Compound fuel and production method thereof

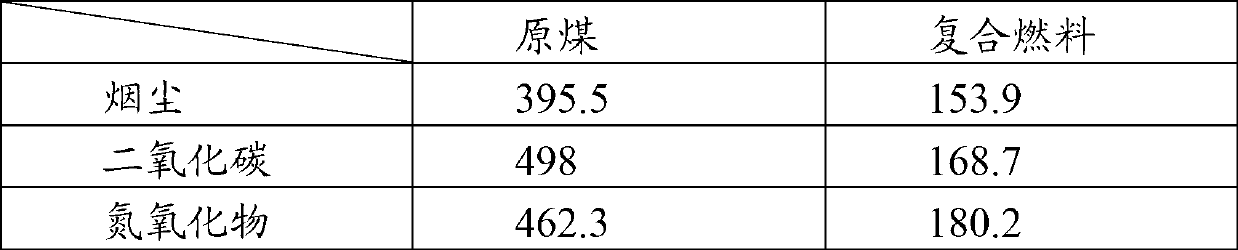

A composite fuel and production method technology, applied in the direction of fuels, solid fuels, biofuels, etc., can solve the problems of consuming large raw coal resources, high cost, and high energy consumption, and achieve the effects of fast fire, easy transportation, and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

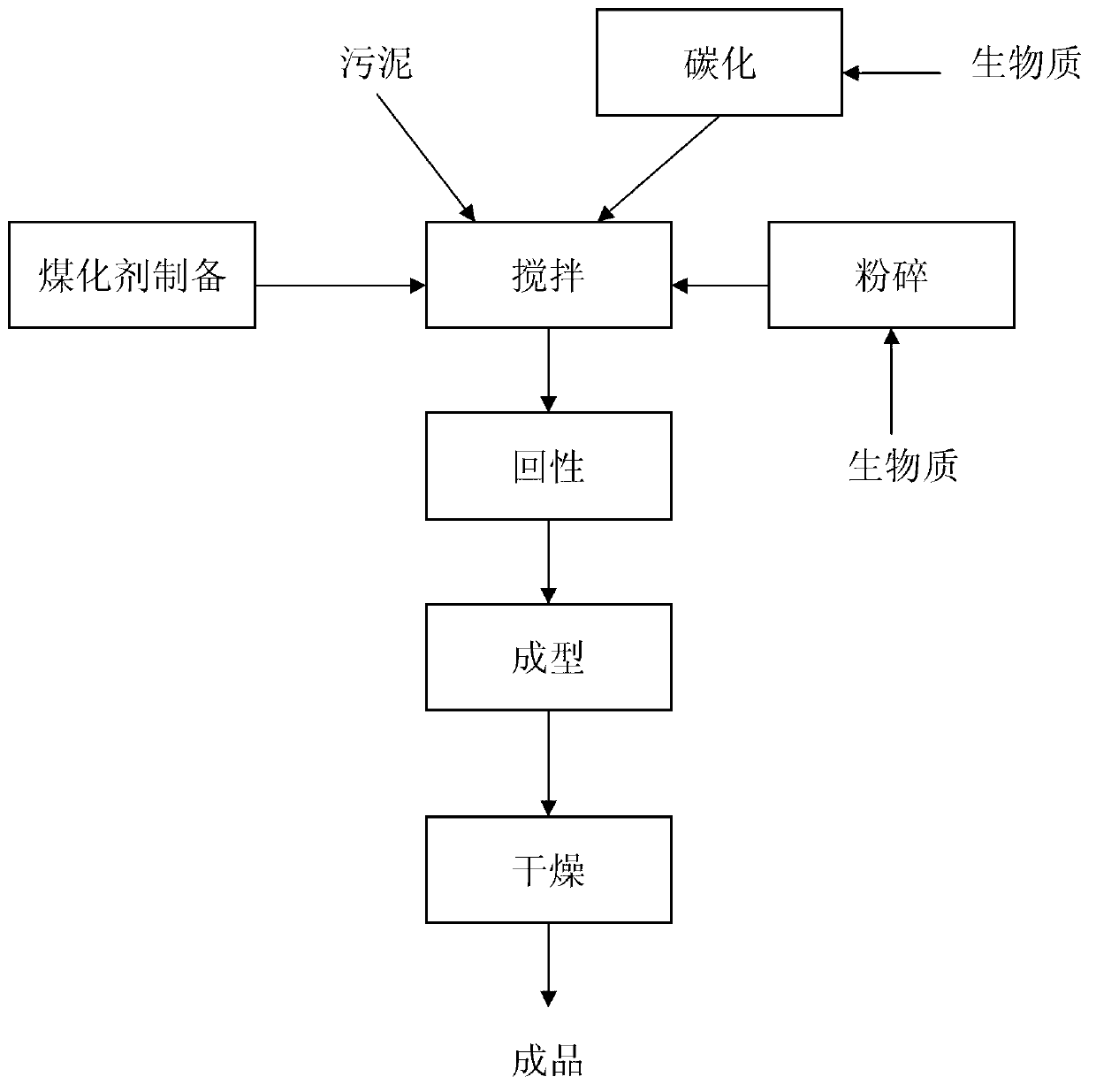

Method used

Image

Examples

Embodiment 1

[0033] The composite fuel of the present invention comprises the following raw materials in terms of weight percentage: 18% of domestic sludge from sewage treatment plants; 60% of carbon powder after biomass carbonization; 20% of uniformly pulverized biomass raw materials; and 2% of coalification agent.

Embodiment 2

[0035] The composite fuel of the present invention comprises the following raw materials in terms of weight percentage: 20% of domestic sludge from a sewage treatment plant; 49.2% of carbon powder after biomass carbonization; 30% of evenly pulverized biomass raw materials; and 0.8% of a coalification agent.

Embodiment 3

[0037] The composite fuel of the present invention comprises the following raw materials in terms of weight percentage: 35% of domestic sludge from a sewage treatment plant; 20% of carbon powder after biomass carbonization; 43.5% of evenly pulverized biomass raw materials; and 1.5% of a coalification agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com