Patents

Literature

168results about How to "Fierce firepower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

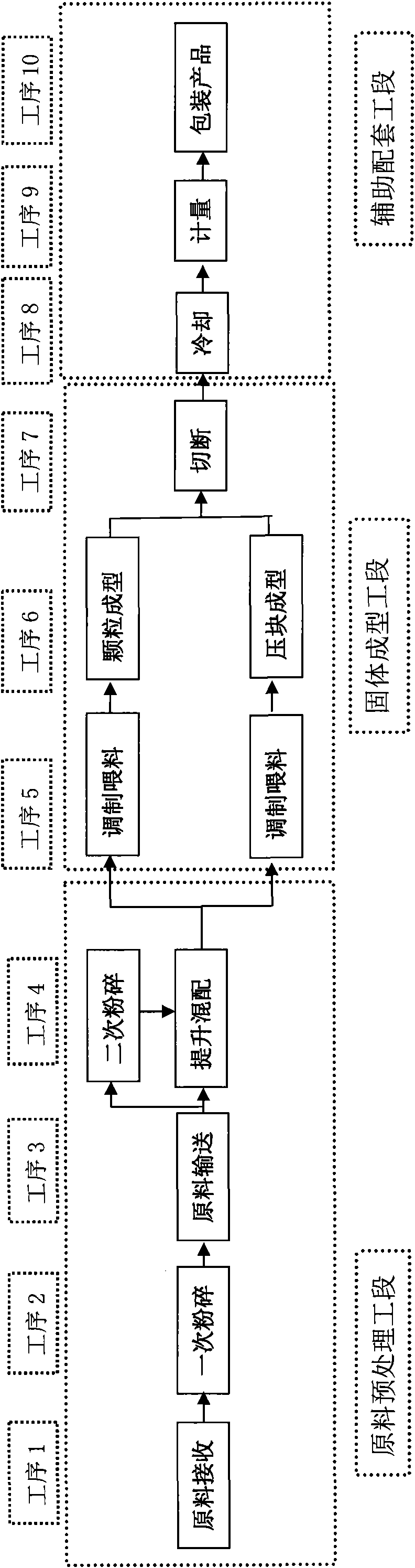

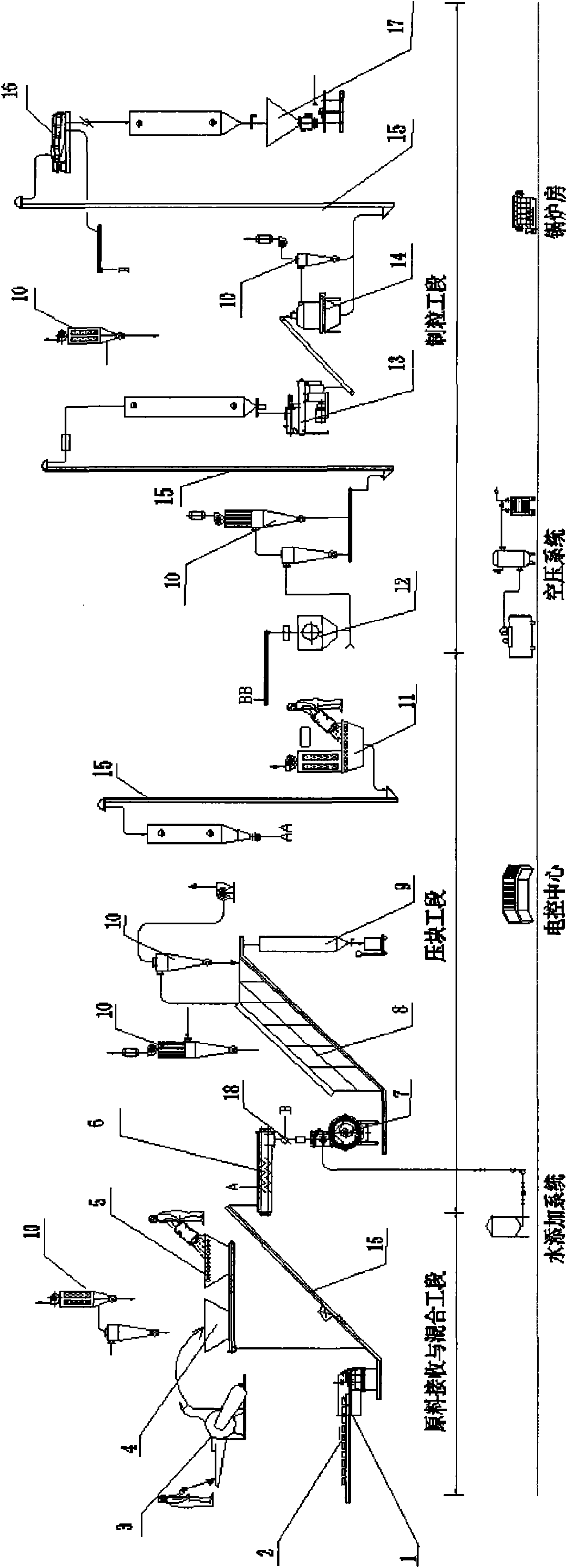

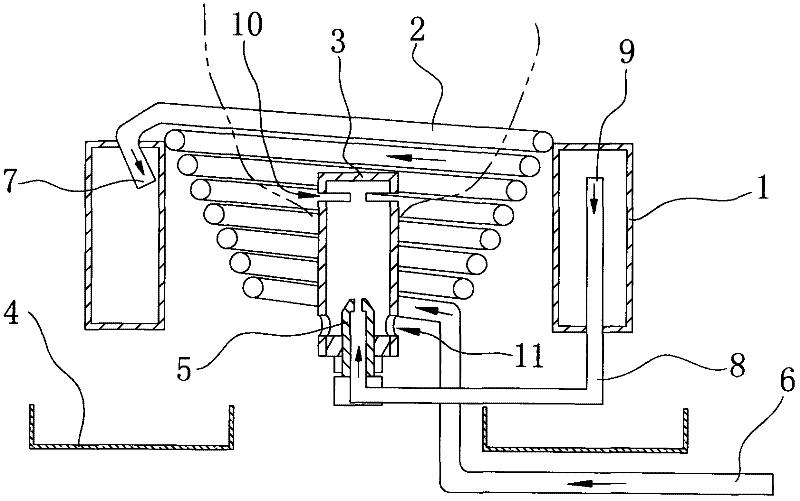

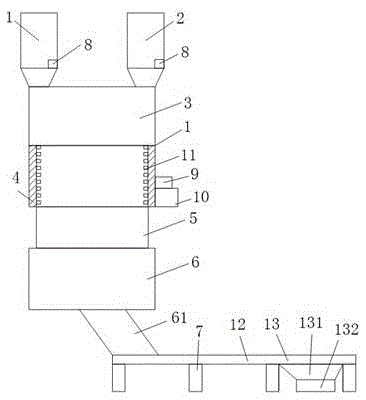

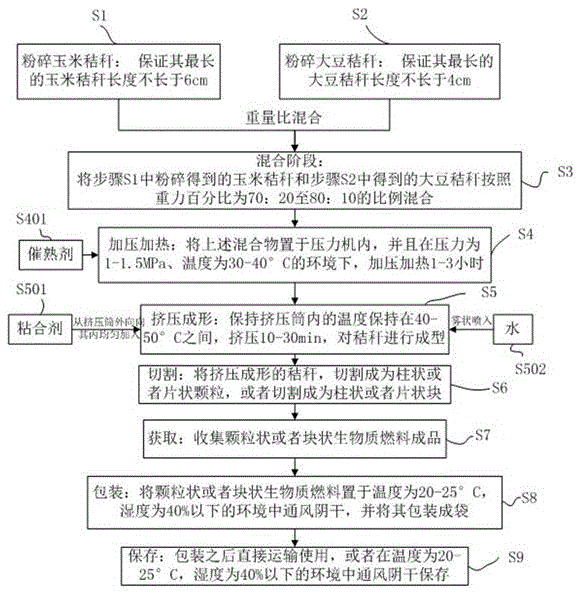

Processing method for biomass solid molding fuel

InactiveCN101555429AImprove processing capacityImprove market competitivenessBiofuelsSolid fuelsBiomassCrop

The invention discloses a processing method for biomass solid molding fuel, which pertains to the technical field of solid fuel and aims at solving problem of comprehensive use of energy and biomass energy in rural areas. The technical proposal is as follows: biomass energy such as crop straws, shrub forest, forestry residues and the like are used as raw materials, and the secondary crushing technique and the mixed technique combining continuous feeding with adjustable feeding are adopted, therefore, two types of solid fuels, namely, block-type and granular fuels, can be produced. The technical proposal comprises three stages namely, pre-treatment of raw materials, solid molding and auxiliary assorting, and the specific working procedures comprise raw material cracking, drying, conveying, mixing, feeding, molding, cutting, cooling and measuring and packaging and adding a compulsory ventilating dust-removing system during the whole process. The processing method for biomass solid molding fuel solves the problem of diversification of biomass raw materials, and the biomass solid fuel production line constructed by adopting the processing method realizes the industrial continuous and stable production, solves the problems of high energy consumption and low production efficiency in the existing small workshop-style production, and is also beneficial to solving the rural energy problem and improving the rural environment.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

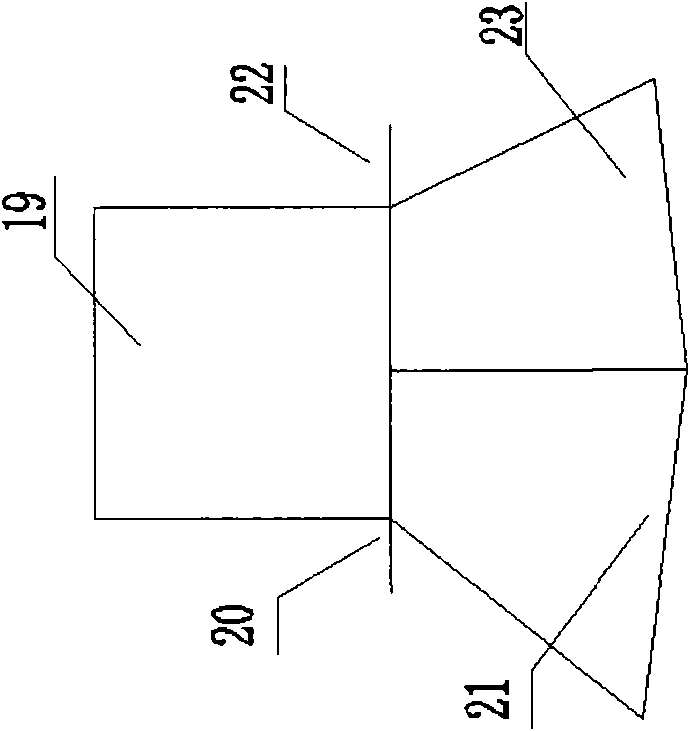

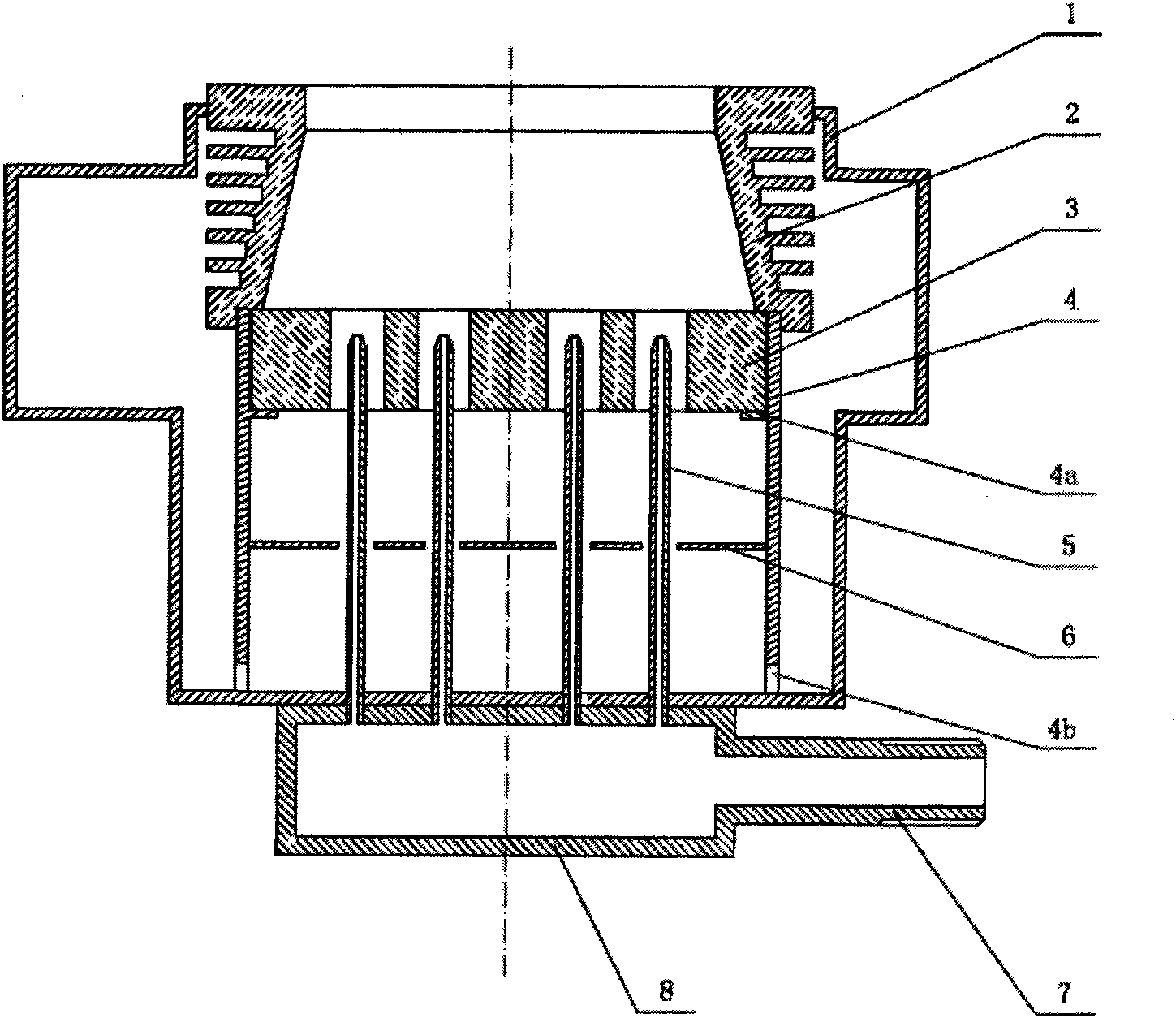

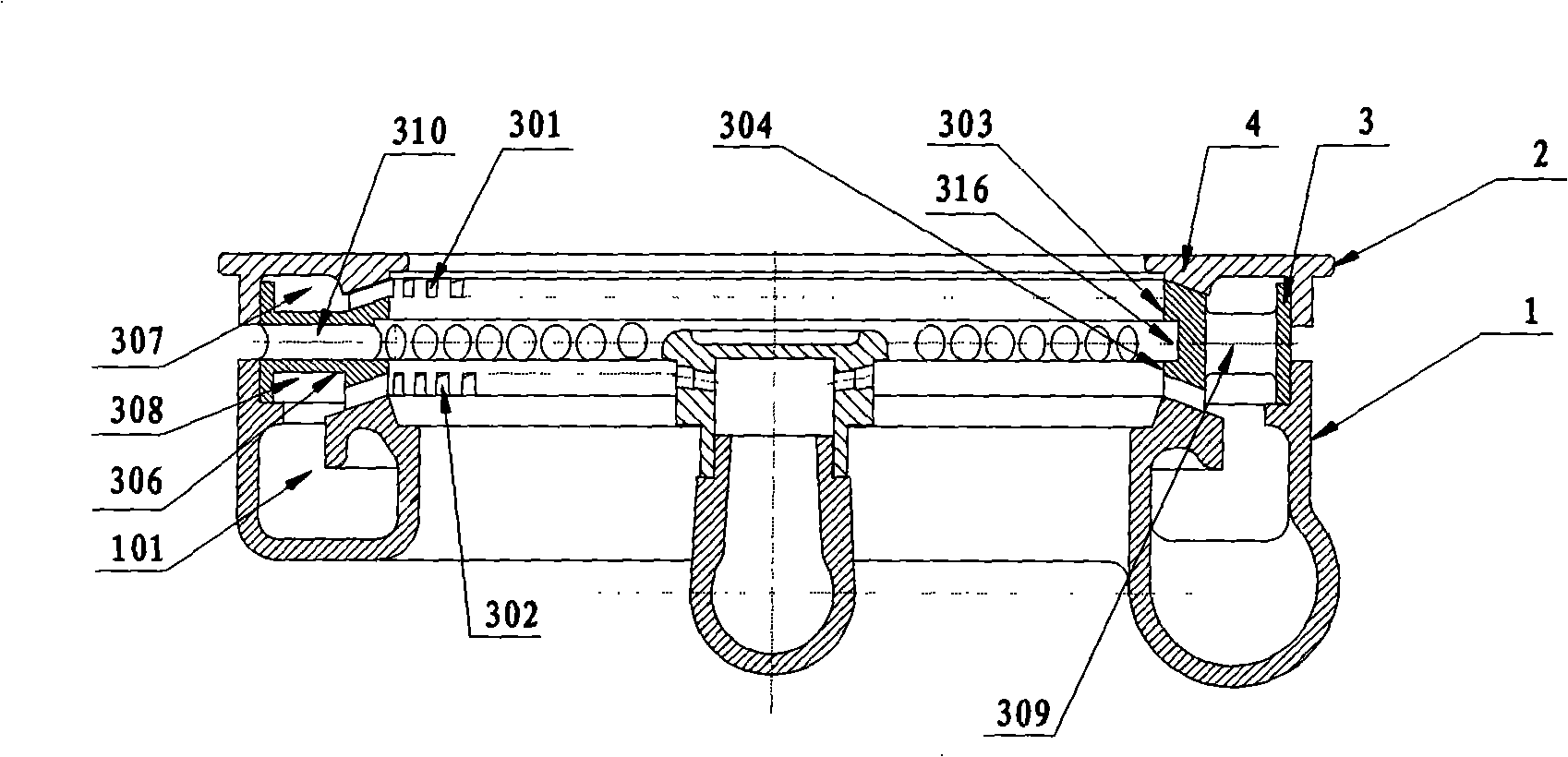

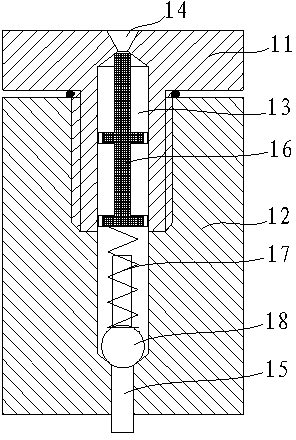

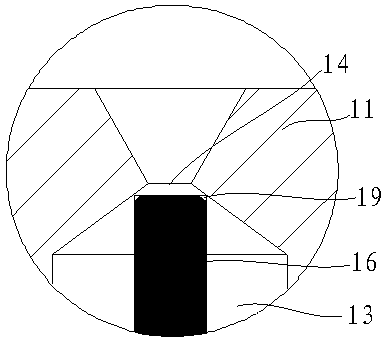

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

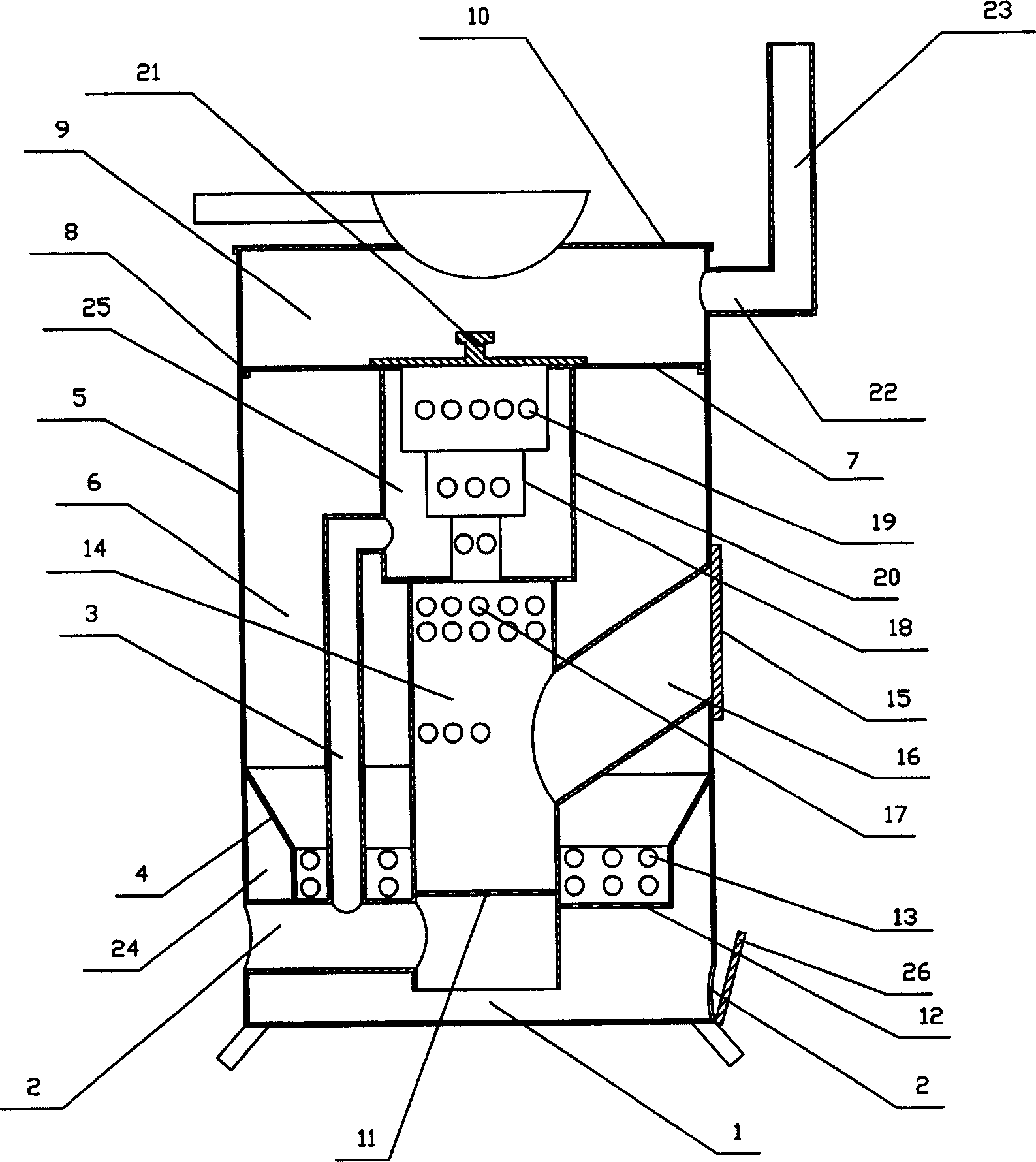

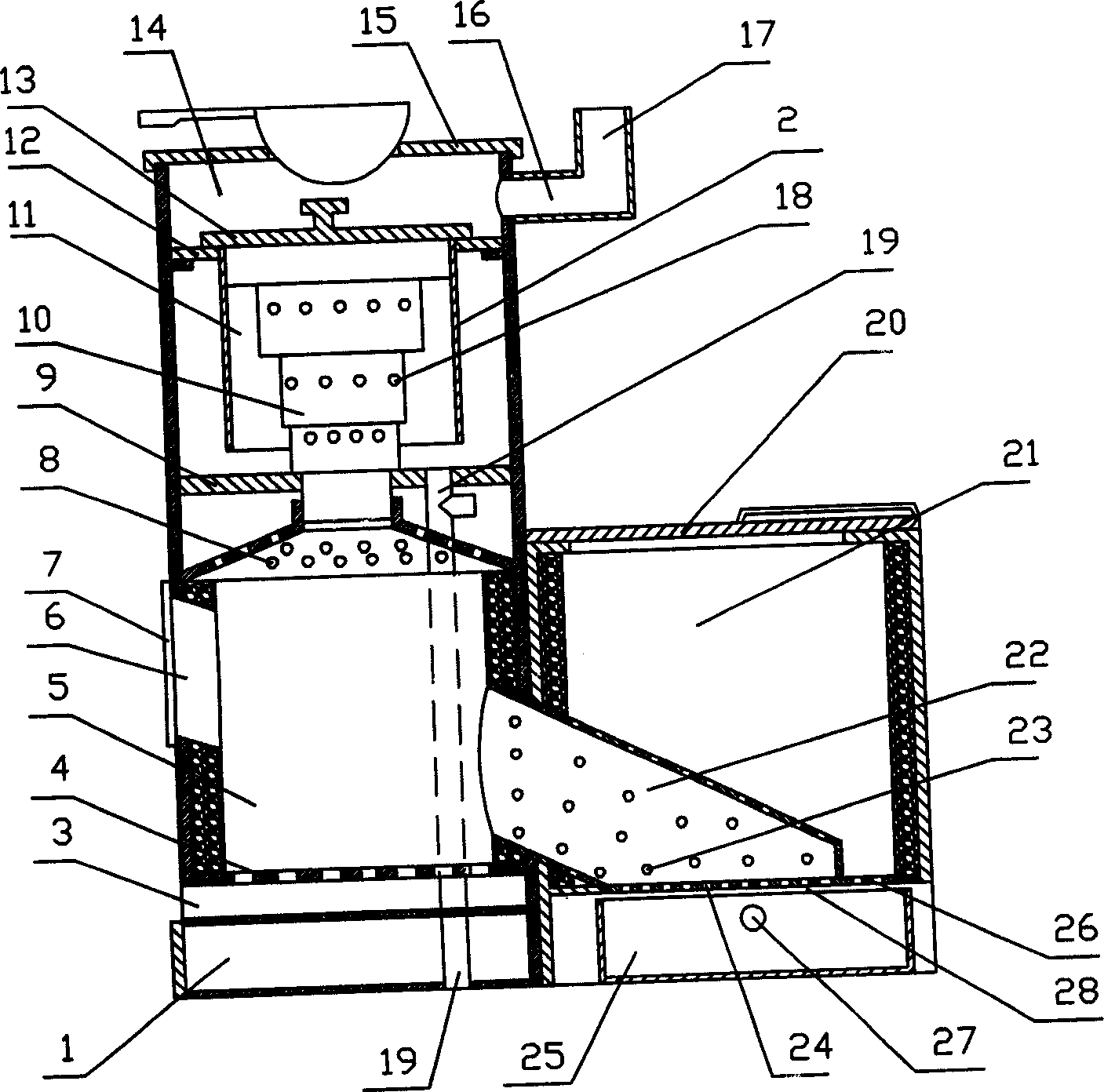

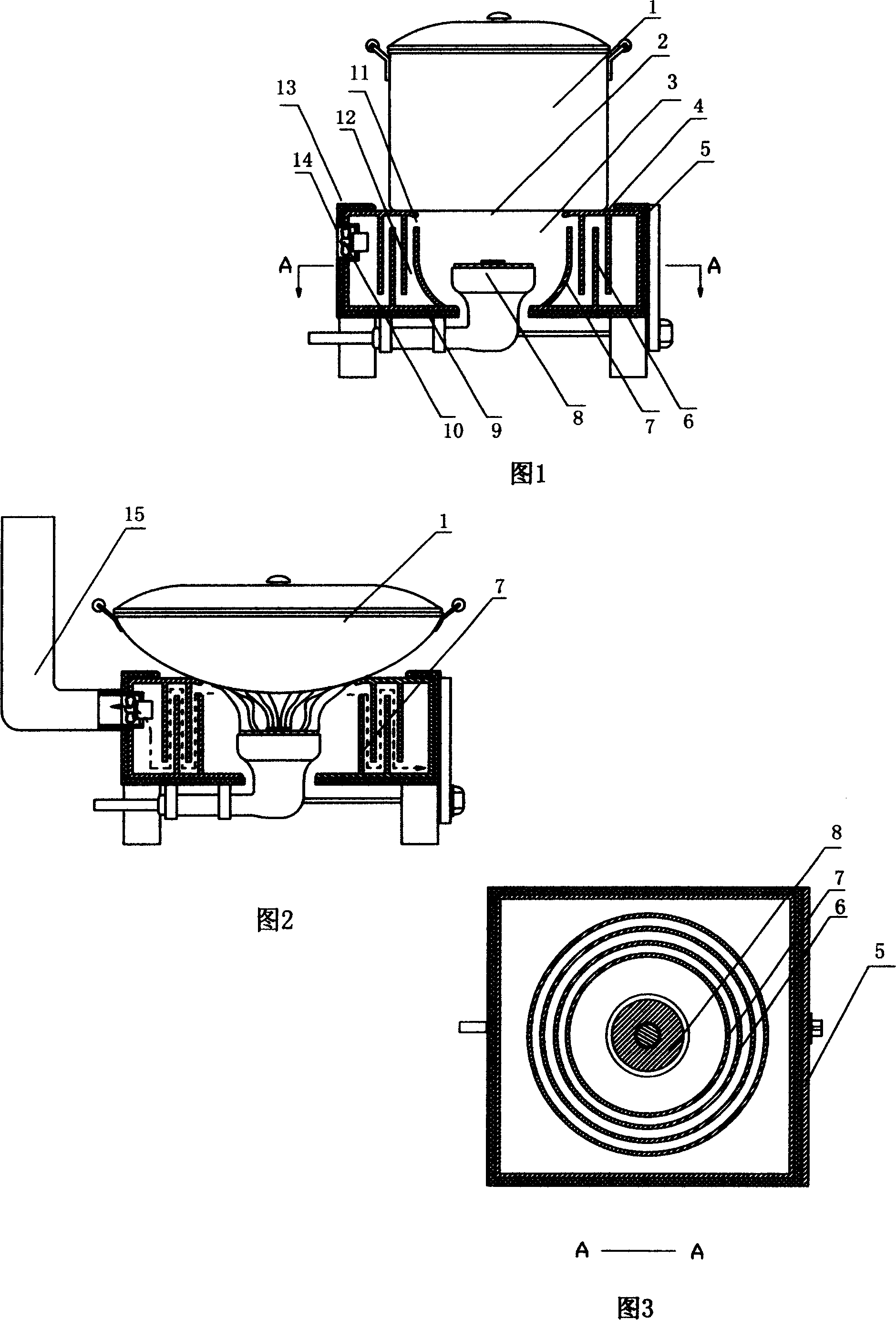

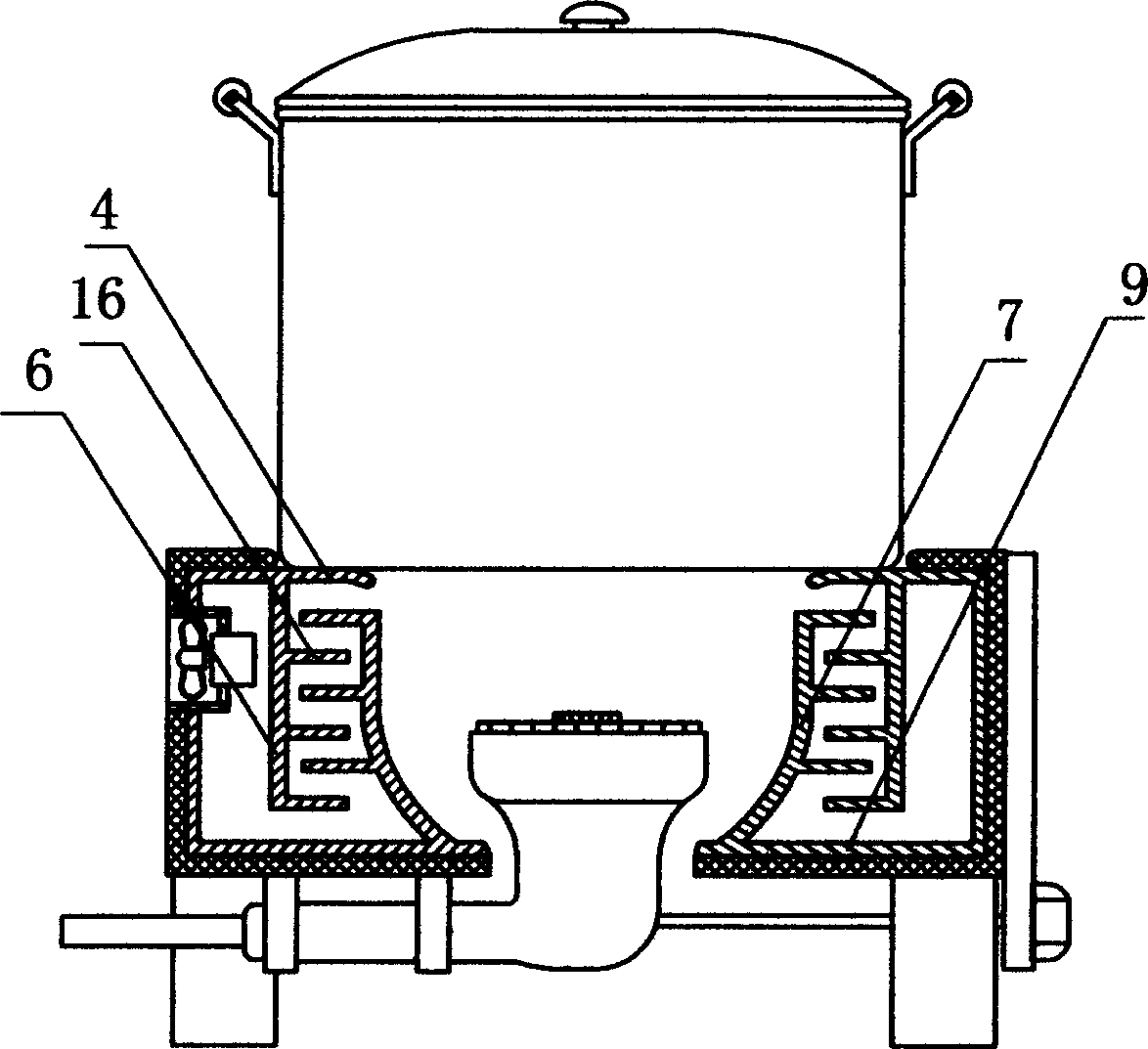

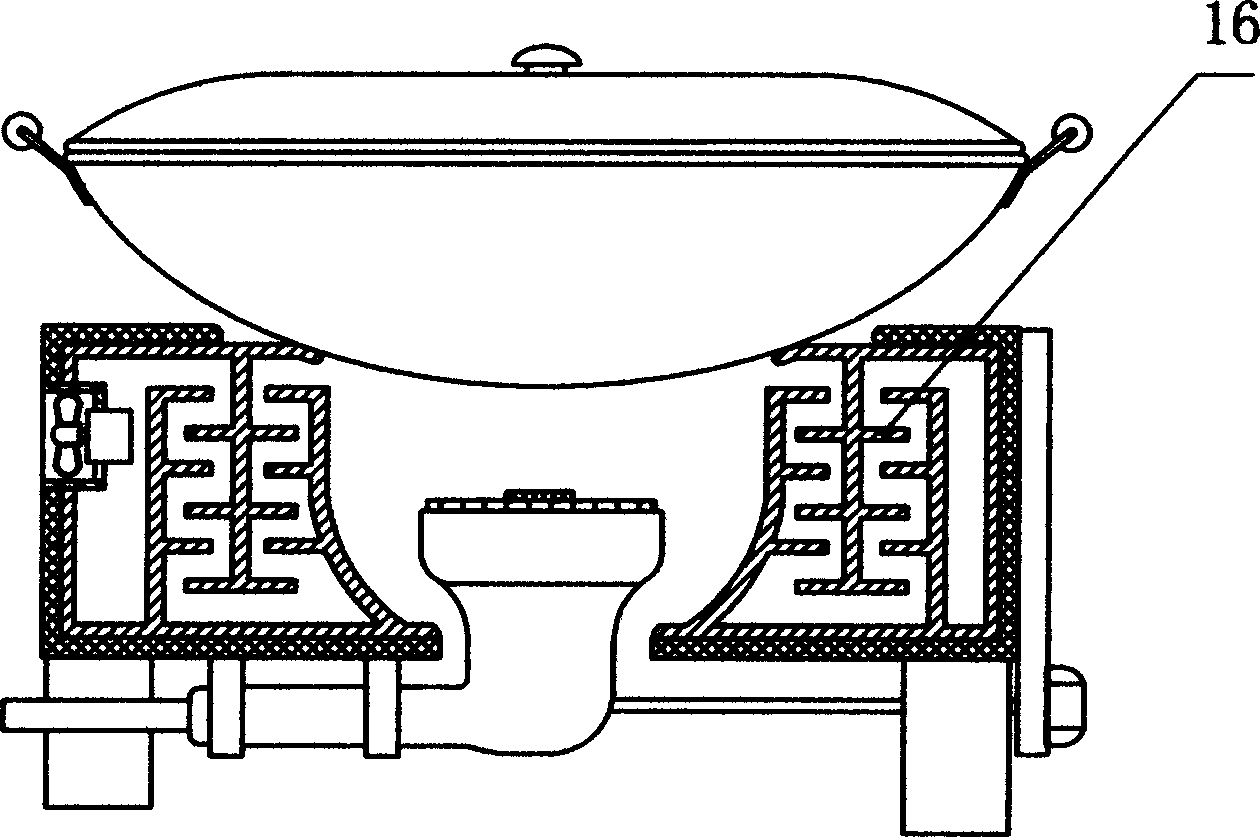

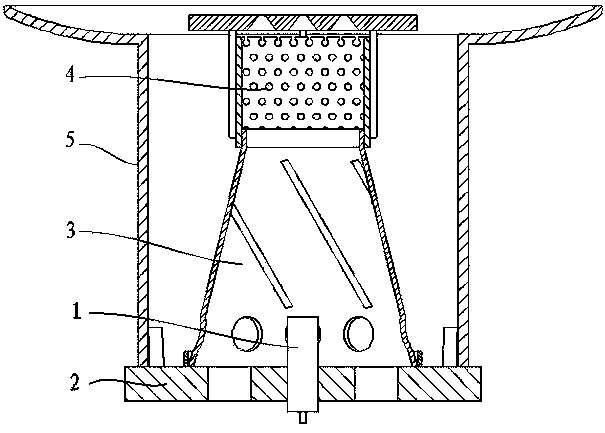

Integral compound gasification stove

InactiveCN101000146AIncrease firepowerFierce firepowerDomestic stoves or rangesLighting and heating apparatusCombustion chamberBiofuel

The invention is an integrated combined gasification stove, a biofuel gasifier, having gasification hearth, oxidization combustion chamber and multiple oxygen distributor, where the oxidization combustion chamber is equipped in the gasification hearth and the upper end of the oxidization combustion chamber is connected with the multiple oxygen distributor, the upper part of the oxidization combustion chamber is made with fuel gas holes at different heights and the side of the oxidization combustion chamber is equipped with material inlet pipe, and the multiple oxygen distributor is connected through multiple oxygen distribution pipe with air inlet. And it has characters of needing no fan, wide raw material sources, saving energy, high heat valve, no smoke dust and tar, stable performance, etc.

Owner:周海军

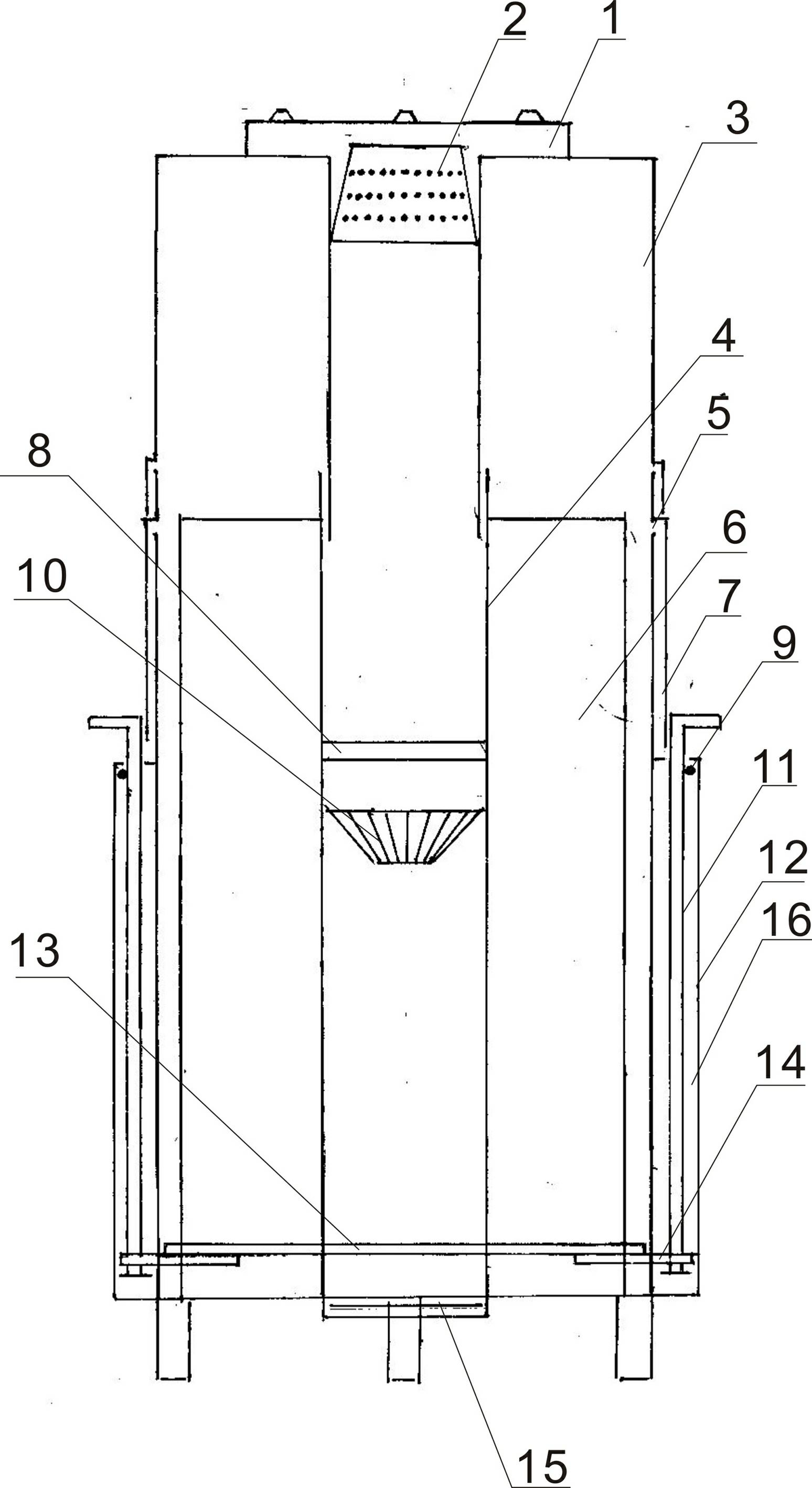

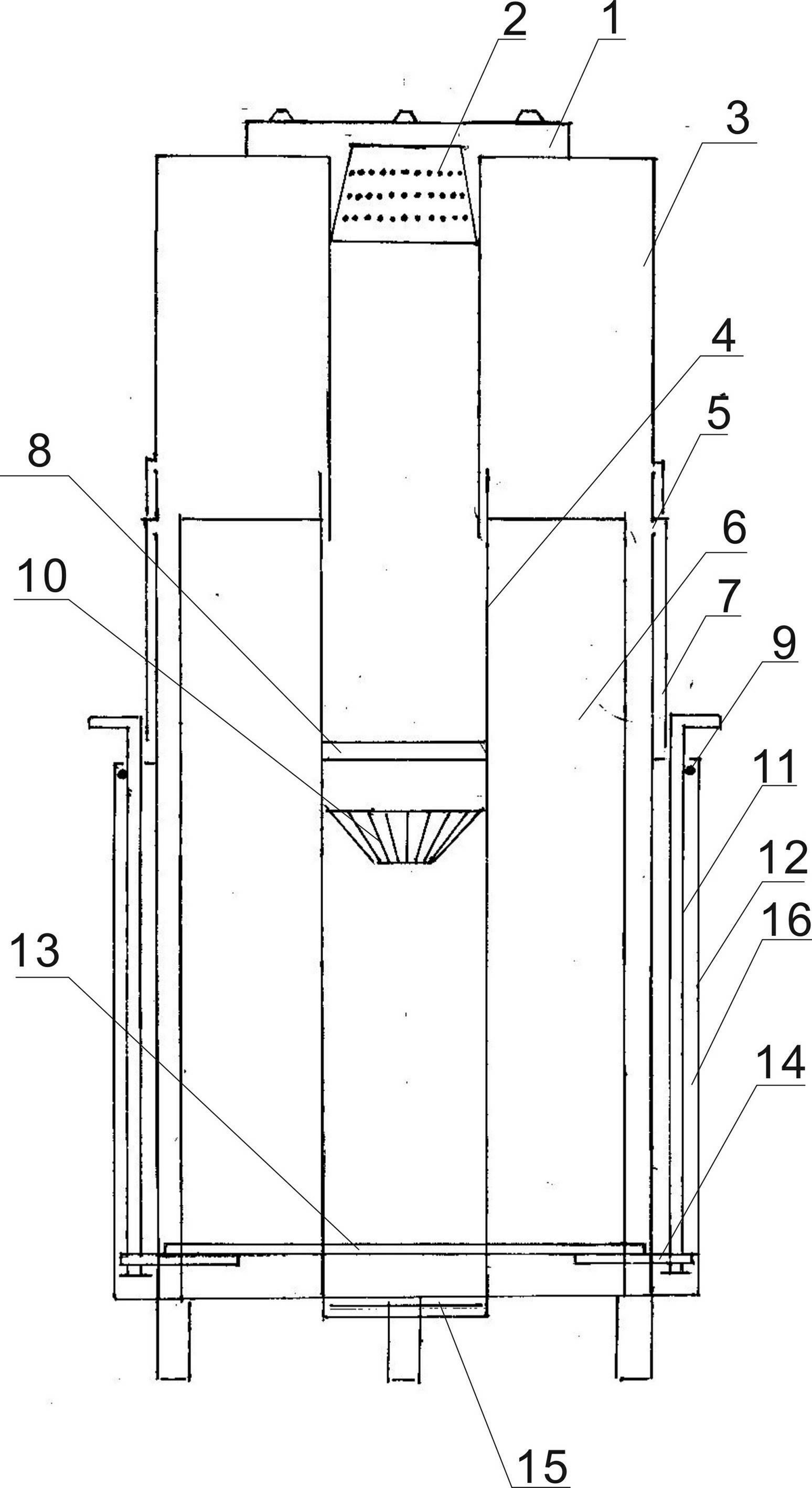

Novel biomass gasification furnace

InactiveCN102486314AFierce firepowerDomestic stoves or rangesLighting and heating apparatusHeat conductingEngineering

The invention relates to a novel biomass gasification furnace, which comprises a furnace head, a furnace cover, a furnace wall, a furnace core and a raw material lifting device. The center of the furnace wall is provided with the furnace core, the periphery of the furnace core is provided with a plurality of heat-conducting plates with the same spacing, the middle part of the furnace core is provided with a ring-shaped gas outlet, a furnace bridge is arranged in the furnace core and under the gas outlet, the bottom of the furnace core is provided with a damper, a material tray is arranged in a material storage chamber, is provided with gaps corresponding to the heat-conducting plates and can move up and down in the material storage chamber, the two sides of the material tray are symmetrically provided with tray connecting rods, the tray connecting rods penetrate through the furnace wall and are connected with a tray lifting rod, the part of the tray lifting rod contacted with the furnace wall is provided with a vertical gap so that the tray lifting rod can move up and down, a sleeve is jacketed outside the tray lifting rod and is connected with the furnace wall, the lower end of the sleeve is closed, and the upper end of the sleeve is provided with a lifting rod clamping spring. By adopting the structure, the novel biomass gasification furnace is particularly suitable for firewood gasification and combustion, the fire is strong, and no smoke, dust or odor can be produced. Moreover, charcoals are produced after gasification and combustion of raw materials and can be reused, and thus the novel biomass gasification furnace is efficient and energy-saving.

Owner:许国贵

Biomass combined type gasification furnace

InactiveCN101021336ASuitable for consumptionFierce firepowerDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

The present invention relates to a biomass combined gasification furnace. It has gas-forming tank, furnace cavity and combustor. The gas-forming tank is positioned in the side portion of said furnace cavity, the combustor is mounted in the top portion of said furnace cavity, in the gas-forming tank an oxidation combustion pipe is set, one end of said oxidation combustion pipe is communicated with atmosphere outside of the furnace body, another end of said oxidation combustion pipe is communicated with furnace cavity, on the oxidation combustion pipe an air-guiding hole is set, the side portion of said furnace cavity is equipped with a feeding hole, the upper portion of said furnace cavity is equipped with can oxygen-supplying hole, the periphery of furnace cavity portion with oxygen-supplying hole is equipped with an oxygen-supplying chamber, said oxygen-supplying chamber is communicated with air inlet pipe communicated with atmosphere, in the combustor interior are set several layers of oxygen-supplying holes, said several layers of oxygen-supplying holes are communicated with atmosphere outside of said furnace body.

Owner:周松林

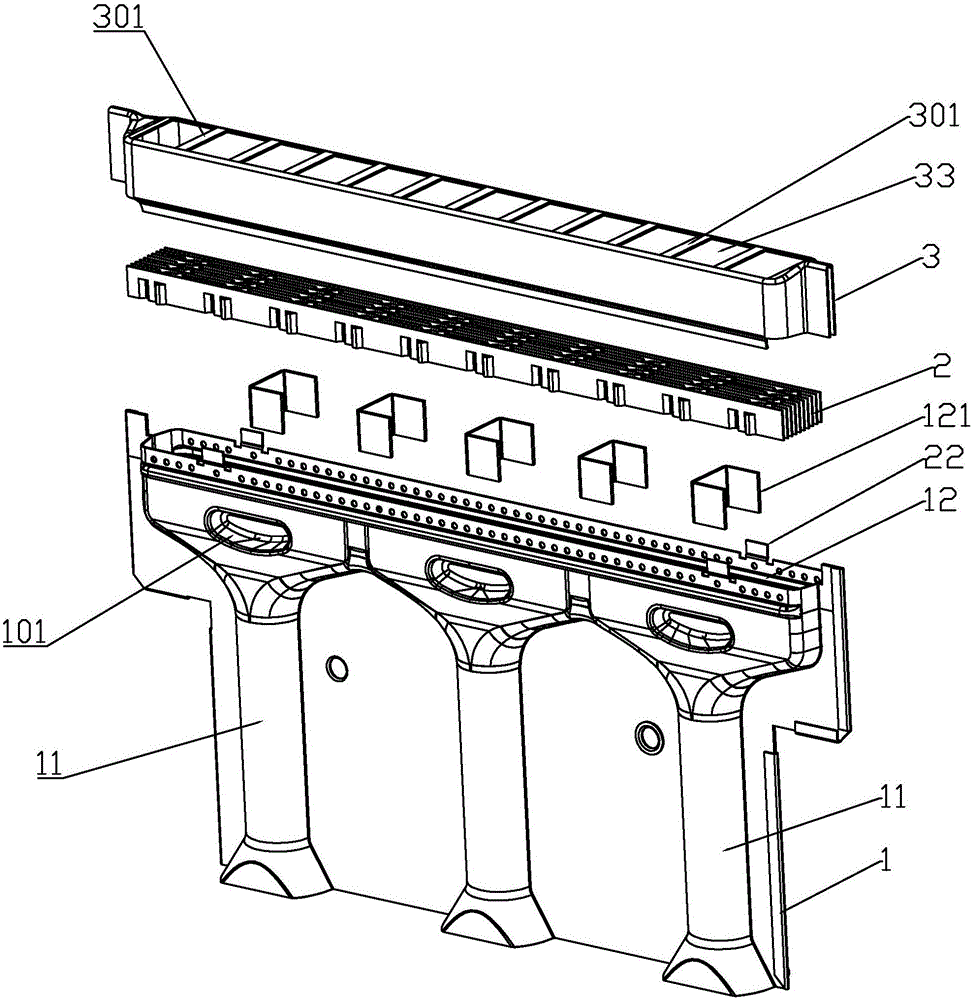

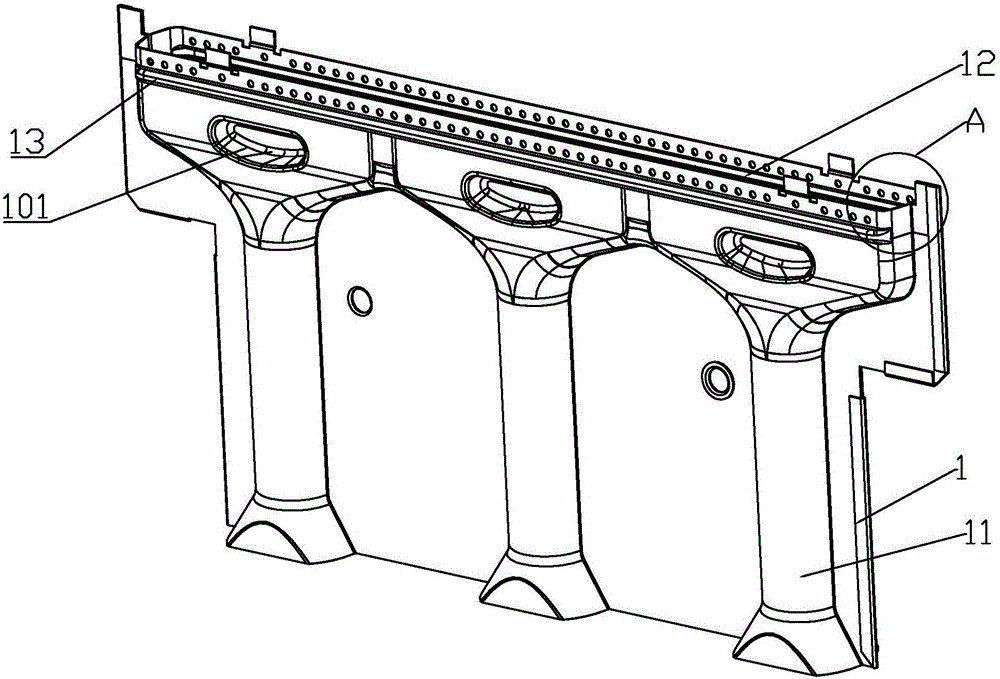

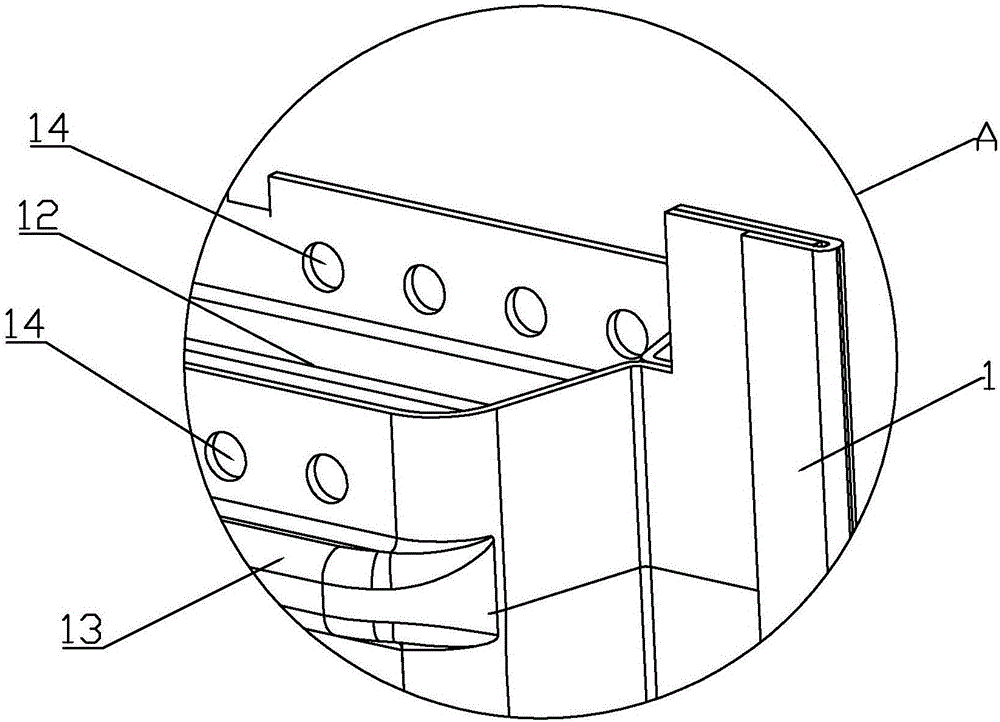

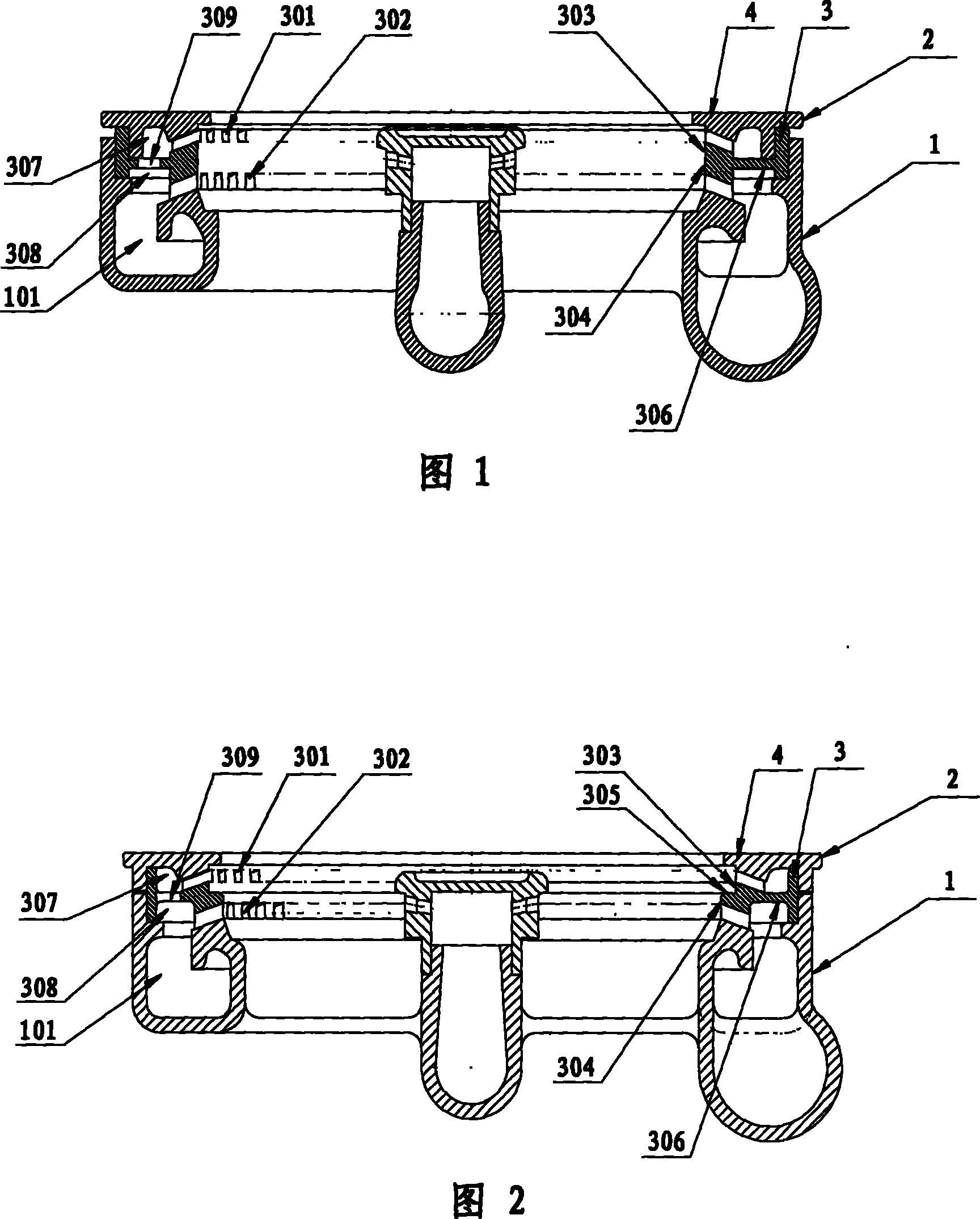

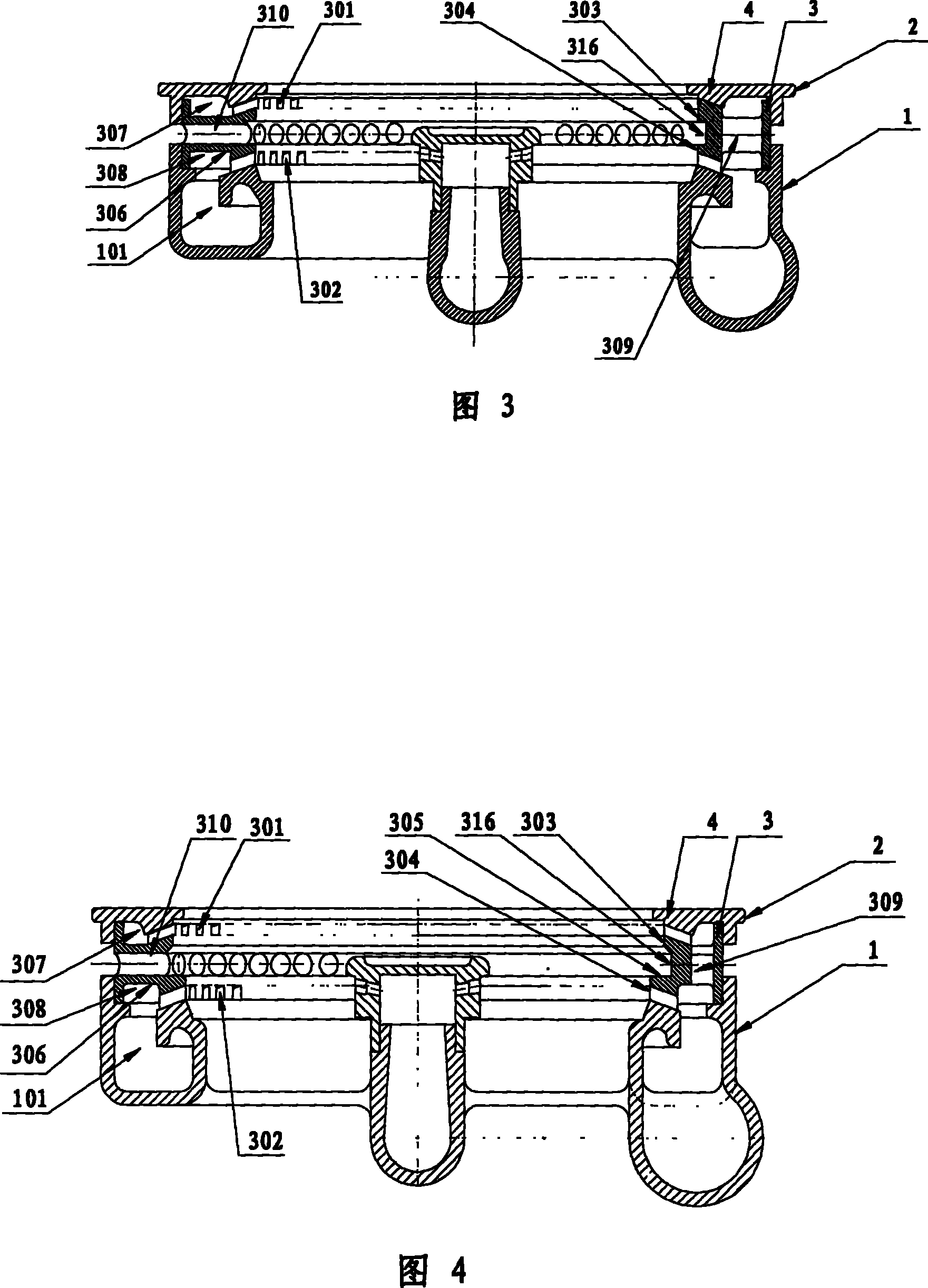

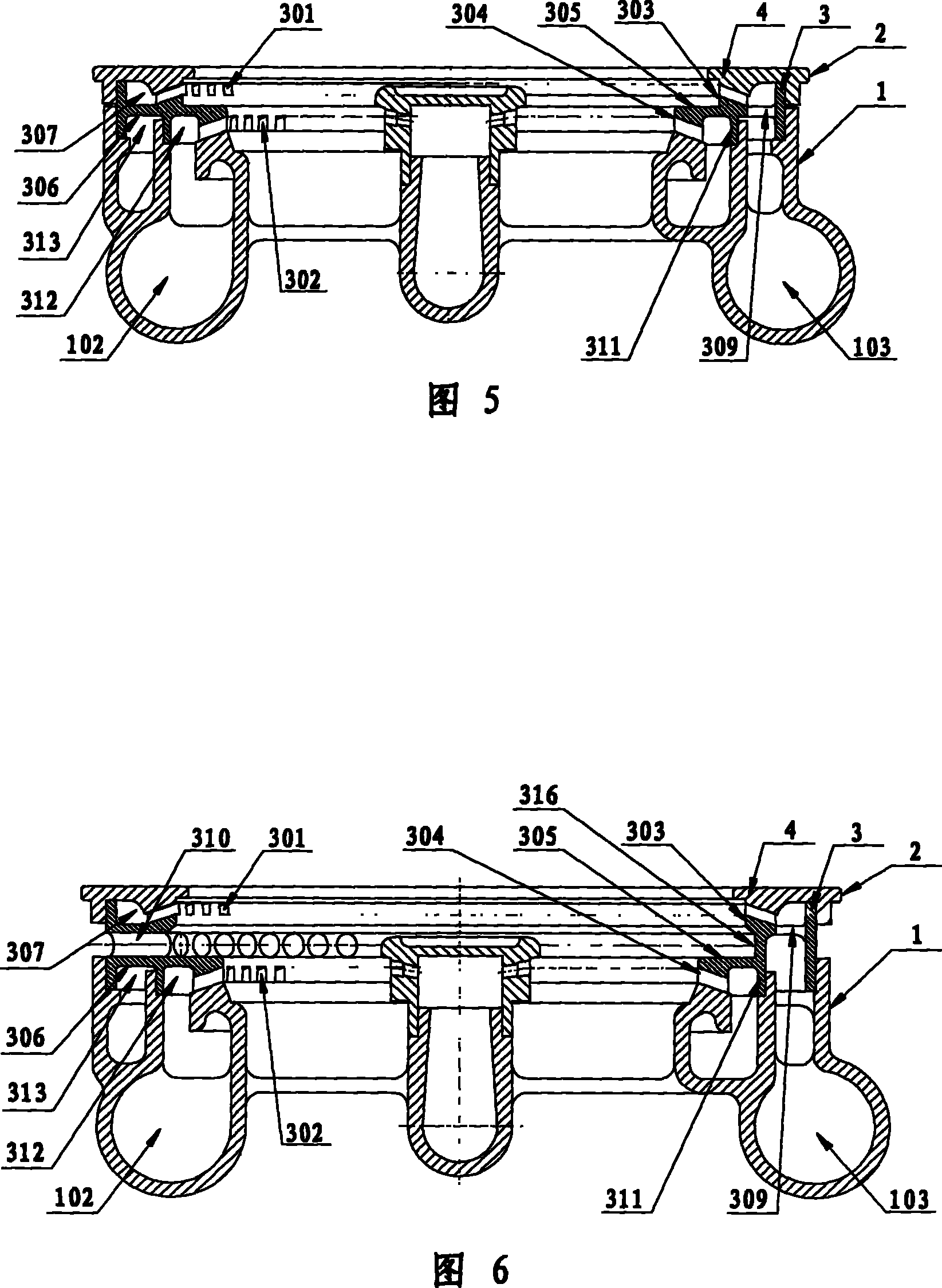

Low nitrogen oxide burner of fuel gas heating water heater

ActiveCN106642109AImprove fire stabilityThe overall thickness is thinGaseous fuel burnerCombustorLow nitrogen

The invention discloses a low nitrogen oxide burner of a fuel gas heating water heater. When the low nitrogen oxide burner is applied, fuel gas and air mixed gas directly rushes upwards through a fuel gas mixing inlet injection pipe; when the fuel gas and air mixed gas collides a fuel gas guide concave bag, due to blocking of the fuel gas guide concave bag, a part of fuel gas and air mixed gas flows to the two sides, the other part of fuel gas and air mixed gas is directly upwards to enter a mixed gas groove, part of fuel gas and air mixed gas is straightly upwards to burn at the top of a fire dividing hole, the other small part of fuel gas and air mixed gas is blocked by a fire receiving hole separating plate to generate positive pressure, and under the influence of the positive pressure, part of gas enter an outer side fuel gas mixing gas dividing groove from a transverse fuel gas and air mixing air flow outlet hole and burns in an outer side burning hole; and the top of a burner shell cover is provided with a plurality of flame burning holes through a plurality of transverse plates in a mesh dividing manner, and the fire power of fire behaviors generated by burning is strong; meanwhile, the flame area is greatly increased, and burning is more sufficient.

Owner:黄婉平

Liquid fuel gasification combustor

The invention relates to industrial or civilian stoves, in particular to a combustor using a liquid fuel. By the combustor, the liquid fuel can be combusted fully. The combustor comprises a fuel inlet pipe for supplying the fuel and a nozzle for spraying the fuel for combustion and is characterized in that: the fuel inlet pipe is connected with a fuel gasifier; the outlet of the gasifier is connected with a gas and liquid separator; and the exhaust port of the gas and liquid separator is connected with the nozzle. In the gasification combustor using the liquid fuel, the gas and liquid separator is arranged creatively, so liquid drops which are not gasified fully can be separated out, the fuel conveyed to the nozzle for combustion is guaranteed to be gaseous and the combustion efficiency is improved greatly. By use of the combustor, the heat efficiency is about 60 percent; compared with the conventional liquid fuel stove, the liquid fuel gasification combustor saves energy by over 50 percent and increases the heating speed by over 30 percent due to the intense fire; furthermore, the liquid fuel gasification combustor avoids environmental pollution caused by fuel volatilization, avoids fuel waste, saves cost and is convenient to use; and social benefits can be obtained.

Owner:CHONGQING XUNNENG ENERGY SAVING GAS EQUIP

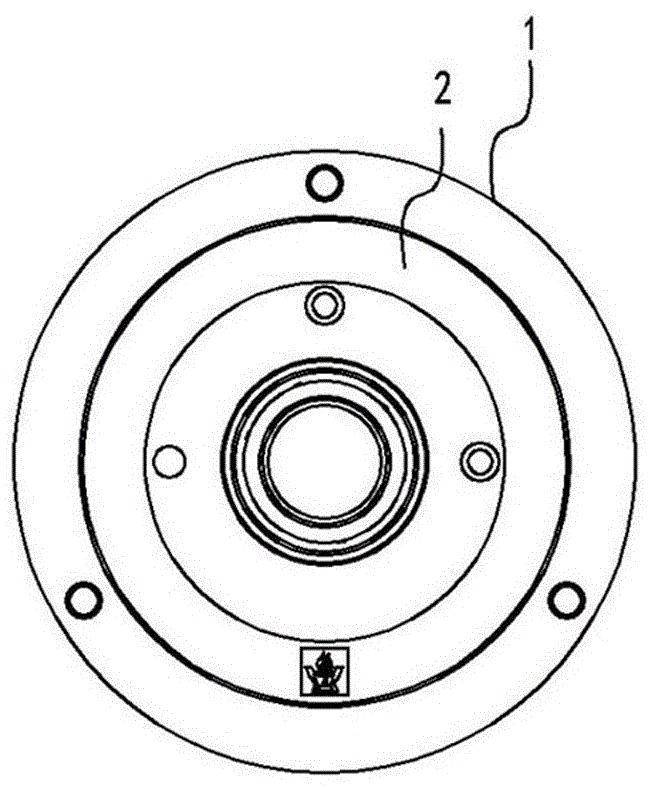

Commercial high-efficiency energy-saving gas burner

InactiveCN101619852AIncrease temperatureFierce firepowerIndirect carbon-dioxide mitigationGaseous fuel burnerGas burnerEngineering

The invention discloses a commercial high-efficiency energy-saving gas stove head comprising a stove head outer sleeve, a stove ring, a stove core, a gas guiding cover, a gas nozzle, an air distributing disk, a gas cavity, an air inlet pipe, and the like. The commercial high-efficiency energy-saving gas burner is characterized in that the stove ring and the stove core which are supported by the gas guiding cover are integrally arranged in the stove head outer sleeve, the lower side wall of the gas guiding cover is provided with an air inlet hole, a stove core through hole which passes through the stove core is evenly arranged on the stove core, the upper part of the stove head outer sleeve is horizontally connected with the air inlet pipe, and the gas nozzle is evenly and vertically arranged on the upper end surface of the gas cavity, passes through the bottom of the stove head outer sleeve and is inserted into the stove core through hole upwards. The commercial high-efficiency energy-saving gas burner can lead cold air to sufficiently absorb heat of the stove ring and the stove core, divide gas into a plurality of blasts, use high-speed gas to roll high-temperature to burn, increase gas burning efficiency and thermal efficiency of the stove head and have strong firepower, does not have temper risks and is suitable for the catering industry.

Owner:HEFEI CENTURIES FIVE STAR CATERING EQUIP LIABILITY

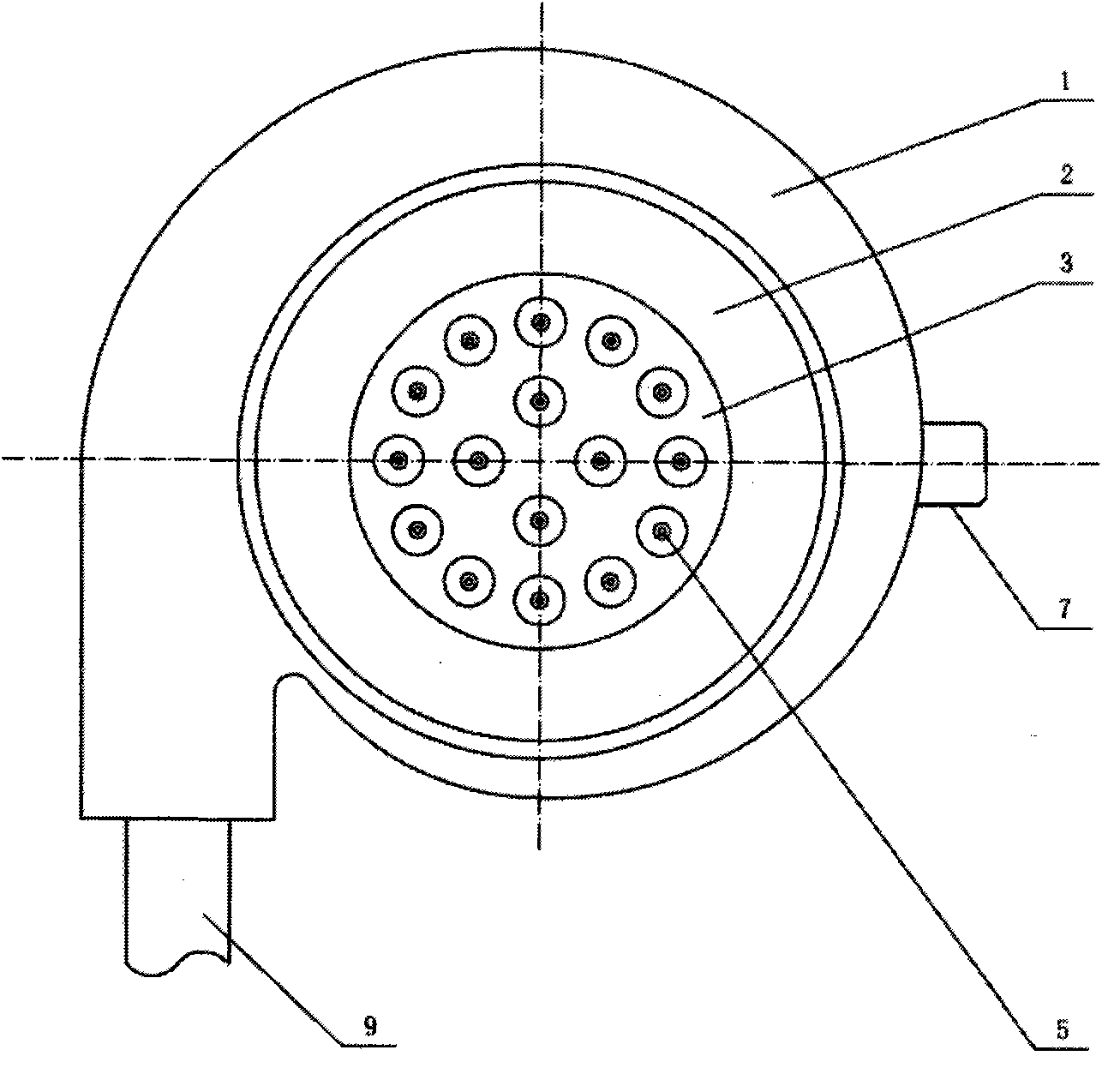

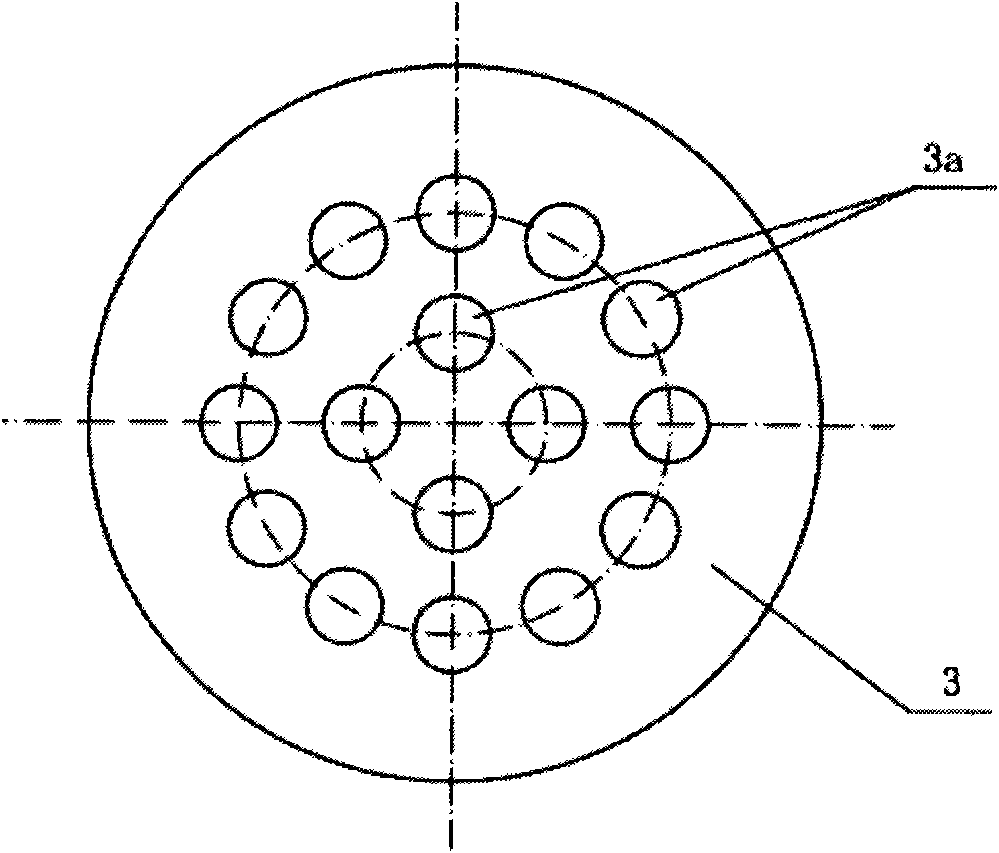

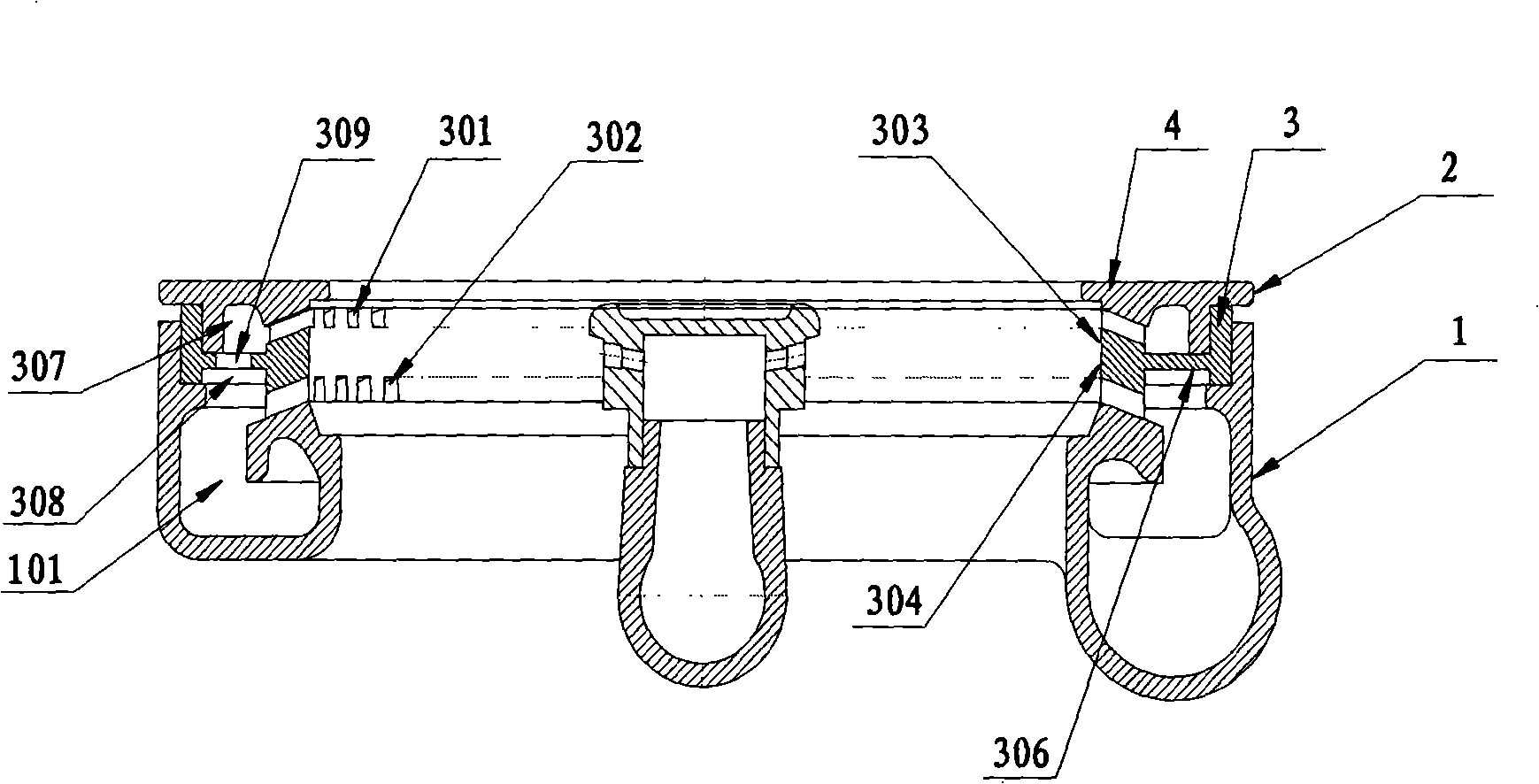

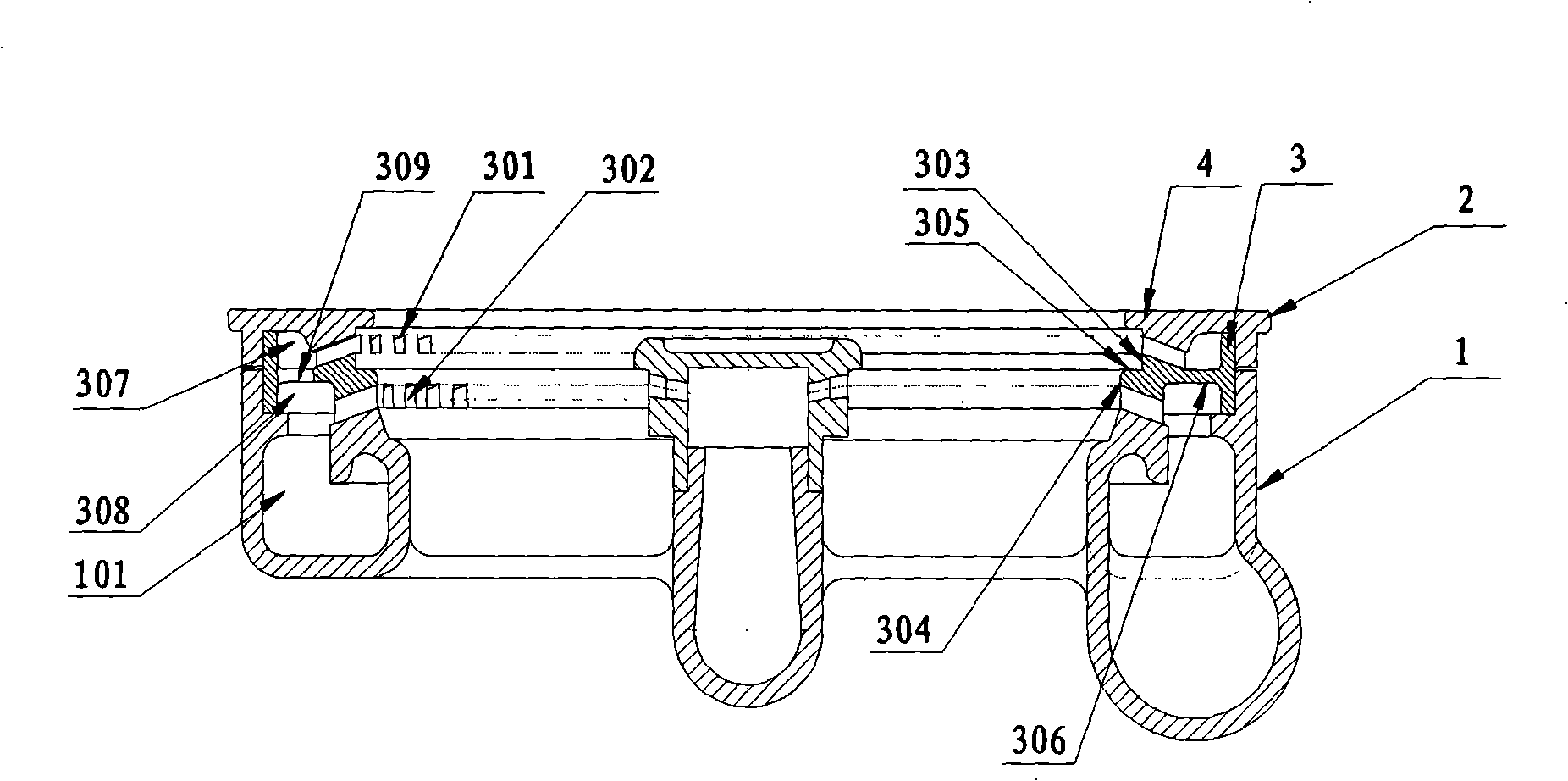

Combustor of inner flame gas range

The invention discloses a burner of an inner flame gas stove, which consists of a burner body and a fire distributer device; an upper layer fire hole and a lower layer fire hole are arranged on the fire distributer device and the direction of the outlets of the fire holes is inward, and an air channel is arranged or not arranged between the upper layer fire hole and the lower layer fire hole; a single inner cavity or two independent inner cavities is or are arranged; the two independent inner cavities are arranged so that the flame at the upper layer and the lower layer can be regulated independently; while the air channel is arranged so that the air supplementation can be more abundant. The burner utilizes multiple-layer fire holes, stratified combustion and multiple-layer cyclonic flame, and has the advantages of large heat flow, fierce fire power, high heat efficiency, low-CO and low-NOx in smoke gas, no fire hole blocking and the like.

Owner:吴成年 +1

Liquid fuel and preparation thereof

InactiveCN101475857AReduce volatilityImprove performanceLiquid carbonaceous fuelsThermal energyHexamethylenetetramine

The invention relates to a liquid fuel and a preparation method thereof. The liquid fuel is mainly prepared from the following raw materials in portion by mass: 150 to 300 portions of water, 650 to 850 portions of methanol, 5 to 20 portions of butyl acetate, 5 to 20 portions of sodium hydroxide, 2 to 10 portions of hexamethylenetetramine, 10 to 30 portions of hydrogen peroxide with a mass concentration of 30 percent, and 50 to 150 portions of ethanol. The liquid fuel has low volatility and steady performance, is safe during the transportation and storage when being distributed to users due to the high temperature resistance, is difficult to ignite if no open flame exists, does not splash liquids and fumigate eyes during the use, can completely burn, is difficult to generate harmful gas such as formaldehyde and the like, has no smoke, no toxicity, no carbon deposition, no pot blackening, violent fire, high heat energy, no pressure, and no explosion danger, has a combustion calorie more than 9,500kcal / kg, can be extinguished by water during the fire extinguishing, and has the characteristics of cleanliness, environment protection, safety, simple and convenient production, and low production cost. The liquid fuel can substitute diesel oil and liquefied gas, and is suitable to be used by diesel furnaces, liquefied gas furnaces, boilers and the like.

Owner:廖新明 +1

Alcohol liquid fuel and preparation method thereof

InactiveCN101880554AFierce firepowerImprove energy savingLiquid carbonaceous fuelsAlcoholLiquid fuel

The invention relates to alcohol liquid fuel and a preparation method thereof. The alcohol liquid fuel comprises the following components in parts by weight: 40-60 parts of fusel oil, 20-30 parts of crude methanol, 10-20 parts of waste ethanol, 5-10 parts of acetone, 5-10 parts of swill-cooked dirty oil, 1-5 parts of emulsifier, 0.5-1 part of potassium permanganate and 0.1-0.5 part of ferrocene. The fuel adopts industrial by-products or waste as main raw materials, has a high calorific value and causes no black smoke during burning. Therefore, the fuel can be used as the fuel of the civilian stove and the industrial boiler.

Owner:郑德明 +3

Alcohol-base liquid fuel and preparation method thereof

The invention relates to an alcohol-group liquid fuel, and a preparation method thereof, pertaining to the technical field of new energy. One ton of alcohol-group liquid fuel comprises 600Kg to 800Kg of water and methanol, 3Kg to 7Kg of sodium carbonate or sodium chloride, 1Kg to 6Kg of furoic acid, 20Kg to 40Kg of light oil, 5Kg to 15Kg of castor oil or cottonseed oil, 10Kg to 20Kg of petroleum ether, 10Kg to 20Kg of C7 or C8, 3Kg to 8Kg of fusel, 5Kg to 15Kg of hydrogen peroxide or 0.1Kg to 0.4Kg of potassium permanganate, 2Kg to 8Kg of isopropyl alcohol, 2Kg to 8Kg of isobutyl alcohol, 2Kg to 10Kg of Tween and 1Kg to 6Kg of camphor oil. The preparation method of the liquid fuel comprises the technological steps: the water and the sodium carbonate or the sodium chloride, the furoic acid, the light oil, the castor oil or the cottonseed oil, the petroleum ether, the C7 or the C8, the fusel, the hydrogen peroxide or the potassium permanganate, the isopropyl alcohol, the isobutyl alcohol, the Tween and the camphor oil are respectively added in the methanol. The alcohol-group liquid fuel has simple technology, low investment and high efficiency and belongs to an economic and safe new energy with environmental protection and energy conservation indeed.

Owner:TIANJIN YIHUAN CHEM

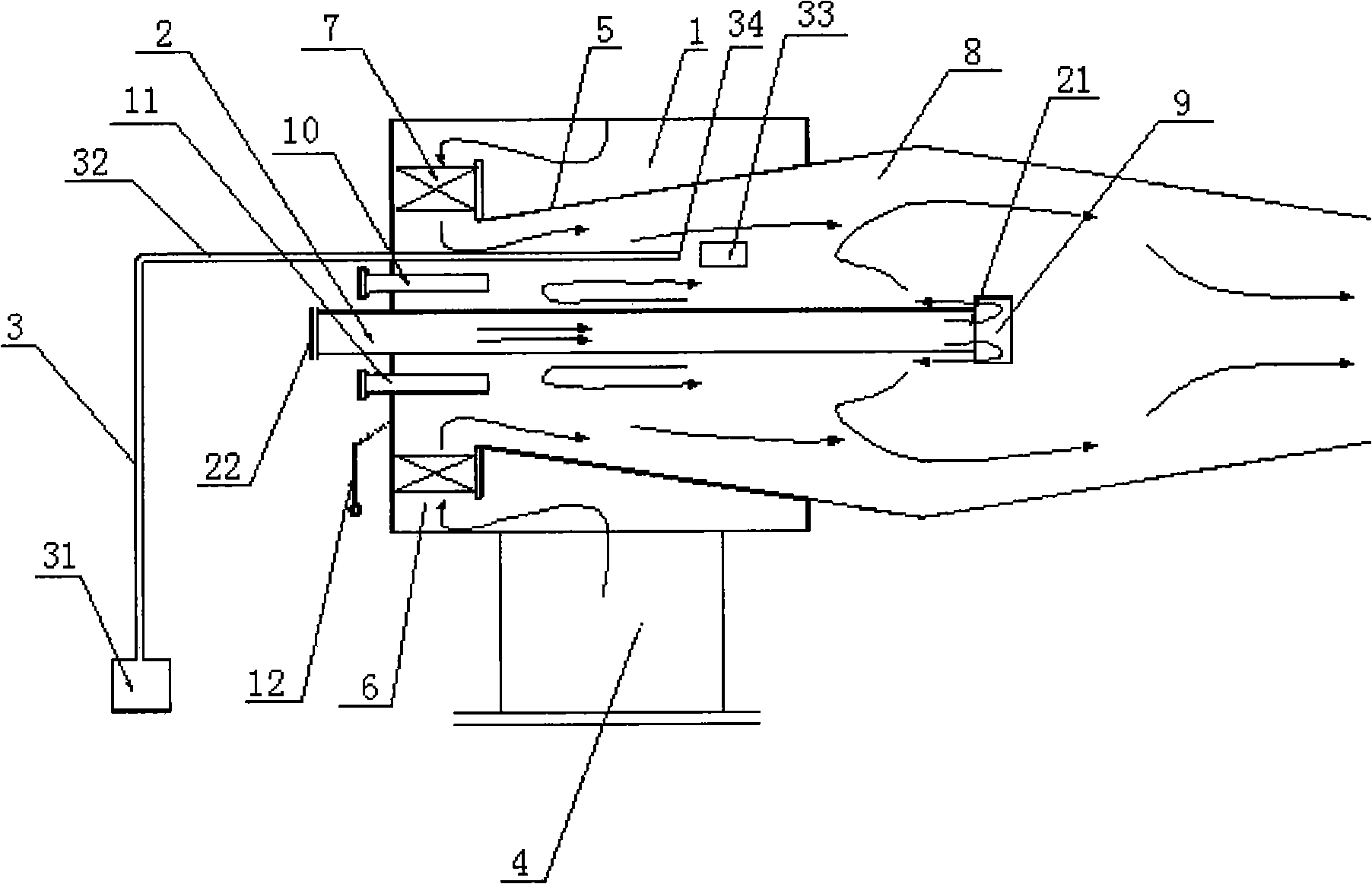

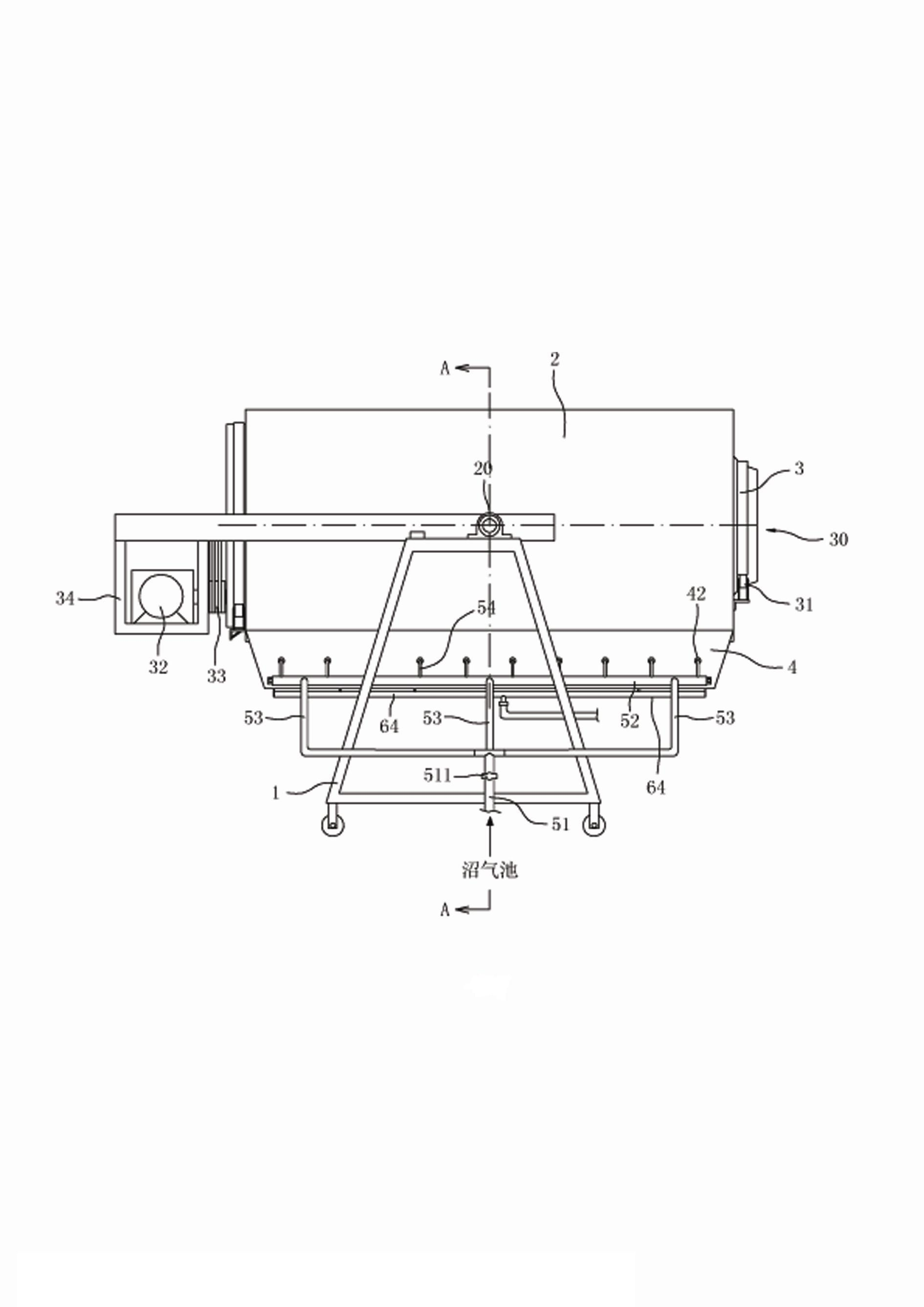

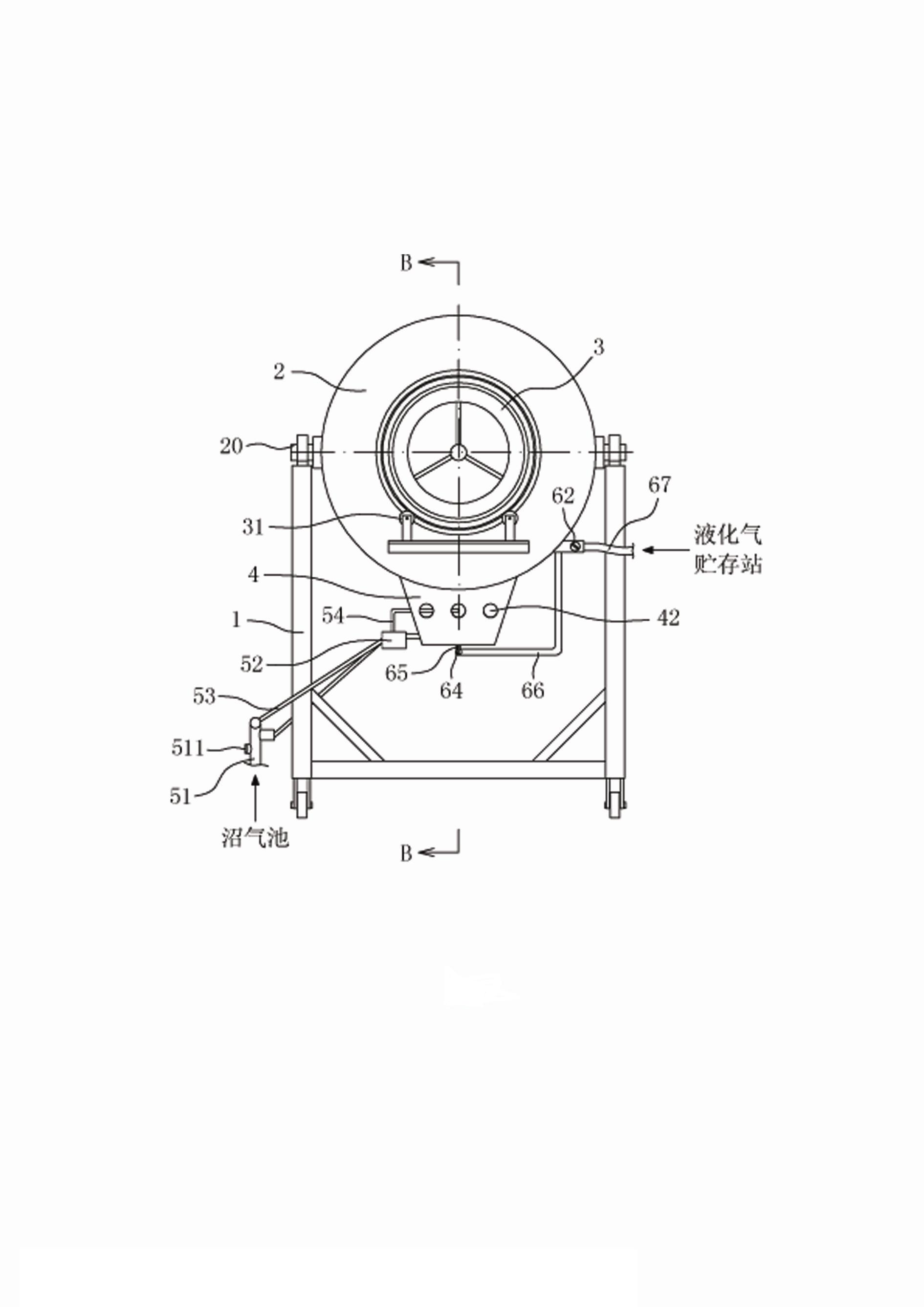

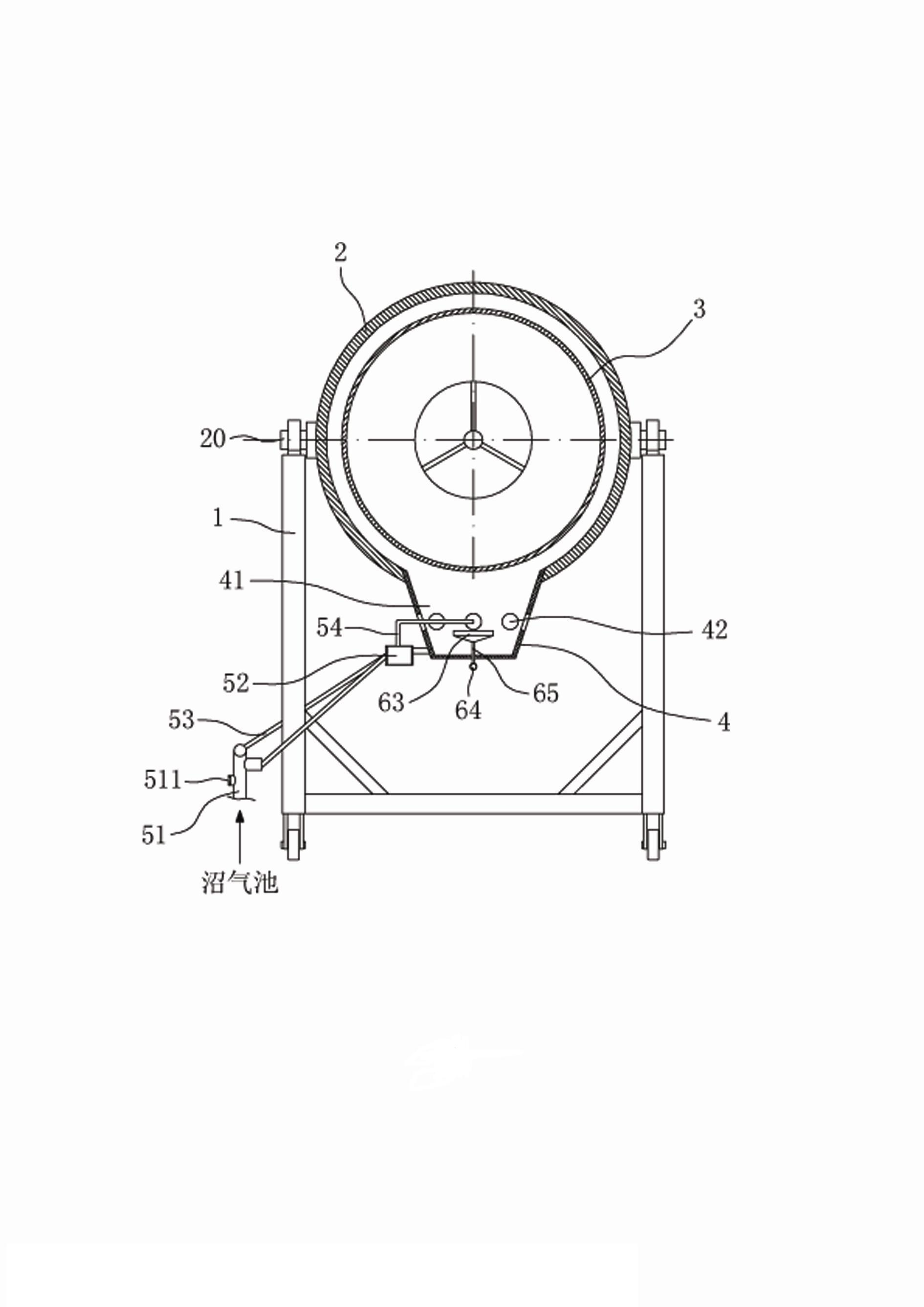

Biogas tea fixing machine

ActiveCN101933544ASmooth air supplySafe and reliable ignitionPre-extraction tea treatmentBiogasTracheid

The invention discloses a biogas tea fixing machine, which comprises a frame, a horizontal tea fixing roller arranged on the frame, a driving device driving the tea fixing roller to roll, and a heating device used for heating the tea fixing roller. The biogas tea fixing machine is characterized in that: the heating device comprises a stove and a biogas combustion device arranged under the tea fixing roller; the biogas combustion device comprises a biogas delivery pipeline which is connected with a biogas digester and provided with a valve, and a plurality of high temperature-resistant biogas ejectors connected with the output end of the delivery pipeline; the biogas ejectors pass through the side wall of the stove to extend into the hearth of the stove; and biogas nozzles of all the biogas ejectors are arranged at equal intervals along the length direction of the hearth. The fixing machine is provided with heat by the combustion of the biogas, and the combustion cost is lower, so the manufacturing cost of tea is reduced; the main component of the biogas is methane, and generates water and carbon dioxide after combustion, so the environment is protected; besides, the combustion value of the biogas is high, so the biogas provides enough heat for the fixing machine; therefore, the produced tea has higher quality.

Owner:福建安溪历山茶仙茶业有限公司

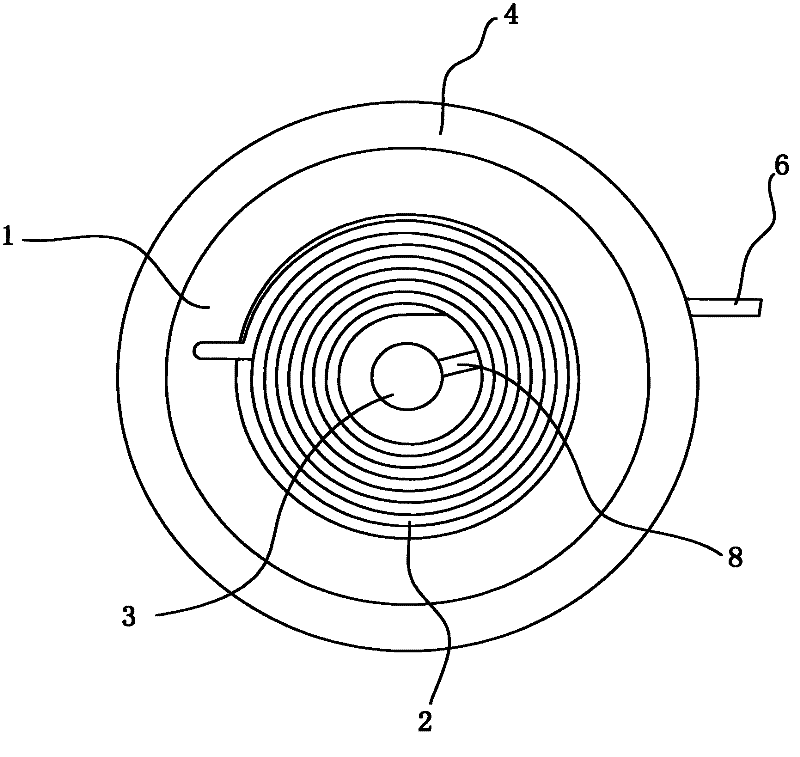

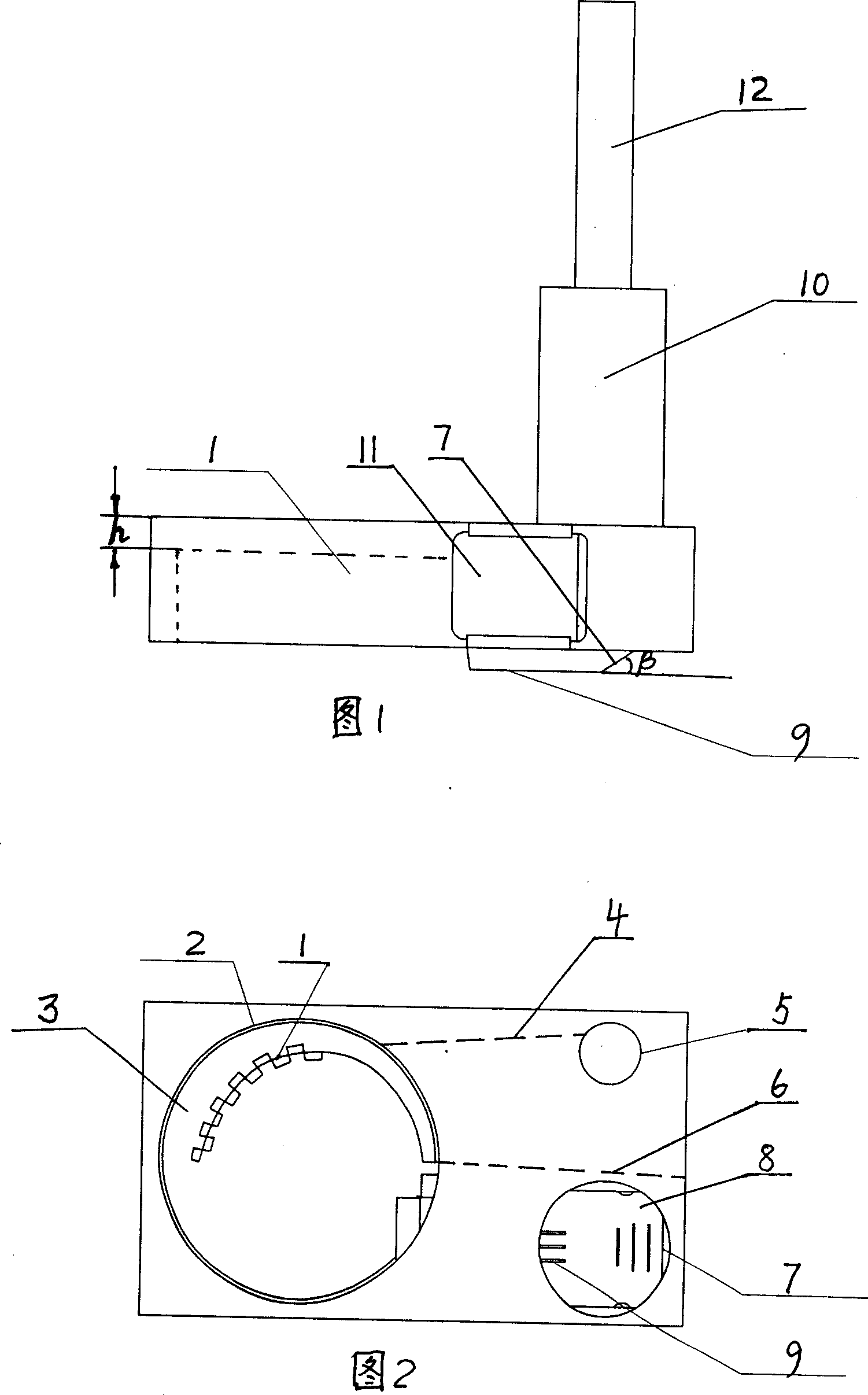

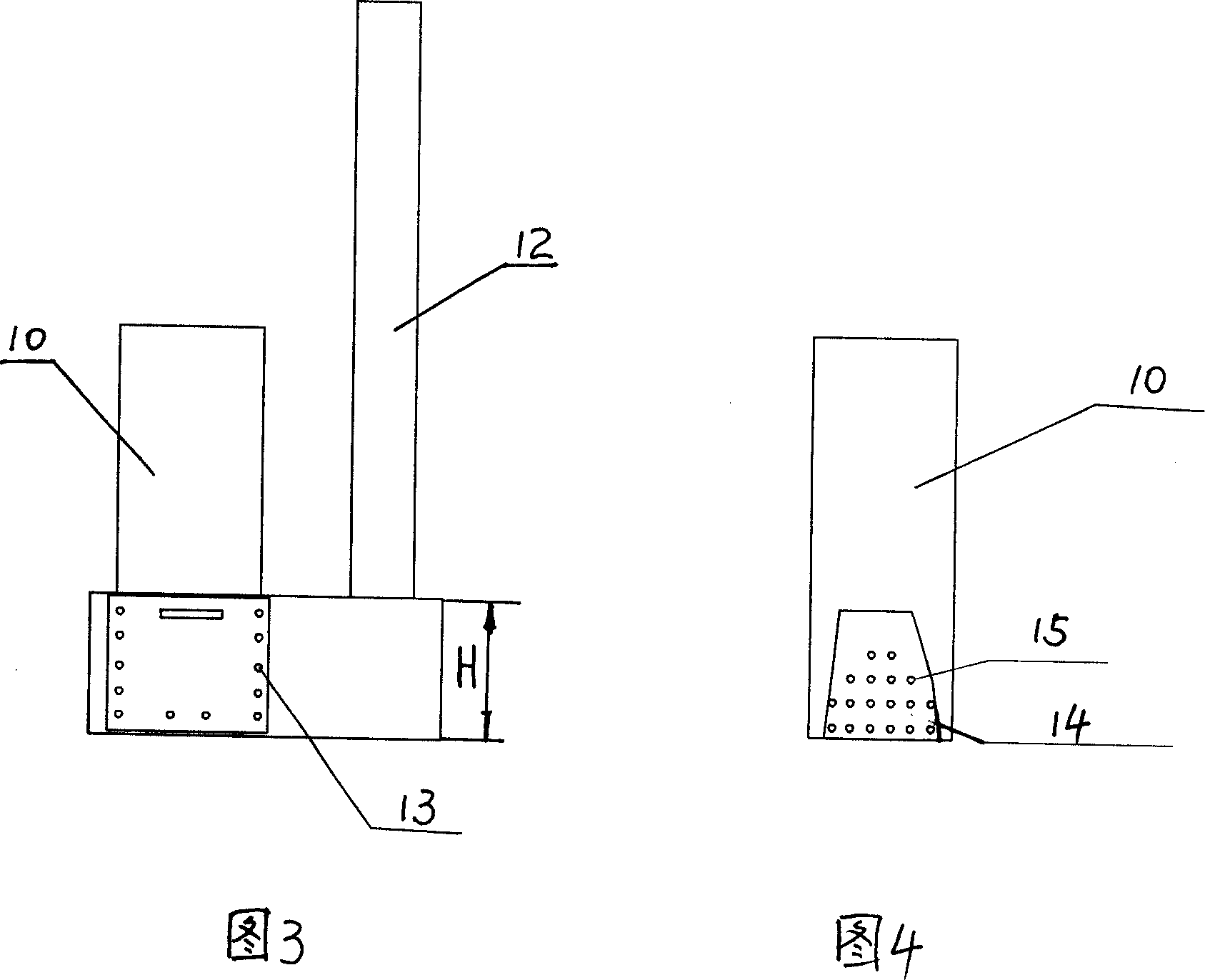

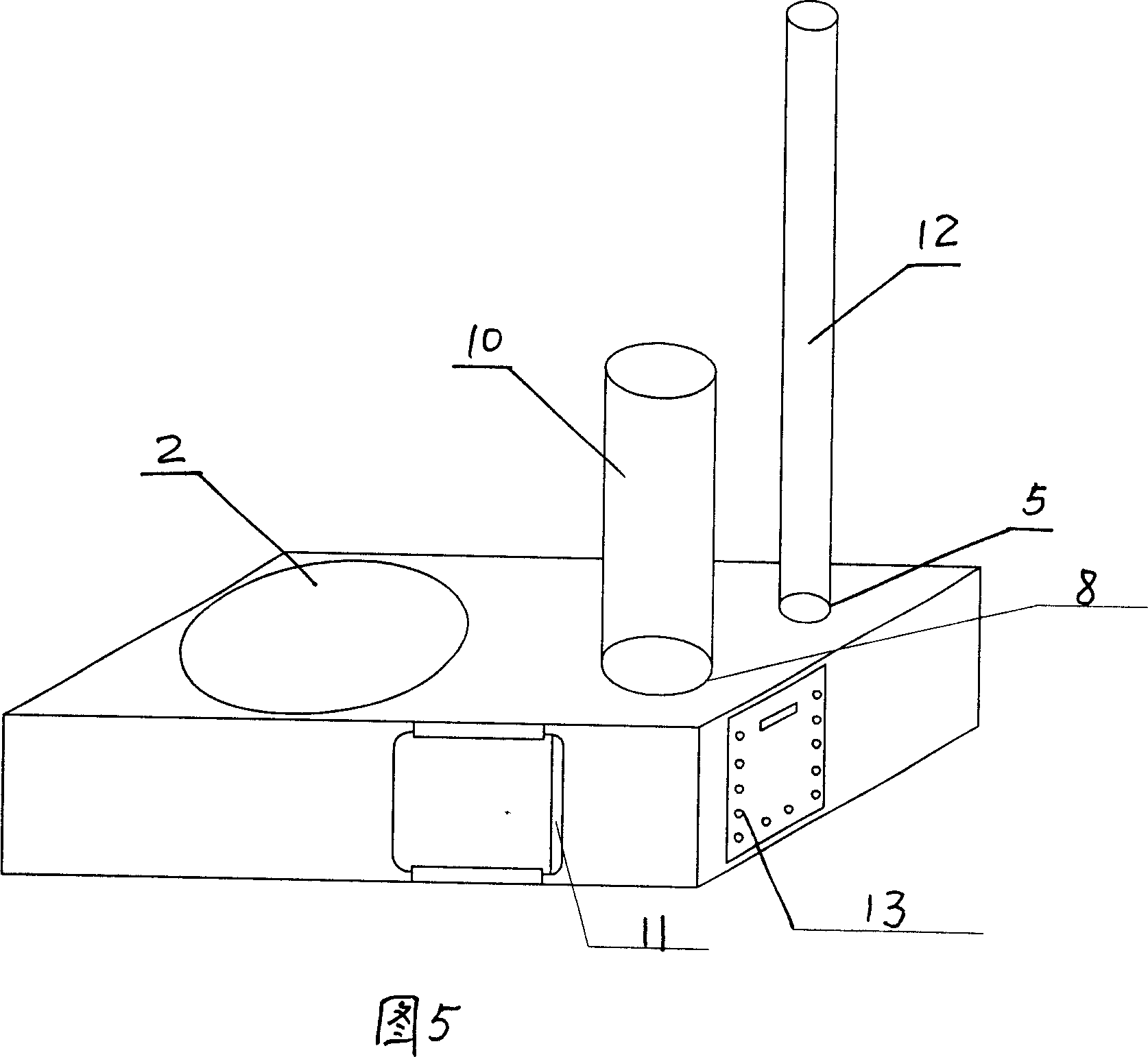

Energy-saving fuel gas combustor

ActiveCN105674268AGood energy saving and environmental protection effectStrong wind resistanceDomestic stoves or rangesGaseous fuel burnerInlet channelDetonation

The invention belongs to the field of combustible gas combustion stoves and particularly relates to an energy-saving fuel gas combustor. The energy-saving fuel gas combustor comprises an outer stove (1) and an inner stove (2), wherein an assembling channel hole (4) is formed in the bottom of the inner stove (2); a fuel gas fire gathering ring (5) is arranged in the middle of the inner stove (2); small fuel gas delivery pipes (7) are arranged in a fuel gas air inlet channel (6) and an air blower pipeline inlet (3); anti-dust caps (8) are arranged at the end parts of the small fuel gas delivery pipes (7); a main fuel gas delivery pipe (10) is transversely arranged between the outer stove (1) and the inner stove (2); a gas delivery port of the main fuel gas delivery pipe (10) is communicated with an annular gas distribution cavity (11) between the fuel gas air inlet channel (6) and the assembling channel hole (4); and a main fuel gas outlet (12) is formed in the outer wall of the annular gas distribution cavity (11). The energy-saving fuel gas combustor has obvious energy-saving and environment-protecting effects, is capable of preventing water and detonation and is excellent in wind resistance, high in safety factor, uniform in flame distribution and wide in application range.

Owner:鞍山科创燃气节能厨房电子设备有限公司

High efficiency energy saving gas range

InactiveCN1858501AFierce firepowerAvoid churnDomestic stoves or rangesLighting and heating apparatusCombustorHigh energy

The high efficiency energy saving gas range includes a combustor, a hearth, and a range body. The combustor is located in the bottom of the hearth, and the range body has casing with furnace hole. Between the casing and the hearth plate, is one curved fume cavity with inlet located in the upper part of the hearth plate, outlet inside the casing and fume exhausting fan at the outlet. The present invention has high energy source utilizing rate and environment friendship.

Owner:吴国成

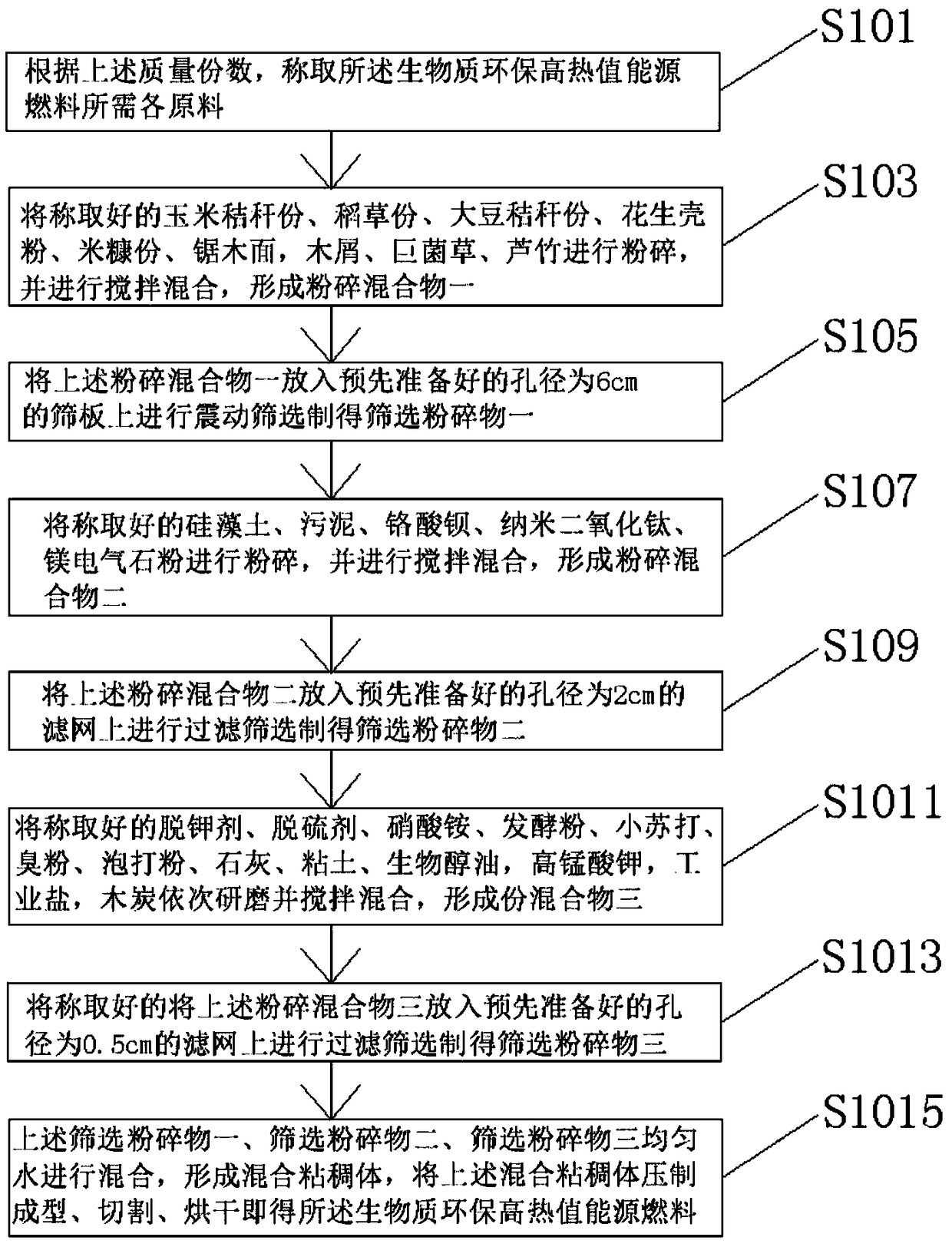

Biomass environment-friendly high-calorific-value energy fuel and preparation method thereof

The invention discloses biomass environment-friendly high-calorific-value energy fuel and a preparation method thereof. The biomass environment-friendly high-calorific-value energy fuel is prepared from the following raw materials in parts by weight: 50-70 parts of corn strawstalks, 35-40 parts of straw, 20-25 parts of soybean strawstalks, 30-70 parts of peanut husk powder, 20-25 parts of rice bran, 20-30 parts of sawdust, 35-55 parts of wood chippings, 25-45 parts of pennisetum sinese, 25-40 parts of arundo donax, 2-5 parts of diatomite, 8-20 parts of sludge, 2-5 parts of barium chromate, 1-4 parts of nano titanium dioxide, 2-6 parts of dravite powder, 10-30 parts of water, 5-10 parts of a potassium removal agent, 5-10 parts of a desulfurizing agent, 2-5 parts of a swelling agent, 20-30of a binding agent and 20-30 parts of a combustion improver. The biomass environment-friendly high-calorific-value energy fuel has the beneficial effects that the low-cost, environment-friendly and high-quality biomass-based fuel is high in combustion rate and convenient to produce in batches.

Owner:梁丰

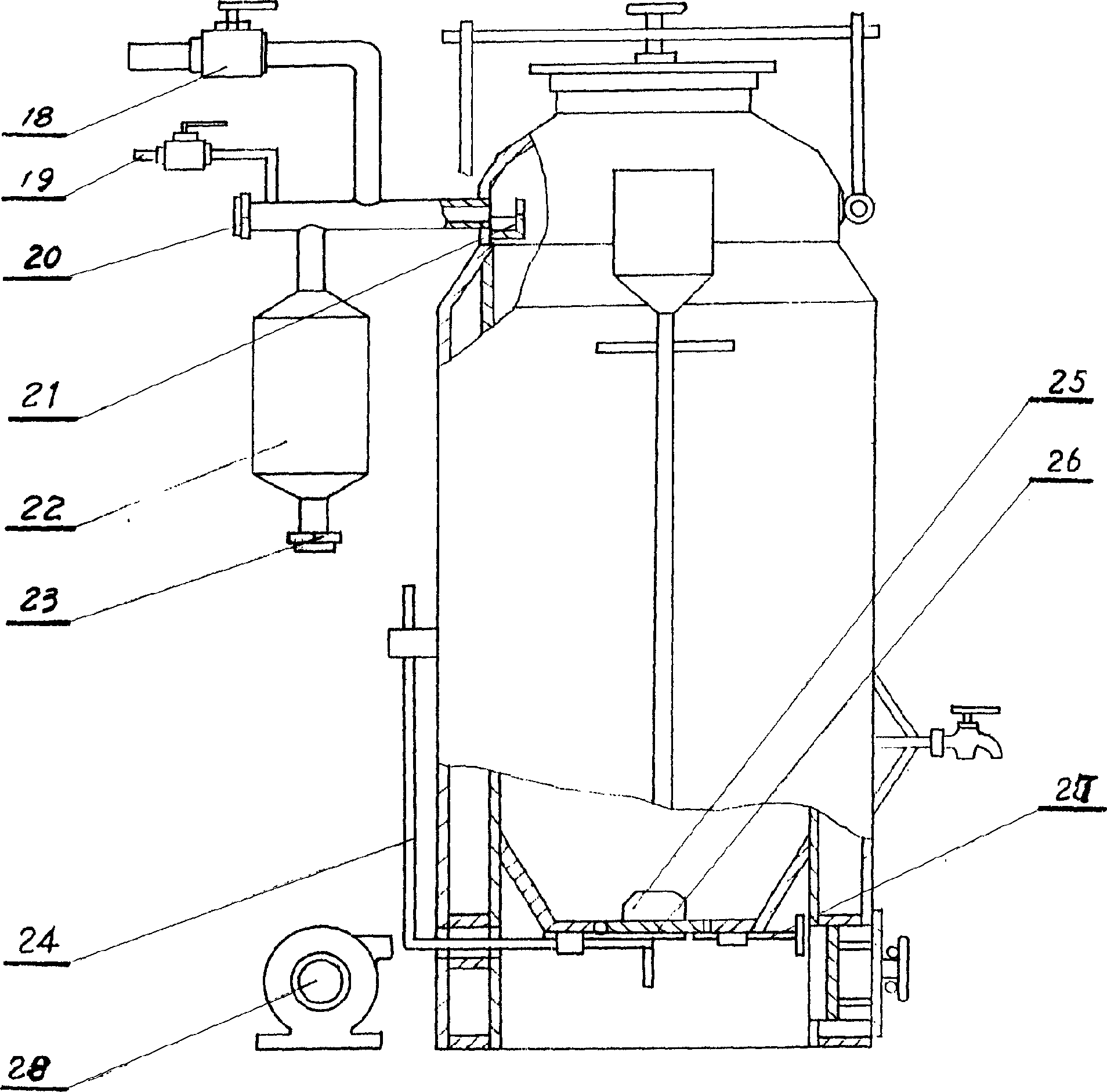

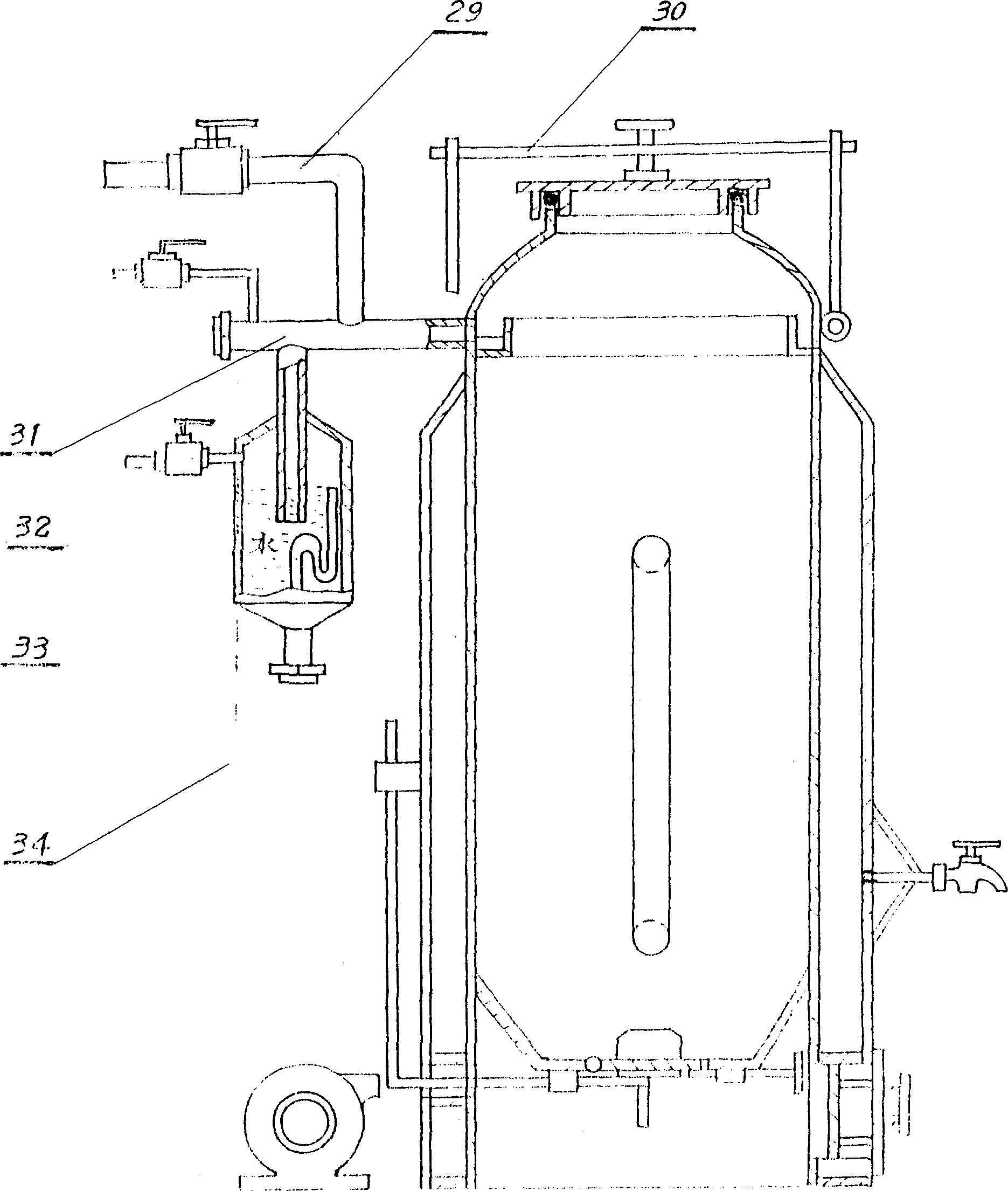

Solid household refuse pyrolysis and gasification power generation device

PendingCN107177380AFull pyrolysis and gasificationImprove gas production efficiencyTransportation and packagingSolid waste disposalCycloneTreatment completed

The invention relates to a solid household refuse pyrolysis and gasification power generation device. The solid household refuse pyrolysis and gasification power generation device is characterized by comprising a feeding tank (1), a magnetic separation conveying belt (2), a pulverizer (4), a spiral feeding machine (7), a gasifier (8), a cyclone removal device (21), a pressurizing induced draft fan (22), a water seal type dust removal explosion prevention device (23), a secondary decoking and cooling tower (24), a ternary decoking and cooling tower (25), a gas test fire head (26), a gas storage cabinet (31), a gas turbine generator (32) and a dust remover (33) which are serially connected with one another by pipes. The solid household refuse pyrolysis and gasification power generation device is high in universality of household refuse; requirements on household refuse composition on original refuse treatment are low; and complicated original refuse treatment procedures are reduced. The solid household refuse pyrolysis and gasification power generation device is simple to operate and use, stable in thermal efficient, high in gas yield and high in safety, and is harmless treatment complete equipment which can treat household refuse harmlessly, and further can carry out gasification by the household refuse secondarily.

Owner:福建龙迪环保设备科技有限公司

High-efficiency energy-saving environment-friendly coal

The invention relates to a high-efficiency energy-saving environment-friendly coal, belonging to the energy source field; the coal is formed by the following raw materials by weight part: 92-97 percent of ground masses and 3-8 percent of sulphur-fixed smoke suppressors, the raw materials are uniformly mixed and crushed to be particles with less than 3mm, the 1-5 per thousand of sulphur-fixed smoke suppressors, which do not contain water weight parts is added when the particles are stirred, the mixture is casted and molded, dried naturally and encapsulated; according to the coal requirements, the ratio is adjusted, so as to lead the coal to be used as civil honeycomb briquette, coal balls for catering industry and boilers, more than 20 percent of coal is saved, and the sulphur fixation efficiency is 75-85 percent, thereby having good economic, social and environmental benefits and having high promotion value.

Owner:范泽文 +1

Coal-water slurry fuel and preparation method thereof

InactiveCN102746912ASave resourcesImprove utilizationLiquid carbonaceous fuelsFly ashEnergy consumption

The invention discloses a coal-water slurry fuel and a preparation method thereof. The coal-water slurry fuel includes components of charcoal, water and additives, wherein the additives comprise a dispersant and a stabilizing agent. The preparation method for the coal-water slurry fuel comprises a first step of performing hydro-thermal charing to the raw material biomass to get a mixture of the charcoal and water, and a second step of adding the additives to the mixture of the charcoal and water to obtain a crude product of the coal-water slurry fuel. According to the invention, the biomass, especially the agriculture residue, is used as a raw material to preparing the novel coal-water fuel which has the properties of environmental protection, high caloric value, and large caloric power. The preparation method for the fuel is low in energy consumption, economical and cheap, and easy for operation. The coal-water slurry product has low sulfur content, and has the advantages of few black smoke, big fire, full burning, no flying ash, clean burning, etc. in use.

Owner:北京雷恩新材料科技有限公司

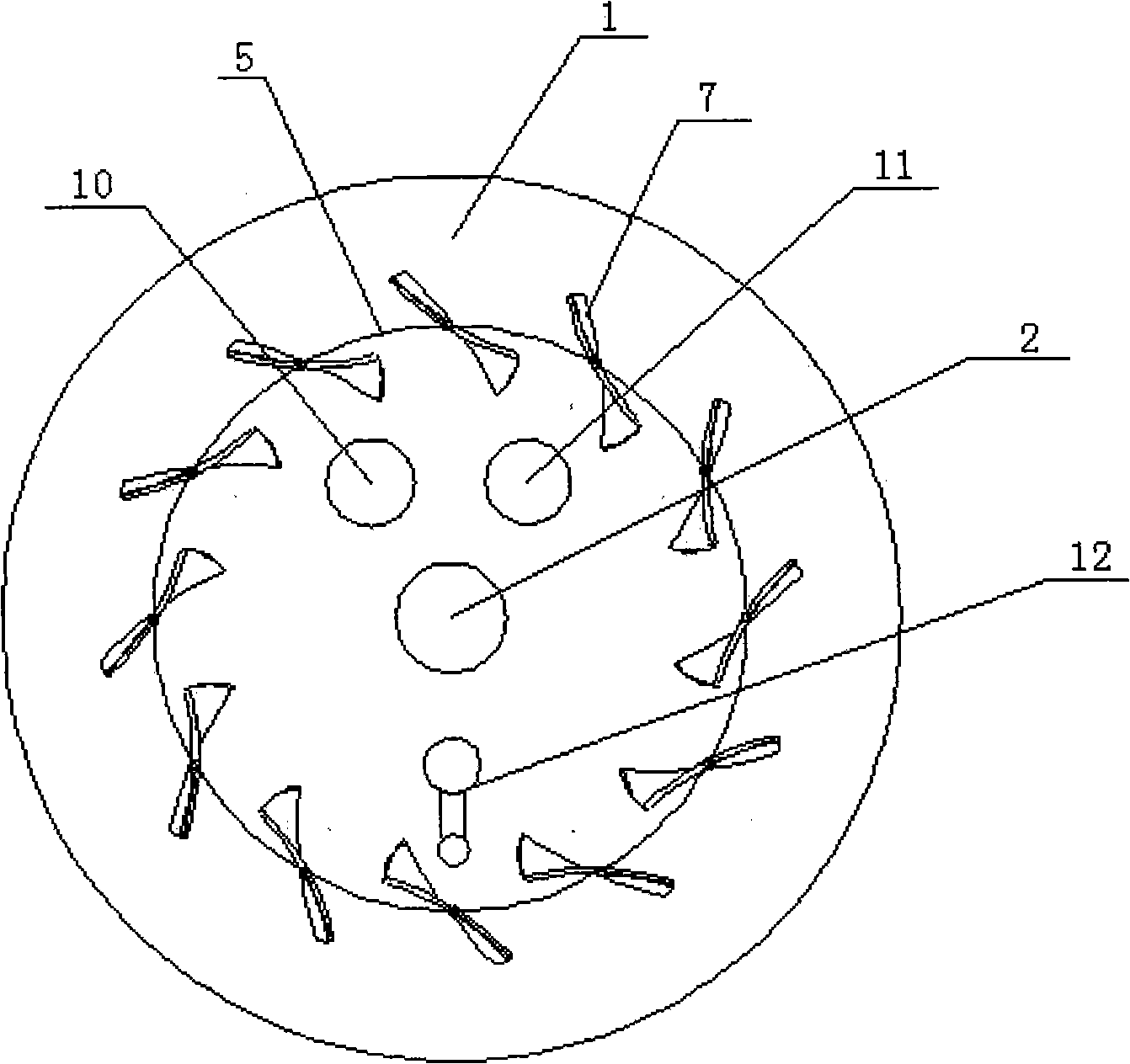

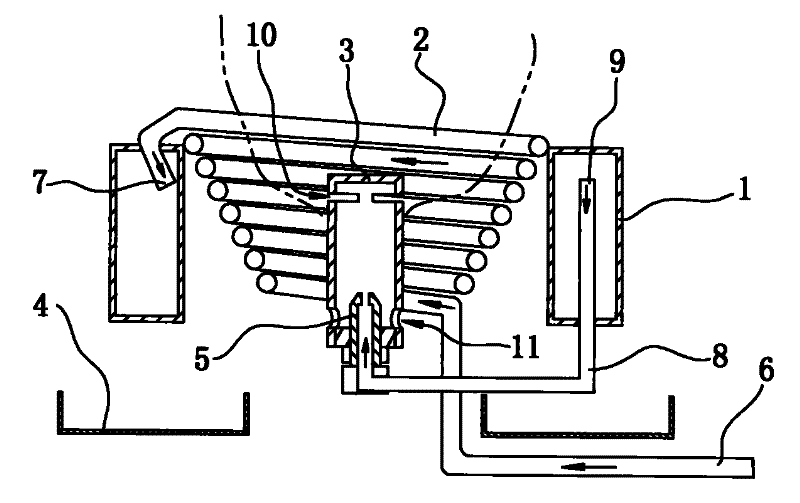

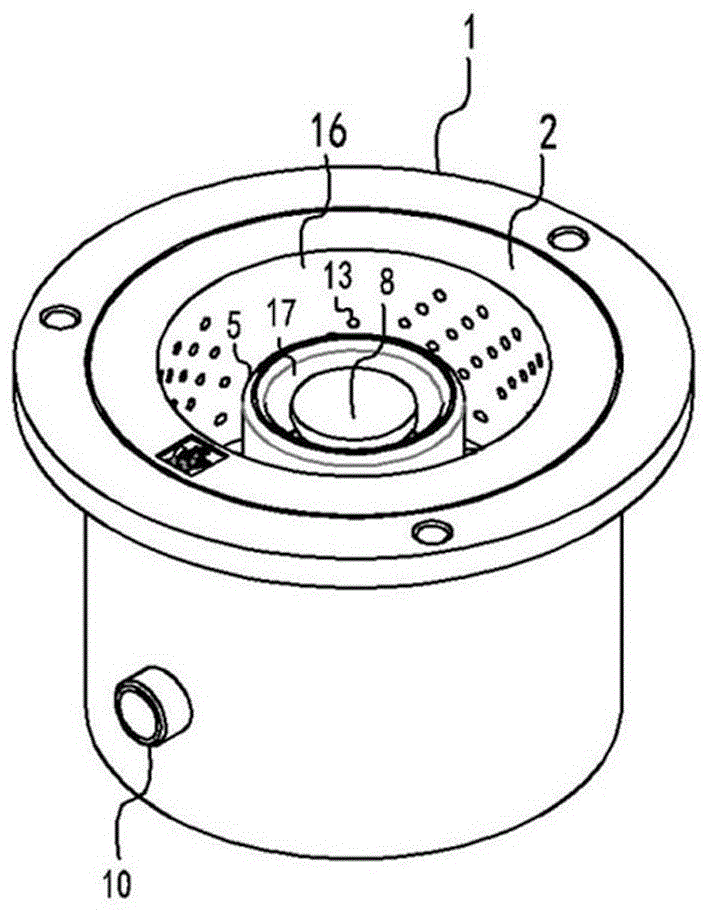

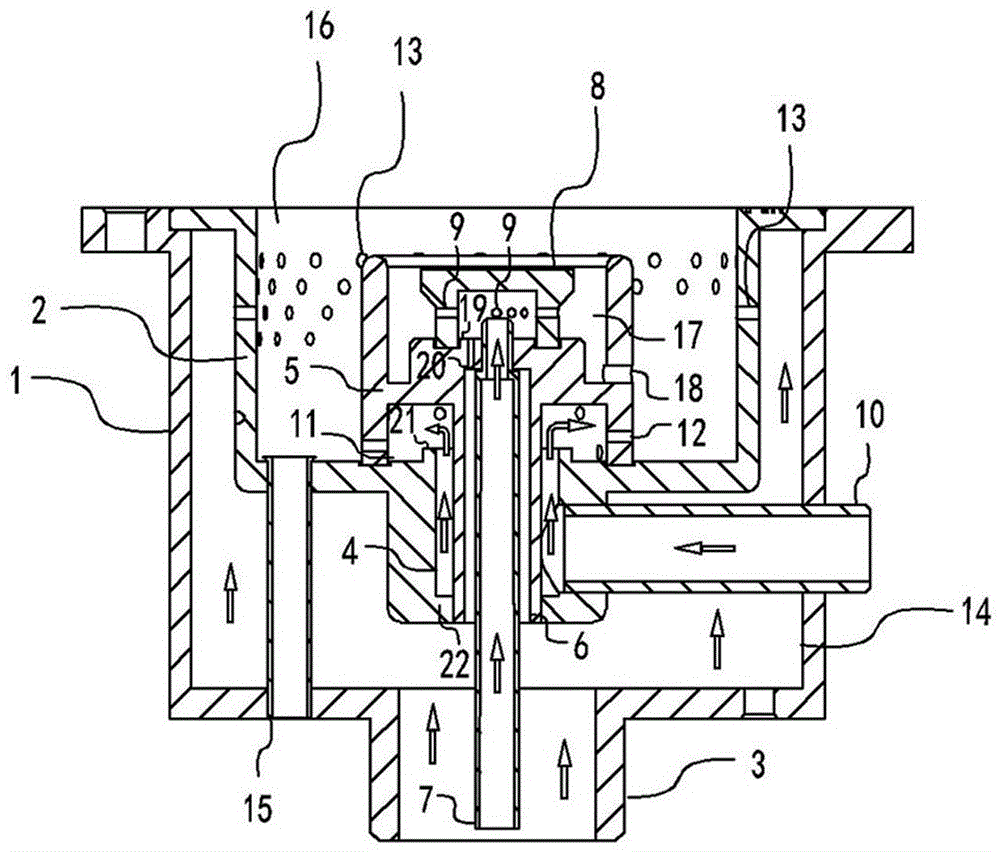

Gasification combustor of solid fuel cooking range

ActiveCN103123109ABurn fullyEasy to igniteSolid fuel combustionCombustion apparatusCombustorSolid fuel

The invention provides a gasification combustor of a solid fuel cooking range which comprises a first core body and a movable whirlwind combustion-supporting device. A plurality of air-in and gasification combustion-supporting holes are arranged on the first core body, a fire-sealing cover baffle plate is arranged on the inner wall of the first core body, and when an air blower is used for compulsorily supporting air for combustion supporting, the movable whirlwind combustion-supporting device is arranged on the fire-sealing cover baffle plate in the first core body. The movable whirlwind combustion-supporting device comprises a second core body, a top wall and a bottom wall, wherein the top wall is arranged on the upper portion of the second core body, and the bottom wall is arranged on the lower portion of the second core body. A plurality of second air-in and gasification combustion-supporting holes are arranged on the periphery of the second core body, and the bottom wall of the second core body is provided with a plurality of third air-in and gasification combustion-supporting holes which are coincident in slant directions. A cold furnace is easy to fire up and fast to inflame; flame rotates for combustion; and heat power is strong. The gasification combustor saves energy and is environment-friendly; and when fire is sealed, the movable whirlwind combustion-supporting holes are taken out, and the movable fire-sealing cover is arranged on the fire-sealing cover baffle plate to seal the fire. The gasification combustor is applicable to a boiler or a hot blast stove with solid fuel combusted, and use of combustion equipment with any structure such as the cooking range in a matched mode.

Owner:陕西华能恒大科技有限公司 +1

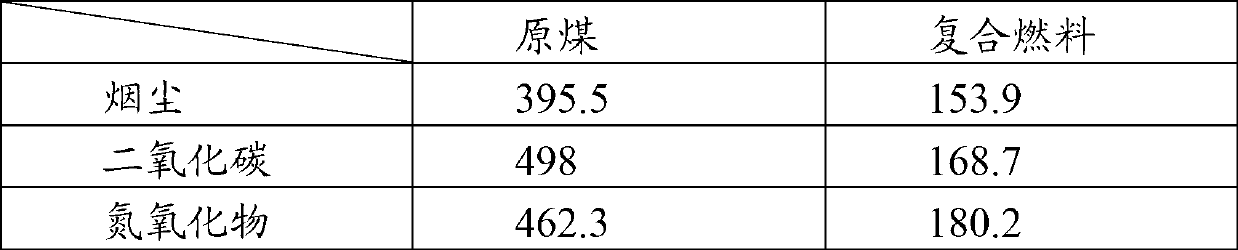

Compound fuel and production method thereof

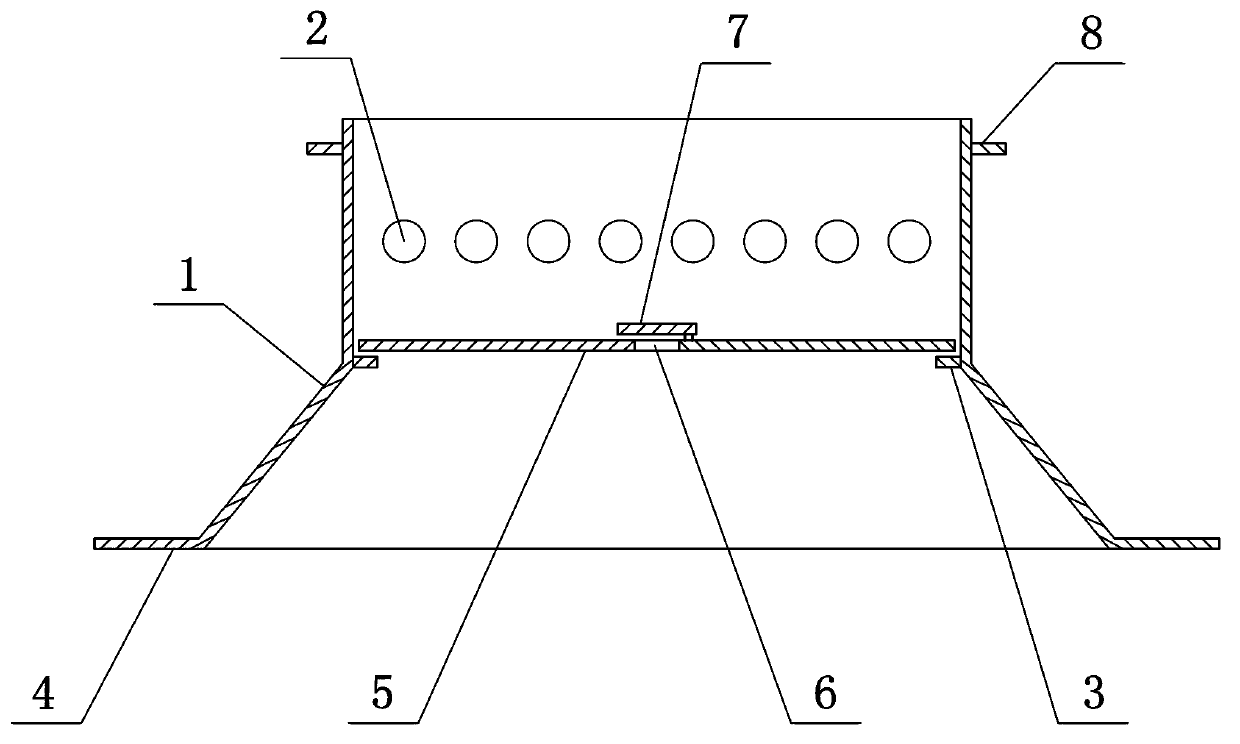

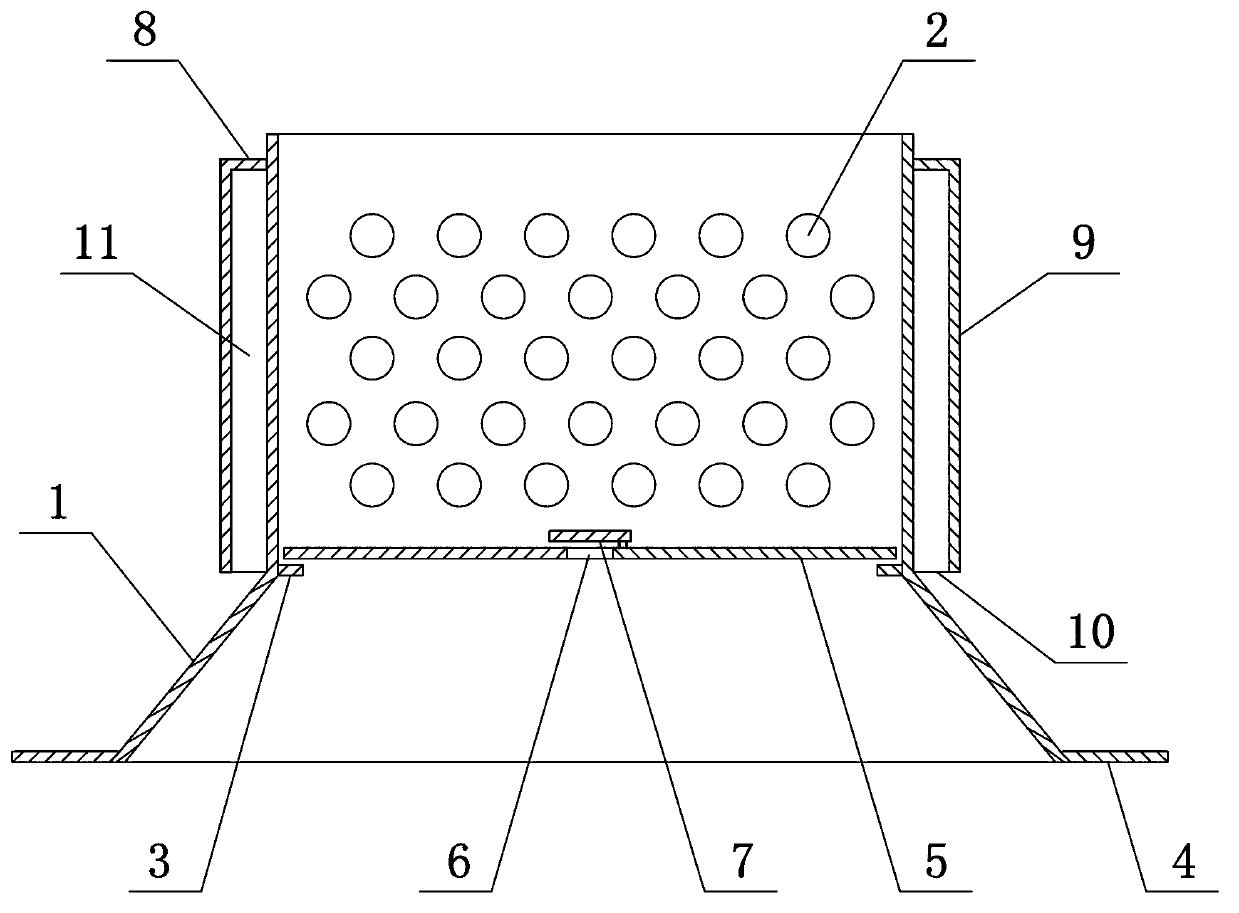

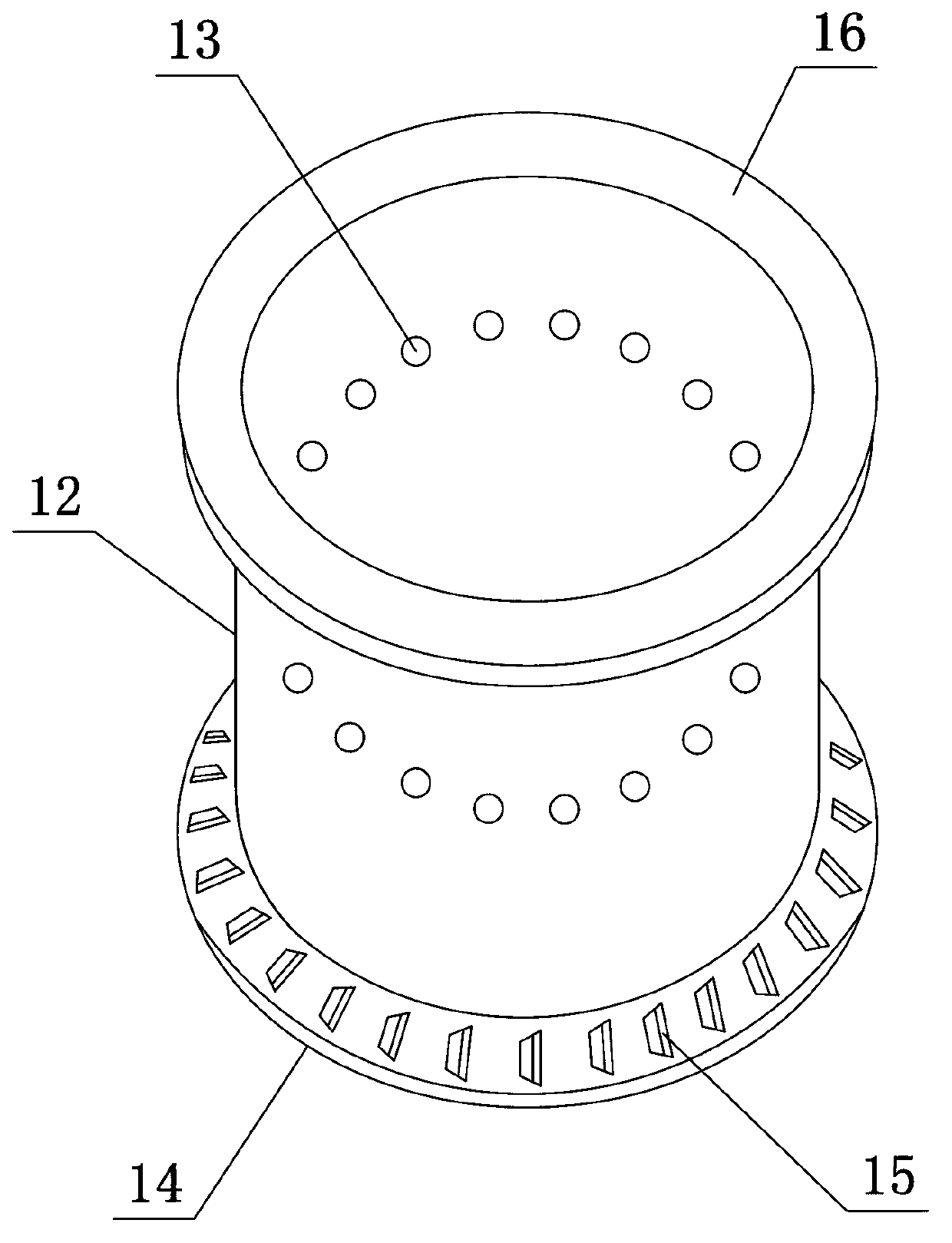

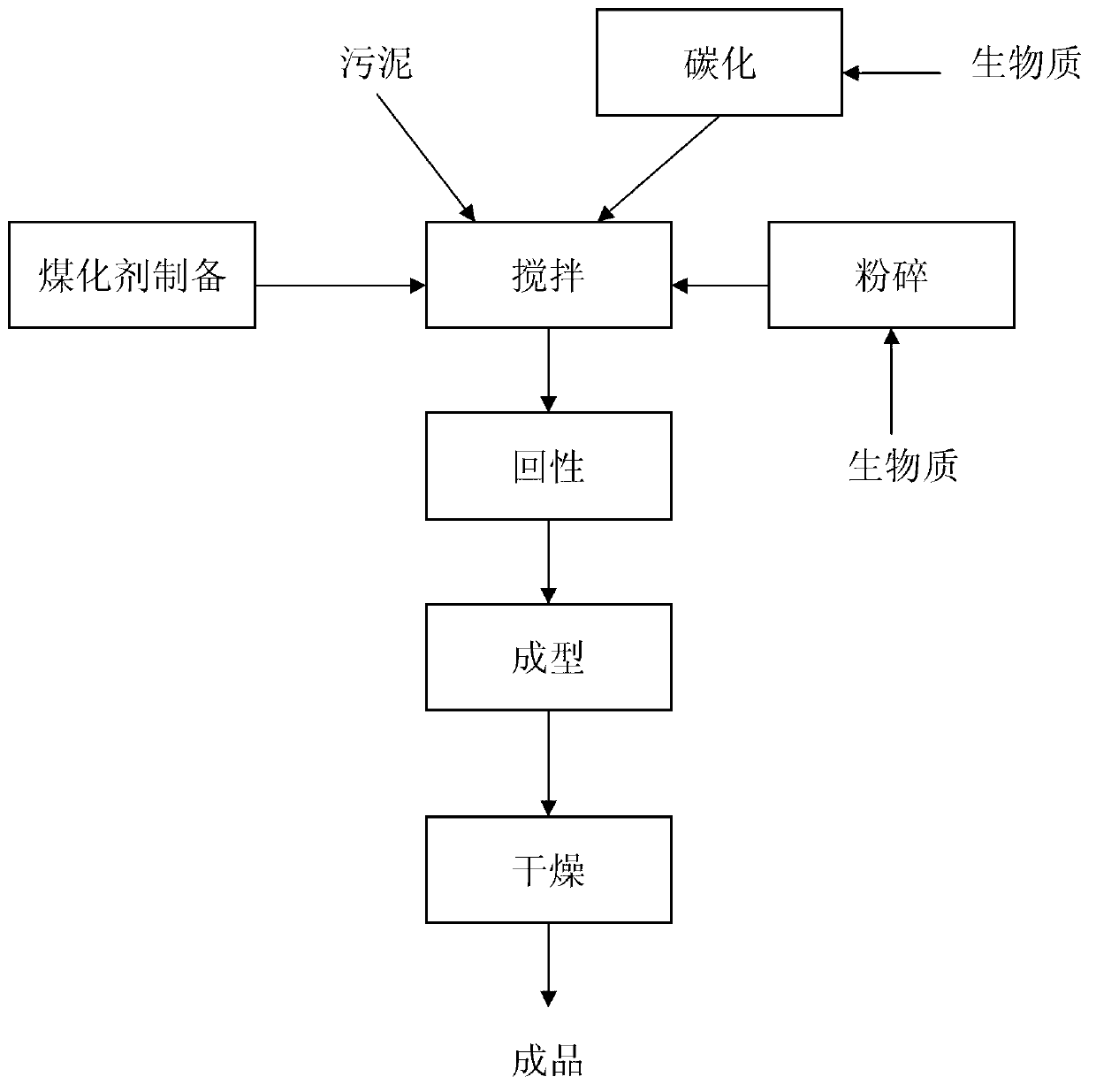

The invention provides a compound fuel and a production method thereof. The compound fuel comprises the following components by weight percent: 15-35% of domestic sludge of a sewage treatment plant, 15-70% of carbon powder after biomass carbonization, 10-50% of biomass raw material which is uniformly crushed and 0.8-2% of coalification agent. The production method comprises the following steps: performing pretreatment on the raw material, including the crushing of the biomass raw material, the carbonization of the biomass raw material into the carbon powder and the preparation of the coalification agent; stirring: adding the sludge, the coalification agent, the carbon powder and the biomass after crushing into a stirring device according to the weight percentage for uniform stirring; tempering: placing a mixture obtained after well stirring for 8-72 hours; forming: preparing and forming the mixture after tempering; and drying: performing drying and dehydration on the mixture after forming. The compound fuel can save energy, protect an environment and reduce cost.

Owner:刘波

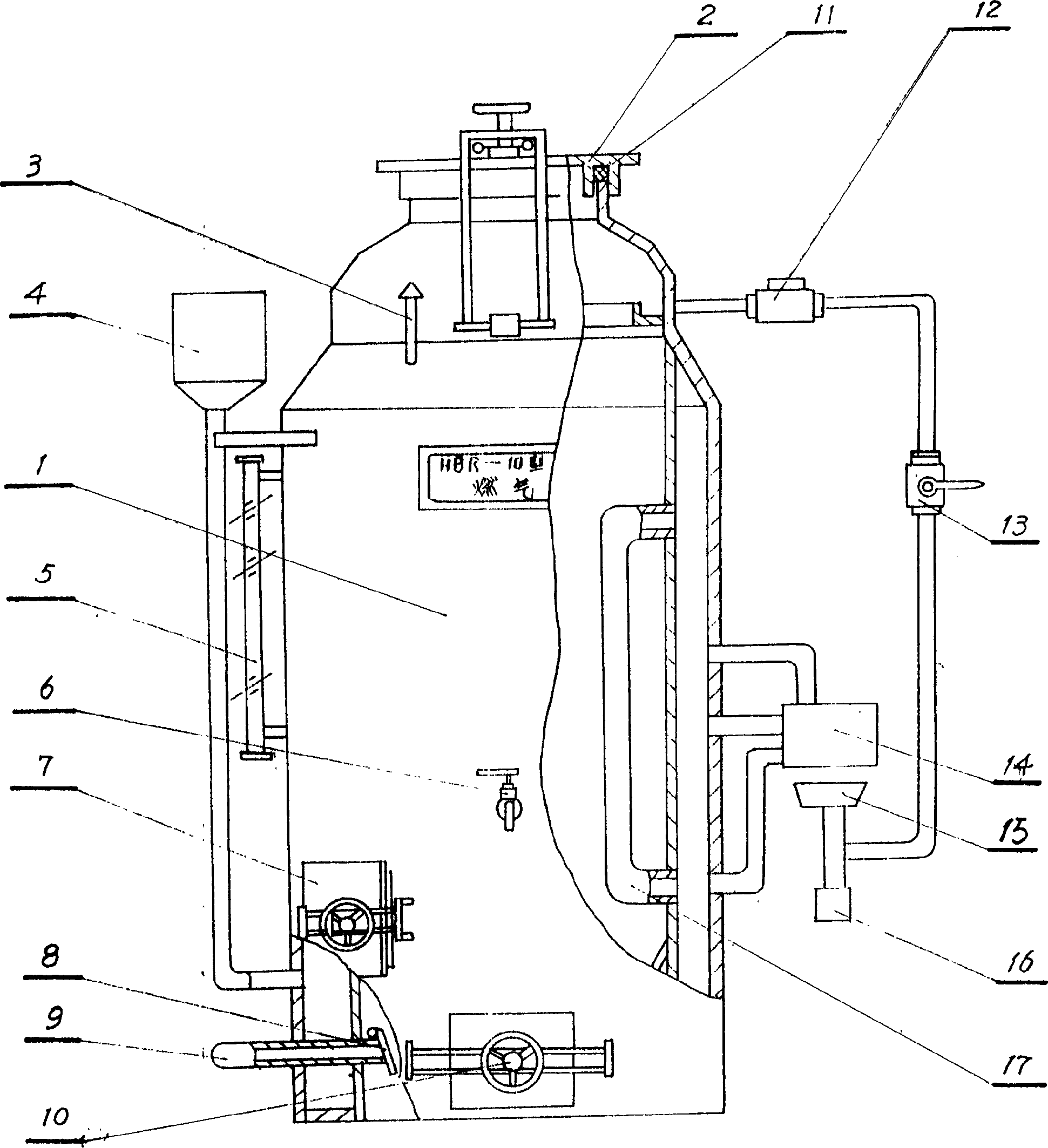

Coal and firewood two purpose gas burning stove

InactiveCN1458250AAvoid poisoningHigh flame temperatureGaseous fuelsCombined combustion mitigationCoalEngineering

The two-purpose gas burning stove for burning coal and firewood includes stove body, annular water tank, smoke exhausting pipe, circular gas and water filter, gas exhaust valve outside the stove body, side boiling water valve, straight pipe heat radiator in the inner wall of the stove body and connected to the circular water jacket, outer pipe connected to the heater, fuel leakage preventer in the bottom of the stove body, stove grate locking unit, coke eliminating door and coke pushing rod, air inlet connected to blower, ash door and wind backing baffle. It can produce gas continuously and high flame temperature and less environmental pollution.

Owner:袁功强

Novel domestic alcohol oil burner

The invention discloses a novel domestic alcohol oil burner which comprises a base, a straight spray nozzle, a big-end-down fire collection cover, a fire distribution cap and a sound insulation barrel, wherein an air inlet is formed in the base, the straight spray nozzle is installed in the center of the base, the top and the side face of the fire distribution cap are provided with fire distribution holes respectively, and the sound insulation barrel is installed on the base and surrounds around the fire collection cover and the fire distribution cap. The upper end of the sound insulation barrel is provided with a fire tray extending out of the barrel. According to the novel domestic alcohol oil burner, the straight spray nozzle is utilized for sufficiently spraying out alcohol oil in an atomization mode, the spraying force of the nozzle is greatly reduced, fire power is prevented from being too excessive, balance distribution of fire power is achieved through the fire collection effect of the fire collection cover and the fire distribution effect of the fire distribution cap, the fire spraying mode is more scientific and reasonable on the condition that the heat value is not lowered, the requirement for domestic miniaturization can be met, the sound insulation barrel can effectively prevent noise produced when the novel domestic alcohol oil burner is used from diffusing and can also play a certain fire collection role, and multiple problems in the prior art are effectively solved.

Owner:张建忠

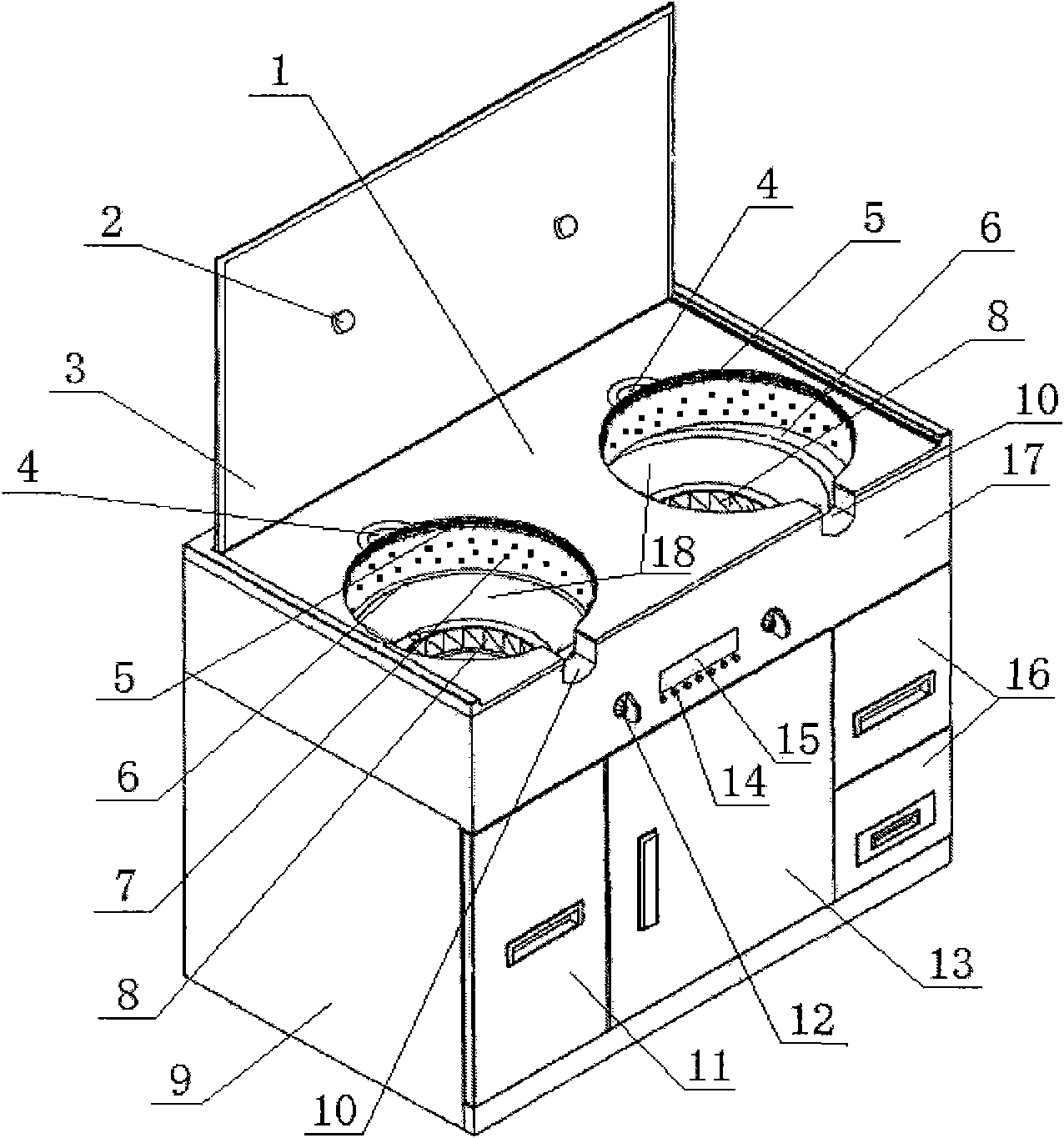

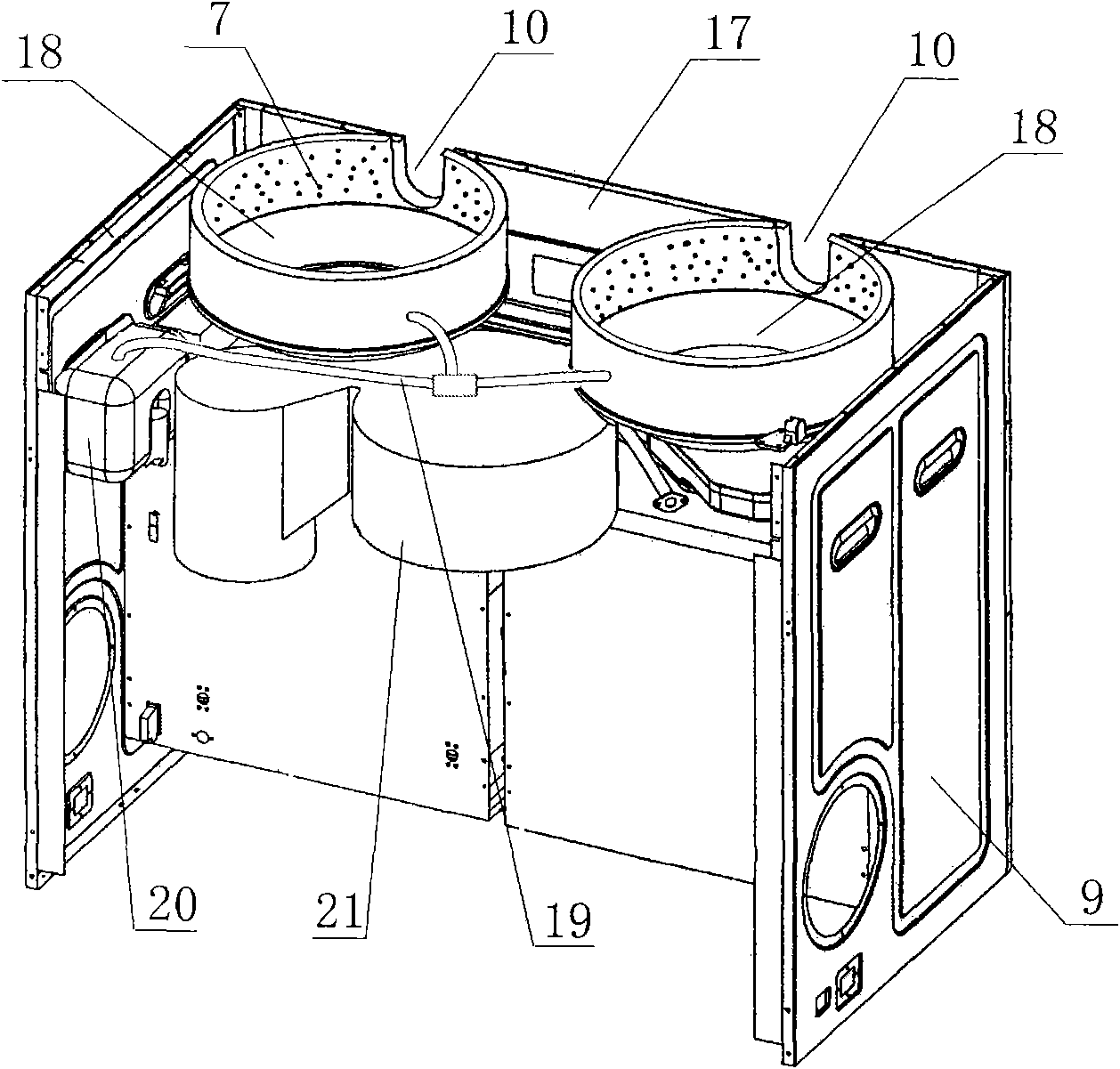

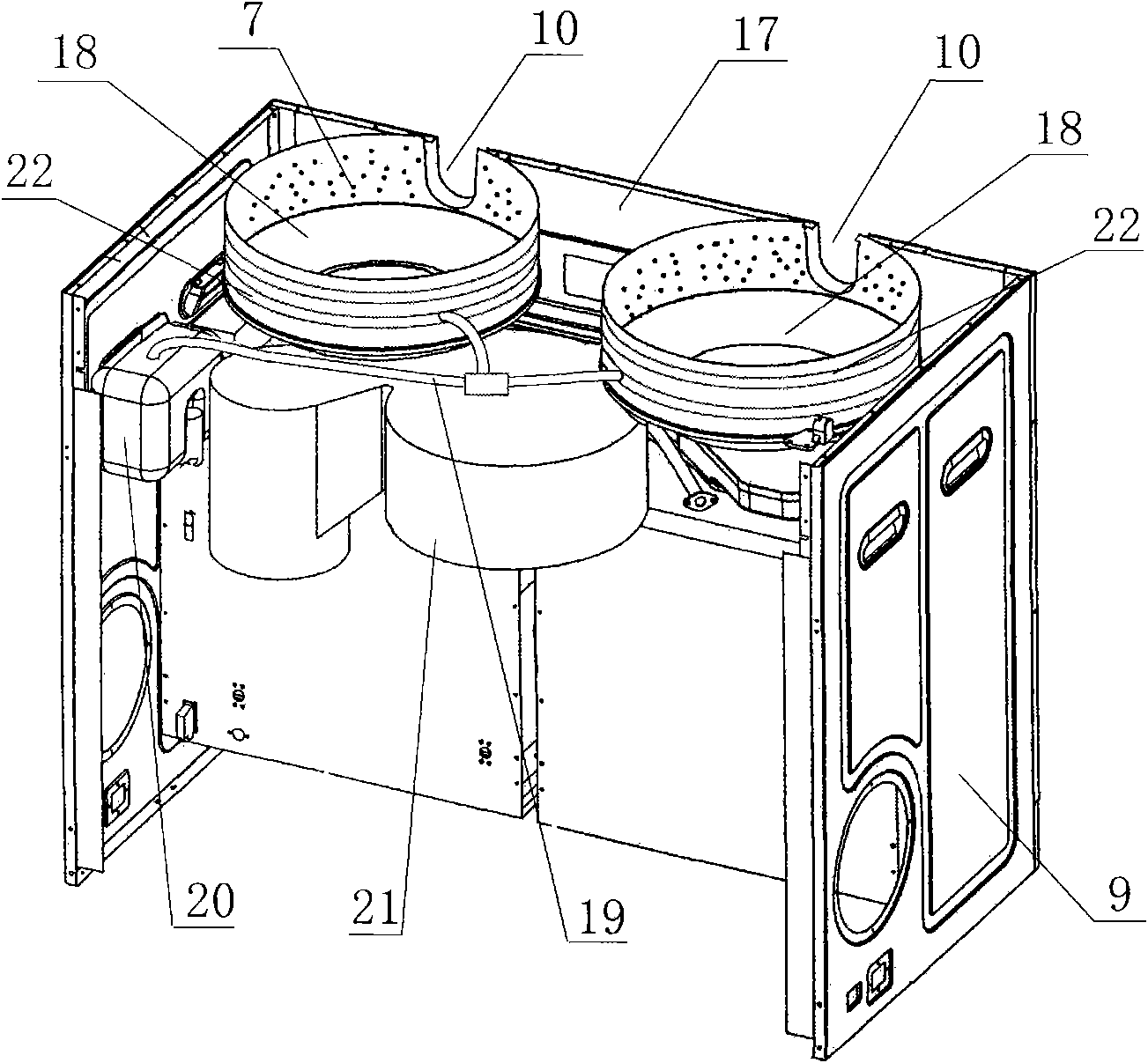

Integrated oven with combustion-supporting device

InactiveCN101818919AFierce firepowerImprove combustion efficiencyDomestic stoves or rangesCooking fumes removalCombustorHearth

The invention relates to an integrated oven with a combustion-supporting device, which comprises a hearth, a ventilator and an integrated oven shell arranged below the hearth, wherein the hearth is provided with at least one oven chamber; a combustor and a bracket for supporting a pot body are arranged in the oven chamber; a lampblack suction hole is formed on the oven chamber; and the lampblack suction hole is connected with the ventilator. The integrated oven with the combustion-supporting device is characterized in that: the integrated oven also comprises the combustion-supporting device which is arranged in the integrated oven shell; and at least one combustion-supporting gas hole is reserved on the oven chamber wall and each combustion-supporting gas hole is communicated with the combustions-supporting device through a gas pipe. The integrated oven with the combustion-supporting device has a smart and rational structure, the combustion-supporting device can greatly improve the combustion efficiency of the gas, save the gas resource and make the flame of the combustion higher, and thus, the quality and efficiency of dish making are improved.

Owner:闵俊峰

Coal-burning energy releasing powder and its prepn

The present invention discloses one kind of coal-burning energy releasing powder and its preparation process. The coal-burning energy releasing powder consists of saltpeter 0.5-1.5 weight portions, ferric dicyclopentadiene or allyl cyanurate 1-2 weight portions, potassium permanganate or potassium bromide 0.3-0.7 weight portions, sodium nitrate or calcium nitrate 0.3-0.7 weight portions, potassium permanganate or potassium persulfate 1.5 -2.5 weight portions, strontium nitrate or sodium bichromate 0.5-1.5 weight portions, calcium fluoride 1.5-2.5 weight portions, coal slag or char slag 1.5-2.5 weight portions, loess or lime 1.5-2.5 weight portions, potassium chlorate or potassium persulfate 0.5-1.5 weight portions, potassium nitrate 0.5-1.5 weight portions, and sodium chloride 80-90 weight portions. It can promote combustion of coal to convert the latent energy of coal into heat completely.

Owner:张学义

Transversely closed burning highly effective environment protective energy-saving direct combustion type biomass stove

InactiveCN101012938AExtended stroke of rotary combustionUnique designDomestic stoves or rangesLighting and heating apparatusDirect combustionEngineering

The invention discloses a horizontal-sealed high-efficiency energy-saving direct-combustion biological furnace, which comprises a furnace formed by front, back, left and right side panels, upper panel and bottom plate. The left of upper panel is arranged with a base opening. The right side of upper panel is arranged with an upper drawing cylinder opening and a lower feeding opening. The lower furnace of feeding opening contains an incline sliding plate screen whose lower end is connected with the furnace screen in the hearth. The right panel of furnace above the sliding plate screen is arranged with a wind inlet. One side of the base opening is arranged with an arc upright baffle plate to form an arc fire channel whose front is communicated with hearth and back is communicated with the drawing cylinder opening. Via the combustion drawing cylinder, the passive pressure in the furnace can be kept from continuous feeding to continuous burning. The semi-round fire channel of arc upright baffle plate can prolong the strike of fire in the channel to burn the fuel second time.

Owner:焦作市洁燃新能源有限公司

Combustor of inner flame gas range

The invention discloses a burner of an inner flame gas stove, which consists of a burner body and a fire distributer device; an upper layer fire hole and a lower layer fire hole are arranged on the fire distributer device and the direction of the outlets of the fire holes is inward, and an air channel is arranged or not arranged between the upper layer fire hole and the lower layer fire hole; a single inner cavity or two independent inner cavities is or are arranged; the two independent inner cavities are arranged so that the flame at the upper layer and the lower layer can be regulated independently; while the air channel is arranged so that the air supplementation can be more abundant. The burner utilizes multiple-layer fire holes, stratified combustion and multiple-layer cyclonic flame, and has the advantages of large heat flow, fierce fire power, high heat efficiency, low-CO and low-NOx in smoke gas, no fire hole blocking and the like.

Owner:吴成年 +1

Biomass nanometer liquid fuel

The invention belongs to the technical field of new energies, in particular relates to a biomass nanometer liquid fuel comprising the following raw materials in percentage by weight: 40-90% of biomass alcohol, 0-25% of wastewater and 5-35% of additive, wherein the main raw material biomass alcohol used by the invention is leftovers or byproducts of a chemical plant, a fertilizer plant, a winery, a pharmaceutical factory and a sugar refinery, and the wastewater is domestic or industrial discharged wastewater, therefore, the waste materials are utilized, the cost is reduced and the resources are saved. The liquid fuel of the invention can not explode, is relatively safer during the storage and transportation, can be applied to the cooking ranges and boilers in the collective canteens, restaurants and hotels instead of diesel oil or heavy oil, has the advantages of fierce fire, sufficient burning, non-poisonous and smokeless properties, environment protection, no-smoky burning and non-smoked meal, and can save the fuel cost by about one third.

Owner:东莞市智造生物科技有限公司

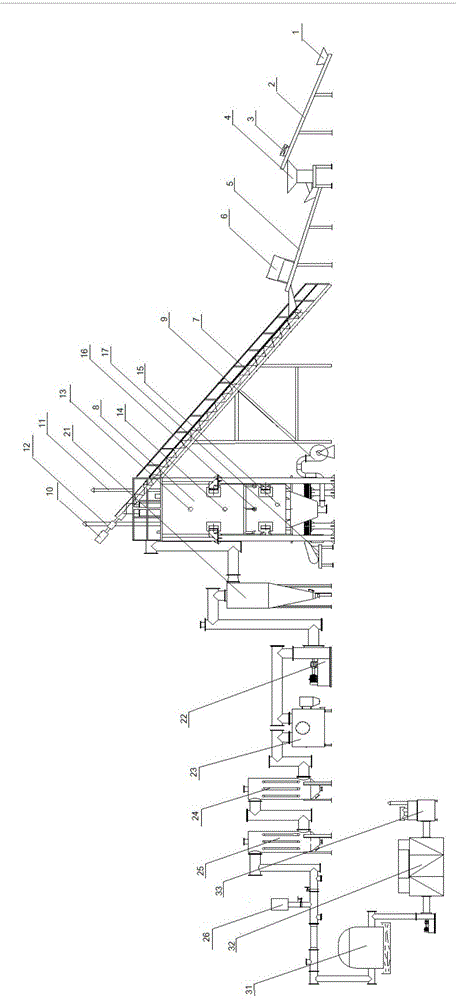

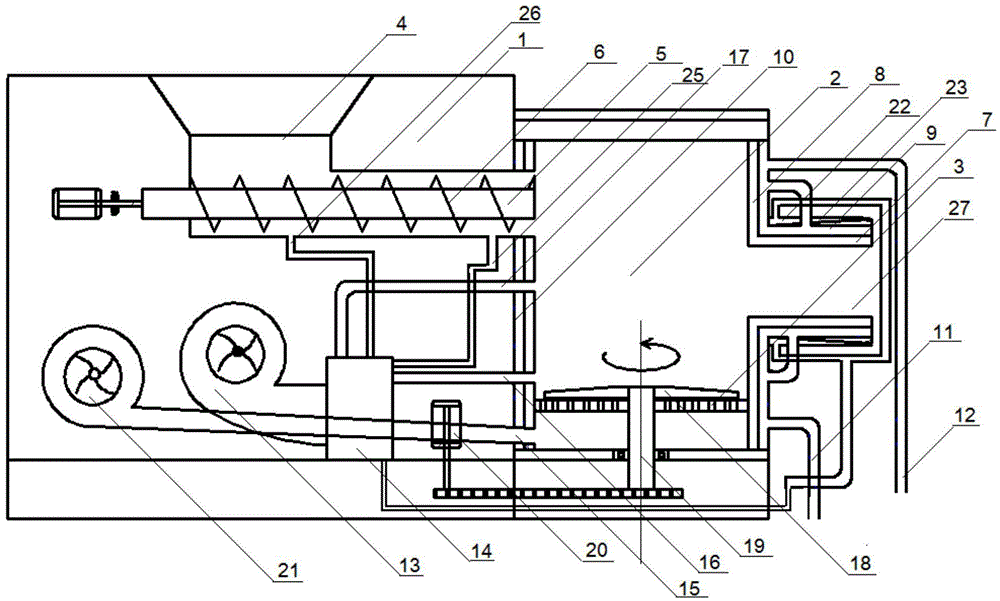

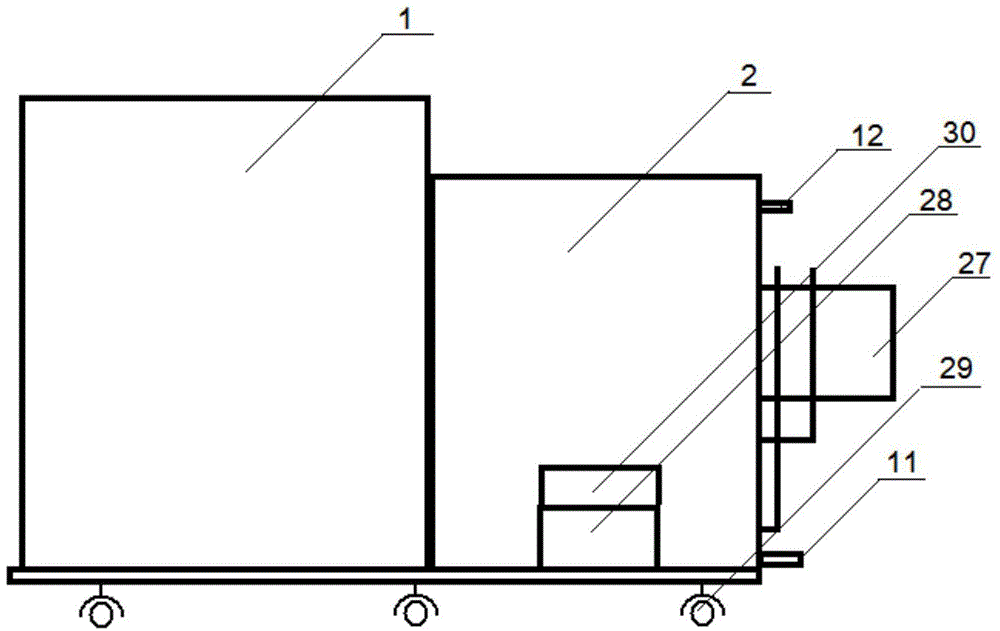

Biomass fuel based on corn straw, and preparation method and preparation production line thereof

The invention discloses a biomass fuel based on corn straw, and a preparation method and a preparation production line thereof; a formula of the biomass fuel is composed of the components by the weight percentage: 60-80% of the corn straw, 20-25% of soybean straw, 0.2-0.5% of an expanding agent, 2-3% of an adhesive, 1-3% of water and 1-5% of a ripening agent. Provided is the biomass fuel based on the corn straw and having the advantages of low production cost, environmental protection, high quality, high burning rate and convenient batch production. When the corn straw biomass fuel prepared through the process and the formula is burnt, the corn straw biomass fuel has no fumes when burning, has the burning efficiency of 96-98%, and has relatively strong firepower and relatively low production cost. Moreover, when the production line is adopted for preparing the corn straw biomass fuel, the production line has the advantages of small occupied places, relatively high production efficiency, low labor cost and better automated production effect, and further controls the cost of the biomass fuel.

Owner:HUANGSHAN JINFU BIOLOGICAL ENERGY

Biomass burning heating jetting furnace with fire grate

InactiveCN104819454AIncrease temperatureRaise the combustion temperatureSolid fuel combustionAir/fuel supply for combustionSpray nozzleEngineering

The invention relates to a biomass burning heating jetting furnace with a fire grate. The jetting furnace is characterized by comprising an equipment cabin (1), a hearth (2) and a nozzle (27). A feeding hopper (4) for adding fuels into a burning furnace is arranged in the equipment cabin (1). The hearth (2) is connected with the equipment cabin (1) and the nozzle (27). A grate bridge (3) is arranged on the lower portion in the hearth (2). A water inlet (11) and a water outlet (12) which are connected with a hearth clamping sleeve (10) are formed in the hearth (2). A nozzle flame retardant layer (7) is arranged on the innermost layer of the nozzle (27). A nozzle clamping sleeve (9) and a rotation air sandwich (22) are arranged in the nozzle (27). A rotation air guide sheet (23) arranged spirally is arranged in the rotation air sandwich (22). By means of the jetting furnace, the thermal efficiency is high, energy is saved by more than 30%, the furnace body temperature can reach more than 1000 DEG C, and the jetting furnace is an ideal biomass fuel furnace.

Owner:HUBEI HUANTAI BIOMASS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com