Steel tube welding shielding gas storage structure

A technology for storing structure and shielding gas, applied in welding accessories, welding equipment, welding equipment, etc., can solve the problems of de-welding of steel pipe 3 welds, reducing the strength of steel pipe 3, reducing the total amount of shielding gas, etc., to prevent escape, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

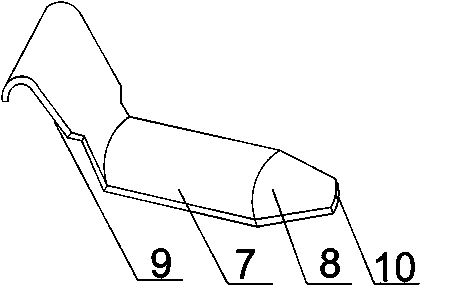

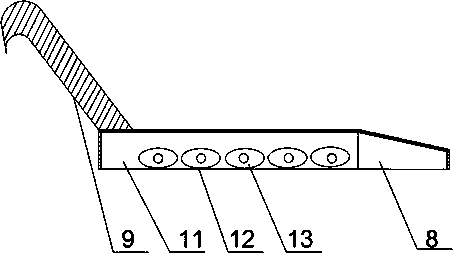

[0023] Such as Figure 1 to Figure 4 As shown, the steel pipe welding shielding gas storage structure of the present invention includes an arc-shaped main body 7, a storage chamber 11 is provided in the arc-shaped main body 7, and one end of the arc-shaped main body 7 is connected with an outlet cavity 8 and the arc main body 7 The other end is connected with a hanging plate 9, which is connected to the external semi-sealed mechanism 2 through a cross bar 6 during operation. The end of the air outlet cavity 8 is provided with an air hole 10, and the air outlet cavity 8 is tapered. It includes rollers 12, which are arranged obliquely on the inner walls of both sides of the storage chamber 11. When the present invention is working, the arc-shaped main body 7 is connected to the external semi-sealed mechanism 2 by the hanging plate 9 through the cross bar 6 to ensure the present invention Stable support is obtained; the shielding gas introduced from the core rod enters the storage...

Embodiment 2

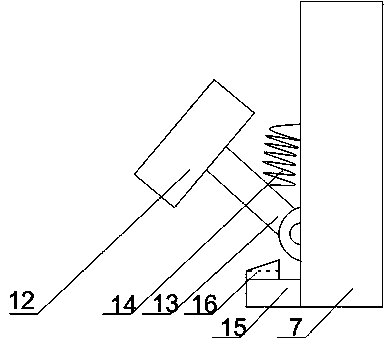

[0025] As shown in the figure, this embodiment is based on embodiment 1, the main shaft 13 of the roller 12 is hinged to the inner wall of the storage chamber 11, and a spring 14 is installed in the middle of the main shaft. The inner wall is connected; it also includes a limit mechanism installed directly below the hinge joint between the main shaft 13 of the roller 12 and the inner wall of the storage chamber 11; the limit mechanism includes a support plate 15 which is provided On the inner wall of the storage chamber 11 and below the main shaft 13 of the roller 12, a protrusion 16 is installed on the support plate 15. The upper surface of the protrusion 16 is an inclined surface; the inclination angle of the inclined surface is 35° ~50°. When welding the steel pipe 3 with a smaller pipe diameter, the inclination angle of the main shaft 13 of the roller 12 is reduced, and the roller 12 is easily in contact with the inner wall of the storage chamber 11, which affects the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com