Methods for in-situ cleaning of abrasive belt/planer surfaces using dry ice and cleaning systems and device related thereto

a technology of in-situ cleaning and abrasive belts, which is applied in the direction of grinding drives, grinding drives, manufacturing tools, etc., can solve the problems of reducing the life of the belt, reducing the quality of the finished product or material, and no longer fitting correctly onto the sanding equipment. , to achieve the effect of reducing the purchase of new abrasive belts, increasing the useable life of the typical sanding, and reducing the purchase of new

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

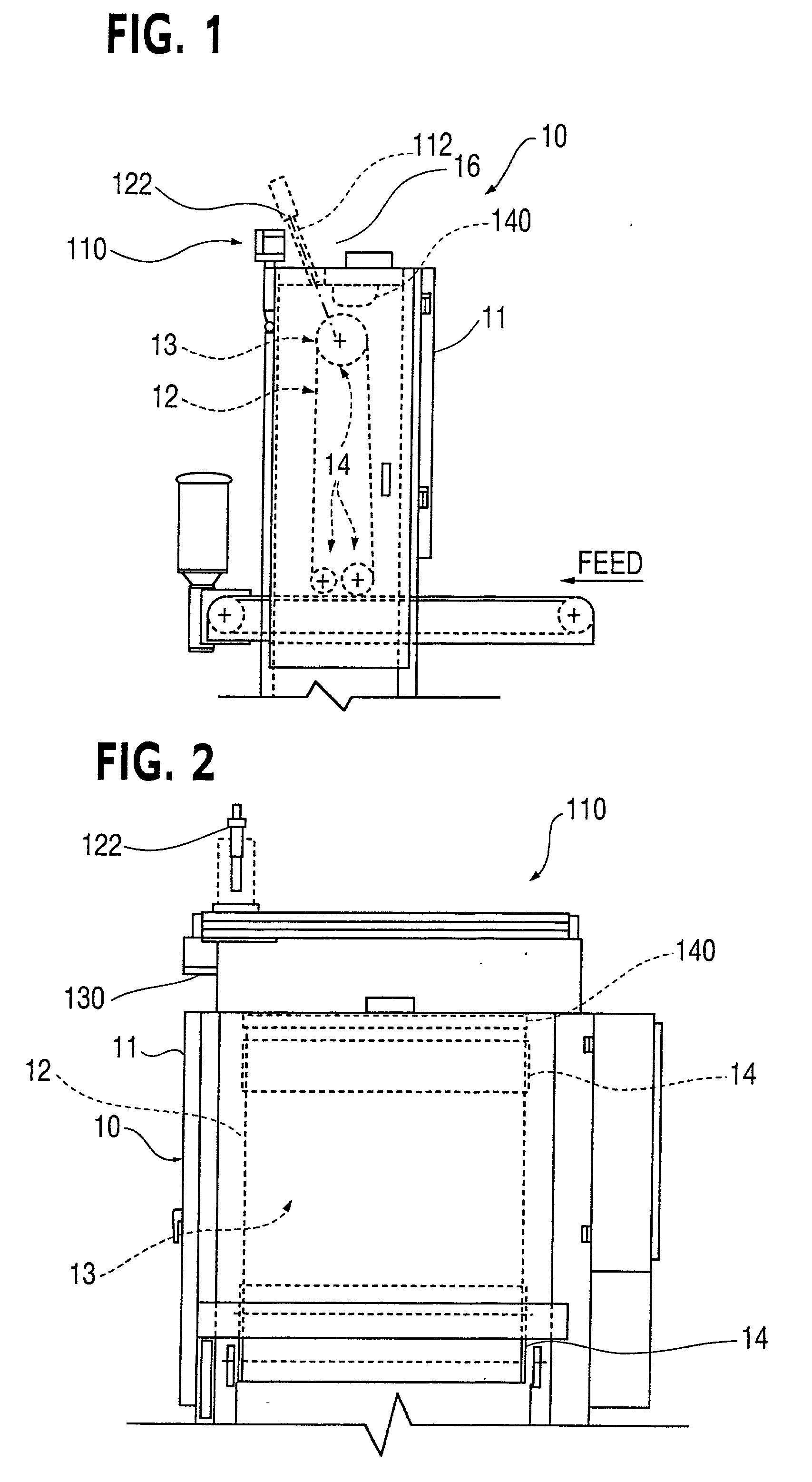

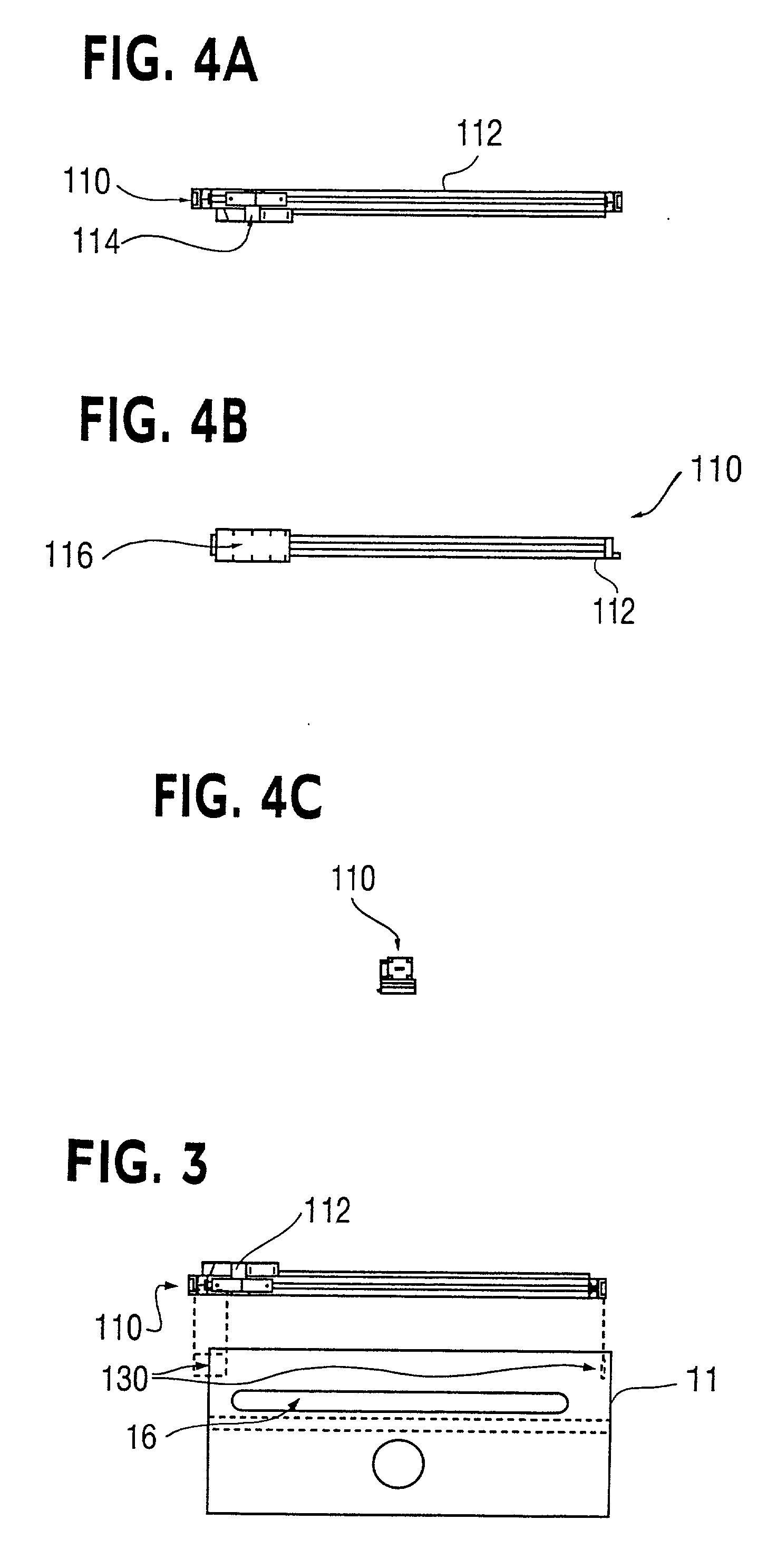

19. Referring now to the various figures of the drawing wherein like reference characters refer to like parts, there is shown in FIGS. 1-3, side, front and top views respectively of an abrasive belt sanding apparatus 10 including a dry ice cleaning system of the present invention. Such an abrasive belt sanding apparatus 10 includes an abrasive belt 12 and a plurality of tension rollers 14 on which is mounted the abrasive belt 12. The tension rollers 14 also rotate the abrasive belt 12 within the sanding apparatus. Typically, material or product is feed or presented to the abrasive belt 12 in a feed direction to prepare or finish a surface of this product or material. As hereinabove described, this preparation or finishing process results in the abrasive surface of the belt 12 becoming "loaded up" with for example, pieces of wood, sap, glue and / or burnt wood particles, and these surface contaminants degrade the abrasive quality of the belt.

20. The abrasive belt sanding apparatus 10 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| surface finish | aaaaa | aaaaa |

| abrasive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com