Patents

Literature

60results about How to "Large production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

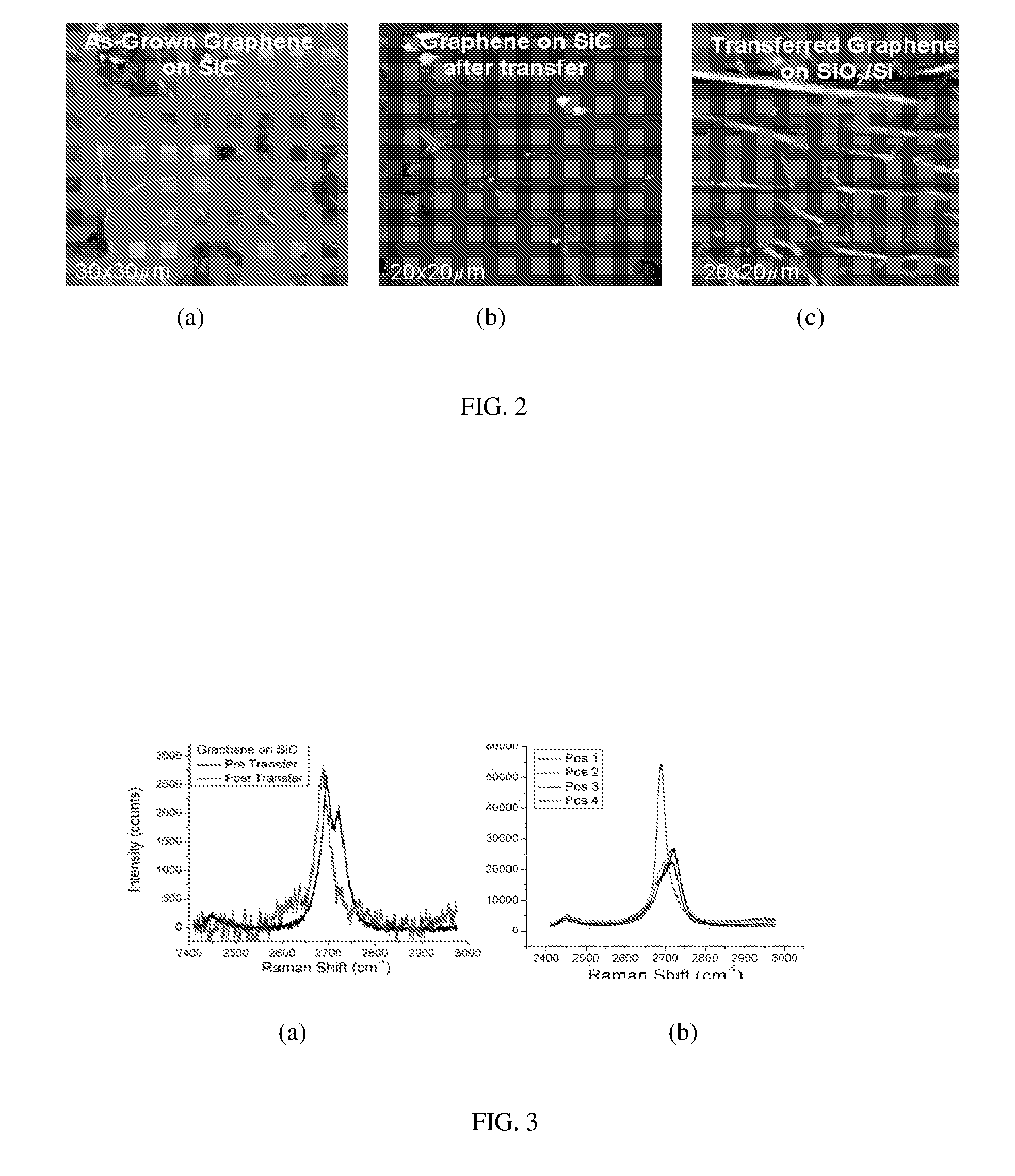

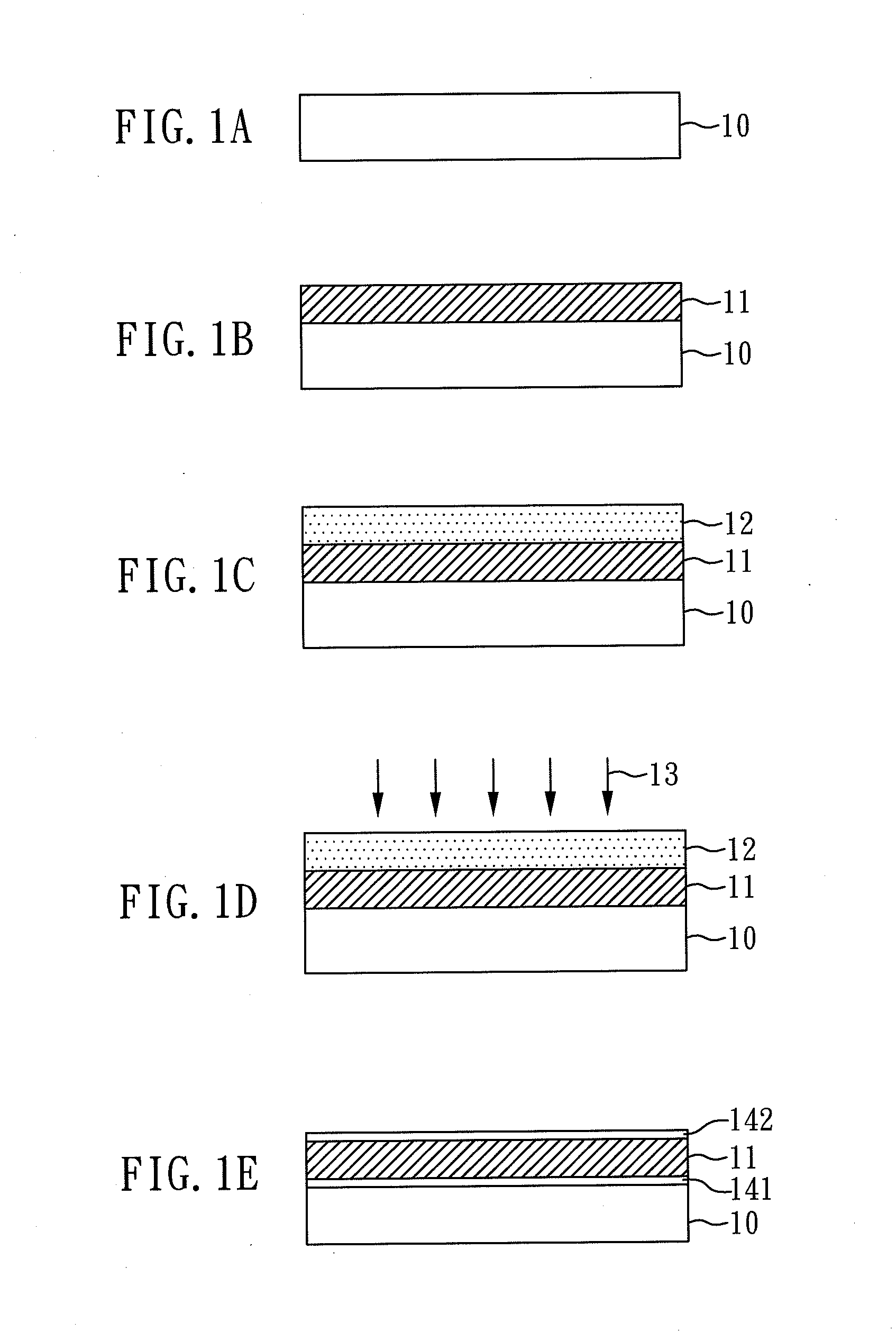

METHOD FOR THE REDUCTION OF GRAPHENE FILM THICKNESS AND THE REMOVAL AND TRANSFER OF EPITAXIAL GRAPHENE FILMS FROM SiC SUBSTRATES

ActiveUS20110048625A1Reduce processingEasily fabricateMaterial nanotechnologyGraphiteSic substrateMetal foil

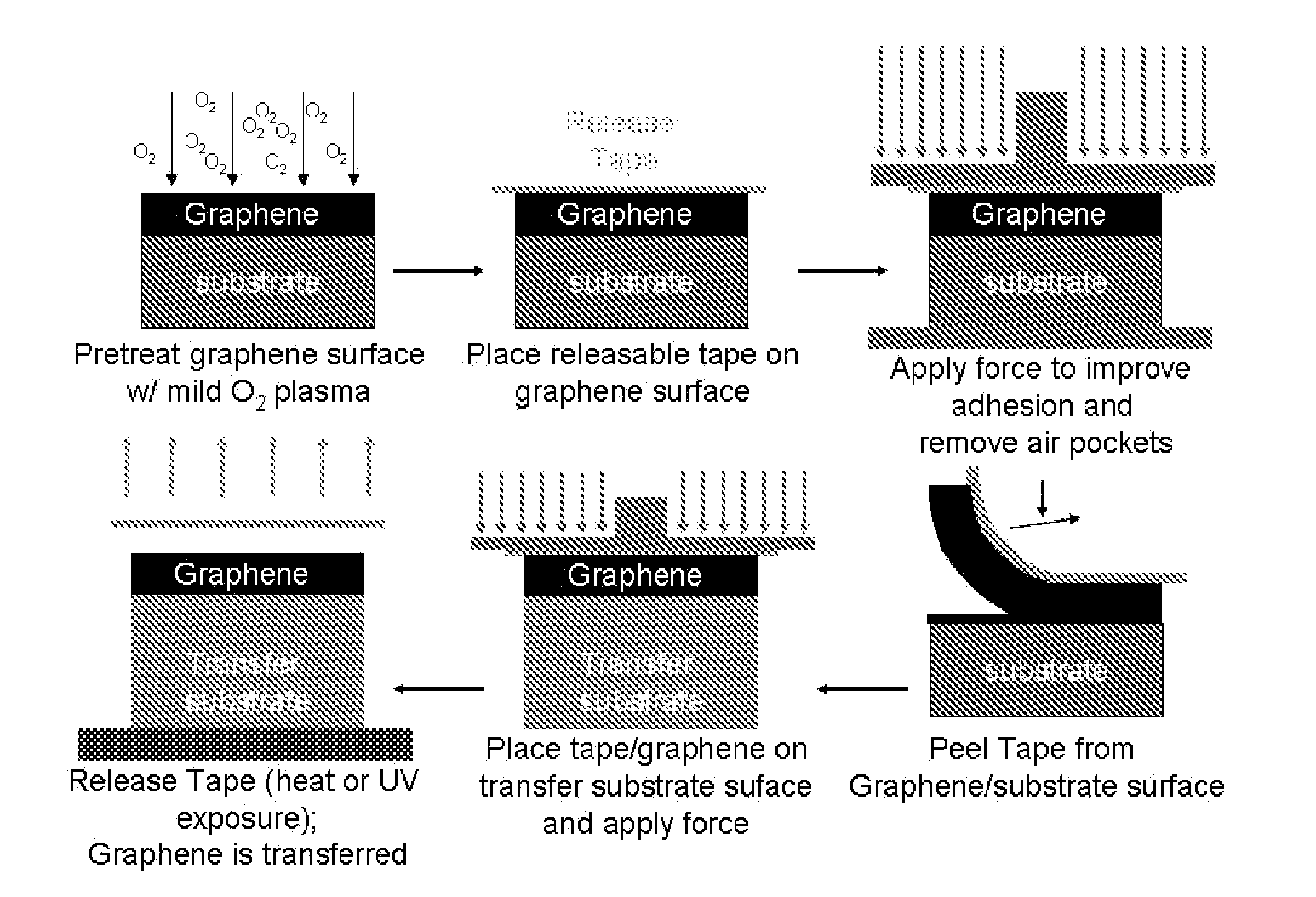

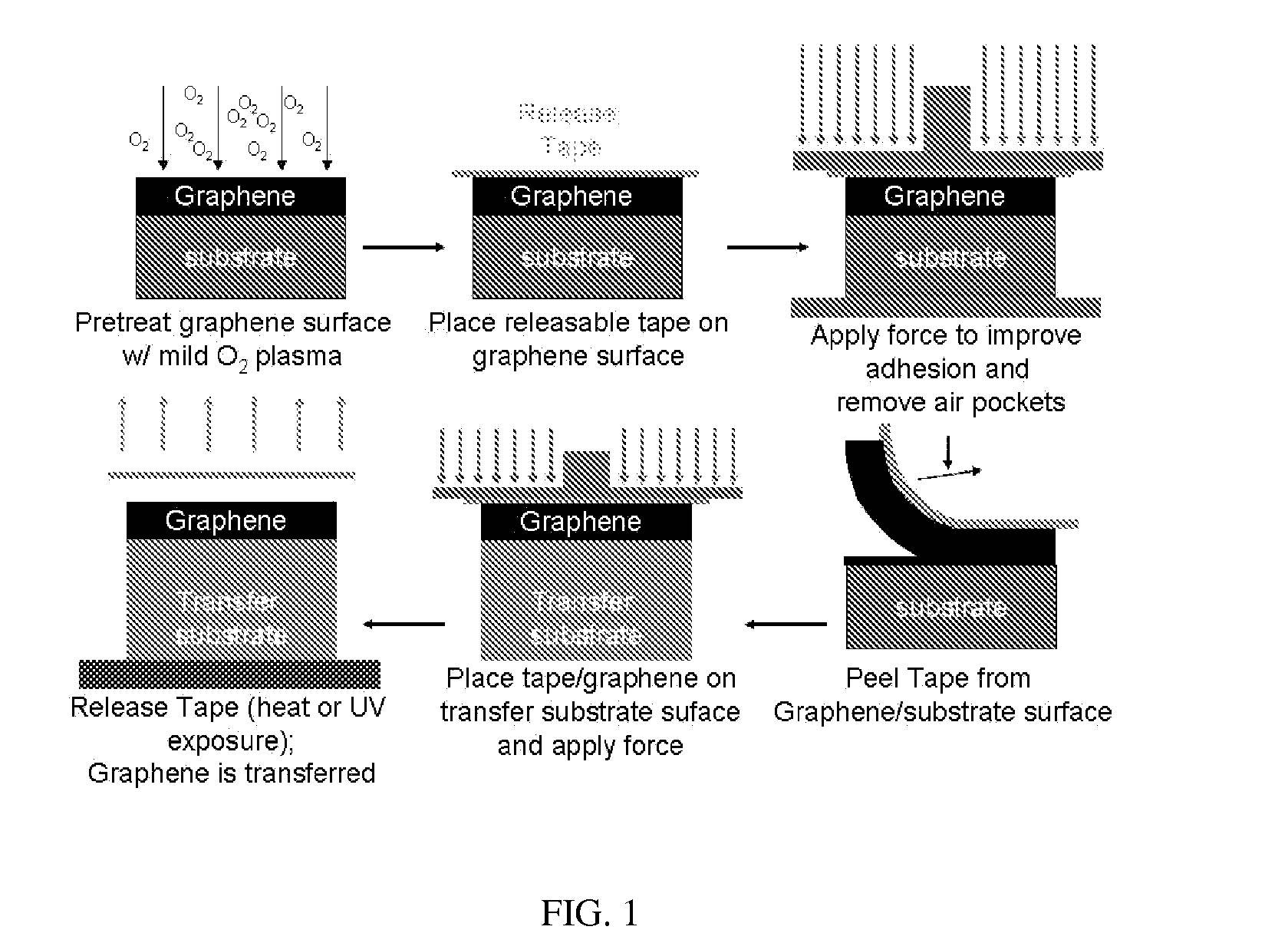

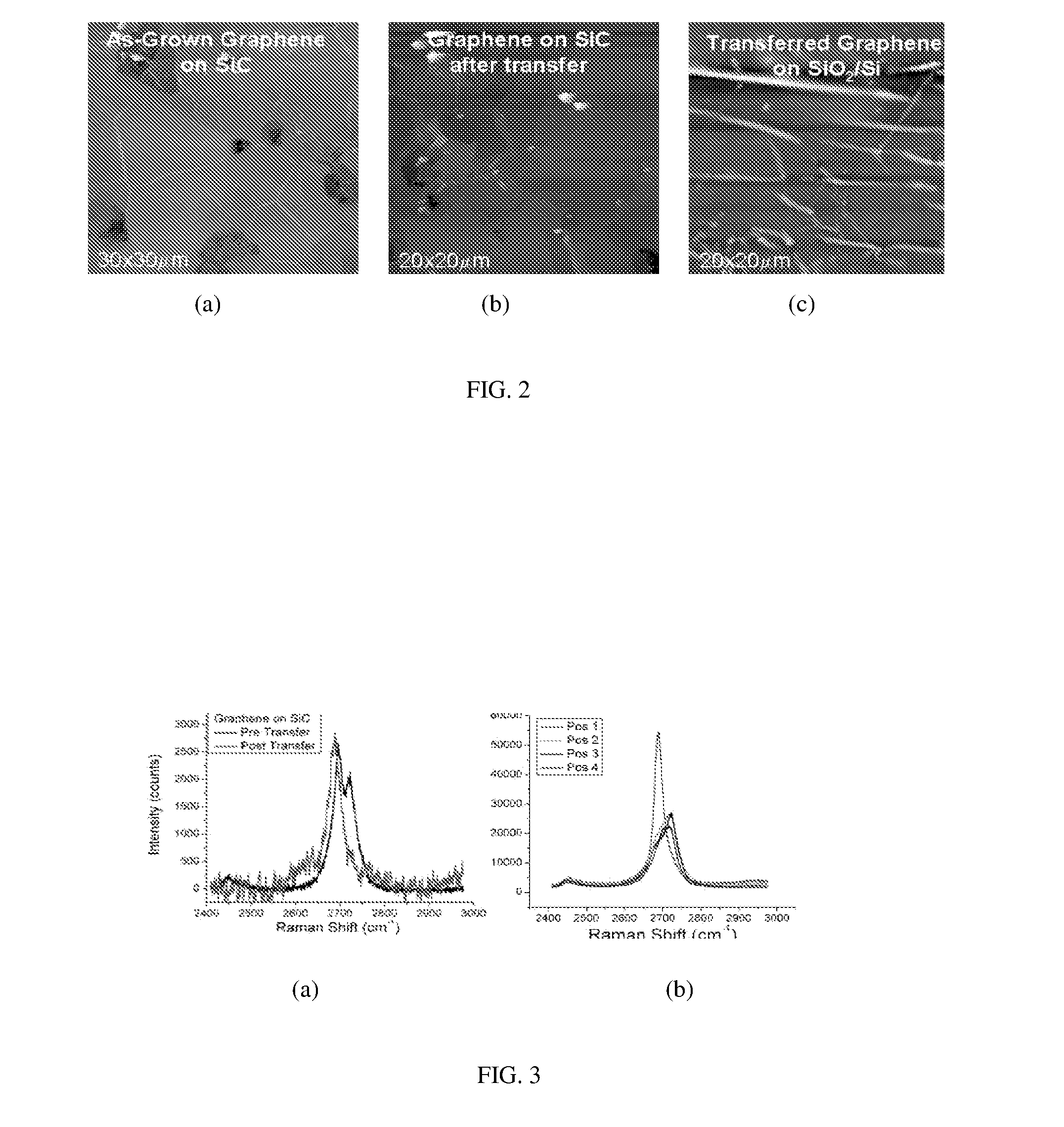

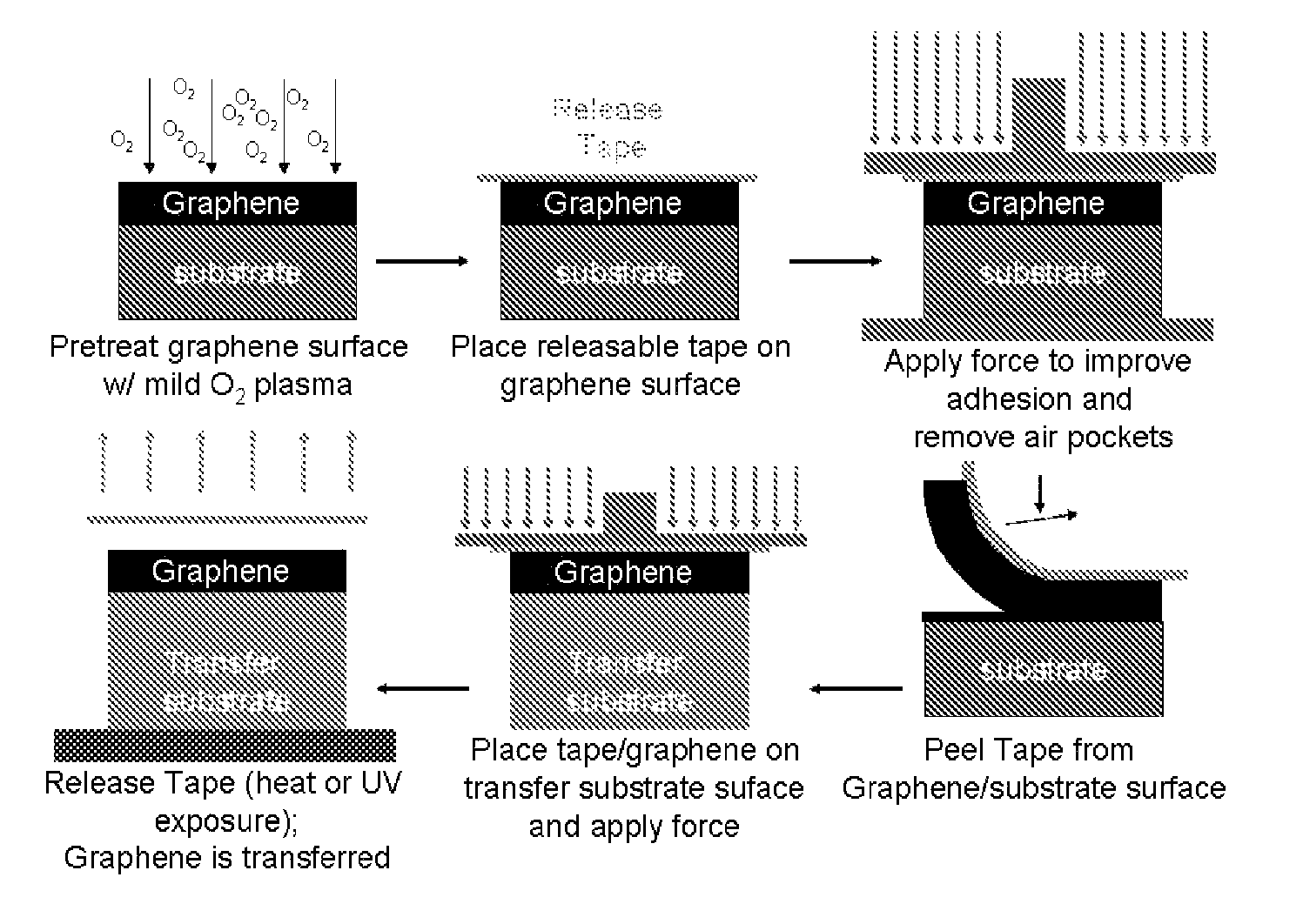

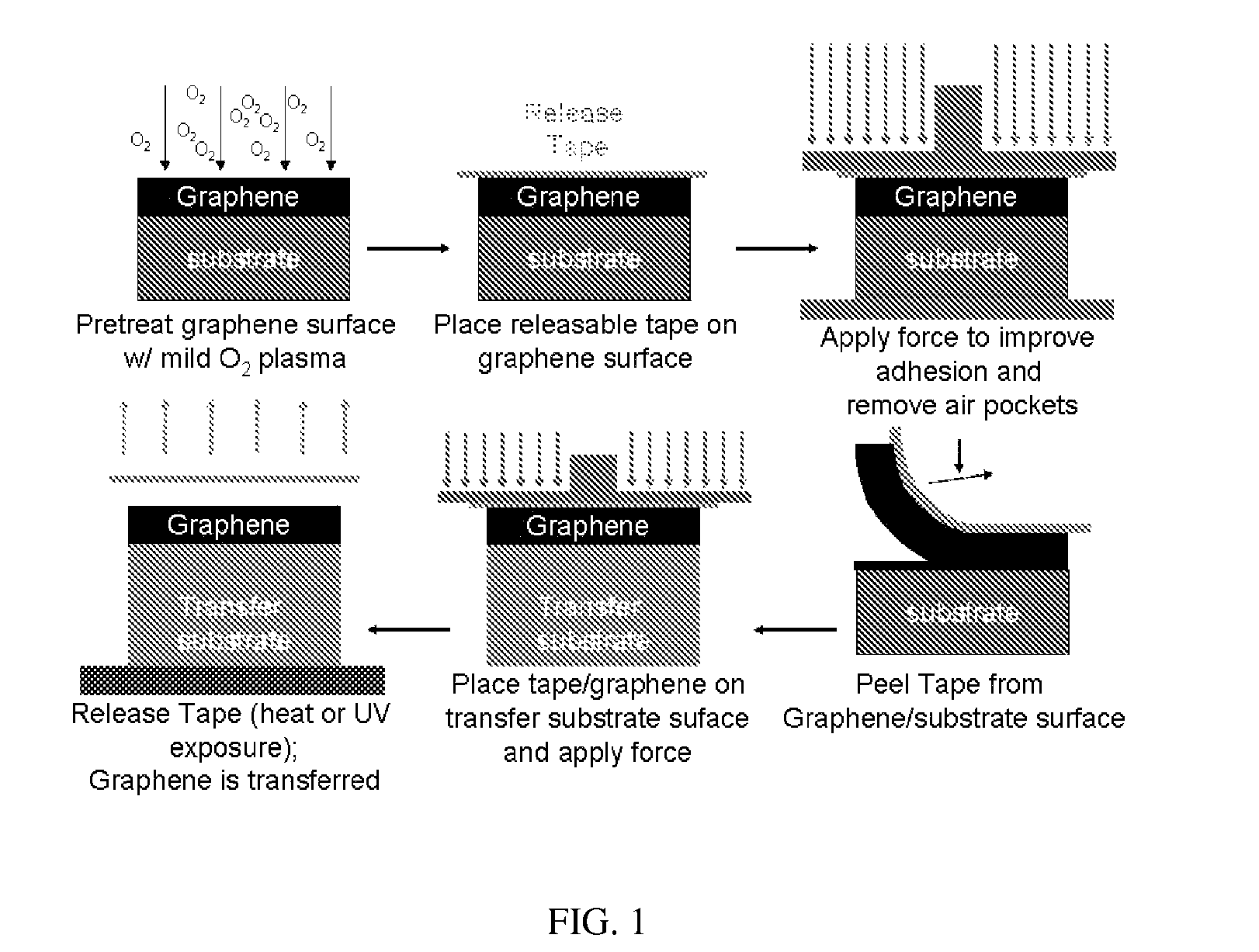

A method for reducing graphene film thickness on a donor substrate and transferring graphene films from a donor substrate to a handle substrate includes applying a bonding material to the graphene on the donor substrate, releasing the bonding material from the donor substrate thereby leaving graphene on the bonding material, applying the bonding material with graphene onto the handle substrate, and releasing the bonding material from the handle substrate thereby leaving the graphene on the handle substrate. The donor substrate may comprise SiC, metal foil or other graphene growth substrate, and the handle substrate may comprise a semiconductor or insulator crystal, semiconductor device, epitaxial layer, flexible substrate, metal film, or organic device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

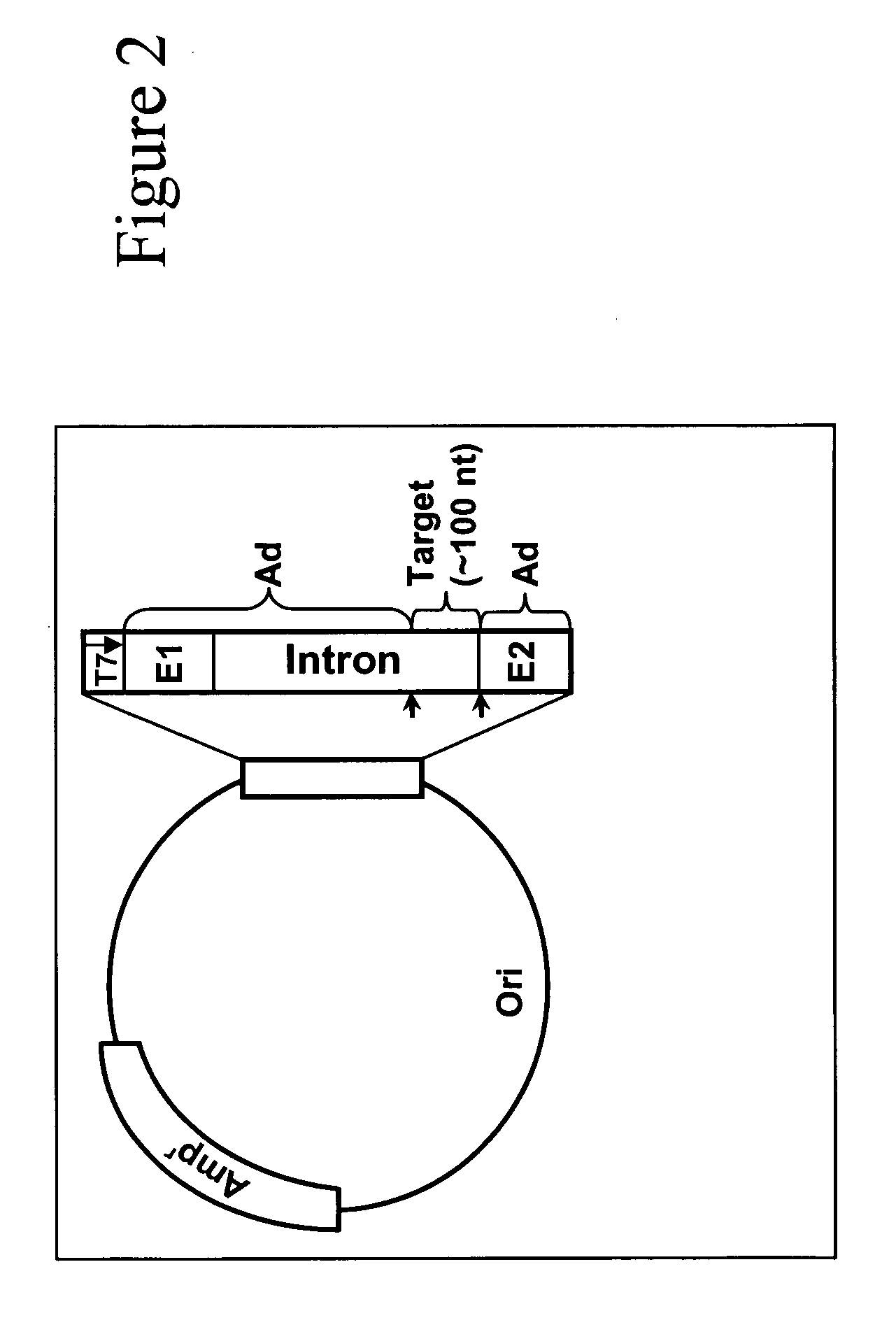

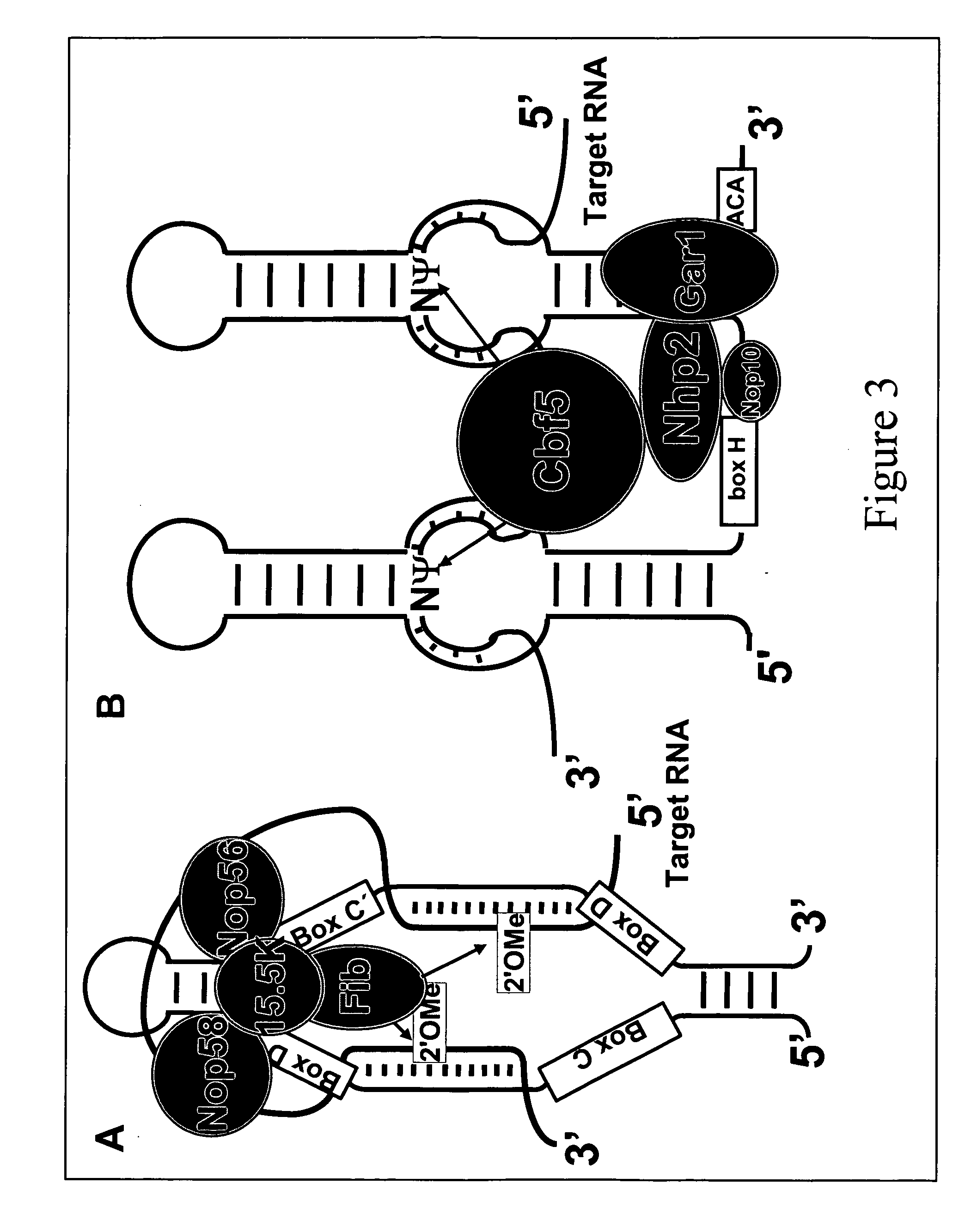

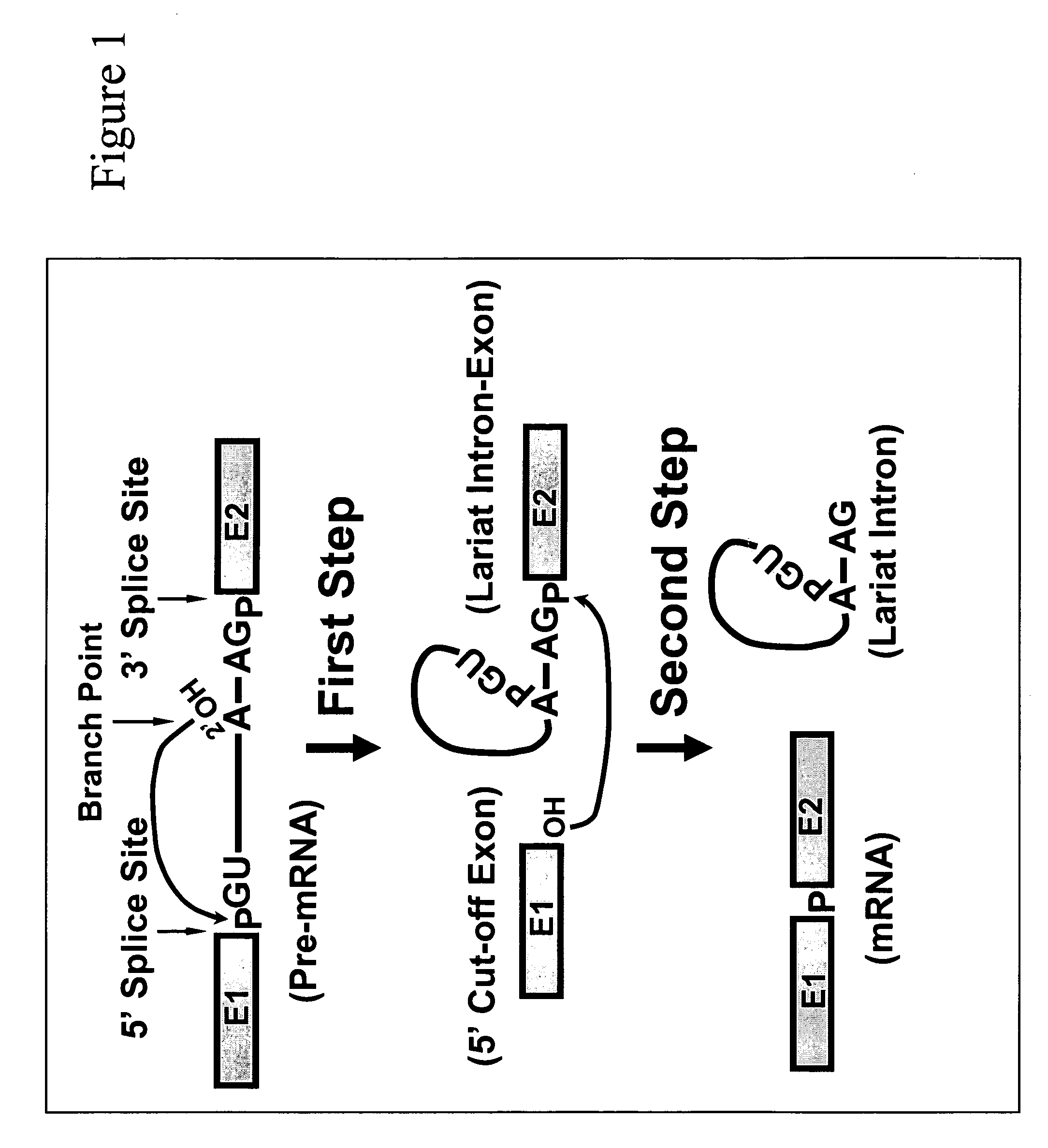

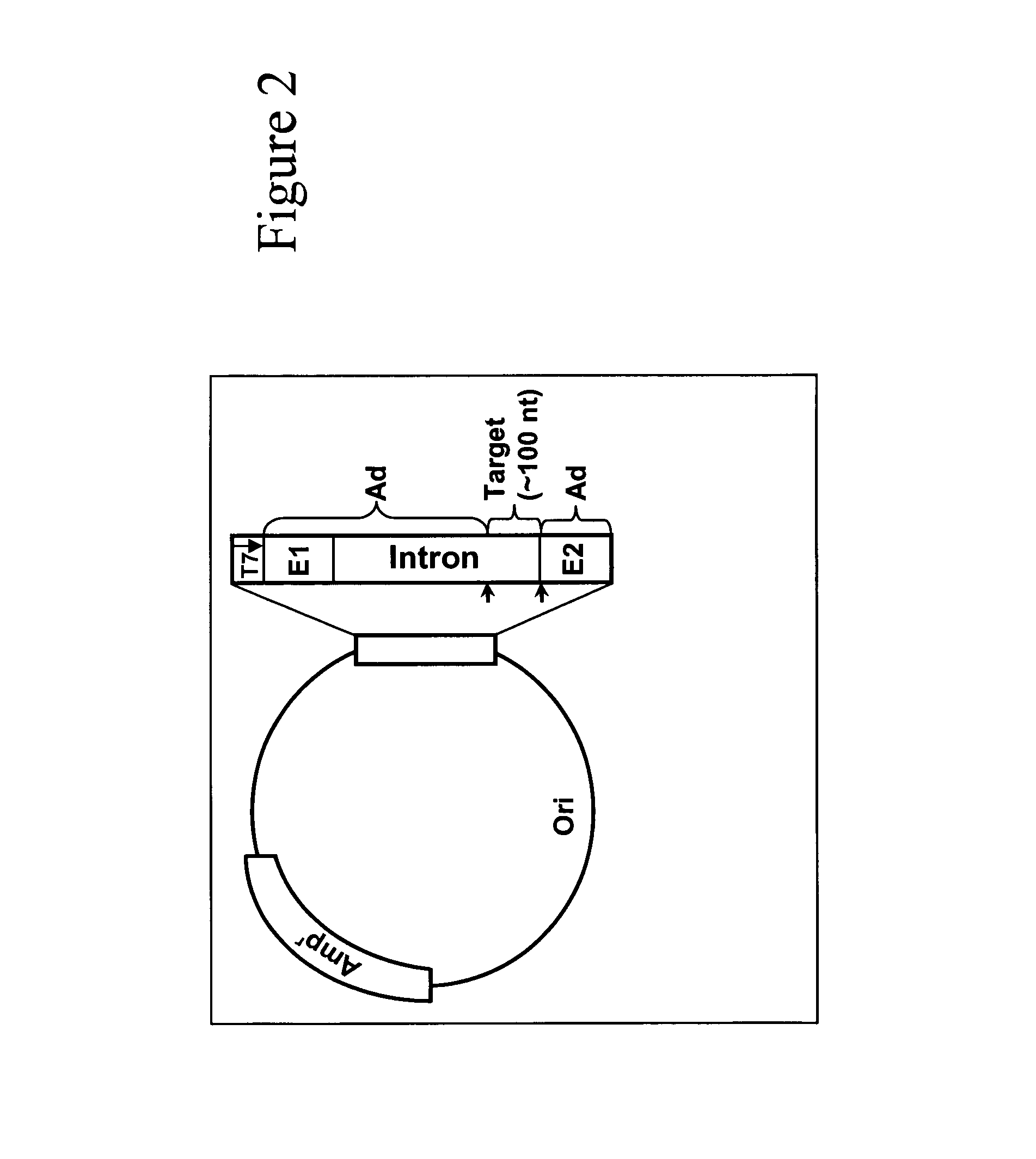

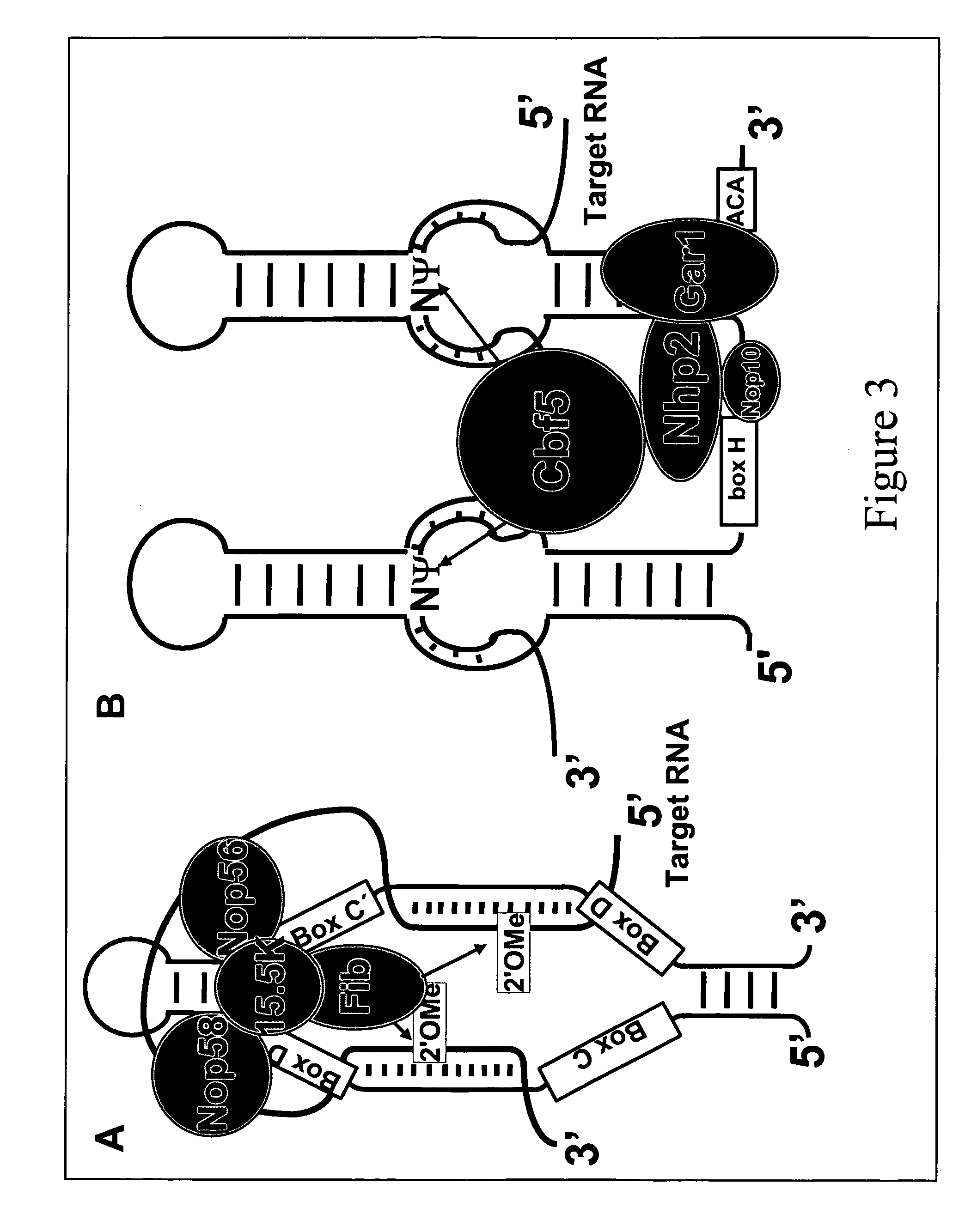

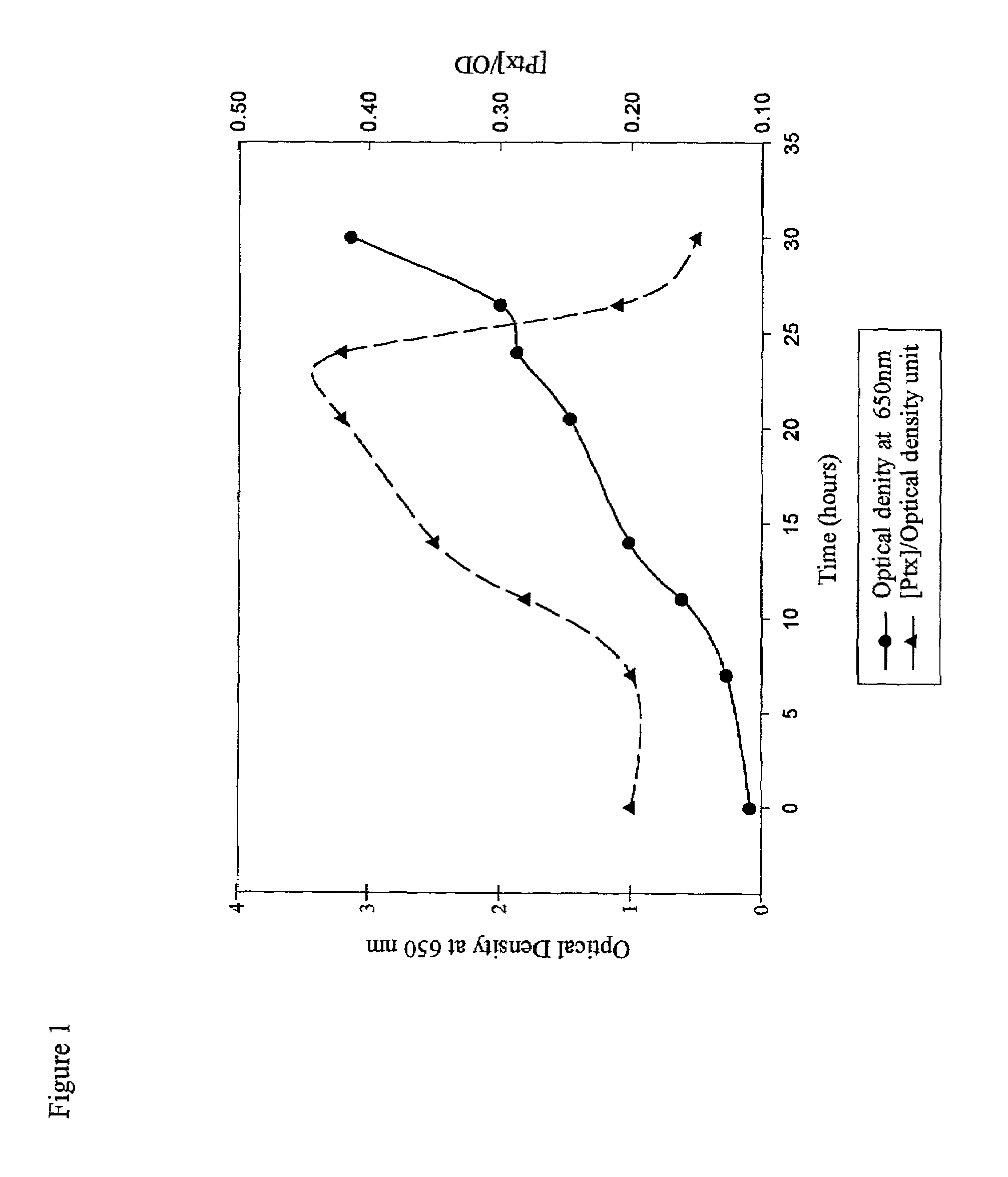

Targeted pre-mRNA/mRNA modification and gene regulation

ActiveUS20070141030A1Easy to identifyLarge productionBiocideGenetic material ingredientsAdenosinePrecursor mRNA

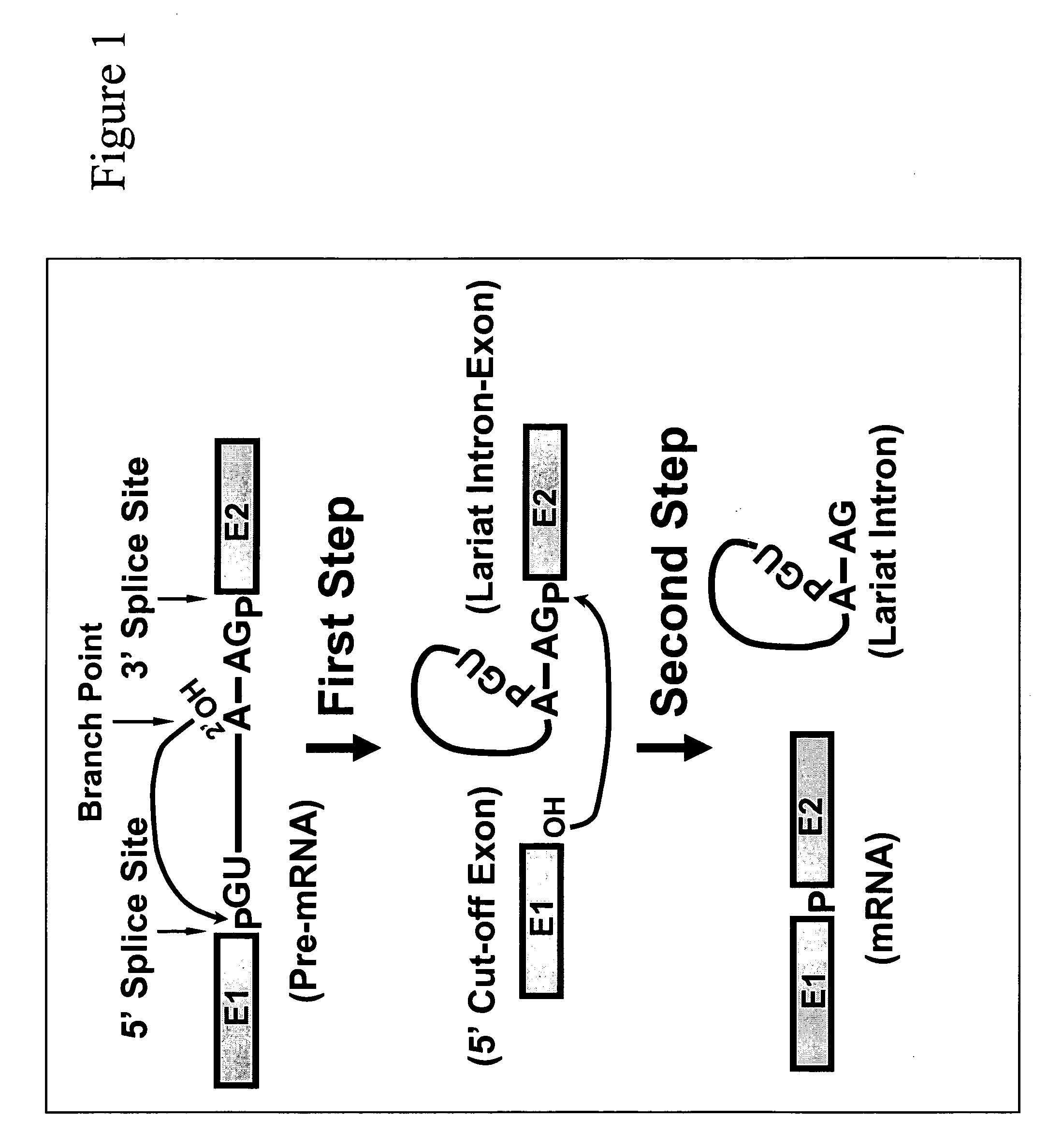

Methods for affecting mRNA expression or translation through the modification of pre-mRNA or mRNA transcripts are described. In one embodiment of the methods of the present invention, the branch point adenosine of a pre-mRNA transcript is 2′-O-methylated to block splicing and subsequent expression of the protein encoded by the transcript. In another embodiment, a uridine residue in a nonsense stop codon may be modified to pseudouridine, causing the translation machinery to read through the nonsense stop codon and translate a full length protein.

Owner:UNIVERSITY OF ROCHESTER

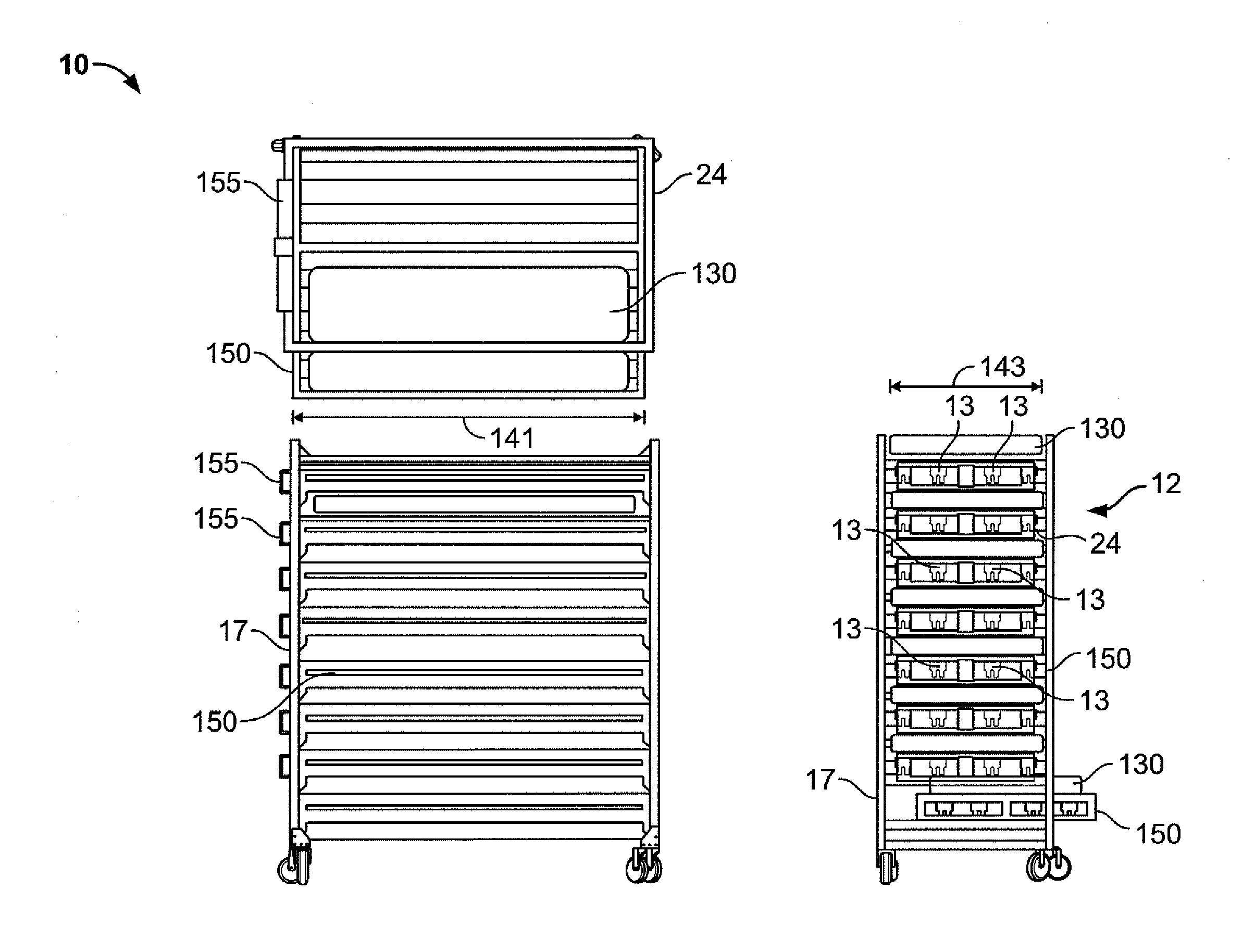

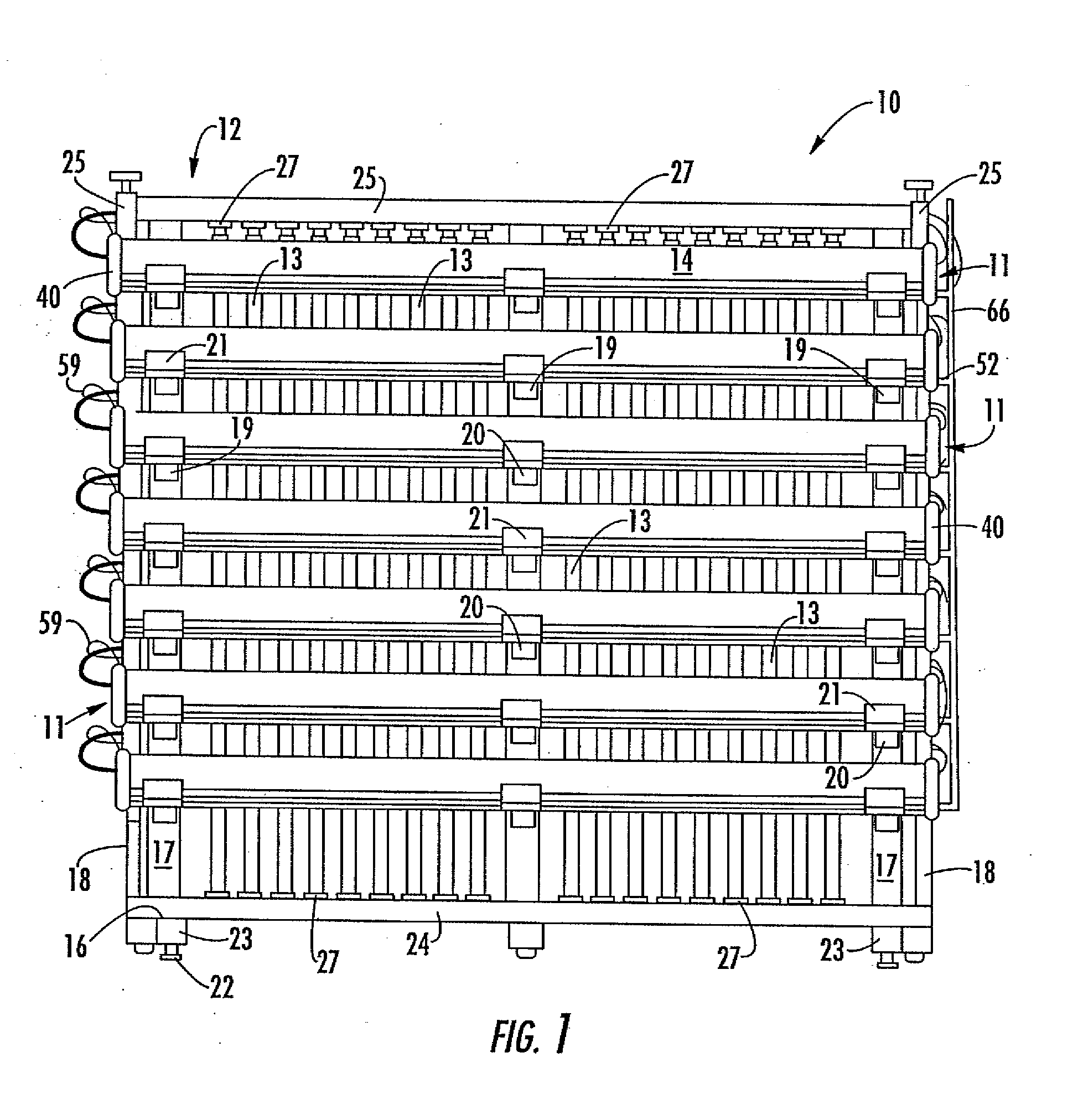

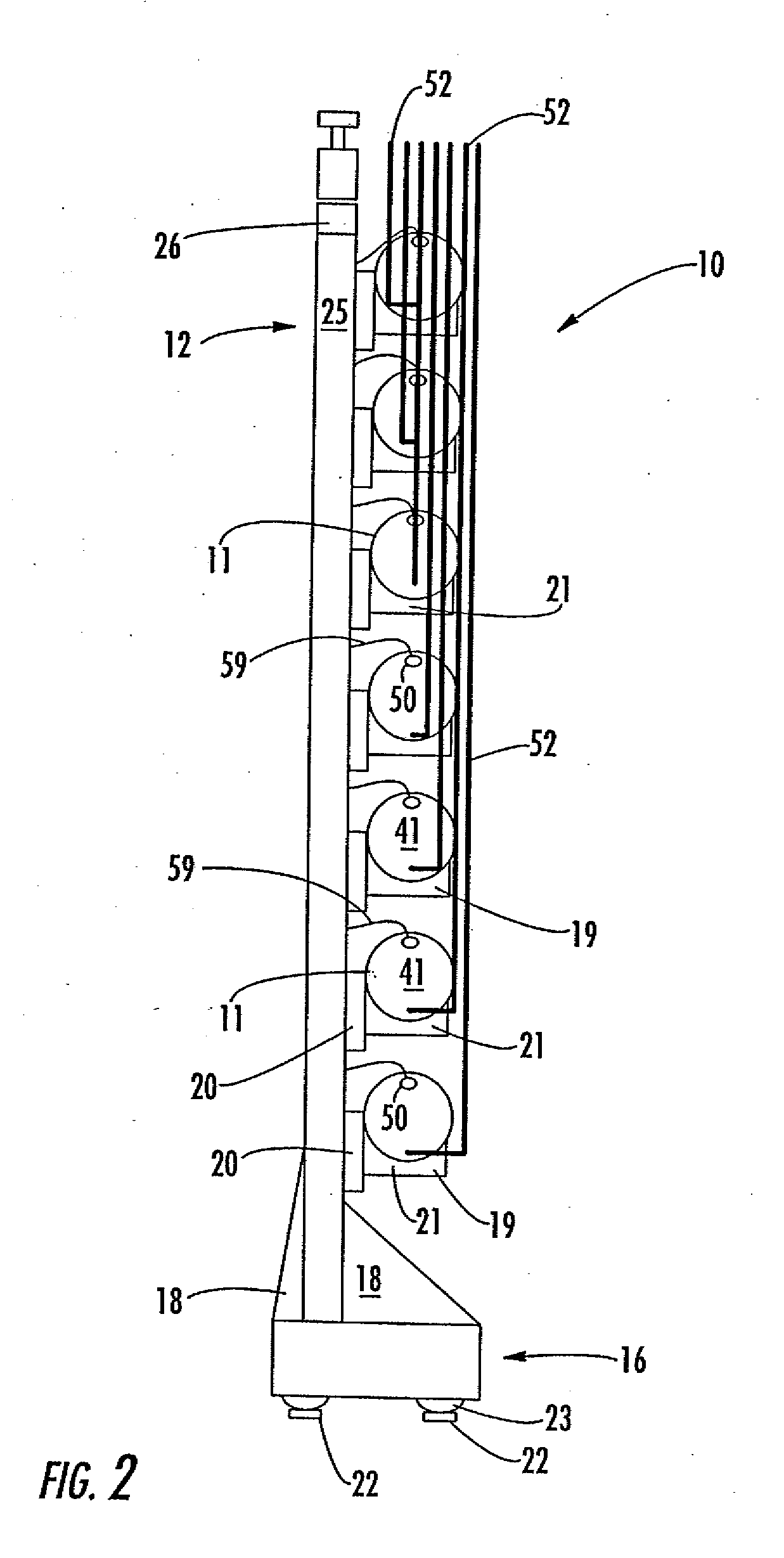

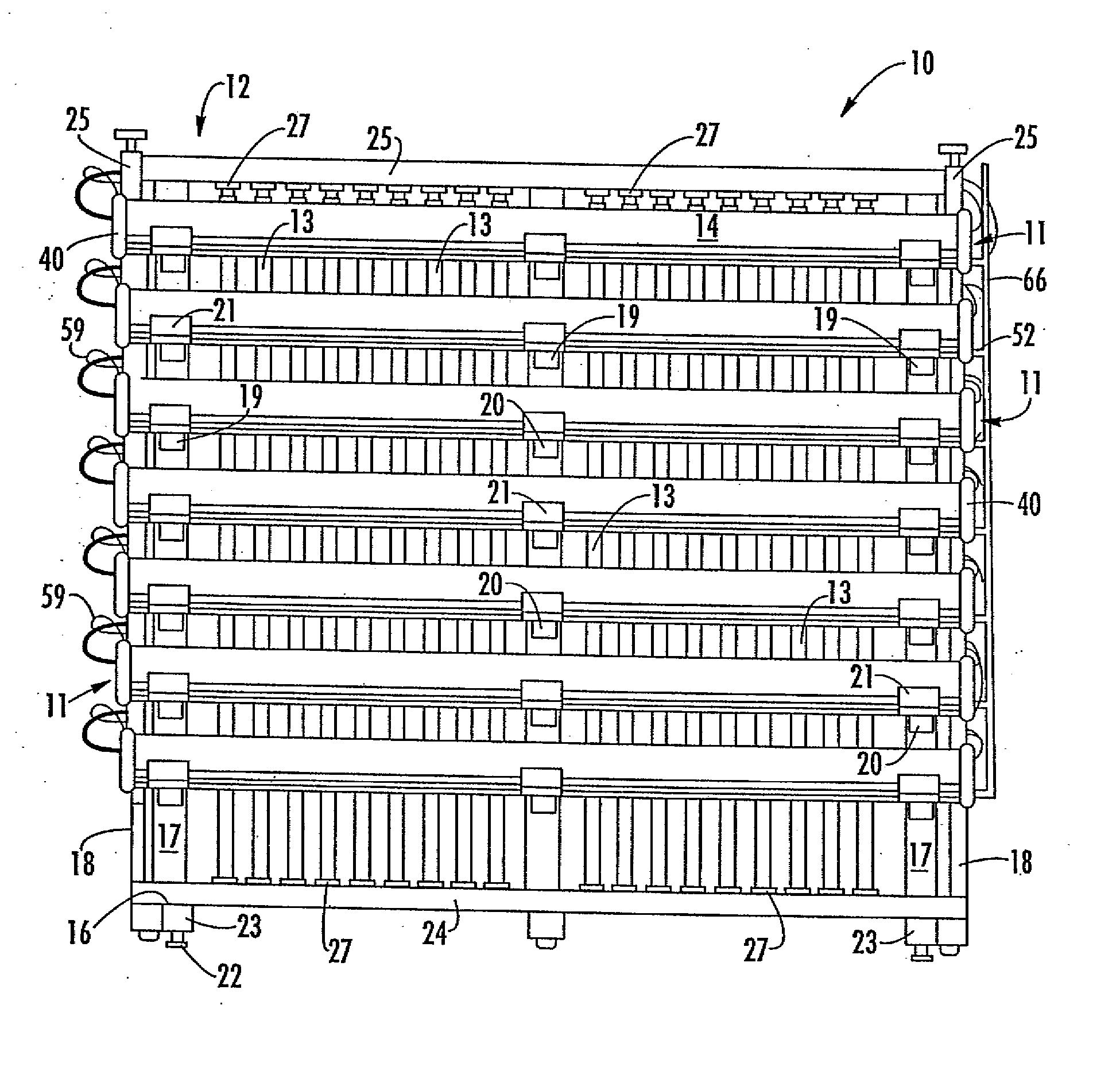

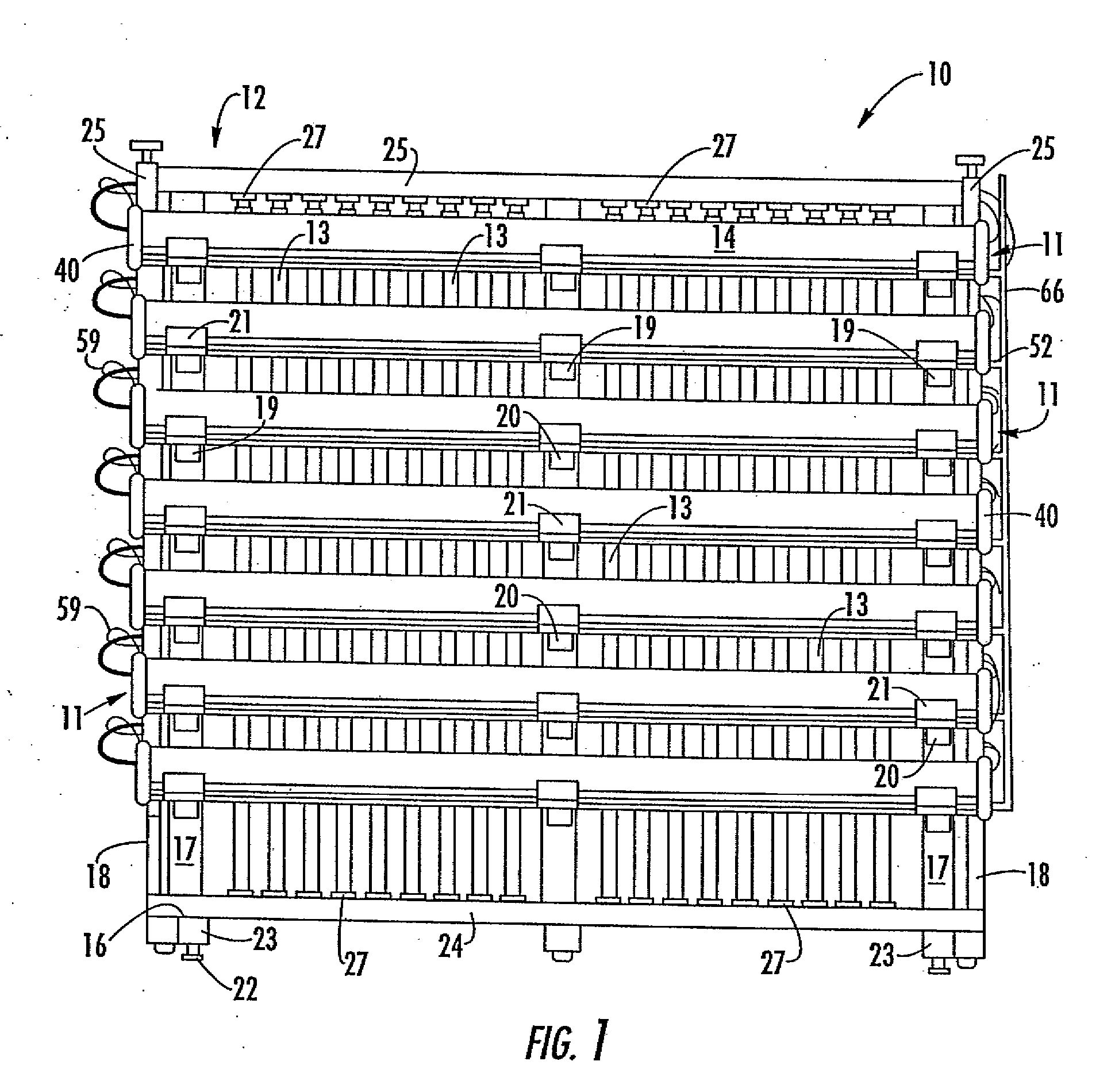

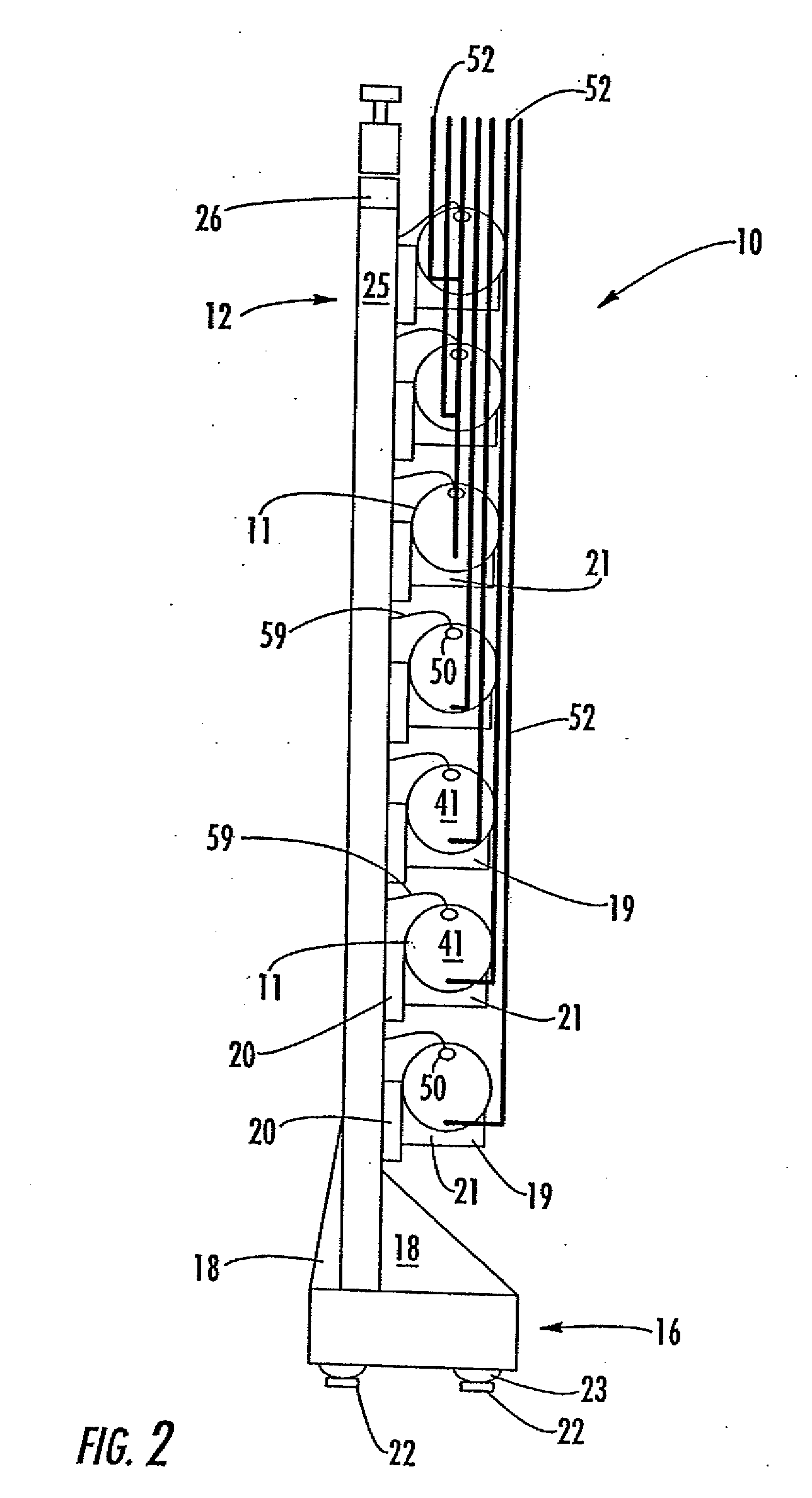

Bioreactor for growing biological materials supported on a liquid surface

InactiveUS20070113474A1Promote growthMaximize growthBioreactor/fermenter combinationsBiological substance pretreatmentsGas compositionEngineering

A bioreactor assembly of the present invention is provided for holding a media and supporting growth of a plurality of plants. The assembly includes a light source and a container having a light transmissive wall structure and defining a reservoir. A major axis of the reservoir is substantially horizontal allowing the reservoir to be filled with media to a partial level and to define a relatively large surface area for support of the plants. The assembly may also include clamps to secure and seal separate wall structure portions of the container together, and end caps to the wall portions, to define an aseptic environment. As another option, the clamps may define openings therethrough that allow passage of various devices for measuring and controlling bioreactor function such as a gas supply nozzle, a gas exit nozzle, an air temperature probe, a pH probe, a sampling drain, a gas composition probe and a media temperature probe.

Owner:SYNTHON BIOPHARMACEUTICALS BV

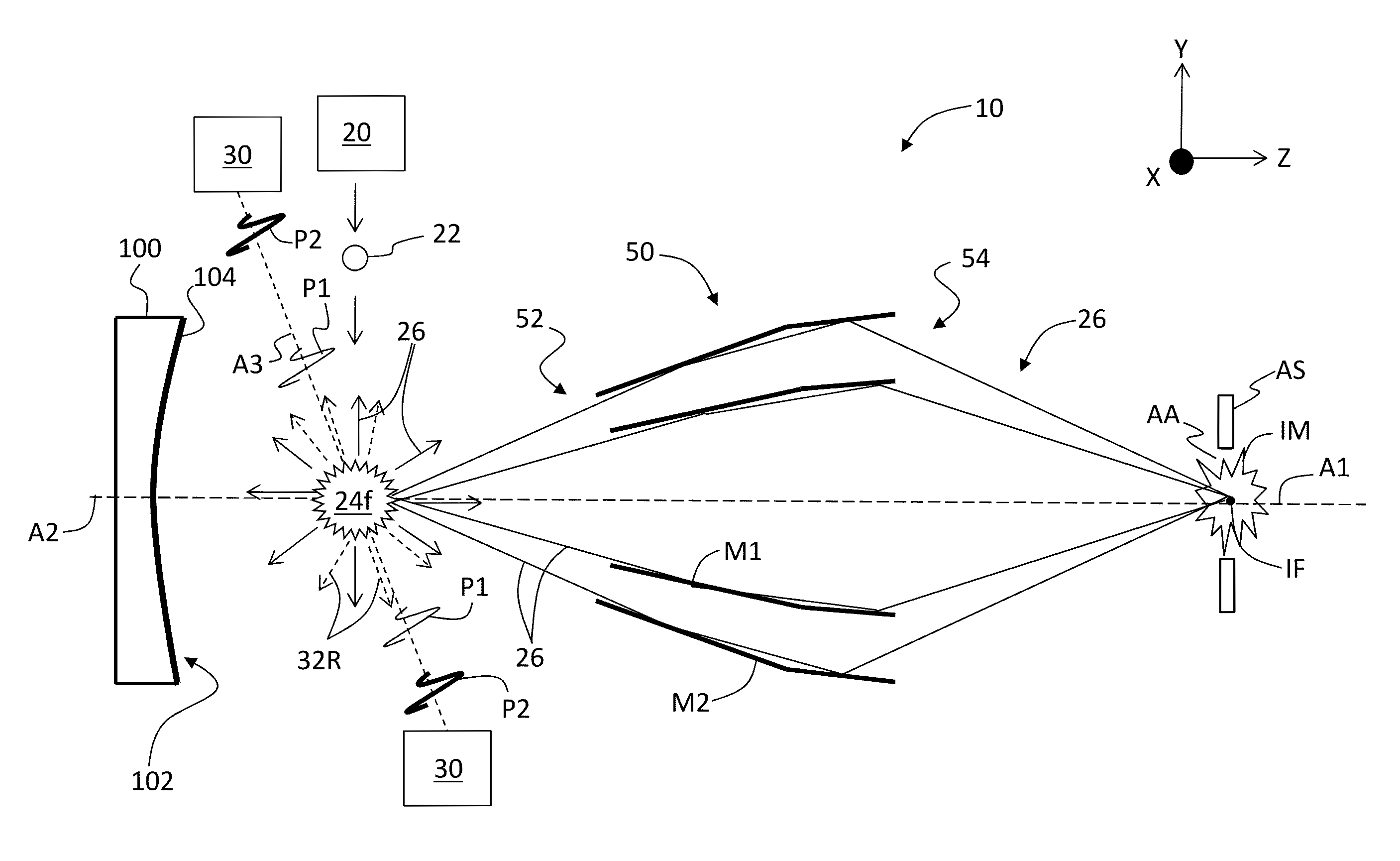

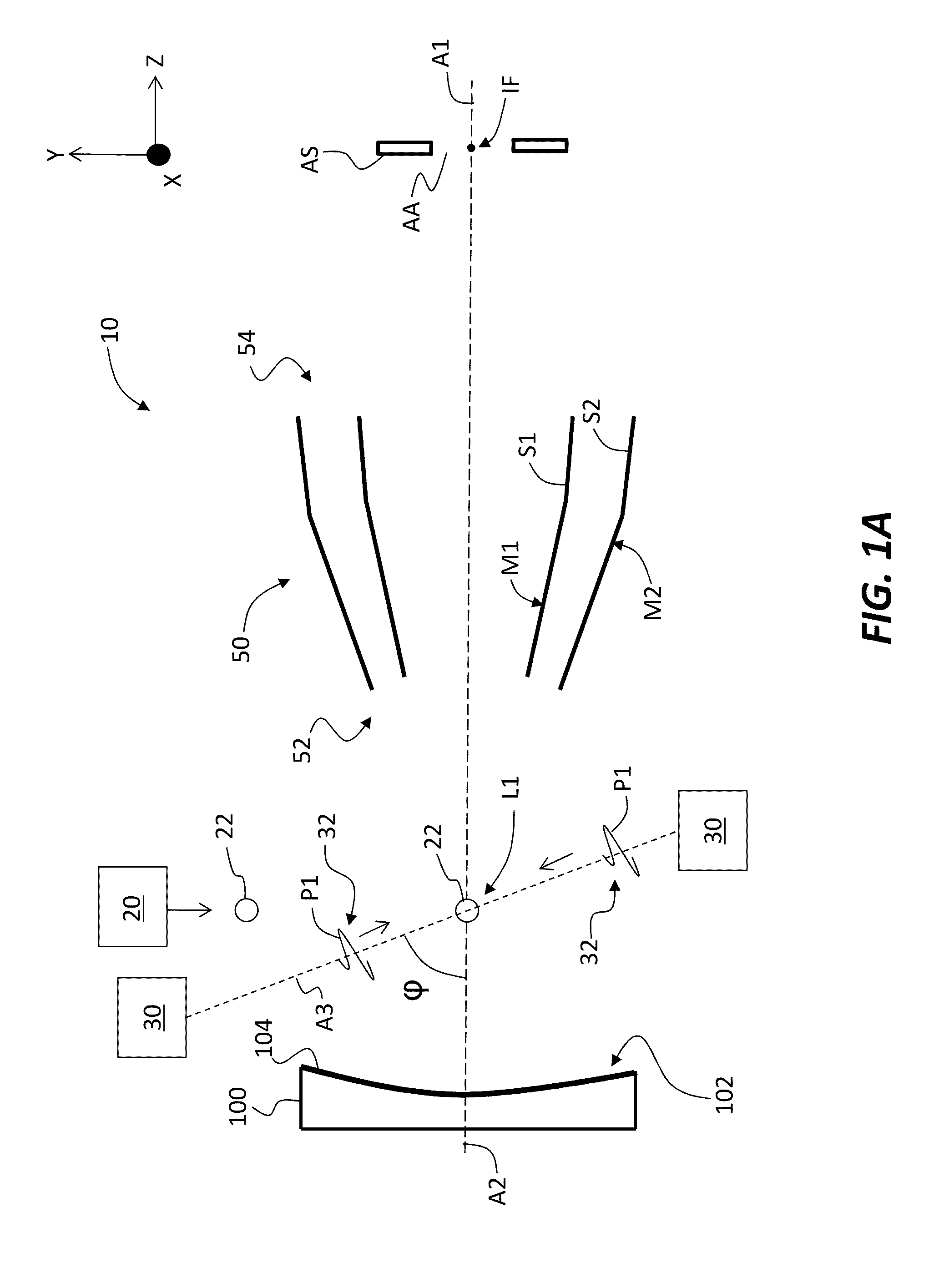

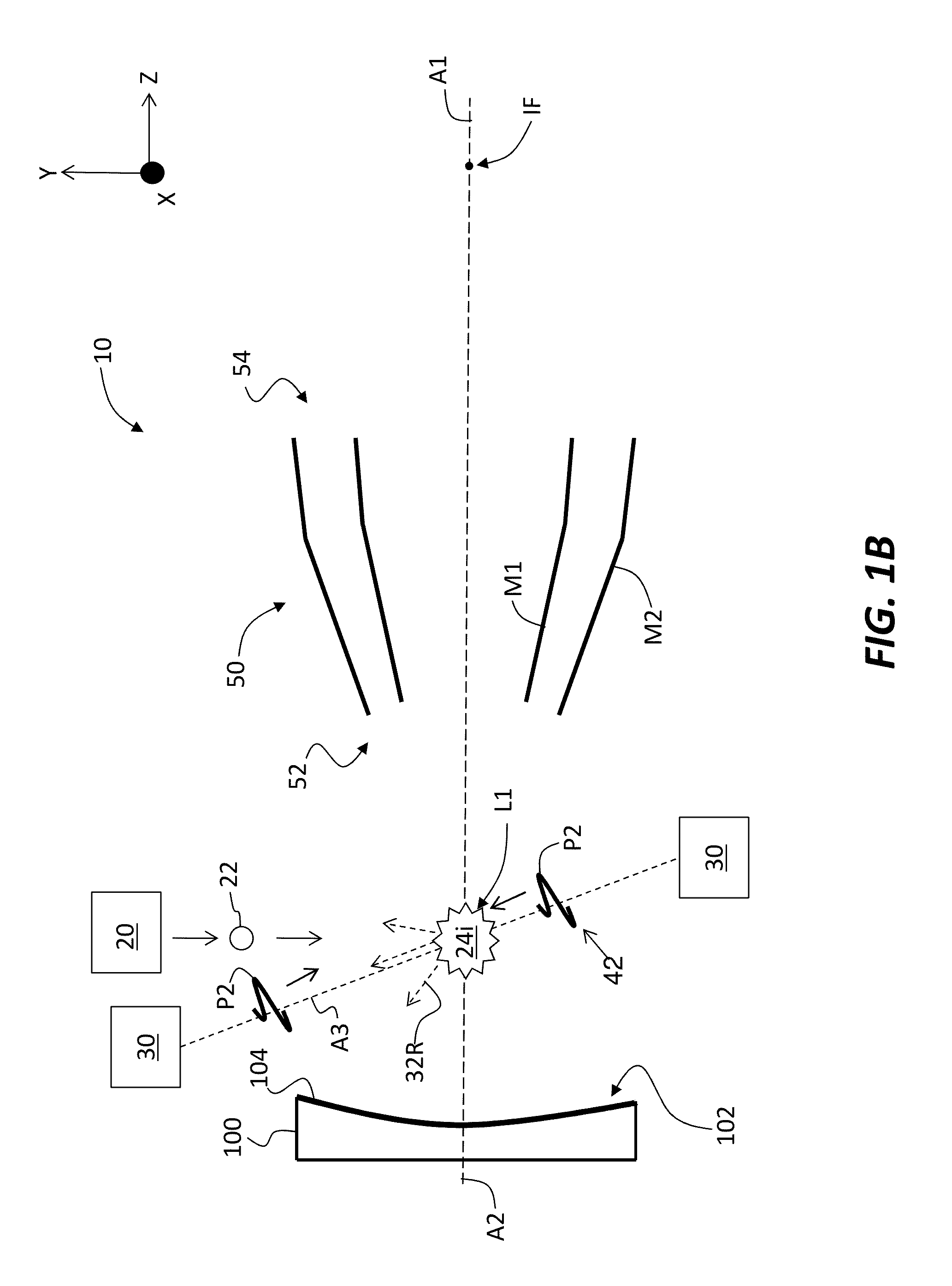

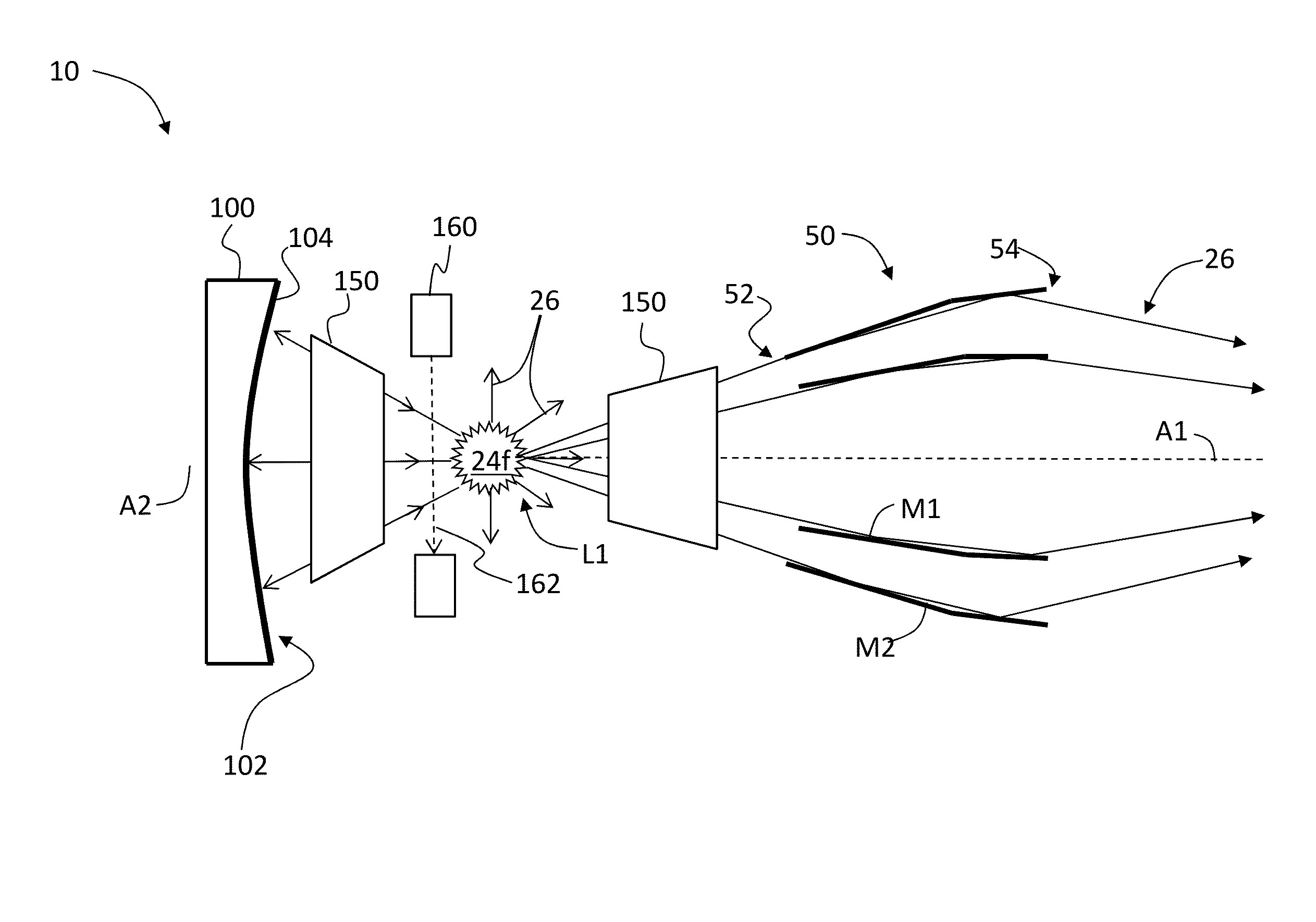

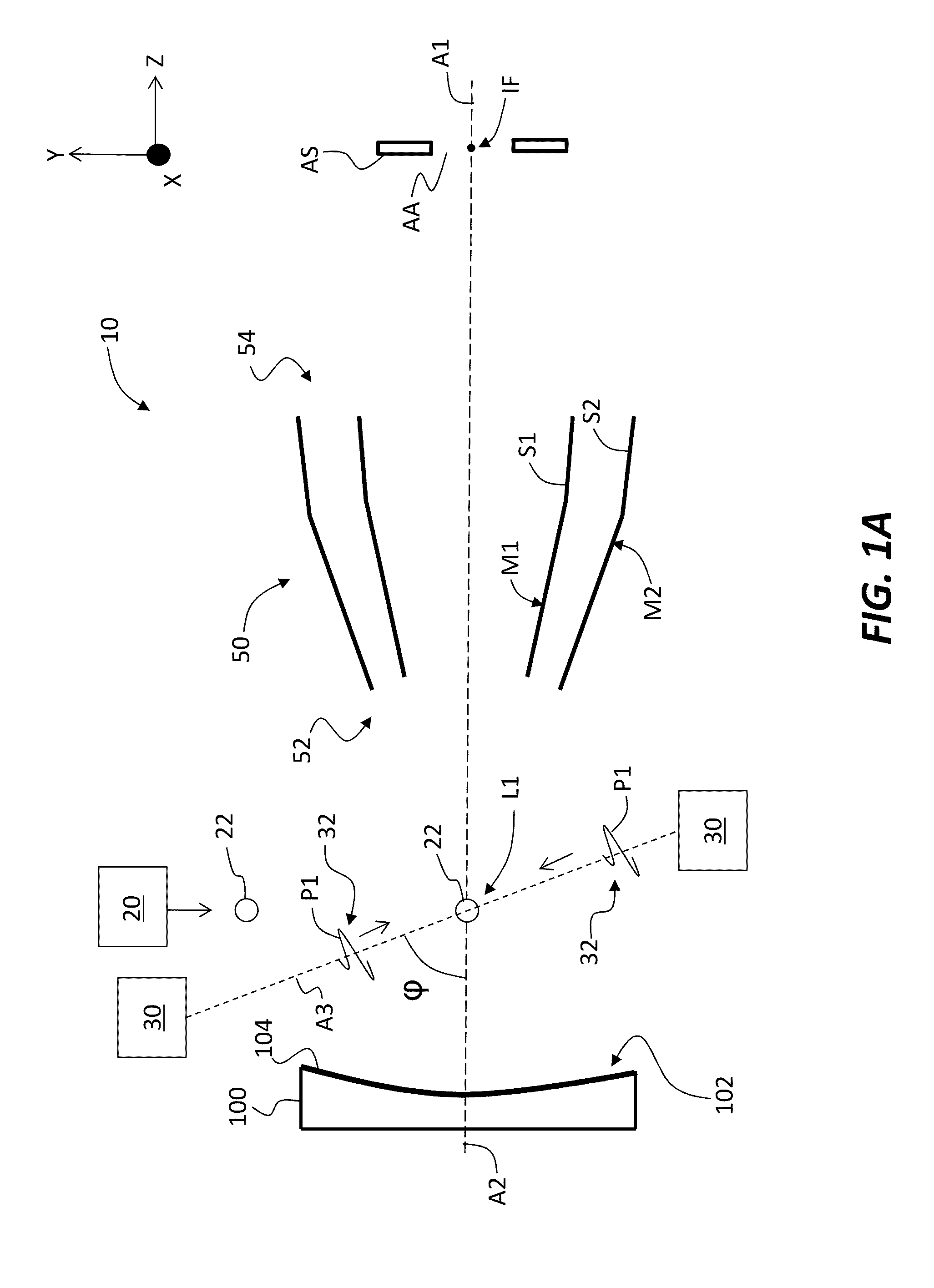

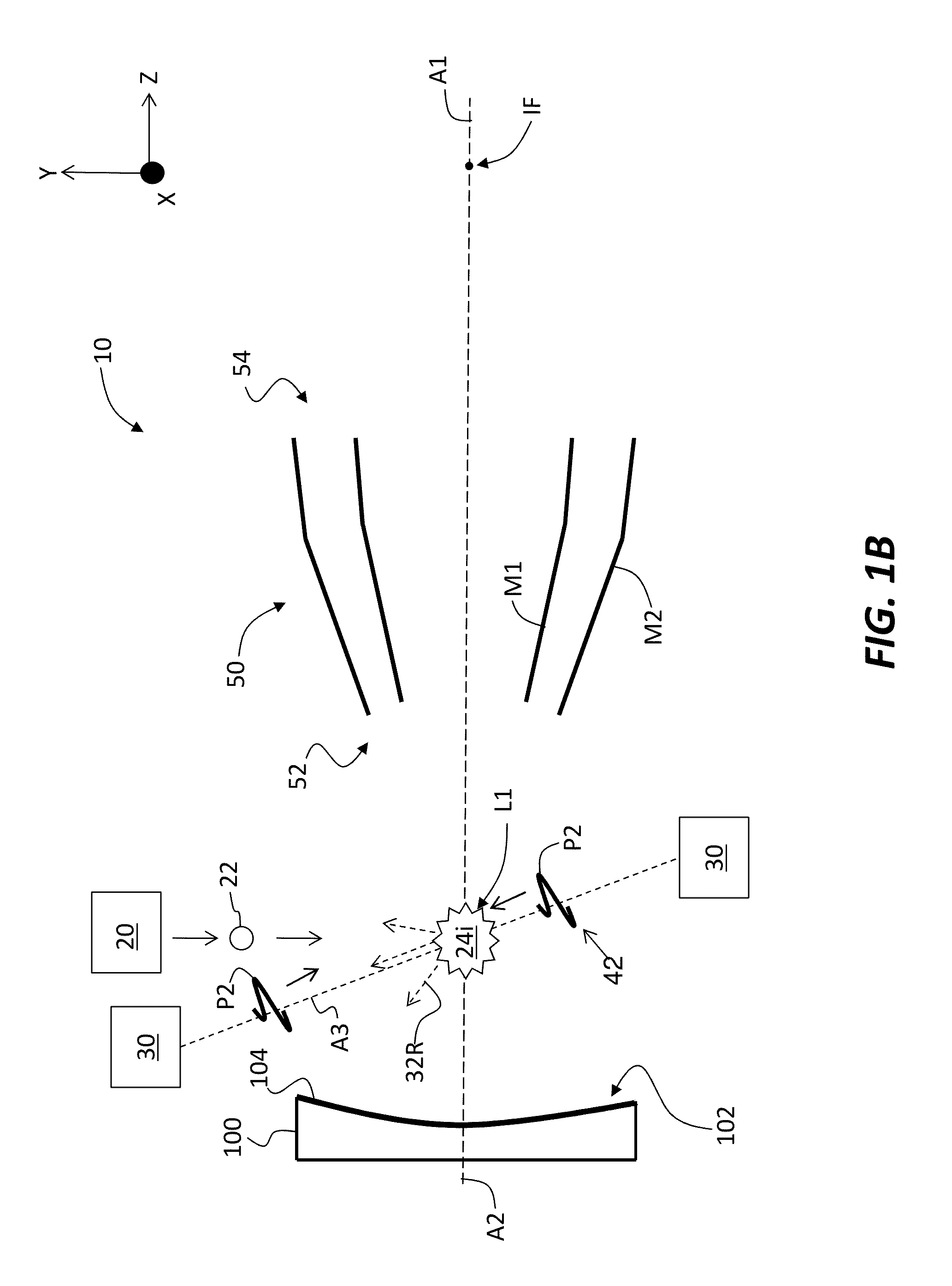

Source-collector modules for EUV lithography employing a GIC mirror and a LPP source

ActiveUS20130207004A1Maximize collectionConvenient amountRadiation pyrometryRadiation/particle handlingGratingLithographic artist

Source-collector modules for use with EUV lithography systems are disclosed, wherein the source-collector modules employ a laser-produced plasma EUV radiation source and a grazing-incidence collector. The EUV radiation source is generated by first forming an under-dense plasma, and then irradiating the under-dense plasma with infrared radiation of sufficient intensity to create a final EUV-emitting plasma. The grazing incidence collector can include a grating configured to prevent infrared radiation from reaching the intermediate focus. Use of debris mitigation devices preserves the longevity of operation of the source-collector modules.

Owner:MEDIA LARIO SRL

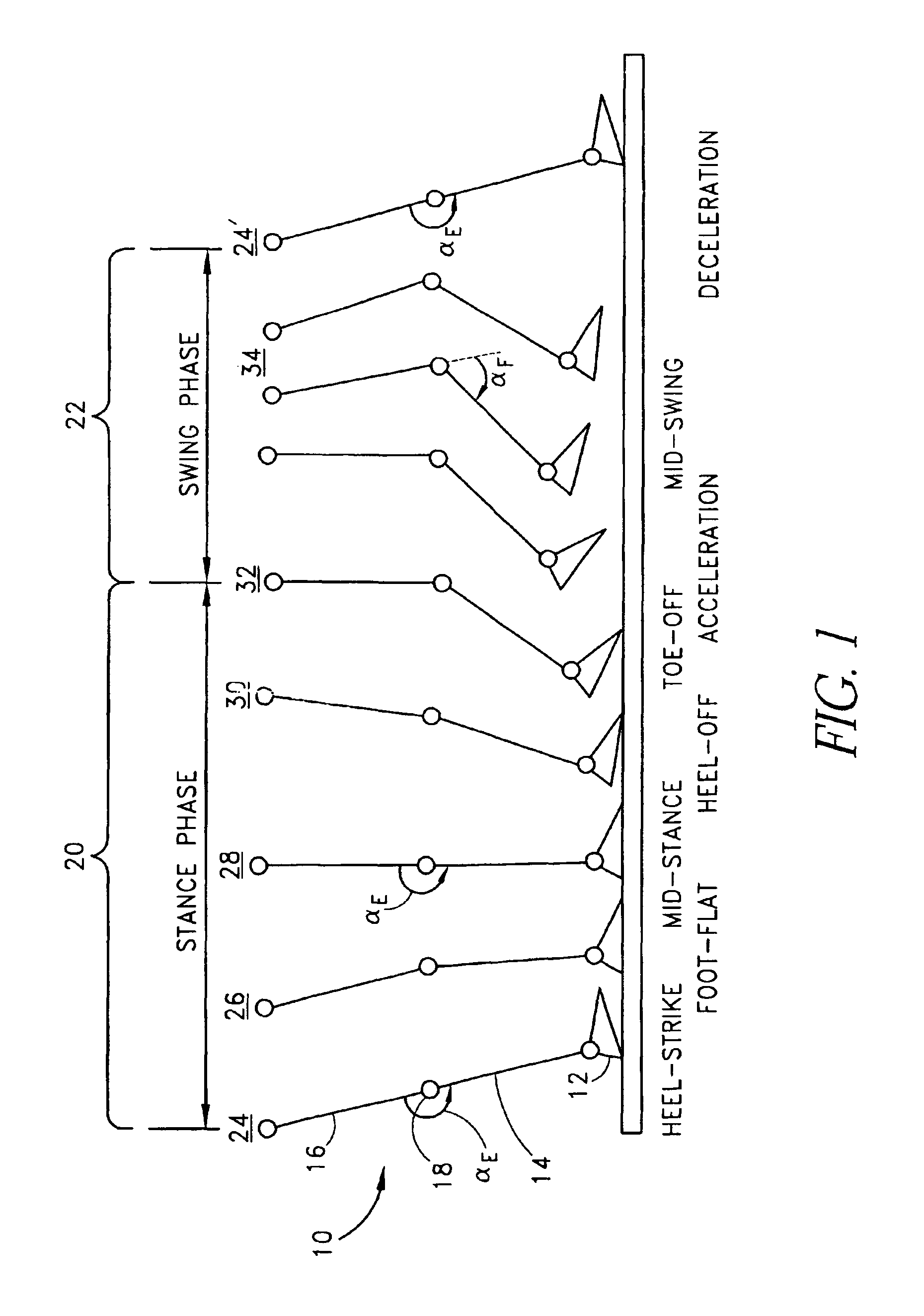

Electronically controlled prosthetic knee

InactiveUSRE42903E1Negligible changeNegligible pressureSpringsNon-rotating vibration suppressionMagnetorheological fluidControl theory

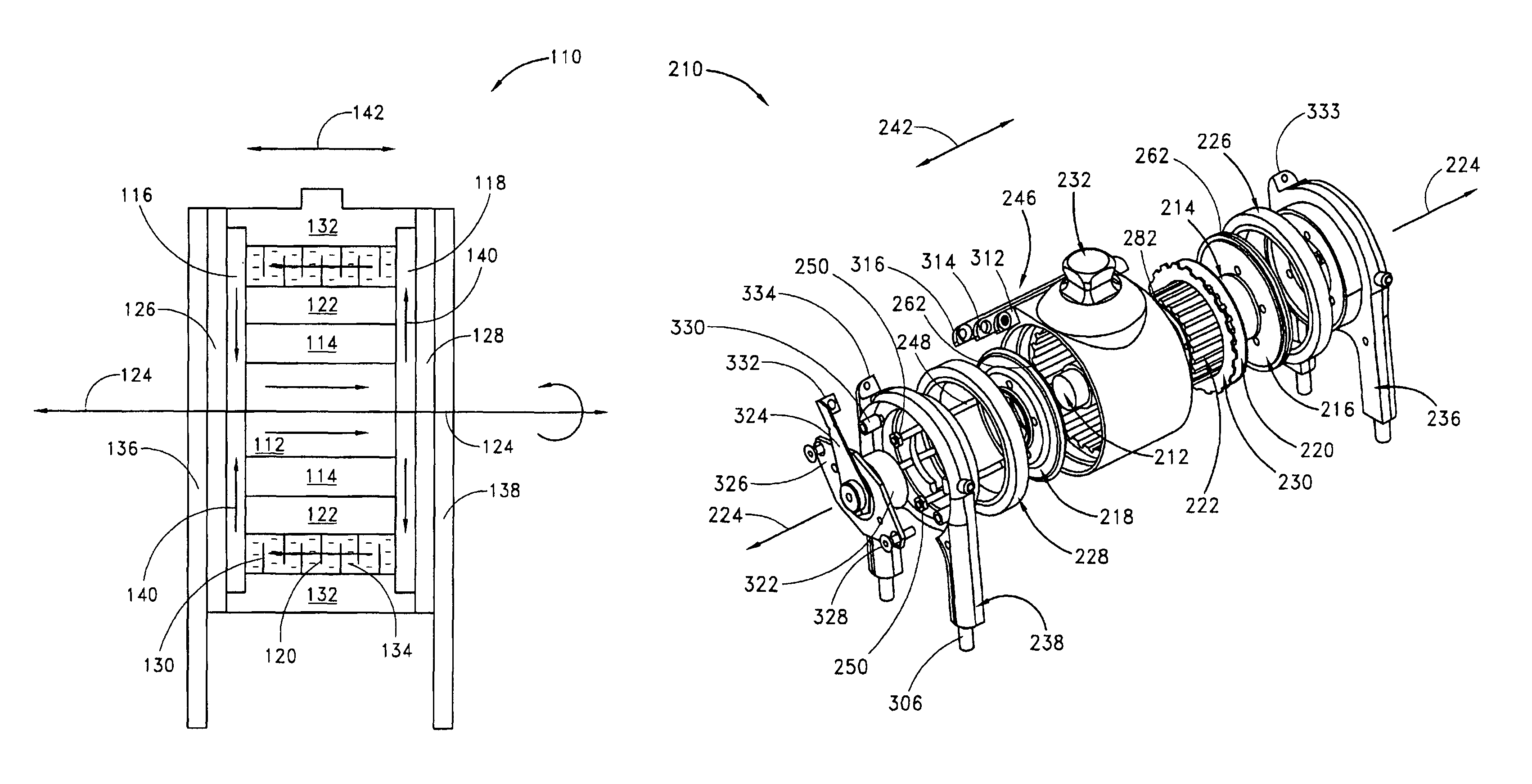

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the “shear mode” there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed—eliminating the need for a transmission—and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a “hybrid” braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

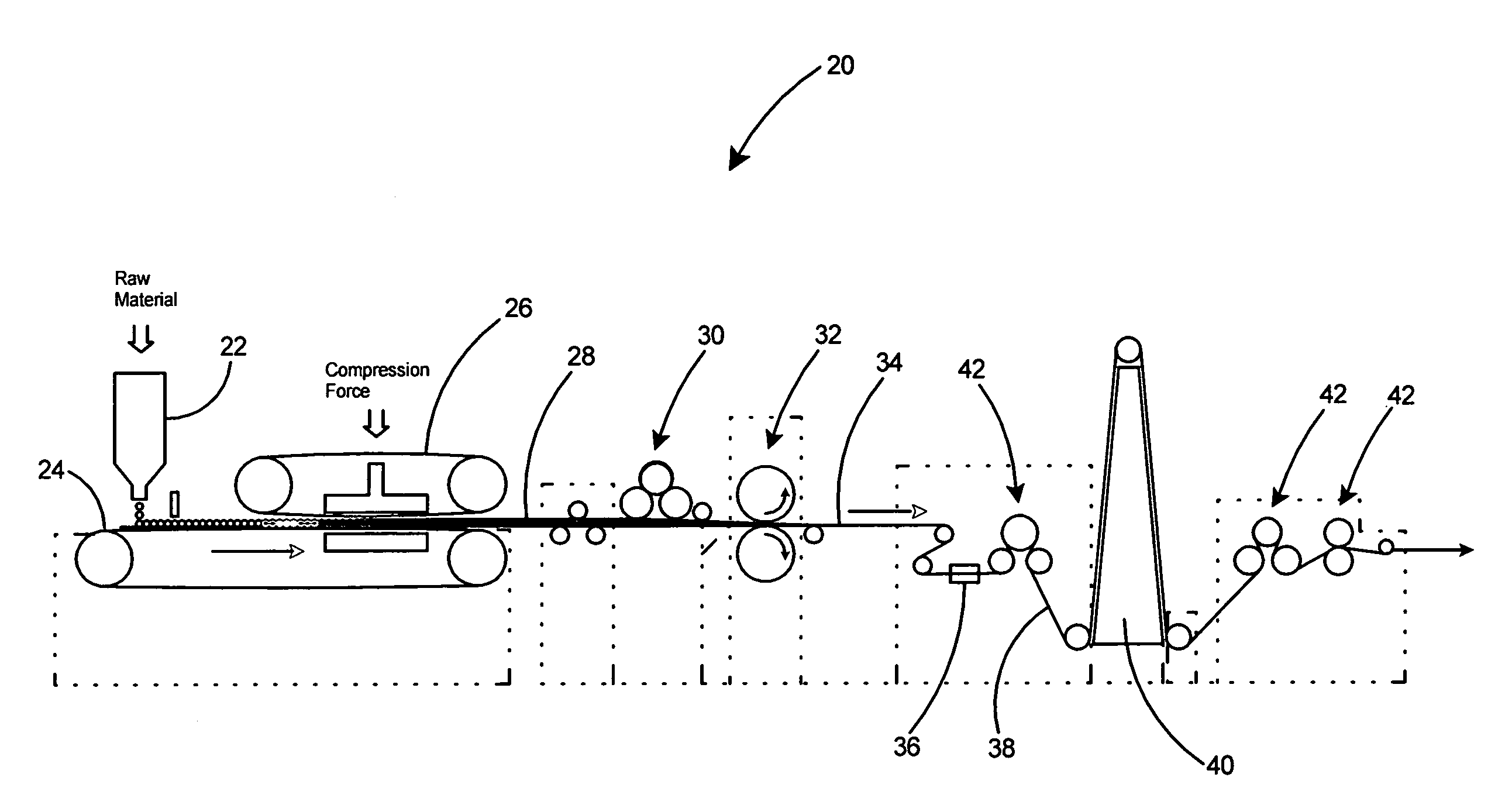

Non-fibrous high modulus ultra high molecular weight polyethylene tape for ballistic applications

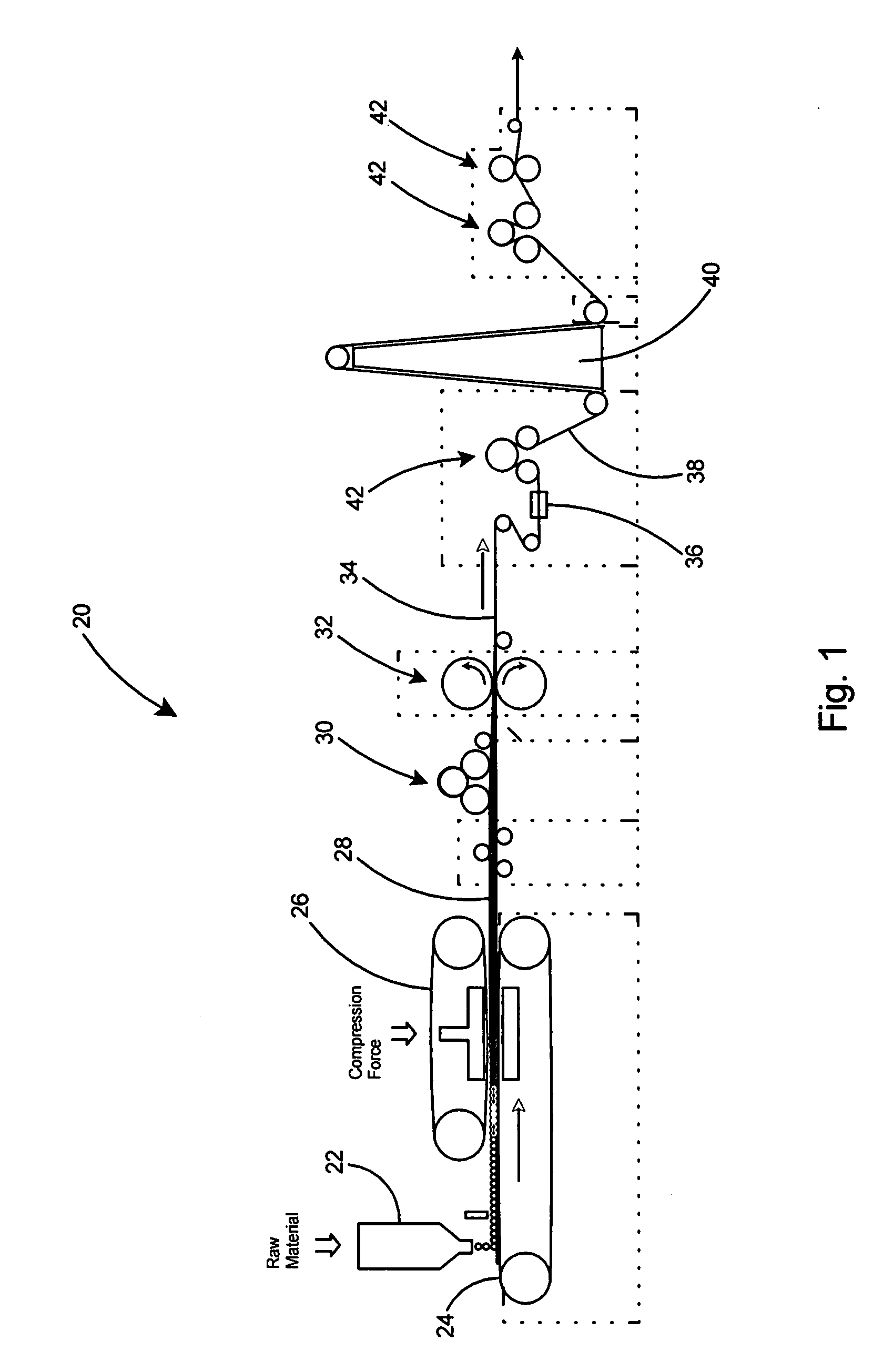

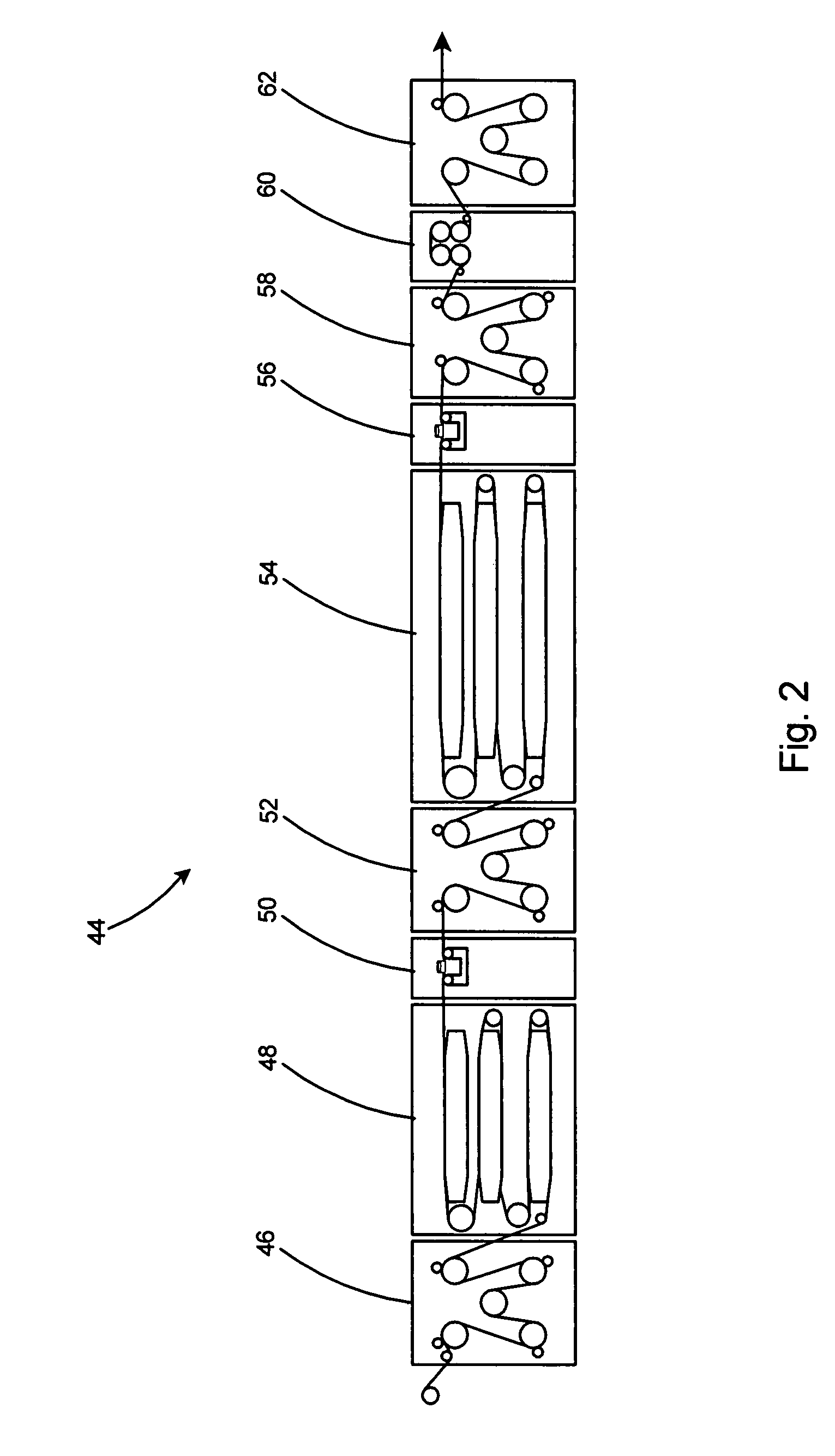

ActiveUS20080318016A1High propertySmall incidenceEngine sealsSynthetic resin layered productsStress concentrationFiber

A non-fibrous ultra high molecular weight polyethylene tape having a width of 1-inch or greater and a modulus of 1,400 grams per denier or greater. The non-fibrous UHMWPE tape is obtained by compression molding ultrahigh molecular weight polyethylene powder at a temperature below its melting point and then drawing and stretching the entire resultant compression molded UHMWPE sheet, with no slitting or splitting of the sheet, at a draw ratio of at least 100:1. The UHMWPE tape can be produced in weights of 6,000 to 90,000 denier or greater. The UHMWPE tape of the present invention minimizes the effect of stress concentrators that are prevalent with fibers and thereby enables the tape to be drawn at much higher draw ratios than is possible with fibrous UHMWPE. When used in ballistics panels, the high modulus high molecular weight polyethylene tape of the present invention improves ballistic performance by providing enhanced dissipation of the impact energy of a projectile.

Owner:DUPONT SAFETY & CONSTR INC

Method for the reduction of graphene film thickness and the removal and transfer of epitaxial graphene films from SiC substrates

ActiveUS8753468B2Cost efficiencyEase in device fabricationMaterial nanotechnologyLamination ancillary operationsMetal foilCvd graphene

A method for reducing graphene film thickness on a donor substrate and transferring graphene films from a donor substrate to a handle substrate includes applying a bonding material to the graphene on the donor substrate, releasing the bonding material from the donor substrate thereby leaving graphene on the bonding material, applying the bonding material with graphene onto the handle substrate, and releasing the bonding material from the handle substrate thereby leaving the graphene on the handle substrate. The donor substrate may comprise SiC, metal foil or other graphene growth substrate, and the handle substrate may comprise a semiconductor or insulator crystal, semiconductor device, epitaxial layer, flexible substrate, metal film, or organic device.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

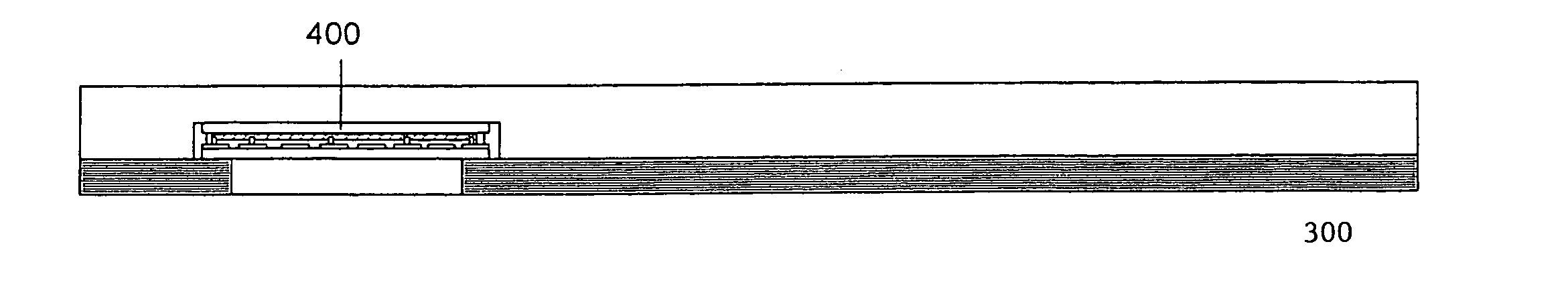

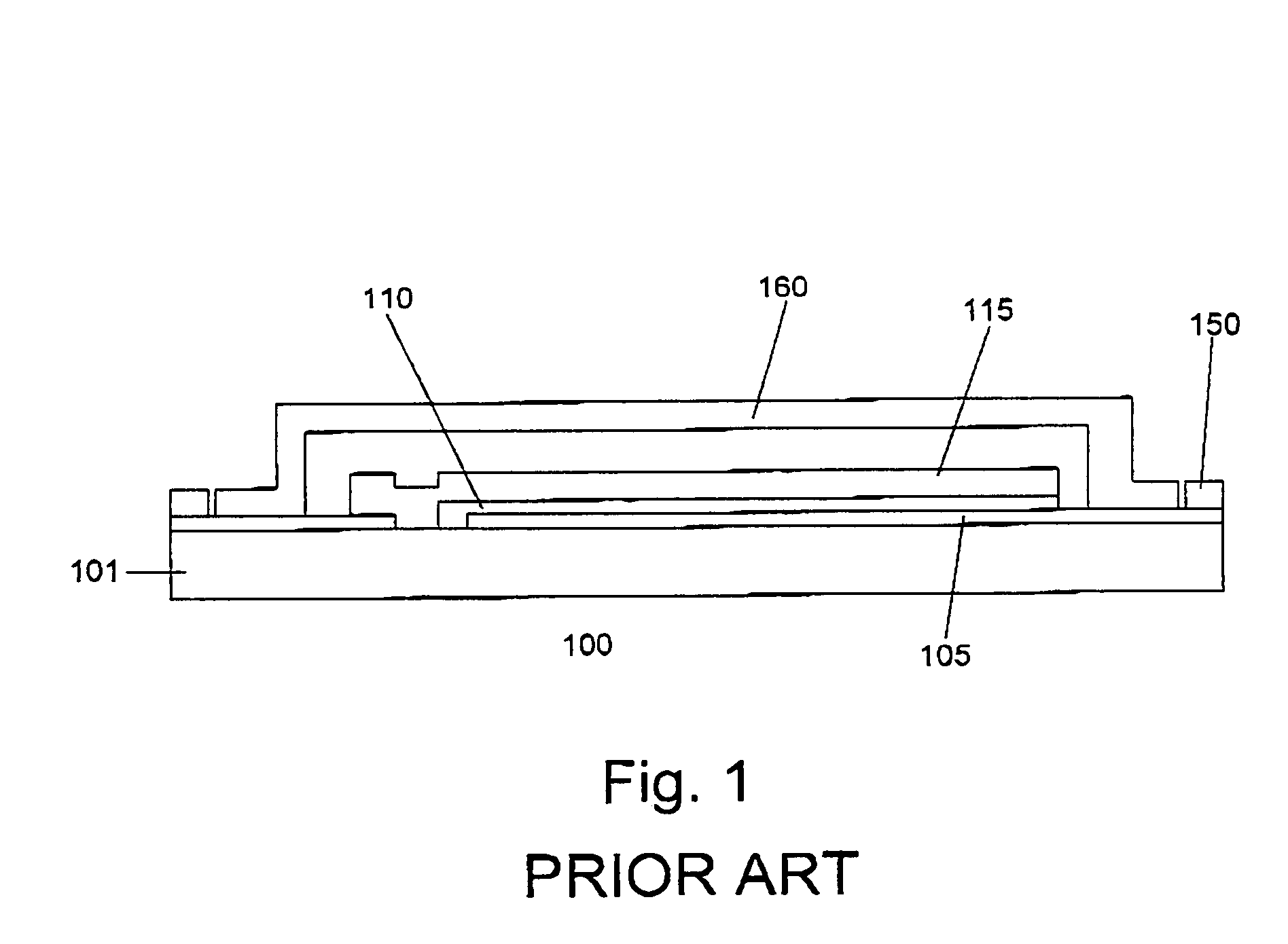

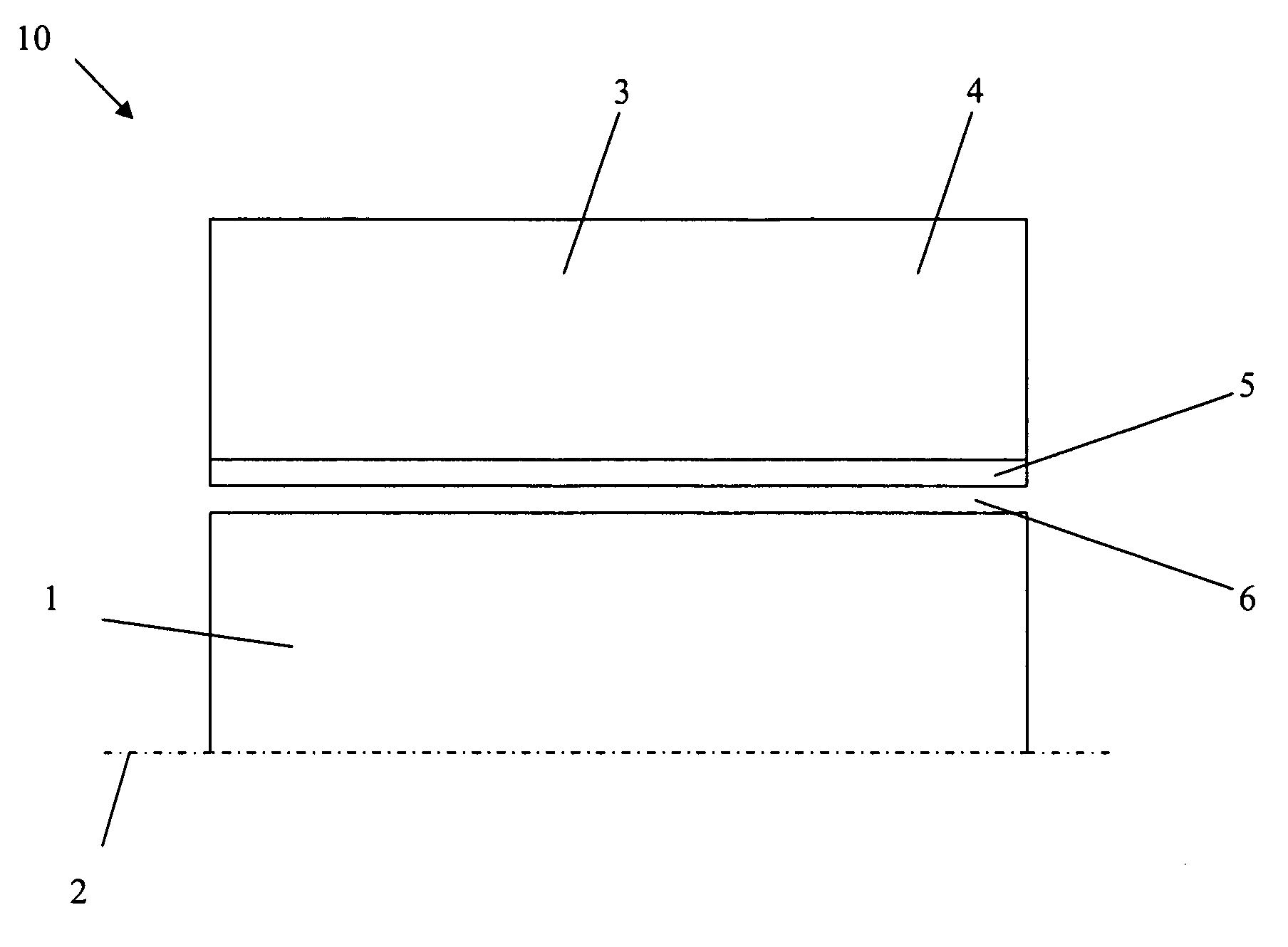

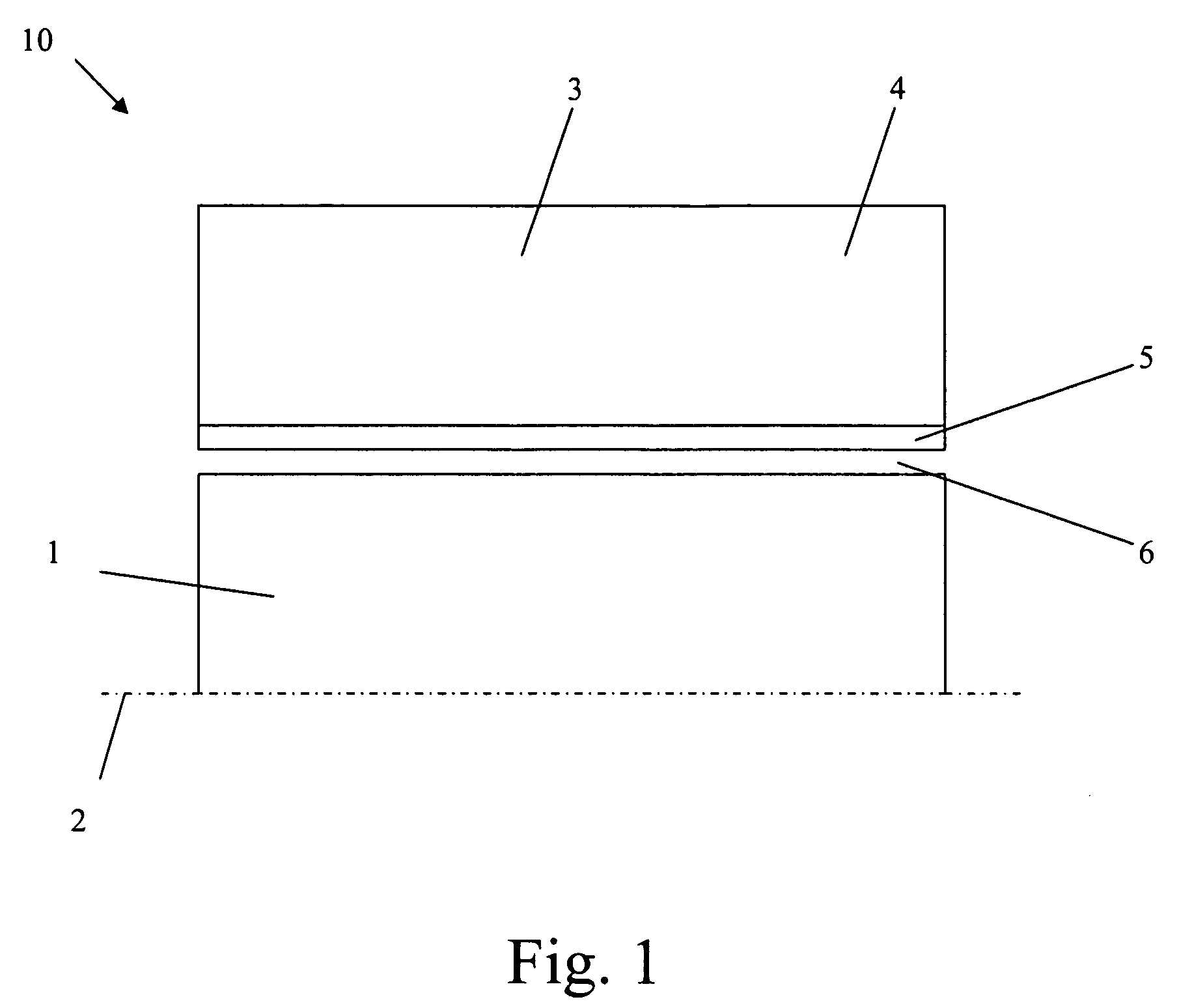

Reinforcement of glass substrates in flexible devices

InactiveUS7026758B2Improve ductilityHigh stiffnessDischarge tube luminescnet screensElectroluminescent light sourcesHigh stiffnessDisplay device

A reinforcement technique used in the fabrication of displays, such as organic light emissive diode (OLED) display, is disclosed. A stiff reinforcement lid is mounted on a thin substrate to encapsulate the OLED cells. The lid serves to reinforce the thin flexible substrate and protect it from breakage. It comprises preferably of metal or other materials that have higher stiffness and ductility than the thin substrate. The fabricated display is compatible for integration into chip cards and other flexible applications.

Owner:PICTIVA DISPLAY INT LTD

Bioreactor for growing biological materials supported on a liquid surface

InactiveUS20070094926A1Promote growthMaximize growth and expressionBioreactor/fermenter combinationsBiological substance pretreatmentsGas compositionEngineering

A bioreactor assembly of the present invention for holding a media and supporting growth of a plurality of plants. The assembly includes a light source and a container having a light transmissive wall structure and defining a reservoir. A major axis of the reservoir is substantially horizontal allowing the reservoir to be filled with media to a partial level and to define a relatively large surface area for support of the plants. The assembly may also include clamps to secure and seal separate wall structure portions of the container together, and end caps to the wall portions, to define an aseptic environment. As another option, the clamps may define openings therethrough that allow passage of various devices for measuring and controlling bioreactor function such as a gas supply nozzle, a gas exit nozzle, an air temperature probe, a pH probe, a sampling drain, a gas composition probe and a media temperature probe.

Owner:BIOLEX THERAPEUTICS INC

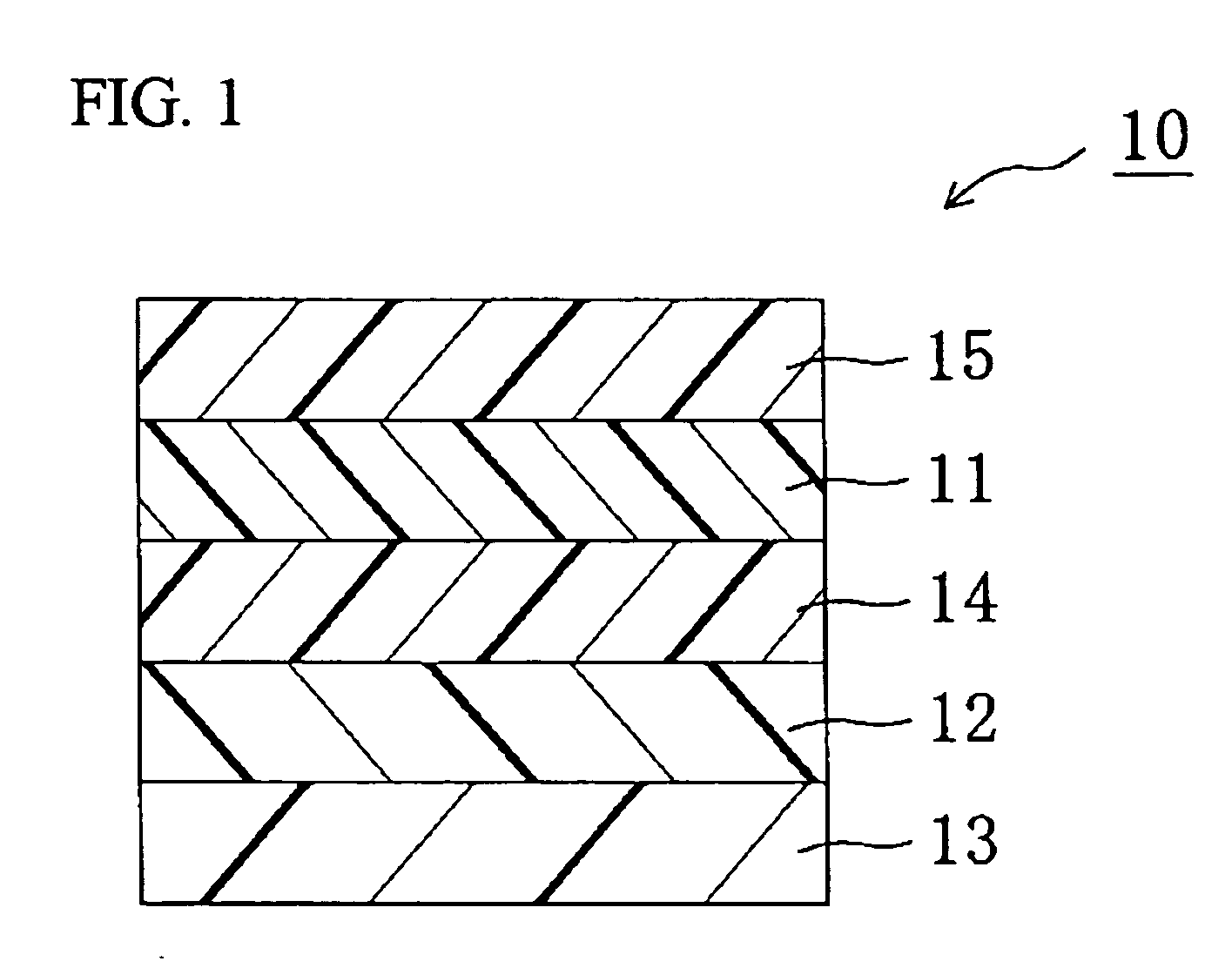

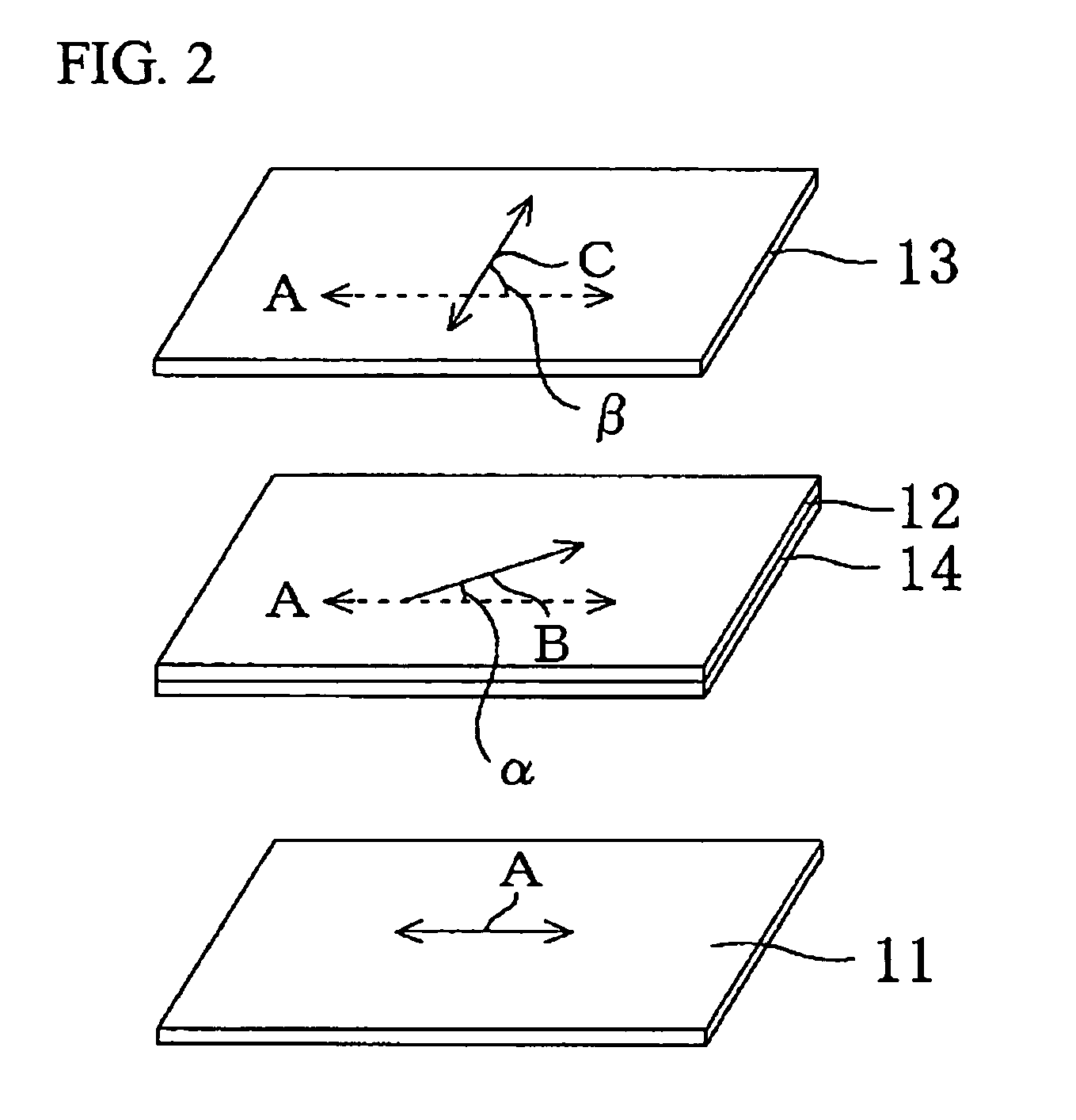

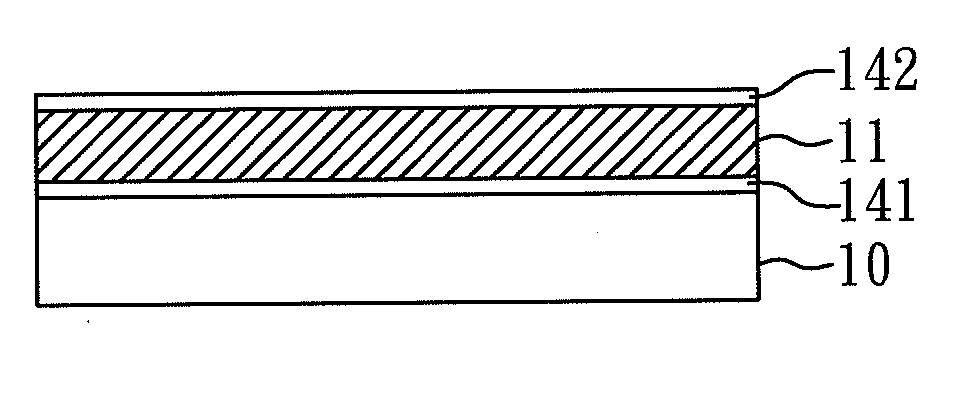

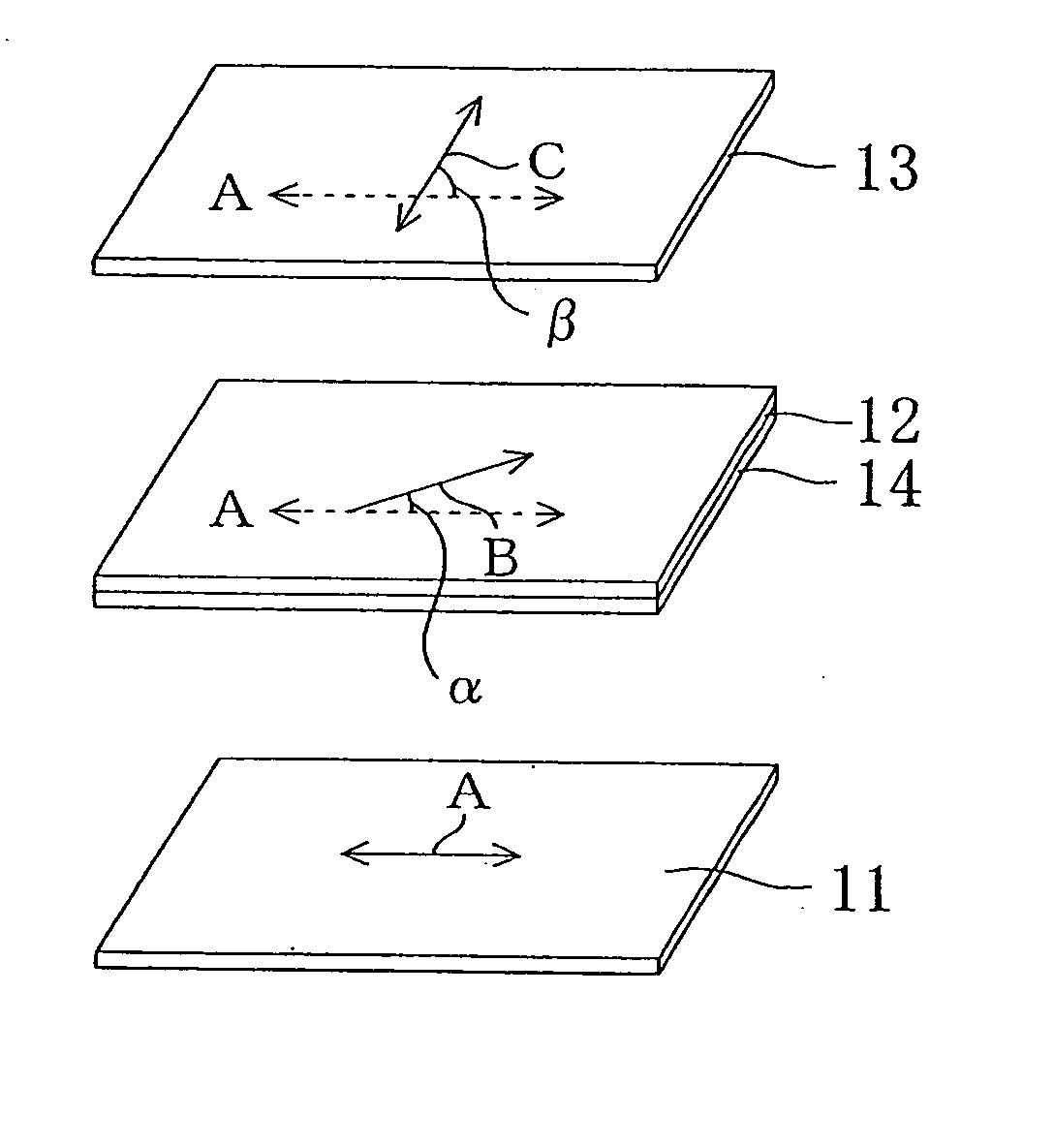

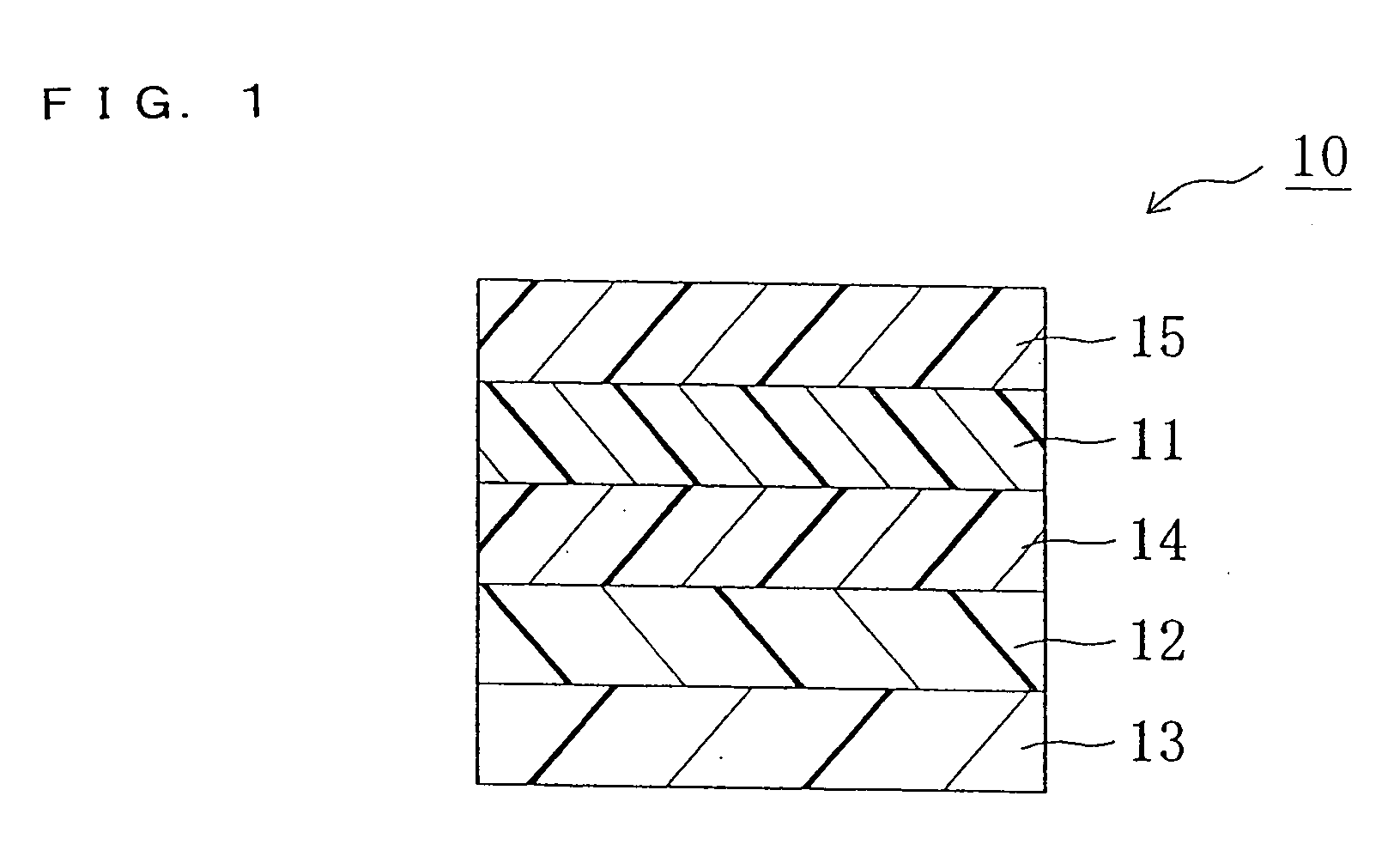

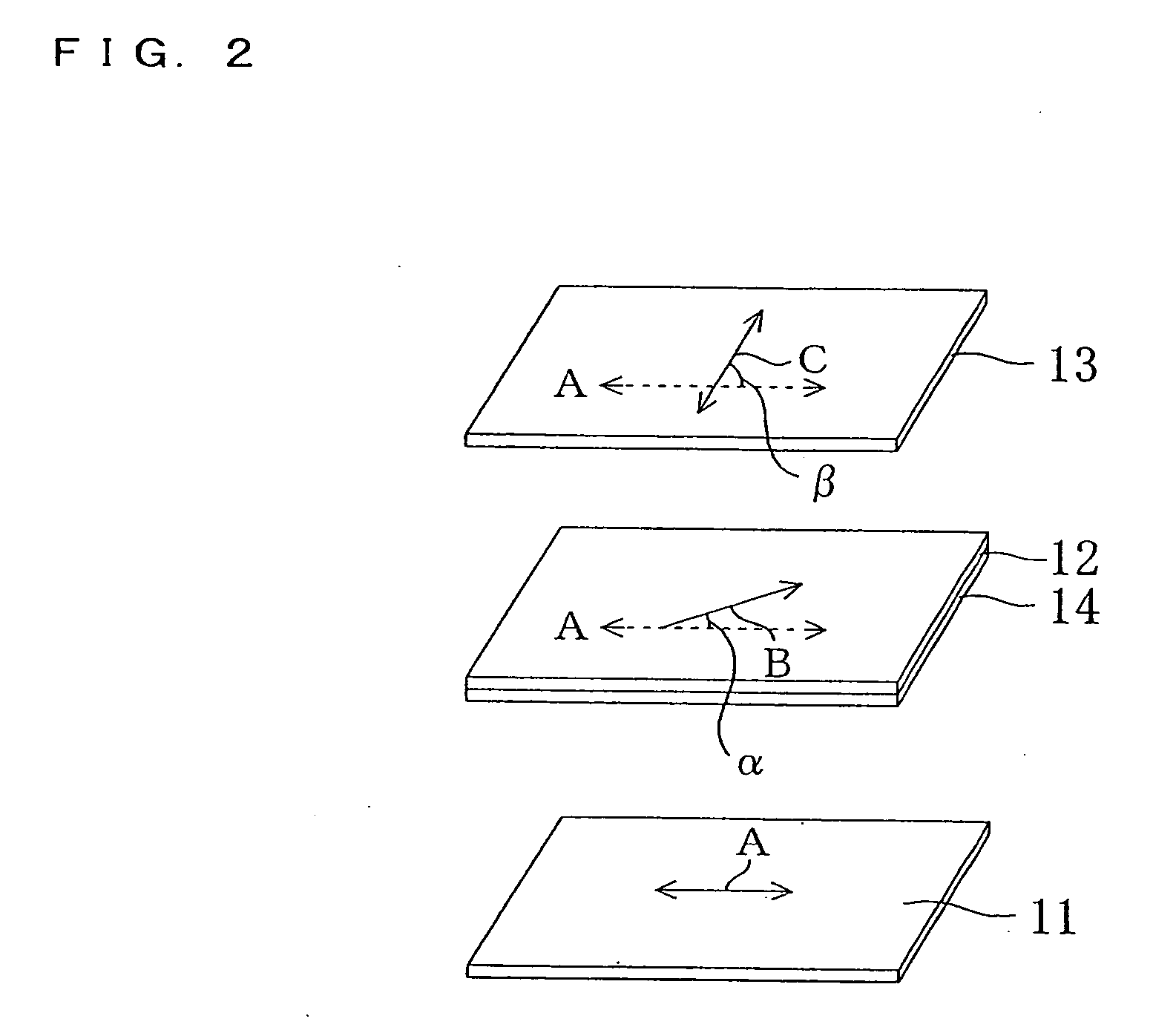

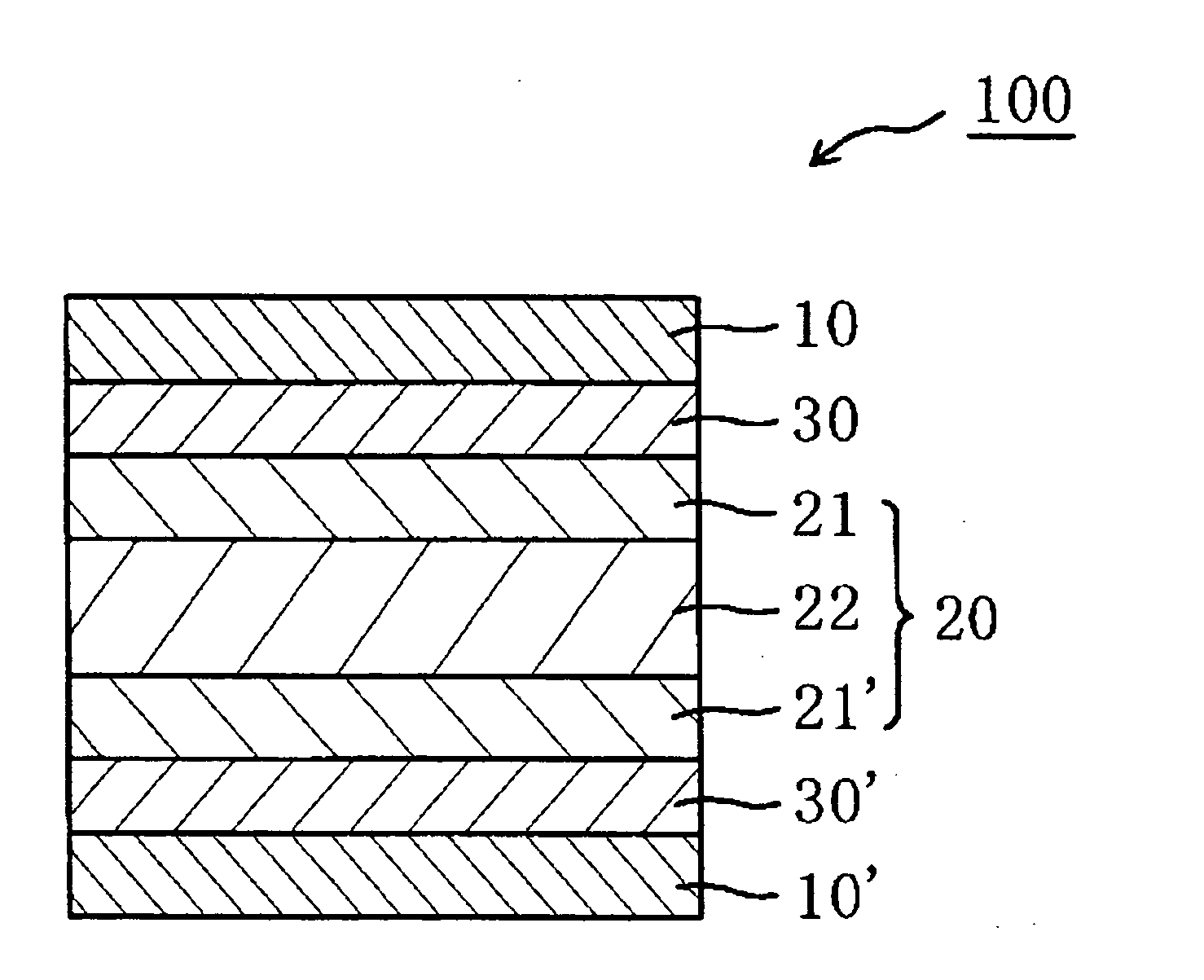

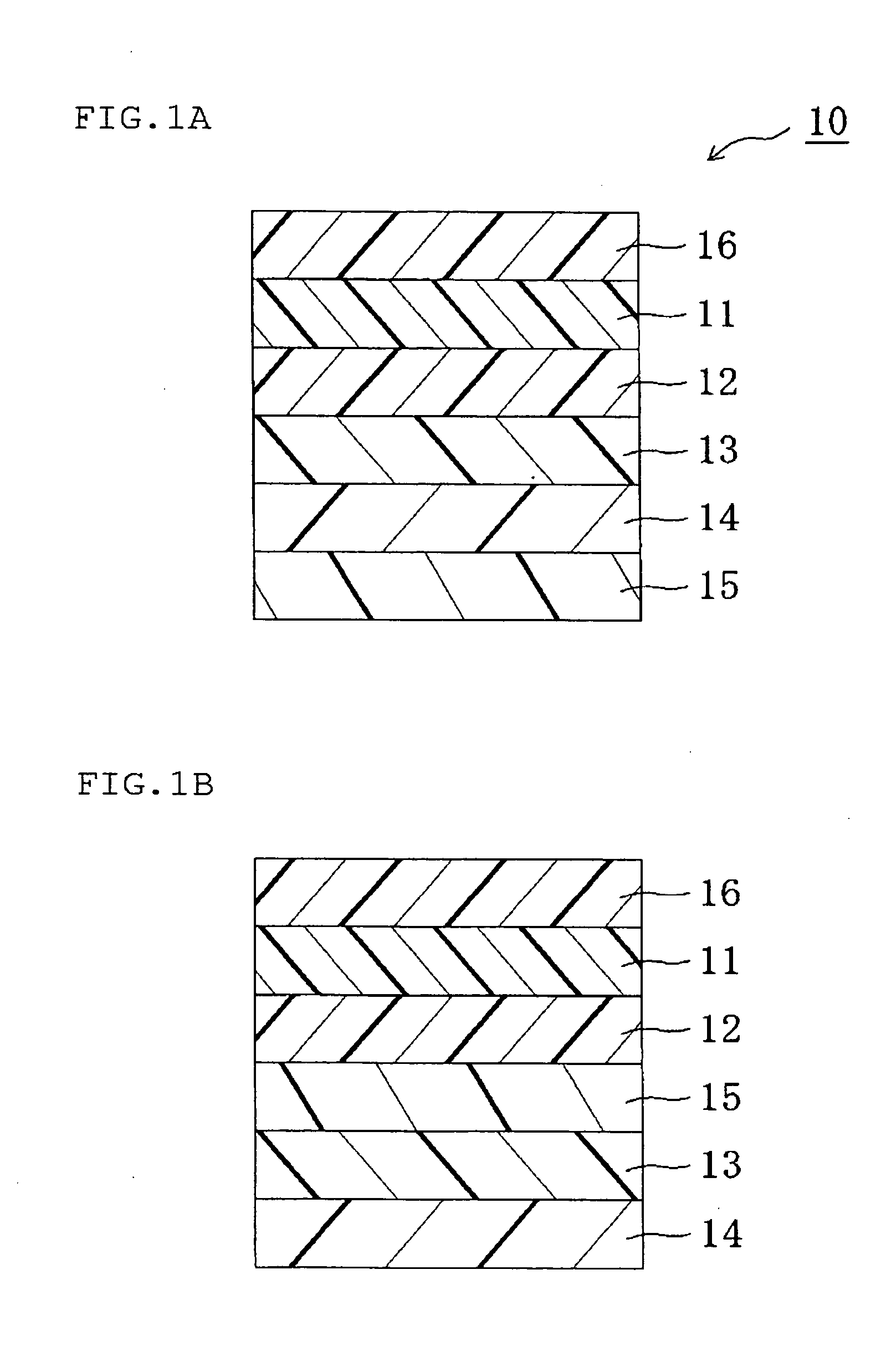

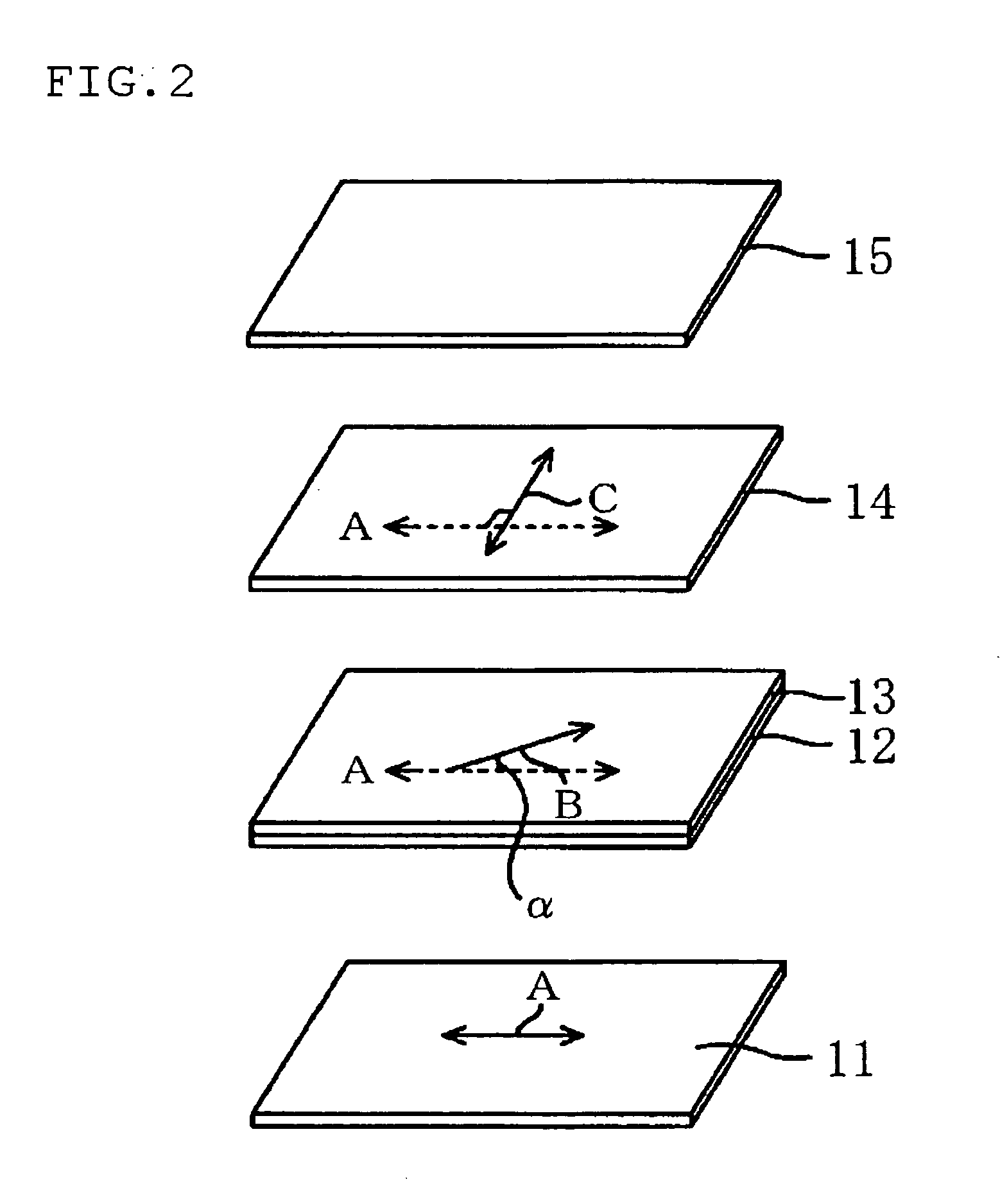

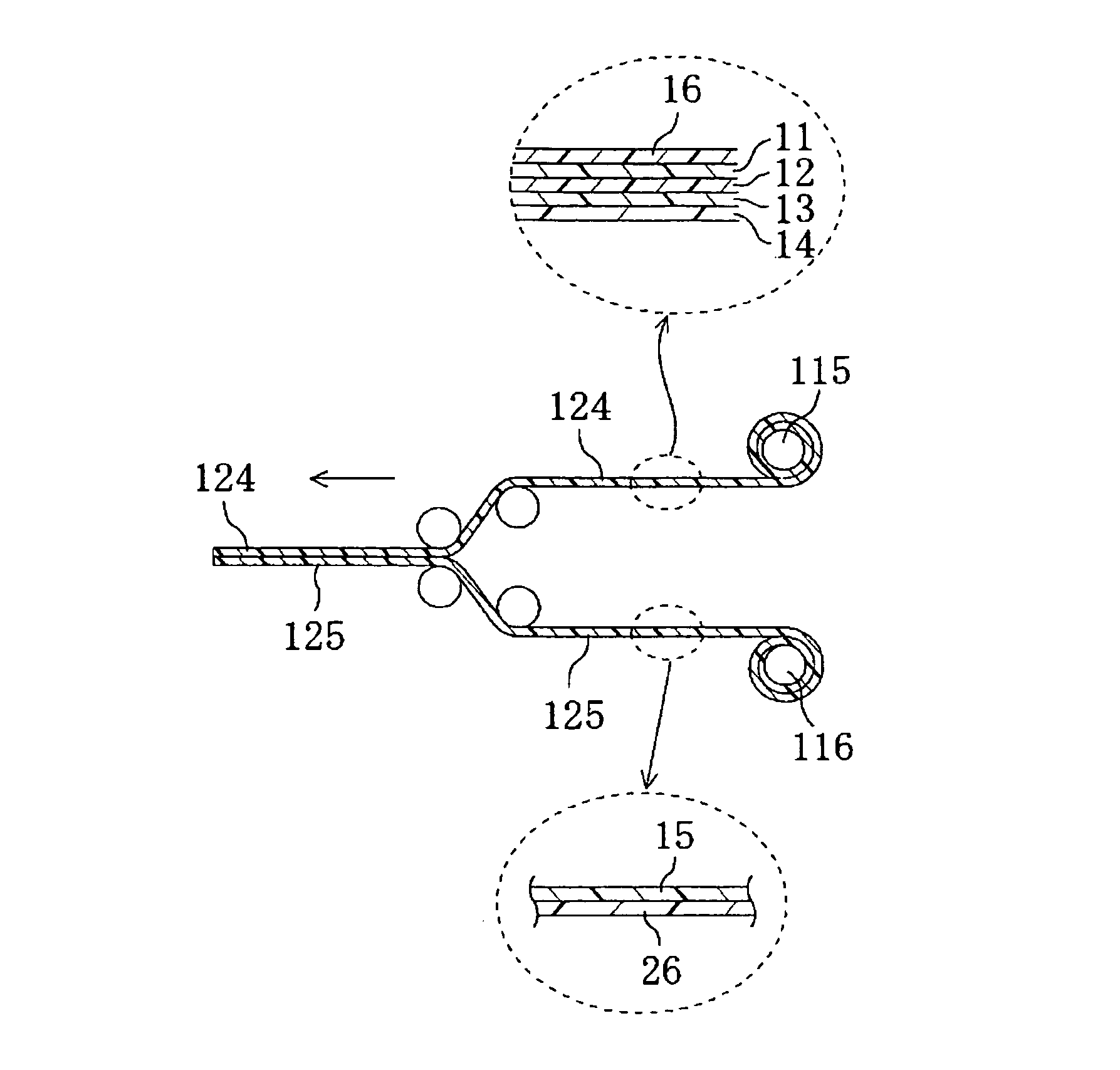

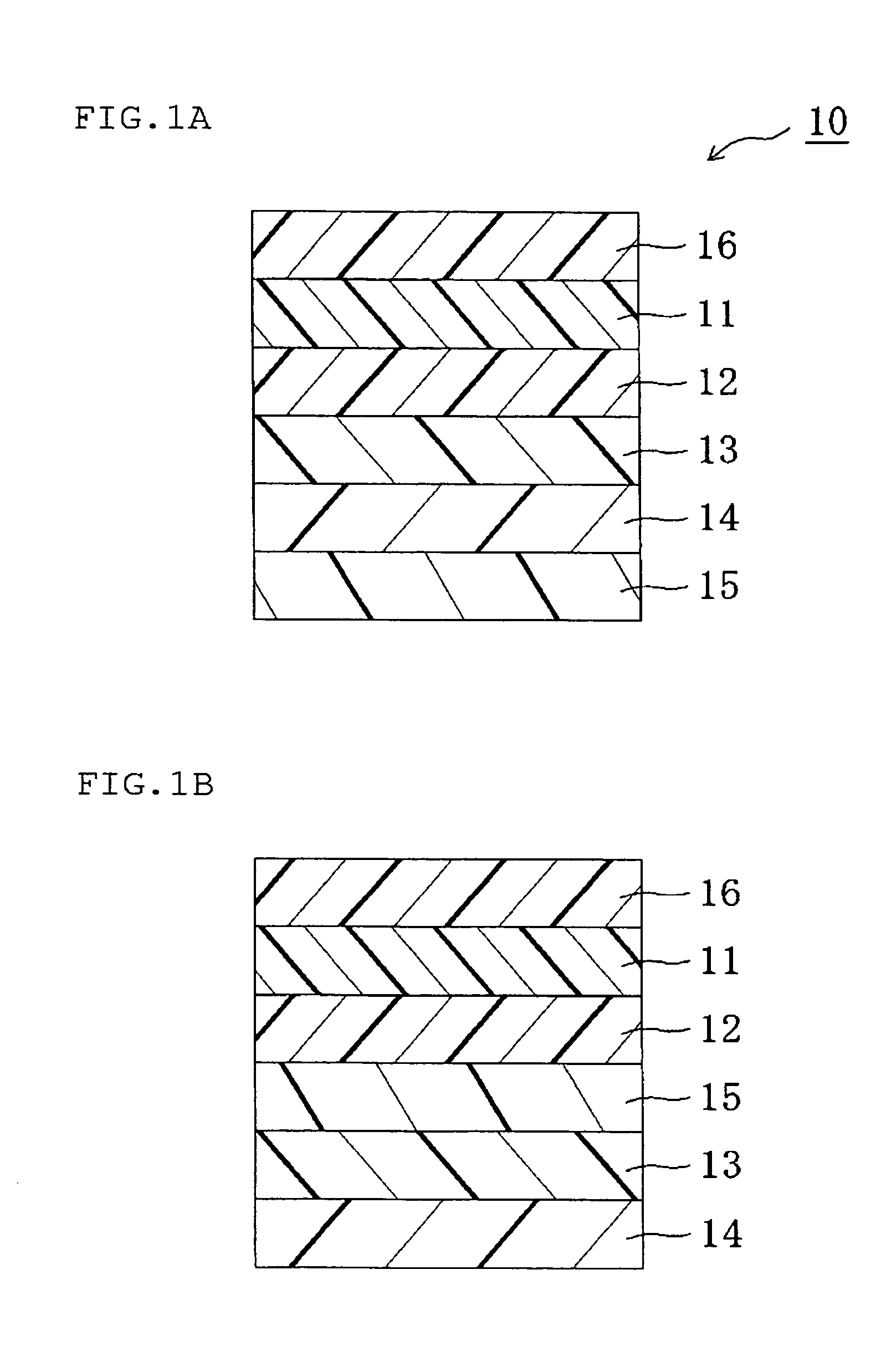

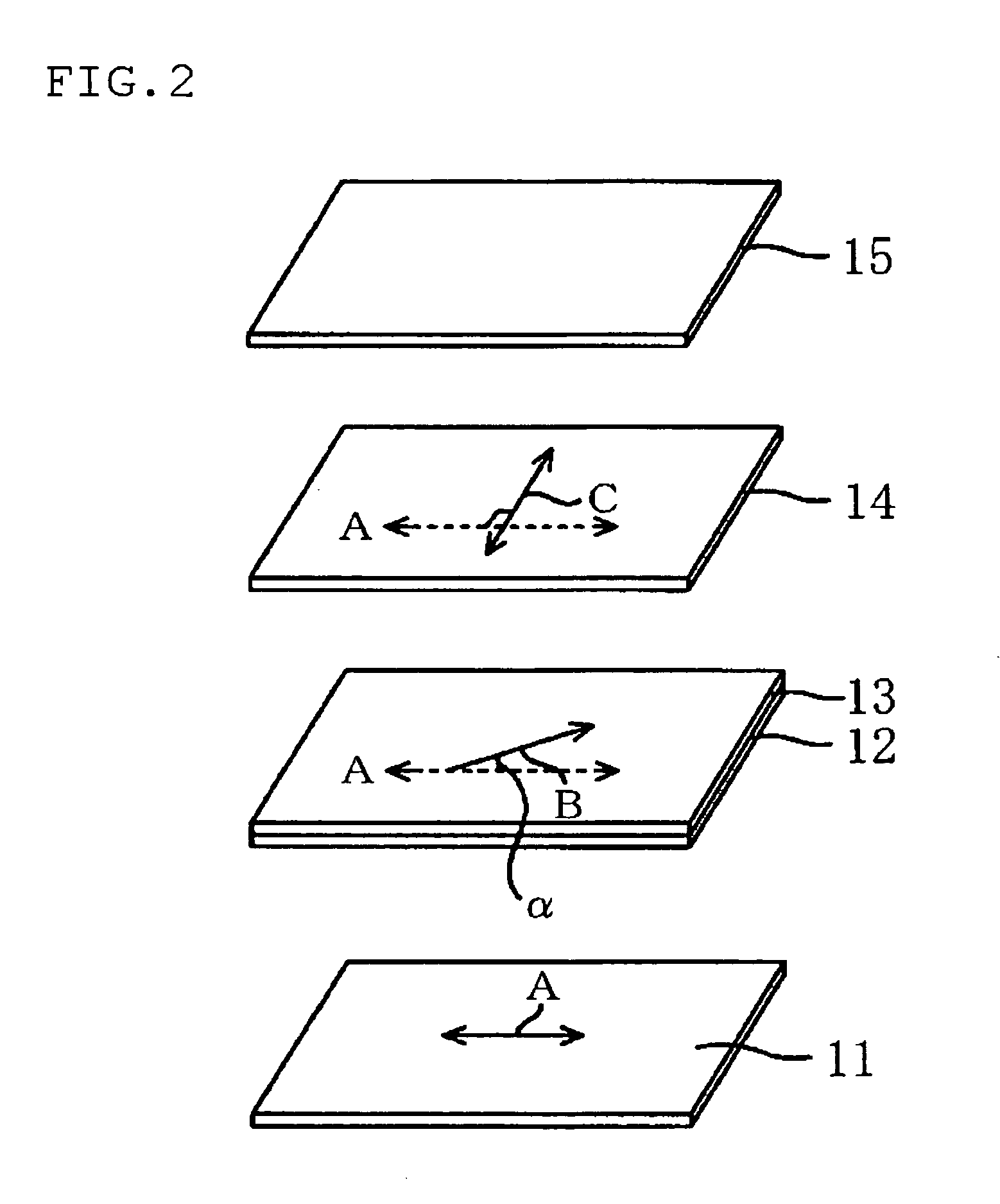

Method of producing elliptically polarizing plate and image display apparatus using the elliptically polarizing plate

InactiveUS20090040434A1Improve production efficiencyLow costPolarising elementsOptical articlesTectorial membraneBroadband

To provide a method of producing a broadband and wide viewing angle elliptically polarizing plate having excellent properties in an oblique direction, the elliptically polarizing plate, and an image display apparatus.The method of producing an elliptically polarizing plate of the present invention includes the steps of: forming a first birefringent layer on a surface of a transparent protective film; laminating a polarizer on a surface of the transparent protective film; and forming a second birefringent layer on a surface of the first birefringent layer, in which: the first birefringent layer and the polarizer are arranged on opposite sides of the transparent protective film; the step of forming a first birefringent layer includes the steps of: applying a liquid crystal material to an alignment substrate; forming a first birefringent layer on the substrate from the liquid crystal material; and transferring the first birefringent layer to a surface of the transparent protective film; and angles α and β satisfy a predetermined relationship (where, α represents an angle formed between a slow axis of the polarizer and a slow axis of the first birefringent layer, and β represents an angle formed between the absorption axis of the polarizer and a slow axis of the second birefringent layer).

Owner:NITTO DENKO CORP

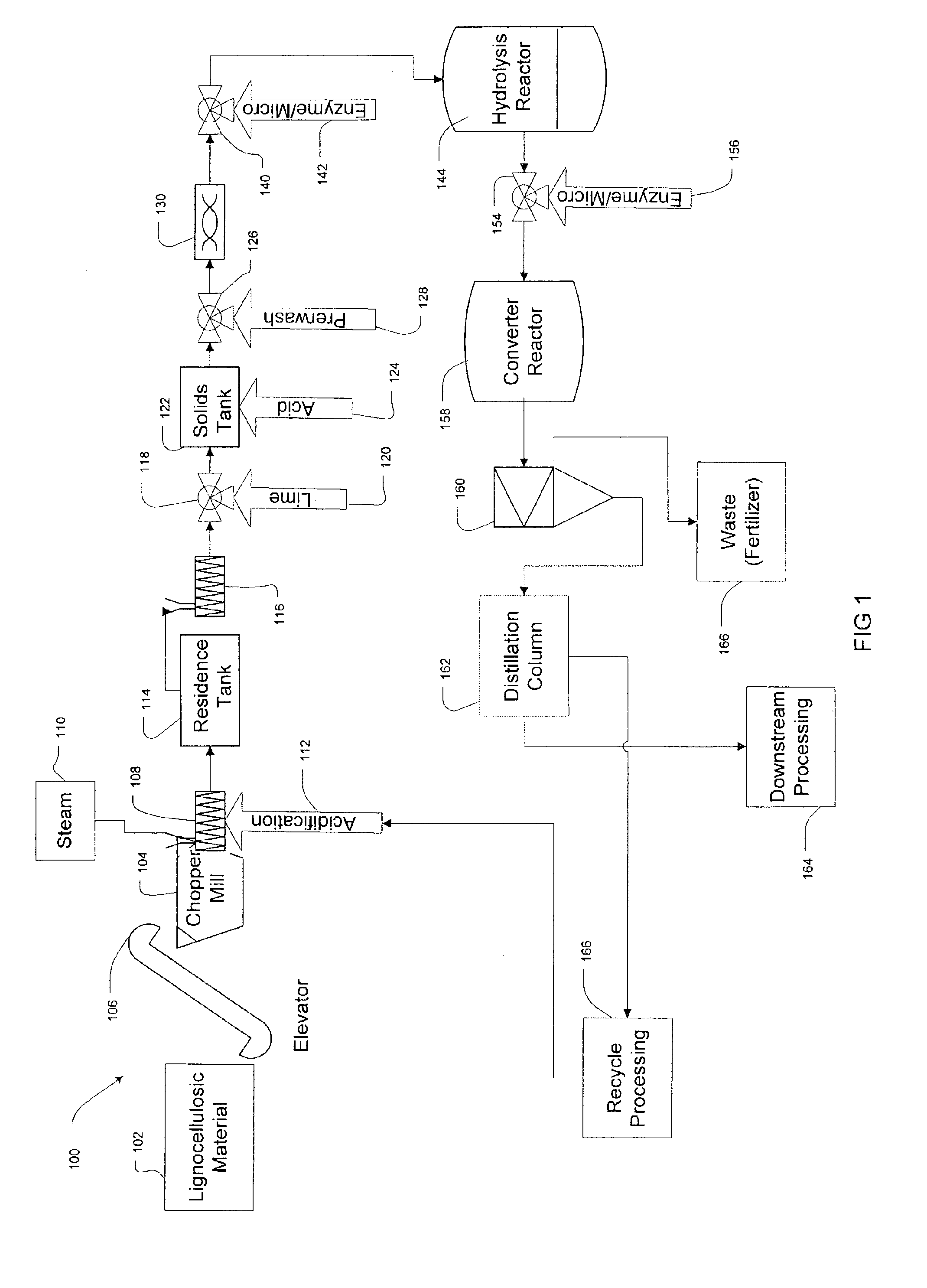

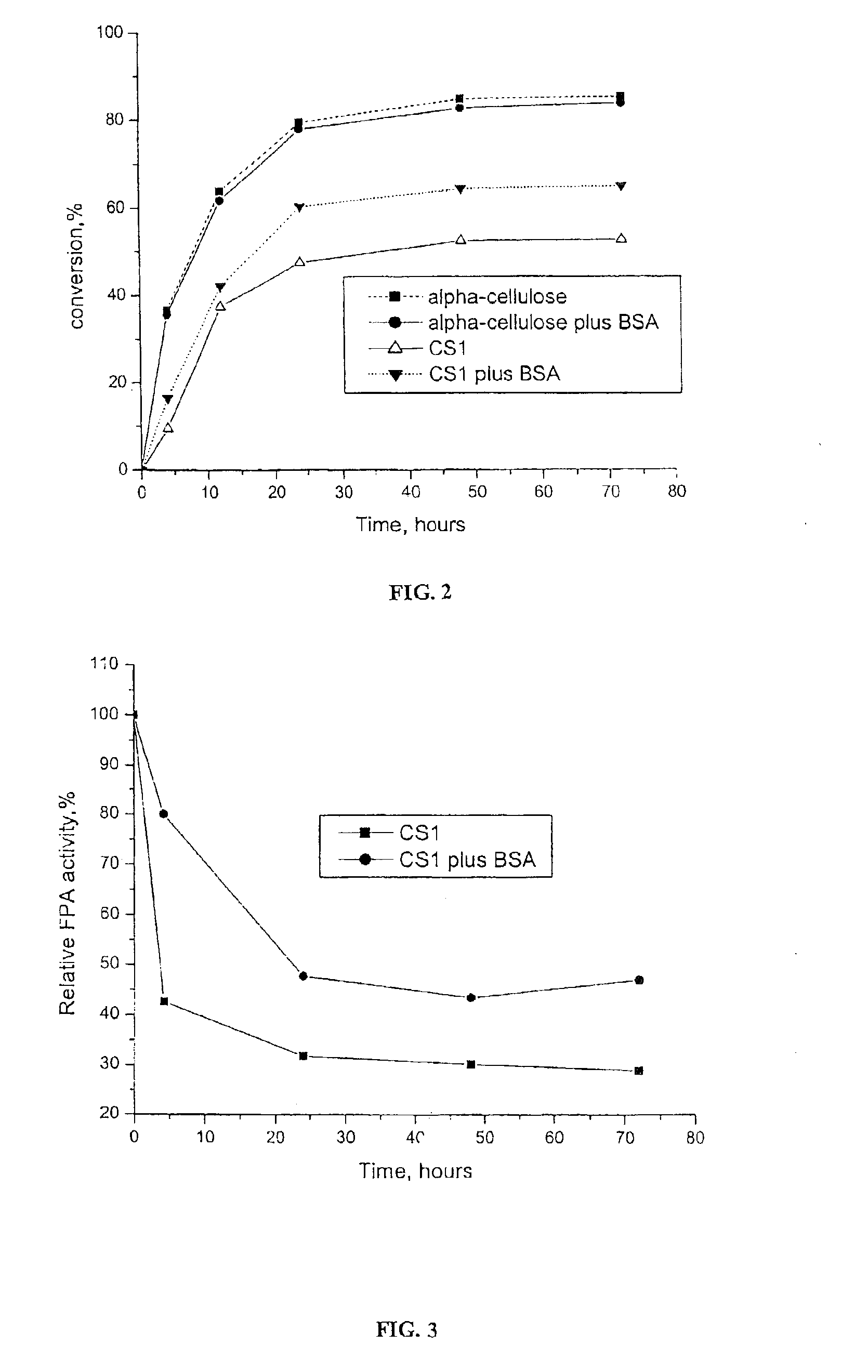

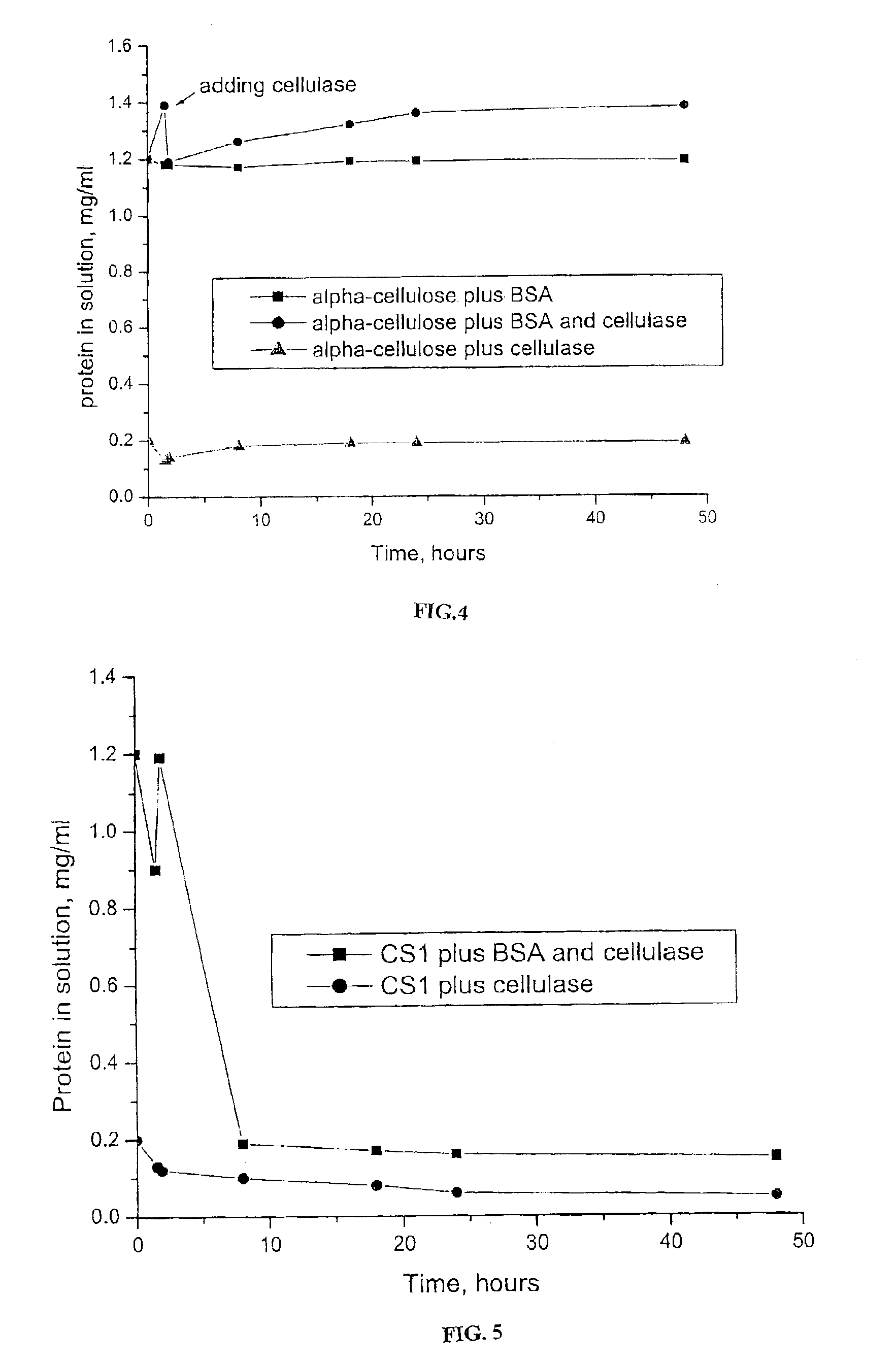

Lignin-blocking treatment of biomass and uses thereof

InactiveUS7604967B2Large productionReducing and eliminating non-productive adsorptionProtein composition from vegetable seedsBiofuelsCombined useLignocellulosic biomass

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion. Cellulase efficiencies are improved by the protein or polypeptide treatment. The treatment may be used in combination with steam explosion and acid prehydrolysis techniques. Hydrolysis yields from lignin containing biomass are enhanced 5-20%, and enzyme utilization is increased from 10% to 50%. Thus, a more efficient and economical method of processing lignin containing biomass materials utilizes a polypeptide / protein treatment step that effectively blocks lignin binding of cellulase.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

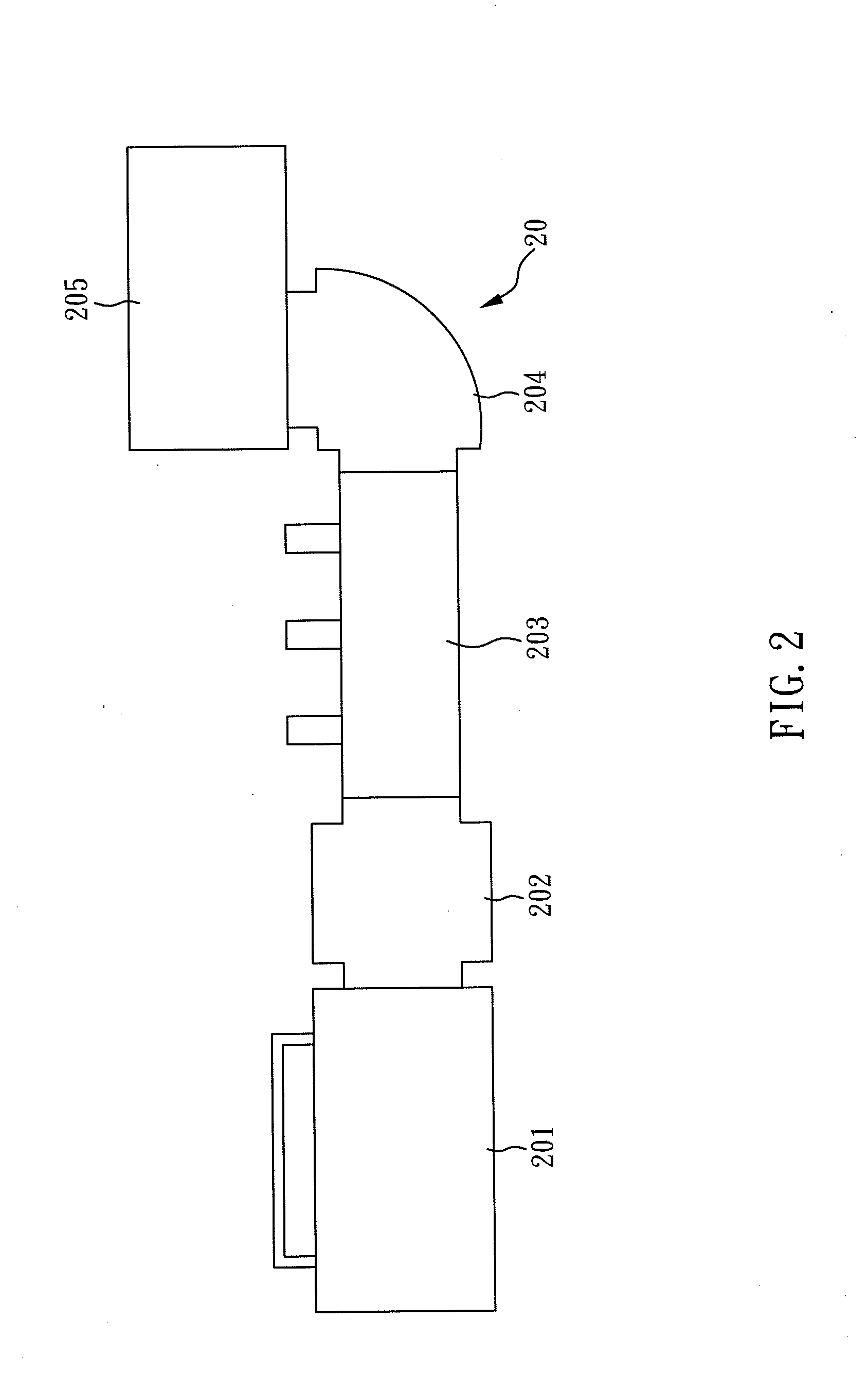

Process of preparing graphene by low-frequency electromagnetic wave

InactiveUS20130202813A1Large productionShort processing timeMaterial nanotechnologyGrapheneThermal energyCarbon source

The present invention relates to a process of inducing grapheme by low-frequency electromagnetic wave, which includes the following steps: (A) providing a substrate; (B) optionally forming a metal layer on the substrate; (C) providing a carbon source to form a carbon-containing layer locating on the metal layer; and (D) performing a treatment of the carbon-containing layer formed on the metal layer by using low-frequency electromagnetic wave, wherein the low-frequency electromagnetic wave is provided by microwave device. The electromagnetic energy from the microwave field device is converted to thermal energy by microwave absorber (for example, SiC) as a media to directly heat the carbon-containing layer, so that carbon atoms get kinetic energy to form grapheme layers on the surface of the metal layer and between the metal layer and the substrate.

Owner:NATIONAL TSING HUA UNIVERSITY

Method of producing elliptically polarizing plate and image display using the elliptically polarizing plate

InactiveUS20070139773A1Improve featuresImprove efficiencyPolarising elementsNon-linear opticsTectorial membraneDisplay device

Owner:NITTO DENKO CORP

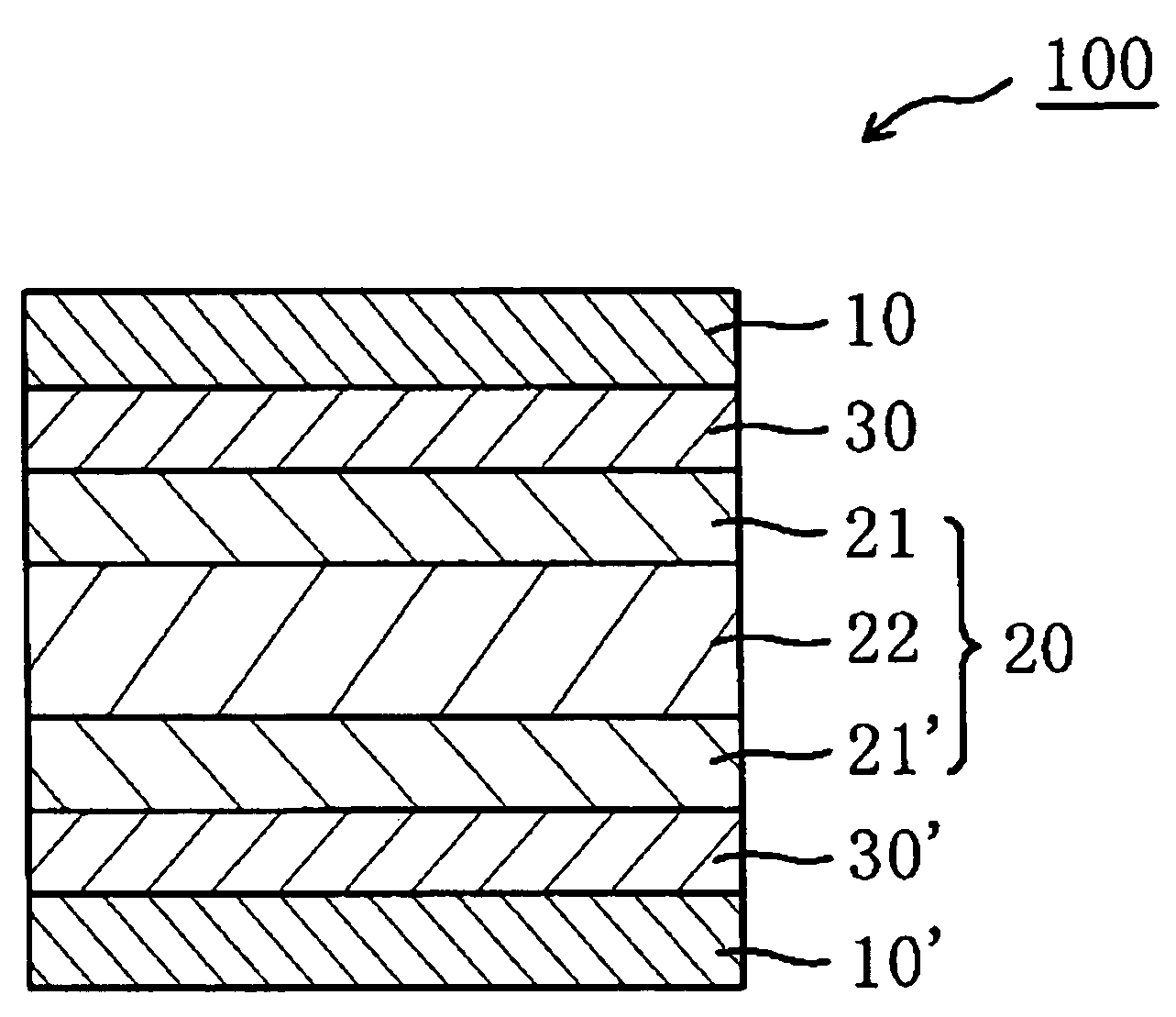

Carbon film laminate

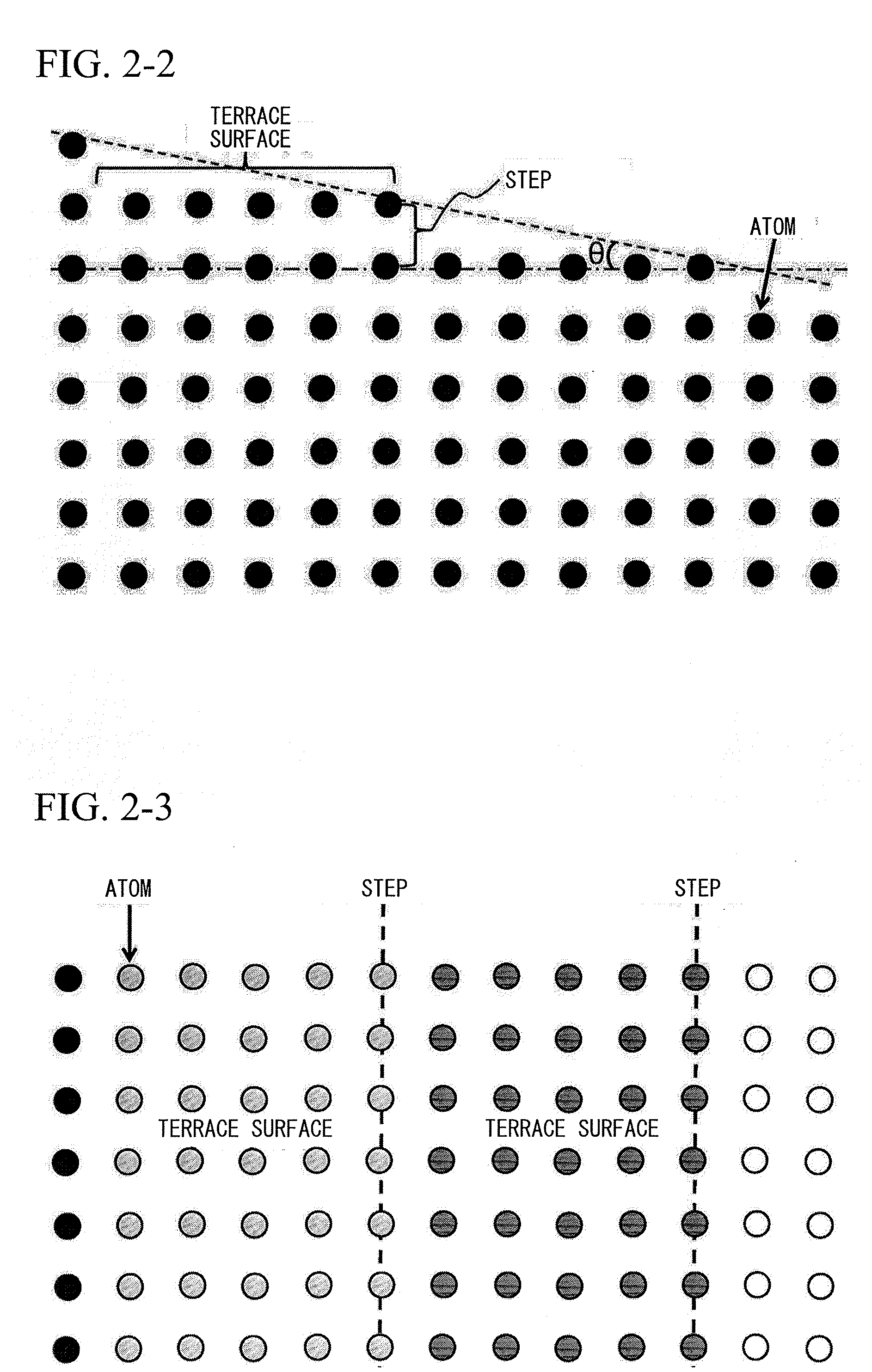

ActiveUS20130052121A1Large productionFacilitate productionMaterial nanotechnologyPolycrystalline material growthCvd grapheneCarbon film

An object of the present invention is to solve a problem such as a small crystal size, which is the issue of a conventional method for formation of a film of graphene by a thermal CVD technique using a copper foil as a substrate, and thus providing a carbon film laminate in which graphene having a larger crystal size is formed. The carbon film laminate is configured to include a sapphire (0001) single crystal having a surface composed of terrace surfaces which are flat at the atomic level, and atomic-layer steps, a copper (111) single crystal thin film formed by epitaxial growth on the substrate and graphene deposited on the copper (111) single crystal thin film, and thus enabling formation of graphene having a large crystal size.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method of producing elliptically polarizing plate and image display using the elliptically polarizing plate

InactiveUS20060203159A1Improve production efficiencyWaste is producedPolarising elementsNon-linear opticsTectorial membranePolarizer

The present invention provides a method of producing an elliptically polarizing plate including the steps of: forming a first birefringent layer on a surface of a transparent protective film; laminating a polarizer on a surface of the transparent protective film; forming a second birefringent layer on a surface of the first birefringent layer; and forming a third birefringent layer on a surface of the second birefringent layer. The first birefringent layer is arranged on the opposite side against the polarizer with respect to the transparent protective film. The step of forming the first birefringent layer includes the steps of: applying a liquid crystal material onto a substrate subjected to an alignment treatment; treating the applied liquid crystal material, so as to form the first birefringent layer on the substrate; and transferring the first birefringent layer onto a surface of the transparent protective film.

Owner:NITTO DENKO CORP

Nonsense suppression and genetic codon alteration by targeted modification

ActiveUS8603457B2Easy to identifyLarge productionBiocideGenetic material ingredientsAdenosineGenetics

Methods for affecting mRNA expression or translation through the modification of pre-mRNA or mRNA transcripts are described. In one embodiment of the methods of the present invention, the branch point adenosine of a pre-mRNA transcript is 2′-O-methylated to block splicing and subsequent expression of the protein encoded by the transcript. In another embodiment, a uridine residue in a nonsense stop codon may be modified to pseudouridine, causing the translation machinery to read through the nonsense stop codon and translate a full length protein.

Owner:UNIVERSITY OF ROCHESTER

Mesoporous Composite Titanium Oxide and a Preparation Method

ActiveUS20120184433A1Simple processLow costElectric discharge heatingCell electrodesPore distributionHydrodesulfurization

The invention discloses a mesoporous composite titanium oxide and a preparation method thereof, wherein the mesoporous composite titanium oxide material is composed of a mesoporous titanium oxide and an inorganic matter is composite on the outside surface and the wall of pores of the mesoporous titanium oxide; said inorganic matter contains at least one element selected from carbon, silicon, sulphur, phosphorus and selenium in an amount of 0.01%-25%, on amount of the element mass, of the mass of said mesoporous composite titanium oxide material; at least one most probable pore diameter of pore distribution of the mesoporous compound titanium oxide material is 3-15 nm, the specific surface area is 50-250 m2 / g, and the pore volume is 0.05-0.4 m3 / g. As a catalyst carrier, the rate of conversion of the hydrodesulfurization reaction of the material reaches as high as 98 percent, and as a lithium ion battery cathode material, the specific capacity of the lithium ion battery cathode material reaches as high as 220 mAh / g. Moreover, the preparation method of the material is simple, has low cost and is suitable for industrial bulk production.

Owner:NANJING UNIV OF TECH +1

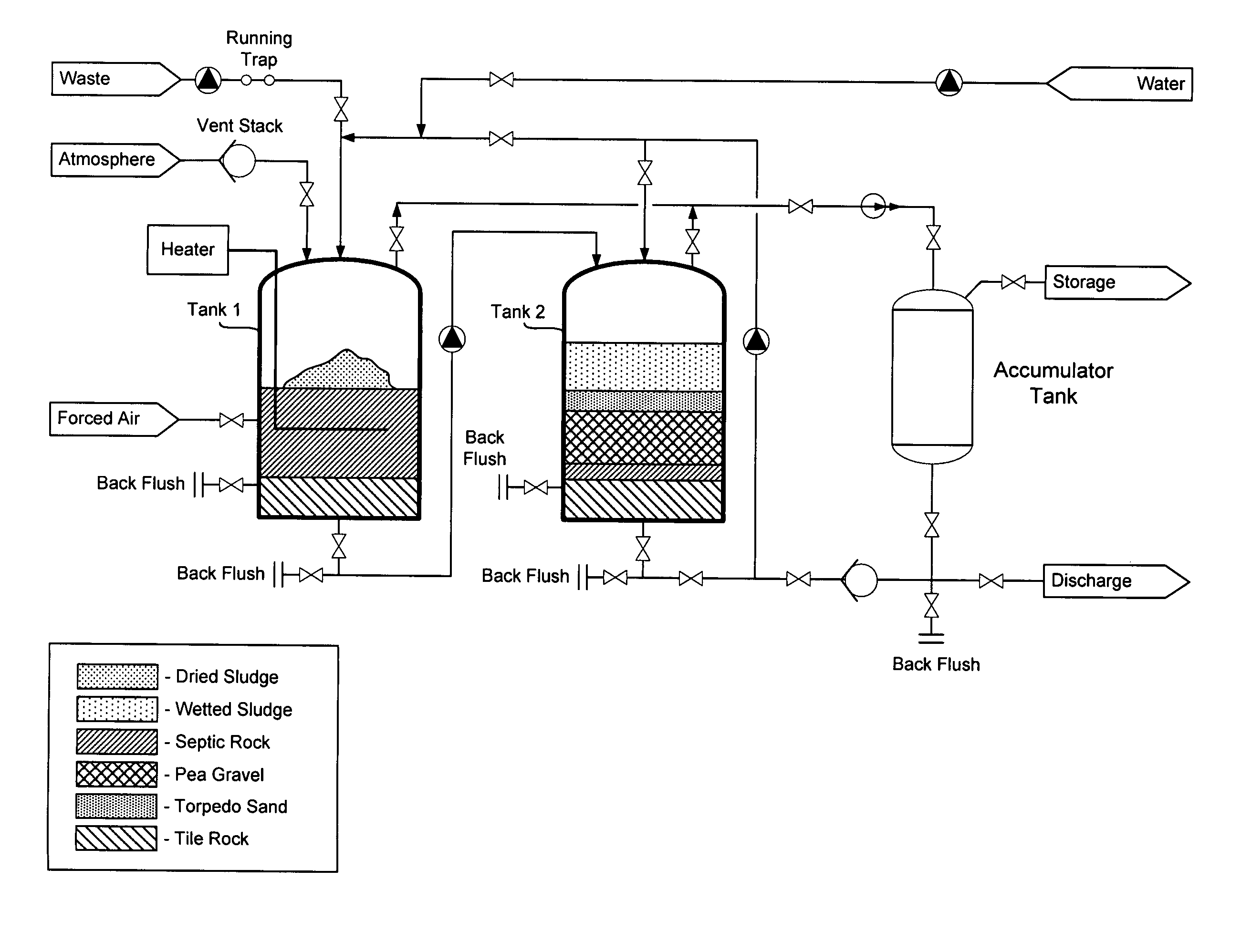

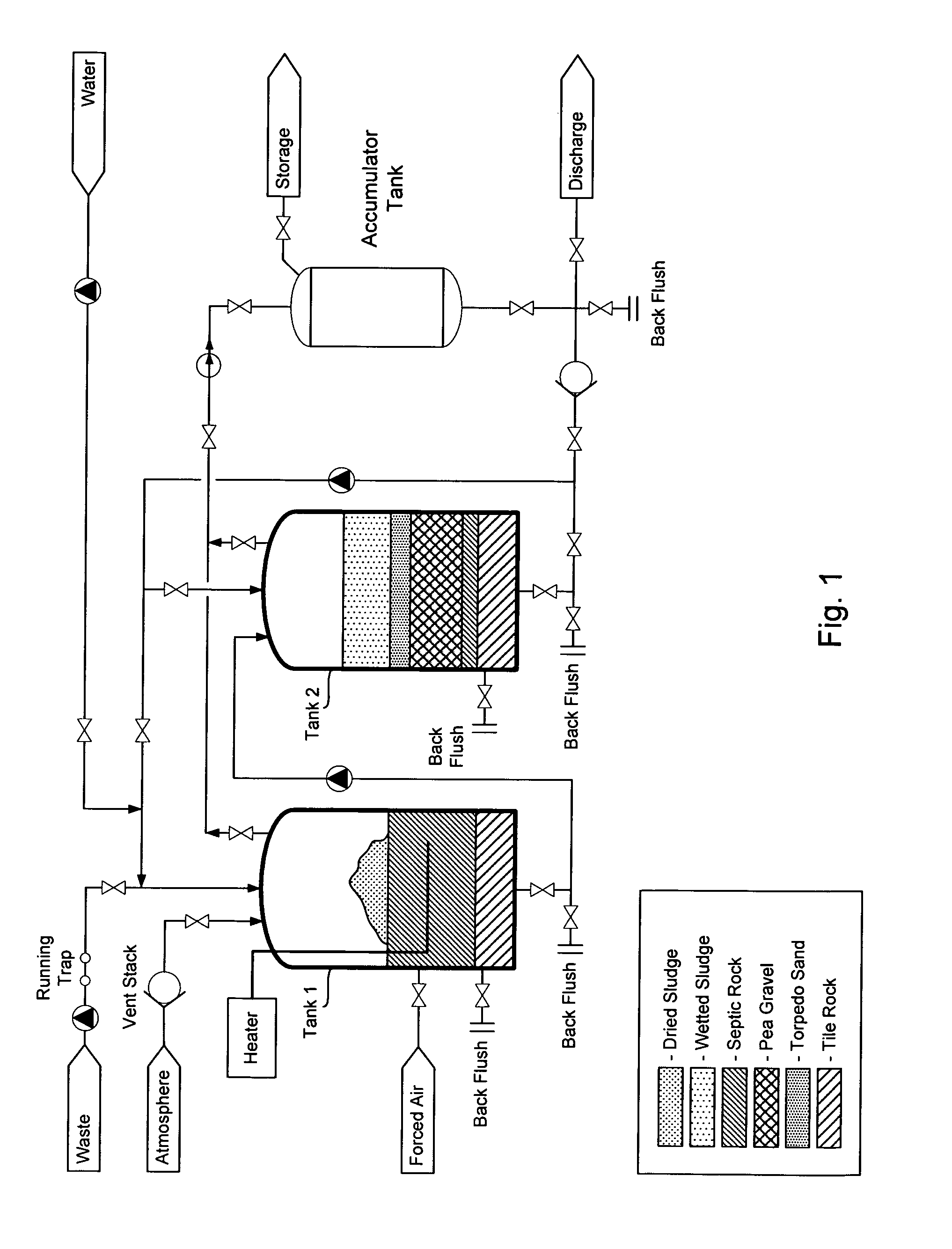

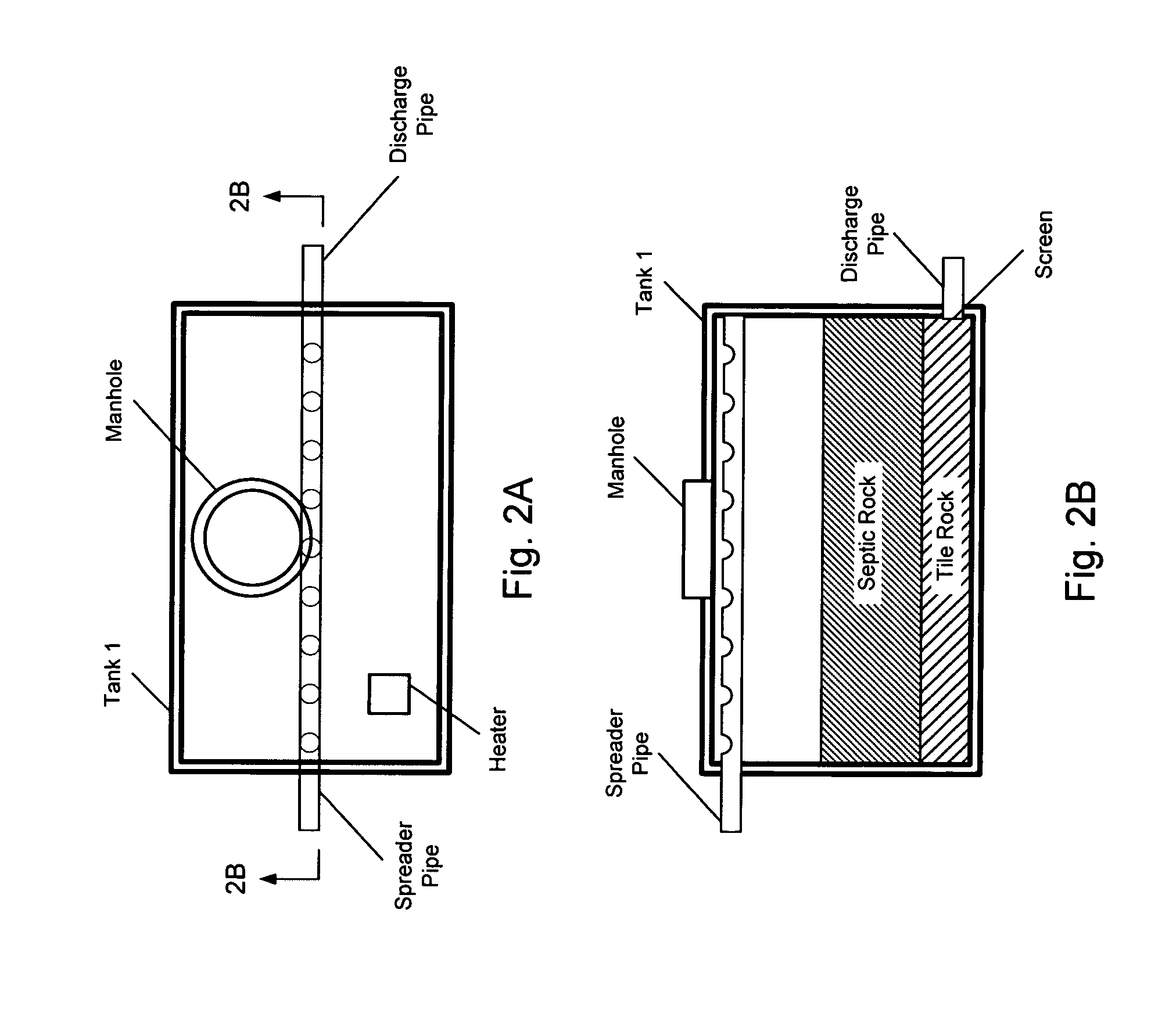

Dry cycle anaerobic digester

ActiveUS7144507B2Variable operationLarge productionWater treatment parameter controlSolid waste disposalAerobic digestion

The present invention provides a digester for handling waste or contaminated materials. A process and an apparatus for processing are disclosed. A Dry Cycle Anaerobic Digester (DCAD) uses tanks to perform aerobic and anaerobic digestion to eliminate the waste, while producing little or no sludge.

Owner:BASWOOD

Encapsulated hydrogenation catalysts with controlled dispersion and activity

InactiveUS20020107139A1Large productionLightweight productionMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsRheniumIridium

The present invention is a coated hydrogenation catalyst that includes a porous support material, an active metal component and a silica precursor, wherein the support material is impregnated with the active metal component and then contacted with the silica precursor. After impregnation, the support material is calcined to form a SiO2 layer. The active metal component can be one or more Group VIII metals, metal oxides, metal sulfides or metal carbides. The support material for the coated catalyst is kieselguhr, alumina, silica or silica-alumina. In a preferred embodiment, the active metal component is platinum, palladium, rhodium, rhenium or iridium and the catalyst includes a zeolite component. The coated catalyst is prepared by first impregnating the support material with the active metal component and then contacting the silica precursor to form an impregnated catalyst. The impregnated catalyst is then calcined to form the coated catalyst having a SiO2 layer. The impregnation with the active metal component and the incorporation of the silica precursor can be repeated two or more times to form a plurality of SiO2 layers on the coated catalyst.

Owner:EXXON RES & ENG CO

Methods for in-situ cleaning of abrasive belt/planer surfaces using dry ice and cleaning systems and device related thereto

InactiveUS20010000165A1Extended service lifeReduce purchasesGrinding drivesBelt grinding machinesDry iceEngineering

Featured is a method and system for cleaning abrasive sanding and / or planing media, for example sandpaper, wide belt sanding belts, planers, grinding wheels or other abrasive surfaces while the media is either in-situ in the sanding, planing, grinding equipment or when removed. Additionally, the cleaning featured method and system can clean the media while the abrasive media is being used as well as when the abrasive media is not being used. In the cleaning method dry ice (CO.sub.2, solid carbon dioxide) particles are propelled towards the abrasive surface at a high velocity so the dry ice particles impact on the surface of the abrasive media at a high velocity. Additionally, the dry ice (CO.sub.2, solid carbon dioxide) particles are propelled as to impact the abrasive surface at varying angles and locations as necessary to effectively clean the abrasive surface. Further, the dry ice particles are propelled towards the abrasive media when it is in motion, for example rotating, so the dry ice particles impact the abrasive media at different locations of the media. The method and system allow the abrasive media to be cleaned while the abrasive media is being used for its' intended purpose. Thereby reducing equipment downtime usually associated with cleaning and / or changing the abrasive media due to becoming dirty and / or worn.

Owner:ARMSTRONG JAY T

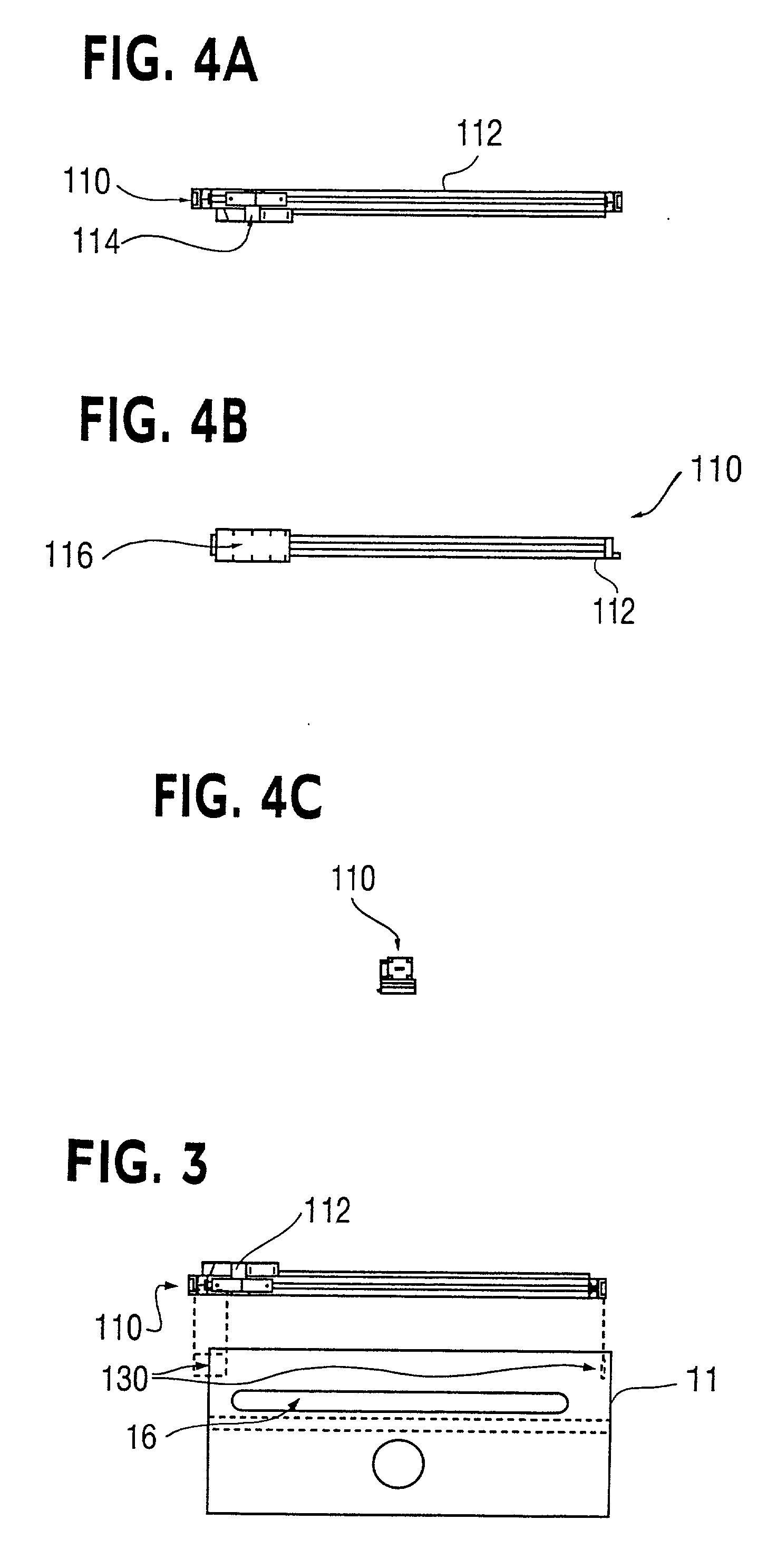

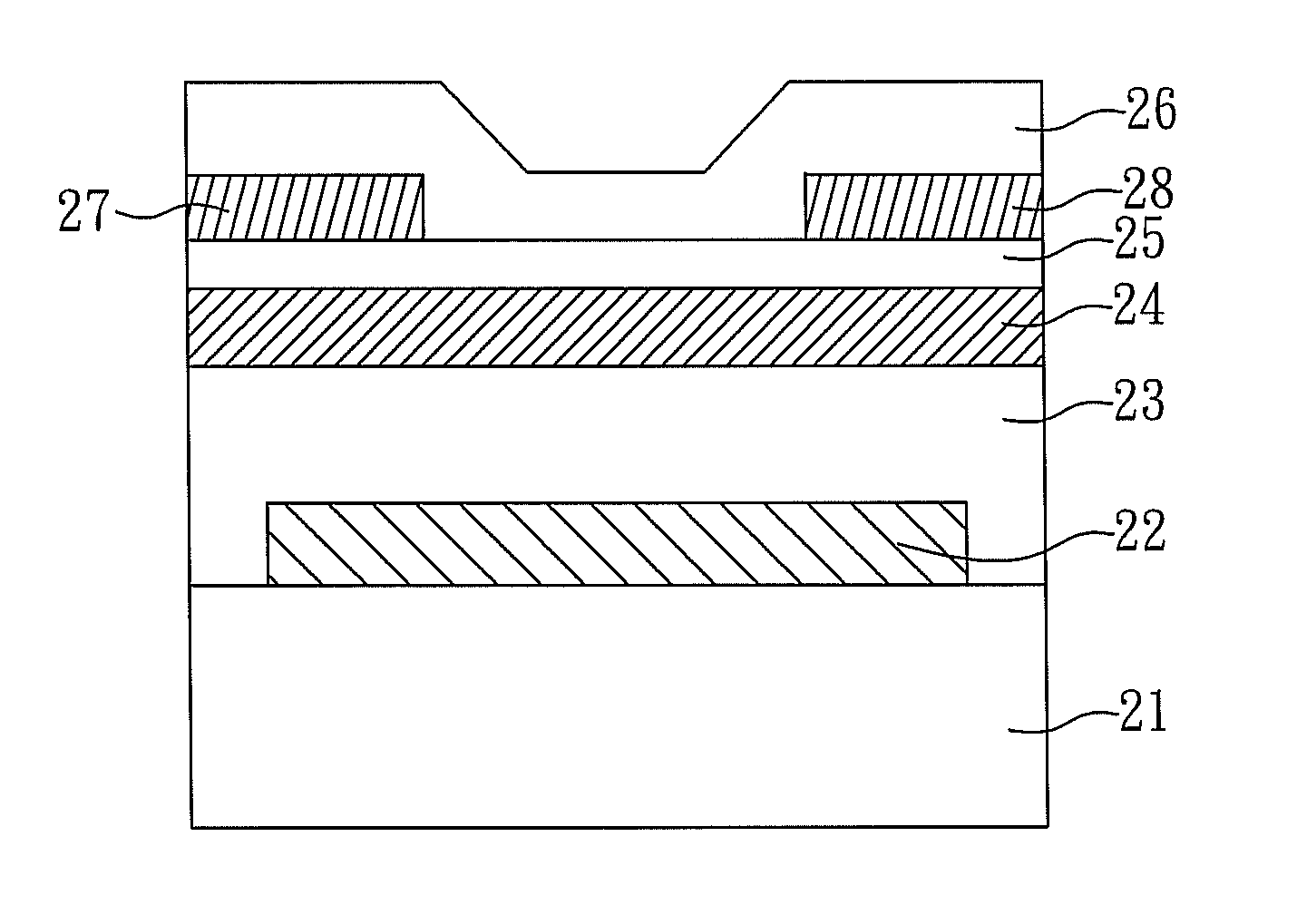

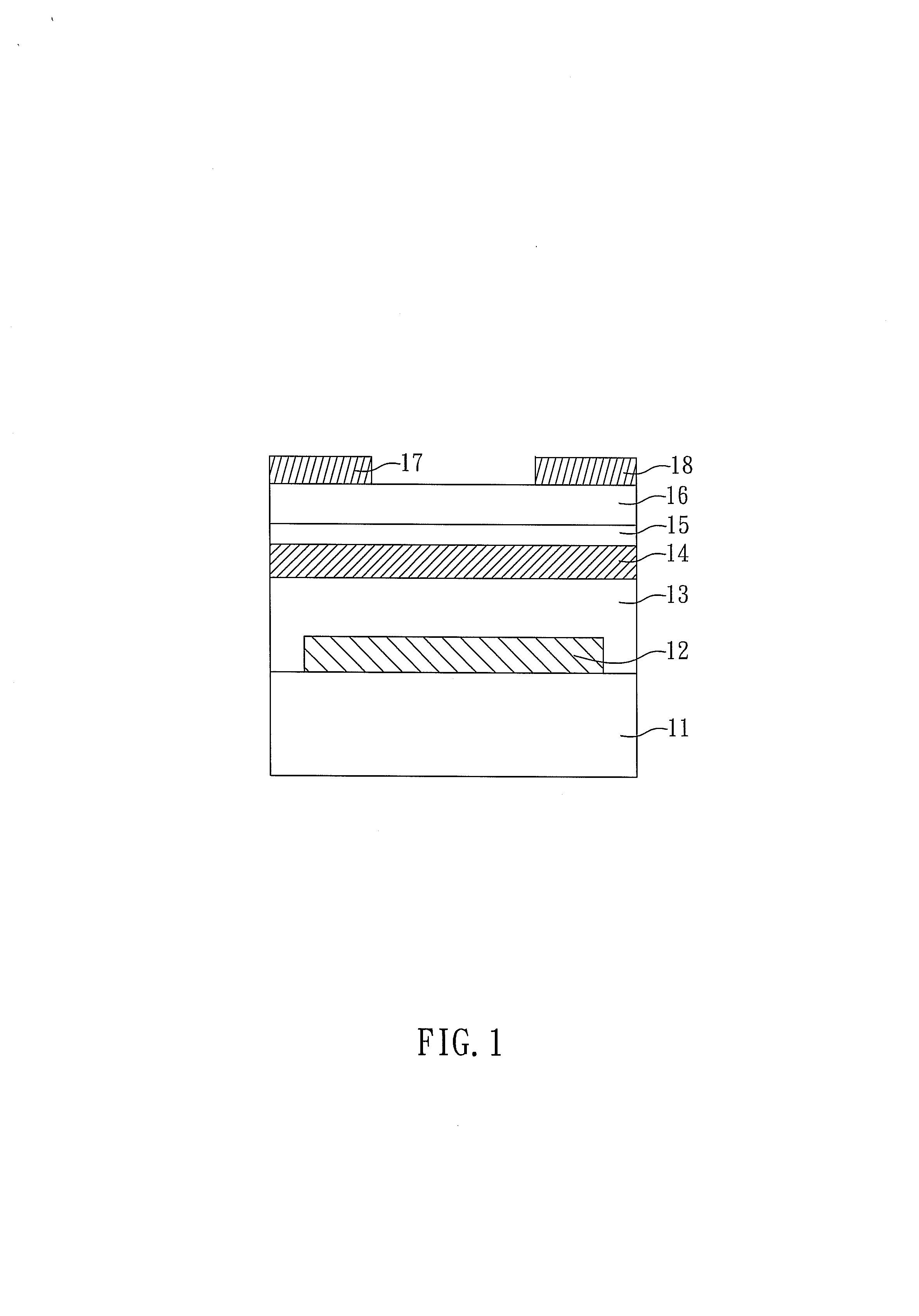

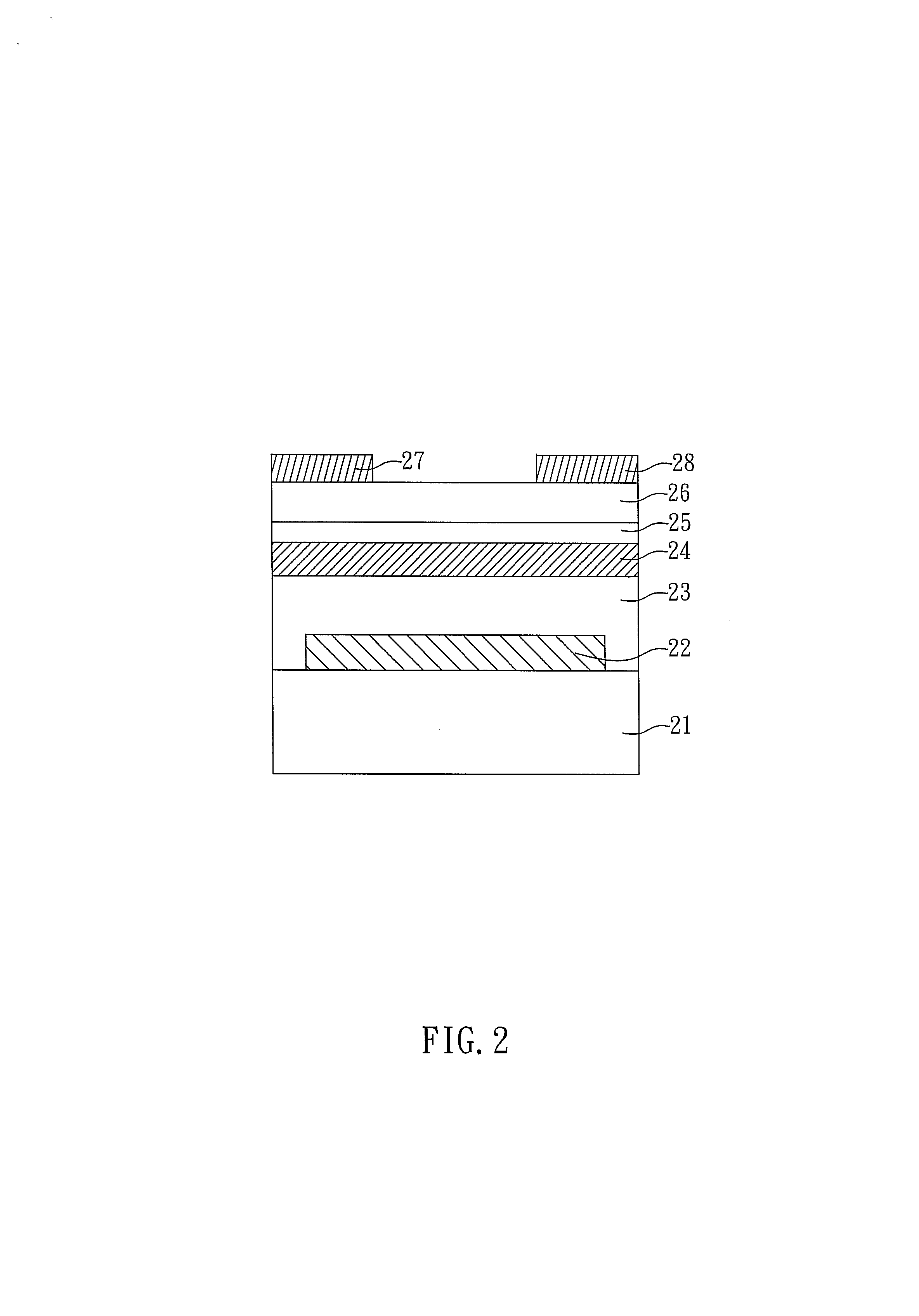

Organic floating gate memory device having protein and method of fabricating the same

InactiveUS20130181192A1Increase flexibilityImprove portabilityNanoinformaticsSolid-state devicesGate dielectricOrganic semiconductor

An organic floating gate memory device having protein and a method of fabricating the same are disclosed. The organic floating gate memory device of the present invention comprises: a substrate; a gate electrode on the substrate; a gate dielectric layer covering the gate electrode; a floating gate on the gate dielectric layer; a protein dielectric layer covering the floating gate; and an organic semiconductor layer, a source and a drain, wherein the organic semiconductor layer, the source and the drain are disposed over the protein dielectric layer

Owner:NATIONAL TSING HUA UNIVERSITY

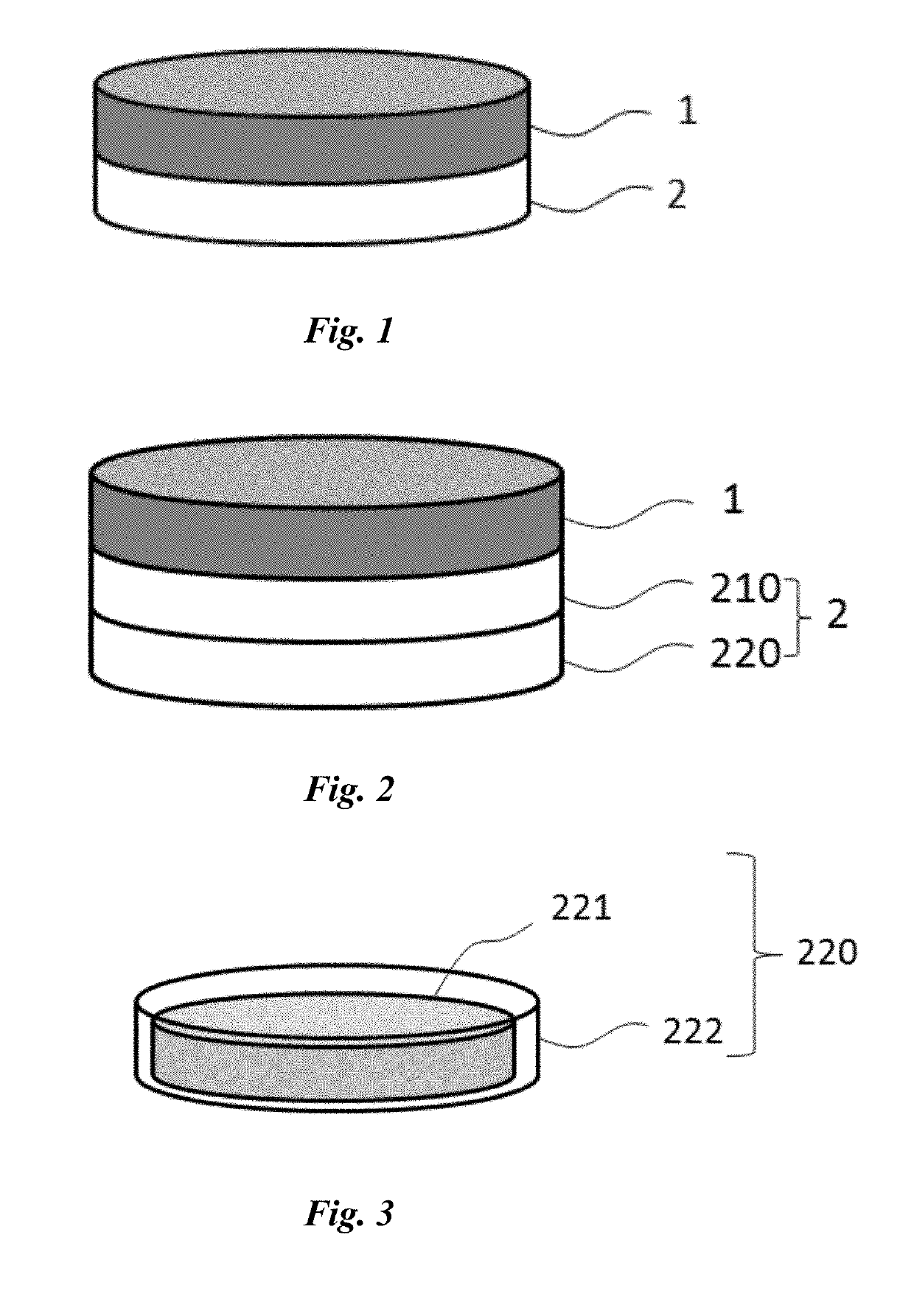

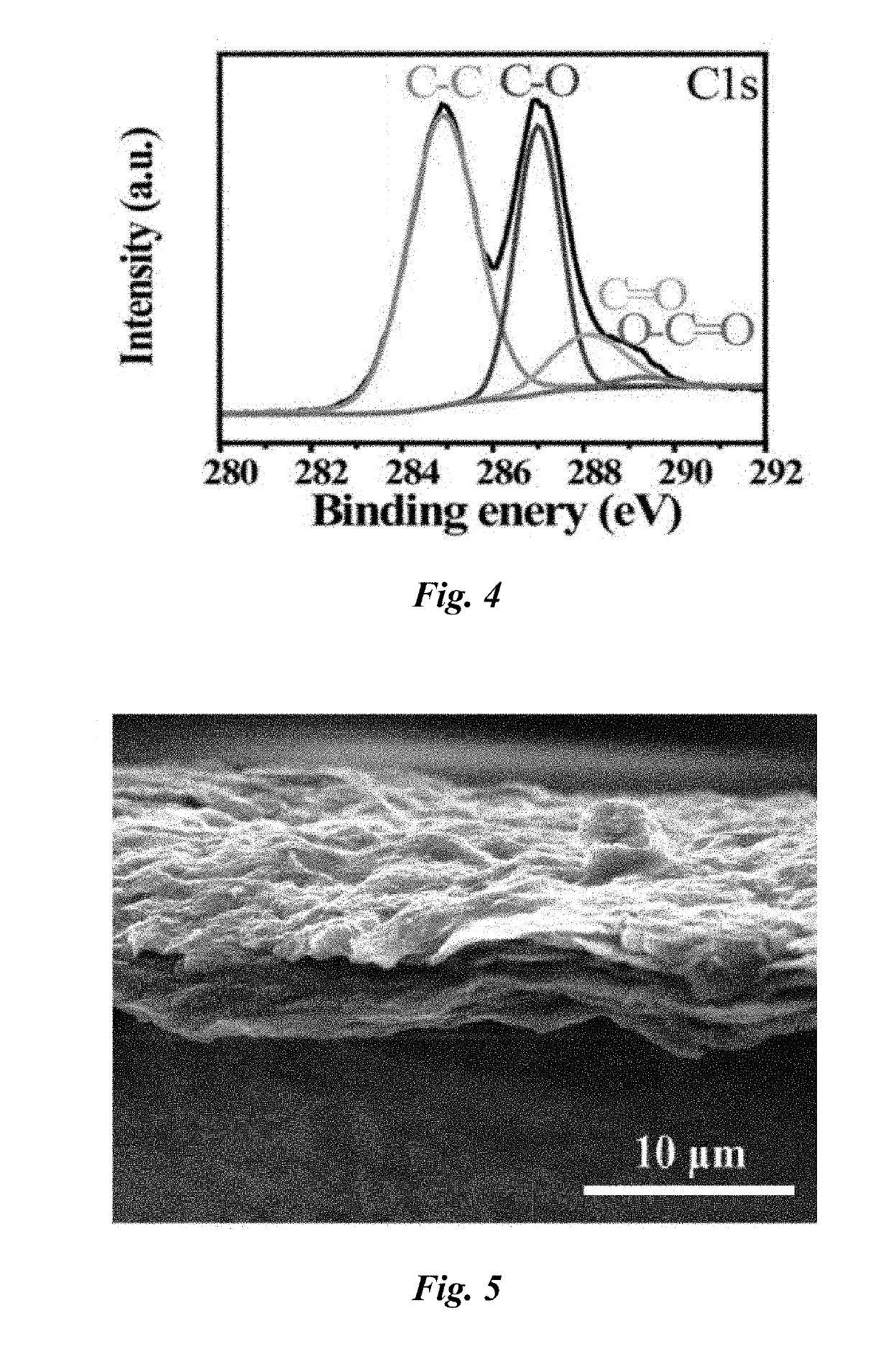

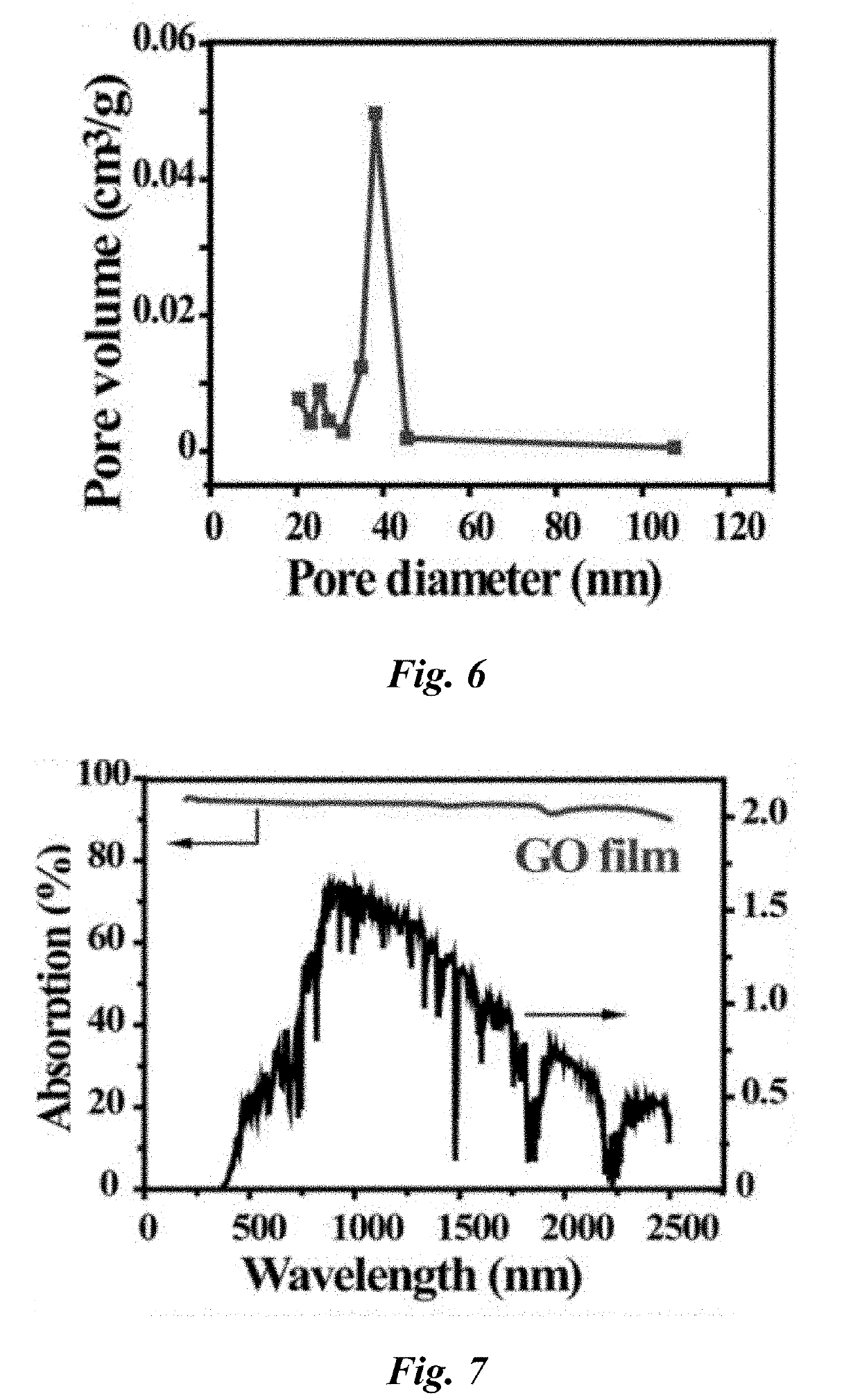

Multilayer body, preparation method therefor and use thereof

ActiveUS20190106335A1Solar energy sufficientlyReduce the amount of solutionSolar heating energyGeneral water supply conservationCarbon nanotubeGraphite

Disclosed is a multilayer body, comprising a base (2) and a carbon material layer (1) on the base (2), wherein the base (2) is water-permeable, and the carbon material comprises one or more of the following materials: graphite, graphene, graphene oxide, a chemical function group-modified graphene and carbon nanotubes. Further disclosed are a method for preparing the multilayer body, the use of the multilayer body, and a light-absorbing device containing the multilayer body.

Owner:NANJING UNIV

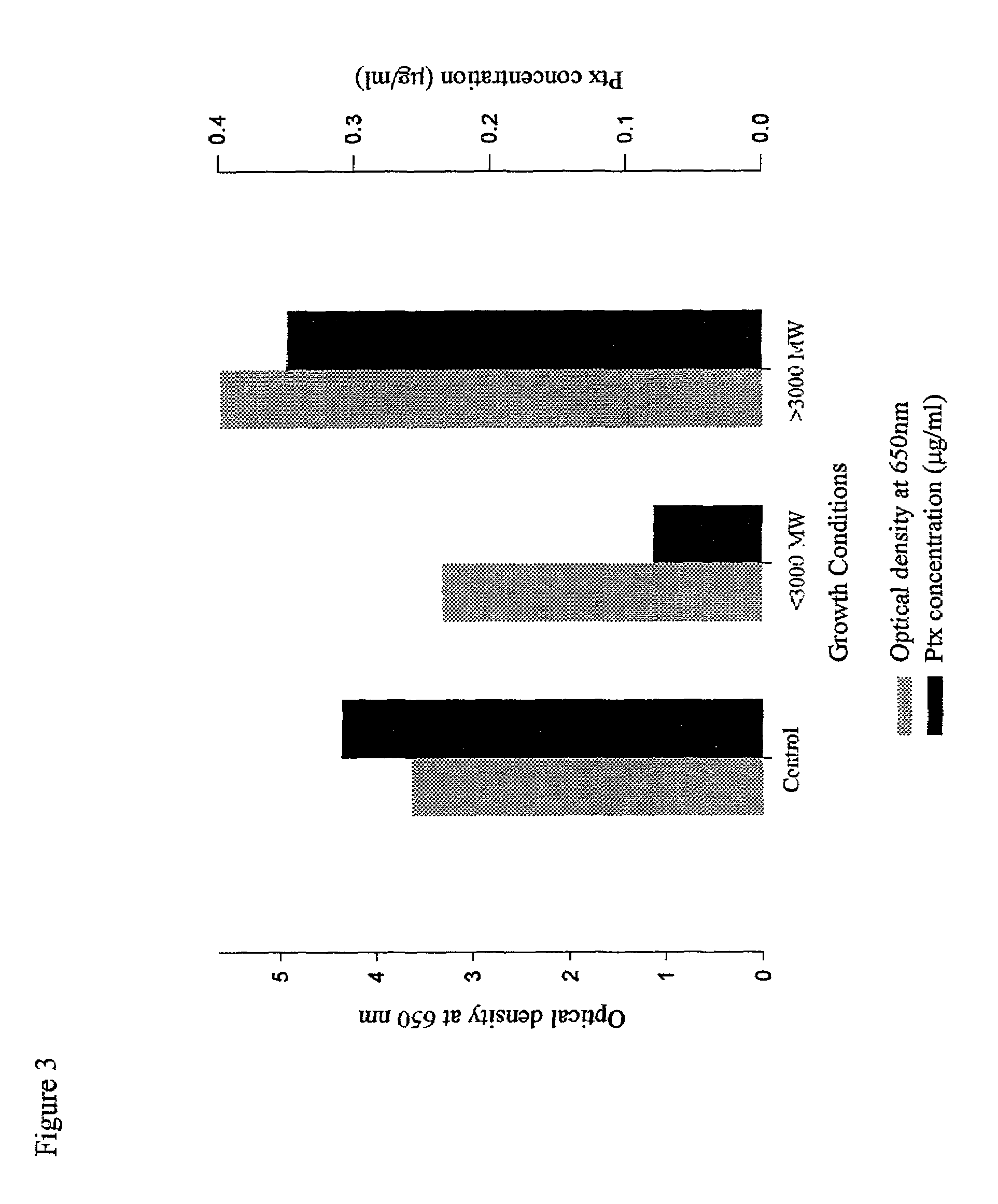

Method for the production of bacterial toxins

InactiveUS7045314B2Large productionReduce PT inhibitorsBacterial antigen ingredientsBacteriaBacteroidesToxin

Methods and compositions are provided for the enhanced production of bacterial toxins in large-scale cultures. Specifically, methods and compositions for reducing bacterial toxin expression inhibitors are providing including, but not limited to, addition of toxin expression inhibitor binding compounds, culture media having reduced concentrations of toxin inhibitor metabolic precursors and genetically modified toxogenic bacteria lacking enzymes required to metabolize the toxin inhibitor metabolic precursors.

Owner:BAXTER INT INC +1

Method of distributing software and a client device having the same

InactiveUS20110138379A1Save network resourcesReduce manufacturing costProgram loading/initiatingMemory systemsClient-sideSoftware

There is described a method of distributing software and supplemental display data and a client device having the same. The method reduces the cost of providing software to a number of devices on a multi-cast network. The software allows the user to gain access to the multi-cast network, and the supplemental display data is transferred to the client device over the network.

Owner:SONY CORP

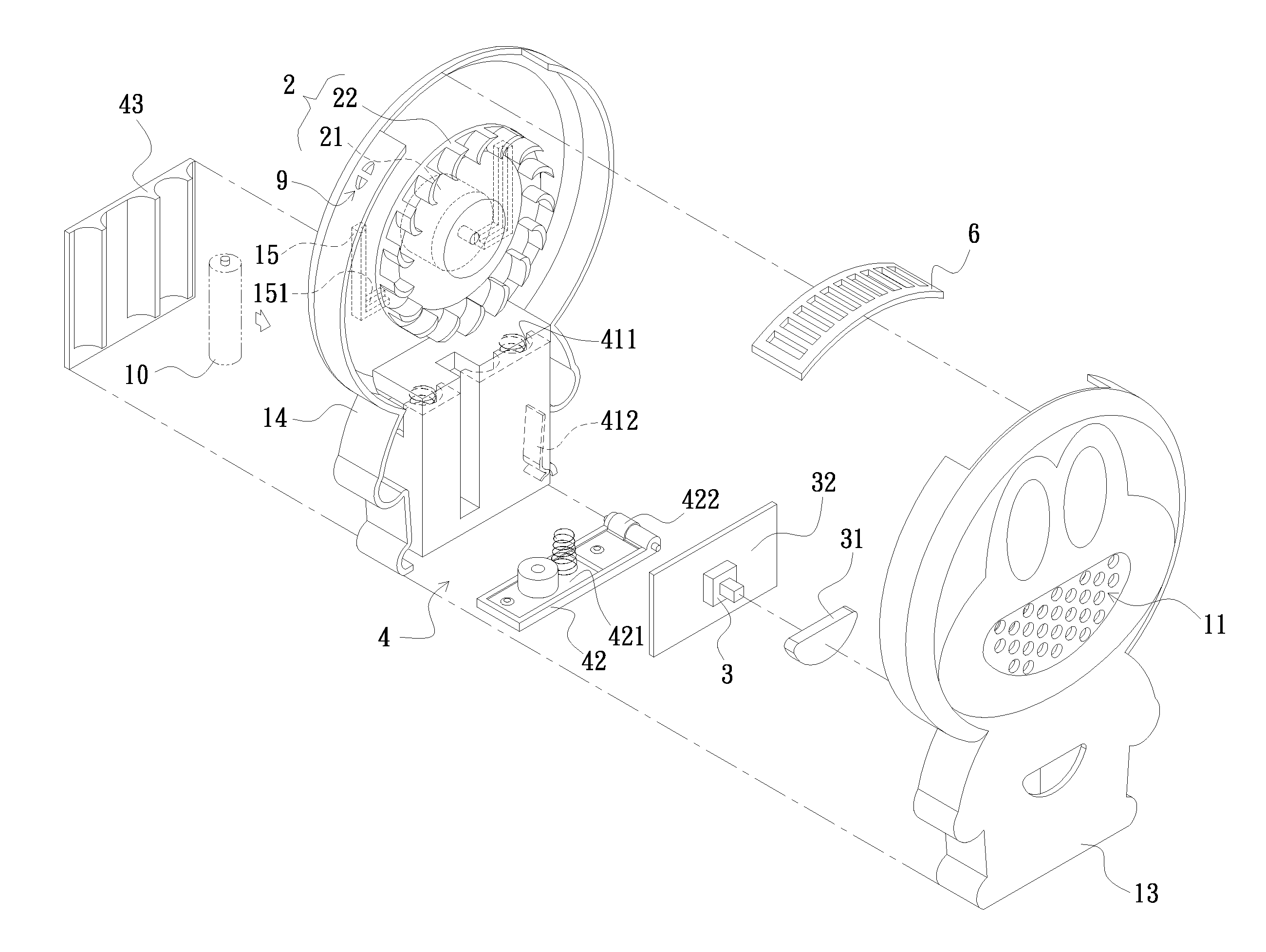

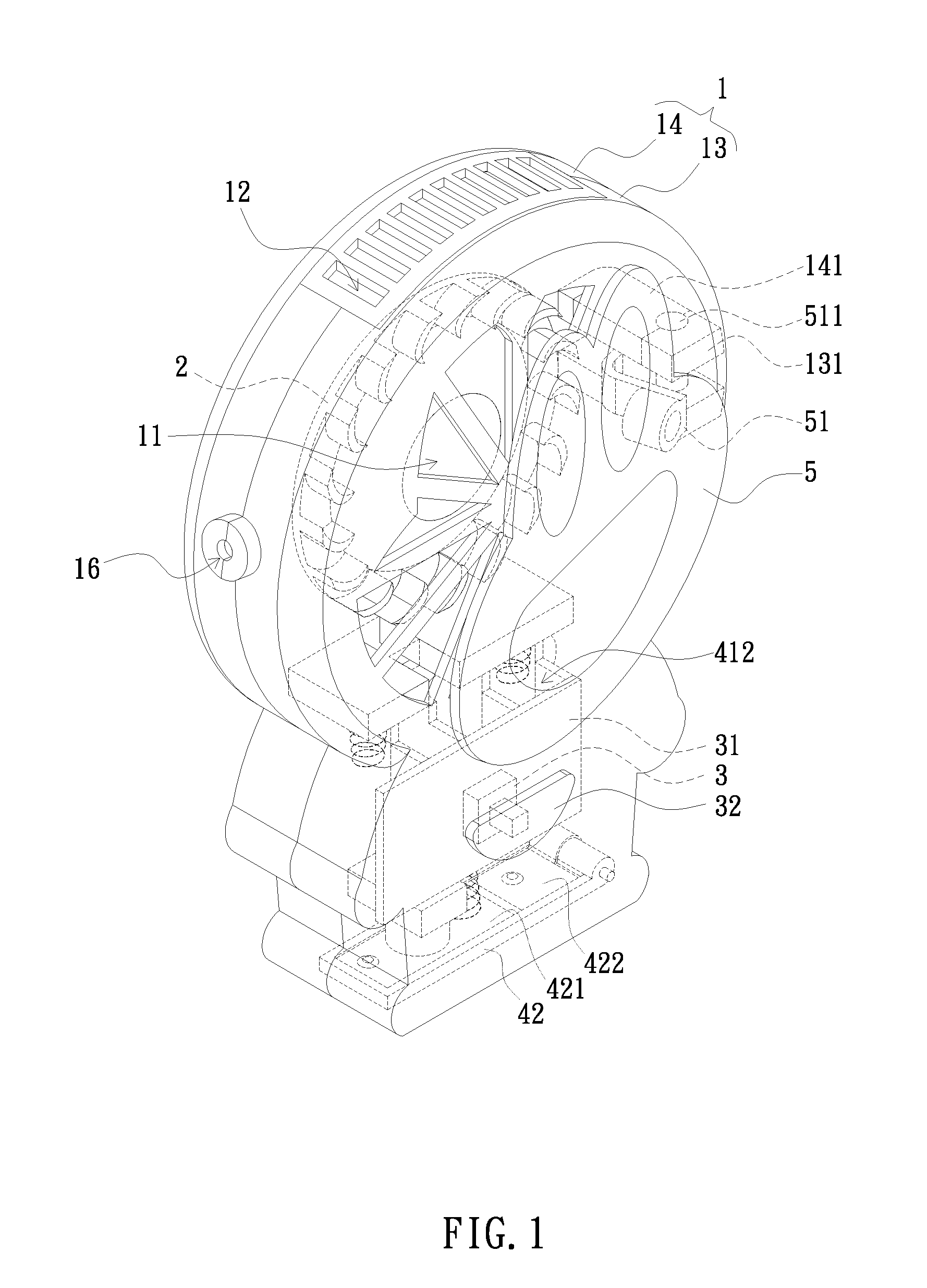

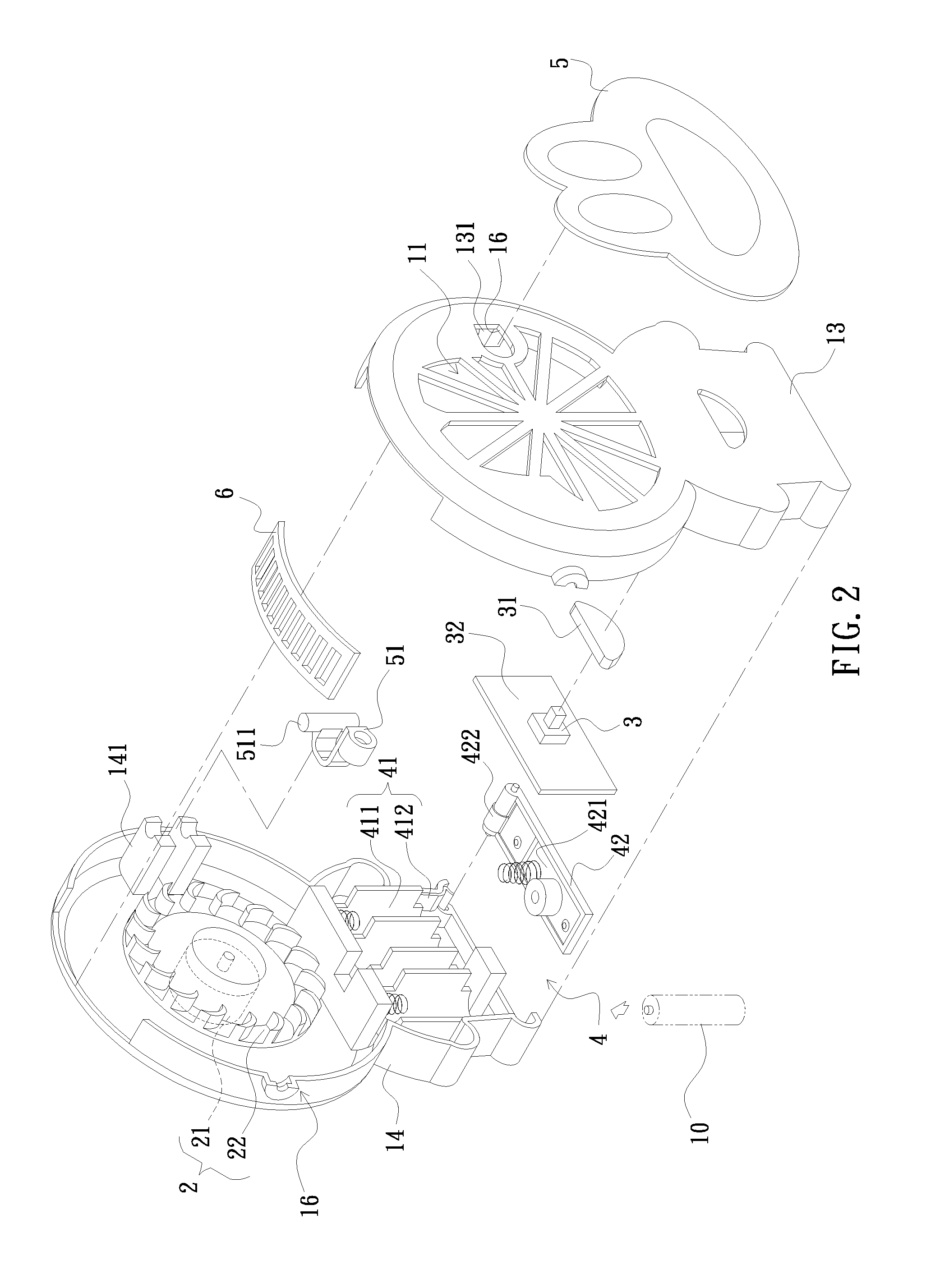

Style of Fan Device

It is an improved style of fan device without much noise. The characters contain a hollow cover, a centrifugal fan, a switch, connected with the centrifugal fan, and a power supply, connected with centrifugal fan; there are at least one inflow part and one outflow part at least; said inflow and outflow fan is vertically designed; the improved style of fan device is characterized in that there is a fan cover in the inflow part area to open and close.

Owner:LEE PAO FENG

Rotor-stator device having an abradable coating film

InactiveUS20060045735A1Large productionEasy to useMolten spray coatingPump componentsThermal sprayingEngineering

A device includes a rotor and a stator enclosing the rotor. The stator includes a deep-drawn workpiece and having a thermally sprayed abradable coating film deposited on the deep-drawn workpiece. A minimal gap is disposed between the rotor and the stator. In addition, a method for manufacturing the device includes the steps of forming a workpiece by deep-drawing into one of the stator and an insert of the stator, depositing an abradable coating film on the stator using a thermal spray coating method, and ablating the abradable coating film using the rotor so as to form the minimal gap.

Owner:DAIMLER AG

Source-collector modules for EUV lithography employing a GIC mirror and a LPP source

ActiveUS8895946B2Maximize collectionConvenient amountRadiation pyrometryOptical filtersGratingLithographic artist

Source-collector modules for use with EUV lithography systems are disclosed, wherein the source-collector modules employ a laser-produced plasma EUV radiation source and a grazing-incidence collector. The EUV radiation source is generated by first forming an under-dense plasma, and then irradiating the under-dense plasma with infrared radiation of sufficient intensity to create a final EUV-emitting plasma. The grazing incidence collector can include a grating configured to prevent infrared radiation from reaching the intermediate focus. Use of debris mitigation devices preserves the longevity of operation of the source-collector modules.

Owner:MEDIA LARIO SRL

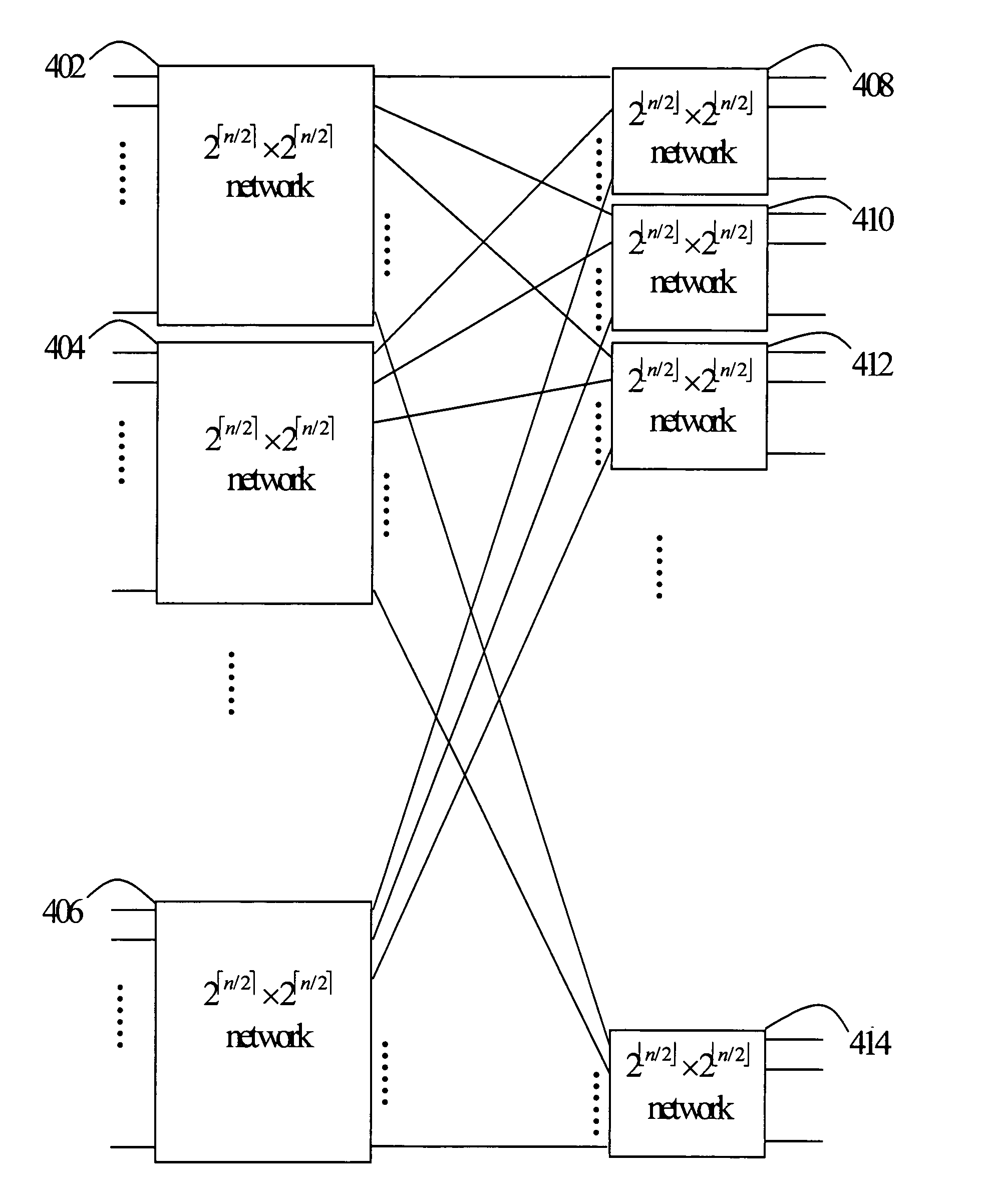

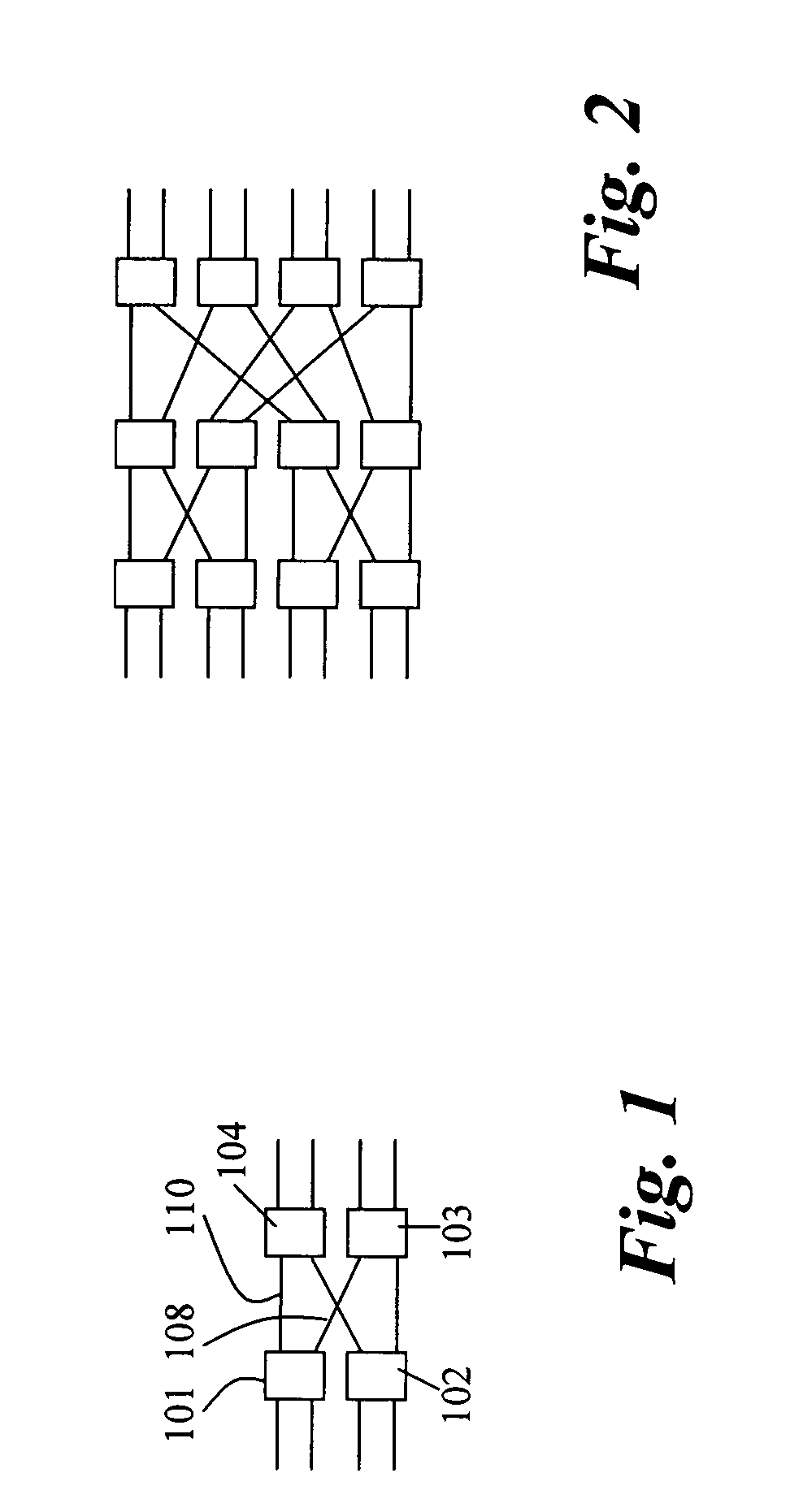

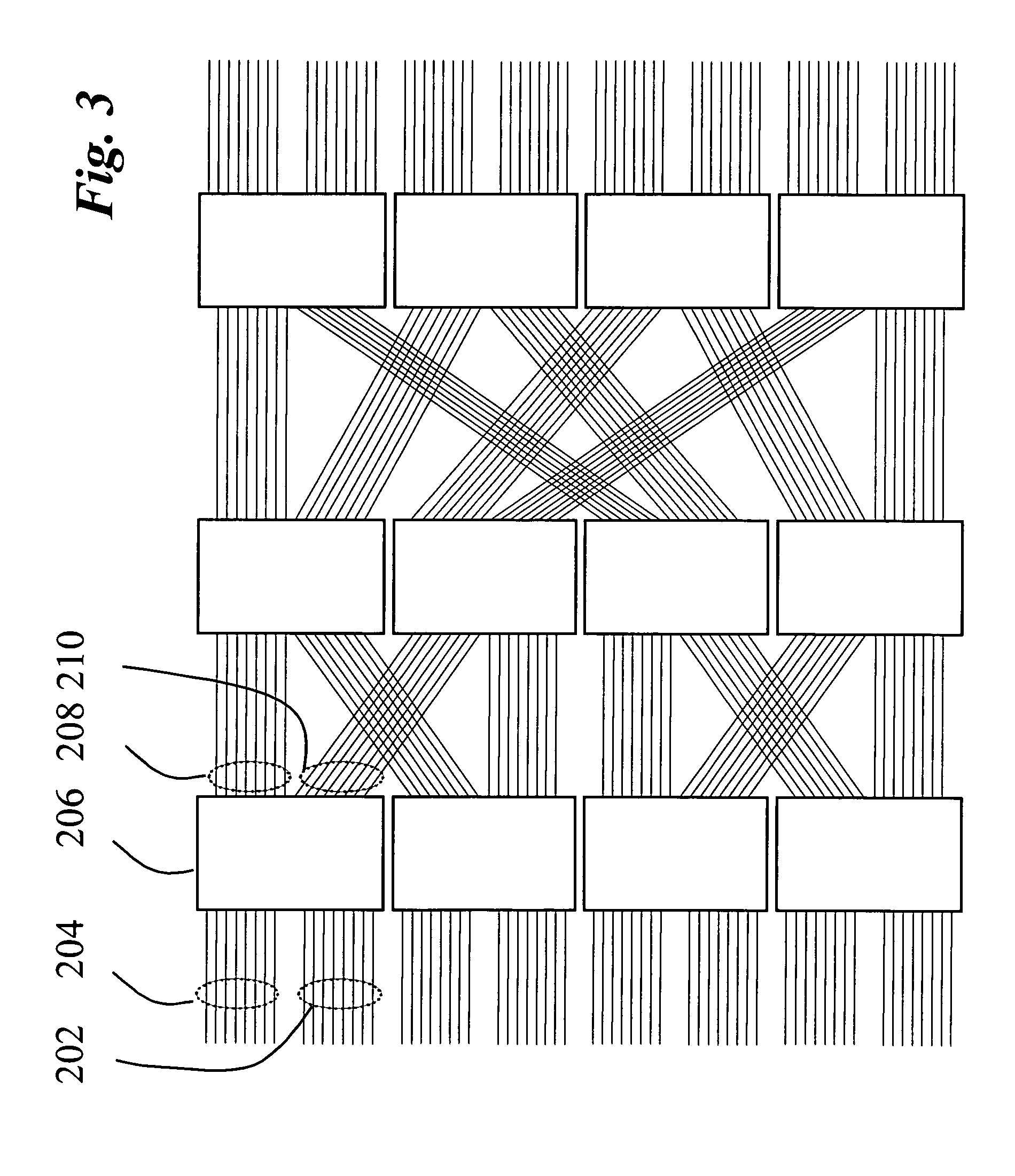

Switching by multistage interconnection of concentrators

InactiveUS7106728B1Reduce blocking rateAvoid problemsMultiplex system selection arrangementsData switching by path configurationModularityTraffic volume

A method and apparatus for performing switching by multistage interconnection of switching elements with improved performance and low layout complexity is disclosed. The techniques of line grouping, concentrators, self-route control through sorting are applied to relieve the output contention problem and uneven incoming traffic. Further a new class of interconnection networks called the divide-and-conquer networks is disclosed, the networks have very modular structure and the optimal layout complexity amongst all multistage interconnection networks.

Owner:IND TECH RES INST

Method of producing elliptically polarizing plate and image display using the elliptically polarizing plate

InactiveUS7468777B2Improve featuresImprove adhesionPolarising elementsNon-linear opticsTectorial membranePolarizer

The present invention provides a method of producing an elliptically polarizing plate including the steps of: forming a first birefringent layer on a surface of a transparent protective film; laminating a polarizer on a surface of the transparent protective film; forming a second birefringent layer on a surface of the first birefringent layer; and forming a third birefringent layer on a surface of the second birefringent layer. The first birefringent layer is arranged on the opposite side against the polarizer with respect to the transparent protective film. The step of forming the first birefringent layer includes the steps of: applying a liquid crystal material onto a substrate subjected to an alignment treatment; treating the applied liquid crystal material, so as to form the first birefringent layer on the substrate; and transferring the first birefringent layer onto a surface of the transparent protective film.

Owner:NITTO DENKO CORP

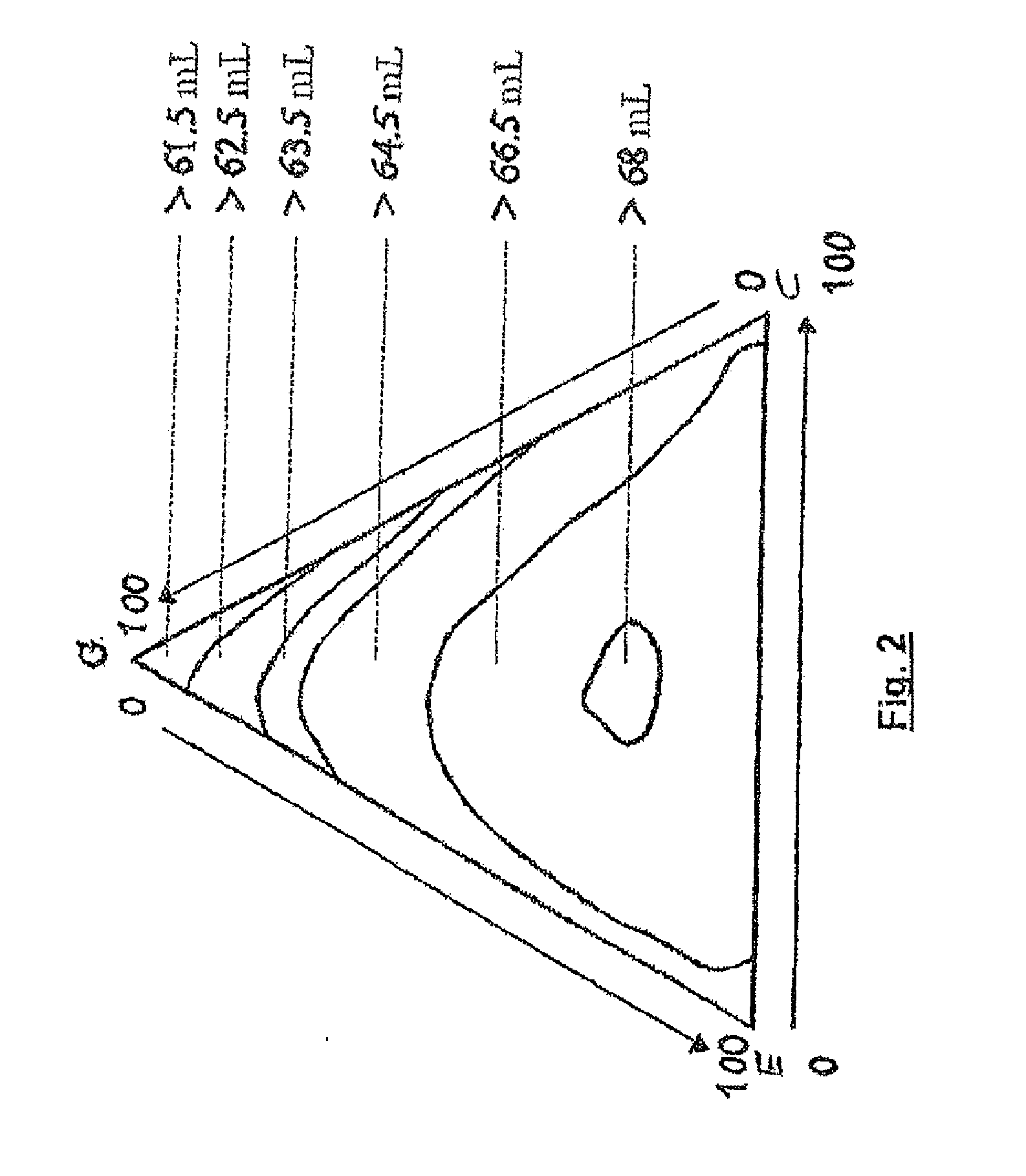

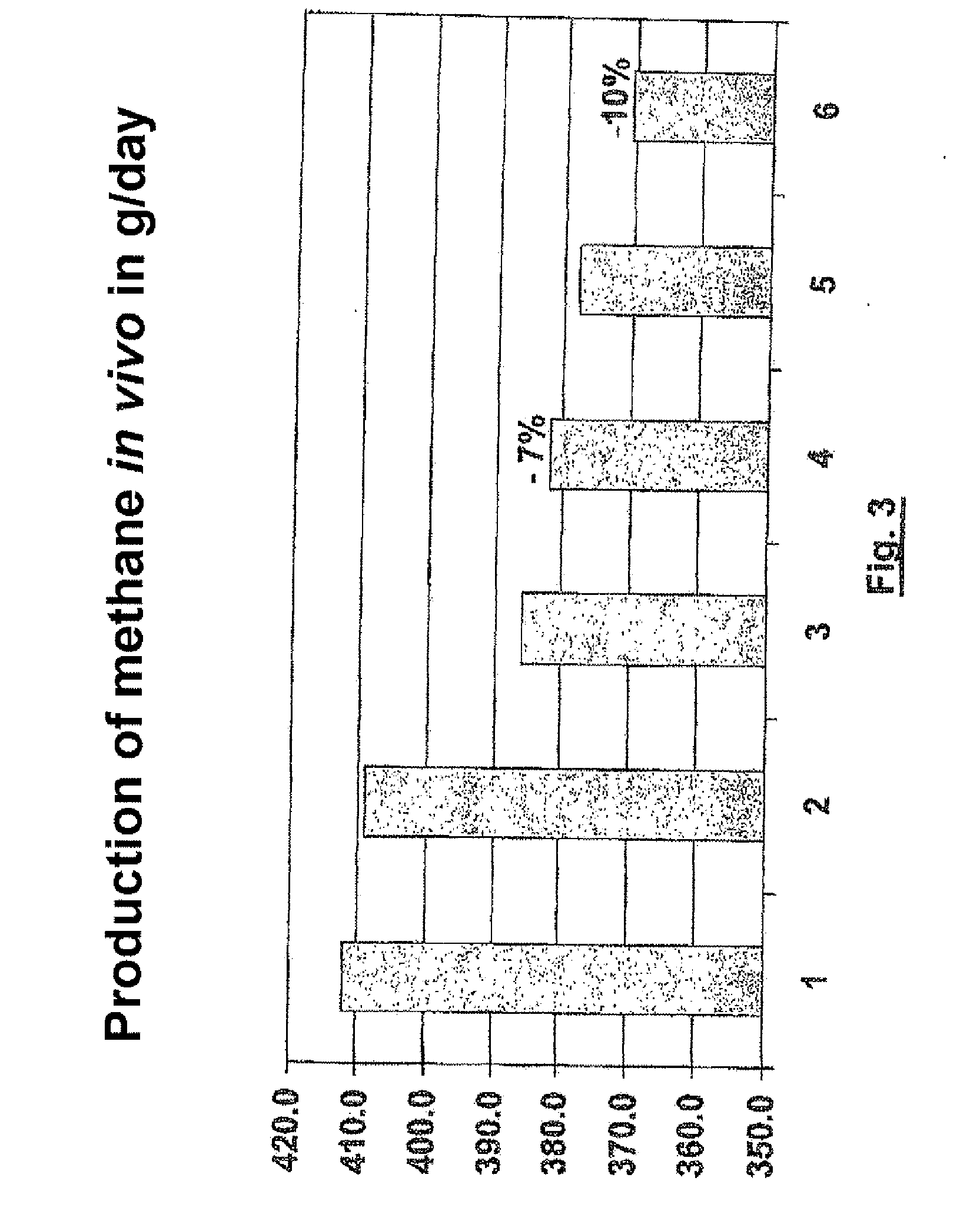

Food Additive Containing Eugenol, Cinnamaldehyde and an Alliaceous Extract

InactiveUS20120171323A1Large in production of methaneLarge productionSolid waste disposalAnimal feeding stuffFood additiveOrganosulphur compound

The invention relates to a food additive including: 30 to 45% of eugenol; 30 to 45% of cinnamaldehyde; 10 to 40% of extract of a plant belonging to the alliaceous family; the remainder up to 100% optionally comprising other compounds, in particular, organosulphur compounds. Such an additive can be added to the feed for certain animals, in particular bovines, with a view to reducing the methane production thereof. The invention also relates to a method for reducing methane emissions into the earth's atmosphere, which includes the following steps: adding a food additive according to the invention to the food ration of a ruminant; and feeding the ruminant the obtained food ration.

Owner:PANCOSMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com