Patents

Literature

119results about How to "Avoid stitching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fusion antibodies

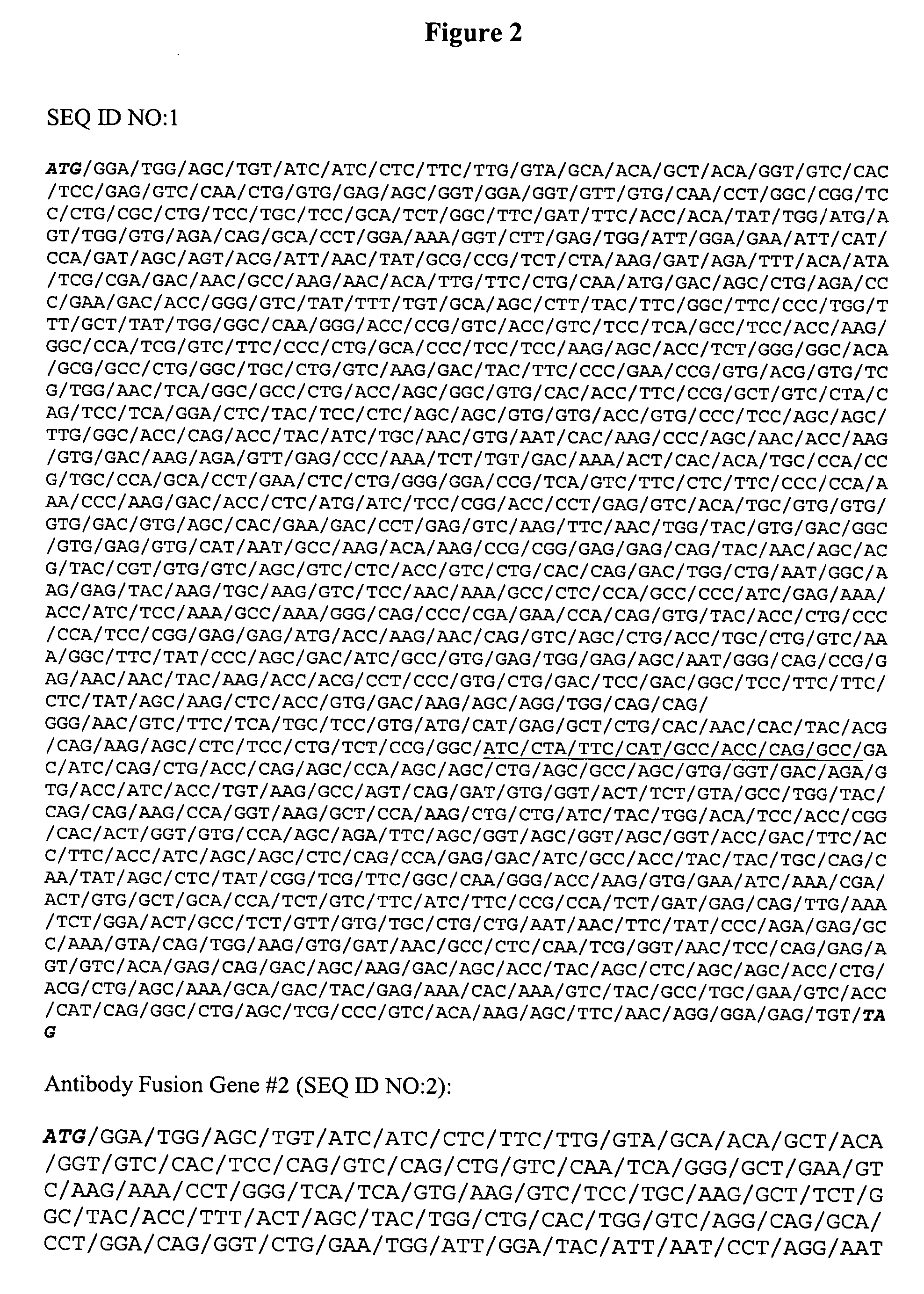

ActiveUS20050069552A1Avoid stitchingHybrid immunoglobulinsAntibody mimetics/scaffoldsHeavy chainGene

The present invention provides novel antibodies. In particular, the present invention provides fusion antibodies comprising antibody heavy and light chain fusions. The present invention further provides multivalent antibodies comprising multiple fusion antibody chains. The present invention further provides methods of generating splice resistant antibody genes.

Owner:CATALENT USA WOODSTOCK INC +3

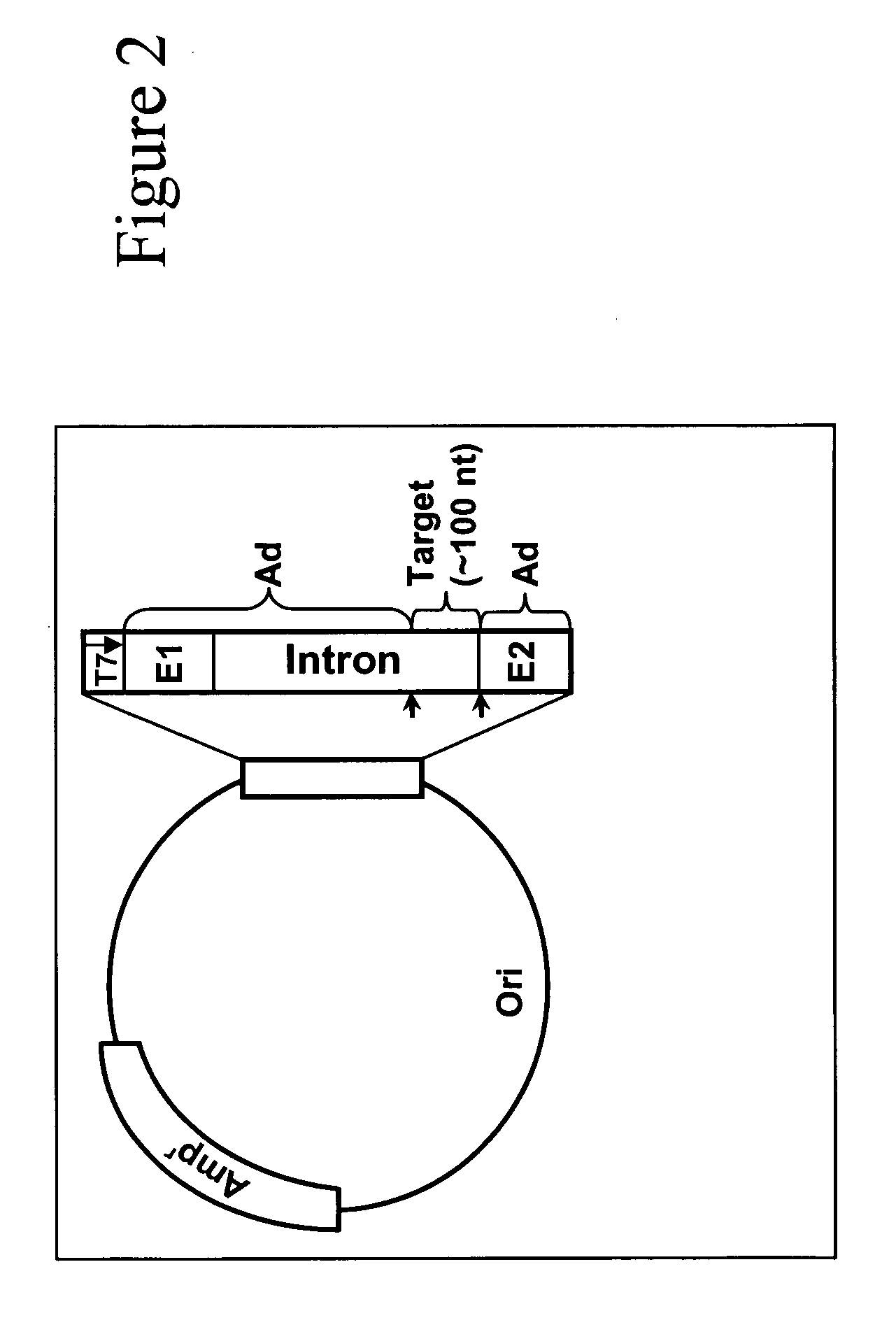

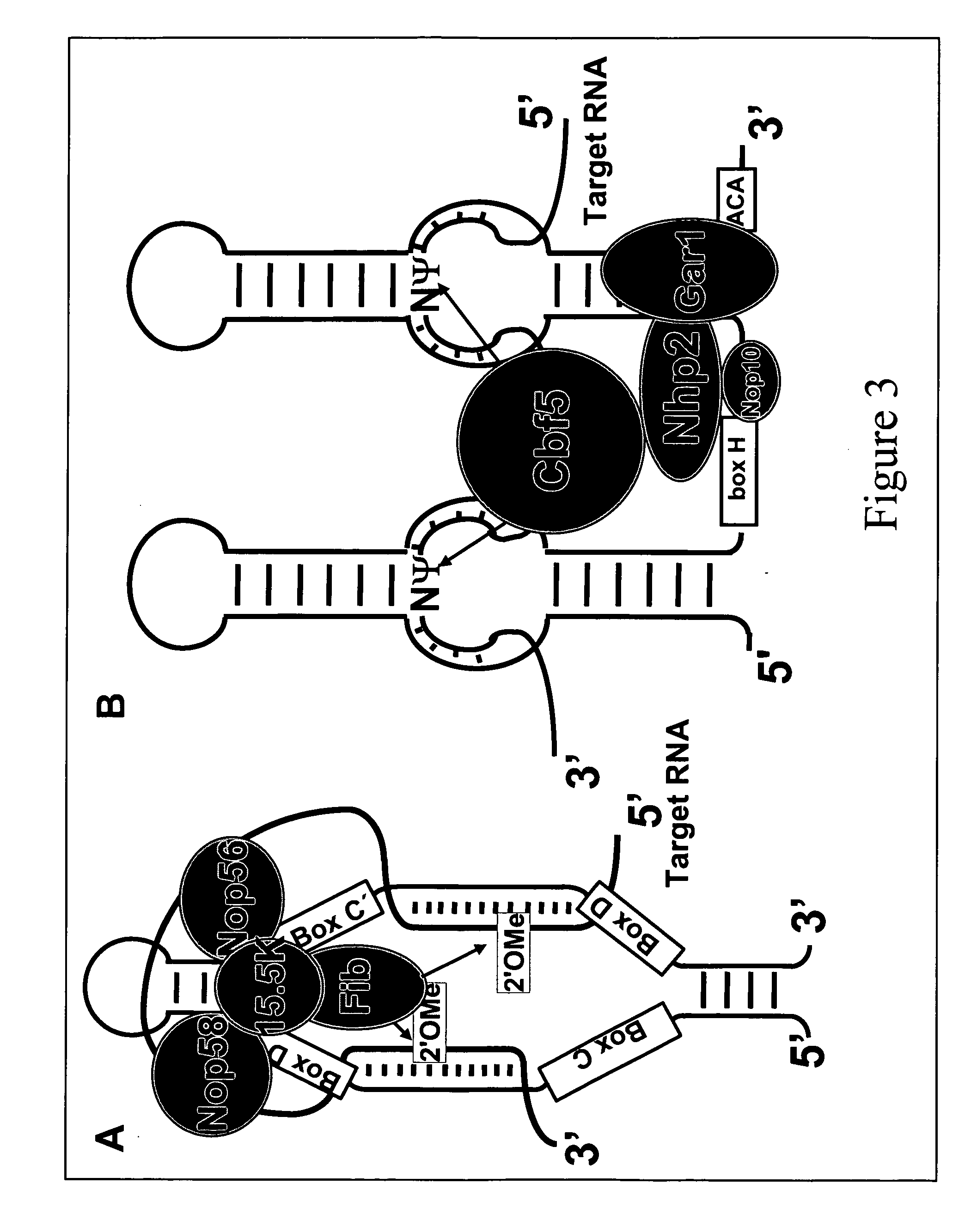

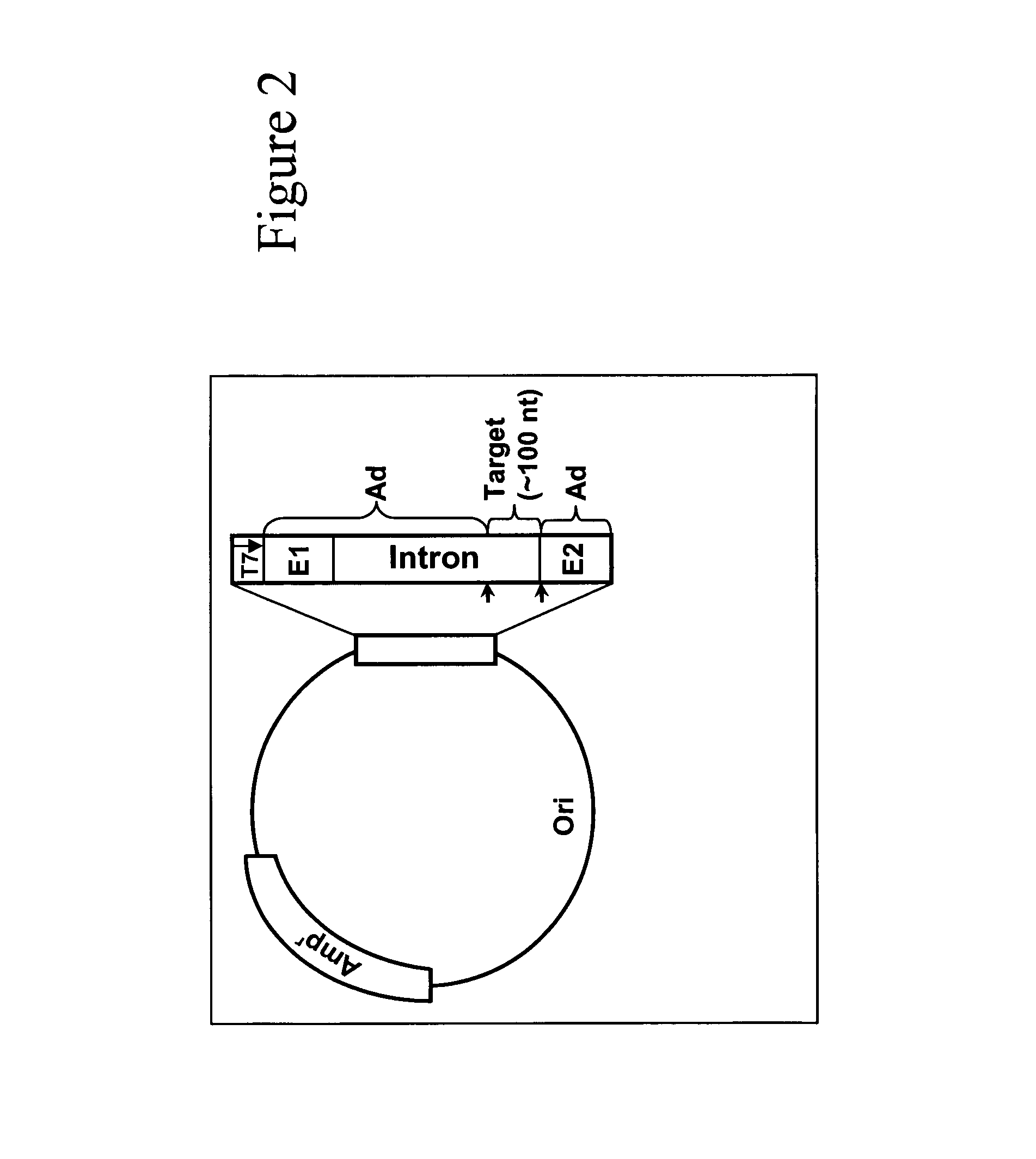

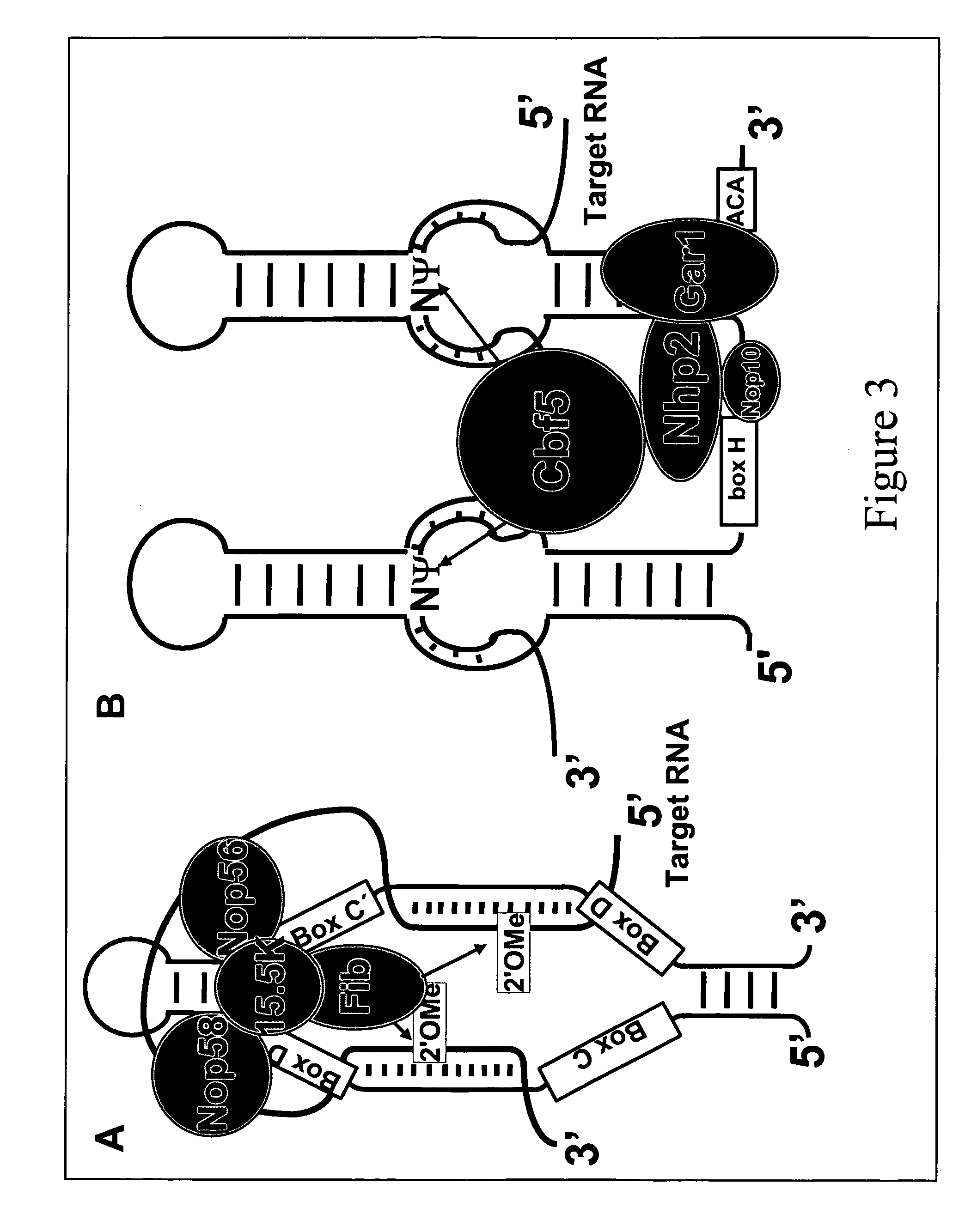

Targeted pre-mRNA/mRNA modification and gene regulation

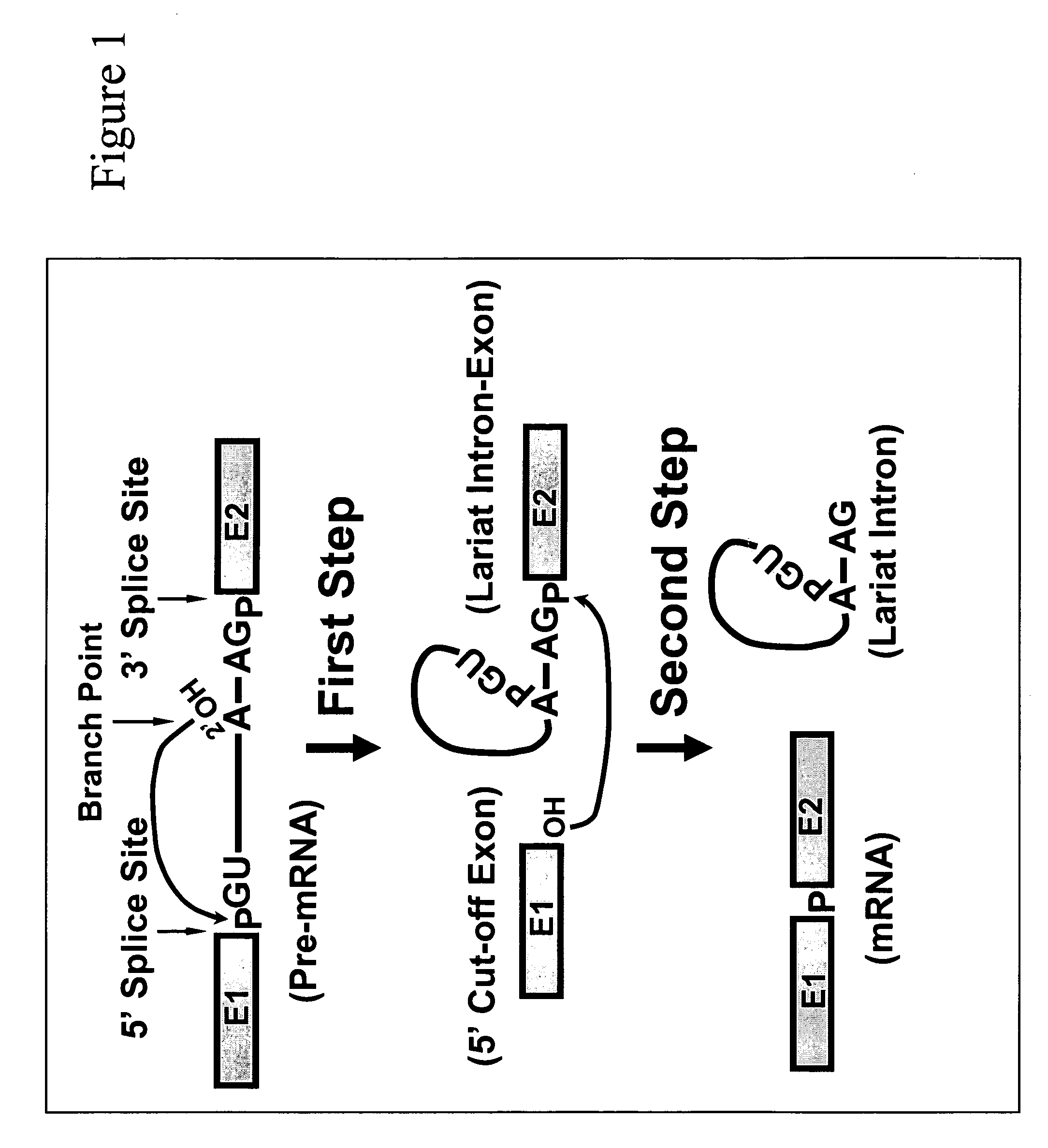

ActiveUS20070141030A1Easy to identifyLarge productionBiocideGenetic material ingredientsAdenosinePrecursor mRNA

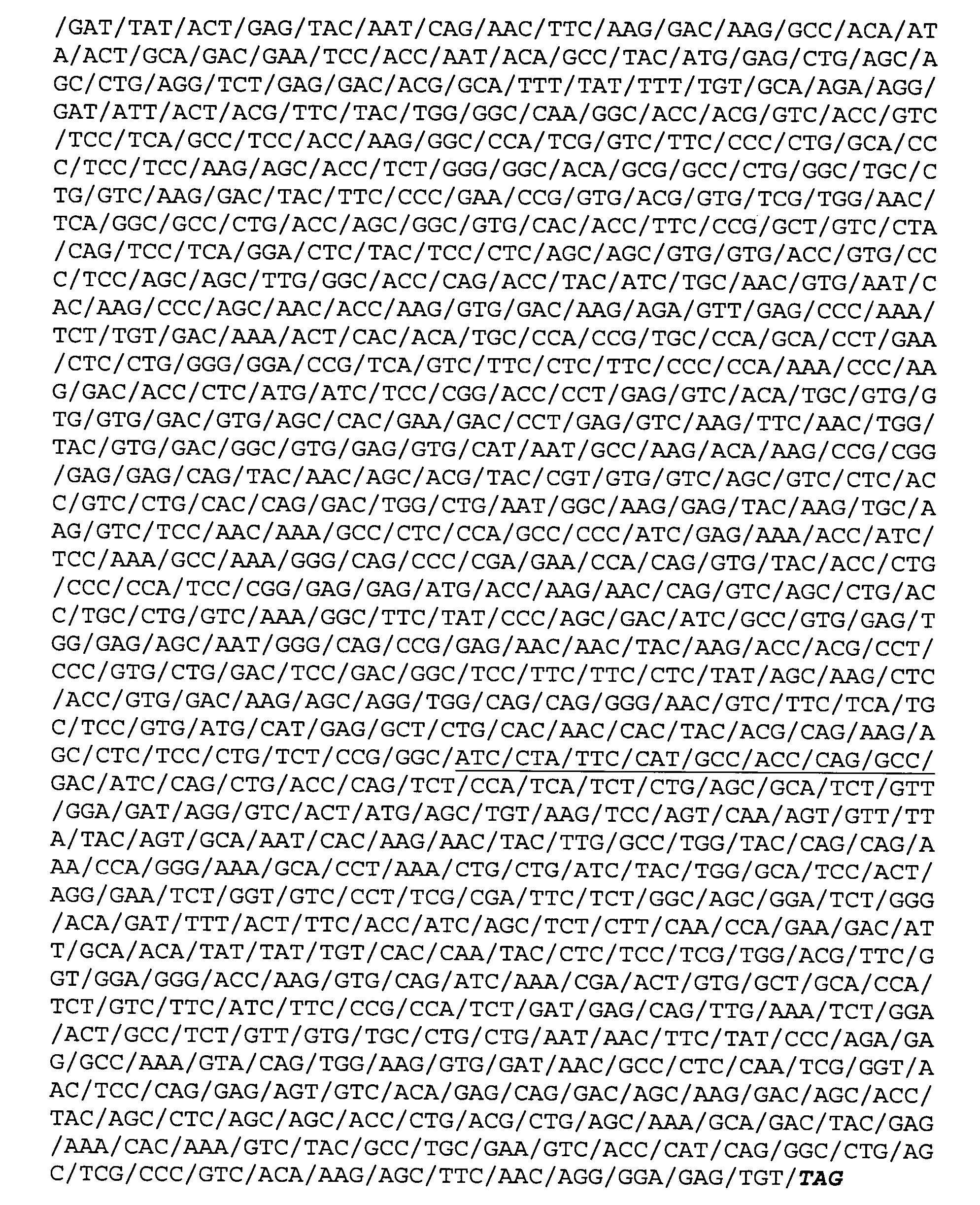

Methods for affecting mRNA expression or translation through the modification of pre-mRNA or mRNA transcripts are described. In one embodiment of the methods of the present invention, the branch point adenosine of a pre-mRNA transcript is 2′-O-methylated to block splicing and subsequent expression of the protein encoded by the transcript. In another embodiment, a uridine residue in a nonsense stop codon may be modified to pseudouridine, causing the translation machinery to read through the nonsense stop codon and translate a full length protein.

Owner:UNIVERSITY OF ROCHESTER

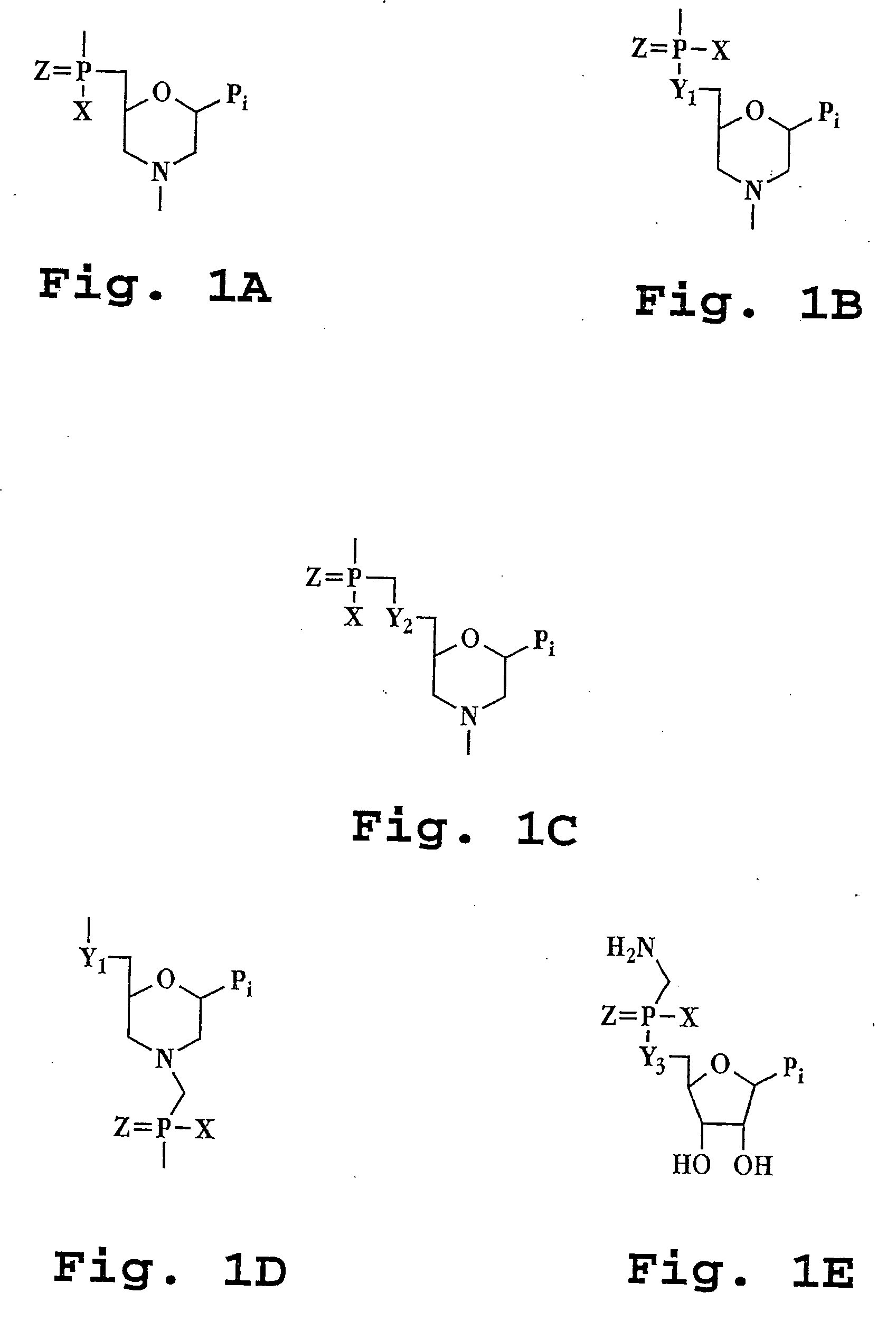

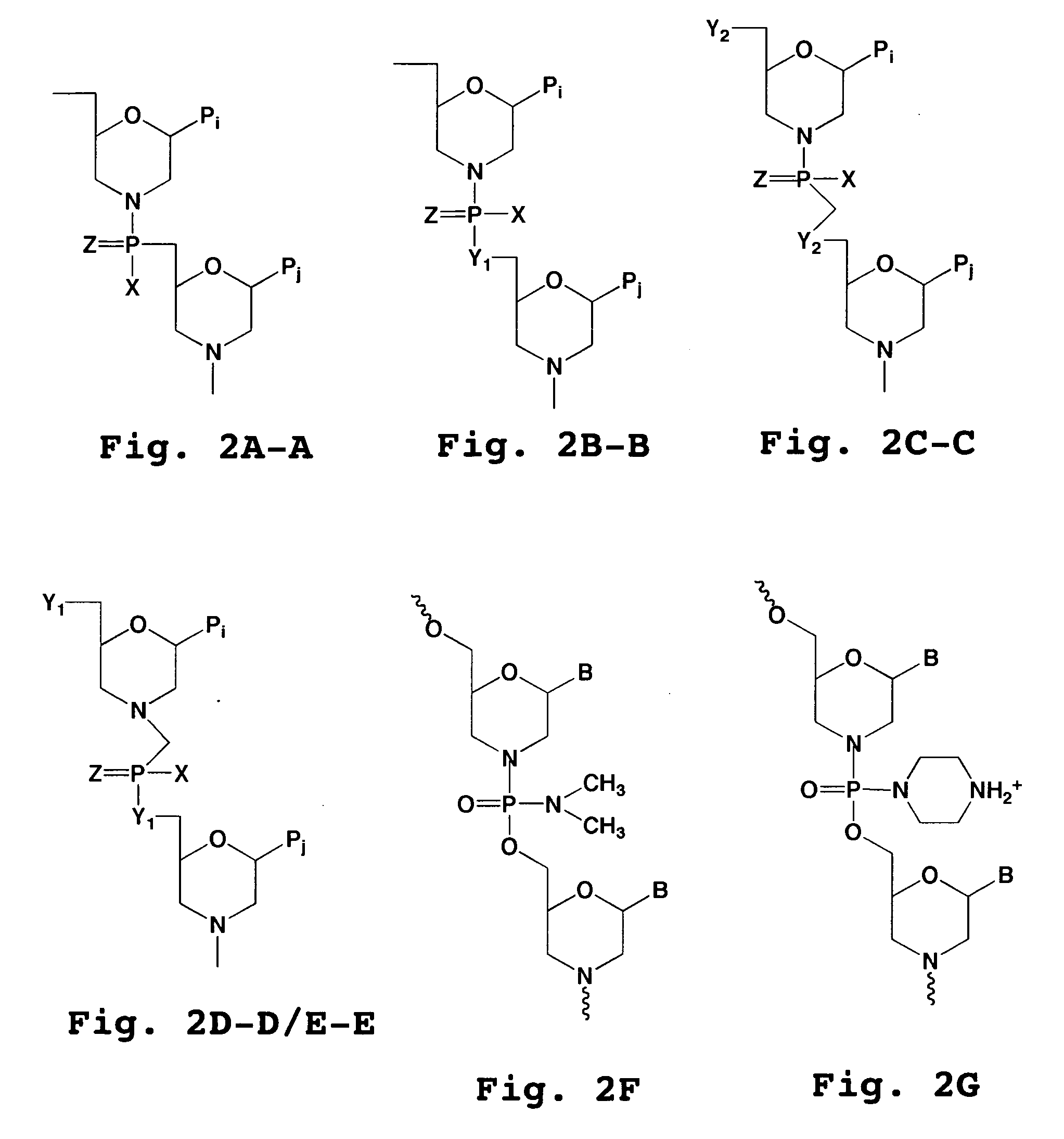

Splice-region antisense composition and method

Antisense compositions targeted against an mRNA sequence coding for a selected protein, at a region having its 5′ end from 1 to about 25 base pairs downstream of a normal splice acceptor junction in the preprocessed mRNA, are disclosed. The antisense compound is RNase-inactive, and is a phosphorodiamidate-linked morpholino oligonucleotide containing uncharged phosphorodiamidate linkages interspersed with cationic phosphorodiamidate linkages. Such targeting is effective to inhibit natural mRNA splice processing, produce splice variant mRNAs, and inhibit normal expression of the protein.

Owner:AVI BIOPHARMA

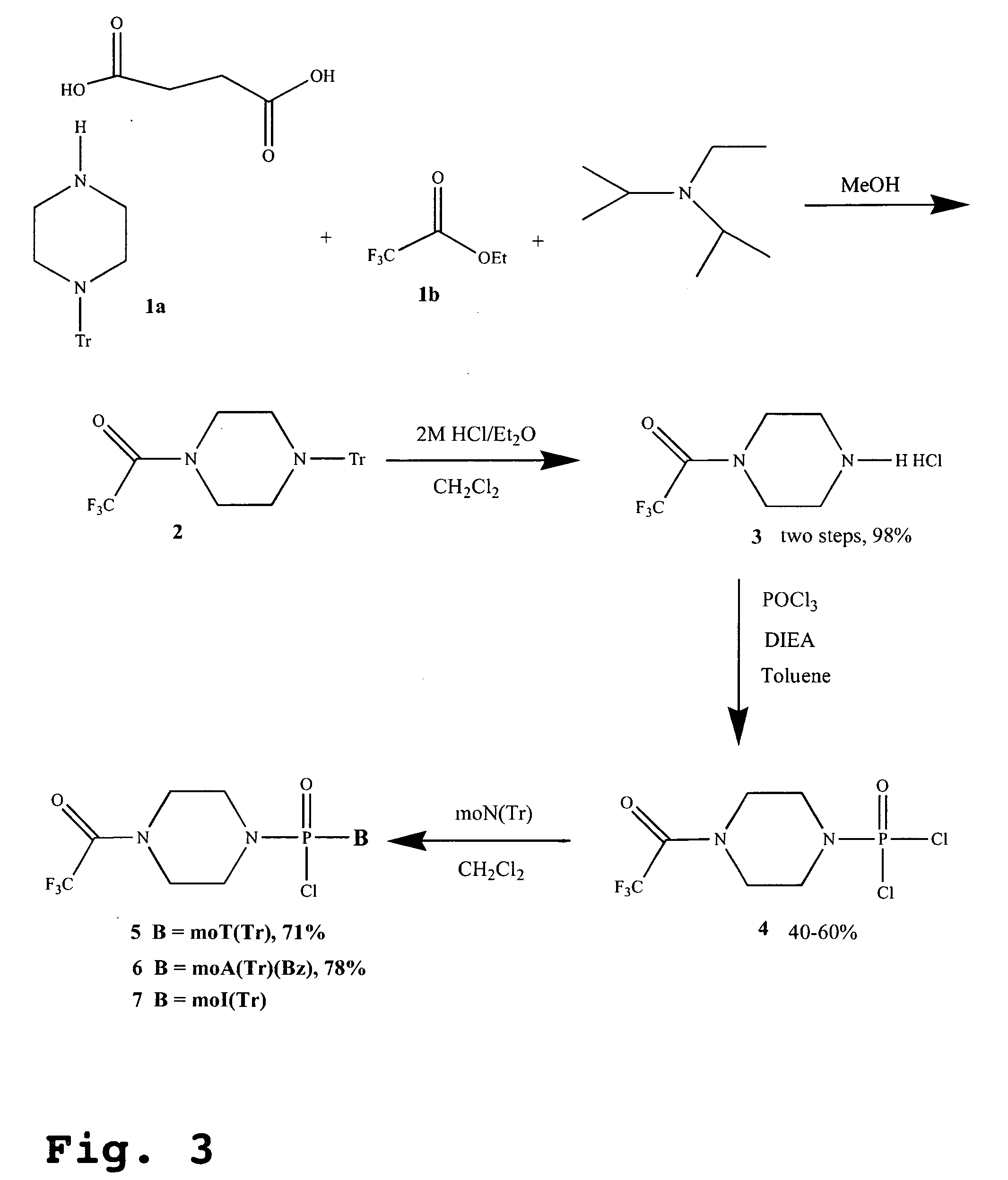

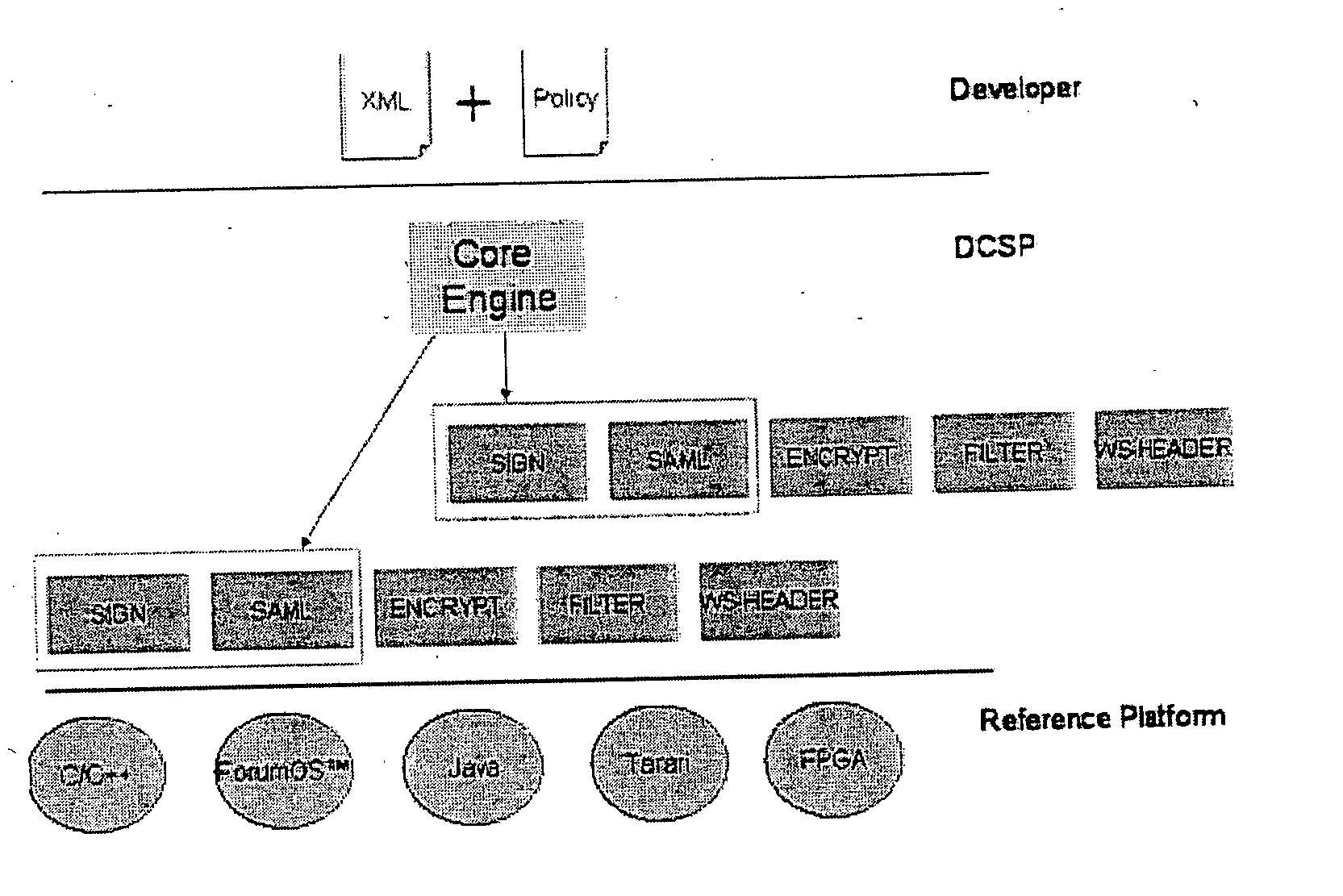

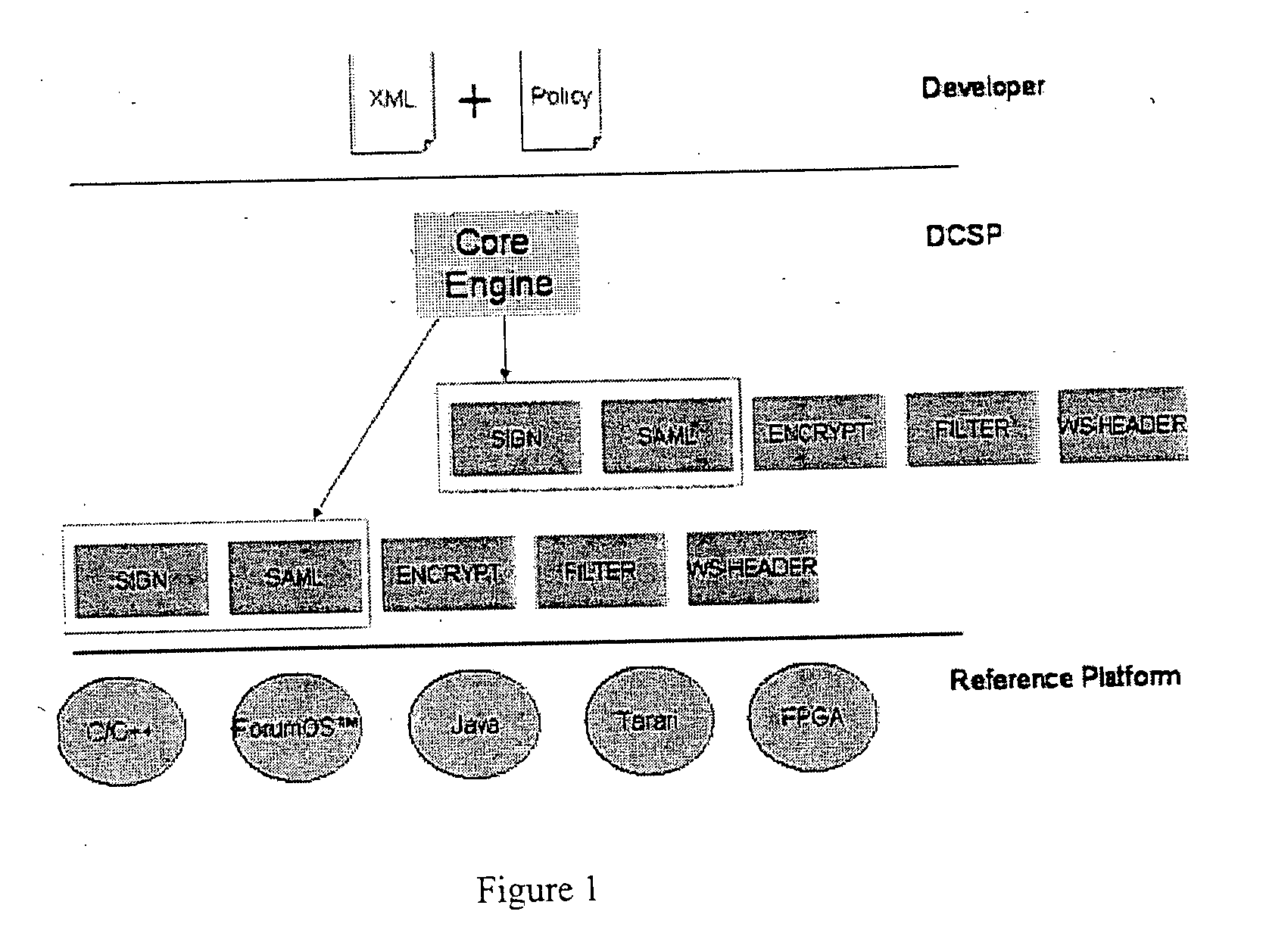

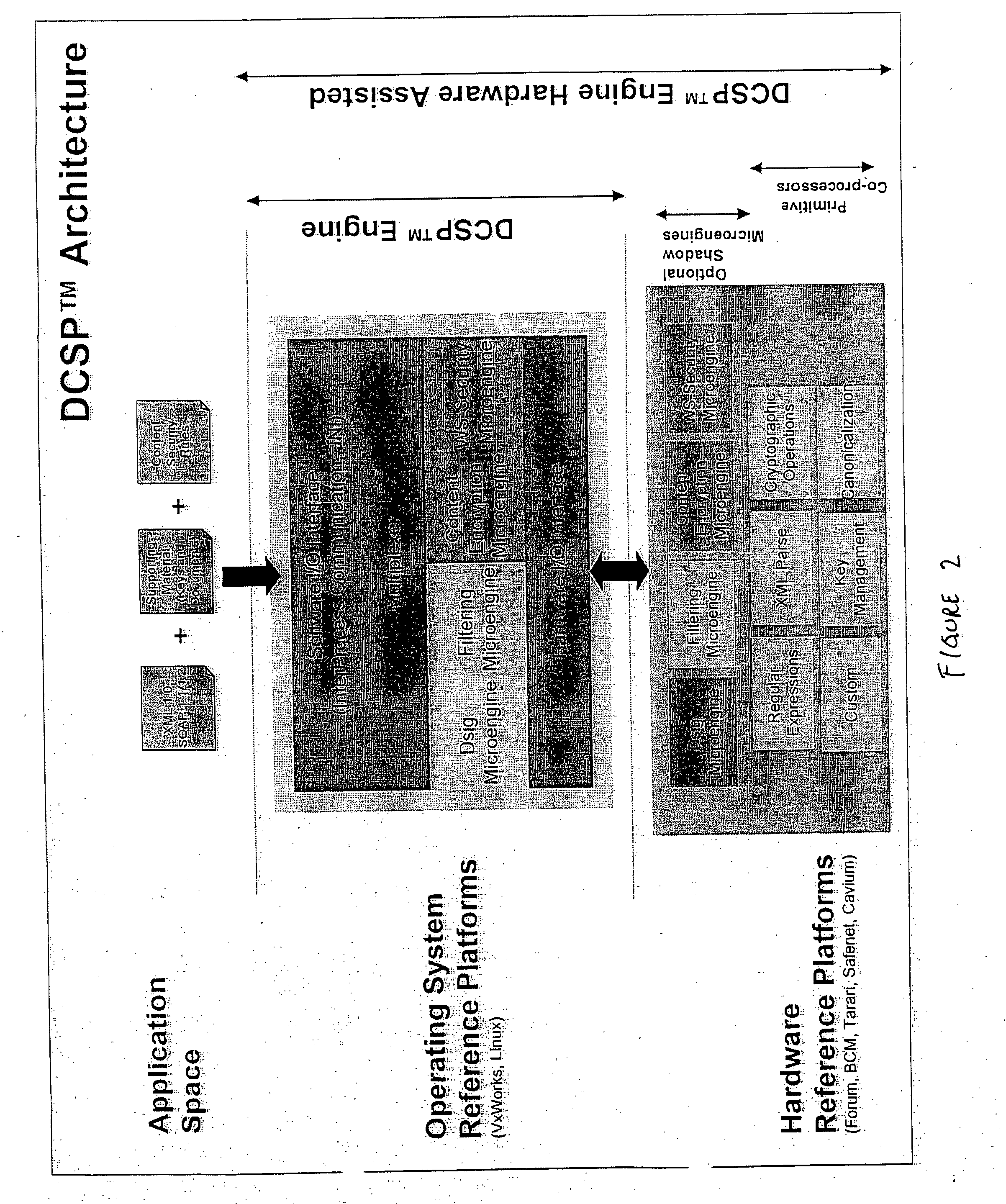

Dynamic content security processor system for XML documents

InactiveUS20050138381A1Enhance performanceIncrease efficiencyUser identity/authority verificationComputer security arrangementsContent Security PolicyEncryption

A dynamic content security parser (DCSP) that provides hardware assisted parallel processing technology for servicing complex web service security transactions at a high rate of throughput as an embeddable software product having a core DCSP engine that utilizes a content security policy to process documents in order to provide digital signature services, content encryption, XML filtering and SAML generation.

Owner:STICKLE THOMAS C +4

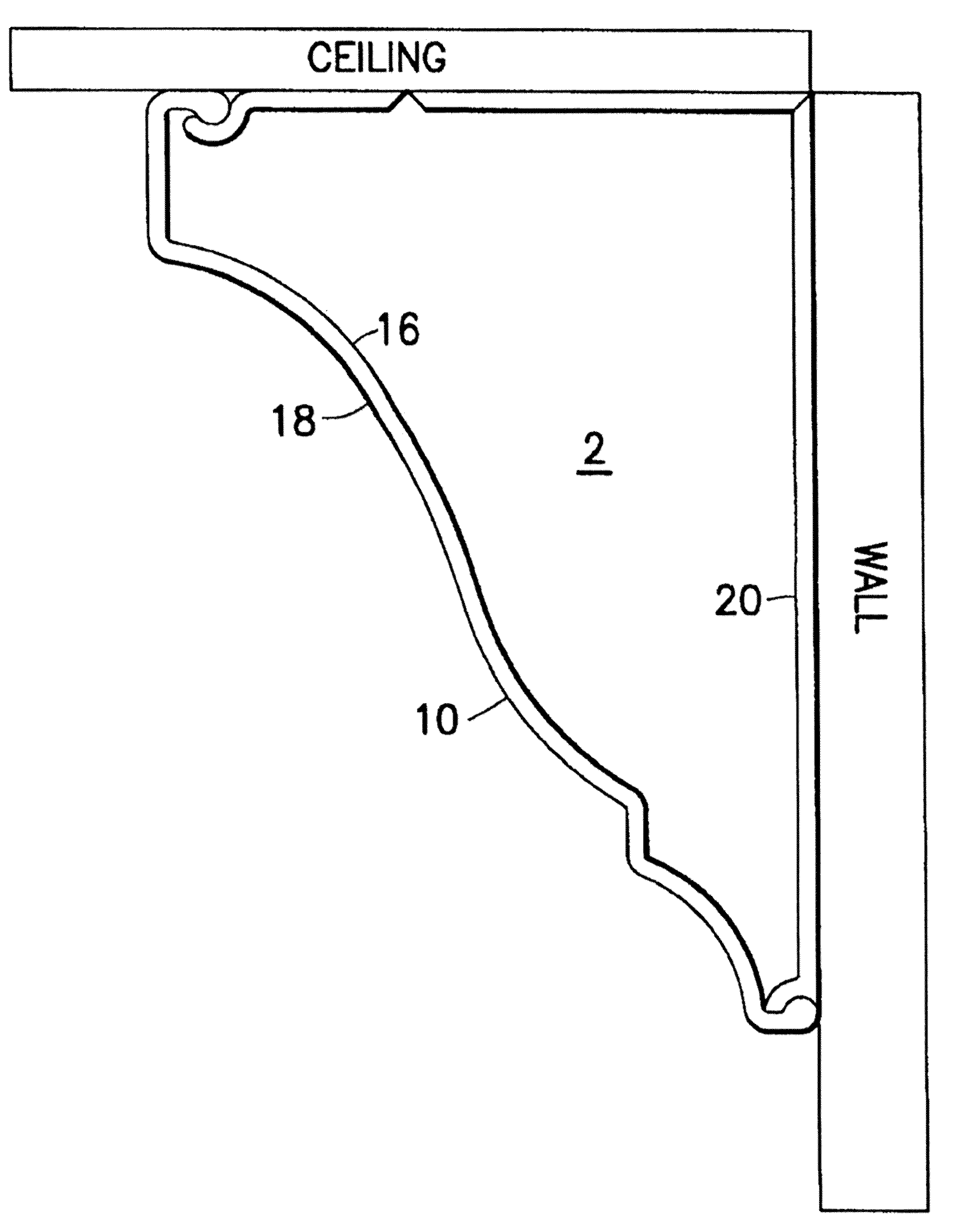

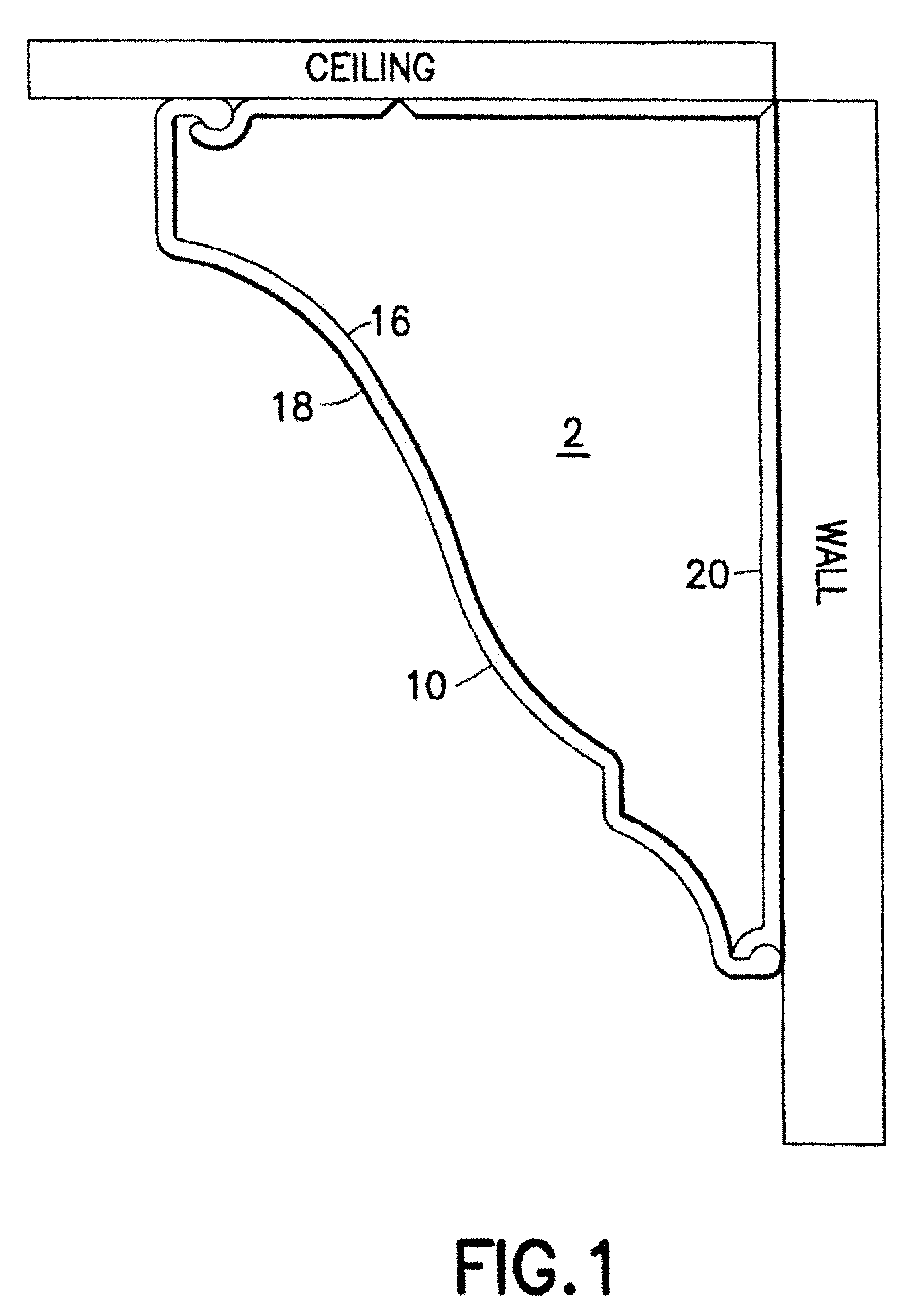

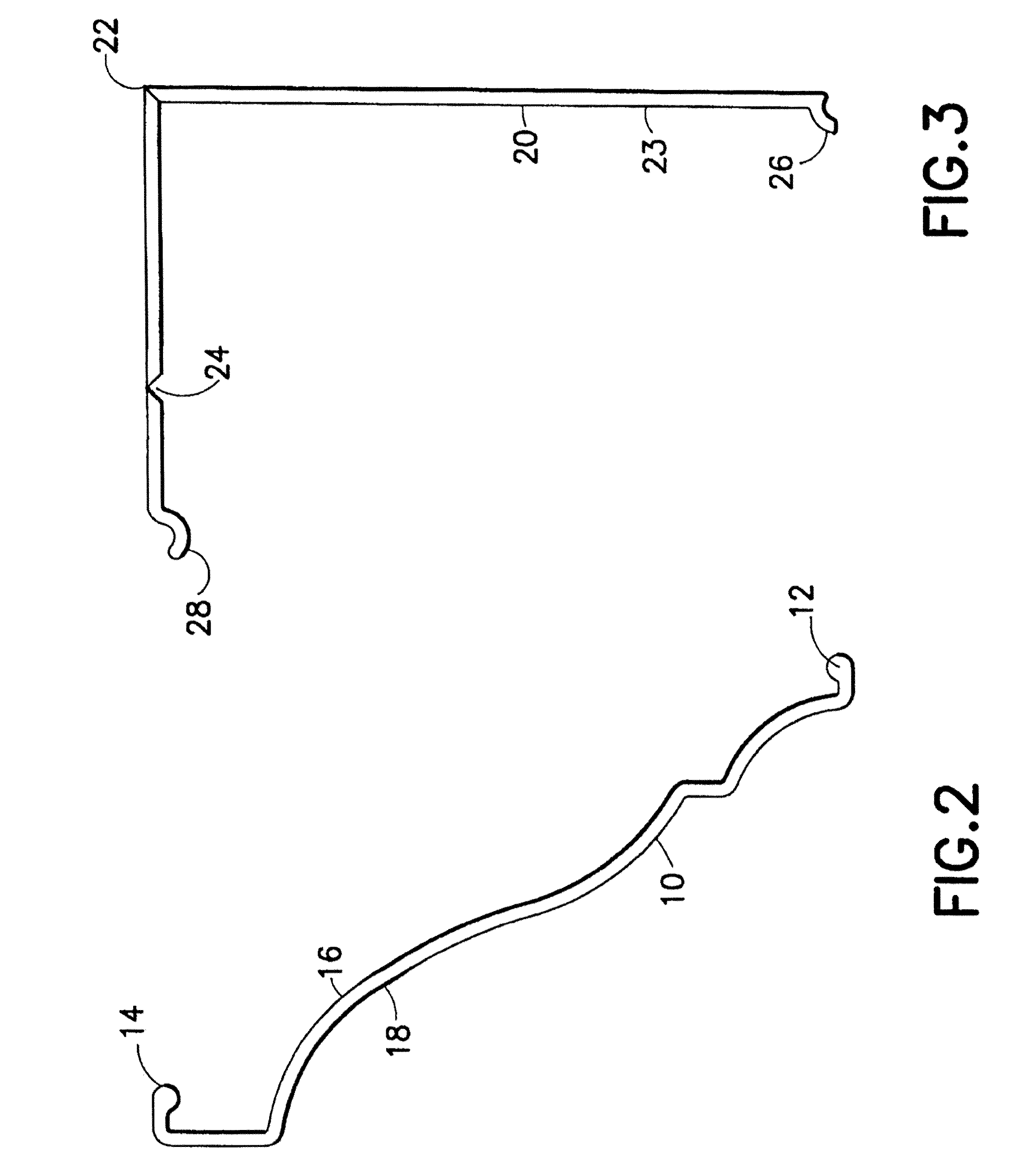

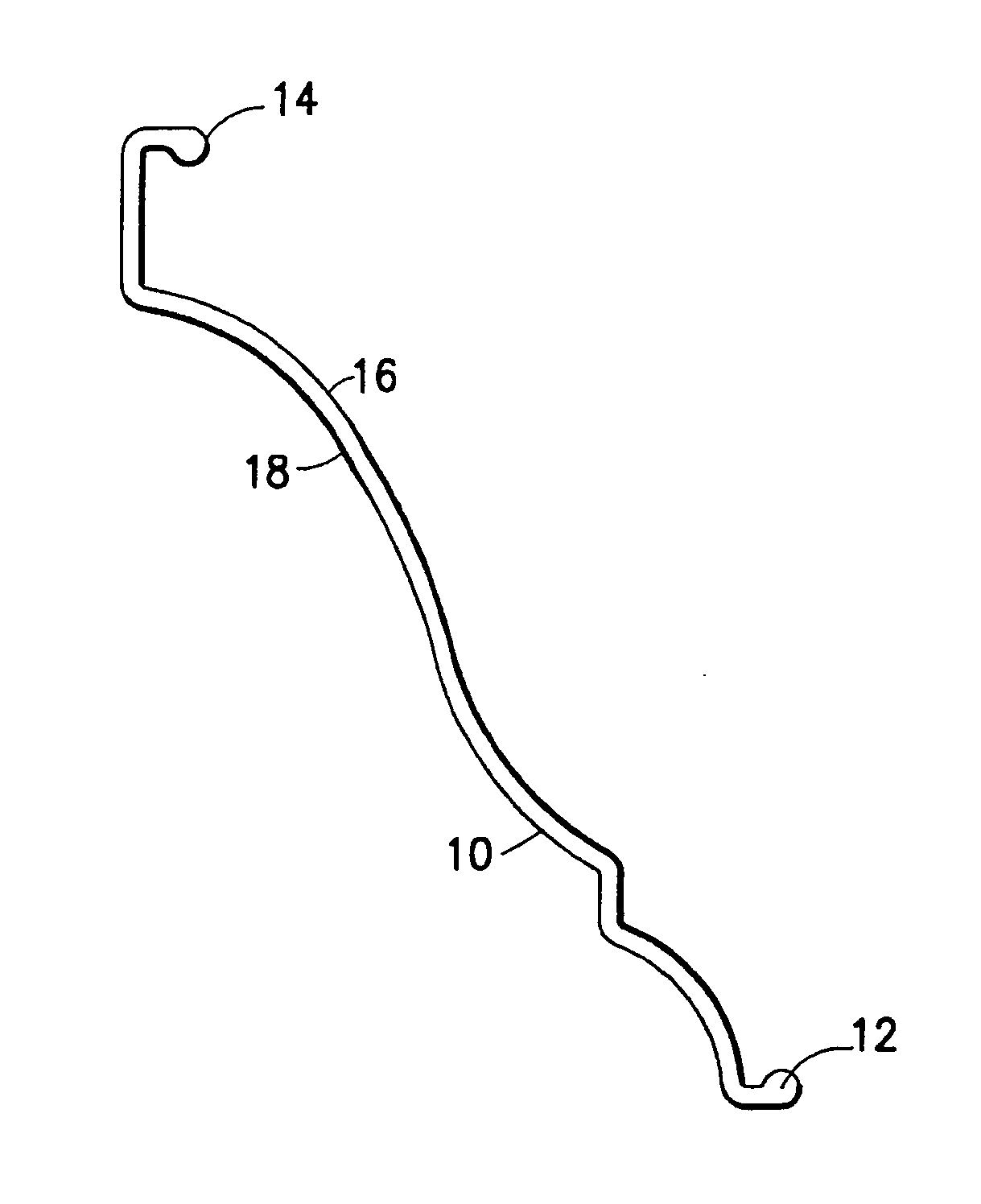

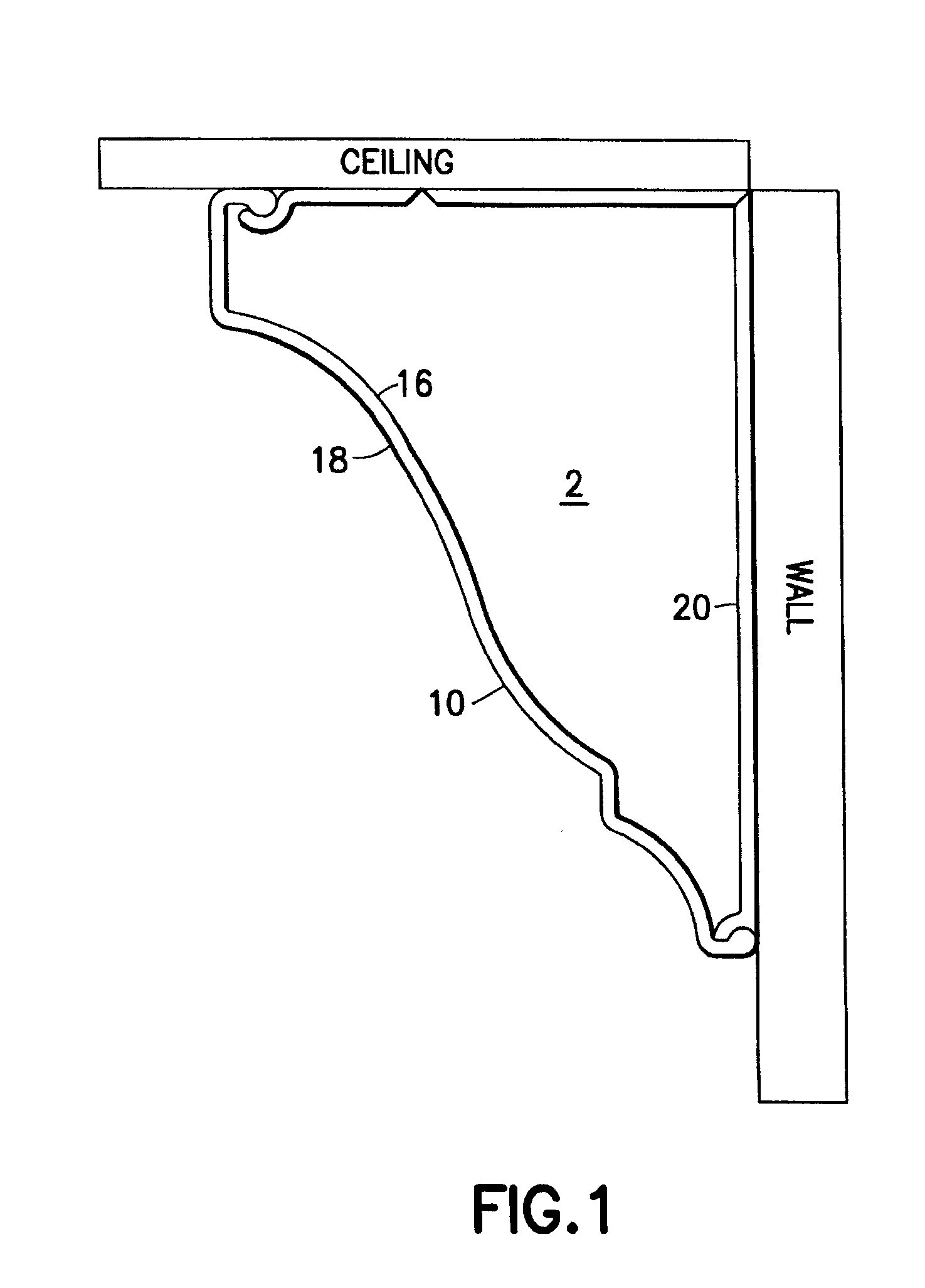

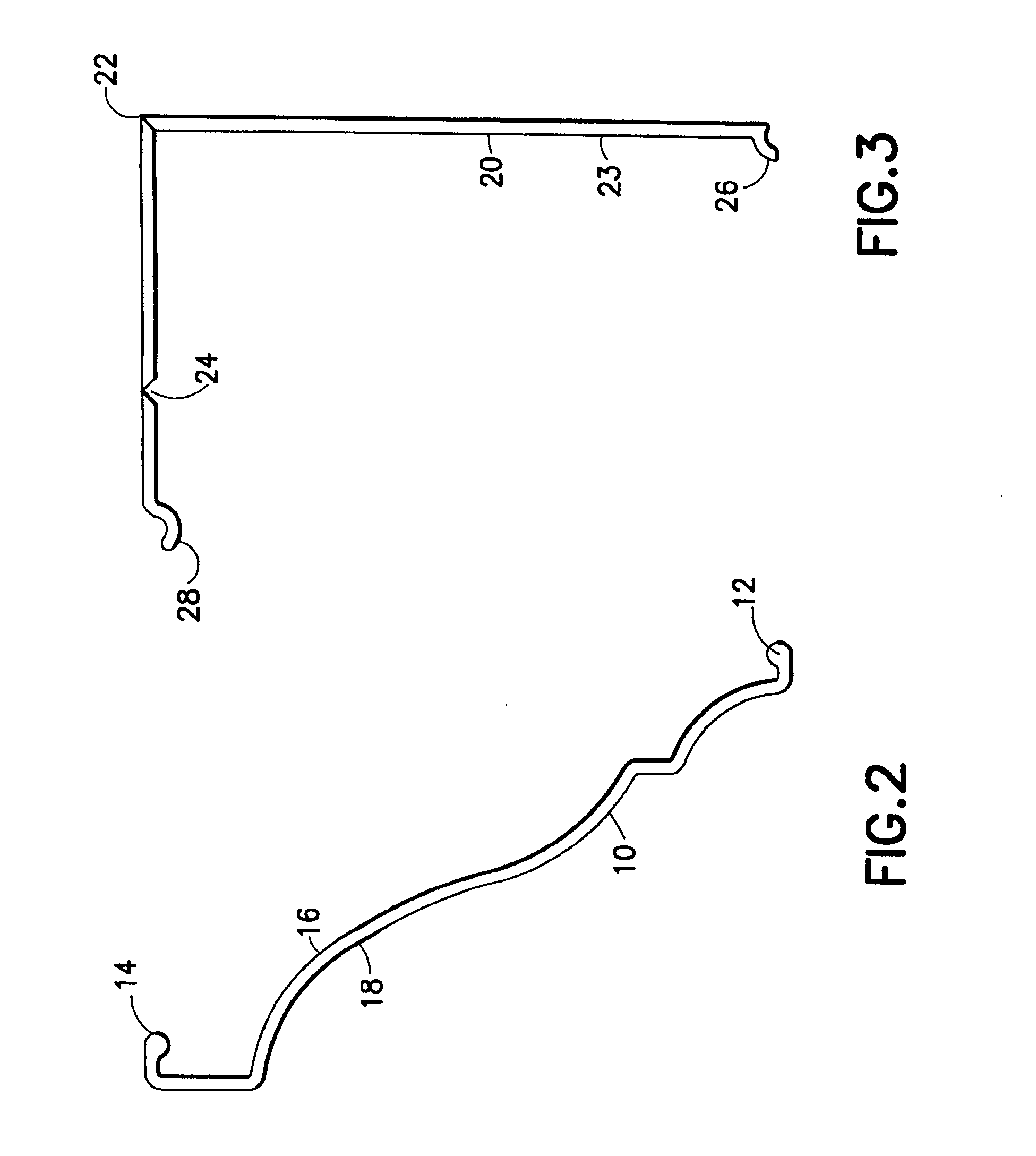

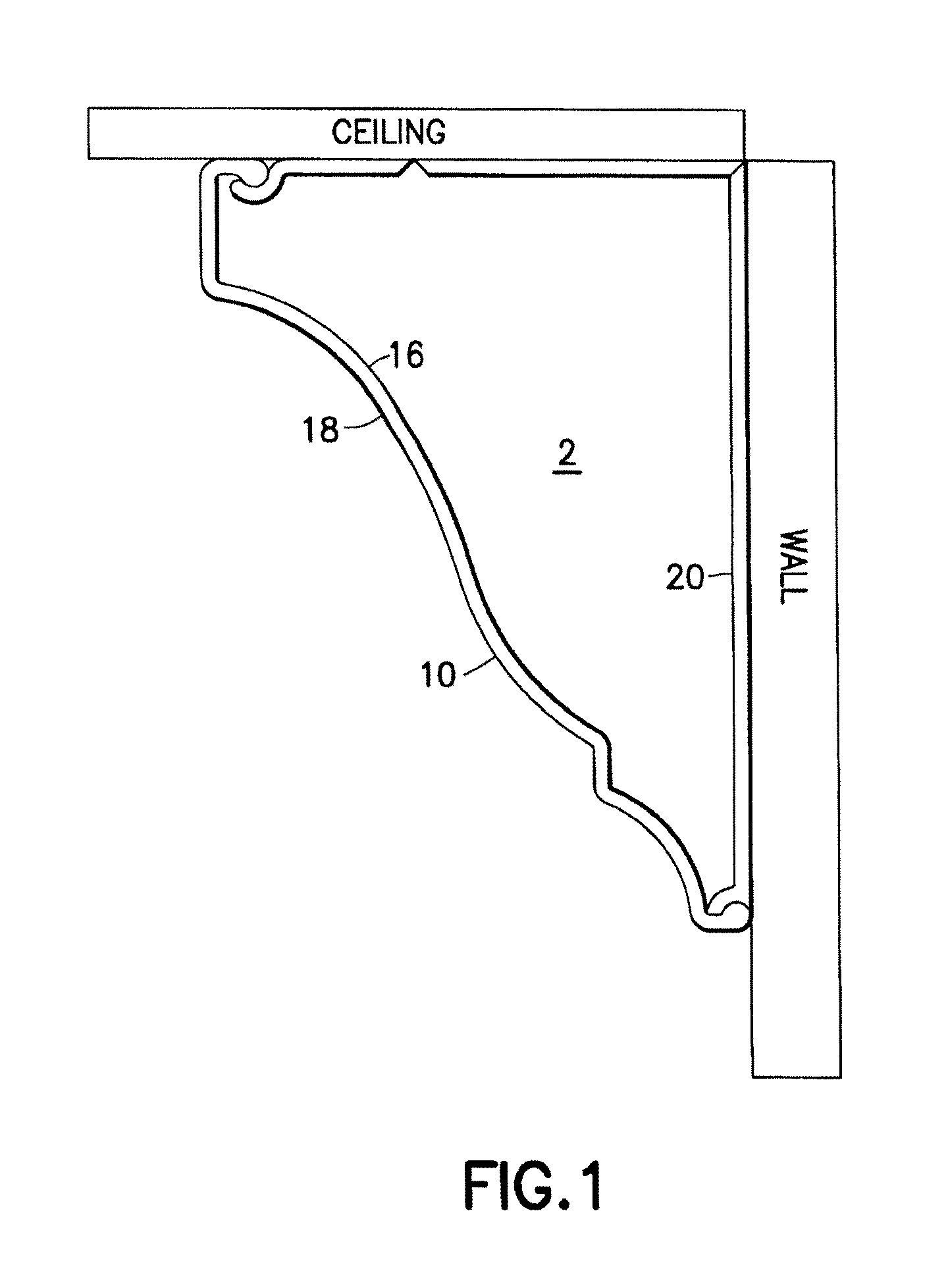

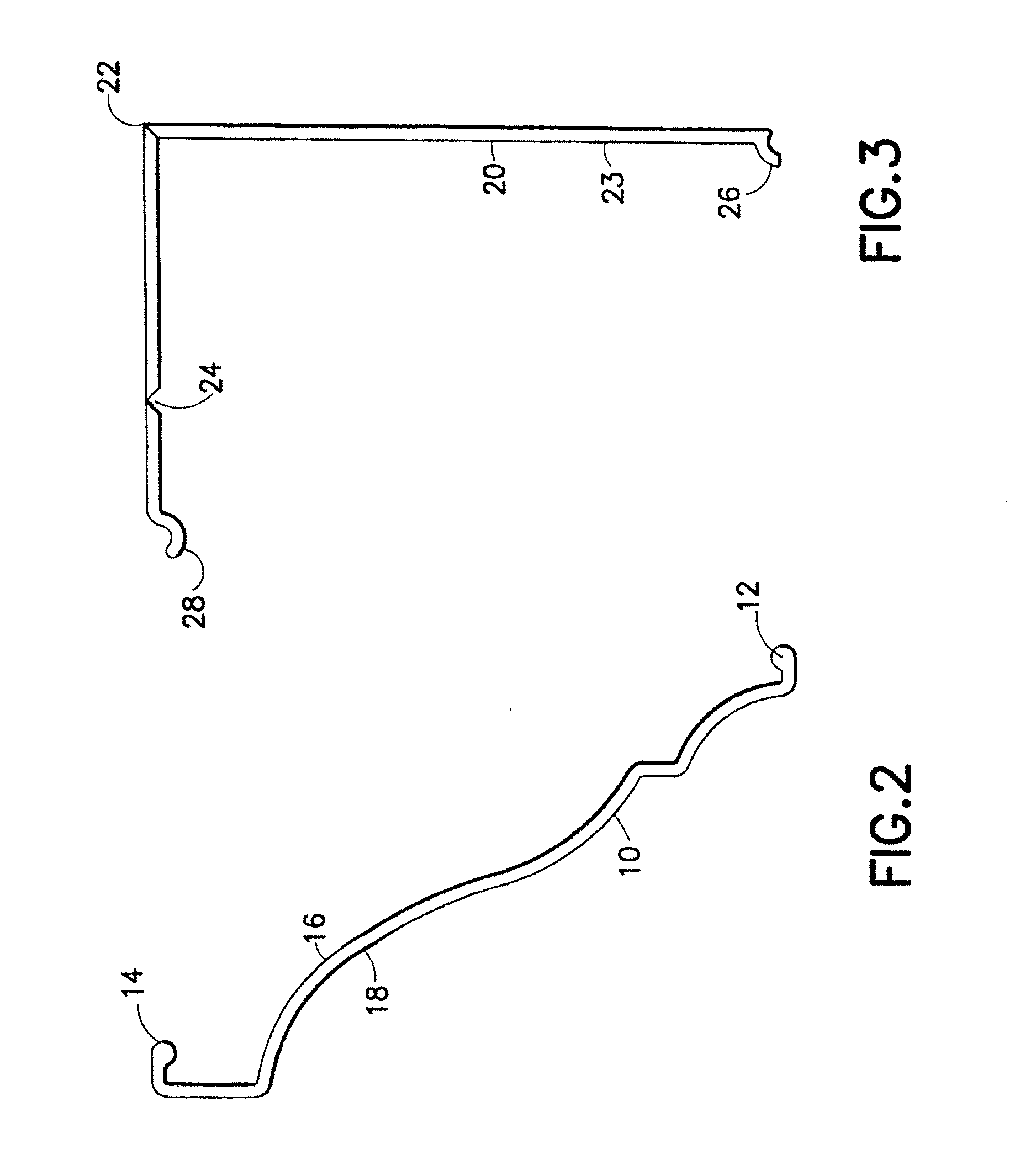

Crown extrusion

A decorative molding system and method of installation is provided that has a base piece and a crown piece that are adapted to be selectively engageable to each other. The molding system is easy to construct and allows for the separation of the base piece and crown piece for placing wiring or other materials behind the molding.

Owner:ROWOHLT TODD

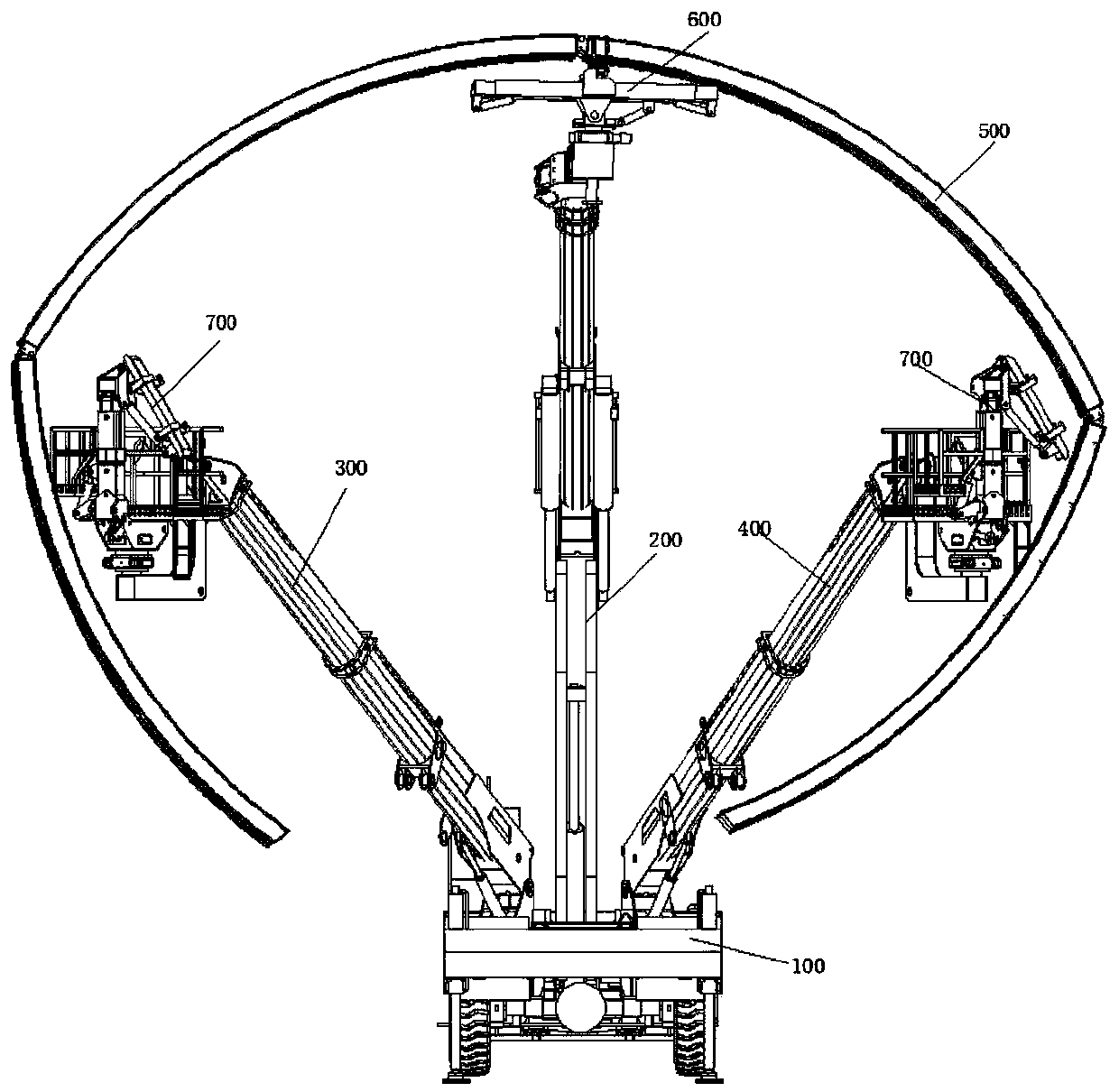

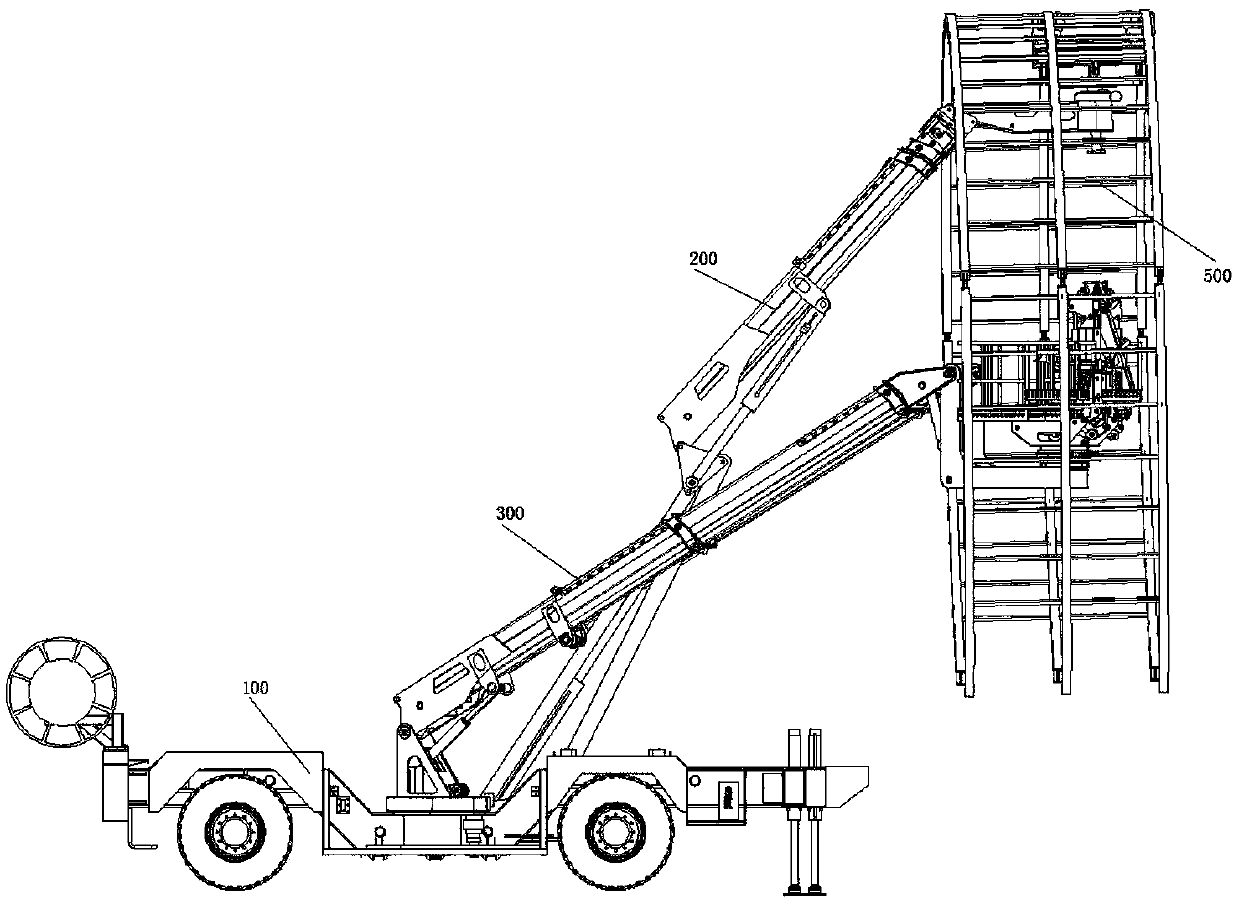

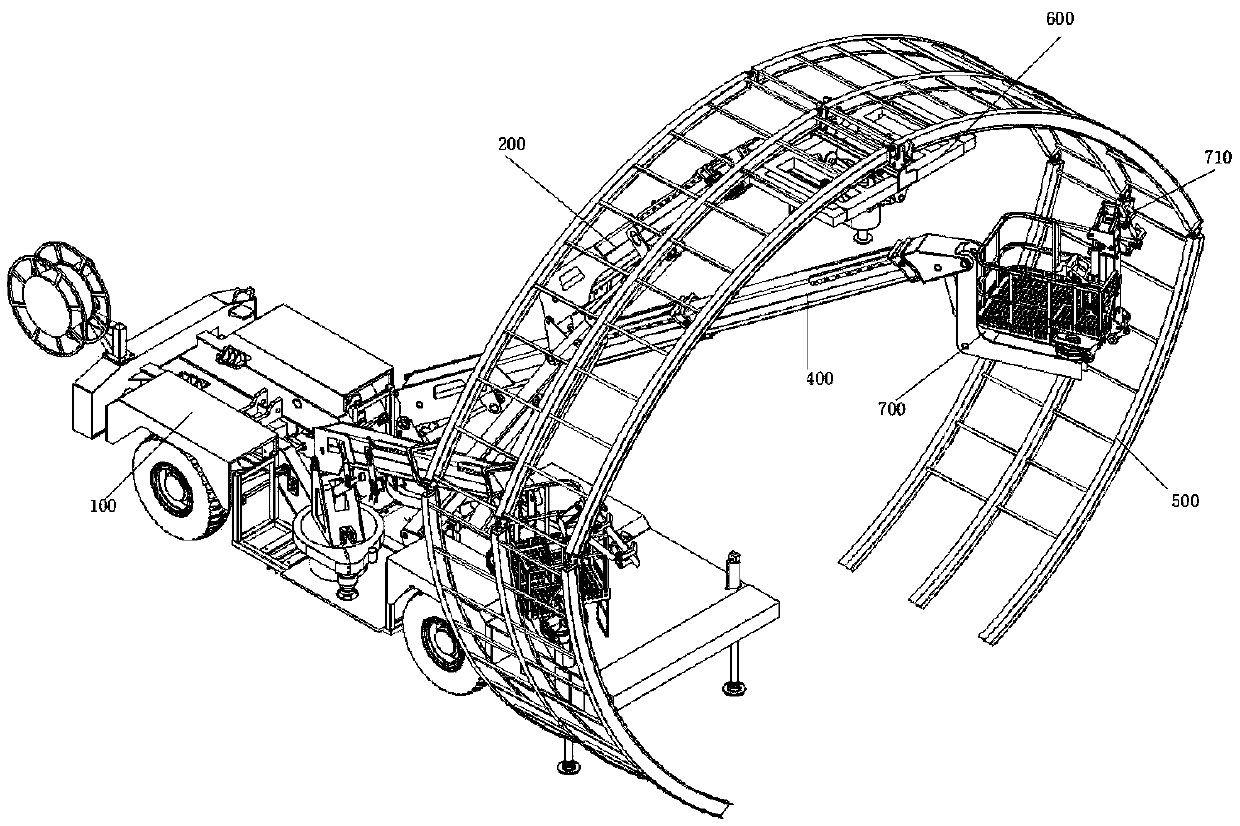

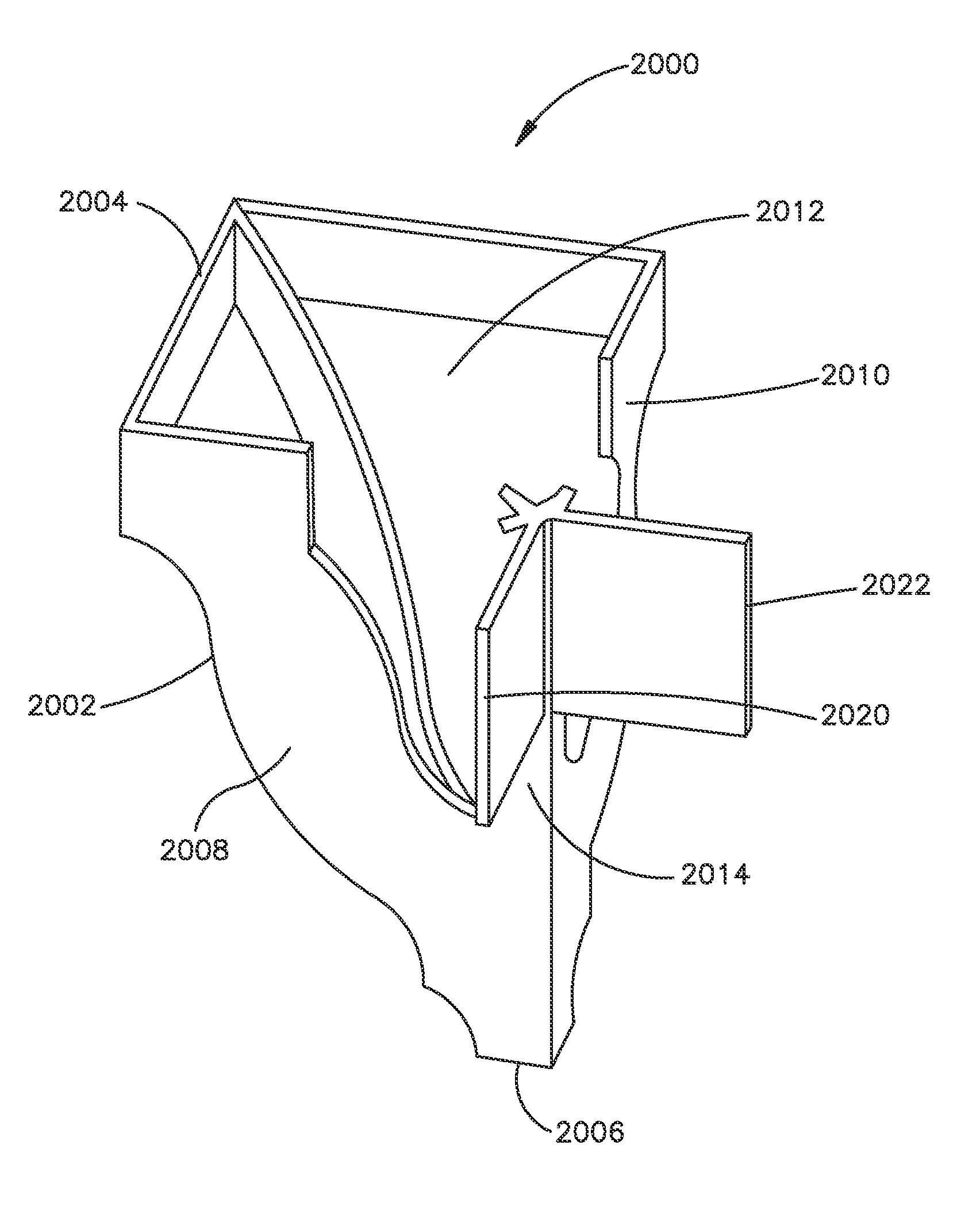

Multifunctional arch support trolley and erection method for multiple arch supports

PendingCN109538252ALifting safetyQuick liftUnderground chambersTunnel liningEngineeringArch supports

The invention belongs to the field of tunnel construction, and discloses a multifunctional arch support trolley. The trolley comprises a trolley body. A main arm frame, a right auxiliary arm frame anda left auxiliary arm frame which the rotation and stretchable functions are arranged on the trolley body. The main arm frame is located between the right auxiliary arm frame and the left auxiliary arm frame. A support clamp for clamping / supporting arch supports is arranged at the end of the main arm frame, and a rotation mechanism is arranged in the support clamp so as to control the arch supports to rotate; the ends of the right auxiliary arm frame and the left auxiliary arm frame are each provided with a worker operation platform. The multifunctional arch support trolley can transport folded steel arch supports into the tunnel stably, and perform direct changes inside the tunnel, meanwhile after the arch supports are transported to a preset place inside the tunnel, the folded steel archsupports can be safely, rapidly and stably lifted to the preset height, and the operation requirement for multi-step long-distance lifting is met.

Owner:SICHUAN LANHAI ENG EQUIP MFG CO LTD

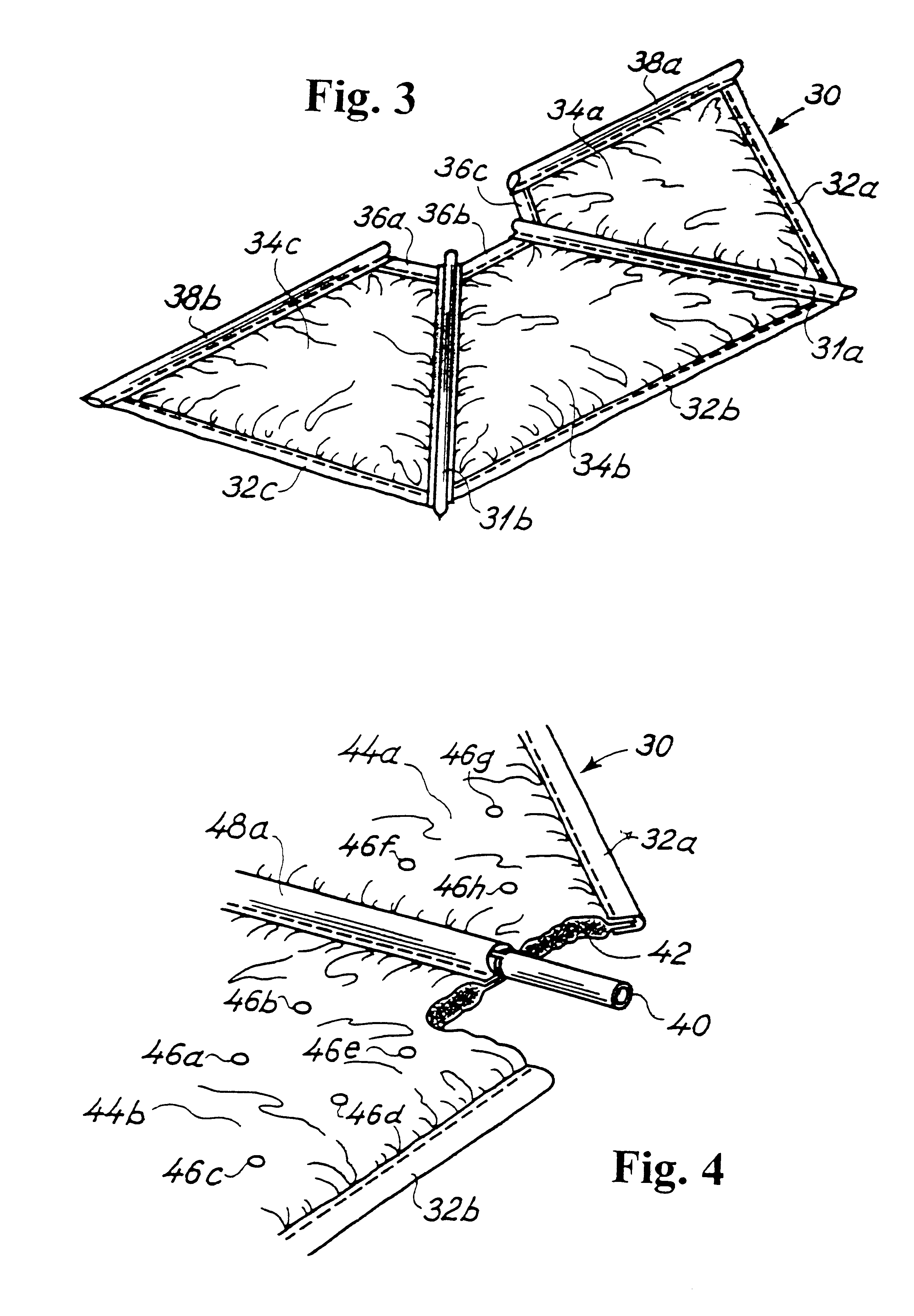

Decorative molding system

A decorative molding system and method of installation is provided that has a base piece and a crown piece that are adapted to be selectively engagable to each other. The molding system is easy to construct and allows for the separation of the base piece and crown piece for placing wiring or other materials behind the molding.

Owner:ROWOHLT TODD

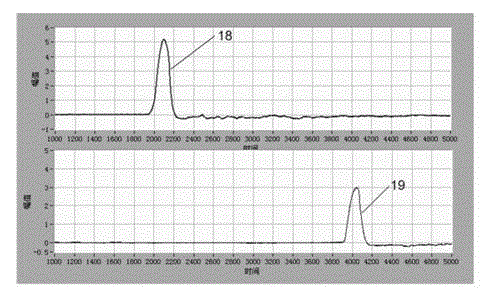

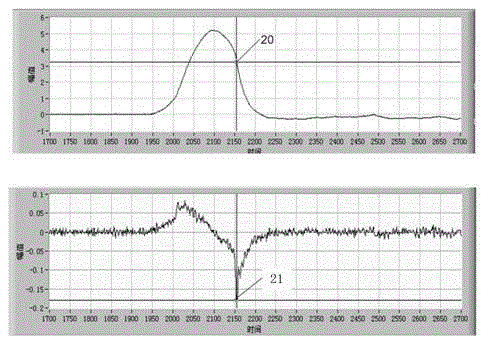

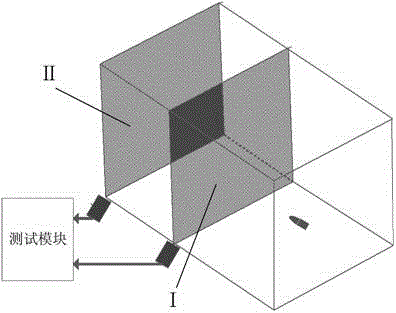

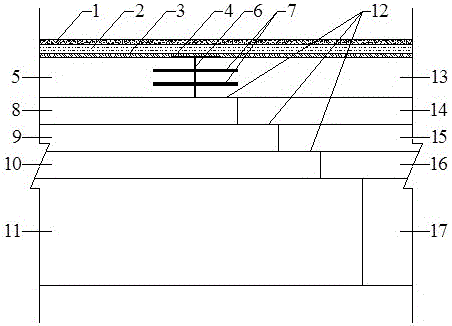

Speed testing device and method of non-spliced large-target surface laser light screen

ActiveCN102721826AAvoid stitchingMake sure the signal respondsDevices using time traversedElectromagnetic wave reradiationSignal responseTarget surface

The invention discloses a speed testing device of a non-spliced large-target surface laser light screen. A set of linear laser light source is adopted for producing the larger-target surface laser light screen with 90-degree coverage, so that the splicing of the light screen can be avoided; a retroreflector with a serrated structure is adopted as a reflection cooperative target, so that the laserreflectivity in each region is improved and the signal response of a shot when the shot flies across all the regions of the large-area light screen can be ensured; a spherical surface reflecting mirror with a laser emergent hole is obliquely arranged before a laser (namely, a light axis of the spherical surface reflecting mirror and an emergent light axis of the laser form an angle), so that a circular arc-shaped light spot is formed by convergence; a three-section type structure or a circular arc structure is adopted for being connected with a spliced light-sensitive tube array in parallel, so that light transmitting and receiving integrated photoelectric detection of the large-target surface laser light screen with the 90-degree coverage can be realized; and by adopting a maximum negative slope point seeking algorithm, the timing time when the shot flies across the two light screens can be precisely determined, and the more precise speed of the shot can be further obtained.

Owner:ZHONGBEI UNIV

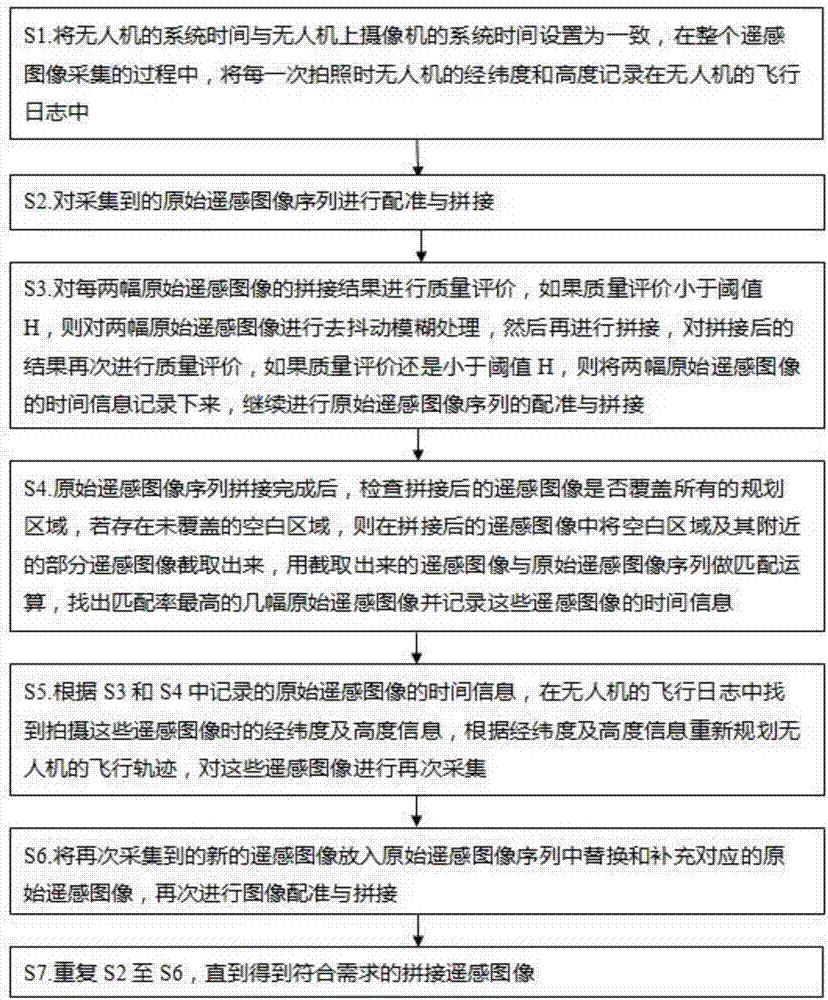

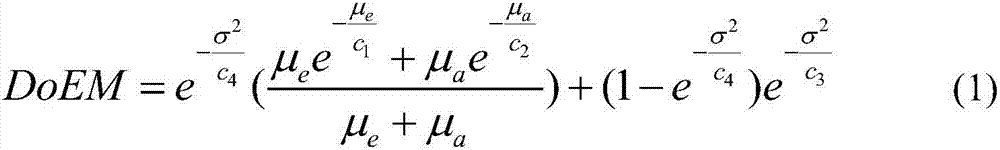

Image splicing quality evaluation-based unmanned aerial vehicle remote sensing image splicing method

ActiveCN107146200AImprove splicing efficiencyAvoid duplicationImage enhancementImage analysisImaging processingLongitude

The present invention relates to the image processing technology field, in particular relates to an image splicing quality evaluation-based unmanned aerial vehicle remote sensing image splicing method. The method comprises the steps of recording the latitude and longitude information and the altitude information of an unmanned aerial vehicle when each frame of remote sensing image is acquired, using a jitter fuzzy removing algorithm to remove the jitter fuzzy of the remote sensing images, adopting the image splicing quality evaluation to find out the remote sensing images not satisfying the splicing requirements in a remote sensing image sequence, using the unmanned aerial vehicle to reacquire the remote sensing images not satisfying the requirements according to the recorded latitude and longitude information and the altitude information, putting the reacquired new remote sensing images in the original remote sensing image sequence to replace and supplement the corresponding original remote sensing images, and carrying out the image registration and splicing again, thereby avoiding the repeated acquisition and splicing of the effective images, improving the image splicing efficiency while reducing the workload.

Owner:GUANGXI UNIV

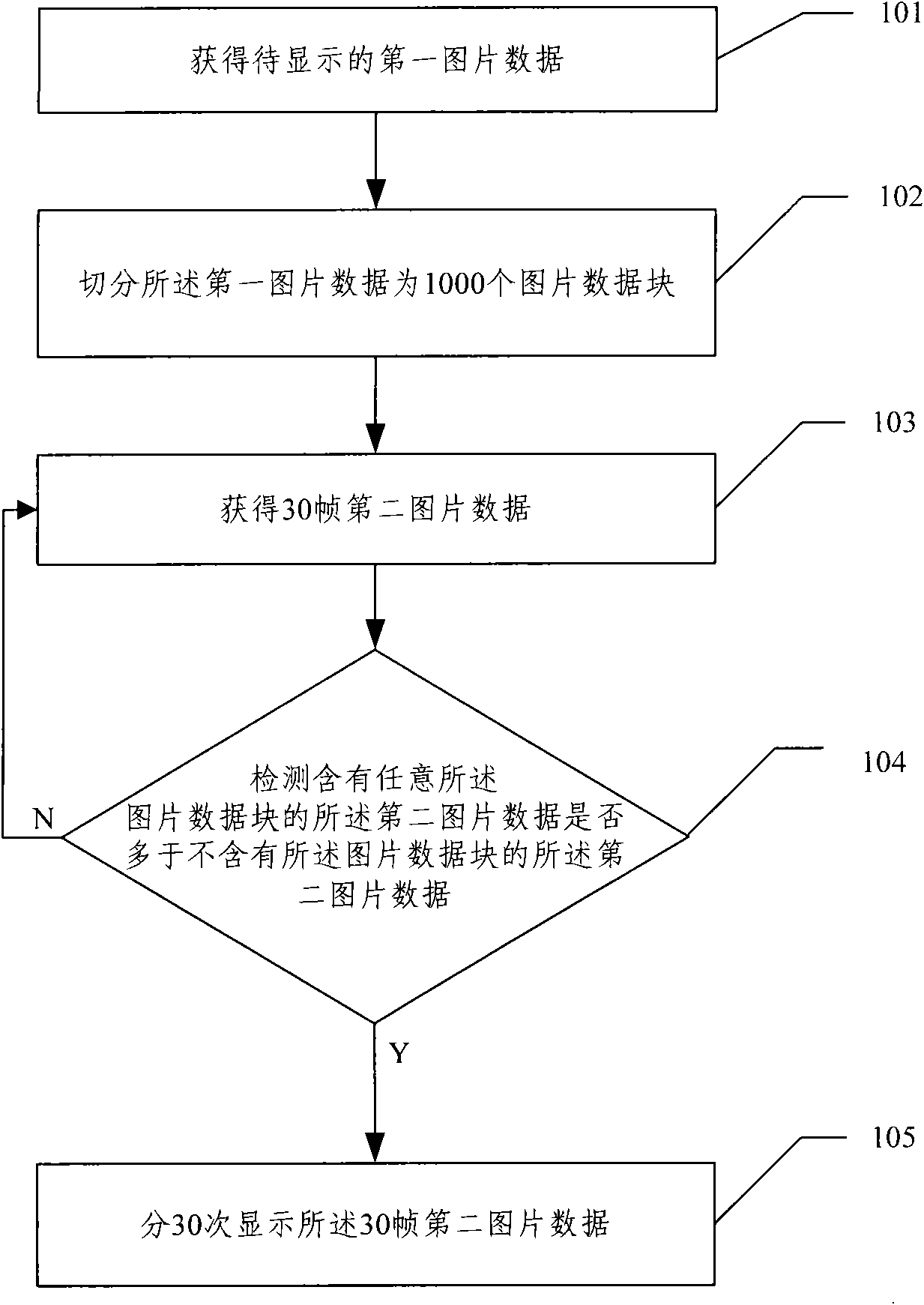

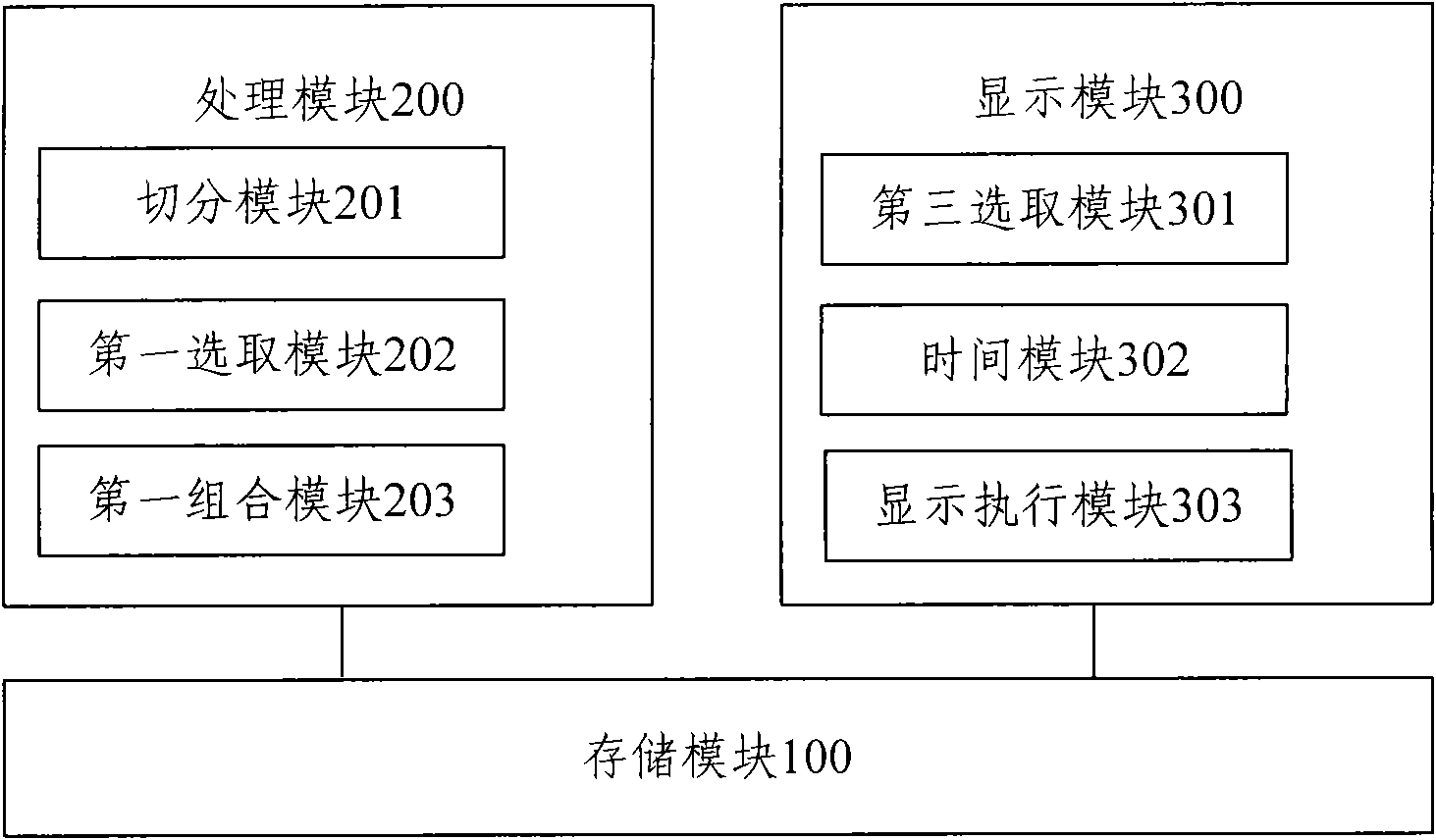

Display method and display device

ActiveCN101561852APrevent copy theftAvoid stitchingDigital data protectionCathode-ray tube indicatorsComputer graphics (images)Display device

The invention discloses a display method which comprises the following steps: acquiring first picture data to be displayed; processing the first picture data into K picture data blocks; acquiring second picture data with N frames, and displaying the second picture data with N frames for N times, wherein N is an integer which is larger than or equal to 2, and each of the second picture data with N frames comprises X picture data blocks in the K picture data blocks and the rest processed X picture data blocks in the K picture data blocks. The invention also discloses a display device which comprises a storage module, a processing module and a display module, wherein the storage module is used for storing data; the processing module is used for processing the first picture data into the second picture data with N frames, and storing the second picture data with N frames into the storage module; and the display module is used for acquiring the second picture data with N frames from the storage module, and displaying the second picture data with N frames for N times. The display method can be used for solving the problem that the picture data is copied by screen capture.

Owner:LENOVO (BEIJING) LTD

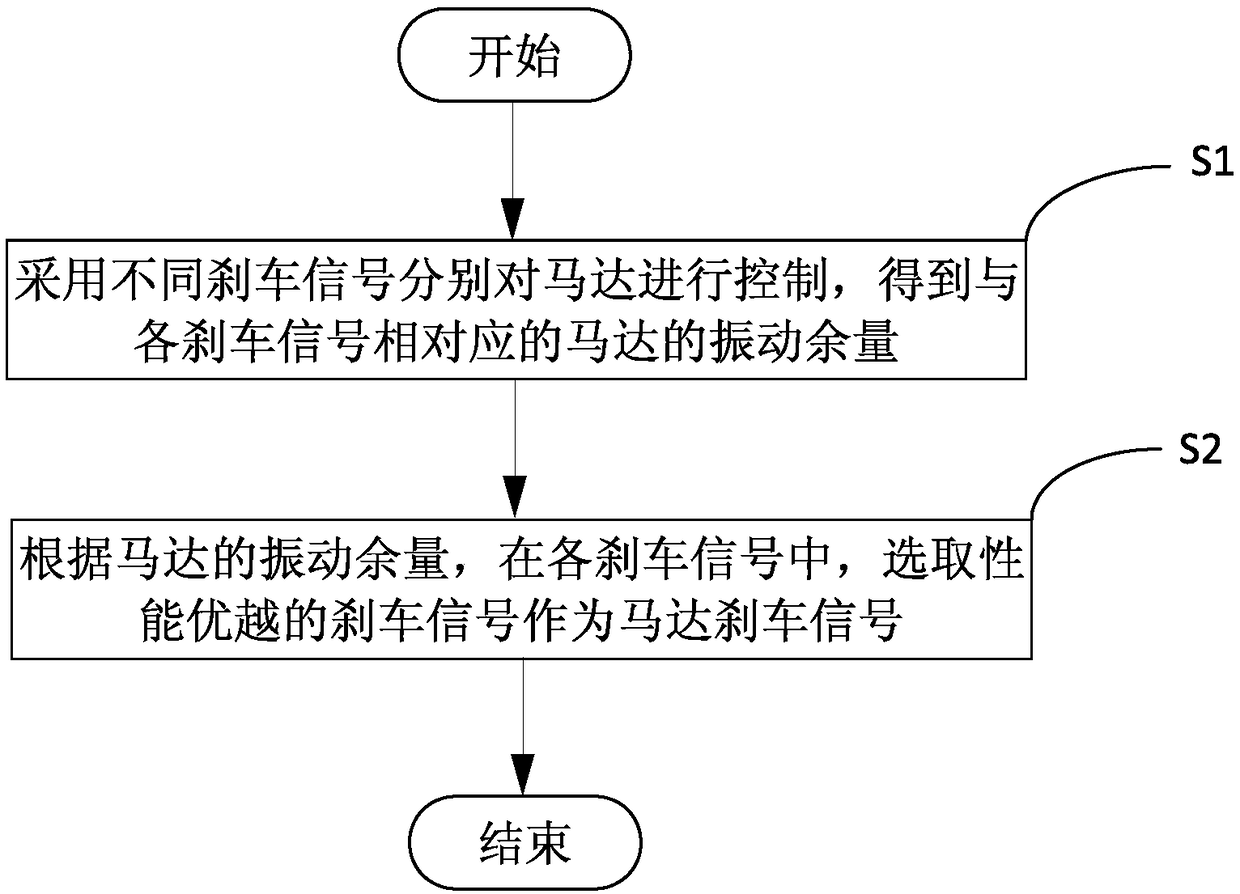

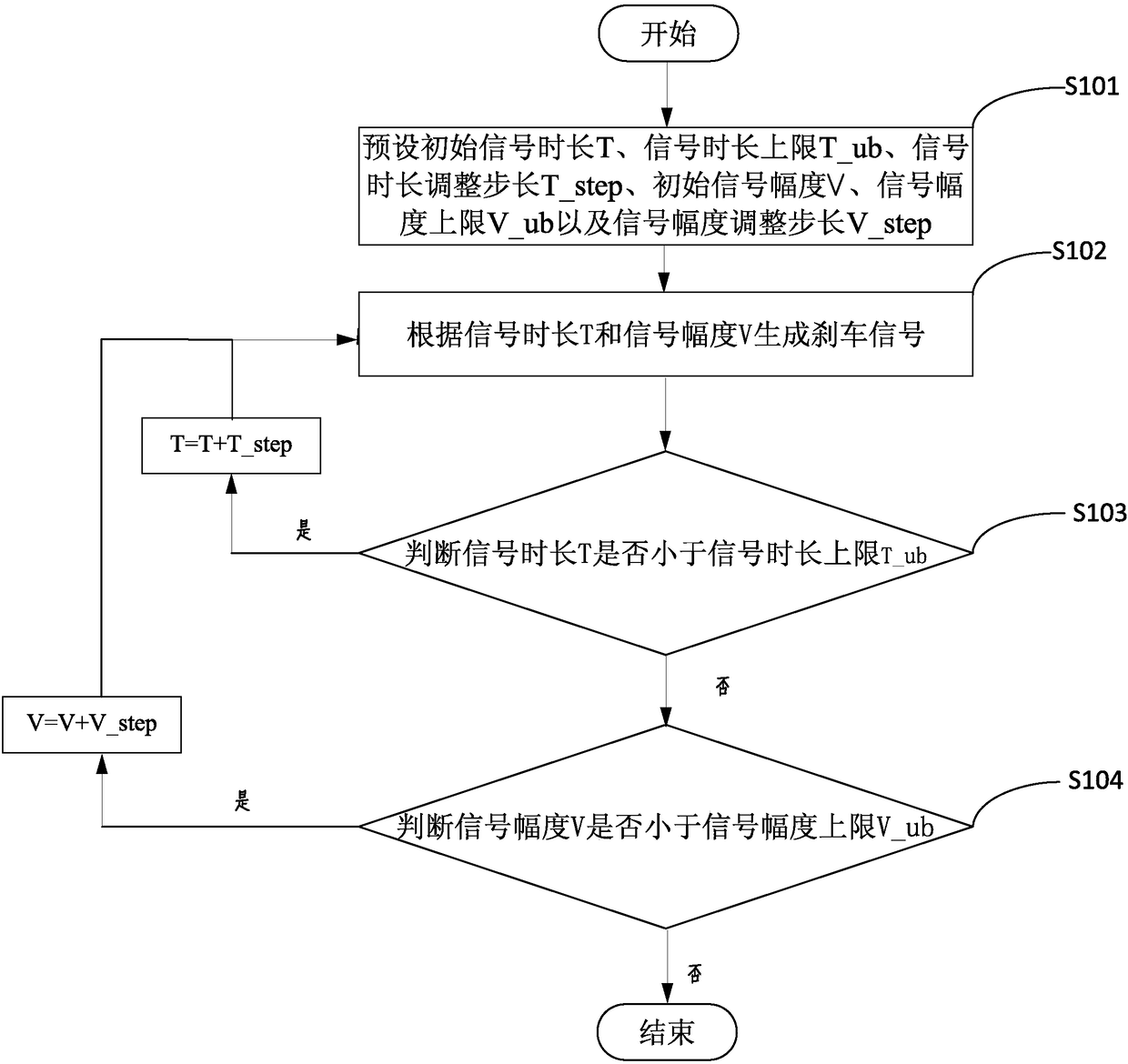

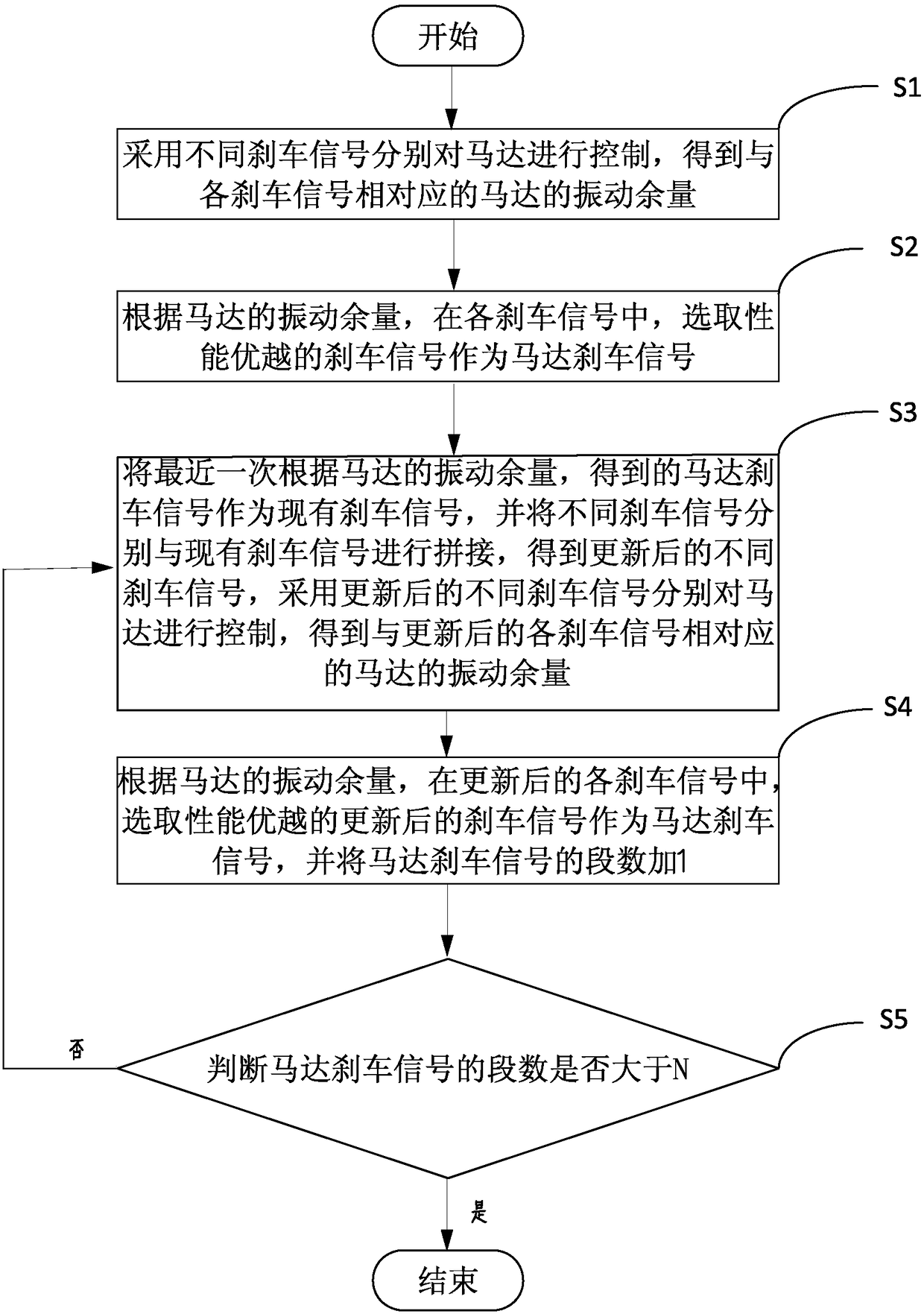

Method and device for generating motor brake signals

ActiveCN108334193AGood braking effectIneffective brakingInput/output for user-computer interactionDevices with sensorAutomotive engineeringElectron device

An embodiment of the invention relates to the technical field of electronic equipment, and discloses a method for generating motor brake signals. The method for generating the motor brake signals includes steps of S1, controlling motors by the aid of different brake signals to obtain vibration allowance of the motors; S2, selecting brake signals with excellent performance from the various brake signals according to the vibration allowance of the motors. The vibration allowance of the motors corresponds to the various brake signals. The selected brake signals with the excellent performance areused as the motor brake signals. The performance of the corresponding brake signals is improved along with decrease of the vibration allowance of the motors. The invention further provides a device for generating the motor brake signals. The method and the device for generating the motor brake signals have the advantage that excellent brake effects can be realized by the motors.

Owner:AAC TECH PTE LTD

Exon skipping therapy for dystrophic epidermolysis bullosa

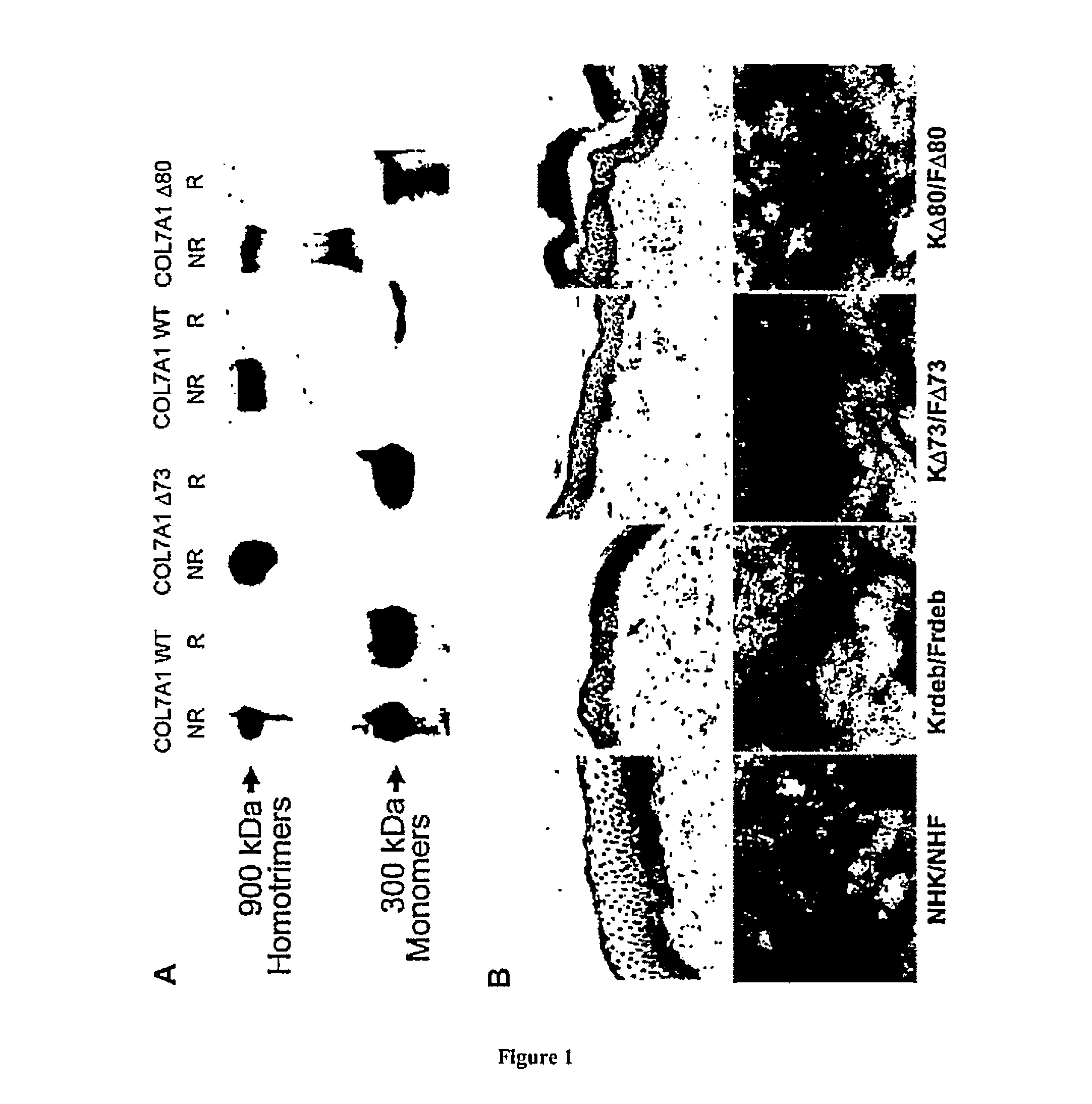

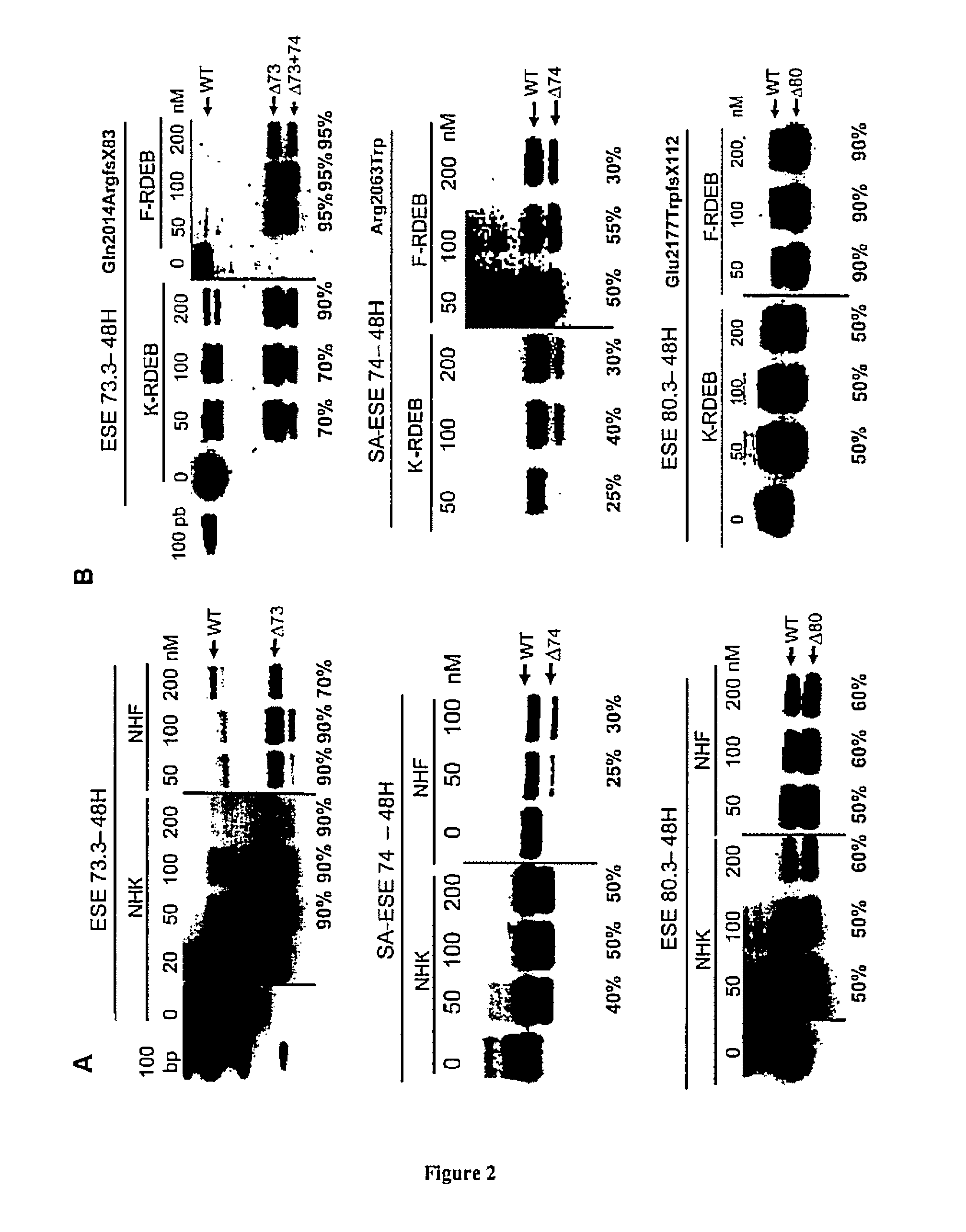

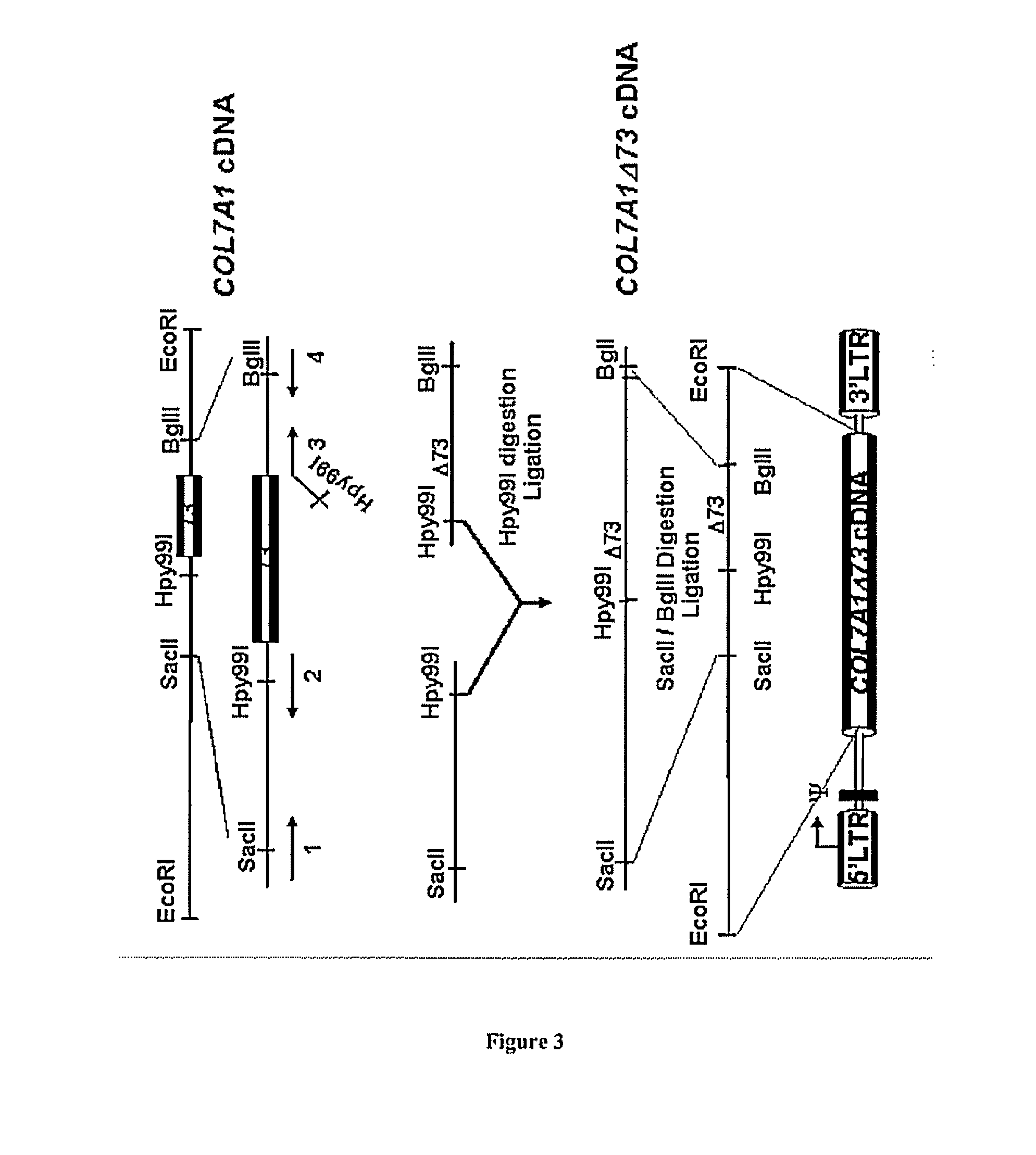

ActiveUS20140288155A1Avoid stitchingIncrease contact timeOrganic active ingredientsSplicing alterationNucleic acid sequencingBiology

The present invention also relates to an antisense oligonucleotide complementary to a nucleic acid sequence of COL7A1 gene that is necessary for correct splicing of one or more exons which encode amino acid sequence of type VII collagen implicated in dysfunction of a mutated type VII collagen wherein said exons are selected from the group consisting of exon 73, 74 or 80 of the COL7A1 gene. The present invention also relates to a method for the treatment of a patient suffering from Dystrophic Epidermolysis Bullosa caused by a dysfunction of a mutated type VII collagen, comprising the step of administering to said patient a least one antisense oligonucleotide according to the invention.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +3

Nonsense suppression and genetic codon alteration by targeted modification

ActiveUS8603457B2Easy to identifyLarge productionBiocideGenetic material ingredientsAdenosineGenetics

Methods for affecting mRNA expression or translation through the modification of pre-mRNA or mRNA transcripts are described. In one embodiment of the methods of the present invention, the branch point adenosine of a pre-mRNA transcript is 2′-O-methylated to block splicing and subsequent expression of the protein encoded by the transcript. In another embodiment, a uridine residue in a nonsense stop codon may be modified to pseudouridine, causing the translation machinery to read through the nonsense stop codon and translate a full length protein.

Owner:UNIVERSITY OF ROCHESTER

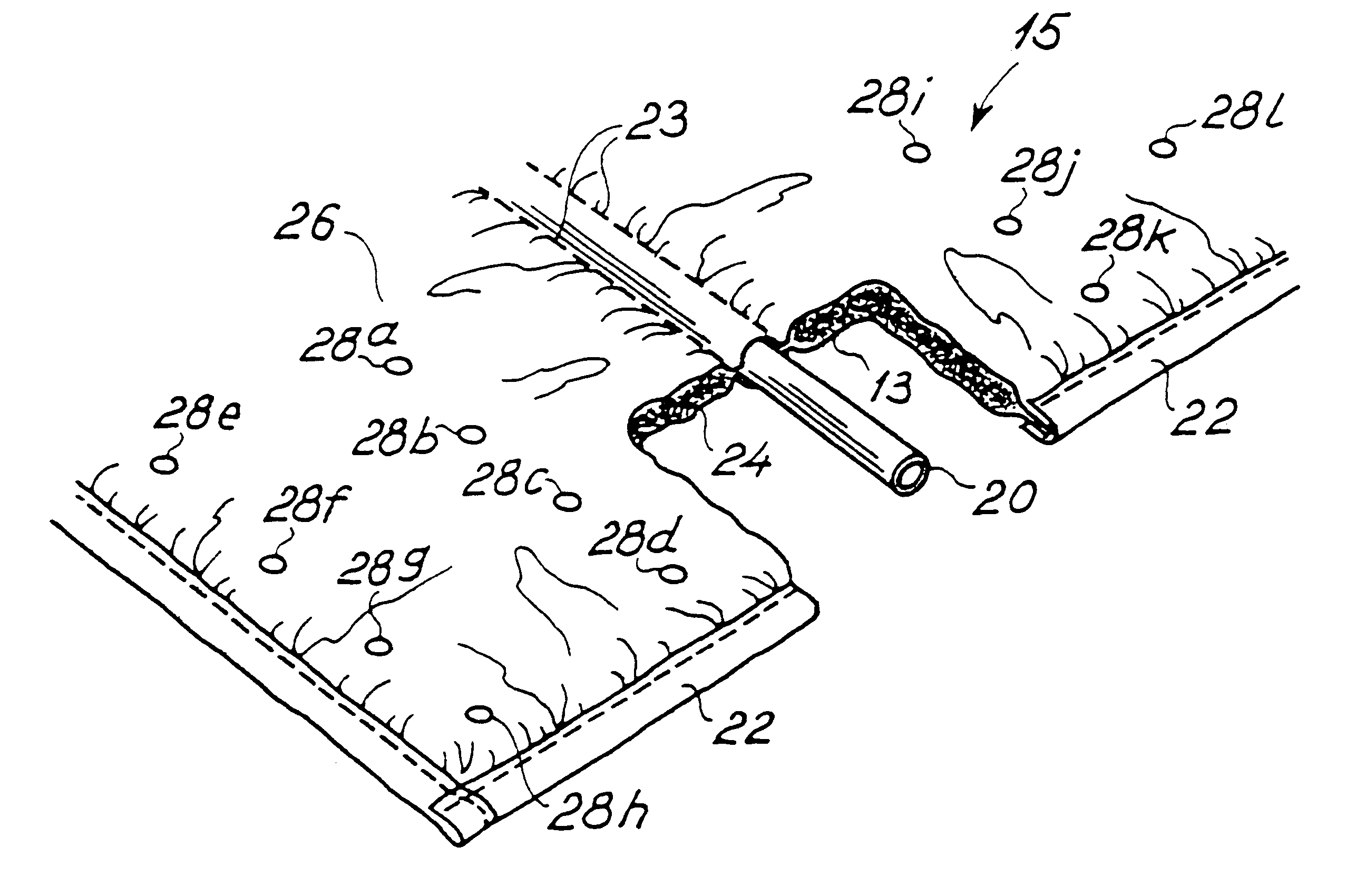

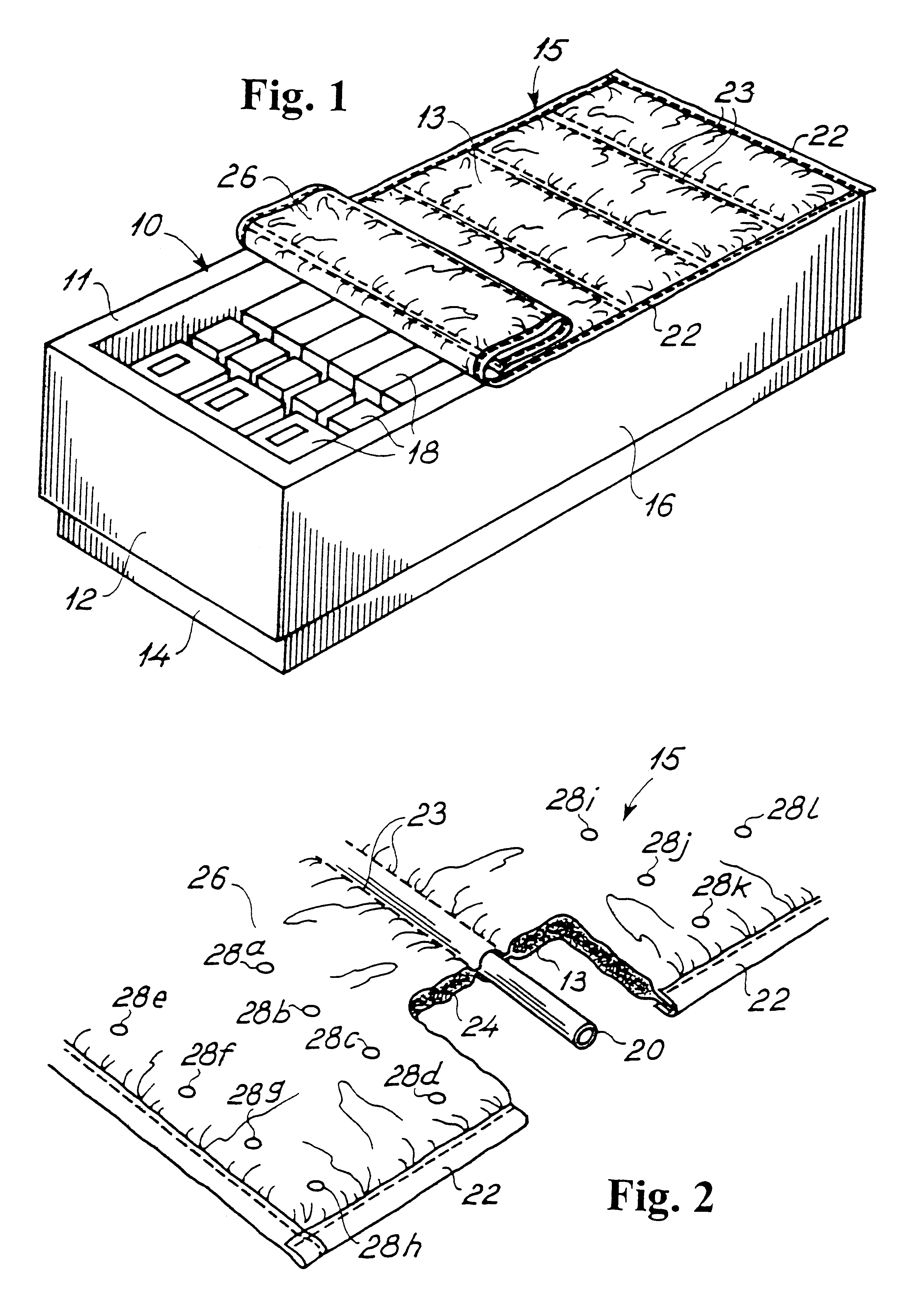

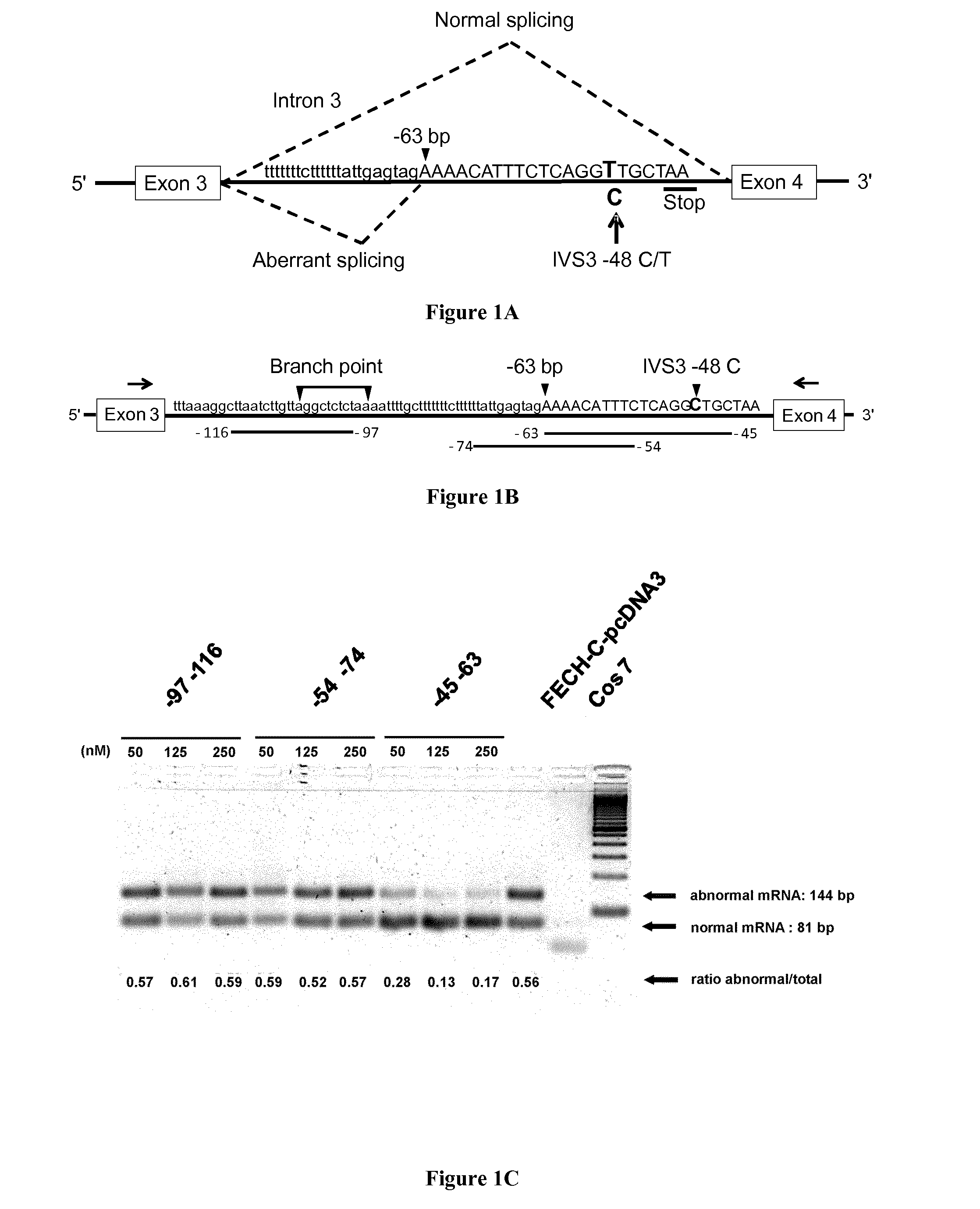

Insulating cover

InactiveUS6329038B1Thermal bridgingImprove insulation performanceShow cabinetsLayered productsElectrical and Electronics engineeringEngineering

The insulating cover comprises a gas and water impermeable first foil (13) which defines a first circumferential outer rim, a gas and water impermeable second foil (26) substantially coextensive with said first foil (13) and defining a second circumferential outer rim. The first (13) and second foil (26) are joined together at the first and second outer circumferential rims of the first (13) and second outer circumferential rims of the first (13) and second foils (26), to define an enclosure between the first (13) and second (26) foils. A body of insulating material (24) is inserted in the enclosure. A plurality of supporting tubular elements (20) in co-planar relationship with said first (13) and second foil (26) provide a stiffness of the insulating cover (15) in axial direction of the plurality of supporting tubular elements (20) and flexibility of the insulating cover (15) in a direction perpendicular to the axial direction.

Owner:COMBI THERM

Pavement splicing method and structure for old cement concrete pavement reconstruction and expansion

ActiveCN106480799AGuaranteed normal operationEasy to handleIn situ pavingsPaving detailsSurface layerCrushed stone

The invention discloses a pavement splicing method and structure for old cement concrete pavement reconstruction and expansion. A cement concrete slab splicing seam is formed in a hard shoulder of an old cement concrete slab, steps are arranged on an old road upper base layer, an old road lower base layer and an old road cushion layer for transition, poor concrete is adopted for a new road upper base layer of an expansion part, and unscreened macadam is adopted for a road bed; a new cement concrete slab and the old cement concrete slab are connected by adopting double-layer reinforcing steel bars; a high-molecular polymer anti-cracking paste is firstly stuck to the cement concrete slab splicing seam, then an asphalt concrete anti-cracking leveling interlayer is paved, and a lower asphalt concrete surface layer and an upper asphalt concrete surface layer are finally paved sequentially, wherein the lower asphalt concrete surface layer is doped with 0.3% by mass of short-cut basalt fiber. According to the method and structure, the problem that the durability of existing old cement concrete pavement reconstruction and expansion engineering is insufficient can be effectively solved, and the important significant is achieved for promoting quicker and better development of transportation industry in China.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

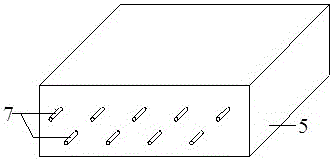

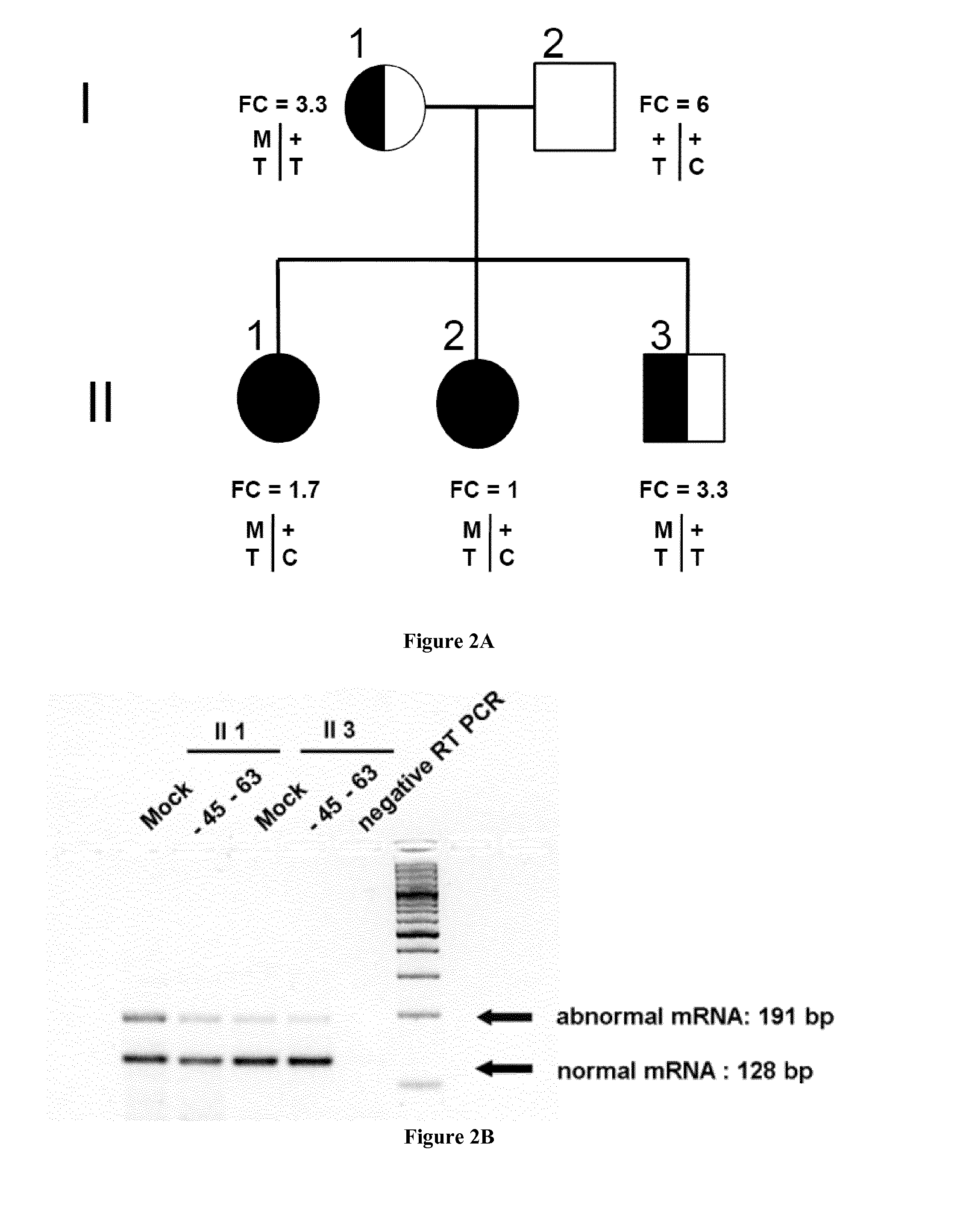

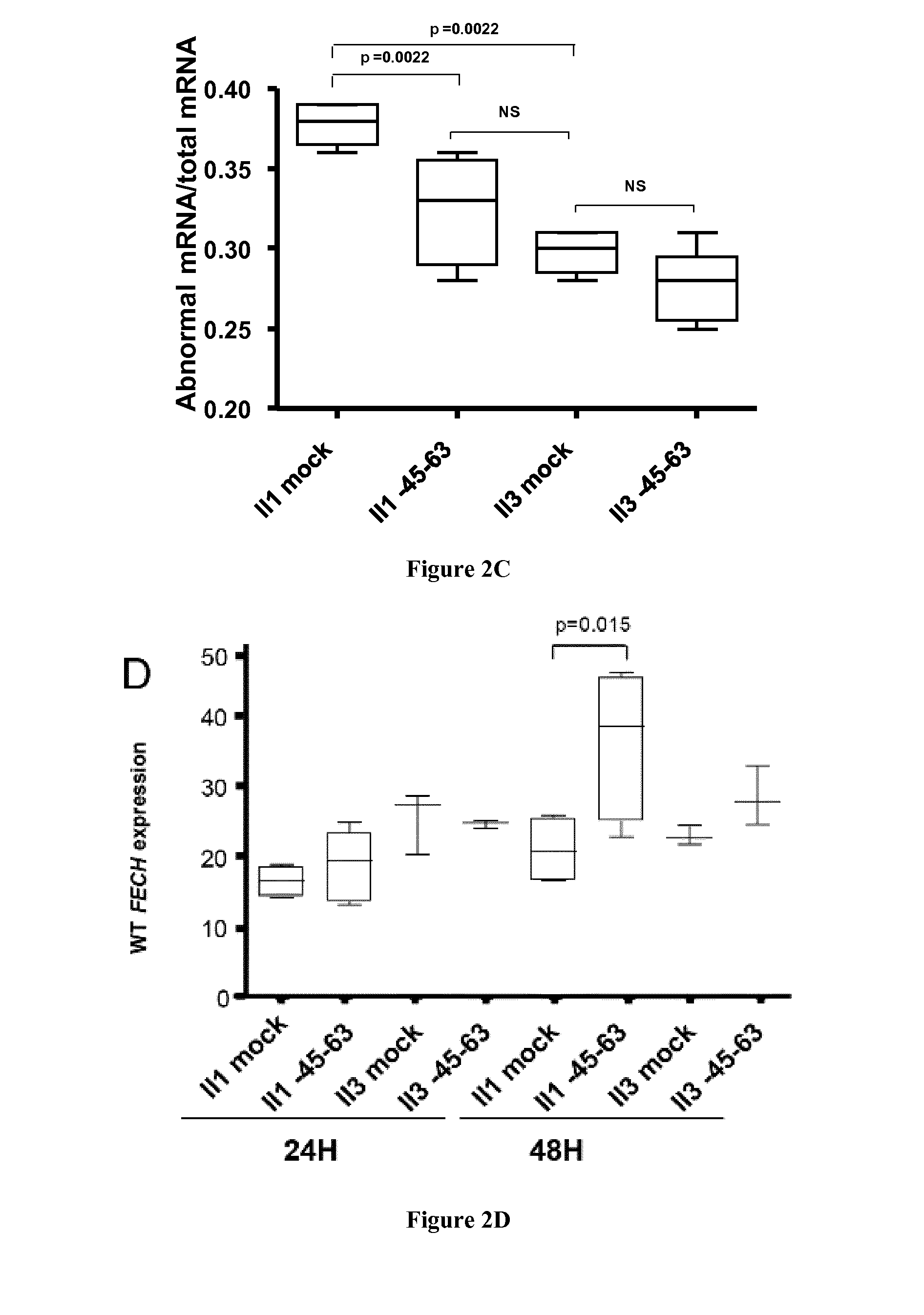

Methods and pharmaceutical compositions for the treatment of erythropoietic protoporphyria

ActiveUS20160122767A1Reduce usageIncrease volumeSplicing alterationPolymorphism usesDrugDeleterious mutation

The present invention relates to methods and pharmaceutical compositions for the treatment of Erythropoietic Protoporphyria. In particular, the present invention relates to a method for increasing the amount of functional FECH in a erythroid cell carrying the hypomorphic allele IVS3 48C / T (rs2272783) in trans to a deleterious mutation in the FECH gene comprising the step of consisting of bringing the erythroid cell into contact with at least one antisense oligonucleotide (ASO) comprising the sequence as set forth by SEQ ID NO: 2 (5′ gcagcctgagaaatgtttt 3′) to prevent splicing of the cryptic exon inserted into the mutant IVS3 48C / T (rs2272783) FECH mRNA.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +3

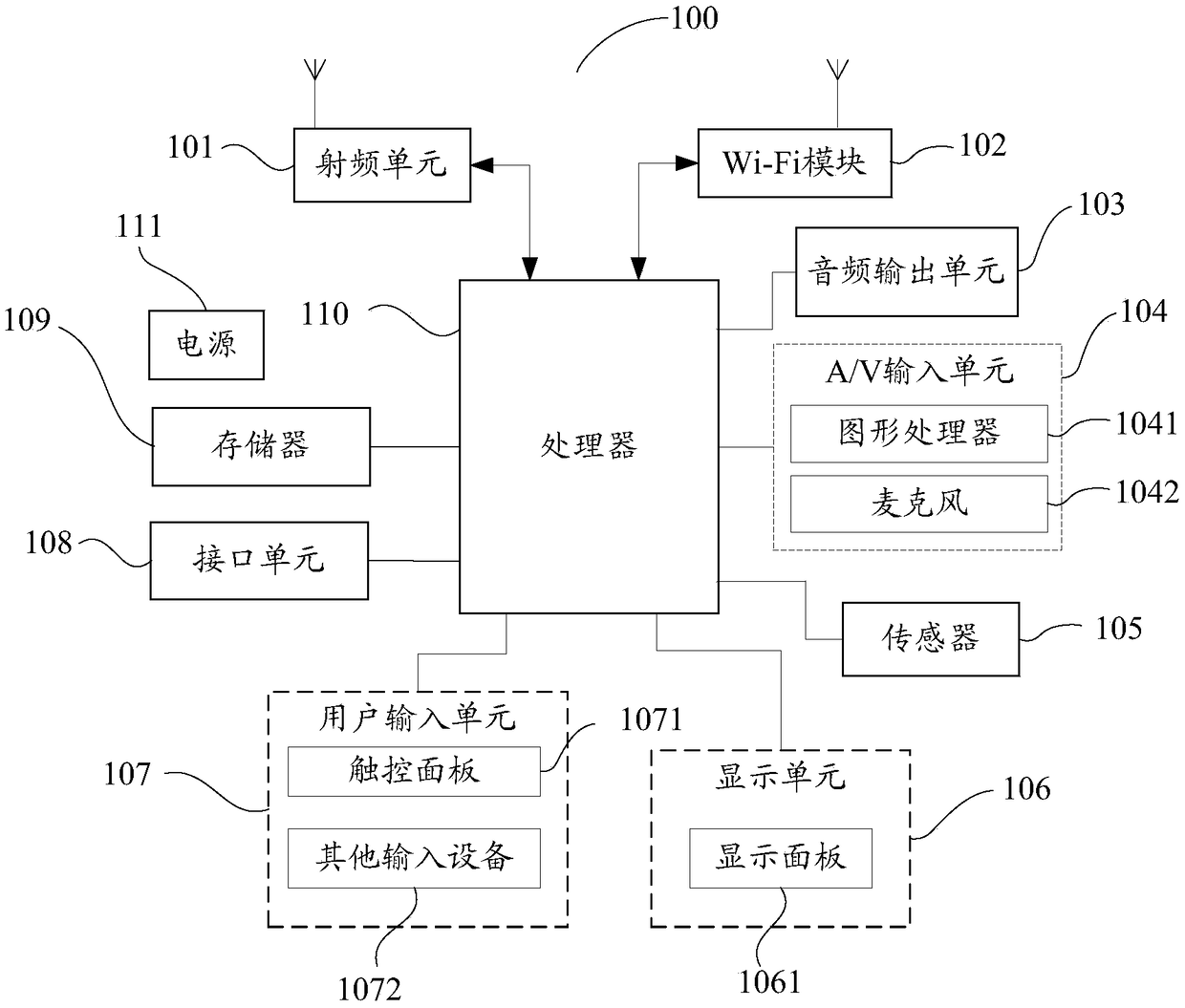

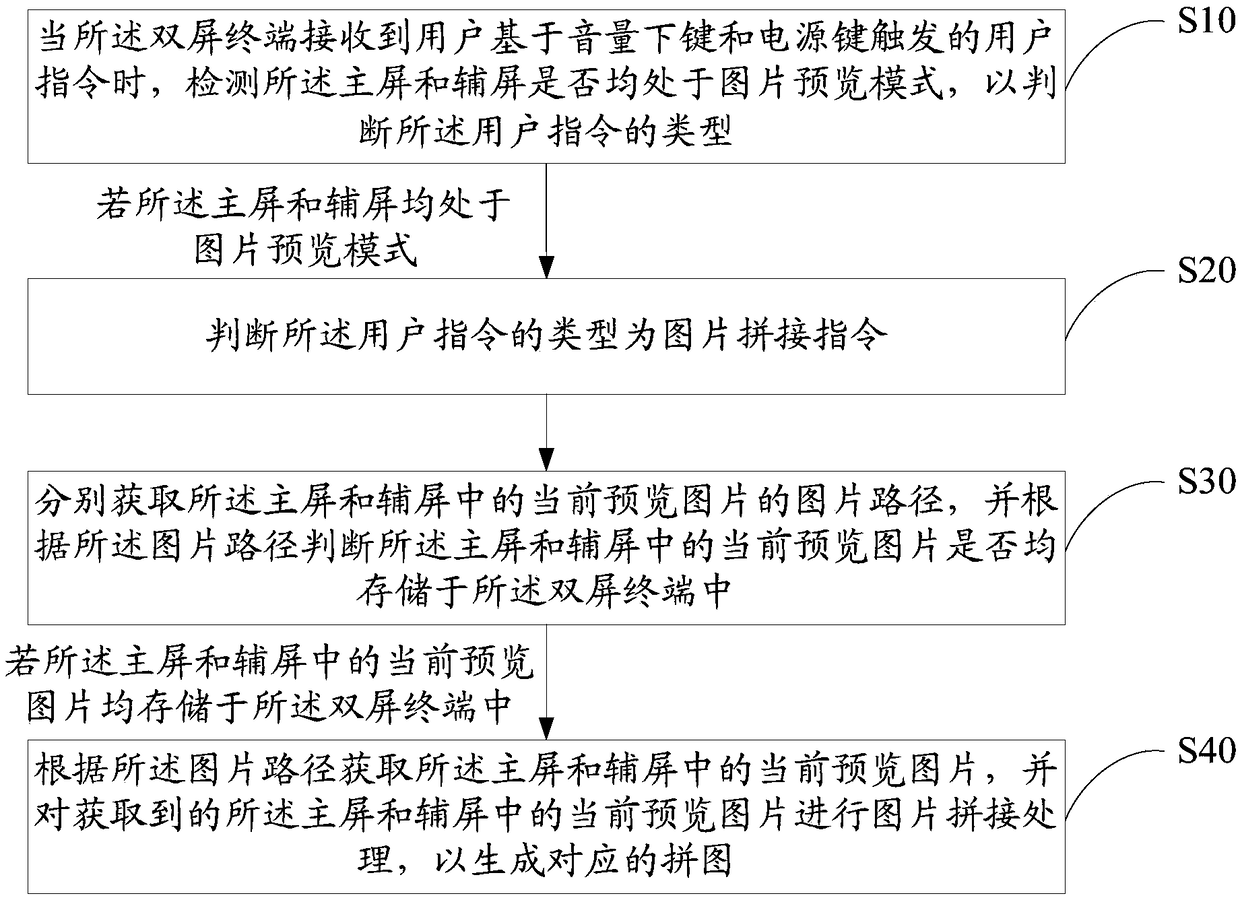

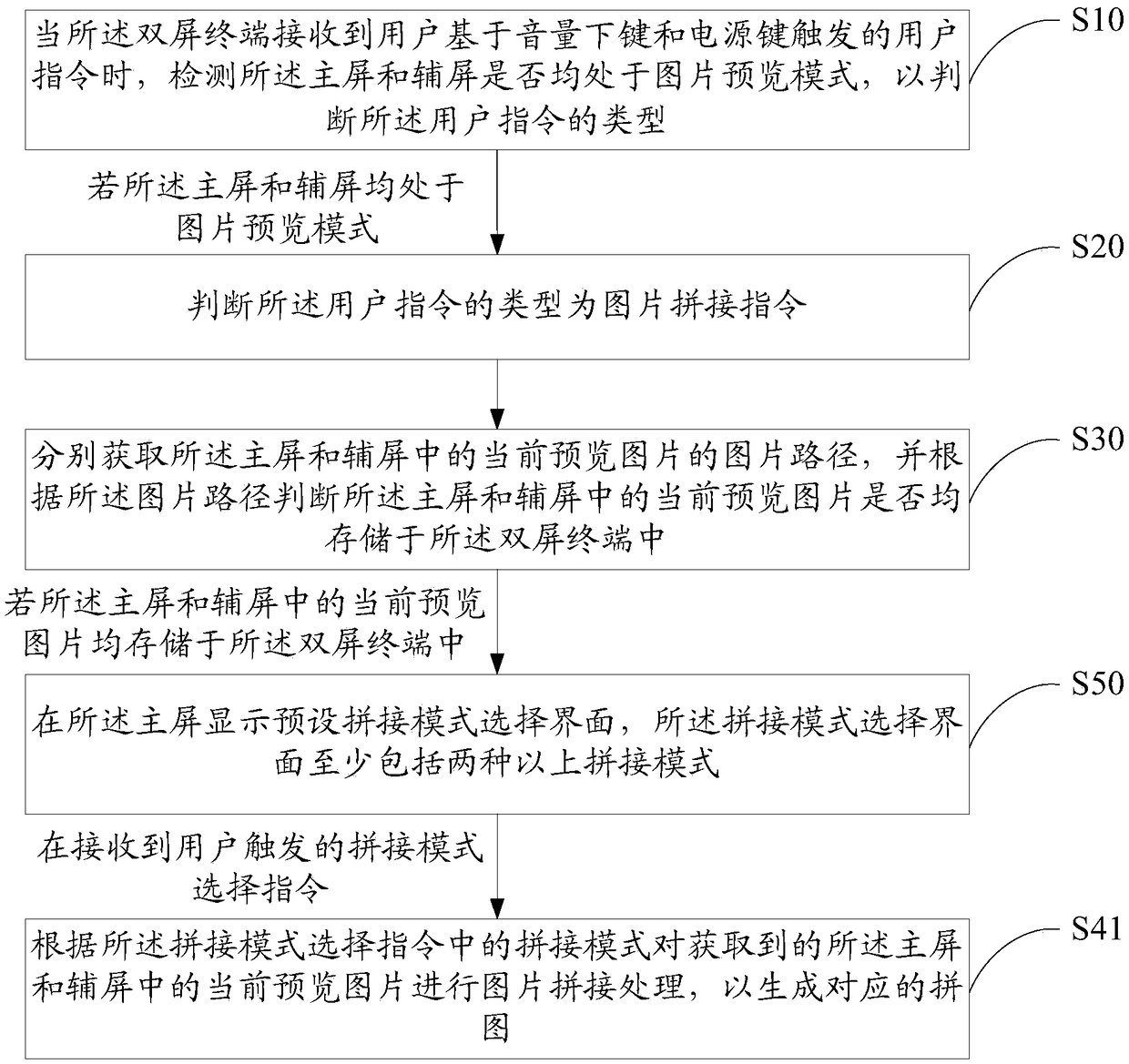

Picture splicing method, dual-screen terminal and computer readable storage medium

ActiveCN108898552AAvoid stitchingRealize quick splicingImage enhancementGeometric image transformationComputer graphics (images)Computer terminal

The invention discloses a picture splicing method, which is applied to a dual-screen terminal including a primary screen and a secondary screen. The method comprises: detecting whether the primary screen and the secondary screen are in a picture preview mode to determine the type of a user instruction when the dual-screen terminal receives the user instruction triggered by the user on the basis ofa volume down key and a power source key; determining that the type of the user instruction is a picture splicing instruction if so; respectively obtaining picture paths of current preview pictures in the primary screen and the secondary screen, and determining whether the current preview pictures in the primary screen and the secondary screen are stored in the dual-screen terminal according to the picture paths; and acquiring the current preview pictures of the primary screen and the secondary screen according to the picture paths if so, and performing picture splicing processing to generatea corresponding puzzle. The invention also discloses a dual-screen terminal and a computer readable storage medium. The method can realize the quick splicing of the current preview pictures in the primary screen and the secondary screen of the dual screen terminal, can save the time of the user and can improve the user experience.

Owner:图为信息科技(深圳)有限公司

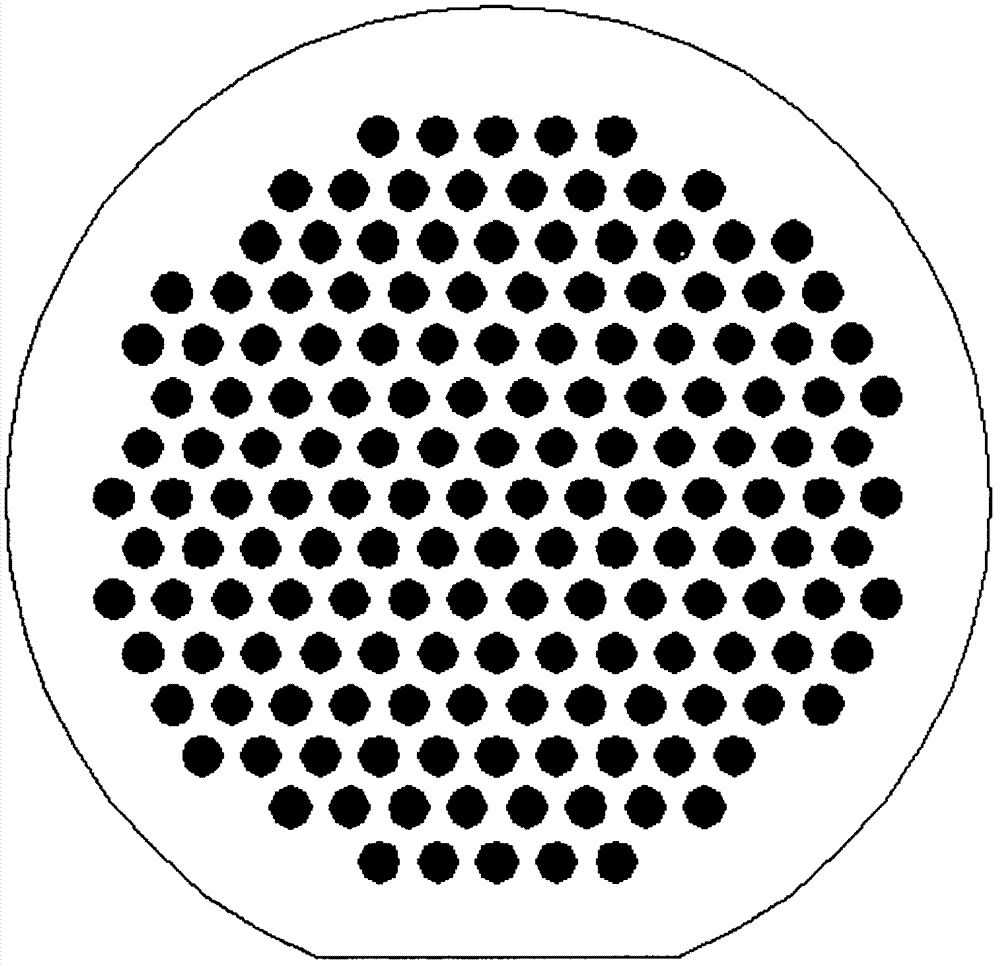

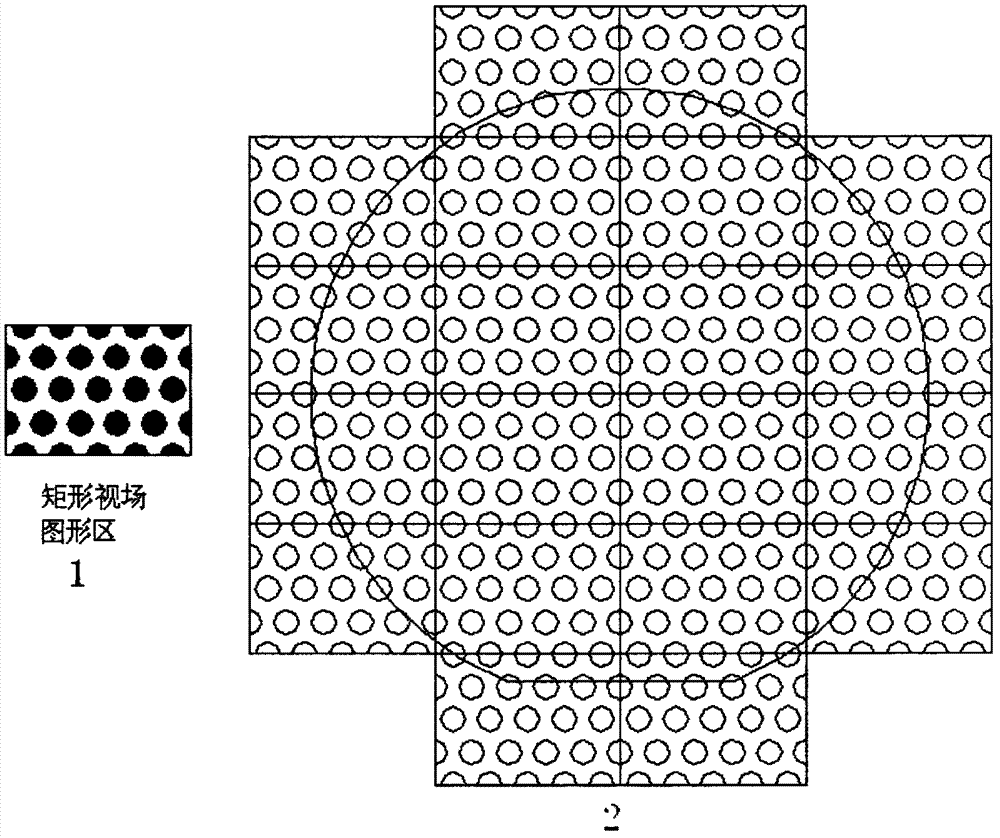

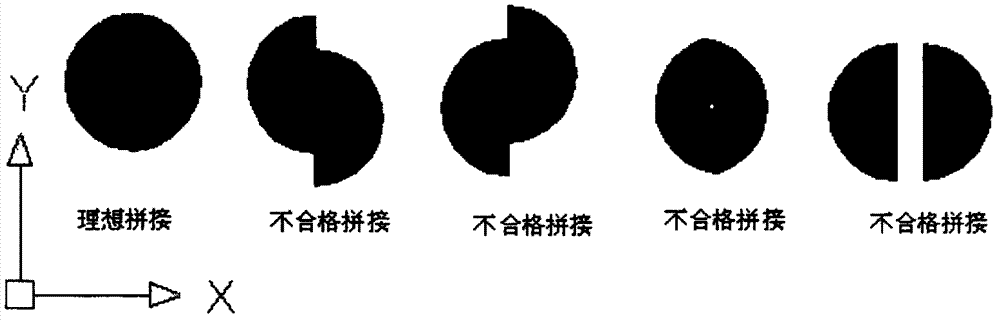

Projection exposure device and splicing method

ActiveCN102955366AIncrease freedomAchieving a non-rectangular field of viewPhotomechanical exposure apparatusMicrolithography exposure apparatusTranslatory motionPhysics

A projection exposure device used for forming an exposure pattern on the surface of a substrate comprises a variable slit comprising a plurality of edges, the edges of the variable slit can translationally move and also can rotatably move, and the edges are adjusted according to the arrangement of the pattern to be exposed to adjust the shape and the dimension of the view field of the variable slit in order to make the view field margin traverse through the pattern to be exposed or in order to make the view field comprise the area of the pattern to be exposed, so a splicing line between the view field does not traverse the exposure pattern.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method for manufacturing curve compact grade laminate

InactiveCN102756533AHigh strengthImprove impact resistanceLaminationLamination apparatusAntioxidantPlasticizer

The invention relates to a method for manufacturing a curve compact grade laminate. The method includes that firstly, a plasticizer, a light stabilizer, an ultraviolet absorber, an antioxidant and an antiaging agent are added in a first adhesive agent, and facial tissues are put into the first adhesive agent to be subjected to steeping and drying; secondly, a diluent agent, the antioxidant, the antiaging agent, the plastizer, dyes and a fire retardant are added in a second adhesive agent, and pieces of kraft paper are put into the second adhesive agent to be subjected to the steeping and the drying; thirdly, a plurality of pieces of dried kraft paper are overlaid, and pieces of dried facial tissues are placed on the upper and lower end surfaces of the overlaid kraft paper respectively; and fourthly, a finished product is formed by compressing the kraft paper and the facial tissues through a press, and the press comprises matched molds which are suitable for compressing U-shaped or arc-shaped compact grade laminates. According to the method, the manufactured curve compact grade laminate has the advantages of being colorful, high in intensity, impact resisting, uvioresistant, water-proofing, weather-proofing, anti-static, anti-fouling and easy to manufacture, so that the manufactured curve compact grade laminate can be widely applied to building outer walls, furniture, facilities, signs and the like, and the problem of splicing of the compact grade laminate at corners can be prevented.

Owner:江苏天润盛凯新材料股份有限公司

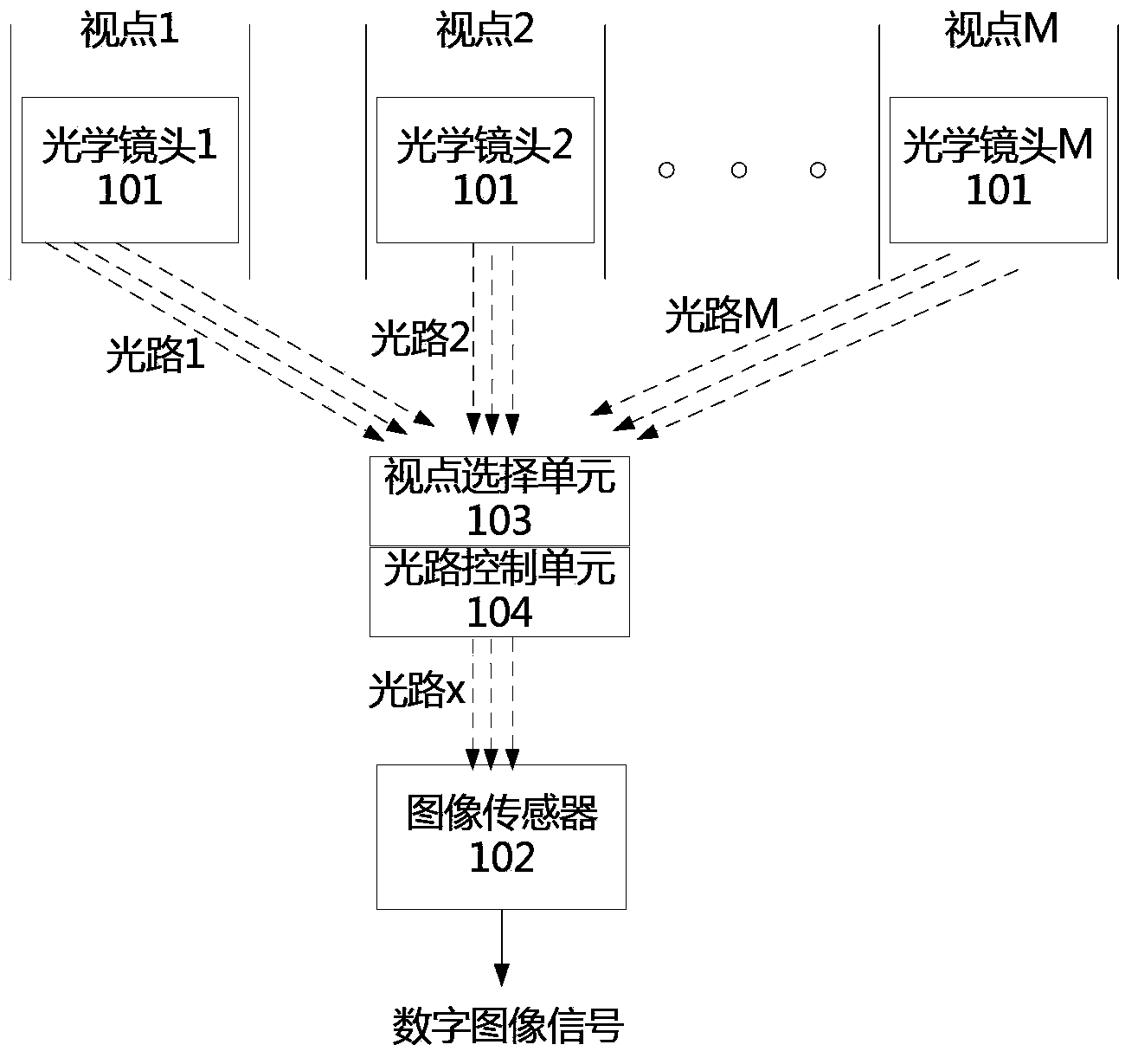

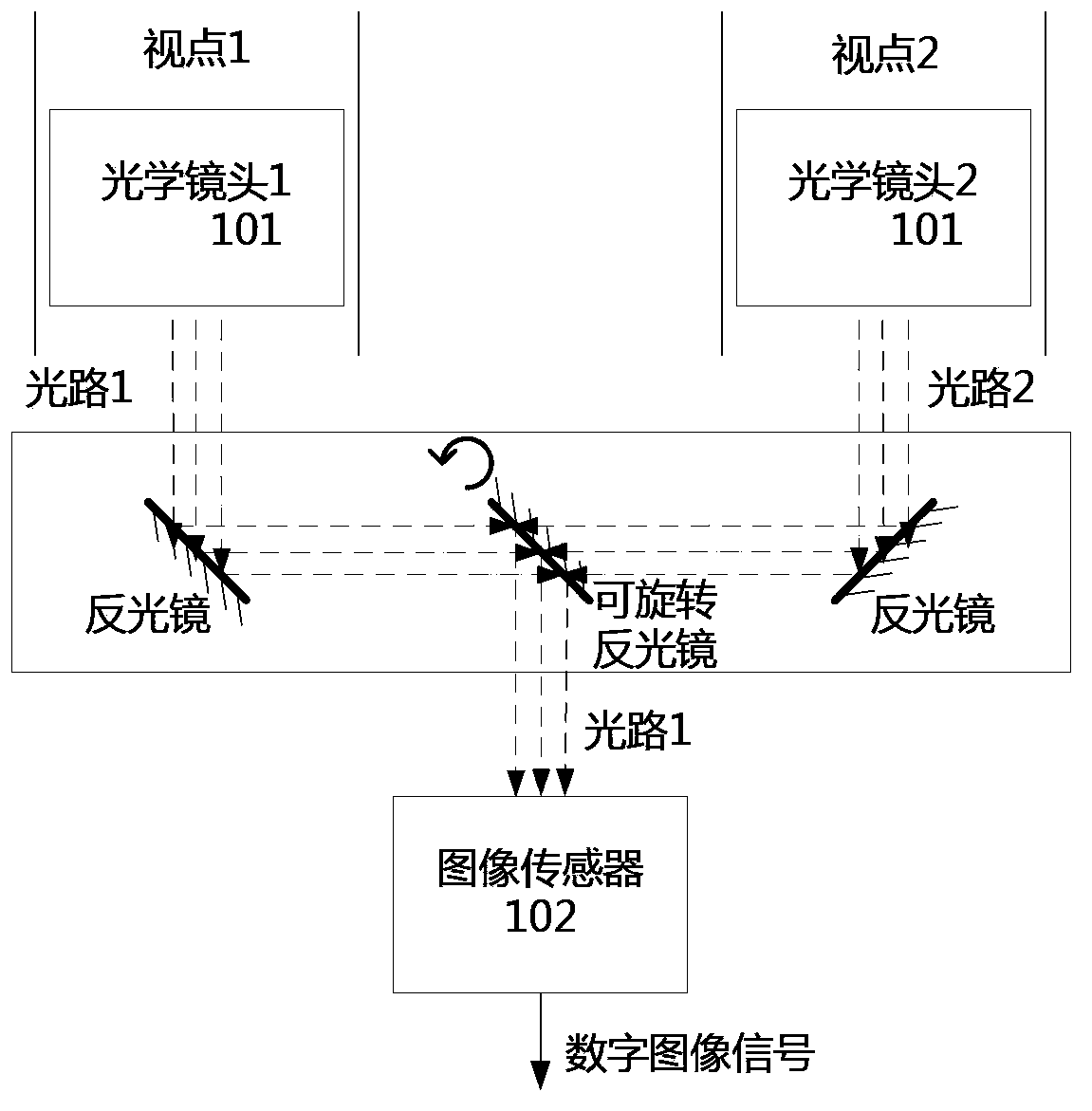

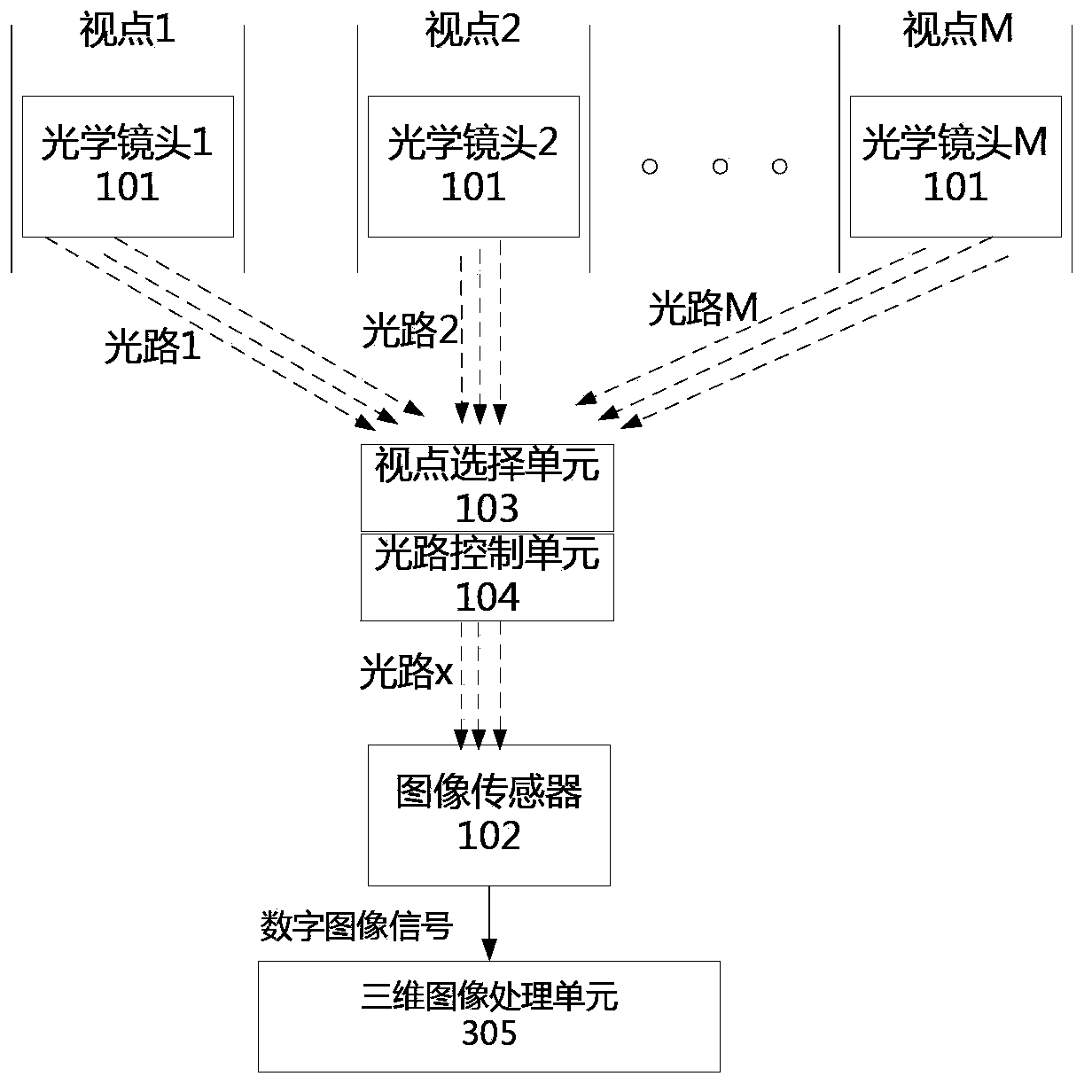

Method and device for multi-viewpoint image acquisition and three-dimensional camera

ActiveCN103813155ARealize time-division multiplexingQuality improvementStereoscopic photographySteroscopic systemsCamera lensDigital image

The invention discloses a method and device for multi-viewpoint image acquisition and a three-dimensional camera. The device comprises a plurality of optical lenses, image sensors, a viewpoint selection unit and an optical path control unit. The number of the optical lenses is equal to that of multiple viewpoints. More than one viewpoint is selected from the viewpoints through the viewpoint selection unit to serve as current processing viewpoints, and the optical path control unit controls multipath optical signals to enable the optical signals of the current processing viewpoints to enter the image sensors so as to convert the optical signals of the current processing viewpoints into digital image signals of the current processing viewpoints and obtain digital images of the current processing viewpoints. On the basis of the technical scheme, on the conditions that digital image quality is not reduced, the fewer image sensors are utilized to obtain the multi-viewpoint digital images.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

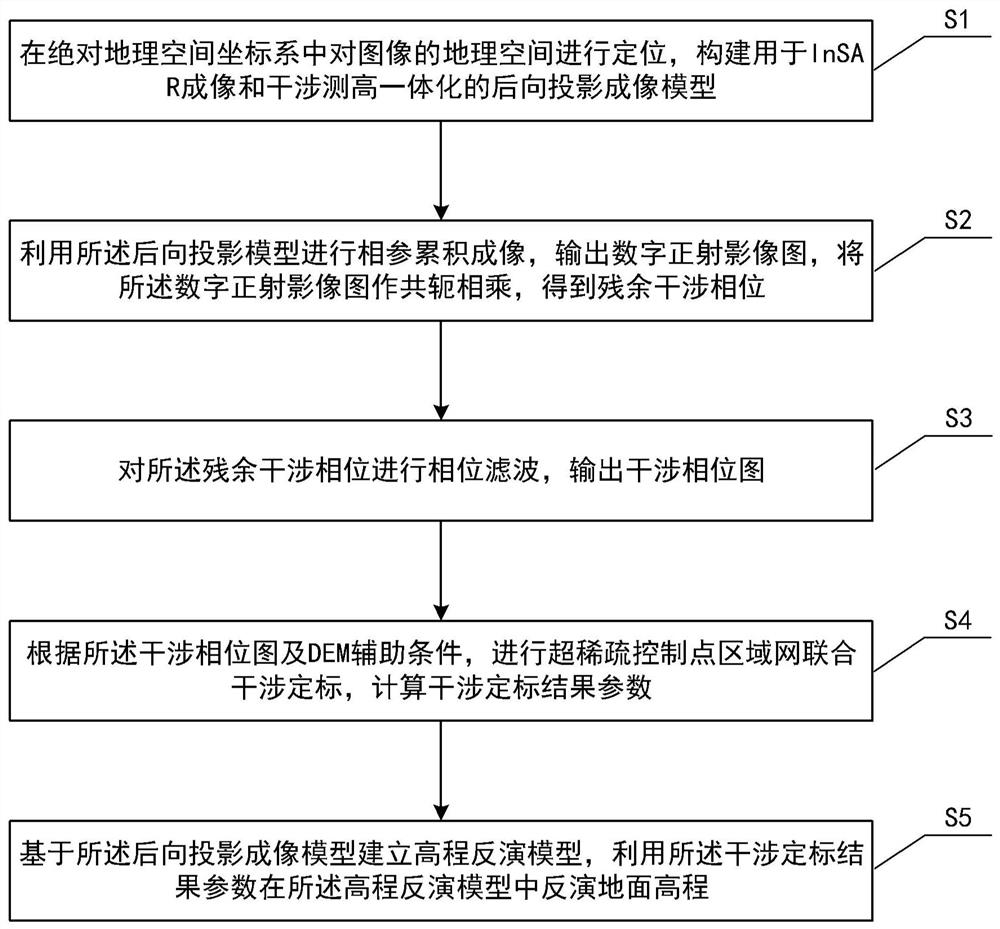

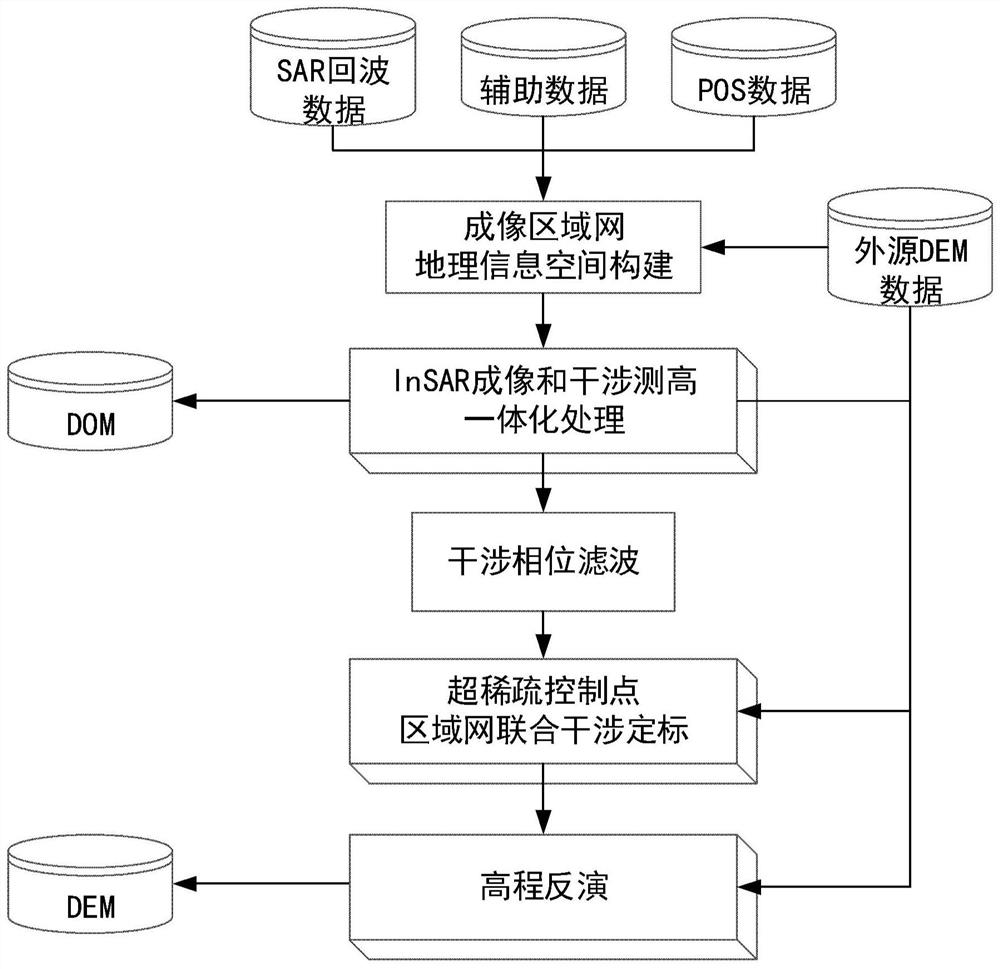

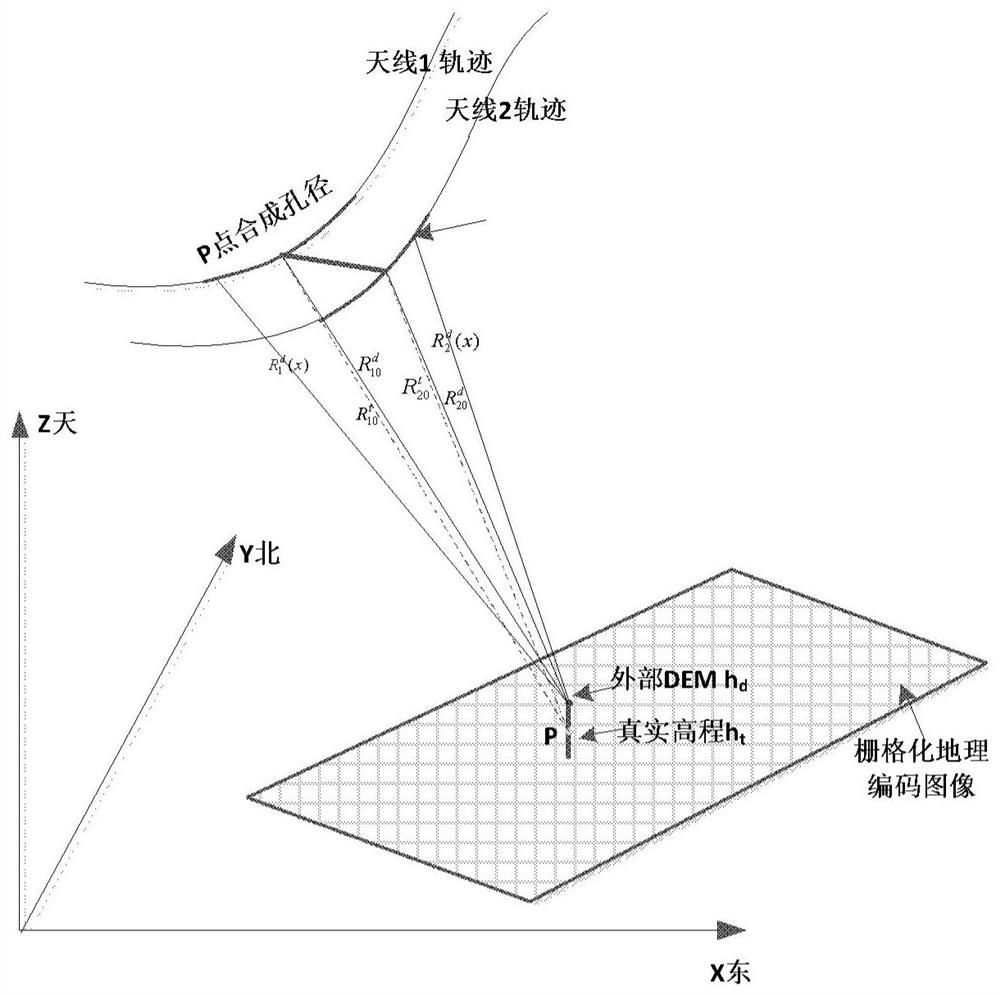

InSAR imaging and interference integrated processing method

ActiveCN112882030AIncrease workloadReduce in quantityRadio wave reradiation/reflectionData matchingPhase filter

The invention provides an InSAR imaging and interference integrated processing method. The method comprises the following steps of: positioning a geographic space of an image in an absolute geographic space coordinate system, and constructing a backward projection imaging model for integrating InSAR imaging and interference height measurement; performing coherent accumulation imaging by using the backward projection model, outputting a digital orthoimage, and performing conjugate multiplication on the digital orthoimage to obtain a residual interferometric phase; performing phase filtering on the residual interferometric phase, and outputting an interferometric phase diagram. according to the interferometric phase diagram and a DEM auxiliary condition, carrying out ultra-sparse control point block joint interference calibration, and calculating an interference calibration result parameter; and establishing an elevation inversion model based on the backward projection imaging model, and inverting the ground elevation in the elevation inversion model by using the interference calibration result parameter. The method has the following remarkable advantages that: InSAR interference processing is simpler; self-registration is completed while imaging is carried out; DEM and SAR data matching is avoided; multi-scene image splicing is avoided; and output products are more friendly to users.

Owner:AEROSPACE INFORMATION RES INST CAS

Crown extrusion

A decorative molding system and method of installation is provided that has a base piece and a crown piece that are adapted to be selectively engageable to each other. The molding system is easy to construct and allows for the separation of the base piece and crown piece for placing wiring or other materials behind the molding.

Owner:ROWOHLT TODD

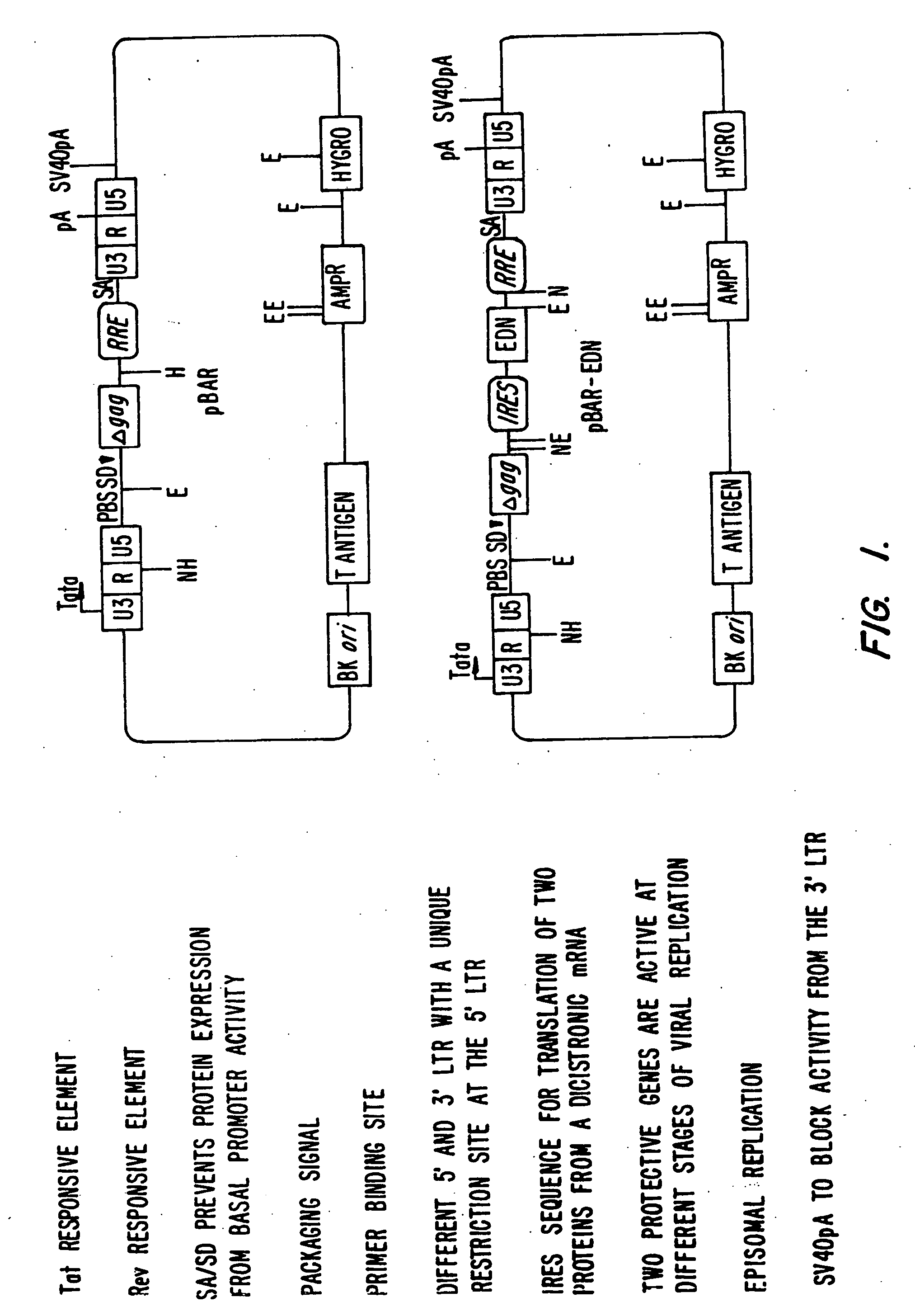

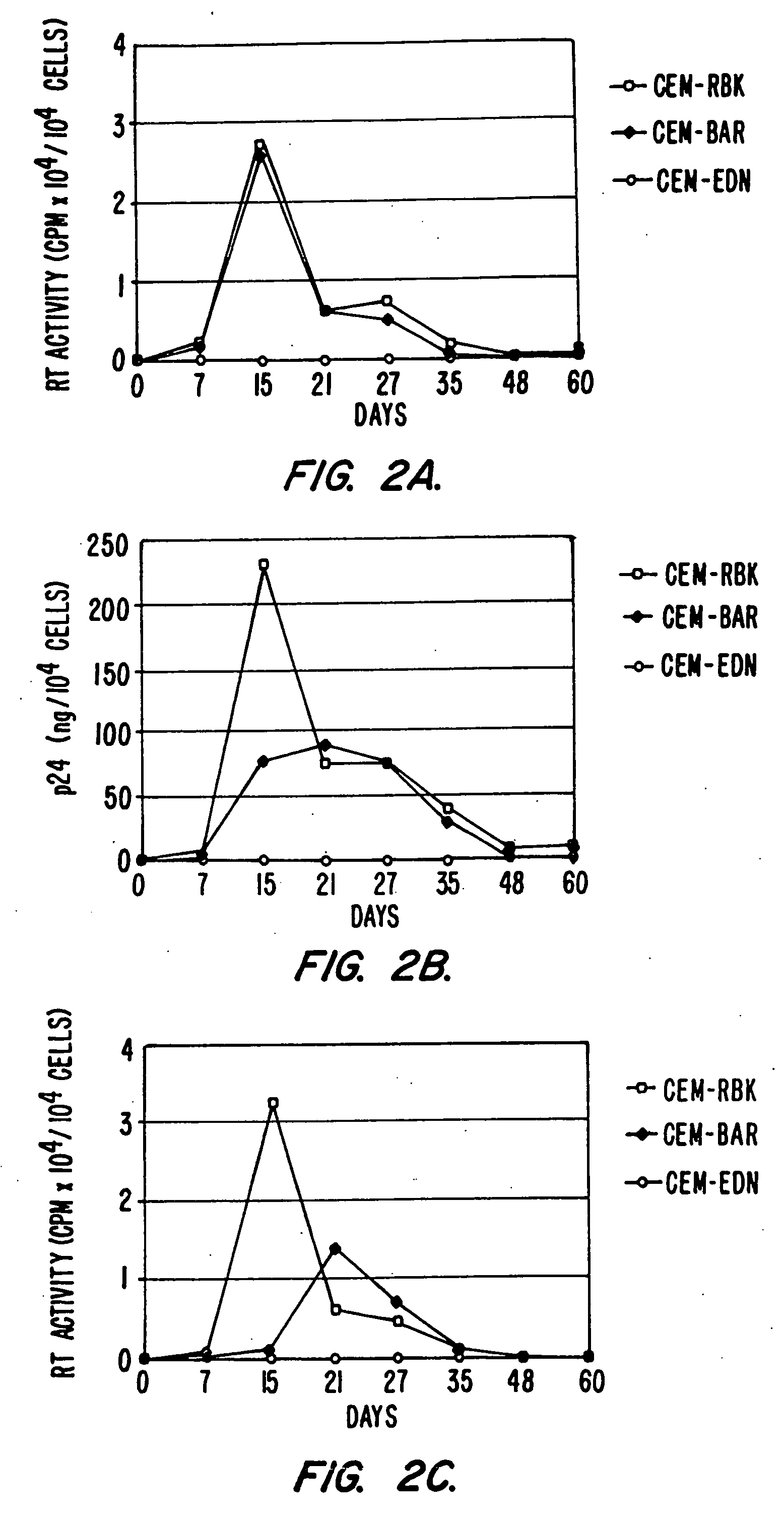

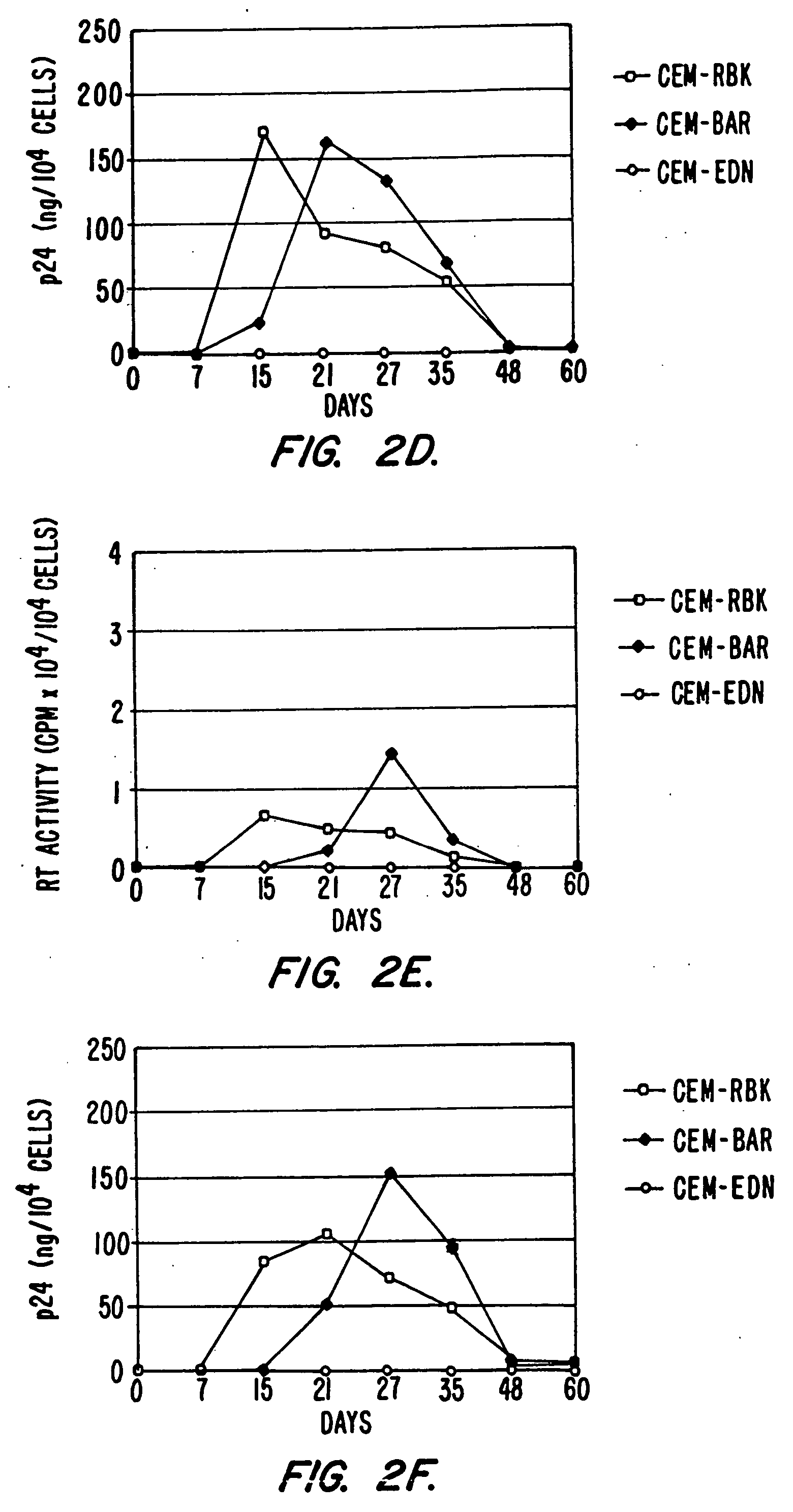

Vectors for delivering viral and oncogenic inhibitors

Owner:UNITED STATES OF AMERICA

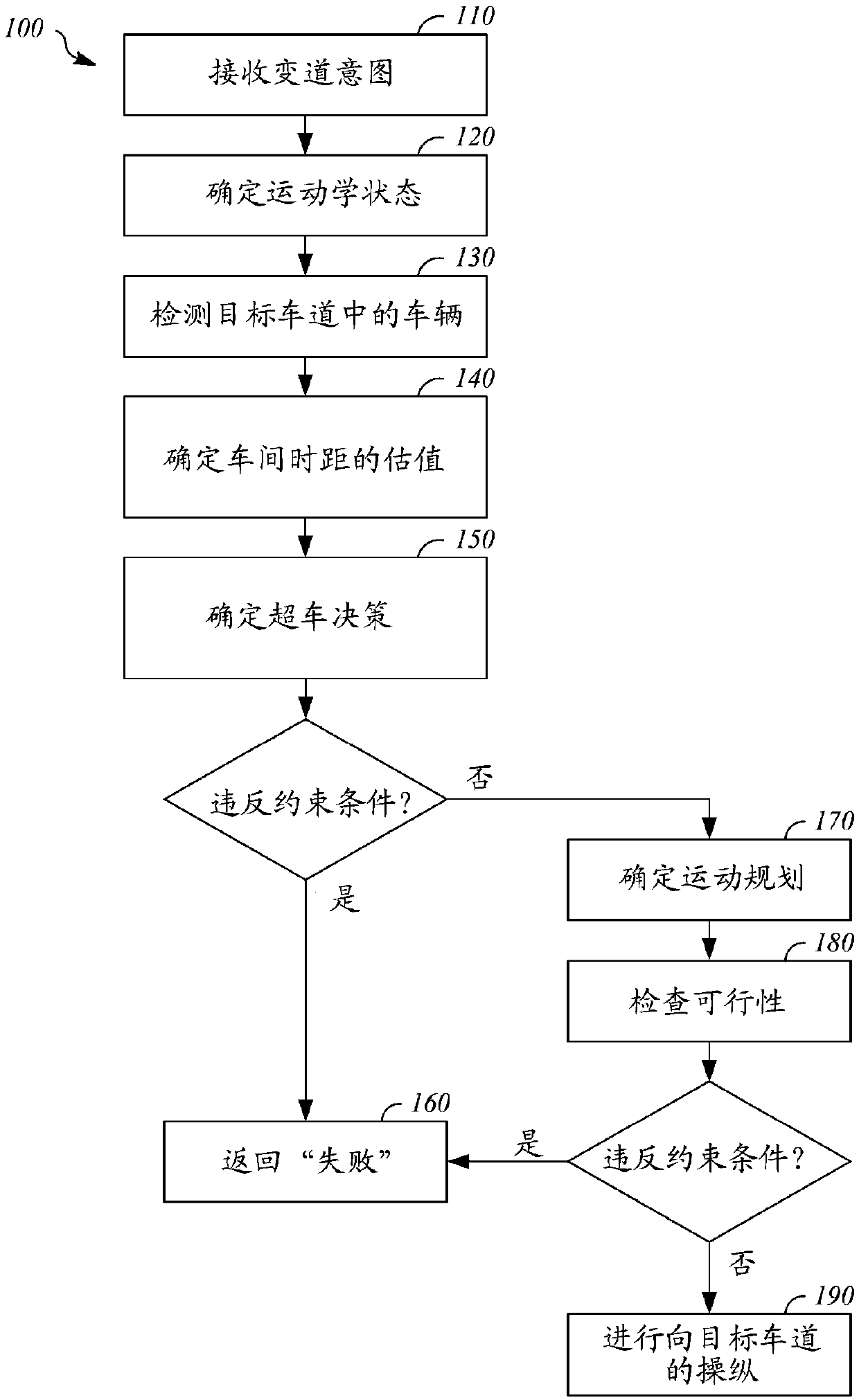

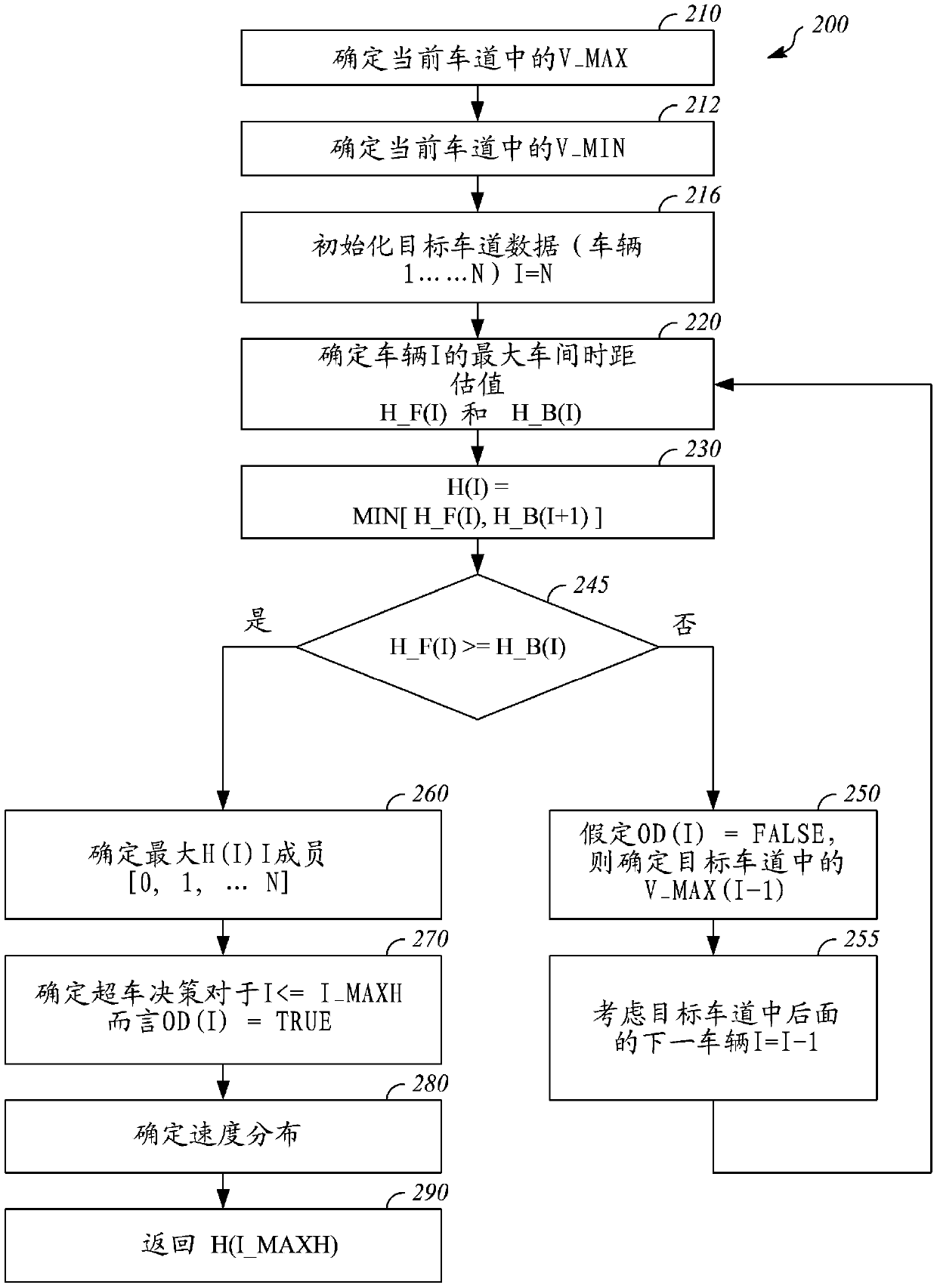

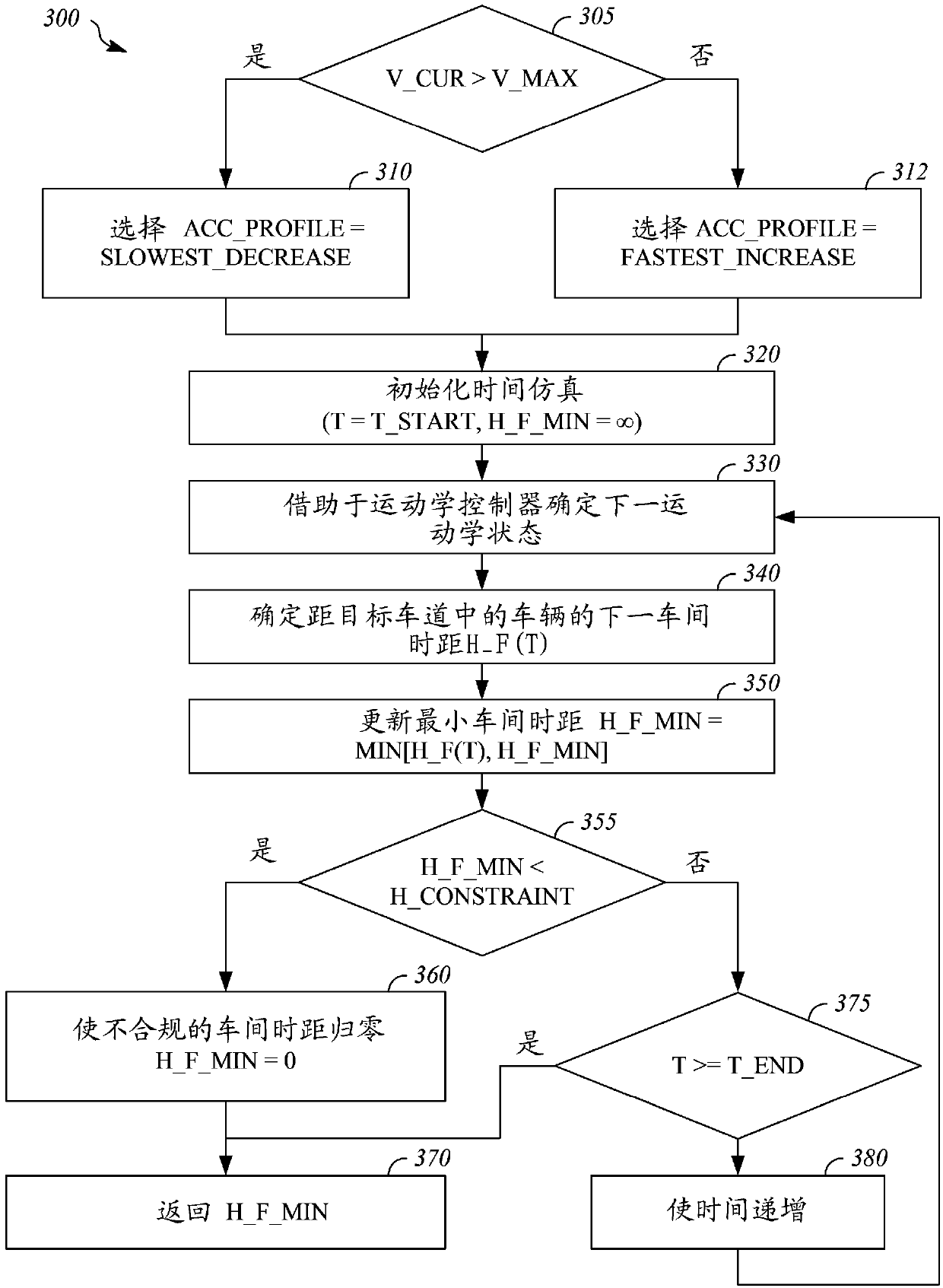

Vehicle control system

ActiveCN109643496AAvoid stitchingRobust Motion PlanningVehicle fittingsAnti-collision systemsControl systemHeadway

Systems and methods for automated control of vehicle lane change maneuvers are disclosed. Some implementations may include detecting, based on data from a sensor in the first vehicle, one or more other vehicles that are moving in a target lane of the road. Some implementations may include determining, based on the kinematic state of the vehicle and a prediction of motion of the one or more other vehicles in the target lane, estimates of headway in relation to at least one of the one or more other vehicles in the target lane. Some implementations may include determining, based at least in parton the estimates of headway, overtake decisions for the one or more other vehicles traveling in the target lane. Some implementations may include determining a motion plan that will transition the first vehicle from the current lane to the target lane based the overtake decisions.

Owner:APPLE INC

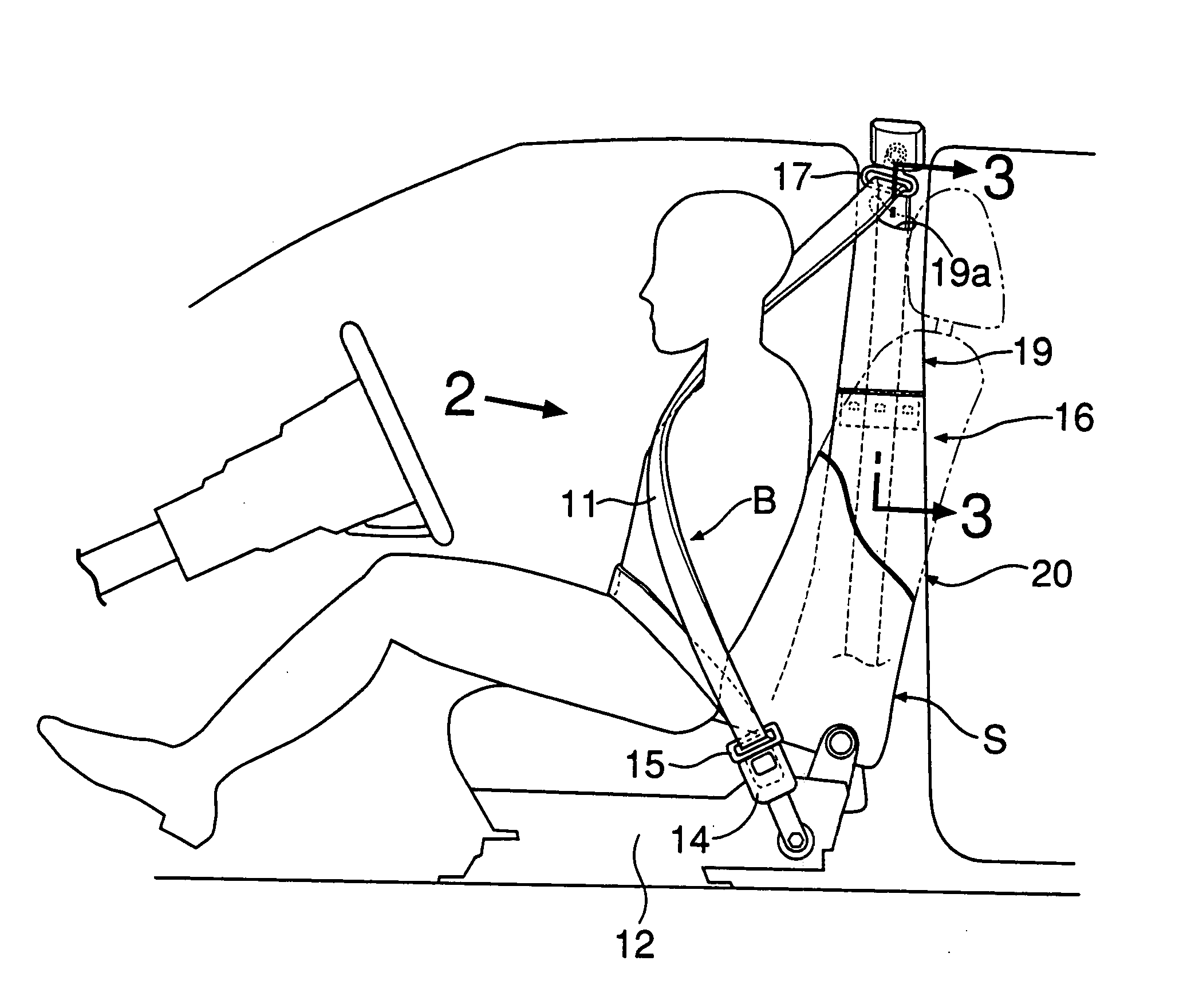

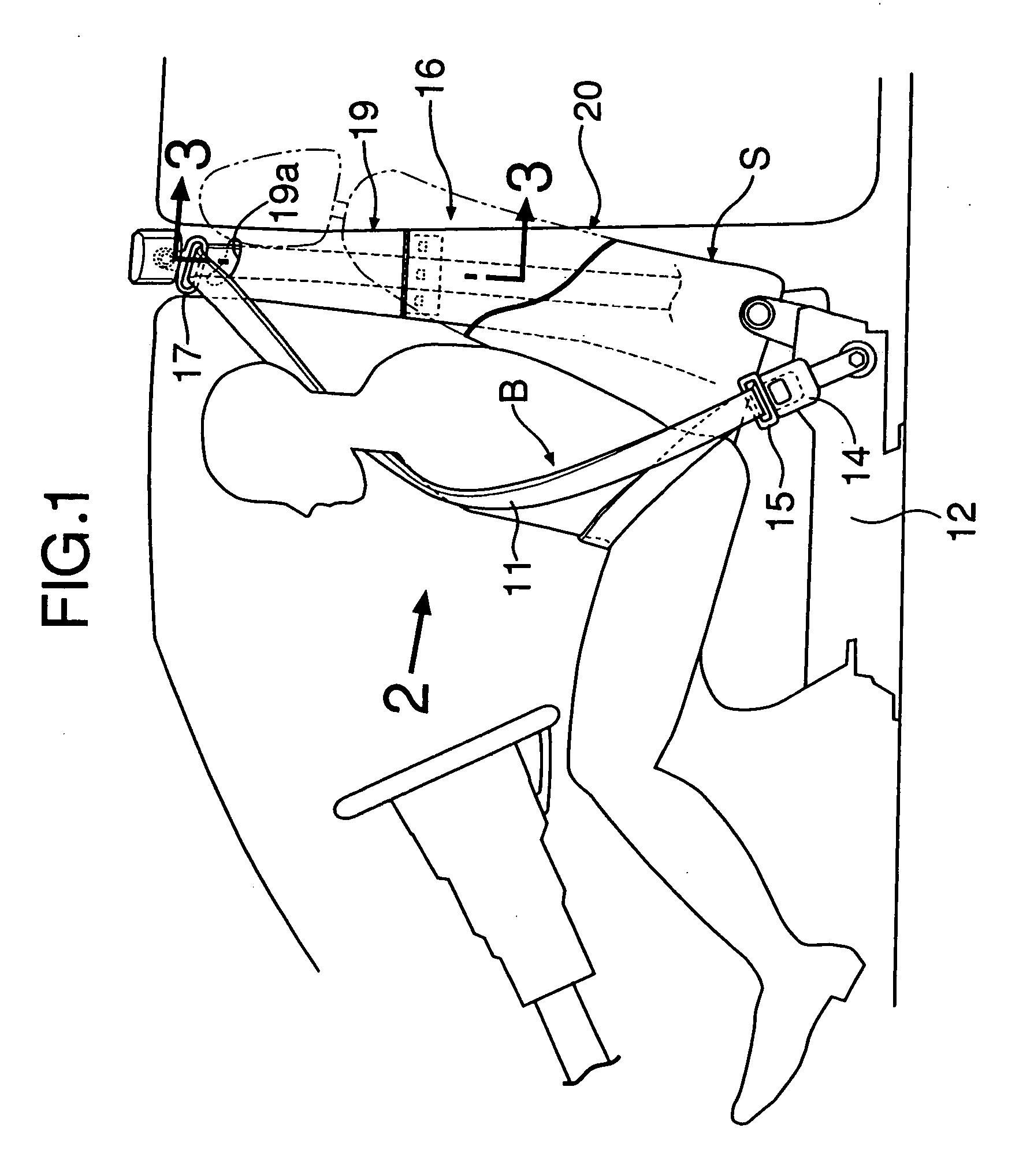

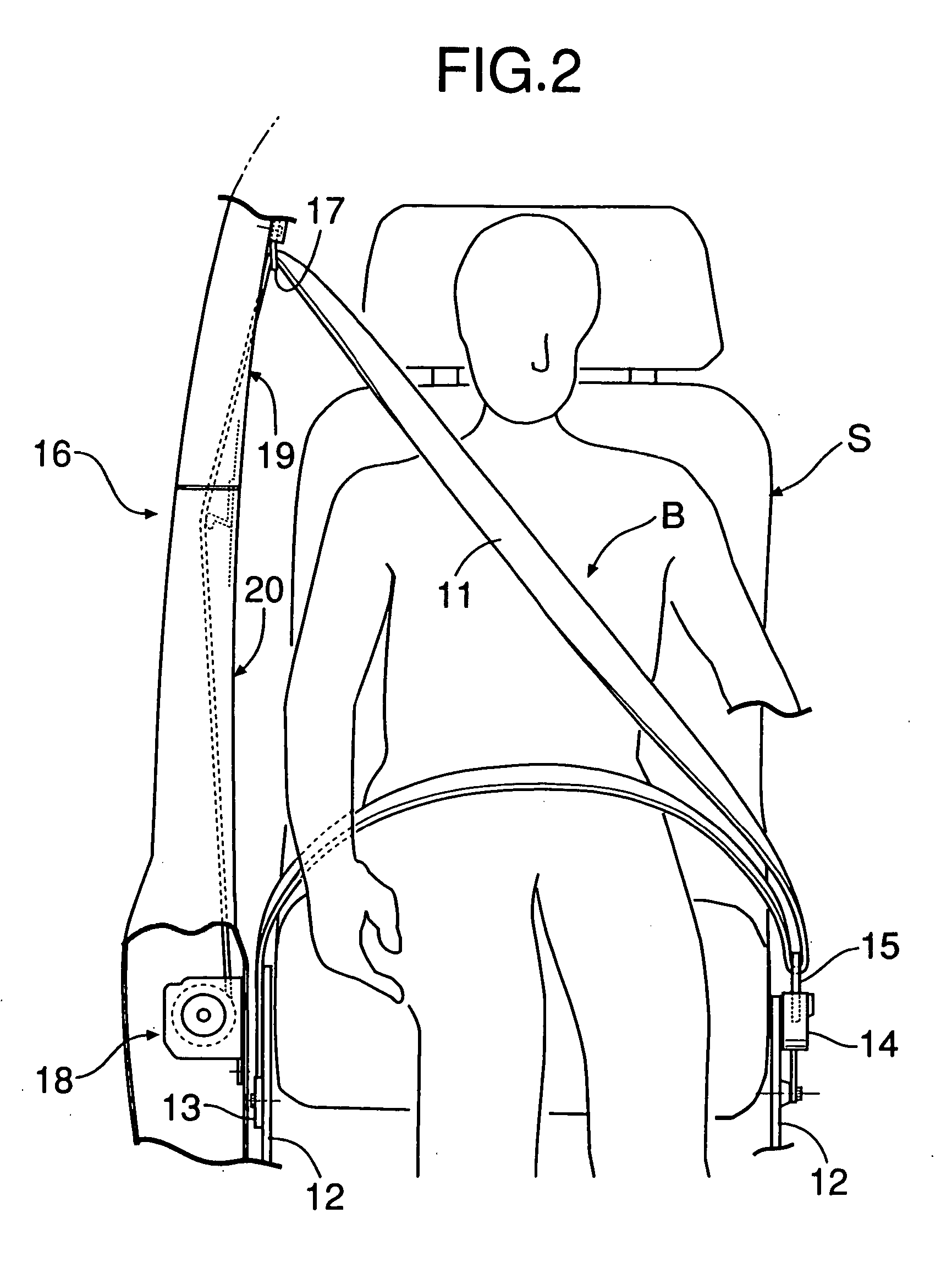

Structure of pillar garnish for automobile

ActiveUS20050206198A1Prevent degradation of appearanceAvoid degradationBelt control systemsPedestrian/occupant safety arrangementEngineeringNewel

In a structure of a pillar garnish for an automobile, a leg is provided to protrude toward a webbing from a lower edge of a step formed at a lower end of one of an upper pillar garnish and a lower pillar garnish which are formed by dividing a pillar garnish section, and webbing guide is provided at a tip end of the leg. Therefore, even if a sink mark is created on a surface of the step of the upper pillar garnish corresponding to the position of the leg, the sink mark is covered with an upper end of the lower pillar garnish and thus invisible from the side of a vehicle compartment, so that it is possible to prevent the degradation of the appearance due to the creation of the sink mark. Moreover, a back of the lower pillar garnish is superposed on a surface of the step formed on the upper pillar garnish. Therefore, it is possible to prevent the generation of a difference in level at a joint between both of the pillar garnishes to enhance the appearance.

Owner:HONDA MOTOR CO LTD

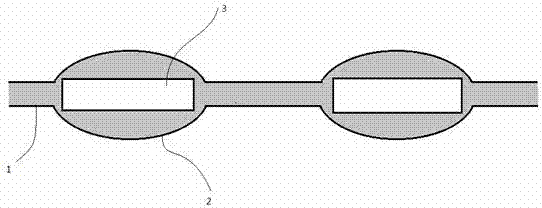

Preparation method for antiskid surgical suture

InactiveCN107874800ANot easy to slipThe method is simpleSuture equipmentsSurgical needlesEngineeringBinding time

The invention relates to the technical field of surgical sutures and concretely relates to a preparation method for an antiskid surgical suture. The preparation method comprises steps of fusion spinning, heating operation, filament pressing, hole drilling operation and cooling and winding operation. The surgical suture prepared by the method comprises steps of first parts and second parts, whereinthe first parts and the second parts are distributed at intervals; a cross section width of the first parts of the surgical suture is even; a cross section width of the second parts is greater than the cross section width of the first parts; the second parts are oval; an elongated hole is formed in each oval shape; the length of the hole is no less than the length of a short shaft of each oval shape; and the width of each hole is no less than the cross section width of the first parts. Compared with the traditional surgical suture, the surgical suture prepared by the method is antiskid, can easily pass through muscles, and requires low production cost; and binding time during the surgical suturing process can be saved, so patient pain can be reduced.

Owner:丽水市正明机械科技有限公司

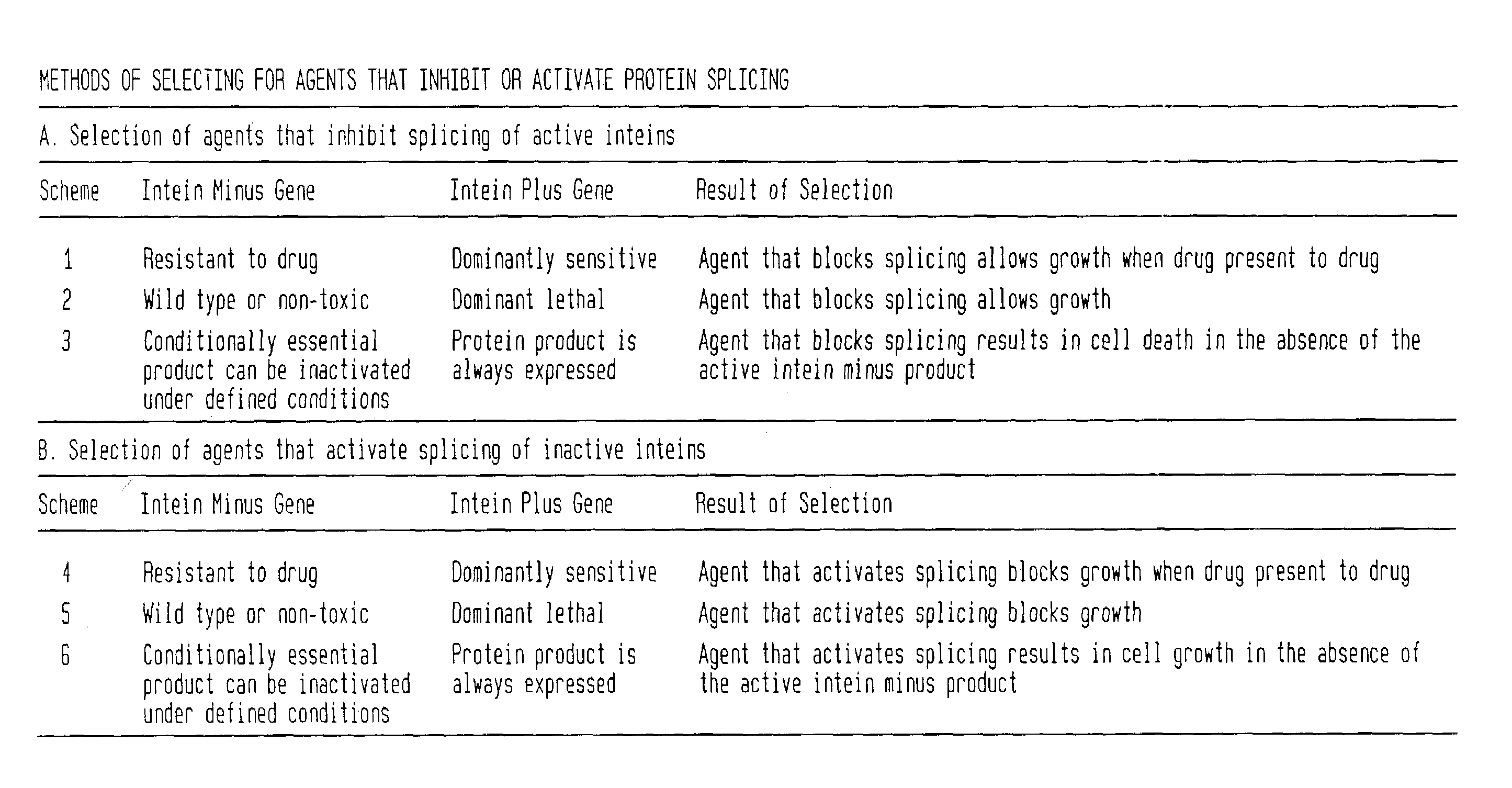

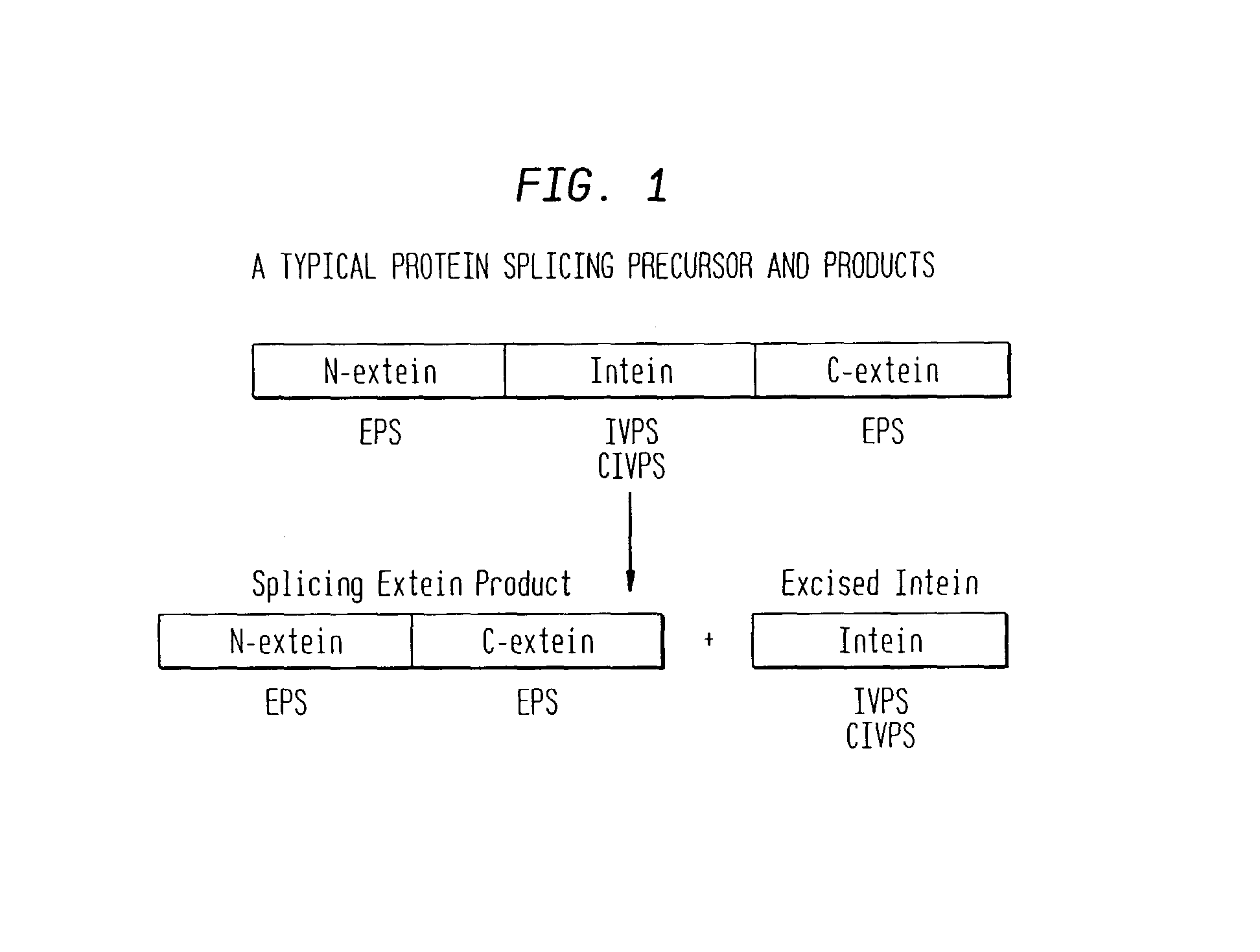

Method for splicing two-sided file fragments cut through paper shredder

InactiveCN103886570AHigh splicing accuracySplicing speed is fastImage enhancementGeometric image transformationAlgorithmDocumentation

The invention belongs to the technical field of information, and relates to a method for splicing two-sided file fragments cut through a paper shredder. The method comprises the steps that firstly, the front faces and the back faces of n file fragments obtained through paper shredder cutting are labeled and scanned to obtain 2n pictures, pixel values of the pictures are read, and the distance between any two pictures is calculated; secondly, the 0-1 variable Xjy is introduced for describing whether two pictures can be connected or not to enable the sum of the distance between the adjacent fragments to be minimal, and a 0-1 programming model is provided for a target function; thirdly, the 2n pictures are connected left and right according to the solution result of Xjy, and files are divided into the front faces and the back faces to be spliced. According to the fragment splicing method, splicing of the two-sided file fragments cut through the paper shredder is achieved with a digital method, and due to introduction of the 0-1 programming method, the fragments can be spliced in a high accurate rate and high splicing speed mode.

Owner:UNIV OF JINAN

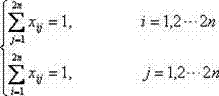

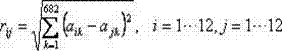

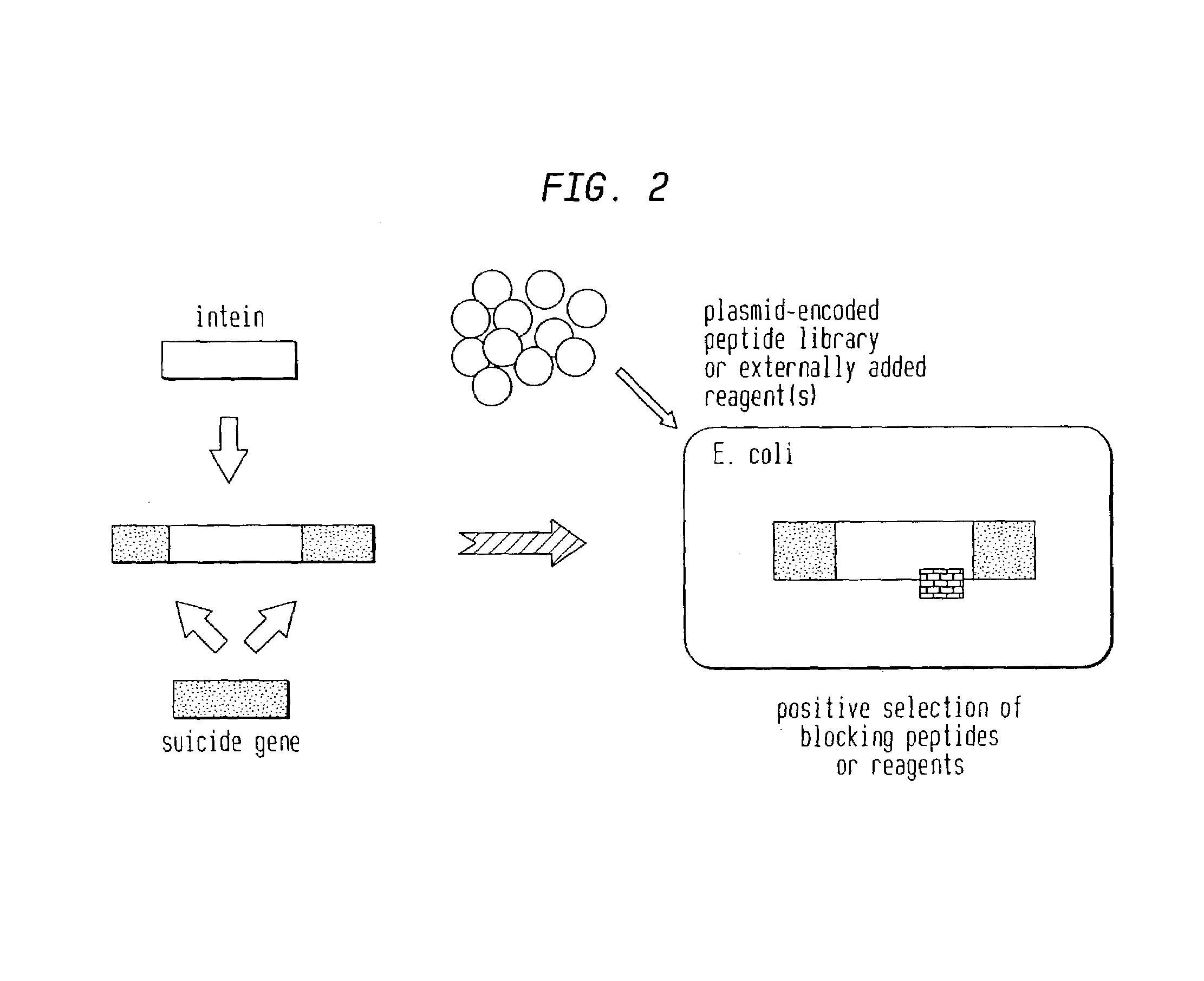

Screening and use of agents which block or activate intein splicing utilizing natural or homologous exteins

In accordance with the present invention, there are provided selection systems and methods for screening for agents that control splicing of inteins in their native host protein (extein) or in homologous exteins. Specifically, there are provided positive genetic selection systems for the screening of agents which inhibit or activate protein splicing which comprise: a host cell containing a chromosomal gene encoding either a drug-resistant form of a target enzyme or a wild-type target enzyme, and a plasmid-borne gene encoding either a drug-sensitive form of the target enzyme, which is dominantly cytotoxic upon interaction with the drug, or a dominantly cytotoxic form of the target enzyme. In these systems the plasmid-borne gene contains an intein, and the inhibition or activation of splicing of the dominant cytotoxic form of the target enzyme by a given reagent results in the survival or death of the host cell. More specifically, positive genetic selection systems which utilize the M. xenopi GyrA intein or M. tuberculosis DnaB helicase intein are provided. Similar reporter systems utilizing native or homologous exteins and systems utilizing controllable inteins are provided, as are methods of controlling in vivo expression of proteins by modulating protein splicing with inhibiting or activating agents, and methods of controlling the delivery of proteinaceous drugs in vivo by modulating protein splicing.

Owner:NEW ENGLAND BIOLABS

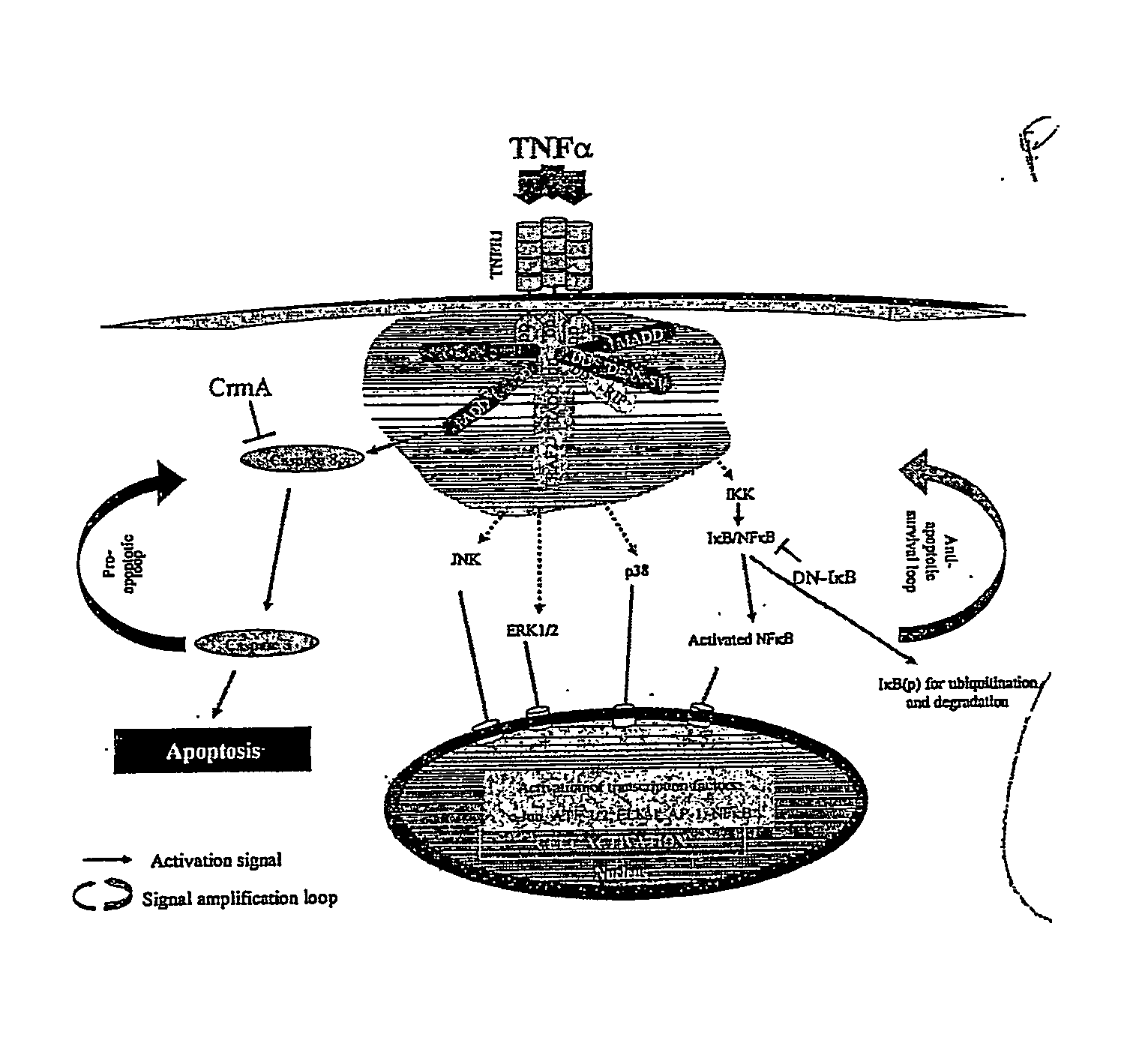

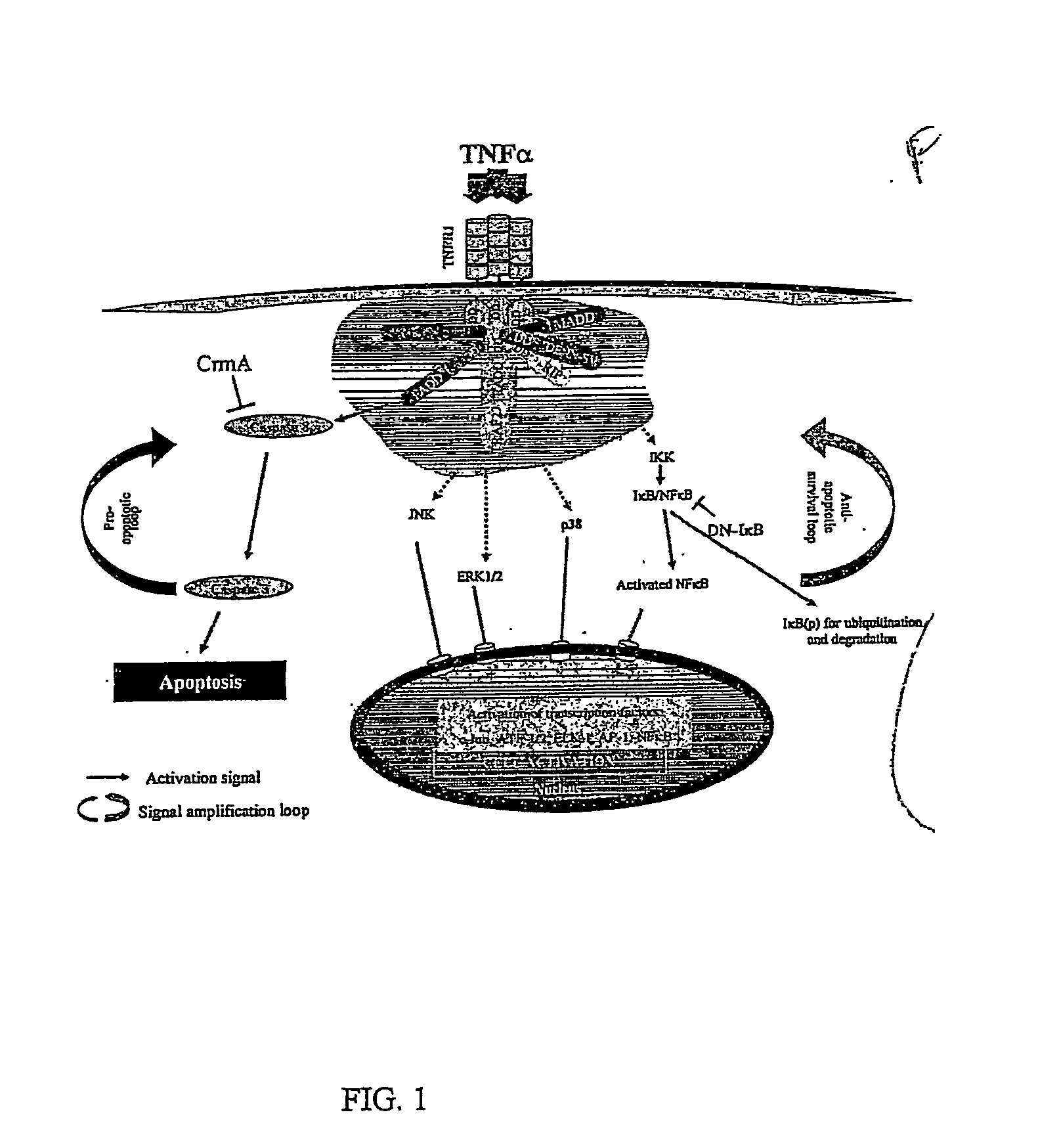

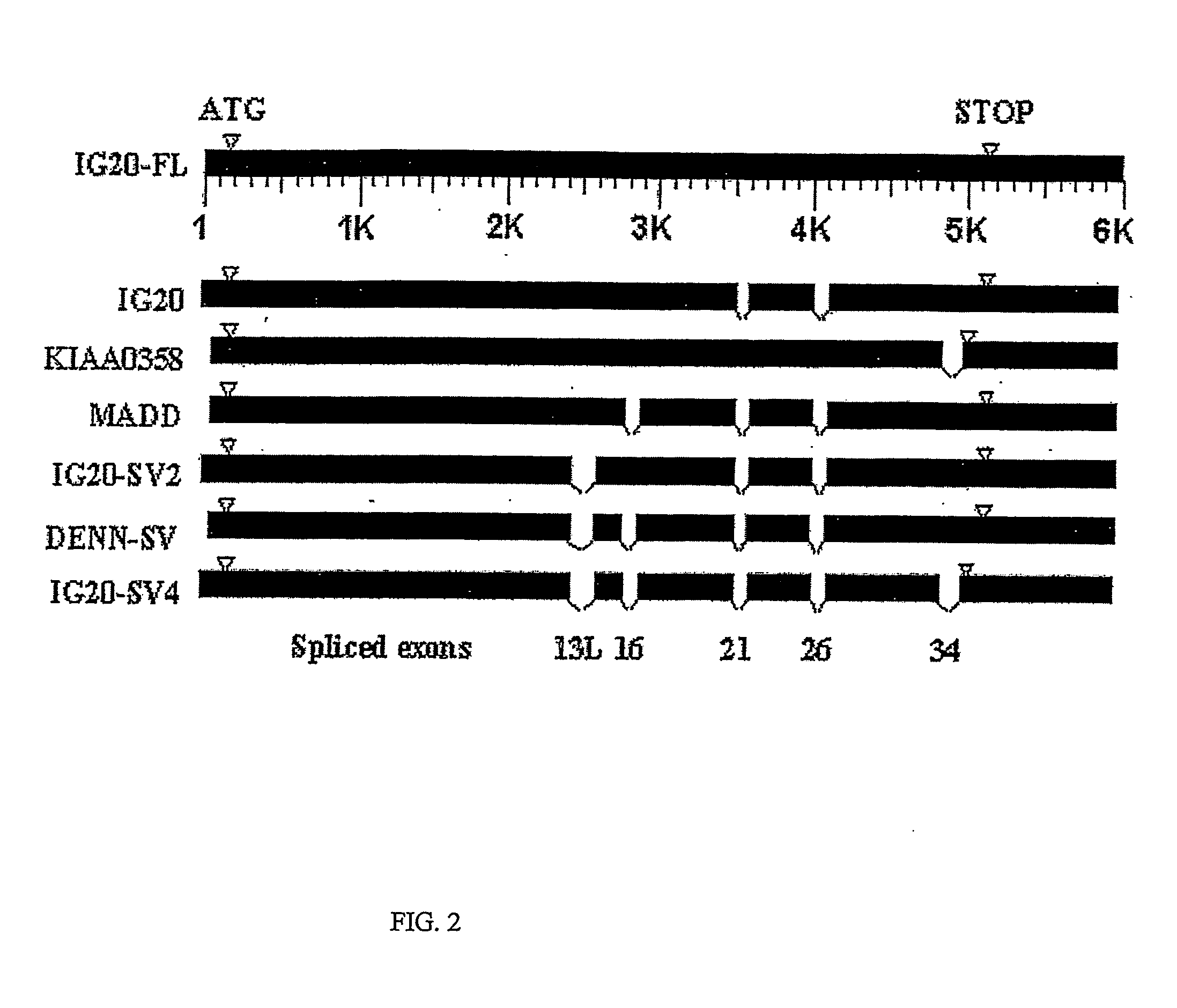

Methods and Compositions of Ig20 and Denn-Sv Splice Variants

InactiveUS20080233645A1Enhancing TRAIL induced apoptosisFacilitating DISC formationSugar derivativesPeptide/protein ingredientsCell survivalCellular death

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

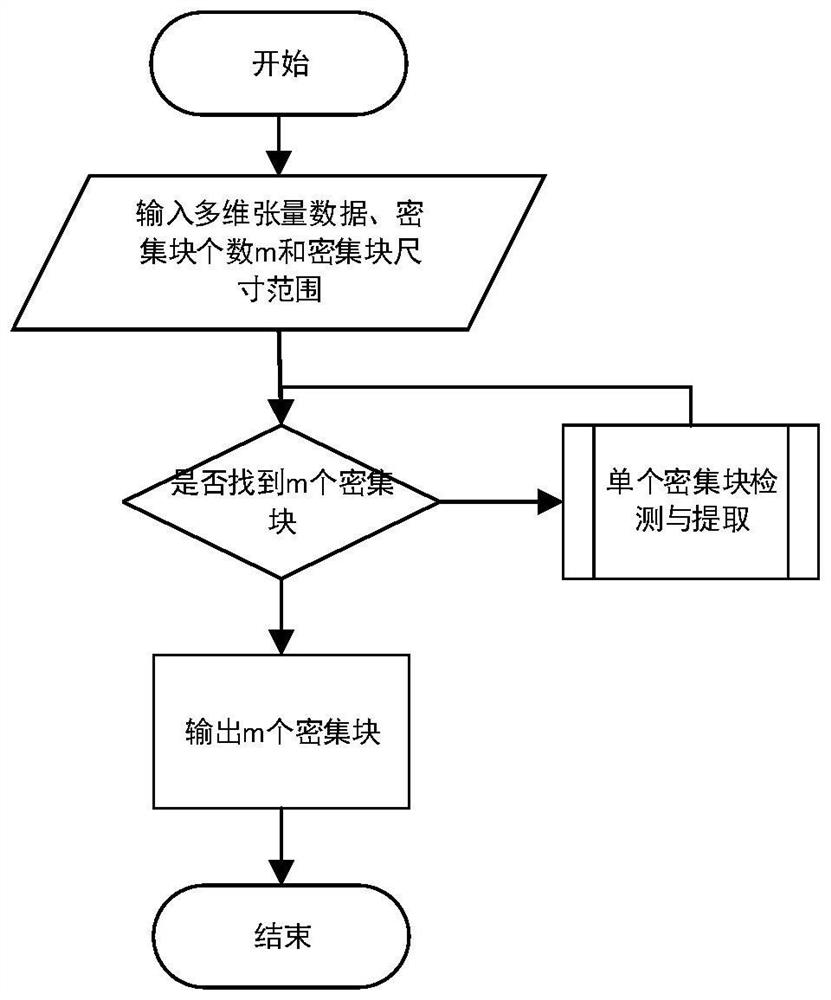

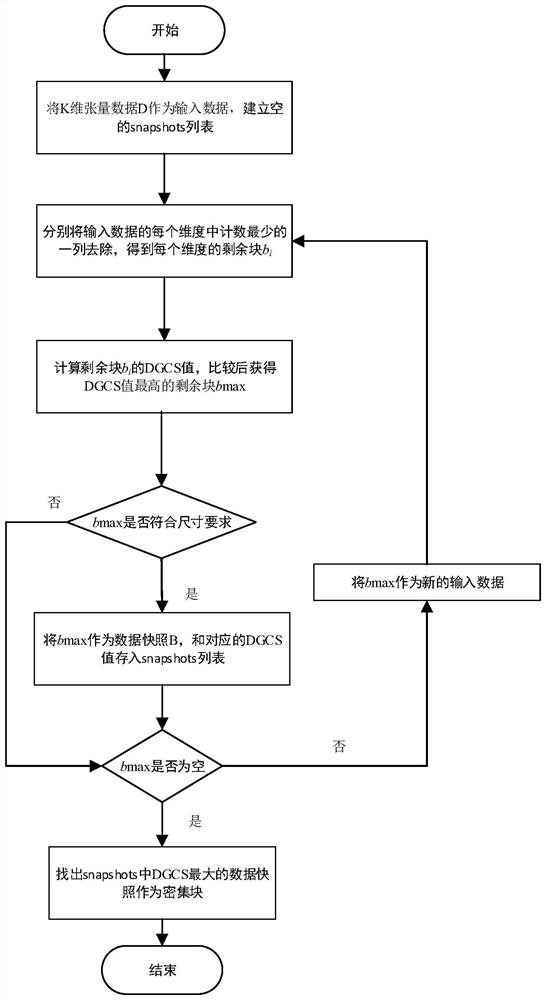

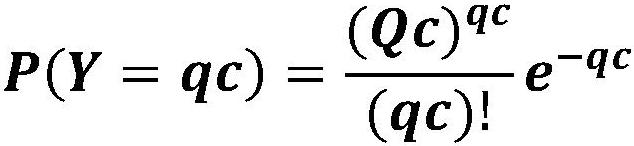

Multi-dense block detection and extraction method based on Possion distribution

ActiveCN114218610AGuaranteed Integrity and IndependenceImprove efficiencyDigital data information retrievalDigital data protectionTheoretical computer scienceComputer engineering

The invention discloses a Possion distribution-based multi-dense block detection and extraction method, which comprises the following steps of: carrying out suspicious degree measurement on multi-dimensional tensor data by utilizing a dense block suspicious degree measurement method to obtain a snapshots list containing a plurality of suspicious data snapshots; according to the snapshots list, extracting a single dense block from the multi-dimensional tensor data; removing the extracted single dense block from the multi-dimensional tensor data to obtain updated multi-dimensional tensor data; generating a new snapshots list according to the updated multi-dimensional tensor data, and extracting new dense blocks until m dense blocks are extracted; wherein the dense block suspicious degree measurement method is obtained through Possion distribution derivation containing double factors of counting and density. According to the method, the accuracy and recall rate of the dense blocks can be effectively improved while the detection efficiency is ensured.

Owner:NANJING COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com