Water-based polyurethane material with hydrophilic outer layer and hydrophobic inner layer, preparation method and application thereof

A water-based polyurethane, hydrophilic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex chemical synthesis, high cost, difficult to scale production, etc., to achieve the effect of mature technology, energy saving and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

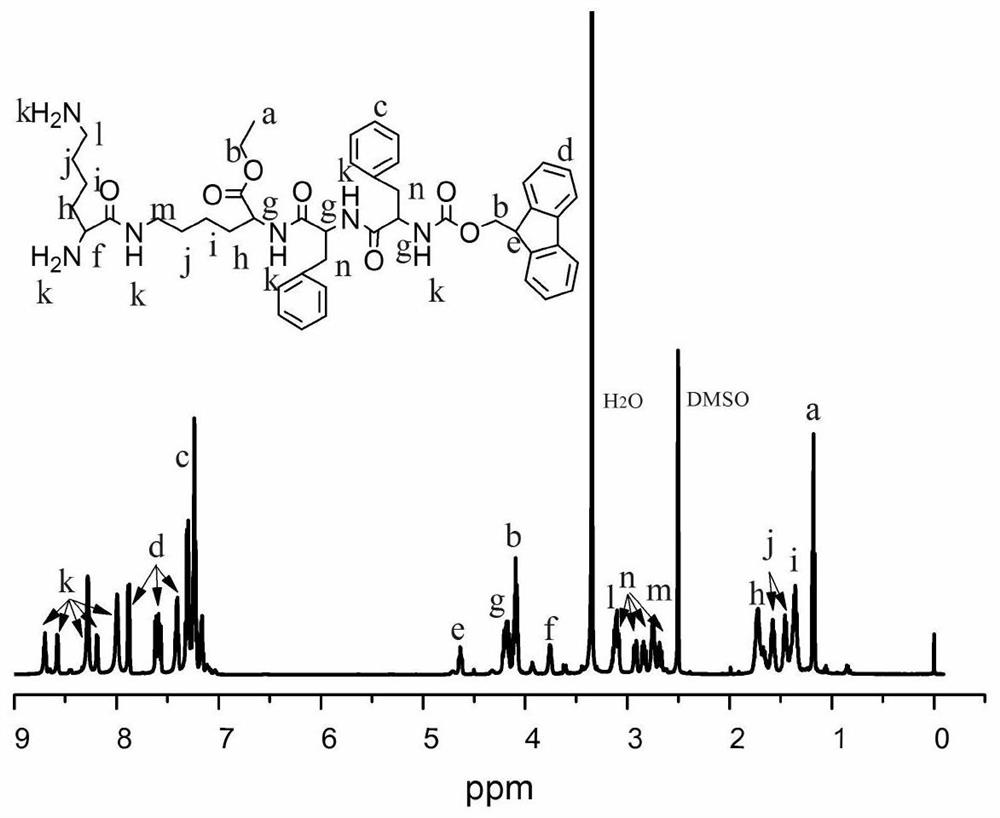

[0075] Fmoc-Phe-OH and H-Phe-O t Add Bu.HCl to tetrahydrofuran according to the molar ratio of 1.0:1.1, then add triethylamine 1.2 times the molar weight of Fmoc-Phe-OH, and add the molar amount of Fmoc-Phe-OH 1.1 times the amount of composite condensing agent, where N,N'-dicyclohexylcarbodiimide:N-hydroxysuccinimide=1.1:1. React at 0°C for 3h, react at room temperature for 12h, filter to remove insoluble matter, The filtrate was concentrated to dryness by rotary evaporation, dissolved in DCM, washed with 1 mol / L dilute hydrochloric acid, saturated aqueous sodium bicarbonate solution, saturated sodium chloride aqueous solution, and distilled water successively for 3 times, dried over anhydrous sodium sulfate, and rotary evaporated After concentration, it was precipitated with ether to obtain the white powder product Fmoc-Phe-Phe-OtBu. Disperse Fmoc-Phe-Phe-OtBu in DCM, add an equal volume of TFA to remove the tert-butyl ester group under ice-bath conditions, react for 6 hours...

Embodiment 2

[0077] Add Fmoc-Phe-Phe-OH and H-Lys(Boc)-OEt.HCl to chloroform according to the molar ratio of 1.0:1.1, and then add 1.2 times the molar weight of Fmoc-Phe-Phe-OH Triethylamine, ice-bathed to 0°C and then added a compound condensing agent 1.1 times the molar weight of Fmoc-Phe-Phe-OH, wherein N,N'-dicyclohexylcarbodiimide: N-hydroxysuccinate Imide=1.1:1. React at 0°C for 3 hours, react at room temperature for 12 hours, remove insoluble matter by filtration, and spin the filtrate successively with dilute hydrochloric acid with a concentration of 1mol / L, saturated aqueous sodium bicarbonate, saturated aqueous sodium chloride, and distilled water. liquid, washed three times, dried over anhydrous sodium sulfate, concentrated by rotary evaporation, and precipitated with ether to obtain the white powder product Fmoc-Phe-Phe-Lys(Boc)-OEt.HCl. Disperse Fmoc-Phe-Phe-OtBu in DCM, add an equal volume of ethyl acetate saturated with hydrogen chloride under ice bath conditions to remove t...

Embodiment 3

[0079] Add Boc-Lys(Boc)-OH and Fmoc-Phe-Phe-Lys(H)-OEt.HCl to chloroform at a molar ratio of 1.0:1.1: N,N dimethylformamide=100:10 (v:v) In the mixed solvent, add 1.2 times of triethylamine based on the molar amount of Boc-Lys(Boc)-OH, and add the molar amount of Boc-Lys(Boc)-OH after ice bathing to 0°C 1.1 times the composite condensing agent, where N,N'-dicyclohexylcarbodiimide:N-hydroxysuccinimide=1.1:1. Reacted at 0°C for 3h, at room temperature for 12h, filtered to remove insoluble matter, and the filtrate Swirl with dilute hydrochloric acid with a concentration of 1mol / L, saturated aqueous sodium bicarbonate solution, saturated aqueous sodium chloride solution, and distilled water, and wash three times with each separation, dry with anhydrous sodium sulfate, concentrate by rotary evaporation, and precipitate with ether to obtain a white powder. Product Fmoc-Phe-Phe-Lys(Boc-Lys(Boc))-OEt.

[0080] Disperse Fmoc-Phe-Phe-Lys(Boc-Lys(Boc))-OEt in DCM, add an equal volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com