High-wear-resistance wood-plastic floor board and preparation method thereof

A technology for wood-plastic flooring and preparation steps, which is applied in construction, building structure, floor, etc., can solve the problems of high production cost and low performance, and achieve the effects of low cost, improved wear resistance, and widened application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

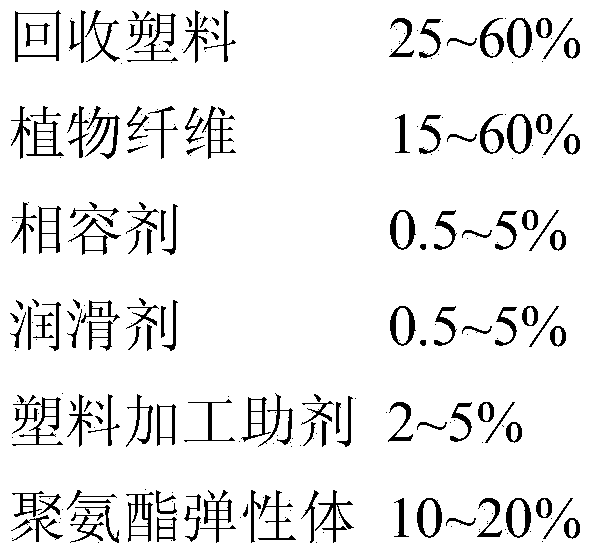

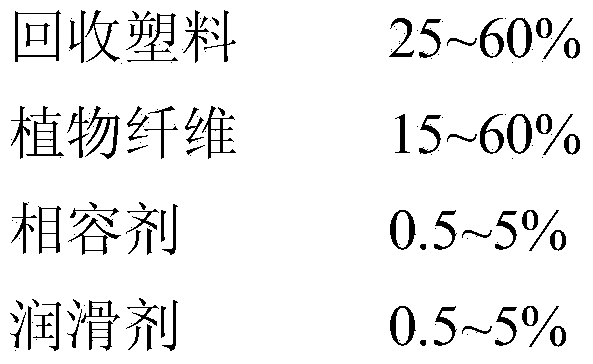

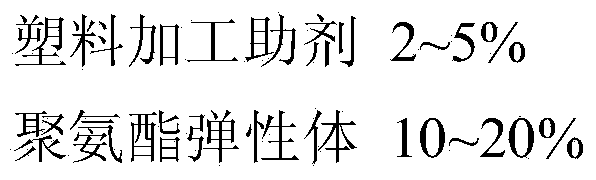

[0032] Embodiment 1. The raw materials used in the manufacture of wear-resistant wood-plastic flooring are as follows by mass percentage:

[0033] Recycled plastic 25%, wood powder 60%, compatibilizer 0.5%, polyethylene wax 1%, zinc stearate 1%, light calcium carbonate 1.5%, ultraviolet absorber 0.2%, antioxidant 0.2%, pigment 0.6 %, polyurethane elastomer 10%.

Embodiment 2

[0034] Embodiment 2. The raw materials used in the manufacture of wear-resistant wood-plastic flooring are as follows by mass percentage:

[0035] Recycled plastic 30%, wood powder 33%, bran powder 20%, compatibilizer 1%, zinc stearate 1%, stearic acid 1.5%, paraffin 0.2%, light calcium carbonate 0.35%, ultraviolet absorber 0.15% , 0.2% antioxidant, 0.6% pigment, 12% polyurethane elastomer.

Embodiment 3

[0036] Embodiment 3. The raw materials used in the manufacture of wear-resistant wood-plastic flooring are as follows by mass percentage:

[0037] Recycled plastic 35%, wood powder 23%, bran powder 20%, compatibilizer 1.5%, zinc stearate 1%, stearic acid 1.5%, polyethylene wax 1%, light calcium carbonate 1%, ultraviolet absorber 0.2%, antioxidant 0.2%, pigment 0.6%, polyurethane elastomer 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com