Patents

Literature

67results about How to "Increase firepower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

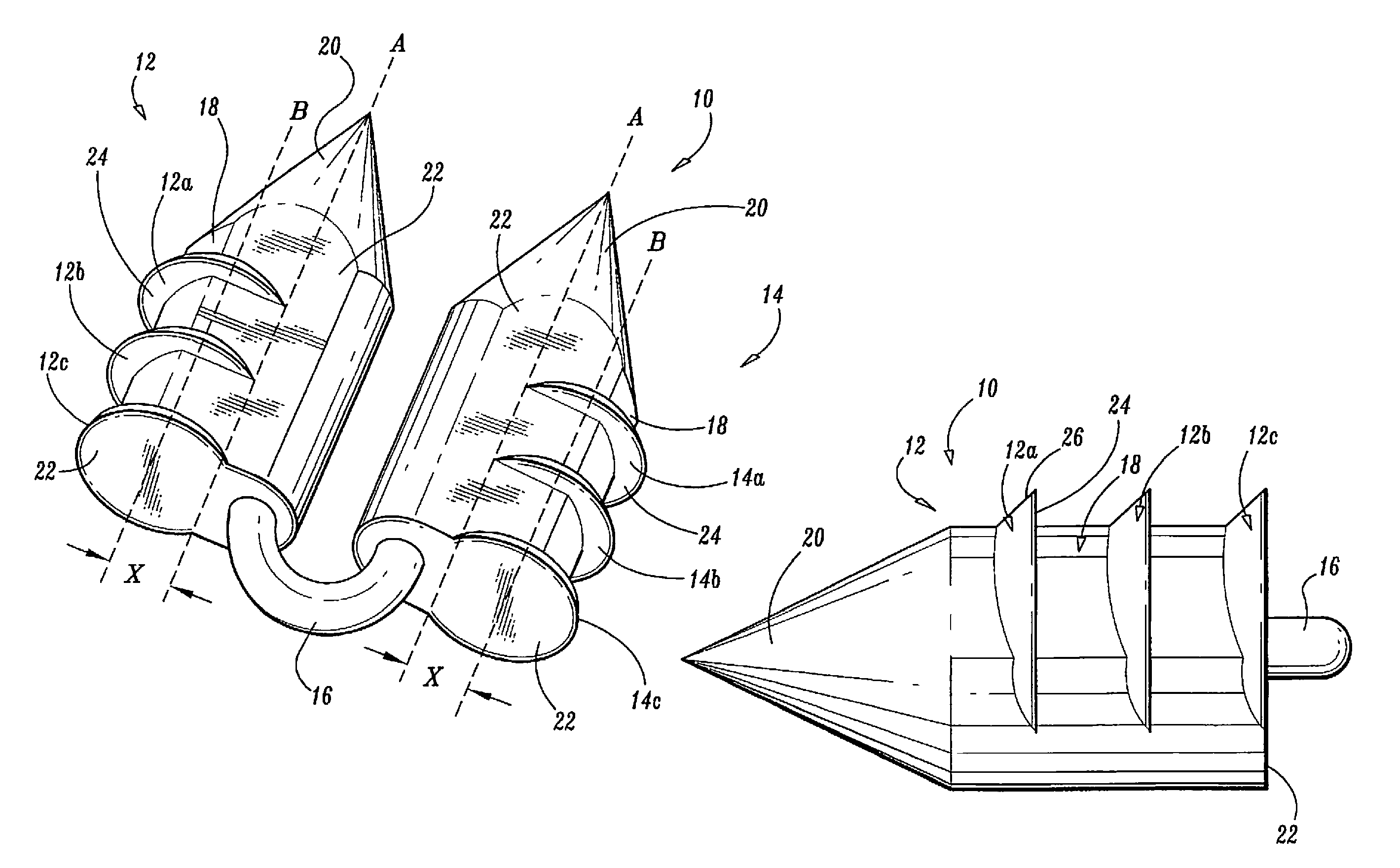

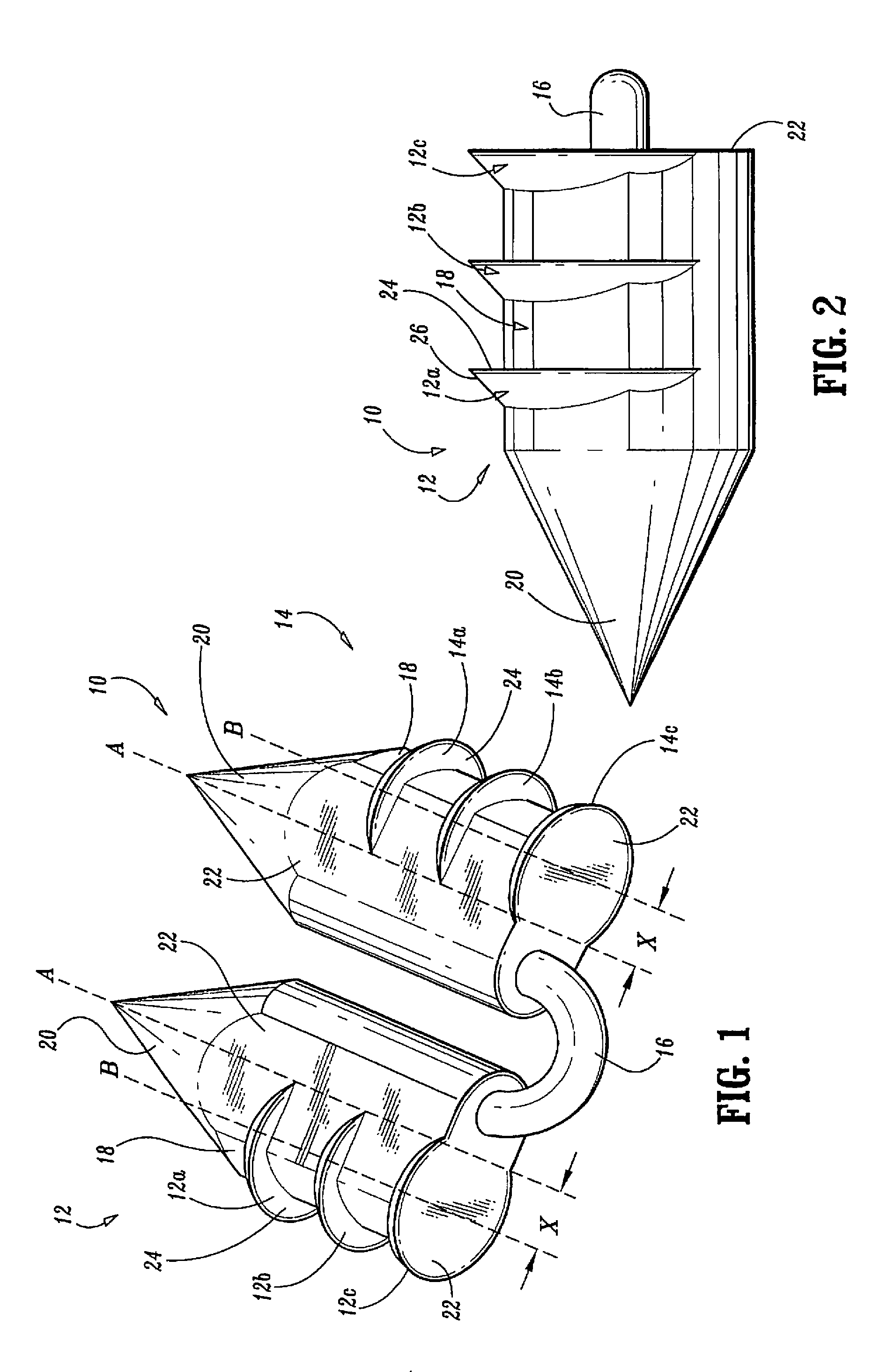

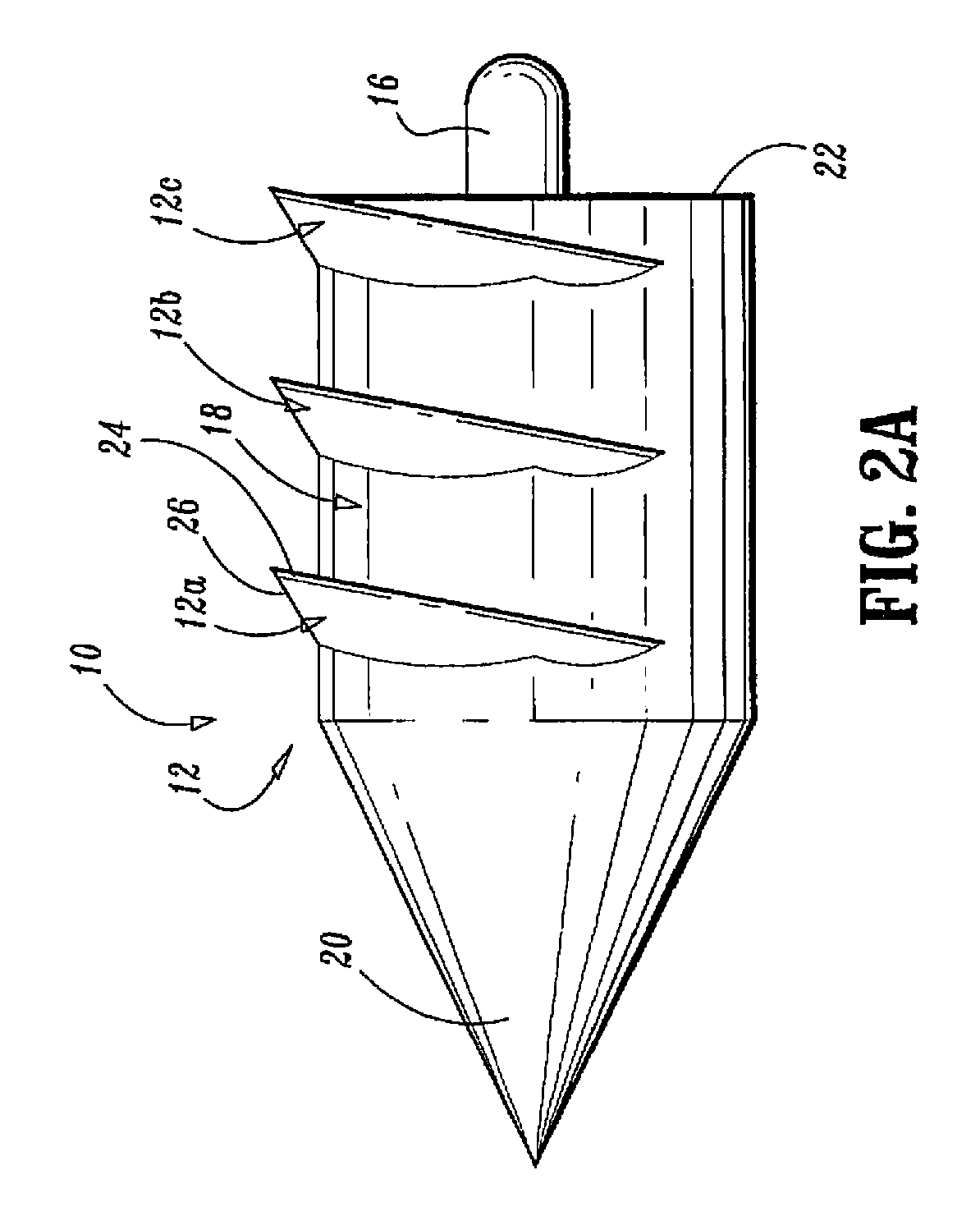

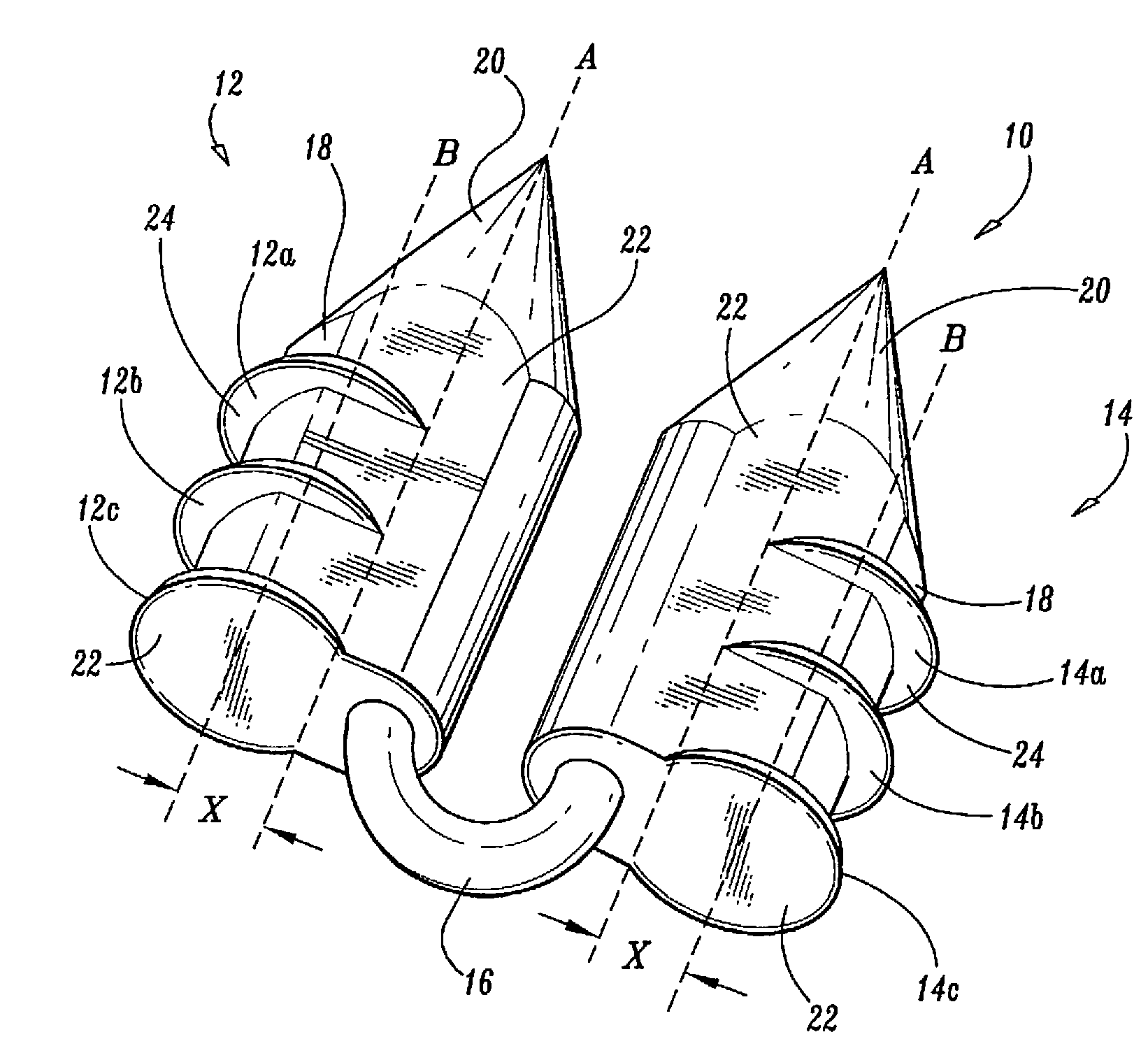

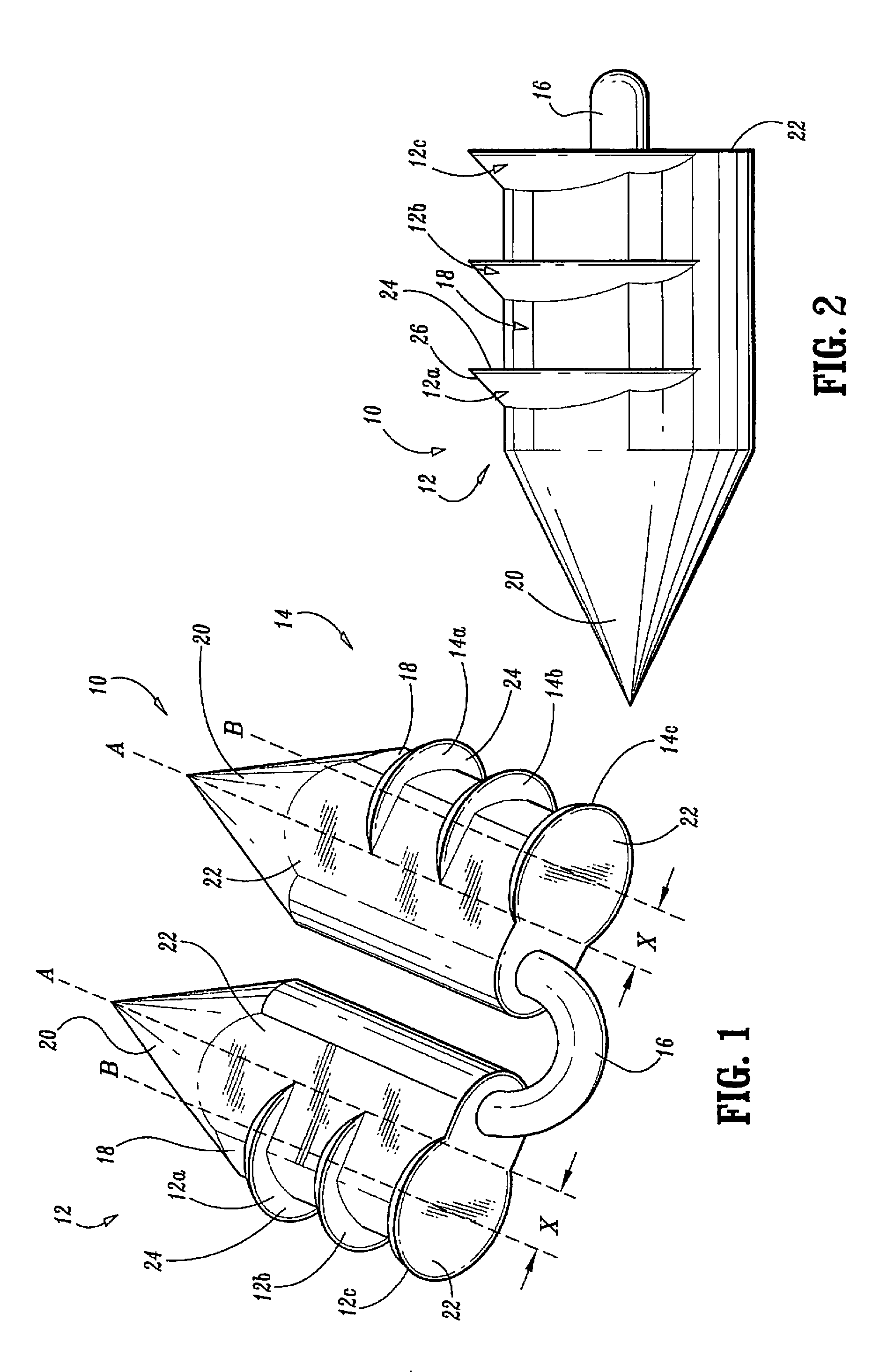

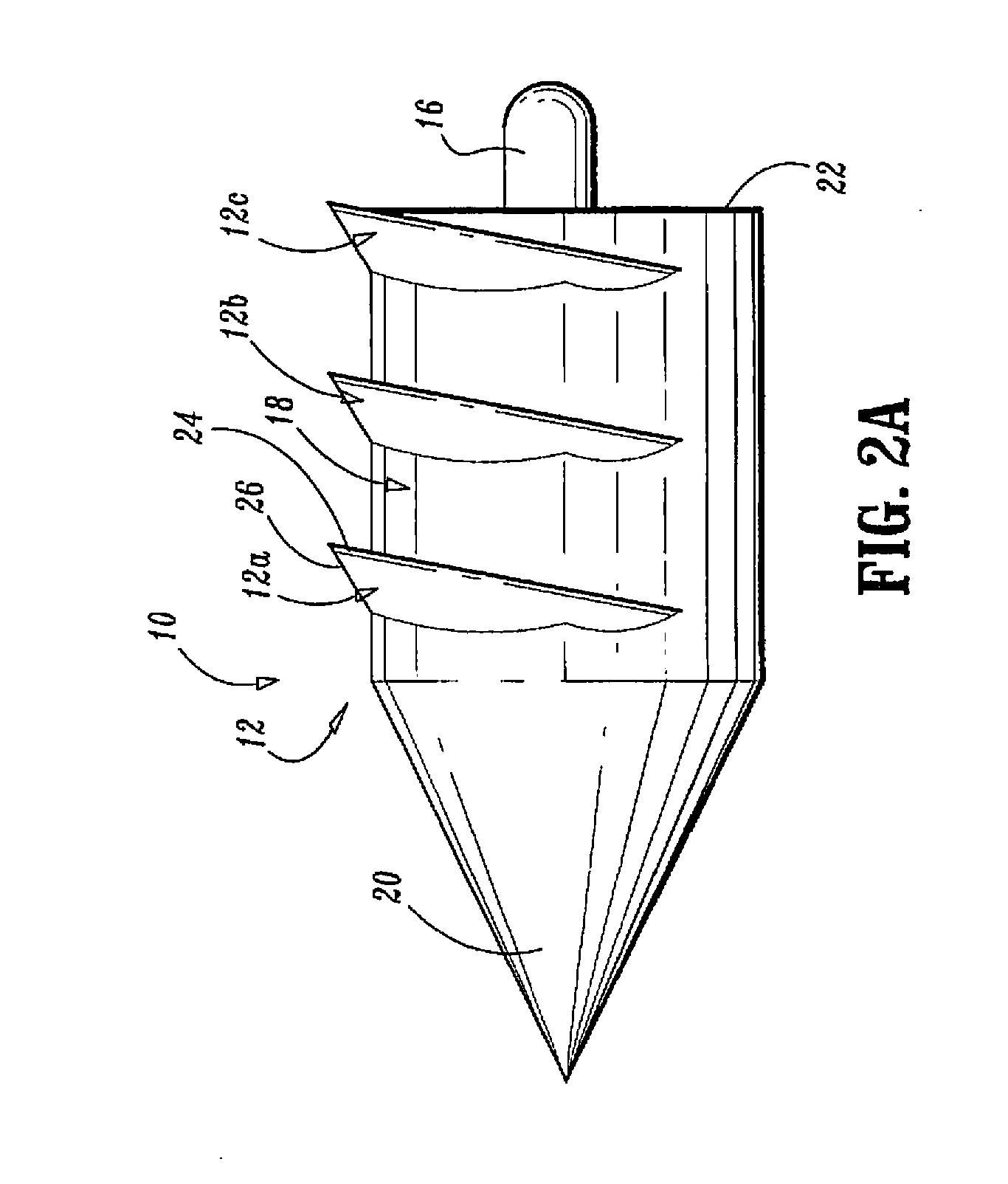

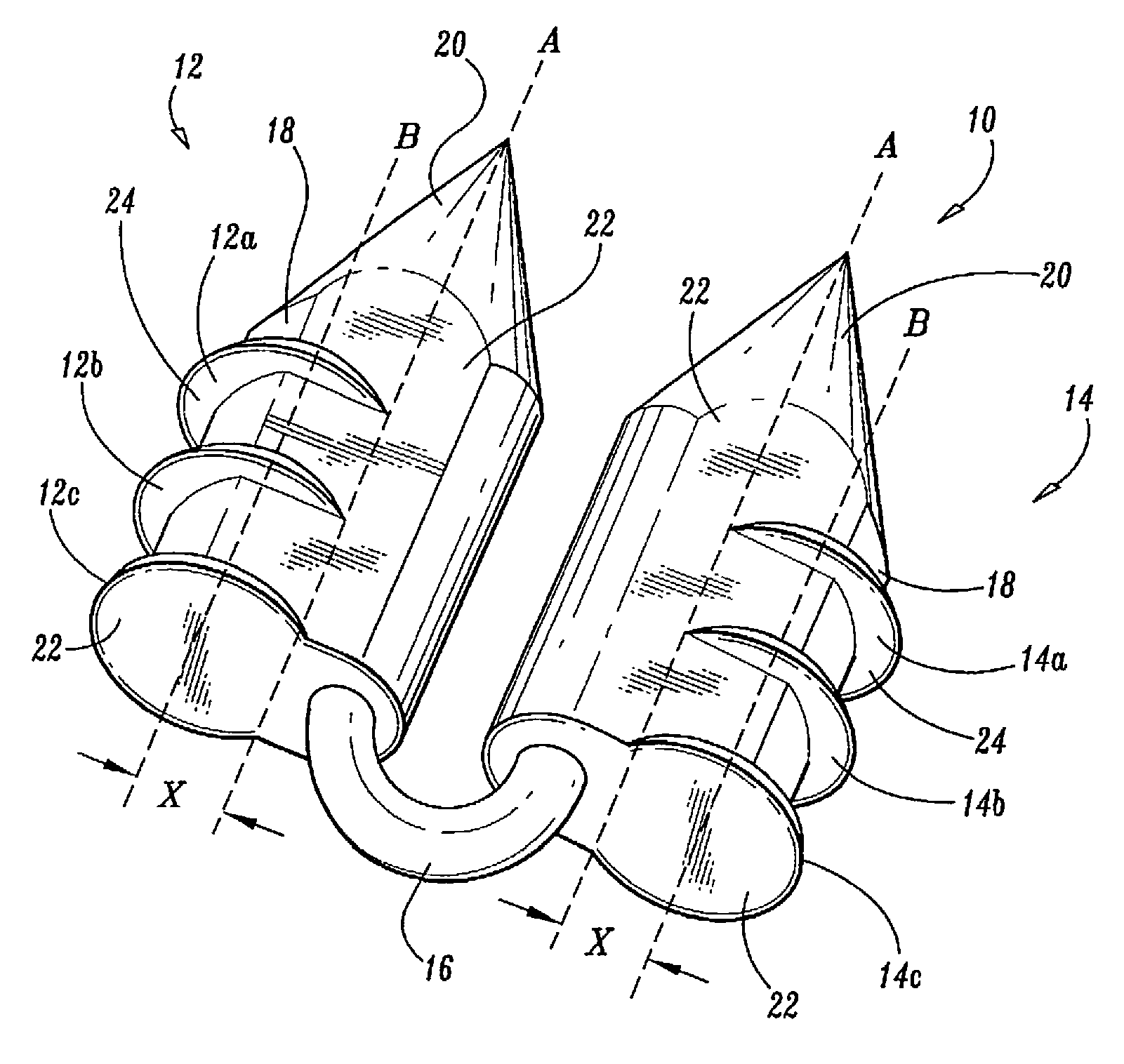

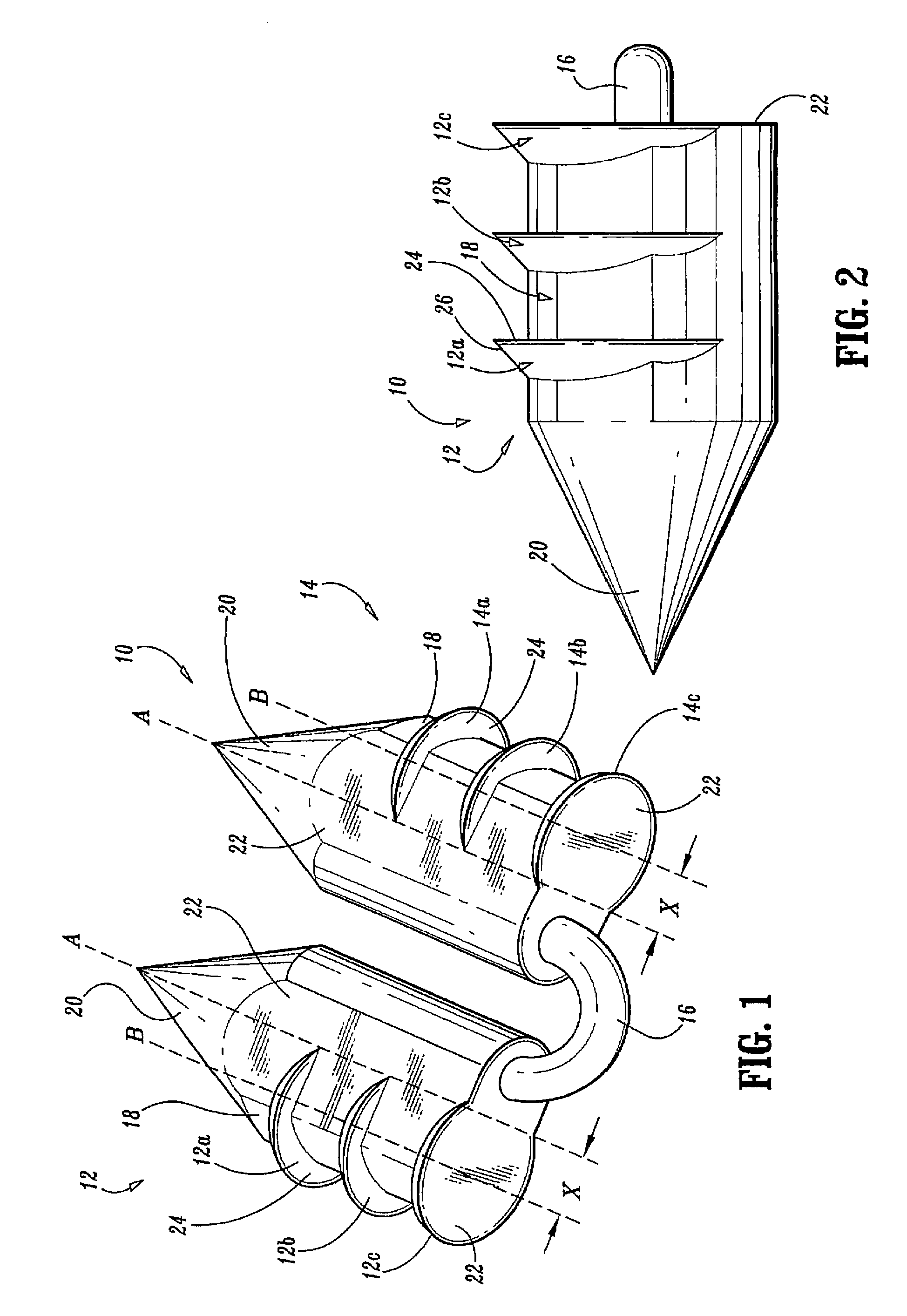

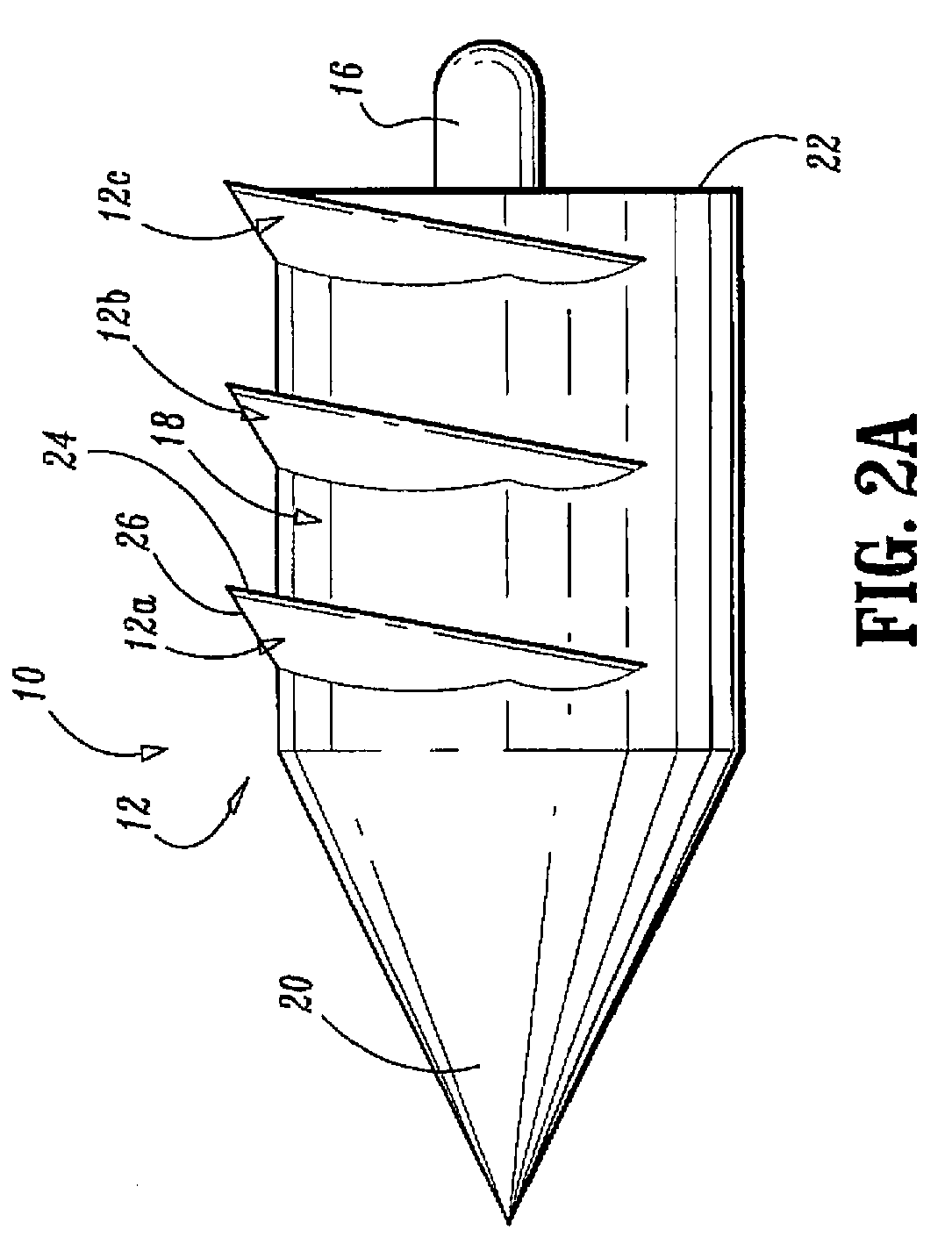

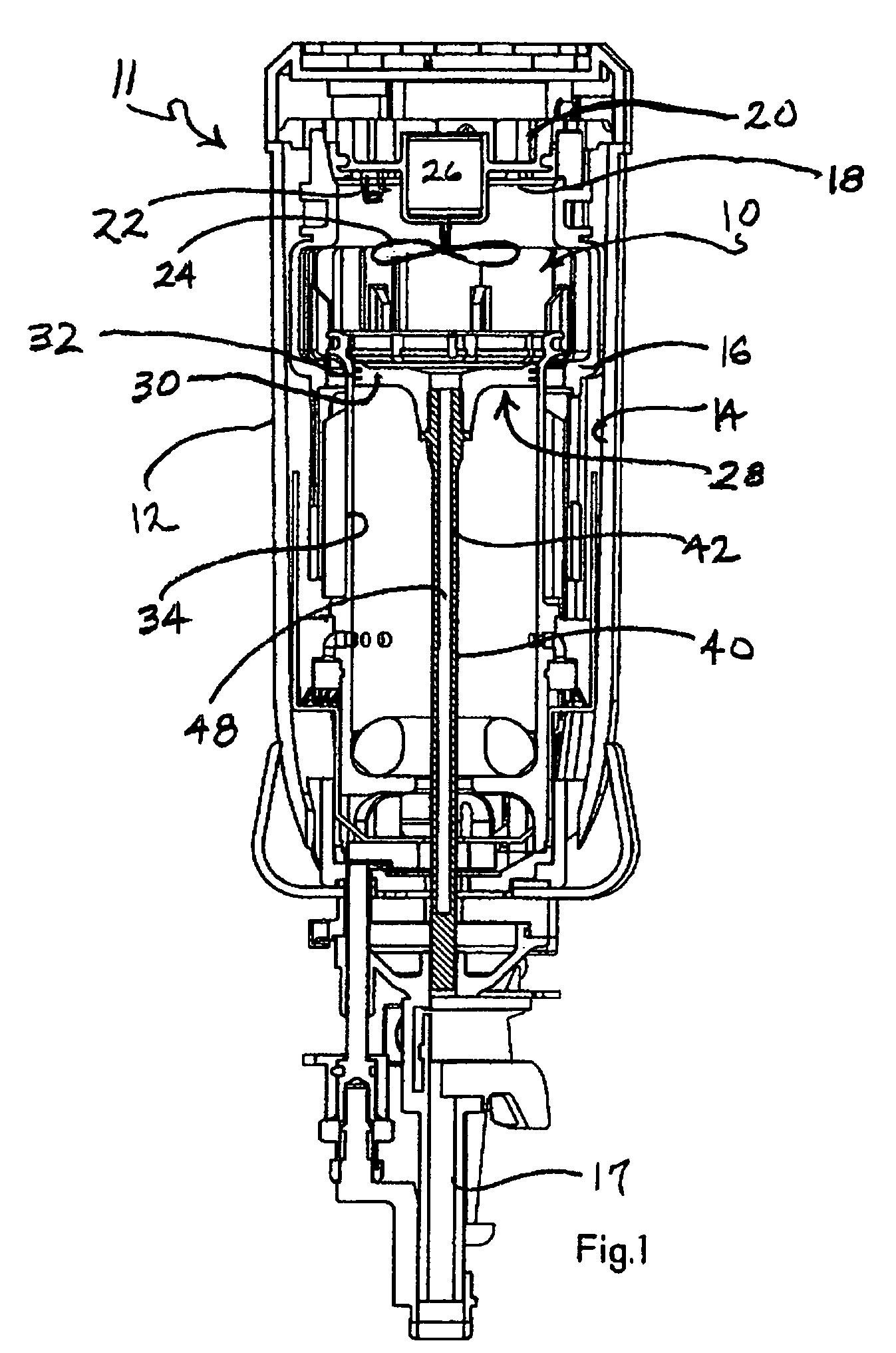

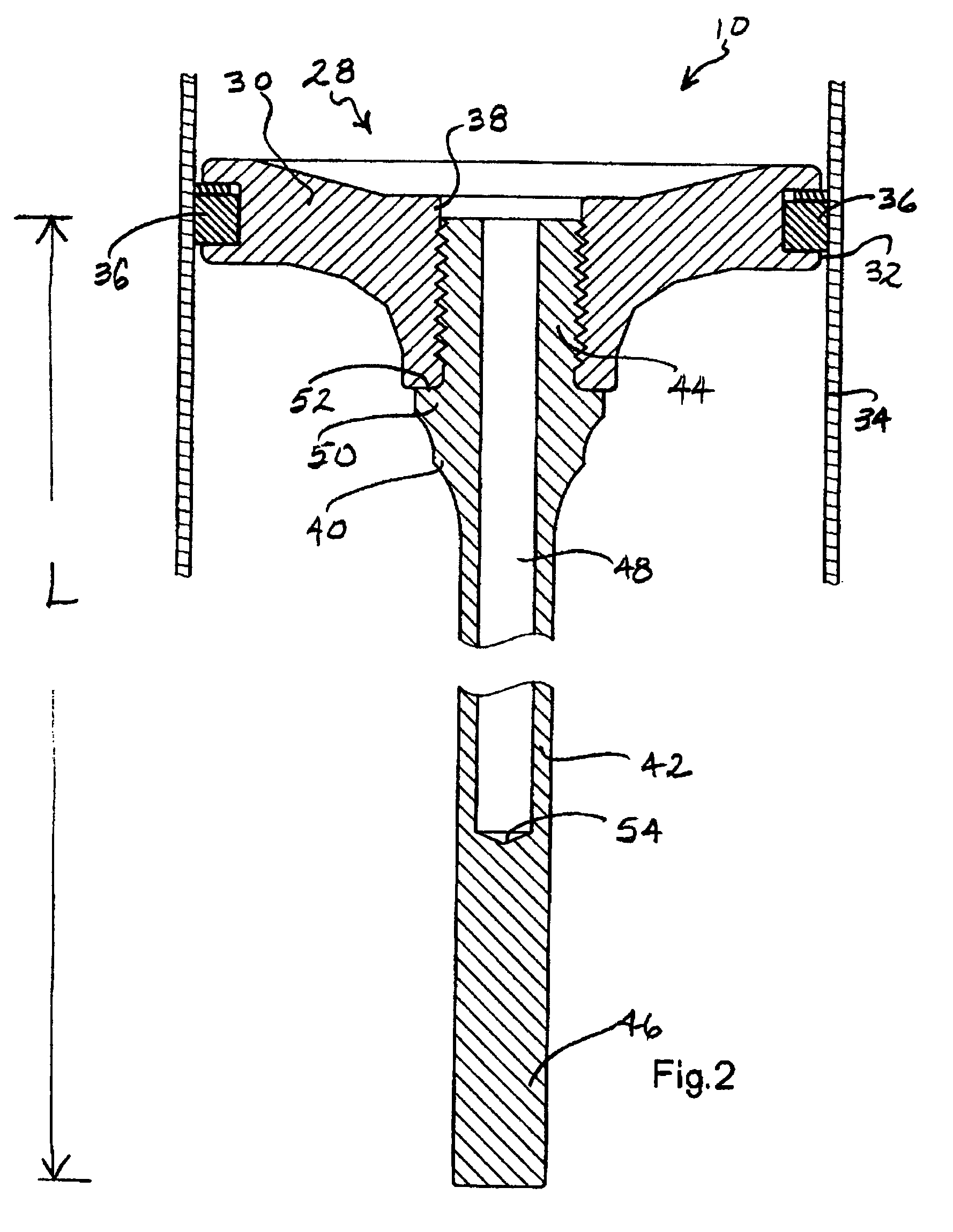

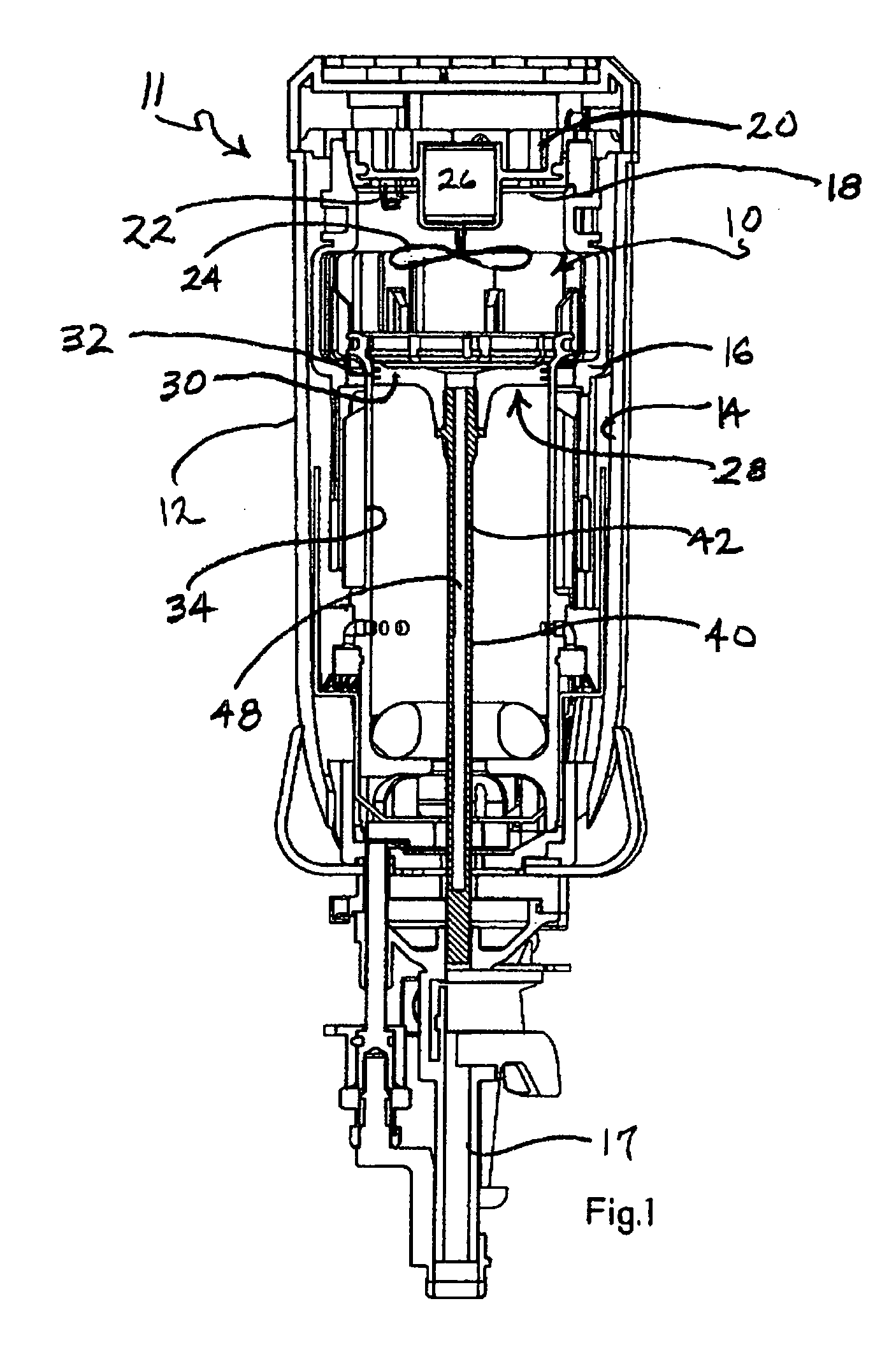

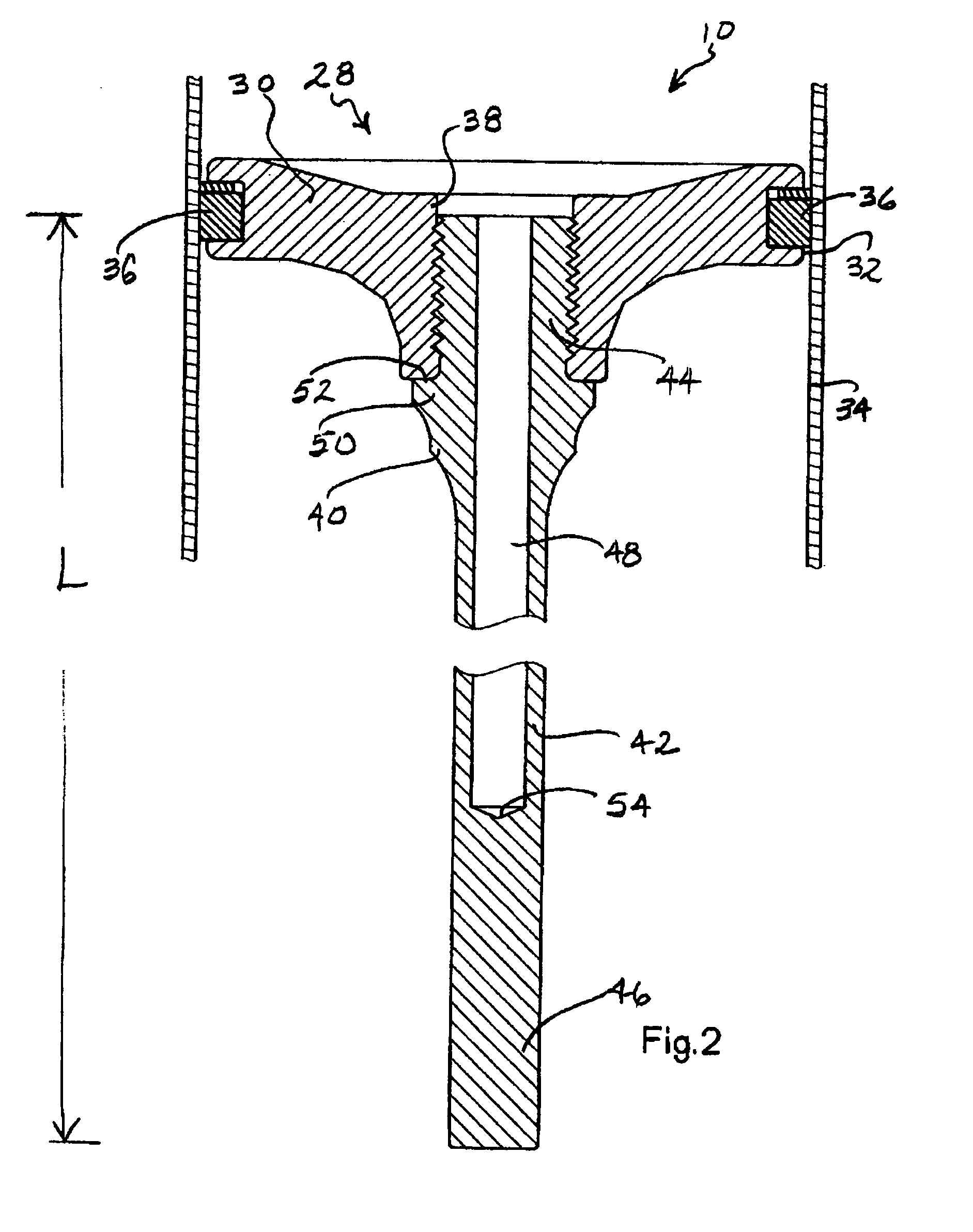

Absorbable fastener and applying apparatus

InactiveUS8034076B2Minimize formationReducing fastener-associated long-term discomfort to the patientSuture equipmentsStaplesAbsorbent materialBody tissue

A surgical fastener apparatus, for securing a surgical mesh material to body tissue including a pair of anchors each having a retaining structure formed on an outer surface thereof; and a suture tether interconnecting the pair of anchors to one another. The pair of anchors have a substantially cylindrical body having a conically tapered distal end and a planar proximal end. The retaining structure includes a series of semi-circular angled projections having a planar proximal surface and a tapered distal end, wherein a center of each of the angled projections is spaced a distance from a longitudinal central axis of the body portion. The surgical fastener is made from a bioabsorbable material which reabsorbs into said body tissue at an appropriate rate, such as for example, polyglycolic acid and polylactic acid.

Owner:COVIDIEN LP

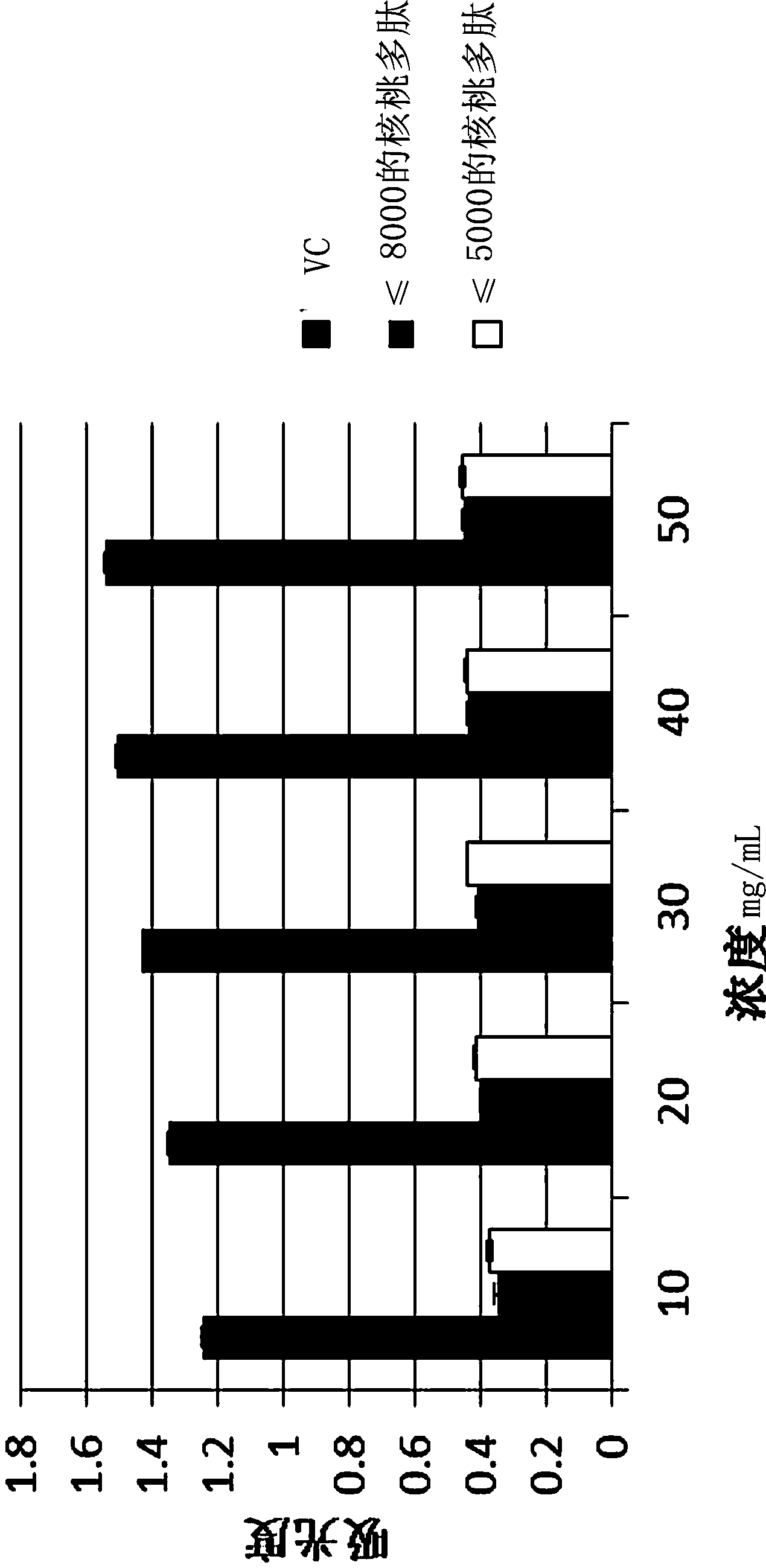

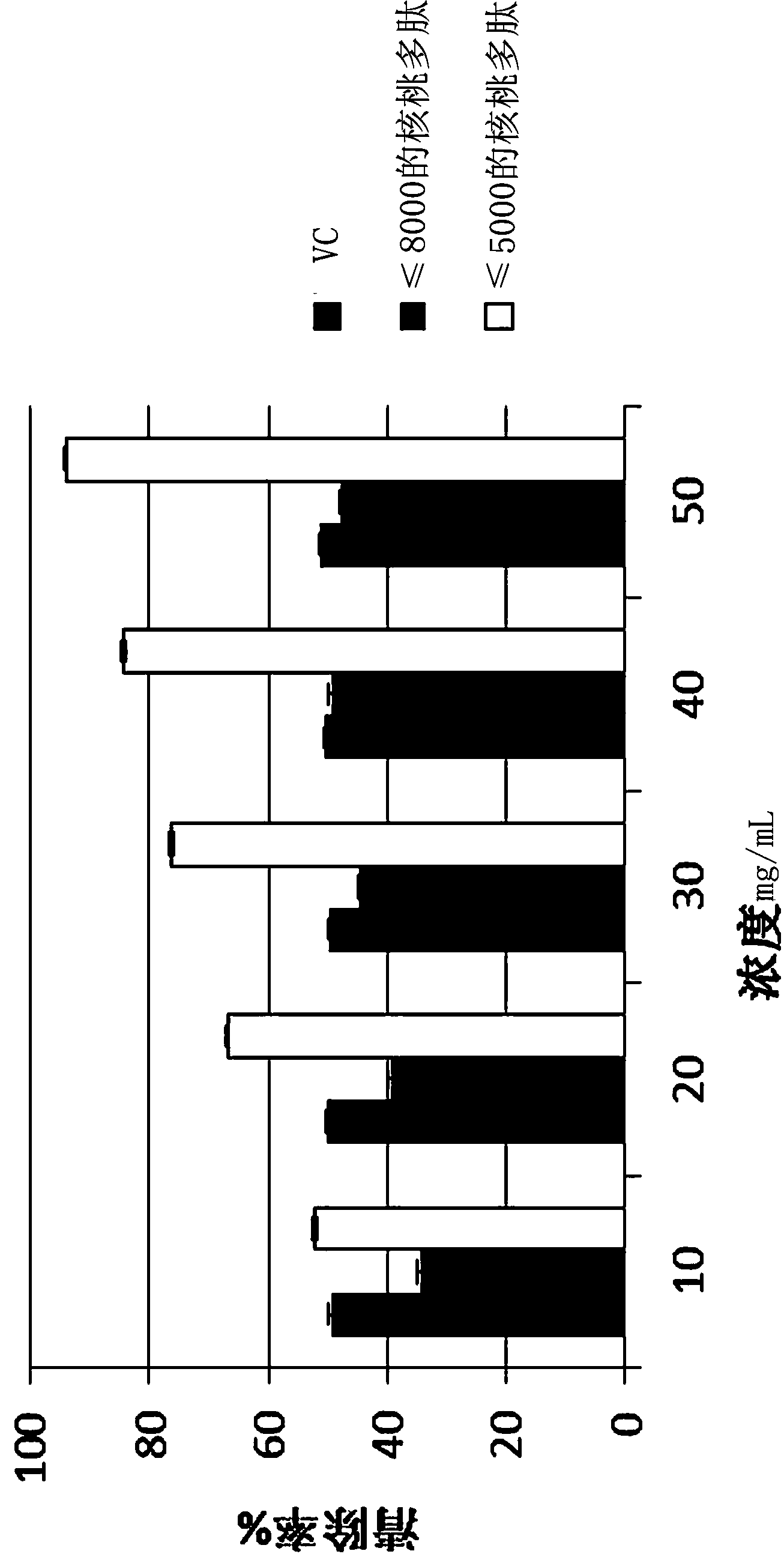

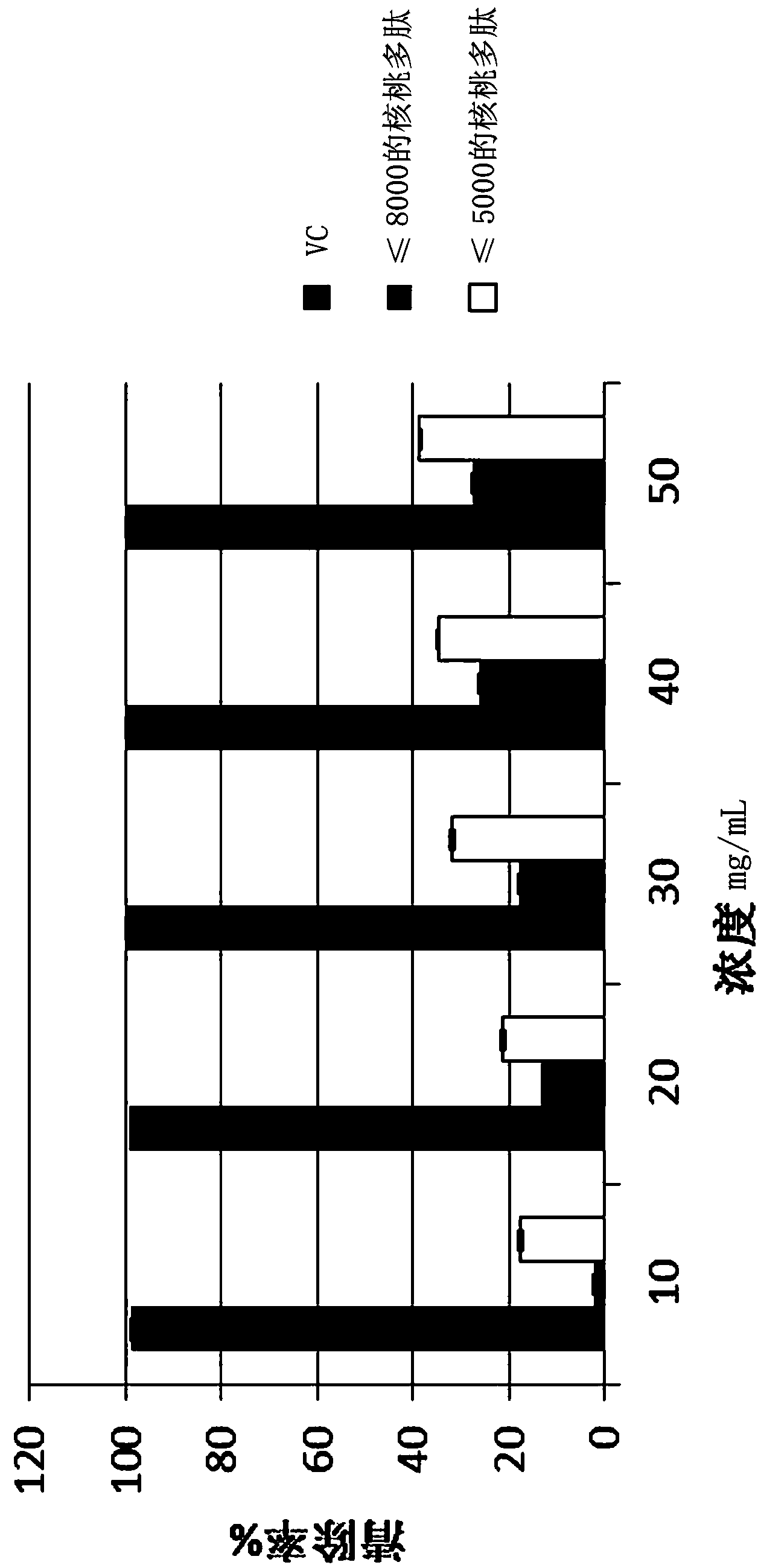

Preparation method of antioxidant walnut polypeptide health product

ActiveCN104293870ALess fatty acidHigh in proteinPeptide preparation methodsChemical recyclingWalnut NutNeutral protease

The invention discloses a preparation method of an antioxidant walnut polypeptide health product. The preparation method comprises the following steps: pre-treating walnut pulp; homogenizing the walnut pulp; extracting walnut proteins; carrying out pre-treatment for enzymolysis; carrying out enzymolysis; separating; desalting; and concentrating and drying to obtain a walnut polypeptide product. Four enzymes: alkaline protease, papain, neutral protease and bromelain are sequentially added in different times in the enzymolysis link. The strength, function and synergy and the like of the effects of the four enzymes which are used for decomposing proteins into polypeptides and amino acids are comprehensively considered and the four enzymes are used for enzymolysis under the optimal enzymolysis conditions, respectively. The reducing capacity of the prepared walnut polypeptide manifests that the absorbancy floats up and down at 0.4, the hydroxyl free radical scavenging rate can reach 95%, the superoxide anion free radical scavenging rate can reach 39.5%, the protein extraction ratio can reach 98.71% and the degree of hydrolysis of the walnut polypeptide can reach 26.37%. Compared with the prior art, those items are greatly enhanced and improved relatively.

Owner:汾州裕源土特产品有限公司

Absorbable fastener and applying apparatus

InactiveUS20080167668A1Minimizing adhesion formationReduce the amount requiredSuture equipmentsLigamentsAbsorbent materialBody tissue

A surgical fastener apparatus, for securing a surgical mesh material to body tissue including a pair of anchors each having retaining means formed on an outer surface thereof; and a suture tether interconnecting the pair of anchors to one another. The pair of anchors having a substantially cylindrical body having a conically tapered distal end and a planar proximal end. The retaining means includes a series of semi-circular angled projections having a planar proximal surface and a tapered distal end, wherein a center of each of the angled projections is spaced a distance from a longitudinal central axis of the body portion. The surgical fastener is made from a bioabsorbable material which reabsorbs into said body tissue at an appropriate rate, such as for example, polyglycolic acid and polylactic acid.

Owner:TYCO HEALTHCARE GRP LP

Absorbable fastener and applying apparatus

InactiveUS20080167667A1Minimizing adhesion formationReduce the amount requiredSuture equipmentsStaplesAbsorbent materialBody tissue

A surgical fastener apparatus, for securing a surgical mesh material to body tissue including a pair of anchors each having retaining means formed on an outer surface thereof; and a suture tether interconnecting the pair of anchors to one another. The pair of anchors having a substantially cylindrical body having a conically tapered distal end and a planar proximal end. The retaining means includes a series of semi-circular angled projections having a planar proximal surface and a tapered distal end, wherein a center of each of the angled projections is spaced a distance from a longitudinal central axis of the body portion. The surgical fastener is made from a bioabsorbable material which reabsorbs into said body tissue at an appropriate rate, such as for example, polyglycolic acid and polylactic acid.

Owner:TYCO HEALTHCARE GRP LP

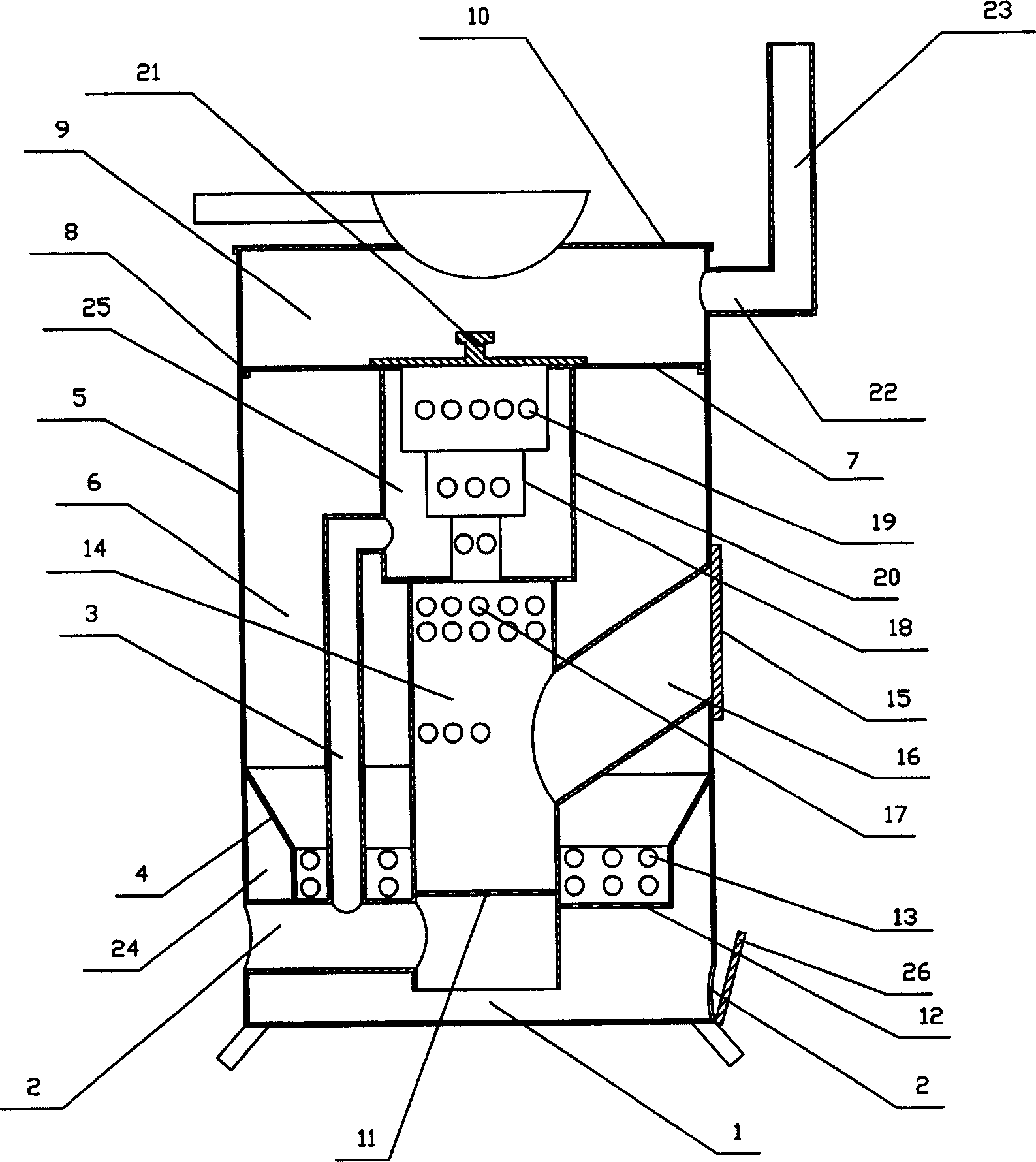

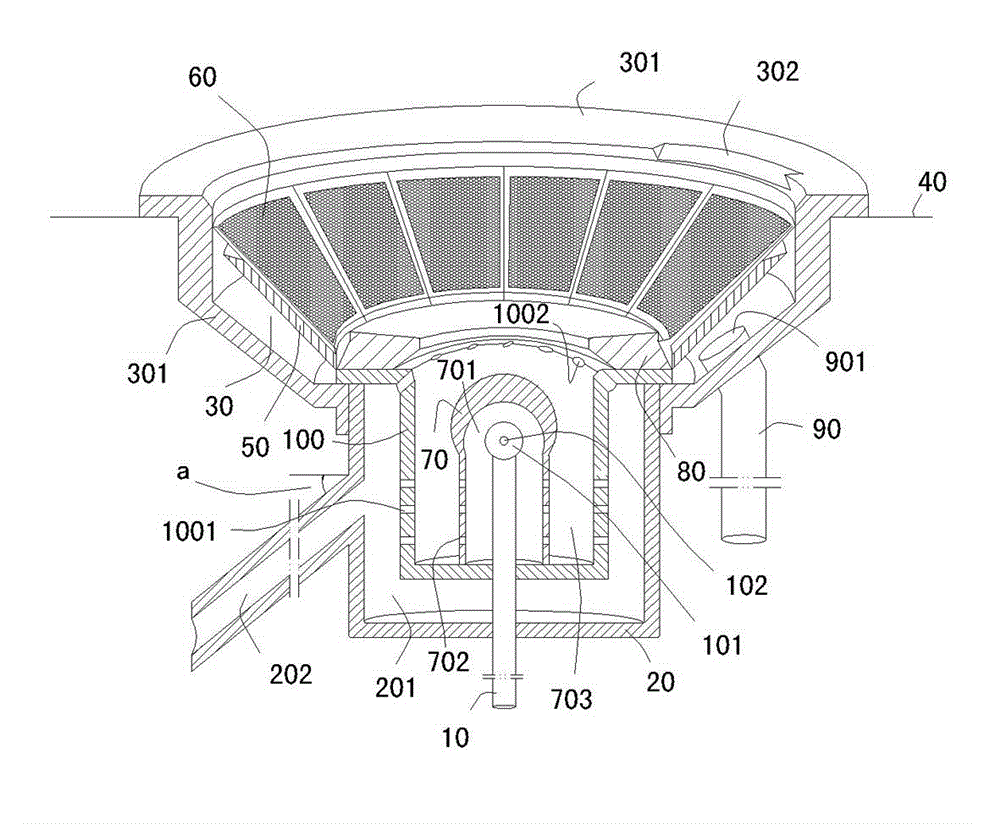

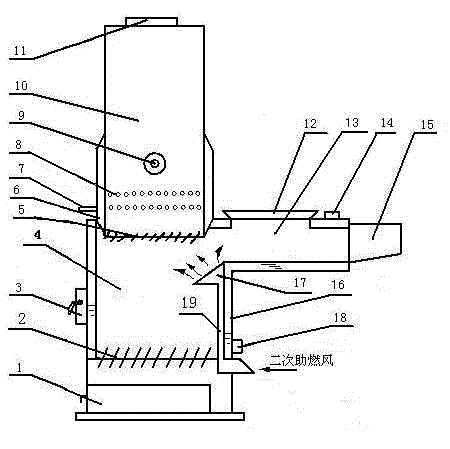

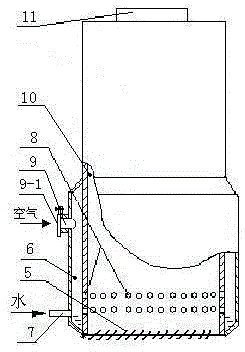

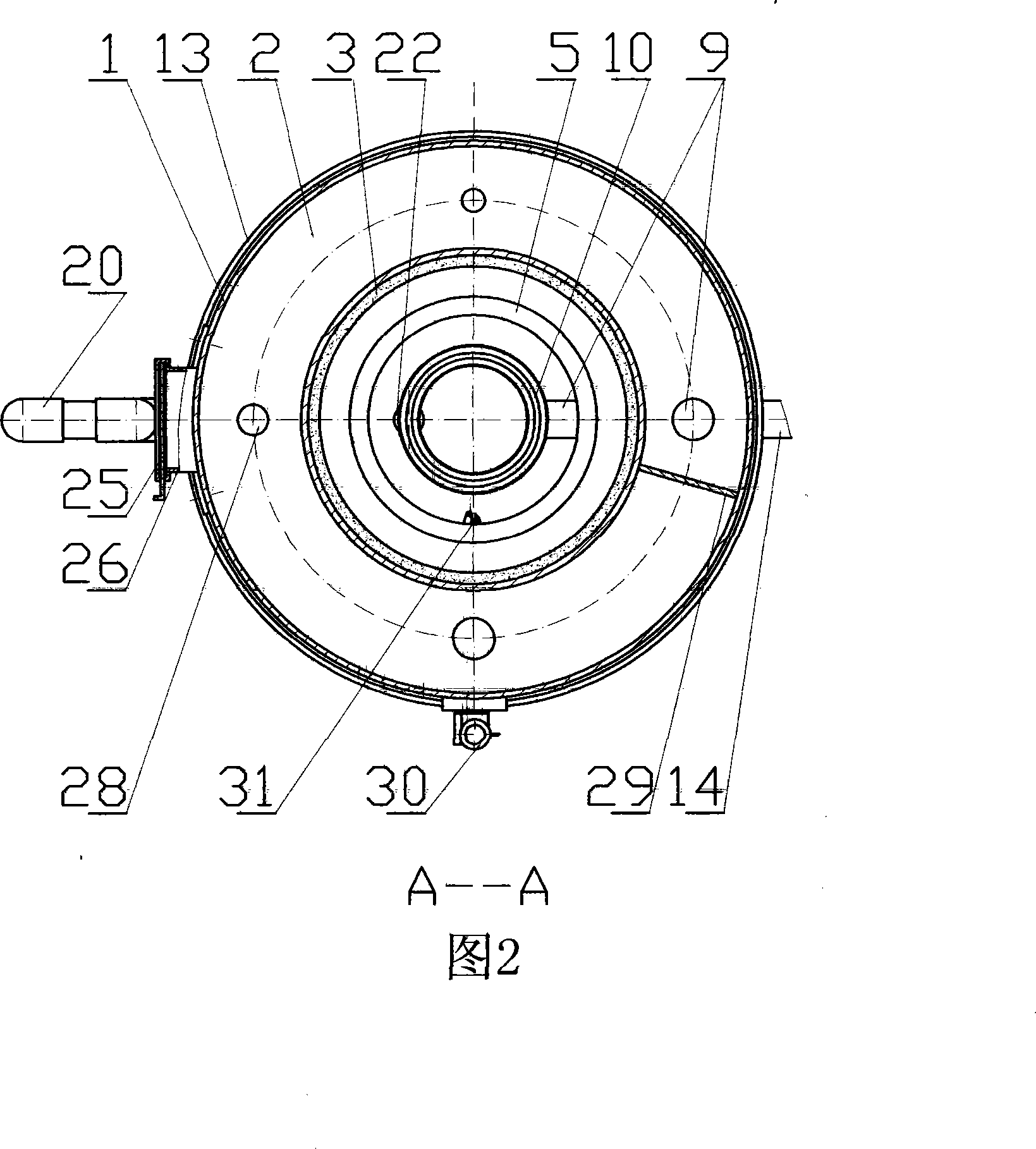

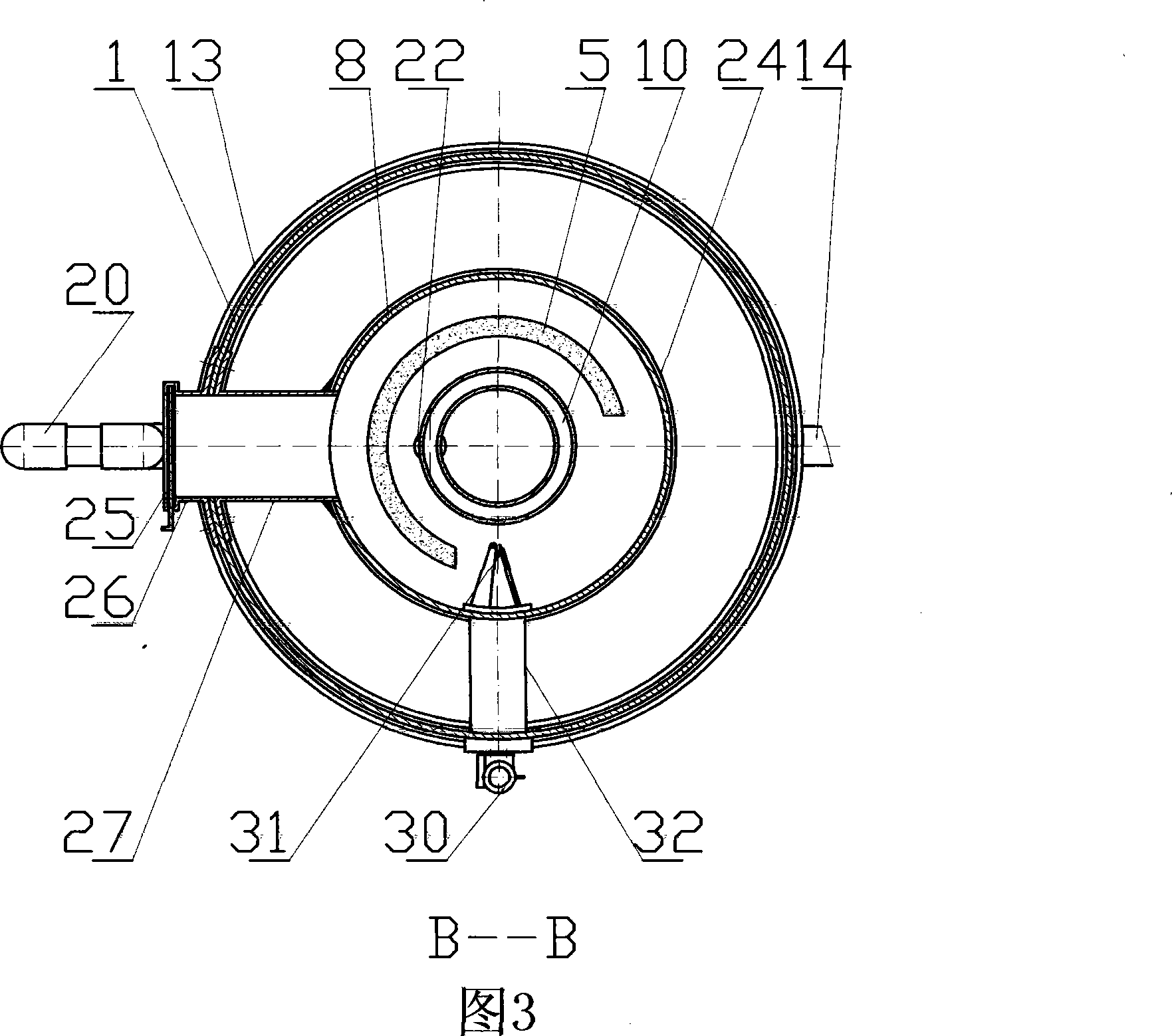

Integral compound gasification stove

InactiveCN101000146AIncrease firepowerFierce firepowerDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention is an integrated combined gasification stove, a biofuel gasifier, having gasification hearth, oxidization combustion chamber and multiple oxygen distributor, where the oxidization combustion chamber is equipped in the gasification hearth and the upper end of the oxidization combustion chamber is connected with the multiple oxygen distributor, the upper part of the oxidization combustion chamber is made with fuel gas holes at different heights and the side of the oxidization combustion chamber is equipped with material inlet pipe, and the multiple oxygen distributor is connected through multiple oxygen distribution pipe with air inlet. And it has characters of needing no fan, wide raw material sources, saving energy, high heat valve, no smoke dust and tar, stable performance, etc.

Owner:周海军

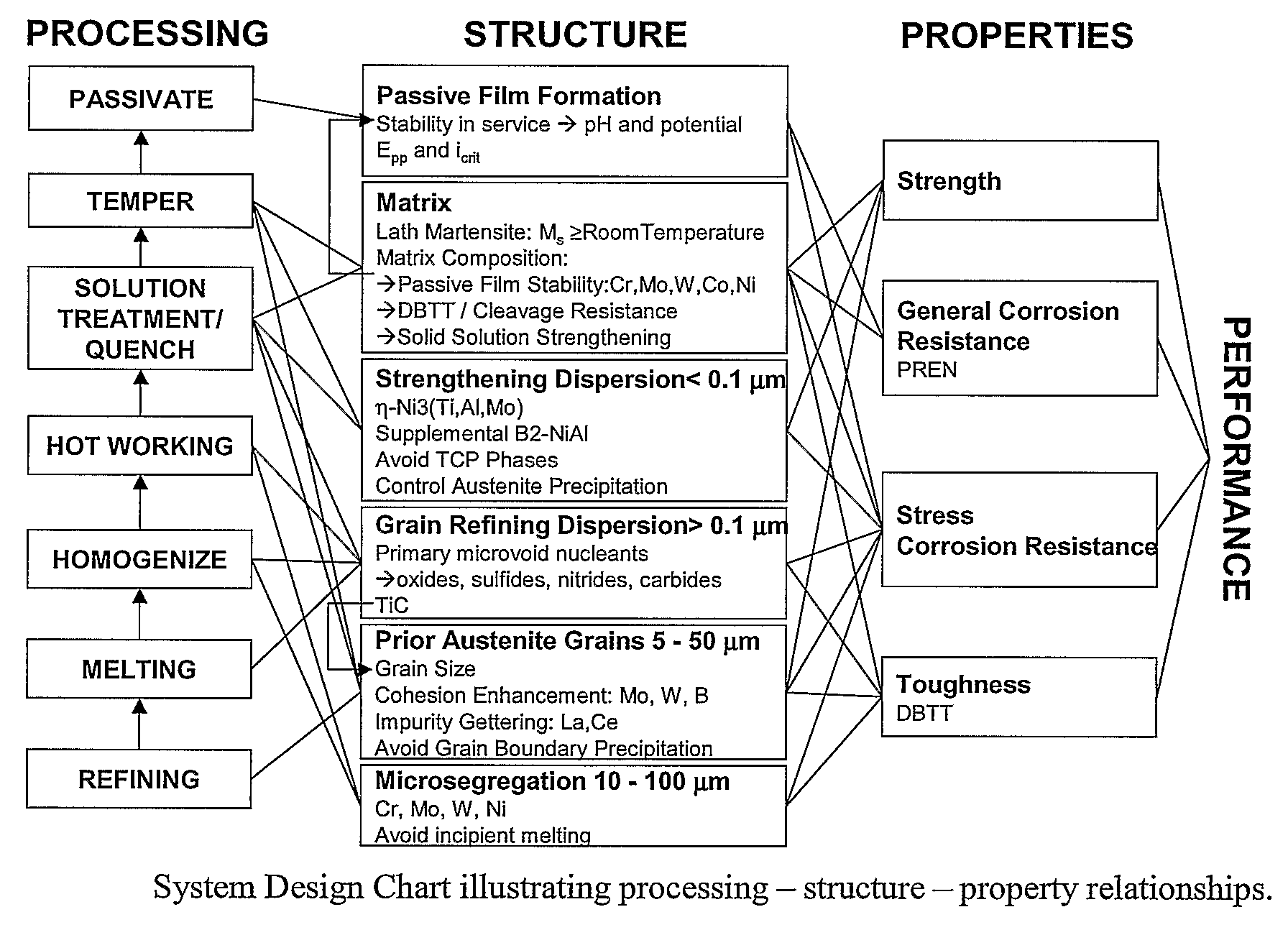

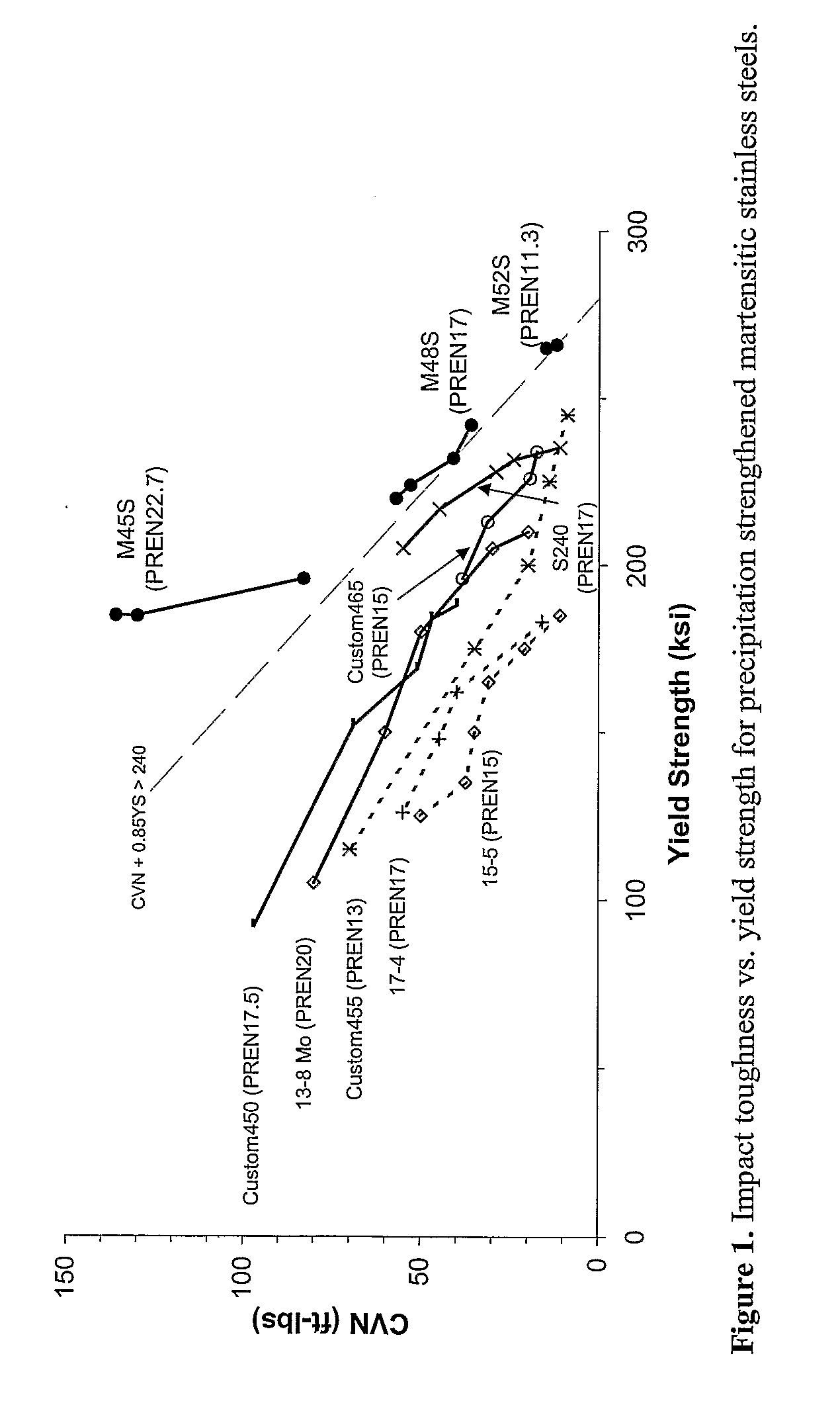

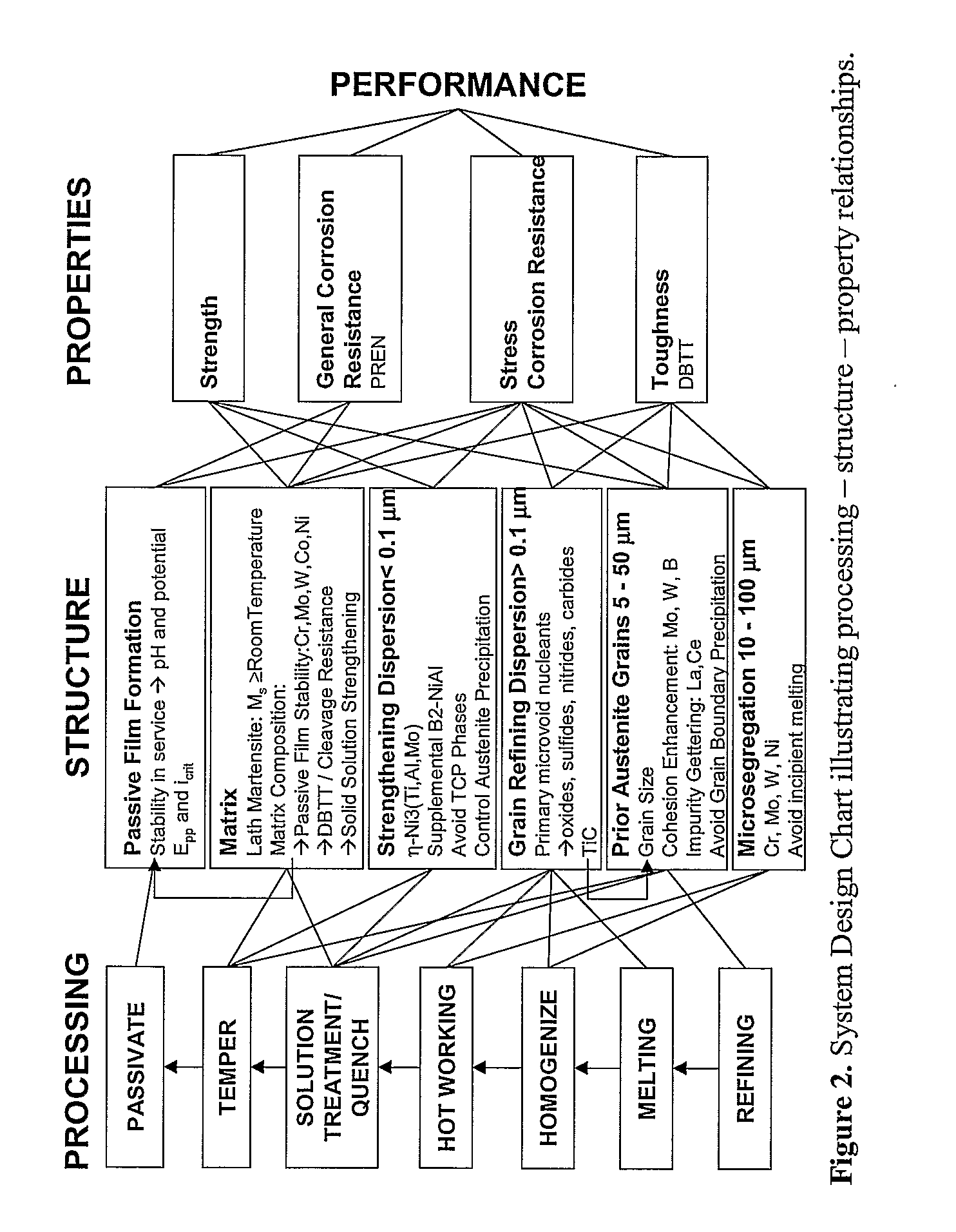

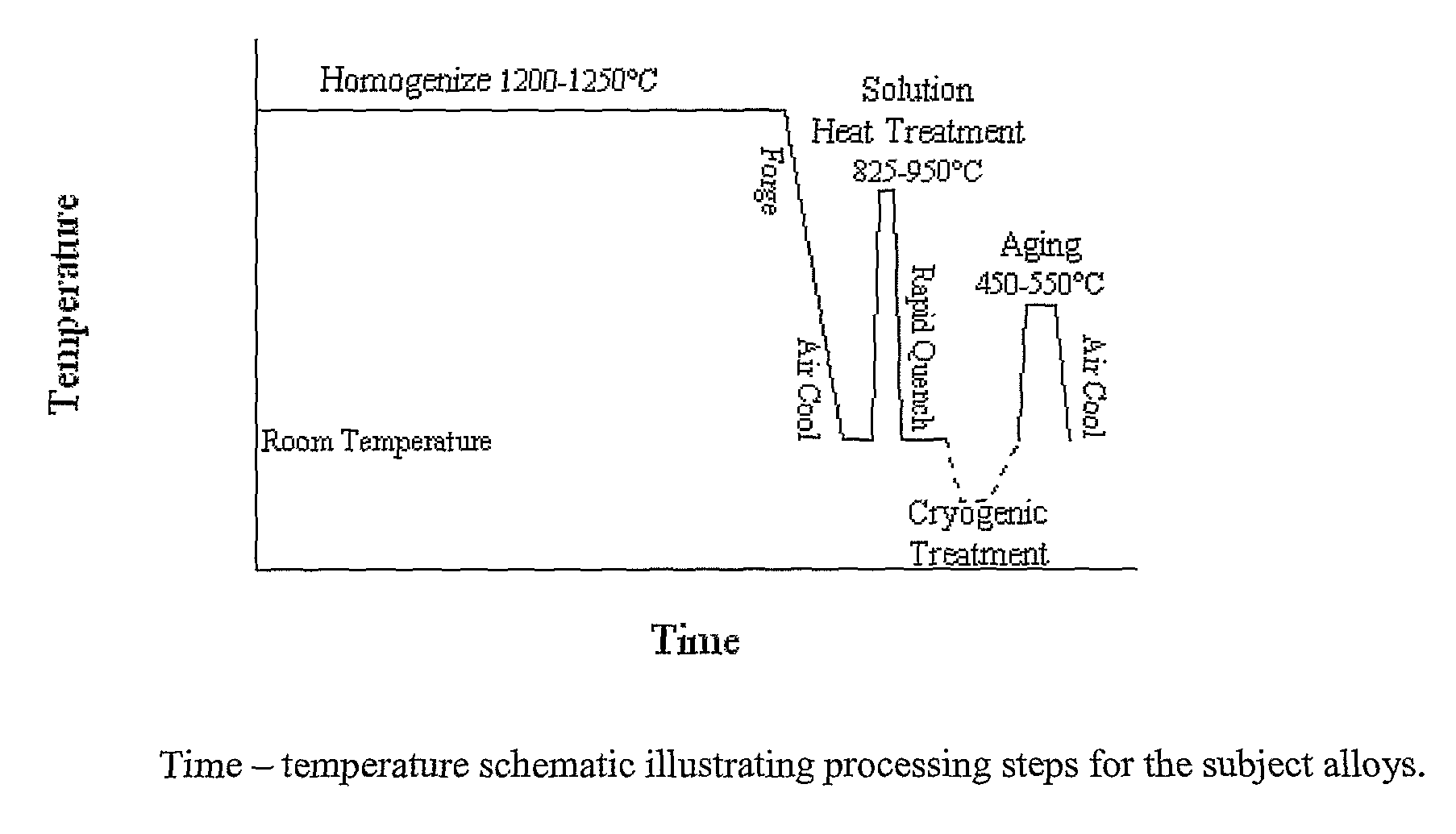

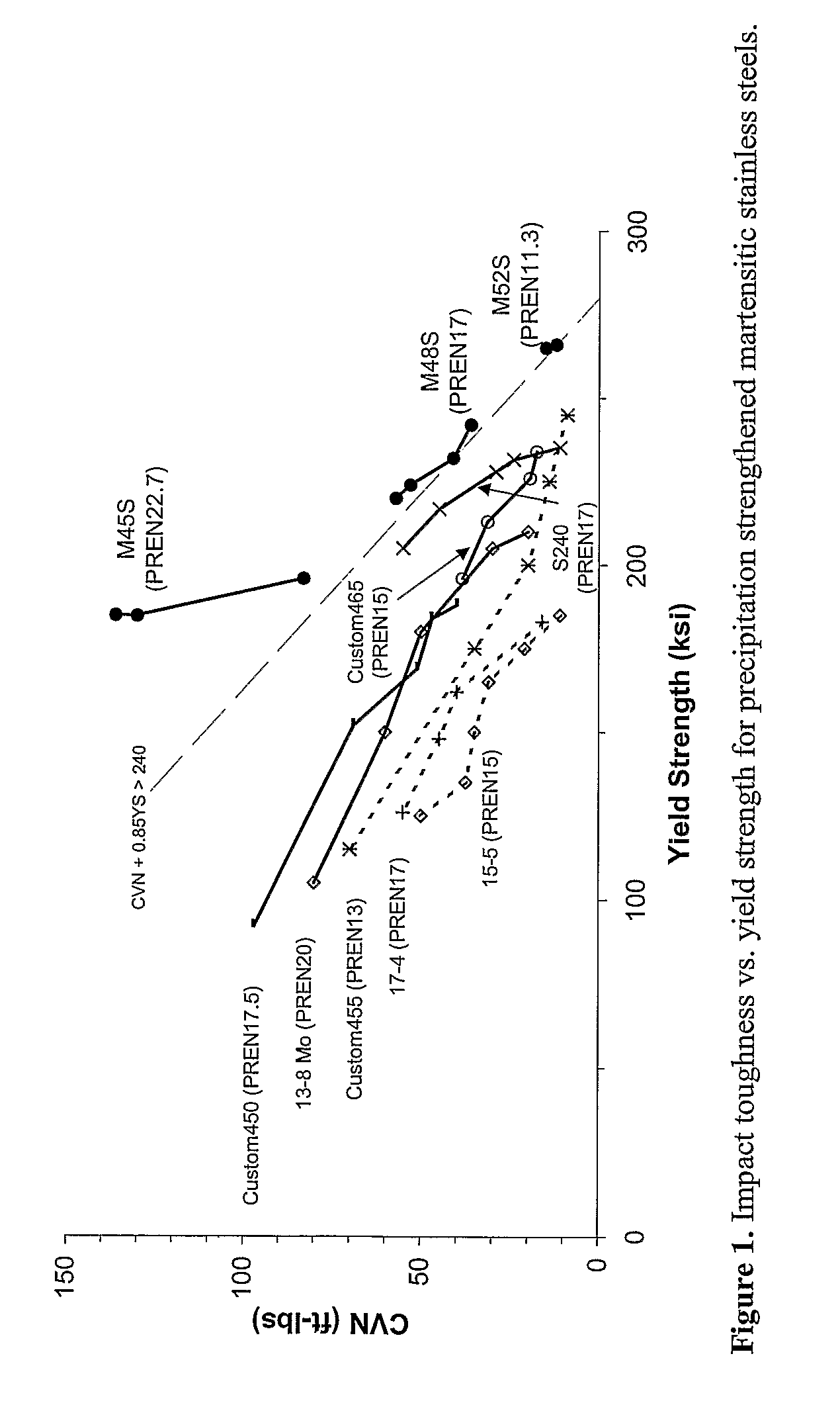

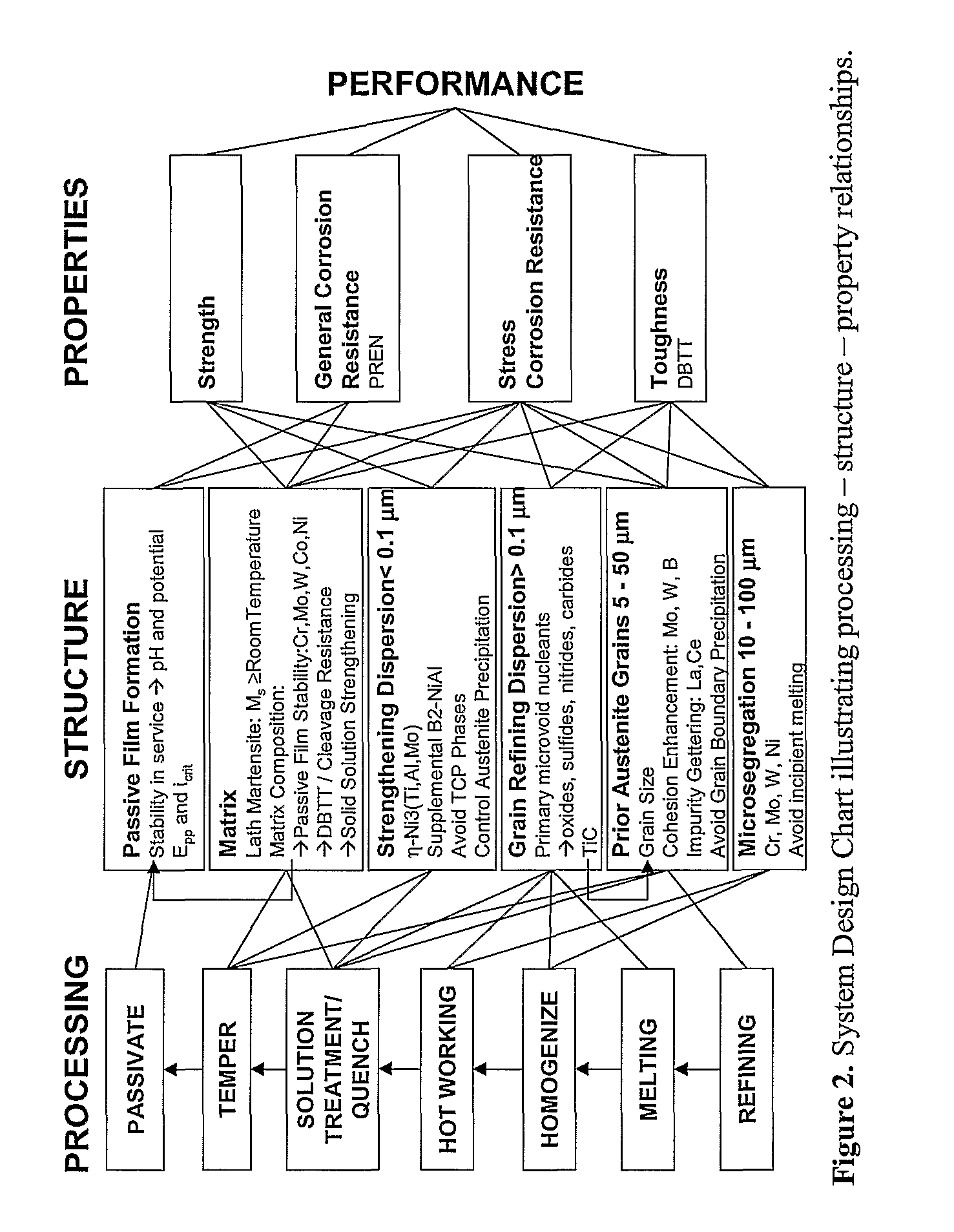

Martensitic Stainless Steel Strengthened By Ni3tin-Phase Precipitation

ActiveUS20080314480A1Corrosion resistance of the alloy,Prevent precipitationMartensitic stainless steelAlloy

A precipitation-hardened stainless maraging steel which exhibits a combination of strength, toughness, and corrosion resistance comprises by weight about: 8 to 15% chromium (Cr), 2 to 15% cobalt (Co), 7 to 14% nickel (Ni), and up to about 0.7% aluminum (Al), less than about 0.4% copper (Cu), 0.5% to 2.5% molybdenum (Mo), 0.4 to 0.75% titanium (Ti), up to about 0.5% tungsten (W), and up to about 120 wppm carbon (C), the balance essentially iron (Fe) and incidental elements and impurities, characterized in that the alloy has a predominantly lath martensite microstructure essentially without topologically close packed intermetallic phases and strengthened primarily by a dispersion of intermetallic particles primarily of the eta-Ni3Ti phase and wherein the titanium and carbon (Ti) and (C) levels are controlled such that C can be dissolved during a homogenization step and subsequently precipitated during forging to provide a grain-pinning dispersion.

Owner:QUESTEK INNOVATIONS LLC

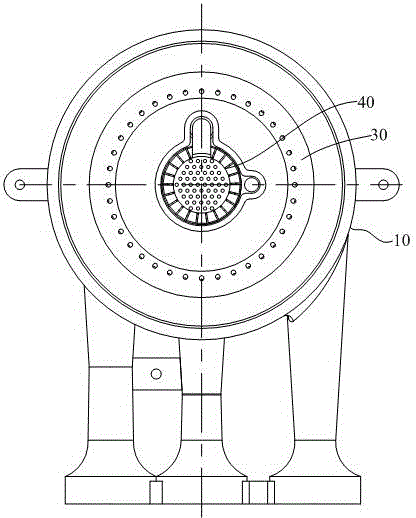

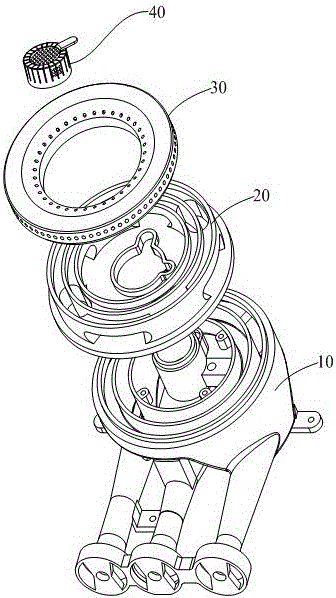

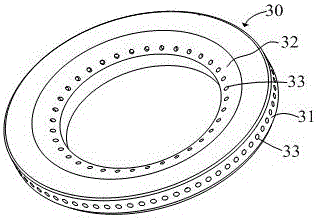

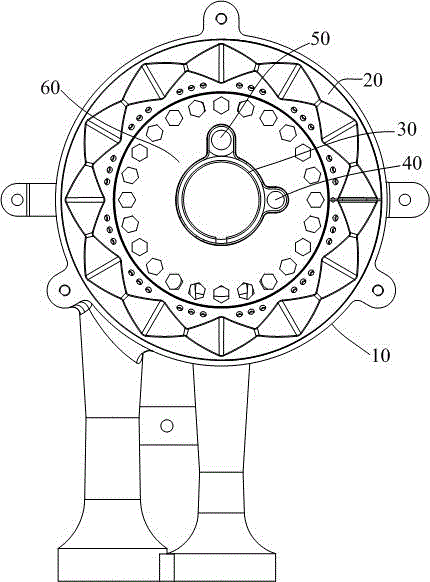

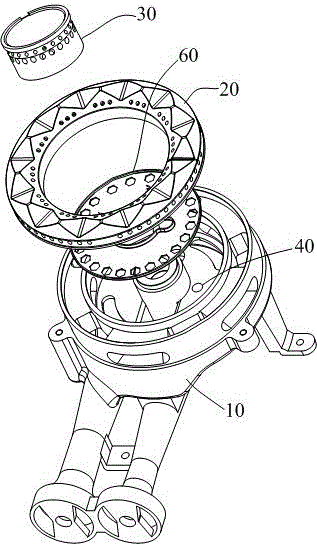

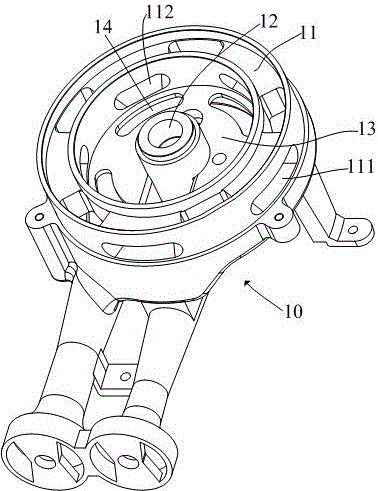

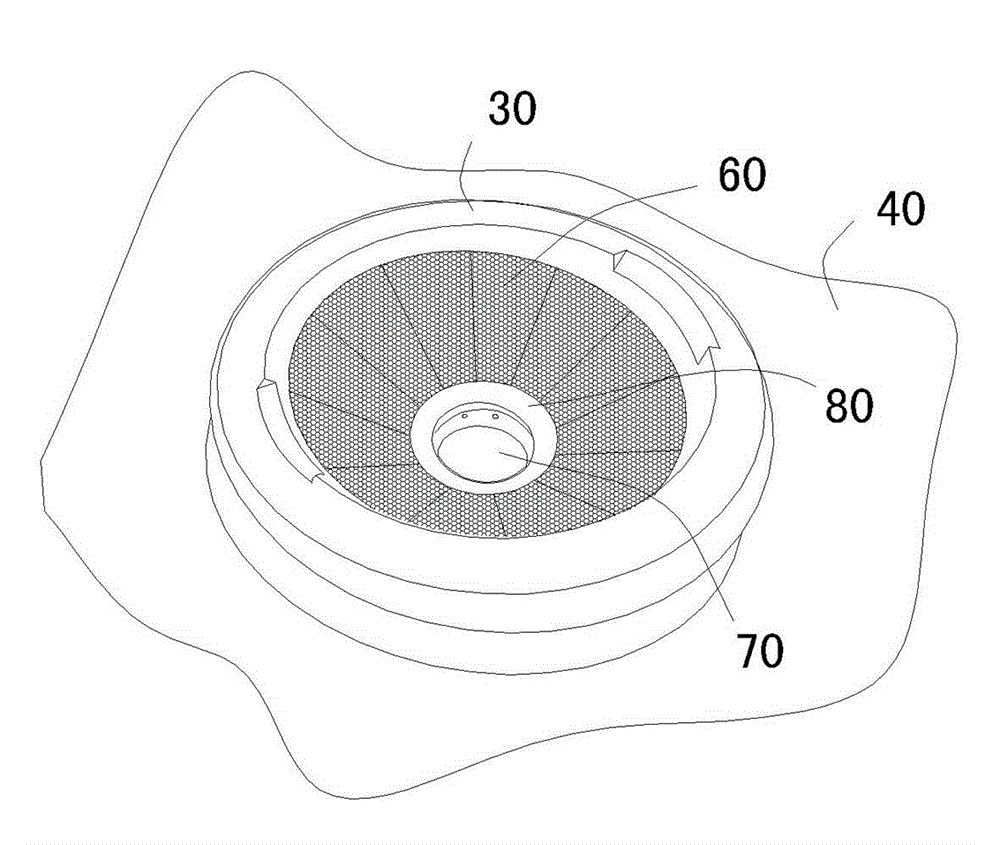

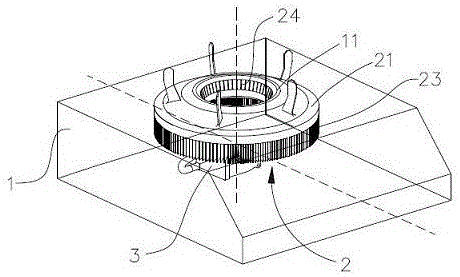

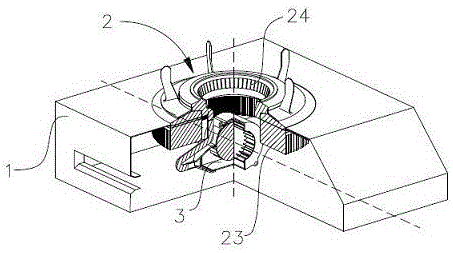

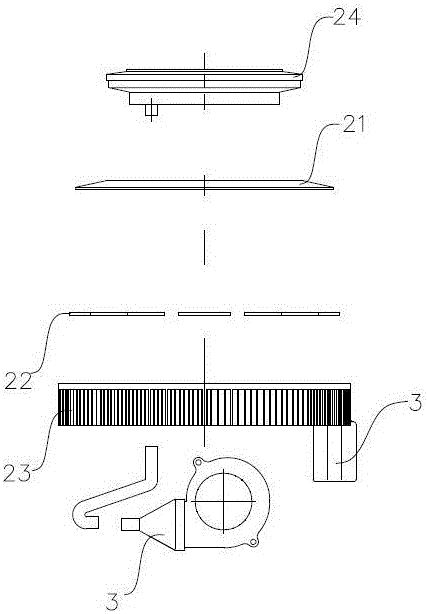

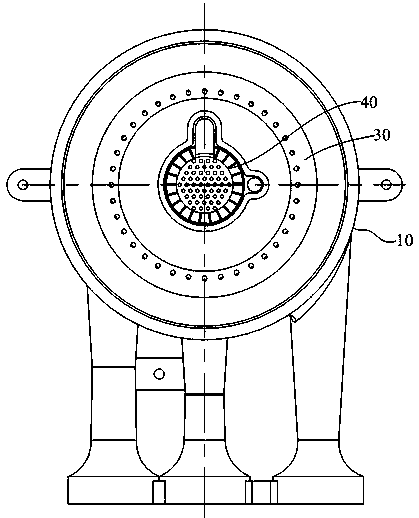

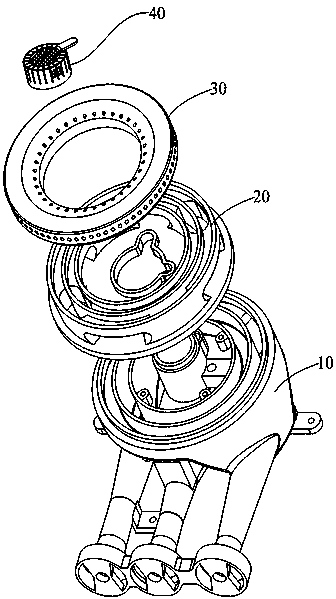

High-efficiency three-ring fire burner and gas stove

The invention provides a high-efficiency three-ring fire burner and a gas stove. On the basis of guaranteeing big fire of three-ring fire, the burner diameter is reduced, the cost is lowered, and the thermal efficiency is improved. According to the high-efficiency three-ring fire burner, a gas cavity is separated into a middle ring fire gas cavity and an outer ring fire gas cavity by virtue of separation ribs arranged on an outer fire cover; a separation ring is arranged in a gas distribution disc, and an outer ring gas channel is divided into a middle ring fire gas channel and an outer ring fire gas channel; and the burner head comprises a central gas mixing chamber, a central ejector pipe, a middle ring gas mixing chamber, an outer gas mixing chamber, an outer ring ejector pipe and an air channel. The outer fire cover is small in diameter, so that the heat exchange time between the pot bottom and flames is long, the heat exchange area is large, the fire and thermal efficiency of the burner are improved, and the cost of the burner is reduced.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

Martensitic stainless steel strengthened by Ni3Ti η-phase precipitation

ActiveUS7879159B2Corrosion resistance of the alloy,Prevent precipitationMartensitic stainless steelAlloy

A precipitation-hardened stainless maraging steel which exhibits a combination of strength, toughness, and corrosion resistance comprises by weight about: 8 to 15% chromium (Cr), 2 to 15% cobalt (Co), 7 to 14% nickel (Ni), and up to about 0.7% aluminum (Al), less than about 0.4% copper (Cu), 0.5 to 2.6% molybdenum (Mo), 0.4 to less than about 0.75% titanium (Ti), up to about 0.5% tungsten (W), and up to about 120 wppm carbon (C), the balance essentially iron (Fe) and incidental elements and impurities, characterized in that the alloy has predominantly lath martensite microstructure essentially without topologically close packed intermetallic phases and strengthened primarily by a dispersion of intermetallic particles primarily of the eta-Ni3Ti phase and wherein the titanium and carbon (Ti) and (C) levels are controlled such that C can be dissolved during a homogenization step and subsequently precipitated during forging to provide a grain-pinnning dispersion.

Owner:QUESTEK INNOVATIONS LLC

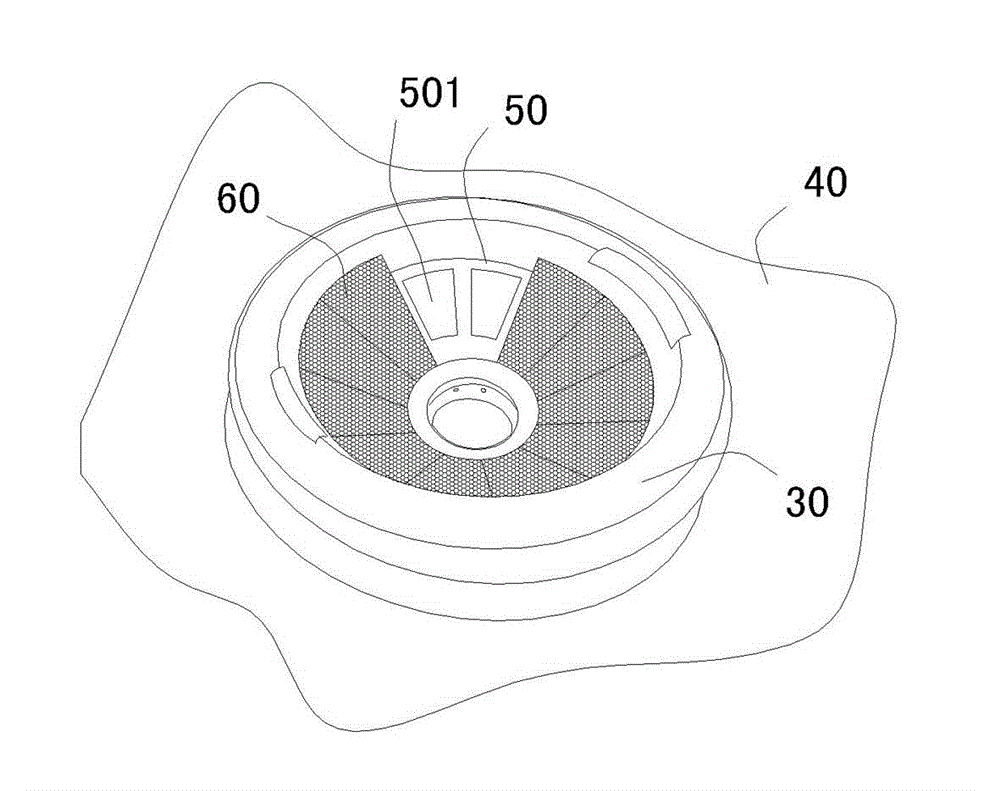

Combustor and gas stove

ActiveCN105864770AReduce manufacturing costGuaranteed clean designDomestic stoves or rangesCooking fumes removalCombustorAtmospheric air

The invention provides a combustor and a gas stove. According to the combustor and the gas stove, the clean design of the combustor can be guaranteed, cost is low, and high-fire combustion can be achieved. The combustor comprises a burner, an outer fire cover and an inner fire cover. The burner comprises an outer-ring mixing cavity and an inner-ring mixing cavity. The outer fire cover is located on the outer-ring mixing cavity, and the inner fire cover is located on the inner-ring mixing cavity. Vent holes are formed in the bottom wall of a channel area, between the outer-ring mixing cavity and the inner-ring mixing cavity, on the burner and are communicated with the atmosphere below the burner. A clean vessel is further arranged in the channel area and is provided with a center through hole, a plurality of air inlet holes and a circle of flange, and the orthogonal projections, on the bottom wall of the channel area, of at least part of air inlet holes are located in the vent holes. The combustor is low in production cost, capable of generating high fire and good in cleaning easiness.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

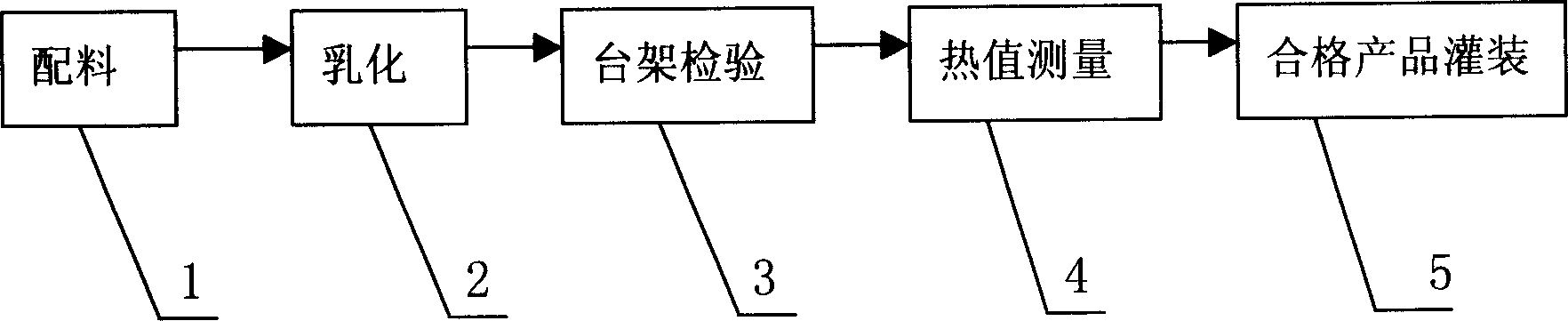

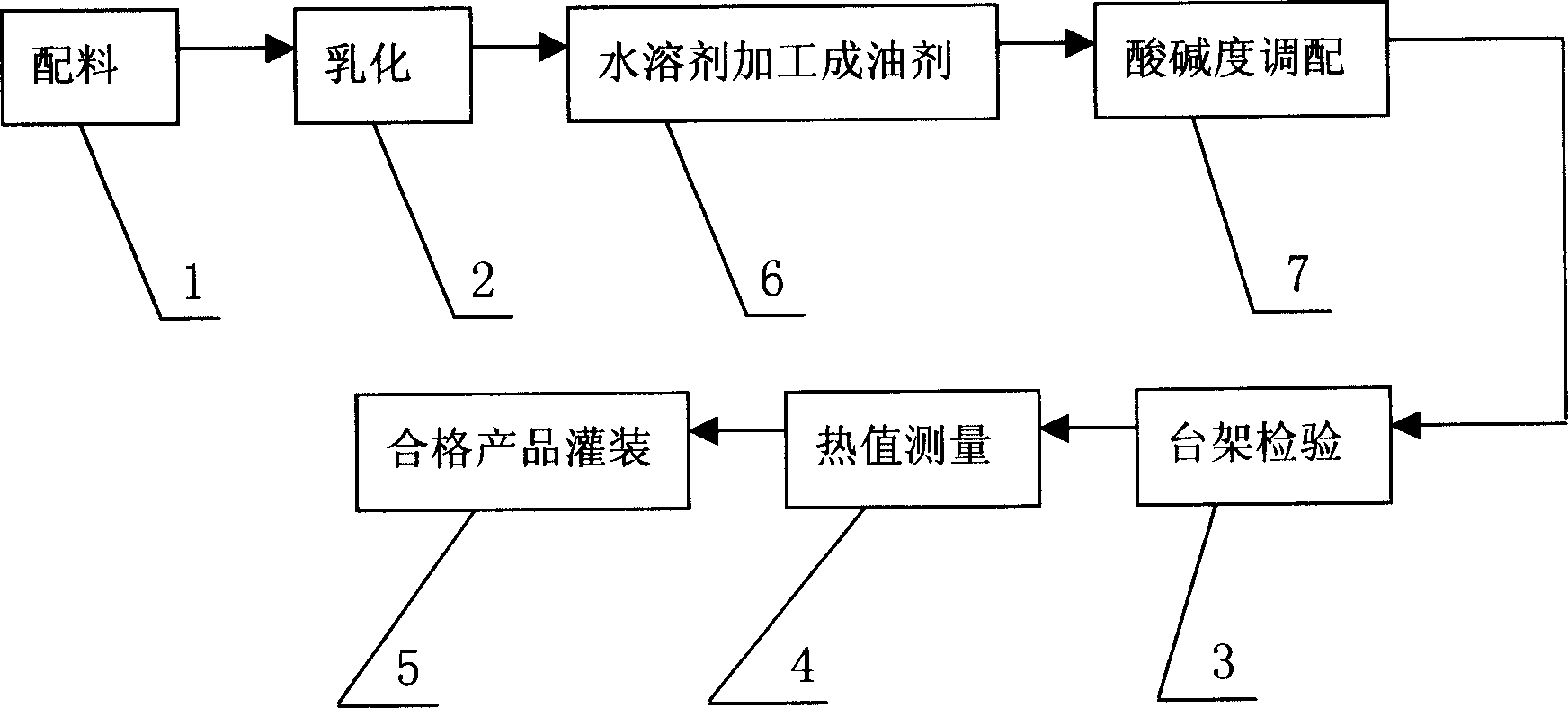

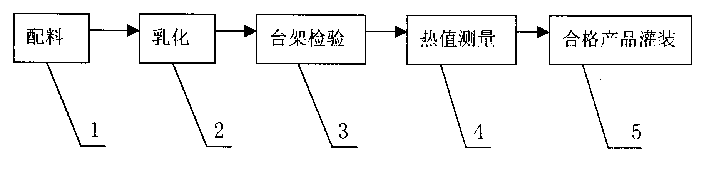

Liquid fuel and preparation thereof

InactiveCN101475857AReduce volatilityImprove performanceLiquid carbonaceous fuelsThermal energyHexamethylenetetramine

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is mainly prepared from the following raw materials in portion by mass: 150 to 300 portions of water, 650 to 850 portions of methanol, 5 to 20 portions of butyl acetate, 5 to 20 portions of sodium hydroxide, 2 to 10 portions of hexamethylenetetramine, 10 to 30 portions of hydrogen peroxide with a mass concentration of 30 percent, and 50 to 150 portions of ethanol. The liquid fuel has low volatility and steady performance, is safe during the transportation and storage when being distributed to users due to the high temperature resistance, is difficult to ignite if no open flame exists, does not splash liquids and fumigate eyes during the use, can completely burn, is difficult to generate harmful gas such as formaldehyde and the like, has no smoke, no toxicity, no carbon deposition, no pot blackening, violent fire, high heat energy, no pressure, and no explosion danger, has a combustion calorie more than 9,500kcal / kg, can be extinguished by water during the fire extinguishing, and has the characteristics of cleanliness, environment protection, safety, simple and convenient production, and low production cost. The liquid fuel can substitute diesel oil and liquefied gas, and is suitable to be used by diesel furnaces, liquefied gas furnaces, boilers and the like.

Owner:廖新明 +1

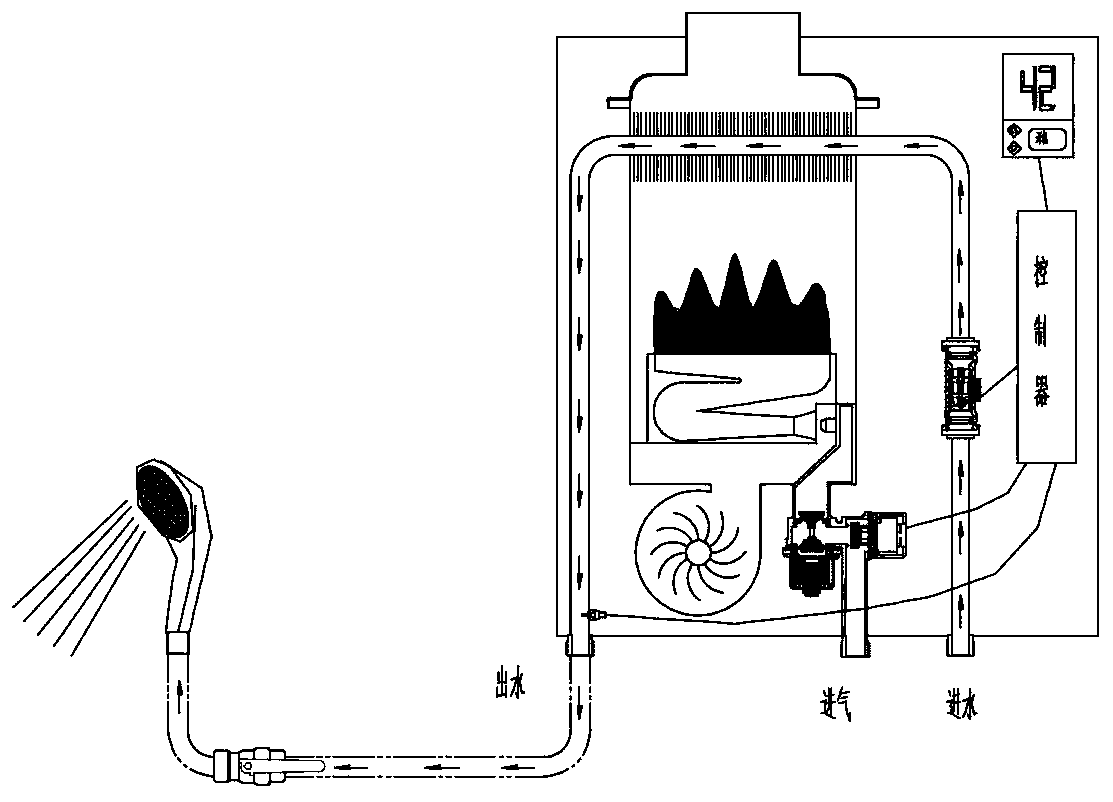

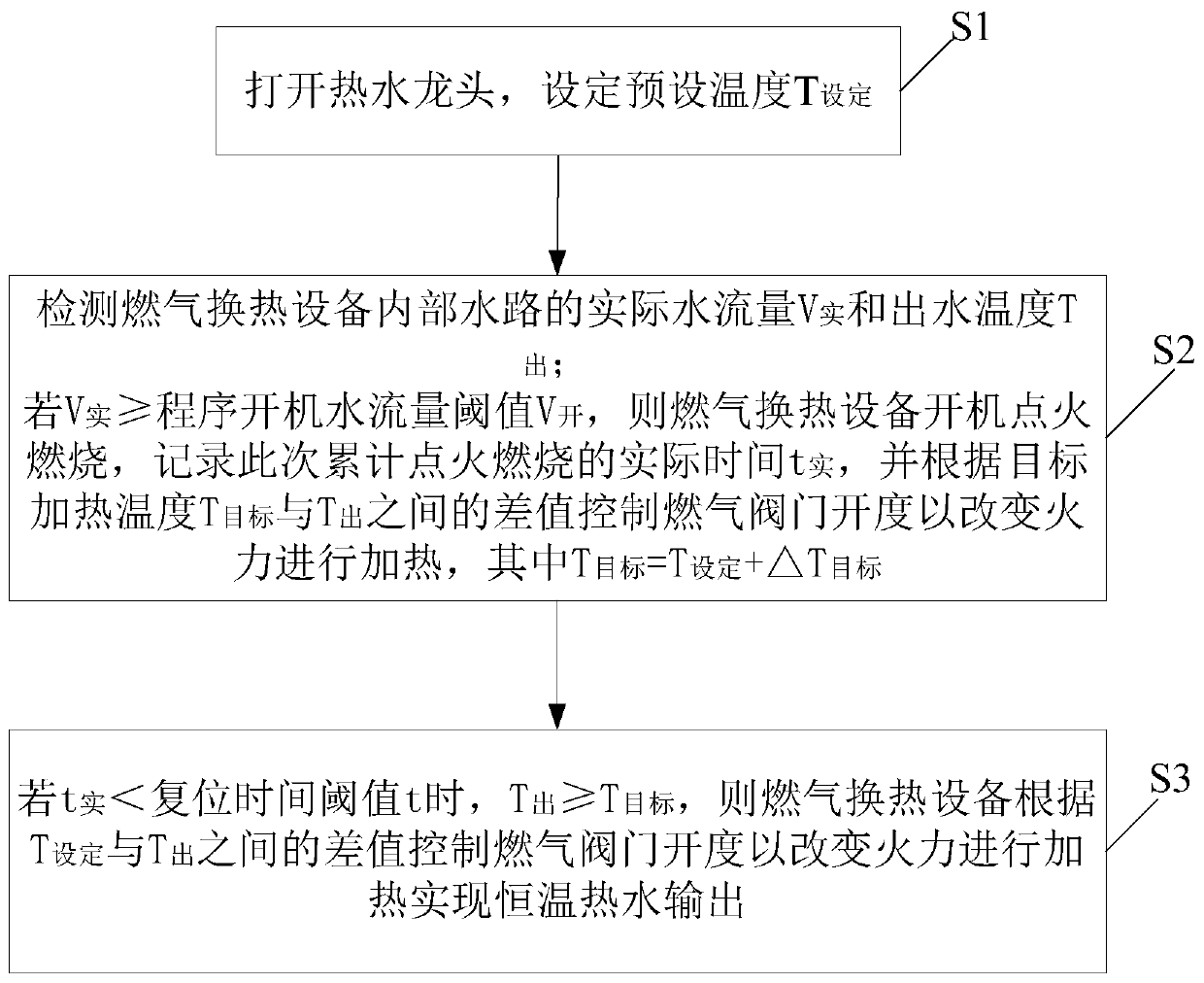

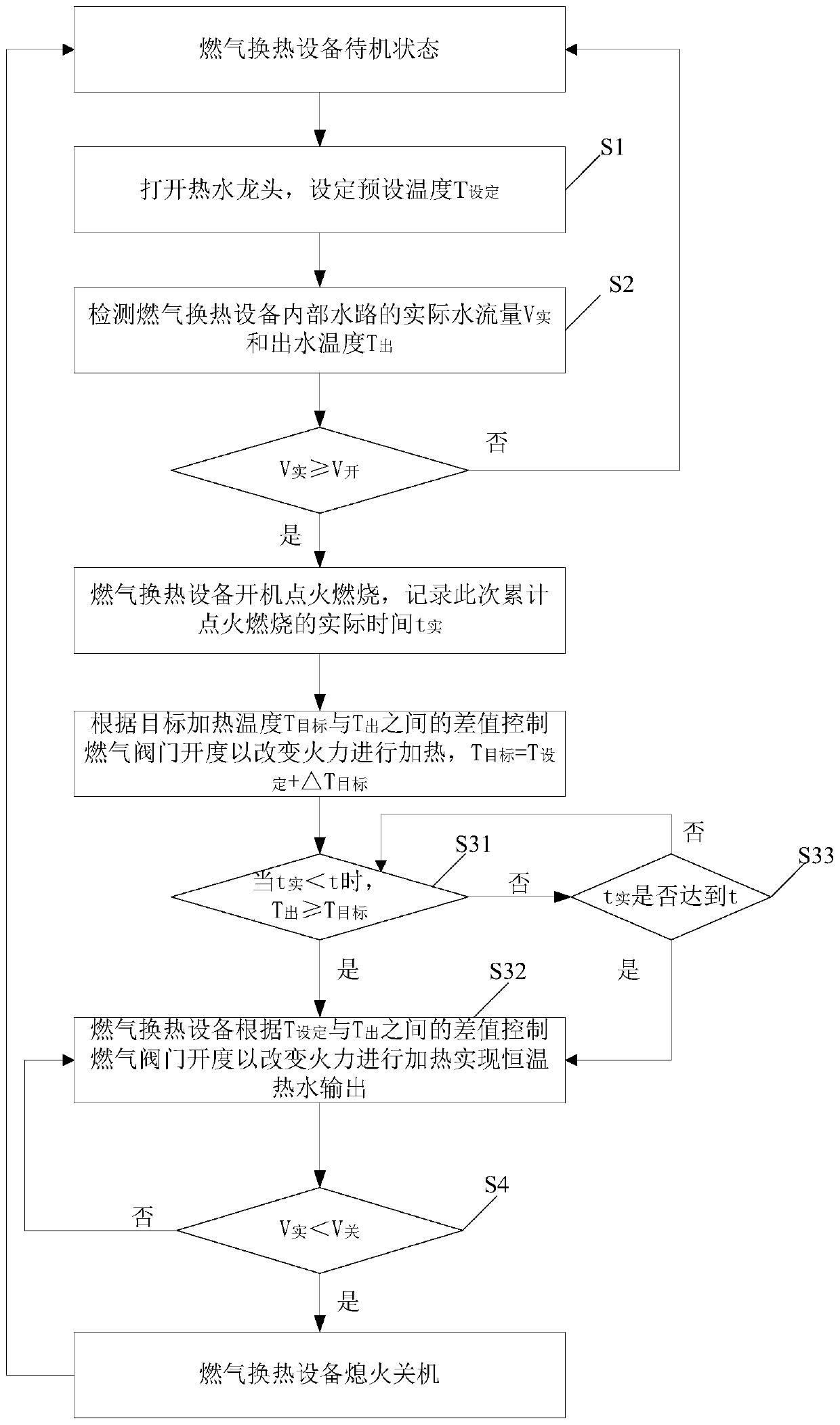

Rapid heating temperature control method of gas heat exchange equipment

The invention belongs to the technical field of gas heat exchange equipment, and discloses a rapid heating temperature control method of gas heat exchange equipment. The method comprises the followingsteps: setting a preset temperature T (setting); detecting actual water flow V (actual) and outlet water temperature T (outlet) of the gas heat exchange equipment ; if V (actual) is greater than or equal to a program starting water flow threshold value V (starting), starting the gas heat exchange equipment to be ignited and combusted, recording actual time t (actual) of accumulated ignition combustion at this time, and controlling the opening degree of a gas valve according to the value of difference between T (target) and T (outlet) so as to change fire power, wherein T (target) is equal tothe sum of T (setting) and delta T (target); and if t (actual) is smaller than reset time threshold value t, and T (outlet) is greater than or equal to T (target), controlling the opening degree of the gas valve according to the value of difference between T (setting) and T (outlet) by the gas heat exchange equipment so as to change the fire power to achieve constant-temperature hot water discharging. According to the method, the problem that a large amount of tap water is wasted due to the fact that the heating speed of existing gas heat exchange equipment is low is solved.

Owner:VATTI CORP LTD

Coal economizing agent

InactiveCN106753681AImprove combustion efficiencyImprove efficiencySolid fuelsFuel additivesCombustionNon compliance

The invention belongs to the technical field of coal combustion additives, and in particular relates to a coal economizing agent. The invention solves the problems of unobvious coal economizing effect, high addition level, pollution of the environment and non-compliance of Green blackness of the existing coal economizing agents. The coal economizing agent is prepared from the components in parts by weight: 22-26 parts of a combustion adjuvant, 28-41 parts of a mixed type strong oxidizer, 18-26 parts of a dispersing agent, 2-5 parts of a catalyst and 15-25 parts of a compound sulfur-fixing agent. The coal economizing agent disclosed by the invention can improve the combustion conditions of a furnace body and increase the air permeability of a coal layer, thus enabling sufficient combustion of coal, improving the coal-burning heat efficiency, reducing discharge amount of smoke, improving the thermal conduction efficiency, fixing sulfur to reduce smoke, reducing emission of CO, SO2 and the like, reducing environmental pollution, and achieving the purposes of combustion supporting, sulfur fixing, energy saving and desulfurization.

Owner:GUANGZHOU AUSPICIOUS CHEM

Special furnace end for alcohol base liquid fuel

The invention discloses a special furnace end for an alcohol base liquid fuel. The special furnace end comprises an oil inlet pipe, a vaporization head, a burning bowl, an air inlet bowl, a furnace cavity wall and an air inlet pipe, wherein an air conveying hole in the air inlet pipe is communicated with an air cavity in the air inlet bowl in the direction of an upward and oblique tangent line through the side wall of the air inlet bowl; a circle of energy collection plate which is provided with cellular through holes and tilts to a burning hole in the burning bowl is arranged in the circumferential direction of the furnace cavity wall; the rear surface of the energy collection plate and the furnace cavity wall form an air return cavity; a downward discharge type air outlet pipe communicated with the outside is arranged in the air return cavity; and a pot body hole on the furnace cavity wall and a pot bottom wall form a contact seal structure when in use. According to the special furnace end, a bottom air introduction mode is changed into a lateral air introduction mode, the energy collection plate is arranged in a furnace cavity, the downward discharge type air outlet pipe is arranged in the air return cavity, and the contact seal combination structure of the pot body hole on the furnace cavity wall is adopted, so that the total heat efficiency is greatly improved. Actual measurement shows that the heat efficiency can be improved by more than 20%. Therefore, the special furnace end is especially suitable for burning and cooking of the alcohol base liquid fuel.

Owner:陈庚

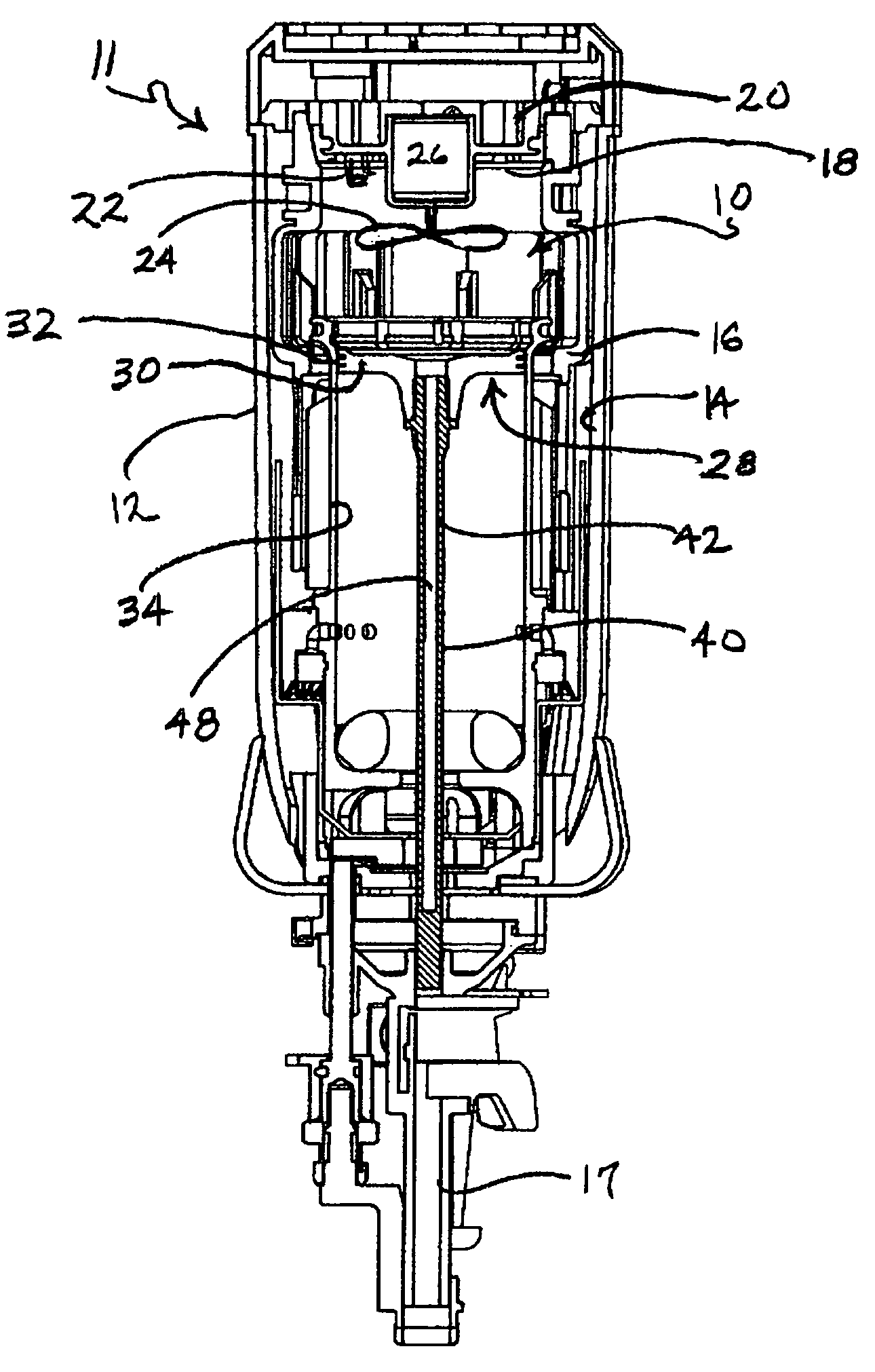

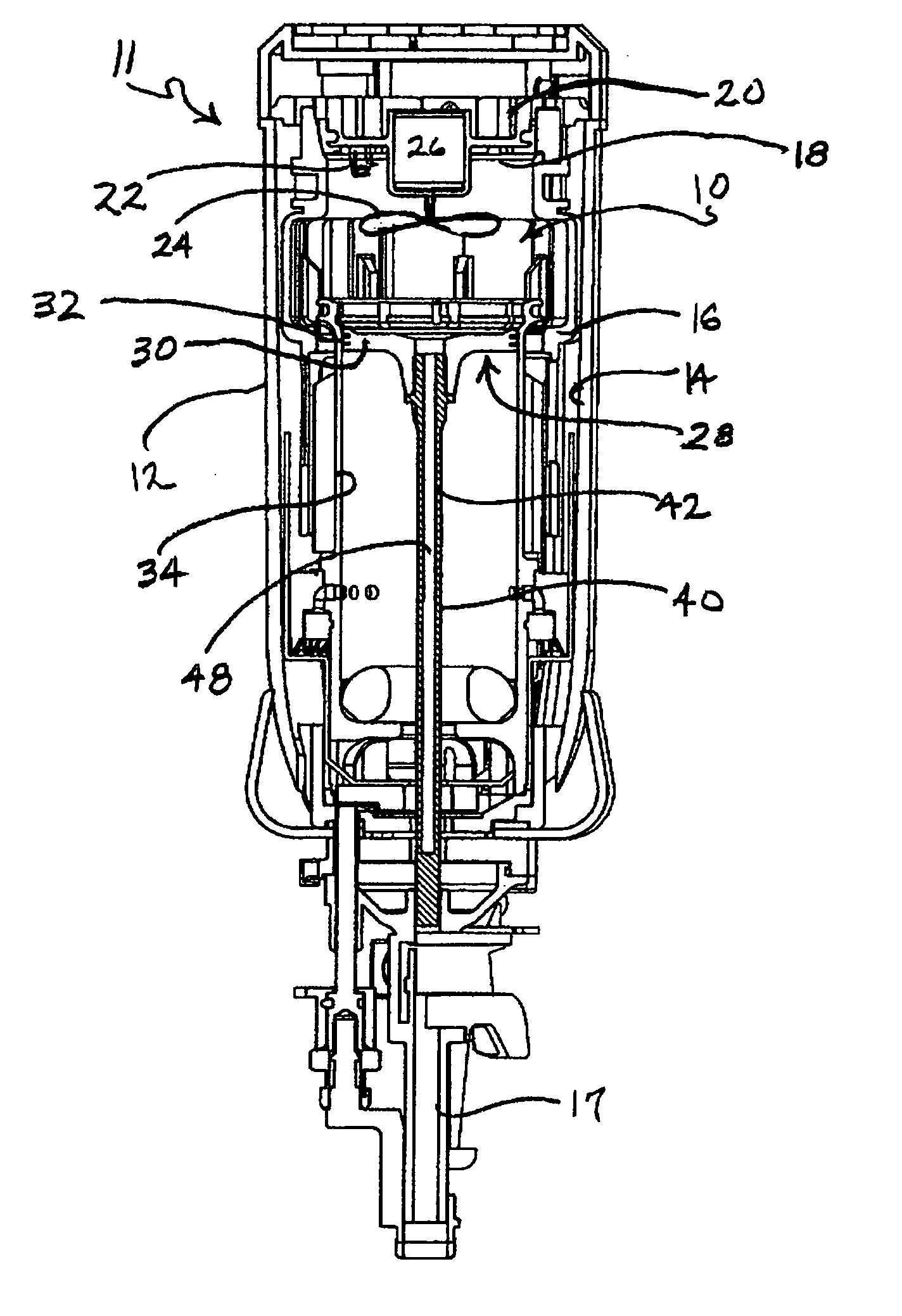

Driver blade with auxiliary combustion chamber for combustion powered fastener-driving tool

InactiveUS7201302B2Increase firepowerEasy to driveStapling toolsReciprocating drilling machinesCombustion chamberEngineering

A driver blade for use in a combustion-powered fastener-driving tool includes an elongate tubular body having a combustion end and a driving end, the combustion end being configured for attachment to a piston, and the driving end having a substantially solid cross-section. The tubular body is in fluid communication with a tool combustion chamber.

Owner:ILLINOIS TOOL WORKS INC

Abstergent of saving oil, gas and coal

InactiveCN1519299AIncrease contact surfaceThoroughly remove carbon depositsLiquid carbonaceous fuelsCombustionHydrogen

A cleaning agent for saving oil, gas or coal features that it can suck the oxygen from air into water, where it reacts on the hydrogen and oxygen in water to become atomic hydrogen and atomic oxygen, and when the fuel is burning, the high-temp atomic hydrogen and atomic oxygen is exploded to break the carbon chains in fuel. Its advantages are full combustion and high heat value of fuel, no carbon deposit, and less exhausted smoke.

Owner:李天山

Cooking range with air supply driven through thermal gradient power self-generation

InactiveCN106016369AIncrease firepowerImprove combustionDomestic stoves or rangesLighting and heating apparatusElectricityCombustion

The invention discloses a cooker for air supply driven by temperature difference self-generation, which comprises a cooker body (1). The cooker body includes a gas supply device, a burner head, an ignition device, and a control device; device (2), the thermoelectric power generation device includes a bracket (21) and several thermoelectric power generation units (22) installed on the bracket, and is characterized in that: it also includes a thermoelectric power generation unit installed on the stove body (1) (22) A connected air supply device (3), the air outlet of the air supply device (3) communicates with the air inlet of the stove body (1). The invention utilizes the technical solution of combustion waste heat temperature difference to self-generate and drive the air supply, and converts the waste heat of the stove into electric energy to drive the air supply device to supply air for the stove, which can have beneficial effects of increasing the firepower and supporting combustion of the stove.

Owner:宁波智宇流体技术有限公司

Coal saving agent and preparation process thereof

The present invention relates to a coal saving agent and a preparation process thereof, wherein the coal saving agent comprises, by weight, 6-12% of catalyst, 1-7% of a combustion-supporting agent, 25-35% of a penetrant, 25-35% of a leavening agent, 7-15% of a cleaning agent, 10-20% of a dispersing agent, and 7-12% of a sulfur-fixing agent. According to the present invention, the coal saving agent has effects of furnace combustion condition improving, coal seam gas permeability improving, complete coal combustion, coal-fired thermal efficiency improving, smoke dust emission reducing, heat conduction efficiency improving, sulfur fixing, smoke reducing, CO and SO2 emission reducing and environmental pollution reducing so as to achieve the purposes of combustion supporting, sulfur fixing, energy saving and desulfurization, wherein the coal can be saved by 5-10%, the fire power can be increased by more than or equal to 10%, the carbon deposition can be eliminated by 50-90%, and the sulfur can be reduced by 20-50%.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

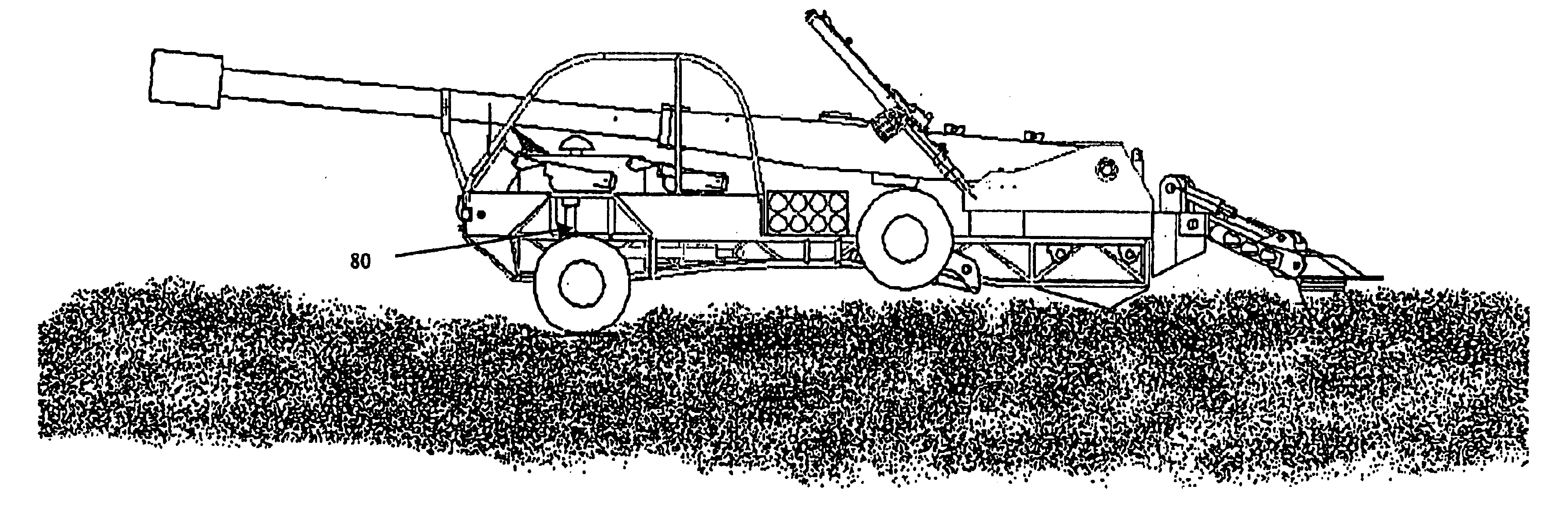

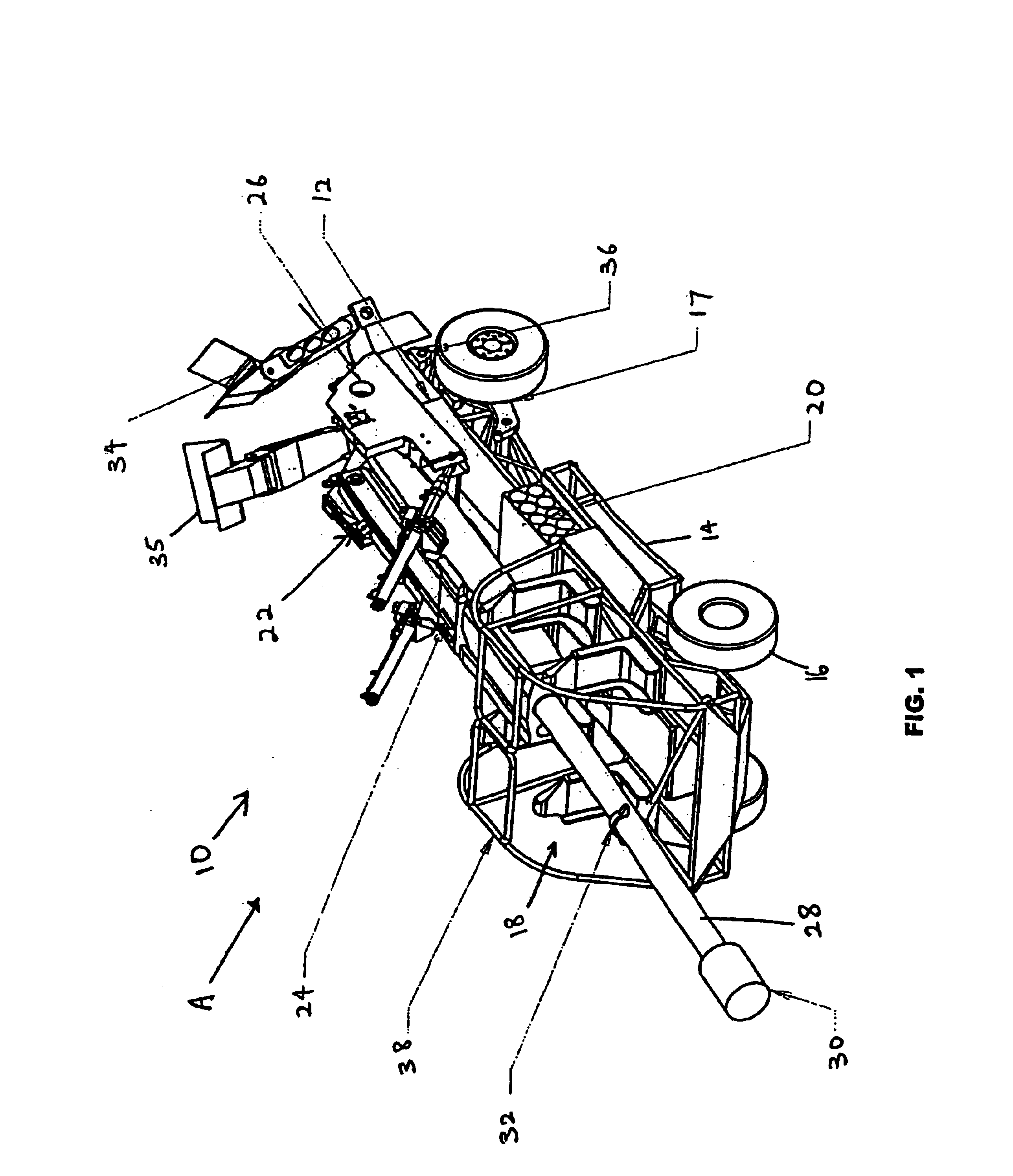

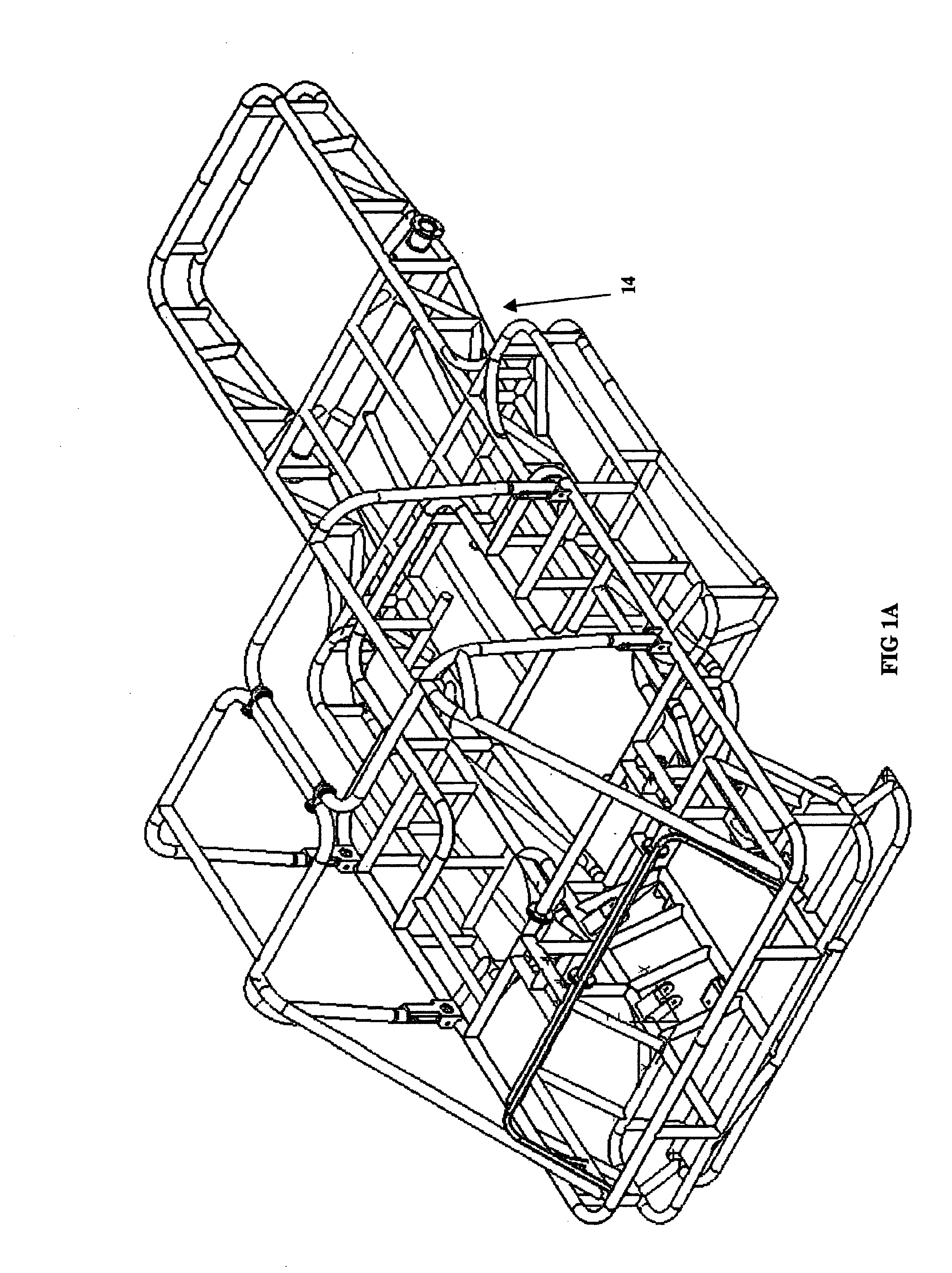

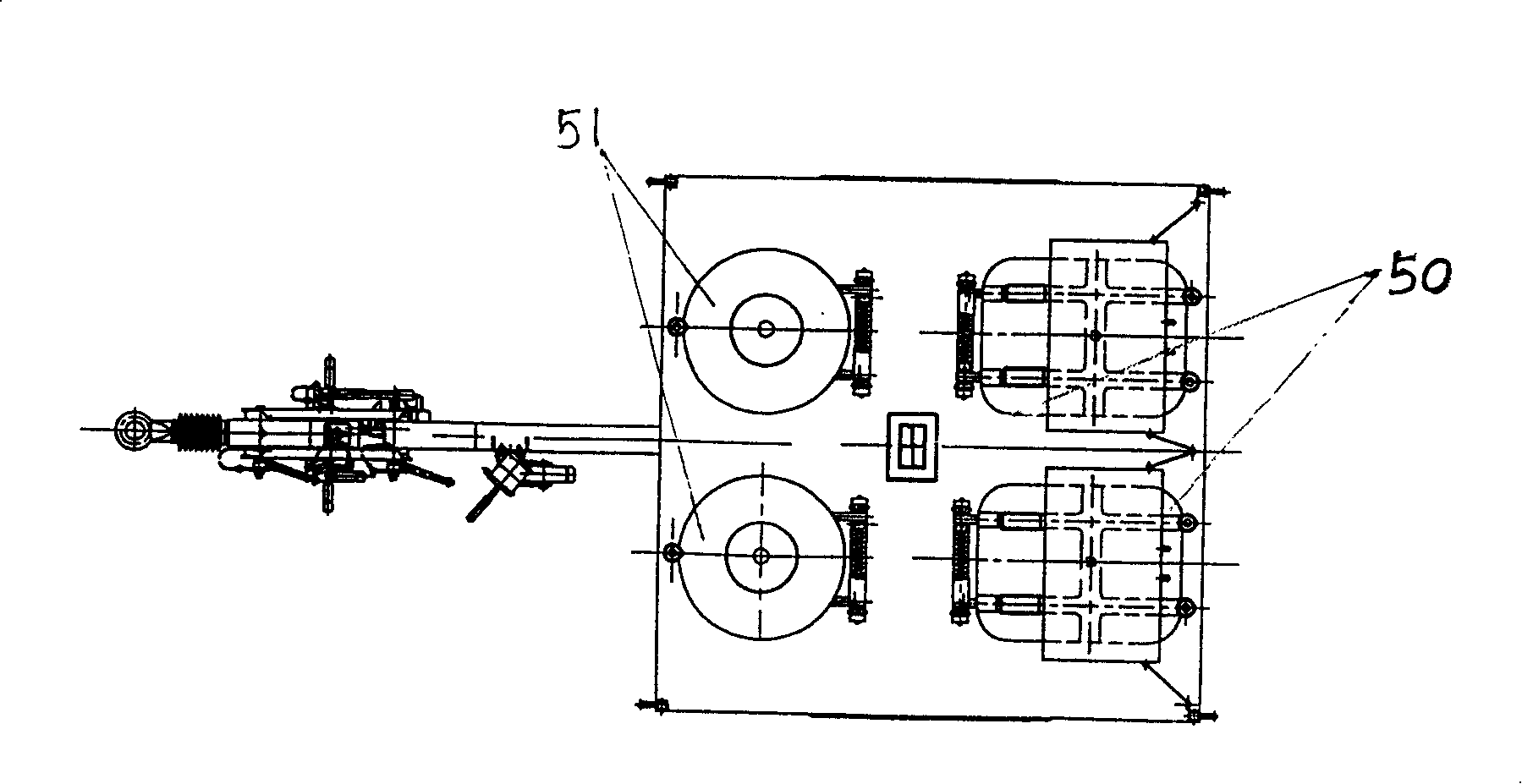

Mobile artillery system

InactiveUS6843159B2Increase firepowerOptimize space allocationFiring/trigger mechanismsGun mountingsEngineeringSpace frame

The invention provides a self-propelled mobile system that is characterized by a lightweight space frame chassis on which is mounted a large caliber artillery piece. The weight of the system is preferably less than 8,000 kg and the artillery piece preferably has a caliber of up to a 155 mm 52 caliber gun. The artillery piece may include a lightweight elevating and traversing mass and gun chassis mounted on a space frame vehicle, such vehicle having a weight which does not exceed 3,800 kg.

Owner:ORDNANCE DEV & ENG CO OF SINGAPORE (1996) PTE LTD

Artificial propagation technical method of Oncorhynchus mykiss

ActiveCN109479772AReduce stickinessIncreased chances of fertilizationClimate change adaptationAccessory food factorsPorcine bloodSulfosalicylic acid

The invention provides an artificial propagation technical method of Oncorhynchus mykiss and belongs to the technical field of fish propagation. The artificial propagation technical method of Oncorhynchus mykiss includes injecting an oxytocic, preparing an isotonic solution, performing artificial egg and semen collection, carrying out artificial semination, hatching eyed eggs, detecting fertilityrate, allowing larvae to emerge and hatch, and carrying out enhanced cultivation of fry, wherein enzymatically-hydrolyzed dried porcine blood cells are added to feed for the enhanced cultivation of fry; the enzymatically-hydrolyzed dried porcine blood cells are prepared via the steps of a, providing anti-coagulating porcine blood; b, providing neutral proteinase; c, providing an accelerant containing sulfosalicylic acid and tea polyphenols; d, pretreating the anti-coagulating porcine blood, allowing the blood to gain contact with the materials of steps b and c to form a hydrolysate, and spray-drying. The artificial propagation technical method of Oncorhynchus mykiss provided herein has the advantages that inter-egg adhesion can be relieved, egg fertility rate is increased, fertilized eggsare never contaminated by pathogens, the fertilize eggs are accelerated to enter a start phase, survival rate and hatching rate of fetuses are increased, and an initial domestication feed with good palatability and sensual experience is provided for assistance.

Owner:ZHEJIANG OCEAN UNIV

Civil multi-purpose furnace capable of economizing firewood and saving coal

InactiveCN103335334AIncrease firepowerFull firepowerLighting and heating apparatusChemical industryThermal energyCombustion chamber

The invention relates to a civil multi-purpose furnace capable of economizing firewood and saving coal. A front furnace mouth is formed in the upper portion of a hearth, wherein the upper portion of the hearth extends to one side to form a gasification combustion chamber, a smoke outlet communicated with a heatable brick bed is formed in the gasification combustion chamber, an opening for cooking is formed in the upper portion of the gasification combustion chamber, a biomass fuel storage box is arranged on the front furnace mouth of the hearth, the lower end of the storage box is provided with a furnace grate which is communicated with the hearth, a clamping sleeve is arranged on the storage box, a water supplement opening and an air inlet with the adjustable size are formed in the outer layer of the clamping sleeve, and a plurality of airflow small holes which are communicated with the storage tank are formed in the inner layer of the clamping sleeve. Coal or firewood or mixture of coal and firewood can be combusted in the hearth, the storage box forms a small biomass fuel gasification device, biomass fuel is converted into flammable gas and made to enter the hearth, no black smoke is produced in the combustion process, the thermal efficiency is high, consumed fuel is greatly saved, and the requirements of a peasant household for cooking thermal energy or other life thermal energy can be met at the same time.

Owner:LIAONING HEBAIYI BIOMASS TECH DEV

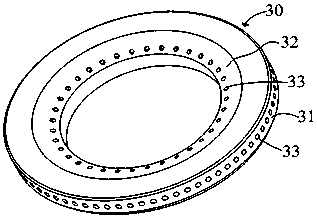

Moxibustion frame

PendingCN106798642AEasy to use and flexibleIncrease firepowerDevices for heating/cooling reflex pointsTherapeutic effectMechanical engineering

The invention discloses a moxibustion frame which comprises a bottom plate and a bendable insertion bar, wherein the bendable insertion bar penetrates through a perforated round hole in the bottom plate; one end of the bendable insertion bar is flush with the bottom and is fixed; the other end of the bendable insertion bar is used for inserting and fixing of a moxa stick. With the adoption of the technical scheme, the bendable insertion bar can be optionally bent according to needs of moxibustion parts so as to adjust the angle of the moxa stick, and the insertion bar is very flexible and convenient to use. Multiple moxibustion frames can be arranged at the moxibustion parts and near the moxibustion parts, so that the heat power is enhanced, and the treatment effect is improved.

Owner:阳文凯

Driver blade with auxiliary combustion chamber for combustion powered fastener-driving tool

InactiveUS20060043140A1Reduce weightReducing overall tool weightStapling toolsReciprocating drilling machinesCombustion chamberPiston

A driver blade for use in a combustion-powered fastener-driving tool includes an elongate tubular body having a combustion end and a driving end, the combustion end being configured for attachment to a piston, and the driving end having a substantially solid cross-section. The tubular body is in fluid communication with a tool combustion chamber.

Owner:ILLINOIS TOOL WORKS INC

Novel biomass flavored healthcare mixed fuel formula and preparation method thereof

InactiveCN106433843ASolve the problem of shortageImprove protectionBiofuelsSolid fuelsLivestock manureAdditive ingredient

The invention discloses a novel biomass flavored mixed fuel formula and a preparation method thereof. The novel biomass flavored mixed fuel formula comprises, by weight, 80 to 90 parts of biomass mixed briquette, 5 to 8 parts of flavored mixed powder, and 2 to 3 parts of the mixed binder, wherein the biomass mixed briquette comprises coal, binder, plant waste, wood processing waste, livestock manure, and traditional Chinese herbal medicine waste. The flavored healthcare mixed powder comprises lavender, rose, jasmine, folium artemisiae argyi, tussilago farfara, aster, cymbopogon, mint, mosquito-repelling vanilla and acorus gramineus; the mixed binder comprises adhesives, water or food waste oil, and the flavored healthcare mixed adhesive powder wraps the briquette. The novel biomass flavored mixed fuel formula makes full use of waste, is energy saving and environment friendly, aroma and the beneficial ingredients to the human body are released during combustion, and the novel biomass flavored mixed fuel formula has the effects of human health and mosquito repellent.

Owner:易小拥 +1

A high-efficiency three-ring fire burner and gas stove

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

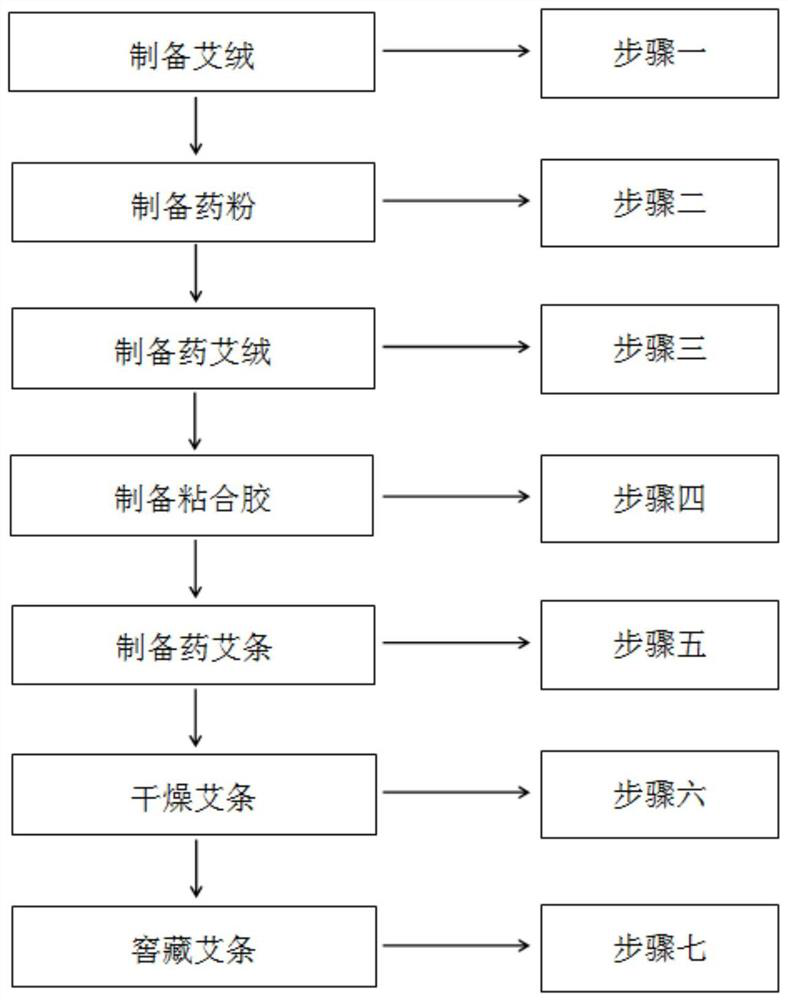

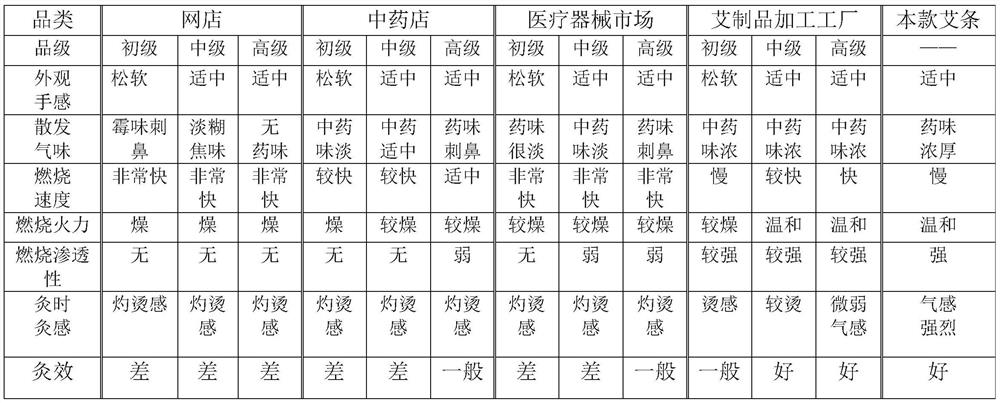

Formula and preparation method of Miao medicine Chinese mugwort moxibustion stick

InactiveCN113134029AImprove permeabilityReduce time and consumable costsDevices for heating/cooling reflex pointsAntipyreticChemistryMyrrh

The invention relates to preparation of a Miao medicine Chinese mugwort moxibustion stick, in particular to a formula and a preparation method of the Miao medicine Chinese mugwort moxibustion stick, and the Miao medicine Chinese mugwort moxibustion stick comprises the following components: cinnamon, clove, cassia twig, knotty pine wood, radix angelicae pubescentis, sulfur, myrrh and ligusticum wallichii. The invention discloses a Miao medicine Chinese mugwort moxibustion stick formula and a preparation method. The preparation method comprises the following steps: step 1, preparing moxa floss; step 2, preparing medicine powder; step 3, preparing medicinal moxa floss; step 4, preparing adhesive glue; step 5, preparing a medicinal moxa stick; step 6, drying the moxa sticks; and step 7, cellaring the moxa sticks. The Chinese mugwort moxibustion stick prepared by the production process is strong in medicine flavor, mild in firepower and strong in permeability.

Owner:中贞生物科技(河南)有限公司

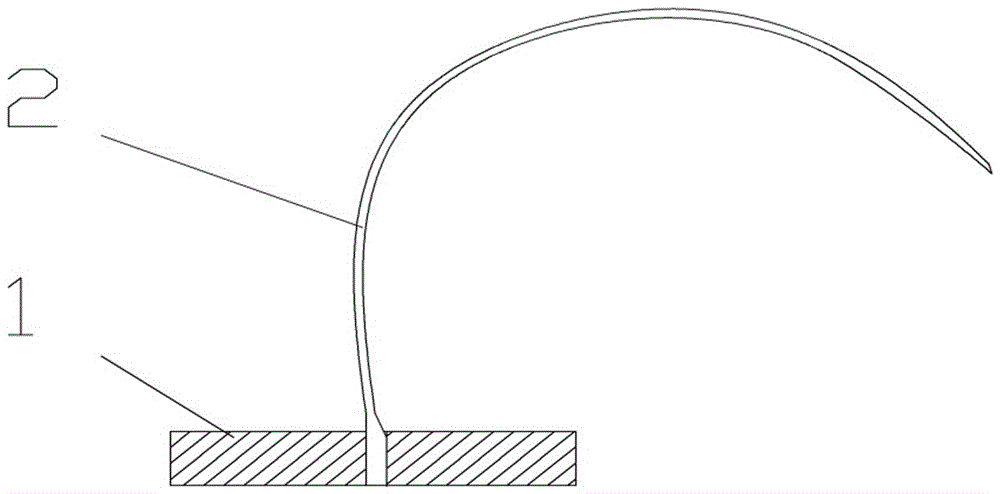

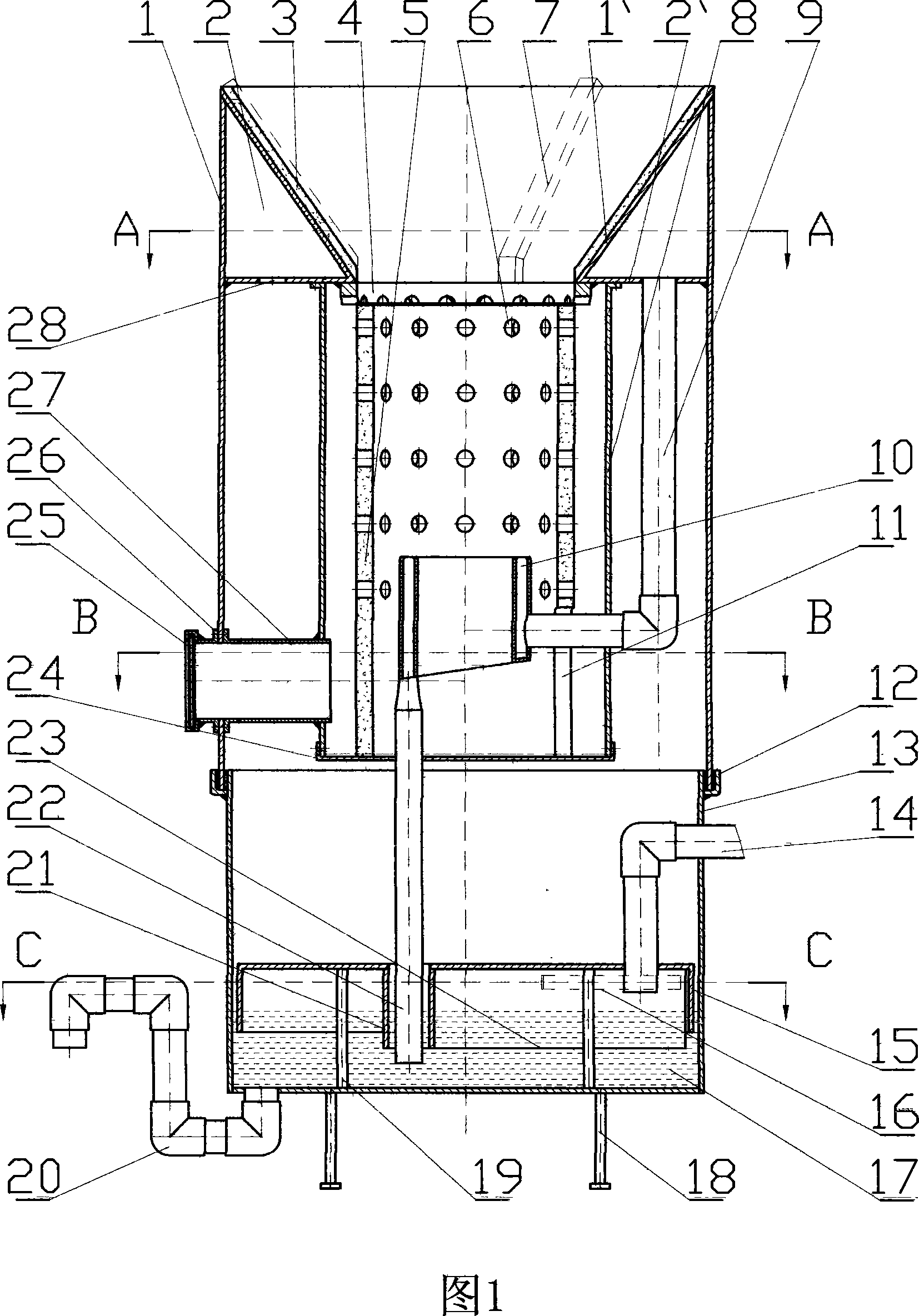

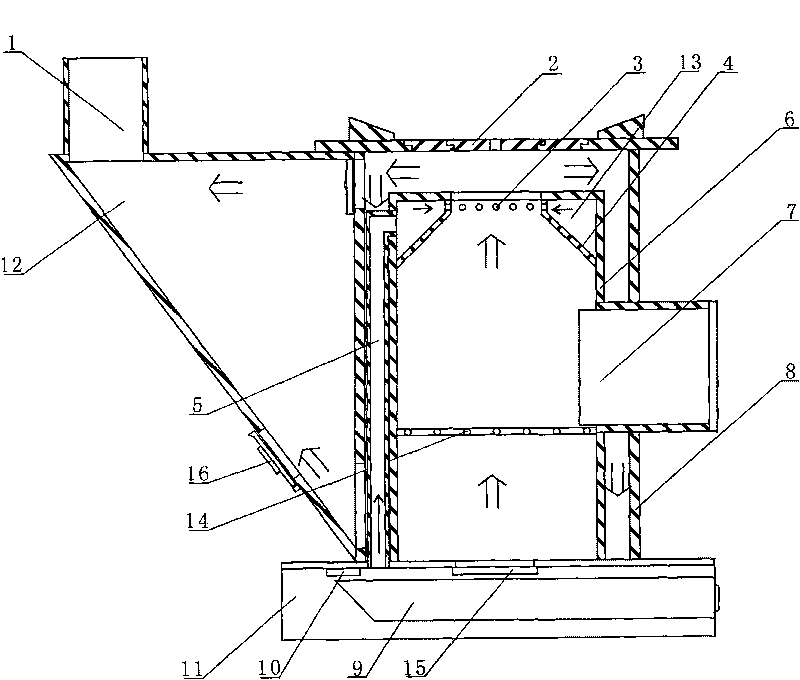

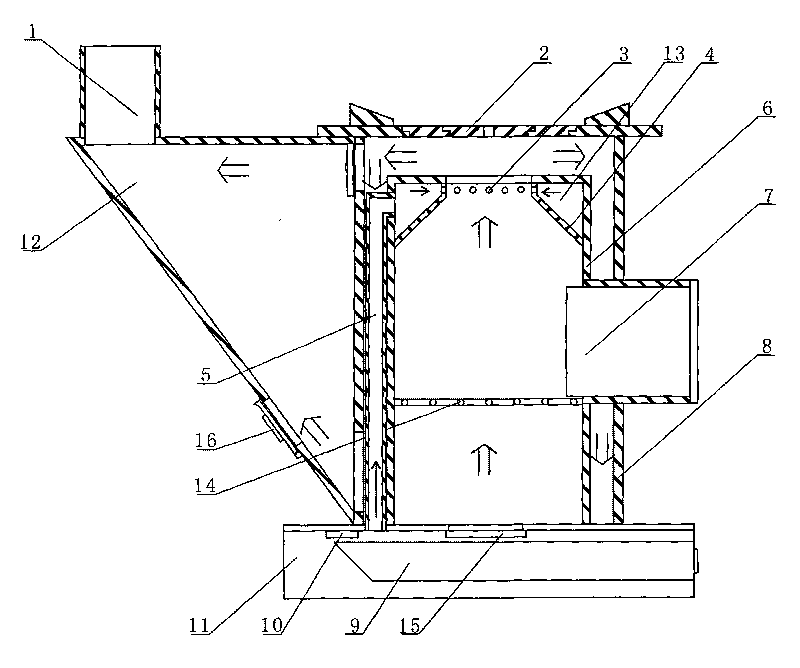

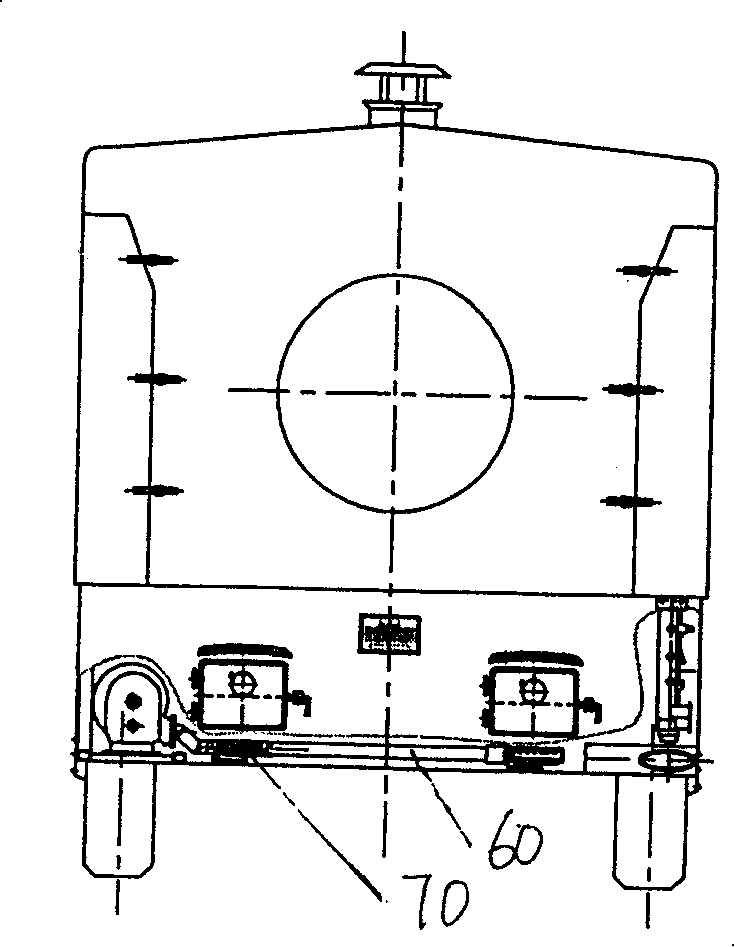

Gas kitchen range and gas generator supplying gas to the same

InactiveCN101162093AIncrease the preheating cavityIncrease pressureDomestic stoves or rangesLighting and heating apparatusRural areaTar

The invention discloses a gas range and a generating furnace supplying gas for the gas range, relating to the industrial and household range field; the gas range consists of a range body(1), a range barrel body(5), a cold-hot gas shielding cover(8), a gas applicator(10), a gas purification barrel(11), an air inlet pipe(14), a gas purification disc(15), rang feet(18), a tar discharge pipe(20), a tar guiding pipe(22), an outer air inlet barrel(26) and an ignition device(30); the generating furnace consists of a furnace barrel body(44), a furnace core(61), an air duct(50), a hot water bucket(42), a furnace cover(35), a back taper place(37), a liquid drainage groove(38), an air applicator(51) and a sealing palace-type gas purification device; the invention has the advantages of convenient use and maintenance, high conversion efficiency of fuel, good effect of gas purification and strong fire power, etc.; the invention can fully use the agriculture crop wastes or flammable industrial and household wastes, thereby the invention is suitable to be used not only by dwellers in rural areas and small towns, but also by enterprises and institutions; moreover, the invention can also be used to dispose wastes for heat supply.

Owner:湖南中正机电设备有限公司

Coal-saving agent and preparation process thereof

InactiveCN108795533APromote combustionImprove combustion conditionsSolid fuelsHeat transmissionSulfur

The invention relates to a coal-saving agent and a preparation process thereof. The coal-saving agent comprises, in weight percent, 6-12% of catalysts, 1-7% of combustion improvers, 25-35% parts of penetrating agents, 25-35% parts of bulking agents, 7-15% of cleaners, 10-20% of dispersing agents and 7-12% of sulfur fixing agents. According to the coal-saving agent, combustion conditions of a furnace body can be improved, coal seam permeability is enhanced, coal is sufficiently combusted, coal burning heat efficiency is improved, soot emission volume is reduced, heat transmission efficiency isimproved, sulfur is fixed, smoke is reduced, emission of CO and SO2 is reduced, environmental pollution is reduced, so that combustion is facilitated, the sulfur is fixed, energy is saved, the sulfuris removed, coal can be saved by 5%-10%,heat power is improved by 10% or more, carbon deposit is removed by 50-90%, and the sulfur is reduced by 20-50%.

Owner:纪和春

Return air gasifier for charging air from bottom

InactiveCN101718440AIncrease profitEasy to openDomestic stoves or rangesLighting and heating apparatusInlet channelHeating effect

The invention discloses a return air gasifier for charging air from the bottom and relates to a civil stove. An air inlet channel is arranged on the top of a hearth, one end of a secondary air inlet pipe is communicated with the air inlet channel, and an opening at the other end is arranged in a base. The opening is provided with a secondary air inlet door, and an opening at the lower end of the hearth is provided with a main air door. The secondary air inlet door is linked with the main air door, namely when the main air door is opened, the secondary air inlet door is closed, and when the secondary air inlet door is opened, the main air door is closed. A return air stove state and a gasifier state can be conveniently switched, thus the invention has the advantages of large firepower of the return air stove and high utilization rate of the gasifier. The secondary air inlet door arranged at the bottom is convenient to open and close and cannot influence the appearance of the stove, the smoke discharge of a flue and the diameter of the hearth, thus ventilation in the hearth is smooth. The invention also has the advantages of fuel saving, high burning efficiency, large firepower and good heating effect.

Owner:张孝文

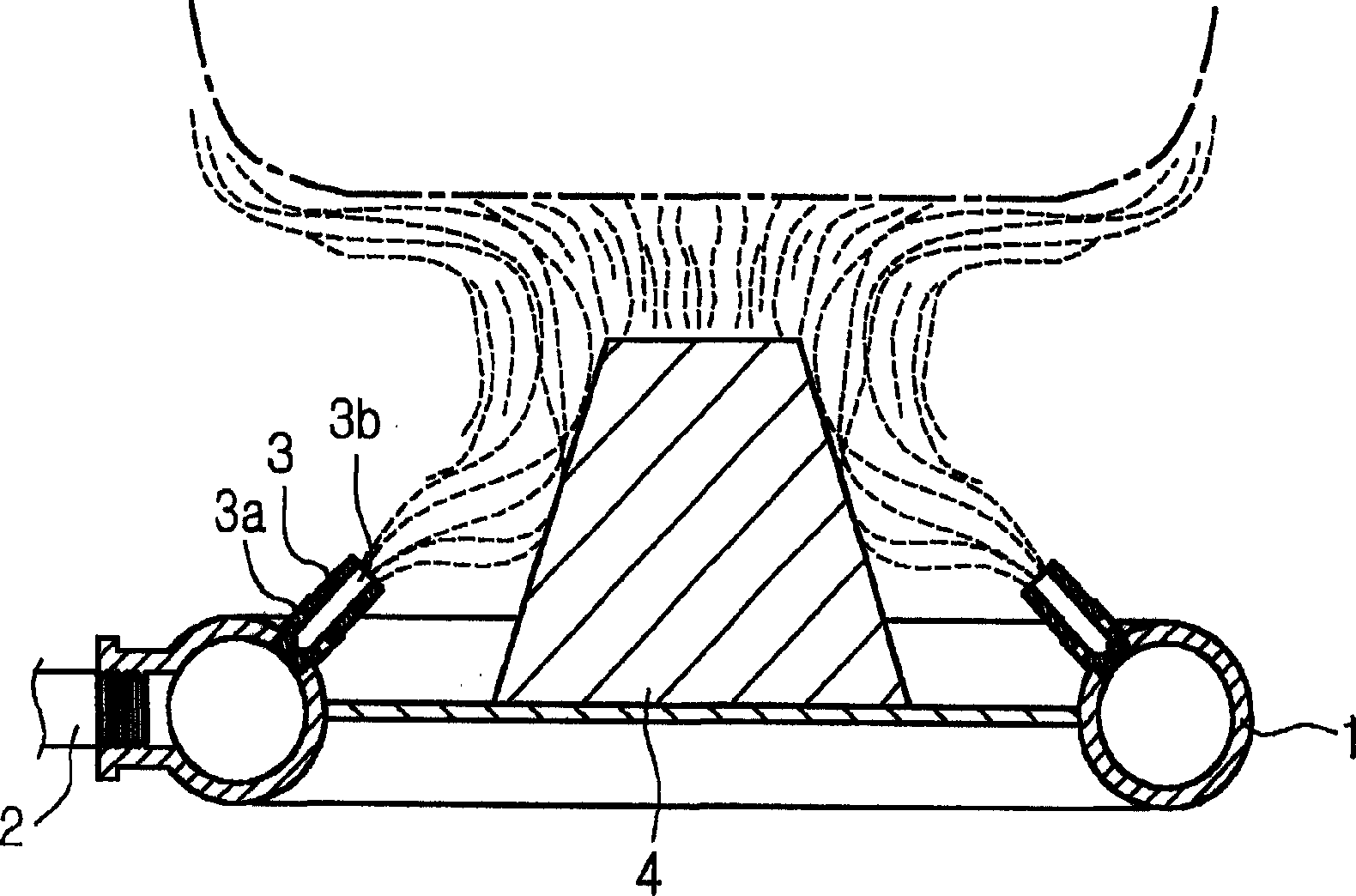

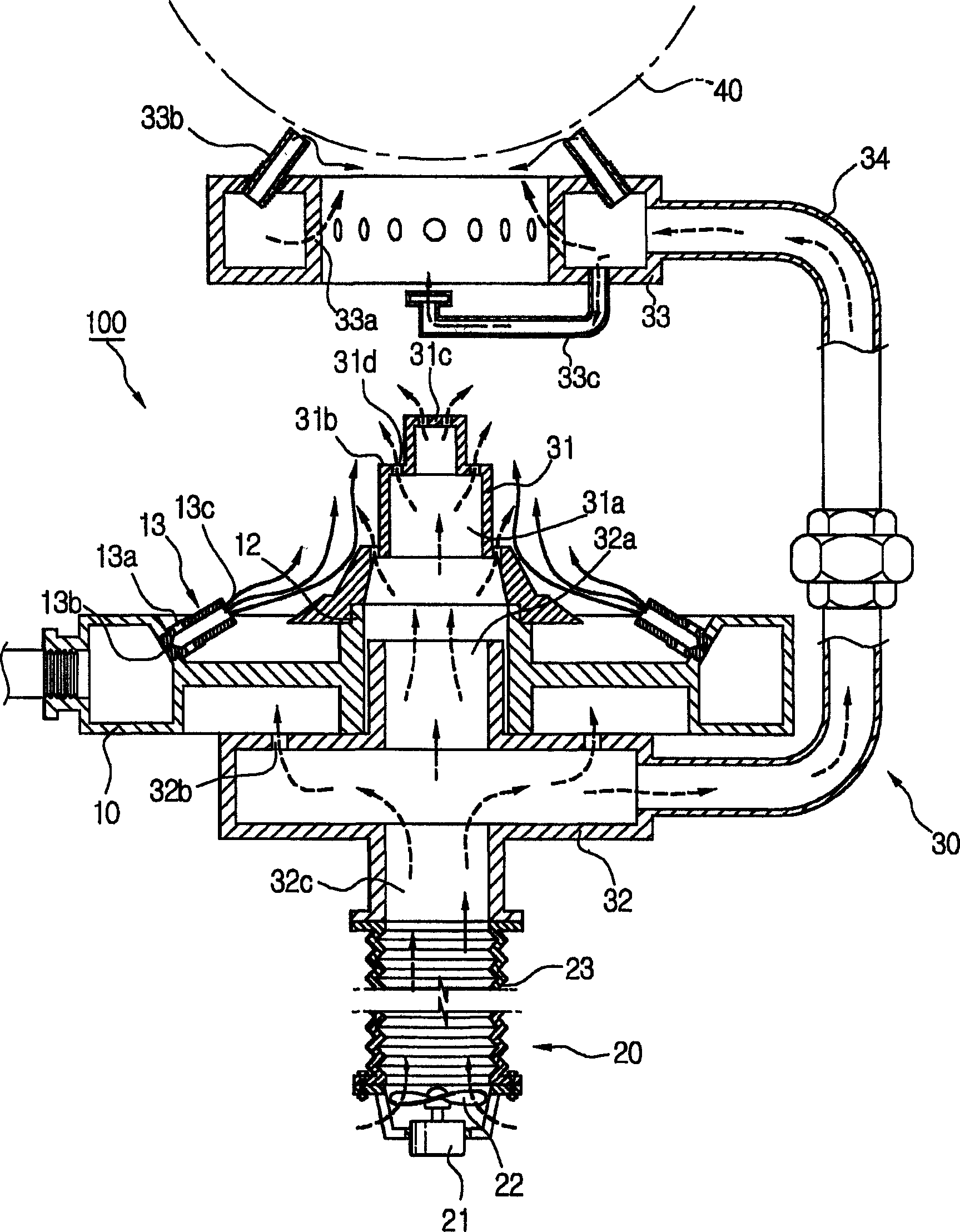

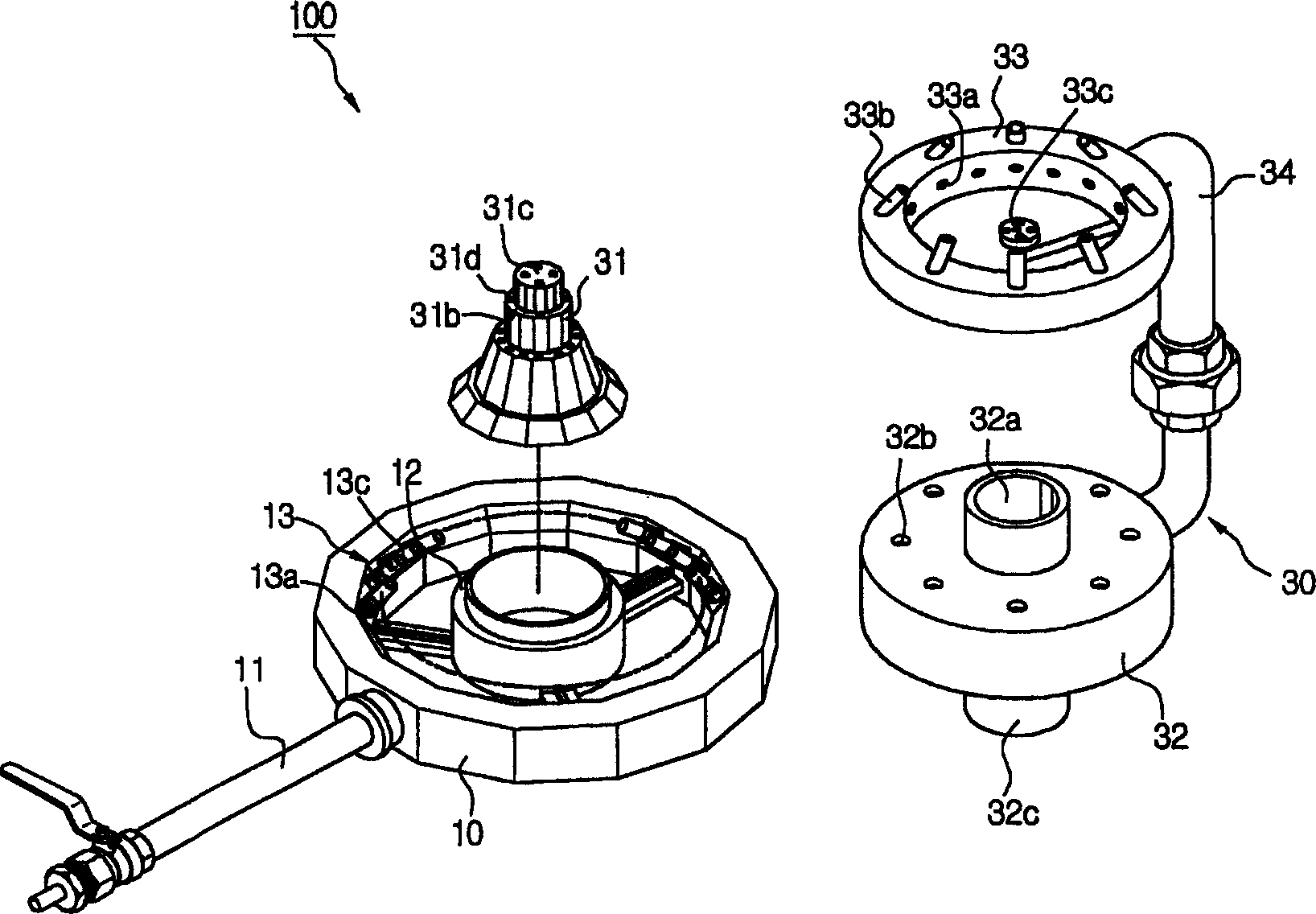

Device for increasing heat power of gas burner

InactiveCN1537211AStrong firepowerIncrease firepowerContinuous combustion chamberStaged combustionGas burnerHeating efficiency

The present invention relates to a device for increasing heat power of a gas burner, and an object of the present invention is to provide a device for increasing heat power of a gas burner, capable of improving heat efficiency by making the supplied gas to the gas burner burn completely and maintaining an intense heat power. The device for increasing heat power of a gas burner is comprised of a gas burner comprising having a gas inlet pipe formed on one side of a burner header, a plurality of burner tips formed on the upper side thereof, and a cap fixed within said burner header; and a heat power increasing means is further provided so that the means increases a heat power as well as aid the combustion of the dispersed gas from said burner tips by discharging the air blown by a blowing fan provided on the lower side of said burner header around said burner header.

Owner:隋丰富 +1

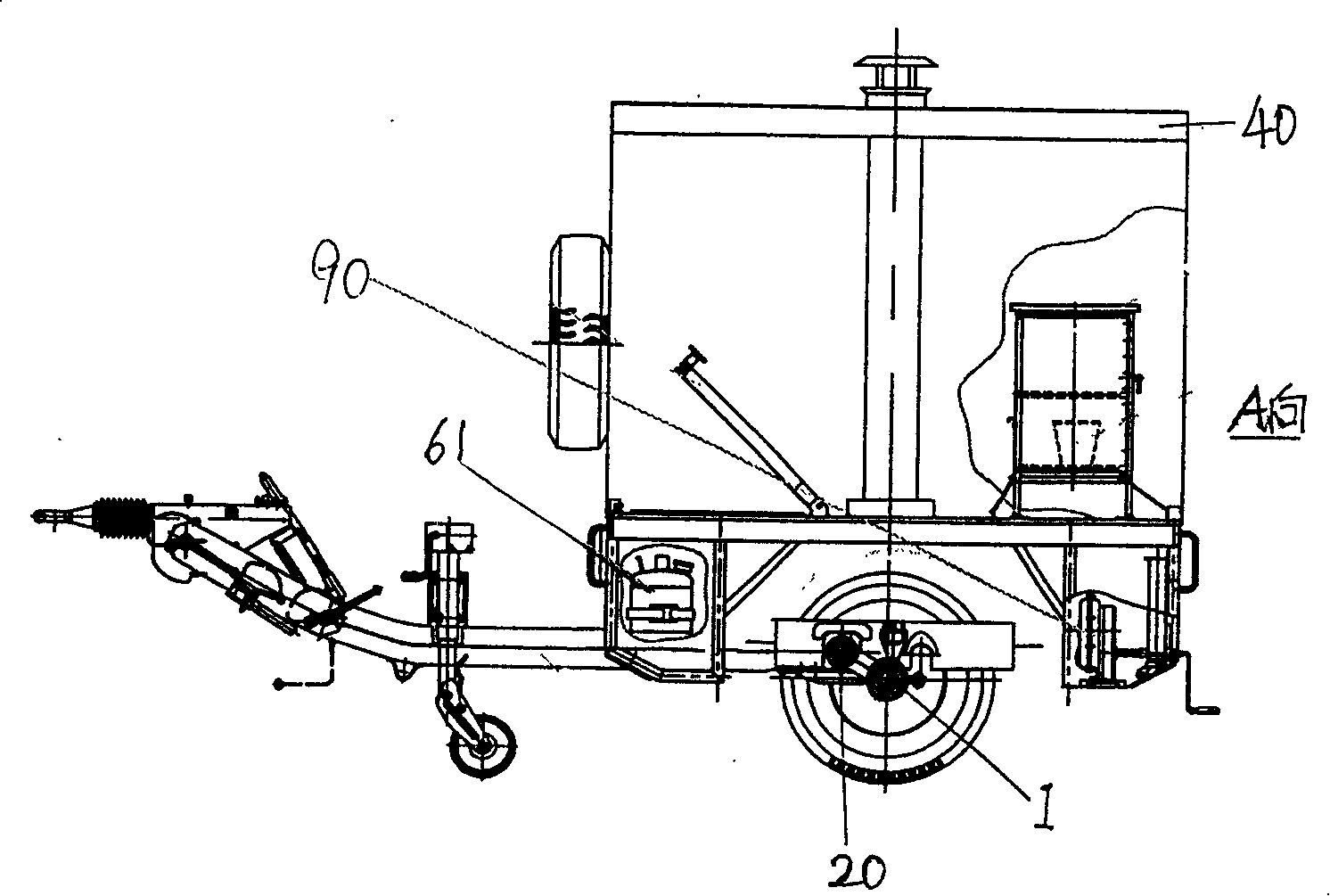

Kitchen trailer

InactiveCN100400319CImprove stabilityRealize terrestrializationBraking element arrangementsVehicle with living accommodationGravity centerEngineering

The kitchen trailer includes chassis, carriage on the chassis, trailer hookup, trailer inertial brake, awning, cooking oven, staple food making apparatus, and non-staple food making apparatus. It features the horizontal concentric torque shaft independent trailer hookup, back running self-inducing inertial brake, servo completely opened umbrella-shaped awning system, multipurpose rice cooker kit, fast preheating diesel oil burner, separate oil-gas converting pipeline and small hand blast blower. The present invention has low gravitational center and other advantages and may be used widely in field cooking operation.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com