Kitchen trailer

A technology of cooking and suspension devices, which is applied to vehicle parts, vehicles including people's daily utensils, elastic suspensions, etc., can solve the problems of small protective area of the canopy, high chassis of trailers, and inability to reverse cars and trains, etc., to achieve protection and covering The effect of increasing the area, reducing labor intensity and realizing the effect of grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

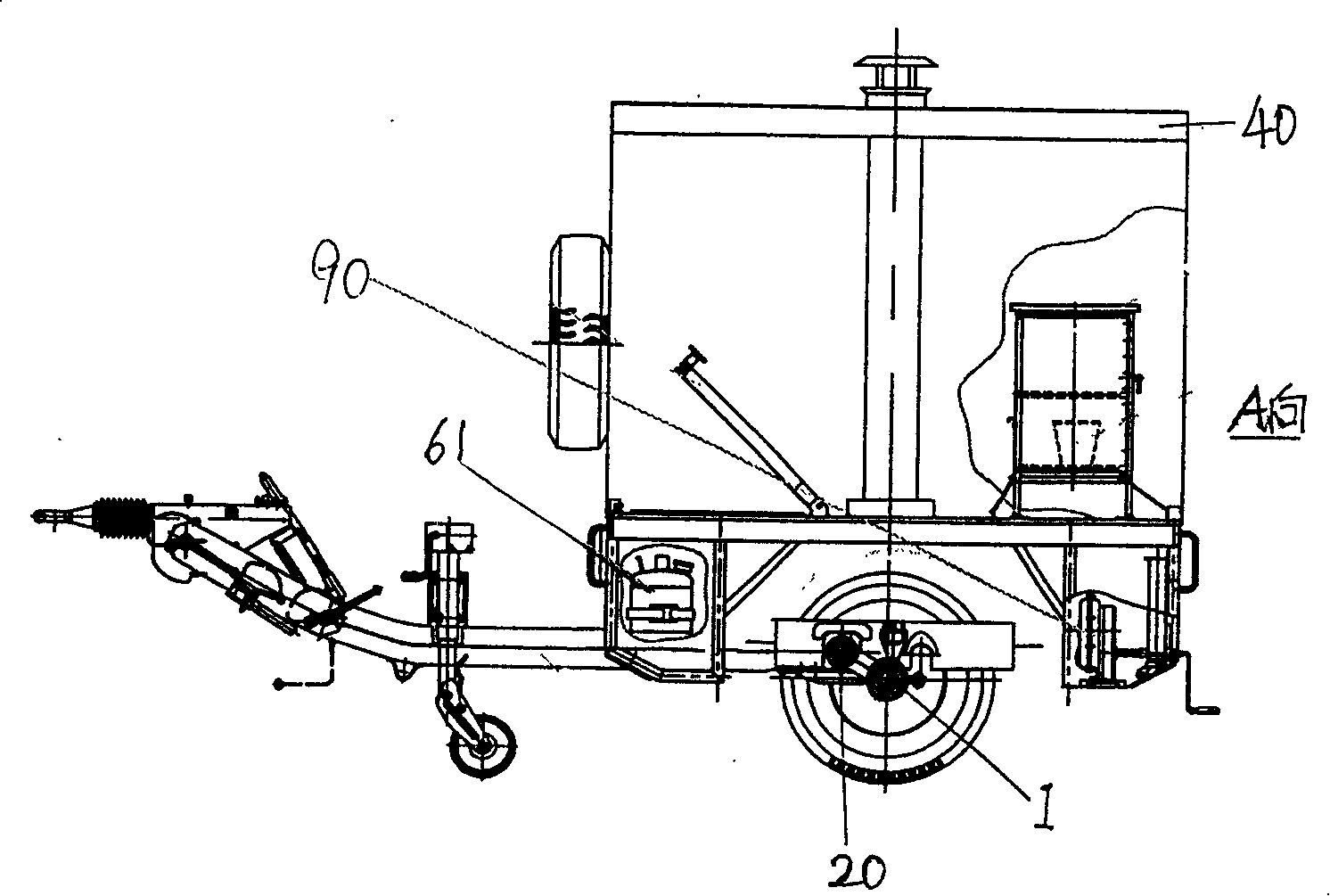

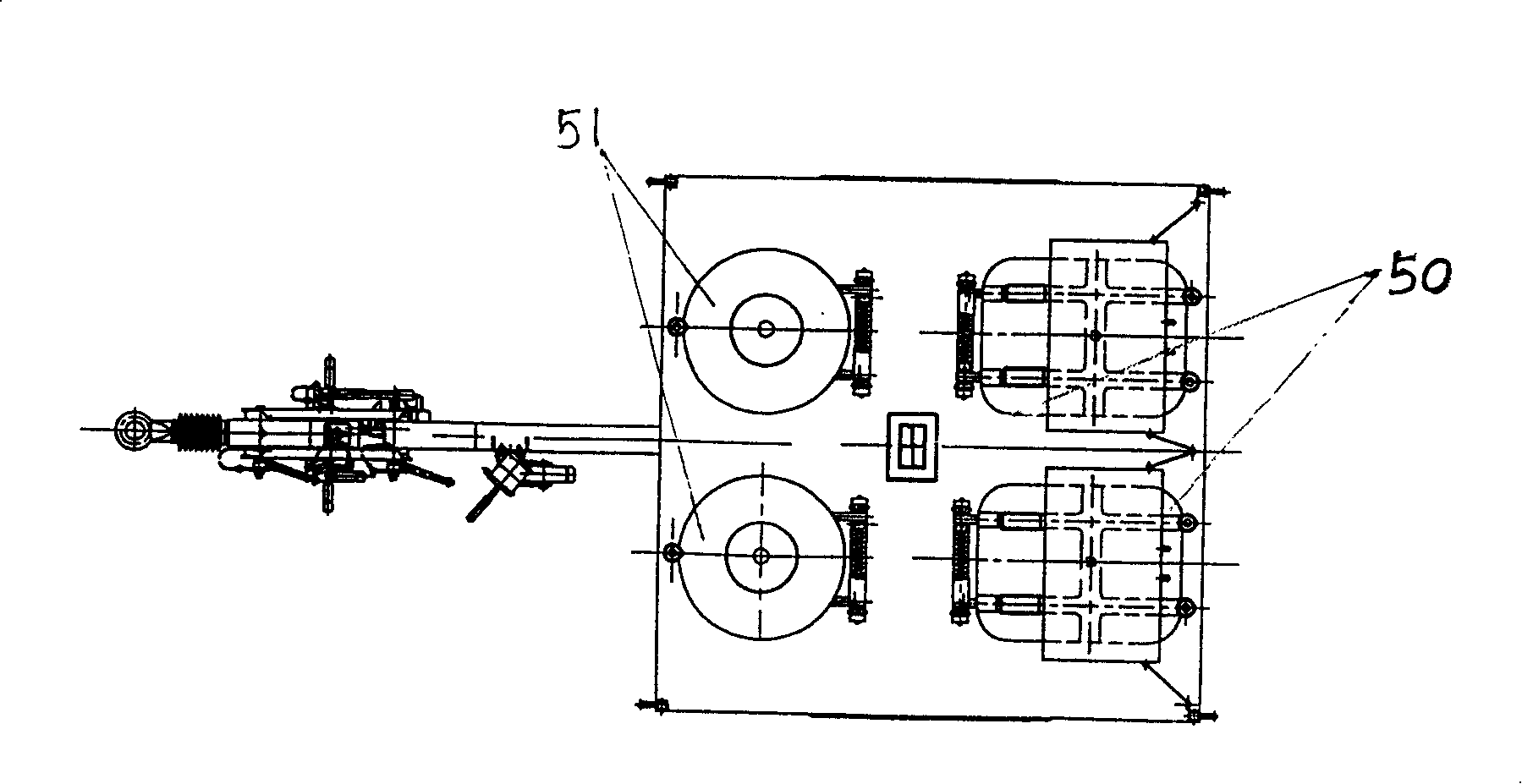

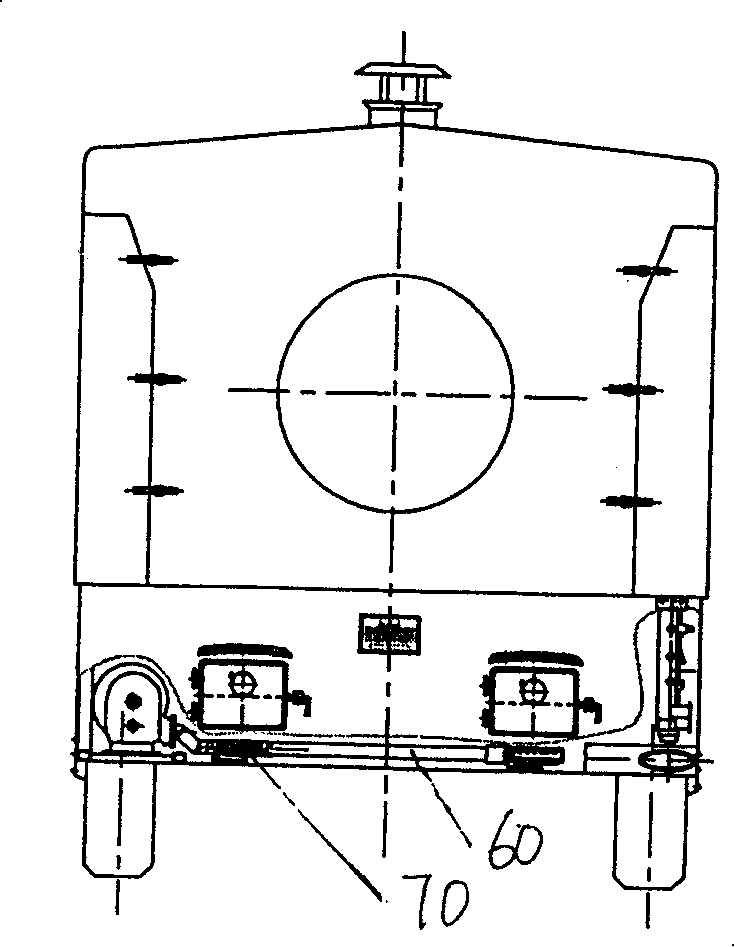

[0027] Such as figure 1 , figure 2 , image 3 As shown, the trailer of the present invention comprises a trailer chassis, a cabin body arranged on the chassis, a trailer suspension device 1, a trailer inertia braking device 20, a trailer cover 40, and main and non-staple food including a staple food pot 50 and a non-staple food pot 51. Processing equipment, cooking appliances including oil and gas inlet pipe 60 and diesel burner 70, and other auxiliary equipment including small hand blower 90.

[0028] Such as figure 1 , Figure 4 As shown, the trailer suspension device 1 of the present invention includes two left and right concentric torsion shafts 2 arranged symmetrically, one end of each torsion shaft 2 is connected to a spline shaft 3 by a spline, and the other end is connected to a small bracket 4 . The spline shaft 3 is connected with the large bracket 7 through two copper bushes 5, 6, the large bracket 7 and the small bracket 4 are respectively welded on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com