Steel 55MnB for domestic gardening tools and preparation method thereof

A gardening tool and household technology, which is applied in the field of steel 55MnB for household gardening tools and its preparation, can solve the problems of poor processability, uneven hardness, low hardness, etc., and achieve avoiding low hardness, excellent hardenability, high The effect of carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

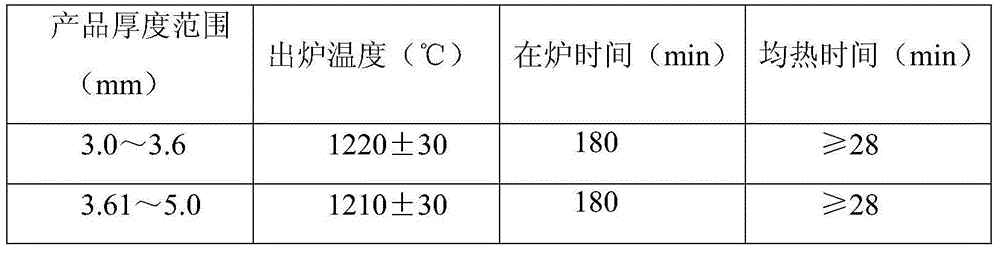

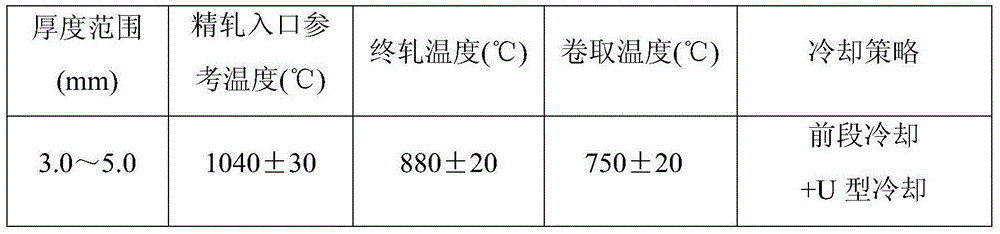

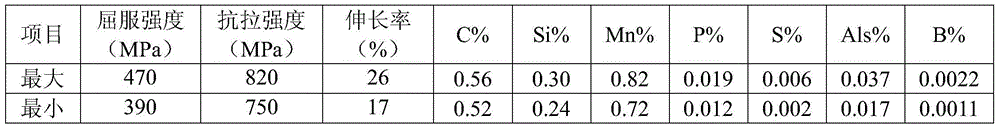

[0025] (1) Quality Design

[0026] The chemical composition of 55MnB steel is: C: 0.52~0.60%, Si: 0.15~0.35%, Mn: 0.70~1.00%, P≤0.025%, S≤0.008%, Als: 0.010~0.060%, B: 0.0005~0.0030 %, the balance is Fe and unavoidable impurities.

[0027] The production process is: hot metal desulfurization, converter blowing, LF refining, RH vacuum refining, continuous casting, hot direct loading, soaking, rough rolling, finish rolling, laminar cooling, coiling, slow cooling and delivery.

[0028] (2) Smelting technology

[0029] Desulfurization of molten iron to [S]≤0.005%;

[0030] Bottom blowing in converter smelting is switched with nitrogen and argon; tap slag is kept out, and the amount of slag dropped in the converter is strictly controlled; tap steel is alloyed with Si, Mn alloys and recarburizers;

[0031] It is required that the argon blowing at the bottom of the ladle is good; the upper LF furnace is used to treat the white slag produced by the ladle furnace, and desulfurize to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com