Preparation method of cold-resistant and seawater-resistant aqueous film-forming foam fire extinguishing agent

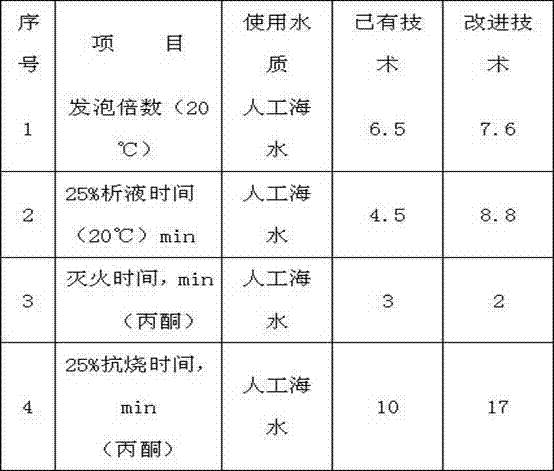

A foam fire extinguishing agent and seawater-resistant technology, applied in fire prevention equipment, etc., can solve the problems of unstable performance of fluorocarbon surfactants and anti-burning agents, great influence on foam performance and fire-extinguishing performance, and achieve long anti-burning time, The effect of short fire extinguishing time and strong anti-burning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific embodiments.

[0021] The preparation method of cold-resistant seawater-type aqueous film-forming foam fire extinguishing agent: start the mixer, add 350 parts of composite anti-scalding agent, add 8 parts of sodium benzoate and 70 parts of urea to dissolve them all, add 7 parts of xanthan gum to dissolve them all, and stop stirring , after swelling for 2 hours, continue to stir and add 300 parts of amphoteric hydrocarbon surfactant, 30 parts of APG, 100 parts of ethylene glycol, 40 parts of ethylene glycol butyl ether, and add 40 parts of FC1203, 20 parts of FC1157, low molecular weight fluorine Add 30 parts of surfactant, stir for 40 minutes, adjust the pH value of the material to 7.8, add 40 parts of buffer, continue stirring for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com