Patents

Literature

189results about How to "No post-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-temperature starch composition for drilling liquid and preparation method thereof

InactiveCN101255333ACreate pollutionAdapt to environmental requirementsDrilling compositionPotato starchWell drilling

A temperature tolerant starch composition for well drilling liquid and method of preparing the same, which includes starch, catalyst, cationic reagent and cross linker, wherein starch comprises potato starch, cassava starch, corn starch, with a weight ratio of 30-80:20-60:10-50; weight ratio between catalyst and starch is 5-30:100, weight ratio between cationic reagent and starch is 1-20:100, and weight ratio between cross linker and starch is 0.01-0.6:100. The inventive temperature tolerant starch composition for well drilling liquid not only inhibits yeastiness thereof effectively and enhances tolerant temperature from 120 DEG C to 150 DEG C, so that application range of the starch is widen, but also protects environment because of biodegradability. Moreover, the preparation is simple in process, mild in reaction condition, high in conversion, low in cost, without subsequent process and waste, which makes it economic and environment protective.

Owner:北京中科日升科技有限公司

High modulus composition for emi shielding and molded articles thereof

InactiveCN102985492AHigh mechanical strengthImprove conductivityShielding materialsLayered productsFiberPolymer science

The high-rigidity electromagnetic shielding composition of the present invention comprises: (A) approximately 10-34 wt% of polyamide resin having an aromatic group in the backbone structure; (B) approximately 65-85 wt% of carbon fiber; and (C) approximately 1-20 wt% of metallic filler. The composition has high modulus, electromagnetic shielding effects, and high surface conductance, and can thus be used to replace frames, brackets and the like for electronic devices.

Owner:CHEIL IND INC

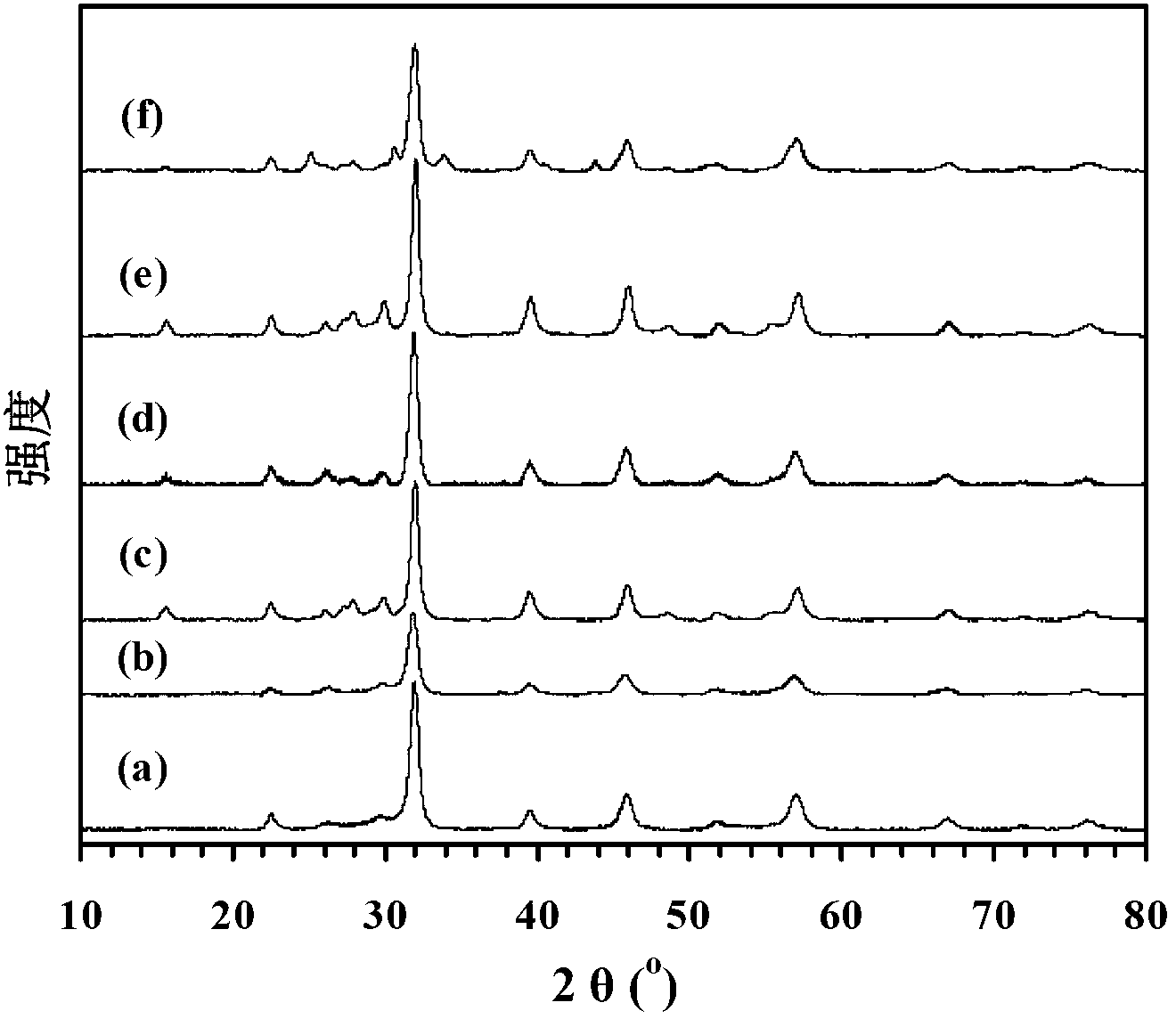

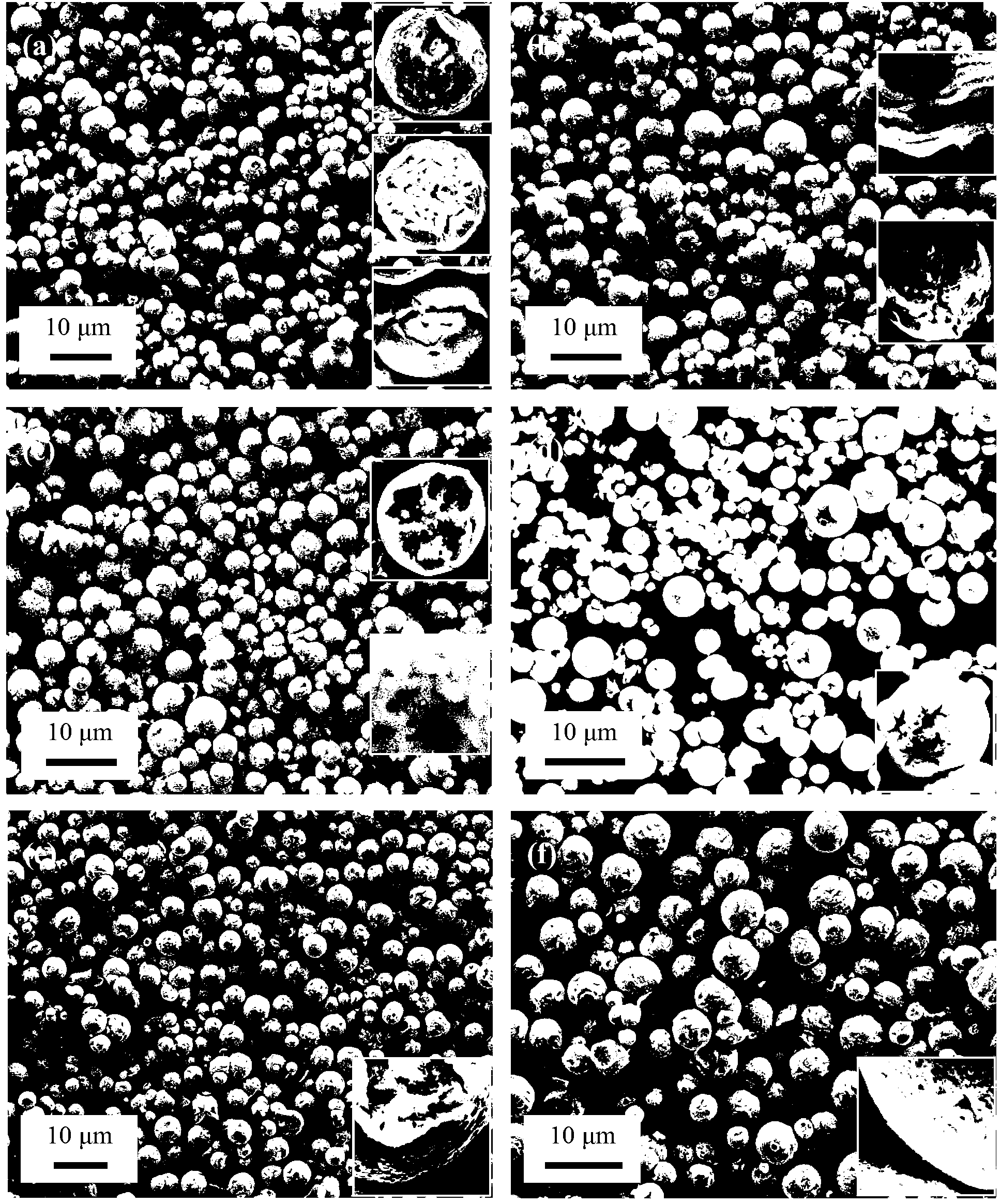

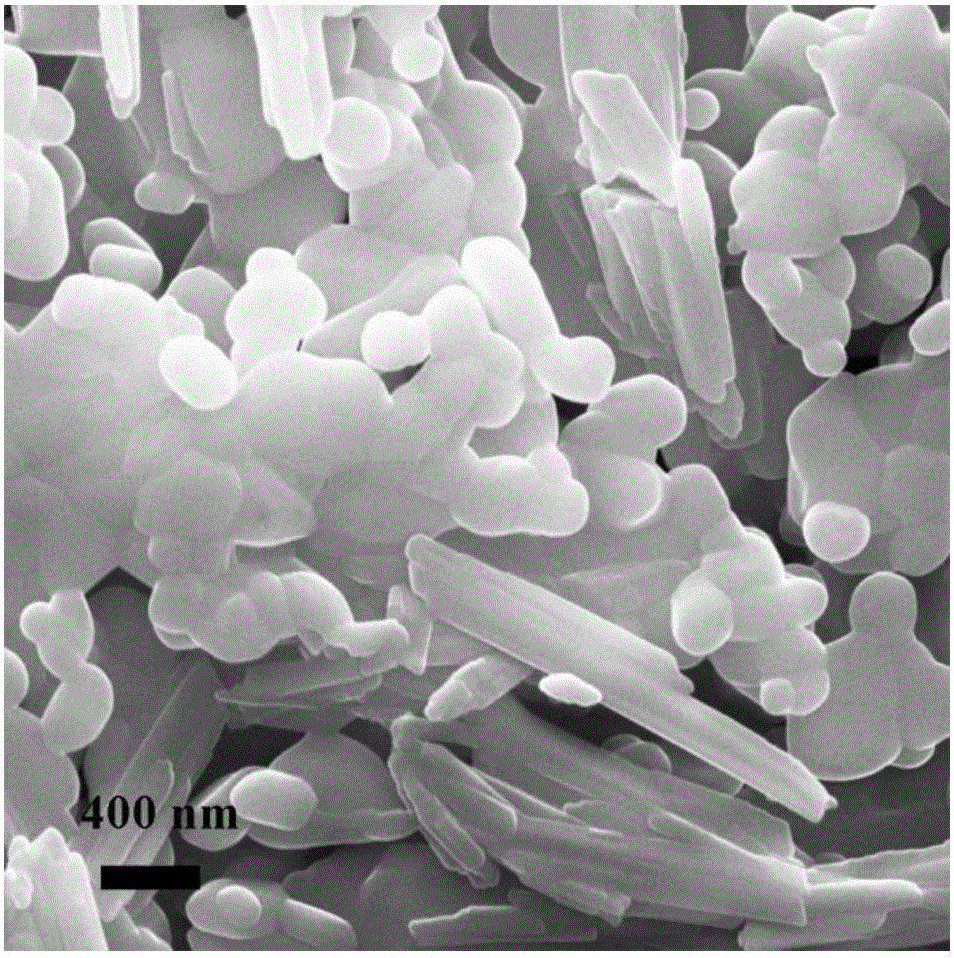

Perovskite composite oxide LaFeO3 monodisperse micrometer hollow balls and preparation method thereof

The invention relates to perovskite composite oxide LaFeO3 monodisperse micrometer hollow balls and a preparation method thereof, and belongs to the technical field of micro nanometer functional materials. The micrometer hollow balls are in a monodisperse state, the outer diameter of each micrometer hollow ball is between 1 and 7 micrometers, and the micrometer hollow balls are in a perovskite crystalline phase. The preparation method comprises the following steps of: stirring a mixed solution containing urea serving as an additive, citric acid serving as a complexing agent, deionized water serving as a solvent and metal nitrate uniformly, transferring the mixed solution to an autogenous pressure kettle, putting into a constant temperature box, keeping temperature for a certain time, cooling naturally, performing suction filtration on the obtained products, drying, grinding, and roasting at high temperature to obtain the highly-monodispersed LaFeO3 micrometer hollow balls. According to the preparation method, a template is not needed to be utilized, the reaction time is short, the preparation process is environment-friendly, and the operation is easy to implement.

Owner:BEIJING UNIV OF TECH

Composite electrode materials, preparation method thereof, and application thereof

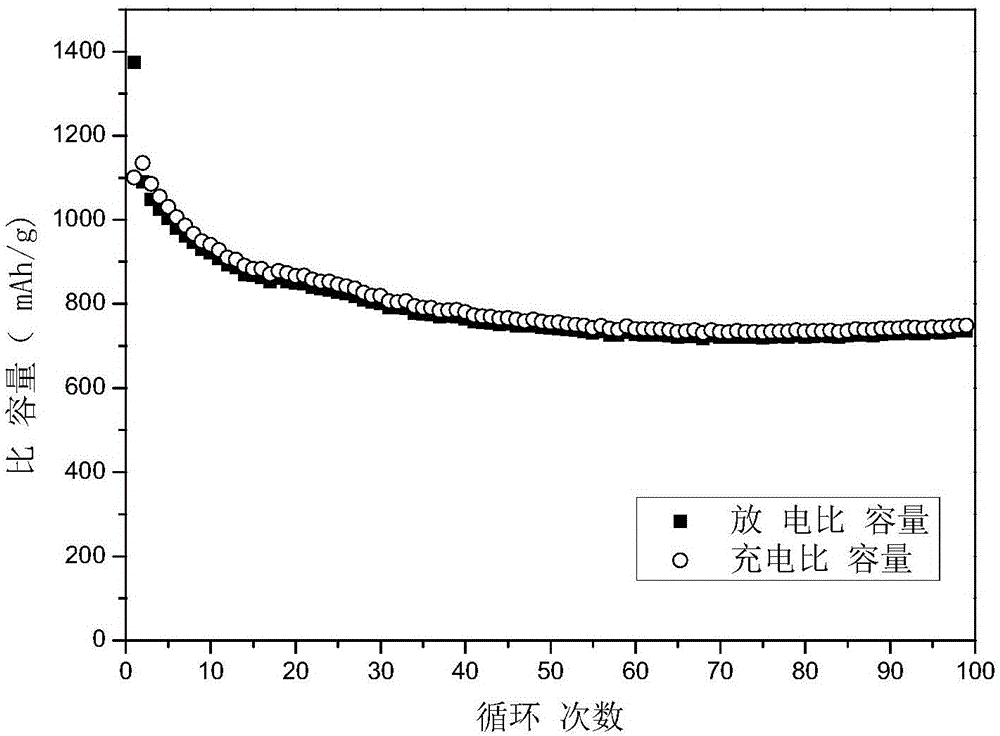

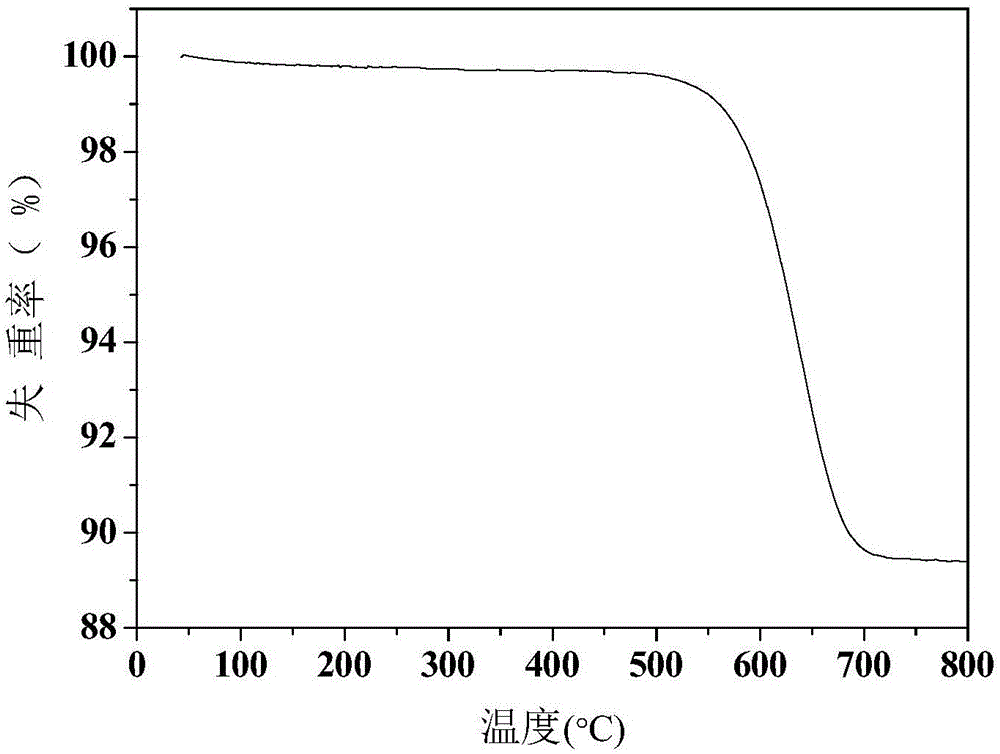

ActiveCN107359054AIncrease profitSmall sizeHybrid capacitor electrodesCell electrodesComposite electrodeNickel oxide hydroxide

The present invention relates to composite electrode materials, a preparation method thereof, and an application thereof. The method comprises: metallic oxide and / or hydroxide solution through coordination solution are mixed with carbon materials, the metallic oxide and / or metal hydroxide are grown in situ at the surface of the carbon materials through evaporation of a ligand solution, and the composite electrode materials are obtained. The method provided by the invention is simple to operate, low in cost, green and environmentally friendly without postprocessing, and provides possibility for industrialization large-scale production of the electrode materials. The composite electrode materials prepared by the method are good in electric energy storage. For example, the 5% capacity nickelous hydroxide-active carbon composite electrode materials are prepared by the method, the full electrode quality specific capacity thereof can reach 294F / g, and the active substance specific capacity thereof can reach 4917F / g.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

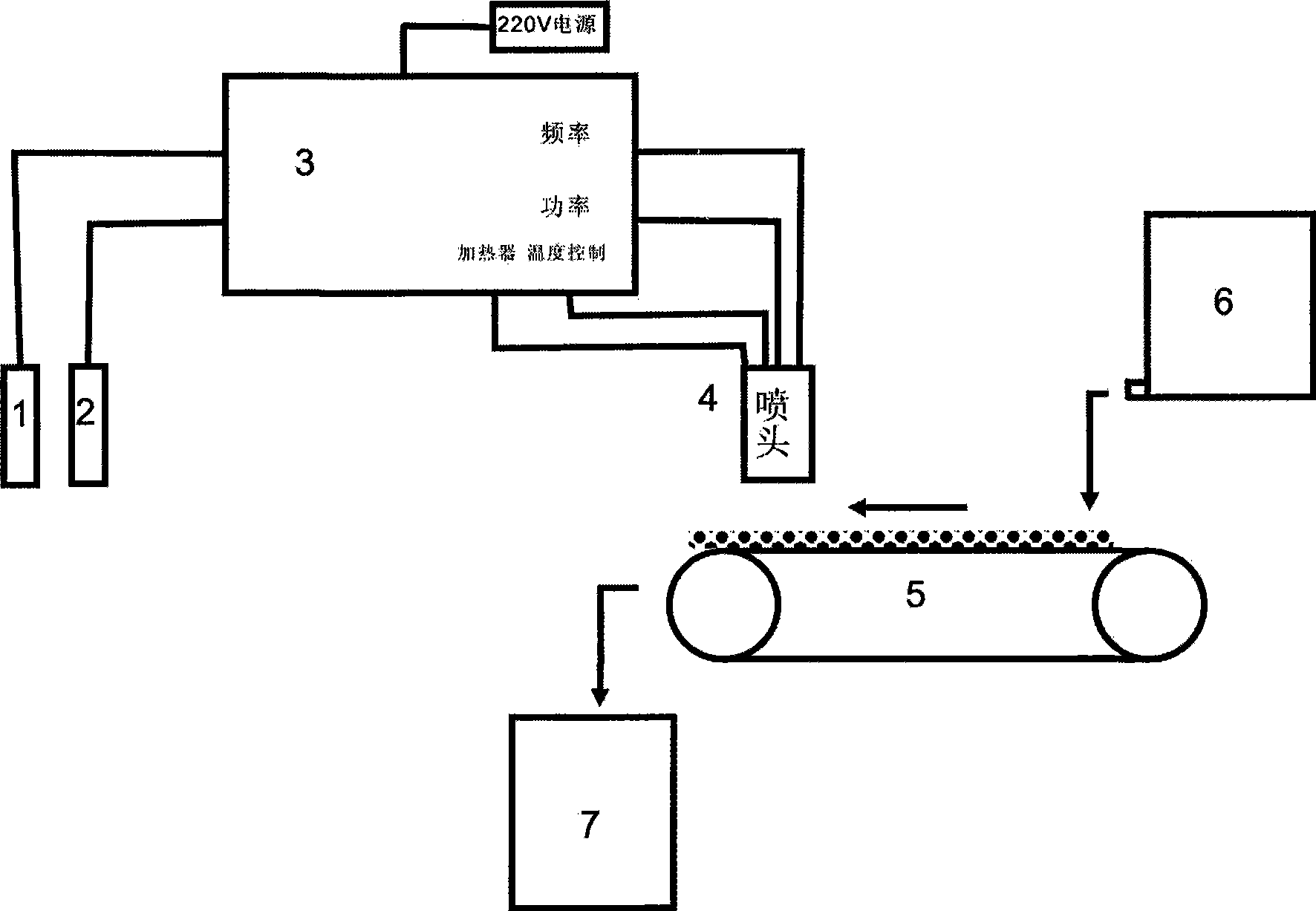

Method for processing barometric pressure, normal-temperature plasma modification on carbon nano-tube surface

InactiveCN101428789AStrong process controllabilitySimple replacement processPigment physical treatmentNanometreSurface modification

The invention relates to a processing method for modifying atmospheric pressure on the surface of a carbon nanometer tube and a normal temperature plasma, which comprises the following steps: placing the carbon nanometer tube on a special transmission device of a plasma processing device; spraying the e plasma to the surface of the carbon nanometer tube under the atmospheric pressure and the openenvironment, so that the carbon nanometer tube moves in the atmosphere of the plasma, wherein the processing power is 10W to 5000W and the time is 0.01s to 6000s; and then generating the surface modification of the carbon nanometer tube. The invention can directly improve the surface property, the structure and the shape of the carbon nanometer tube for one step under the atmospheric pressure andthe normal temperature, and has the advantages of strong process controllability, simple replacement process and less environmental pollution by adopting the dry process. The effect of isosexual repulsion is generated on the particle surface of the carbon nanometer tube, so that the possibility on the reunion of nanometer particles is reduced.

Owner:DONGHUA UNIV +1

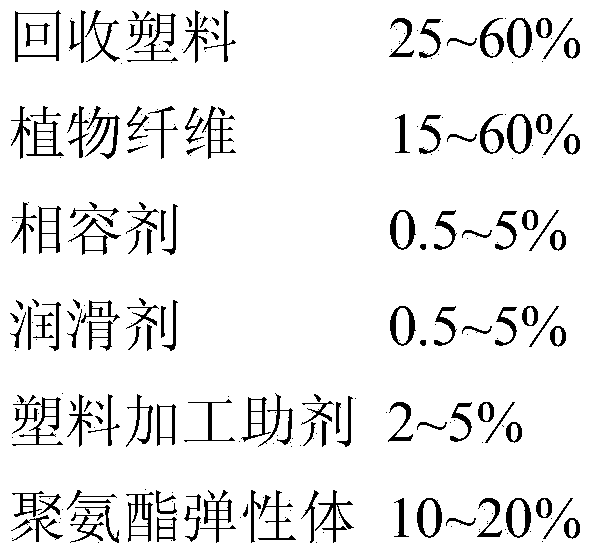

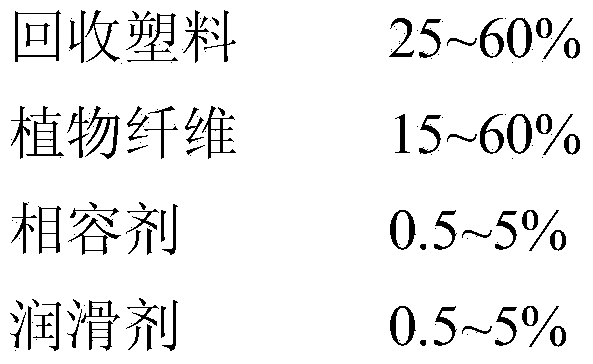

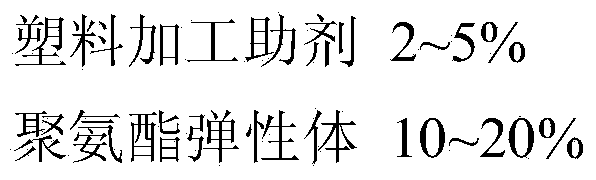

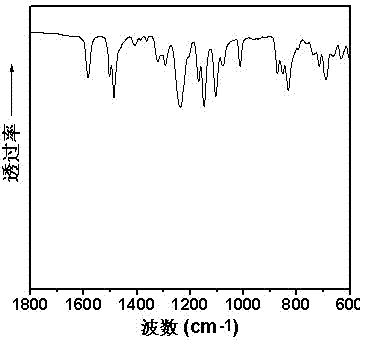

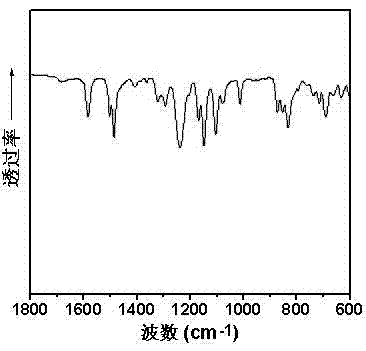

High-wear-resistance wood-plastic floor board and preparation method thereof

The invention relates to a high-wear-resistance wood-plastic floor board and a preparation method thereof. The preparation method comprises the following steps: adding a polyurethane elastomer and a compatilizer into a high-speed mixer, and carrying out melt blending at the high temperature of 130-150 DEG C for 20-30 minutes to obtain modified polyurethane; adding recycled plastic, plant fiber and the modified polyurethane into the high-speed mixer, and mixing and stirring at 100-130 DEG C for 20-30 minutes to obtain a blend compound I; and mechanically mixing the blend compound I with a lubricant and plastic processing assistants for 15 minutes, melting at high temperature, plastifying and granulating; and melting the granules with a special wood-plastic extruder, setting, cooling, cutting, and carrying out after-treatment according to the demands of customers to obtain the high-wear-resistance wood-plastic floor board. The preparation method has the advantages of simple production technique, low cost, no need of after-treatment, no use of any organic solvent, and no emission of toxic or harmful gas. On the premise of enhancing the wear resistance, the method does not lower the strength of the material, obviously enhances the wear resistance of the material, greatly lowers the water absorptivity, prolongs the service life and widens the application range.

Owner:DALIAN HUANMEI SCI & TECH GRP

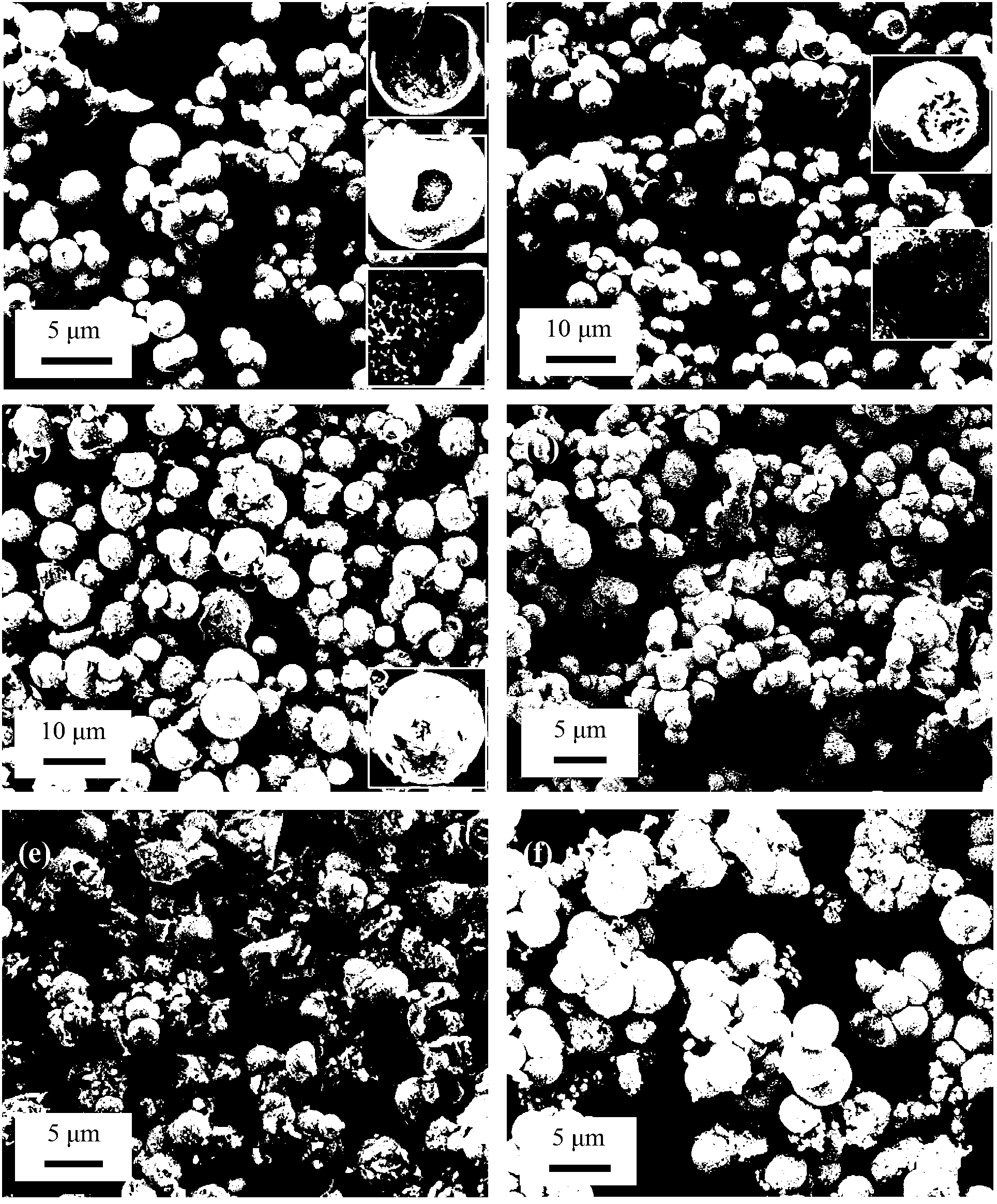

A kind of polysulfone-polypyrrole nanoparticle composite asymmetric ultrafiltration membrane and preparation method thereof

InactiveCN102258950AGood hydrophilic surfaceGood biocompatibilityUltrafiltrationHemodialysisUltrafiltration

The invention discloses a preparation method of a polysulfone-polypyrrole nano particle composite asymmetric ultrafiltration membrane. That is, using polysulfone as the matrix membrane material and highly dispersed polypyrrole nanoparticles as the filler, polysulfone-polypyrrole nanoparticles composite asymmetric ultrafiltration membranes with different compositions were prepared by solvent blending and phase transfer. The preparation method of the invention requires simple equipment, convenient operation, low production cost and no post-treatment. The polypyrrole nanoparticles in the obtained composite membrane are uniformly dispersed in the polysulfone, and the obtained membrane has no pollution. During the preparation process, the pore structure, hydrophilicity and chargeability of the membrane are controlled by adjusting the content, particle size and concentration of the casting solution of polypyrrole nanoparticles, so as to optimize the separation performance of the membrane. The resulting composite ultrafiltration membrane is suitable for terminal filtration of various Chinese and Western medicine injections, oral liquids, eye drops, etc., protein separation and purification, and human hemodialysis, etc., especially has a good selective separation function for bovine serum proteins.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

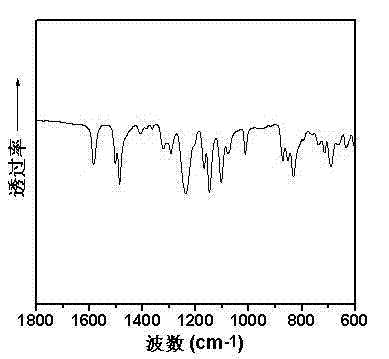

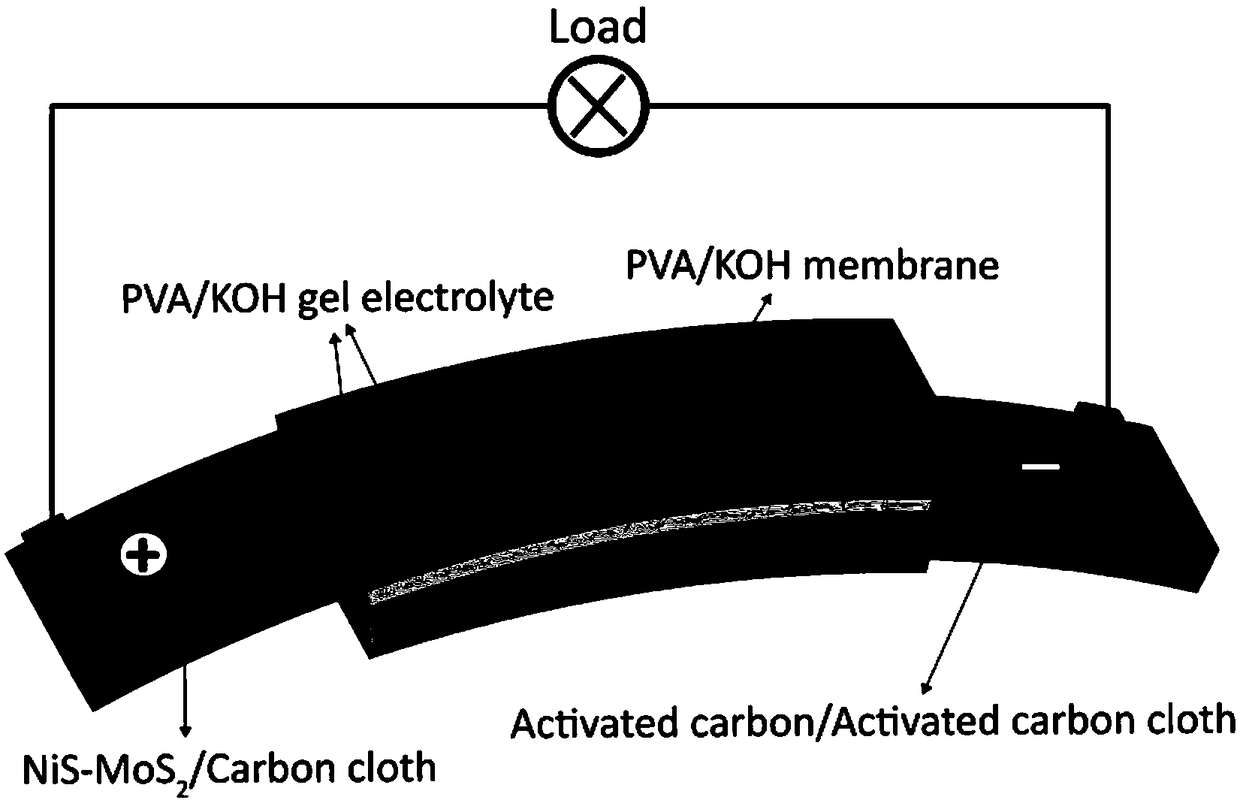

Flexible supercapacitor with nickel sulfide-molybdenum sulfide heterogeneous nano-sheet array structure based on carbon cloth loading and preparation method thereof

ActiveCN109065368ALarge capacityImprove charge and discharge stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNew energy

The present invention relates to a flexible supercapacitor with with NiS-MoS2 heterogeneous nano-sheet array structure based on carbon cloth loading and a preparation method thereof, belonging to thetechnical field of new energy material and device preparation. The flexible supercapacitor grows high-purity, high-density and high-orientation carbon cloth-loaded NiS-MoS2 heterogeneous nanosheet array by using anode material, carbon cloth coated with activated carbon as cathode material, PVA / KOH gel as diaphragm and electrolyte respectively. The anode has the advantages of high purity, high density, tidy appearance, strict controllable growth condition, simple equipment and process, low cost, high capacitance and good charge-discharge stability. The cathode material has excellent conductivity and large double-layer capacitance. The preparation process of the capacitor is simple, economical and environmentally friendly, and no post-treatment is needed. The supercapacitor provided by the invention has the advantages of light weight, large capacity, good cycle charging and discharging stability, and good flexibility, and can be used for power supply equipment of wearable electronic devices.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Method for preparing biodiesel by utilizing high-acid value oil

InactiveCN103173293ALow acid valueNo post-processingFatty acid esterificationBiofuelsMonoglyceridePtru catalyst

The invention relates to a method for preparing biodiesel by utilizing high-acid value oil. The method comprises the following steps of: esterifying the raw materials of the high-acid value oil, enabling glycerol and the raw materials of the high-acid value oil to esterify with each other under the catalyzing action of an ionic liquid, and thus obtaining a mixture of a low-acid value esterification product-monoglyceride, diglyceride or triglyceride; then carrying out interesterification on the esterified oil, namely carrying out interesterification on the mixture of the low-acid value esterification product-monoglyceride, diglyceride or triglyceride and methanol under the action of a base catalyst, and thus generating crud low-acid value biodiesel fatty acid methyl ester; and vacuum distilling and refining the low-acid value biodiesel fatty acid methyl ester so as to obtain the high-purity low-acid value fatty acid methyl ester biodiesel. The details of the method are described in a specification. The method has the advantages that the method does not need post treatment and is shortened in reaction process, lowered in technological energy consumption and clean in process, equipment corrosion caused by conventional sulfuric acid catalyzing is eliminated, the equipment investment and production cost are lowered, and the yield of a target product-biodiesel (fatty acid methyl ester) is high.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

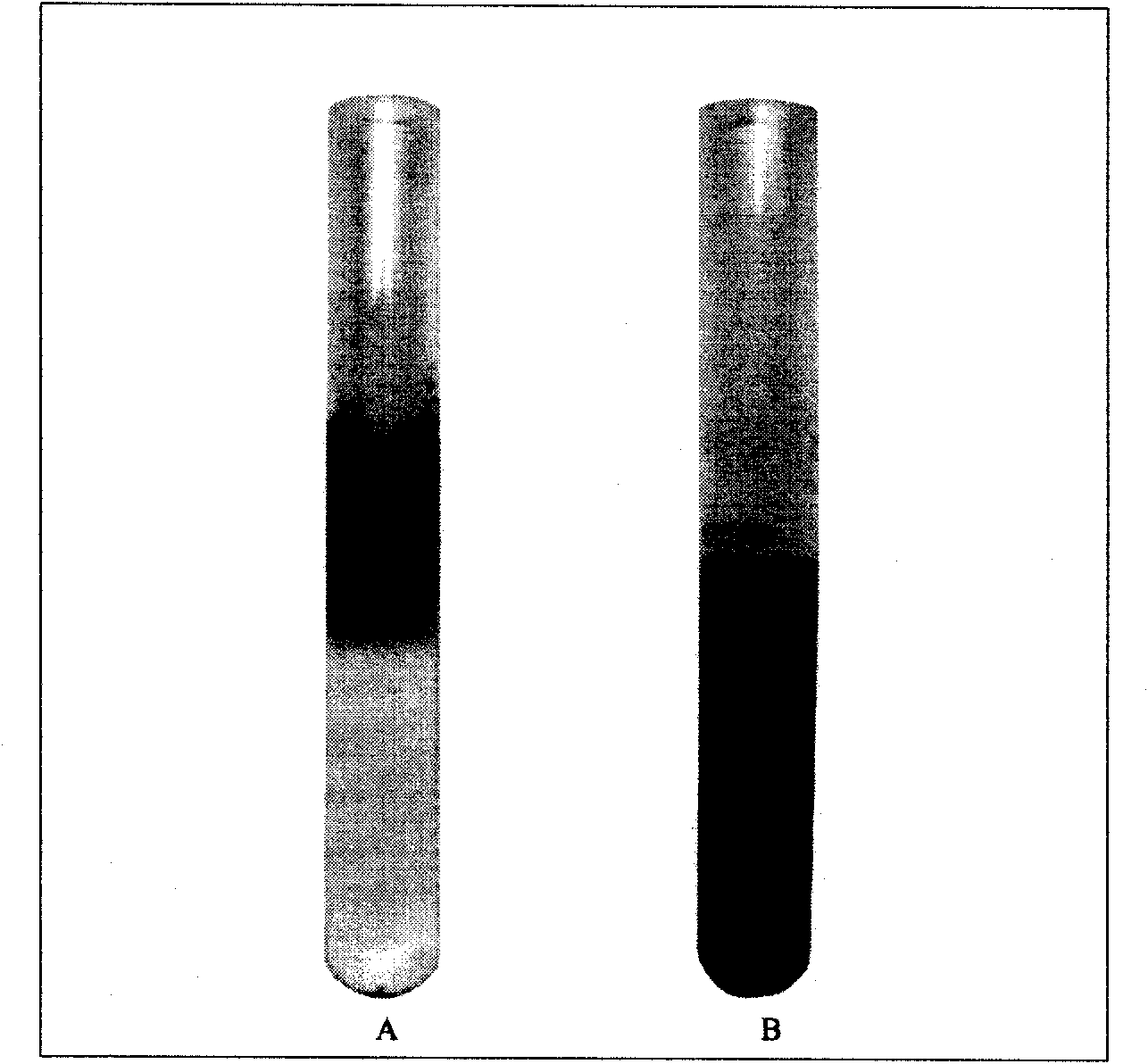

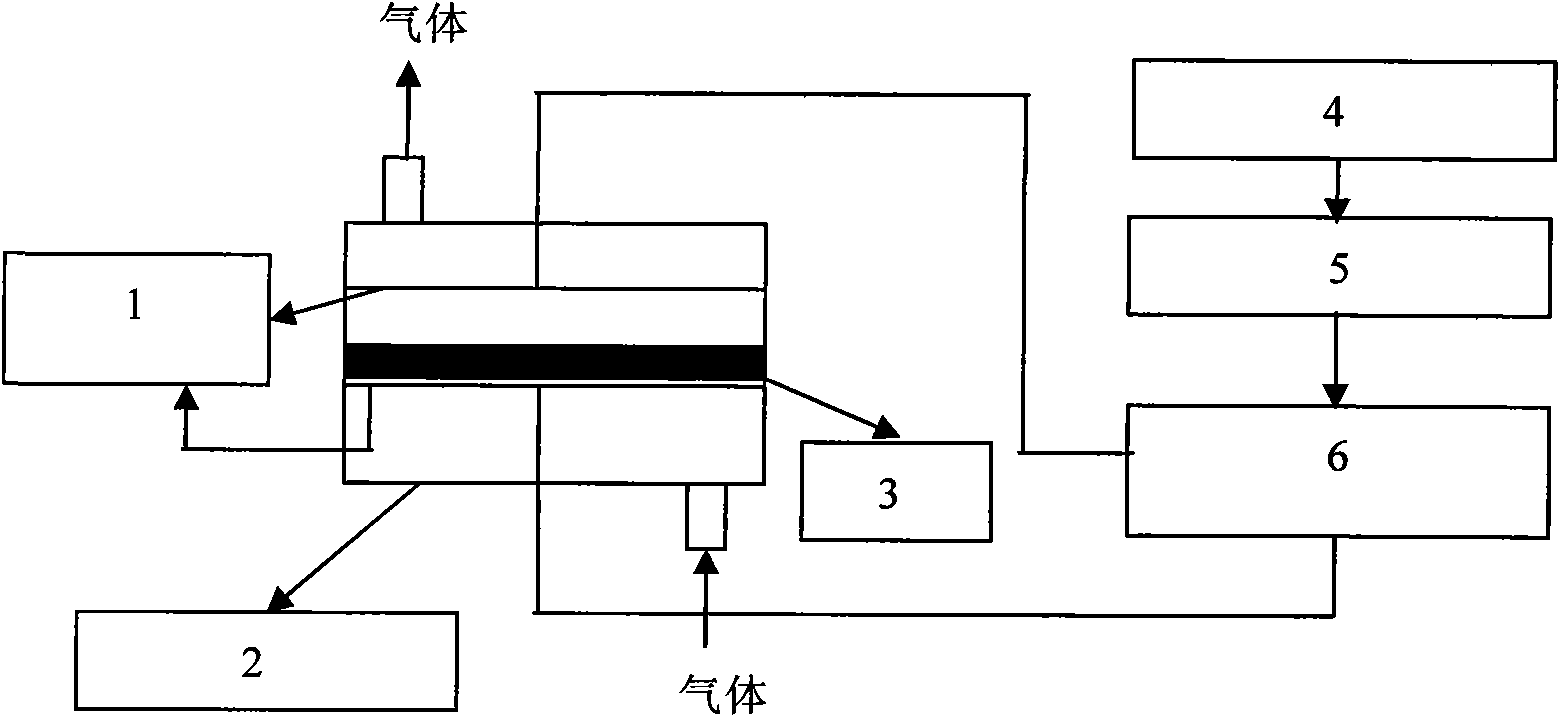

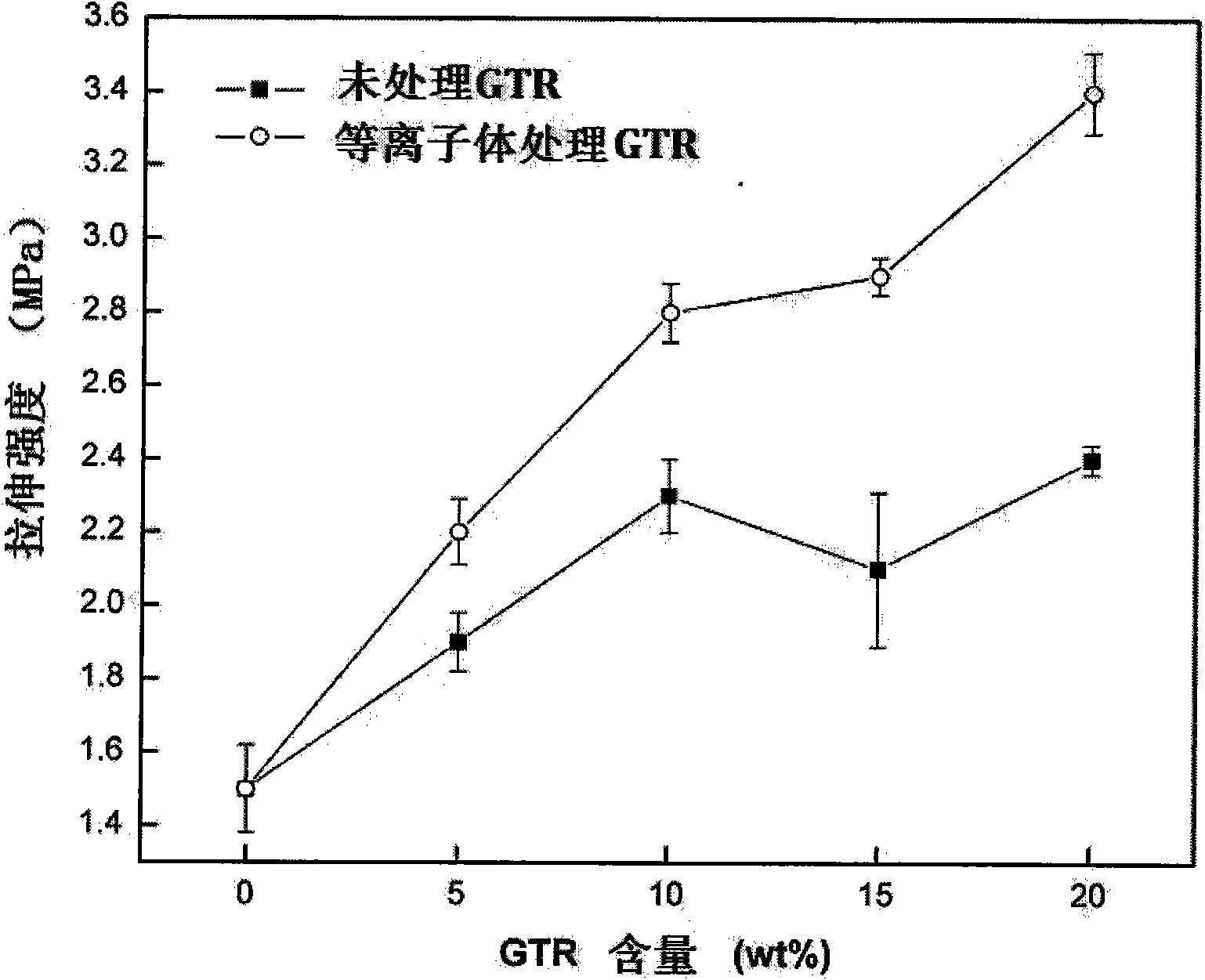

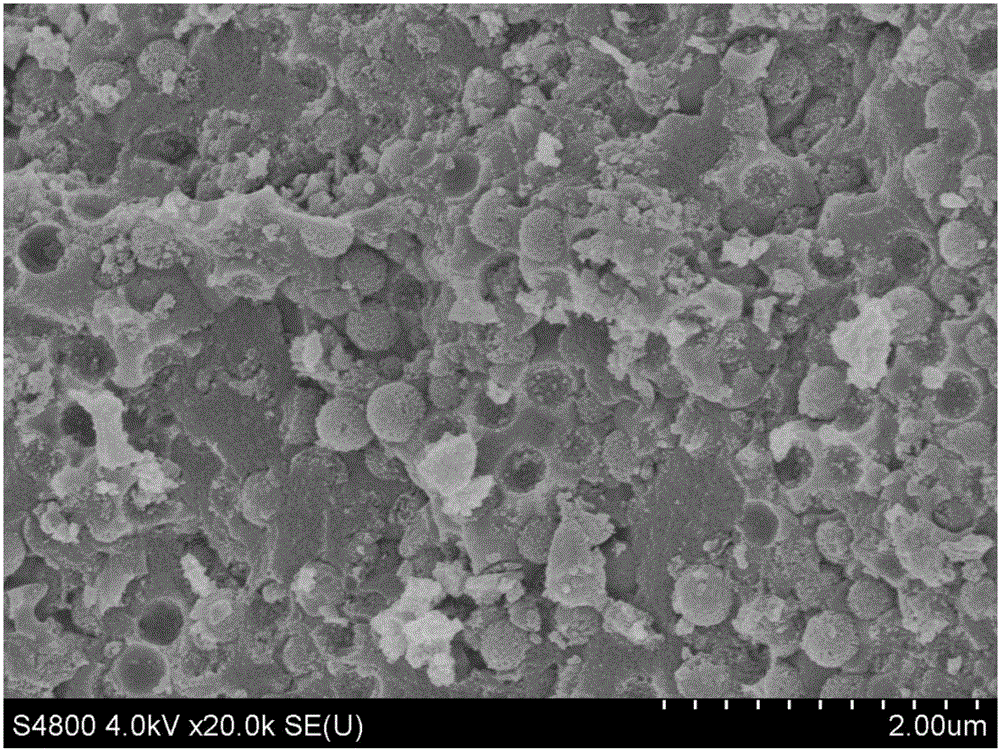

Method for improving surface hydrophilicity of waste rubber powder

The invention discloses a method for improving surface hydrophilicity of waste rubber powder, which is characterized by comprising the following steps of: putting 10 to 100 weight parts of the waste rubber powder into a plasma processing device; and jetting plasma to the surface of the waste rubber powder in an open environment with room temperature and atmospheric pressure to ensure that the waste rubber powder moves and is processed in a plasma atmosphere, wherein the power for processing the waste rubber powder is 10 to 5,000 W, and the time is 2.0 to 300 s. After the plasma processing, the surface polarity of the waste rubber powder is increased, the surface oxygen and nitrogen are increased, and the surface hydrophilicity is significantly improved. The method is a one-step method, which improves the surface property, the structure and the shape of the waste rubber powder and improves the added amount in a polymer. The method has the advantages of simple process, strong controllability, simple and convenient operation and high efficiency, needs no organic solvent and is environmentally-friendly.

Owner:SICHUAN UNIV

Process for preparing quaternary ammonium cation starch by semi-dry method

The semi-dry quaternary ammonium cation starch preparing process includes material compounding, catalyst solutino compounding and heating, and features the molar ratio between the catalyst and 3-chloro-2-hydroxypropyl trimethyl ammonium chloride reagent 1.4-2.8, the molar ratio between the reagent and starch 0.05-0.15, the atomized spray of the catalyst solution to the reactor, heating with circular hot water during reaction and reaction temperature controlled in 50-90 deg.C. The said cation starch preparing process has the advantages of both wet process and dry process, including no materialring break, no starch caking, no need of post-treatment, no "three waste" exhaust, simple process, short reaction period, mild reaction condition, high conversion rate, etc.

Owner:YUEYANG FOREST & PAPER CO LTD

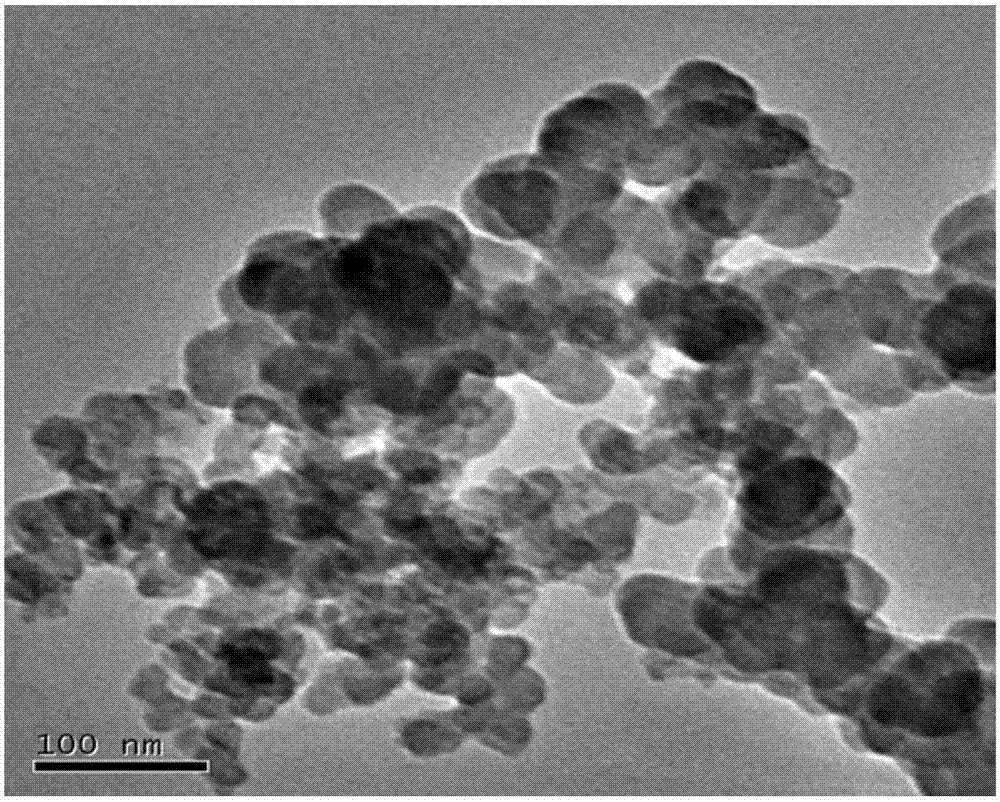

Honeycomb porous silicon/carbon composite material and preparation method thereof

ActiveCN105958047AAvoid the hassle of using solventsEffectively control the distributionMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention discloses a honeycomb porous silicon / carbon composite material and a preparation method thereof. The silicon-carbon composite material is of a hybrid structure that nano silicon spheres are distributed in a honeycomb three-dimensional continuous porous carbon matrix. The method comprises the steps of: adopting spherical silicon dioxide nanoparticles as a silicon source and thermosetting difunctional acrylate unsaturated resin as a carbon source; firstly, mixing silicon dioxide and magnesium powder and then carrying out magnesiothermic reduction in an inert atmosphere to form a continuous porous silicon matrix containing the silicon dioxide nanoparticles; pickling a product obtained by reduction by a hydrochloric acid, evenly dispersing the product into a resin monomer for solidifying, and carrying out high-temperature calcination in the inert atmosphere for in situ carbon formation; and finally etching silicon dioxide which does not completely react by a hydrofluoric acid to obtain the honeycomb porous silicon / carbon composite material and applying the honeycomb porous silicon / carbon composite material to a negative electrode material of a lithium-ion battery. Through in-situ polymerization of vinyl thermosetting resin, the cumbersome problem that traditional thermosetting resin needs to utilize a solvent is solved; post-treatment is not needed; the operation is simple and convenient; and the honeycomb porous silicon / carbon composite material is green and environment-friendly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

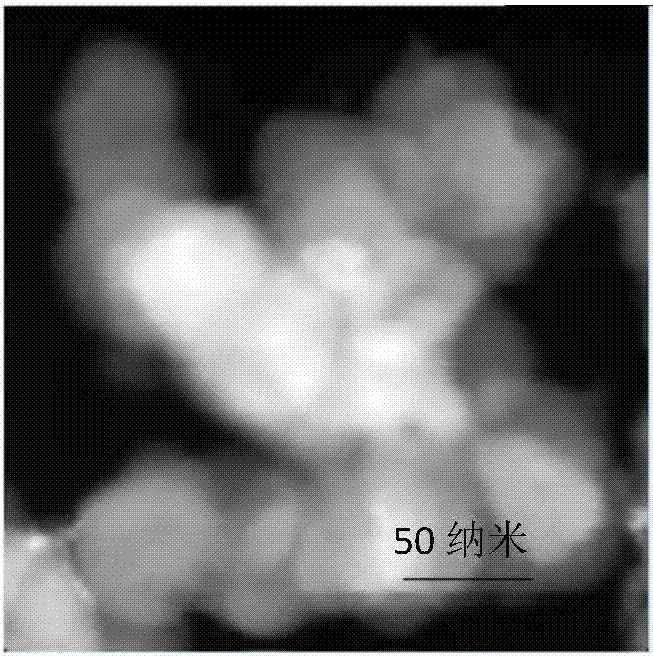

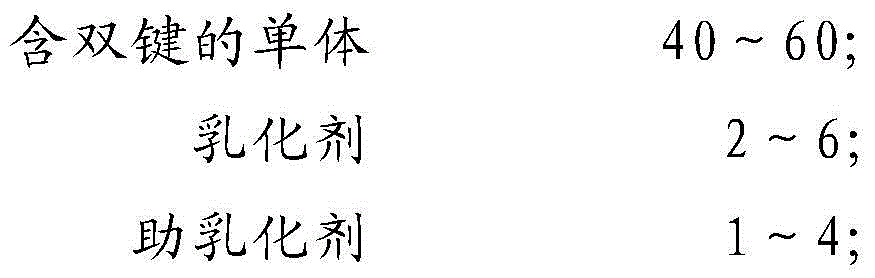

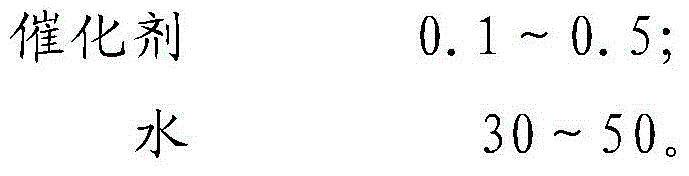

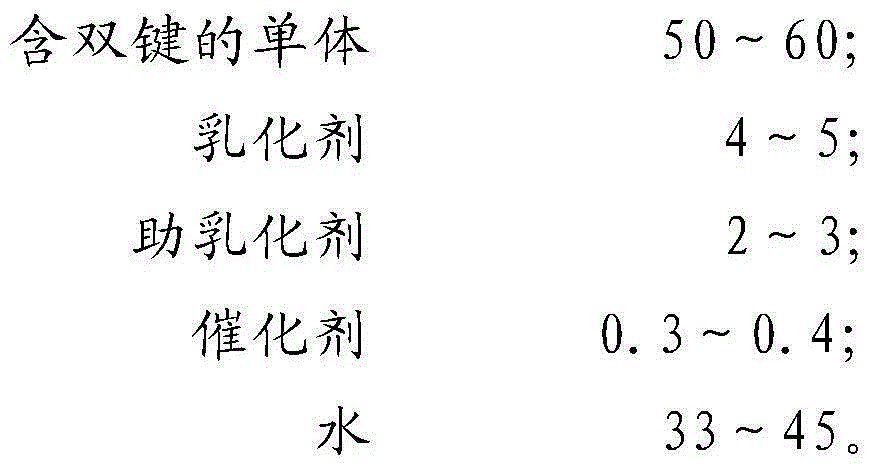

Nanometer emulsion blocking agent used for drilling fluid, and preparation method and application thereof

InactiveCN104927802AReduce fluid lossImprove the blocking effectDrilling compositionPressure transmissionDifferential pressure

The invention relates to a nanometer emulsion blocking agent used for drilling fluid, and a preparation method and application thereof. The nanometer emulsion blocking agent is prepared through polymerization by dispersing at least two double-bond-contained monomers into water containing an emulsifier and a co-emulsifier in an weak alkali environment under the action of a catalyst; and raw materials participating in reaction comprise, by weight, 40 to 60 parts of the double-bond-contained monomers, 2 to 6 parts of the emulsifier, 1 to 4 parts of the co-emulsifier, 0.1 to 0.5 part of the catalyst and 30 to 50 parts of the water. Accordingn to the invention, a particle size of a dispersed particle in the nanometer emulsion blocking agent is distributed in a nanoscale and is less than 500 nm, so the nanometer emulsion blocking agent has good blocking effect, cen block micropores and be casted into microcracks, and is capable of reducing pore pressure transmission, maximumly reducing differential pressure sticking and effectively inhibiting hydration dispersion of clay; the nanometer emulsion blocking agent is stable in high salinity and has the advantages of convenient use, no toxicity, no pollution and easy degradation; and the preparation method of the nanometer emulsion blocking agent has the advantages of reasonable process, mild and controllable conditions, no post treatment, low cost and benefit ratio, and facilitation to industrial production.

Owner:北京中科日升科技有限公司

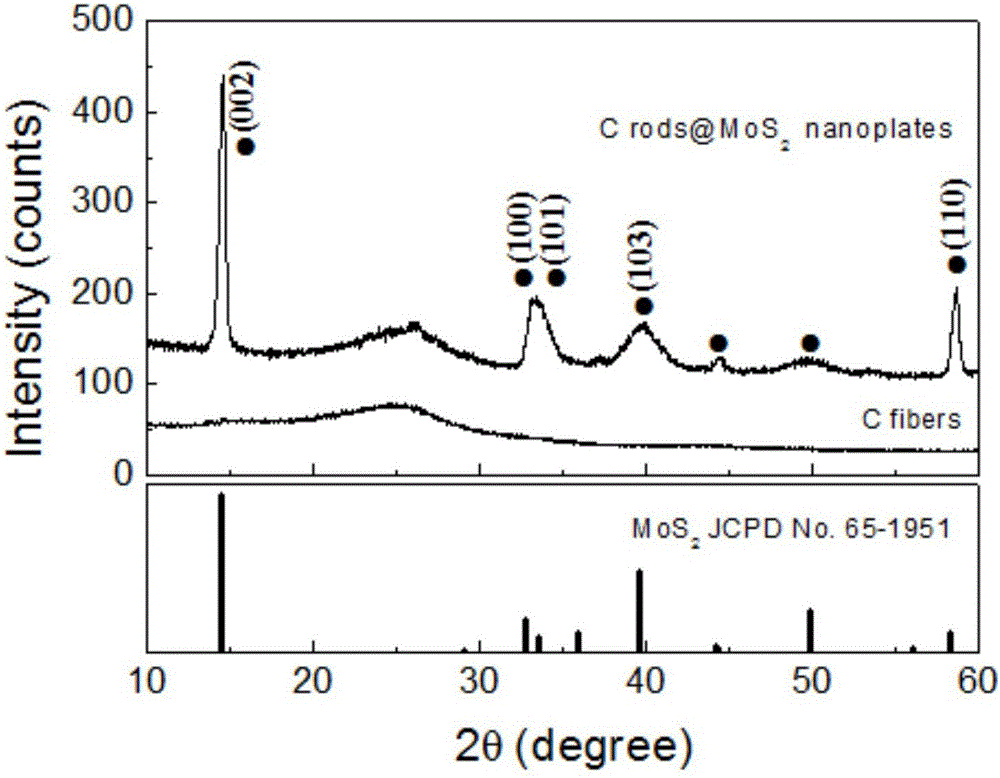

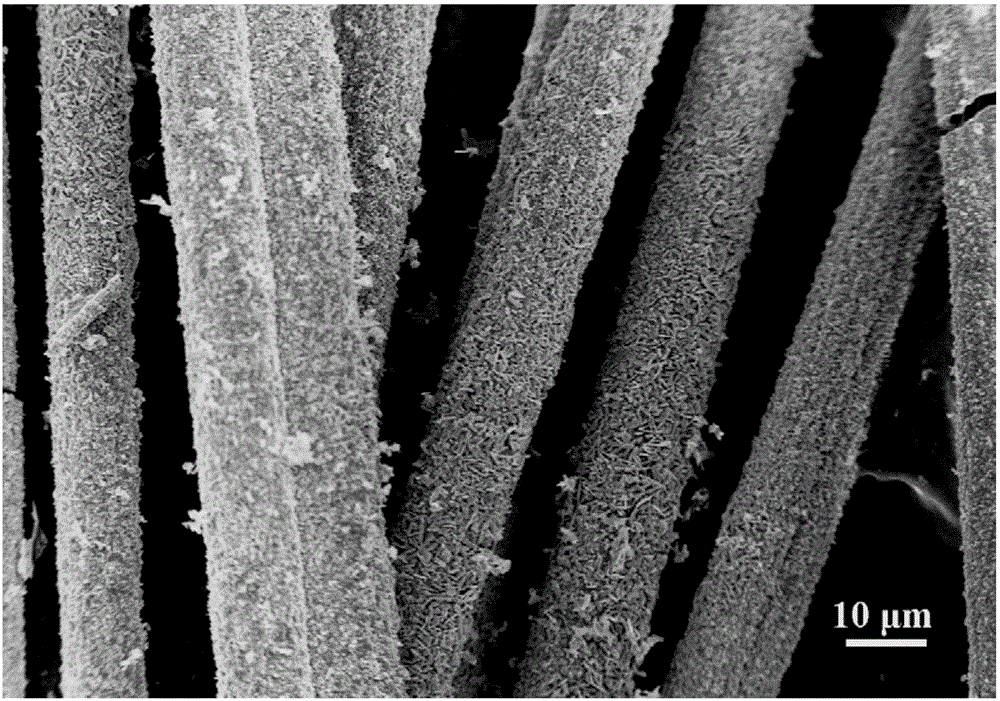

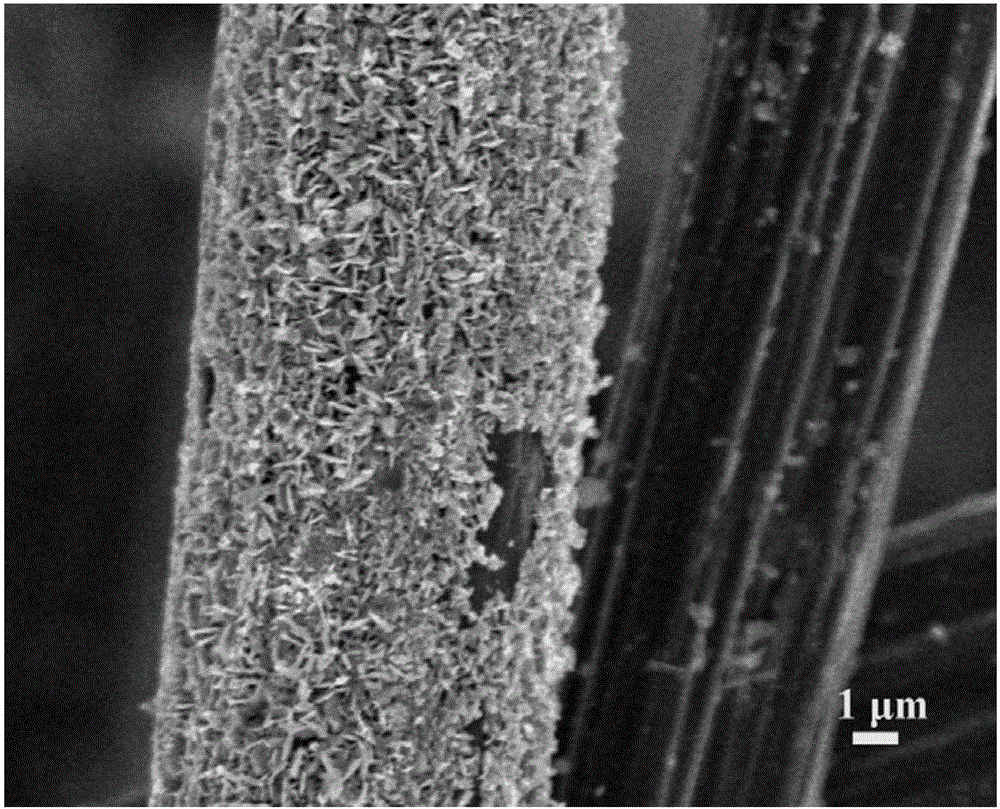

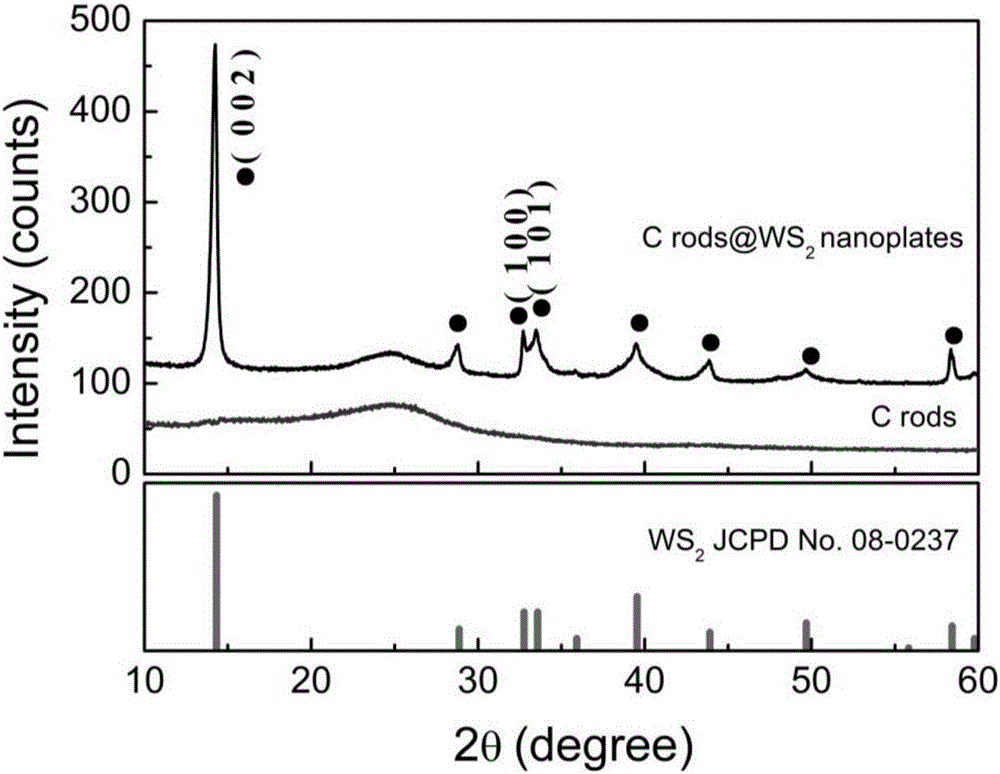

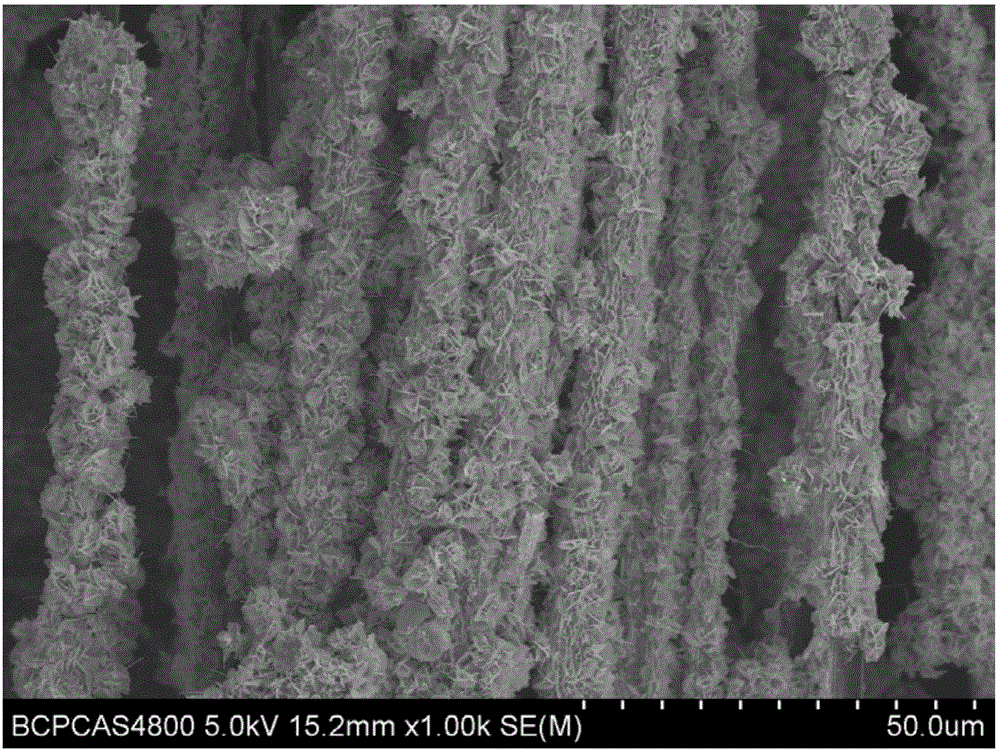

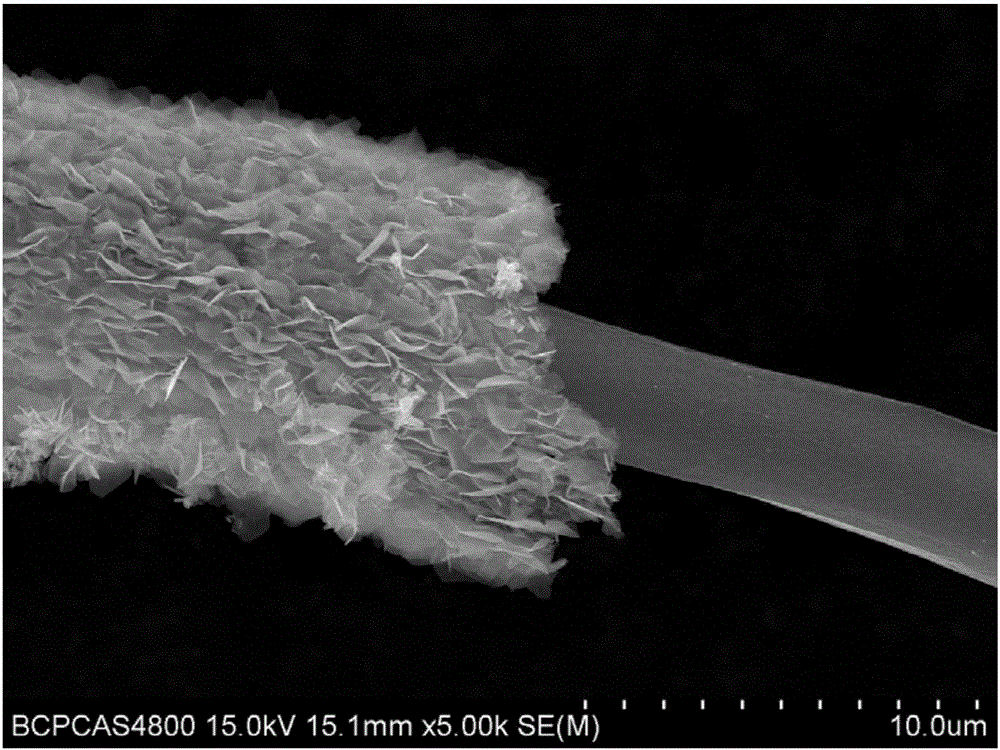

Carbon fiber@molybdenum disulfide nanosheet core-shell composite structure and preparation method thereof

InactiveCN106238077ASimple equipment and processSynthetic growth conditions are tightly controlledPhysical/chemical process catalystsElectrolysis componentsTube furnaceLithium electrode

The invention relates to a carbon fiber@molybdenum disulfide nanosheet core-shell composite structure and a preparation method thereof, and belongs to the technical field of material preparation. Carbon fibers serve as an inner core of the composite structure, and molybdenum disulfide nanosheets which are arranged in an array mode serve as a shell of the composite structure. The preparation method comprises the steps that in a vacuum tubular furnace, sulfur powder is directly evaporated through a thermal evaporation technique to serve as a sulfur source, pre-oxidized polyacrylonitrile fibers soaked with MoO3 turbid liquid are fumigated at high temperature under the action of carrier gas, simultaneous synthesis of the carbon fibers and the molybdenum disulfide nanosheets is achieved, and the carbon fiber@molybdenum disulfide nanosheet core-shell composite structure can be prepared at high yield. The product prepared through the method is high in yield, density and purity and controllable in morphology and does not need aftertreatment; the method has the advantages that equipment and the process are simple, the synthesis growth conditions are strict and controllable, the product yield is high, the cost is low, and the production process is clean and environmentally friendly; the obtained material is an excellent visible light catalyst, hydrogen desulfurization catalyst, electrocatalyst, lithium ion battery electrode material and the like.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Surface modified method for high strength and high modulus polyimide fiber and application thereof

ActiveCN103966833AImprove wettabilityImprove modification effectPhysical treatmentFibre typesRadio frequencyInductive coupling

The invention provides a surface modified method for a high strength and high modulus polyimide fiber and application thereof, and belongs to the field of fiber surface modification and application thereof. The method comprises the following step: the high strength and high modulus polyimide fiber is exposed into plasma for modification, wherein the plasma is generated in process gas under effect of a radio frequency inductive coupling device, and the process gas comprises at least one from oxygen, nitrogen, argon gas and helium. According to the surface modified method for the high strength and high modulus polyimide fiber, under the circumstance that the decline of mechanical strength of the fiber is less than 5 % , the soaking performance of the fiber is effectively improved, and the surface free energy of the fiber is increased by 20% - 70%; modified fiber can be applicable to preparing a composite material with epoxy resin; compared with composite materials prepared by untreated fibers, the interlayer shearing strength of the composite material is increased by 5-40%.

Owner:BEIJING UNIV OF CHEM TECH

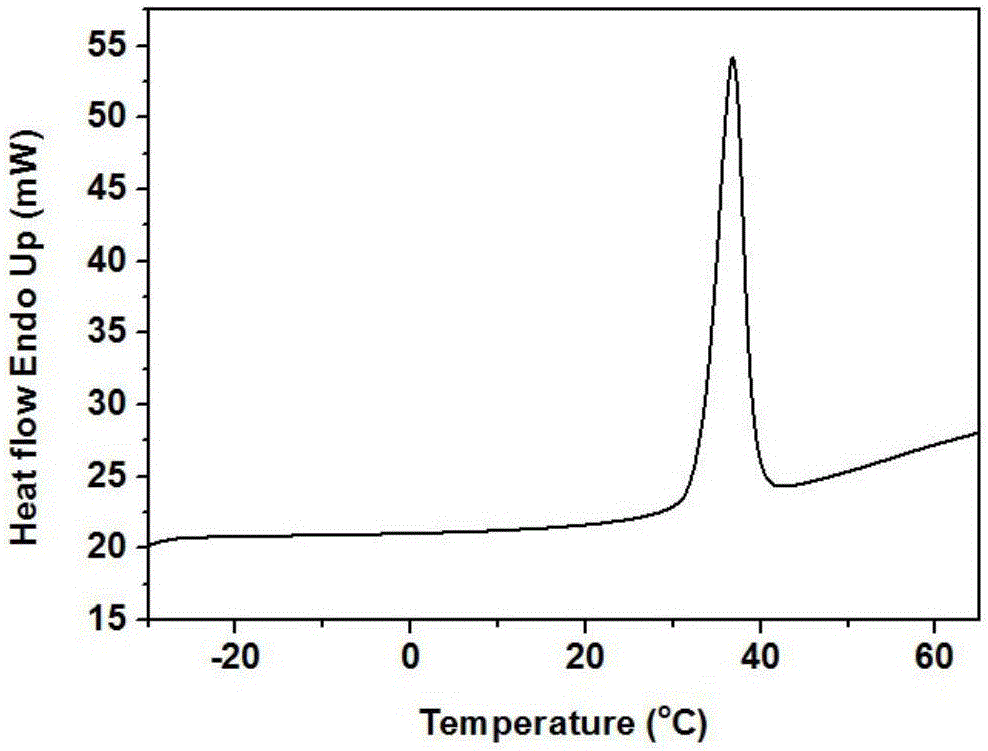

Preparation method of hydrous salt-metal organic framework composite phase change material

InactiveCN105694820AImprove thermal storage performanceAvoid Phase Separation and SupercoolingHeat-exchange elementsCyclic stabilityComposite phase change material

The invention belongs to the field of nano-composites and composite phase change materials and particularly relates to a preparation method of a hydrous salt-metal organic framework composite phase change material. The specific scheme is as follows: firstly, proper metal salt, a proper ligand and a proper inorganic phase change material base material are selected, and the size of pore canals of a metal organic framework is designed and regulated according to the type of core materials, so that to-be-supported phase change core materials are better matched; the metal salt, the ligand, the inorganic phase change material and an additive are blended, heat preservation is performed for a period under an airtight condition, then the mixture is supplemented with a proper amount of water, and thus the hydrous salt-metal organic framework composite phase change material is obtained. The preparation method has the advantages as follows: the heat storage property of the prepared composite phase change material can be improved, and problems of phase change separation, supercooling degree and the like can be effectively avoided; the compound phase change material prepared with the method is excellent in heat transfer property and good in cyclic stability; the preparation process of the compound phase change material requires simple technology, is finished in one step, is free of by-products, requires no after-treatment and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

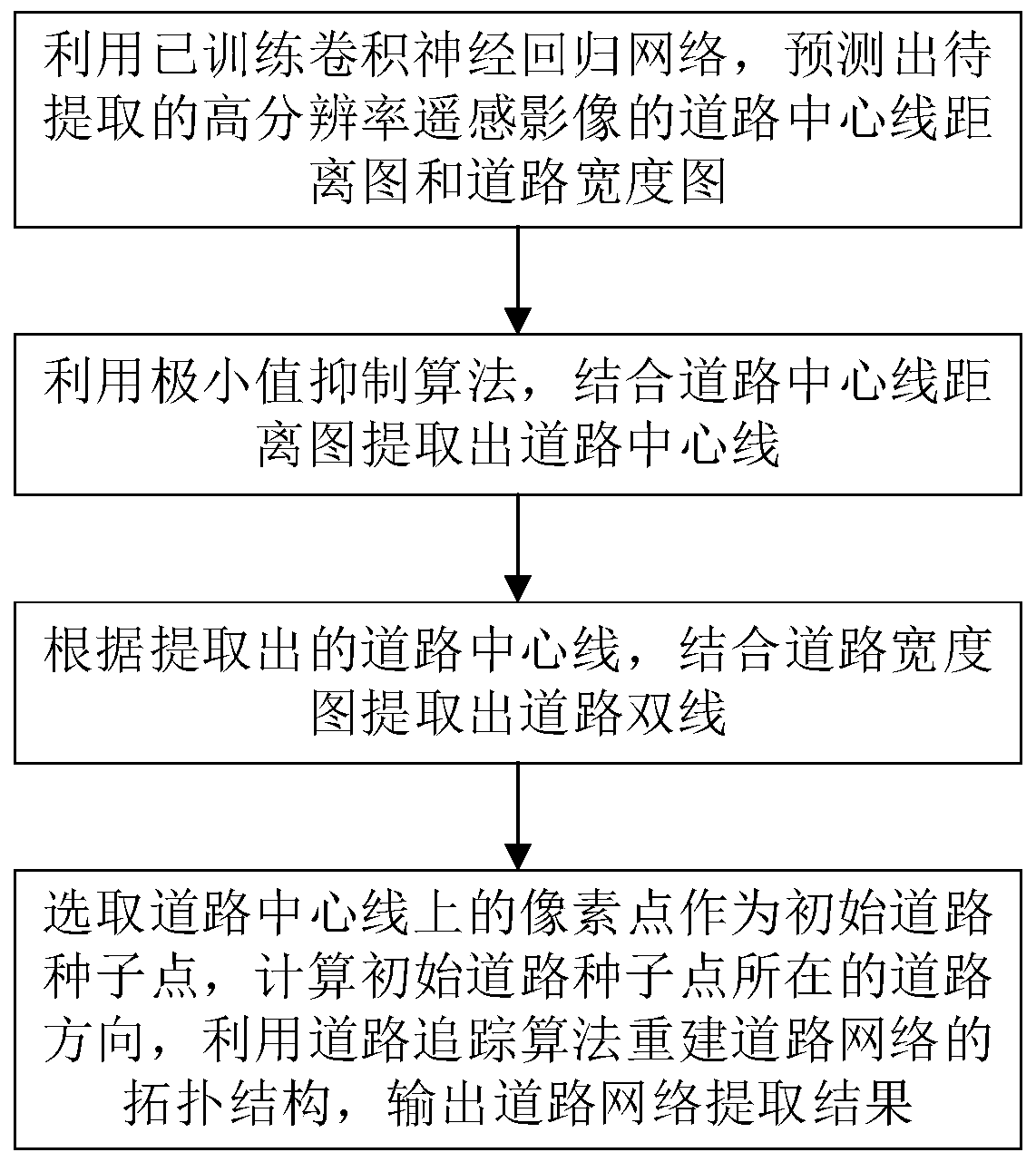

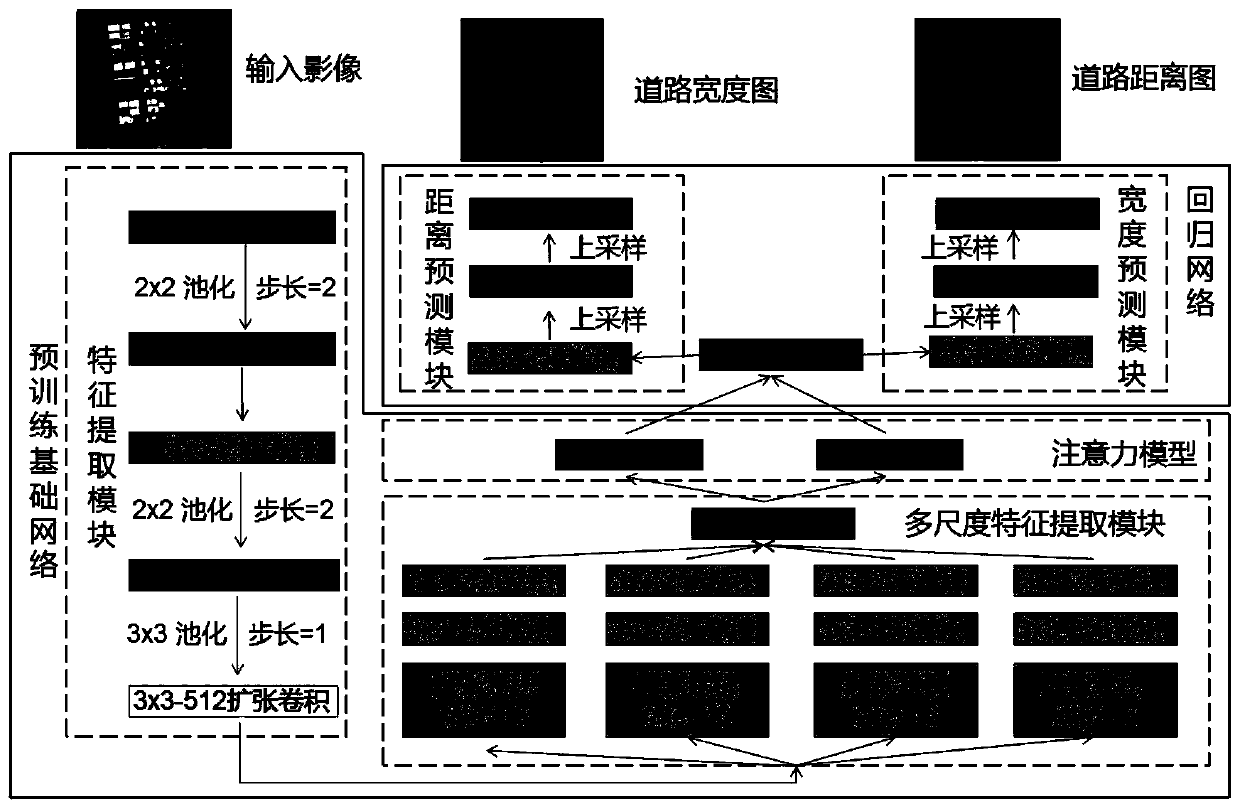

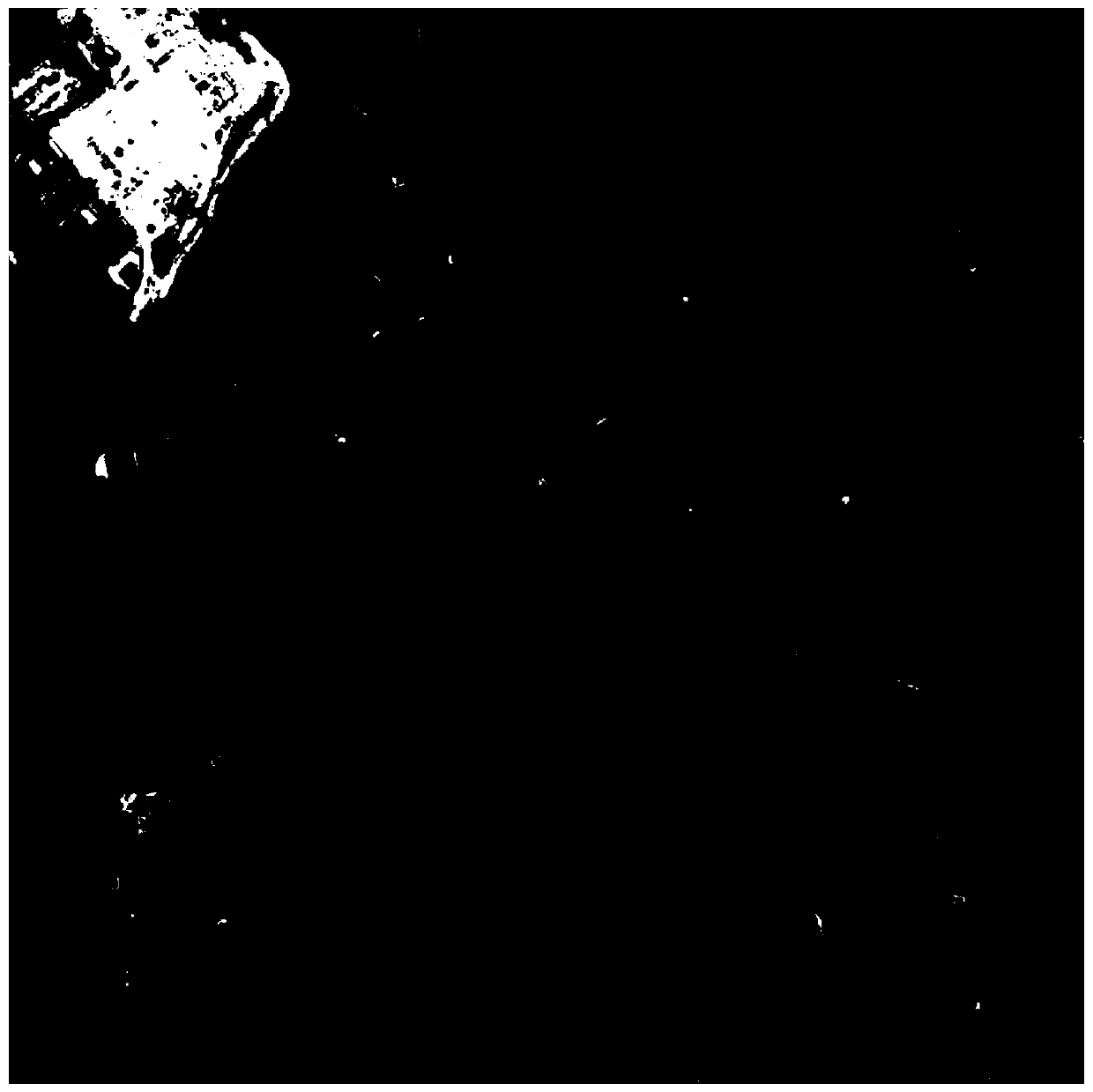

Road center line and double-line extraction method based on convolutional neural network regression

ActiveCN110348383AStrong generalization abilityGood generalization abilityCharacter and pattern recognitionHigh resolutionConvolutional neural network

The invention discloses a road center line and double-line extraction method based on convolutional neural network regression, and the method comprises the following steps: predicting a road center line distance map and a road width map of a to-be-extracted high-resolution remote sensing image through employing a trained convolutional neural network; extracting a road center line by using a non-minimum suppression algorithm in combination with the road center line distance map; according to the extracted road center line, extracting road double lines in combination with a road width map; and selecting pixel points on the road center line as initial road seed points, calculating the road direction of the initial road seed points, reconstructing the topological structure of the road networkby using a road tracking algorithm, and outputting a road network extraction result. According to the method, through end-to-end training, the features easy to classify are directly learned from the training data, no post-processing is needed to extract the road centerline and sideline, the generalization ability is stronger, the road extraction precision is high, and the fine road extraction effect is better.

Owner:CHONGQING GEOMATICS & REMOTE SENSING CENT +1

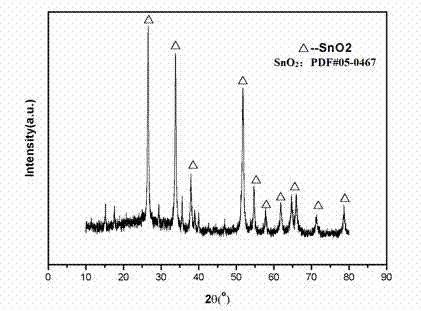

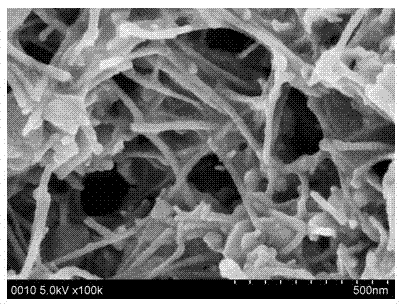

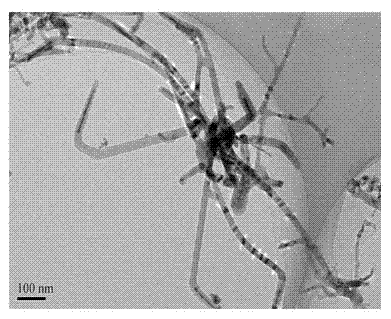

Method for preparing precious metal gold particle catalytically-grown stannic oxide nanowire

ActiveCN103043712AHigh purityHigh crystallinityMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsNanowireGas detector

The invention discloses a method for preparing a precious metal gold particle catalytically-grown stannic oxide nanowire. The method comprises the following steps of: introducing a precursor into a flame reaction chamber under the drive of an injection pump and atomization diffusion of the oxygen by using tetrachlorostannane pentahydrate and absolute ethyl alcohol solution of chloroauric acid as the precursor; assisting the burning of diffusion flame and precursor solution to provide heat energy at the reaction temperature of 1,600-2,000 DEG C to obtain a highly-crystallized stannic oxide nanowire under a catalytic induction function of the precious metal gold particles and high-temperature flame atmosphere. The stannic oxide nanowire prepared by the method, of which the sharp end is provided with the precious metal gold particles, can generate interface plasma resonance effect together with stannic oxide serving as a semiconductor and can be widely applied to the fields of dye-sensitized solar cells, gas sensitive sensors and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Water-based filtrate reducer for drilling fluid and preparation method thereof

ActiveCN106854259AGood filter loss reduction effectEasy to prepareDrilling compositionSaline waterWater based

The invention relates to a water-based filtrate reducer for a drilling fluid and a preparation method thereof. The preparation method comprises the following steps: successively adding monomers containing sulfo groups, organosilicon monomers containing unsaturated double bonds and polyanion fibers into water in proportion, adjusting a pH value to 7 to 8 and carrying out a reaction in the presence of an initiator. The water-based filtrate reducer provided by the invention has excellent filtrate reducing performance both in salt water and saturated salt water, and can resist a high temperature of 180 DEG C; the preparation method and desired equipment are simple; and the preparation method is easy to implement.

Owner:CHINA PETROLEUM & CHEM CORP +1

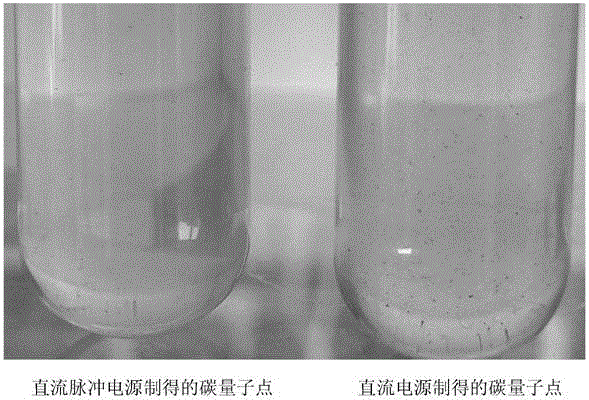

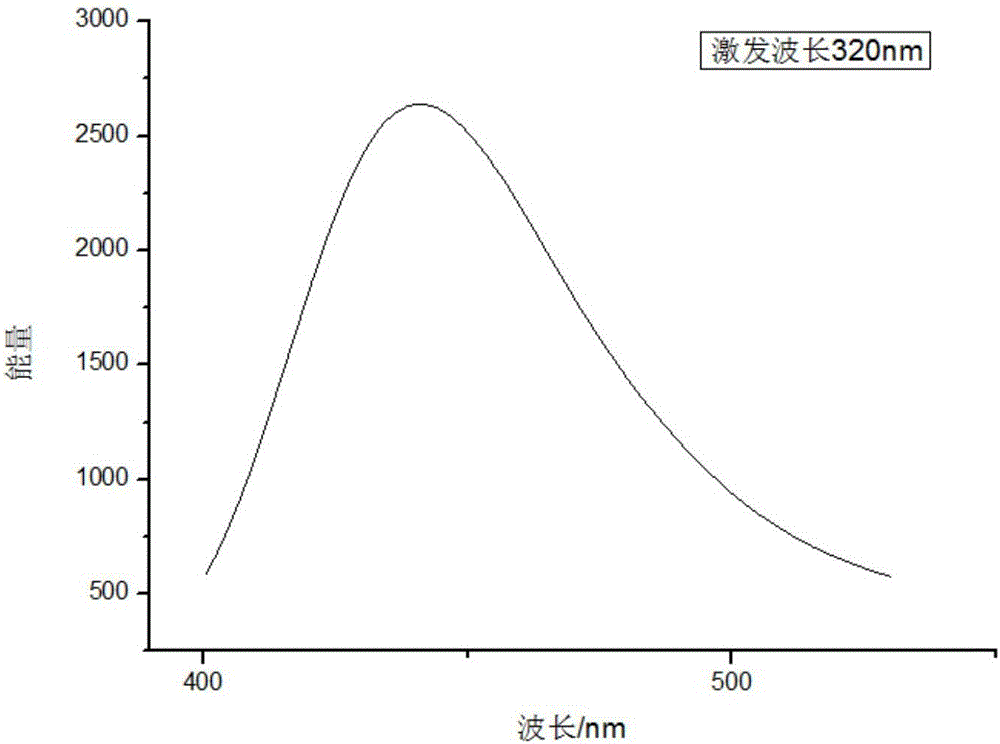

Method for rapidly preparing fluorescent carbon quantum dot by using direct-current pulse process

ActiveCN105714323AGood water solubilityGood dispersionElectrolysis componentsNanoopticsGraphite carbonElectrolysis

The invention relates to a method for preparing a fluorescent carbon quantum dot, belonging to the field of carbon quantum dot preparation. The method comprises the steps of placing deionized water into an electrolytic tank, electrolyzing for a certain time by taking graphite carbon rods as an anode and a cathode and using a direct-current pulse power supply to obtain a gray black water solution; and filtering to obtain a water-soluble fluorescent carbon quantum dot solution. By using the method, the preparation process of the carbon quantum dot is simple, and the reaction time is greatly shortened.

Owner:CHANGZHOU UNIV

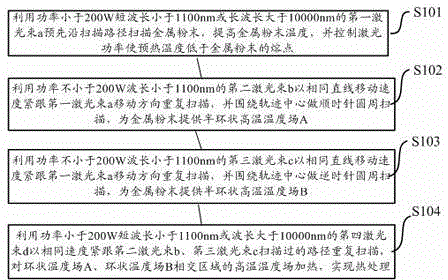

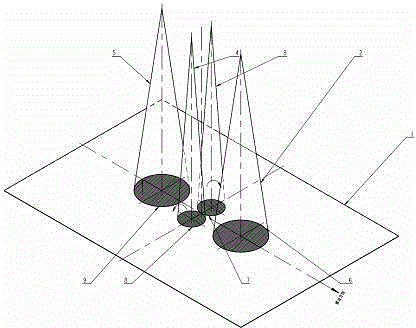

Method forming high-melting-point high temperature alloy part via multi-laser head multi-laser beam path scanning

The invention provides a method forming a high-melting-point high temperature alloy part via multi-laser head multi-laser beam path scanning .First, metal powder is scanned by a first laser beam with power less than 200 W and short wavelength less than 1100 or long wavelength more than 10000nm in advance along a scanning path; the laser power is controlled, so pre-heat temperature is lower than a melting point of the metal powder; then a second laser beam with power no less than 200W and wavelength smaller than 1100nm to keep up with a moving direction of the first laser beam to repeatedly scan at the same linear moving speed; clockwise circular scanning surrounding the track center is conducted; a semi-annular high temperature field A is provided for the metal powder; a third laser beam keeps up with the moving direction of the first laser beam to repeatedly scan at the same linear moving speed; anticlockwise circular scanning surrounding the track center is conducted; a semi-annular high temperature field B is provided for the metal powder; a fourth laser beam keeps up with the scanning paths of the third and second laser beams to repeatedly scan at the same linear speed; an intersected area between the annular temperature field A and annular temperature field B is heated; and heat processing is conducted.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

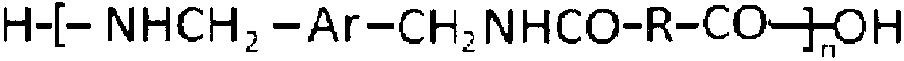

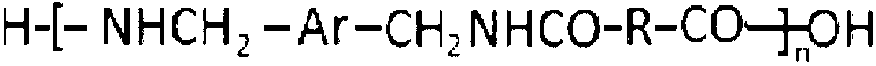

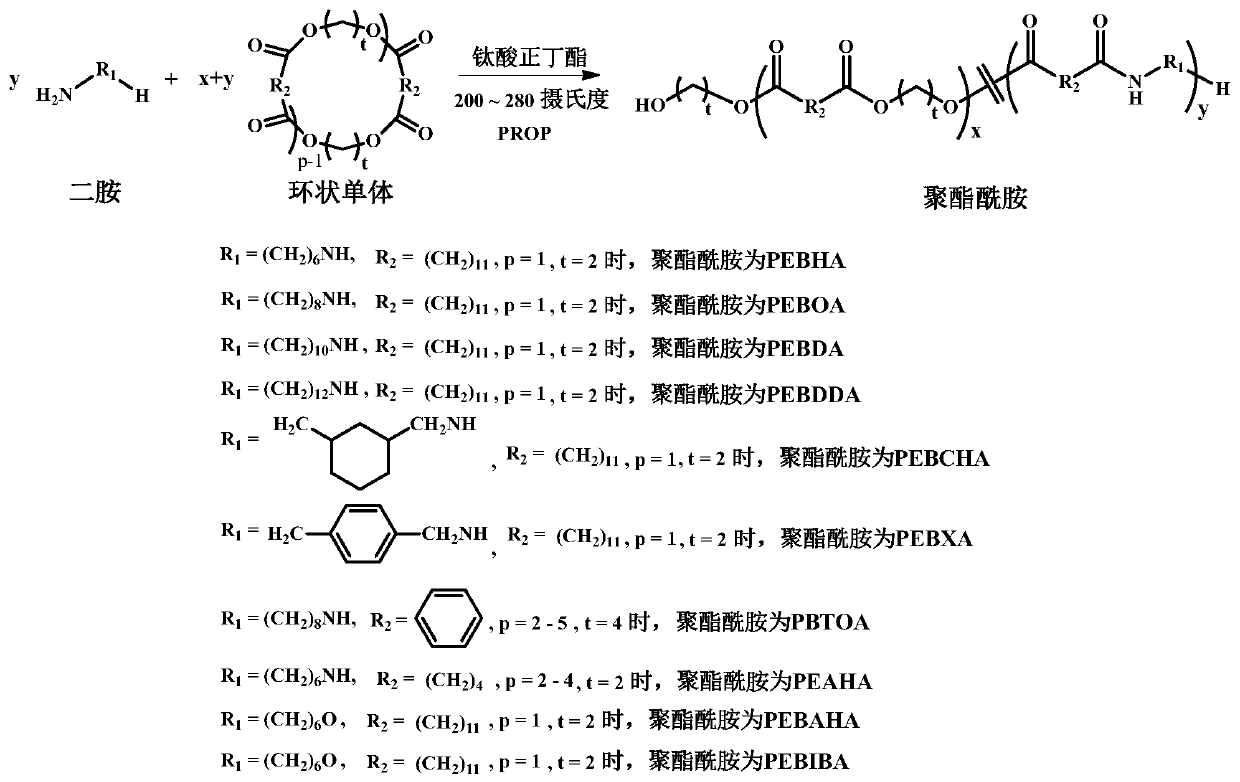

Polyesteramide and preparation method thereof

ActiveCN111019126AExpand the scope of applicationThe reaction steps are simpleDiamineTissue engineering

The invention discloses polyesteramide and a preparation method thereof. According to the preparation method, a diamine or an amino alcohol is used as an initiator, a macrolide based on a diacid diolis used as a monomer, and the polyesteramide is prepared through ring opening-condensation cascade polymerization reaction in the presence of a catalyst. The polyesteramide copolymer prepared by the preparation method disclosed by the invention has good biocompatibility and biodegradability and excellent mechanical properties, solvent resistance and thermal stability; the performance of the polyesteramide material can be regulated and controlled by changing the ratio of ester bonds to amide bonds, the molecular weight and distribution of the polymer and other factors, so that the polyesteramide can be widely applied to the fields of engineering plastics, thermoplastic elastomers, tissue engineering, controlled release and the like.

Owner:SUZHOU UNIV

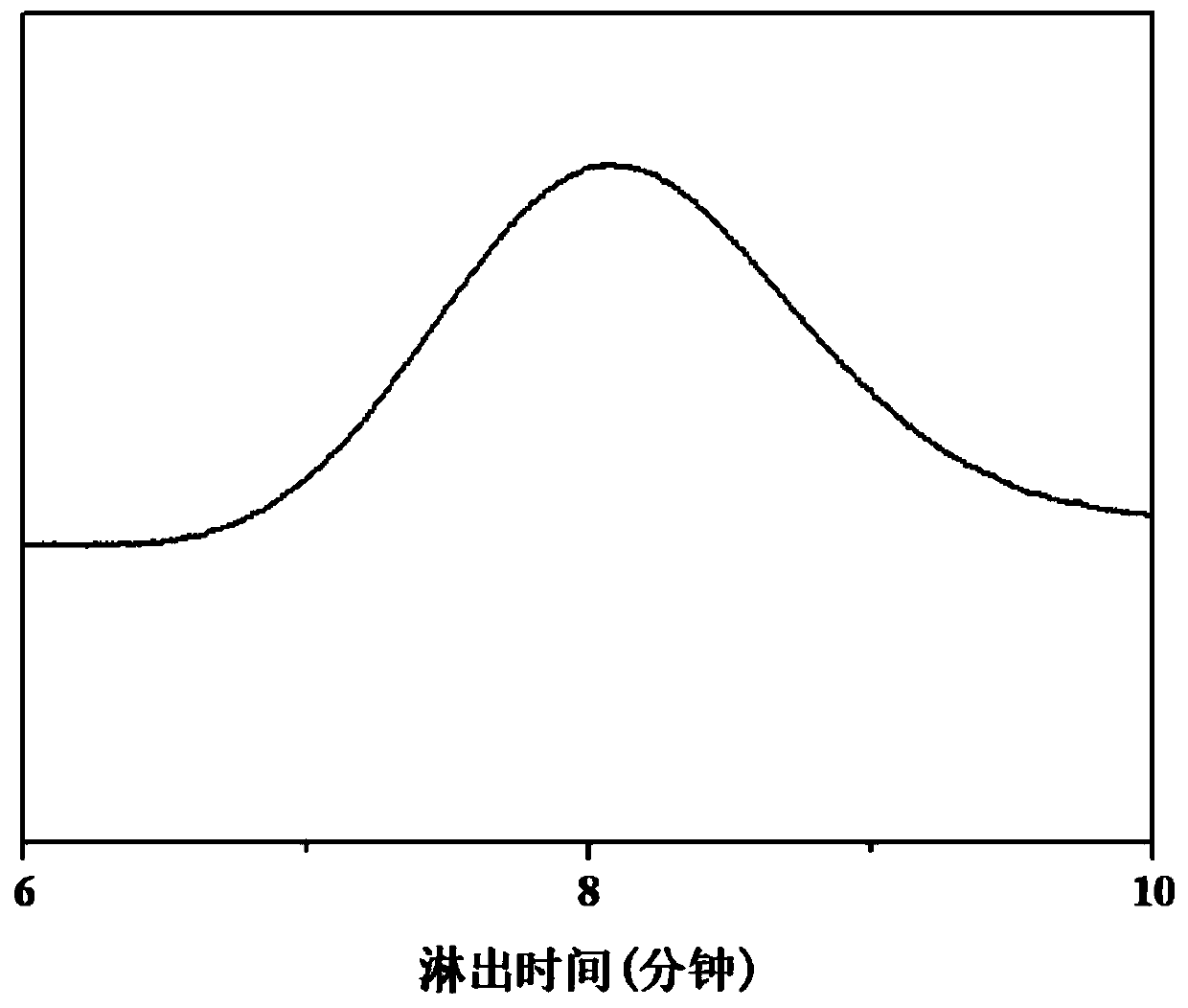

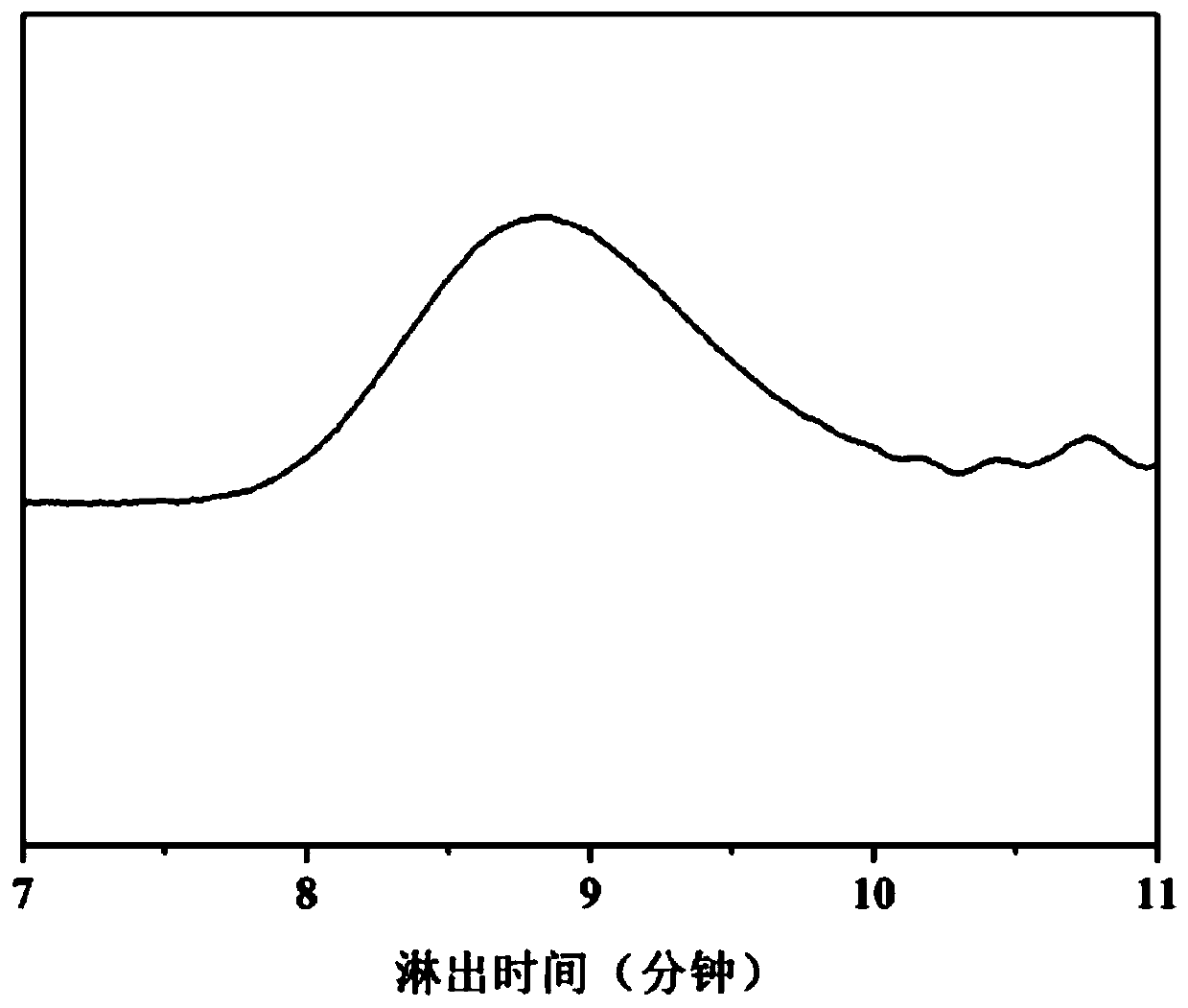

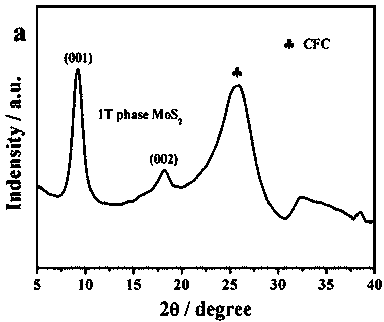

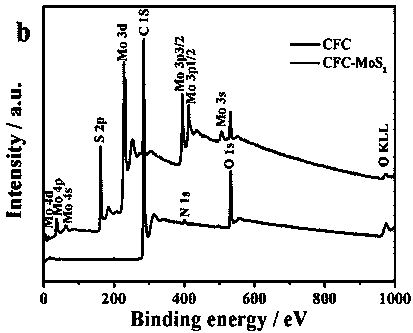

Synthesis method of 1T-phase molybdenum disulfide/carbon fiber cloth nano composite material

InactiveCN110258104AEasy to prepareNo post-processingPhysical/chemical process catalystsCarbon fibresFiberSynthesis methods

The invention discloses a method for synthesizing a 1T-phase molybdenum disulfide / carbon fiber cloth nano composite material through a hydrothermal process. The method includes: respectively utilizing carbon fiber cloth, a molybdenum source, a sulfur source and a reductant as reactants, and synthesizing the composite material through hydrothermal reaction. The method is low in raw material cost and simple in operation, and the composite material can be prepared in one step through hydrothermal reaction. The method is simple and mild in reaction condition, the composite material is stable and less prone to phase change, and the composite material has extremely wide application prospect.

Owner:信阳学院

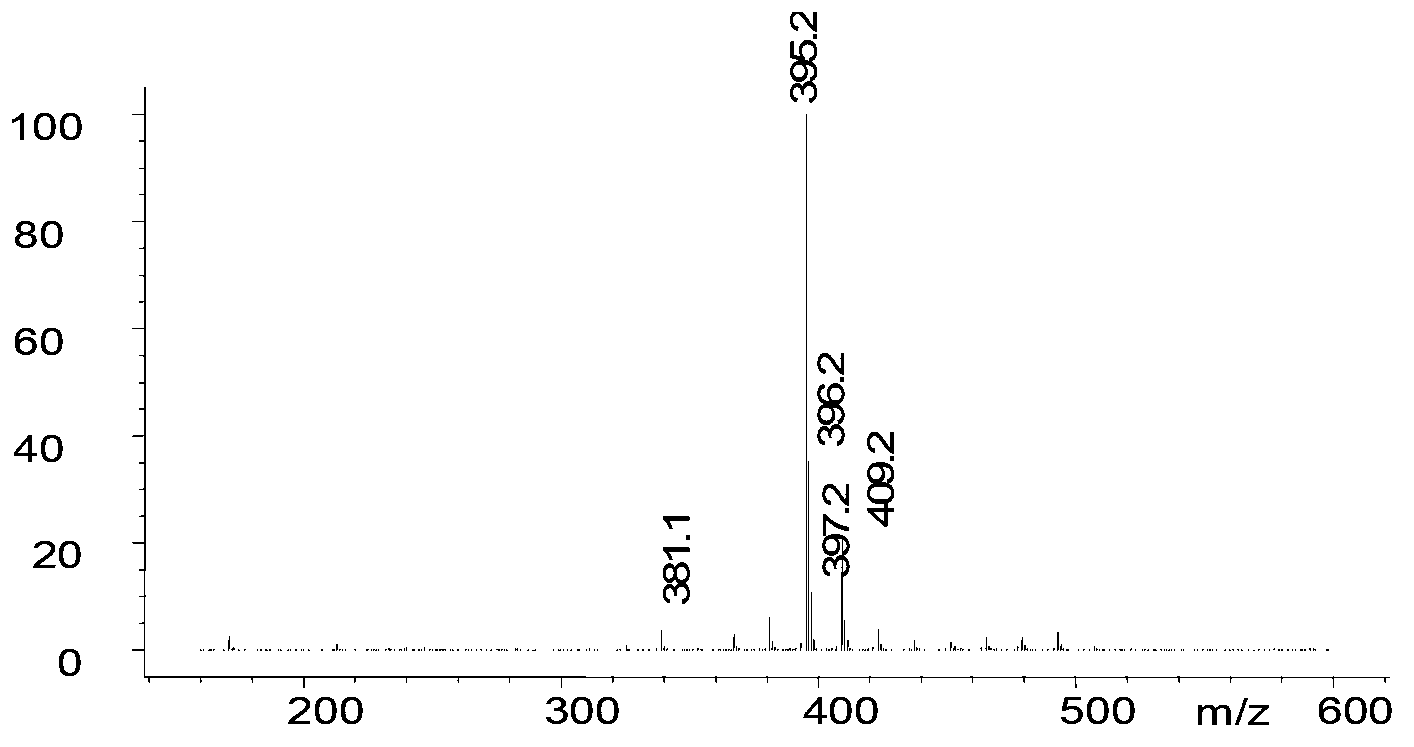

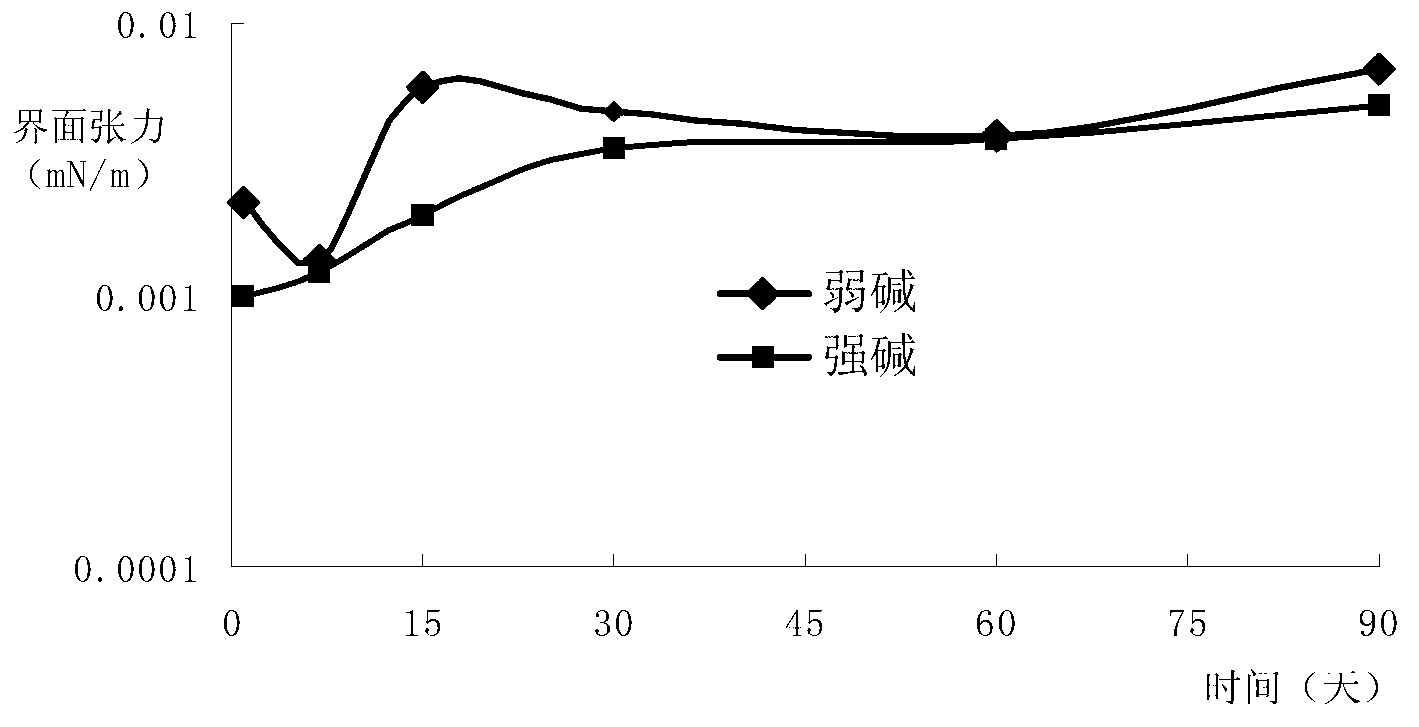

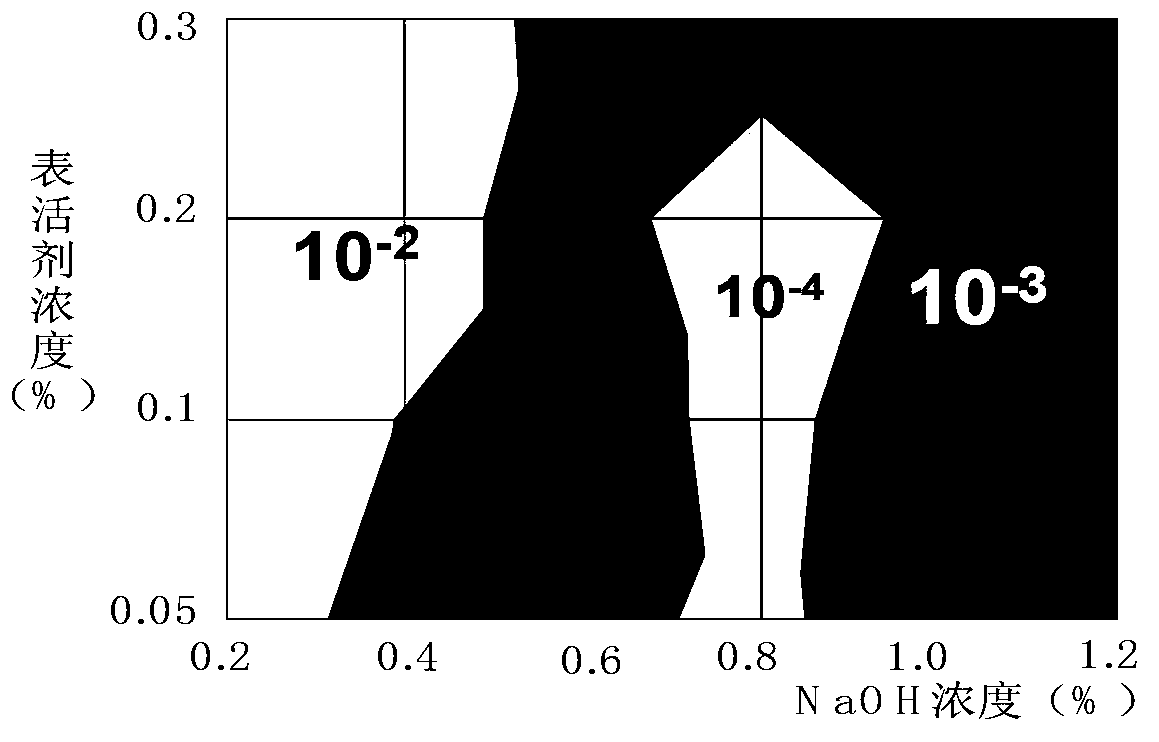

Hexadecyl toluene sulfonate for flooding and preparation method thereof, surfactant and application thereof

ActiveCN103193689ALow cost of preparationGood interface activitySulfonic acids salts preparationDrilling compositionTolueneSystem stability

The invention discloses hexadecyl toluene sulfonate for flooding and a preparation method thereof, a surfactant and application thereof. The surfactant prepared from the hexadecyl toluene sulfonate or an industrial product thereof and alcohol has good interfacial activity, strong capacity of resisting dilution and low use concentration (0.05-0.3wt%), can enable the oil-water interfacial tension to be ultralow (order of magnitude of 10<-3>mN / m) in wider or narrower alkali concentration ranges (0.4-1.2wt%) and under the strong and weak alkali conditions and has good composite system stability and high flooding efficiency. The recovery ratio of core flooding experiments is enhanced by more than 20% than that of water flooding. The surfactant which is single in composition, definite in structure and excellent in properties and is stable is provided for popularization and application of tertiary oil recovery, not only can oil recovery be substantially enhanced but also the domestic formula of the surfactant is achieved and the cost of ASP (alkaline-surfactant-polymer) flooding is greatly reduced.

Owner:PETROCHINA CO LTD +1

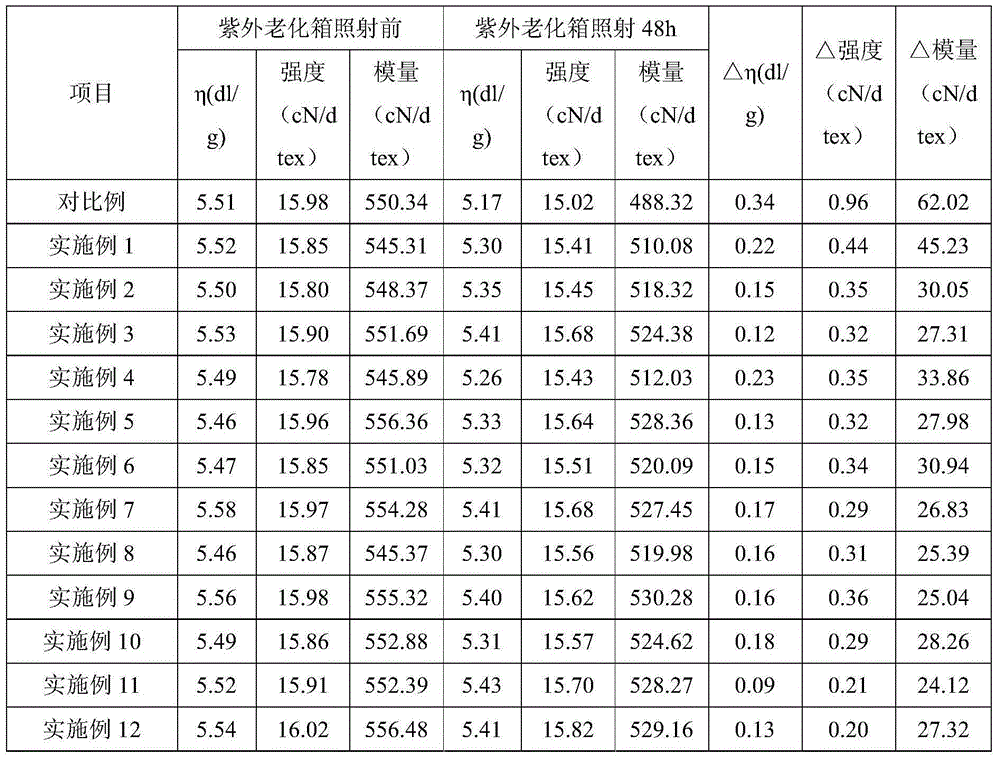

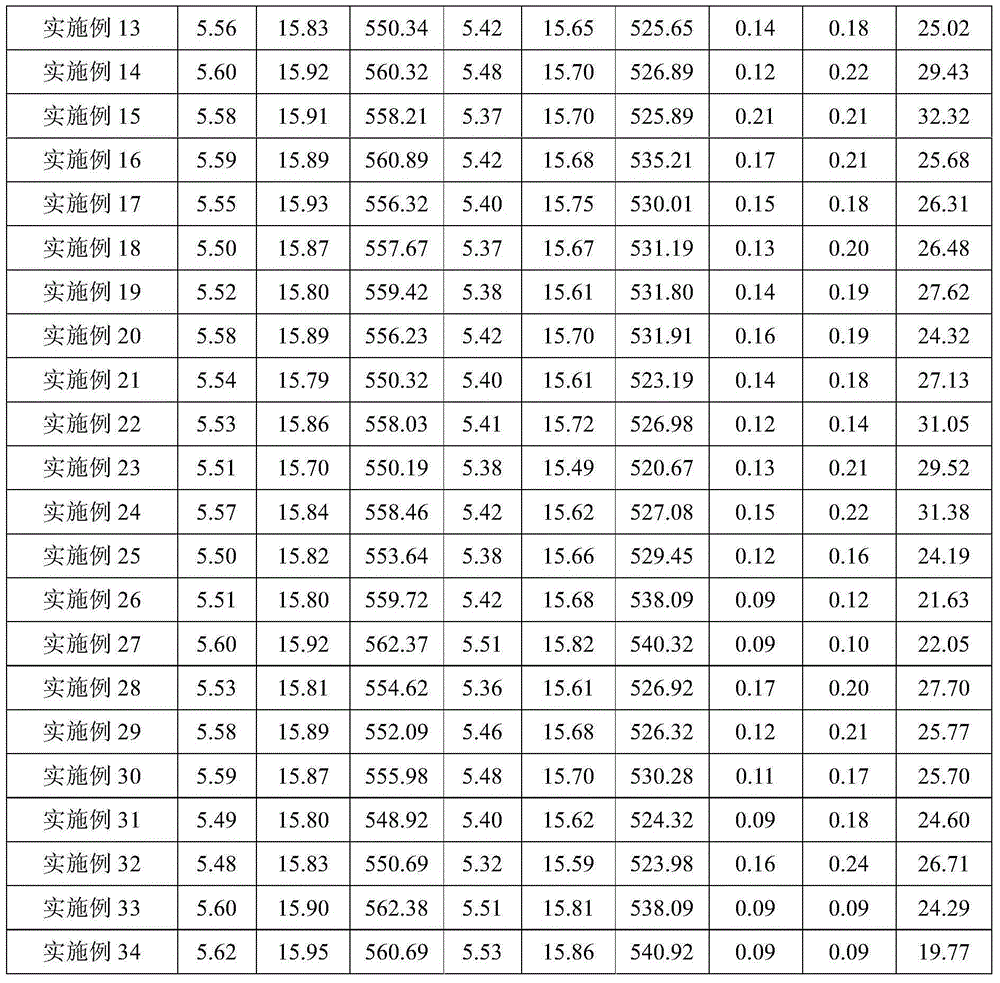

Preparation method of uvioresistant aramid fiber

InactiveCN106592216AImprove UV resistanceGood UV resistanceFibre typesHindered amine light stabilizersChemistry

The invention relates to a preparation method of uvioresistant aramid fiber. The method comprises the steps that in the para-aramid spinning production process, an appropriate amount of benzinidazole, an appropriate amount of substituted acrylonitrile, an appropriate amount of triazine and an appropriate amount of hindered amine uvioresistant absorbent are added into spinning oil, the mixture is uniformly sprayed on the surface of the aramid fiber through nozzle oil equipment, and the aramid fiber with the surface uniformly attached with the uvioresistant absorbent is produced through spinning equipment. The problems that para-aramid ultraviolet-resistant property is poor, oxidative degradation is likely to occur under ultraviolet light are better solved, and the preparation method can be used for spinning industrial production for preparing the uvioresistant aramid fiber.

Owner:SINOPEC YIZHENG CHEM FIBER +1

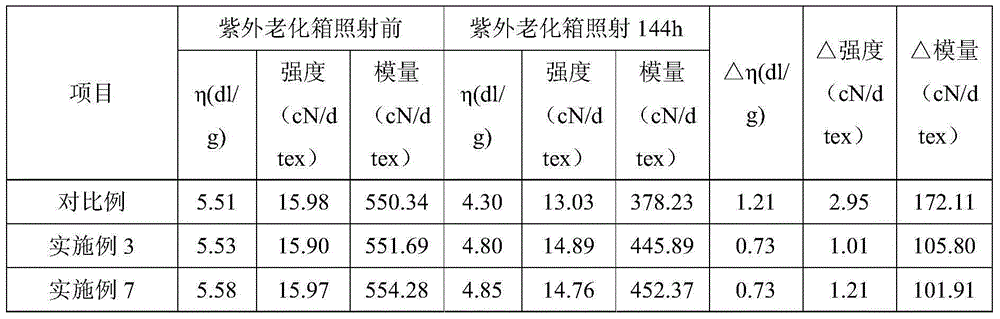

Borehole stabilizer for drilling fluid, preparation method and applications thereof

InactiveCN104830288AImprove temperature resistanceQuality improvementDrilling compositionChemical reactionTransformation ratio

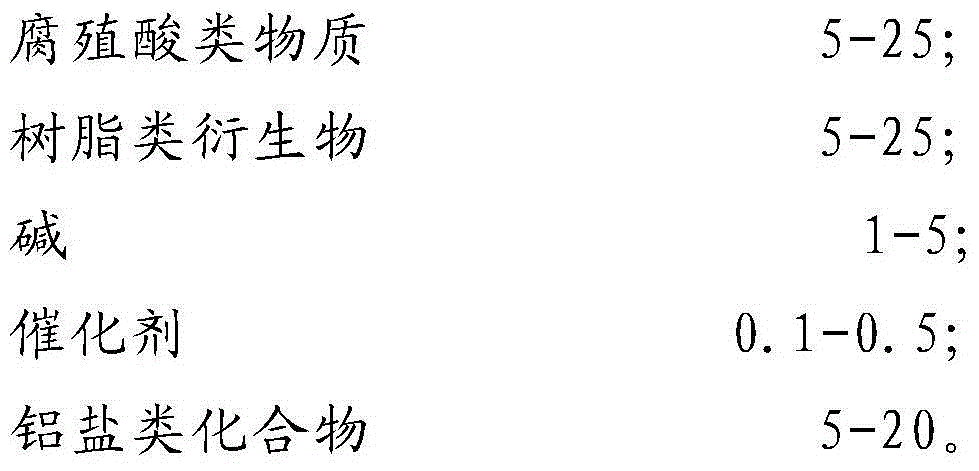

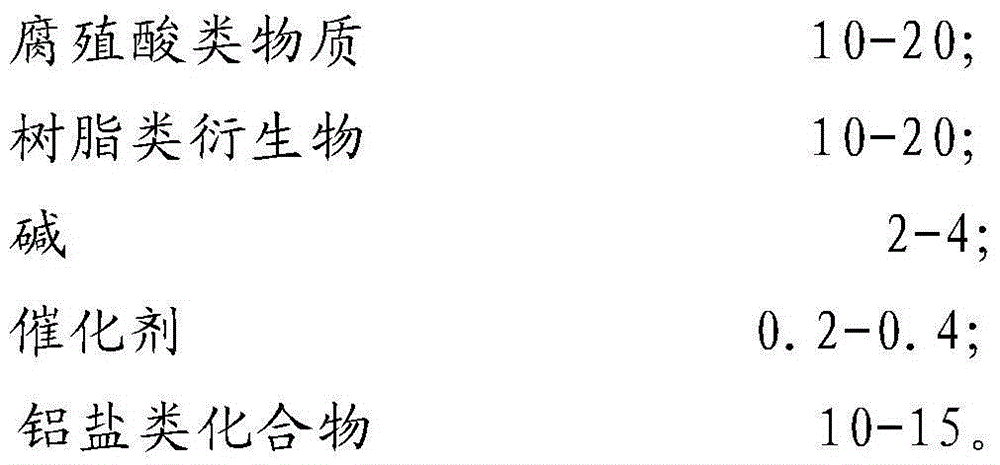

The invention relates to a borehole stabilizer for drilling fluid, a preparation method and applications thereof. The borehole stabilizer is prepared by reacting humic acid substances (5 to 25 parts by weight) and resin derivatives (5 to 25 parts by weight) with aluminum salts (5 to 20 parts by weight) in the presence of alkali (1 to 5 parts by weight) and catalyst (0.1 to 0.5 parts by weight). The borehole stabilizer has a good temperature resistant performance, can improve the mud cake quality at a high temperature, reduces the filter loss, and inhibits the clay hydration. Moreover, the borehole stabilizer can generate aluminum compound precipitate through physical and chemical reactions to seal the cracks in stratum during the drilling process so as to stabilize the borehole, the preparation method is simple, the conditions are mild, the conversion rate is high, the cost is low, no post-treatment is required, no waste gas, waste water or waste solid is generated, and the borehole stabilizer is green and environment-friendly.

Owner:北京中科日升科技有限公司

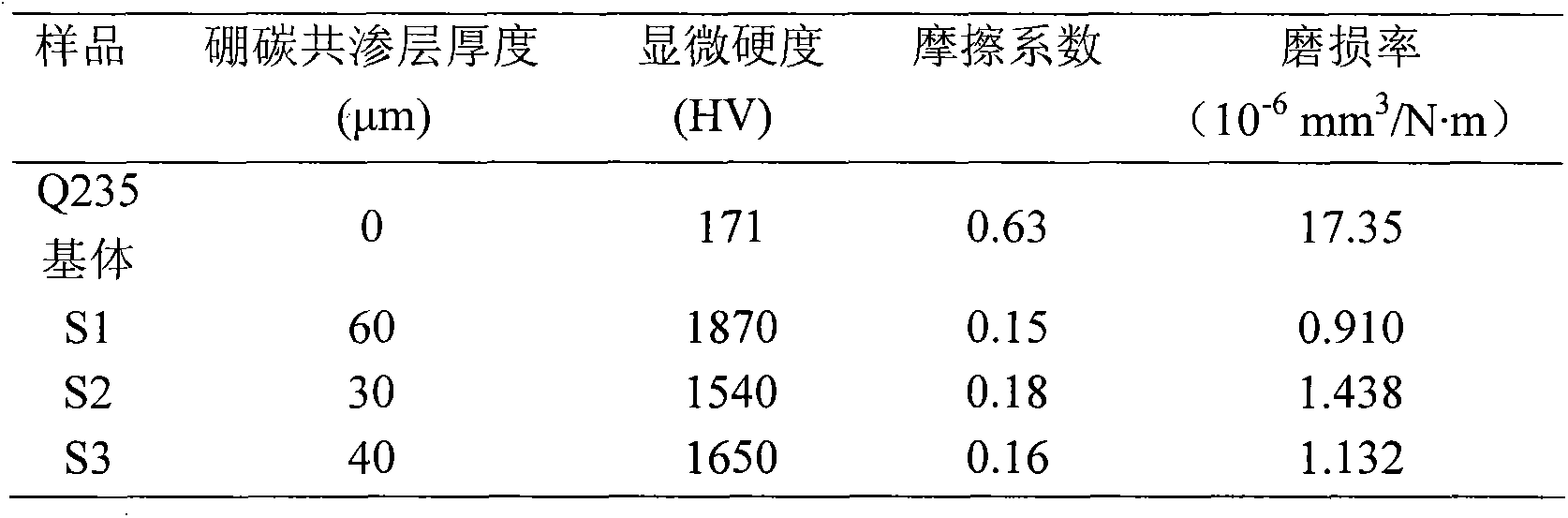

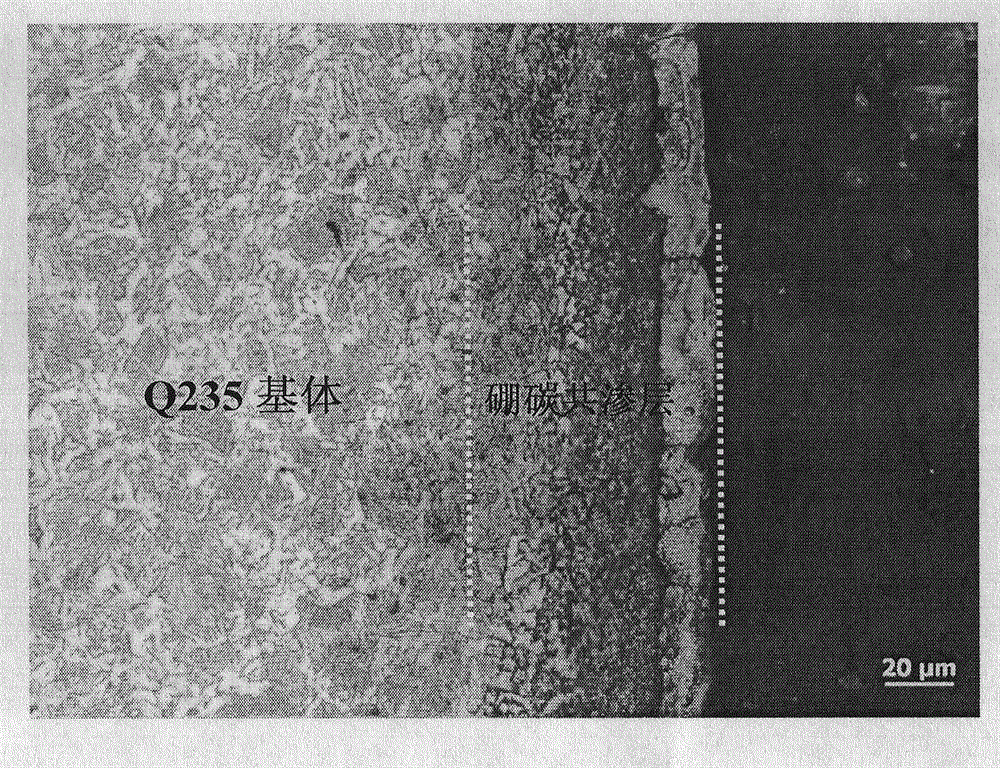

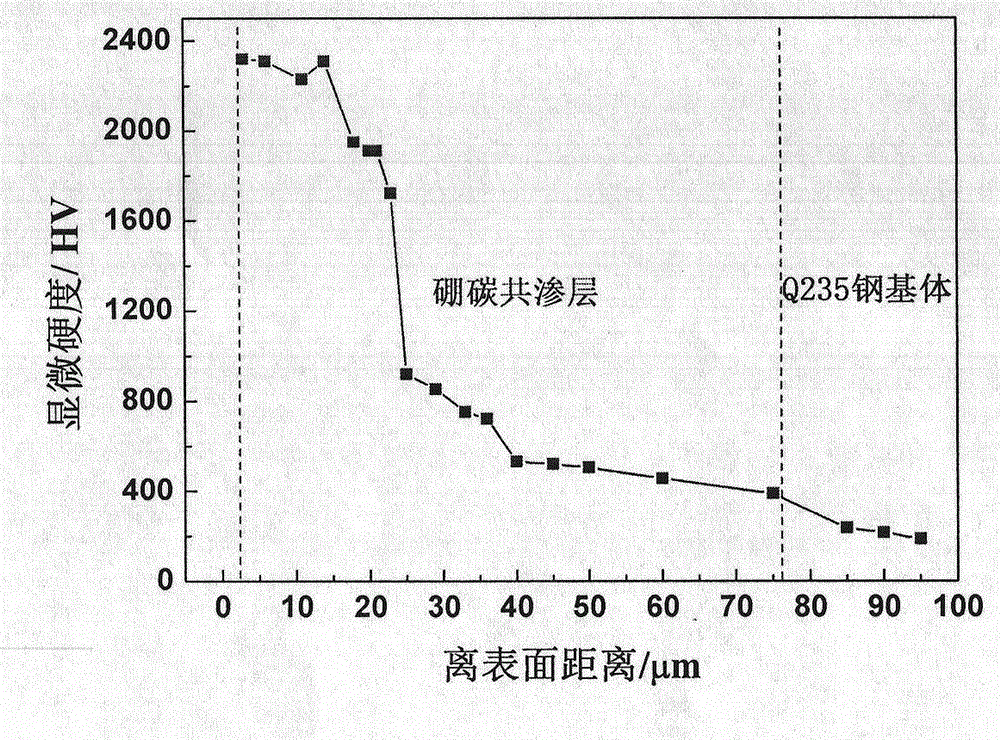

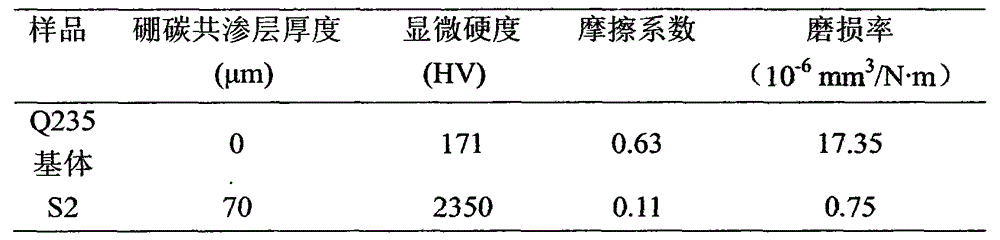

Solution used for steel surface quick plasma electrolysis boro-carbonization and boro-carbonization method

InactiveCN104131249ASlight heatReduce distortionSolid state diffusion coatingSodium bicarbonateElectrolysis

A solution used for steel surface quick plasma electrolysis boro-carbonization and a boro-carbonization method which belong to the technical field of steel surface treatment. The method is particularly a boron-carbon binary penetration method. Components of the solution, which is used as an electrolyte, include, by mass, 25-50% of borax, 10-30% of glycerin, 5-15% of sodium bicarbonate, 5-15% of sodium sulfate, 2-5 parts of potassium chloride and 20-50% of deionized water. A steel sample, being used as a cathode, is soaked in the solution and a graphite material is used as an anode. Under a room temperature condition, a 200-500V voltage is applied to the two electrodes and a boro-carbonization layer with a thickness being 15-80 [mu]m can be obtained after a treatment being carried out for 5-50 min, wherein a hardness of the boro-carbonization layer is 1500-2000 HV and is 8-12 times than a steel substrate. Meanwhile, a friction coefficient is reduced to 1 / 3-1 / 5 of the friction coefficient of the steel substrate and a wear rate is reduced to 1 / 12-1 / 20 of the wear rate of the steel substrate. By means of the plasma electrolysis boro-carbonization treatment, a frictional wearing resistant performance of steel is significantly improved. The method is free of post-treatment, is simple, is small in deformation of a workpiece and can reduce cost.

Owner:BEIJING NORMAL UNIVERSITY

TiB2 direct-current magnetron sputtering coating target prepared through vacuum gas shield pressure sintering

InactiveCN105018890AHigh hardnessCoating process is stableVacuum evaporation coatingSputtering coatingDirect current magnetron sputteringWork in process

The invention provides a TiB2 direct-current magnetron sputtering coating target prepared through vacuum gas shield pressure sintering. Ball mill is conducted on TiB2 powder with the purity being 99.95%, and then die filling is conducted; sintering is conducted at the temperature of 1000 DEG C, pressure is increased to 1 MPa, and then a semi-product is obtained; mechanical machining is conducted, it is guaranteed that all planes are kept level and the angles are right angles, and the TiB2 coating target is obtained. By the adoption of material design and an activated sintering technology, the hardness of a TiB2 film is improved, and the coating process is stable; the film layer is even, and the cost is low; the preparing cycle is short, and post-processing and other processes are not needed; and the TiB2 direct-current magnetron sputtering coating target prepared through vacuum gas shield pressure sintering is suitable for industrial production and has outstanding application value.

Owner:GEMCH MATERIAL TECH SUZHOU

Steel surface composite processing method using plasma electrolytic carburization and then boro-carbonization

InactiveCN105887001APrevent peelingReduce distortionSolid state diffusion coatingElectrolysisWear resistant

The invention belongs to the technical field of steel surface modification heat treatment technology, and specifically relates to a steel surface composite processing method using plasma electrolytic carburization and then boro-carbonization. The method comprises the following steps: (1) putting a steel sample into a carburizing solution, taking the steel sample as the negative electrode and a graphite material as the positive electrode, applying a voltage of 220 to 400 V on two electrodes at a room temperature, and carrying out a treatment for 3 to 5 minutes to obtain a carburization layer with a thickness of 15 to 90 [mu]m; (2) taking the sample which has been subjected to a carburization treatment as the negative electrode, putting the sample into a boro-carbonization solution, taking graphite as the positive electrode, applying a voltage of 200 to 500 V on two electrodes, carrying out a treatment for 10 to 30 minutes to obtain a boro-carbonization layer with a thickness of 20 to 100 [mu]m. The hardness of the obtained boro-carbonization layer can reach 1500 to 2400 HV, the hardness is improved by 10 to 15 times, compared with the steel matrix, and moreover, the wear resistant performance and durability are greatly improved. At the same time, the friction coefficient and wear rate of the boro-carbonization layer are 1 / 5-1 / 8 and 1 / 21-1 / 25 of those of steel matrix. The friction and wear resistant performance of steel is prominently improved by the plasma electrolysis-boro-carbonization treatment. Furthermore, the technology does not need any post treatment, and is simple, the deformation of workpiece is little, and the cost is reduced.

Owner:BEIJING NORMAL UNIVERSITY

Carbon fiber@ tungsten disulfide nanosheet kernel-shell composite structure and preparation method thereof

InactiveCN106006740AHigh densityHigh purityMaterial nanotechnologyPhysical/chemical process catalystsFiberCarbon fibers

The invention relates to a carbon fiber@ tungsten disulfide nanosheet kernel-shell composite structure and a preparation method thereof and belongs to the technical field of material preparation. Carbon fibers serve as the kernel of the composite structure, and tungsten disulfide nanosheets in an array shape serve as the shell. In a vacuum tube type furnace, a thermal evaporation technology is utilized to directly evaporate powdered sulfur which serves as a sulfur source, under the effect of carrier gas, pre-oxidized polyacrylonitrile fibers soaked with WO3 turbid liquid are fumigated at a high temperature, synchronous synthesis of the carbon fibers and the tungsten disulfide nanosheets is achieved, and the carbon fiber@ tungsten disulfide nanosheet kernel-shell composite structure can be prepared with a high yield. By means of the method, the yield of the product is large, density is high, purity is high, appearance is controllable, and postprocessing is not needed; the method has the advantages of being simple in equipment and process, strict and controllable in synthesis and growth conditions, high in product yield, low in cost, clean and environmentally friendly in production process and the like. Obtained materials are excellent visible light catalysts, electrocatalysts, lithium ion anode materials and light-emitting transistor materials.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com