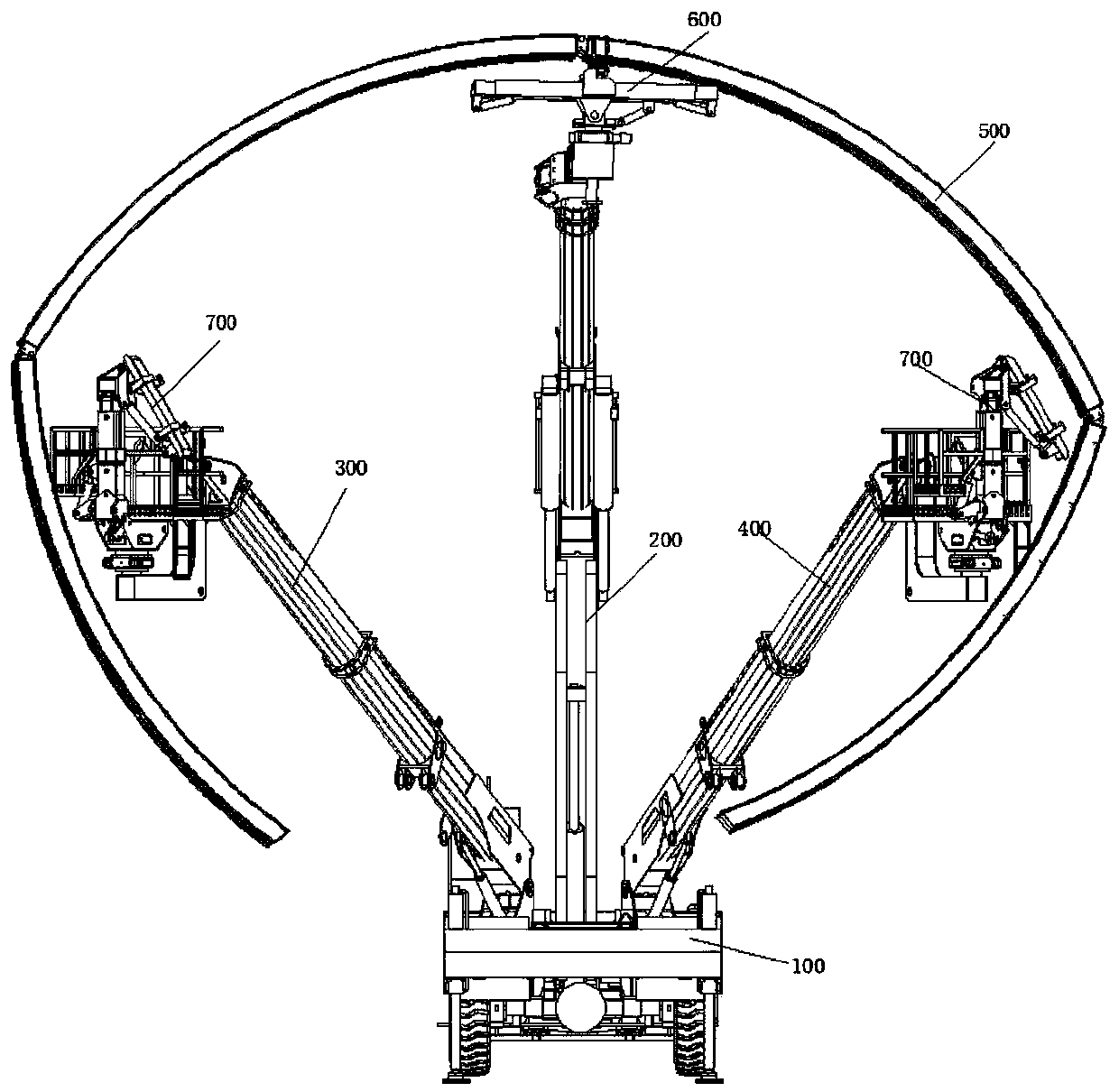

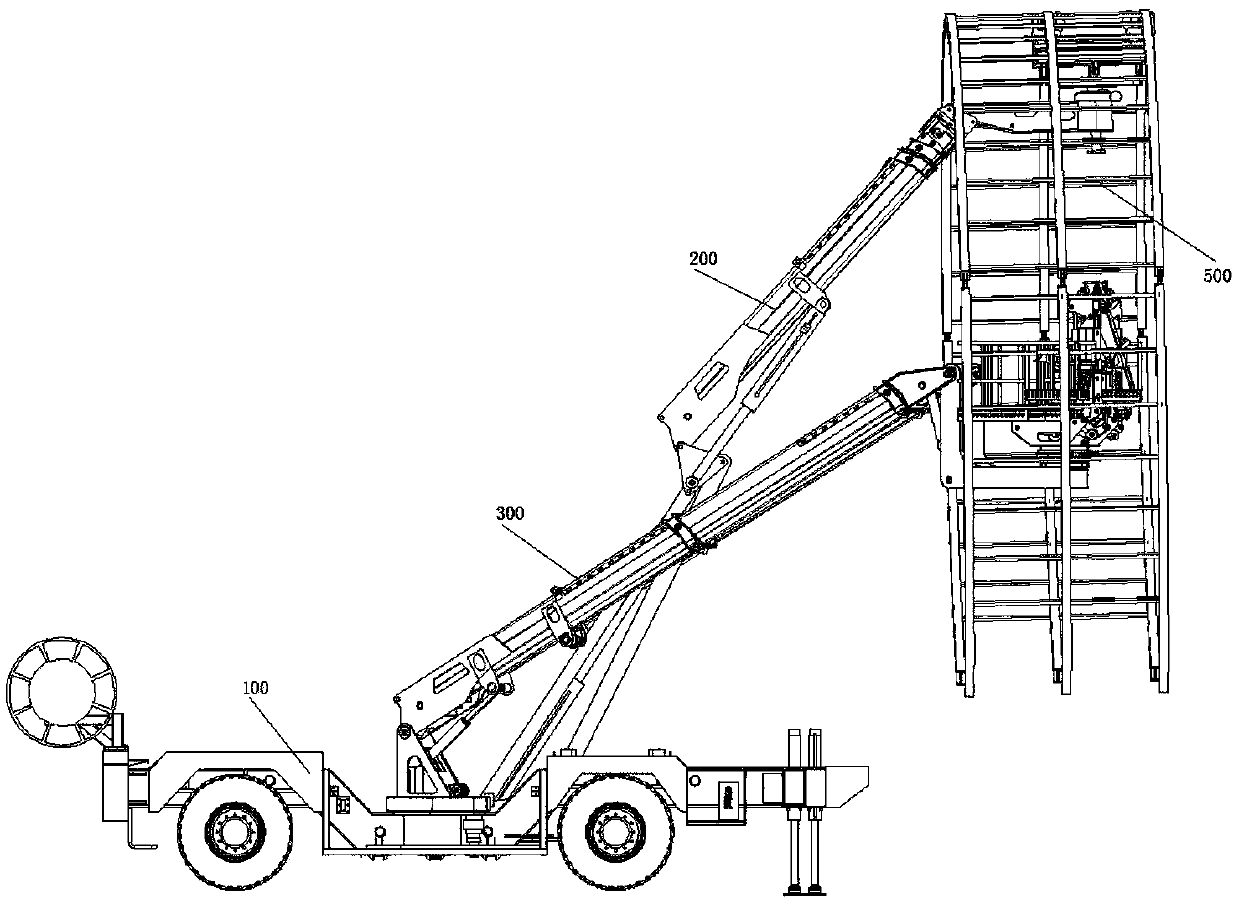

Multifunctional arch support trolley and erection method for multiple arch supports

A multi-functional, arched technology, applied in mining equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of inability to cooperate with mechanized on-site construction of arches, heavy steel arches, and more labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

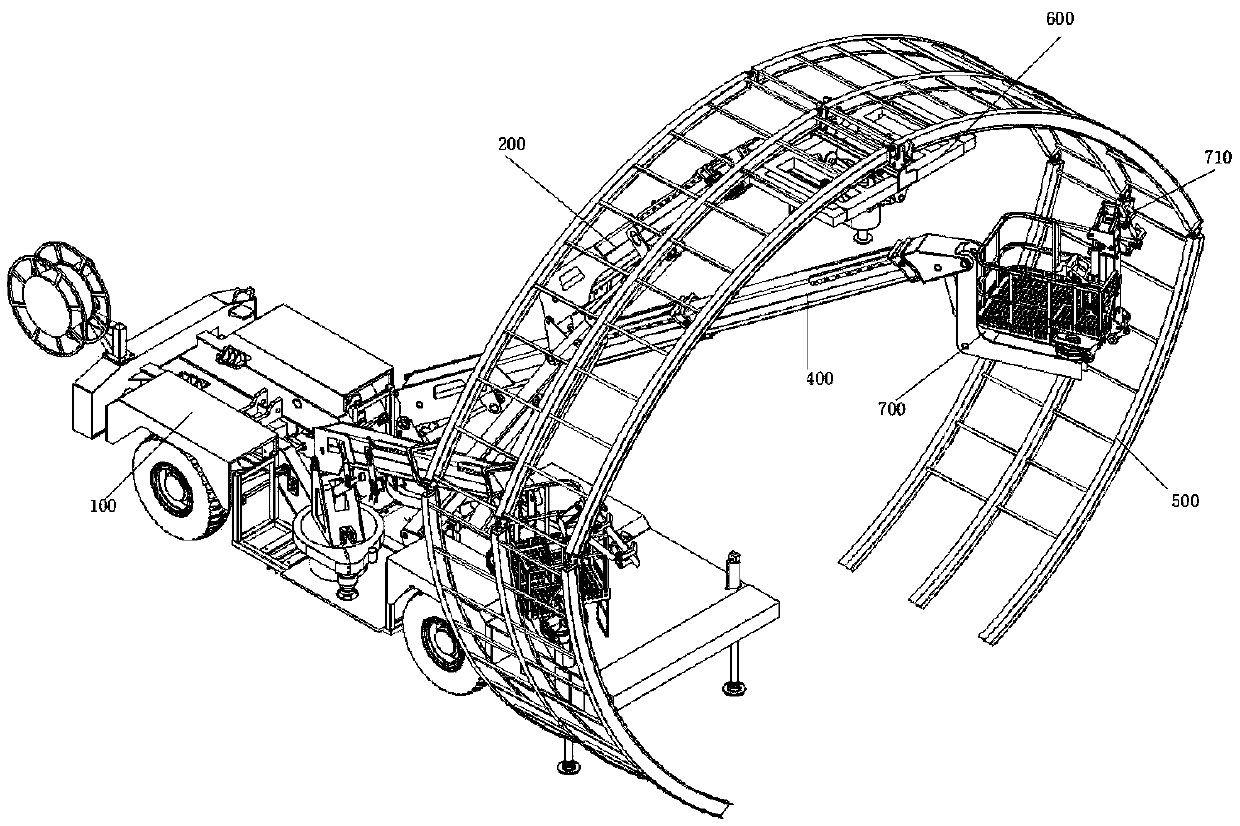

[0059] A method for erecting a multi-arch arch, using the multi-functional arch trolley in Embodiment 1 to erect a multi-arch arch, comprising the following steps:

[0060] Step 1: Make a multi-arch frame: Arrange two or more folded arch frames in parallel, and then connect them with several strengthening connecting rods to form a multi-arch frame;

[0061] Step 2: Fold the multiple arches on the support fixture 600: place the support fixture 600 under the top arch section, and control the support fixture 600 to lift the top arch section to a certain height through the main arm frame 200. The left arch section and the right arch section are symmetrically folded towards the inner side of the top arch section; when the support fixture 600 is slowly lowered through the main boom 200, the left arch section and the right arch section gradually move toward the top arch section. The inner side of the arch is folded until the folding of the multi-arch arch frame is completed; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com