Patents

Literature

185results about How to "Prevent dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

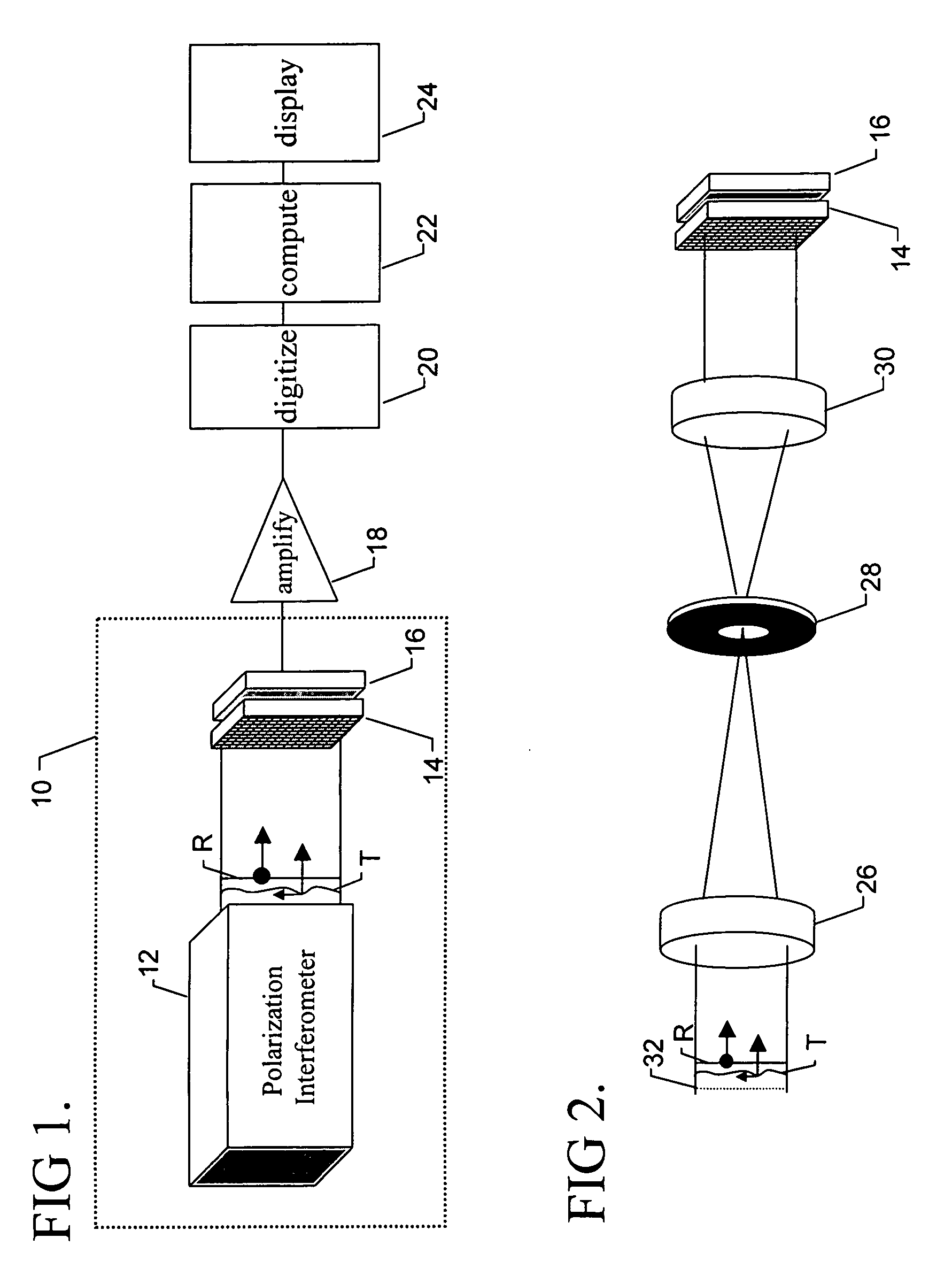

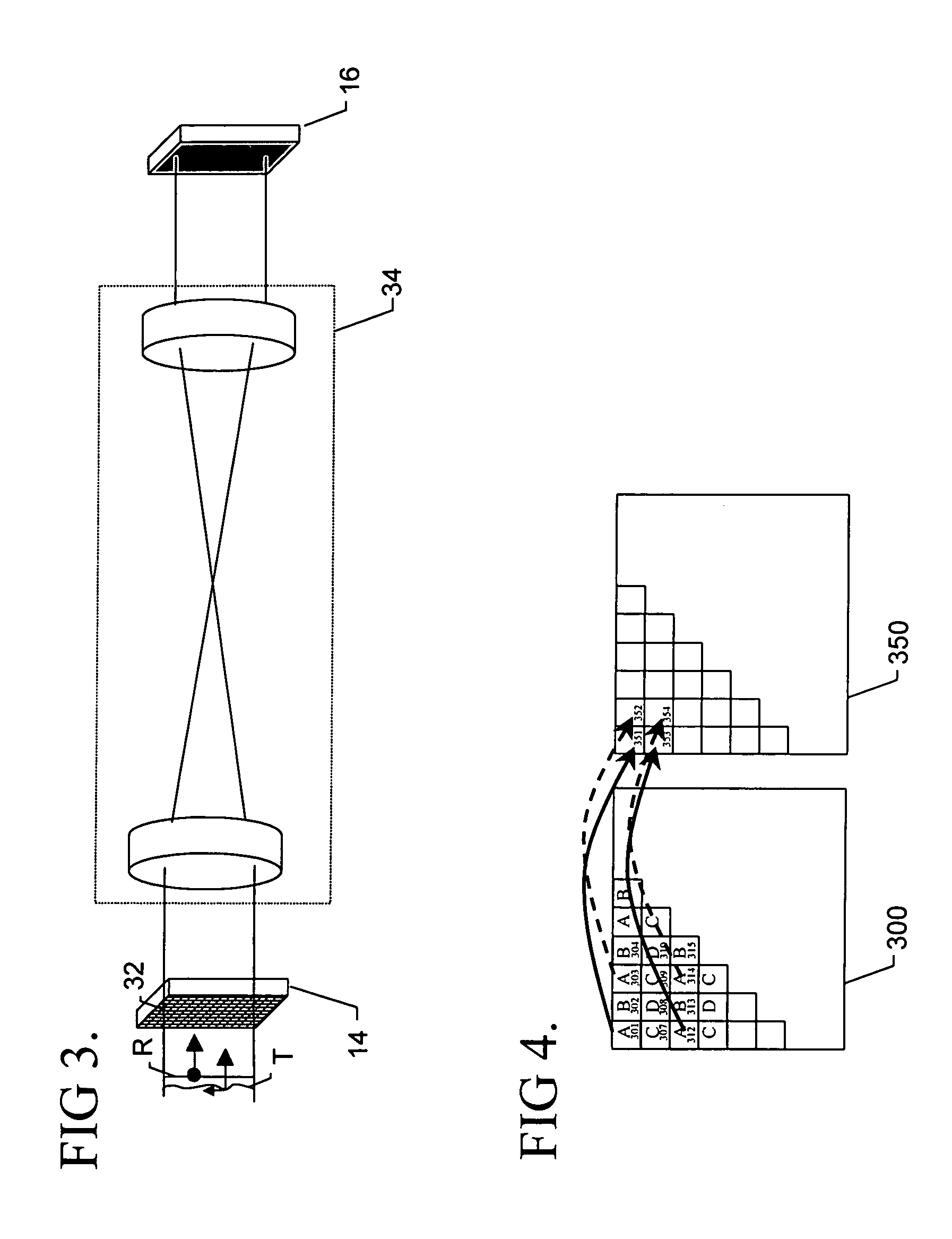

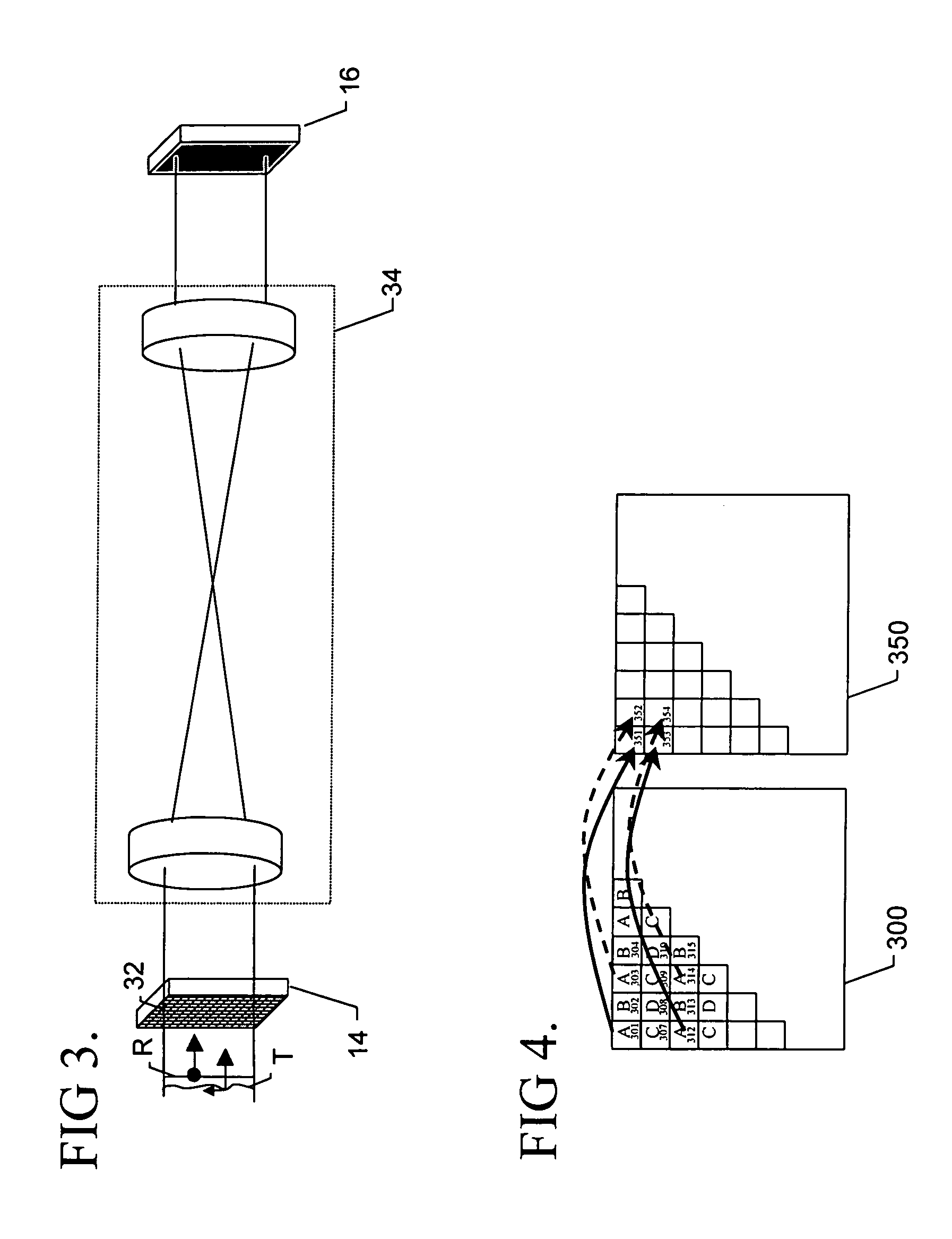

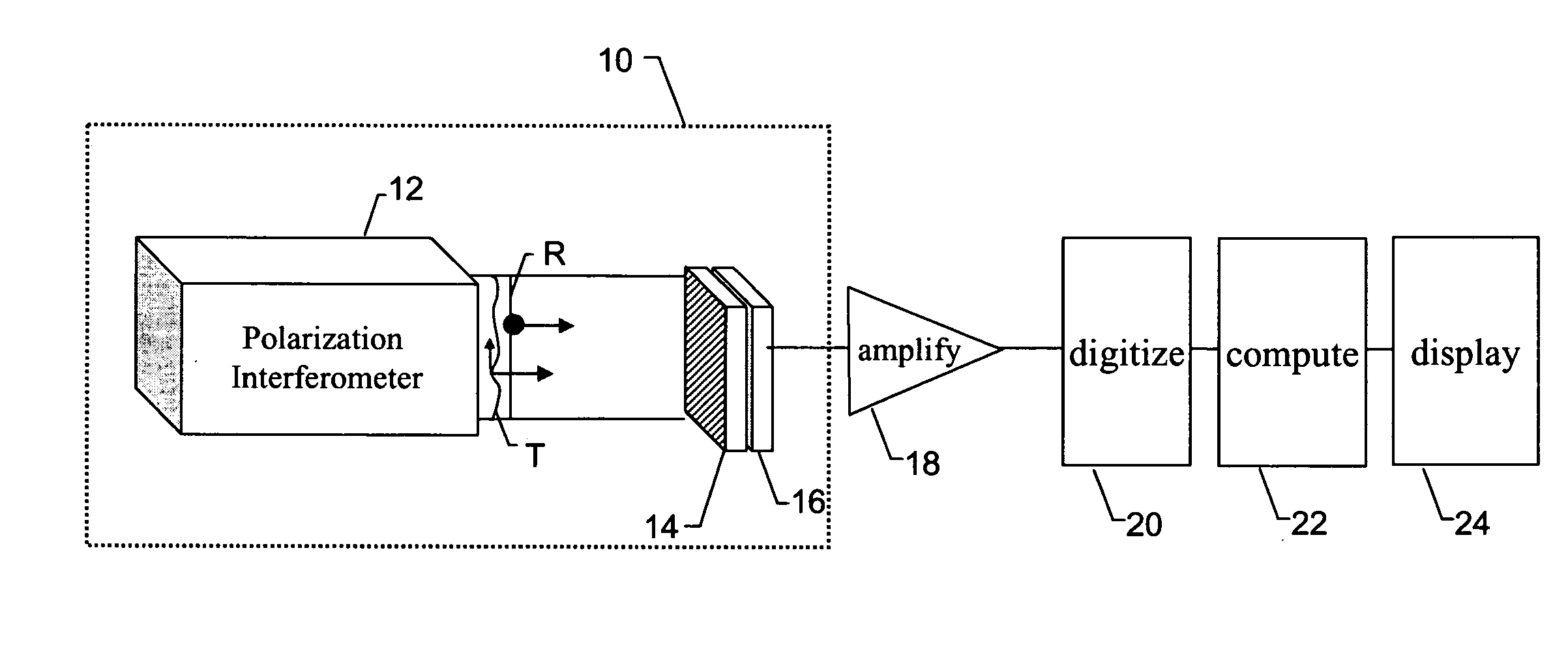

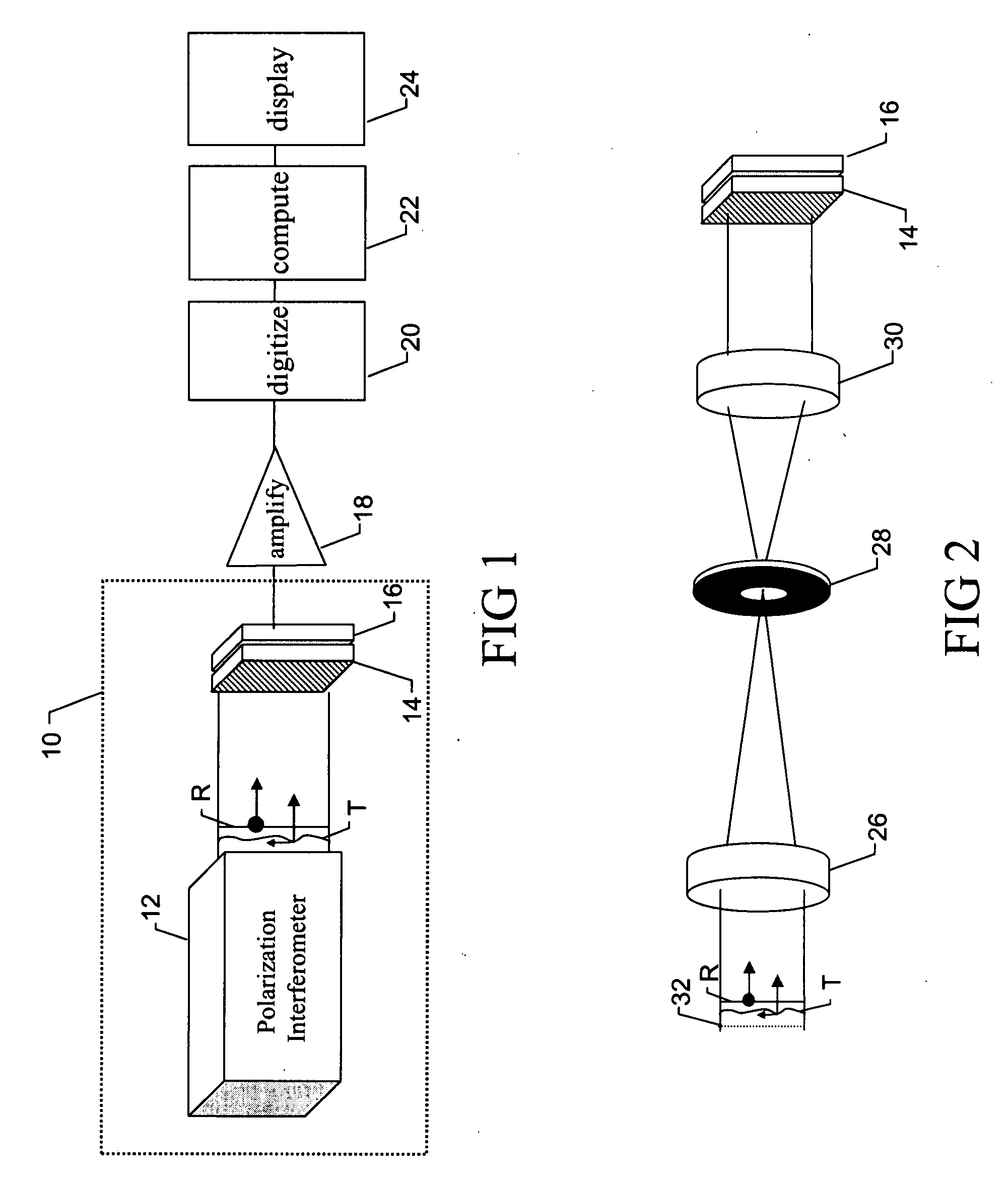

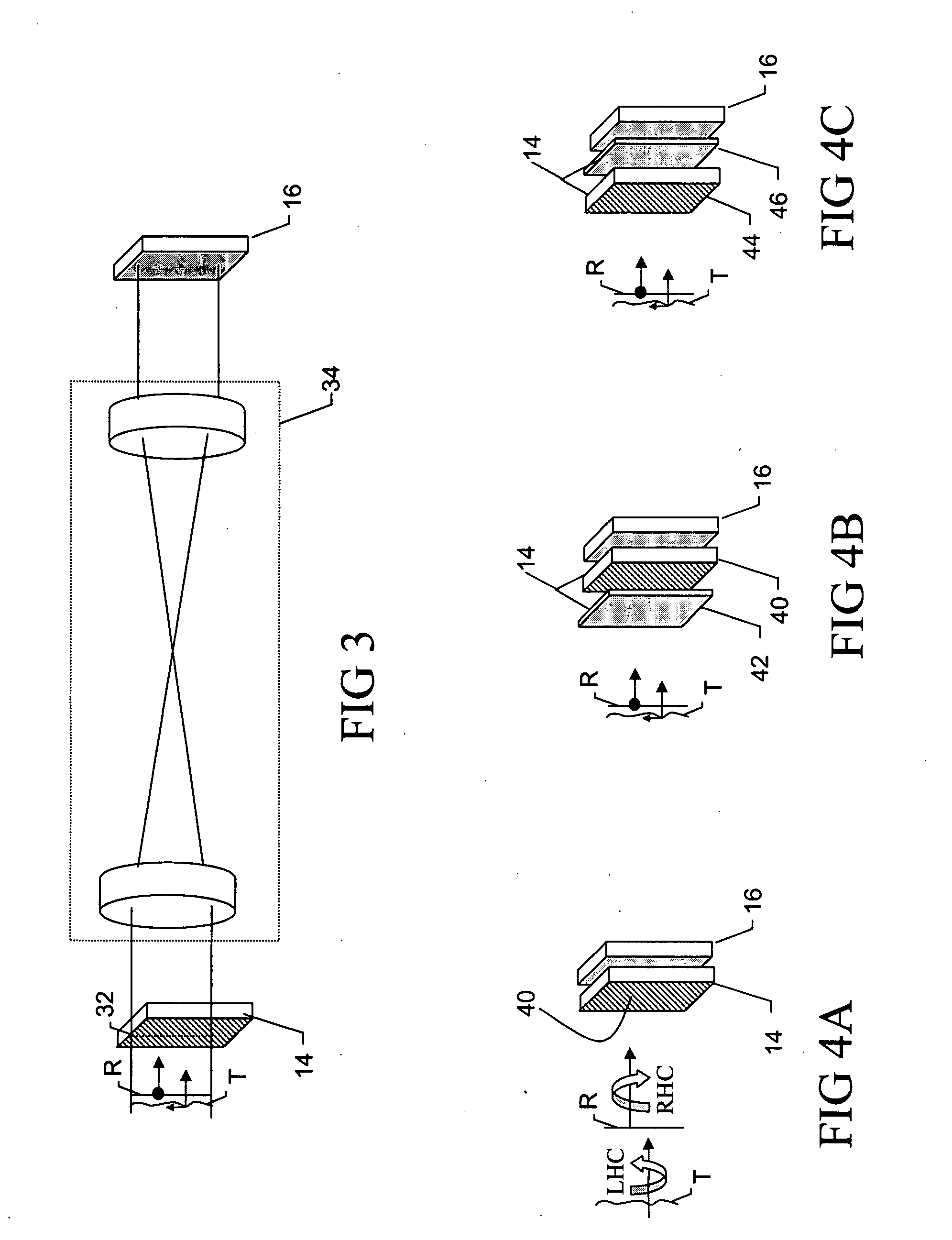

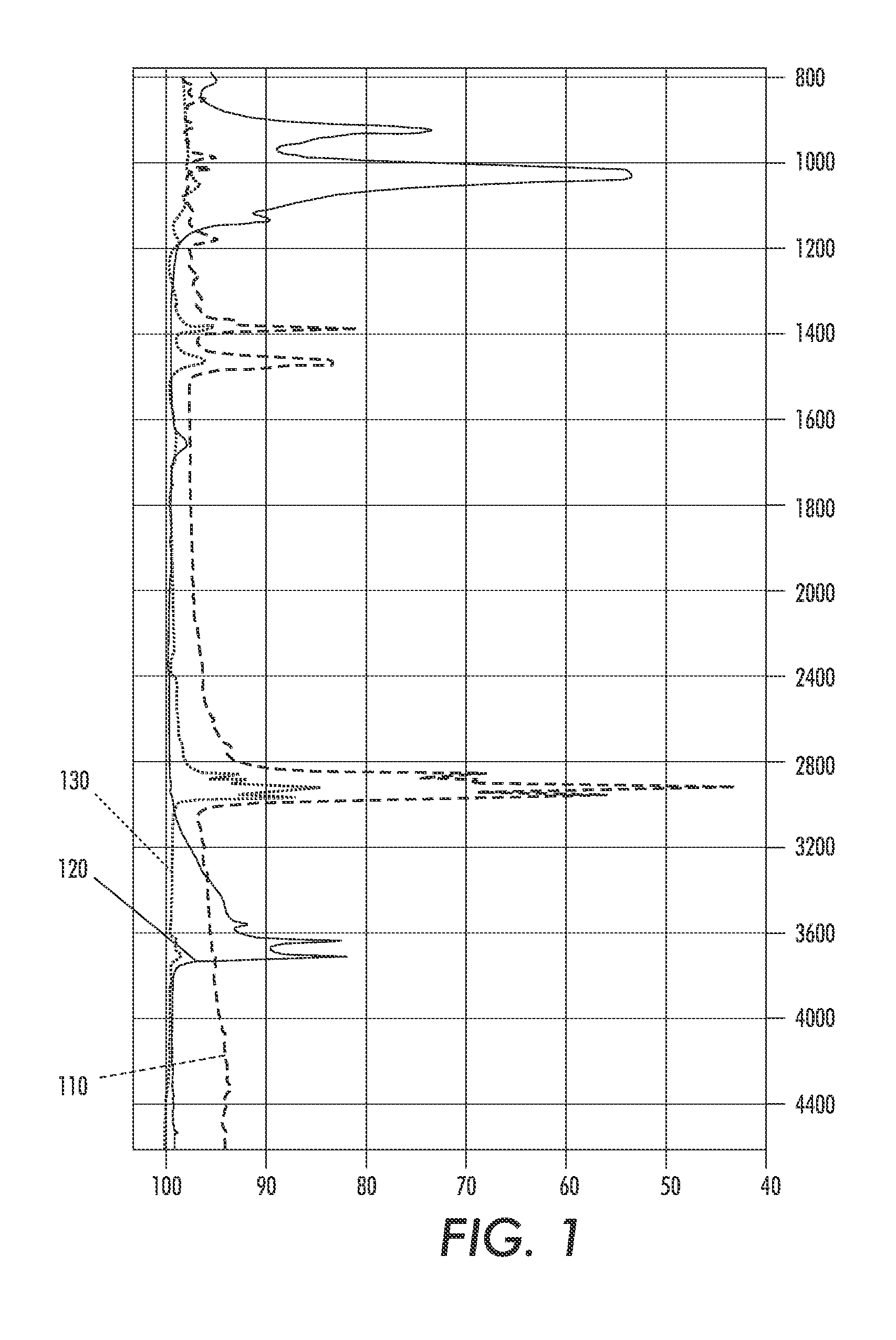

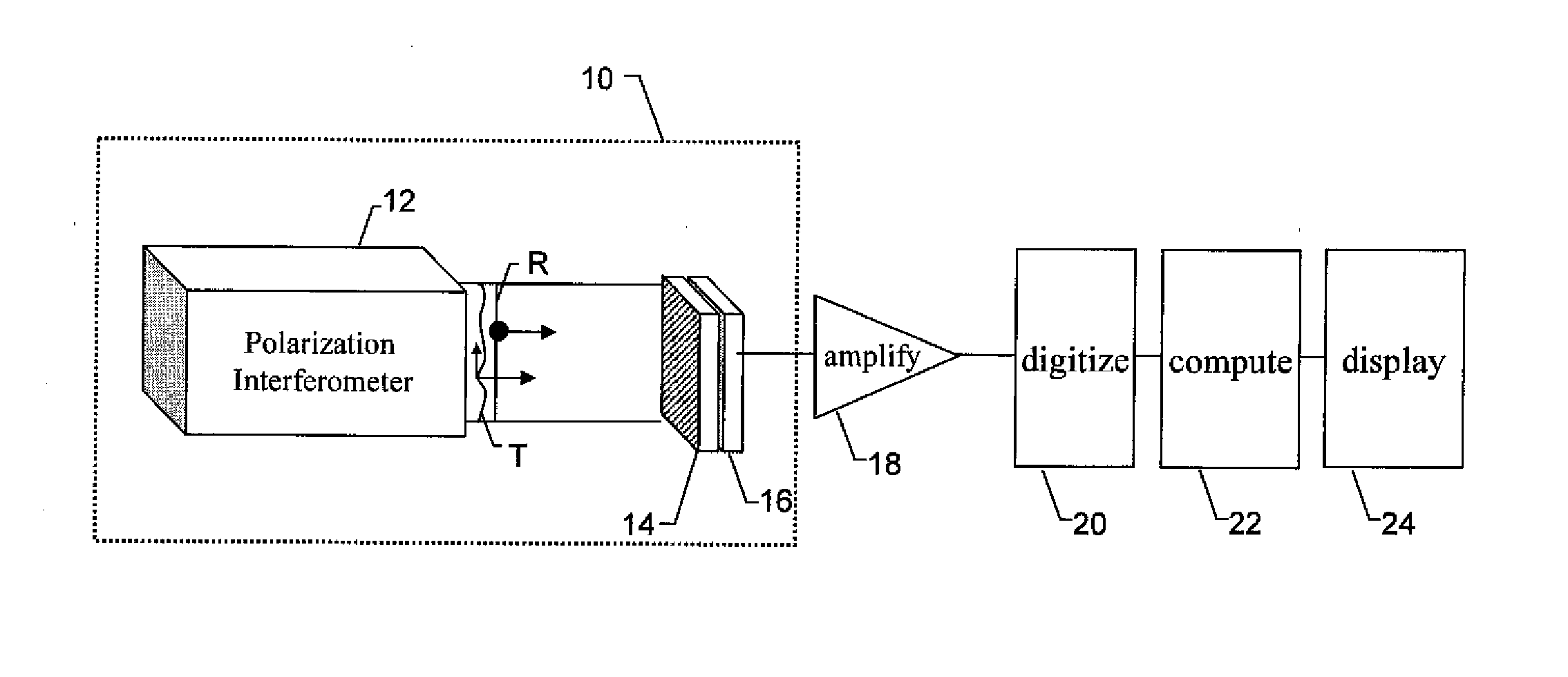

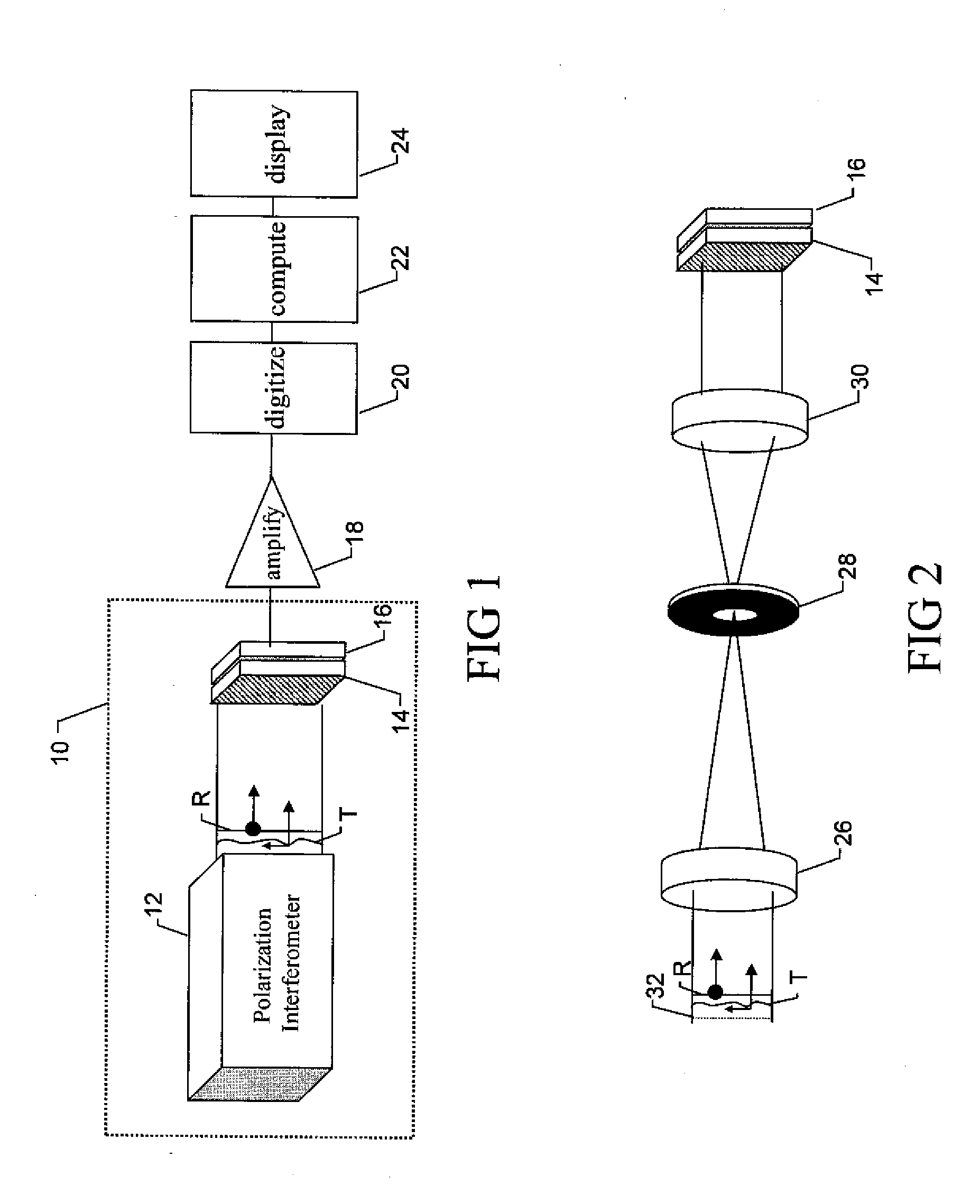

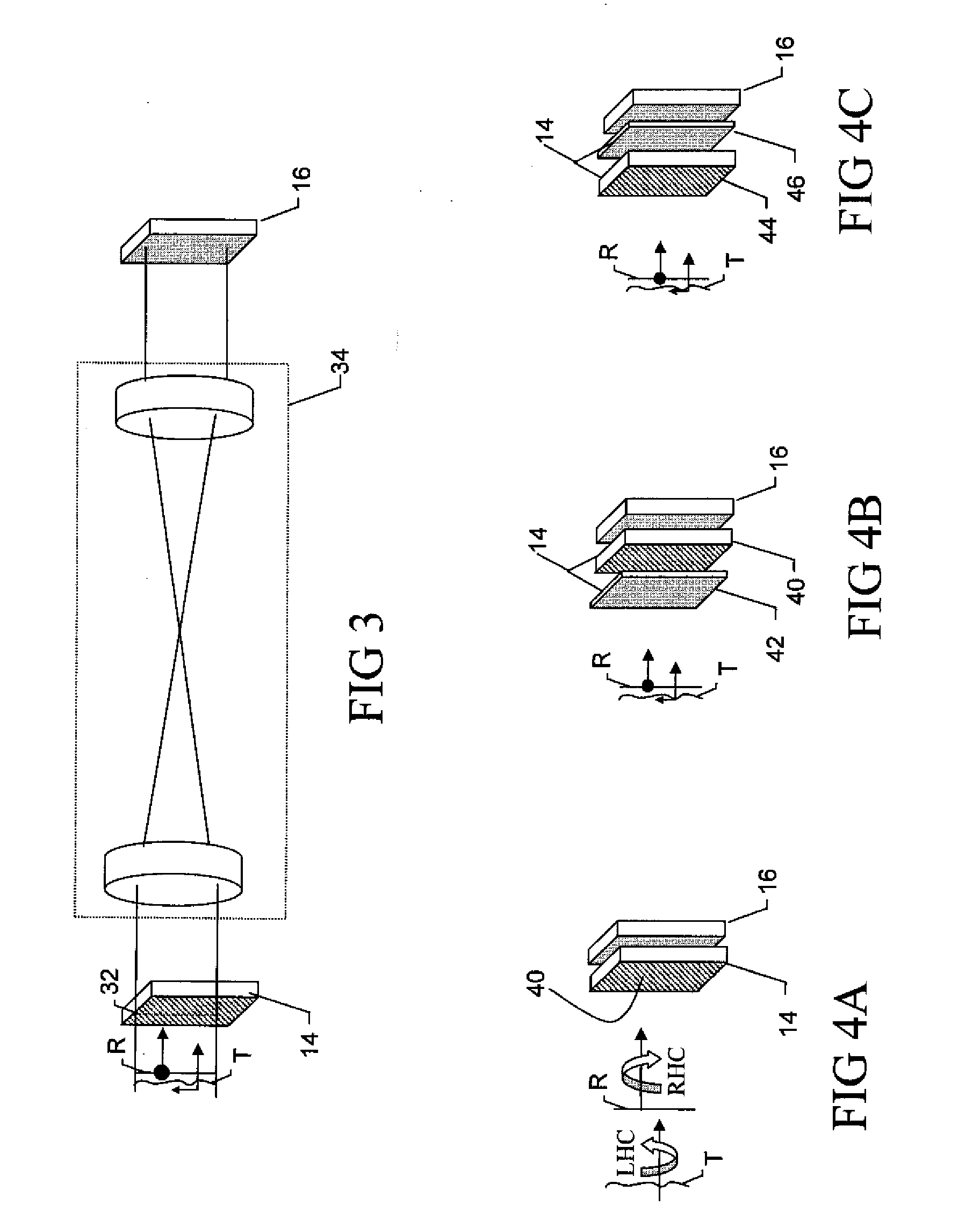

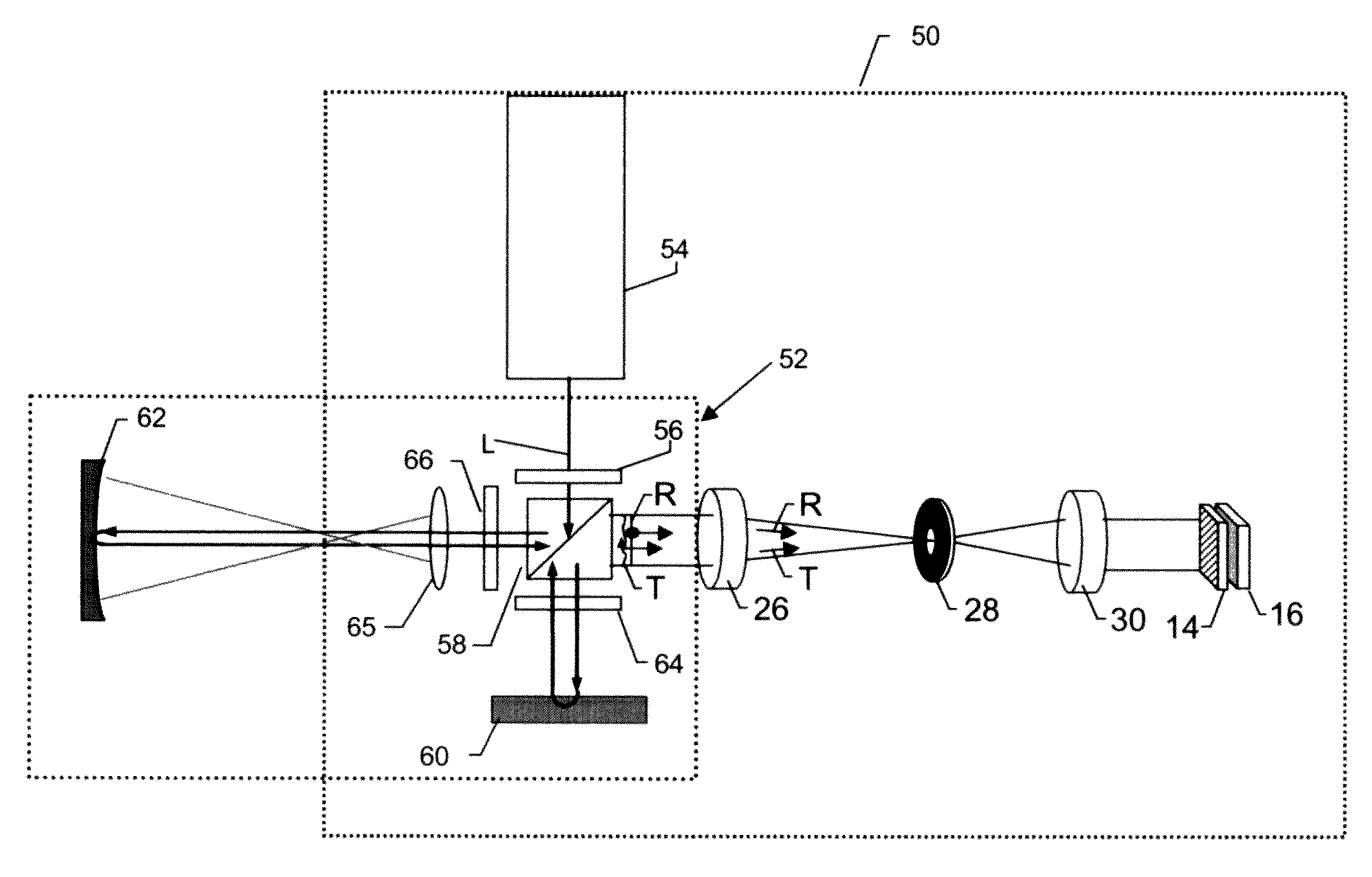

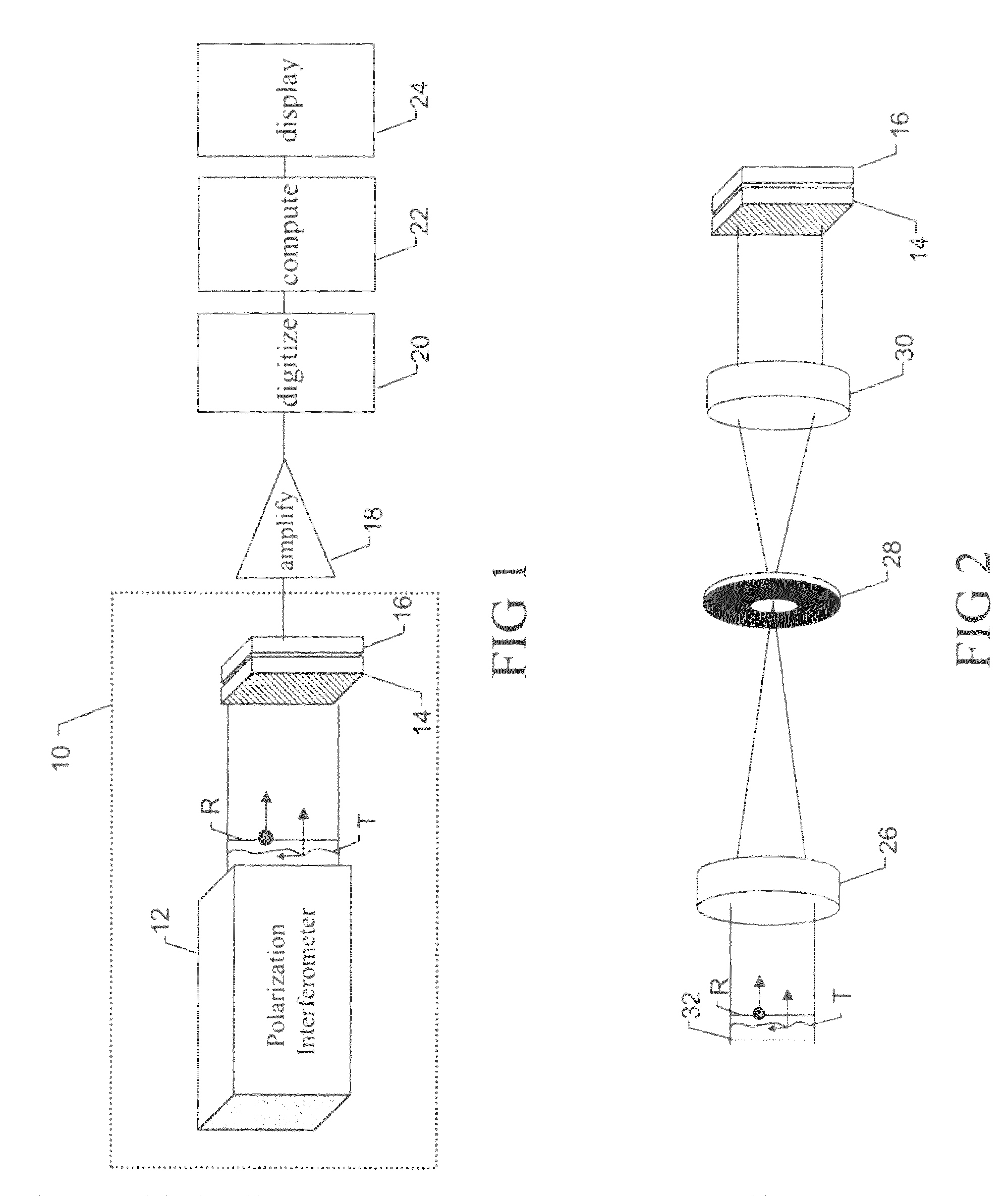

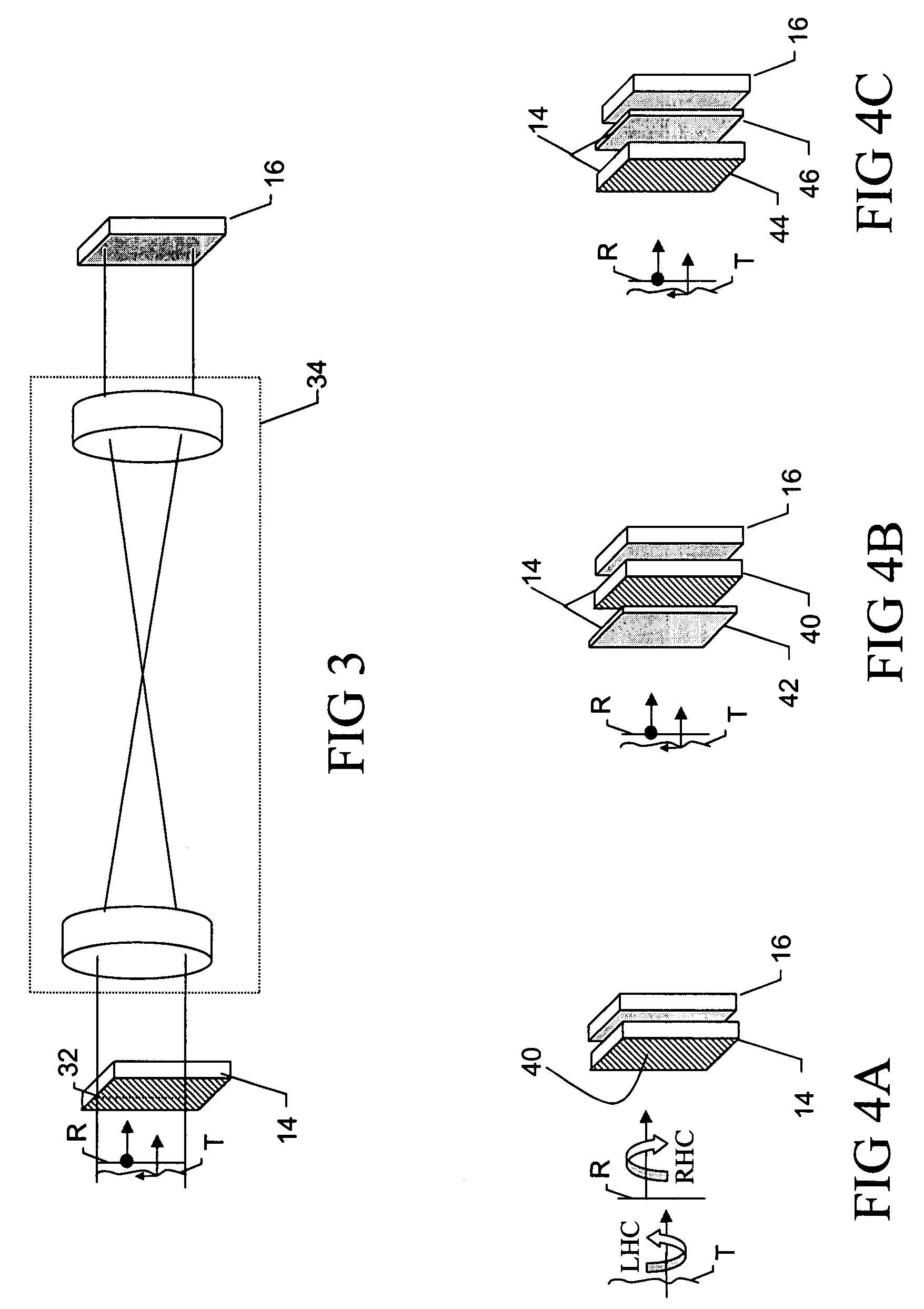

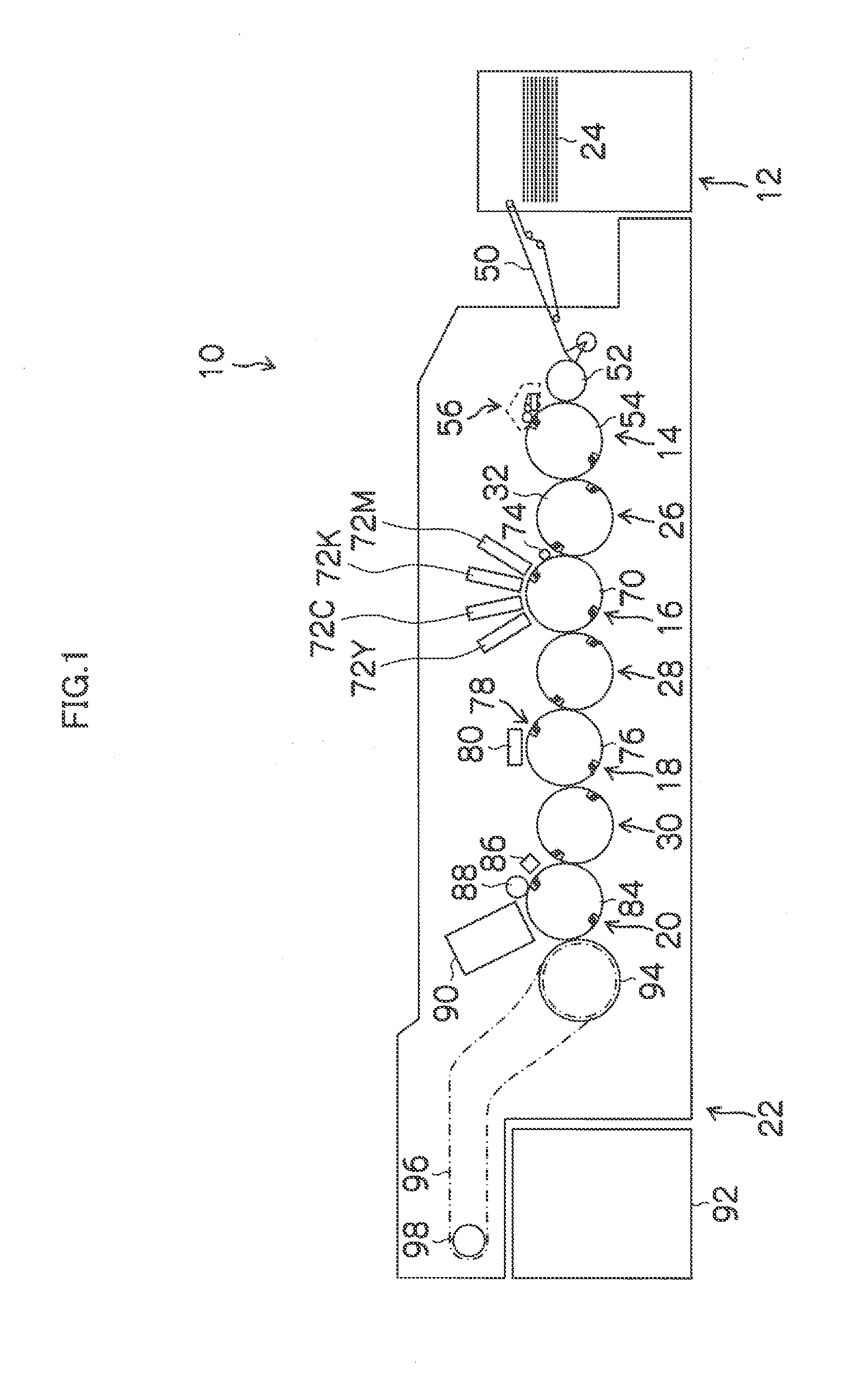

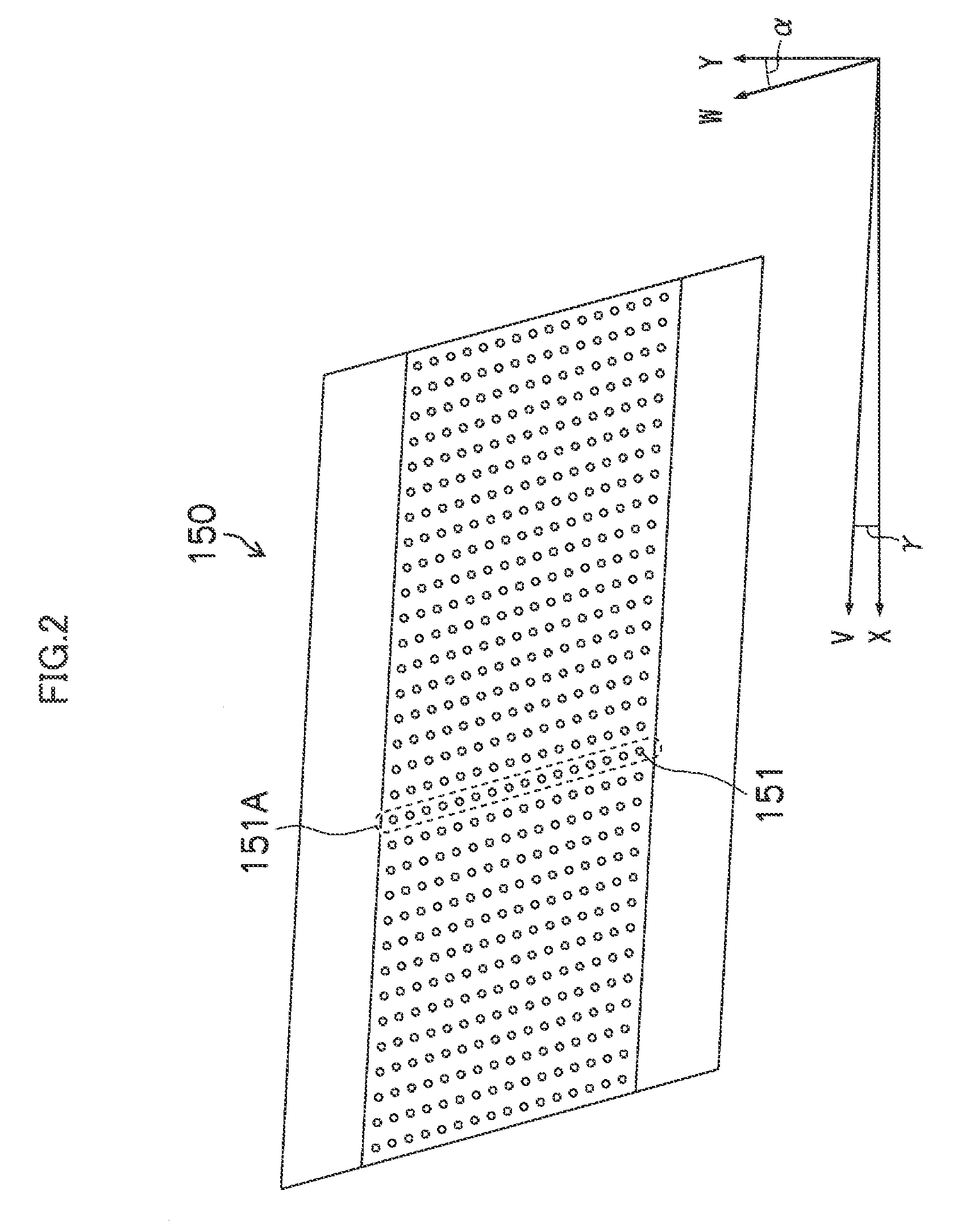

Pixelated phase-mask interferometer

ActiveUS20050046865A1Avoiding chromatic dispersionAvoid complexityInterferometersUsing optical meansPhase differenceDetector array

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

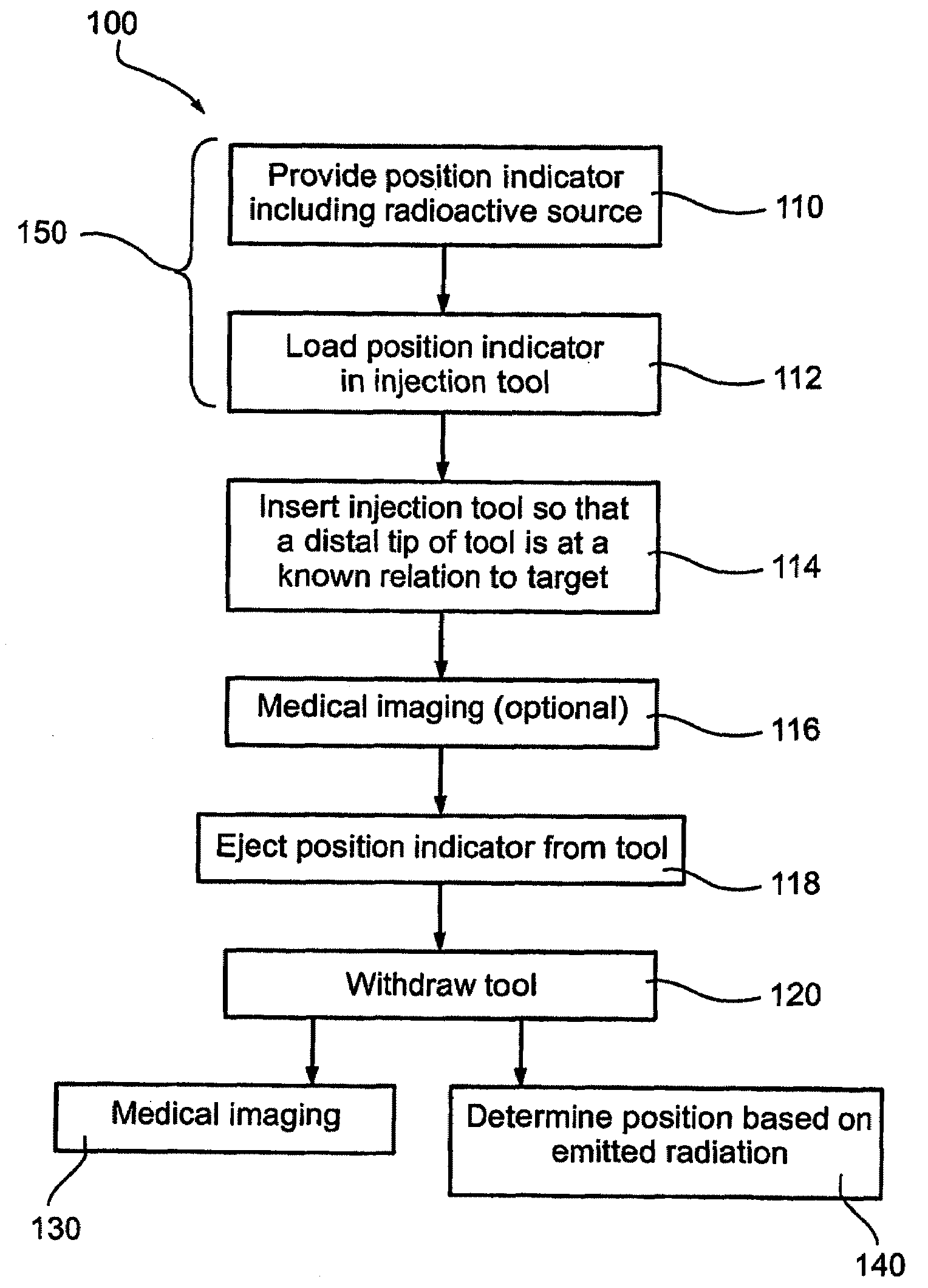

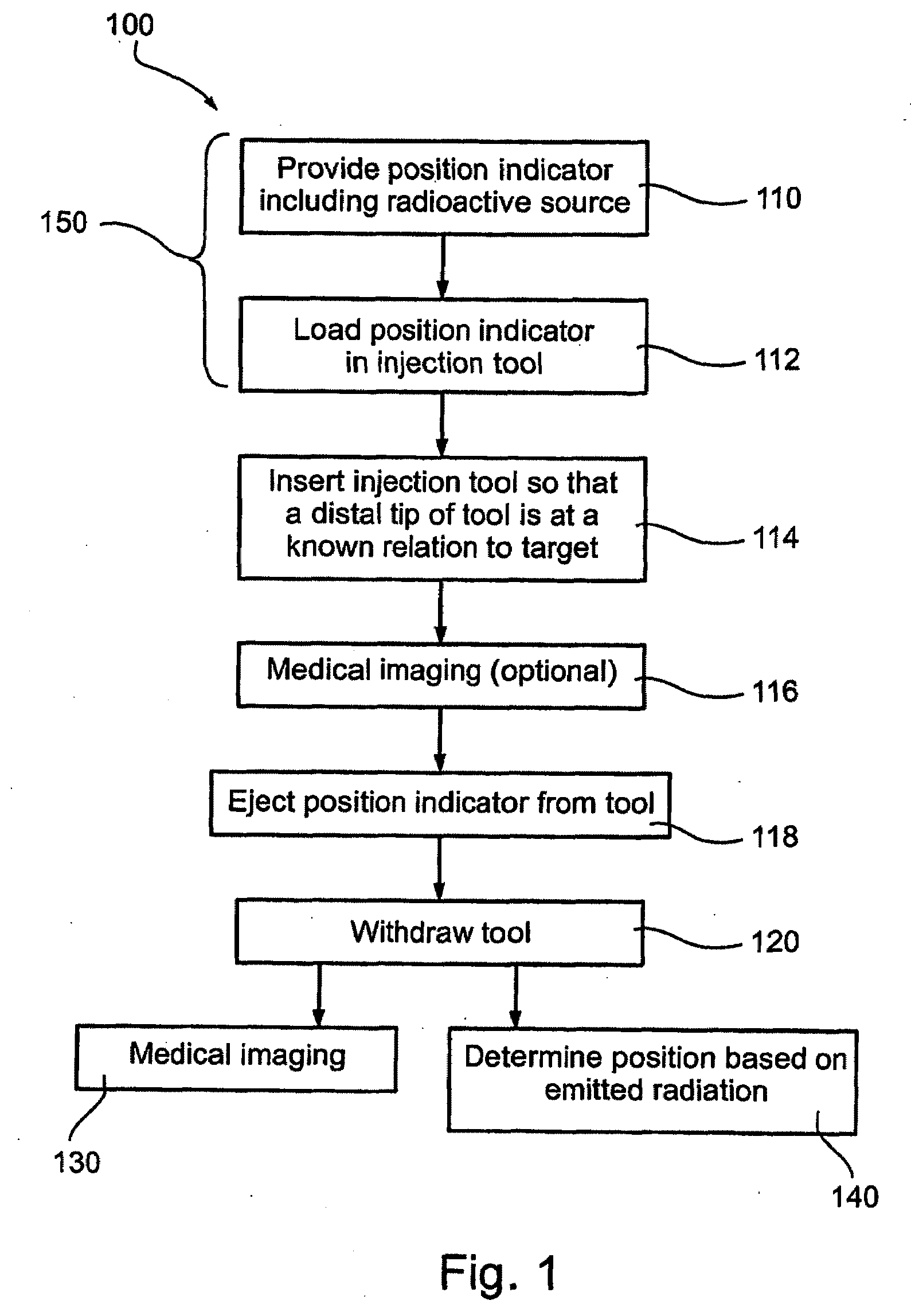

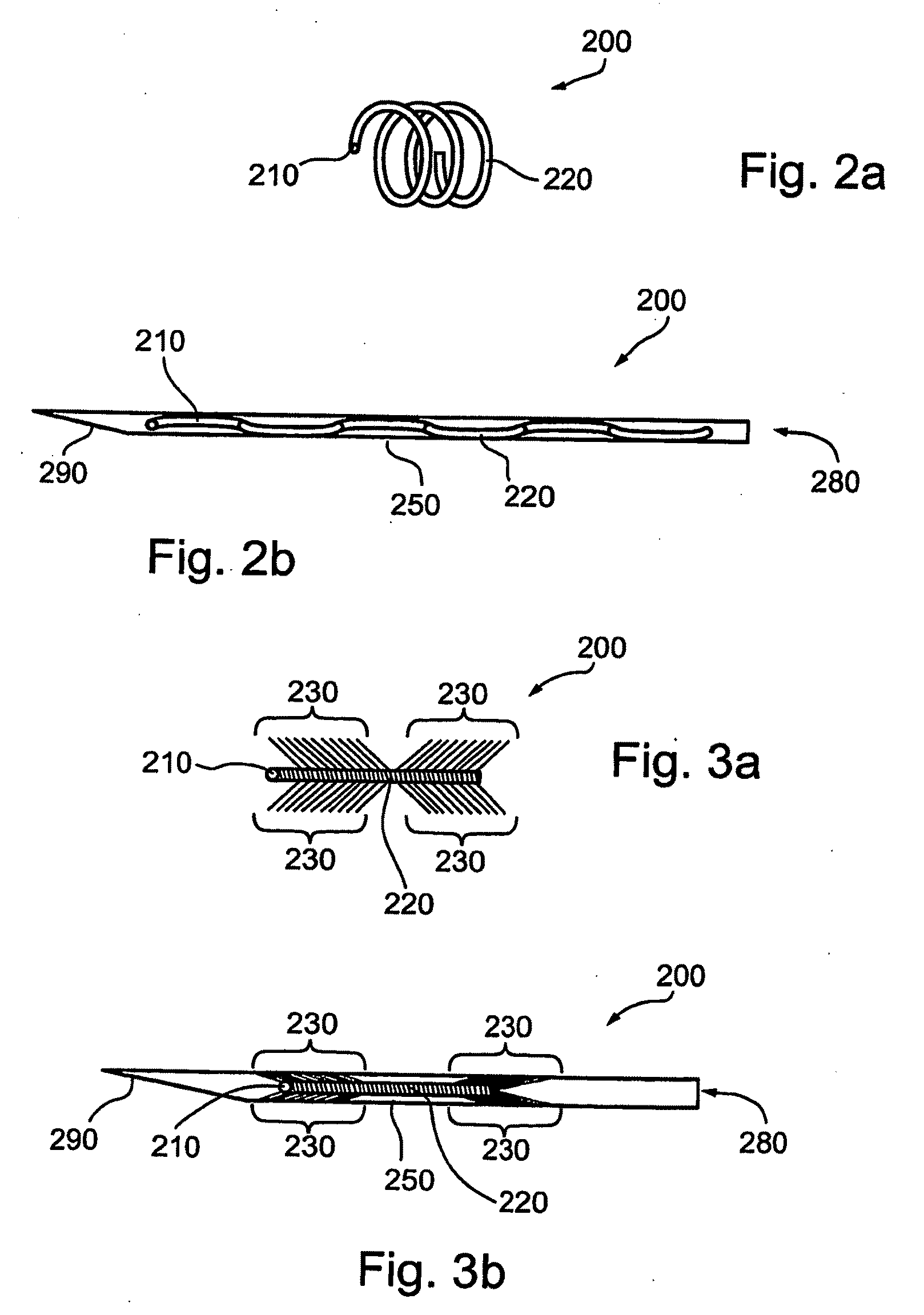

Implantable medical marker and methods of preparation thereof

InactiveUS20090131734A1Prevent dispersionIncrease awarenessSurgical navigation systemsDiagnostic markersHuman bodyRadiation

An implantable medical marker, the marker comprising a marker body adapted for insertion via a needle and adapted to define a volume with a smallest dimension larger than an inner diameter of the needle; and a radiation source—characterized by gamma emissions sufficient to exit the human body.

Owner:NAVOTEK MEDICAL

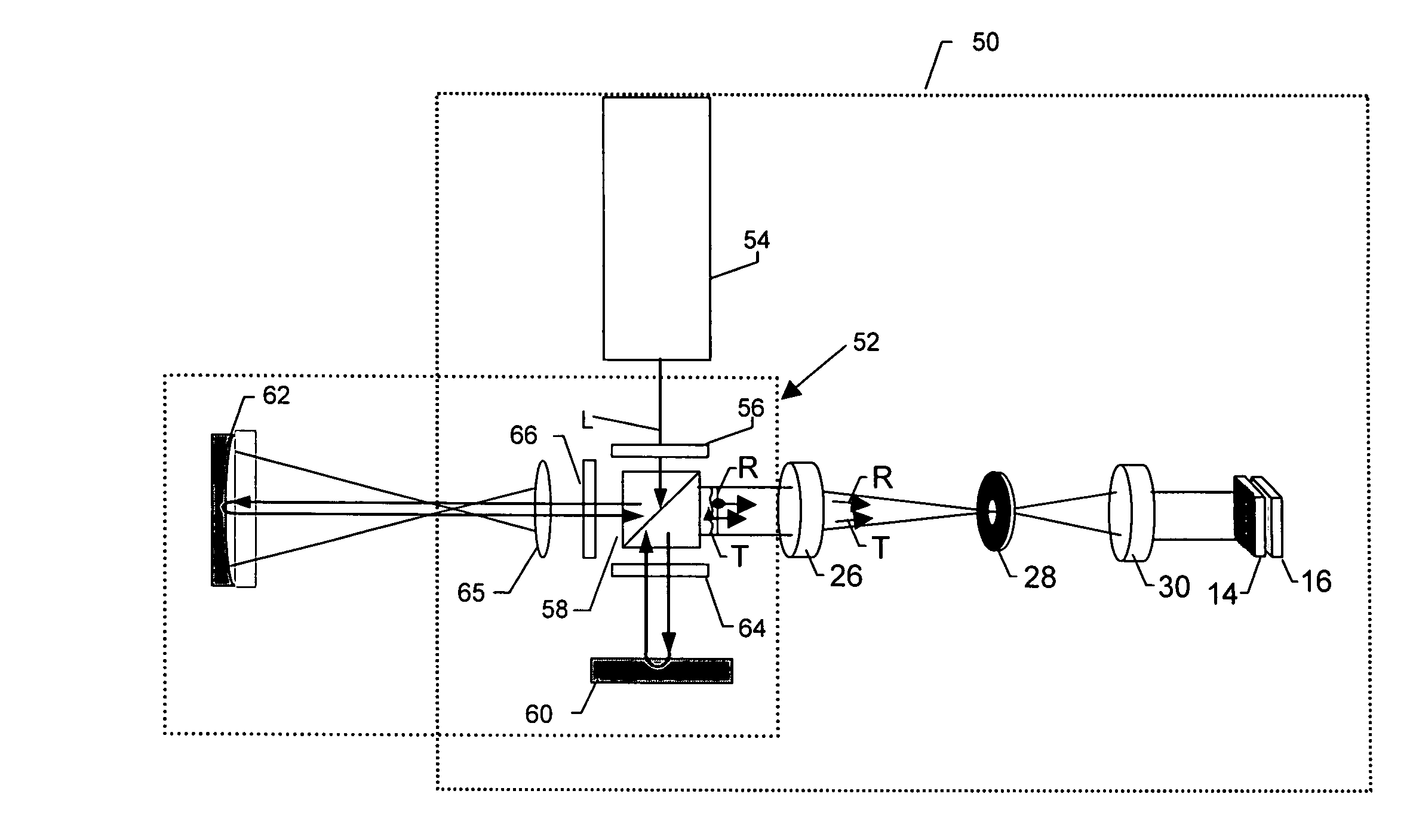

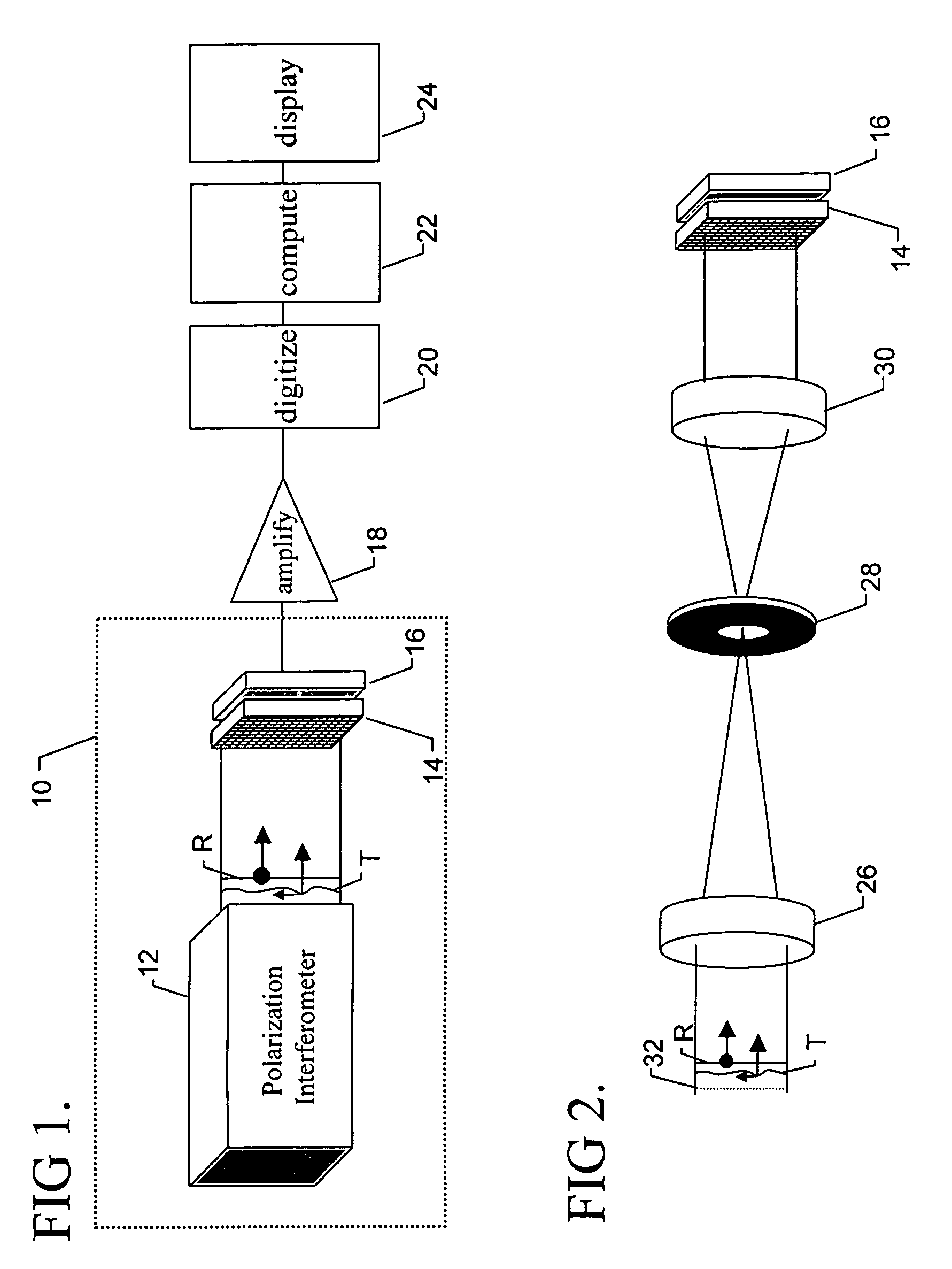

Pixelated phase-mask interferometer

ActiveUS7230717B2Increase rangeReduce complexityInterferometersUsing optical meansPhase differenceDetector array

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a pixelated phase-mask aligned to and imaged on a pixelated detector array. Each adjacent pixel of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide, single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

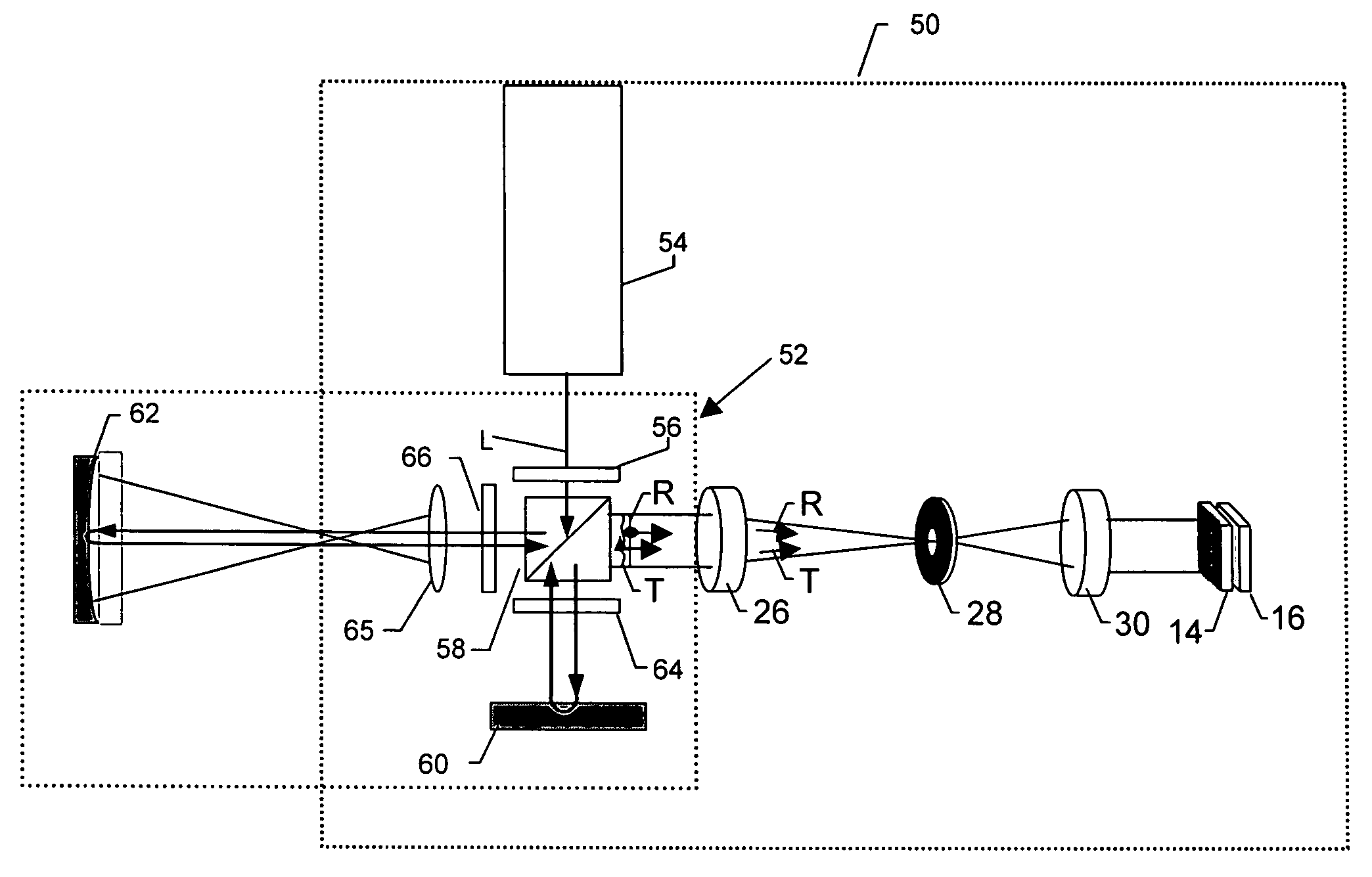

Linear-carrier phase-mask interferometer

ActiveUS20070211256A1Avoiding chromatic dispersionAvoid complexityImage analysisInterferometersPhysicsWavefront

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a linear-carrier phase-mask aligned to and imaged on a linear-carrier detector array. Each adjacent element of the phase-mask measures a predetermined relative phase shift between the orthogonally polarized reference and test beams. Thus, multiple phase-shifted interferograms can be synthesized at the same time by combining pixels with identical phase-shifts. The multiple phase-shifted interferograms can be combined to calculate standard parameters such as modulation index or average phase step. Any configuration of interferometer that produces orthogonally polarized reference and object beams may be combined with the phase-difference sensor of the invention to provide single-shot, simultaneous phase-shifting measurements.

Owner:ONTO INNOVATION INC

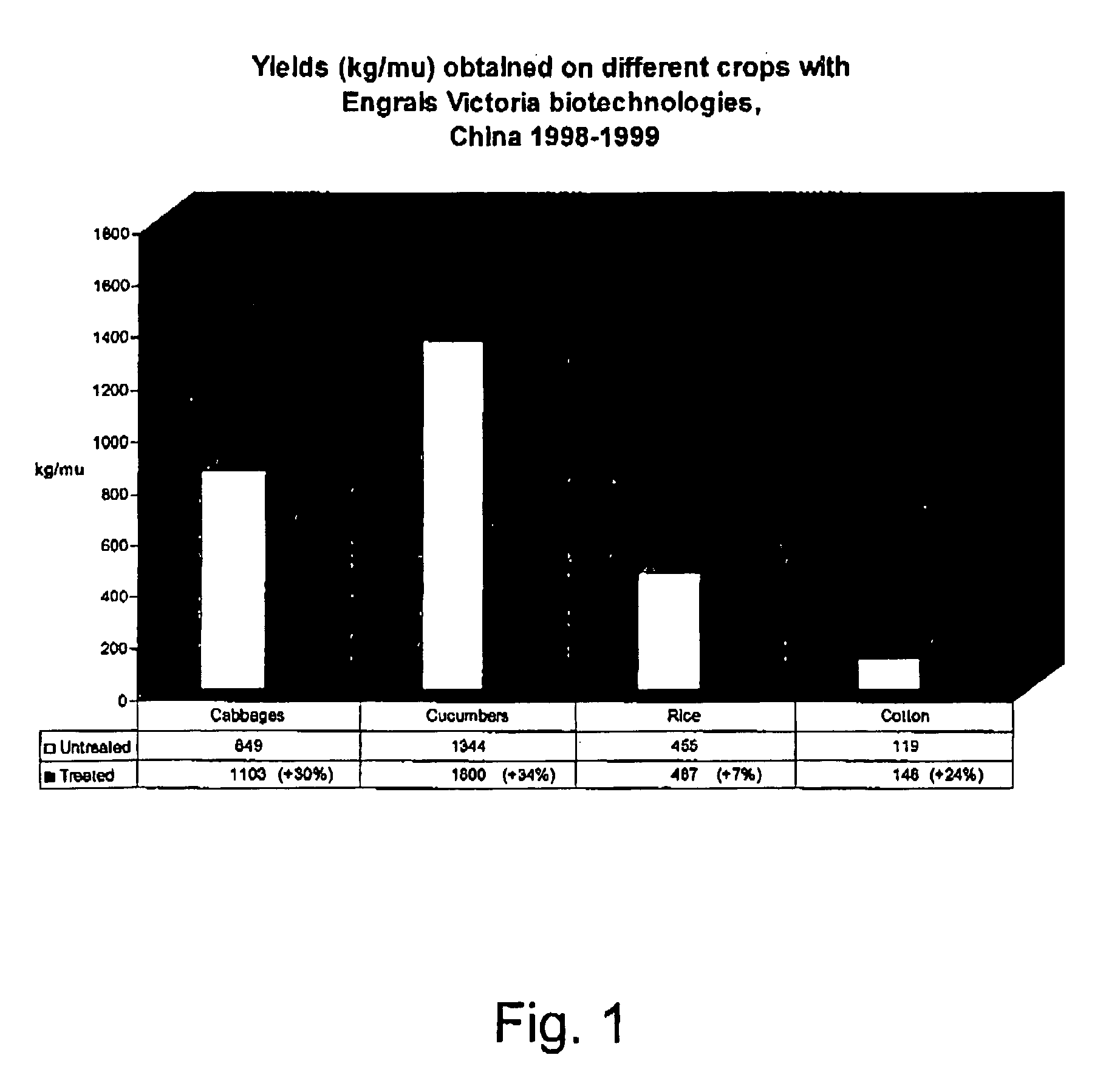

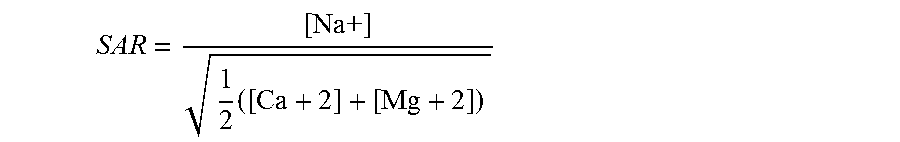

Fertilizer and method for producing same

ActiveUS20050020449A1Avoid distractionImprove concentrationPowder deliveryBiocideBiotechnologyVegetation

In accordance with the present invention, there is provided a method for producing an enhanced fertilizer, comprising the step of mixing a granular fertilizer with a ferment comprising active bacteria in a fermentation medium, to obtain an enhanced fertilizer. The ferment is used at a rate of at most 3 liters of ferment per ton of fertilizer. In accordance with the present invention, there is also provided an enhanced fertilizer comprising a fertilizer and bacteria chosen for their specific properties on crops or vegetation.

Owner:EVL INC

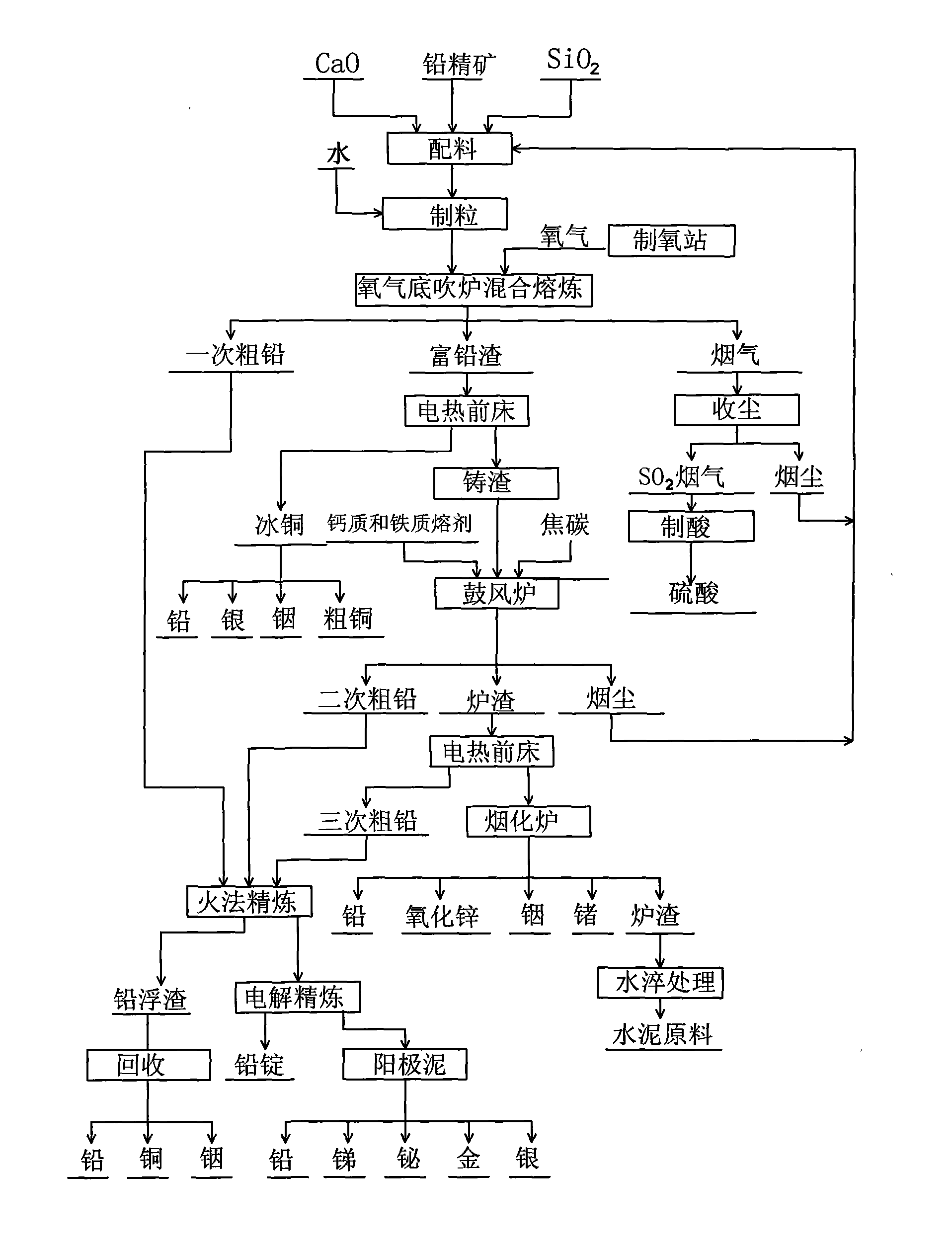

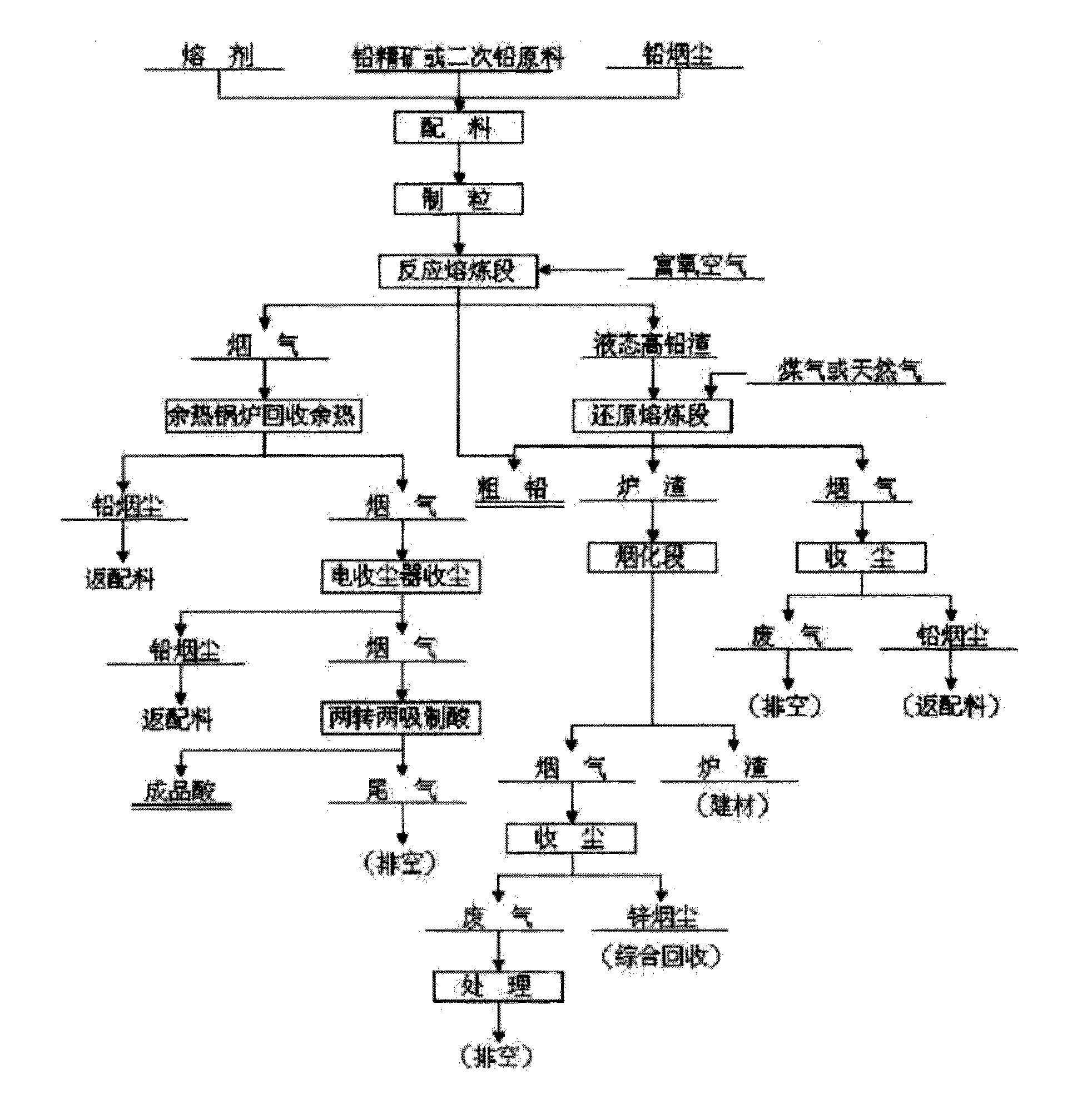

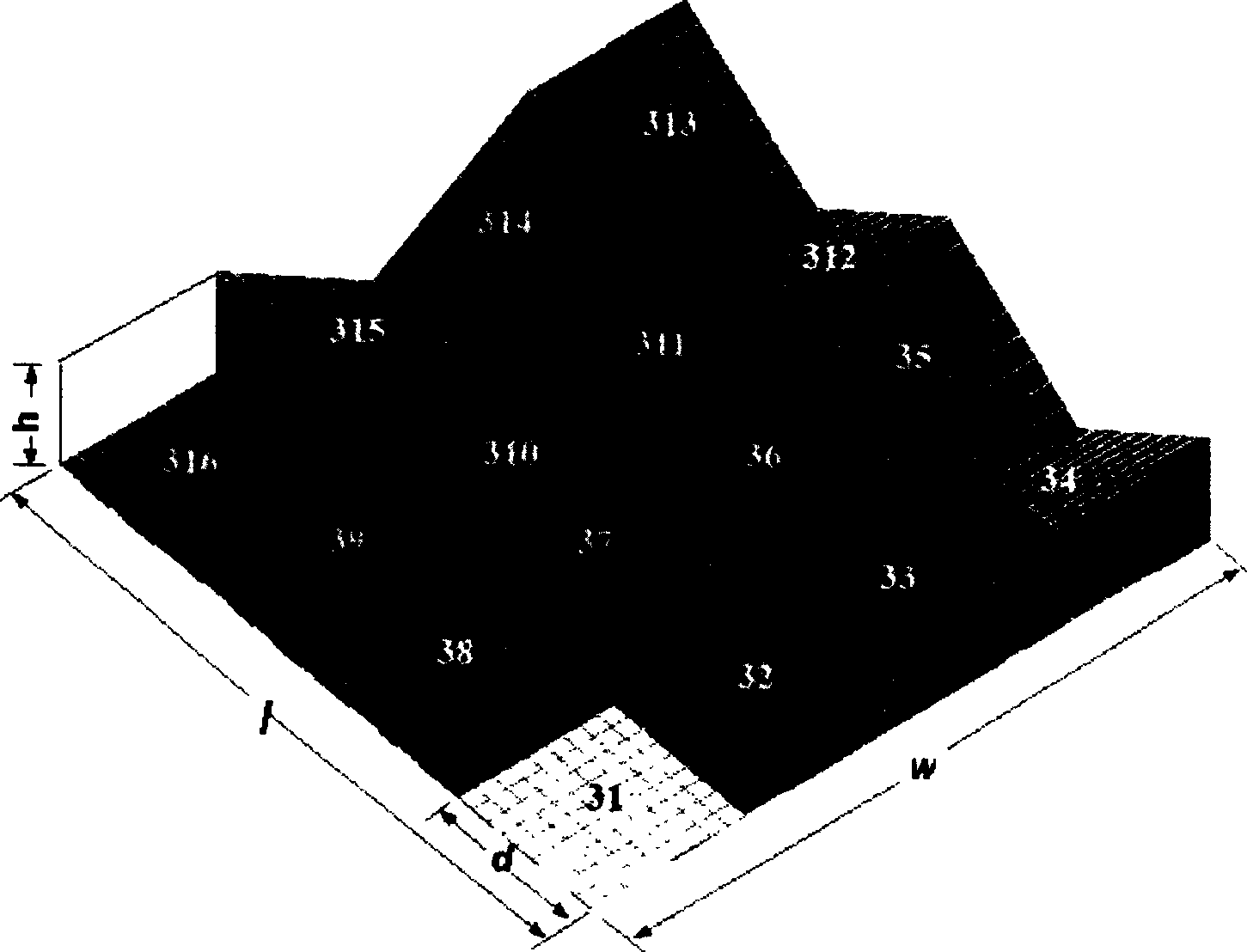

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

Nanocomposite master batch composition and method of manufacture

Disclosed are a polymer nanocomposite material and methods for the formation of the polymer nanocomposite material.

Owner:NATURALNANO

Electrode including multi-layered electrode active material layer and secondary battery including the same

ActiveUS20130224584A1Maintenance contentEvenly dispersedFinal product manufactureActive material electrodesElectrical batteryEngineering

The present invention relates to an electrode comprising multi-layered electrode active material layer and a secondary battery comprising the same. According to the embodiments of the present invention comprises electrode having multi-layered electrode active material layer, wherein the content of the active materials which forms the electrode active material layers is equally maintained and the loading amounts at each layer are either the same or different from each other, thereby solving the problem of performance deterioration caused by an increase in battery resistance due to non-uniform dispersion of a binder or the like.

Owner:LG ENERGY SOLUTION LTD

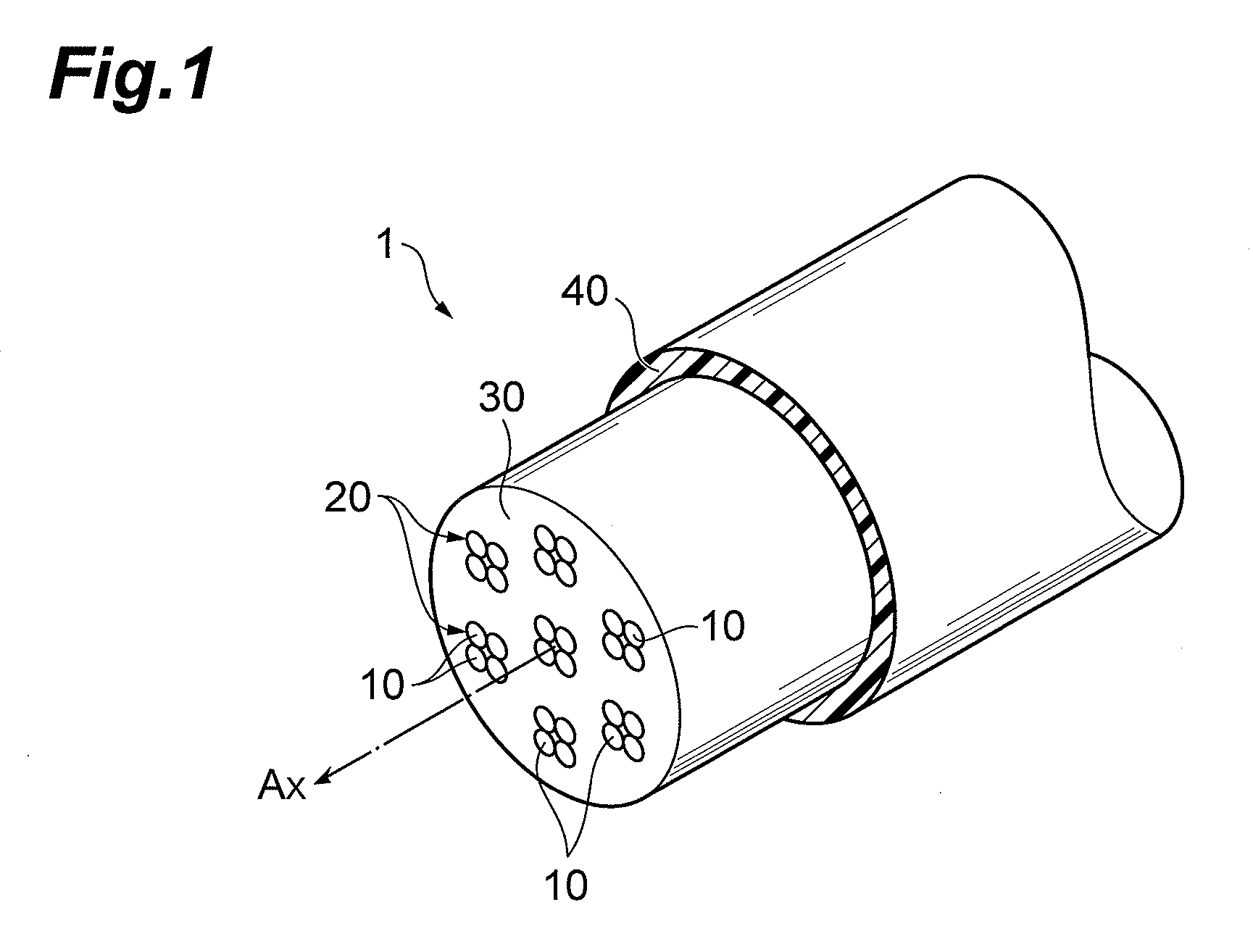

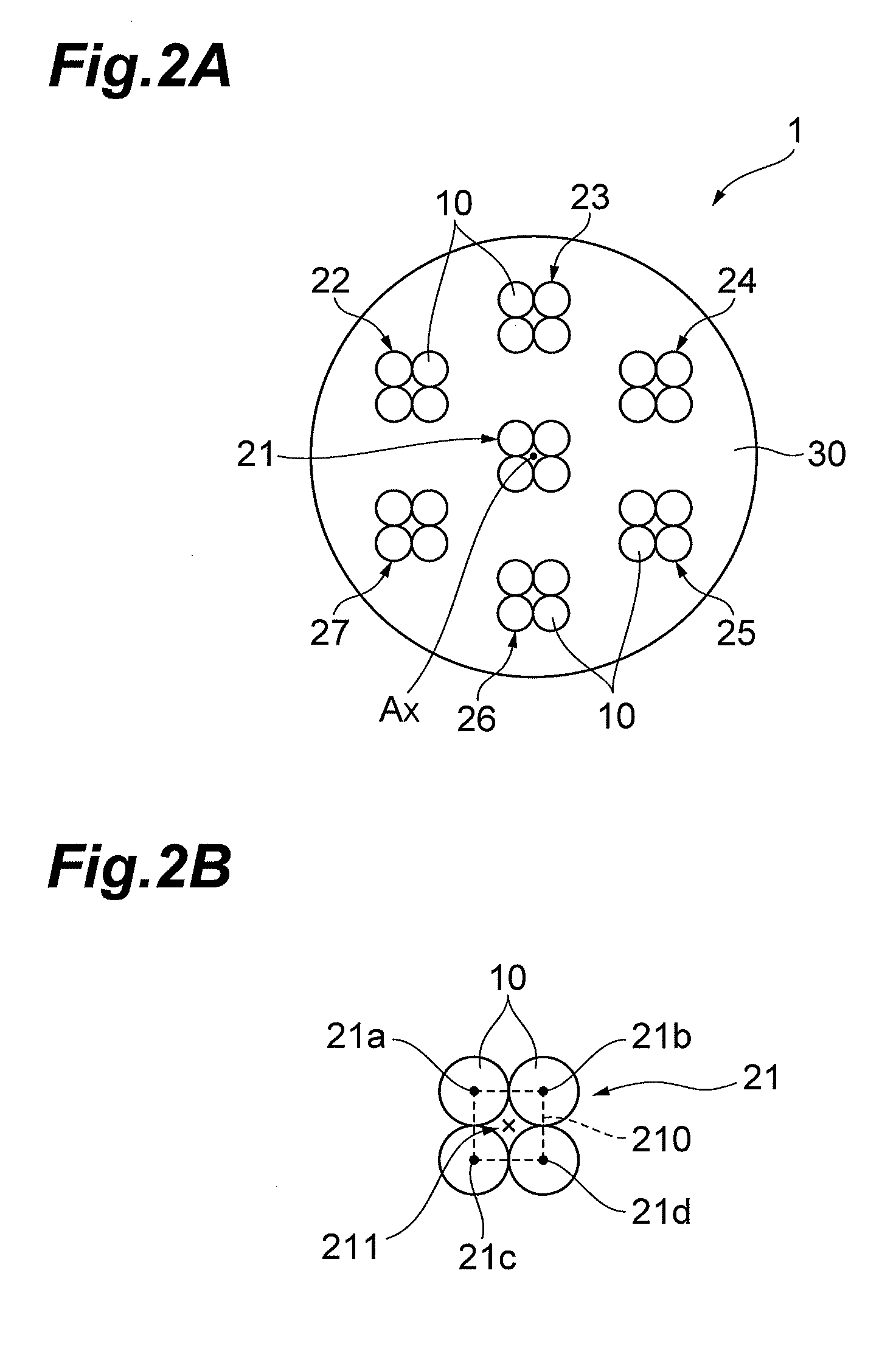

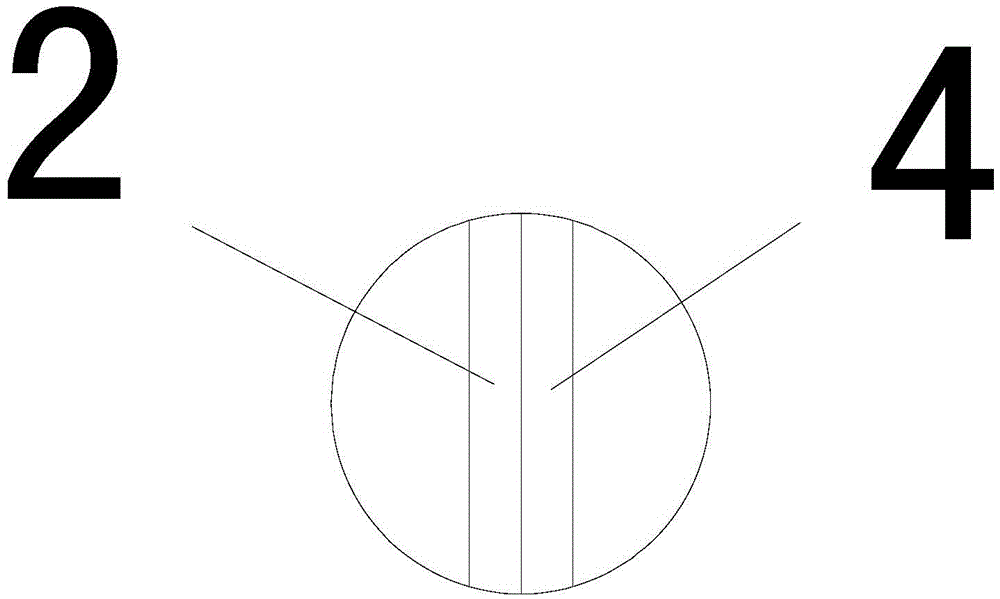

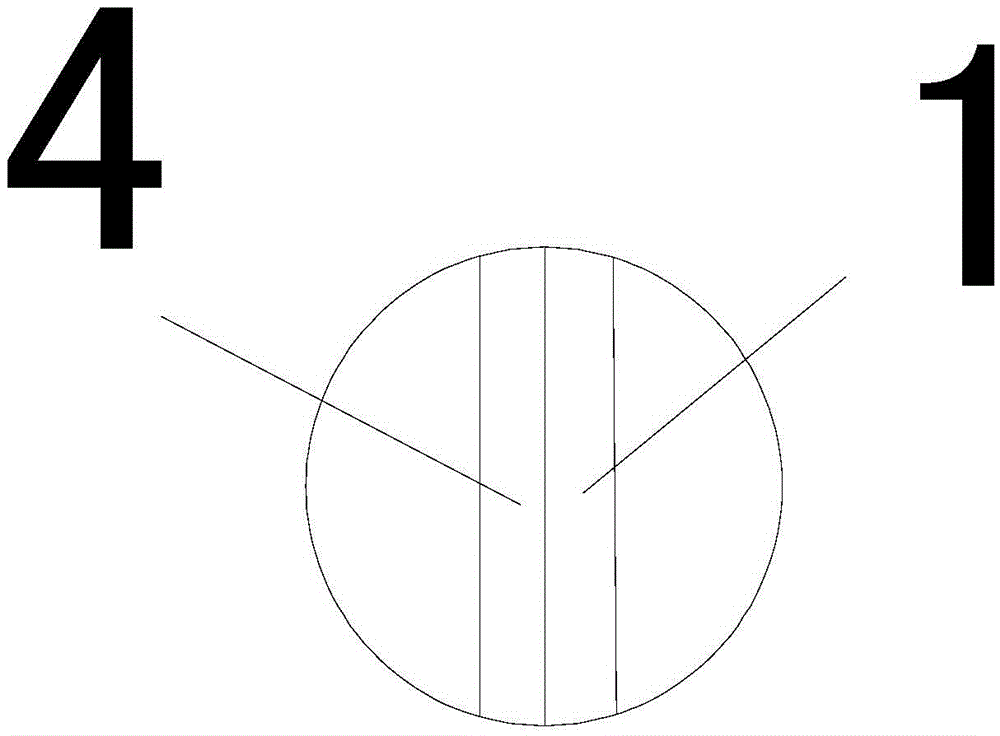

Multicore optical fiber

ActiveUS20110206330A1Reduce mode couplingEliminate the effects ofOptical fibre with multilayer core/claddingMulticore optical fibreEngineeringPlastic optical fiber

The present invention relates to a multicore optical fiber having a structure for effectively inhibiting polarization mode dispersion from increasing, and the multicore optical fiber comprises a plurality of multicore units and a cladding region integrally covering the plurality of multicore units while separating the multicore units from each other. Each of the plurality of multicore units includes a plurality of core regions arranged such as to construct a predetermined core arrangement structure on a cross section orthogonal to an axis. The core arrangement structure of each multicore unit on the cross section has such a rotational symmetry as to coincide with the unrotated core arrangement structure at least three times while rotating by 360° about a center of the multicore unit, thereby reducing the structural asymmetry of each multicore unit. This lowers the structural birefringence in each multicore unit, thereby inhibiting the polarization mode dispersion from increasing in the multicore optical fiber.

Owner:SUMITOMO ELECTRIC IND LTD

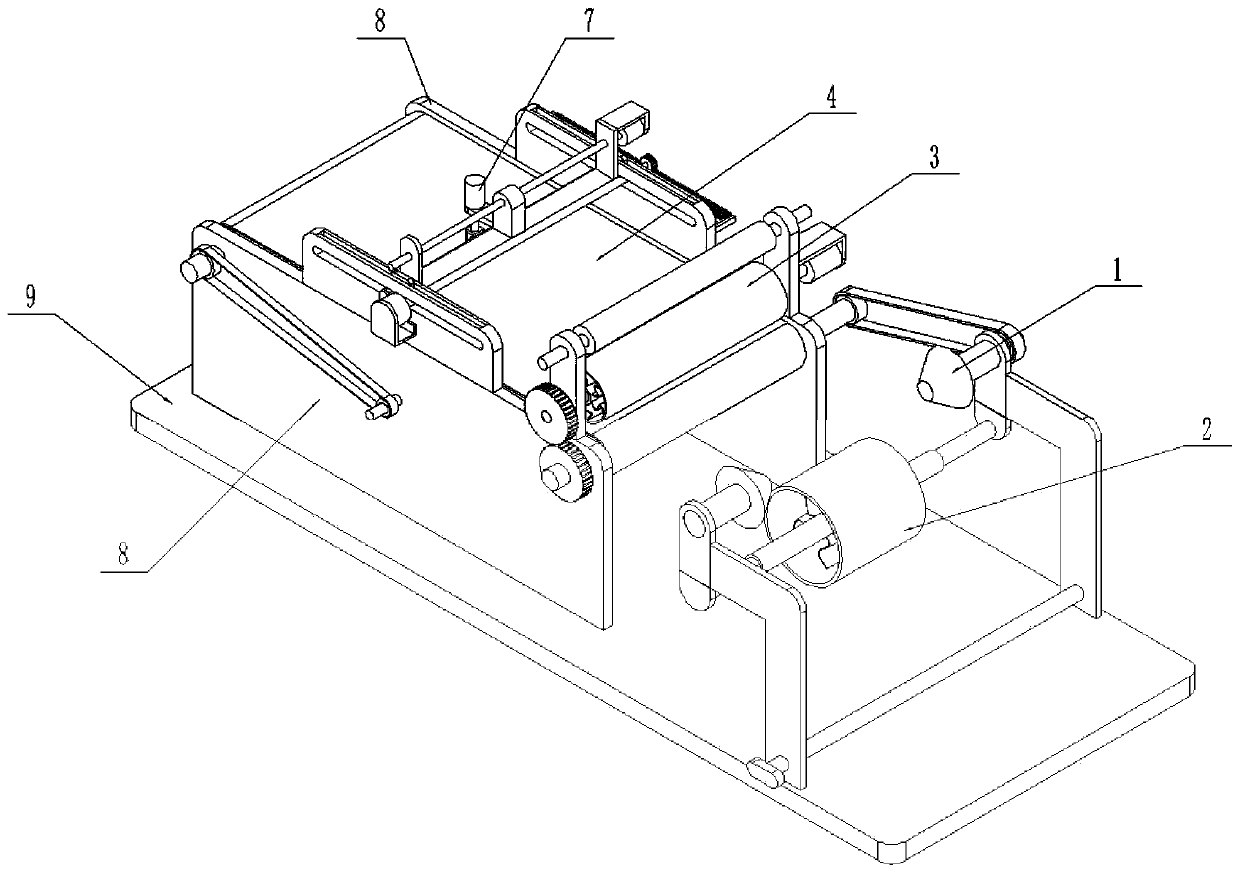

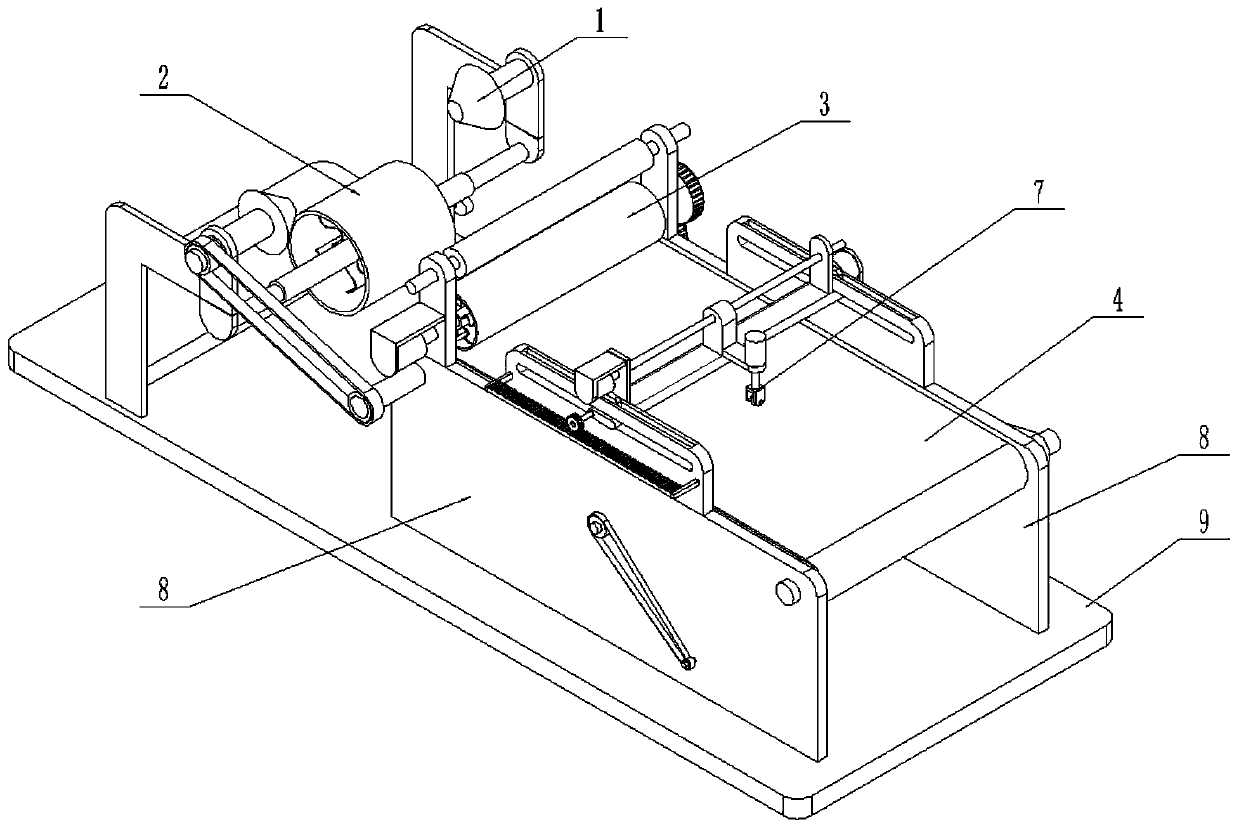

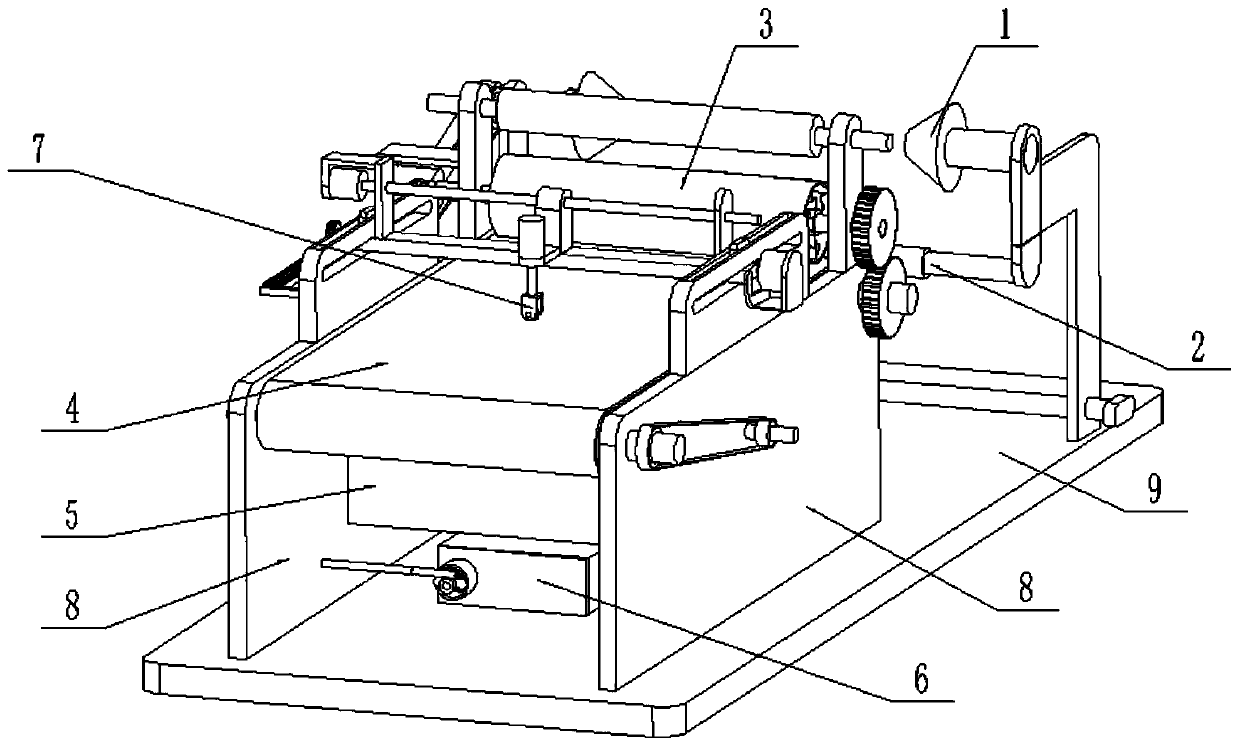

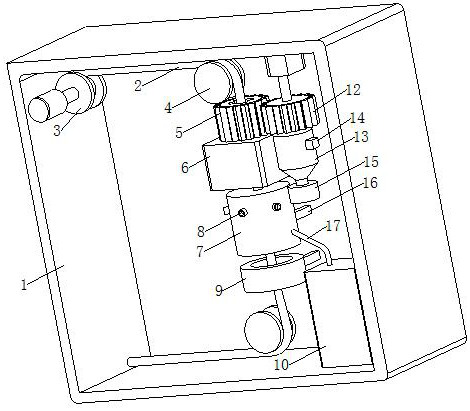

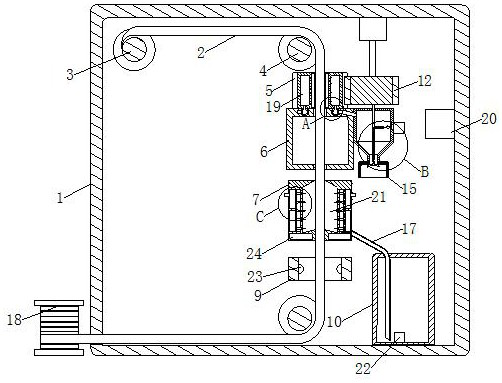

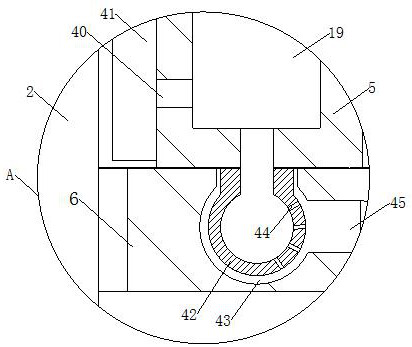

Cloth cutting device for textile production

ActiveCN109736065AImprove cutting efficiencyKeep healthyMechanical cleaningPressure cleaningScrapEngineering

The invention relates to the field of textile processing equipment and in particular relates to a cloth cutting device for textile production. The cloth cutting device comprises a cloth roll fixing mechanism, a cloth roll pressing mechanism, a cloth roll unwinding mechanism, a cloth conveying mechanism, a cleaning mechanism, a cloth scrap recovery mechanism, a cloth cutting mechanism, side frame plates and a base plate; totally two side frame plates are arranged; the two side frame plates are fixedly connected to the left and right sides of the front end of the top surface of the base plate; the lower end of the cloth roll fixing mechanism is connected to the rear end of the top surface of the base plate; and the cloth roll pressing mechanism is fixedly connected onto the cloth roll fixingmechanism. The cloth roll fixing mechanism and the cloth roll pressing mechanism are arranged inside the cloth cutting device, so that cloth rolls of different sizes can be fixed; and the cloth rollunwinding mechanism is arranged inside the cloth cutting device, rapid unwinding of the cloth rolls can be realized by matching the cloth roll unwinding mechanism and the cloth roll fixing mechanism,and the cloth cutting efficiency is conveniently improved.

Owner:泸溪县康葳服装有限公司

Linear-carrier phase-mask interferometer

ActiveUS20100309476A1Increase rangeReduce complexityInterferometersUsing optical meansSpatially resolvedWavefront

A phase-difference sensor measures the spatially resolved difference in phase between orthogonally polarized reference and test wavefronts. The sensor is constructed as a linear-carrier phase-mask aligned to and imaged on a linear-carrier detector array. Mireau and Fizeau polarization interferometric objectives are implemented with a thin conductive wire grid optically coupled to the objective beam splitter.

Owner:ONTO INNOVATION INC

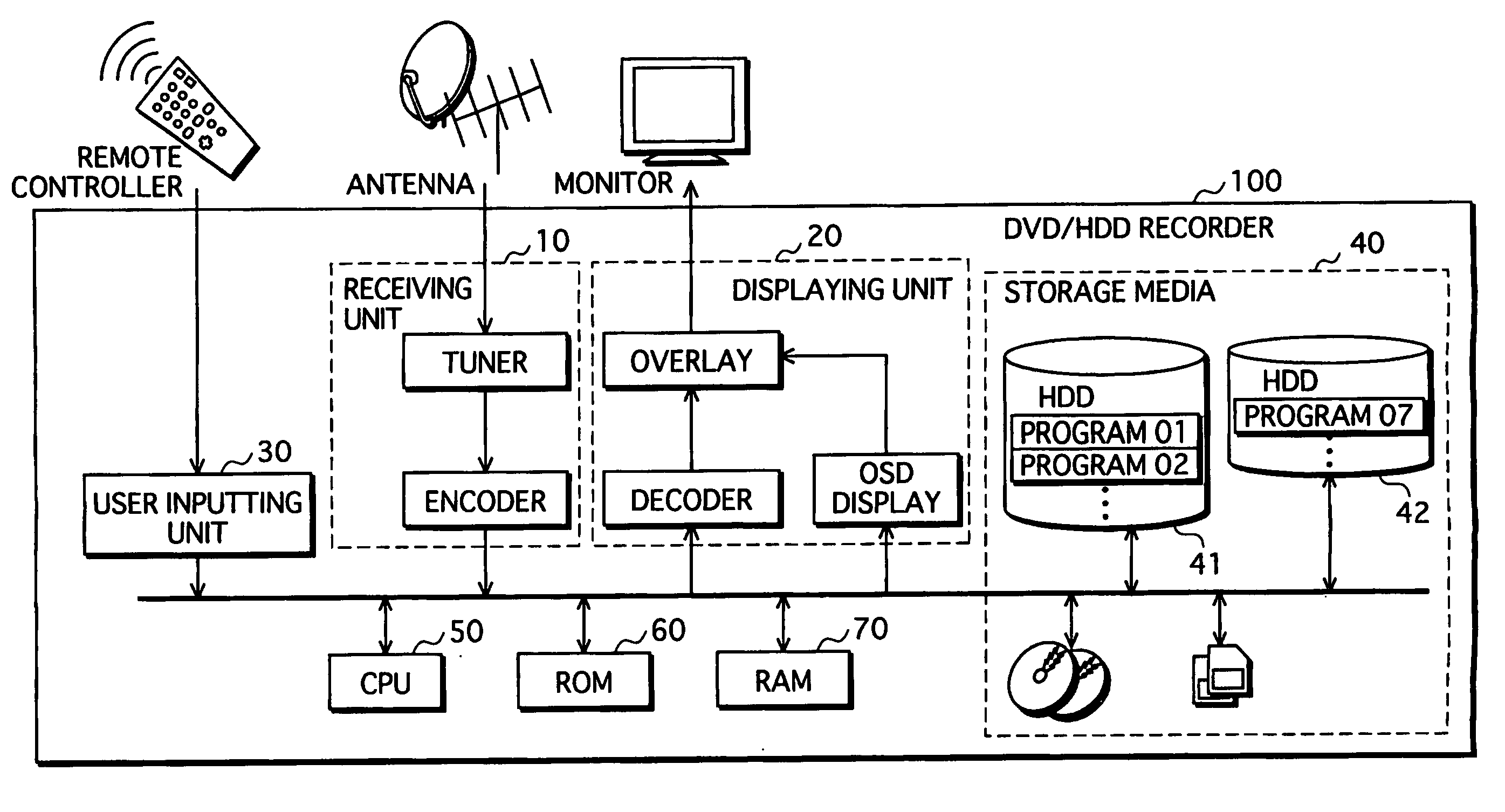

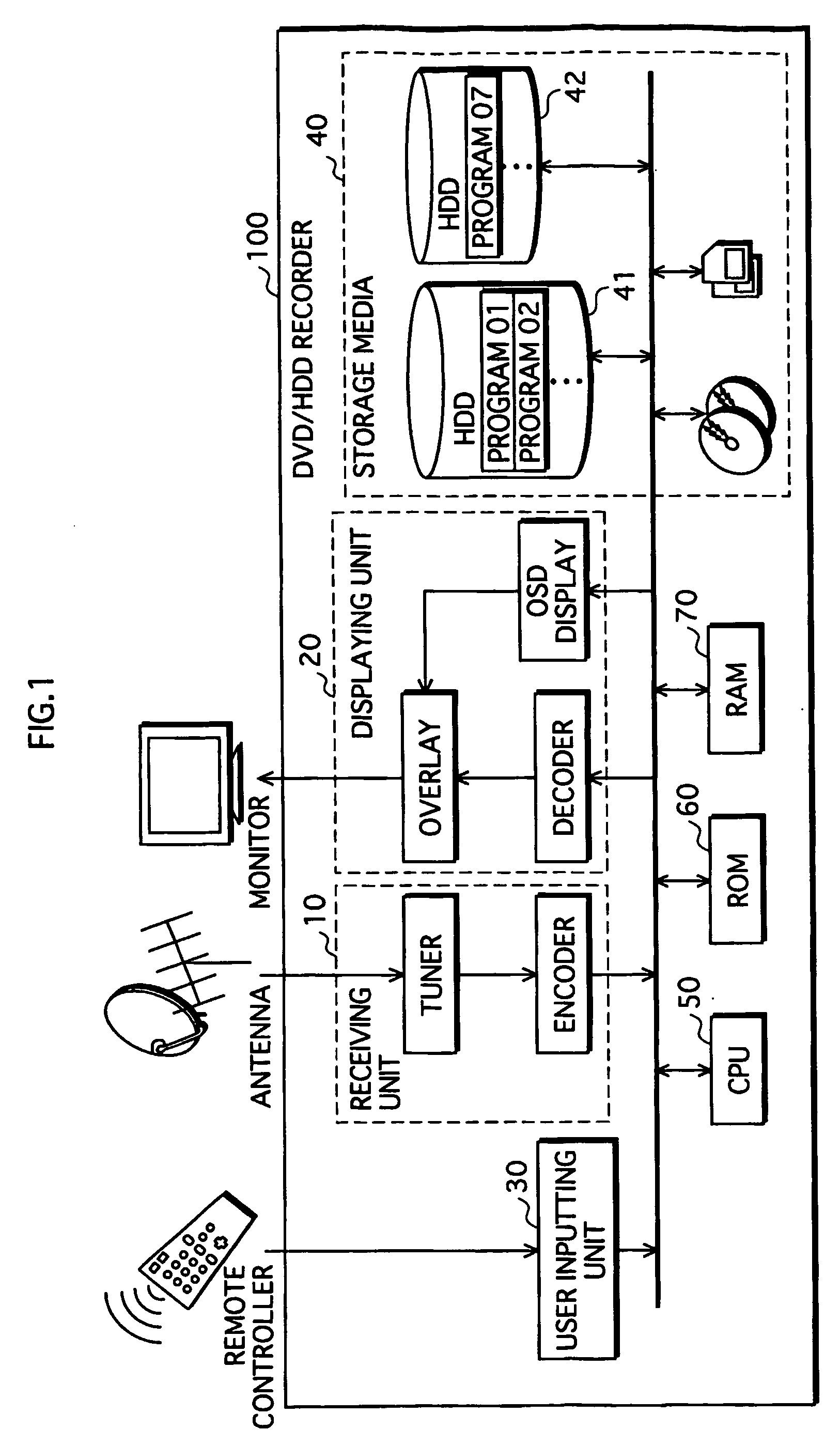

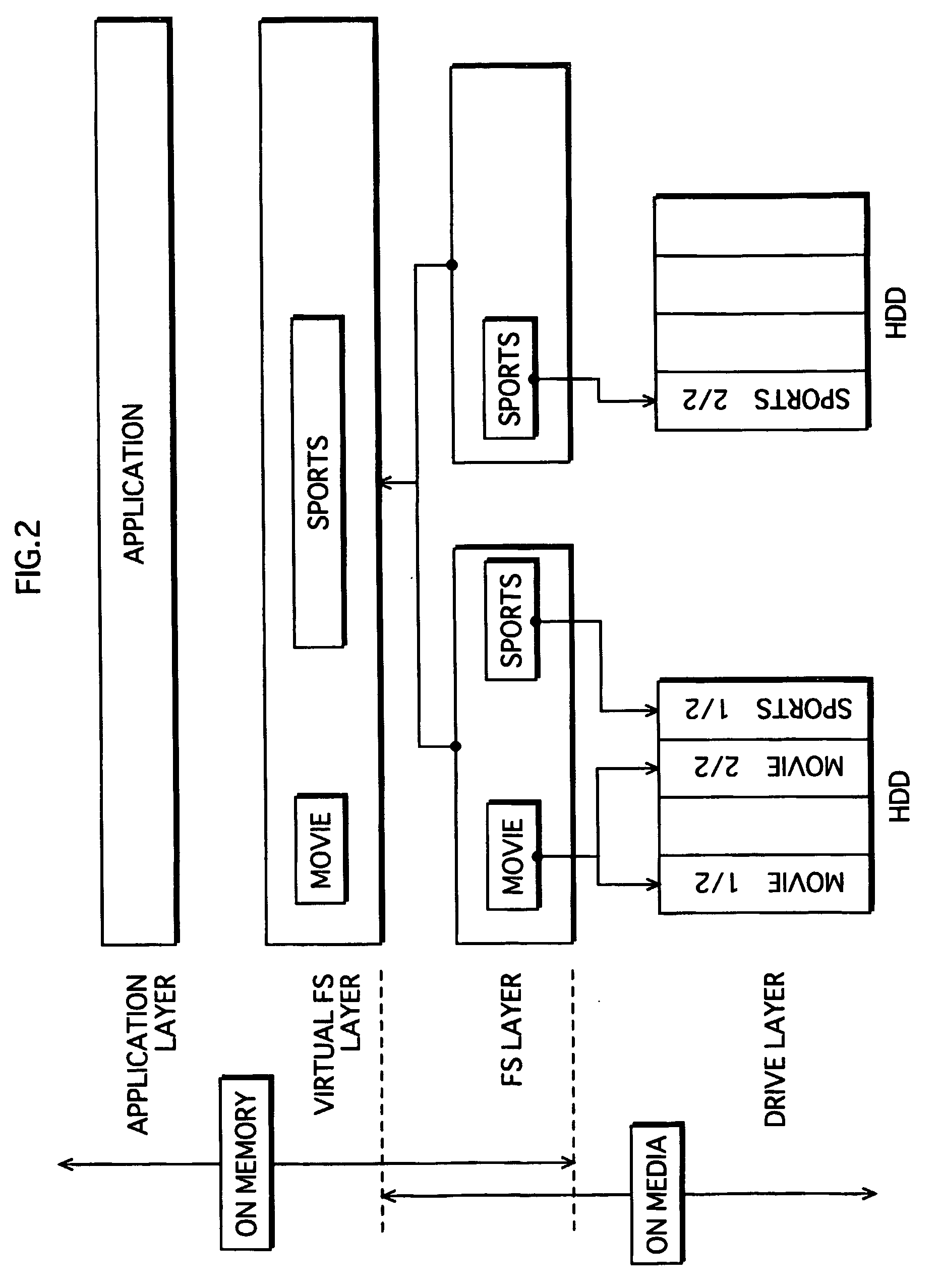

Apparatus for managing removable storage media that can be connected thereto, and method, program, and system lsi for managing removable storage media

InactiveUS20060028936A1Raise possibilityPrevent dispersionTelevision system detailsInput/output to record carriersContent managementGenerating unit

A storage media management apparatus includes a dividing unit 63e that divides a content into a plurality of content parts, a management information generating unit 63c that generates a plurality of pieces of content management information in correspondence to the plurality of content parts, each piece of content management information including (a) reconstruction information for reconstructing the content by concatenating a corresponding content part with the other content parts, and (b) individual information for making the corresponding content part individually usable, a content recording 63d unit 63d that records each content part together with a corresponding piece of content management information onto a different one of the storage media, and a table editing unit 61 that judges whether the content is to be concatenated and made usable, or the content parts are to be individually made usable.

Owner:PANASONIC CORP

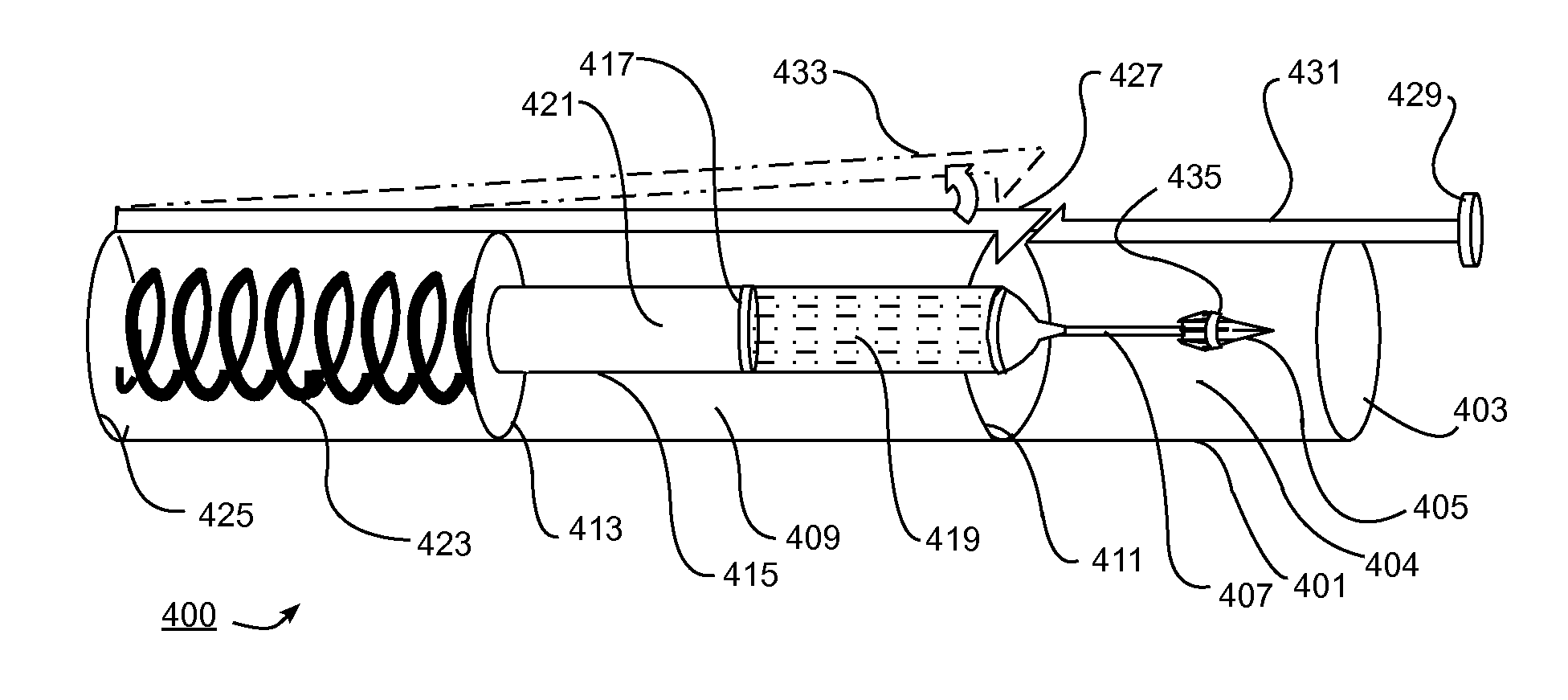

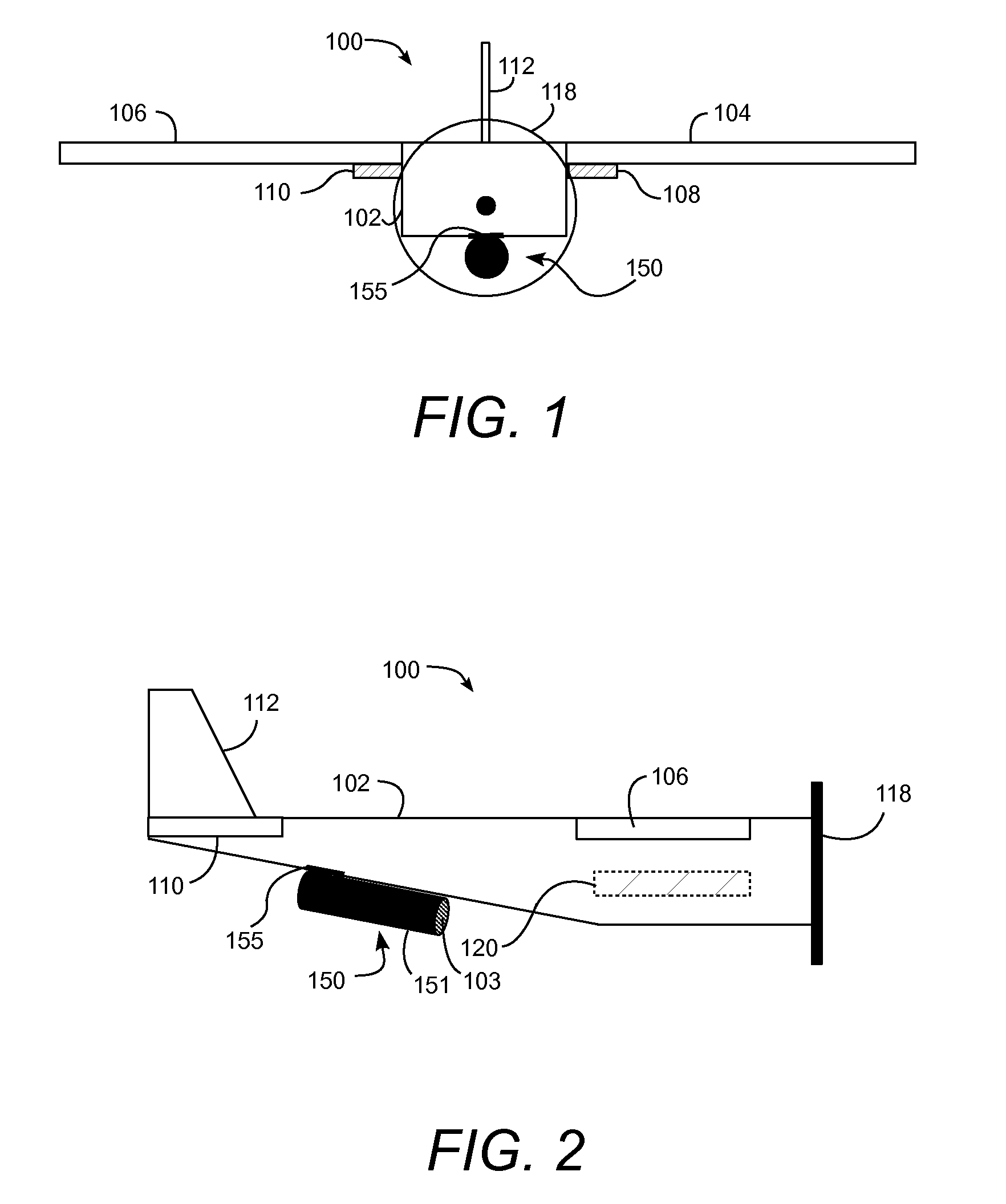

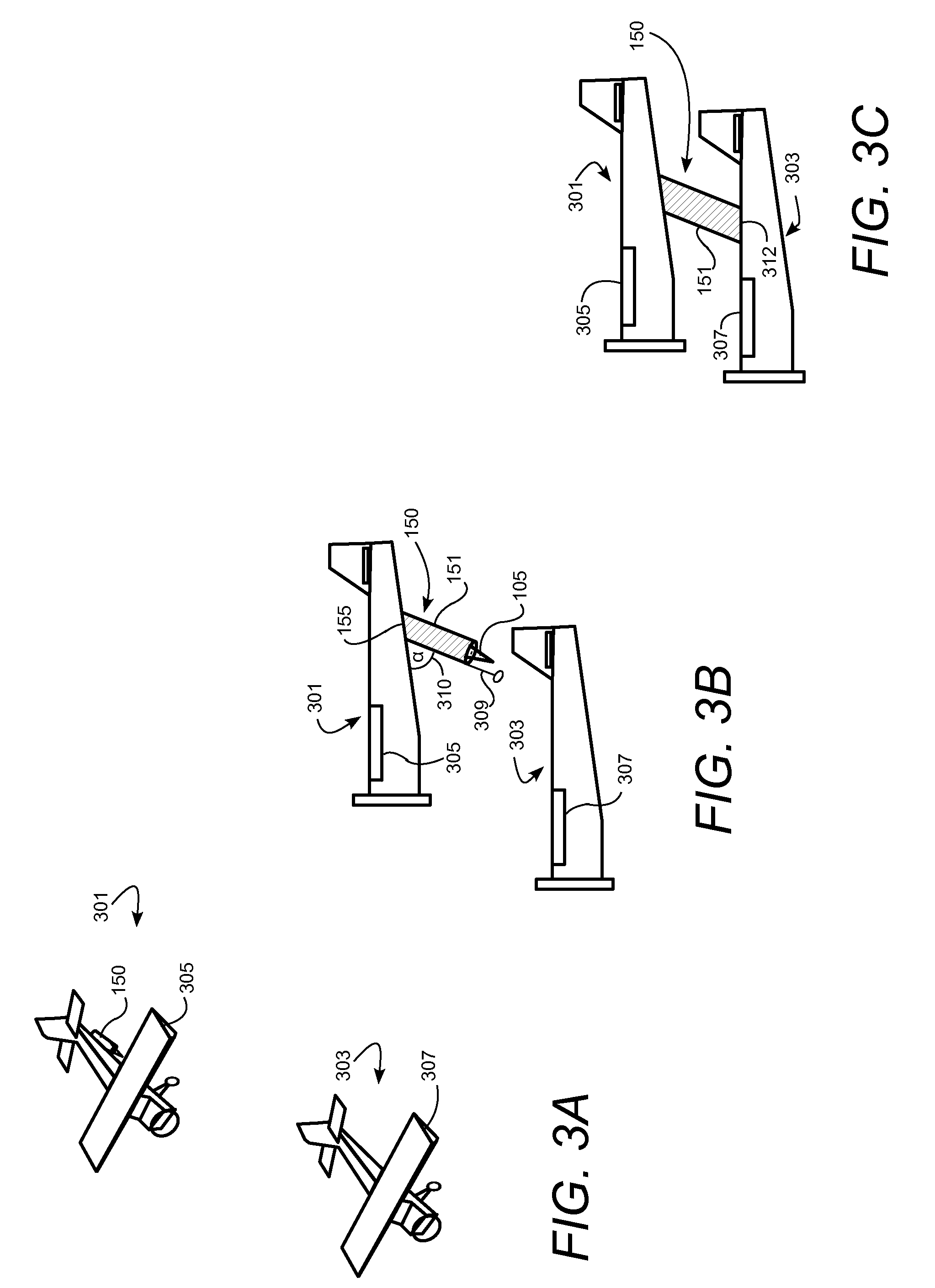

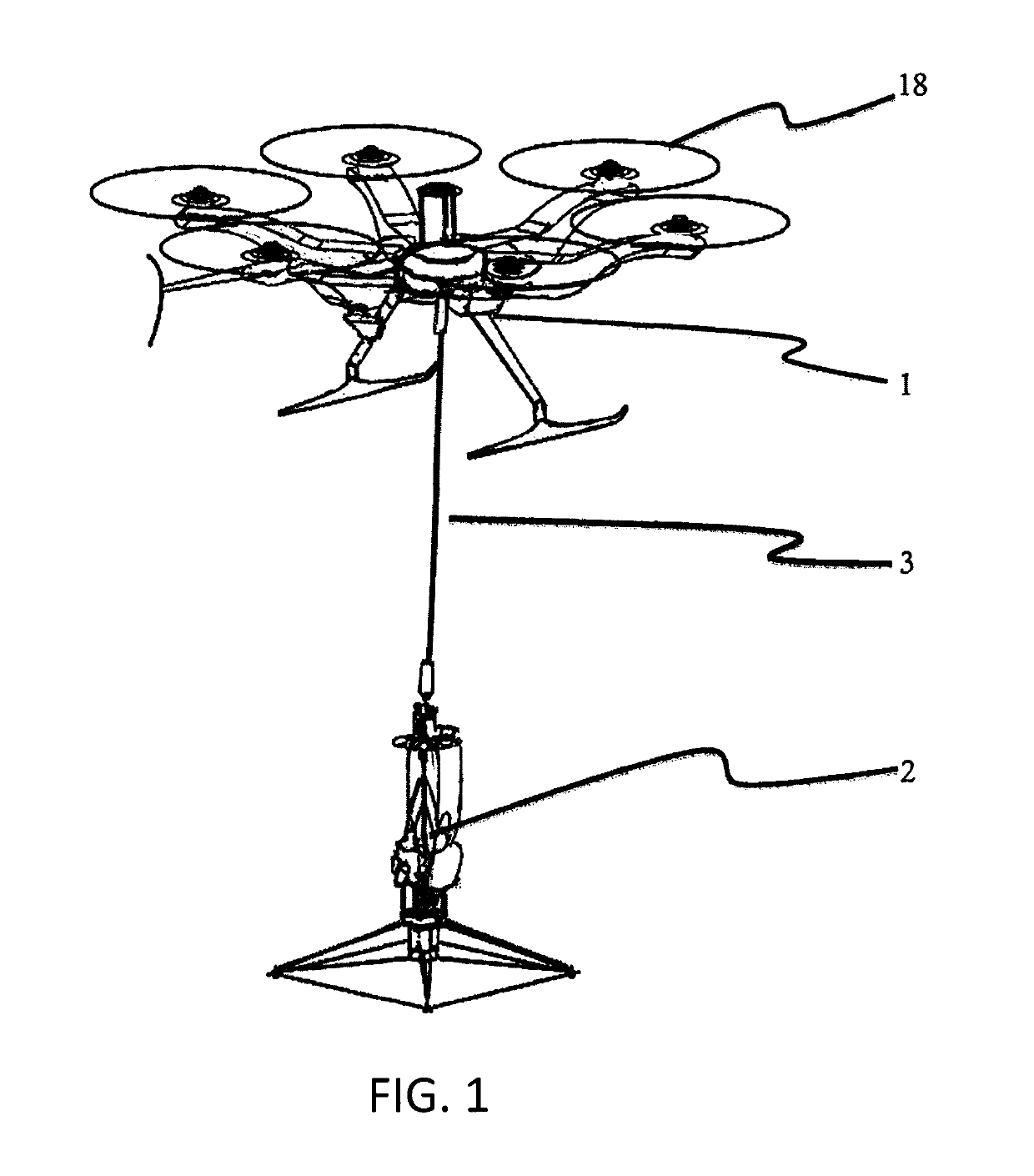

Auto-injector countermeasure for unmanned aerial vehicles

ActiveUS9175934B1Prevent dispersionAvoid distractionDefence devicesAircraft componentsInjectorCountermeasure

An injector device configured to mount to a predatory unmanned aerial vehicle (UAV) for non-destructively disabling and controlling a threat UAV comprises a rigid housing having a hollow interior. A controllable mount structure attaches the rigid housing to the predatory UAV and aligns the housing opening with the fuselage or payload of the threat UAV. A rigid penetrator rod disposed in the interior of the housing is configured to pierce the fuselage and hence payload of the threat UAV. A conduit coupled to the penetrator rod enables a disabling substance to be conveyed through the penetrator rod and into the payload of the threat UAV. An ejector propels the penetrator rod from the housing and into the payload of the threat UAV in response to a trigger when the threat UAV is within a predetermined range.

Owner:LOCKHEED MARTIN CORP

Substituted Alkoxylated Phenols and Branched Sulfates for Use in Emulsion Polymer Latexes

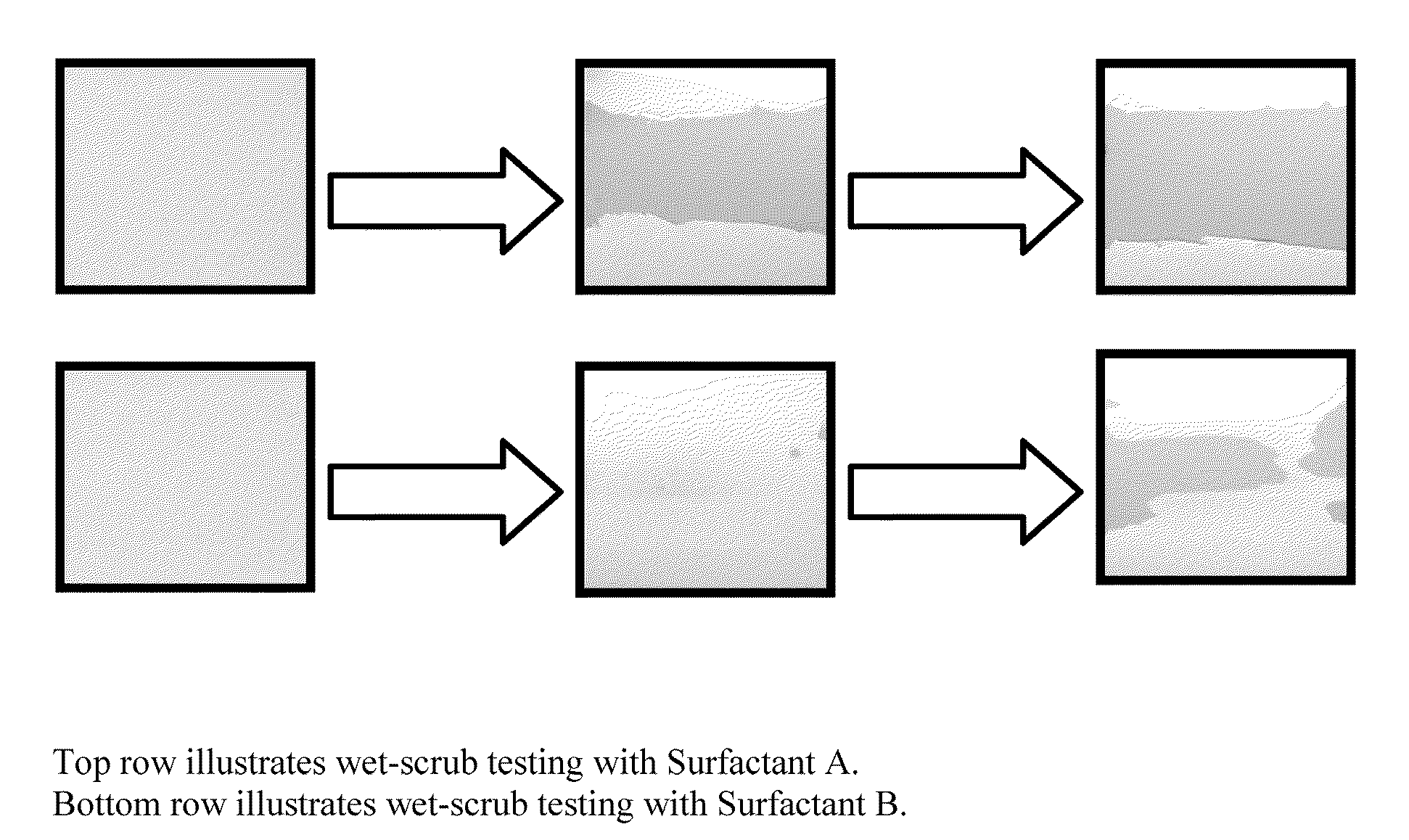

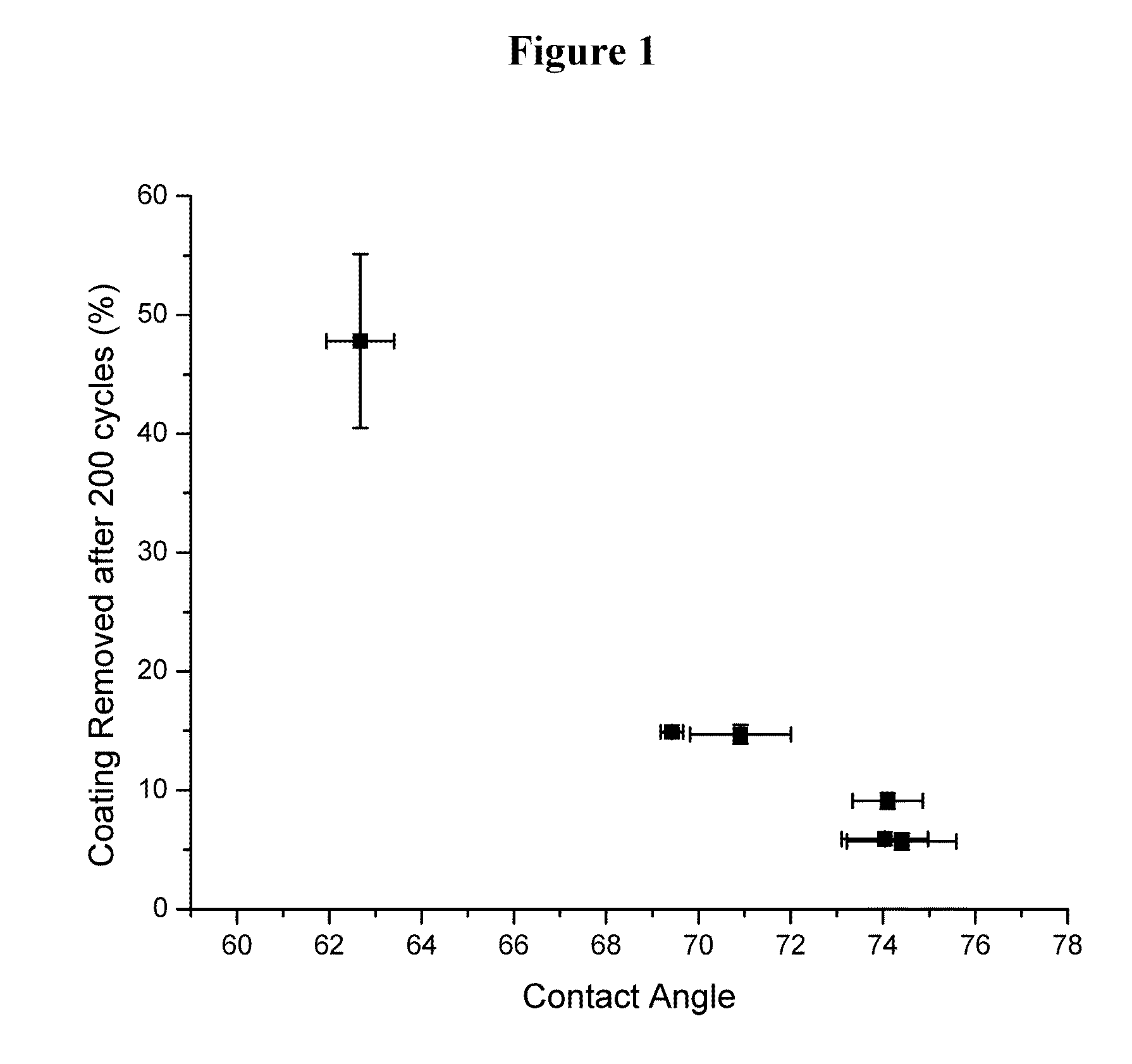

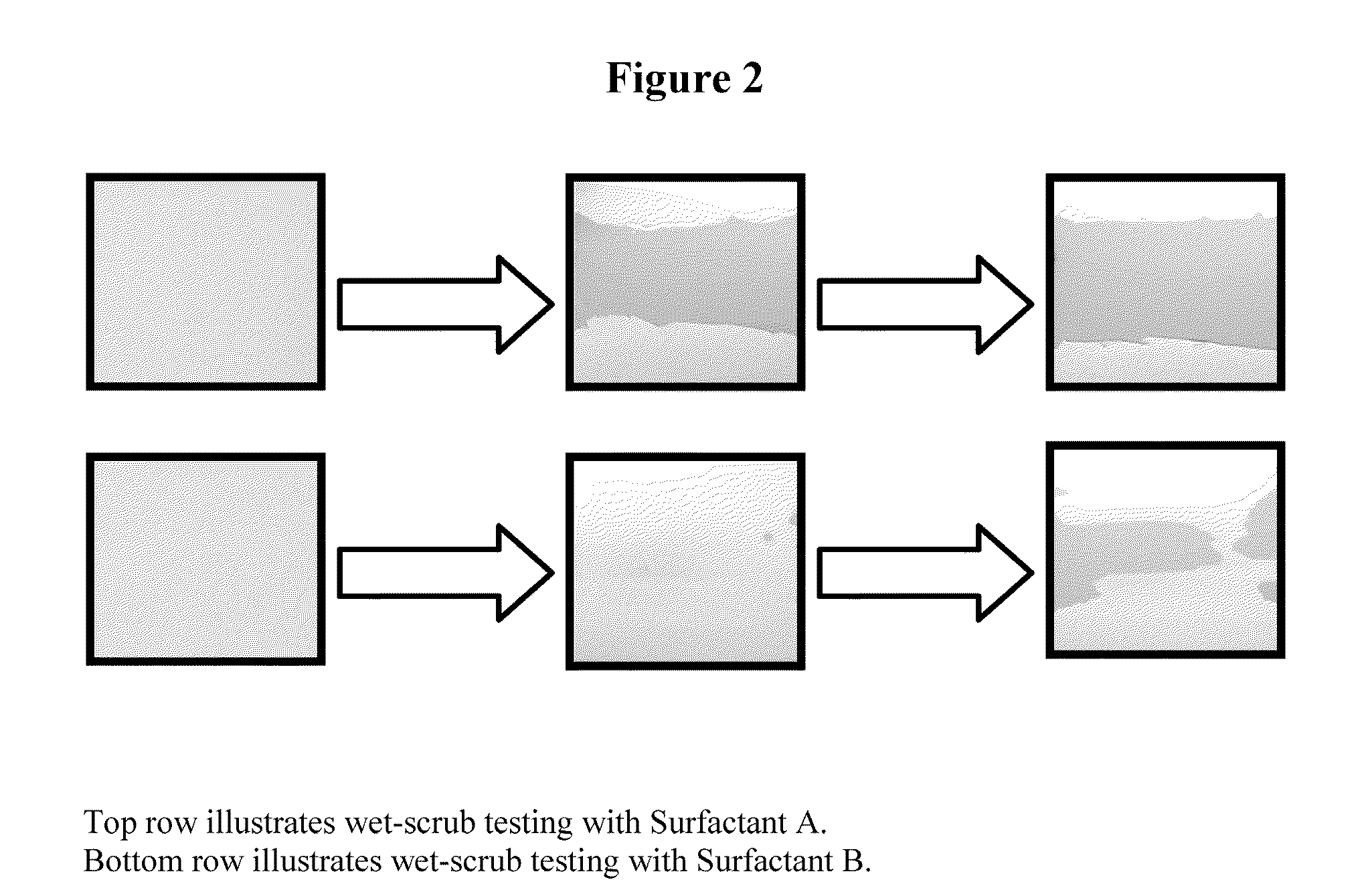

ActiveUS20090076202A1Improve adhesionImprove blister resistanceOrganic chemistryPlastic/resin/waxes insulatorsPolystyrenePhenol

The present technology generally relates to emulsion polymer latexes, particularly those used in pressure sensitive adhesives, paints and coatings. Surfactant compositions of the present technology for use in forming at least one emulsion polymer latex comprise at least one branched surfactant, at least one sterically bulky surfactant, or a mixture of branched and sterically bulky surfactants. One preferred surfactant composition comprises at least one alkoxylated polyaryl substituted aromatic compound or at least one alkoxylated polyalkyl substituted aromatic compound. Another preferred surfactant composition comprises a mixture of at least one branched-alkyl sulfate and at least one ethoxylated polystyrylphenol. Another preferred surfactant composition comprises at least one sulfated polystyrylphenol.

Owner:STEPAN COMPANY

Linear-carrier phase-mask interferometer

Owner:ONTO INNOVATION INC

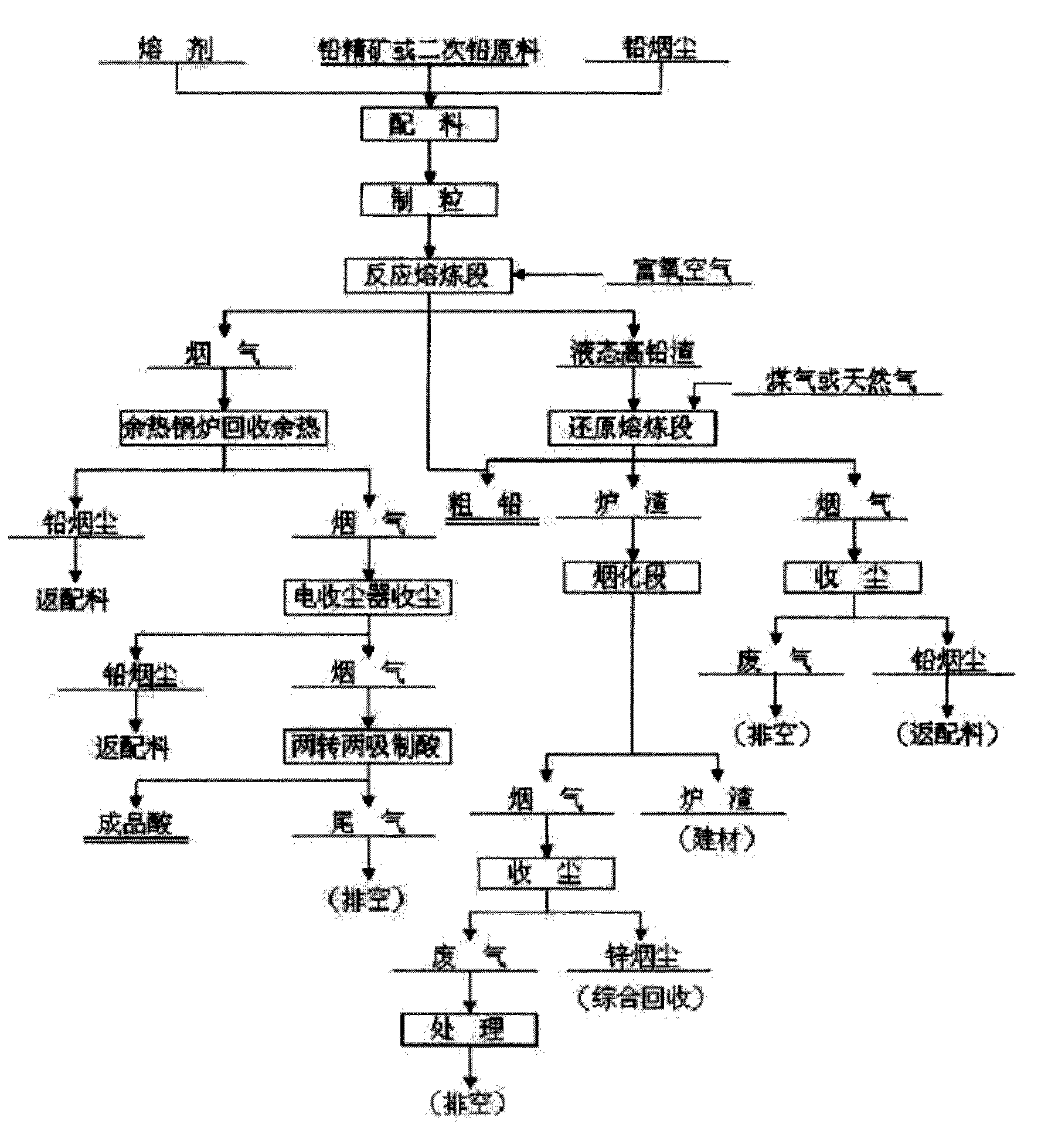

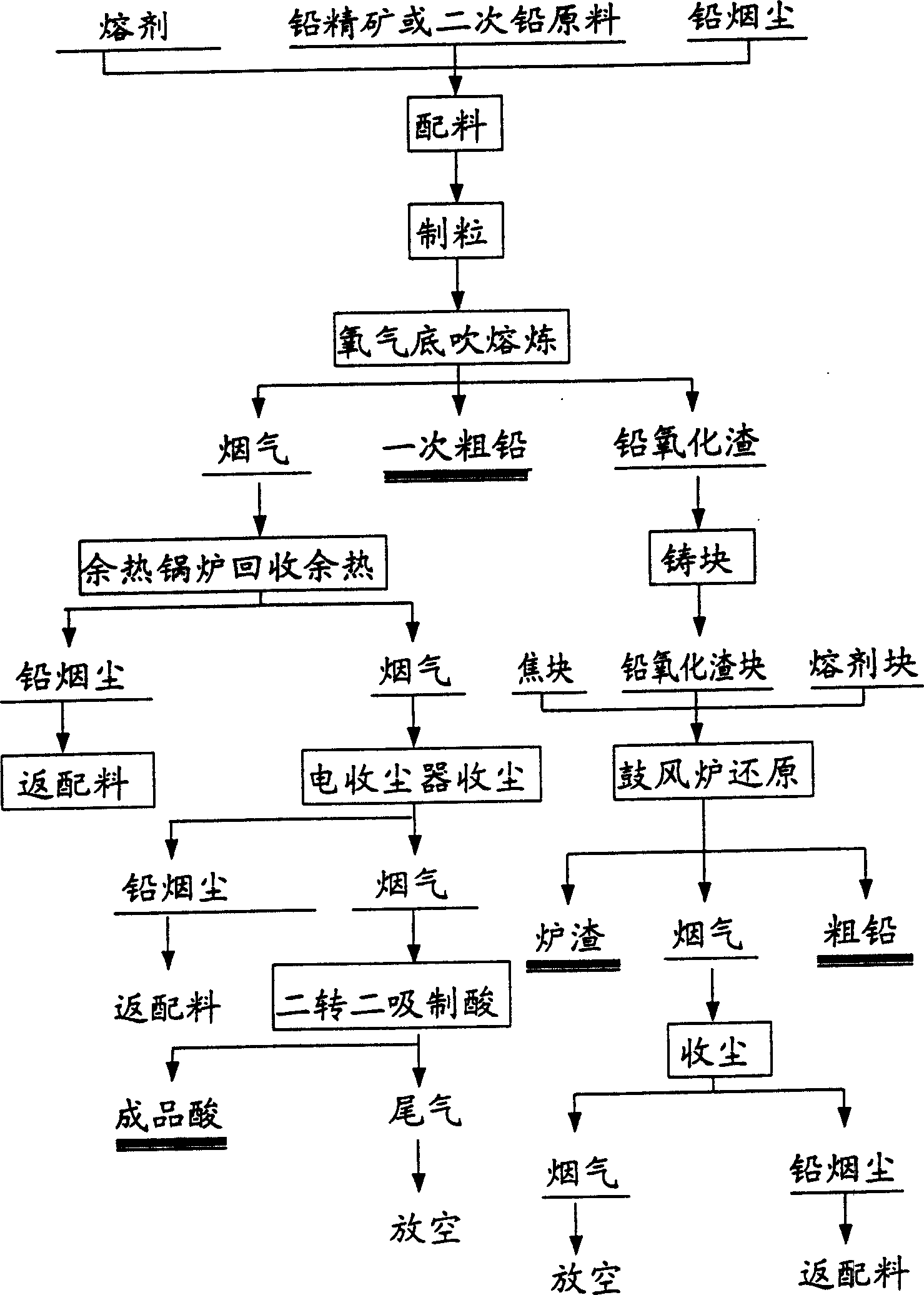

Continuous lead smelting clean production process

InactiveCN102031393APrevent escapeImprove recycling ratesProcess efficiency improvementLead smeltingLiquid state

The invention discloses a continuous lead smelting clean production process. The process comprises the following steps of: proportioning materials such as lead sulfide concentrate or a secondary lead raw material, a flux, lead dust and the like as required; performing a mixed granulation process; feeding a reaction smelting section of the entire equipment; smelting by an oxygen enriched bottom blowing method; directly feeding liquid-state high-lead slag into a reduction smelting section to perform reduction smelting so as to produce coarse lead; and directly feeding the reduced liquid-stage slag into a fuming section to perform fuming treatment so as to comprehensively recover valuable metals from the liquid-stage slag. Therefore, continuous clean production is realized in the true sense.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

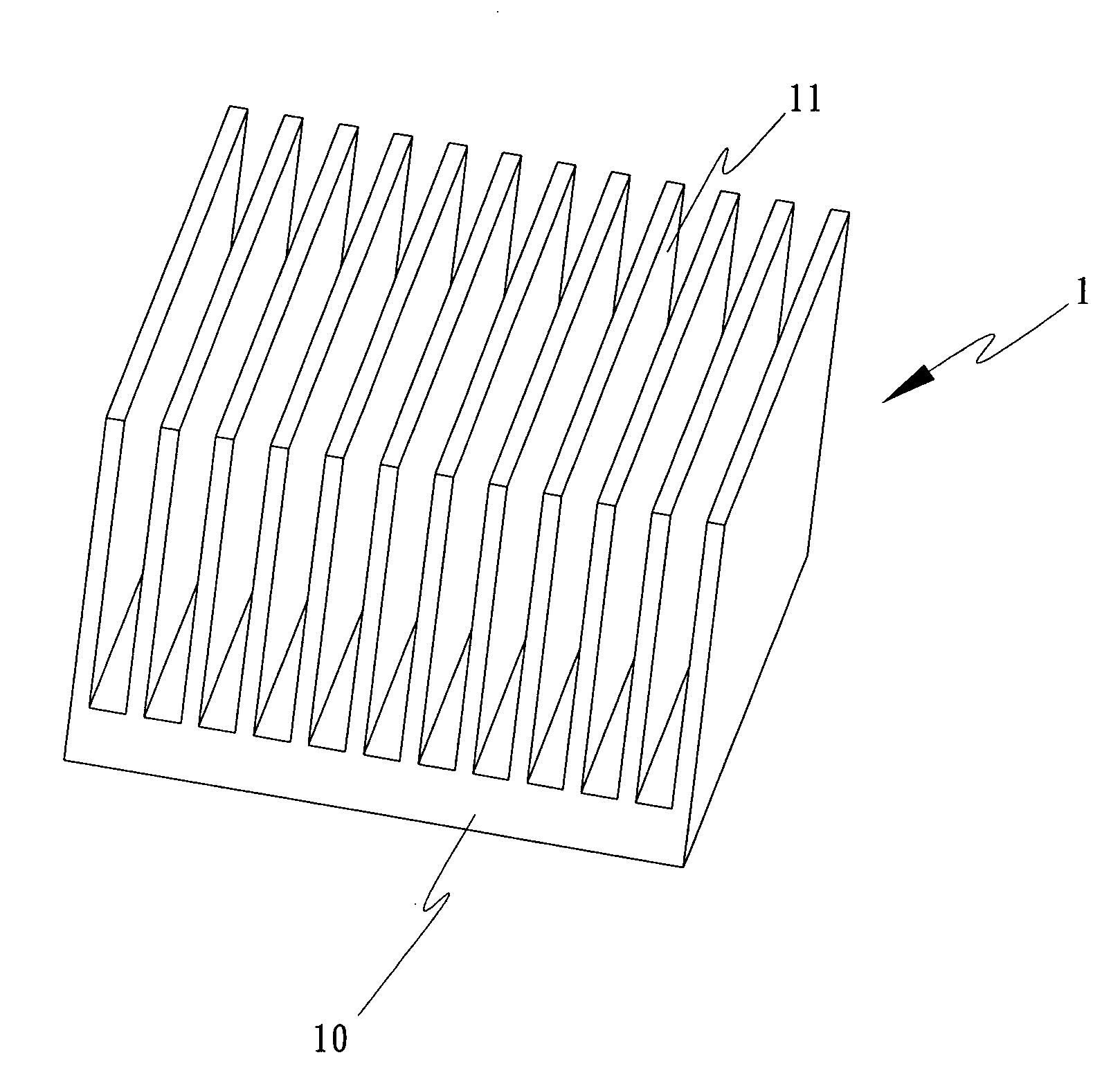

Graphite product and its fabrication method

InactiveUS20070218284A1Beautiful appearanceAvoid distractionLayered productsThin material handlingGraphiteMetal

Owner:LOTES

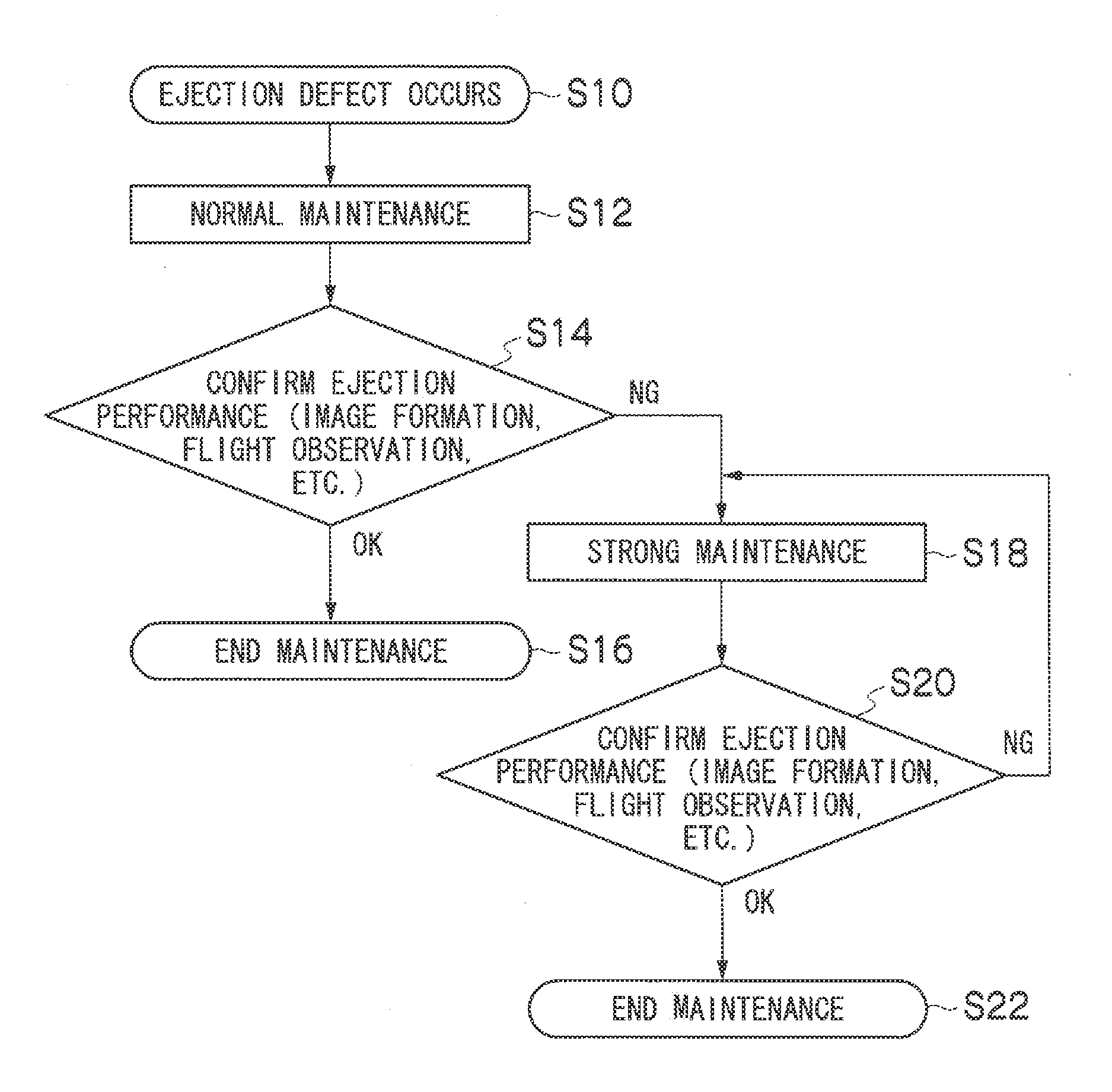

Liquid Ejection Apparatus And Head Maintenance Method

InactiveUS20100277523A1Prevent dispersion of pressureImprove maintenance efficiencyInking apparatusOther printing apparatusLiquid jetOrganic solvent

A liquid ejection apparatus includes: an inkjet head including a plurality of nozzles which eject liquid containing a water-soluble high-boiling-point organic solvent having an SP value of 30 or lower at a concentration of 10 weight percent or higher and 25 weight percent or lower, a plurality of liquid chambers connected to the plurality of nozzles respectively, and a plurality of supply flow channels to any of which each of the plurality of nozzles is connected and which supply the liquid to the plurality of nozzles via the plurality of liquid chambers; a capping device configured to simultaneously cap the nozzles connected to the same supply flow channel, from a liquid ejection surface side of the inkjet head; a pressure application device which applies pressure to the liquid inside the nozzles via the capping device; and a pressure control device which controls the pressure application device so as to repeat pressurization and depressurization with respect to the liquid inside the nozzles.

Owner:FUJIFILM CORP

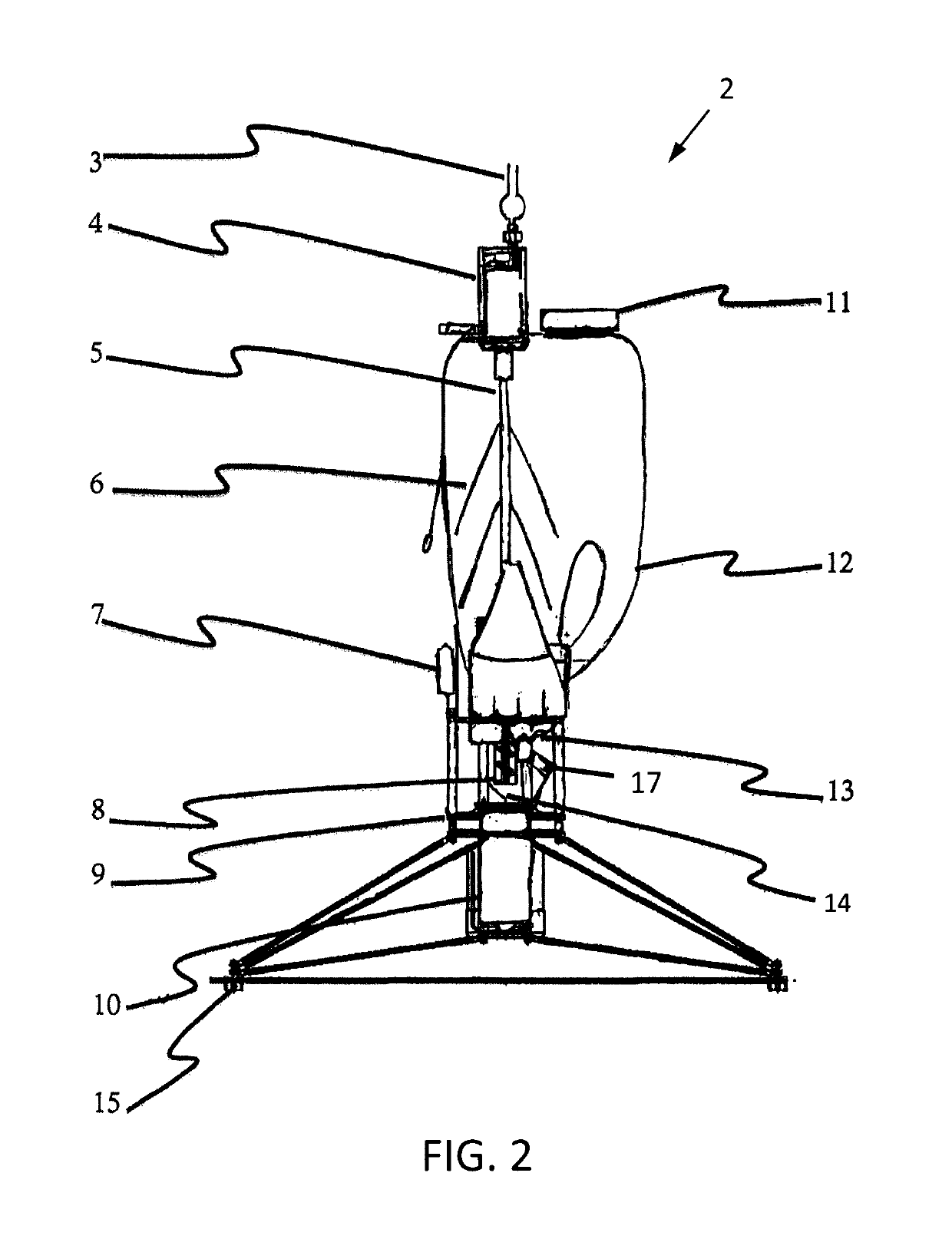

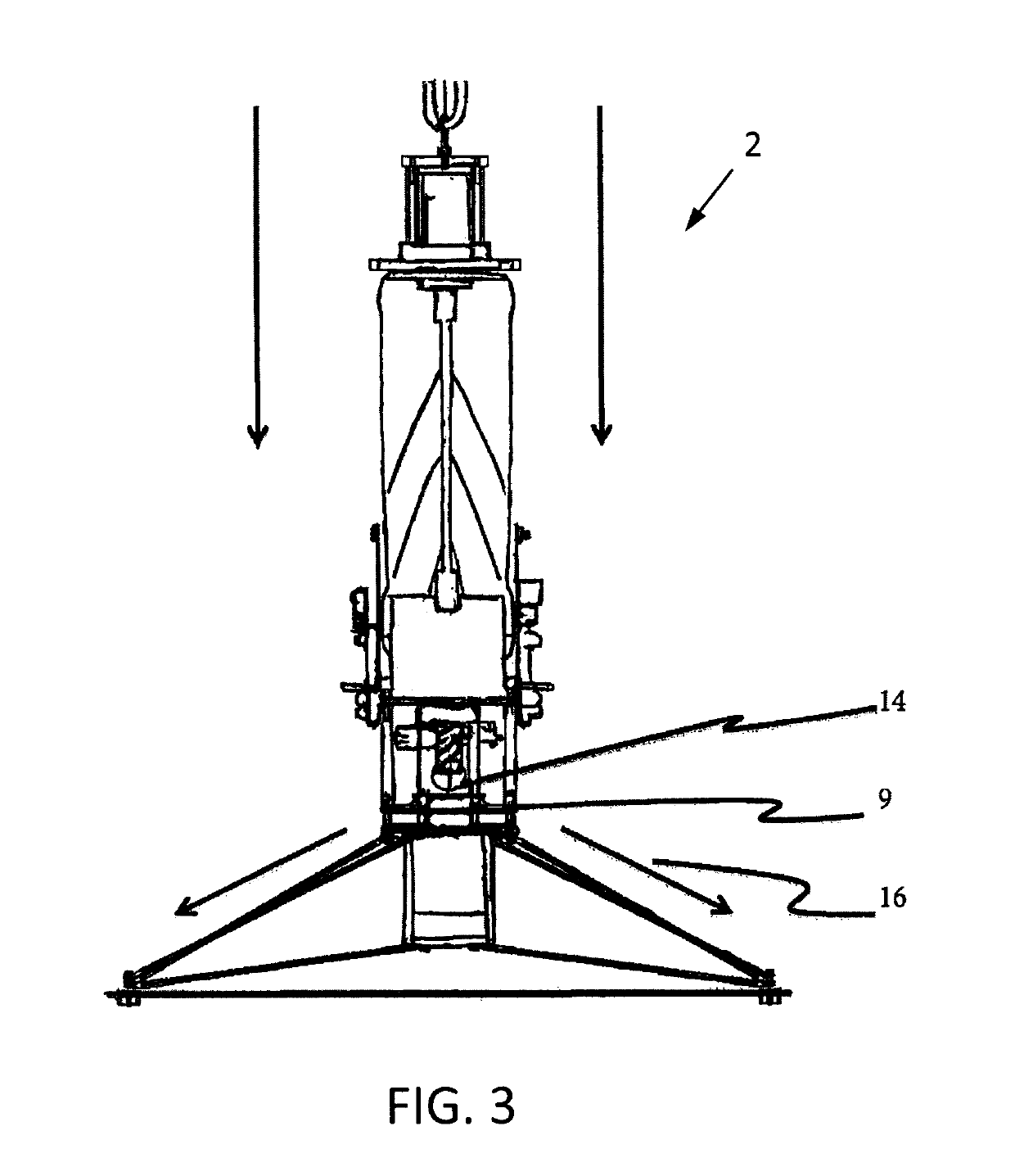

Apparatus and method for delivering a dry material with an unmanned aerial vehicle

ActiveUS10377491B1Prevent dispersionFlow rate of the dry material can be increasedAircraft componentsUnmanned aerial vehiclesEngineeringDry powder

A delivery device coupled to a drone can be used to distribute dry powdered materials to a target area. The powdered materials can be stored in a hopper having an auger at the lower end of the hopper. An auger motor can be actuated to transport the powdered material to an aeration chamber where the powdered material is mixed with turbulent air. The aerated powdered materials can then be emitted from the delivery device from a slinger disc onto a target area.

Owner:DROPCOPTER INC

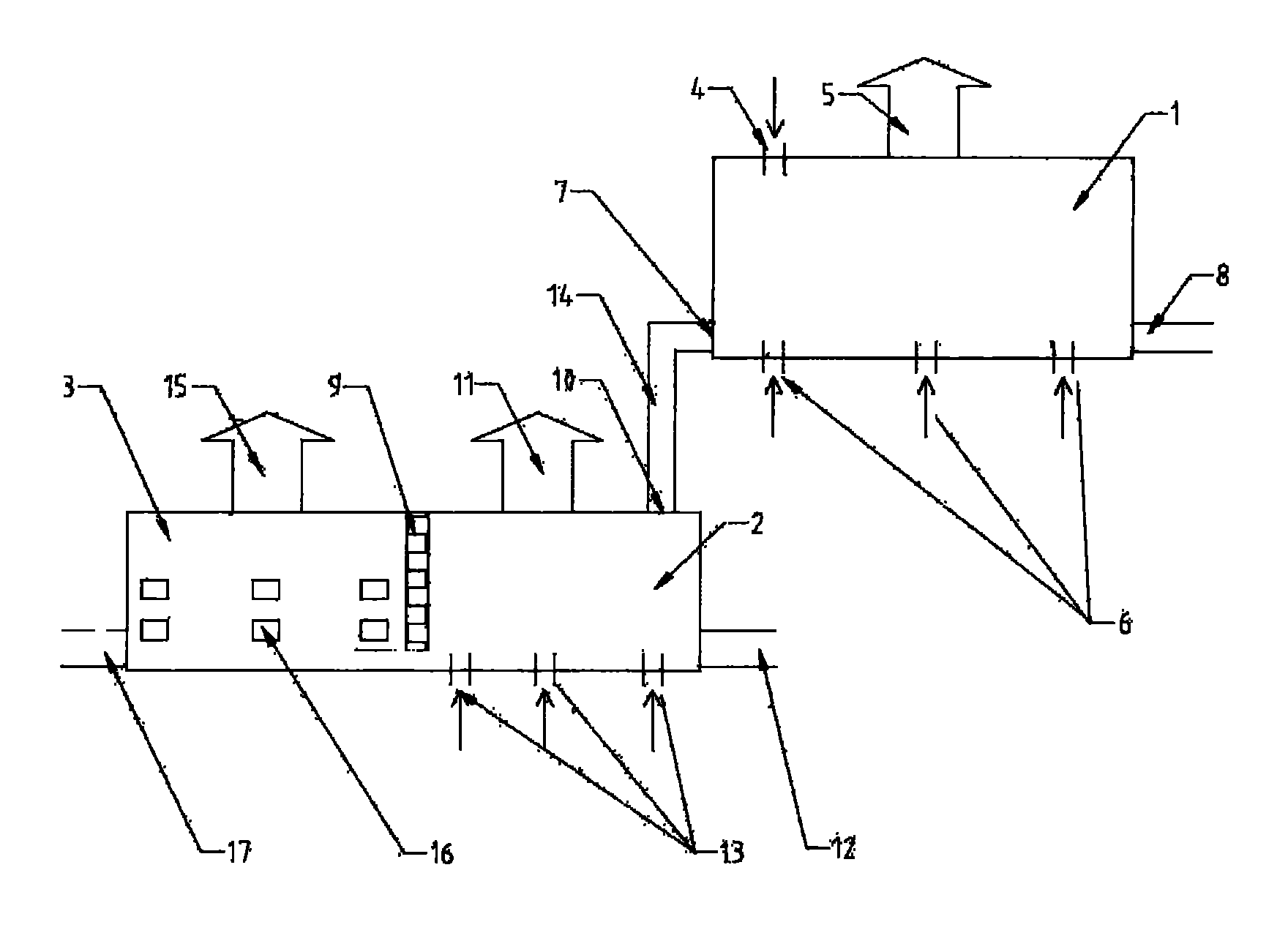

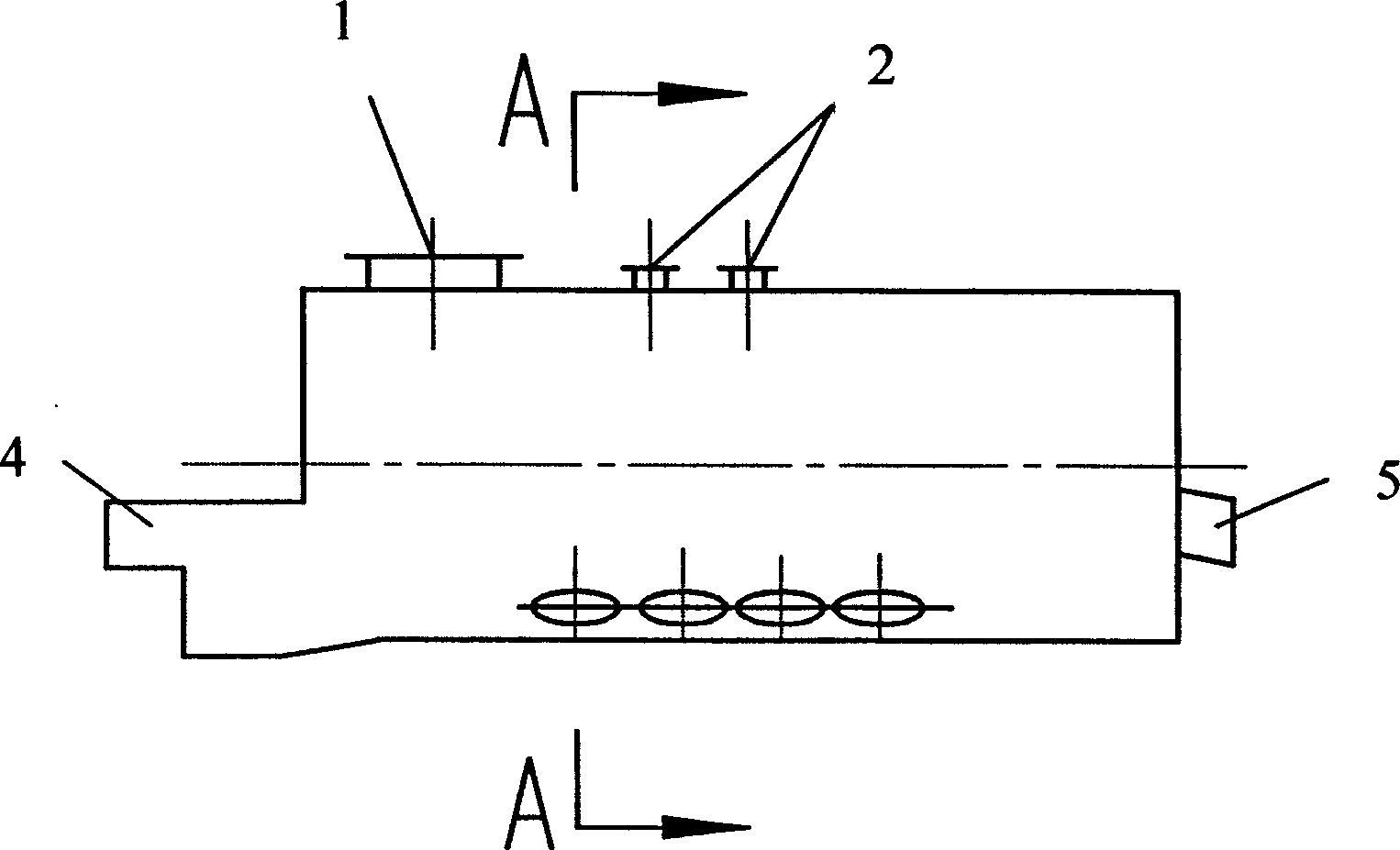

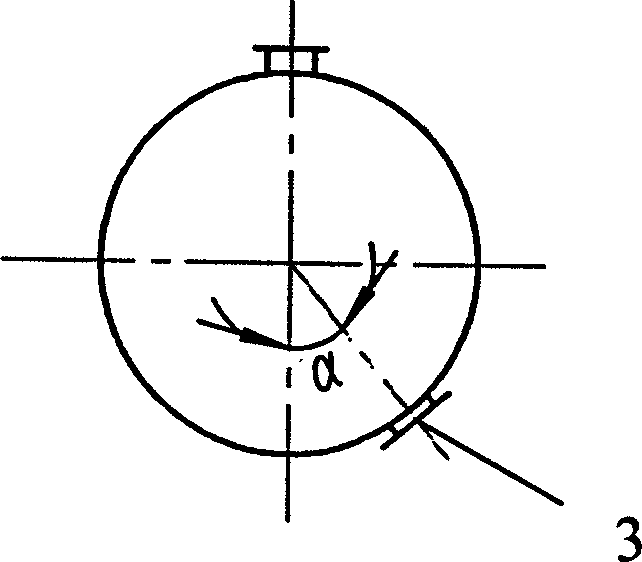

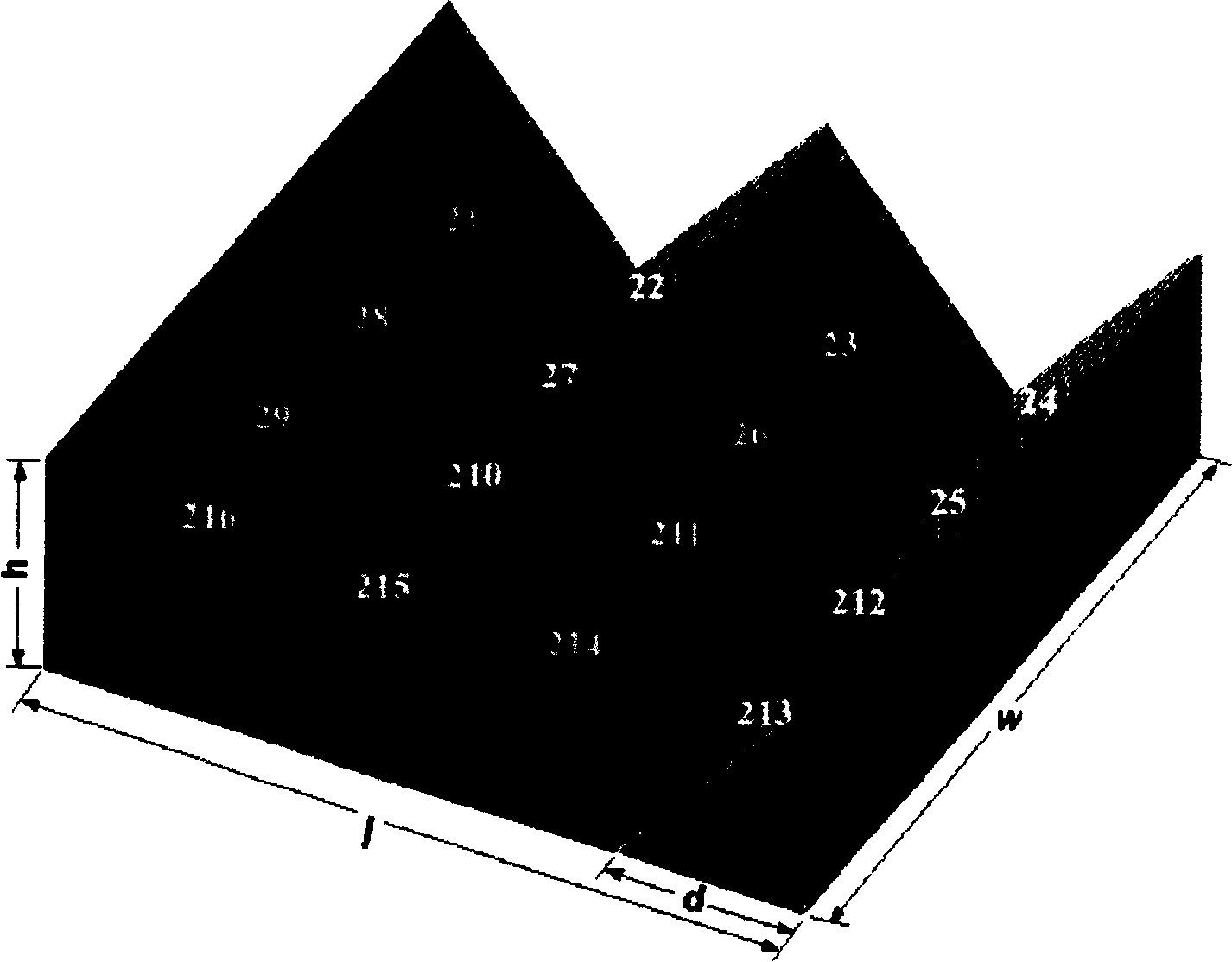

Oxygen bottom-blowing-blast furnace reduction process for lead smelting and apparatus therefor

The invention provides a lead smelting method and device, and its characteristic: it adopts oxygen bottom blowing method to smelt lead-containing raw material, where the included angle alpha of the direction of oxygen spout with plumb line: 0 deg.<=alpha<=90 deg.. It has the advantages of environmental protection, low energy consumption, economic investment, low production cost, strong adaptability to raw materials, and high automation level.

Owner:中国有色工程有限公司 +1

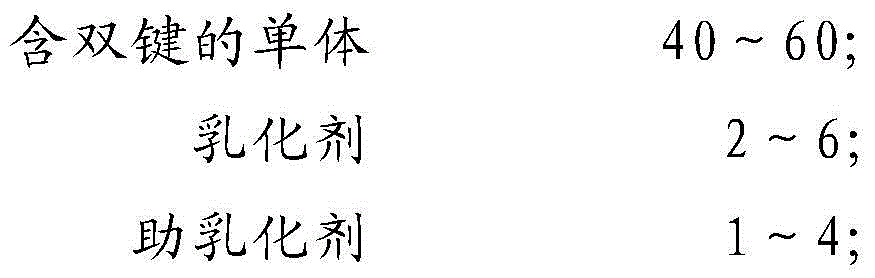

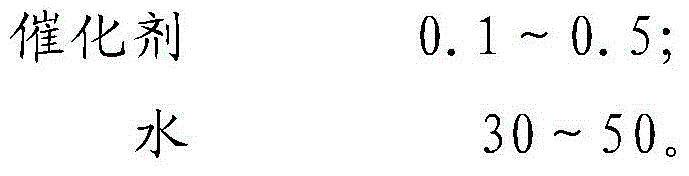

Nanometer emulsion blocking agent used for drilling fluid, and preparation method and application thereof

InactiveCN104927802AReduce fluid lossImprove the blocking effectDrilling compositionPressure transmissionDifferential pressure

The invention relates to a nanometer emulsion blocking agent used for drilling fluid, and a preparation method and application thereof. The nanometer emulsion blocking agent is prepared through polymerization by dispersing at least two double-bond-contained monomers into water containing an emulsifier and a co-emulsifier in an weak alkali environment under the action of a catalyst; and raw materials participating in reaction comprise, by weight, 40 to 60 parts of the double-bond-contained monomers, 2 to 6 parts of the emulsifier, 1 to 4 parts of the co-emulsifier, 0.1 to 0.5 part of the catalyst and 30 to 50 parts of the water. Accordingn to the invention, a particle size of a dispersed particle in the nanometer emulsion blocking agent is distributed in a nanoscale and is less than 500 nm, so the nanometer emulsion blocking agent has good blocking effect, cen block micropores and be casted into microcracks, and is capable of reducing pore pressure transmission, maximumly reducing differential pressure sticking and effectively inhibiting hydration dispersion of clay; the nanometer emulsion blocking agent is stable in high salinity and has the advantages of convenient use, no toxicity, no pollution and easy degradation; and the preparation method of the nanometer emulsion blocking agent has the advantages of reasonable process, mild and controllable conditions, no post treatment, low cost and benefit ratio, and facilitation to industrial production.

Owner:北京中科日升科技有限公司

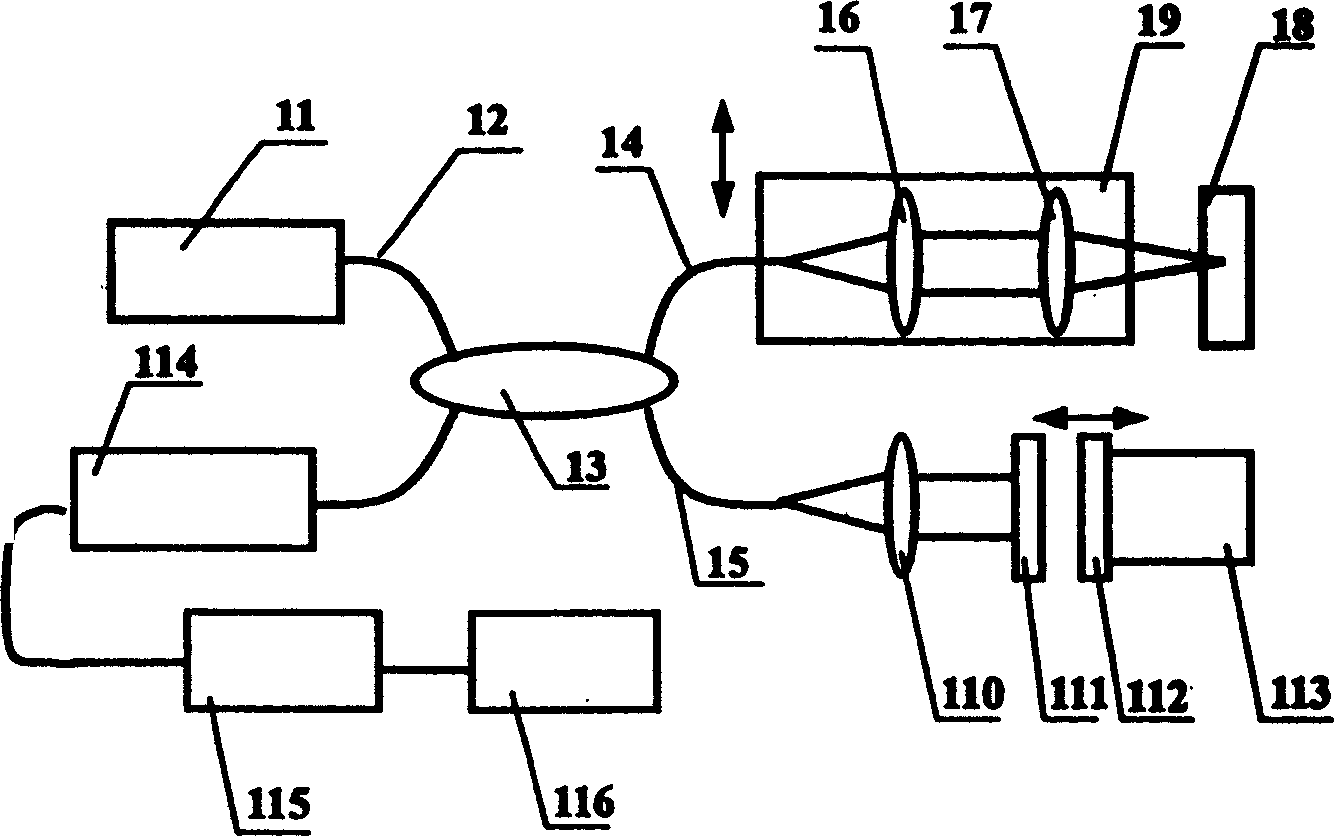

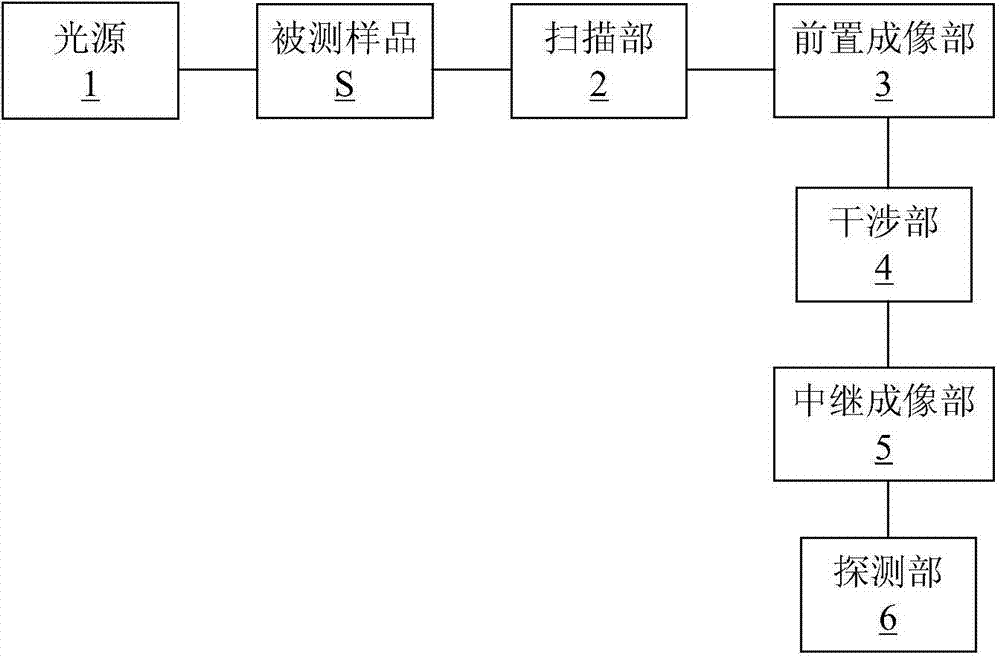

Longitudinal scanning method and device in optical image system of coherent faults

InactiveCN1539376AImprove machining accuracyQuick responseMaterial analysis by optical meansRadiation diagnosticsIt equipmentLight beam

A method for longitudinal scan in optically coherent tomographic imaging system features that a prism system composed of moving prism group and static prism group is used in a longitudinal scanner and a microshifting device is used to drive said moving prism group for realizing high-speed high-precision linear longitudinal scanning. Its equipment is composed of light source, optical fibre, optical fibre coupler, lens, said prism system and microshifting device.

Owner:SICHUAN UNIV

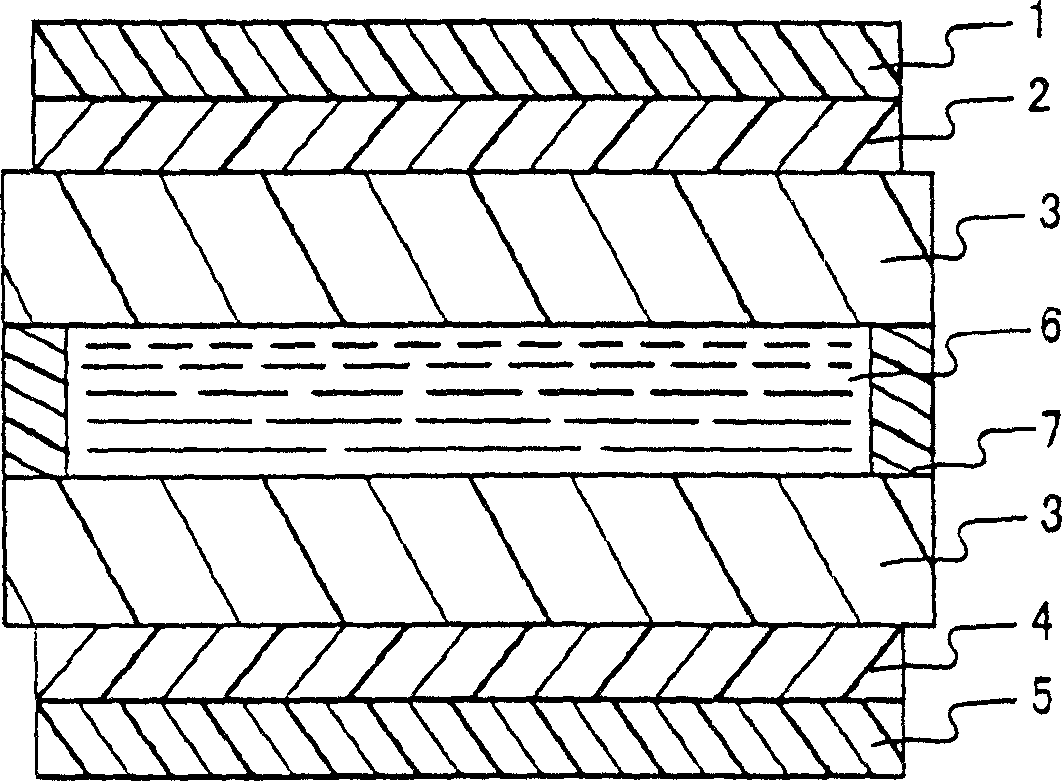

Polarizing plate and liquid crystal display device using the same

InactiveCN1595249ASmall color differenceAvoid chromatic aberrationPolarising elementsMountingsLiquid-crystal displayThin membrane

The present invention provides a polarizer and a polarizing plate having less dimensional changes to heat stress. The present invention provides also a liquid crystal display that includes the polarizer and the polarizing plate, and is free of color irregularity or decoloration. The polarizer has shrinkage force of not more than 4.0 N / cm in the absorption axis direction after being heated at 80 DEG C. for 30 minutes. A protective film is laminated on at least one surface of the polarizer in order to form a polarizing plate, and the polarizing plate has a following relationship of 0.01<=A / B<=0.16 when A denotes a thickness of the polarizer and B denotes a thickness of the protective film.

Owner:NITTO DENKO CORP

Electrode including multi-layered electrode active material layer and secondary battery including the same

ActiveUS9543568B2Increase of volumeIncrease of weightActive material electrodesElectrode collector coatingEngineeringCell resistance

The present invention relates to an electrode comprising multi-layered electrode active material layer and a secondary battery comprising the same. According to the embodiments of the present invention comprises electrode having multi-layered electrode active material layer, wherein the content of the active materials which forms the electrode active material layers is equally maintained and the loading amounts at each layer are either the same or different from each other, thereby solving the problem of performance deterioration caused by an increase in battery resistance due to non-uniform dispersion of a binder or the like.

Owner:LG ENERGY SOLUTION LTD

Titanium vacuum cup with high-airtightness vacuum thermal insulation cavity

InactiveCN105595743AGuaranteed vacuumPrevent dispersionDrinking vesselsThermal insulationNano copper

The invention discloses a titanium vacuum cup with a high-airtightness vacuum thermal insulation cavity. The titanium vacuum cup comprises a shell, an inner container and the vacuum thermal insulation cavity, wherein the inner container is arranged in the shell, and the vacuum thermal insulation cavity is formed between the shell and the inner container. The titanium vacuum cup is characterized in that each of the inner wall of the shell and the outer wall of the inner container is coated with a nano copper coating. Since the vacuum thermal insulation cavity is coated with the nano copper coatings all around to realize hermetic protection, air is prevented from diffusing into the vacuum thermal insulation cavity through the inner container and the shell, vacuum degree of the vacuum thermal insulation cavity is effectively kept, thermal preservation and thermal insulation performances of the cup are guaranteed against reduction, and thermal preservation time of the vacuum cup is greatly prolonged while durability and quality of the vacuum cup are greatly improved.

Owner:SUZHOU XINJINGYI TITANIUM PROD

Method for producing sodium acetate trihydrate and anhydrous sodium acetate as byproducts

ActiveCN101671246ASolve environmental problemsReduce manufacturing costCarboxylic acid salt preparationCarboxylic compound separation/purificationSolid phasesChemistry

The invention relates to a method for producing sodium acetate trihydrate and anhydrous sodium acetate as byproducts, which comprises the following steps: firstly, taking sodium acetate solution which is a byproduct generated in the production process of trimellitic anhydride, pouring into a material mixing kettle, stirring, and neutralizing until the pH value is 6-9; secondly, evaporating and concentrating; thirdly, putting the concentrated sodium acetate solution in a crystallization kettle, cooling to 60-57 DEG C, adding sodium acetate trihydrate crystals accounting for 0.05-0.5% by mass of the solution in the kettle to provoke the crystallization, and stirring for more than 12 hours; fourthly, centrifugally separating to obtain the solid phase which is the sodium acetate trihydrate; and fifthly, drying the sodium acetate trihydrate in a vortex drier to obtain the anhydrous sodium acetate. The method can prevent the sodium acetate solution from being supercooled, avoids the processes with high energy consumption, such as brine cooling and the like, and does not need to add other crystal nuclei so as to avoid introducing impurities into the product. The vortex drier is used for drying by one step so as to avoid the complicated energy-consuming processes of vacuum concentration, crystallization by cooling, centrifugal separation, drying and the like in the prior production technique of anhydrous sodium acetate.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

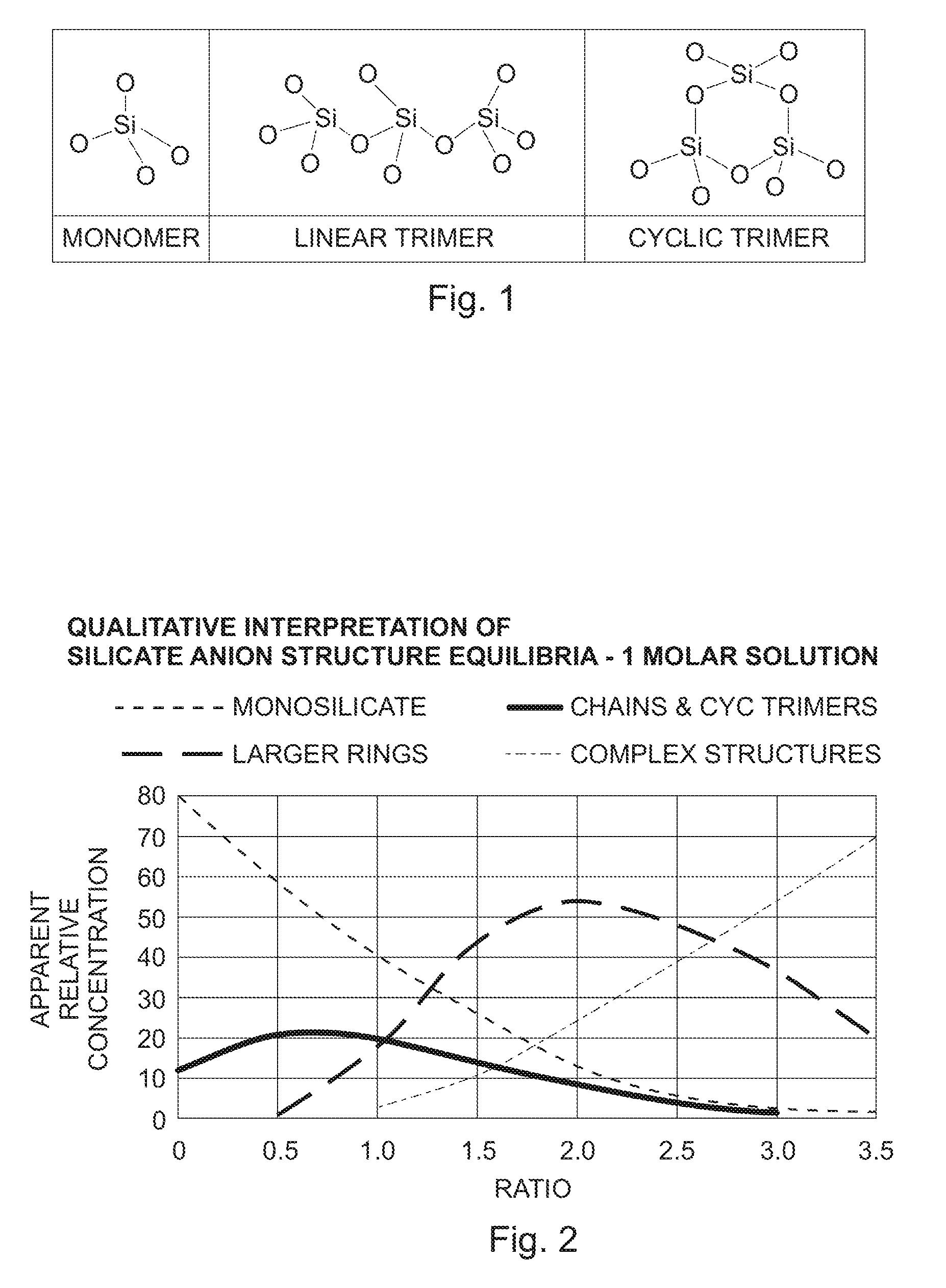

Use of high ratio aqueous alkali silicates in drilling fluids

ActiveUS9212304B2Prevent dispersionInhibition of hydrationDrilling compositionPotassium silicatePotassium

An improved drilling and completion fluid can be used in subterranean drilling for oil and gas. Sodium silicate and potassium silicate-based drilling fluids are commonly used drilling fluids with the notable attributes of exceptional shale stabilization characteristics coupled with exceptional environmental performance Environmental and wellbore stabilization characteristics are improved by using high ratio aqueous silicates wherein ratio is defined as the molar ratio of SiO2:Me2O, where Me is an alkali and is most commonly sodium or potassium (i.e. Na2O and K2O). For high ratio aqueous alkali silicates, the molar ratio of SiO2:Me2O can range from just over 4.0 to about 12.0.

Owner:PQ LLC

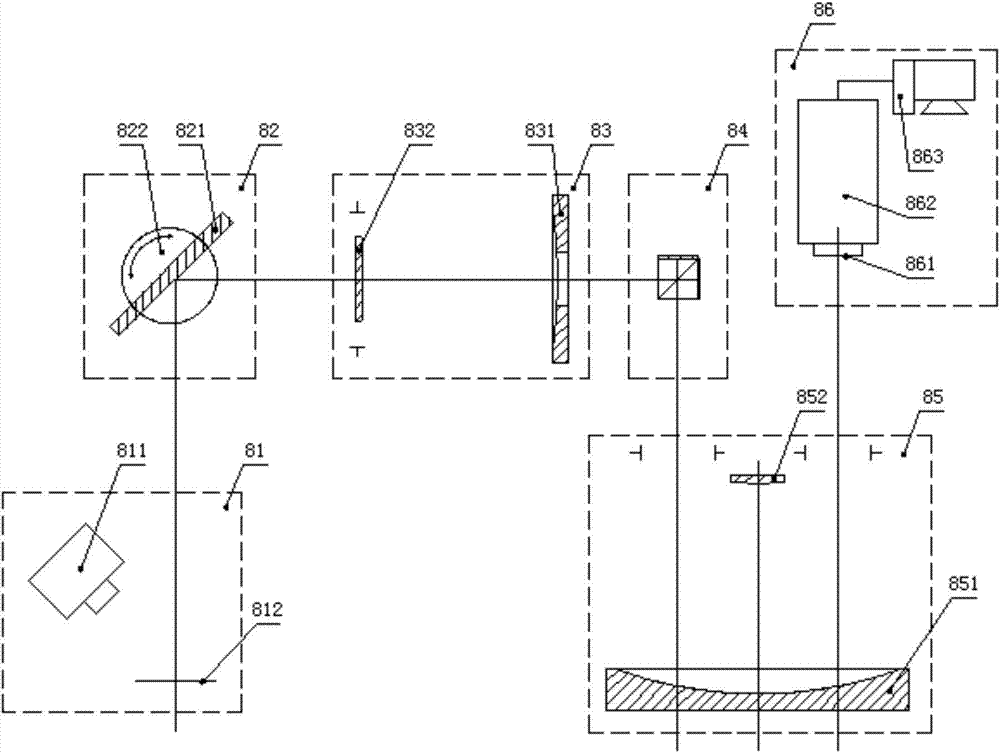

Broadband close shot ultraviolet imaging spectrum device

InactiveCN103940514ABroaden the band rangeSensitive detectionInterferometric spectrometryColor/spectral properties measurementsTest sampleUltraviolet

The invention provides a broadband close shot ultraviolet imaging spectrum device which is used for solving the problem that an existing ultraviolet imaging spectrum device can not flexibly detect an object within a wide ultraviolet spectrum range, and relates to the field of photoelectricity. The broadband close shot ultraviolet imaging spectrum device comprises a scanning portion, a front imaging portion, an interfering portion, a relay imaging portion and a detecting portion, wherein the scanning portion is used for scanning a tested sample according to a preset step length, the front imaging portion is used for conducting zooming and focusing on reflection light in a reflection mode, the reflection light is generated each time when the scanning portion conducts scanning, the interfering portion is used for conducting imaging on the reflection light, coming from the front imaging portion and generated each time when scanning is conducted, to form a first image and a second image, the content of the first image and the content of the second image in the same set are the same, the difference between the phase of the first image and the phase of the second image is a preset phase, the relay imaging portion is used for conducting superposition and interference on the first image and the second image in each set in a reflection mode to form a third image, and the detecting portion is used for converting optical signals of each third image obtained through superposition and interference into electric signals and conducting data processing.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

On-line detection system for film thickness on surface of enameled wire

ActiveCN113304940AAffect qualityHave a supercharging effectMeasurement devicesSpray boothsElectric machineStructural engineering

The invention discloses an on-line detection system for the film thickness on the surface of an enameled wire, and relates to the field of thickness detection. The on-line detection system comprises a detection ring and a thickness monitor, wherein the thickness monitor is located on the inner wall of the detection ring; the detection ring sleeves a cable; the bottom end of the cable extends out of a sealing box and is wound on the edge of a setting-out roller; the top end of the cable bypasses guide rollers at the bottom and the top of the sealing box and is wound around the edge of the winding roller; the winding roller is fixedly connected with a rotating shaft of a driving motor; a paint repairing device is arranged at the position, located above the detection ring, of the outer portion of the cable; and a polishing device for polishing redundant paint on the edge of the cable is arranged at the position, located above the paint repairing device, of the outer portion of the cable. According to the on-line detection system, the film thickness of the cable can be detected through the thickness monitor on the inner wall of the detection ring, and meanwhile, the paint repairing device and the polishing device are arranged to conduct remedy treatment on the stage which does not meet the thickness requirement of the cable, so that the film thickness on the cable meets the national standard requirement.

Owner:CHANGZHOU WELLYUN ELECTRICAL

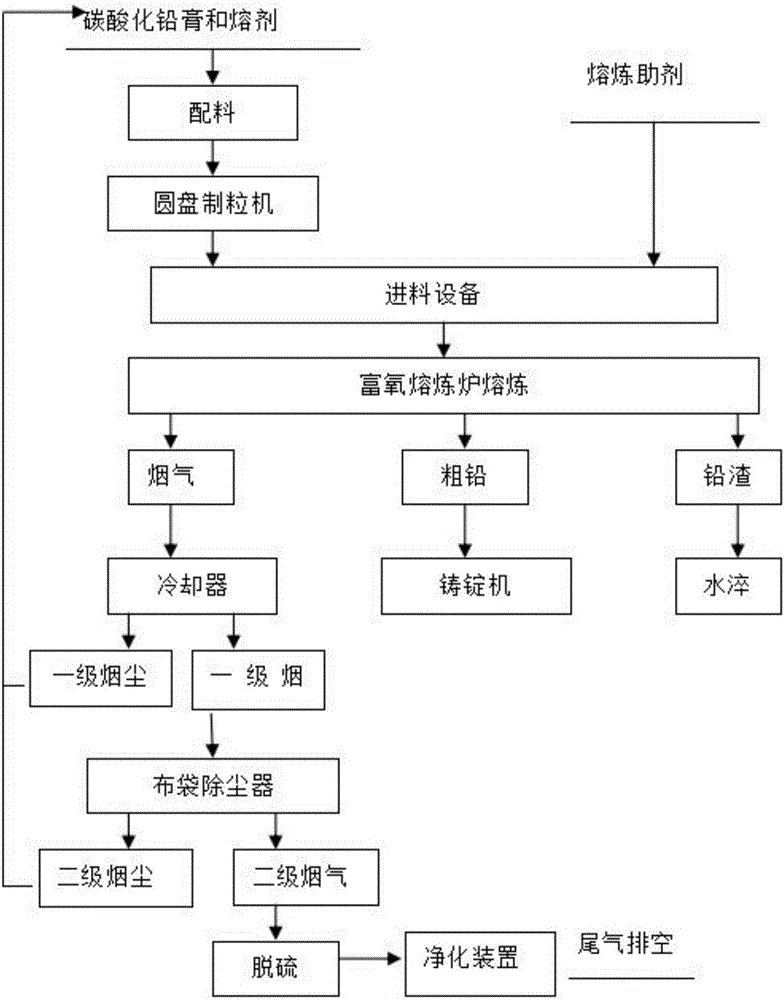

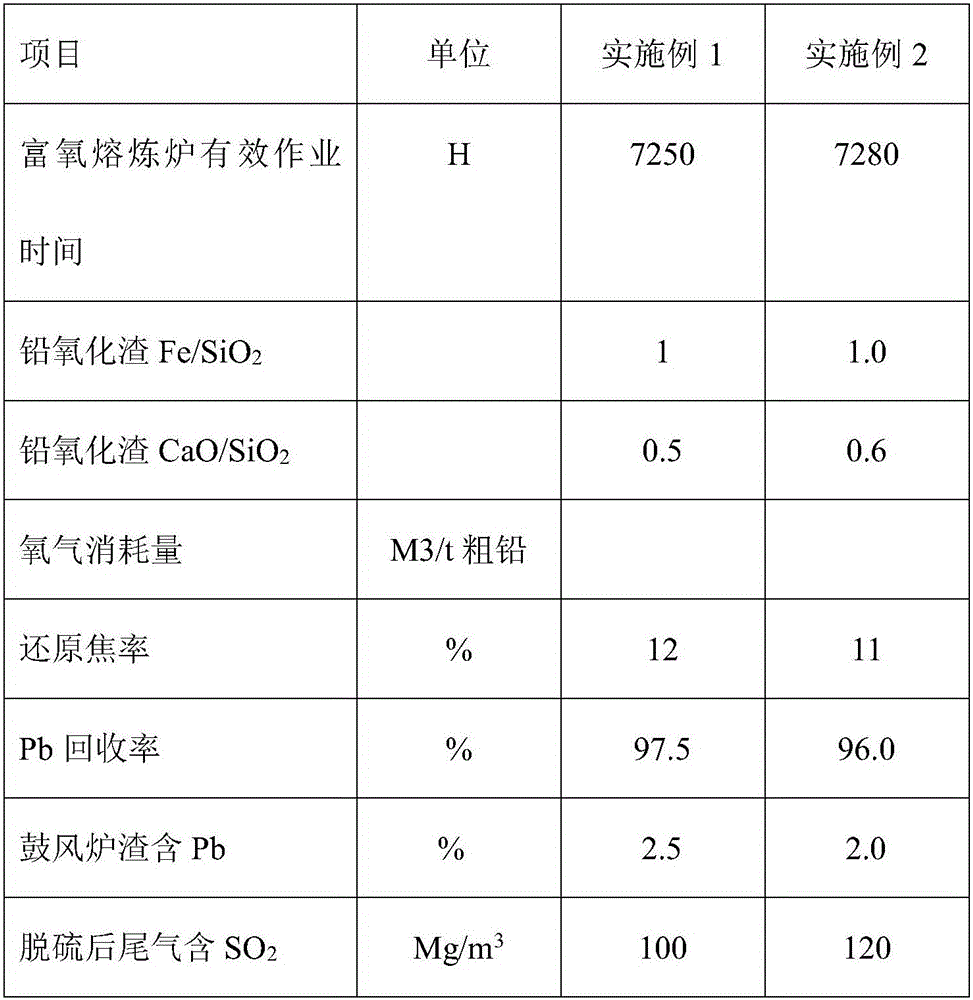

Smelting process for efficient and energy-saving secondary lead

The invention relates to a smelting process for efficient and energy-saving secondary lead. The smelting process comprises the following process steps that after burdening of lead paste which is separated out through automatic disassembly of a waste lead-acid battery and is carbonated and solvent, burdenings are sent into an oxygen-enriched smelting furnace to be subjected to smelting, and crude lead, lead slag and low-concentration SO2 flue gas are produced; and after residual heat recovery and dust collection through a dust collector, the SO2 flue gas is sent to a desulfurization system, is desulfurized and is discharged with standard level, wherein the lead slag, serving as vitrified general wastes, is sold to a cement plant as a raw material; the crude lead is electrolytically refined to obtain refined lead and anode slime, and the refined lead and the anode slime are sold; and a system of realizing the process is composed of an oxygen-enriched side-blown smelting furnace, feeding equipment, slag water quenching equipment, cooling equipment, dust collection equipment and desulfurization equipment. According to the smelting process, with process design and system improvement, elements including Pb, Ag, Cu, Sb and Sn are cleanly and efficiently recovered.

Owner:ANHUI HUAXIN LEAD IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com