Emulsion type wood starch adhesive and preparation method thereof

A starch adhesive, emulsion type technology, applied in the direction of adhesives, graft polymer adhesives, polymer adhesive additives, etc., can solve the problems to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

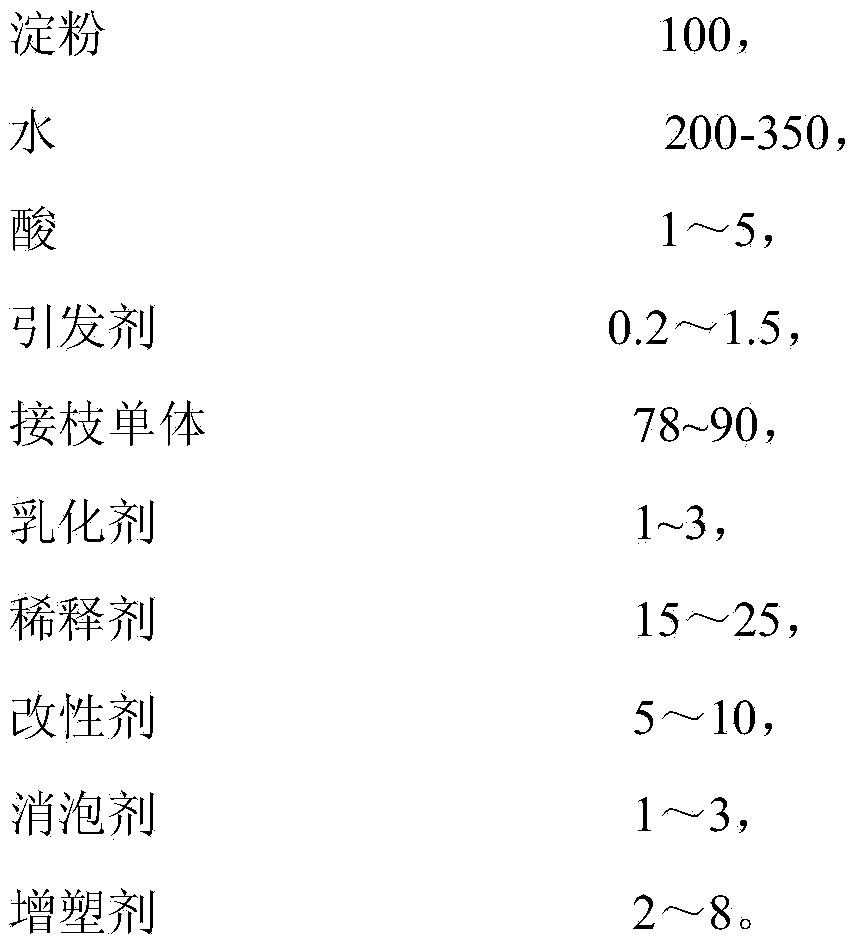

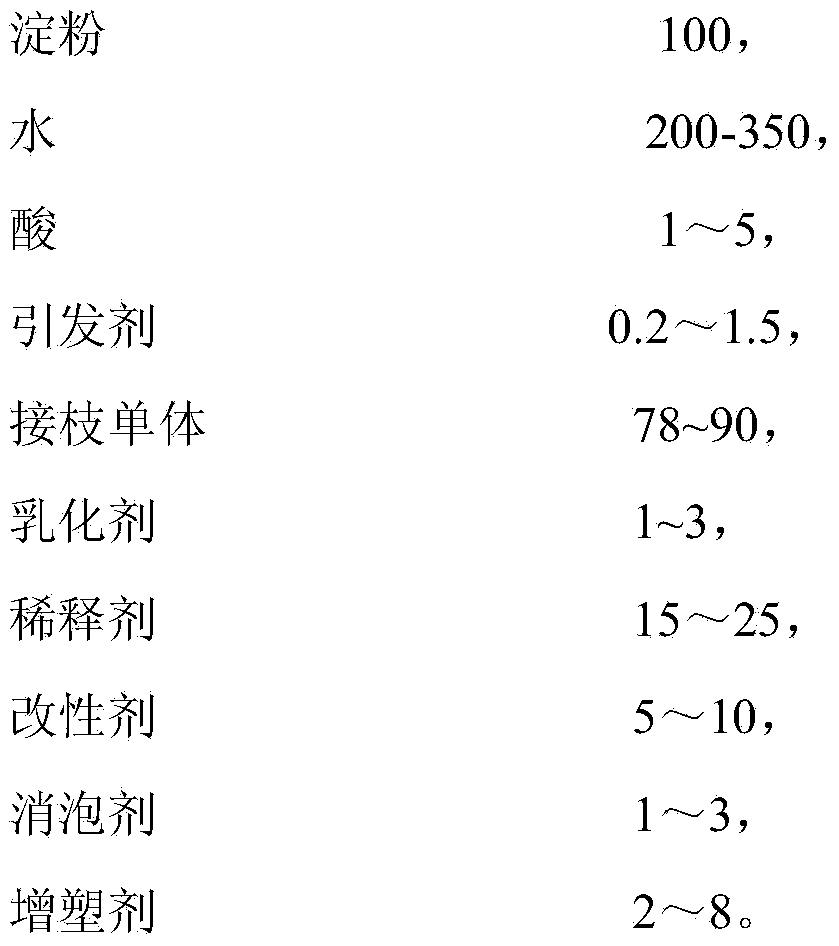

[0025] Formula (mass percentage, %):

[0026] Tapioca Starch 100

[0027] water 260

[0028] Hydrochloric acid aqueous solution (36%, m / m) 4

[0029] Vinyl acetate 88

[0030] Ammonium persulfate 1

[0031] Sodium Lauryl Sulfate 1.5

[0032] Polyvinyl alcohol 10

[0033] Urea 22

[0034] Glycerin 8

[0035] Tributyl phosphate 3

[0036] crafting process:

[0037] (1) Mix cassava starch and hydrochloric acid solution diluted to 1.5% to prepare high-concentration starch milk of 40% (w / w) based on starch dry basis, acid hydrolyze at 60°C for 2 hours, and use 0.2mol / L sodium hydroxide solution Adjust the pH to 4.0, add the initiator ammonium persulfate accounting for 50% of the total amount of the initiator added and the emulsifier sodium lauryl sulfate accounting for 50% of the total amount of the emulsifier added, adjust the temperature of the system to 70 ° C, slowly drop the The graft monomer vinyl acetate of graft monomer total addition 20%;

[0038] (2) Take out 1...

Embodiment 2

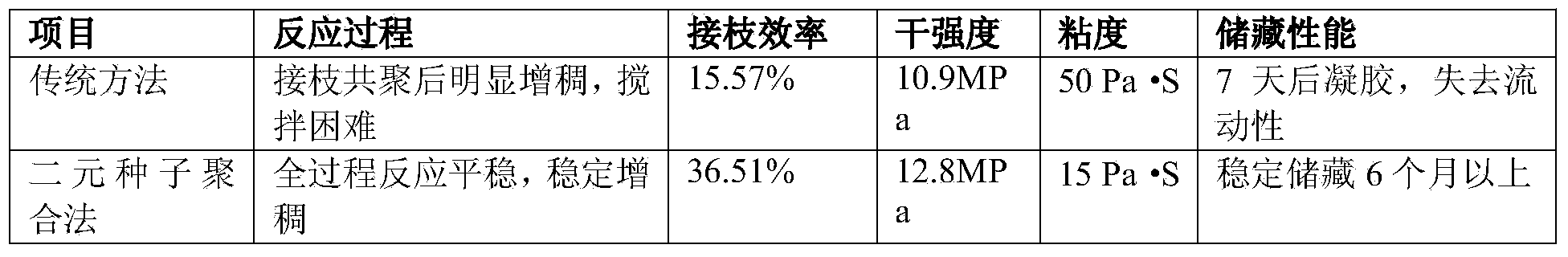

[0045] This example gives the comparison of the main properties of the starch adhesive for wood prepared by the traditional process and the starch adhesive for wood prepared by the binary seed method.

[0046] Formula (mass percentage):

[0047] cornstarch 100

[0048] Hydrochloric acid aqueous solution (38%, m / m) 4.5

[0049] water 240

[0050] Vinyl acetate 86

[0051] Potassium persulfate 1

[0052] Cetyltrimethylammonium bromide 2

[0053] Polyvinyl alcohol 7

[0054] Urea 16

[0055] Glycerin 4

[0056] Tributyl phosphate 2

[0057] Method 1 (process without binary seed method):

[0058] Mix cornstarch and hydrochloric acid solution into starch milk of 45% (w / w) on dry basis of starch, acidify at 65°C for 2.5h, adjust pH to 4.5 with 0.1mol / L sodium hydroxide solution, add 50% Initiator potassium persulfate and all emulsifier cetyltrimethylammonium bromide, slowly drop graft monomer vinyl acetate, add remaining potassium persulfate after 3h, react for 2h, add polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com