Oxygen bottom-blowing-blast furnace reduction process for lead smelting and apparatus therefor

An oxygen bottom blowing and smelting furnace technology, applied in the field of lead smelting method and devices used to realize the lead smelting method, can solve the problems of high implementation cost, environmental pollution, etc., achieve high labor efficiency, avoid escape, and invest in infrastructure effect of province

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this embodiment, the lead raw material used is lead concentrate, and its main components in terms of total mass percentage are as follows:

[0043] Pb: 55%, S: 18%, SiO2: 6%, Fe: 11%, CaO 3.5%, Au 15g / t, Ag 800g / t.

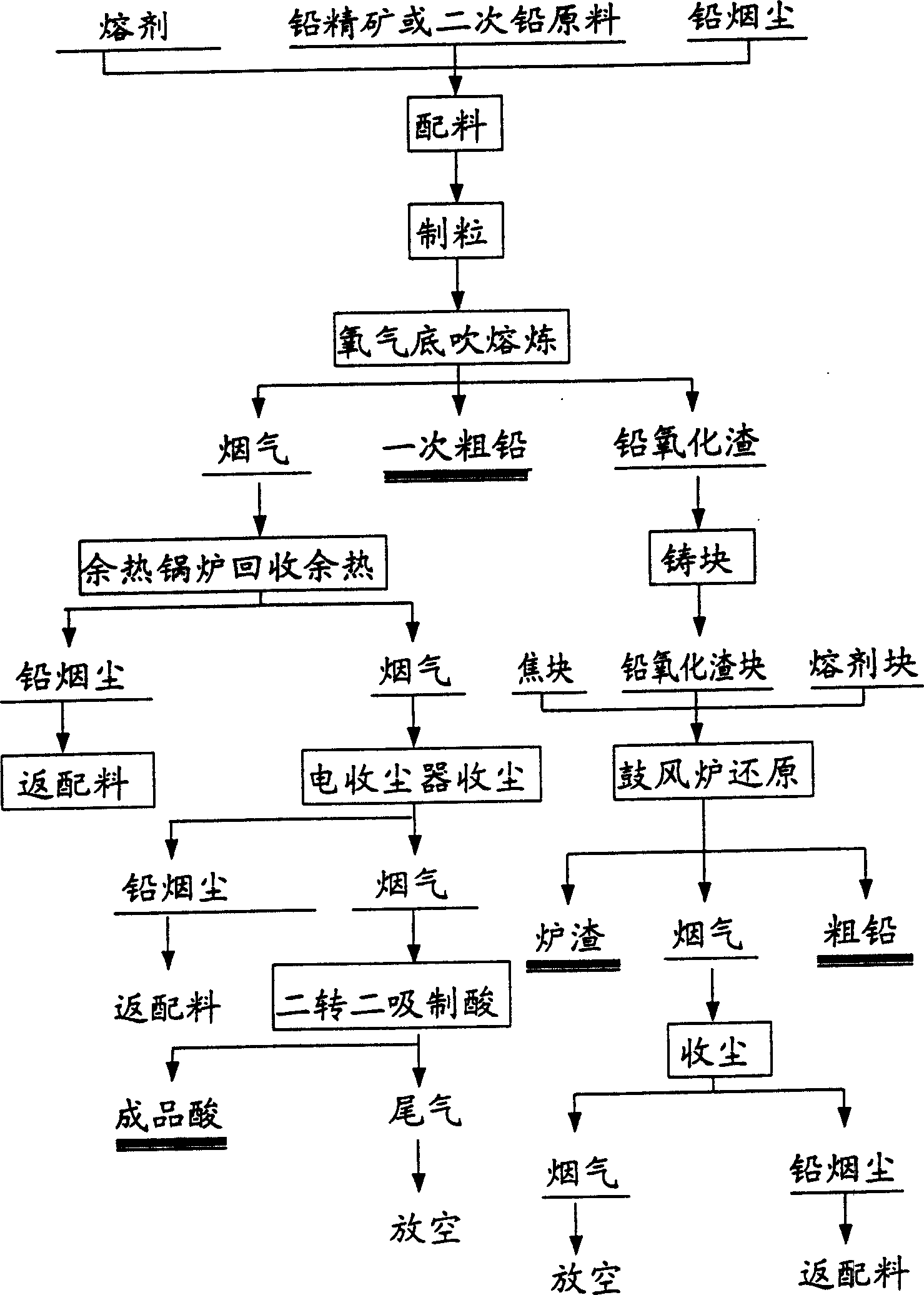

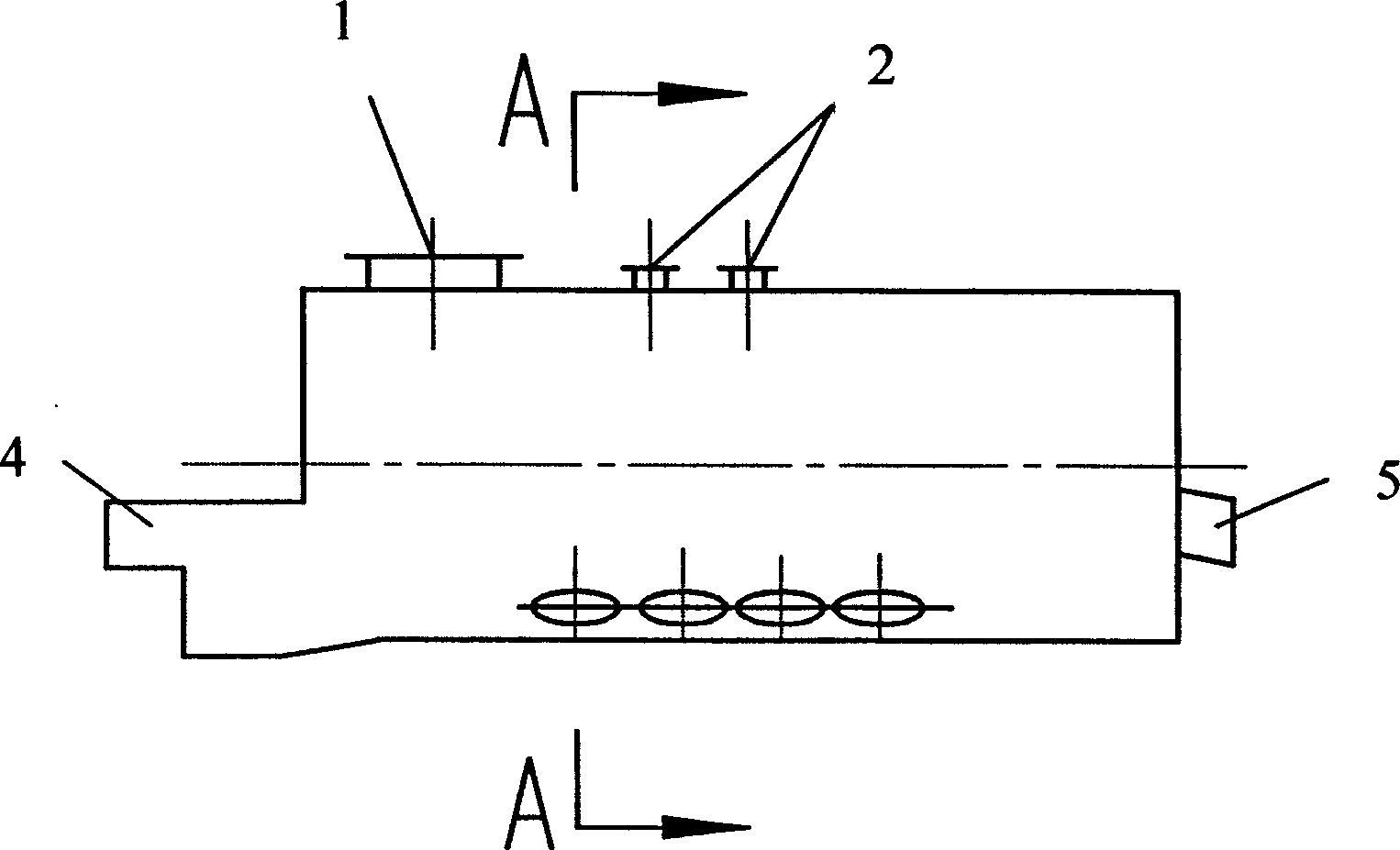

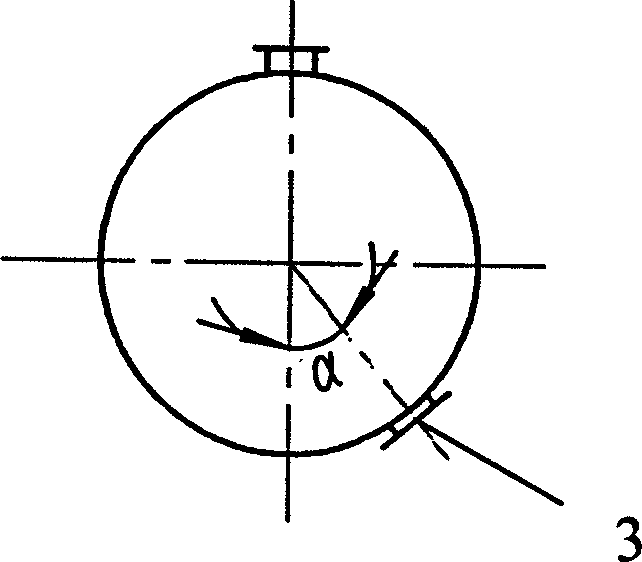

[0044] Such as figure 1 As shown, the lead concentrate and flux are mixed and pelletized, and then sent to the bottom-blowing furnace for smelting, and the temperature of the molten pool of the smelting furnace is 1050°C. There are 3 oxygen injection inlets at the bottom of the smelting furnace, and industrial oxygen containing O295% (total volume percentage) is injected into the furnace through a quaternary oxygen lance. The oxygen lance is protected by nitrogen and demineralized water; the produced flue gas contains SO 212-15% (percentage of the total volume) is sent to the waste heat boiler to recover waste heat, and after electric dust collection, it is sent to the sulfuric acid system for two rotations and two suction to produce acid; the tail gas of a...

Embodiment 2

[0047] In this embodiment, mixed lead raw materials are used, and the main components in terms of total mass percentage are as follows:

[0048] Pb: 50%, S: 17%, SiO2: 7.5%, Fe: 9%, CaO 4.5%, Au 20g / t, Ag 500g / t.

[0049] Such as figure 1 As shown, after batching and granulating the lead concentrate and flux, it is sent to a bottom-blowing furnace for smelting, and the temperature of the molten pool of the smelting furnace is 1100°C. There are 4 oxygen injection inlets at the bottom of the smelting furnace, containing oxygen (O 2 ) 95% (total volume percentage) of industrial oxygen is sprayed into the furnace through a quaternary oxygen lance. The oxygen lance is protected by nitrogen and softened water; the produced flue gas contains SO 2 10-12% (percentage of the total volume) is sent to the waste heat boiler to recover waste heat, and after electric dust collection, it is sent to the sulfuric acid system for two rotations and two absorption for acid production; the tail gas of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com