A kind of microstructure cladding single crystal optical fiber and its preparation method

A microstructure and cladding technology, applied in cladding optical fiber, multi-layer core/cladding optical fiber, optical waveguide light guide, etc., can solve the problems of uneven diffusion, poor product performance stability, poor controllability, etc., to achieve Fiber characteristics are easy to control and improve the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

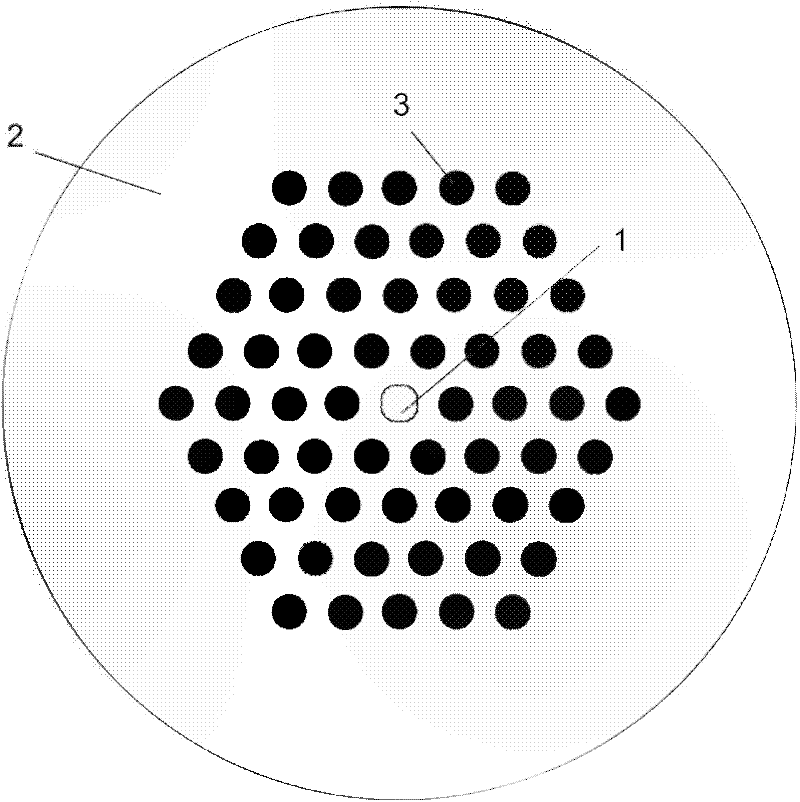

[0033] Such as figure 1 As shown, the core 1 is lithium niobate single crystal with a diameter of 10um, the low-refractive-index background material 2 is pure quartz material, and the high-refractive-index column 3 is a cylinder with a cross-sectional diameter of 8um. For germanium-doped quartz of 1.55, the high-refractive-index columns 3 are distributed in a regular hexagonal lattice, and the distance between two adjacent high-refractive-index columns 3 is 15um; the working wavelength of this microstructure-clad single crystal fiber is 1550nm.

[0034] Due to the existence of high refractive index columns 3 distributed in a regular hexagonal lattice, the equivalent refractive index of the cladding (referring to the part of the microstructure cladding single crystal fiber except the core) is between the refractive index of pure silica material and germanium-doped silica Between the refractive indices, the difference between the equivalent refractive index of the cladding and t...

Embodiment 2

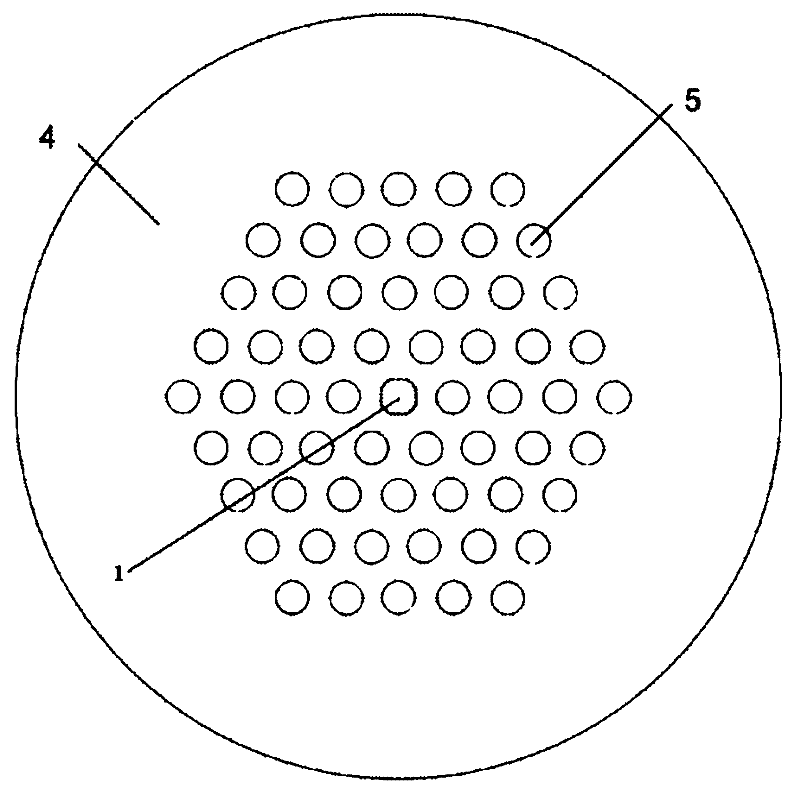

[0044] Such as figure 2 As shown, the core 1 is a sapphire single crystal with a diameter of 100um, the high refractive index background material 4 is a pure quartz material, and the low refractive index column 5 is a cylinder (air column) with a cross-sectional diameter of 10um. Germanium-doped quartz with a ratio of 1.55, the low-refractive-index columns 5 are distributed in a regular hexagonal lattice, and the distance between two adjacent low-refractive-index columns 5 is 20um; the working wavelength of this microstructure-clad single crystal fiber is 4um.

[0045] Due to the existence of the low-refractive-index columns 5 distributed in periodic lattices, the refractive index of the pure silica background material 4 is reduced, and the effective refractive index of the cladding (referring to the part of the microstructure cladding single crystal optical fiber except the core) is between that of pure silica Between the refractive index of the material and the refractive i...

Embodiment 3

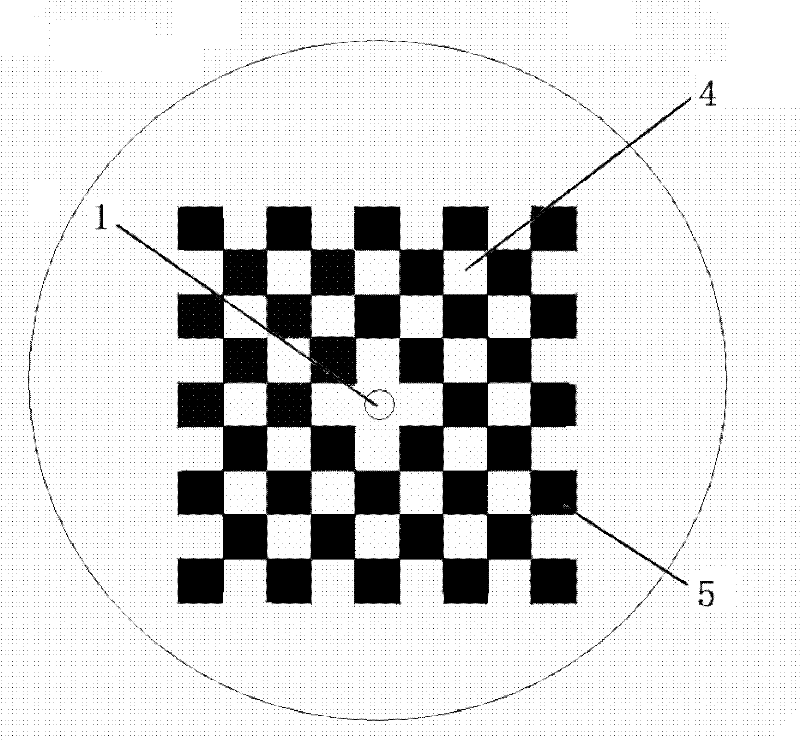

[0054] Such as image 3 As shown, the fiber core 1 is a silver bromide single crystal with a diameter of 300um, the high-refractive-index background material 4 is pure quartz material, and the low-refractive-index column 5 is a regular square prism with a bottom side length of 100um. Fluorine-doped quartz with a ratio of 1.4, the low refractive index columns 5 are distributed in a square lattice; the working wavelength of this microstructure cladding single crystal fiber is 10.6um.

[0055] Due to the existence of the low-refractive-index columns 5 distributed in periodic lattices, the refractive index of the pure silica background material 6 is reduced, and the effective refractive index of the cladding (referring to the part of the microstructure cladding single crystal optical fiber except the core) is between that of pure silica Between the refractive index of the material and the refractive index of fluorine-doped silica, the difference between the effective refractive in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com