Nanometer emulsion blocking agent used for drilling fluid, and preparation method and application thereof

A technology of nanoemulsion and plugging agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of micro-fractures that cannot be plugged, wellbore instability, large particle size, etc., and achieve the purpose of inhibiting hydration Effects of dispersing, reducing fluid loss, and reducing negative charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

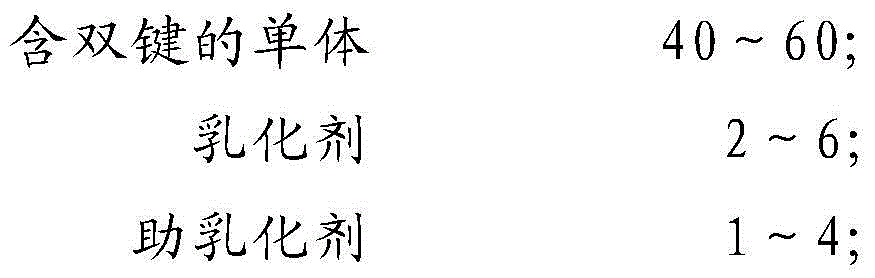

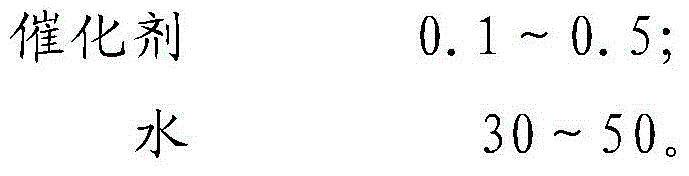

Method used

Image

Examples

Embodiment 1

[0035] Add 36Kg of deionized water into the reaction kettle, turn on the heating device, and raise the temperature to 30°C; weigh 2.0Kg of octadecyltrimethylammonium chloride and add it to the reaction kettle, keep the temperature at about 30°C, and turn on the stirring device , stir at 200r / min to make it evenly mixed; weigh 1.2Kg polyglycerol ester and add it to the reaction kettle, stir it at 30°C to make it evenly mixed; add 20.0Kg styrene and 20.0Kg methyl methacrylate to the reaction kettle In the kettle, fully stir at 40°C for 15 minutes to disperse the monomer evenly; continue to add 0.7Kg of disodium hydrogen phosphate into the reaction kettle, and after stirring evenly (pH is 8), dissolve 0.3Kg of potassium persulfate in 4.0Kg of water Prepare an aqueous solution and add it to the reactor, stir at a speed of 300r / min, while raising the temperature to 50°C, adjust the pressure of the reactor to 2.0MPa, and keep the reaction for 4.0 hours; after the reaction, cool to ro...

Embodiment 2

[0037] Add 27.0Kg of deionized water into the reactor, turn on the heating device, and raise the temperature to 40°C; weigh 2.0Kg of dioctyl sodium succinate sulfonate and 2.0Kg of polysorbate into the reactor, and keep the temperature at 40°C At about ℃, turn on the stirring device, stir at a speed of 200r / min to make it evenly mixed; weigh 2.5Kg of glycerol monostearate into the reaction kettle, stir at 40°C to make it evenly mixed; mix 25.0Kg of acrylonitrile and 25.0 Kg of methyl methacrylate was added to the reaction kettle, fully stirred at 40°C for 20 minutes to disperse the monomer evenly; continue to add 0.5Kg of sodium hydroxide to the reaction kettle, after stirring evenly (pH was 9), 0.1Kg Potassium persulfate was dissolved in 3.0Kg water to make an aqueous solution, then added to the reactor, stirred at a speed of 300r / min, at the same time, the temperature was raised to 60°C, the pressure of the reactor was adjusted to 2.5MPa, and the reaction was kept for 5.0 hou...

Embodiment 3

[0039] Add 40.0Kg of deionized water into the reactor, turn on the heating device, and raise the temperature to 50°C; weigh 3.0Kg of polyoxyethylene nonylphenol ether and 3.0Kg of sodium 4,8-dibutylsulfonate into the reactor, Keep the temperature at about 50°C, turn on the stirring device, stir at a speed of 200r / min to make it evenly mixed; weigh 4.0Kg of ethylene glycol into the reaction kettle, stir at 50°C to make it evenly mixed; mix 30.0Kg of vinyl acetate and Add 30.0Kg of methacrylic acid into the reaction kettle, fully stir at 50°C for 30 minutes to disperse the monomer evenly; continue to add 1.0Kg of sodium bicarbonate into the reaction kettle, after stirring evenly (pH is 7), add 0.5Kg of sulfur Sodium sulfite was dissolved in 10.0Kg water to make an aqueous solution, then added to the reactor, stirred at 300r / min, while raising the temperature to 80°C, adjusting the pressure of the reactor to 3.0MPa, and keeping the reaction for 3.0 hours; after the reaction, coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com