Patents

Literature

177 results about "Drainage time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

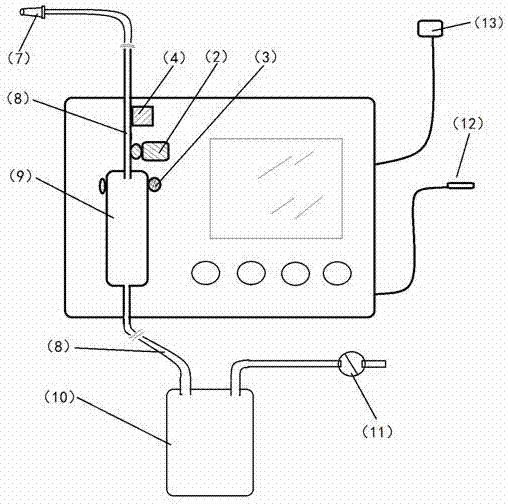

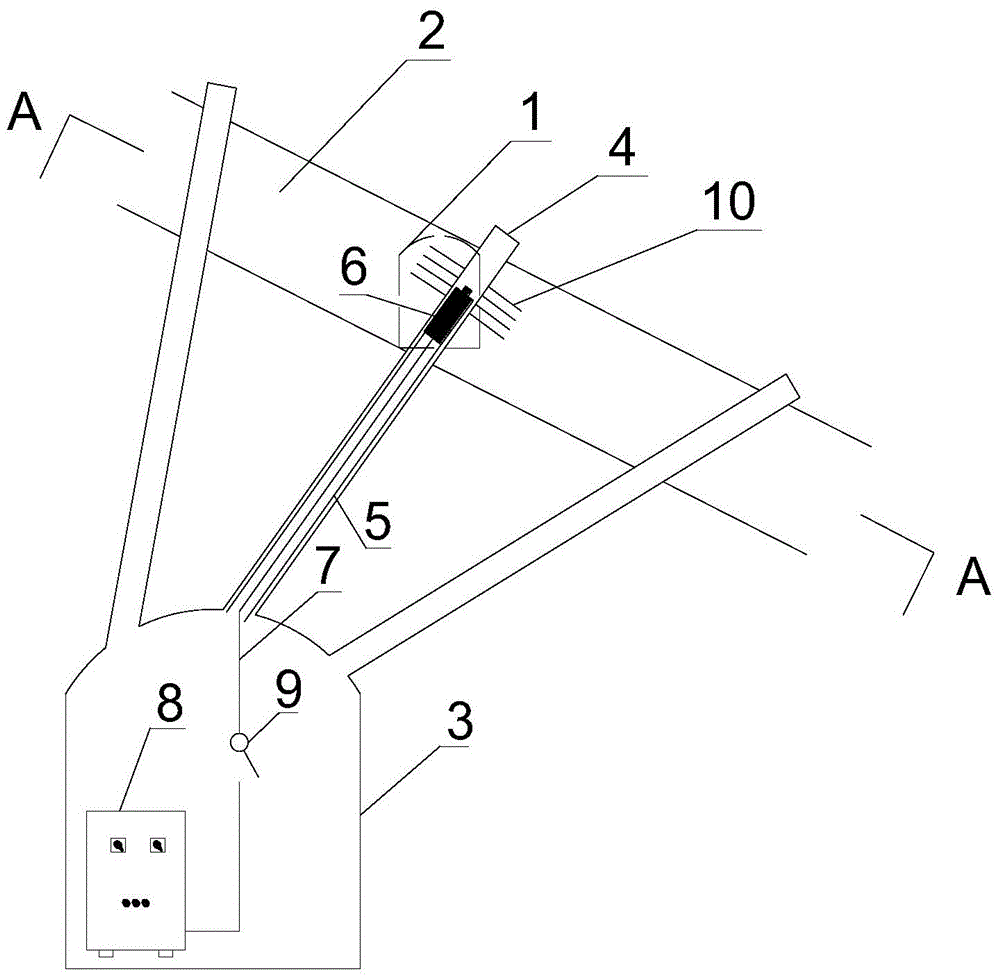

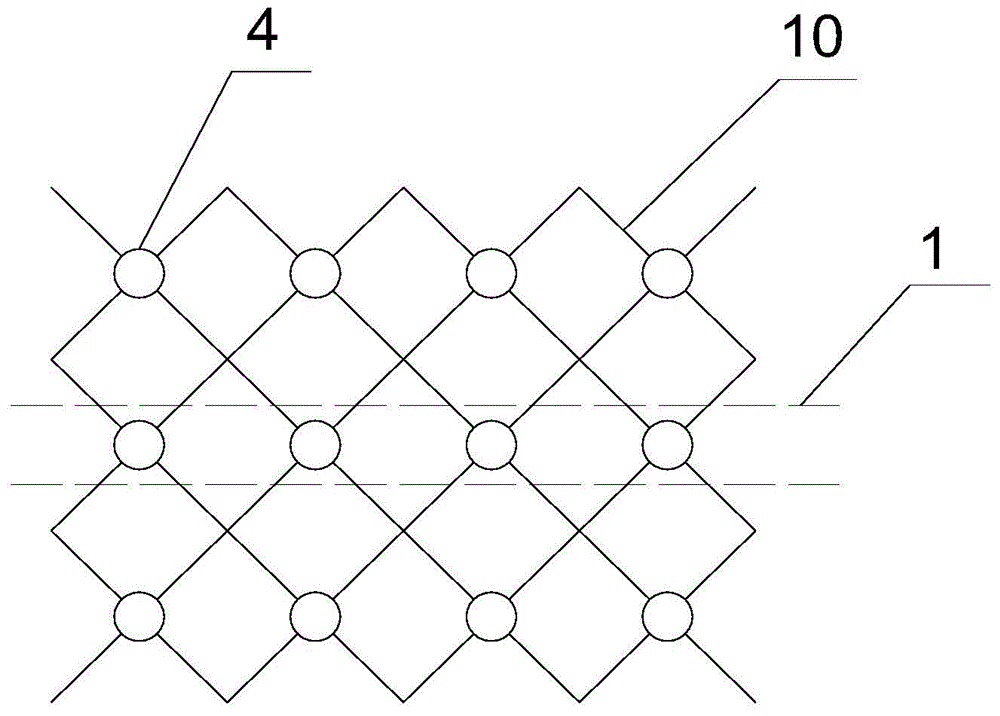

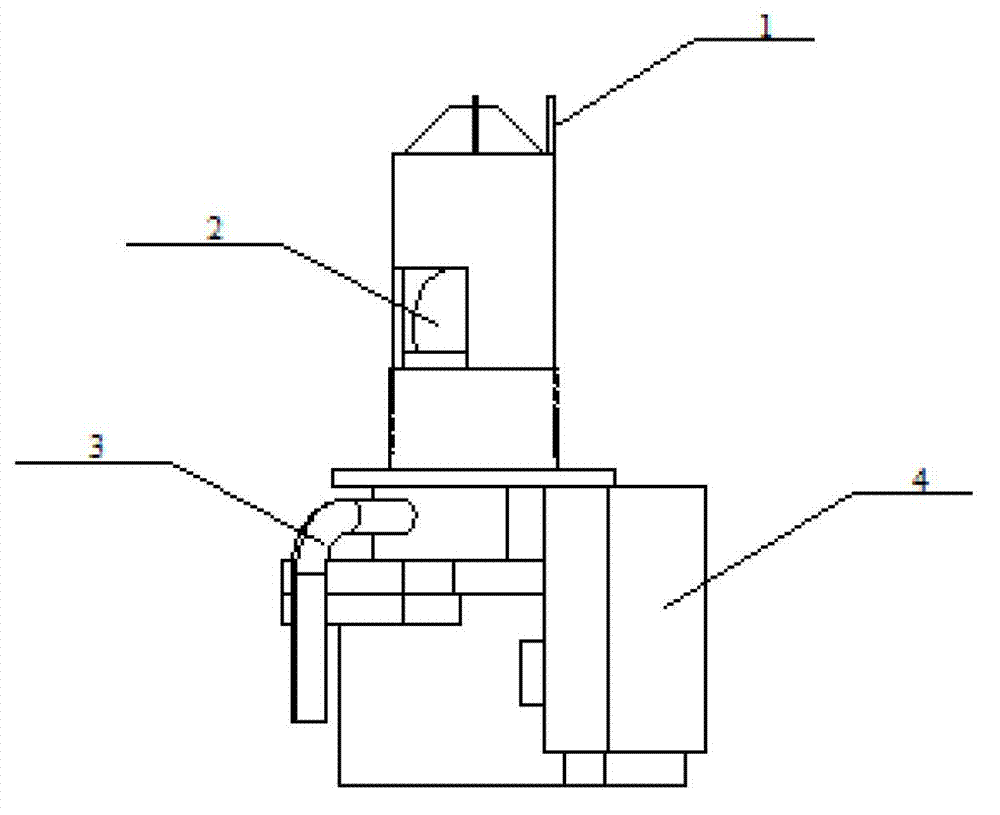

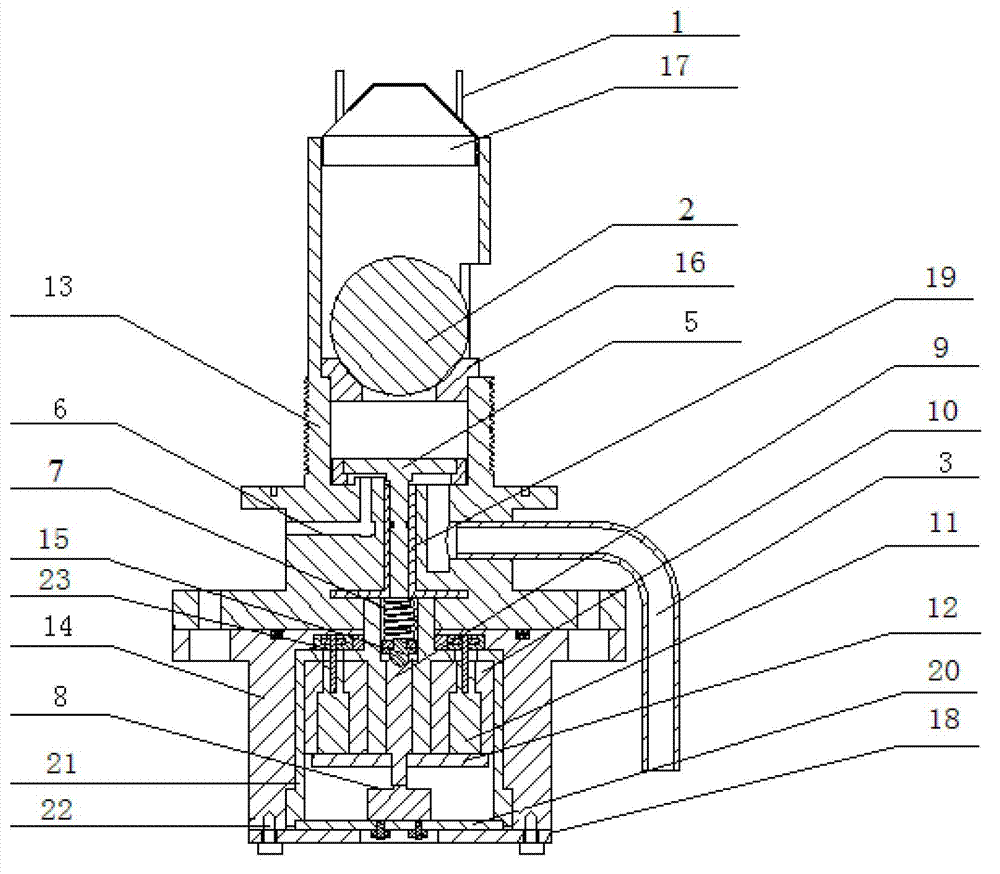

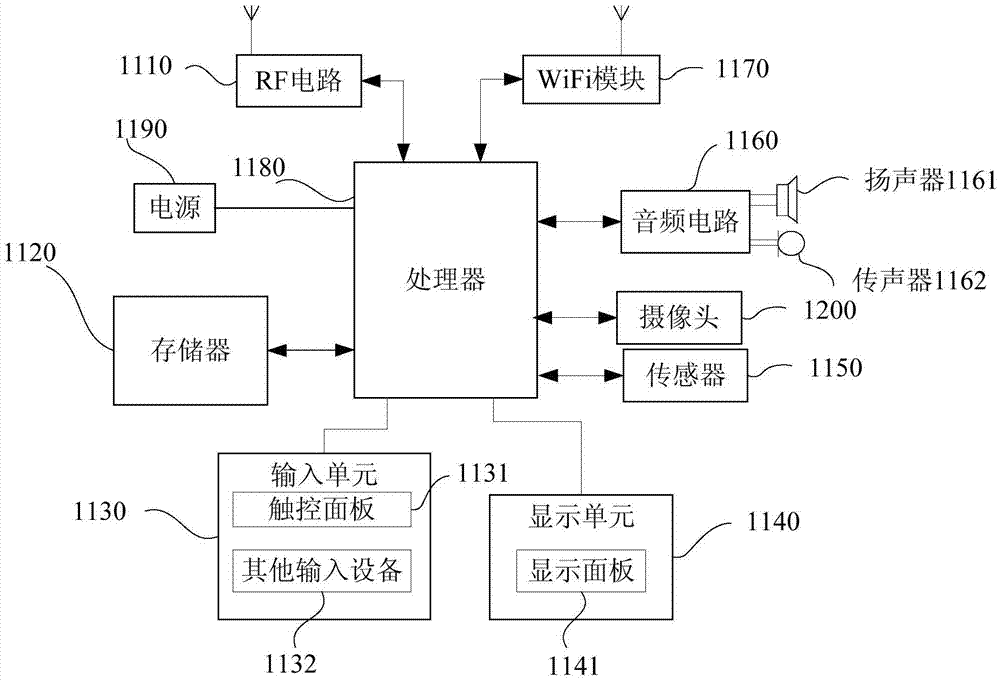

Intelligent cerebrospinal fluid drainage control and recognition warning system

PendingCN107497004AImprove securityEarly bindingMedical devicesIntravenous devicesPattern recognitionMicrocomputer system

An intelligent cerebrospinal fluid drainage control and recognition warning system mainly comprises a microcomputer system (1), a flow control device (2), an infrared drop number sensor (3), a color recognition sensor (4), a pressure sensor (5), a communication module (6), a human-computer interaction interface (7) and a radio frequency recognition device (13). The intelligent cerebrospinal fluid drainage control and recognition warning system can independently set the discharge speed, the drainage amount per unit time, the drainage time interval and the drainage pressure of cerebrospinal fluid according to individual differences of patients or clinical needs so as to achieve fixed-speed discharge, quantitative discharge, timed discharge and personalized-pressure discharge of the cerebrospinal fluid; meanwhile, in the drainage process, the color recognition sensor (4) can make timely prewarning when the cerebrospinal fluid has a hemoglobin reaction.

Owner:XIAN WINZISS MEDICAL GRP CO LTD

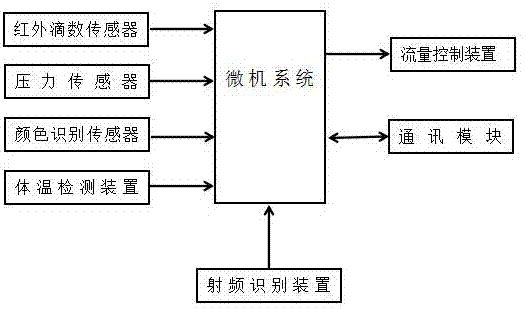

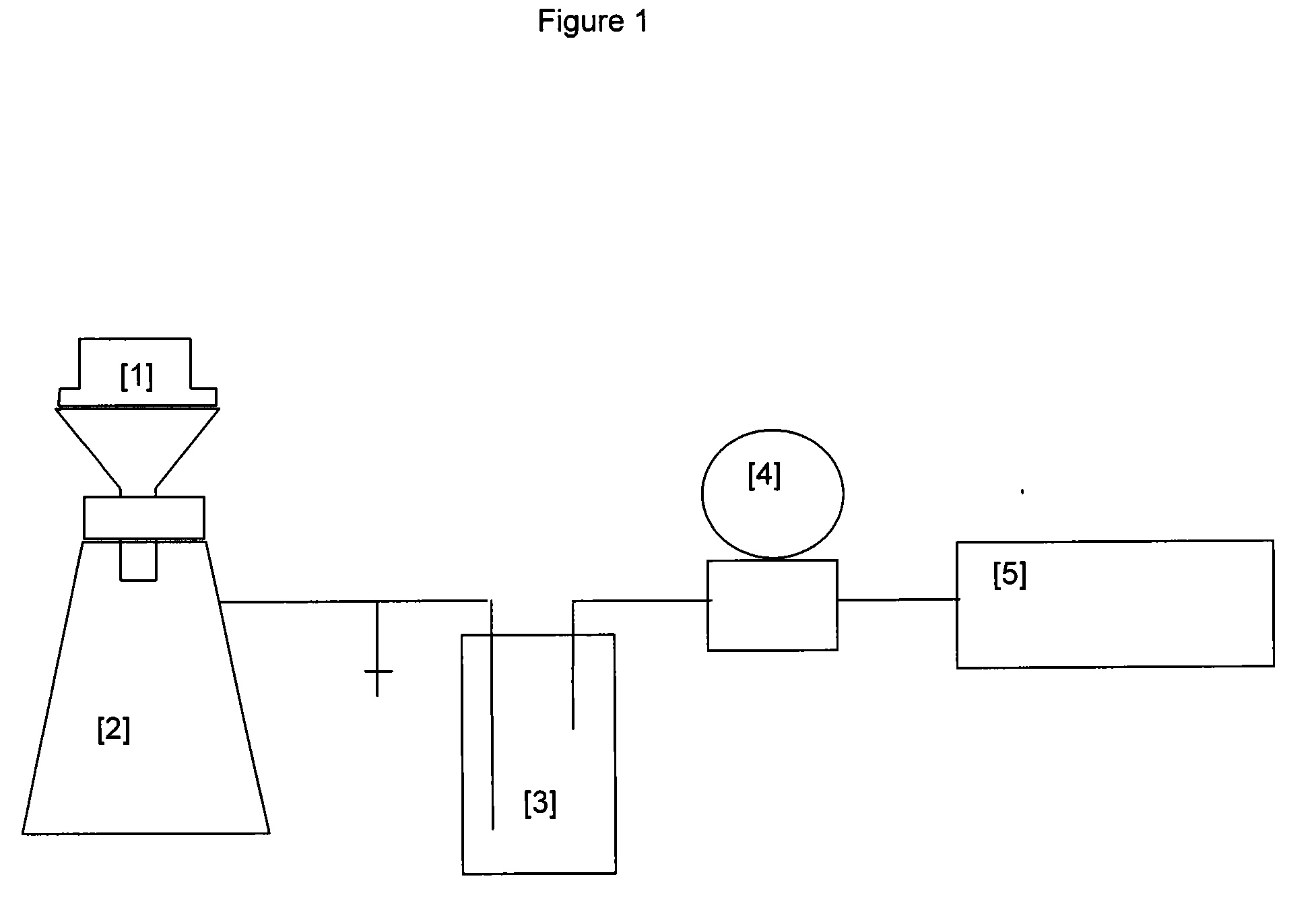

Manufacture of cellulosic pulp sheets

InactiveUS20150027651A1Natural cellulose pulp/paperPulp properties modificationEthylene HomopolymersWater soluble

A pulp making process in which fibrous cellulosic material is pulped to form an aqueous suspension of cellulosic material, the suspension is drained through a screen to form a pulp sheet and that the pulp sheet is dried to form a dry market pulp, in which a water soluble cationic polymer is added to the suspension as the sole drainage aid wherein the water-soluble cationic polymer is either,i) a copolymer comprising (a) between 1 and 70 mole % (meth) acrylamide and (b) between 30 and 99 mole % (meth) acryloyloxyethyltrimethyl ammonium chloride with an intrinsic viscosity between 5 and 9 dl / g; orii) a hydrolysed homopolymer of vinylformamide comprising between 1 and 100 mole % vinyl amine units and having a K value of between 45 and 240.The process of the invention provides improved drainage time and solids content of the dewatered pulp.

Owner:SOLENIS TECH CAYMAN

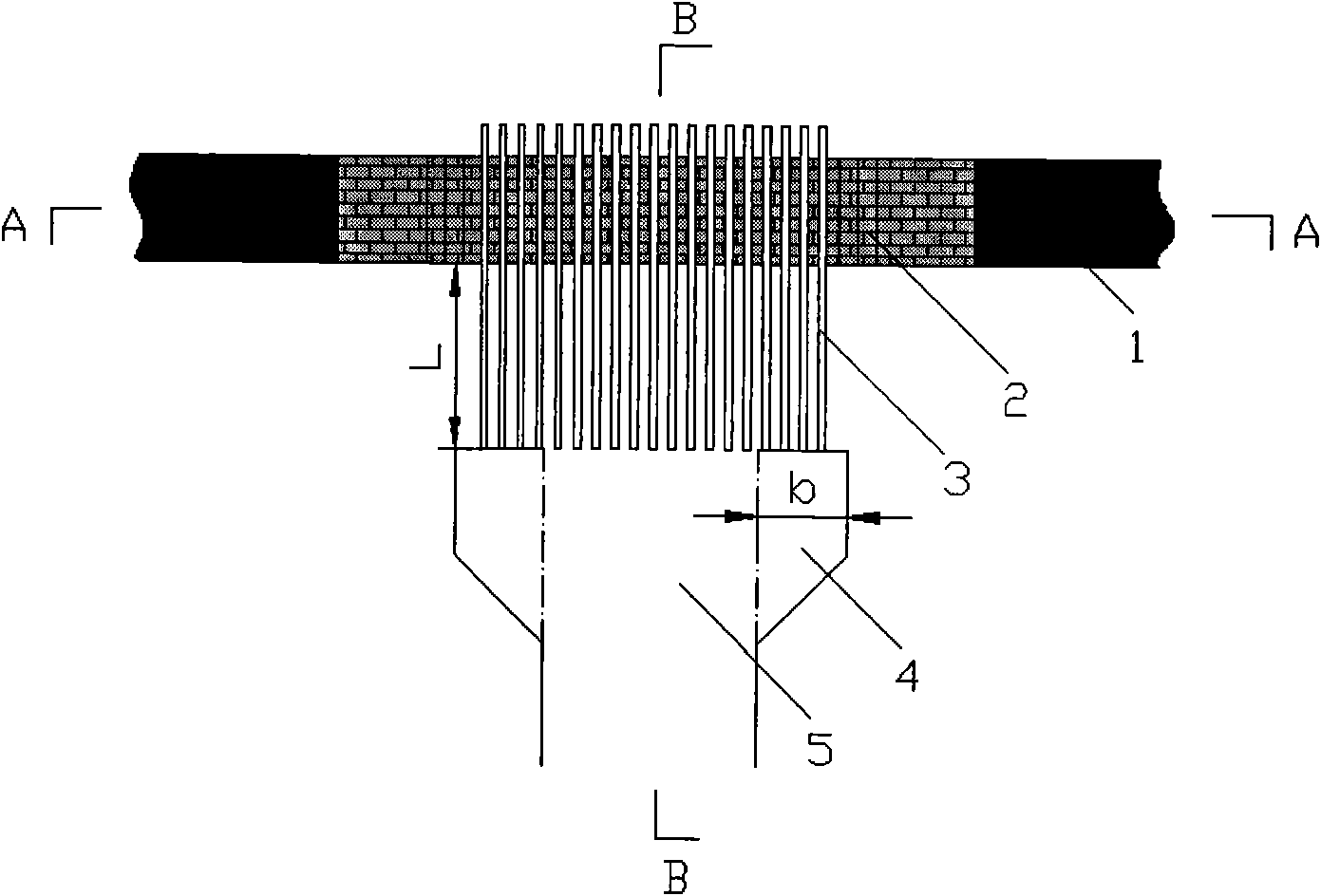

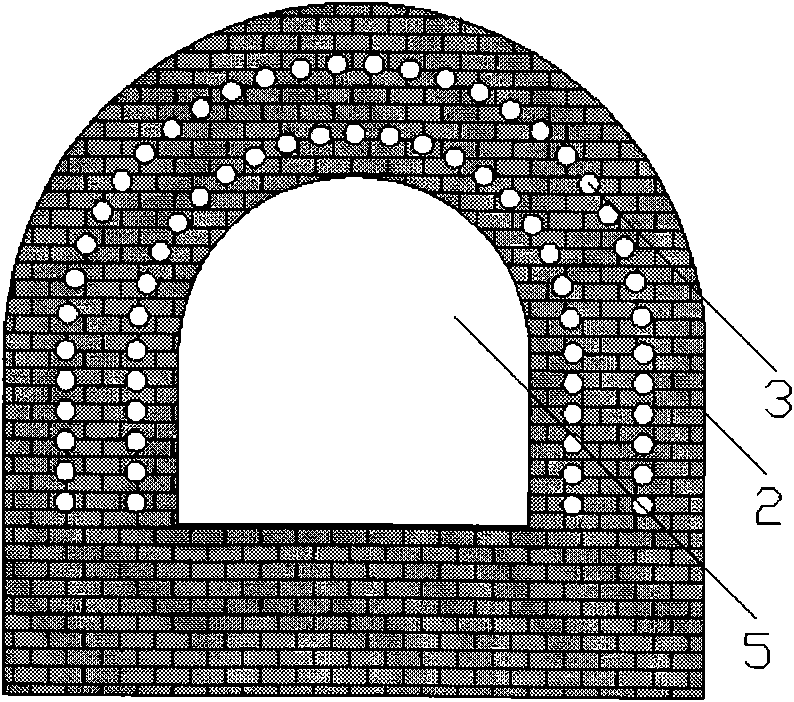

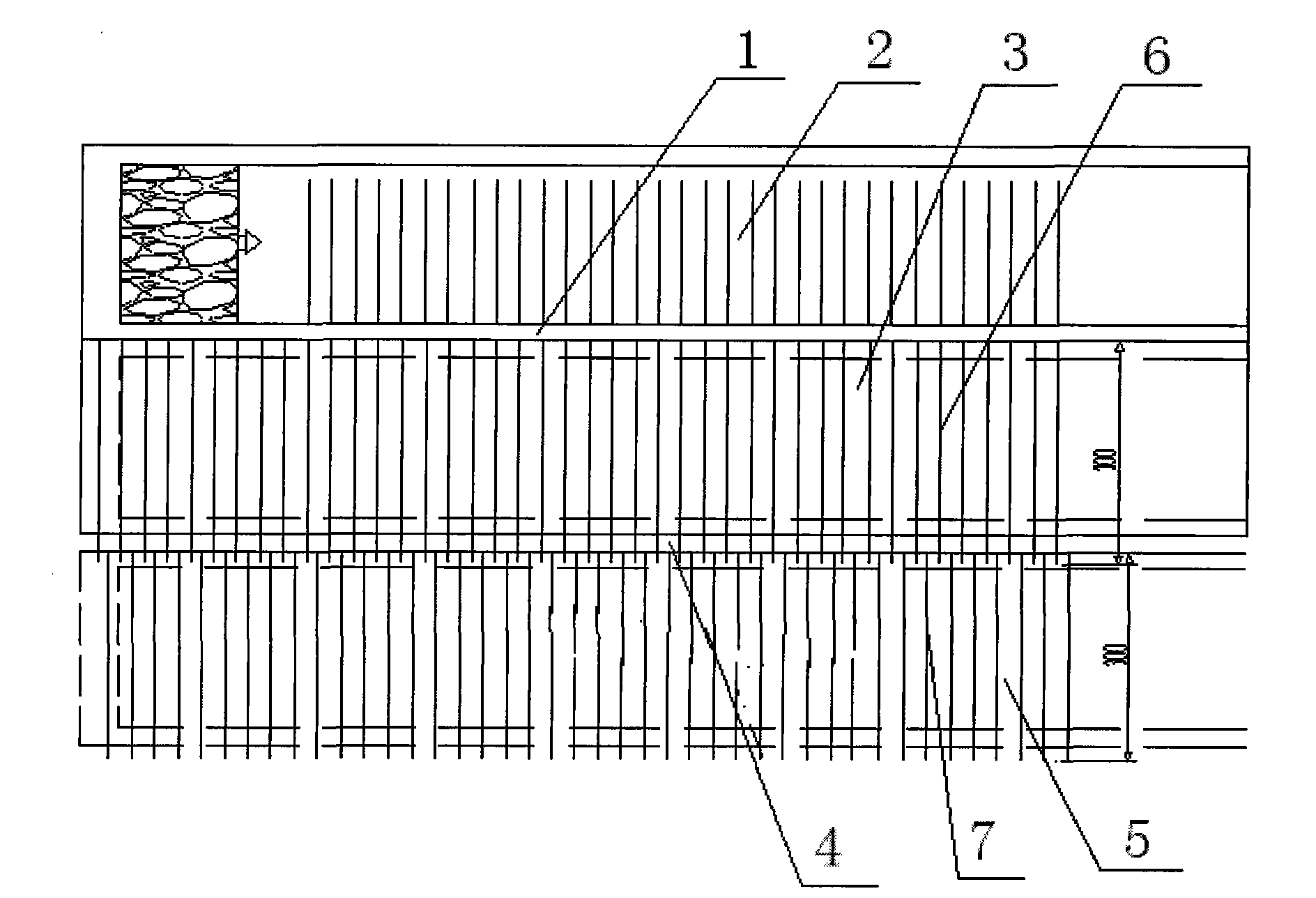

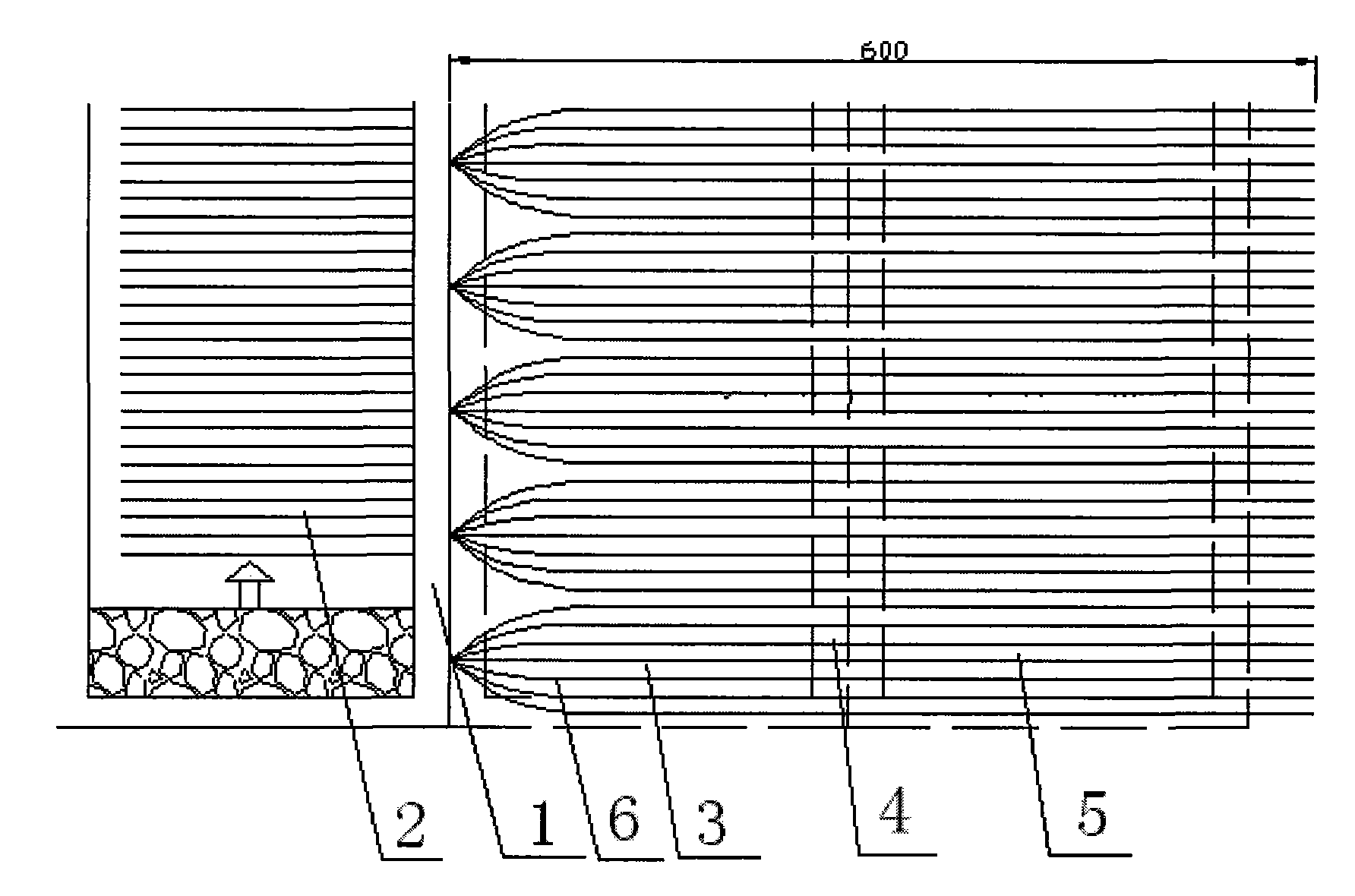

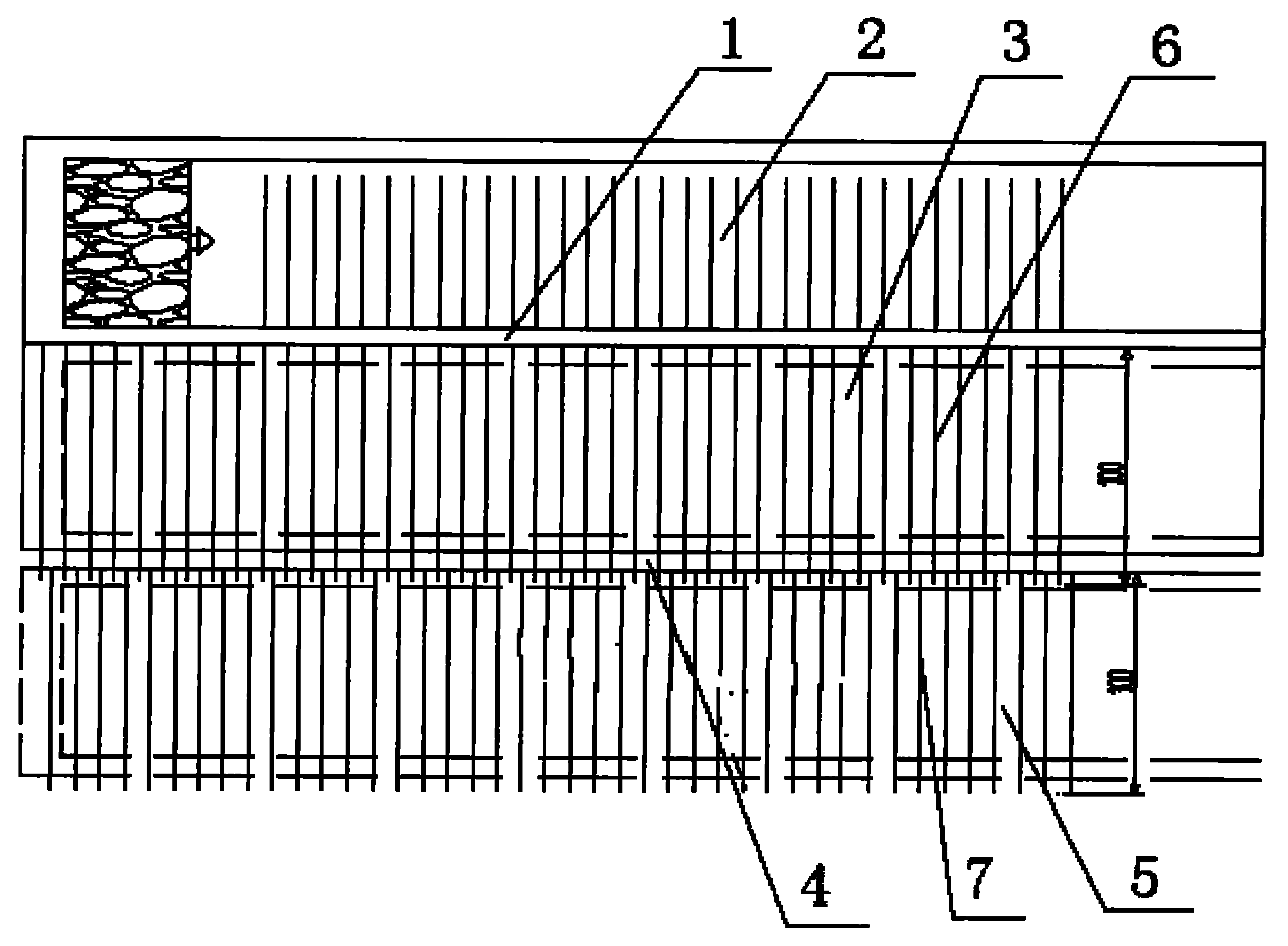

Method for reinforcing outburst-prone coal seam cross-cut coal uncovering

InactiveCN101603431AHigh strengthImprove toughnessUnderground chambersGas removalCross cutDrainage time

The invention discloses a method for reinforcing cross-cut coal uncovering at an outburst-prone coal seam and is particularly suitable for cross-cut quick coal uncovering at a coal seam having outburst dangers and a horizontal thickness of less than 8 meters in a coal mine. The method comprises the following steps: firstly, drilling and pre-extracting gas in a coal seam in front of a cross cut to reduce the gas content and gas potential of the coal seam; manufacturing an reinfrocing ring having a thickness which is 0.4 to 1 time of that of the cross cut on the periphery of the cross cut and using an anchor cable for joint reinforcement to improve the reinforcing effect of the coal seam and realize safe coal uncovering; drilling discharge holes inside the reinforcing ring, controlling distances within 4 to 8 meters on the two sides of a laneway and connecting pipes to drain the gas, reduce gas pressure and the destructive effect of a high gas pressure on the coal seam; and after the drainage of gas, using related gas discharge holes as injection holes and injecting a reinforcing material around the cross cut to reinforce coal rocks, form a reinforcing structure with a framework and improve the reinforcing effect. The method can reduce outburst elimination work amount by 20 to 40 percent under a condition of ensuring safe coal uncovering, reduce gas drainage time construction period and improve safe coal uncovering speed by 25 to 50 percent.

Owner:CHINA UNIV OF MINING & TECH

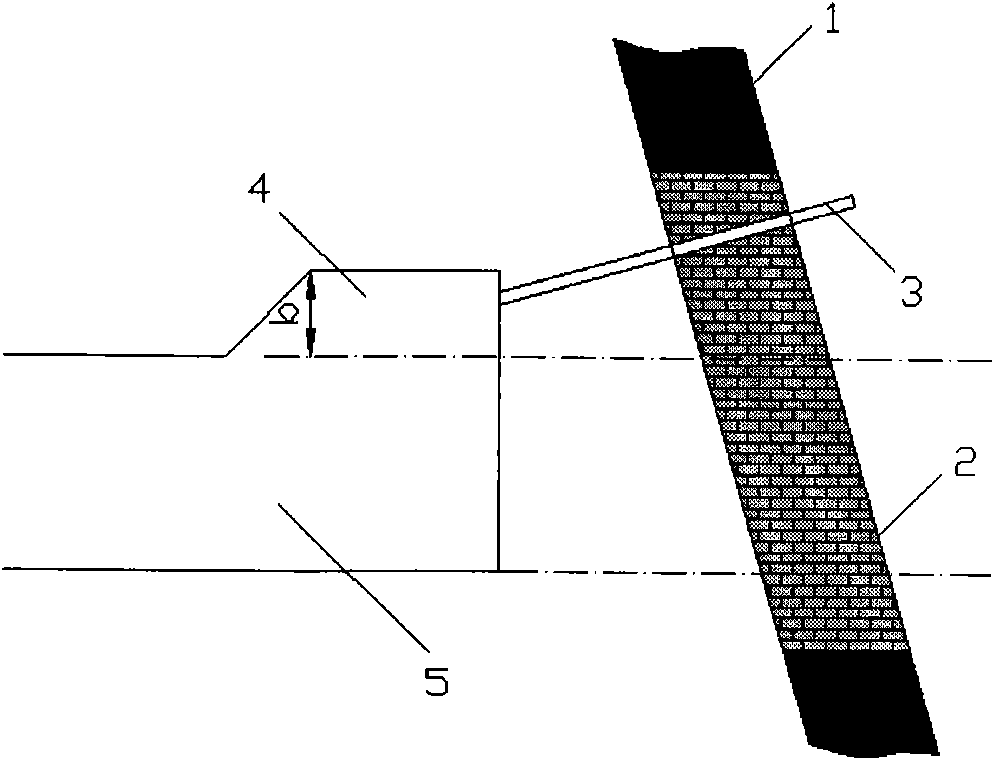

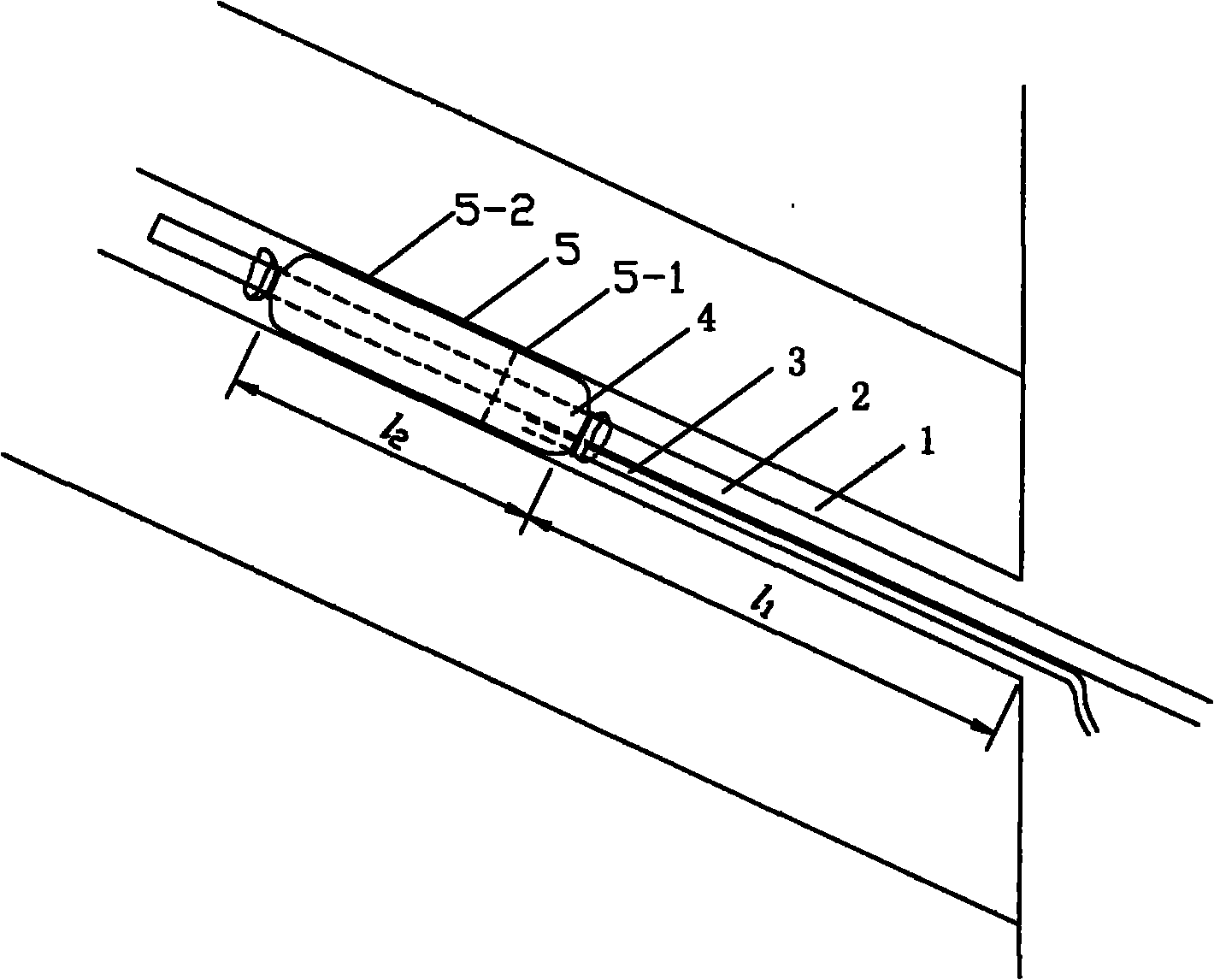

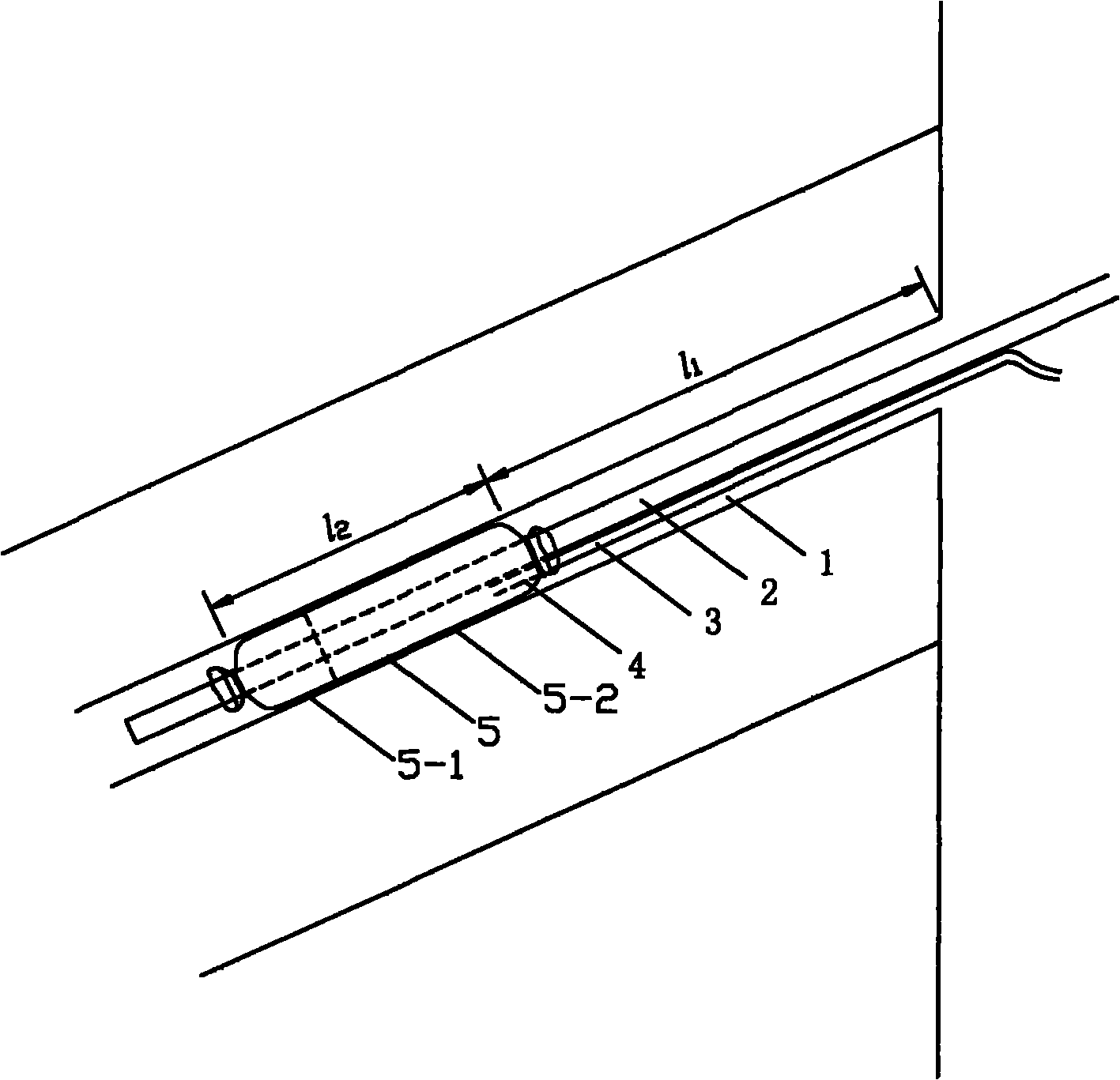

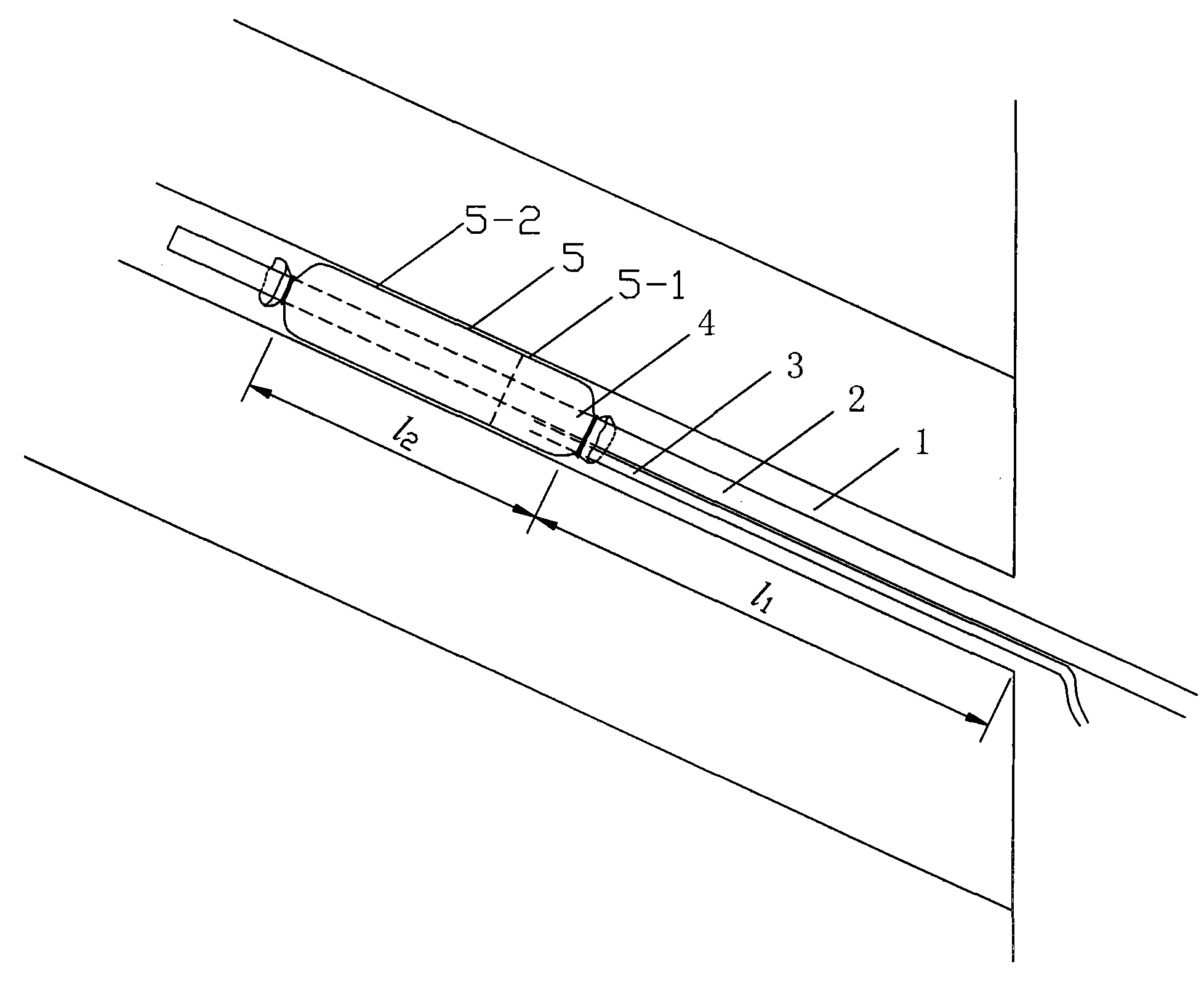

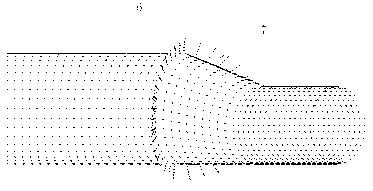

Method for sealing gas drainage boreholes at specified positions

ActiveCN101845944AIncrease the sealing depthPrecisely control the sealing positionDrilling rodsSealing/packingCotton clothDrainage tubes

The invention relates to a method for sealing gas drainage boreholes at specified positions, which comprises a drainage tube, an injection tube and a flexible sleeve, the flexible sleeve is sleeved on the front part of the drainage tube, the injection tube is inserted into the flexible sleeve, and both ends of the flexible sleeve are then tightly bound on the drainage tube; the drainage tube and the injection tube are put into the specified position of a gas drainage borehole together, the injection tube injects sealing filling material into the hermetic flexible sleeve until the flexible sleeve is filled up with the sealing filling material, and after the filling material is expanded, the borehole is sealed. The distance between the outer end of the flexible sleeve and the orifice of theborehole is larger than 8m, and the length of the flexible sleeve is larger than 2m; the flexible sleeve consists of a cotton cloth sleeve section and an antistatic waterproof cloth sleeve section, and the waterproof cloth of the flexible sleeve is used for preventing the seepage of the sealing filling material; and the diameter of the flexible sleeve is larger than the diameter of the gas drainage borehole, so that the radially expanded sealing filling material can be tightly combined with the wall of the borehole. The method has the advantages of good borehole sealing effect, high drained gas concentration, long effective drainage time and simple and quick operation.

Owner:CHINA UNIV OF MINING & TECH

Coal bed gas drainage effective radius measuring method

InactiveCN101824982AImprove accuracyIncrease the pumping rateSurveyGas removalEffective radiusProtection layer

The invention provides a coal bed gas drainage effective radius measuring method, relating to designing of spacing of wells for coal bed gas drainage and adapting to occasions of water power slit drainage, intensive hole stripping drainage, hydrofracturing drainage, hydraulic holing drainage, and coal bed gas drainage with enhanced drainage of protection layer mining. According to the correspondence of coal bed gas pressure and gas content, the effective radius of the coal bed gas drainage is determined by utilizing the gas pressure change conditions so as to direct the implementation of the effective radius determination of the coal bed gas drainage. An observing hole is constructed on a design point as required, then is sealed and is provided with a pressure gage; When the pressure is stable, a drainage hole is constructed and networked for drainage, the pressure changing condition of gas at the observing hole is observed and well recorded so as to obtain the effective radius of the coal bed gas drainage corresponding to the specific drainage time, thus laying a foundation for designing a drainage scheme and achieving the purpose of safe and efficient production.

Owner:CHINA UNIV OF MINING & TECH

Soft measurement method for sewage pumping station flow of urban drainage converged network

ActiveCN102032935ASolve the problem of drainage delay differenceSave resourcesVolume/mass flow measurementNeural learning methodsGrey correlation analysisNetwork model

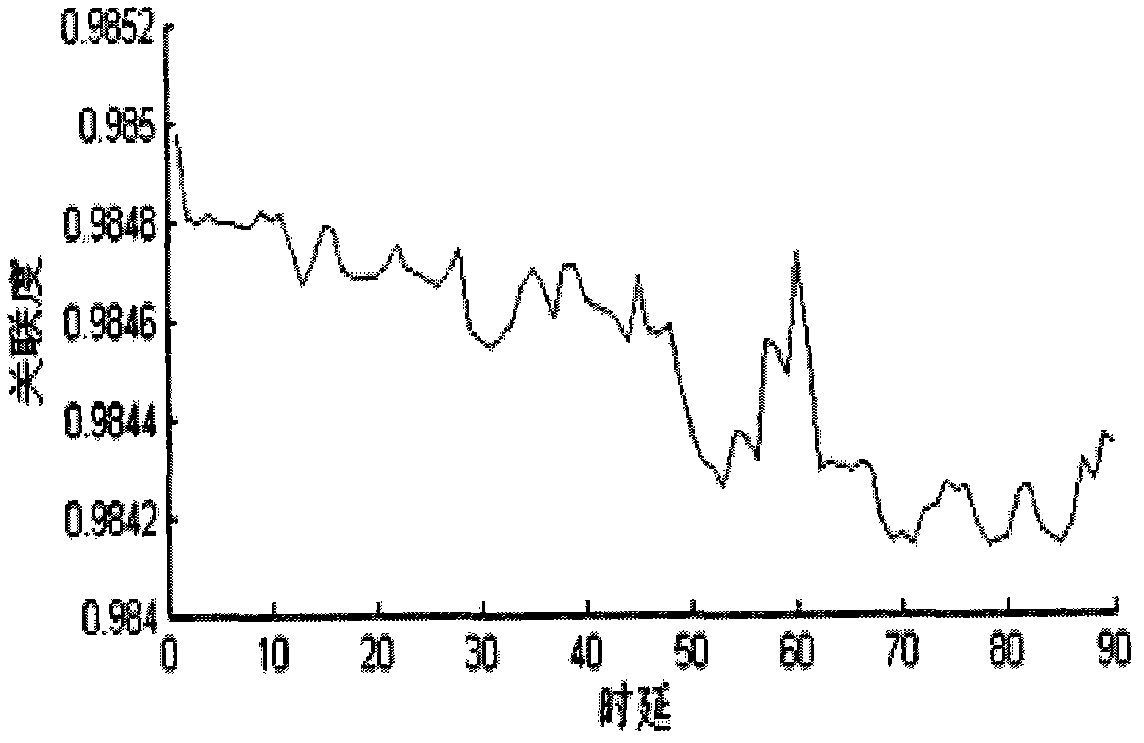

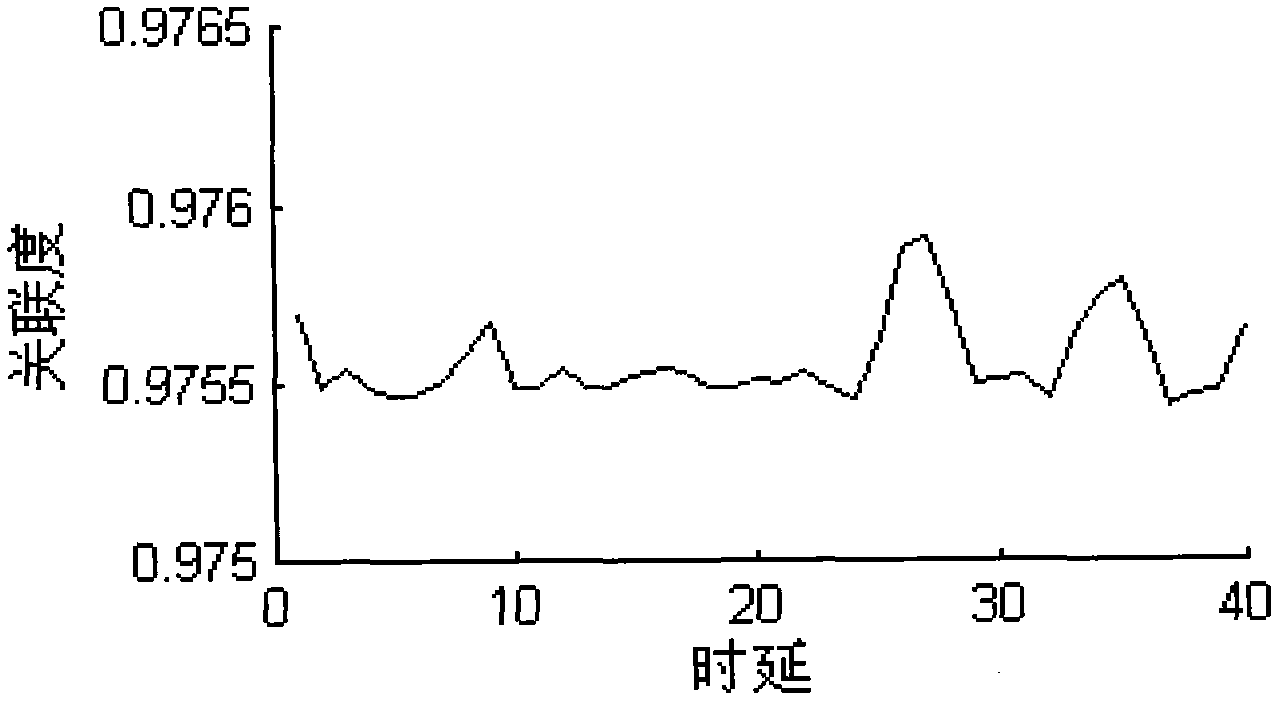

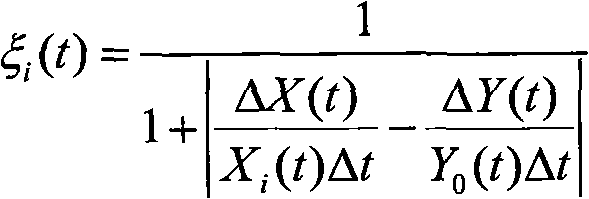

The invention discloses a soft measurement method for sewage pumping station flow of an urban drainage converged network. The conventional drainage pipe network system has lots of uncertain factors and high measurement hardware cost. The method comprises the following steps of: analyzing main influencing factors of converged node pumping station flow by using mechanism analysis and priori information, and primarily determining influencing factors of a back-propagation (BP) neural network, namely determining input / output variables; determining lag time of different upstream pumping station flows by using a grey correlation analysis method; and establishing a grey neural network model on the basis of pumping station historical operating data, and predicting the converging node pumping station flow. By combining two methods of grey correlation analysis and grey neural network, the method solves the problem of difference of drainage time delay of different upstream pumping stations, well simulates the nonlinear pipe network drainage process, realizes soft measurement of converged node sewage pumping station flow, saves the hardware resources, and is low in cost and high in accuracy.

Owner:ZHEJIANG SUPCON INFORMATION TECH CO LTD

Method for fracturing and permeability improvement to shield coal road excavation by utilizing pulse detonation waves

The invention discloses a method for fracturing and permeability improvement to shield coal road excavation by utilizing pulse detonation waves, and is suitable for quick excavation of a coal bed and a coal road with high gas and low permeability. The method comprises the following steps: firstly constructing a detonation extraction drill hole from a bed plate tunnel to the coal bed by utilizing a drilling machine, then sending a high-voltage electric pulse generator into the detonation extraction drill hole, controlling the high-voltage electric pulse generator to release the high-energy pulse detonation waves to the detonation extraction drill hole repeatedly through an anti-explosion control table, after a large number of fractures are formed in the coal body around the detonation extraction drill hole, connecting the detonation extraction drill hole into a gas extraction pipeline, and after the gas extraction reaches the standard, conducting the coal road excavation. According to the method, the coal body is subjected to high-energy fracturing by utilizing the pulse detonation waves, a fracture network is formed in the coal bed to provide passages for gas flow, the efficiency of penetrating a layer to drill a hole for coal bed gas pre-drainage is improved, the gas pre-drainage time is shortened, and quick coal road excavation is realized.

Owner:CHINA UNIV OF MINING & TECH

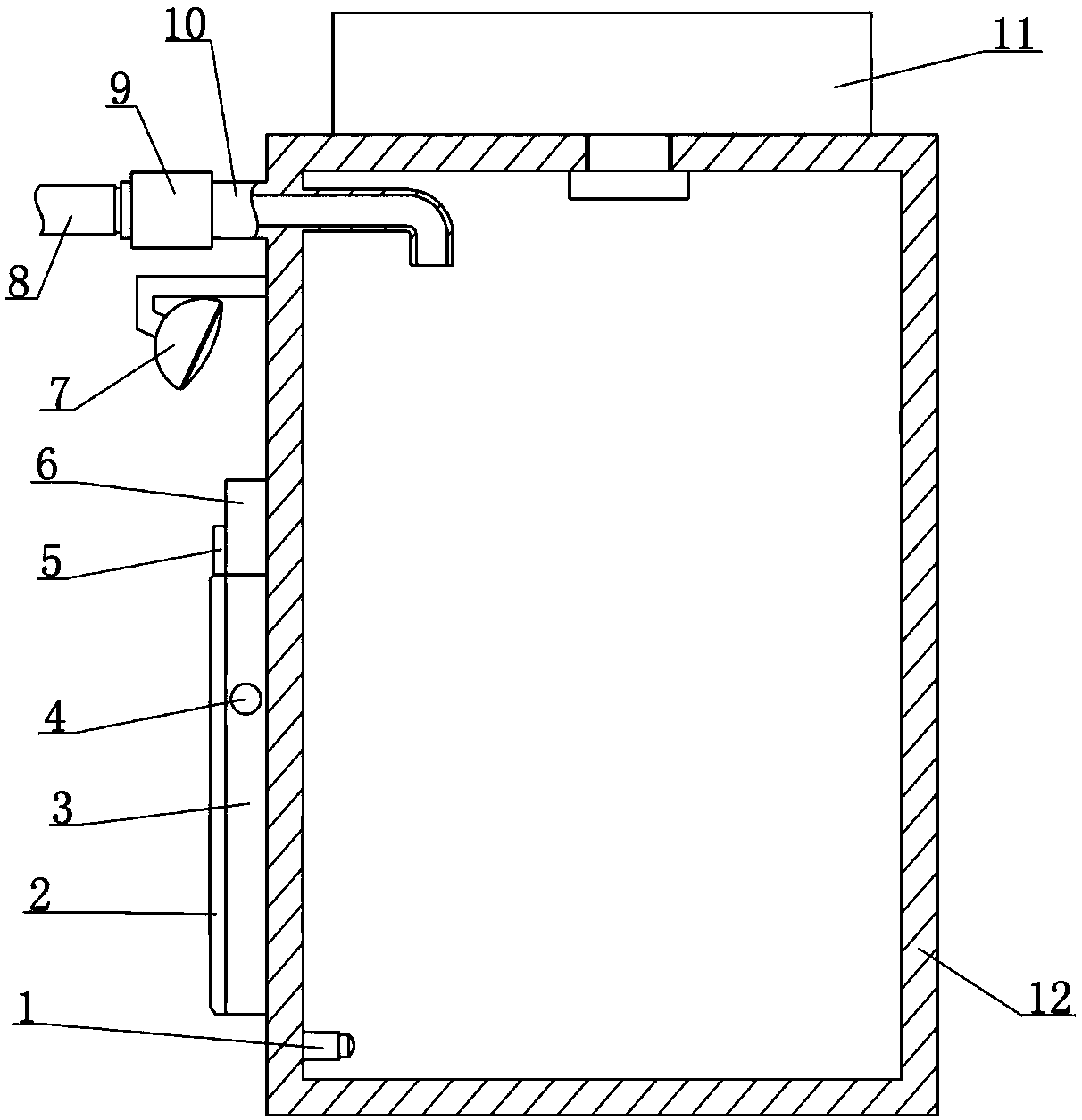

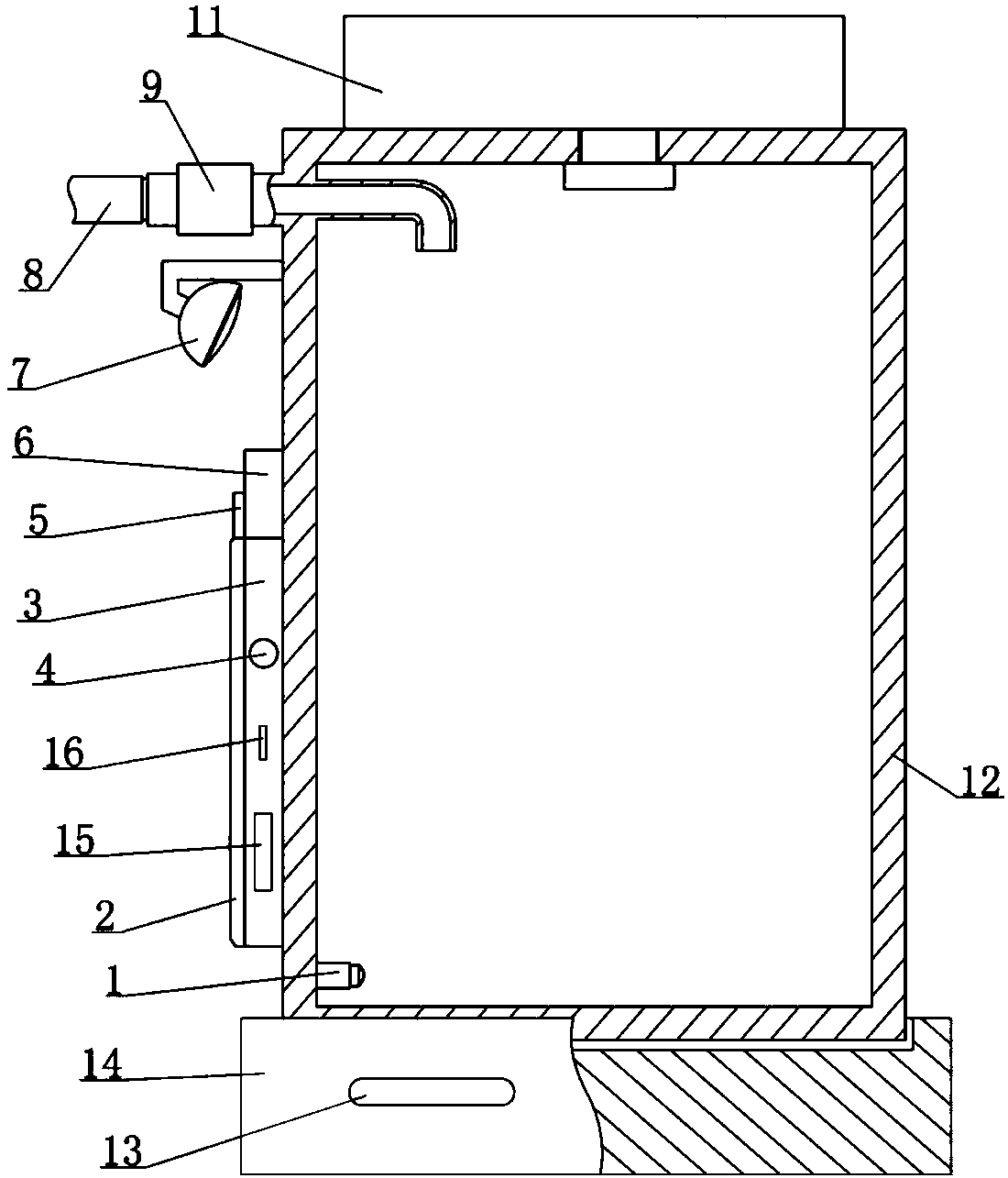

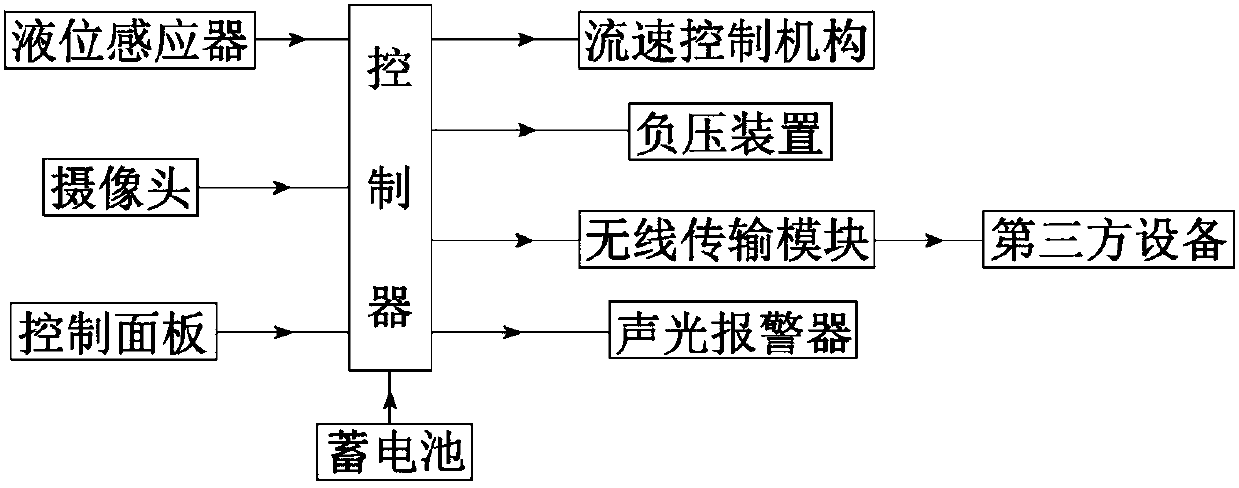

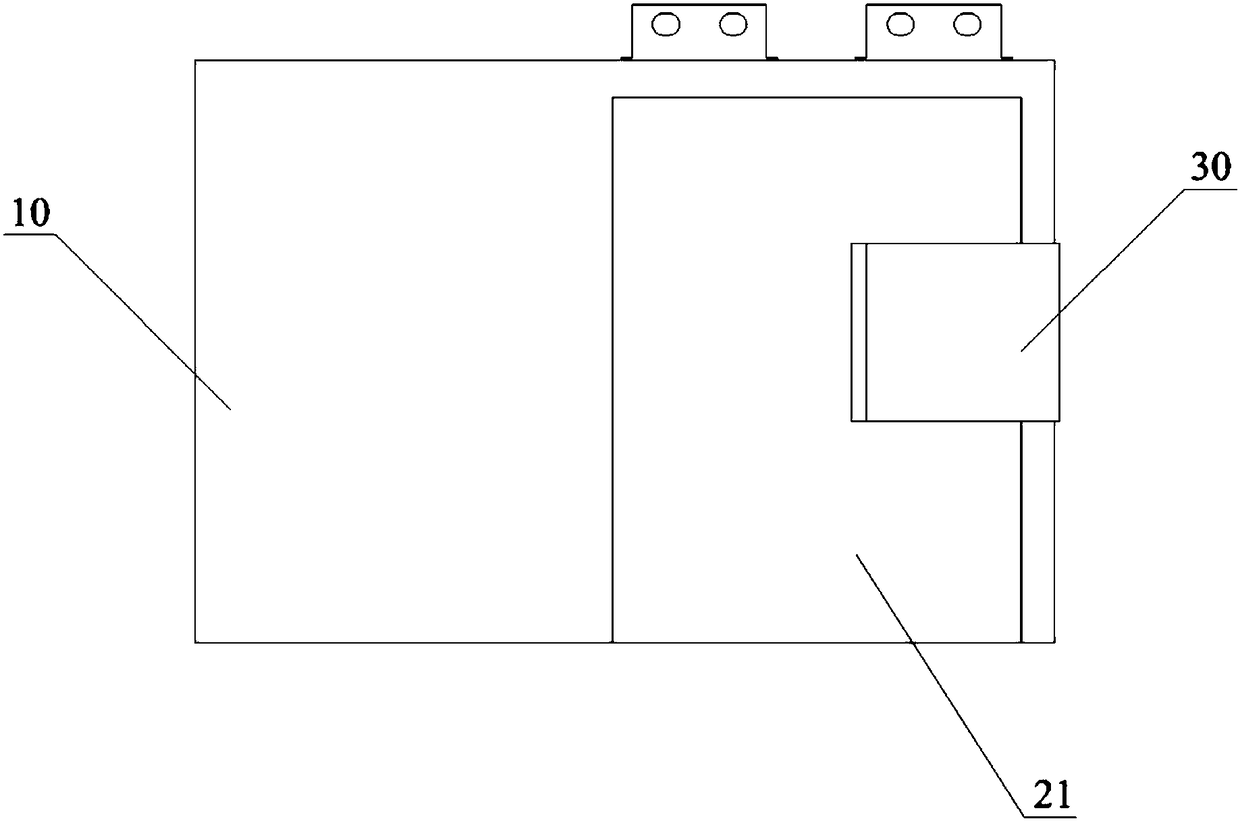

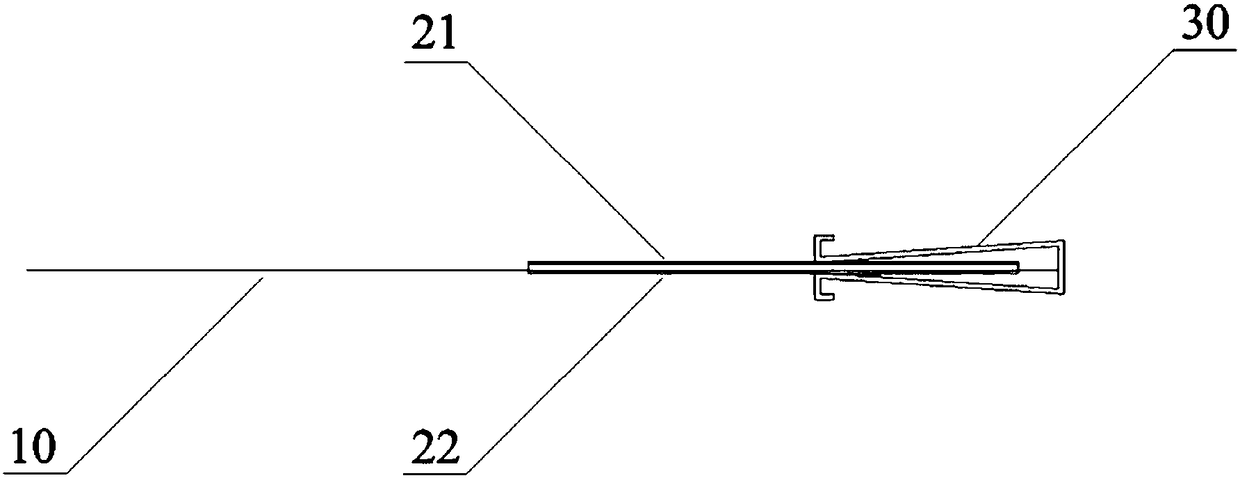

Intelligent chest drainage device

InactiveCN108030966AEasy to adjustReduce human operationsMedical devicesIntravenous devicesAutomatic controlEffusion

The invention relates to the technical field of medical instruments, and discloses an intelligent chest drainage device. A negative-pressure device, a liquid inlet end, a liquid level sensor, a camera, a controller and a storage battery are arranged on a drainage bottle, the liquid inlet end is used for connecting with a drainage pipe, the liquid level sensor is used for sensing effusion quantityin the drainage bottle, the camera is used for shooting the inside state of the drainage bottle, a flow rate control mechanism is arranged at the liquid inlet end, the controller can calculate effusion increment in the drainage bottle through signals fed back by the liquid level sensor, working states of the negative-pressure device and the flow rate control mechanism can be adjusted based on theeffusion increment, preset drainage quantity and drainage time, and regular and quantitative drainage is achieved. The chest drainage device intelligently designed, drainage states can be automatically controlled, regular and quantitative drainage can be achieved, a manual operation link is decreased, adverse effects caused by improper manual operation can be avoided, the shortcoming of overflow of effusion in the drainage bottle is overcome, and the device is particularly applicable to clinical drainage of a lot of effusion in the chest.

Owner:张福帅 +2

Use of High Molecular Weight Acrylic Polymers in Fire Fighting Foams

Aqueous firefighting composition concentrates are provided that contain an effective amount of a high molecular weight water soluble anionic acrylic polymer, an effective amount of at least one high molecular weight polysaccharide gum; and an effective amount of at least one surfactant. In the present context, a high molecular weight water-soluble anionic acrylic polymer is a polymer with an average molecular weight Mw of at least one million (1000 kDa). The combination of the acrylic polymer and the gum provide a concentrate that generates foam with highly desirable firefighting properties, including high foam expansion ratio, long burnback time, and slow drainage time while avoiding problems with previous gum-containing foam concentrates, such as high viscosity and component separation upon storage.

Owner:TYCO FIRE PRODS LP

Method for progressive gas drainage in high gas medium-hard coal seam

The invention relates to a coal seam gas drainage method, specifically to a method for progressive gas drainage in high gas medium-hard coal seam, which solves the problem of areal gas extraction efficiency. When stopes in multiple roadways are excavated, a long borehole, the length of which is required to be capable of at least running through the distance of reserved roadway strips at two sides of the next stope, is constructed in advance for a next adjacent stope area inside a column outside the stope, drainage in the mining area of the next stope area is performed in advance during excavation of this stope, in order to guarantee that the next adjacent stope area has sufficient drainage time, roadway excavation of the next stope area is performed at the drained strip position, the adjacent stope area is then mined, and simultaneously, the long borehole is constructed for the next adjacent stope area to continue gas drainage in such a progressive, circulative advancing manner. Thus normal alternation of drainage, excavation and mining is ensured.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

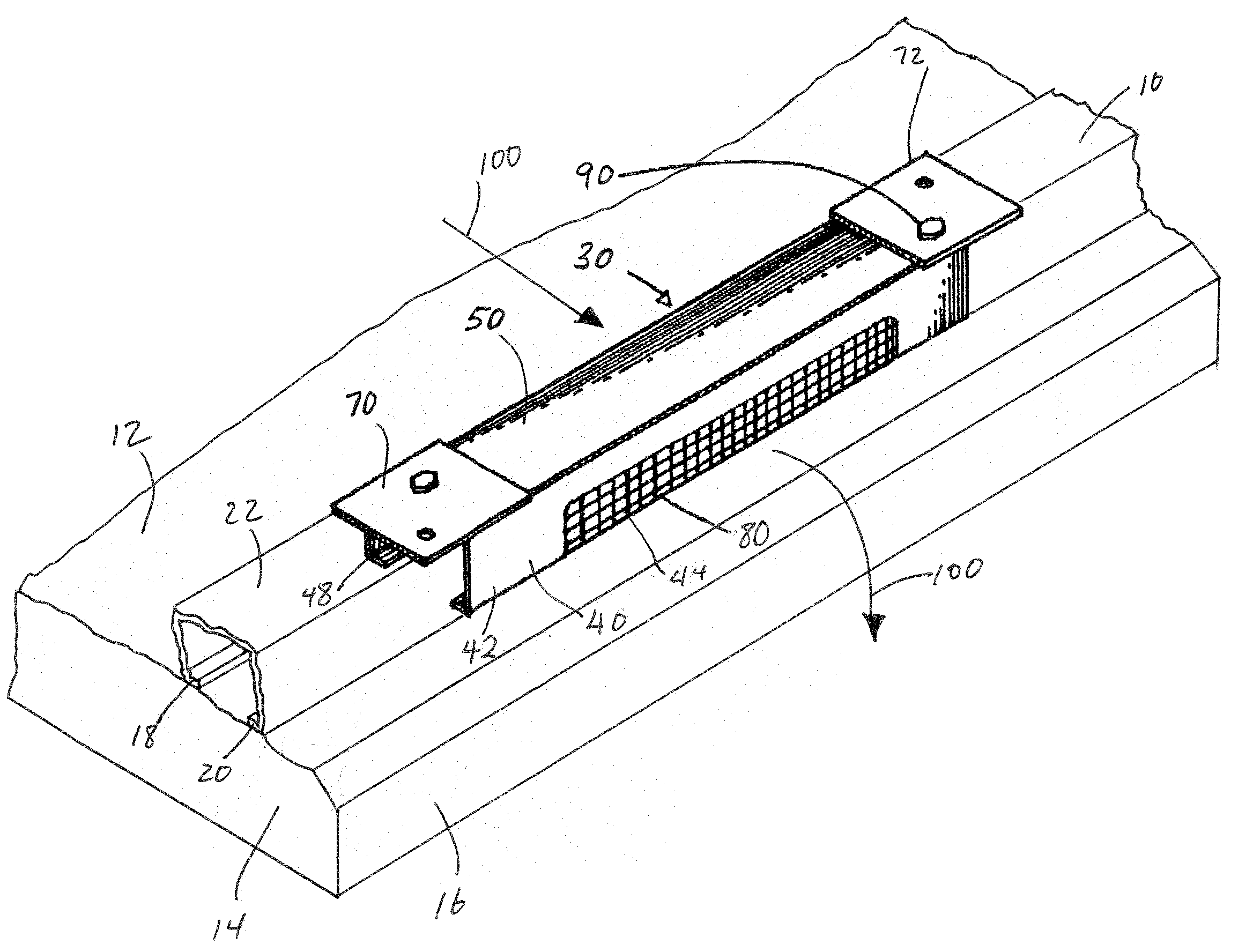

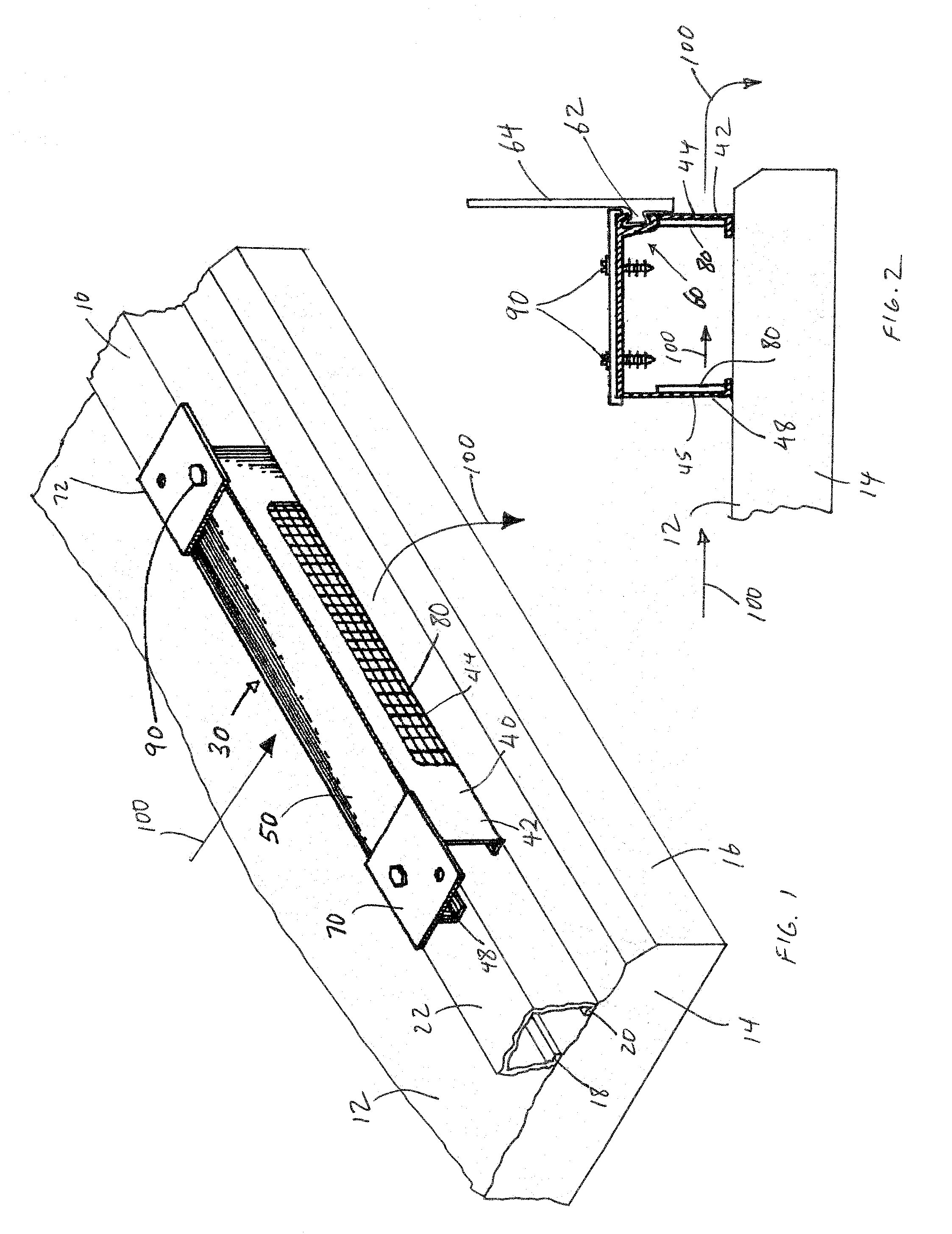

Drainage System For A Floor

InactiveUS20090223147A1Eliminate rainwater build-upExtended drainage timeRoof coveringFoundation engineeringDrainage timeCivil engineering

A drain system for draining water from a lanai floor to eliminate rainwater build-up on lanai floors and speed-up draining time on such floors. The device is attached to the edge of the Lanai floor and acts as a scupper.

Owner:SPIGNESI LEO

Methanol high-efficiency alcohol resistant aqueous film-forming foam fire extinguishing agent and preparation method thereof

The invention provides a methanol high-efficiency alcohol resistant aqueous film-forming foam fire extinguishing agent and a preparation method thereof. The composition formula comprises the following components in parts by weight: 300-400 parts of deionized water, 6-10 parts of sodium benzoate, 50-100 parts of urea, 5-9 parts of xanthan gum, 10-40 parts of cocoalkanoylamido propyl betaine, 100-400 parts of APG (Alkyl Polyglycoside), 80-200 parts of ethylene glycol, 10-60 parts of ethylene glycol monobutyl ether, 10-60 parts of F115710, 10-60 parts of F1203, 10-40 parts of F1460 and 10-60 parts of phosphate buffer. The product has the advantages of low cost, suitability for fighting a methanol fire disaster, suitability for not only fresh water foam fire extinguishing but also seawater foaming fire extinguishing, extremely small change in foam property and fire extinguishing performance after being mixed with seawater or fresh water according to a use mixing ratio, high foaming multiple, long 25 percent drainage time and stable foaming.

Owner:TIANJIN FIRE RES INST +1

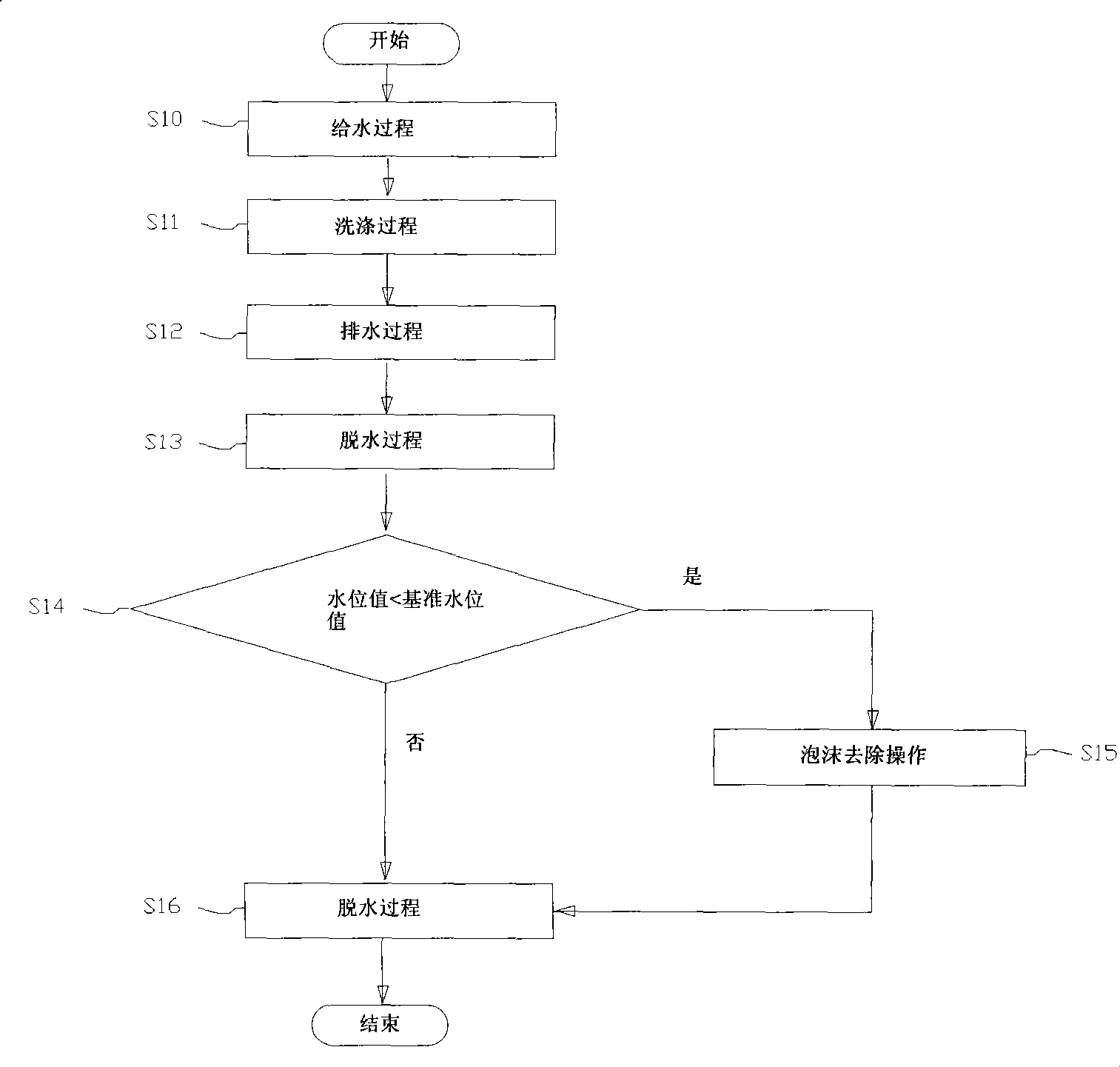

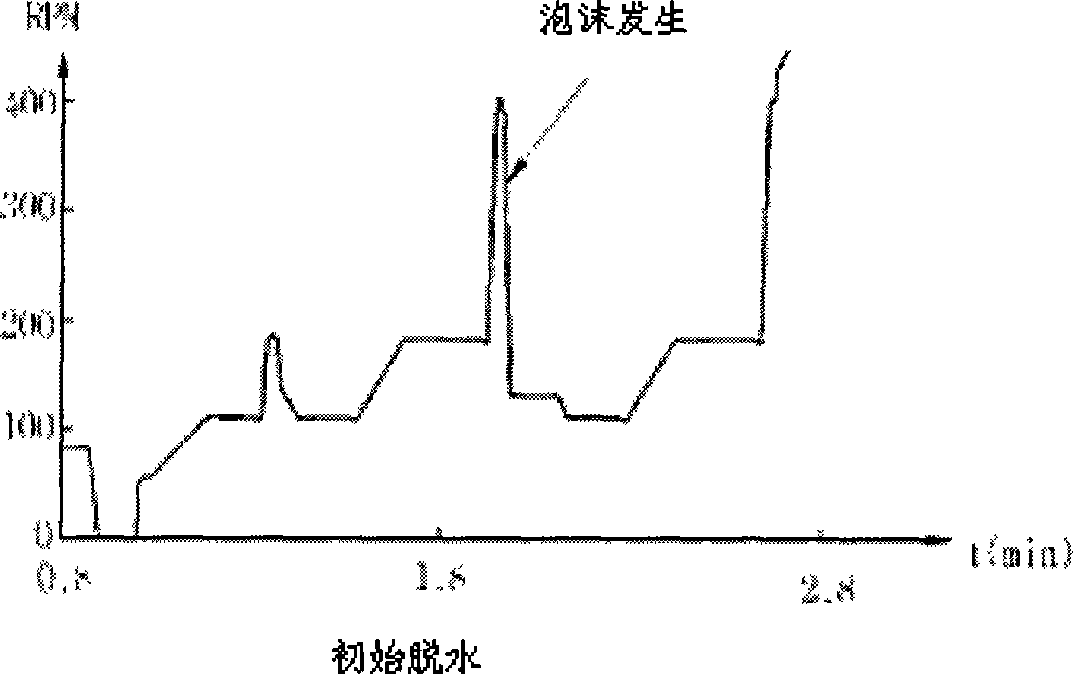

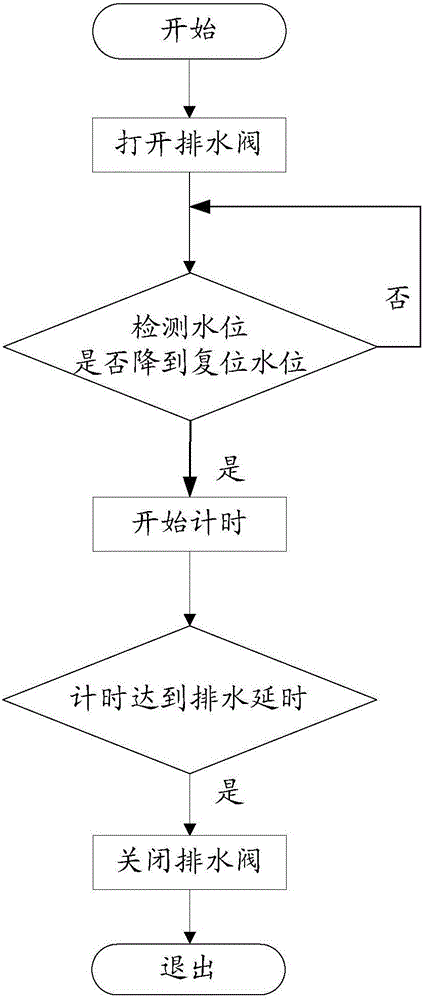

Foam detecting method of washing machine

InactiveCN101363181APrevent overflowPrevent slippingOther washing machinesControl devices for washing apparatusEngineeringDrainage time

The invention relates to a foam detecting method of a washing machine. The foam detecting method of a washing machine in the invention judges whether the foam is generated in the washing process after the unwatering process, rather than by comparing the drainage time and foam drainage time prior to the occurrence of the bubble to determine whether or not. Because of judging the emergence of the foam or not in advance in the course of draining off water, rather than judge in the unwatering process, and carrying out the foam to remove and operate according to judged result, thus the invention can avoid the adverse effect caused by happening in bubble.

Owner:NANJING LG PANDA APPLIANCES

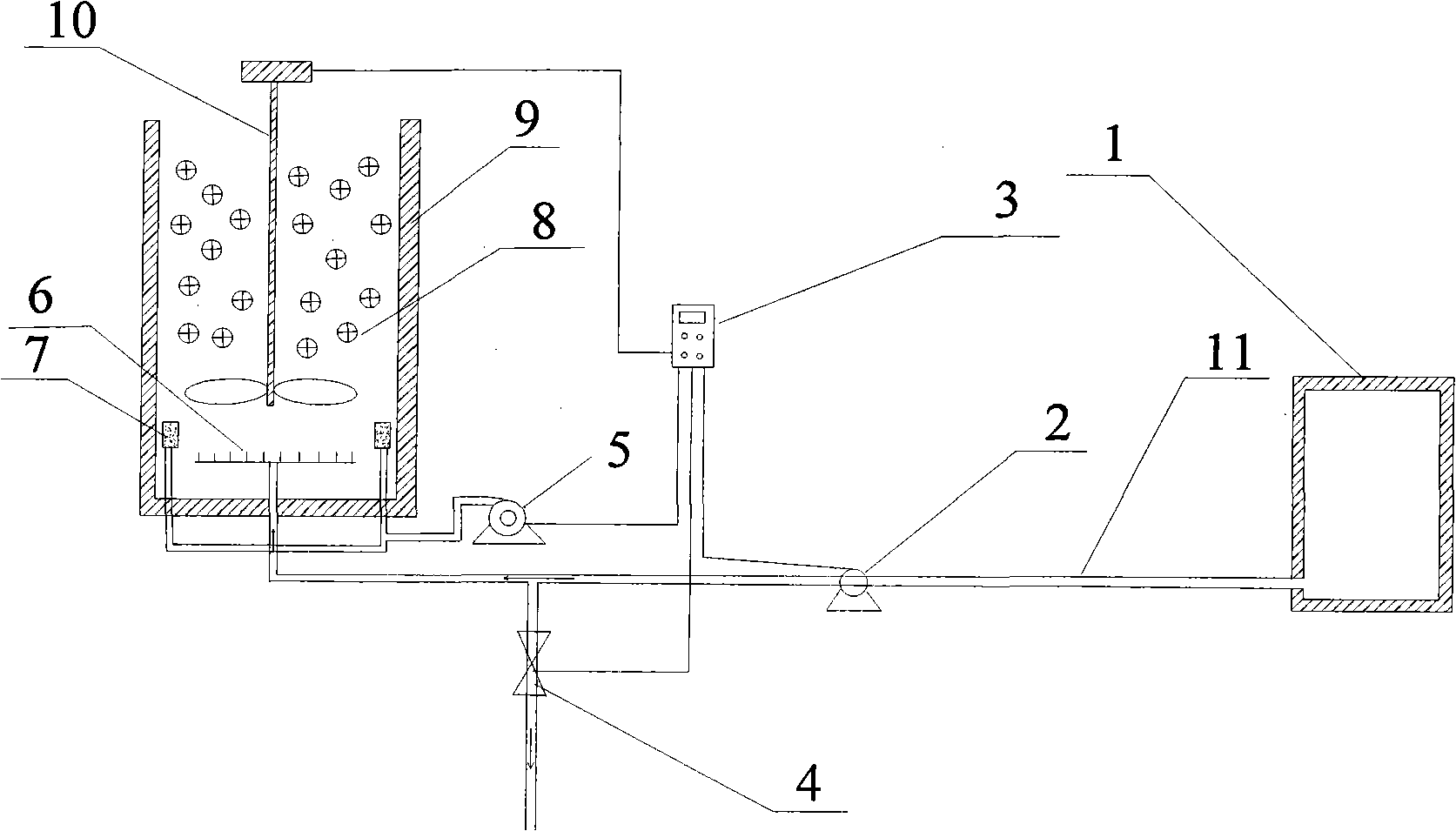

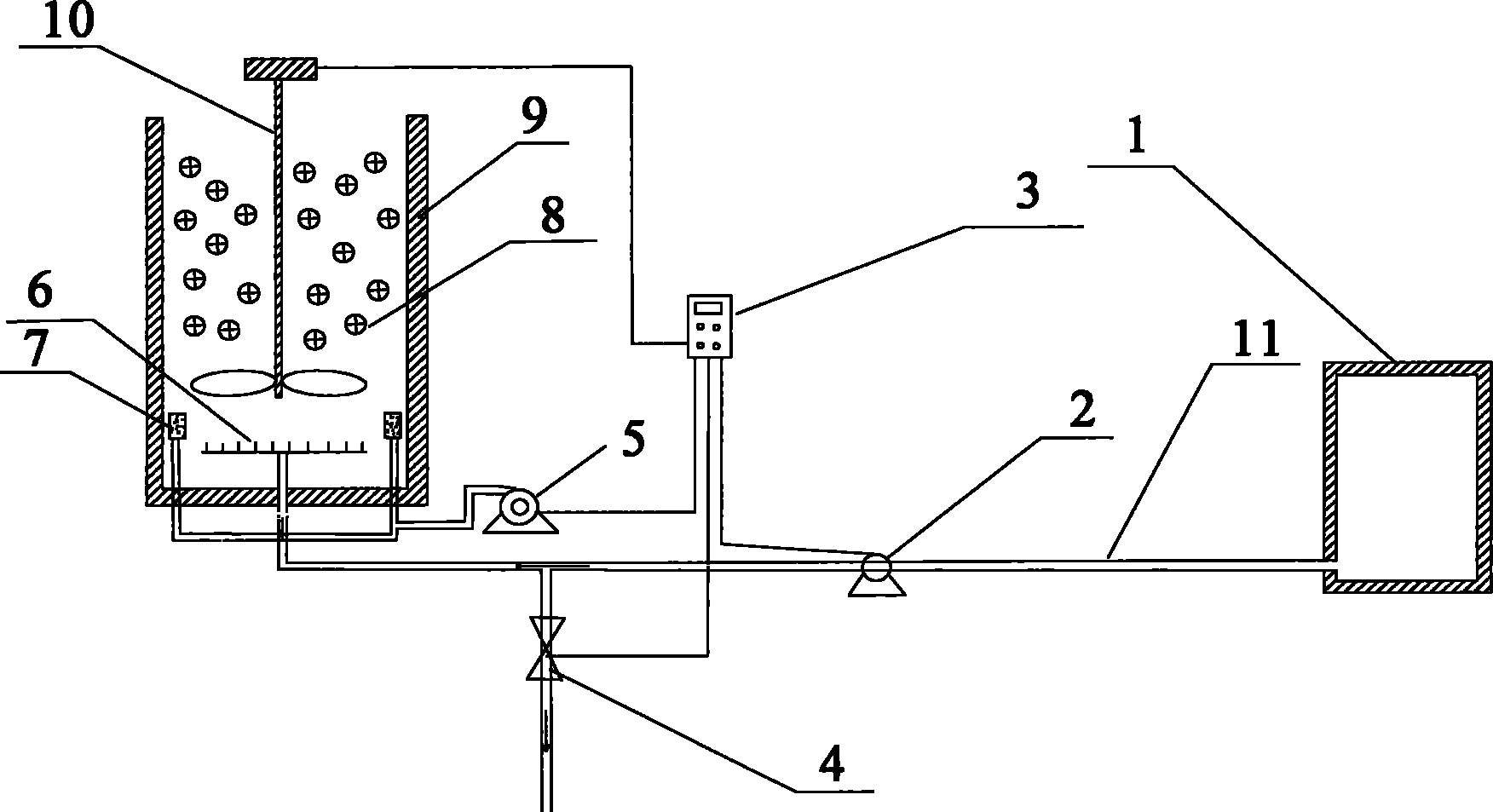

Sequencing batch type suspended filler biofilm sewage treatment device

InactiveCN101913732AIncrease the amount of fixationGood removal effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeAutomatic control

The invention relates to a sequencing batch type suspended filler biofilm sewage treatment device. The device comprises a water tank, wherein the water tank is connected with a reactor through a pipeline, a water pump and a water distribution head; a helical stirrer, an aeration head and the water distribution head are arranged in the reactor; the aeration head is connected with an aerator; the water distribution head is connected with the water pump; the water pump, the aerator, the helical stirrer and a valve are connected with a time controller; the device is characterized in that a suspended filler is also filled in the reactor; the suspended filler is plastic polyhedral hollow balls or polyurethane netlike sponge blocks; and the water distribution head is also communicated with the valve and plays a role in drainage. The device of the invention has the advantages of both a biofilm method and an active sludge method and an improved sequencing batch type operating mode is adopted, so the device can automatically control the water feeding time, aeration time, sedimentation time, drainage time and stirring time and ensure the removal effect of COD, ammonia nitrogen and total nitrogen and thus is one sequencing batch type suspended filler sewage treatment device suitable for various kinds of sewage / waste water and river water.

Owner:OCEAN UNIV OF CHINA

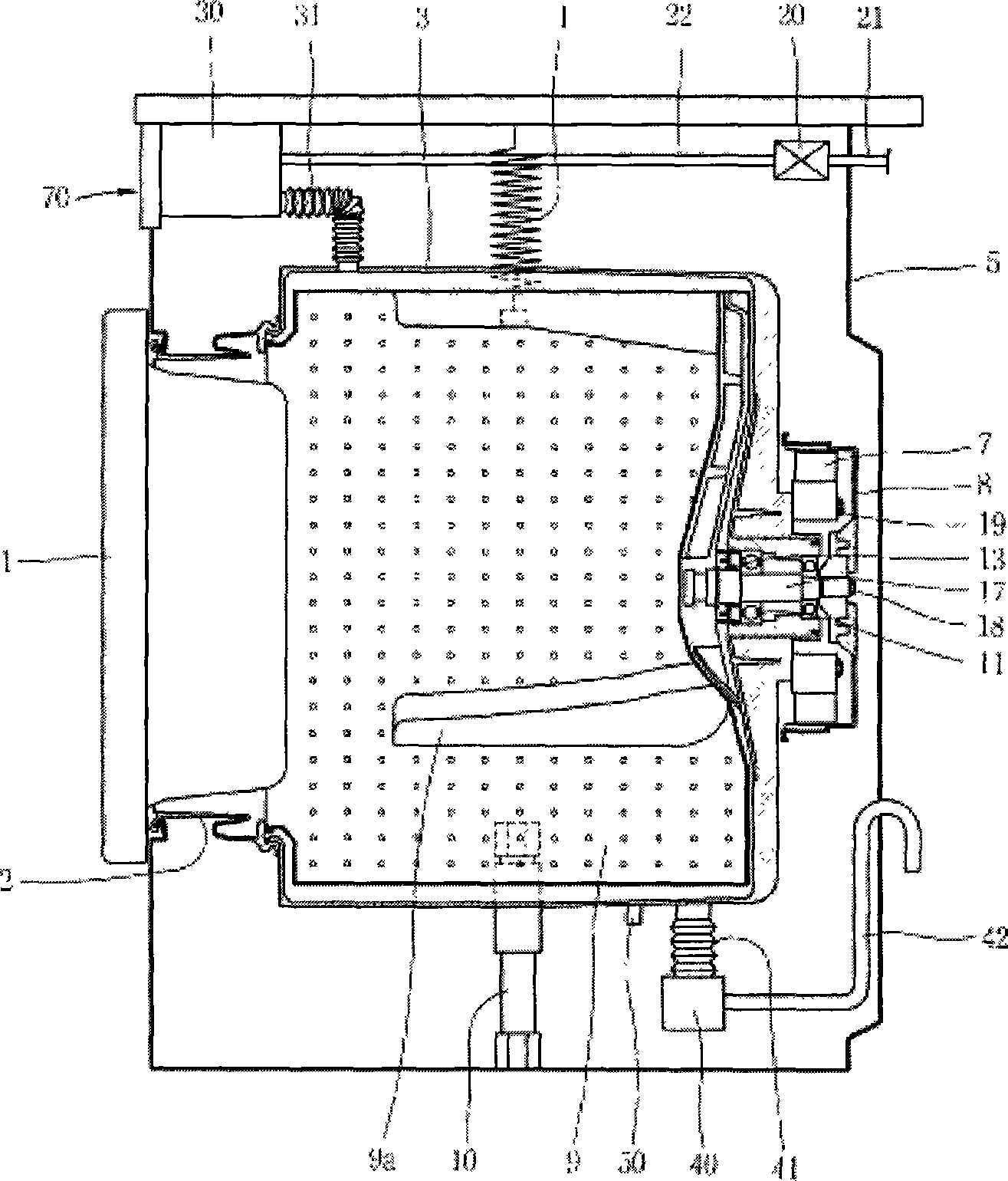

Washing machine water drainage control method

ActiveCN105734887AHygienic useEnvironmental protectionControl devices for washing apparatusTextiles and paperPulp and paper industryLoad cell

The invention discloses a washing machine water drainage control method. The washing machine comprises an outer barrel and an inner barrel arranged in the outer barrel. The inner barrel is a water-containing barrel, the upper part of the barrel body of the inner barrel is provided with a water outlet hole, and the rotating speed of the inner barrel is controlled by stages by means of detecting the change case of the residual water amount of the inner barrel; or the rotating speed of the inner barrel is controlled by stages in dependence on the water drainage time, and the longer the water drainage time is, the higher the rotating speed of the inner barrel is controlled in the next stage. A flow sensor is used for measuring the amount of water which is discharged from the washing machine, the residual water amount of the inner barrel is obtained by subtracting the discharged water amount from the water intake amount of the washing machine, or the residual water amount of the inner barrel is detected by a weighing sensor. The water intake amount of the washing machine is measured through a water intake flow sensor or the weighing sensor or other ways. The weighing sensor is installed on the joint of a suspension rod and the casing of the washing machine, or is installed on the joint of the suspension rod and an outer barrel suspension rod base, or is installed on a bottom foot of the casing of the washing machine. According to the invention, the water drainage speed is fast, and the water drainage efficiency is high.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

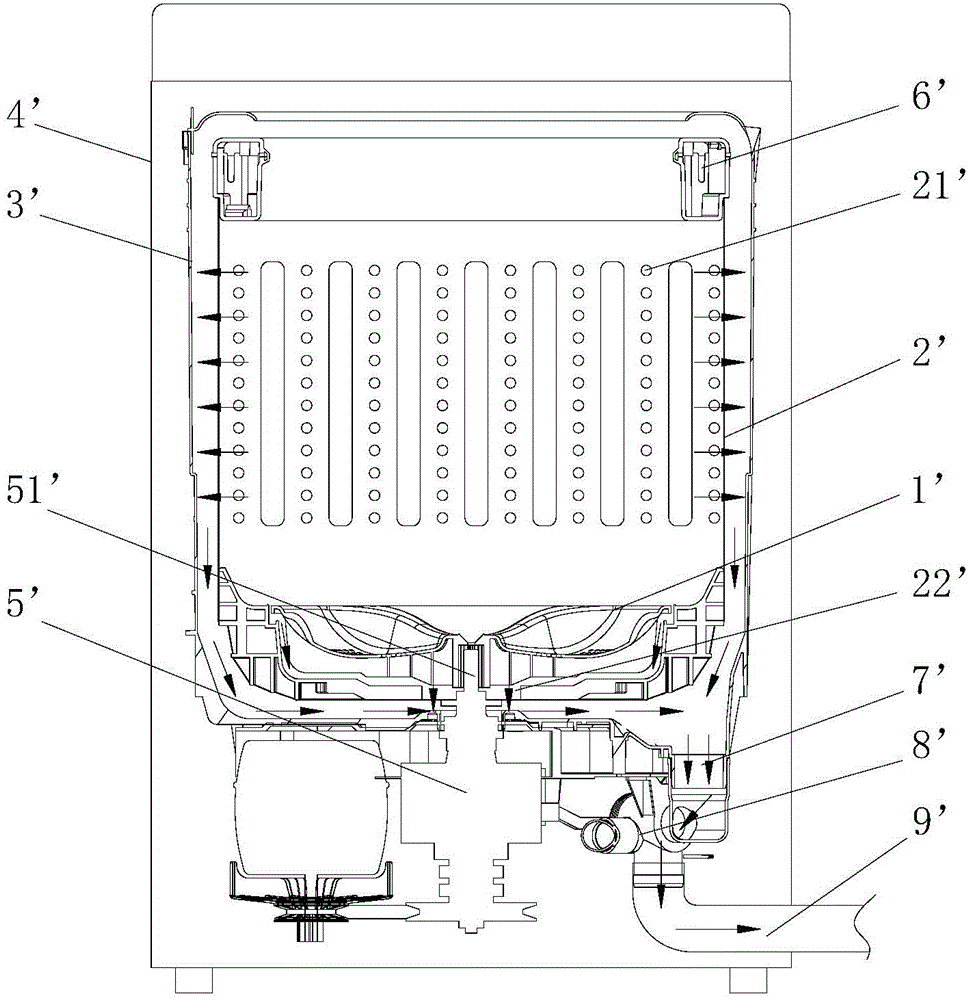

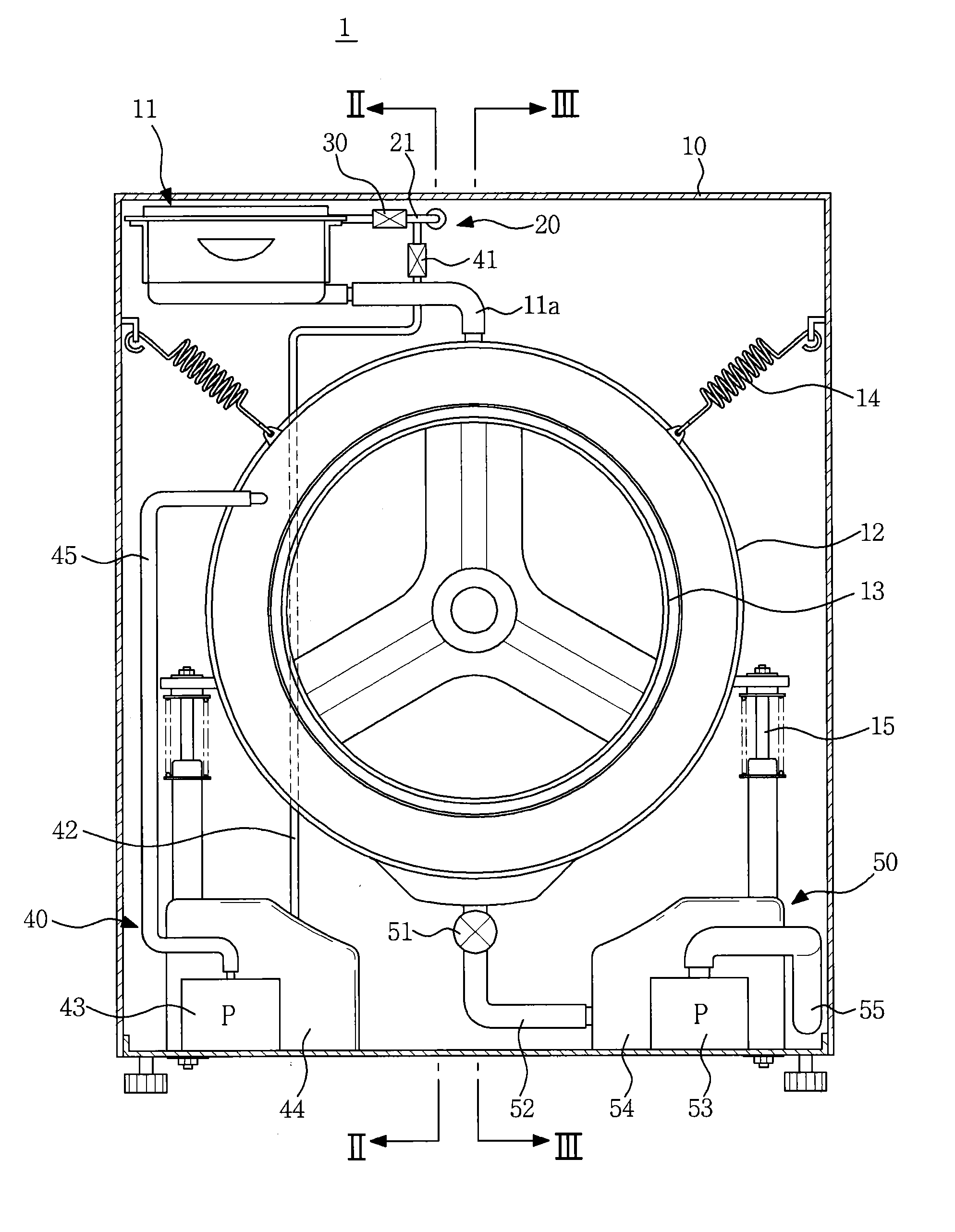

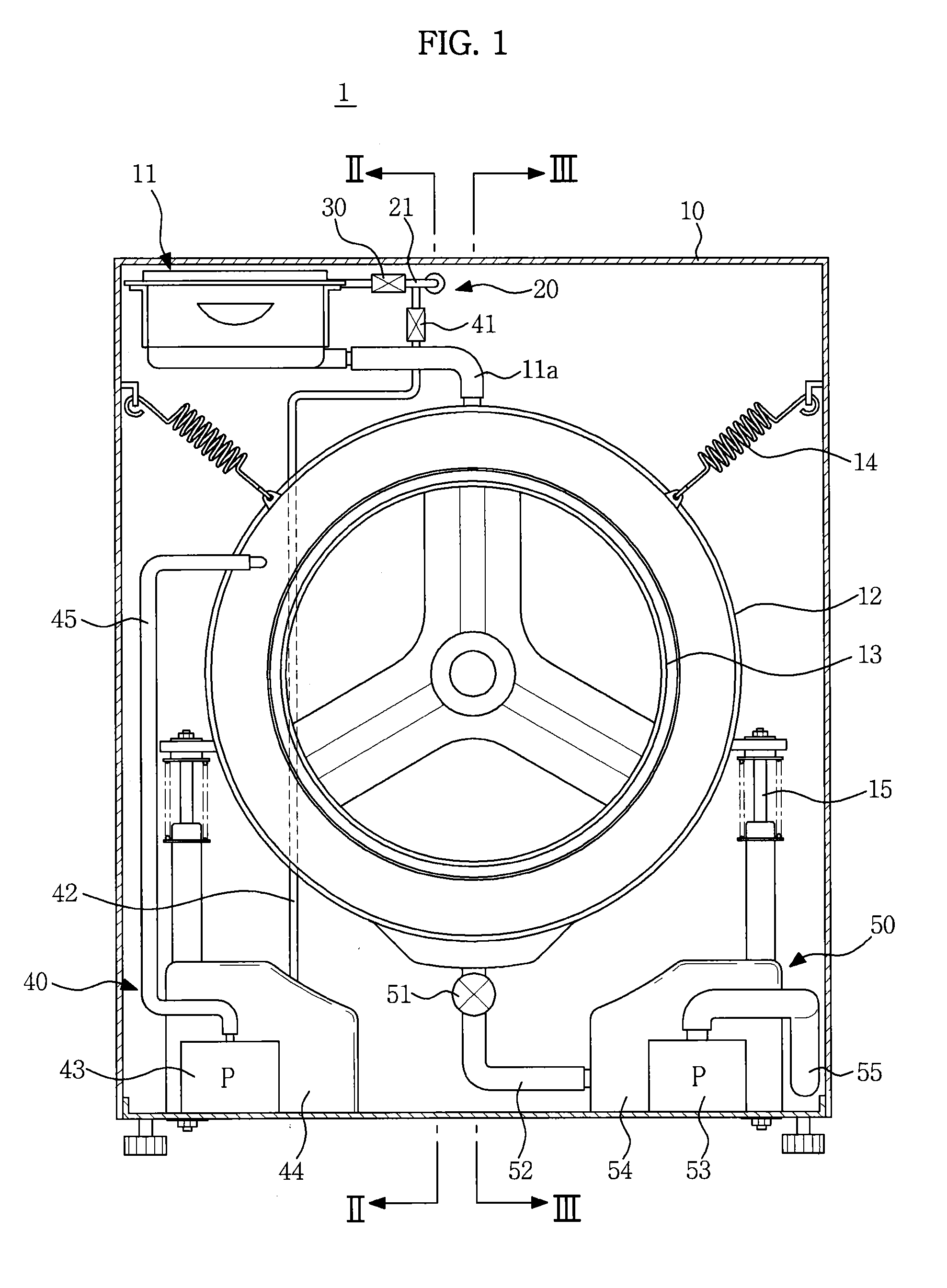

Drum type washing machine

InactiveUS20130117943A1Shorten washing timeImprove washing efficiencyOther washing machinesControl devices for washing apparatusDrainage timeStorage tank

A drum type washing machine capable of reducing water supply time and water drainage time, thereby reducing time of an entire washing cycle, the drum type washing machine including a body; a tub provided at an inside the body to accommodate washing water therein; a drum rotatably installed at an inside the tub; a water supply unit connected to the tub and provided to supply washing water; and a first storage unit connected to the water supply unit and provided to store washing water that is to be supplied to the tub, wherein the first storage unit includes a first storage tank configured to store washing water; a first connecting pipe configured to connect the first storage tank to the water supply unit; and a second connecting pipe configured to connect the first storage tank to the tub.

Owner:SAMSUNG ELECTRONICS CO LTD

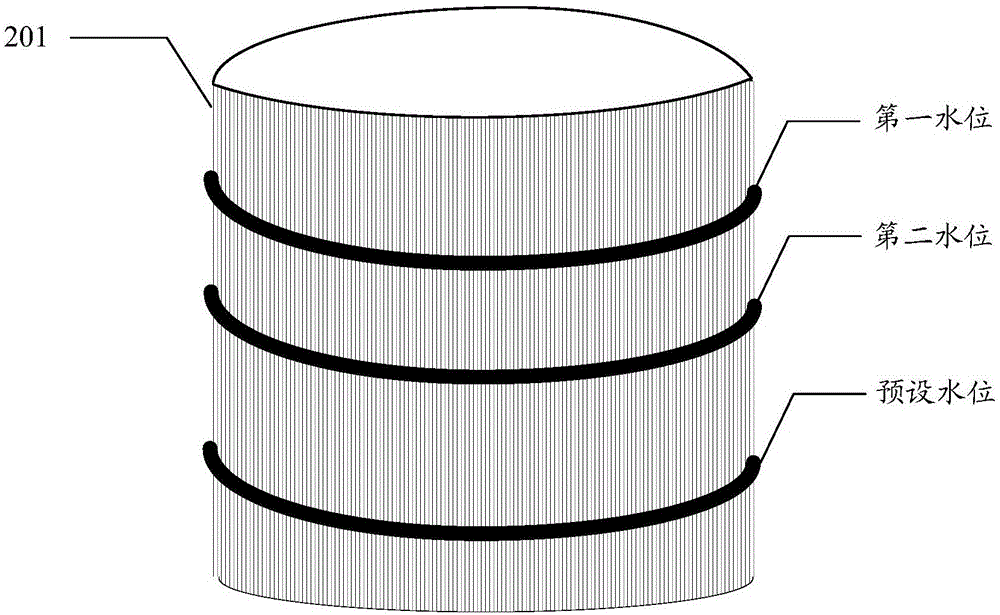

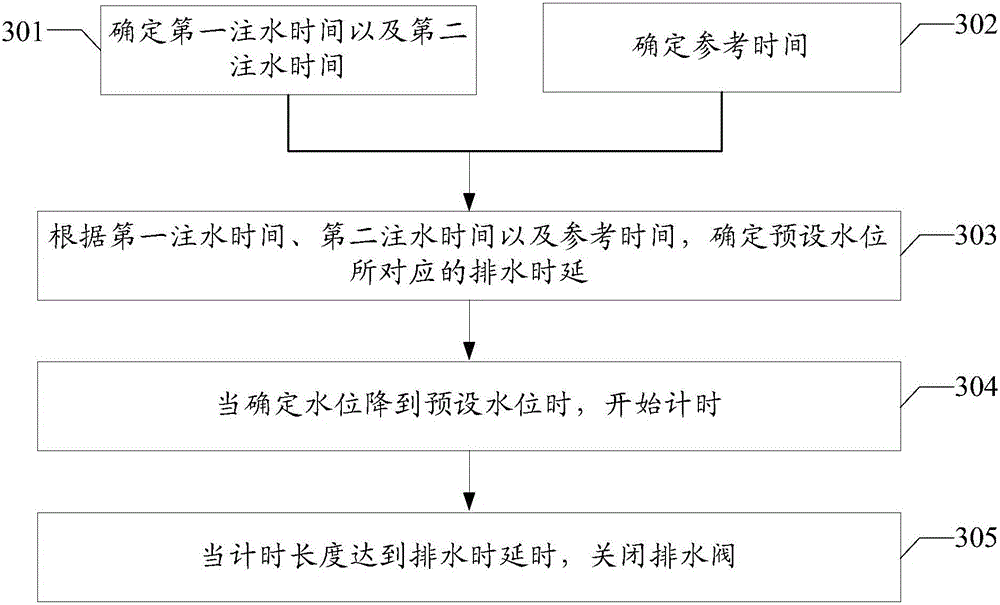

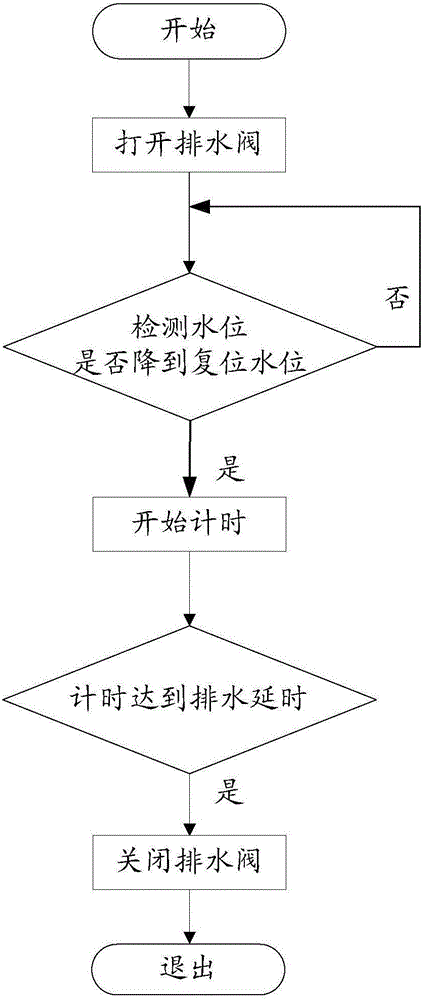

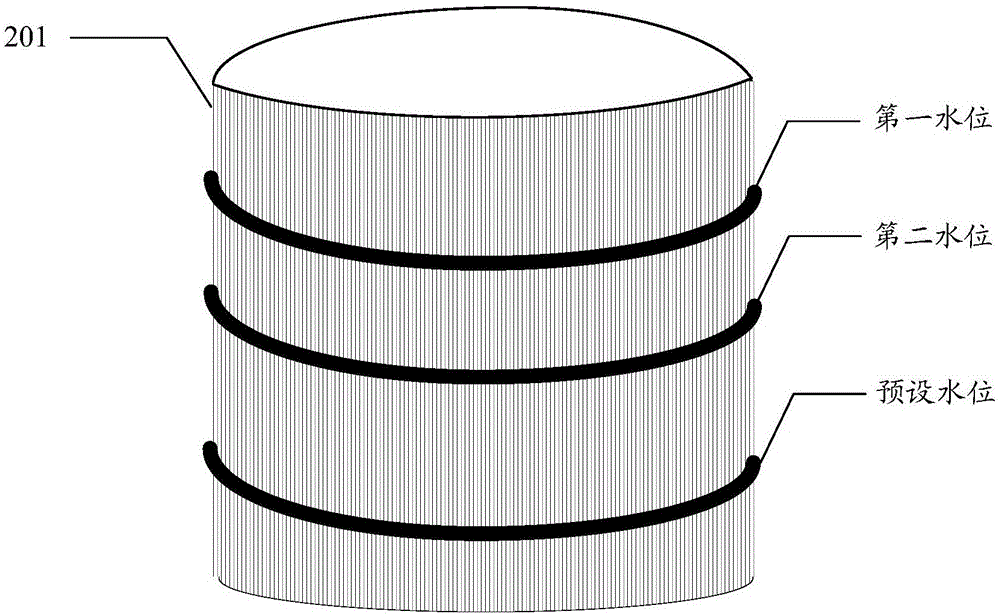

Washing machine control method, controller and washing machine

ActiveCN105671860AOther washing machinesControl devices for washing apparatusMachine controlEngineering

The embodiment of the invention provides a washing machine control method, a controller and a washing machine so that drainage time delay can be set more accurately and relates to the field of household appliances. According to the specific scheme, the method comprises the steps of determining first water injection time and second water injection time, wherein the first water injection time is the time for increasing the water level from 0 to a preset water level value at a certain water injection rate, the second water injection time is the time for increasing the water level from a second water level value to a first water level value at the water injection rate, the preset water level value is equal to or smaller than the second water level value, and the second water level value is smaller than the first water level value; determining reference time, wherein the reference time is the time for reducing the water level from the first water level value to the second water level value during drainage; determining drainage time delay corresponding to the preset water level value according to the first water injection time, the second water injection time and the reference time, wherein the drainage time delay is in positive correlation with the reference time. The washing machine control method, the controller and the washing machine are used for manufacturing of washing machines and controllers.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Formation method capable of prolonging cycle life of soft package power battery, battery formation clamp, applications and soft package power battery

PendingCN108306062AImprove cycle lifeFormation method to improve cycle lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPower batteryElectrical battery

The invention provides a formation method capable of prolonging the cycle life of a soft package power battery, a battery formation clamp, applications and the soft package power battery and relates to the technical field of soft package power batteries. The formation method comprises the steps of adopting multi-echelon vacuum standing and vacuum sealing treatment on the battery subject to liquidinjection, putting the vacuum sealed battery into the battery formation clamp for carrying out the steps of aging, precharge treatment and standing, wherein an immersion method of echelon vacuum standing is adopted after liquid injection, so that the absorption rate of an electrolyte can be reduced and the drainage time is shortened; pressure standing is adopted in the aging process, so that infiltration of the electrolyte can be fuller under certain pressure; and the battery formation clamp is adopted for precharge treatment, so that a positive plate and a negative plate of the battery can bein close contact, the formed SEI film is consistent in components, and the surface thickness is uniform and stable. The invention further provides the battery formation clamp. The clamp is simple instructure, convenient to use and suitable for industrial production.

Owner:BEIJING NAT BATTERY TECH

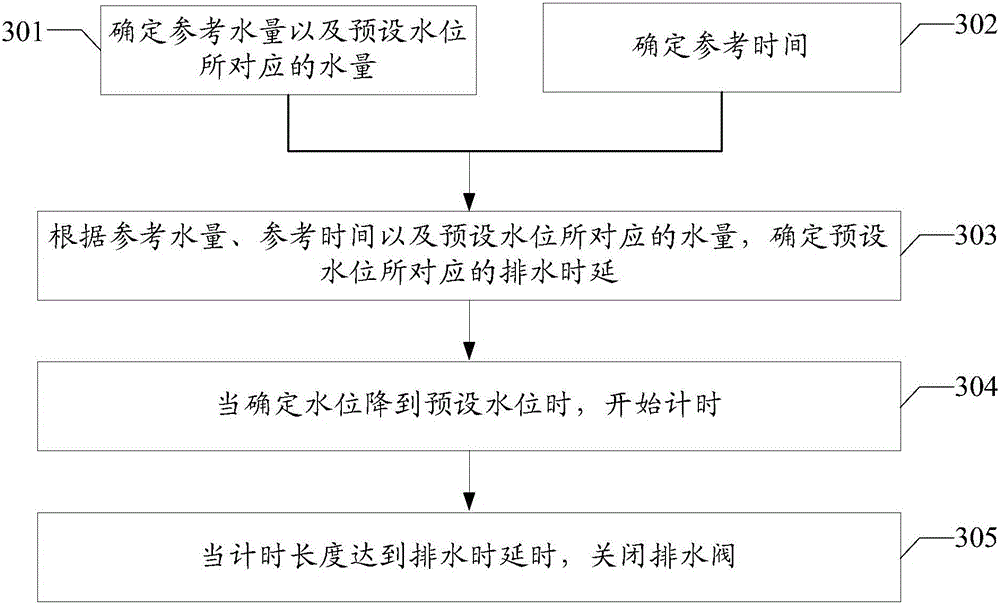

Washing machine control method, controller and washing machine

ActiveCN105671861AOther washing machinesControl devices for washing apparatusWater volumeMachine control

The embodiment of the invention provides a washing machine control method, a controller and a washing machine so that drainage time delay can be set more accurately and relates to the field of household appliances. According to the specific scheme, the method comprises the steps of determining reference water volume and water volume corresponding to a preset water level, wherein the reference water volume is the difference between water volume corresponding to a first water level and water volume corresponding to a second water level, the second water level is lower than the first water level, and the preset water level is equal to or lower than the second water level; determining reference time, wherein the reference time is the time for reducing the water level from the first water level to the second water level during drainage; determining drainage time delay corresponding to the preset water level according to the reference water volume, the reference time and the water volume corresponding to the preset water level, wherein the drainage time delay is in positive correlation with the reference time. The washing machine control method, the controller and the washing machine are used for manufacturing of washing machines and controllers.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

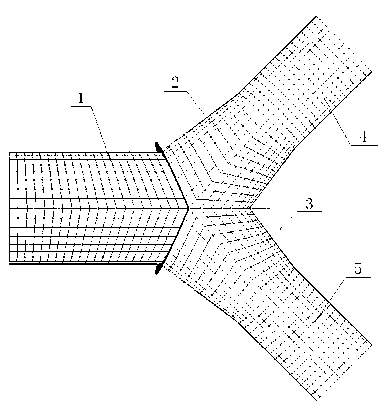

Flat steel bifurcated pipe and manufacturing method thereof

InactiveCN102853193ABalanced forceReasonable forceBranching pipesStress concentrationArchitectural engineering

The invention relates to a flat steel bifurcated pipe and a manufacturing method thereof. The flat steel bifurcated pipe comprises a main pipe, a left branch cone and a right branch cone, wherein one end of the left branch cone is communicated with one end of the main pipe; one end of the right branch cone is communicated with one end of the main pipe; one side of the left branch cone leans against and is welded with one side of the right branch cone; another end of the left branch cone and another end of the right branch cone are respectively communicated with a left branch pipe and a right branch pipe; bottoms of the main pipe, the left branch cone, the right branch cone, the left branch pipe and the right branch pipe are located at the same one altitude. The flat steel bifurcated pipe has the advantages that the shape of the flat steel bifurcated pipe is different from the principle of the same one altitude of axial lines of various pipe joints of the other steel bifurcated pipes and ensures the same one altitude on the bottom of the various pipe joints; the same one altitude on the bottom of the pipe has independent goodness; water can flow freely to be discharged when high-pressure pipes are maintained without pumping the water by a water pump or arranging holes on the steel bifurcated pipe and connecting with a special drainage system; the drainage time is shortened greatly, and the effective work time for maintenance is prolonged; the flat steel bifurcated pipe has the advantages of regular shape, no deformity portions, reasonable force and no stress concentration phenomenon.

Owner:WUHAN UNIV

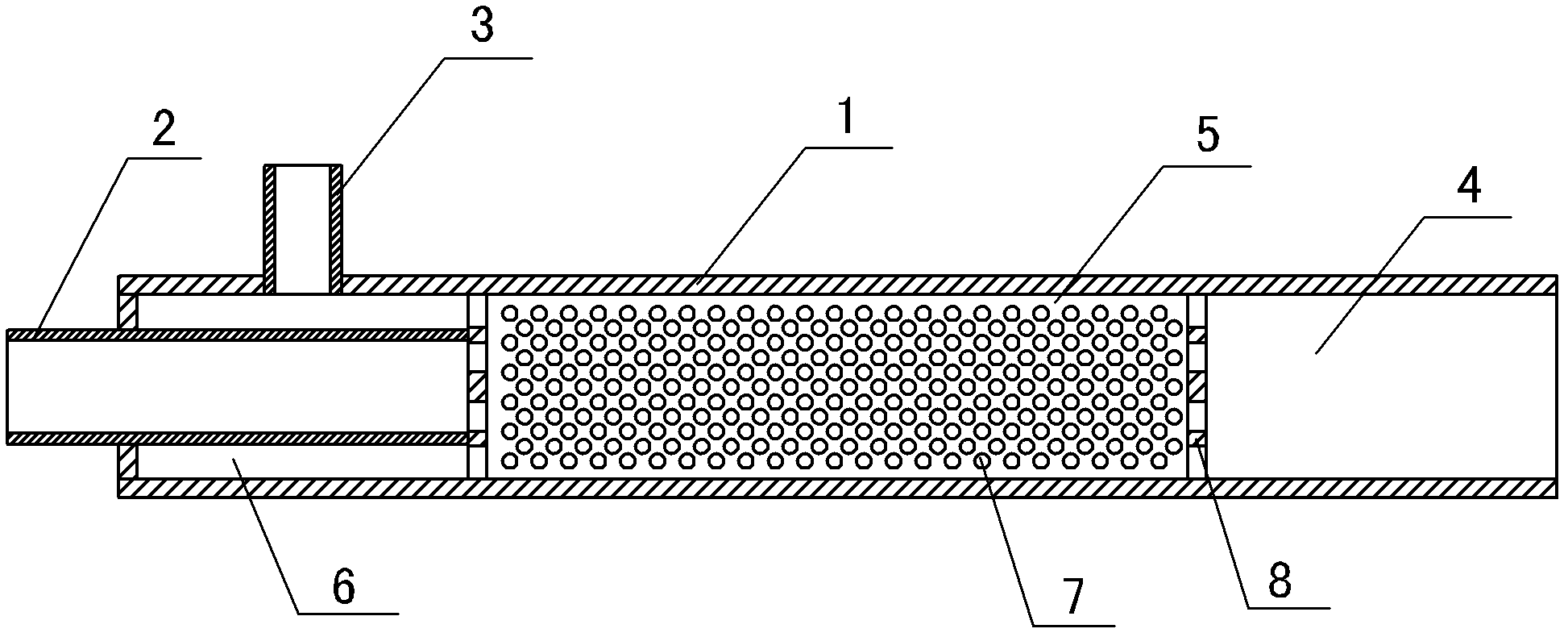

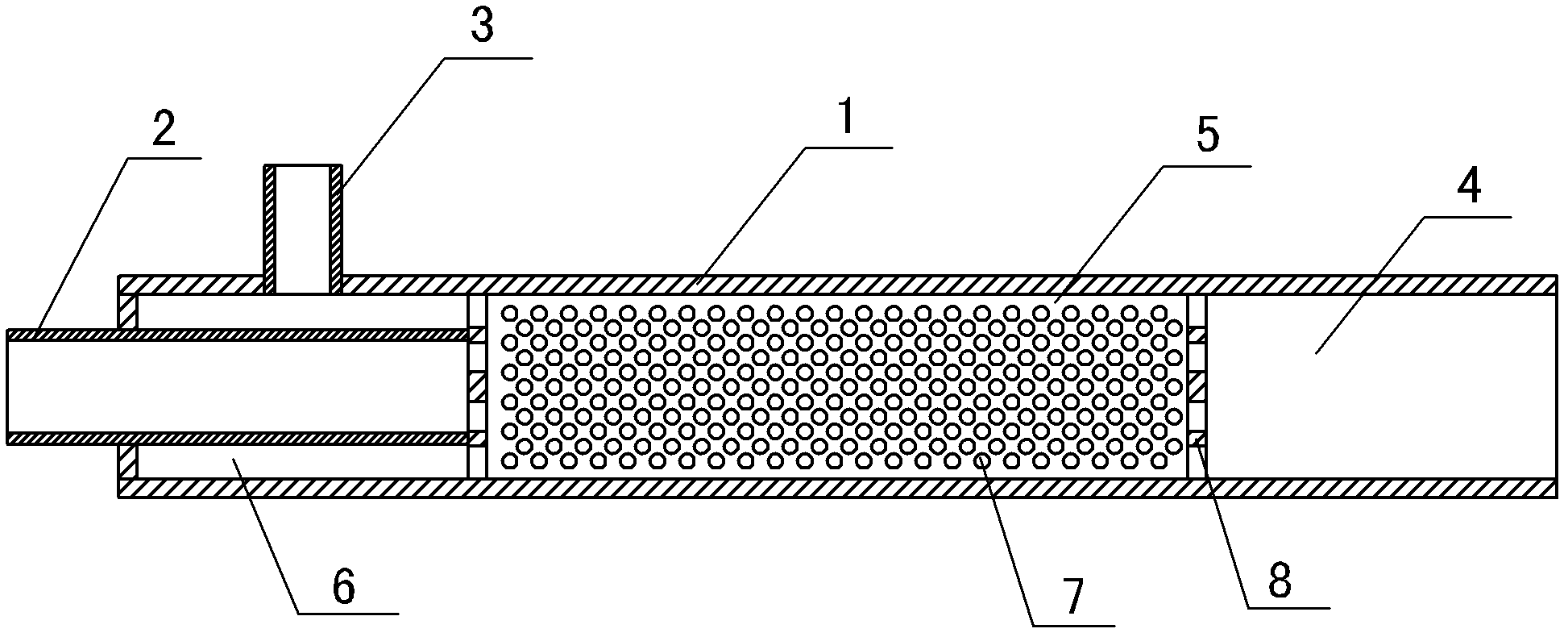

Gas-liquid proportioning mixed foam maker of compressed gas foam fire-fighting system

The invention relates to an equipment part of a foam fire-fighting system, in particular to a gas-liquid proportioning mixed foam maker of a compressed gas foam fire-fighting system. The gas-liquid proportioning mixed foam maker of the compressed gas foam fire-fighting system comprises a shell and a mixed foaming chamber, wherein the mixed foaming chamber fully occupies the middle inside the shell; the input end of the mixed foaming chamber is communicated with a foam liquid inlet pipe and a gas chamber; the gas chamber is communicated with a compressed gas inlet pipe; the output end of the mixed foaming chamber is communicated with an output chamber; and an auxiliary mixed foaming medium is arranged in the mixed foaming chamber. In the gas-liquid proportioning mixed foam maker disclosed by the invention, the mixed foaming chamber is additionally arranged, and the auxiliary mixed foaming medium is arranged in the mixed foaming chamber, therefore, foaming multiples are increased, foaming efficiency reaches 100 percent and high utilization ratio of water and foam liquid and a good fire-fighting effect are achieved; output fire-fighting foams can be adhered to protected objects and have long drainage time and burn resistant time, and therefore, after-combustion is effectively prevented; and the output fire-fighting foams have light weight so that a water hose filled with the fire-fighting foams is very light, and the water hose can be moved to a very high position and easily and forcedly deliver the fire-fighting foams to a height more than 200 meters.

Owner:山东吉孚消防科技有限公司

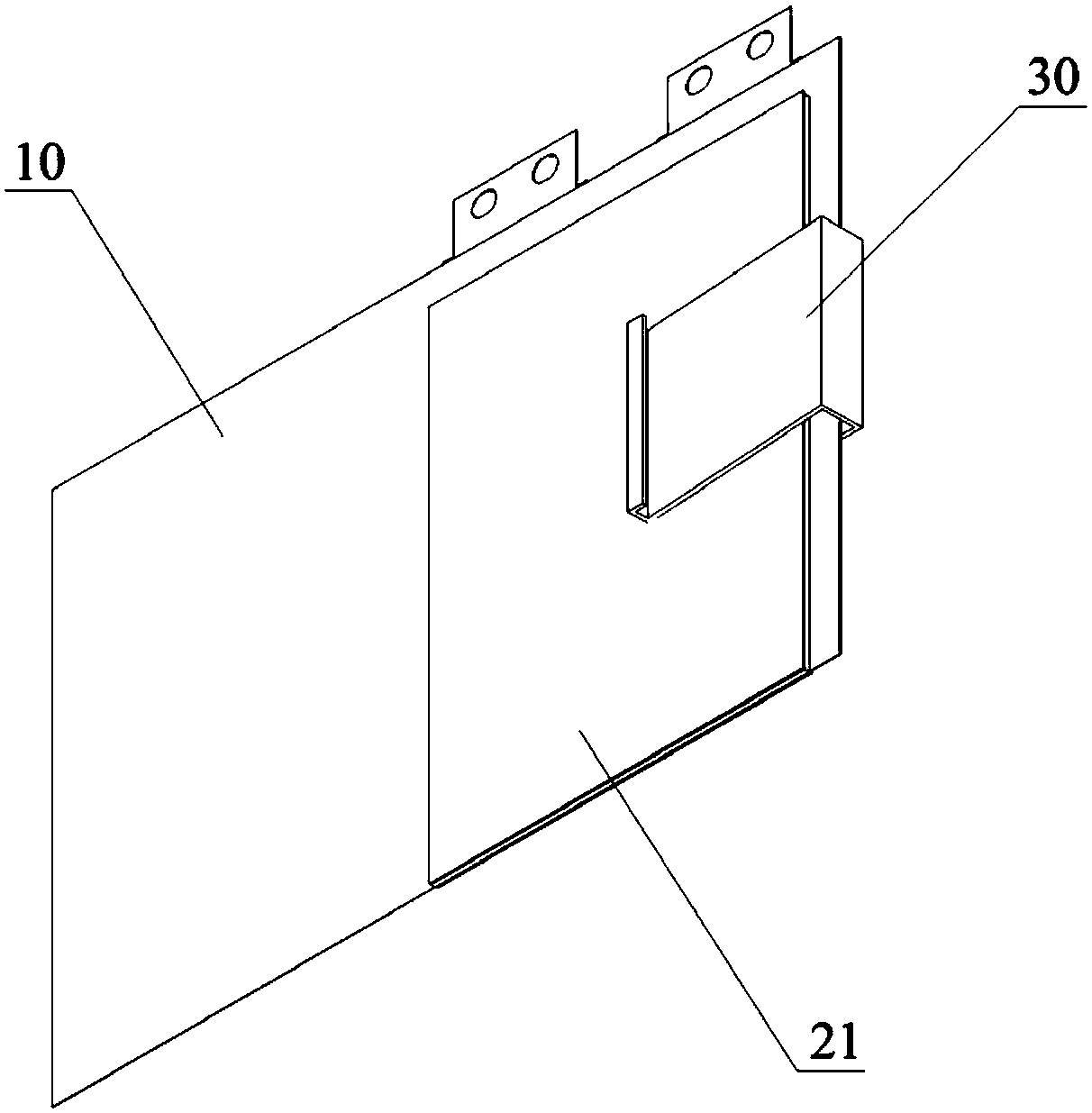

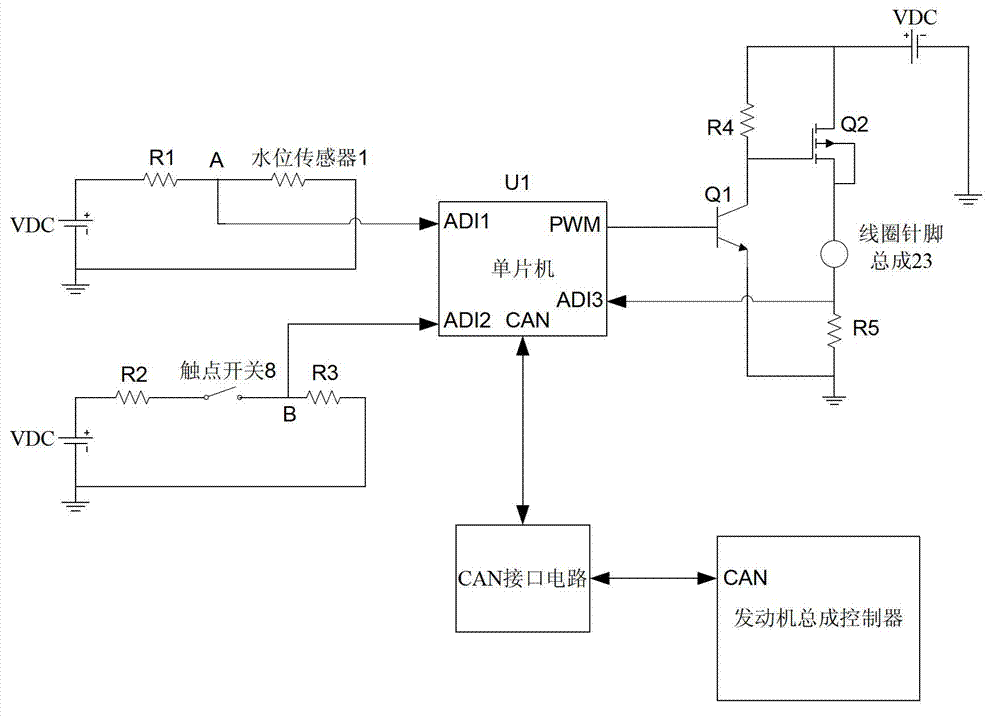

Fuel filter automatic drain valve with operating state self-detection function

ActiveCN103090058AAvoid wastingAvoid damageOperating means/releasing devices for valvesMultiple way valvesElectricityFuel filter

The invention discloses a fuel filter automatic drain valve with an operating state self-detection function. The fuel filter automatic drain valve with the operating state self-detection function comprises a valve body, an electromagnetic valve and a controller, wherein the valve body is fixedly connected with the electromagnetic valve and the controller is connected with the valve body and the electromagnetic valve in an electric mode. The fuel filter automatic drain valve with the operating state self-detection function is capable of automatically detecting water level conditions of water in a fuel filter, achieving automatic drainage when the water level surpasses a limiting value, and automatically and intelligently controlling water drainage time. Therefore, damage to a vehicle due to the fact that water can not be drained in time manually is avoided, fuel is prevented from being drained mistakenly due to long-time water drainage, waste of the fuel is avoided, troubles caused by manual operation are eliminated, a user is prevented from carrying out water drainage operation in a narrow and small space, and intellectualization of the vehicle is improved.

Owner:辽宁新风企业集团大连亿特科技有限公司

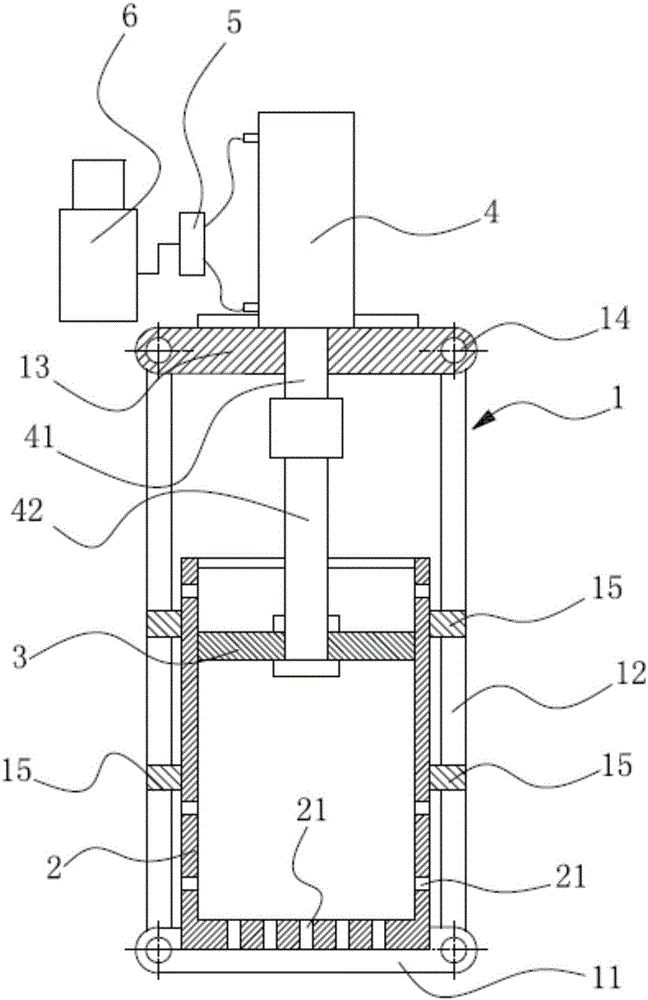

Sugarcane squeezing device for laboratory and squeezing method

InactiveCN106079523ASolve the problems of uneven cane feeding, short juice discharge time and low extrusion degreeAccurately measure sugarPreparing sample for investigationPress ramFiberEngineering

Owner:广西糖业集团红河制糖有限公司

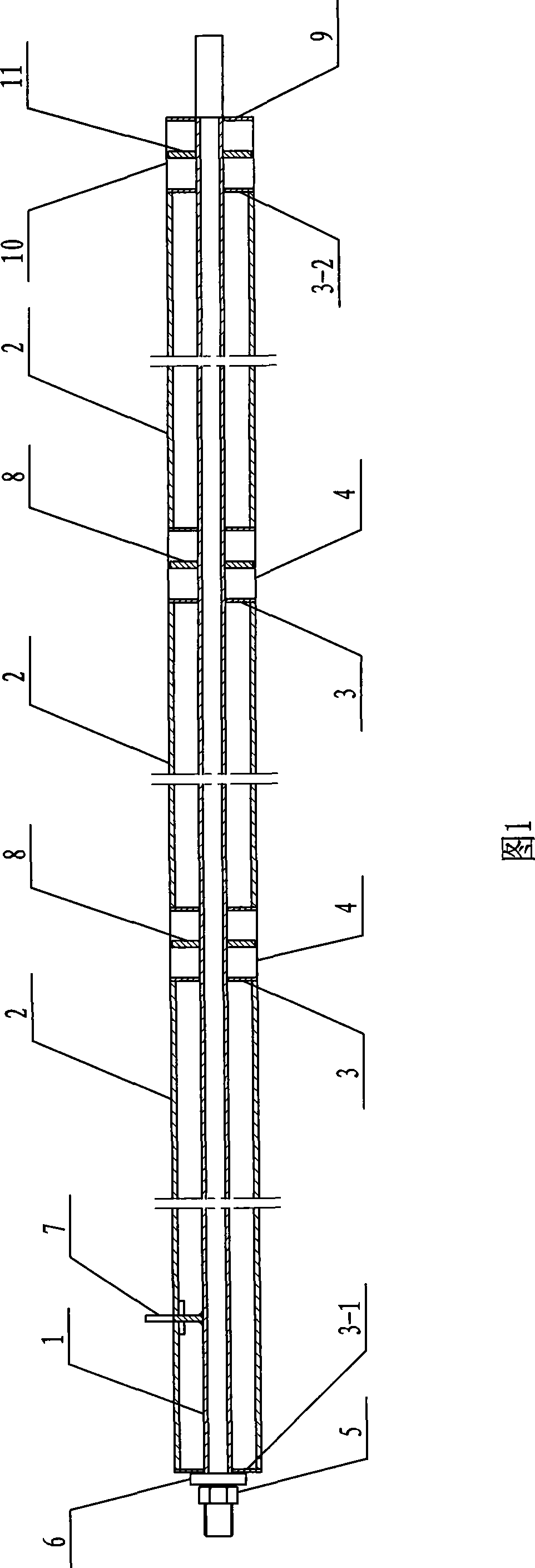

Telescopic type pulling hole packer

ActiveCN101457654AImprove compactnessPrevent simultaneous rotationDust removalFire preventionReusabilityEngineering

The invention discloses a telescopic drainage hole sealer which comprises a drainage pipe; wherein, at least two coaxial hole seal pipes are sheathed on the drainage pipe, the drainage pipe is longer than the hole seal pipes, both ends of each hole seal pipe are respectively provided with a closure plate, and a coaxial cylindrical air sac is arranged between the hole seal pipes; the drainage pipe penetrates through and is connected with the closure plate and the air sac through rotation fit, and a holding apparatus outside the closure plates on the ends of the hole seal pipes is arranged on the drainage pipe. The telescopic drainage hole sealer has the advantages of simple structure, easy production and installation and convenient operation, can be suitable for draining or injecting liquid into holes of different hole diameters through the dimension change of the components of the telescopic drainage hole sealer, solves the fault problems of pipeline cracking, ventilation and liquid leakage and even breakage, prolongs the service life of the main device, shortens the working time, increases the working efficiency, reduces the drainage times and the maintenance workload and cost, has high drainage or liquid injection speed, high reusability and easy maintenance, and guarantees the quality and the safety of liquid drainage or injection.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

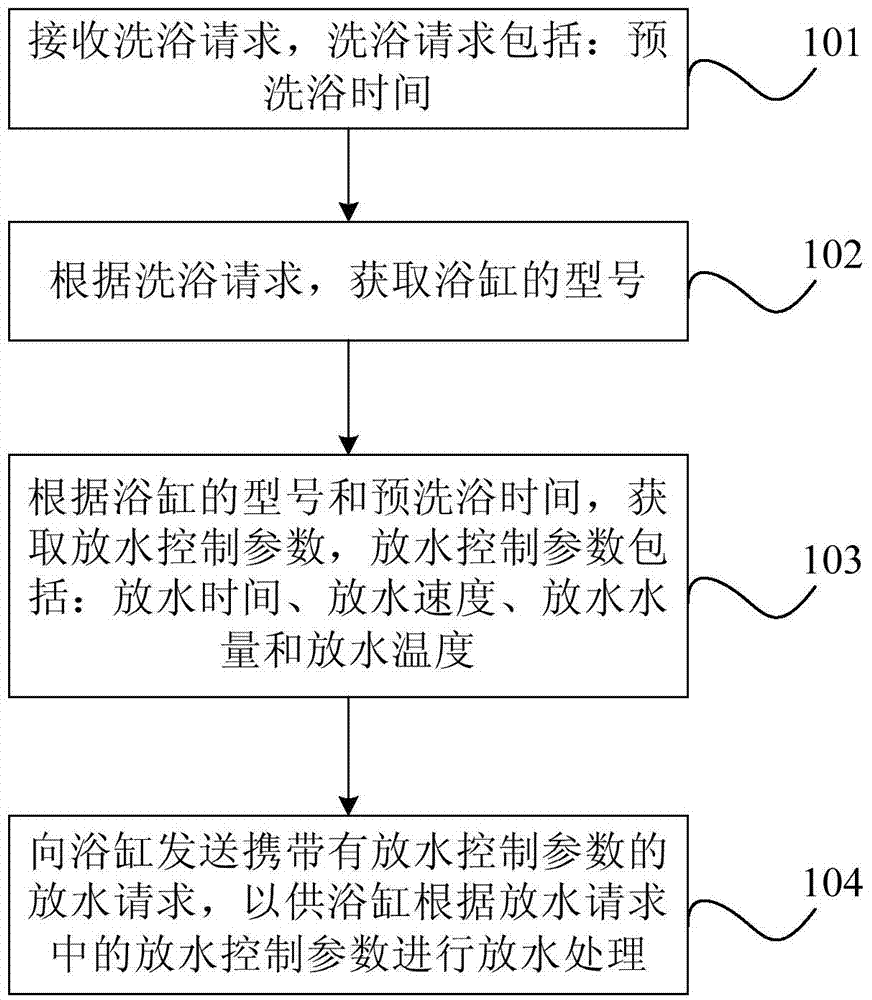

Drainage control method and device based on bathtub

InactiveCN106869253AIntelligent controlImprove experienceDomestic plumbingDrainage timeComputer science

The invention provides a drainage control method and a drainage control device based on a bathtub. The method comprises the following steps: receiving a bath request containing a pre-bath time; in accordance with the bath request, acquiring the model of the bathtub; acquiring drainage control parameters in accordance with the model of the bathtub and the pre-bath time, wherein the drainage control parameters include drainage time, drainage speed, drainage water quantity and drainage temperature; and transmitting a drainage request carrying the drainage control parameters to the bathtub, so that the bathtub can conduct drainage treatment in accordance with the drainage control parameters in the drainage request. By determining the model of the bathtub in accordance with the acquired pre-bath time and by determining the drainage control parameters, the bathtub can be controlled by a user in an intelligent mode, so that a user's time utilization rate is improved, an operating complexity of controlling the bathtub is reduced and user experience is enhanced.

Owner:BEIJING QIHOO TECH CO LTD +1

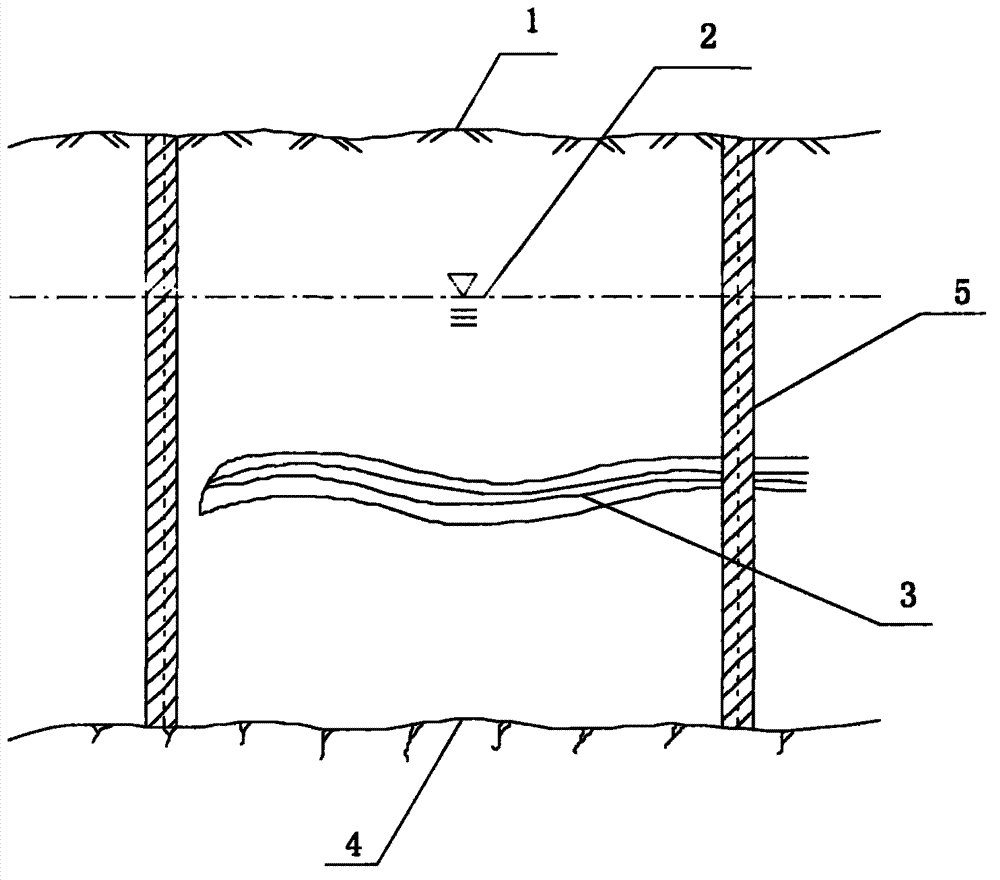

Method for realizing water-preserved mining by utilizing curtain grouting technology

InactiveCN102767371APrevent infiltrationProtect water resourcesUnderground miningSurface miningBedrockSlurry

The invention discloses a method for realizing water-preserved mining by utilizing a curtain grouting technology. The method comprises the following steps: first determining mining area and a mining depth; determining a depth of an impermeable bedrock (4) at a lower part of a coal bed (3) to be measured; drilling deep holes, along borders of the mining area with intervals of a certain distance, from ground (1) to the impermeable bedrock (4) at the lower part of the coal bed (3) by utilizing the curtain grouting technology; then pouring slurry into pores or fissures around the holes by high pressure, wherein the slurry connects soil or rock surrounding the pores or fissures into a cylindrical impermeable water body, and if hole spacing is suitable, these cylindrical impermeable water bodies connect to form a complete water blocking curtain in order to achieve the purpose of seepage prevention; and draining groundwater in the upper part of the coal bed to be mined in the range of the curtain, and mining the coal bed to be mined, wherein if there are more than two coal beds in the scope, the coal beds can be mined one by one. The method provided by the invention can effectively prevent water inrush accident in mining, as well as greatly reduce the drainage time and cost, and achieve the target of water-preserved mining, and has obvious social and economic benefits.

Owner:XIAN UNIV OF SCI & TECH +1

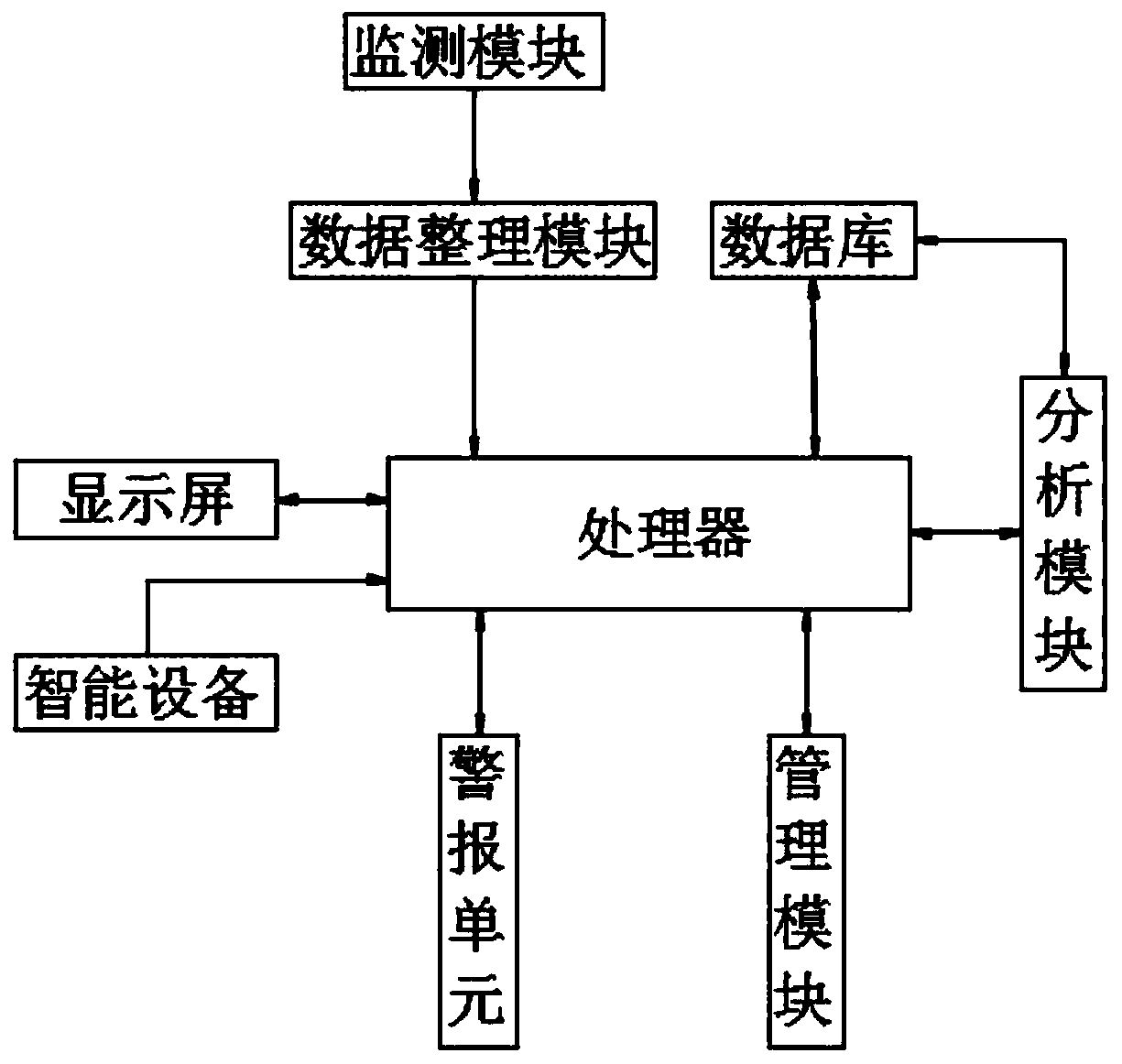

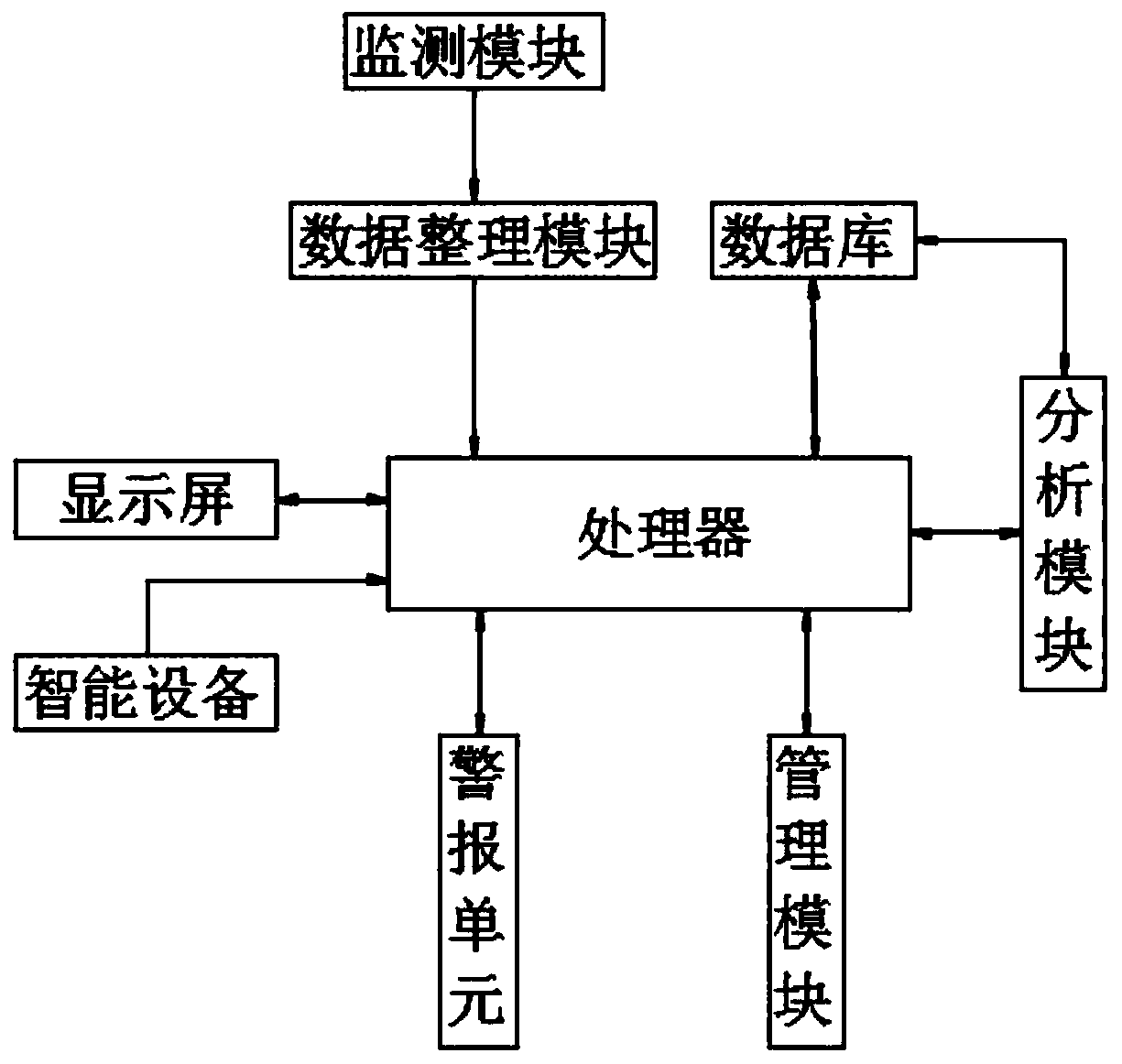

Big-data-based urban drainage network monitoring and control system

PendingCN109960200AEasy to classify and calculateClassified Calculation SavingsProgramme controlComputer controlData sortingStreamflow

The invention discloses a big-data-based urban drainage network monitoring and control system comprising a monitoring module, a data sorting module, a comparison unit, a database, an analysis module,a processor, an acquisition module, an alarm unit, a smart device and a display screen. The monitoring module is configured to monitor sewage drainage information in real time, wherein the sewage drainage information includes a liquid level of a sewage pool, drainage time of the sewage pool, and harmful gas information and the harmful gas includes molecular weight information of harmful gas, temperature information of harmful gas, and gas pressure intensity information. According to the invention, with the analysis module, the sewage drainage flow rate is calculated and the drainage speed of the sewage is obtained, so that the staff member can carry out adjustment conveniently, the too fast or too slow drainage is prevented, and the workload of the staff is reduced. Meanwhile, the alarm unit is used for carrying out corresponding prompting on the mass concentration of toxic gas, thereby enhancing the safety of drainage work and improving the work efficiency.

Owner:温州洪启信息科技有限公司

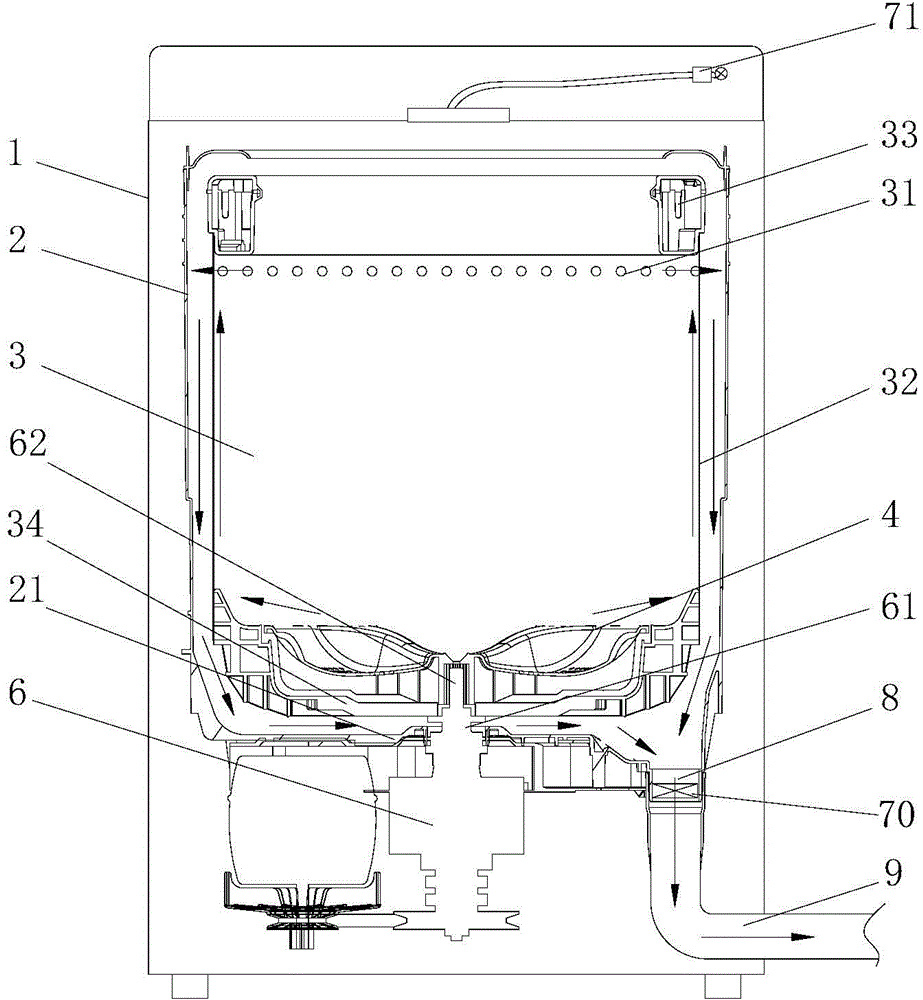

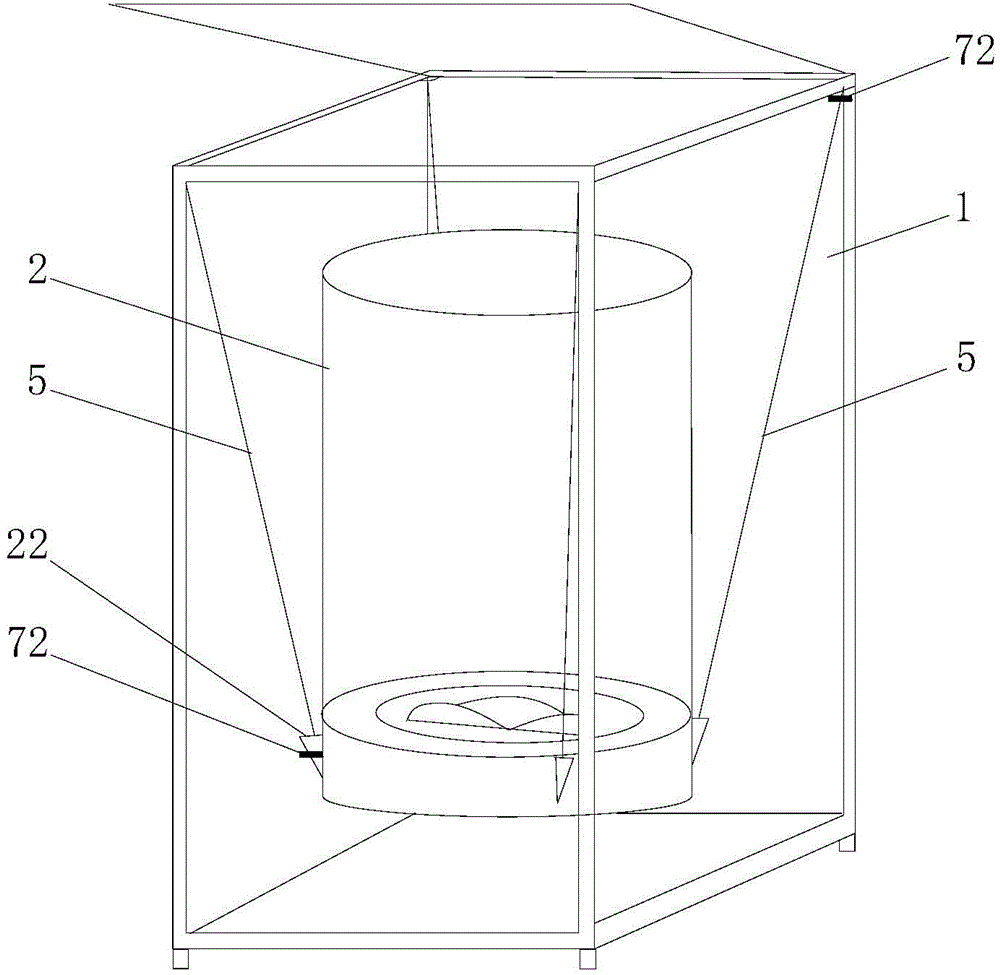

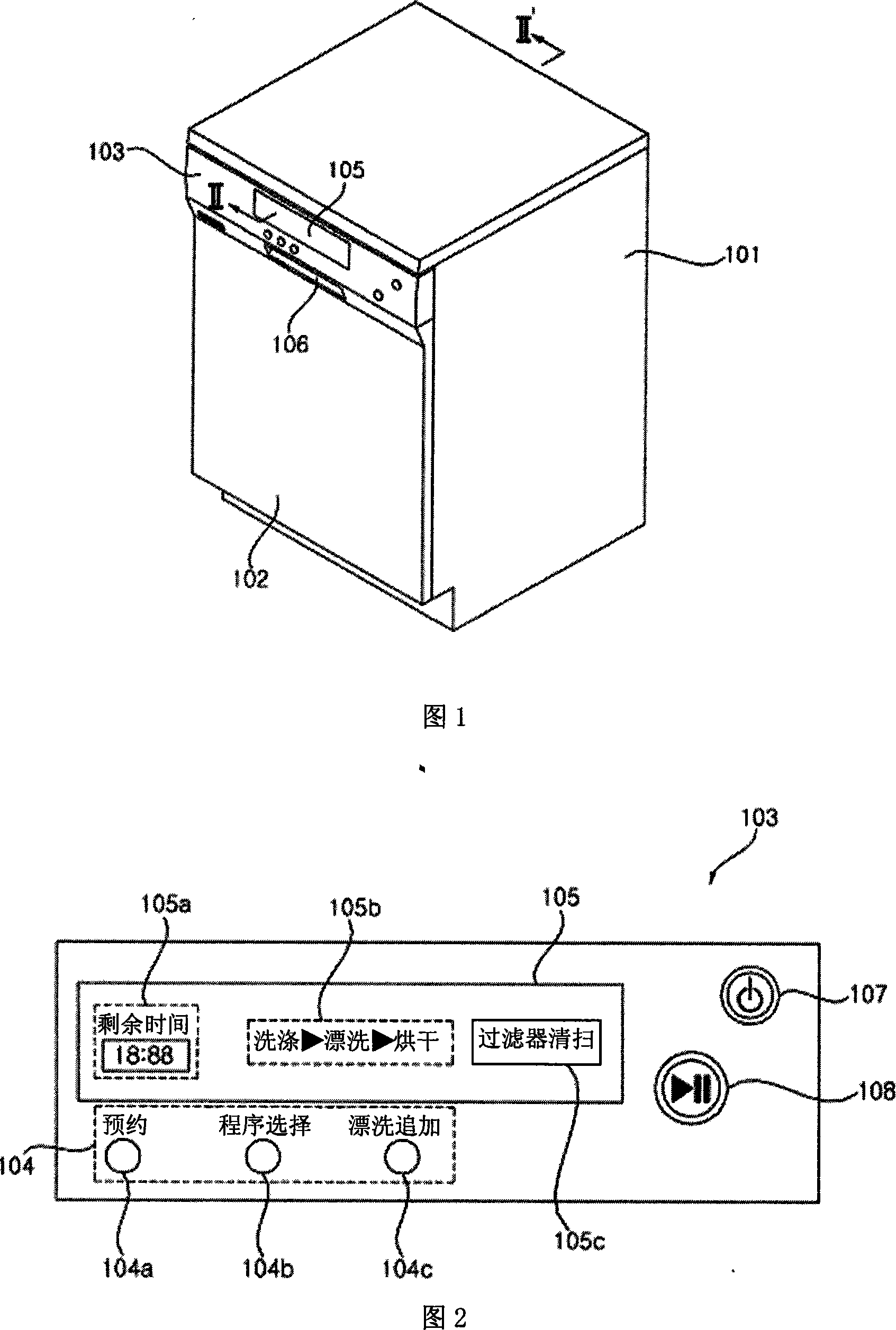

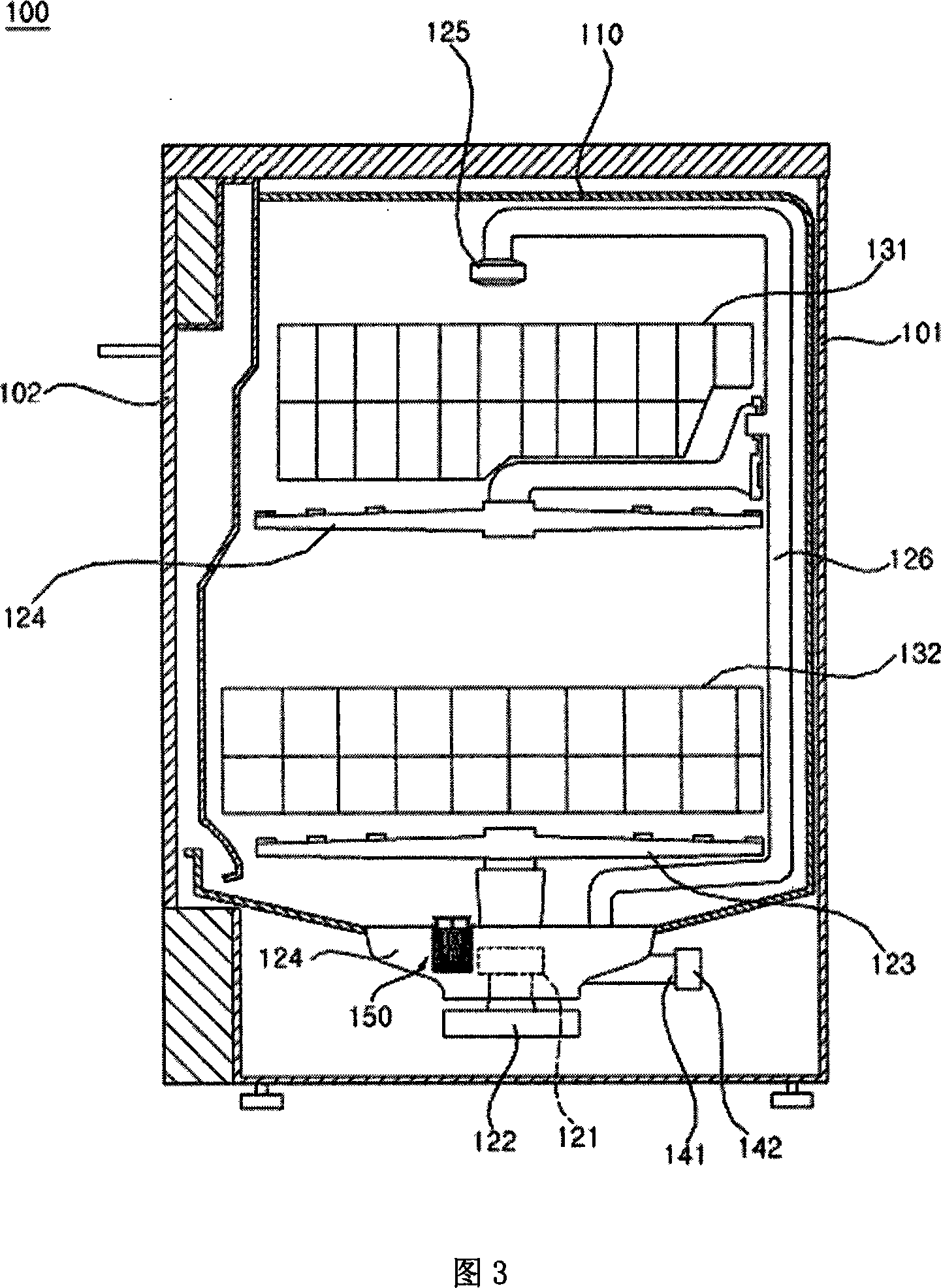

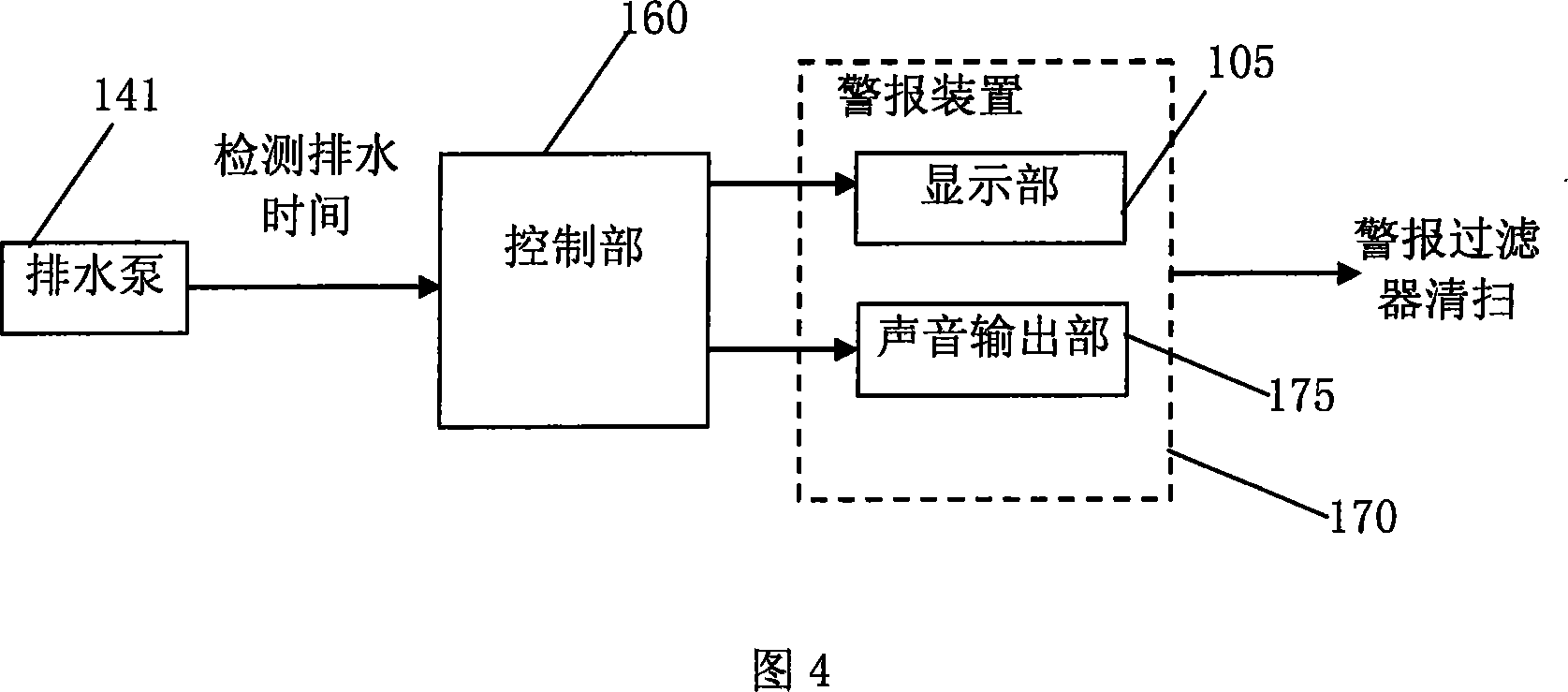

Dishwasher

InactiveCN101176642ATableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionEngineeringDrainage time

The invention relates to a invention which can judge the cleaning time of the filter device based on the drainage time that the drainage pump discharges the washing water and can display the judged cleaning time to users through an alarm device, so that user can know whether need to clean the filter device of the dishwasher or not based on directly confirming the food residue accumulated on the filter device.

Owner:NANJING LG PANDA APPLIANCES

Dynamic detection method for mine mining-induced fracture

ActiveCN102155213AImprove rationalityConducive to formulating the mining system scientificallySurveyWater leakageDrainage time

The invention discloses a dynamic detection method for a mine mining-induced fracture. The difficulty and blindness of gas drainage level position gives rise to problems that the level position of the gas drainage borehole arrangement is too high, the mining-induced fracture is underdeveloped, the gas drainage difficulty is big and the efficiency is low; the excessive lower level position of the gas drainage borehole arrangement easily gives rise to problems that a working surface seriously leaks wind, the normal running of a mine ventilation system is affected, the stability of the rock stratum is bad, and the effective gas drainage time is short. The method comprises the following steps of: detecting positions, parameters and numbers of boreholes by design; constructing before mining a stopping line and detecting the boreholes, carrying out the water leakage detection and recording data; taking a vertical height as a standard to normalize detection data, forecasting the development height of the mining-induced fracture after different mining times. The method can improve conditions of blind hole arrangement, short service life and low efficiency aiming at high position gas mining, increases the reasonableness of the hole arrangement and prolongs the mining time; and the method is beneficial to the scientific formulation of an under-water-body mining system, reduces the possibility of water outgoing of the water body, reduces the cost of coal mining and gas mining and improves the economic efficiency.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

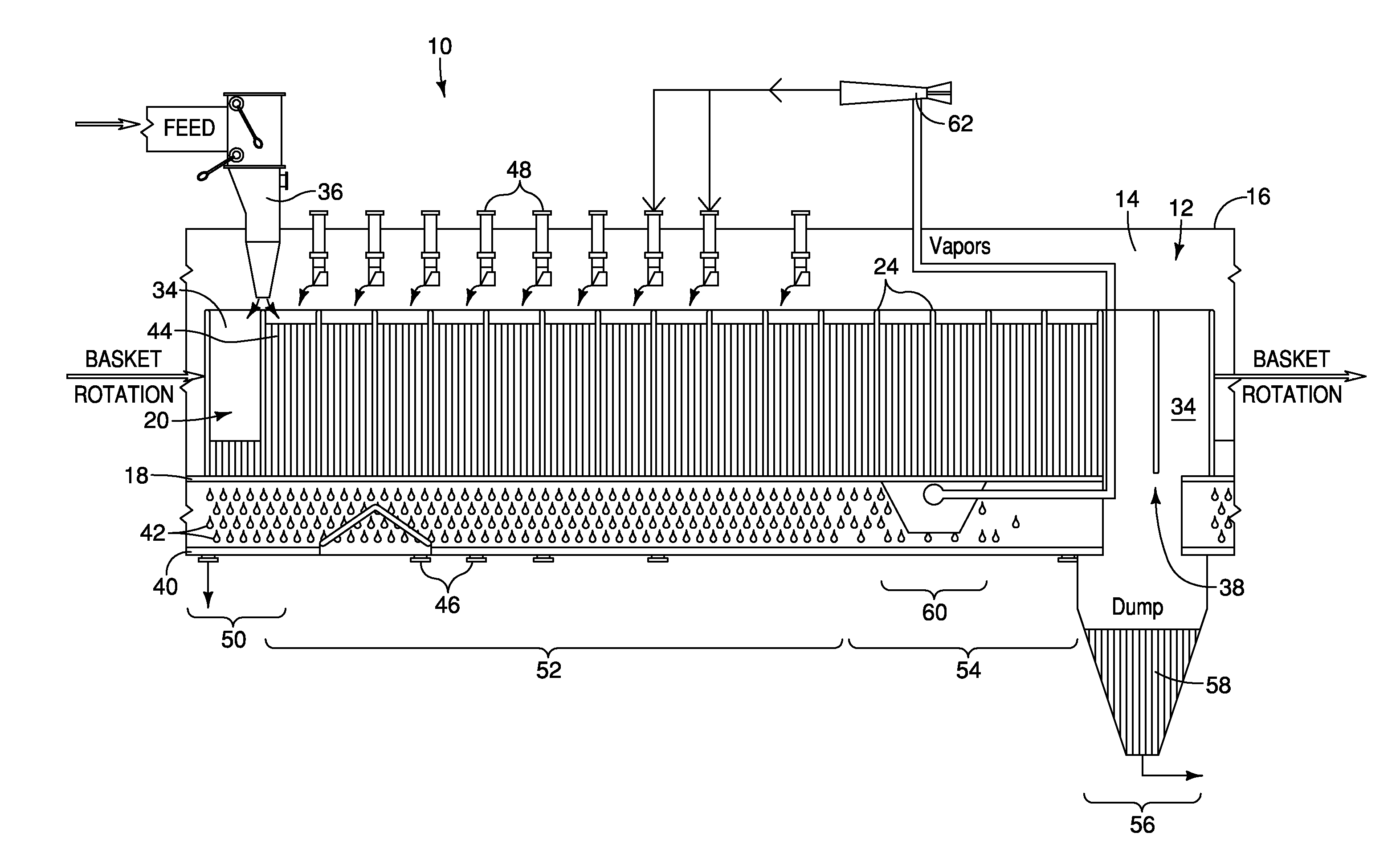

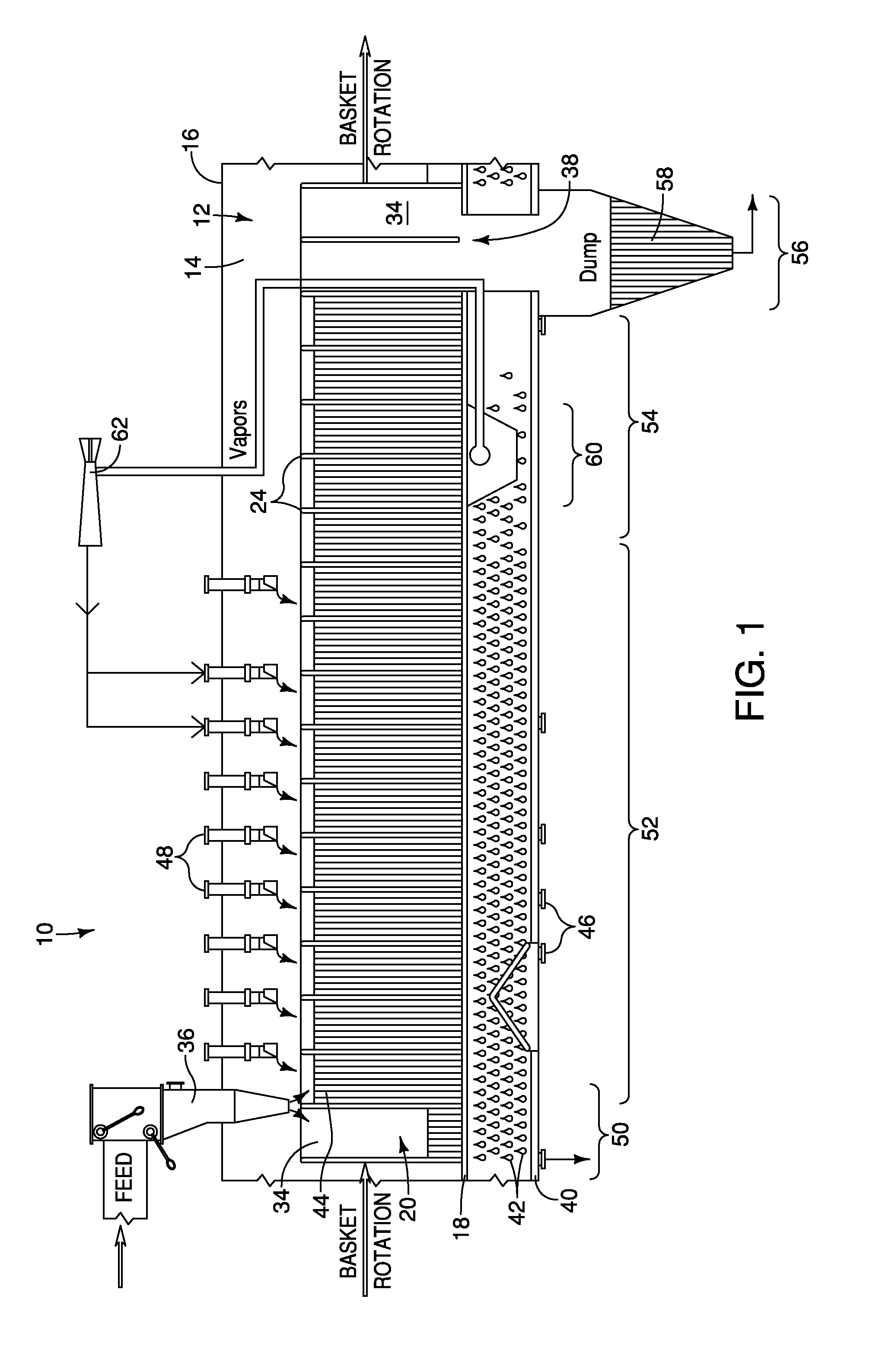

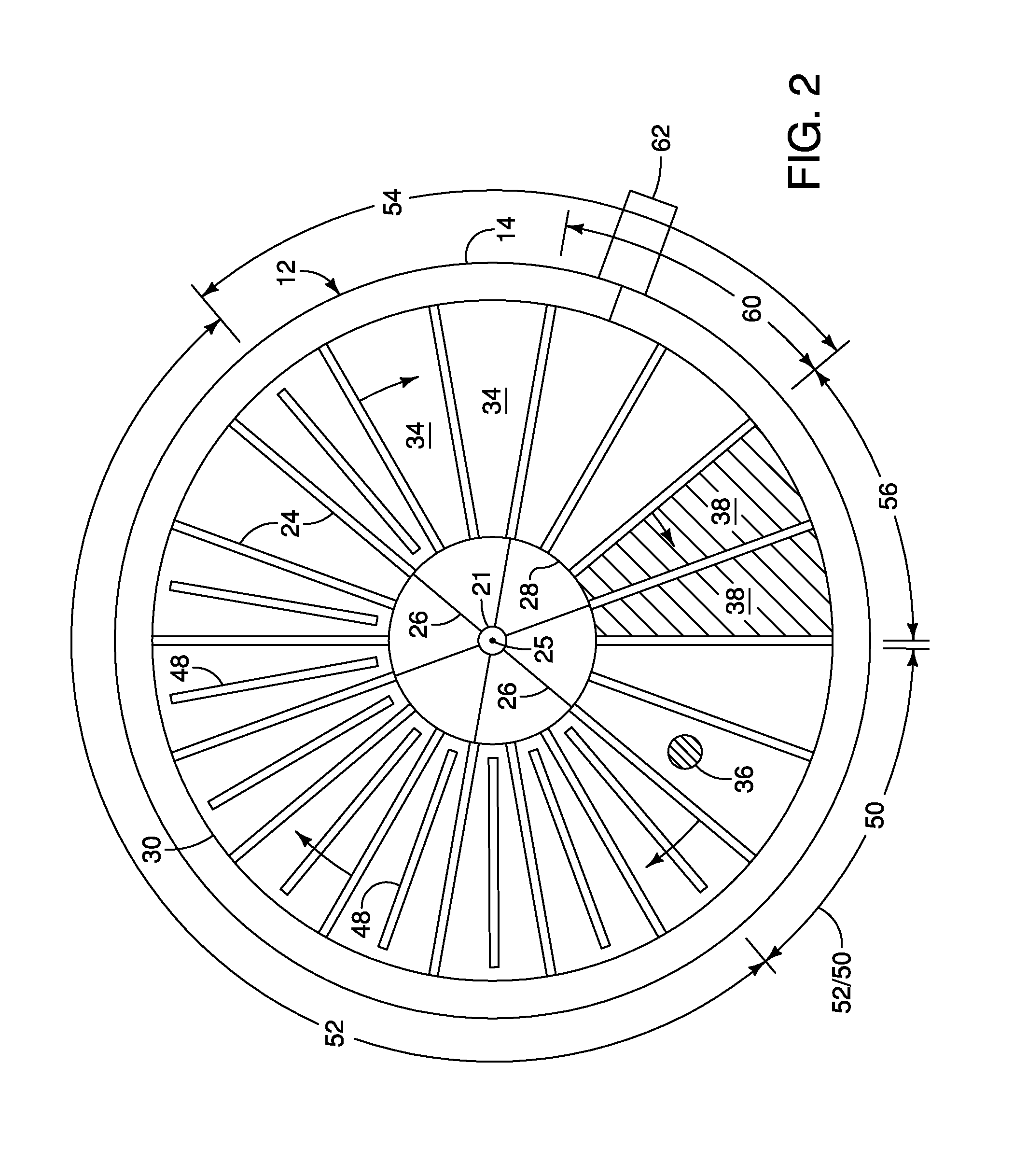

Rotatable basket extractor

ActiveUS20140110329A1Solid solvent extractionMoving filtering element filtersEngineeringDrainage time

A rotatable basket extractor for use in extracting oil from oleaginous feed material is disclosed. The extractor includes a rotatable rotor that includes a plurality of baskets extending radially outward from a central shaft, and the baskets receive and transport the oleaginous feed material while a motor rotates the baskets between a feed inlet and a feed outlet. The rotor is located within a housing and positioned above a screen through which miscella that drains from the feed material passes. The miscella is collected in a trough located below the screen and is sprayed onto the feed material bed positioned within the baskets in a counter-current manner. A suction device pulls vapor down between the particles of the feed material bed to decrease the drainage time of the miscella through the feed material.

Owner:DESMET USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com