Environment-friendly high-fluidity lubricating oil and preparation method thereof

A high fluidity, lubricating oil technology, applied in the field of lubricating oil, can solve the problems of strong ecotoxicity accumulation, low fluidity, easy solidification, etc., and achieve the effect of improving oxidation stability, improving lubricating effect, and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

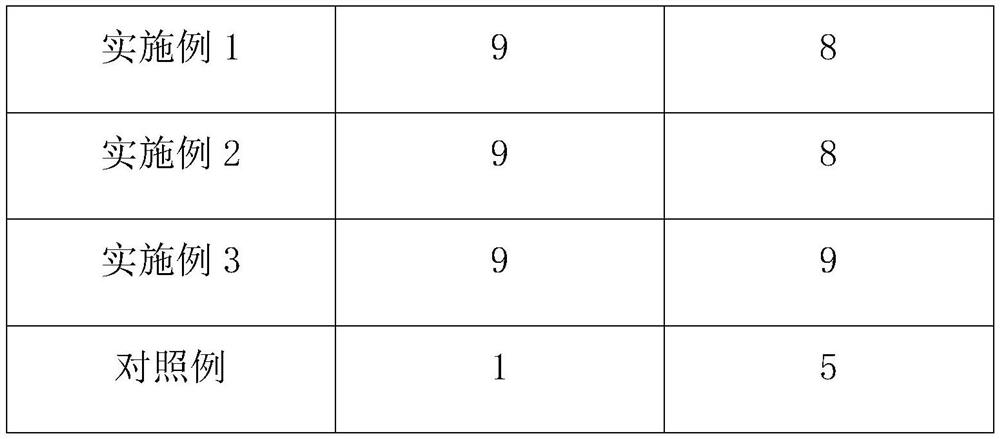

Embodiment 1

[0026] An environment-friendly high fluidity lubricating oil, the formula includes: environment-friendly base oil, flow modifier, high alkali value sulfurized alkyl phenate calcium, allyl mercaptan, dimercaptothiadiazole, primary and secondary sulfur phosphorus alkyl zinc salt and Fatty alcohol polyoxyethylene ether, the parts by weight of each component are: 185-245 parts of environmental protection base oil, 6-10 parts of flow modifier, 7-9 parts of high alkali value sulfurized calcium alkylphenate, 4-6 parts of allyl mercaptan, 3-5 parts of dimercaptothiadiazole, 1-3 parts of primary-secondary alkyl zinc salt of sulfur phosphorus and 1-3 parts of fatty alcohol polyoxyethylene ether.

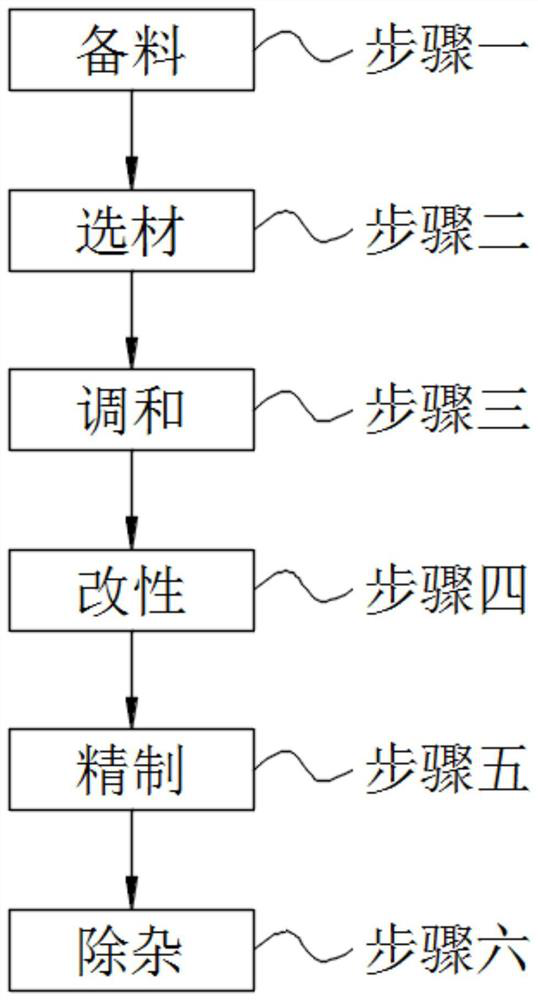

[0027] A method for preparing an environment-friendly and high-fluidity lubricating oil, comprising the following steps: Step 1, preparing materials; Step 2, selecting materials; Step 3, blending; Step 4, modifying; Step 5, refining; Step 6, removing impurities;

[0028] Wherein in the above s...

Embodiment 2

[0035]An environment-friendly and high-fluidity lubricating oil, the formula includes: environment-friendly base oil, flow modifier, high base number sulfurized alkyl phenol calcium, allyl mercaptan, dimercaptothiadiazole, sulfur phosphorous primary and secondary alkyl zinc salt and Fatty alcohol polyoxyethylene ether, the parts by weight of each component are: 185-245 parts of environmental protection base oil, 6-10 parts of flow modifier, 7-9 parts of high base number sulfurized alkyl phenol calcium, 4-6 parts of allyl mercaptan, 3-5 parts of dimercaptothiadiazole, 1-3 parts of sulfur phosphorus primary and secondary alkyl zinc salt and 1-3 parts of fatty alcohol polyoxyethylene ether.

[0036] A method for preparing an environment-friendly and high-fluidity lubricating oil, comprising the following steps: step 1, material preparation; step 2, material selection; step 3, blending; step 4, modification; step 5, refining; step 6, impurity removal;

[0037] Wherein in the above...

Embodiment 3

[0044] An environment-friendly and high-fluidity lubricating oil, the formula includes: environment-friendly base oil, flow modifier, high base number sulfurized alkyl phenol calcium, allyl mercaptan, dimercaptothiadiazole, sulfur phosphorous primary and secondary alkyl zinc salt and Fatty alcohol polyoxyethylene ether, the parts by weight of each component are: 185-245 parts of environmental protection base oil, 6-10 parts of flow modifier, 7-9 parts of high base number sulfurized alkyl phenol calcium, 4-6 parts of allyl mercaptan, 3-5 parts of dimercaptothiadiazole, 1-3 parts of sulfur phosphorus primary and secondary alkyl zinc salt and 1-3 parts of fatty alcohol polyoxyethylene ether.

[0045] A method for preparing an environment-friendly and high-fluidity lubricating oil, comprising the following steps: step 1, material preparation; step 2, material selection; step 3, blending; step 4, modification; step 5, refining; step 6, impurity removal;

[0046] Wherein in the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com