Hot-pressing apparatus

a technology of hot press and heat press, which is applied in the direction of heat treatment apparatus, manufacturing tools, shaping tools, etc., can solve the problems of insufficient cooling rate of small hardness of some parts in the workpiece, and gap formed between the workpiece and the die, so as to prevent the hardness of some parts and the cooling rate is sufficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

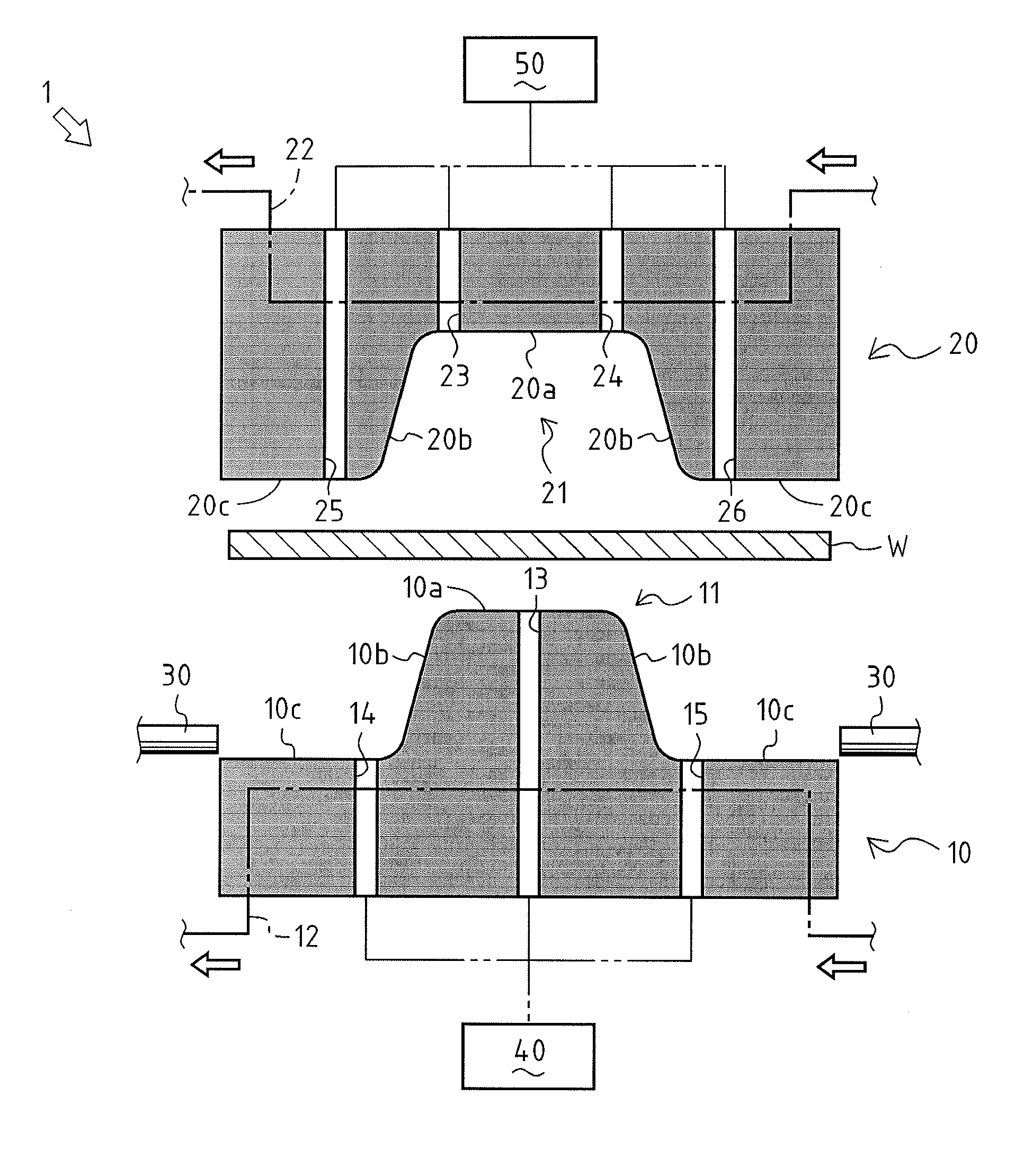

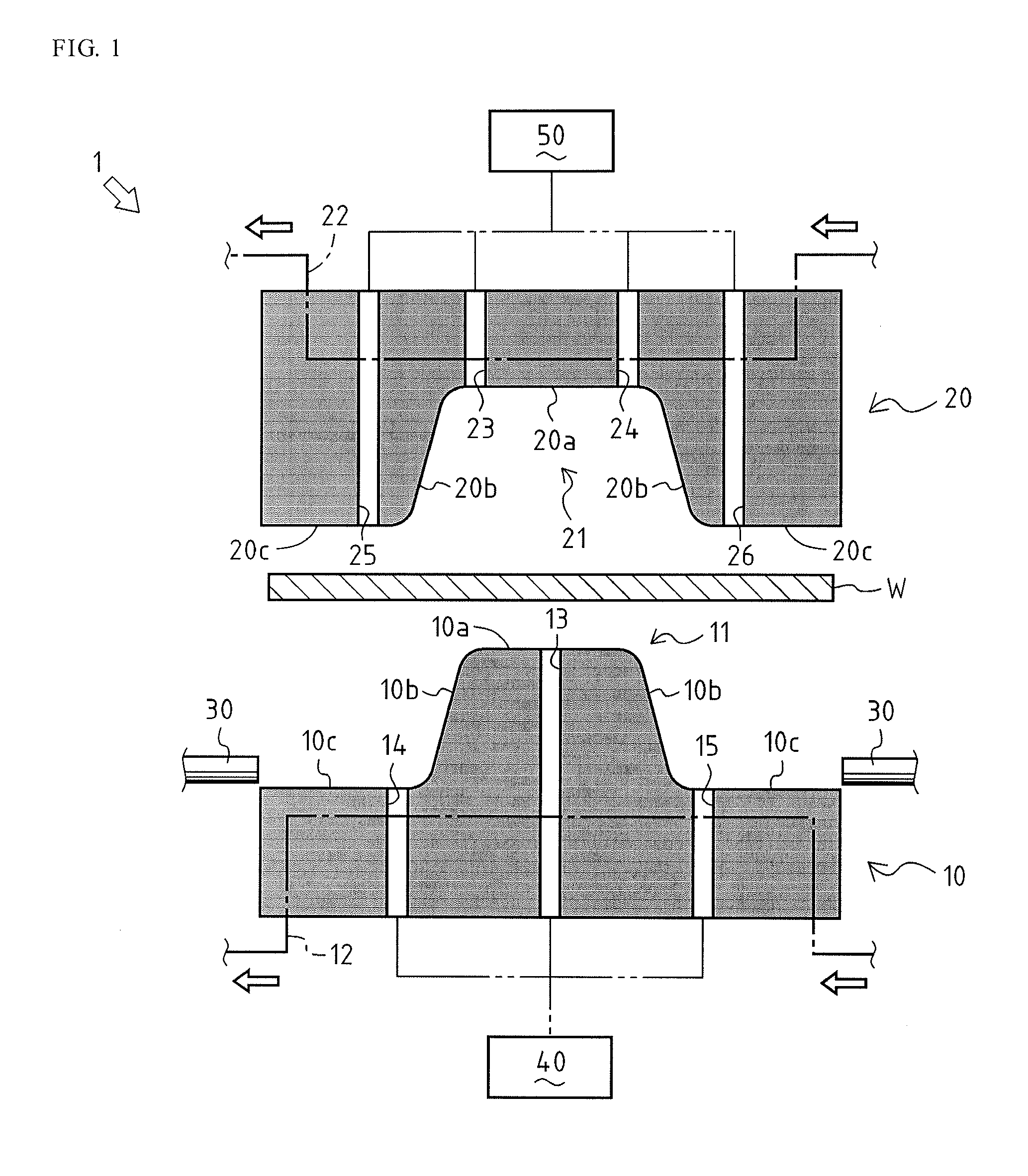

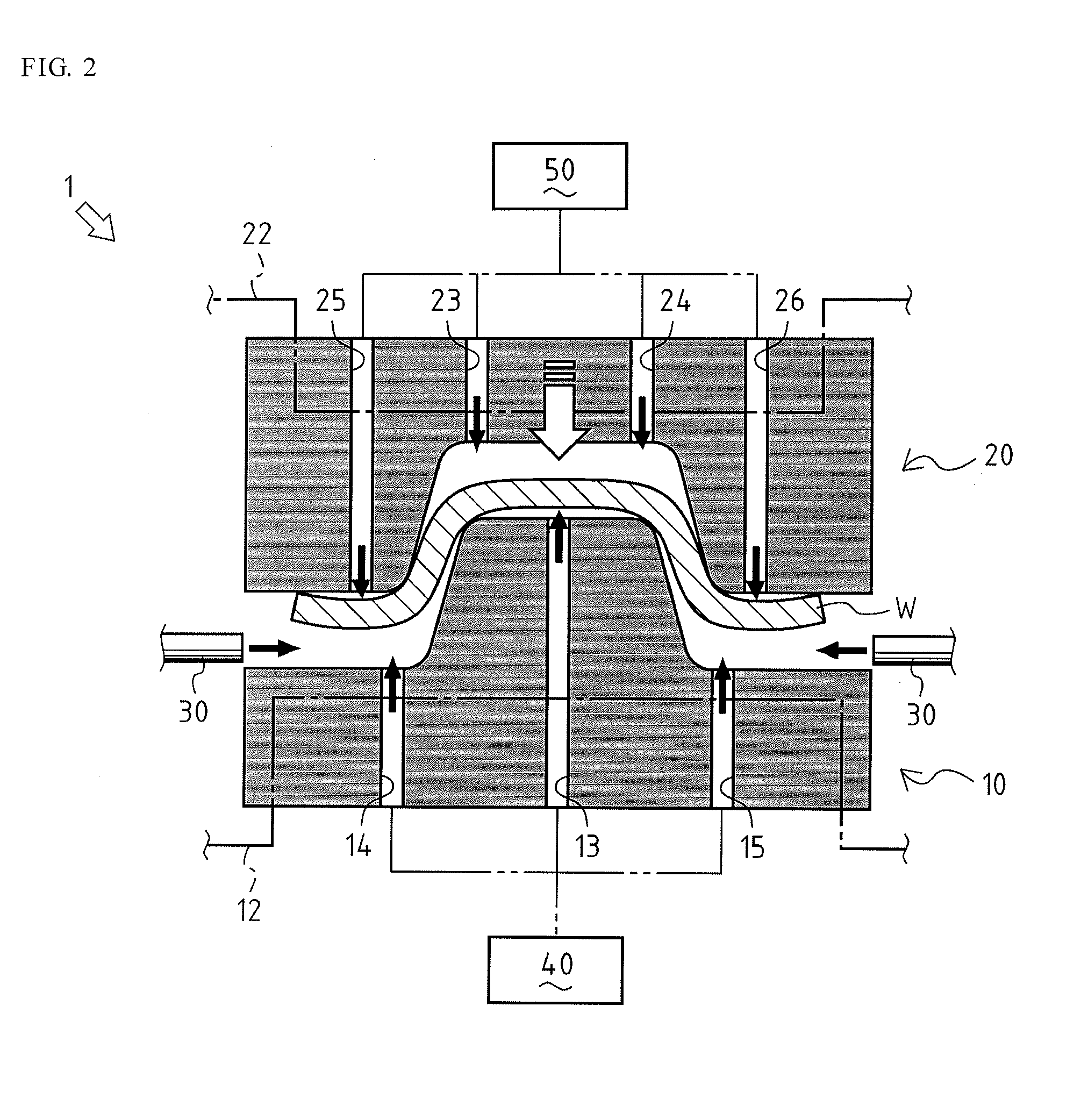

[0014]With reference to FIGS. 1 to 3, described below is a hot-pressing apparatus 1 as an embodiment of a hot-pressing apparatus according to the present invention.

[0015]The hot-pressing apparatus 1 performs hot-press forming of a workpiece W.

[0016]The workpiece W is a steel plate to be pressed by the hot-pressing apparatus 1, and is heated to above a temperature at which an austenite structure appears by ohmic heating and the like.

[0017]For convenience, a top-bottom direction in FIG. 1 is defined as a top-bottom direction of the hot-pressing apparatus 1, and a right-left direction in FIG. 1 is defined as a right-left direction of the hot-pressing apparatus 1. In addition, this side in FIG. 1 is defined as a front side of the hot-pressing apparatus 1, and the far side in FIG. 1 is defined as a rear side of the hot-pressing apparatus 1, thereby a front-rear direction of the hot-pressing apparatus 1 being defined.

[0018]As shown in FIG. 1, the hot-pressing apparatus 1 includes a lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com