Patents

Literature

369 results about "Space frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture and structural engineering, a space frame or space structure (3D truss) is a rigid, lightweight, truss-like structure constructed from interlocking struts in a geometric pattern. Space frames can be used to span large areas with few interior supports. Like the truss, a space frame is strong because of the inherent rigidity of the triangle; flexing loads (bending moments) are transmitted as tension and compression loads along the length of each strut.

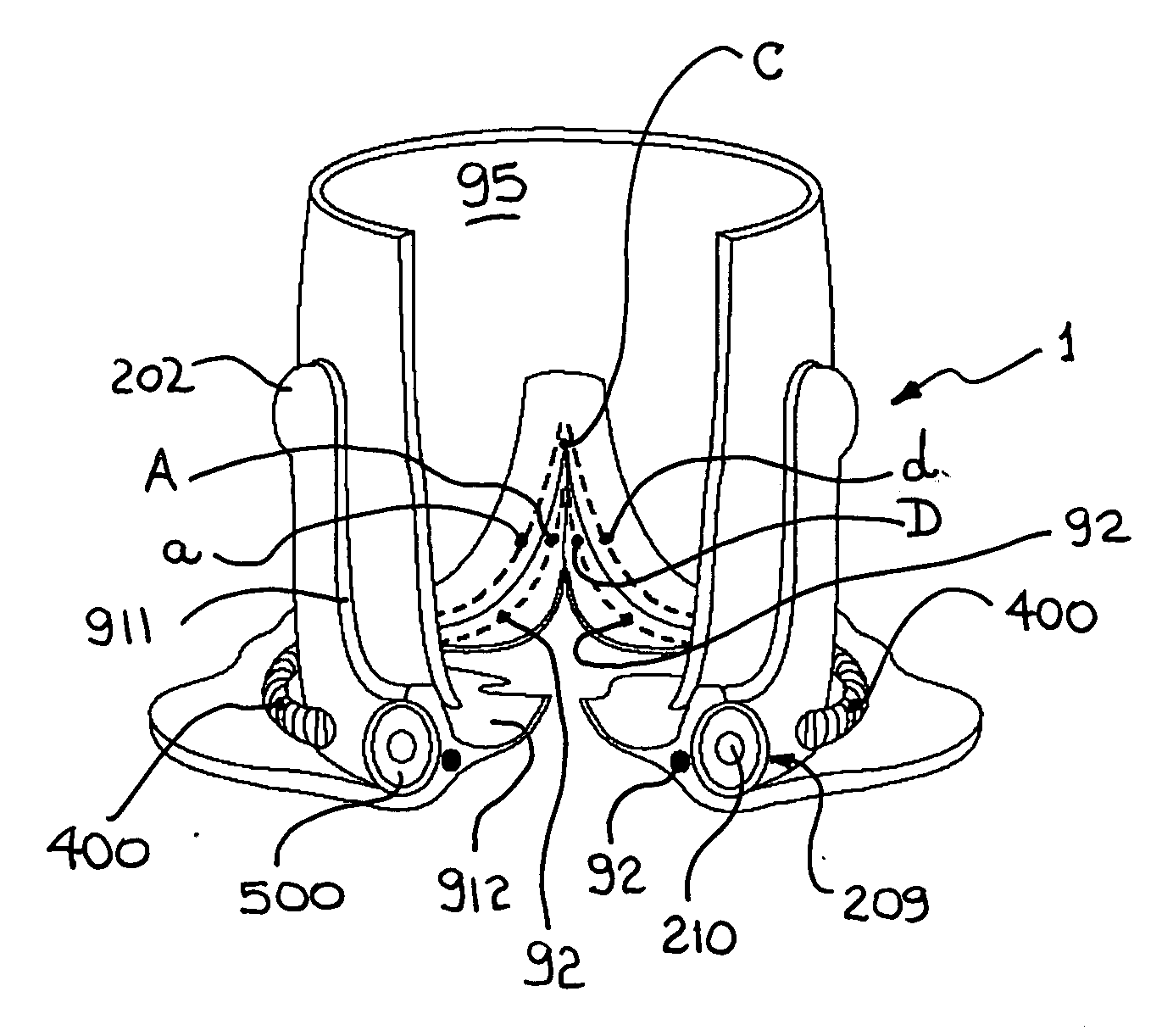

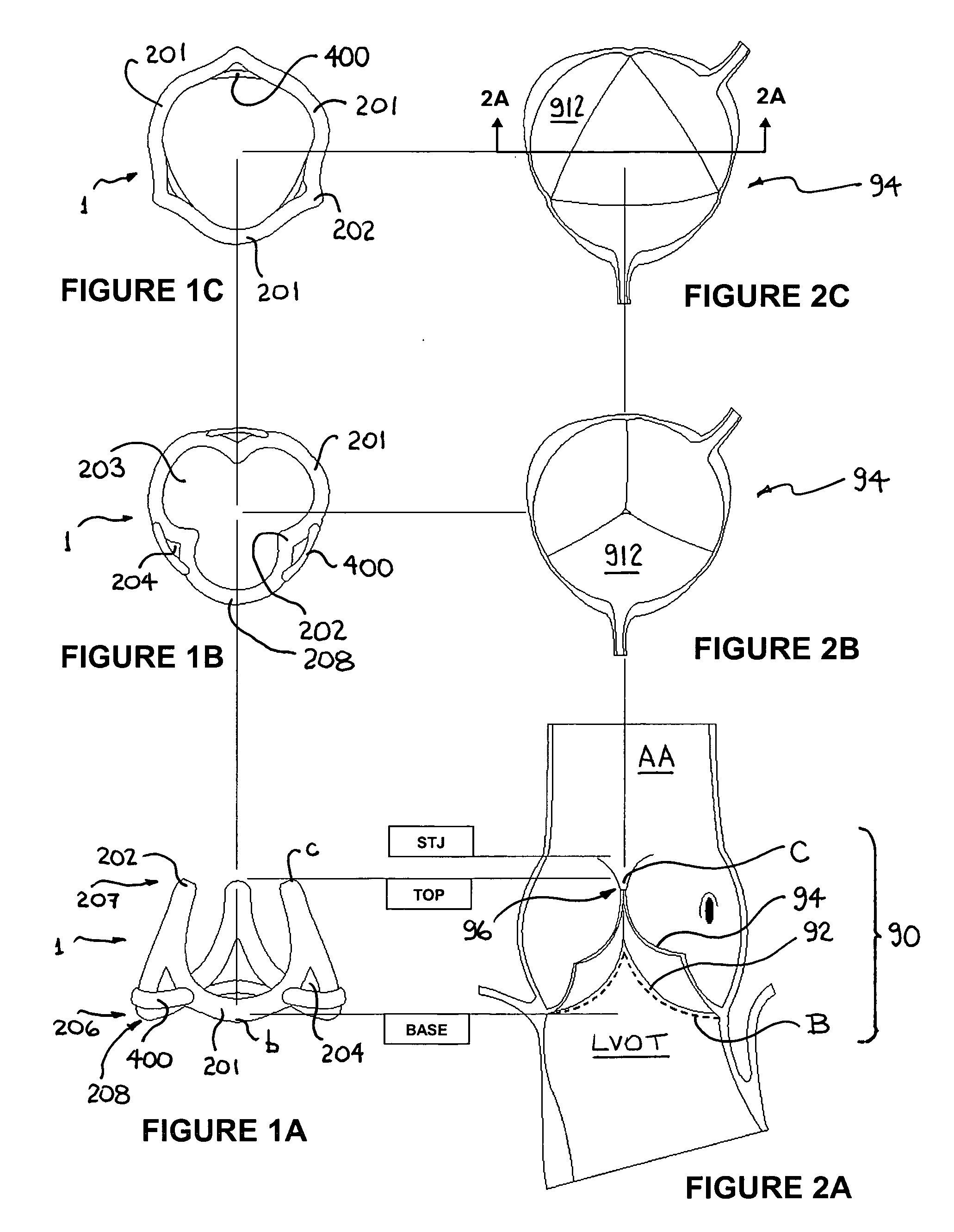

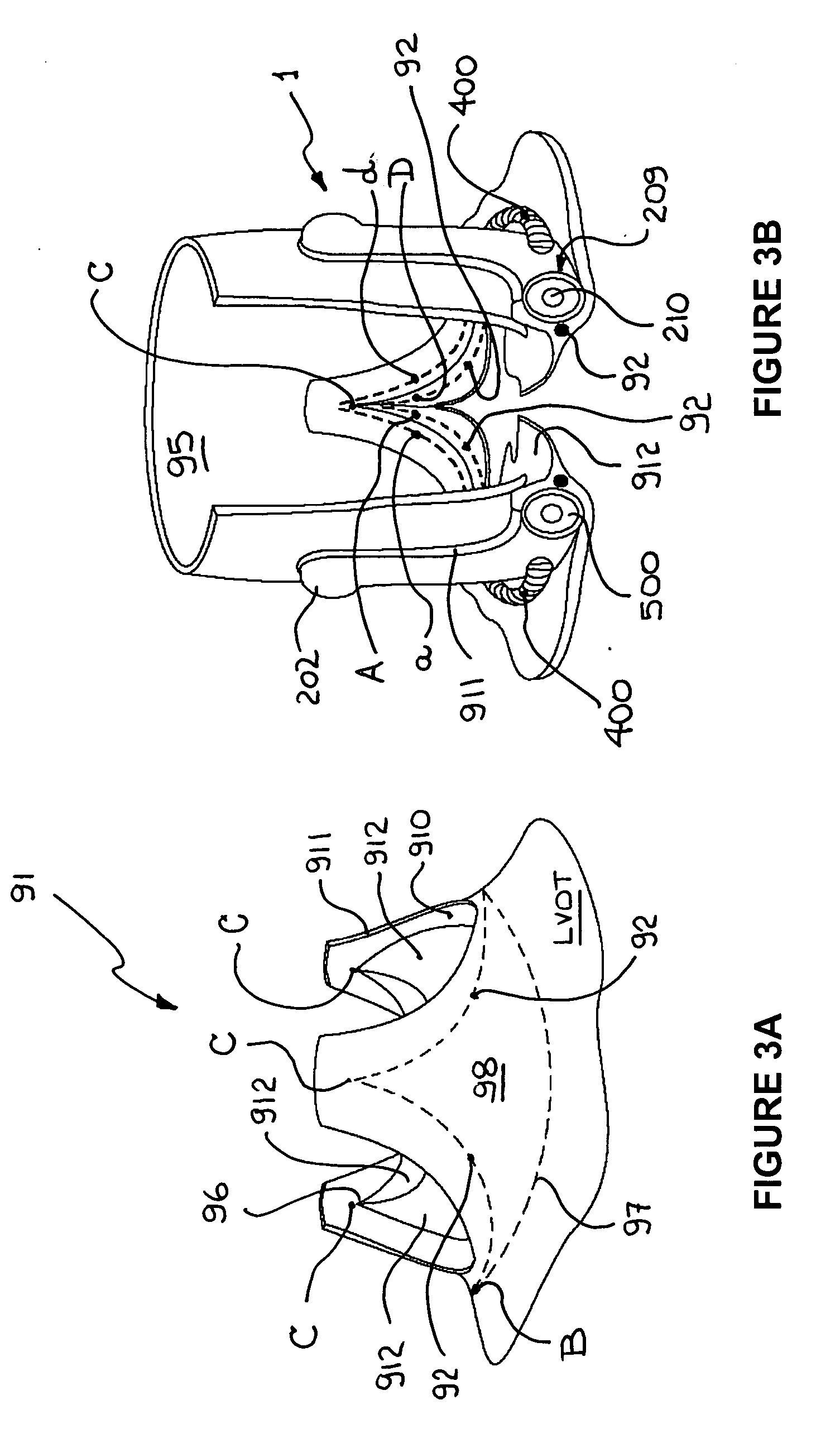

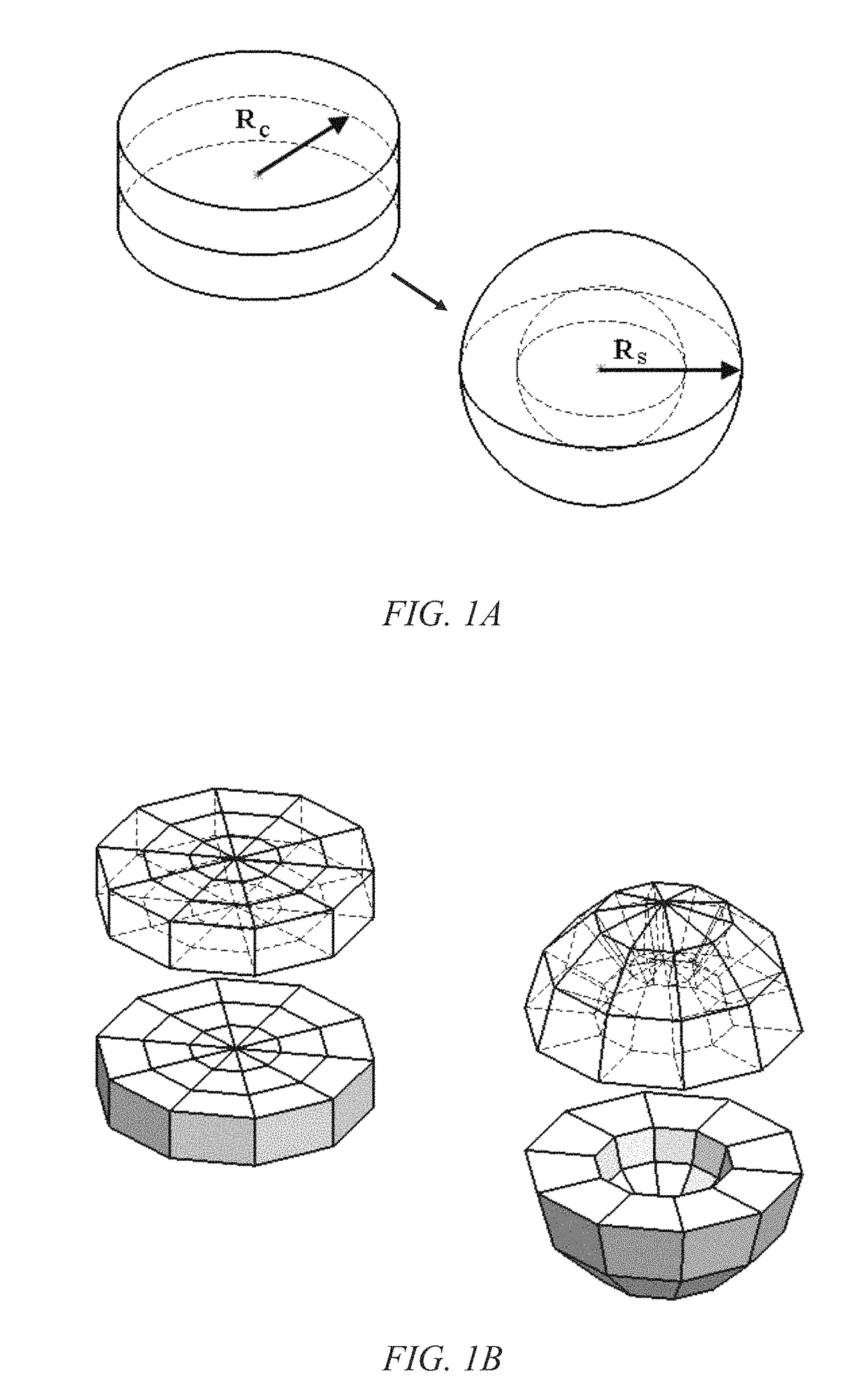

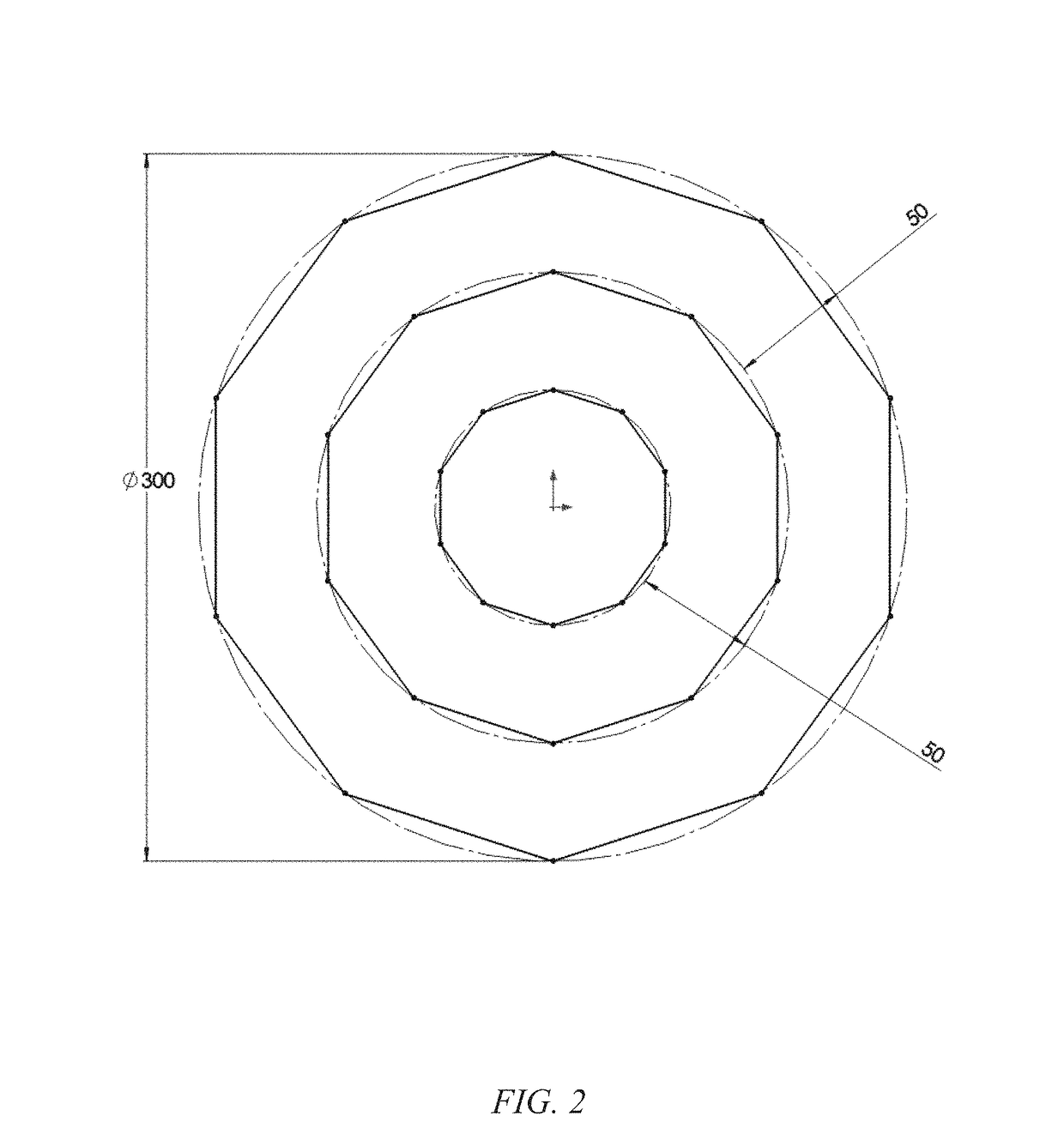

Aortic annuloplasty ring

ActiveUS20060015179A1Preserve and restore normal aortic rootPreserve and restore and valve leafletAnnuloplasty ringsBlood vesselsCardiac cycleAnnuloplasty rings

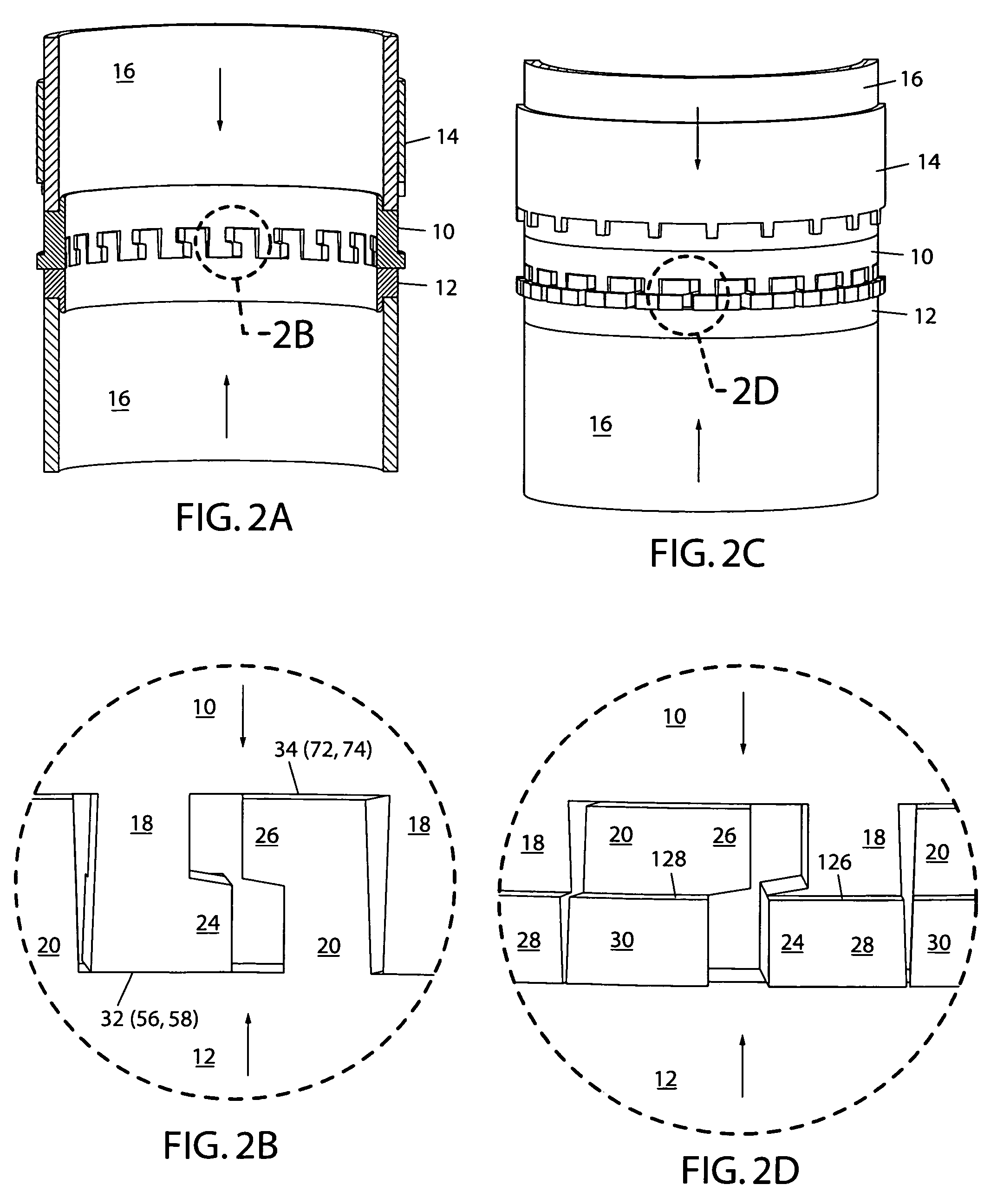

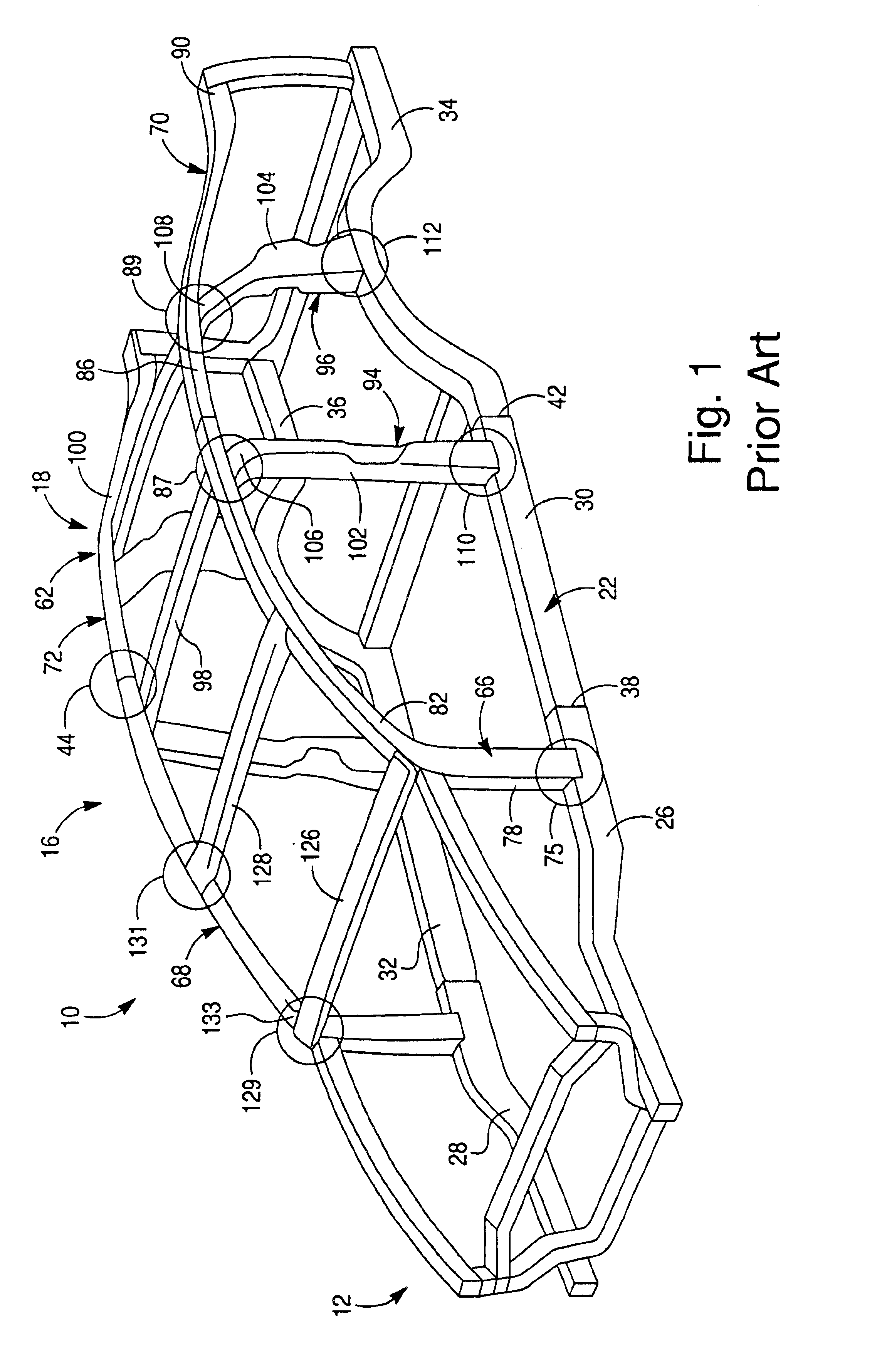

An annuloplasty ring to resize a dilated aortic root during valve sparing surgery includes a scalloped space frame having three trough sections connected to define three crest sections. The annuloplasty ring is mounted outside the aortic root, and extends in height between a base plane and a spaced apart commissure plane of the aortic root. At least two adjacent trough sections are coupled by an annulus-restraining member or tether that limits the maximum deflection of the base of the annuloplasty ring. In use, the tether is preferably located in proximity to the base plane of the aortic root. The annuloplasty ring is movable between a first, substantially conical configuration occurring during a diastolic phase of the cardiac cycle, and a second, substantially cylindrical configuration occurring during a systolic phase of the cardiac cycle. The attachment of the annuloplasty ring in proximity to the cardiac valve annulus allows the ring to regulate the dimensions of a dynamic aortic root during the different phases of the cardiac cycle.

Owner:CORONEO

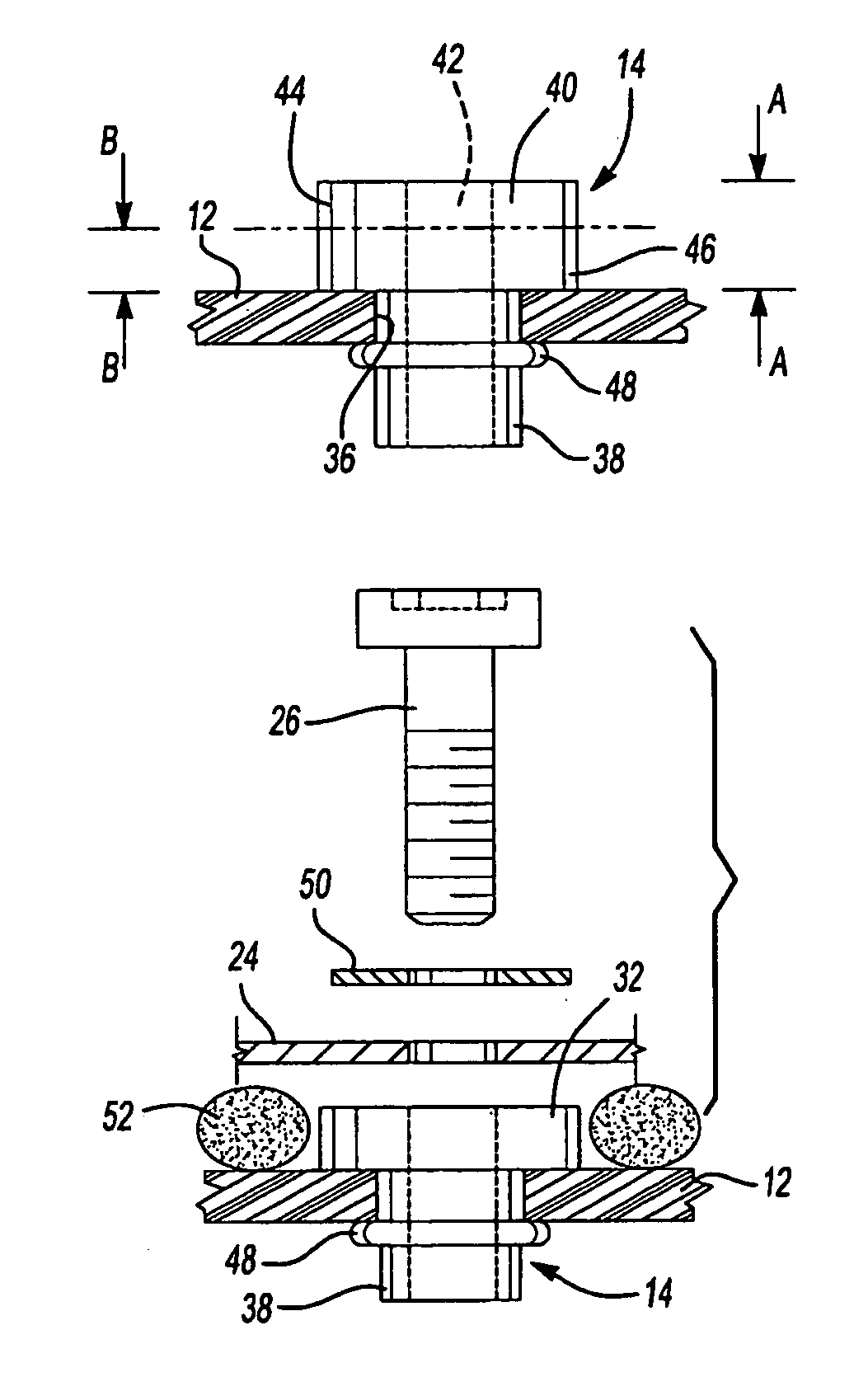

Rivet nut with machinable head and method of making a vehicle body

A method of securing body panels to a space frame of a vehicle is disclosed. Body panels are secured to rivet nuts that are assembled to frame members. The location of the rivet nuts or rivet nuts supporting surface is measured and the rivet nuts are milled or machined to correspond to reference body coordinates. The rivet nuts function as a integral shim pack and obviate the need for shims between the space frame and body panels. The rivet nuts may be milled or formed to predetermined thicknesses before or after assembly to the frame.

Owner:JAGUAR LAND ROVER LTD +1

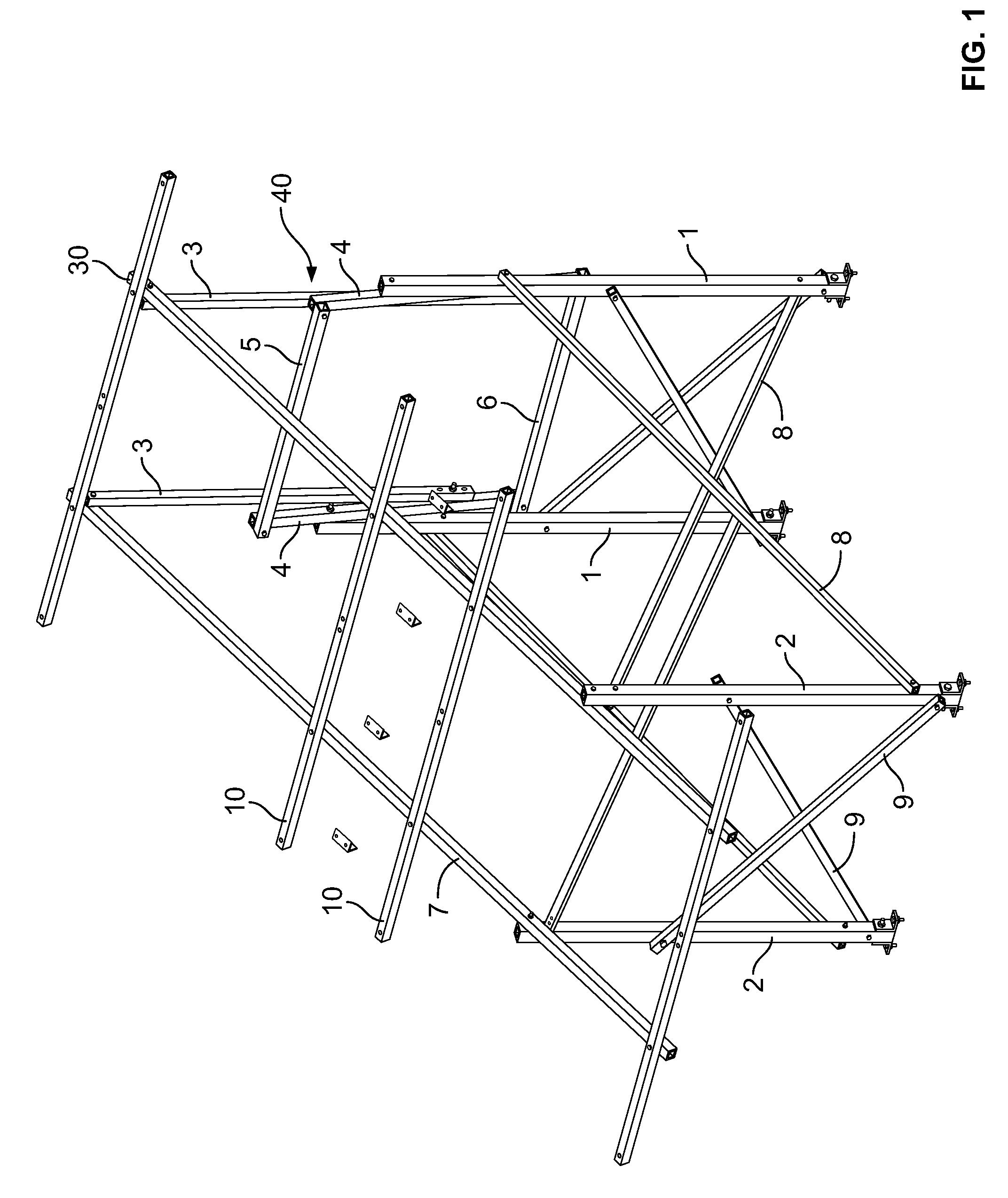

Space frames and connection node arrangement for them

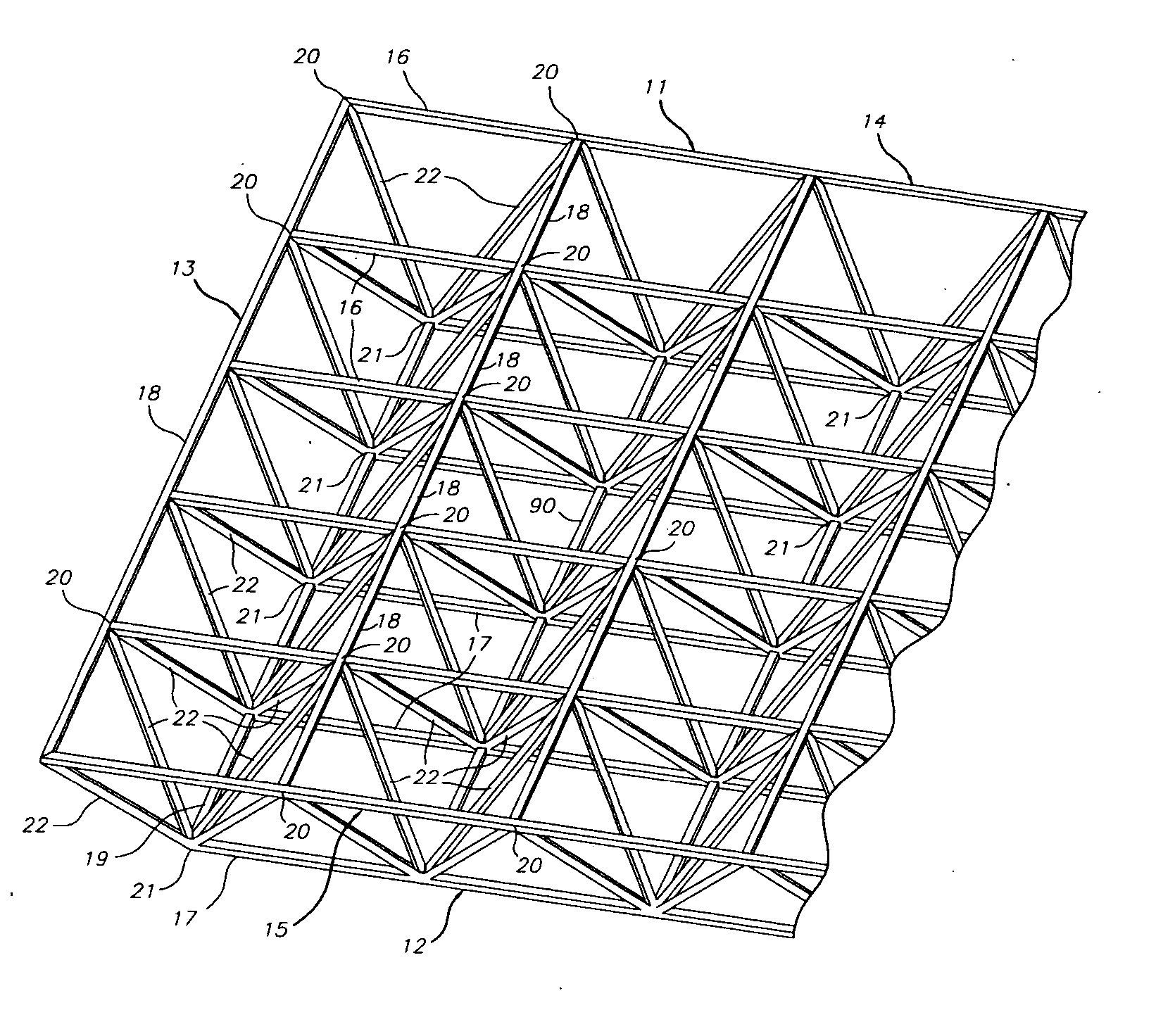

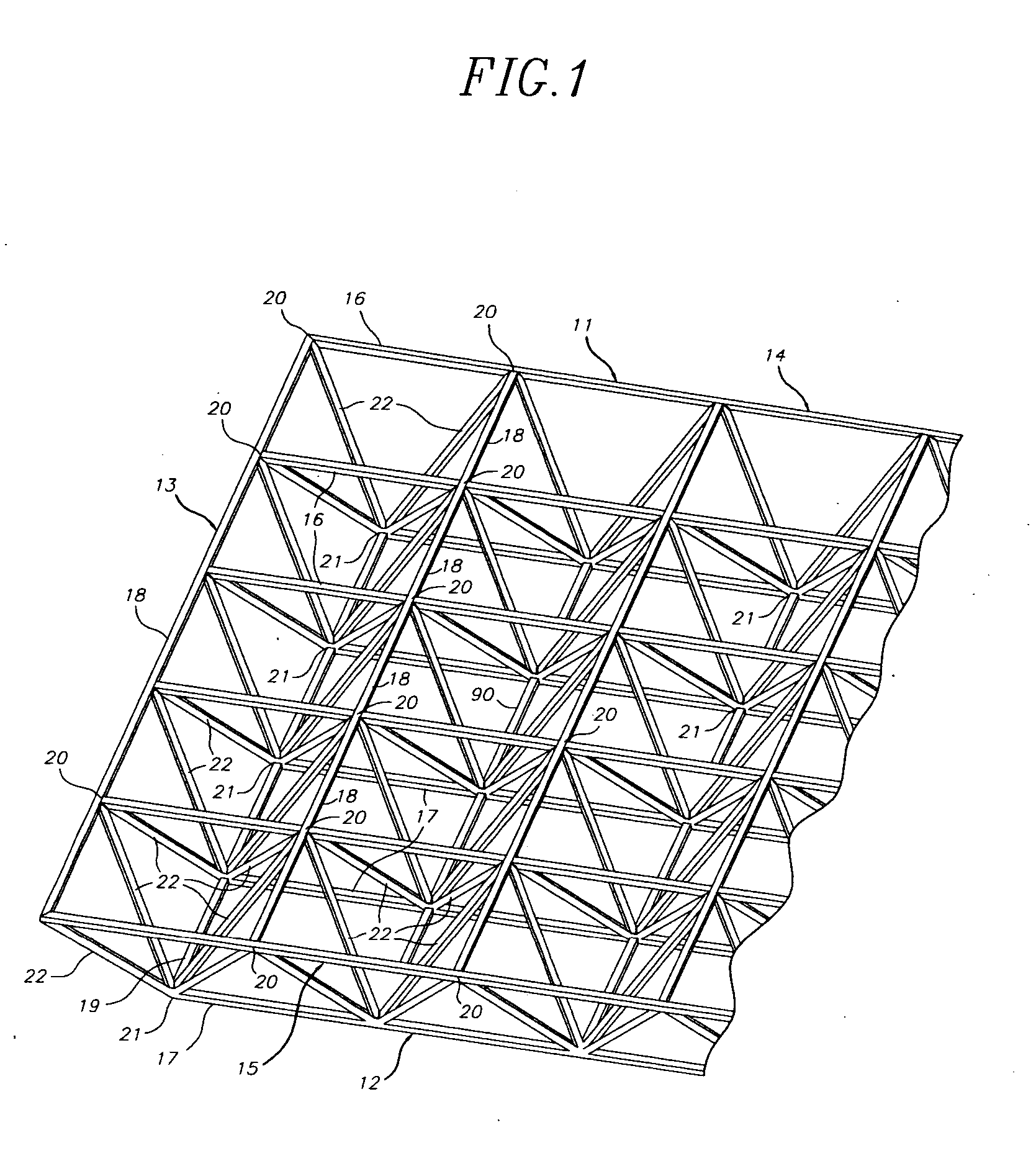

ActiveUS20070011983A1Easy to useEfficiently carry design loadSolar heating energySolar heat devicesEngineeringSpace frame

A node connector in a double layer grid-type of space frame preferably is an extrusion which includes an open-ended tubular portion for snugly at least substantially encircling a frame chord member of desired cross-sectional configuration which is disposable in the passage. The node connector has fixed external elements which extend along the connector parallel to the passage. Those elements define facing parallel flat surfaces arranged in at least two pairs of such surfaces. The surfaces of each pair lie equidistantly from a center plane between them. Each center plane is parallel to the passage axis and preferably includes the passage axis. Each pair of facing flat surfaces of the node connector can cooperate closely with opposite flat surfaces at the end of each of other frames framing member placed between the facing surfaces. The node connector can be secured to a chord member in its passage and to ends of other framing members by shear pins which have zero clearances in node connector holes and in holes or passages through the respective framing members. The space frame can be a movable armature for a curved solar reflector, the space frame having a V-shaped major surface. At least some of the framing members can be thin wall tubes modified to have opposing, flat-exterior wall zones along the length of each tube and in which the wall thickness is locally increased and through which shear pin holes are defined.

Owner:GOSSAMER SPACE FRAMES

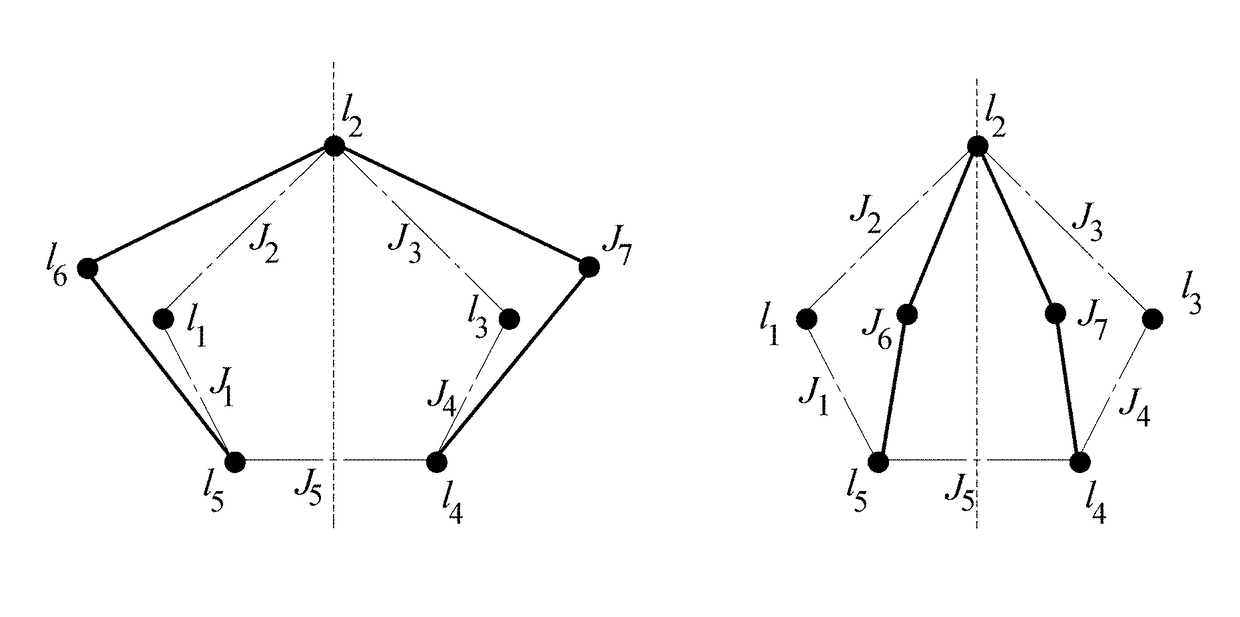

Shape-morphing space frame apparatus using unit cell bistable elements

ActiveUS9783977B2Facilitate behaviorSufficient flexibilityElongated constructional elementsExtraordinary structuresMorphingCompliant mechanism

Unit cell bistable elements, and particular arrangements thereof, that can transform or morph a structure from one shape to another. In certain embodiments, the current invention includes unit cell bistable elements, and particular arrangements and uses thereof, that can transform or morph a structure from one shape to another. In an embodiment, the current invention provides a method / ability to transform any four-bar compliant mechanism into a bistable compliant mechanism. It is an object of the current invention to facilitate structures morphing from one specific shape to another specific shape using unit cell bistable elements.

Owner:UNIV OF SOUTH FLORIDA

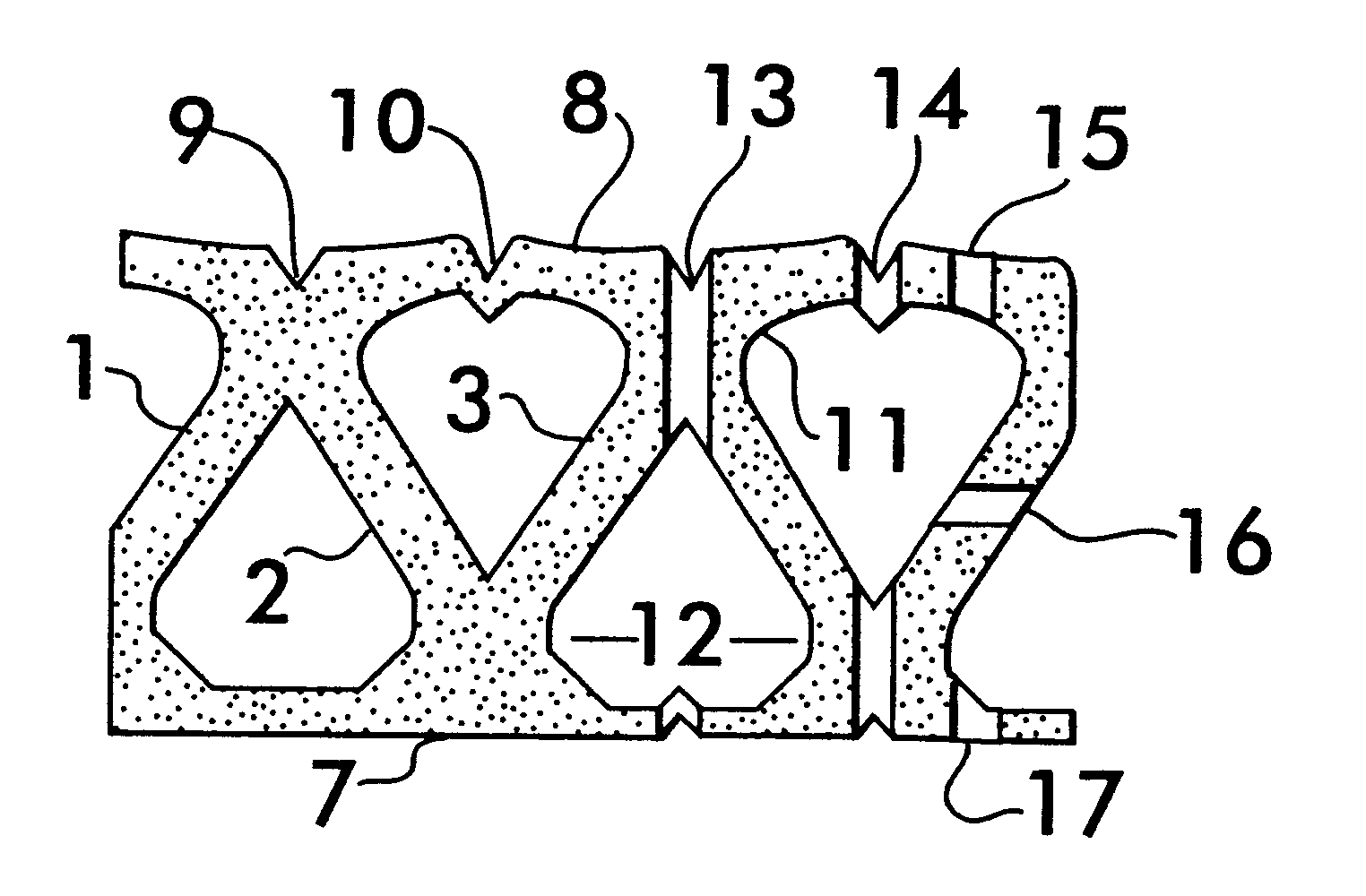

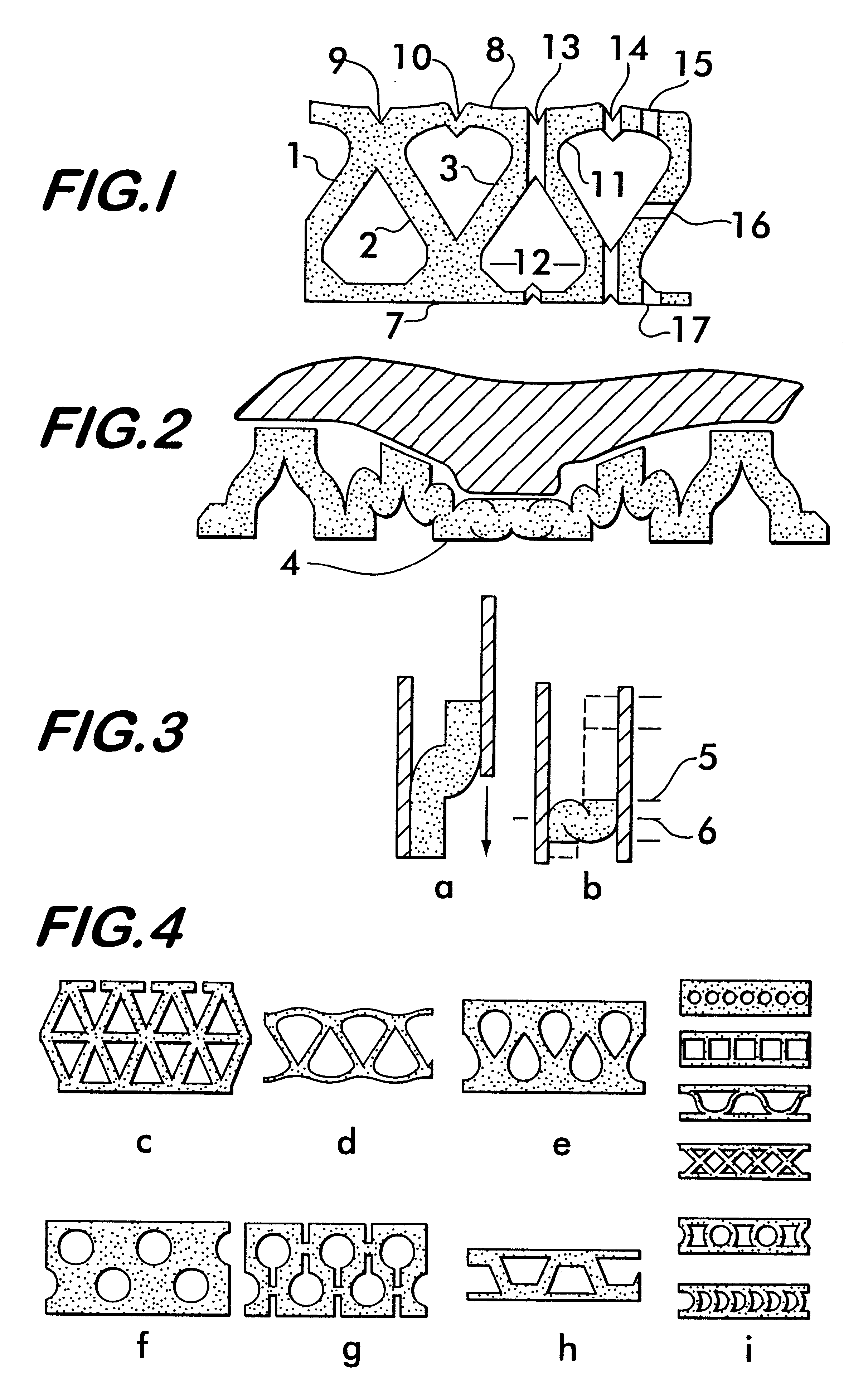

Macrocellular cushion and folding elastomer truss

InactiveUS6284346B1Reducing effective buckling lengthPreventing unnecessary outward (lateral) bucklingLayered productsLight effect designsElastomerCardboard

An improved closed-cell foam sheet stock and method for producing constant force characteristics in elastomer cushions. A closed cell foam is formed as a corrugated cardboard with regular cavities and support elements between two surface sheets. The resulting stock material possesses similar flexibility to foam stock but with an elongated force curve. A method for modifying this or other corrugated elastomers for efficient constant force curves is further provided where alternating support members are conjoined or buttressed to fold in controlled sigmoid shape under load. The resulting collapsible truss or space frame structure produces a cushion with improved cushioning, load distribution, shock absorption and resistance from lateral collapse while folding uniformly and efficiently to a smooth, compact and comfortable support under full compression. The orthopedic constant force profile allows uses in shoes, furniture, mattresses, sports padding, aircraft seats or packaging applications and extends the dynamic range of more resilient elastic, plastic or foam materials including very lightweight closed cell foam. For packaging applications both the collapsing truss or the less sophisticated corrugated profiles provide lighter weight and improved impact absorption over solid closed-cell foams.

Owner:SHERIDAN TIMOTHY BRIAN

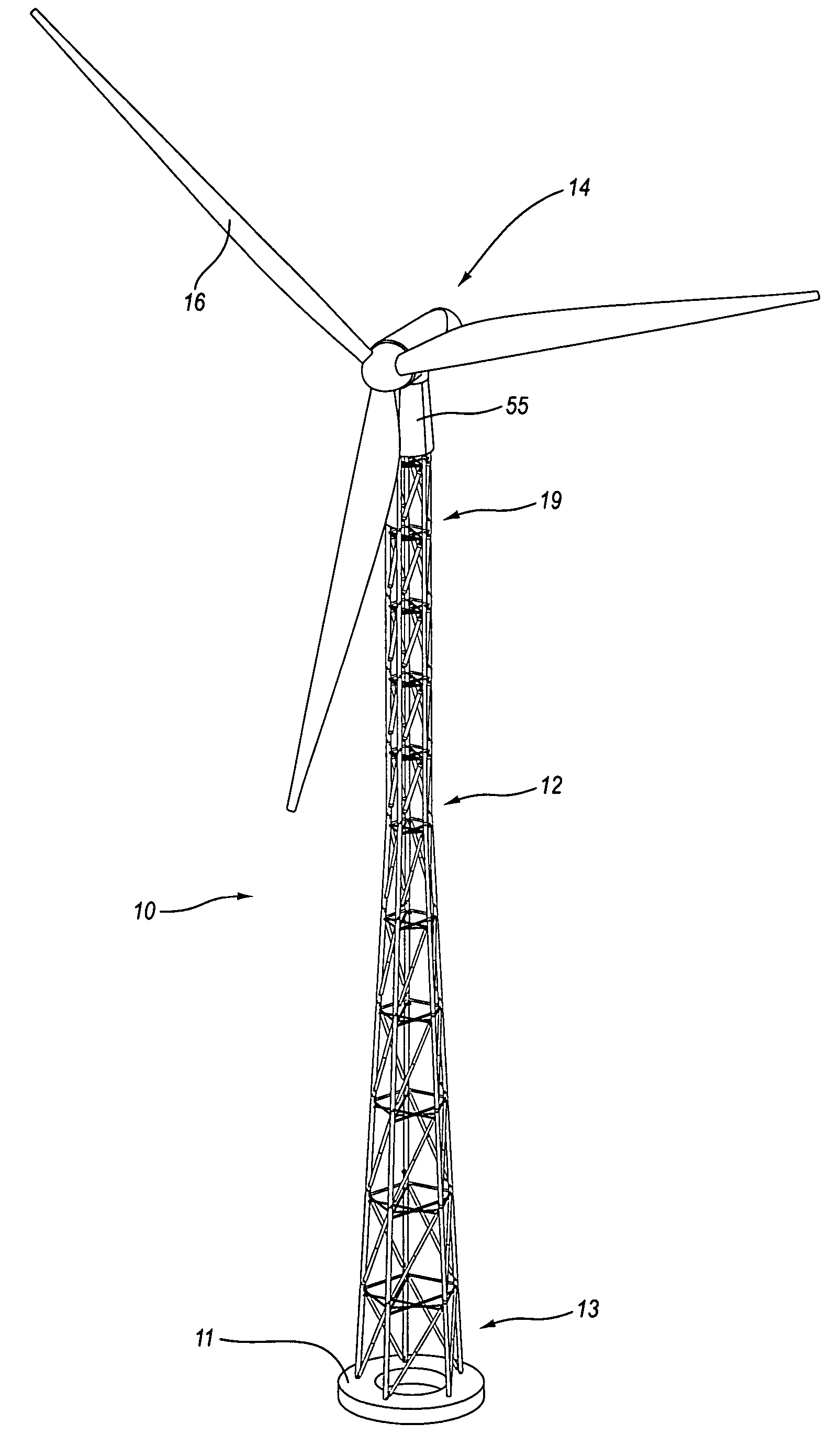

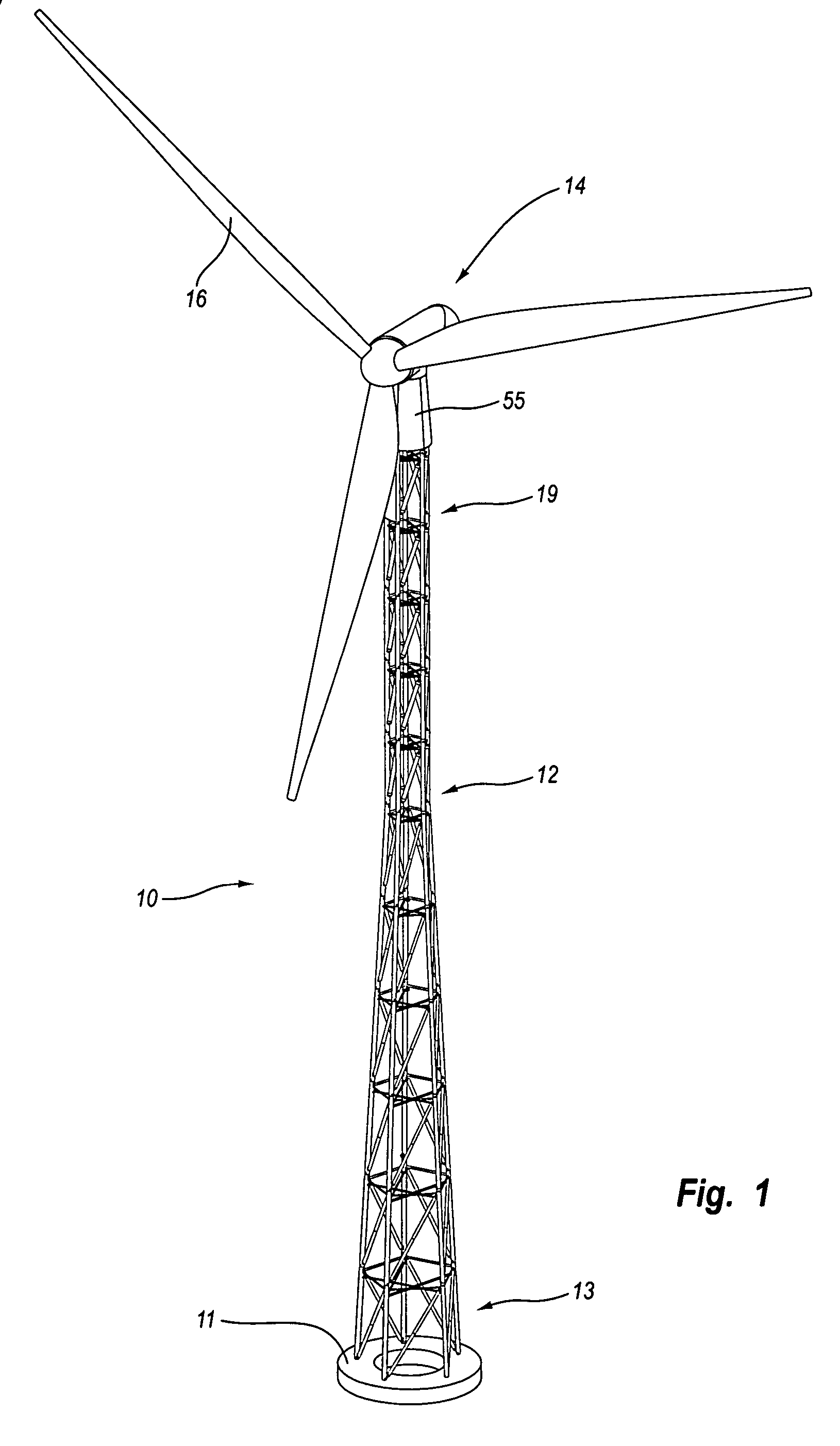

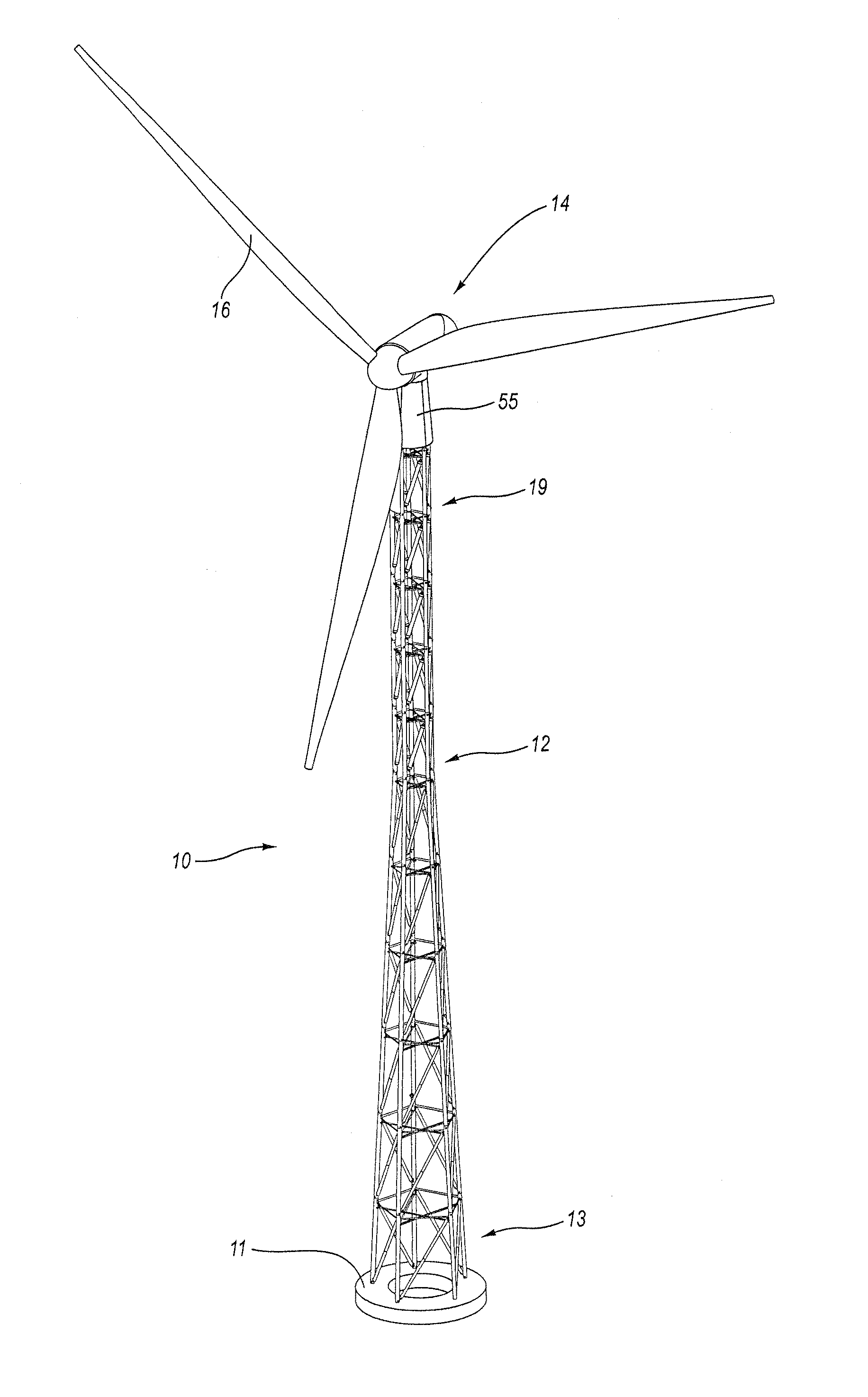

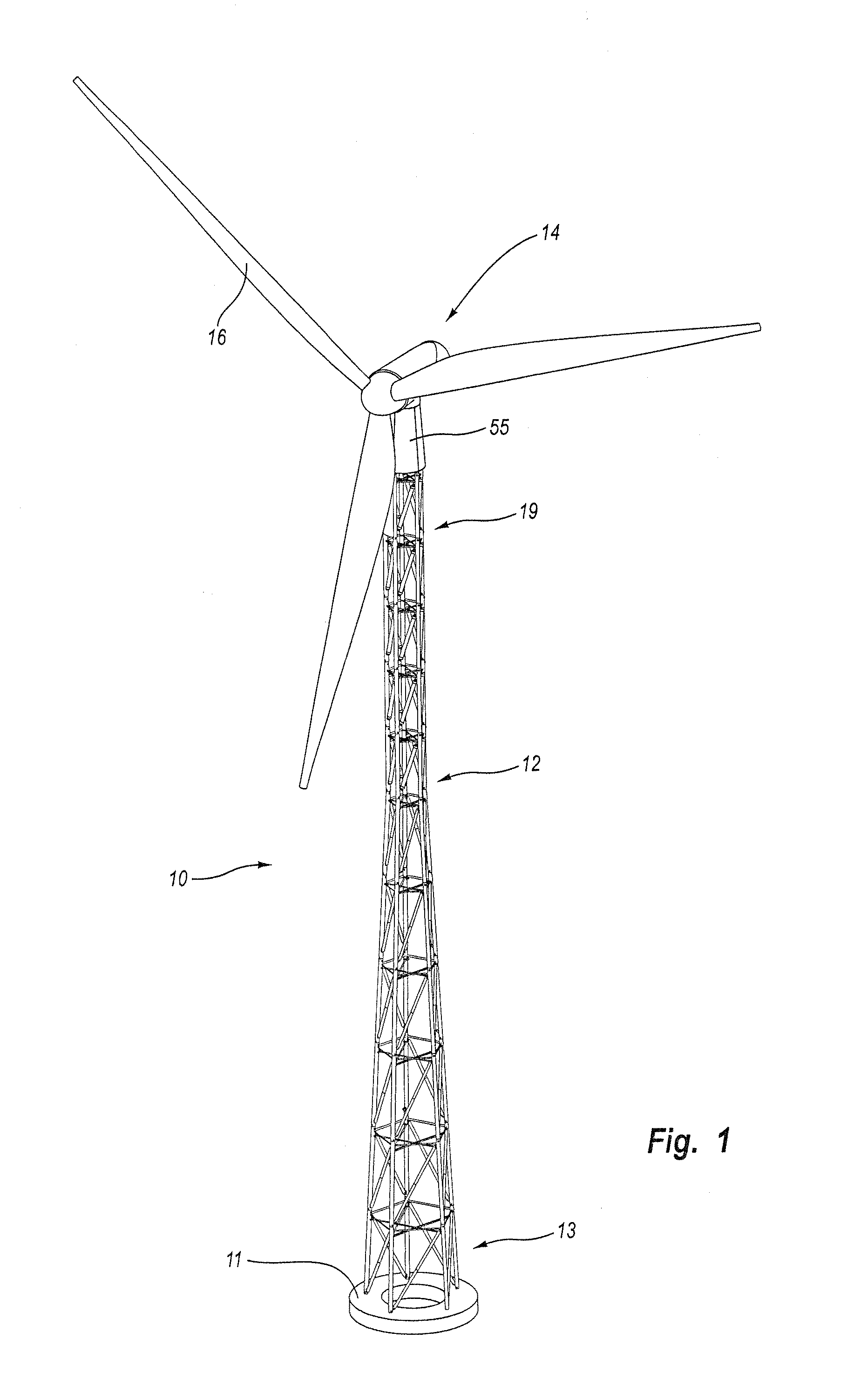

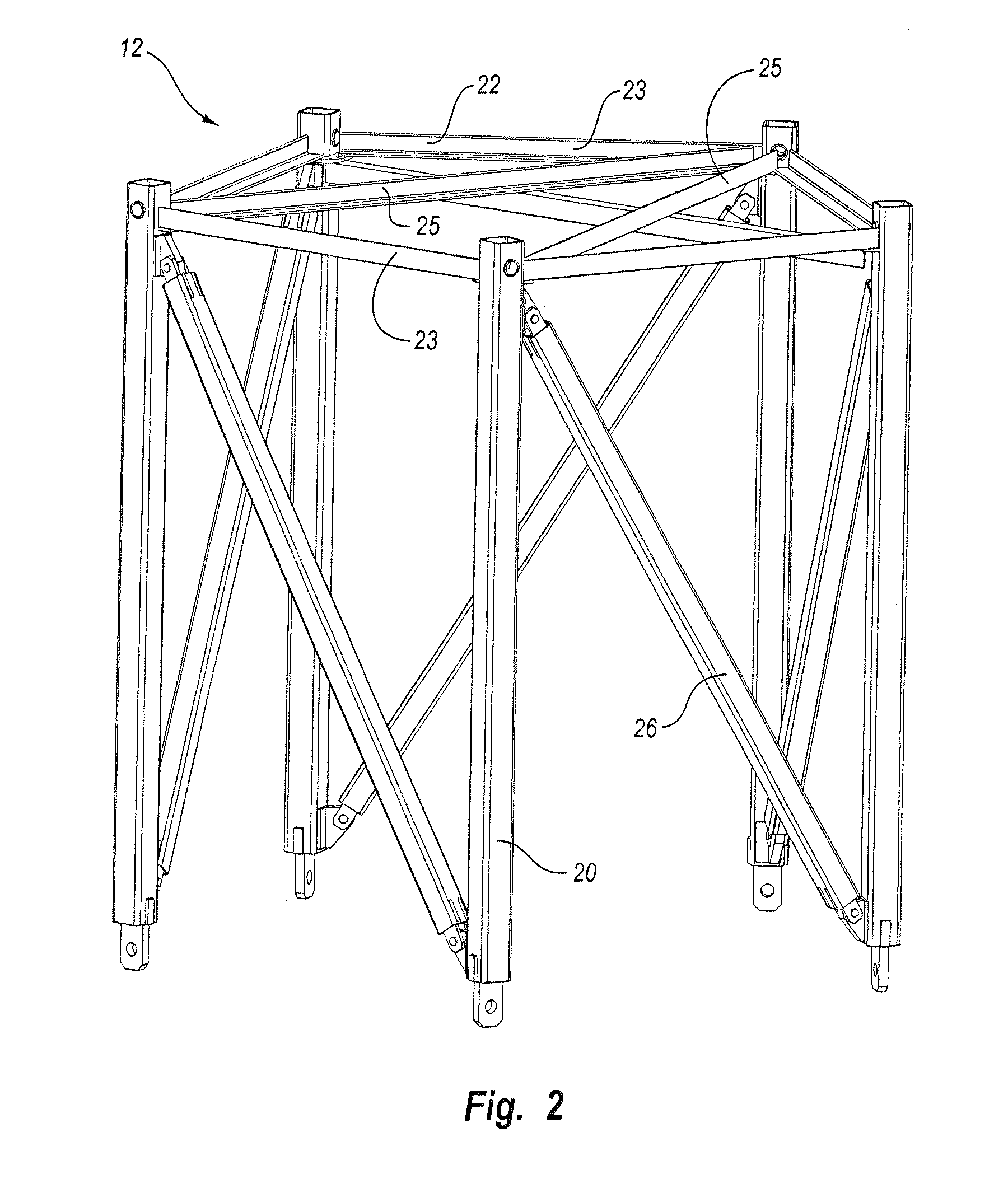

Structural tower

InactiveUS20060277843A1Reduce energy costsGenerate efficientlyCollapsable antennas meansEngine manufactureHigh elevationDiagonal

A structural tower having a space frame construction for high elevation and heavy load applications is disclosed, with particular application directed to wind turbines. The structural tower includes damping or non-damping struts in the longitudinal, diagonal or horizontal members of the space frame. One or more damping struts in the structural tower damp resonant vibrations or vibrations generated by non-periodic wind gusts or sustained high wind speeds. The various longitudinal and diagonal members of the structural tower may be secured by pins, bolts, flanges or welds at corresponding longitudinal or diagonal joints of the space frame.

Owner:LIVINGSTON TRACY +1

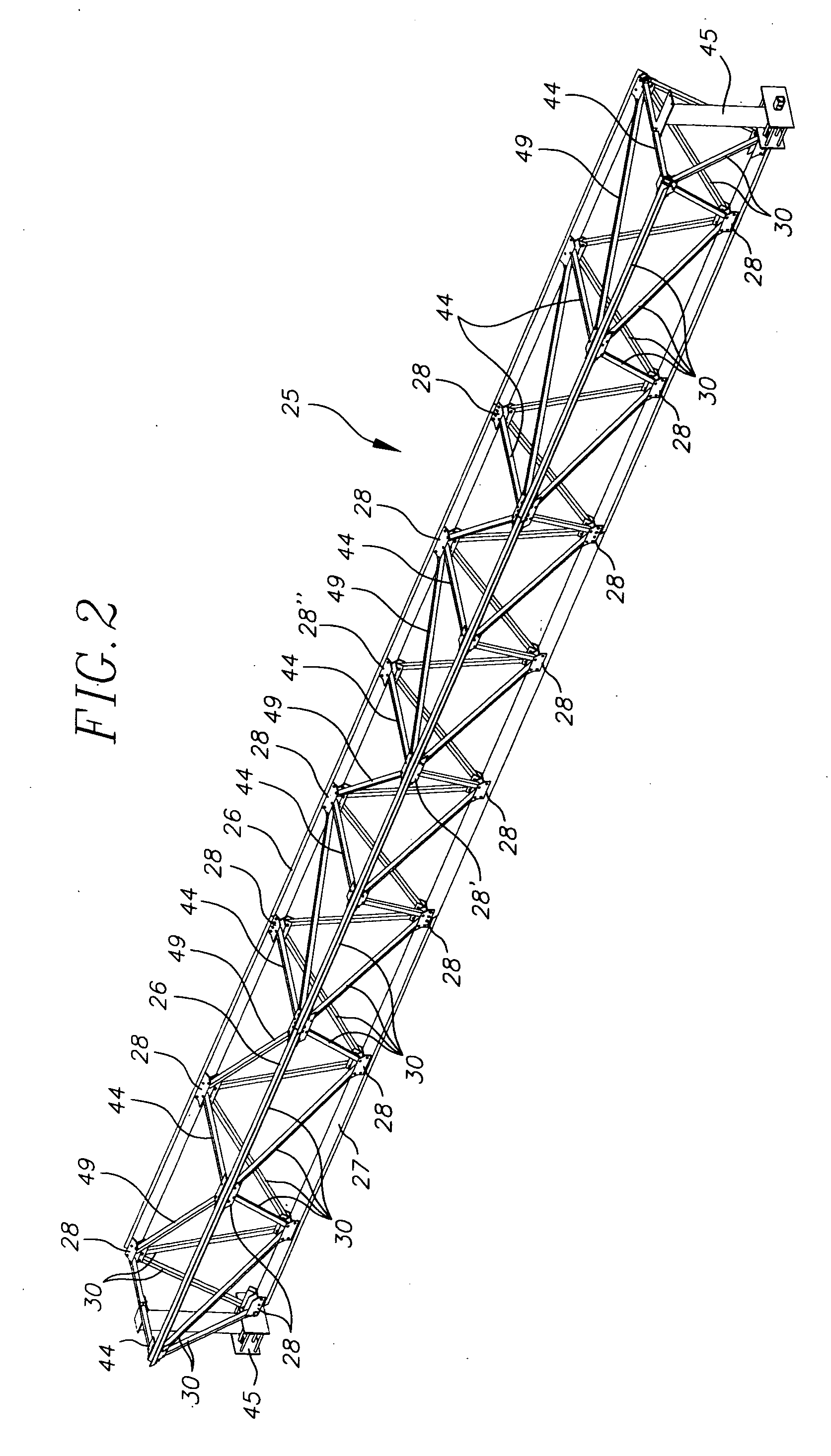

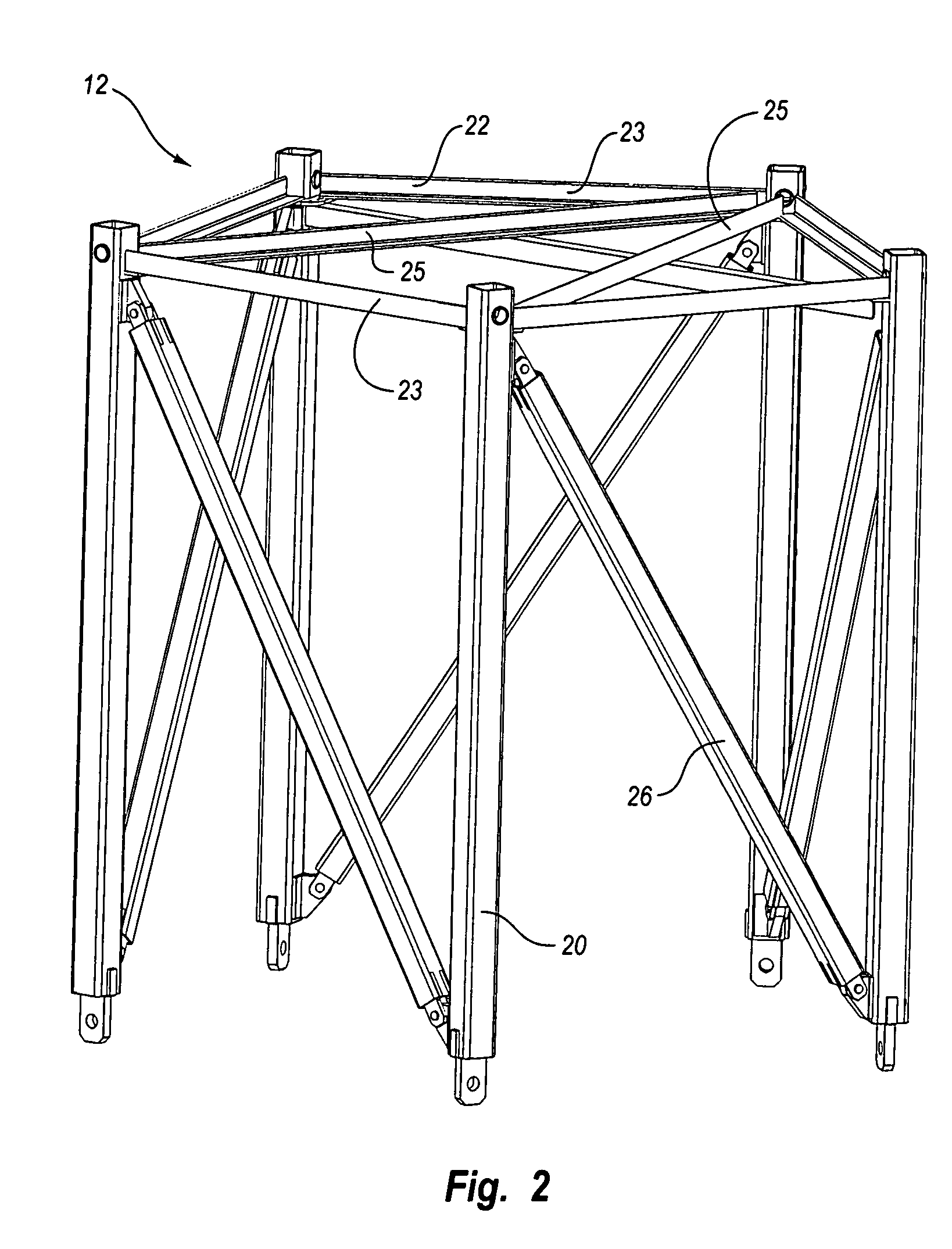

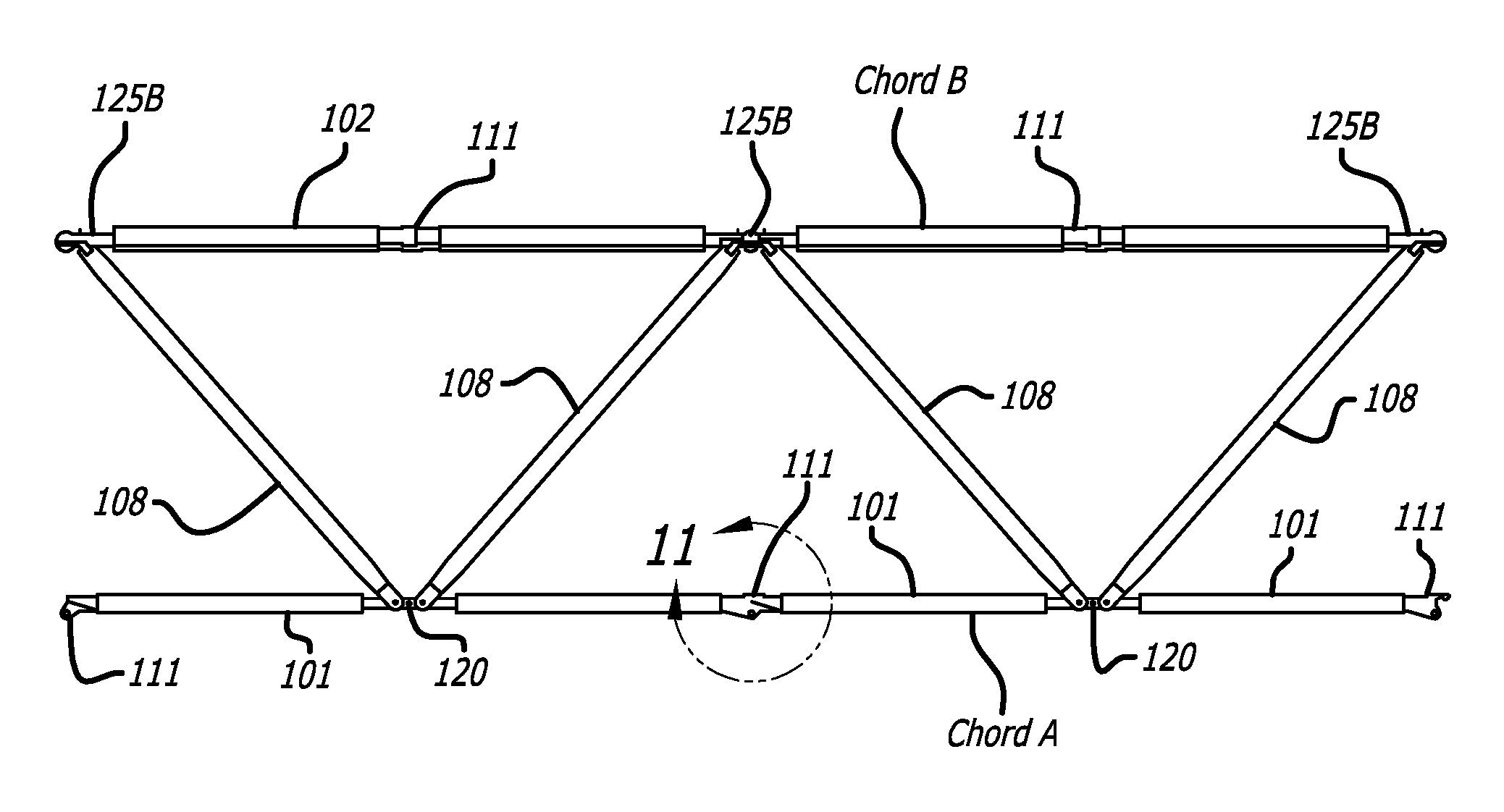

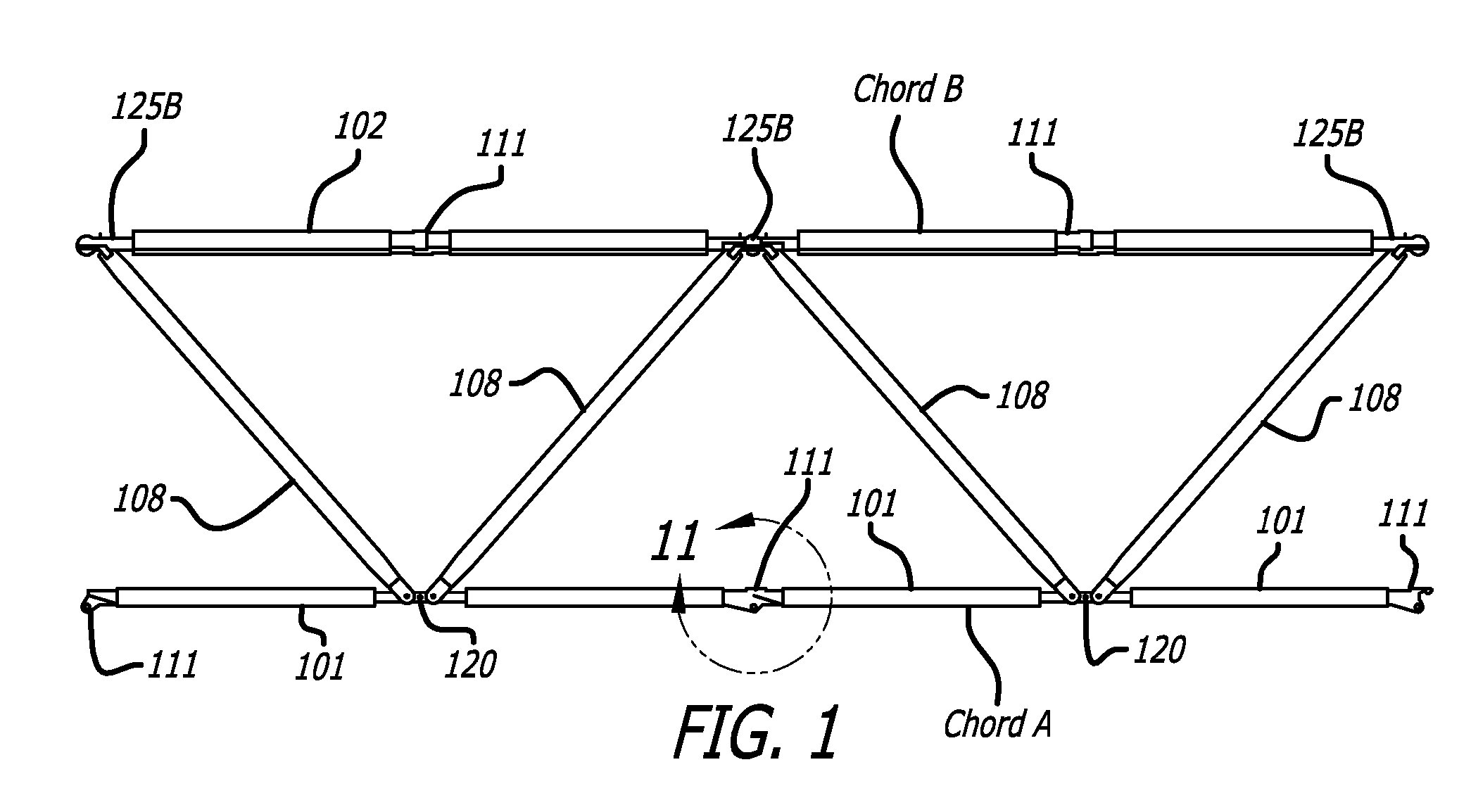

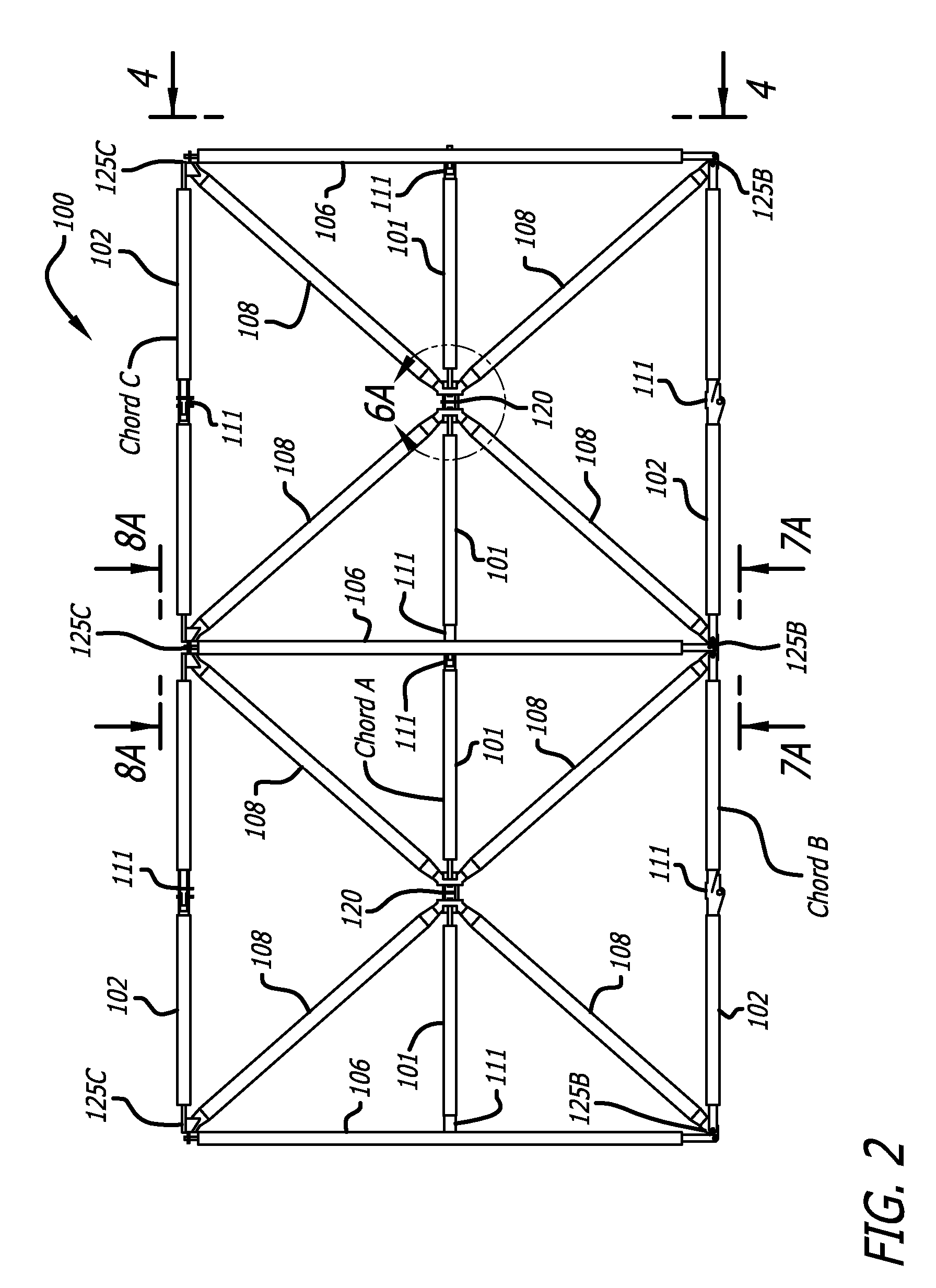

Deployable triangular truss beam with orthogonally-hinged folding diagonals

A synchronously deployable tetrahedral truss beam with orthogonally-hinged diagonals, having uniquely-connected transverse members and folding chordal members, where a plurality of bays can extend and retract in a coordinated manner without need for a deployment canister mechanism or other assembling means. The triangular cross-section truss can be adapted to deploy pre-attached panels or nodally-attached payload components. These triangular beams can be mounted side-by-side with a common chord to create a synchronously deployable trapezoidal cross-section beam or space-frame. Both the triangular and trapezoidal configurations can be adapted to deploy with a prescribed curvature of the longitudinal axis, and form perimeter trusses which can be post-tensioned for maximum structural performance.

Owner:CPI TECH

Quick torque coupling

Owner:LUFT PETER A

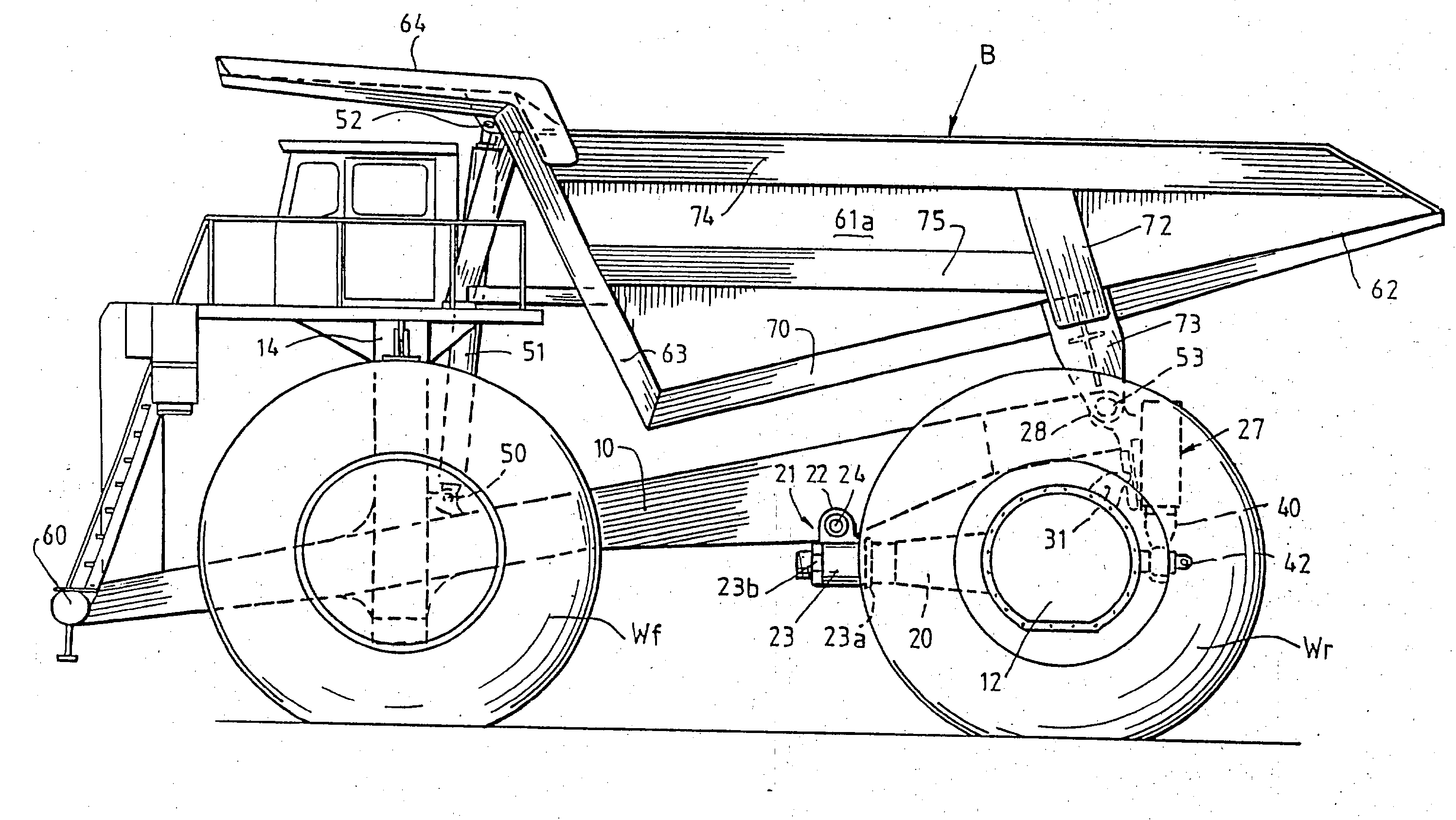

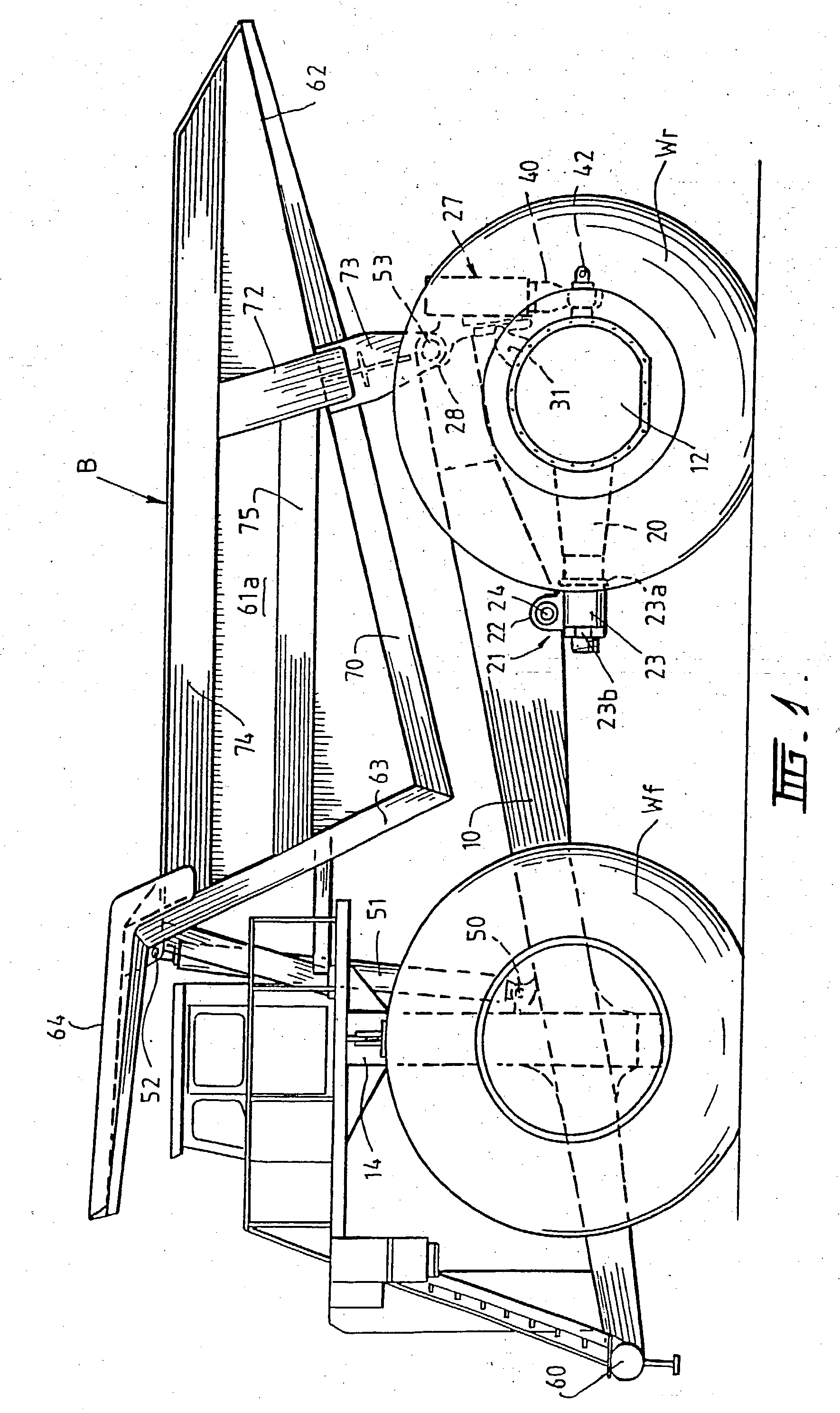

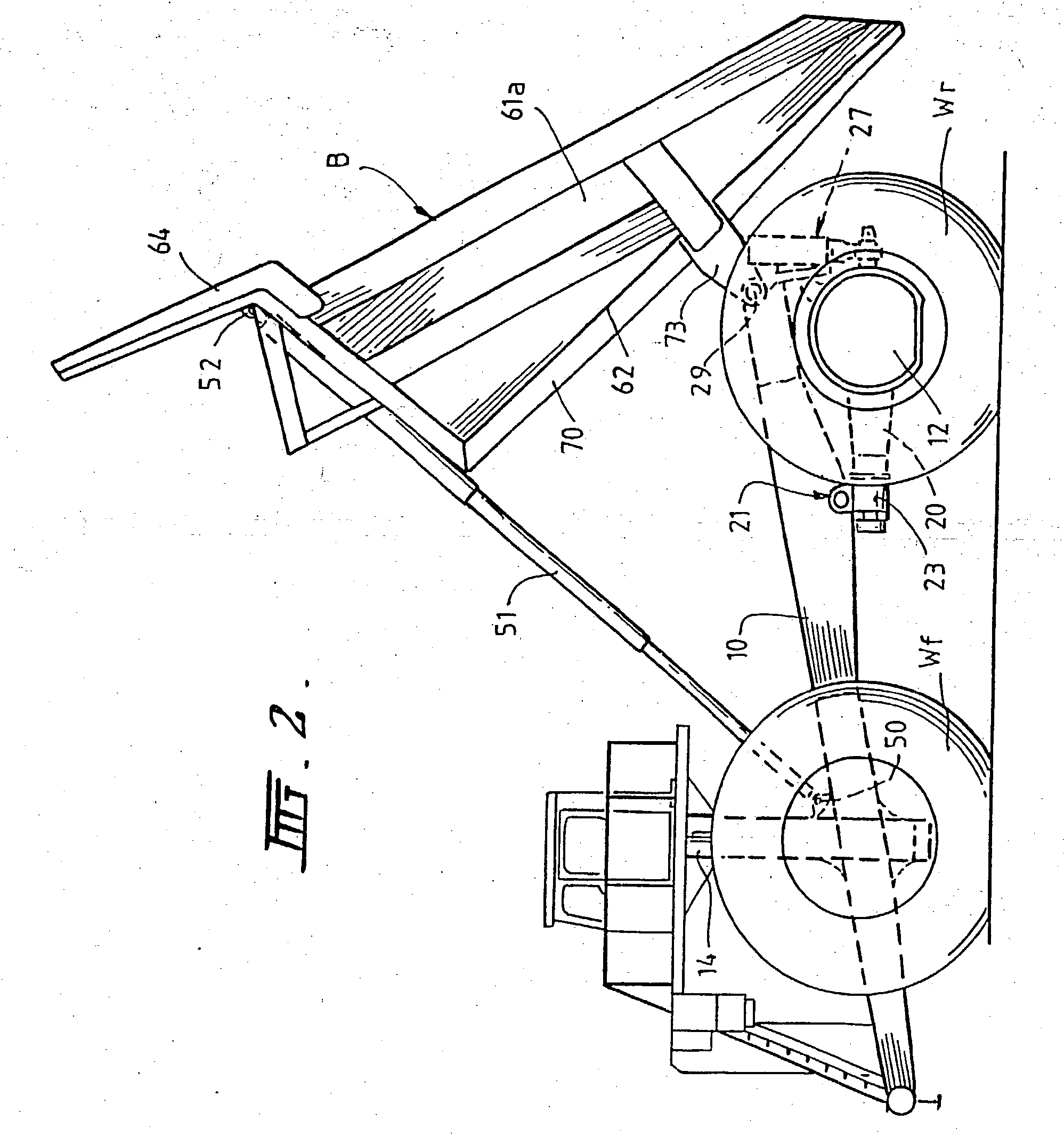

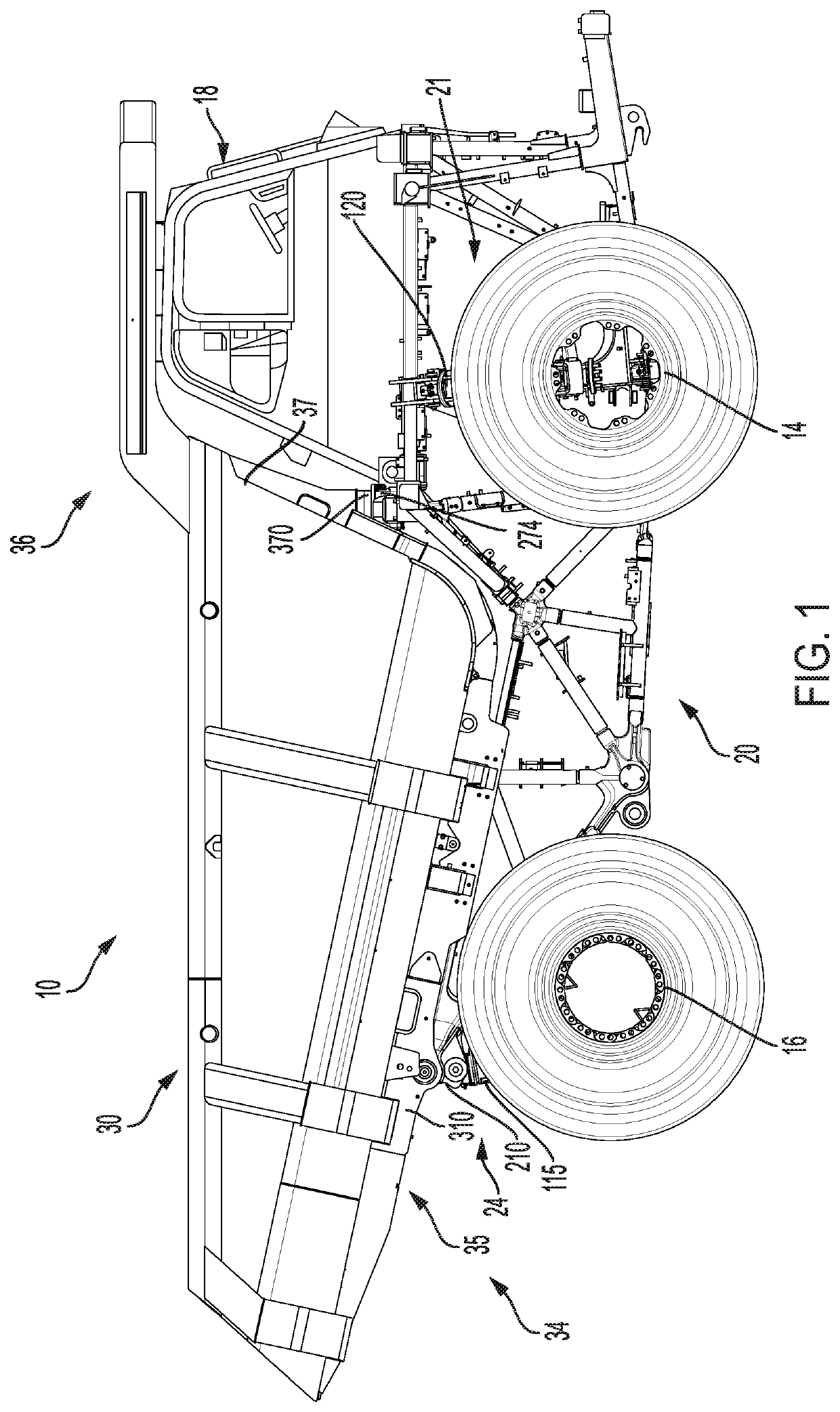

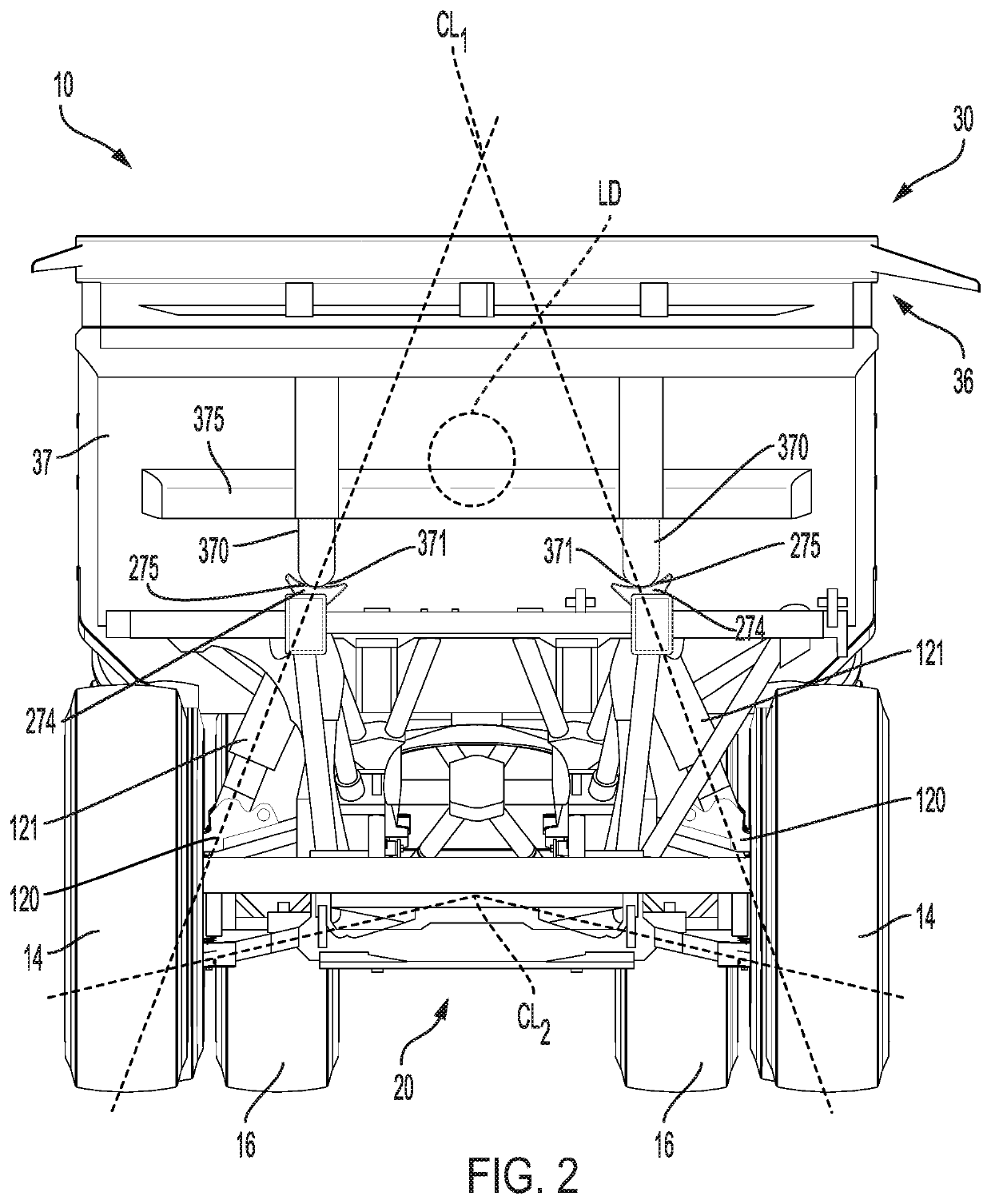

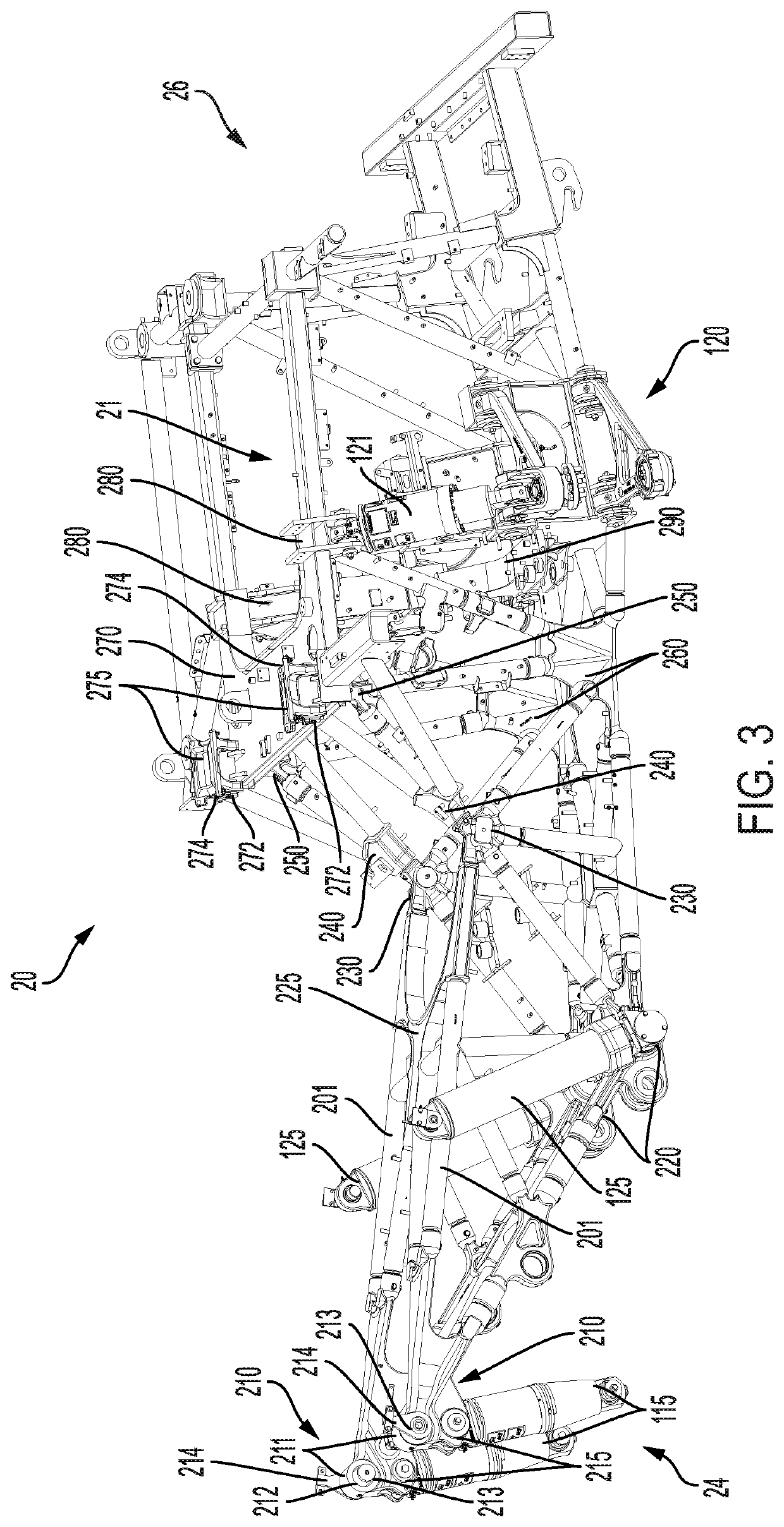

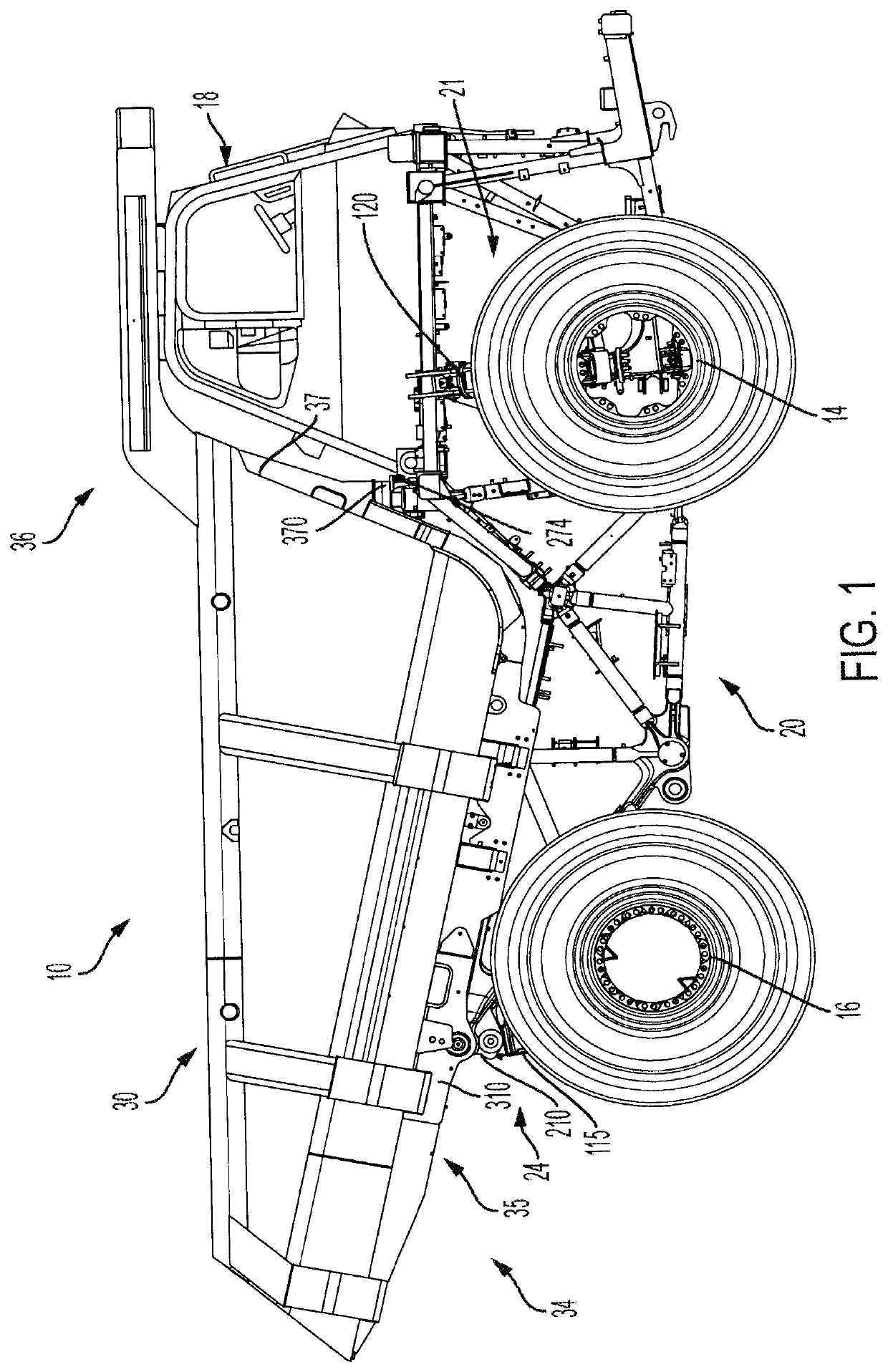

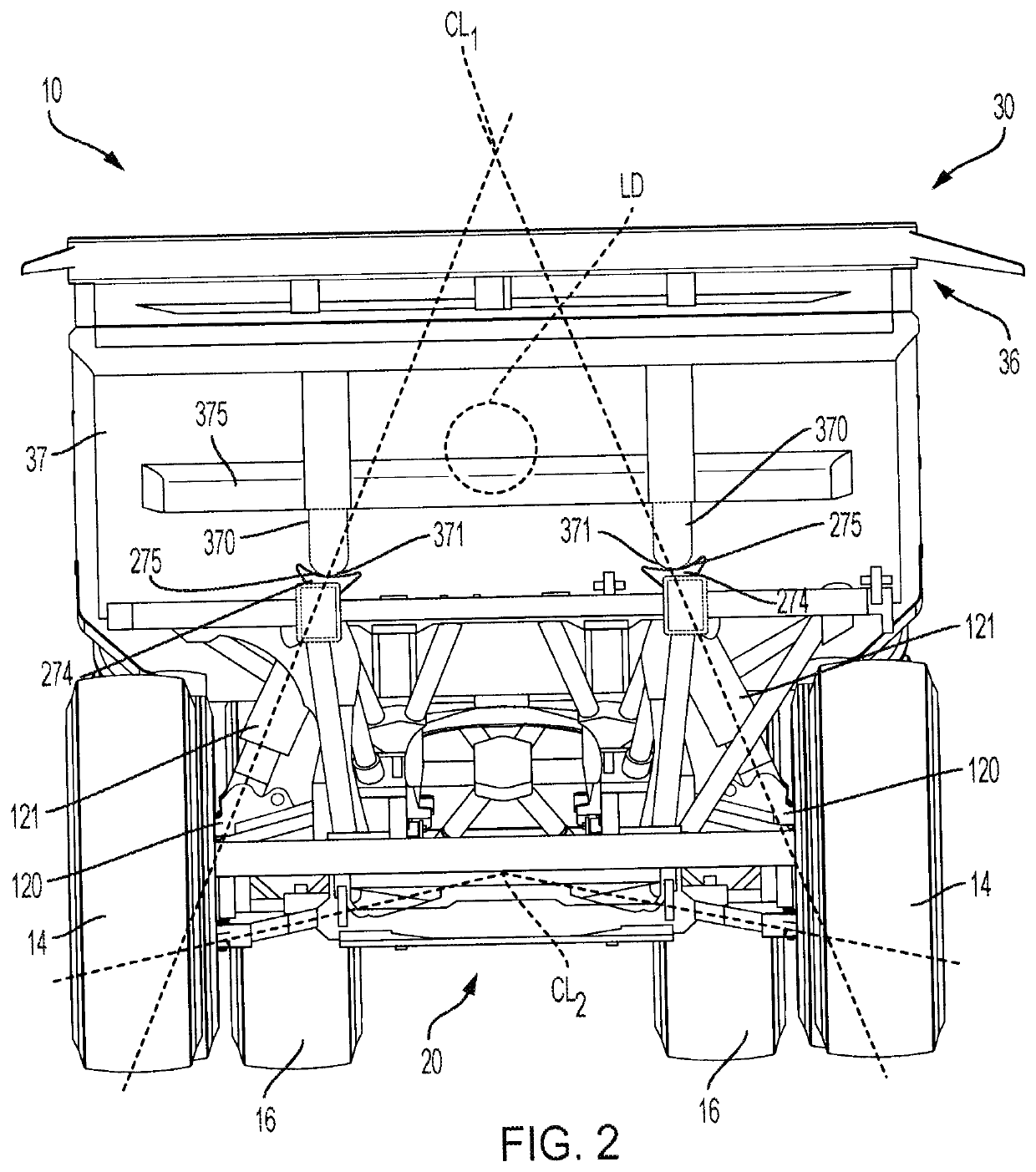

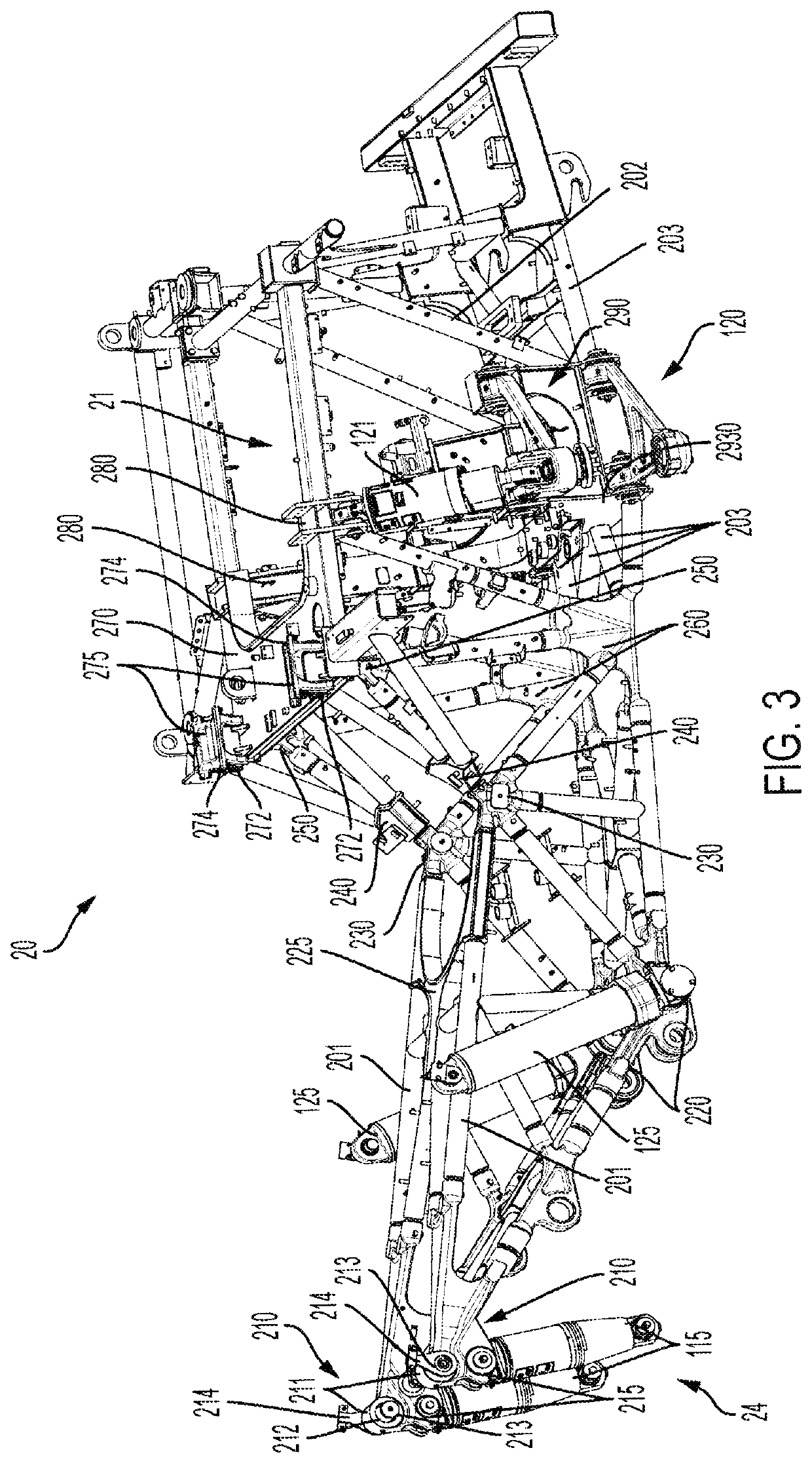

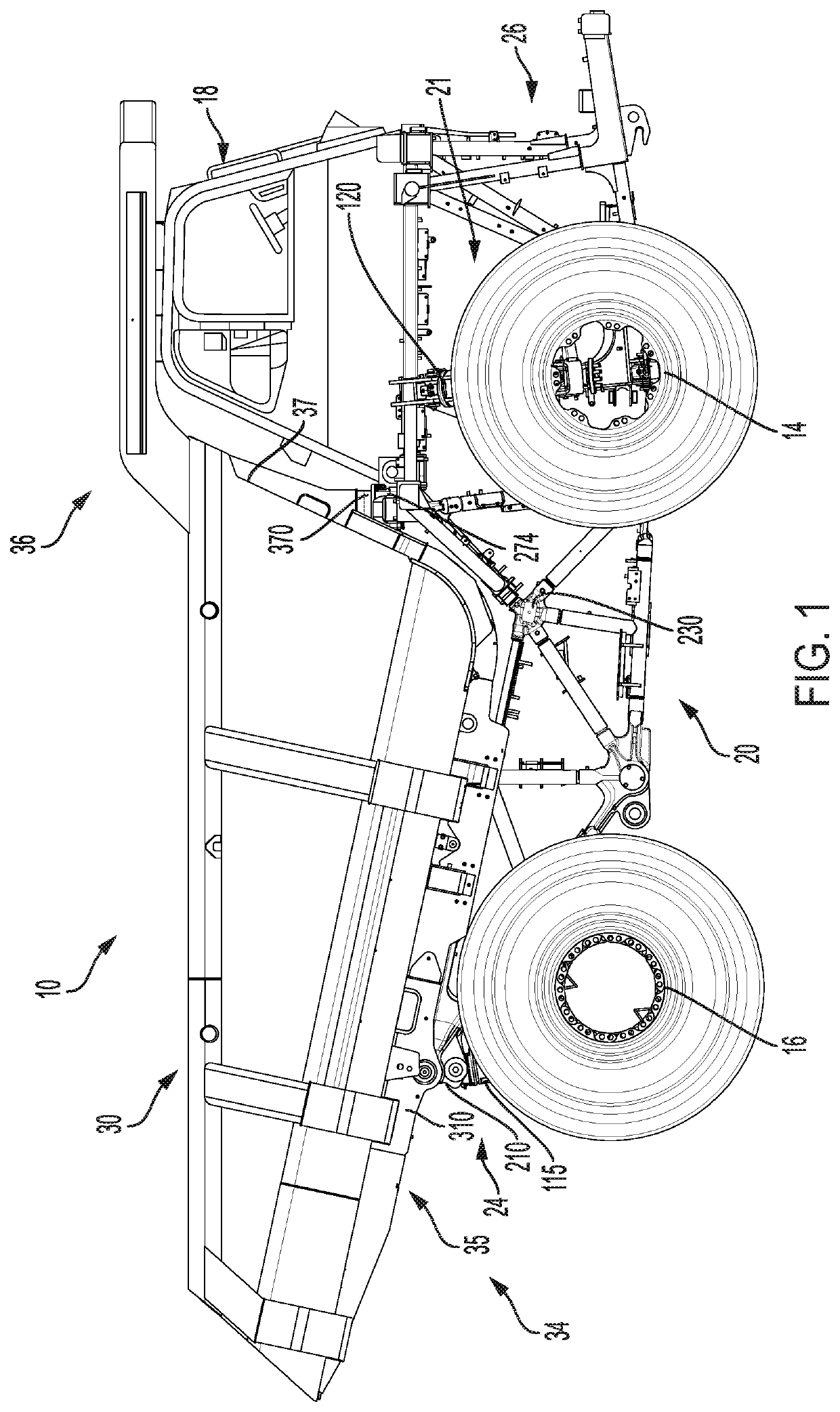

Large dump truck suspension

InactiveUS6086076APrevent rotationEliminate torsional loadsInterconnection systemsResilient suspensionsSpherical bearingEngineering

PCT No. PCT / AU96 / 00180 Sec. 371 Date Jul. 11, 1997 Sec. 102(e) Date Jul. 11, 1997 PCT Filed Mar. 29, 1996 PCT Pub. No. WO96 / 30223 PCT Pub. Date Oct. 3, 1996A suspension system for a large dump truck. The dump truck having a main frame with laterally spaced frame members each associated with a rear wheel mounting hub with a wheel on each of its sides. Each hub is attached to a respective frame member by an attachment member pivotally attached to the respective frame member by a pivotal mounting and a suspension spring pivotally attached to the hub by a spherical bearing and to the respective frame member at a pivot mounting. The connections of the hub allow for limited pivotal movement of the hub about transverse and longitudinal axes relative to the frame members. A dump body is pivotally attached to the frame members at the pivot mounting or to the rear and above a suspension pivotal connection at a body pivotal connection.

Owner:BHP AUSTRALIA COAL PTY LTD

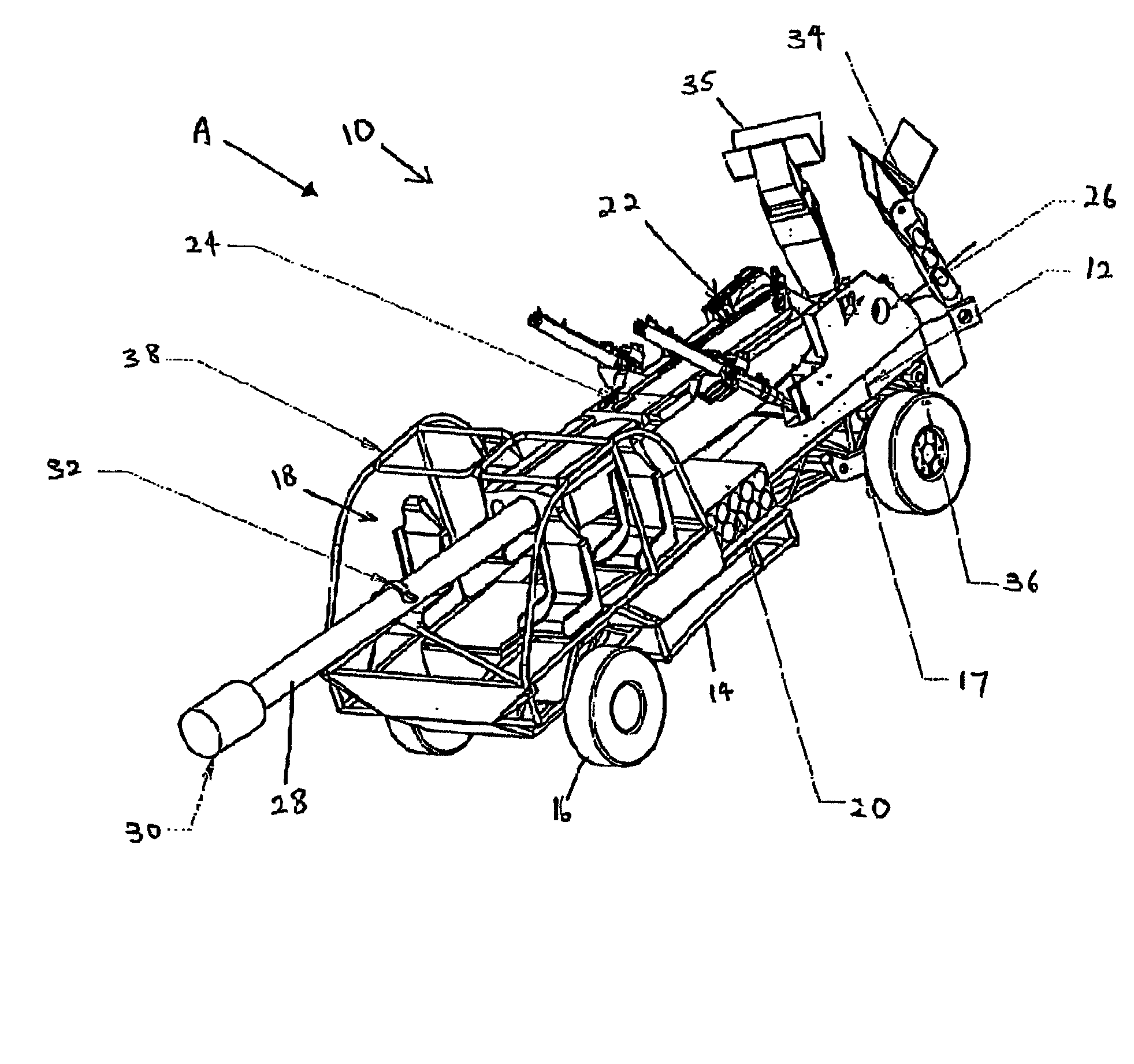

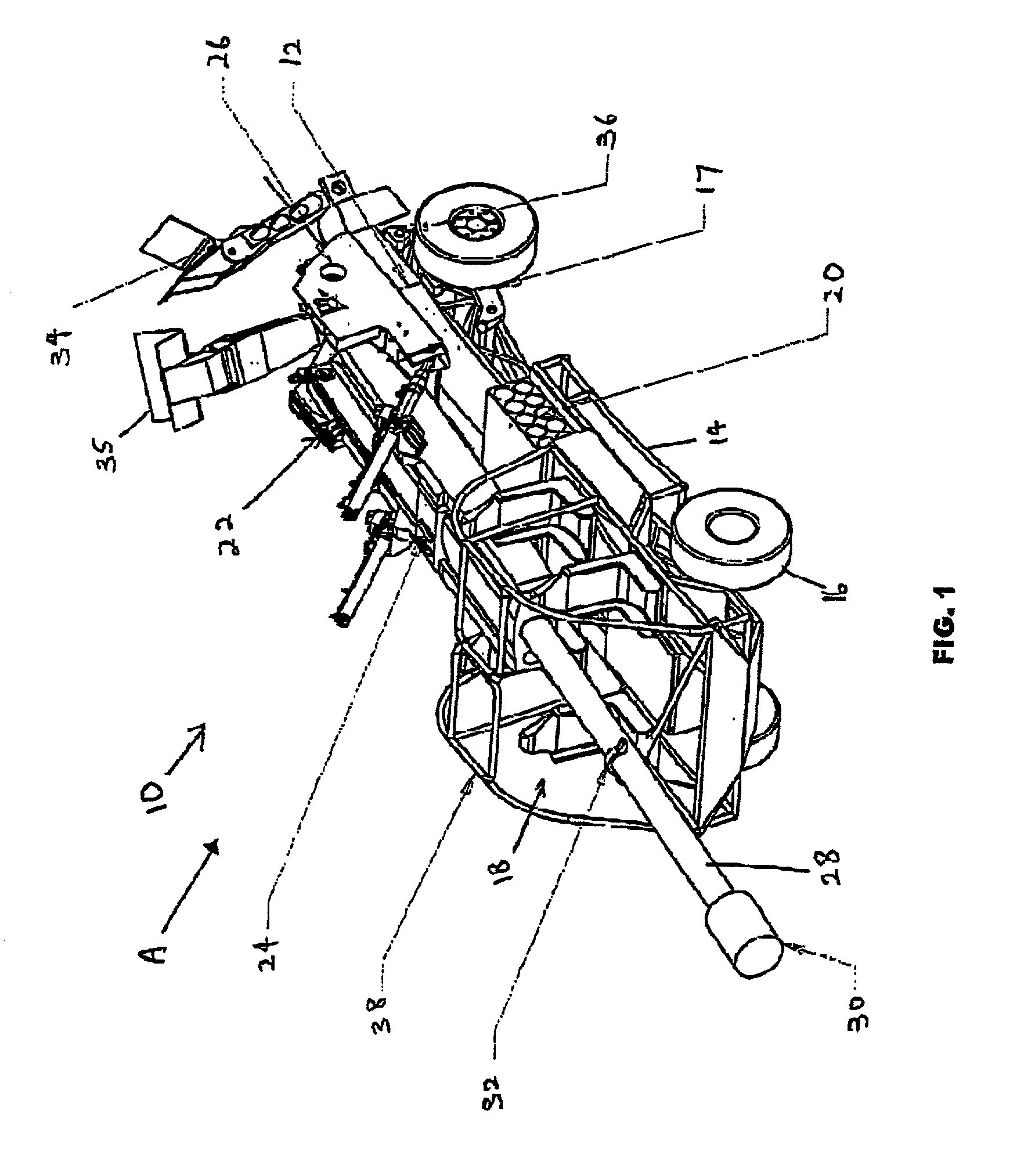

Mobile artillery system

InactiveUS20020129696A1Increase firepowerFiring/trigger mechanismsGun mountingsEngineeringSpace frame

The invention provides a self-propelled mobile system that is characterized by a lightweight space frame chasis on which is mounted a large caliber artillery piece. The weight of the system is preferably less than 8.000 kg and the artillery piece preferably has a calibre of up to a 155 mm 52 caliber gun. The artillery piece may include a lightweight elevating and traversing mass and gun chasis mounted on a space frame vehicle, such vehicle having a weight which does not exceed 3,800 kg.

Owner:ORDNANCE DEV & ENG CO OF SINGAPORE (1996) PTE LTD

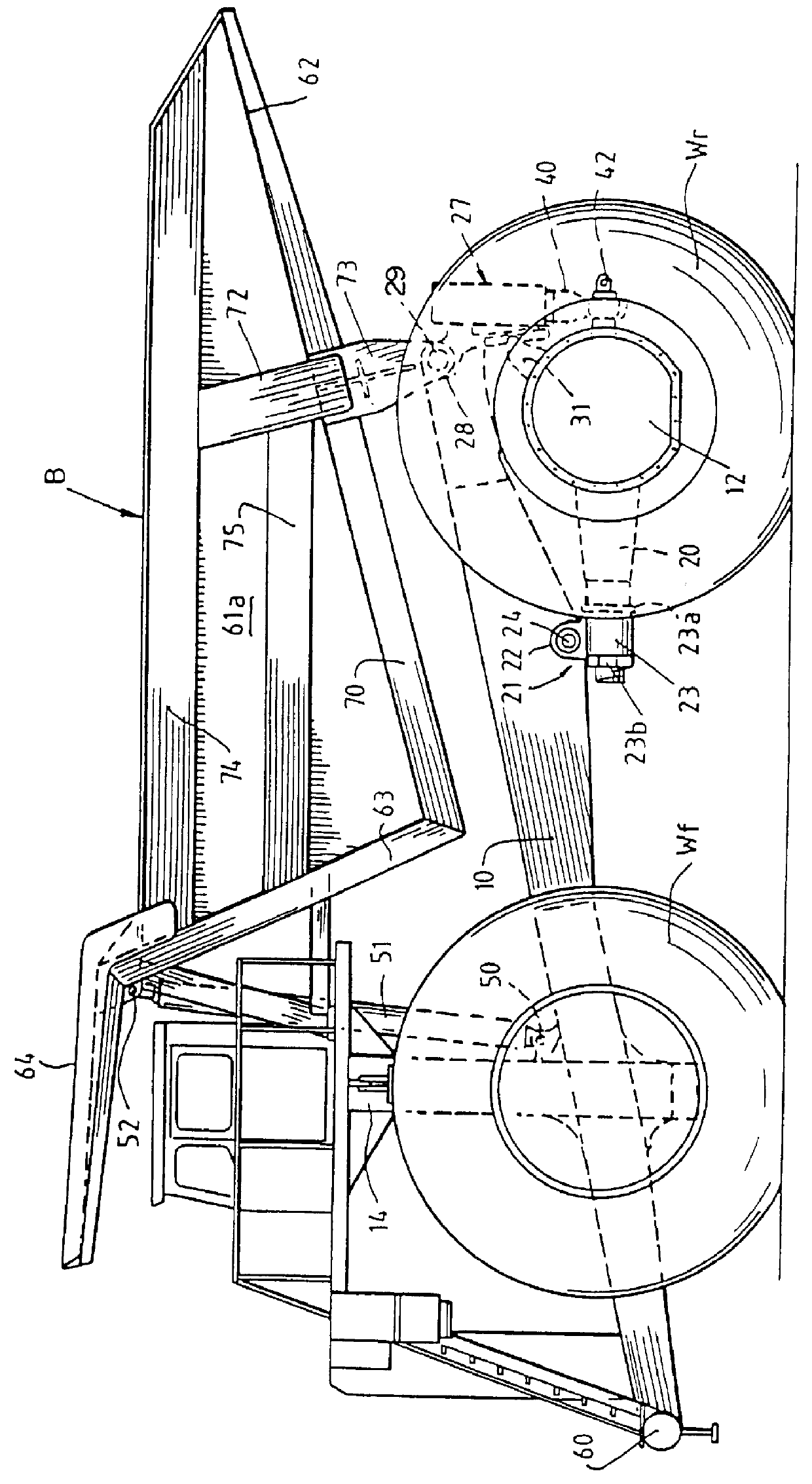

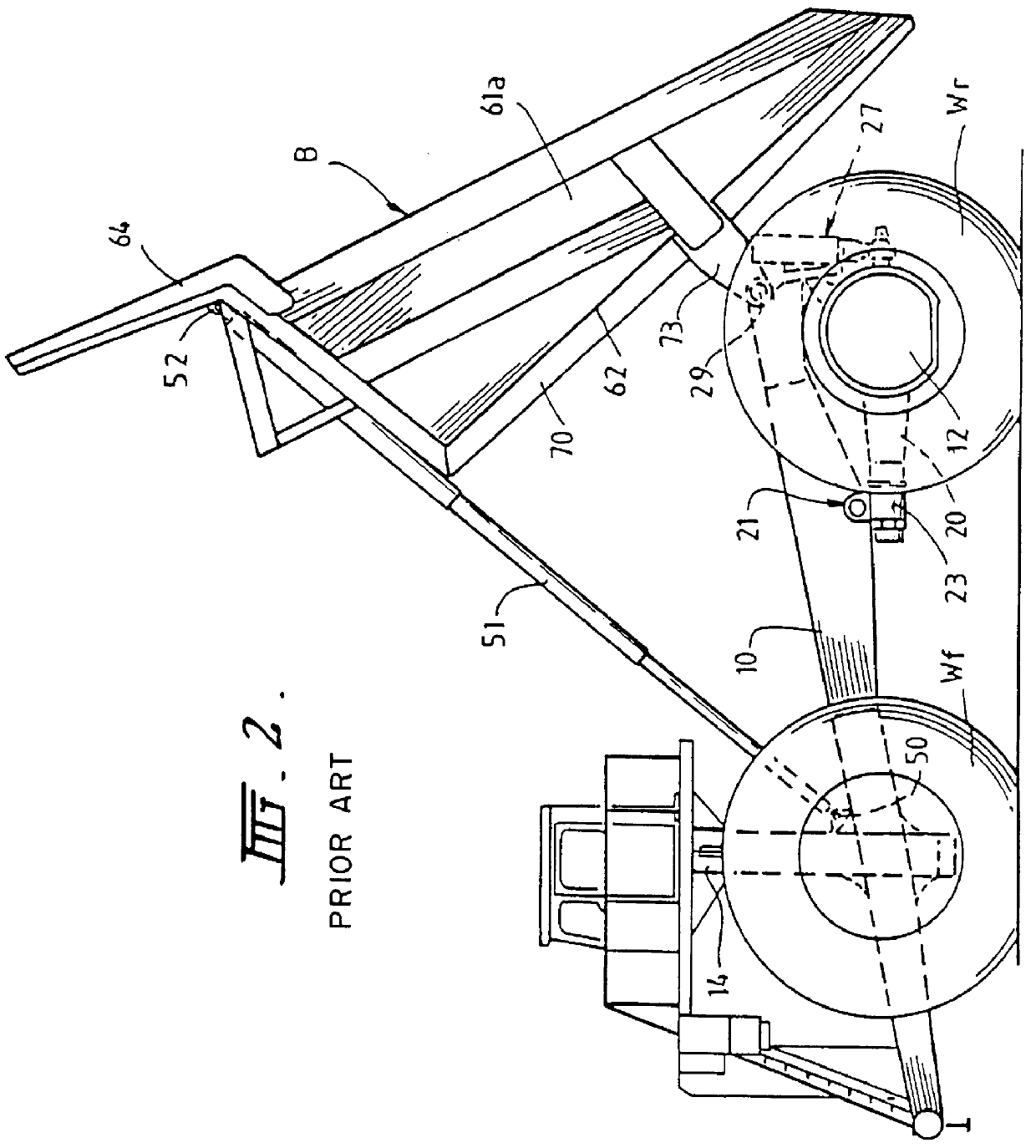

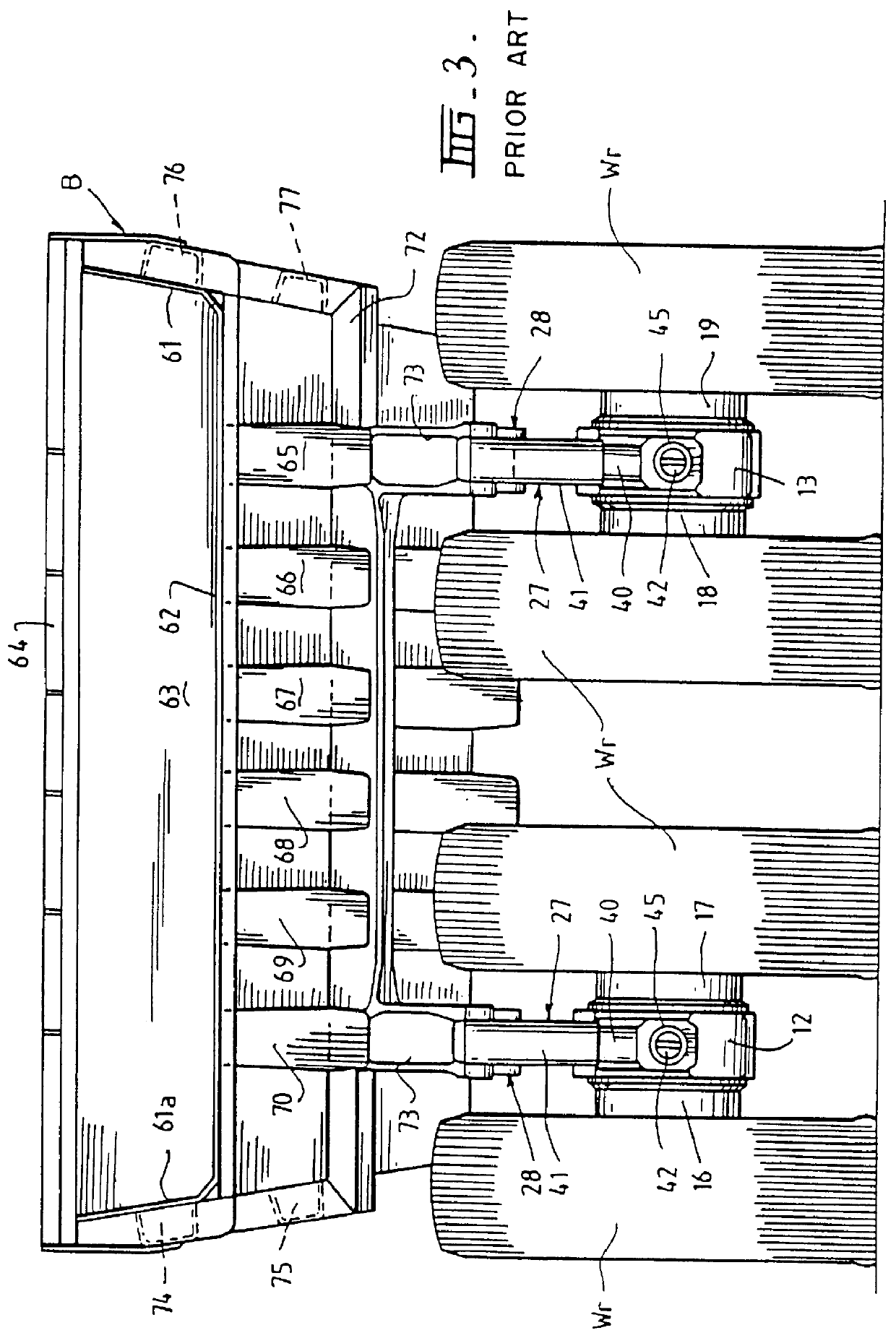

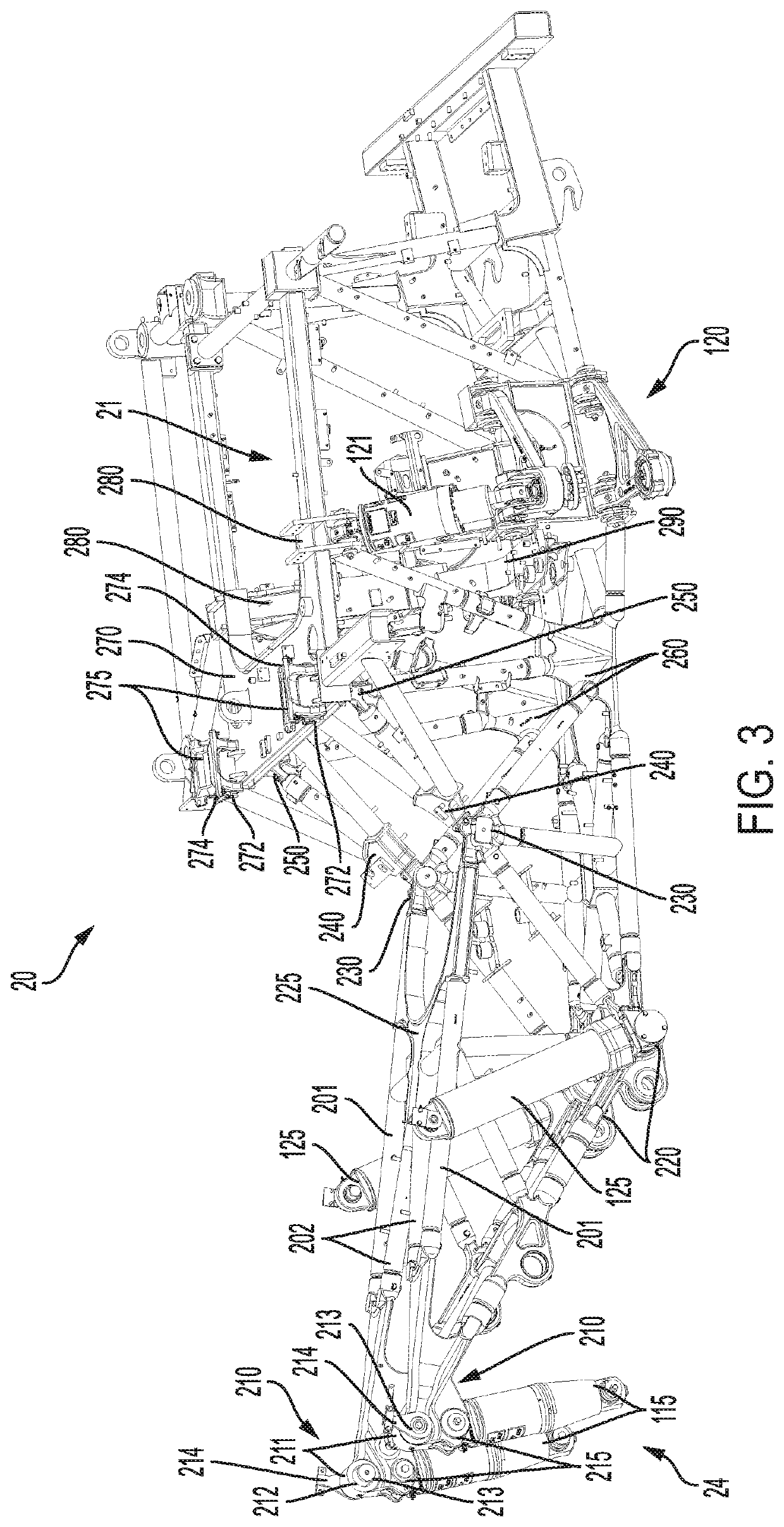

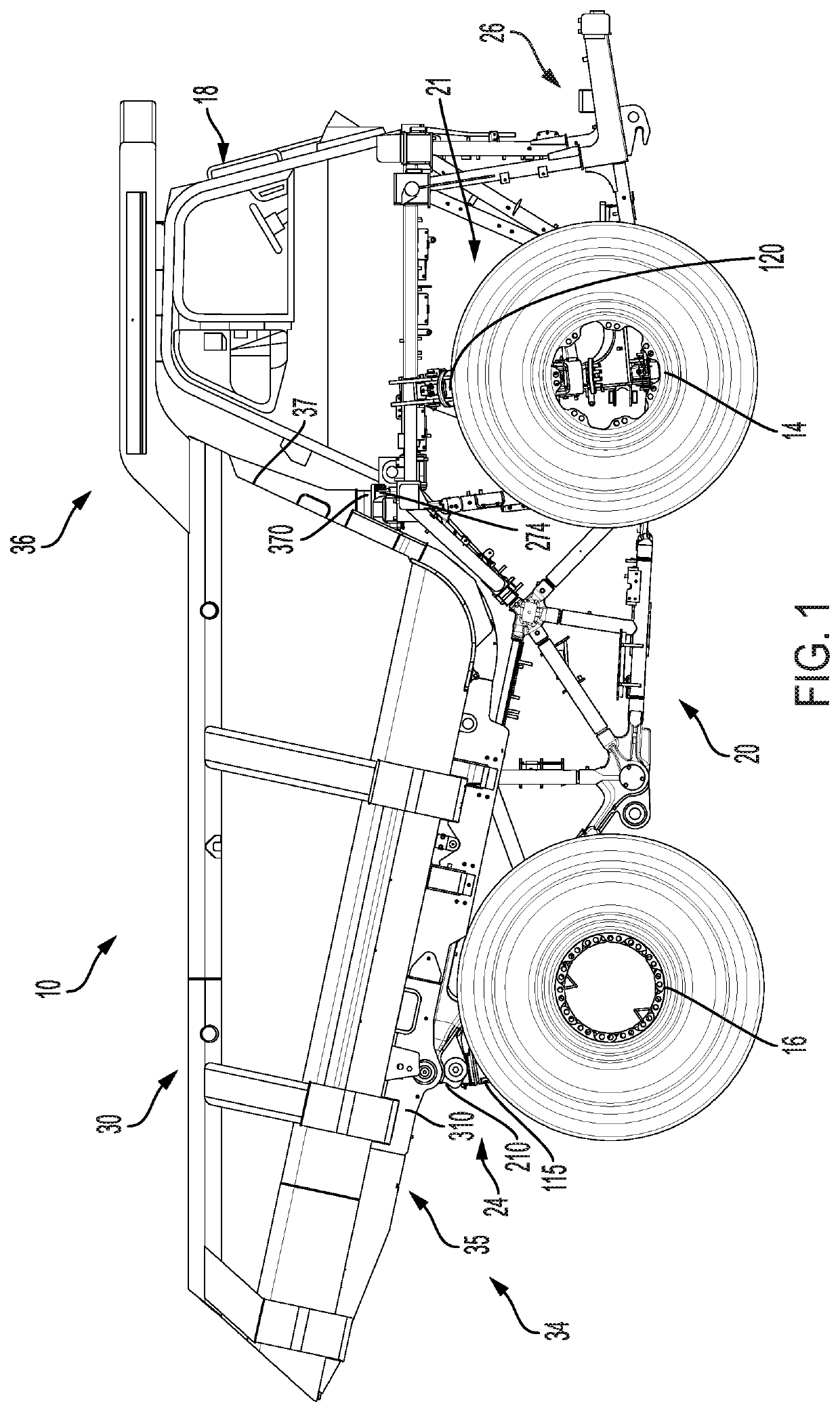

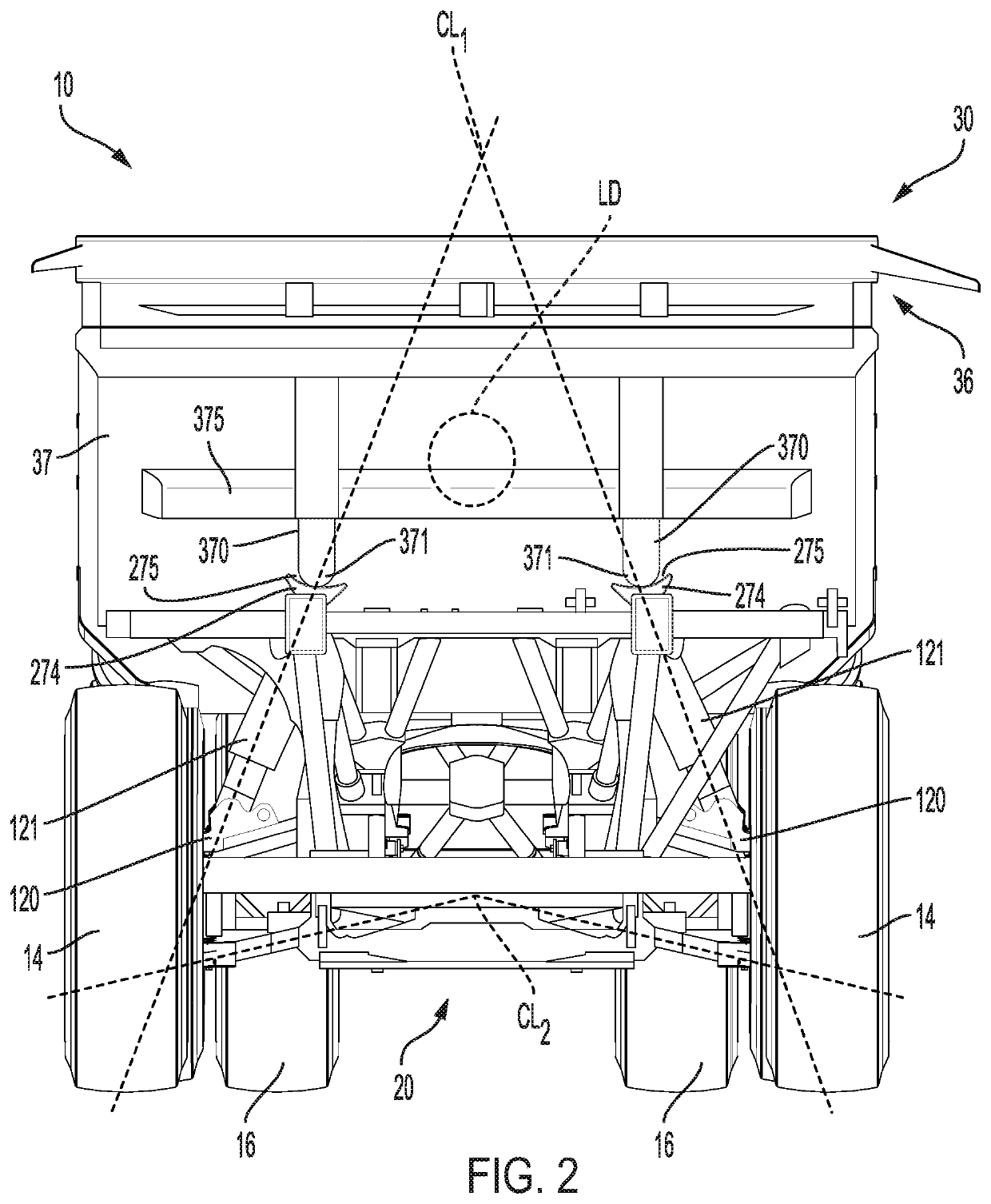

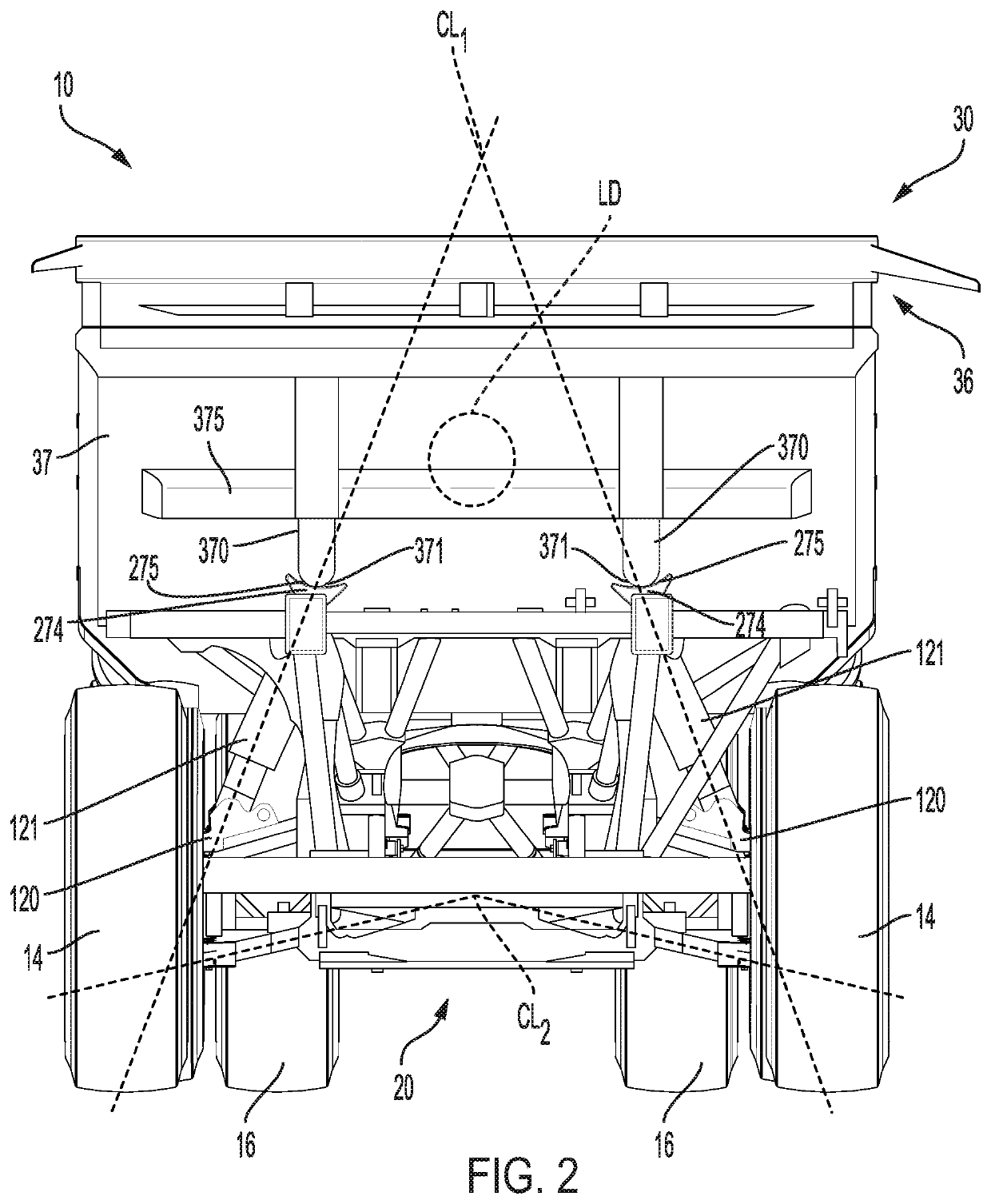

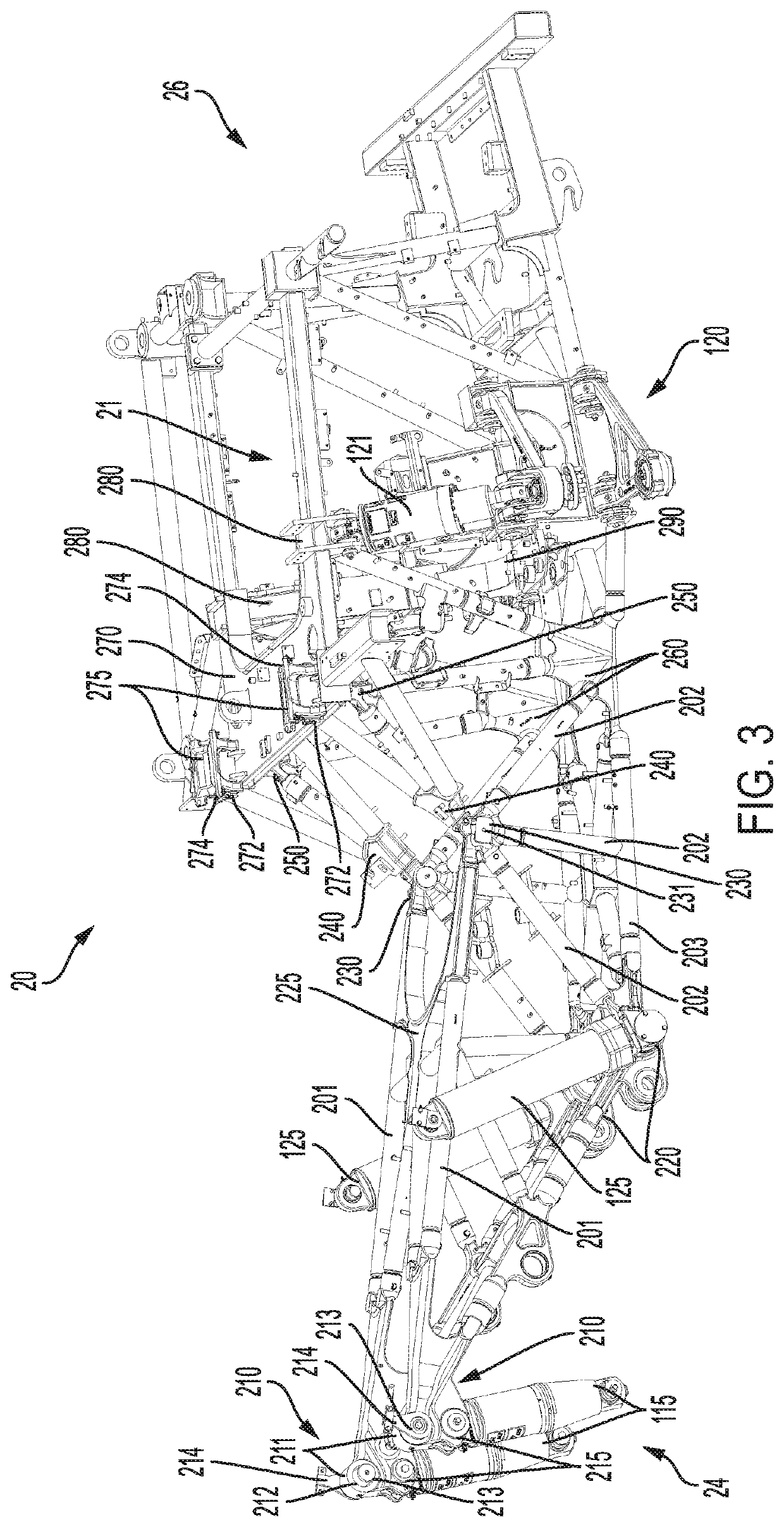

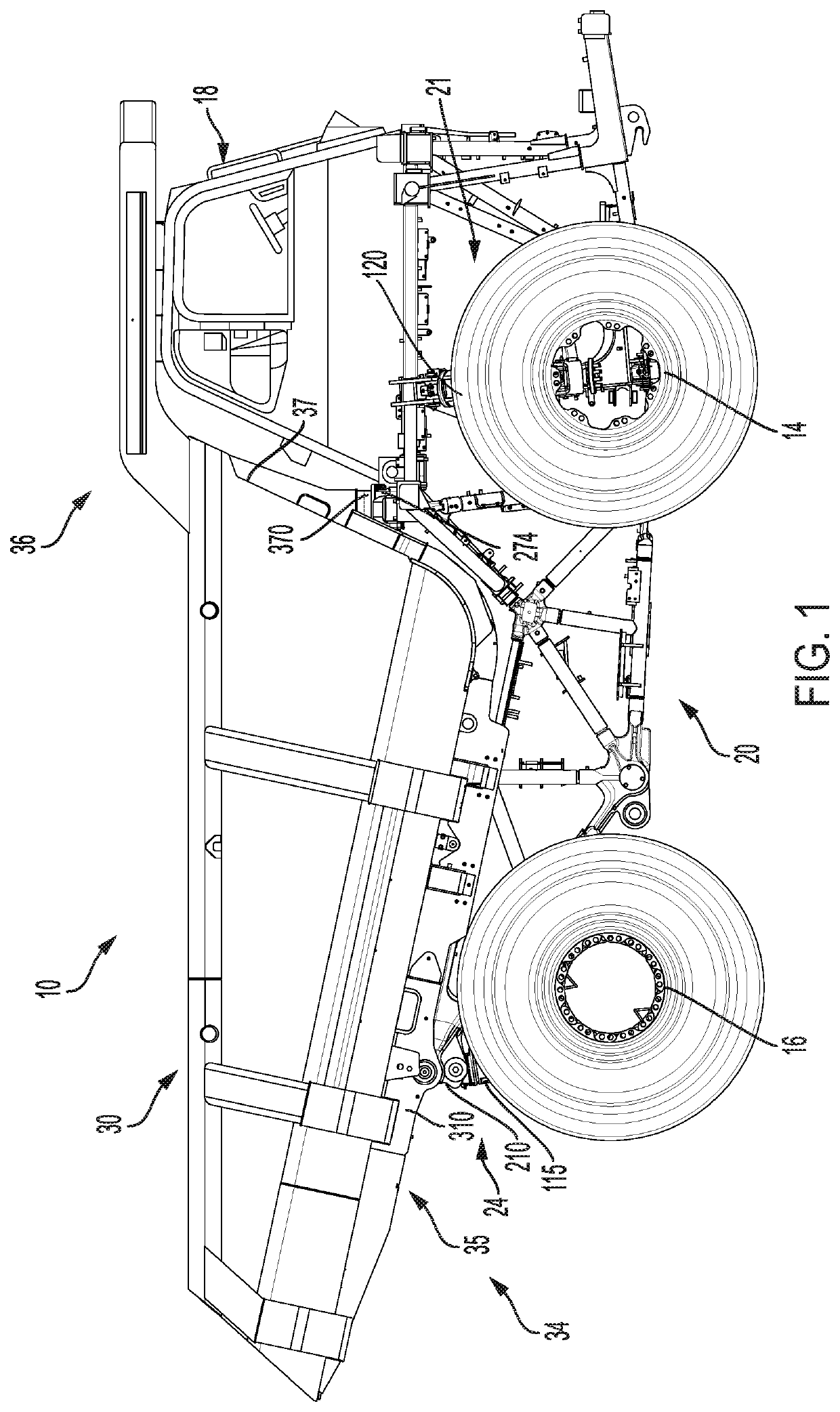

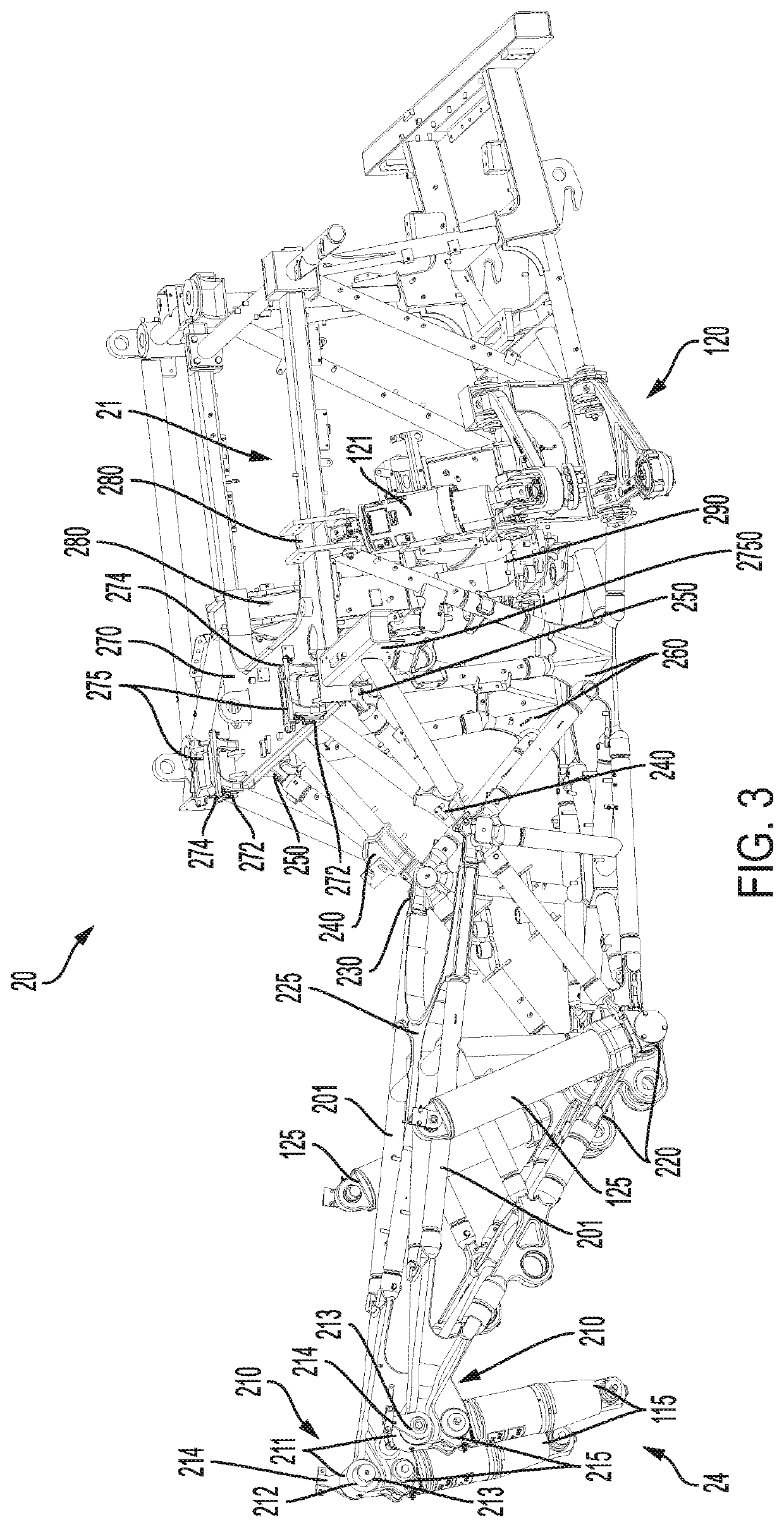

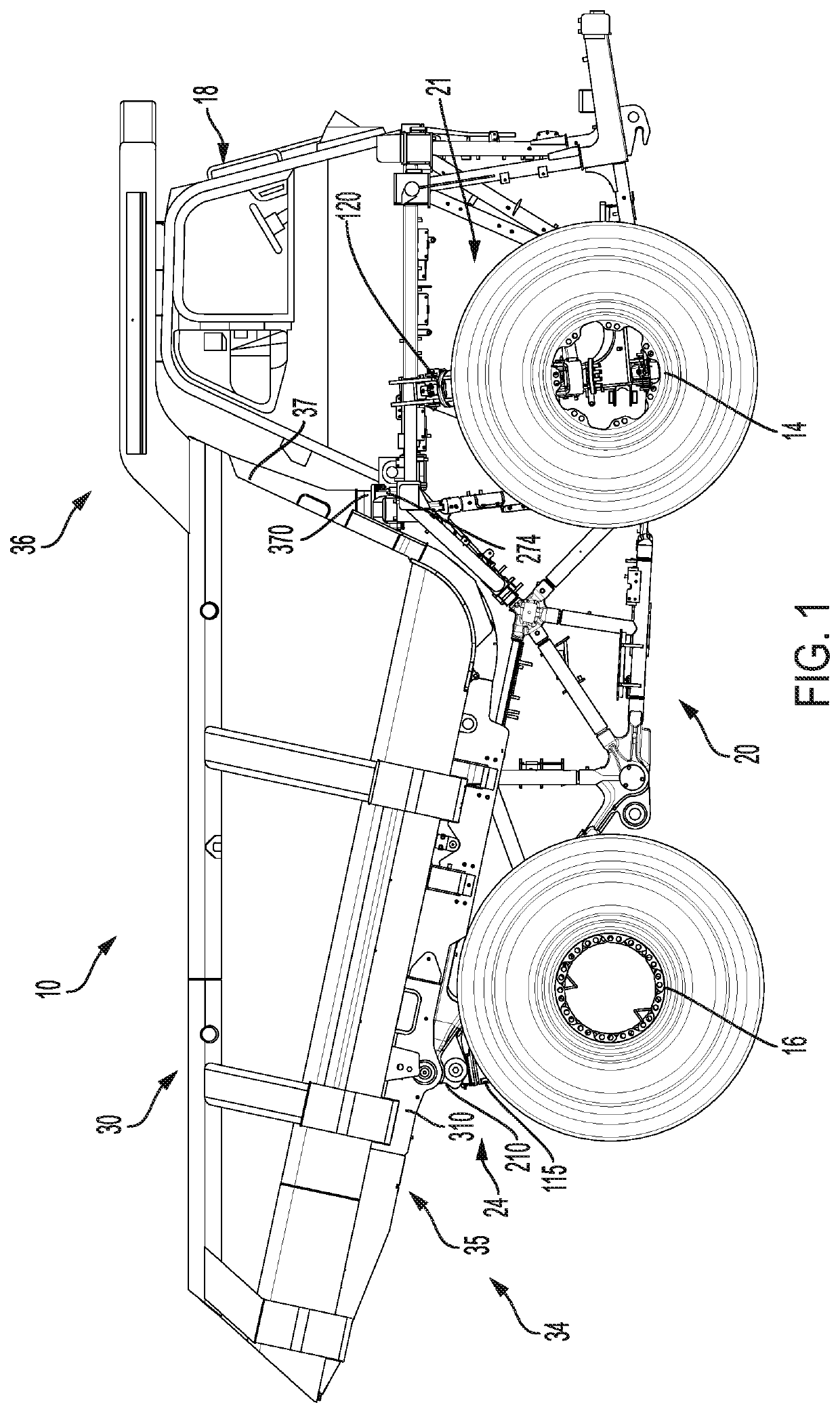

Suspension system and body for large dump trucks

InactiveUS20040036245A1Easy dischargeWear minimizationElectric propulsion mountingInterconnection systemsTransverse axisVehicle frame

A suspension system for the main frame of a large dump truck having laterally spaced frame members (10) each associated with a wheel mounting hub (12) the system comprising, for each hub (12), a hollow forward attachment arm (20) supported by a bearing block (21) having a longitudinal journal (23) and a transverse journal (22), the longitudinal journal (23) receiving the attachment arm (20) and the transverse journal (22) receiving the ends of a shaft rigidly secured to the frame members (10) and extending therebetween to define a cross member and a vertically compliant suspension strut comprising a cylinder (41) rigidly attached to a support (28) secured to the frame member (10) and receiving a piston (40) attached to a rear extension (42) from the hub (12) via a bearing which allows each hub (12) to rotate about longitudinal and transverse axes relative to the respective frame member (10). Also disclosed is dump truck body (B) having side walls (61), a floor (62) and an end wall (63), the floor (62) being reinforced by longitudinal reinforcing beams and by only one transverse beam (72). The side walls (61) slope inwardly, the floor (62) slopes downwardly and forwardly and the width of the floor (62) increases towards the rear of the body (B).

Owner:LIEBHERR WERK BIBERACH

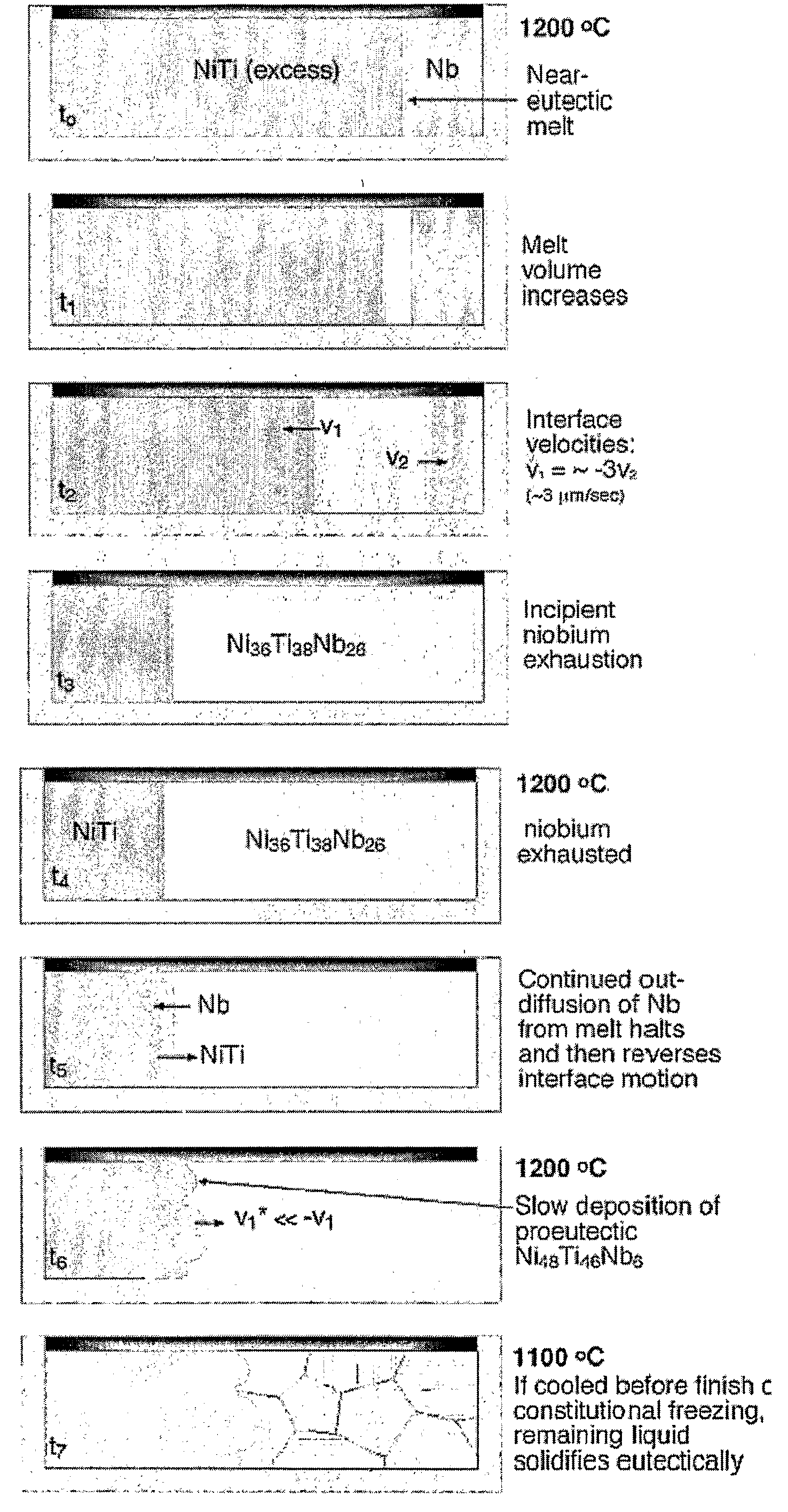

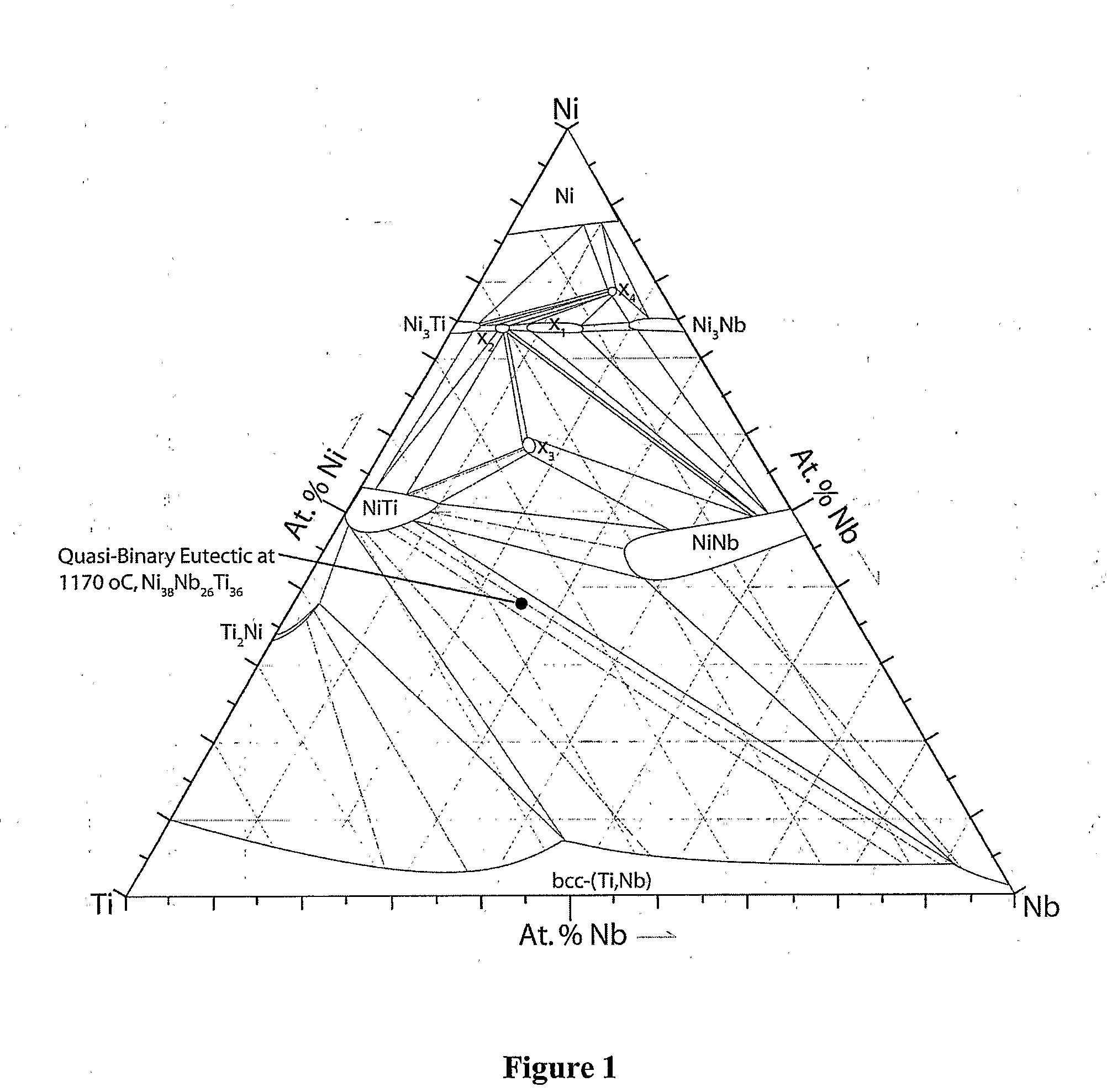

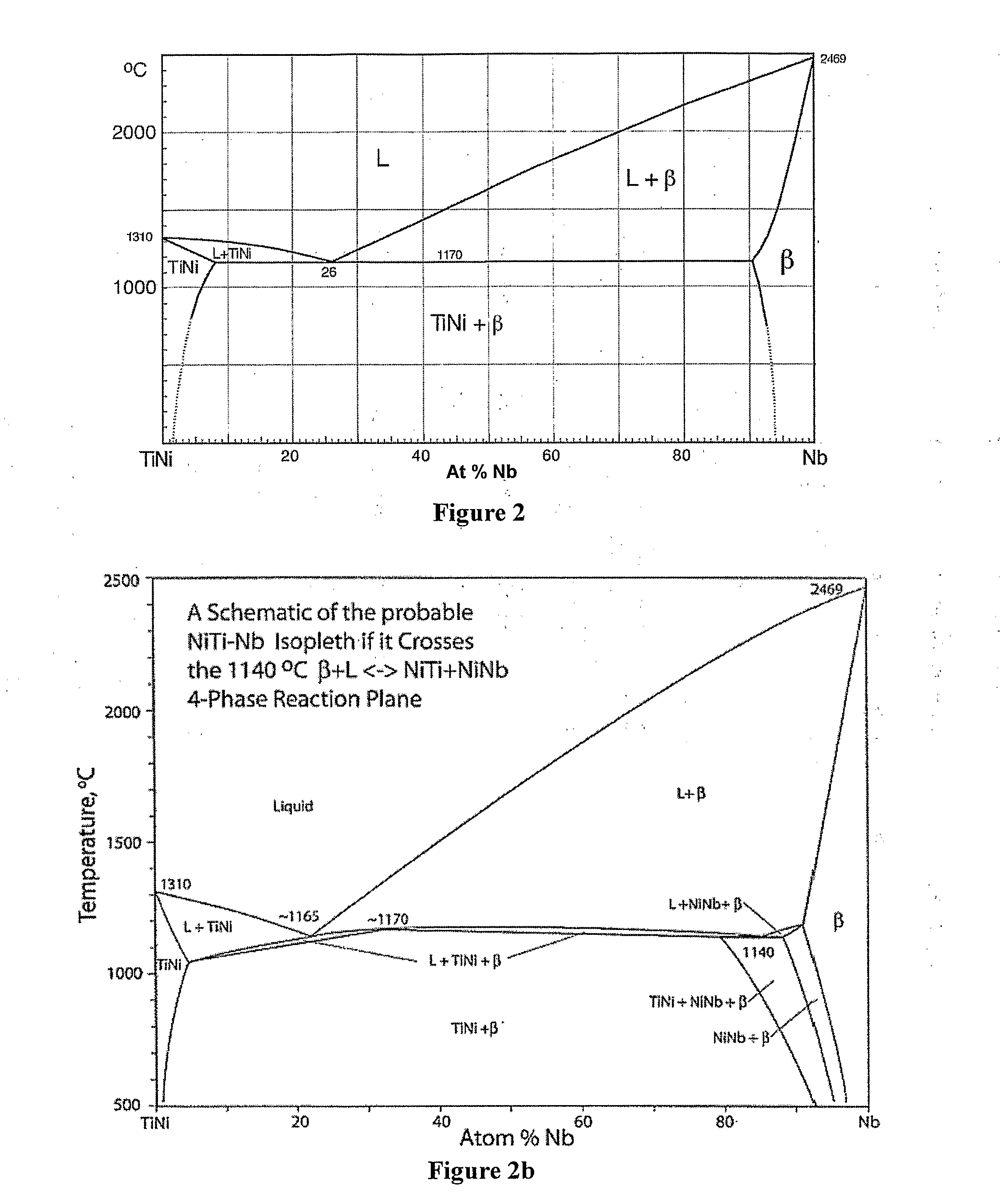

Manufacture of Shape Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining

ActiveUS20080290141A1Low densityMaintain good propertiesPortable framesLayered productsNiobiumHoneycomb structure

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

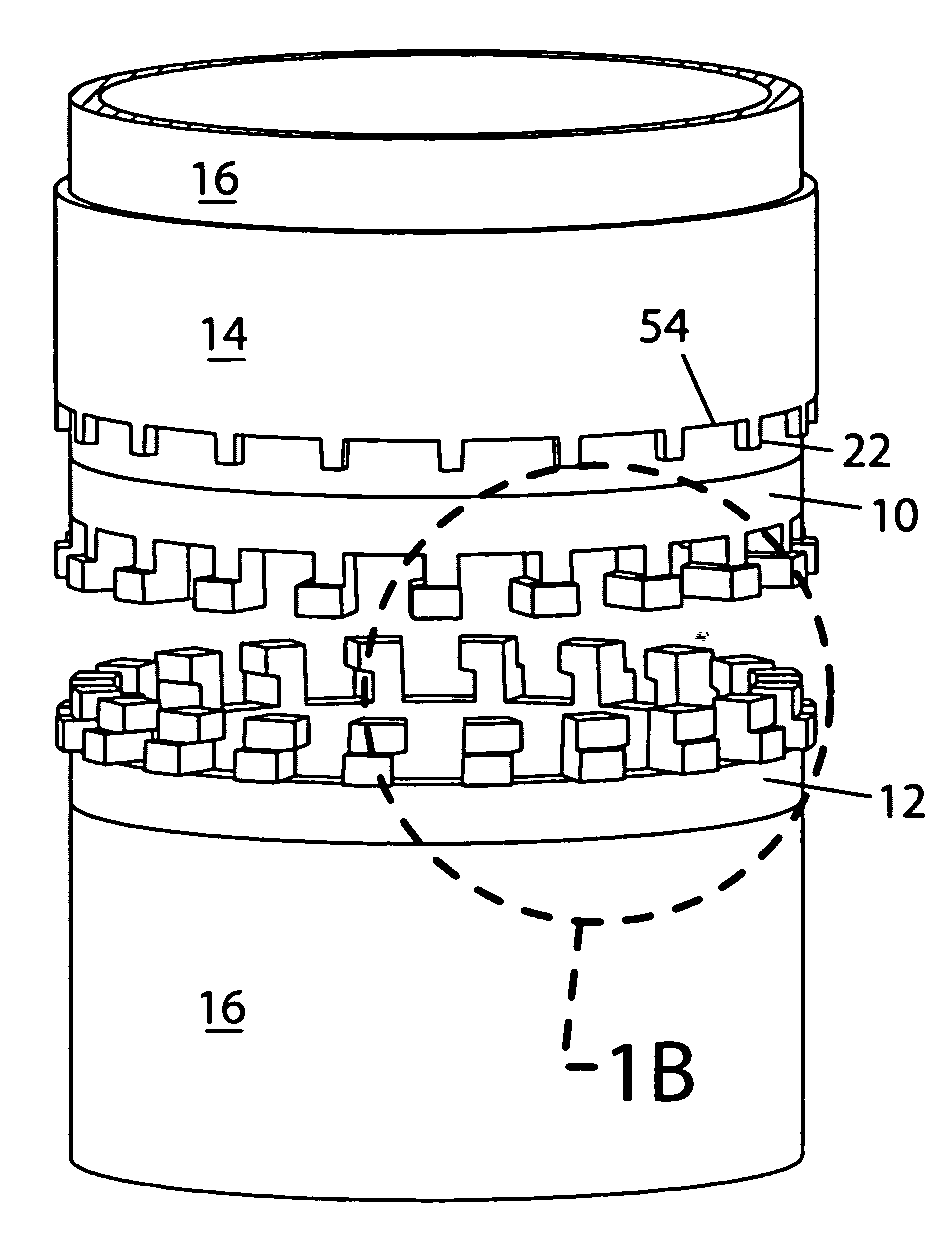

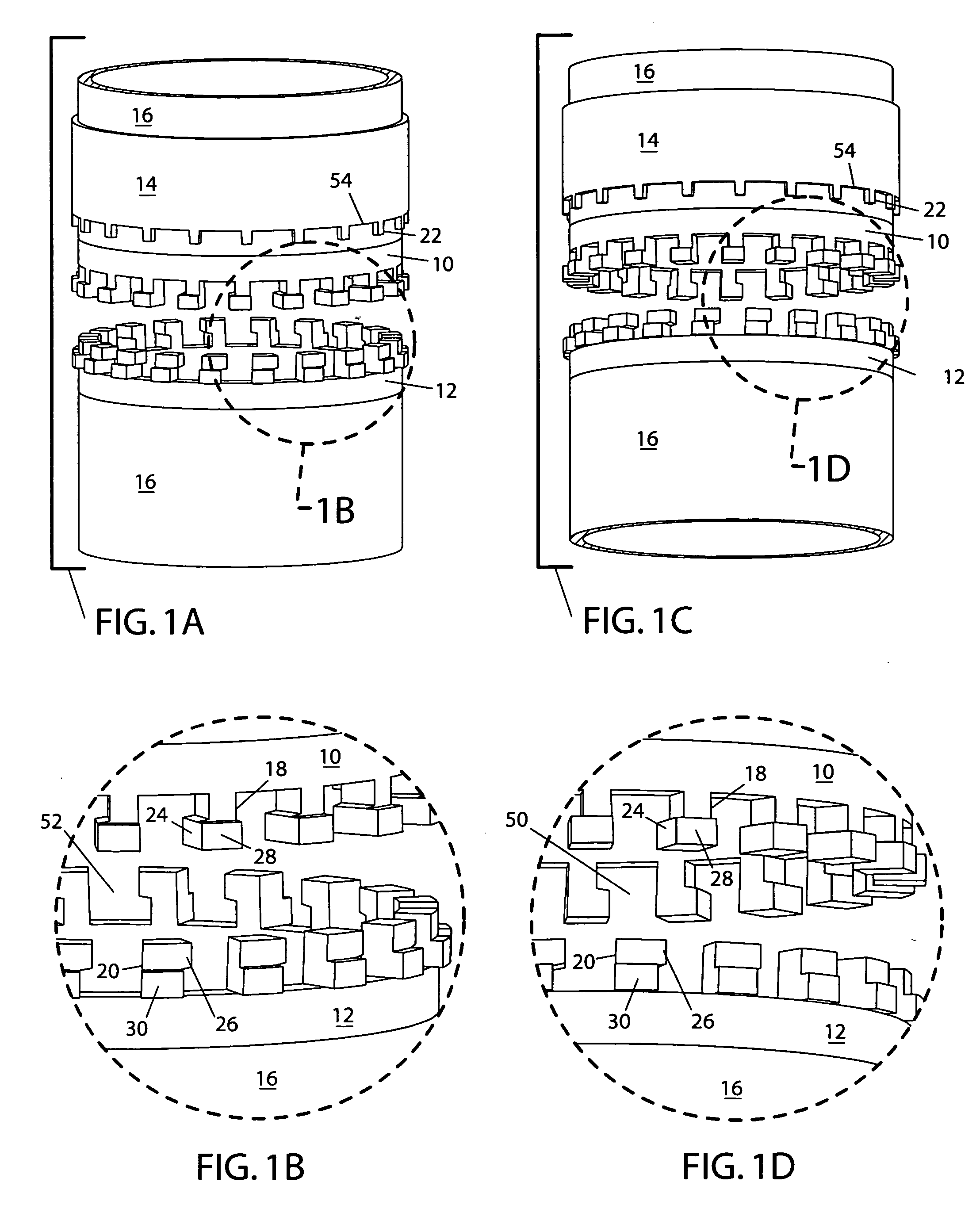

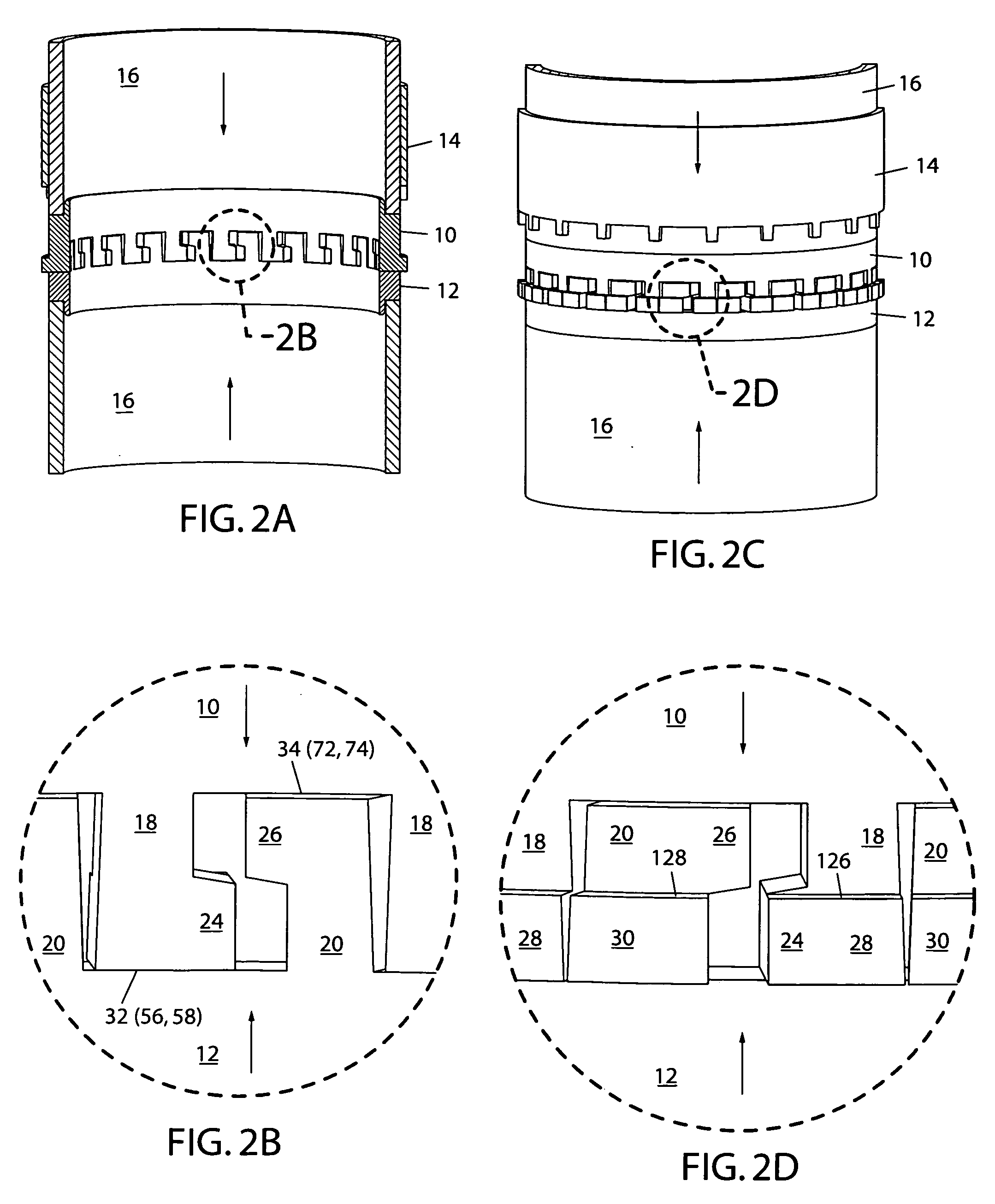

Quick torque coupling

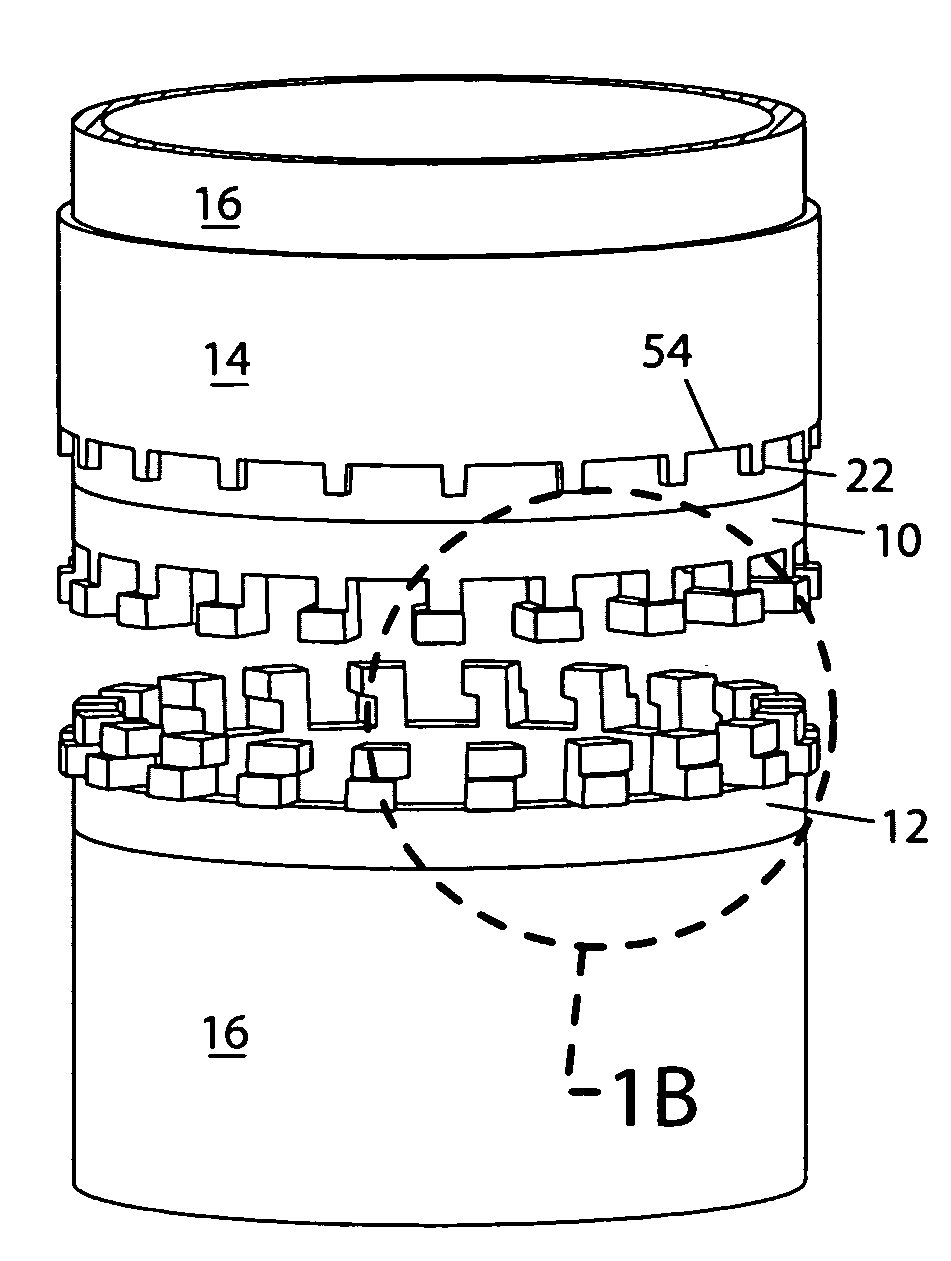

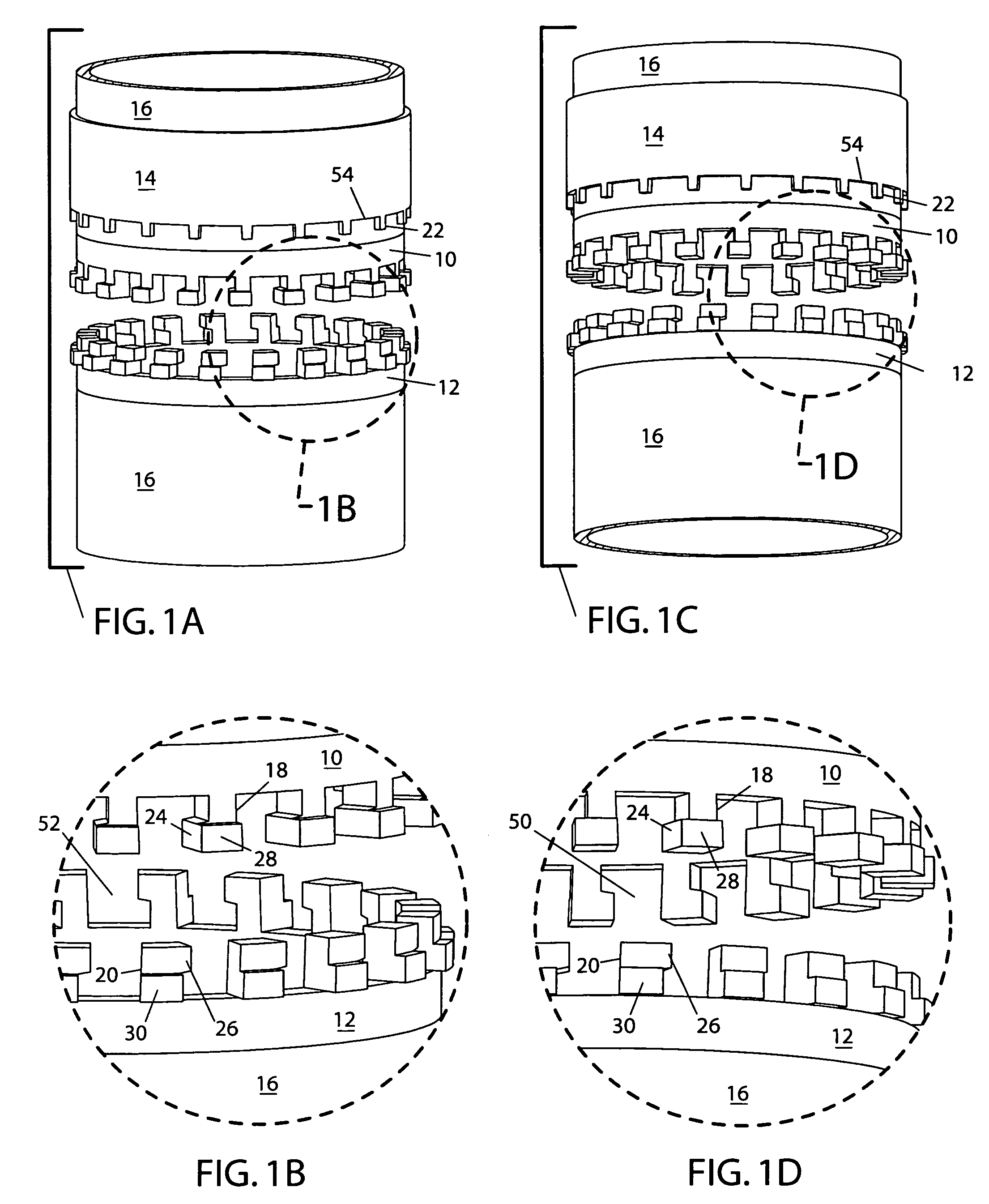

InactiveUS20060171776A1Suitable for fail-safe applicationImprove reliabilitySleeve/socket jointsRod connectionsCouplingModularity

A coupling for mechanically connecting modular tubular struts of a positioning apparatus or space frame, comprising a pair of toothed rings (10, 12) attached to separate strut members (16), the teeth (18, 20) of the primary rings (10, 12) mechanically interlocking in both an axial and circumferential manner, and a third part comprising a sliding, toothed collar (14) the teeth (22) of which interlock the teeth (18, 20) of the primary rings (10, 12), preventing them from disengaging, and completely locking the assembly together. A secondary mechanism provides a nesting force for the collar, and / or retains it. The coupling is self-contained and requires no external tools for installation, and can be assembled with gloved hands in demanding environments. No gauging or measured torque is required for assembly. The assembly can easily be visually inspected to determine a “go” or “no-go” status. The coupling is compact and relatively light-weight. Because of it's triply interlocking teeth, the connection is rigid. The connection does not primarily rely on clamps, springs or friction based fasteners, and is therefore reliable in fail-safe applications.

Owner:LUFT PETER A

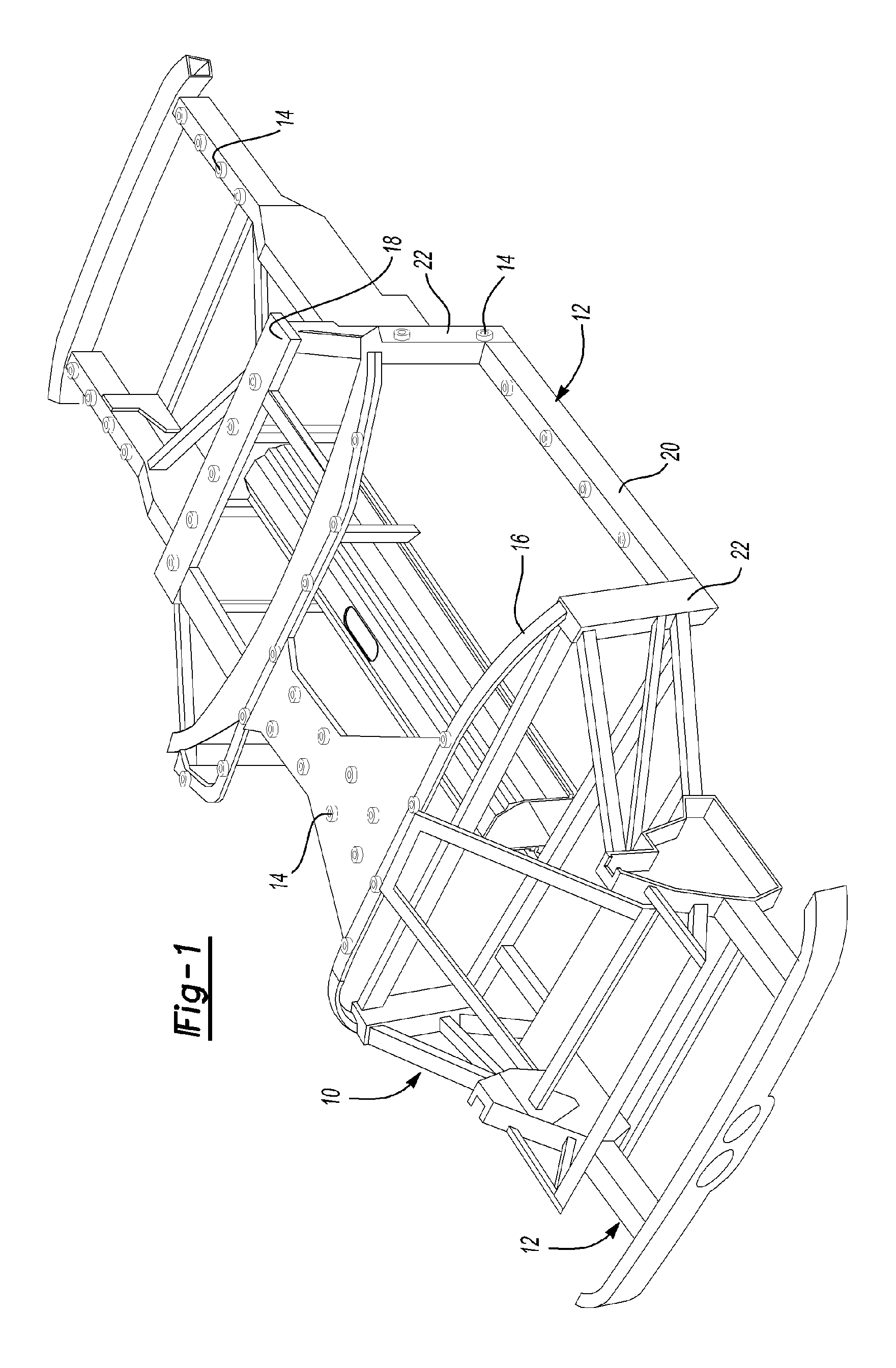

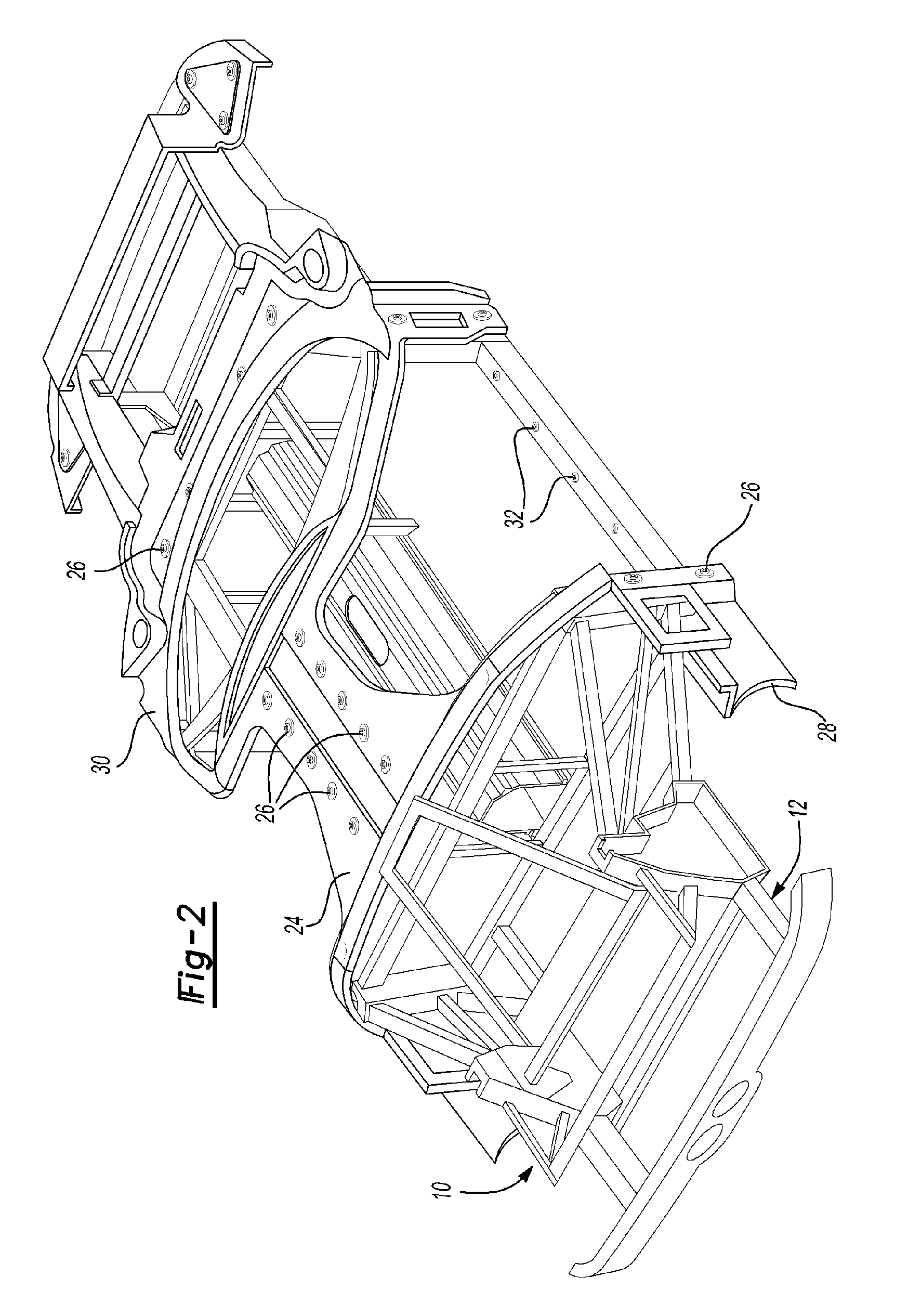

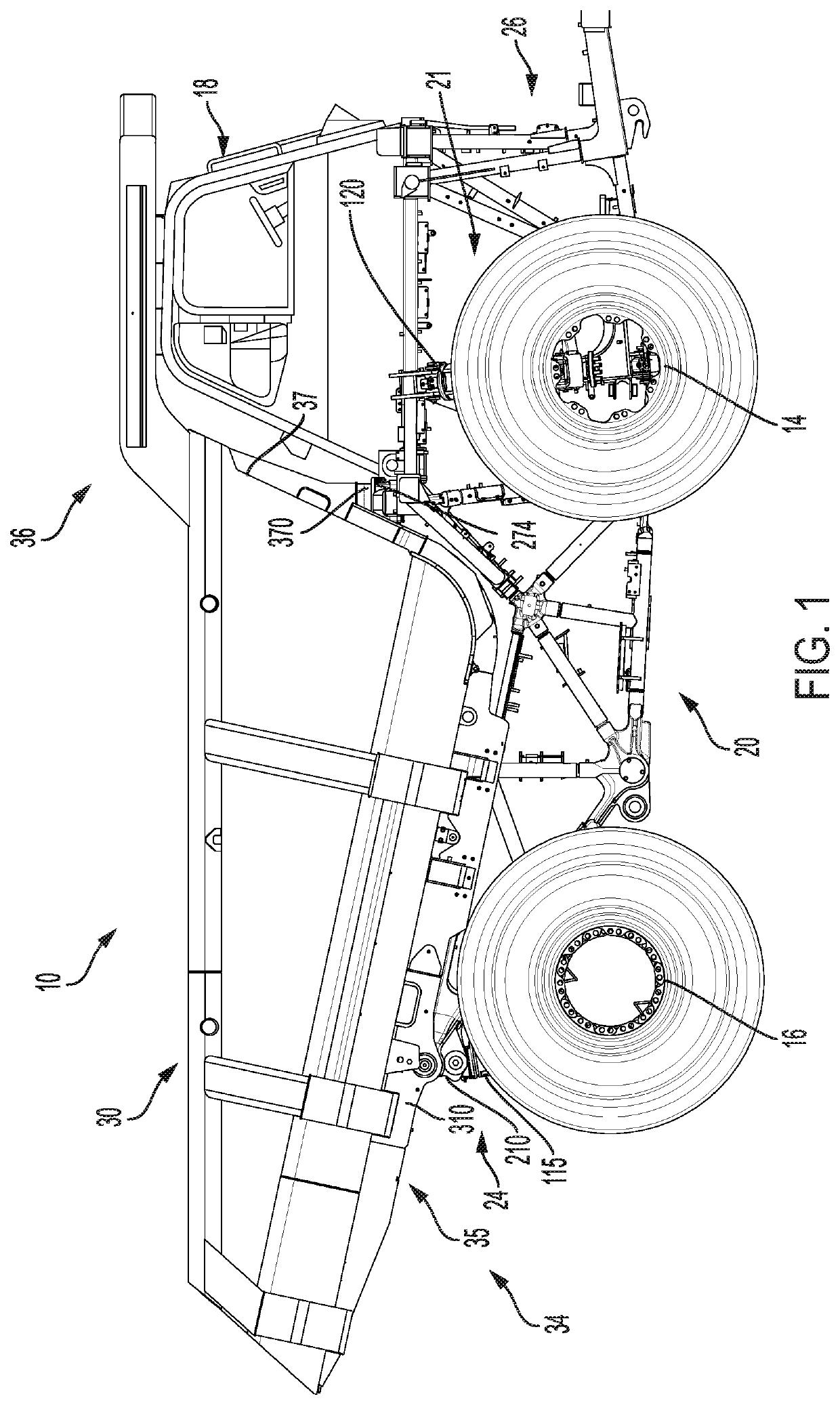

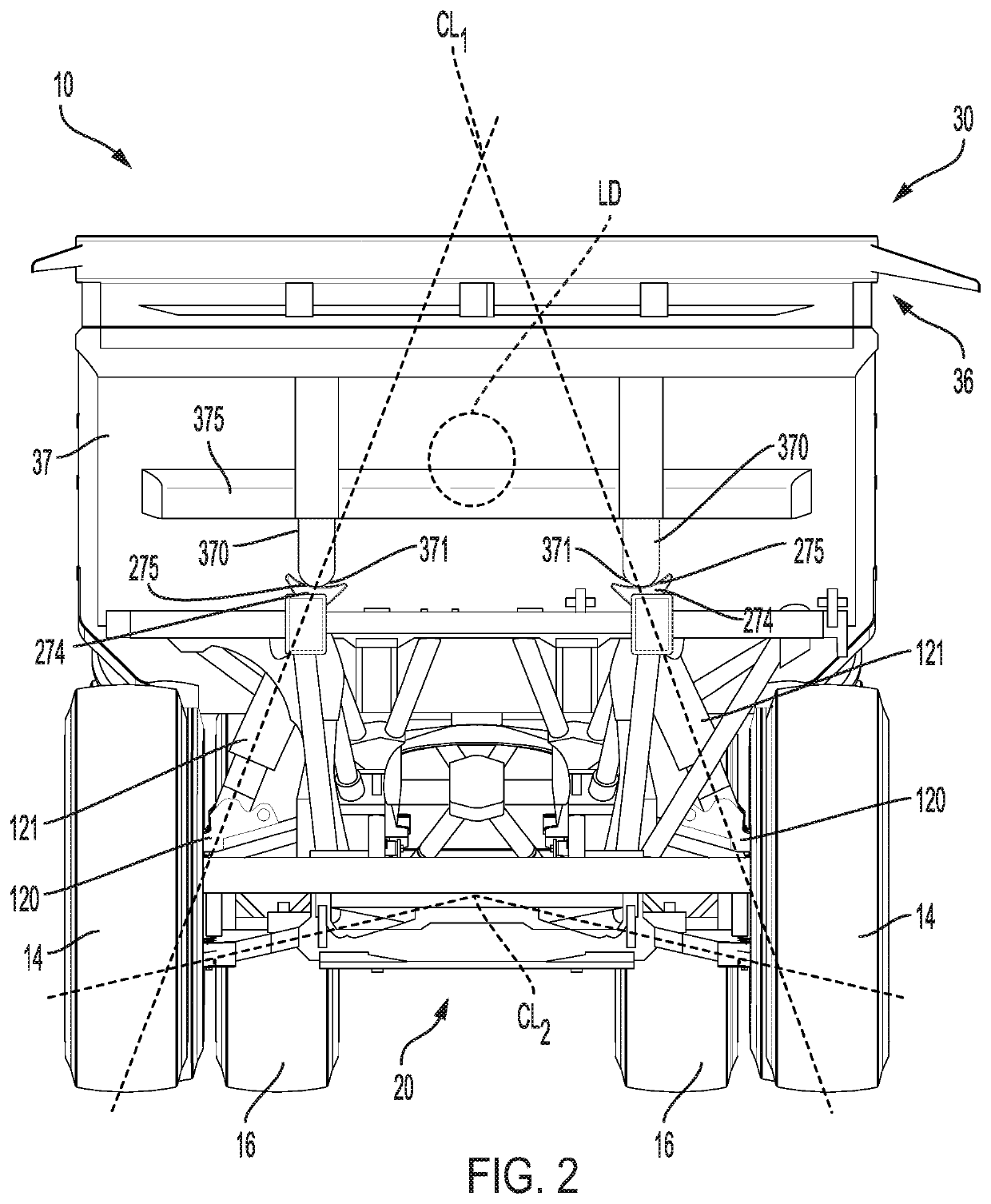

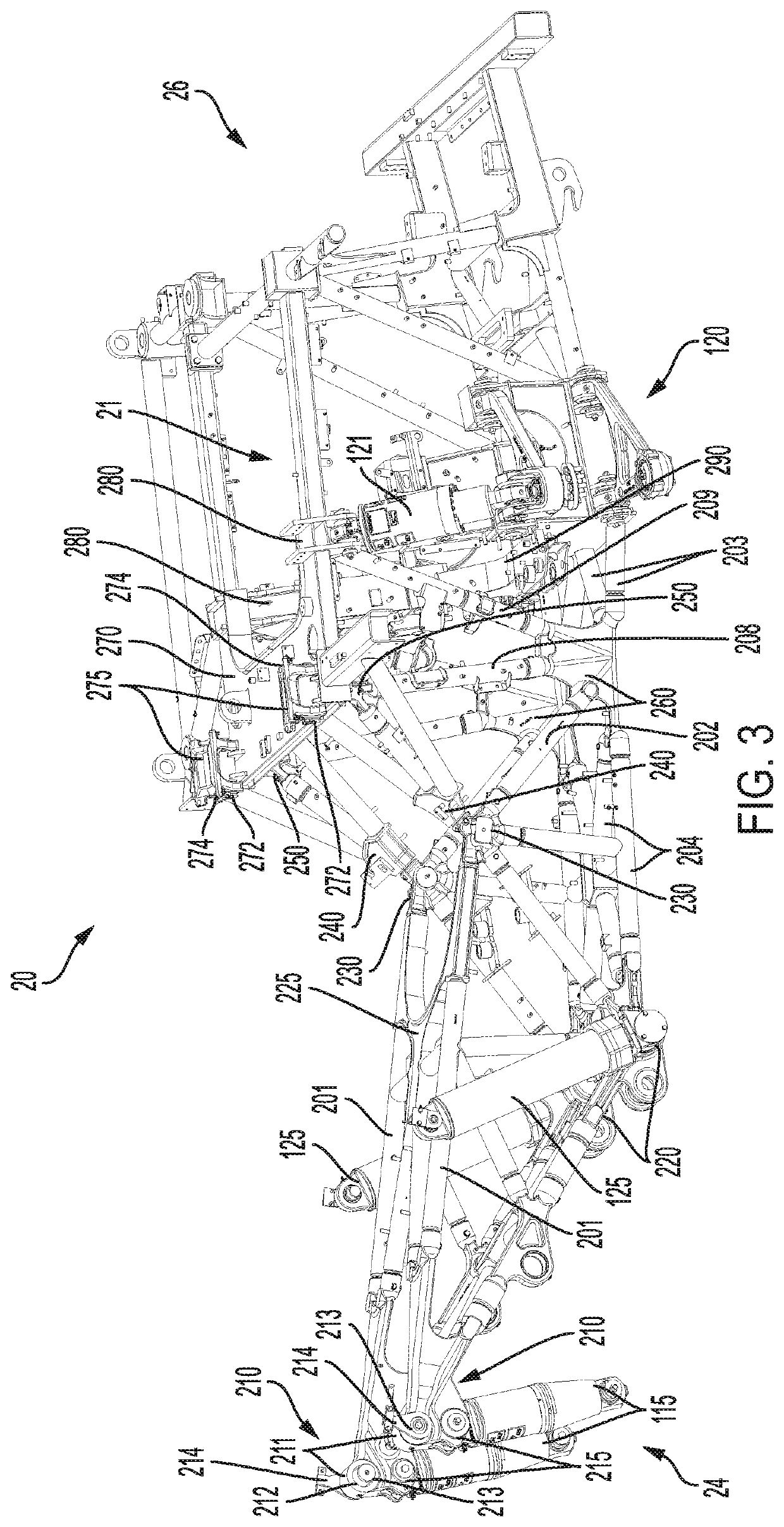

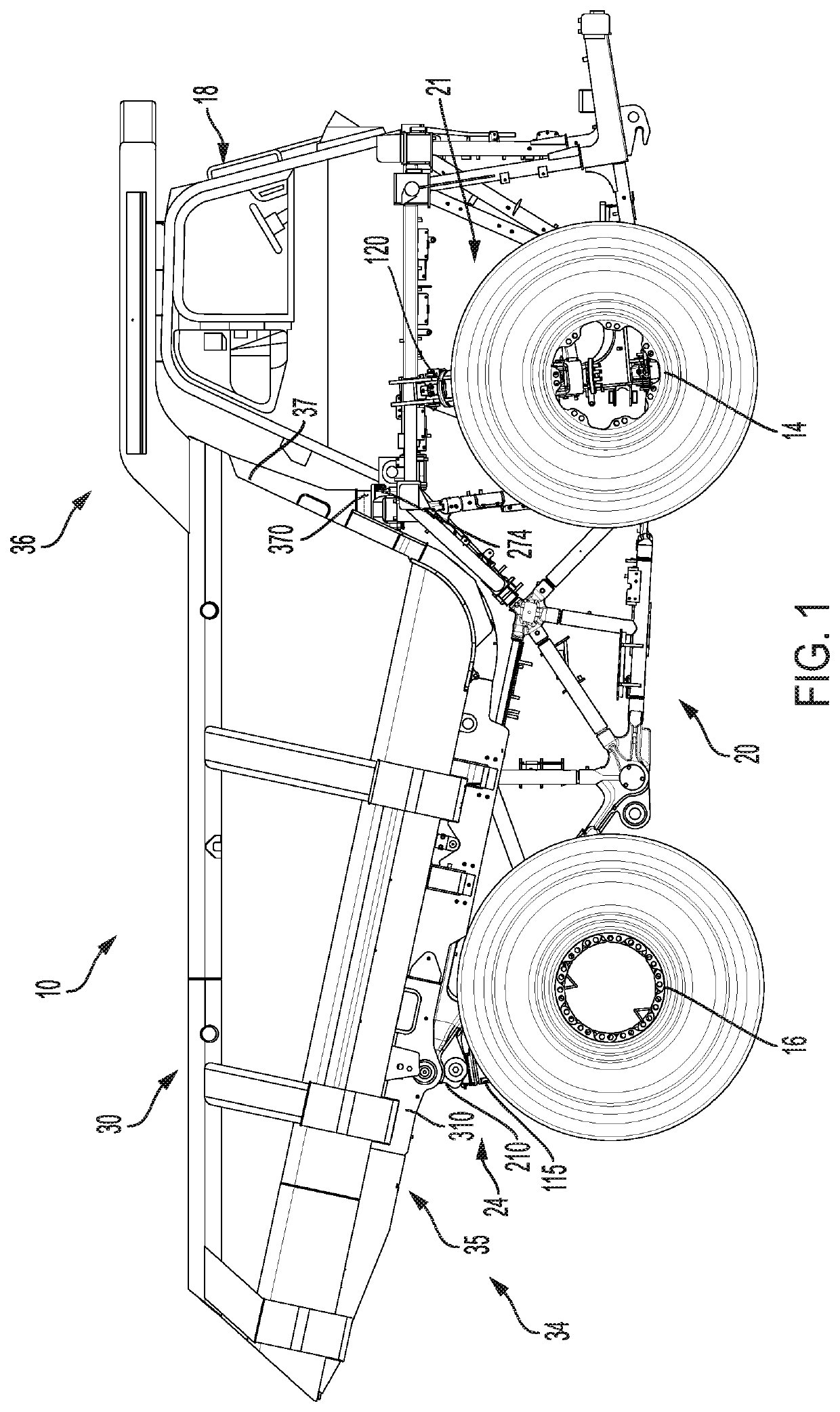

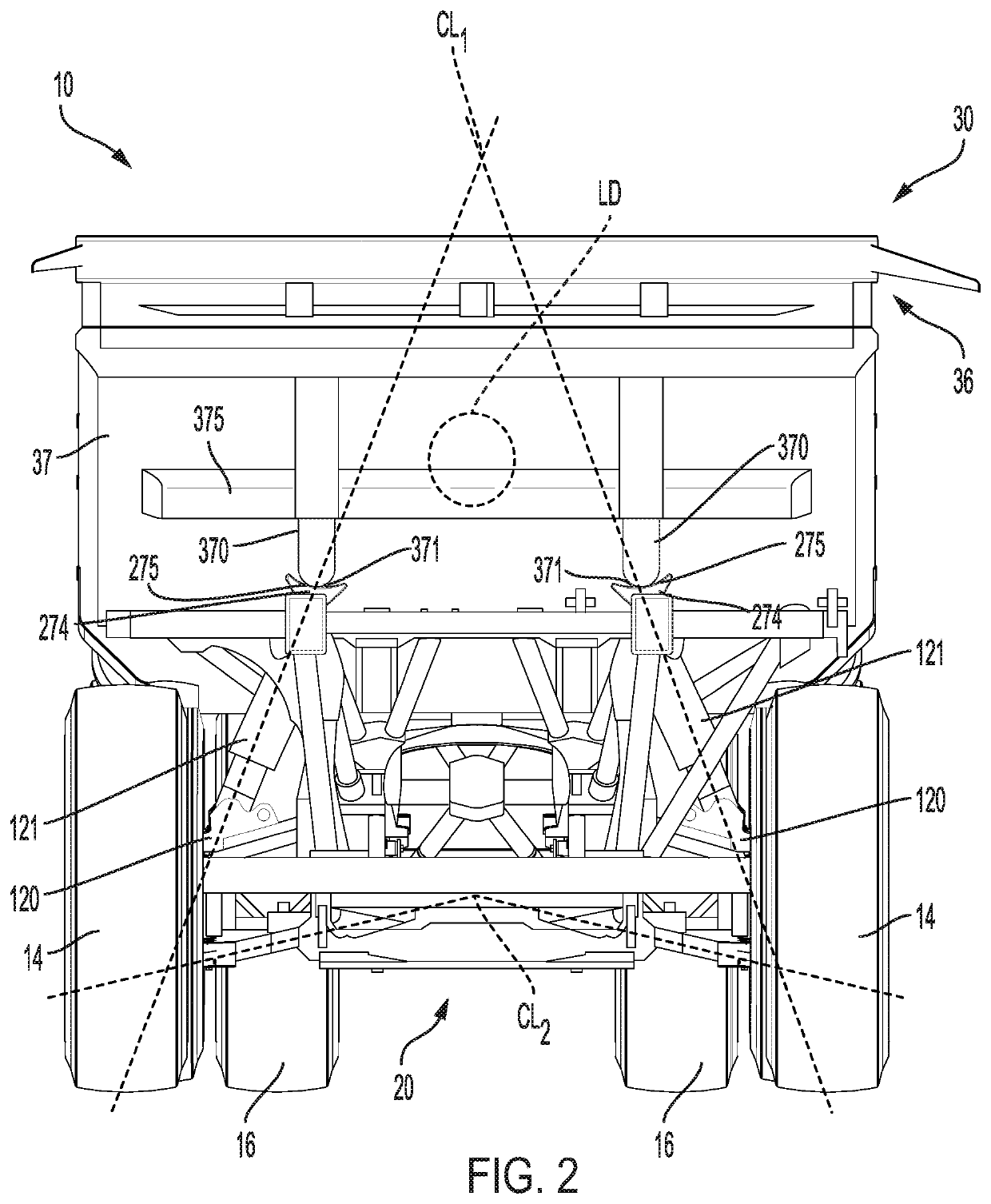

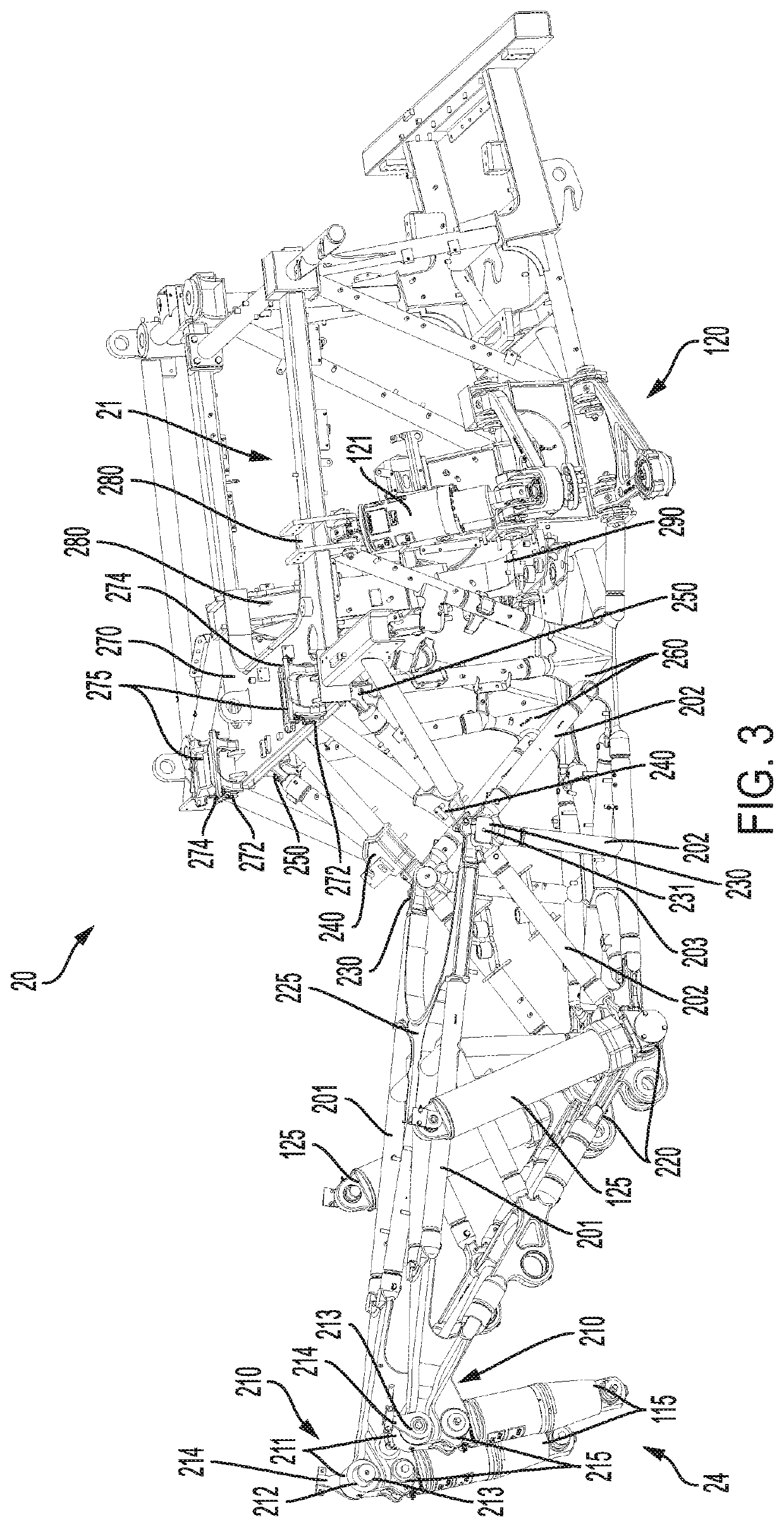

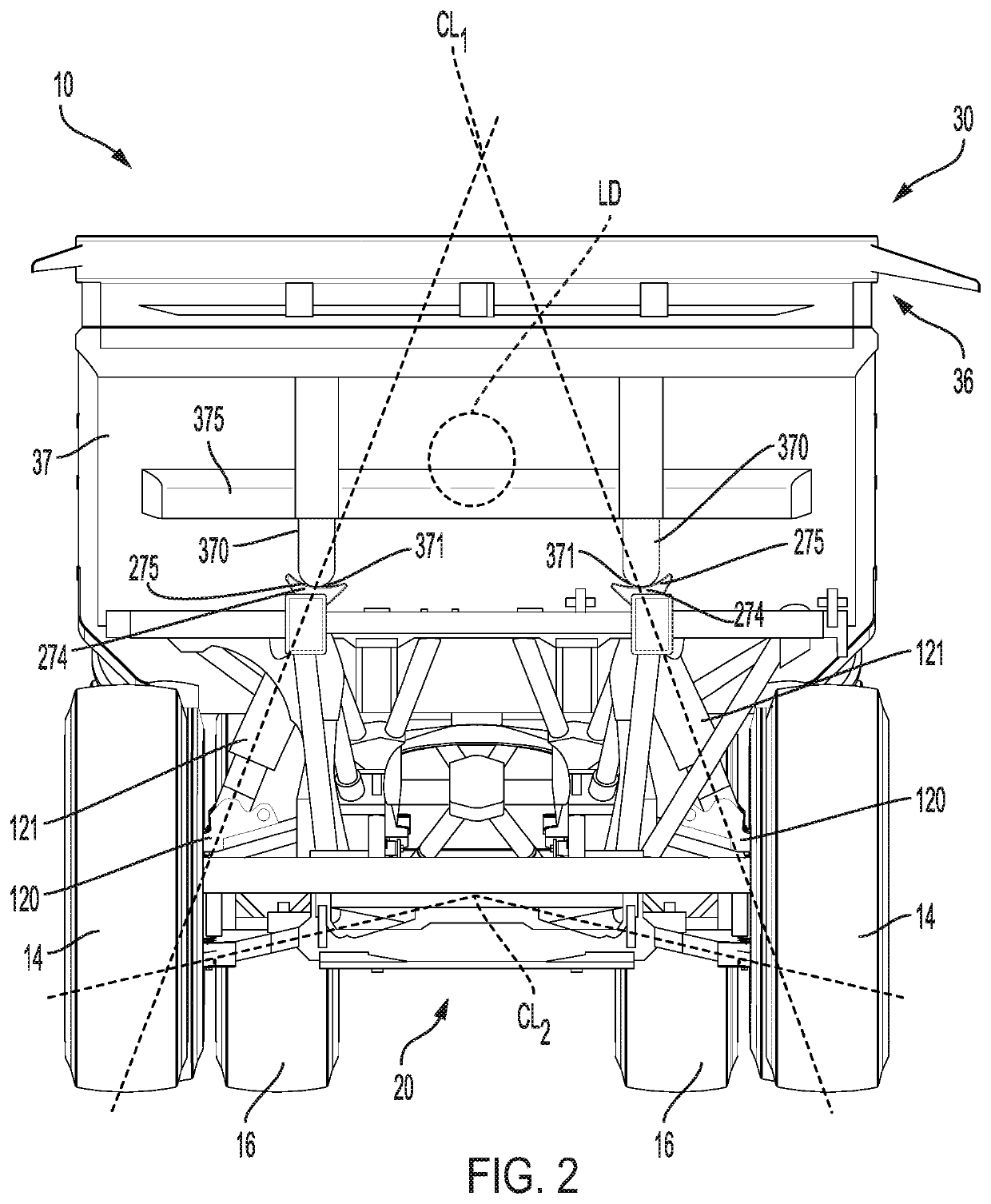

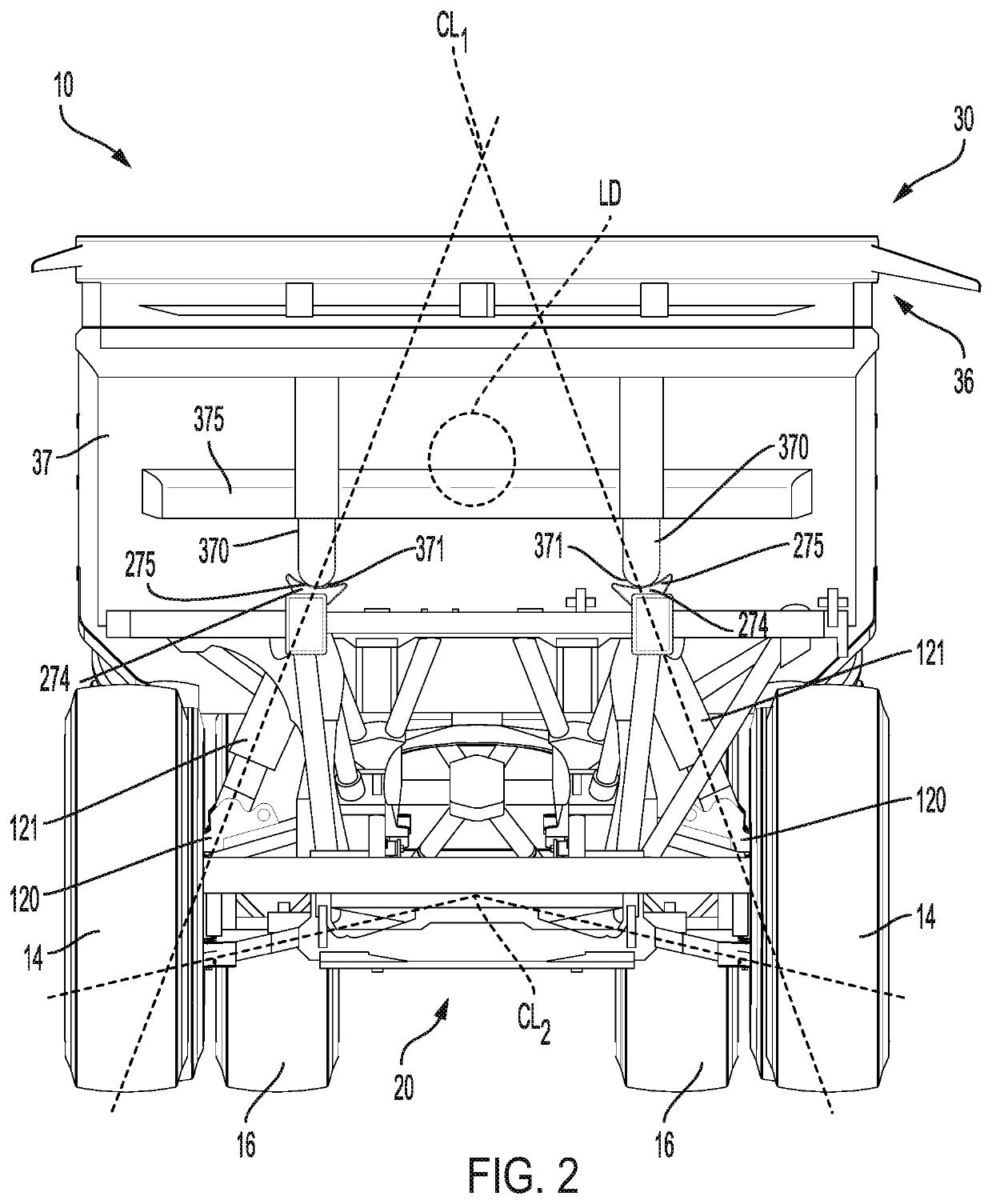

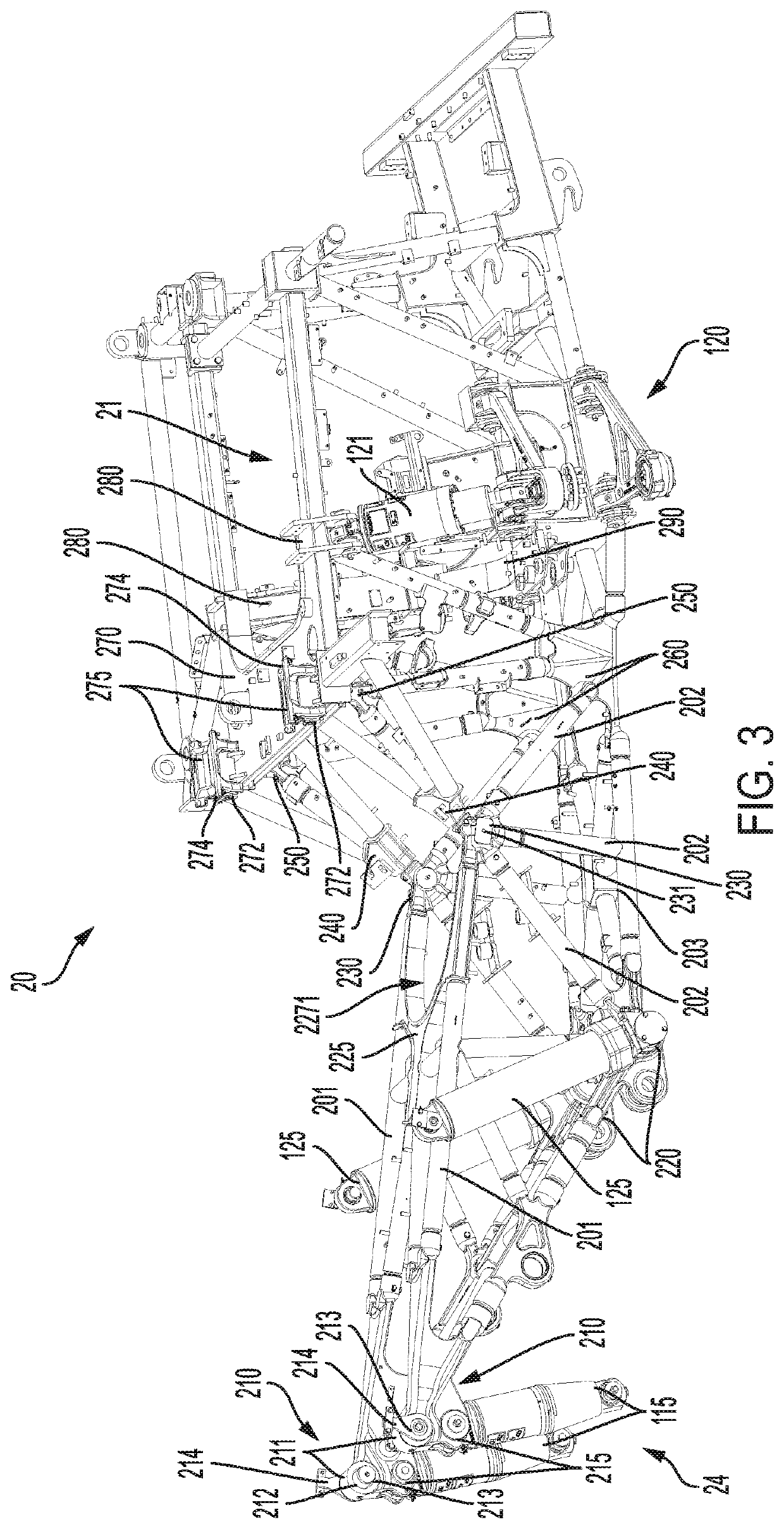

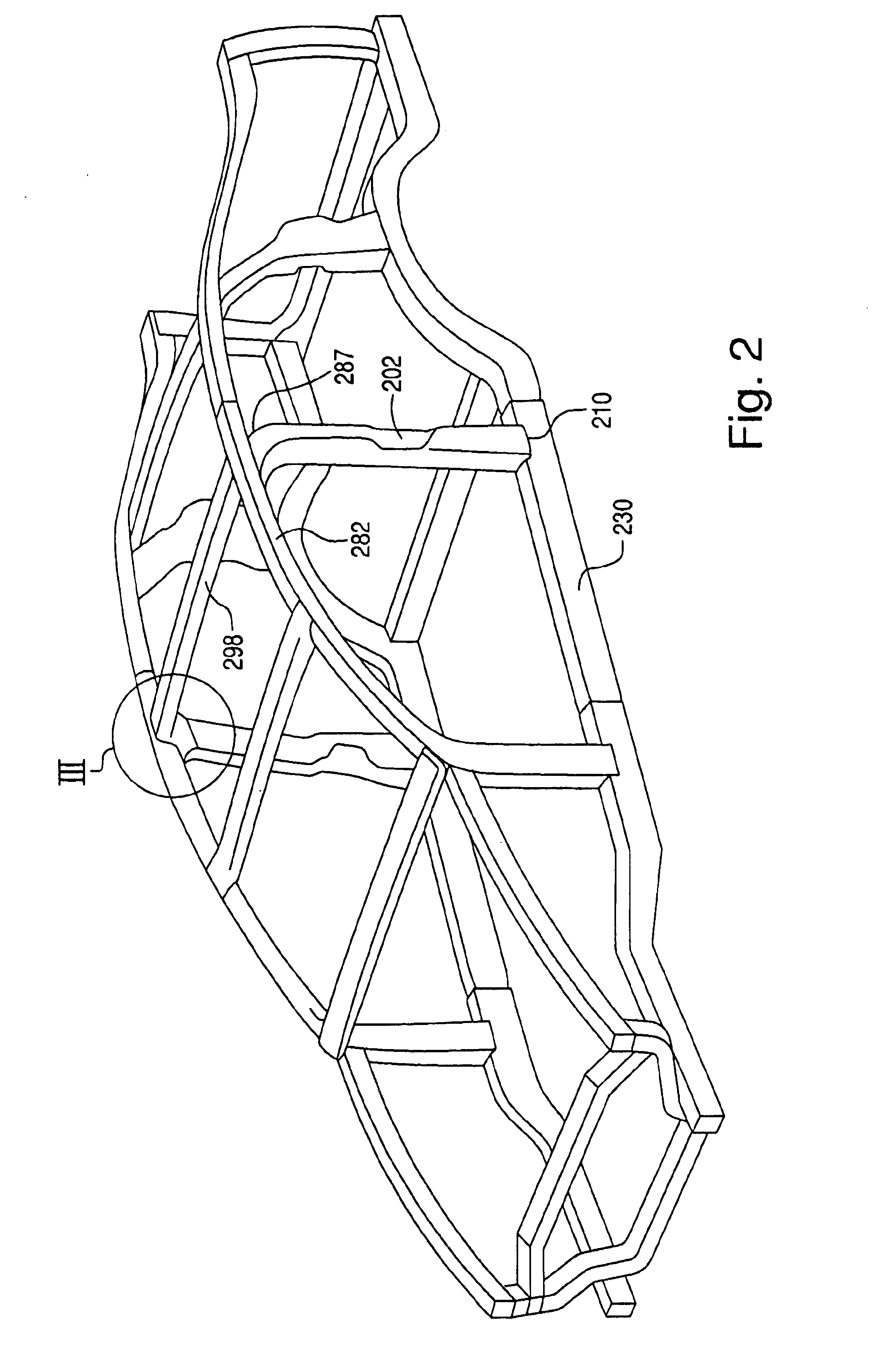

Space frame dump body pivot, suspension node, and rear frame connection

Owner:CATERPILLAR INC

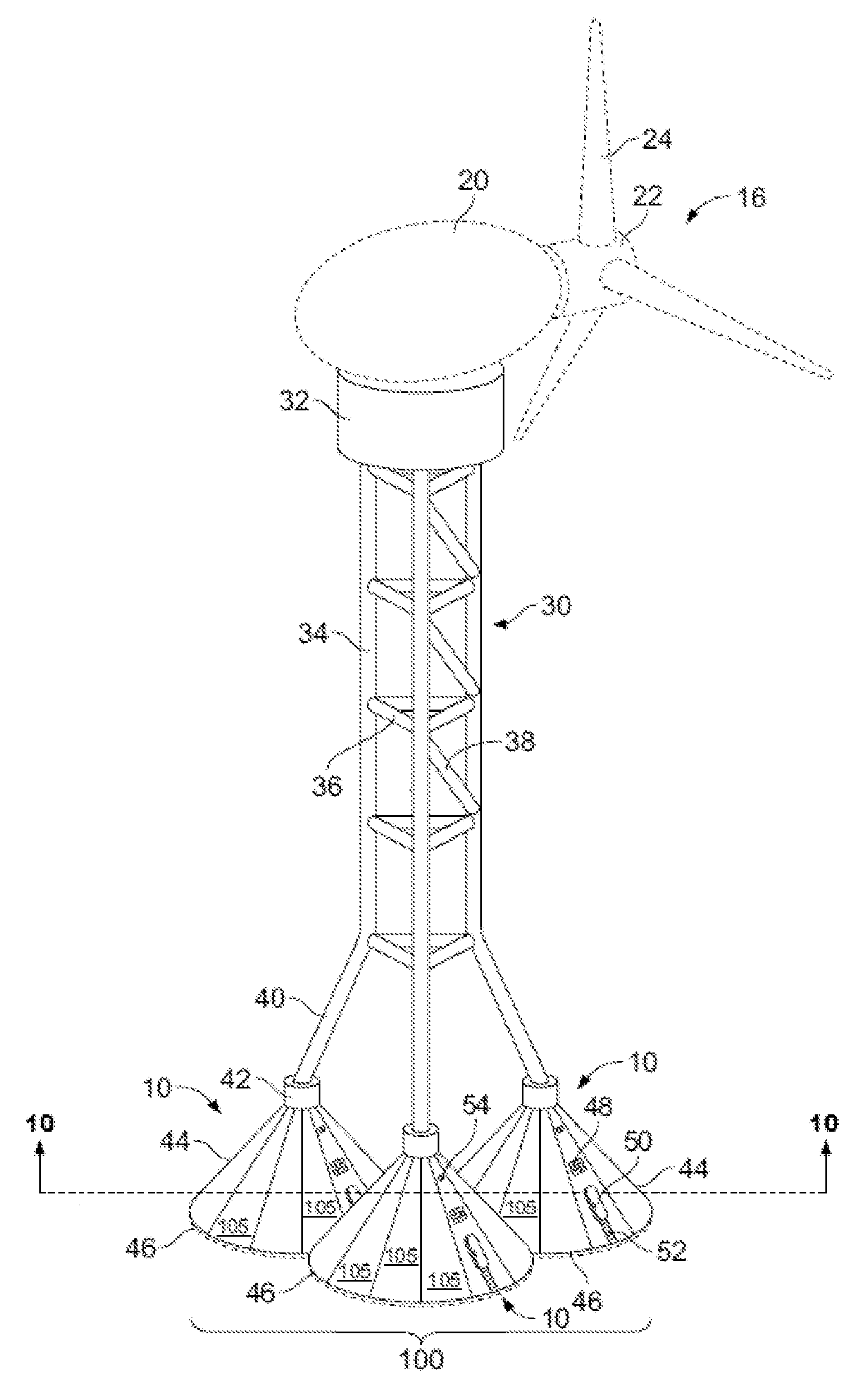

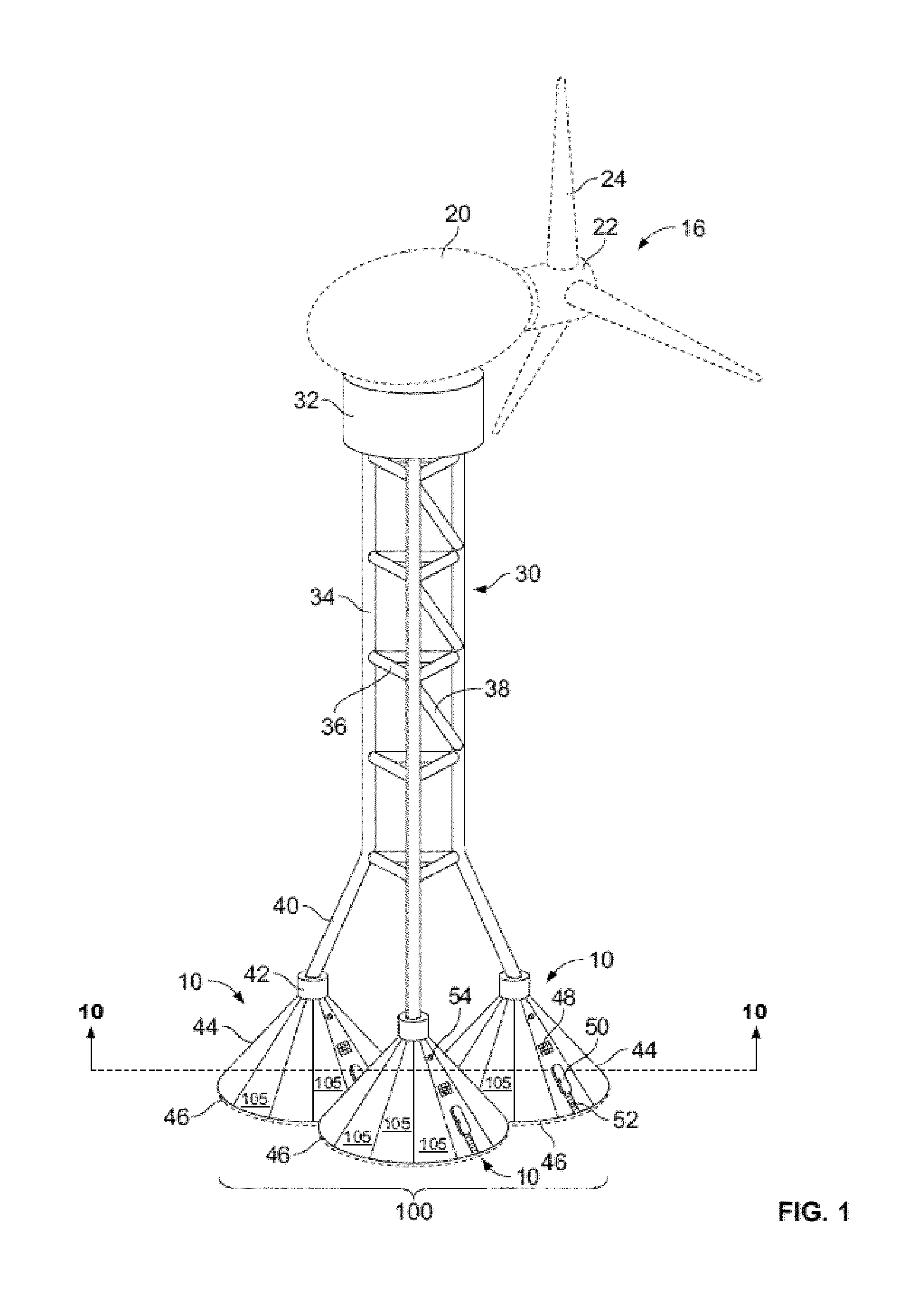

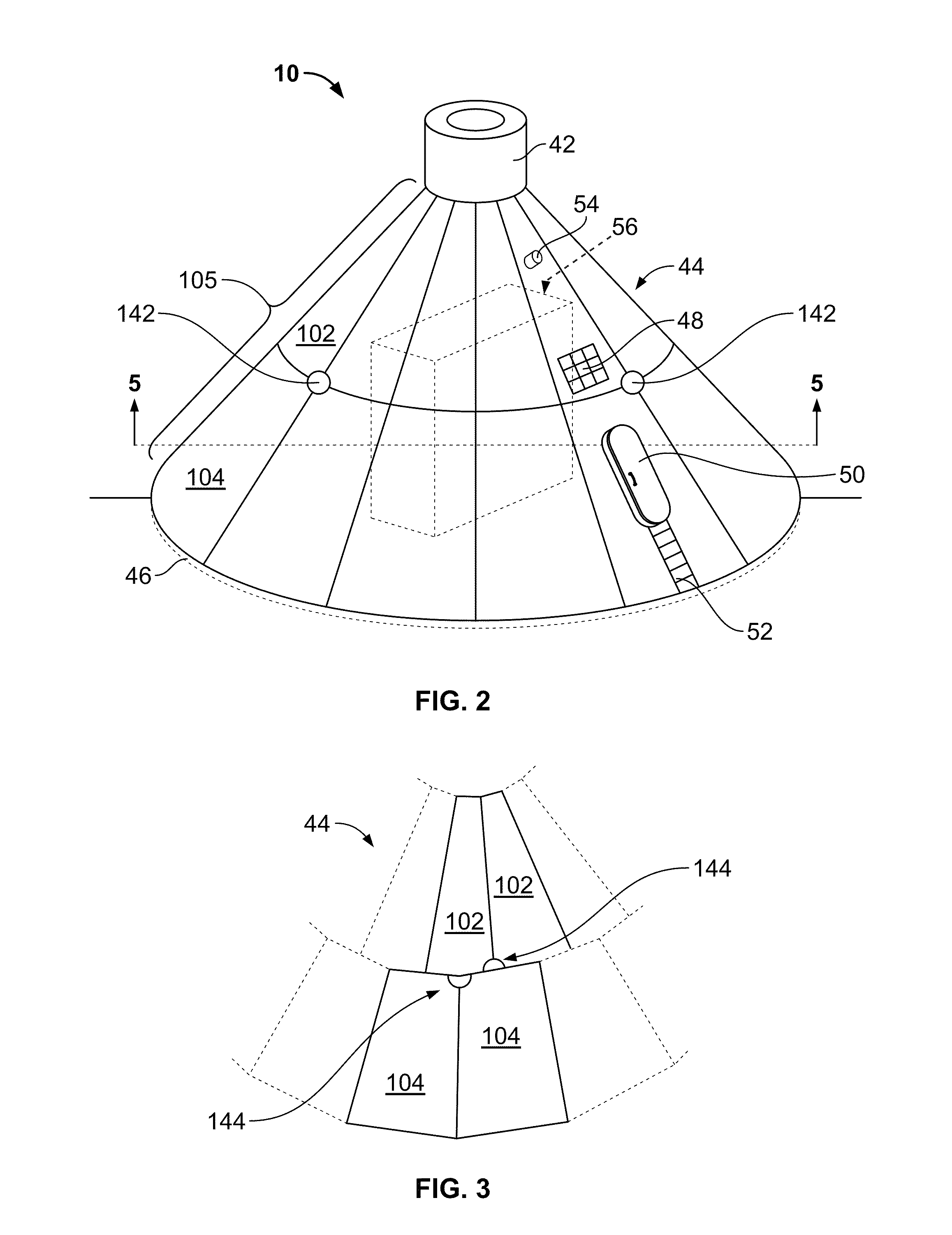

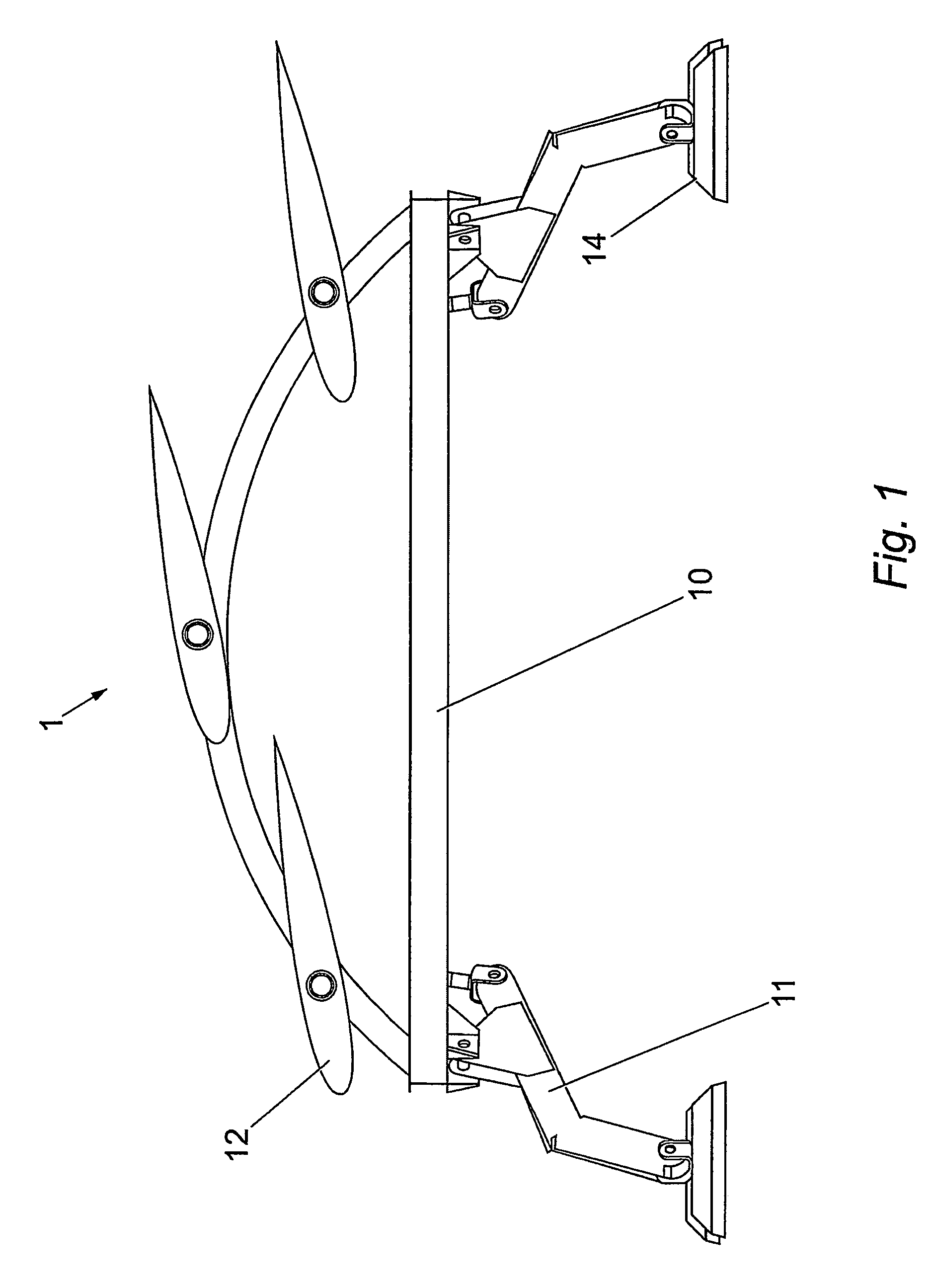

Modular surface foundation for wind turbine space frame towers

InactiveUS20100132270A1Reduce excavation costsLess material to installTransformer housesWind motor assemblyInterior spaceTower

A modular surface foundation for wind turbine space frame towers, an apparatus to form panels of housing members of modular surface foundation, and method of forming the modular surface foundation for wind turbine space frame towers is provided. The modular surface foundation comprises a plurality of footing members, and a housing member disposed on each of the footing members, the housing members extending from the footing members and attaching to one or more structural members forming a portion of a wind turbine tower, wherein the housing member provides support and increased height for the space frame tower and includes an interior space.

Owner:GENERAL ELECTRIC CO

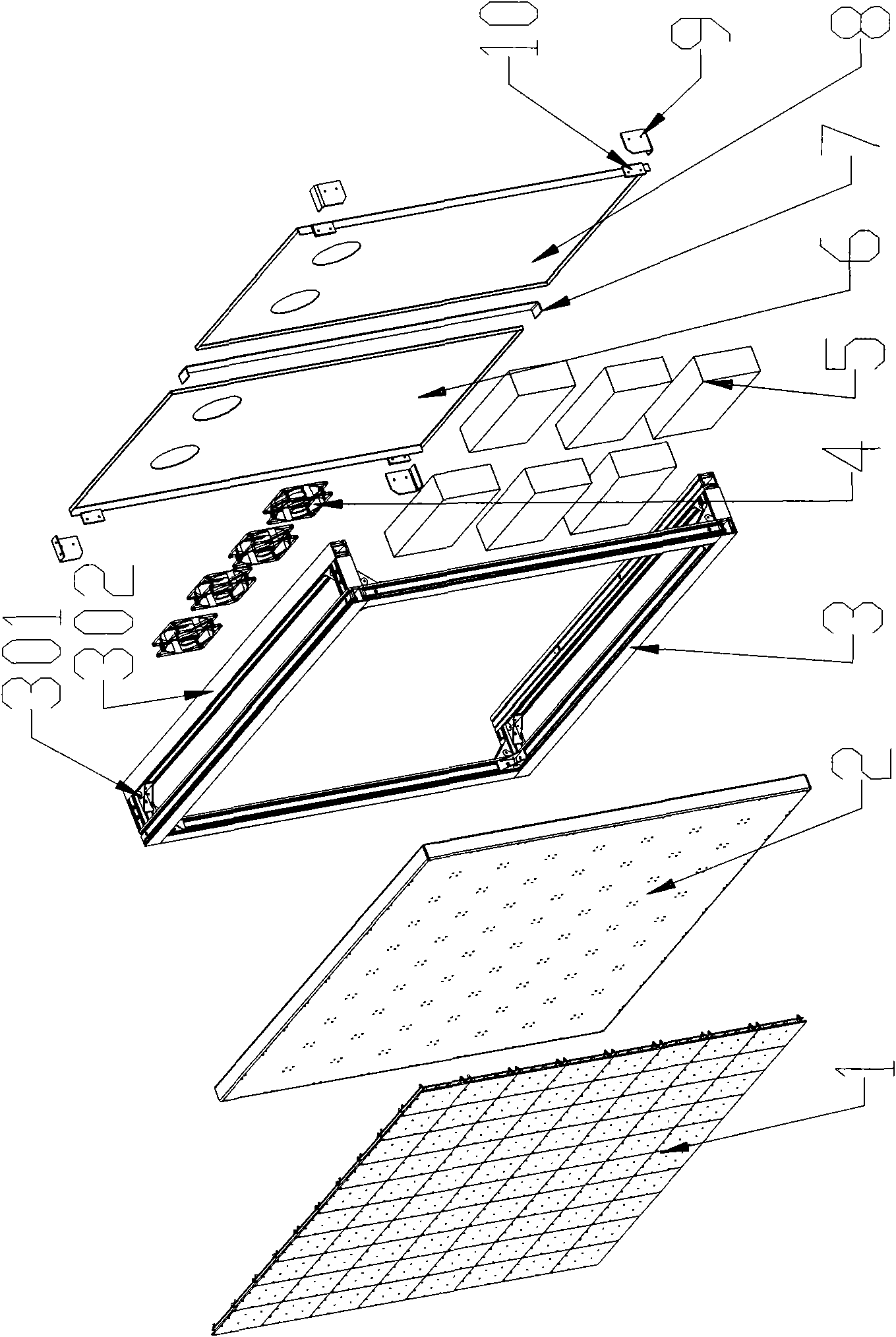

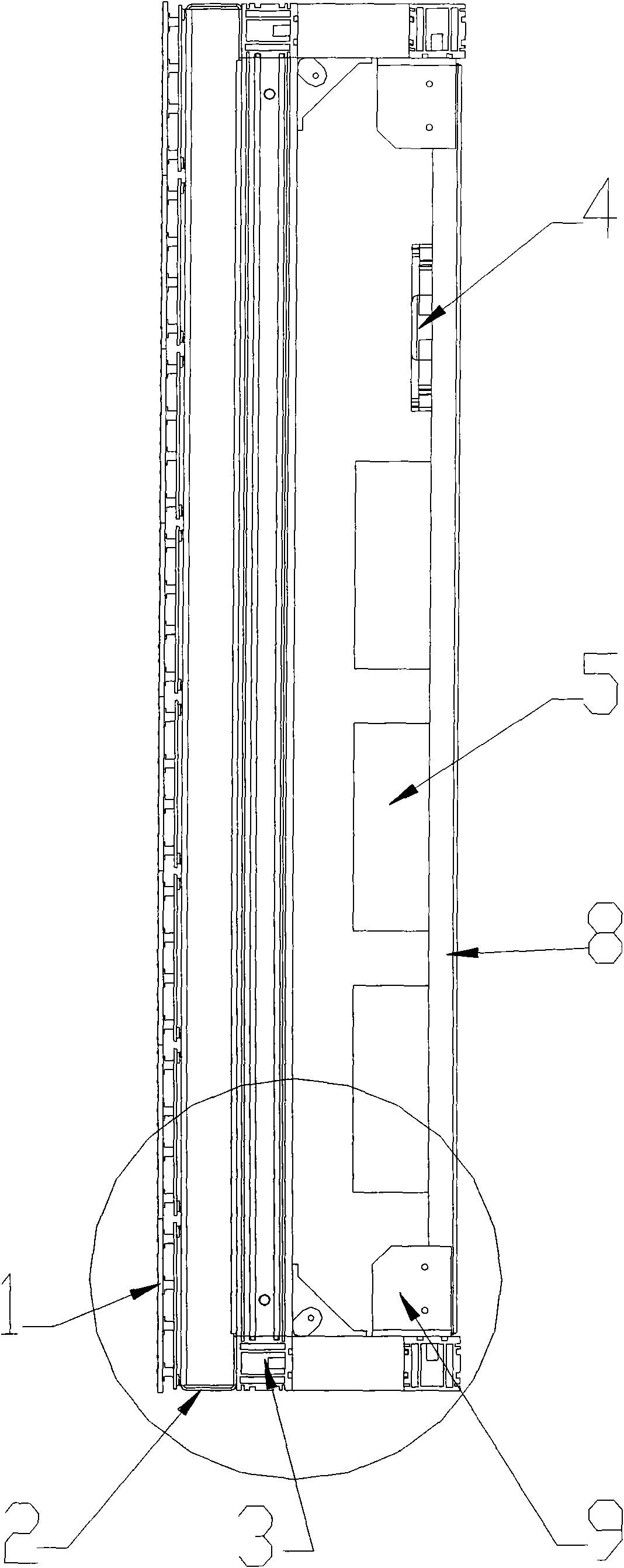

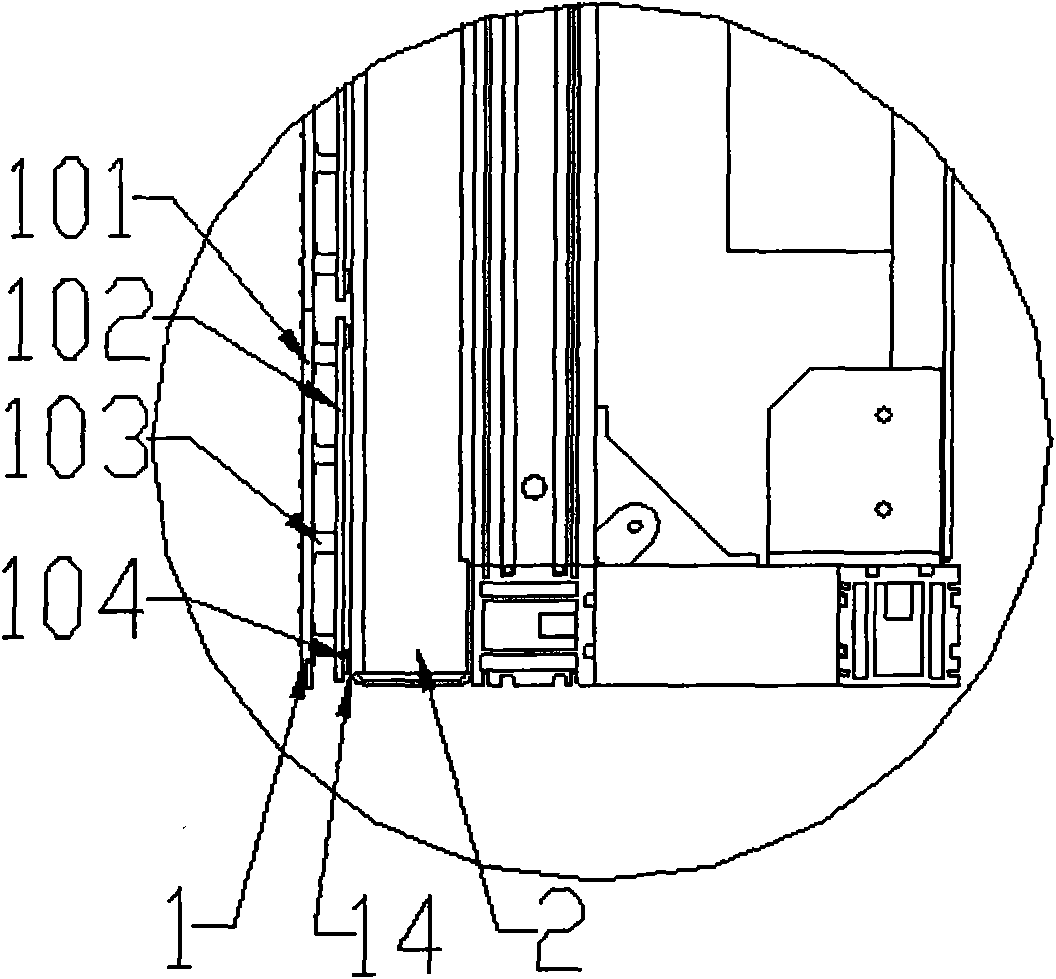

LED display screen

The invention discloses an LED display screen. The LED display screen is composed of a plurality of display screen units which are spliced by virtue of a display screen mounting frame; wherein the display screen unit comprises a display module, a display screen tank body, a heat sink and a connecting device; the display module is connected with the display screen tank body by virtue of the connecting device, and the display screen tank body is connected with the heat sink by virtue of the connecting device; the display screen tank body is a space frame structure composed of ten support elements which are mutually vertical, namely four transverse long support elements, two vertical long support elements and four short support elements, wherein the front of the display screen tank body is composed of two transverse long support element and two vertical long support elements, the four corners at the front of the display screen are respectively connected with two transverse long support elements by virtue of the short support elements; and all the support elements are fixed by virtue of connecting pieces, and the connecting pieces are connected with the support elements by virtue of fastening pieces. The invention has the advantages of good stability, good heat dissipation, lower cost, debugging convenience and simple structure.

Owner:GUANGDONG VTRON TECH CO LTD

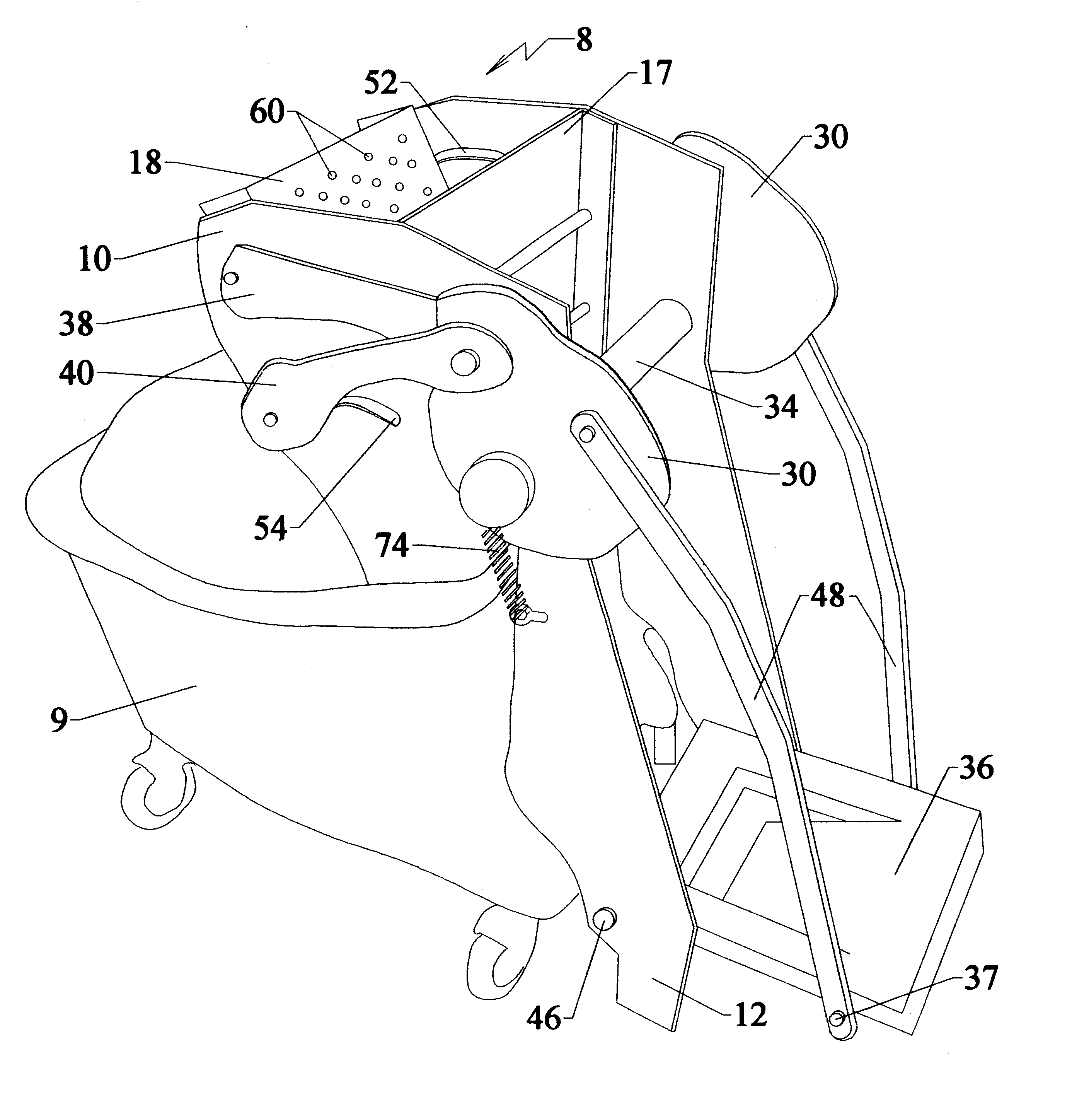

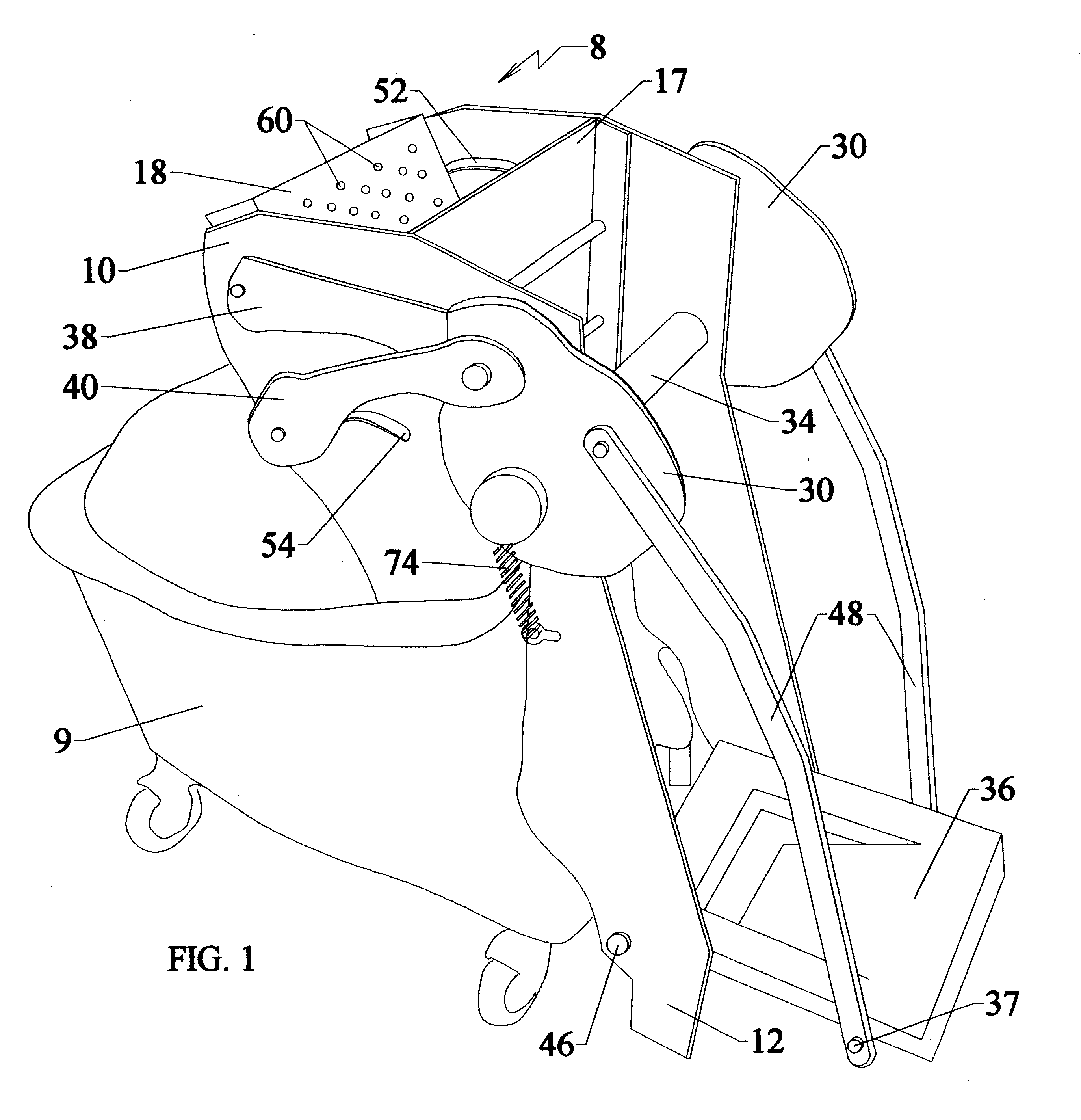

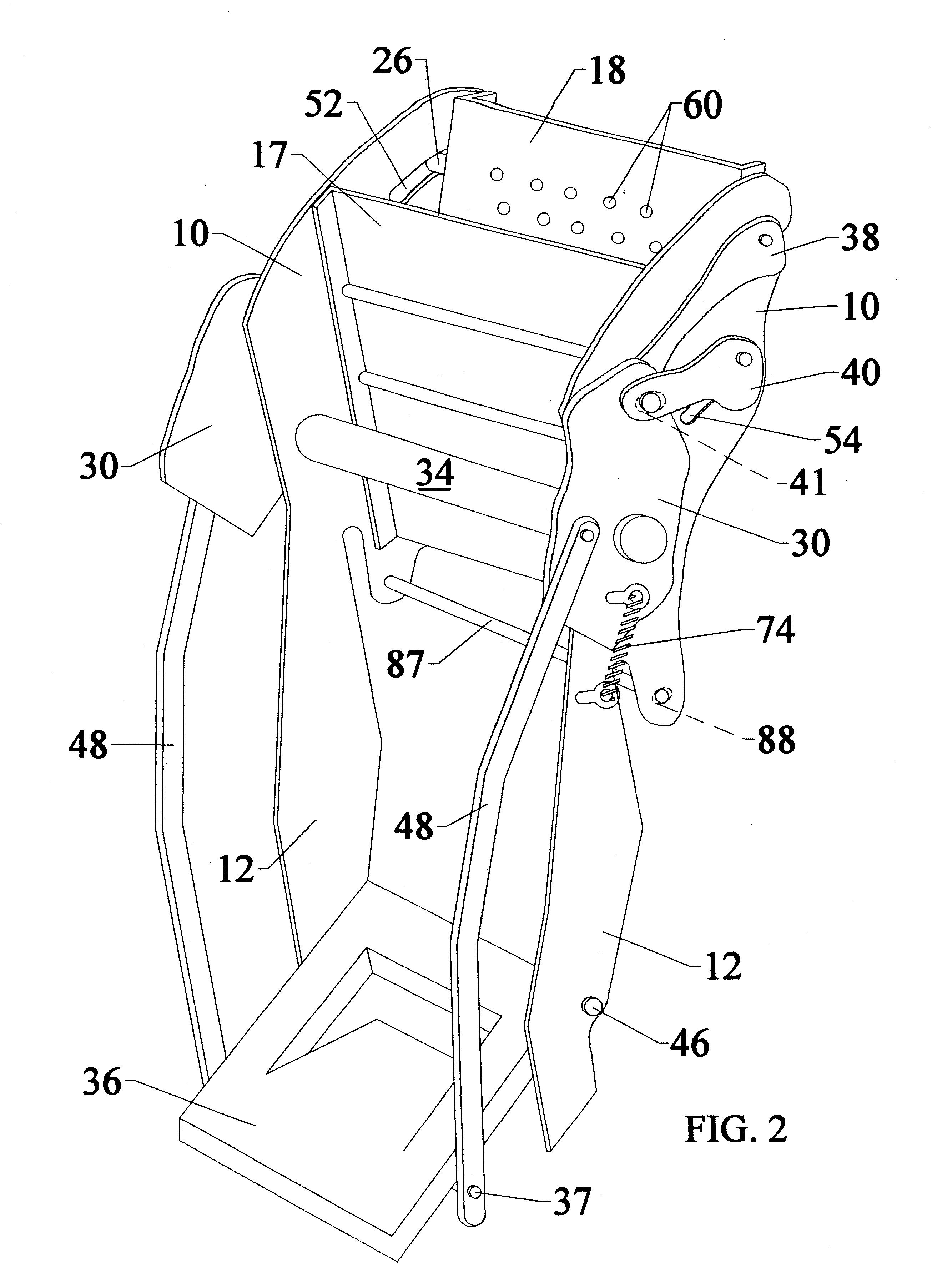

Mop wringer

InactiveUS6671923B2Easy to wringImprove productivityCarpet cleanersFloor cleanersRest positionEngineering

A mop wringer having a pair of spaced frame members or lateral plates, each having a lower leg member, and includes structure for attaching the wringer to a receptacle. A stationary squeeze plate and a movable squeeze plate are located in the space between the frame members and between which the mop may be placed for wringing, the movable squeeze plate pivoting about a middle axle extending between the frame members. A foot pedal is pivotally connected to the lower leg members about a lower-most axle. An upper axle, disposed above the middle axle, extends through and between the frame members. One or more disks are mounted about the upper axle adjacent each of the frame members, the disk being connected to an upper portion of the movable squeeze plate by one or more connecting arms. Second connecting arms interconnect the foot pedal to the outside disks. A coiled steel spring, is operatively connected between the disks and the adjacent frame member and one of the connecting arms between the outside disk and the movable squeeze plate. When the user depresses the foot pedal, the movable squeeze plate is pivoted toward the stationary squeeze plate, and when released, the movable squeeze plate is returned to a rest position.

Owner:GROMWELL

Space frame front upper body support and frame connection

A front upper frame connection for a space frame can comprise a top surface; a bottom surface opposite the top surface; a right-side surface; a left-side surface opposite the right-side surface; a front surface; a rear surface opposite the front surface; a pair of forward support plates provided on the front surface; a pair of forward flat mounting surfaces; and a pair of rocker attachment interfaces located on the top surface adjacent to the rear surface and respectively the right-side surface and the left-side surface. The front surface and the forward support plates can define a cutout section. Each of the forward support plates is curved and runs outward from a transverse centerline of the top surface and then forward.

Owner:CATERPILLAR INC

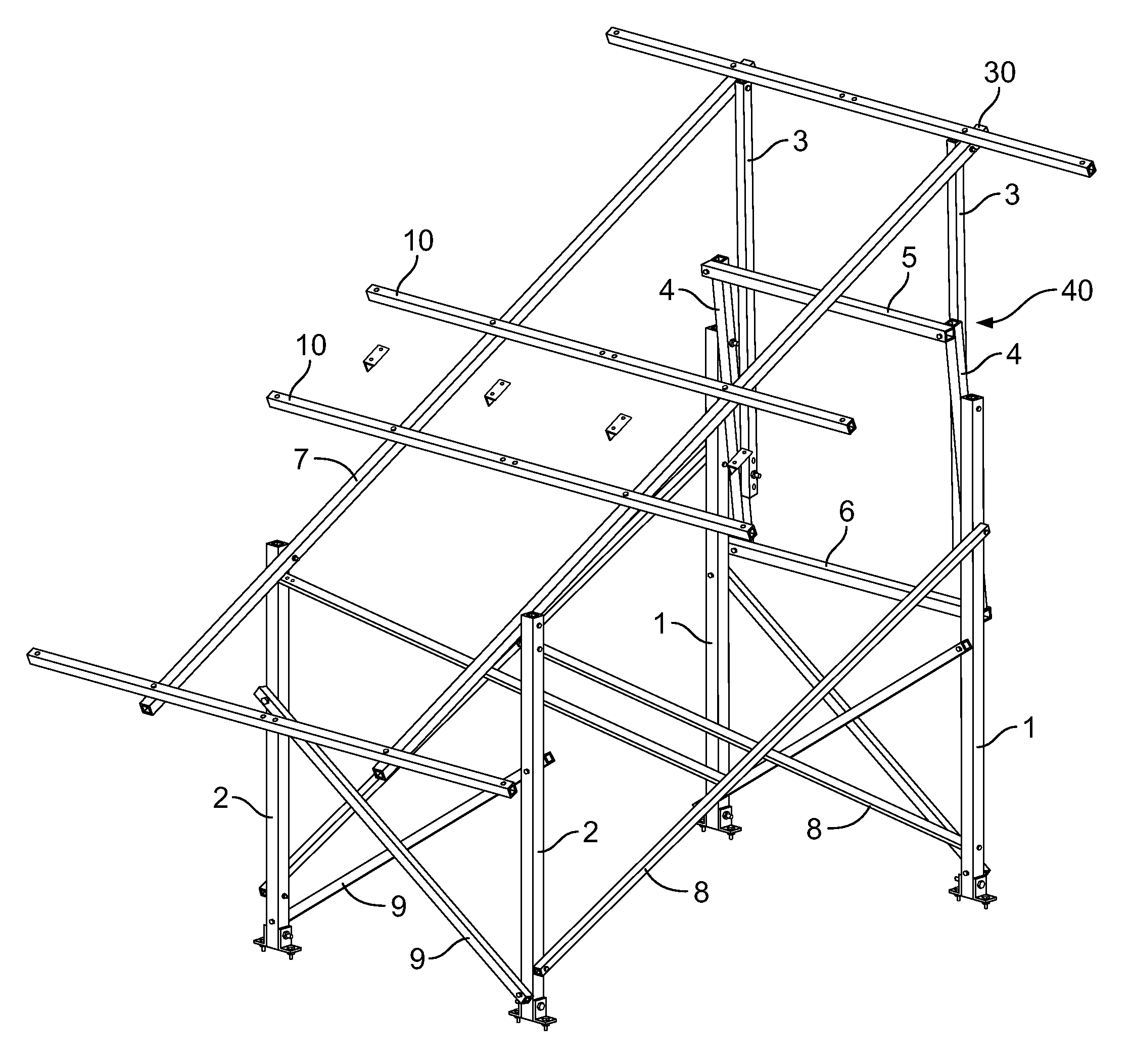

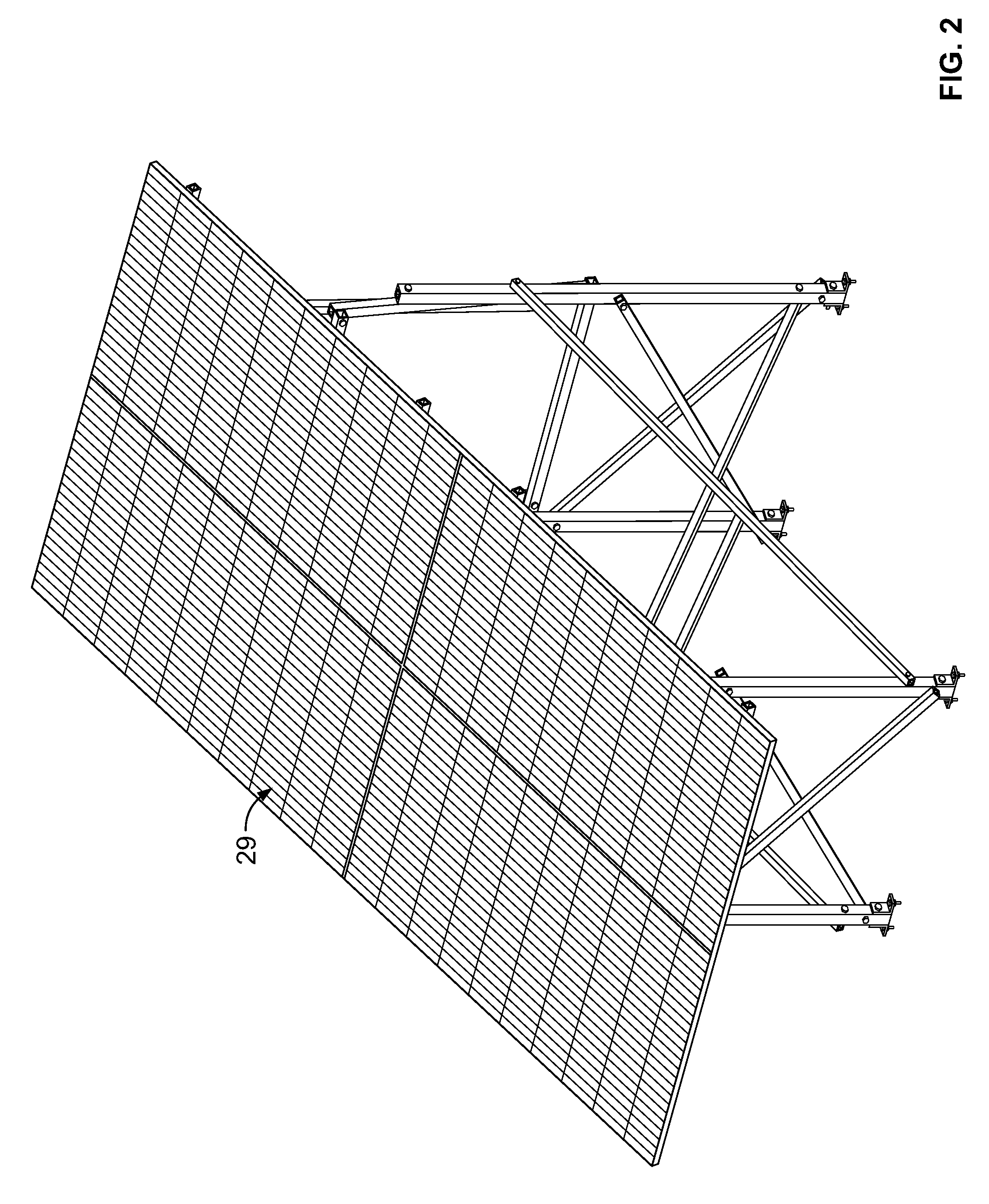

Multi-position solar panel rack

ActiveUS8684190B2Material minimizationMaximized strengthPhotovoltaic supportsSolar heating energySpace frameSolar energy

The present racking system uses space frame technology to minimize materials while maximizing strength. The rack has multi-position racking capability, using a simple swing arm and pin system to move the solar array into an optimum position for the appropriate time of the year.

Owner:ABAR WARREN

Space frame front lower suspension connection

A front lower suspension connection for a space frame comprises a U-shaped base and upper suspension control arm support sections on the U-shaped base. The U-shaped base can have a cross-beam section and suspension column support beam sections positioned at opposite ends of the cross-beam section, where each suspension column support beam section may include lower suspension control arm pivot joint supports located at opposite ends of the suspension column support beam sections. Each upper suspension control arm support section can have a first support column and a second support column spaced from the first support column, where the first support column may include a first upper suspension control arm pivot joint support, and the second support column may include a second upper suspension control arm pivot joint support and a front mounting surface. A rear mounting may be provided on a rear surface of the front lower suspension connection.

Owner:CATERPILLAR INC

Space frame center upper frame connection

A center upper frame connection for a space frame can comprise a center boss; a rearward mounting surface facing rearward; a rearward angular center upper frame tube connection boss oriented downward and rearward; a vertical center upper frame tube connection boss oriented downward; a forward angular center upper frame tube connection boss oriented forward and downward; and a forward angular mounting surface facing forward and upward. The rearward mounting surface can fixedly attach a center upper horizontal frame connection, the rearward angular center upper frame tube connection boss can fixedly attach a first elongate support structure, the vertical center upper frame tube connection boss can fixedly attach a second elongate support structure, the forward angular center upper frame tube connection boss can fixedly attach to a third elongate support structure, and the forward angular mounting surface can fixedly attach a center upper frame nodal connection.

Owner:CATERPILLAR INC

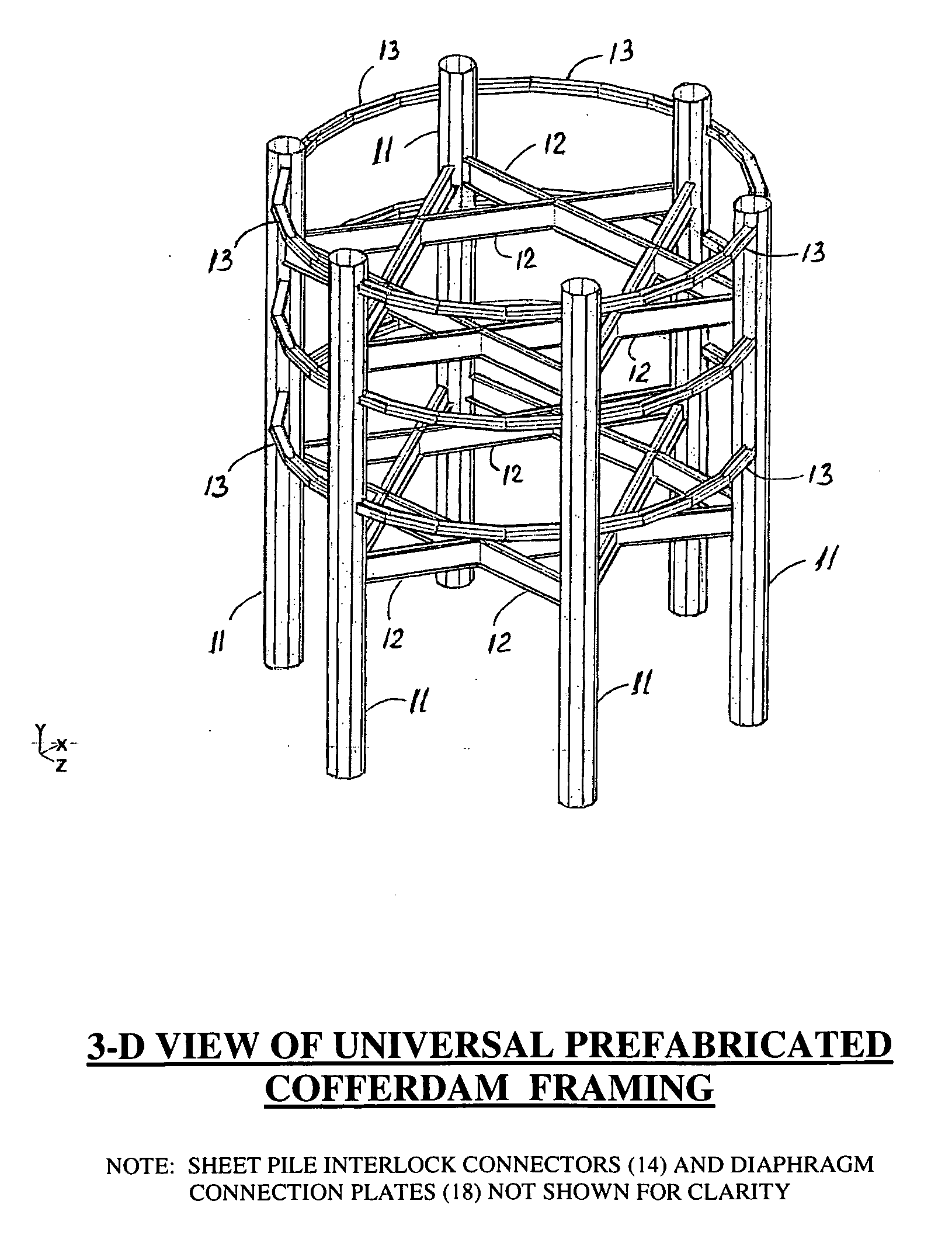

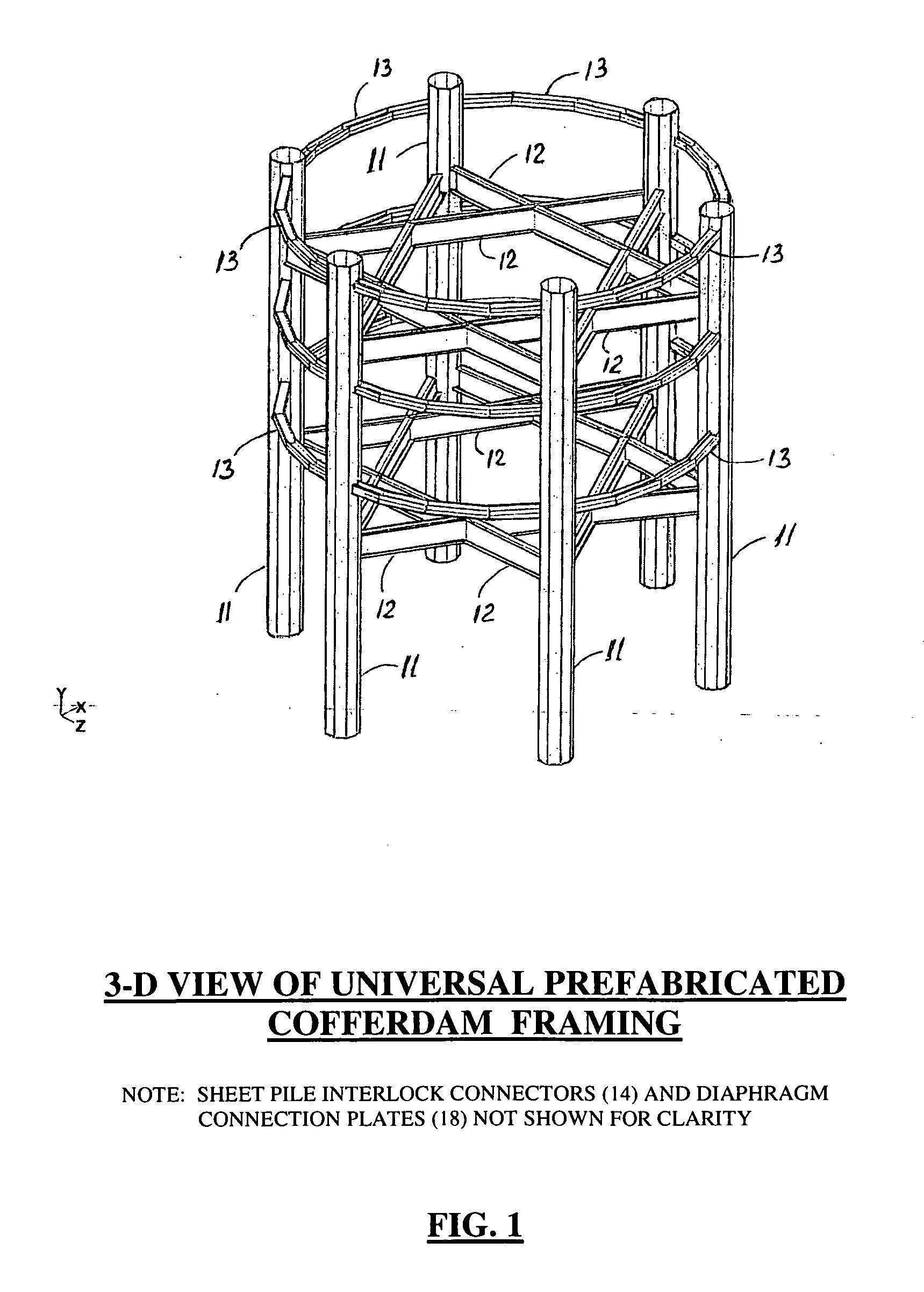

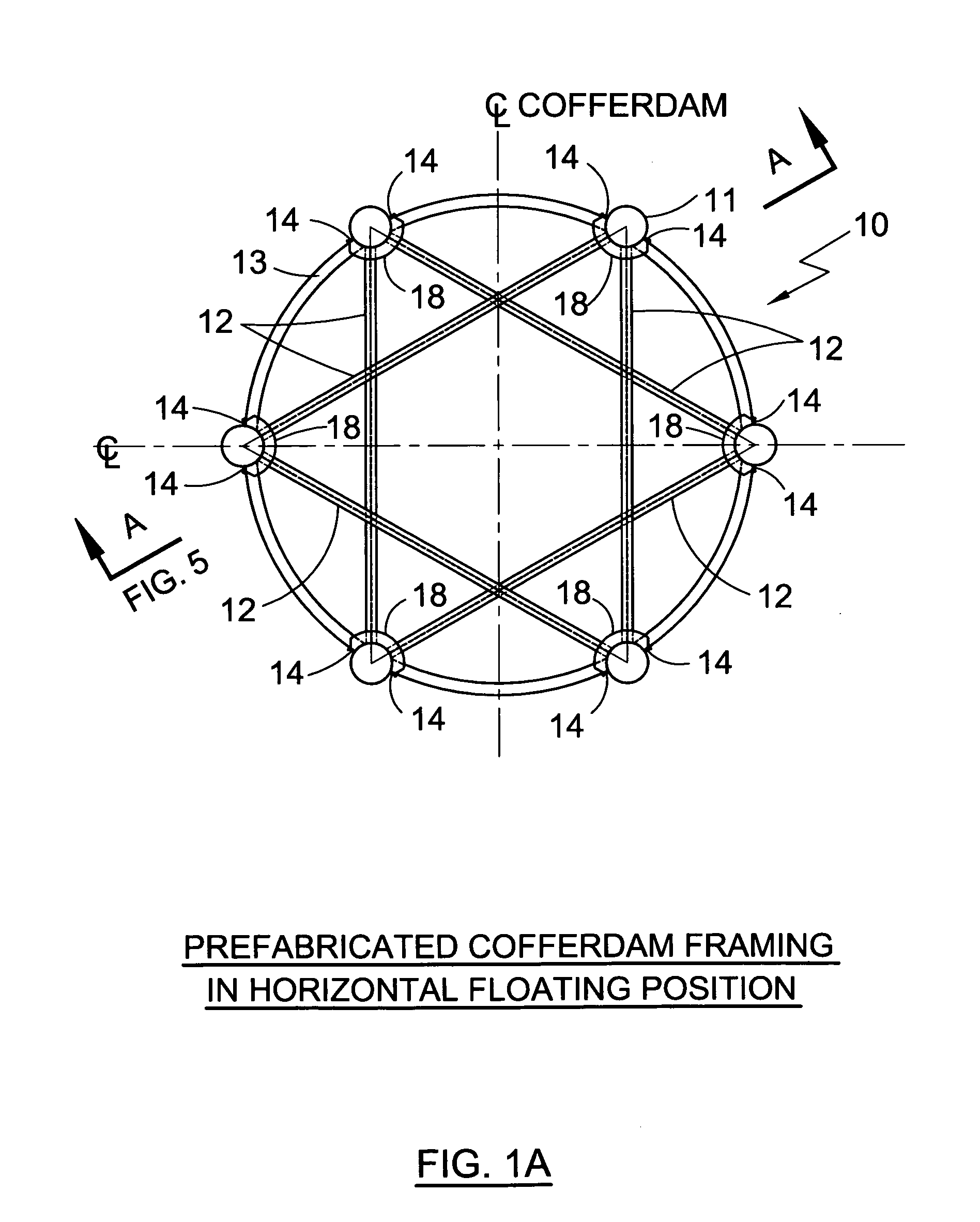

Universal Framed Cofferdam

Universal Framed Cofferdam has prefabricated skeletal steel space framing formed from multiple steel vertical pipes and two levels of horizontal diaphragm trusses rigidly connected to pipe columns. Beams of each diaphragm truss are attached to vertical pipes of the framing with rigid moment connections creating a rigid space frame of the perfectly round form that is used as a false work of the Cofferdam. Wales of the Cofferdam and short pieces of the flat sheet piling are attached to the vertical pipes forming a skeleton of the Cellular structure. The Skeleton of the Universal Framed Cofferdam is prefabricated in the convenience of the Dry Dock and than floated to the site. Buoyancy of the framing allows Cofferdam skeleton transportation without using the barge or otherwise necessary floating devices. Once brought to the site of installation Cofferdam skeleton is installed vertically in position and leveled on the bottom of the river bed. If necessary river silt can be jetted and pumped out of pipe annular space and pipe columns of framing can be simultaneously lowered in position by using vibro—hummer. After space framing installation, rock sockets are predrilled through the annular space of vertical pipes and rock anchors installed. Sheet pile skin of the Cofferdam installed between pipe columns concludes Cofferdam Can erection. Universal Framed Cofferdam Can than filled with compacted gravel and becomes a Hybrid Gravity Caisson / Columnar water front or marine structure that has the best features of the Conventional Cellular Cofferdam and of Columnar Dolphin structure. It has enhanced sliding and overturning stability provided by Rock anchors preloaded by Cofferdam granular fill and has effective mechanism that prevents concave or convex surface of rupture failure that may be suffered by conventional Cellular Cofferdams, and has mechanism that more effectively resists deep surface sliding failure of the Cofferdam base.

Owner:FEYGIN VITAL BORIS +1

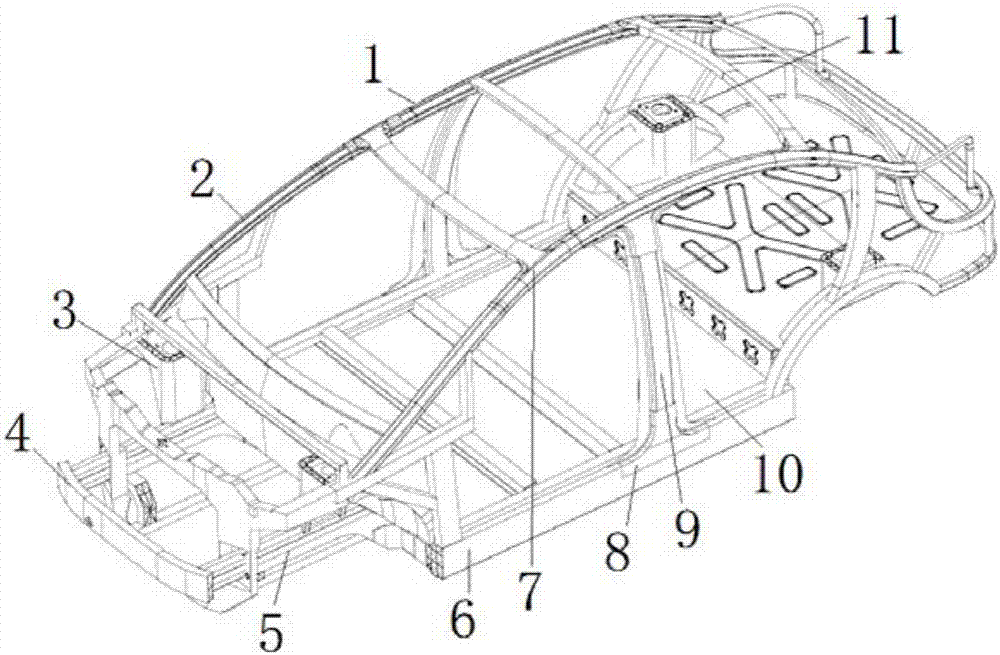

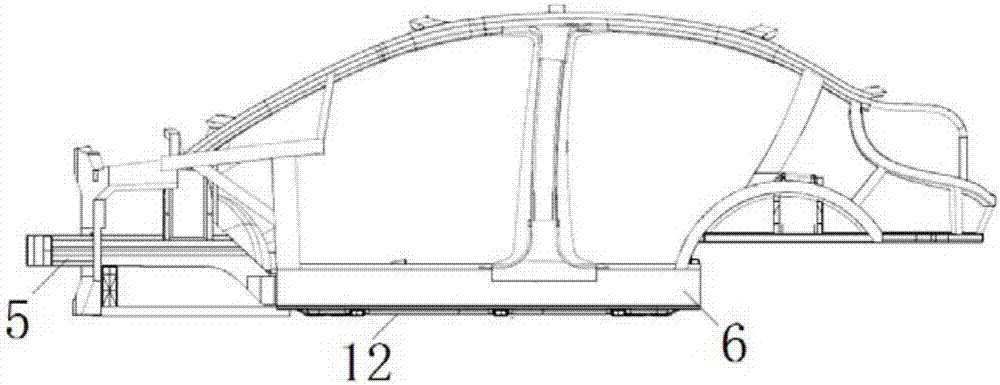

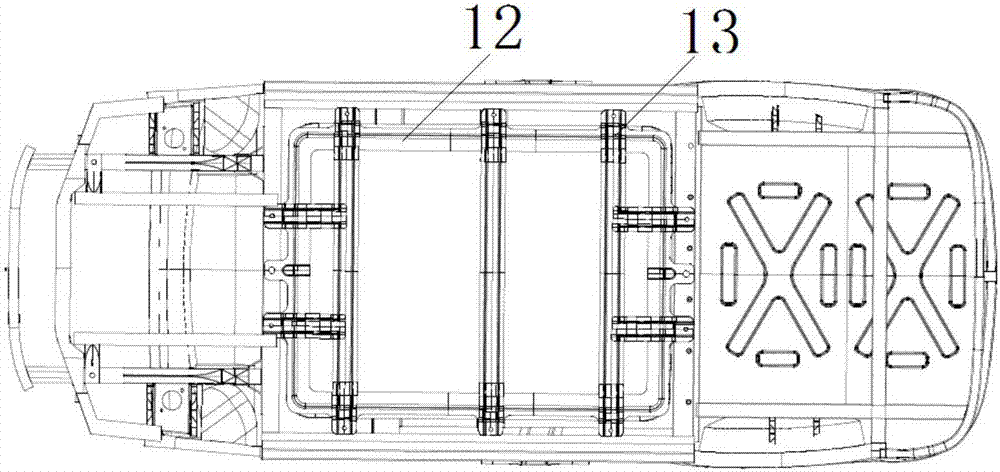

Lightweighting pure electric automobile body and design method thereof

InactiveCN107097851AReasonable structural designPromote structural optimizationGeometric CADSuperstructure subunitsFiberIntegrated design

The invention discloses a lightweighting pure electric automobile body. The lightweighting pure electric automobile body comprises an automobile body framework and a battery pack frame, wherein an outer covering piece, a fender, an automobile body floor, a front bumper structure, a rear bumper structure and an energy absorbing structure are arranged on the automobile body framework; the automobile body framework and the battery pack frame separately adopt an aluminum alloy section space frame structure; and the outer covering piece, the fender, the automobile body floor, the front bumper structure, the rear bumper structure and the energy absorbing structure separately adopt carbon fiber compound materials., The lightweighting and the industrialization requirements of an electric automobile can be met, and besides, integrated design of an automobile body adopting an aluminum alloy frame and distributed carbon fiber integrated structure, capable of improving the safety performance of a high-speed electric automobile is adopted, so that the total mass of the electric automobile is reduced, and the safety performance of the structure of the electric automobile is improved.

Owner:奇瑞新能源汽车股份有限公司

Space frame front lower frame connection

Owner:CATERPILLAR INC

Space frame center lower frame connection

A center lower frame connection for a space frame comprising an outer lift cylinder connection boss, an inner drop tube connection boss, a center cylinder between the outer lift cylinder connection boss and the inner drop tube connection boss, a suspension connection boss, an outer rearward angular center lower frame tube connection boss, an inner rearward angular center lower frame tube connection boss, a vertical center lower frame tube connection boss, a forward angular center lower frame tube connection boss, an outer forward horizontal center lower frame tube connection boss, and an inner forward horizontal center lower frame tube connection boss. The outer lift cylinder connection boss, the inner drop tube connection boss, and the center cylinder can have a common center axis. The center lower frame connection can also have a rearward angular beam and a forward horizontal beam.

Owner:CATERPILLAR INC

Space frame center upper frame nodal connection

A center upper frame nodal connection fabrication comprising a top surface, a bottom surface opposite the top surface, two side surfaces, a front surface having a plurality of integral planes oriented at angles relative to each other, and a rear surface opposite the front surface. The top surface, the bottom surface, and the two side surfaces can be weldably attached to each other and the front and rear surfaces to form a structure of the center upper frame nodal connection fabrication. The integral planes of the front surface are configured to weldably attach to respective elongate support members of a space frame. The rear surface is configured to weldably attach to a center upper frame connection casting of the space frame.

Owner:CATERPILLAR INC

Space frame center upper frame connection

A center upper frame connection for a space frame can comprise a pair of outer support beams spaced from each in a width direction, a rearward center support between the outer support beams, and support beam arch. Each outer support beam can have a rearward frame connection boss and a forward center frame nodal connection boss. The rearward center support can have a pair of rearward frame connection bosses oriented at an angle relative to each other, and a pair of side frame connection bosses provided on opposing sides of the rearward center support. The support beam arch can be provided adjacent to the outer support beams and the rearward center support. The rearward center support can be located on a longitudinal centerline of the support beam arch and can be parallel to the outer support beams.

Owner:CATERPILLAR INC

Structural tower

InactiveUS20100226785A1Reduce energy costsGenerate efficientlyEngine manufactureEngine fuctionsHigh elevationDiagonal

Owner:GE WIND ENERGY

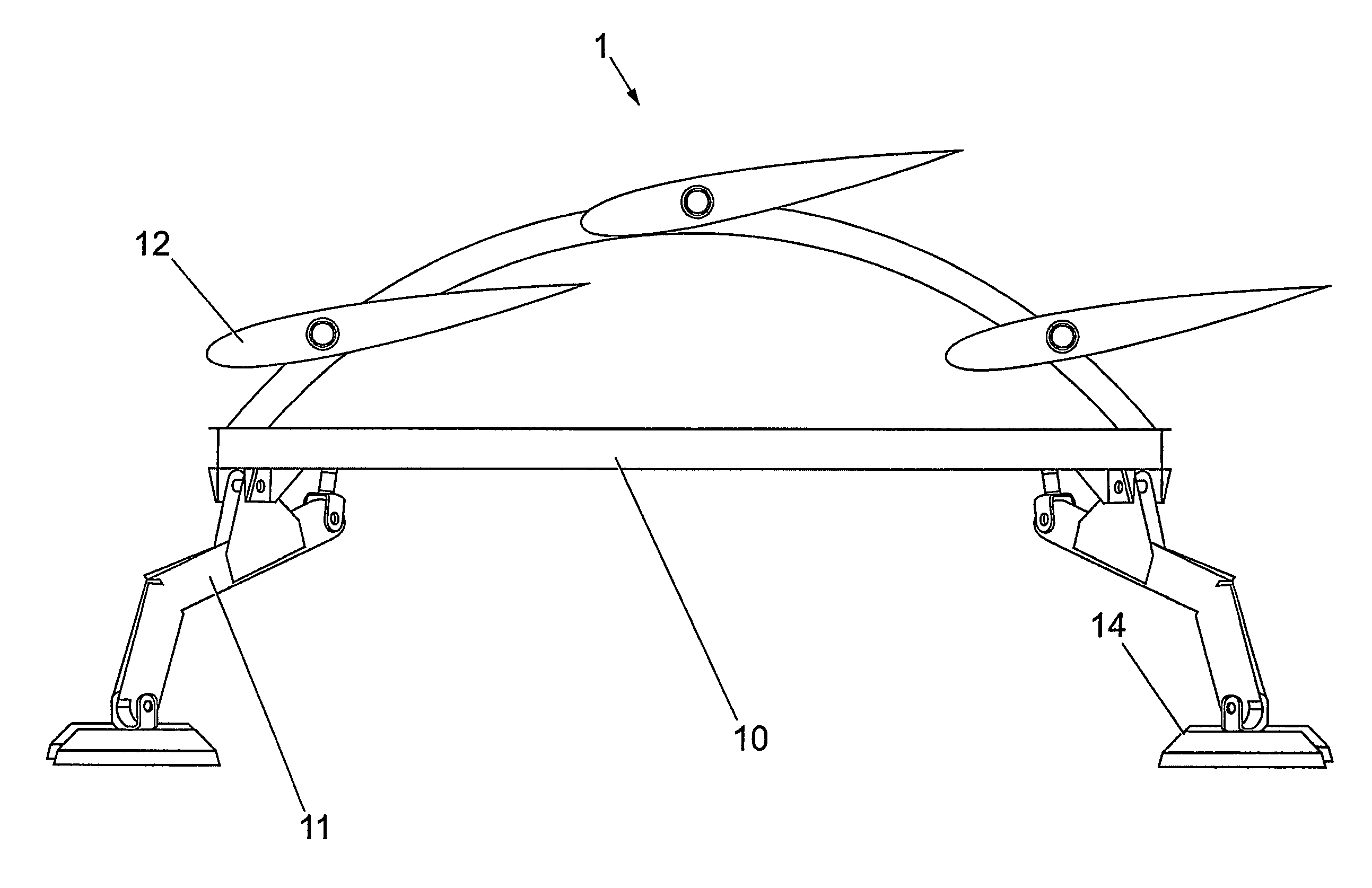

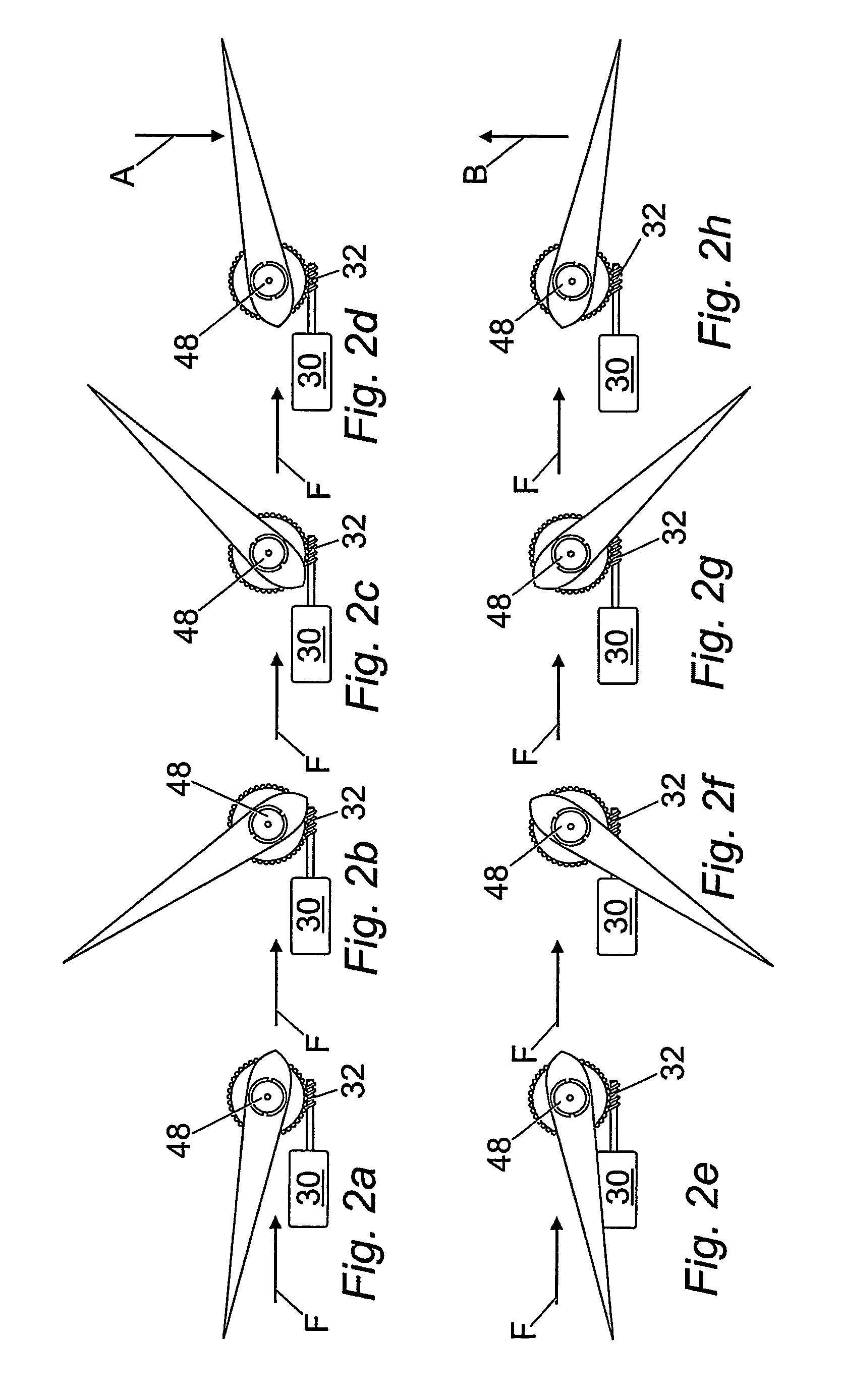

Apparatus for controlling underwater based equipment

The apparatus may include a space frame on which is mounted at least one hydrofoil for generating positive or negative lift. The frame is attachable to underwater equipment such as a turbine. The hydrofoils are adapted to produce negative lift when a flow of liquid passes over them and so in use cause the apparatus and attached equipment to sink to the seabed. The flow of water over the hydrofoils continue to produce negative life and so maintain the apparatus on the seabed. In certain embodiments, the hydrofoils can typically be set to a passive configuration in which they flip over when the current flow changes direction. Furthermore, the hydrofoils are selectively rotatable to provide an angle of attack such that they may be adapted to provide positive lift when it is necessary to remove the apparatus from the water.

Owner:ROBERT GORDON UNIVERSITY

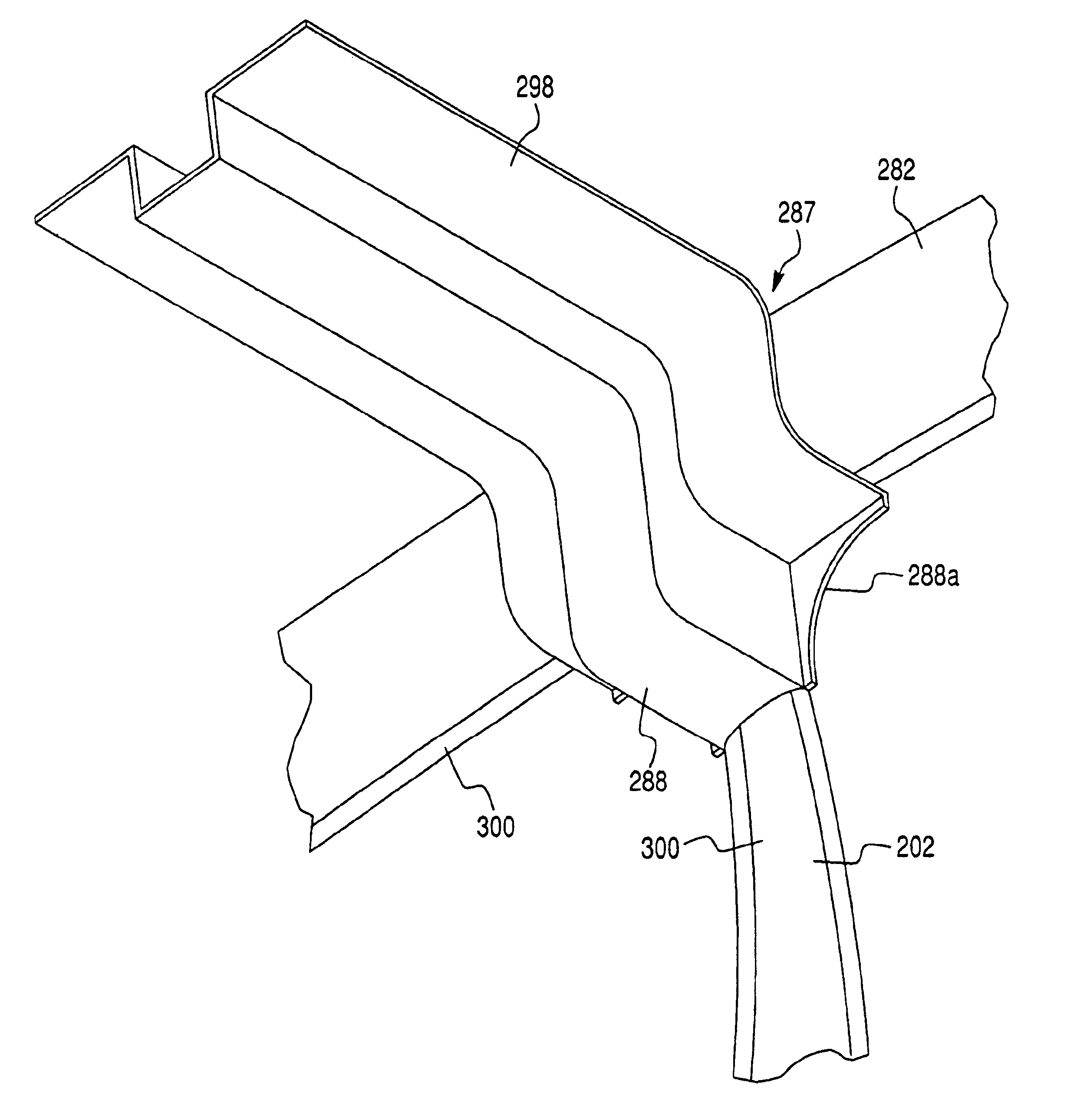

Space frame cross member with integrated door seal feature

A vehicle frame assembly comprises a hydroformed vertical member (e.g., b-pillar), a hydroformed longitudinal member (e.g., roof rail), and a cross member with a transition flange wrapping above or below the longitudinal member. The transition flange provides rounded corners to enhance the door seal feature. In the preferred embodiment, the transition flange may be integrally formed as part of a stamped cross member or may be a separately formed transition bracket member attached to the cross member.

Owner:METALSA SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com