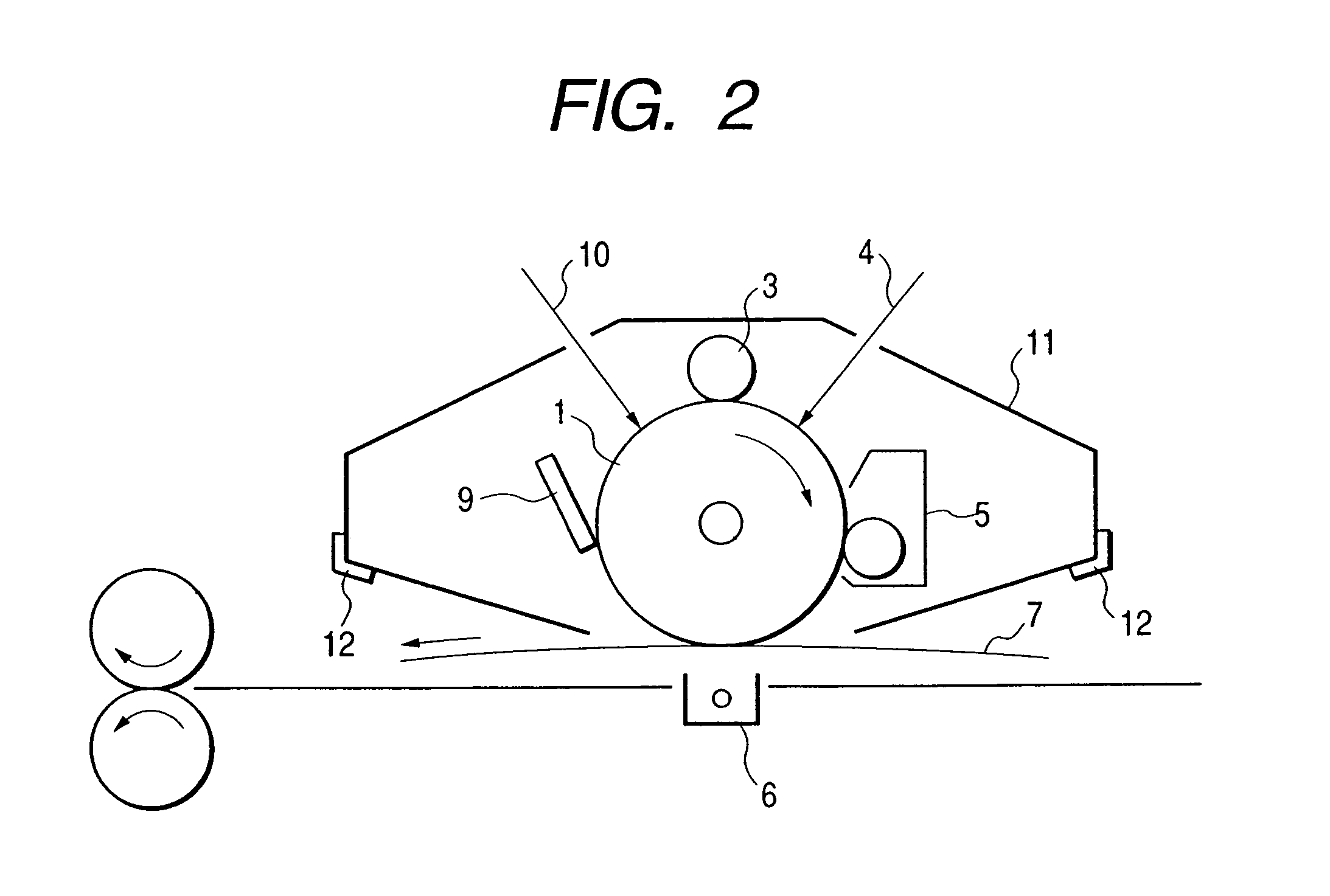

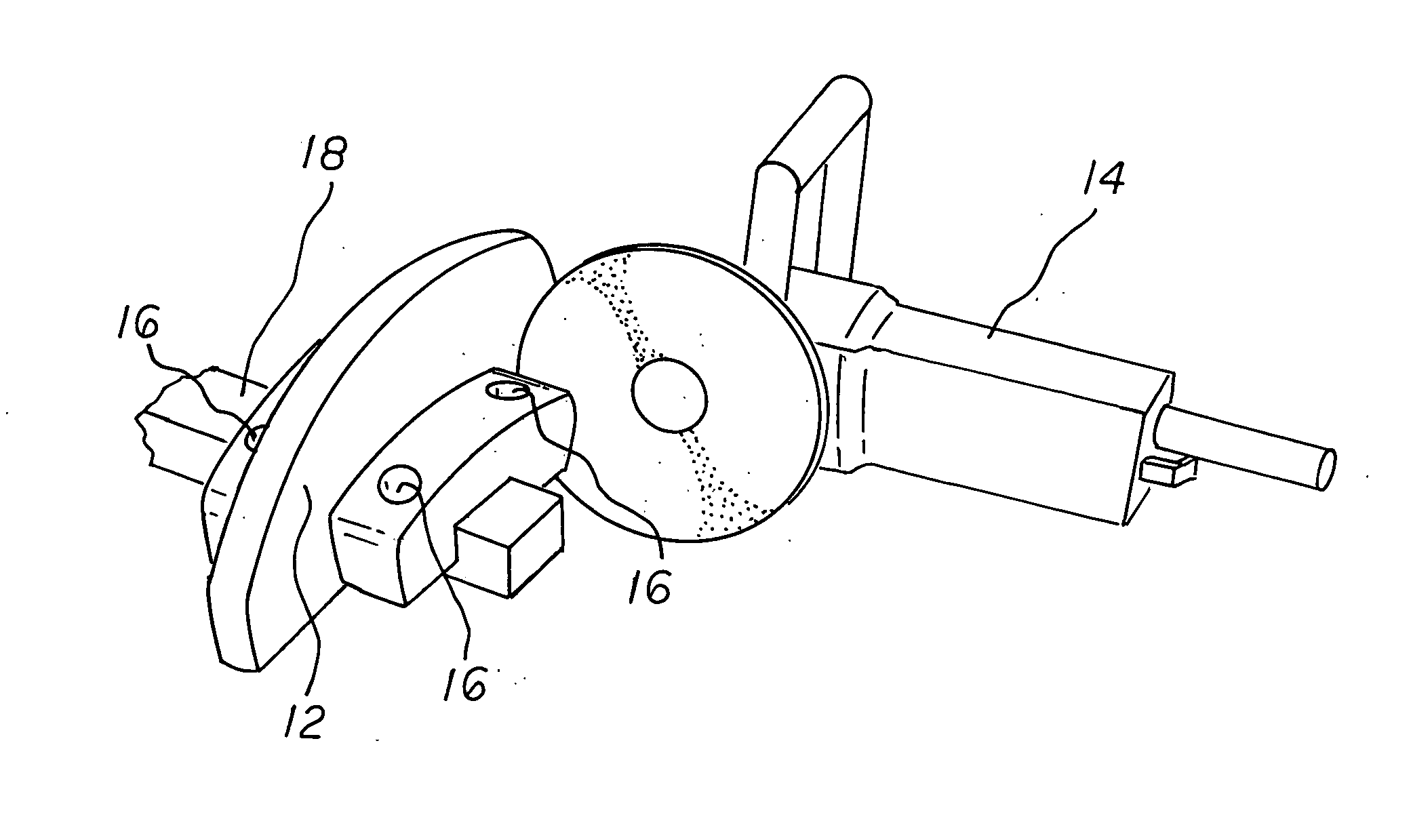

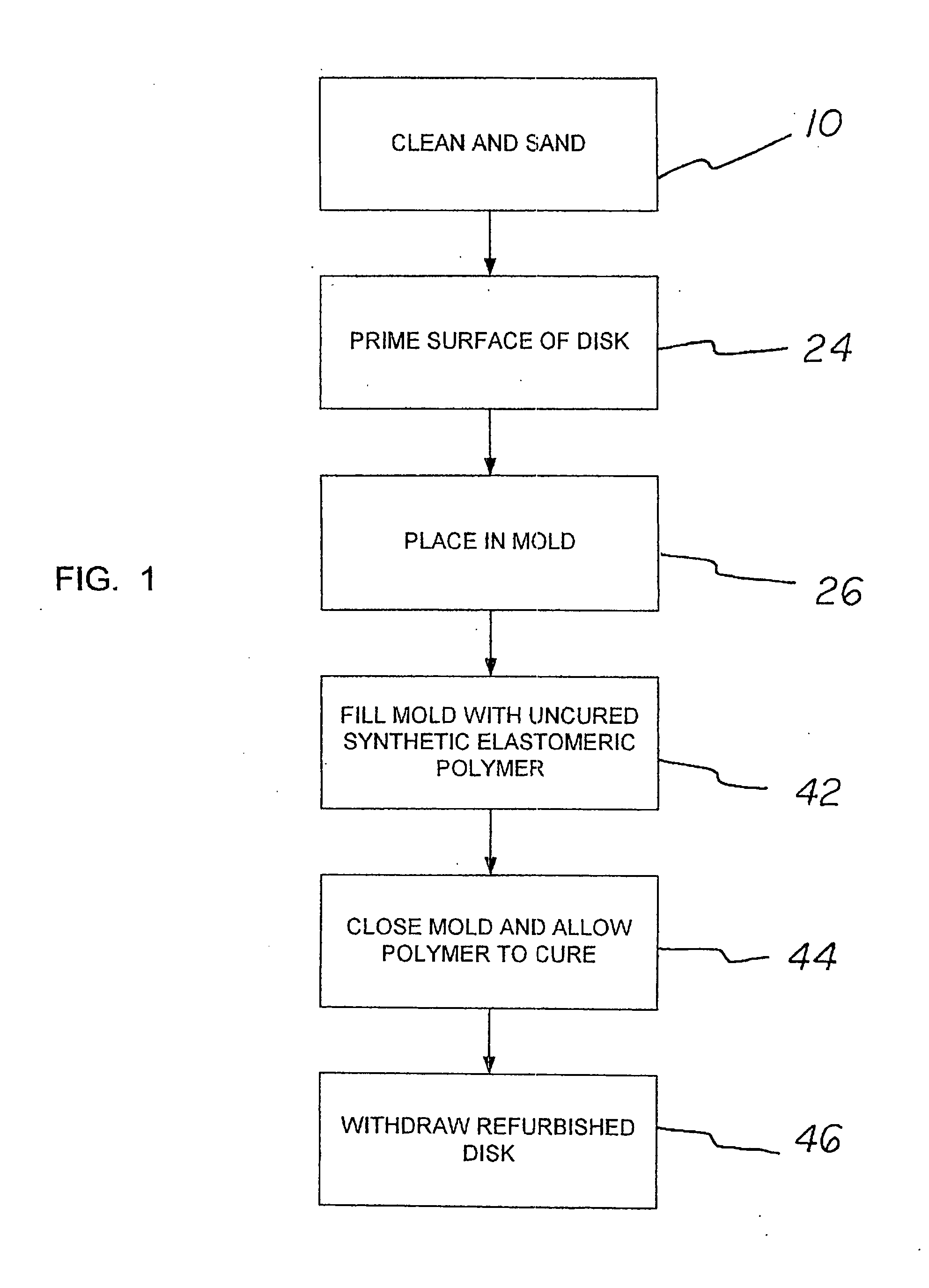

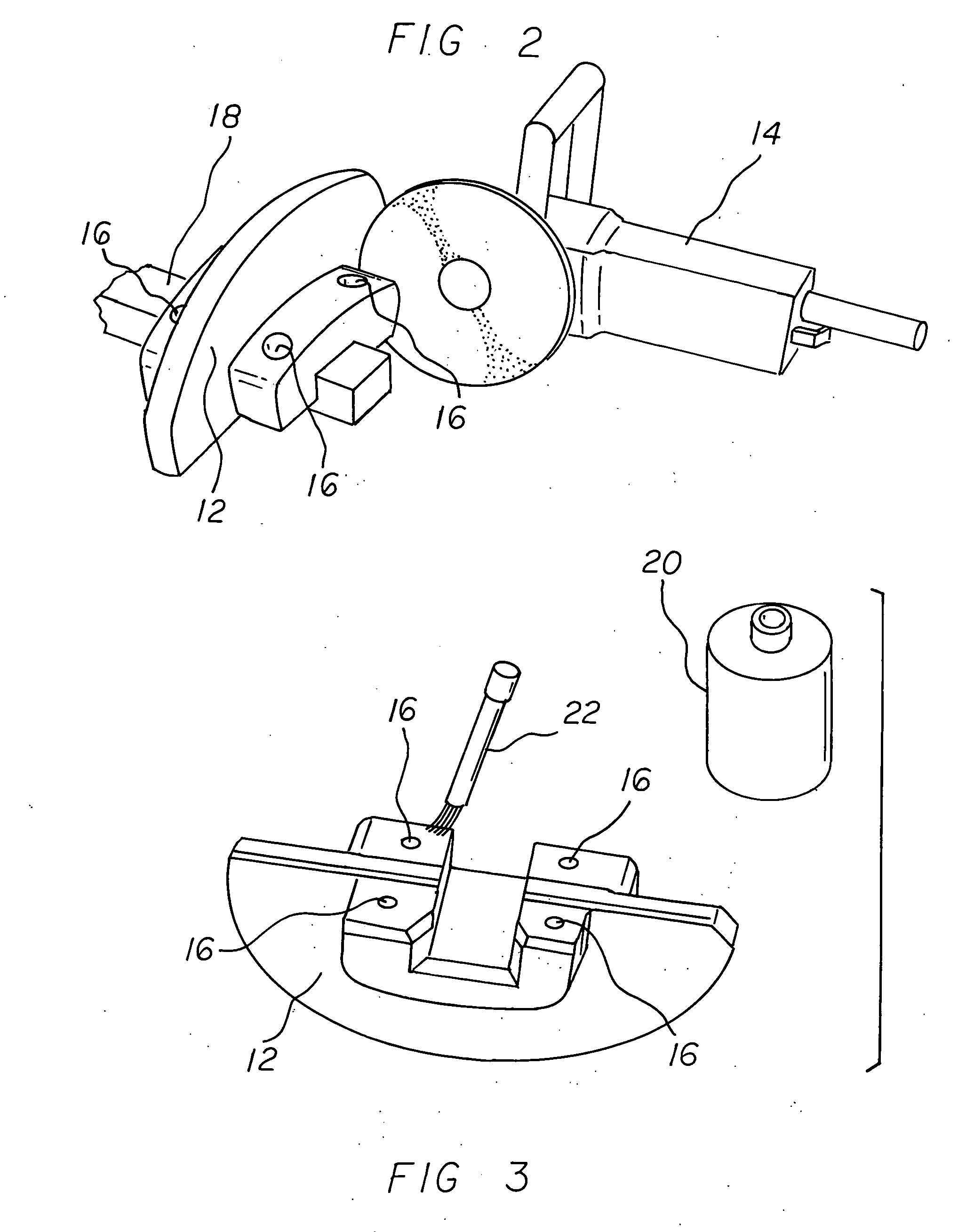

Method of refurbishing recycle disc

A novel method for refurbishing a rubber disc used in a recycle machine comprises the steps of cleaning and sanding the surface of the disc; priming at least the surface of the disc with a liquid primer or interfacing agent (adhesive); placing the disc in a portion of a mold; charging or filling the mold with a polymer (synthetic rubber or elastomer) mixed with a suitable catalyst, hardener or activator; allowing the synthetic rubber polymer to exothermally cure inside the mold; and withdrawing the disc from the mold. The resulting refurbished disc is characterized by a new outer surface layer (synthetic rubber) adhered to the original rubber disc. In an alternatively preferred method, one or more relatively small holes are formed in the surface of the disc prior to molding the new outer surface layer on the disc whereupon the strength of the bond between the new outer layer and the original disc is enhanced.

Owner:SEIKO INSTR INC

Outstandingly abrasion resistant and pollution resistant coating composition and coating film

InactiveUS20120045594A1Abrasion resistance be excellentExcellent resistanceLiquid crystal compositionsMaterial nanotechnologyPhotoinitiatorNano sized particle

The present invention provides a coating composition and a coating film, which comprises a) a binder resin containing a UV-curable functional group; b) a compound containing a fluorine UV-curable functional group; c) a photoinitiator; d) nano-sized particles; and e) conductive inorganic particles.

Owner:LG CHEM LTD

Optically transparent pressure-sensitive adhesive sheet, laminate, process for producing laminate, and display device with touch panel

ActiveUS20180282586A1Excellent resistanceExcellent flexibilityPolyureas/polyurethane adhesivesSynthetic resin layered productsPressure sensitiveIsocyanate

The present invention provides an optically clear adhesive sheet using a heat-curable polyurethane composition, wherein the optically clear adhesive sheet can, when bonded to an adherend such as a glass plate, prevent the occurrence of air bubbles even at high temperature and normal humidity and maintain a stable bonded interface. The optically clear adhesive sheet of the present invention is an optically clear adhesive sheet containing: a cured product of a heat-curable polyurethane composition, the heat-curable polyurethane composition containing a polyol component and a polyisocyanate component, the polyol component having an olefin skeleton, the polyisocyanate component containing an acyclic aliphatic polyisocyanate and / or an alicyclic polyisocyanate.

Owner:BANDO CHEM IND LTD

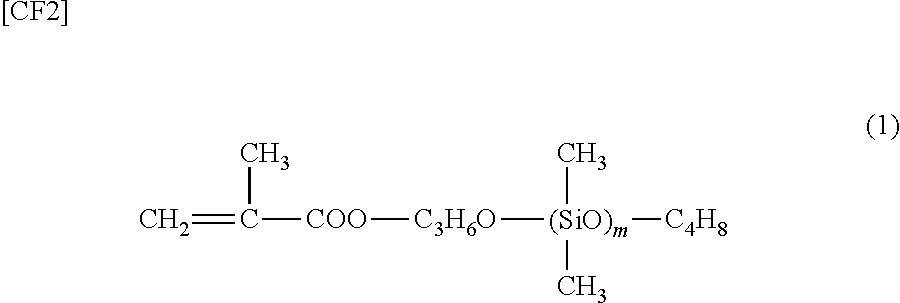

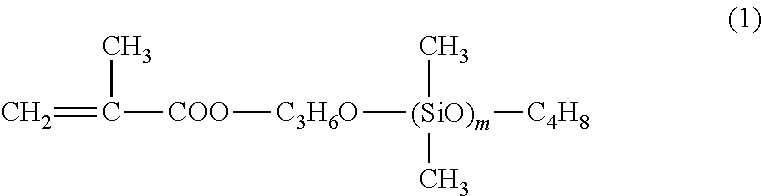

Surface property improving agent for molded bodies made of polyolefin resins, resin composition containing the same, and resin molded body made thereof

InactiveUS20150210842A1Abrasion resistance be enhanceExcellent resistanceEmulsion paintsWaxPolyolefin

A surface property-improving agent for molded bodies made of polyolefin resins contains 50.0 parts to 90.0 parts by mass of a non-polar wax with a melting point of 50° C. to 100° C. and 10.0 parts to 50.0 parts by mass of a vinyl copolymer obtained by copolymerizing two types of monomers (b1) and (b2). The sum of the non-polar wax and the vinyl copolymer is 100.0 parts by mass. The monomer (b1) is styrene and / or acrylonitrile. The vinyl copolymer contains 0.1 parts to 49.9 parts by mass of the monomer (b1) and 0.1 parts to 9.9 parts by mass of the monomer (b2) wherein the sum of the monomer (b1) and the monomer (b2) is 10.0 parts to 50.0 parts by mass. To 100.0 parts by mass of a polyolefin resin, 0.5 parts to 10.0 parts by mass of the agent is added. The monomer (b2) is a methacryloxypropyl polyorganosiloxane.

Owner:NOF CORP +1

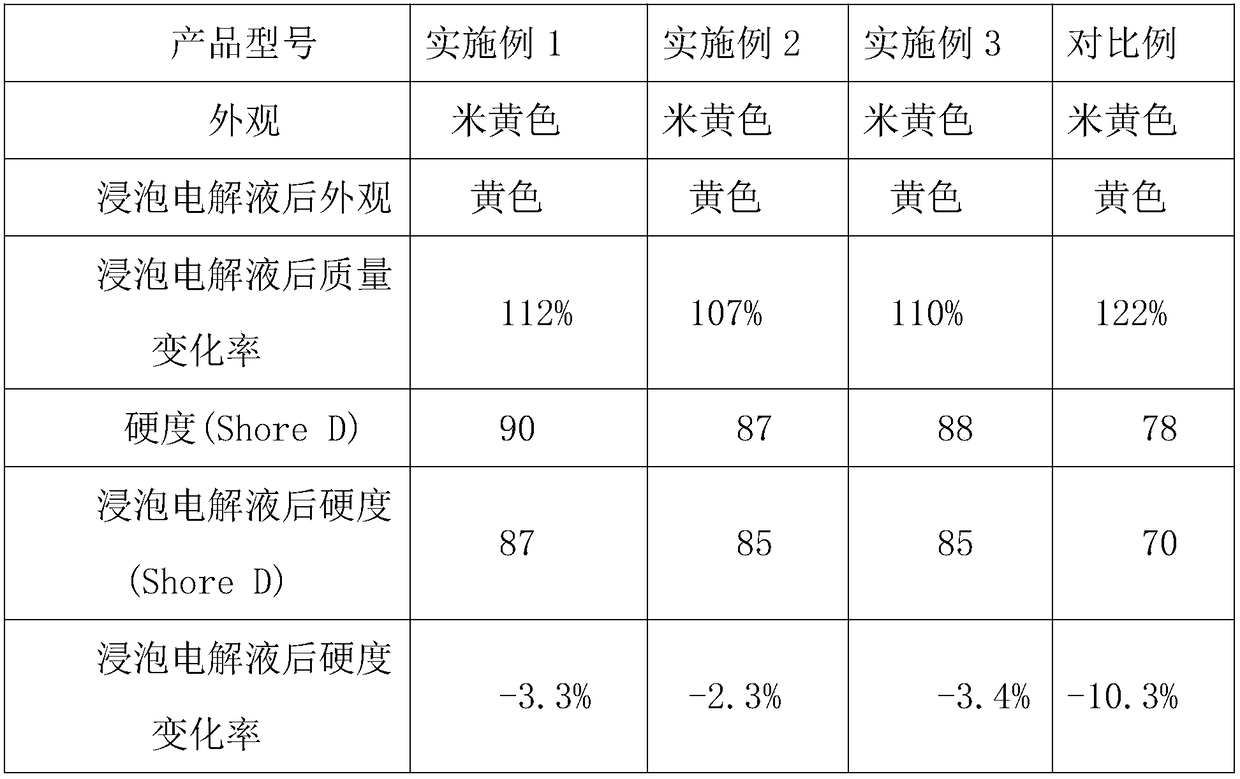

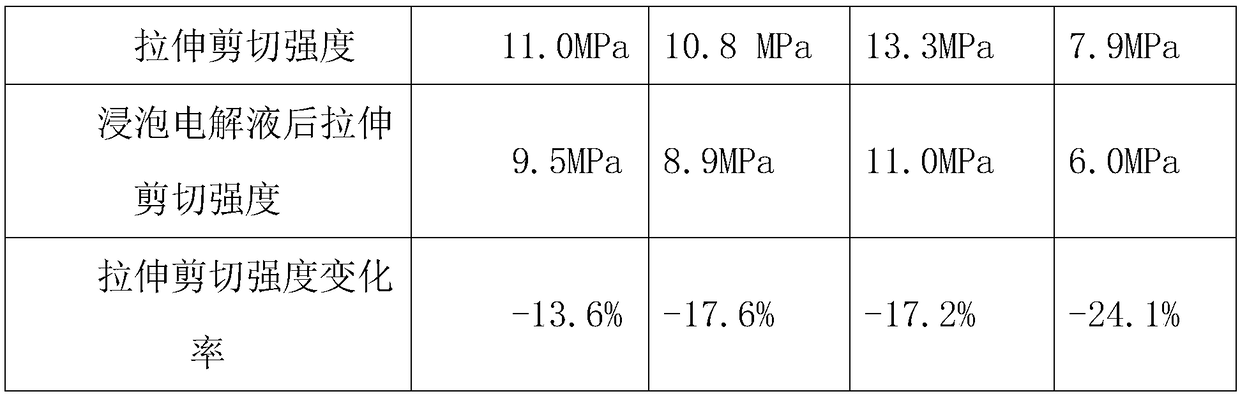

Preparation method of lithium ion battery electrolyte corrosion resisting double-component epoxy adhesive

InactiveCN109456722AStable performanceExcellent resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesElectrical batteryCorrosion

The invention discloses a lithium ion battery electrolyte corrosion resisting double-component epoxy adhesive and a preparation method thereof. The lithium ion battery electrolyte corrosion resistingdouble-component epoxy adhesive is composed of a component A and a component B, wherein the component A is composed of raw materials including, by weight part, 30-50 parts of bisphenol A type epoxy resin, 20-40 parts of polyurethane modified epoxy resin, 1-4 parts of coupling agent, 2-8 parts of active diluent and 15-35 parts of filler; the component B is composed of raw materials including, by weight part, 50-70 parts of modified amine hardener, 2- parts of amine hardener, 0-2 parts of imidazole hardener, 1-3 parts of accelerator and 20-40 parts of filler. The lithium ion battery electrolytecorrosion resisting double-component epoxy adhesive is stable in performing when in electrolytes, excellent in resistance to corrosion of lithium ion battery electrolytes, high in heat resistance andelectrochemical stability and capable of maintaining high strength in the electrolytes, thereby being applicable to bonding and sealing of parts exposed in electrolyte environment during lithium ion battery manufacturing and meeting the demands of lithium battery manufacturing industry on adhesive application diversity.

Owner:广州市垠瀚能源科技有限公司

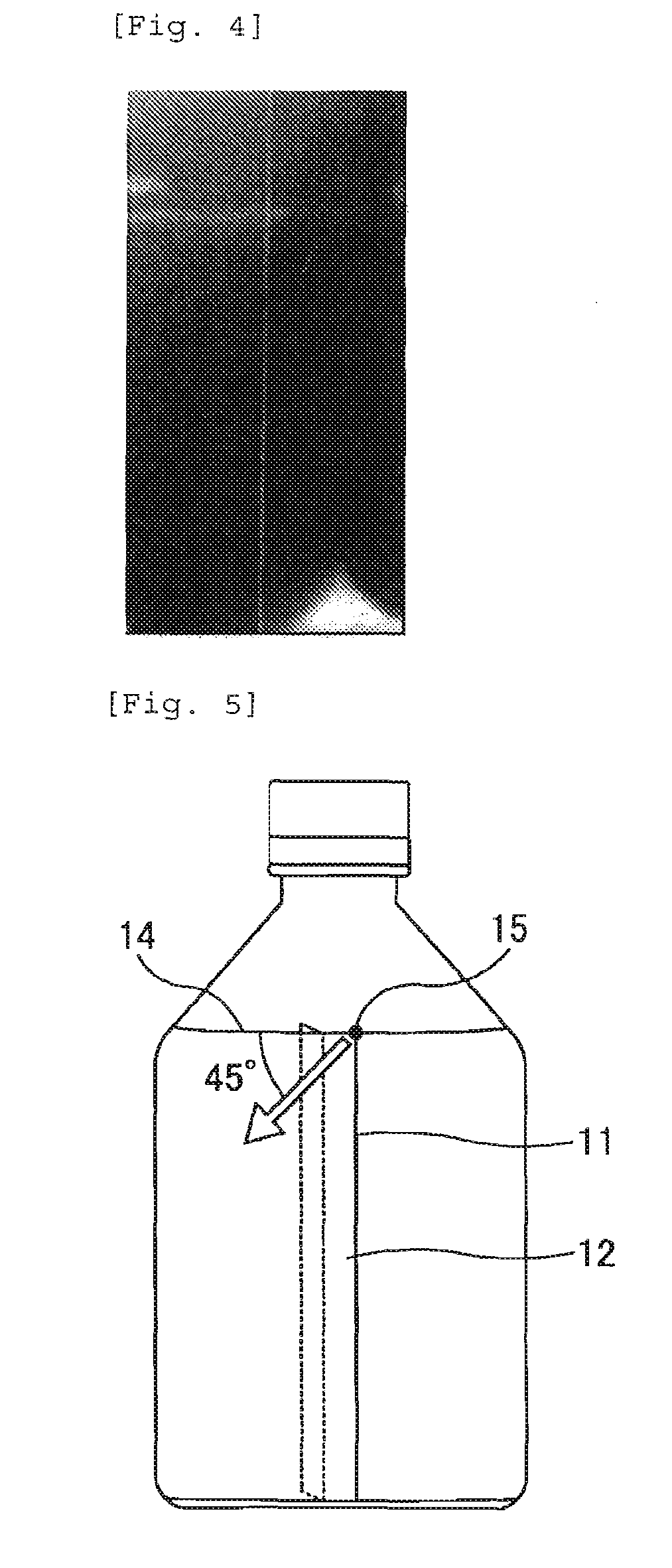

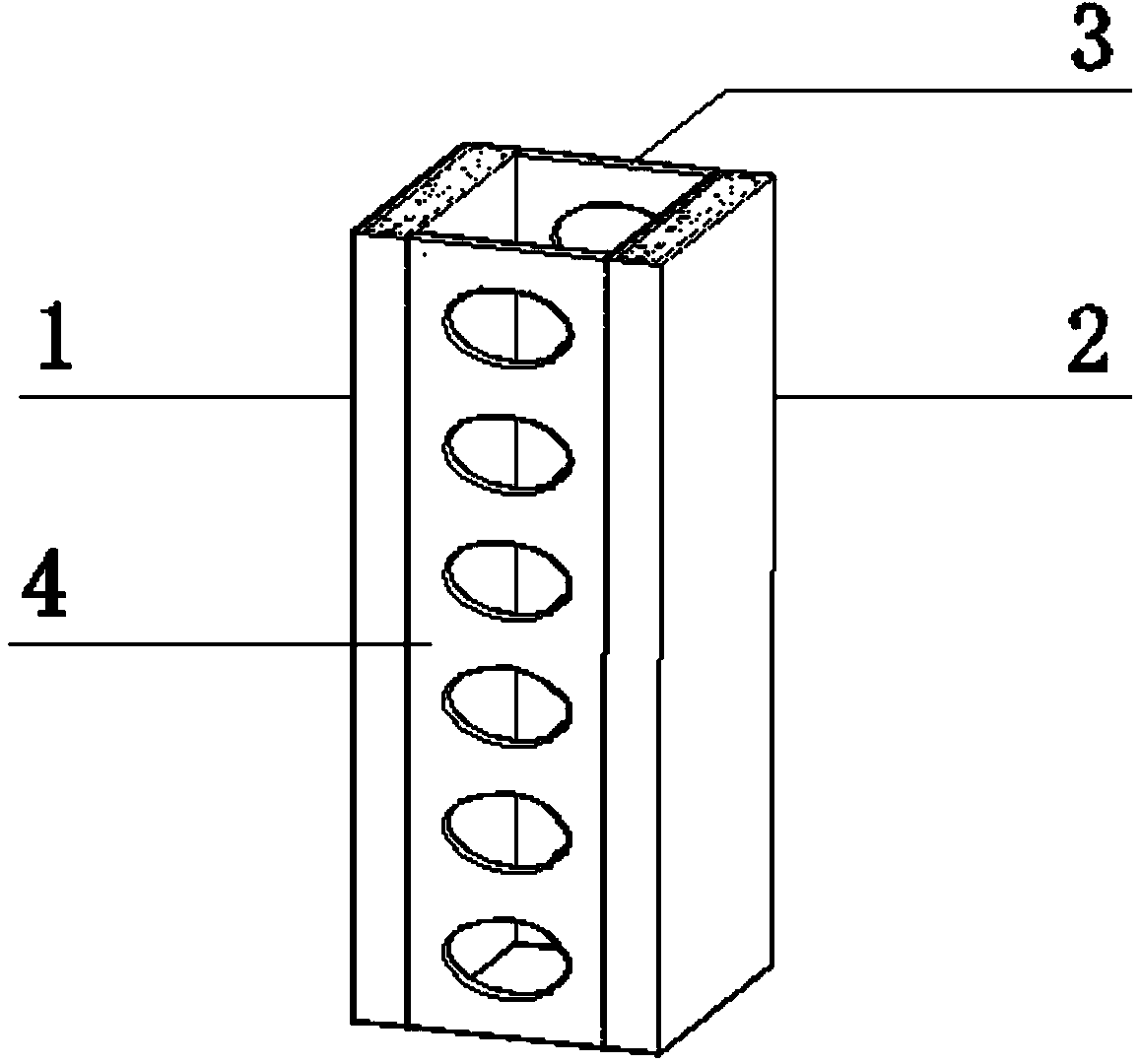

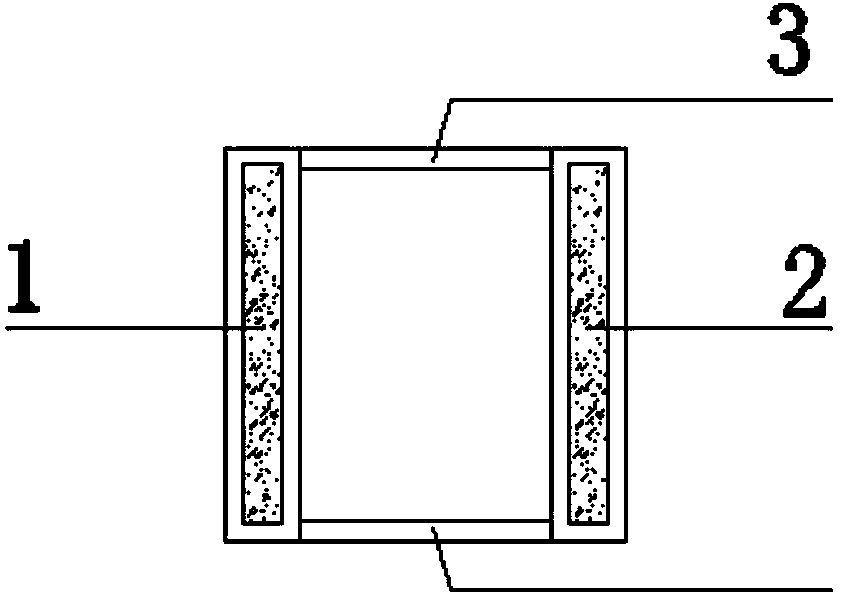

Cellular connection steel plate-double-limb steel pipe concrete composite column

The invention discloses a cellular connection steel plate-double-limb steel pipe concrete composite column, comprising a steel pipe concrete limb part 1, a steel pipe concrete limb part 2, a steel connection plate 1 and a steel connection plate 2, wherein two ends of the steel pipe concrete limb part 1 and the steel pipe concrete limb part 2 are respectively connected with each other through the steel connection plate 1 and the steel connection plate 2 to form a battened steel column; the steel connection plate 1 and the steel connection plate 2 are cellular connection plates with holes in the centers; the steel connection plate 1 and the steel connection plate 2 are respectively composed of two steel plates which are the same in shape and are provided with gaps in the edges; and the two steel plates are welded through a butt weld joint to form the cellular connection plate. According to the cellular connection steel plate-double-limb steel pipe concrete composite column, the mechanical behavior is improved, and the stability performances of a real axis and a virtual axis are fully approximate, so that the materials in the directions of two principal axes can bring into full play, the steel consumption is lowered, and the comprehensive cost of engineering is reduced.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com