Patents

Literature

126results about How to "Avoid hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paint Compositions With Low- or Zero-VOC Coalescence Aids and Nano-Particle Pigments

InactiveUS20090149591A1High mechanical strengthDesirable blocking propertyOther chemical processesAlkaline-earth metal silicatesWater basedOrganic content

The invention is related to glossy, low- or zero-VOC aqueous paint compositions, comprising water based latex polymer, a hiding pigment, at least one low-VOC coalescence aid having a volatile organic content of less than 50 g / L, and a second inorganic pigment with particle size ranging from about 1 to 100 nanometers. The paint composition gives good block resistance and mechanical strength and can be adopted for paints with at least glossy and semi-gloss finishes.

Owner:COLUMBIA INSURANCE CO

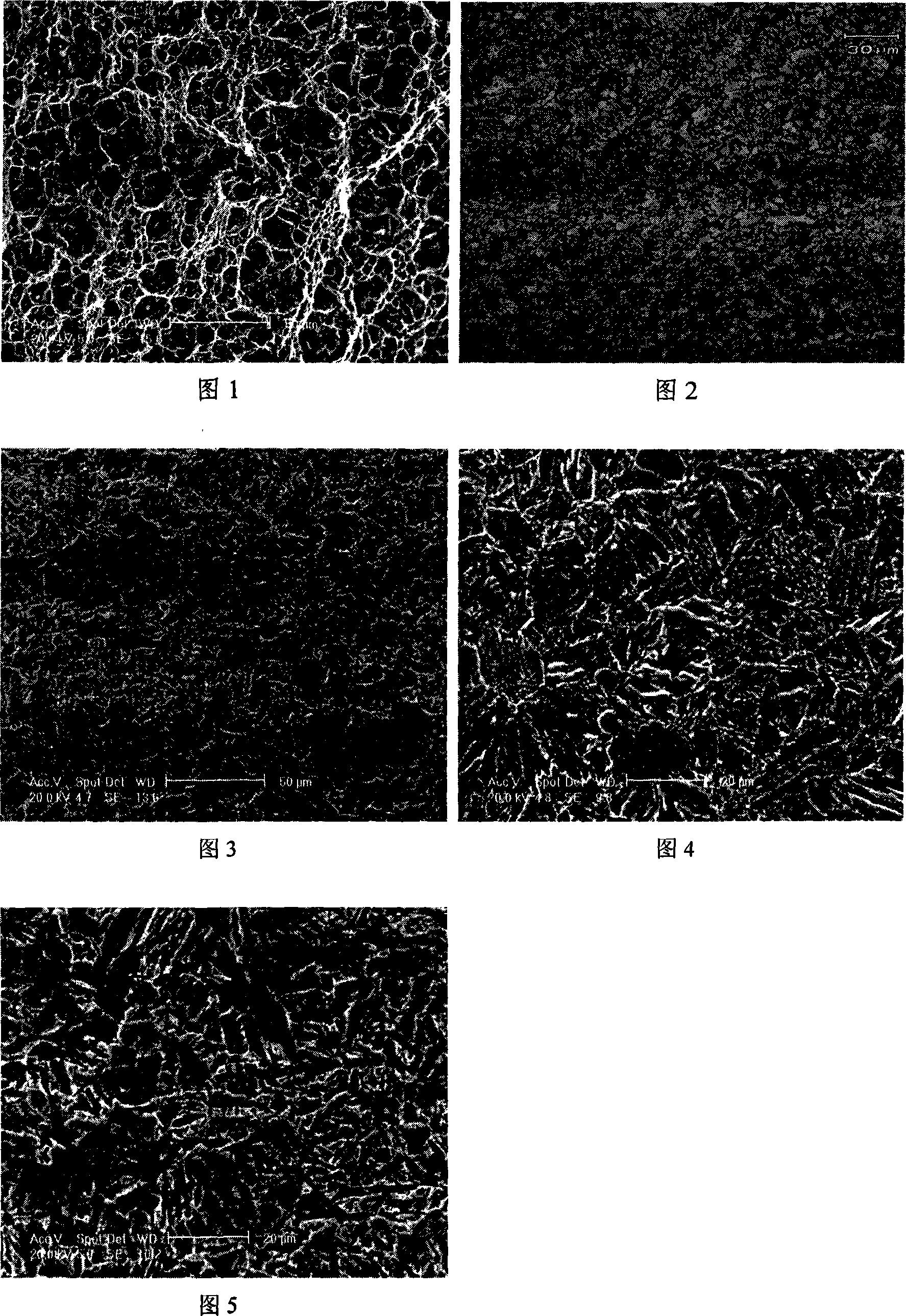

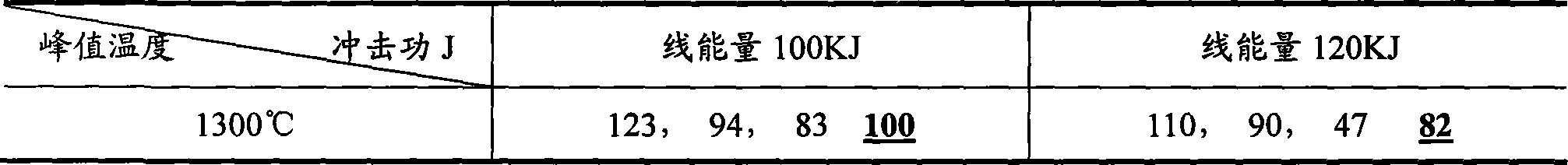

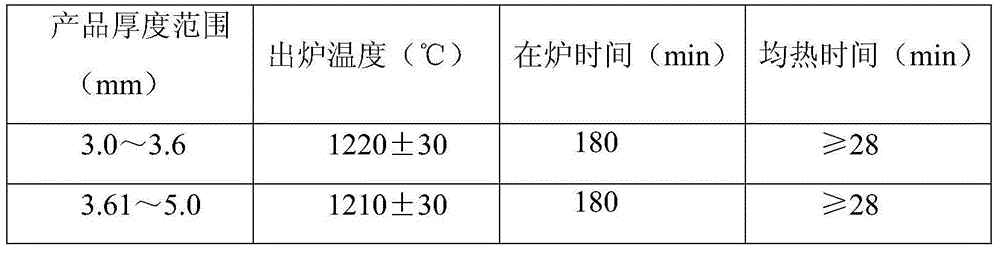

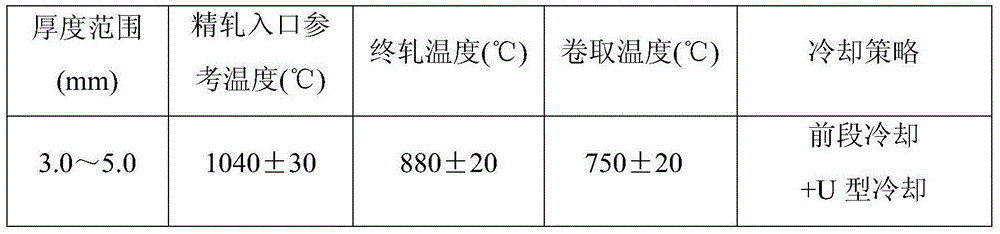

High-strength thick steel plate for large-scale petroleum storing tank and low-cost manufacturing method thereof

InactiveCN101215669AReduce weld crack susceptibility componentsInhibit grain growthTemperature control deviceFurnace typesPetroleumHigh intensity

The invention relates to a method for preparing a high strength thick steel plate for a large oil storage tank in a low cost, the method particularly applies to a high strength thick steel plate for a large oil storage tank, which is welded by line energy which is equal or less than 120 KJ / cm. The weight percentages of chemical constituents are that carbon is 0.01-0.12 percent, silicon is 0.15-0.35 percent, manganese is 1.45-1.80 percent, phosphorus is equal or less than 0.010 percent, sulfur is equal or less than 0.003 percent, aluminum is 0.02-0.06 percent, vanadium is 0.02-0.06 percent, nickel is 0.20-0.40 percent, nitrogen is 0.003-0.006 percent, and the other is ferric, other alloying elements and inevitable impurities. The invention uses on-line quenching and off-line tempering processes, thereby reducing valuable alloying elements, obtaining high strength high toughness thick steel plate which has excellent welding performance and does not need to preheat above 0 DEG C, reducing the producing cost, saving energy, increasing production efficiency and improving welding construction conditions, and the invention is capable of being widely used for constructions of a 10-30 cubic myriametre of large oil storage tank.

Owner:SHANDONG IRON & STEEL CO LTD

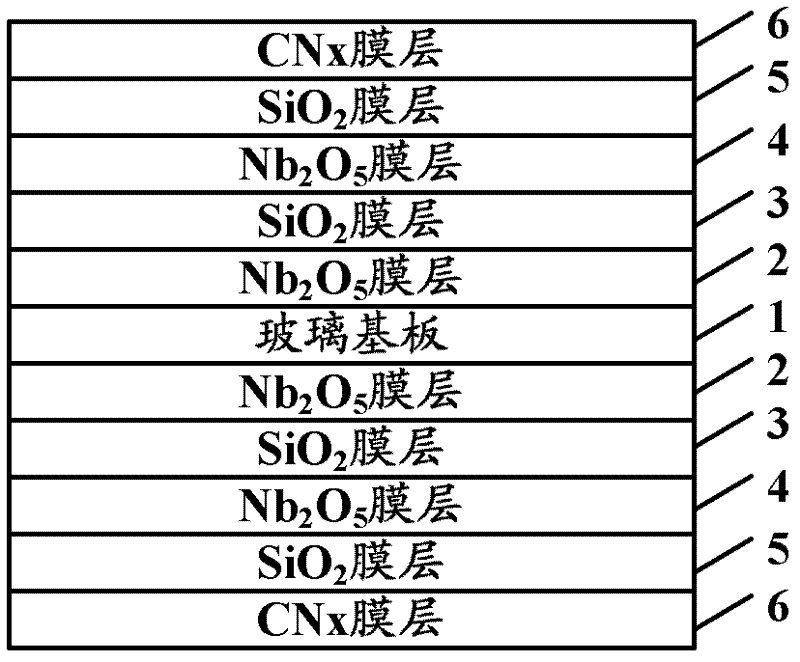

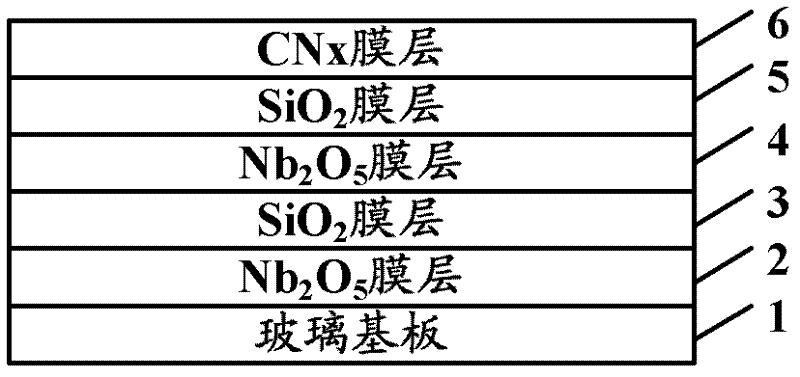

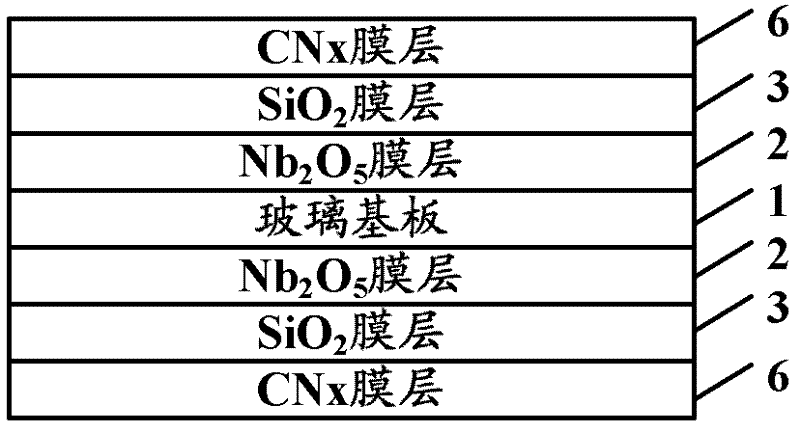

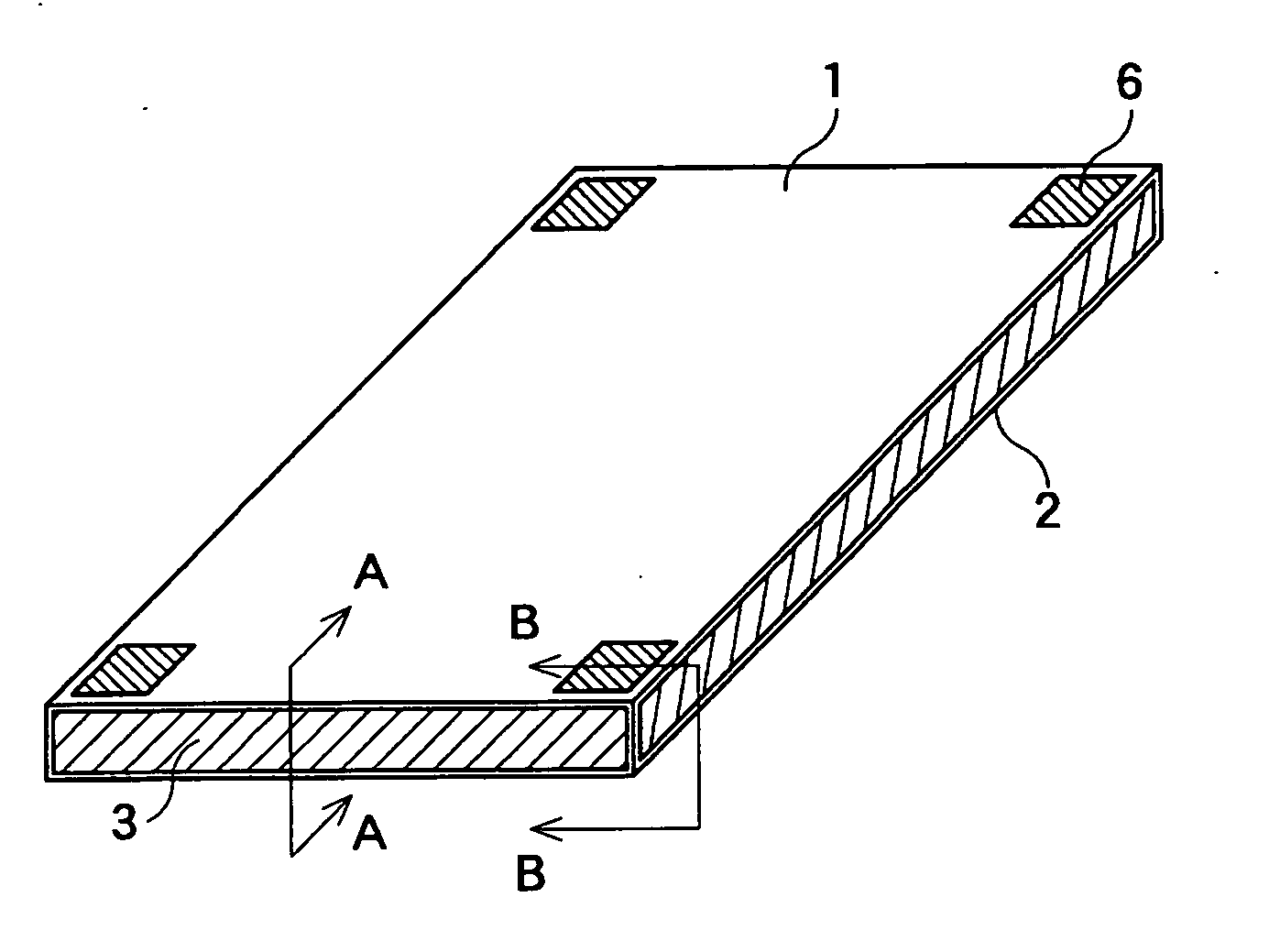

Method for preparing membrane on glass substrate and glass substrate and membrane system structure

InactiveCN102351438AImprove wear resistanceImprove bindingGlass/slag layered productsCarbon nitrideRefractive index

An embodiment of the invention discloses a method for preparing a membrane on a glass substrate. A magnetron sputtering method is employed to generate antireflective anti-reflecting mixing membrane, which is a stacked structure containing a low refractive index membrane and a high refractive index membrane, on one side or double sides of the glass substrate; and the magnetron sputtering method is employed to generate a carbon nitride compound membrane on the other side of the antireflective anti-reflecting mixing membrane. The invention also discloses a membrane system structure, a glass substrate plated with the membrane and another method for preparing membrane on glass substrate and another glass substrate plated with membrane. According to the invention, a protective screen has a guaranteed quality, strong anti scuffing performance, wear resistance, superhardness and scratch resistance.

Owner:SHENZHEN SANXIN JMT GLASS

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

Method

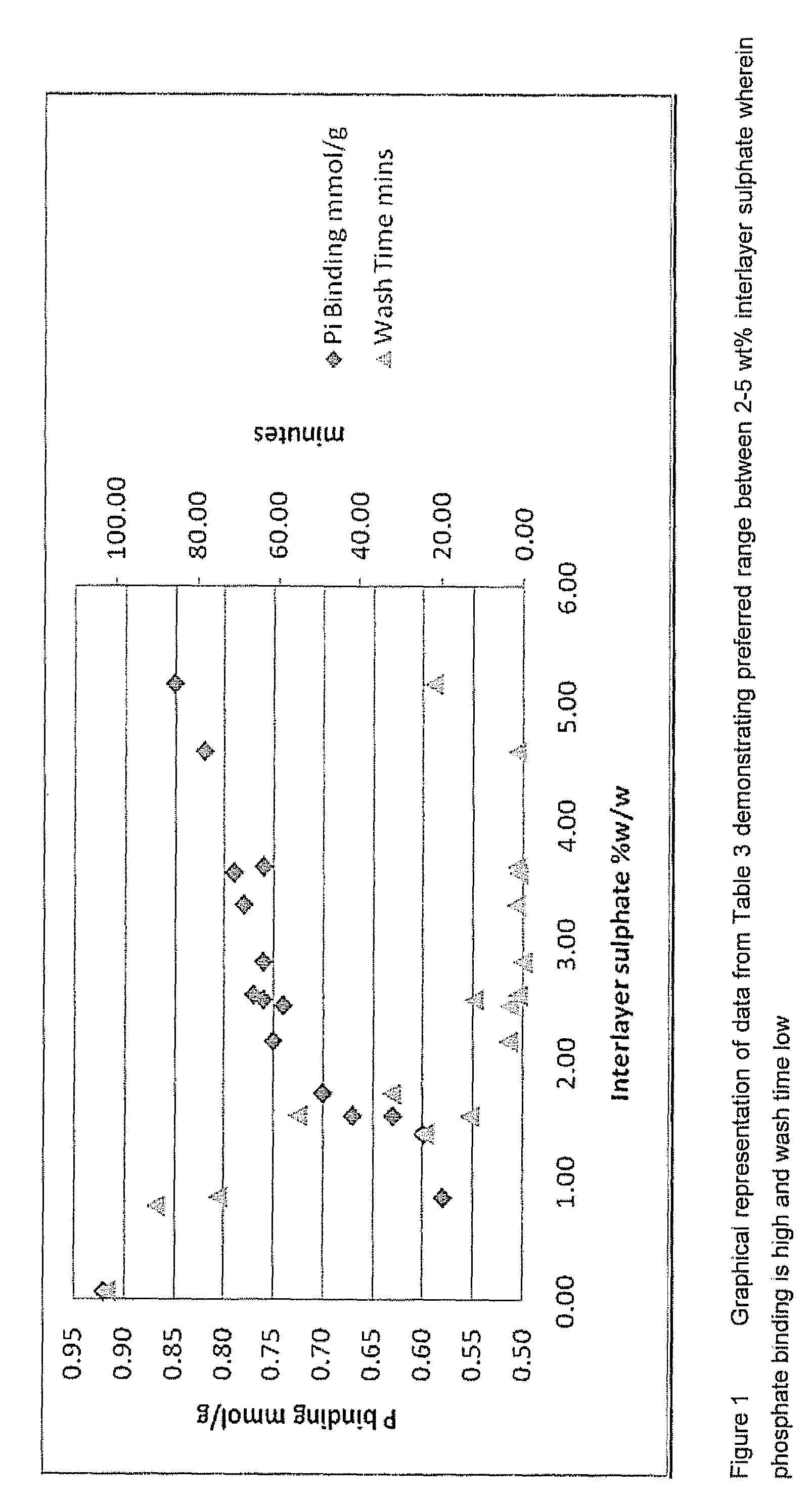

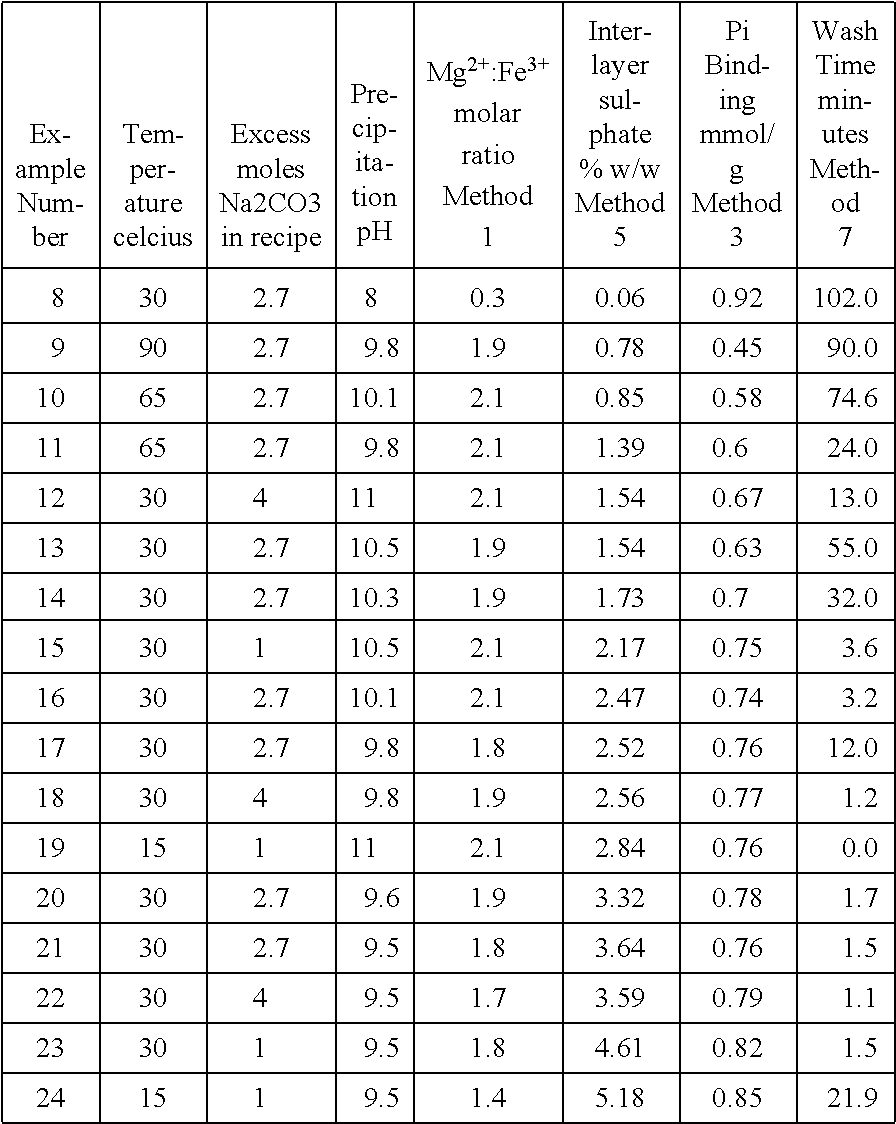

ActiveUS20120201864A1Easy to controlLow magnesium releasePowder deliveryHeavy metal active ingredientsAluminiumUnit volume

There is provided a method of producing a mixed metal compound comprising at least Mg2+ and at least Fe+ having an aluminium content of less than 10000 ppm, having an average crystal size of less than 20 nm (200 A) comprising the steps of: (a) combining a Mg2+ salt and a Fe3+ salt with Na2CO3 and NaOH to produce a slurry, wherein the pH of the slurry is maintained at from 9 5 to 1 1, and wherein the Na2CO3 is provided at an excess of 0 to 4.0 moles than is required to complete the reaction (b) subjecting the slurry to mixing under conditions providing a power per unit volume of 0 03 to 1.6 kW / m3 (c) separating the mixed metal compound from the slurry, to obtain a crude product having a dry solid content of at least 10 wt % (d) drying the crude product either by (i) heating the crude product to a temperature of no greater than 150° C. and sufficient to provide a water evaporation rate of 0.05 to 1 5 kg water per hour per kg of dry product, or (H) exposing the crude product to rapid drying at a water evaporation rate of 500 to 50000 kg water per hour per kg of dry product.

Owner:EIRGEN PHARMA LTD

Sealing material

InactiveUS20060155074A1Sufficient sealabilityImprove liquidityCasingsEngine sealsFuel cellsHydrosilylation

A sealing material, which comprises a curing product of a composition comprising (A) an acrylic polymer having at least one alkenyl group capable of undergoing hydrosilylation reaction, (B) a hydrosilyl group-containing compound and (C) a hydrosilylation catalyst as essential components, is suitable for use as cam cover seals and oil pan seals for automobile engines, fuel cell cooling medium seals, automobile wire harnesses seals, HDD cover gasket or vibration-insulating HDD cover gasket seals, etc.

Owner:KANEKA CORP +1

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

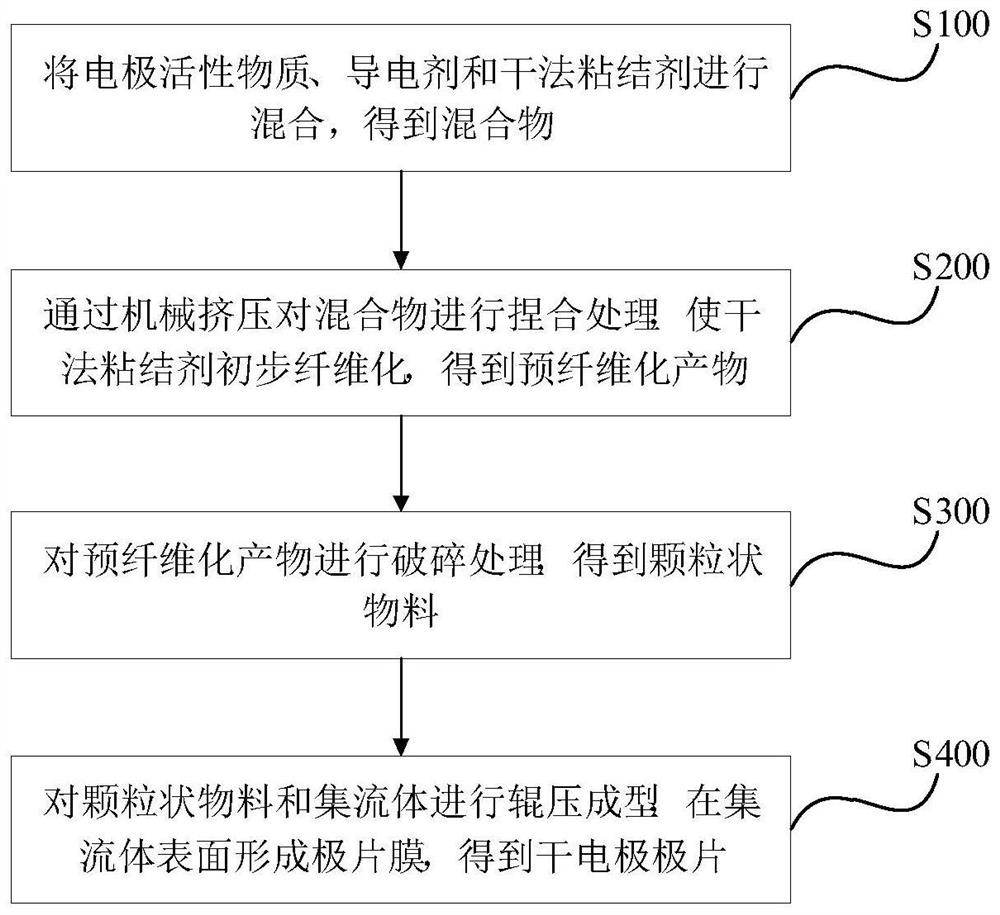

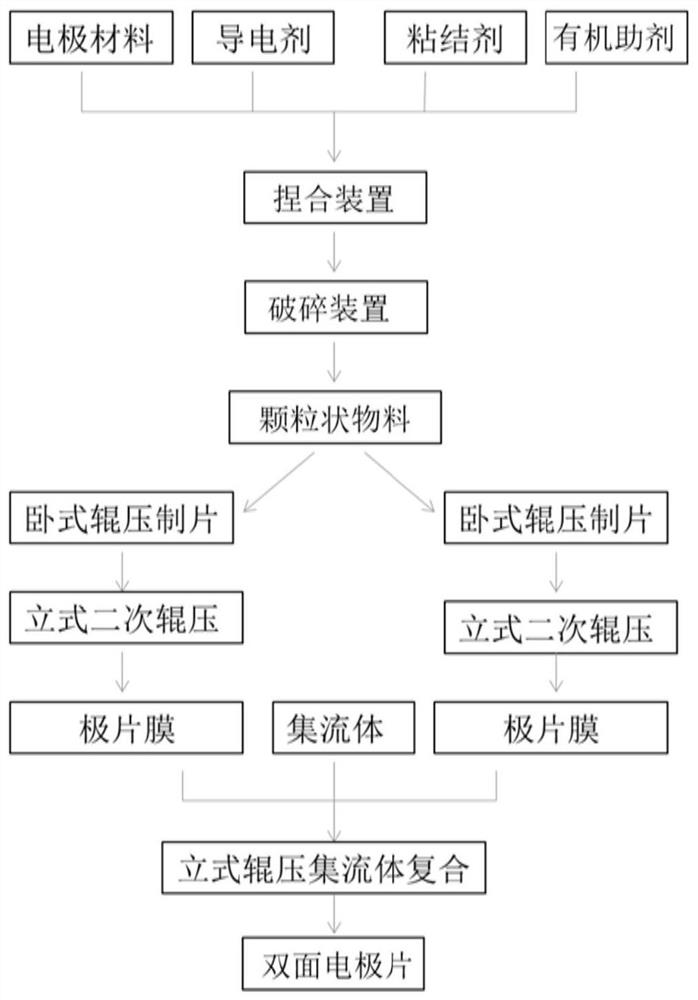

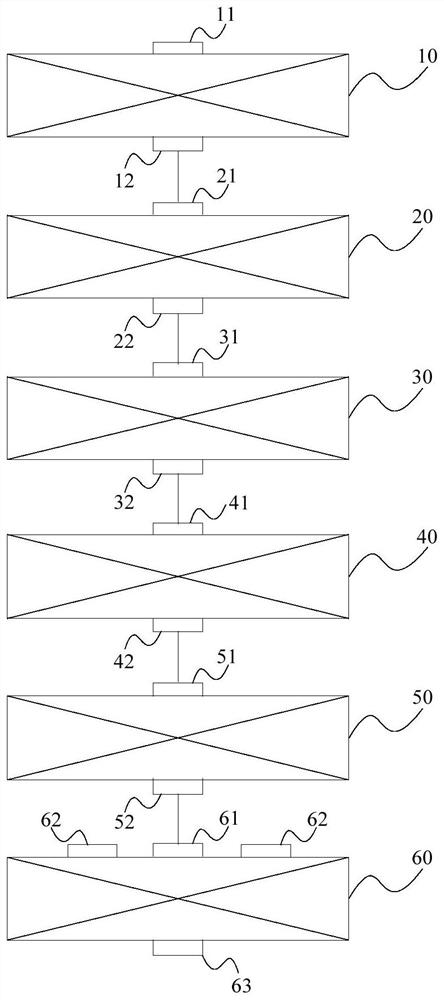

Method and system for preparing electrode plate by dry process, and application

PendingCN113675362AIncrease productivityAffect the electrochemical performanceElectrode rolling/calenderingHybrid/EDL manufactureNew energyProcess engineering

The invention discloses a method and a system for preparing an electrode plate by a dry process, and application. The method comprises the following steps: mixing an electrode active material, a conductive agent and a dry binder to obtain a mixture; carrying out kneading treatment on the mixture through mechanical extrusion so as to carry out preliminary fibration on the dry-method binder to obtain a blocky and / or flocculent pre-fibration product; carrying out crushing treatment on the pre-fibration product so as to obtain a granular material; and carrying out roll forming on the granular material and the current collector so as to form a pole piece film on the surface of the current collector, thereby obtaining the dry electrode plate. The method is simple and feasible, required equipment is simple, the problem that the electrode active material structure is damaged in the material crushing treatment process can be effectively solved, the production efficiency is higher, amplification is easy, the method is more suitable for large-scale mass production of the dry electrode technology, development of the new energy industry is promoted, and the method has wide application prospects.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Steel bar for high-ductility and superhigh-strength pre-stressed concrete and machining method thereof

ActiveCN103484789AReduce intensityImproved resistance to hysteresis fractureUltra high pressurePre stress

The invention discloses a steel bar for high-ductility and superhigh-strength pre-stressed concrete and a machining method of the steel bar. The steel bar comprises, by weight, 0.3-0.5% of C, 0.3-1.8% of Si, 0.6-1.5% of Mn, 0.02-0.2% of Nb, 0.01-0.1% of V, 0.01-0.2% of Ni, 0.1-0.5% of Cr, 0.01-0.1% of Mo, 0.001-0.005% of B and the balance Fe, wherein the Ceq is smaller than 0.8%. Because an online continuous superhigh-pressure quenching control technology is adopted, the strength of the steel bar can be larger than 1860MPa or even larger than 2000MPa; because an online continuous quenching heat insulation and control technology is adopted, the ductility of the steel bar can be larger than 7%, the structural state of few ultra fine ferrites and tempered troostite is kept, and the steel bar has the advantages of being good in ductility and resistant to delayed fractures.

Owner:江苏森林建筑新材料股份有限公司

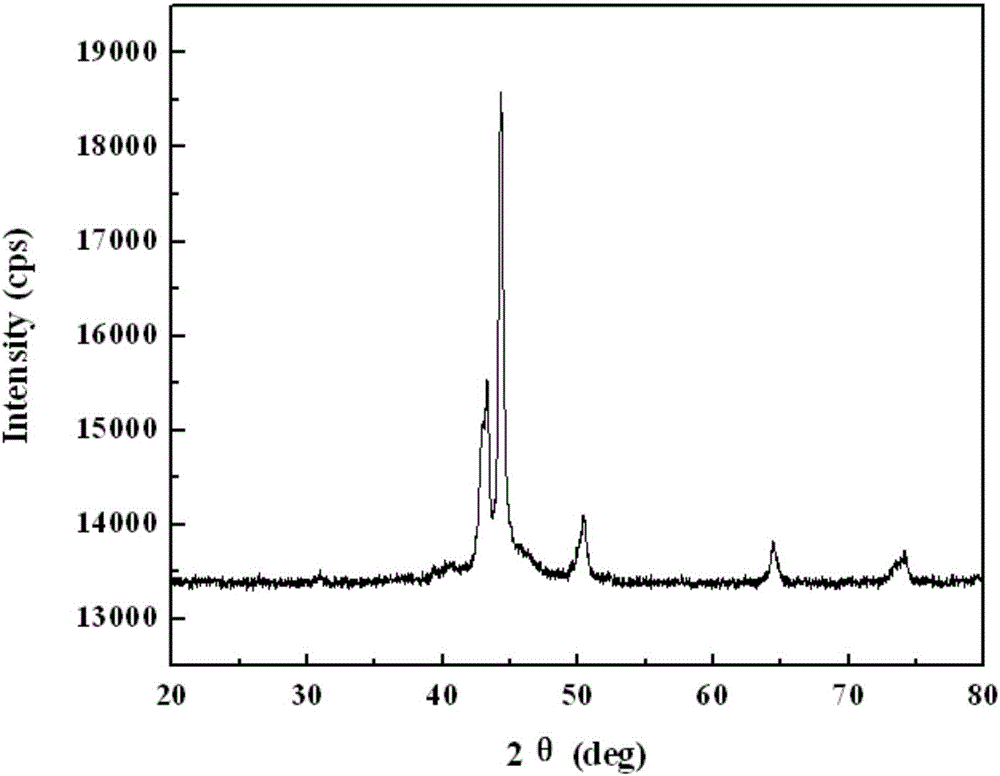

High-entropy alloy powder used on surface of riding wheel of rotary cement kiln, preparation method thereof and coating preparation method

ActiveCN106191621AHigh hardnessImprove wear resistanceMolten spray coatingChemical compositionHigh entropy alloys

The invention discloses high-entropy alloy powder used on the surface of a riding wheel of a rotary cement kiln, a preparation method thereof and a coating preparation method. The alloy powder comprises, by weight, 18%-20% of Fe, 17%-19% of Al, 17%-19% of Cr, 19%-20% of Mn, 19%-21% of Ni, 2.8%-4% of W, 0.6%-0.8% of B and 1.0%-2% of C. The alloy powder is prepared through a medium-frequency induction melting atomization one-step method. The high-entropy alloy powder and the preparation method thereof have the characteristics that pollution is small, environmental protection is realized, the steps are simple and energy consumption is low. A coating obtained through the hypersonic flame spraying process is suitable for the surface of the riding wheel of the rotary cement kiln. Bonding strength of the coating and a base body is high, the heat effect on the base body is small, tissue is good, and abrasion resistance of the riding wheel is improved after repair.

Owner:ANHUI RUITAI NEW MATERIALS TECH +1

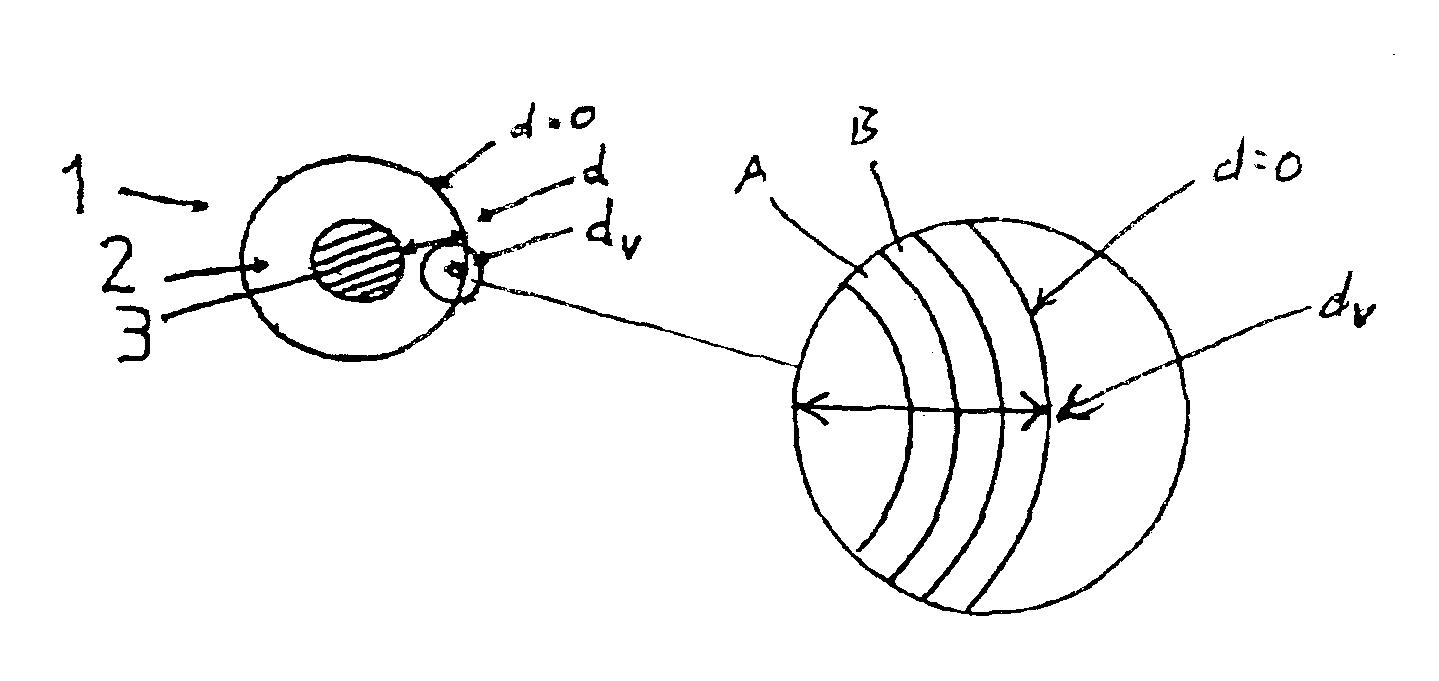

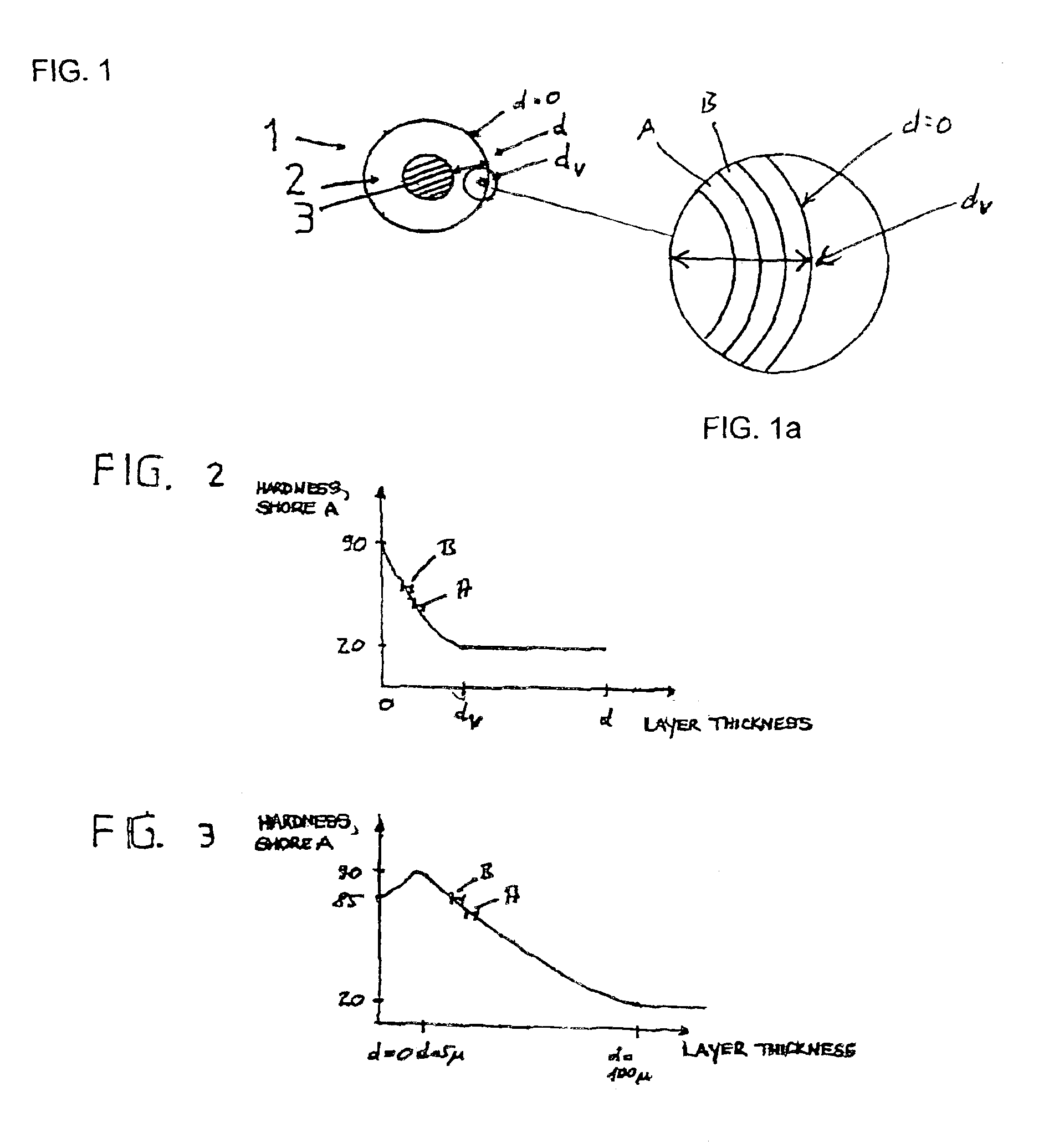

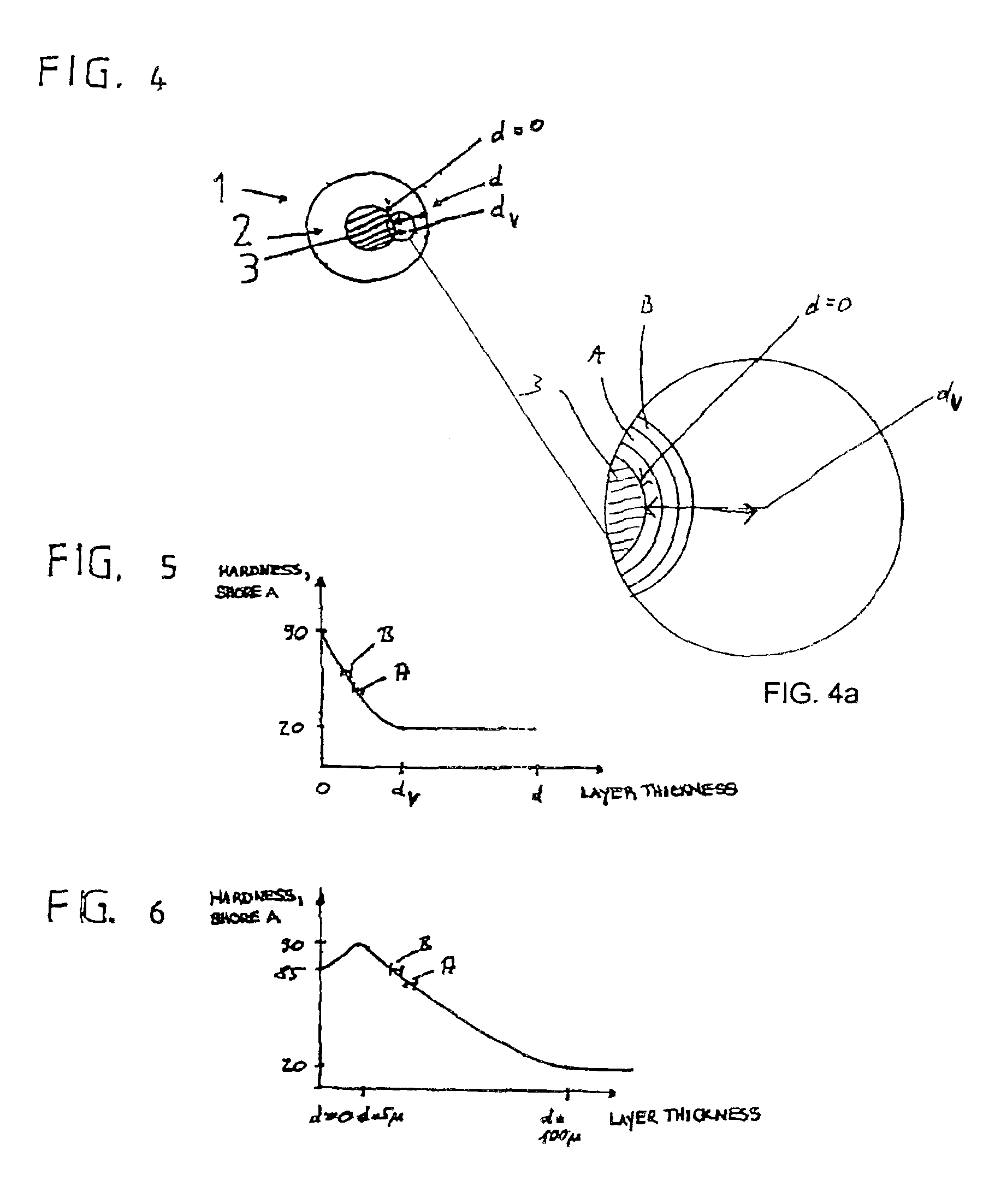

Roller for fluid film preparation or application

InactiveUS6935995B2Cost efficient to manufactureAvoid unevennessLiquid surface applicatorsShaft and bearingsHardnessLayer thickness

The invention relates to a roller for fluid film preparation, such as for offset printing, having an inside core, a first layer which surrounds the core and has a first hardness, and a second layer which surrounds first layer A and has a second hardness different from that of the first layer. The roller coating, including the first and second layers, is provided, at least in certain sections, with an essentially continuous hardness gradient through the layer thickness. The hardness gradient can be produced by incorporating a gradient of a hardness-modifying substance or agent, or a precursor thereof, e.g. an agent that increases the degree of cross-linking, by means of diffusion or migration of the substance or agent from at least one surface of the roller coating.

Owner:WESTLAND GUMMIWERKE GMBH & CO

High strength steel bar for pre-stressed concrete and production technology thereof

ActiveCN104404380AImproved resistance to hydrogen-induced delayed fractureAvoid inhalationSpinningChemical composition

The invention discloses a high strength steel bar for pre-stressed concrete. The steel bar is composed of the following chemical components in percentage by weight: 0.20 to 0.25% of C, 1.50 to 1.85% of Si, 0.20 to 0.50% of Mn, 0.07 to 0.09% of Cr, 0.30 to 0.35% of Mo, 0.25 to 0.35% of V, 0.05 to 0.08% of Nb, 0.42 to 0.61% of Ti, 0.15 to 0.25% of Ni, 0.25 to 0.40% of Ca, not more than 0.025% of S, not more than 0.025% of P, not more than 0.20% of Cu, 0.15 to 0.30% of composite rare earth, and the balance being Fe. The invention further discloses a production technology of the steel bar. The production technology comprises the following steps: smelting to obtain a steel blank, rolling the steel blank, cooling the rolled steel blank, rolling the steel blank for a second time, carrying out a thermal treatment and a stabilizing treatment, performing a gas nitrogenation treatment, spinning, winding, bundling, and storing the bundles in a warehouse.

Owner:溧阳市万兴特种建材有限公司

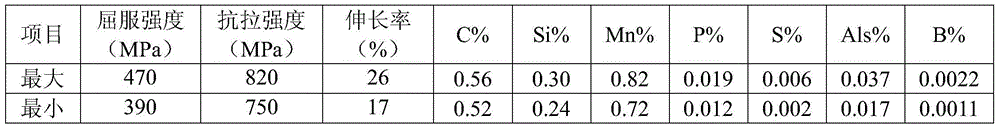

Steel 55MnB for domestic gardening tools and preparation method thereof

The invention relates to a steel 55MnB for domestic gardening tools and a preparation method thereof. The steel 55MnB for domestic gardening tools comprises 0.52-0.60% of C, 0.15-0.35% of Si, 0.70-1.00% of Mn, at most 0.025% of P, at most 0.008% of S, 0.010-0.060% of Als, 0.0005-0.0030% of B, and the balance of Fe and inevitable impurities. The preparation method adopts medium-carbon steel and comprises the following steps: molten iron desulfurization, converter blowing, LF (ladle furnace) refining, RH vacuum refining, continuous casting, hot direct charging, soaking, rough rolling, finish rolling, laminar cooling, coiling, slow cooling and factory leaving. The steel 55MnB for domestic gardening tools has higher carbon content and excellent hardenability, avoids hardness nonuniformity and overlow hardness of the medium-carbon steel after heat treatment, and enhances the processing yield; and the steel 55MnB for domestic gardening tools has favorable hardenability.

Owner:NINGBO IRON & STEEL

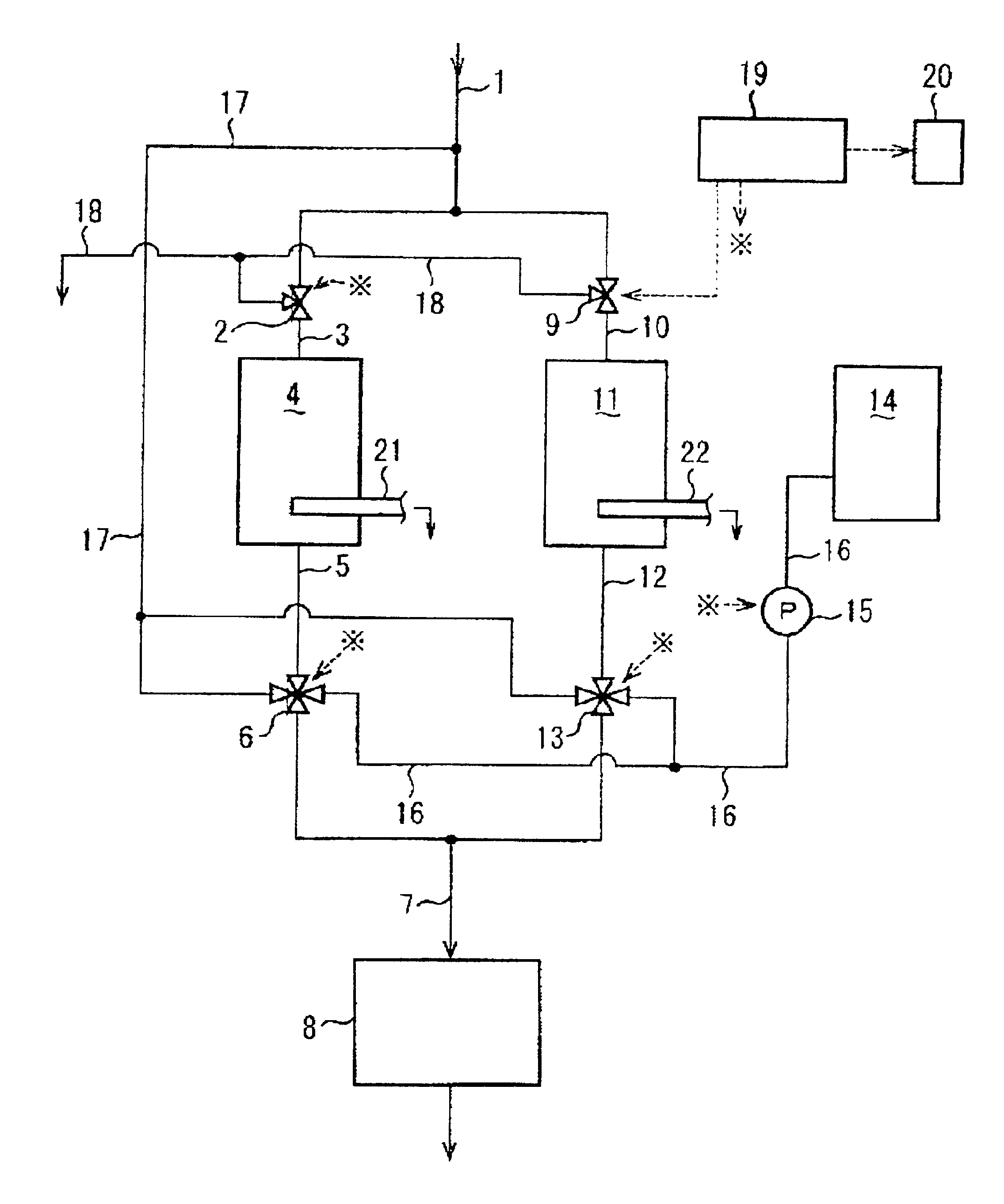

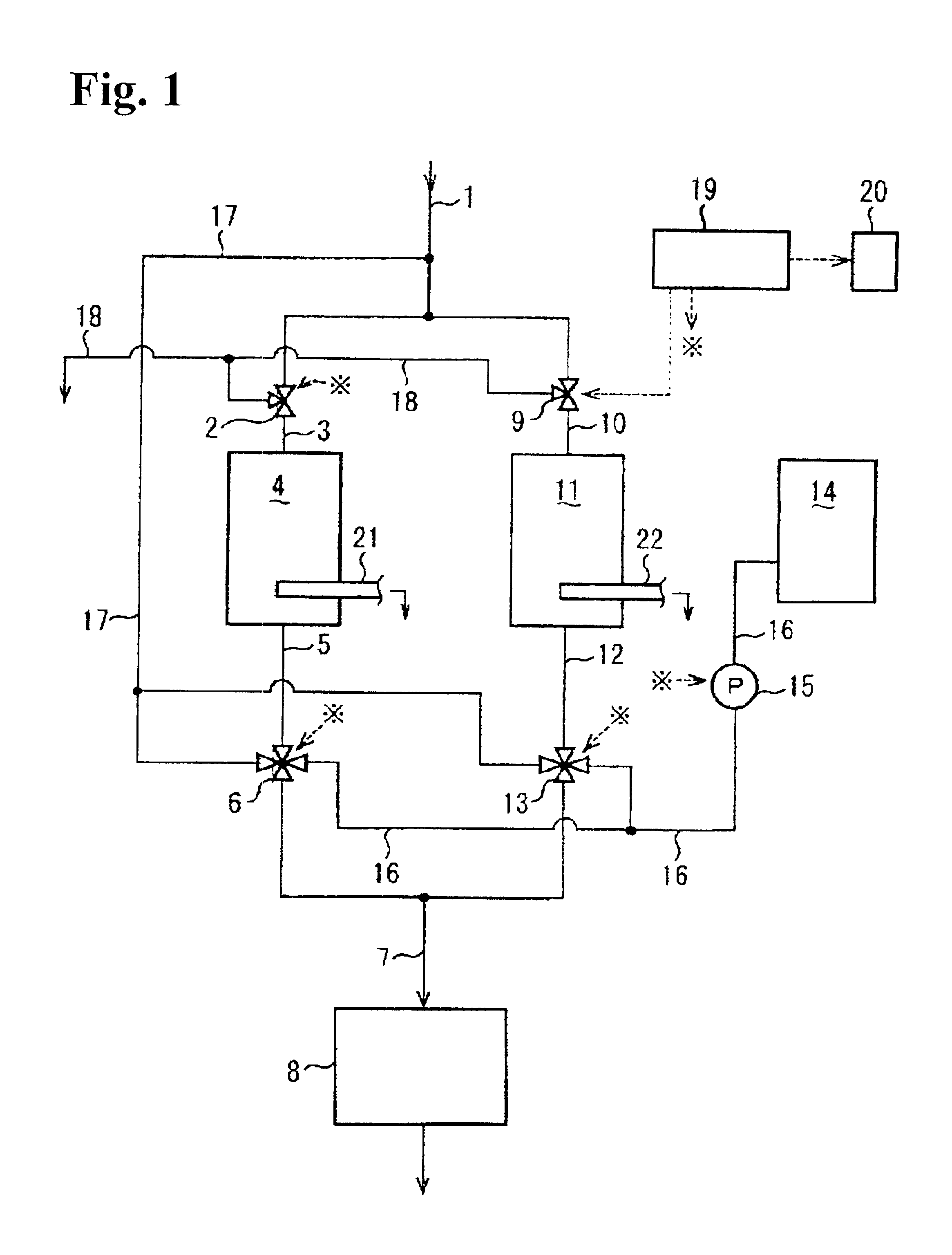

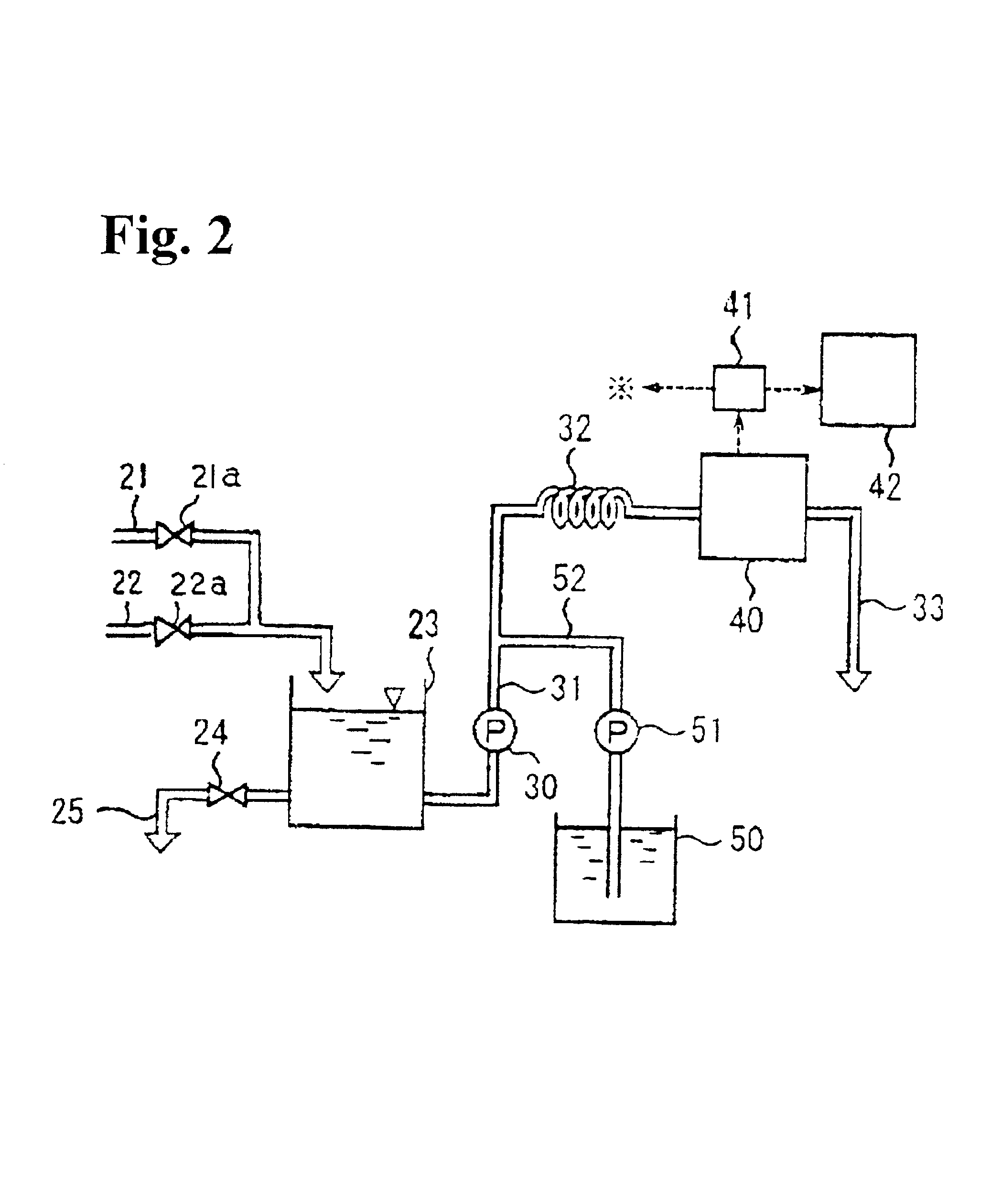

Water softening device

InactiveUS6926835B2Reliably prevents leakageAvoid hardnessIon exchange regulation/controlIon-exchanger regenerationWater softeningSalt water

Sampling pipes 21 and 22 are inserted, separated from outlet openings, into first and second water softeners 4 and 11. Raw water flows through first water softener 4, and raw water does not flow through second water softener 11. Once the hardness component concentration of the treatment water sampled by sampling pipe 21 reaches a specified concentration, the watercourse selection of valves 2 and 6 and valves 9 and 13 are switched, causing raw water to flow through second water softener 11. First water softener 4 is regenerated by salt water from a salt water chamber 14. The resulting water softening device prevents the leaking of hardness components, even with there is a fluctuation in the water quality of the raw water or when there is performance deterioration in the ion exchange resin.

Owner:KURITA WATER INDUSTRIES LTD

Processing method of above-600MPa-grade high-strength steel bar connection sleeve

ActiveCN103643124AImprove toughnessIncrease elasticityBuilding reinforcementsRebarMechanical engineering

The invention discloses a processing method of an above-600MPa-grade high-strength steel bar connection sleeve. The sleeve selects No.45 round steel as a raw material, and the No.45 round steel comprises 0.38-0.43wt% of C, 0.8-1.1wt% of Cr, 0.75-1.0wt% of Mn, 0.15-0.25wt% of Mo, 0.15-0.3wt% of Si, below 0.035% of S, below 0.035wt% of P, below 0.035wt% of N, and the balance Fe. The designed processing method of the above-600MPa-grade high-strength steel bar connection sleeve substantially improves the tensile strength and the elongation rate, guarantees the external diameter dimension and fineness of a steel tube, and reduces the friction stress between a tap and the inner wall of the sleeve.

Owner:江苏森林建筑新材料股份有限公司

Nickel-chromium alloy powder-coated steel bar manufacturing method

ActiveCN103643086AHigh strengthImprove safety and reliabilityMolten spray coatingNickel Chromium AlloysHeating furnace

The present invention discloses a nickel-chromium alloy powder-coated steel bar manufacturing method, which is characterized in that (1) the chemical components of the nickel-chromium alloy powder comprise, by weight, 0.2-3.3% of Re, 45-55% of Ni, 16-33% of Cr, 1.5-5.0% of Si, 0.25-0.5% of S, 0.2-1.5% of C, 10-16% of Fe, 0.8-10% of Mn, and 1-2% of composite rare earth; (2) the smelted steel bar is conveyed into a heating furnace to heat to achieve a temperature of 900-1000 DEG C; (3) the nickel-chromium alloy powder mixed according to a certain ratio is uniformly sprayed on the steel bar surface through a spraying gun; (4) the heated steel bar is conveyed into a quenching device; (5) the quenched steel bar is heated through a tempering heating furnace to achieve a temperature of 450-480 DEG C; and (6) the tempered steel bar is naturally cooled to achieve a room temperature. According to the invention, the nickel-chromium alloy is coated the steel bar surface so as to increase the wear resistance.

Owner:TIANSHUN GROUP

Special quenching liquid for preparing large axial forgings from 35CrMo

The invention discloses special quenching liquid for preparing large axial forgings from 35CrMo, and belongs to the technical field of heat treatment quenching. The quenching liquid disclosed by the invention is composed of a mixture of polypropylene-methacrylic acid and polyacrylamide, an ethylene oxide and epoxypropane random copolymer, polyamide polyethylene glycol, a defoaming agent and water. The quenching liquid is mainly suitable for quenching large axial forgings prepared from 35CrMo steel, the process is simple, the traditional double-liquid and triple-liquid quenching processes are changed to effectively avoid quenching crack of the large axial forgings of 35CrMo steel, the quenching effect is good, and the defects of common quick quenching oil that the hardness after quenching is insufficient, the internal organizational form is non-uniform and cracking is liable to produce can be overcome.

Owner:马鞍山金泉工业介质科技有限公司

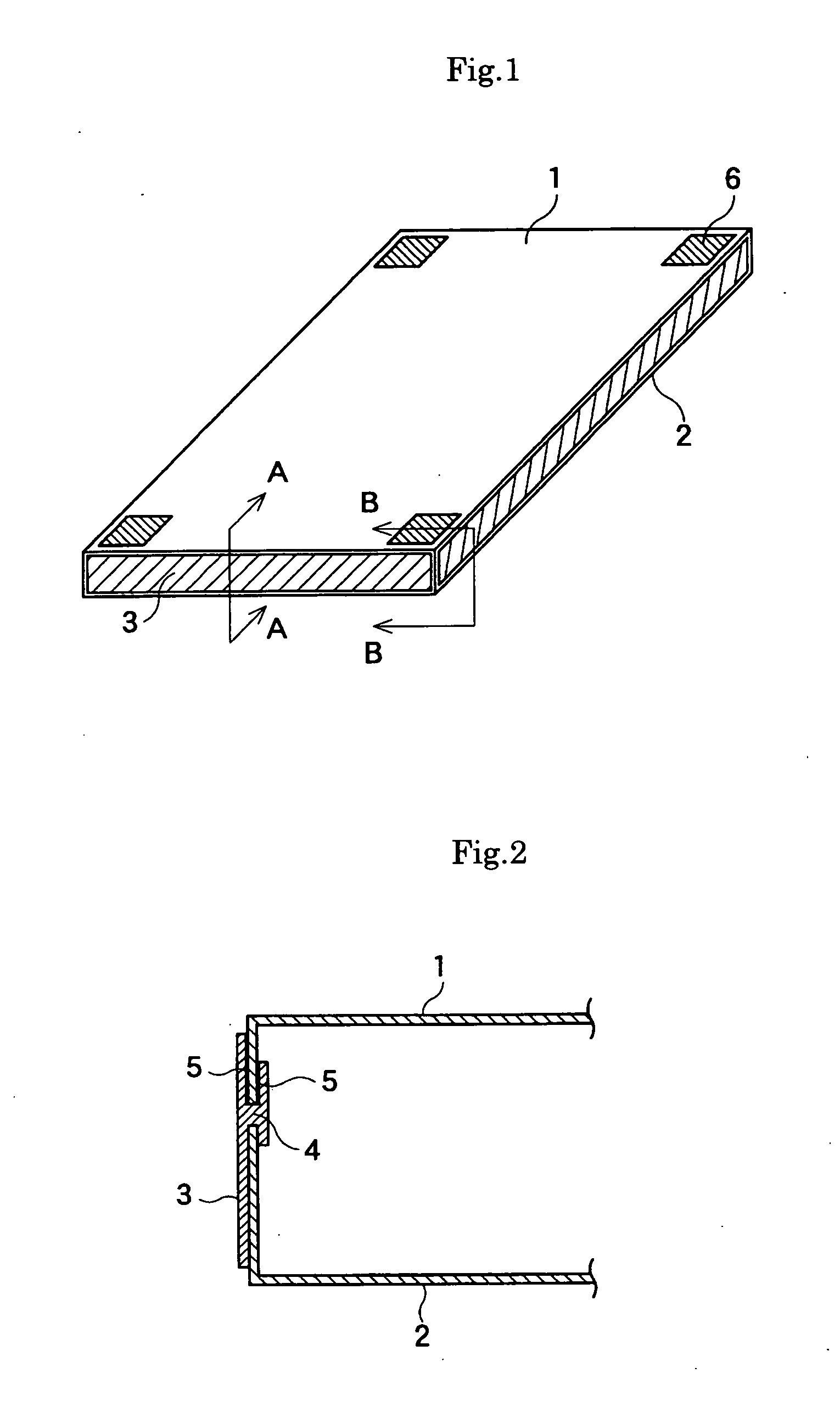

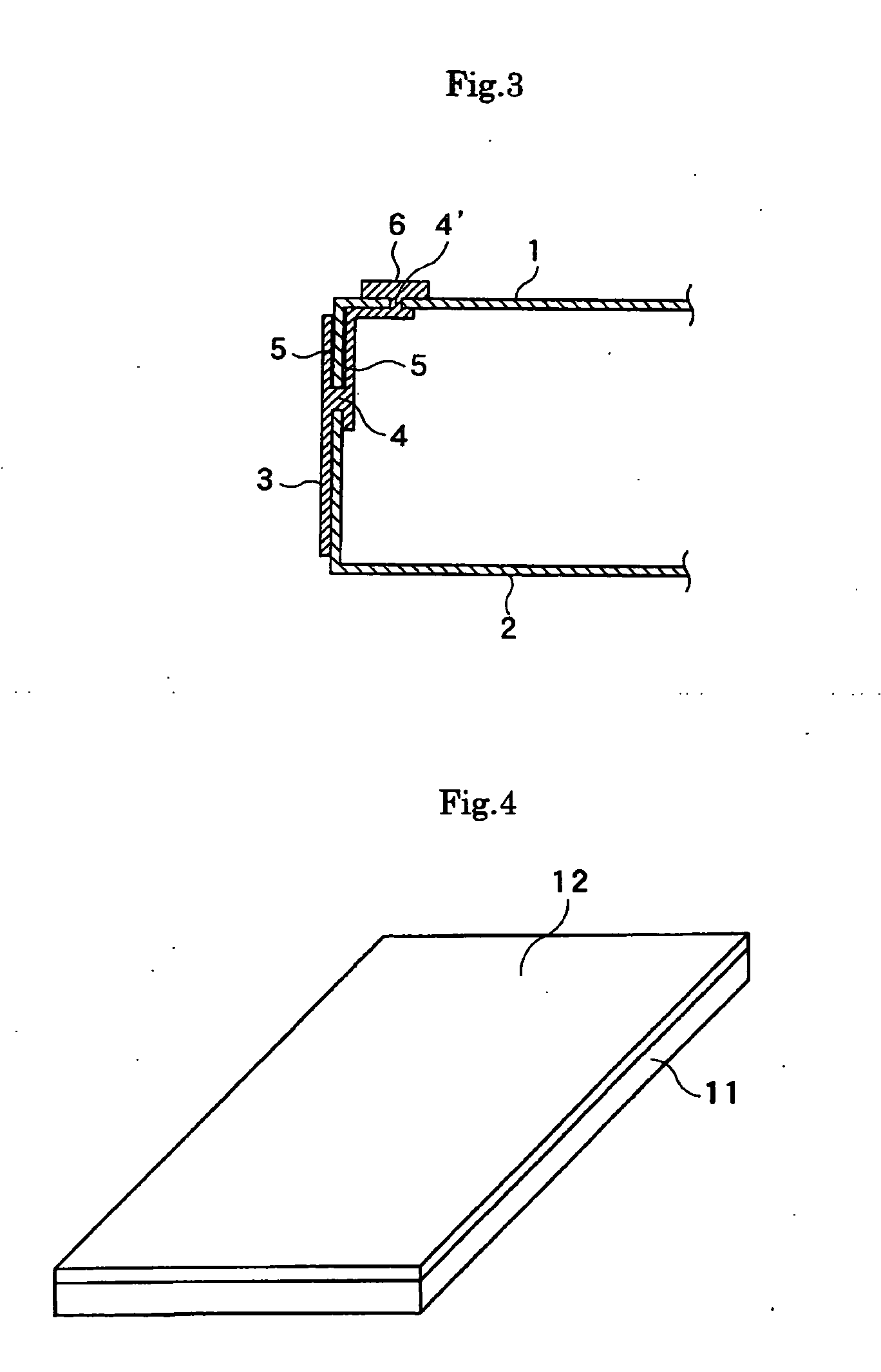

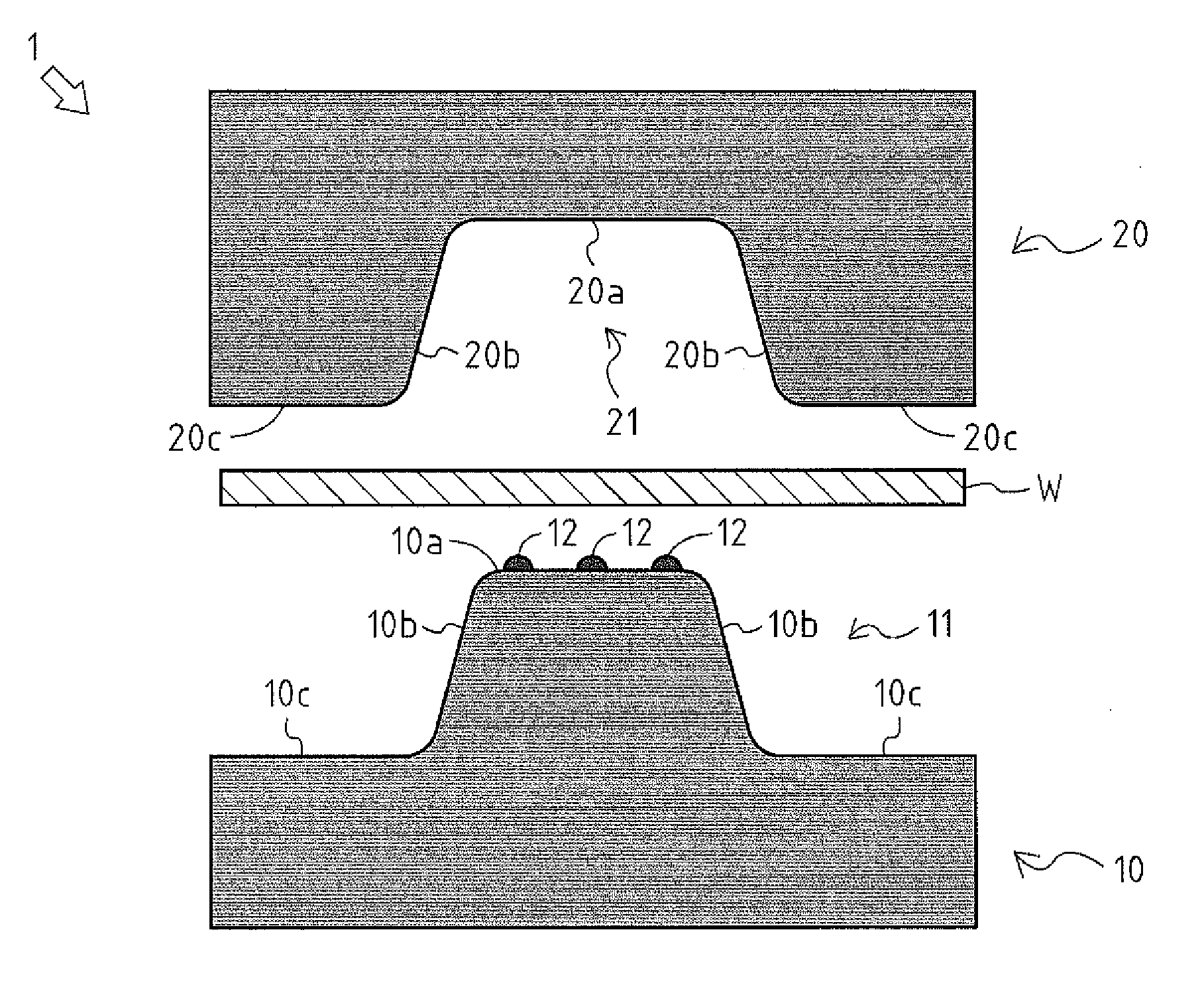

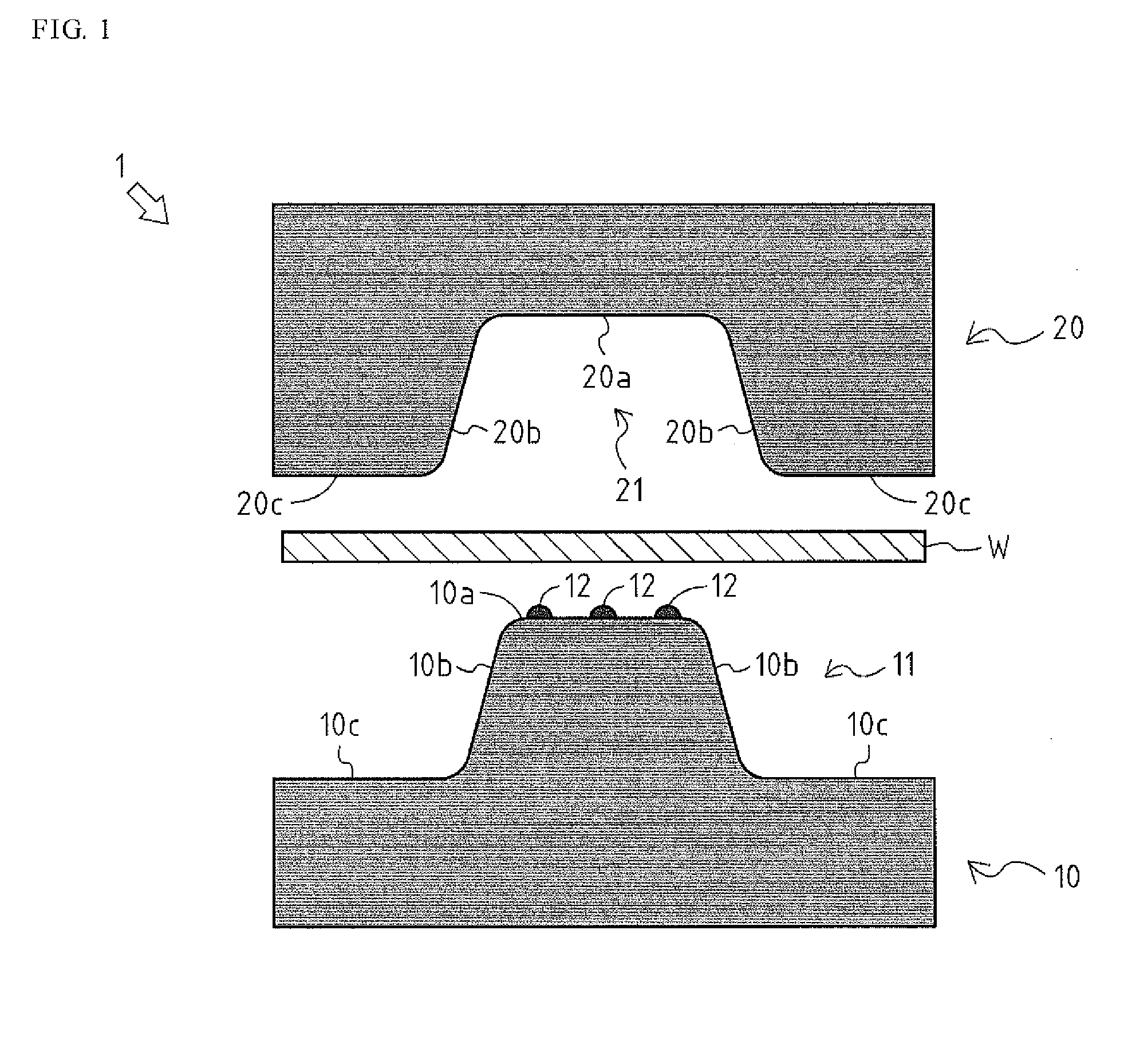

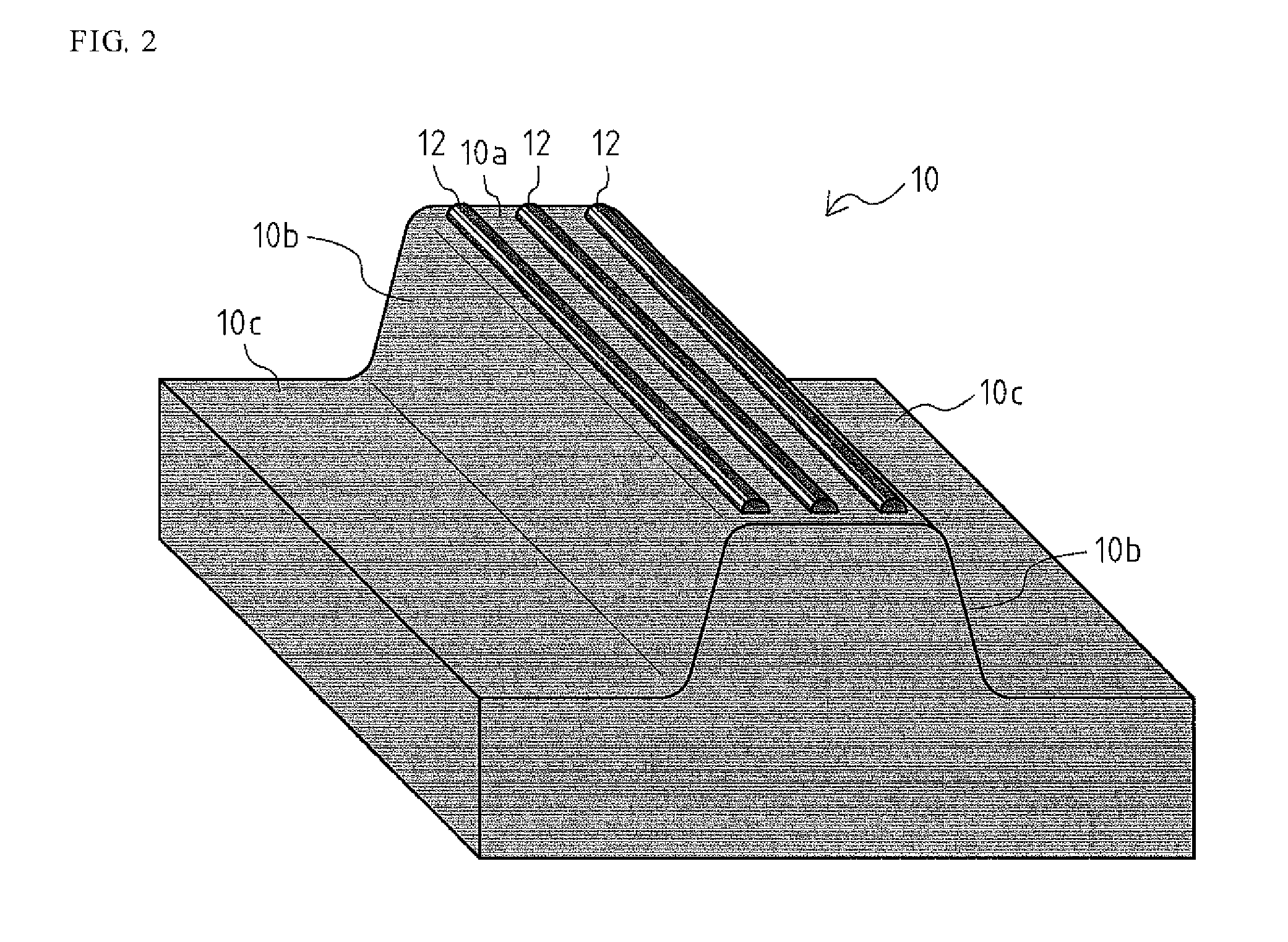

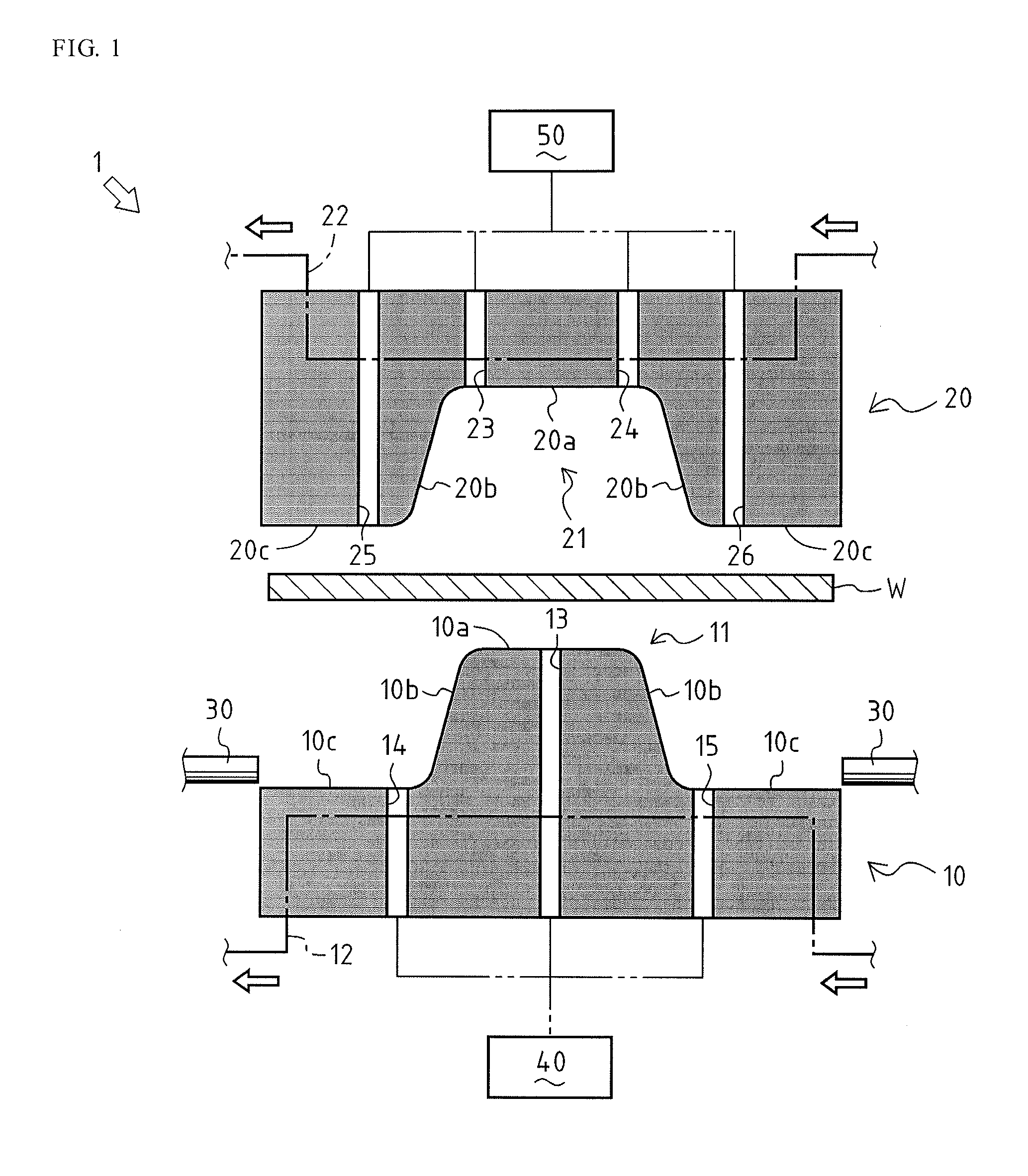

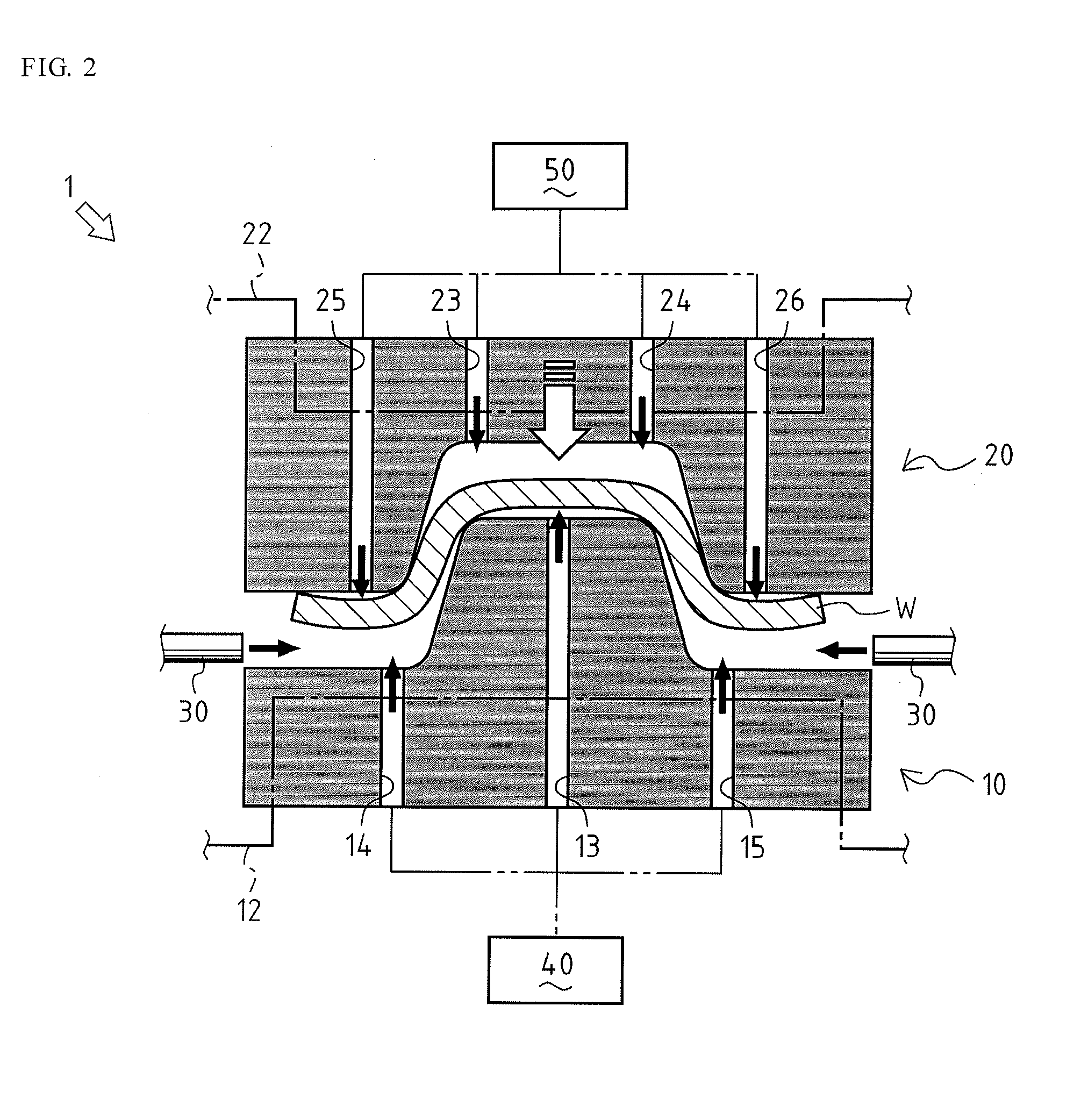

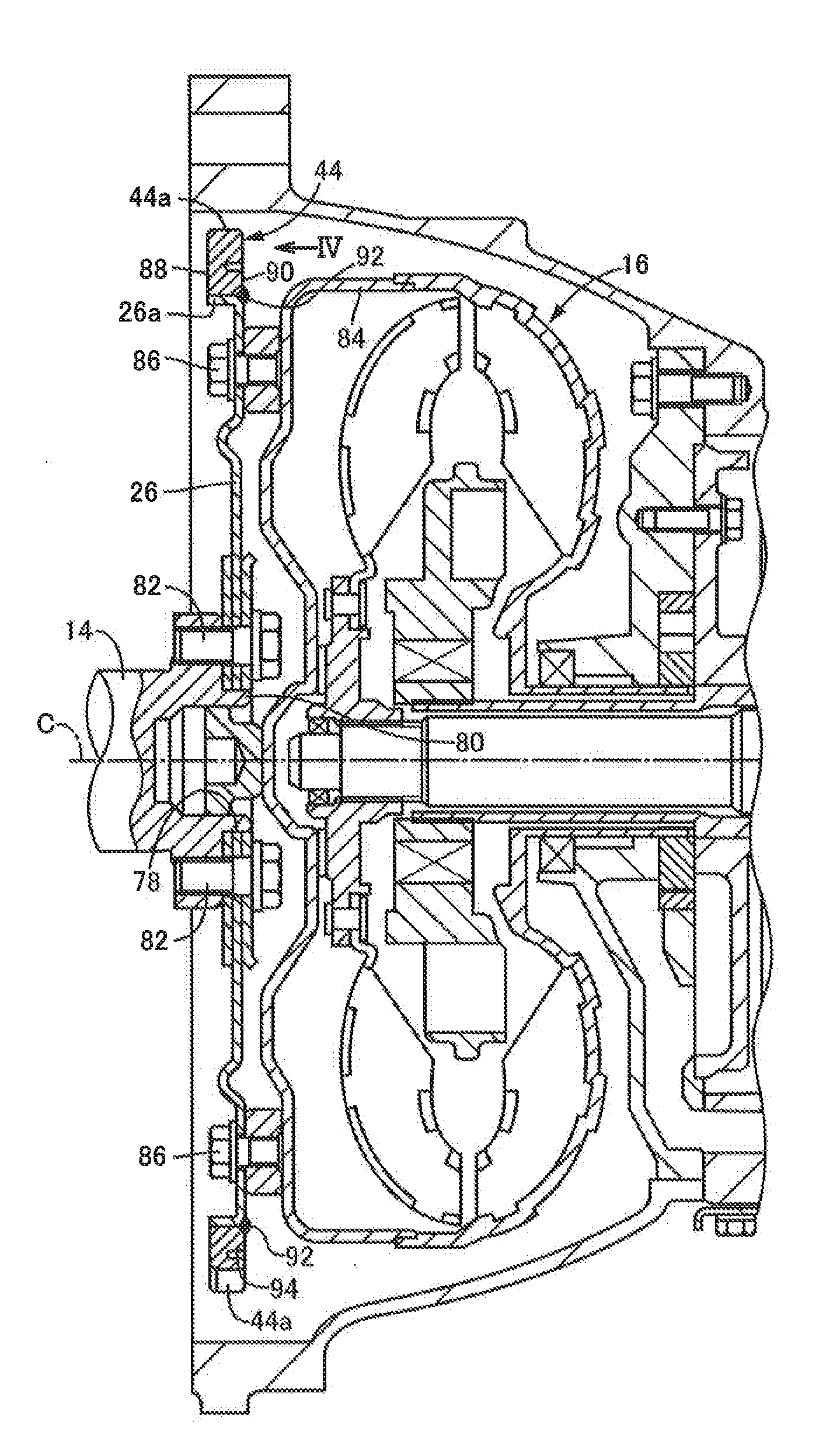

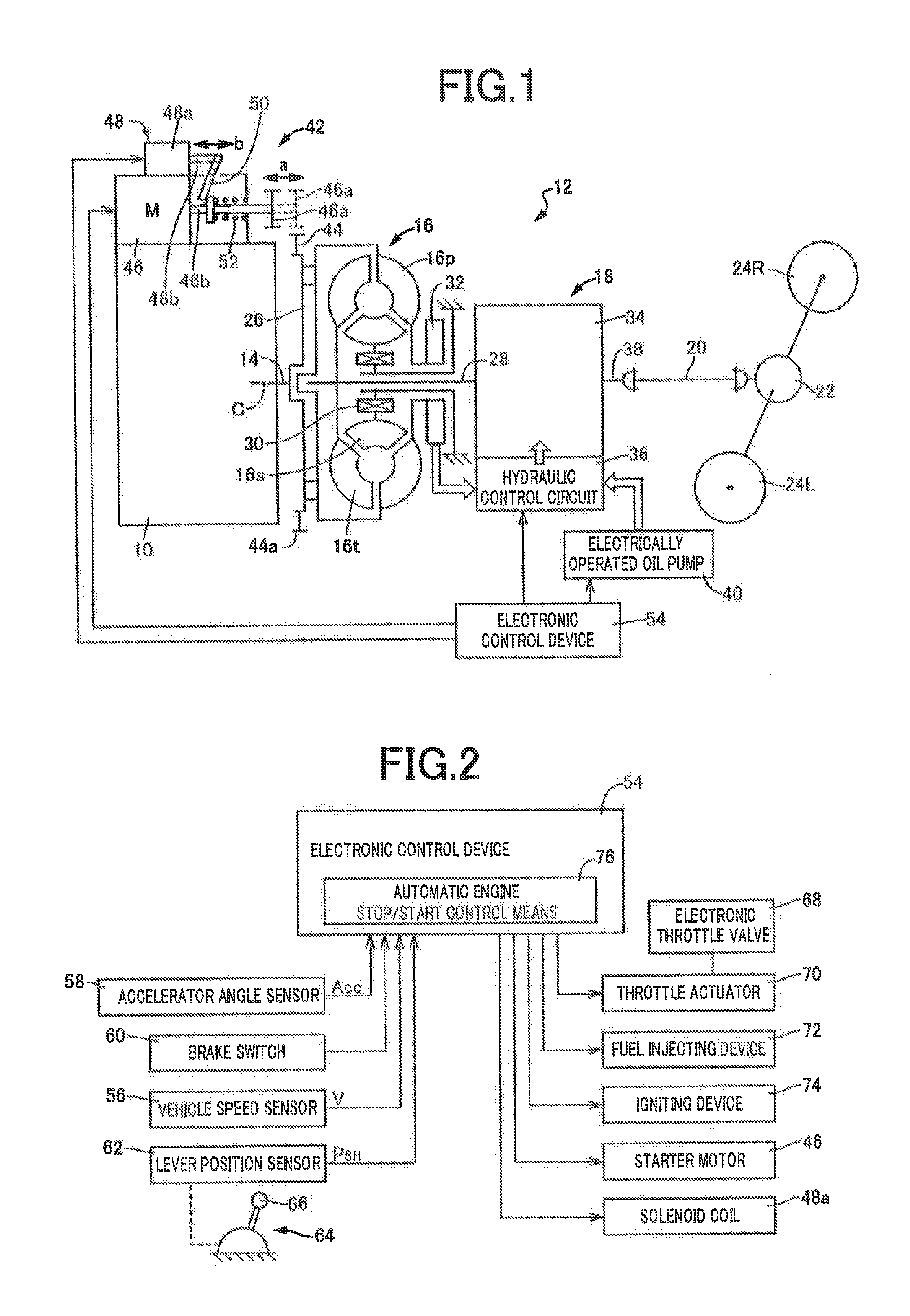

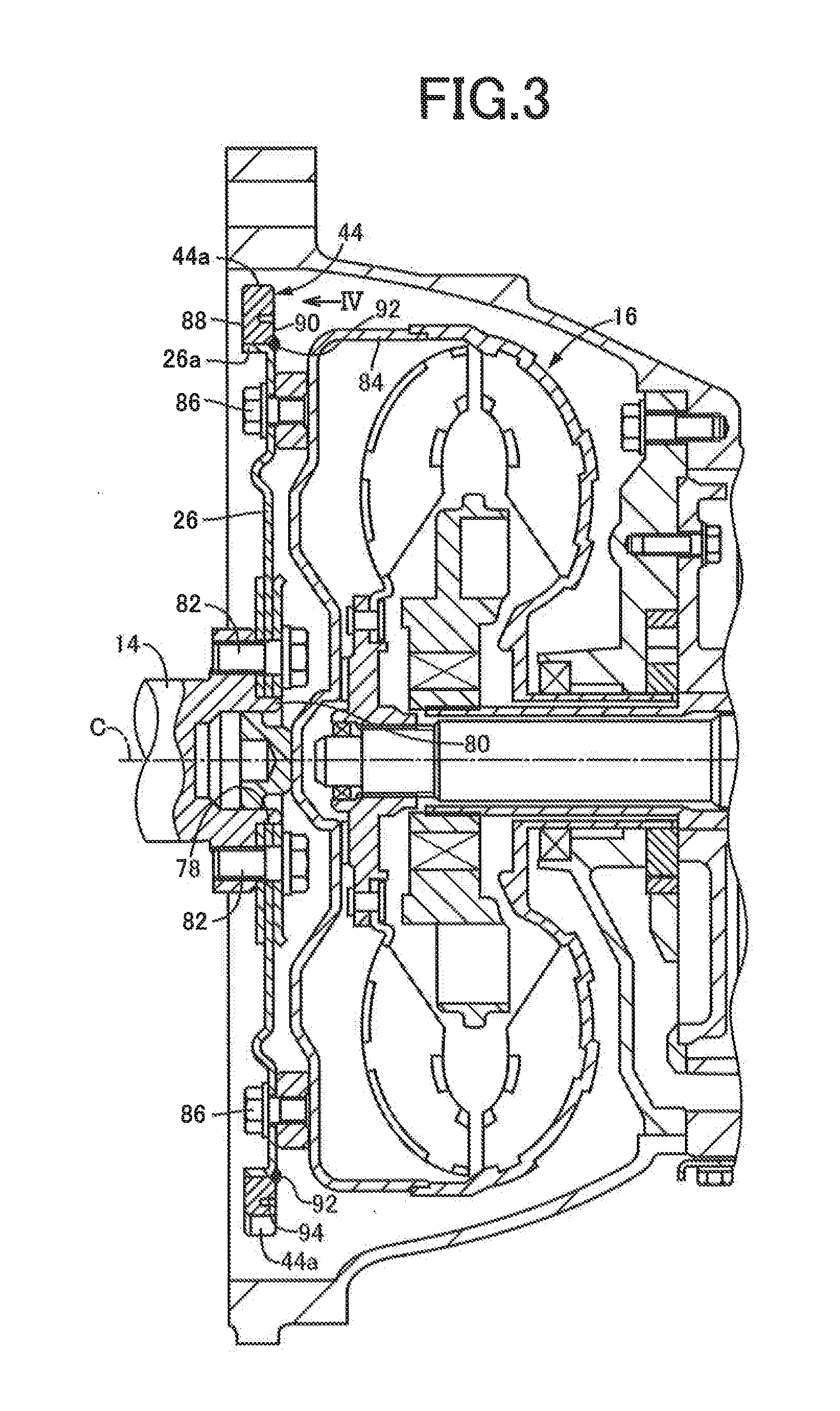

Hot-pressing apparatus

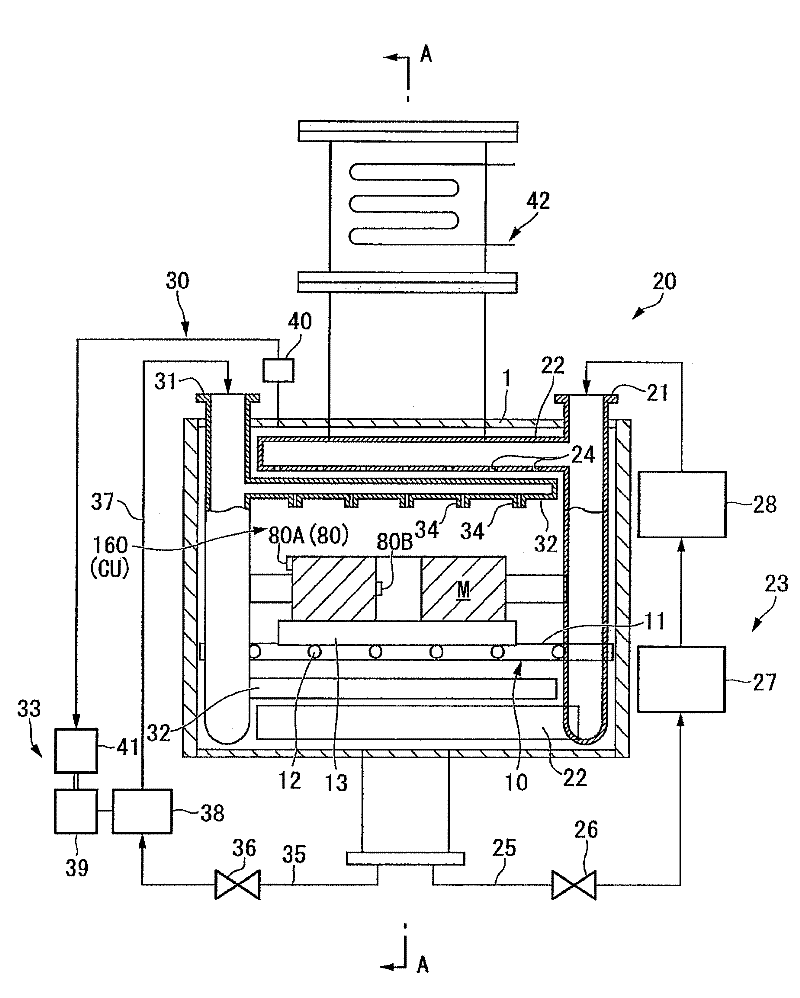

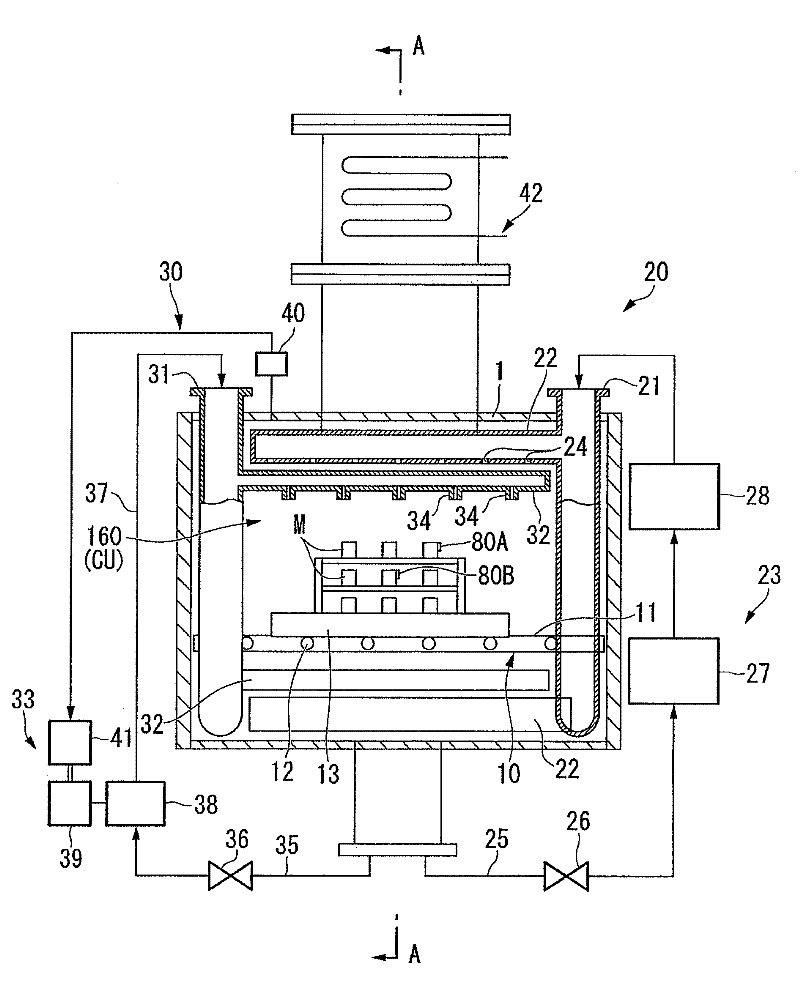

InactiveUS20140130564A1Sufficient cooling rateAvoid hardnessShaping toolsQuenching devicesMaterials scienceHot press

This invention relates to a hot-pressing method and a hot-pressing apparatus capable of quenching a workpiece at a sufficient cooling rate. In a hot-pressing step, a hot-pressing apparatus presses and cools a workpiece at the same time. The hot-pressing apparatus includes a lower die and an upper die whose forming surfaces face each other. A top surface of the lower die is provided with a plurality of beads so that a part of the workpiece difficult to come in contact with the forming surface of the lower die and the forming surface of the upper die positioned at the bottom dead center is formed into a stepped shape.

Owner:TOYOTA JIDOSHA KK

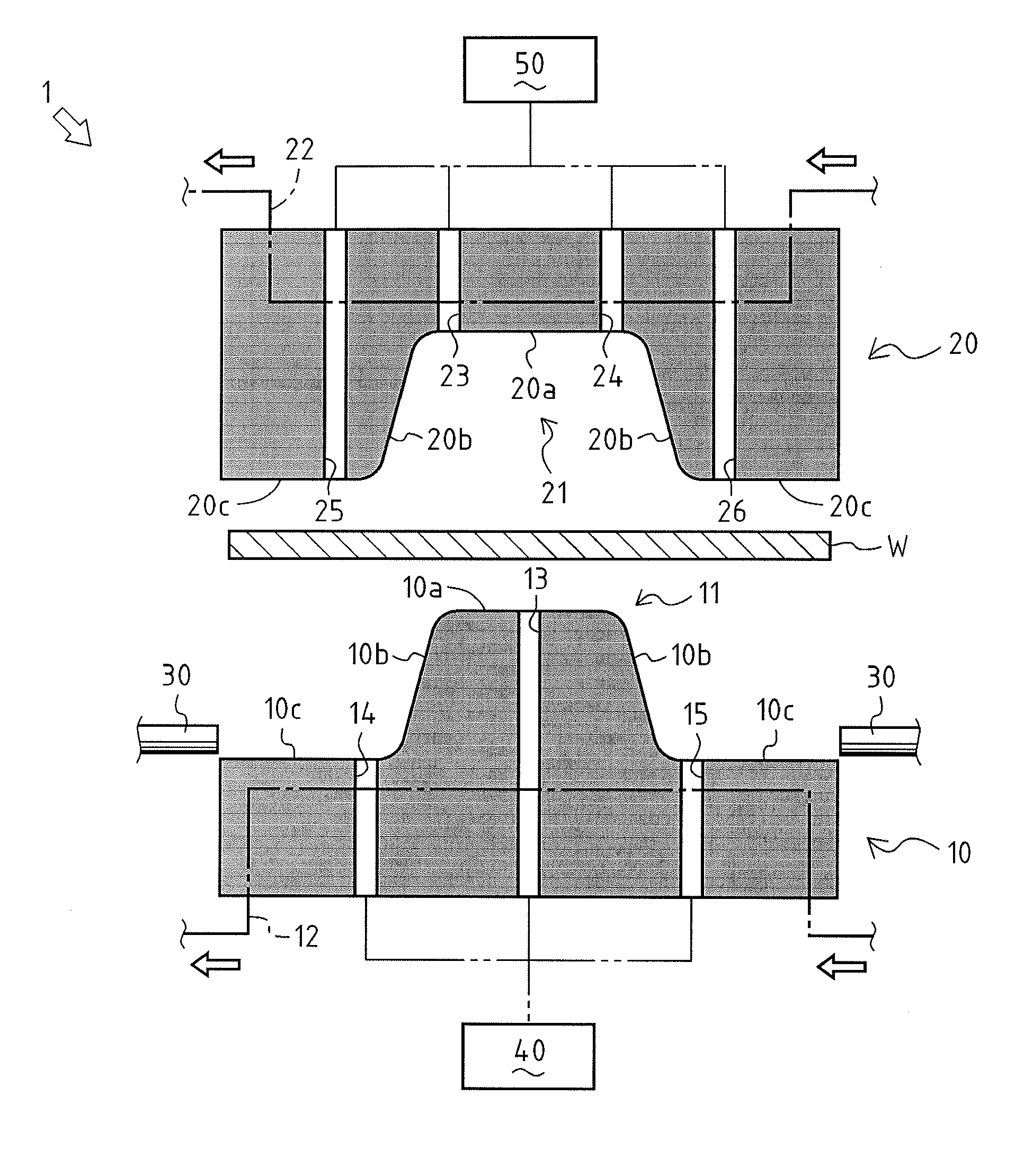

Hot-pressing apparatus

InactiveUS20140137619A1Sufficient cooling rateAvoid hardnessShaping toolsMetal rolling arrangementsHeat conductingCooling channel

Disclosed is a hot-pressing apparatus capable of quenching a workpiece at a sufficient cooling rate. The hot-pressing apparatus performs a hot-press forming of a workpiece using a lower die and an upper die, in which a cooling channel and a cooling channel, and a plurality of gas-introduction paths and a plurality of gas-introduction paths through which heat-conducting gas flows are provided in the lower die and the upper die. The plurality of gas-introduction paths penetrate through the dies. The hot-press forming is performed while the heat-conducting gas is supplied to the areas between the dies and the workpiece from the plurality of gas-introduction paths opening on the forming surfaces of the dies.

Owner:TOYOTA JIDOSHA KK

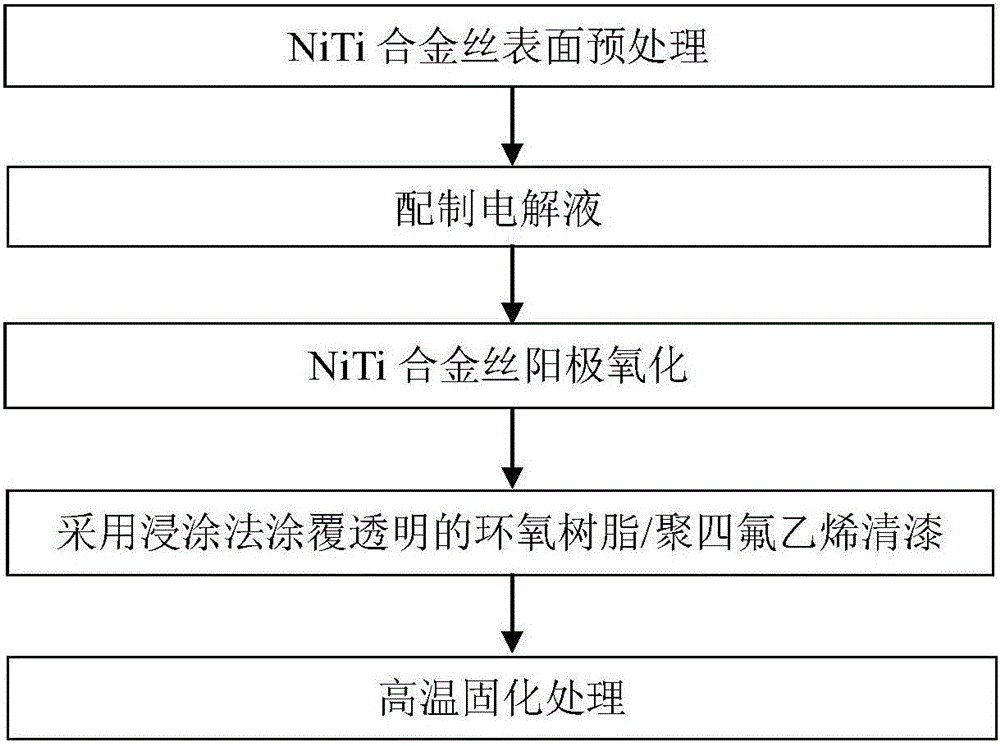

Preparation method of NiTi alloy tooth arch wire for orthodontics

InactiveCN105019001AImprove mechanical propertiesGood biocompatibilityArch wiresAnodisationNiti alloyEpoxy

The invention discloses a preparation method of a NiTi alloy tooth arch wire for orthodontics. The preparation method comprises the steps of: 1) surface pretreatment of a NiTi alloy wire; 2) preparation of electrolyte; 3) anodizing of the NiTi alloy wire; 4) coating of transparent epoxy resin / polytetrafluoethylene varnish by a dip coating method; and 5) high-temperature curing treatment and final obtaining of the NiTi alloy tooth arch wire having invisible double-layer protection. Compared with a traditional method, the preparation method can effectively prevent such problems as nonuniform dispersion of TiO2 pigment in organic high molecular emulsion and reduction of coating mechanical performance and corrosion resistance caused by TiO2; and in addition, the method has such advantages as low cost and adaptation to batch production.

Owner:XIAN UNIV OF TECH

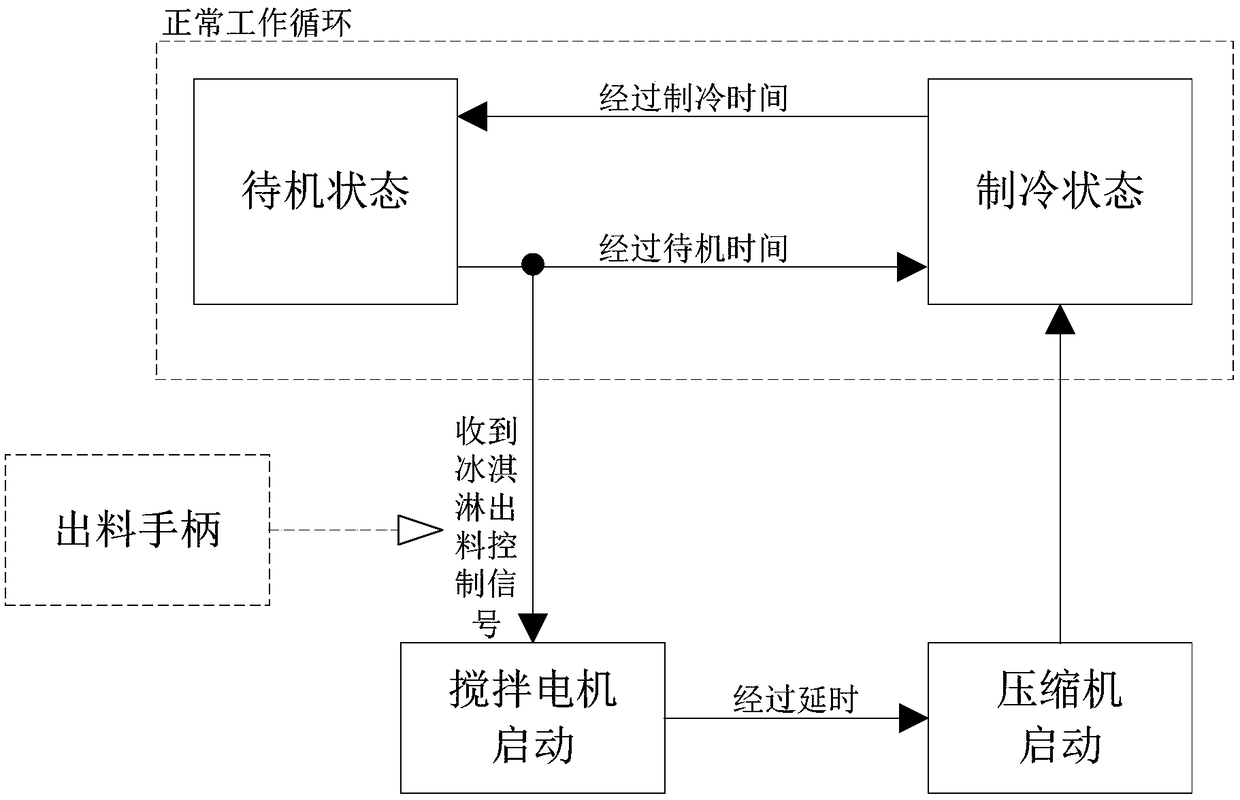

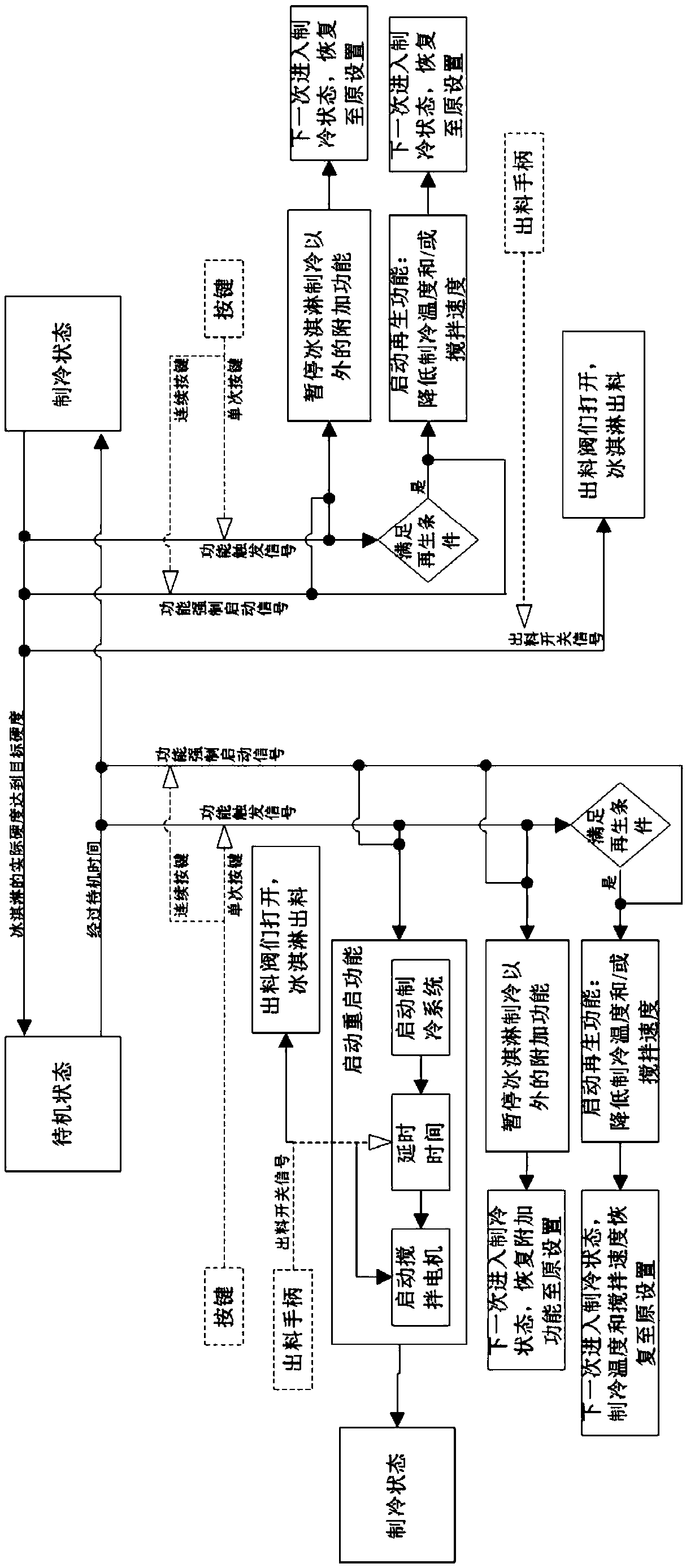

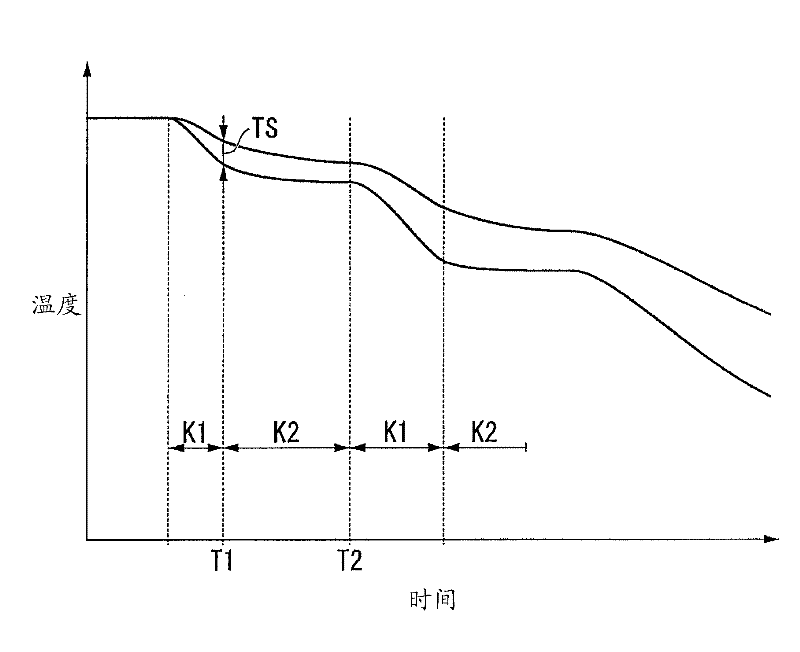

Ice cream machine with restart and regeneration functions

The invention discloses an ice cream machine with restart and regeneration functions. By setting the restart function, regeneration conditions and the regeneration function, when the ice cream machineis in use, firstly, an operator sends a function trigger signal to a control system, then, the ice cream machine in a refrigeration state starts the regeneration function when the regeneration conditions are met, and the ice cream machine in a standby state starts the restart function and starts the regeneration function when the regeneration conditions are met so that a compressor can be startedin advance for refrigeration to regenerate ice cream in a freezing vat and improve the hardness and mouthfeel of the ice cream in the freezing vat; secondly, the operator controls a discharge valve to be switched on through a discharge handle, and then the ice cream in the freezing vat is discharged. Thus, the ice cream machine can avoid discharging of ice cream meeting the regeneration conditions, and it is ensured that ice cream discharged in the whole use process of the ice cream machine has good hardness and mouthfeel.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

Making method of alloy coat coated prestressed steel wire

ActiveCN103643196AImprove machinabilityReduce rust generationMolten spray coatingFurnace typesHeating furnaceAlloy coating

The invention discloses a making method of an alloy coat coated prestressed steel wire. The method comprises the following steps: 1, preparing an alloy coat which is powdery; 2, sequentially carrying out pickling treatment phosphatization treatment and surface drying treatment of a prestressed steel wire rod; 3, sending the above obtained treated prestressed steel wire into a drawing machine, drawing to obtain the prestressed steel wire having required specifications and dimensions, and cleaning the prestressed steel wire; 4, sending the prestressed steel wire into a hot spraying device, uniformly spraying the surface of the prestressed steel wire with the prepared alloy powder by a spray gun, allowing the sprayed prestressed steel wire to an intermediate frequency heating furnace, and heating the prestressed steel wire to 550-570DEG C within 5-8s; and 5, allowing the prestressed steel wire to enter a quenching cooling device, cooling through a second cooling operation, air-cooling to room temperature, allowing the prestressed steel wire to a take-up machine, examining, and warehousing to obtain the alloy coat coated prestressed steel wire. The method increases the strength of the prestressed steel wire, further improves the wear resistance and the corrosion resistance of the prestressed steel wire, and prolongs the service life of the prestressed steel wire.

Owner:TIANSHUN GROUP

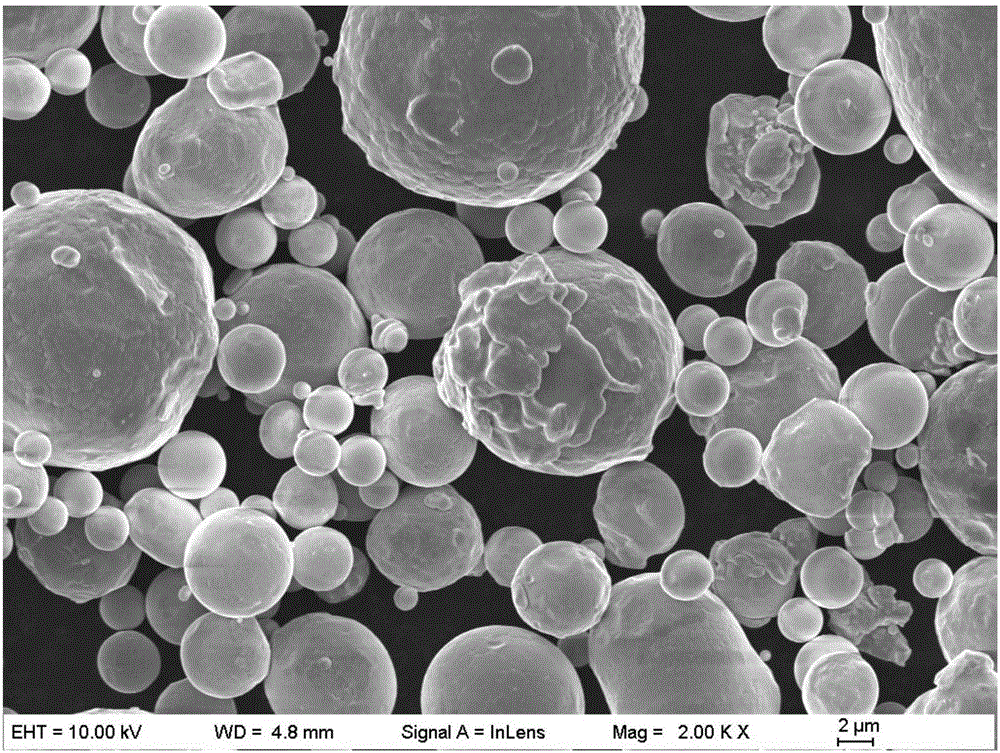

Preparation method of CD133 immunomagnetic beads

InactiveCN107389916AUniform particle size distributionNo aggregation stateBiological testingCoatingsBüchner funnelMagnetic bead

The invention discloses a preparation method of CD133 immunomagnetic beads. The preparation method comprises the following steps: preparing magnetic beads; preparing magnetic chitosan microspheres; weighing 10 g of chitosan, and adding the weighed chitosan into 200 ml of a 2% acetic acid solution for overnight soaking to enable dissolution; adding 1 g of Fe2O4 nano magnetic beads into the mixed solution, and performing stirring at the room temperature under the condition of 300 r / min; adding 200 ml of saxoline, and performing stirring at 40 DEG C under the condition of 300 r / min; raising the temperature to 50 DEG C, adding 40 ml of formaldehyde, and performing stirring under the condition of 300 r / min; adding 20 ml of glutaraldehyde with the volume concentration of 50% into the mixed solution, performing stirring at 60 DEG C under the condition of 170 r / min, adjusting the pH to be 10, and performing stirring for 2-6 h; adding 100 ml of petroleum ether into a reaction system after finish of reaction, fully performing stirring, performing suction filtration by use of a Buchner funnel to obtain magnetic chitosan microsphere particles, then fully performing stirring and washing by use of ethyl alcohol, washing with distilled water after removal of ethyl alcohol, and performing vacuum drying at 50 DEG C; performing carboxylation on the magnetic chitosan microspheres; and coupling immunomagnetic beads subjected to carboxylation with an anti-body. The preparation method has the advantages of good stability, high sensitivity and the like.

Owner:安徽安龙基因科技有限公司

Supporting hanger for grooved cable bridge and preparation process of supporting hanger

ActiveCN104862608AHigh elastic limitIncrease yield pointSolid state diffusion coatingCable trayElectric cables

The invention discloses a supporting hanger for a grooved cable bridge. The supporting hanger comprises the following constituents: C, Cr, B, Ni, N, Mo, Cu, Al, V, W, Si, Mn, Nb, Ti, S, P, and the balance of Fe and inevitable impurities. The invention further provides a preparation process of the supporting hanger for the grooved cable bridge. The preparation process is simple and feasible, low in manufacture cost and pollution-free in the manufacture process, and the prepared supporting hanger is abrasion-proof, corrosion resistant, high in strength and long in service life.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

ActiveCN103484780AAvoid excessive corrosion rate and hardnessStrong hysteresis fracture resistanceRebarDuctility

The invention relates to a reinforcement bar and a production technology thereof, in particular to a high-strength hot-rolled reinforcement bar of the 830 MPa level, and a production technology of the reinforcement bar. The reinforcement bar comprises the following chemical components by weight: 0.38 to 0.43% of C, 0.7 to 0.9% of Cr, 0.6 to 0.8% of Mn, 0.15 to 0.25% of Mo, 0.2 to 0.3% of Si, 1.6 to 2% of Ni, 0.035% of S, 0.035% of P, 0.035% of N and the balance of Fe. The shear strength of the reinforcement bar can reach 830 MPa; the reinforcement bar has the advantages of high strength, good ductility, high lagging and fracture resistance, economy of steel material, underrelaxation, easiness in welding, high upset performance and the like, can enable carbide to dissolve fully and diffuse uniformly, and avoids that intercrystalline corrosion and pitting exceeding are caused due to intercrystalline separation of carbide.

Owner:江苏森林建筑新材料股份有限公司

Heat treatment device and heat treatment method

InactiveCN102308008ASuppress uneven temperature distributionAvoid deformationFurnace typesHeat treatment process controlHeat treating

Owner:IHI CORP

Chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method

ActiveCN103639231AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesManganeseChromium

The present invention discloses a chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy zinc-plating steel strand manufacturing method designed by the present invention, the prepared chromium-molybdenum low-alloy zinc-plating steel strand has characteristics of high strength, good hardenability good, cracking resistance, low relaxation degree, and smooth and uniform surface zinc plating.

Owner:TIANSHUN GROUP

Vehicular starter ring gear

InactiveUS20130061716A1Avoid heat conductionRestrains degree of annealingPower operated startersGearingGear wheelPinion

A vehicular starter ring gear in the form of an annular member which has external teeth and which is welded at a plurality of positions to a disc member rotated with an engine, such that the vehicular starter ring gear is fitted on an outer circumferential surface of the disc member, so that the vehicular starter ring gear is rotated to start the engine, by a starter motor having a pinion gear engageable with the external teeth, includes: a thermal resistor portion provided in a radial portion between an inner circumferential surface and peak surfaces of the external teeth, and radially outwardly of at least welding portions bridging the vehicular starter ring gear and the disc member, the thermal resistor portion restraining conduction of a heat generated during an operation to form the welding portions, to the external teeth.

Owner:TOYOTA JIDOSHA KK +1

Chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method

ActiveCN103643146AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesPre stressManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

Manufacture method for valve core of stop valve used in fermentation

The invention discloses a manufacture method for a valve core of a stop valve used in fermentation. According to the invention, Cr-Mo low alloy steel is adopted as a blank, and the Cr-Mo low alloy steel comprises the following components in percentage by mass: 0.3%-0.31% of carbon, 0.18%-0.36% of silicon, 0.50%-0.70% of manganese, 0.90%-1.10% of chromium, 0.20%-0.30% of molybdenum, 0-0.02% of phosphorus, 0-0.025% of sulfur, 0-1.8 ppm of hydrogen, 0-0.40% of nickel, 0-0.03% of vanadium, 0-0.30% of copper, 0-0.9% of residual elements and the balance of Fe, and the valve core is obtained by coating polytetrafluoroethylene upon the blank through a wet method. According to the invention, the valve core of the stop valve used in fermentation, obtained through adopting the designed manufacture method provided by the invention is good in toughness and has an excellent corrosion resistance and antibacterial property.

Owner:ZHENJIANG FENGZE BIOTECH EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com