Patents

Literature

68results about How to "Easily fabricate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

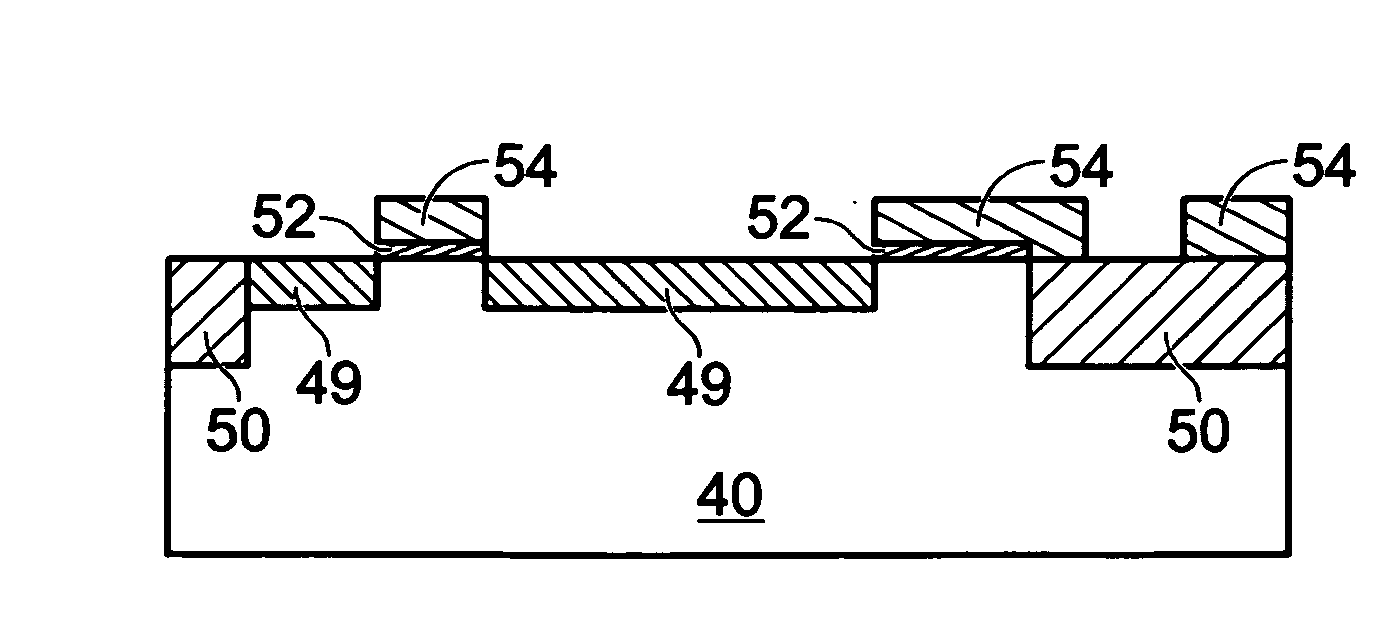

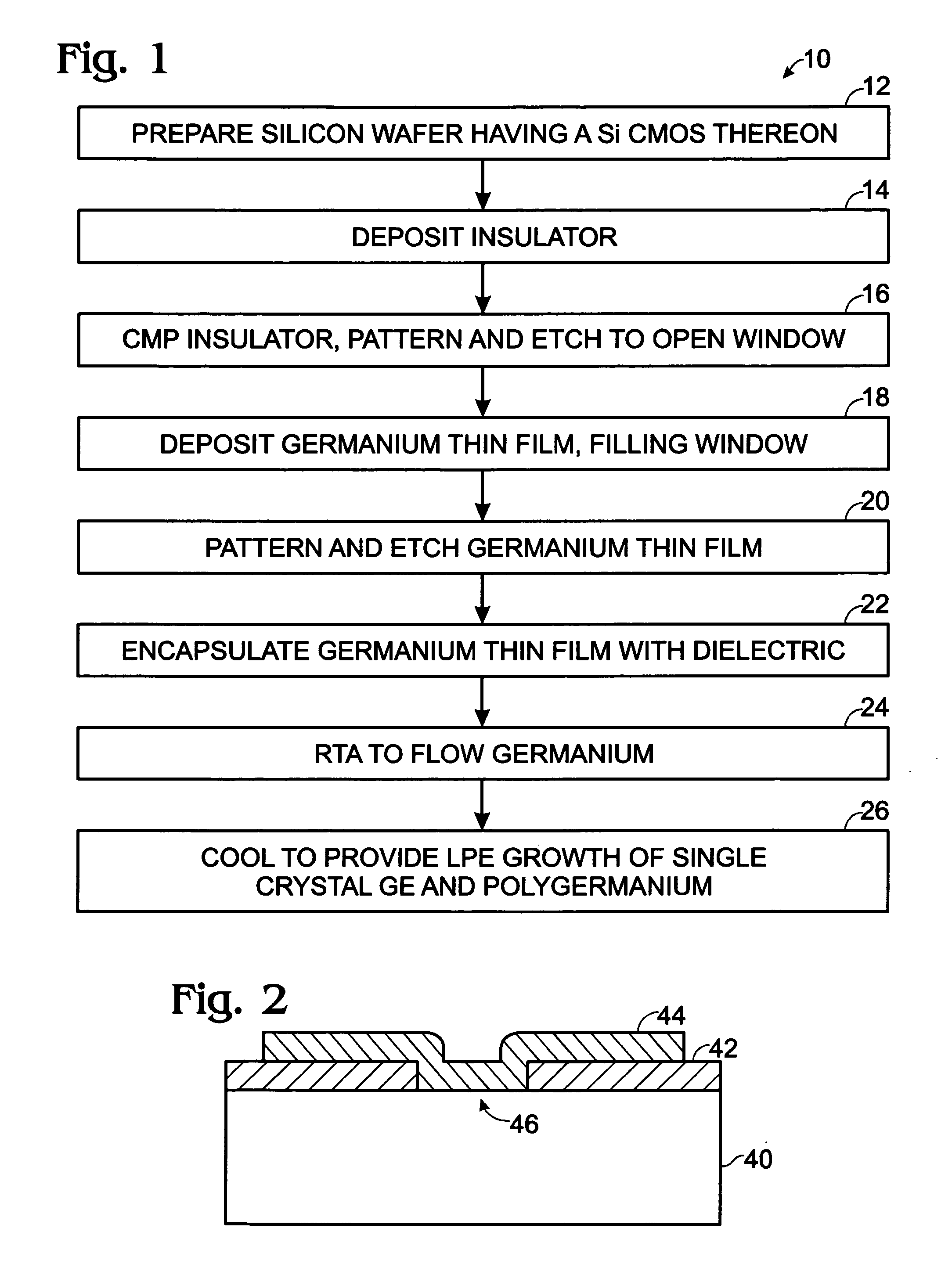

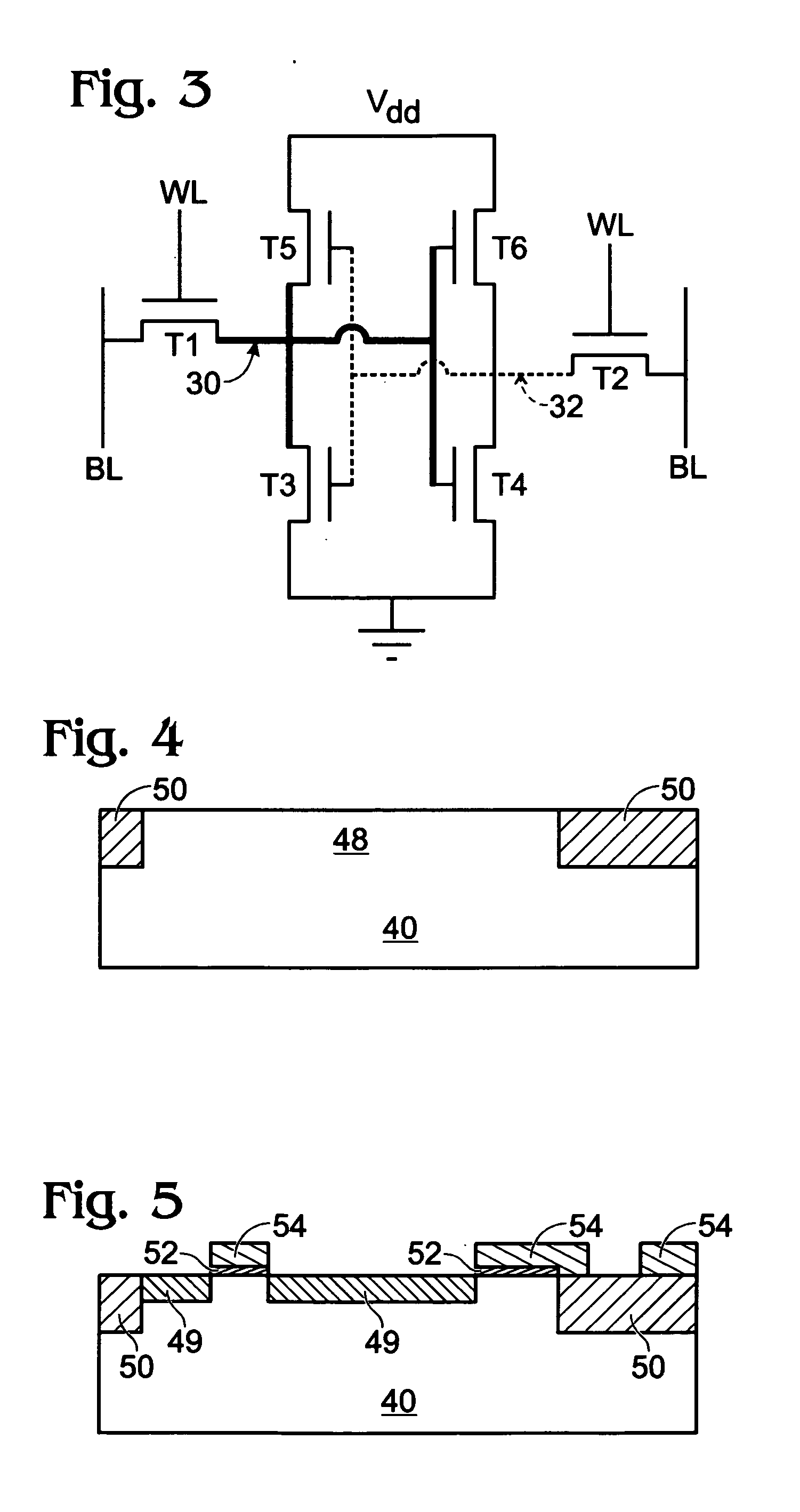

Method of fabricating local interconnects on a silicon-germanium 3D CMOS

A method of fabricating local interconnect on a silicon-germanium 3D CMOS includes fabricating an active silicon CMOS device on a silicon substrate. An insulator layer is deposited on the silicon substrate and a seed window is opened through the insulator layer to the silicon substrate and to a silicon CMOS device gate. A germanium thin film is deposited on the insulator layer and into windows, forming a contact between the germanium thin film and the silicon device. The germanium thin film is encapsulated in a dielectric material. The wafer is heated at a temperature sufficient to flow the germanium, while maintaining the other layers in a solid condition. The wafer is cooled to solidify the germanium as single crystal germanium and as polycrystalline germanium, which provides local interconnects. Germanium CMOS devices may be fabricated on the single crystal germanium thin film.

Owner:MICROSOFT TECH LICENSING LLC +1

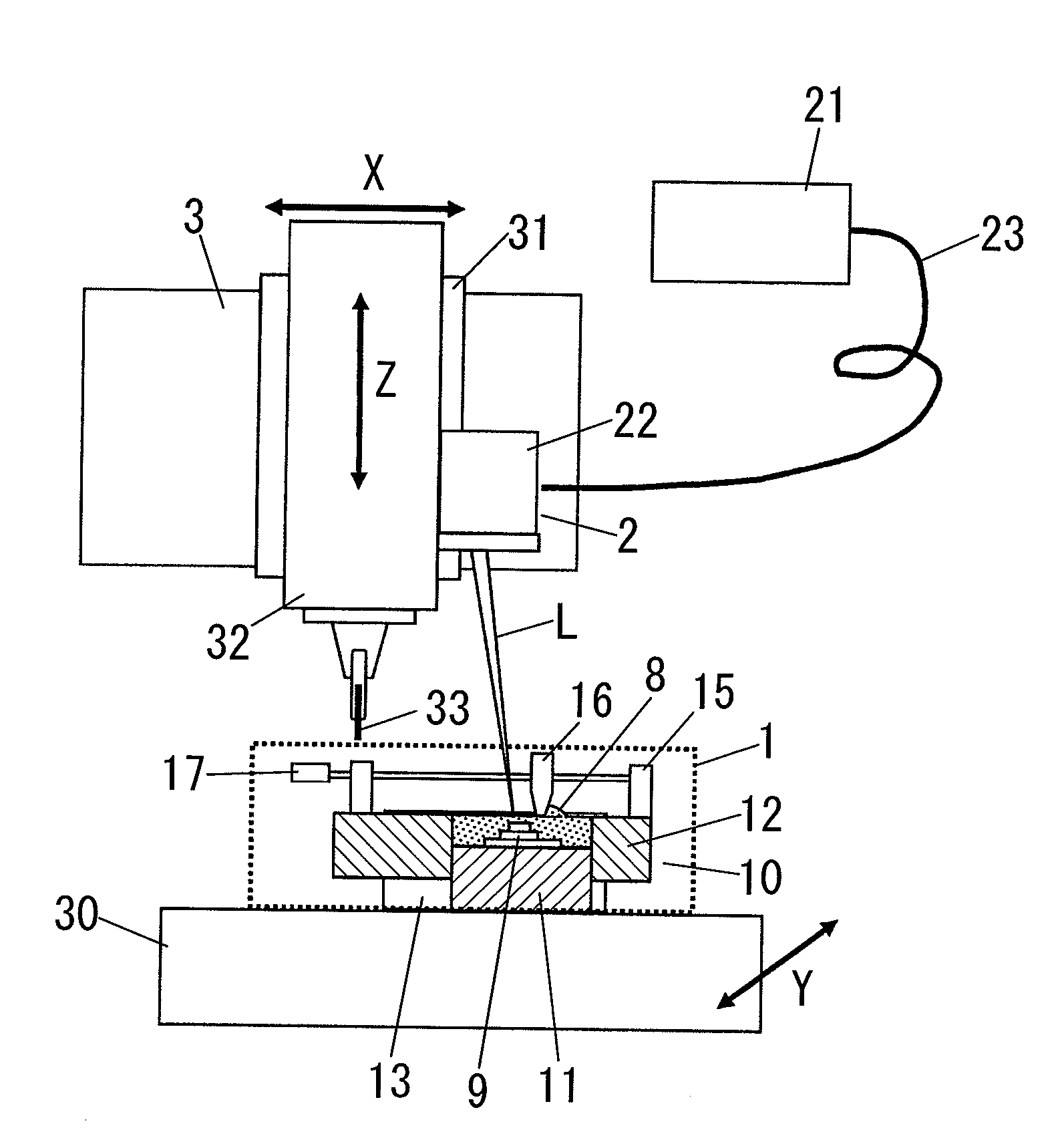

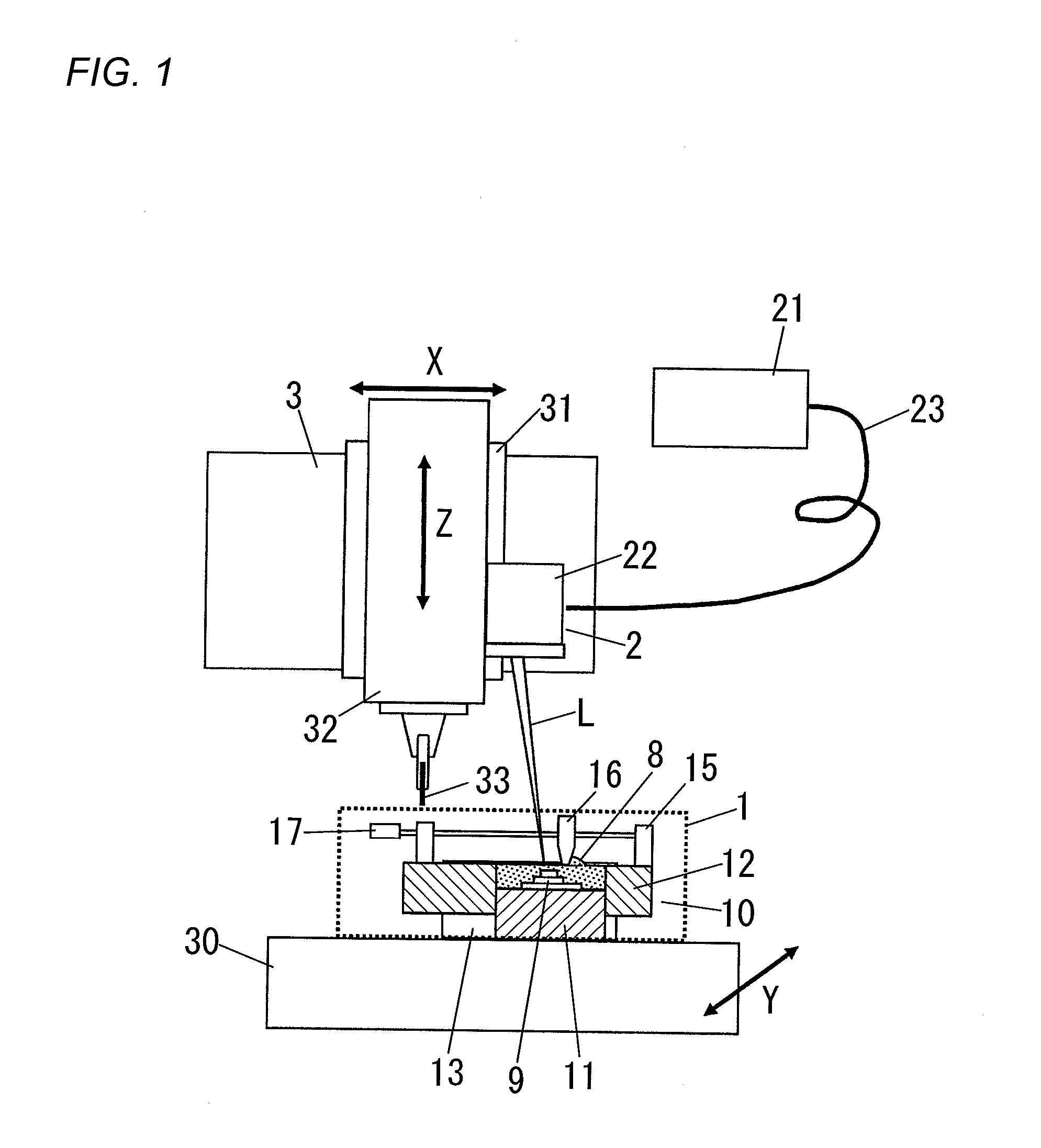

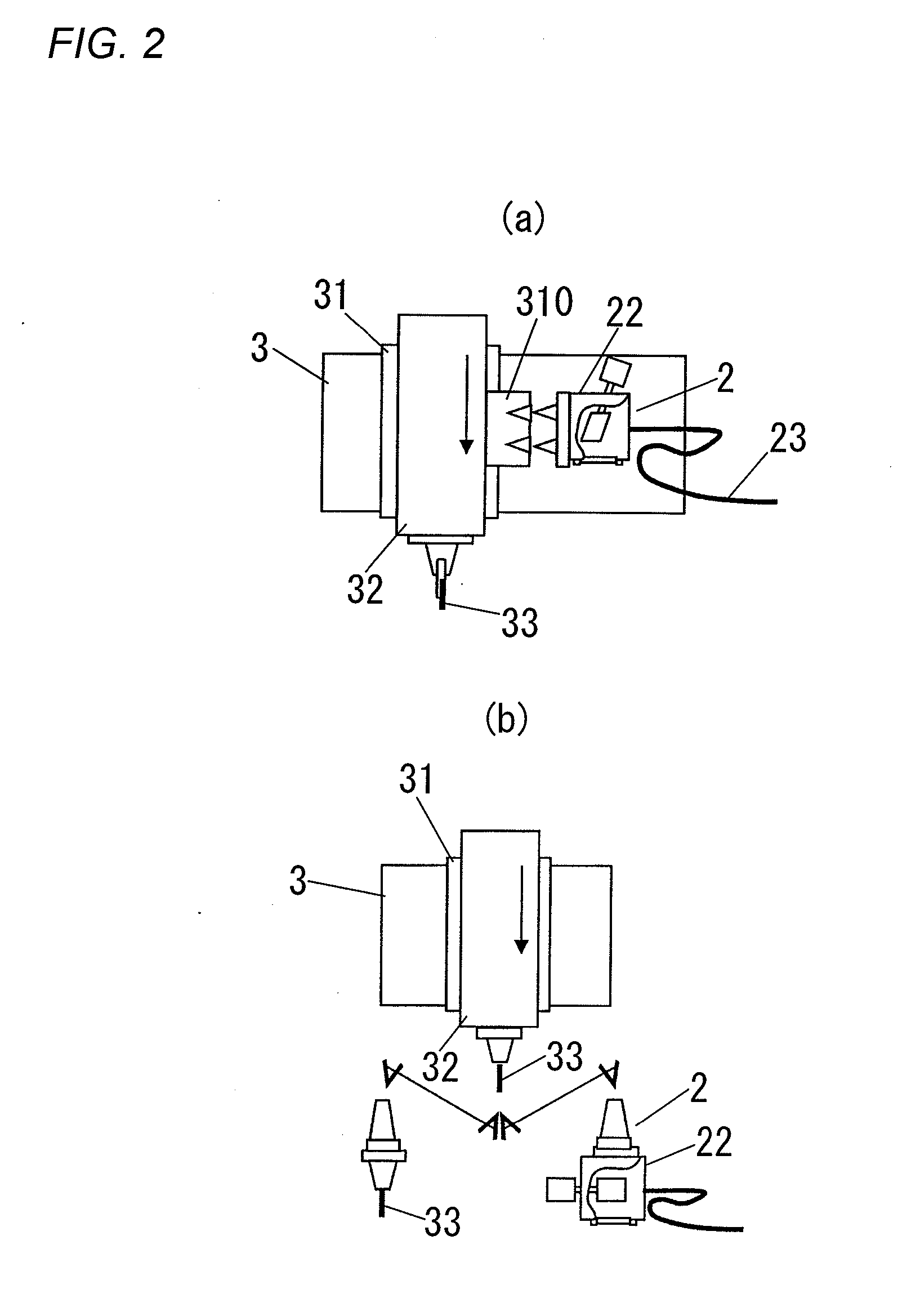

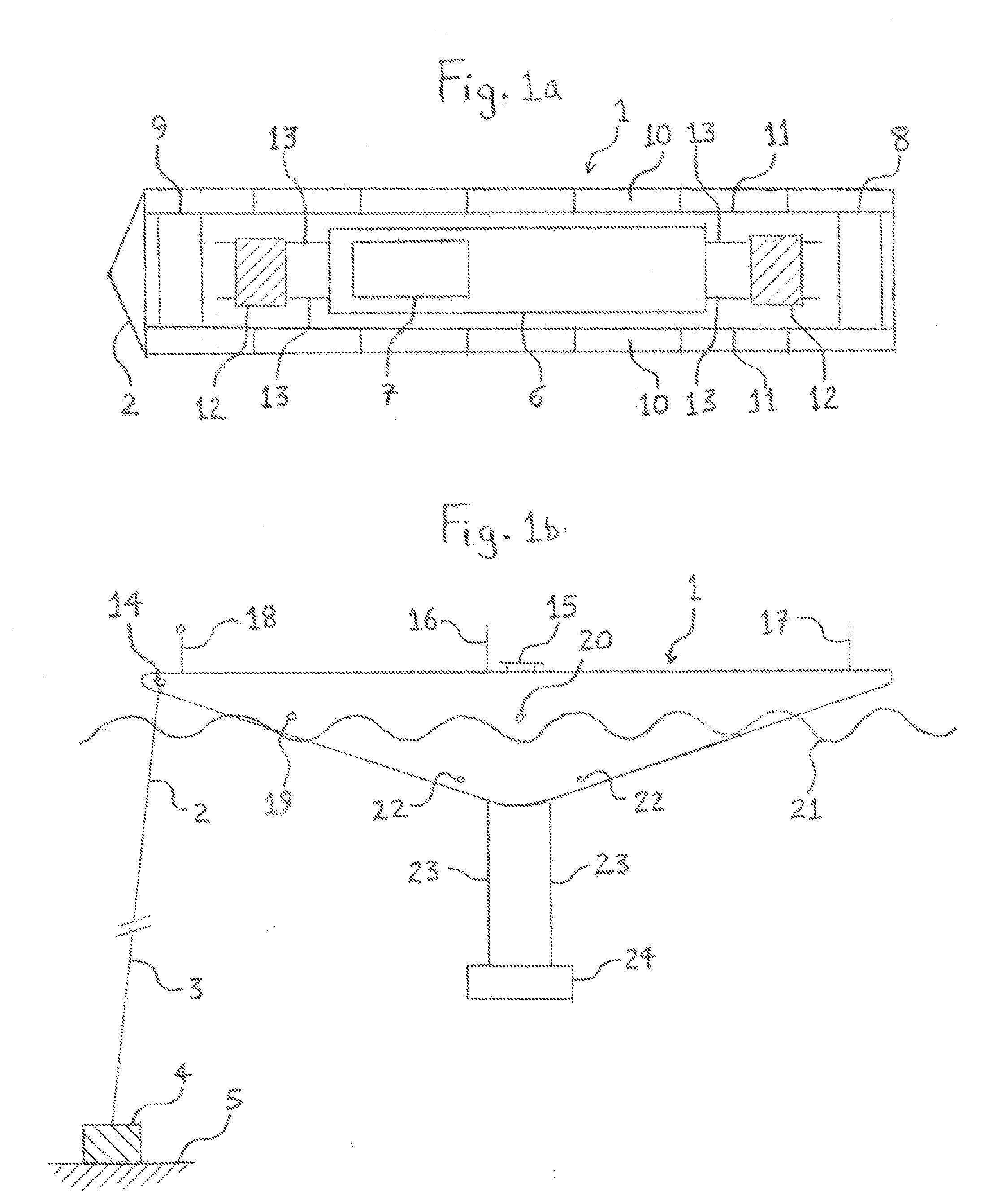

Lamination shaping apparatus

ActiveUS20100006228A1Easily fabricateAccuracy be degradeLiquid surface applicatorsMechanical working/deformationFixed positionEngineering

A lamination shaping apparatus has a powder layer preparing means and an optical unit which irradiates a light beam to an intended portion of a powder layer so as to sinter or melt for solidifying the portion into a cured layer. Preparation of the powder layer and curing of the cured layer are repeated to fabricate a three-dimensional object in which a plurality of the cured layers are laminated and integrated. The apparatus includes a fixed base carrying thereon the powder layer and the cured layer, an elevator frame surrounding a periphery of the fixed base, and driving means for driving the elevator frame to move vertically. The powder layer is formed within a space above the base and surrounded by an interior surface of the elevator fame such that the powder layer (cured layer) can be stacked on the base with the base being kept at a fixed position, thereby facilitating to fabricate a precisely shaped object.

Owner:MATSUSHITA ELECTRIC WORKS LTD

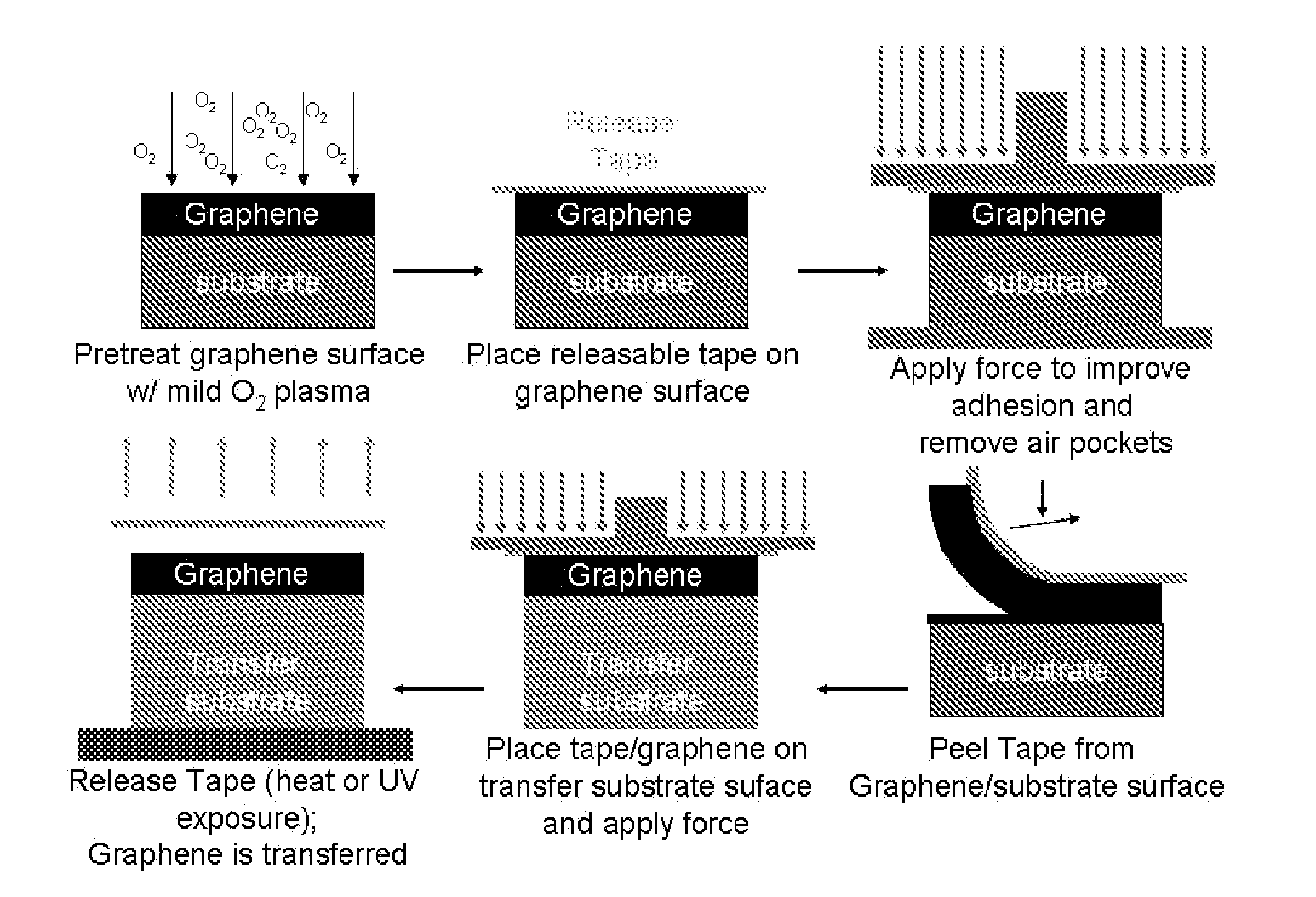

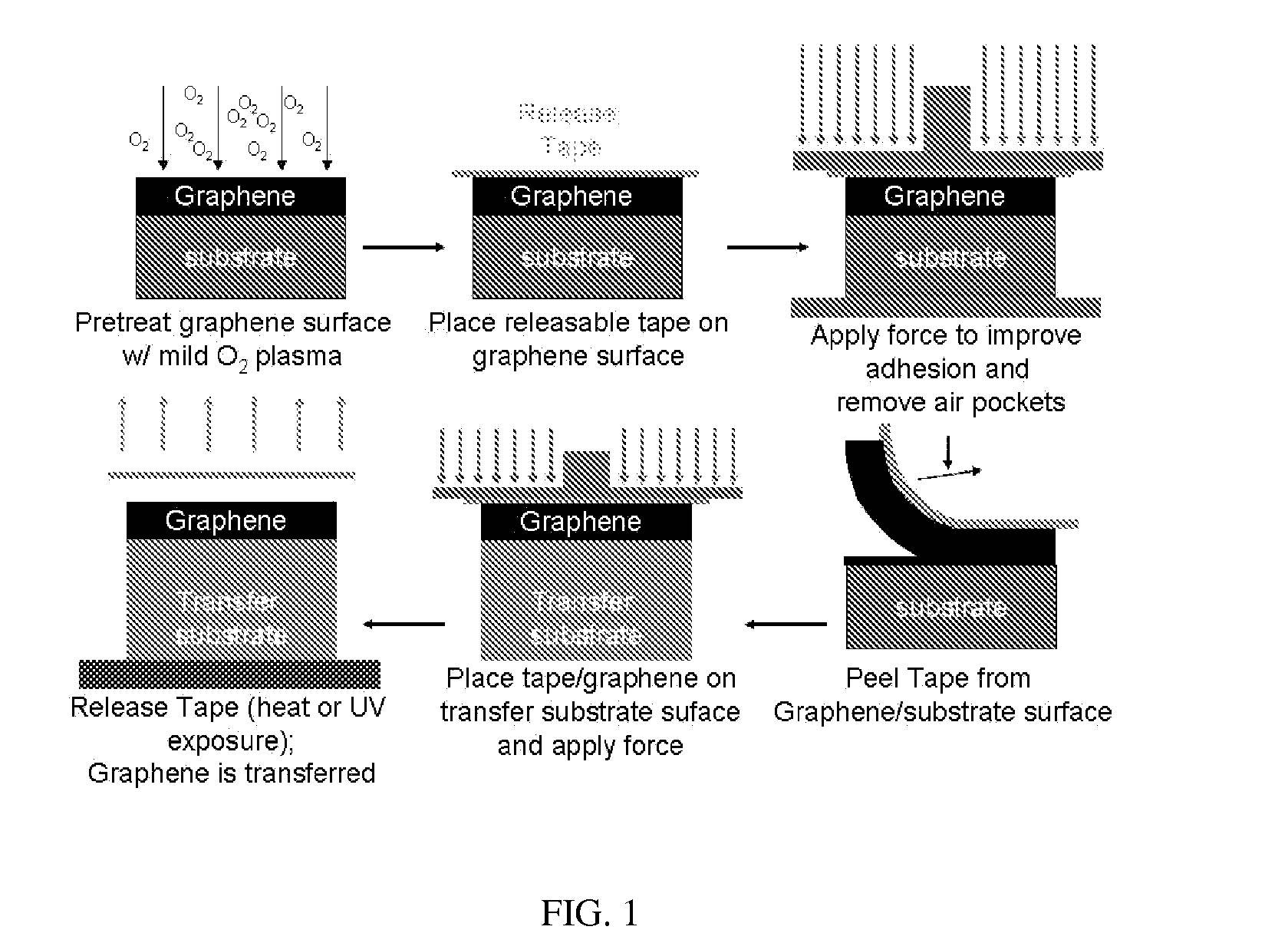

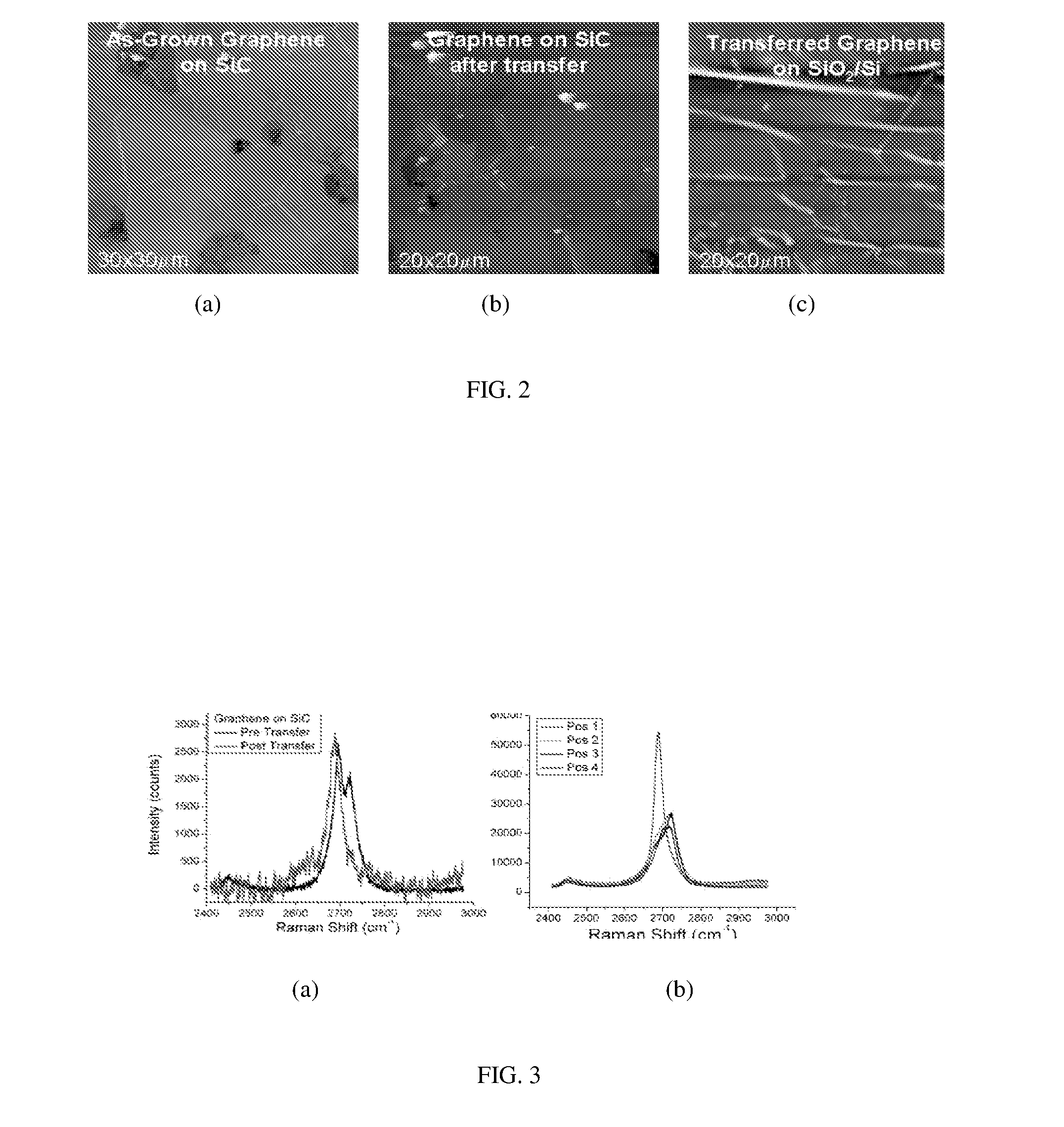

METHOD FOR THE REDUCTION OF GRAPHENE FILM THICKNESS AND THE REMOVAL AND TRANSFER OF EPITAXIAL GRAPHENE FILMS FROM SiC SUBSTRATES

ActiveUS20110048625A1Reduce processingEasily fabricateMaterial nanotechnologyGraphiteSic substrateMetal foil

A method for reducing graphene film thickness on a donor substrate and transferring graphene films from a donor substrate to a handle substrate includes applying a bonding material to the graphene on the donor substrate, releasing the bonding material from the donor substrate thereby leaving graphene on the bonding material, applying the bonding material with graphene onto the handle substrate, and releasing the bonding material from the handle substrate thereby leaving the graphene on the handle substrate. The donor substrate may comprise SiC, metal foil or other graphene growth substrate, and the handle substrate may comprise a semiconductor or insulator crystal, semiconductor device, epitaxial layer, flexible substrate, metal film, or organic device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

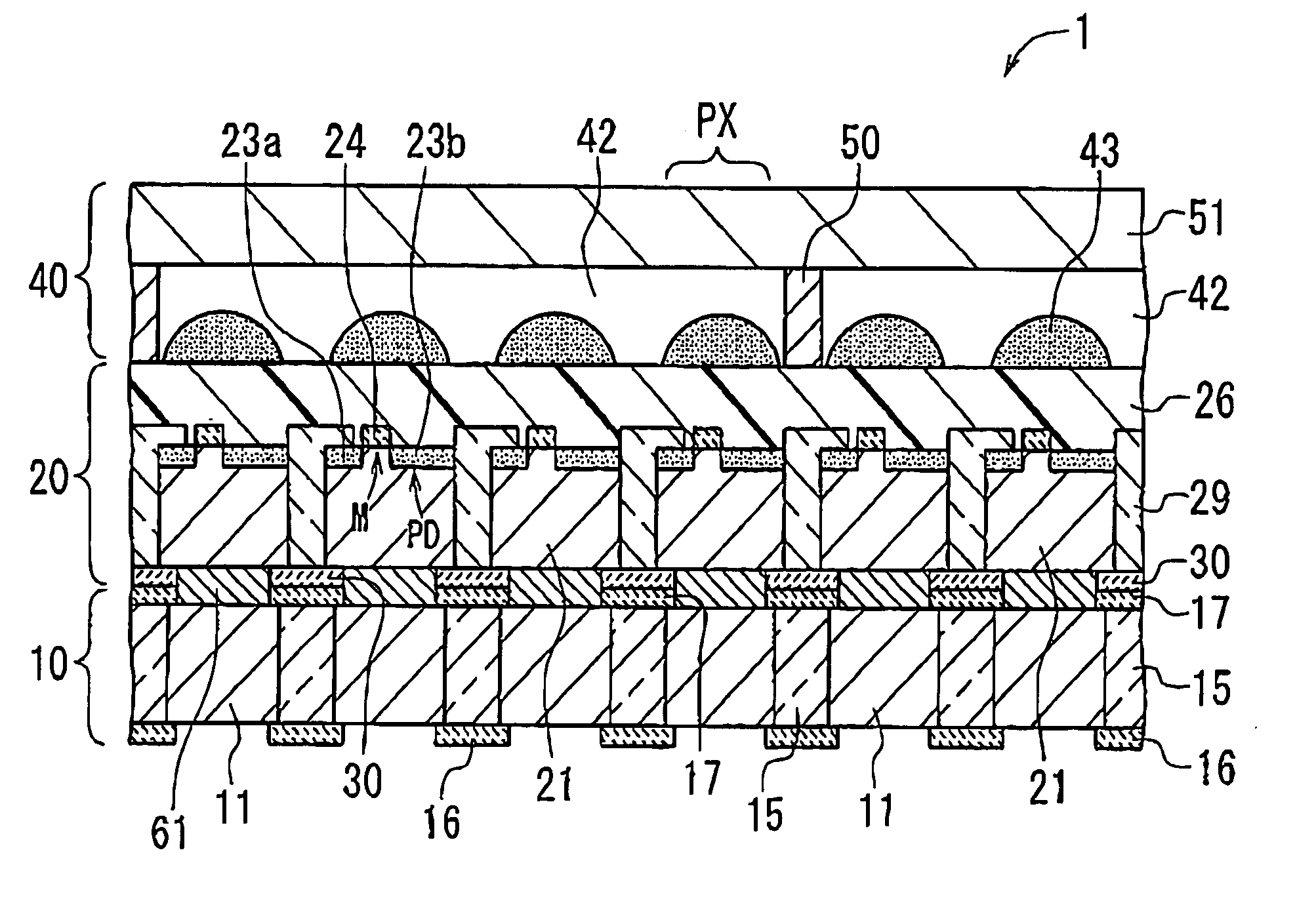

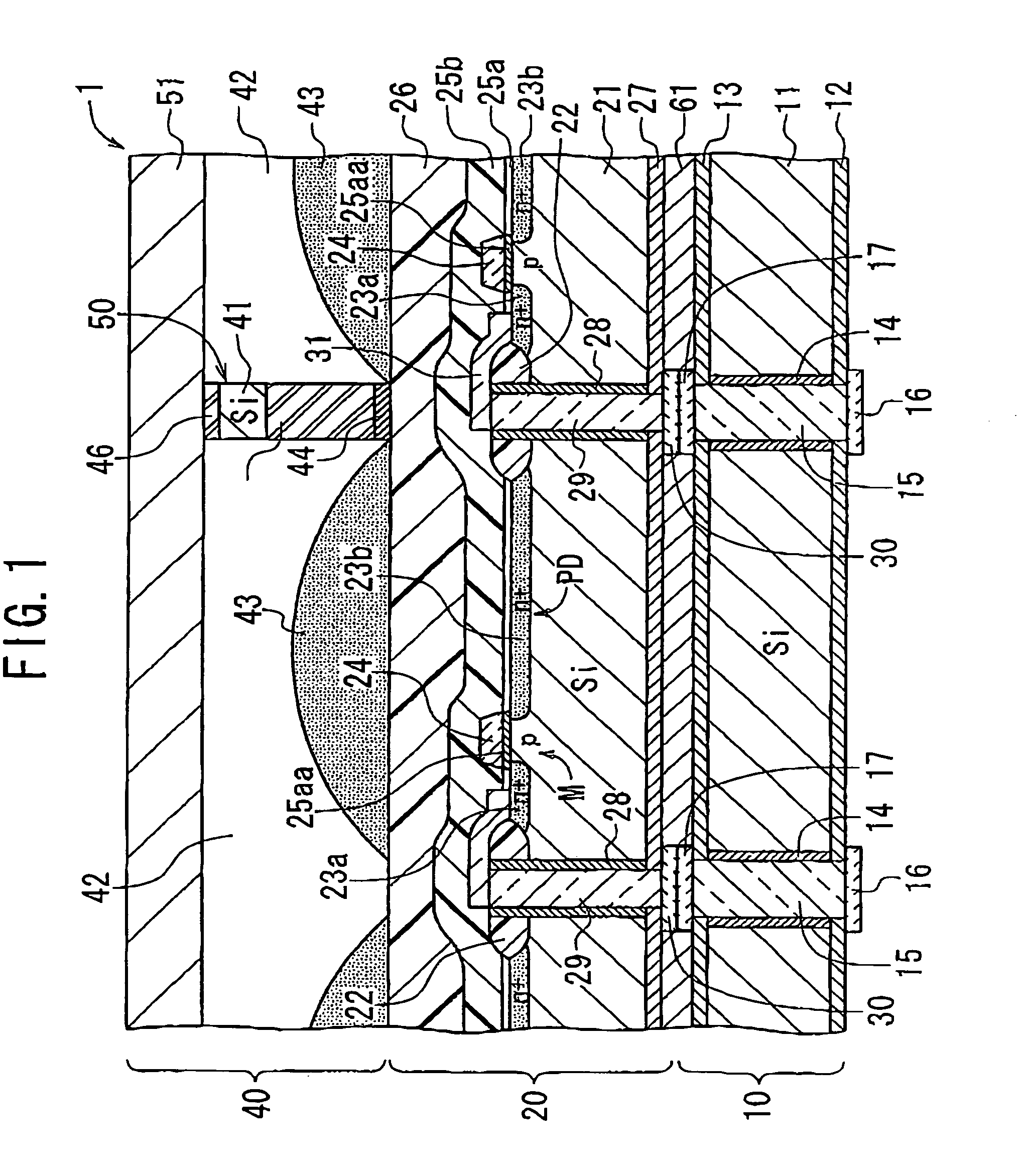

Solid-state image sensor and its production method

InactiveUS20050029643A1Easily fabricateEasy to makeSemiconductor/solid-state device detailsSolid-state devicesMicrolensSolid-state

A solid-state image sensor has a chip-size package, which can be easily fabricated. The element-formation regions are formed in the semiconductor substrate (21) of the light-receiving element layer (20) corresponding to the pixel regions. The semiconductor light-receiving elements (PD) are formed in the respective element-formation regions and covered with the light-transmissive insulator films (25a), (25b) and (26). The light-introducing layer (40), which includes the light-introducing cavity (42) and the quartz cap (51) for closing the cavity, is formed on the film (26). The microlenses (43) are incorporated into the cavity (42). The electric output signals of the semiconductor light-receiving elements (PD) are taken out to the bottom of the substrate (21) by way of the buried interconnections of the substrate (21) and then, derived to the outside of the image sensor by way of the output layer (10) or the interposer (10A).

Owner:RAMBUS INC

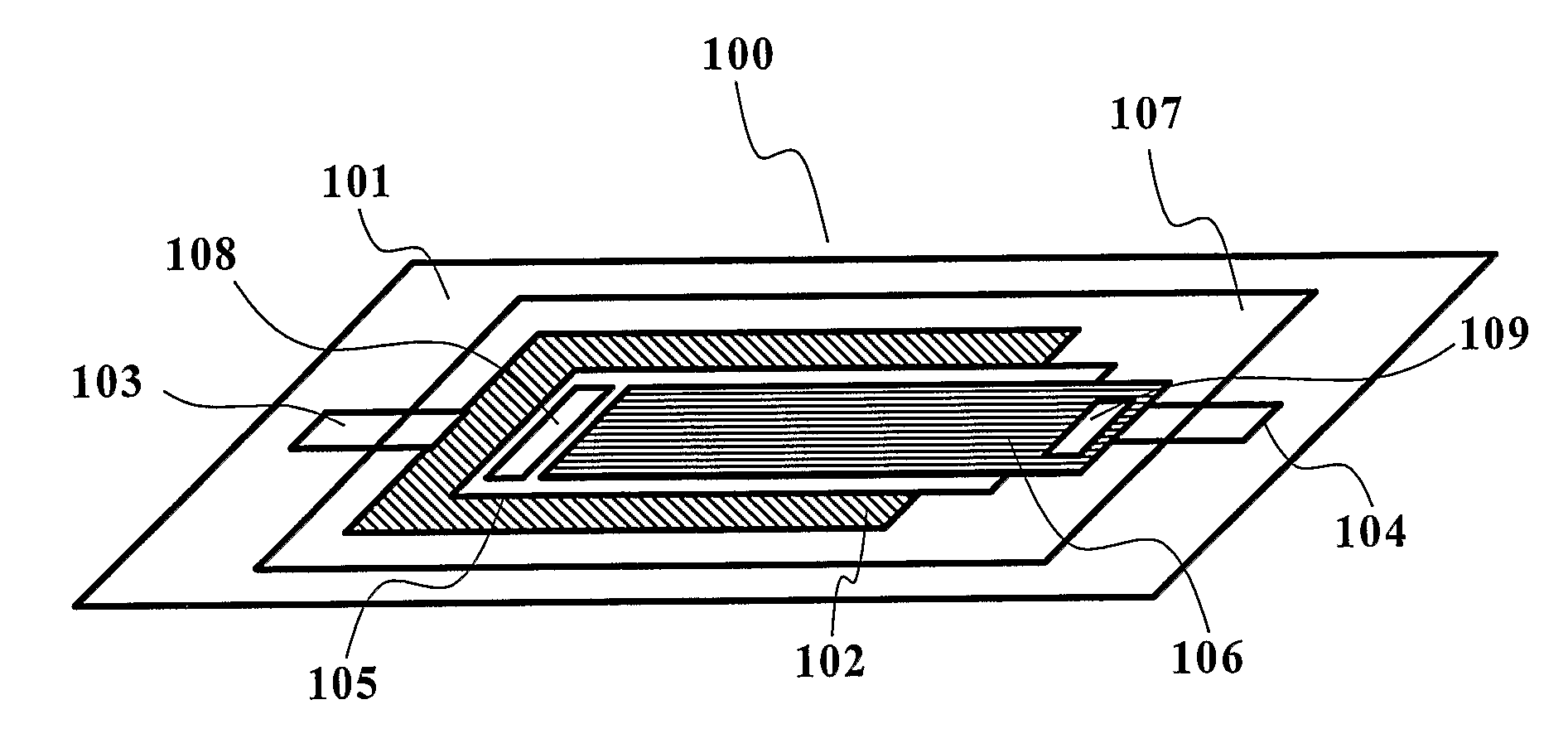

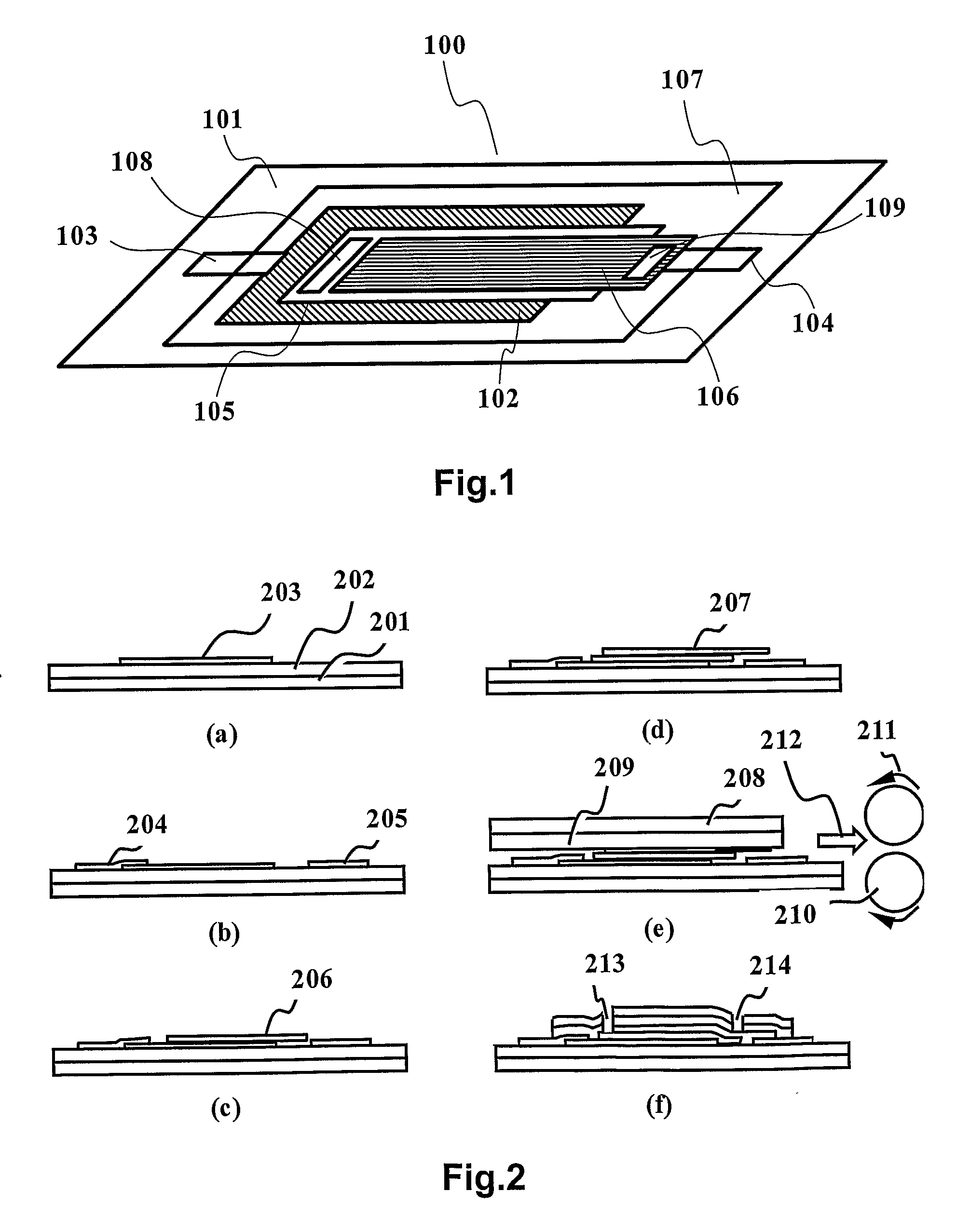

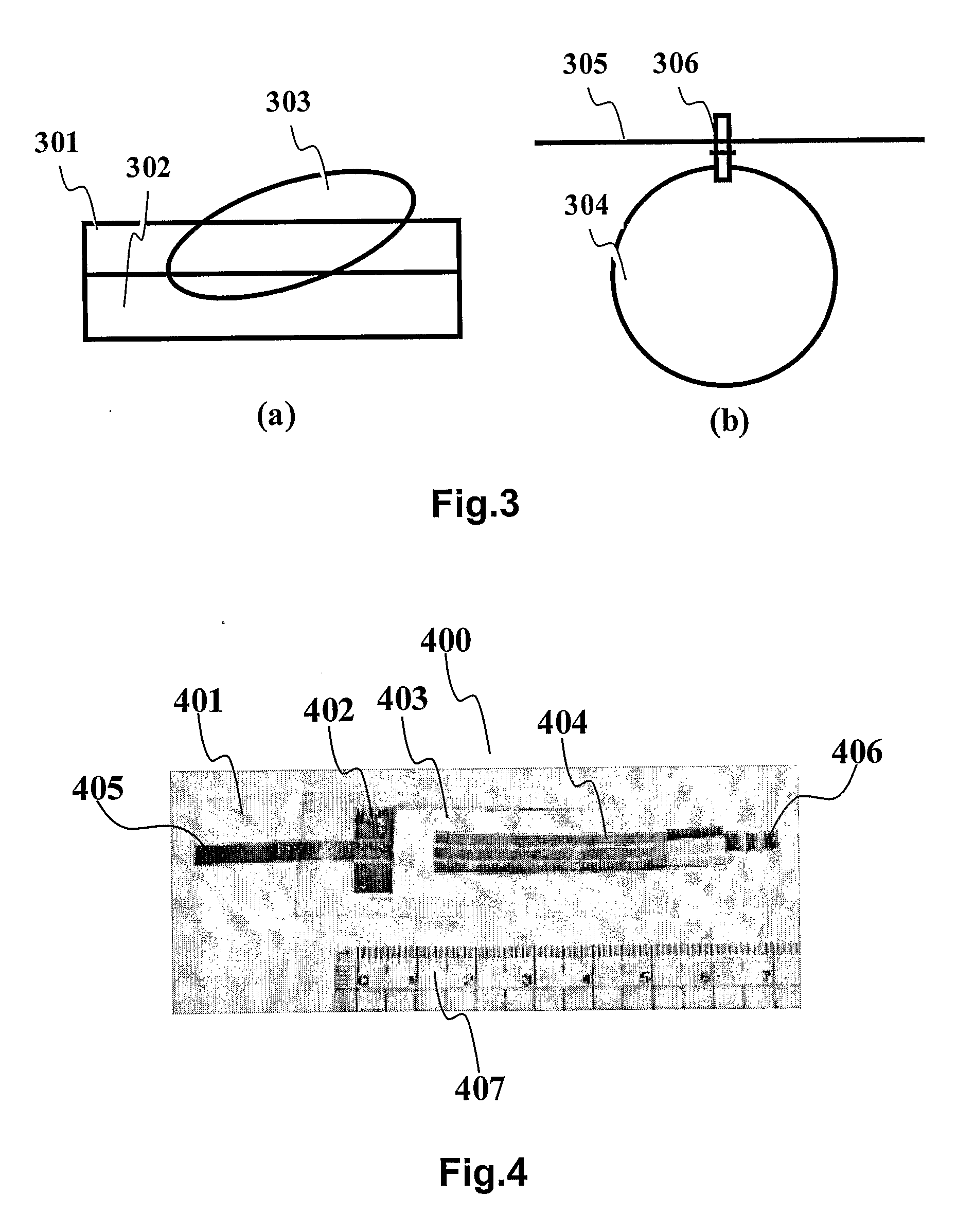

Battery With Porous Material and Fabrication Method Thereof

InactiveUS20080038588A1Easily fabricateEasily integrateDeferred-action cellsElectrode carriers/collectorsMicro fluidicSingle-Use Device

The present invention relates to batteries that can be activated by liquid. The battery with porous material is suitable for disposable healthcare test kits, bioMEMS (bio Micro Electro Mechanical Systems) and biosystems such as DNA chips, lab-on-a-chip or micro fluidics and can be easily integrated with disposable devices / systems.

Owner:LEE KI BANG

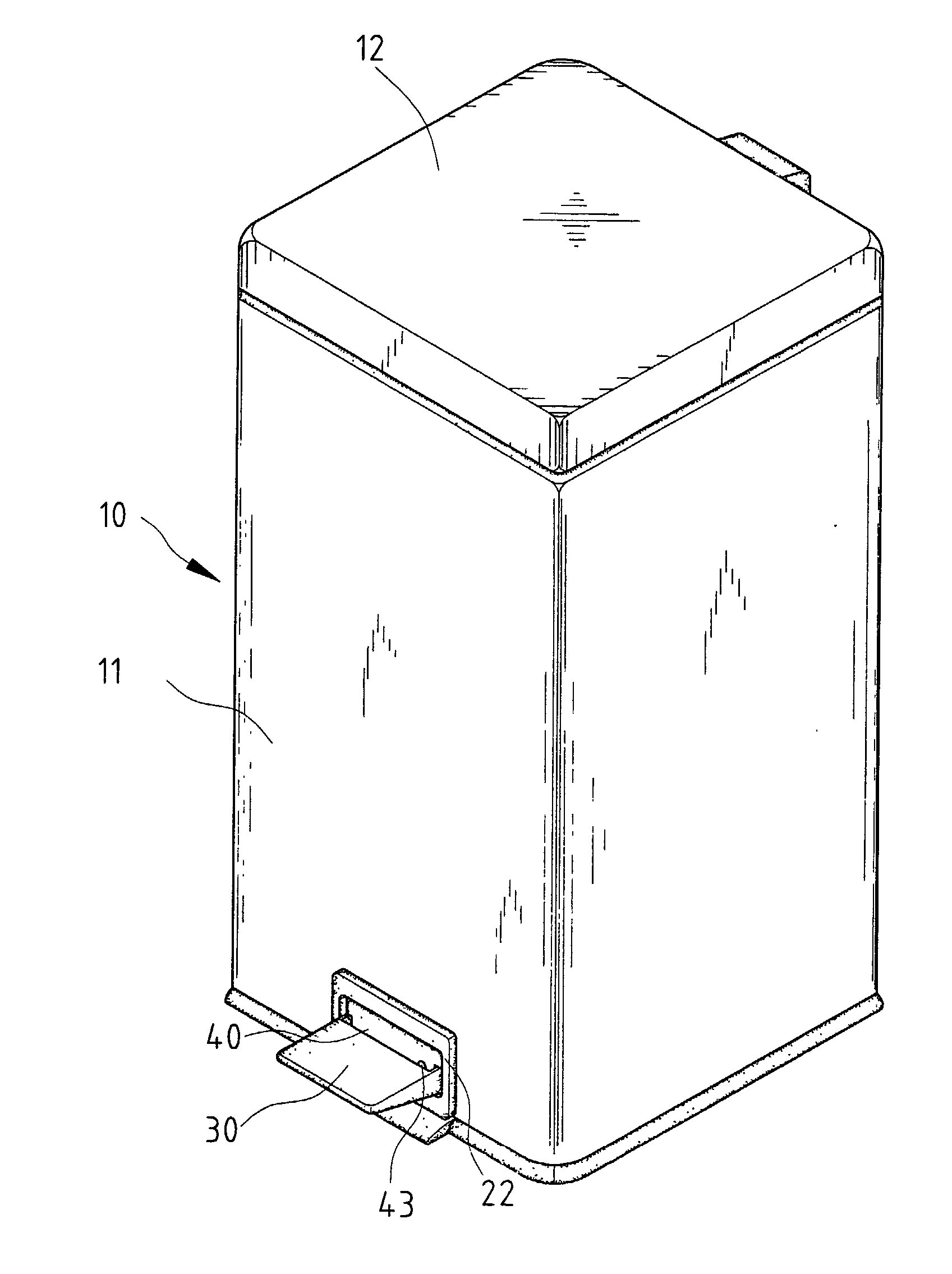

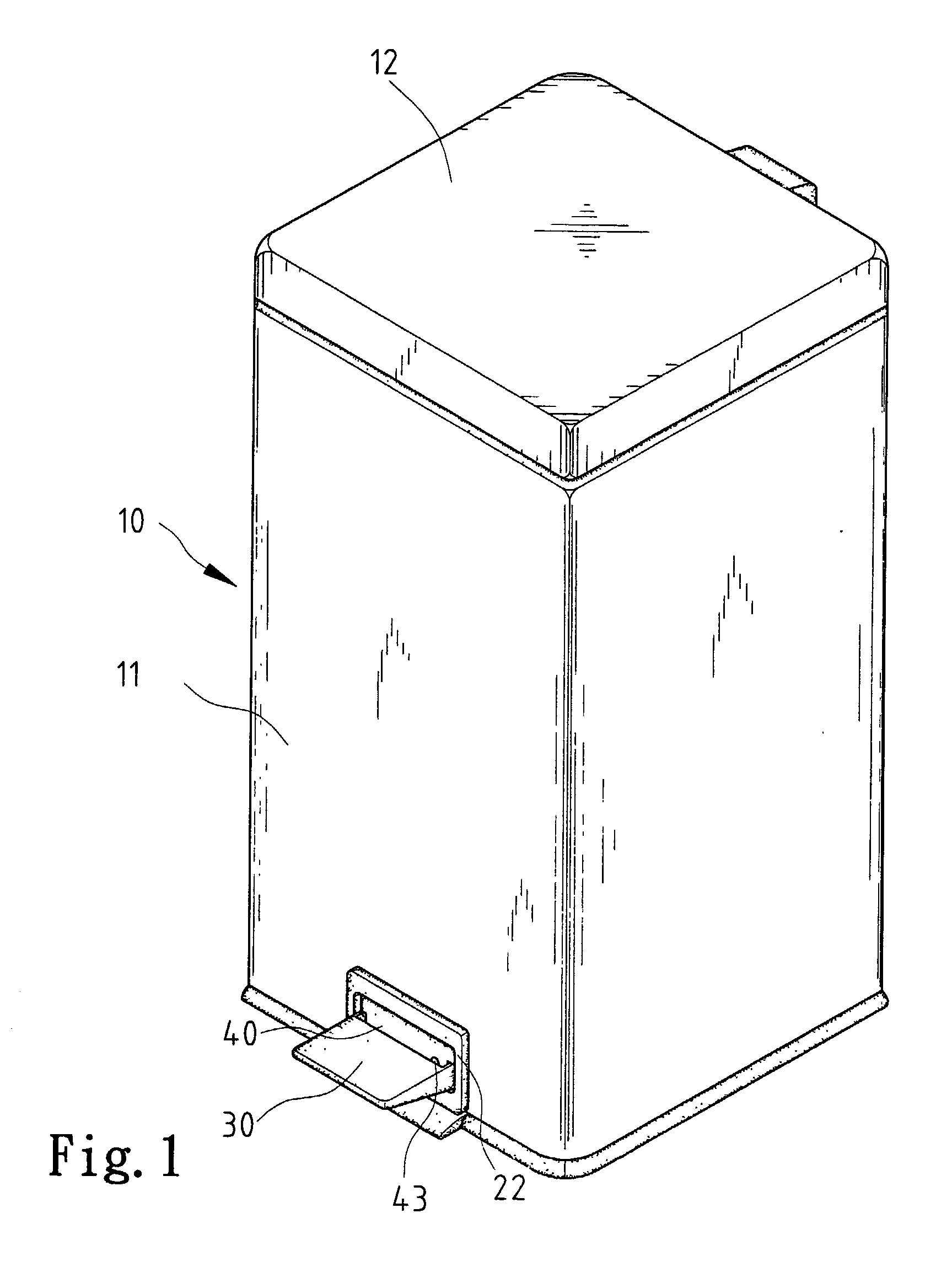

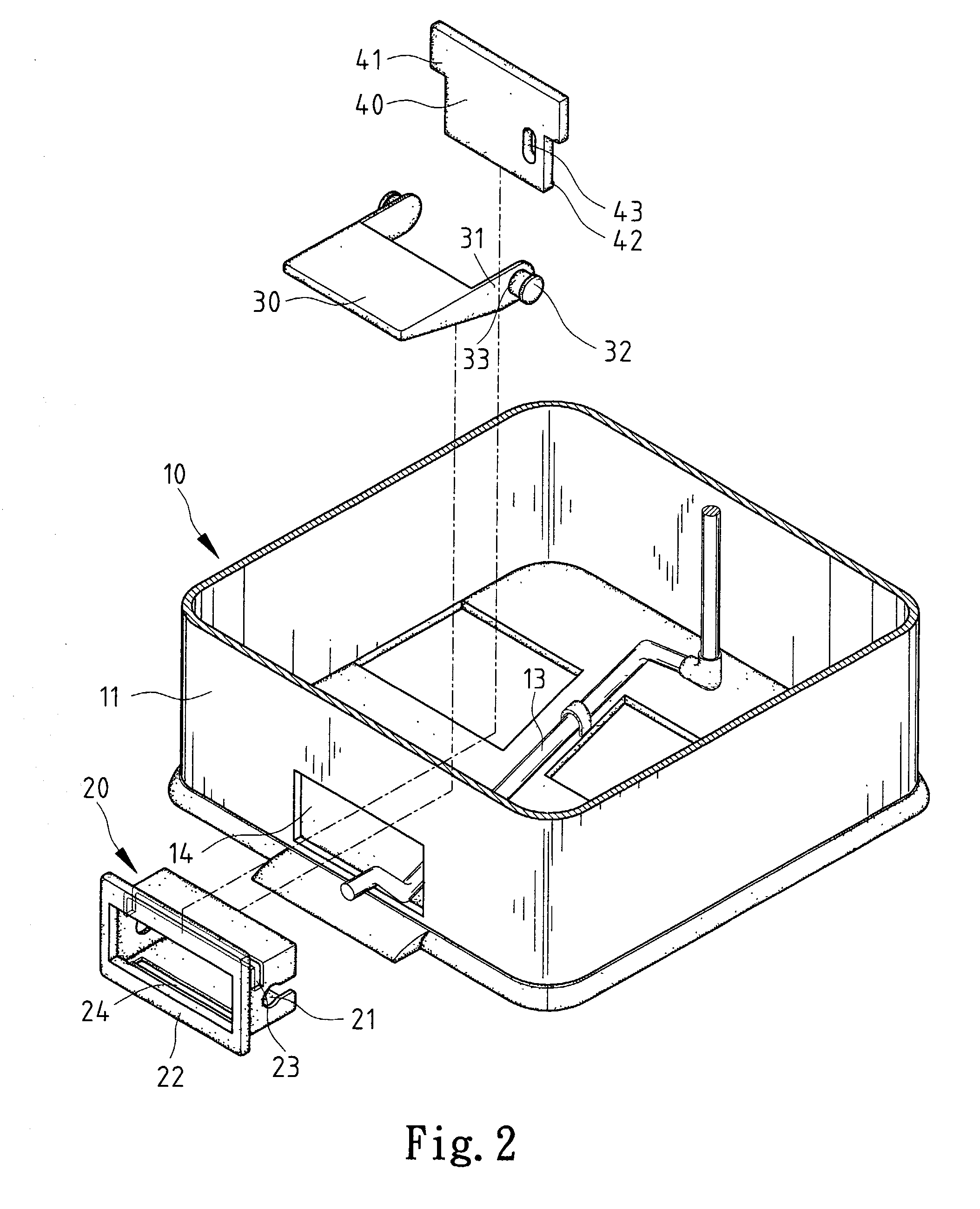

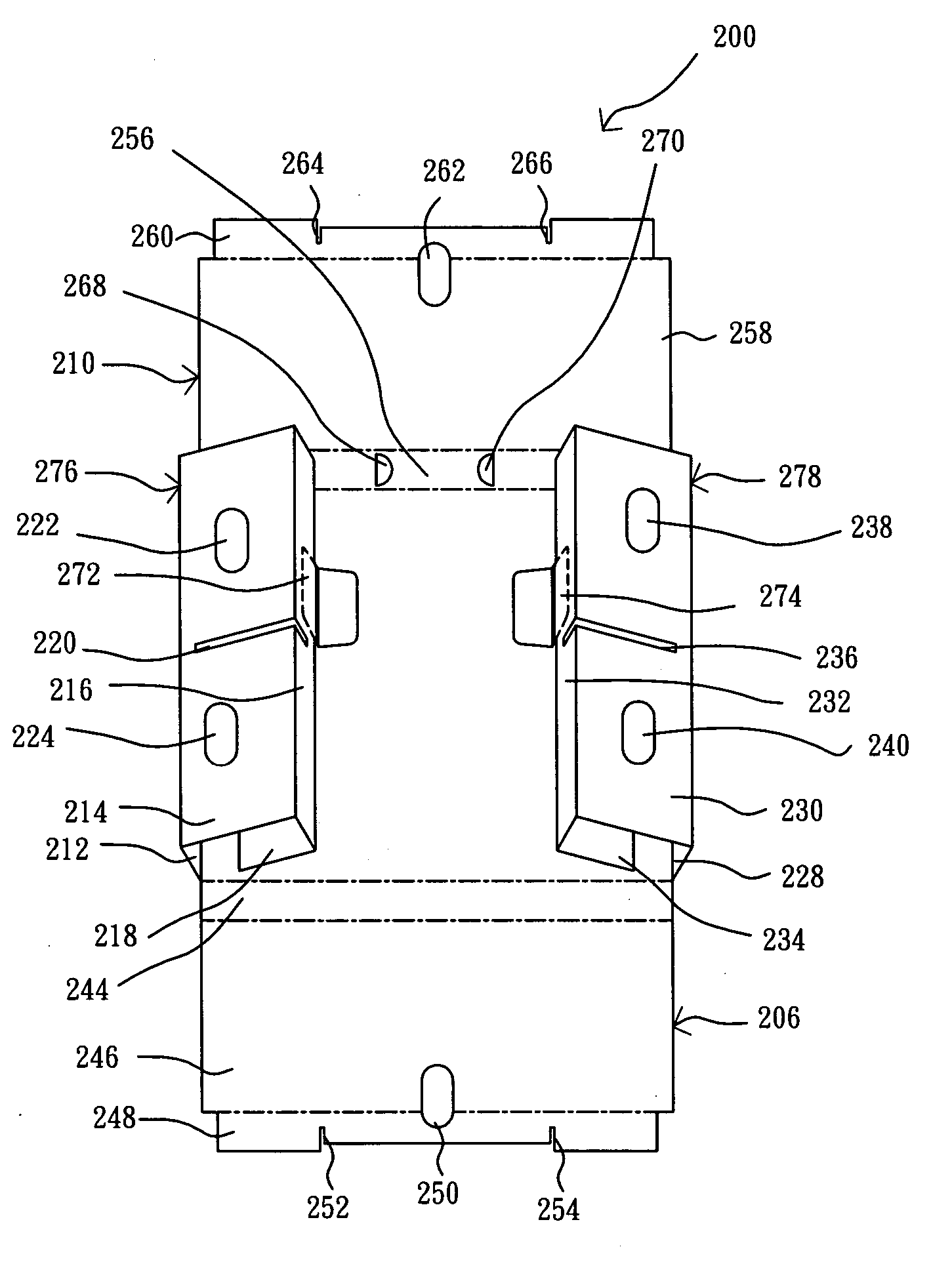

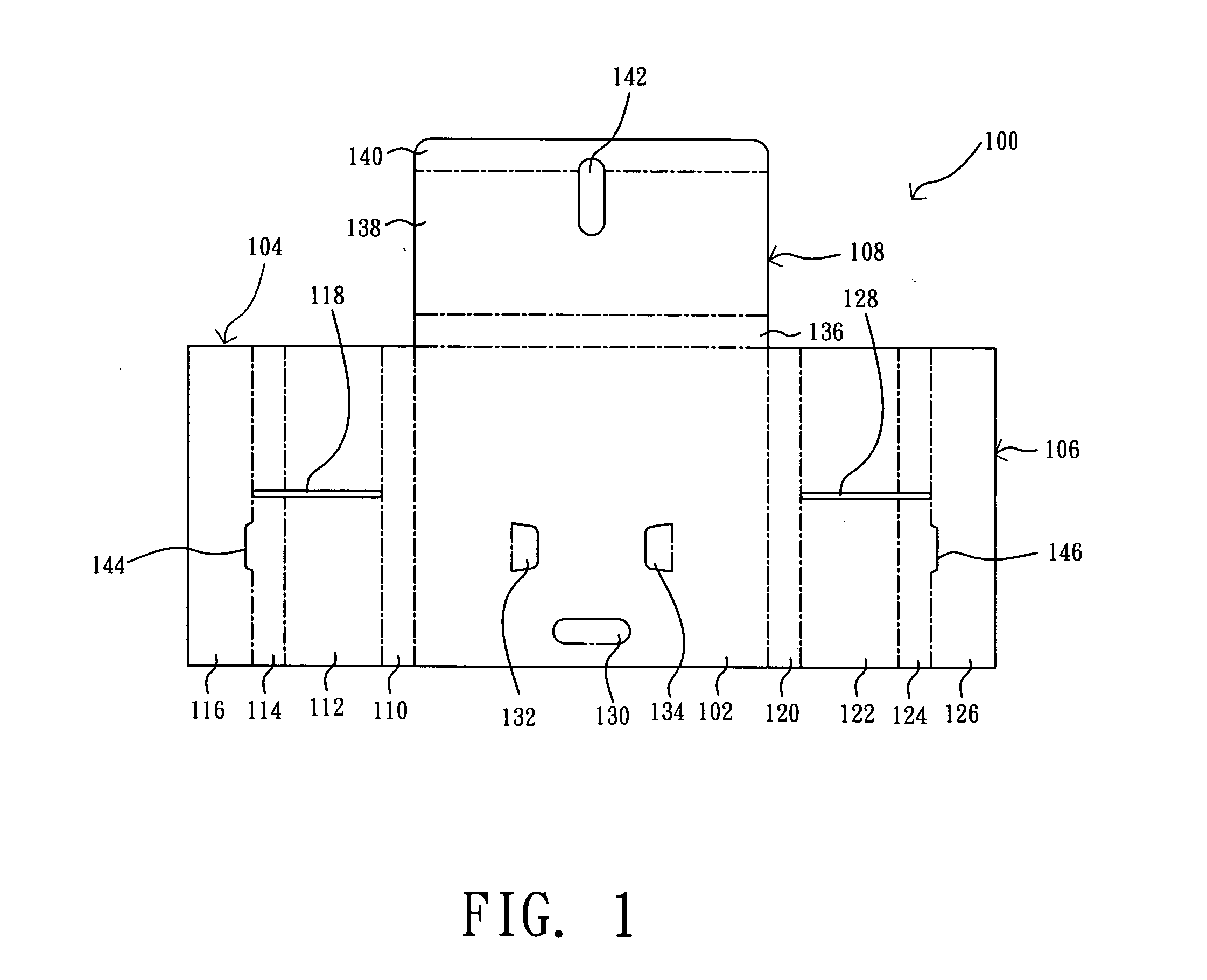

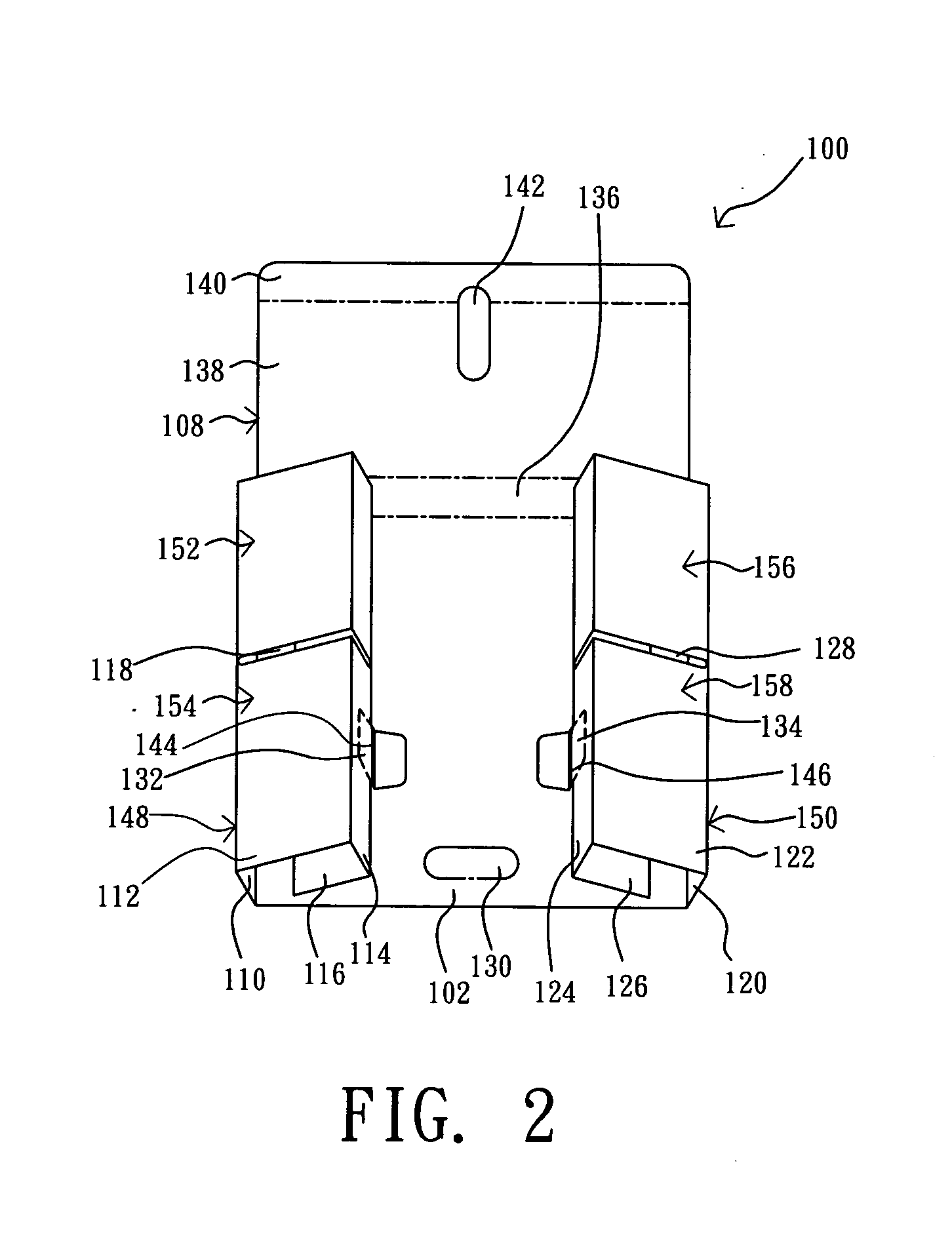

Pedal assembly

A storage device includes a bin, a cover mounted on the bin, a pedal assembly mounted on the bin and a linkage connected between the cover and the pedal assembly. The pedal assembly can be trod so as to pivot the cover via the linkage. The pedal assembly includes a frame mounted on the bin and a pedal pivotally mounted on the frame. The frame includes two side plates each defining a cutout. The pedal includes two shafts formed thereon and inserted in the cutouts. Each of the shafts includes a head formed thereon for avoiding axial escape thereof from one of the side plates. The frame includes a flange formed thereon. In an aspect, a portion of the bin is restrained between the flange and the heads. In another aspect, a latch may be used to lock the frame to the bin and the pedal to the frame. The latch includes two fins formed thereon. Each of the side plates defines a slot for receiving one of the fins or alternatively the frame includes an upper plate defining a slot for receiving the latch. Thus, the latch is retained on the frame in order to avoid disengagement of the frame from the bin. The portion of the bin is restrained between the flange and the latch. The frame includes a lower plate defining a slot through which the latch is inserted. The latch includes a hook formed on a lower edge thereof for hooking the lower plate.

Owner:LIN TSONG YOU

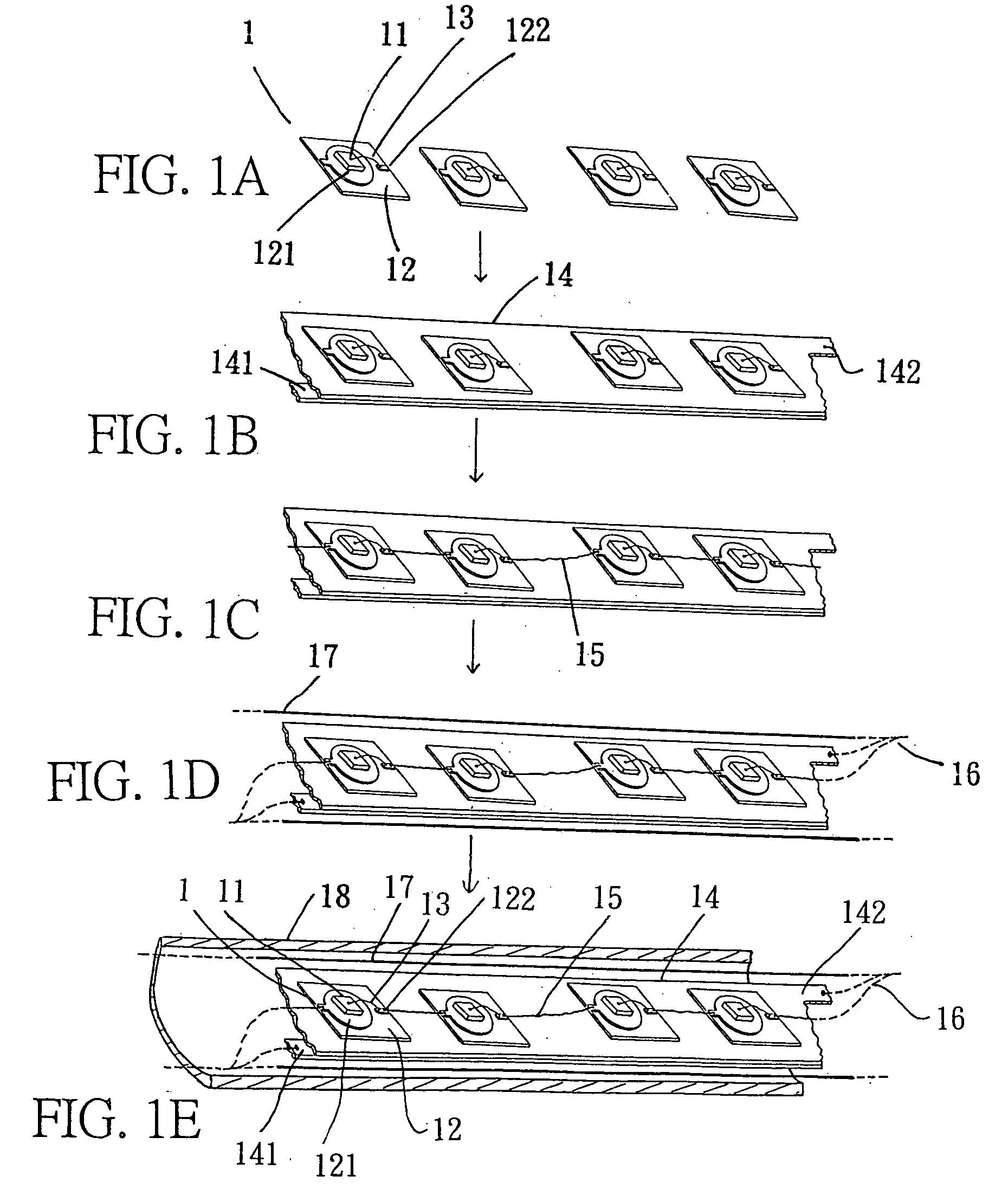

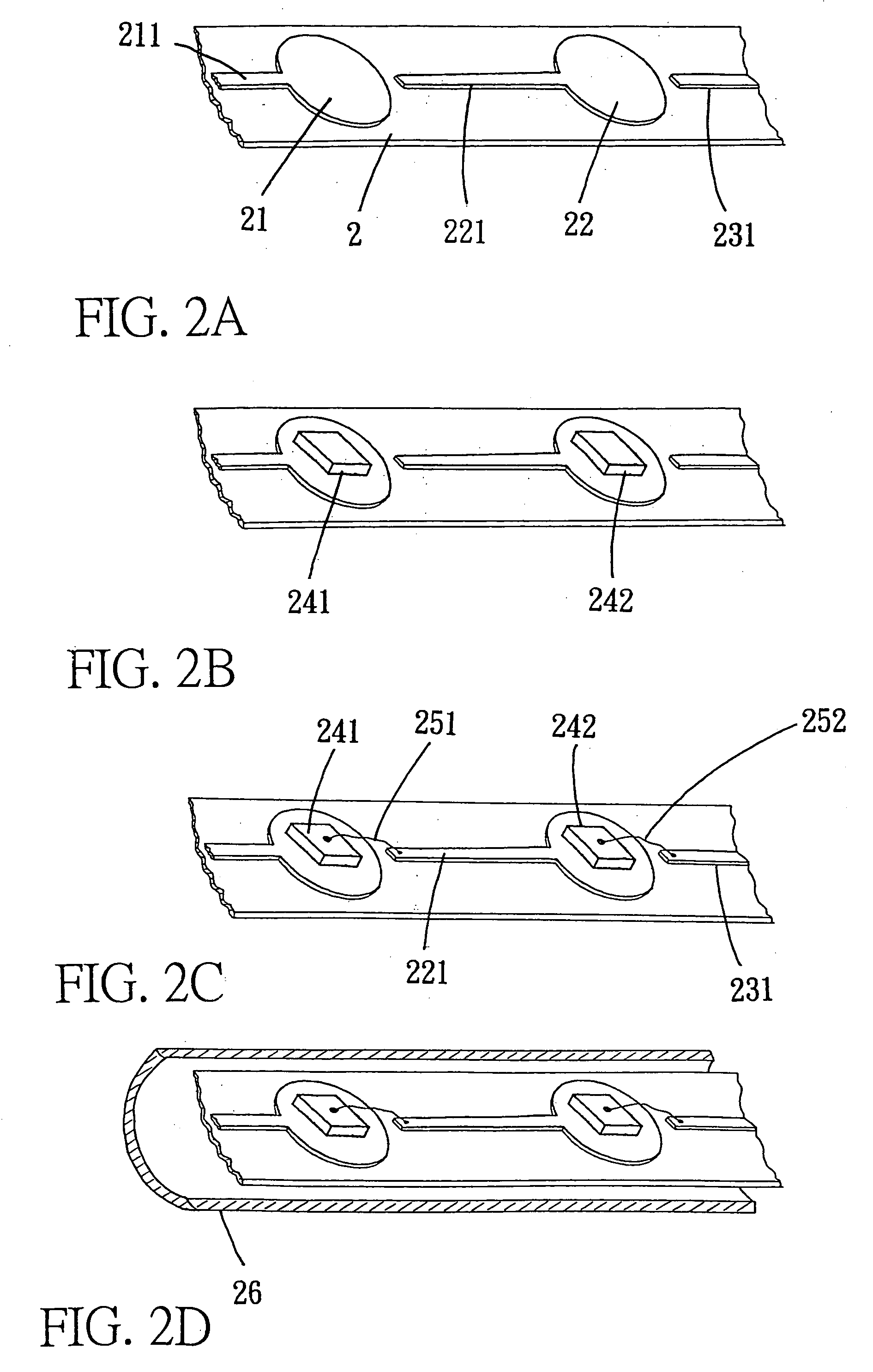

Elongated flexible lighting equipment and fabricating method of same

InactiveUS20050146870A1Easily fabricateEasy to makePoint-like light sourceSolid-state devicesElectricityLight source

The present invention discloses an elongated flexible lighting equipment and fabrication method of same, wherein the fabrication method comprises the steps: connecting a plurality of non-vacuum or non-gas filled lighting elements in series, parallel, or series-parallel with conductors to form a string of lighting source with electrical connection means provided at its both terminals thereof, disposing a power supply basbus formed of several conductors of similar or different polarity in parallel to the string of lighting source for connecting both terminals of the string of lighting source to preformed electrodes, enclosing the string of lighting source with a soft PVC insulation material using a plastic extrusion press with a specific die block so as to form a flexible main body of lighting equipment enclosed in an insulation housing.

Owner:WU JENG SHYONG

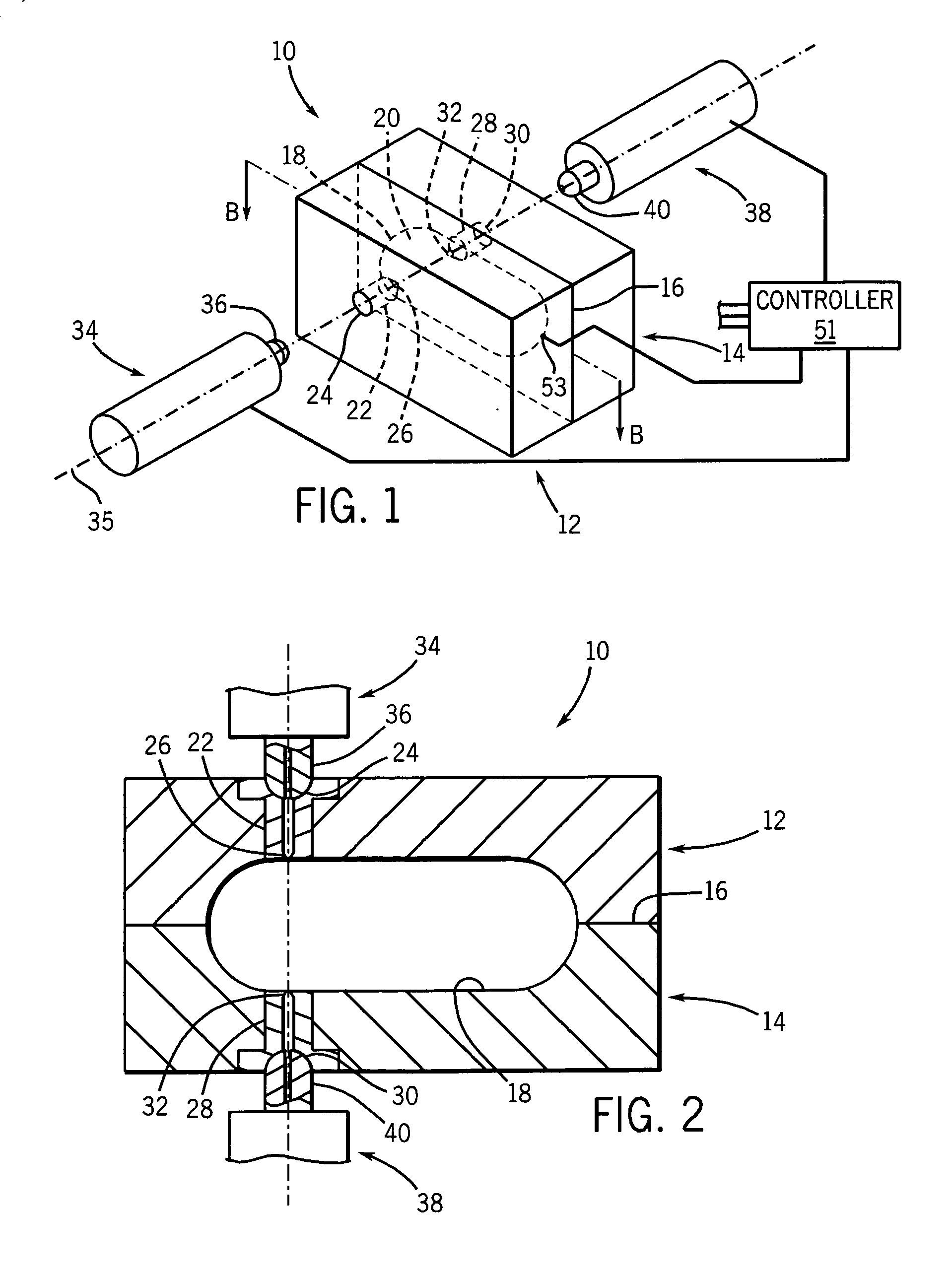

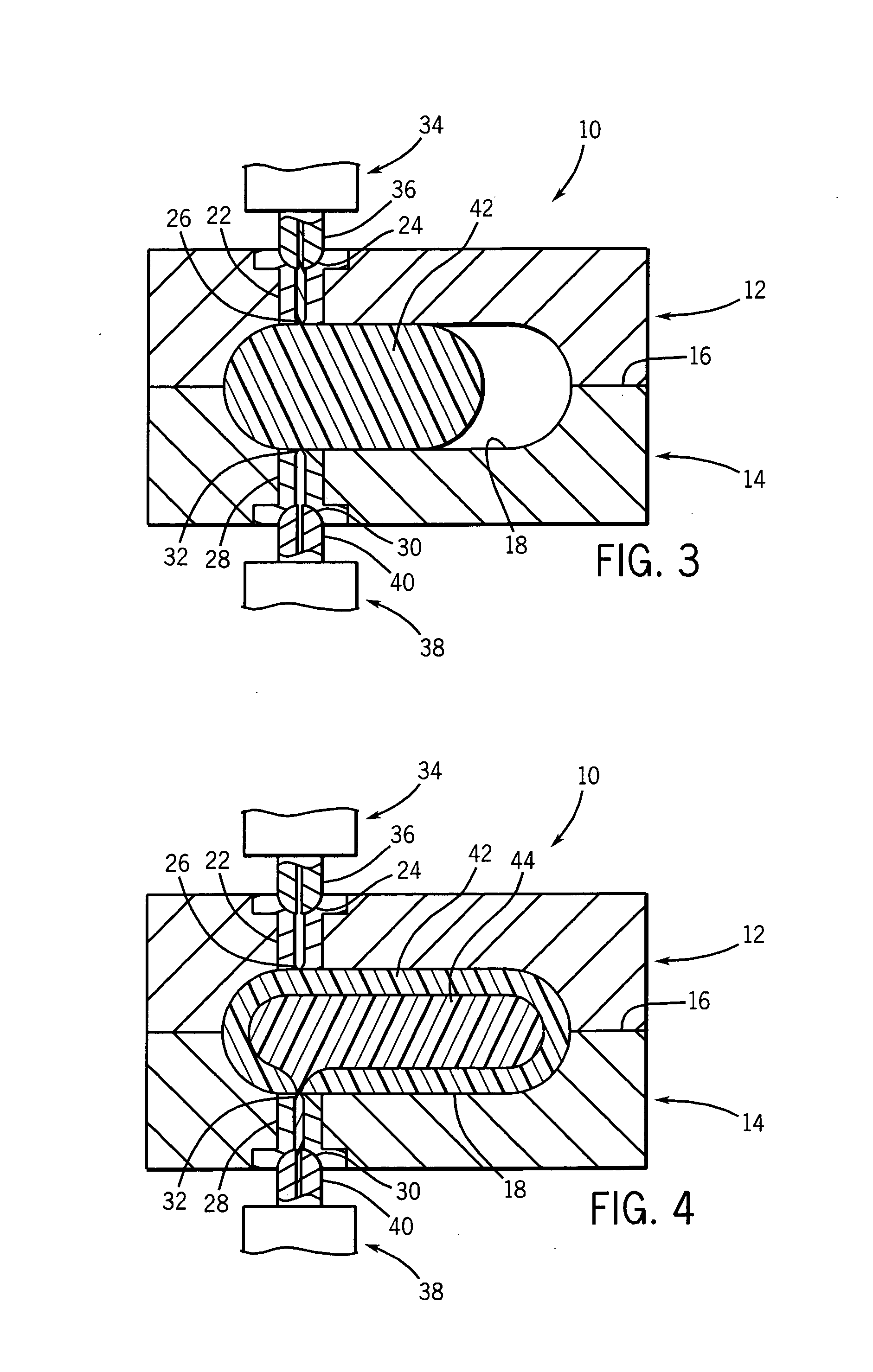

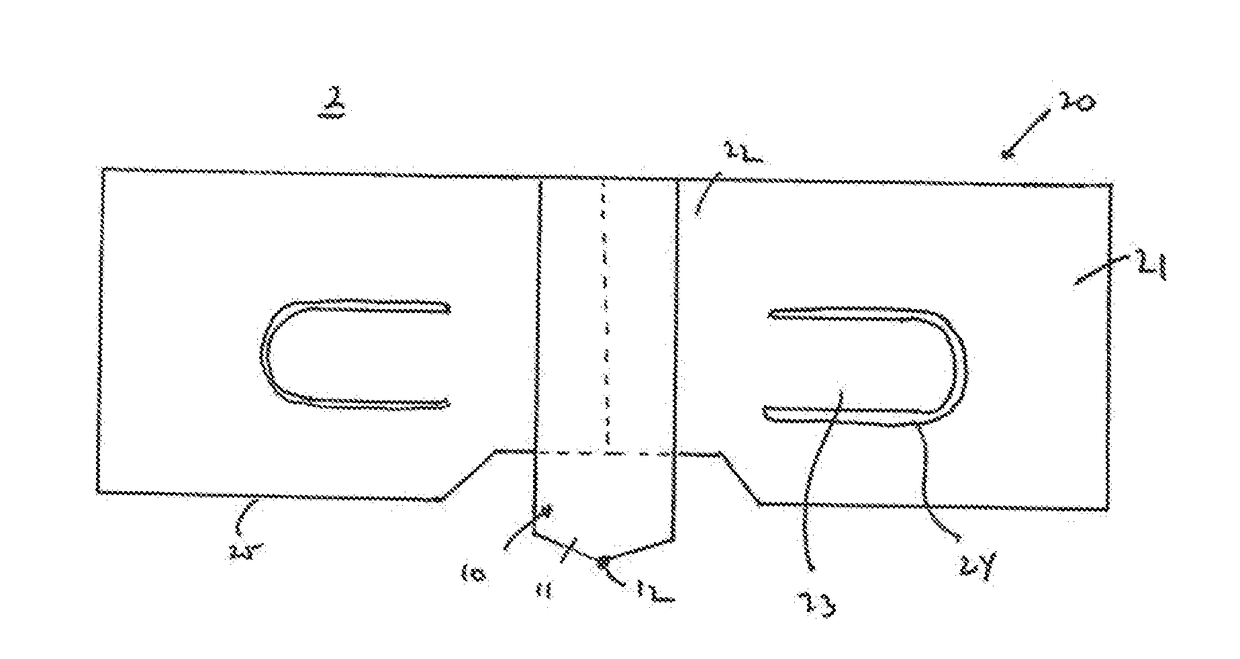

Sandwich molding system with independent runner passages

InactiveUS20070096364A1Easily balanceEasily fabricateMouldsAuxillary shaping apparatusHot runnerEngineering

A method of sandwich molding employs independent runners for each of the first and second thermoplastic materials simplifying the construction of the mold and runner passages, facilitating use of hot runner systems and the like, and simplifying the balancing of flow in multiple cavity molds.

Owner:MGS MFG GROUP

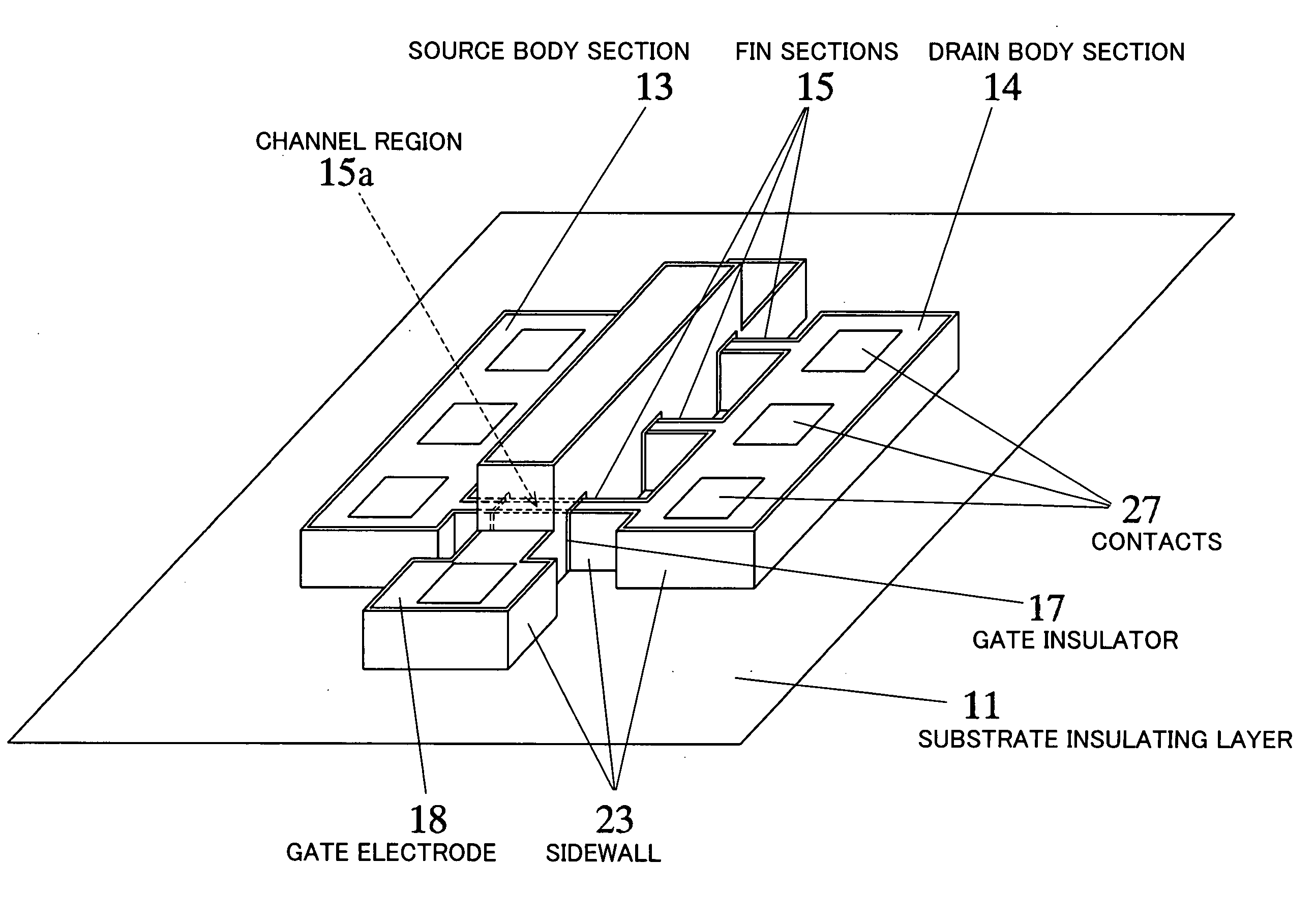

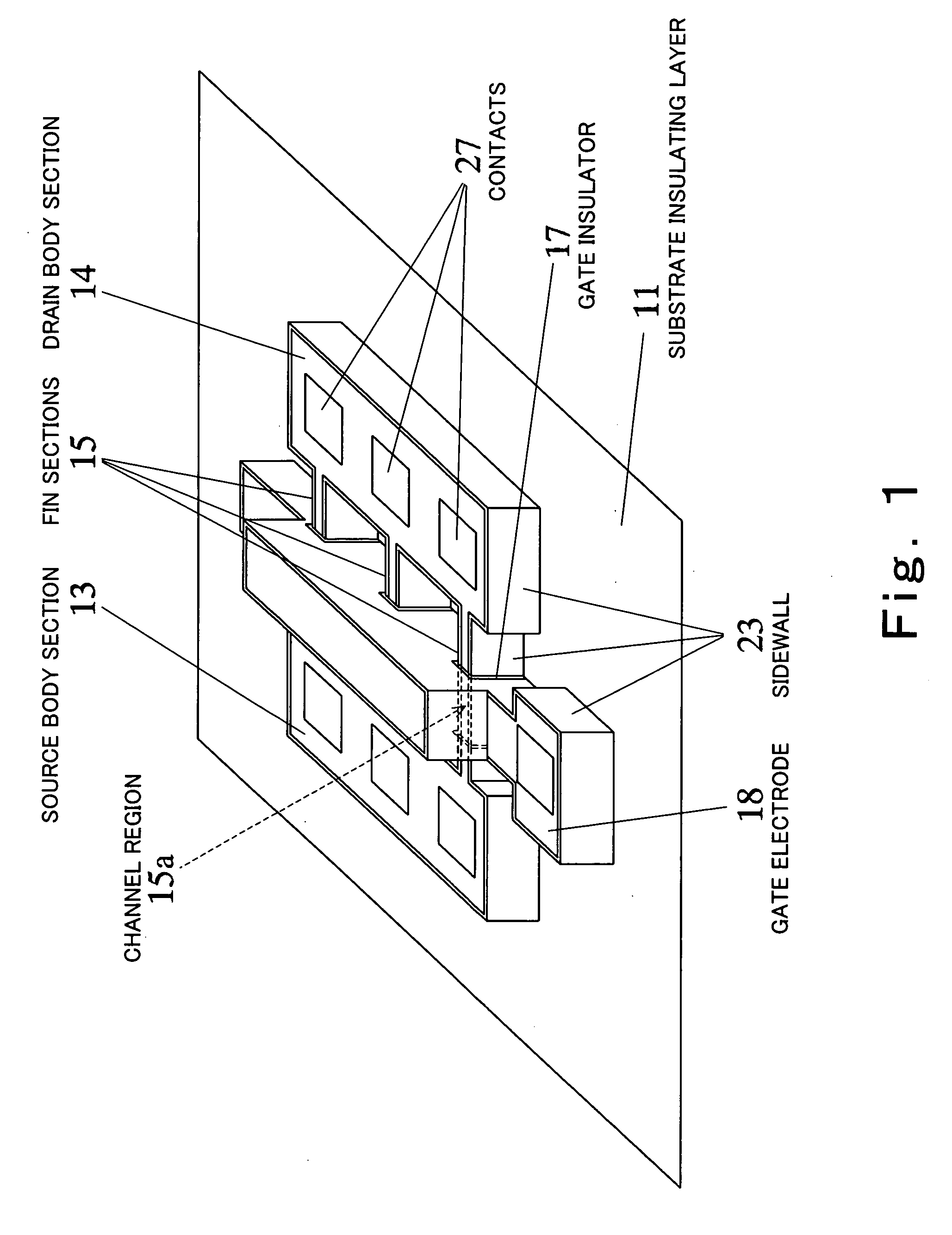

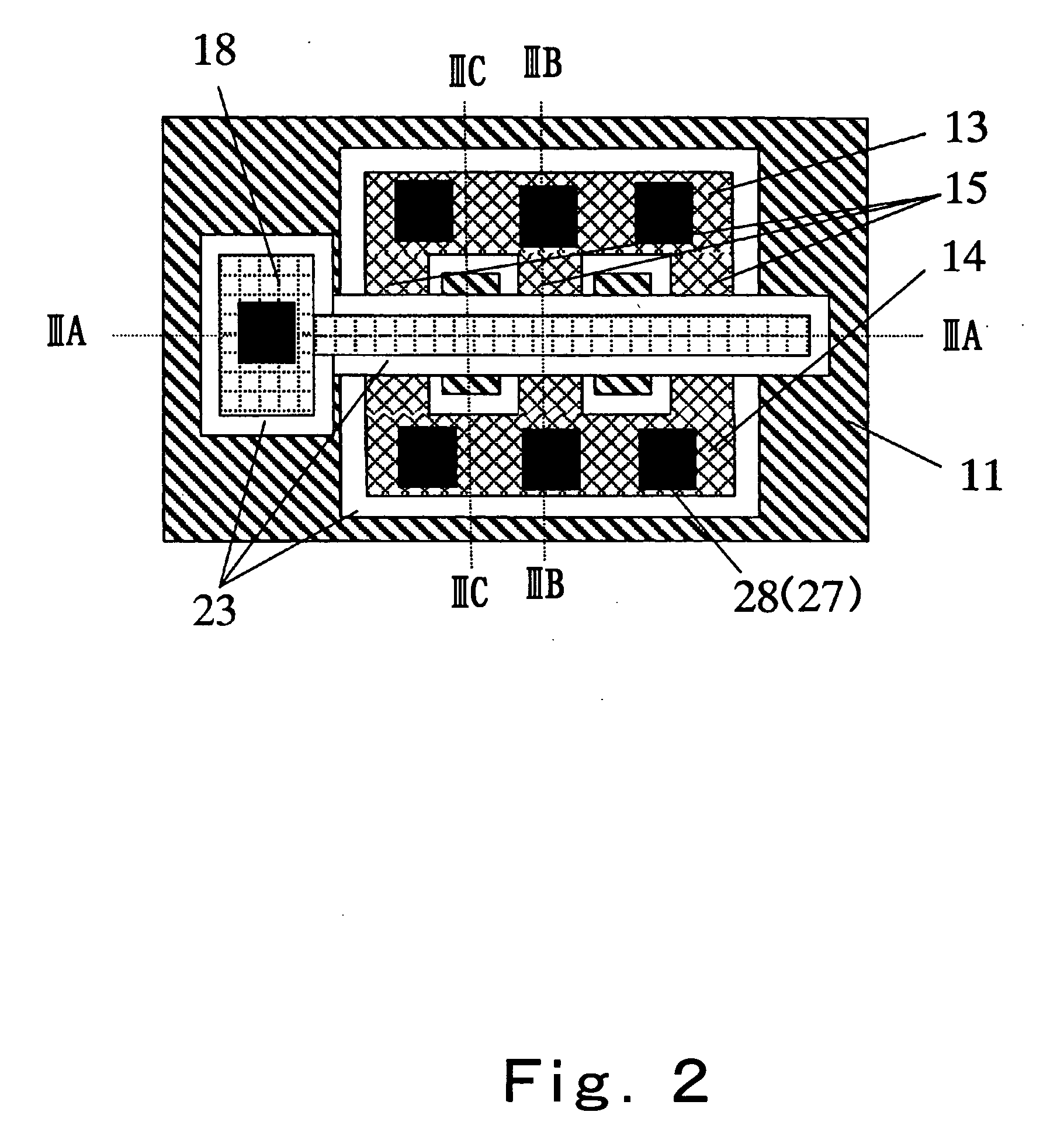

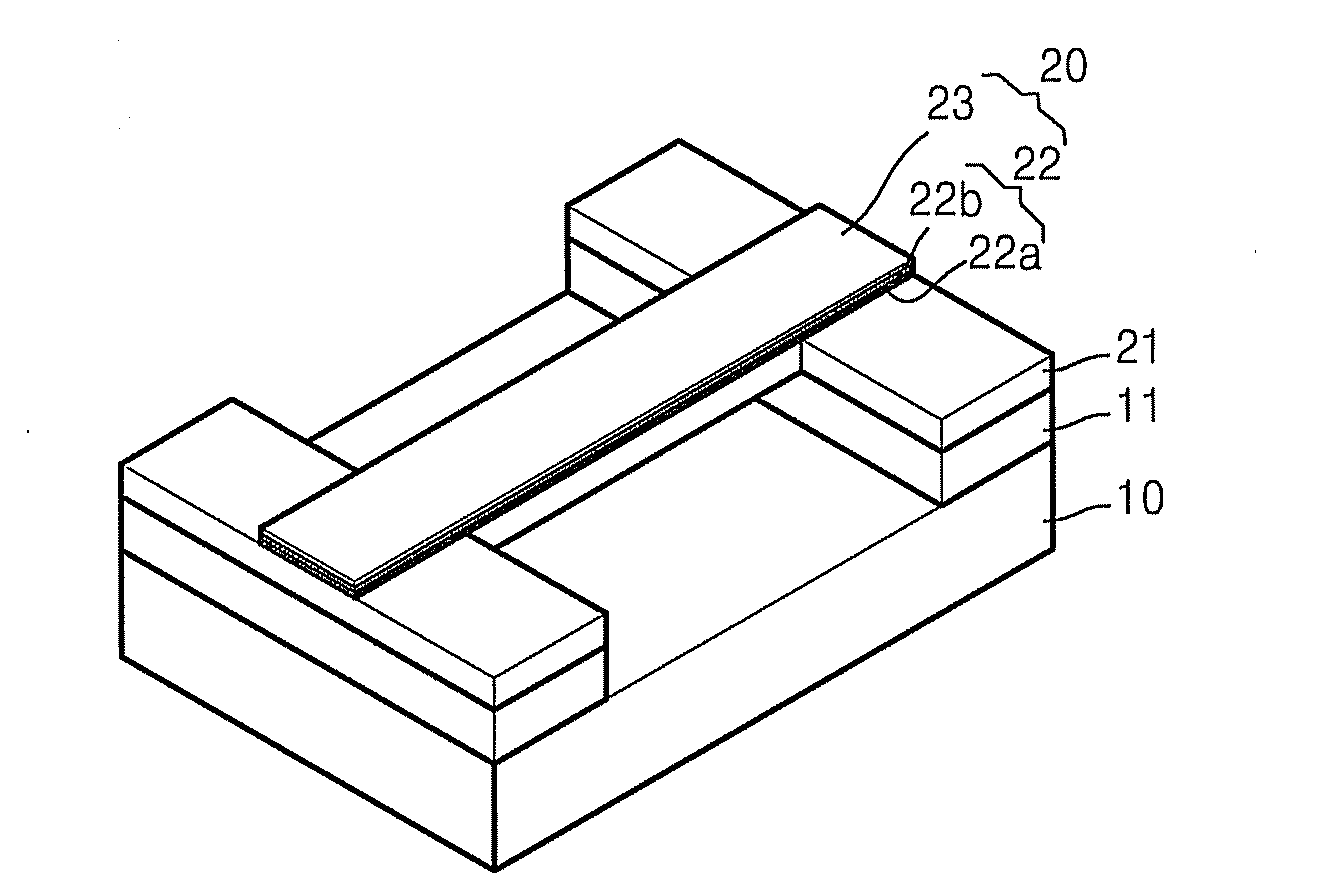

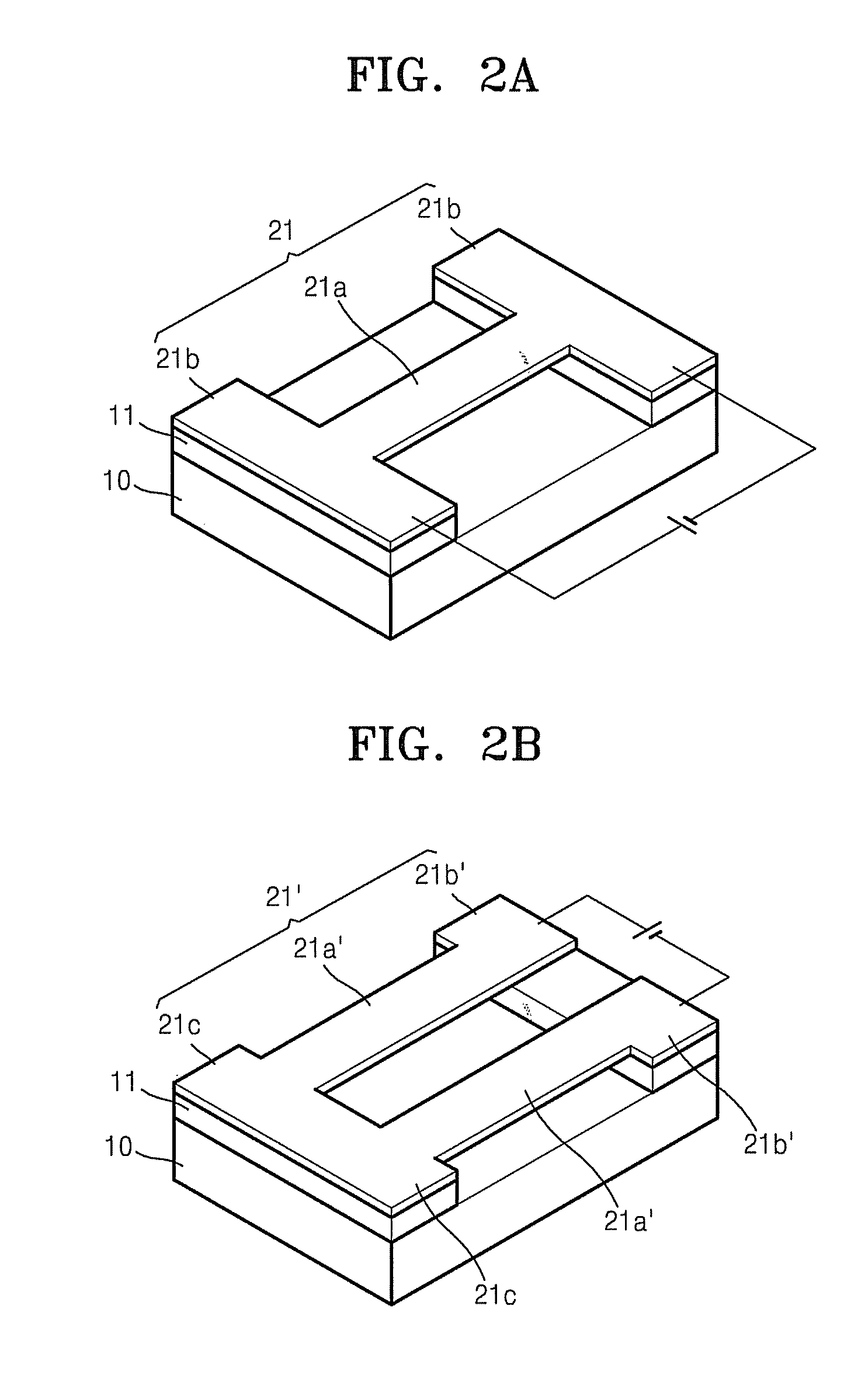

Semiconductor device and method of fabricating the same

InactiveUS20070052041A1Easily fabricateReduce difficultyTransistorSolid-state devicesEngineeringRidge

A semiconductor device according to this invention includes: a first insulating layer (11); a first body section (13) including an island-shaped semiconductor formed on the first insulating layer; a second body section (14) including an island-shaped semiconductor formed on the first insulating layer; a ridge-shaped connecting section (15) formed on the first insulating layer to interconnect the first body section and the second body section; a channel region (15a) formed by at least a part of the connecting section in lengthwise direction of the connecting section; a gate electrode (18) formed to cover a periphery of the channel region, with a second insulating layer intervening therebetween; a source region formed to extend over the first body section and a portion of the connecting section between the first body section and the channel region; and a drain region formed to extend over the second body section and a portion of the connecting section between the second body section and the channel region, wherein a semiconductor forming the channel region has a lattice strain.

Owner:PANASONIC CORP

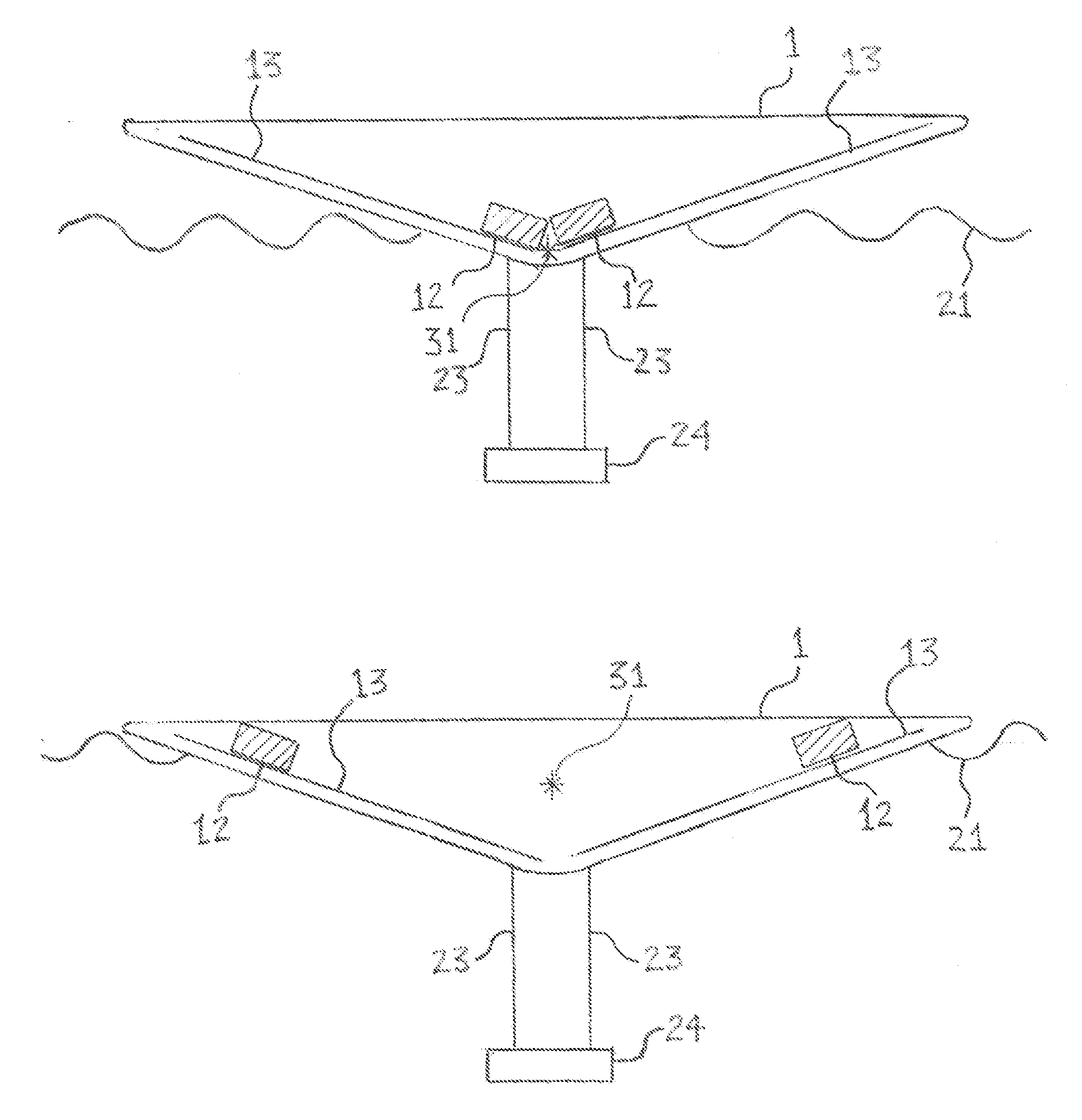

Dynamically Tuned Wave Energy Converter

ActiveUS20110089689A1Reduce riskEasily fabricateEngine fuctionsMachines/enginesSurface oceanMoment of inertia

A wave energy converter comprises a pitching floating vessel and means for converting the pitching motion to electrical power.By varying the distribution of the ballast mass in the vessel and by varying the vessel's immersed length the moments of inertia of mass and of added mass are varied and wave-bridging is controlled.The immersed length of the vessel is varied by changing the draft of a v-shaped hull. Roll and yaw are suppressed by a vertical fin held at a substantial depthInside the vessel is a compact pendulum that is a combination of tracked and folding pendulums.Both vessel and compact pendulum can be simultaneously and dynamically tuned over the range of periods that characterize high-energy ocean swells.

Owner:GREGORY BRUCE

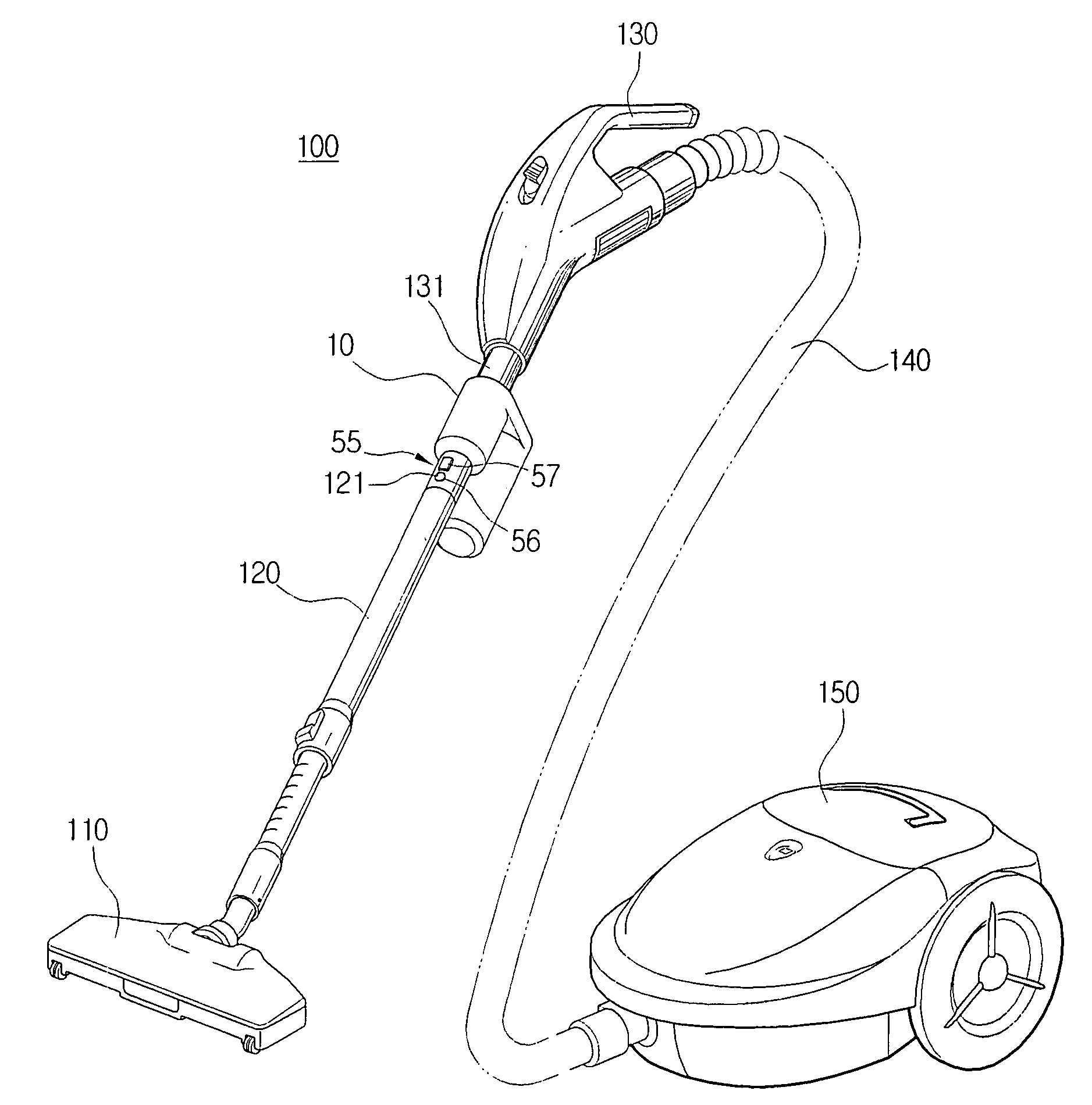

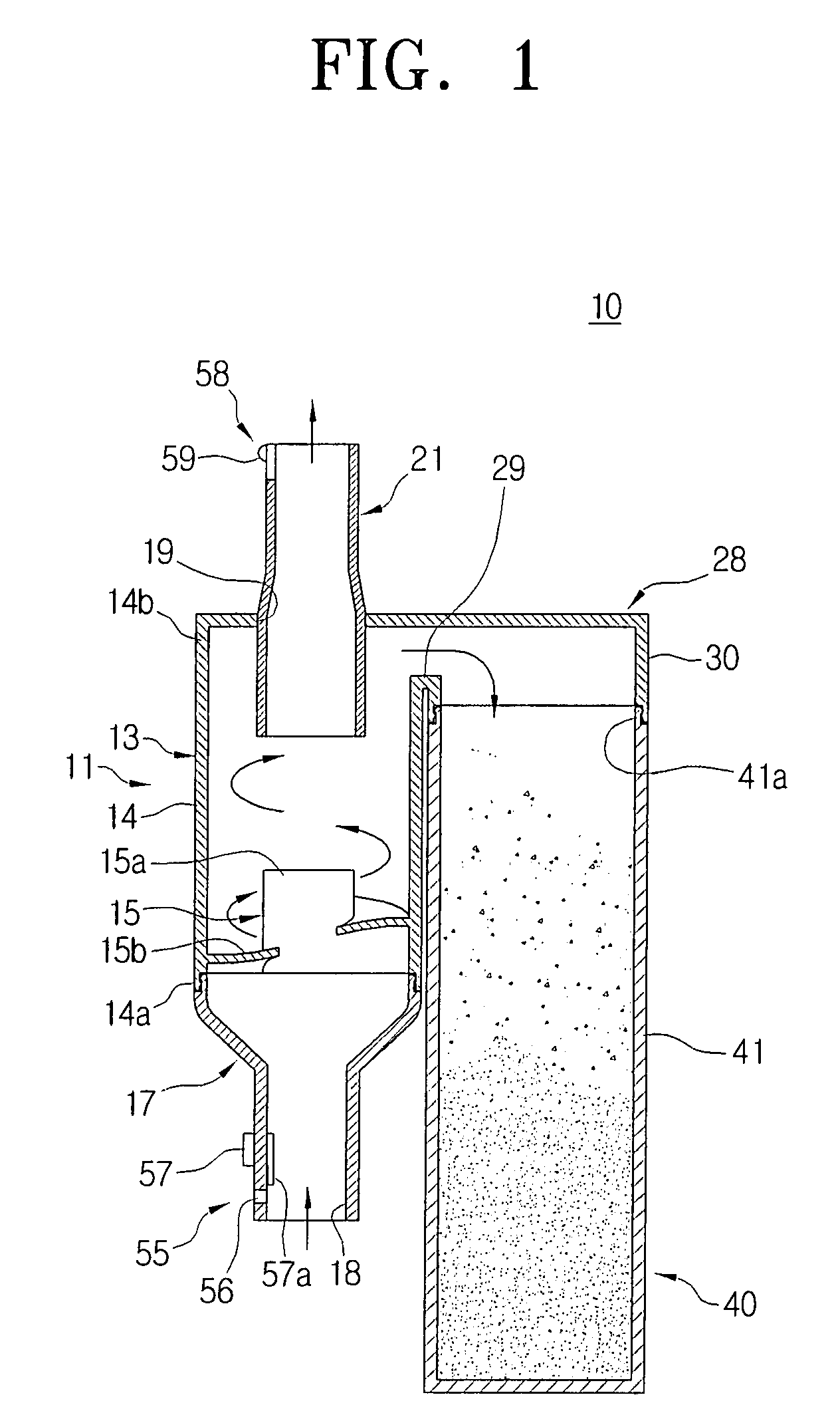

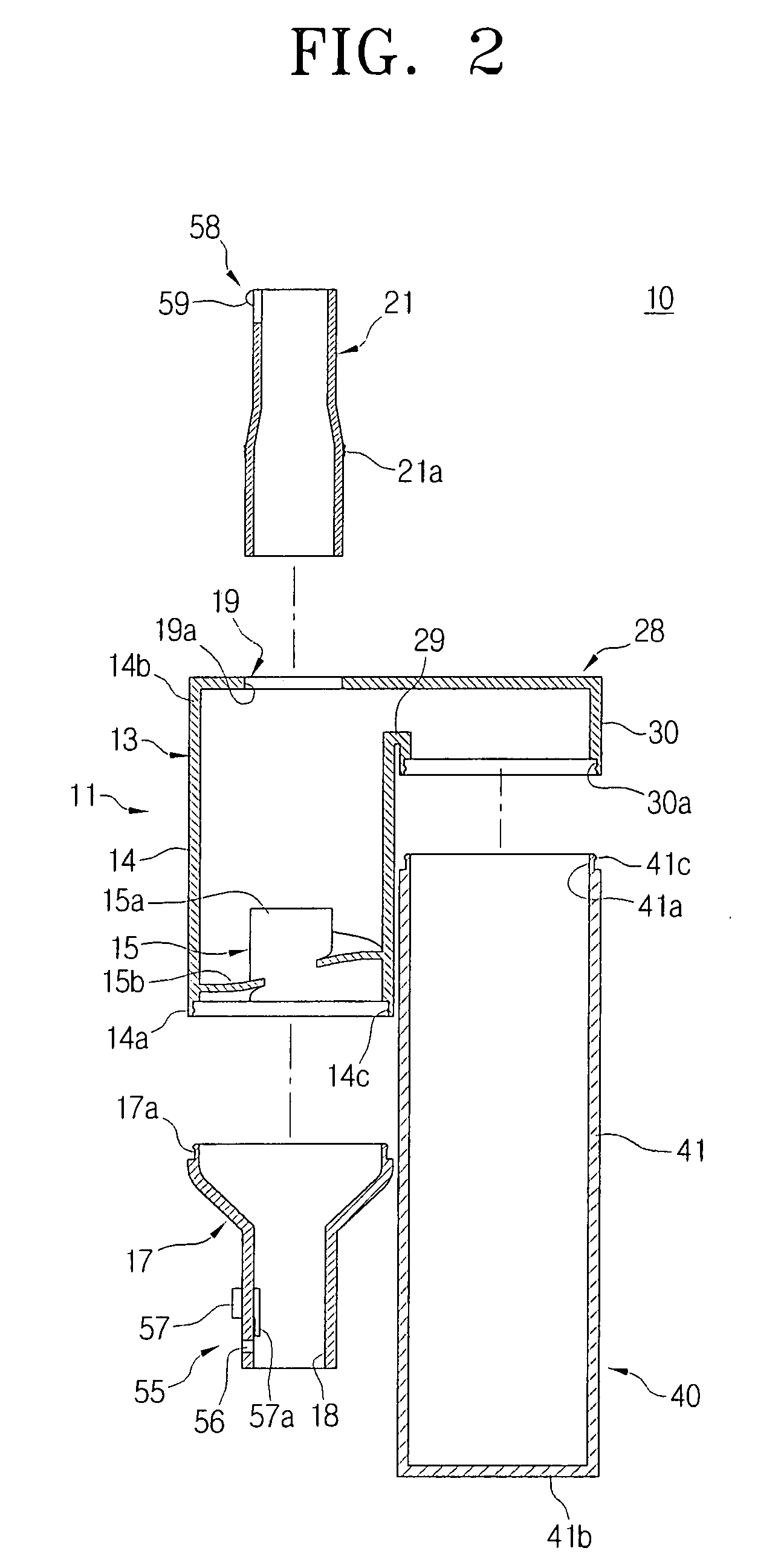

Cyclone dust-separating unit for use in vacuum cleaner

InactiveUS20080289306A1Improve efficiencySimple structureSuction filtersReversed direction vortexPower flowEngineering

A cyclone dust-separating unit is provided that includes a whirling current generating unit to rotate air drawn in through a suction nozzle, and a dust collecting bin having opened and closed ends to collect and store dust separated by a whirling current. The generating unit and the bin are separate tube members, and the generating unit includes a cyclone body having a first end with an air inlet and a second end with an air outlet, a spiral guide member on the first end to guide air flowed in through the air inlet in a spiral shape, an outflow pipe on the second end to extend to the outside of the cyclone body while penetrating through the air outlet, and a dust guide to connect a dust discharging opening with the opened end and to guide dust or dirt discharged through the dust discharging opening, to the opened end.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

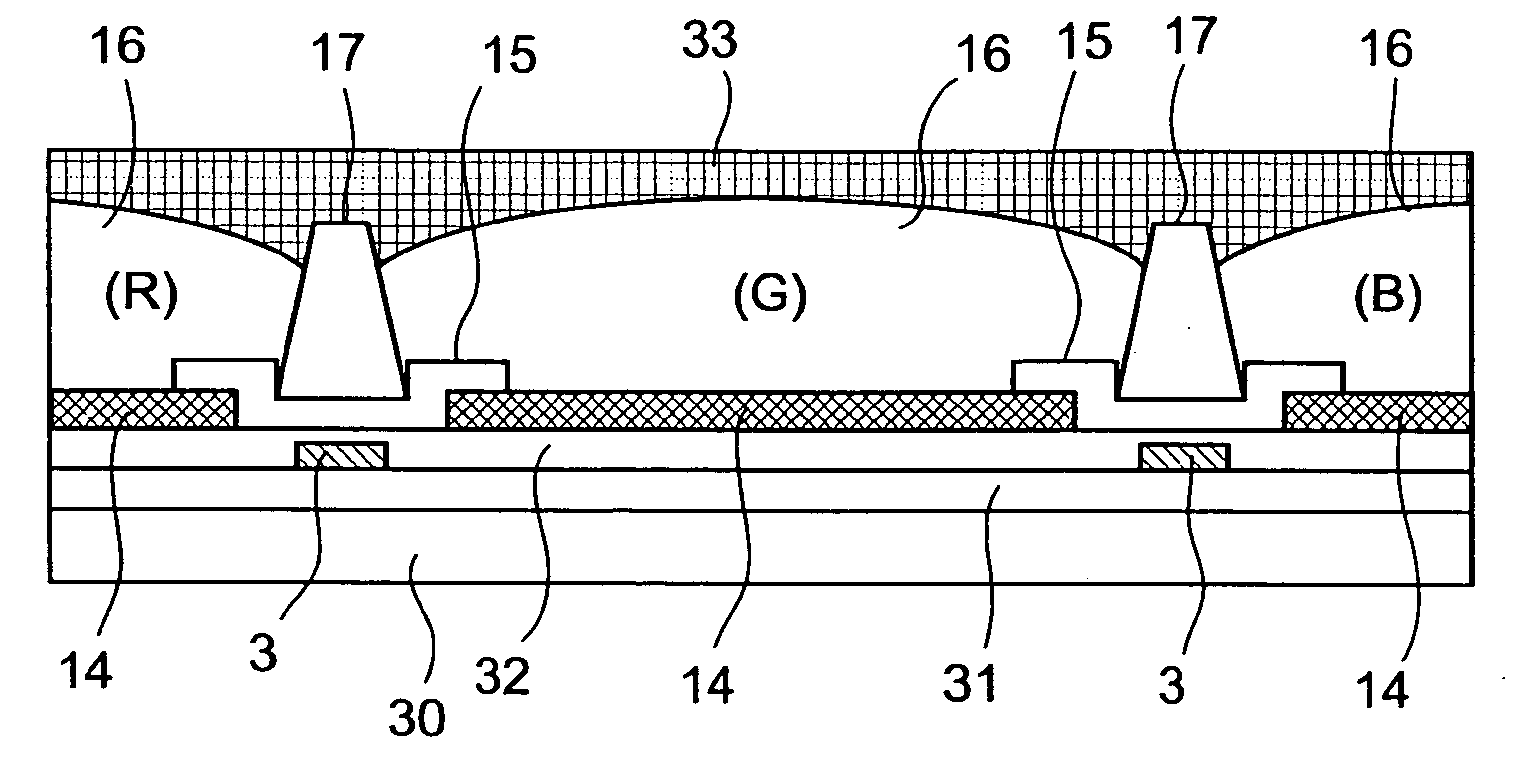

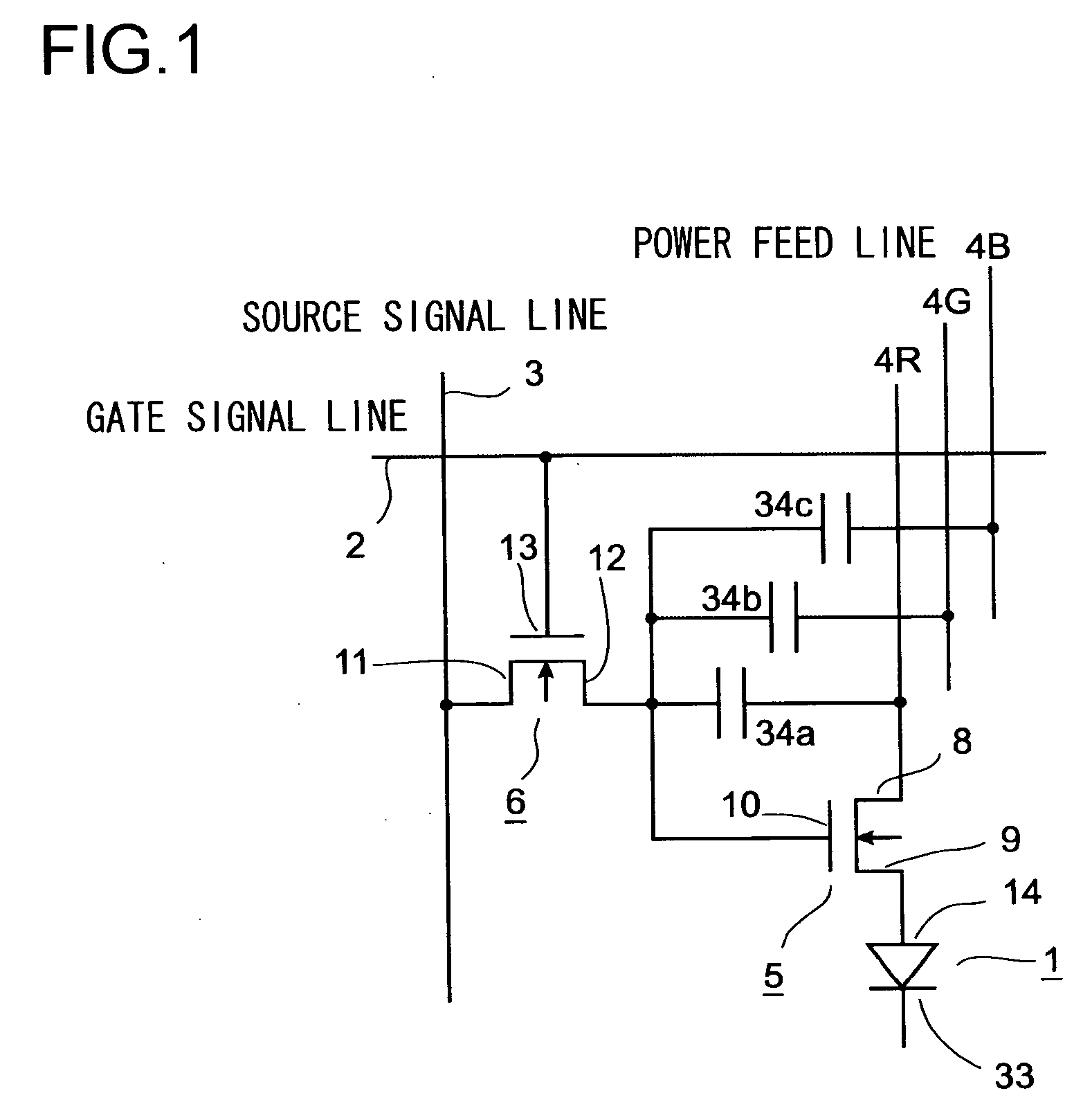

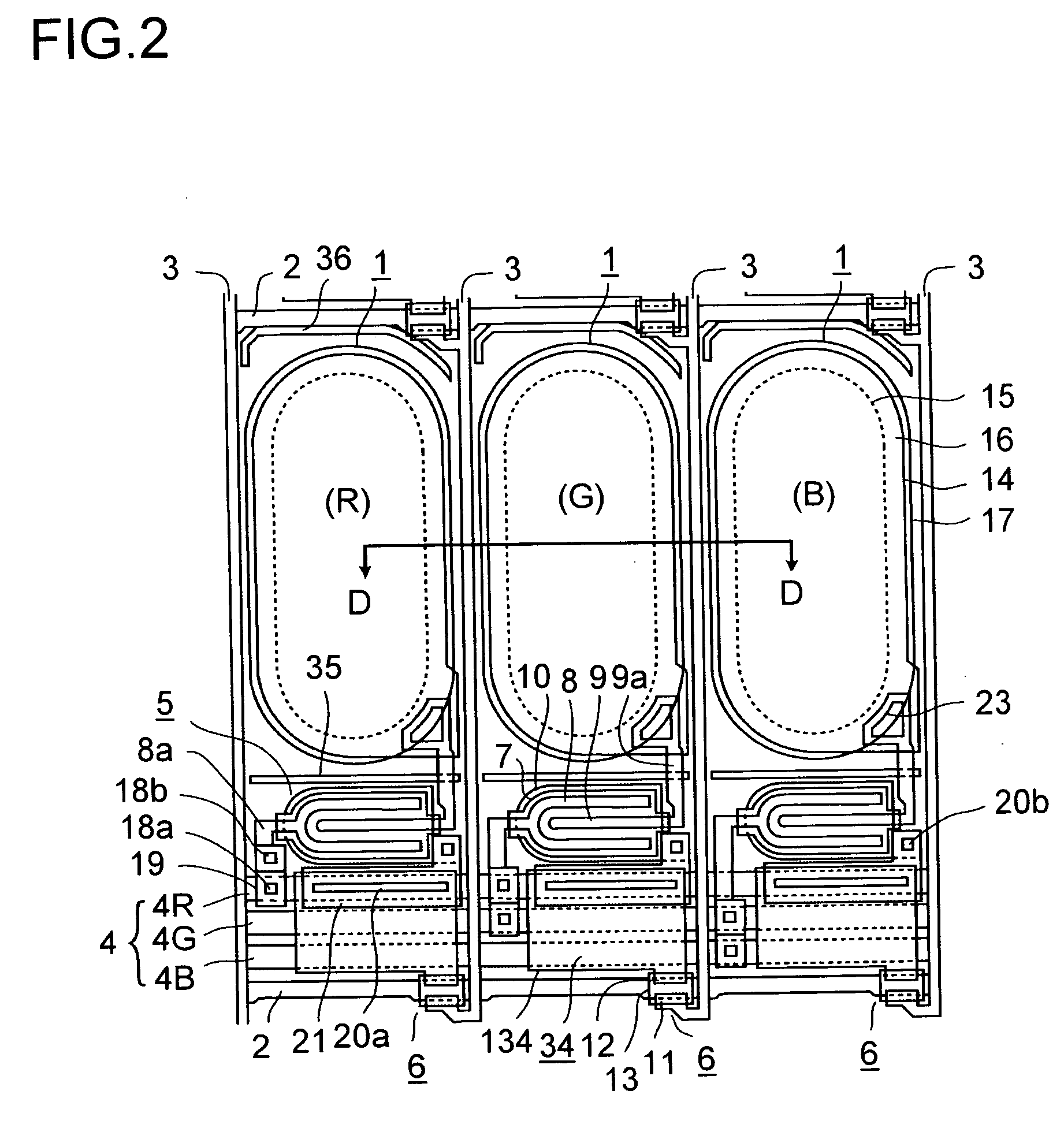

Display device

ActiveUS20050051817A1Easily fabricateEasy to makeStatic indicating devicesElectroluminescent light sourcesCapacitanceSignal lines

A display device includes a plurality of light emitting elements arranged in a matrix. A scan signal is made to flow into a gate signal line and a data signal is made to flow into a source signal line so that the data signal is applied to a source electrode and the scan signal is supplied to a gate electrode of a control TFT arranged at a portion where the both signal lines intersect when viewed from above. Thus, when the control TFT is turned ON, a drive TFT having a gate electrode connected to the drain electrode is turned ON, so that current is supplied from a power supply line via the source electrode and the drain electrode of the drive TFT to an organic EL element and the organic EL element emits light. A holding capacity is present between the control TFT and the drive TFT. Even when the scan signal becomes LOW level and the control TFT turns OFF, the gate potential of the drive TFT is held for a predetermined period of time by the holding capacity and the organic EL element continues to emit light.

Owner:SANYO ELECTRIC CO LTD +1

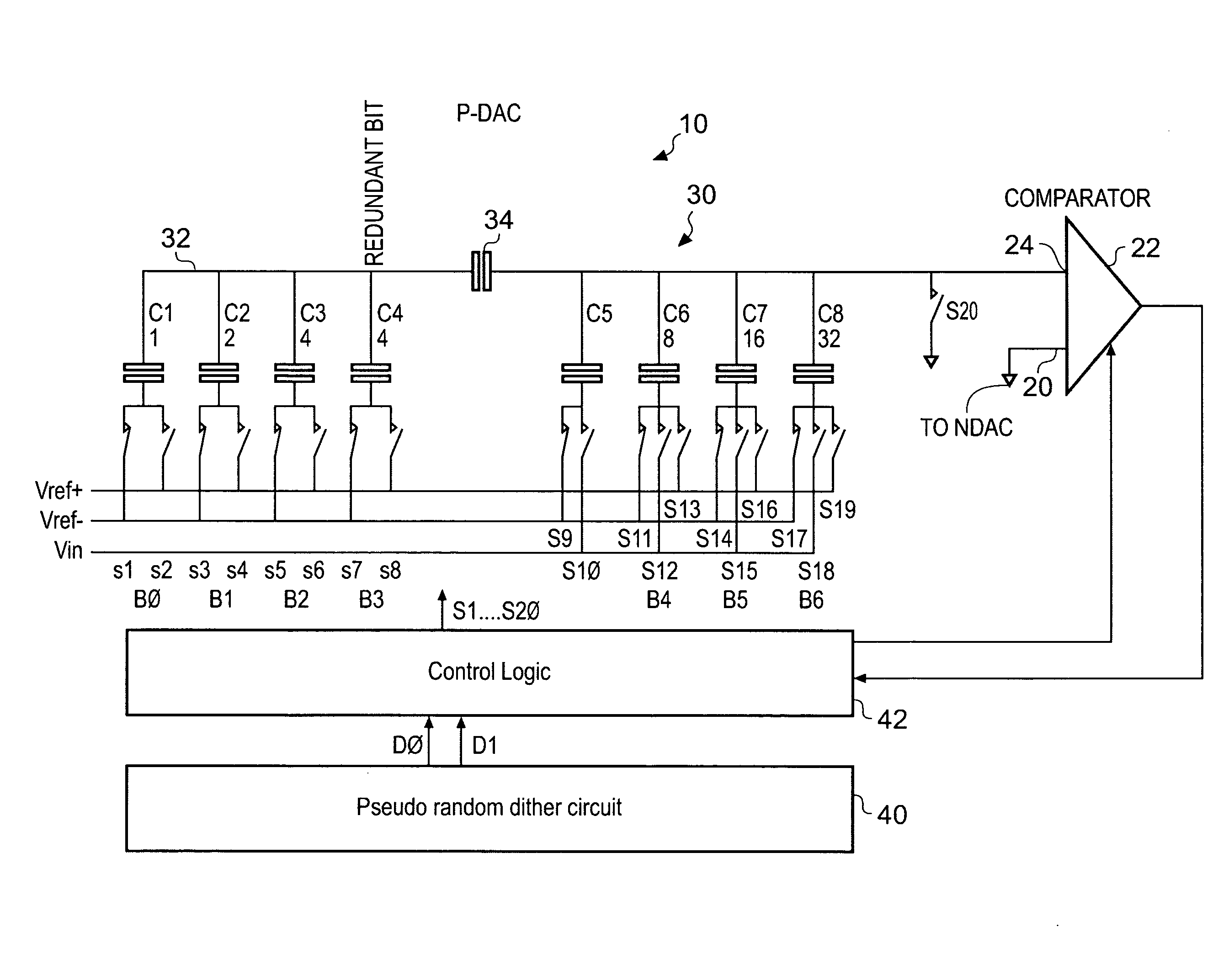

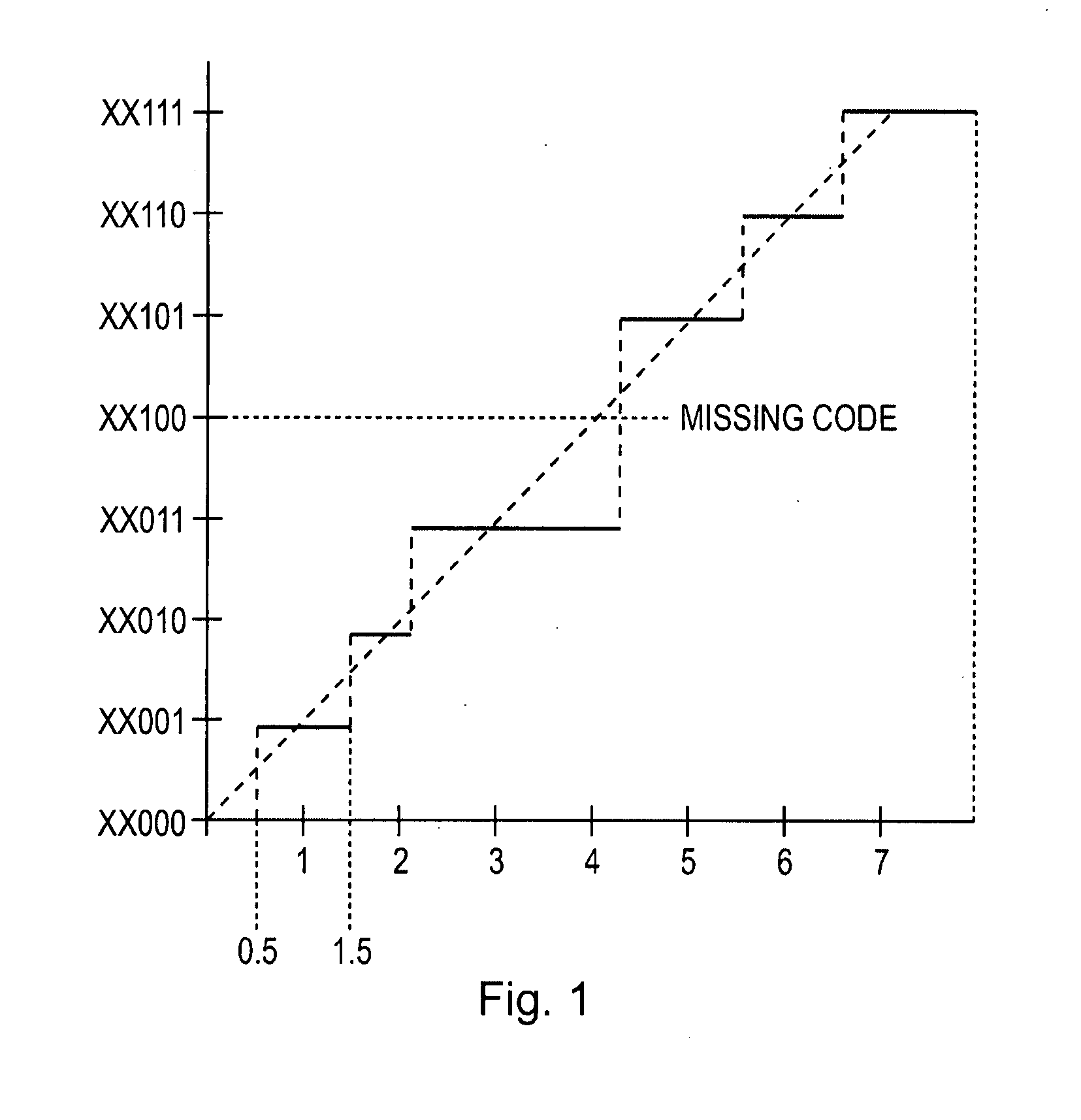

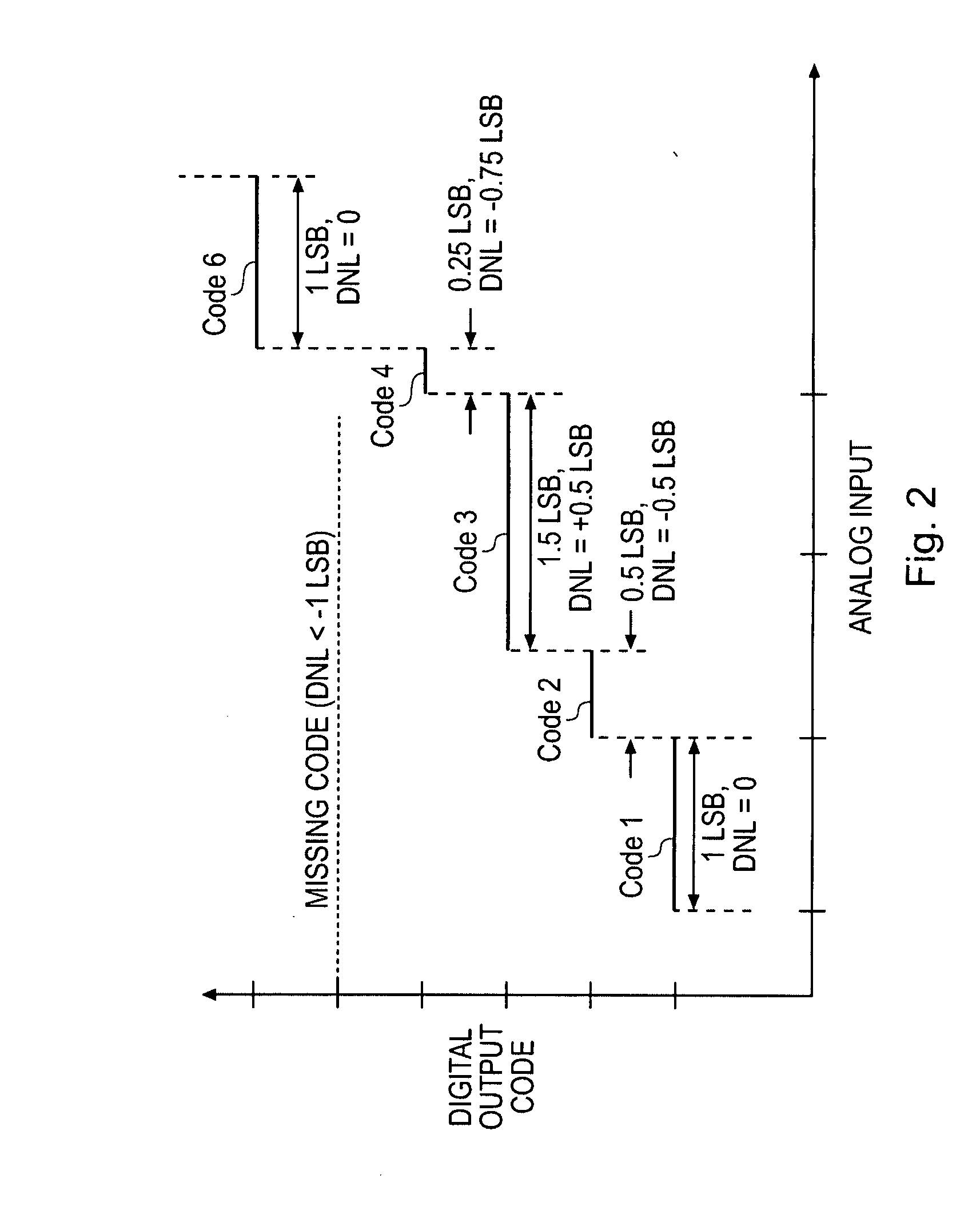

Dither technique for improving dynamic non-linearity in an analog to digital converter, and an analog to digital converter having improved dynamic non-linearity

ActiveUS20080084340A1Easily fabricateEasy to makeElectric signal transmission systemsAnalogue-digital convertersAnalog to digital conversionAnalog-to-digital converter

An analog to digital converter comprising a conversion engine having redundancy therein; and a dither device for applying a dither to the conversion engine; and a controller adapted to operate the conversion engine to perform a successive approximation conversion of the analog input, and wherein the dither is removed prior to completion of the analog to digital conversion.

Owner:ANALOG DEVICES INC

Method of forming crystalline layer, and thin film solar cell and method of fabricating the solar cell adopting the method of forming crystalline layer

InactiveUS20090223557A1Easily fabricateHigh efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingThin film solar cellCrystallization

Owner:SAMSUNG ELECTRONICS CO LTD +1

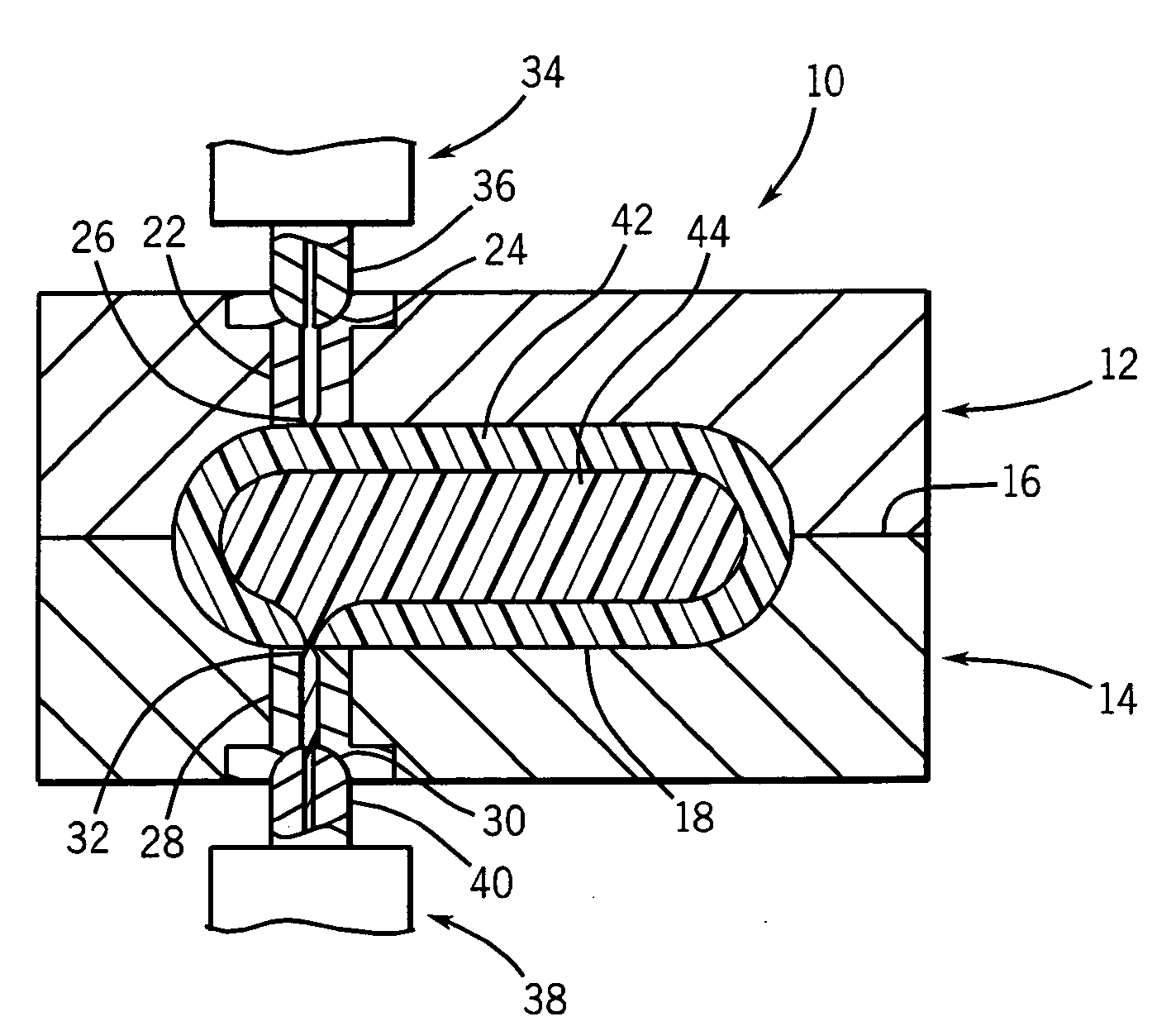

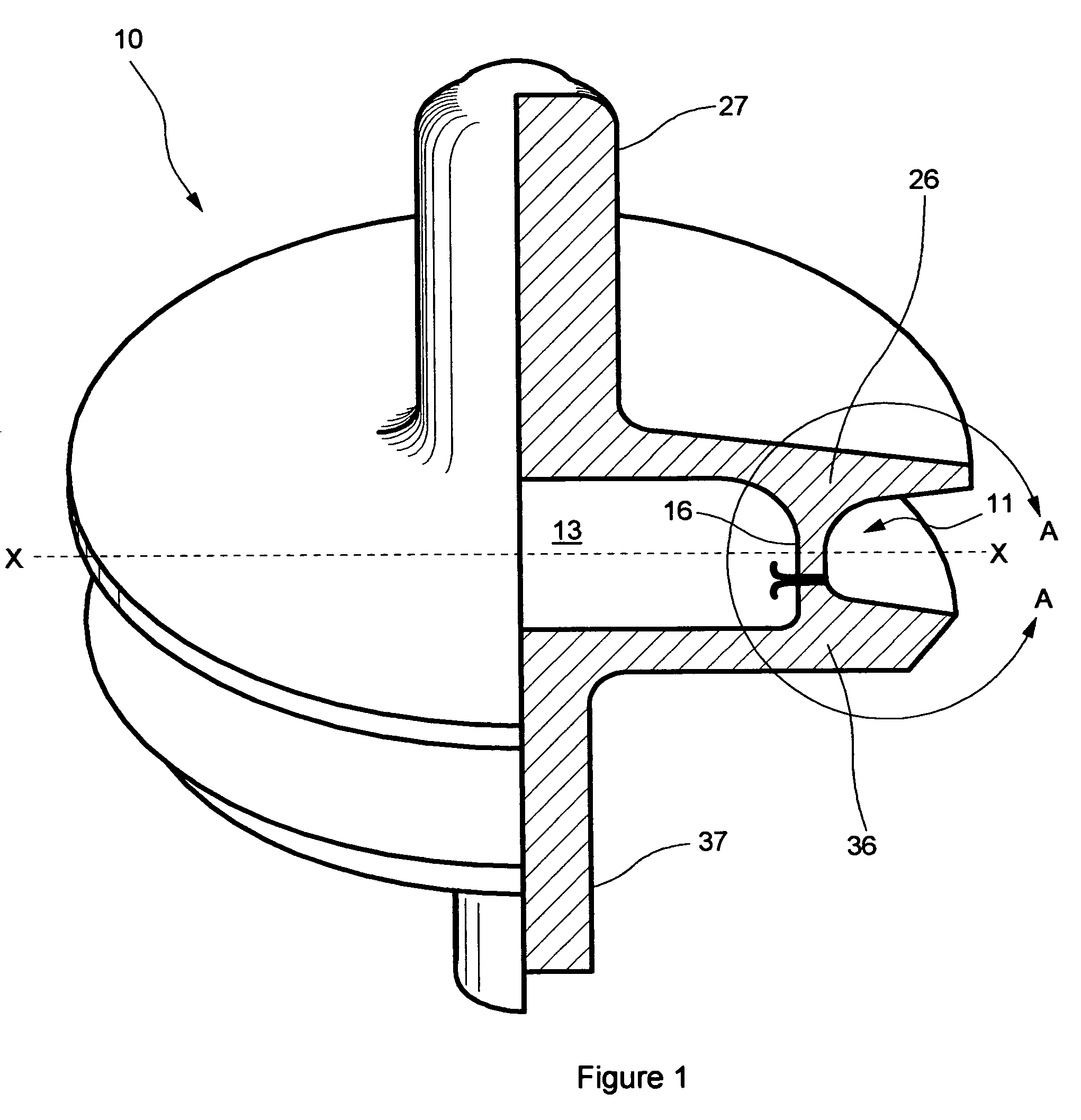

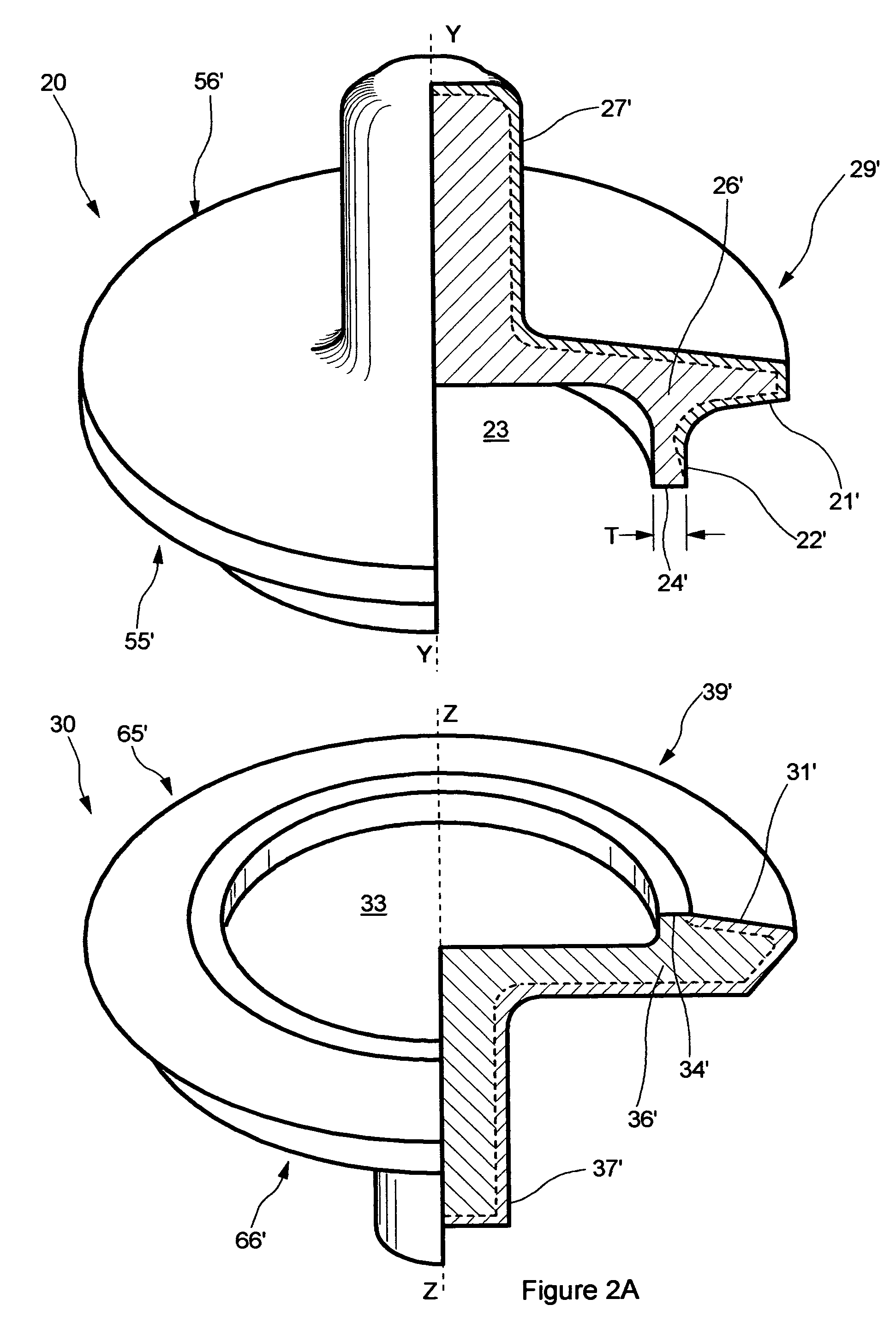

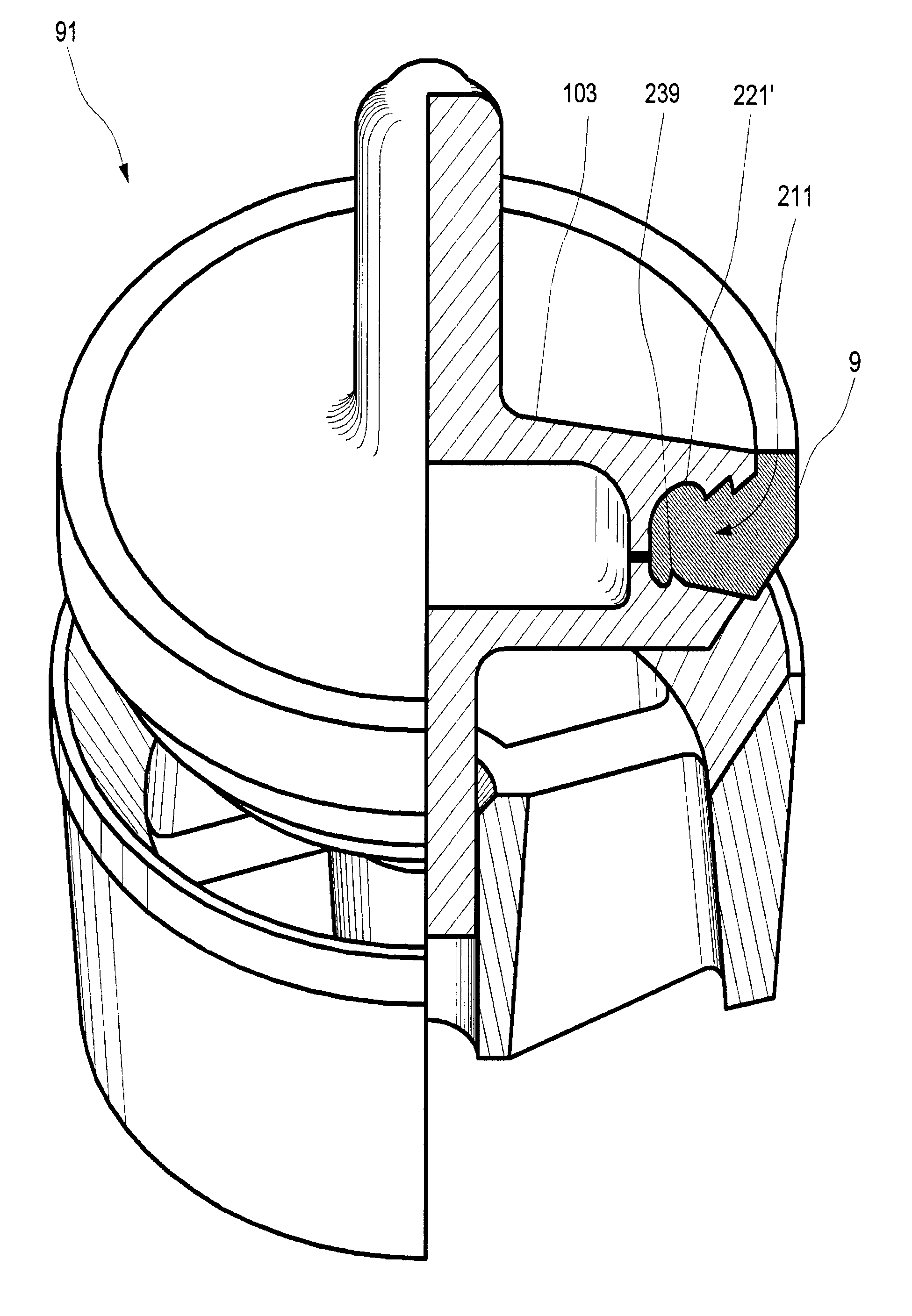

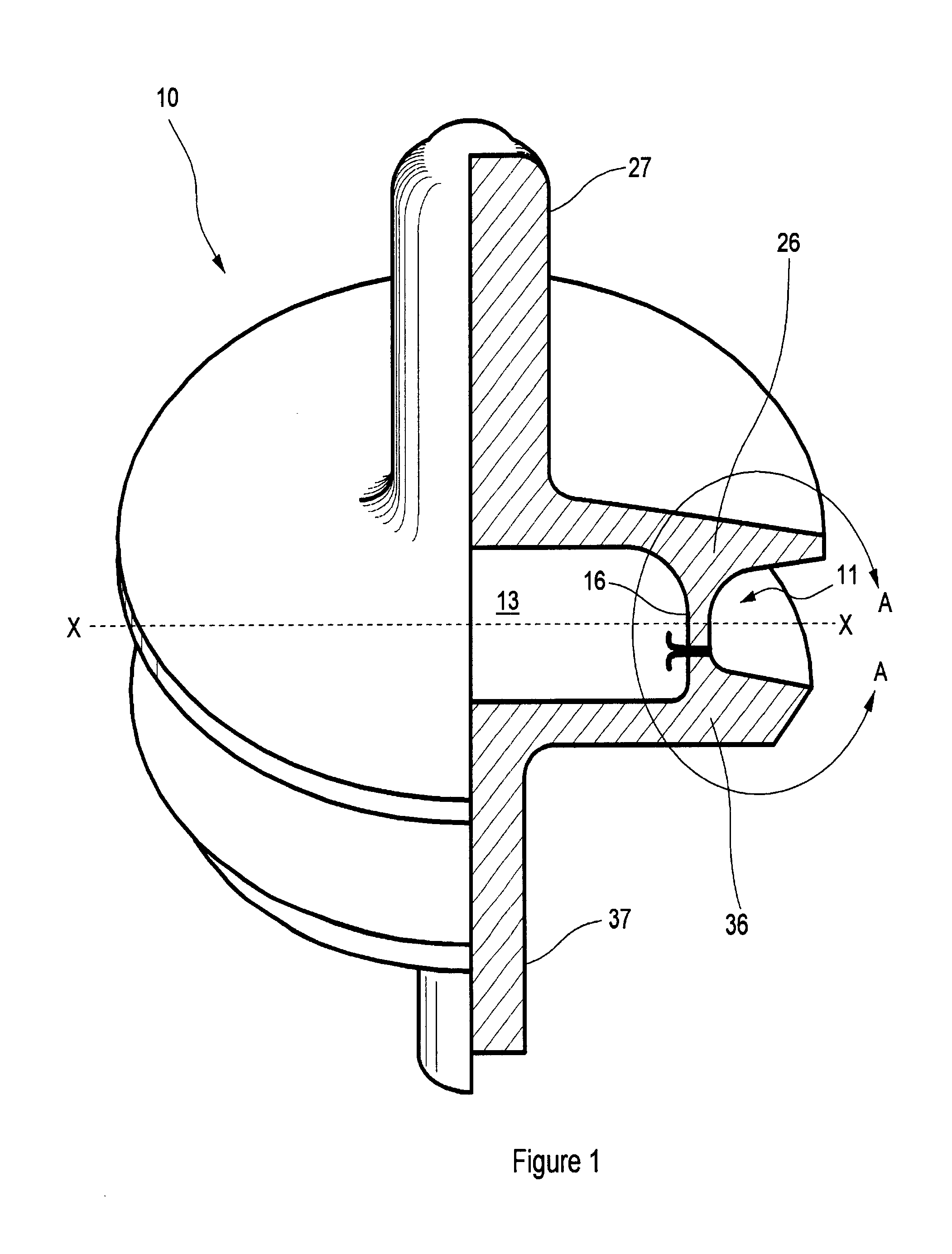

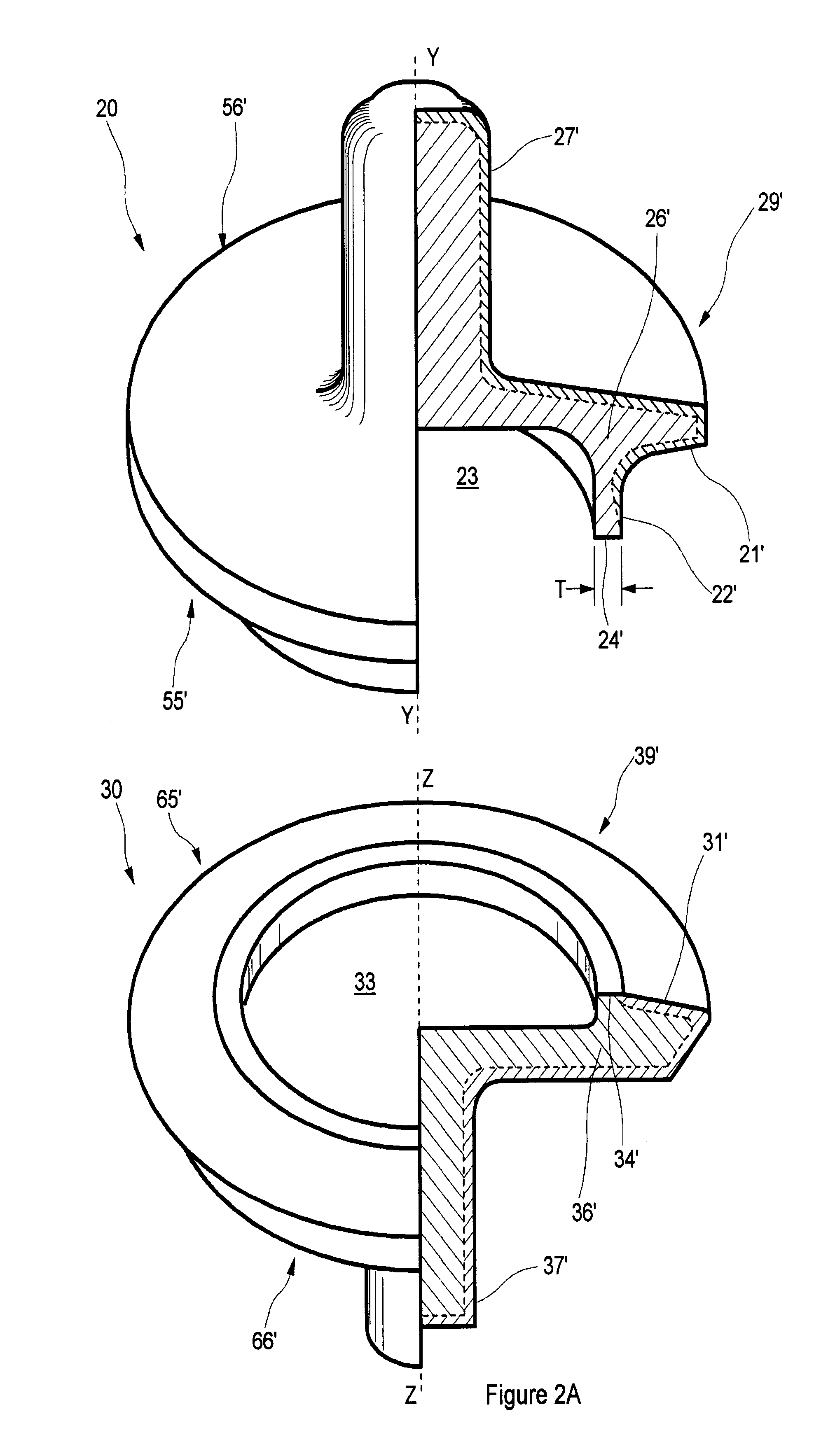

Valve body with integral seal retention groove

InactiveUS6955339B1Easily fabricateImprove durabilityPiston ringsBraking action transmissionEngineeringNear net shape

A valve body has one or more integral seal retention grooves and one or more interior hollows which may be manufactured using frictional or other types of welding to join two previously formed portions through at least one cylindrical web. Forging or casting valve body portions to near-net-shape prior to joining minimizes machining necessary to achieve a final desired shape. One or more interior hollows and an integral seal retention groove are formed in the welded valve body from features present on the portions joined by welding to form the body. Increased valve durability and reduced metal wear arise from the reduced valve body weight and correspondingly reduced impact loading. An elastomeric seal may be cast and cured in place in a seal retention groove.

Owner:NOVATECH HLDG CORP

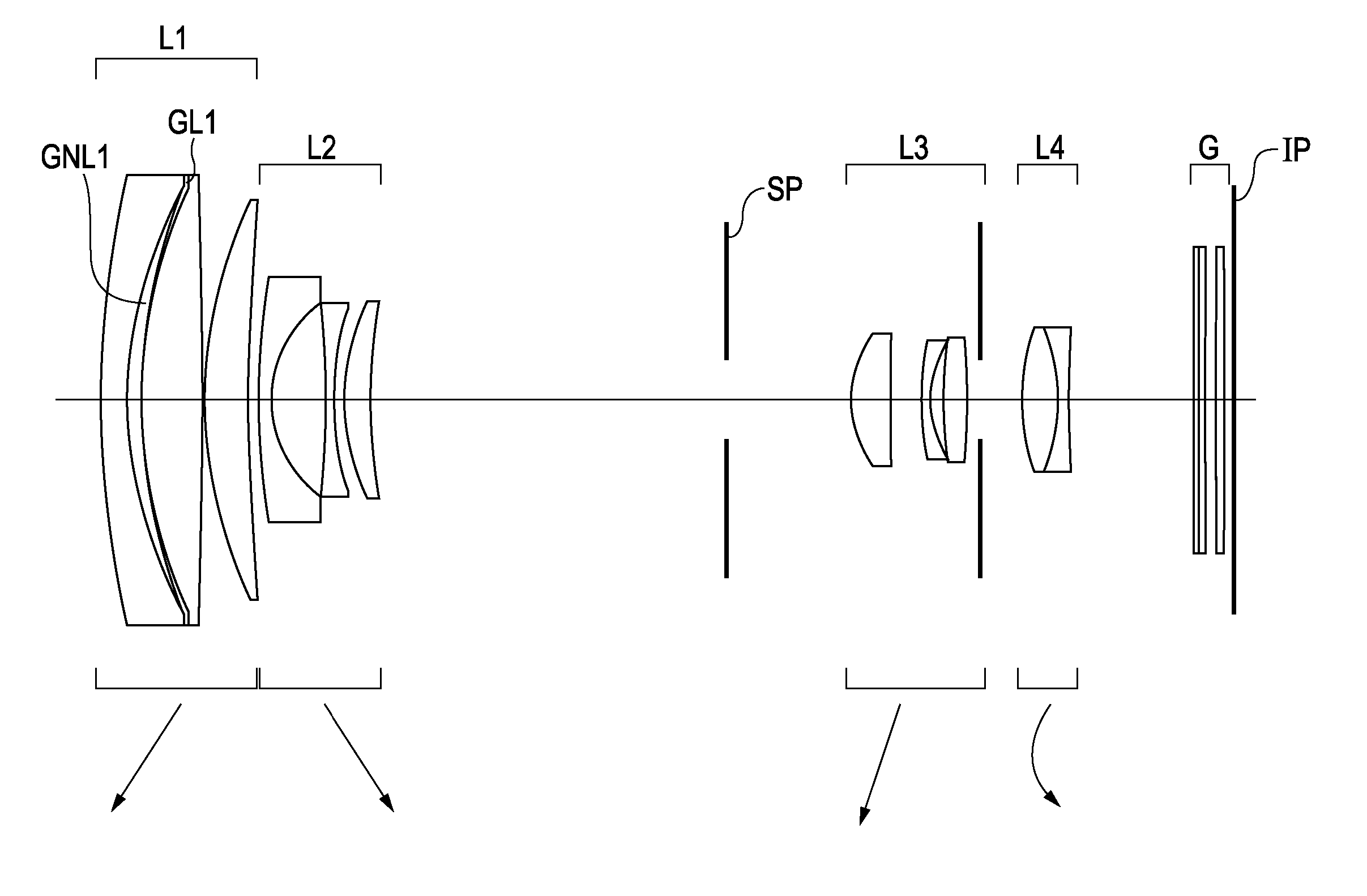

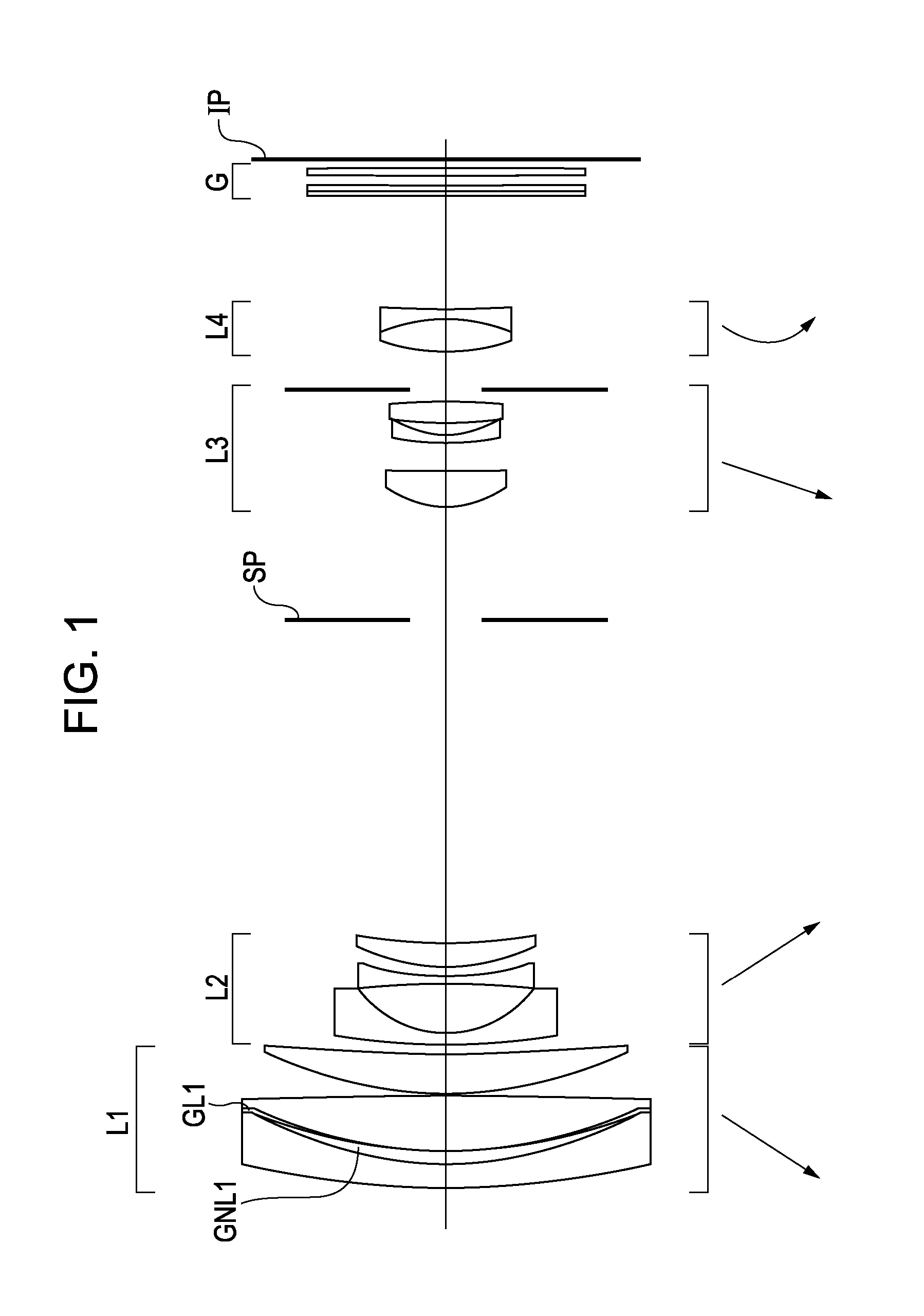

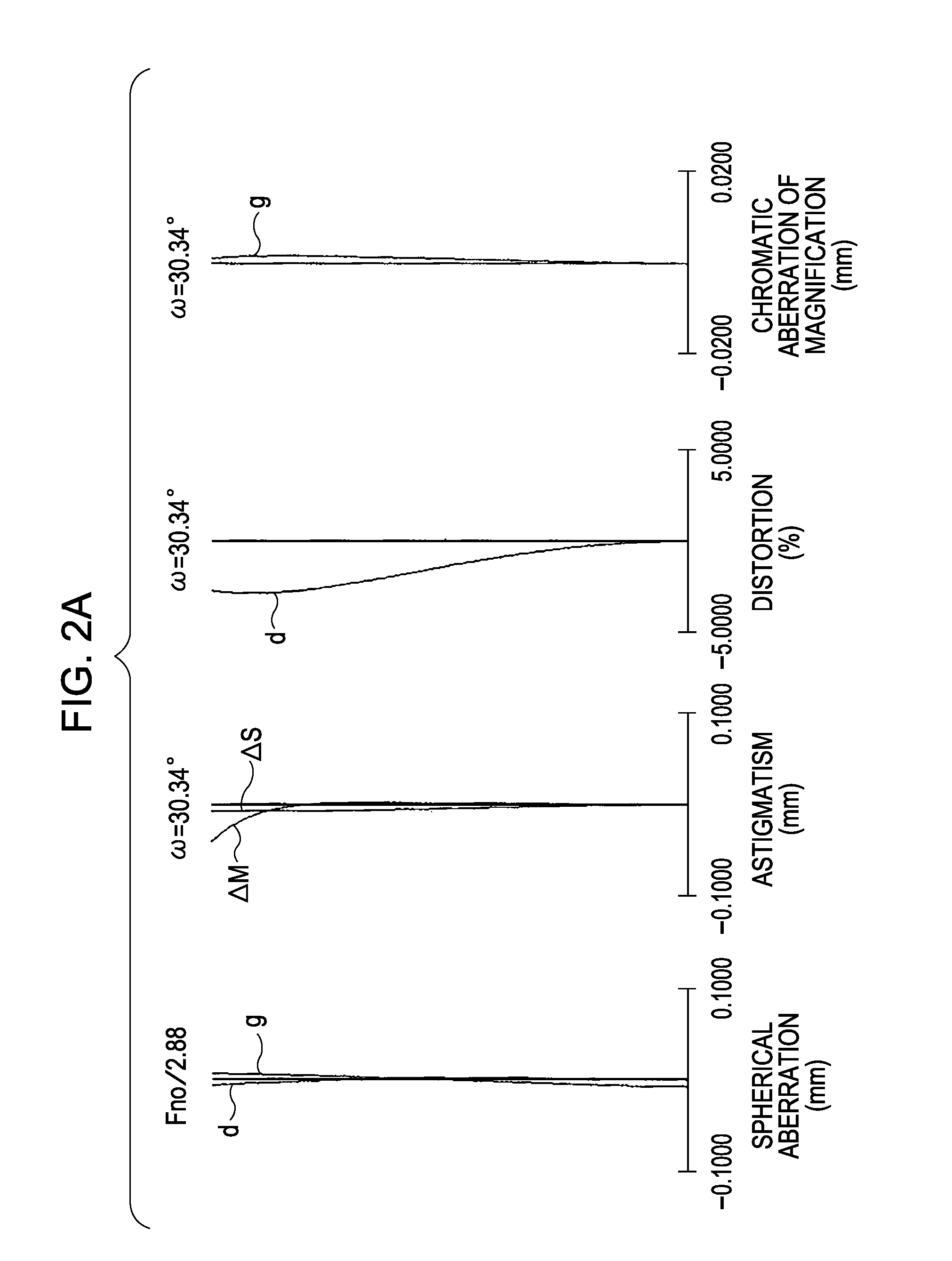

Optical system and optical apparatus including optical system

InactiveUS20080130141A1Easily fabricateExcellent resistanceOptical elementsConditional expressionOptical axis

An optical system includes a first optical element and a second optical element on at least one of an enlargement side and a reduction side relative to a point P at which a light axis and a paraxial chief ray intersect. Each of the first optical element and second optical element is composed of a solid material having a refractive light incident surface and a refractive light emergent surface. The optical system satisfies the following conditional expressions: ΔθgF1>0.0272, ΔθgF2<−0.0278, and f1×f2<0 where ΔθgF1 and ΔθgF2 denote anomalous partial dispersion values of the first and second optical elements for the g-line and F-line, respectively, and f1 and f2 denote focal lengths of the first and second optical elements, respectively, when the light incident surfaces and the light emergent surfaces of the first and second optical elements are in contact with air.

Owner:CANON KK

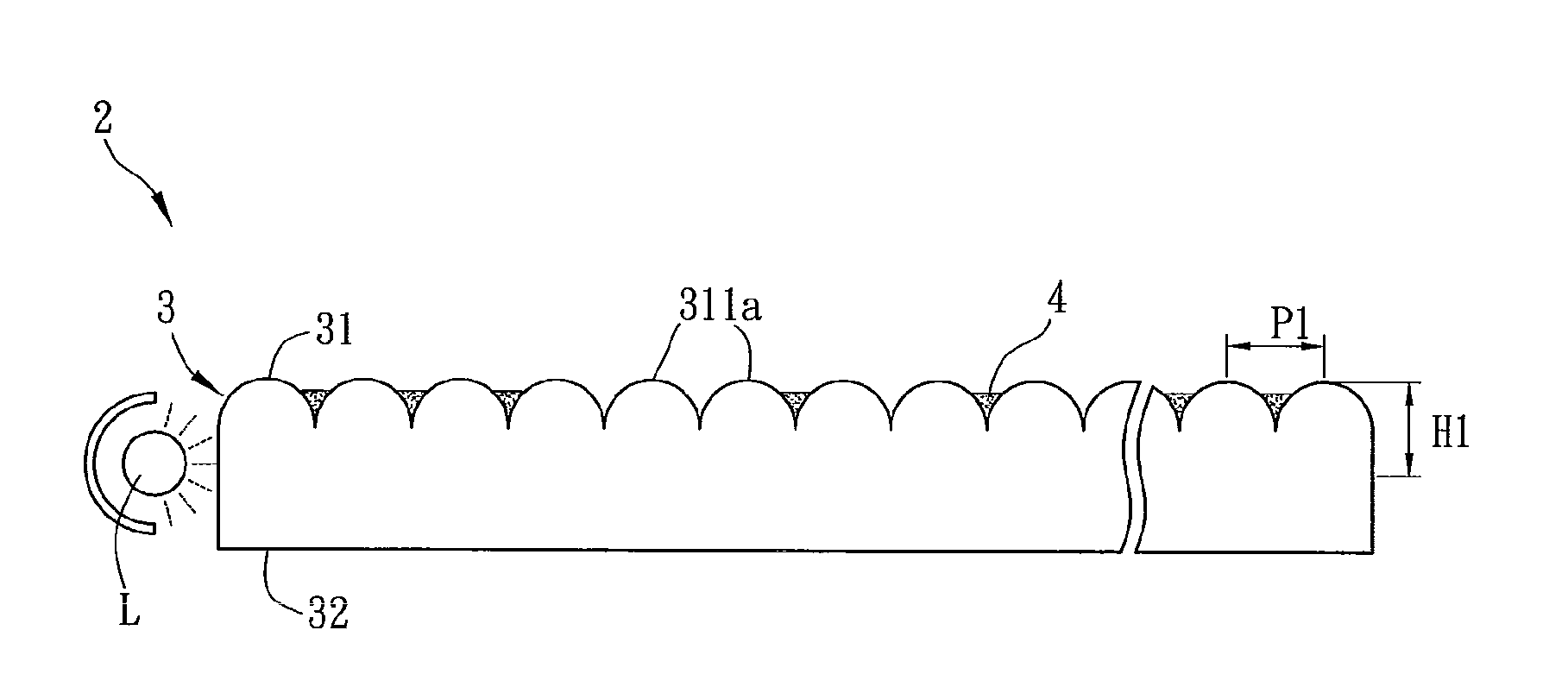

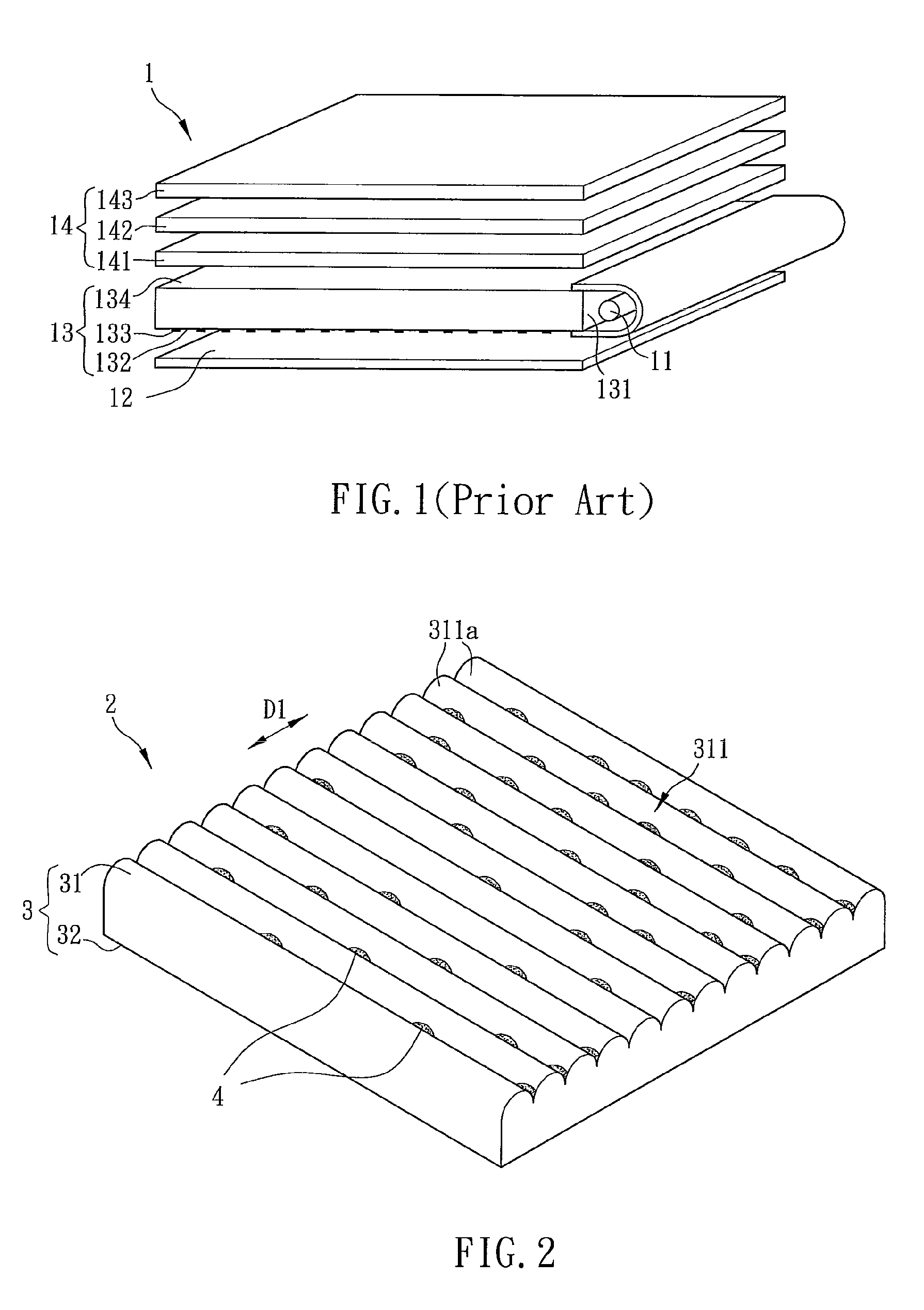

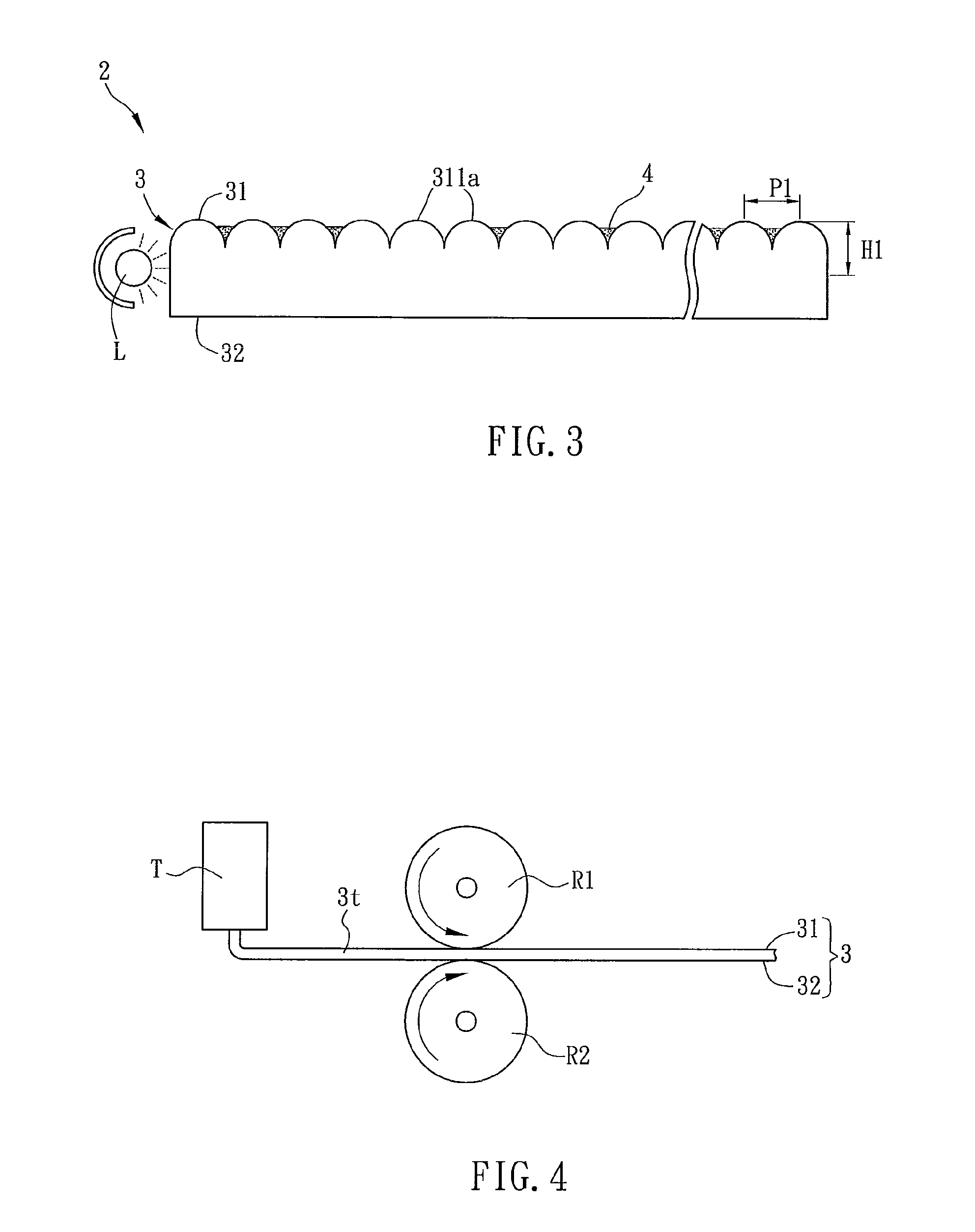

Light guiding plate

InactiveUS20100085771A1Easily fabricateEnhance uniformityOptical light guidesReflectorsMicrostructureTotal internal reflection

A light guiding plate includes a light guiding plate body and a plurality of total internal reflection destruction materials. The light guiding plate body has a first surface and a second surface opposite to the first surface. The first surface has a first microstructure array. The material of the total internal reflection destruction materials is different from the material of the light guiding body. The total internal reflection destruction materials are unevenly distributed on the first surface and / or the second surface.

Owner:LIN FENG LI

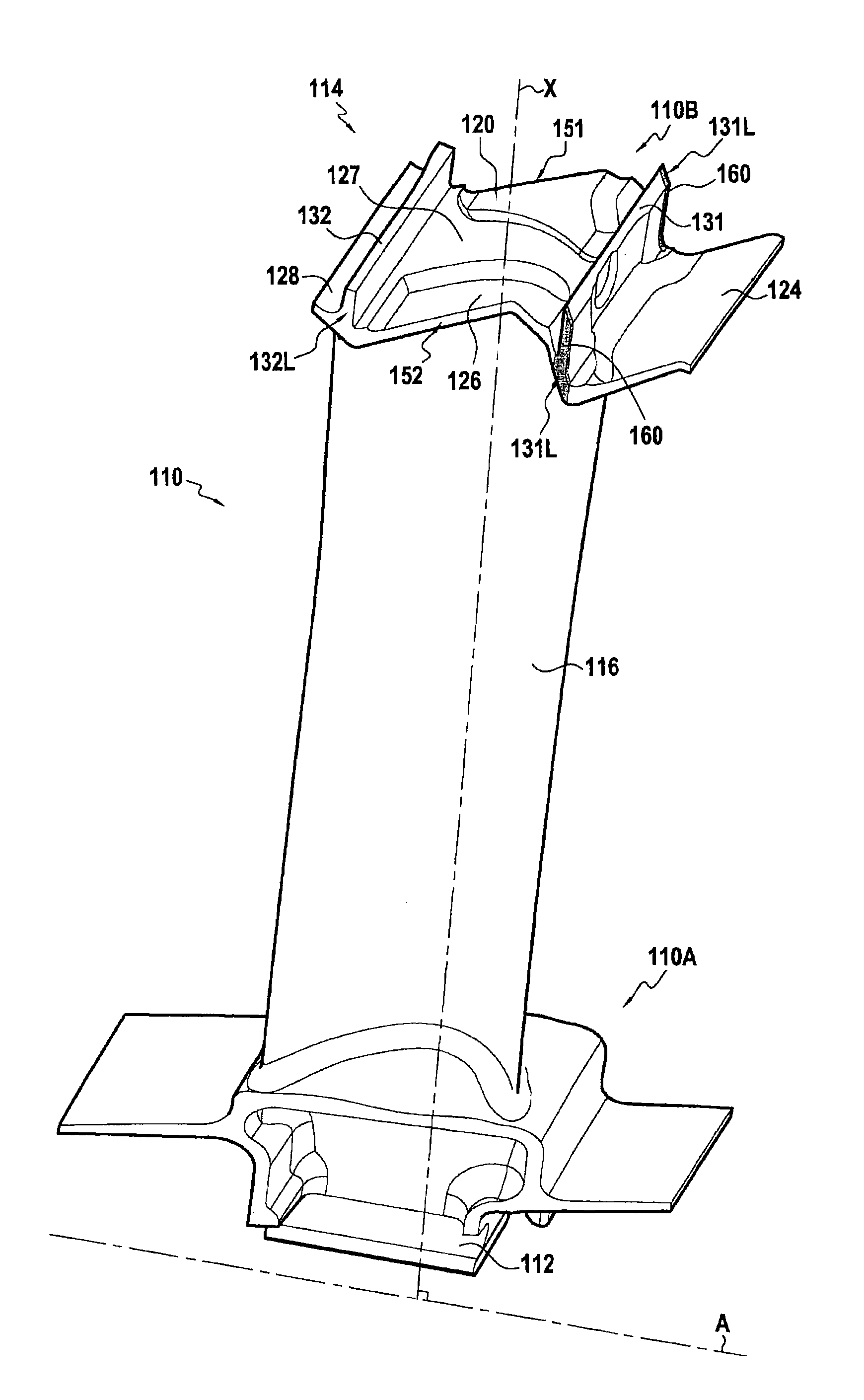

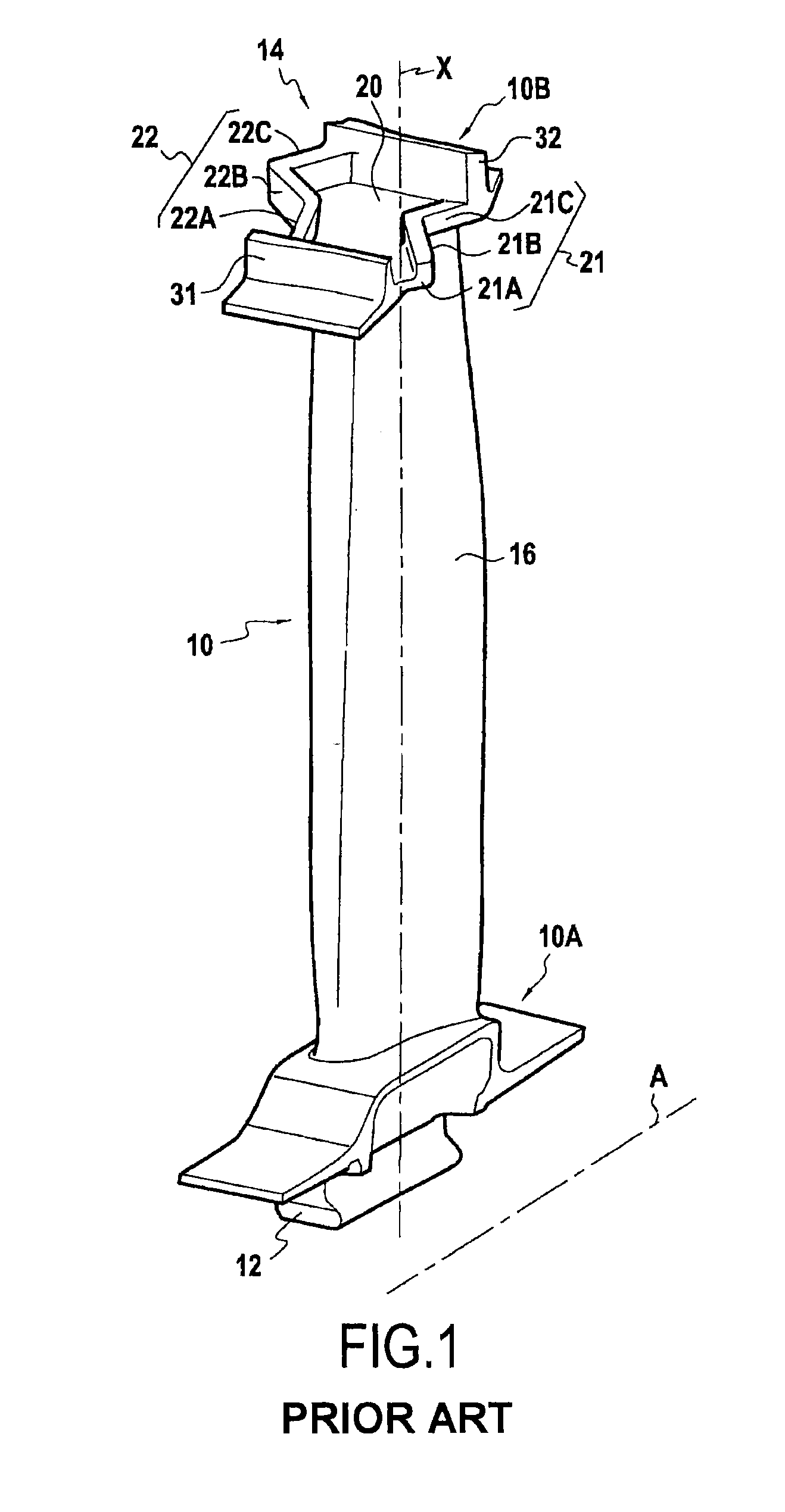

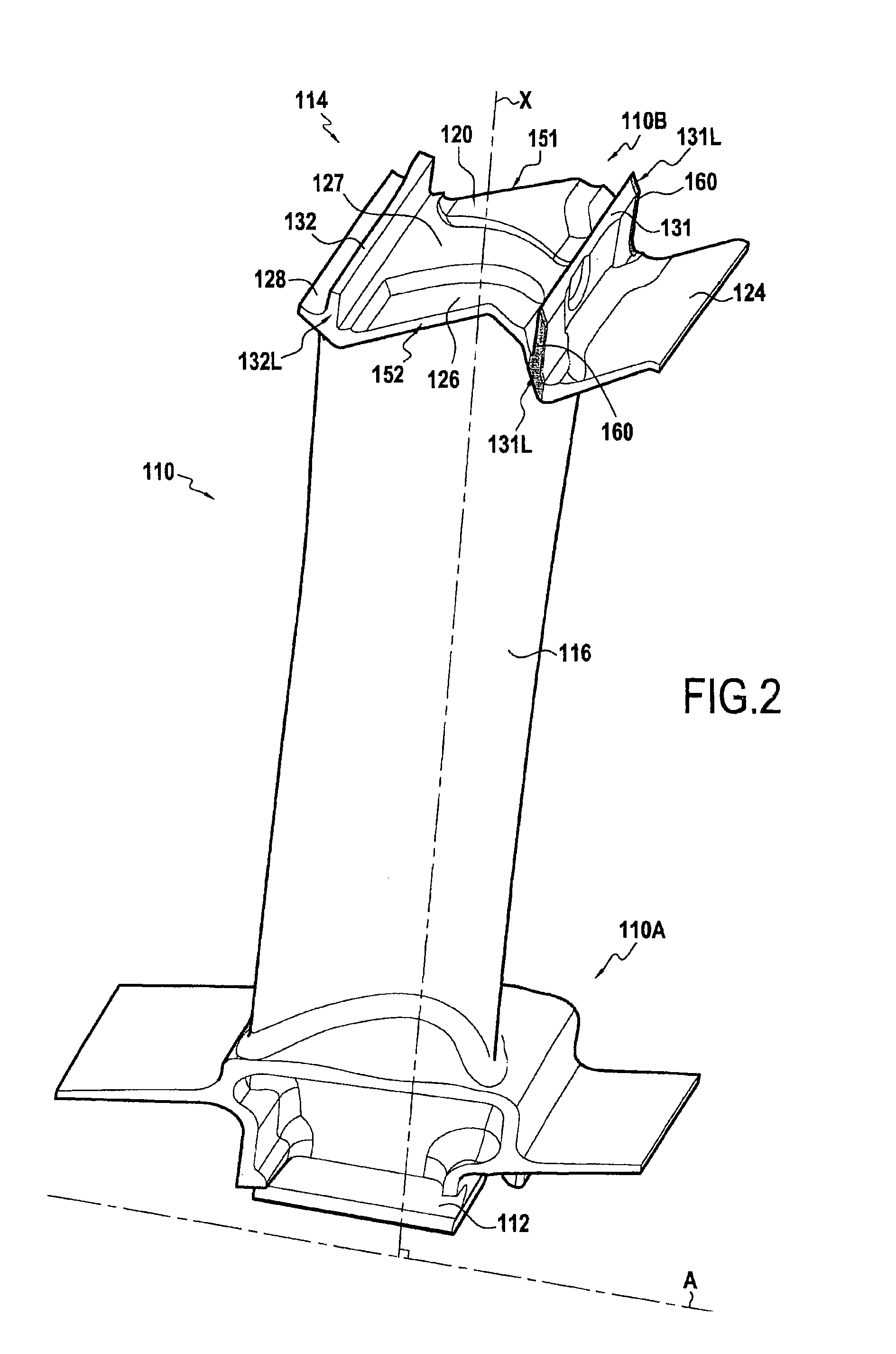

Turbomachine rotor blade

ActiveUS20150023793A1Improve abilityEasily fabricateBlade accessoriesEfficient propulsion technologiesMechanical engineeringGas passing

A turbomachine rotor blade presenting an outer part (314) at its distal end (310B), the outer part comprising a platform (320) defining the outside surface of the passage for gas passing through the turbomachine and presenting first (351) and second opposite side edges; and upstream and downstream sealing wipers (331, 332) extending outwards from said platform (320), each wiper extending between two lateral faces (331L, 332L) situated respectively at the first (351) and second side edges. The lateral faces (331L, 332L) of the upstream and downstream wipers (331, 332) are covered at least in part in an anti-wear material (360).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Composite Preventing Ice Adhesion

InactiveUS20140234579A1Easily fabricateEasily scalableOther chemical processesDecorative surface effectsRough surfaceEngineering

The present invention relates to a novel composite preventing ice adhesion. A plurality of micro-roughened surfaces or organometallized micro-roughened surfaces wetted with a hydrophobic, low freezing-point liquid results in a durable, renewable anti-icing composite. The preparation method for novel icing and rain protecting composite is disclosed.

Owner:WANG LIANG +1

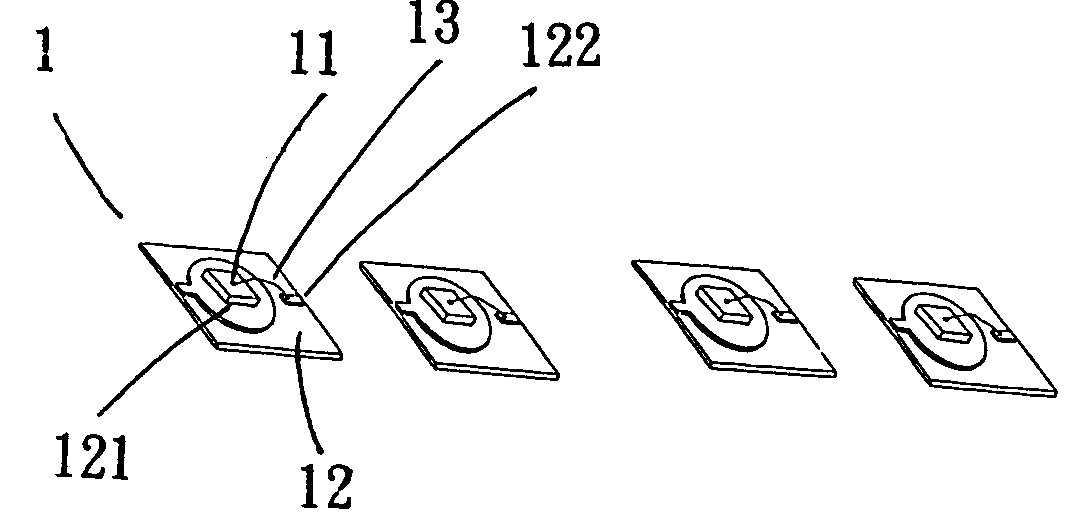

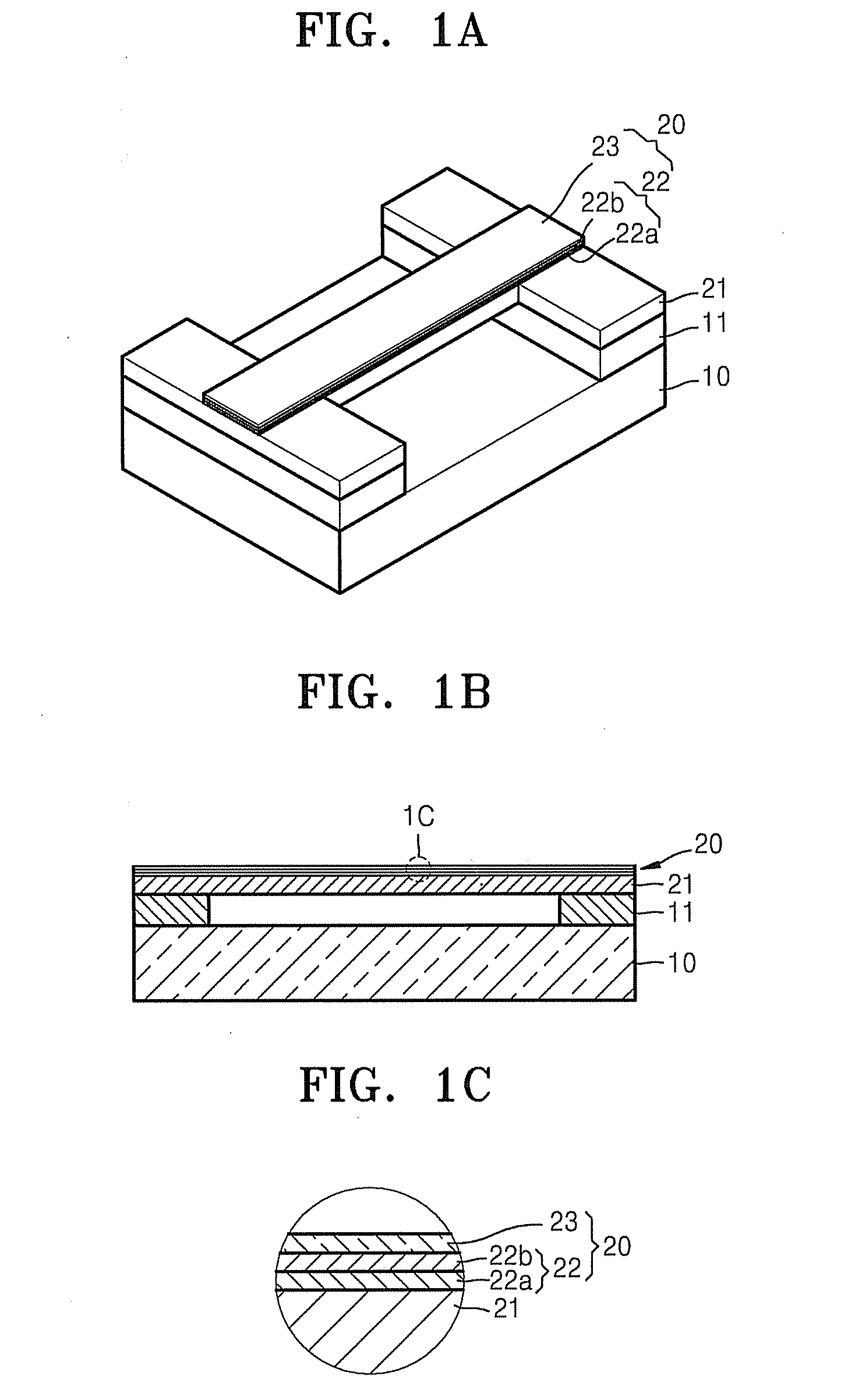

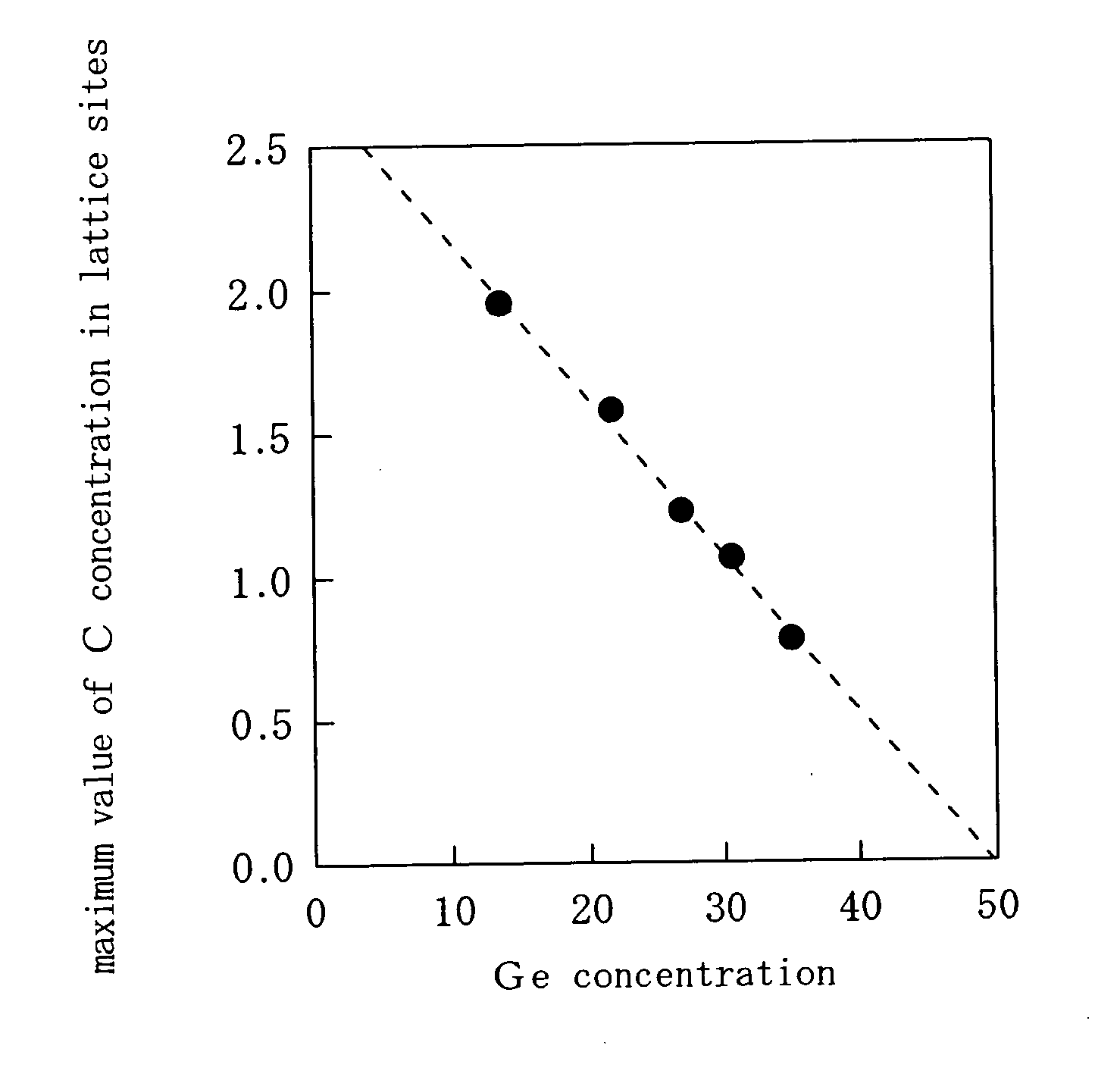

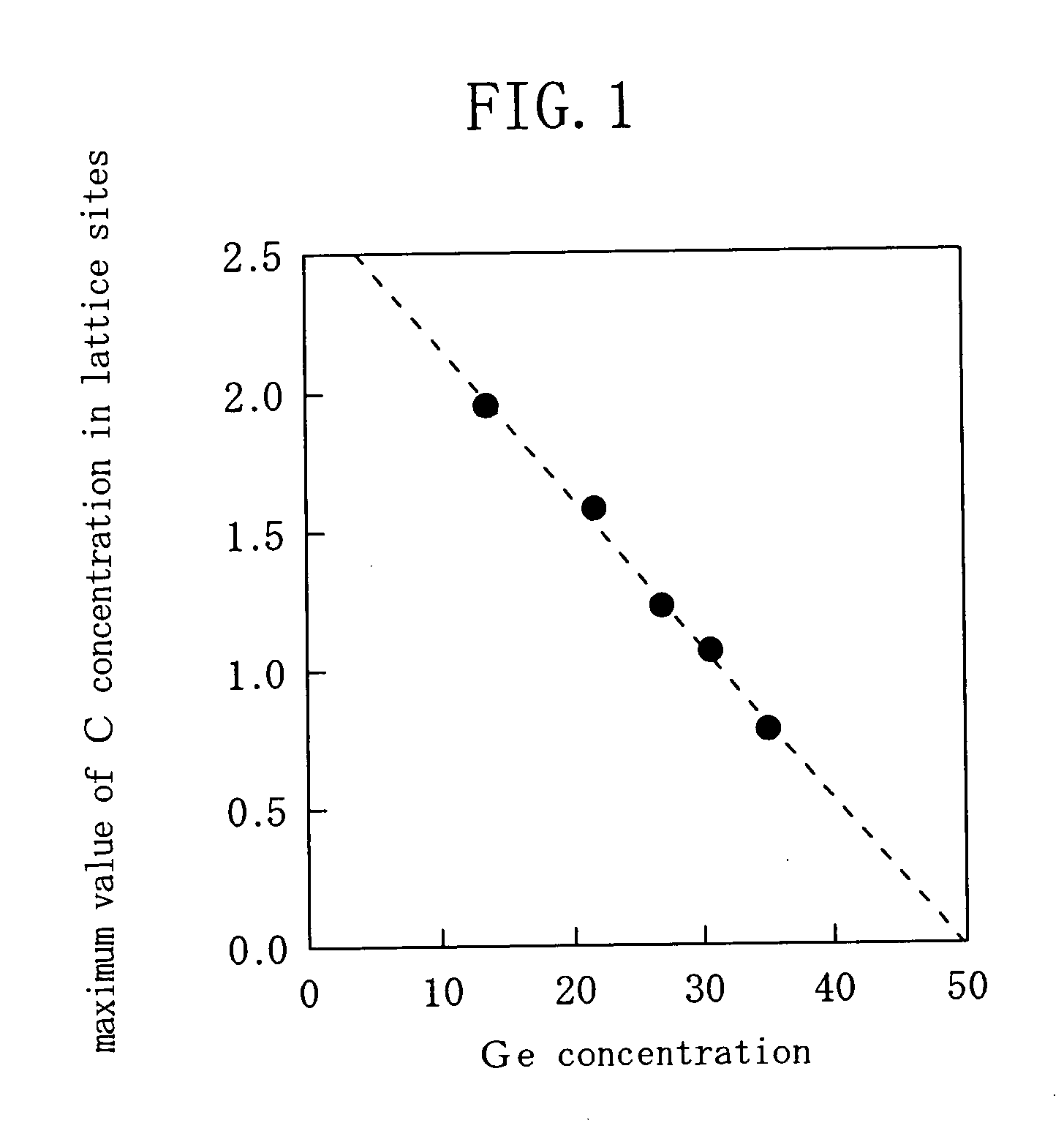

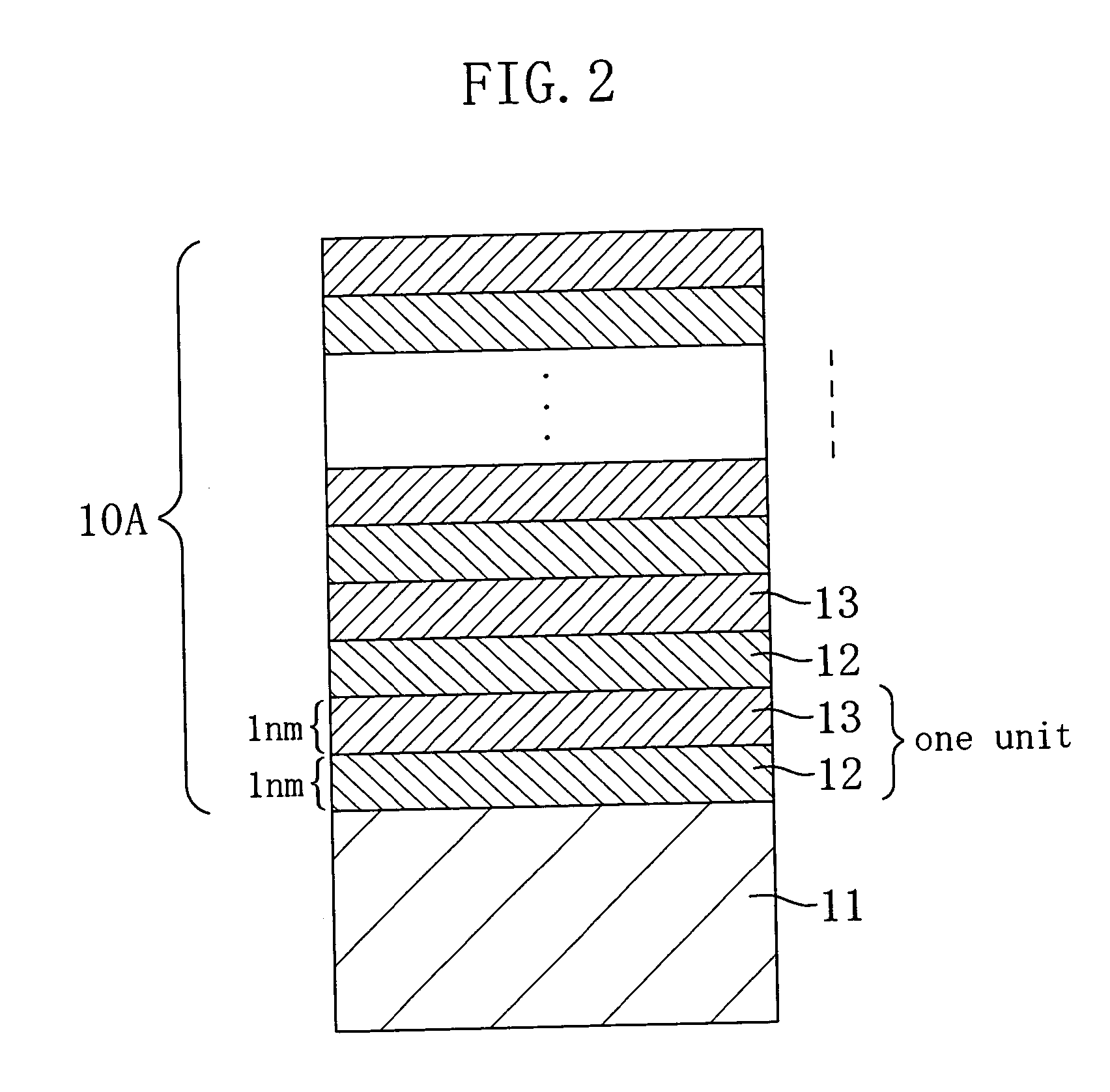

Semiconductor crystal film and method for preparation thereof

InactiveUS20040092085A1Easily fabricatePromote stratificationTransistorFrom solid stateChemistrySemiconductor

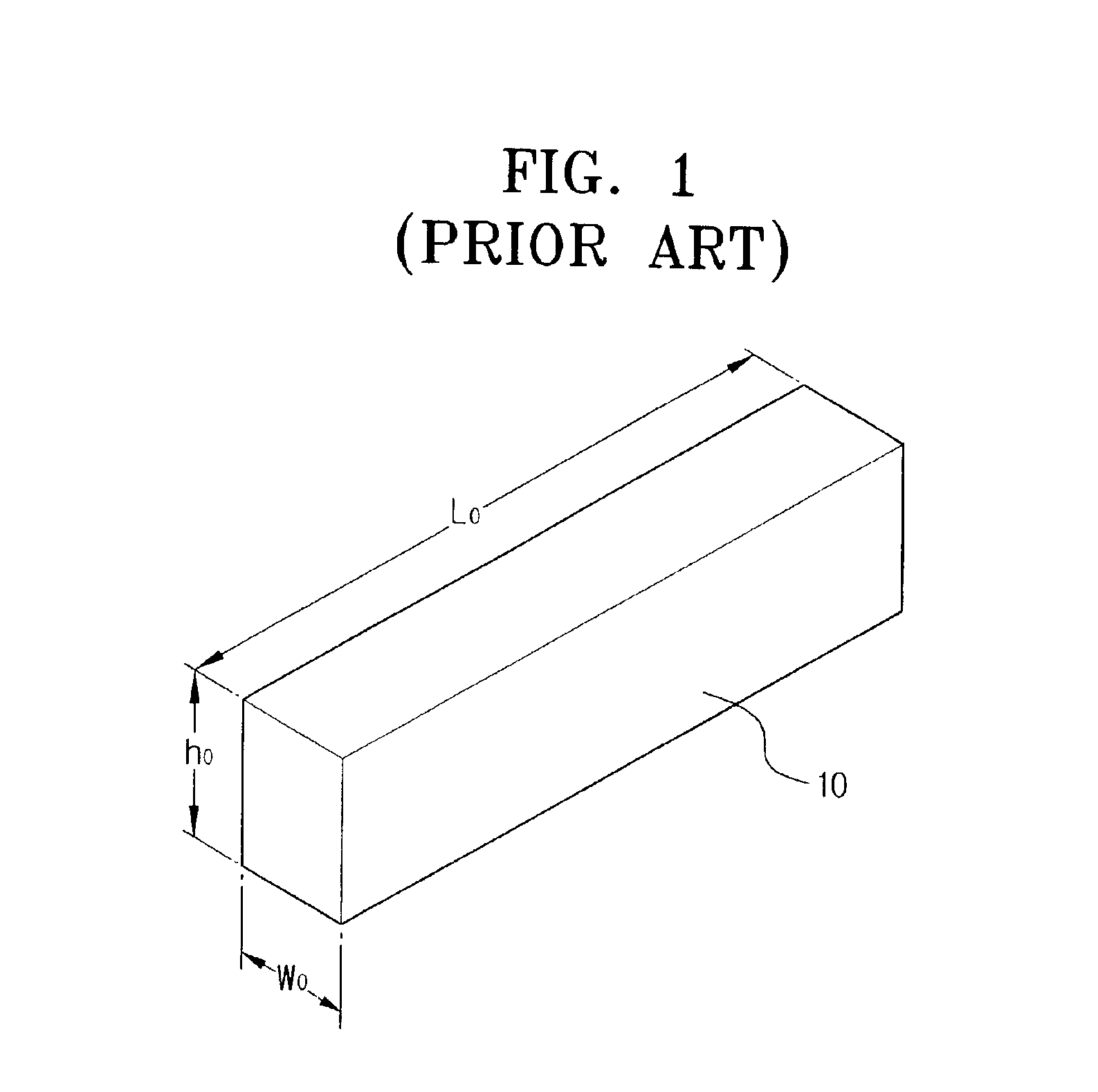

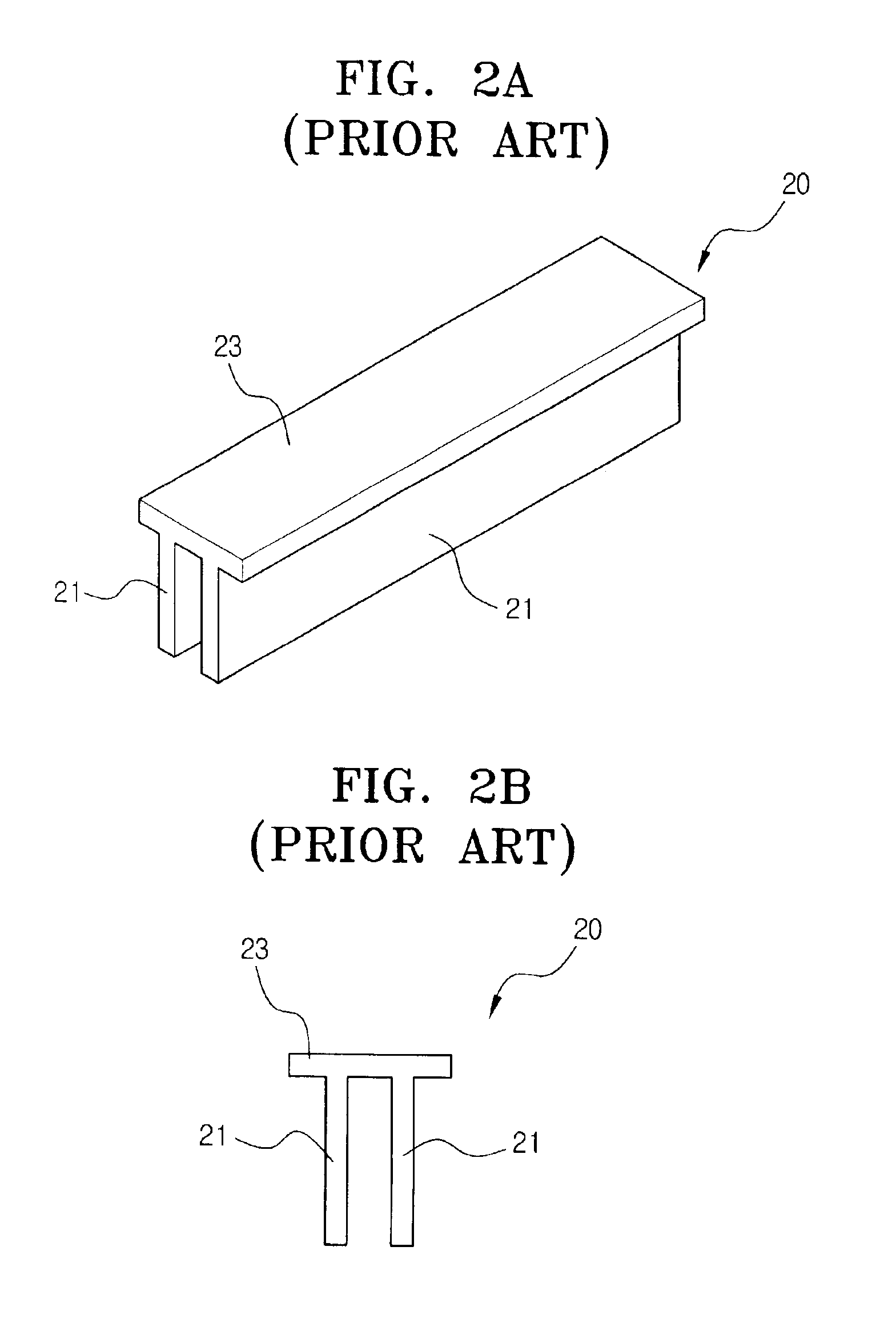

A multi-layer film 10 is formed by stacking a Si1-x1-y1Gex1Cy1 layer (0<=x1<1 and O<yl<1) having a small Ge mole fraction, e.g., a Si0.785Ge0.2C0.015 layer 13, and a Si1x-2-y2Gex2Cy2 layer (0<x2<=1 and 0<=y2<1) (where x1<x2 and y1>y2) having a high Ge mole fraction, e.g., a Si0.2Ge0.8 layer 12. In this manner, the range in which the multi-layer film serves as a SiGeC layer with C atoms incorporated into lattice sites extends to high degrees in which a Ge mole fraction is high.

Owner:PANASONIC CORP

Portable accessory box

InactiveUS20050023161A1Easily fabricateProduction cost be reduceOther accessoriesContainers to prevent mechanical damageBackplaneEngineering

Owner:QUANTA COMPUTER INC

Method for fabricating a III nitride film, an underlayer for fabricating a III nitride film and a method for fabricating the same underlayer

InactiveUS6989202B2Easily fabricateLow dislocation densitySemiconductor/solid-state device manufacturingFrom chemically reactive gasesMaterials scienceNitride

A method for fabricating a Group III nitride film is provided, including the steps of preparing a substrate, forming an underfilm and then forming the Group III nitride film on the underfilm. The underfilm is a Group III nitride including at least 50 atomic percent of elemental Al for each of the Group III elements of the underfilm Group III nitride. The surface of the underfilm includes a contoured portion and a flat region, and less than 50% of the surface is occupied by the flat region.

Owner:NGK INSULATORS LTD

Torsion spring for MEMS structure

ActiveUS6921952B2Easy torsionEasily fabricateAcceleration measurement using interia forcesTorsion springsTorsion springFlexural rigidity

A torsion spring for a MEMS structure has a plurality of beams, each beam having two ends wherein both ends are fixed to a predetermined area, and at least one connection bar disposed at a right angle to a lengthwise direction of the plurality of beams, wherein the at least one connection bar connects the plurality of beams. Preferably, the distance between the connection bars is equal to or greater than the width of one of the plurality of beams. Accordingly, a torsion spring according to the present invention has a bending stiffness greater than a torsional stiffness, which allows easier torsion. Further, a torsion spring according to the present invention may be easily fabricated by etching.

Owner:SAMSUNG ELECTRONICS CO LTD

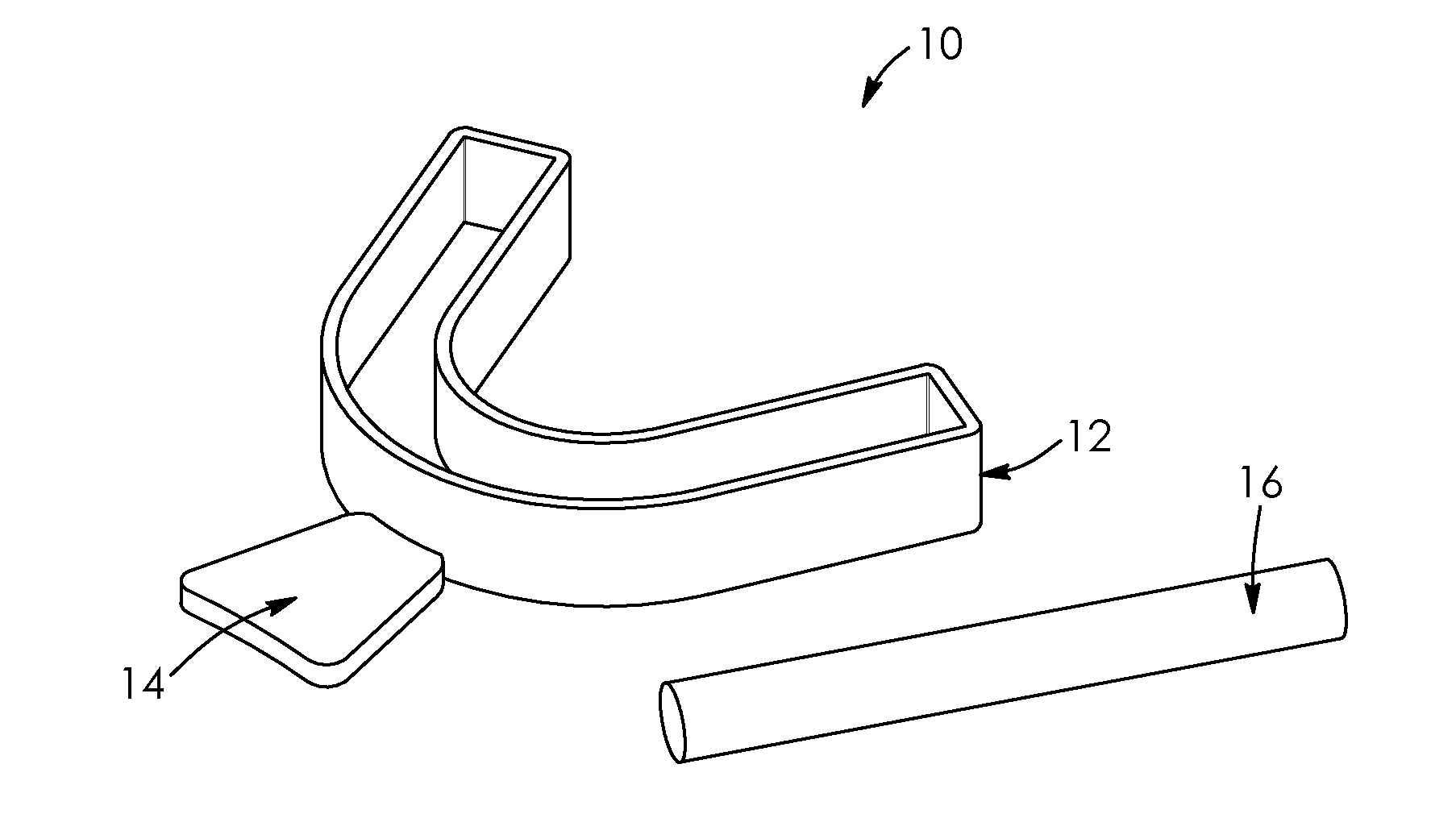

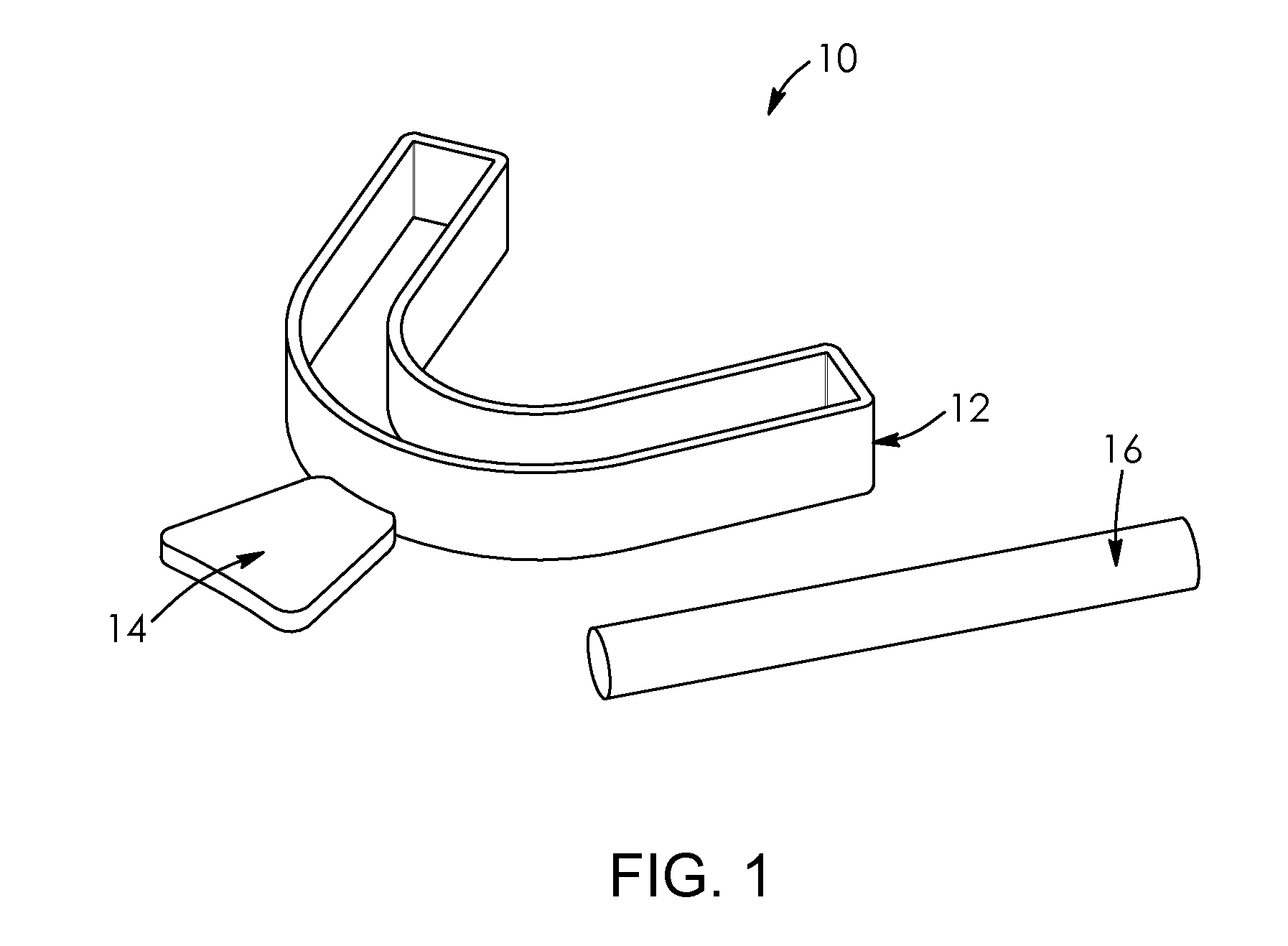

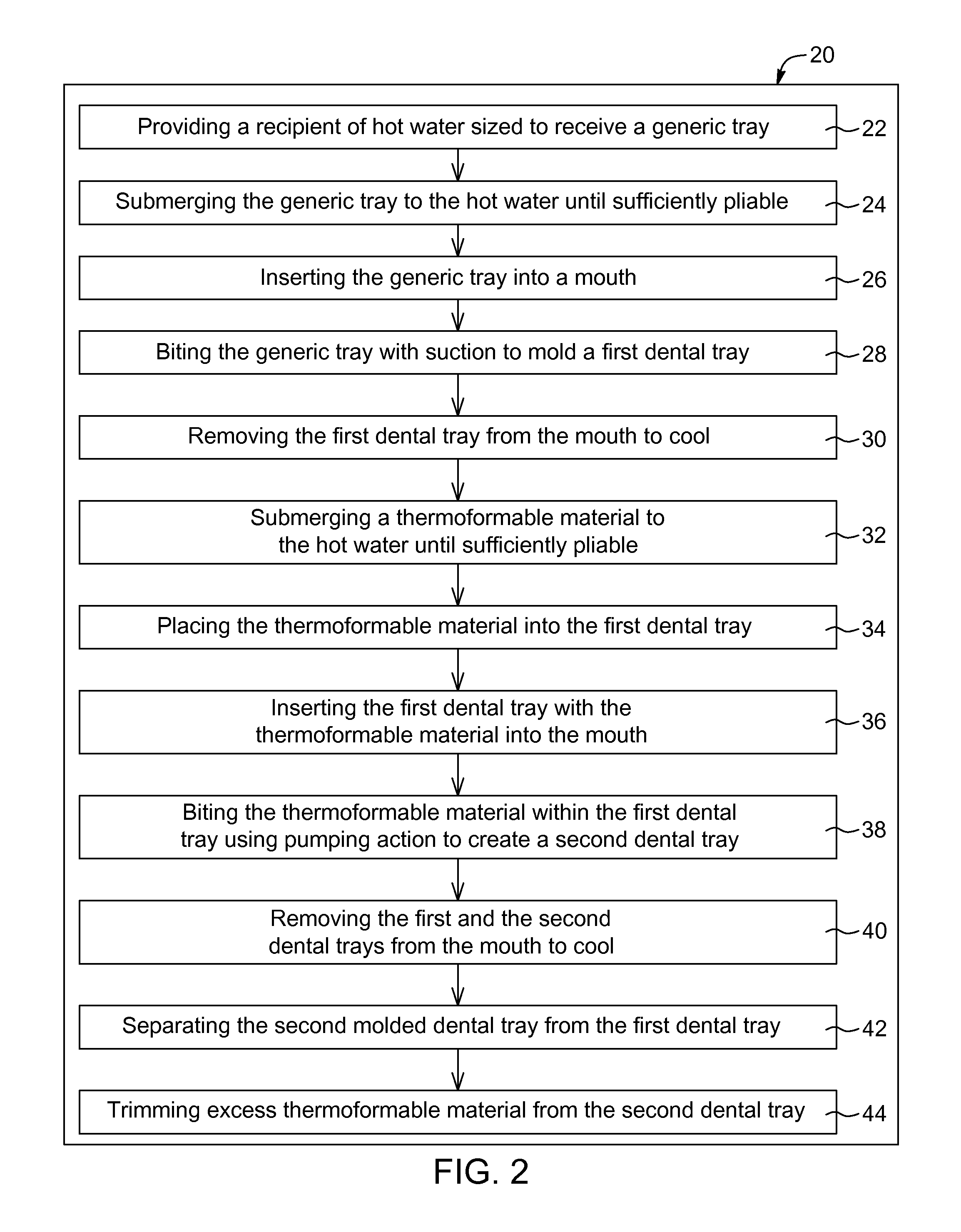

Dental tray molding kits and methods

InactiveUS20150257859A1Easily manipulateEasily fabricateImpression capsTeeth fillingImpression traysEngineering

Owner:AKL GILBERT

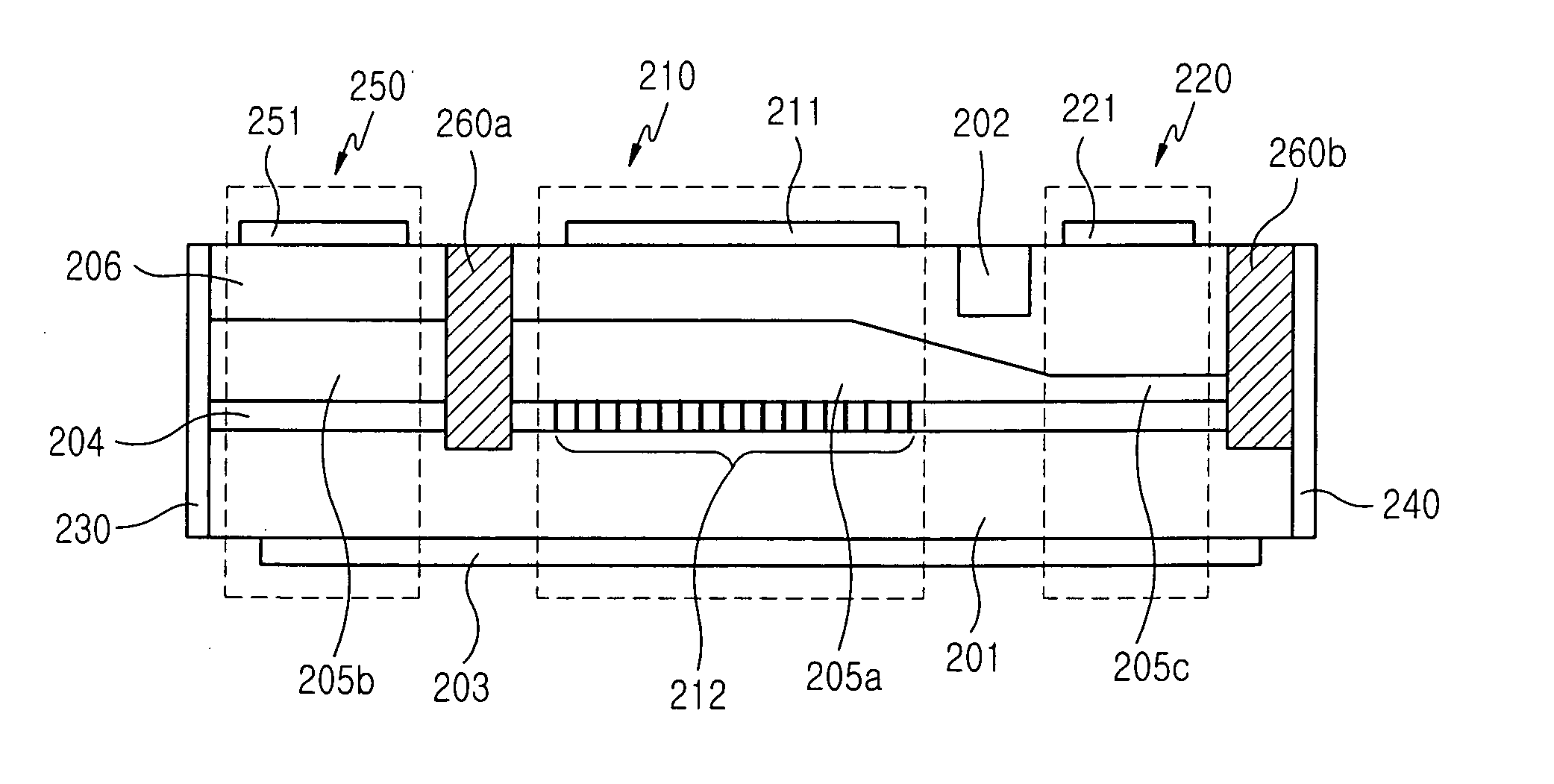

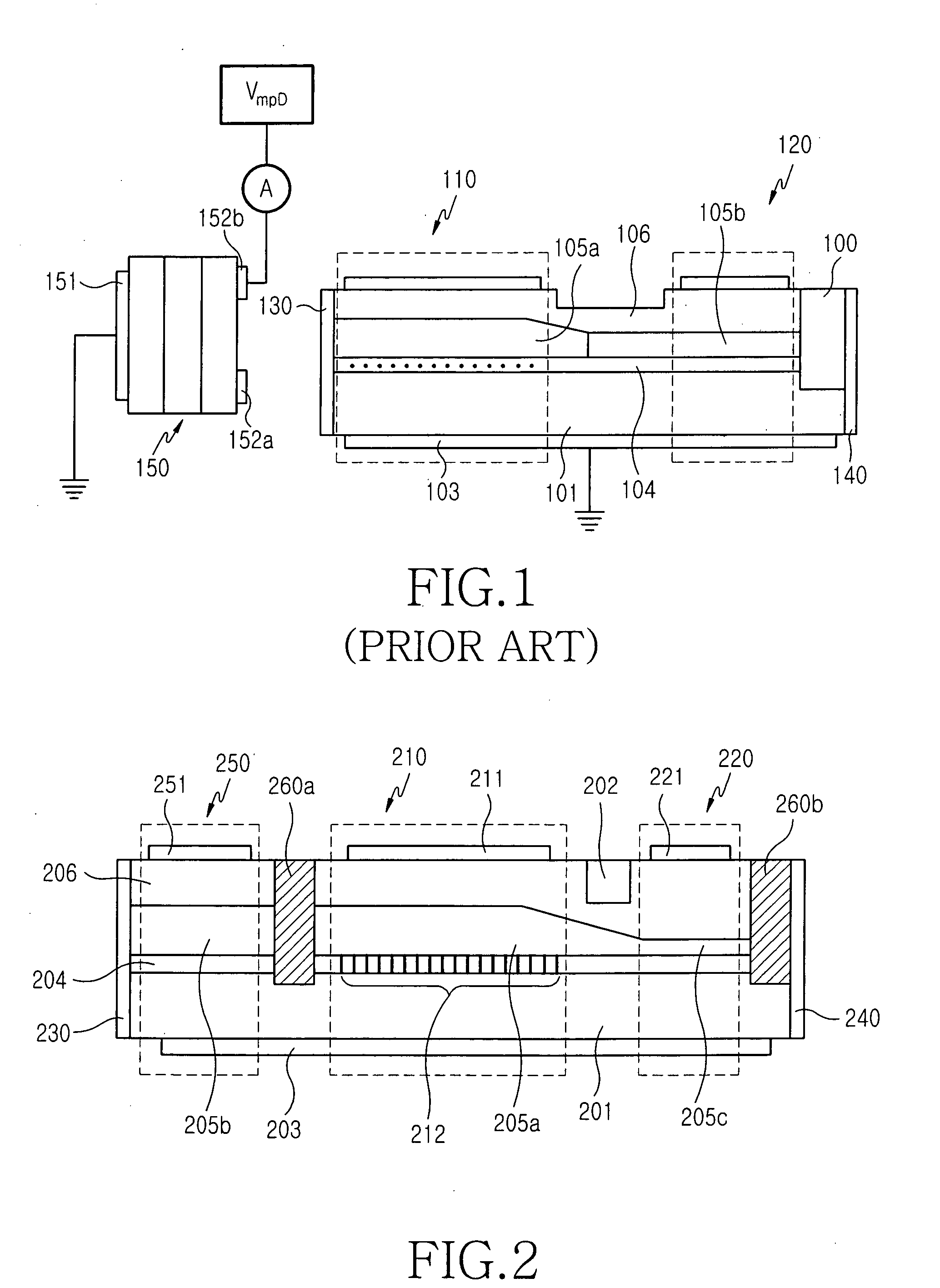

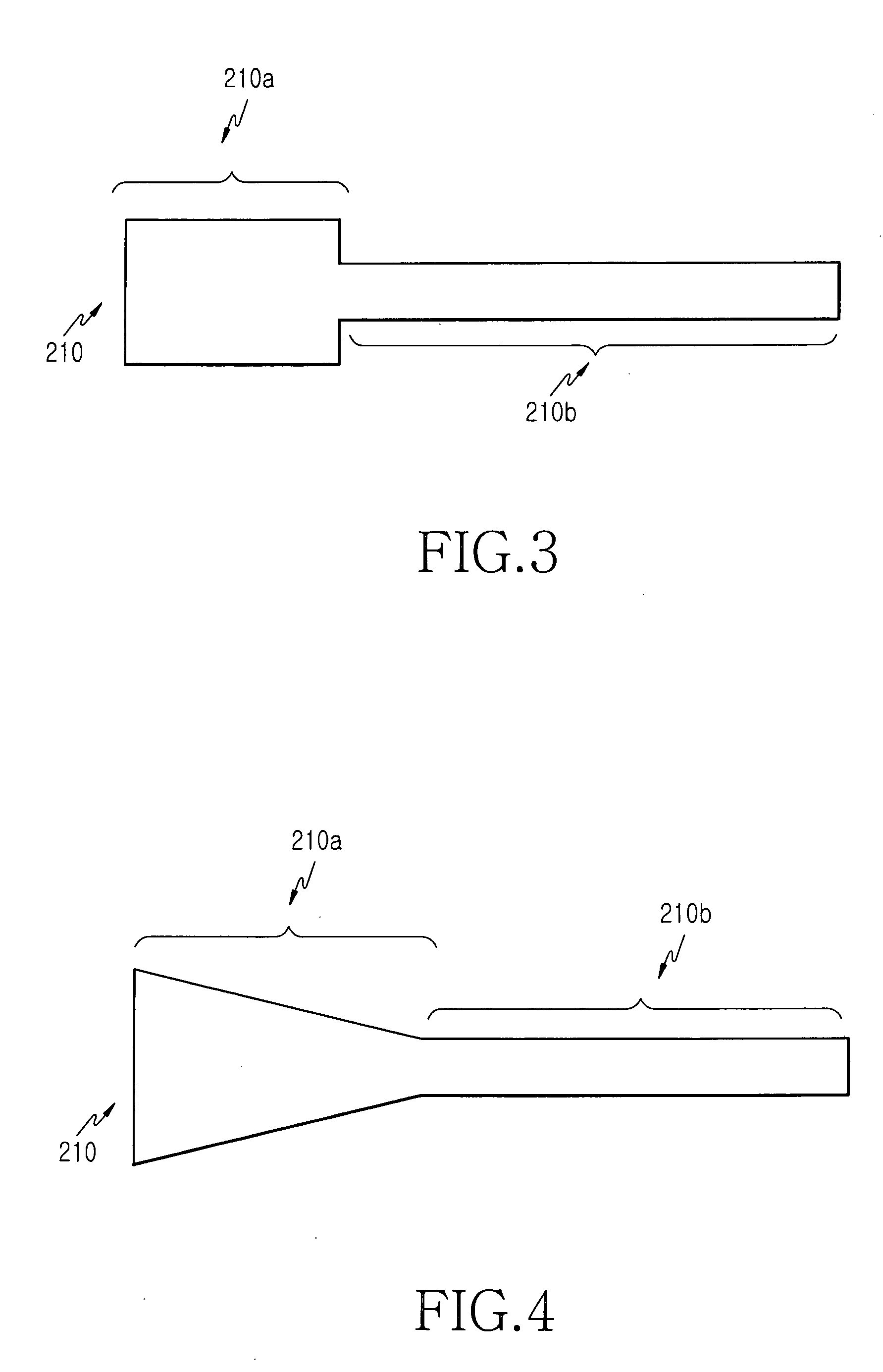

Electro-absorptive optical modulator module having monolithic integrated photo detector

ActiveUS20050128557A1Easily fabricateEasy to makeLaser detailsLaser optical resonator constructionOptical detectorsErbium lasers

An electro-absorptive optical modulator module monolithic-integrated on a semiconductor substrate, which includes a distributed feedback laser having a grating for oscillating light and to output the oscillated light through a first end and a second end of the module. An electro-absorptive modulator modulates a first light output through the first end of the distributed feedback laser, and an optical detector provides detection of a second light output through the second end of the module. The optical detector is formed opposite to the second end of the distributed feedback laser on the semiconductor substrate. A first inner window permits attenuation of the intensity of the second light and electrically insulates the distributed feedback laser and the optical detector from each other, with the first inner window being arranged between the distributed feedback laser and the optical detector.

Owner:SAMSUNG ELECTRONICS CO LTD

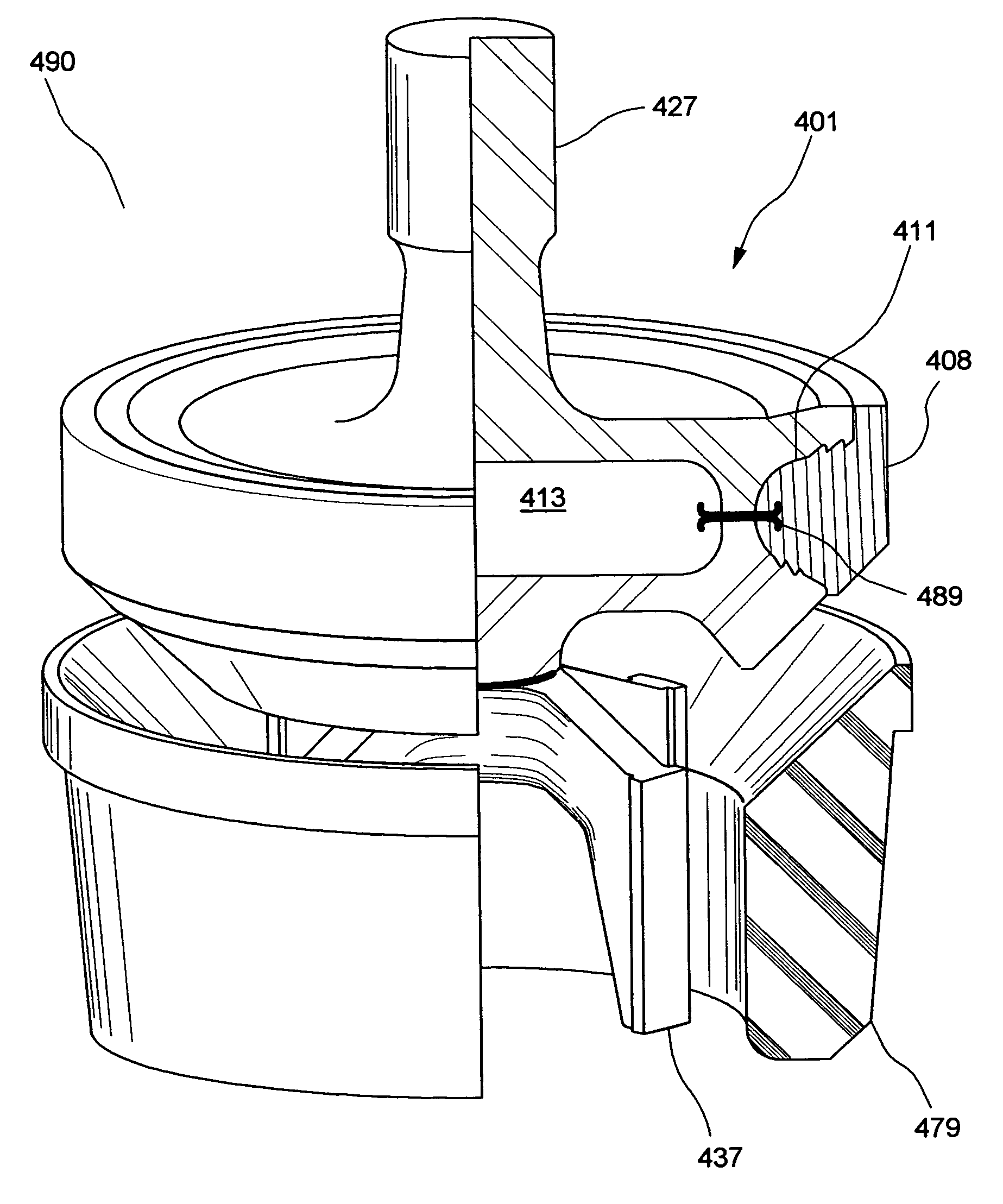

Valve body with integral seal retention groove

InactiveUS6679477B1Easily fabricateImprove durabilityPiston ringsBraking action transmissionEngineeringNear net shape

A valve body having one or more integral seal retention grooves and one or more interior hollows which may be manufactured using frictional or other types of welding to join two previously formed portions through at least one cylindrical web. Forging or casting valve body portions to near-net-shape prior to joining minimizes machining necessary to achieve a final desired shape. Finish machining of certain valve body surfaces prior to joining is optional. One or more interior hollows and an integral seal retention groove are formed in the welded valve body from features present on the portions joined by welding to form the body. Such valve bodies have relatively high stiffness for their weight and require only limited machining to achieve a final shape. Increased valve durability and reduced metal wear arise from the reduced valve body weight and correspondingly reduced impact loading as the valve body moves to seal against a valve seat. An elastomeric seal may be cast and cured in place in a seal retention groove, coupled thereto through welding flash protruding into the groove and / or through at least one serration in the groove.

Owner:NOVATECH HLDG CORP

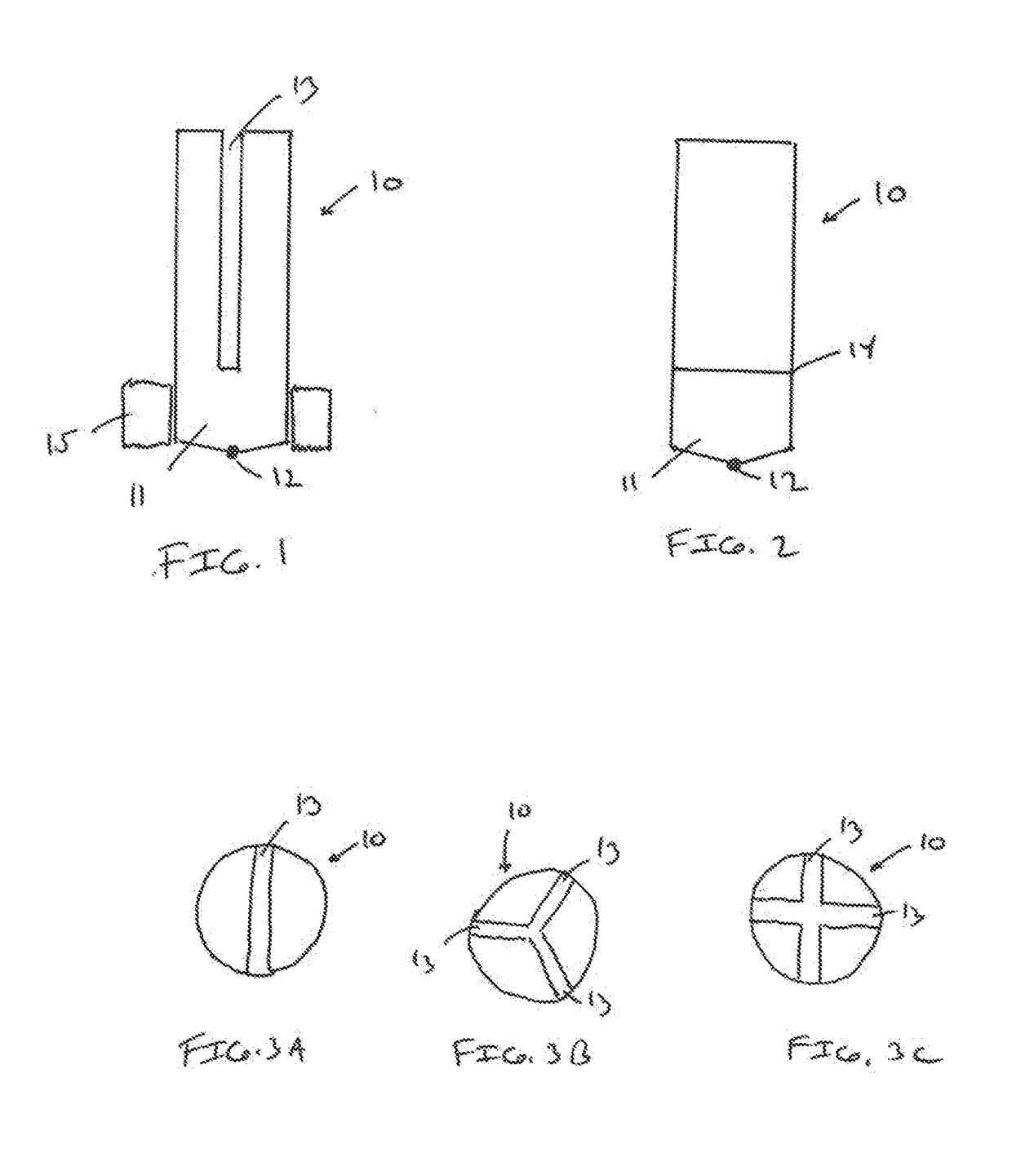

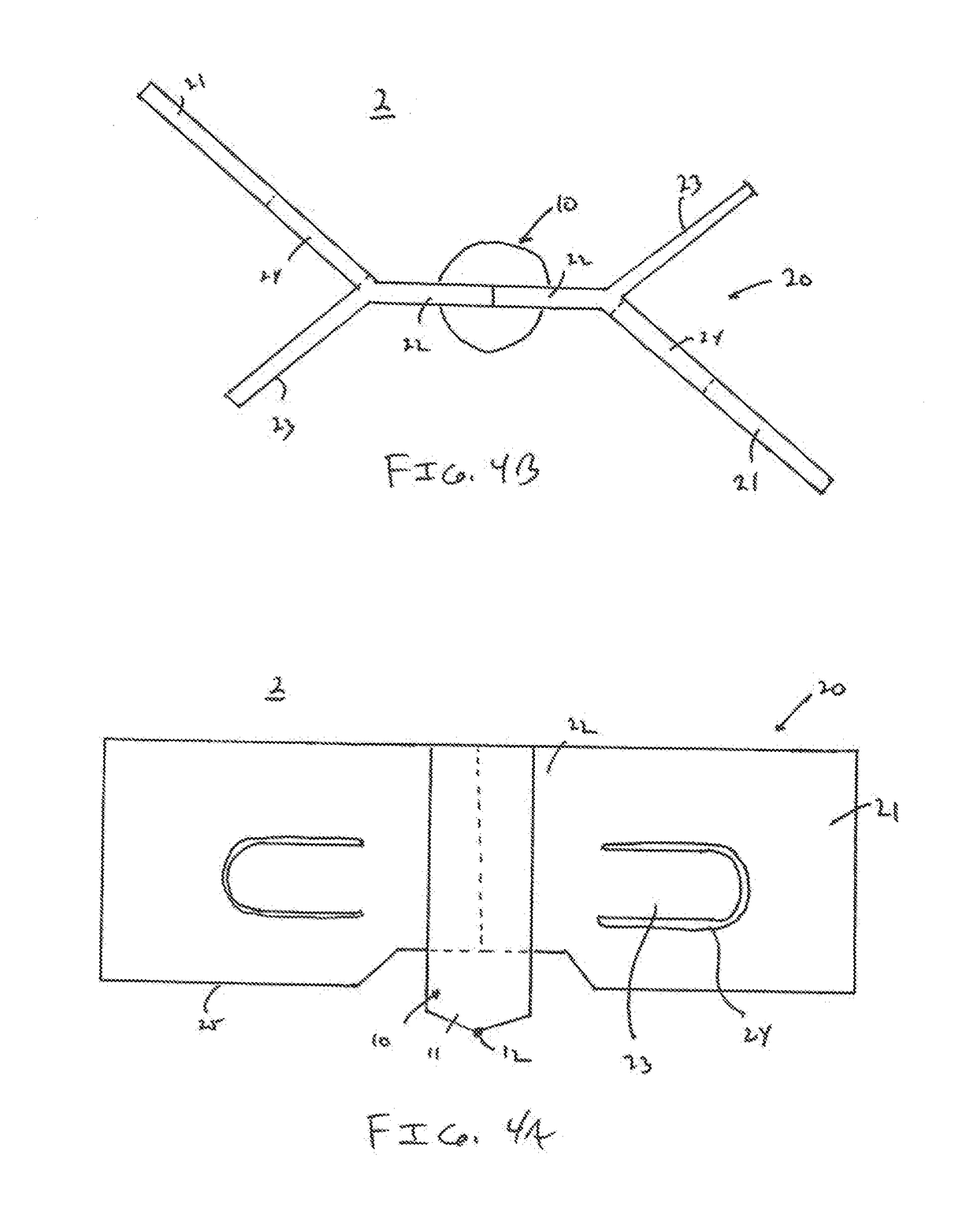

Refractory anchor assembly and method for installing the same

ActiveUS20180320973A1Easily instalEasily fabricateLining supportsChemical/physical/physico-chemical processesComponent fixationBiomedical engineering

An anchor assembly for anchoring refractory materials within a vessel is disclosed that provides for a more reliable refractory anchor and resultant refractory lining system that is easier to install both in terms of the refractory lining and the anchor assembly itself when compared to prior art anchor assemblies. The anchor assembly includes a base pin assembly, and at least one anchor leg connected to and extending from the base pin assembly. The base pin assembly includes a mounting end formed on one end of the pin assembly adapted for securing the base pin assembly to the vessel. The mounting end has an electrical resistance contact point formed thereon. The electrical resistant contact point preferably has a flux material located thereon.

Owner:EXXON RES & ENG CO

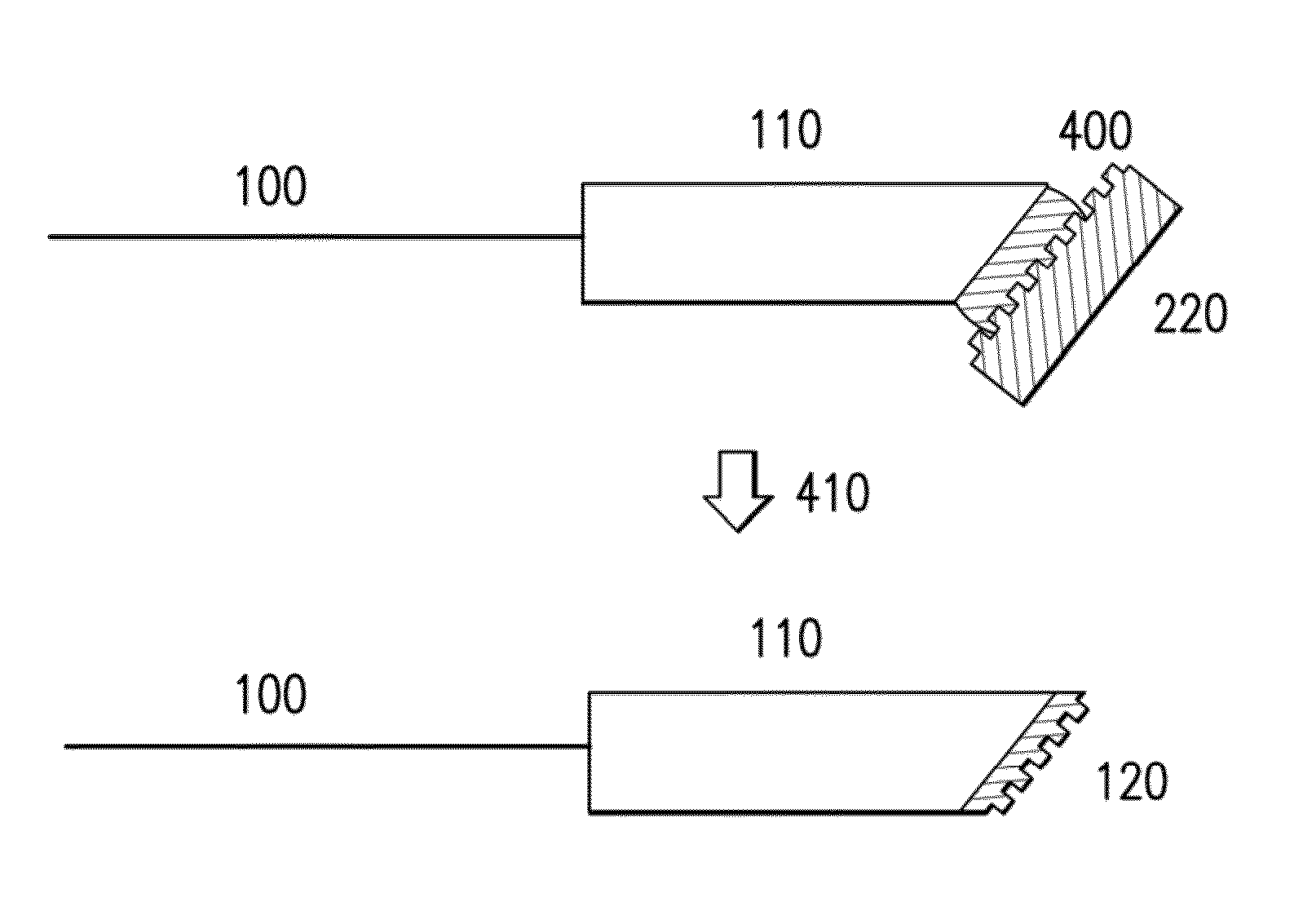

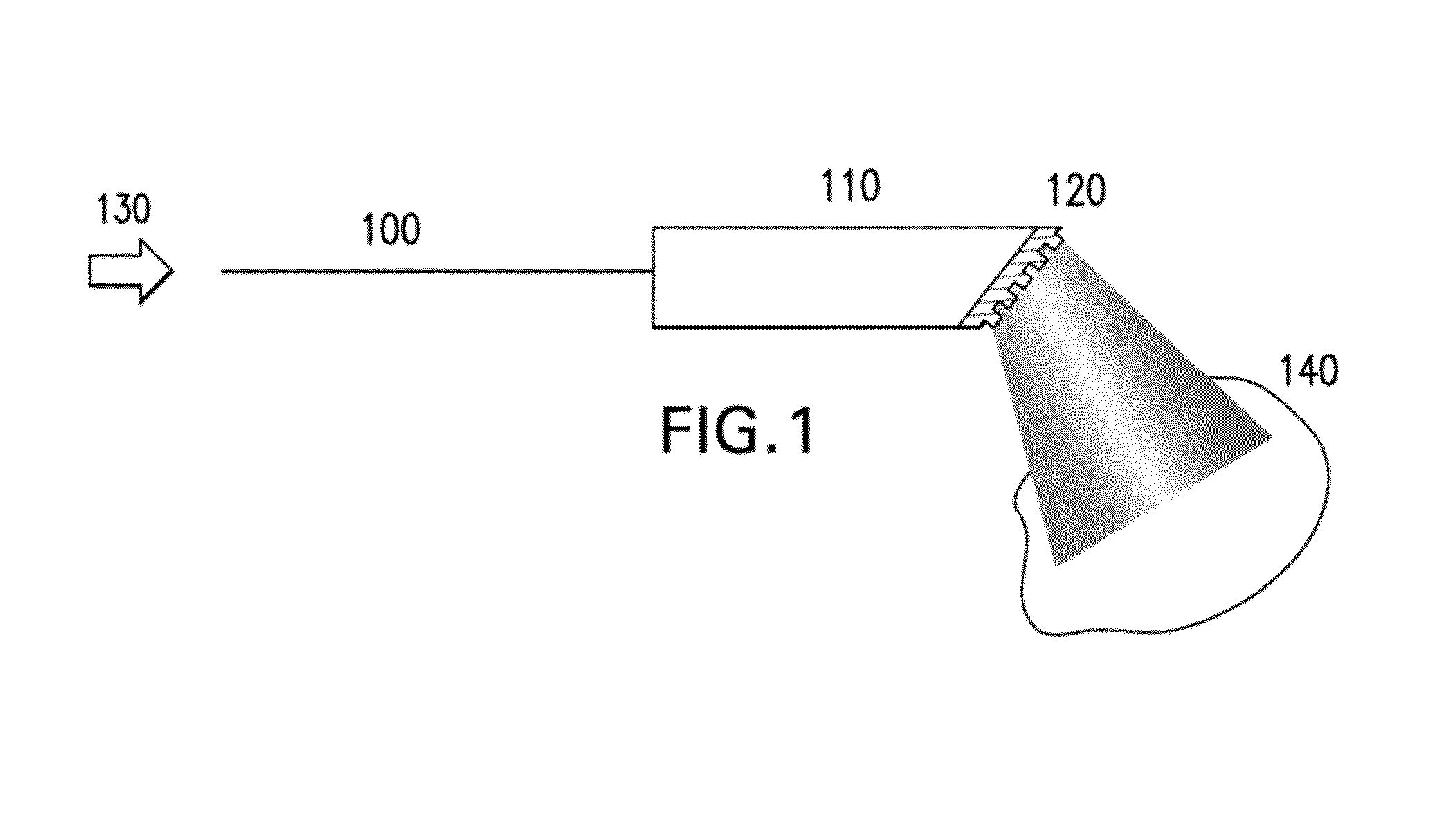

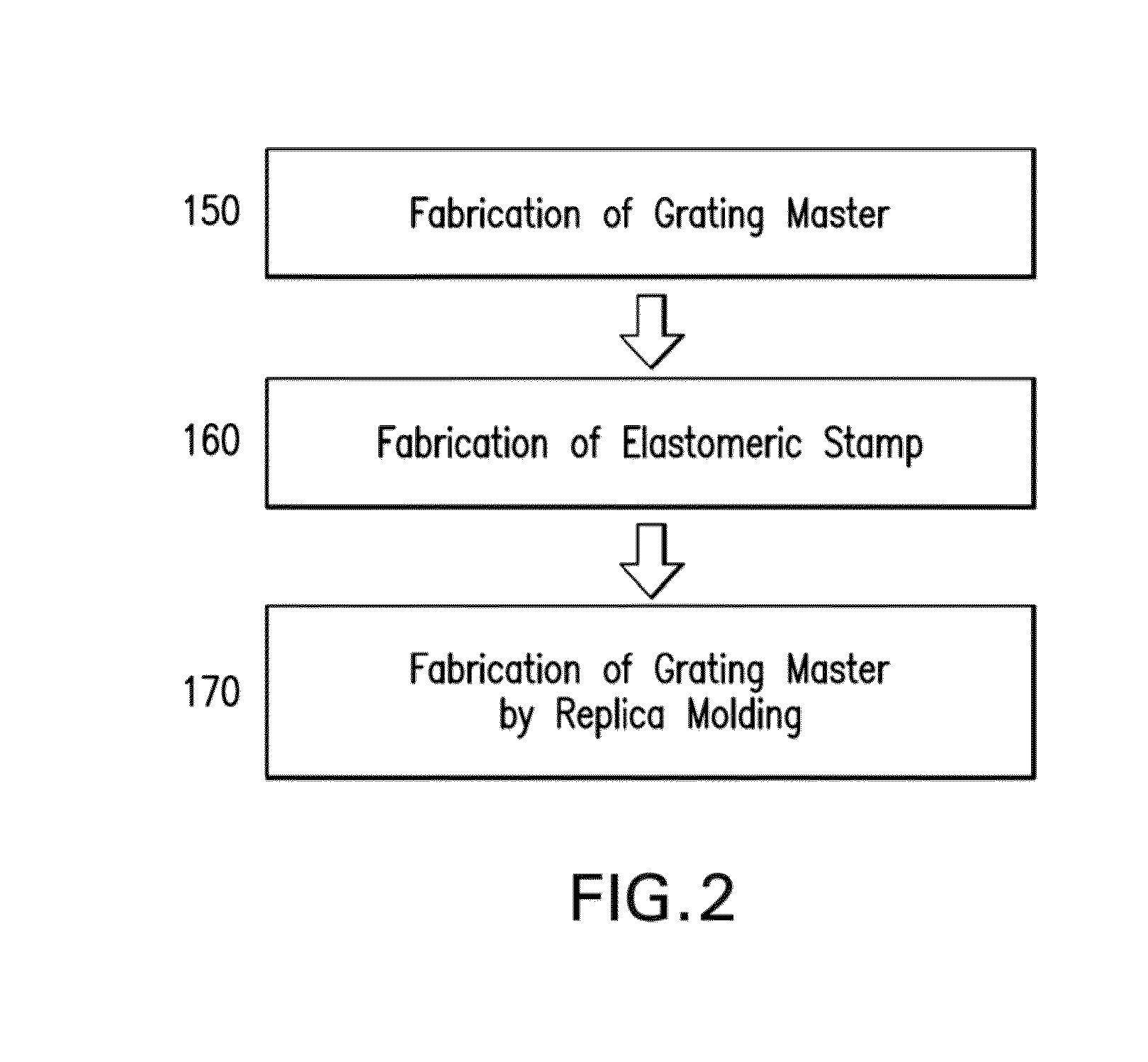

System, method, and computer-accessible medium for frabrication minature edoscope using soft lithography

ActiveUS20150231841A1Easily fabricateEasy to makeLamination ancillary operationsOptical articlesSoft lithographyEngineering

Exemplary method and system can be implemented and / or used for providing a diffractive configuration in an optical arrangement can be provided. For example, an elastomeric material can be provided with at least one patterned surface. The elastomeric material can be connected with at least one portion of a waveguide arrangement using a pre-polymer adhesive composition. Further, the pre-polymer adhesive composition can be caused to polymerize so as to form the diffractive configuration which at least approximately replicate a structure or at least one feature of an elastomeric mold.

Owner:THE GENERAL HOSPITAL CORP +1

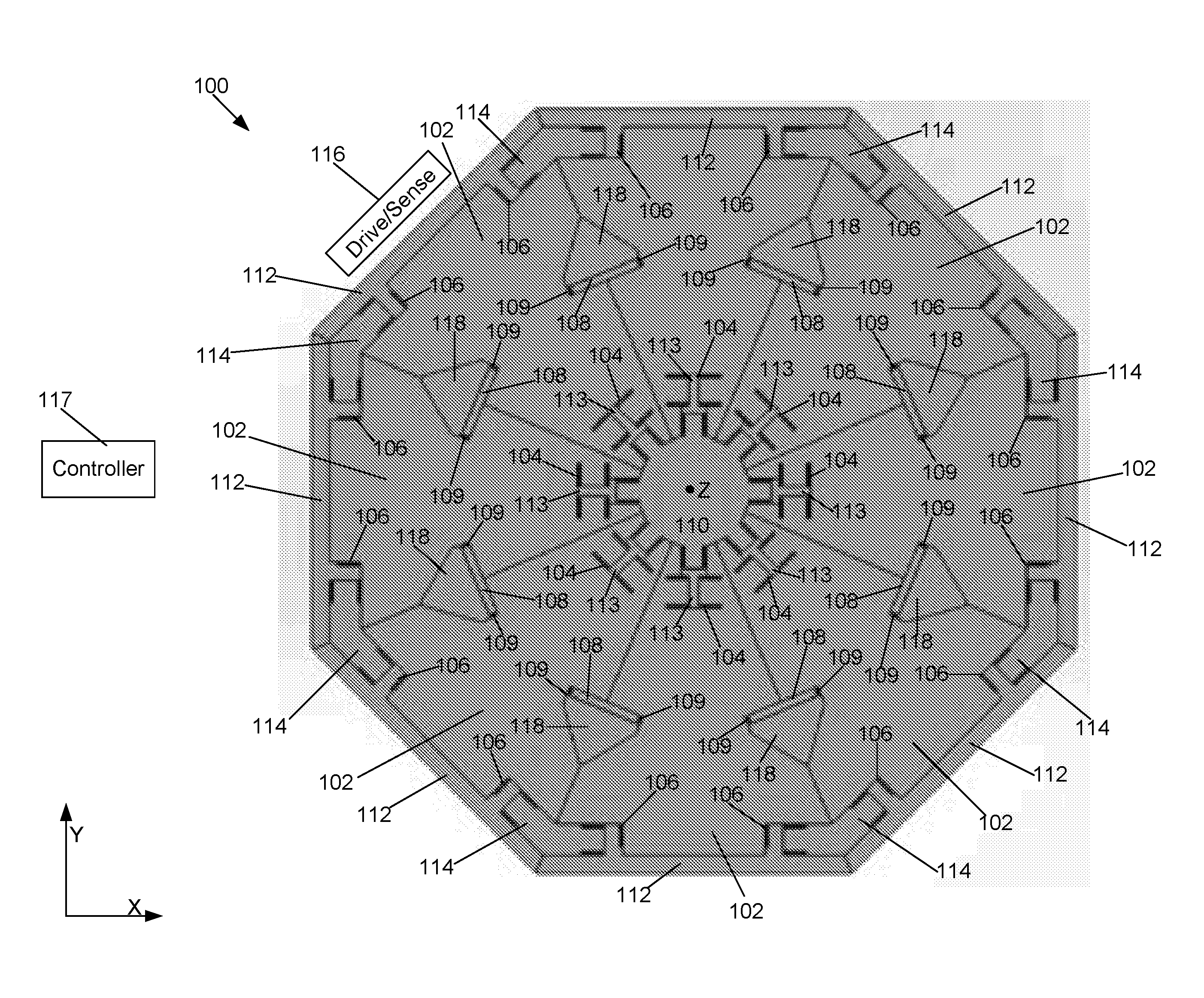

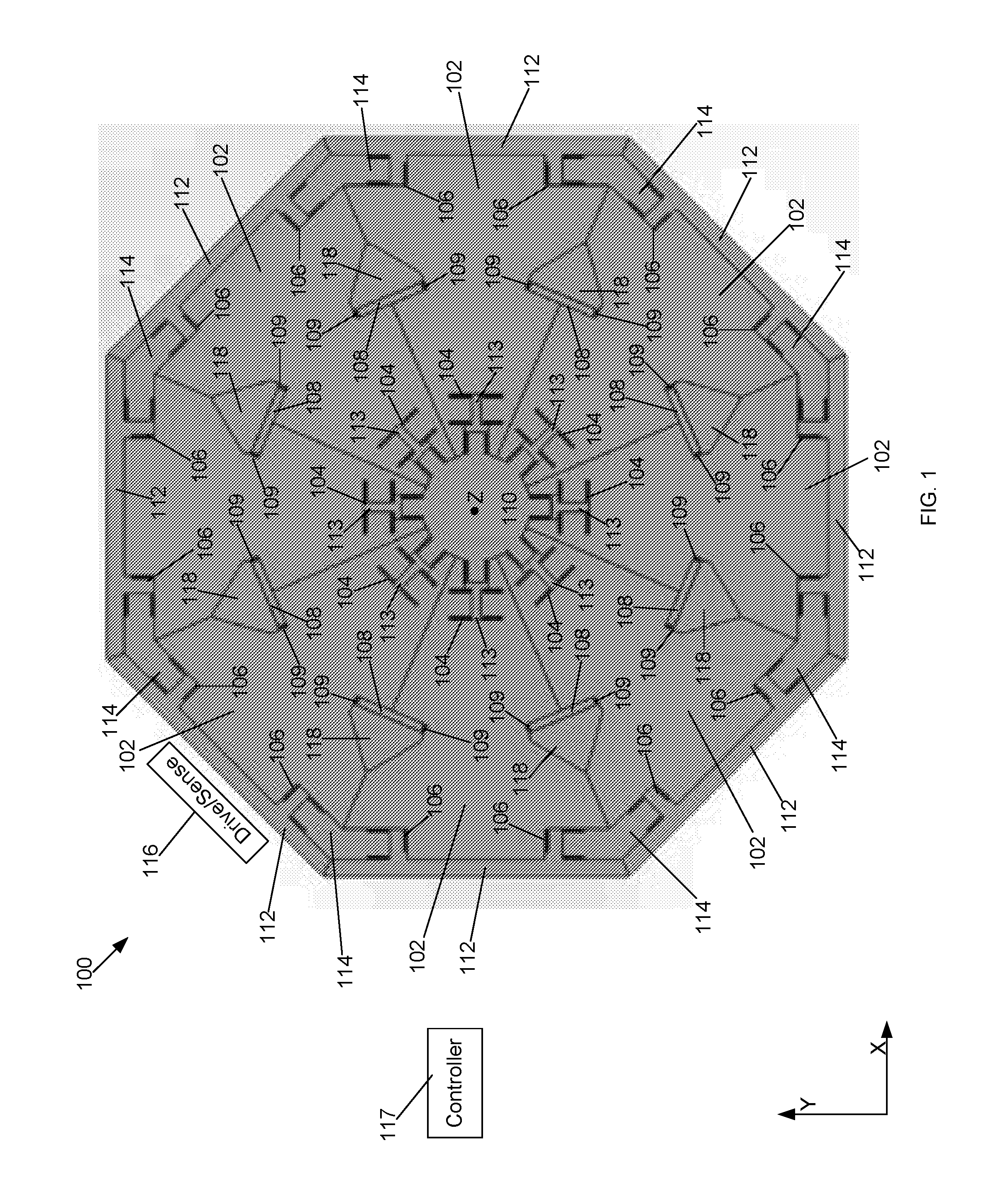

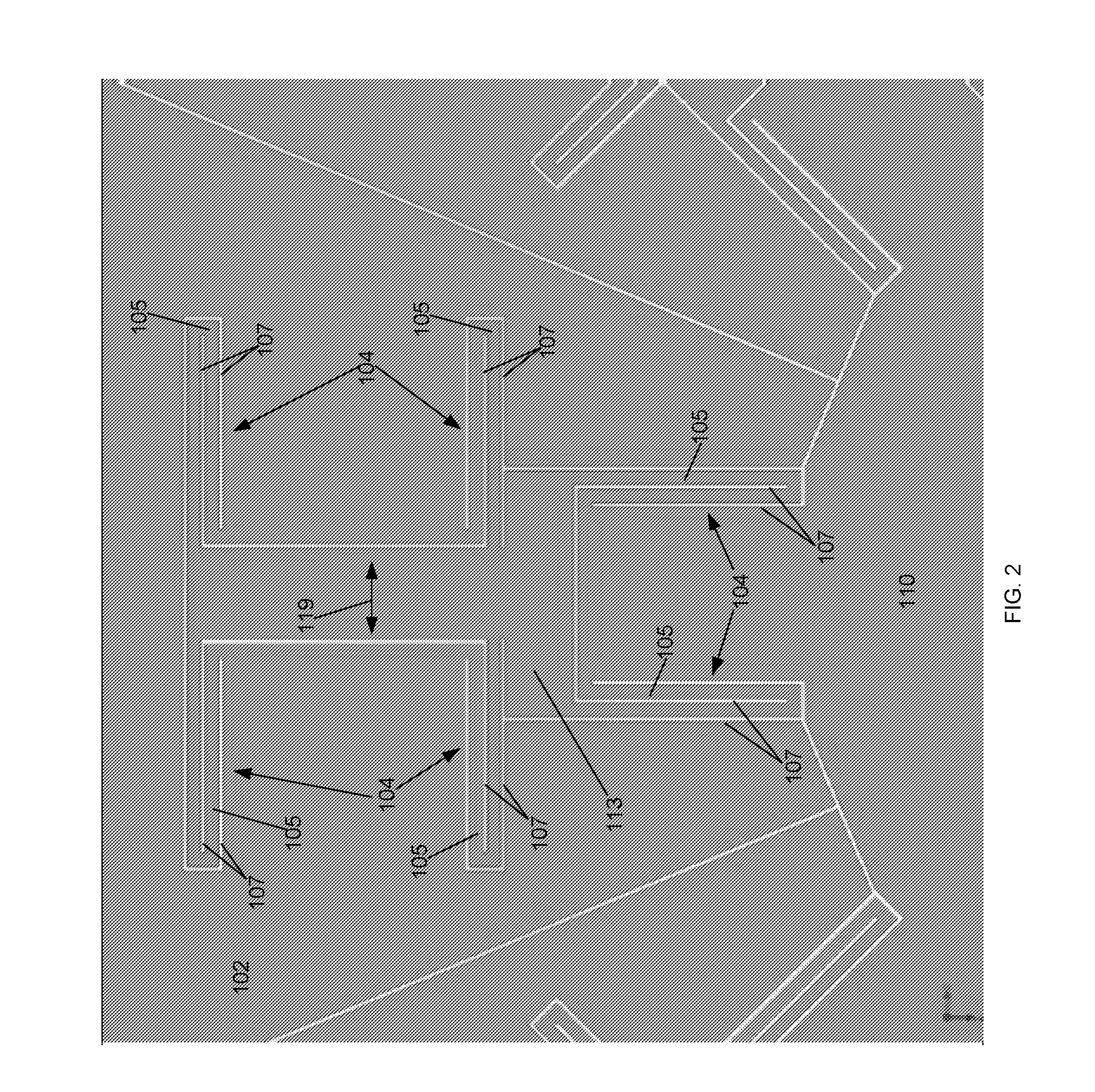

Whole angle MEMS gyroscope on hexagonal crystal substrate

ActiveUS20160341552A1Low costEasily fabricateSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesEngineeringTransducer

According to one aspect, embodiments herein provide a gyroscope comprising an axially symmetric structure, and a plurality of transducers, each configured to perform at least one of driving and sensing motion of the axially symmetric structure, wherein the plurality of transducers is configured to drive the axially symmetric structure in at least a first vibratory mode and a second vibratory mode, and wherein the gyroscope is implemented on a hexagonal crystal-based substrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

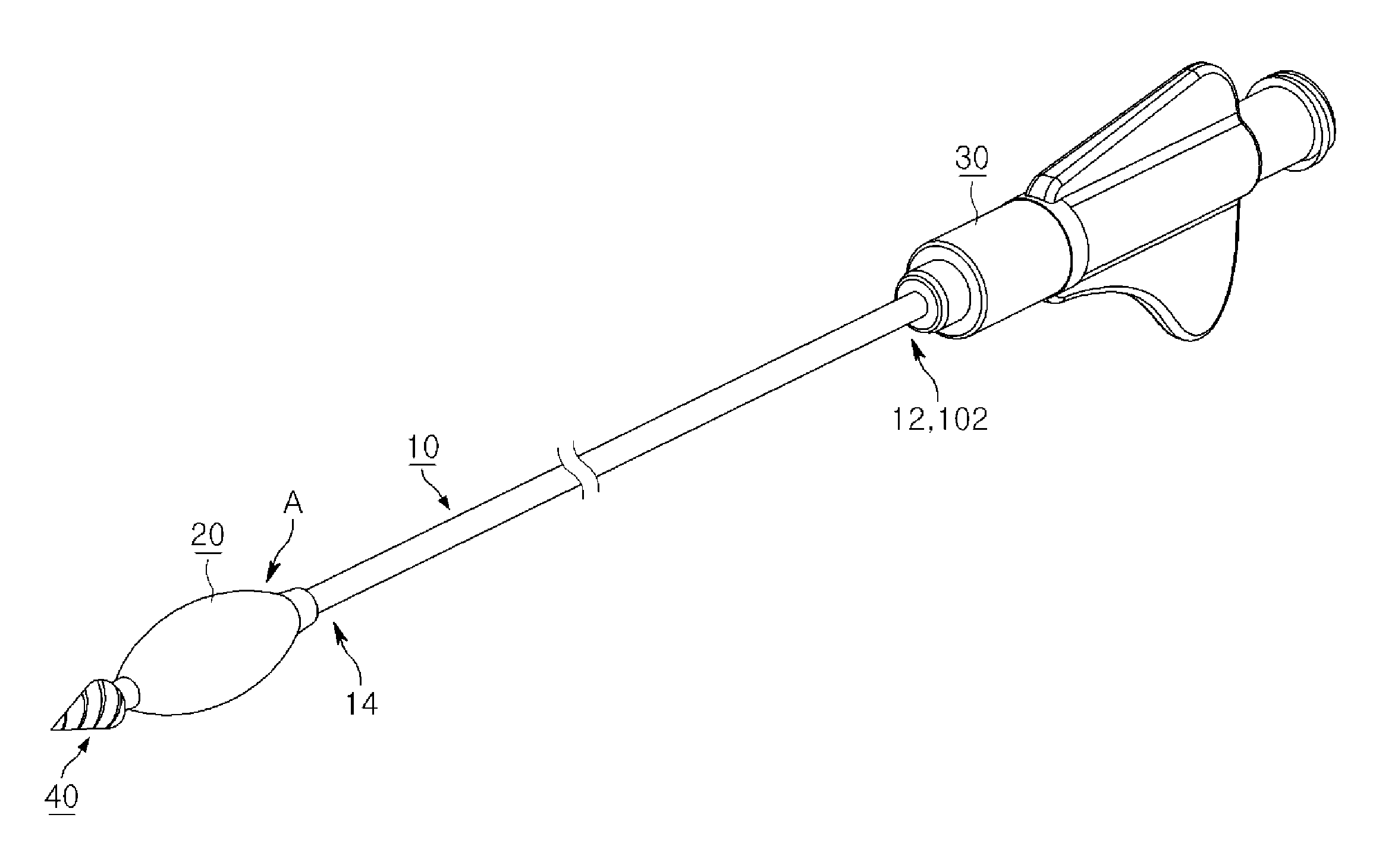

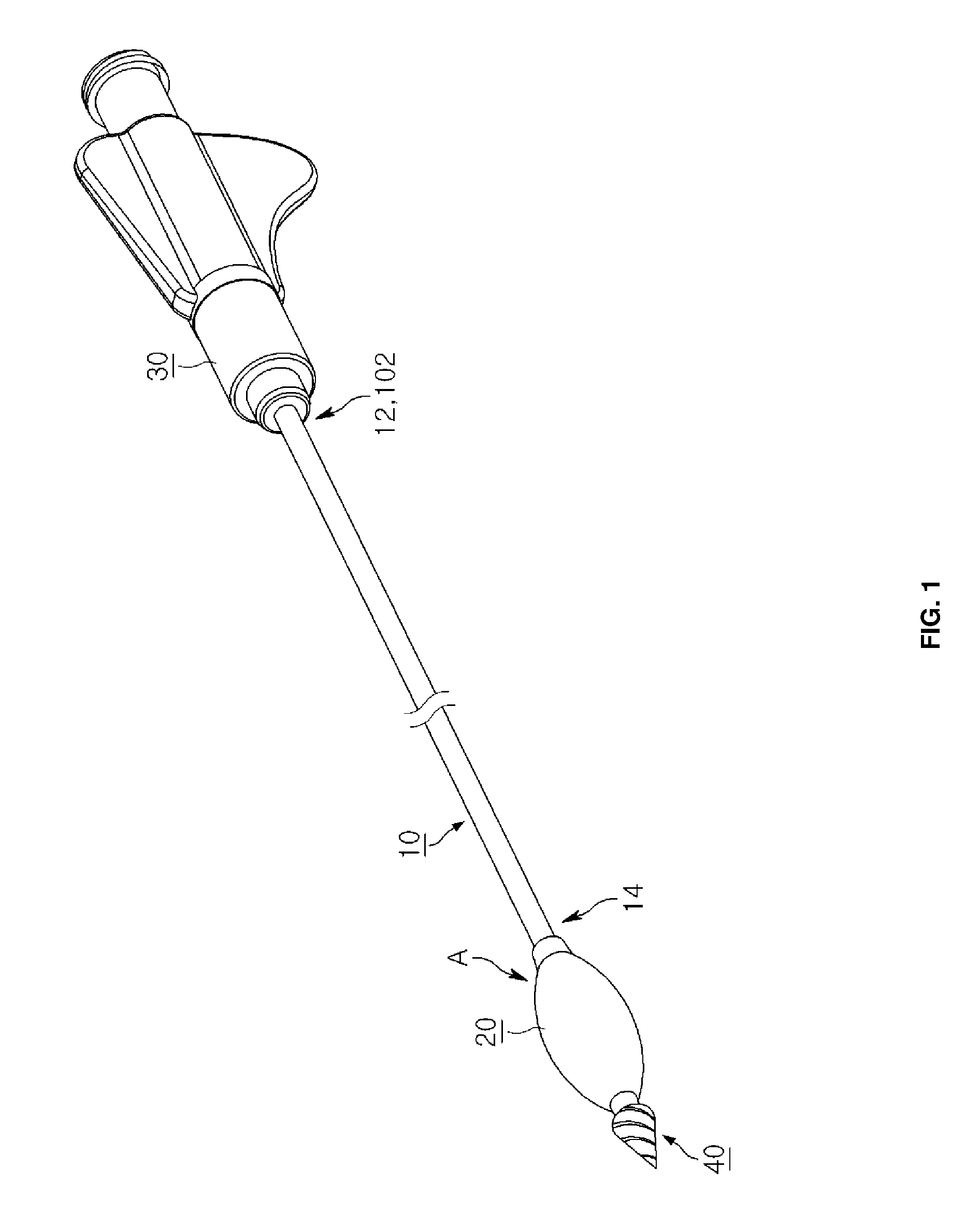

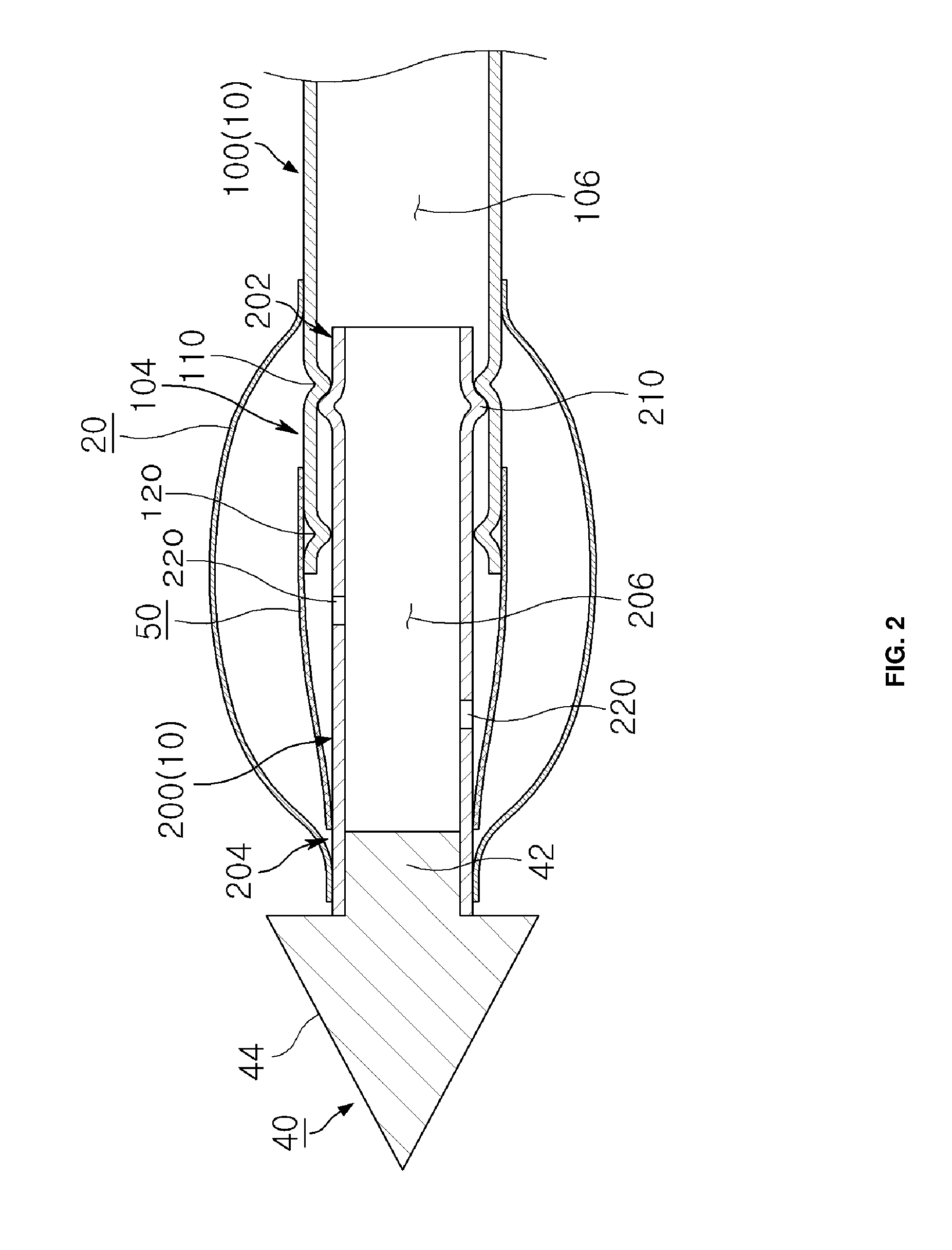

Balloon catheter

InactiveUS20160250455A1Easily fabricateLow costBalloon catheterOsteosynthesis devicesGuide wiresBalloon catheter

The present invention provides a balloon catheter comprising: an elastic catheter tube in which a second tube is slidably inserted into a first tube; and an elasticity restriction means for restricting the elasticity of the catheter tube with an elasticity rate thereof by connecting the first tube and the second tube, or a balloon catheter in which an inflation lumen and a guide wire lumen of a catheter tube are integrated.

Owner:AHN YONG CHUL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com