A kind of polysulfone-polypyrrole nanoparticle composite asymmetric ultrafiltration membrane and preparation method thereof

A nano-polypyrrole, asymmetric technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of uneven dispersion of polypyrrole in composite membranes, easy residual oxidants and monomers, etc., and achieve good selective separation. Function, high charge response performance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

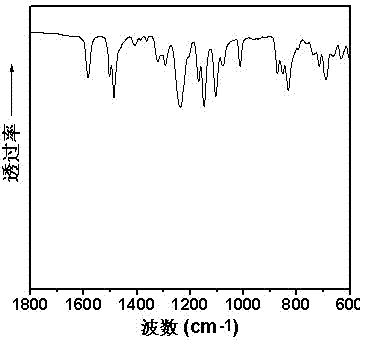

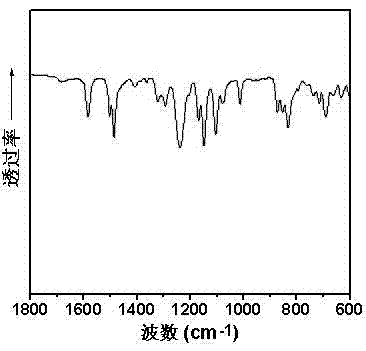

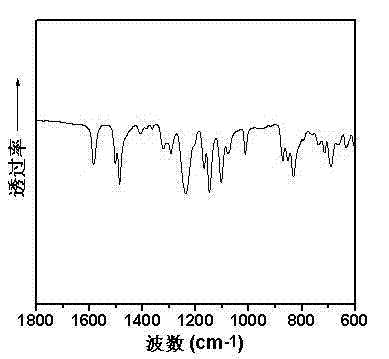

Image

Examples

Embodiment 1

[0098] Preparation of pure polysulfone membranes

[0099] (1) Preparation of casting solution

[0100] Weigh 1.5g polysulfone and add to 6.83g N -in methylpyrrolidone, magnetically stirred at 50°C for two days to form a light yellow homogeneous polysulfone solution with a concentration of 18wt%, which is ready for use;

[0101] (2) Coating film

[0102] With the aid of water-resistant adhesive tape, the polyester non-woven fabric was spread very smoothly on the glass plate, and the Doctor Blade adjustable film applicator was used to coat the film, and the thickness of the film was controlled to 152 μm; the polysulfone solution after degassing was placed in a straight line Apply it evenly on the polyester non-woven fabric horizontally, and then use a Doctor Blade type film applicator to apply the film;

[0103] (3) Film formation

[0104] Place the glass plate coated with the casting solution in the above step (2) horizontally and immerse it in th...

Embodiment 2

[0109] A method for preparing a polysulfone-polypyrrole nanoparticle composite asymmetric ultrafiltration membrane with a polypyrrole nanoparticle content of 2.0%, comprising the steps of:

[0110] (1) Preparation of casting solution

[0111] Weigh 0.03g of hydrochloric acid-doped polypyrrole nanoparticles with a diameter of 80-100nm and add 6.83g N -Methylpyrrolidone, after ultrasonic dispersion at 50°C for 6h, then magnetic stirring at the same temperature for 24h, so that the polypyrrole nanoparticles are uniformly dispersed in the N -in methylpyrrolidone; then 1.47g of polysulfone was added to each of the above dispersions, magnetically stirred at 50°C for 24h, and then ultrasonicated for 2h to form a polysulfone-polypyrrole nanoparticle blend solution with a polypyrrole content of 2.0%. stand-by;

[0112] (2), coating film

[0113] Replace the pure polysulfone solution with the polypyrrole content of 2.0% polysulfone-polypyrrole nanoparticle blend s...

Embodiment 3

[0118] A method for preparing a polysulfone-polypyrrole nanoparticle composite asymmetric ultrafiltration membrane with a polypyrrole nanoparticle content of 4.0%, comprising the steps of:

[0119] (1) Preparation of casting solution:

[0120] Weigh 0.06g of hydrochloric acid-doped polypyrrole nanoparticles with a diameter of 80-100nm and add 6.83g N -Methylpyrrolidone, after ultrasonic dispersion at 50°C for 6h, then magnetic stirring at the same temperature for 24h, so that the polypyrrole nanoparticles are uniformly dispersed in the N - into methylpyrrolidone; then add 1.44g of polysulfone to each of the above dispersions, stir magnetically at 50°C for 24h, and then sonicate for 2h to form a polysulfone-polypyrrole nanoparticle blend solution with a polypyrrole content of 4.0%. ,stand-by;

[0121] (2), coating film

[0122] The pure polysulfone solution is replaced by the polysulfone-polypyrrole nanoparticle blend solution with a polypyrrole content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com