Water-soluble quenching oil composition

A technology of composition and quenching oil, applied in the directions of lubricating composition, quenching agent, petroleum industry, etc., can solve the problems of cracking of the treated body and fast cooling speed, and achieve sufficient cooling speed, low cooling speed and sufficient characteristic seconds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~4

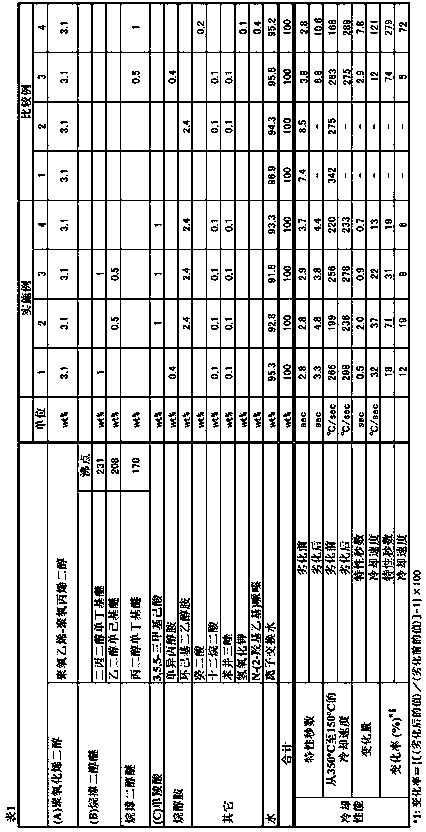

[0093] A water-soluble quenching oil composition was prepared with the ingredients and ratios shown in Table 1.

[0094] Regarding the above-mentioned water-soluble quenching oil compositions, cooling performance and durability thereof were evaluated for each water-soluble quenching oil composition by the following evaluation method. The results are shown in Table 1 together.

[0095] [Evaluation method]

[0096] (1) Cooling evaluation

[0097] According to the cooling test specified in JIS K 2242:2012: Appendix A (Method B), the cooling curves were obtained for each water-soluble quenching oil composition obtained at a liquid temperature of 40°C.

[0098] (1.1) Characteristic seconds

[0099] From the above cooling curve, the time until reaching the characteristic temperature (the temperature at which the vapor film phase ends) (characteristic seconds) is obtained.

[0100] (1.2) Cooling rate

[0101] In the above cooling curve, the cooling rate from 350°C to 150°C was c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com