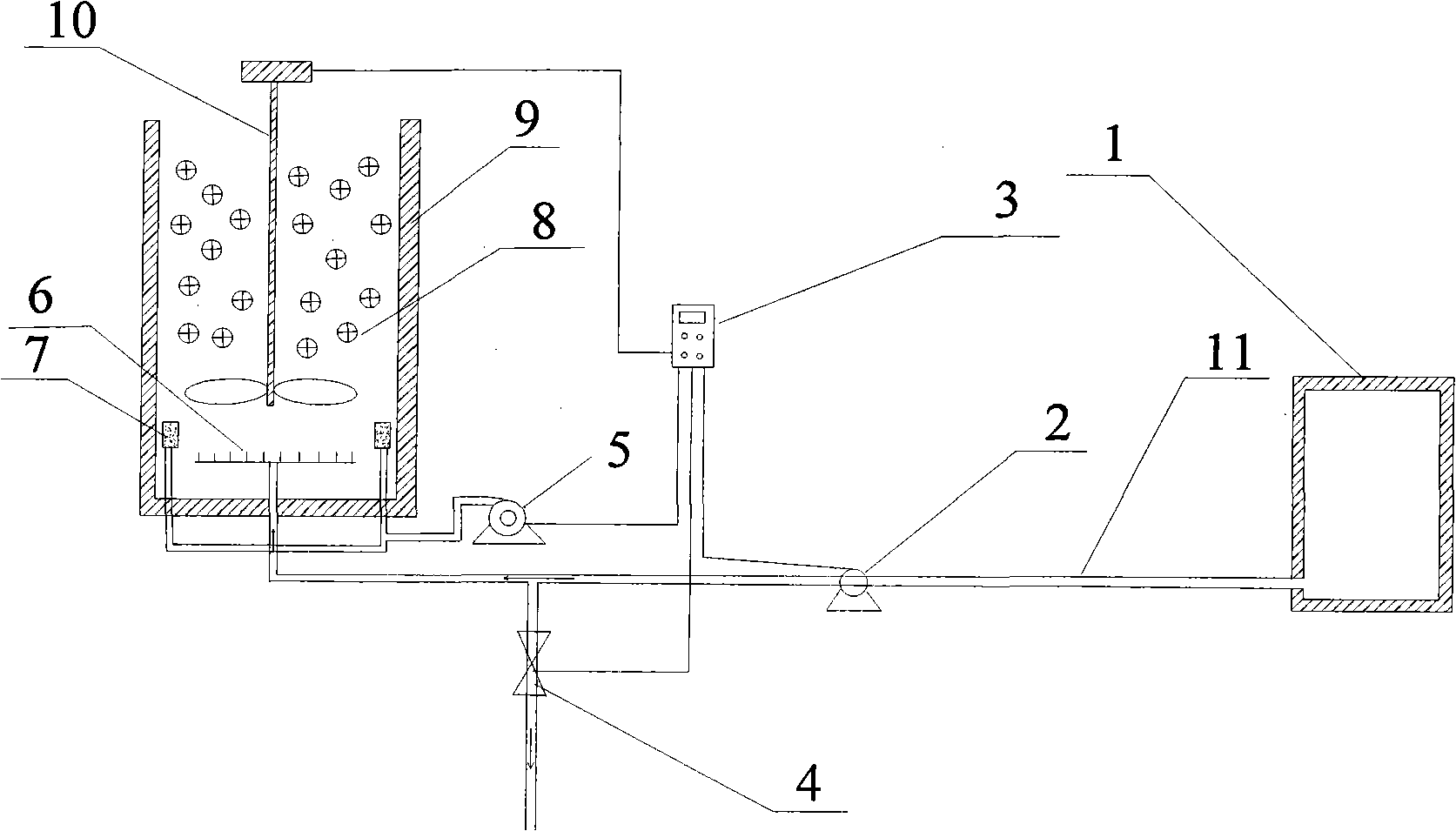

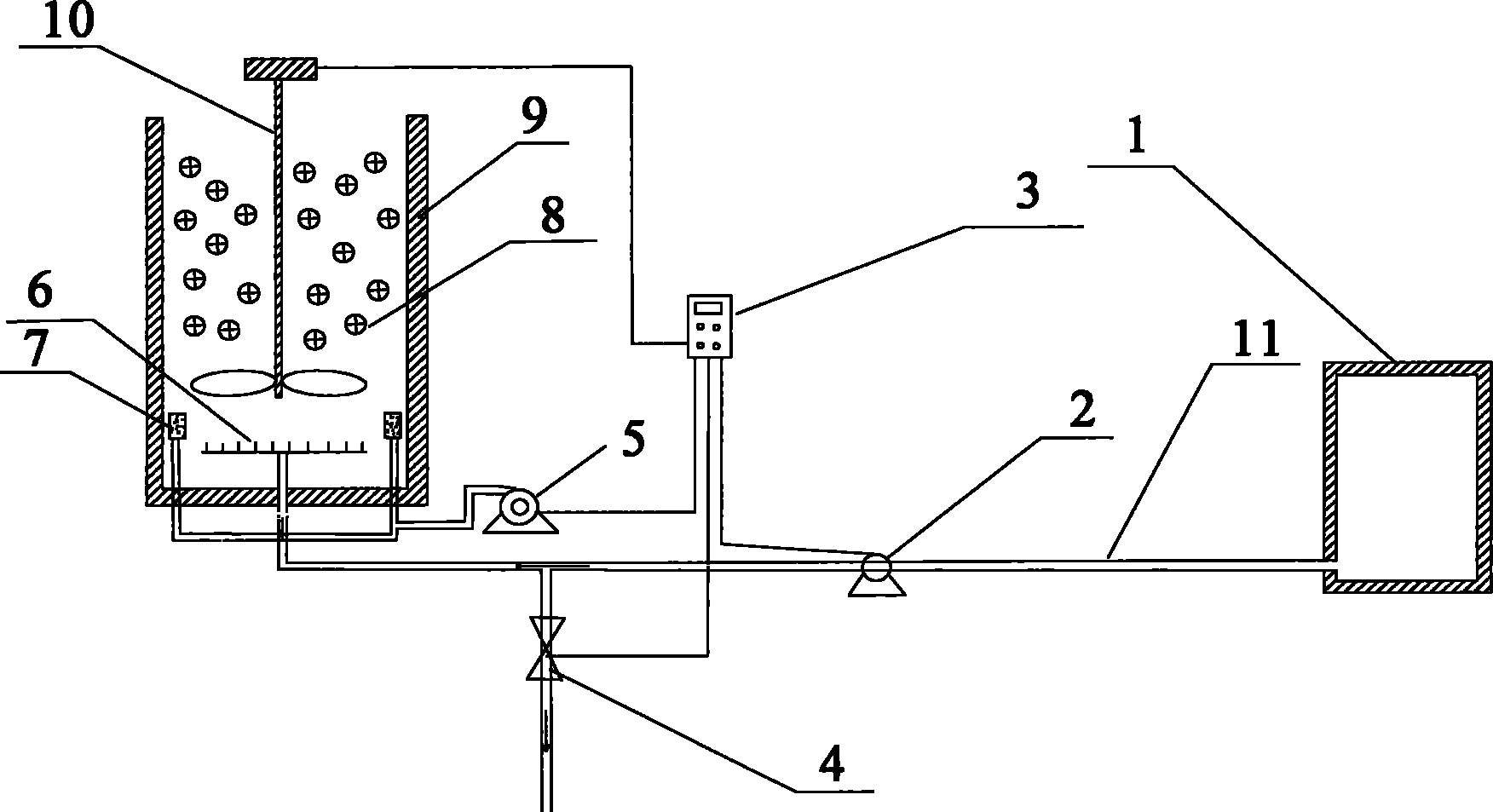

Sequencing batch type suspended filler biofilm sewage treatment device

A technology of sewage treatment device and suspended packing, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc. It can solve the problem that the growth of nitrifying bacteria and denitrifying bacteria cannot be fully satisfied , total nitrogen and total phosphorus removal capacity is weak, and the low concentration sewage treatment effect is poor, so as to achieve the effect of good sewage treatment effect, good effluent quality, and enhanced ability to resist changes in the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The volume of the above-mentioned reactor 9 is 10L, and the suspension filler 8 is a plastic multifaceted hollow ball filler (radius 20mm, density 0.13g / cm2) inside. 3 ), after the film hanging is successfully started, the water starts to enter, and the water quality of the sewage entering the water is: COD Cr 120~140mg / L, NH 4 + -N25~30mg / L, TN 30~35mg / L, pH 7~7.2. The operating conditions adopted are: instantaneous water inflow, anoxic stirring reaction for 2 hours, aerobic aeration reaction for 6 hours, anoxic stirring reaction for 3 hours, precipitation for 1 hour, and instantaneous drainage. Treatment effect: The COD removal rate is 85.6%, the ammonia nitrogen removal rate is 100%, the total nitrogen removal rate is 67.3%, and the effluent water quality meets the first-class discharge standard of urban sewage.

Embodiment 2

[0022] The volume of the above-mentioned reactor 9 is 10L, and the suspending filler 8 added inside is a polyurethane mesh sponge block. After the successful start-up of the film, the water starts to enter, and the quality of the sewage entering the water is: COD Cr 120~140mg / L, NH 4 + -N 25~30mg / L, TN 30~35mg / L, pH 7~7.2. The operating conditions adopted are: instantaneous water inflow, anoxic stirring reaction for 2 hours, aerobic aeration reaction for 6 hours, anoxic stirring reaction for 3 hours, precipitation for 1 hour, and instantaneous drainage. The removal rate of COD of the present invention is 81.2%, NH 4 + The removal rate is 100%, and the total nitrogen removal rate is 62.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com