Integral compound gasification stove

A gasification furnace, an integrated technology, applied in the field of stoves that produce gas from biomass fuels, can solve the problems of wood tar, easy to generate smoke, quantity and density that cannot meet the requirements, etc., to achieve wide adaptability of raw materials and easy operation Convenience and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

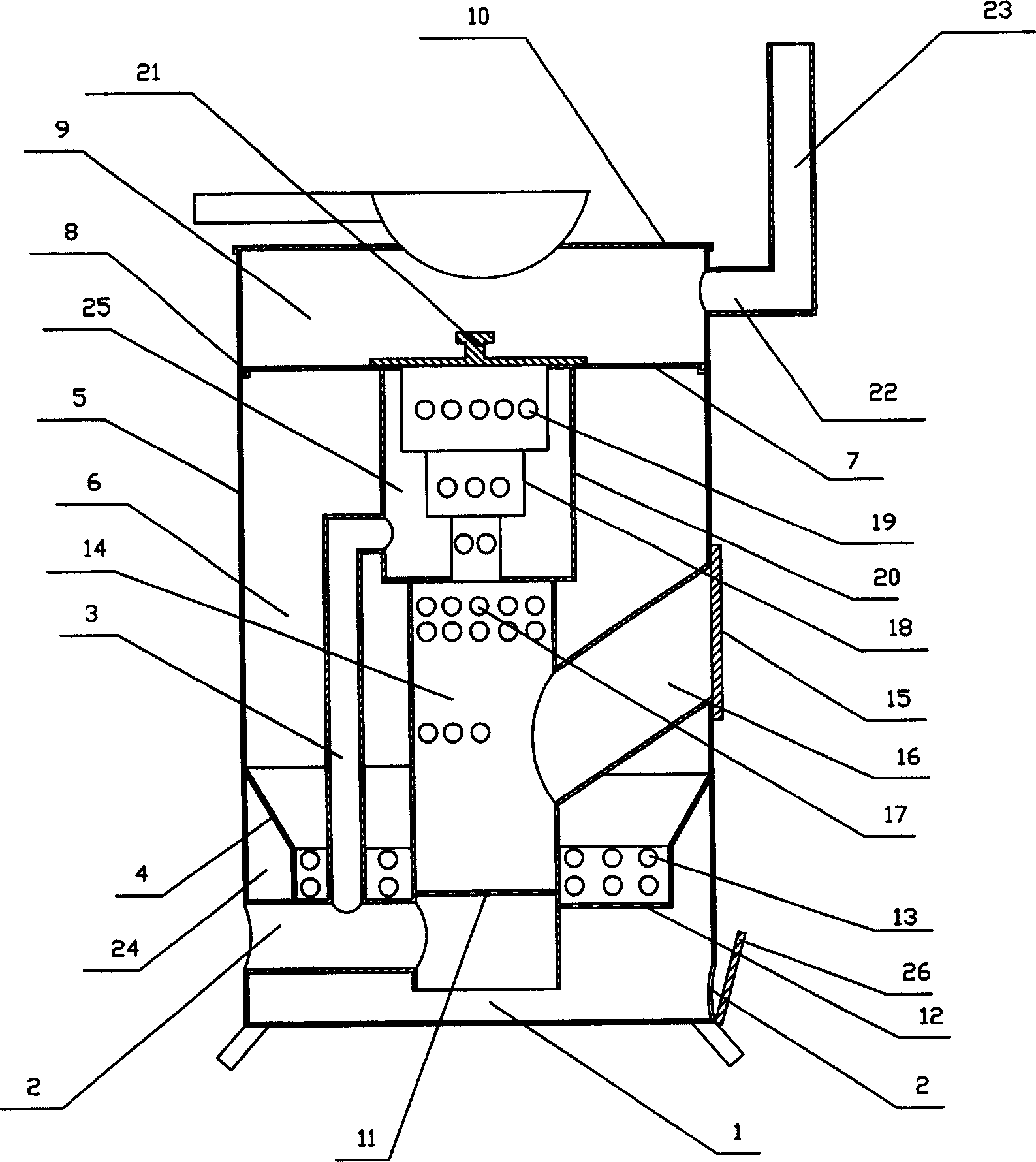

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] In the accompanying drawings, there is an oxidation combustion chamber 14 in the gasification furnace hall 6, and the upper end of the oxidation combustion chamber 14 is connected with multiple oxygen distributors 20. The multi-time oxygen distributor 20 has three cylindrical oxygen distribution plates 18 with different diameters. There are many evenly distributed oxygen supply holes 19 on the oxygen distribution plate 18. An oxygen supply ring 25 is formed between them, and the oxygen supply ring 25 communicates with the air inlet 2 through the multiple oxygen distribution pipe 3, and the multiple oxygen distribution device 20 is also equipped with a fire extinguishing cover 21. There are a plurality of gas holes 17 at different heights on the upper part of the chamber wall of the oxidation combustion chamber 14, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com